Patents

Literature

102results about How to "High degree of prefabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

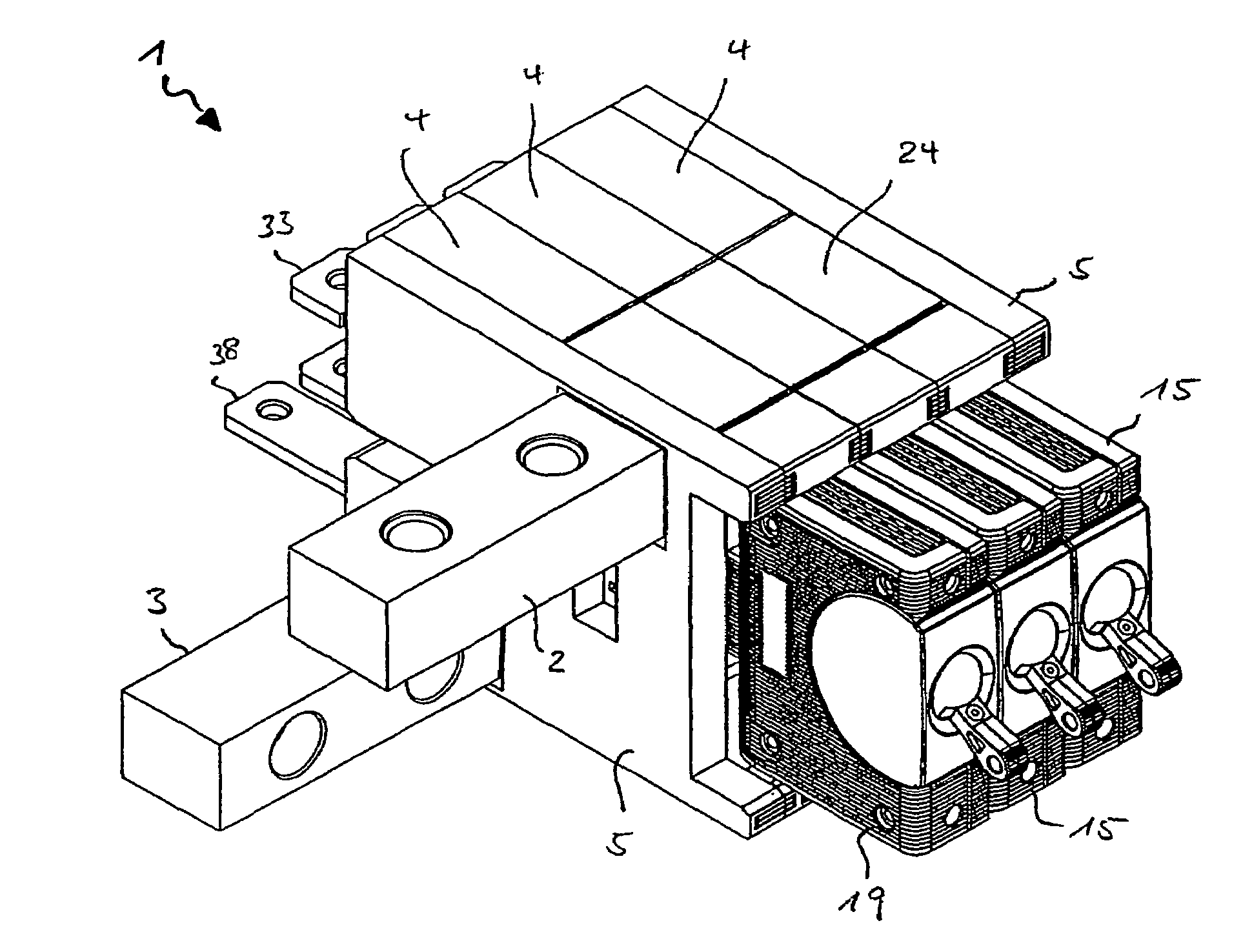

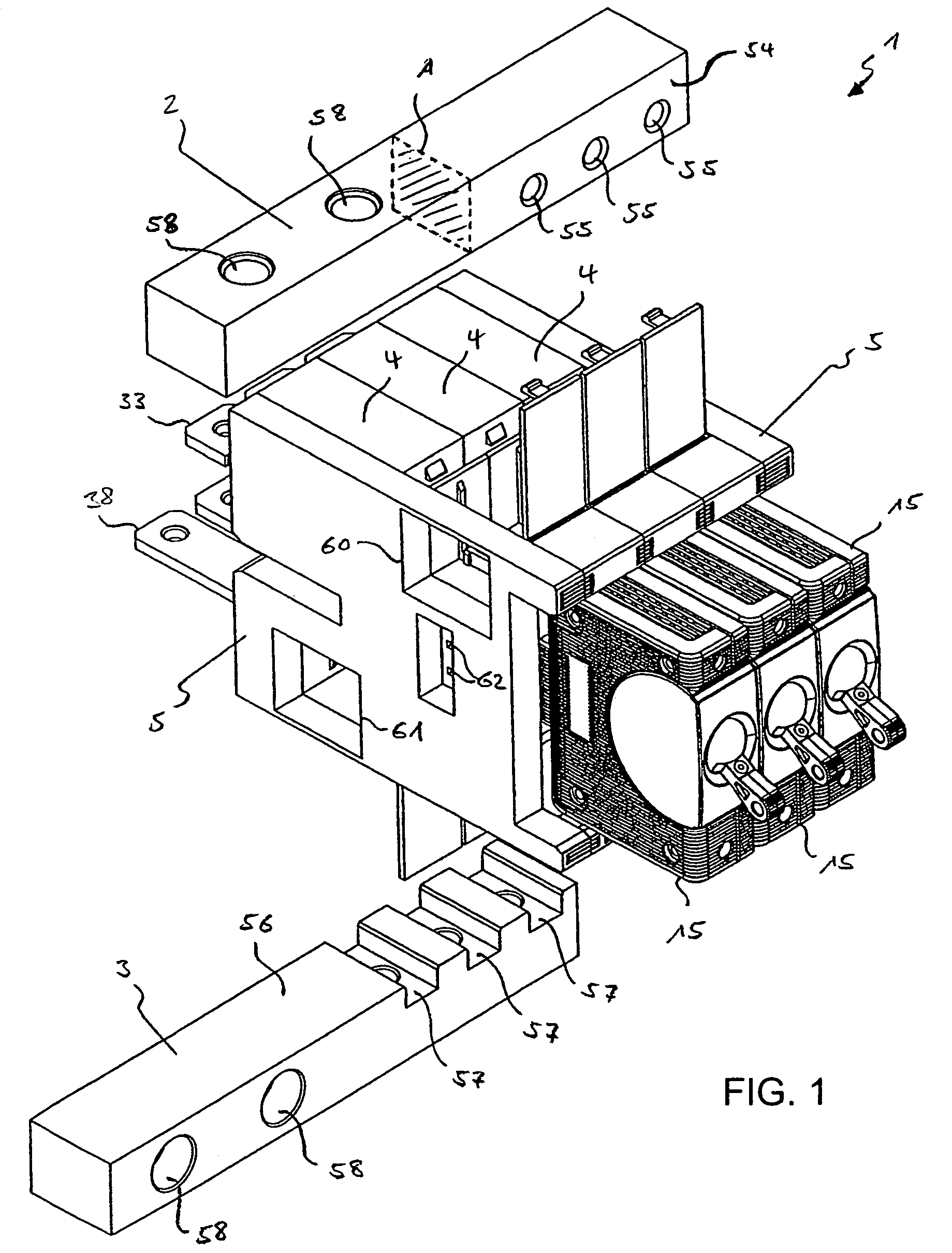

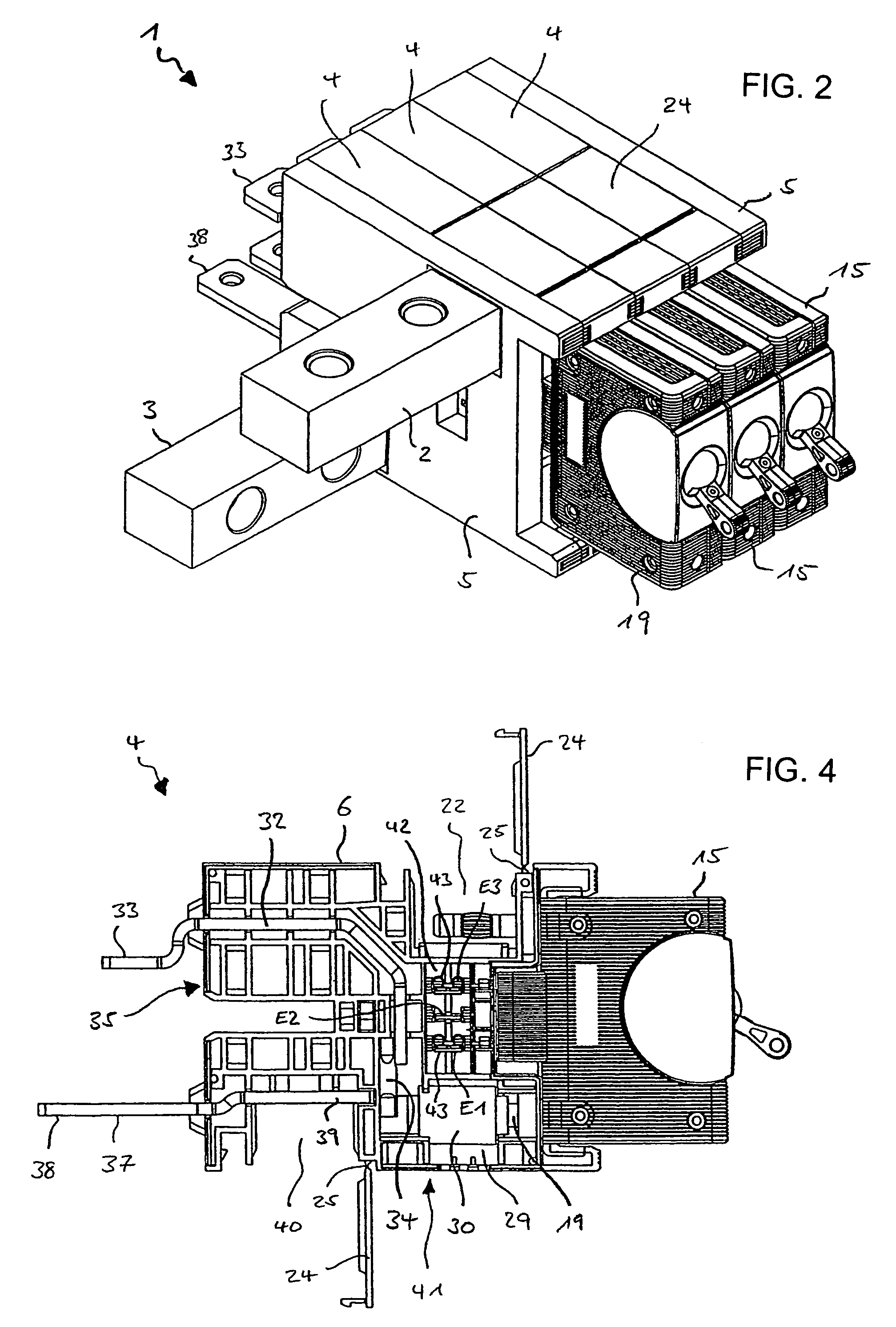

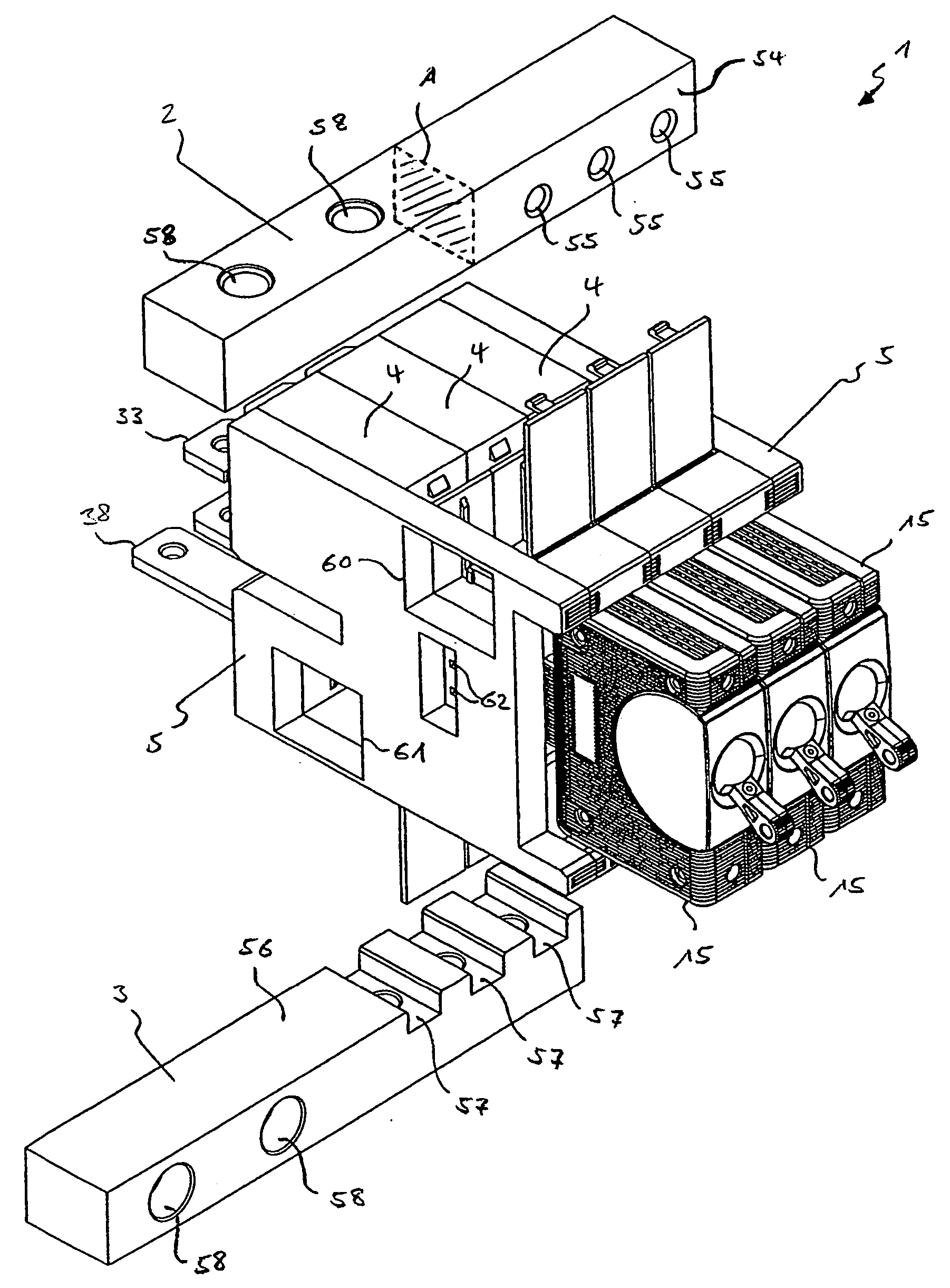

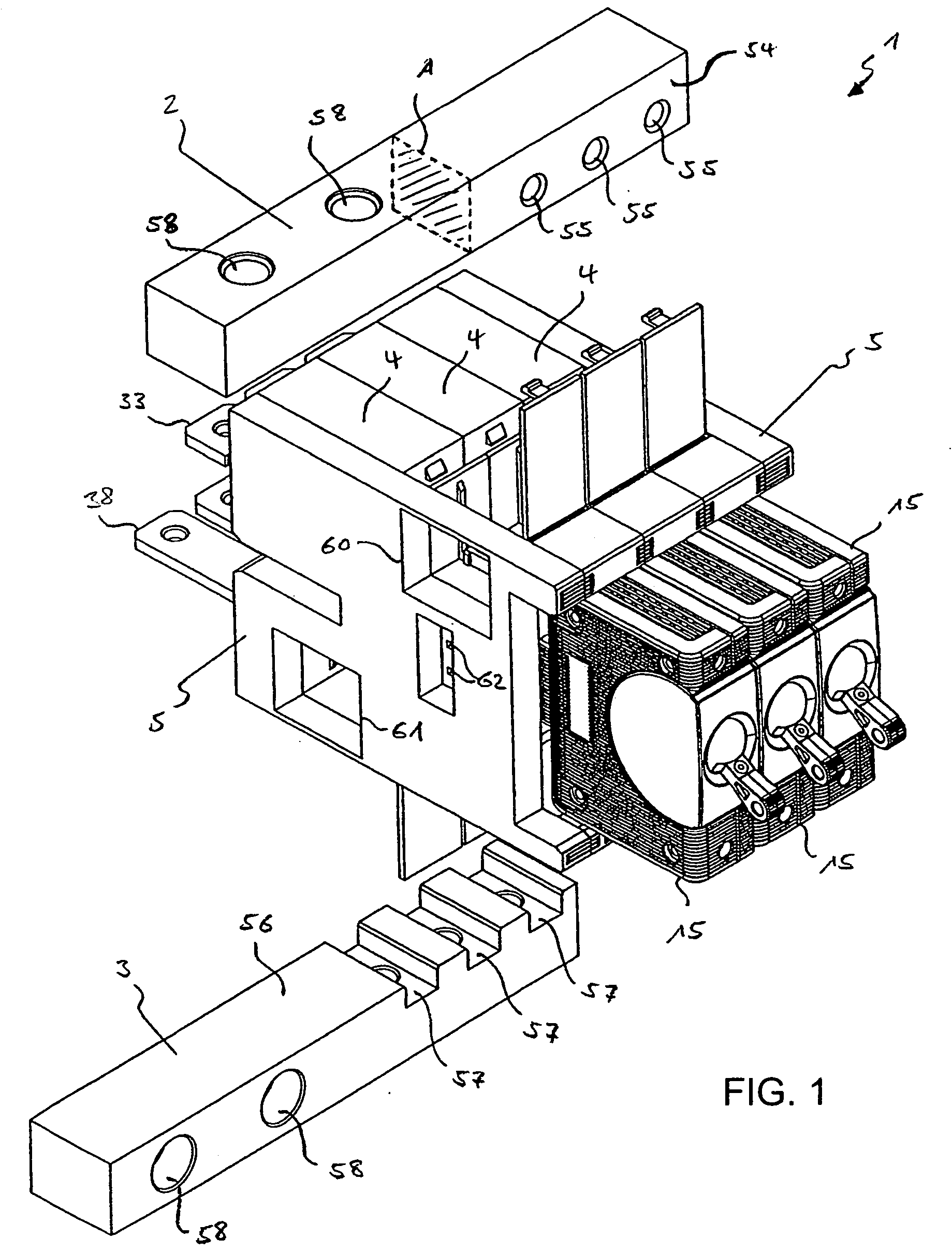

Modular current distributor for high currents

InactiveUS7414828B2Easy to useHigh degree of prefabricationNon-enclosed substationsBus-bar/wiring layoutsLoad circuitBusbar

A current distributor includes a common, uninterrupted first main busbar as a main current supply and a number of current distributor modules which are each associated with a respective circuit breaker and can be disposed in a row along the main busbar. The current distributor module or each current distributor module has a first connection line for supplying current to a load circuit. The current distributor module or each current distributor module has a housing, a slot formed on a front side of the housing for plugging on an associated circuit breaker, and a first channel which passes through the housing in a transverse direction for accommodating the first main busbar. A first contact opening of the slot corresponds to the first channel and a second contact opening of the slot corresponds to a housing receptacle for a connection socket of the first connection line.

