Patents

Literature

149results about How to "Realize automatic reclaiming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

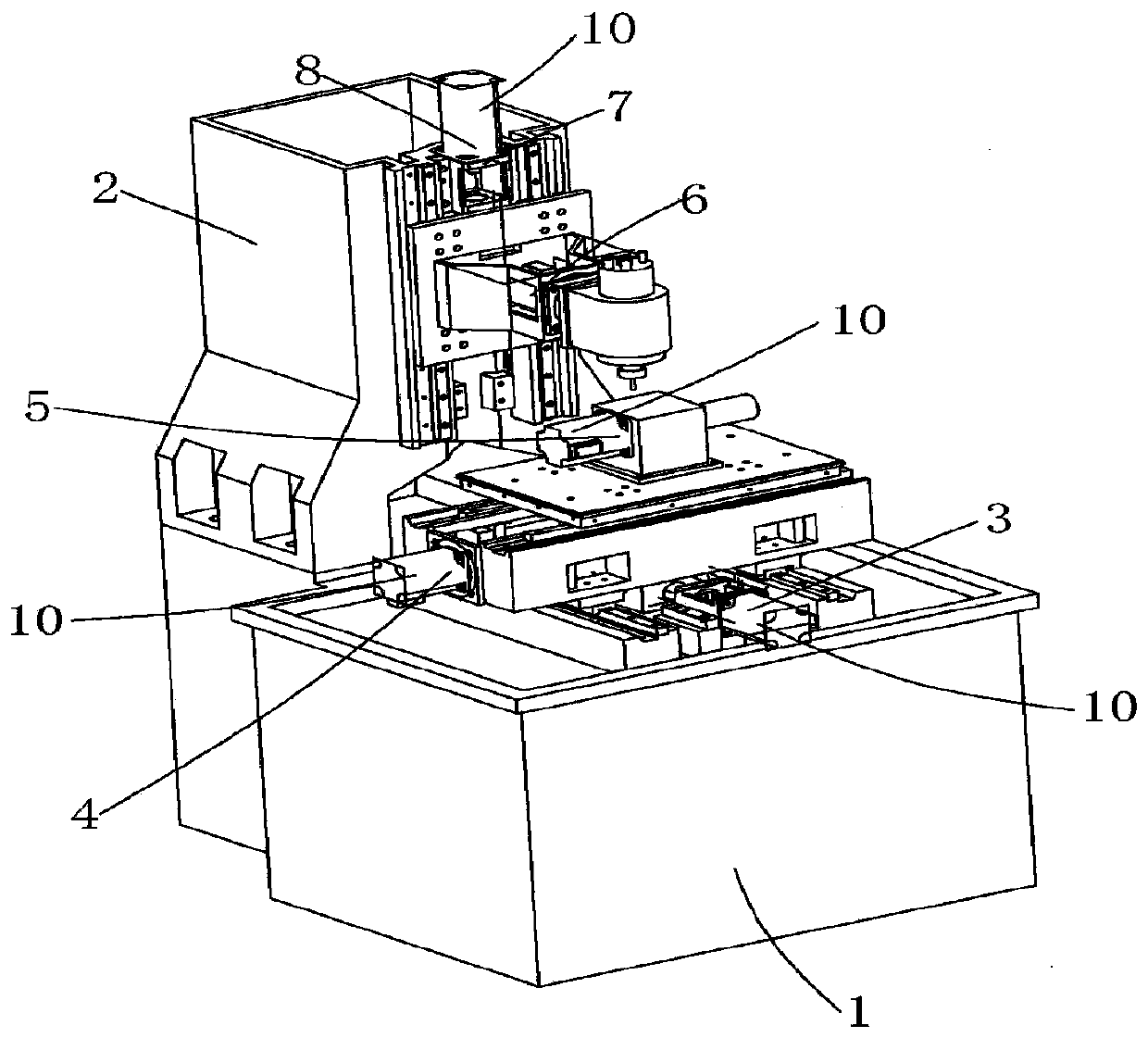

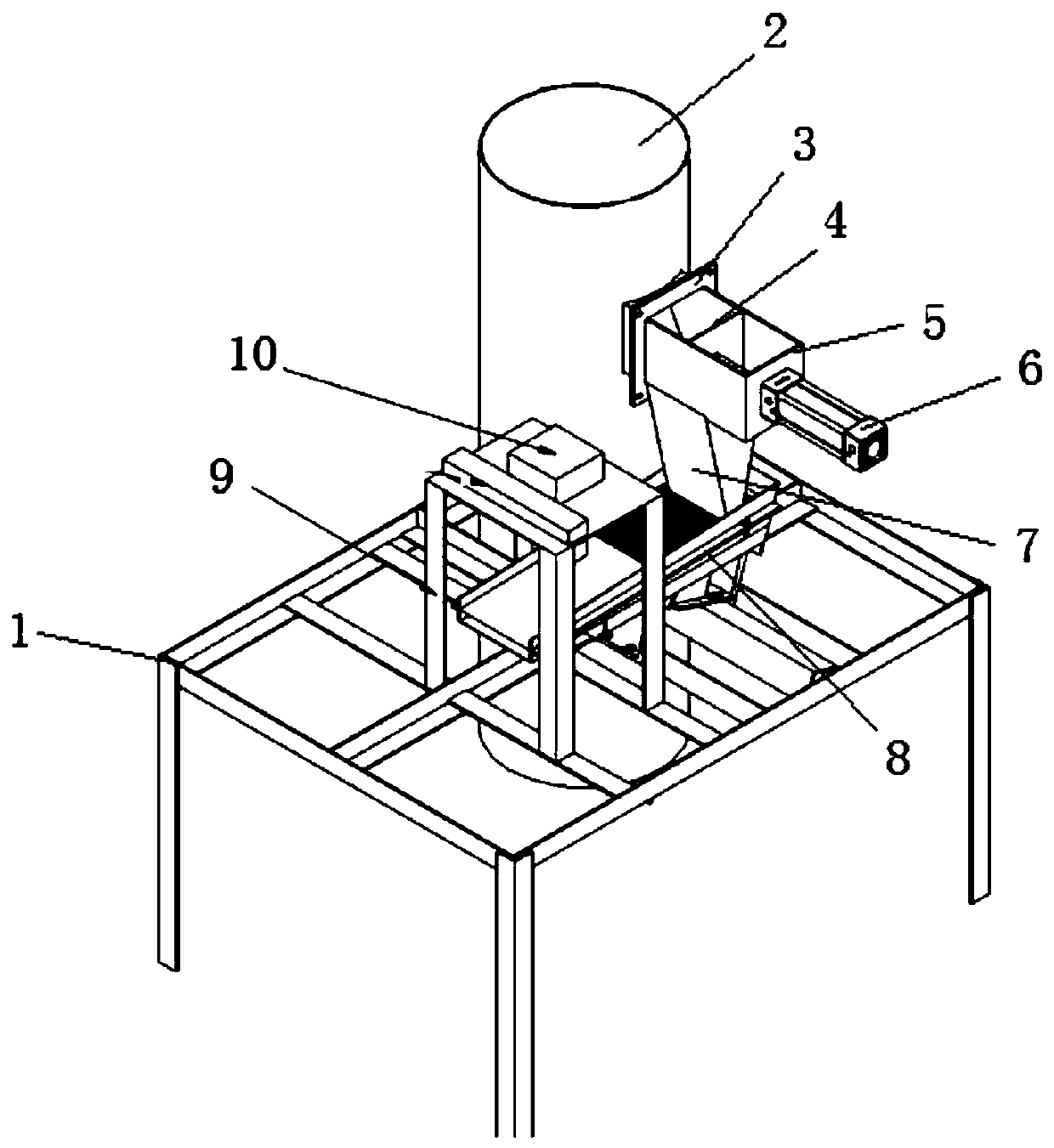

Automatic feeding device

InactiveCN103754630AHigh degree of automationIncrease productivityConveyor partsMechanical engineering

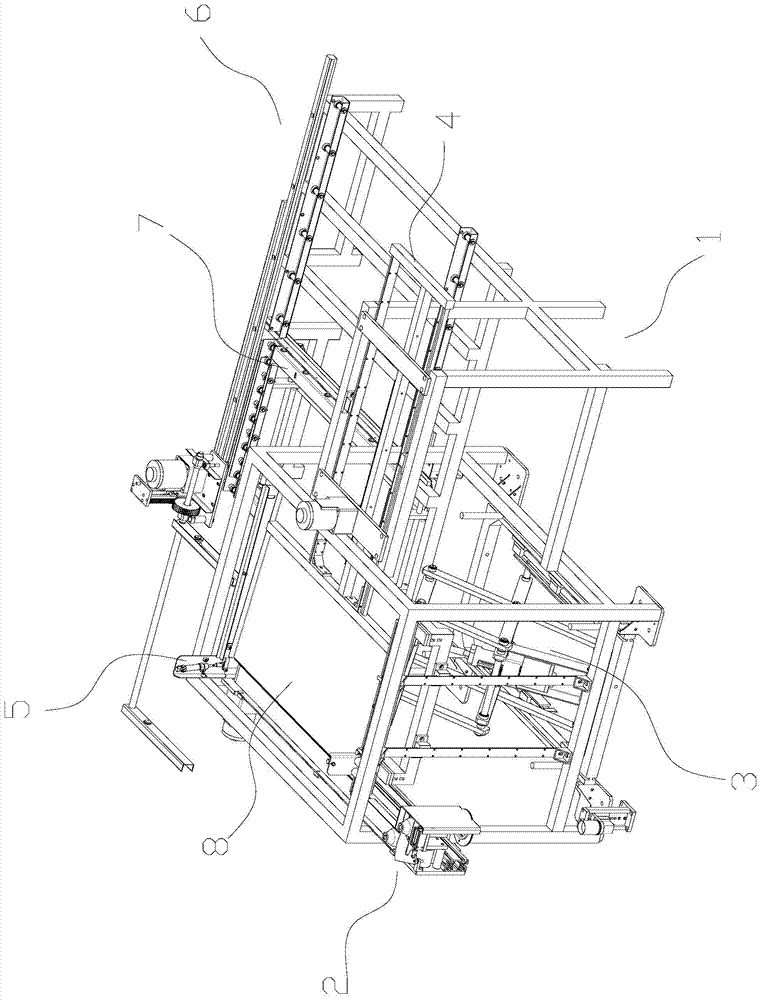

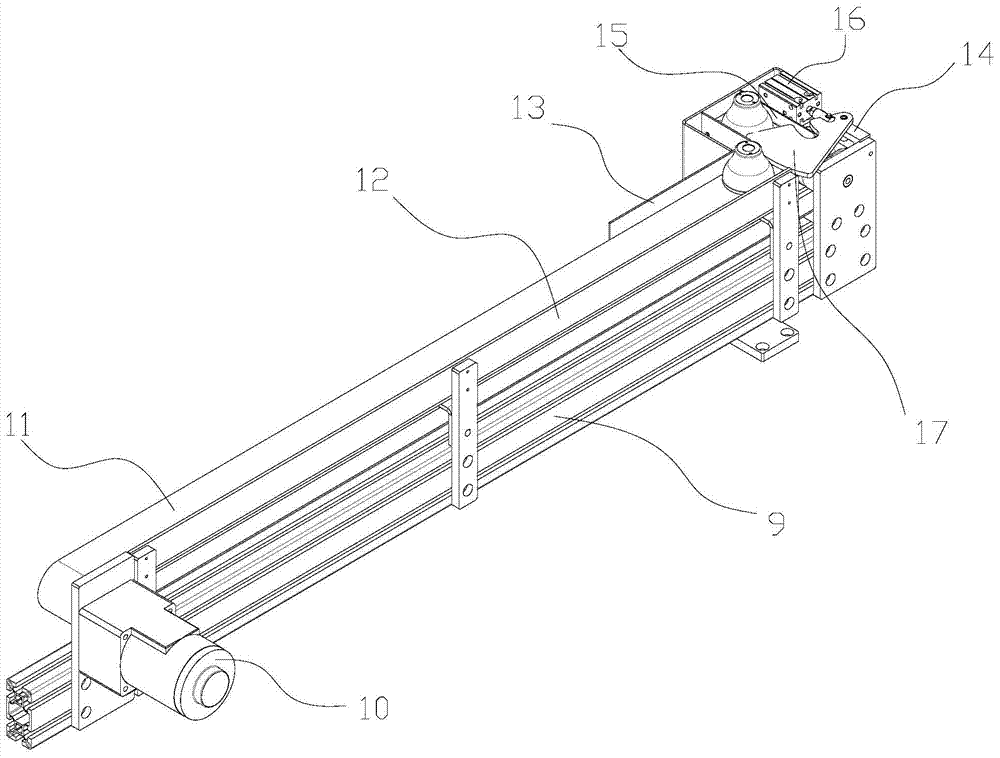

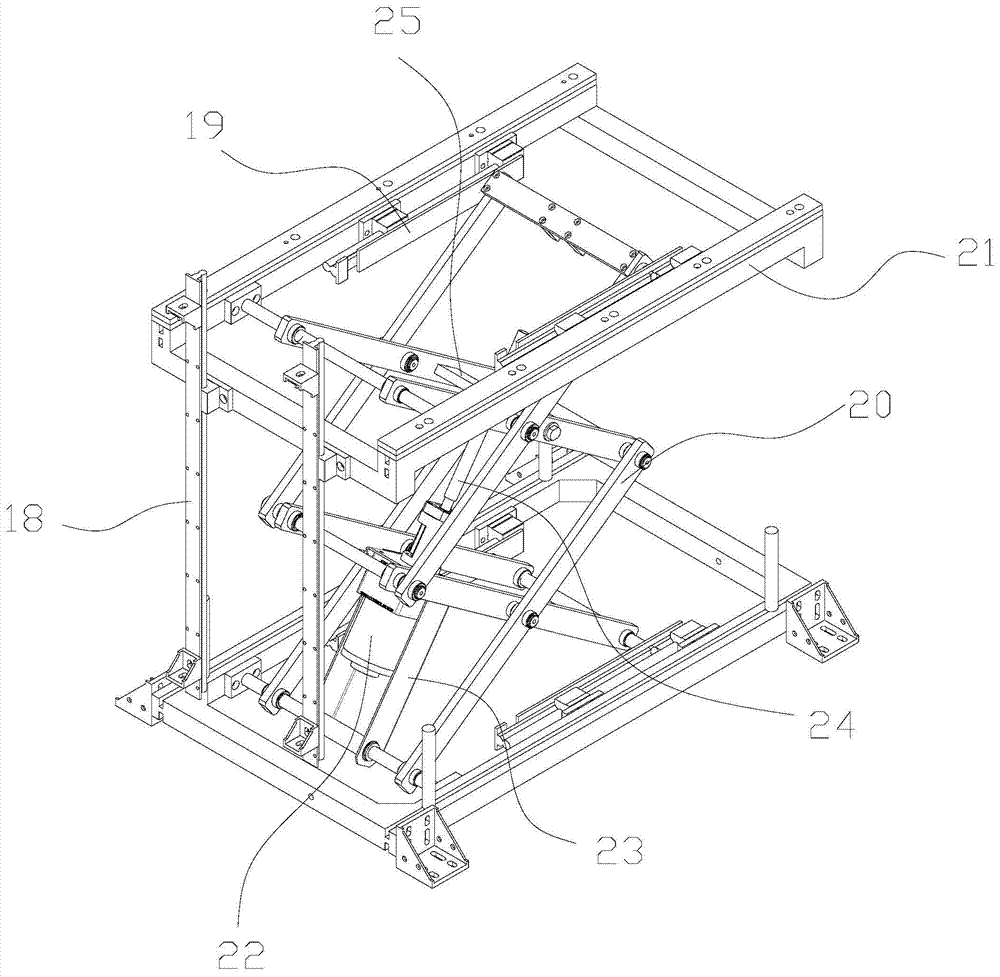

An automatic feeding device comprises a machine frame, a transmission mechanism, a lifting mechanism, a pushing mechanism, pulling mechanisms, a material taking mechanism, a rolling wheel frame and a product component tray; one side of the transmission mechanism is connected with the machine frame; the transmission mechanism which is arranged at a front row of the machine frame is arranged at a higher position of the machine frame; the pulling mechanisms, the lifting mechanism and the pushing mechanism are sequentially installed on the machine frame on the other side of the transmission mechanism; the pulling mechanisms are installed on bilateral sides at two ends of the transmission mechanism; the lifting mechanism can vertically rise and fall between the higher position and the lower position; the pushing mechanism is arranged at the higher position of the machine frame; the material taking mechanism which is installed on the machine frame is located at the rear row of the machine frame and the lower position of the machine frame; the rolling wheel frame moves between the material taking mechanism and the lifting mechanism; the product component tray is arranged on the rolling wheel frame and the material taking mechanism. The automatic feeding device has the advantages of achieving automatic material taking and feeding of the product components, being high in automatic degree, greatly improving the production efficiency by a large margin and meanwhile effectively protecting the product components.

Owner:AD TOYO LIGHTING GUANGZHOU

Automatic punching machine and punching method thereof

ActiveCN104325001AEasy to take outPrevent superimpositionMetal-working feeding devicesPositioning devicesPunchingMachining process

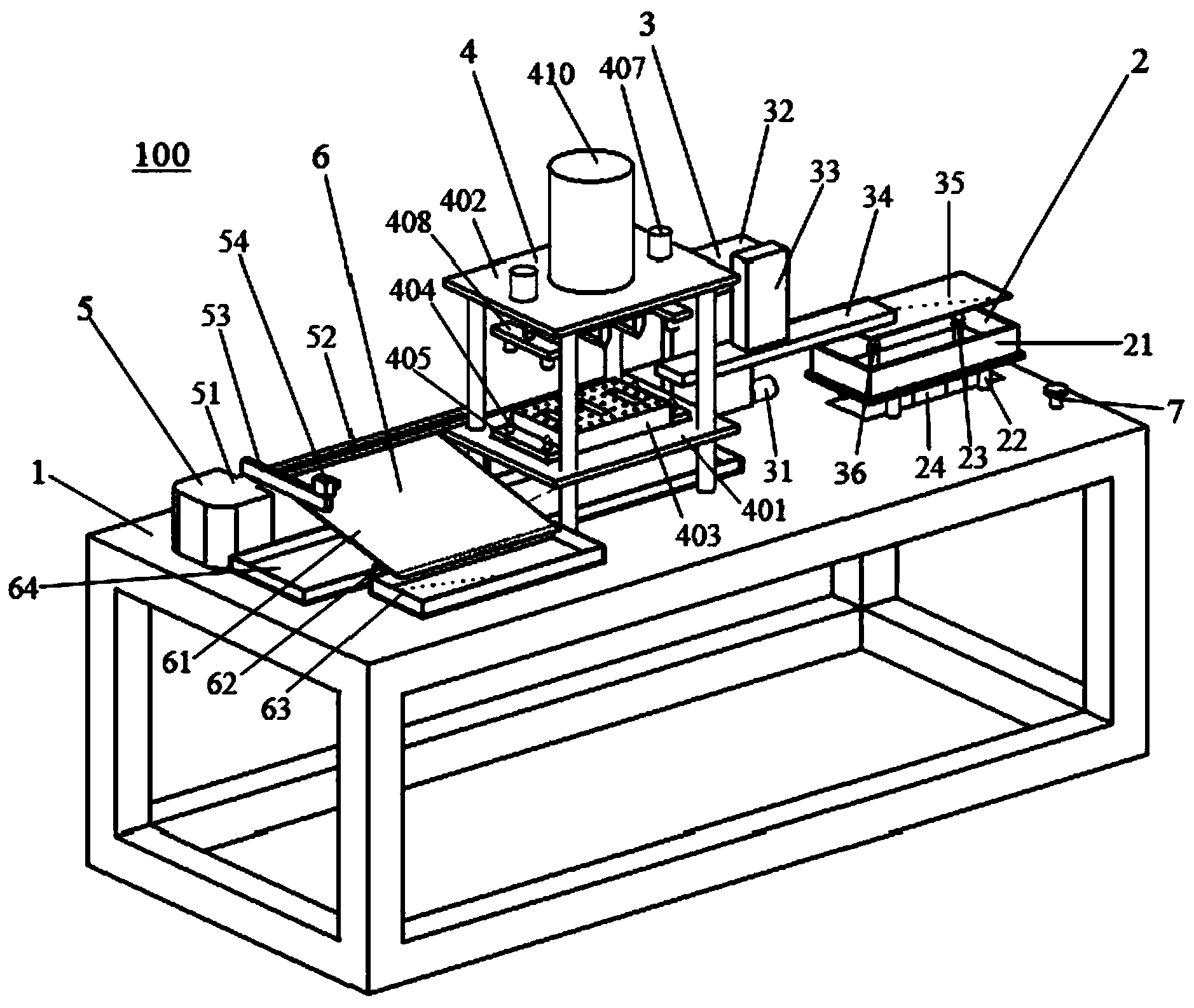

The invention provides an automatic punching machine and a punching method thereof. The automatic punching machine comprises a supporting base and a punching device positioned on the supporting base, and also comprises a material storage device positioned on the supporting base and used for storing raw materials, a conveying device positioned between the material storage device and the punching device and used for conveying the raw materials, a blanking device positioned behind the punching device and used for blanking and a material collecting device for collecting processed materials; the punching device comprises a first locating column with a locating function, a press plate with a locating correction function and a lower die with an air suction hole. The automatic punching machine is provided with the dual locating device and the die with levelling and stabilizing functions, so that the punching precision is greatly improved, the whole processing process is a full-automatic process, the manpower is saved, the production efficiency is also improved and the product quality is improved.

