Patents

Literature

270results about How to "Accurate positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

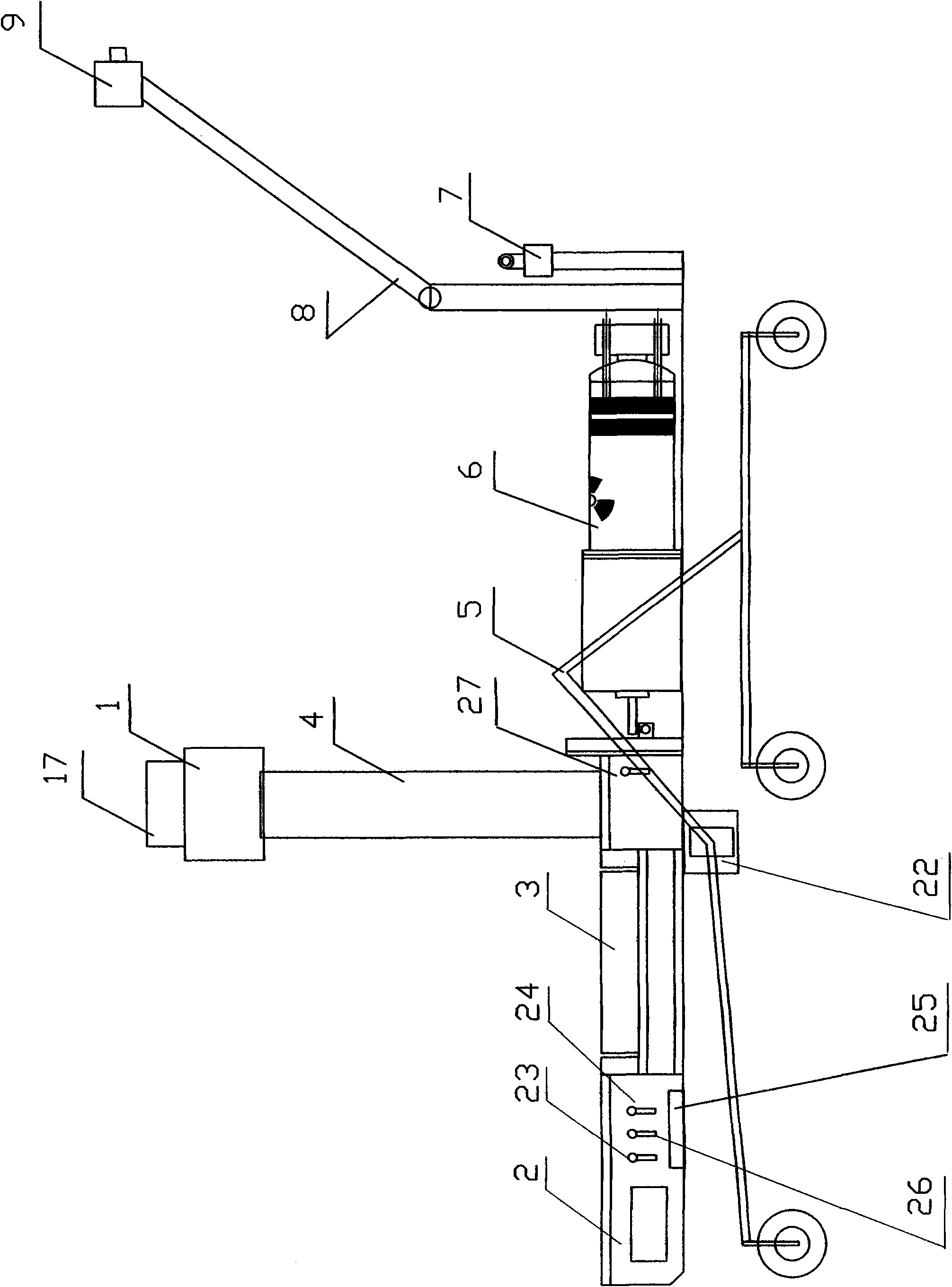

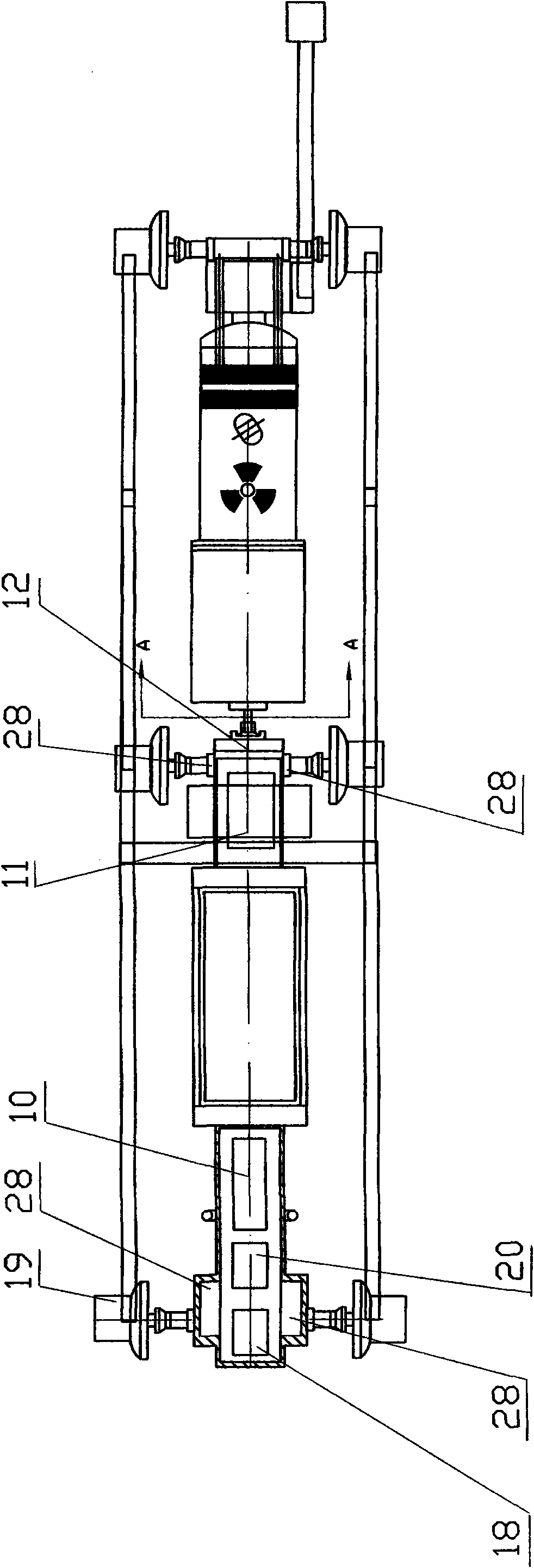

Wheel-type X-ray flaw detection robot device

InactiveCN101887037AEasy to operateHigh precisionManipulatorMaterial analysis by transmitting radiationVIT signalsVideo transmission

The invention relates to a wheel-type X-ray flaw detection robot device which comprises an X-ray flaw detection device, a remote wireless transmission device, a computer control device, a differential GPS (Global Positioning System), a fuel battery (or lead acid battery pack) and a robot body, wherein four infrared cameras are arranged on the robot body, and real-time images are remotely transmitted to an operator through video transmission equipment; a direct current voltage regulator is adopted in the controller of an X-ray generator; and the regulator is connected with an inverter by a tube voltage regulation knob, so that the tube voltage of the X-ray generator can be regulated. The operational control and operational state of the robot body are as follows: a digital data radio is adopted to transmit filed signals to an upper control computer; video signals are displayed on a display with visual display and convenient operation; isotope sources are not used, thereby meeting the requirement for environment protection; and a suspension system enables the robot body not to deflect and turn laterally on pipelines and rocks.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

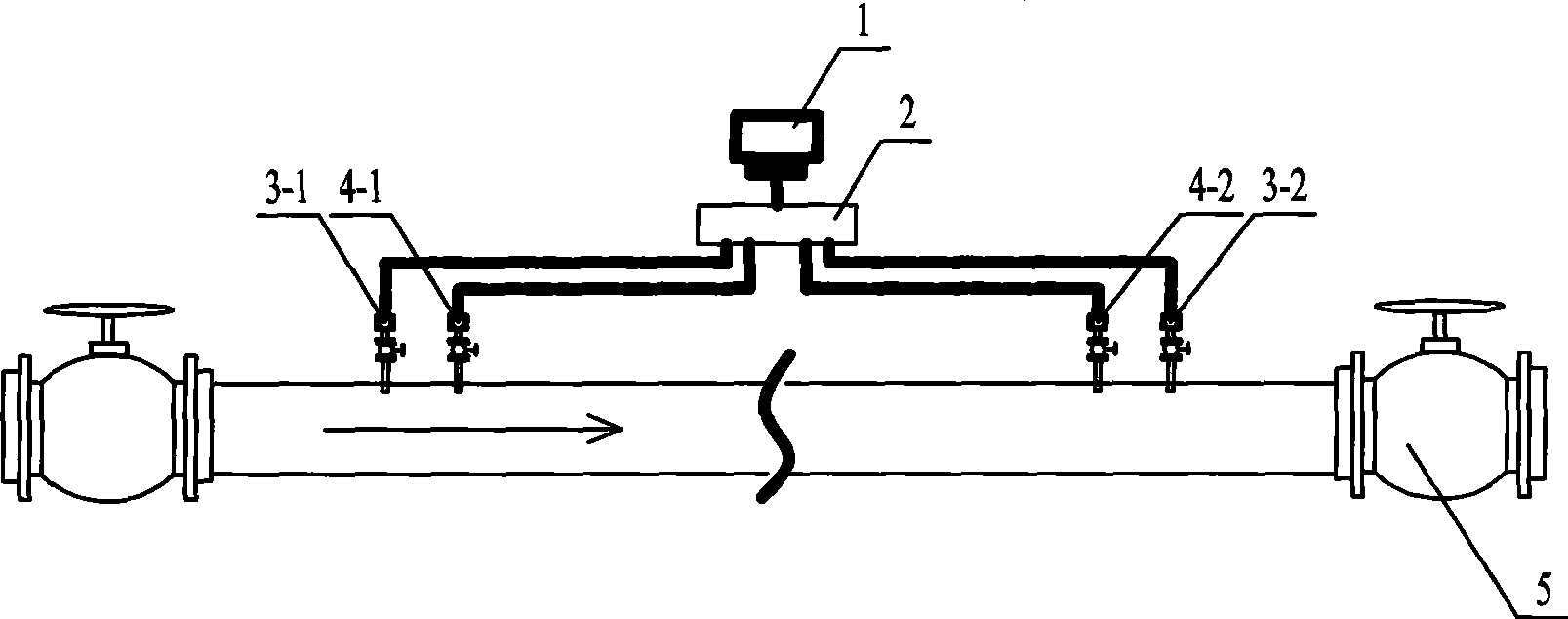

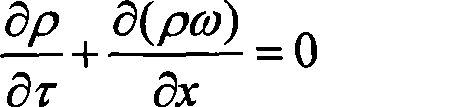

Method for performing gas pipeline leakage position by using instant change on-line diagnosis coupling excitation frequency response

InactiveCN101413628ARealize online real-time detectionReduce false alarm ratePipeline systemsEngineeringPressure response

The invention provides a method which uses transient online diagnosis coupling frequency response to position the leakage of natural gas pipeline, and relates to a natural gas pipeline failure detection and positioning method which can solve the problems that the existing method for detecting and positioning the leakage of the natural gas pipeline can not detect in real time, has long detection period, low positioning precision and high error report rate; real-time pressure value and real-time flux value are respectively collected at the upstream and downstream of the pipeline; the real-time downstream pressure value and the real-time flux value when the pipeline runs stably are reduced by the practical real-time pressure value and the practical real-time flux value at the downstream; if both of the two differences exceed the valve value, the leakage is considered to occur, otherwise the values are collected again; an excitation pressure wave is generated at the downstream end of the pipeline and the wave speed of the response wave of the excitation pressure wave is gained; according to the wave speed of the excitation pressure response wave and the time difference when the excitation pressure response wave is transmitted to the upstream and the downstream, the position of the leakage point is gained. The measurement and collection of the values are completed by normal equipments and the method can be used both in the built pipeline or pipelines under construction.

Owner:HARBIN INST OF TECH

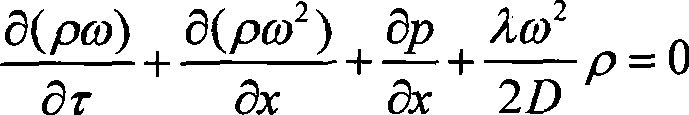

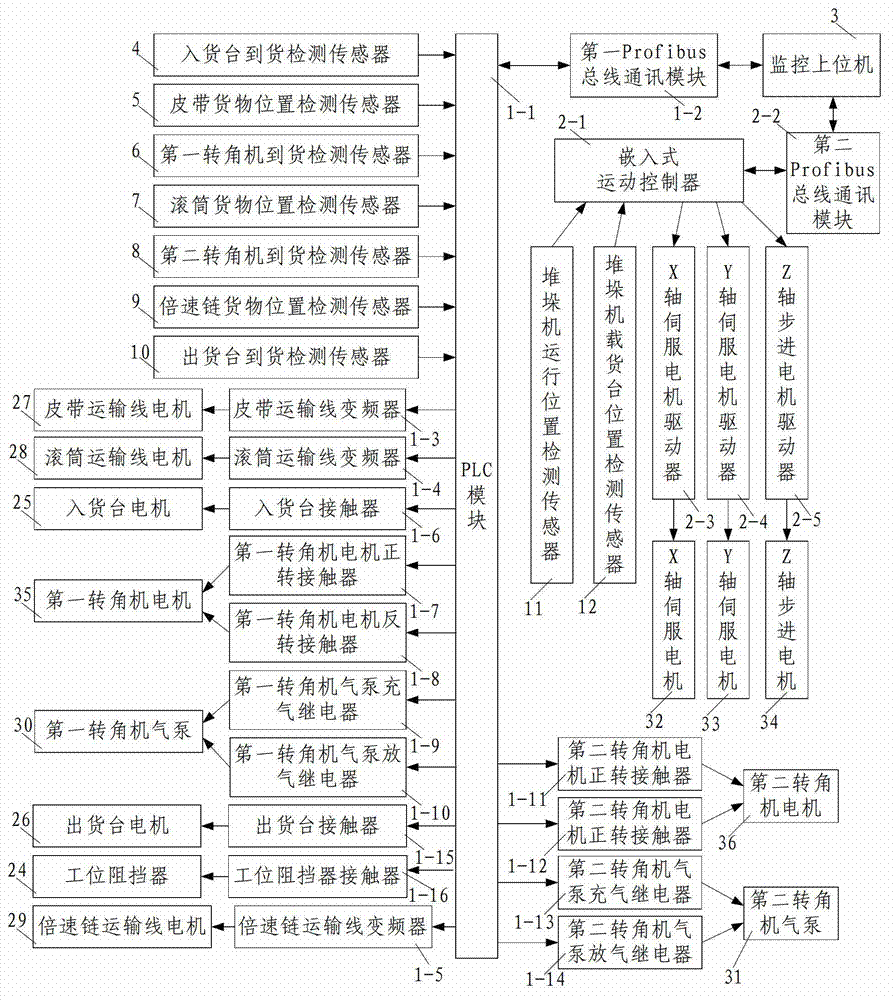

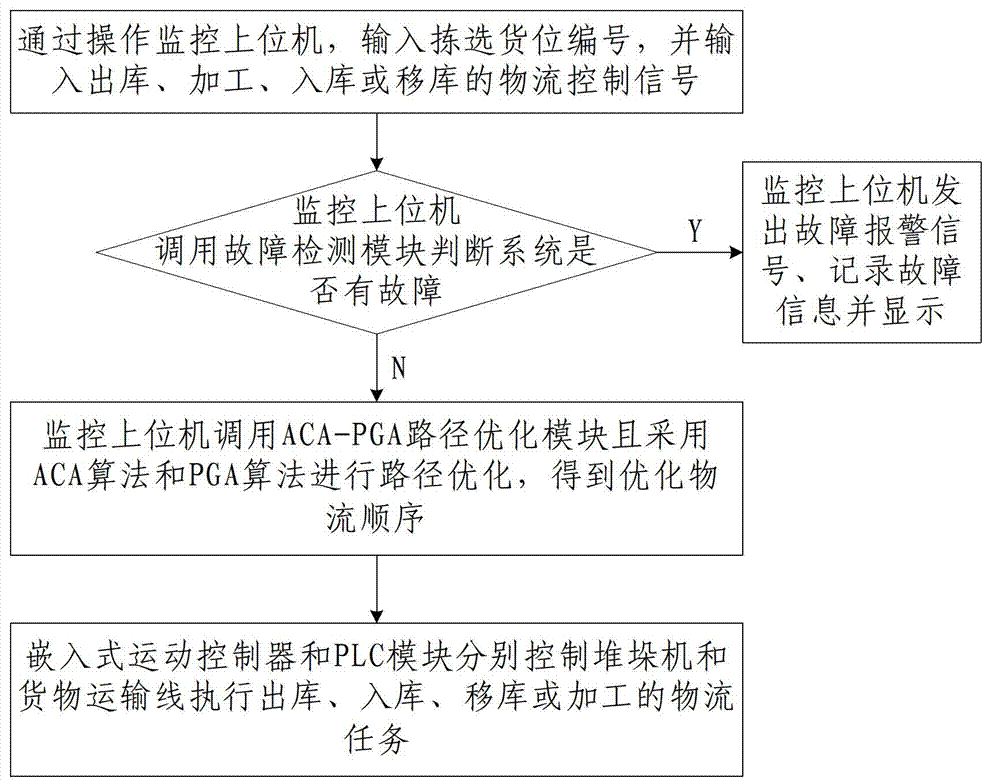

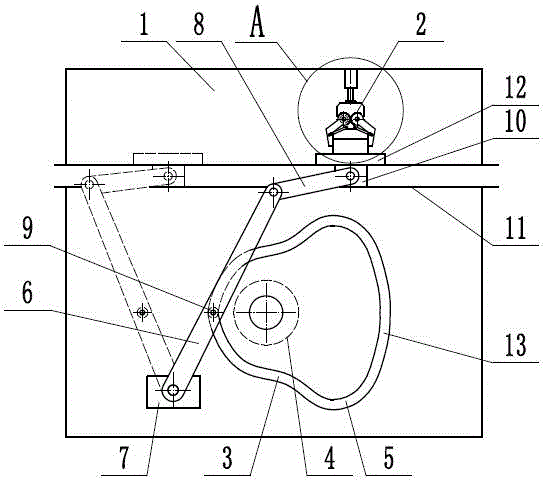

Stereo logistics system access cargo path optimization control system and method

InactiveCN103112680ASimple structureReasonable designStorage devicesLogistics managementControl system

The invention discloses a stereo logistics system access cargo path optimization control system and a method. The stereo logistics system access cargo path optimization control system comprises a monitoring upper computer, a programmable logic controller (PLC) module and an embedded motion controller, wherein an input end of the PLC module is connected with a plurality of cargo arrival detection sensors and a plurality of cargo position detection sensors, and an output end of the PLC module is connected with a plurality of frequency converters and a plurality of contactors. An input end of the embedded motion controller is connected with a piler state detection sensor, and an output end of the embedded motion controller is connected with an X-axis servo motor driver, a Y-axis servo motor driver and a Z-axis stepper motor driver. The method comprises the following steps: a logistics task signal is input, the upper computer is monitored to conduct path optimization, and the embedded motion controller and the PLC module respectively control the piler and a cargo conveying line to execute corresponding logistics tasks. The stereo logistics system access cargo path optimization control system and the method are reasonable in design, convenient and fast to use and operate, high in control precision, reliable in working reliability and stability, high in logistics efficiency, strong in practicability and high in popularization and application values.

Owner:XIAN UNIV OF SCI & TECH

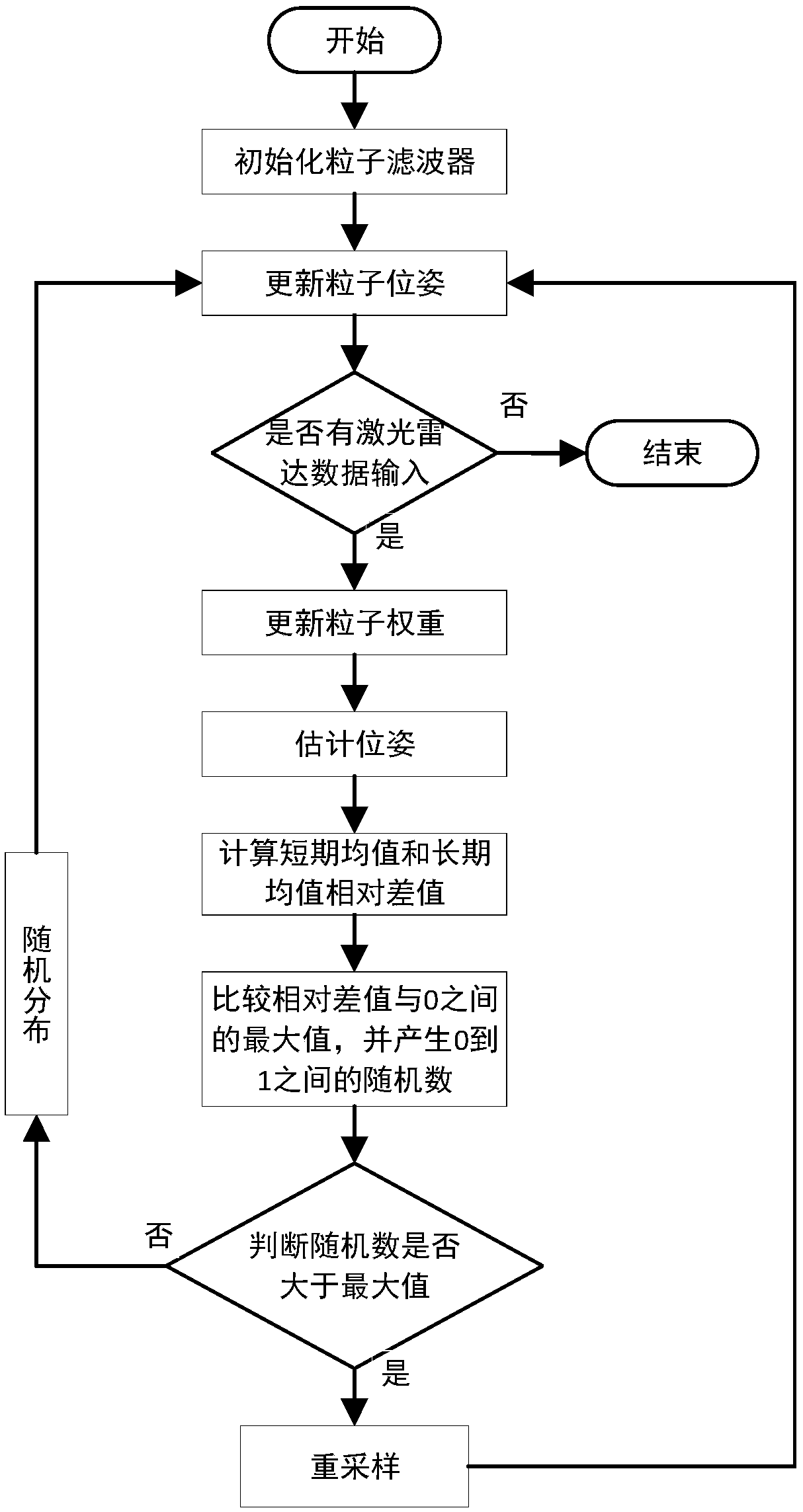

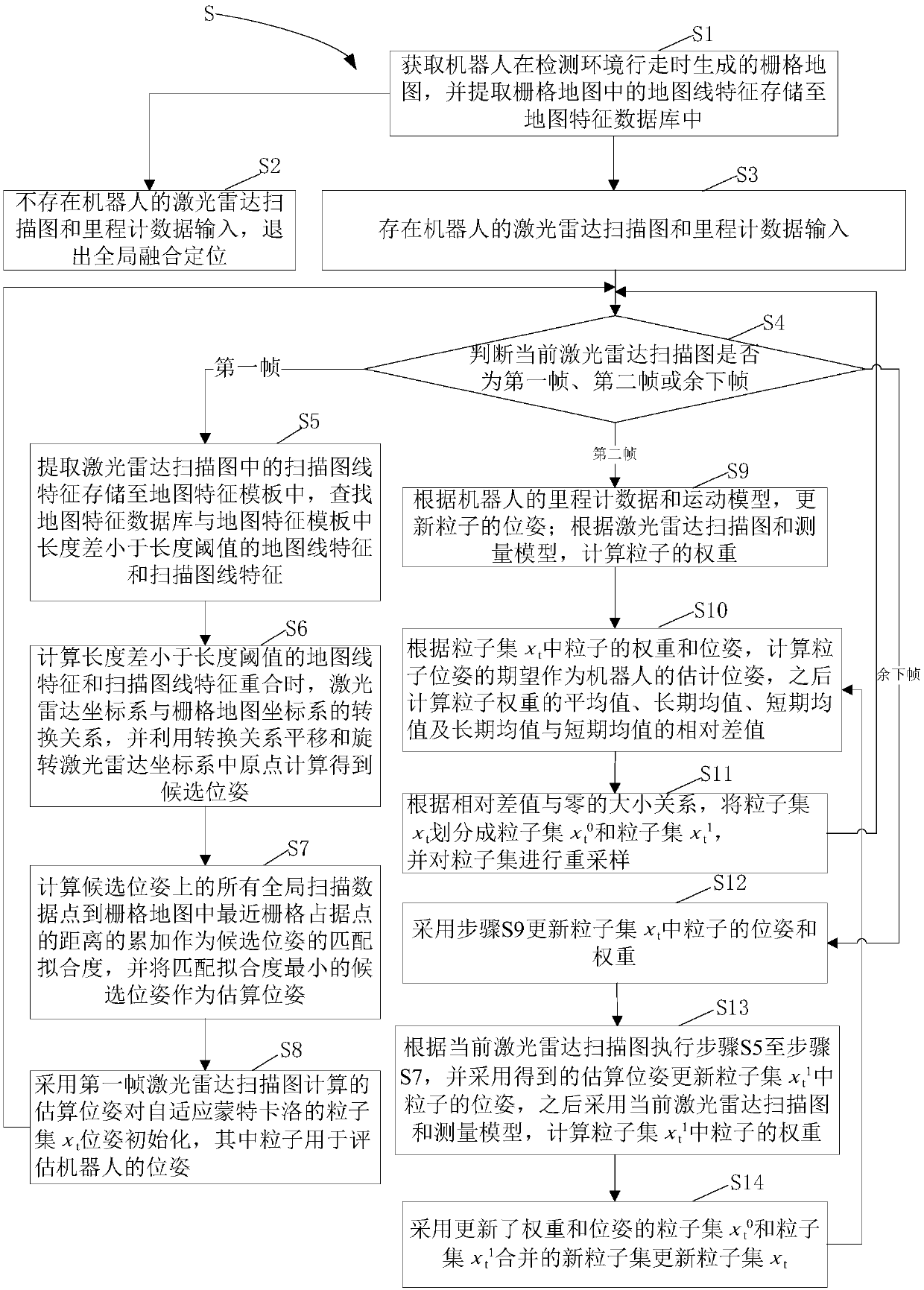

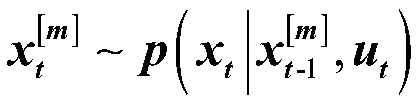

Global fusion positioning method based on self-adaptive Monte Carlo and feature matching

ActiveCN109682382AHigh positioning accuracyAccurate positioning accuracyNavigational calculation instrumentsElectromagnetic wave reradiationFeature matchingSelf adaptive

The invention discloses a global fusion positioning method based on self-adaptive Monte Carlo and feature matching, which comprises the following steps of: extracting map line features in a grid map and storing the map line features in a map feature database; extracting the scan line features of a non-second frame of a laser radar scan map, and initializing the particle set pose of the self-adaptive Monte Carlo by adopting the estimated pose calculated by the first frame of the laser radar scan map; updating the pose and weight of the particles by adopting odometer data, a motion model, a laser radar scan map and a measurement model for a second frame of laser radar scan map; updating the initial pose of a part of particles in a particle set by adopting the estimated pose calculated by thelaser radar scan map for the remaining frames of the laser radar scan map; updating the weight of corresponding particles; and meanwhile, updating the pose and weight of the rest particles in the particle set by adopting the odometer data, the motion model, the laser radar scan map and the measurement model, and finally combining the two particle sets updated with the pose and the weight into a new particle set.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

