Connecting structure of hoop type precast tubular pile and precast bearing platform

A technology of prefabricated pipe piles and prefabricated caps, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as low degree of prefabrication of components, pollution, and large volume of wet work on site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

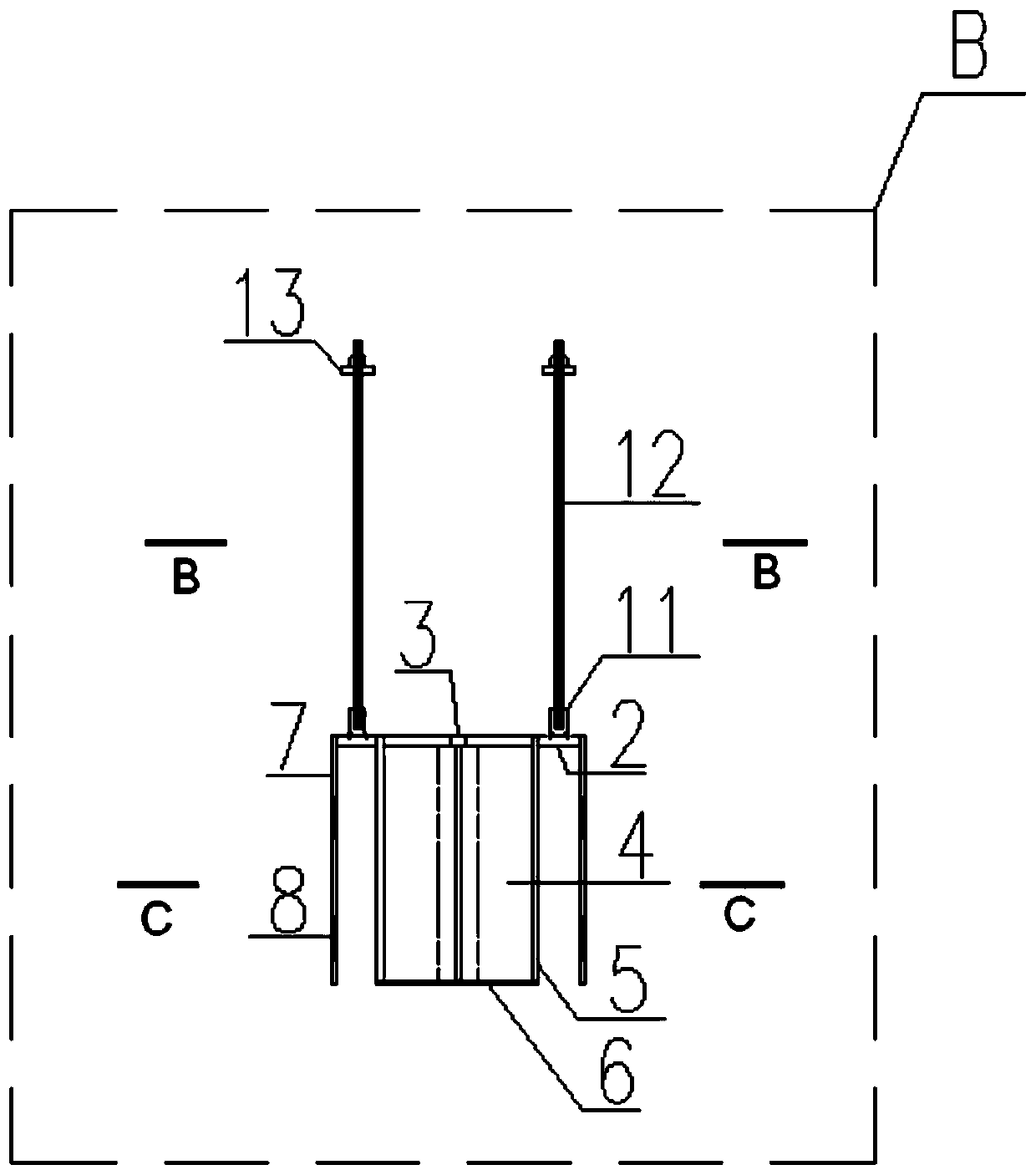

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

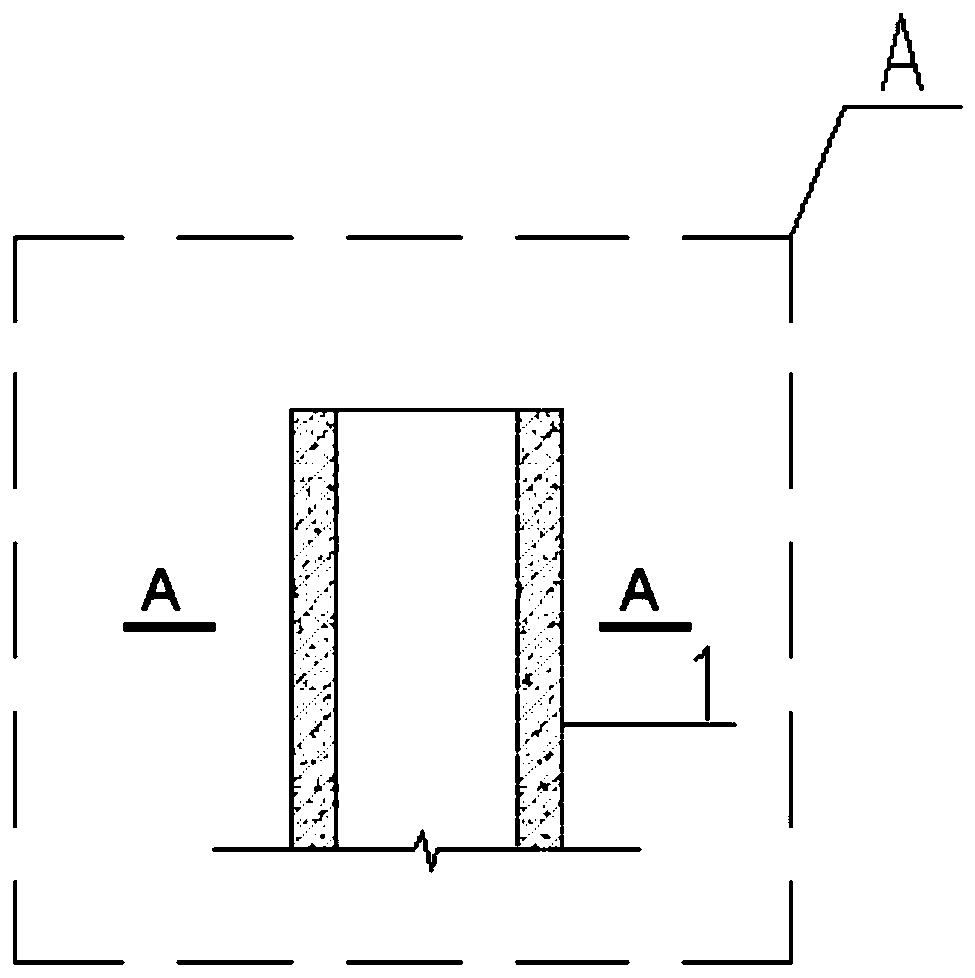

[0033] Such as figure 1 As shown, a connection structure between a hoop-type prefabricated pipe pile and a prefabricated cap in the present invention includes a prefabricated pipe pile part A and a prefabricated cap part C connected through a steel structure hoop-type connector part B.