Owner:KUNSHAN LONGPENG PRECISION ELECTRONICS

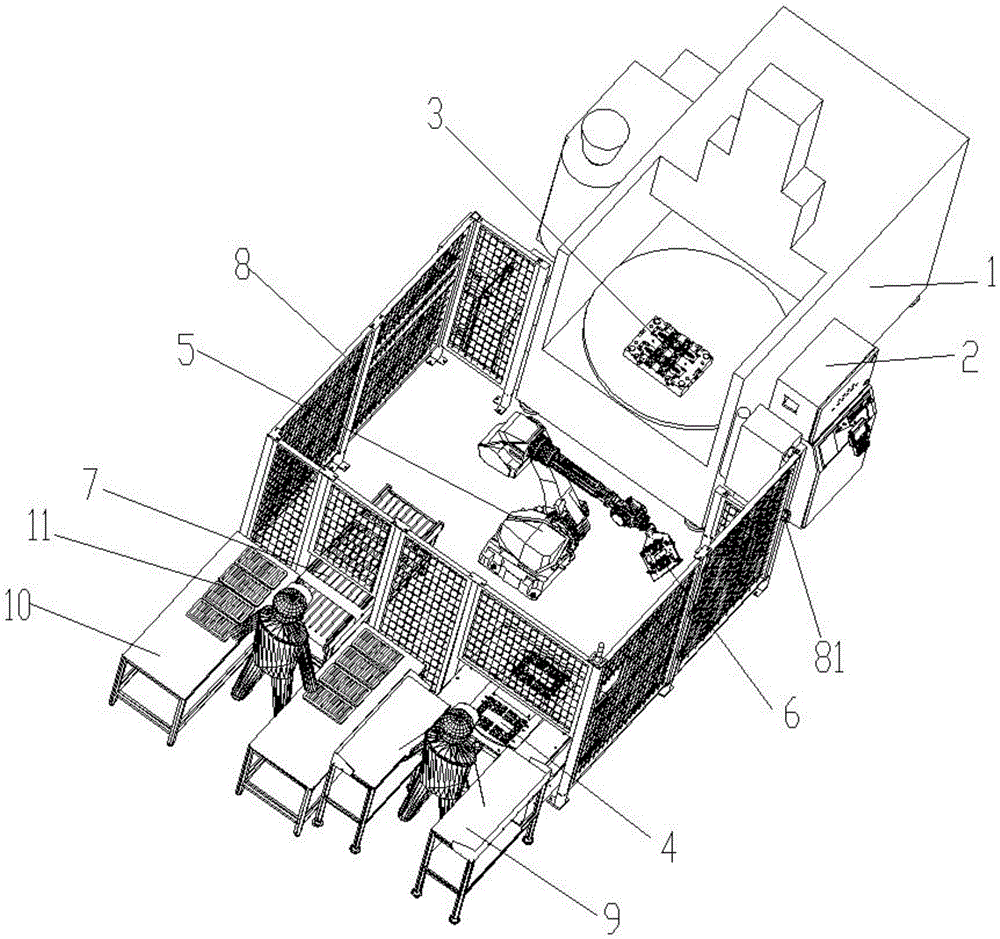

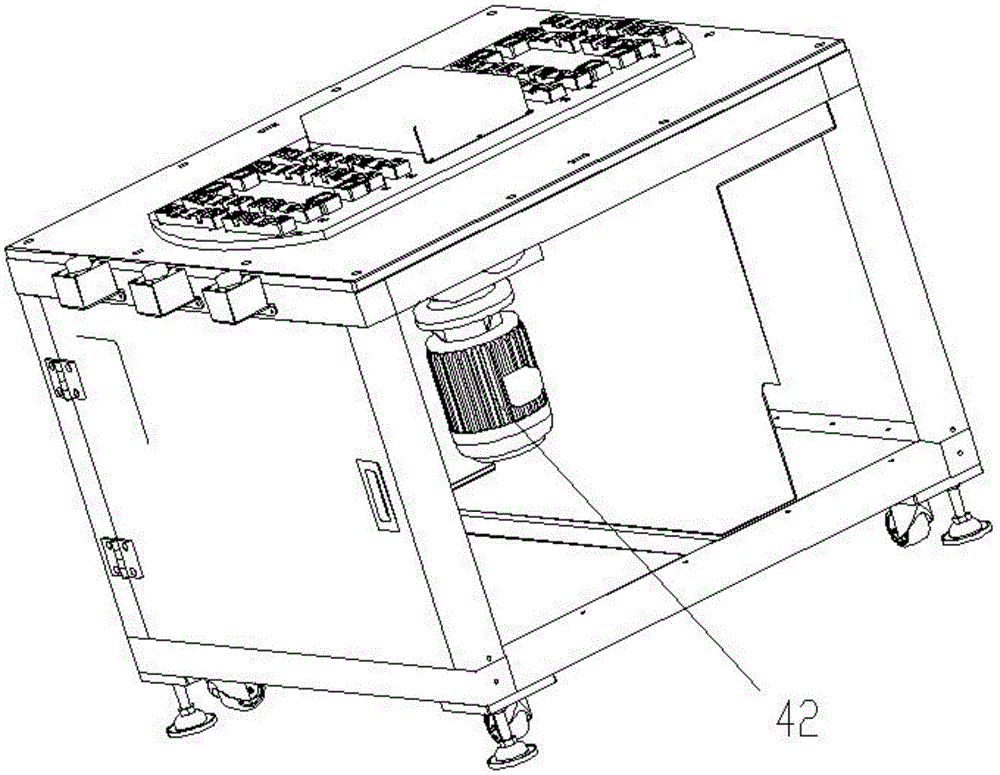

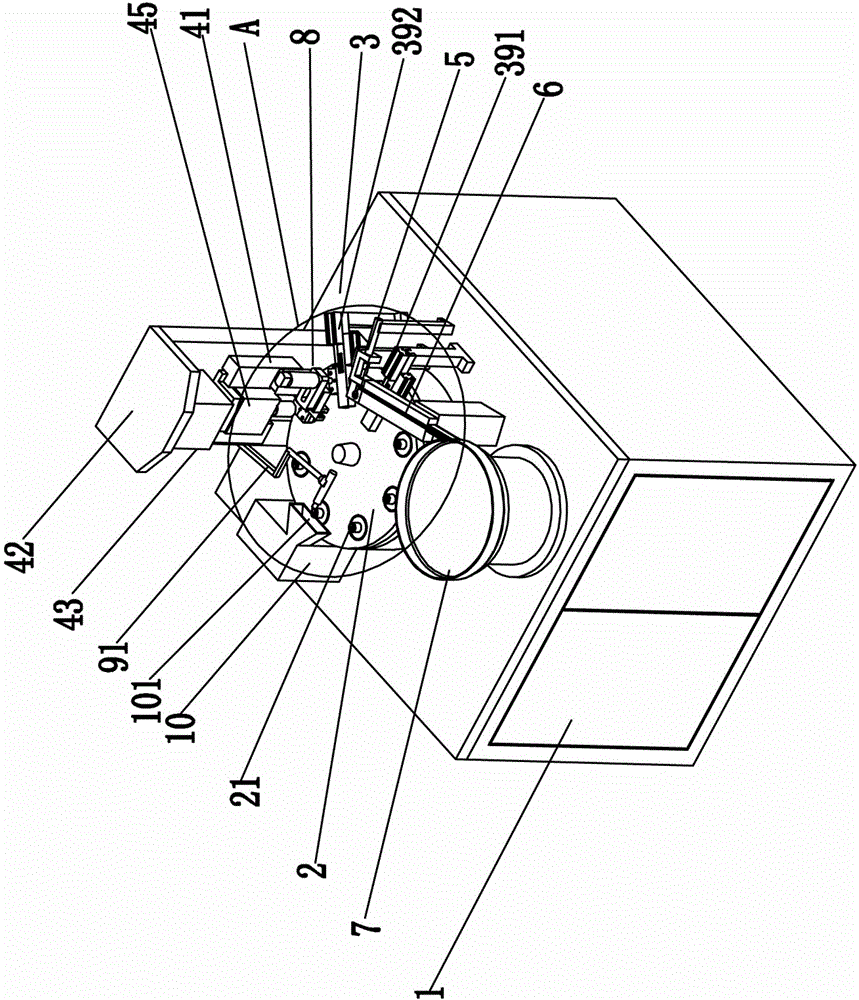

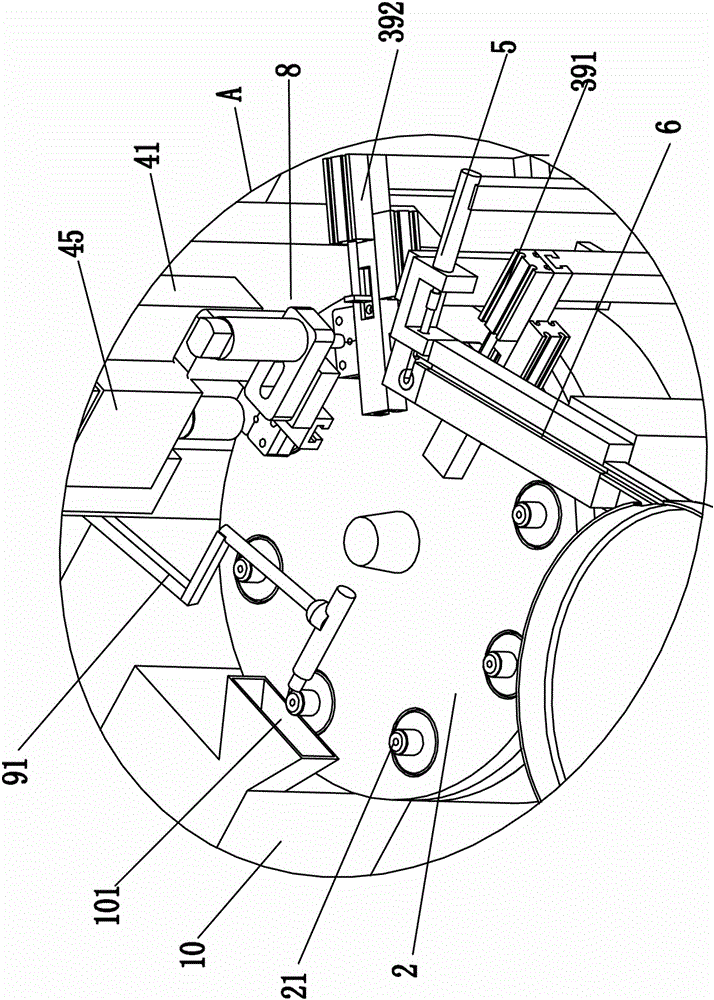

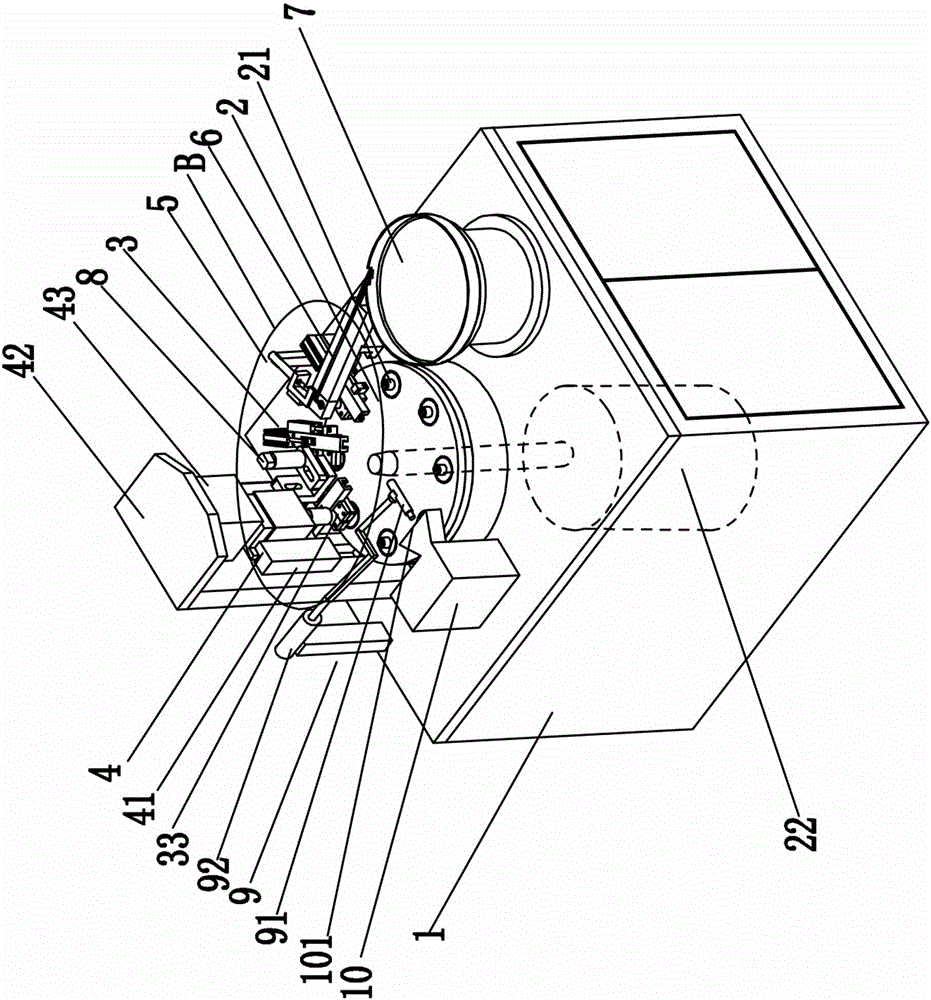

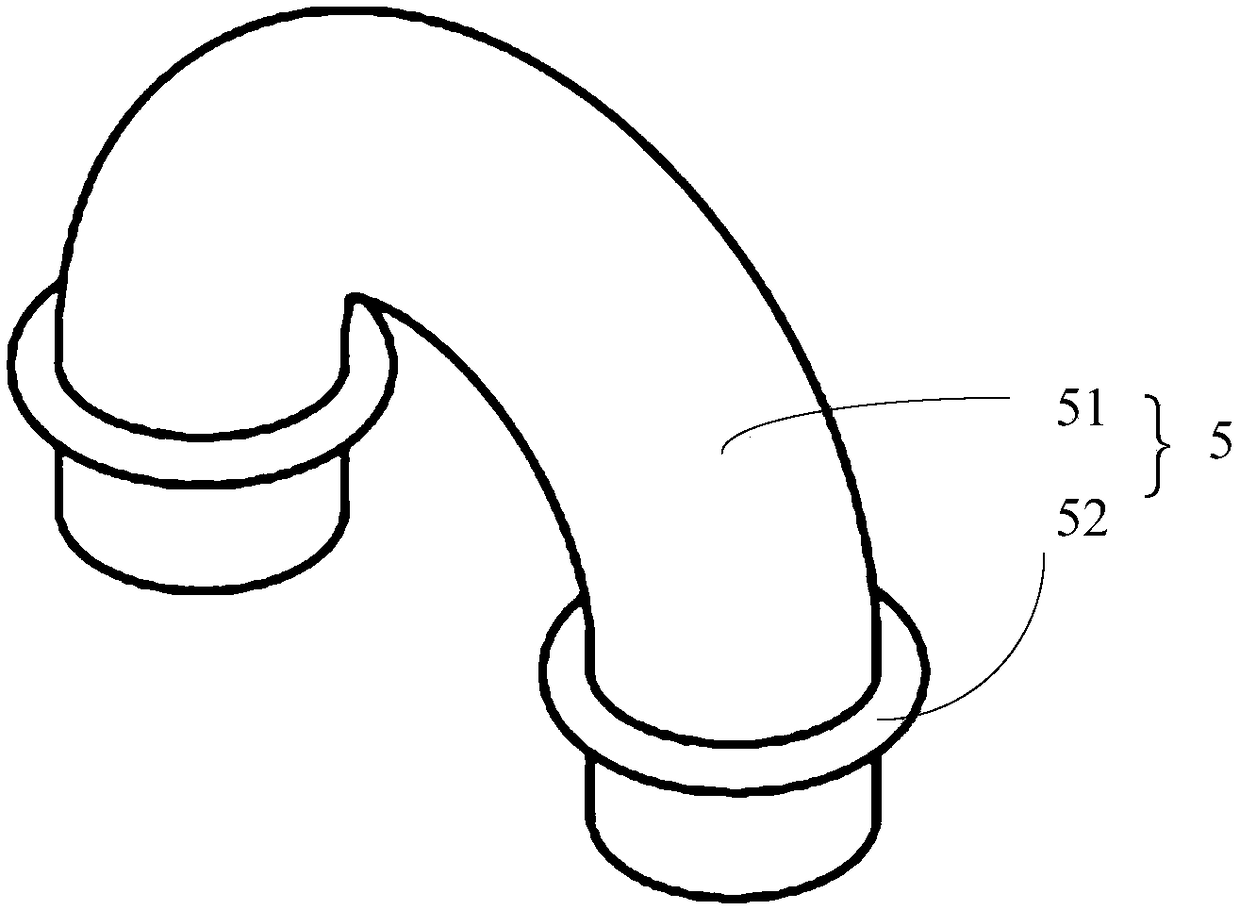

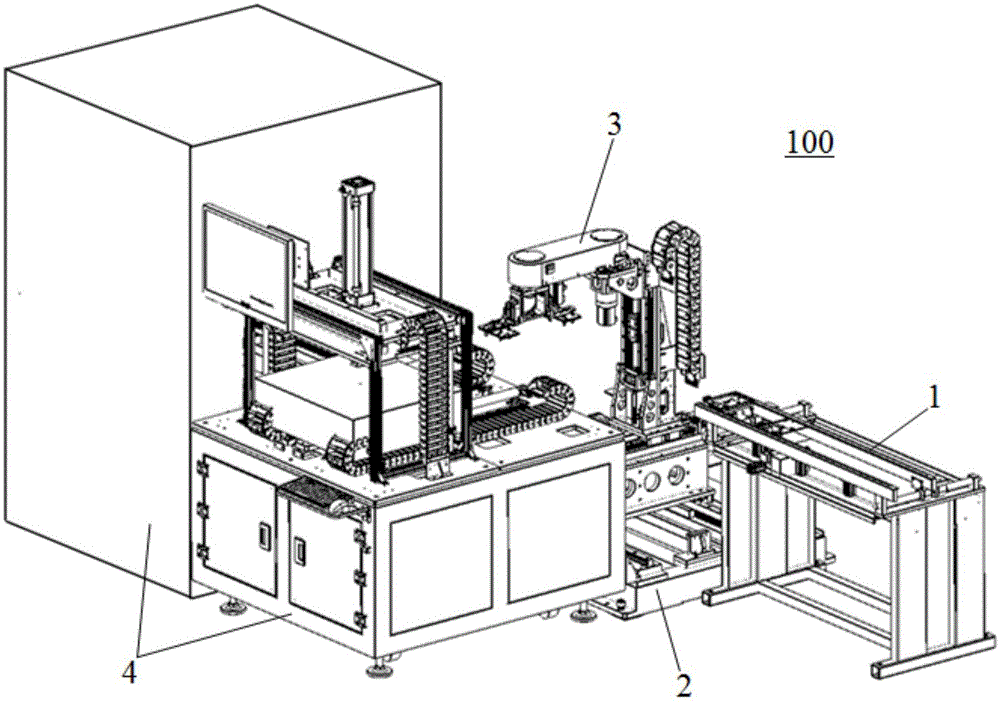

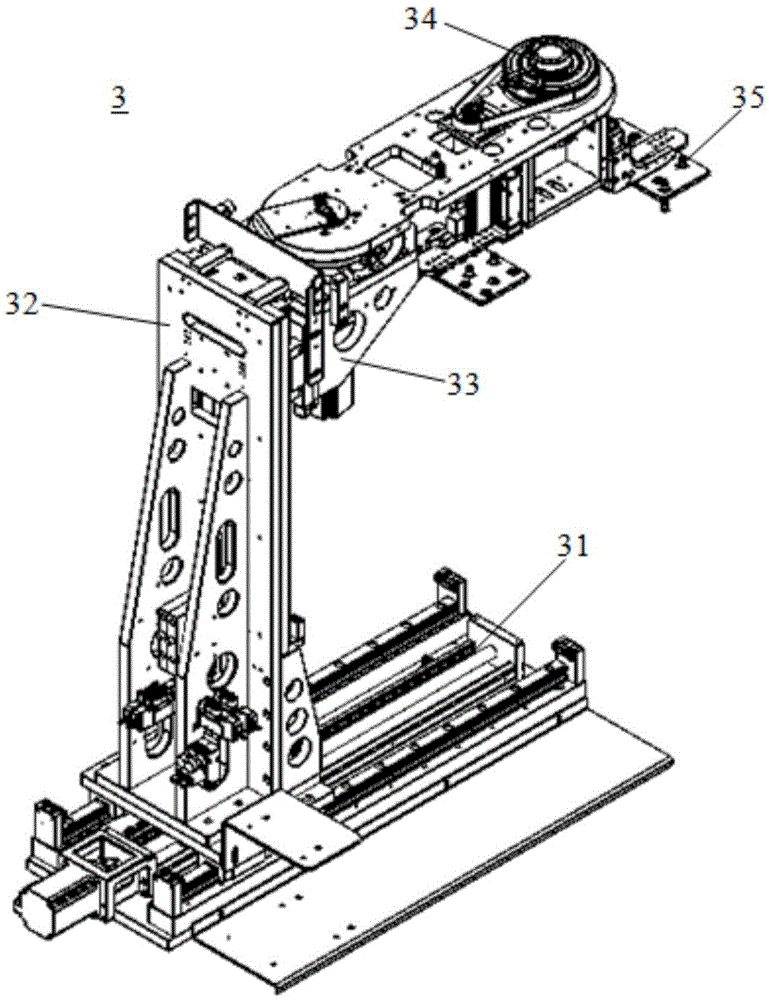

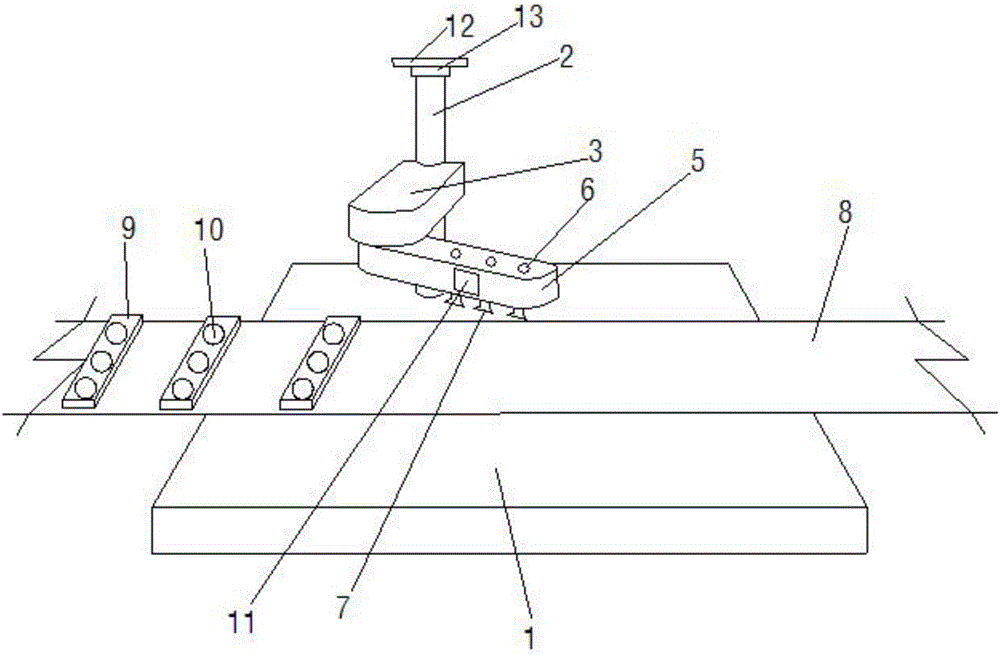

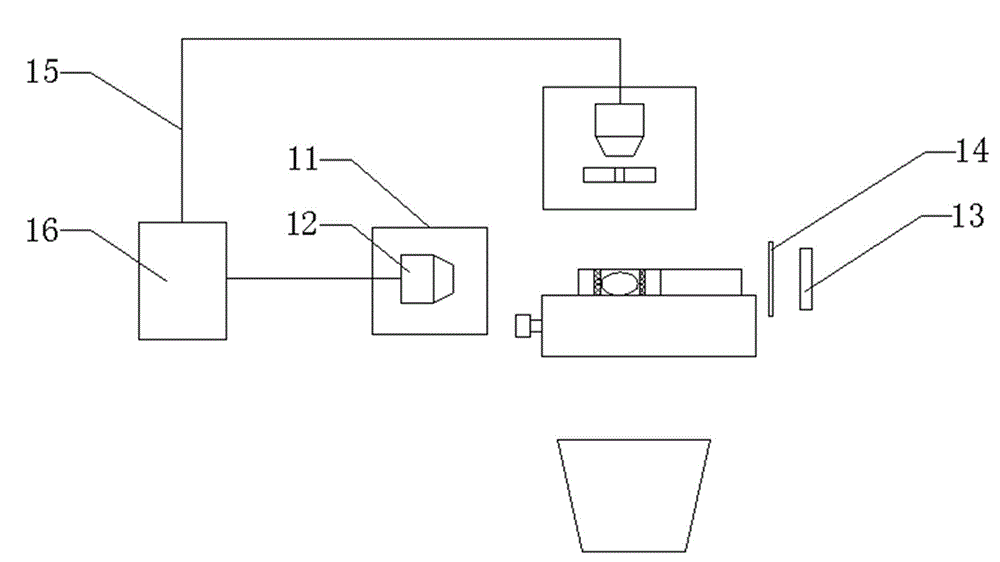

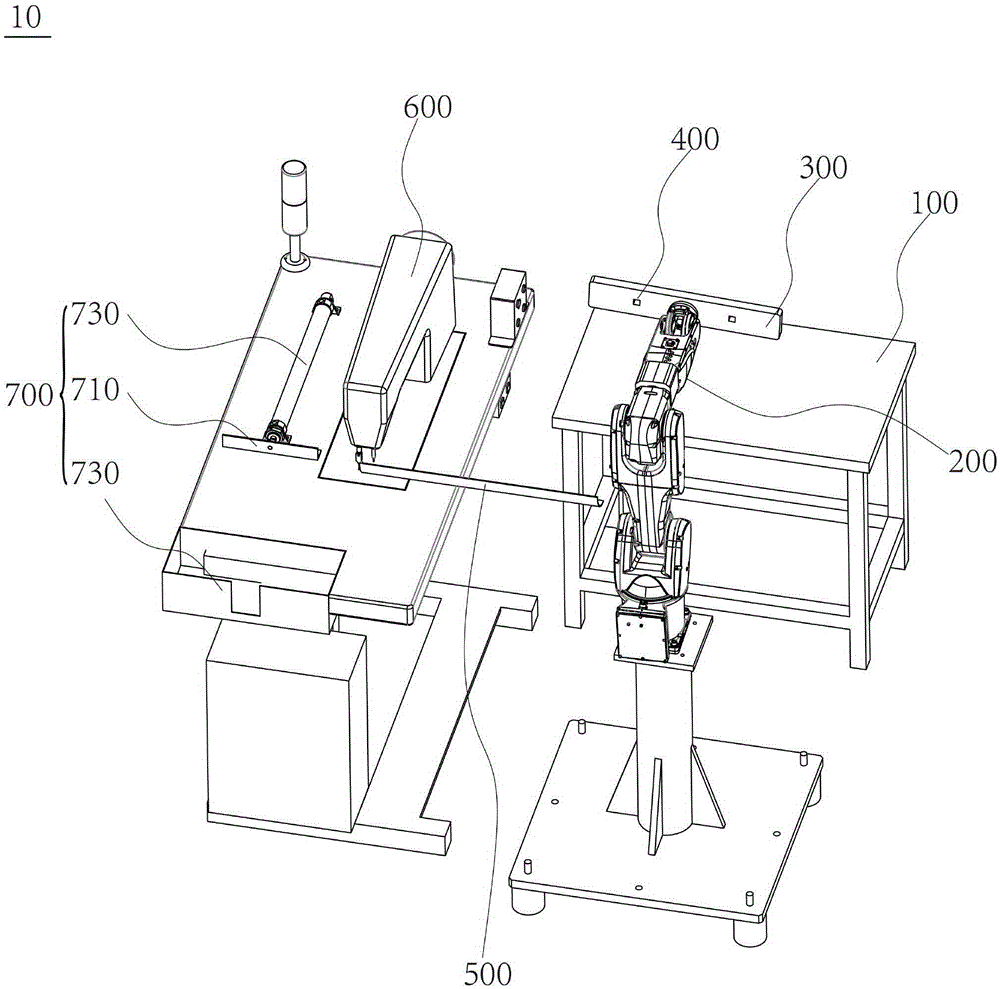

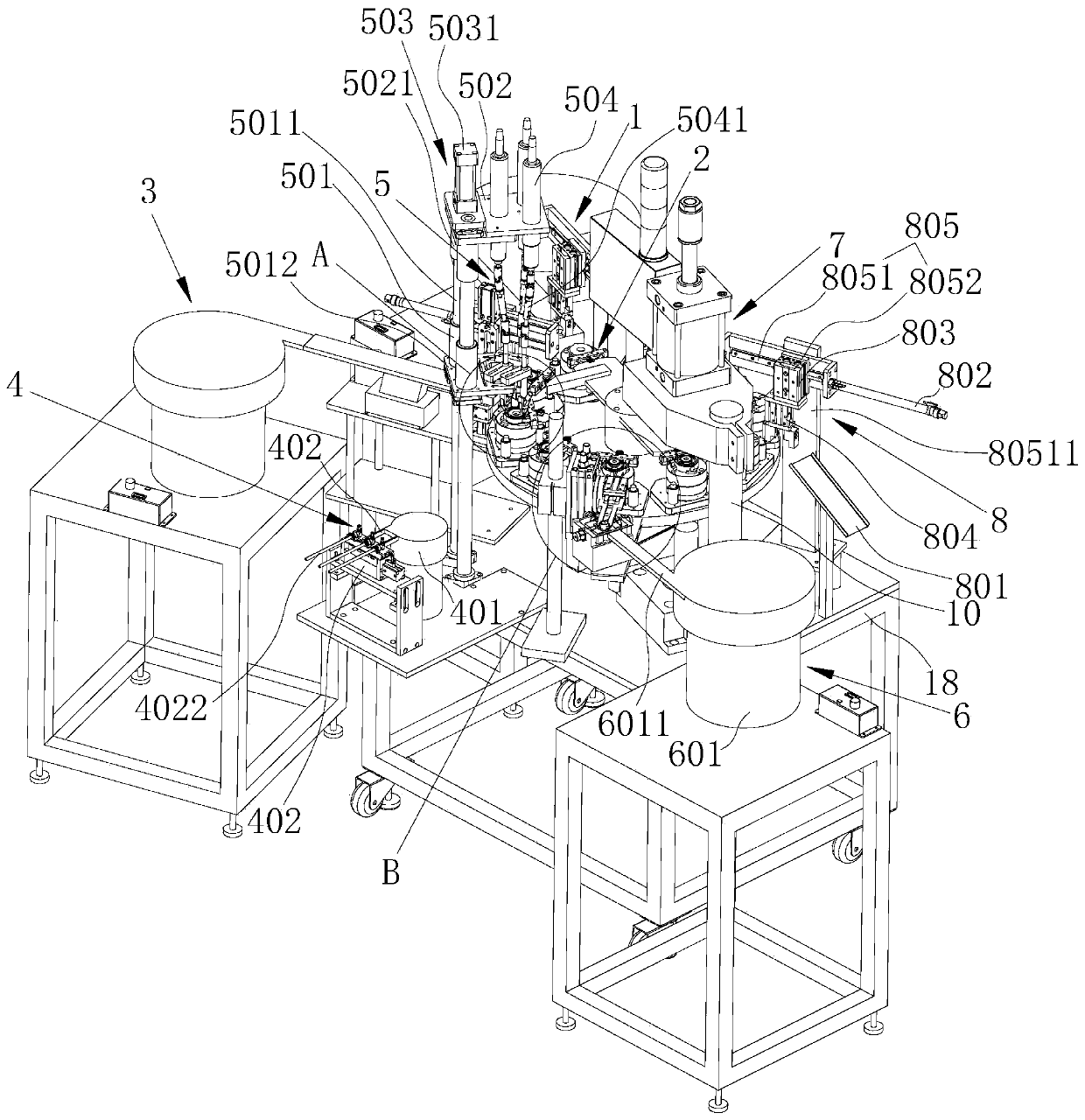

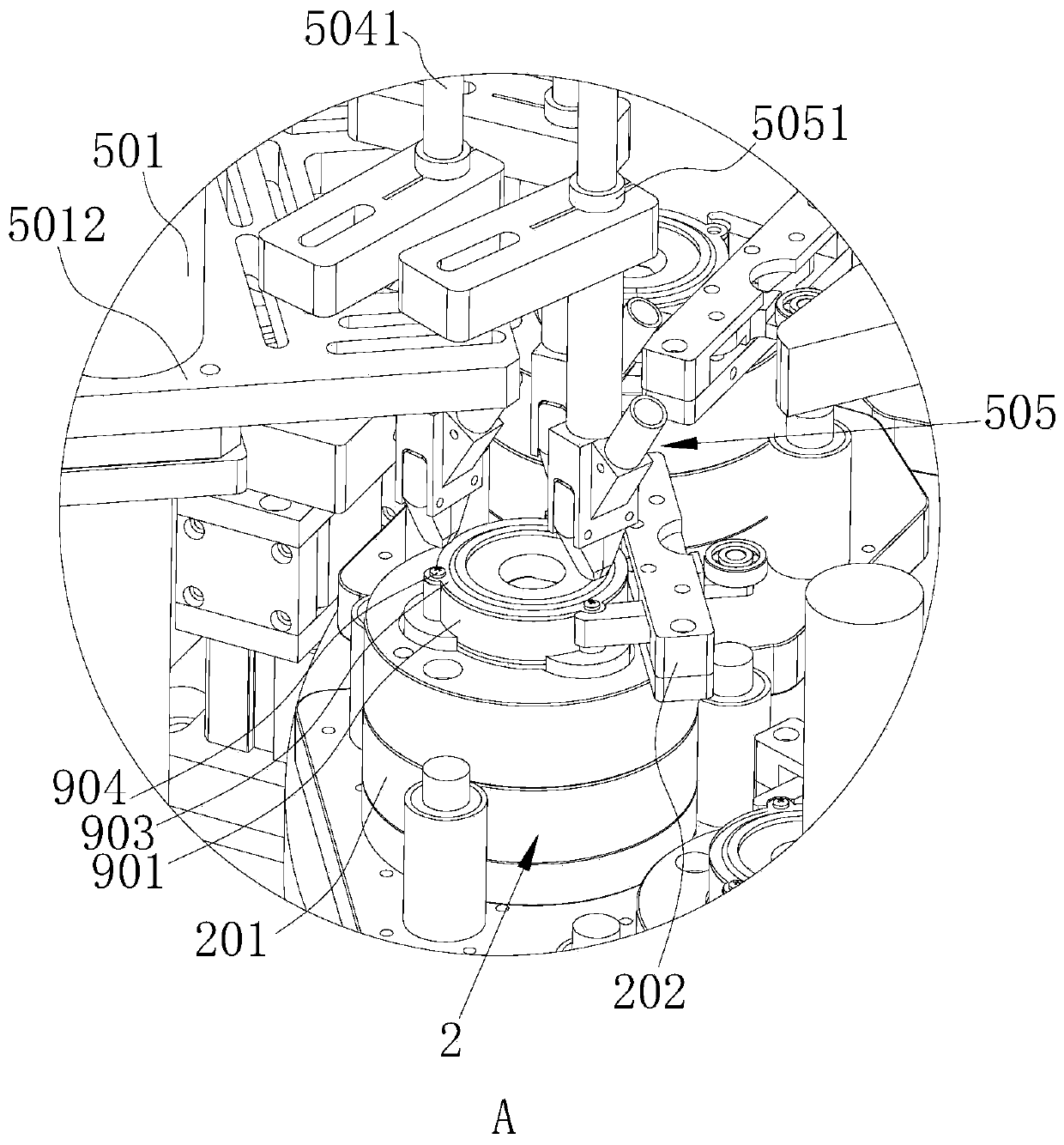

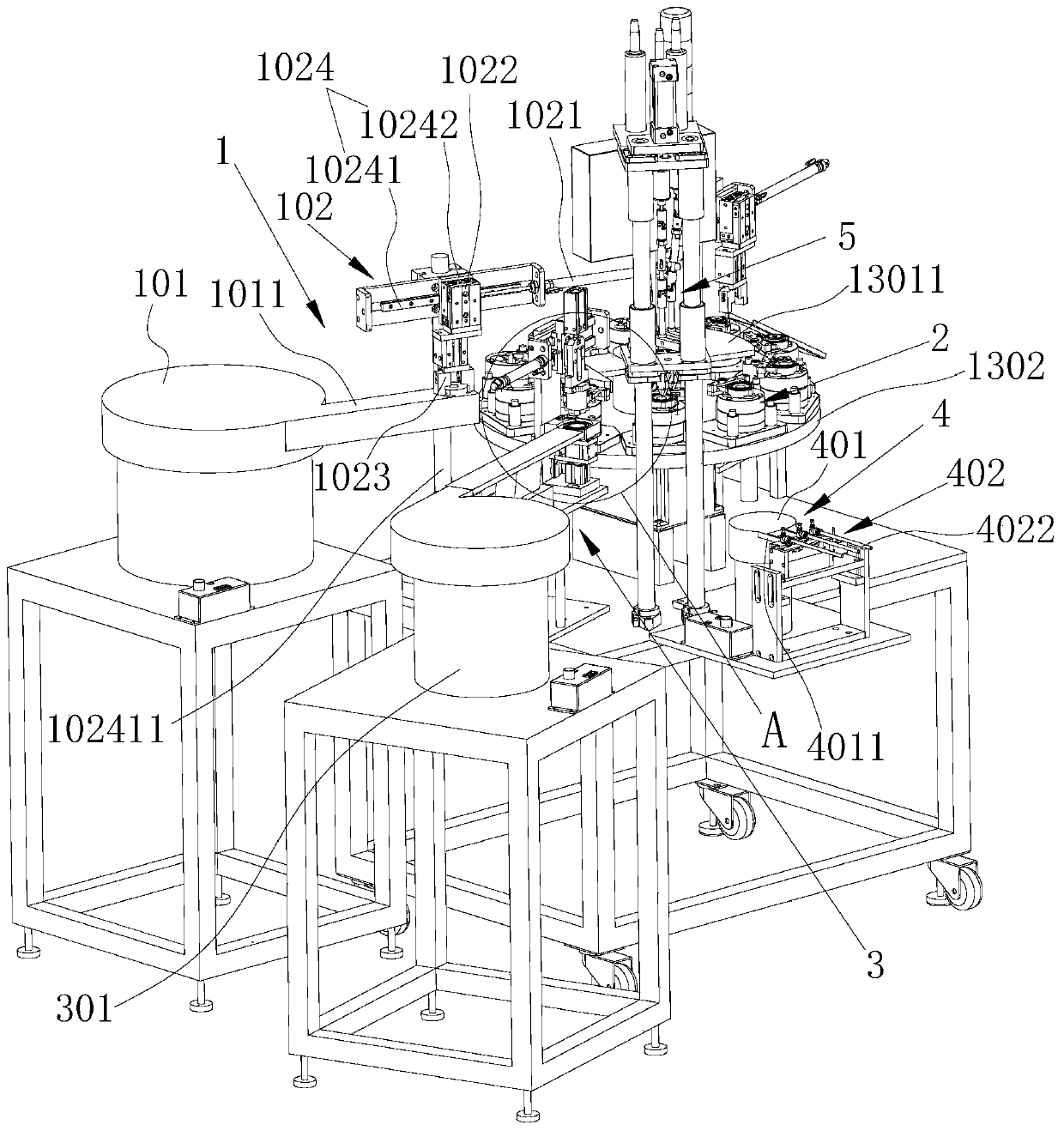

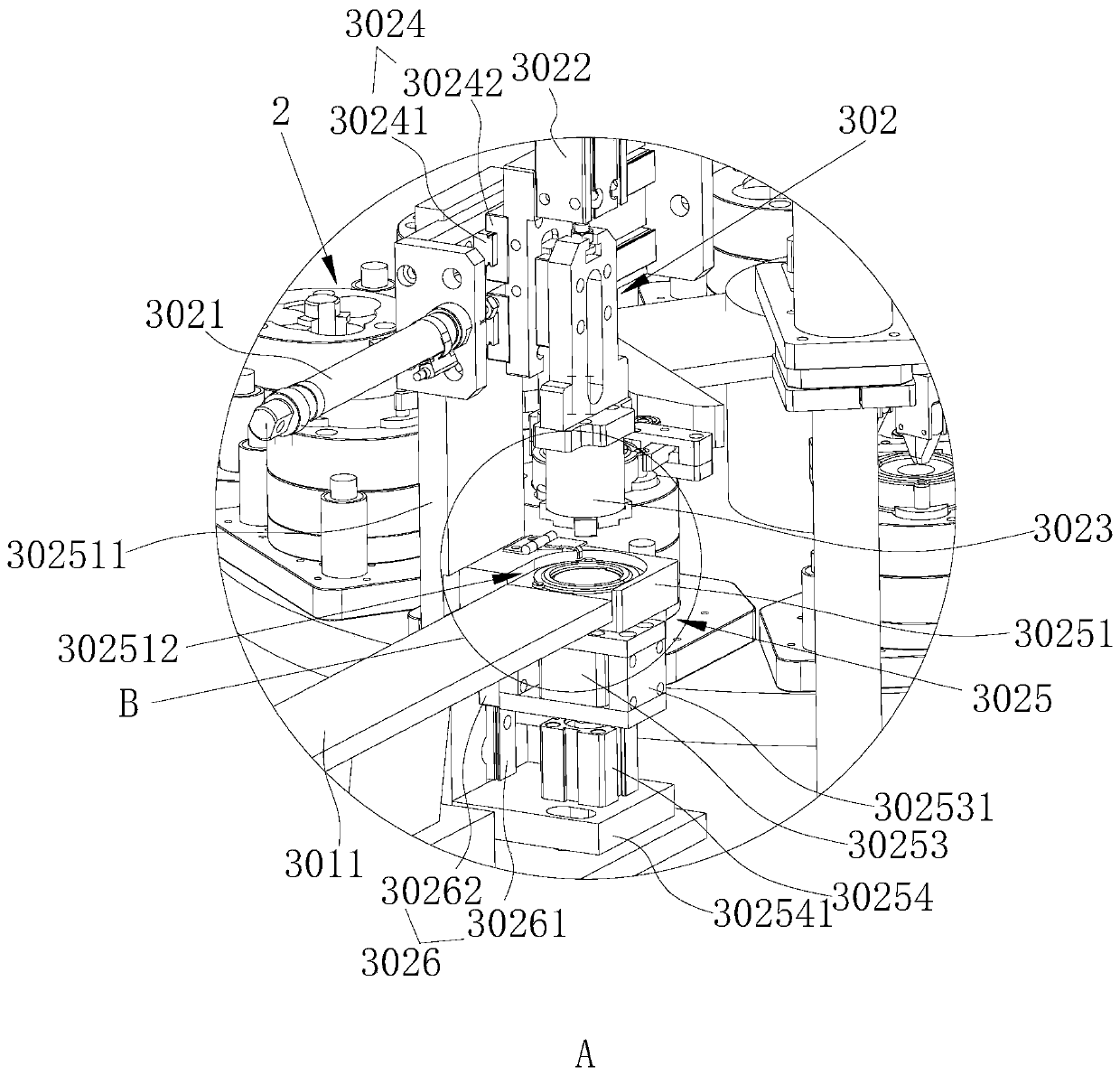

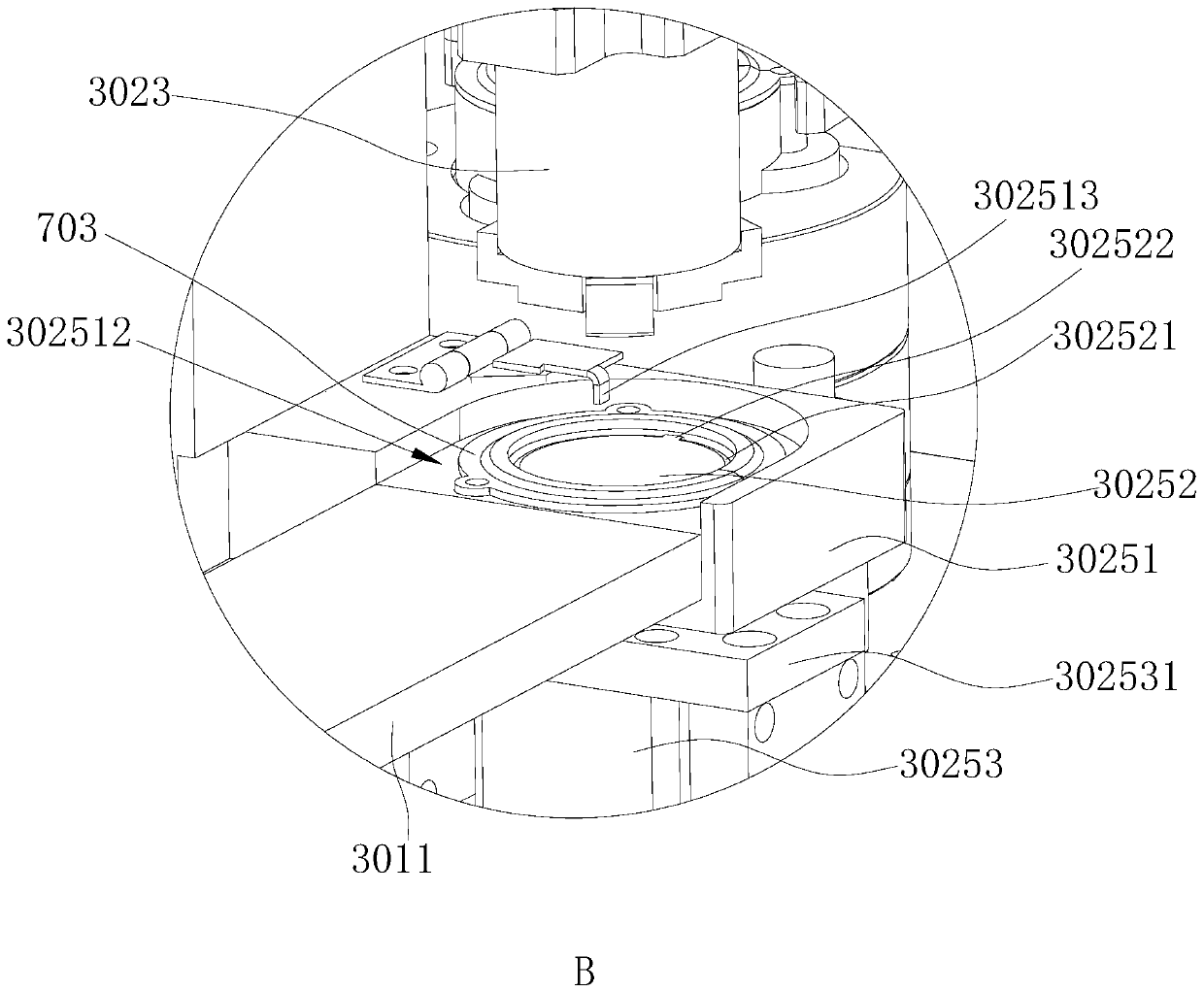

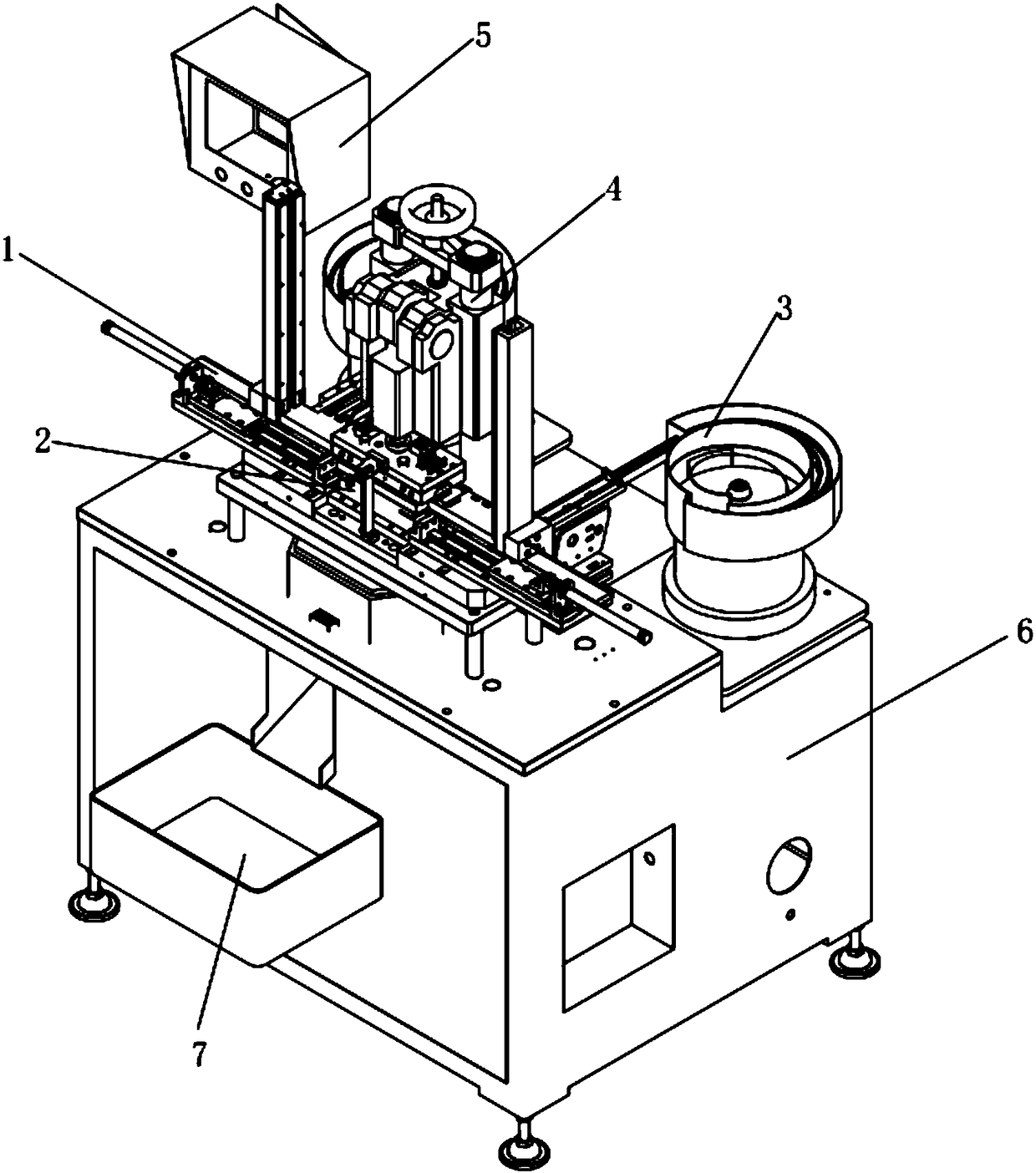

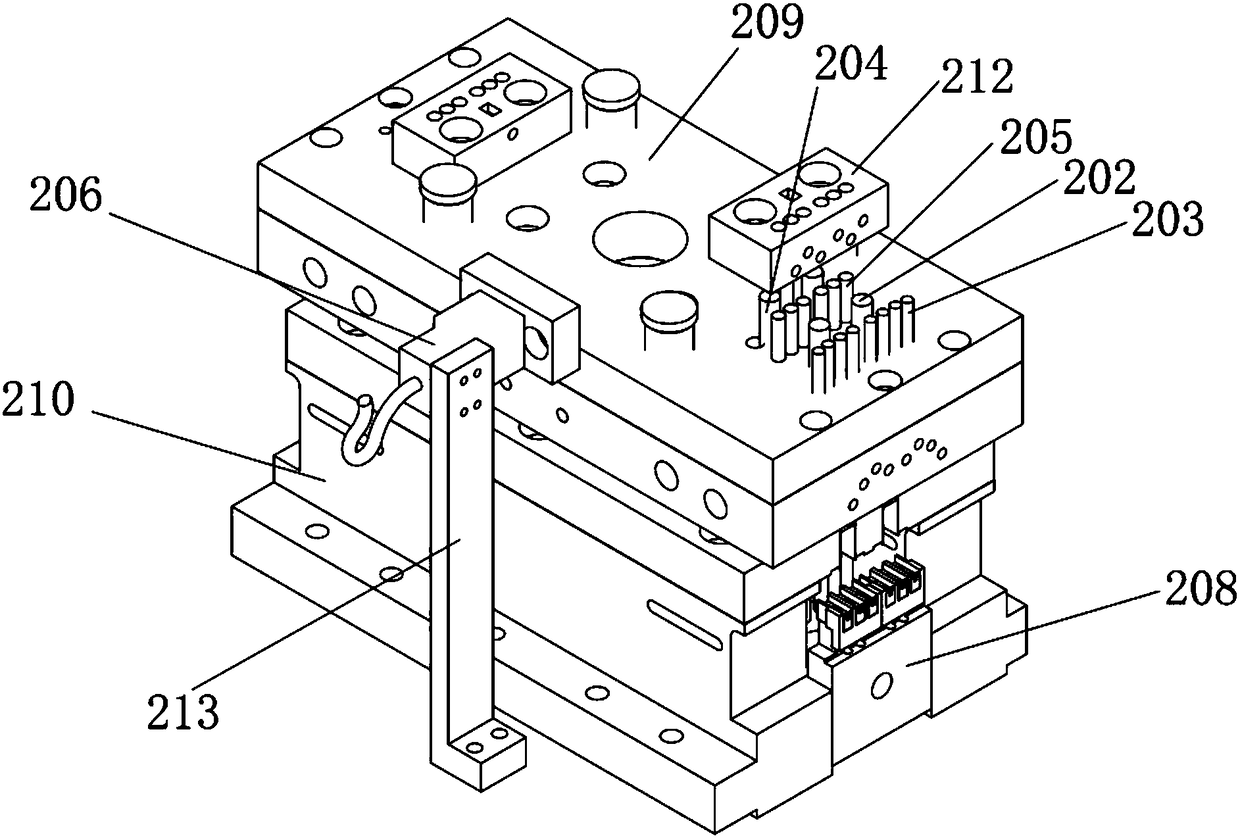

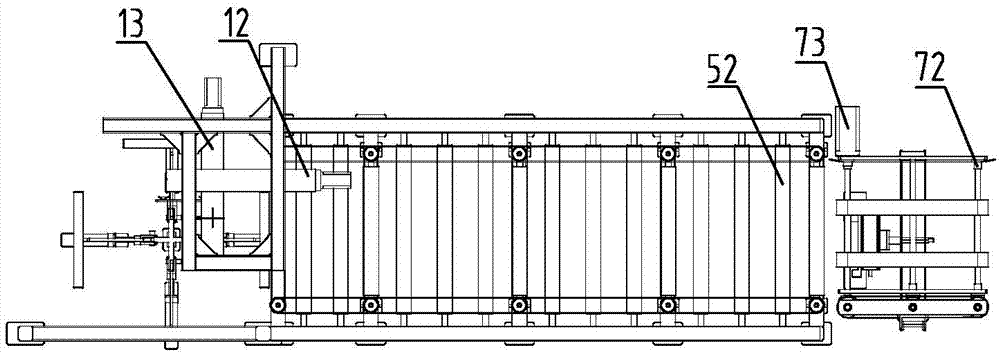

Automatic production device for encapsulation and injection molding of inserts

ActiveCN105538595ARealize automatic reclaimingRealize semi-automatic productionCoatingsSemi automaticInjection molding machine

The invention discloses an automatic production device for encapsulation and injection molding of inserts. The automatic production device comprises an injection molding machine, a controller, a die, a rotary feeding device, a feeding robot, a product grabbing and putting gripper and a belt conveying device. The use direction serves as the benchmark. The die is installed on the injection molding machine. The controller is arranged on the side edge of the injection molding machine. The rotary feeding device and the belt conveying device are arranged in front of the injection molding machine side by side in a spaced manner. The feeding robot is arranged between the injection molding machine and the rotary feeding device. The product grabbing and putting gripper is rotationally connected to the feeding robot. The controller is connected with the rotary feeding device, the feeding robot and the belt conveying device through communication. According to the automatic production device for encapsulation and injection molding of the inserts, semi-automatic production of encapsulation and injection molding of the inserts can be achieved, at least two laborers are saved, production time is shortened, production efficiency is improved, and cost is reduced.

Owner:KUNSHAN SPEED AUTO MACHINERY CO LTD

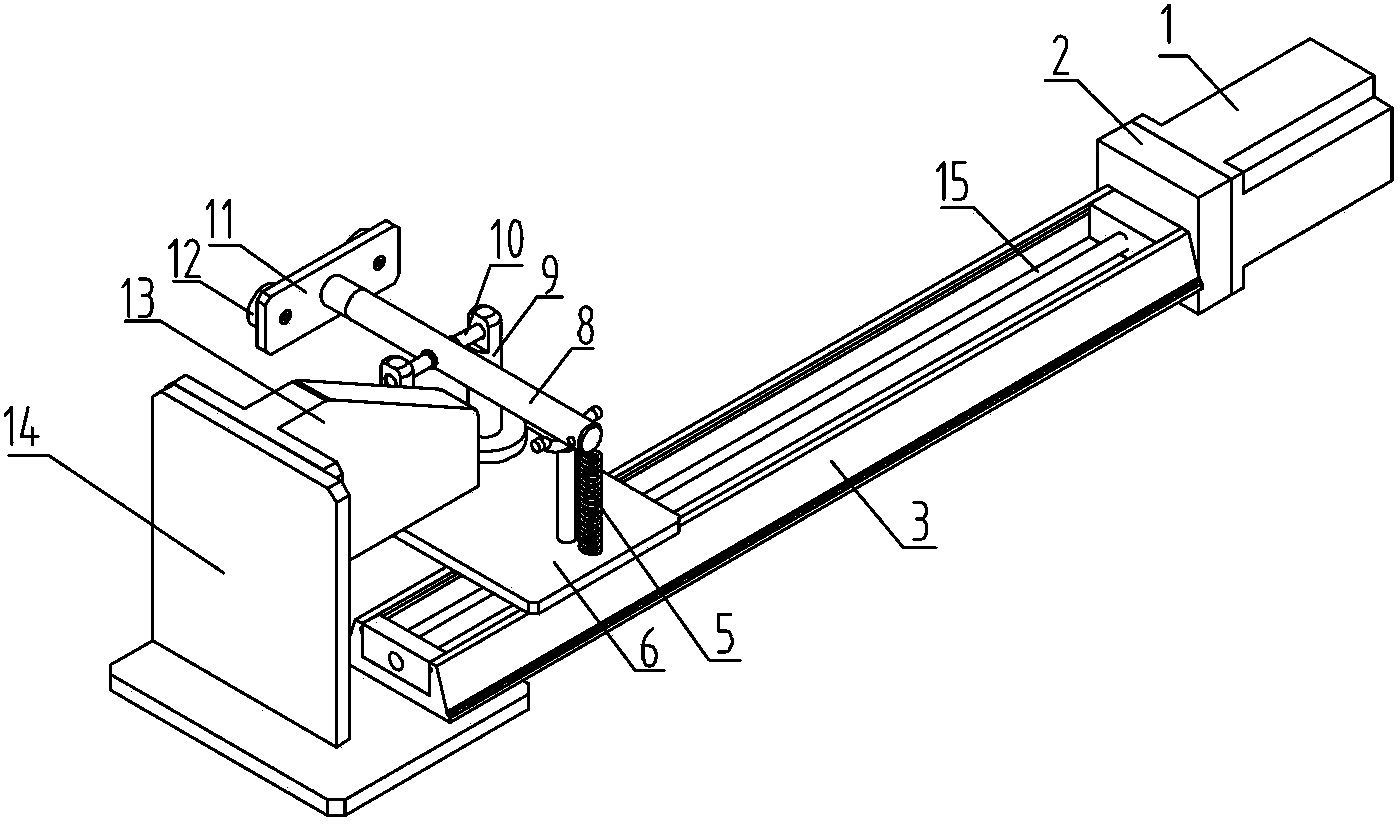

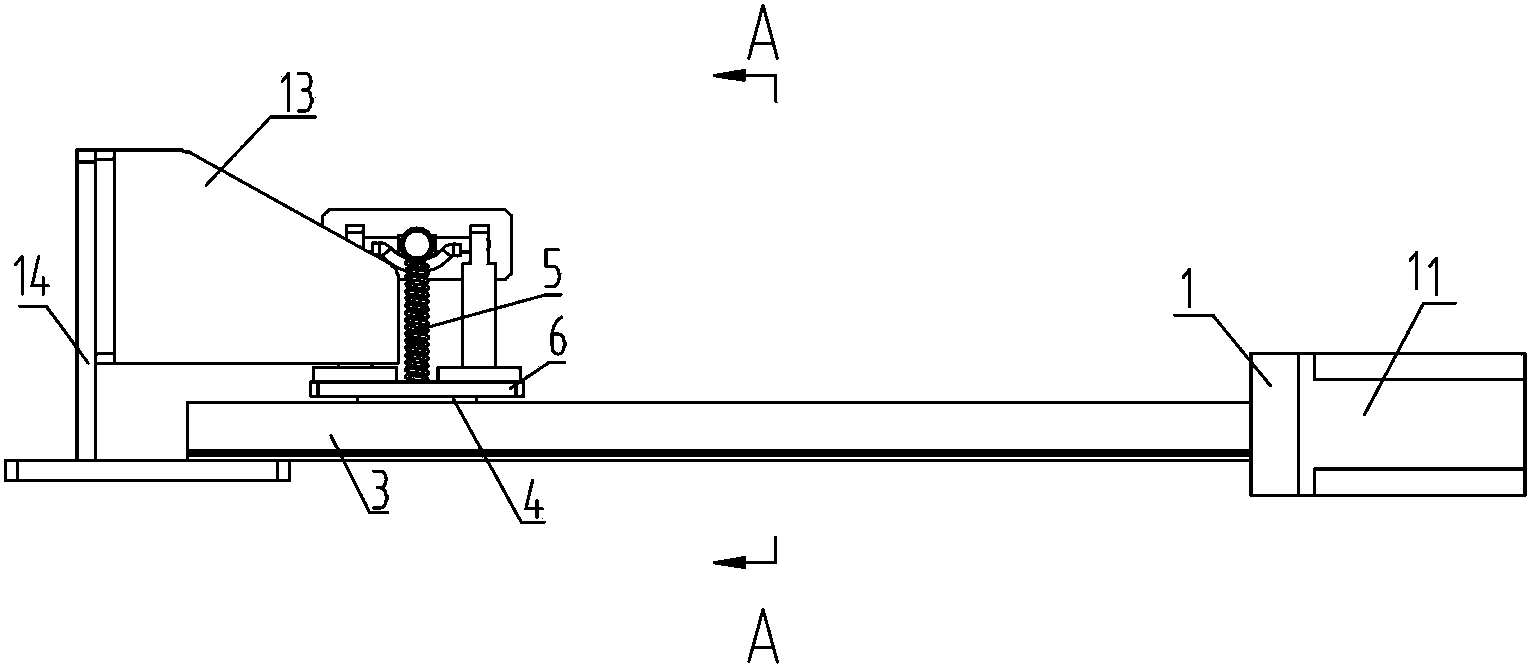

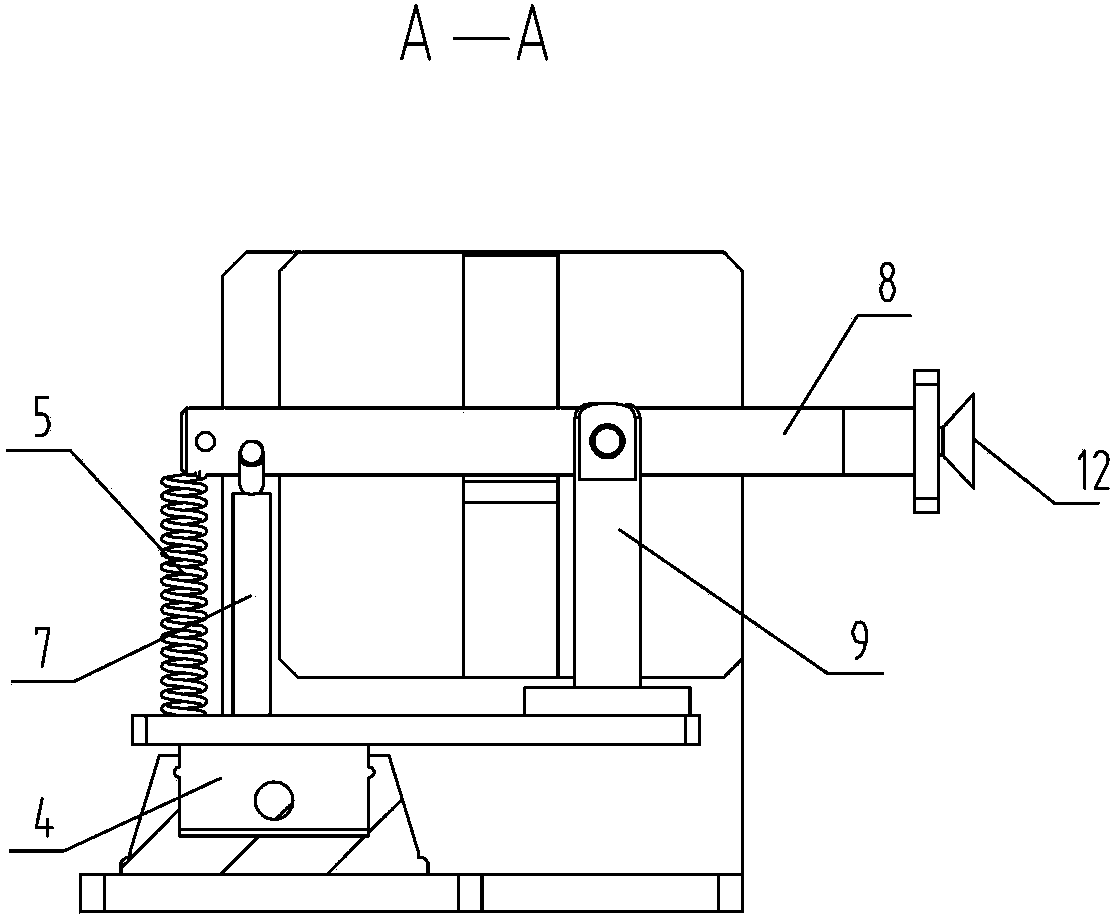

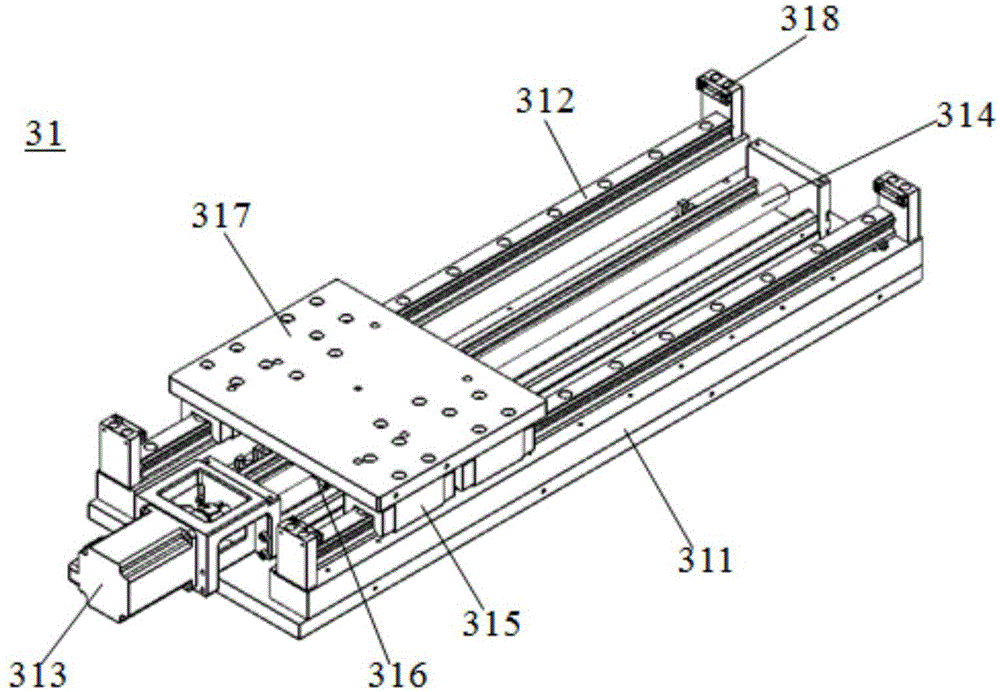

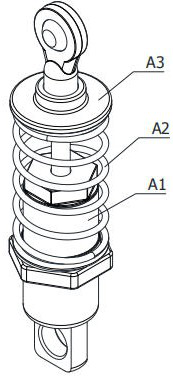

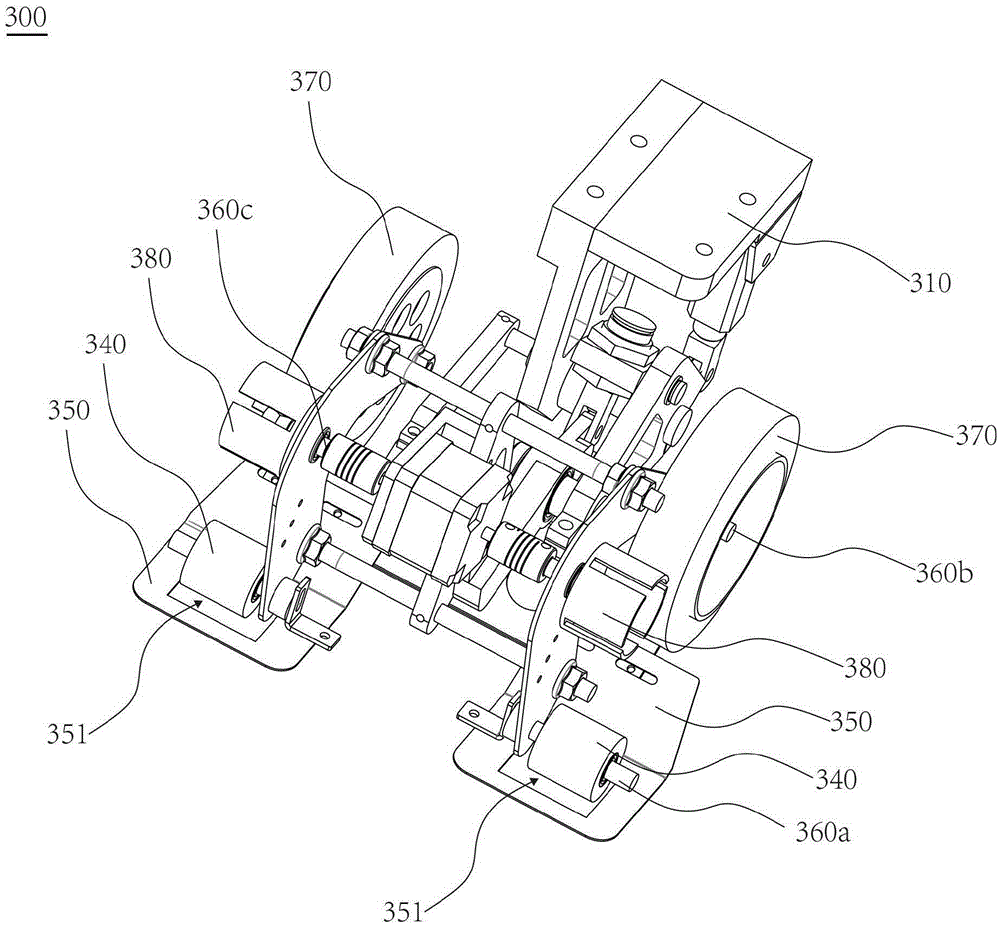

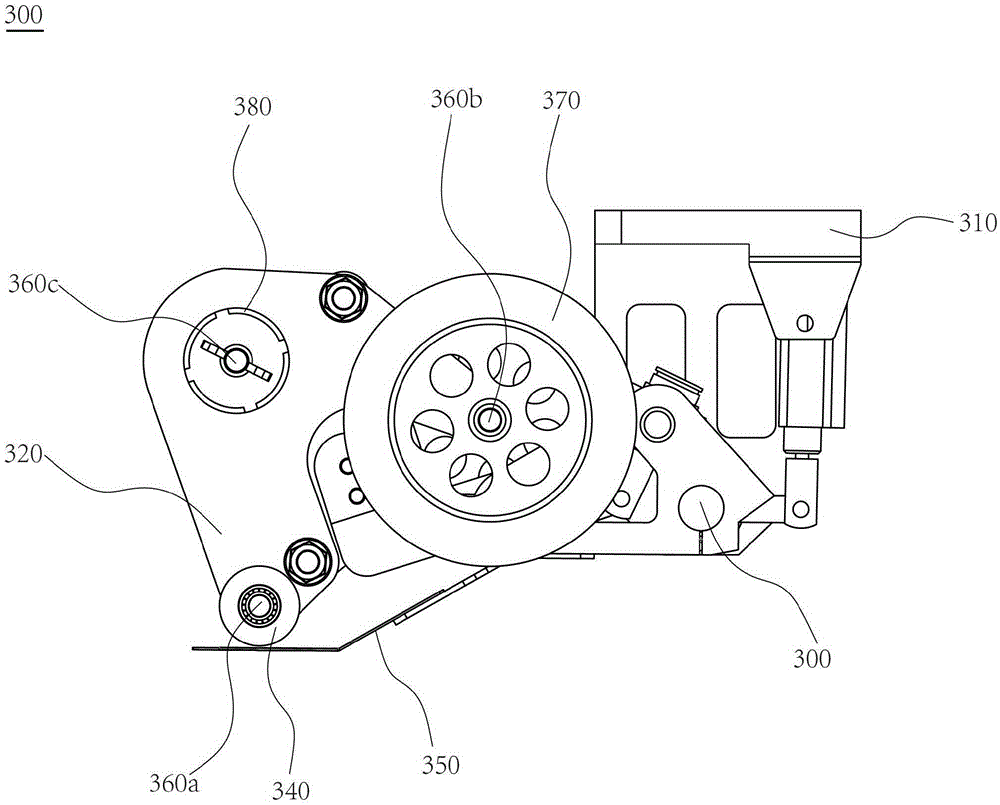

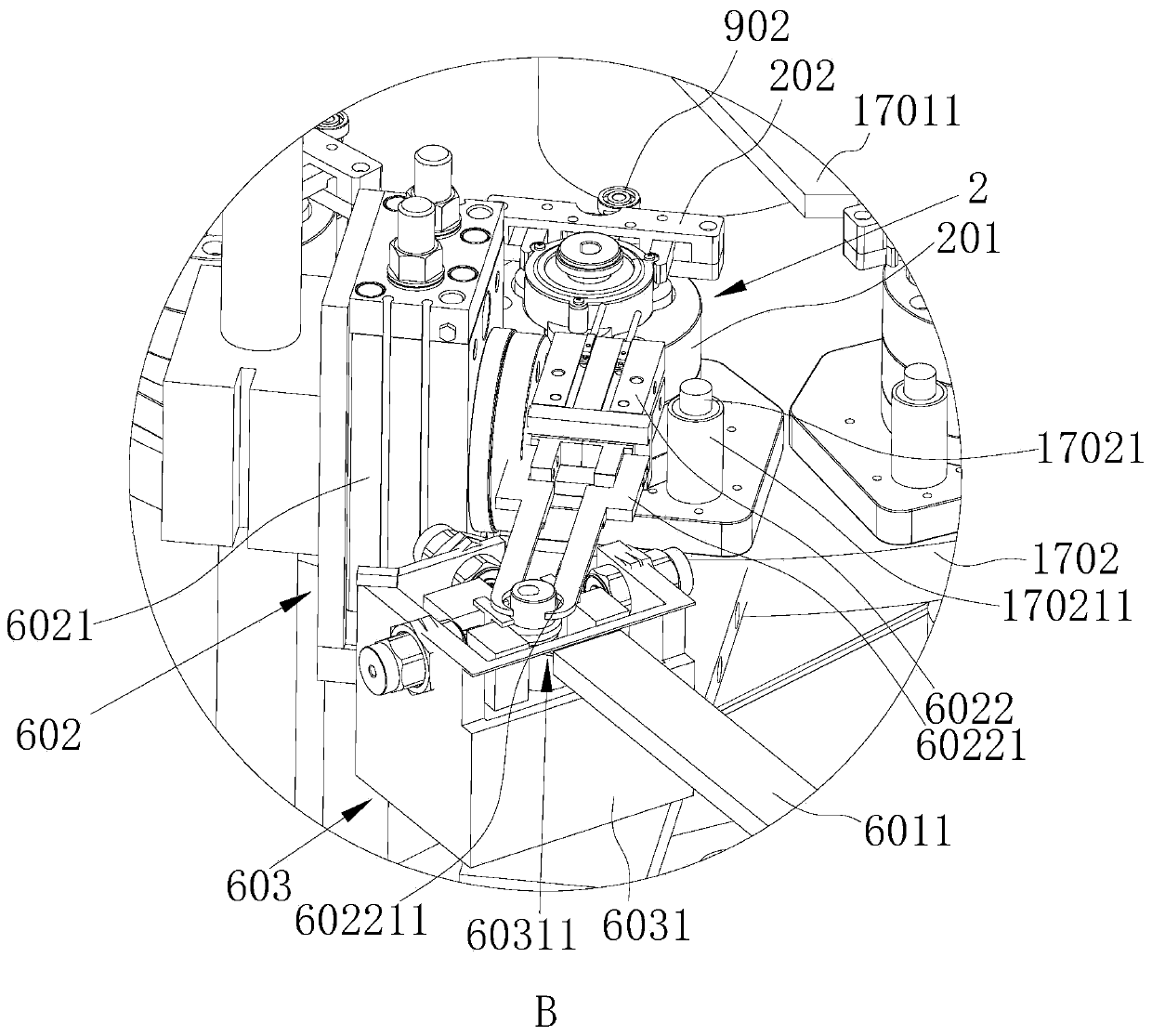

Polar plate reclaiming mechanism of full-automatic plate coating machine for accumulator plate