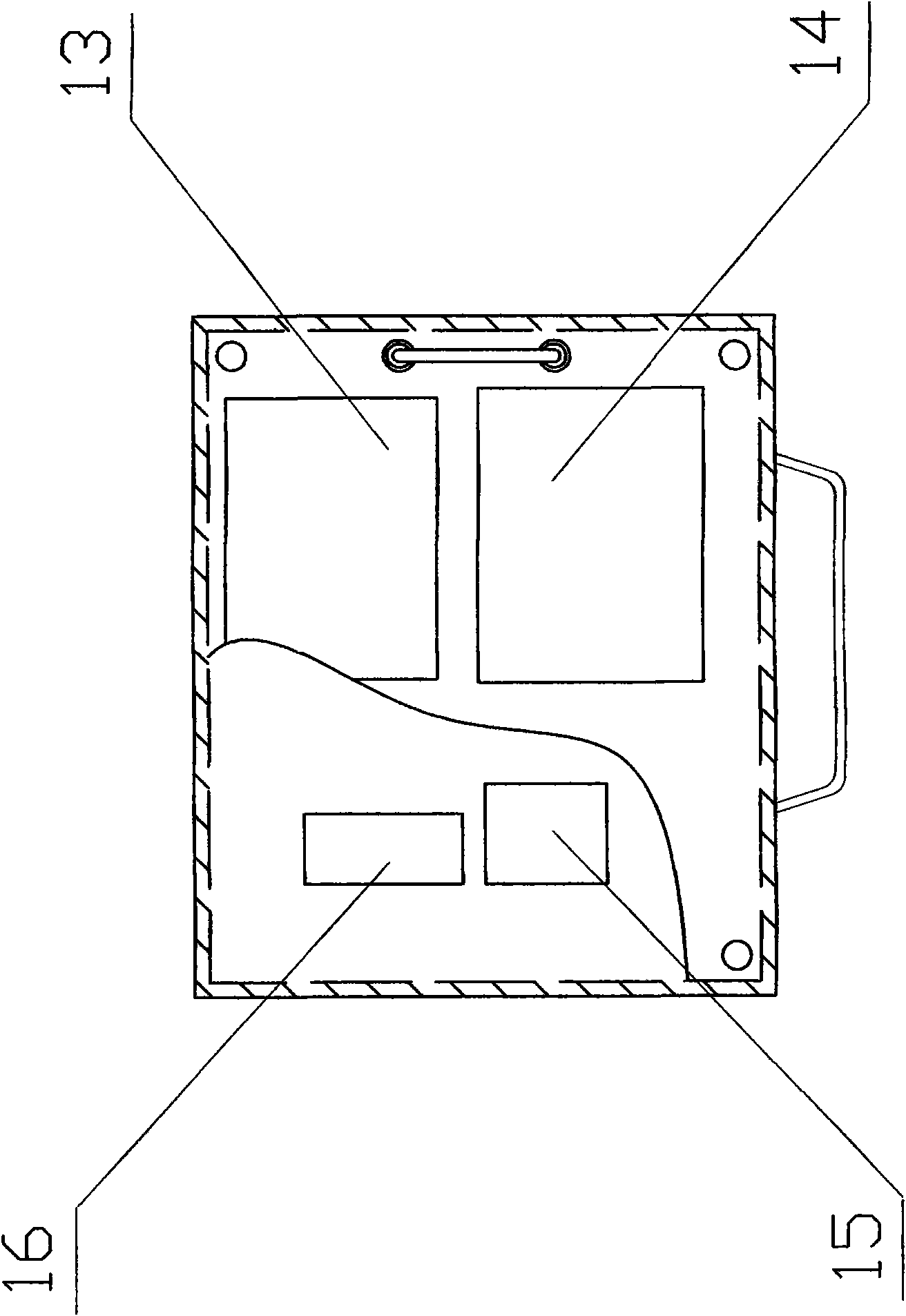

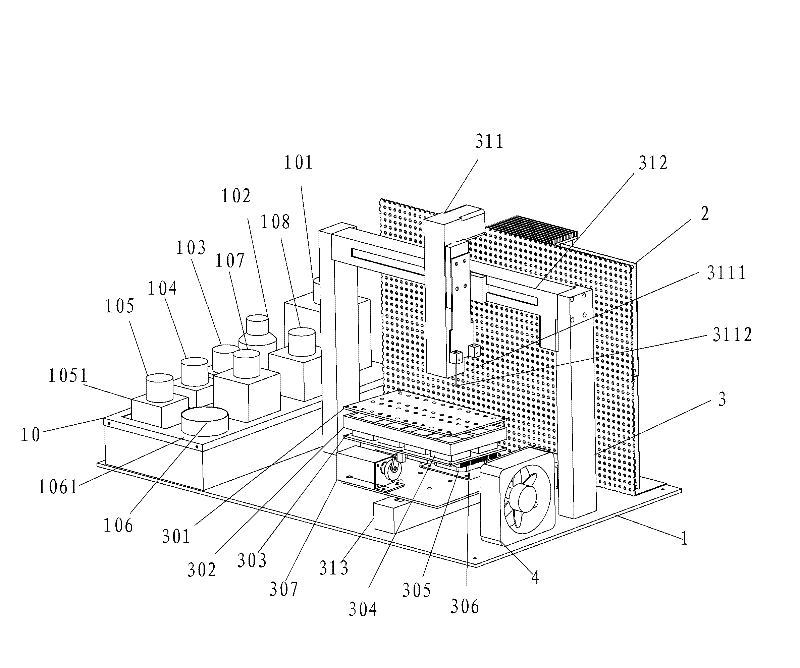

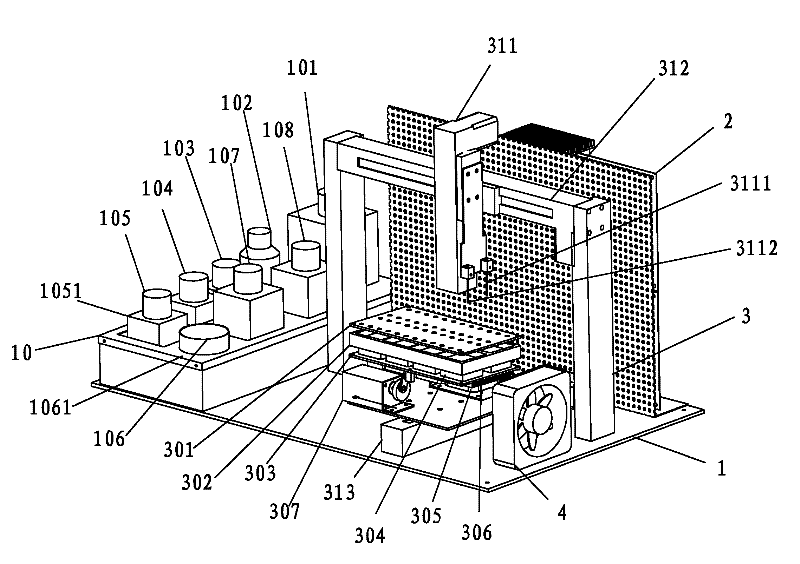

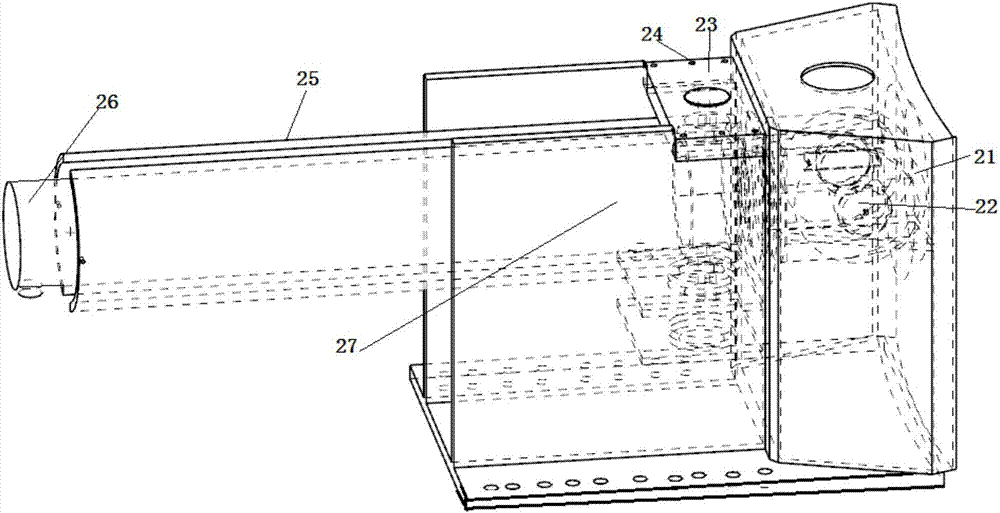

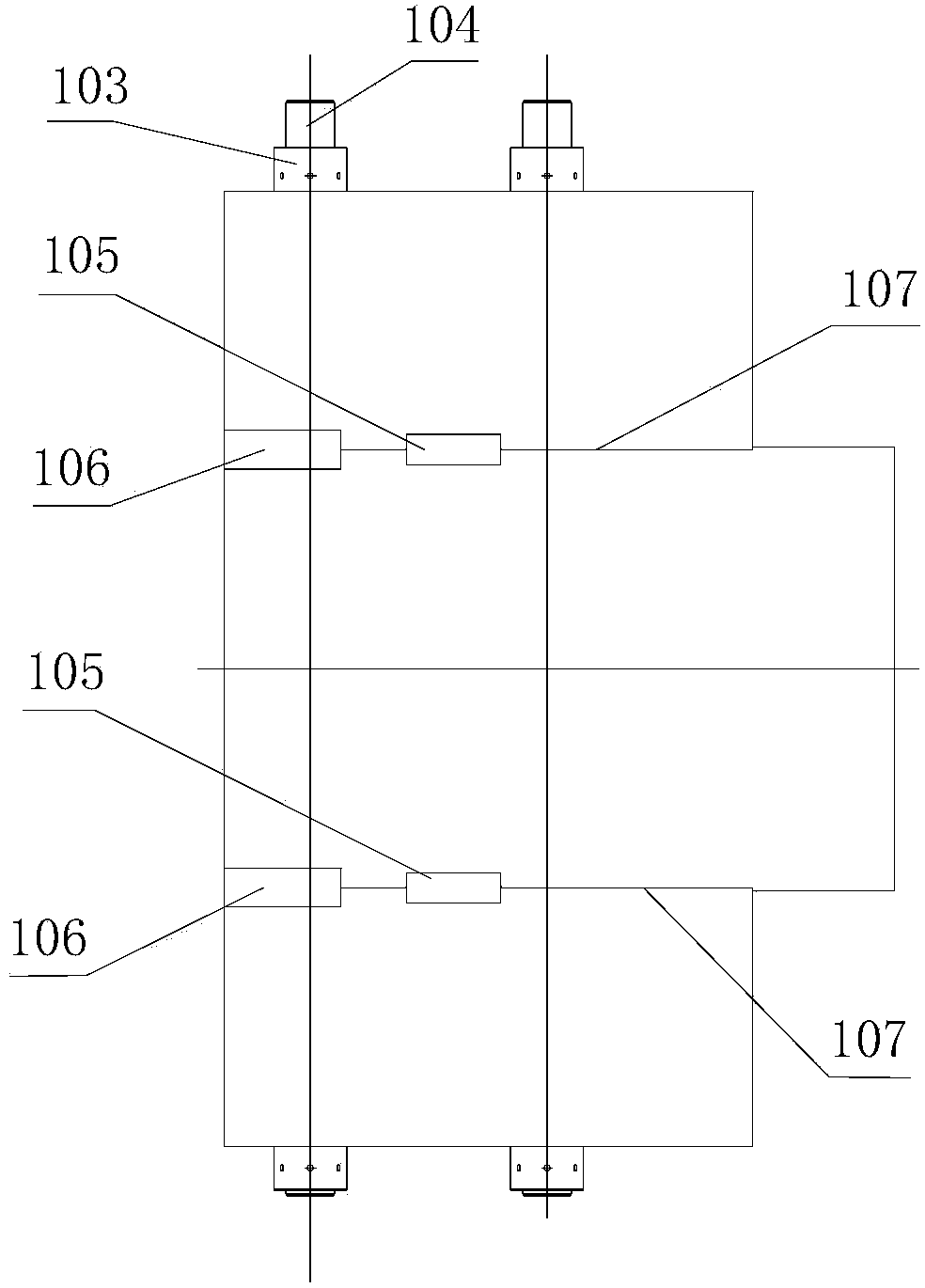

Full-automatic hybridization appliance

ActiveCN102533525APromote the "civilization"Promote "civilianization"Bioreactor/fermenter combinationsBiological substance pretreatmentsHybridization reactionEngineering

The invention discloses a full-automatic hybridization appliance, which comprises a hybridization platform, a machine frame and a back plate. The machine frame and the back plate are fixed on the hybridization platform which is provided with a reagent supply device and a reagent preheating device, wherein the reagent supply device is matched with the reagent preheating device. The machine frame is provided with a hybridization reaction box, a feeding device for feeding reagent in the reagent supply box into the reaction box, an X-axis synchronous belt mechanism for driving the feeding device to reciprocate along the X-axis direction, a Z-axis synchronous belt mechanism for driving the feeding device to reciprocate along the Z-axis direction and a Y-axis synchronous belt mechanism for driving the hybridization reaction box to reciprocate along the Y-axis direction. The full-automatic hybridization appliance can achieve full-automatic operation of steps of washing, hybridizing, enzyme incubation, developing and the like in the gene chip operation technology, is low in manual participation, can greatly reduce production cost and effectively pushes generalized and wide application of gene chips.

Owner:亚能生物技术(深圳)有限公司

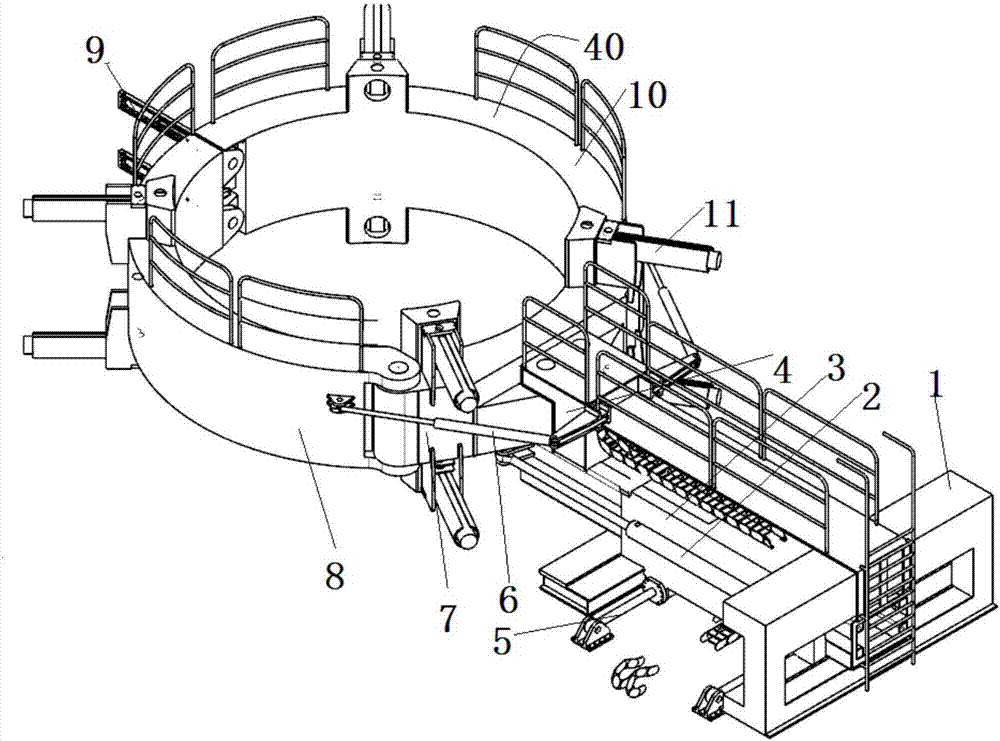

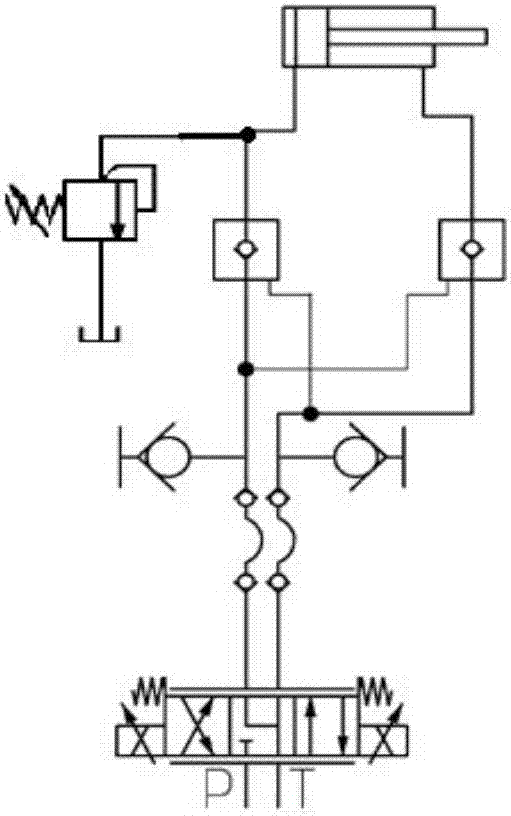

Pile gripper for offshore piling

The invention relates to a pile gripper for offshore piling. The pile gripper for offshore piling is composed of a pile gripper mechanism system, a hydraulic system and an electrical control system. A large base is connected with a sliding base through a sliding rail. A cross beam is installed in a sliding groove of the sliding base. A lateral thrust cylinder is installed on the portion, between a deck and the sliding base, of a mounting base. A main thrust cylinder is installed on the portion, between the sliding base and the cross beam, of the mounting base. A hoop is installed at the front end of the cross beam. The left side and the right side of the front end of a hoop base are connected with a left hoop body and a right hoop body separately. The left hoop body and the right hoop body are connected with the two sides of the cross beam through hoop opening and closing cylinders correspondingly. The hoop is provided with a pile gripping and clamping mechanism. Two sets of locking mechanisms are installed at the front end of the left hoop body. The right hoop body is provided with pin holes corresponding to taper pins of the locking mechanisms. Each pile gripping cylinder is connected with a proportional valve and controlled to act by the proportional valve. A programmable logic controller (PLC) performs closed-loop control over the opening degree and direction of the proportional valves according to a feedback signal of a magnetostrictive displacement sensor, so that the pile gripping cylinders are controlled to perform pile jacking guidance on steel piles and keep guidance on the steel piles within a required range.

Owner:SHANGHAI HUNTER MARINE EQUIP CO LTD +1

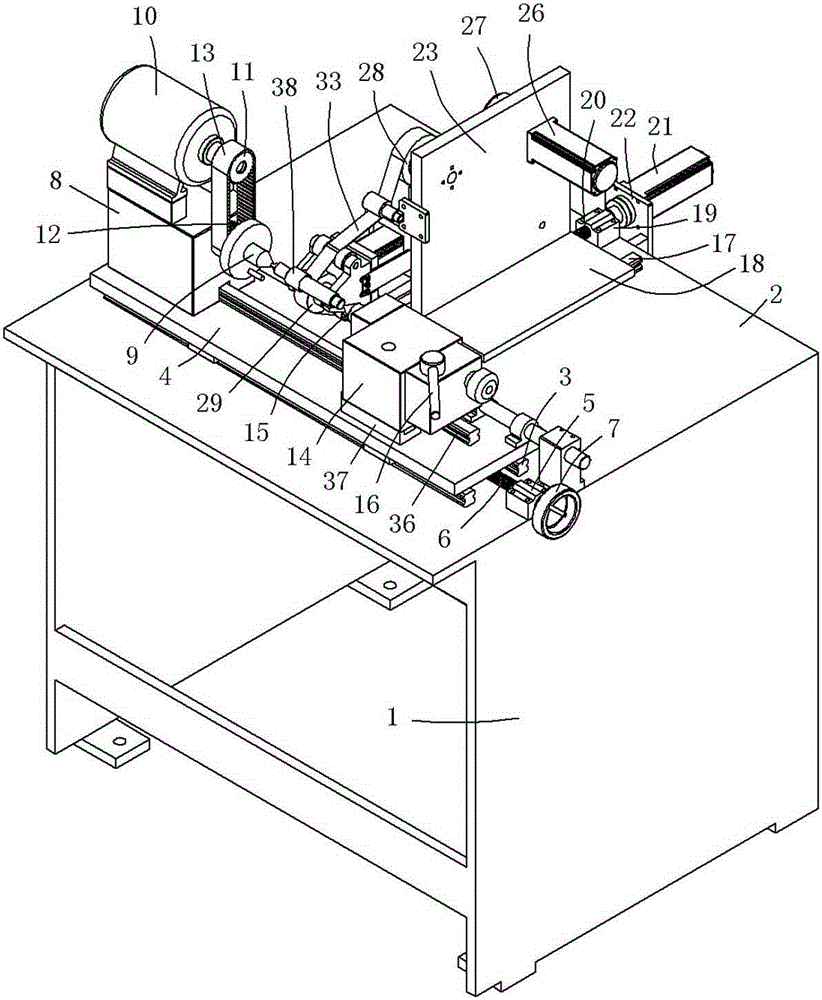

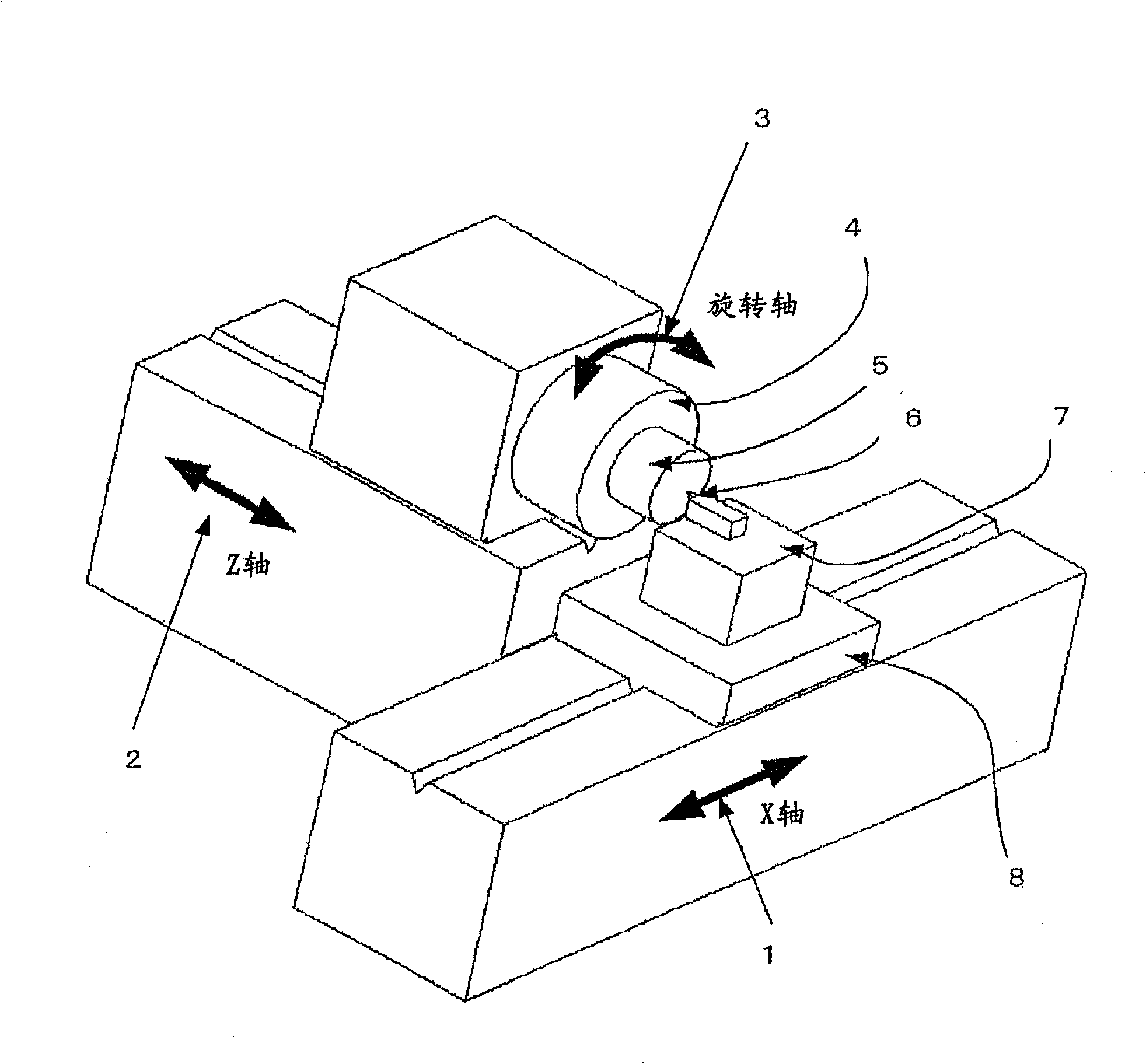

External cylindrical superfinishing machine

The invention provides an external cylindrical superfinishing machine. The machine comprises a frame, a workbench and an abrasive belt, wherein a transverse guide rail, a transverse sliding table, a transverse motion driving mechanism, a longitudinal guide rail, a longitudinal sliding table and a longitudinal motion driving mechanism; a headstock, a headstock center and a rotary driving mechanism are arranged on one side of the transverse sliding table; a tailstock, a sleeve, a tailstock center and a center adjustment mechanism are arranged on the other side of the transverse sliding table; an abrasive belt rack, an abrasive belt driving shaft, an abrasive belt driven shaft, an abrasive belt motor, a rolling abrasive belt wheel, a releasing abrasive belt wheel, a polishing wheel, a polishing wheel rack and a polishing motor are arranged on the transverse sliding table; one end of the abrasive belt winds the releasing belt wheel, and the other end of the abrasive belt moves around the polishing wheel and is fixedly arranged on the releasing abrasive belt wheel. The external cylindrical superfinishing machine has the beneficial effects of simple and compact structure, convenience in operation, integral operation stability and reliability and high processing accuracy, and cannot cause scrap of axial parts.