Owner:ELLENBERGER & POENSGEN GMBH

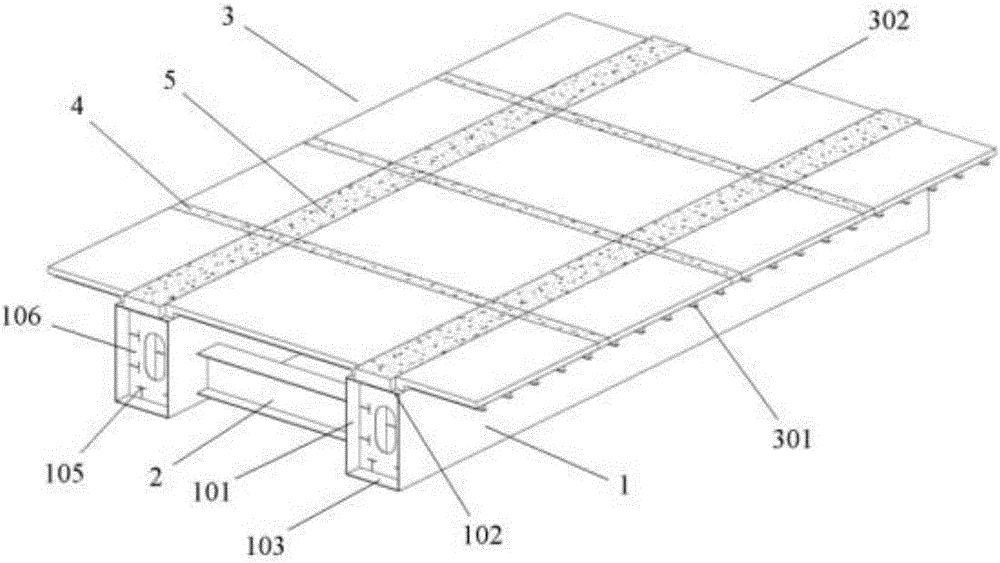

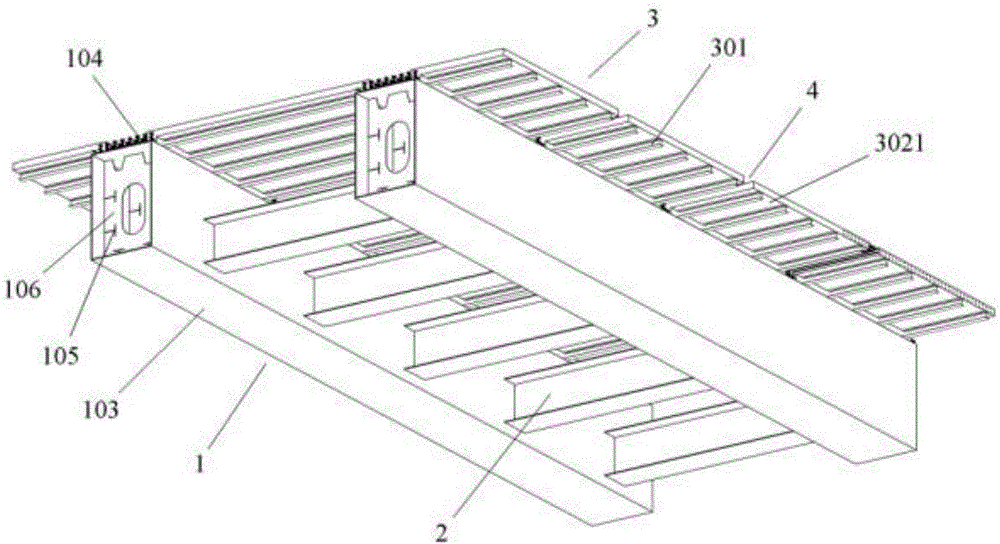

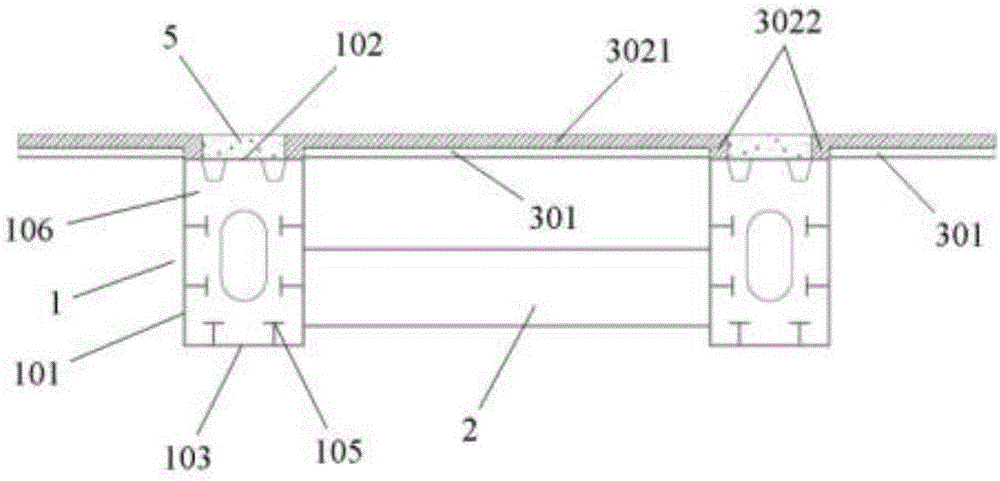

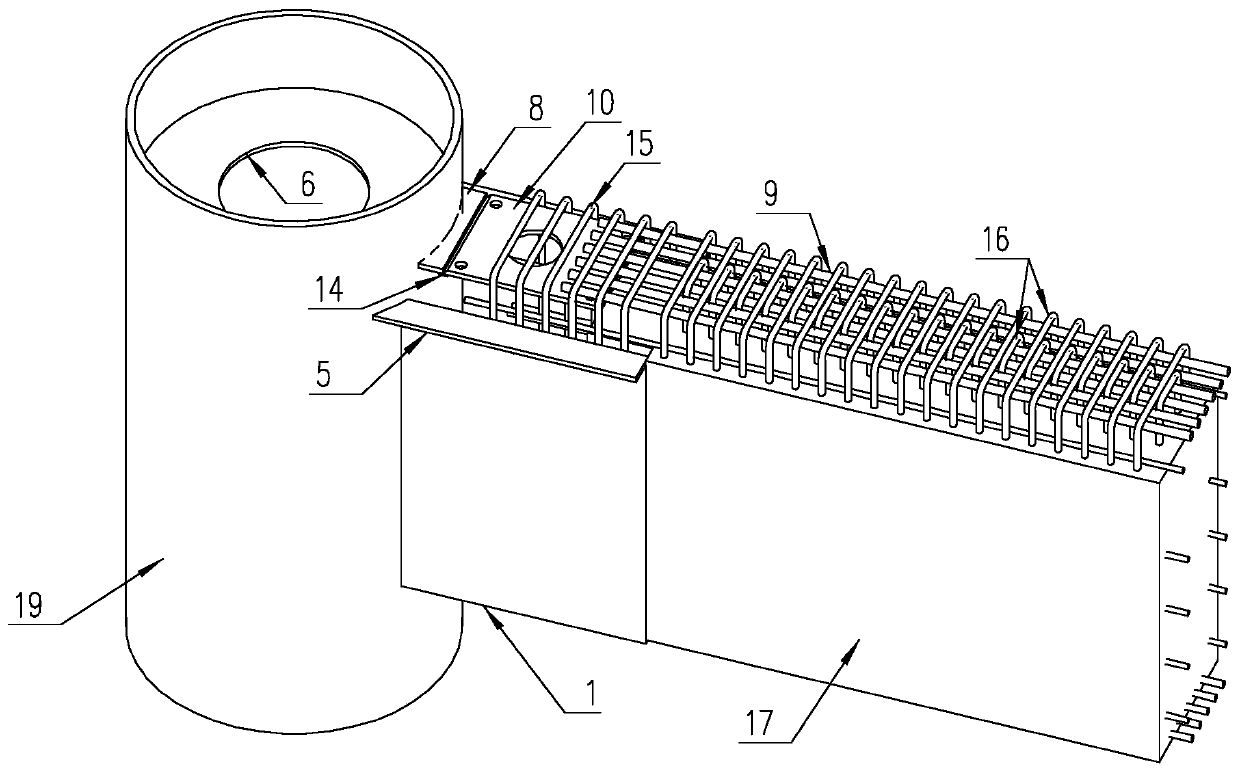

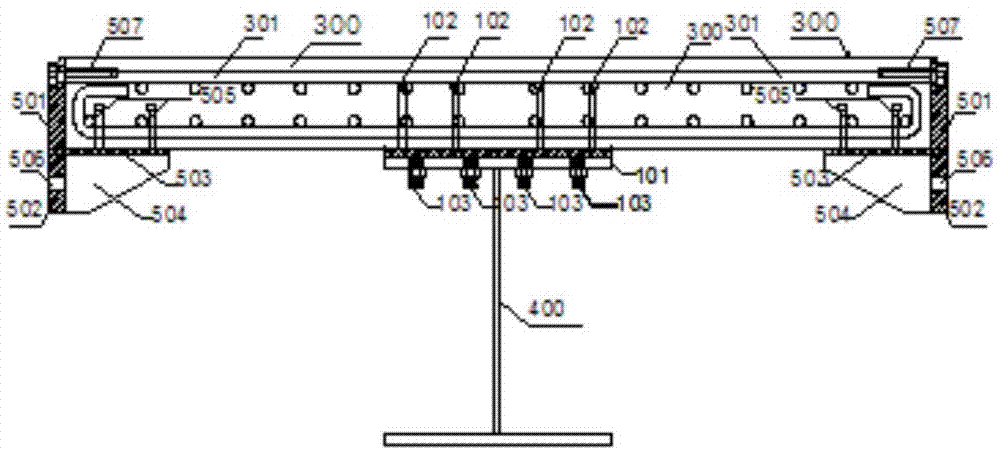

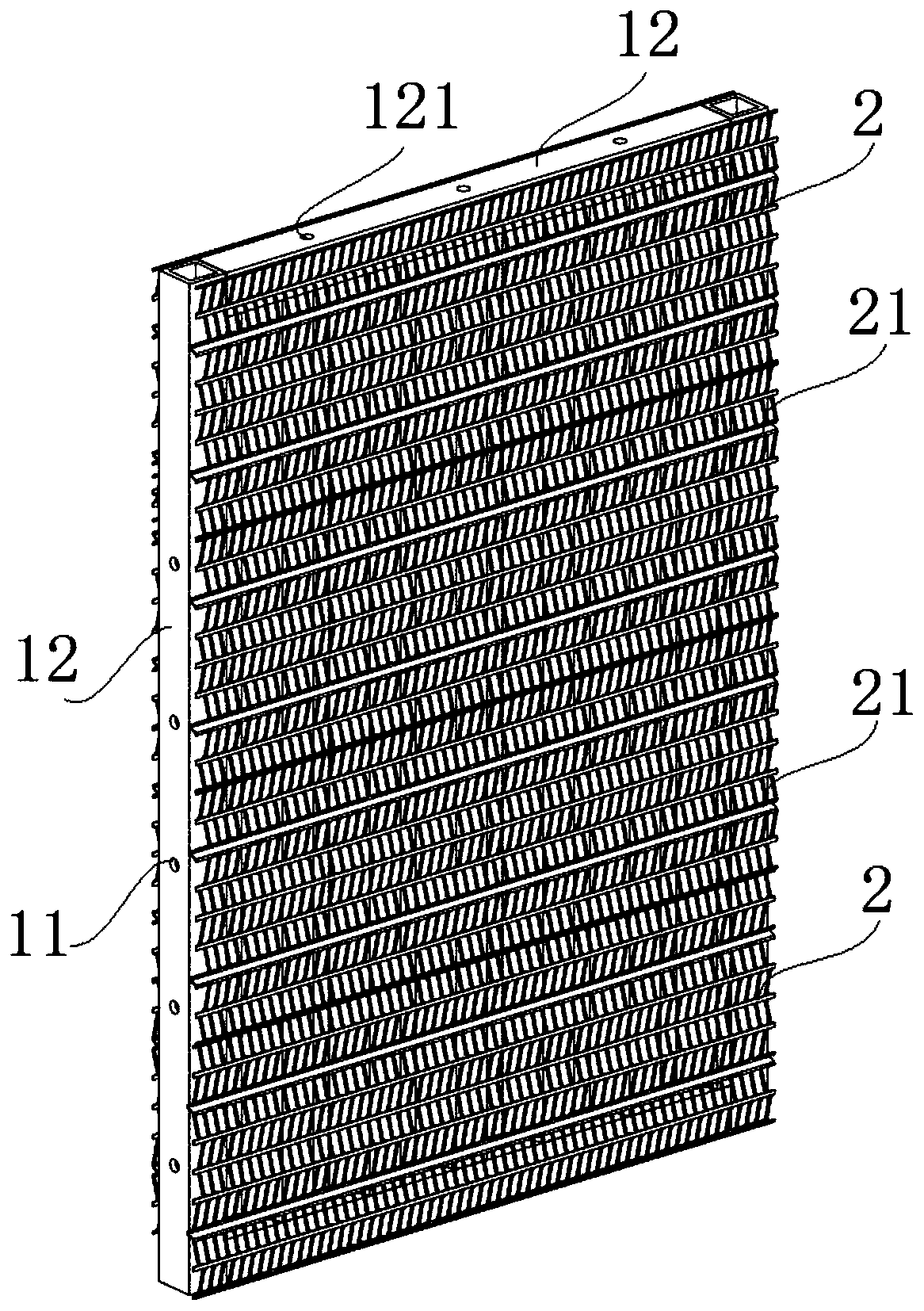

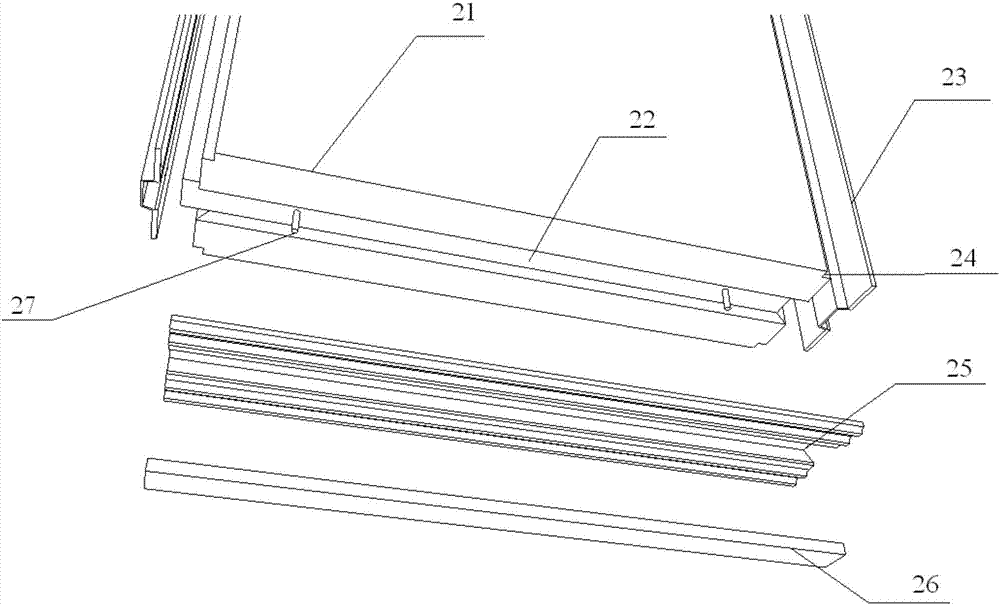

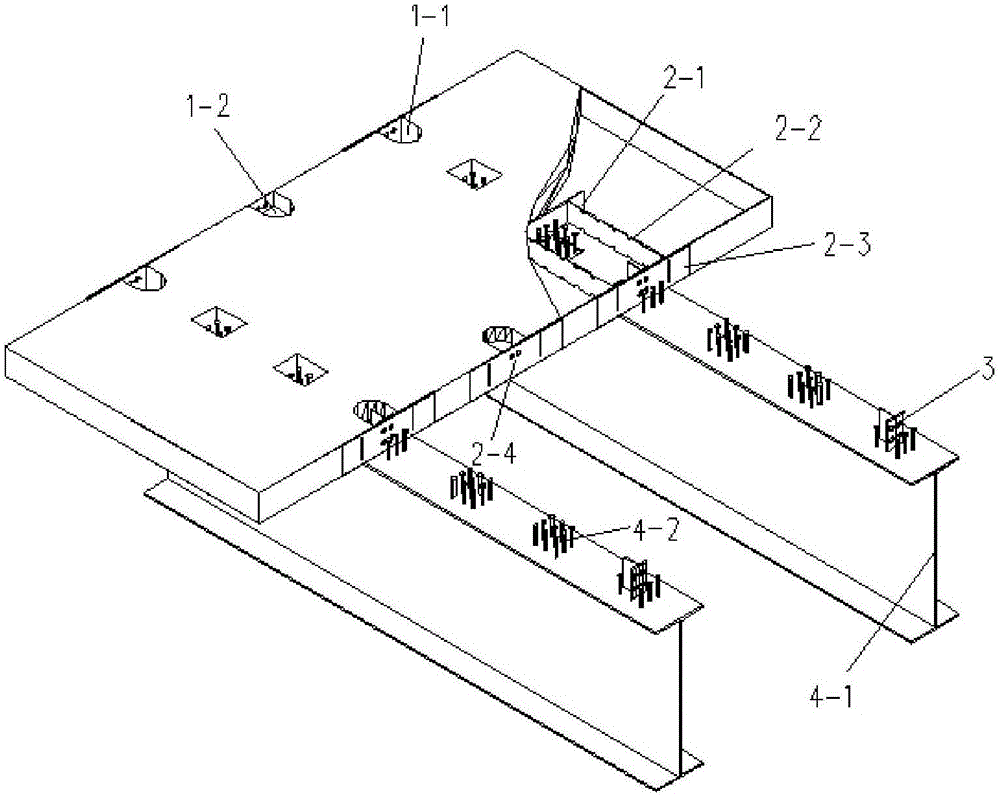

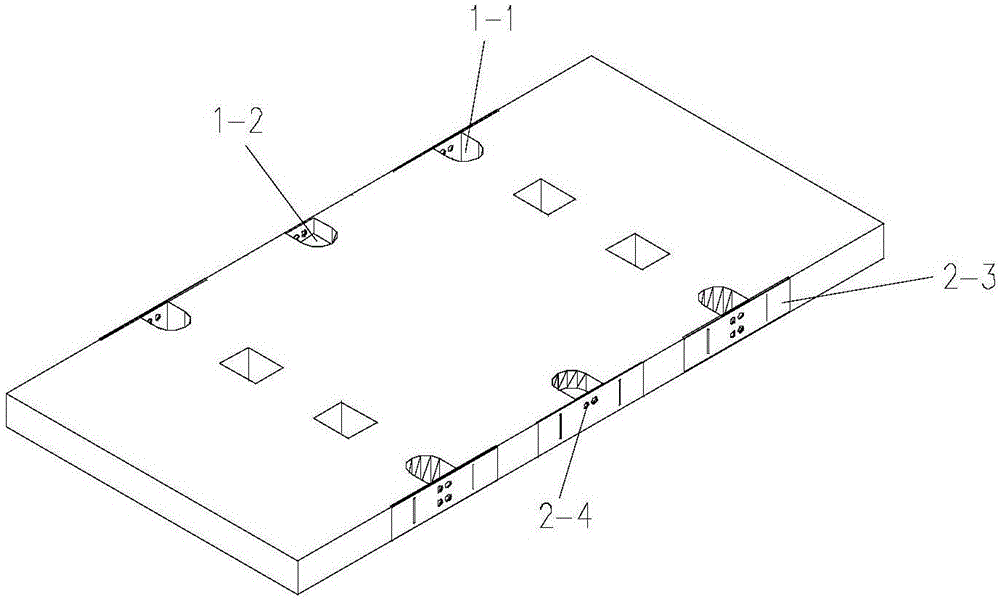

Secondary main beam composite beam bridge using prefabricated composite bridge deck slabs and construction method of secondary main beam composite beam bridge

ActiveCN106638254ALose weightIncrease horizontal spanBridge structural detailsBridge deckEngineering

The invention discloses a secondary main beam composite beam bridge using prefabricated composite bridge deck slabs and a construction method of the secondary main beam composite beam bridge. The secondary main beam composite beam bridge includes steel box beams, steel cross beams and the prefabricated composite bridge deck slabs, a horizontal wet joint is formed between every two adjacent bridge deck slabs, the prefabricated composite bridge deck slabs include a plurality of pieces of structural steel and prefabricated concrete layers cast on the structural steel, the bottom of the structural steel is welded to the steel box beams, longitudinal wet joints are formed in the prefabricated composite bridge deck slabs and in the range of the top of the steel box beams, a plurality of through holes are formed in the structural steel and in the range of the longitudinal wet joints, perforated steel bars connected with the structural steel pass through the through holes, and vertical and horizontal direction steel bar meshes are arranged in the prefabricated concrete layers, stretch out of the prefabricated range of the prefabricated composite bridge deck slabs and are connected with the perforated steel bars; wet joint concrete is cast in situ in the horizontal wet joints and the longitudinal wet joints. The secondary main beam composite beam bridge is light in dead weight, large in bearing capacity, reasonable in loading, good in integrality and large in adaptation width.

Owner:湖南省交通水利建设集团有限公司 +1

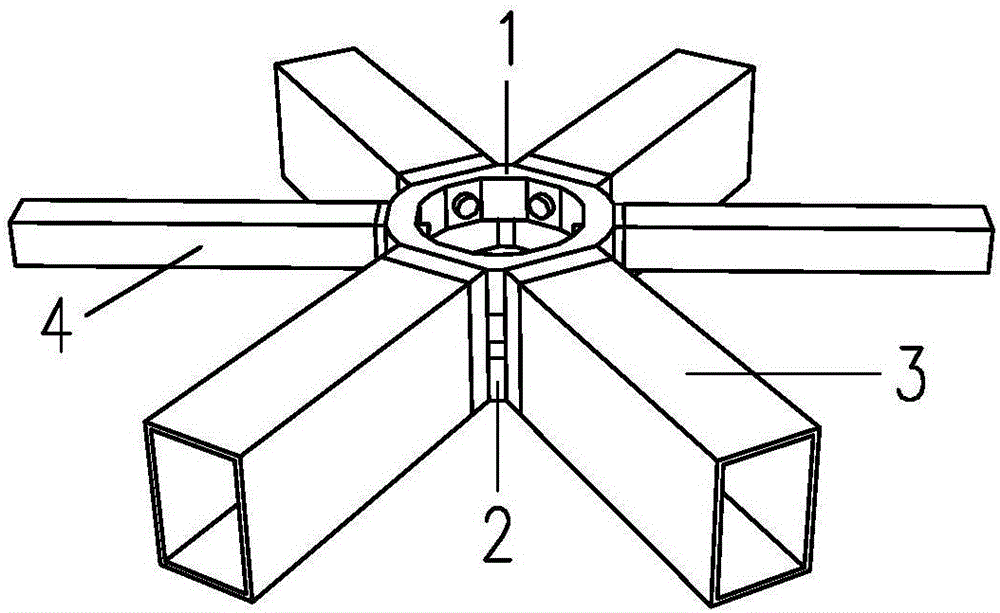

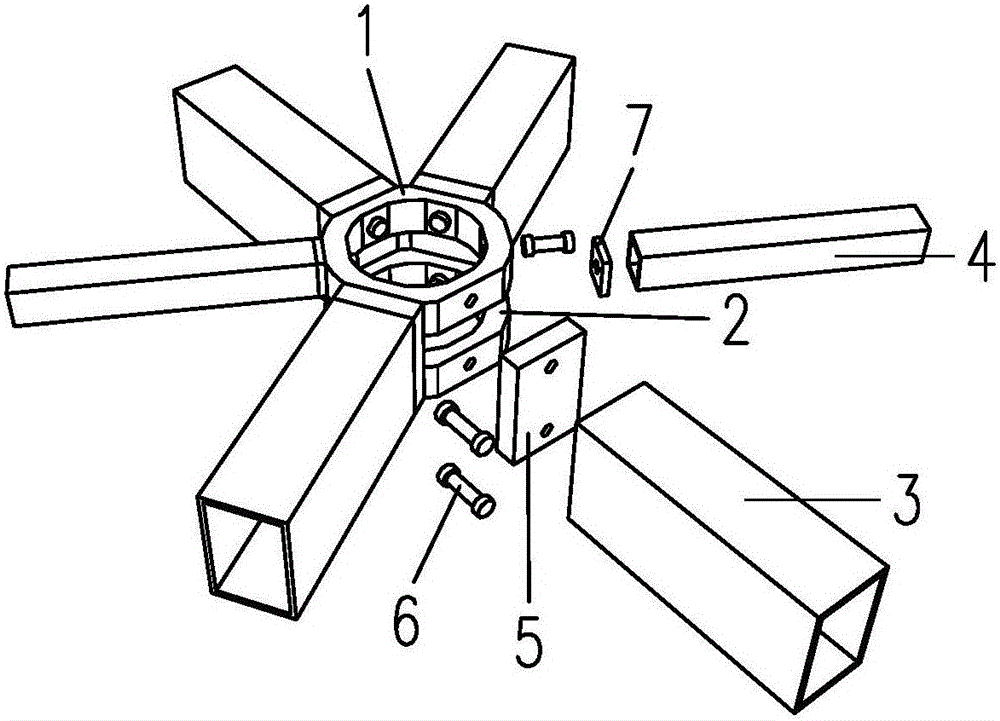

Single-layer space lattice structure assembled double-ring node

InactiveCN105821963ALow machining accuracy requirementsReduce the impactBuilding constructionsStructural engineeringMechanical property

The invention discloses a single-layer space lattice structure assembled double-ring node, which mainly comprises five parts including center upper and lower node rings, I-shaped connecting elements, a large sealing plate, a small sealing plate, high-strength screw bolts, major rod elements and minor rod elements, wherein the center upper and lower node rings are provided with screw bolt holes; the wing edge parts of the I-shaped connecting elements are provided with screw bolt holes; the large sealing plate and the small sealing plate are rectangular steel plates; the large sealing plate is welded with the I-shaped connecting elements; the small sealing plate is provided with screw bolt holes, and is welded with the rod ends of the minor rod elements; the high-strength screw bolts are connected with the upper and lower node rings and the I-shaped connecting elements; the upper node ring and the small sealing plate are connected; the major rod elements and the minor rod elements are rectangular steel pipes. The node rings can be only connected with the major rod elements and can be connected with both the major rod elements and the minor rod elements; a certain angle can be formed between the node rings and the rod elements. The node provided by the invention can be applicable to a single-layer space lattice structure, and has the characteristics that the mechanical property is good; the assembling performance is high; the construction speed is high; the construction quality can be easily controlled; the construction cost is low, and the like.