InactiveCN103413963ARealize automatic reclaimingSimple structureFinal product manufactureSecondary cells manufactureEngineeringCell processing

The invention relates to a cell processing equipment module, especially a polar plate reclaiming mechanism of a full-automatic plate coating machine for accumulator plates. The reclaiming mechanism comprises a servo motor, a KK module group, a transposition block and a reclaiming lever. One end of the reclaiming lever is provided with a sucker mount, which is equipped with two negative pressure suckers; and the other end of the reclaiming lever is connected to a spring. The transposition block is in an inclined trapezoid shape; slope part faces the reclaiming lever; a side surface closes to two vertical support bars; and the front upper surface of the trapezoid is lower than the height of the reclaiming lever in a horizontal state. The polar plate reclaiming mechanism of the full-automatic plate coating machine for accumulator plates has simple structure, realizes automatic reclaiming, changes vertical polar plate into horizontal state after reclaiming, and increases working efficiency.

Owner:ZHANGJIAGANG ZHIZHOU IND TECH

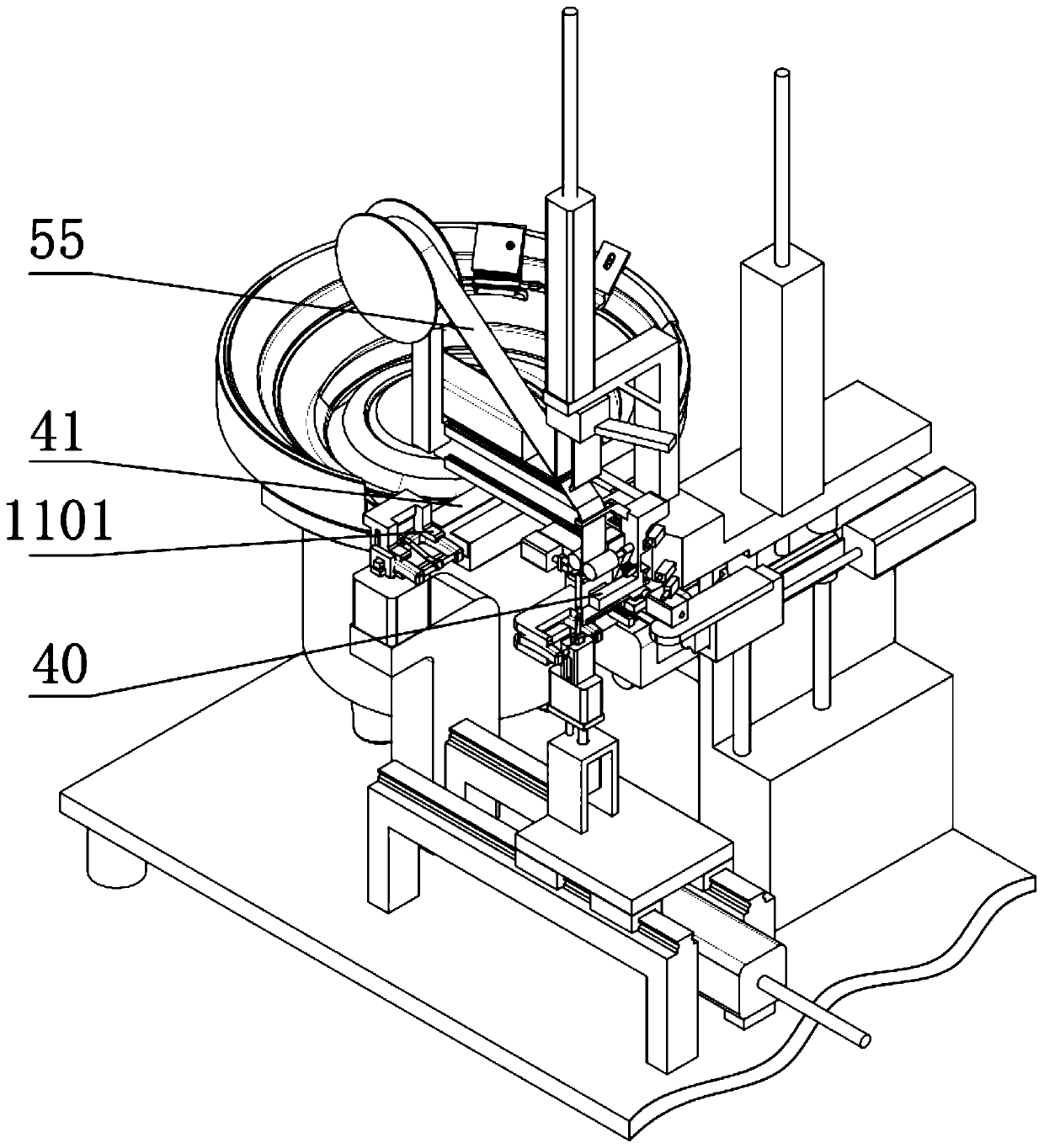

Automatic hollow bead forming machine

ActiveCN105105434AImprove work efficiencyImprove product qualification rateJewelleryPunchingMolding machine

The invention relates to an automatic hollow bead forming machine. According to the automatic hollow bead forming machine, a metal pipe blank is conveyed to a lower forming die of a turntable through a vibration feeding plate, a material guide slot and a material pushing mechanism, and is corrected by a correction mechanism; then the turntable rotates to convey the metal pipe blank on the lower forming die, so that the metal pipe blank is punched by an upper forming die mechanism to form thin-wall hollow beads; therefore, the automatic hollow bead forming machine realizes full automation of material screening, material conveying, material swinging and punching, and the specifications of the thin-wall spherical hollow beads punched by the automatic hollow bead forming machine are uniform; meanwhile, the potential safety hazard is eliminated; compared with the conventional hollow bead forming machine, the automatic hollow bead forming machine disclosed by the invention is high in automation degree, and the technical problems of large artificial operation error and low efficiency are solved; and the labor intensity of a worker and the production cost are effectively reduced, and the working efficiency and the product yield are improved, so that full automatic production of the thin-wall hollow beads is realized.

