Group of silos and single silo of square steel structure

A steel structure and material storage technology, applied in the field of storage, can solve the problems of affecting unloading, easily damaged supports, aggregates, etc., and achieve the effects of easy loading, less material loss, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

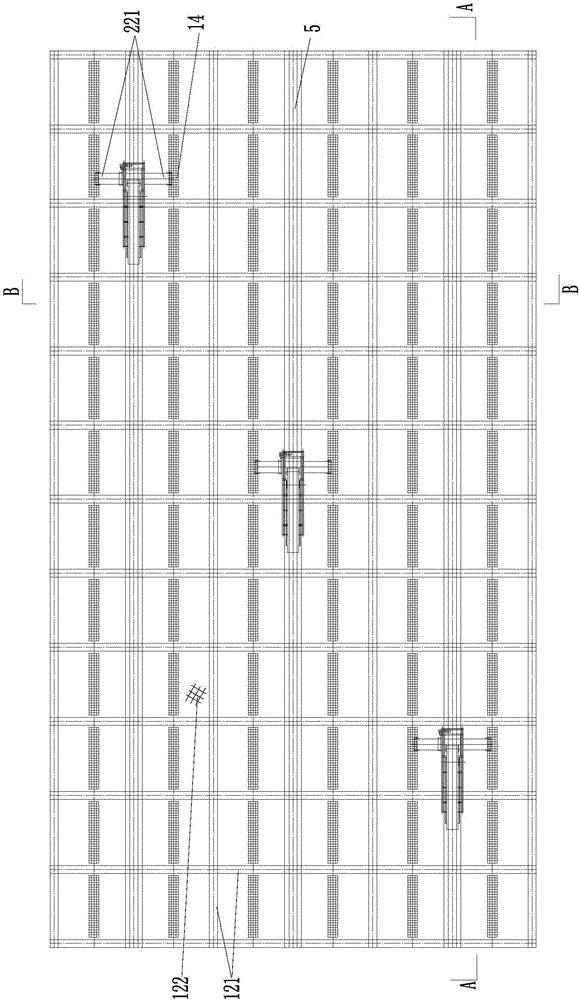

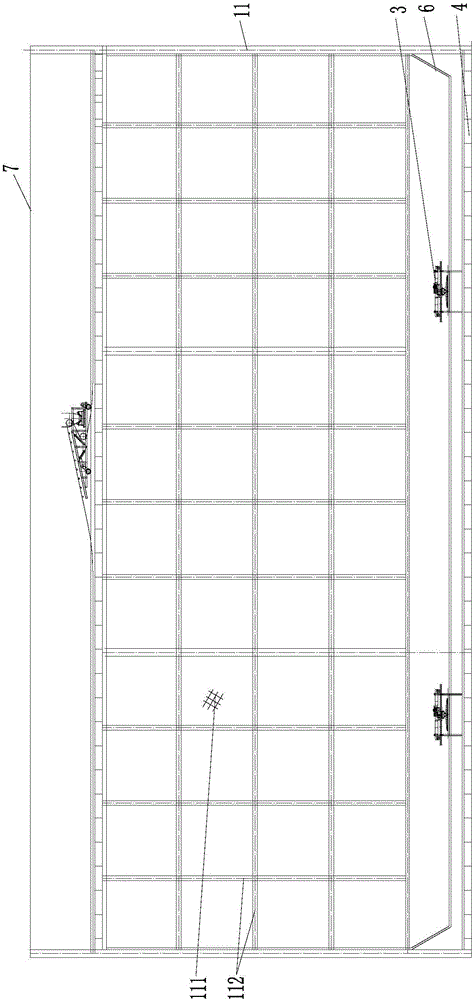

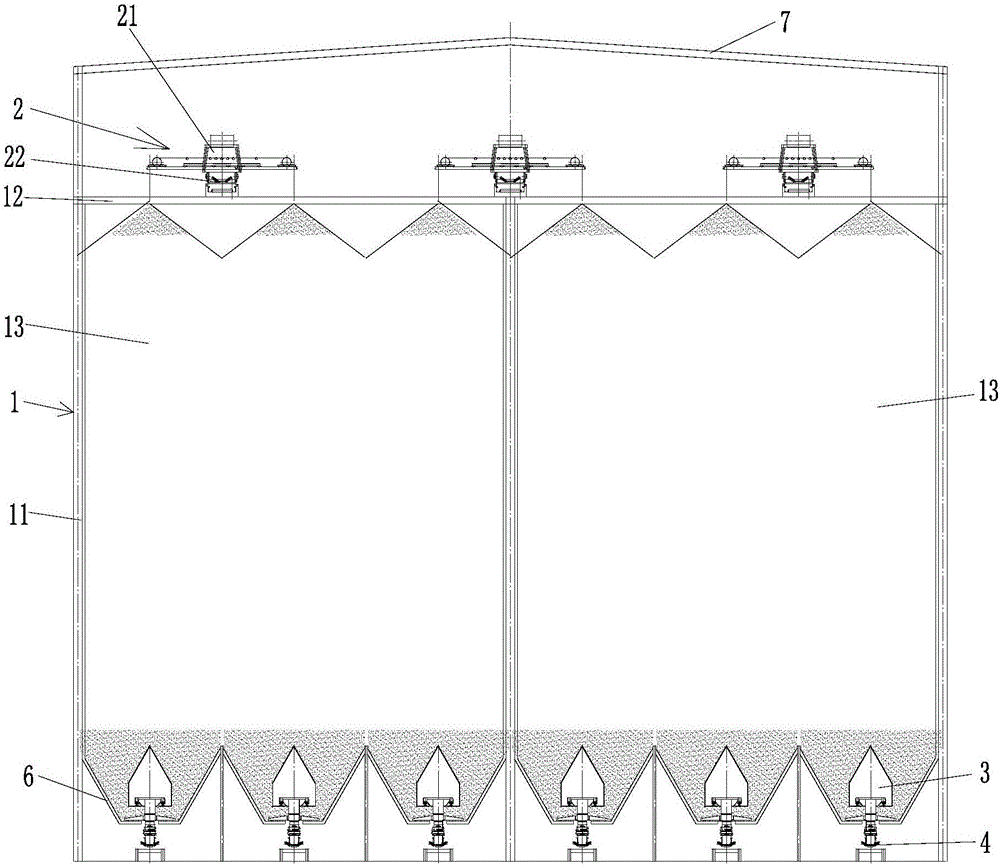

[0040] Such as figure 1 As shown, the present invention provides a square steel structure storage group warehouse, which includes a rectangular group warehouse, a feeding conveyor 2, a feeder 3 and a discharge conveyor 4, and the rectangular group warehouse includes more than two Each single bin 1 includes four vertically arranged rectangular bin walls 11 and a horizontally arranged rectangular bin roof 12, and the four bin walls 11 are sequentially connected to form a storage space 13, and the storage space 13 To store materials, the top 12 of the warehouse is buckled between the tops of the four warehouse walls 11 to close the storage space 13. Each warehouse wall 11 includes a warehouse wall 111 and a main structure connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com