Owner:SOUTHEAST UNIV

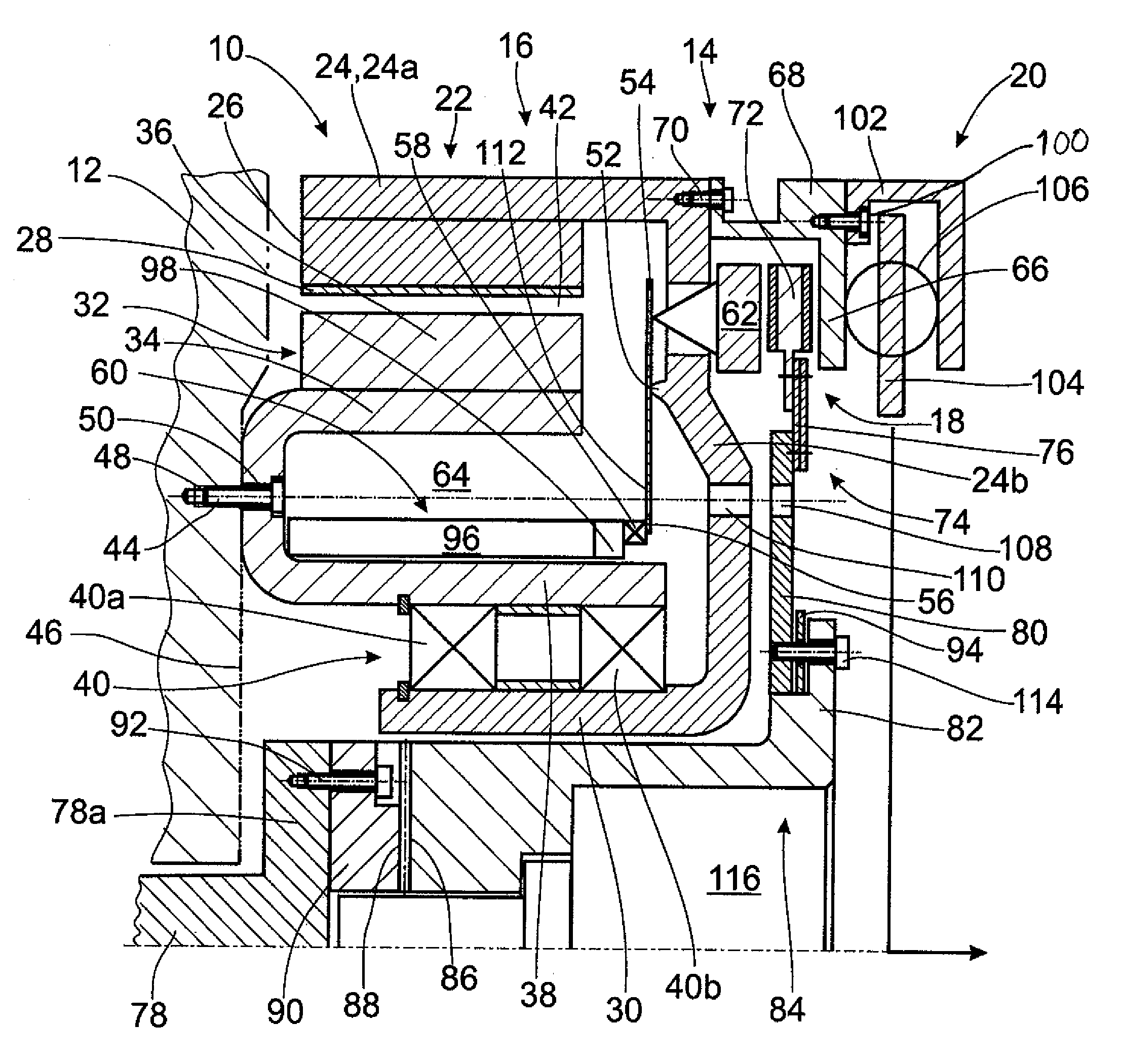

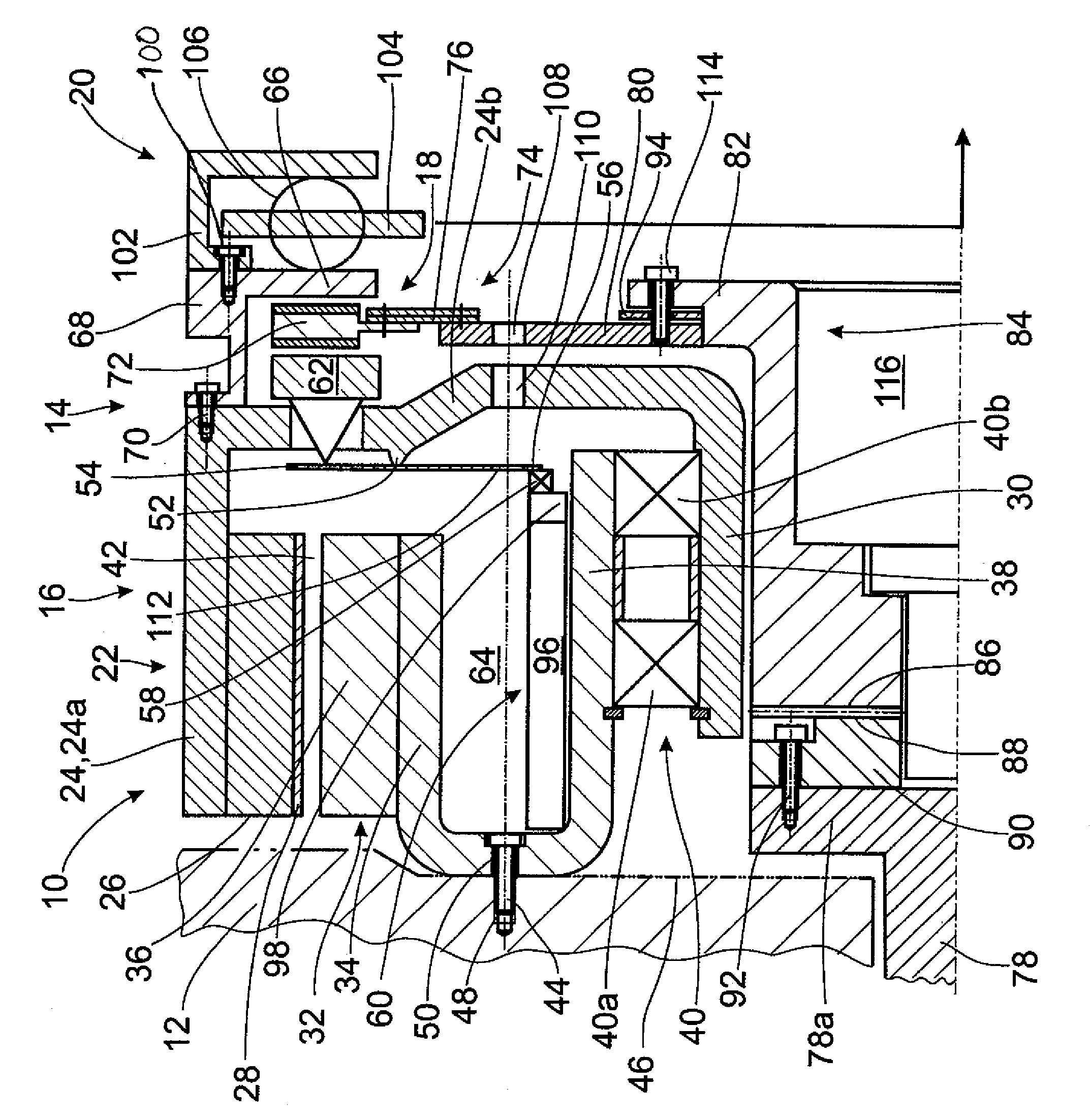

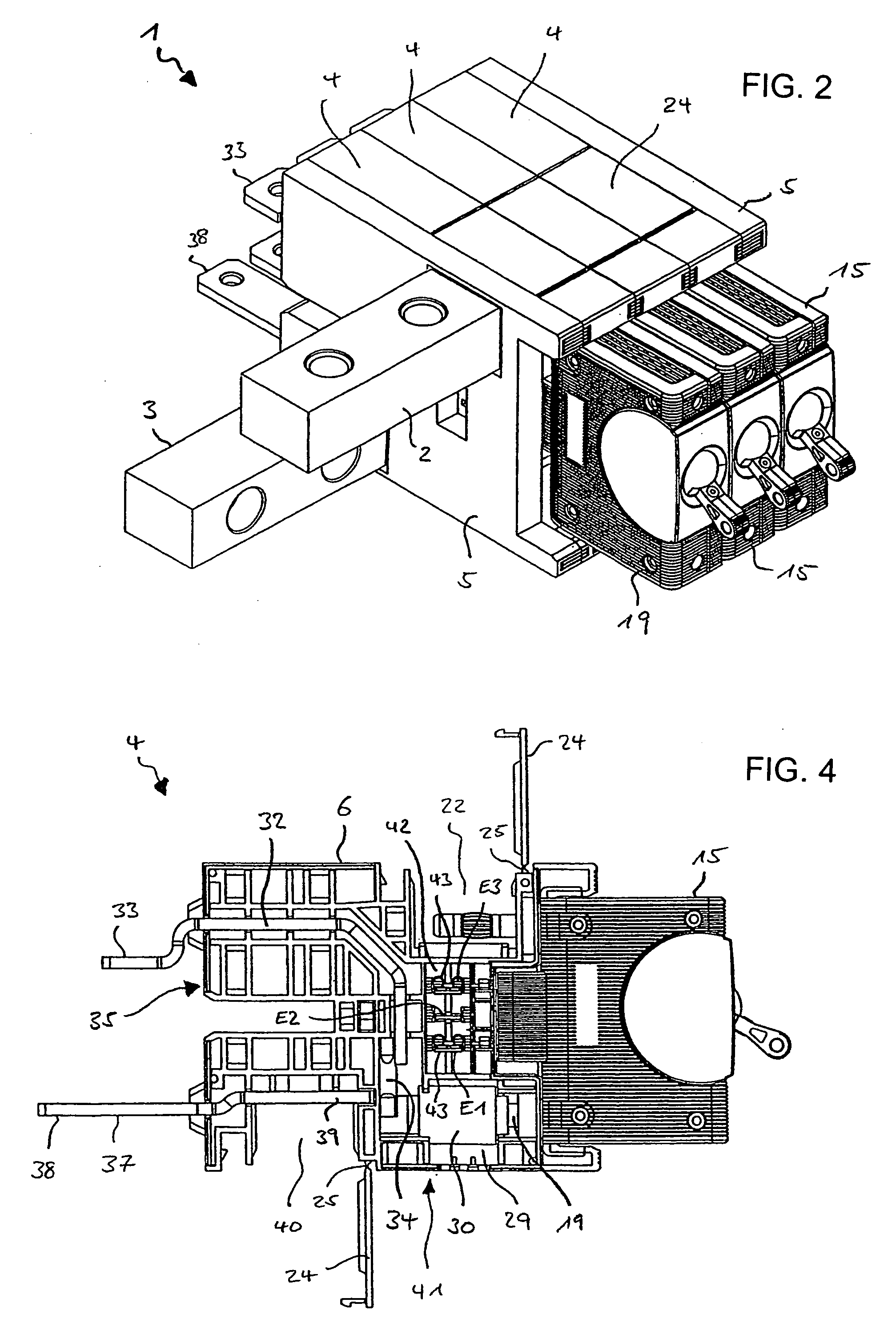

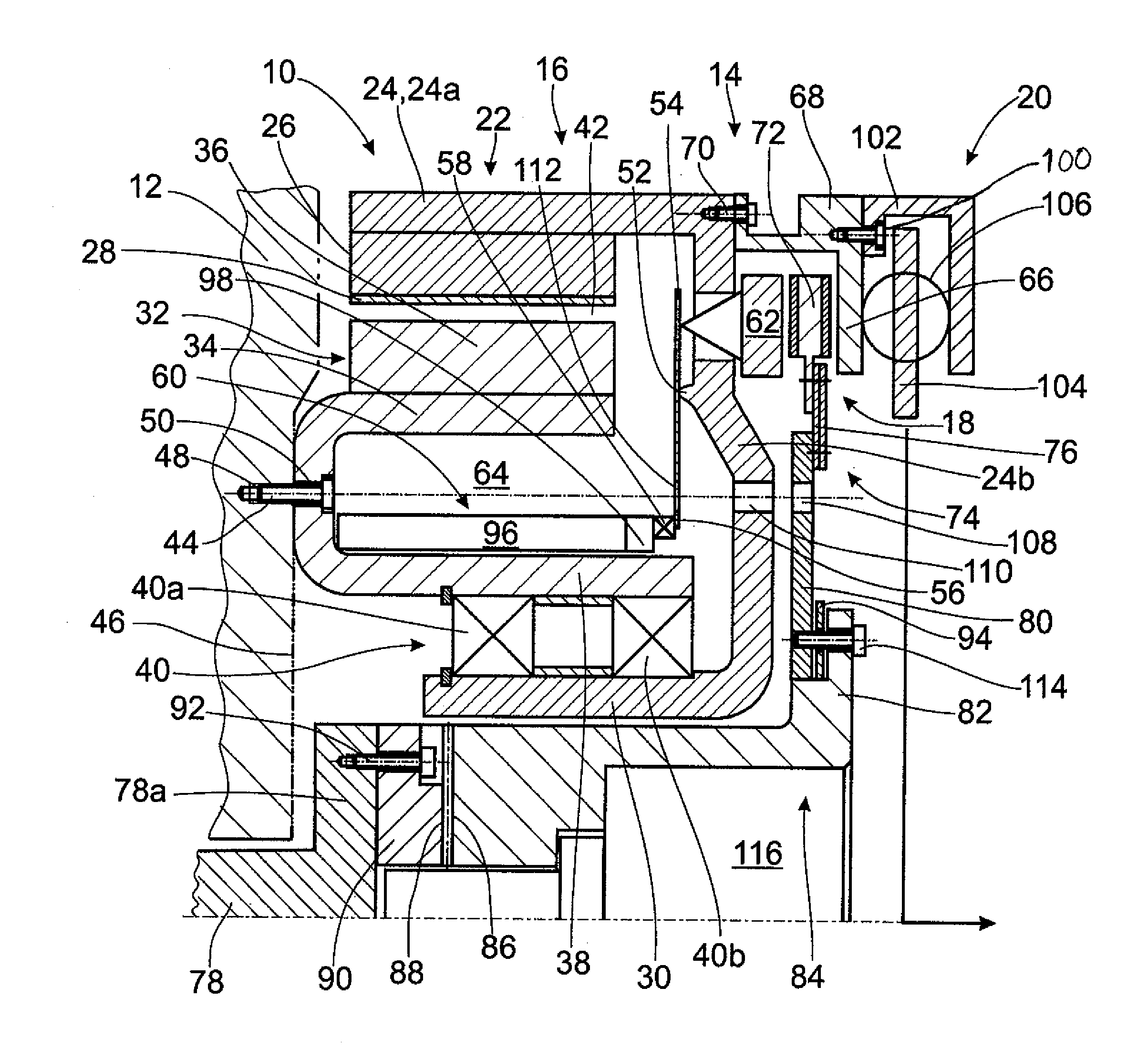

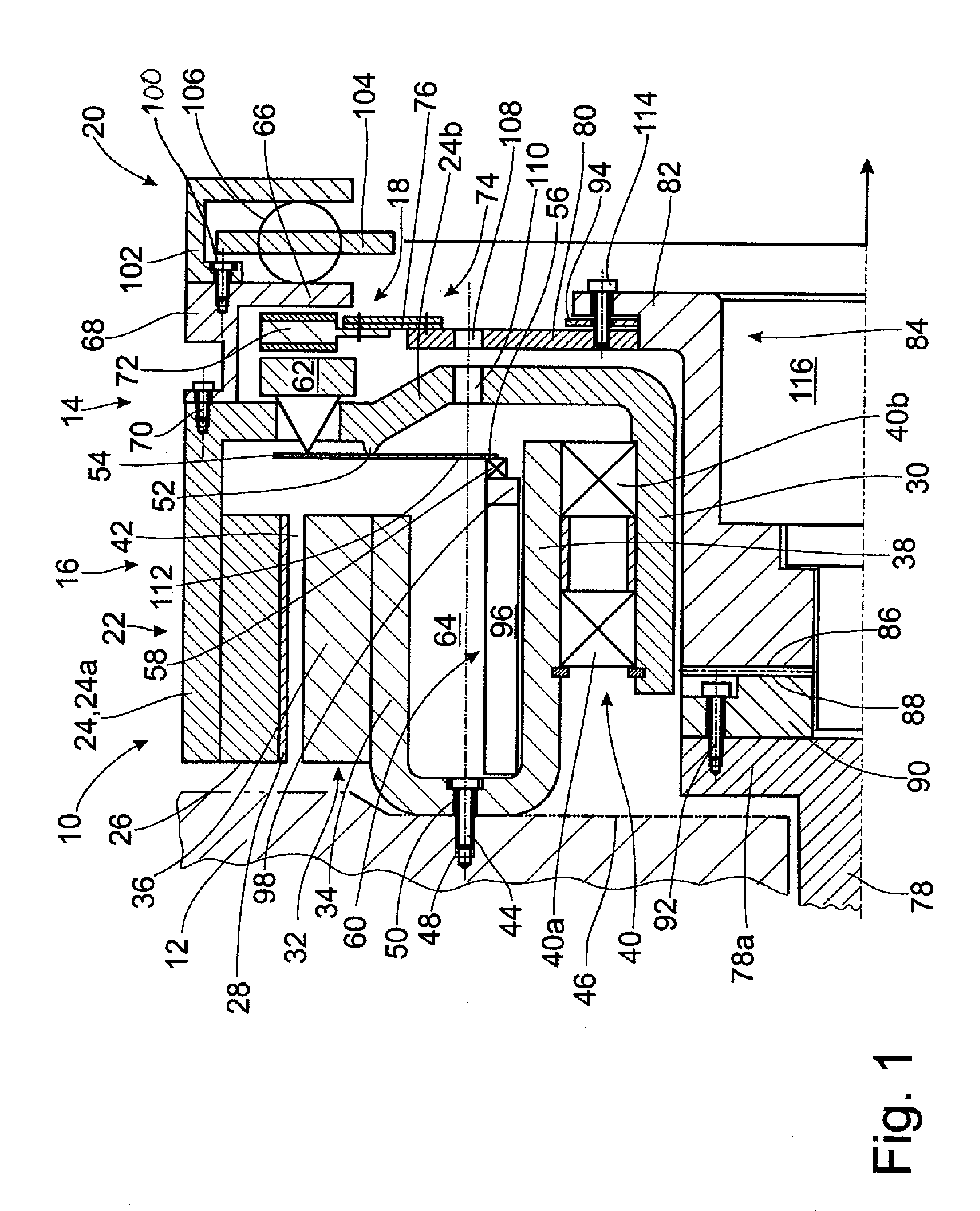

Drive unit for a hybrid vehicle and method of assembly

InactiveUS8267208B2Simple and low-cost methodReduce the amount requiredElectric devicesElectric propulsion mountingElectric machineEngineering

A drive unit for a hybrid vehicle includes an internal combustion engine with a crankshaft, a friction clutch with a pressure plate, which can be moved in the axial direction by an actuating arrangement, with a clutch plate, and with a clutch disk arrangement, positioned between these first two components and is connected to the crankshaft. The drive unit also includes an electric machine, which is arranged between the internal combustion engine and the friction clutch, with a stator attached to a stator carrier and with a rotor. The friction clutch comprises a clutch hub, which serves to create at least an indirect connection of the clutch disk arrangement to the crankshaft is detachably connected to the clutch disk arrangement outside the radial dimension of the pressure plate and the clutch plate. An assembly method for assembling such a drive unit is also described, where a preassembled unit including at least the electric machine and the friction clutch is attached to an internal combustion engine.

Owner:ZF FRIEDRICHSHAFEN AG

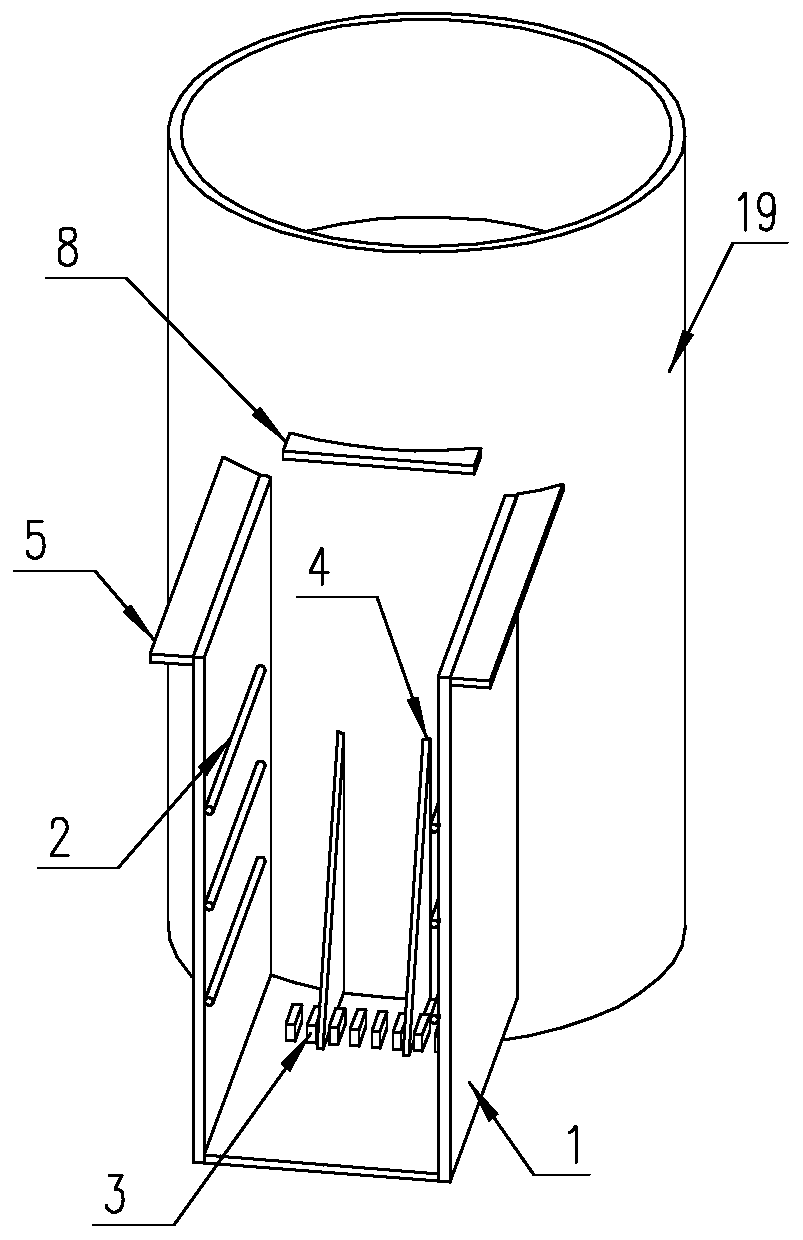

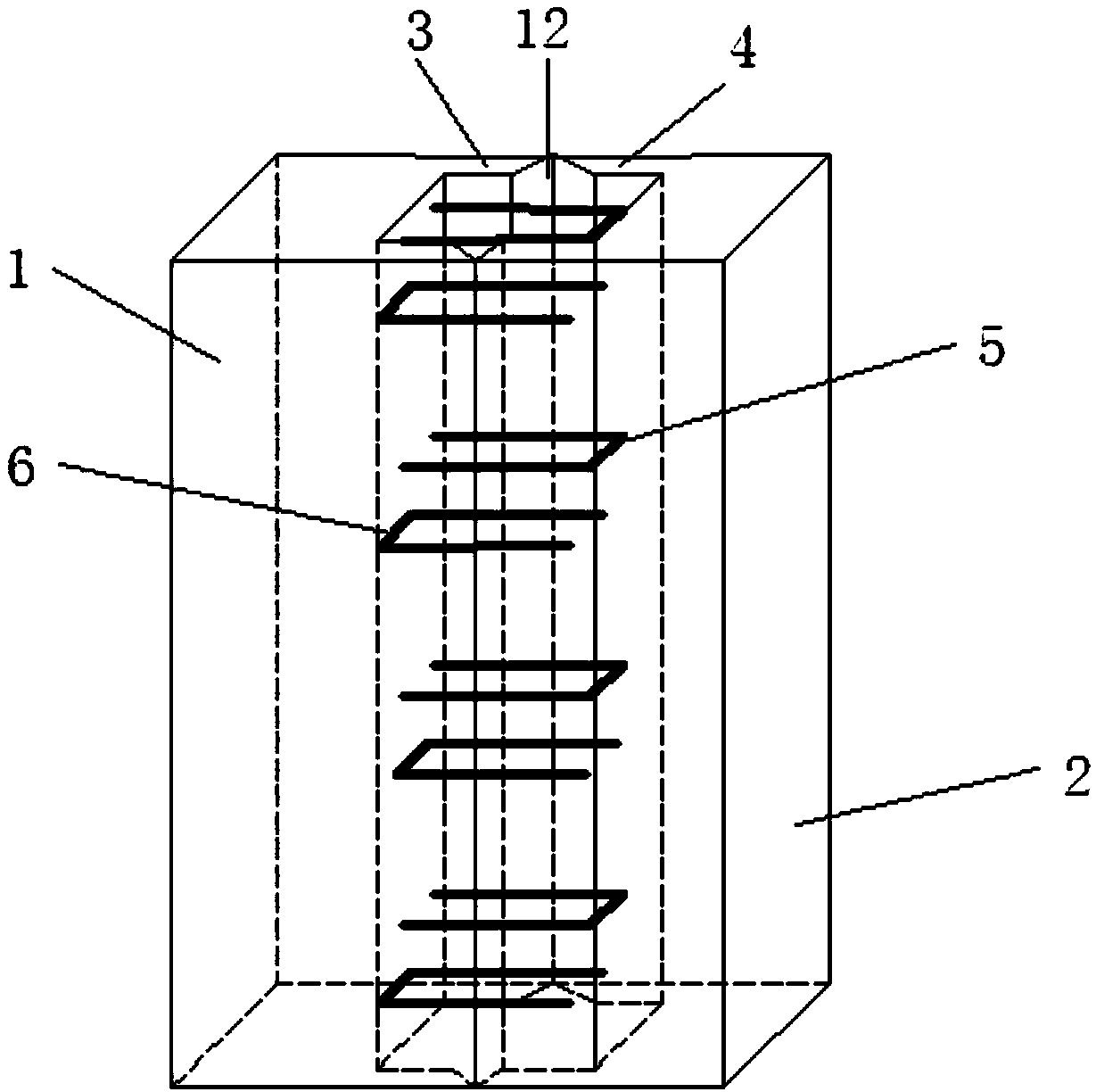

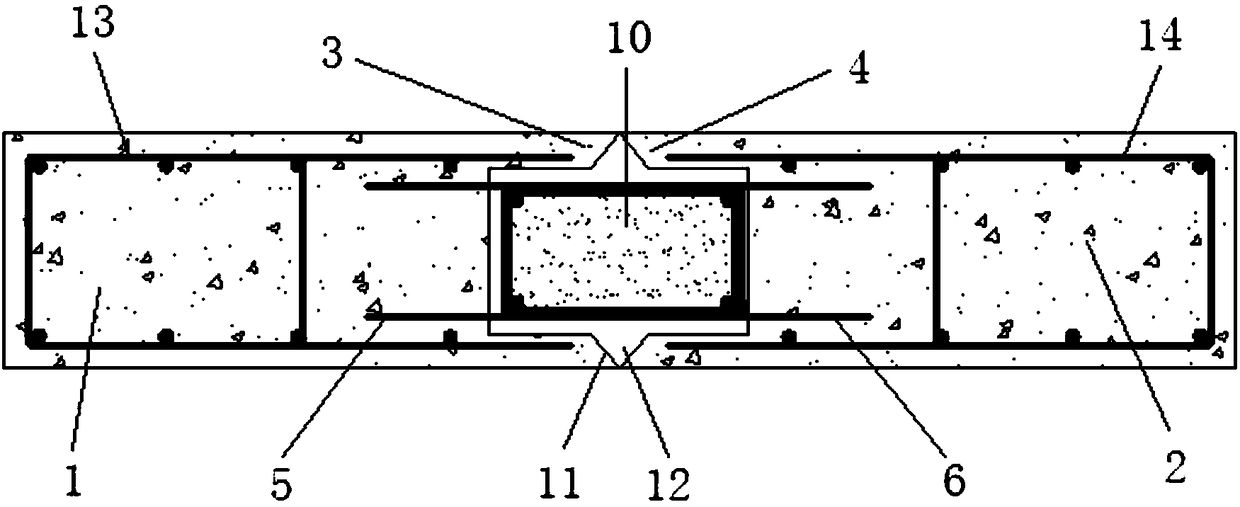

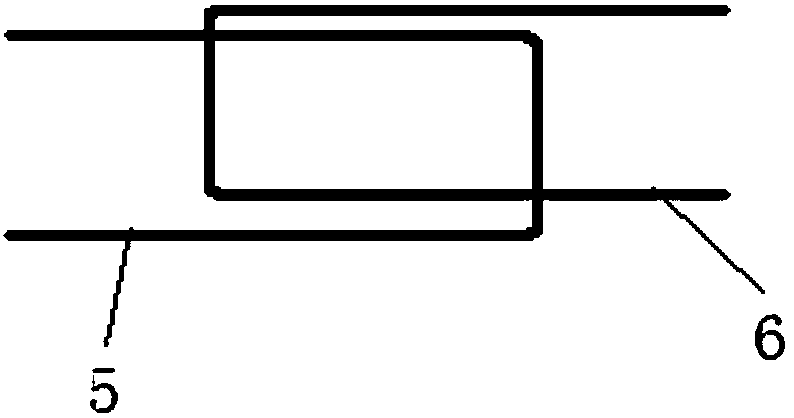

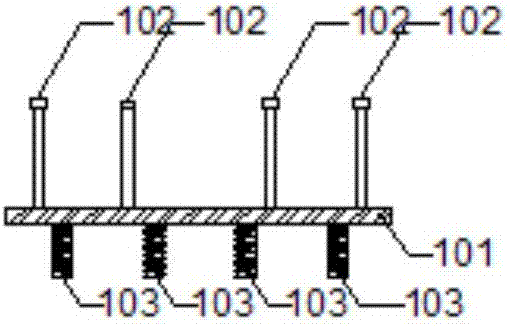

Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

The invention discloses a steel pipe concrete column-precast concrete superposed beam assembly type building connection node. The steel pipe concrete column-precast concrete superposed beam assembly type building connection node comprises a steel pipe concrete column and a precast concrete superposed beam, wherein the outer wall of the steel pipe concrete column is provided with a U-shaped steel tank and a prewelded outer ring steel plate in a welded manner, the prewelded outer ring steel plate is horizontally arranged and located above the U-shaped steel tank, the U-shaped steel tank is provided with a bottom plate and side plates, the bottom plate is provided with bottom steel bar clamping buckle devices, and the tops of the side plates are provided with upper flanges being folded outwards; and the precast concrete superposed beam is installed inside the U-shaped steel tank in an inserted manner, the bottom of the precast concrete superposed beam is connected with the bottom steel bar clamping buckle devices in a clamped manner, the top of the precast concrete superposed beam is welded to the prewelded outer ring steel plate, a mutual plug-in mounting area of the precast concretesuperposed beam and the U-shaped steel tank is a superposed area, and concrete is poured into the superposed area after lap joint and assembly of the precast concrete superposed beam. The steel pipeconcrete column-precast concrete superposed beam assembly type building connection node is convenient and fast to install without bolts and mold supporting, and the production and construction efficiency can be effectively improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and manufacturing method thereof

ActiveCN110318495AGive Full Play to the "Hoop Effect"Give full play to the "ring effect"MouldsClimate change adaptationConcrete beamsLong term durability

The invention discloses an assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and a manufacturing method thereof. The assembled permanent formwork overlapped FRPrib seawater sea sand recycled concrete beam comprises a prefabricated assembled permanent formwork and an FRP rib seawater sea sand recycled concrete beam. The prefabricated assembled permanent formwork is formed by assembling corer strip assembly blocks, first panels, second panels and positioning connecting parts, and the formwork is manufactured from an engineering cement-based composite (ECC)and a fiber woven mesh. The FRP rib seawater sea sand recycled concrete beam comprises seawater sea sand recycled concrete poured into the prefabricated assembled permanent formwork and an FRP rib framework fixedly arranged in the seawater sea sand recycled concrete. As the TRE formwork and the FRP rib seawater sea sand recycled concrete are compounded, the engineering manufacturing cost of the formwork is effectively reduced, the ductility of the FRP rib seawater sea sand recycled concrete beam is improved, the long-time durability of FRP ribs is guaranteed, and meanwhile the problems that an existing integral formwork is large in occupied space and not easy to transport are solved.