Owner:宁波华表机械制造有限公司

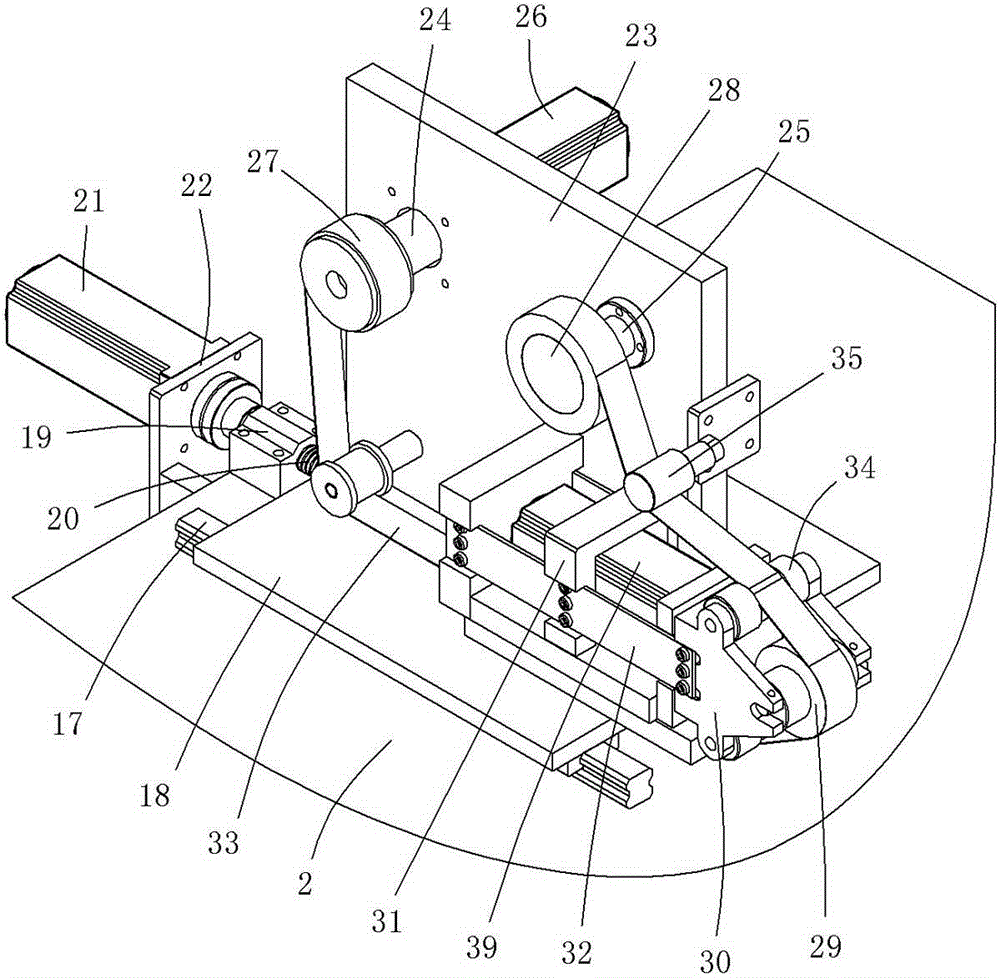

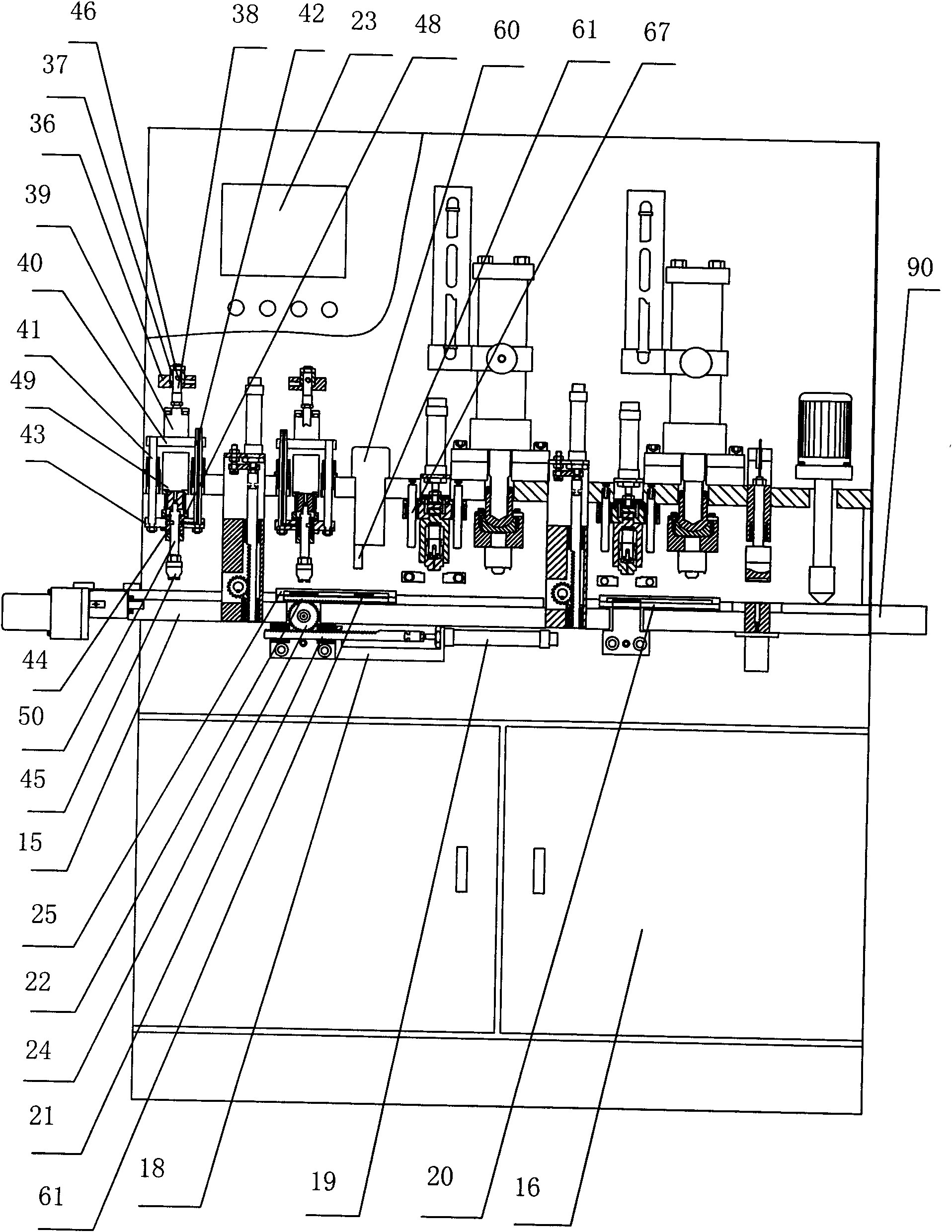

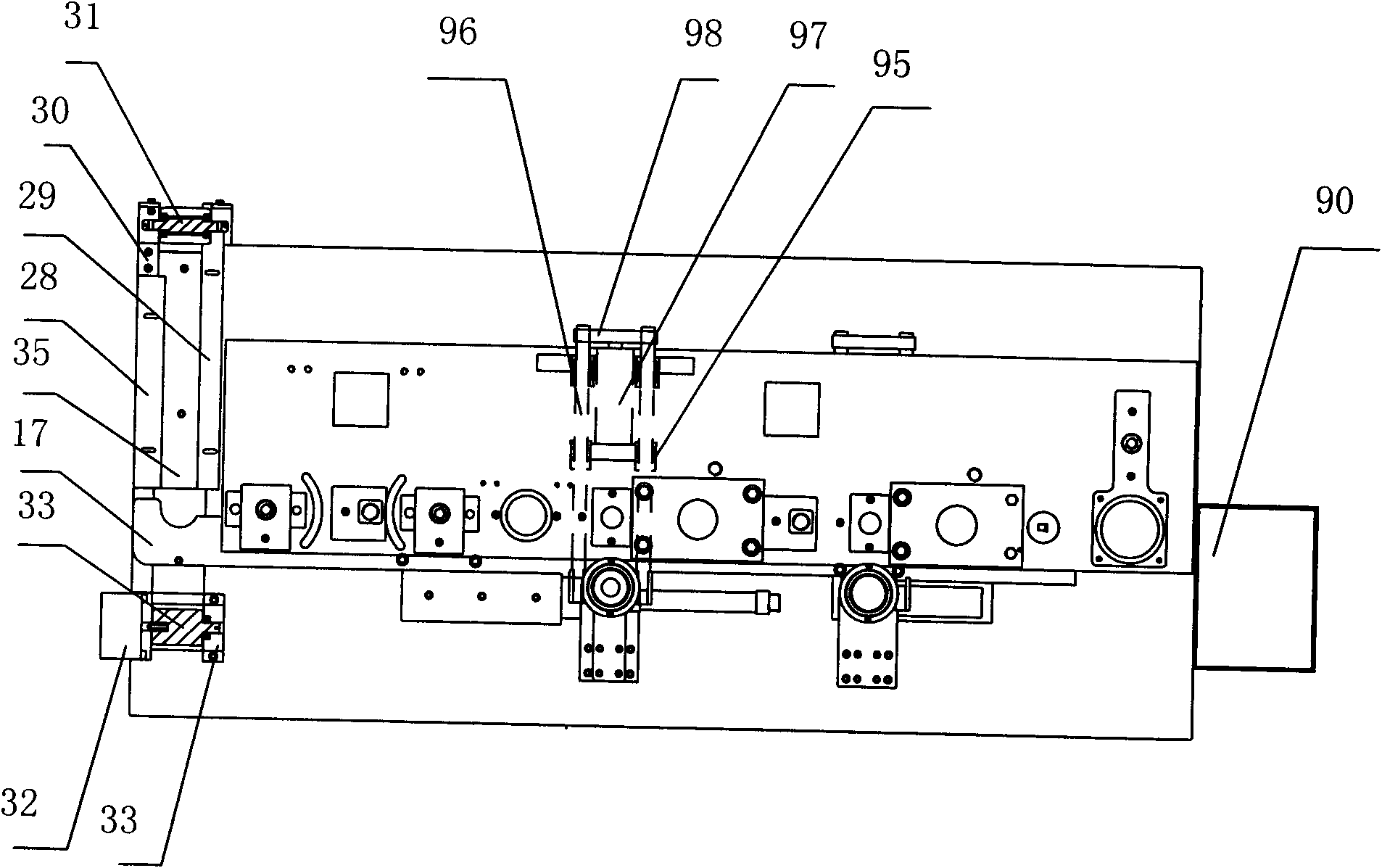

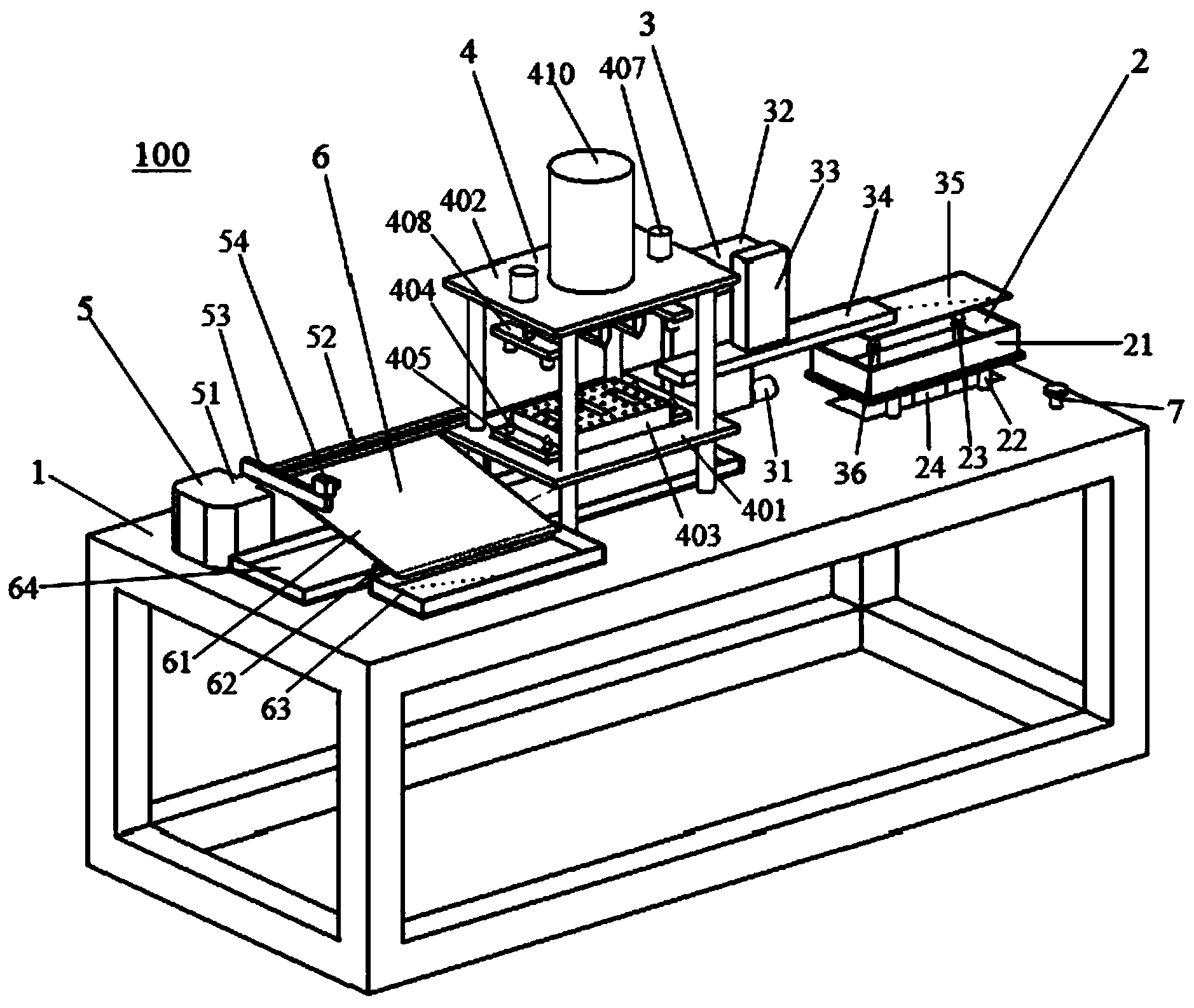

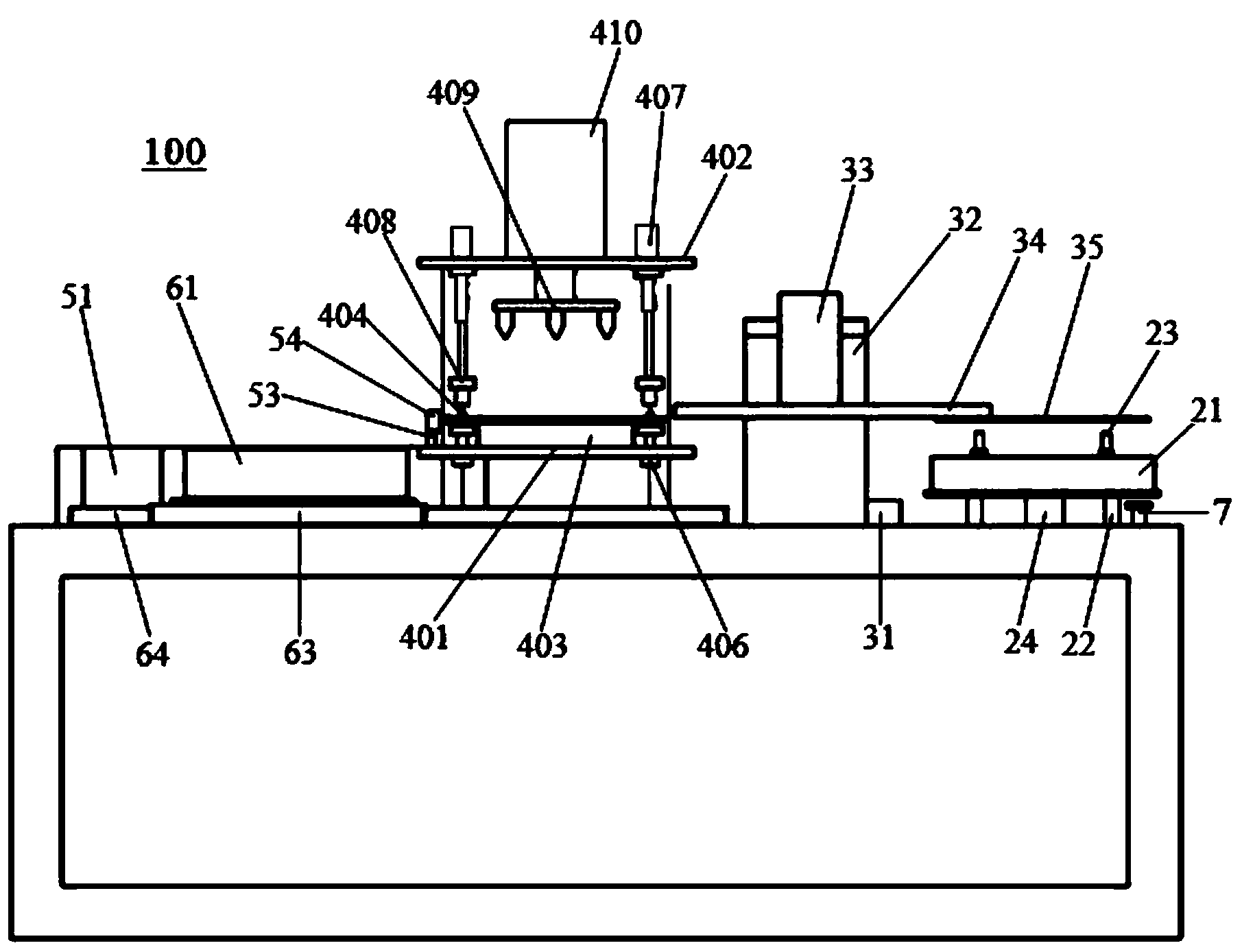

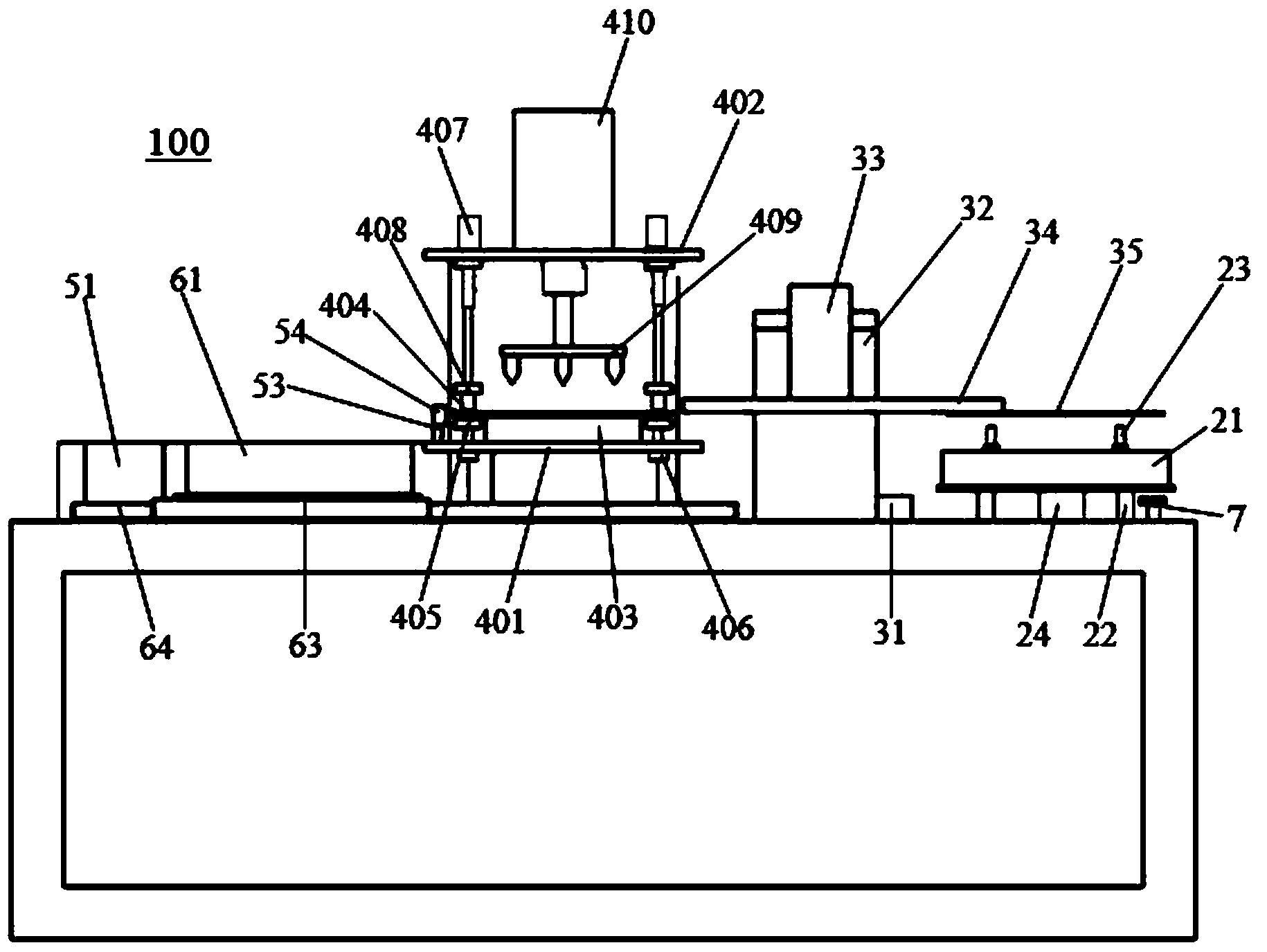

Full-automatic bearing greasing and capping machine

InactiveCN101982699ACompact structureEasy to debugProportioning devicesConveyorsFailure rateEngineering

The invention discloses a full-automatic greasing and capping machine, relating to a device for adding grease and a dust cap to a bearing. A workbench is fixed on a machine frame; a mounting base is fixed on the workbench; the front part of the mounting base is provided with a material support plate; the upper part of the mounting base is provided with a control device; the left side of the workbench is provided with a material conveyor, and the right side of the workbench is provided with an unacceptable product removing device; according to the processing sequence, two greasing devices, a grease quantity detection device, two capping devices, a dust cap height detection device and a grease equalizer are sequentially arranged on the mounting base from left to right; turning devices are respectively arranged between the two greasing devices and between the two capping devices; and a front reciprocating device and a rear reciprocating device are respectively arranged below the workbench. The full-automatic greasing and capping machine disclosed by the invention integrates the stations and the mounting base into a whole, is high in positioning accuracy and facilitates debugging and installation of a fixture mold; and the total seal shell is convenient for cleaning and maintenance, thus, the invention has the advantages of strong dustproof capacity, low danger coefficient, low failure rate and high product qualification rate.

Owner:SHANDONG XUNJIE PRECISION EQUIP

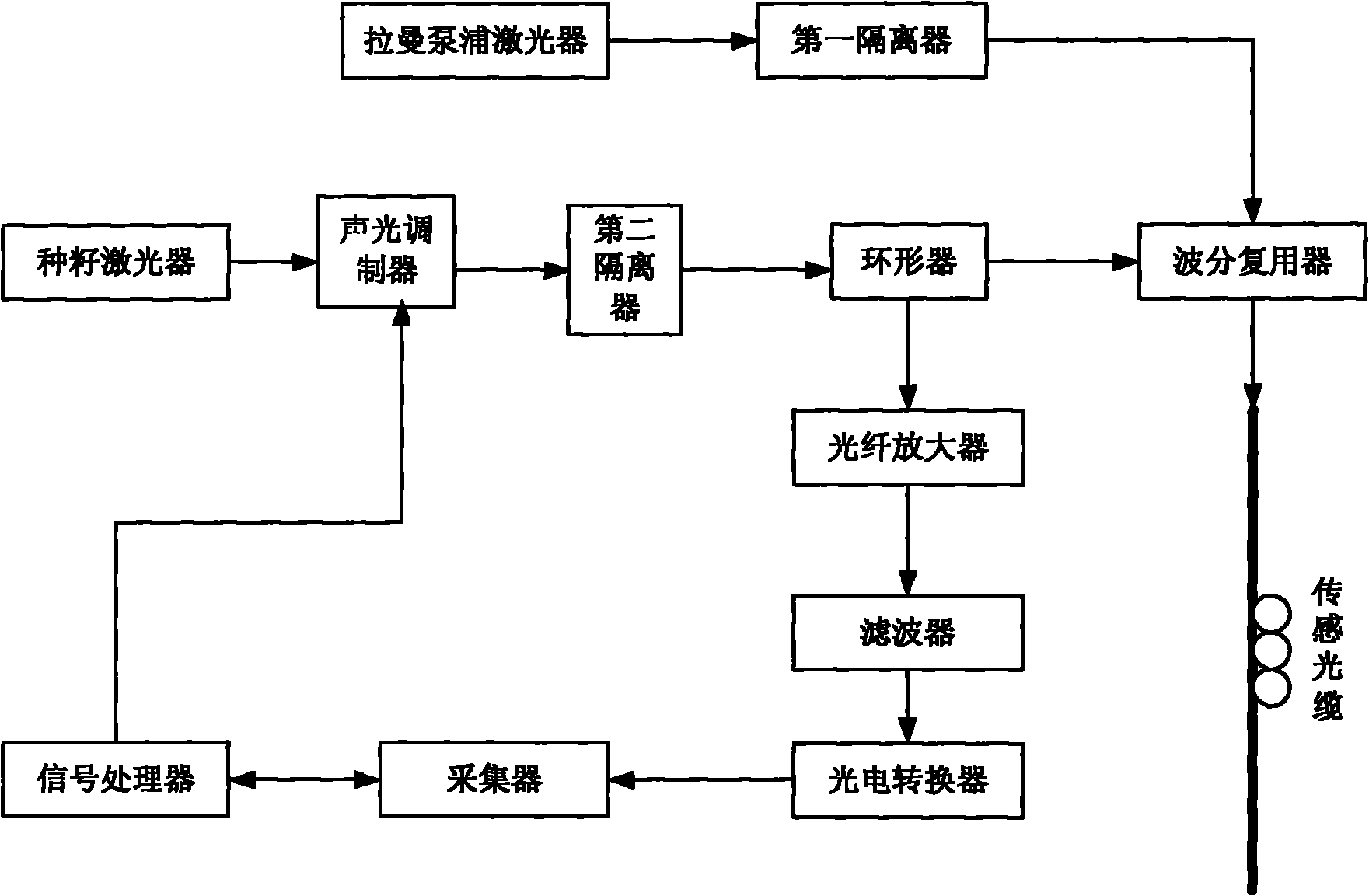

Long-distance optical fiber vibration sensing system with distributed amplification

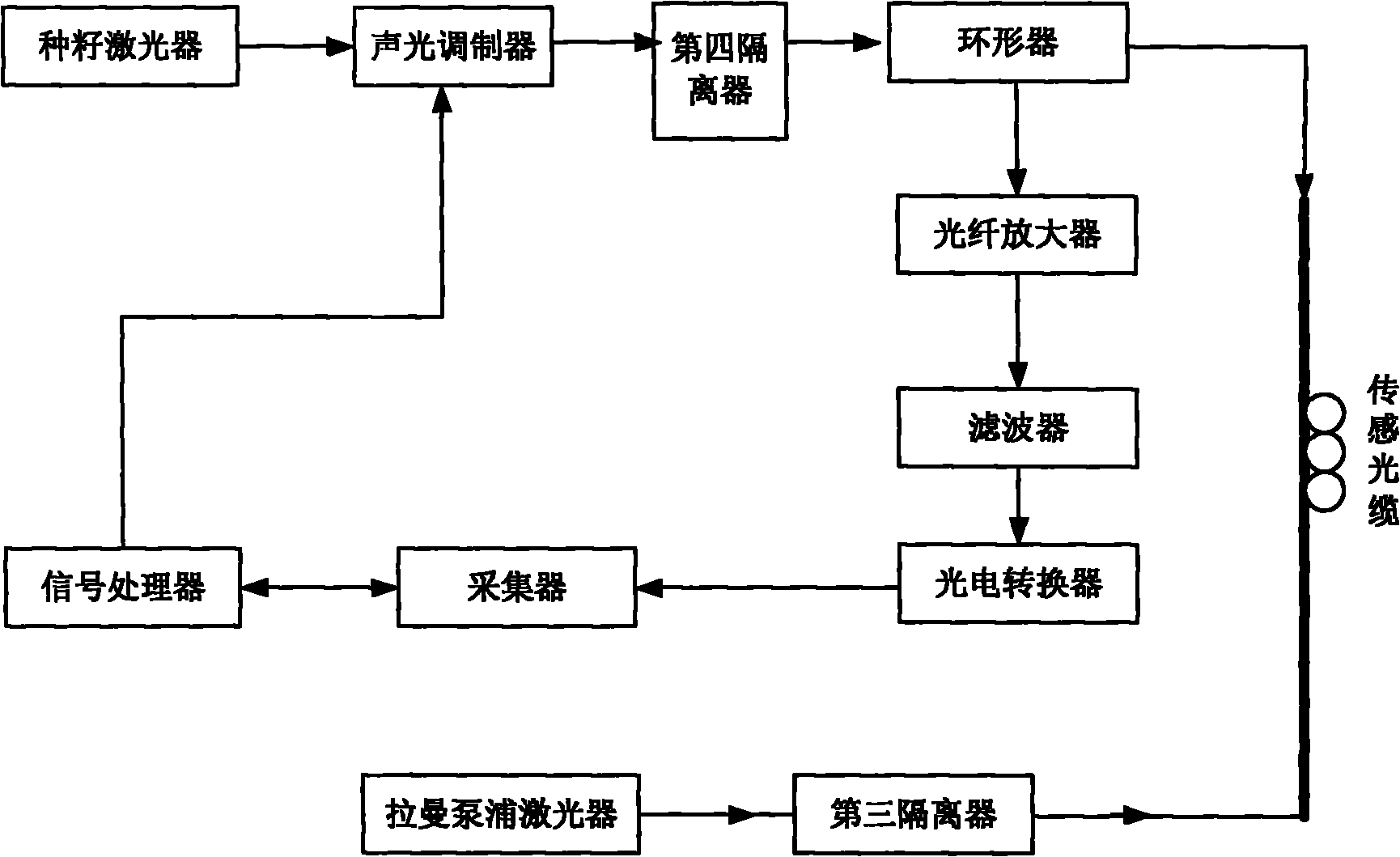

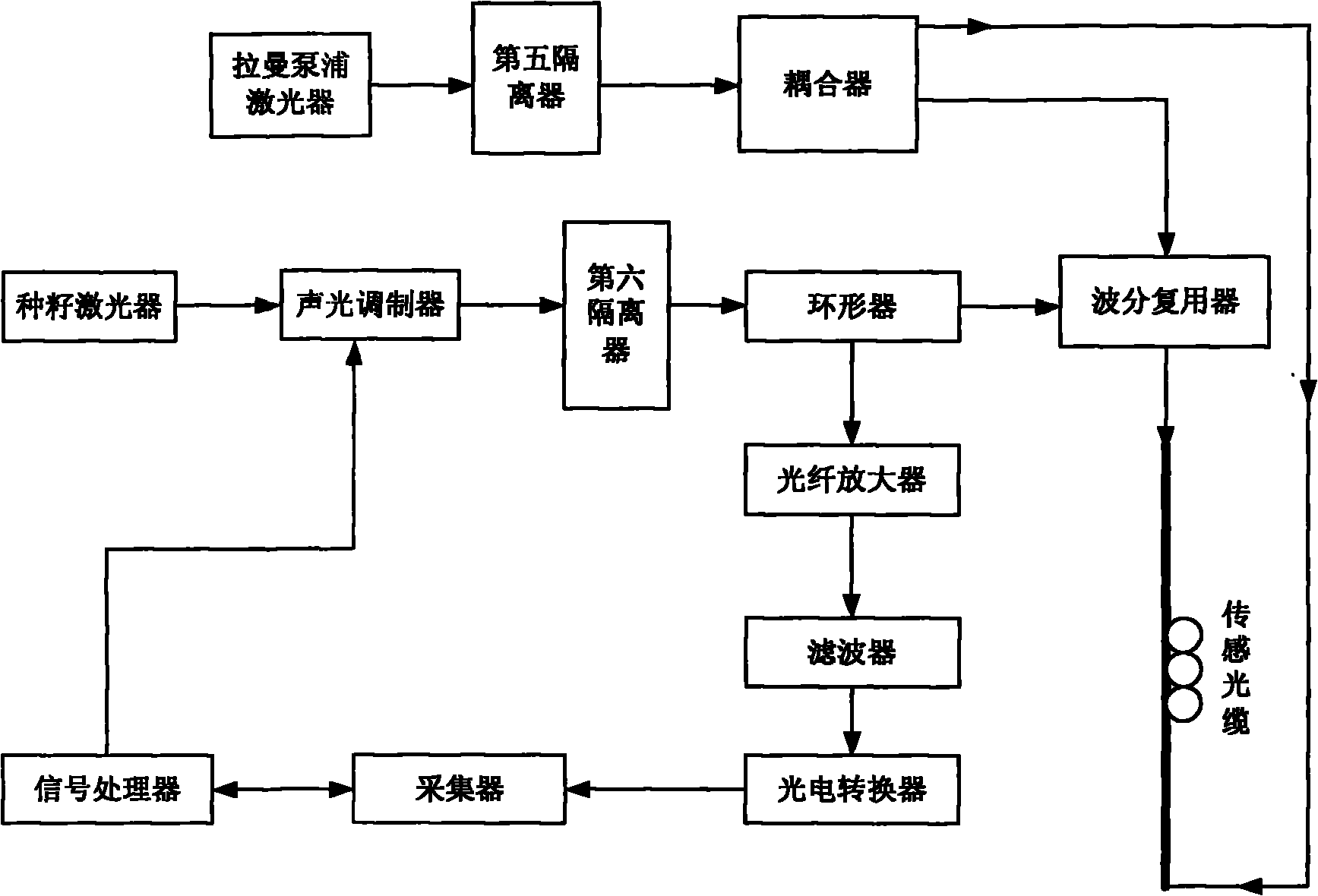

InactiveCN101893476AHigh sensitivityAccurate positioning accuracySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansTransducerBorder line

The invention discloses a long-distance optical fiber vibration sensing system with distributed amplification. The system comprises a Raman pump laser, a seed laser, a modulator connected with the seed laser, a circulator connected with the modulator, an optical fiber amplification filter connected with the circulator, a photoelectric transducer connected with the optical amplification filter, a collector connected with the photoelectric transducer, and a signal processor connected with the collector. The system has the advantages of capacity of monitoring long-distance border lines, high sensitivity and exact positioning accuracy.