Owner:佛山市顺德区汇伦生产力促进服务中心有限公司 +1

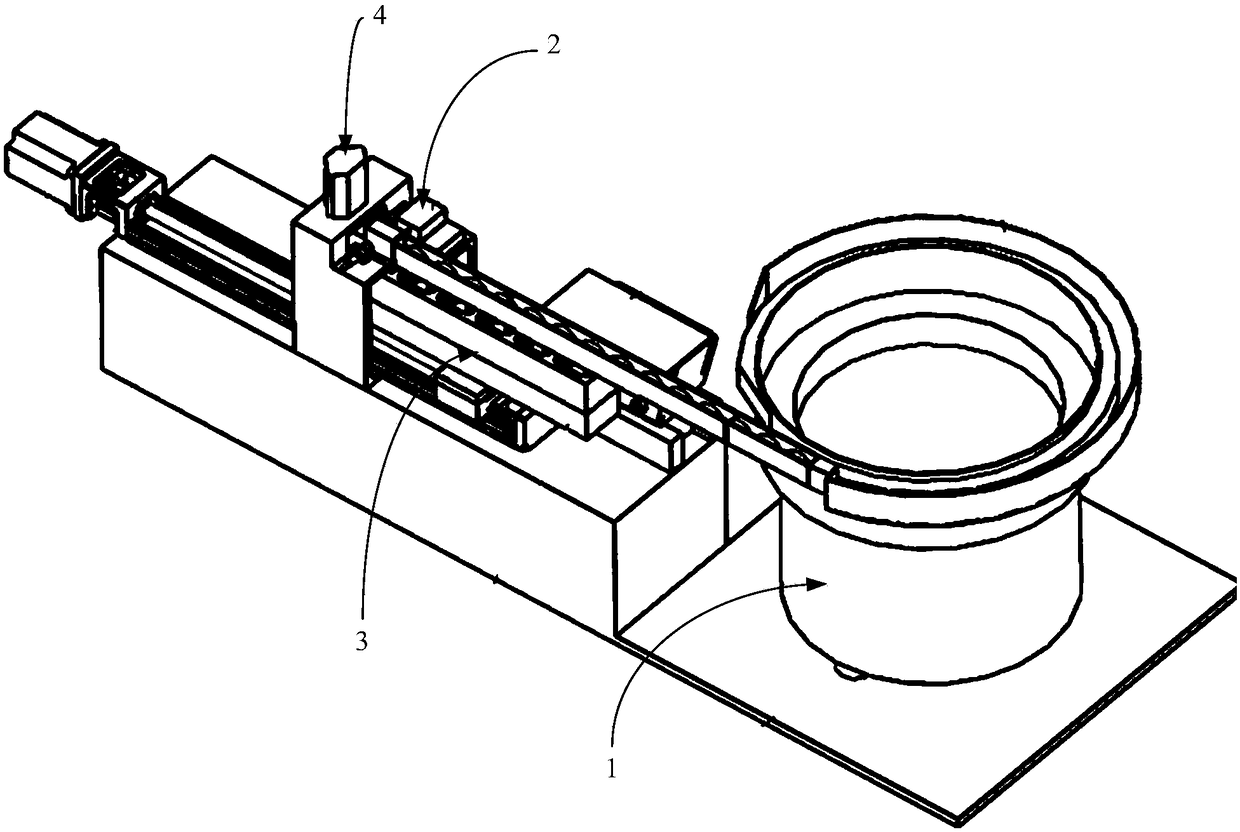

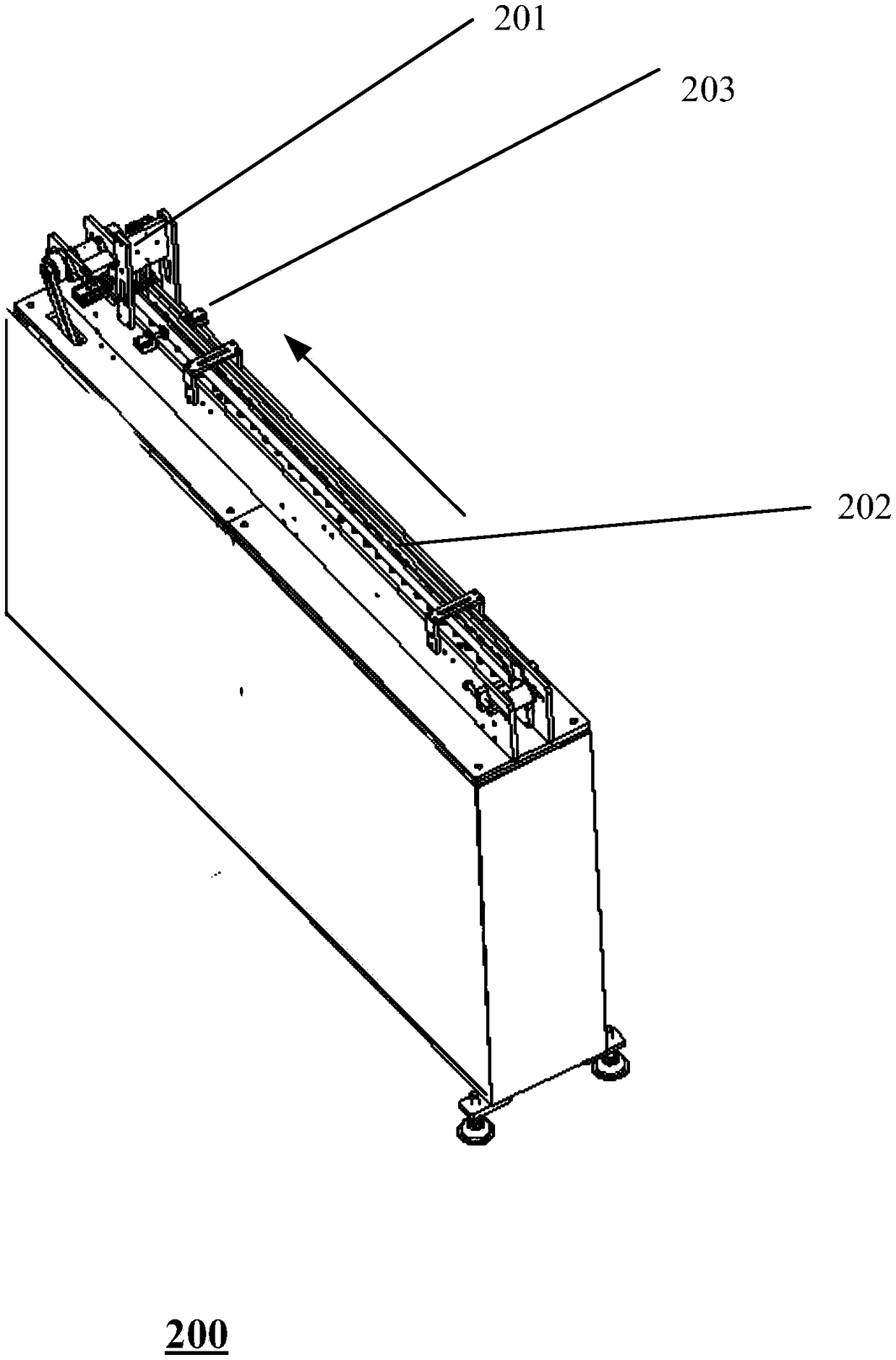

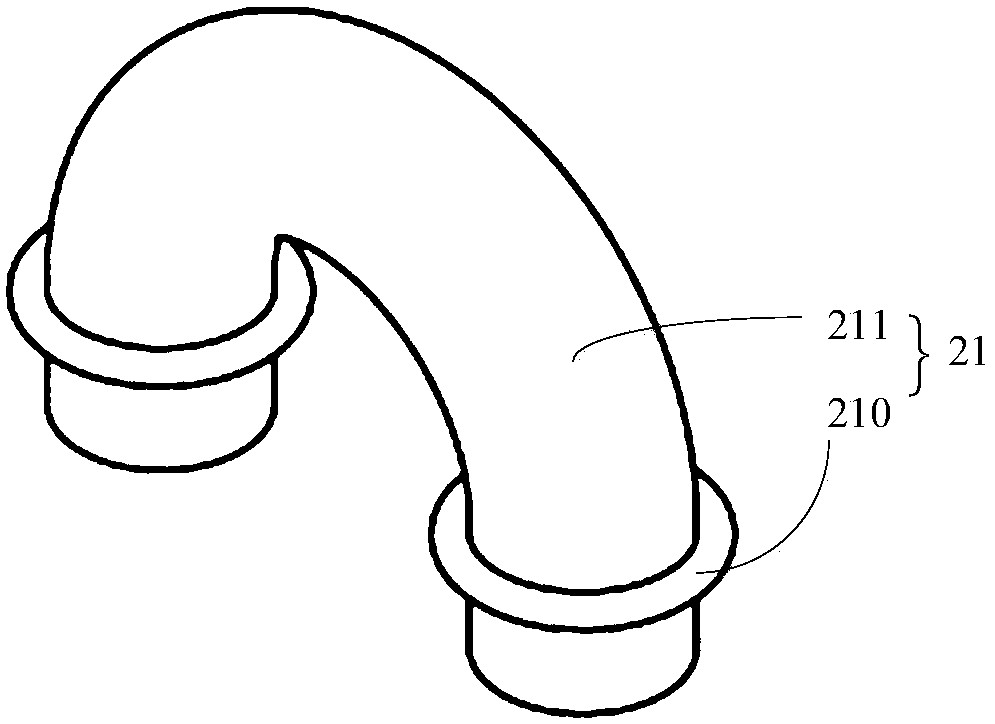

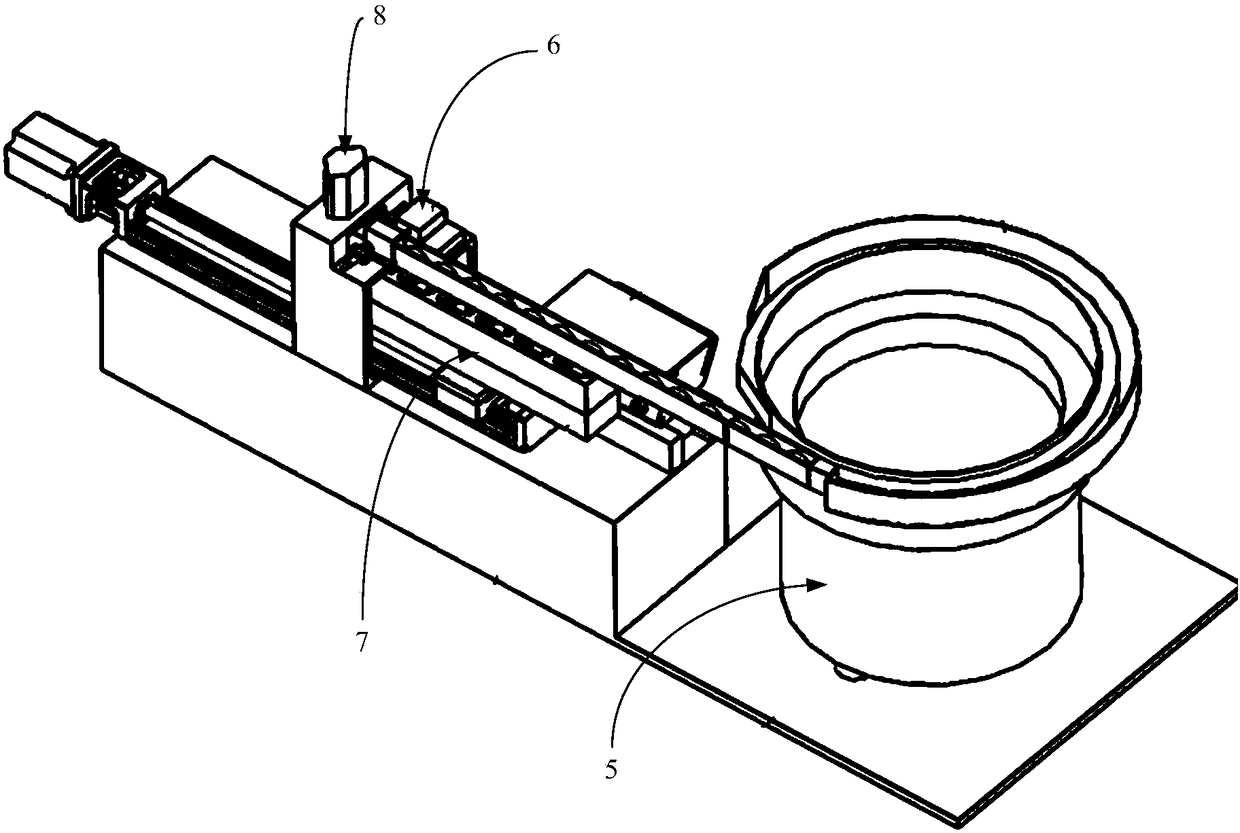

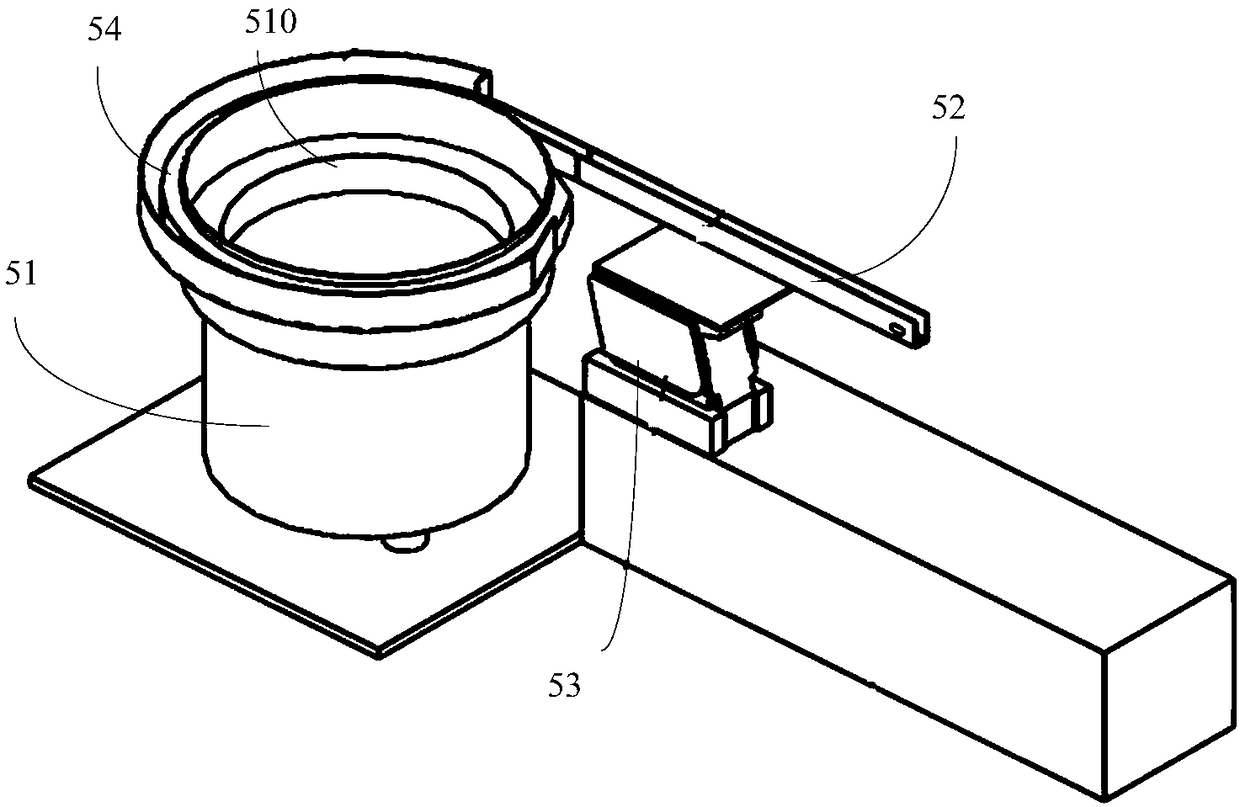

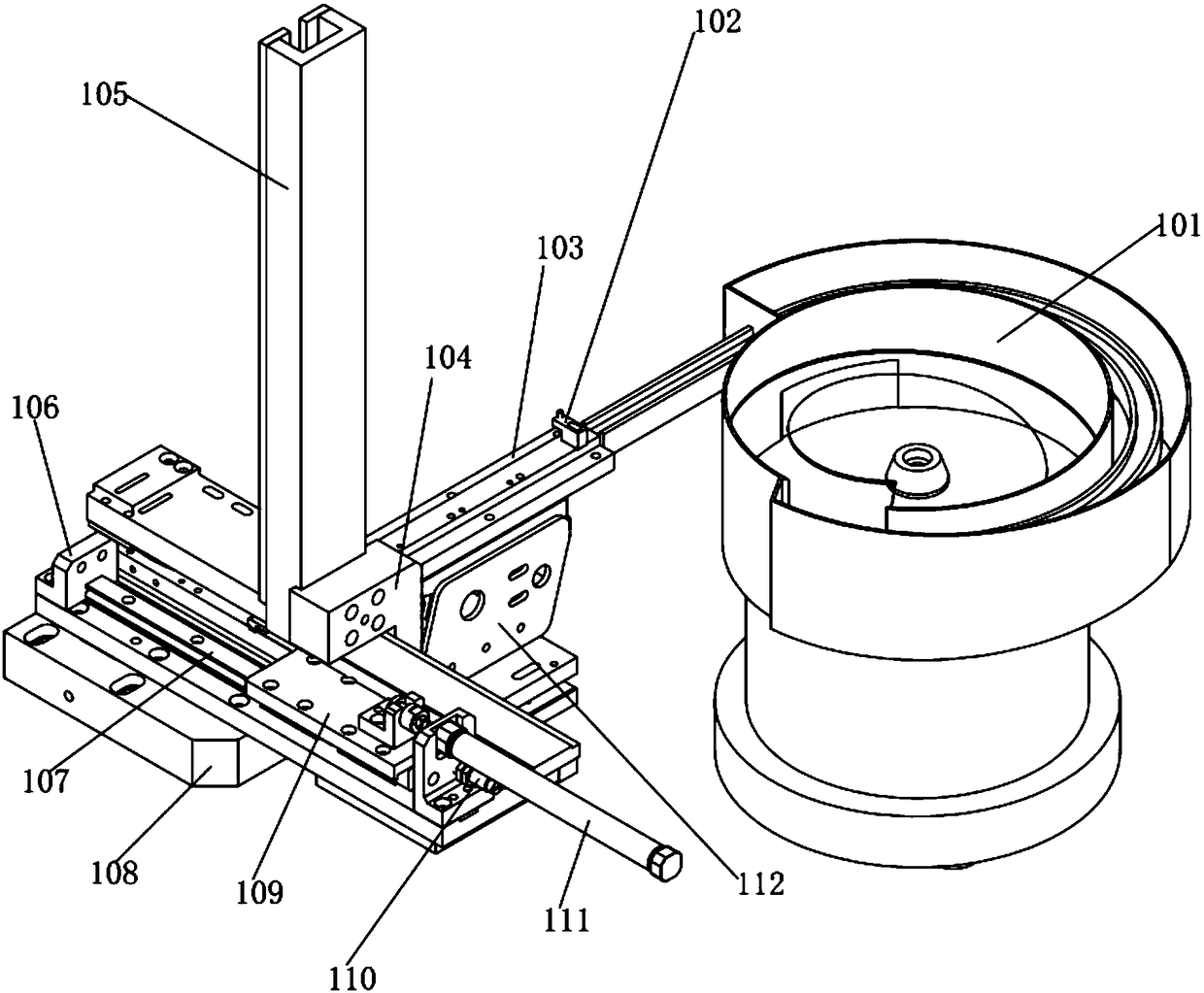

Feeding system with welding ring semicircular tube

ActiveCN108455232AImprove efficiencyRealize automatic reclaimingConveyor partsEngineeringTubes types

The invention discloses a feeding system with a welding ring semicircular tube, and belongs to the field of material automatic and accurate feeding. The feeding system with the welding ring semicircular tube comprises a vibration conveying mechanism, a material separating and separating mechanism, a jacking material taking mechanism and a shaping and correcting mechanism; and the vibration conveying mechanism can be used for screening welding ring semi-circular pipes with missing welding rings, and the shaping and correcting mechanism can be used for adjusting the height of the welding rings.According to the feeding system, the high-efficiency screening of the semi-circular tube with the welding ring and the precise regulation and control of the height of the welding ring are realized inthe production process of the tube-type heat exchanger, compared with a traditional manual production mode, the efficiency is higher, and the product quality is better.

Owner:武汉船舶通信研究所

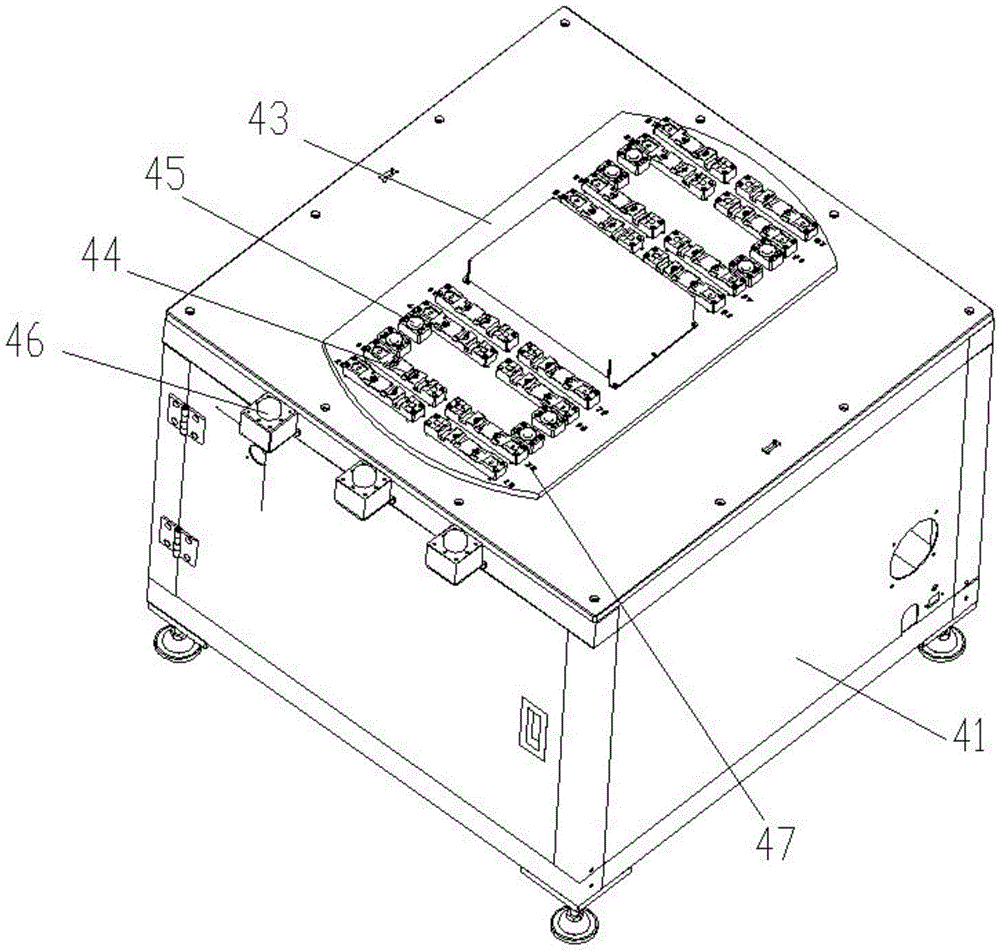

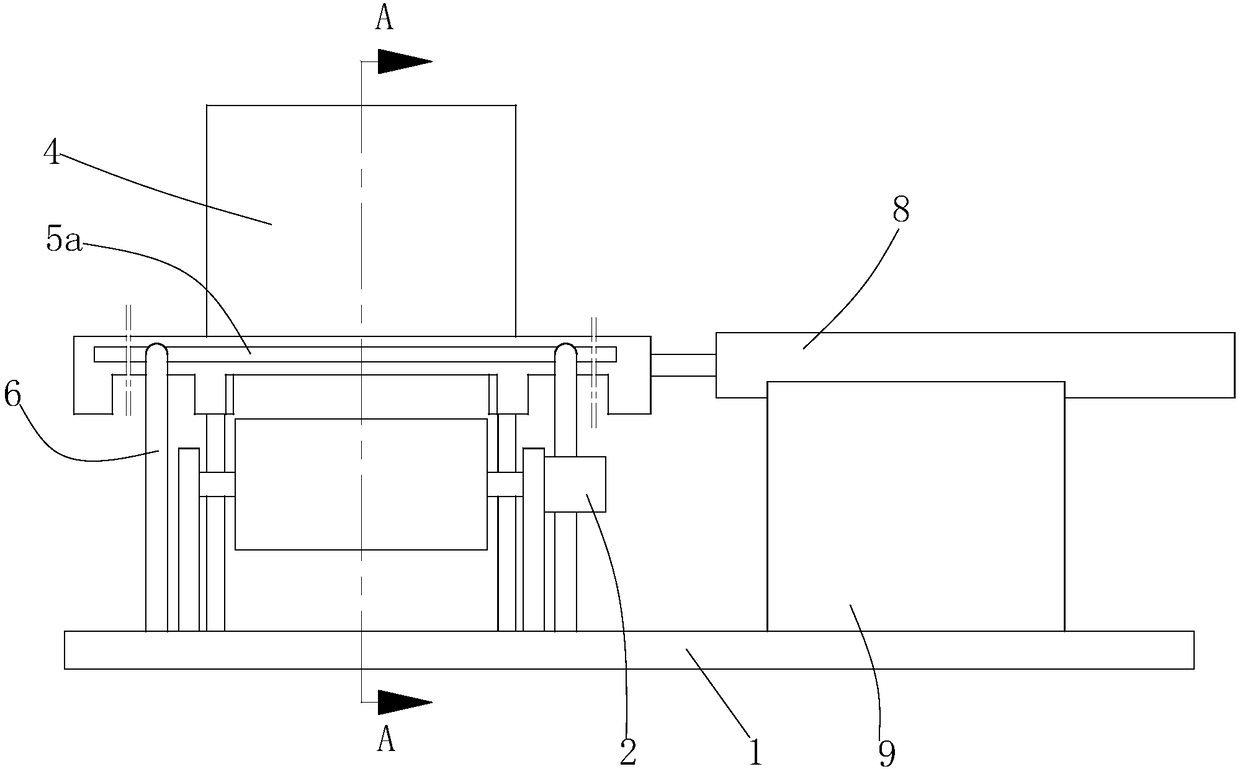

Automatic precise electronic product substrate function detection device

ActiveCN105158676ARealize automatic reclaimingImprove work efficiencyElectronic circuit testingConveyor partsEngineeringDegrees of freedom

Owner:OHNISHI ELECTRONICS (KUNSHAN) CO LTD

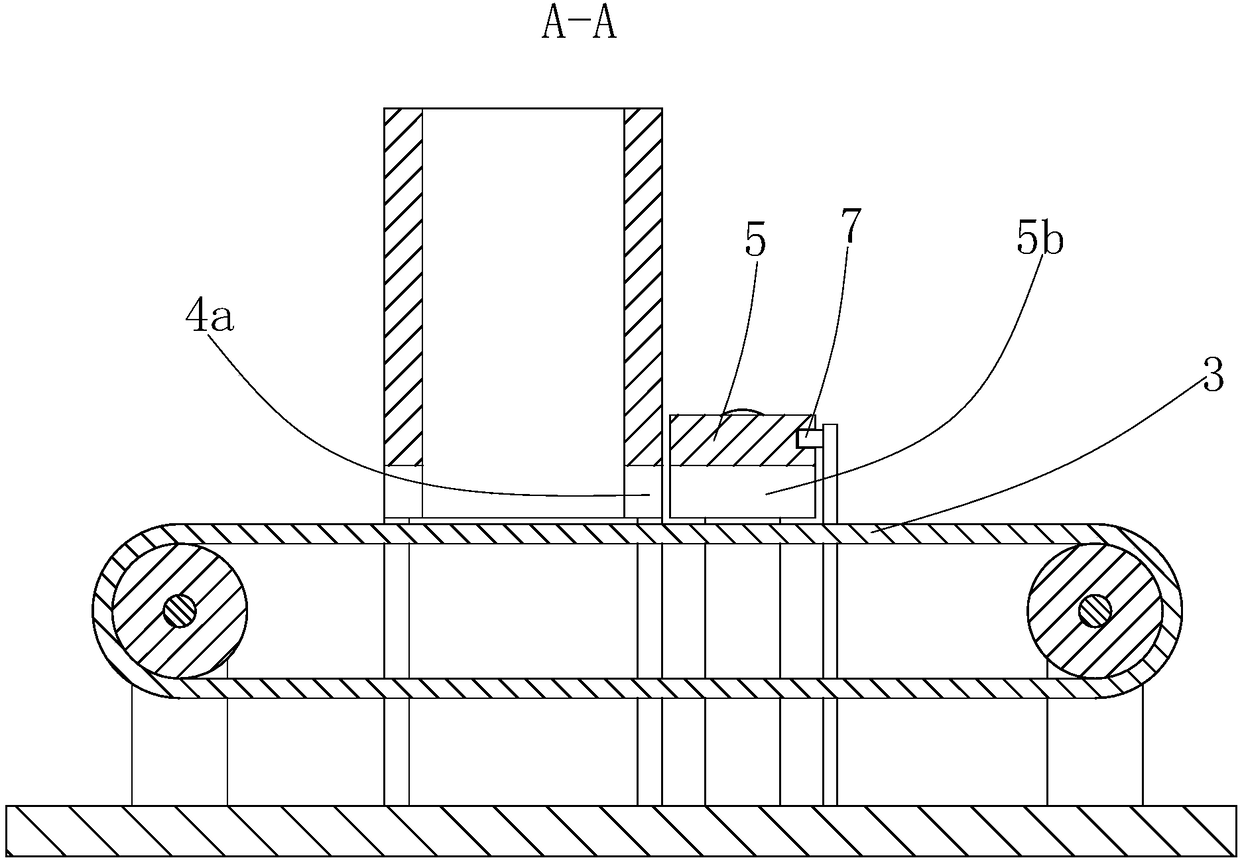

Multi-station mechanical arm

The invention discloses a multi-station mechanical arm. The mechanical arm comprises a base (1), a vertical displacement device (2) is arranged on the base (1) and is provided with a sliding plate (3) in the horizontal direction, the lower surface of the free end of the sliding plate (3) is connected with the input end of a rotating device, the output end of the rotating device is connected with one end of a rotating arm (5), and a plurality of vacuum holes (6) are formed in the rotating arm (5); and after the vacuum holes (6) penetrate the rotating arm (5), the bottom end is communicated with a suction cup (7), and the top end is connected with a vacuum pump. The multi-station mechanical arm is simple in structure, low in cost and capable of carrying out batched material taking.

Owner:SUZHOU GAOTONG MACHINERY TECH CO LTD

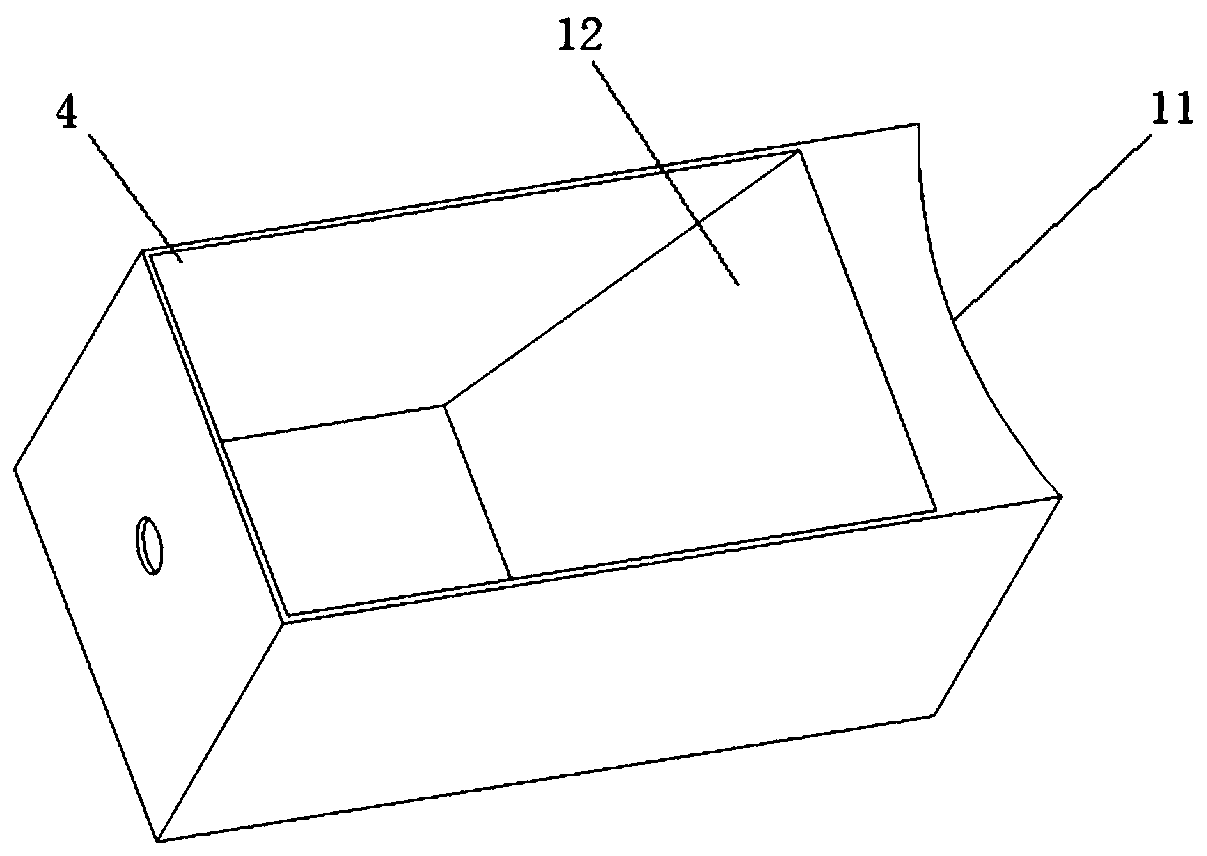

Storage device

InactiveCN108455050ARealize automatic reclaimingControl the output speedDischarging meansDe-stacking articlesHydraulic cylinderOn board

The invention relates to a storage device. The storage device comprises a base plate. A conveying belt is mounted on the base plate. A storage box is arranged above the middle of the conveying belt. Both the upper portion and the lower portion of the conveying belt are open. An opening is formed in the lower portion of the front side of the storage box. The right end of the storage box abuts against a long frame. A discharging groove which is matched with an opening is formed in the bottom of the long frame in the front-back direction. A hydraulic cylinder is connected to the rear end of the long frame. The storage device is convenient to use; and on the basis that wooden boards are stored in a stacked mode, the wooden boards are conveyed through the belt, and cooperation between the discharging groove and the opening is controlled so that the wooden boards can be automatically fetched, and the discharging speed of the wooden board can be controlled.