Owner:CHINA UNIV OF MINING & TECH

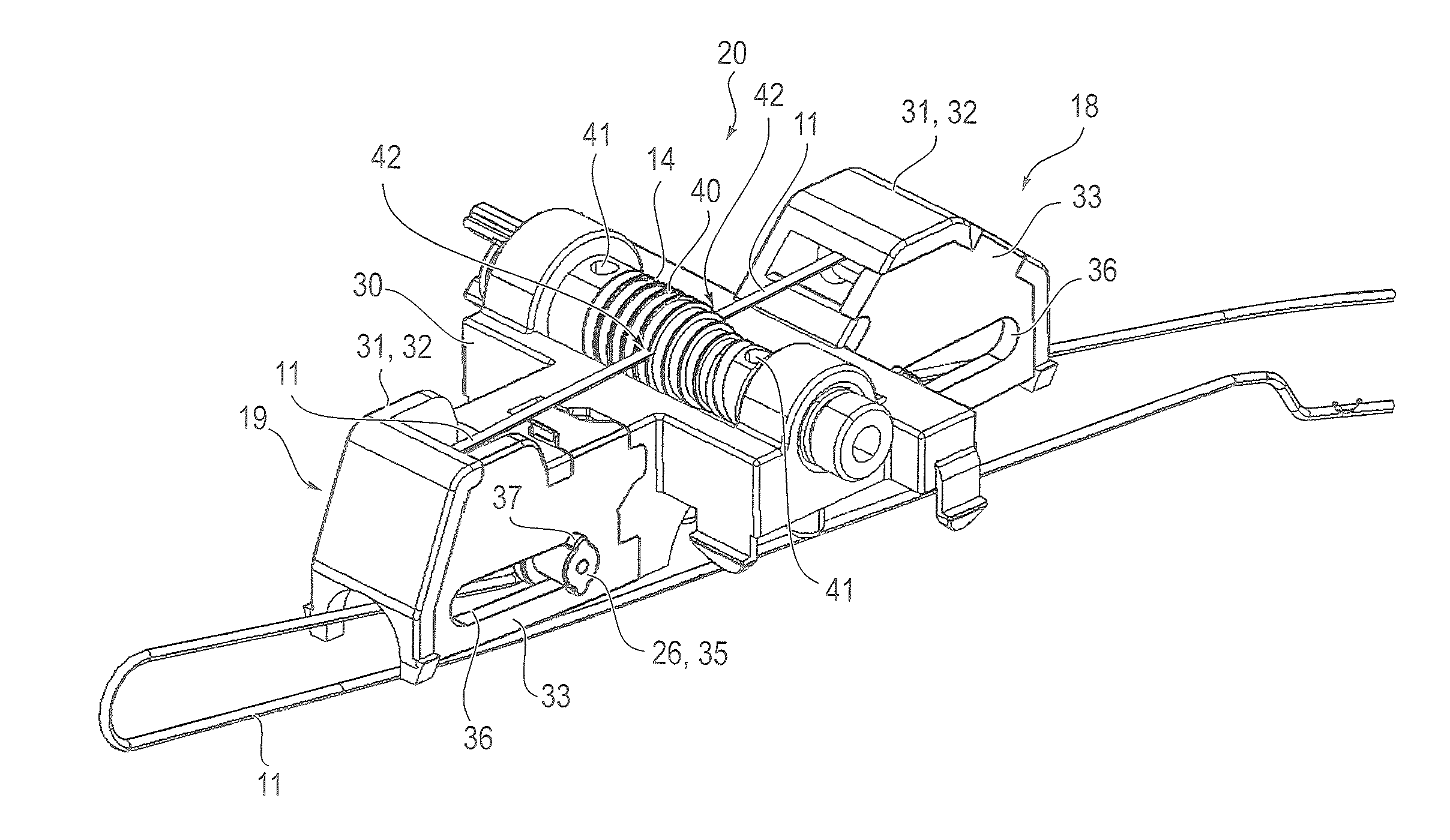

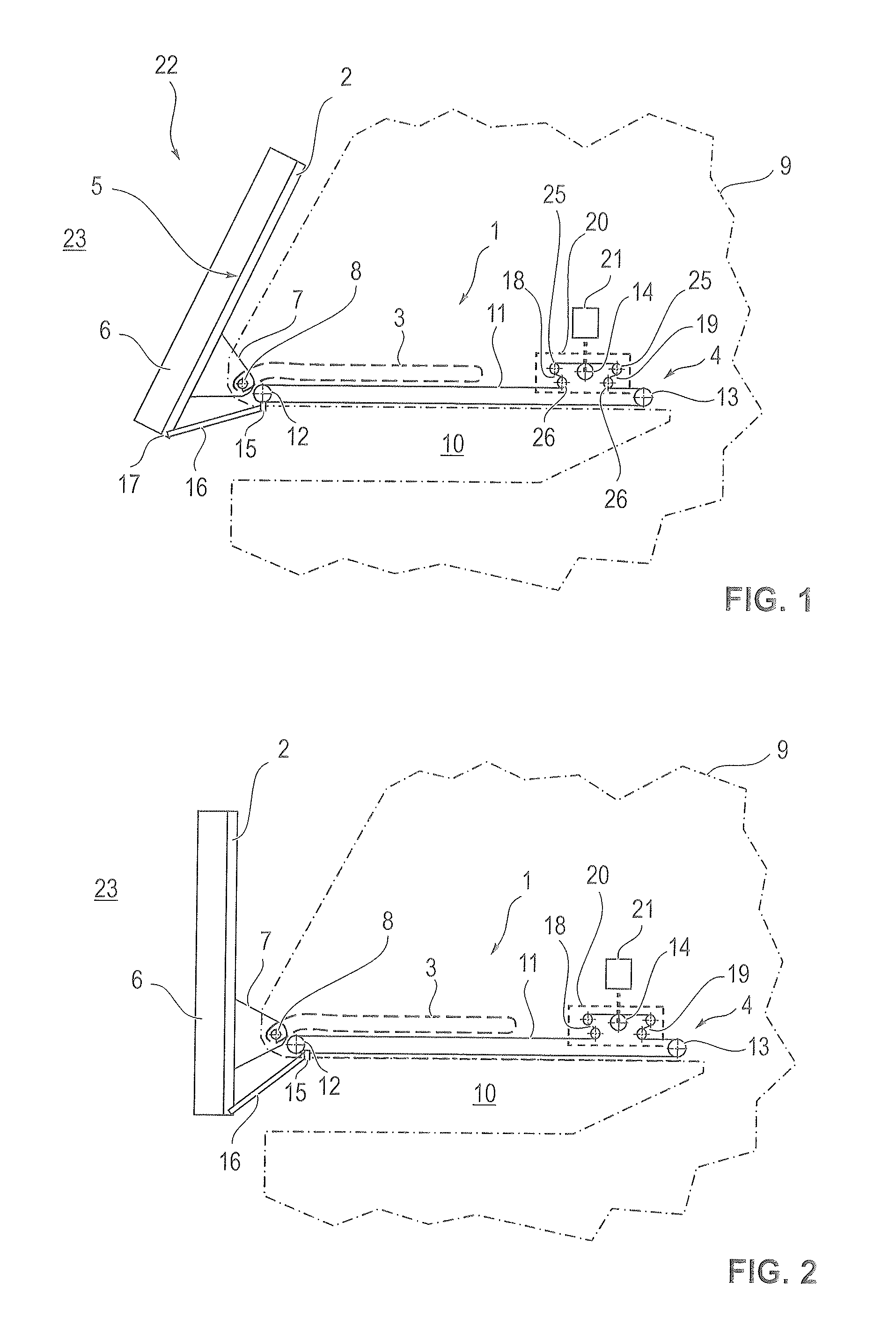

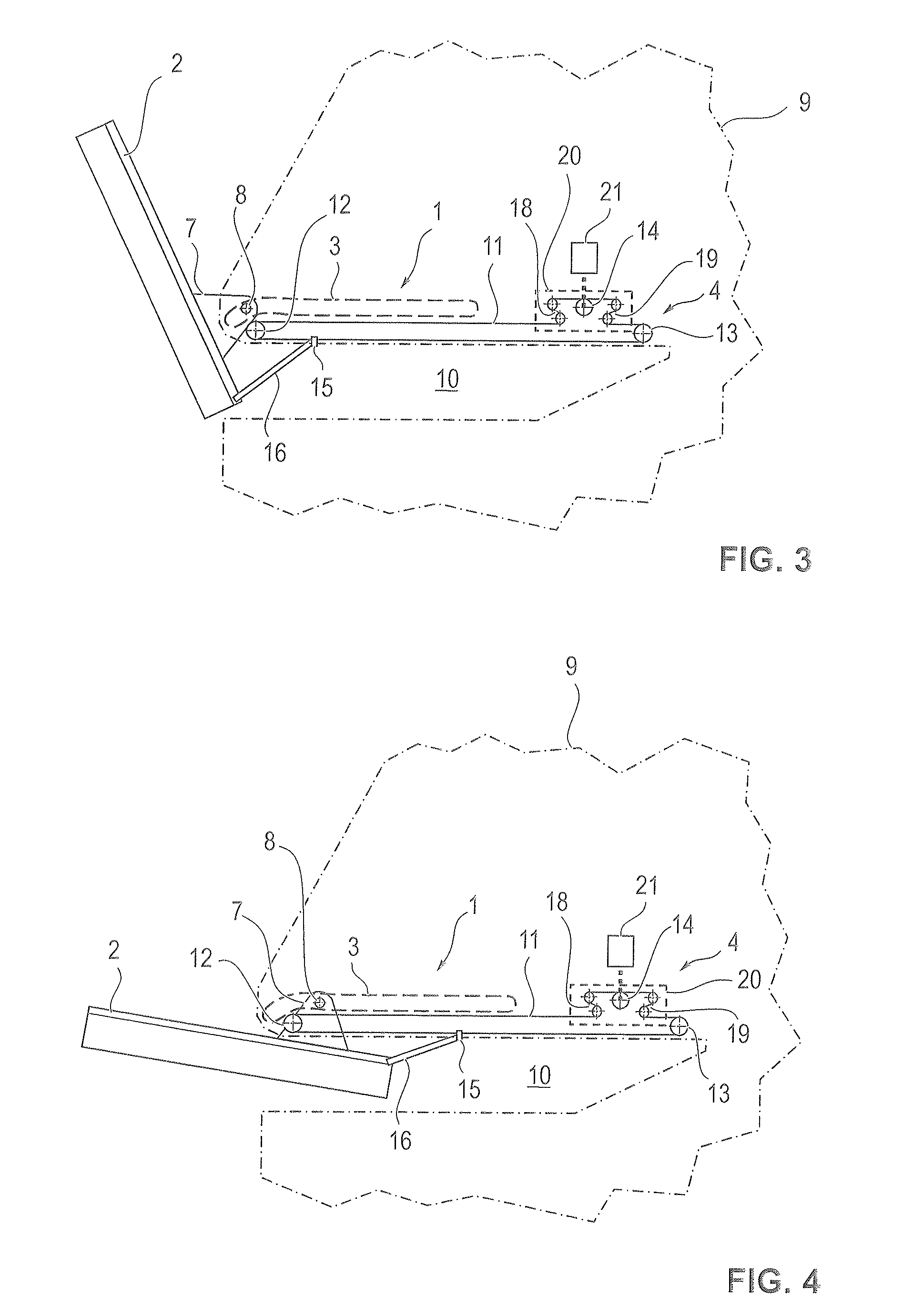

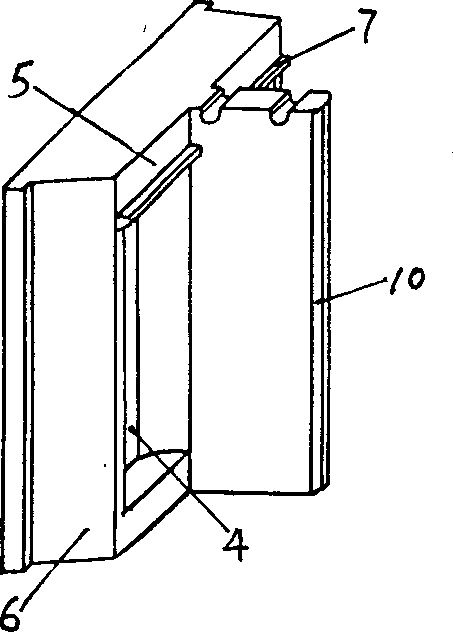

Screen Adjustment Device for a Motor Vehicle

ActiveUS20110247770A1High degree of prefabricationFlexible and straightforward adaptationInstrument arrangements/adaptationsStands/trestlesDrive motorMotorized vehicle

A screen adjustment device (1) for a motor vehicle has a screen (6) or screen carrier (2) for mounting a screen, and a control cable drive (4) for adjusting the screen or screen carrier between an open (screen-accessible) position (22) and a parked (screen-hidden) position (24). The control cable drive has a control cable (11), which is coupled to the screen or screen carrier by a driver (15) and which at the two ends is guided over two return elements (12, 13) and at least one cable tensioning unit (18, 19) onto a winding reel (14) coupled to a drive motor (21). The control cable drive has a bearing block (30) for supporting the winding reel, the block together with the cable tensioning unit forming a self-contained pre-assembled unit (20) or being capable of pre-assembly to form such a unit.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Autoclaved aerated concrete plate with pre-buried pipes and preparation method of autoclaved aerated concrete plate

InactiveCN108177240AQuick assemblyReduce pollutionCeramic shaping apparatusBuilding componentsElectrical conduitAutoclaved aerated concrete

The invention discloses an autoclaved aerated concrete plate with pre-buried pipes and a preparation method of the autoclaved aerated concrete plate. The autoclaved aerated concrete plate with the pre-buried pipes comprises an autoclaved aerated concrete plate body, the pre-buried pipes and wire inserting boxes, wherein the pre-buried pipes and the wire inserting boxes are arranged in the interiorof the autoclaved aerated concrete plate body, and the wire inserting boxes are arranged at one ends of the pre-buried pipes. According to the autoclaved aerated concrete plate with the pre-buried pipes, a socket and an electric pipeline can be installed without opening a groove in the concrete plate, dust pollution is small, furthermore, the prepared autoclaved aerated concrete plate can be quickly assembled during construction, the construction period is short, the prefabrication degree is high, and the cost is reduced.

Owner:HENAN XIAN NEW BUILDING MATERIALS

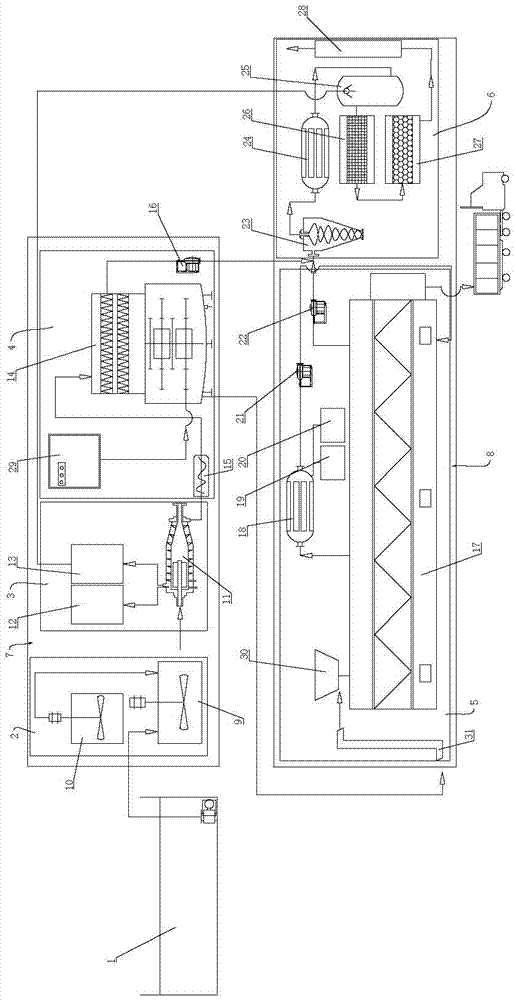

Refinery oily sludge disposal system and method

PendingCN107500501ARealize harmless disposalEliminate hazardsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCentrifugationSludge

The present invention provides a refinery oily sludge disposal system which realizes non-hazardous treatment of oily sludge and effectively solves the problem of resource treatment and utilization of the oily sludge, the refinery oily sludge disposal system has the advantages of skid-mounted design, compact structure and small floor area, the refinery oily sludge disposal system includes an oily sludge reservoir, a quenching and tempering unit, a centrifugal processing unit, a pelletizing and drying unit, a thermal cracking unit and an exhaust gas treatment unit, the quenching and tempering unit, the centrifugal processing unit and the pelletizing and drying unit are respectively arranged on a quenching and tempering centrifugation drying integrated skid body, the exhaust gas treatment unit and the thermal cracking unit are respectively arranged on a thermal cracking exhaust gas integrated skid body, and the invention also provides a refinery oily sludge disposal method.

Owner:无锡雪浪康威环保科技有限公司

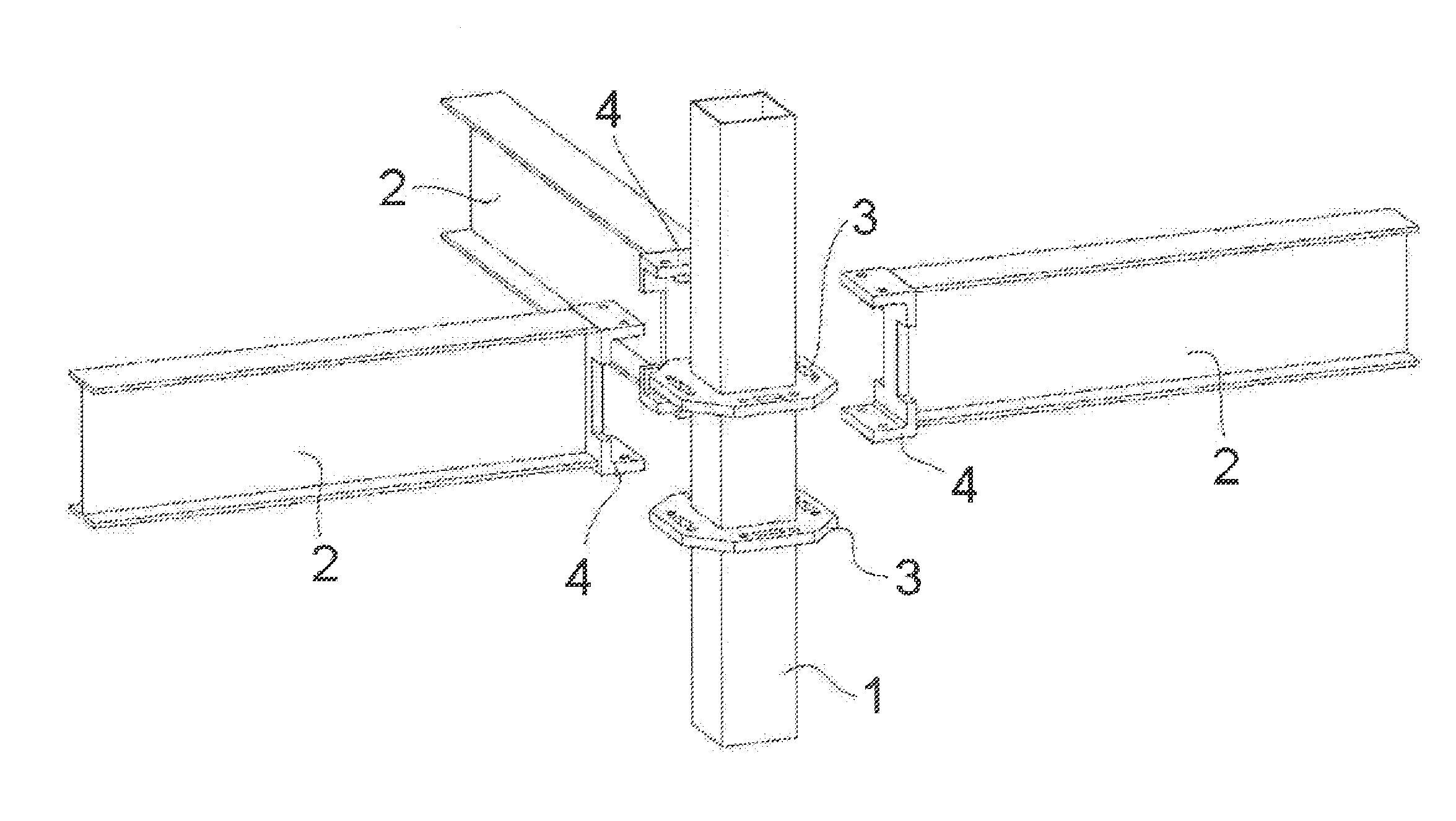

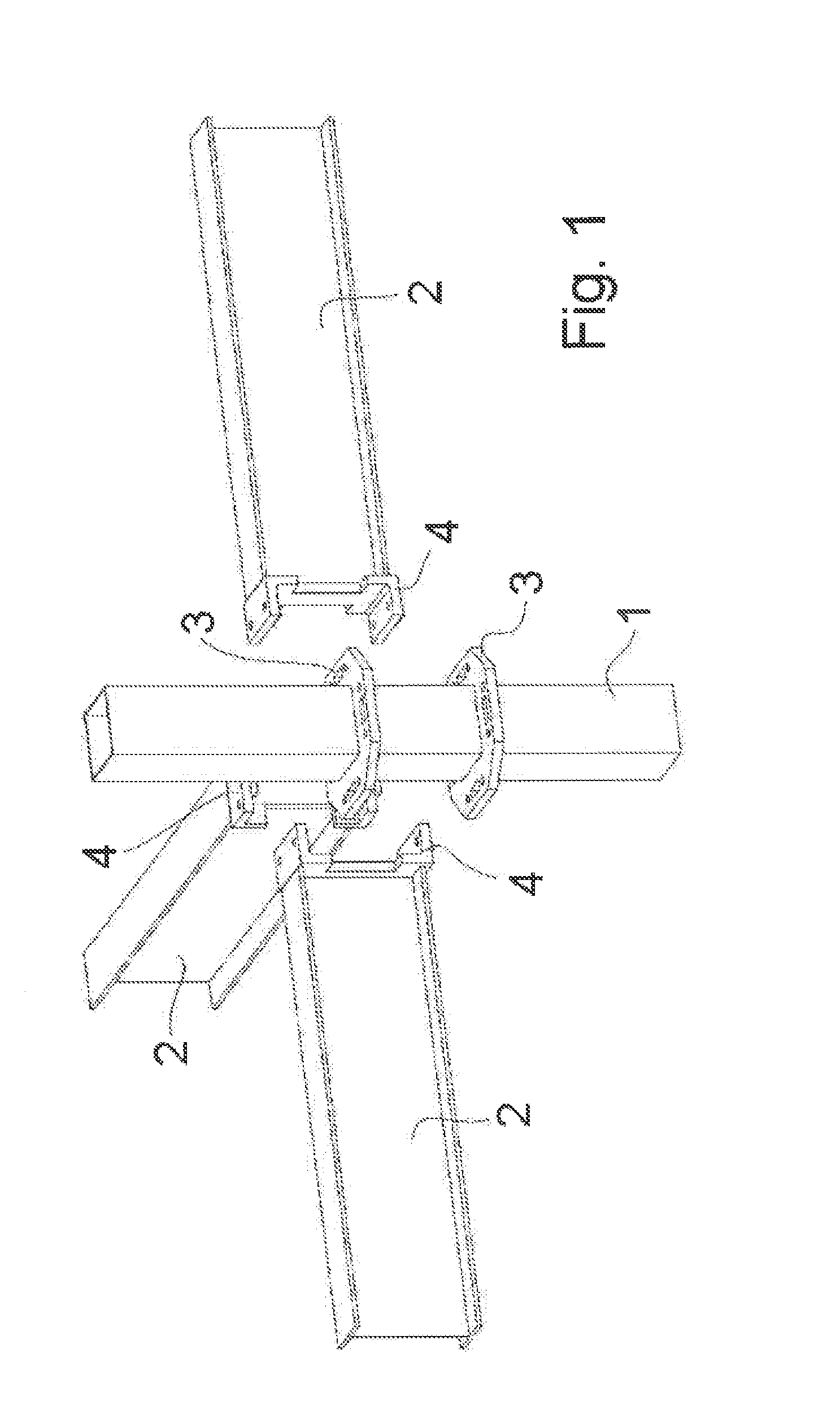

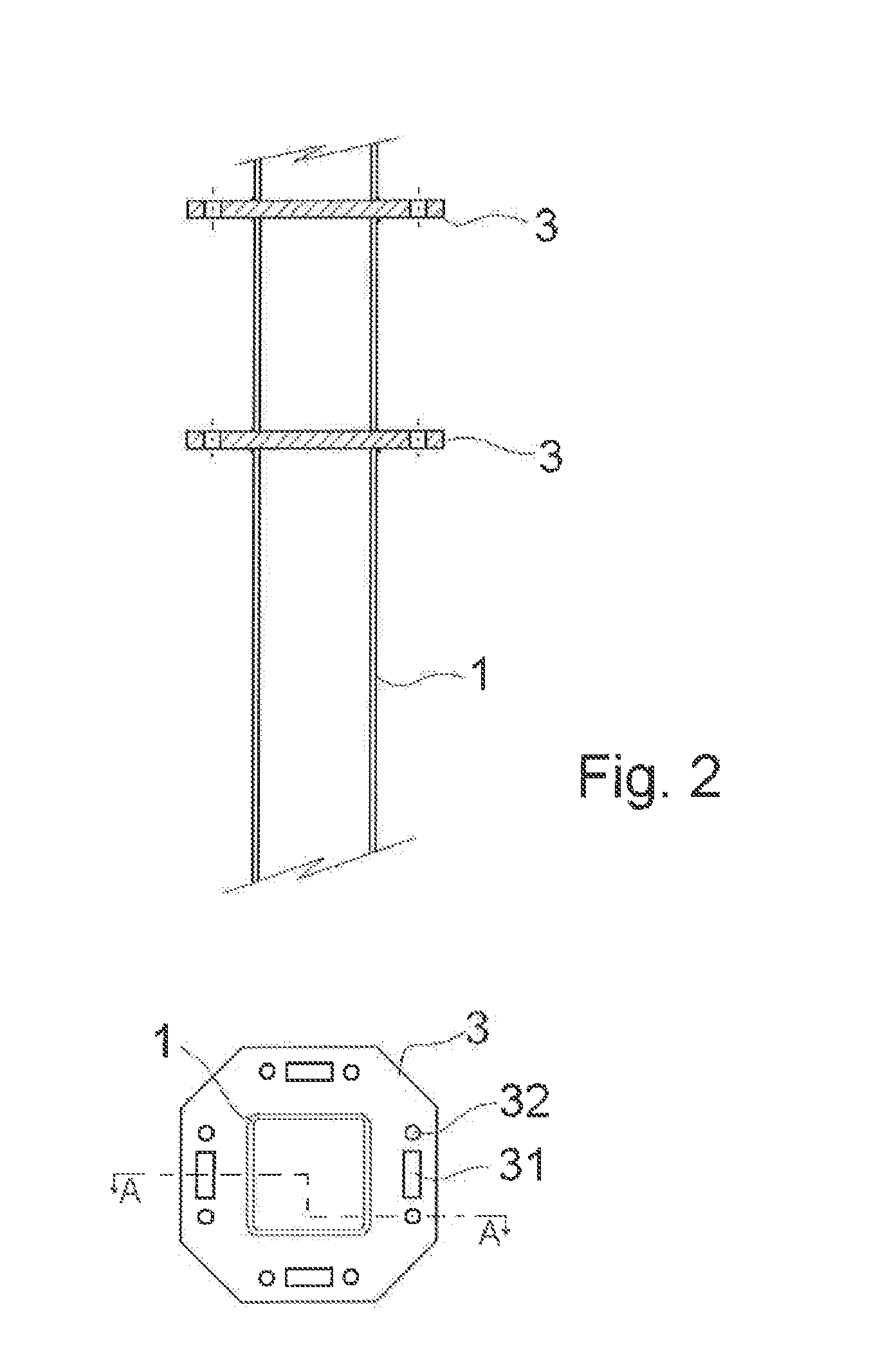

Connection Point For Metal Structure

InactiveUS20160097192A1High degree of prefabricationConstruction safetyGirdersTowersEngineeringStructure based

Owner:IND METALICAS ANRO

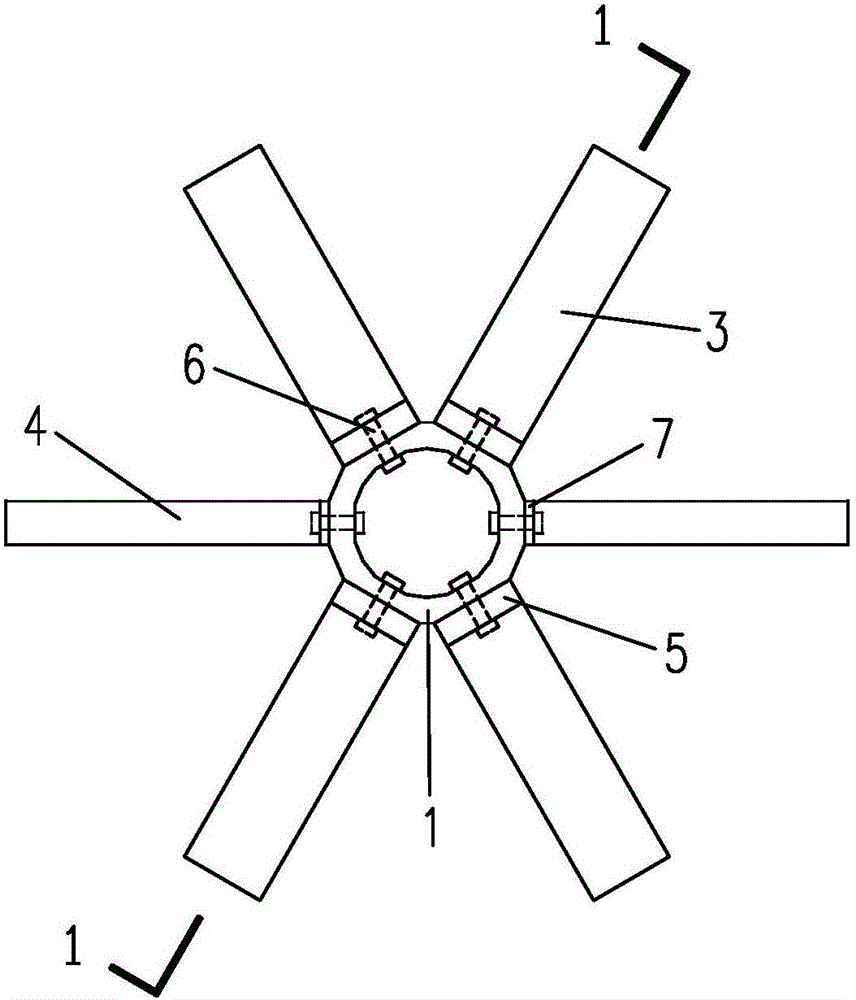

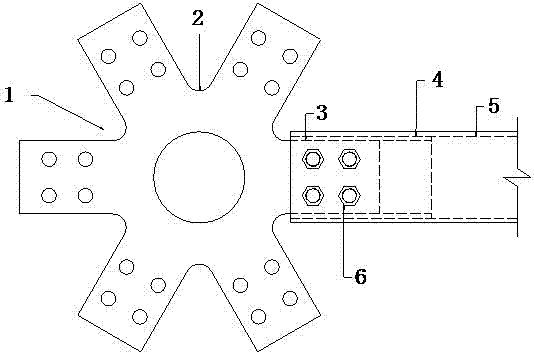

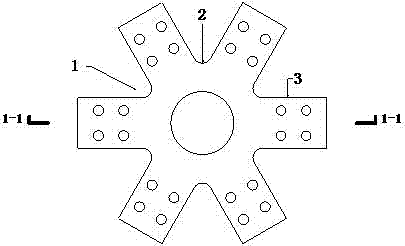

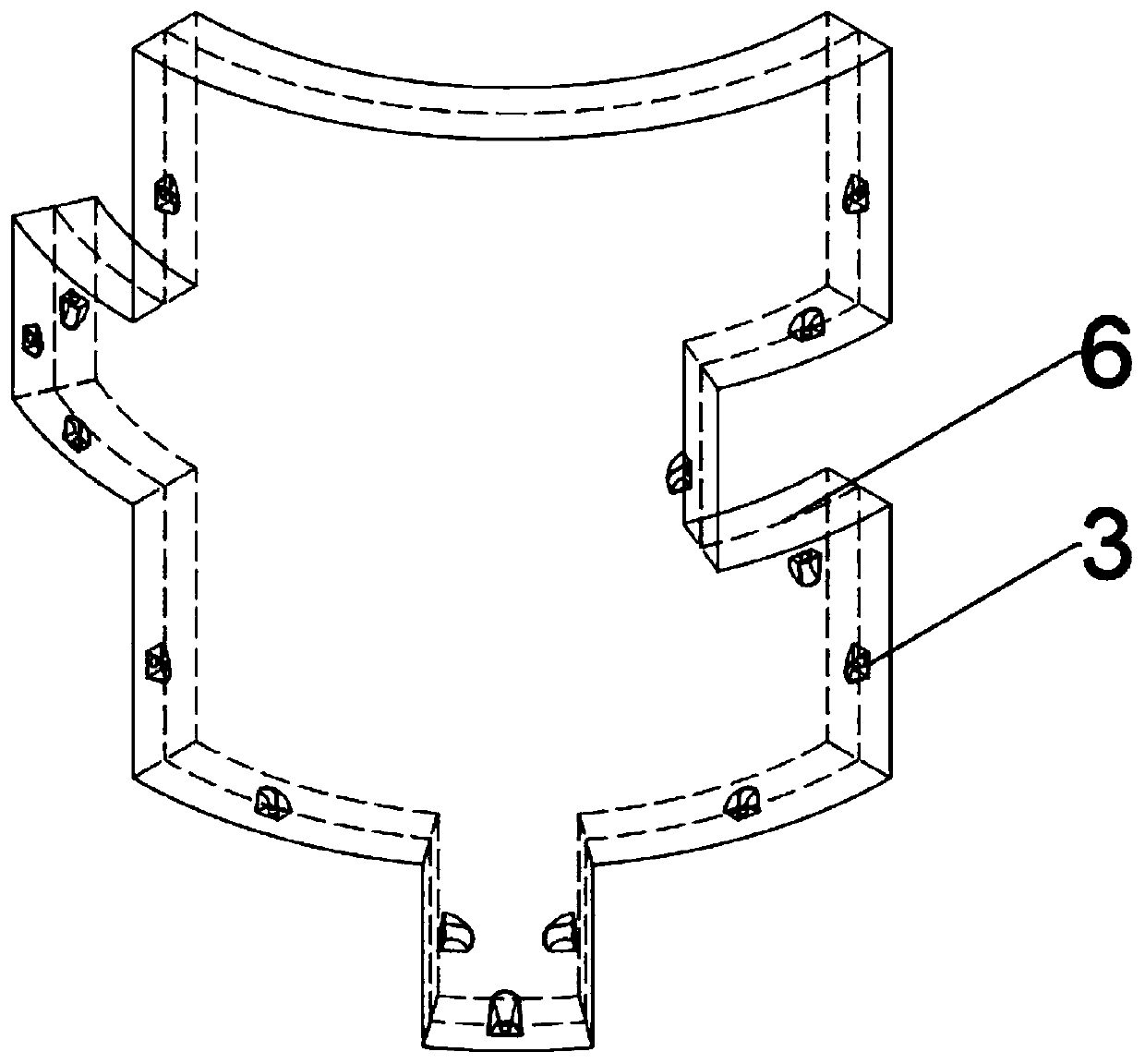

Assembled joint applicable to monolayer triangular space grid structure

InactiveCN104847015AHigh degree of prefabricationSimple on-site installationBuilding constructionsEngineeringAxial force

The invention discloses a novel assembled joint applicable to a monolayer triangular space grid structure. The novel assembled joint is mainly composed of five parts, namely a center joint, connecting sleeves, high-strength bolts, upper and lower cover plates and a center bolt. The center joint is composed of a center circular ring and six connecting arms in connection. The connecting sleeves are machined from steel tubes. Bolt holes are arranged in corresponding positions of the center joint, the sleeves and road pieces. During assembly, one end of each sleeve is sleeved with one connecting arm while the other end of the same is sleeved with one rectangular steel tube, the sleeves, the connecting arms and the rectangular steel tubes are connected through the high-strength bolts, bending moment and axial force of the rod pieces are transmitted through the bolts and friction and mechanical squeezing among the steel tubes, the sleeves, the connecting arms and the center ring, and the triangular space grid structure joint is formed by all the connections. The assembled joint is wide in application range, convenient for industrialized batch production, good in assembling capacity, convenient to construct, high in construction and assembly quality, capable of meeting the requirement of the monolayer space grid structure on joint bearing capacity and rigidity and broad in application prospect.