Owner:江西华神智能物联技术有限公司

Granular-material-clogging-based hybrid driving rigidity-controllable continuum robot

InactiveCN108453703AIncrease stiffnessAdaptableProgramme-controlled manipulatorJointsRange of motionEngineering

The invention belongs to the technical field of flexible robots, in particular to a granular-material-clogging-based hybrid driving rigidity-controllable continuum robot. The robot comprises a plurality of identical single continuum units which are connected end to end in series; each single continuum unit comprises a flexible supporting outer barrel which is provided with multiple flexible supporting outer barrel through holes and is internally coaxially provided with a plastic inner pipeline; a plurality of separation plates are arranged in an annular zone between each flexible supporting outer barrel inner wall and the outer wall of the corresponding plastic inner pipeline, so that each annular zone is divided into multiple sealing cavities which are filled with granular materials; manual pneumatic muscles are inserted in the plastic inner pipelines; upper and lower sealing end covers are provided with upper and lower steel wire passage holes as well as upper and lower sealing end cover through holes; the lower sealing end covers are provided with manual pneumatic muscle drafting holes and sealing cavity drafting holes; and the upper sealing end covers, the flexible supporting outer barrels and the lower sealing end covers are integrally connected by steel wire ropes. The granular-material-clogging-based hybrid driving rigidity-controllable continuum robot is high in supporting rigidity, wide in moving range and accurate in positioning precision.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

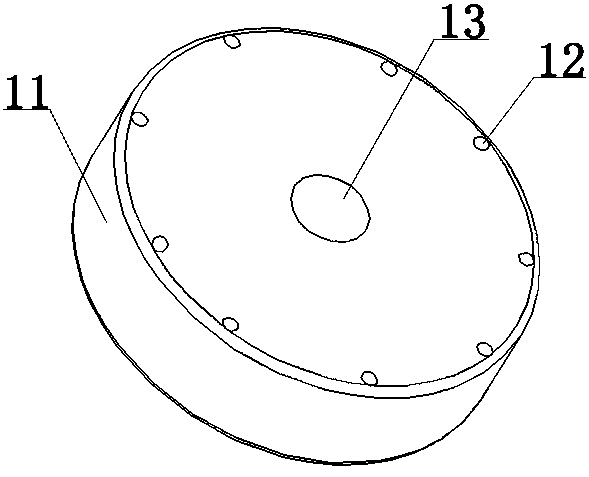

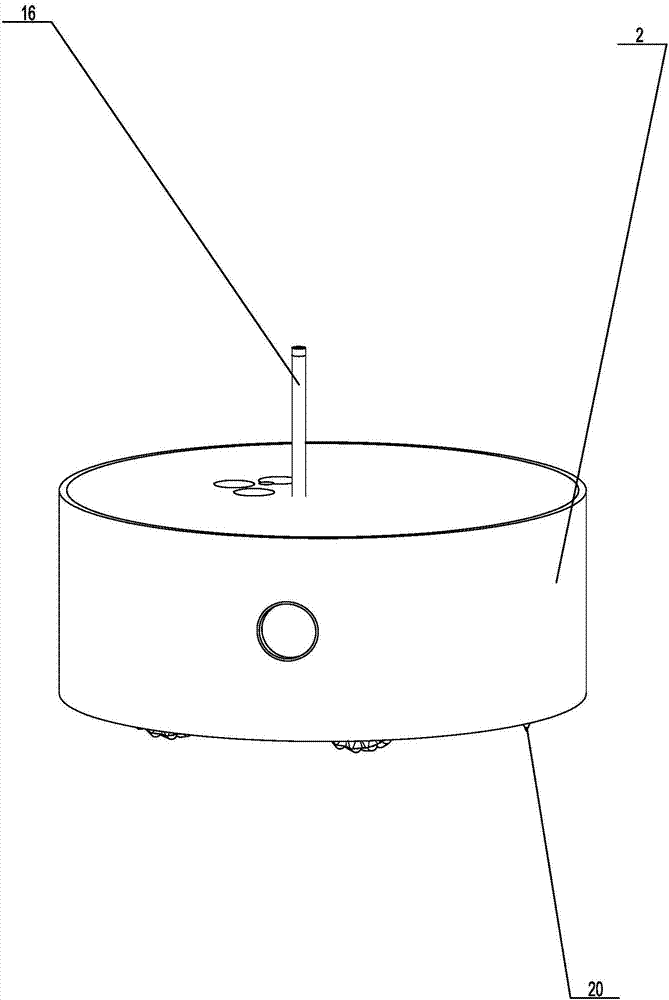

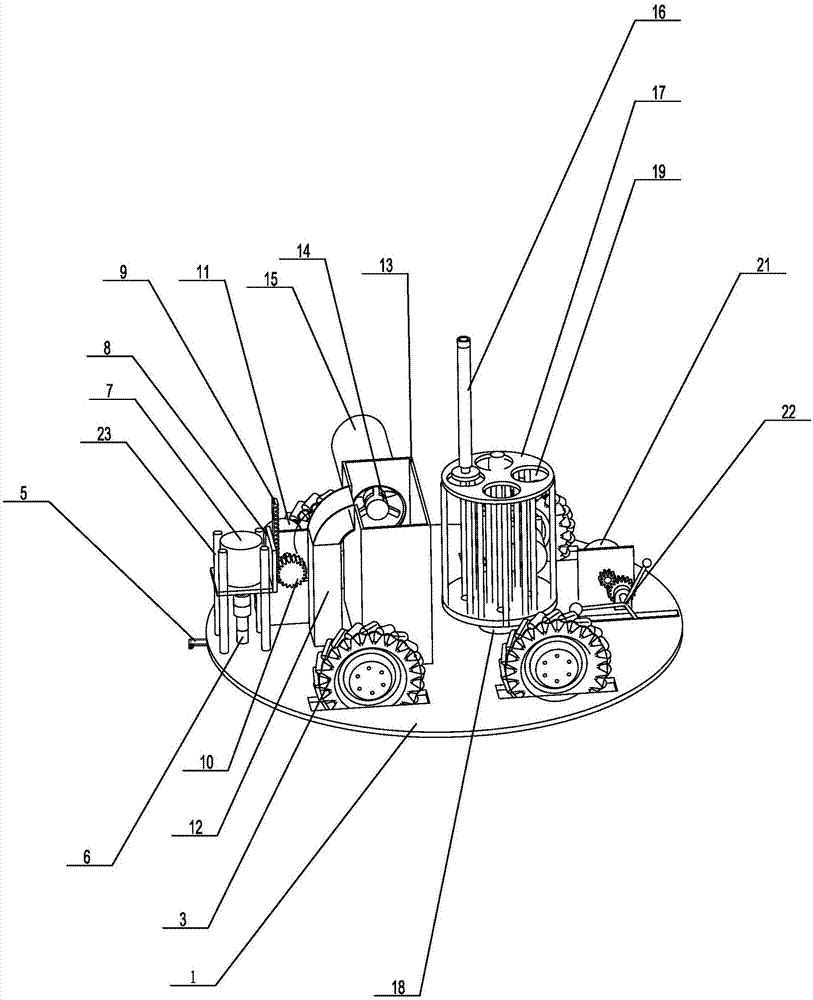

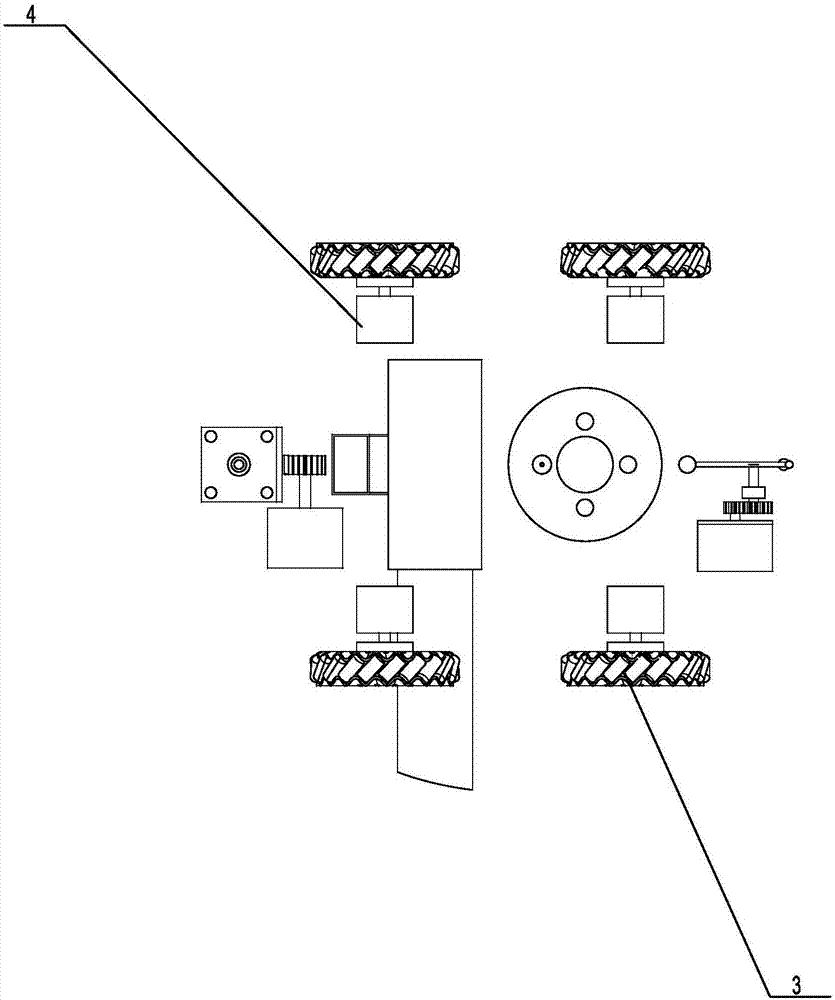

Robot for ceramic tile seam beautifying

ActiveCN106988513AChange the defects of manual operationImprove work efficiencyBuilding constructionsSpray nozzleEngineering

The invention discloses a robot for ceramic tile seam beautifying. The robot for ceramic tile seam beautifying comprises a chassis, a main shell, a driving mechanism, a cleaning mechanism, and a seam beautifying mechanism and a seam pressing mechanism; the driving mechanism comprises four mecanum wheels, four running driving motors and an industrial camera; the cleaning mechanism comprises a cleaning cutting tool, a cutting tool motor, a rack, a gear, a geared motor, a sweep-up pipe, a dust suction box, an exhaust fan and an exhaust pipe; the seam beautifying mechanism comprises an electric push rod, a sealant drum, a drum motor and a nozzle; the seam pressing mechanism comprises a seam pressing motor and a seam pressing ball rod; and the running driving motors, the driving mechanism, the cleaning mechanism and the seam beautifying mechanism are all controlled by an intelligent control system. The robot for ceramic tile seam beautifying can complete polishing, dedusting, agent injecting, seam pressing and other procedures in the ceramic tile seam beautifying working one time, the defects of existing manual operations are changed, mechanical automatic operation is achieved, and the robot for ceramic tile seam beautifying not only is high in working efficiency, but also is good in seam beautifying effect, low in seam beautifying cost, and easy to popularize.

Owner:QINZHOU UNIV

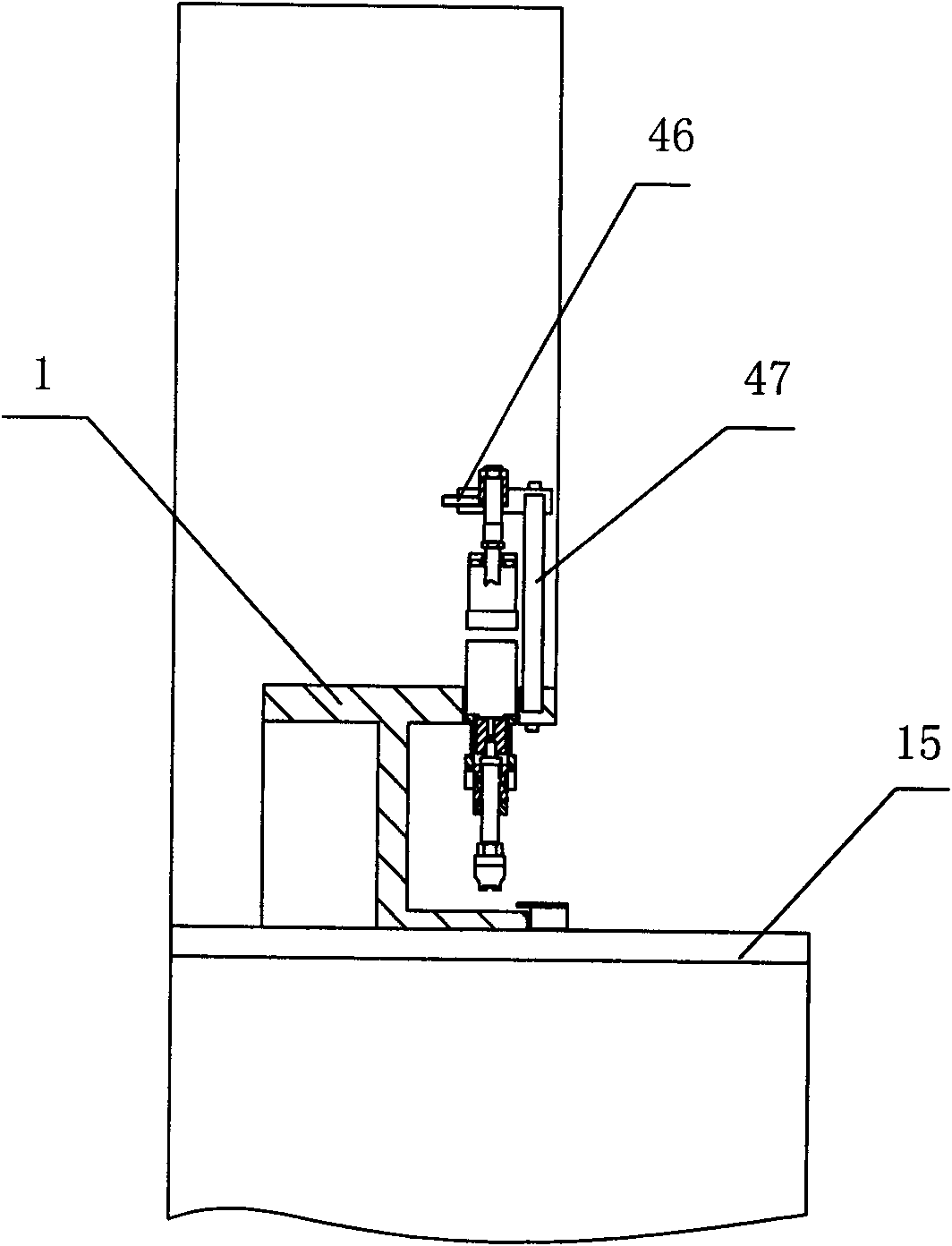

Automatic punching machine and punching method thereof

ActiveCN104325001AEasy to take outPrevent superimpositionMetal-working feeding devicesPositioning devicesPunchingMachining process

The invention provides an automatic punching machine and a punching method thereof. The automatic punching machine comprises a supporting base and a punching device positioned on the supporting base, and also comprises a material storage device positioned on the supporting base and used for storing raw materials, a conveying device positioned between the material storage device and the punching device and used for conveying the raw materials, a blanking device positioned behind the punching device and used for blanking and a material collecting device for collecting processed materials; the punching device comprises a first locating column with a locating function, a press plate with a locating correction function and a lower die with an air suction hole. The automatic punching machine is provided with the dual locating device and the die with levelling and stabilizing functions, so that the punching precision is greatly improved, the whole processing process is a full-automatic process, the manpower is saved, the production efficiency is also improved and the product quality is improved.

Owner:KUNSHAN LONGPENG PRECISION ELECTRONICS

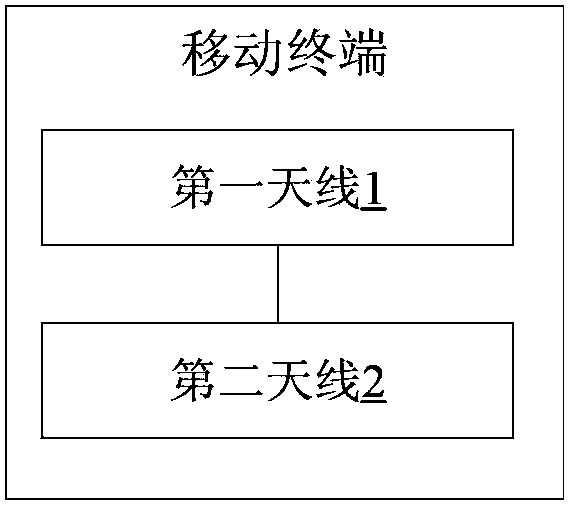

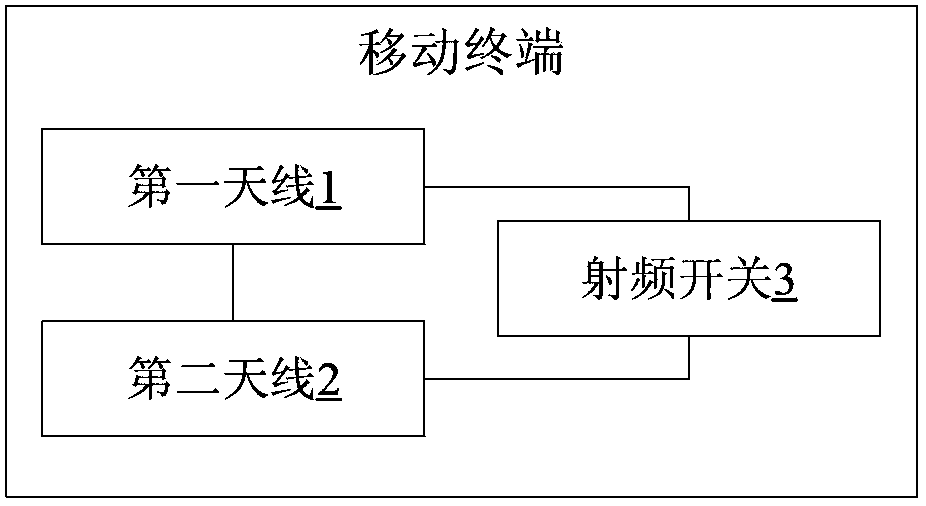

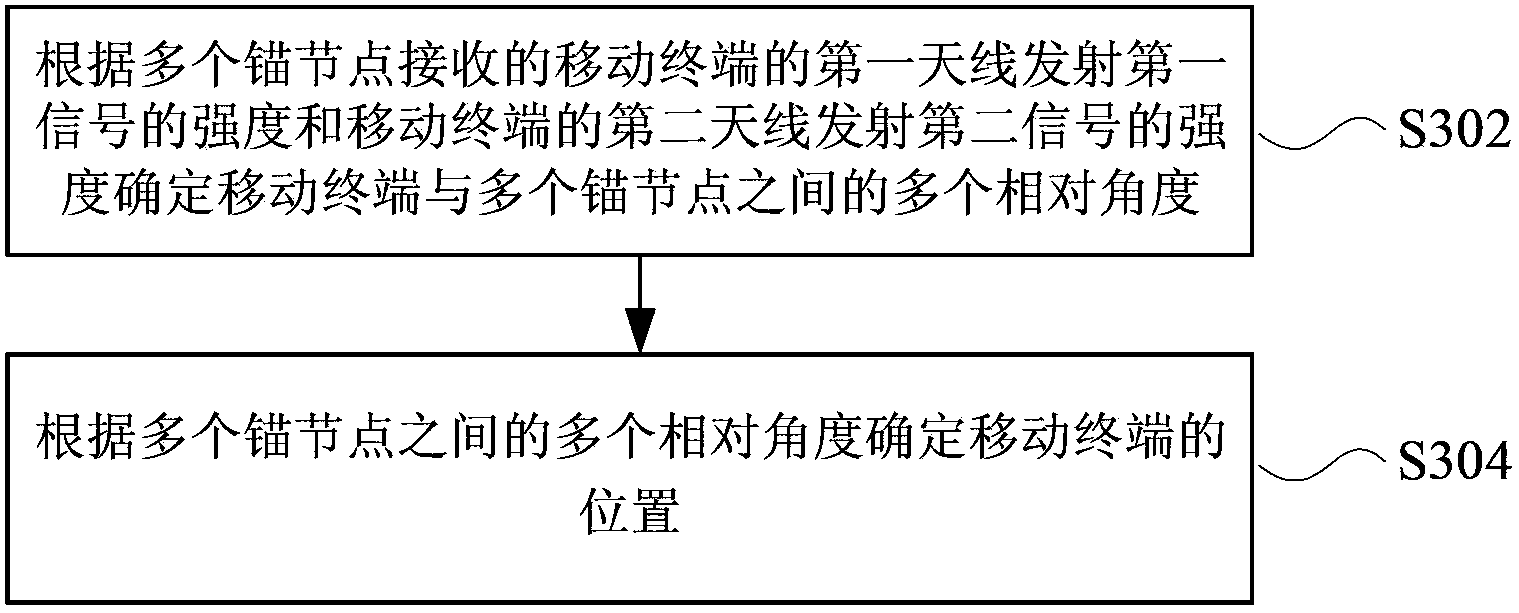

Mobile terminal, and positioning method and apparatus

ActiveCN104053229AFlexible positioningFlexible real-time positioningRadio wave finder detailsRadio wave direction/deviation determination systemsEngineeringComputer terminal

Disclosed are a mobile terminal and a locating method and device. The mobile terminal comprises: a first antenna set to transmit a first signal to an anchor node, the first signal being used by the anchor node to detect the signal strength of the first antenna; and a second antenna arranged with the first antenna in accordance with a preset angle and set to transmit a second signal to the anchor node, the second signal being used by the anchor node to detect the signal strength of the second antenna, the preset angle enabling the coverage ranges of the first antenna and the second antenna to be overlapped, and the signal strength of the first antenna and the signal strength of the second antenna being used for determining the location of the mobile terminal. The present invention is applied to solve the problem that in a WLAN locating process, real-time locating cannot be achieved, or the locating process is complex, and the environment is restricted in the related art, thereby being able to achieve flexible real-time locating through a mobile terminal with two antennas without environmental restriction and with more accurate locating accuracy.

