Patents

Literature

46results about How to "Affect cutting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

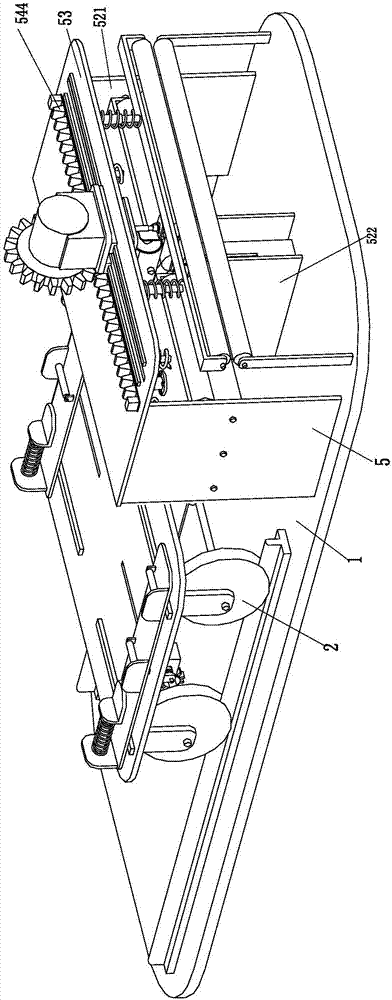

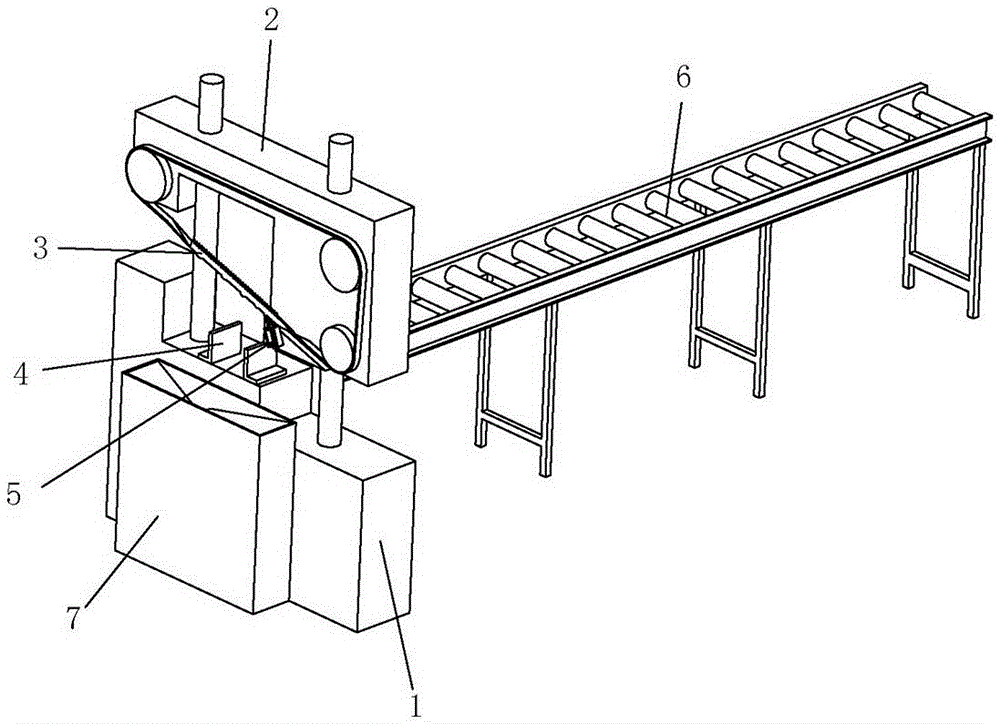