Owner:SOUTHEAST UNIV

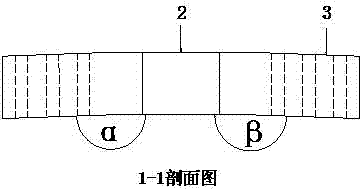

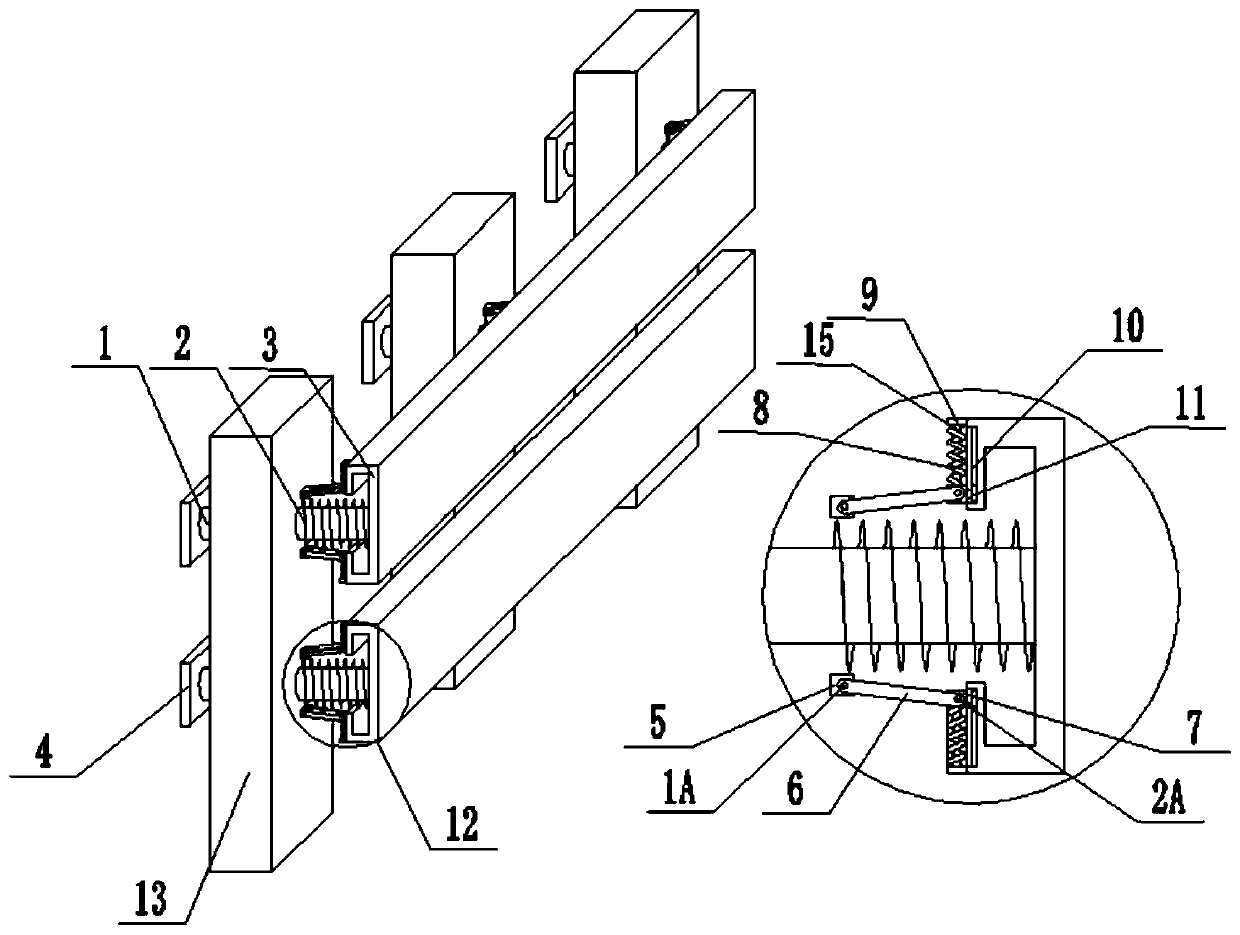

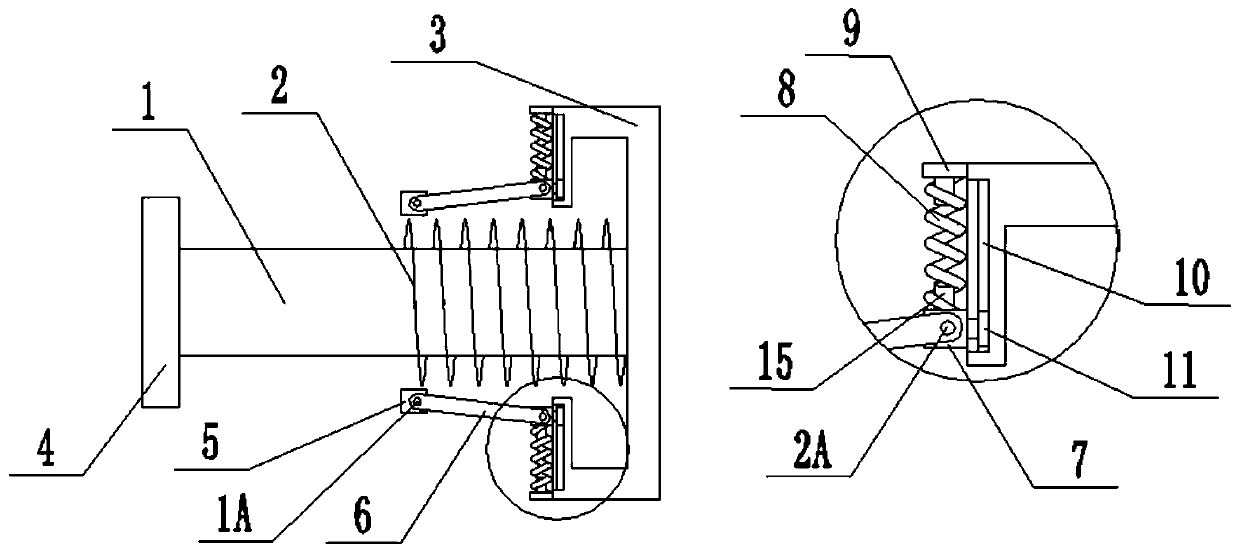

Elastic buffer device of anti-collision guardrail for bridge and implementation method thereof

InactiveCN111236112AProtection securityImprove buffering effectNon-rotating vibration suppressionRoadway safety arrangementsStructural engineeringMechanical engineering

The invention discloses an elastic buffering device of an anti-collision guardrail for a bridge and an implementation method of the elastic buffering device. The elastic buffering device comprises a stand column [-shaped cover plate, a sliding rod, a check block and a buffering device body. The two sliding rods penetrate through the stand column in the height direction, one ends of the sliding rods are fixedly connected with the [-shaped cover plate, the other ends of the sliding rods are fixedly connected with the check blocks, and the buffering device is arranged between the stand column andthe [-shaped cover plate. The vertical buffer device comprises a first hinge block, a connecting rod, a second hinge block, a vertical spring, a fixing block, a T-shaped sliding groove and a T-shapedsliding block. The horizontal springs and the vertical buffer devices are good in buffer effect and high in energy consumption, all the components can be conveniently connected together through the hinge rods, and construction is convenient, rapid and efficient.

Owner:SOUTHEAST UNIV

Modular current distributor for high currents

InactiveUS20070035914A1Easy to useHigh degree of prefabricationNon-enclosed substationsBus-bar/wiring layoutsLoad circuitBusbar

A current distributor includes a common, uninterrupted first main busbar as a main current supply and a number of current distributor modules which are each associated with a respective circuit breaker and can be disposed in a row along the main busbar. The current distributor module or each current distributor module has a first connection line for supplying current to a load circuit. The current distributor module or each current distributor module has a housing, a slot formed on a front side of the housing for plugging on an associated circuit breaker, and a first channel which passes through the housing in a transverse direction for accommodating the first main busbar. A first contact opening of the slot corresponds to the first channel and a second contact opening of the slot corresponds to a housing receptacle for a connection socket of the first connection line.

Owner:ELLENBERGER POENSGEN

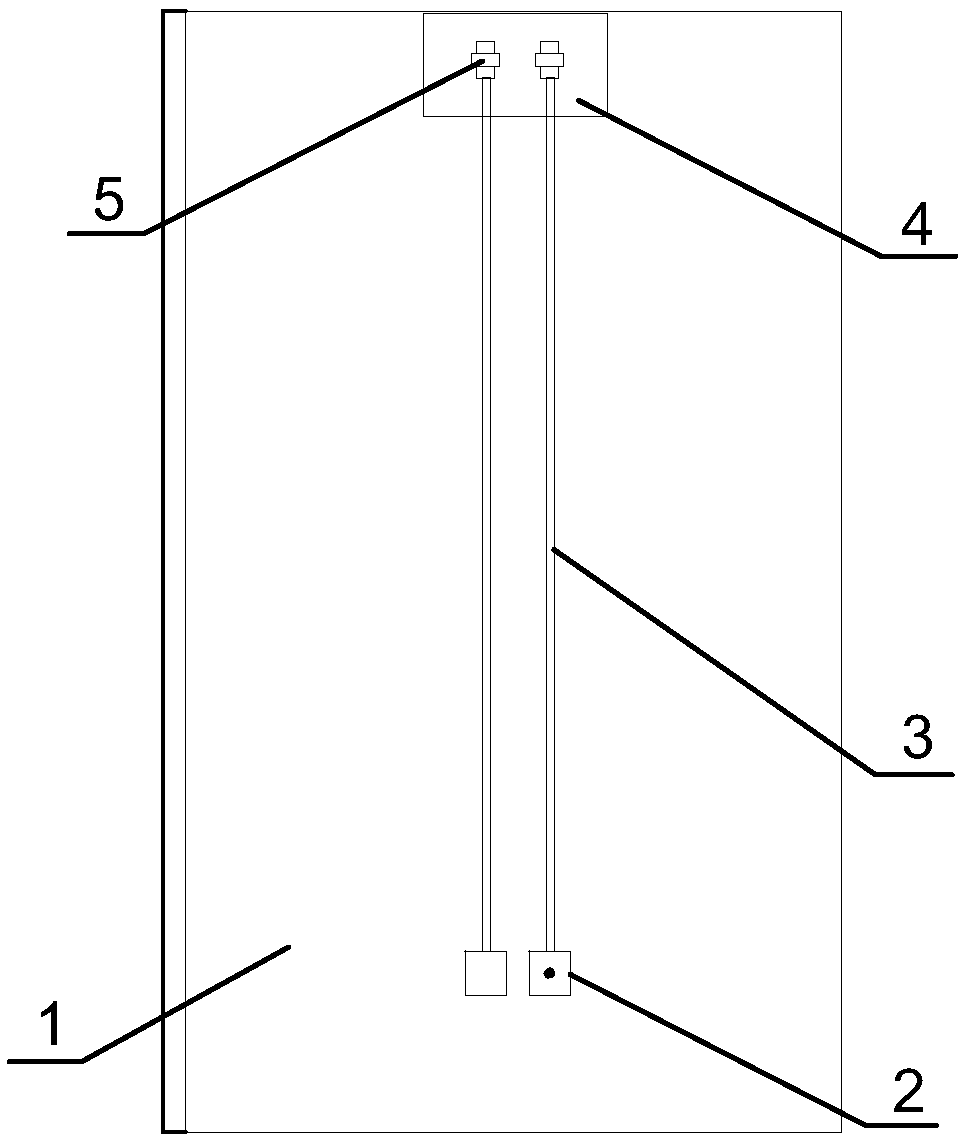

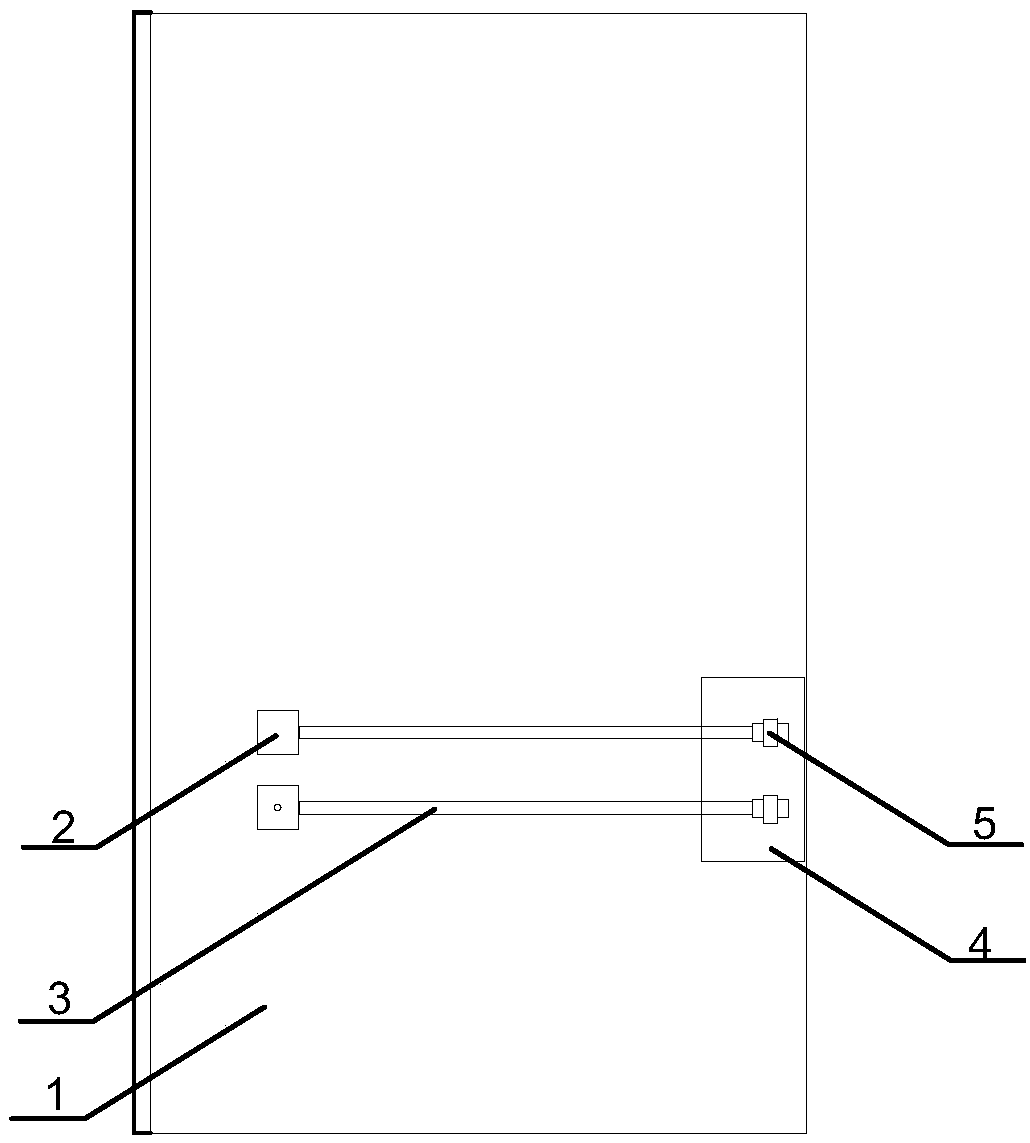

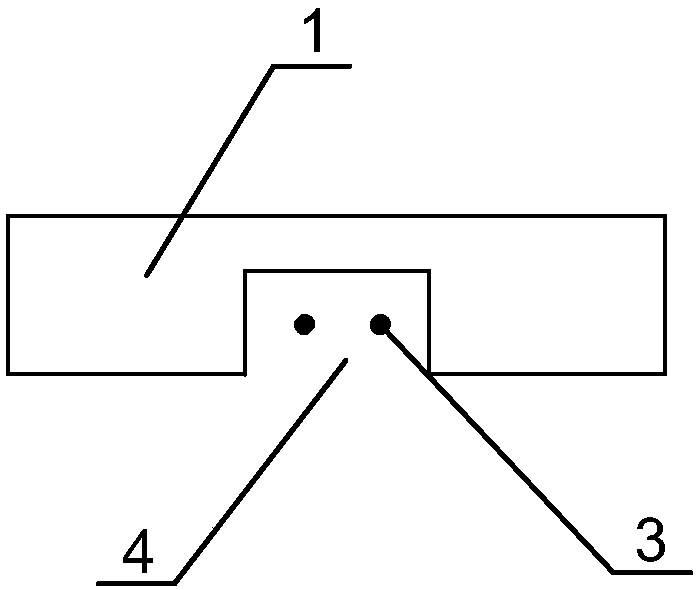

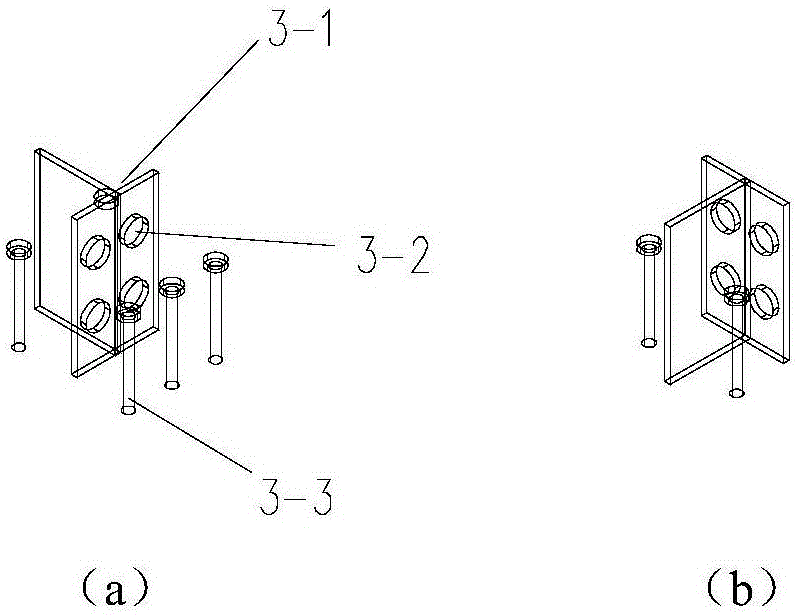

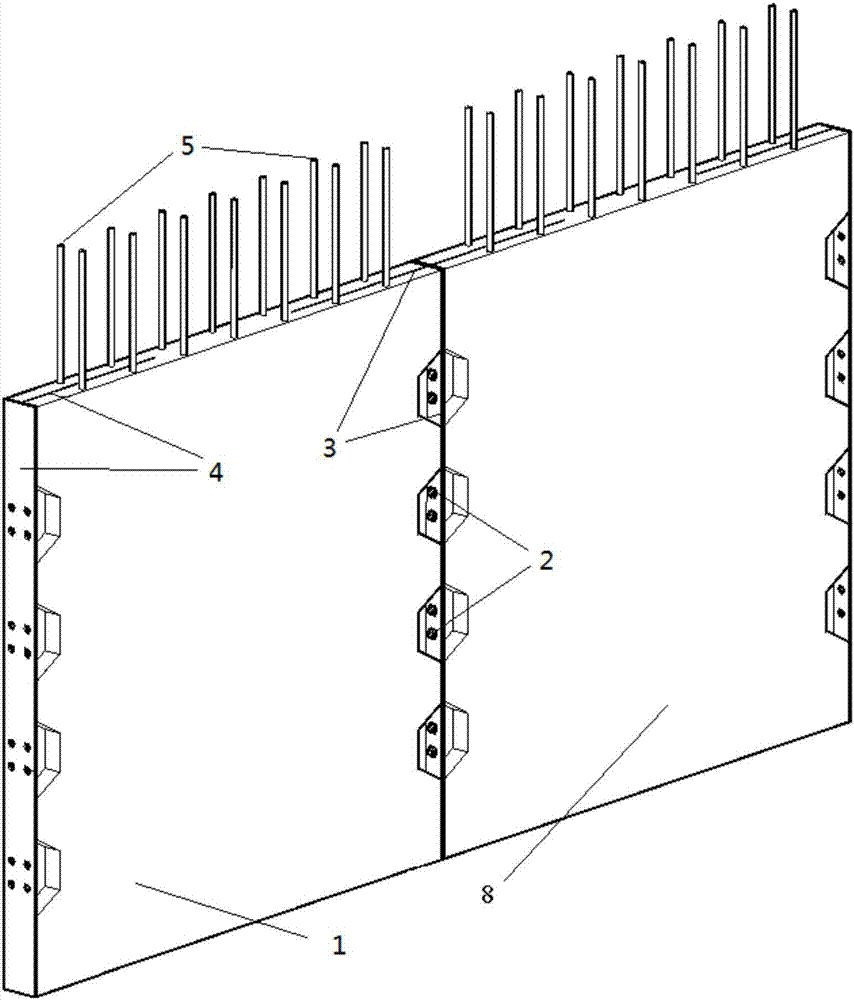

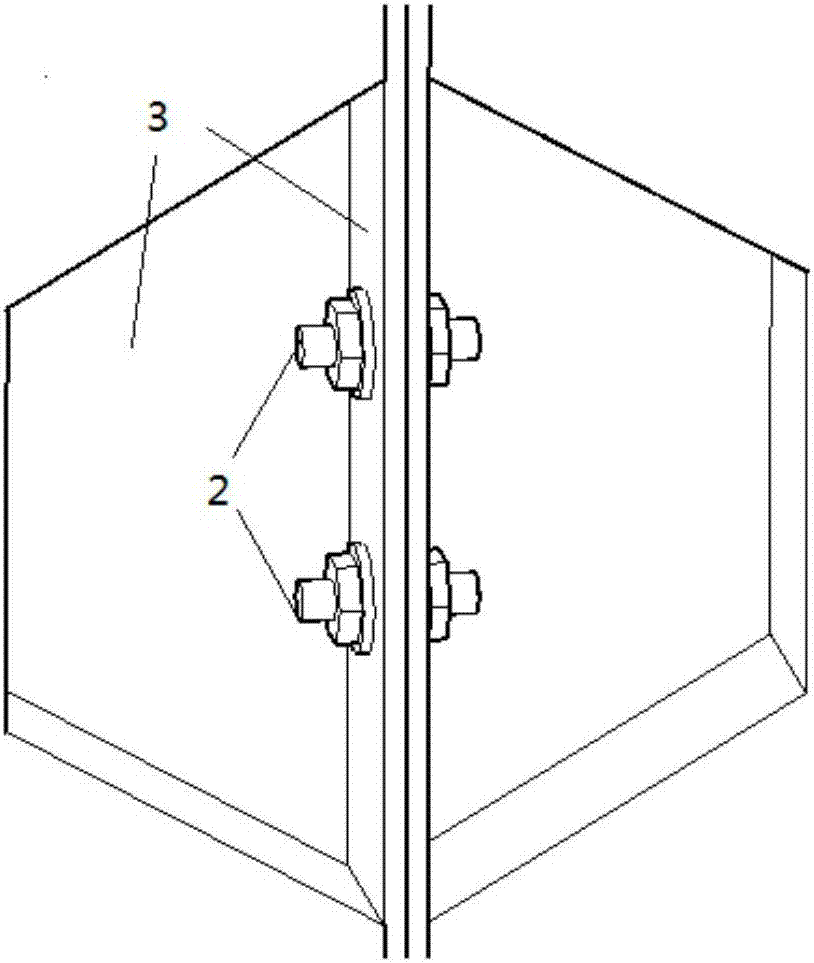

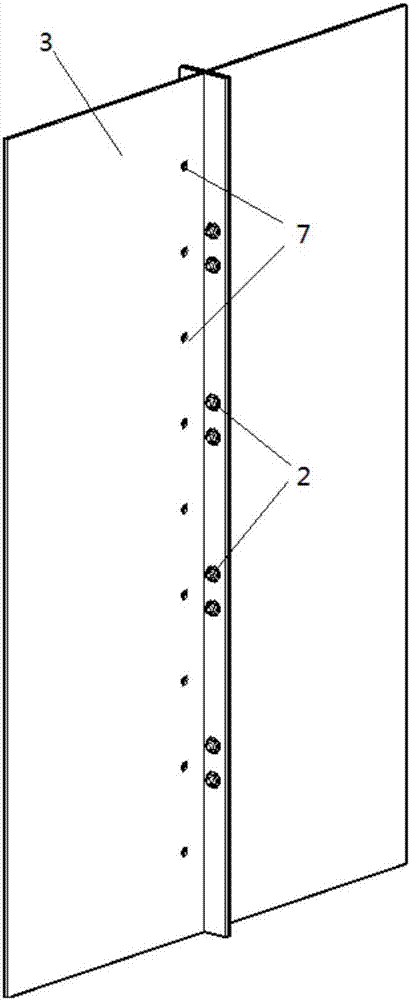

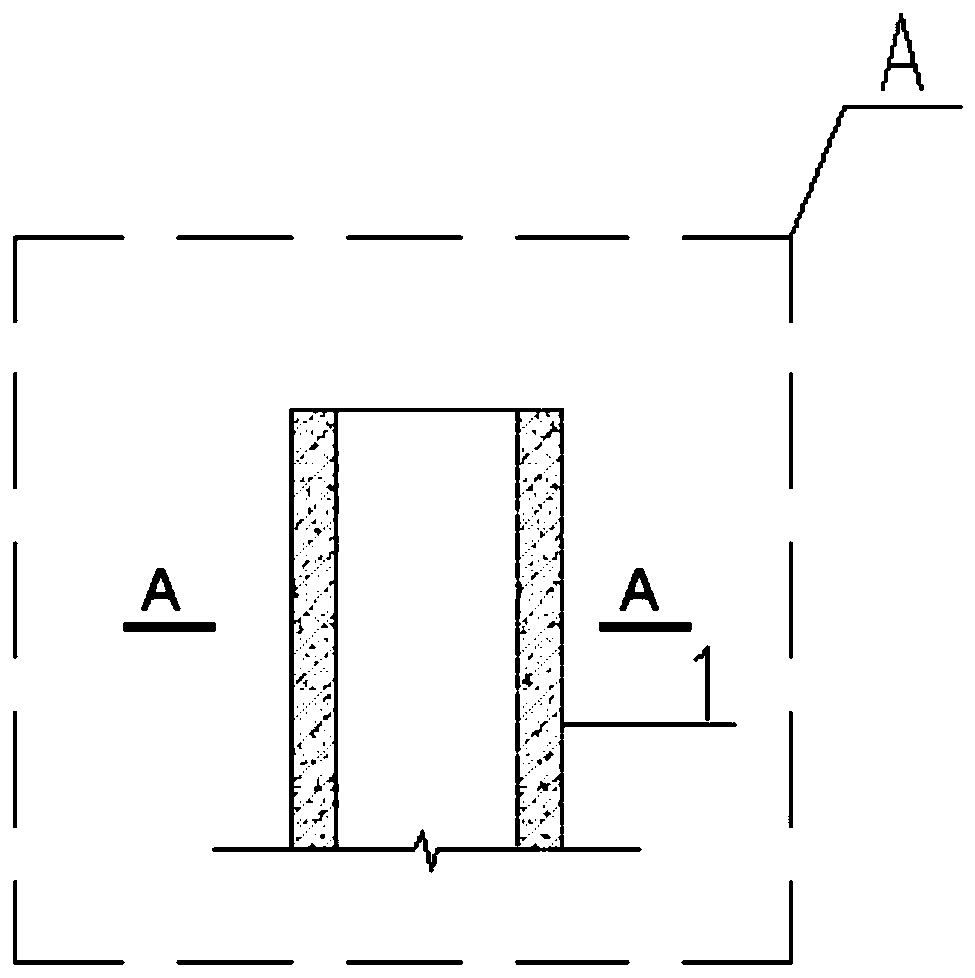

Prefabricated shear wall groove grouting anchor horizontal connection structure

The invention provides a prefabricated shear wall groove grouting anchor horizontal connection structure. The prefabricated shear wall groove grouting anchor horizontal connection structure comprisesa first shear wall and a second shear wall which are laterally arranged side by side, and a first convex plate and a second convex plate are separately disposed on the end faces, facing each other, ofthe first shear wall and the second shear wall. First U-shaped stirrups and second U-shaped stirrups are disposed in a cavity structure in a staggered mode in the vertical direction, wherein the cavity structure is formed by the first and second shear walls and the first and second convex plates in a surrounding mode. Mouth structures formed by overlapping portions of the first and second U-shaped stirrups are provided with reinforcement cages in an inserted mode, and concrete is poured in the cavity structure. Manpower is saved, on-site operation time is reduced and construction is more simple and convenient, the staggered first and second U-shaped stirrups reduce the use of steel bars, and cost is saved; the reinforcement cages inserted in the stirrups improve the shear capacity of theshear walls, the first and second U-shaped stirrups transmit force to the reinforcement cages, and the transmission force is clear, the integrity is improved, and the shear performance is good; and when an earthquake occurs, the reinforcement cages form an embedded column in the shear walls to prevent the shear walls from collapsing.

