Patents

Literature

54results about How to "Avoid affecting cutting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for improving strip tracking accuracy

ActiveCN102298351AEasy to detectImprove accuracyProgramme control in sequence/logic controllersCommunication interfaceProgrammable logic controller

The invention provides a method for improving band steel tracing precision. In the method, an alsthom programmable logic controller is used for programming and modifying programs related to the PLC (Programmable Logic Controller), detection means and communication interfaces are added, a system and a partition structure are both improved, the system and each component function are developed, datadetection and storage accuracy of export final coils is improved by effective communication and contact between a material tracing system and related systems, and data of steel coils is avoided from being lost; precision of an on-line tracing system is improved, a correction speed for processing a welding seam is doubled; system architecture is optimized, so that processing time is shortened to be 500 ms, an error value of program computation for the welding seam is reduced by five times; quantity and quality of online steel band data are both improved, double-hole detection alarming and realtime display are both implemented, unqualified coils are automatically judged, spoilage and defective work losses can be reduced, and yield of products is improved.

Owner:ANGANG STEEL CO LTD

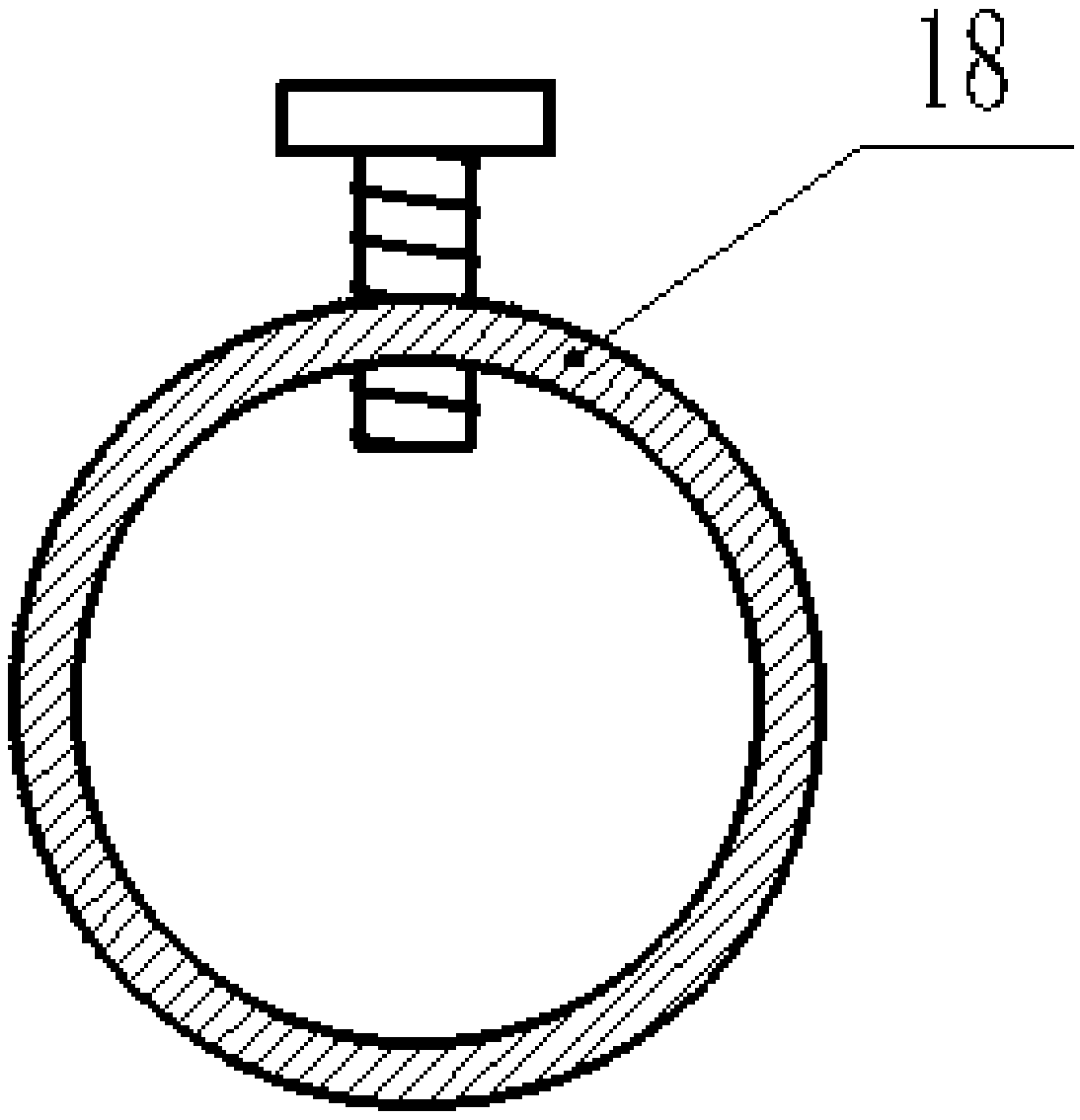

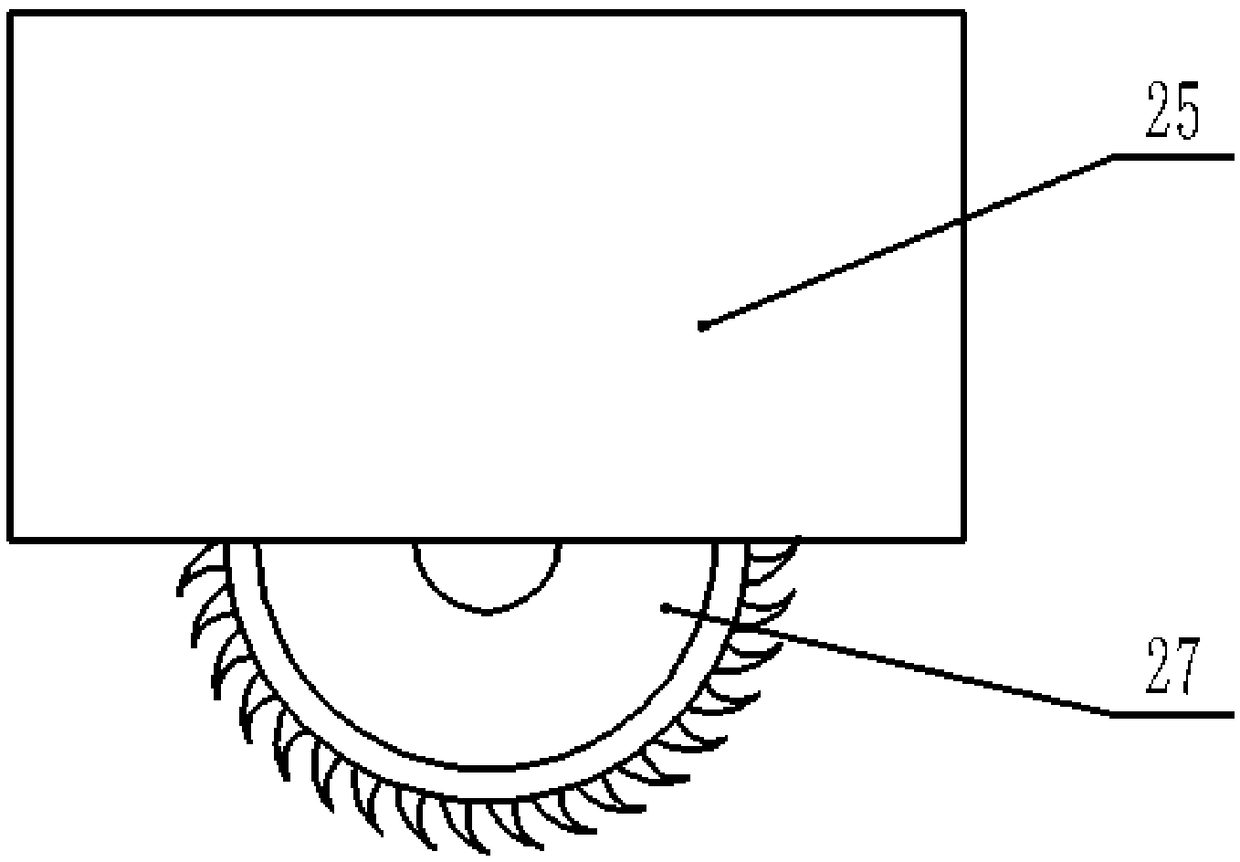

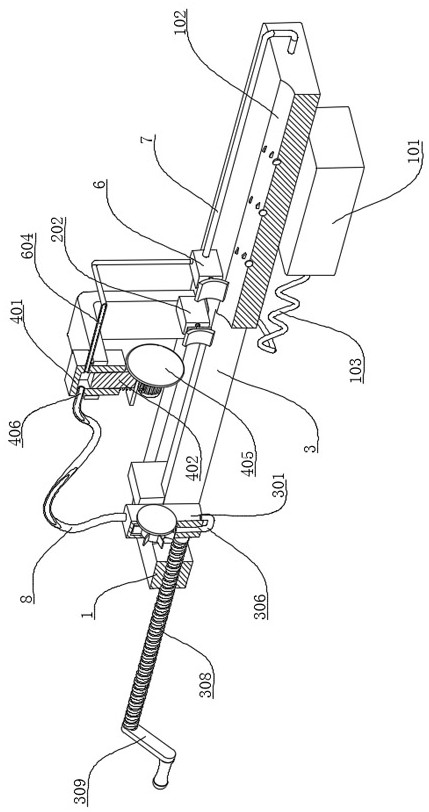

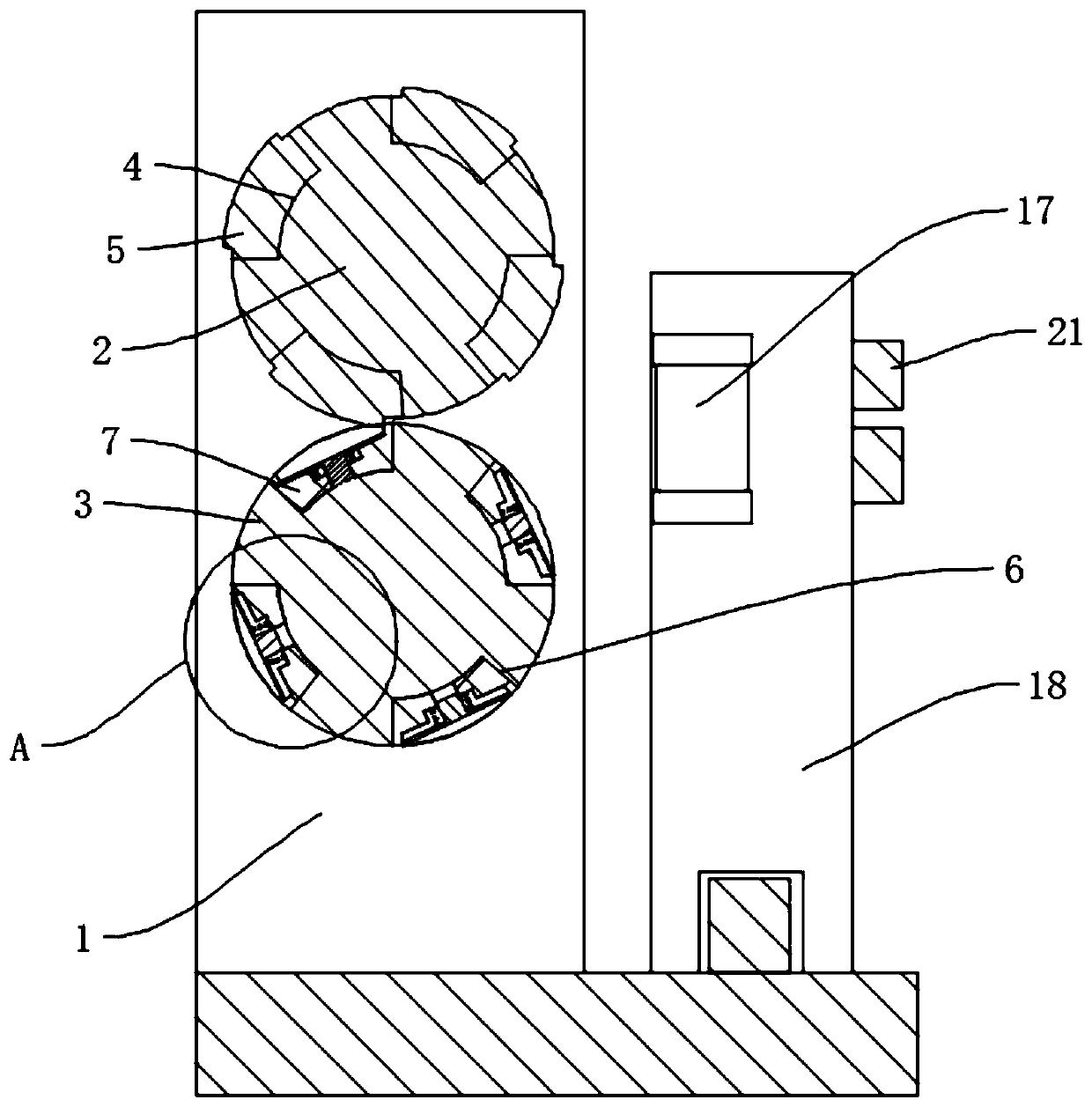

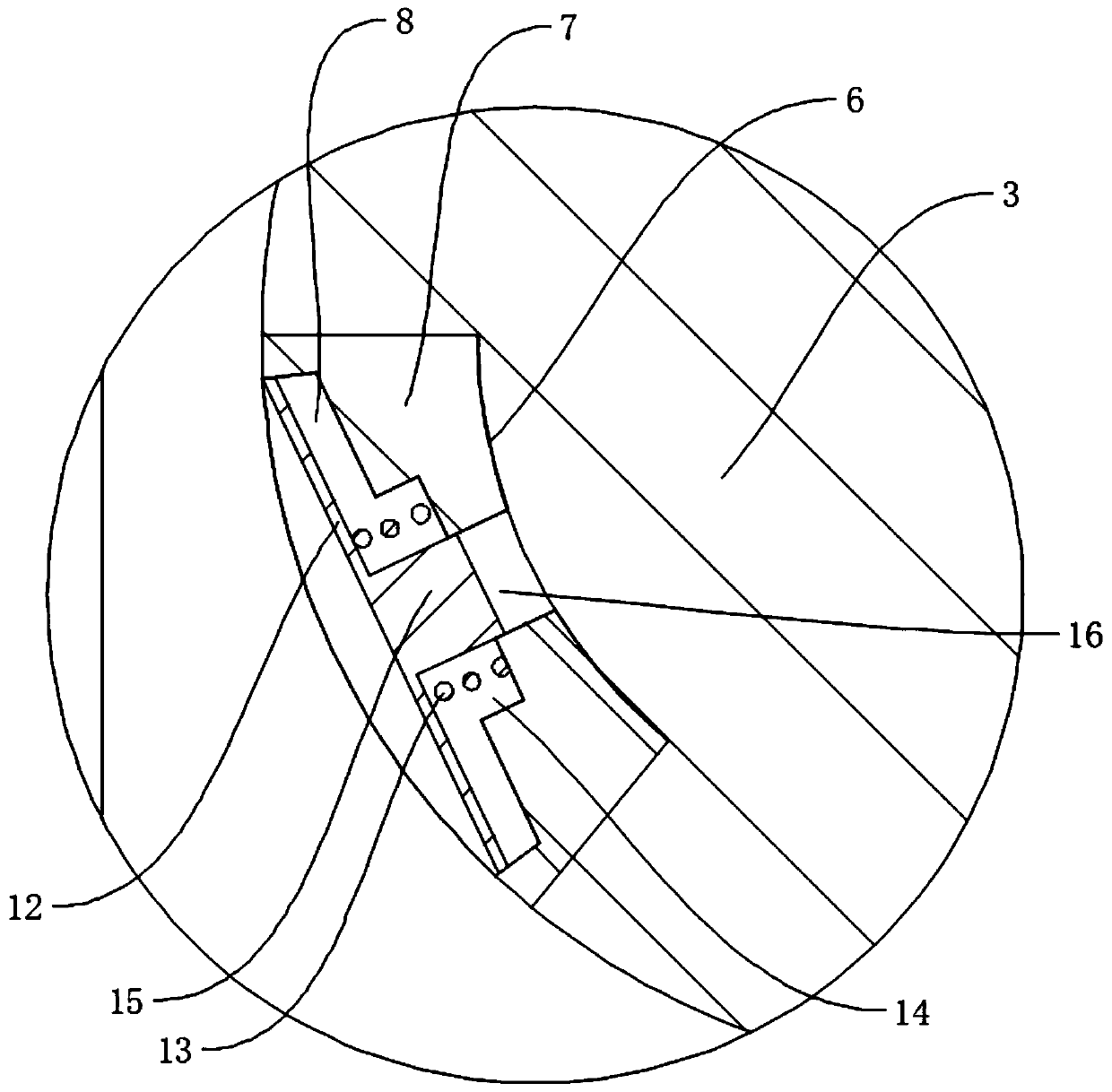

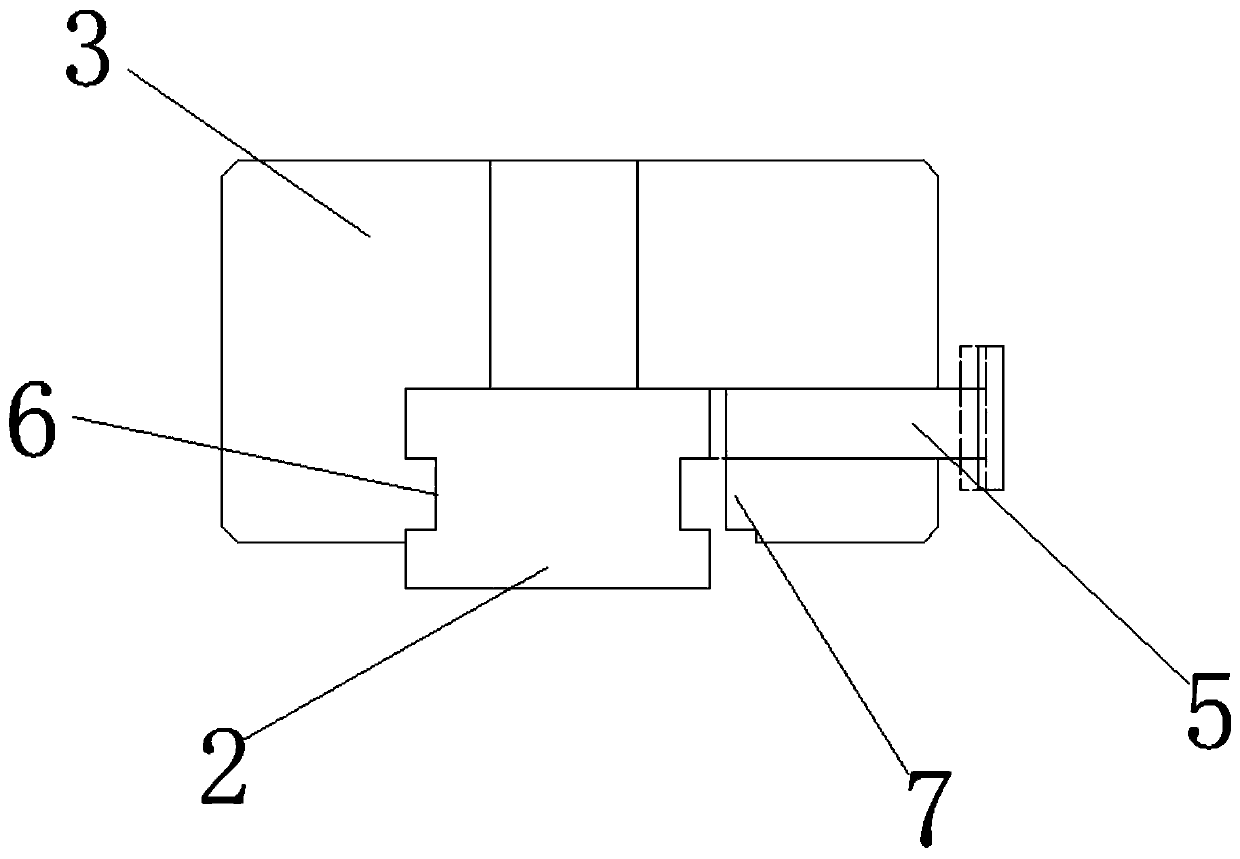

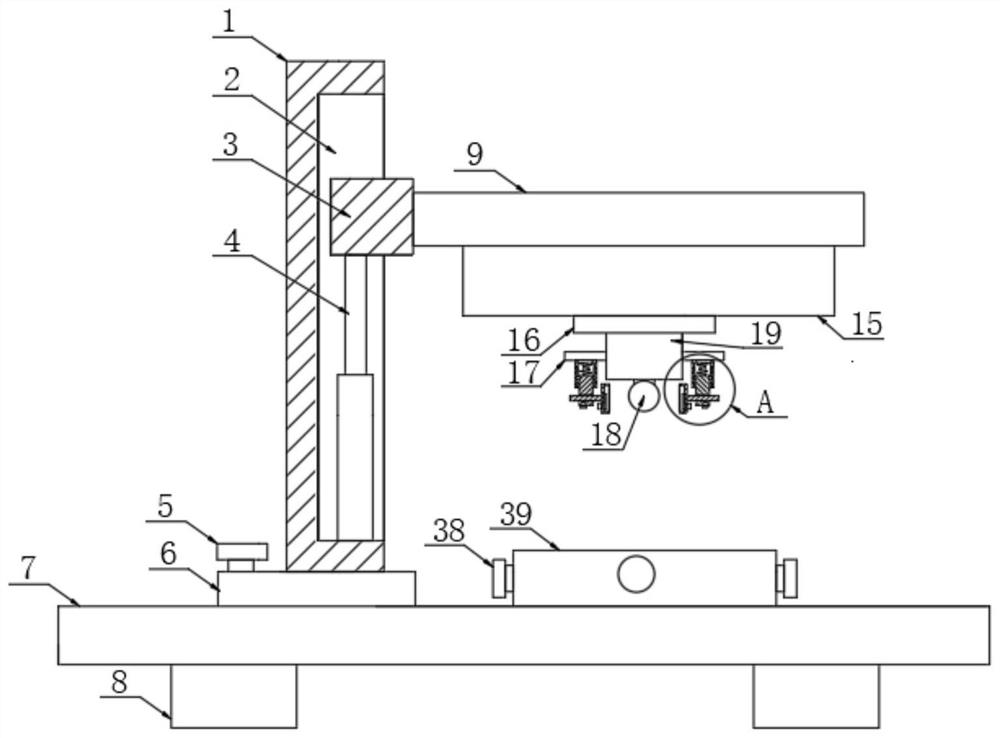

Adjustable efficient cutting device for stainless steel seamless circular tubes

The invention discloses an adjustable efficient cutting device for stainless steel seamless circular tubes. The adjustable efficient cutting device comprises a base, sliding blocks, a lifting table, sleeves, a second driving motor and cutting motors; a first driving motor is fixedly mounted on the upper side of a supporting table through a bracket, output shafts at the two ends of the first driving motor are fixedly connected with first screw rods through a coupling, the thread directions of the left and right parts of each first screw rod are opposite, and a left sliding block and a right sliding block are mounted on threads at the left and right parts of each first screw rod in a threaded mode; and the sleeves are fixedly welded to the upper sides of each left sliding block and each right sliding block, and the openings of the sleeves on the two sides face the middle. The spacing between the sleeves on both sides is adjusted, the fact that the stainless steel seamless circular tubesof different lengths can be clamped is met, the versatility of the device is greatly improved, and the operation is simple; and by changing the position of cutting wheels, the fact that the stainlesssteel seamless circular tubes of different lengths can be cut is met, the positioning of the cutting wheels is accurate, the offset in the cutting process cannot occur, and the cutting accuracy is greatly improved.