Owner:ANHUI GUANGMING GRAIN & OIL IND

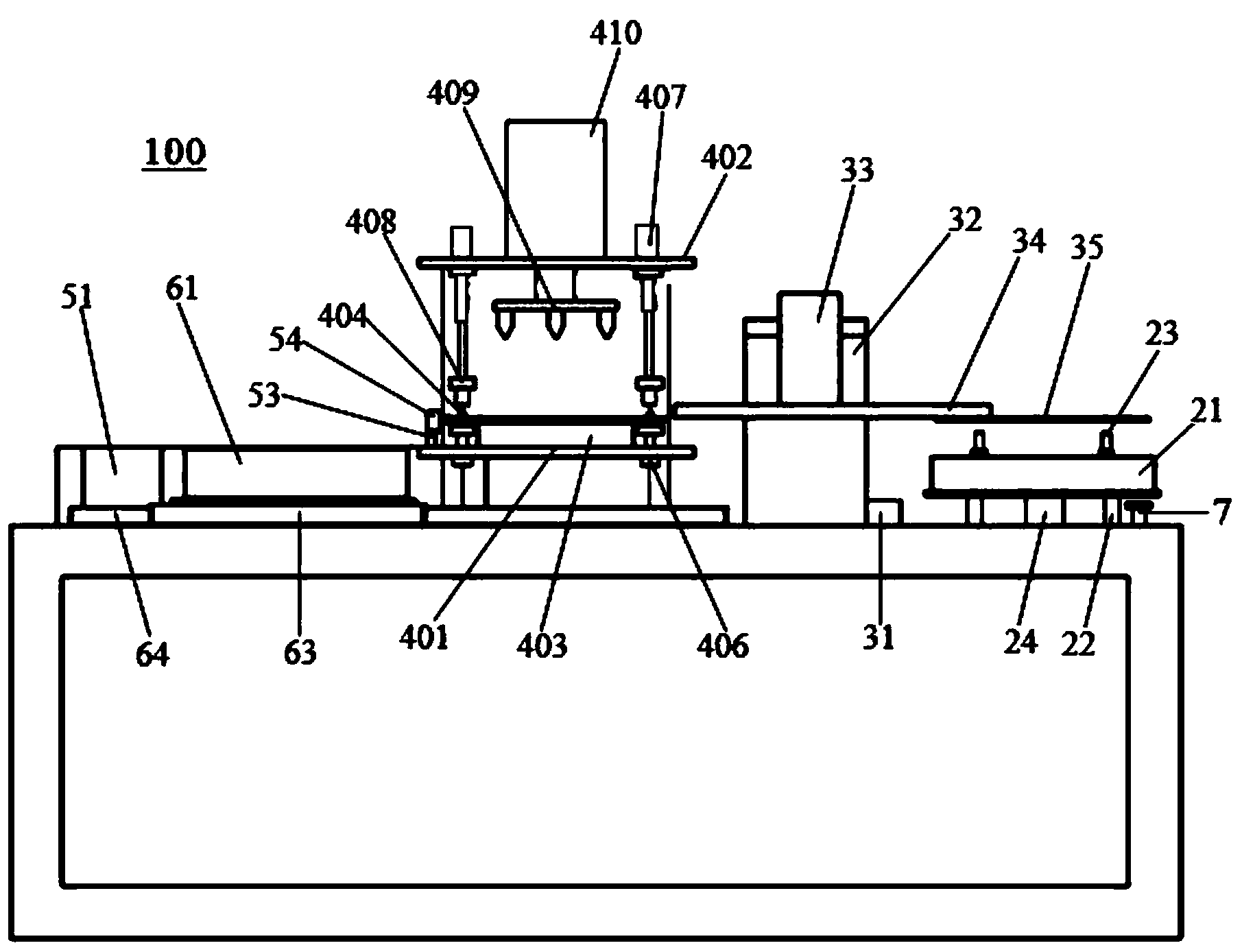

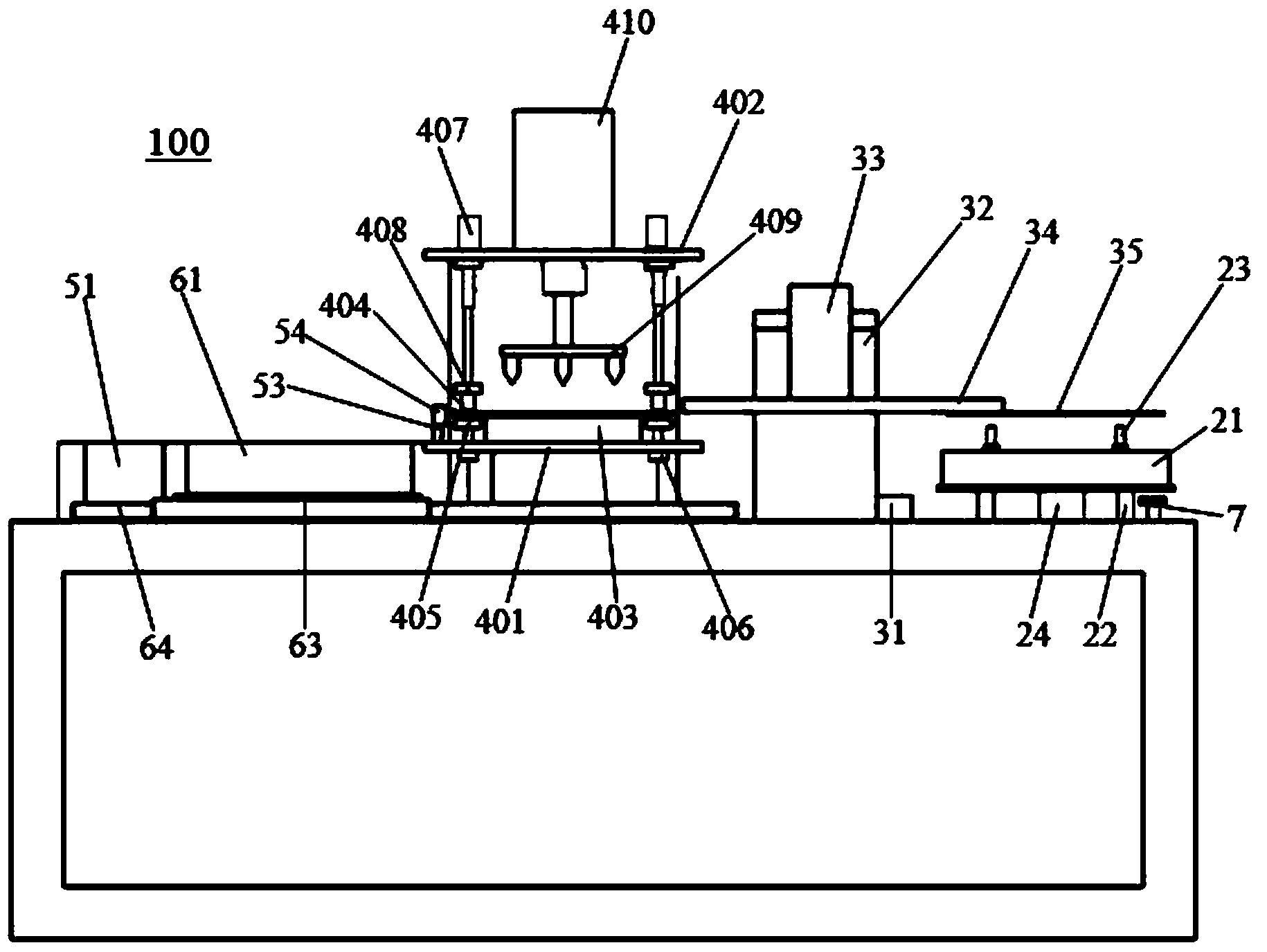

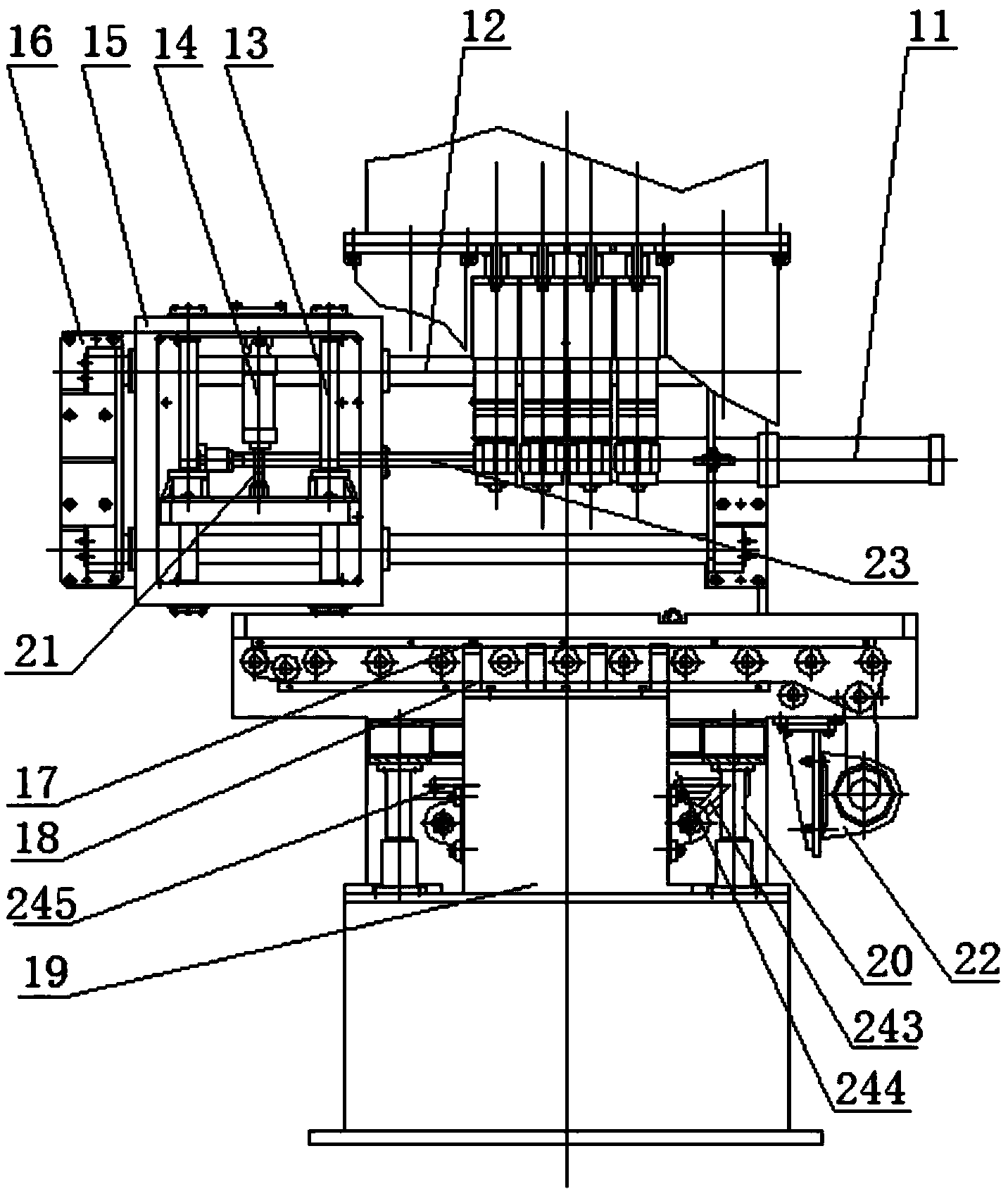

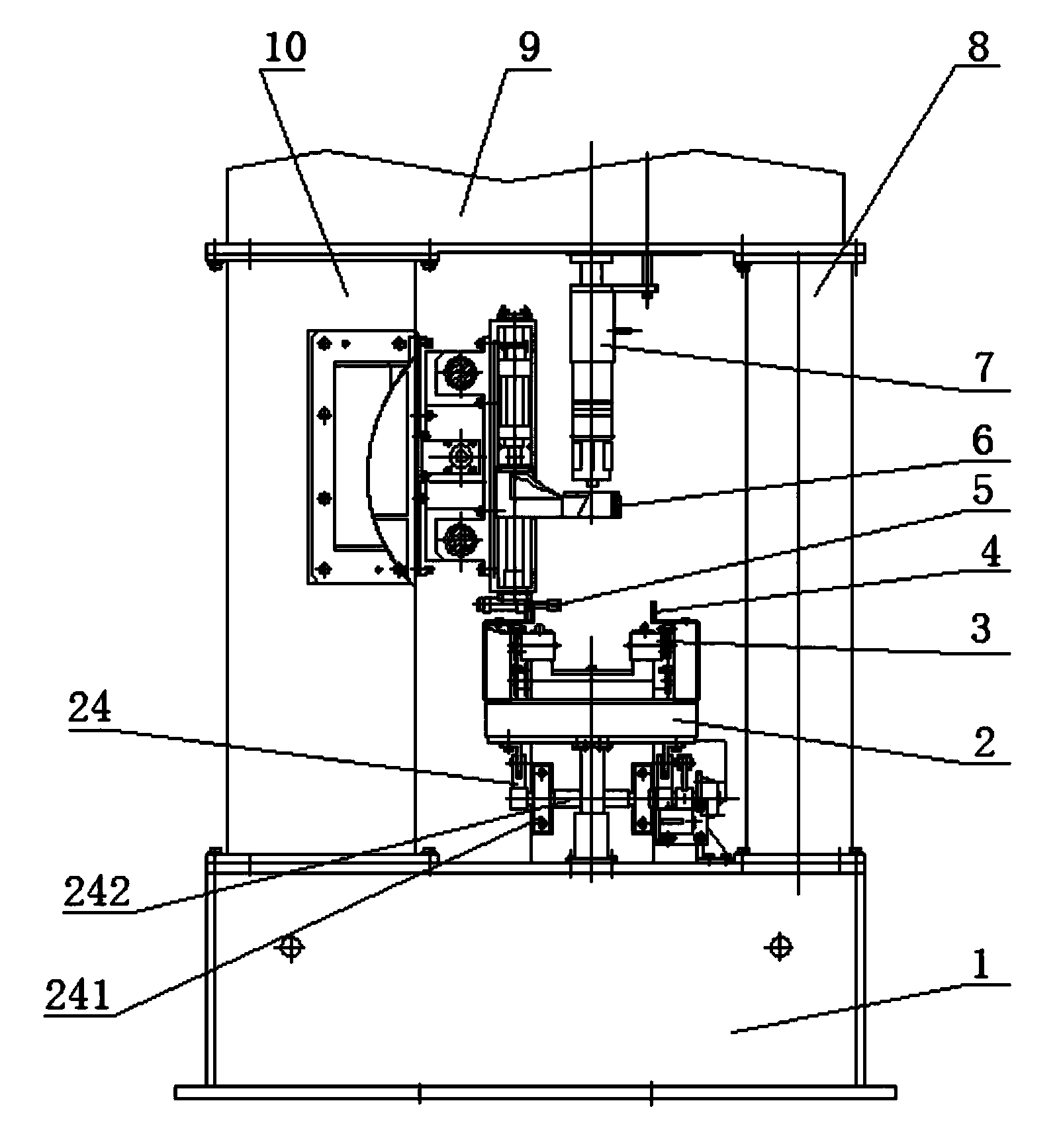

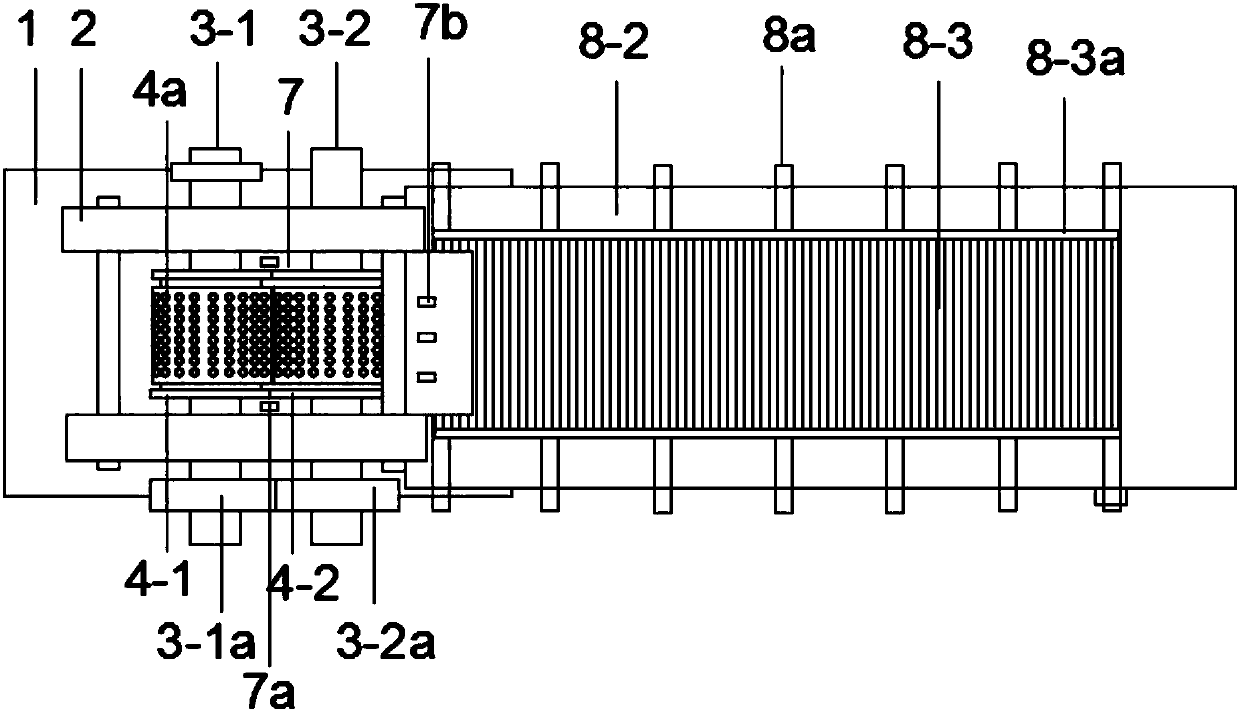

Engine cylinder liner press

ActiveCN103481053ARealize fully automatic feedingRealize high-precision automatic positioningMetal working apparatusCarrying capacityCylinder block

The invention discloses an engine cylinder liner press and belongs to the field of machinery. The engine cylinder liner press comprises a base, a top seat, a rear pillar, a front pillar, a cylinder liner feeding mechanism, a cylinder feeding mechanism, a cylinder liner head pressing device and a positioning and carrying device. The front of the base is connected with the front of the top seat through the front pillar. The rear portion of the base is connected with the rear portion of the top seat through the rear pillar, the cylinder liner head pressing device is arranged below the top seat and fixedly connected with the same. The cylinder liner feeding mechanism is mounted on the inner side of the rear pillar. The feeding portion of a cylinder liner feeder in the cylinder liner feeding mechanism is arranged right below the cylinder liner head pressing device. The cylinder feeding mechanism and the positioning and carrying device are arranged on the base. Full-automatic feeding of cylinder liners and cylinders is realized, and high-precision automatic positioning and high carrying capacity of the cylinders can be achieved.

Owner:金湖县项目服务中心

Water drill blank compressing device

InactiveCN108046575AAvoid accumulationUnfavorable natural coolingGlass transportation apparatusGlass shaping apparatusEngineeringDrill

The invention relates to a water drill blank compressing device which comprises a compressing machine. The compressing machine comprises a first hollow rotating shaft, a second hollow rotating shaft,a first roller, a second roller, a gear motor, an air conditioner, an air flue pipe and a discharging mechanism; the first hollow rotating shaft and the second hollow rotating shaft are arranged in parallel, the first roller and the second roller are fixed to the first hollow rotating shaft and the second hollow rotating shaft respectively, and the discharging mechanism is arranged below the firstroller and the second roller; an air outlet of the air conditioner is communicated with the air flue pipe, the air flue pipe is communicated with a plurality of first air jet holes and a plurality ofsecond air jet holes formed in the discharging mechanism, and a discharging outlet of the discharging mechanism is located above a transmission mechanism; the transmission mechanism comprises a box,and a plurality of cooling fans are evenly arranged on the two sides of the box. A blank can be conveniently disengaged from the surfaces of the rollers, the compressing efficiency and quality are improved, and materials can be automatically obtained.

Owner:通山德福水晶玻璃制品有限公司

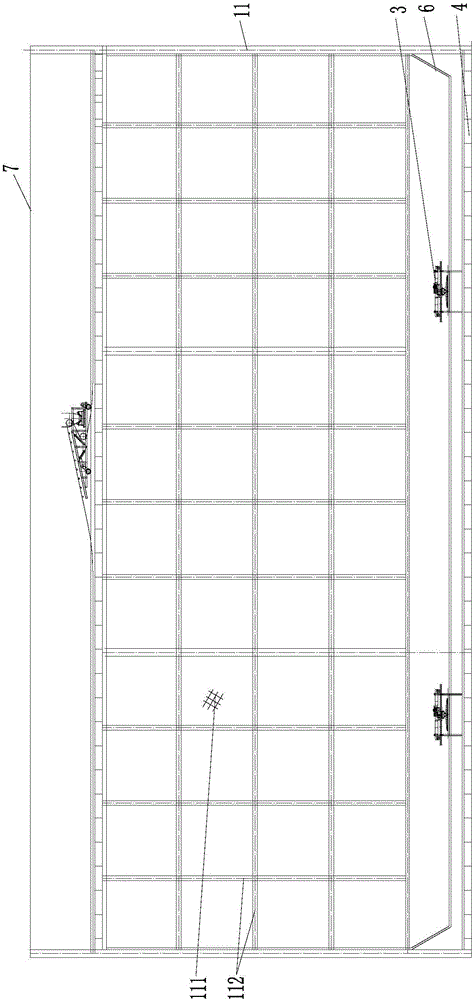

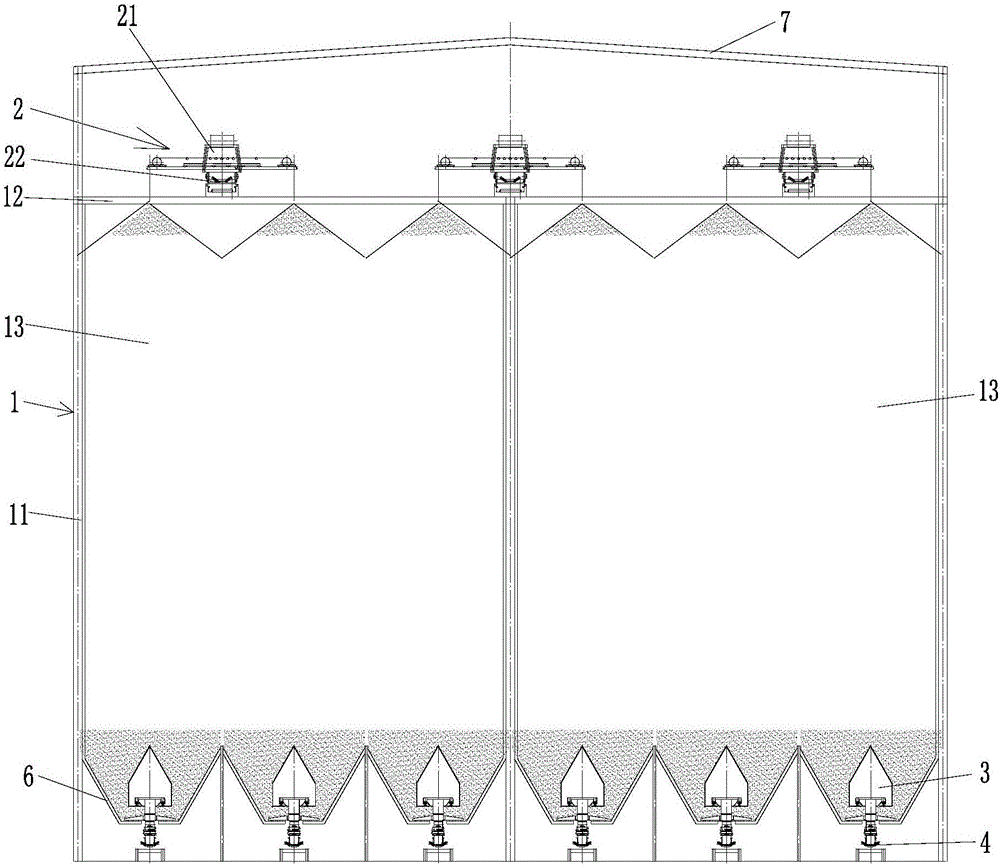

Group of silos and single silo of square steel structure

InactiveCN106628683ARealize automatic feeding processRealize automatic reclaimingLarge containersLoading/unloadingEngineeringProviding material

The invention discloses a group of silos and a single silo of square steel structure. The group of silos and the single silo of square steel structure comprise a rectangular group of silos which comprise more than two single silos arranged in matrix. Every single silo comprises four vertical rectangular silo walls and a horizontal silo roof. The four silo walls are connected in turn to form a silo space and the silo roof is on the top of the four silo walls. Every silo wall comprises silo wall boards and main body structure connected with the outer side of the silo wall boards. The main structure is steel structure and the two adjacent single silos share a silo wall. An in-feed conveyor is arranged on the top of the silo roof, which can convey feed to every top of silo space and unloads into each silo space. A feeder is arranged on the bottom of the silo space. A discharging conveyor is connected with the lower part of the feeder and is arranged outside the silo space. The feeder can provide materials which are in the silo space to the discharging conveyor. The group of silos and a single silo of square steel structure can realize the automatic in-feeding and automatic unloading with high structural strength, no support in the silo body, easy feeding and low cost.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

Package separating device and package separating method thereof

The invention discloses a package separating device and a package separating method of the package separating device. The package separating device comprises a bag opening mechanism and an unloading mechanism. The bag opening mechanism comprises a bag separating support, a first clamping component, a second clamping component and a cutting component, the first clamping component is installed on the bag separating support for obtaining the top of a cotton yarn package, the second clamping component is installed on the bag separating support for obtaining the top of the cotton yarn package, andthe cutting component is movably connected to the bag separating support for cutting the top of the cotton yarn package. The unloading mechanism comprises an unloading support, an unloading bearing component, an unloading fixing component and an unloading driving component, the unloading bearing component is rotationally connected to the unloading support, the unloading fixing component is arranged on the unloading bearing component for fixing the opened cotton yarn package, the unloading driving component is arranged on the unloading support and connected to the unloading bearing component, and the unloading driving component is used for driving the unloading bearing component to rotate to pour out cheese in the cotton yarn package. The package separating device is high in bag separatingefficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

An automatic device for sleeving O-shaped ring

The invention relates to an automatic device for sleeving an O-shaped ring. The device comprises a fixed main body, a shell, a O-shaped ring sleeving mechanism and a driving mechanism; the O-shaped ring sleeving mechanism comprise a material stripping sleeve, an elastic returning part, a moving rod, a plurality of material taking claws which are positioned in the material stripping sleeve and arein linkage fit with the moving rod and a material stripping rod which corresponds to the position above the material stripping sleeve and is in linkage with the moving rod; and a through hole allowingone ends of the plurality of material taking claws to penetrate through is formed in the material stripping sleeve, the plurality of material taking claws are distributed in an annular array and aremovably arranged on the moving rod, returning components are arranged between the moving rod and the plurality of material taking claws, one ends of the plurality of material taking claws act along with the moving rod and can penetrate through the through hole of the material stripping sleeve and are mutually supported to be opened, and the material stripping rod moves along with the moving rod and can be used for driving one end of the material stripping sleeve to extend out of the shell. The device has the advantages of being simple in structure, stable and reliable in performance, high in efficiency and capable of saving manpower.

Owner:ZHEJIANG BLCH PNEUMATIC SCI & TECH

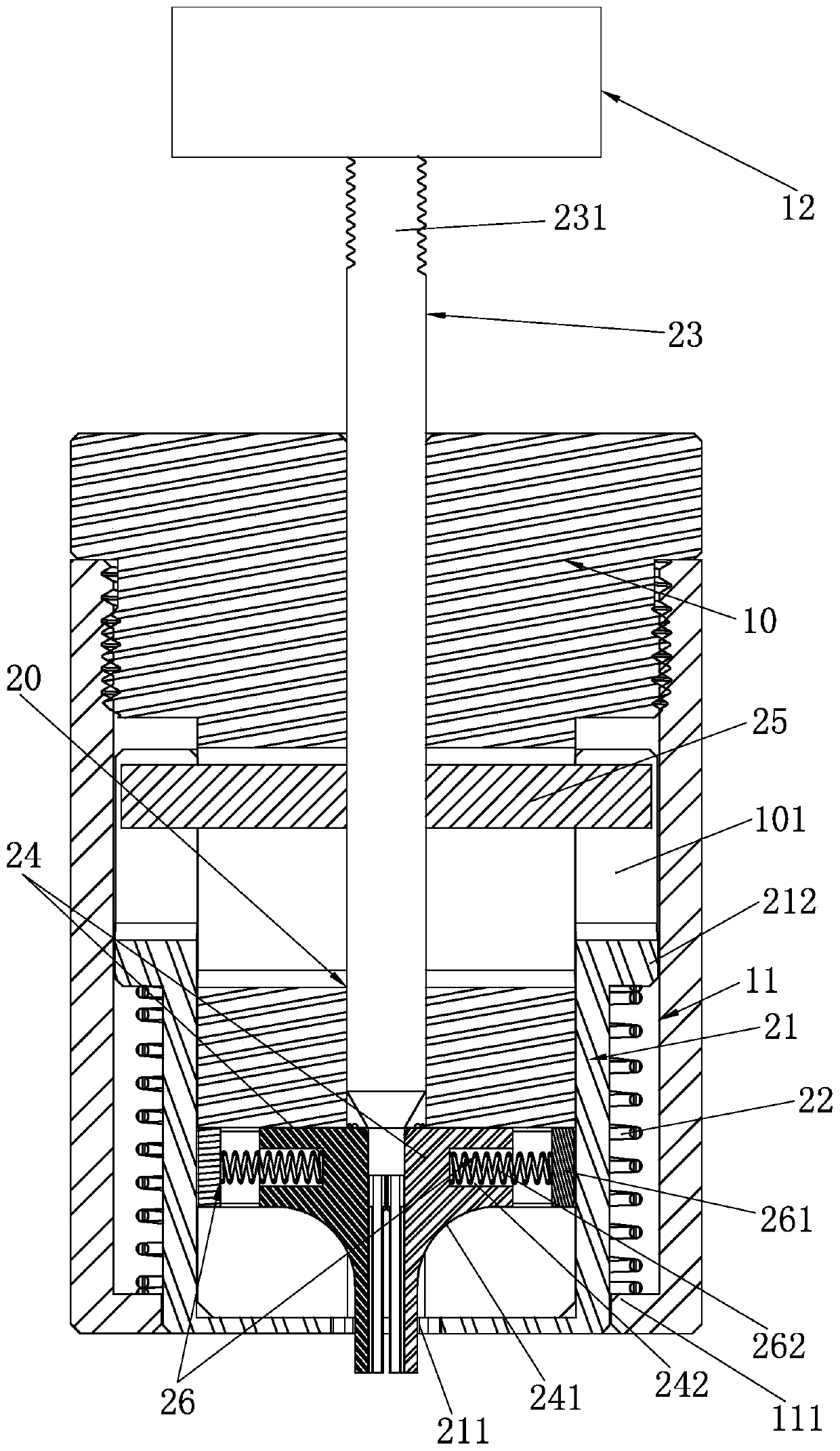

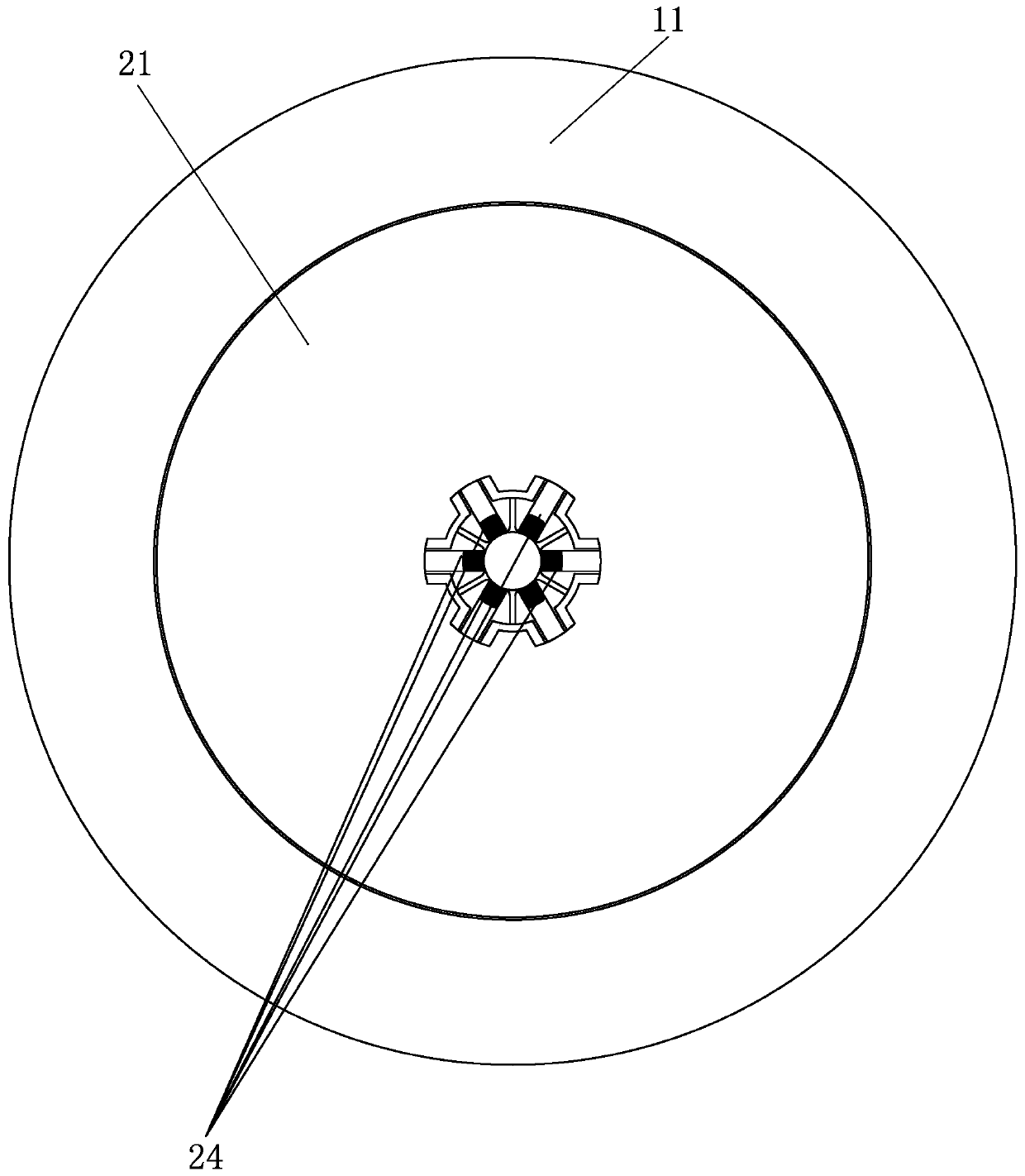

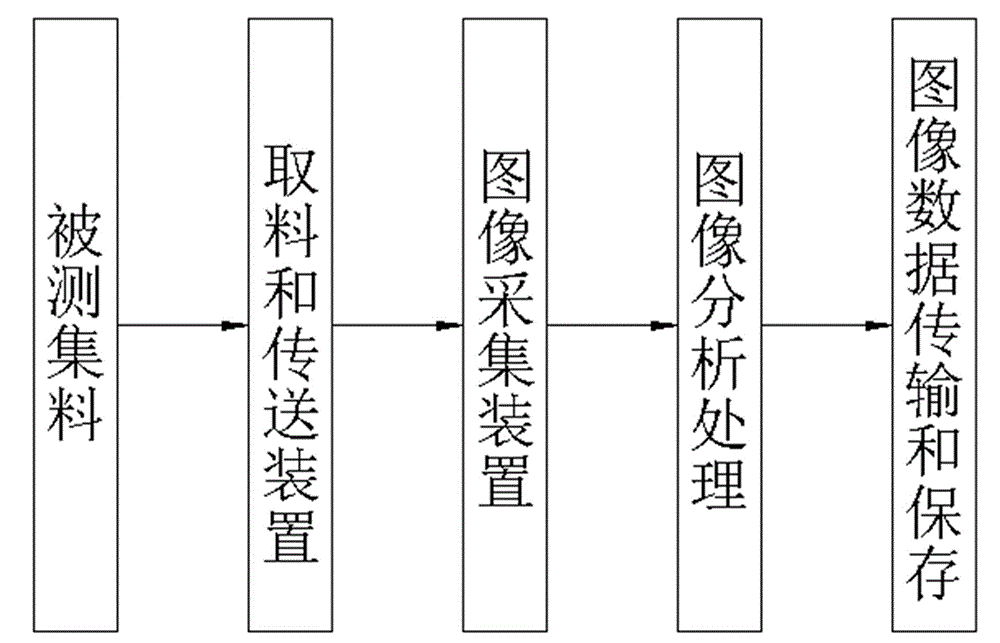

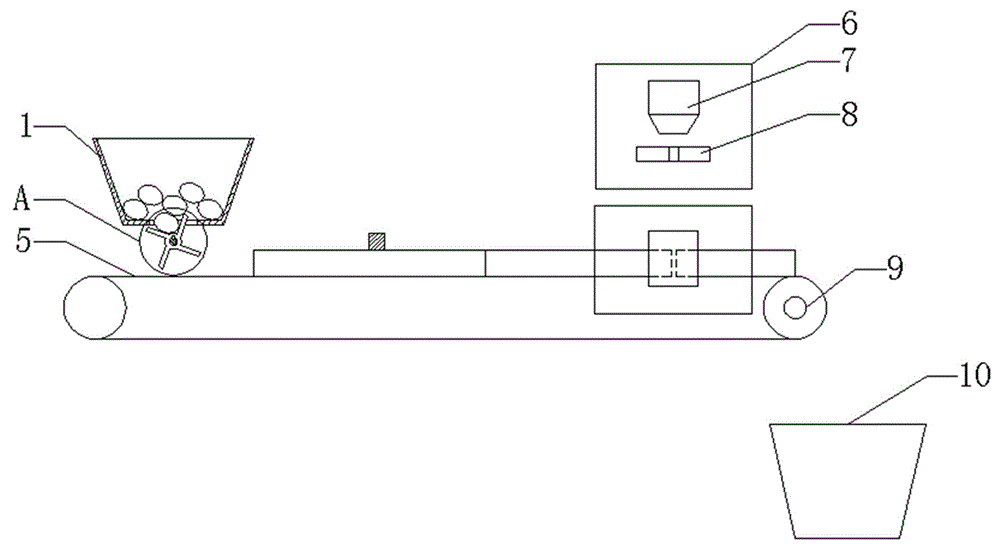

Aggregate morphological characteristic acquisition device based on multi-view linear array camera

InactiveCN105783783AReduce the influence of human factorsRealize automatic reclaimingTelevision system detailsColor television detailsOptical processingThree dimensional shape

The invention discloses an aggregate morphological characteristic acquisition device based on multi-view linear array cameras. The aggregate morphological characteristic acquisition device is characterized by comprising a material fetching mechanism, as well as an aggregate conveying mechanism, an image acquisition mechanism, an optical processing optimization mechanism, a communication and storage mechanism and an aggregate recycling mechanism which are connected with the material fetching mechanism in sequence, wherein the aggregate recycling mechanism is arranged below the aggregate conveying mechanism. The aggregate morphological characteristic acquisition device effectively solves the difficulties that the material cannot be fetched automatically, the measurement of three-dimensional shape of the aggregate cannot be completed by using a single camera and the aggregate passes through measuring equipment in a disorder mode, can demonstrate morphological characteristics of the aggregate comprehensively, and has the advantages of simple structure, convenient use and easy popularization and use.