Owner:SHENYANG JIANZHU UNIVERSITY

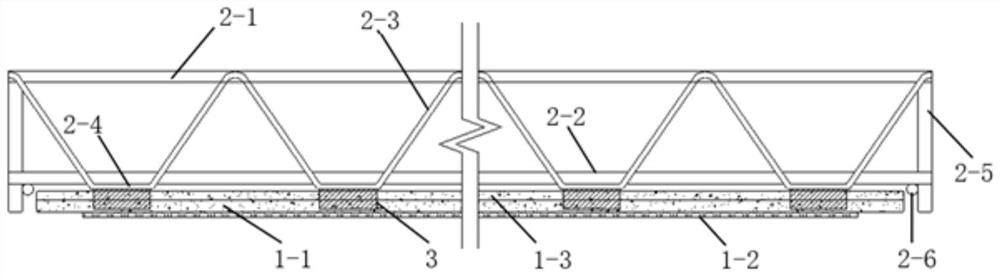

Dry-connected prefabricated assembled steel-concrete composite beam

InactiveCN107227821ALow costHigh degree of prefabricationLoad-supporting elementsSheet steelSteel bar

Owner:崔冰 +2

T-type multifunctional small block and its production forming method

InactiveCN1341798AReduce dosageIncrease productivityConstruction materialCeramic shaping apparatusMultiple formsAdditional values

The present invention relates to a T-type multifunctional small block and its production forming method. Said invention adopts T-shaped block type series and composite forming process to solve the problem of combination of several layer materials in the production of concrete small blocks, and greatly raise technical content and additional value of product, implement high prefabrication extent ofsmall blocks, improved reinforcement scheme of block and block bonding body, and can more flexibly and reaonsably arranged steel bar, can conveniently make construction and can flexibly form various structures with different forms, and can obviously raise strength of block hollow bonding body so as to raise quality and efficiency of building construction.

Owner:虞新华

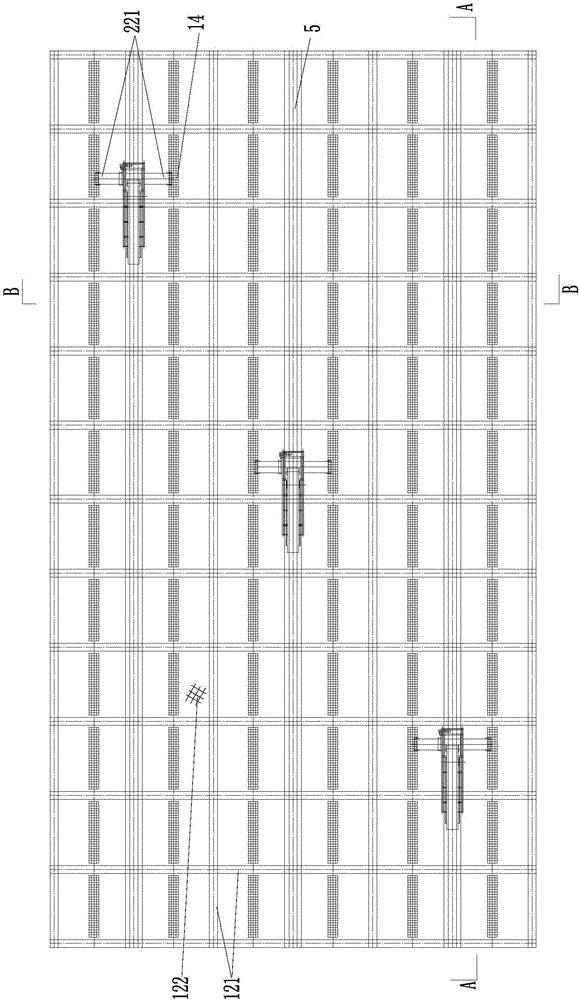

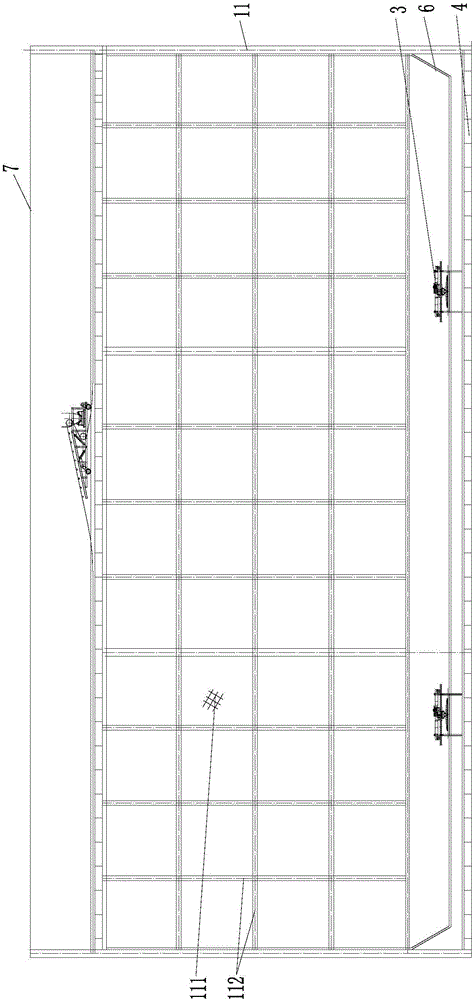

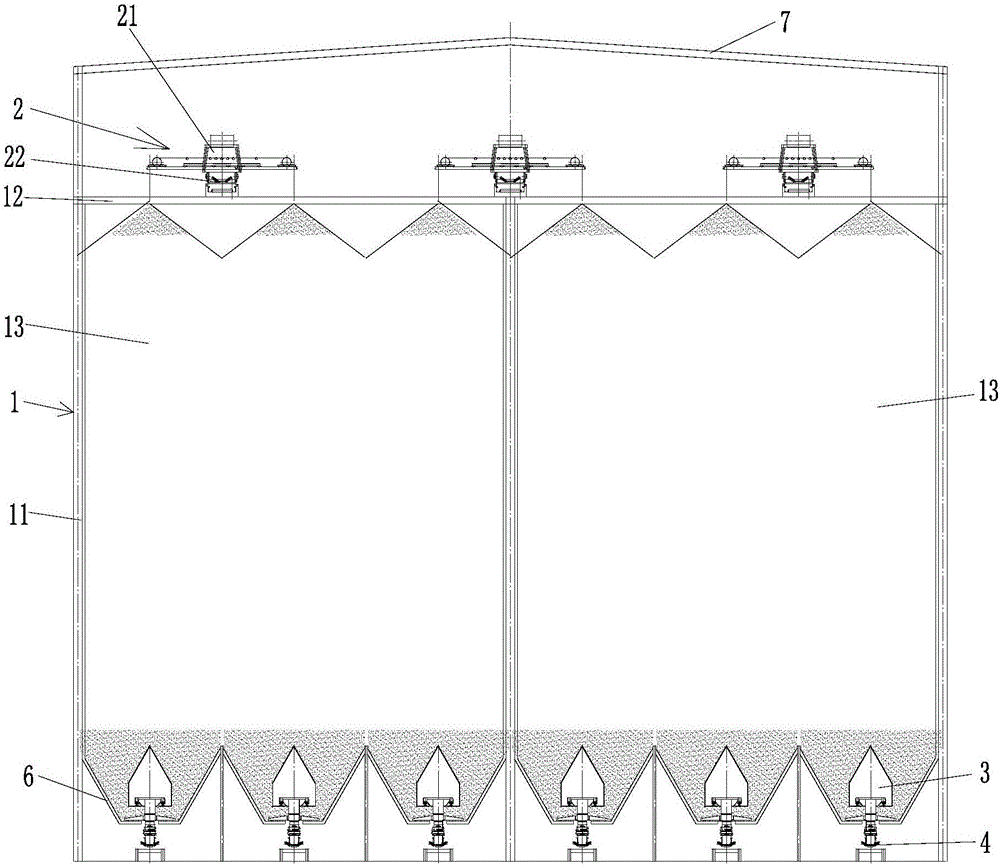

Group of silos and single silo of square steel structure

InactiveCN106628683ARealize automatic feeding processRealize automatic reclaimingLarge containersLoading/unloadingEngineeringProviding material

The invention discloses a group of silos and a single silo of square steel structure. The group of silos and the single silo of square steel structure comprise a rectangular group of silos which comprise more than two single silos arranged in matrix. Every single silo comprises four vertical rectangular silo walls and a horizontal silo roof. The four silo walls are connected in turn to form a silo space and the silo roof is on the top of the four silo walls. Every silo wall comprises silo wall boards and main body structure connected with the outer side of the silo wall boards. The main structure is steel structure and the two adjacent single silos share a silo wall. An in-feed conveyor is arranged on the top of the silo roof, which can convey feed to every top of silo space and unloads into each silo space. A feeder is arranged on the bottom of the silo space. A discharging conveyor is connected with the lower part of the feeder and is arranged outside the silo space. The feeder can provide materials which are in the silo space to the discharging conveyor. The group of silos and a single silo of square steel structure can realize the automatic in-feeding and automatic unloading with high structural strength, no support in the silo body, easy feeding and low cost.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

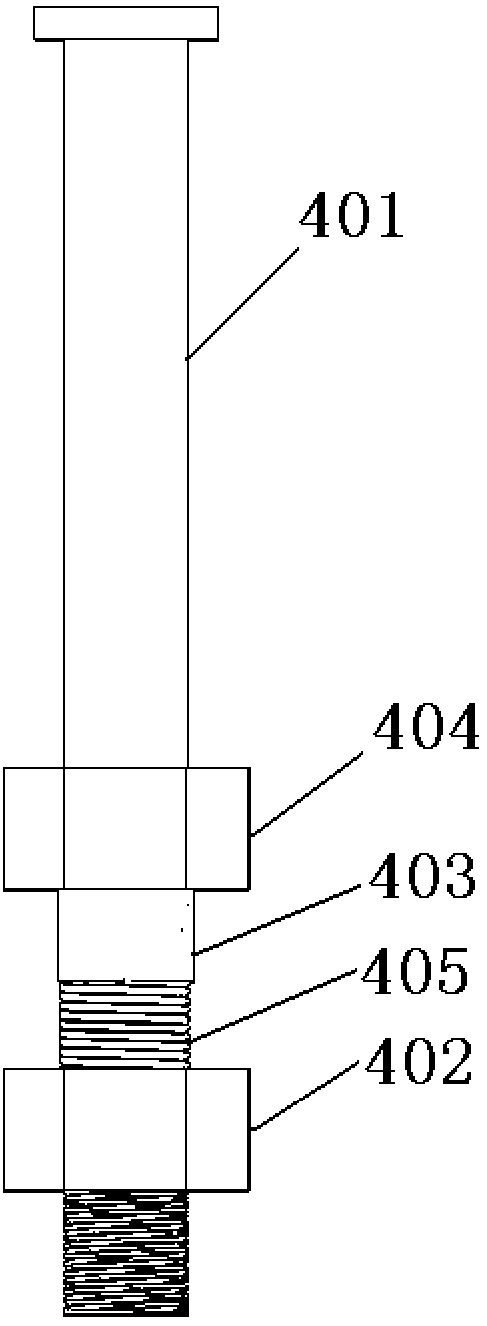

Friction-type stud shearing-force connection part and construction method thereof

InactiveCN107642031AHigh degree of prefabricationReduce labor costsBridge structural detailsBridge erection/assemblyTransfer modeSemiconductor

The invention discloses a friction-type stud shearing-force connection part and a construction method thereof. The friction-type stud shearing-force connection part includes a stud shearing-force connection part main body, a mounting nut, a sleeve, a fixing nut and a semiconductor spring; the stud shearing-force connection part main body comprises a thread section, a thread-free extrusion sectionand a pulling-resistant pier in sequence from bottom to top; during factory prefabrication, the stud shearing-force connection part main body is sleeved with the fixing nut, the sleeve and the semiconductor spring from the thread section in sequence, the upper end face of the fixing nut is located at the top of the thread section and is fixed, the upper end of the sleeve is fixed to the lower endface of the fixing nut, the upper end of the semiconductor spring and the lower end of the sleeve are connected into one, and the shearing-force connection parts are mounted on a maim beam at intervals according to needed shearing resistant requirements. By the adoption of the friction-type stud shearing-force connection part and the construction method thereof, force transferring modes of traditional shearing force connection parts are improved, interface friction is reasonably utilized, the pretension force of the friction-type stud shearing-force connection part can be monitored and controlled, and the design philosophy of combining resistance and releasement can be achieved. The factory prefabrication degree is high, bolt splicing is conducted on the spot, and the labor cost is saved.

Owner:HOHAI UNIV

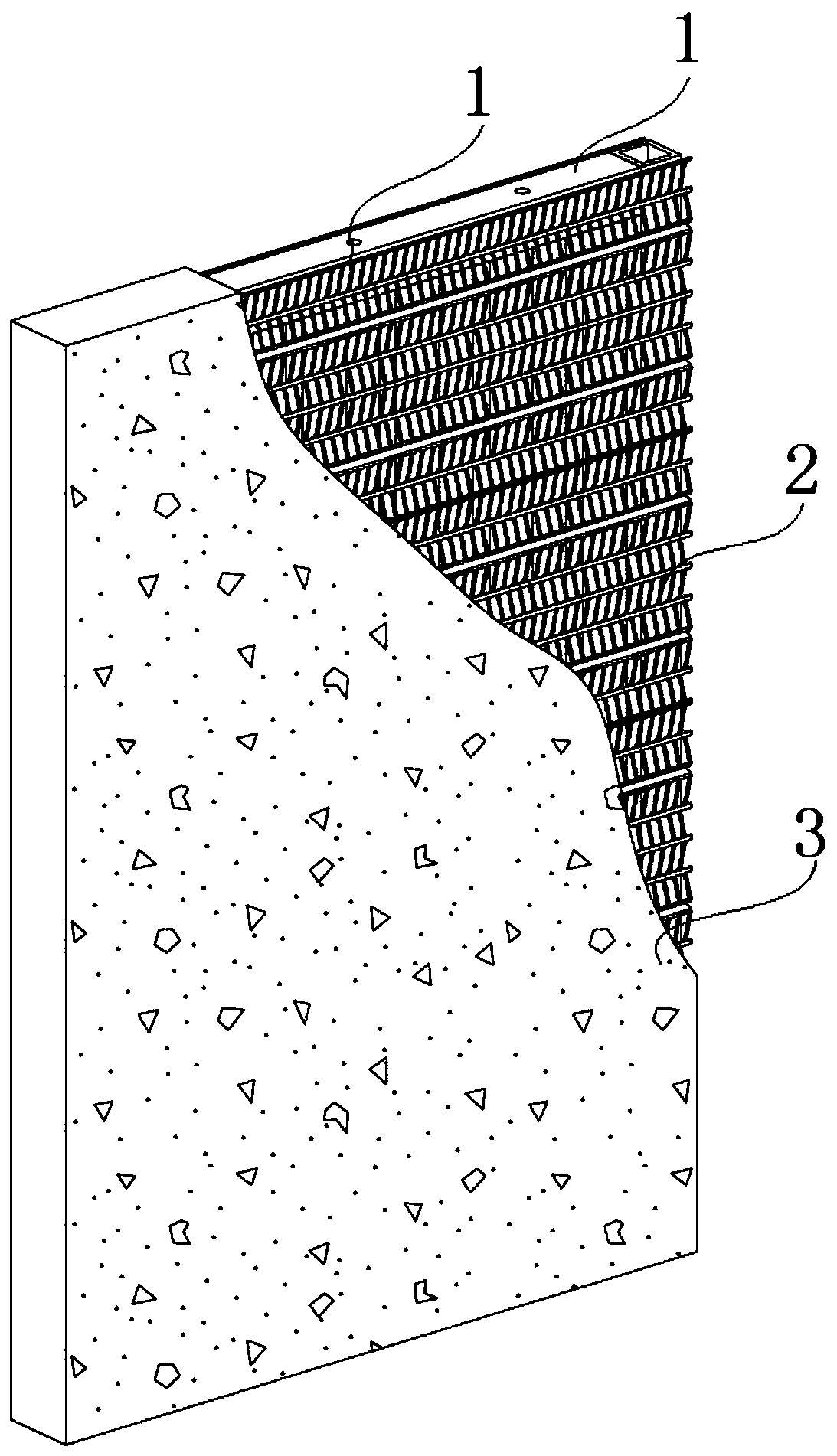

Fireproof composite wall for building protection

PendingCN110607853AReduce thicknessSmall thickness, can increase the use of small spaceWallsHeat proofingEarthquake resistancePre stress

The invention discloses a fireproof composite wall for building protection. The simple wall comprises a bearing wall (1); multiple prestress dispersion layers (2) are transversely bonded on the two sides of the bearing wall (1) end to end; sandwich layer fillers (3) are cast in two space formed by the prestress dispersion layers (2) and the bearing wall (1); the sandwich layer fillers (3), the prestress dispersion layers (2) and the bearing wall (1) are integrally injected to form a simple wall main body. The simple wall is simple in structure and novel in design, improves the earthquake resistance of the overall wall structure, reduces the design strength and cost of wall components, meanwhile, greatly improves the shear resistance and the integrity, and has such advantages as excellent integrity, excellent earthquake resistance, higher bonding and anti-shearing capacity and excellent finished wall molding effect.

Owner:金国洪

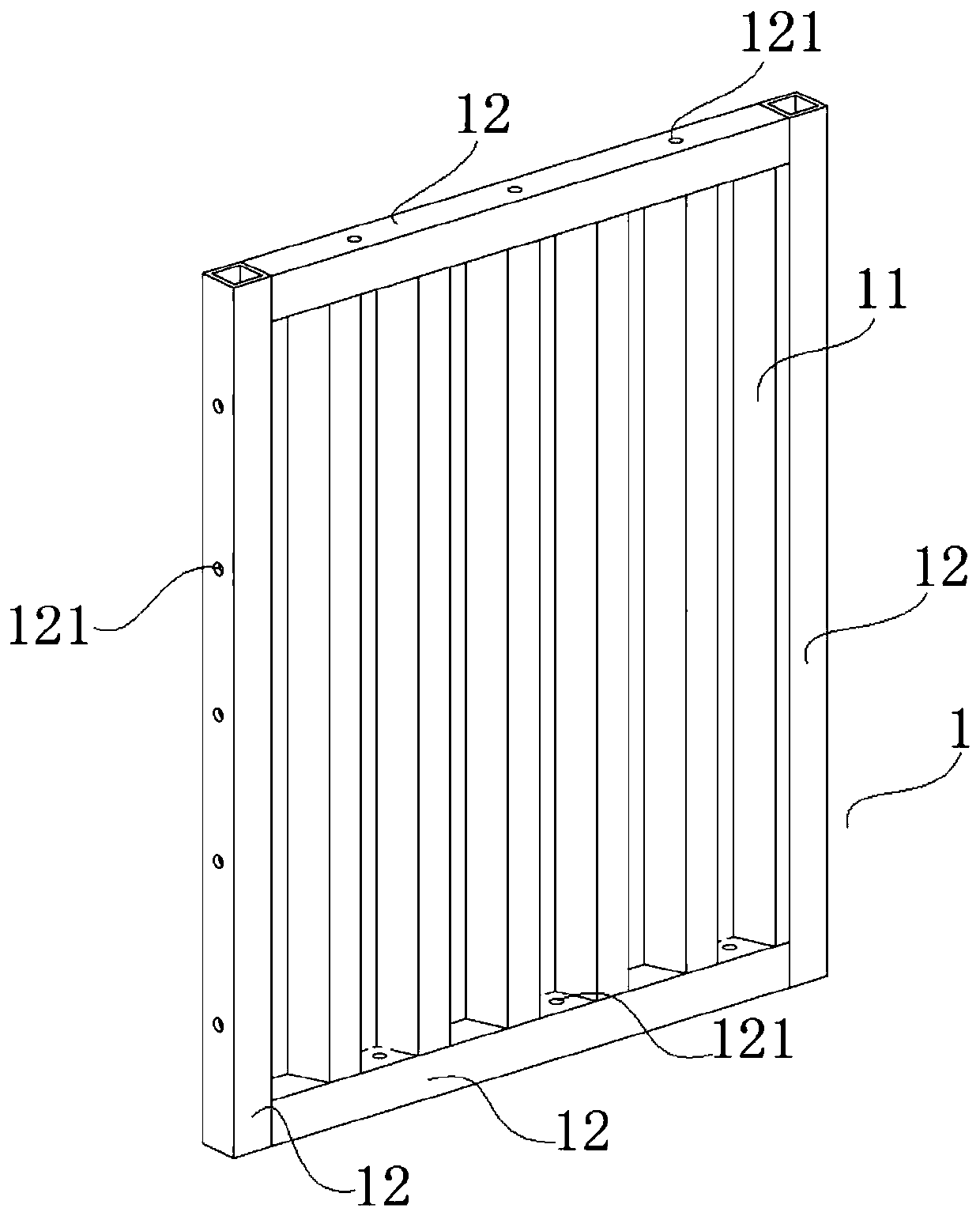

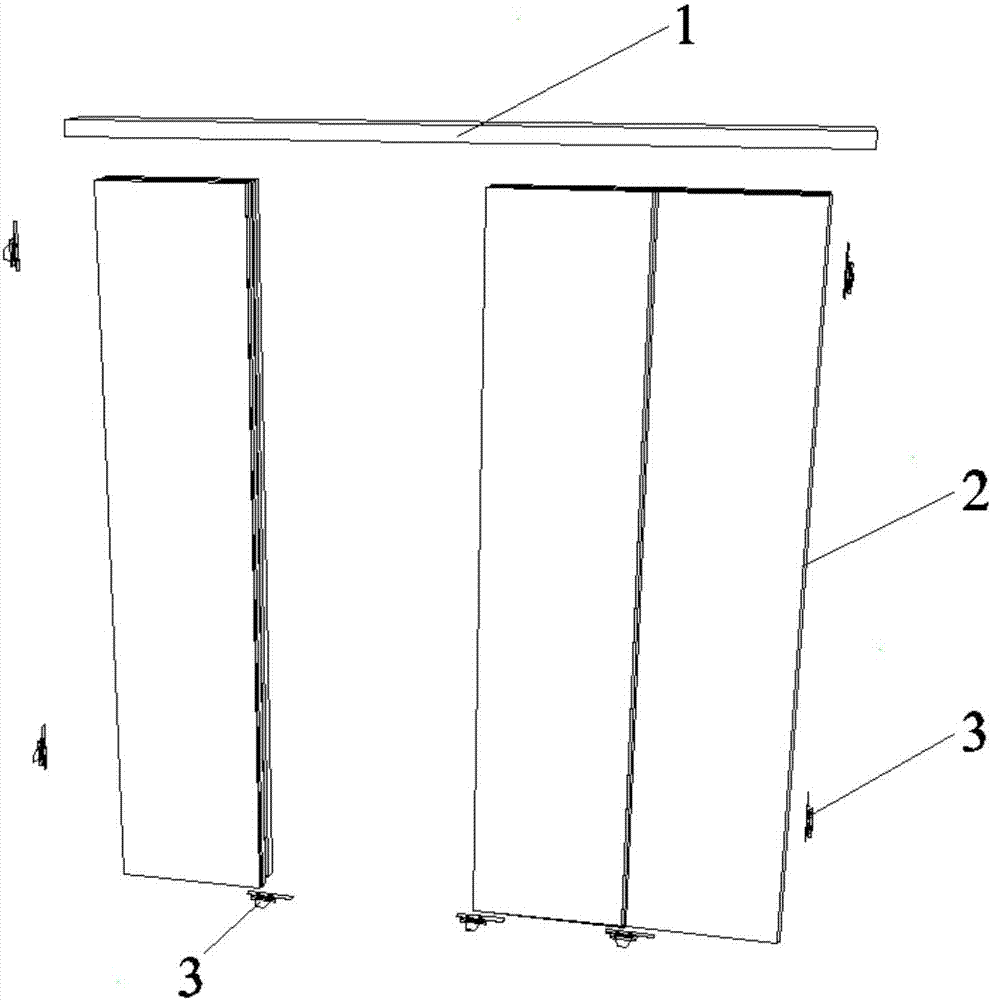

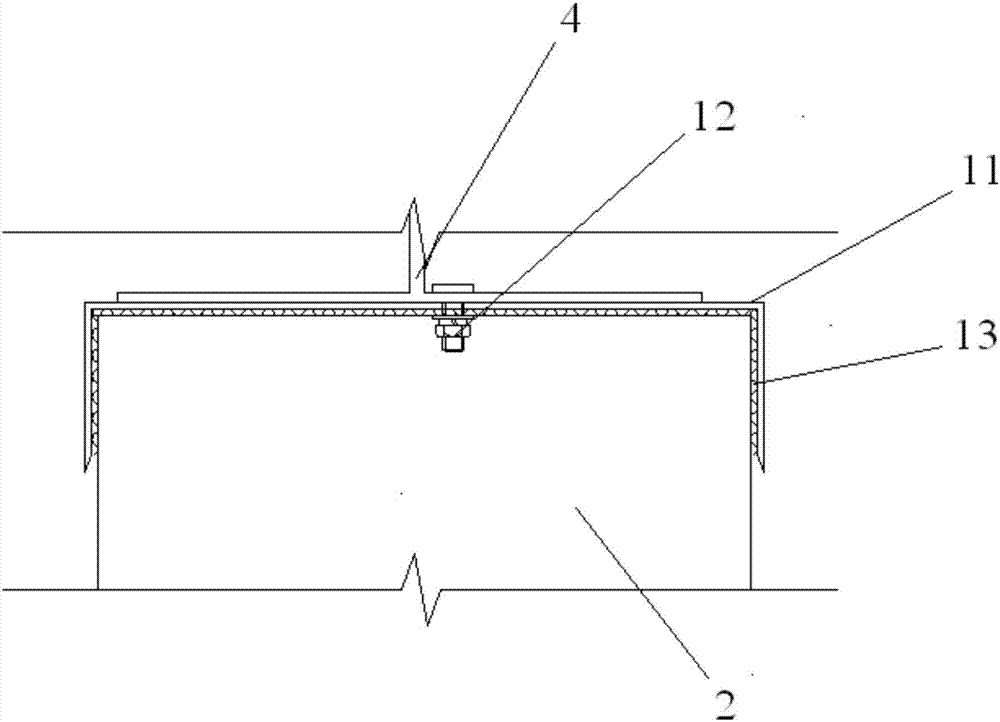

Non-bearing assembling type sound insulation partition wall suitable for steel structure building

ActiveCN107419827AHigh degree of prefabricationReduce construction stepsWallsAdhesiveClassical mechanics

The invention discloses a non-bearing assembling type sound insulation partition wall suitable for a steel structure building. The non-bearing assembling type sound insulation partition wall suitable for the steel structure building comprises a fixing groove, a partition wall plate and a connecting part. The fixing groove is used for fixing the partition wall plate and consists of a steel groove, a first fixing bolt and a rubber blanket. The steel groove is fixed on the lower portion of a steel beam through the first fixing bolt. The rubber blanket is arranged in the steel groove through an adhesive. The partition wall plate is composed of a partition wall plate material, an adhesive layer, a rubber blanket layer and a sound absorbing mineral wool strip. Grooves are formed in the bottom of the partition wall plate materialand one side of the side edge. Bulges matched with the shapes of the grooves are formed in the other side of the side edge of the partition wall plate material. Square grooves are formed in the four corners of the partition wall plate material. The rubber blanket layer and the sound absorbing mineral wool strip are arranged in the grooves from inside to outside in sequence. The connecting part is composed of a supporting plate, a hinge piece, a rotating shaft, a fixing plate and a second fixing bolt. According to the non-bearing assembling type sound insulation partition wall suitable for the steel structure building, by advancing an installing way and a structural joint of the partition wall, dry type operation is adopted, construction procedures are reduced, the construction speed is improved, and meanwhile, the good sound insulation effect is achieved.

