Adjustable efficient cutting device for stainless steel seamless circular tubes

A technology of seamless round pipe and cutting device, applied in sawing machine device, metal sawing equipment, metal processing equipment and other directions, can solve the problems of operator's hand injury, inability to meet the steel pipe cutting work, etc., to avoid cutting accuracy and positioning Precise, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

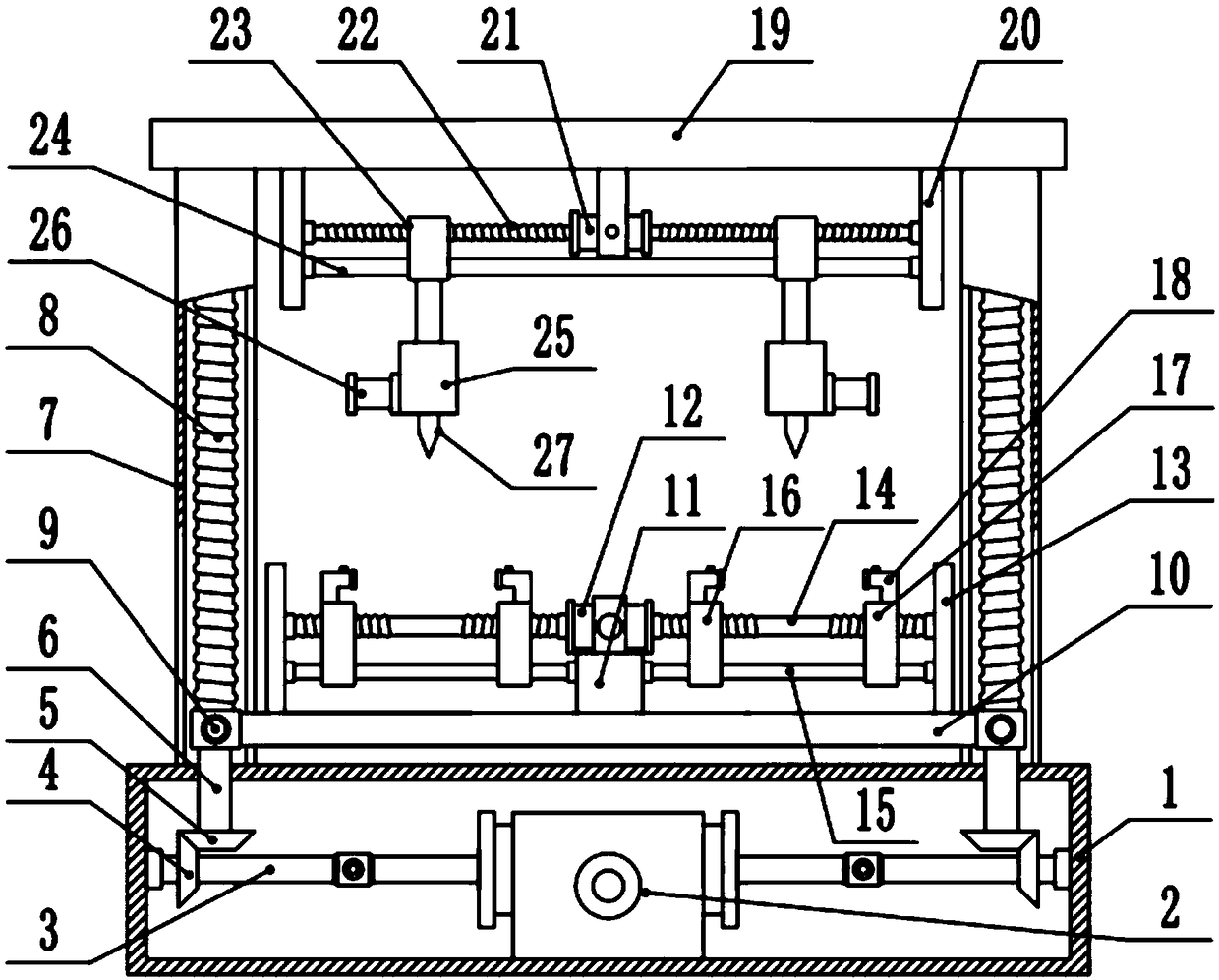