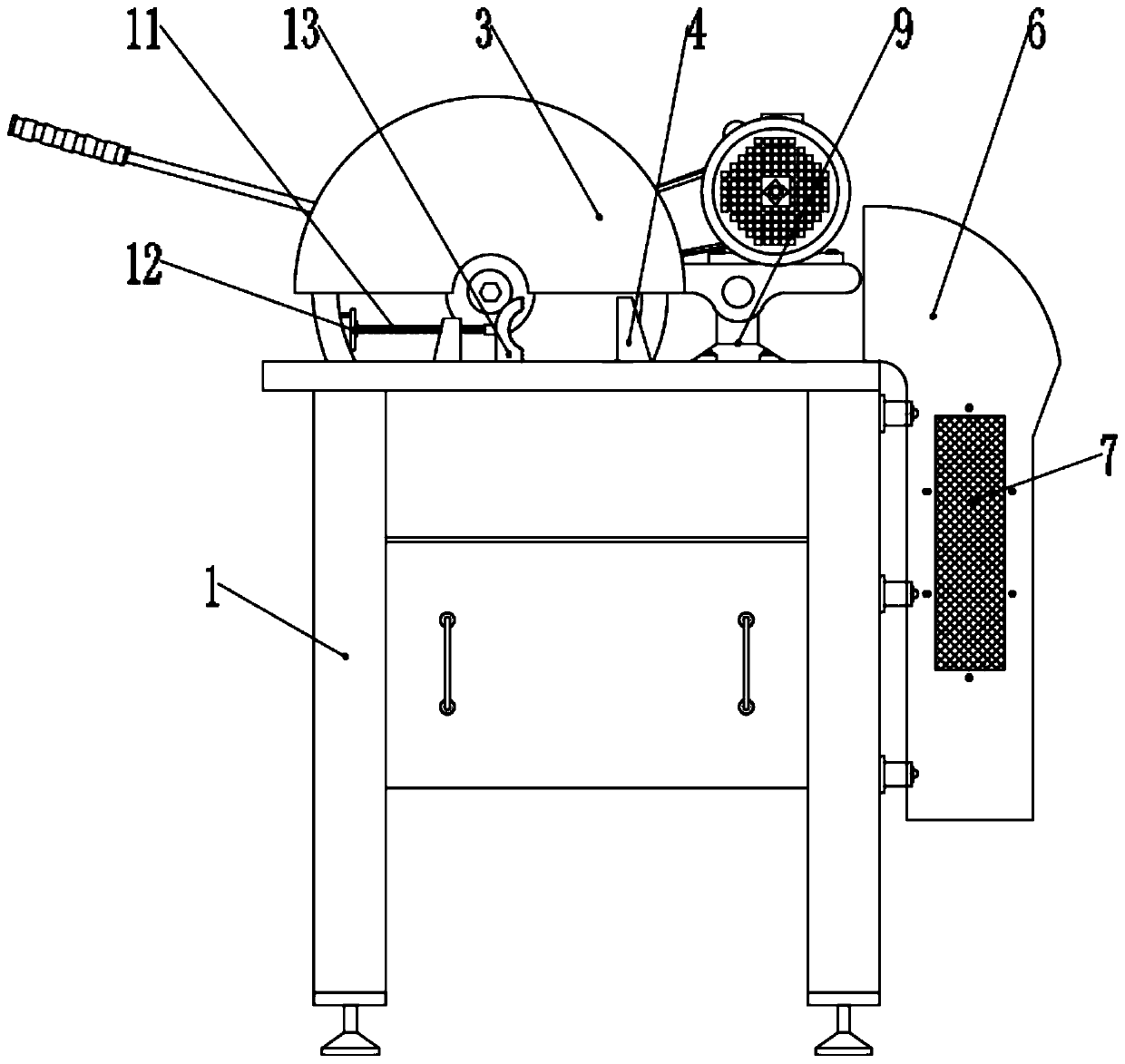

Automatic cutting machine for artificial wood fiber board

InactiveCN107127827ARealize the function of automatic cuttingReduce labor intensityGuide fencesGripping devicesFiberEngineering