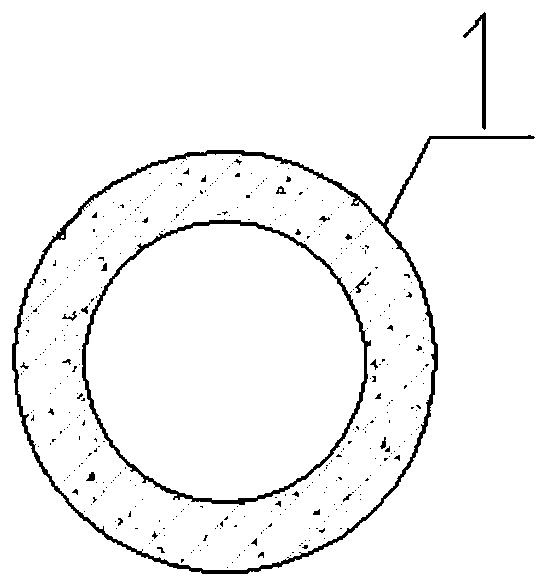

[0034] The prefabricated pipe pile part A is a prefabricated pipe pile 1;

[0035] The steel structure hoop type connector part B includes a welded ring top plate 2, a cross-shaped top plate 3 embedded in the inner peripheral surface of the ring, a cross-shaped vertical plate stiffener 4, a circular bottom cover plate 6 at the bottom, and a support The inner arc vertical plate 5, the outer arc vertical plate 7 and the horizontal horizontal connecting plate belt 8 connected as a whole with the outer arc vertical plate 7 of the connecting parts; the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com