Owner:GUILIN UNIV OF ELECTRONIC TECH

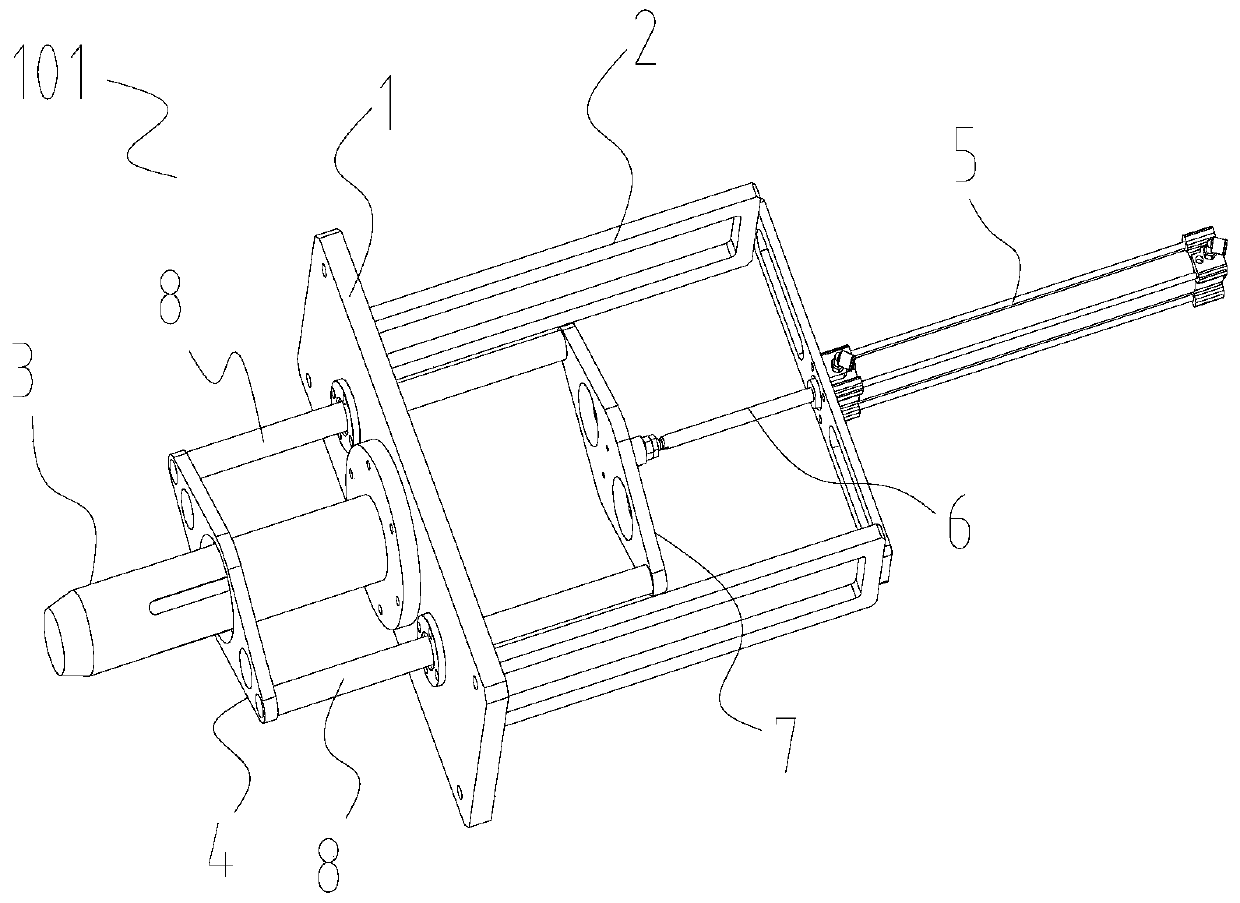

Feeding component and feeding robot adopting same

PendingCN110304438AUniform forceRealize automatic reclaimingConveyor partsWebs handlingMechanical engineeringManual handling

The invention discloses a feeding component and a feeding robot adopting the same. The feeding component comprises a substrate, wherein a mounting frame is fixedly arranged on one side of the substrate; an air expansion shaft for feeding is arranged on the other side of the substrate; a push plate is also arranged at the axial peripheral part of the air expansion shaft; an air cylinder is arrangedon the mounting frame; during work, a piston rod of the air cylinder moves along the direction perpendicular to the substrate; the push plate is arranged on the air expansion shaft in a sleeving manner; and a connecting component is also arranged between the air cylinder and the push plate. The feeding robot is used for handling coil stock with a center hole from a rack to the unreeling positionand is provided with an automatic guided vehicle and a feeding component. The feeding robot disclosed by the invention can realize automatic taking, handling and feeding action of the coil stock by combined application of the automatic guided vehicle with the feeding component, so that labor intensity of workers is greatly reduced, and automatic level of equipment is improved; and meanwhile, misplaced and reverse loading of the coil stock in the manual handling and feeding process can be reduced and the operation stability of the equipment is improved.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

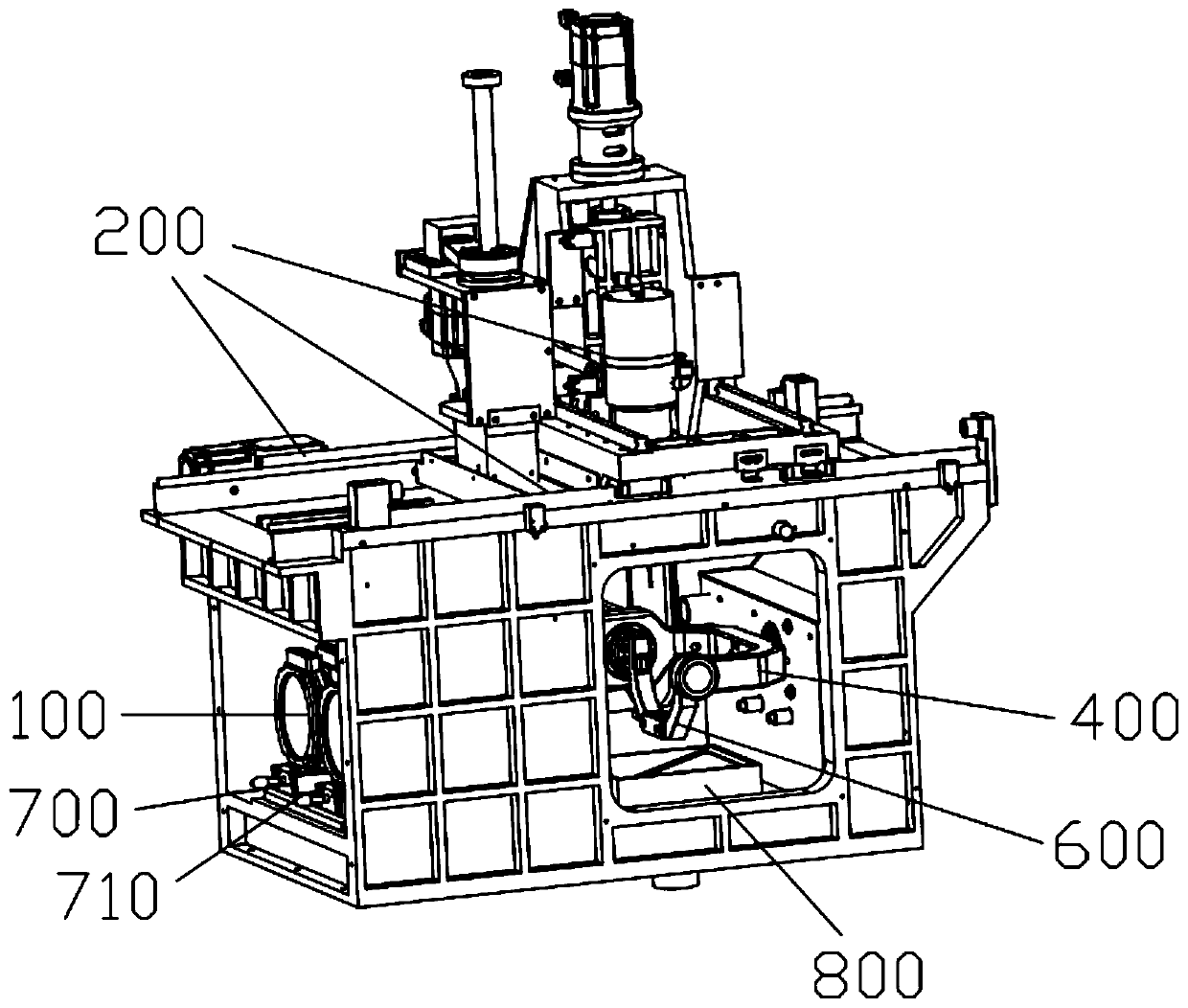

Novel denture carving machine and denture processing method

PendingCN111358587AAvoid retrievingRealize automatic reclaimingArtificial teethModel makingEngineeringDentistry

The invention provides a novel denture carving machine and a denture processing method. The novel denture carving machine comprises material carrying plates, a material clamping mechanism, a three-axis transfer mechanism, a processing frame, a rotary driving mechanism and a processing spindle; the material clamping mechanism is connected with the three-axis transfer mechanism, and is used for clamping the material carrying plates at a first preset position and loosening the material carrying plates at a second preset position so as to place the material carrying plates on the processing frame;the three-axis transfer mechanism is used for driving the material clamping mechanism to move back and forth between the first preset position and the second preset position; the processing frame islocated right below the processing spindle, is installed on the rotary driving mechanism, and is used for receiving materials when being in a first posture, and making the materials face towards the processing spindle when being in a second posture; and the rotary driving mechanism is used for driving the processing frame to rotate back and forth between the first posture and the second posture. Automatic material fetching, discharging and processing are realized, and thereby, manual operation is saved, and the mechanization degree of denture processing is improved.

Owner:美立得科技(深圳)有限公司

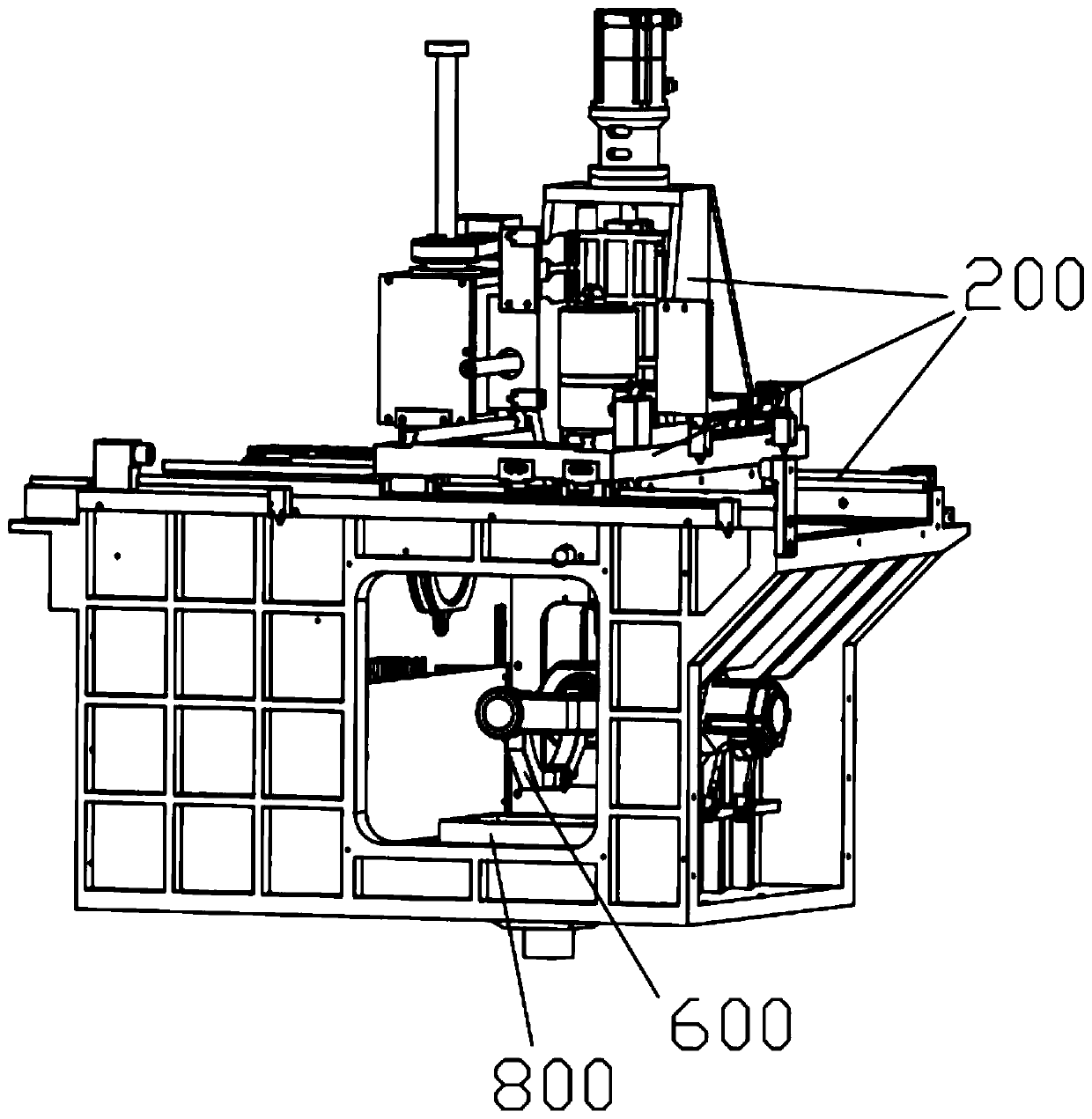

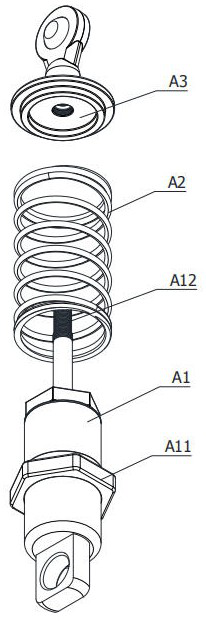

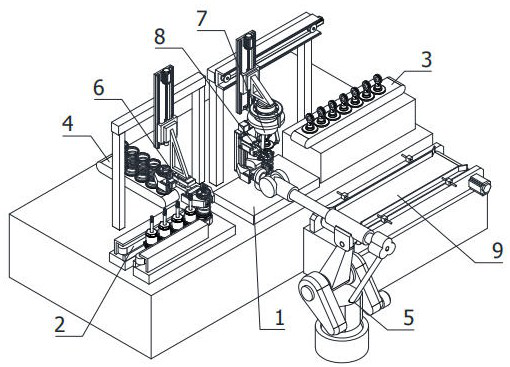

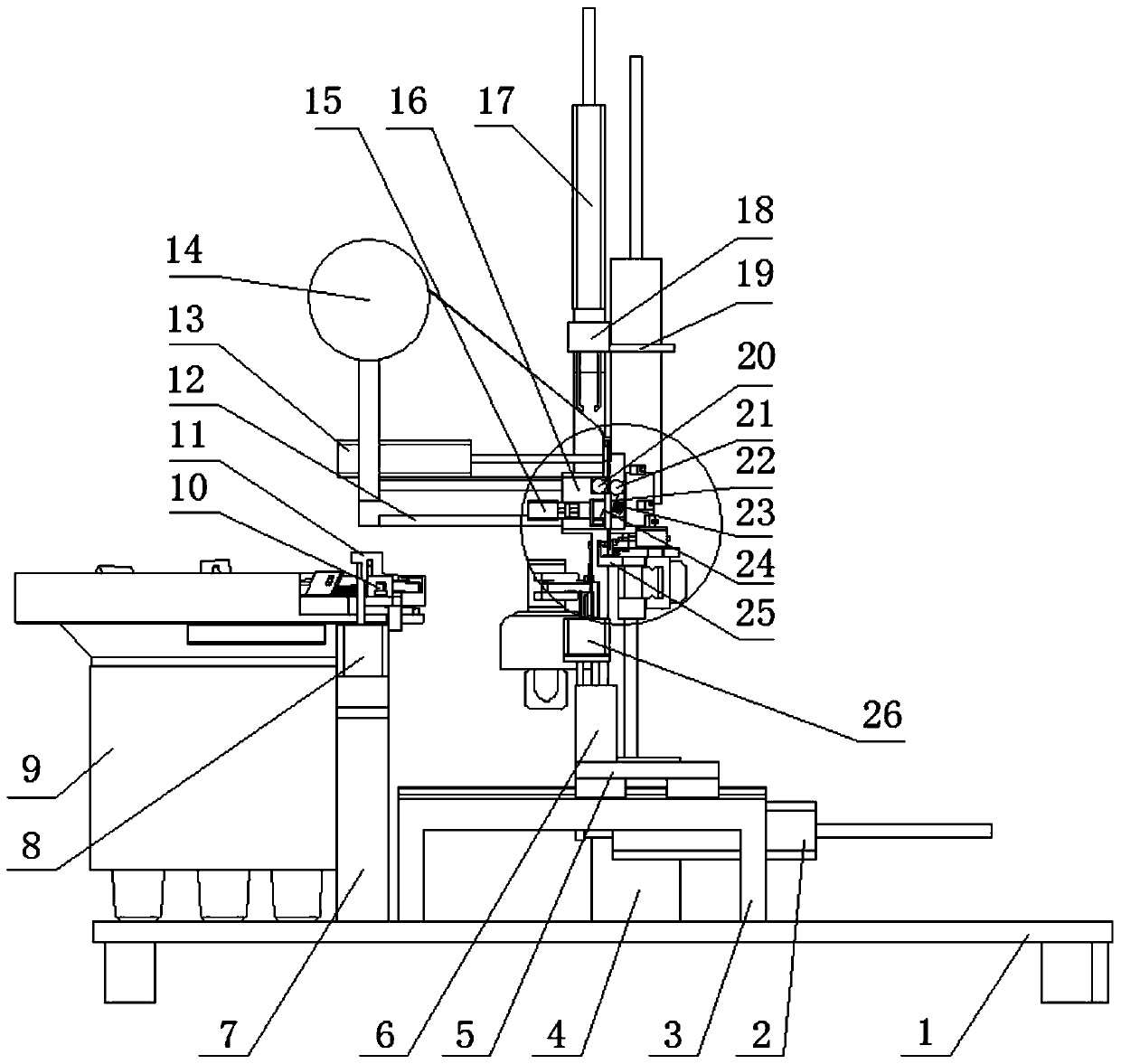

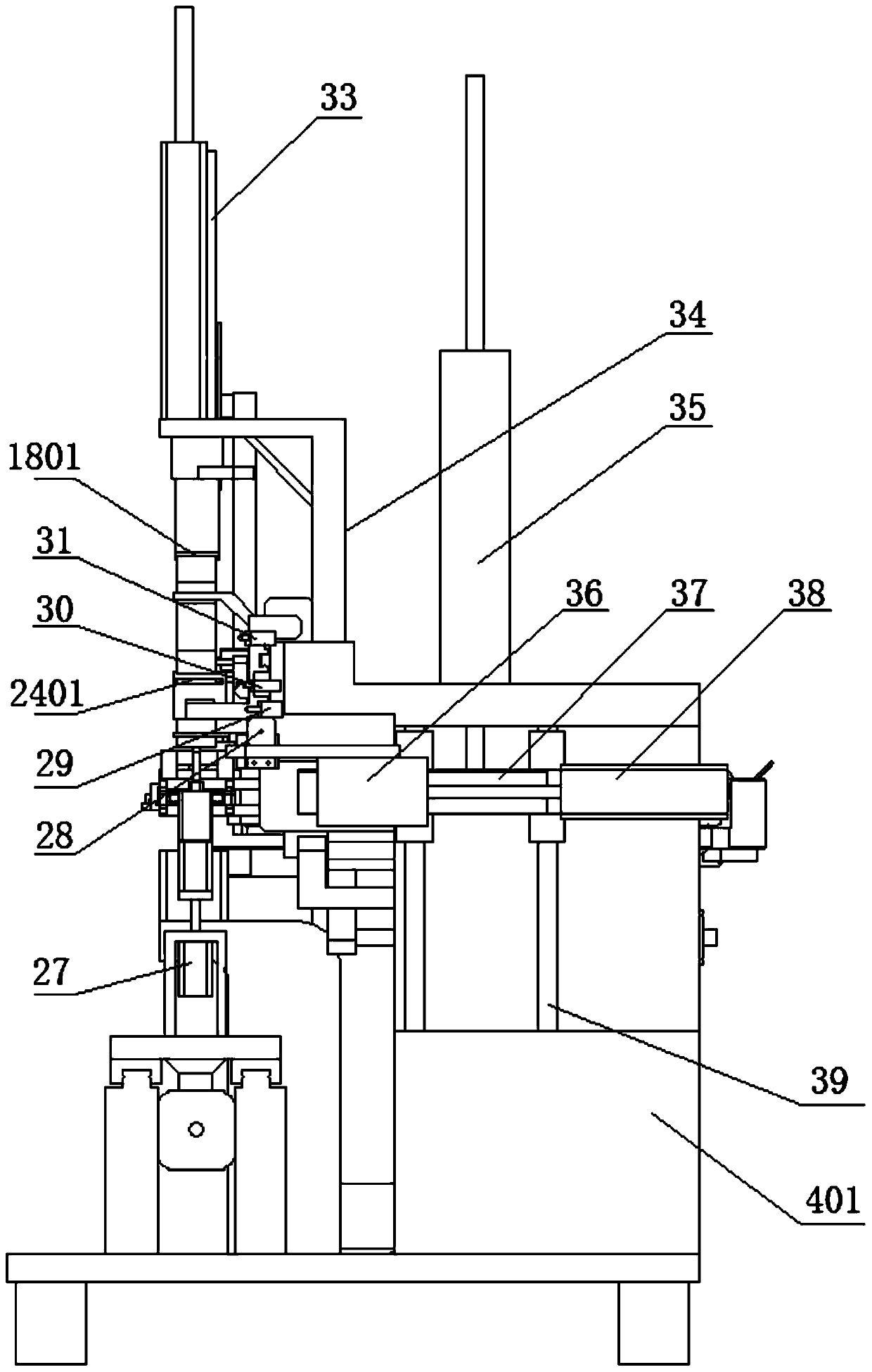

Automatic assembling equipment for automobile shock absorber

ActiveCN111805234AEasy to transportNot easy to break awayAssembly machinesEngineeringIndustrial robotics

The invention relates to the technical field of automobile shock absorber machining, in particular to automatic assembling equipment for an automobile shock absorber. The automatic assembling equipment is applied to automatic assembling of the shock absorber, the shock absorber comprises a damper, a spring and an internal thread spring cap, wherein an adjusting nut is arranged on the damper, and threads are arranged at an output shaft of the damper; and the assembling equipment comprises a fixing workbench, a clamping type damper conveying belt, a spring cap conveying belt, a spring conveyingbelt, an industrial robot, a rotary spring assembler, a three-jaw clamping rotary assembler, a spring downward-pressing shaft clamping device, and a finished product conveyor, wherein the clamping type damper conveying belt and the spring cap conveying belt are arranged on the two sides of the fixing workbench; the spring conveying belt is perpendicular to the clamping type damper conveying belt,and the output end of the spring conveying belt is located on one side of the output end of the clamping type damper conveying belt; the industrial robot is arranged on the outer side of the fixing workbench; the rotary spring assembler is arranged at the tops of the clamping type damper conveying belt and the spring conveying belt; the three-jaw clamping rotary assembler is arranged at the top ofthe fixing workbench; the spring downward-pressing shaft clamping device is arranged on the outer side of the fixing workbench; and the finished product conveyor is arranged on the outer side of thefixing workbench. The equipment is high in assembling precision and working efficiency.

Owner:广州具茨自动化设备有限公司

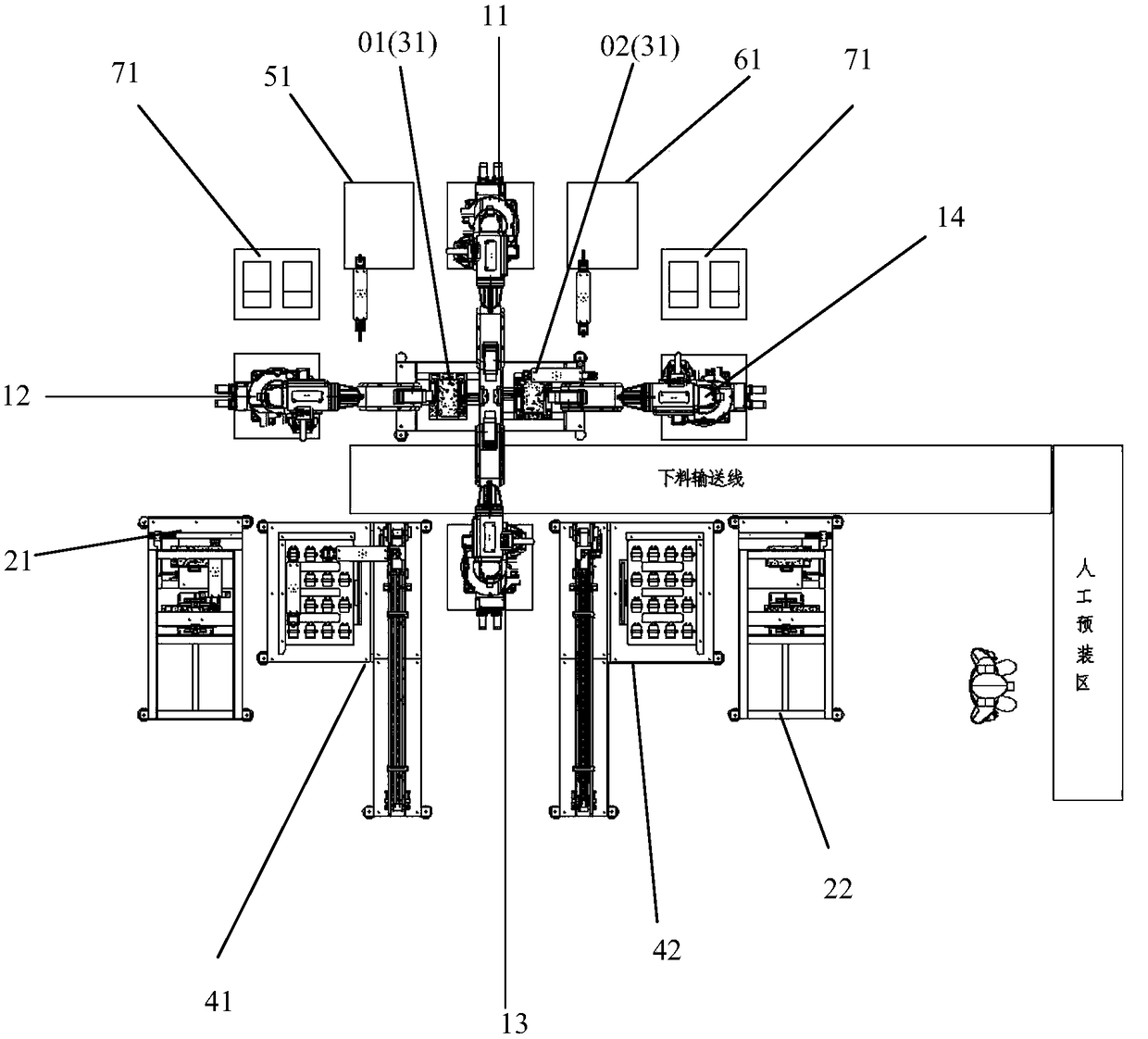

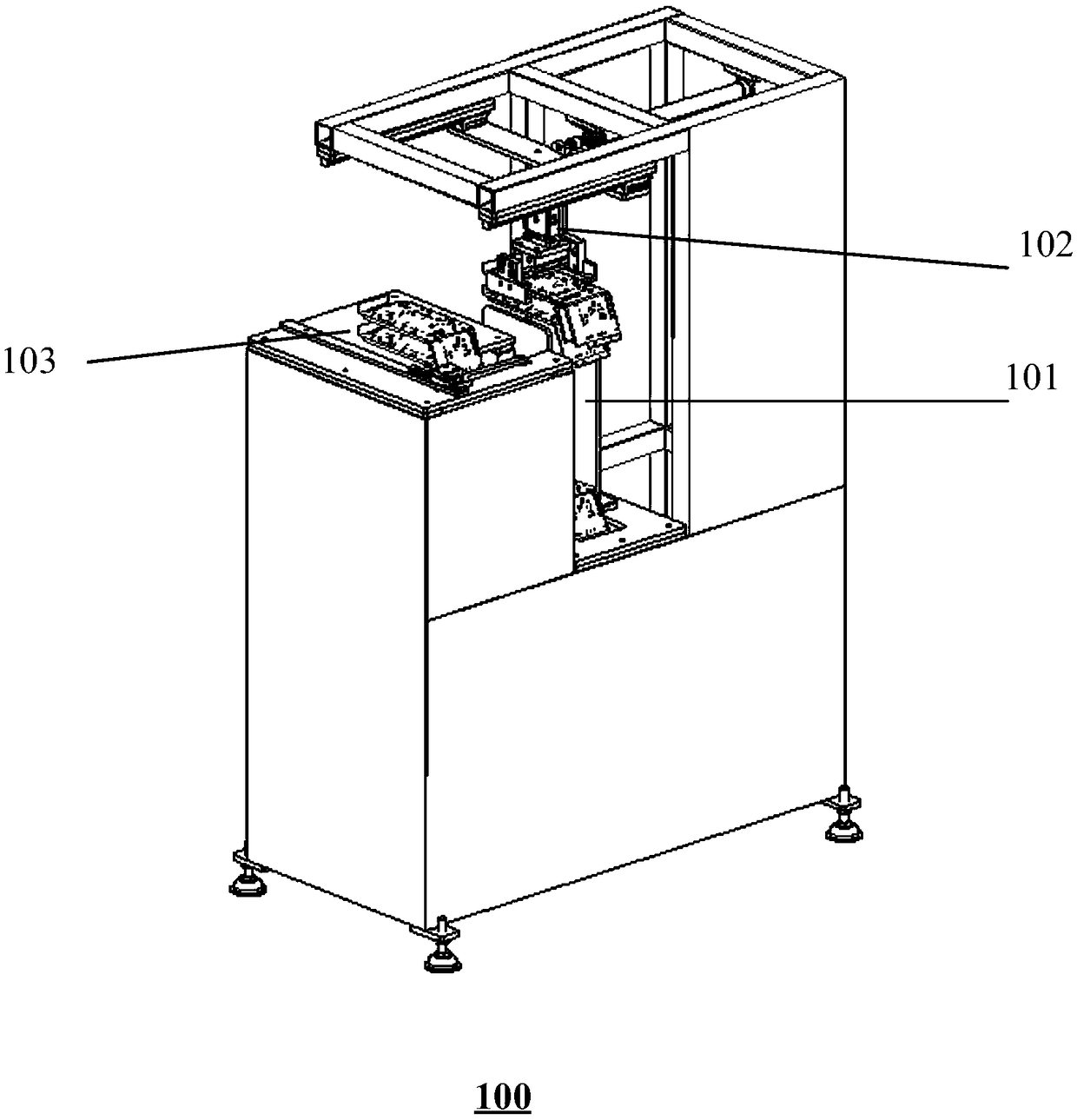

Automatic assembling system and method

InactiveCN108994602AImplement automatic assemblyIncrease productivityAssembly machinesCapacitanceEngineering

The invention provides an automatic assembling system and method which are used for improving electric appliance box production efficiency and quality, reducing the labor intensity of workers and saving person cost. The automatic assembling system comprises a control subsystem and a mechanical assembly subsystem, the mechanical assembly subsystem comprises a sheet metal part feeding device, a capacitance feeding device, an operation positioning device and a robot; and the control subsystem and the mechanical assembly subsystem are in communication connection, and the control subsystem is usedfor controlling mechanical assembly subsystem to conduct assembly operation on sheet metal parts.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