Owner:TIANJIN UNIV

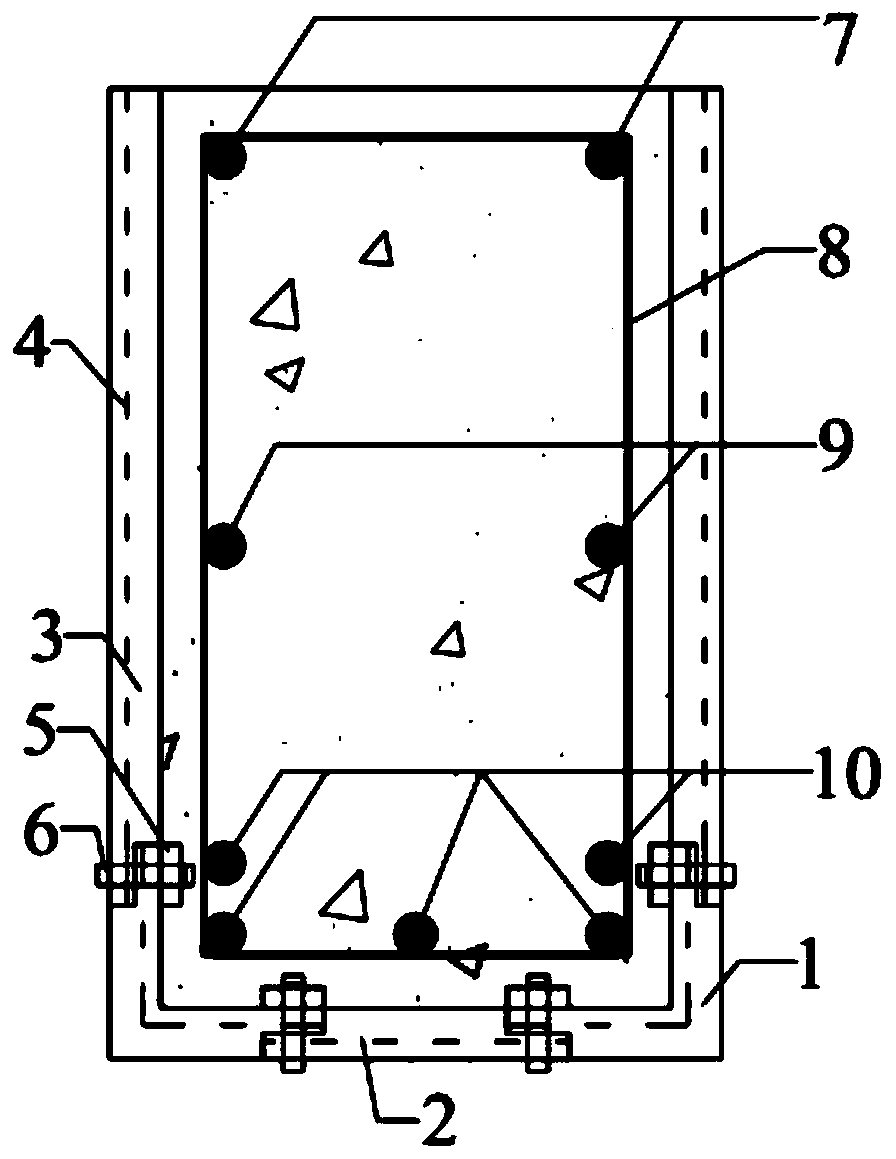

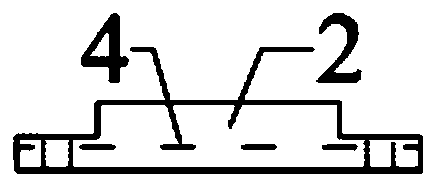

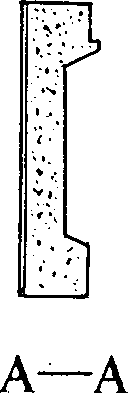

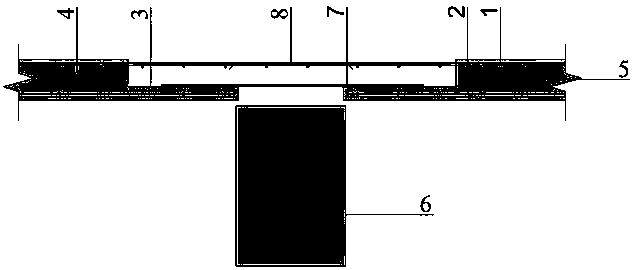

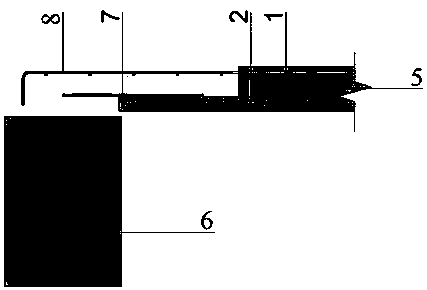

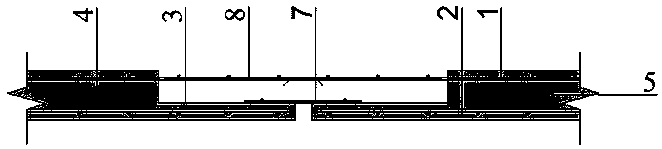

Prefabricated-slab connecting structure

PendingCN108265822AHigh degree of prefabricationImprove prefabrication rateFloorsSteel barComposite slab

The invention relates to a prefabricated-slab connecting structure, and belongs to the field of prefabricated components in constructional engineering. According to the connecting structure between composite slabs, the composite slabs are composed of slab prefabricated parts and slab cast-in-place parts; the slab cast-in-place parts are located at connecting areas between the composite slabs; theslab prefabricated parts are each in a step shape with the middle being protruding and the periphery being sunken; upper layer steel bars of the slab prefabricated parts extend out of the middle protruding areas of the slab prefabricated parts, and lower layer steel bars of the slab prefabricated parts do not extend out of the periphery sunken areas of the slab prefabricated parts; additional lower layer steel bars are arranged on the lower layers of the slab cast-in-place parts, and the additional lower layer steel bars and the lower layer steel bars are indirectly connected in an overlappedmode; and steel bar meshes are laid on the upper layers of the slab cast-in-place parts, and the steel bar meshes and the upper layer steel bars are connected in an overlapped mode. Similarly, the prefabricated-slab connecting structure can also be used for connecting between the composite slabs and composite beams as well as between the composite slabs and a wall. According to the prefabricated-slab connecting structure, the prefabrication rate is increased, the manufacturing cost is low, the stiffness is large, and the formwork removing and hoisting requirements can be met.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

Drive Unit for a Hybrid Vehicle and Method of Assembly

InactiveUS20100187028A1Simple and low-cost methodReduce the amount requiredElectric devicesElectric propulsion mountingElectric machineEngineering

A drive unit for a hybrid vehicle includes an internal combustion engine with a crankshaft, a friction clutch with a pressure plate, which can be moved in the axial direction by an actuating arrangement, with a clutch plate, and with a clutch disk arrangement, positioned between these first two components and is connected to the crankshaft. The drive unit also includes an electric machine, which is arranged between the internal combustion engine and the friction clutch, with a stator attached to a stator carrier and with a rotor. The friction clutch comprises a clutch hub, which serves to create at least an indirect connection of the clutch disk arrangement to the crankshaft is detachably connected to the clutch disk arrangement outside the radial dimension of the pressure plate and the clutch plate. An assembly method for assembling such a drive unit is also described, where a preassembled unit including at least the electric machine and the friction clutch is attached to an internal combustion engine.

Owner:ZF FRIEDRICHSHAFEN AG

Seam bolt connection type prefabricated concrete bridge deck and prefabricating method

ActiveCN106087741AFast constructionSpeed up prefabricationBridge structural detailsBridge erection/assemblyRear quarterSheet steel

The invention provides a seam bolt connection type prefabricated concrete bridge deck and a prefabricating method. The prefabricating method comprises the following steps: erecting a steel main girder and mounting a concrete bridge deck, wherein a bridge deck connection steel plate is mounted when the concrete bridge deck is prefabricated, an outer edge plate is mounted on the outer side of a connection rabbet, an inner edge plate and a side plate with a hole are mounted in the concrete bridge deck and a main girder connection part is welded on the steel main girder, and the main girder connection part is connected with the outer edge plate through a high-strength bolt; and then constructing a bridge deck shearing force rabbet and the connection rabbet. The seam bolt connection type prefabricated concrete bridge deck is simple in structure and relatively high in prefabricating and splicing degree; field construction time is shortened and a construction period is shortened; and prefabricating production and field assembling connection of structural parts can be realized better.

Owner:CHANGAN UNIV

Assembly type shear wall

InactiveCN106948510AImprove seismic performanceReduce workloadWallsProtective buildings/sheltersEngineeringTension field

The invention provides an assembly type shear wall comprising a shear wall body, a first energy dissipation plate and a second energy dissipation plate. The first energy dissipation plate and the second energy dissipation plate are arranged on the two sides of the shear wall body correspondingly and each comprise a web plate and a flange which are mutually perpendicular. The web plates of the first energy dissipation plate and the second energy dissipation plate are embedded on the two sides inside the shear wall body correspondingly. Connecting holes are formed in the flanges of the first energy dissipation plate and the second energy dissipation plate. The adjacent shear wall bodies are fixedly connected through connecting pieces in matched connection with the connecting holes. Energy is consumed through a tension field formed by an energy dissipation device after buckling at a joint of the shear wall; on the one hand, structural ductility and deformation capacity are strengthened effectively, and the anti-seismic performance of the assembly type concrete shear wall is improved; and on the other hand, the shear wall body, the energy dissipation plate and the second energy dissipation plate are designed in advance and processed in a prefabricate mode, wet operation is not conducted on the site, and assembly operation is mainly conducted, so that the operation amount is small, the mounting efficiency is high, and the construction cost is low.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

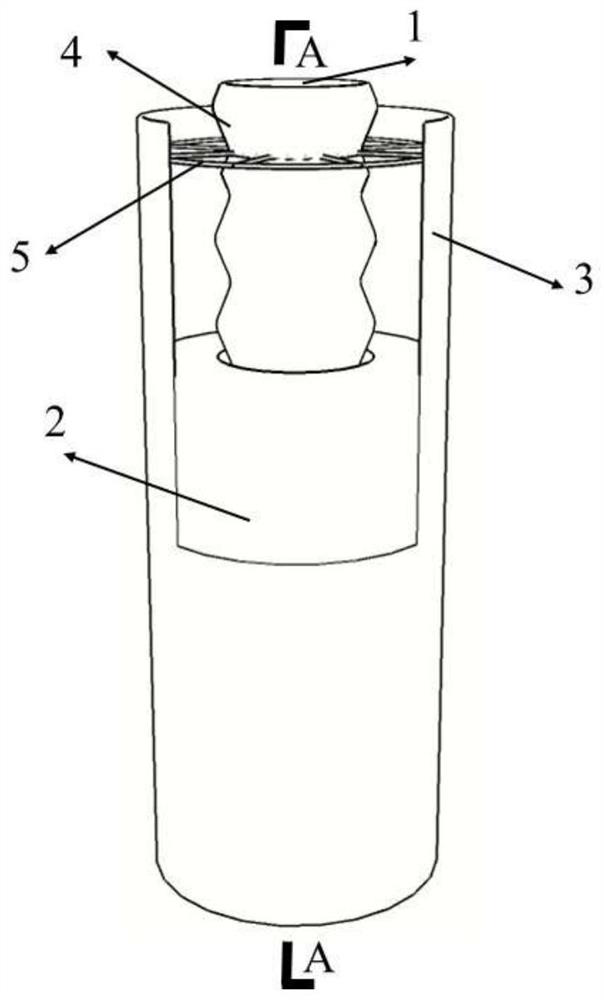

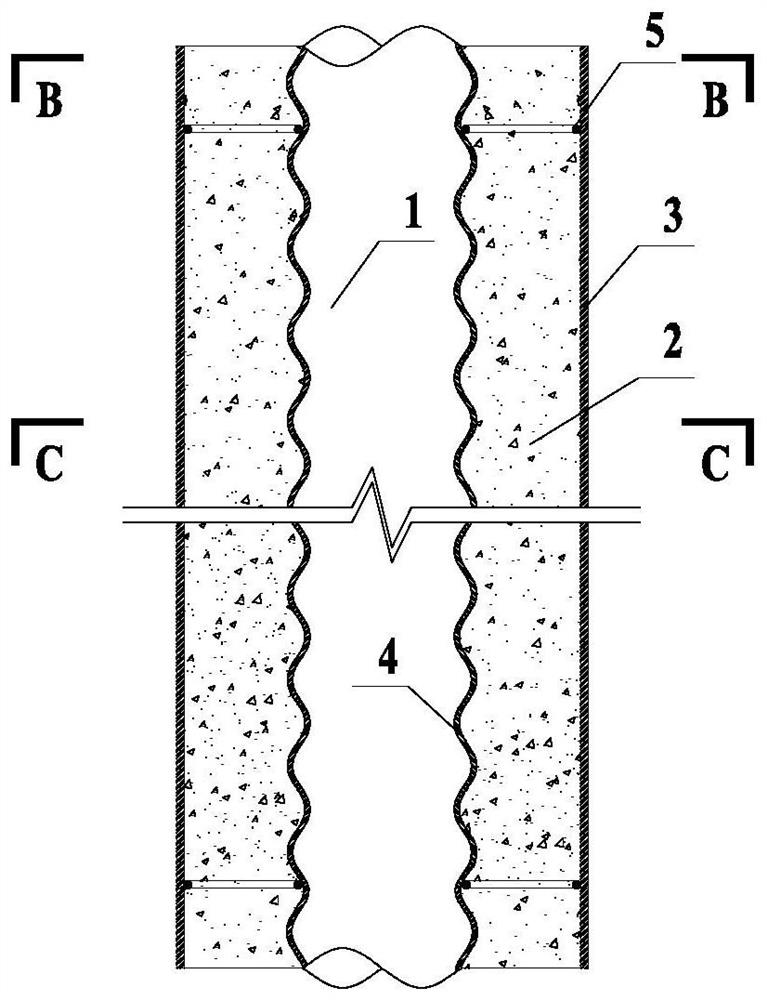

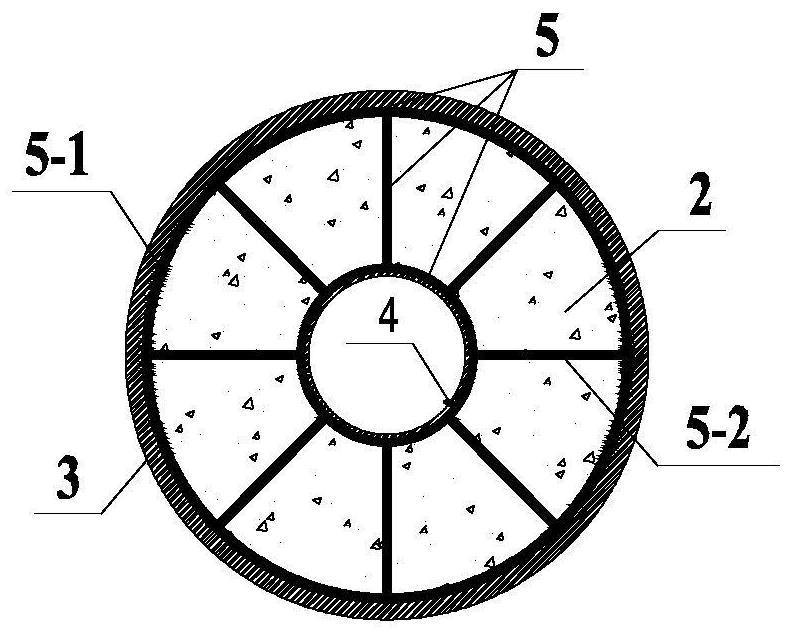

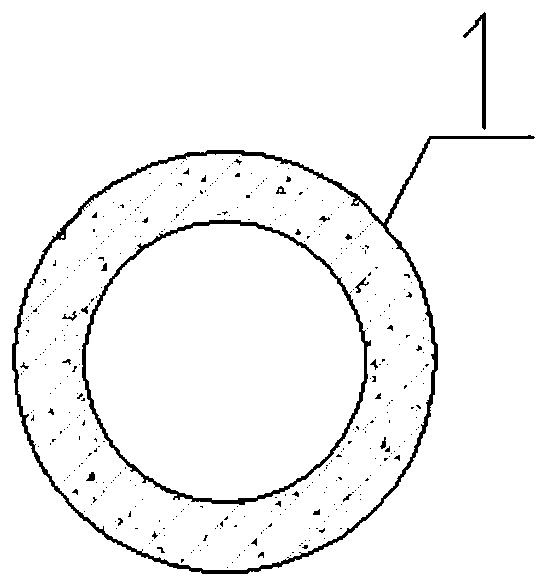

Hollow corrugated pipe interlayer concrete-filled steel tubular column

InactiveCN112854602AShrinkage creep is smallReduce the adverse effects of shrinkage and creepStrutsBridge structural detailsIndustrial constructionBridge engineering

The invention relates to a hollow corrugated pipe interlayer concrete-filled steel tubular column, and belongs to the field of industrial buildings, high-rise buildings, large-span buildings and bridge engineering. An inner steel pipe of the hollow corrugated pipe interlayer concrete-filled steel tubular column is arranged in a pipe body of an outer steel pipe, and the outer steel pipe and the inner steel pipe are coaxially arranged; a pipe cavity between the outer steel pipe and the inner steel pipe is filled with self-compacting concrete; and the inner steel pipe is a hollow corrugated pipe body. The hollow corrugated pipe interlayer concrete-filled steel tubular column has the advantages of being high in bearing capacity, good in ductility, high in buckling resistance, capable of enhancing the core concrete constraint effect, good in durability, high in factory prefabrication degree, capable of achieving standardized production and the like.

Owner:SOUTHEAST UNIV

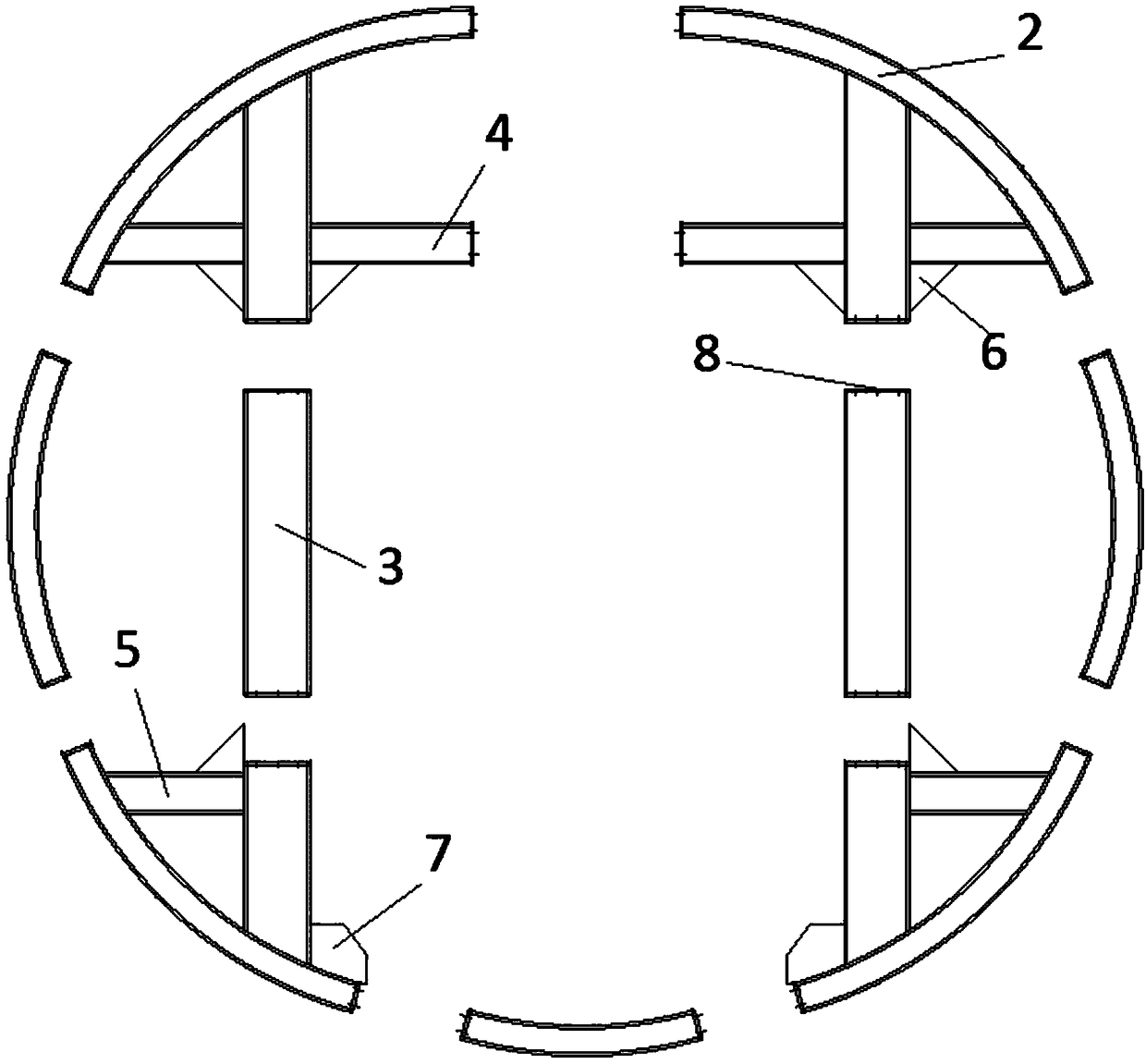

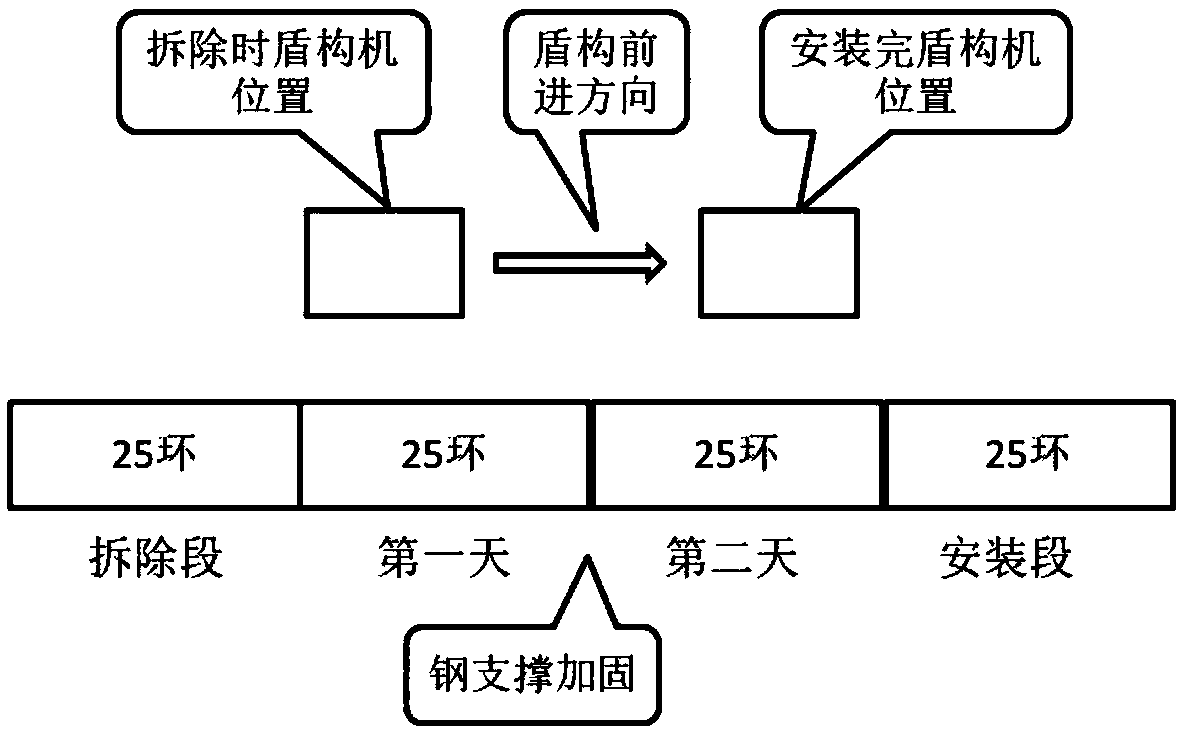

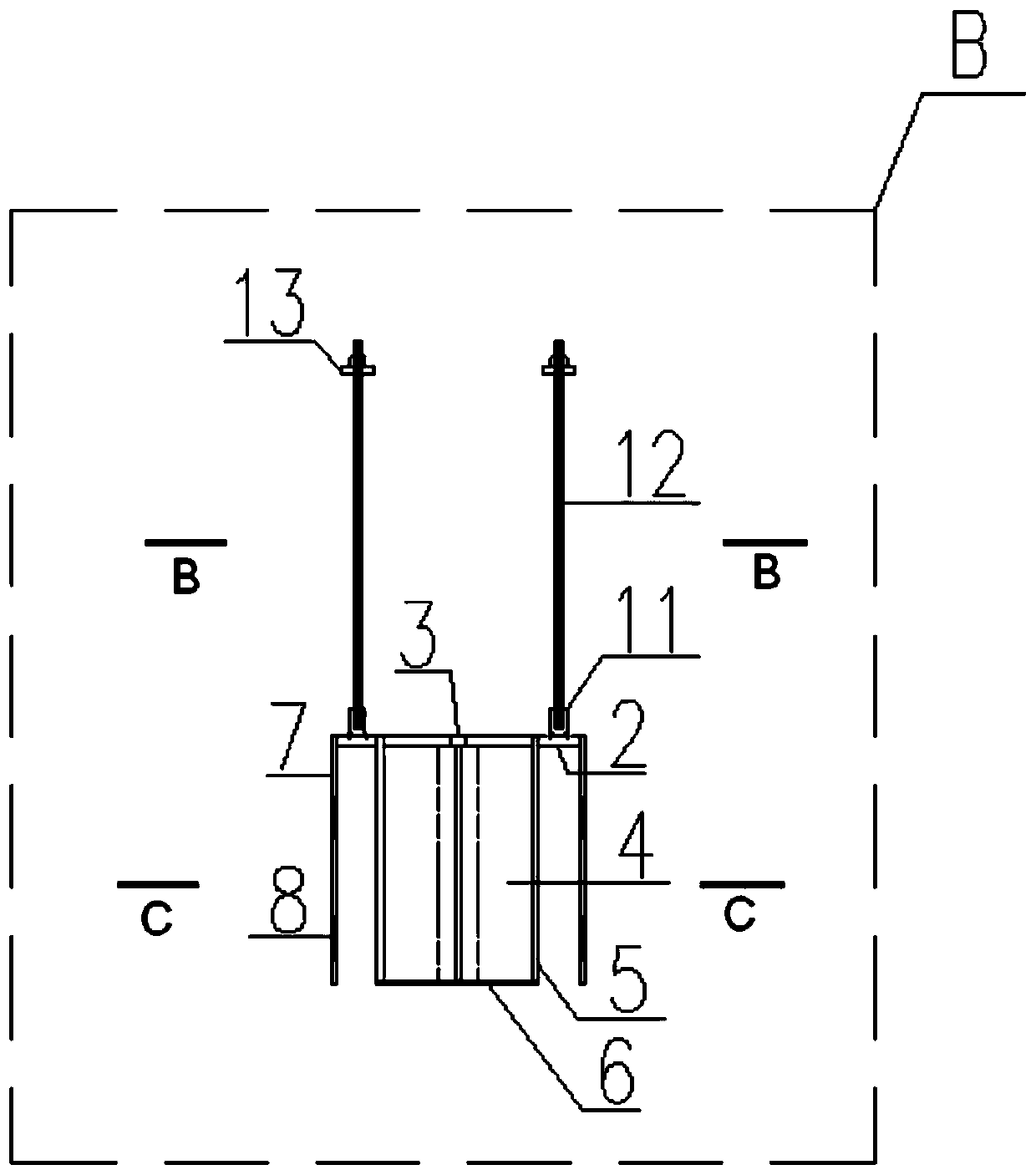

Stacking shield modular steel support reinforcement structure capable of being installed and disassembled quickly

