External cylindrical superfinishing machine

A technology of ultra-finishing machines and racks, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of damaging shaft parts, affecting processing accuracy, and scrapping shaft parts. The effect of high processing precision and small impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

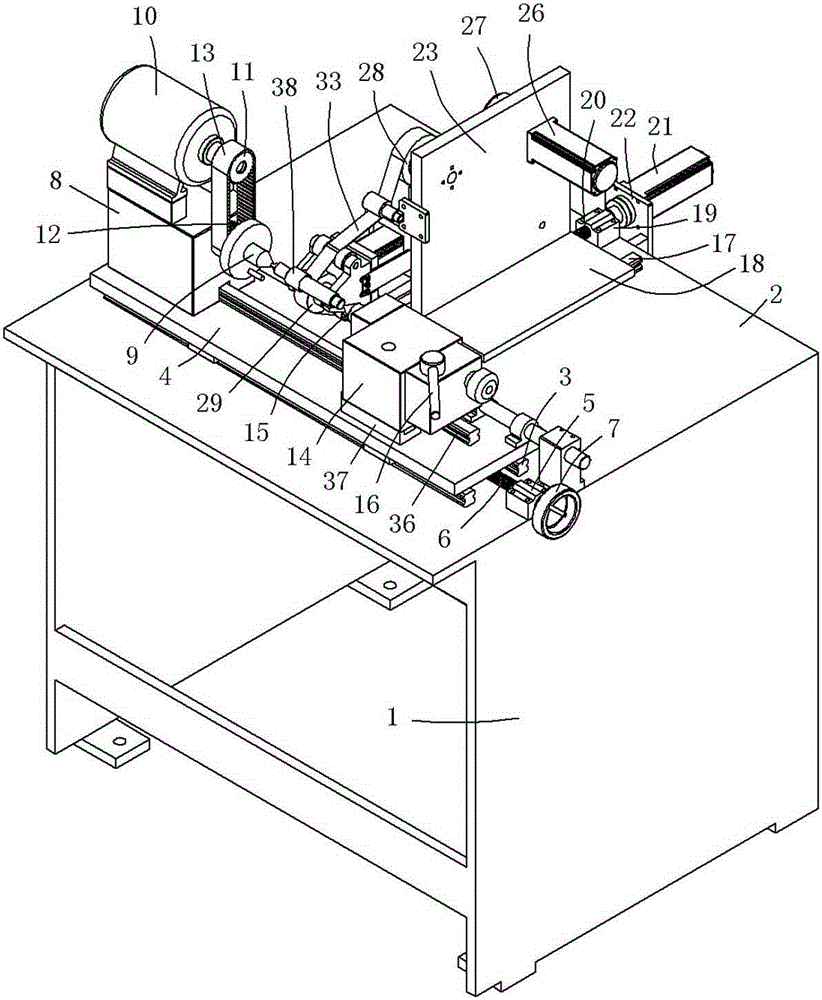

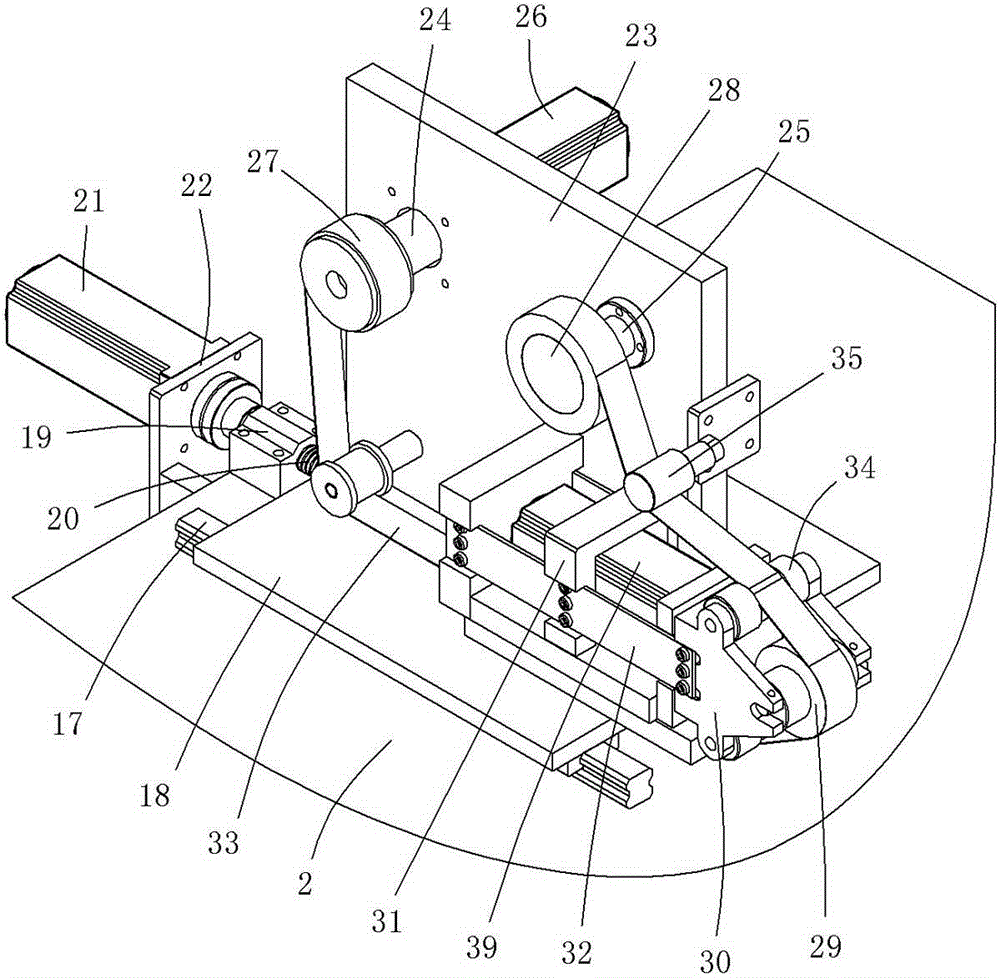

[0033] refer to figure 1 , figure 2 , a kind of outer circle superfinishing machine, comprise frame 1, be located at the workbench 2 on this frame, described workbench is horizontally provided with transverse guide rail 3, and this transverse guide rail is provided with transverse sliding table 4, and this The transverse sliding platform is driven by the transverse movement driving mechanism so as to move laterally along the transverse guide rail. The horizontally moving nut seat on the bottom surface of the bottom surface, the horizontal lead screw 6 that passes through the horizontally fixed nut seat and the laterally movable nut seat, and the end that is located on the horizontal lead screw and drives the horizontal lead screw to rotate hand wheel 7;

[0034] A head frame 8 is provided on one side of the horizontal slide table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com