Owner:ZTE CORP

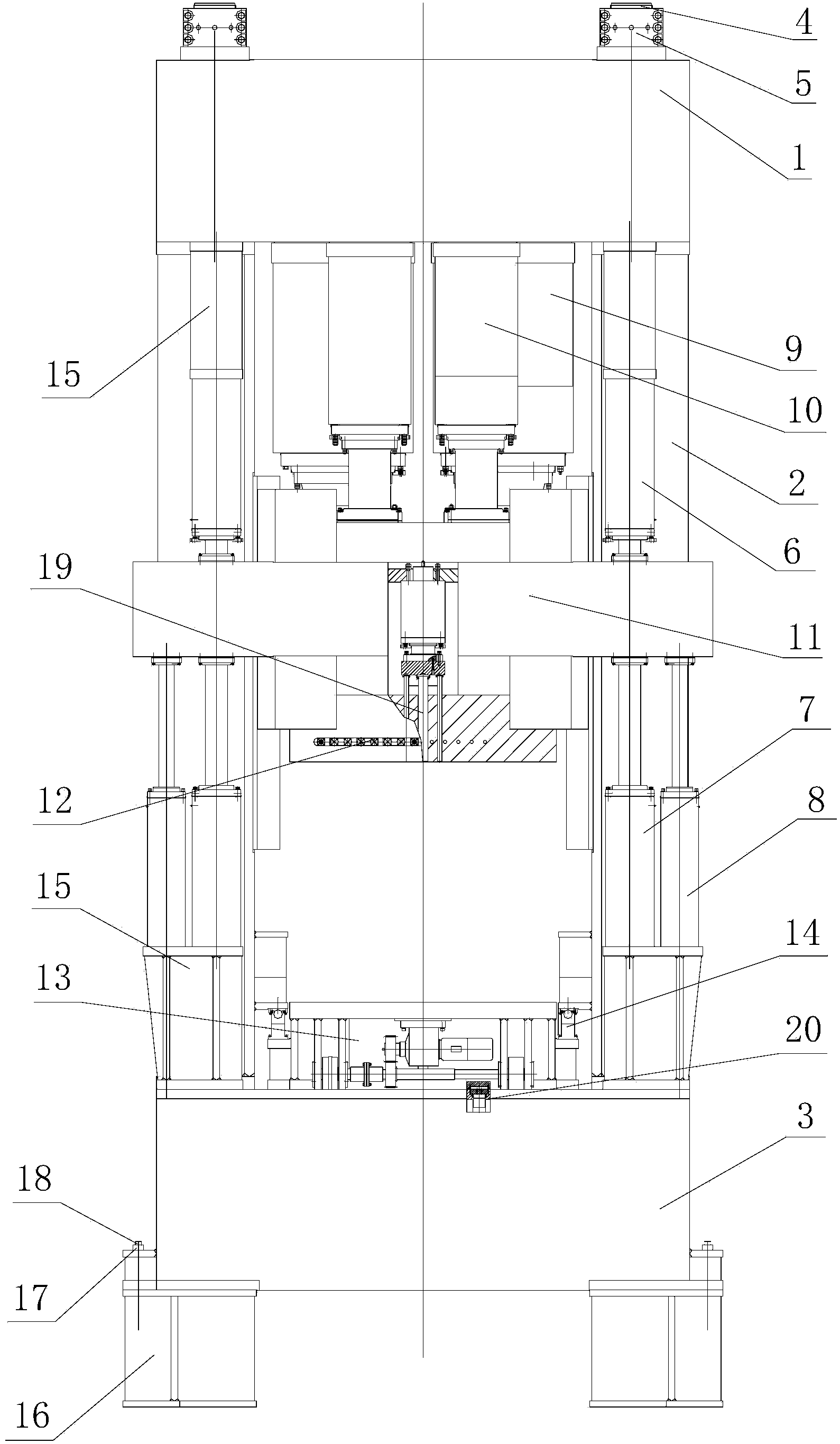

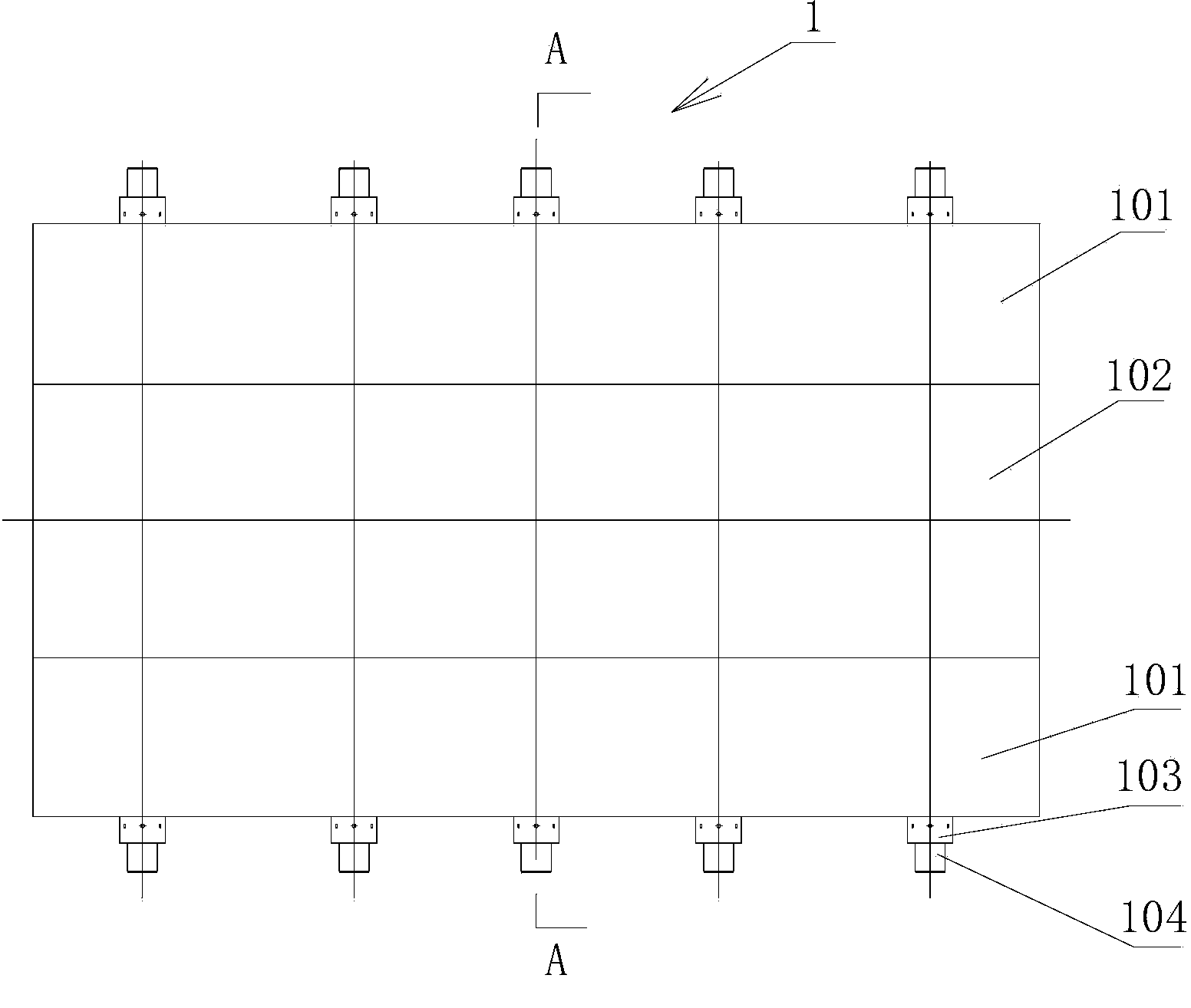

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

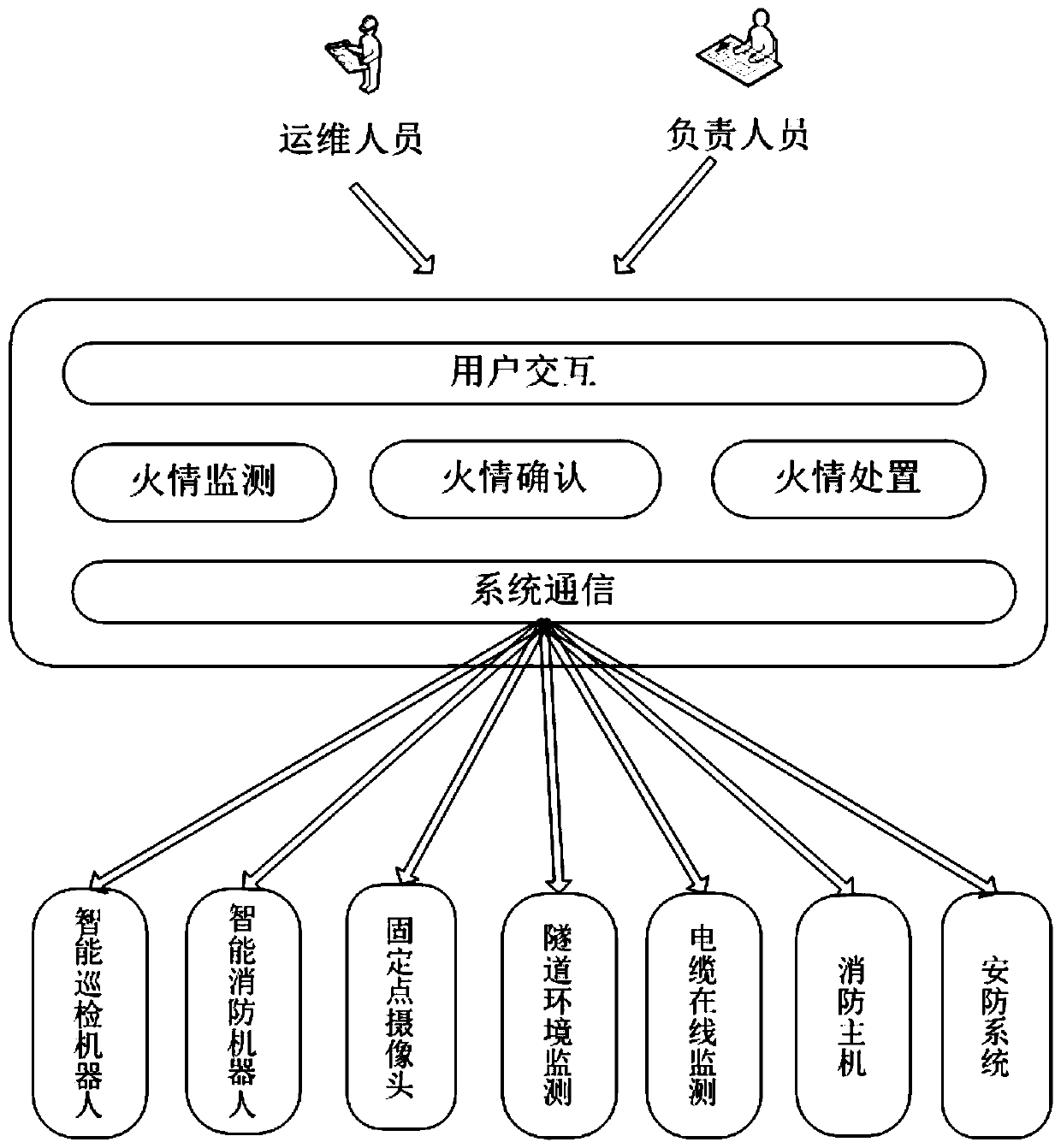

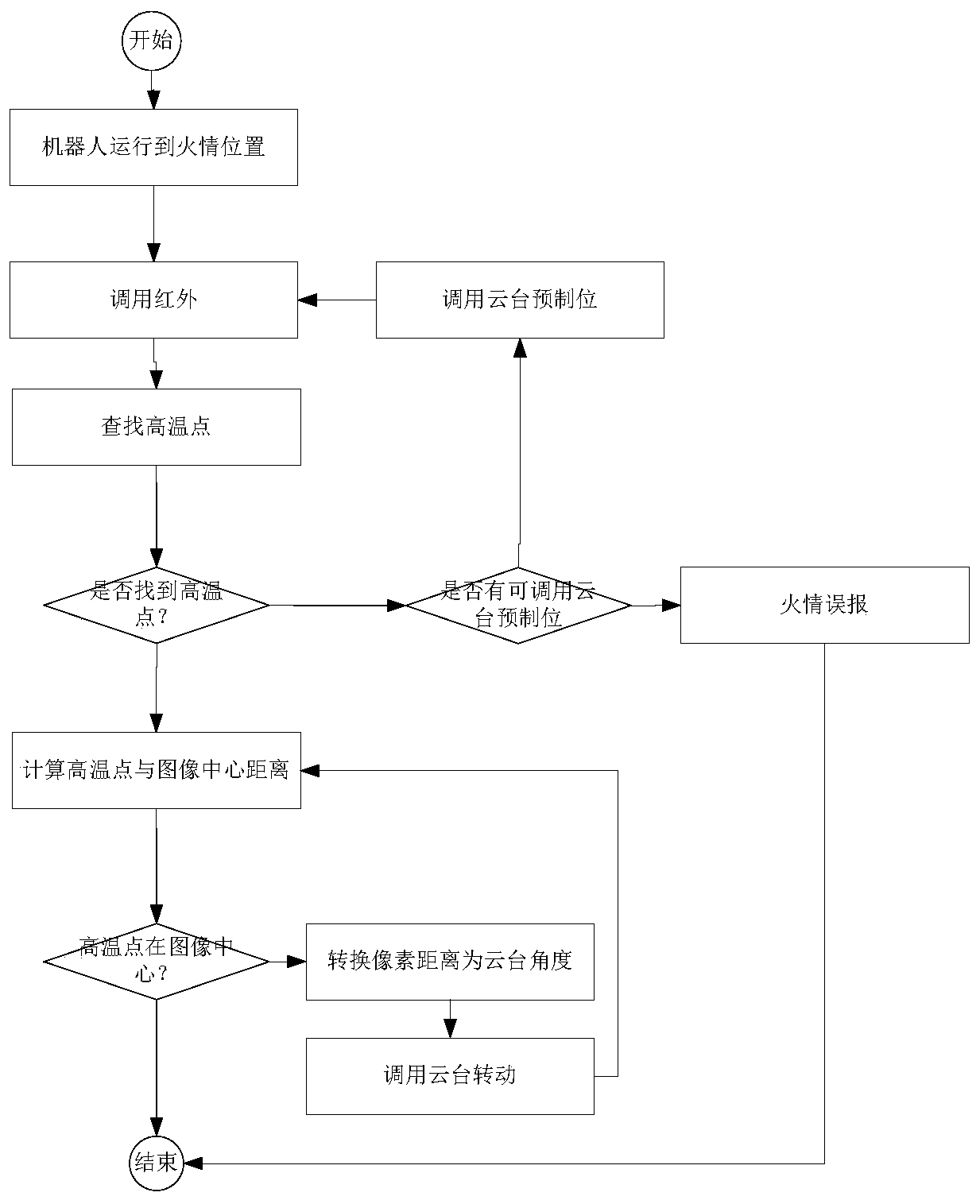

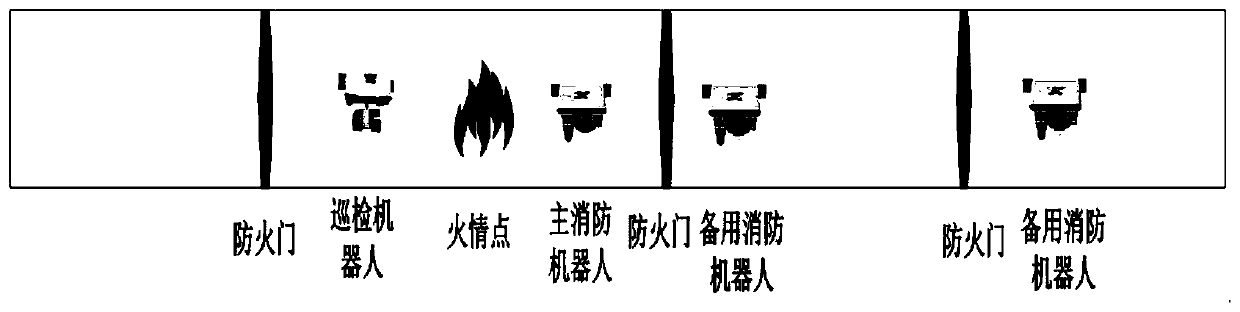

Fire monitoring and disposal system and method used in cable tunnel environment

ActiveCN110841219AImprove accuracyAccurate positioning accuracyFire rescueEnvironmental resource managementFire safety

The invention discloses a fire monitoring and disposal system and method used in a cable tunnel environment. The system comprises a fire monitoring module, a fire confirming module and a fire disposalmodule, wherein the fire monitoring module is arranged to be used for obtaining tunnel environment monitoring data and cable monitoring data and judging whether tunnel fire early warning and cable fire early warning are generated according to a determined tunnel fire early warning rule and a cable fire early warning rule; the fire confirming module is arranged to be linked with a fire-fighting robot to move to the position near an early warning position after tunnel fire early warning or cable fire early warning is generated, linked with a monitoring device in a cable tunnel to monitor environment conditions in the tunnel and linked with an intelligent patrol robot to move to the early warning position and judge whether a fire happens or not; and the fire disposal module is configured toperform emergency disposal on the confirmed fire according to a fire disposal plan after the fire occurs. The system can effectively improve the fire safety inspection accuracy and improve the fire disposal accuracy and timeliness.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

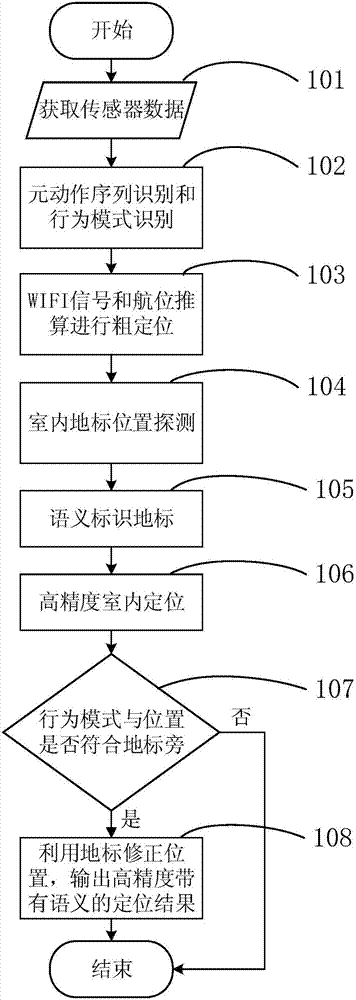

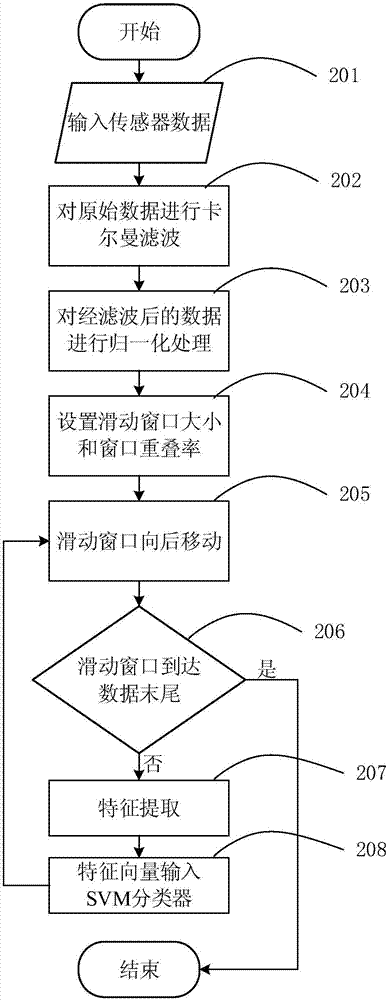

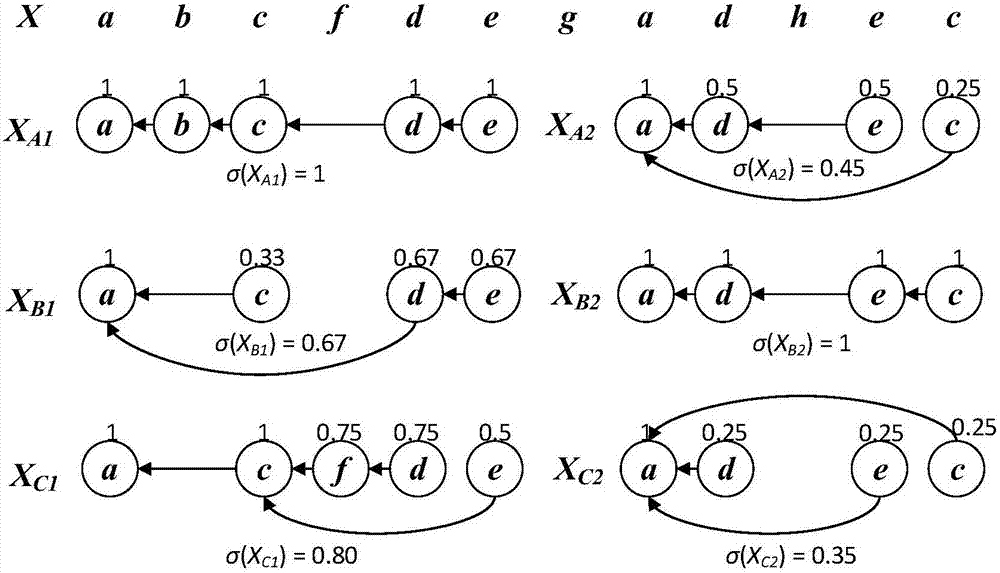

Indoor localization and landmark semantic identification method based on behaviors

ActiveCN107339992AImprove experienceDifficult to locateNavigational calculation instrumentsSupport vector machineFeature extraction

The invention discloses an indoor location and landmark semantic identification method based on behaviors. The method comprises steps as follows: on the basis of action modes of an indoor person, data of the designed action modes is collected by a built-in inertial sensor arranged in a smart phone, the data is subjected to preprocessing and characteristic extraction, and action sequences are identified by a support vector machine and are recognized as behavior patterns with a fuzzy pattern recognition algorithm; an initial locating point is determined according to WIFI signals, and an approximate walking track is determined with a dead reckoning method; the behavior patterns and locations are analyzed respectively; more accurate indoor location is realized by continuously updating landmarks, and the landmarks are subjected to semantic identification according to attributes of the landmarks. When the indoor pedestrian is located, drift errors produced through dead reckoning are corrected according to the behavior patterns and a landmark set. According to the method, the location errors can be corrected by the landmarks, disturbance of environmental factors and noise of the sensor are effectively treated, and precision of indoor location is remarkably improved.

Owner:WUHAN UNIV

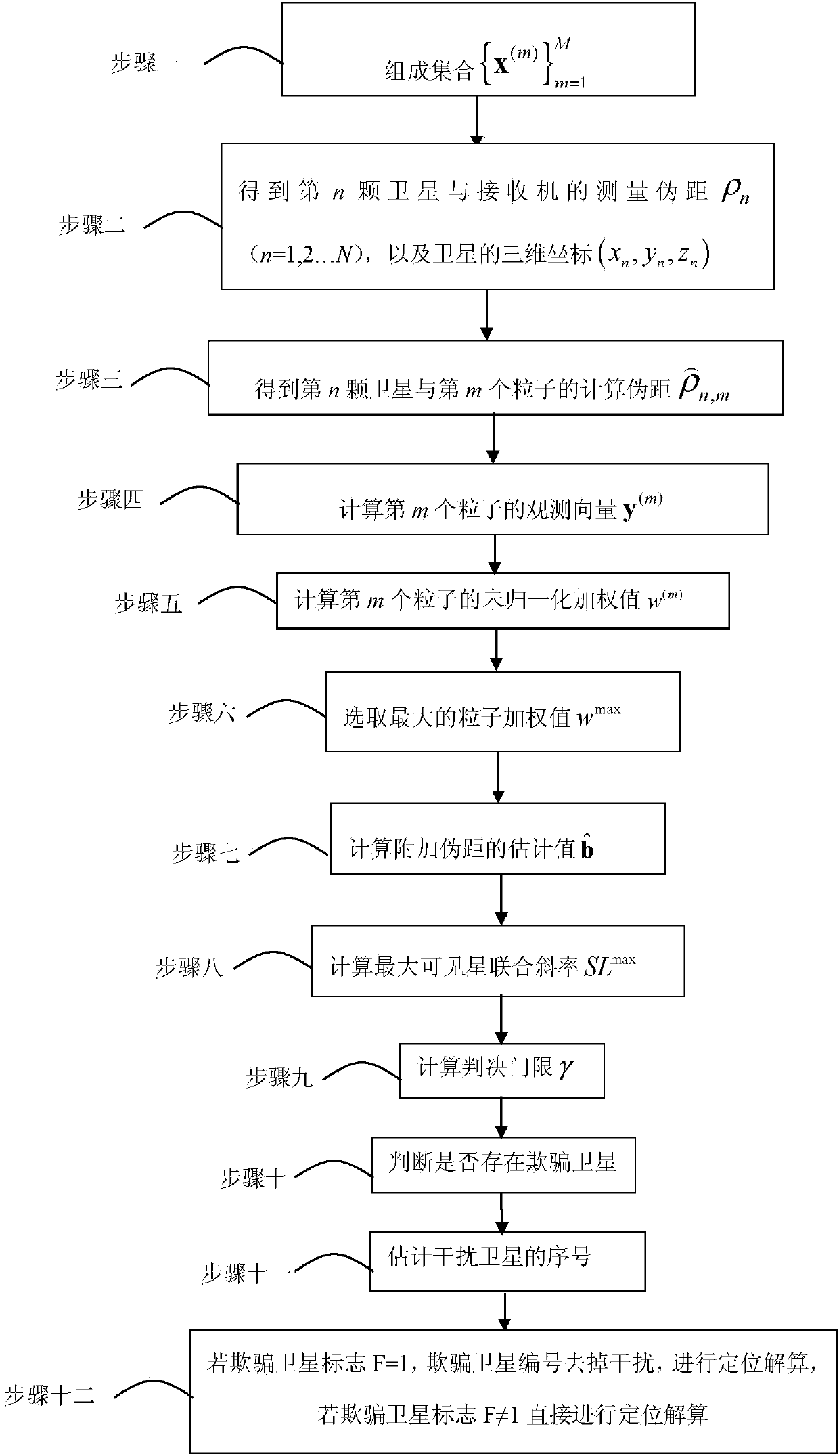

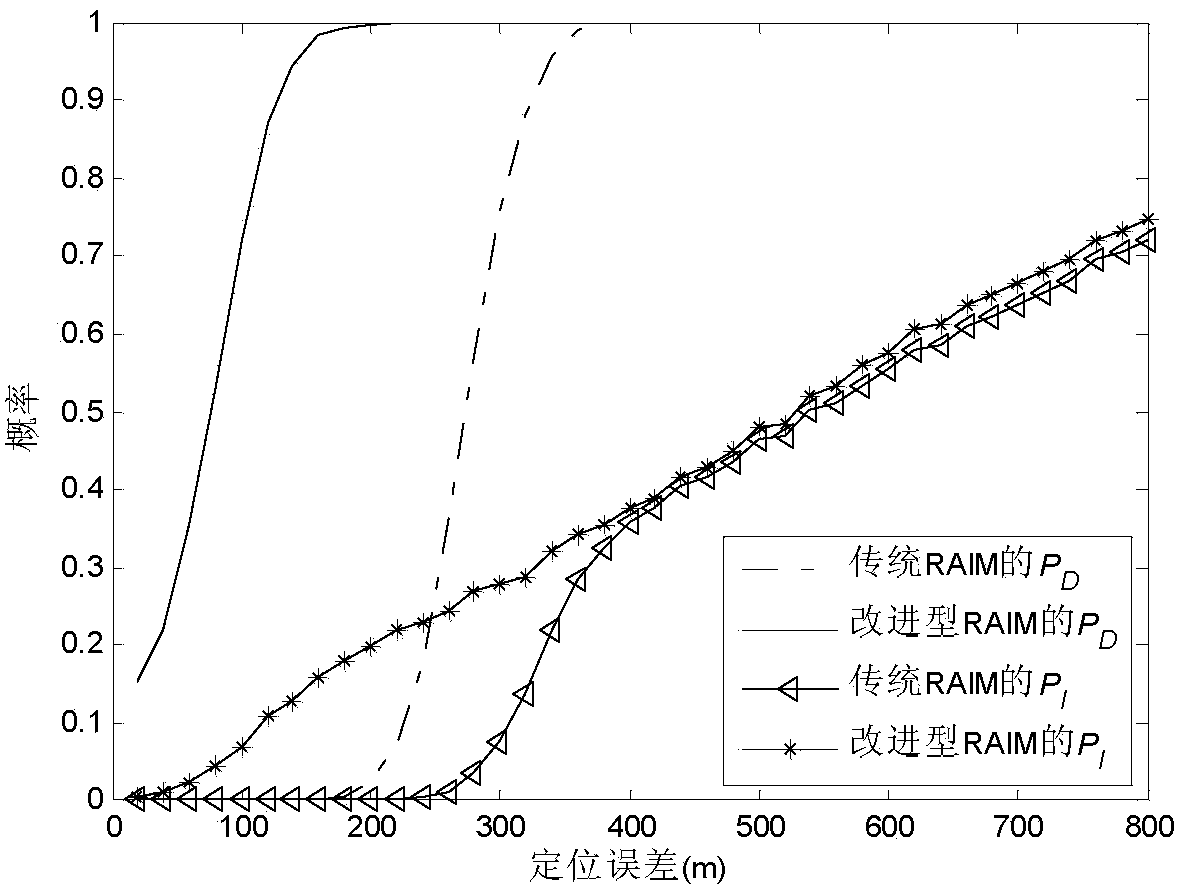

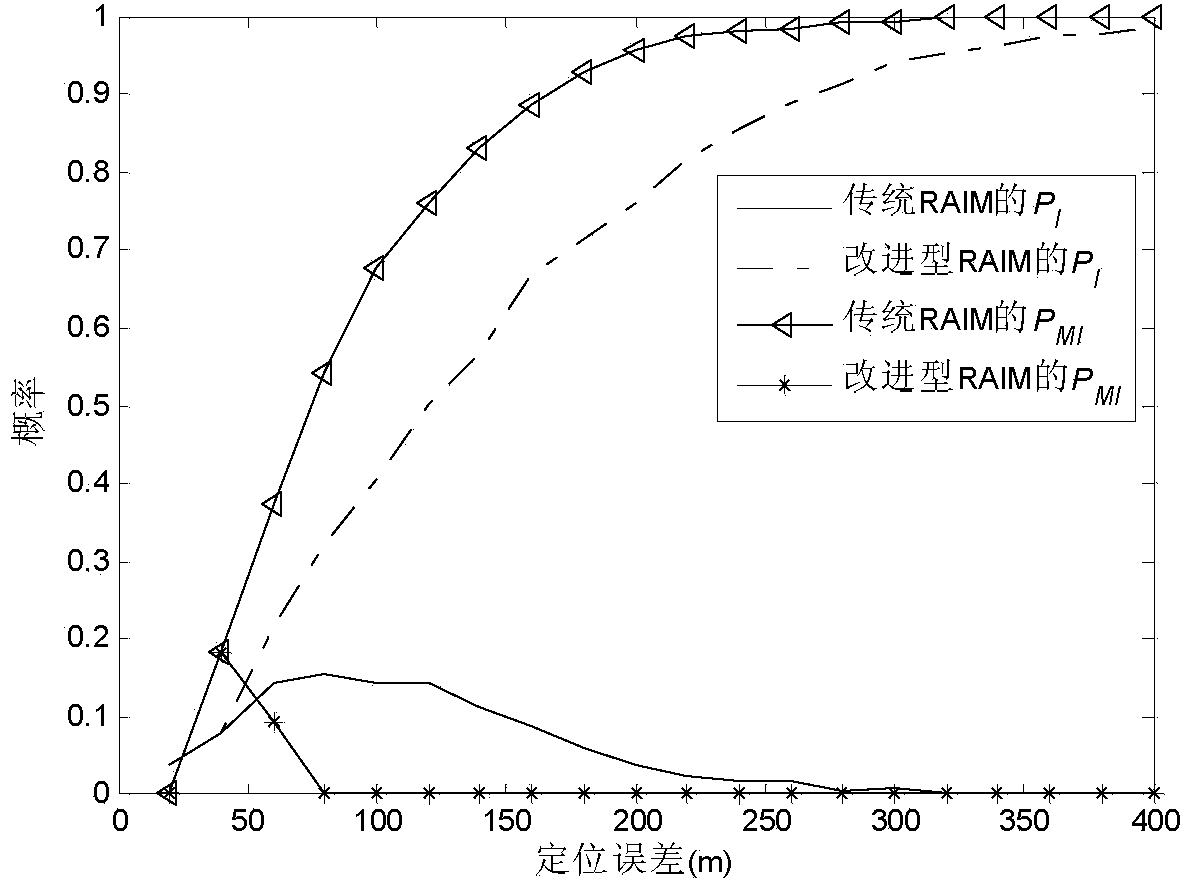

Particle filter-based improved RAIM (Receiver Autonomous Integrity Monitoring) anti-deception jamming method

ActiveCN103983986AEasy to detectAchieving identifiabilitySatellite radio beaconingComputational physicsReceiver autonomous integrity monitoring

The invention discloses a particle filter-based improved RAIM (Receiver Autonomous Integrity Monitoring) anti-deception jamming method. The invention relates to an improved RAIM anti-deception jamming method. For solving the problems of measurement failure of a single satellite, positioning misleading of a receiver by a control resolving flow, and neglecting of dependency and similarity among remaining vectors by RAIM, the invention provides a particle filter-based improved RAIM anti-deception jamming method. The particle filter-based improved RAIM anti-deception jamming method comprises the following steps: 1, forming a formula described in the specification; 2, obtaining a Rho n and three-dimensional coordinates of the satellite; 3, calculating a parameter described in the specification; 4, calculating y (m); 5, calculating w (m); 6, selecting wmax; 7, calculating a parameter described in the specification; 8, calculating a maximal visible satellite SLmax; 9, calculating a judgment threshold gamma; 10, judging the existence of a deception satellite; 11, estimating a sequence number of the deception satellite; and 12, if the mark F of the deception satellite is equal to 1, removing jamming, carrying out positioning resolving, and if F is not equal to 1, carrying out positioning resolving. The particle filter-based improved RAIM anti-deception jamming method is applied to the field of improved RAIM anti-deception jamming.