Owner:安徽广美钢业有限公司

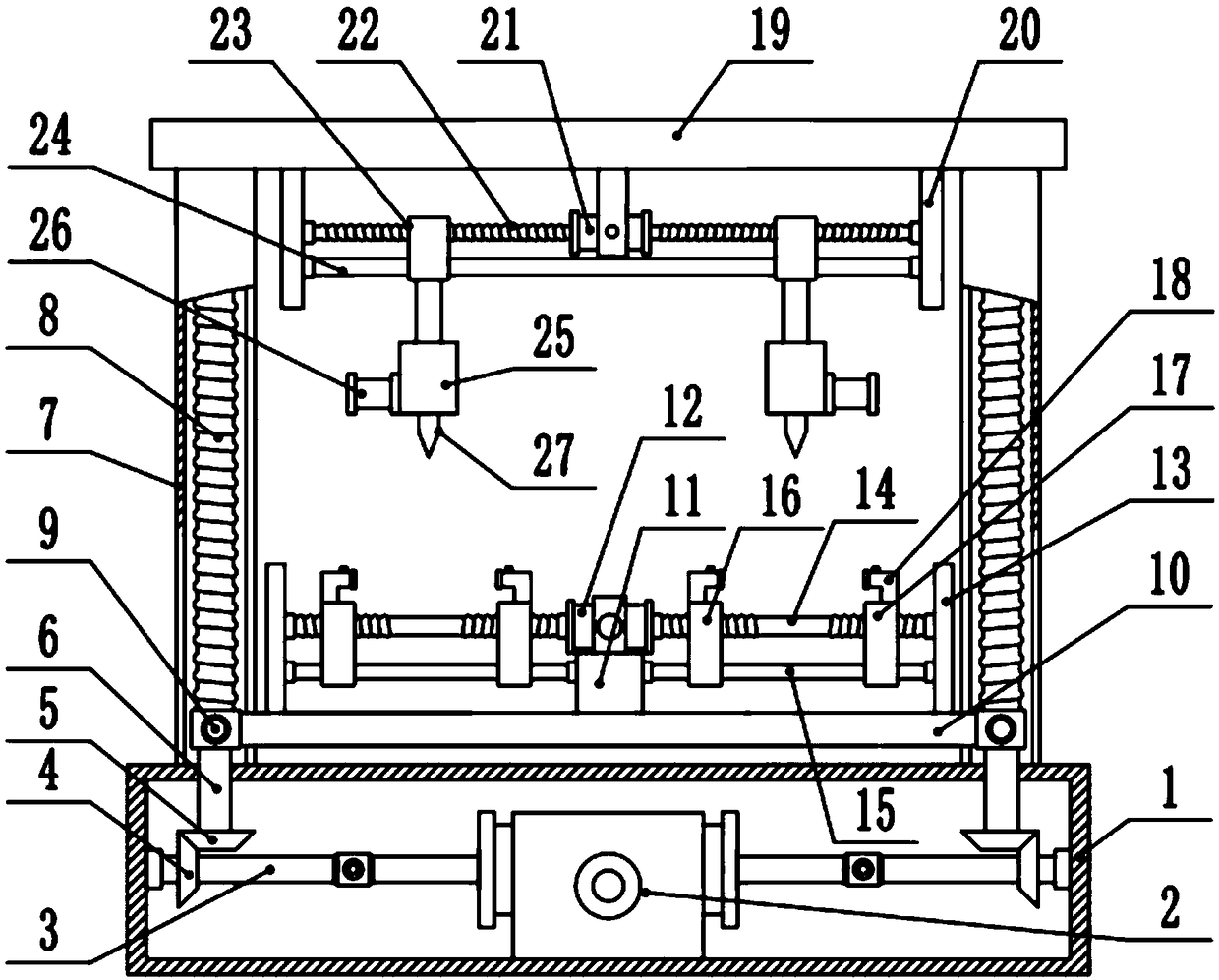

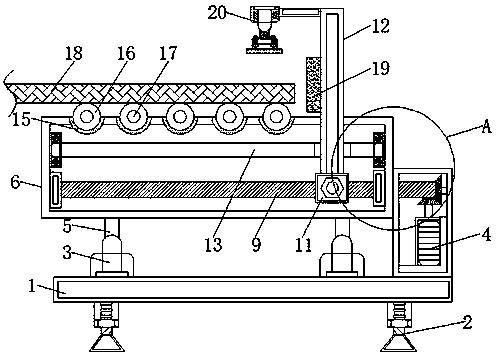

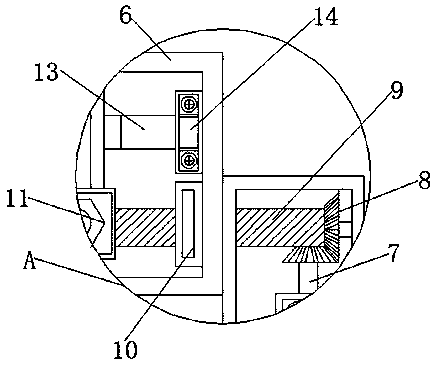

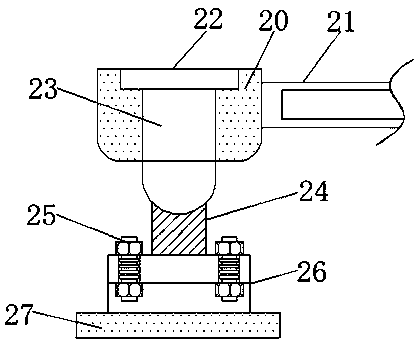

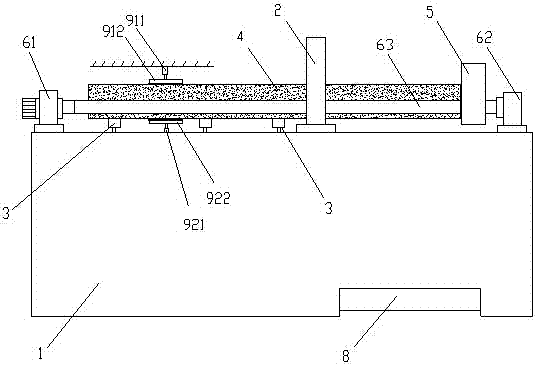

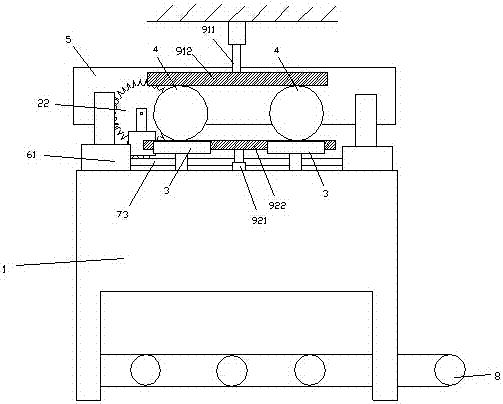

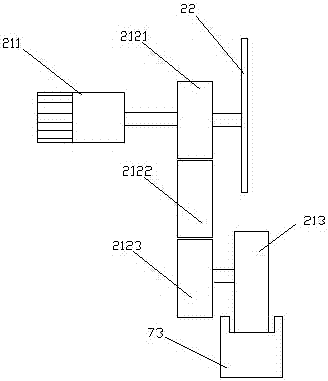

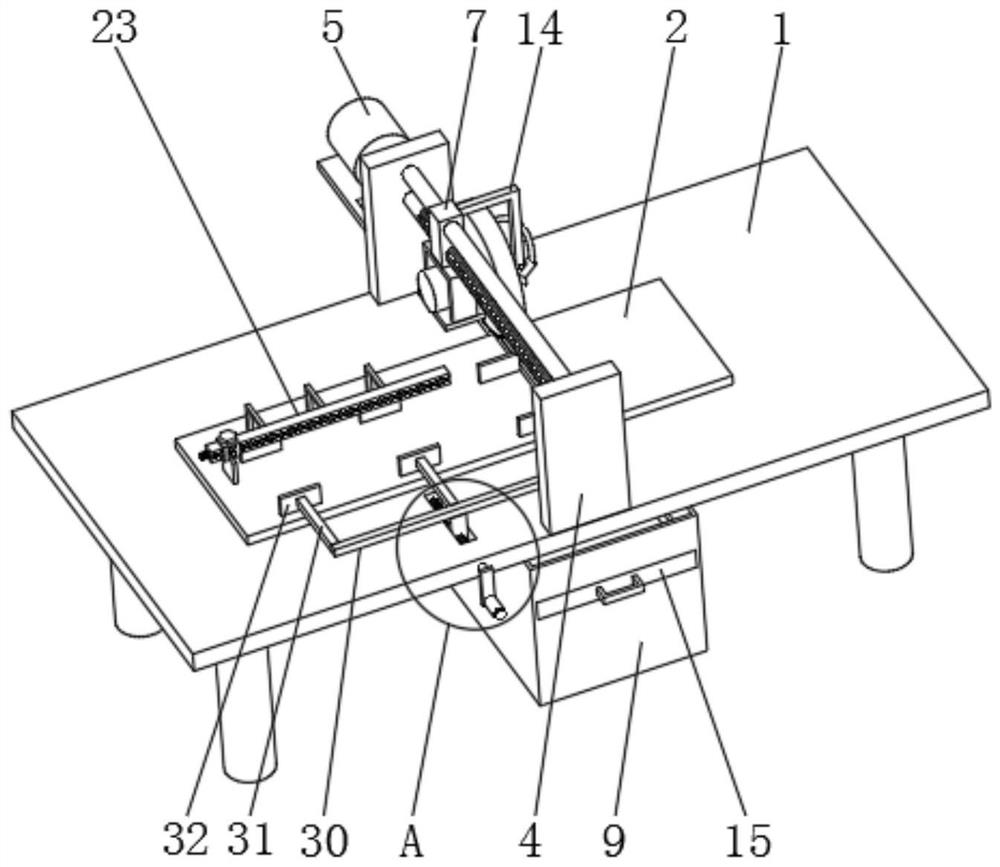

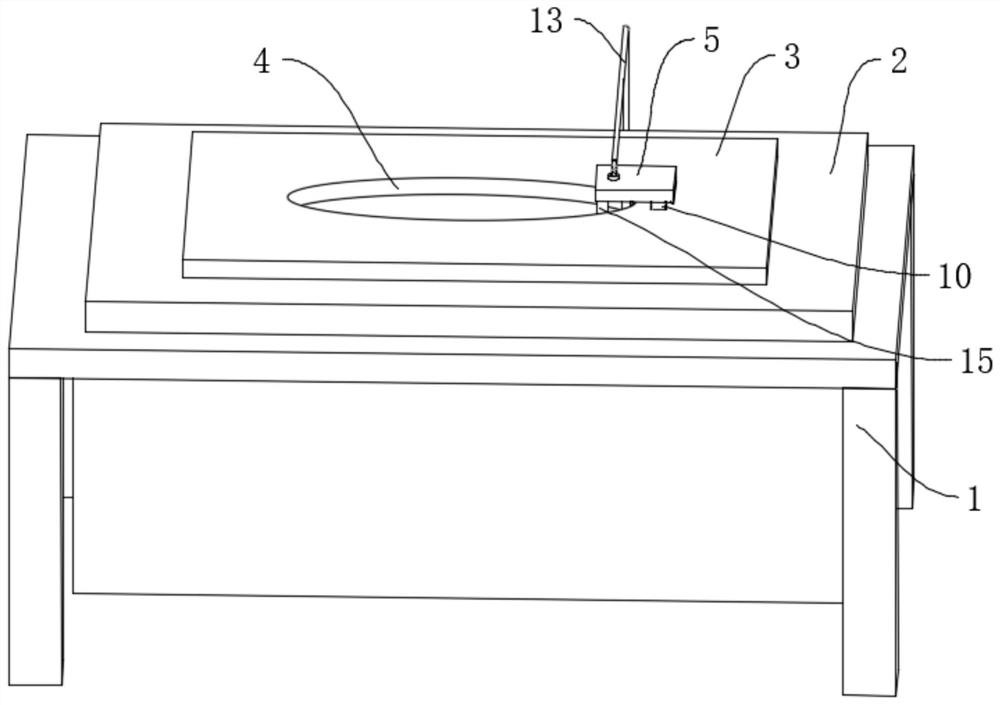

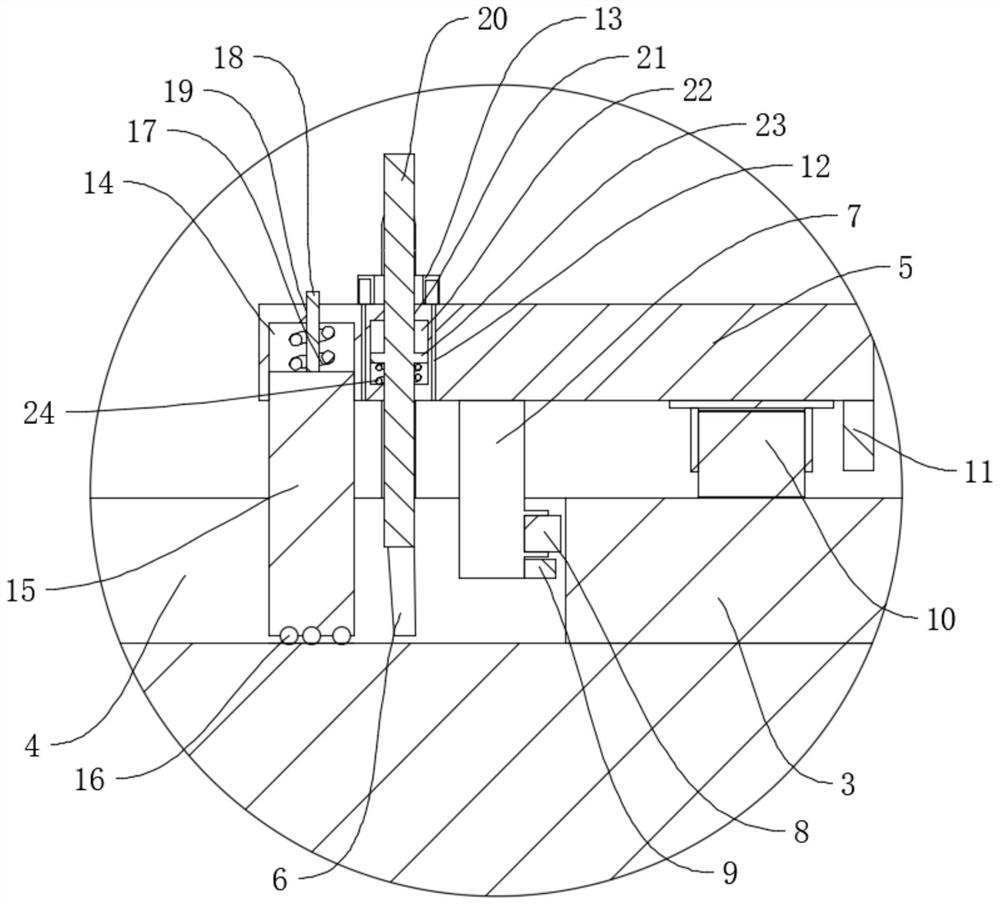

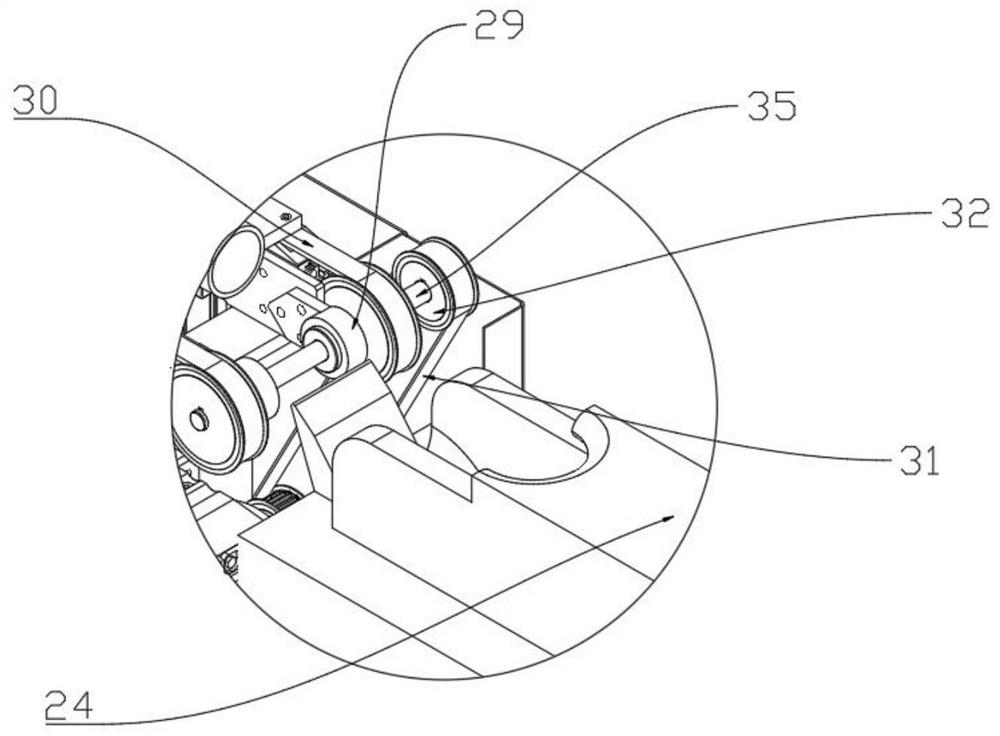

Cutting device for glass table board of integrated cooker and cutting method by adopting cutting device

ActiveCN108943446AAvoid harmAvoid hard frictionWorking accessoriesStone-like material working toolsDrive wheelMotor drive

The invention discloses a cutting device for a glass table board of an integrated cooker. The cutting device comprises a workbench, a cutting mechanism and clamping devices, a movable seat is arrangedbelow the workbench, a mounting plate is arranged between the workbench and the movable seat, a rotating motor, a driven wheel and a rotating screw rod are arranged on the mounting plate, the rotating motor drives the driven wheel to rotate through a belt wheel, the driven wheel drives the rotating screw rod to rotate, the cutting mechanism is located above the workbench, and the clamping devicescomprise supporting rods and clamping pressing plates. A cutting method comprises the following steps that (1) a to-be-cut raw material is fed; (2) positioning and clamping are carried out on the glass plate raw material; (3) the position of the cutting mechanism is adjusted; and (4) cutting machining is carried out. According to the cutting device, the overall structural design is ingenious andreasonable, omni-directional adjustment of the position of the cutting mechanism can be realized, and accurate positioning between the cutting mechanism and the to-be-cut position is ensured; and meanwhile, the clamping devices are designed so that the to-be-cut raw material can be clamped and fixed, and the application range is wide.

Owner:浙江欧帝智能厨电有限公司

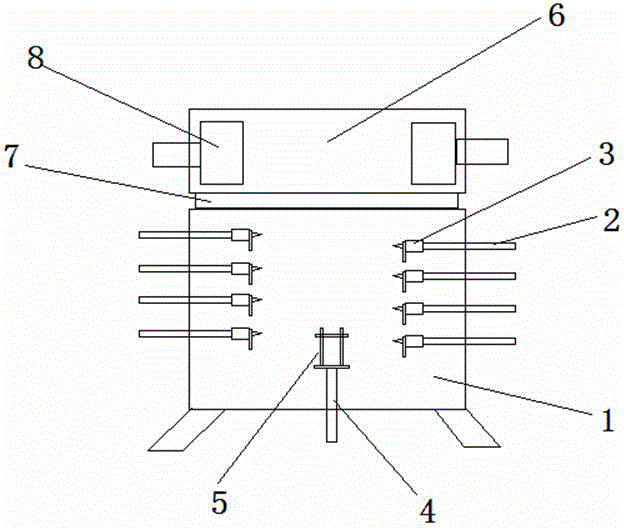

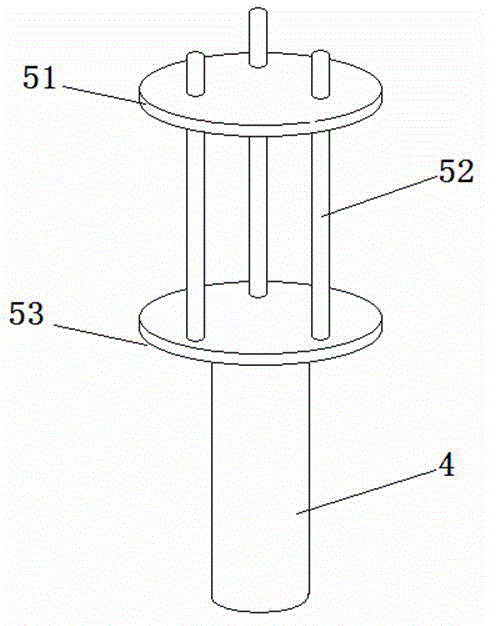

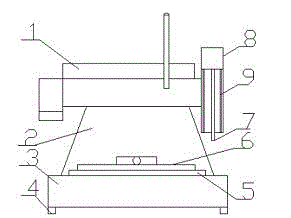

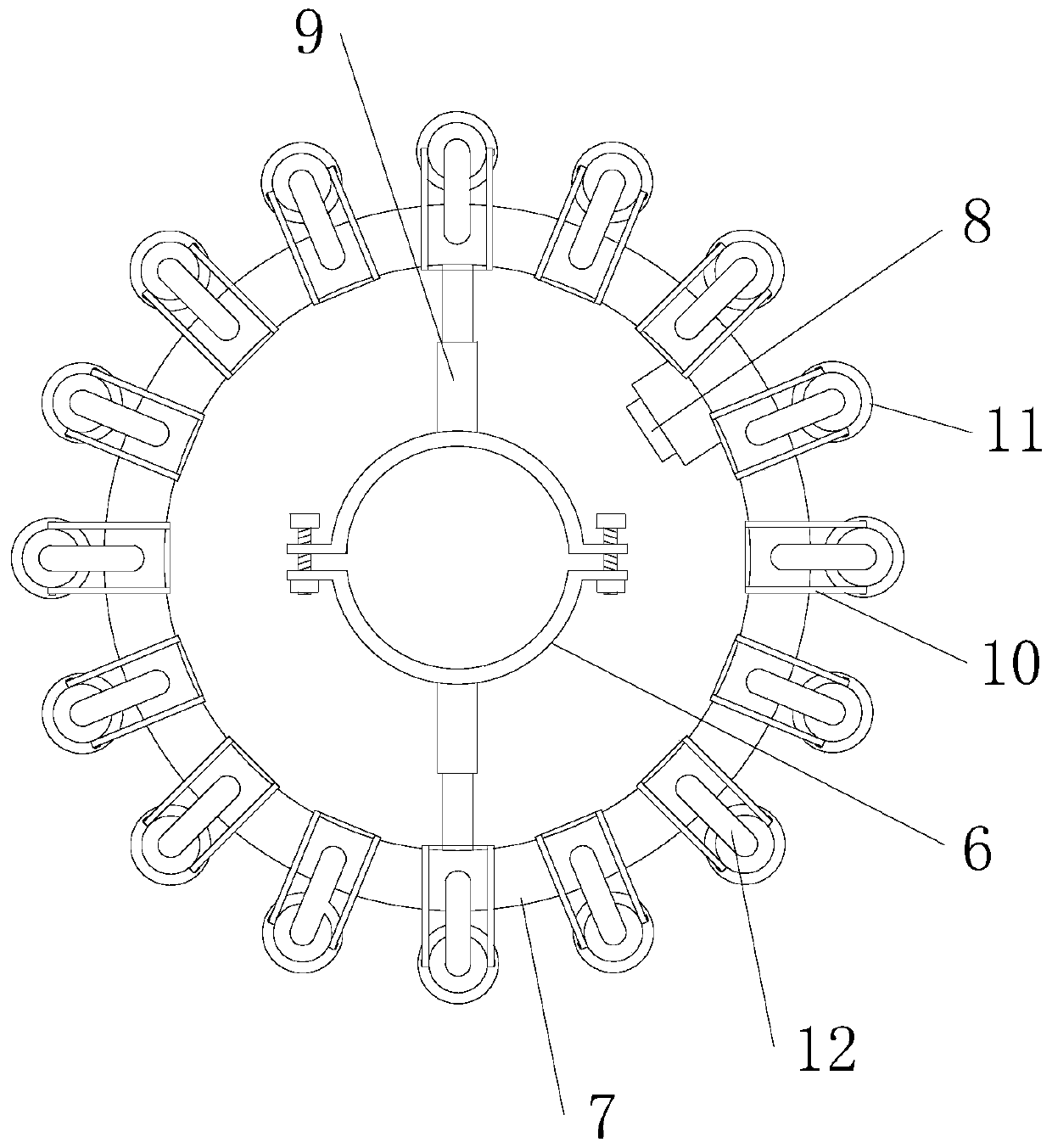

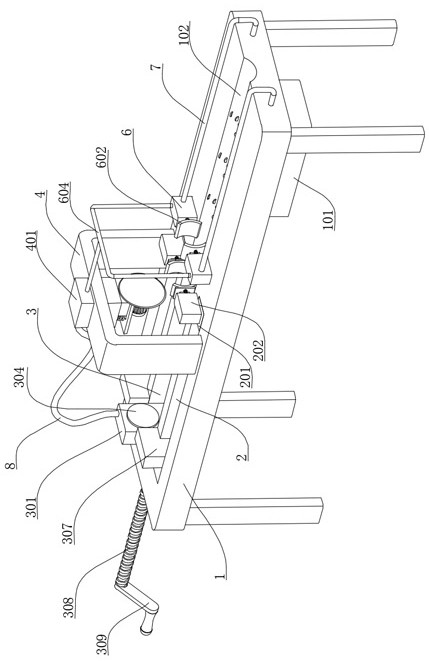

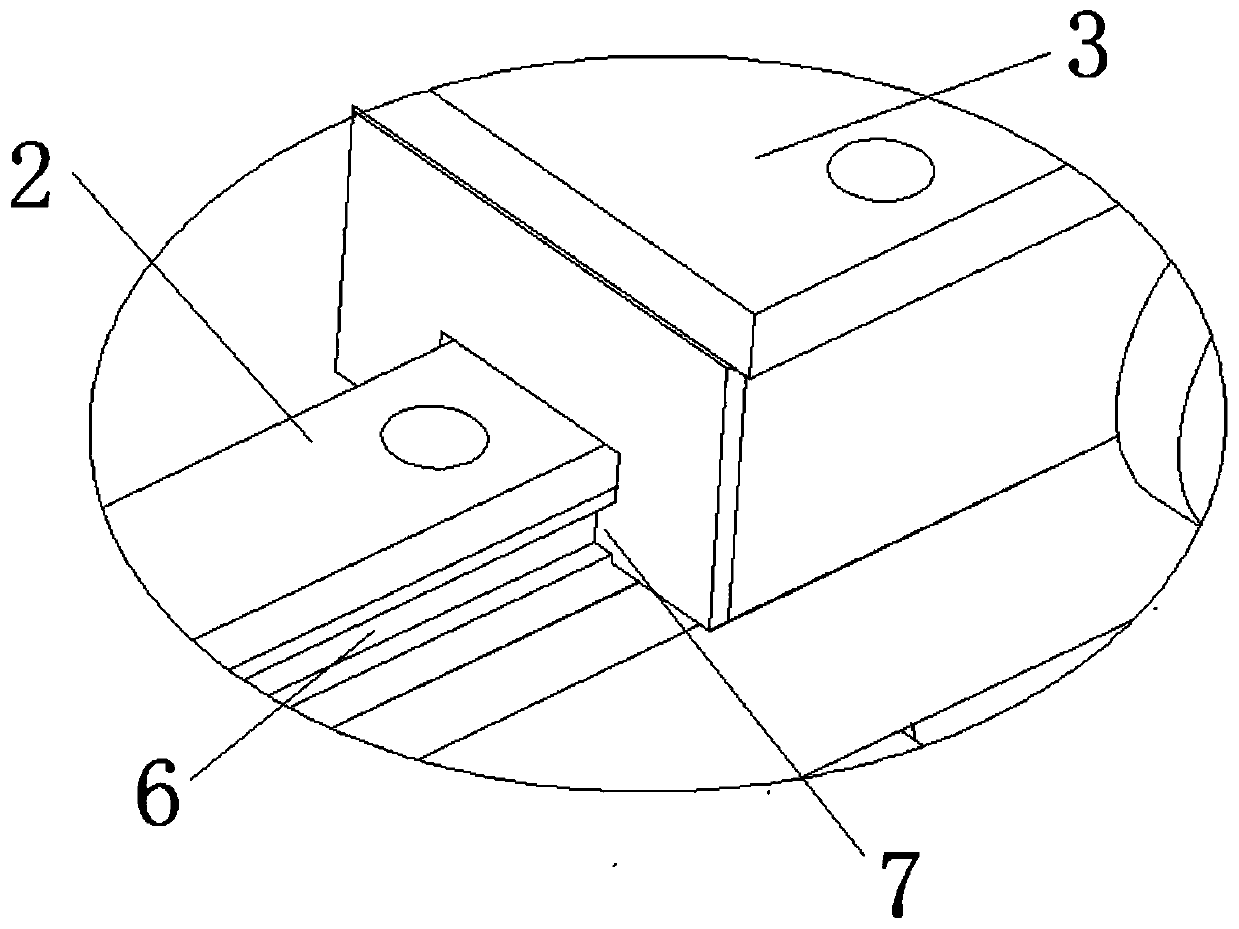

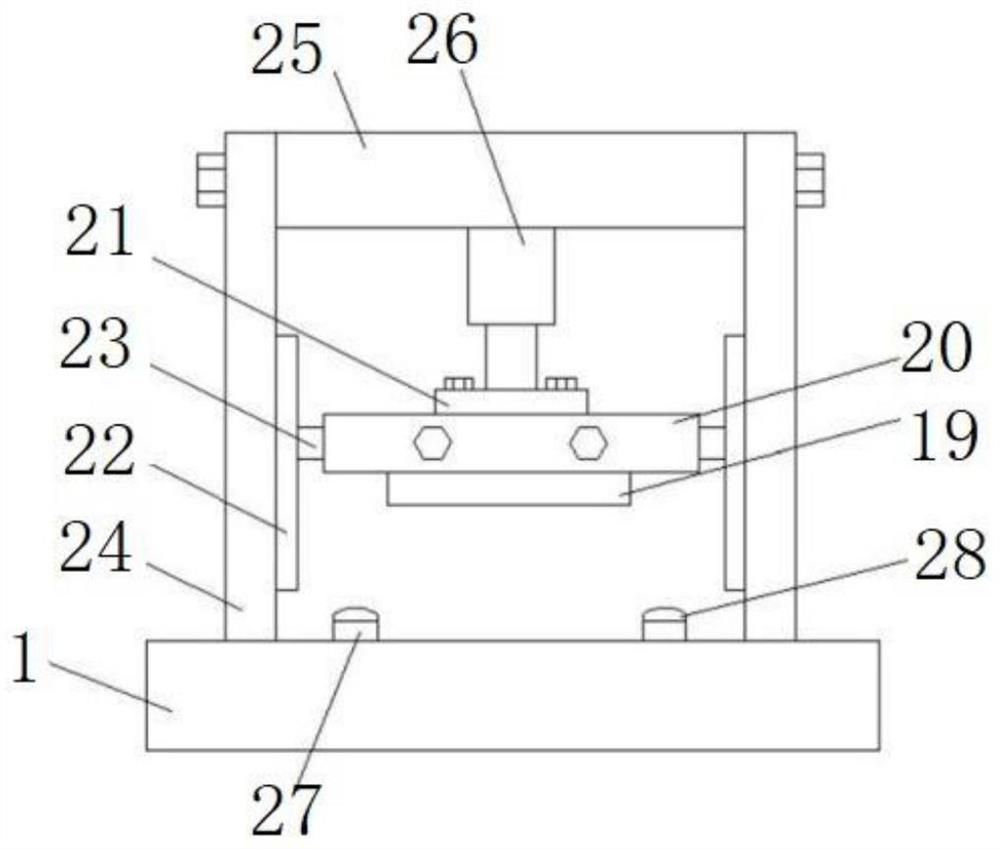

Irregular blank workpiece clamping table for vertical milling machine

ActiveCN104924113ALarge clamping forceGood effectWork clamping meansPositioning apparatusMaterial resourcesMachine

The invention discloses an irregular blank workpiece clamping table for a vertical milling machine, and belongs to the field of machining. The irregular blank workpiece clamping table comprises a workpiece groove, fixing rods are arranged on the side walls of the workpiece groove, and fasteners are arranged at the ends, placed in the workpiece groove, of the fixing rods. Each fastener comprises a casing structure, and a clamping piece is arranged at one end of each casing structure. The clamping pieces and the casing structures are hinged to each other, and bore spines are arranged on the clamping pieces. A telescopic supporting rod is arranged at the bottom in the workpiece groove, and a pressure-bearing mechanism is arranged at one end of the telescopic supporting rod. A clamping layer is arranged on the upper portion of the workpiece groove, and a pair of opposite edges of the clamping layer are each provided with a movable vice jaw. Compared with the prior art, through the horizontal clamping of multiple supporting points and the multi-point fixing to workpieces of the clamping layer, blank pieces in various shapes can be clamped; the phenomenon that the blank pieces need to be subjected to rough machining first to be in regular shape so as to be clamped conveniently is needless, and large cutting allowance is reserved for subsequent machining; and moreover the labor intensity is lowered, and manpower and material resources are saved.

