Lid for functional part and process for producing the same

A manufacturing method and component technology, applied in manufacturing tools, semiconductor/solid-state device parts, electrical components, etc., can solve problems such as problems with brazing, poor brazing, and inability to join, and achieve simple manufacturing, improved bonding strength, The effect of ensuring wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

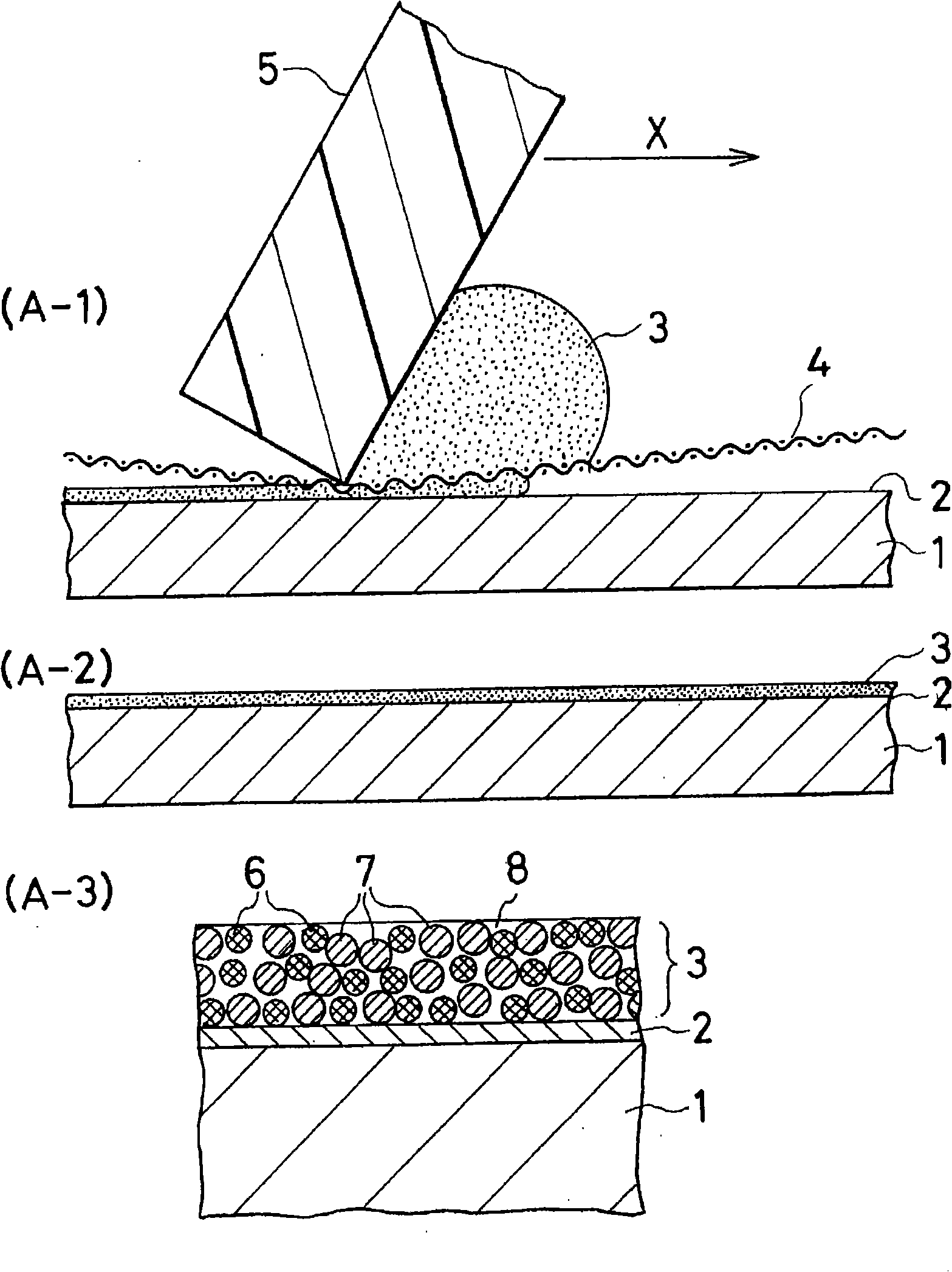

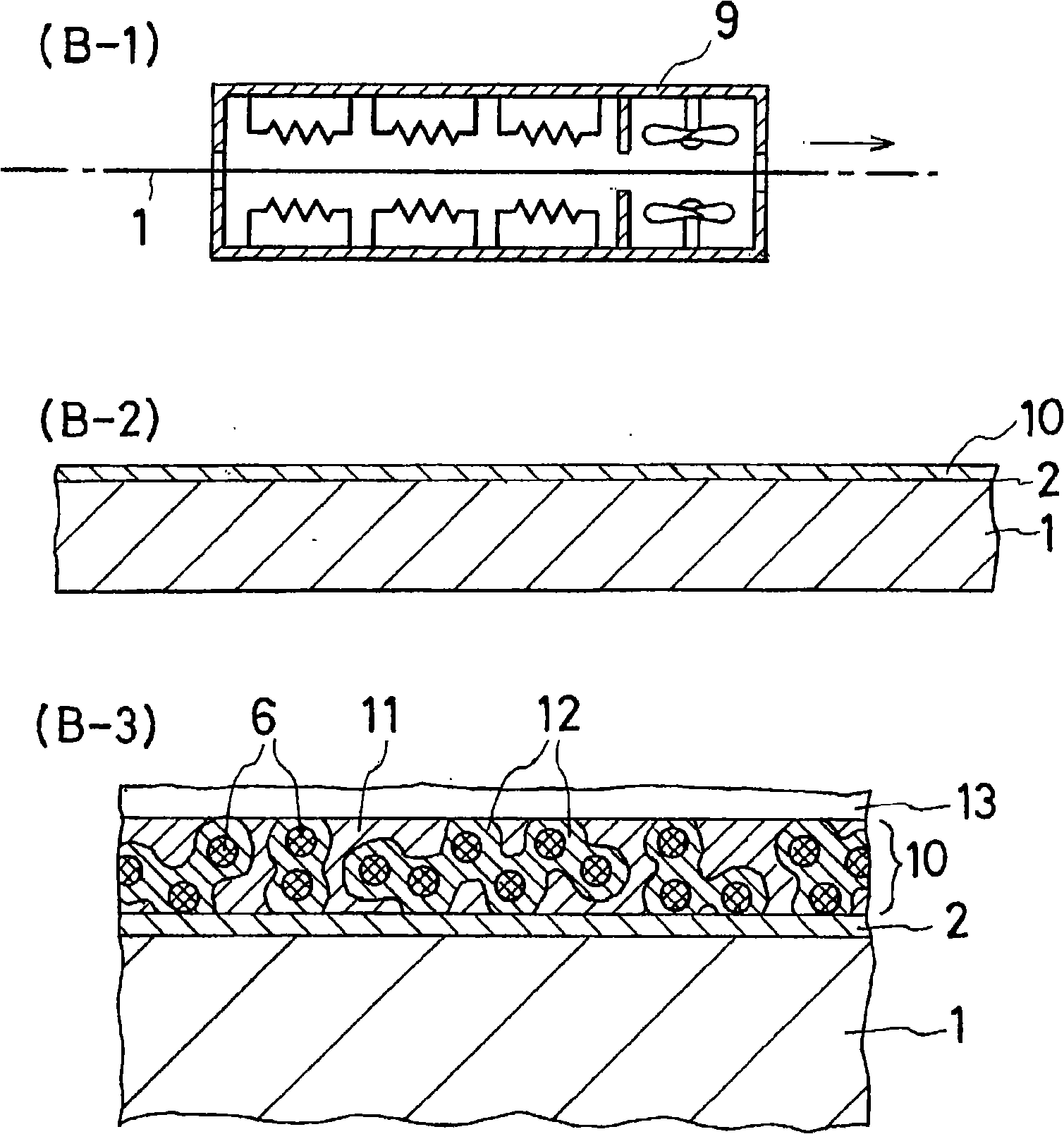