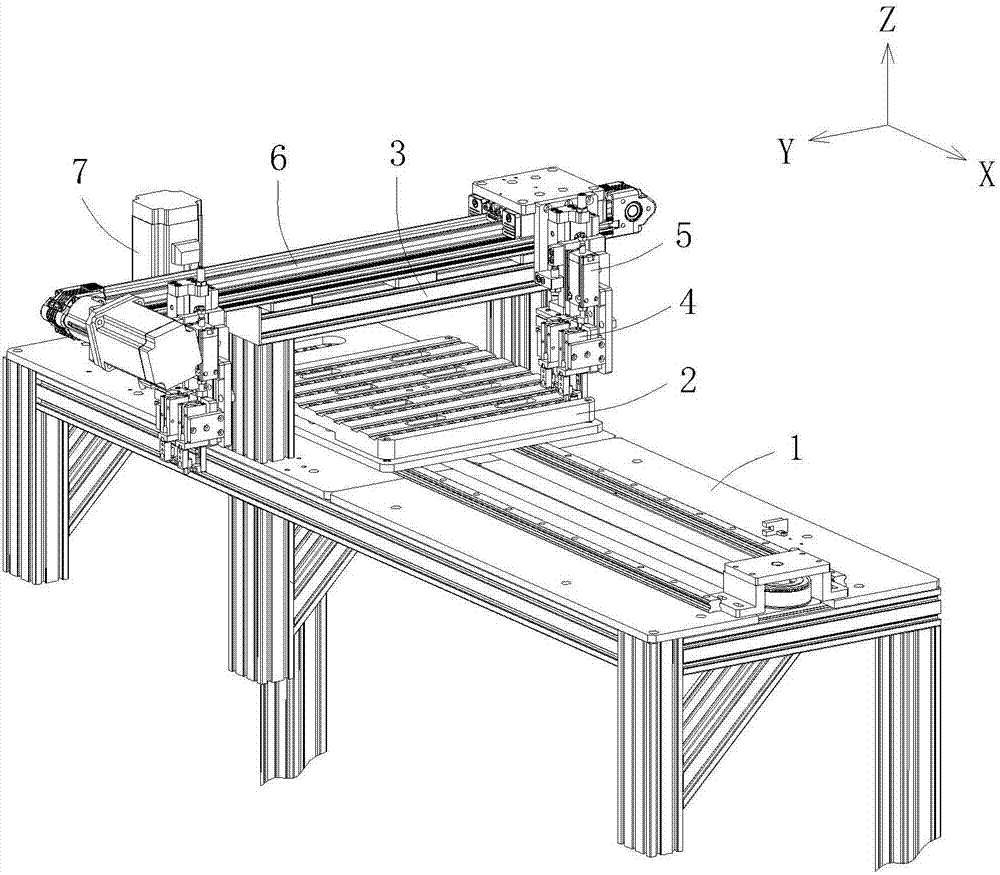

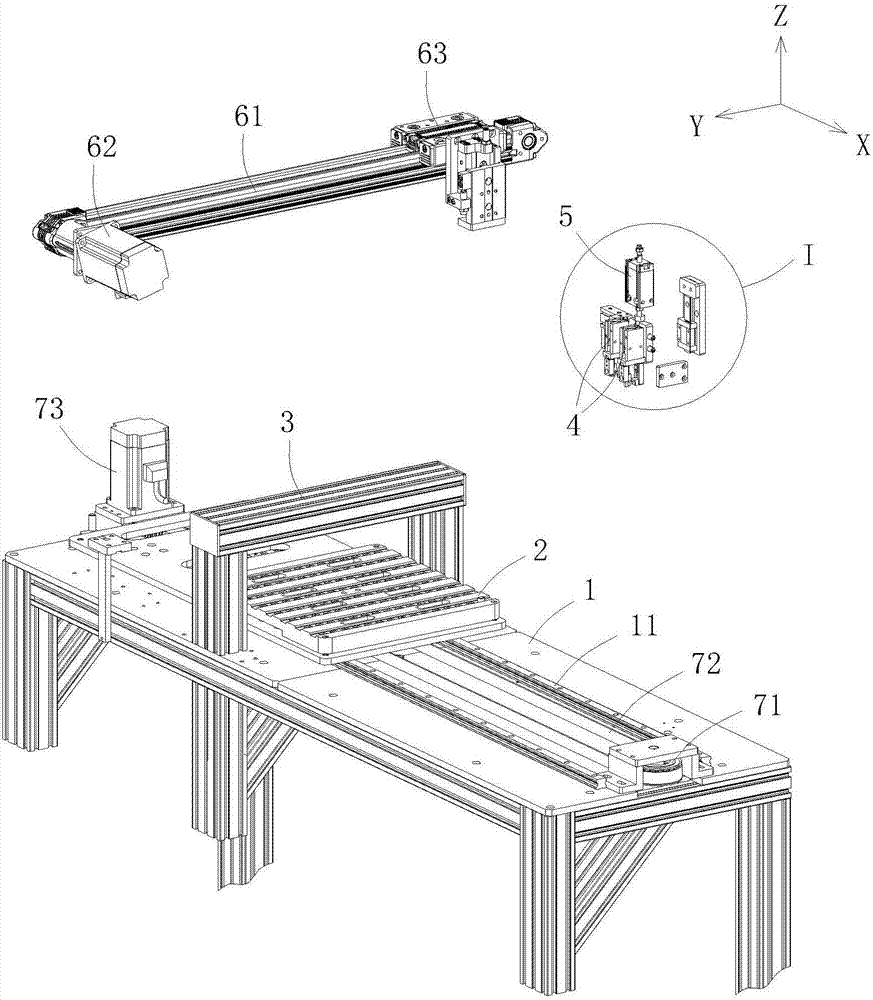

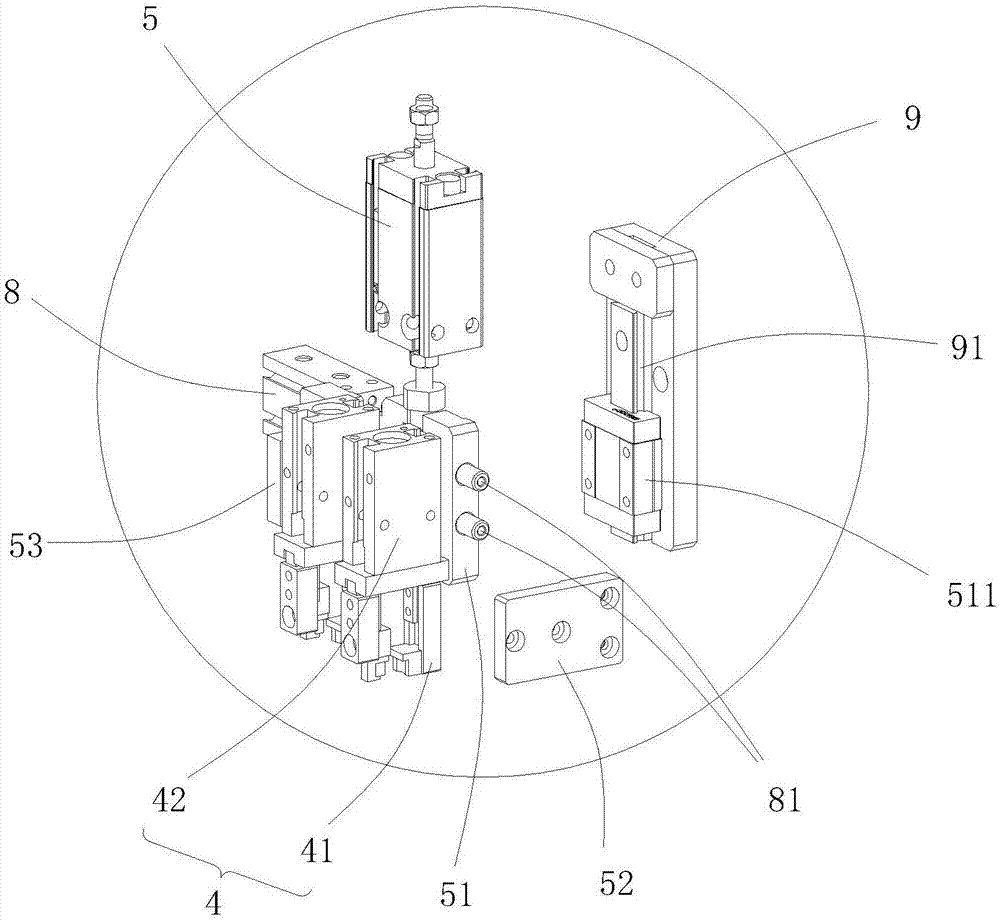

Automatic fetching and conveying device

PendingCN107399602ARealize automatic reclaimingFully automatedMetal working apparatusConveyor partsSoftware engineeringManual handling

The invention discloses an automatic fetching and conveying device. The automatic fetching and conveying device comprises a workbench, a fetching unit and a conveying unit, wherein a carrier used for storing a plurality of workpieces at intervals is arranged on the top surface of the workbench, and a support is connected to the top surface of the workbench; the fetching unit is arranged above the workbench and comprises a connecting plate, at least one clamping unit connected with the connecting plate and used for clamping the workpieces carried by the carrier, and a first driving unit connected with the connecting plate and used for driving the connecting plate and the clamping units to move in the Z-axis direction; and the conveying unit is connected to the support, connected with the first driving unit and used for conveying the first driving unit and the clamping unit in the Y-axis direction. According to the automatic fetching and conveying device, the fetching step and the conveying step which originally need to be operated manually can be made mechanized, so that the working efficiency and the mounting precision are improved.

Owner:LUXSHARE PRECISION INDUSTRY (CHUZHOU) CO LTD

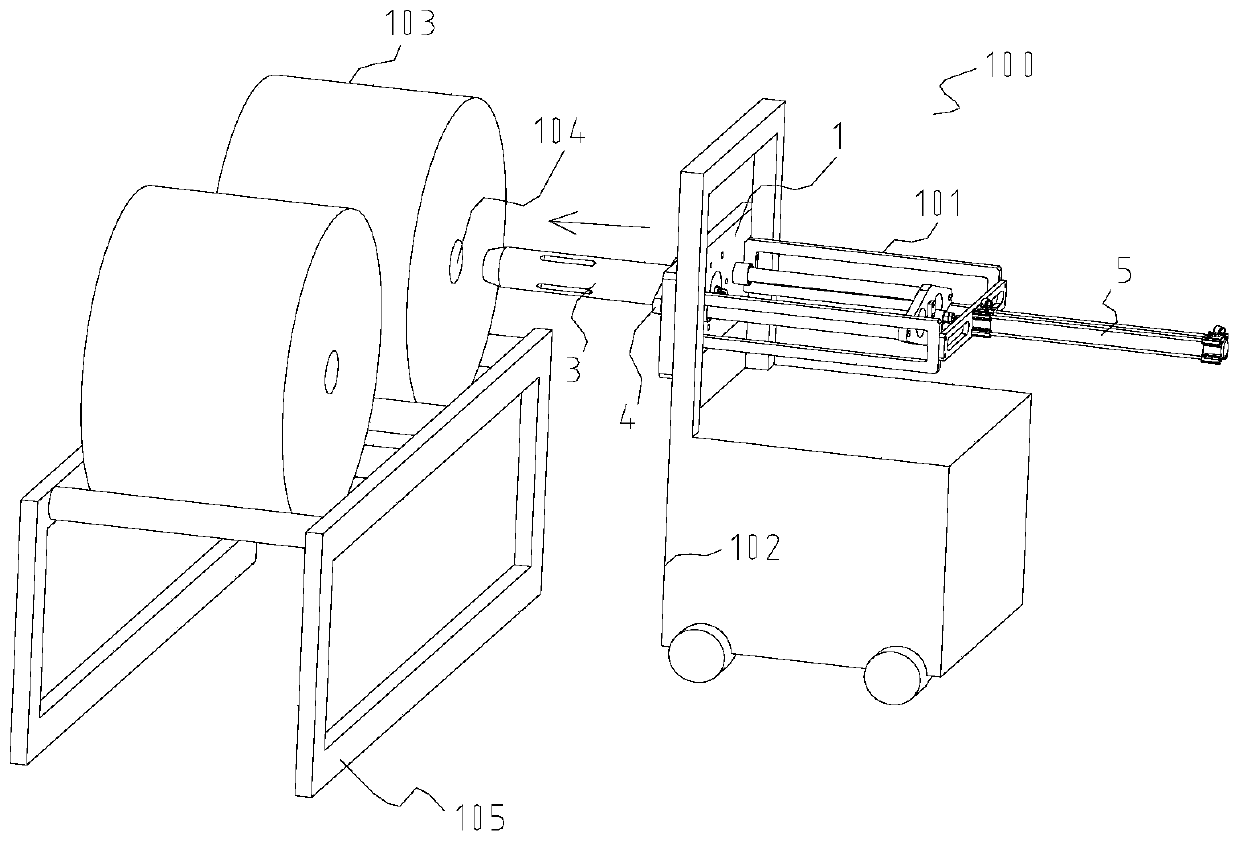

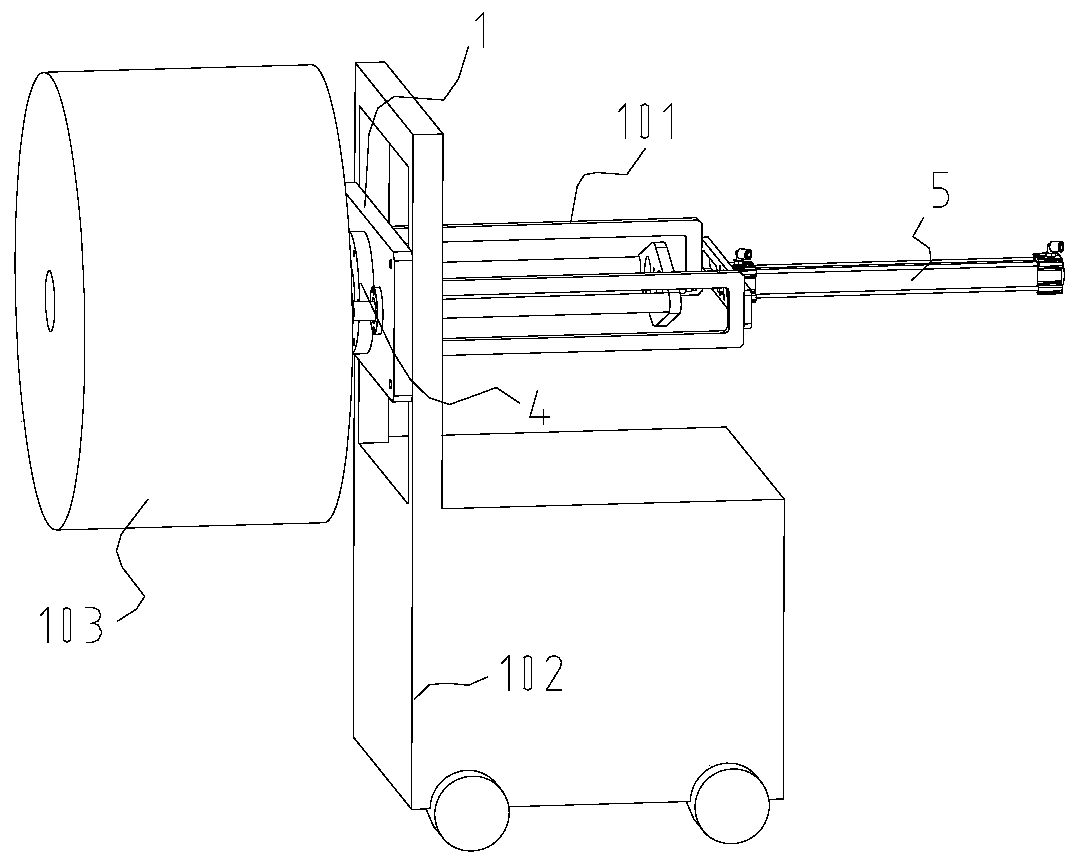

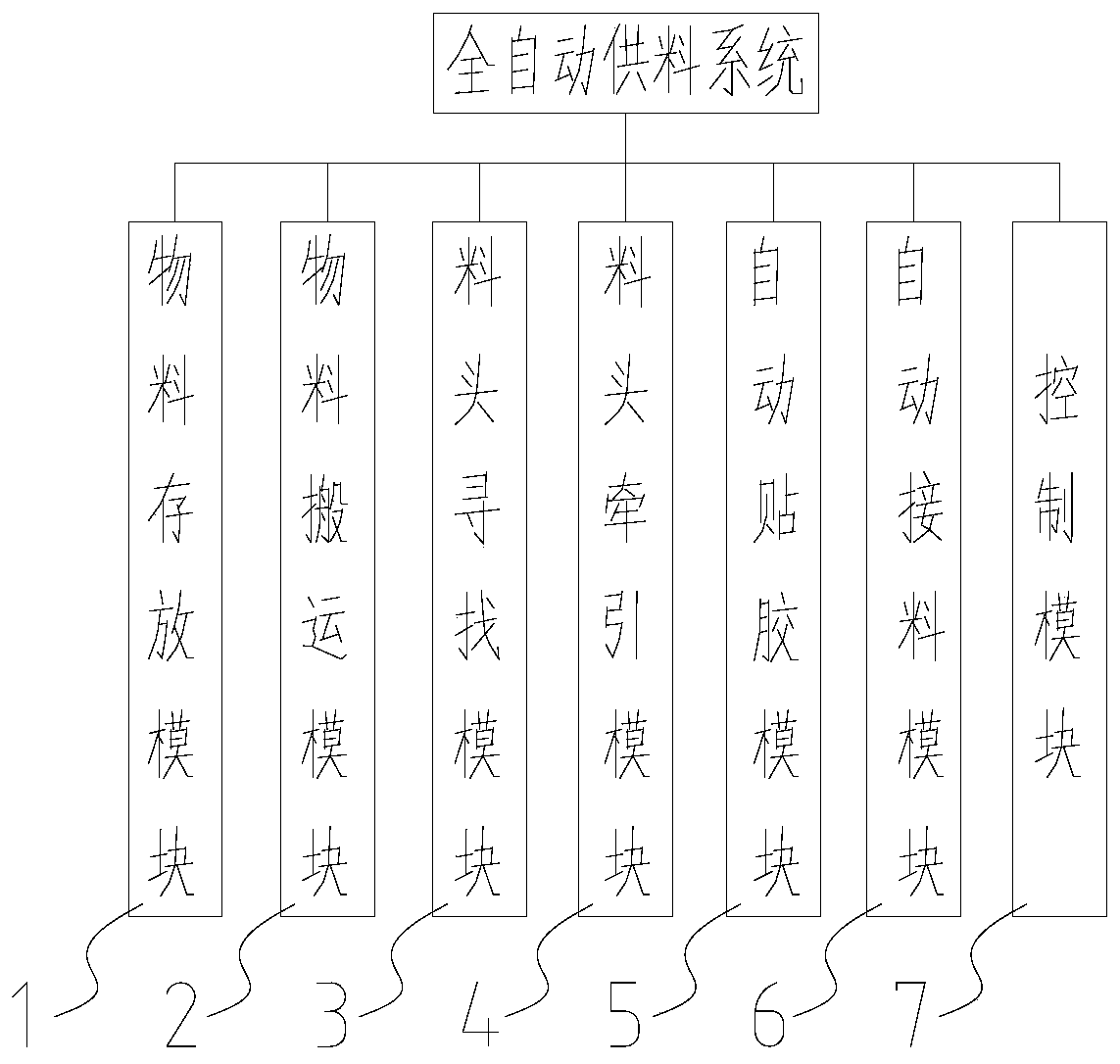

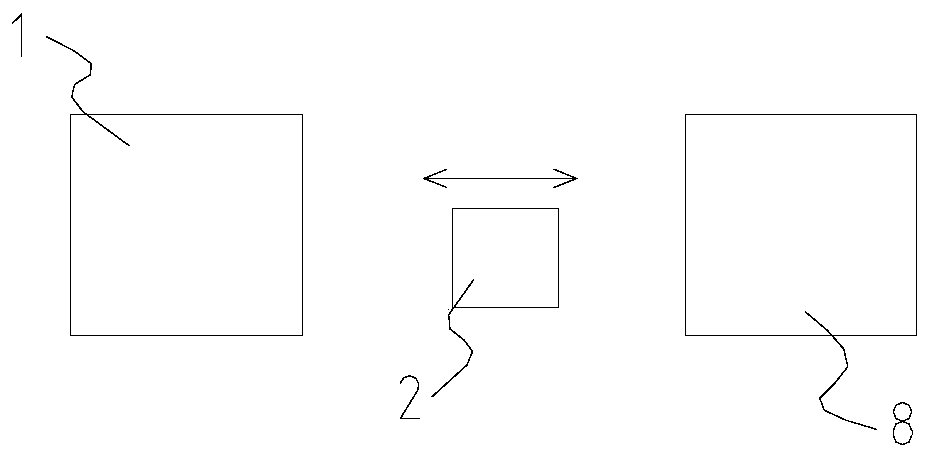

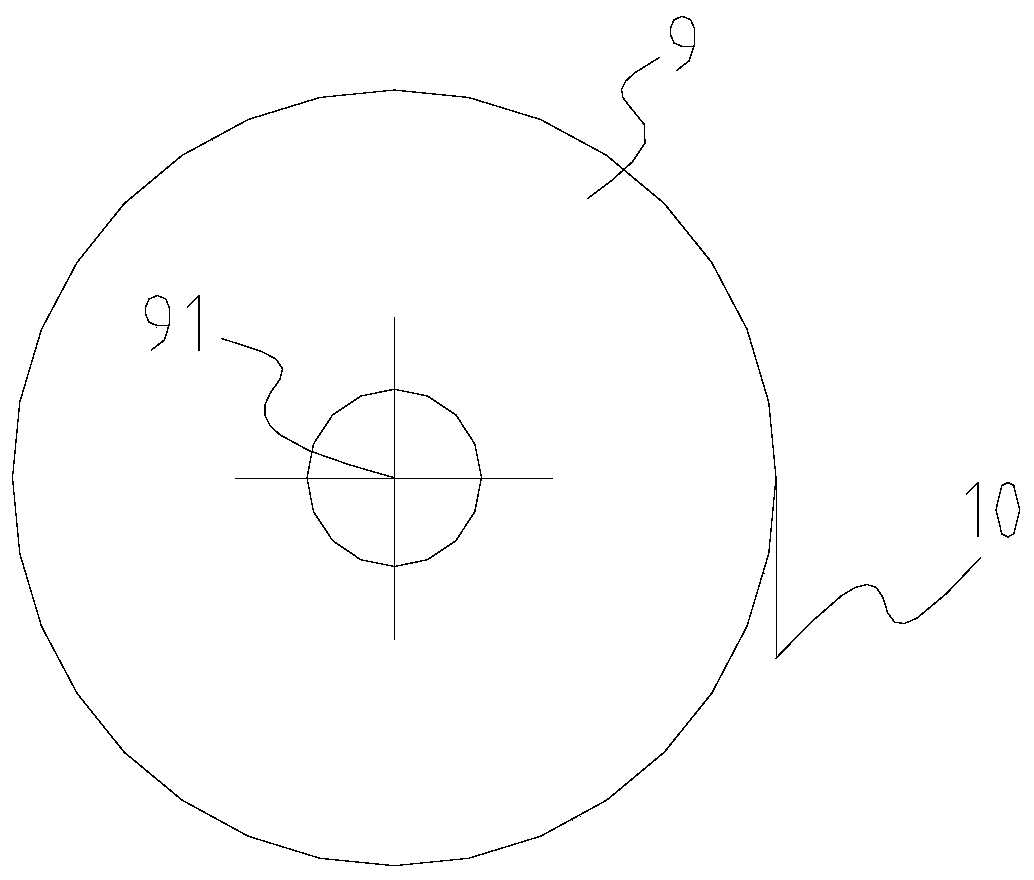

Fully-automatic supply method

ActiveCN110371739AReduce labor intensityAvoid Kind of MistakesArticle deliveryWebs handlingMaterial typeComputer module

The invention discloses a fully-automatic supply method. The fully-automatic supply method comprises the following steps ofa carrying step of carrying materials to a using station; a process of searching material heads on the surfaces of the materials after carrying the materials to the using station; a step of pulling the material heads to a rubberizing station to accomplish material head surfacerubberizing; and a step of pulling the material heads to an automatic material receiving module to accomplish material receiving. The fully-automatic supply method is extremely high in automatic andintelligent level, greatly increases production speed of equipment, greatly improves the automatic production level of the equipment, reduces labor intensity of a worker, can effectively avoid material type errors and material mounting errors in a loading process of rolled materials, and reduces an equipment failure shutdown rate caused by the material problem.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Automatic laying and sewing system and method

InactiveCN105386248AFree laborSave labor resourcesWork-feeding meansWork-collecting devicesManipulatorElectrical and Electronics engineering

The invention discloses an automatic laying and sewing system and method. The automatic laying and sewing system comprises a workbench, a manipulator, an induction part, a grabbing device, a sewing device, a pushing device and a control device. The manipulator is arranged on the workbench, and the induction part is arranged on the grabbing device which is arranged on the manipulator to be used for grabbing an object to be sewn. The sewing device is arranged on the workbench to be used for sewing the object to be sewn. The pushing device is arranged on the workbench to be used for pushing the object to be sewn, which is grabbed by the grabbing device, into the sewing device. The control device is electrically connected with the manipulator, the induction part, the grabbing device, the sewing device and the pushing device. The automatic laying and sewing system is capable of laying the object to be sewn automatically and high in production efficiency.

Owner:GUANGDONG ESQUEL TEXTILES +1

Automatic assembling equipment for eccentric cam and check ring of three-convex balance wheel seat and assembling process of automatic assembling equipment

PendingCN111069899AEven by forceQuality improvementAssembly machinesMetal working apparatusControl engineeringCam

The invention discloses automatic assembling equipment for an eccentric cam and a check ring of a three-convex balance wheel seat and an assembling process of the automatic assembling equipment. According to the scheme, the automatic assembling equipment comprises a balance wheel seat feeding device, a balance wheel seat positioning and clamping device, a check ring feeding device, a screw feedingdevice, a screw screwing device, an eccentric cam feeding device, an eccentric cam press fitting device and a discharging device; the screw screwing device comprises a supporting frame, a movable platform, a platform driving assembly, an electric screwdriver and a screw positioning assembly; the eccentric cam press fitting device comprises a press fitting rod, a universal press fitting head and apress fitting driving piece, positioning and clamping are conducted through the balance wheel seat feeding device, the check ring feeding device, the screw feeding device, the eccentric cam feeding device and the balance wheel seat positioning and clamping device, fastening screws are fixed to a balance wheel seat through the screw screwing device, therefore, the check ring is mounted, the universal press fitting head is arranged at the lower end of the press fitting rod, the press fitting quality is improved, finally, discharging is conducted through the discharging device, the production efficiency is improved, and the strength is reduced.

Owner:FOSHAN CITY SANJIAOZHOU ELECTRICAL TECH CO LTD

Automatic shoelace buckle threading machine and application thereof

A shoelace buckle automatic threading machine and application thereof are disclosed. The shoelace buckle automatic threading machine comprises a machine base, and a buckle head feeding device and a leather strip rotating wheel are arranged on the machine base and used for feeding metal buckle heads and leather strips respectively; an intermittent linear reciprocating mechanism is arranged on the machine base in the horizontal direction, and a head buckling mechanical arm is arranged on a sliding base of the intermittent linear reciprocating mechanism. A supporting base is arranged on the machine base and located behind the intermittent linear reciprocating mechanism, a first air cylinder and a horizontally-arranged first sliding way are arranged on the supporting base, and the first air cylinder is connected with a traction base arranged on the first sliding way. A traction feeding mechanism and a cutting and tapping mechanism which are arranged up and down are arranged on the tractionseat; an automatic two-axis displacement table is arranged on the supporting base in the longitudinal direction, and a strap mechanical arm is arranged on an X-axis platform of the automatic two-axisdisplacement table. A buckle head clamping mechanism is arranged on the supporting base in the transverse direction. The upper end of the supporting base is provided with a buckle penetrating mechanical arm in the longitudinal direction. The machine is high in production efficiency, capable of effectively reducing the labor intensity of workers, good in product consistency and beneficial to subsequent operation.

Owner:重庆丰盛鞋业有限公司

Automatic assembling equipment for check ring of three-convex balance wheel base

PendingCN111015218AIncrease productivityReduce intensityAssembly machinesMetal working apparatusControl engineeringIndustrial engineering

The invention discloses automatic assembling equipment for a check ring of a three-convex balance wheel base. According to the scheme, the automatic assembling equipment comprises a balance wheel basefeeding device, a balance wheel base positioning and clamping device, a check ring feeding device, a screw feeding device, a screw screwing device and a discharging device. The screw screwing devicecomprises a supporting frame, a moving platform, a platform driving assembly, a plurality of electric screw drivers and a screw positioning assembly. Balance wheel bases, check rings and fastening screws are fed to the balance wheel base positioning and clamping device through the balance wheel base feeding device, the check ring feeding device and the screw feeding device correspondingly; the balance wheel base positioning and clamping device is used for positioning and clamping the balance wheel bases; the platform driving assembly drives the moving platform to descend, so that the electricscrew drivers fix the fastening screws to the balance wheel base through descending of the moving platform, so that the check ring is installed; and finally, discharging is conducted through the discharging device. The automatic production process of feeding, press fitting and discharging is achieved, the production efficiency is improved, and the labor intensity is reduced.

Owner:FOSHAN CITY SANJIAOZHOU ELECTRICAL TECH CO LTD

Crushing and identifying device for pulverizer screen

PendingCN110449250AReduce workloadRealize automatic reclaimingFeeding-stuffGrain treatmentsEngineeringMechanical engineering

The invention discloses a crushing and identifying device for a pulverizer screen. The device comprises a supporting frame table, a chute pipe, a photographing frame, a vibration feeder, a material taking box and a discharging channel, wherein the chute pipe, the photographing frame and the vibrating feeder are arranged on the supporting frame table, the material taking box is fixed on the circumferential wall of the chute pipe through a connecting sleeve, the discharging channel is welded to the material taking box, the feeding end of the discharging channel is arranged right below the material taking box, and the discharging end of the discharging channel is located right above the vibration feeder. Automatic material taking and automatic screening and recognizing can be realized, the workload of workers is reduced, and the working efficiency is improved.

