Automatic punching machine and punching method thereof

A punching machine, automatic technology, applied in the field of punching, can solve the problems of inconvenient processing, low production efficiency, heavy body and other problems, and achieve the effect of saving labor, improving production efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

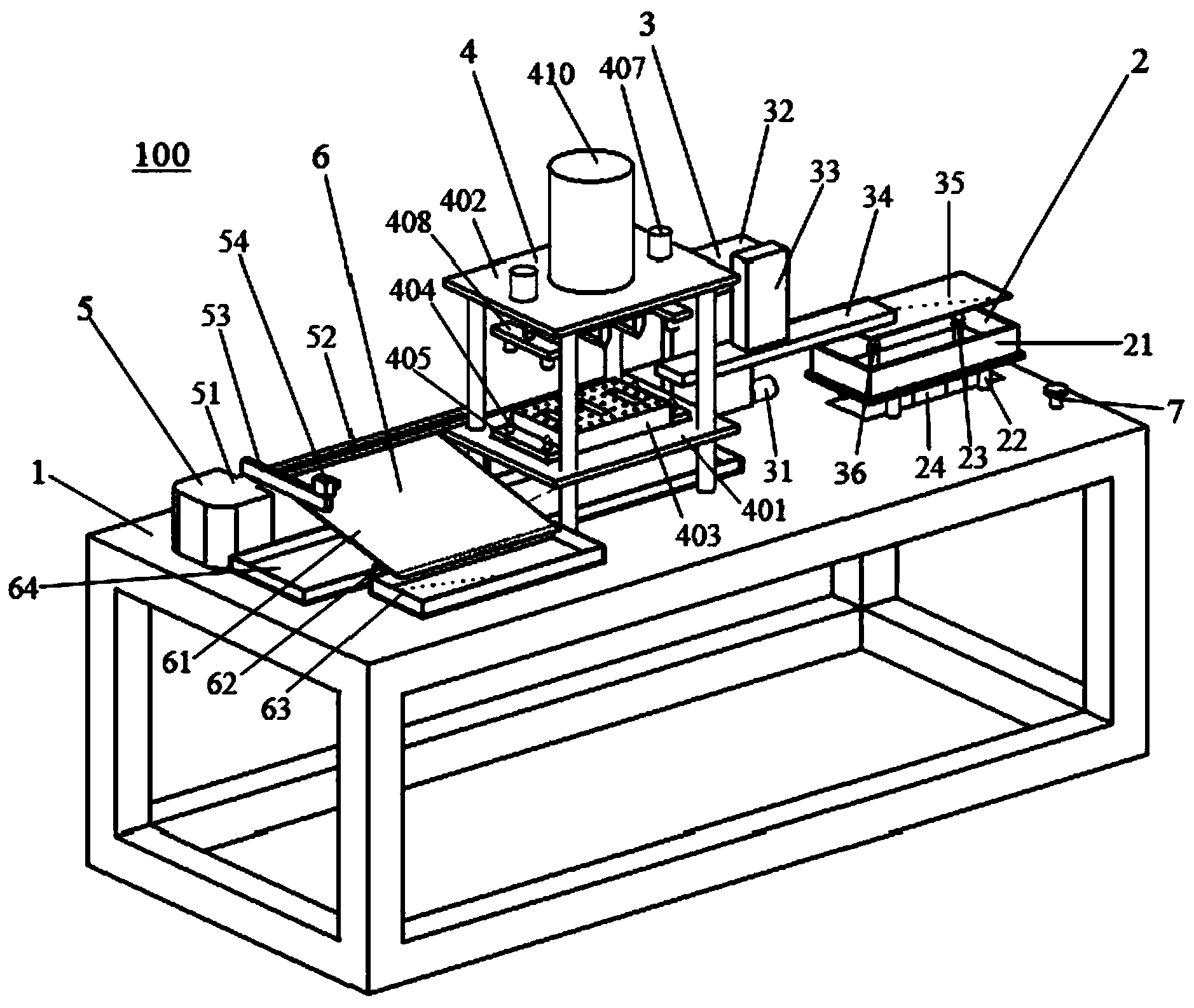

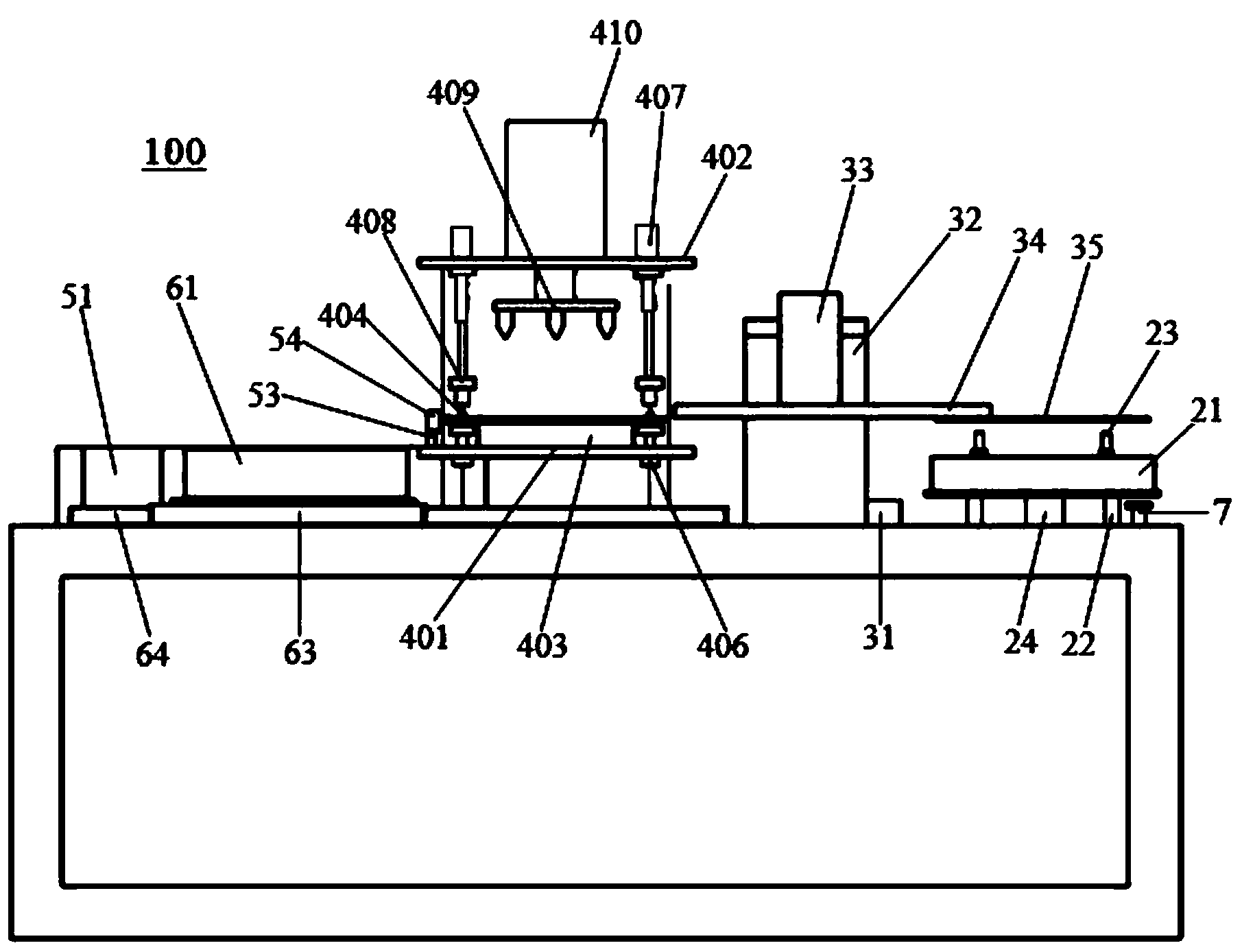

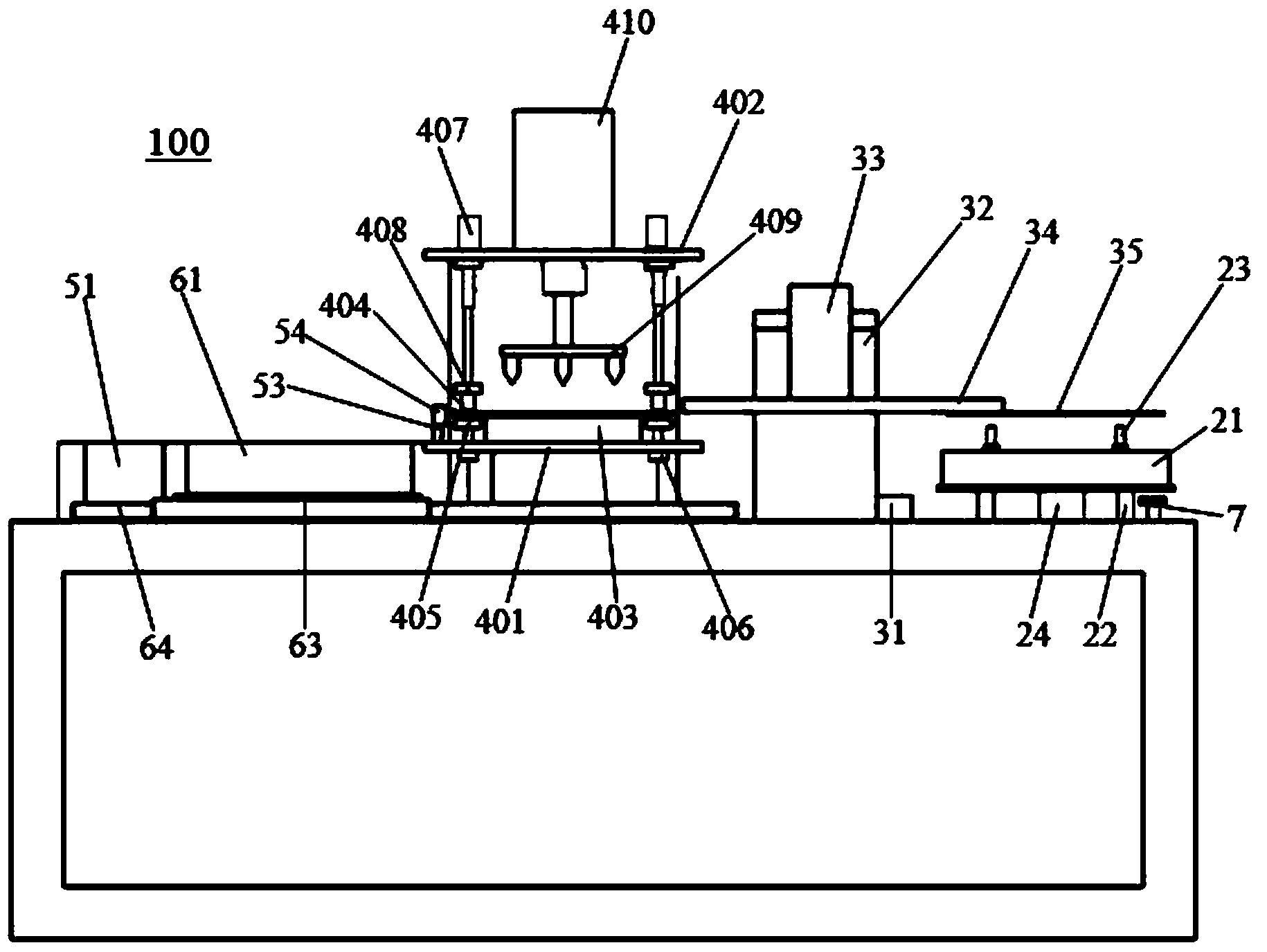

[0044] Please refer to figure 1 , the present invention is an automatic punching machine 100, which includes a support base 1, a control switch 7 arranged in a certain order on the support base 1 to control the opening or closing of the automatic punching machine 100, a storage device 2, a feeding device 3, a stamping press Device 4, unloading device 5 and collecting device 6.

[0045] Please refer to figure 1 , Figure 5 , Figure 6 and Figure 7The material storage device 2 includes a material storage box 21 for storing materials, a support column 22 supporting the material storage box 21, a second positioning column 23 located in the material storage box 21 and facilitating separation of materials, and a second positioning column 23 located below the material storage box 21 and The fourth driving device 24 fixed on the support base 1. The material storage box 21 includes a surrounding part 211 that prevents the material from slipping and collapsing and a bottom plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com