Owner:HARBIN INST OF TECH

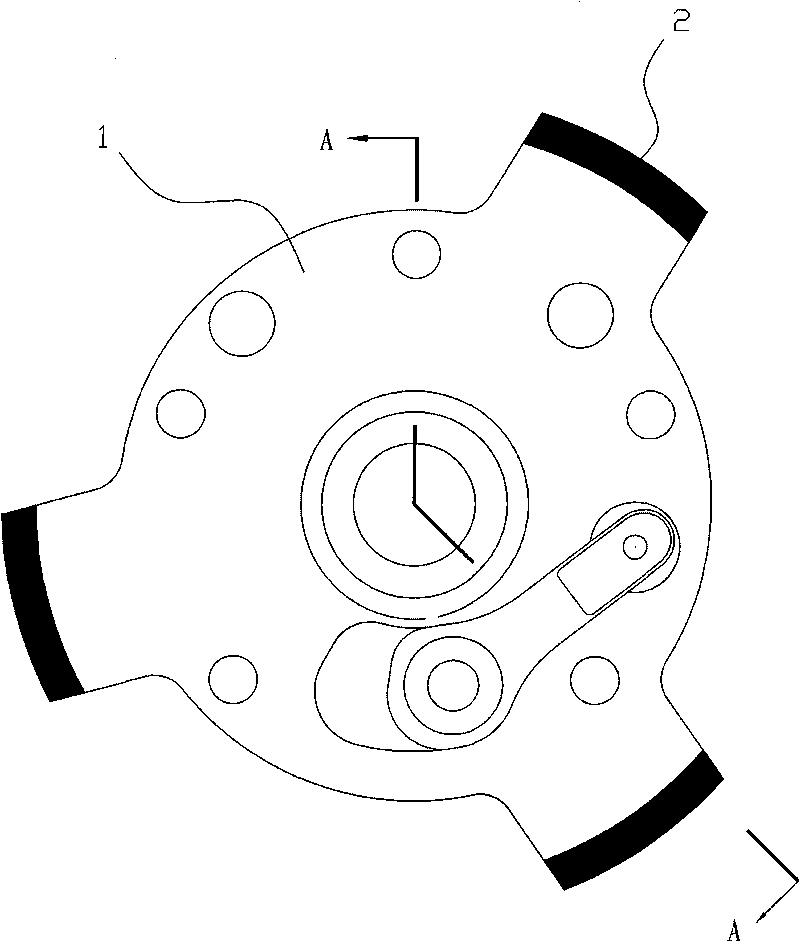

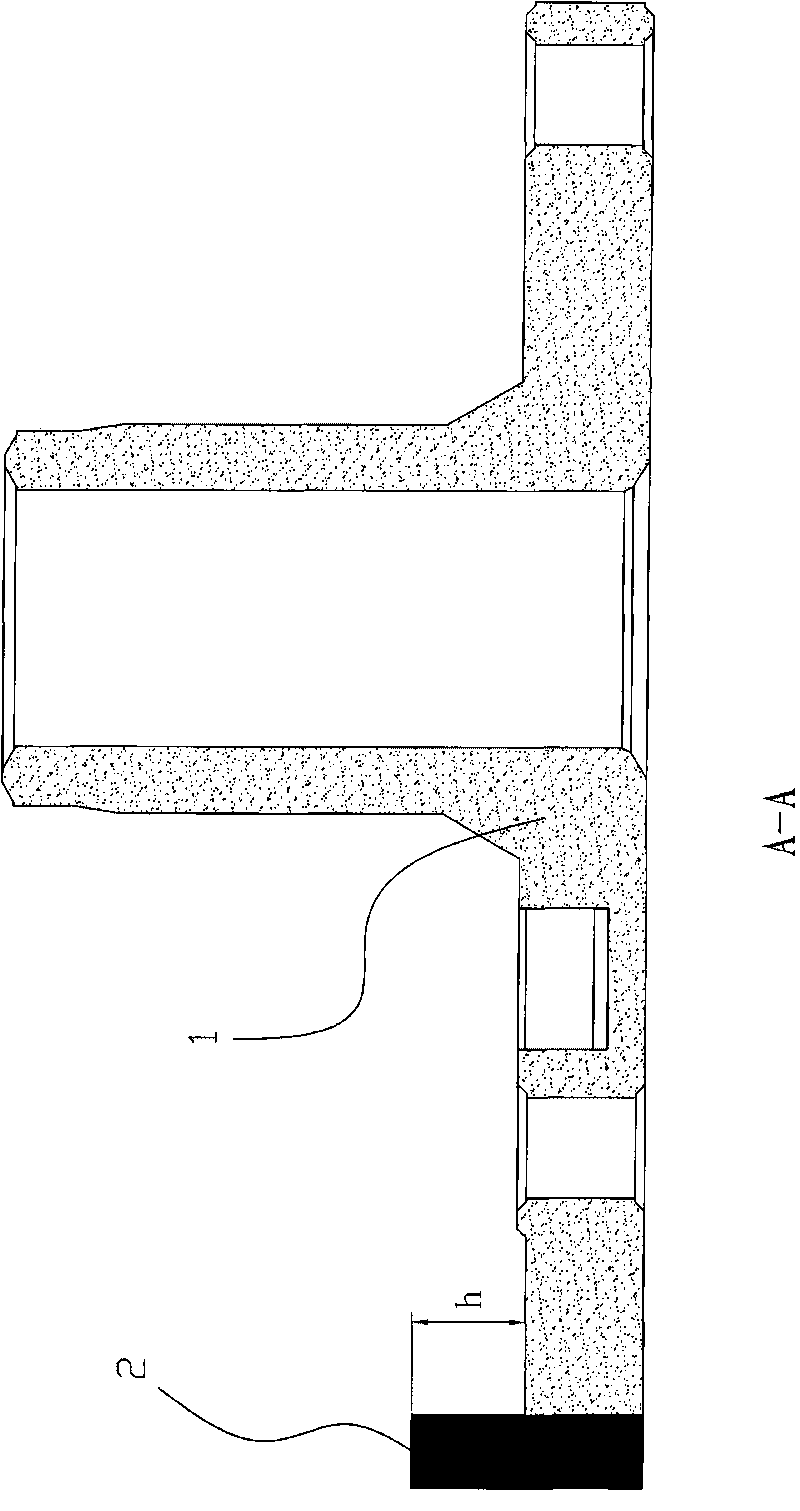

Method for manufacturing powder metallurgy supporting seat

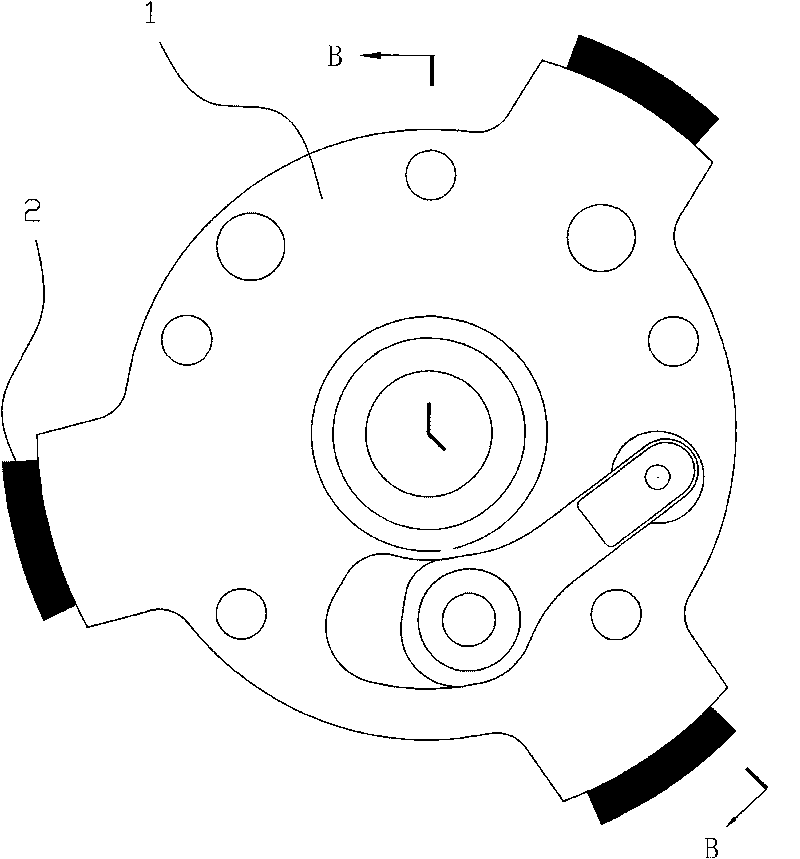

The invention relates to a method for manufacturing a powder metallurgy supporting seat, which sequentially comprises the following steps: (1) pressing a supporting seat base body (1), and arranging a structure for placing a transition block (2) on the supporting seat base body (1); (2) processing the transition block (2); (3) arranging the transition block on the structure for placing a transition block (2) on the supporting seat base body (1), positioning soldering flux between the supporting seat base body (1) and the transition block (2), and then putting the supporting seat base body (1) assembled with the transition block (2) in to a sintering furnace at the temperature of 1000-1300 DEG C under the condition of vacuum or filling with assistant welding gas sintering atmosphere for sintering for 5-50min; (4) after welding, measuring the size and accuracy to determine whether machining and adjusting are needed for correcting the position of the transition block (2) on the supporting seat base body (1); and (5) carrying out steam treatment on the supporting seat base body (1) welded with the transition block (2); therefore, the manufacturing process of powder metallurgy supporting seat can be completed. Compared with the prior art, as the transition block is welded with the supporting seat base body by a powder metallurgy sintering and soldering method, the supporting seat base body has high position, accurate locating accuracy and good connecting strength; and the whole welding process is simple and easy to operate.

Owner:NBTM NEW MATERIALS GRP

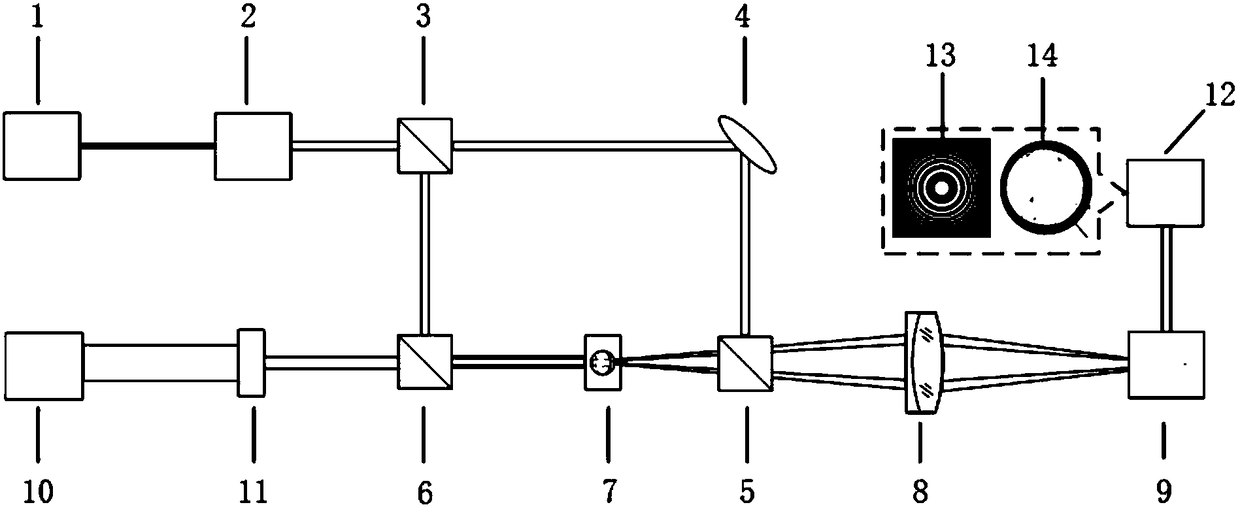

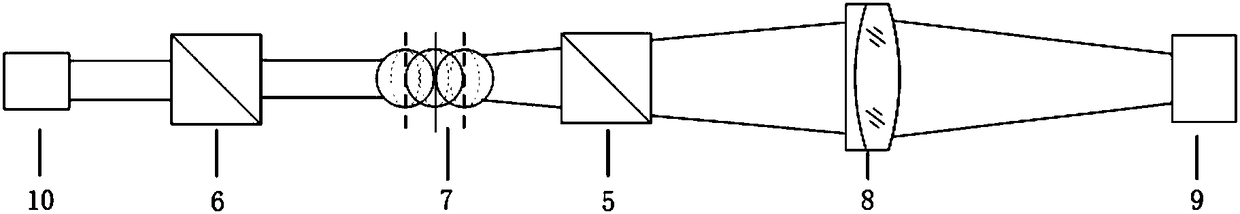

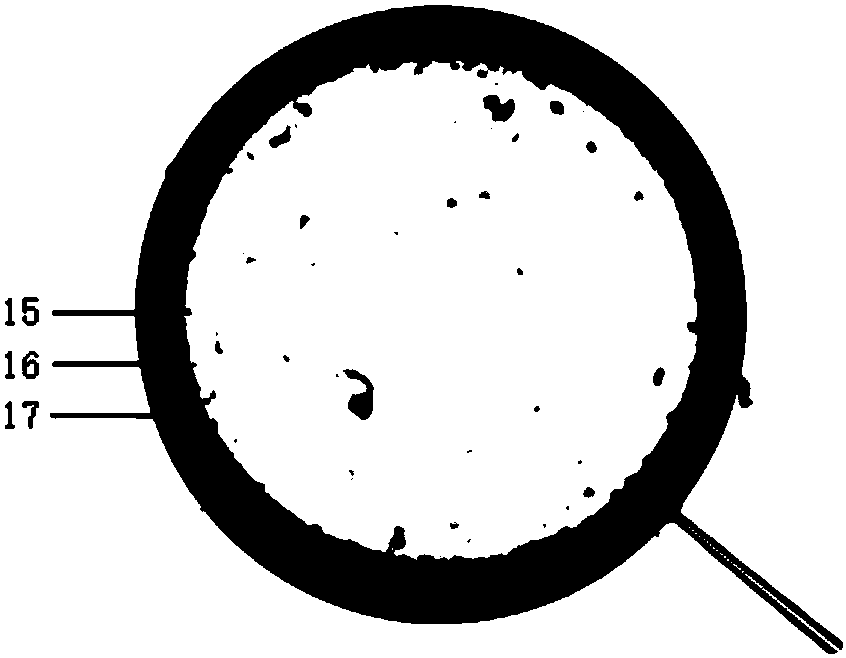

Novel ICF (initial confinement fusion) pellet detection device and positioning method

ActiveCN108333145AUnable to solveAccurate positioning accuracyPhase-affecting property measurementsUsing optical meansBeam expanderBeam splitter

The invention relates to a novel ICF (initial confinement fusion) pellet detection device and a positioning method. The device comprises a laser, a beam expander, a first bean splitter, a second beamsplitter, a third beam splitter, a plane mirror, a to-be-detected pellet, a lens, a CCD image sensor, a computer, a high-power LED and a diaphragm. The pellet is moved at the internal of 10 mu m, a backlight projection image in each position is collected, image preprocessing work such as filtering and aperture extraction is performed, the acutance of an area near a bright ring is calculated, and the position with the largest acutance meets the object-image conjugate relation. The pellet is moved in the interval of 10 mu m at the interval of 1 mu m continuously after being moved to the position. The steps of collection, image preprocessing and acutance calculation are repeated, the pellet is moved to the new position with the largest acutance, and positioning is finished. The novel pellet detection device and the positioning method are applicable to conventional cylindrical vacuum space and can realize automatic positioning quickly and accurately.

Owner:ZHEJIANG UNIV

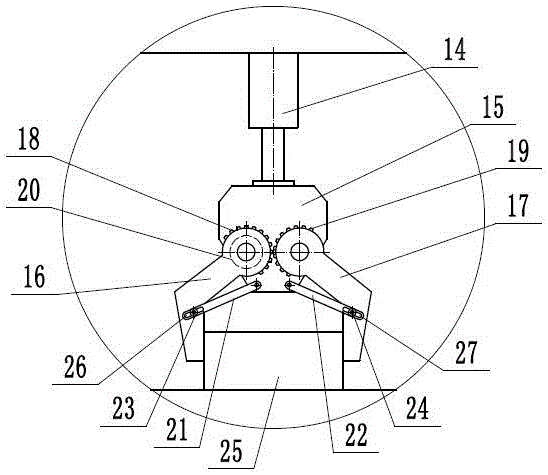

Workpiece feeding device

InactiveCN105729217AImprove stabilityControllable speedGripping headsMetal working apparatusCamEngineering

The invention belongs to the technical field of machining and provides a workpiece feeding device. The workpiece feeding device comprises a clamping mechanism and a feeding mechanism, a cam of the feeding mechanism is provided with a cam groove, the lower end of a rocker is hinged to a rocker supporting seat, one end of a connecting rod is hinged to the upper end of the rocker, and the other end of the connecting rod is hinged to a slider. The slider is bilaterally slidably arranged on a guide rail, and a roller is rotatably arranged on the connecting rod and positioned in the cam groove. A left clamping jaw and a right clamping jaw of the clamping mechanism are symmetrically and rotatably arranged on a clamping support frame, and a left intermittent gear and a right intermittent gear are meshed with each other. One end of a left supporting rod is hinged to the clamping support frame, a left hinge pin is arranged on the left clamping jaw and positioned in a left U-shaped groove, one end of a right supporting rod is hinged to the clamping support frame, and a right hinge pin is arranged on the right clamping jaw and positioned in a right U-shaped groove. The workpiece feeding device has the advantages of quickness and accuracy in feeding of workpieces 25, reasonable structure and high reliability.

Owner:桐乡市红旗塑料包装袋厂

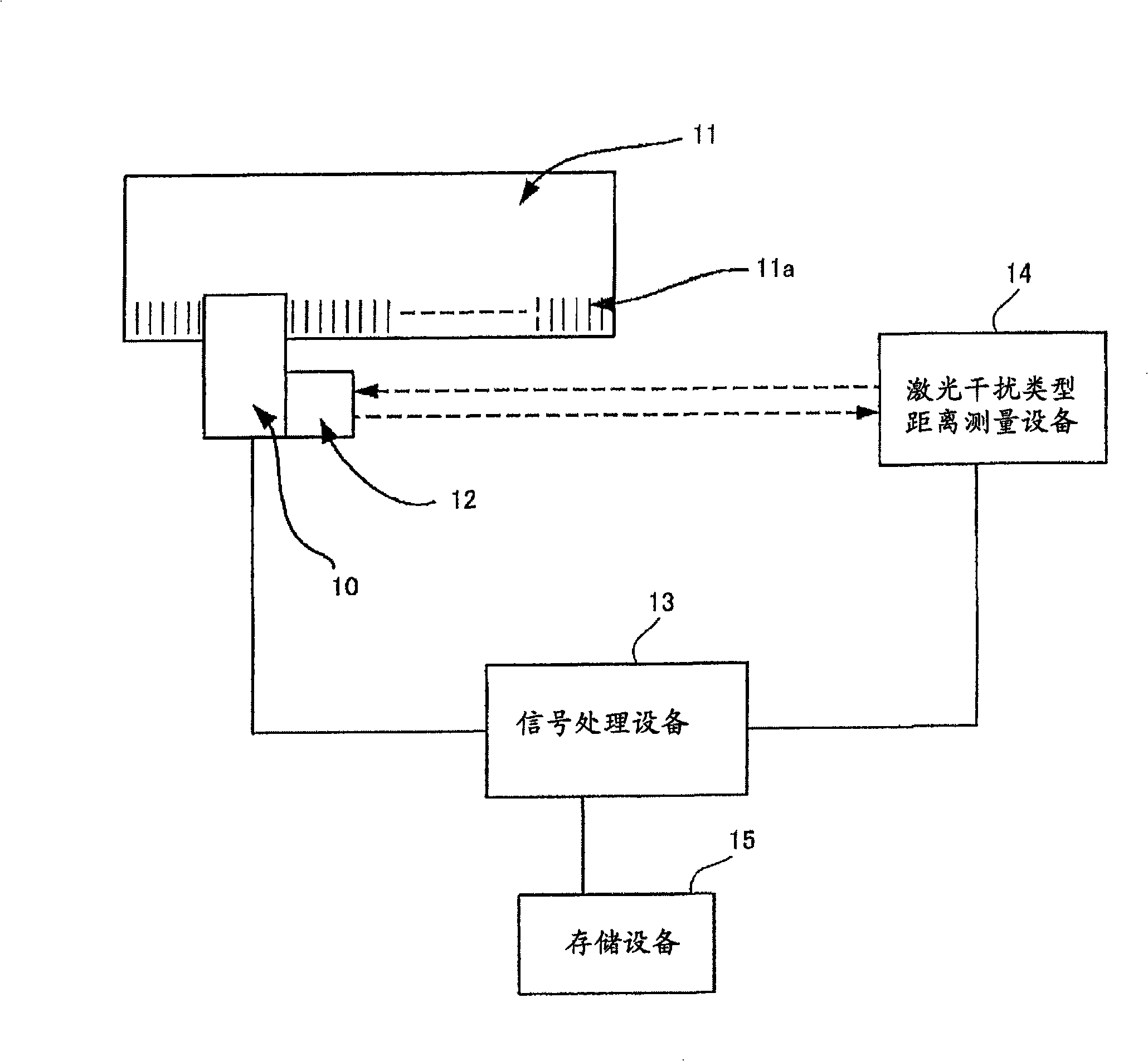

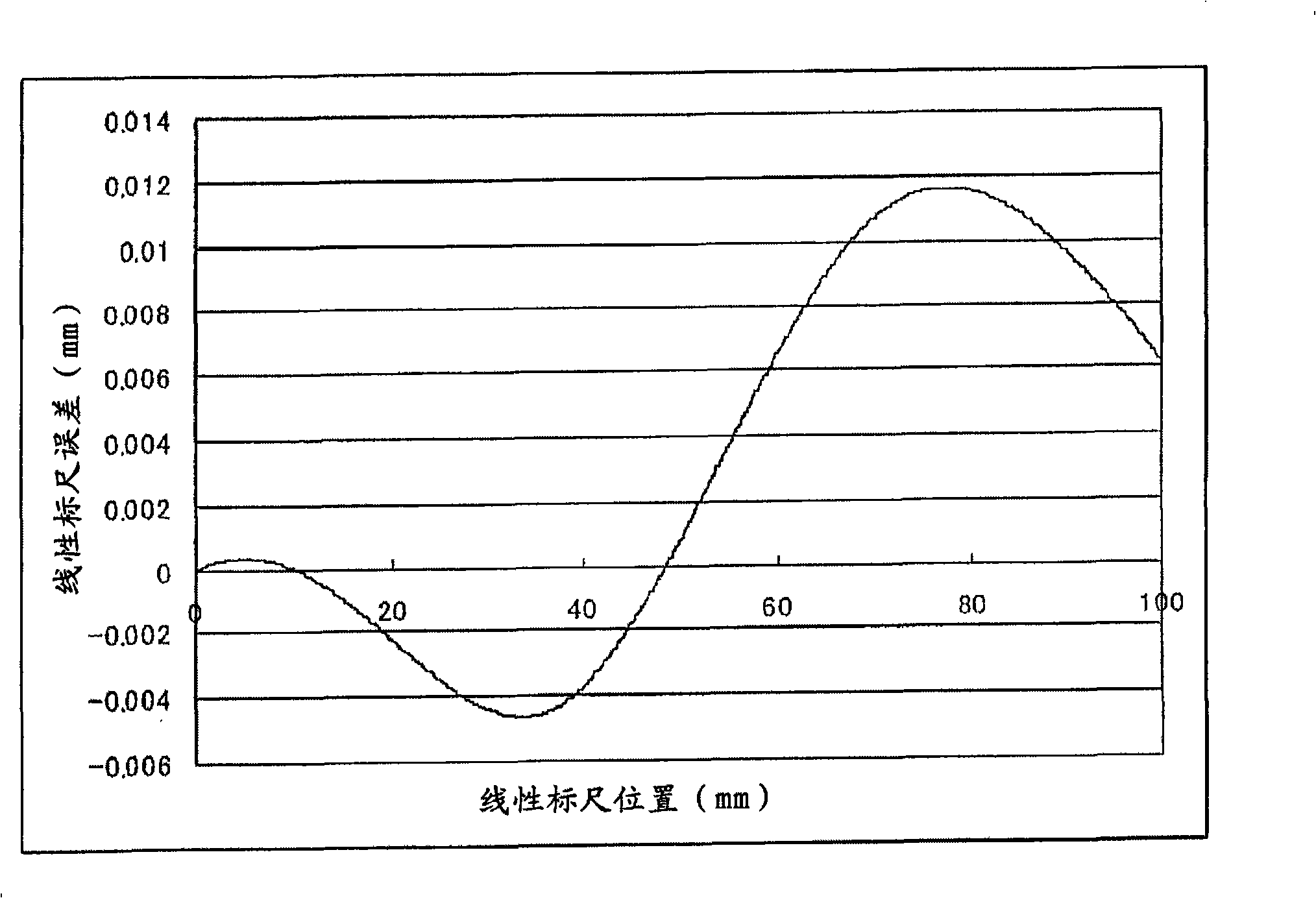

Method of measuring position detection error in machine tool

InactiveCN101352817AAccurate positioning accuracyRealize position detection error measurementOptical rangefindersMeasurement/indication equipmentsLocation detectionControl theory

A machine tool position detection error measurement method eliminates the effects of pitch, yaw, and roll of the axes at the point of machining of a CNC machine tool, and improves machining accuracy. The method comprises a step of compensating positioning accuracy of a positioning-error-measuring linear scale using a laser distance-measuring device, a step of mounting the compensated positioning-error-measuring linear scale parallel to a linear axis of the machine tool, and a step of comparing a motion amount obtained from the position detector by moving the linear axis a certain amount and a motion amount read from the positioning-error-measuring linear scale mounted parallel to the linear axis and storing a difference therebetween as error data of the position detector for the machine tool.

Owner:FANUC LTD

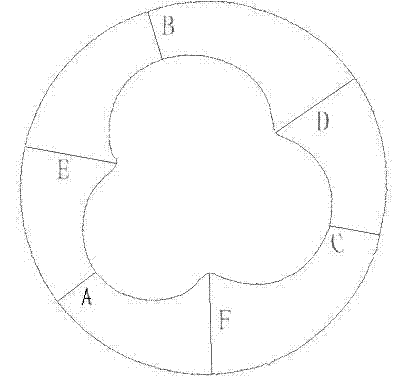

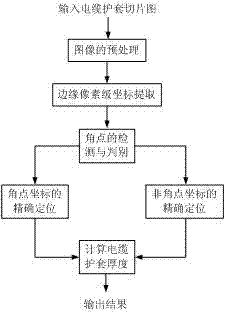

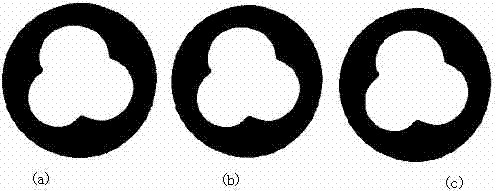

Method for measuring thickness of cable protecting bush accurately

InactiveCN104764407AHigh measurement accuracyReduce measurement errorUsing optical meansSobel edge detectionAngular point

The invention discloses a method for measuring thickness of a cable protecting bush accurately, and solves the defects that the accuracy is low, the error is large, and the efficiency is low by using a traditional geometrical measurement. The method includes the steps that firstly, preprocessing is conducted on a collected slice image of the cable protecting bush, edge pixel coordinates are obtained by using an Sobel edge detection method and a contour tracing technology, detection and distinguishing are conducted on angular points based on gradient correlation matrixes, as for the angle points, sub pixel position is conducted by using a support line fitting method based on angle point neighborhood supporting points, as for non-angle points, accurate positioning of the non-angle points is completed by using an edge re-positioning algorithm based on ZOM sub pixels. By means of the method, the measuring accuracy of the cable protecting bush is further improved, and the method is easy to carry out.

Owner:南京龙蟠电线电缆有限公司

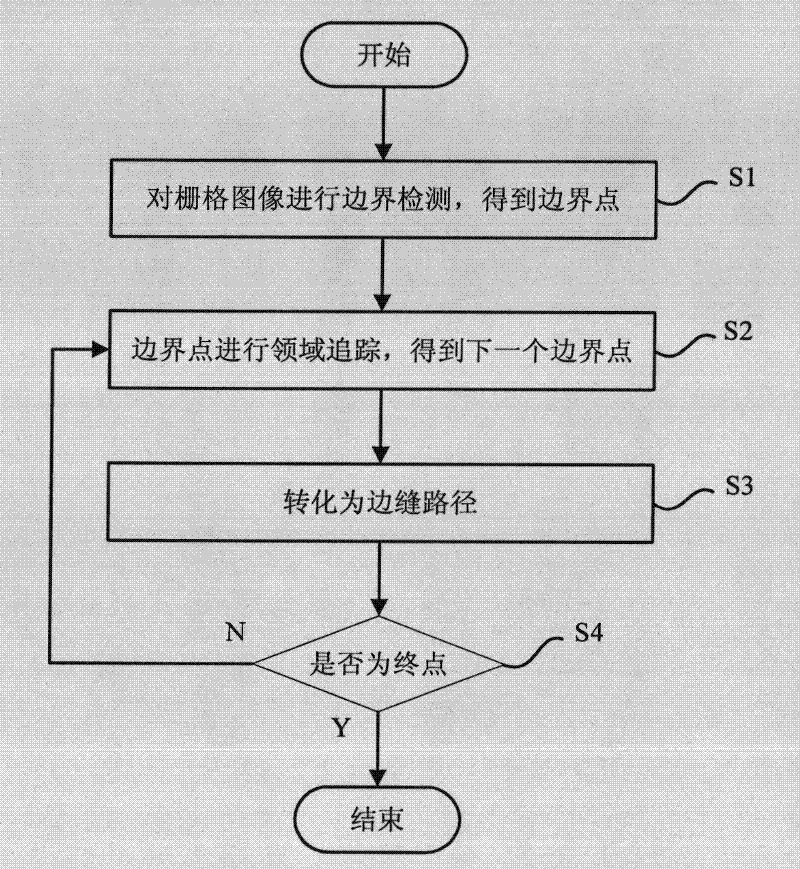

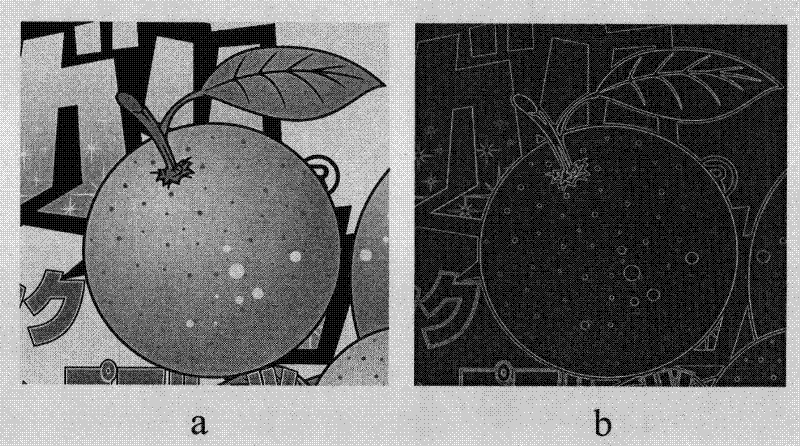

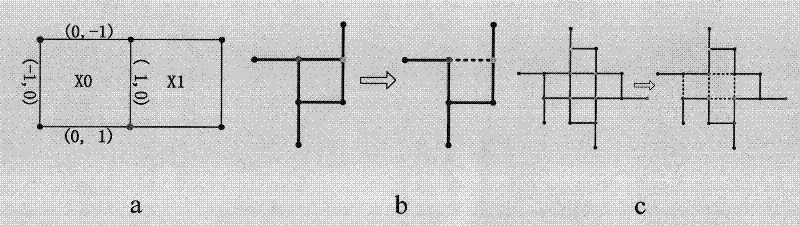

Method and system for generating edge seam path and edge seam topological structure of raster image

ActiveCN102542555APrecise positioningAccurate positioning accuracyImage enhancementImage analysisBoundary detectionImage edge

The invention discloses a method and a system for generating edge seam path and edge seam topological structure of raster image, which belongs to technical field of image edge detection. The method comprises S1, selecting a raster image, and carrying out edge detection calculation by calculating a gradient magnitude diagram to obtain boundary points of the image; S2, selecting a boundary point of step S1, and carrying out neighborhood tracing according to gradient magnitude of pixels to obtain the second boundary point; S3, converting the edge seam gradient of the second boundary point in the vertical direction in reference to the first boundary point to the edge seam path; and S4, repeating the steps of S2 and S3 until the edge seam path of the whole raster image is completed; and recording information of the edge seam path and intersection points to generate the edge seam topological structure. The boundary generated by the method has high location accuracy, good continuity and abundant boundary information, and can meet the application requirement for boundary detection in each hot field of image processing.