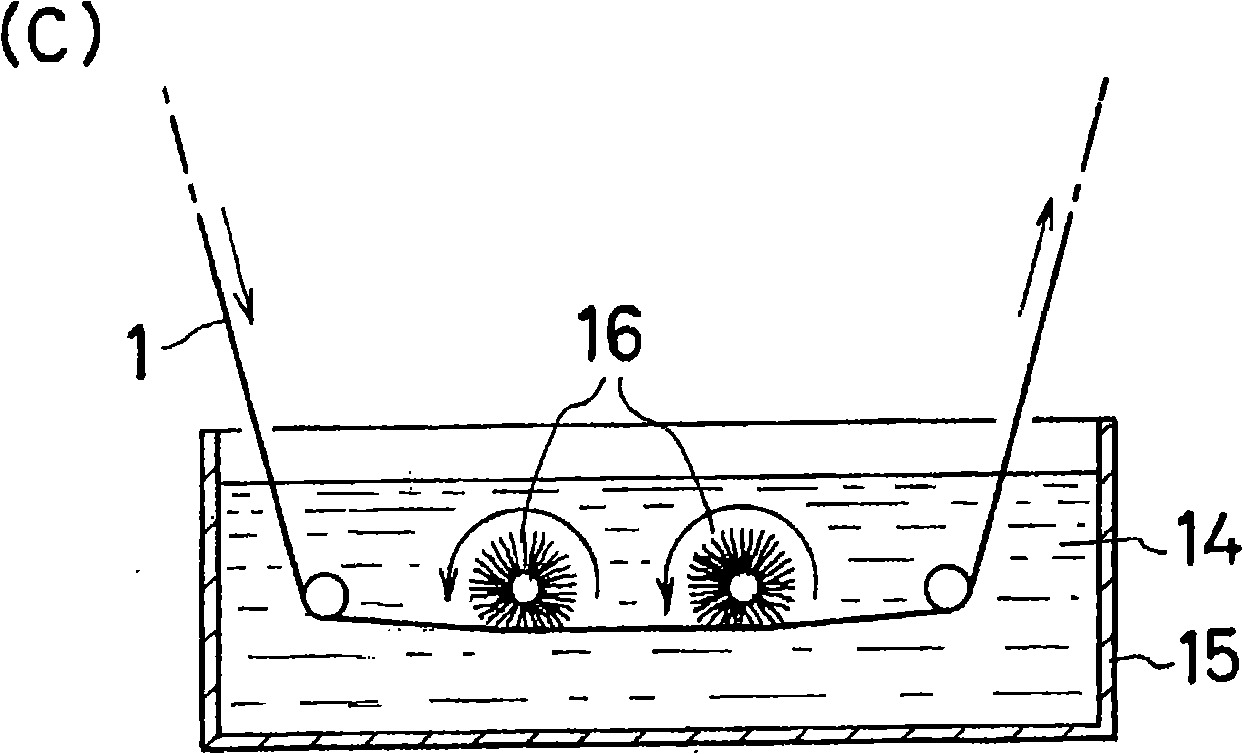

[0063] The manufacturing method of the cap of the present invention is carried out in the method shown in the drawings.

[0064] Figure 1~4 Each process in the manufacturing method of the cap of this invention is demonstrated.

[0065] An example of the lid material sheet used in the manufacturing method of the lid of this example, the plating of the lid, and the solder paste is as follows.

[0066] Cover material plate: Kovar alloy (thickness 0.1mm, width 40mm long shape)

[0067] Plating of the cover material plate: Ni substrate (thickness 0.1 μm), Sn plating (thickness 3 μm), implemented by electroless plating.

[0068] solder paste

[0069] Pure Cu powder (Cu-based metal powder): 27% by mass (average particle size 7 μm)

[0070] Pure Sn powder (lead-free solder powder): 63% by mass (average particle size 10μm)

[0071] Flux: 10% by mass

[0072] Flux composition

[0073] Resin (polymerized rosin) 56% by mass

[0074] Active agent (diphenyl guanidine) 1% by mass

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com