Owner:WUHU ZHONGSHEN MACHINERY MFG

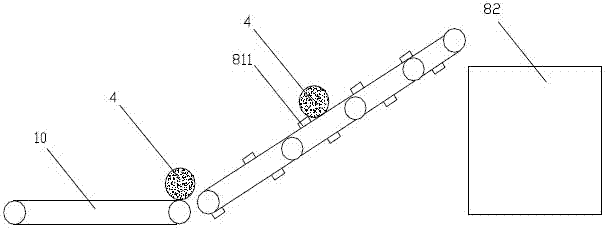

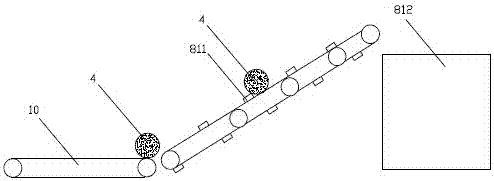

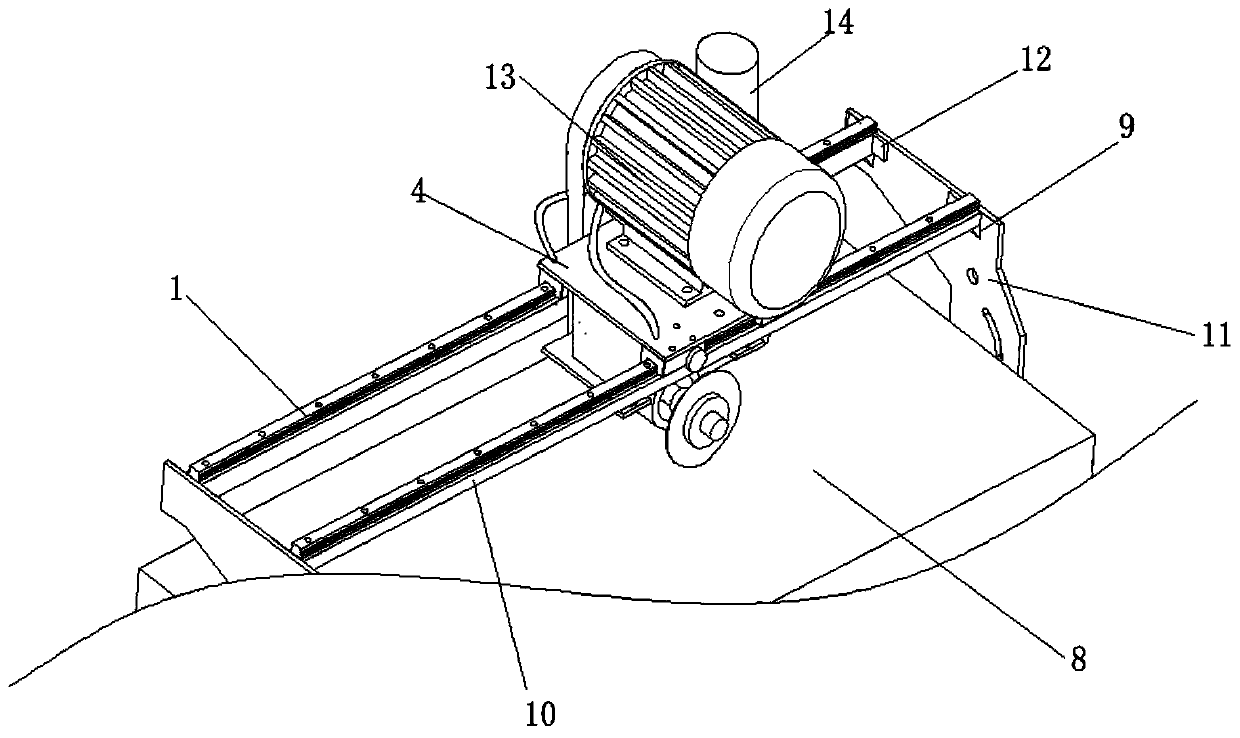

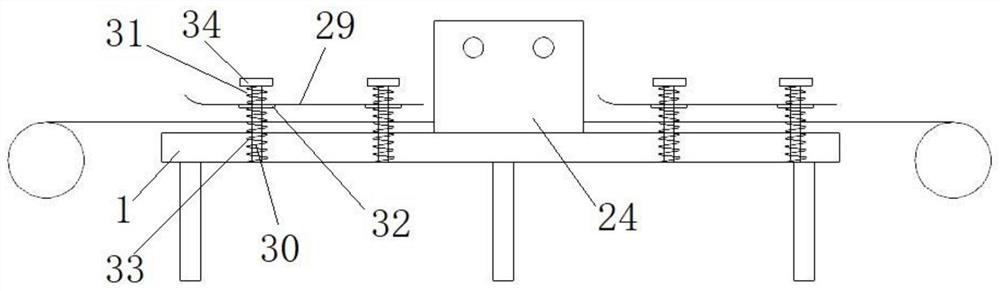

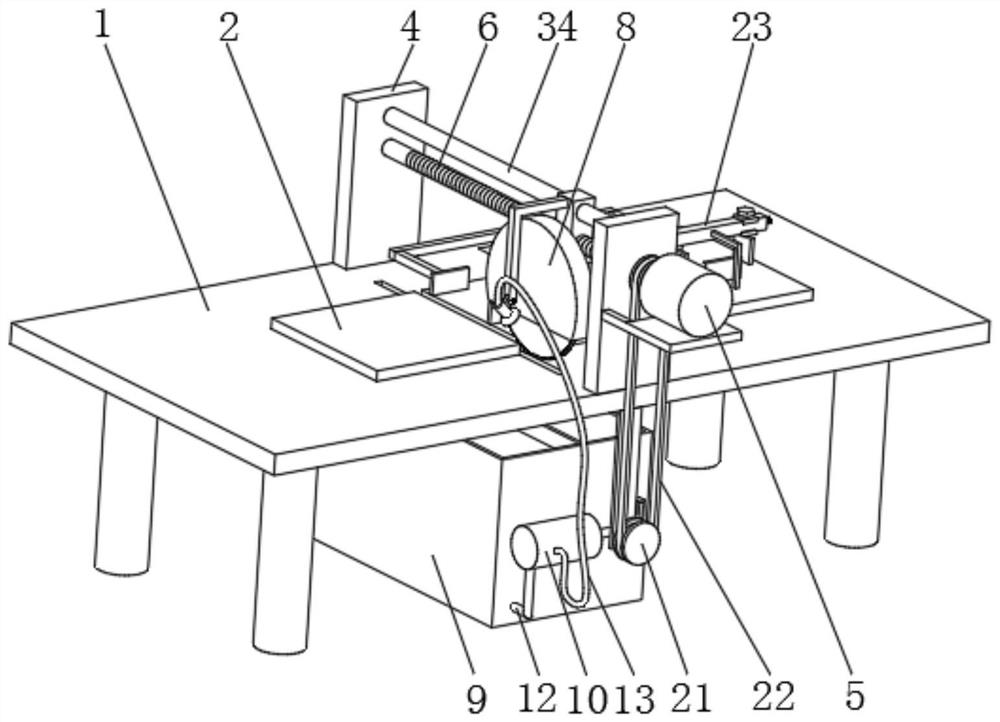

Wood transporting and cutting integrated mechanism

InactiveCN107127829AIncrease the number ofNo need for manual markingGuide fencesFeeding devicesEngineeringWorkbench

The invention discloses a wood transporting and cutting integrated mechanism. The wood transporting and cutting integrated mechanism comprises a workbench, a cutting device and a wood transporting device. The wood transporting device is close to the wood feeding start end of the workbench or the wood transporting device makes contact with the wood feeding start end of the workbench. The wood transporting device comprises a slope type conveying device and a horizontal conveying platform. The workbench is provided with wood supporting frames. The multiple wood supporting frames in the same row are distributed from the wood feeding start end of the workbench to the wood feeding stop end of the workbench in the length direction of the workbench at intervals. A fixed length baffle is arranged at the wood feeding stop end of the workbench, and a pushing mechanism is arranged between the horizontal conveying platform and the workbench. The pushing mechanism is used for pushing woods to the position abutting against the fixed length baffle. The wood transporting and cutting integrated mechanism has the beneficial effects that the length fixing working procedure is easy and convenient, the cutting defective percentage is low, tool abrasion is slight, the cutting speed is high, and the multiple woods can be cut at the same time.

Owner:薛忠来

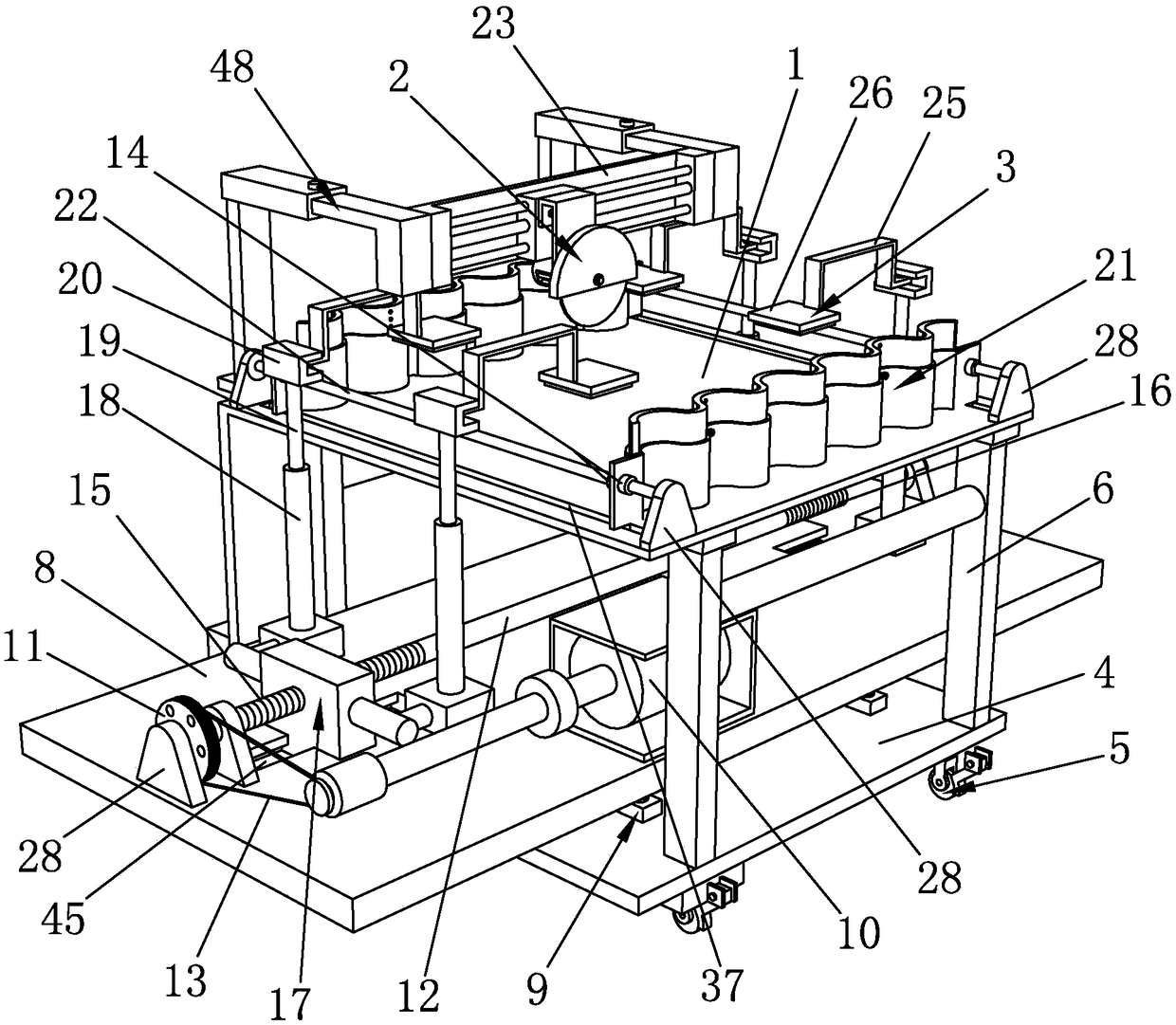

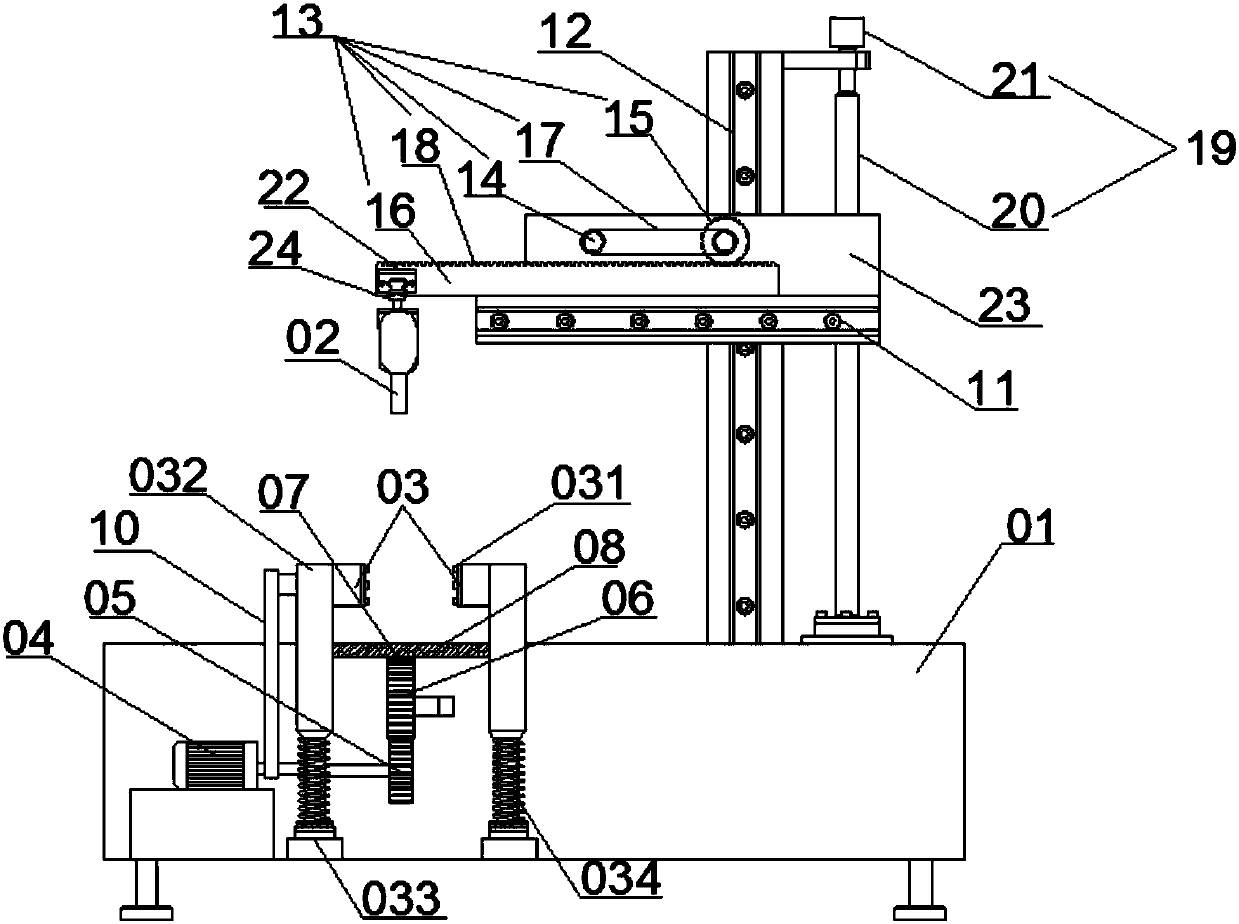

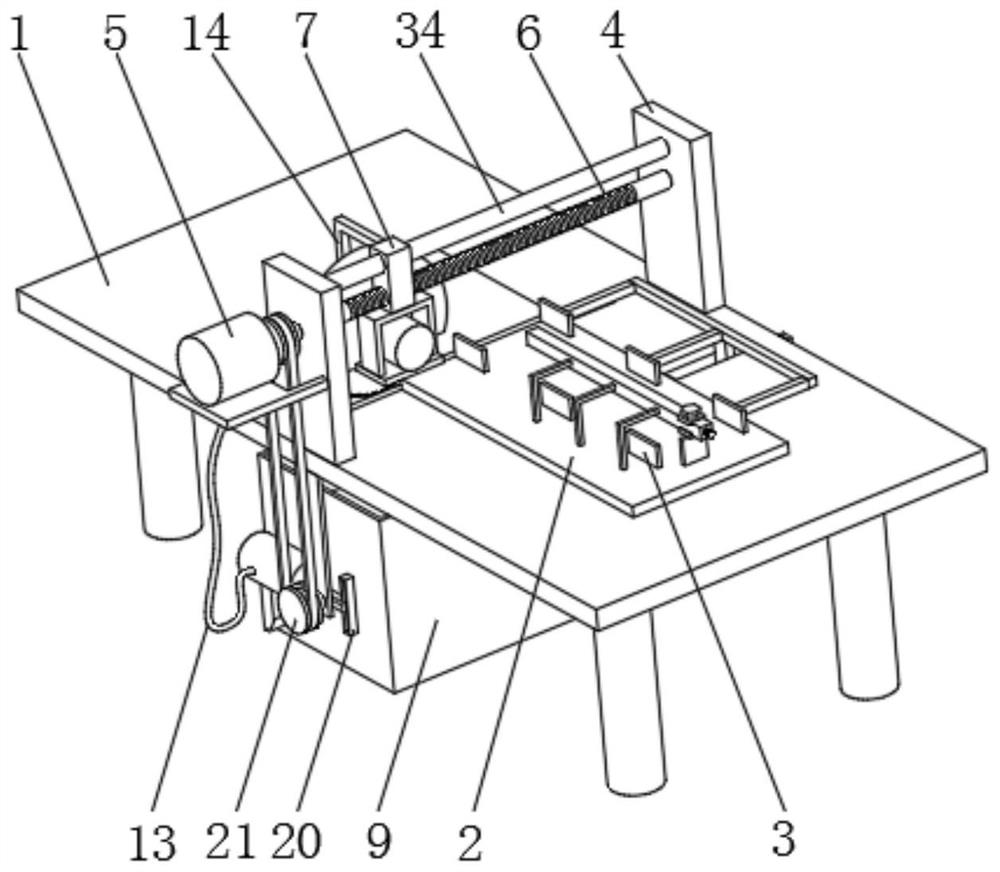

Machine tool for wood processing based on feeding, cutting and blanking production integration

InactiveCN107139268AAffect cutting accuracyAvoid damageFeeding devicesCircular sawsReciprocating motionWood machining

The invention discloses a machine tool for wood processing based on feeding, cutting and blanking production integration. The machine tool comprises a worktable, a cutting device, a wood transporting device and a wood clamping device. The wood transporting device comprises a ramp type conveying device and a horizontal conveying platform. The ramp type conveying device is arranged on the side face of the horizontal conveying platform and used for transporting wood onto the horizontal conveying platform. Partitioning plates are arranged on the conveying path of the ramp type conveying device at intervals. The horizontal conveying platform is used for transporting the wood onto the worktable. A set length baffle cutting device is arranged at the wood feeding terminating end in the worktable to be in slide fit with the worktable and can make reciprocating motion in the width direction of the worktable. The machine tool has the technical effects that the set length process is simple and convenient, the cutting defective rate is low, tool abrasion is less, the cutting speed is high, and multiple pieces of the wood can be cut simultaneously.

Owner:薛忠来

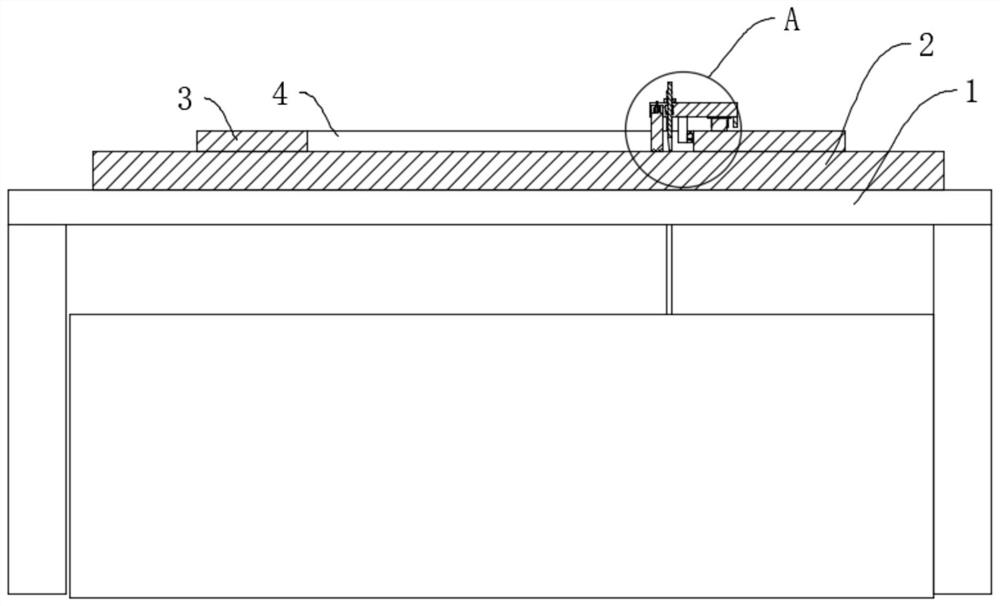

Glass cutting machine

InactiveCN108793710ANo offsetFlexible position adjustmentGlass severing apparatusEngineeringMechanical engineering

The invention discloses a glass cutting machine which comprises a cutting plate; a slide rail is fixedly arranged on the cutting plate; clamping devices are symmetrically and movably arranged on the slide rail; an operating panel is arranged above glass; a guide rod is symmetrically provided with guide grooves; a fixing device comprises a buffer block; the buffer block is provided with a buffer groove; a limited block is fixedly connected with the buffer block; and an extruding plate is fixedly connected to one end, far from the buffer groove, of an extruding block, and is connected onto the limited block through an extruding spring. According to the glass cutting machine, the built-in clamping devices can ensure that the glass cannot deflect in the cutting process, a cutting knife can perform cutting according to the preset route in a guiding structure, so that the influence on the cutting precision caused by human errors is avoided, the positions of the glass and the cutting knife and the distance between the glass and the cutting knife are relatively fixed, mutual deflection is avoided, the cutting precision is improved, the action force of the cutting knife to the glass is uniform, and glass breakage due to non-uniform stress is avoided.