PendingCN109441490AReliable support reinforcement measuresEnsure construction safetyUnderground chambersTunnel liningComputer moduleModular design

The invention discloses a stacking shield modular steel support reinforcement structure capable of being installed and disassembled quickly. An annular I-shaped steel main support is arranged on the inner side of a the lower shield tunnel segment; the annular I-shaped steel main support is in an annular shape, and is composed of a plurality of arc-shaped annular I-shaped steel supports; two top end modules are connected with each other through the annular I-shaped steel supports and a first horizontal steel support which are corresponding to the two top end modules; two bottom end modules areconnected by the other annular I-shaped steel support; the two top end modules and the two bottom end modules are in one-to-one correspondence; and the corresponding top end module and the bottom endmodule are connected by another annular I-shaped steel support and vertical steel supports. The stacking shield modular steel support reinforced structure capable of being installed and disassembled quickly can provide reliable support and reinforcement measures for the lower shield, through the modular design of a steel support reinforcement system, the on-site operation procedures are simplified, and the beneficial effects of rapid installation and disassembly of the steel supports are realized.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

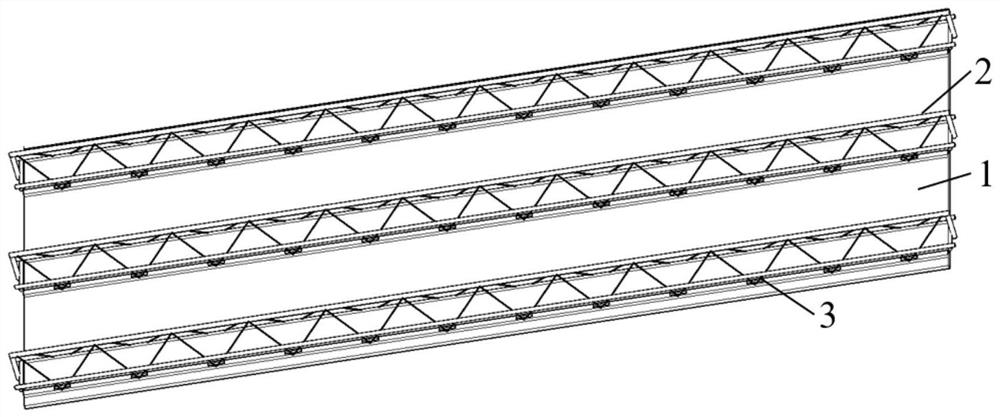

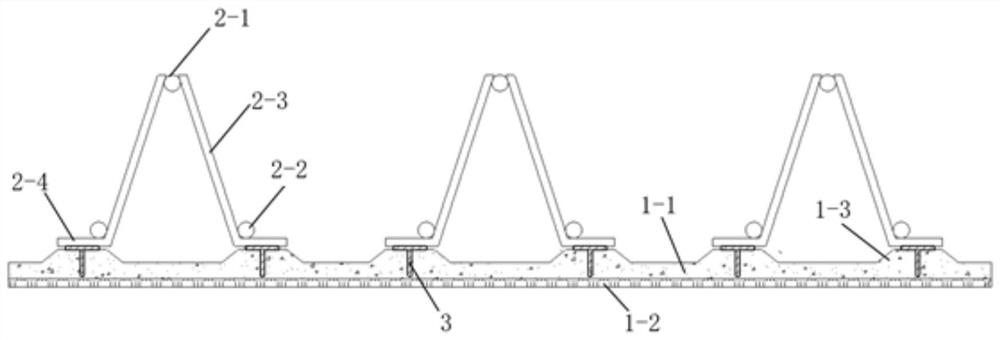

Assembled form-removal-free steel bar truss floor support plate

PendingCN112982782AImprove mechanical propertiesReduce thicknessFloorsBuilding reinforcementsFloor slabArchitectural engineering

The invention discloses an assembled form-removal-free steel bar truss floor support plate. Each floor unit comprises a concrete bottom plate, a steel bar truss and a connecting piece, wherein the steel bar truss is connected with one surface of the concrete bottom plate through the connecting piece, a decorative layer is arranged on the other surface of the concrete bottom plate, and the end parts of the decorative layers of the adjacent floor units are staggered with the end parts of the concrete bottom plates. The concrete bottom plates are adopted as formworks for pouring concrete during construction, and do not need to be removed after construction is completed, so that the construction period is shortened, and the construction cost is reduced; and meanwhile, the mechanical property of the concrete bottom plates is good, the concrete bottom plates can be used as a part of a floor structure, and are stressed cooperatively with concrete of an upper cast-in-place structure layer, so that the thickness of a floor plate can be reduced, the use amount of upper cast-in-place concrete and truss steel bars is reduced, and the floor clearance is increased. The end parts of the decorative layers of the adjacent floor units are staggered with the end parts of the concrete bottom plates, so that the decorative layers of the adjacent plate ends can be overlapped and meshed with the concrete bottom plates when the floor support plates are laid in the construction stage, and slurry leakage is effectively avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

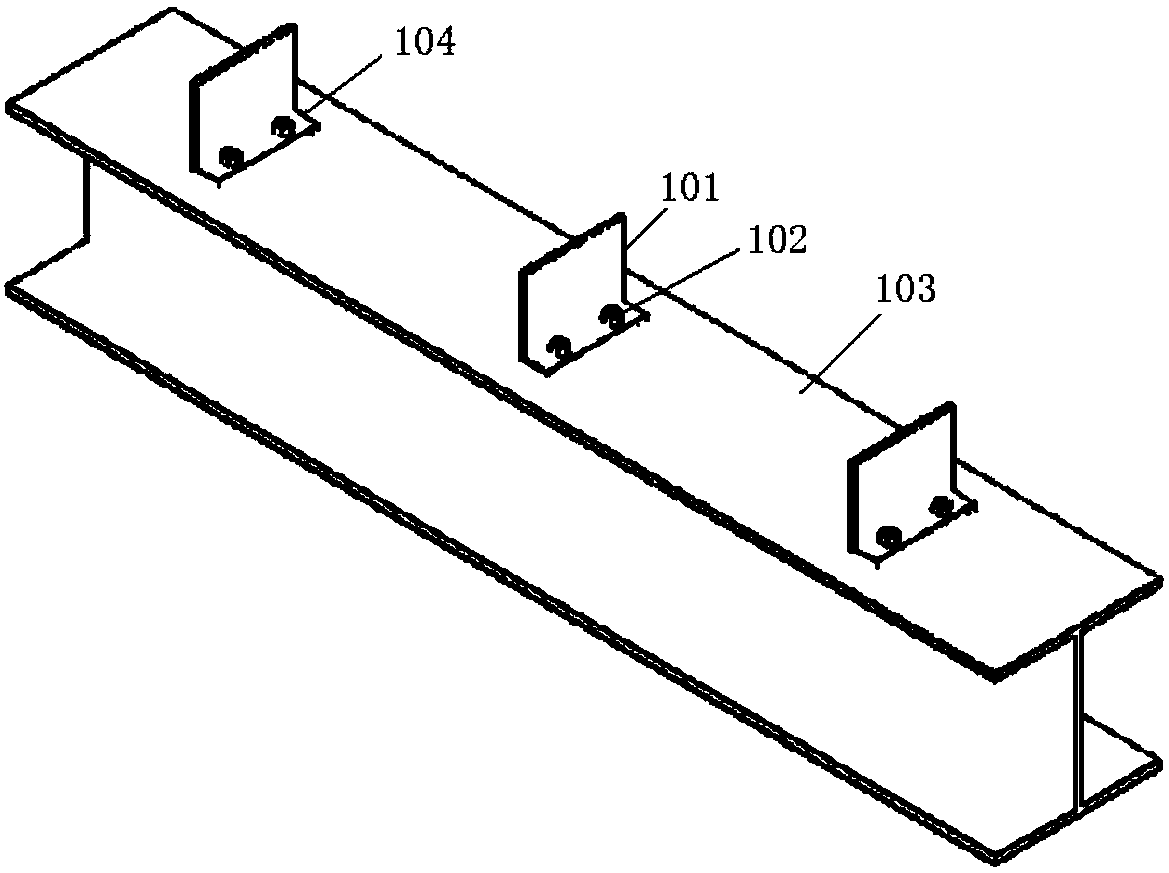

Shearing-resistant and not-pull-resistant friction-type shearing force connection part and construction method thereof

ActiveCN107642170AHigh degree of prefabricationReduce labor costsBuilding constructionsTransfer modeHigh intensity

The invention discloses a shearing-resistant and not-pull-resistant friction-type shearing force connection part and a construction method thereof. The shearing force connection part includes a shearing force connection part main body and a high-strength bolt assembly; the shearing force connection part main body is angle steel, a plurality of bolt holes matched with the high-strength bolt assembly are formed in one flange edge, and the shearing force connection part main body is connected with a main beam through the high-strength bolt assembly. According to the shearing-resistant and not-pull-resistant shearing force connection part, force transferring modes of traditional shearing force connection parts are improved, interface friction between the shearing force connection part main body and a plate is reasonably utilized, bolts are reasonably designed, shearing force of the bolts can be monitored and controlled in real time, the factory prefabrication degree is high, bolt splicingis conducted on the spot, and therefore the labor cost is saved. The shearing-resistant and not-pull-resistant friction-type shearing force connection part is not provided with a fixed end and has theeffects of being resistant to shearing and not resistant to pulling.

Owner:HOHAI UNIV

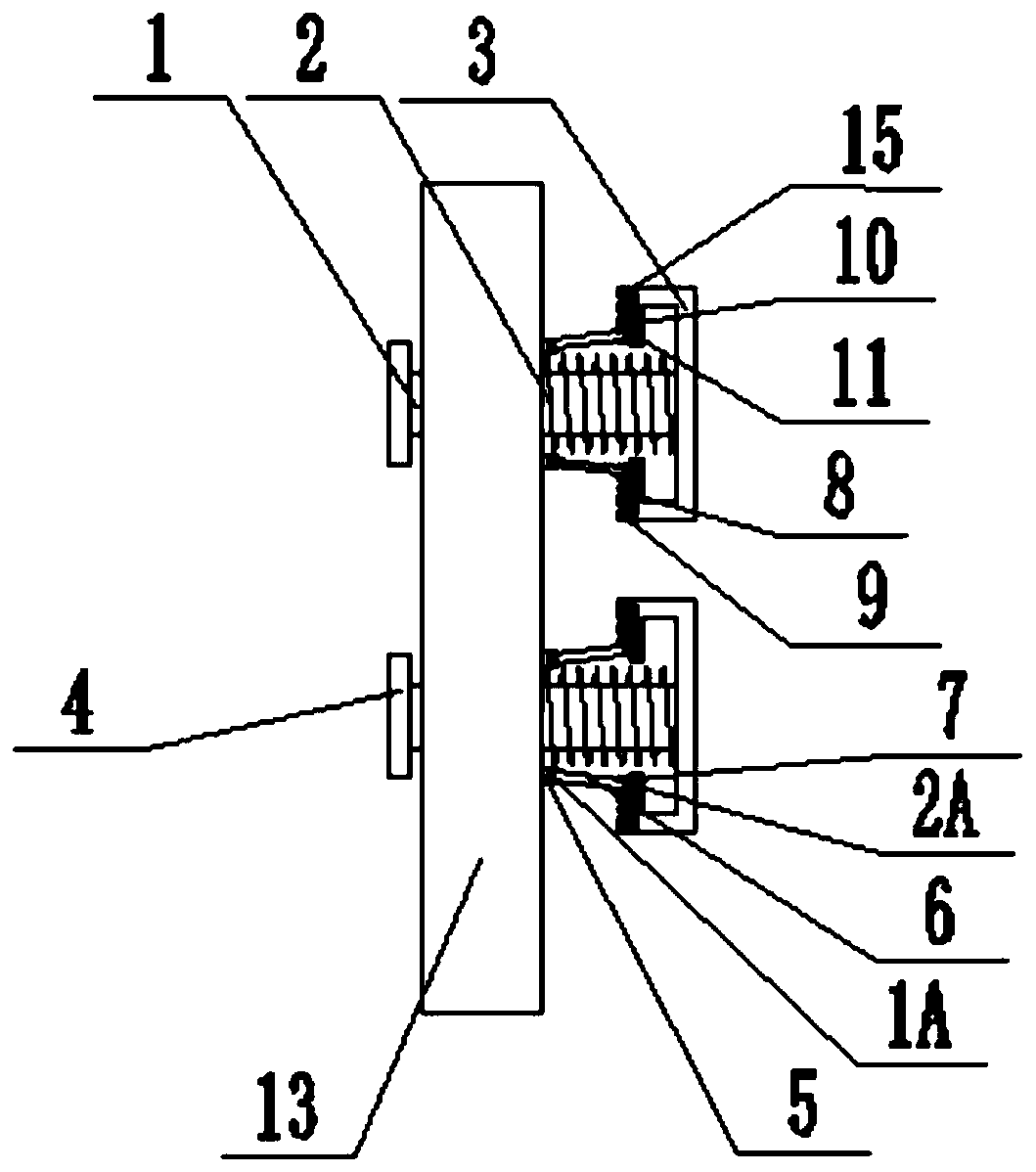

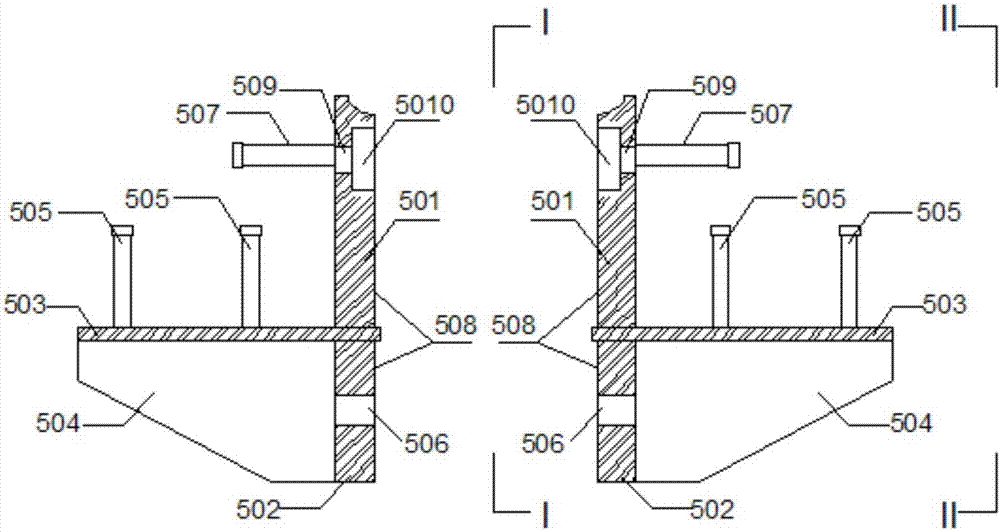

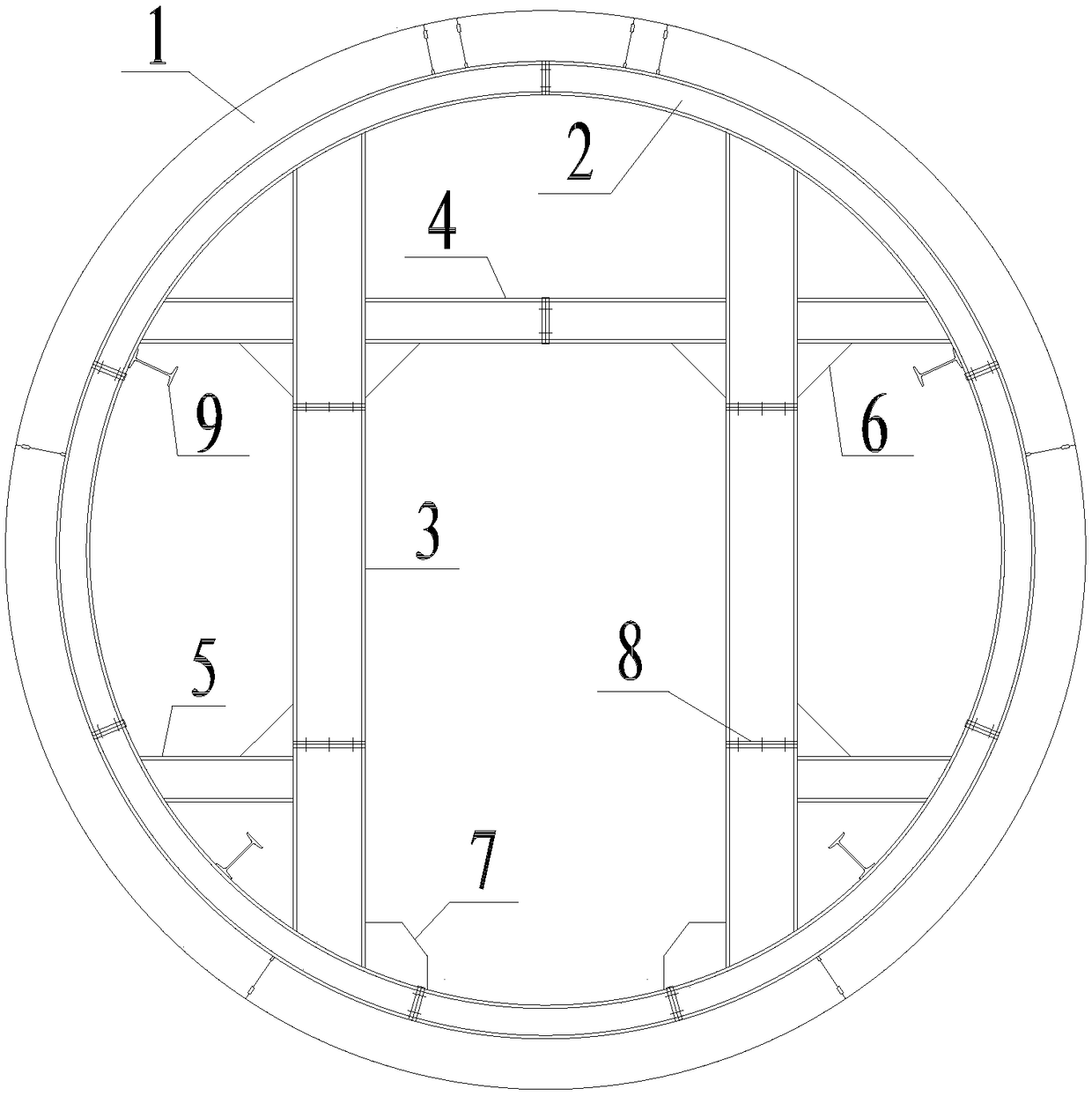

Connecting structure of hoop type precast tubular pile and precast bearing platform

PendingCN110644471AQuick connectionFirmly connectedBulkheads/pilesCavity wallArchitectural engineering

The invention discloses a connecting structure of a hoop type precast tubular pile and a precast bearing platform. The connecting structure of the hoop type precast tubular pile and the precast bearing platform comprises a precast tubular pile part A and a precast bearing platform part C which are connected through a steel structure hoop type connecting piece part B. The connecting structure of the hoop type precast tubular pile and the precast bearing platform has the beneficial effects that rapid and reliable connection of the precast tubular pile and the precast bearing platform is realizeddue to the adoption of the steel structure hoop type connecting piece part; slurry can be fully injected in a tubular pile upper cavity, a tubular pile top and bearing platform bottom space and a hole passage space of a pile head reserved threaded rod in the bearing platform by means of pressure and a ventilation vertical hole passage in the bearing platform so that the integrity and reliabilityof connection are improved; a cross-shaped vertical plate stiffening rib is included in the tubular pile, the tubular pile is filled with core filling slurry, and therefore, the shear-bearing capacityof a pile head is obviously enhanced; in the case that a foundation is in tension, stress transmission between the precast bearing platform and the precast tubular pile depends on friction between tubular pile grouting material external leather and the cavity wall of the tubular pile and extruding friction between an external annular connecting plate strip and the external wall of the tubular pile; and therefore, the bearing capacity is high, the structure safety defense line is not single; and the shear-bearing capacity of the pile head is enhanced, and the prefabrication degree is enhanced.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

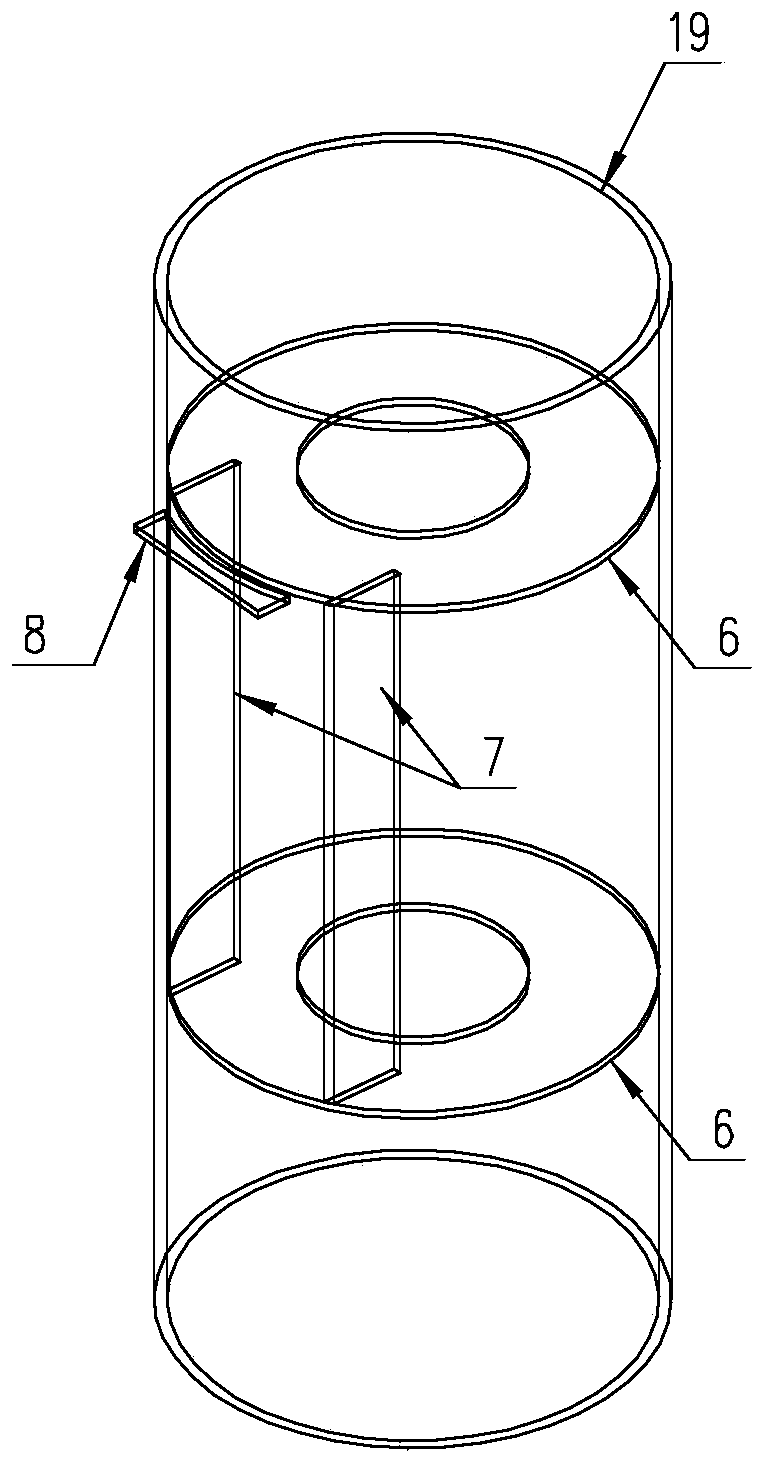

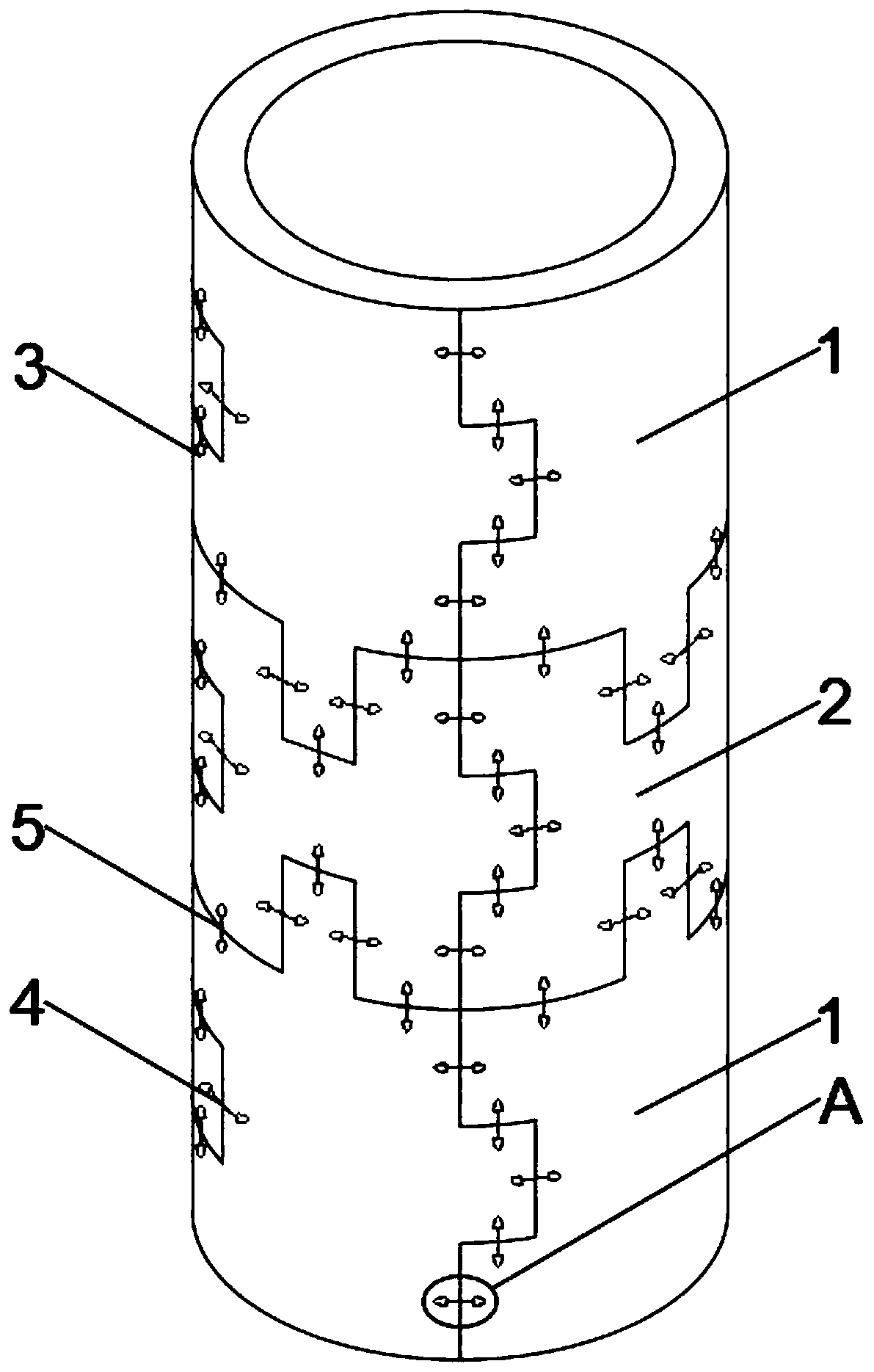

TRE assembled permanent cylindrical form and manufacturing method thereof

ActiveCN111424971AReduce lossIncreased durabilityClimate change adaptationMould auxillary partsReinforced concreteConstruction engineering

The invention discloses a TRE assembled permanent cylindrical form and a manufacturing method thereof, and belongs to the technical field of reinforced concrete building construction. The TRE assembled permanent cylindrical form comprises first plates, second plates, circumferential bolts, longitudinal bolts, nuts and gaskets, wherein the form is made of engineered cementitious composites ECC anda fiber woven mesh, the first plates are used for assembling two cylinder ends of the cylindrical form, the second plates are used for assembling a middle section of the cylindrical form, bolt holes are reserved in the plates, hole positions of the plates are in one-to-one correspondence and are used for bolt connection, and the bolts comprise the circumferential bolts and the longitudinal bolts.By using the TRE permanent cylindrical form, the material loss is reduced, the labor cost is reduced, and the construction cost is saved; and meanwhile, the plates have the advantages of being easy toassemble, firm in assembly, convenient to transport, low in manufacturing cost and the like, and the form has great development prospects.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com