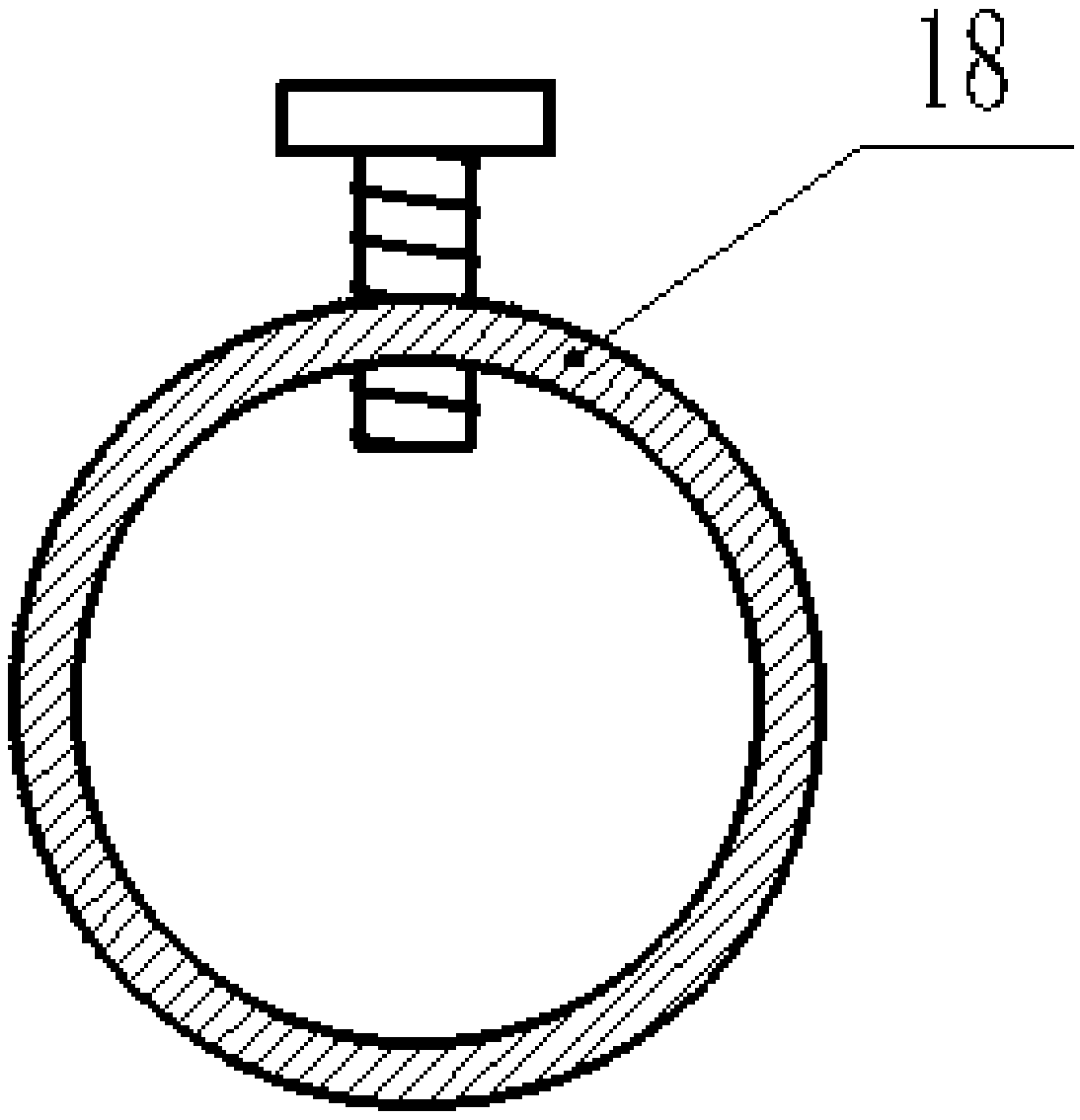

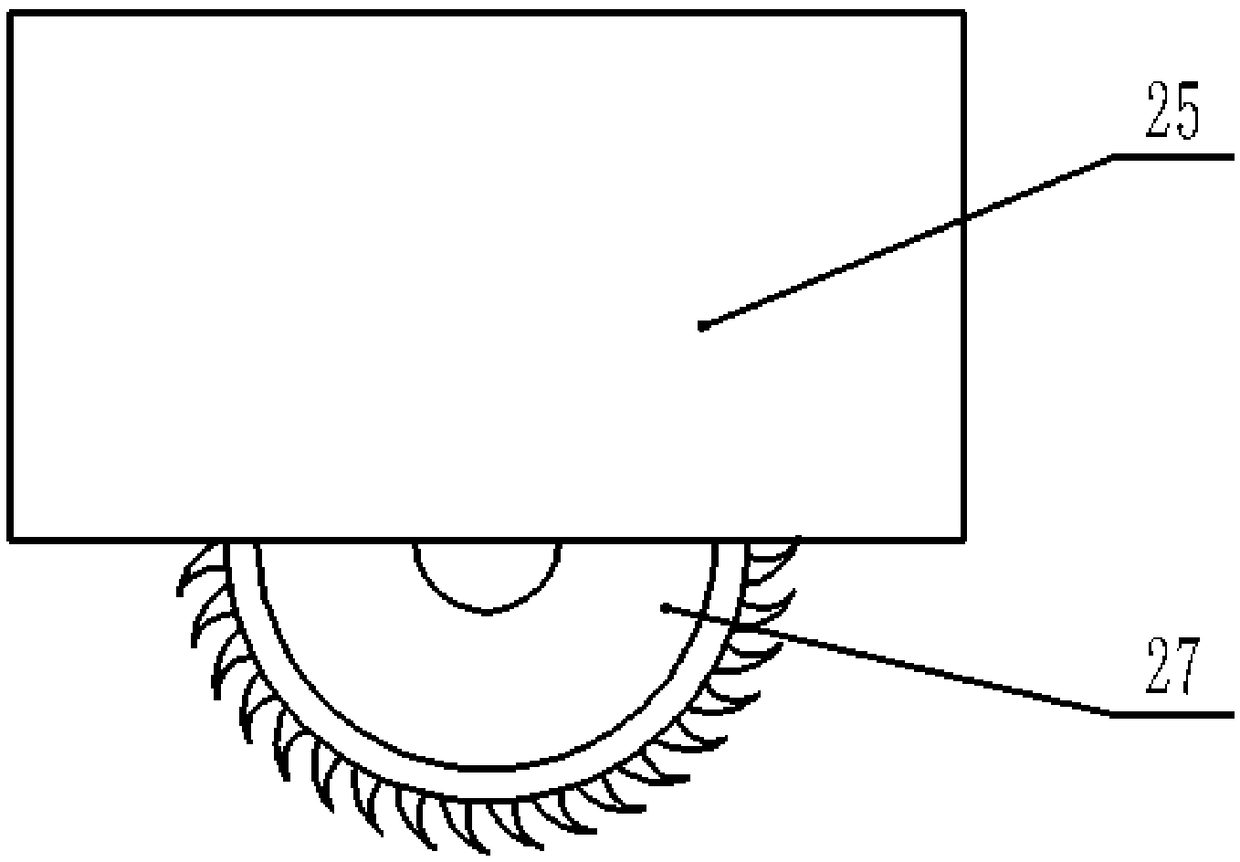

[0023] see Figure 1-3 , an adjustable high-efficiency cutting device for stainless steel seamless round pipes, including a base 1, a slider 9, a lift table 10, a sleeve 18, a second drive motor 21 and a cutting motor 26, the base 1 is a hollow structure inside, the base The inner center of 1 is fixed with a double-axis motor 2 through a bracket. The double-axis motor 2 is a double-axis servo motor and the motor model is YSK120-30-4K. The output shafts at both ends of the double-axis motor 2 are fixedly connected by couplings. There is an extension shaft 3, and the other end of the extension shaft 3 is fixedly installed on the inner walls of both sides of the base 1 through bearings, and an active bevel gear 4 is installed on the extension shaft 3 with an interference fit, and the upper side of the active bevel gear 4 is meshed with a driven gear. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com