Owner:蚌埠龙淮建筑科技有限公司

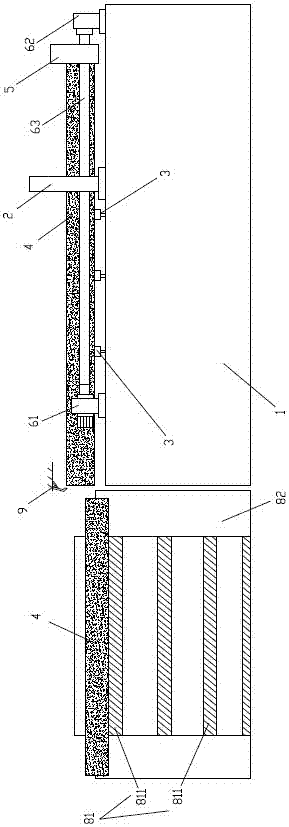

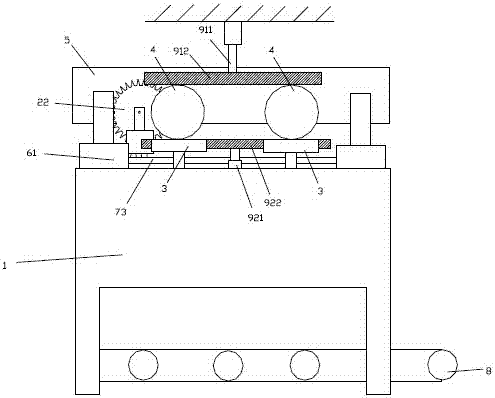

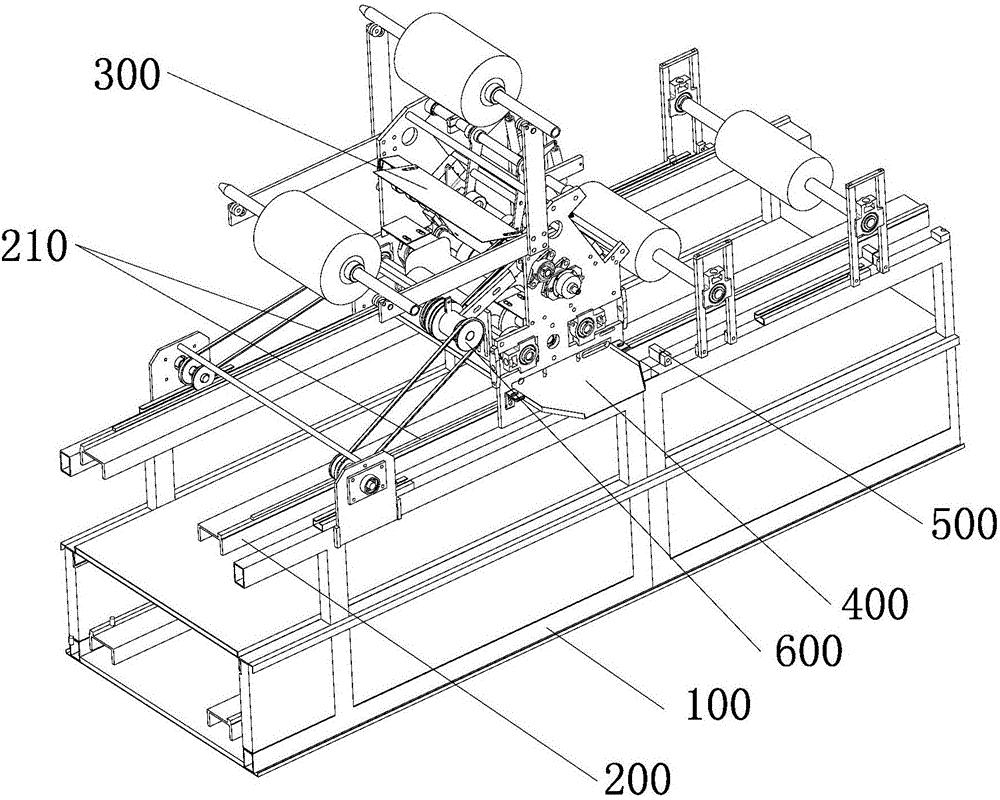

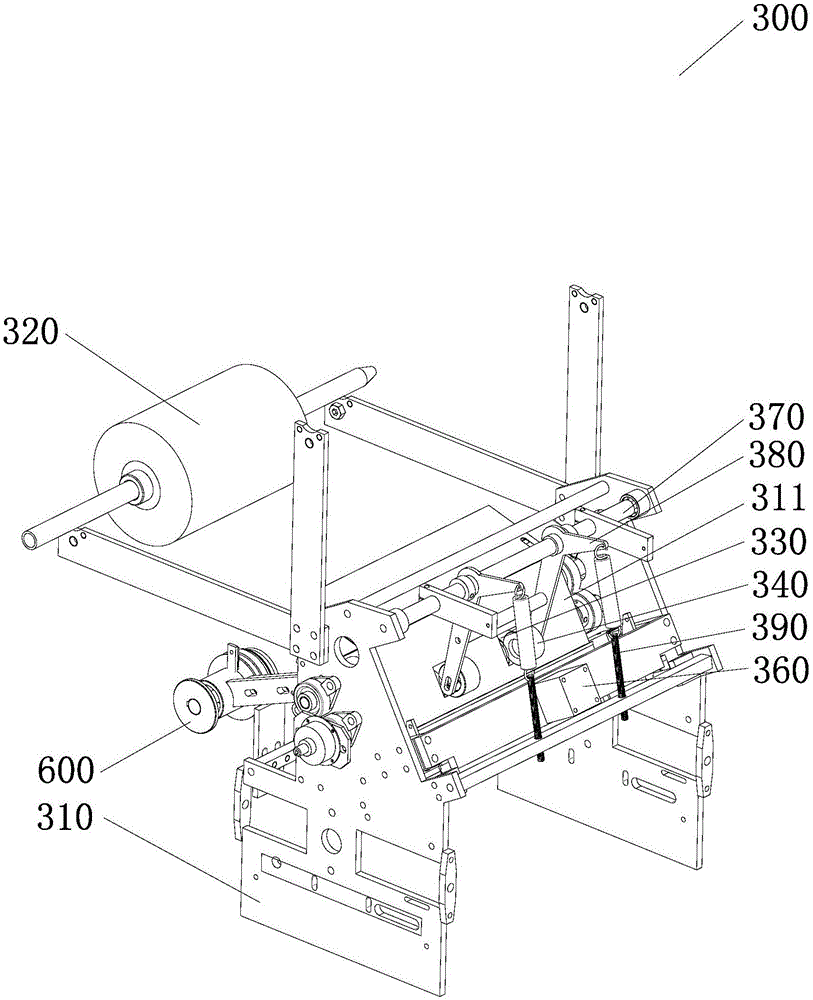

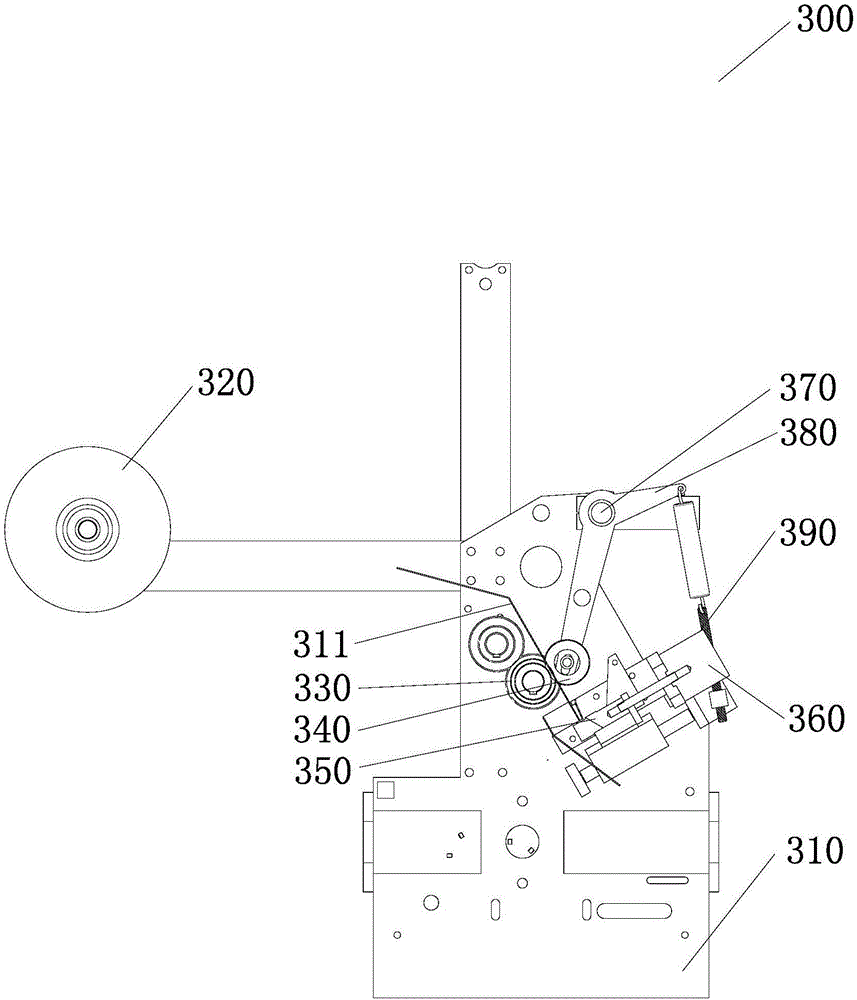

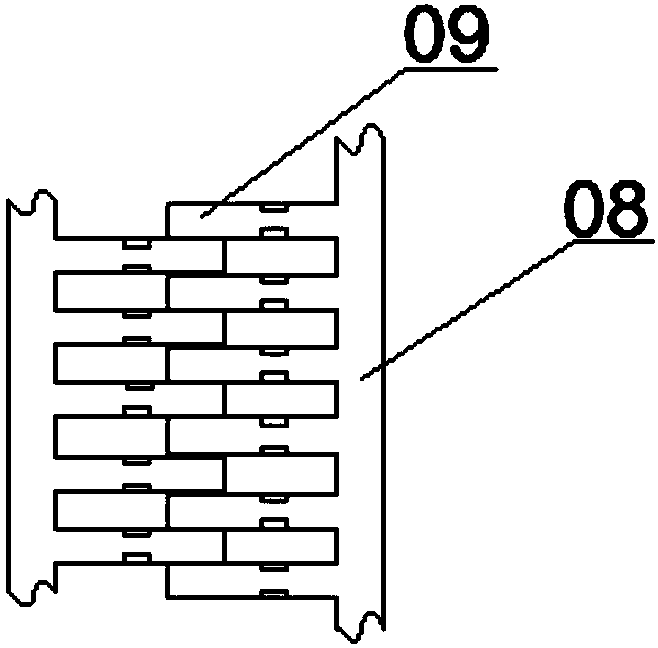

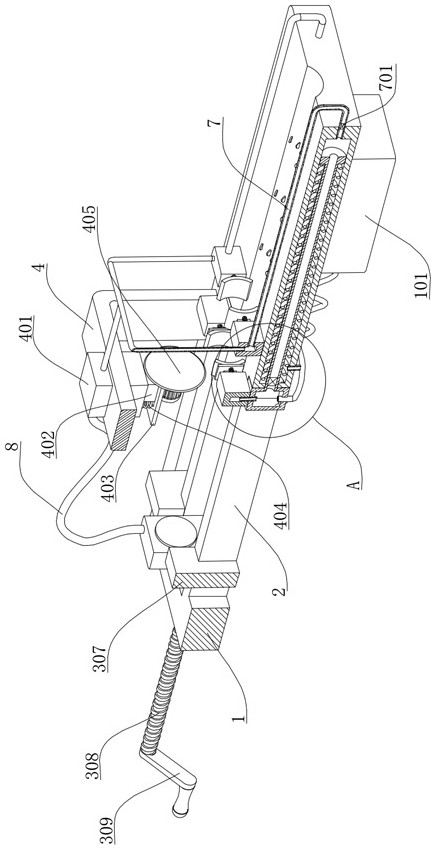

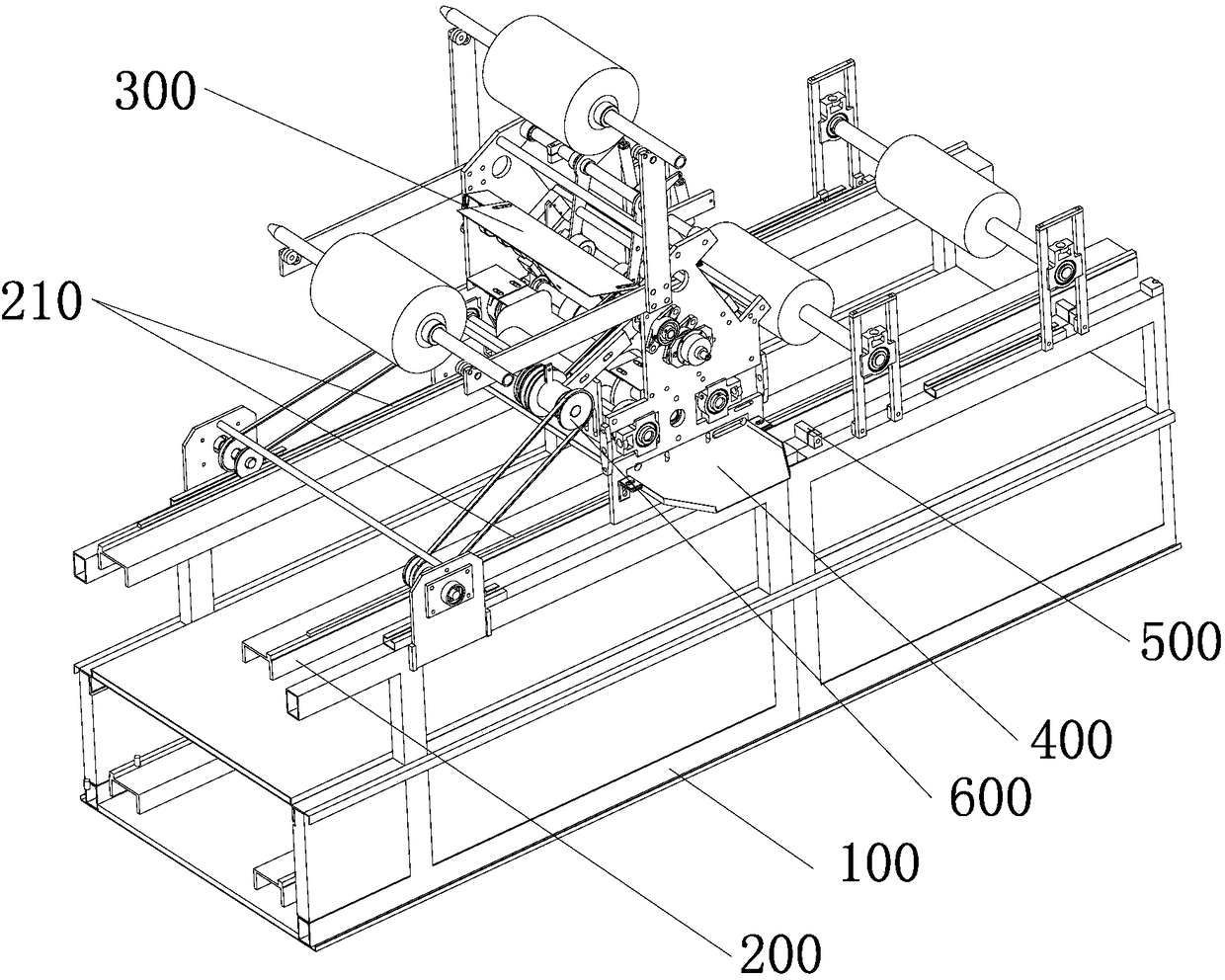

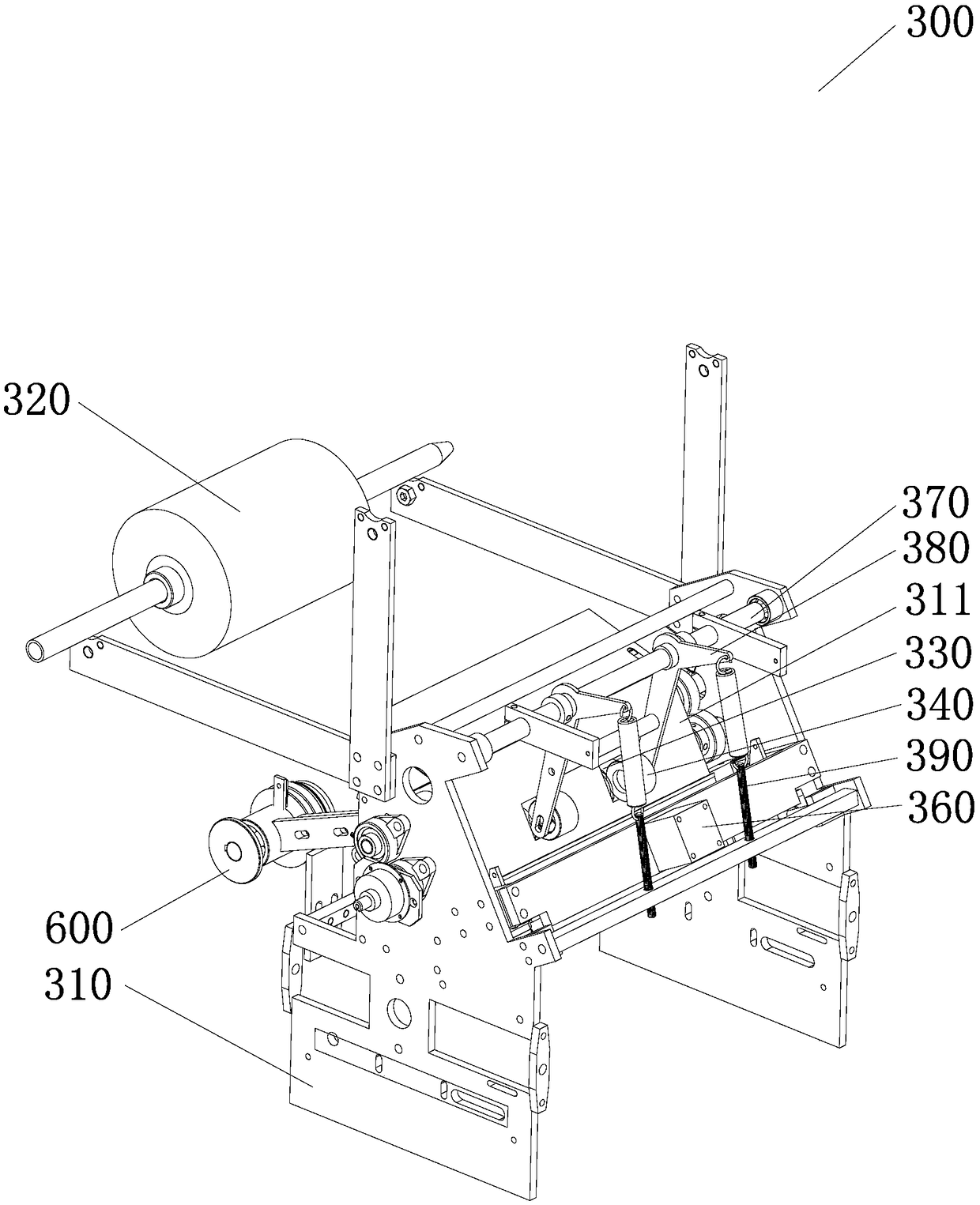

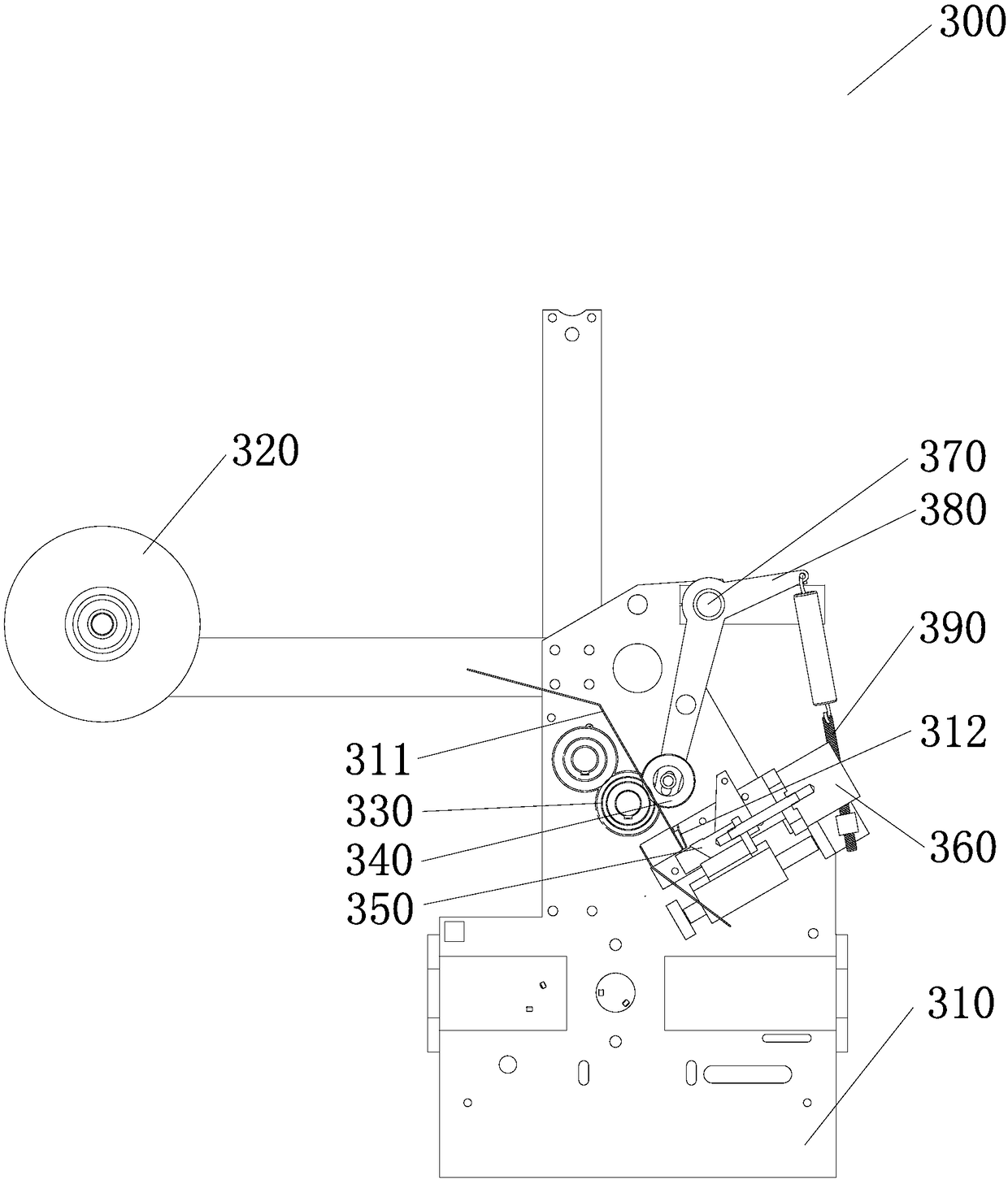

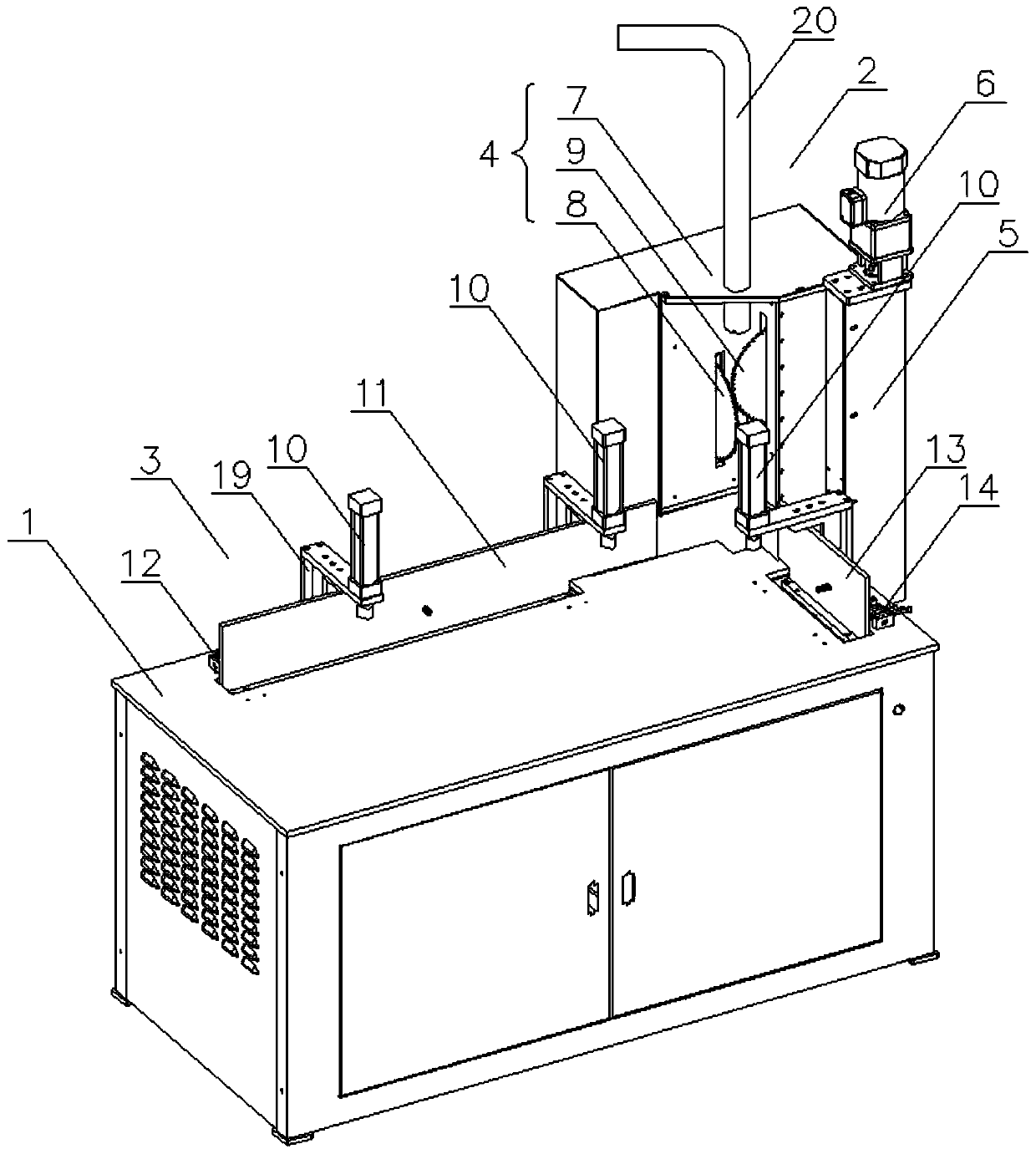

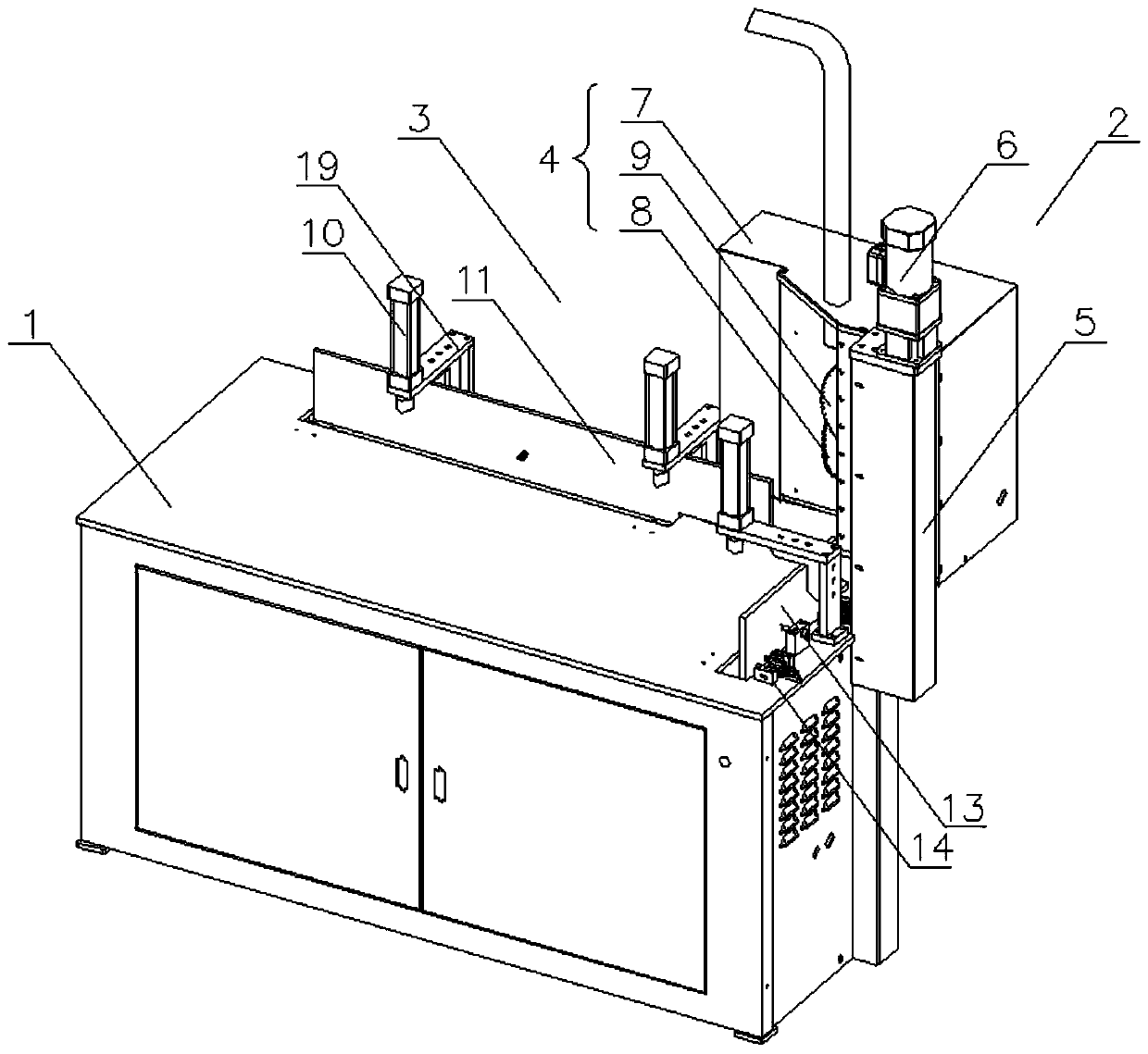

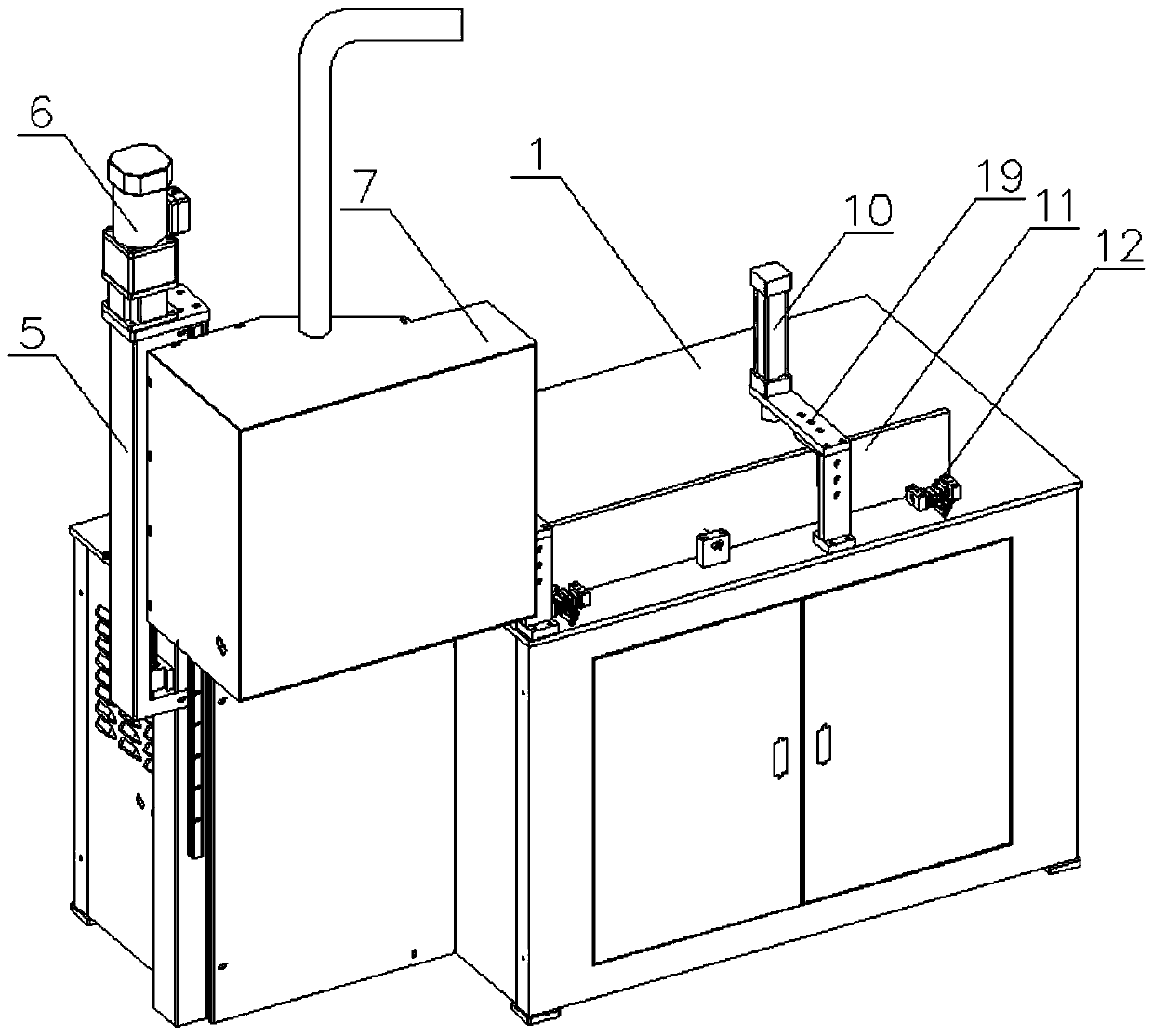

Tile automatic paper cutting and sticking device

ActiveCN106628358ALow costImprove cutting accuracyLiquid surface applicatorsWrapping material feeding apparatusPaper cutEngineering

The invention provides a tile automatic paper cutting and sticking device. The tile automatic paper cutting and sticking device comprises a machine frame and a control module. A chain conveying mechanism which is used for conveying tiles is arranged on the machine frame. A paper cutting mechanism, an adhesive coating mechanism and a detection module are arranged on the chain conveying mechanism, wherein the detection module is used for detecting the position of the tiles. The paper cutting mechanism and the adhesive coating mechanism are in transmission connection with conveying chains of the chain conveying mechanism, and the paper cutting mechanism, the adhesive coating mechanism and the detection module are in communication connection with the control module. Due to the fact that the paper cutting mechanism and the adhesive coating mechanism are in transmission connection with the conveying chains of the chain conveying mechanism, the paper cutting mechanism and the adhesive coating mechanism can obtain the power from the conveying chains, the paper cutting mechanism, the adhesive coating mechanism and the conveying chains conduct synchronous actions, and compared with the conventional technical scheme, the scheme has the advantages that the situation that a complicated control system is adopted to achieve synchronous actions is avoided, and the cost is relatively low. Meanwhile, due to the fact that the adhesive coating mechanism is arranged, automatic adhesive coating is achieved, and the tile automatic paper cutting and sticking device is suitable for the paper sticking working procedure of the tiles with the small size.