Owner:PEKING UNIV +1

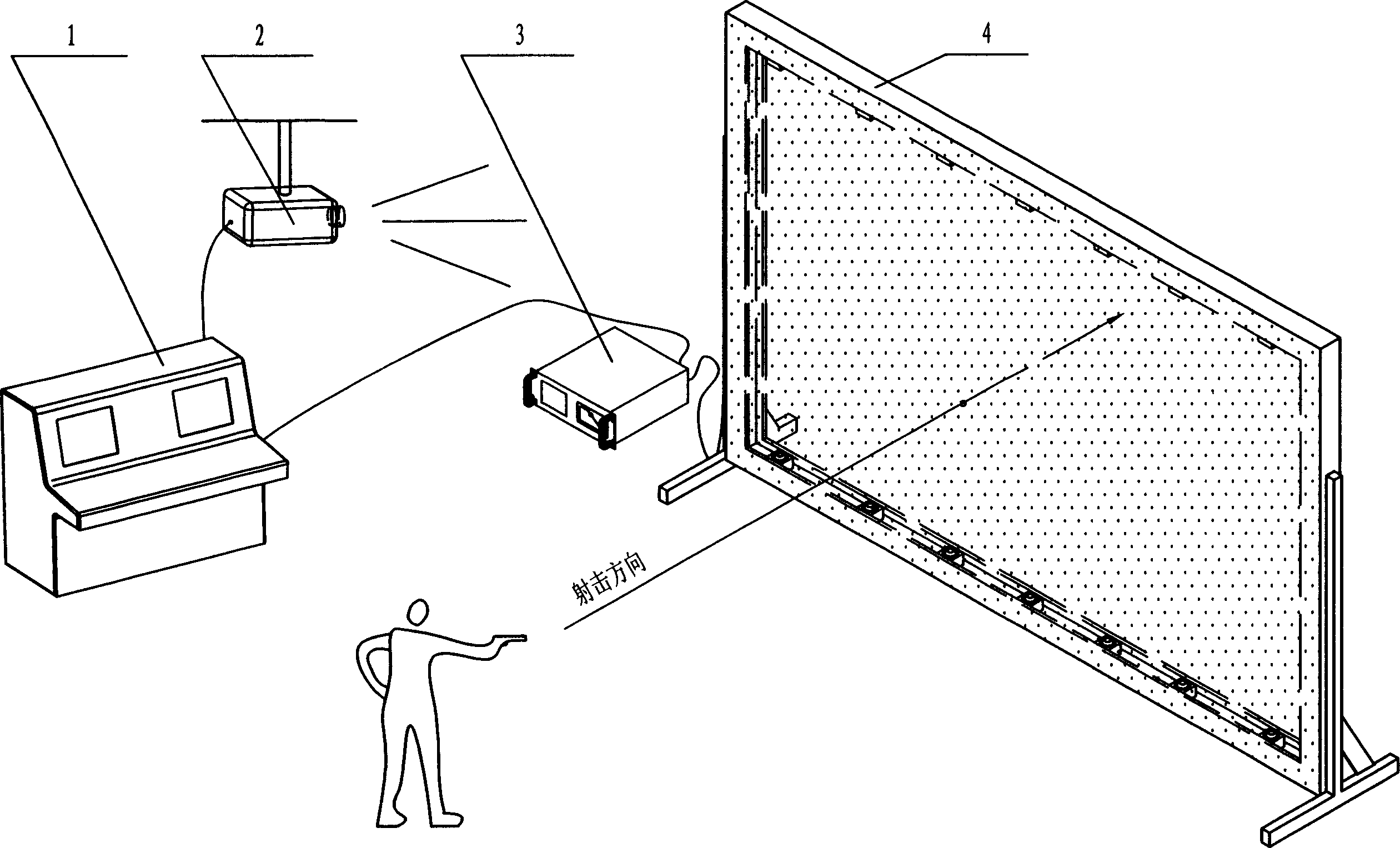

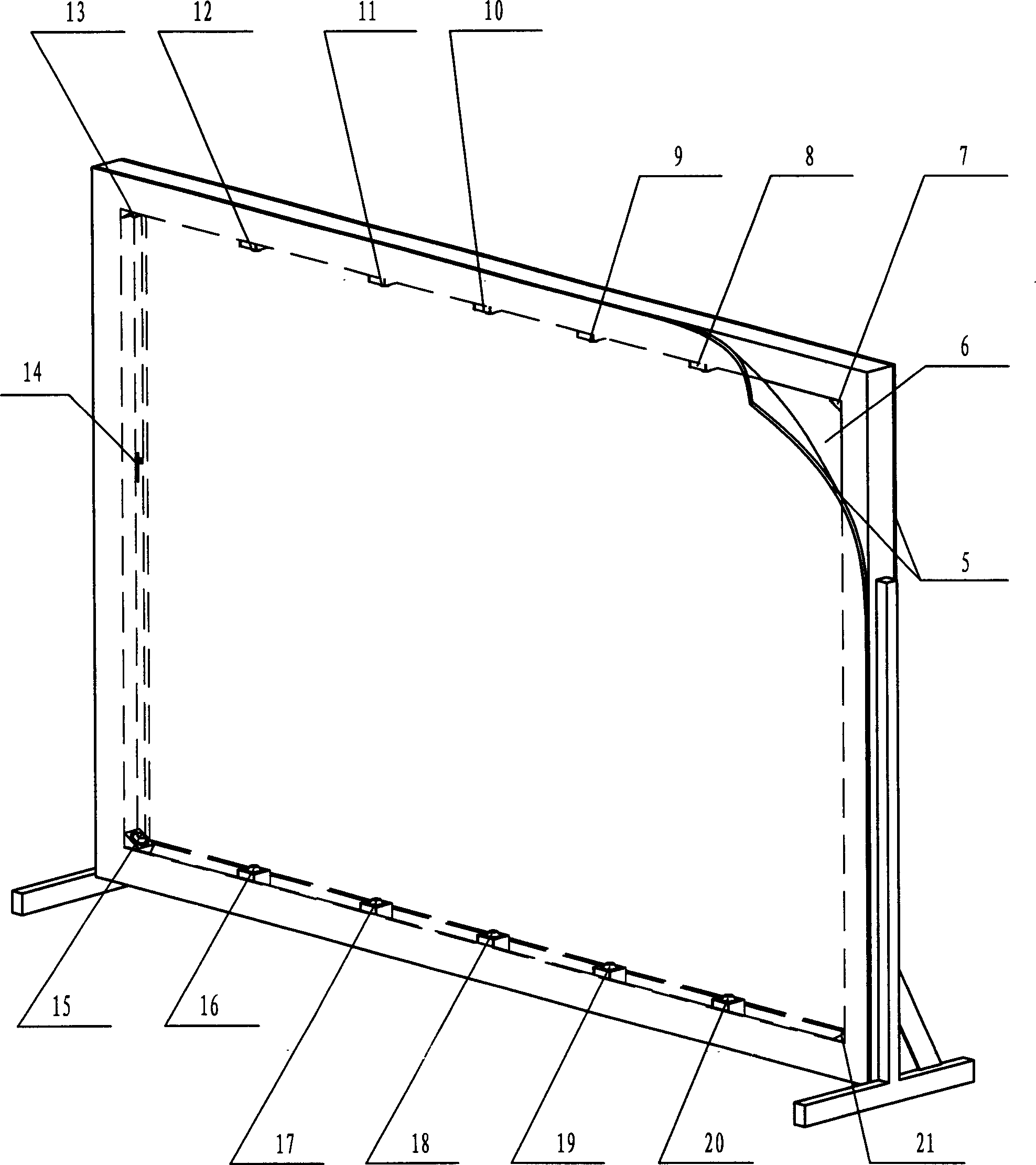

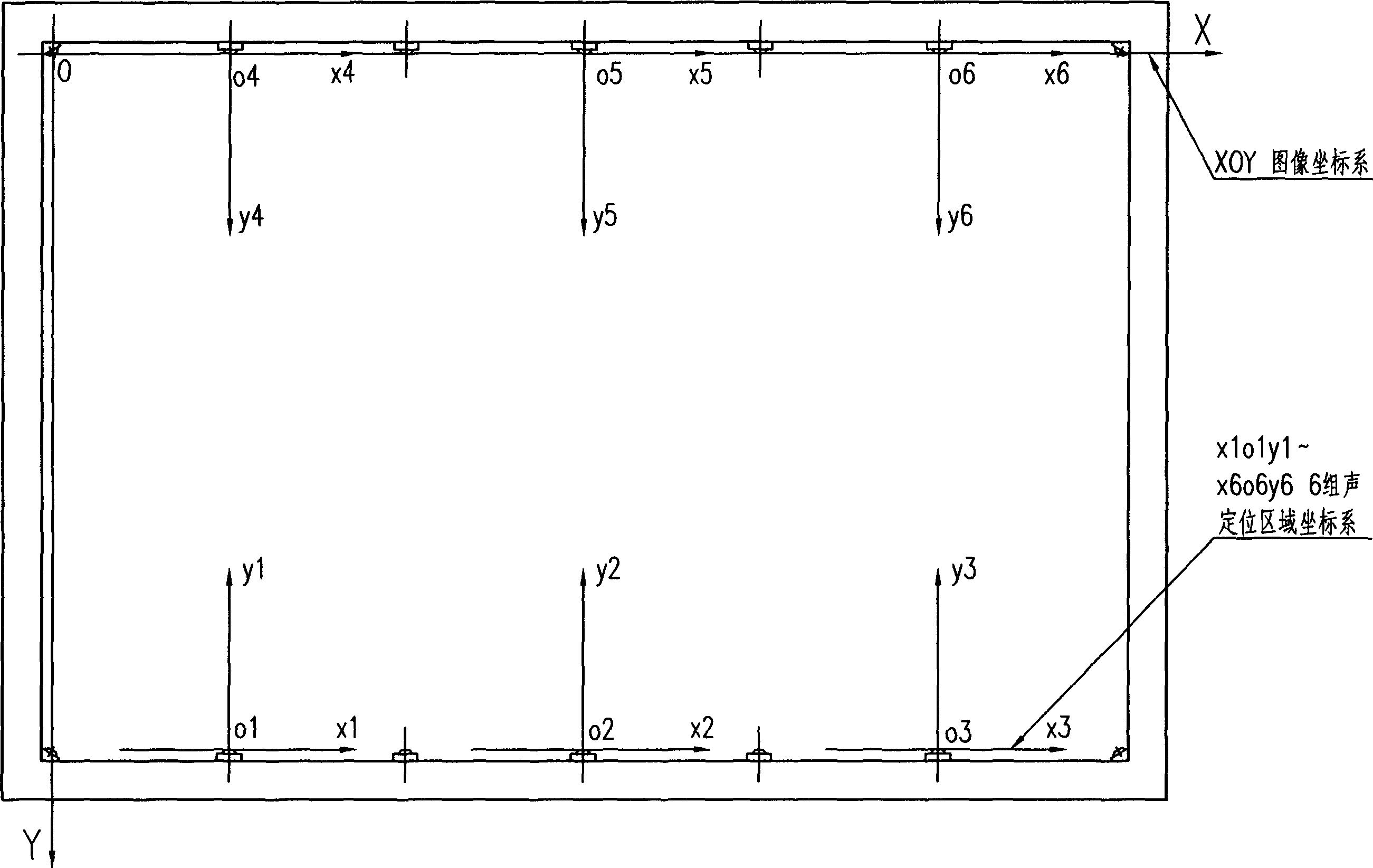

Ultrasonic image shoot training system

ActiveCN1560556AImprove environmental adaptabilityStrong real-time positioningTraining adaptationMovable targetsSensor arraySonification

The invention is a supersonic image fire training system especially relating to carrying on live firing or simulated firing train on the moving image. The system includes supersonic image big screen, signal gathering processor, allocation resolution industrial control computer, communication circuit, image control and display computer, CCD camera, video image gathering card, projector; the supersonic image screen has a frame, on the two surfaces of the frame there arranges with high purity rubber board, a acoustic cavity is formed in the middle of the frame, some acoustic sensors arrays are arranged on the upper and lower rows of the cavity, a temperature compensation sensor is arranged in the acoustic cavity, the acoustic sensor and temperature compensation sensor are connected to the signal gathering processor; the processor includes a signal amplifying and filtering circuit, region judging circuit, counting circuit, microchip MCU, temperature gathering compensation circuit, allocation resolution industrial control computer, and power switcher.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA +1

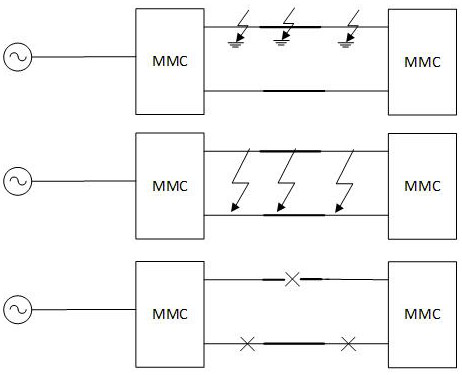

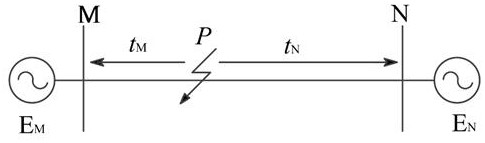

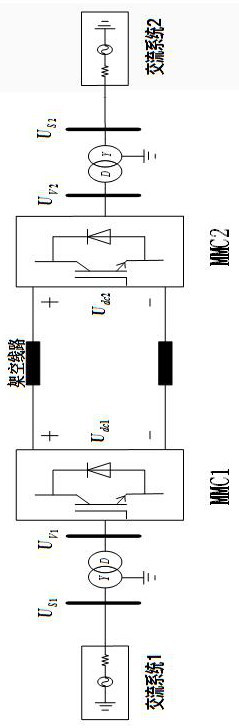

MMC-HVDC direct current transmission line fault positioning method

PendingCN111948493APrecise positioningAccurate positioning accuracyFault location by conductor typesInformation technology support systemBipolar voltageSymmetrical components

The invention discloses an MMC-HVDC direct-current transmission line fault positioning method, which comprises the steps of decoupling bipolar voltage through a symmetric component transformation matrix to obtain a line mode component and a zero mode component of the bipolar voltage; carrying out VMD decomposition on the line mode component and the zero mode component, and carrying out parameter alternate optimization on the modal number k and the penalty factor in the decomposition process, so as to enable the values of the modal number k and the penalty factor to be more reasonable; performing analyzing by utilizing S transformation, positioning a fault mutation point, and accurately detecting the time when the wave head of the traveling wave arrives at two sides; and achieving accuratepositioning of the fault of the high-voltage direct-current transmission line by using a fault distance measurement algorithm for eliminating the wave velocity influence. According to the method, thenumber K of modes and the penalty factor are optimized through an alternate parameter optimization method, on the basis, the VMD is used for decomposing the traveling wave signal and extracting the intrinsic mode component of the traveling wave signal, then S transformation is used for accurately positioning a fault mutation point, and finally accurate fault positioning is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

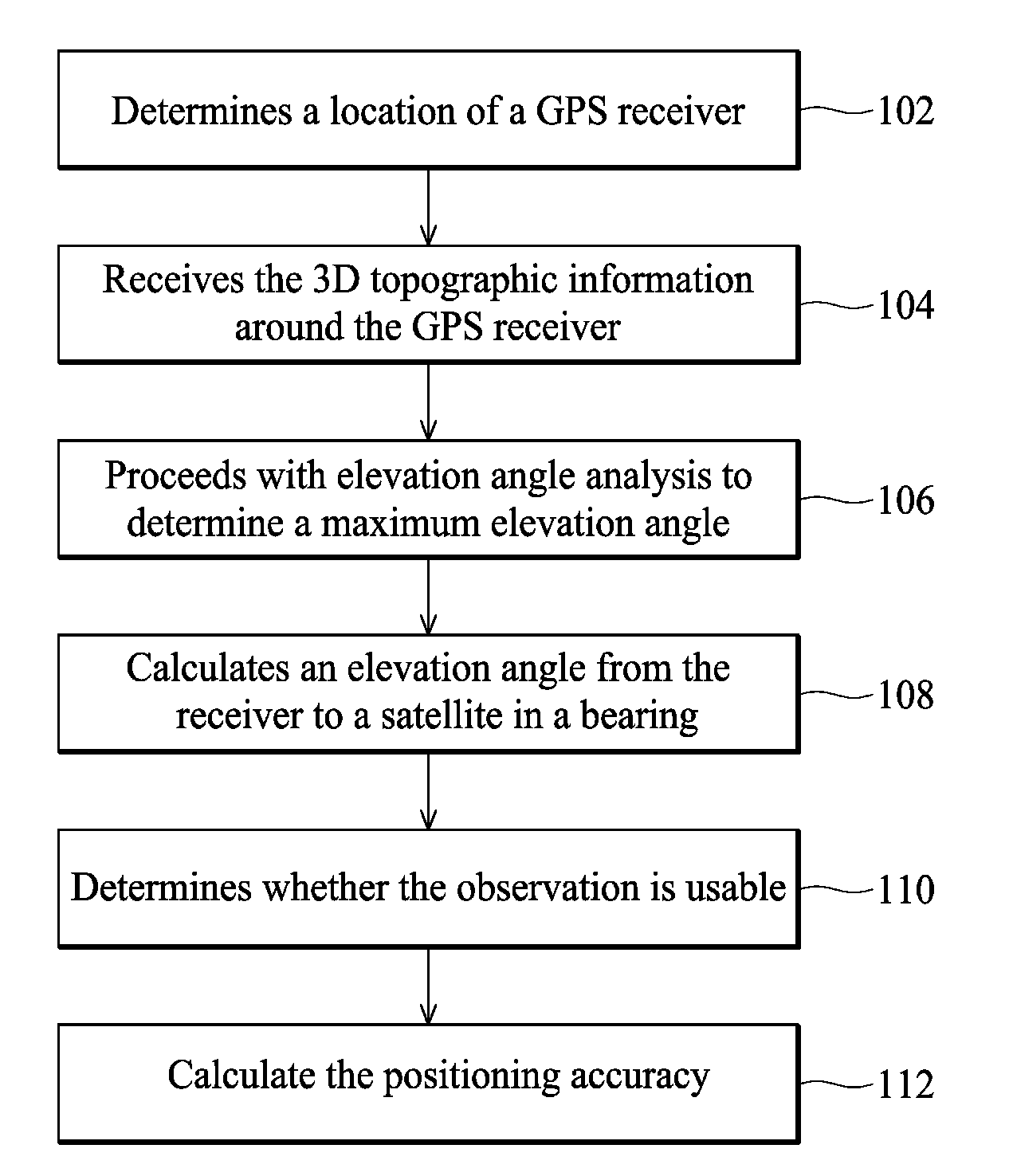

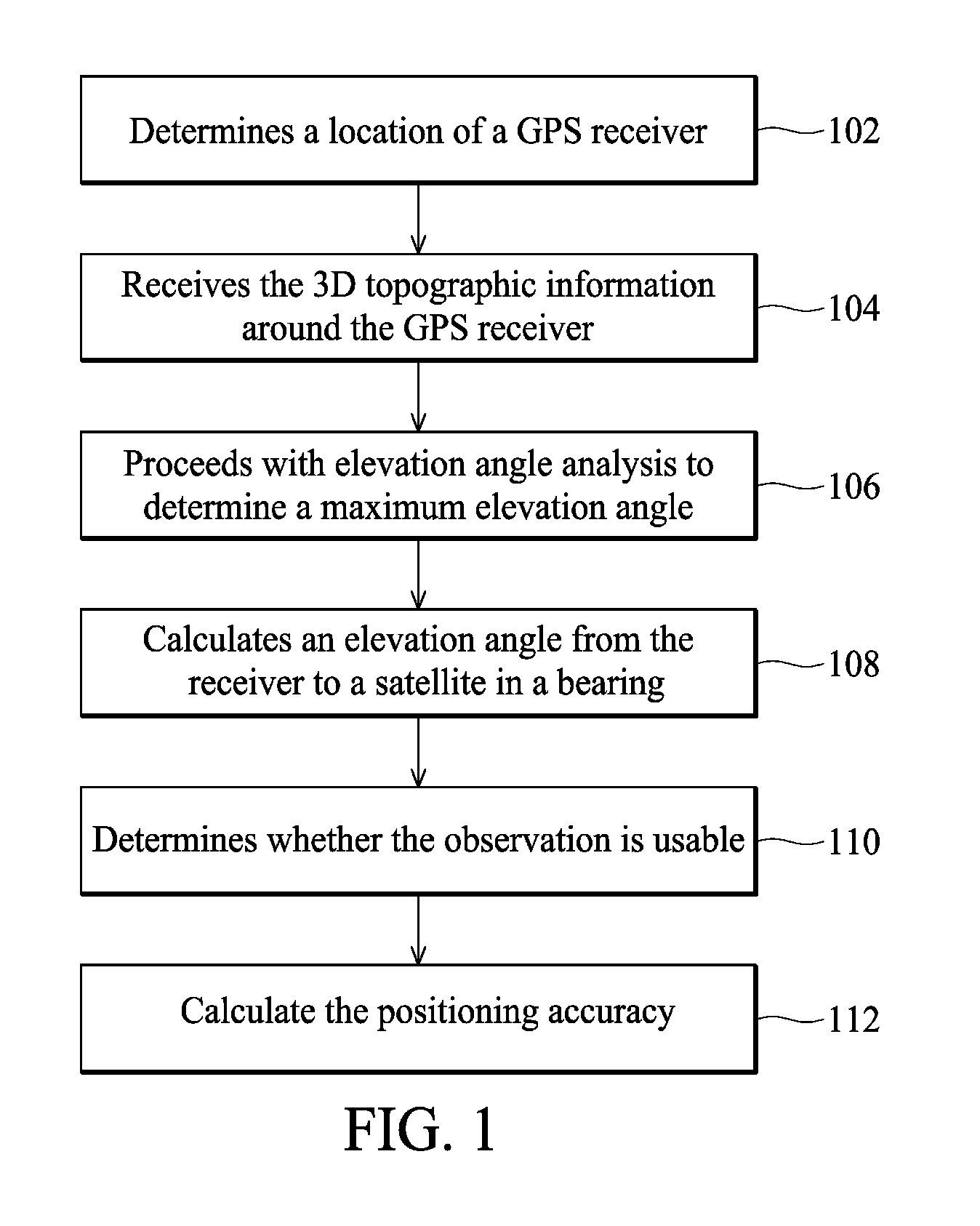

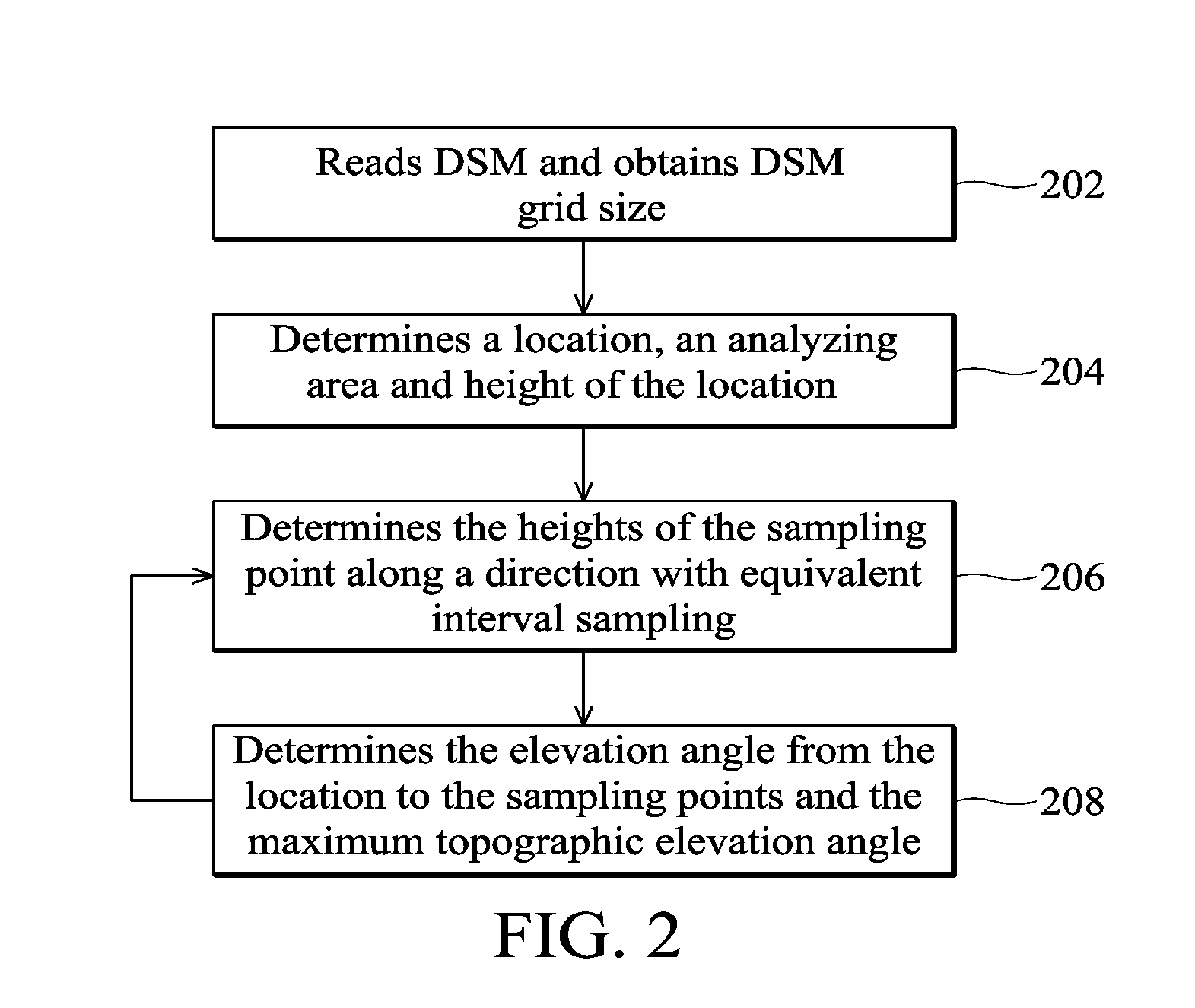

Method for implementing GPS surveying field work planning using 3D topographic informaiton and method for analyzing 3D topographic information

InactiveUS20100201568A1Improve planning efficiencyAccurate positioning accuracyBeacon systemsSatellite radio beaconingTerrainElevation angle

A method for implementing GPS surveying field work planning by using three dimensional topographic information is provided, comprising the steps of: obtaining three dimensional topographic information according to the location of a GPS receiver; obtaining maximum topographic elevation angle information from the GPS receiver to the terrain for each azimuth using the three dimension topographic information; obtaining elevation angle of satellites from the GPS receiver according to the satellite ephemeris or almanac; determining whether observation is usable according to the maximum topographic elevation angle information along the satellite bearings, and the elevation angle of satellites; and estimating the positioning accuracy according to the usable satellite observations.