Owner:HUAZHONG AGRI UNIV

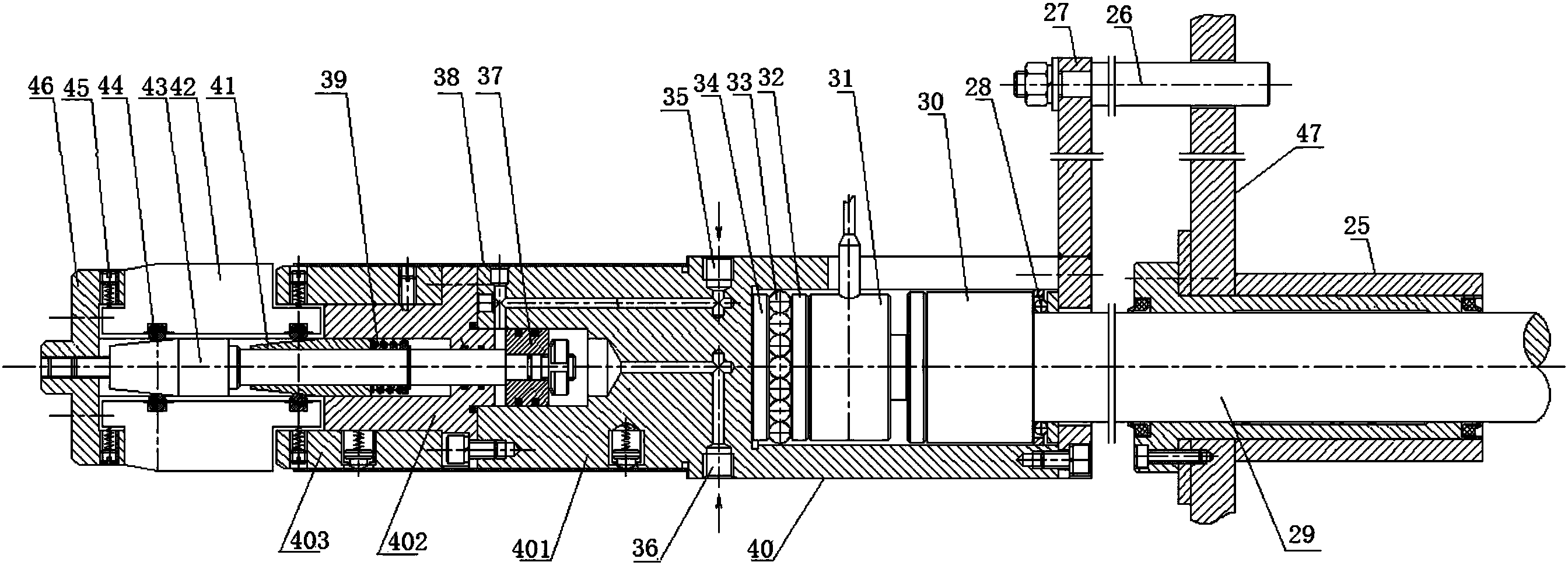

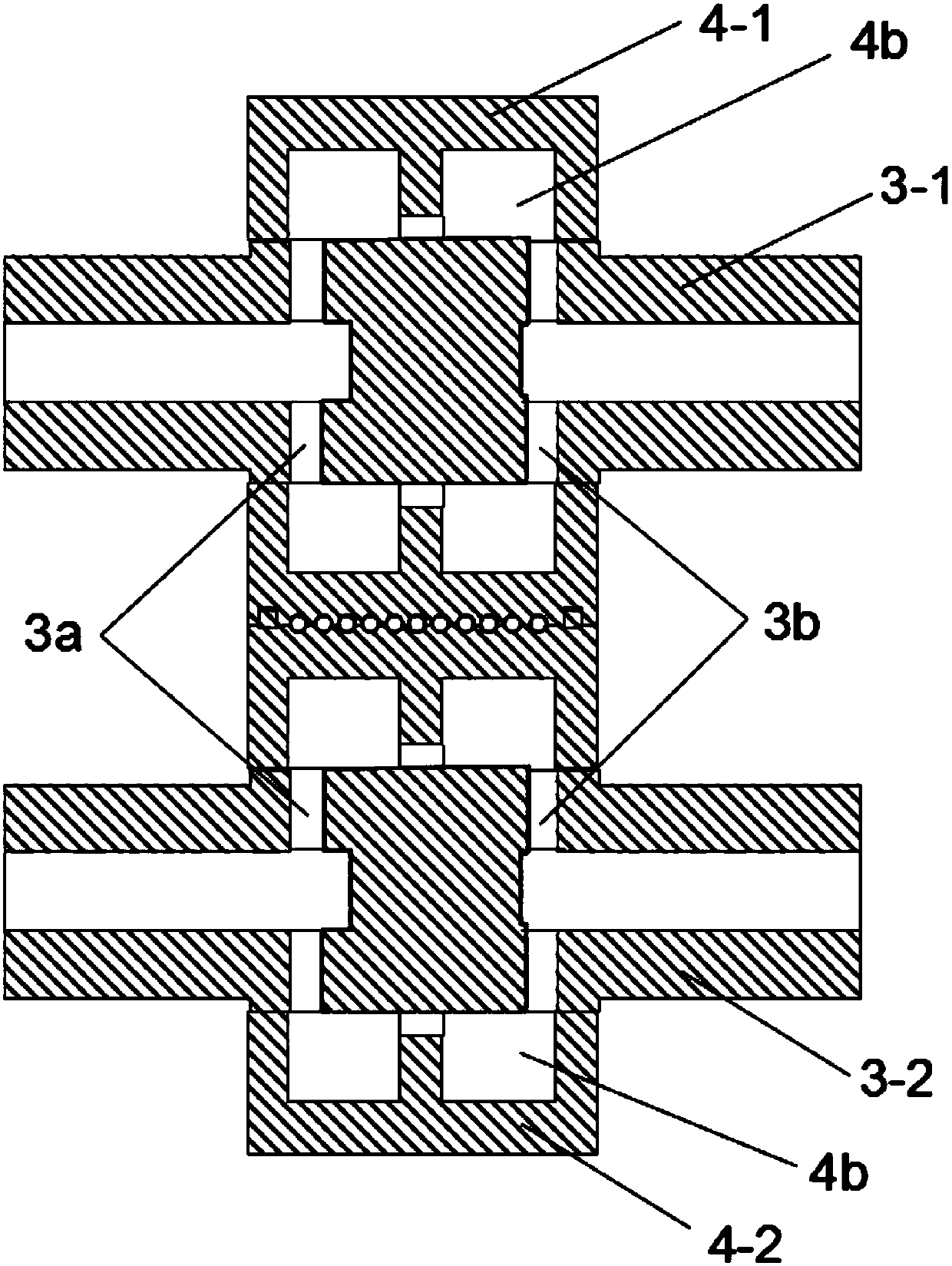

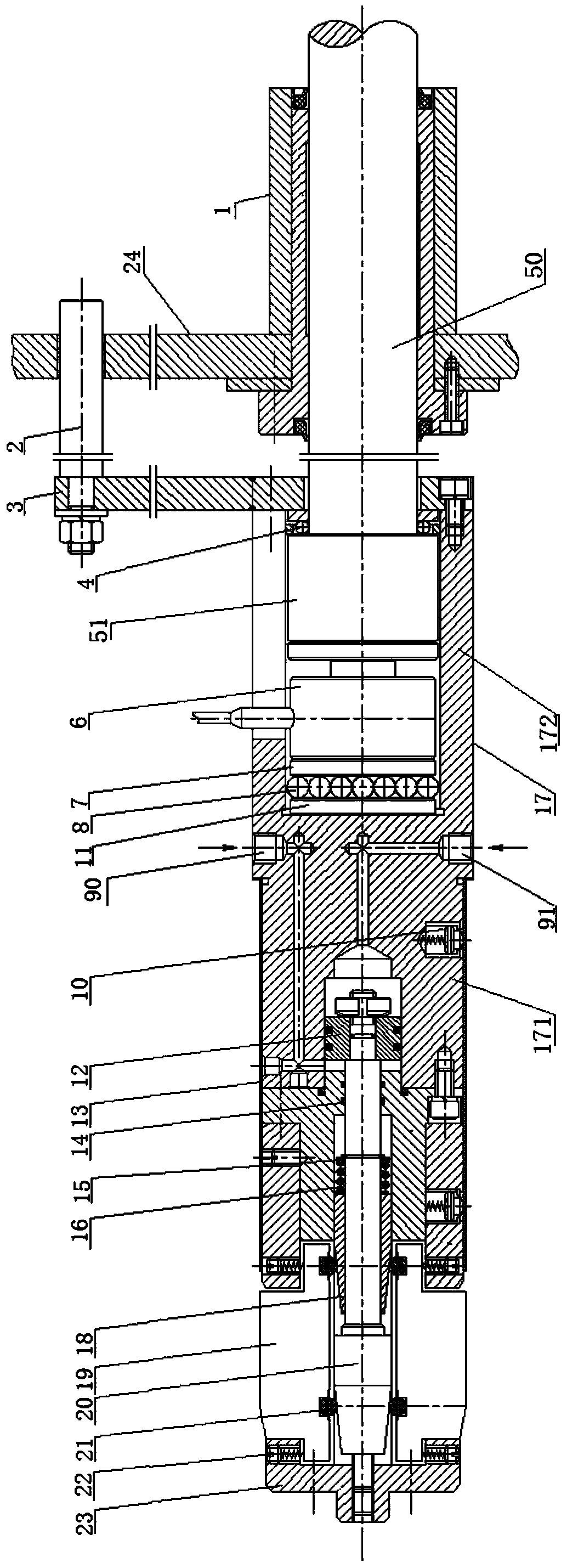

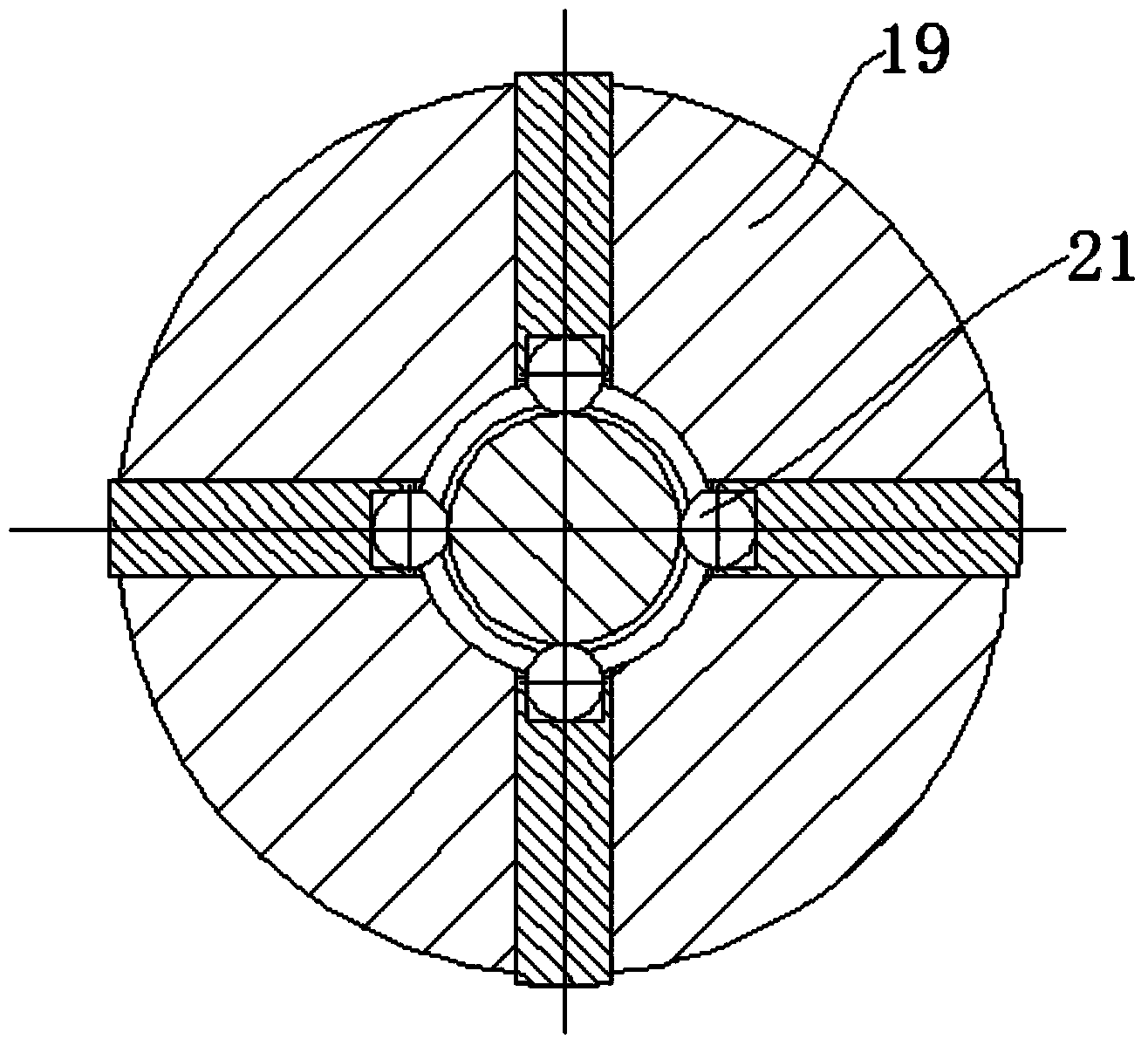

Cylinder sleeve pressing head device

ActiveCN103481052ARealize automatic reclaimingRealize the function of expansion and contractionMetal working apparatusEngineeringMechanical engineering

The invention discloses a cylinder sleeve pressing head device, and belongs to the field of cylinder sleeve press fitting tools. The cylinder sleeve pressing head device comprises a guiding block, a pressing head body, a guiding sleeve, an oil cylinder piston rod, an adjusting screw seat and a conical shaft, wherein the lower portion of the conical shaft is connected with the adjusting screw seat after penetrating in the guiding block; the lower portion of the guiding block is in the shape of an inverted cone; the lower portion of the pressing head body is connected with the guiding block through the upper portion of the conical shaft; the outer diameter of the lower portion of the pressing head body is the same with that of the guiding block when the pressing head body is in a contraction state; and the upper portion of the pressing head body is connected with the guiding sleeve through the oil cylinder piston rod. The cylinder sleeve pressing head device has the advantages that a cylinder sleeve cannot be out of round while the cylinder sleeve pressing head device takes materials automatically, a function of automatic centering can be realized, namely, the pressing head can be ensured to be pressed in the cylinder sleeve, and the cylinder sleeve can also be ensured to be accurately pressed in a cylinder body; and moreover, the pressure change condition can be timely and automatically fed back in a sleeve pressing process, can be monitored in real time, and then is controlled in real time.

Owner:金湖县综合检验检测中心

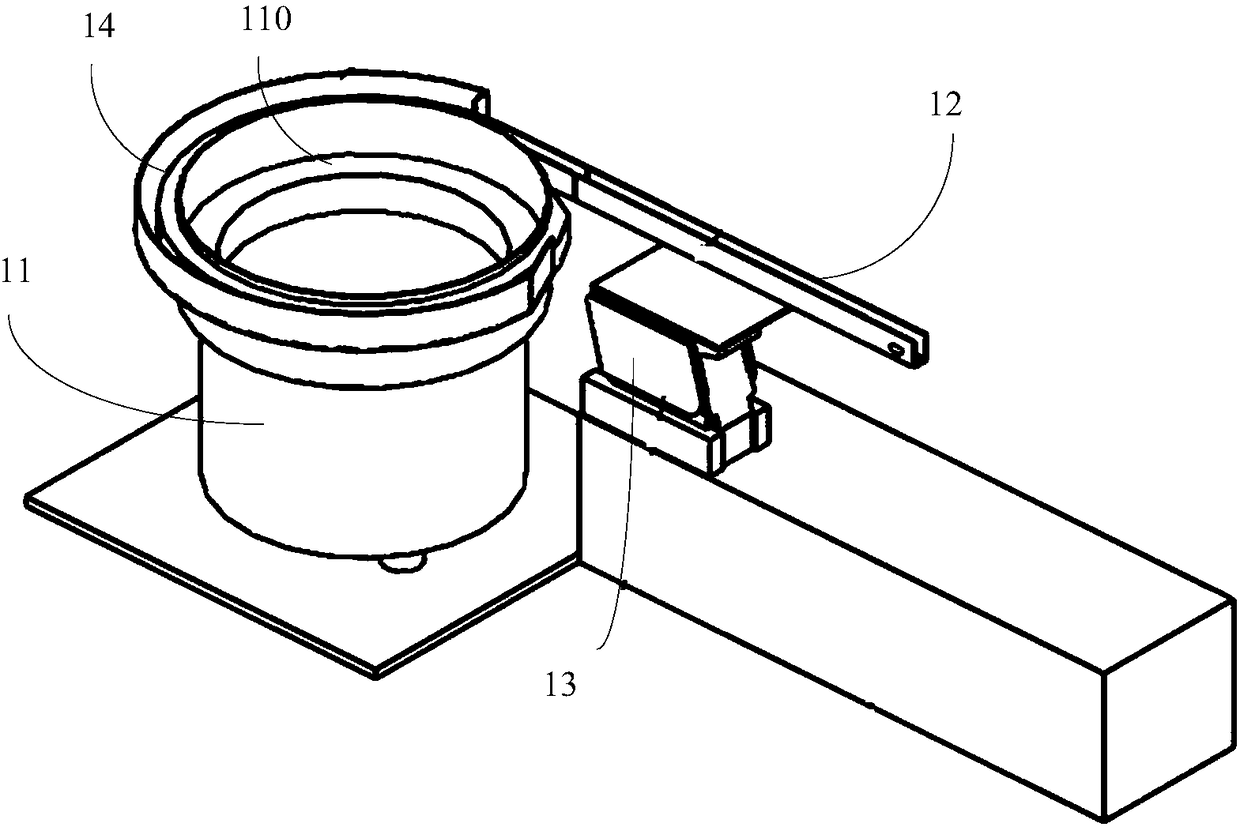

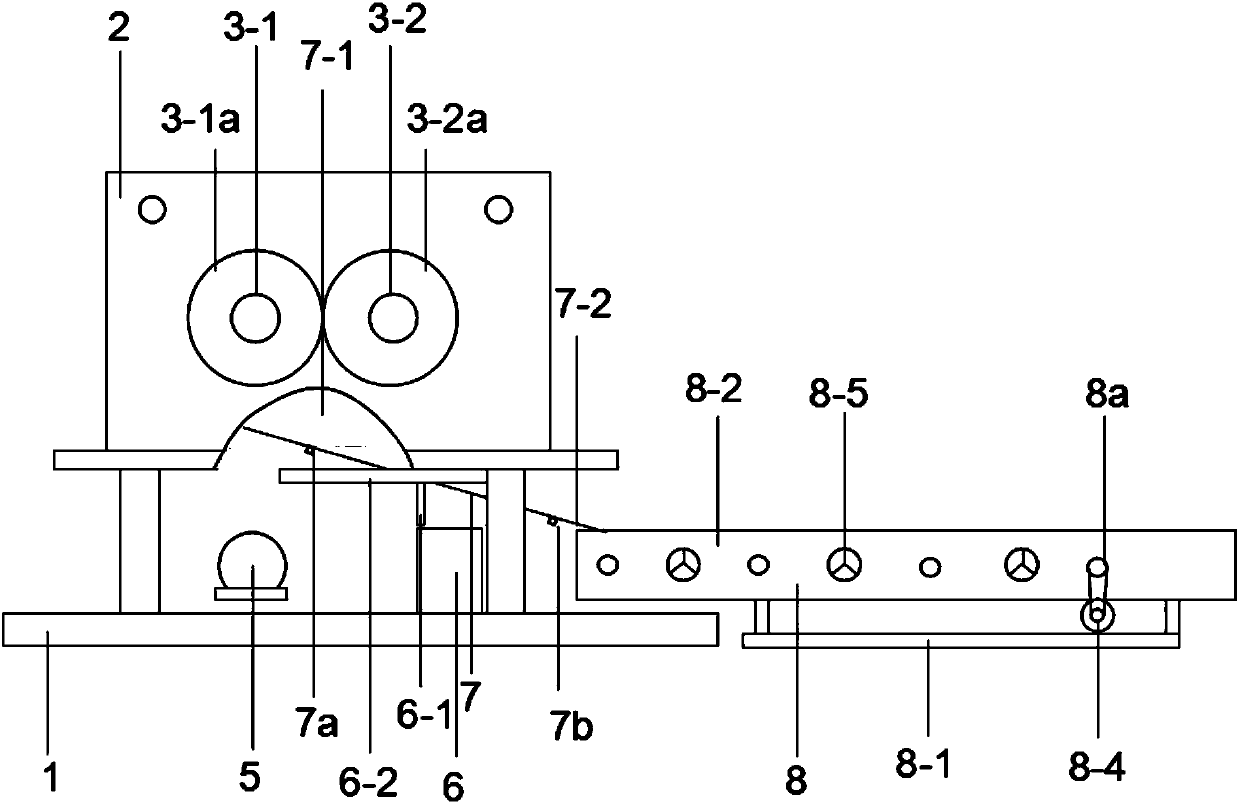

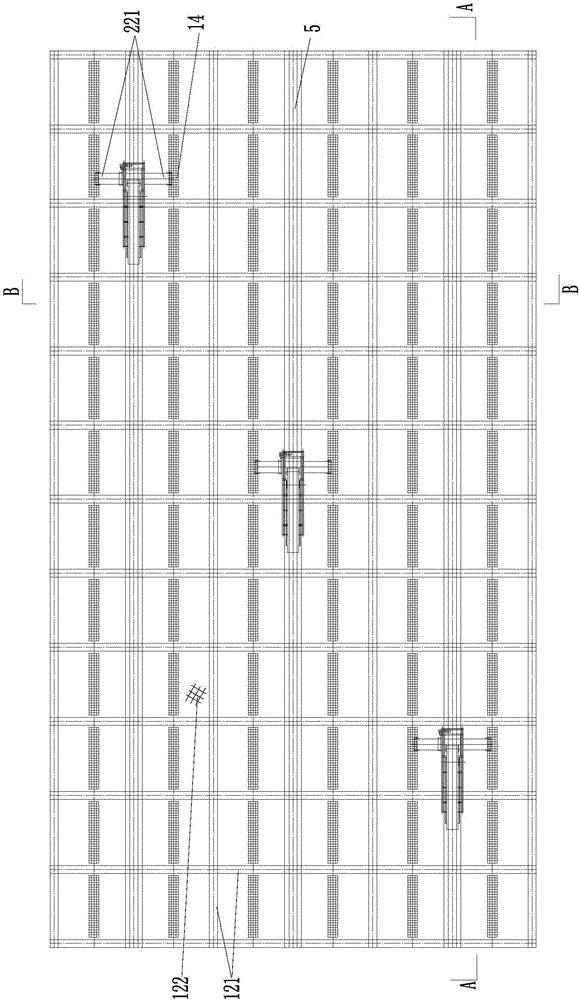

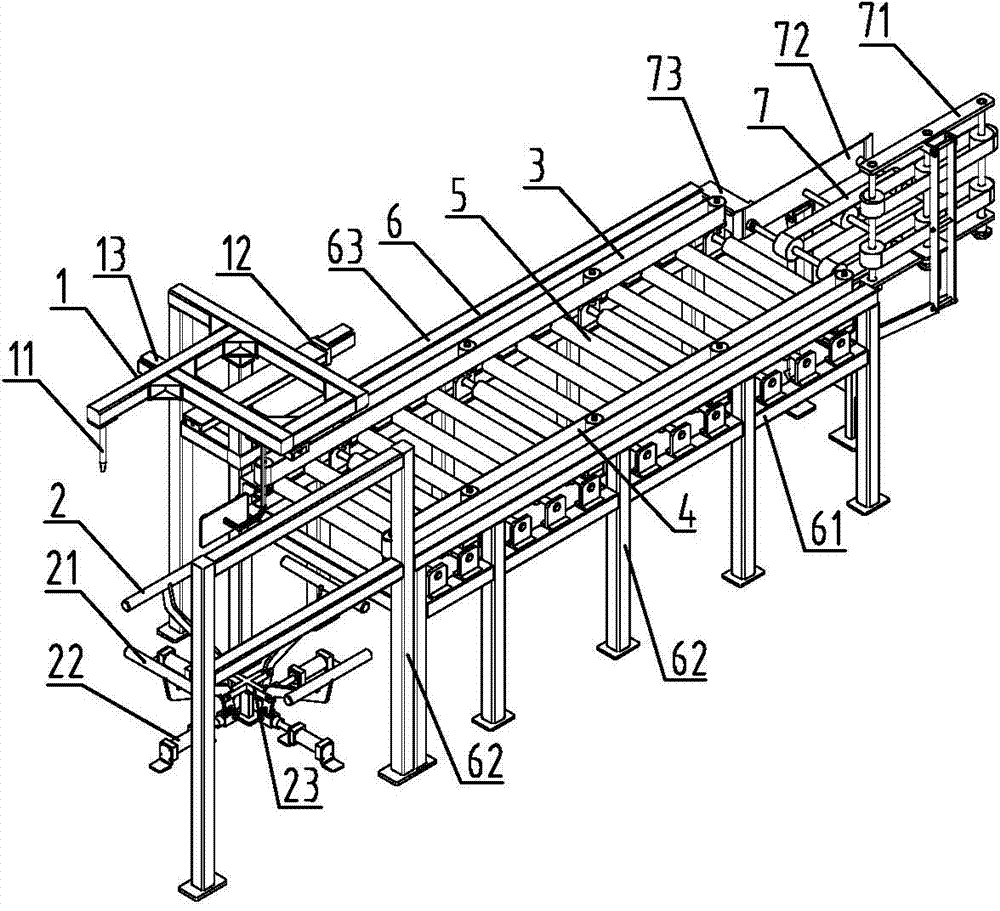

Assembling system of semi-circular pipes with welding rings

InactiveCN108296730AReduce labor intensityImprove efficiencyMetal working apparatusIsolating mechanismsEngineering

The invention discloses an assembling system of semi-circular pipes with welding rings. The assembling system of the semi-circular pipes with the welding rings comprises a material supplying device, atransmission positioning device and a robot inserting device, the material supplying device comprises a vibrating conveying mechanism, a distributing and isolating mechanism, a jacking material taking mechanism and a shaping and rectifying mechanism, and the transmission positioning device comprises a first conveying line, a transmitting part and a second conveying line. The robot inserting device comprises a four-axis robot, a clamping jaw fixing seat, a clamping jaw air cylinder and a floating clamping jaw. According to the assembling system of the semi-circular pipes with the welding rings, through the material supplying device, the efficiency of sleeving of the semi-ring-shaped copper pipes with the welding rings is improved, meanwhile through the robot inserting device, the semi-circular pipes sleeved with the welding rings by the material supplying device are accurately inserted on fins, a manual assembling mode is avoided, and thus the assembling efficiency of the semi-circularpipes with the welding rings is improved.

Owner:武汉船舶通信研究所

A resistor sheet riveting press

ActiveCN106734658BRealize automatic reclaimingIncrease productivityMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses a resistance chip riveting machine. The machine comprises a first taking mechanism fixedly arranged on a main frame, a mold, a second taking mechanism, a punching machine and a touch screen; the first taking mechanism and the second taking mechanism are oppositely placed; two ends of the mold are respectively connected with output ends of the first taking mechanism and the second taking mechanism; an output end of the punching machine is connected above the mold; an opening is formed in the mold, and is connected with a receiving box through an aslant downward way; and the first taking mechanism, the second taking mechanism and the punching machine control and are connected with the touch screen. The resistance chip riveting machine has the following beneficial effects: the machine can realize automatic taking and automatic mold feeding in the riveting process of resistance chips, realizes once two-step installation of materials in the mold in place, is high in production efficiency, has no need to treat the resistance chips after prepressing, repressing and cutting, is high in production efficiency, is excellent in product consistency, and effectively improves the product quality.

Owner:DONGGUAN XINLIANGDIAN AUTOMATION EQUIP TECH

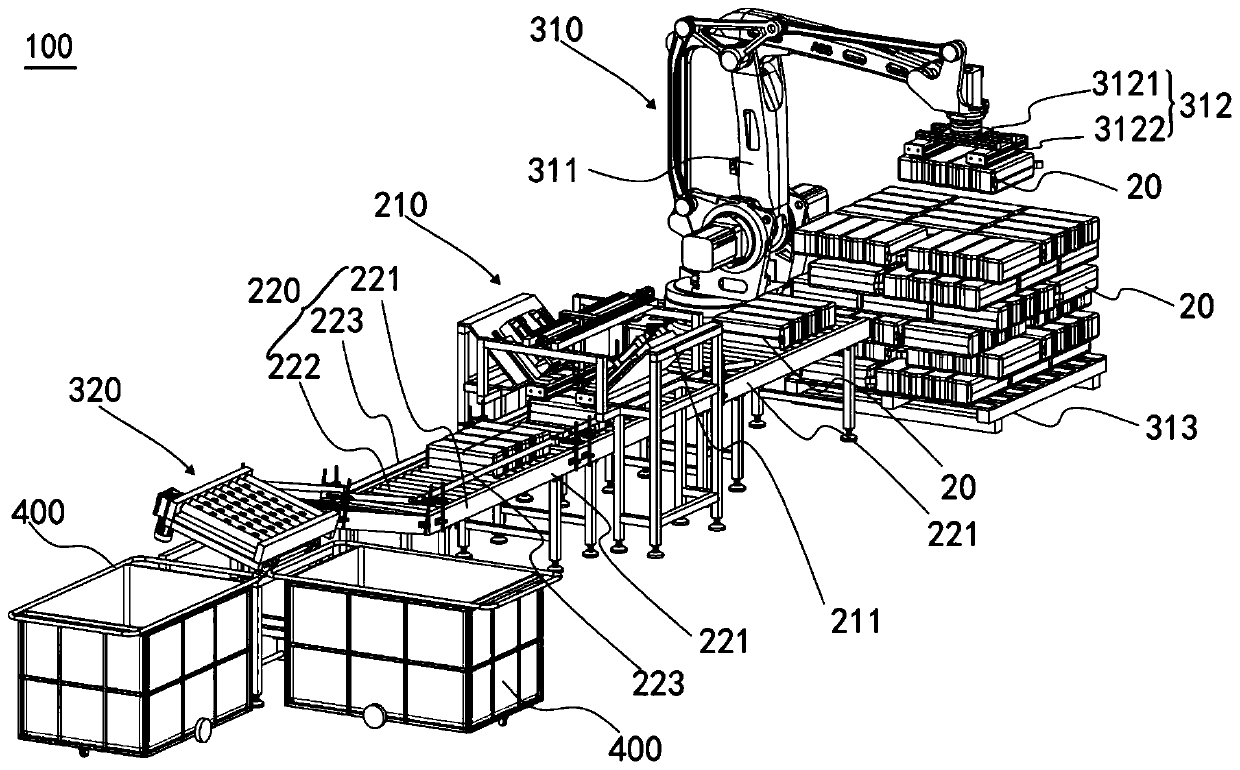

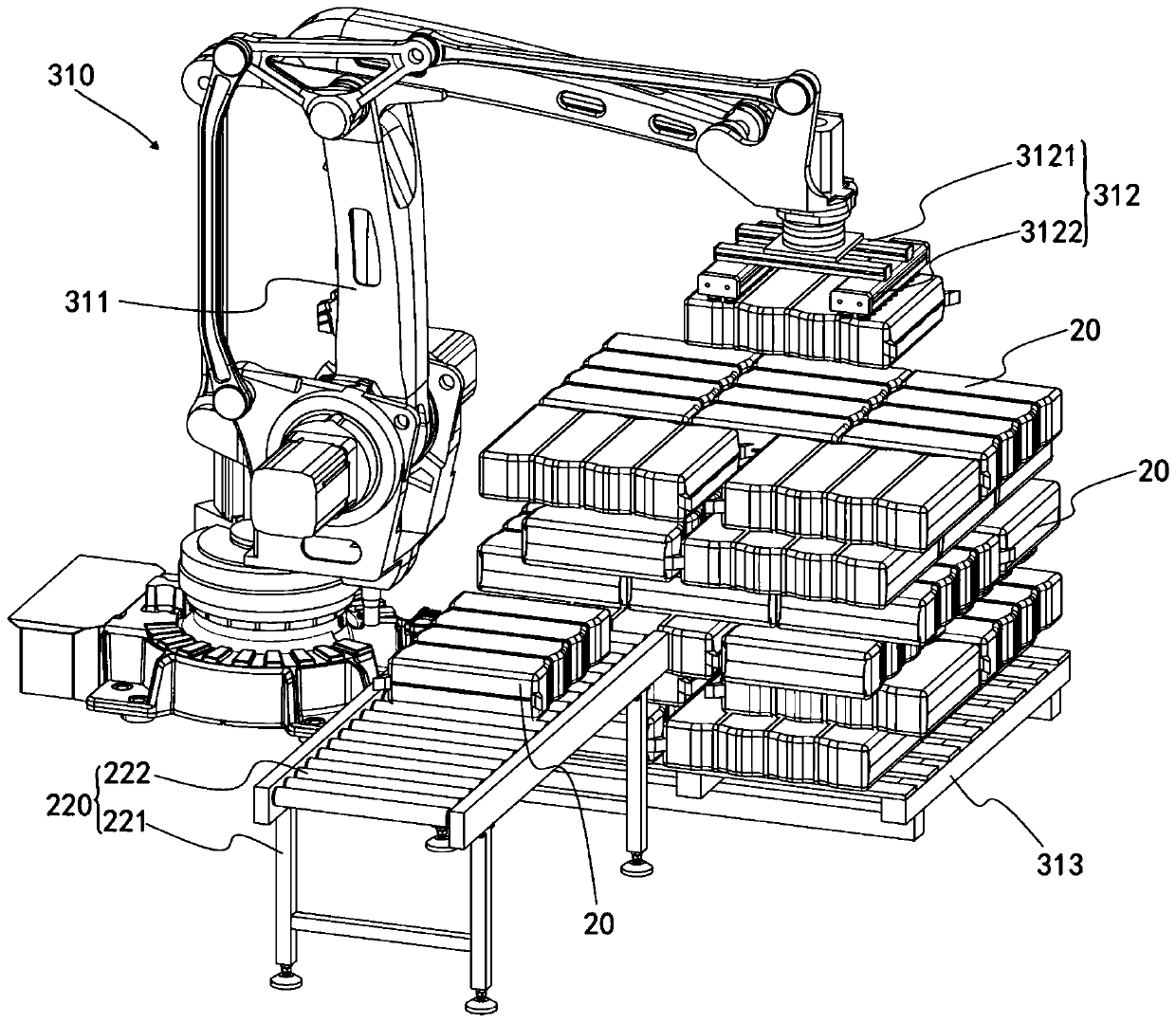

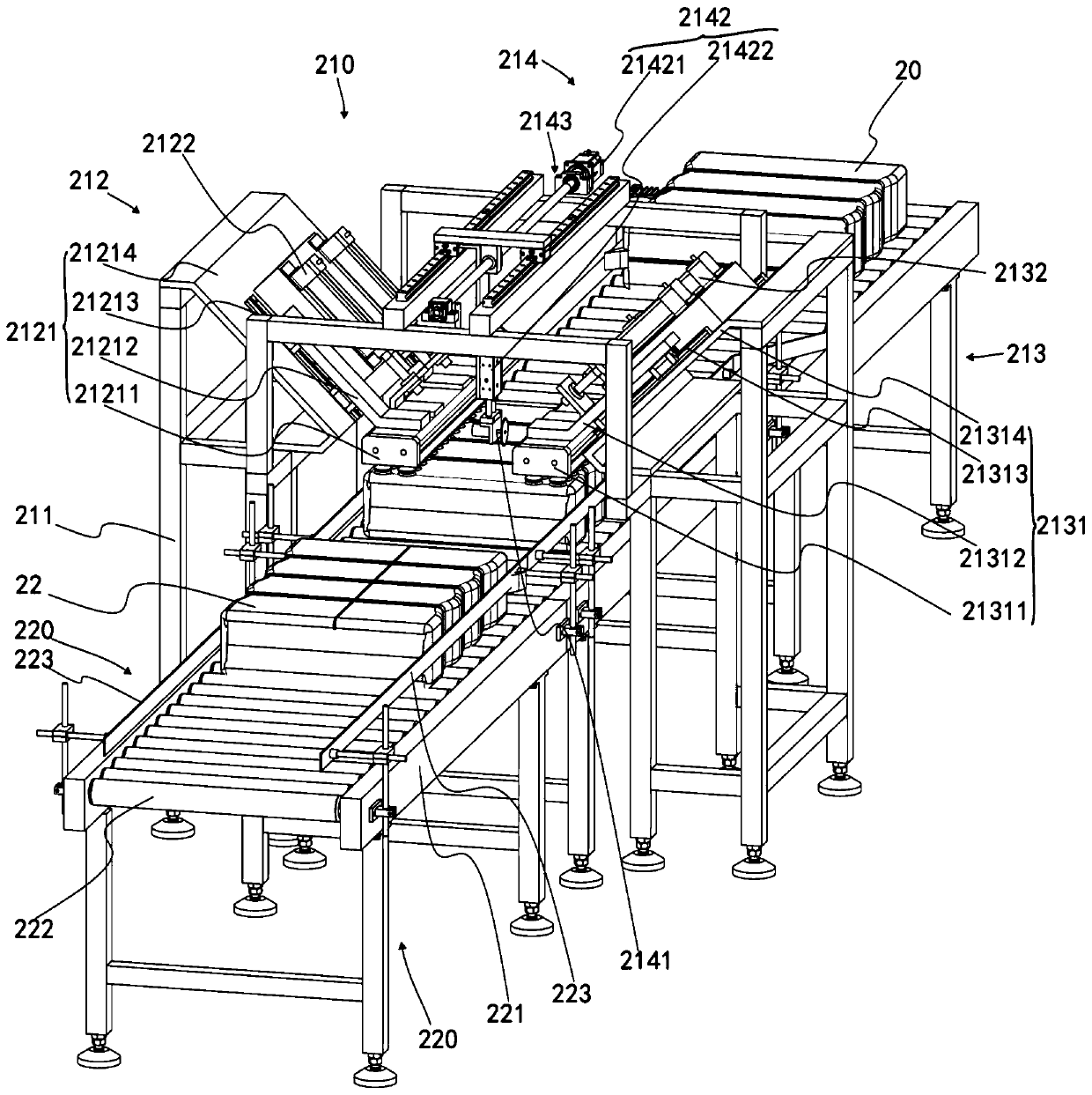

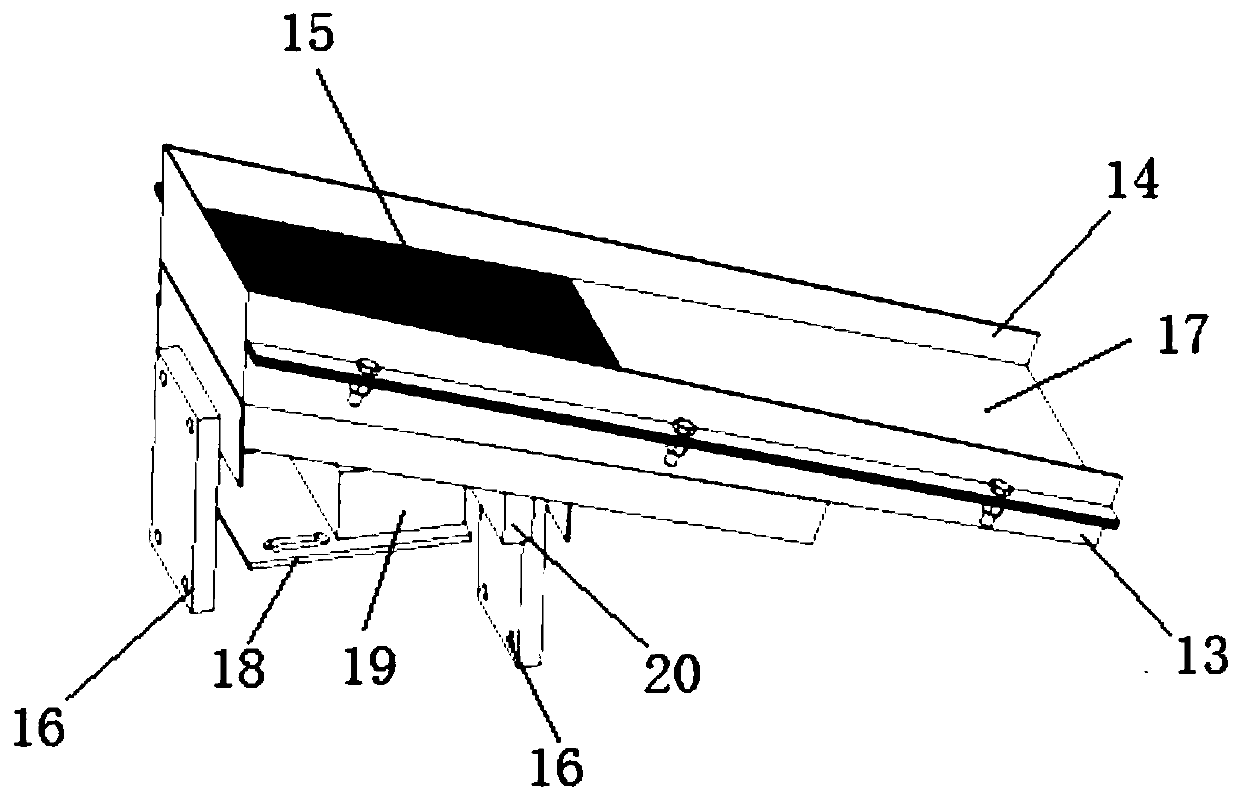

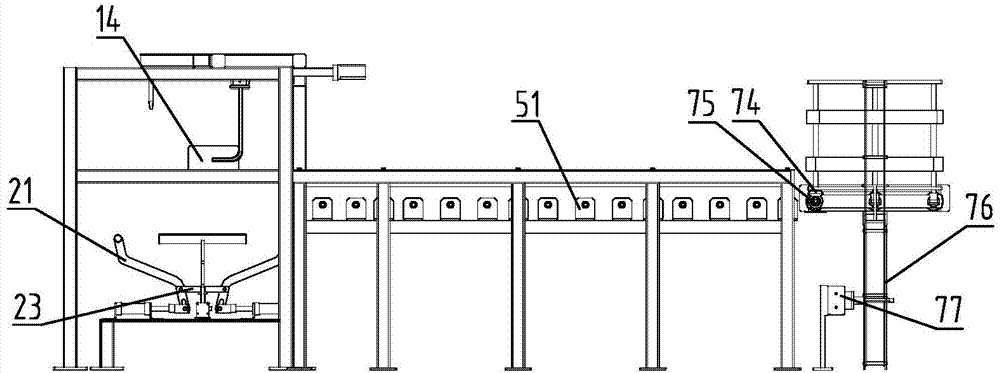

Paper box lower portion folding and conveying mechanism of battery subsequent unmanned packing device

The invention relates to battery processing equipment, particularly to a paper box bower portion folding and conveying mechanism of a battery subsequent unmanned packing device. The mechanism comprises a taking mechanism, a lower portion folding mechanism, a frame, an unpowered rolling table, two lateral belt conveying devices, a conveying frame rolling mechanism. The taking mechanism is mounted at the front end of the frame, the lower portion folding mechanism and the unpowered rolling table are mounted in the same straight line and arranged under the taking mechanism, the two lateral belt conveying devices are mounted on the left and the right of the frame and are higher than the unpowered rolling table, the conveying frame rolling mechanism is mounted at the rear end of the frame and comprises a horizontal conveying frame, a vertical conveying frame and a rotating air cylinder, and the horizontal conveying frame is level with the unpowered rolling table.

Owner:ZHANGJIAGANG ZHIZHOU IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com