Owner:QUANZHOU INST OF EQUIP MFG

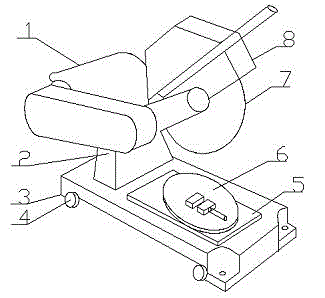

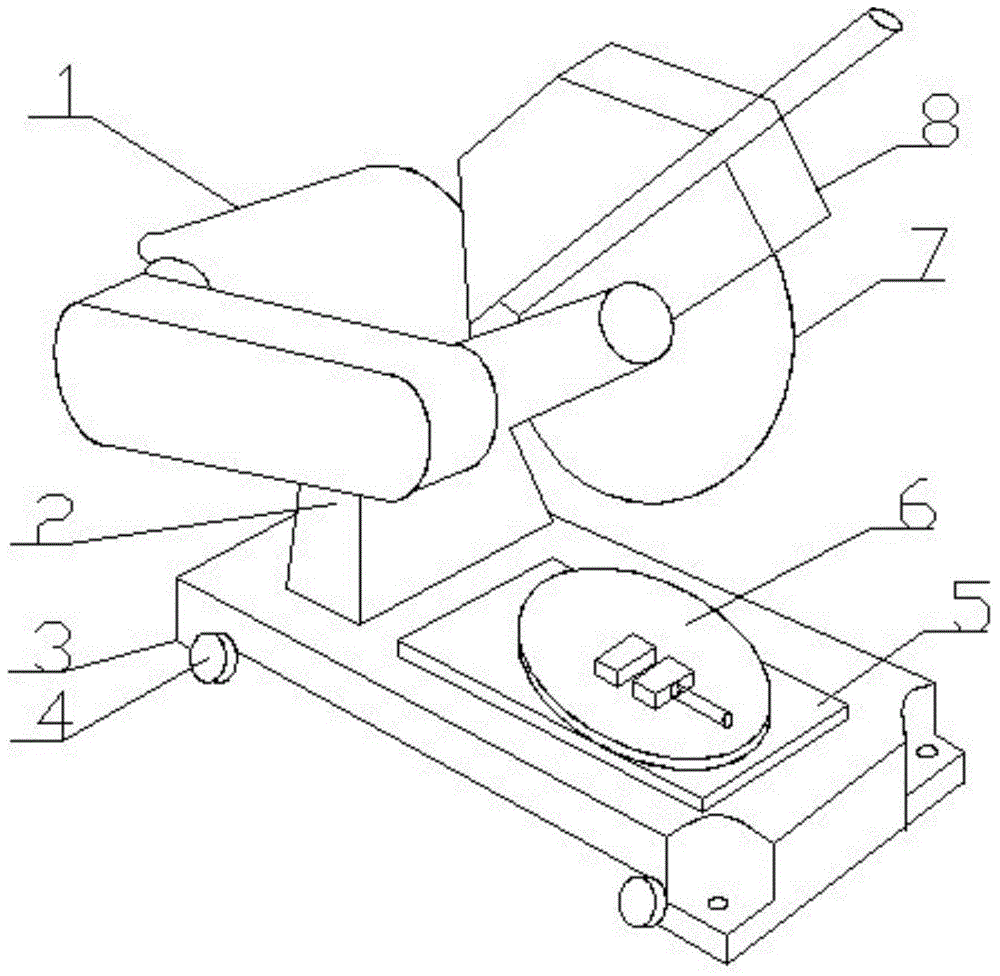

Multi-purpose abrasive wheel cutting machine

InactiveCN104416442AReduce vibrationEasy to moveGrinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a multi-purpose abrasive wheel cutting machine, and relates to the field of industrial machinery. The machine comprises a base, an abrasive wheel, a motor, a bracket and a protective cover; the motor is fixedly arranged on the bracket, wherein the bracket is fixedly arranged on the base; a rotary component clamping device is arranged on the base, and a vibration absorbing device is arranged below the rotary component clamping device; a nanometer silencing layer is arranged at the inner side of the protective cover; the rotary component clamping device is detachably connected with the base and the vibration absorbing device. According to the multi-purpose abrasive wheel cutting machine, a component can be cut in a plurality of directions, so as to meet different processing demands; in addition, the vibration produced by the abrasive wheel cutting machine in running can be effectively reduced, and therefore, the cutting precision of the component is avoided being influenced; the convenience of replacement and maintenance is ensured, and the service life is prolonged.

Owner:SHANGHAI XIWANG ELECTRONICS TECH

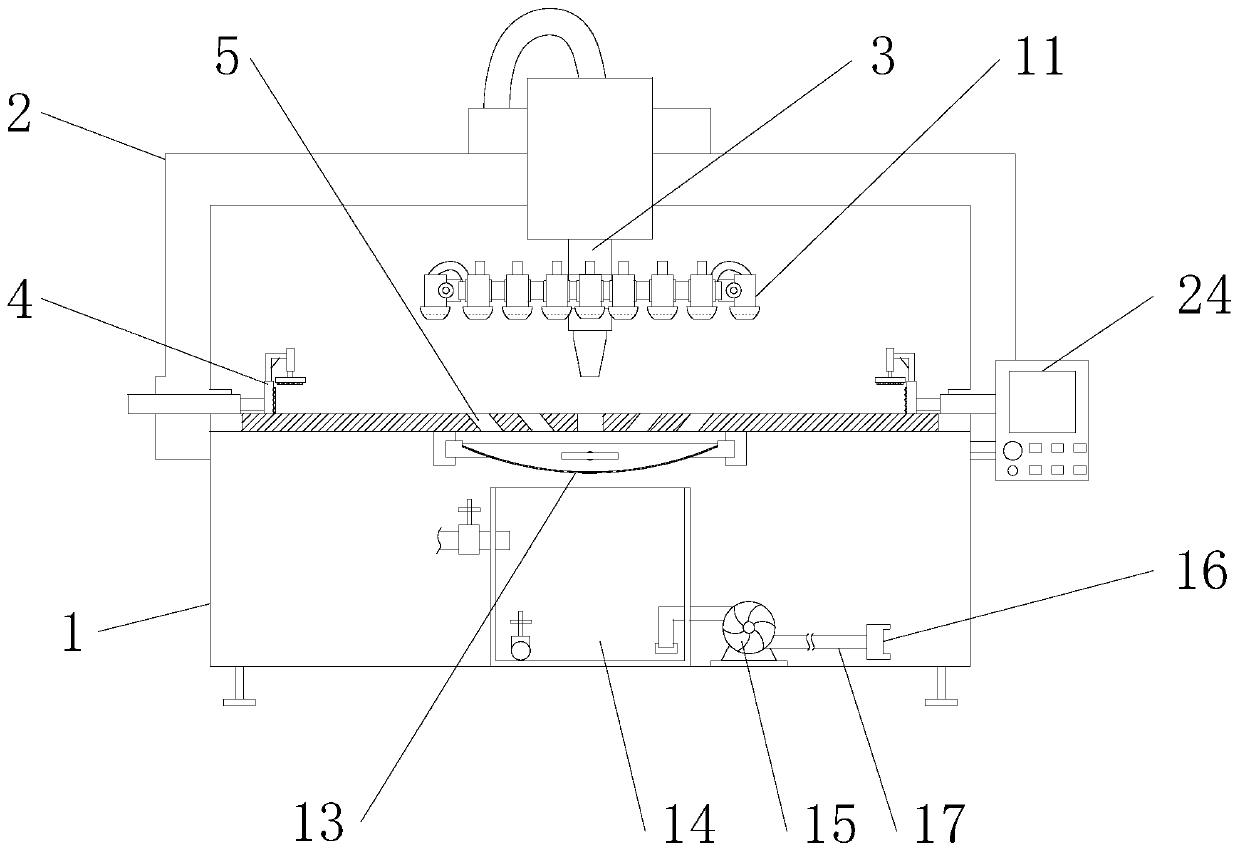

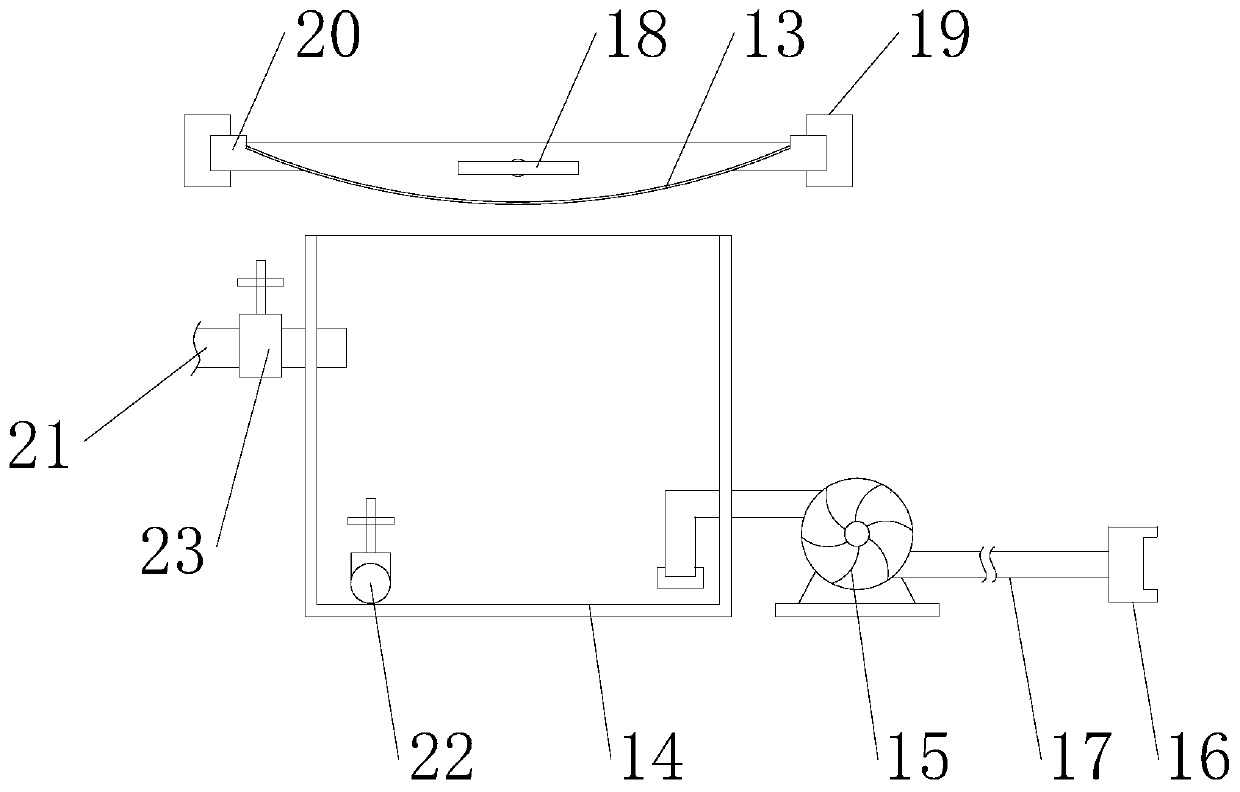

Cutting device for sheet metal processing

PendingCN110842380AAvoid causing harmEliminate fire hazardsLaser beam welding apparatusWater circulationFire hazard

The invention relates to a cutting device for sheet metal processing. The cutting device comprises a lathe body, a walking frame and a laser cutting head, the lathe body is provided with a clamping device and a flow guide hole, a water circulation mechanism is arranged in the lathe body, the outer periphery of the laser cutting head is provided with a protective mechanism, the protective mechanismincludes a clamp, a hollow ring and a plurality of water spray components, each water spray component include a connection seat, a water curtain nozzle and a connection pipe, the water circulation mechanism includes a filter screen, a water tank, a circulation pump and a water supply joint, and the clamping device includes a jacking air cylinder, a clamping plate and a plurality of pressing components. In the cutting device for sheet metal processing, a water curtain can be used for cooling and intercepting high-temperature sparks to prevent the sparks from harming operators and prevent hidden fire hazards; collection of waste debris such as the sparks is simple and convenient to realize, and the difficulty of equipment cleaning is reduced; water recycling is realized, and water resourcesand processing cost are saved; and sheet metal parts in different shapes and sizes can be fixed, the application scope is wide, and the fixing effect is good.

Owner:苏州市金典精密制造有限公司

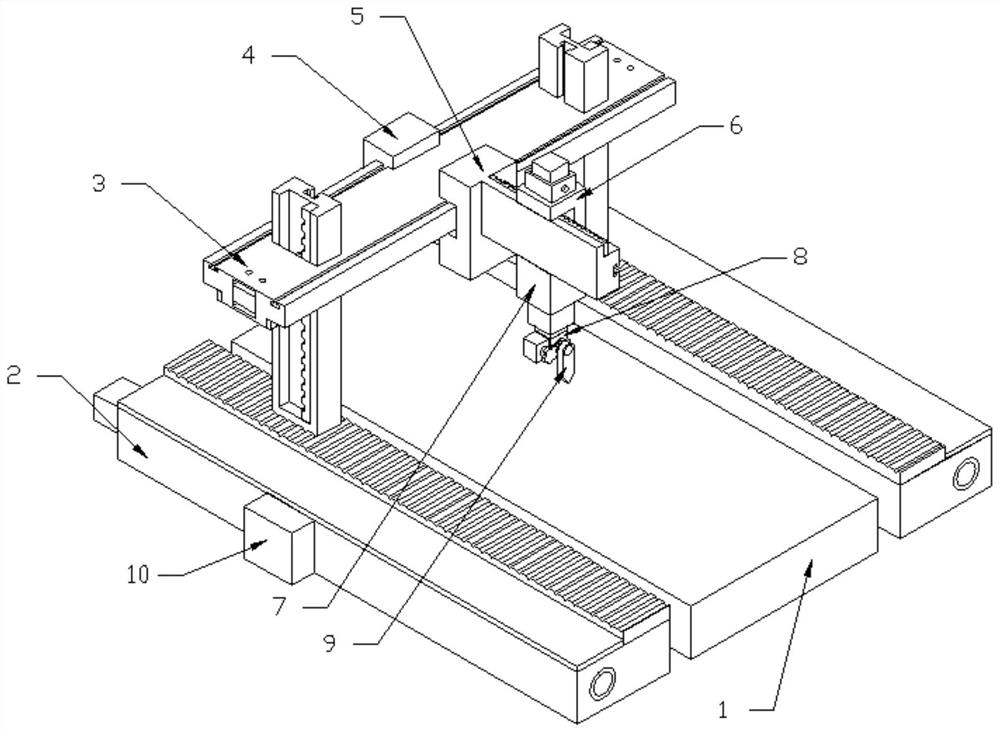

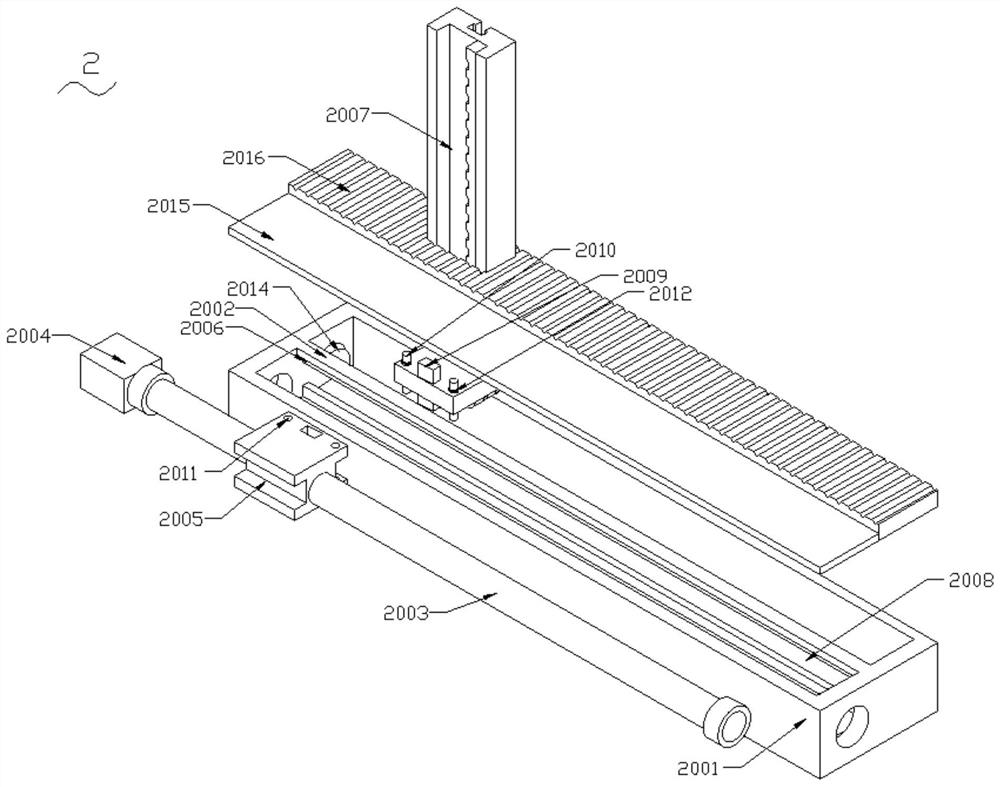

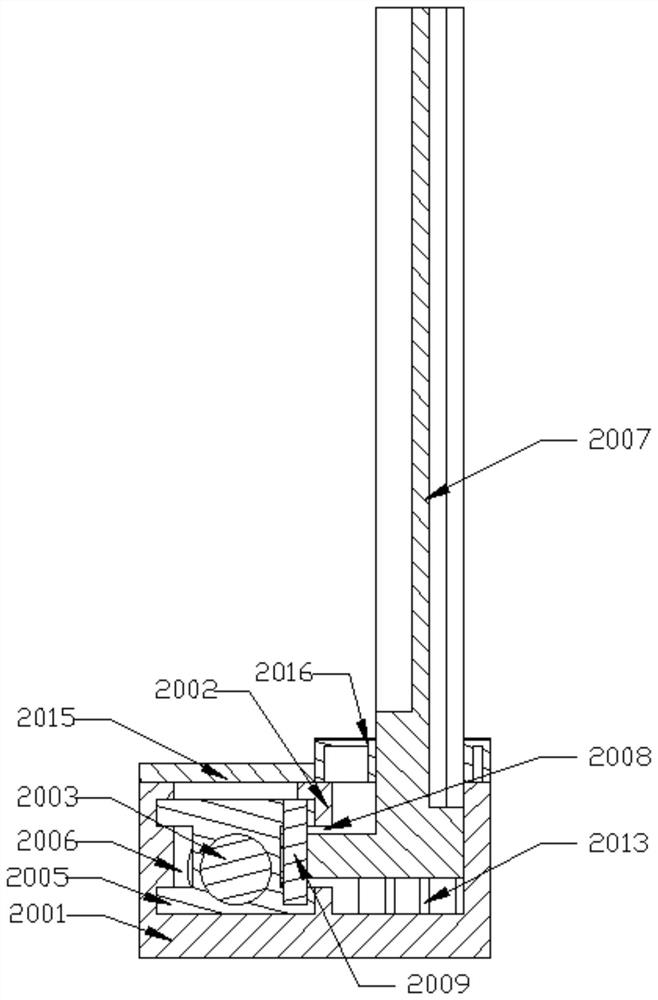

Plasma positioning cutting device based on X-Y-Z-axis system

InactiveCN107755866AImprove processing efficiencyAvoid harmPlasma welding apparatusDrive motorEngineering

The invention discloses a plasma positioning cutting device based on an XYZ three-axis system, relates to the technical field of plasma cutting, and solves the problem in the prior art that parts after cutting cannot be directly transported away and easily cause personal injury; it includes a processing table, a plasma The spray gun, the clamping device for clamping the plasma spray gun, and the XYZ axis movement assembly that is arranged on the processing table to drive the plasma spray gun to move freely along the X-axis direction, the Y-axis direction and the Z-axis direction, and also includes a conveyor belt and drives the clamping device The driving motor that drives the conveyor belt to move while rotating, the driving motor is arranged in the processing table, the output shaft of the driving motor is connected with the clamping device through the toothed belt A, and the output shaft of the driving motor is connected through the rack and pinion mechanism Connect with conveyor belt. By implementing the technical proposal, it is possible to drive the cut part away from the cutting position while driving the jig to rotate, so as to save energy and improve the safety factor.

Owner:弘毅天承知识产权股份有限公司

Feeding device for TTS NC front feeding swing-type plate shearing machine

InactiveCN108161115AReduce frictionSolve problems that seriously threaten the personal safety of operatorsShearing machinesShearing machine accessoriesHydraulic cylinderGear wheel

The invention relates to the technical field of plate shearing machine equipment, and discloses a feeding device for a TTS NC front feeding swing-type plate shearing machine. The feeding device comprises a base plate. Pedestals are fixedly installed at the bottom of the base plate. Main hydraulic cylinders and a motor are sequentially arranged at the top of the base plate from left to right. The output ends of the main hydraulic cylinders are fixedly connected with main hydraulic rods. The tops of the main hydraulic rods are fixedly connected with a fixing plate. According to the feeding device for the TTS NC front feeding swing-type plate shearing machine, a screw rod and balls are arranged, the screw rod at one side of a cone gear is driven to rotate with the motor, the screw rod can drive a feeding plate to move left and right on a fixing rod, and thus boards can be driven to move on the balls. The balls are arranged in corresponding grooves, and the friction between the boards andthe fixing plate can be reduced; and then a shear knife is used for shearing, the problem that operators need to push the boards to the lower side of the shearing knife and thus the personal safety ofthe operators can be seriously threatened is solved, the mechanical feeding purpose is achieved and the working efficiency is improved.

Owner:安徽省天坛重工机床制造有限公司

Cutting machine for production and processing of fitness equipment

ActiveCN113042806AImprove performanceAvoid manual cuttingOther manufacturing equipments/toolsTube shearing machinesGrindingEngineering

The invention discloses a cutting machine for production and processing of fitness equipment. The cutting machine comprises an operation table and a stretching mechanism; two mounting grooves and a positioning groove are formed in the operation table, a groove is formed in the top wall of the operation table, an air pump is fixedly connected to the bottom wall of the operation table, and extending mechanisms are slidably connected into the mounting grooves; the stretching mechanism is used for stretching out a pipe, the stretching mechanism further comprises mounting blocks, air inlet pipes, a first hose, a piston column, an air storage cavity, a return spring and a first pressure release valve, the mounting blocks are slidably connected into the corresponding mounting grooves in a sleeved manner and are of a hollow structure, and clamping mechanisms are fixedly connected to the upper surfaces of the mounting blocks; and the air inlet pipes are fixedly connected with the bottom walls of the corresponding mounting blocks in a penetrating manner. Compared with the prior art, the cutting machine has the advantages that the efficiency is higher, the use is convenient, the automation degree is high, the production efficiency is higher, automatic grinding can be carried out while cutting is carried out, manual grinding is avoided, and the labor intensity is reduced.

Owner:南通力人健身器材有限公司

Wood rough machining mechanism

InactiveCN107253235AIncrease the number ofPrevent the phenomenon of rolling downFeeding devicesCircular sawsEngineeringTool wear

The invention discloses a wood rough machining mechanism. The mechanism comprises a wood transport device, a work table, a cutting device and a wood bit collecting device; the wood transport device is close to the wood feeding starting end of the work table or the wood transport device makes contact with the wood feeding starting end of the work table, the wood transport device comprises a slope type conveying device and a horizontal conveying table, the cutting device is used for cutting wood placed on the work table, and the wood bit collecting device is used for collecting wood bits generated after cutting of the cutting device. The mechanism has the beneficial effects of being simple in procedure, convenient, low in cutting defective percentage, small in tool wear, high in cutting speed, and capable of achieving simultaneous cutting of multiple pieces of wood and removing bits.

Owner:薛忠来

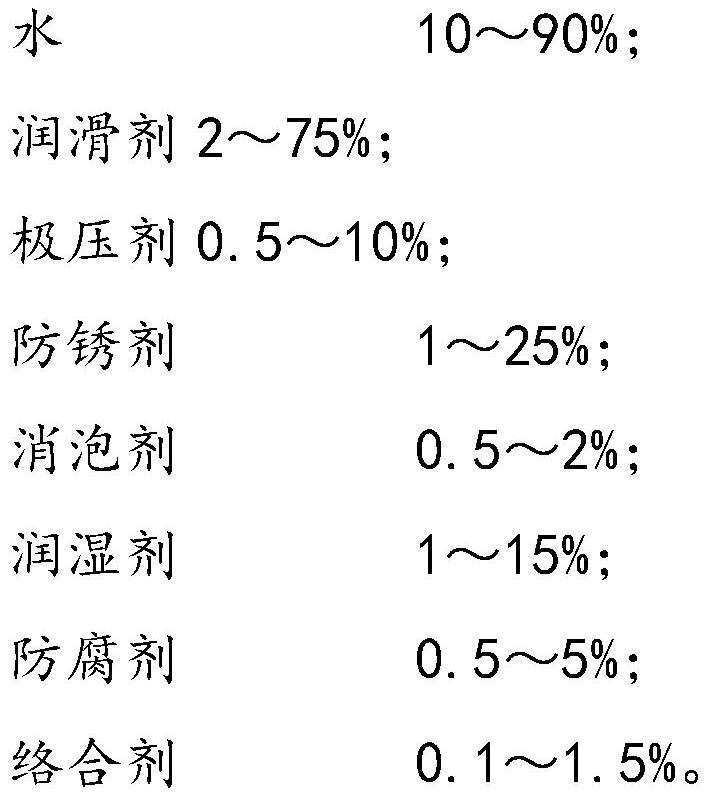

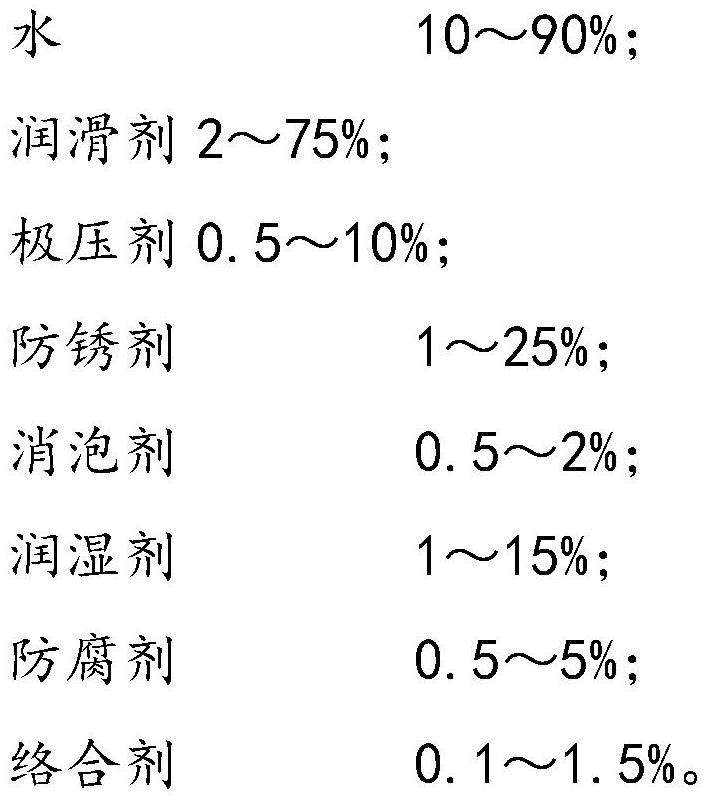

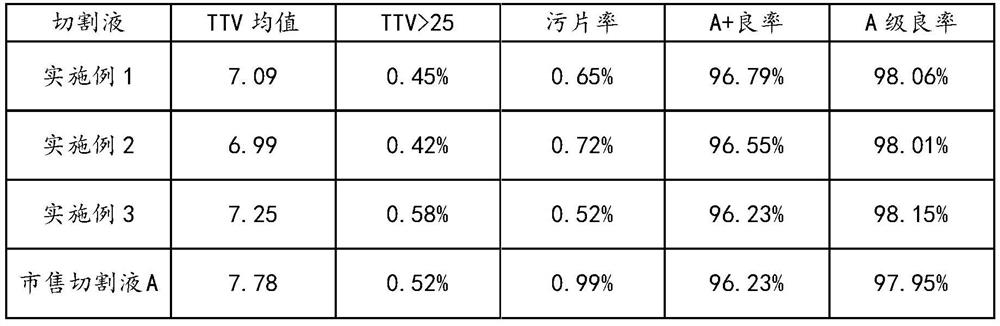

Cutting fluid for cutting large-size silicon wafer by diamond wire and preparation process of cutting fluid

PendingCN112961726AImprove the lubrication effectImprove permeabilityLubricant compositionDicing tapeWire cutting

The invention relates to the technical field of cutting fluids, and discloses a cutting fluid for cutting a large-size silicon wafer by a diamond wire and a preparation process of the cutting fluid. The cutting fluid comprises the following components in parts by mass: a defoaming agent, a wetting agent and a lubricating agent are compounded, so that the lubricity and seepage force of the cutting fluid are improved, and the cutting fluid can permeate into a space between a wire net of a diamond wire and a silicon wafer or a space between the wire net and silicon wafer scraps so as to form a layer of lubricating film, so that damage, stress and micro cracks caused by cutting are reduced. Meanwhile, the surface of a large-size silicon wafer which is being cut can be rapidly cooled, micro powder generated in the cutting process can be effectively dispersed into a mixed solution composed of water, a lubricating agent and a wetting agent, and the situation that silicon powder is gathered on the cutting local part, and consequently cutting of the silicon wafer is affected or damaged is avoided.