Owner:NAT TAIWAN UNIV

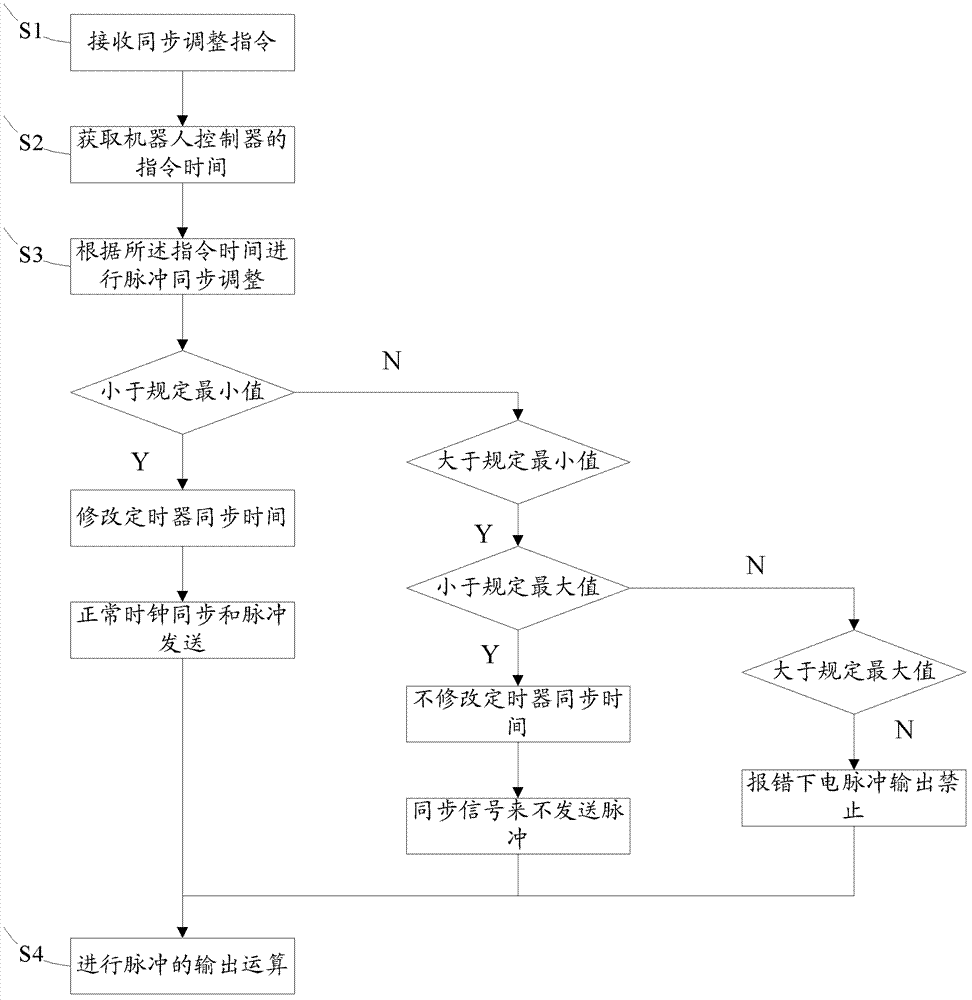

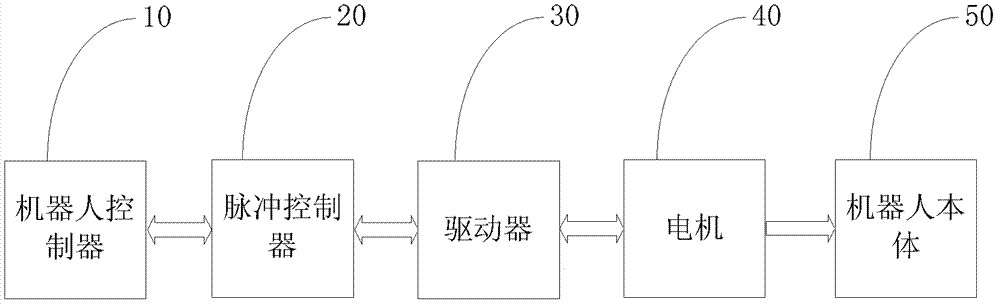

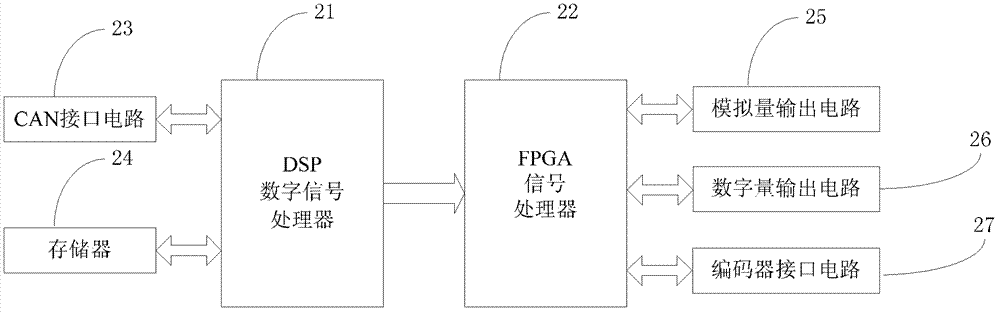

Method and device for robot controller pulse synchronous adjustment

ActiveCN103197577AGuaranteed uptimeAccurate positioning accuracyProgramme controlComputer controlSimulationElectric machinery

Provided are a method and a device for robot controller pulse synchronous adjustment. The method includes the steps of receiving a command for carrying out synchronous adjustment sent by a robot controller; acquiring command time of the robot controller; carrying out pulse synchronous adjustment according to a contrastive result between the command time and a periodic quantity of the robot controller; and carrying out pulse output calculation according to the result of the synchronous adjustment. The invention further provides a device for robot controller pulse synchronous adjustment. The fact that motion of a robot body is controlled through a motor according to a scheduled target is achieved. Through the embodiment of the method and the device, the motor controls the motion of the robot body according to the scheduled target, the motor stably operates on actual operation of spot welding robots and arc welding robots, and positioning of the robots is accurate.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

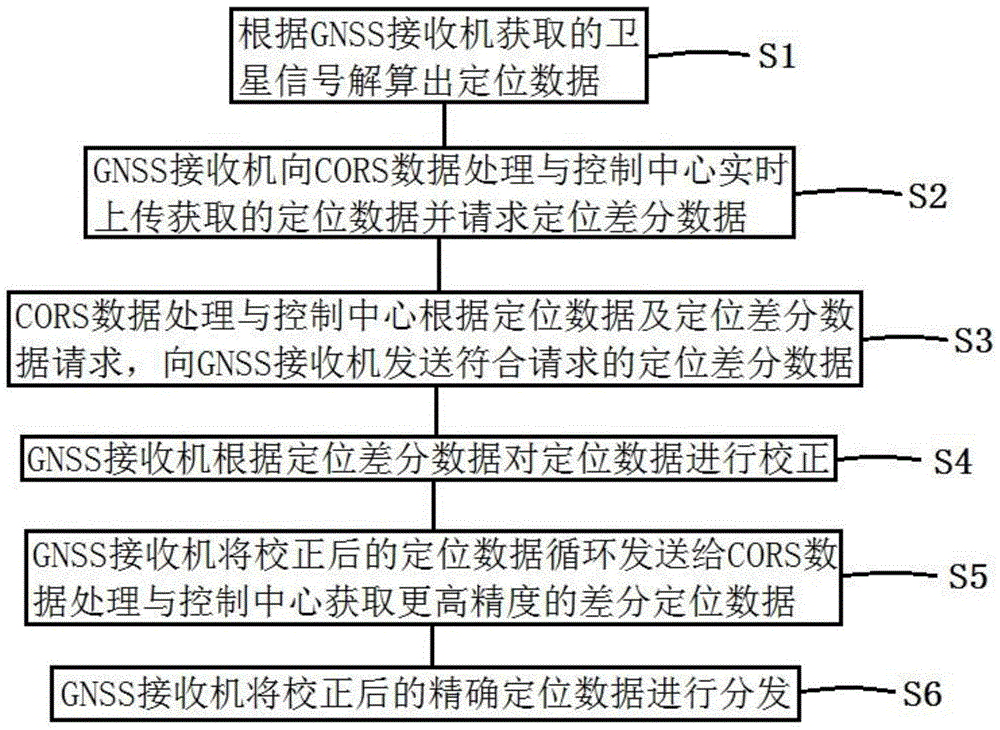

Method and system for improving positioning accuracy of navigation satellite

InactiveCN105738930AHigh positioning accuracyEliminate common error termsSatellite radio beaconingCommon errorSatellite

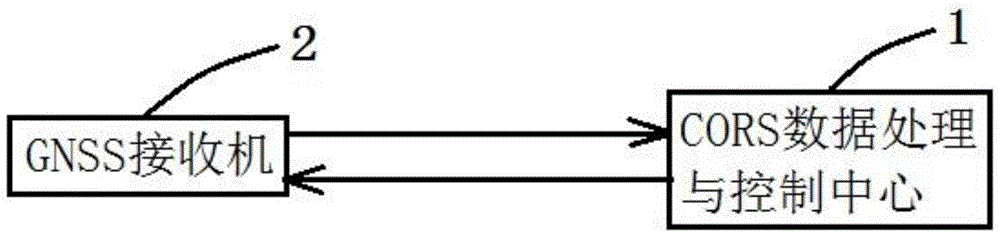

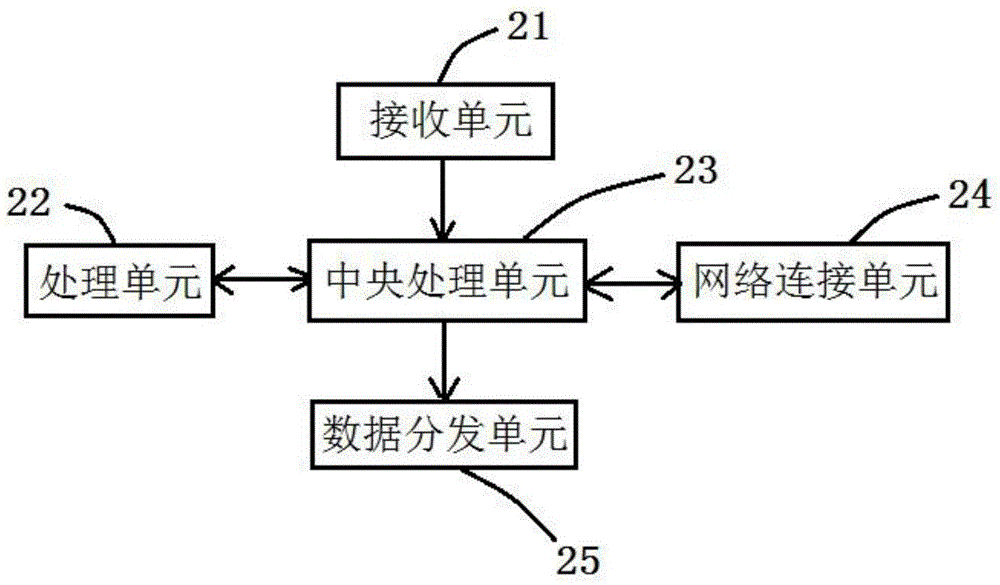

The invention discloses a method and system for improving the positioning accuracy of a navigation satellite. The method for improving the positioning accuracy of the navigation satellite includes the following steps that: positioning data are calculated according to satellite signals obtained by a GNSS receiver; the GNSS receiver uploads the obtained positioning data to a CORS data processing and controller center in real time and requests positioning differential data; the CORS data processing and control center sends requested positioning differential data to the GNSS receiver according to the positioning data and the positioning differential data request; the GNSS receiver corrects the positioning data according to the positioning differential data; the GNSS receiver sends the corrected positioning data circularly to the CORS data processing and control center so as to obtain higher-precision positioning differential data; and the GNSS receiver distributes corrected and precise positioning data. The method and system for improving the positioning accuracy of the navigation satellite can correct and eliminate common error terms in real time and effectively reduce the influence of correlated errors, so as to obtain more accurate positioning results and improve positioning accuracy.

Owner:SHANGHAI HUACE NAVIGATION TECH

Rectify deviation control system and method based on GPS data track

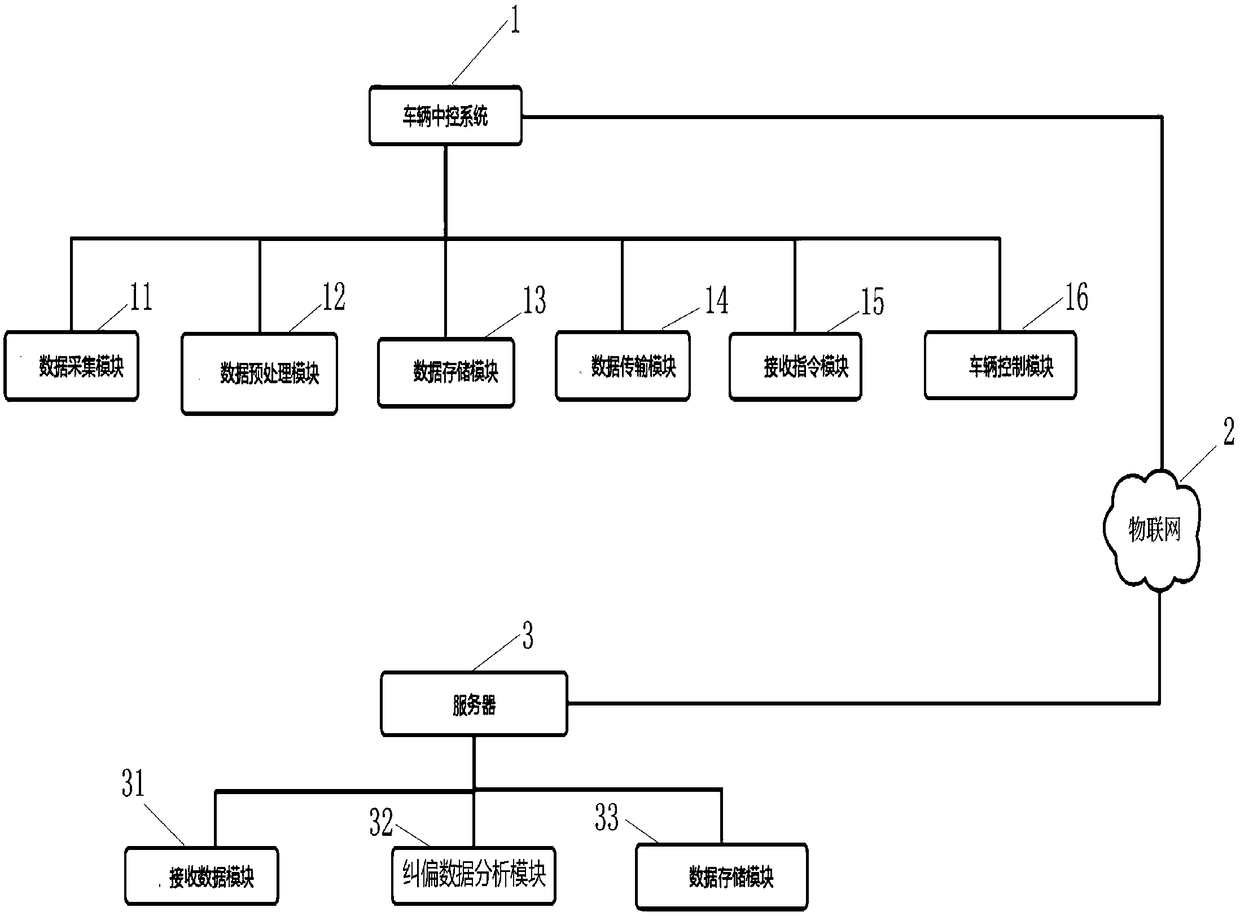

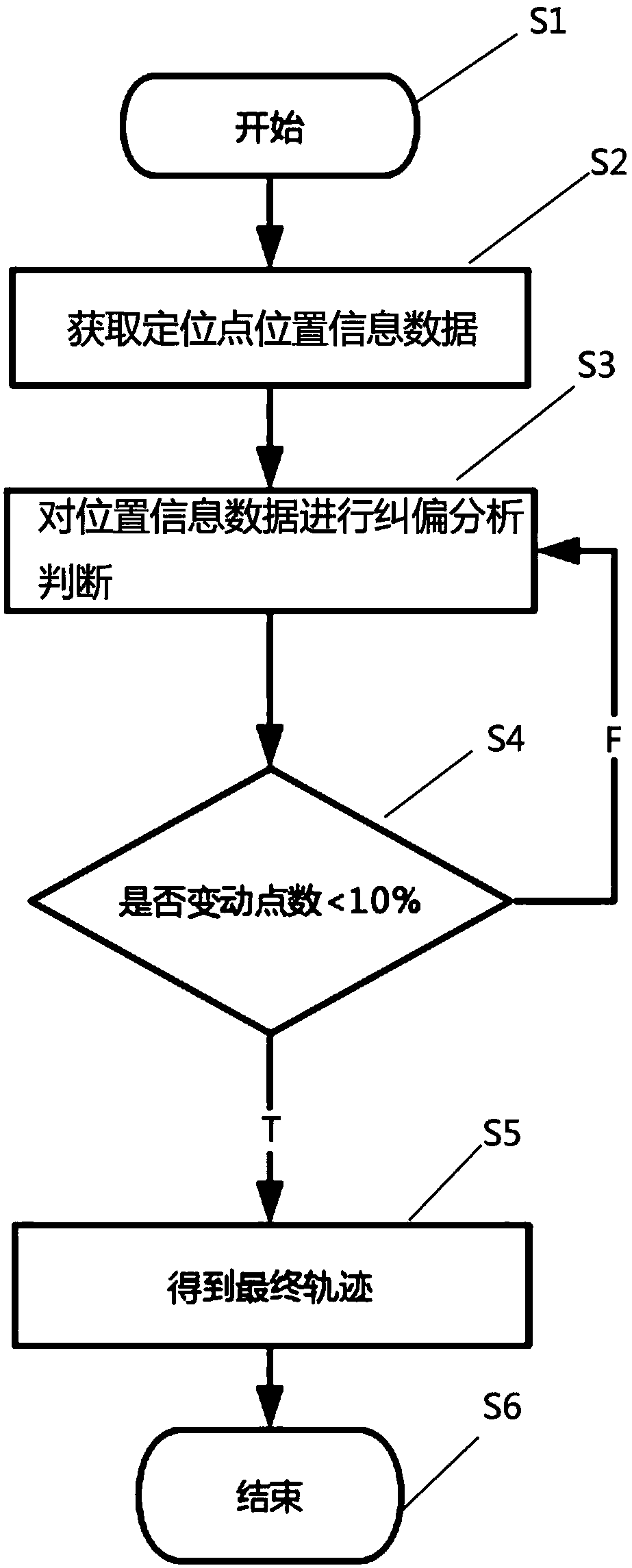

PendingCN109212565AVehicle positioning data error is smallAccurate positioning accuracySatellite radio beaconingTotal factory controlGps dataData acquisition module

The invention discloses a rectify deviation control system and method based on a GPS data track. The system comprises a vehicle central control system and a server. The vehicle central control systemcomprises a data acquisition module and a vehicle control module. The server comprises a data receiving module and a rectify deviation data analyzing module. The vehicle central control system transmits the collected vehicle information and vehicle control information to the server through the Internet of Things, and the server analyzes and processes the received information to control the vehicleoperation. The method comprises the following steps of: 1. obtaining positioning information of a positioning point; 2. performing analysis and judgment on the data rectify deviation of the GPS position information track; 3. judging whether the change number of the pointing track data of the GPS position is less than 10%; and 4. obtaining the final track of the GPS data according to the analysisof the rectify deviation data analyzing module. The invention provides the rectify deviation control system and method based on the GPS data track, which is small in positioning error range, accuratein positioning, low in positioning cost and high in efficiency.

Owner:武汉小象创意科技有限公司

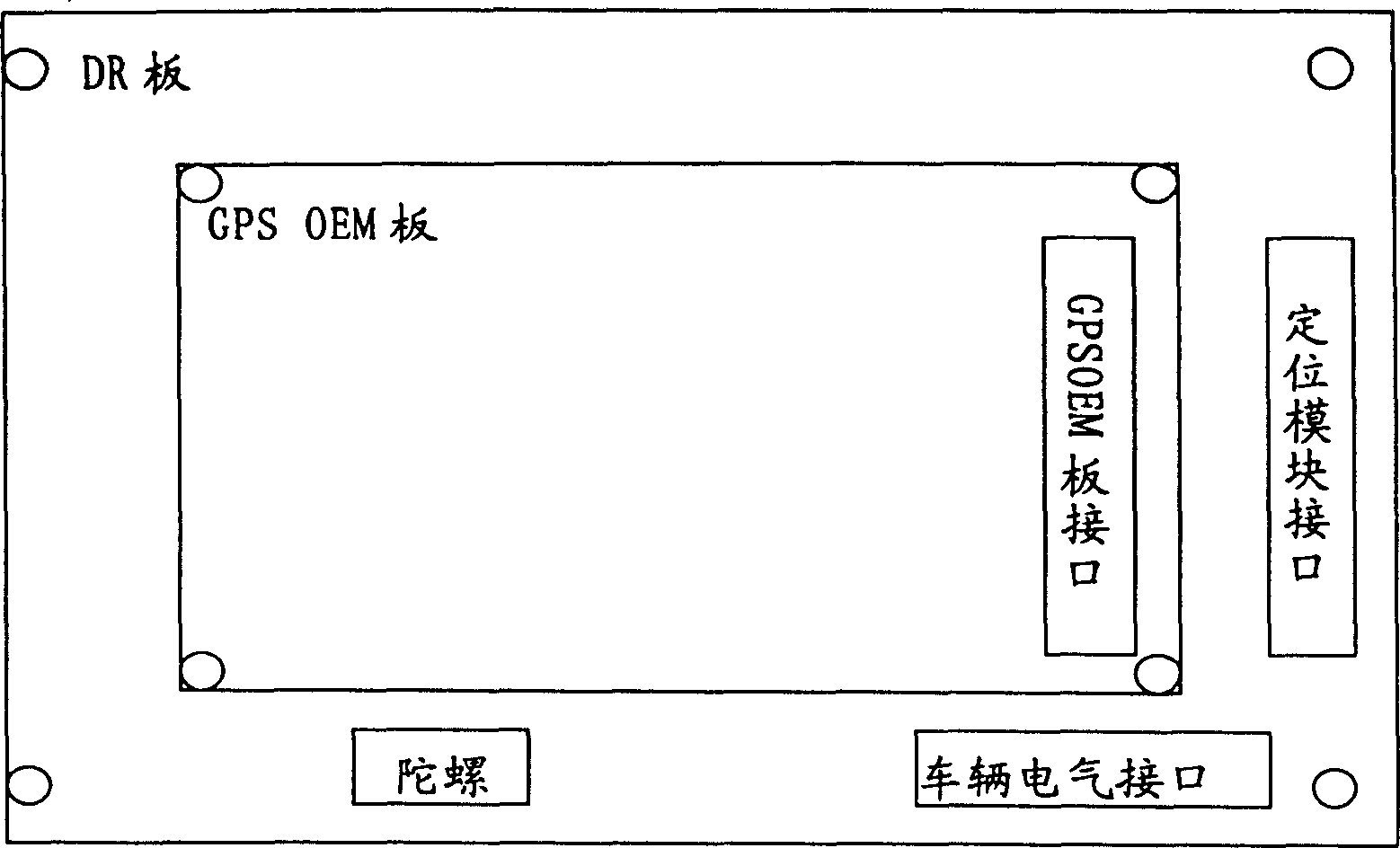

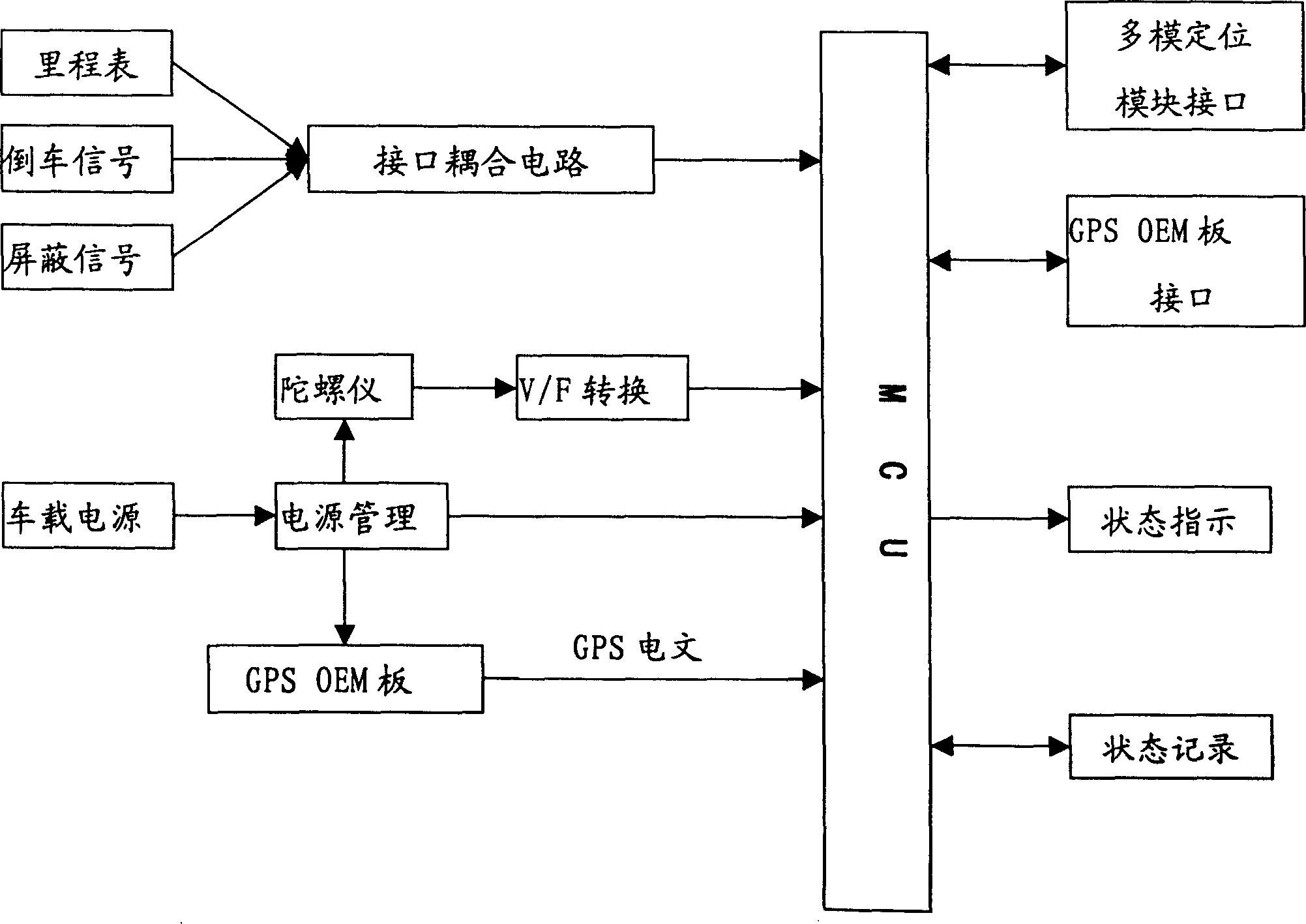

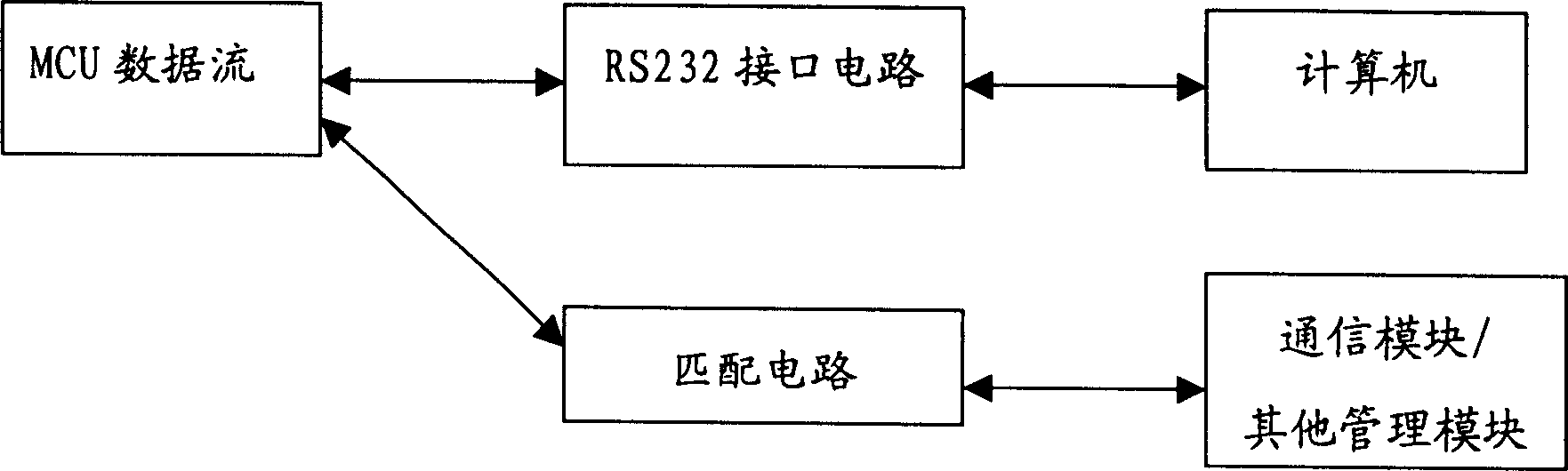

Multi-mode positioning module based on satellite positioning

InactiveCN1755390AContinuous and accurate positioningEffectively determine the movementInstruments for road network navigationNavigation by speed/acceleration measurementsCommunication interfaceComputer module

The invention discloses a multi-module position module based on the satellite position, which comprises a GPS OEM board with up-and -down structure and a DR circuit plate, wherein the two parts are connected with each other by the interface; the multi-module position module also possesses a position beacon interface, a matching electric map interface, an angle speed measuring unit, a car mileage and reverse signal matching receiving circuit, a MCU CPU, a computer communication interface and a power managing module.

Owner:BEIJING SPACE DINGYI SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com