Owner:JINWAN GAOJING SOLAR ENERGY TECH CO LTD +1

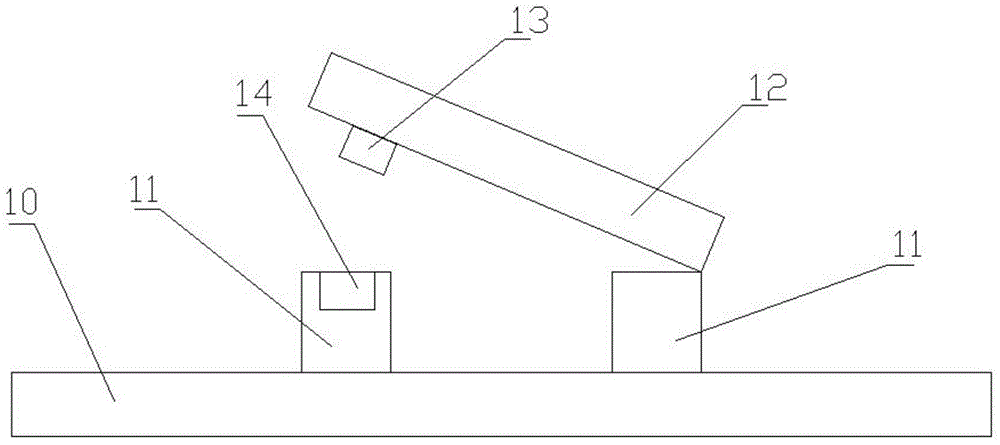

Wood fixed-length cutting mechanism

InactiveCN107042544AIncrease the number ofNo need for manual markingCircular sawsReciprocating motionEngineering

The invention discloses a wood fixed-length cutting mechanism. The wood fixed-length cutting mechanism comprises a workbench and a cutting device, wherein the cutting device is used for cutting wood placed on the workbench; wood support frames are arranged on the workbench, and the plurality of wood support frames in the same row are distributed at intervals from a wood feeding beginning end in the workbench to a wood feeding ending end in the workbench in the length direction of the workbench; wood can be supported on the plurality of wood support frames in the same row; a fixed-length baffle is arranged at the wood feeding ending end in the workbench, and the fixed-length baffle is in slide fit with the workbench and used for limiting the reached position of wood feeding on the workbench; and the cutting device is in slide fit with the workbench and capable of carrying out reciprocating motion in the width direction of the workbench. The wood fixed-length cutting mechanism disclosed by the invention has the technical effects of being simple and convenient in fixed-length procedure, low in cutting defective rate, less in tool wear, high in cutting speed and capable of realizing simultaneous cutting for a plurality of pieces of wood.

Owner:薛忠来

A tile automatic paper cutting and pasting device

ActiveCN106628358BLow costPrevent slippingLiquid surface applicatorsWrapping material feeding apparatusControl systemCoating

The invention provides a tile automatic paper cutting and sticking device. The tile automatic paper cutting and sticking device comprises a machine frame and a control module. A chain conveying mechanism which is used for conveying tiles is arranged on the machine frame. A paper cutting mechanism, an adhesive coating mechanism and a detection module are arranged on the chain conveying mechanism, wherein the detection module is used for detecting the position of the tiles. The paper cutting mechanism and the adhesive coating mechanism are in transmission connection with conveying chains of the chain conveying mechanism, and the paper cutting mechanism, the adhesive coating mechanism and the detection module are in communication connection with the control module. Due to the fact that the paper cutting mechanism and the adhesive coating mechanism are in transmission connection with the conveying chains of the chain conveying mechanism, the paper cutting mechanism and the adhesive coating mechanism can obtain the power from the conveying chains, the paper cutting mechanism, the adhesive coating mechanism and the conveying chains conduct synchronous actions, and compared with the conventional technical scheme, the scheme has the advantages that the situation that a complicated control system is adopted to achieve synchronous actions is avoided, and the cost is relatively low. Meanwhile, due to the fact that the adhesive coating mechanism is arranged, automatic adhesive coating is achieved, and the tile automatic paper cutting and sticking device is suitable for the paper sticking working procedure of the tiles with the small size.

Owner:QUANZHOU INST OF EQUIP MFG

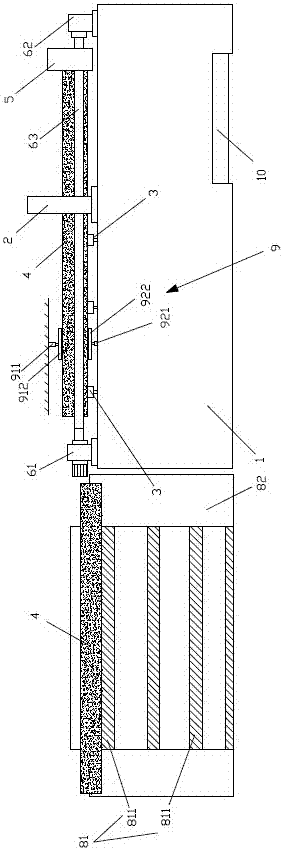

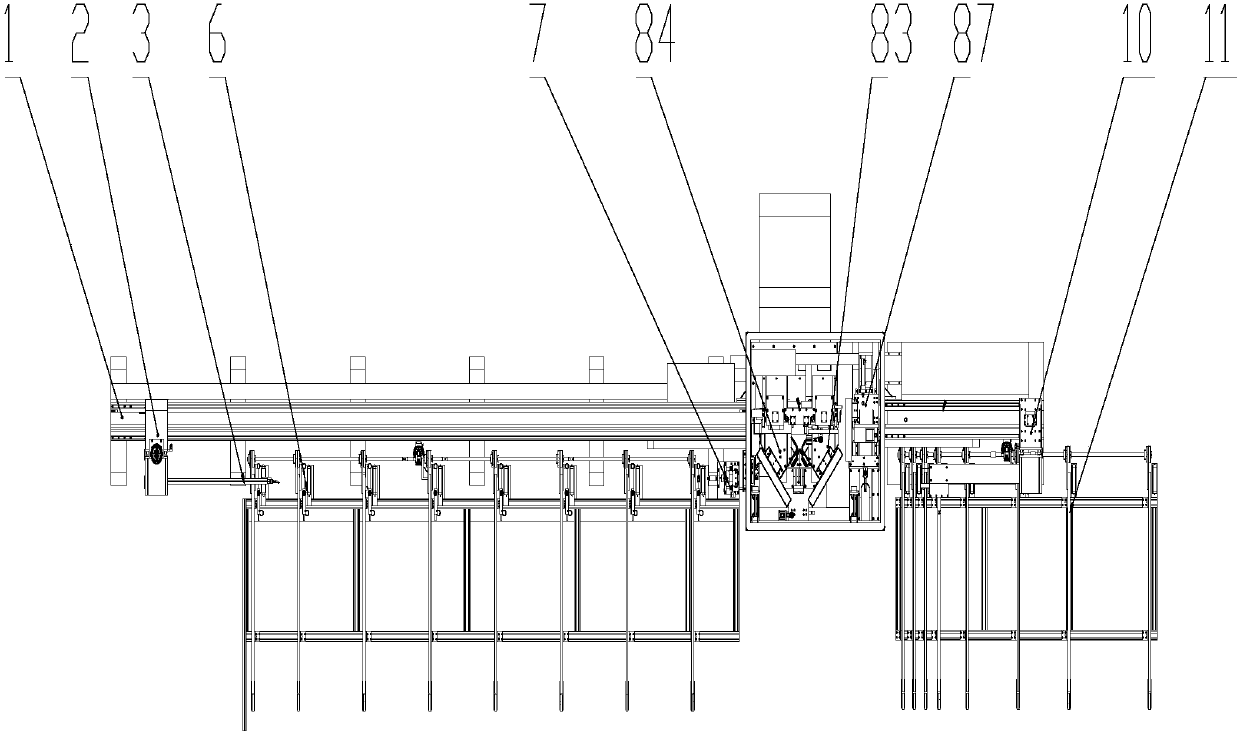

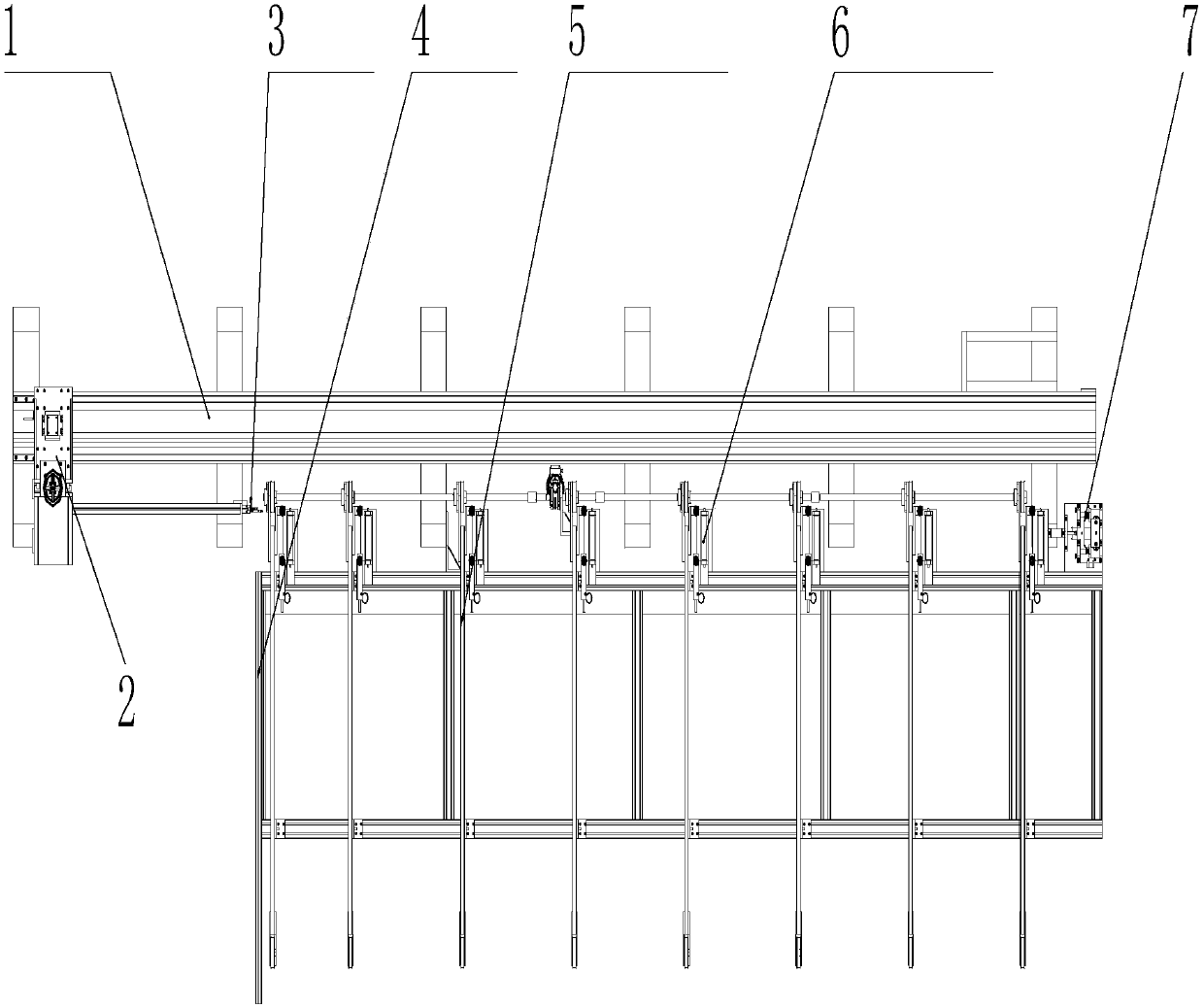

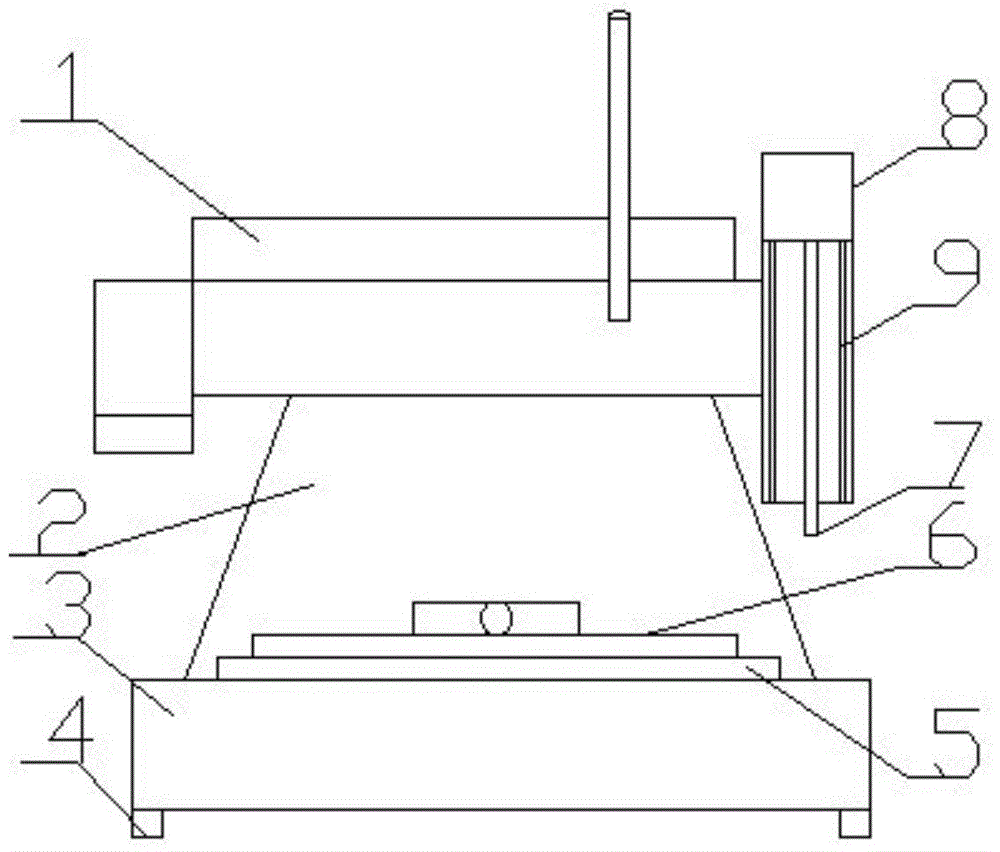

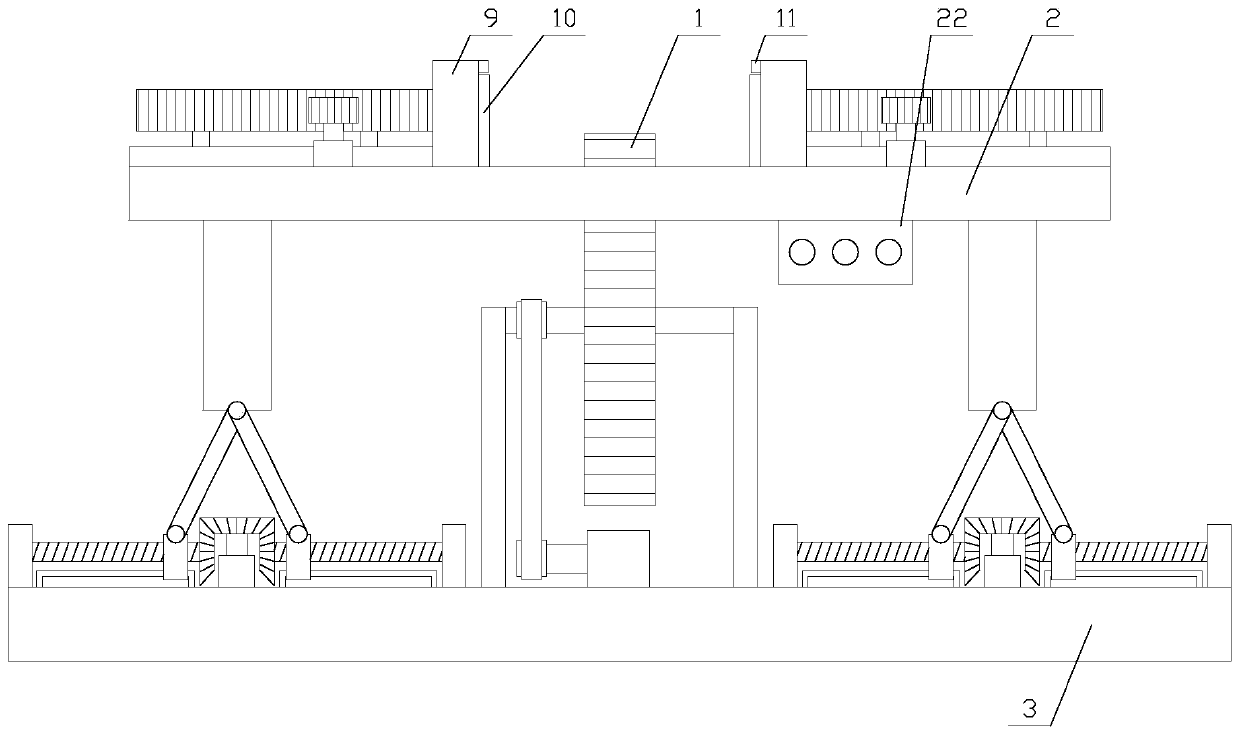

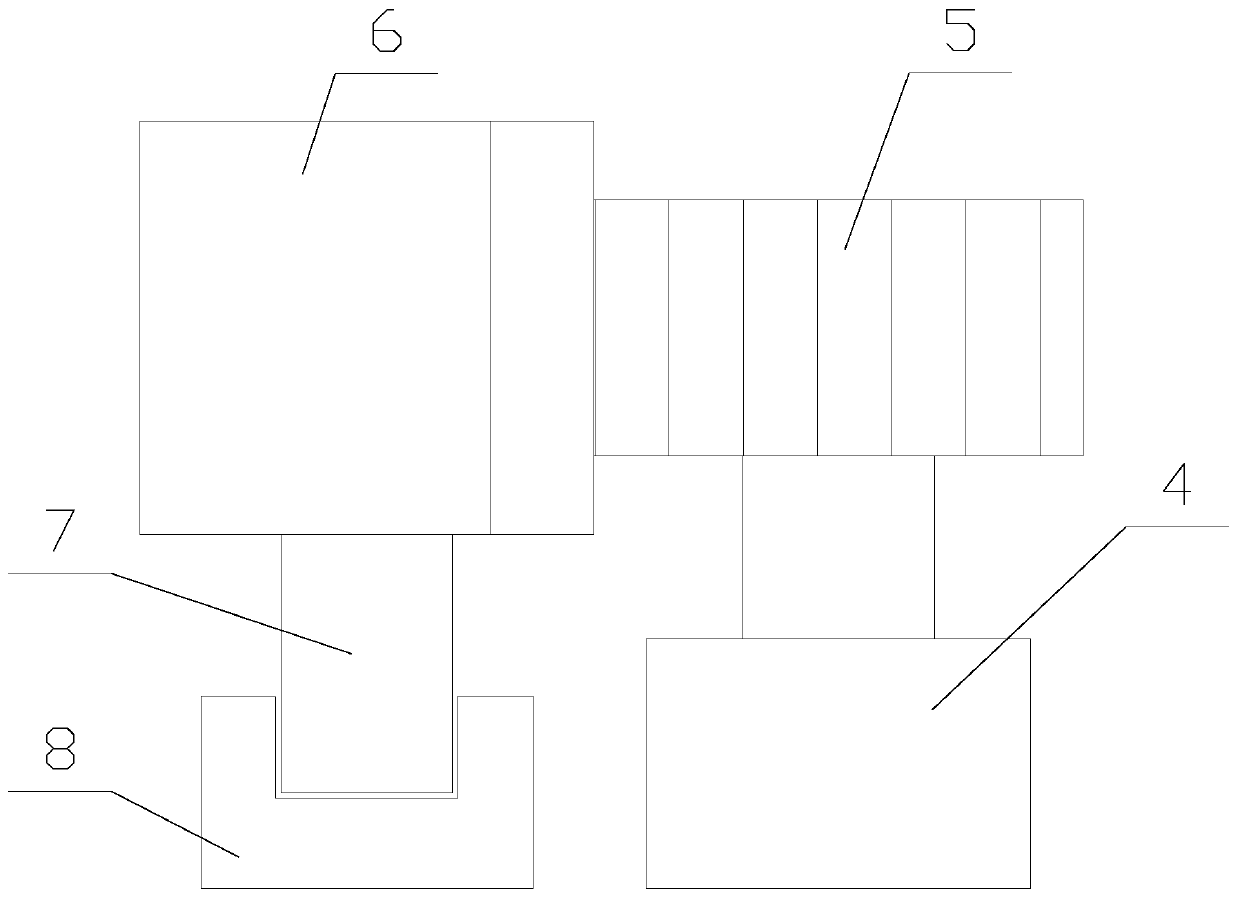

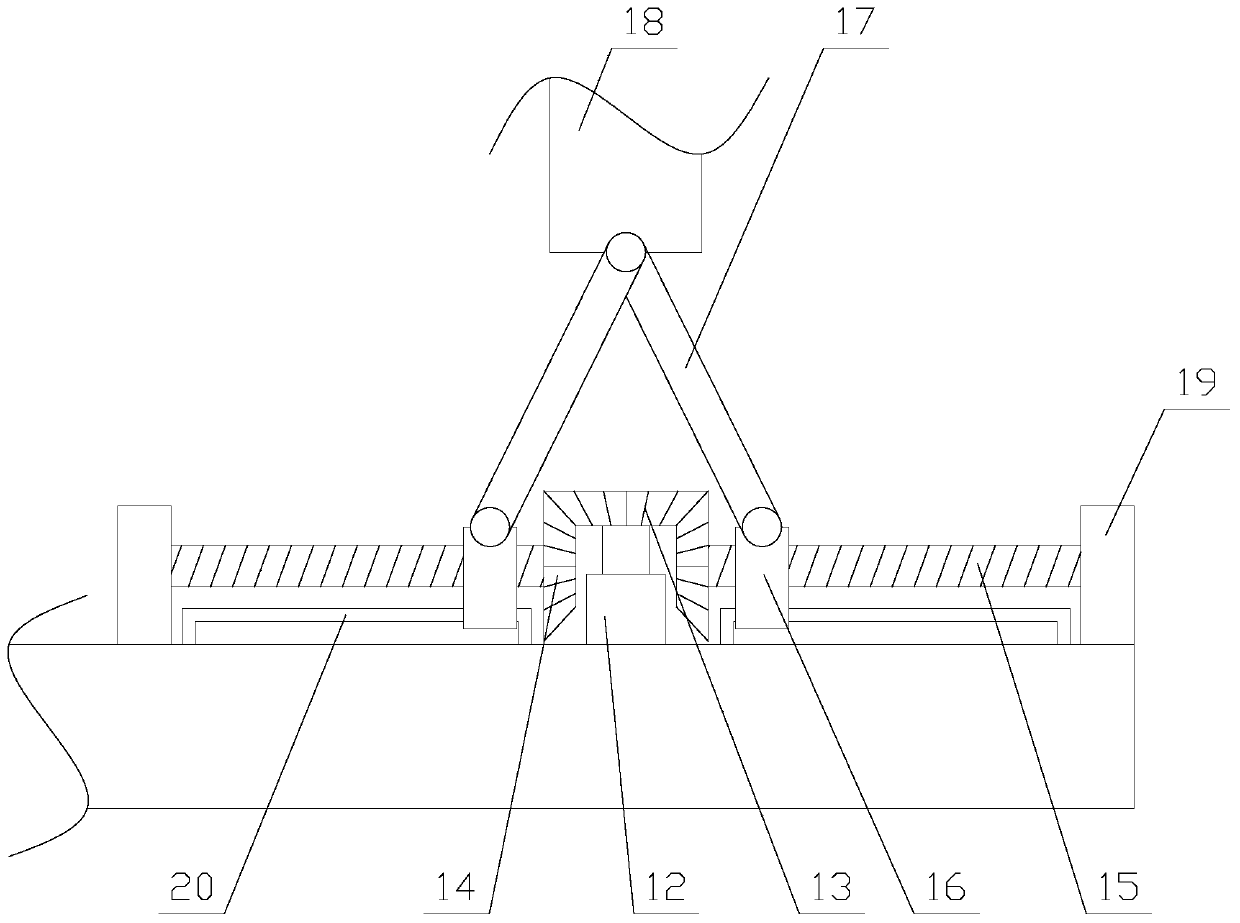

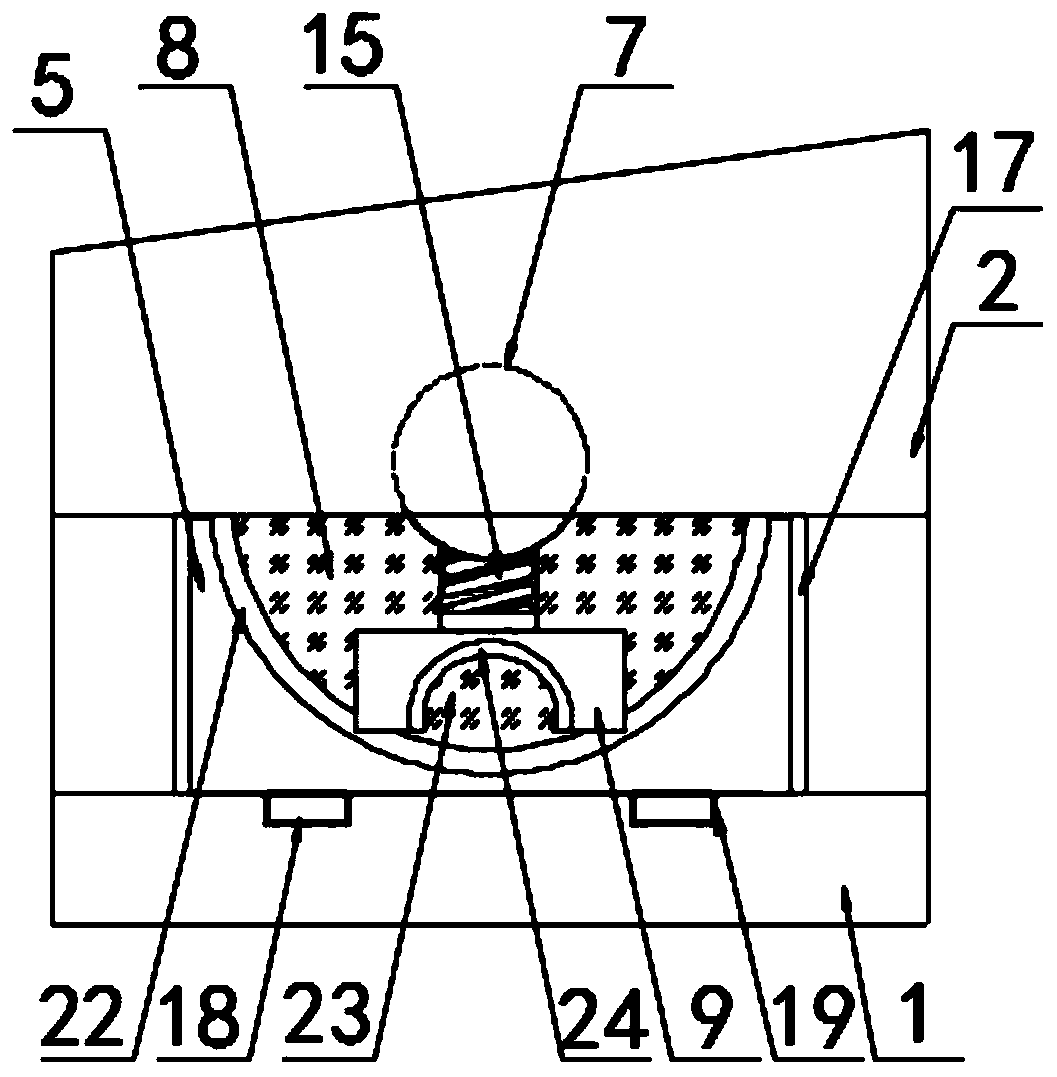

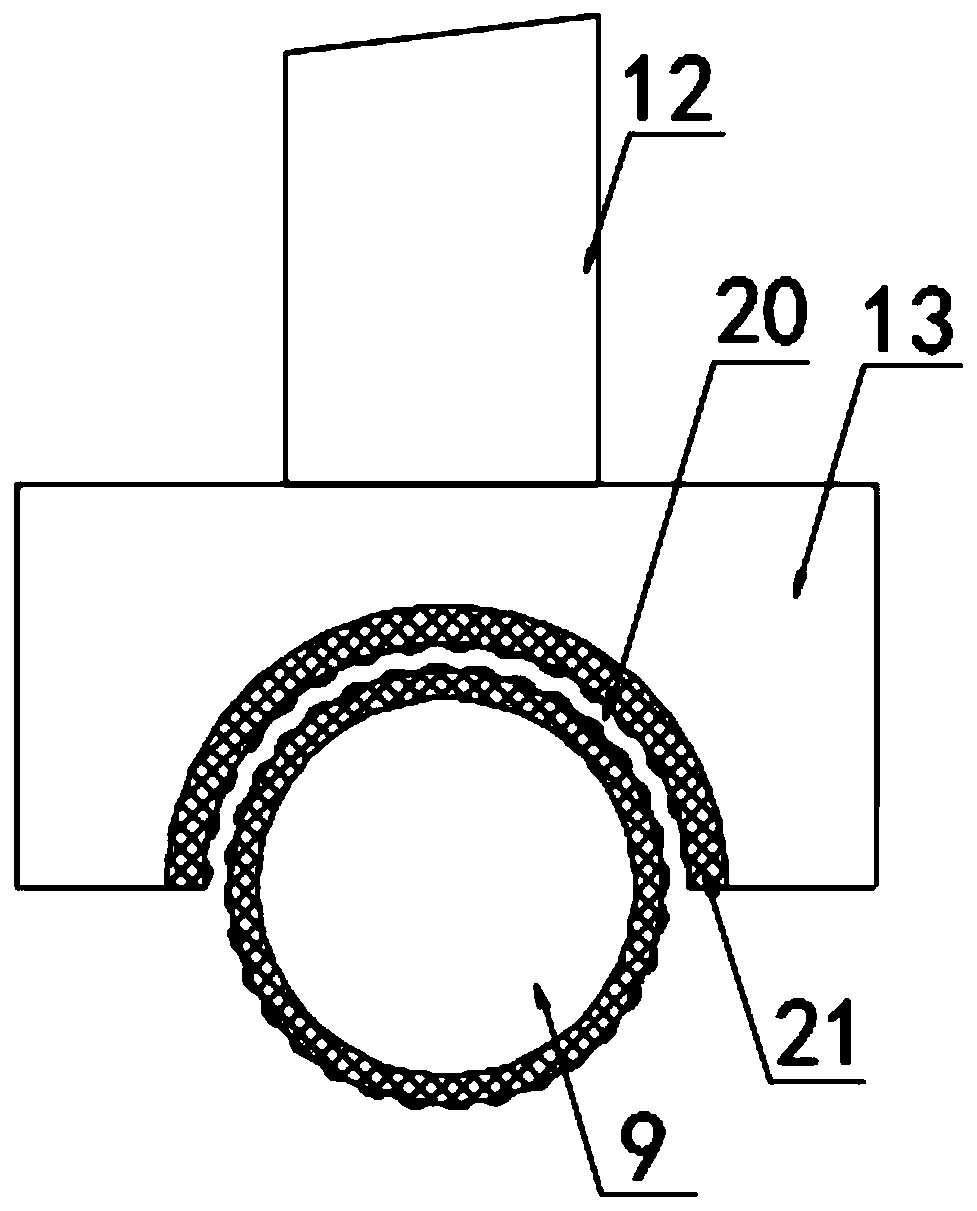

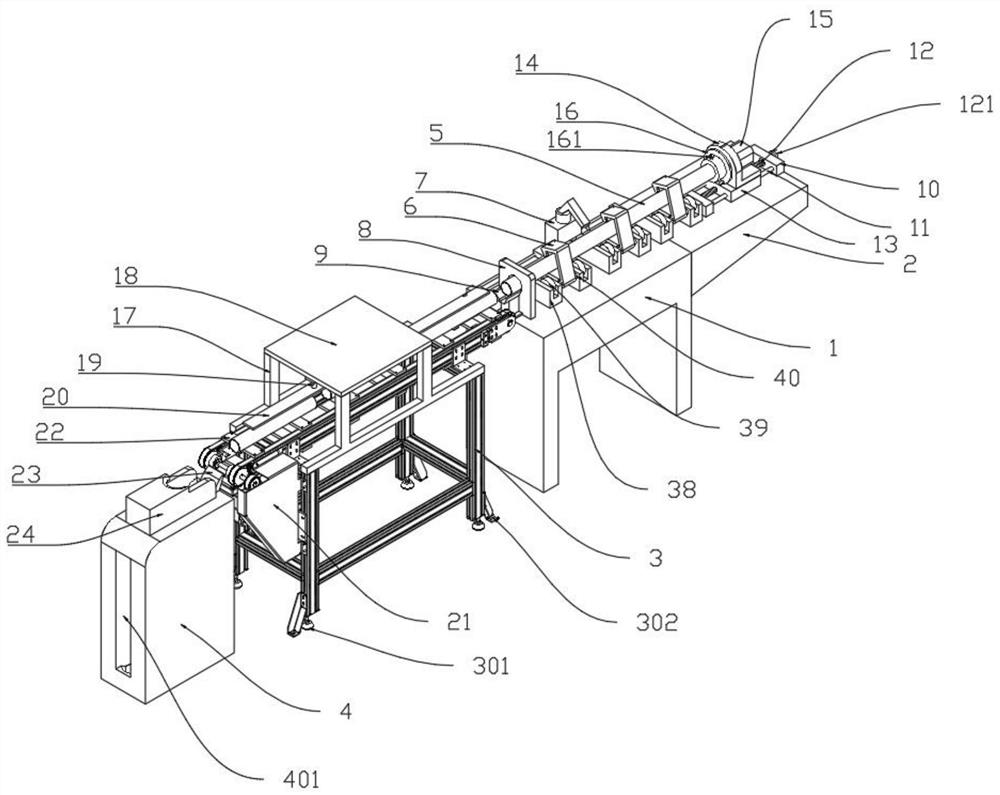

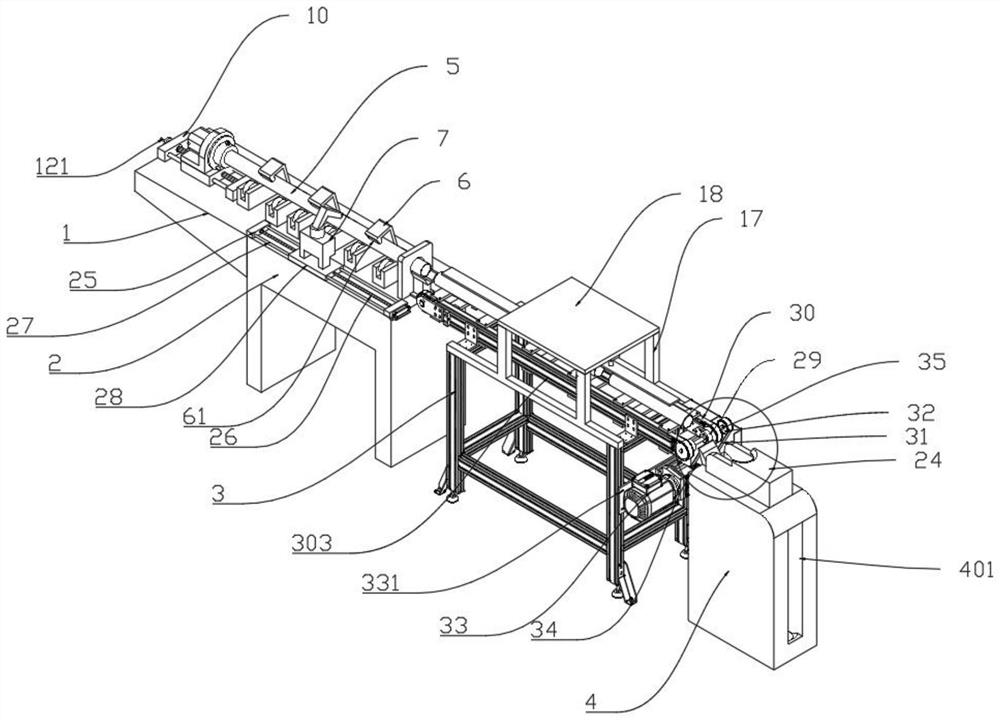

Sectional material sawing equipment

PendingCN110193628APrevent up and downAvoid the problem of shaking from side to sideMetal sawing devicesMechanical engineering

The invention relates to the technical field of aluminum plastic door and window sawing equipment, in particular to sectional material sawing equipment. The sectional material sawing equipment comprises an automatic feeding mechanism, a machine head mechanism and an automatic discharging mechanism, wherein the automatic feeding mechanism, the machine head mechanism and the automatic discharging mechanism are sequentially designed according to the feeding direction of a sectional material; the automatic feeding mechanism comprises a feeding machine frame, a feeding power mechanism on the feeding machine frame is used for controlling a feeding pneumatic claw, one side of the feeding pneumatic claw is provided with a positioning backup plate, an automatic input frame is arranged above the positioning backup plate, a plurality of material supporting and pressing mechanisms are arranged on the automatic input frame, and an initial positioning mechanism is arranged at the tail end of the automatic input frame; the machine head mechanism comprises a machine head frame, a middle working table is arranged on the machine head frame, a left machine head and a right machine head are arranged on the middle working table, a middle horizontal pressing block is arranged between the left machine head and the right machine head, a right machine head receding mechanism is arranged on one side ofthe right machine head, and a working table receding mechanism is arranged on the machine head frame on one side of the middle working table. The sawing equipment has the beneficial effects that the cutting precision is improved, and left and right shaking of the sectional material is avoided.

Owner:JINAN CGMA CNC MACHINERY CO LTD

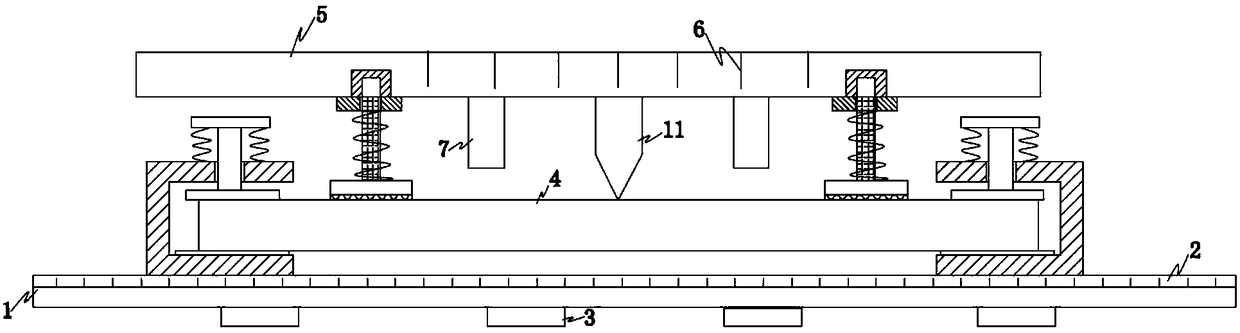

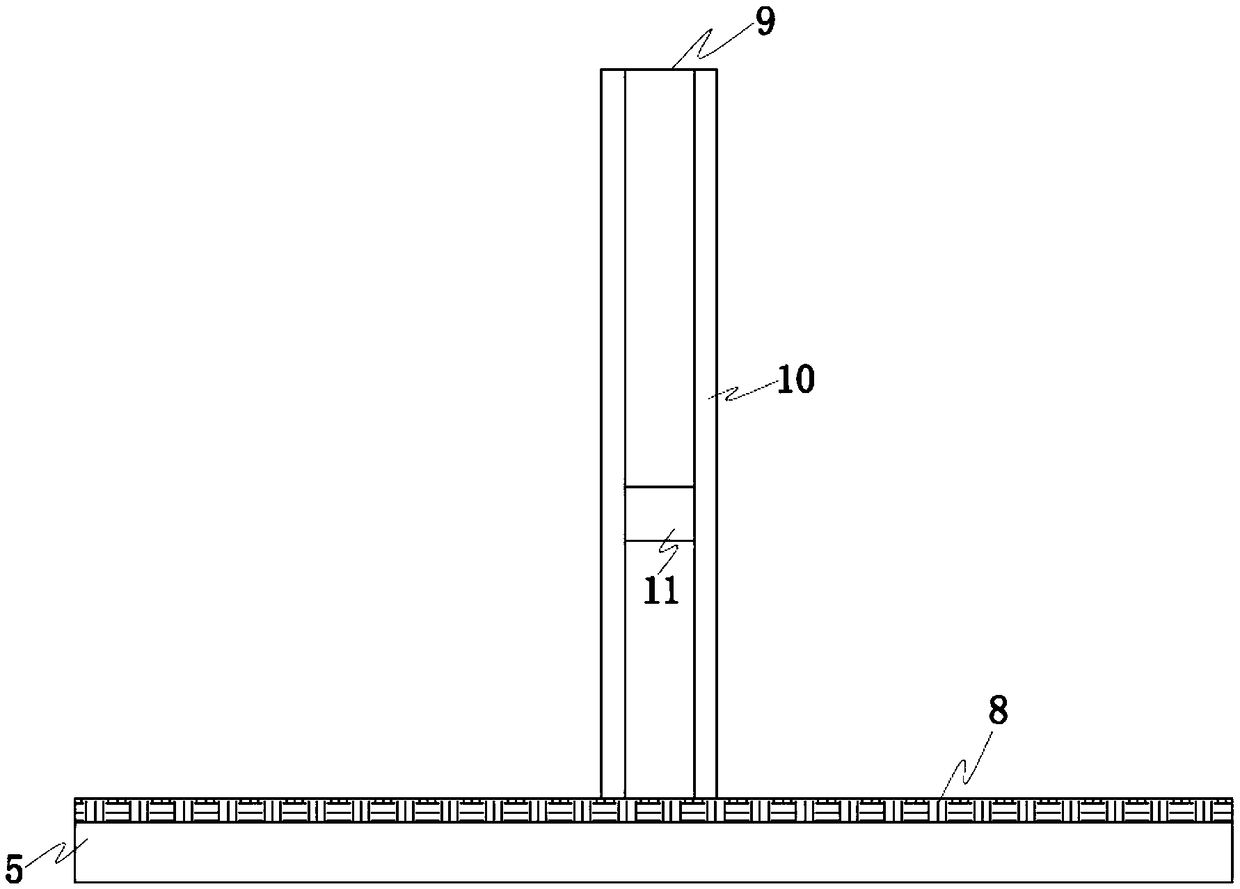

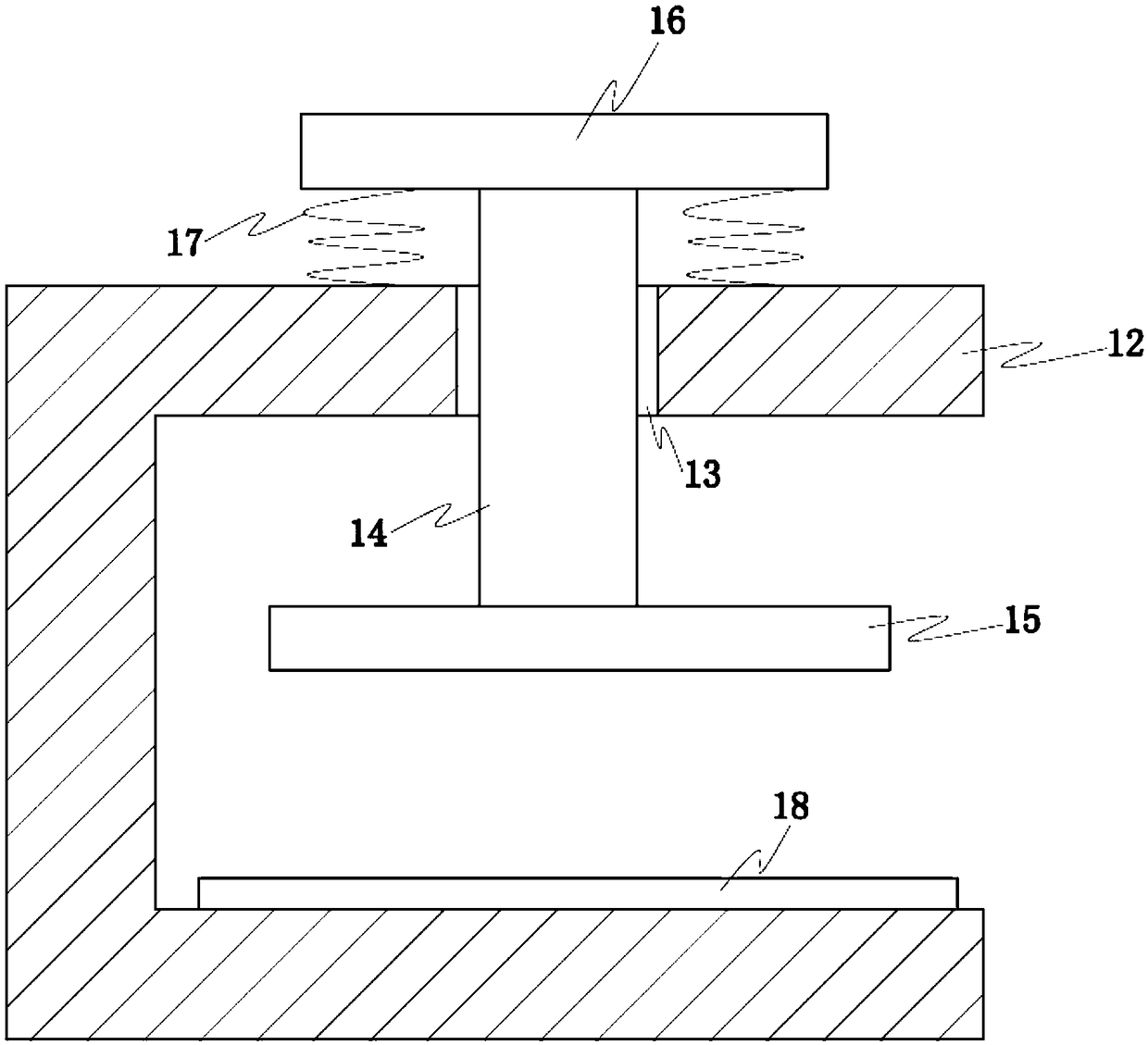

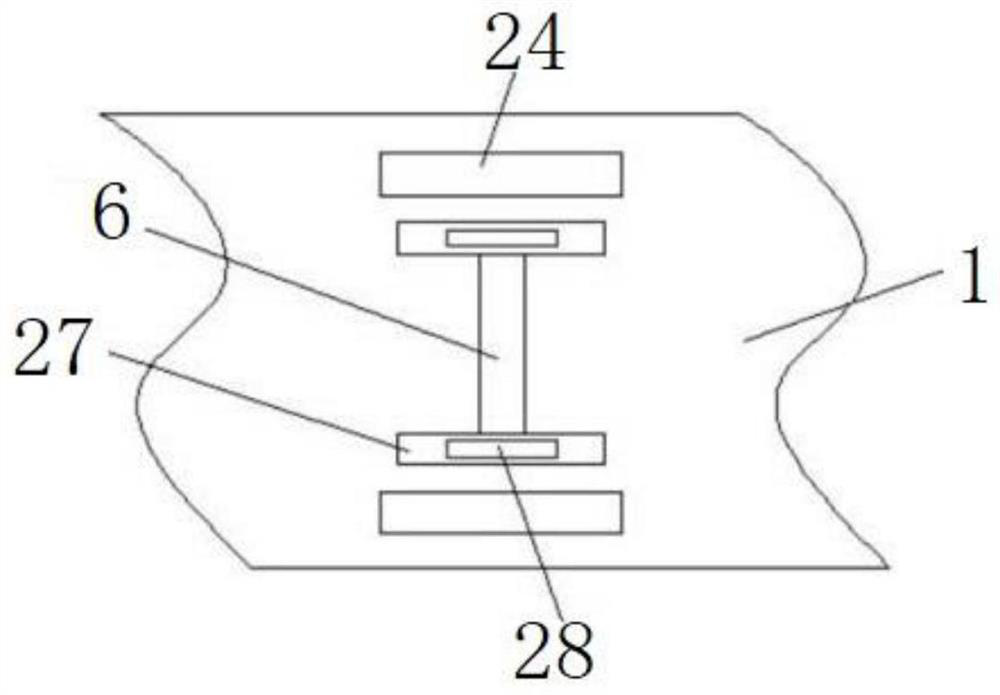

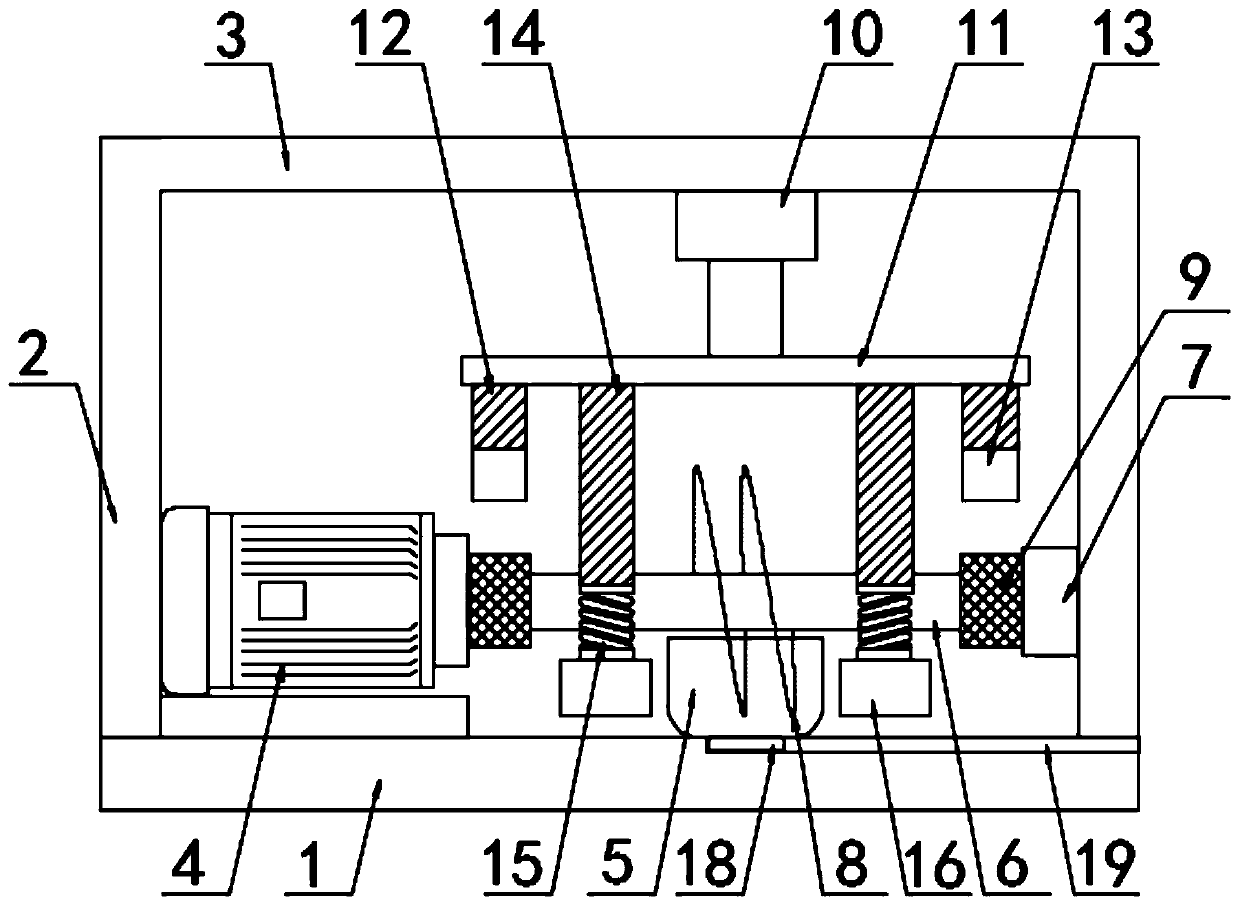

Building material cutting machine

InactiveCN104551959AReduce vibrationAvoid affecting cutting accuracyGrinding machinesGrinding wheelBuilding material

The invention discloses a building material cutting machine, and relates to the field of machinery industry. The building material cutting machine comprises a base, a grinding wheel, a motor, a bracket and a protecting cover, wherein the motor is fixedly arranged on the bracket, the bracket is fixedly arranged on the base, a rotary building material clamping device is arranged on the base, a damping device is arranged under the rotary building material clamping device, a nanometer silencing layer is arranged on the inner side of the protecting cover, the rotary building material clamping device is detachably connected with the base, and the damping device is detachably connected with the rotary building material clamping device. The building material cutting machine has the advantages that a building material can be cut along different directions, so the different processing requirements are met; the vibration of the building material cutting machine in the running process is effectively reduced, so the influence on cutting accuracy of the building material is avoided; the replacement and maintenance are convenient, and the service life is prolonged.

Owner:HENAN GAODUAN FLOOR ENG

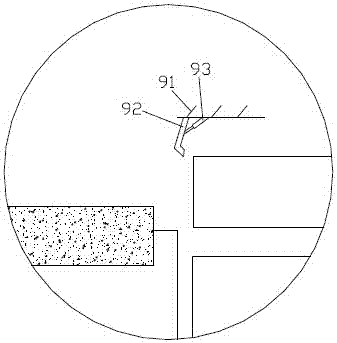

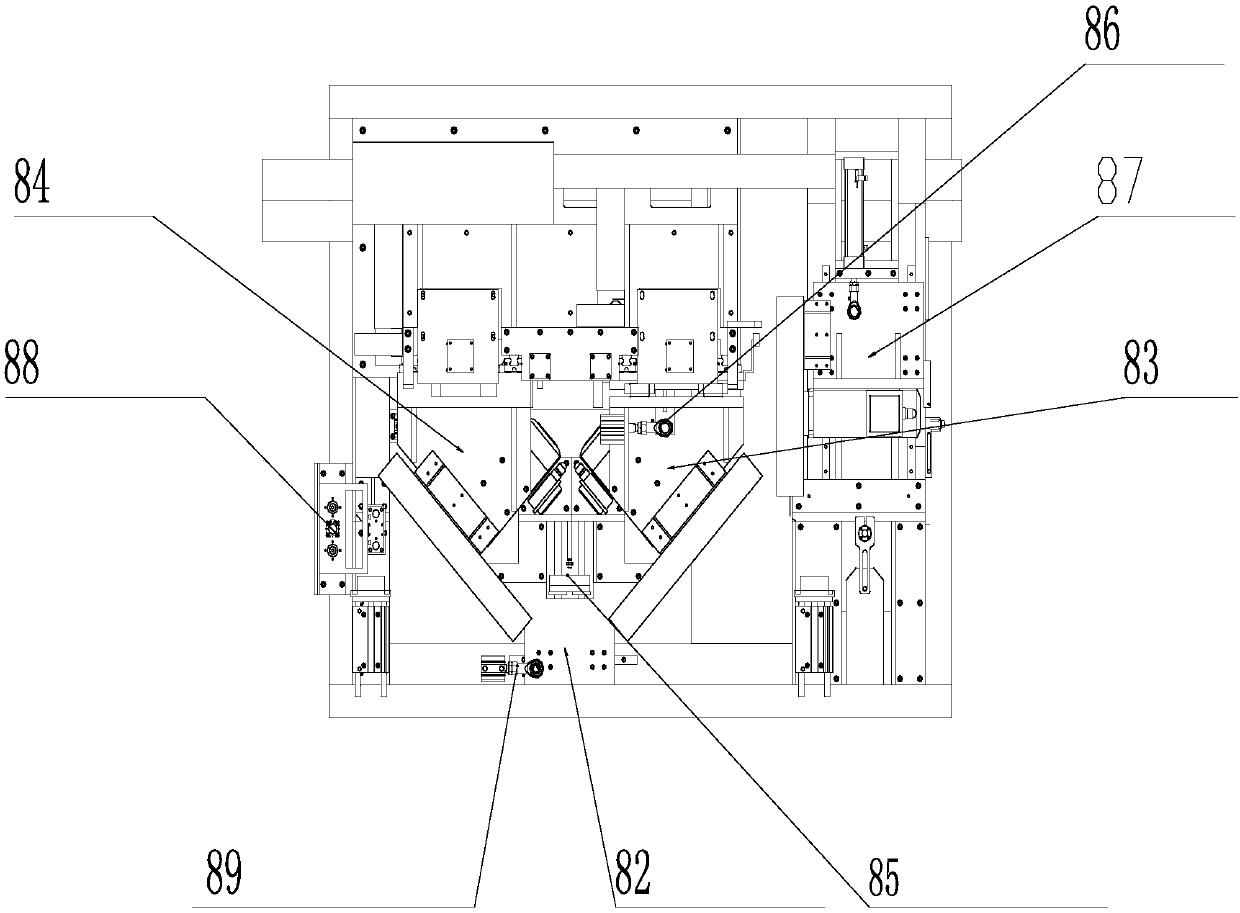

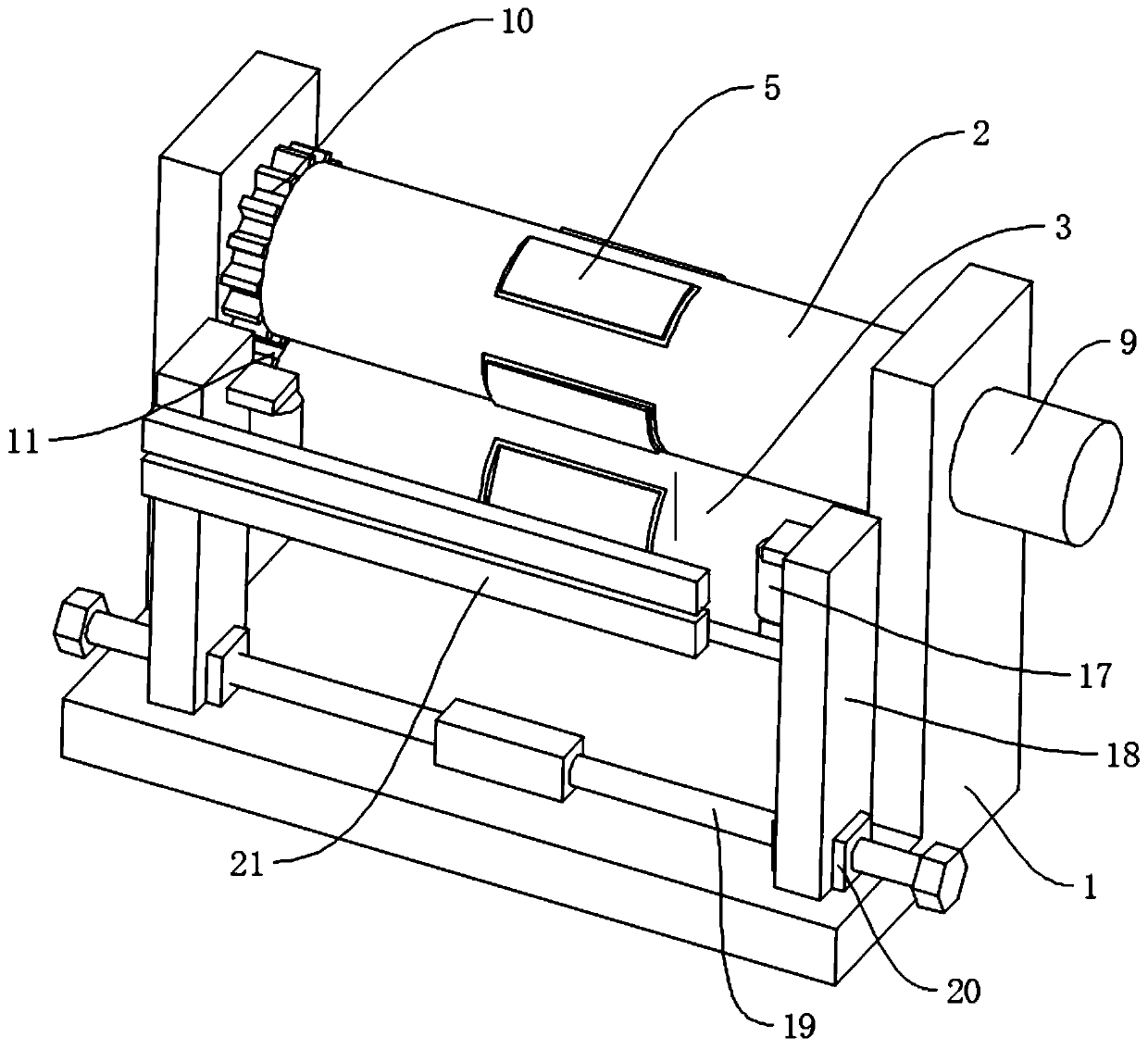

Full-automatic right-angle cutting device

PendingCN110270715AGuaranteed cutting accuracyImprove cutting efficiencyMetal sawing devicesMechanical engineeringEngineering

The invention relates to a full-automatic right-angle cutting device. The full-automatic right-angle cutting device comprises a workbench, a cutting assembly and a positioning assembly; the cutting assembly comprises a cutting module capable of achieving vertical lifting; the positioning assembly is used for positioning a to-be-cut workpiece to the workbench and enabling one corner of the to-be-cut workpiece to be located under the cutting assembly; and the cutting module is used for cutting the corners of the to-be-cut workpiece when the cutting module moves downwards, and then a right-angle cutting opening is formed in each corner of the to-be-cut workpiece. According to the full-automatic right-angle cutting device, the to-be-cut workpiece is positioned on the workbench through the positioning assembly, one corner of the to-be-cut workpiece is located under the cutting assembly, and then the cutting precision is guaranteed; the corners of the to-be-cut workpiece are cut at a time when the cutting module in the cutting assembly moves downwards, the right-angle cutting openings are formed in the corners of the to-be-cut workpiece, and no portion needs to be cut at twice; and in addition, multiple pieces of to-be-cut workpieces stacked together can be cut each time, therefore, the cutting efficiency is greatly improved, automatic cutting is achieved, and the manual labor intensity is reduced.

Owner:武汉汉沙斯德自动化设备有限公司

Rapid sheet cutting device

InactiveCN111055338AEasy dischargeEnsure radial movementMetal working apparatusThin slabStructural engineering

The invention discloses a rapid sheet cutting device. According to the technical scheme, the rapid sheet cutting device comprises a machine base; the machine base is rotationally connected with a driving cutting roller and a driven cutting roller; a cutting die cavity is formed in the side wall of the driving cutting roller; a cutting die is arranged in the cutting die cavity; a cutting cavity isformed in the side wall of the driven cutting roller; a collecting die is arranged in the cutting cavity; a collecting groove is formed in the collecting die; the machine base is provided with a driving assembly used for driving the driving cutting roller and the driven cutting roller to rotate; the collecting die is provided with a falling mechanism facilitating falling of copper sheets from thecollecting groove; the falling mechanism comprises a stripping plate connected with the collecting groove in a sliding mode, a spring groove formed in the bottom face of the collecting groove, and a spring which is arranged in the spring groove and drives the stripping plate to move away from the bottom face of the collecting groove. According to the invention, a thin plate can be quickly cut, anda copper sheet is machined; and the copper sheet can be conveniently and quickly discharged from the collecting groove.

Owner:嘉善卓润五金制品有限公司

Tile cutting machine

PendingCN109834856AIncrease stiffnessIncreased load-bearing capacityWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a tile cutting machine. The tile cutting machine comprises a sliding assembly for driving displacement of a cutting assembly, the sliding assembly comprises sliding rails andsliding blocks sliding on the sliding rails, the sliding rails are square sliding rails, and the sliding blocks are square sliding blocks. According to the tile cutting machine, the sliding rails in the tile cutting machine are the square sliding rails, and the sliding blocks in the tile cutting machine are the square sliding blocks, so that the feeding precision is better in the process of relative sliding, shaking is not prone to occurring, the square sliding rails are better in rigidity and better in bearing capacity and are not prone to being bent, and the cutting precision is ensured.

Owner:四川省万光机械设备有限公司

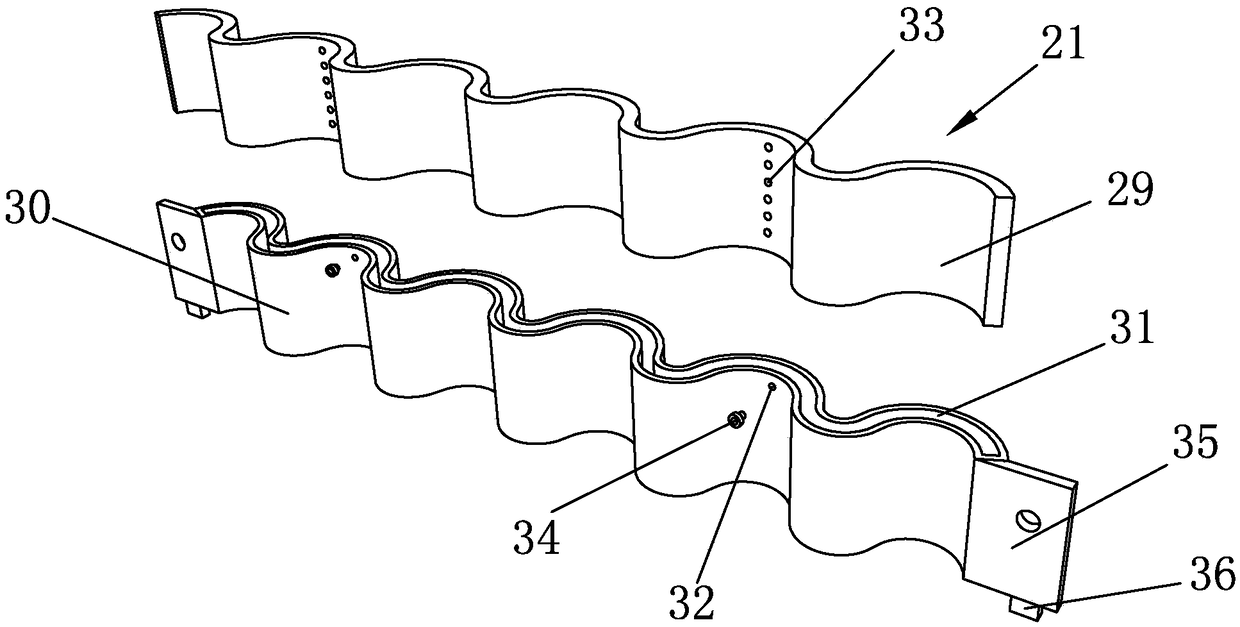

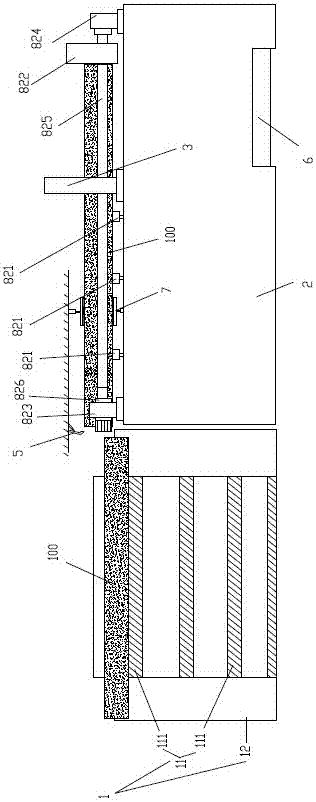

Stainless steel band cutting device

PendingCN112958823APlay a limiting roleAvoid affecting cutting accuracyShearing machinesMaintainance and safety accessoriesStructural engineeringSS - Stainless steel

The invention provides a stainless steel band cutting device which comprises a working platform; the working platform is provided with a steel band cutting mechanism used for cutting a steel band, a first elastic pressing and positioning mechanism and a second elastic pressing and positioning mechanism; the first elastic pressing and positioning mechanism and the second elastic pressing and positioning mechanism are arranged on the two sides of the steel band cutting mechanism and used for elastically extruding and positioning the steel band; the two sides of the cut steel belt can be limited; the situation that the steel belt deviates in the cutting process, and the shearing precision is affected is avoided; the distance between the pressing plate and the pressing cover of the working platform is elastically adjusted; limiting of steel belts with different thicknesses can be achieved; and adaptability is higher.

Owner:安徽达顺不锈钢有限公司

High-reliability wood cutting machine for building construction

InactiveCN109968465AImprove reliabilityImprove practicalityProfiling/shaping machinesGear wheelPulp and paper industry

The invention relates to a high-reliability wood cutting machine for building construction. The high-reliability wood cutting machine comprises a workbench, a cutting device and a bottom plate, and further comprises a fixing mechanism and two adjusting mechanisms; the fixing mechanism comprises two fixing assemblies; each fixing assembly comprises a first motor, a driving gear, a rack and a fixingplate; each adjusting mechanism comprises a lifting rod, a second motor, a driving bevel gear and two adjusting assemblies; and each adjusting assembly comprises a driven bevel gear, a screw rod, a slide block and an adjusting rod. According to the high-reliability wood cutting machine for building construction, through the adjusting mechanisms, the height of the workbench can be adjusted, accordingly, the height of the position, exposed out of the workbench, of the cutting device is adjusted, and the cutting requirements for different thicknesses of wood are met; and through the fixing mechanism, the to-be-cut wood can be fixed, and the situation that the wood shakes during cutting, and the cutting precision is influenced is avoided.

Owner:蒙泽喜

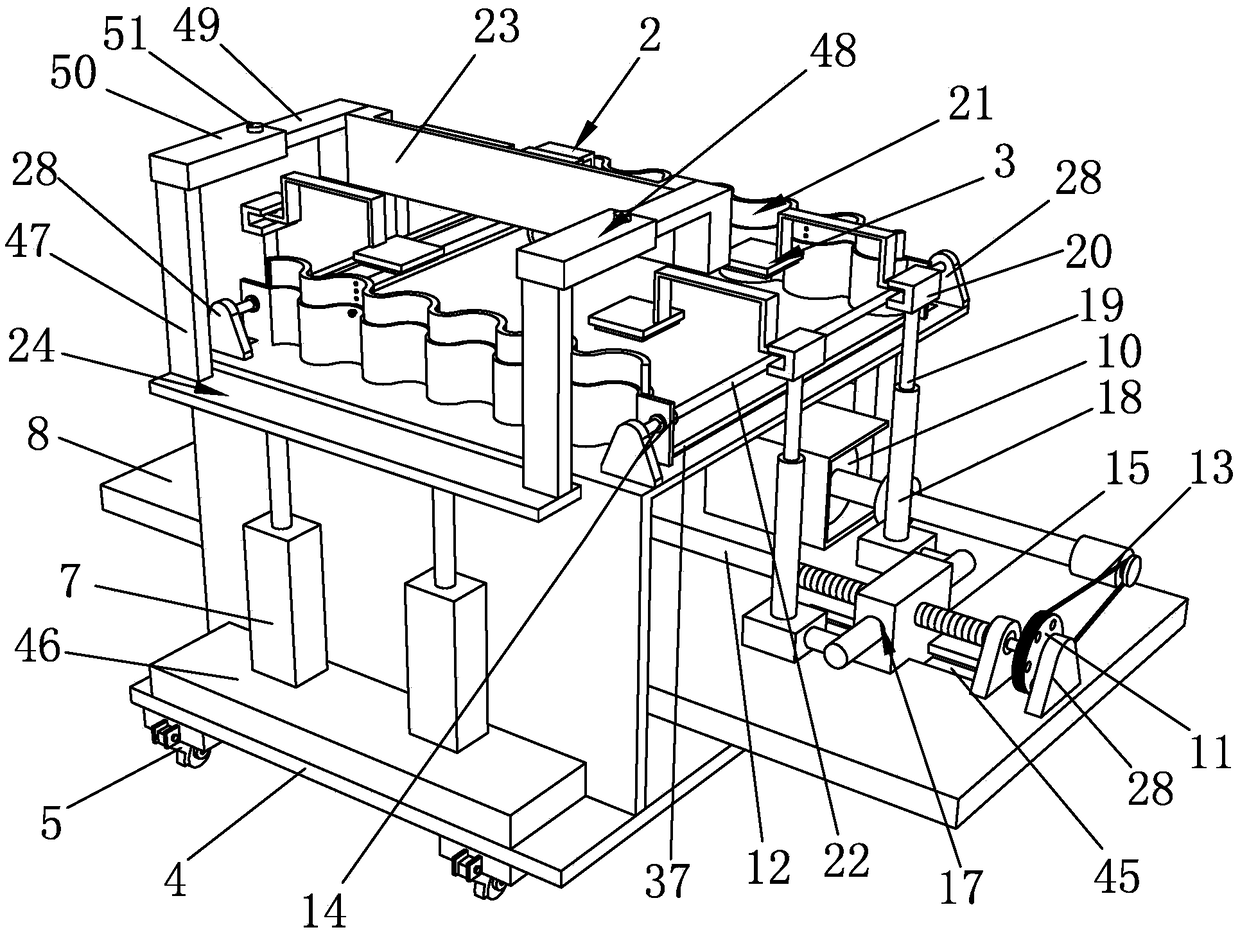

Cable tray pre-cutting device for ocean engineering

InactiveCN113319906AReduce labor intensityAffect healthMetal working apparatusPhysical healthWater storage tank

The invention discloses a cable tray pre-cutting device for ocean engineering and relates to the field of cable trays for ocean engineering. The cable tray pre-cutting device comprises a pre-cutting table and a cutting machine arranged on the pre-cutting table, wherein a tray placement table is fixedly mounted at the top of the pre-cutting table; a water storage tank is arranged at the bottom of the pre-cutting table; and a strip-shaped hole is formed in the tops of the pre-cutting table and the tray placement table. Through the arrangement of a movable cutting part, the cable tray pre-cutting device can perform cutting treatment on various brackets of different widths at a time; through the arrangement of an adjusting and fixing part, the purposes of accurately measuring and fixing a tray can be fulfilled, the labor intensity of workers can be reduced, and the cutting and pre-cutting accuracy of the cable tray pre-cutting device can be guaranteed; and through the arrangement of a spraying and cooling part, the purposes of cooling and dust falling can be fulfilled in the cutting process, the situation that the cutting accuracy is influenced by the high-temperature deformation of a cutting blade and a cutting part can be prevented, and the influence of generated smoke dust on the physical health of the workers can be avoided.

Owner:广州从益网络科技有限公司

Cutting device for LED screen processing

ActiveCN112171764AFix damageImprove cooling effectMetal working apparatusHydraulic cylinderEngineering

The invention discloses a cutting device for LED screen processing, and relates to the technical field of LED screen processing. The cutting device comprises a bottom plate; a vertical plate is detachably and fixedly arranged on one side of the top of the bottom plate; a first sliding groove is longitudinally arranged at the inner side of the vertical plate; a sliding block is slidably arranged inthe first sliding groove; a hydraulic cylinder is fixedly arranged at the top in the first sliding groove; the top end of the hydraulic cylinder is fixedly connected with the sliding block; a transverse plate is fixedly arranged on the inner side of the sliding block; a long plate is fixedly arranged at the bottom of the transverse plate; a second mounting block is fixedly arranged at the bottomof the long plate; a supporting rod is fixedly arranged at the bottom of the second mounting block; a cutter is fixedly arranged at the bottom end of the supporting rod; and protective mechanisms arerespectively fixedly arranged at the two sides of the supporting rod. According to the cutting device for the LED screen processing provided by the invention, the problems that an existing cutting device is not provided with a protective mechanism, sparks or trivial scraps generated when the cutting device cuts an LED screen splash around, and the sparks or trivial scraps easily enter human eyes to injure workers are solved.

Owner:上海义辰信息科技有限公司

Negative-pressure cutting device for artificial fur

ActiveCN111636183APrecise cuttingAvoid cutsSevering textilesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a negative-pressure cutting device for artificial fur. According to the technical scheme, the negative-pressure cutting device for the artificial fur comprises a rack, the rackis provided with a containing table for containing the artificial fur, and the rack is provided with a cutting mechanism for cutting the artificial fur placed on the containing table; the cutting mechanism comprises a cutting positioning plate placed on the artificial fur, an opening, a cutting frame, a cutting knife, a positioning assembly, a plush attracting assembly and a compaction assembly,the opening is formed in the cutting positioning plate and is larger than the to-be-cut position of the artificial fur, the cutting frame is placed on the cutting positioning plate, the cutting knifeis arranged on the cutting frame and used for cutting the artificial fur, the positioning assembly is arranged on the cutting frame and positions the accurate cutting position of the cutting knife, the plush attracting assembly is connected to the cutting frame and attracts plush, and the compaction assembly is used for fixing the artificial fur and preventing the artificial fur from being sucked.According to the negative-pressure cutting device, it is ensured that the plush is vertical when the artificial fur is cut, and therefore the plush is effectively prevented from being cut off, and the length of the plush is kept consistent.

Owner:JIASHAN LONGXIANG ARTIFICIAL FUR

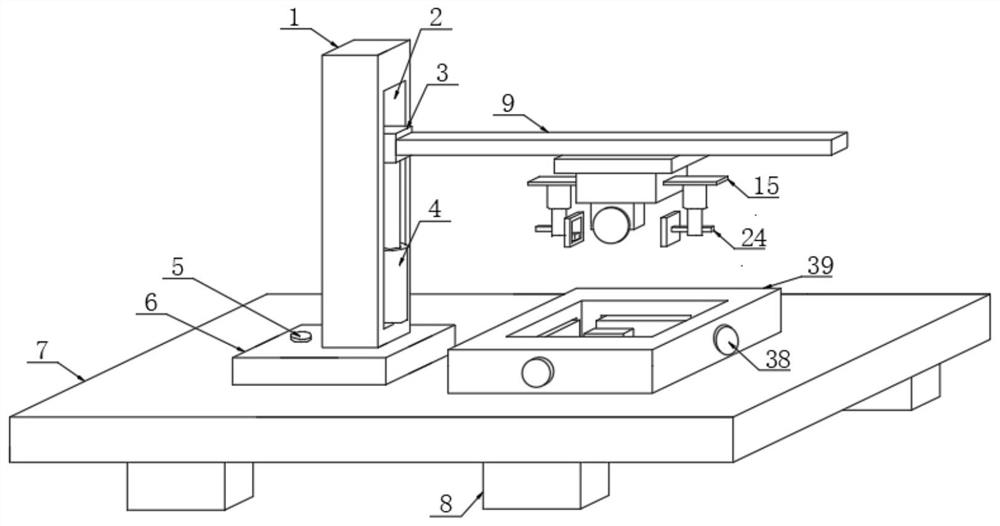

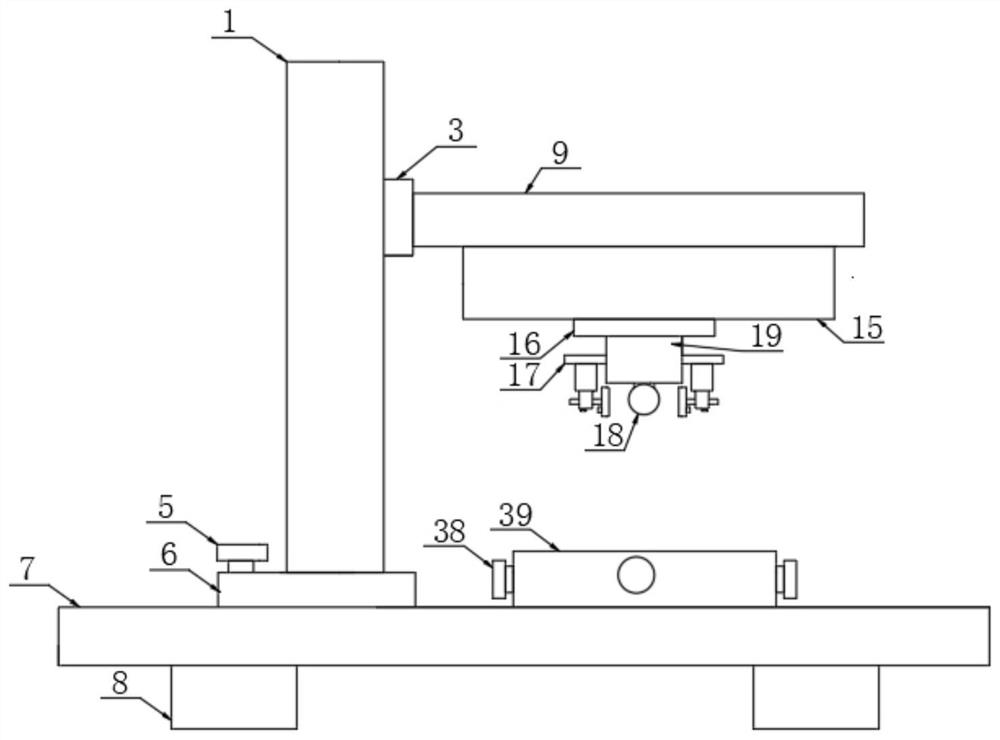

Five-axis spherical laser cutting device

The invention discloses a five-axis spherical laser cutting device. The five-axis spherical laser cutting device comprises a cutting platform, first longitudinal moving devices are arranged on the two sides of the cutting platform, a lifting cross beam is arranged between the two first longitudinal moving devices, a balance weight device is arranged on one side face of the lifting cross beam, and a transverse moving device is arranged on the other side face of the lifting cross beam; and a second longitudinal moving device is arranged on one side face of the transverse moving device, a telescopic arm is arranged on the lower end face of the second longitudinal moving device, a rotating device is arranged on the lower end face of the telescopic arm, a laser cutter is arranged on one side face of the rotating device, and a control module is arranged on one side face of the first longitudinal moving device. According to the device, five-axis freedom degrees can be formed, slope cutting is facilitated, the cutting precision can be improved, cutting errors are avoided, and the device production cost is reduced.

Owner:杭州圣通智能科技有限公司

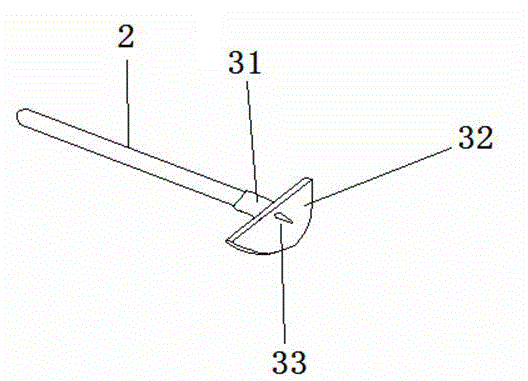

An intelligent bone crusher for spinal surgery

InactiveCN109225512BSmooth brakingAvoid affecting cutting accuracyGrain treatmentsSpinal columnHydraulic cylinder

The invention discloses an intelligent bone crusher for spinal surgery. The intelligent bone crusher comprises a working table, wherein side plates are arranged at the tops of two sides of the workingtable, top plates are arranged at the tops of the side plates, a servo motor and a striker plate are arranged on the working table, a rotating shaft is arranged at one end of the servo motor, a bearing is arranged at the end of the rotating shaft, a spin cutting blade is fixedly arranged on the rotating shaft, brake cylinders are fixedly sleeved outside the rotating shaft corresponding to two sides of the spin cutting blade, hydraulic cylinders are arranged at the bottoms of the top plates, pressure plates are arranged at the bottoms of the hydraulic cylinders, first pressure rods are arranged on two sides of the bottoms of the pressure plates, brake plates are arranged at the bottoms of the first pressure rods, and two second pressure rods are arranged on an inner side of each first pressure rod. According to the invention, by movably clamping a sliding foot with a sliding chute, the striker plate is convenient to move. When the striker plate is moved to the bottom of the spin cutting blade, debris caused by spirally cutting can be prevented from splashing out. After bone crushing work is completed, the striker plate can be removed from an open feeding hole and cleaned, thus being convenient to use.

Owner:孙元亮

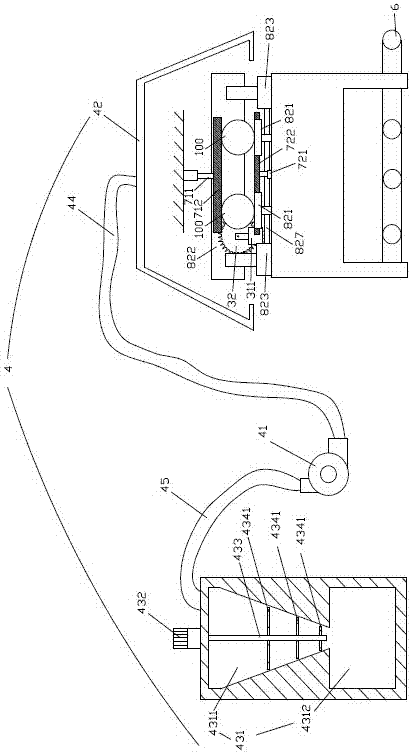

Pipe fitting cutting and transporting device

PendingCN113927179AAvoid affecting cutting accuracyImprove sexual functionLaser beam welding apparatusPipe fittingDrive shaft

The invention discloses a pipe fitting cutting and transporting device, which comprises a cutting table; an adjusting table is arranged on one side of the cutting table; an adjustable clamping mechanism is arranged on the adjusting table; a pipe fitting is clamped on the clamping mechanism; a rotary supporting mechanism is arranged below the pipe fitting; a movable laser cutting machine is arranged on the cutting table; a positioning plate is arranged on the cutting table; a through hole matched with the pipe fitting is arranged in the positioning plate; a pipe frame is arranged on one side of the positioning plate; a conveying frame is arranged on the other side of the cutting table; two symmetrically-distributed guide rails are arranged at the top of the conveying frame; conveying wheels are installed at the two ends of the guide rails; conveying chain plates are installed on the conveying wheels; lining plates are connected to the conveying chain plates through bolts; driving shafts are assembled in the conveying wheels; and one end of each driving shaft is connected with a driving device of which one side is provided with a receiving mechanism. Compared with the prior art, collection of cut pipe fittings can be effectively guaranteed, the situation that the cut pipe fittings directly fall to the ground and are damaged after being cut is avoided, the production quality of the pipe fittings is greatly improved, the labor cost is reduced, and the production efficiency is improved.

Owner:无锡水登机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com