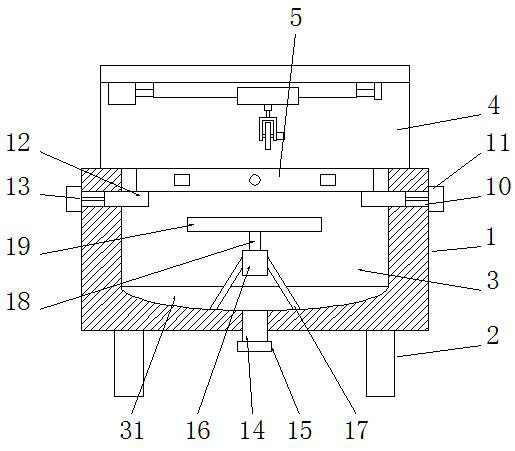

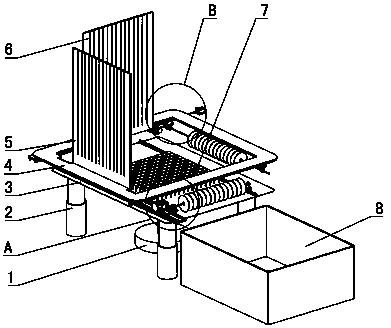

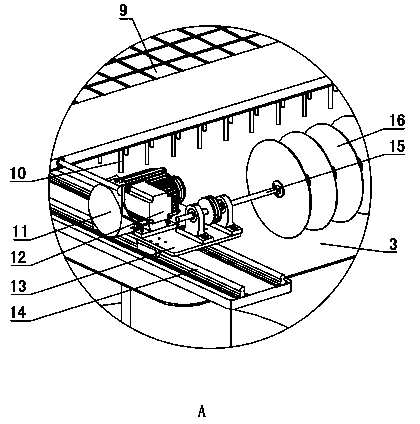

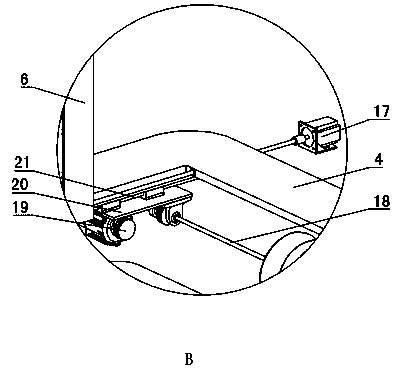

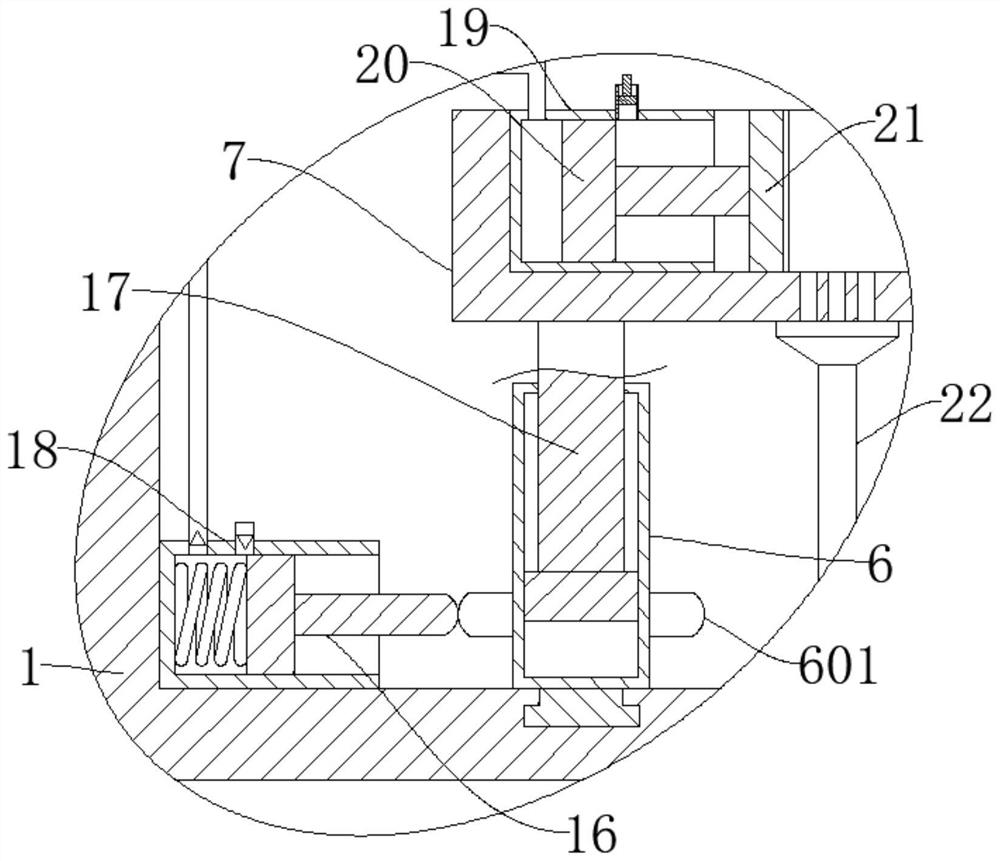

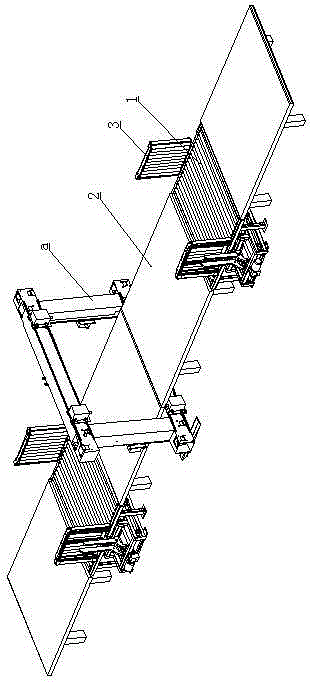

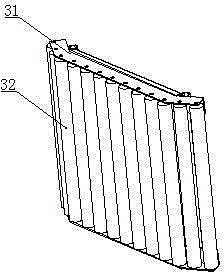

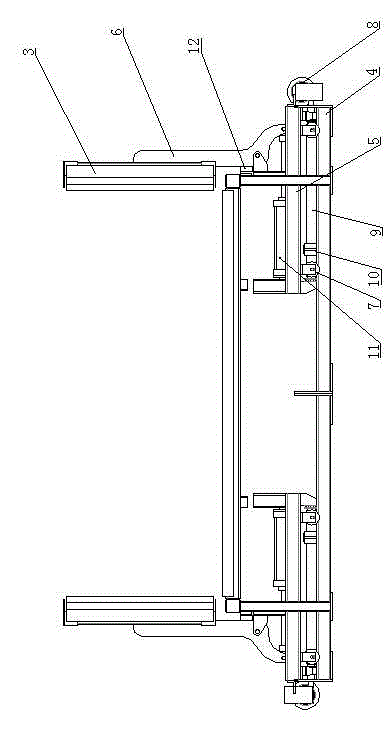

The invention relates to an automatic cutting machine for an artificial wood fiber board. The automatic cutting machine for the artificial wood fiber board comprises a base board, a movable pushing device is mounted at the rear end of the base board, two supporting boards are symmetrically mounted in the middle of the base board, a first supporting roller is mounted between the inner walls of the upper ends of the two supporting boards through a bearing, a cutting device is mounted at the front end of the base board, and the movable pushing device and the cutting device cooperate with each other to complete the automatic processing technology of boards. The automatic cutting machine can solve the problems that workers need to use clamps to push the boards and use a disk saw to cut the boards when using a traditional cutting method to conduct cutting processing in small-sized board processing factories, the cutting precision is low, clamps need to be replaced manually according to needs of different board widths, the labor intensity is high, the traditional board cutting method can only conduct cutting in one direction, the boards need to be processed for a second time, and the working efficiency is low; and the automatic cutting machine can achieve the function that the boards are cut automatically.

Owner:广西鹿寨通用人造板有限公司

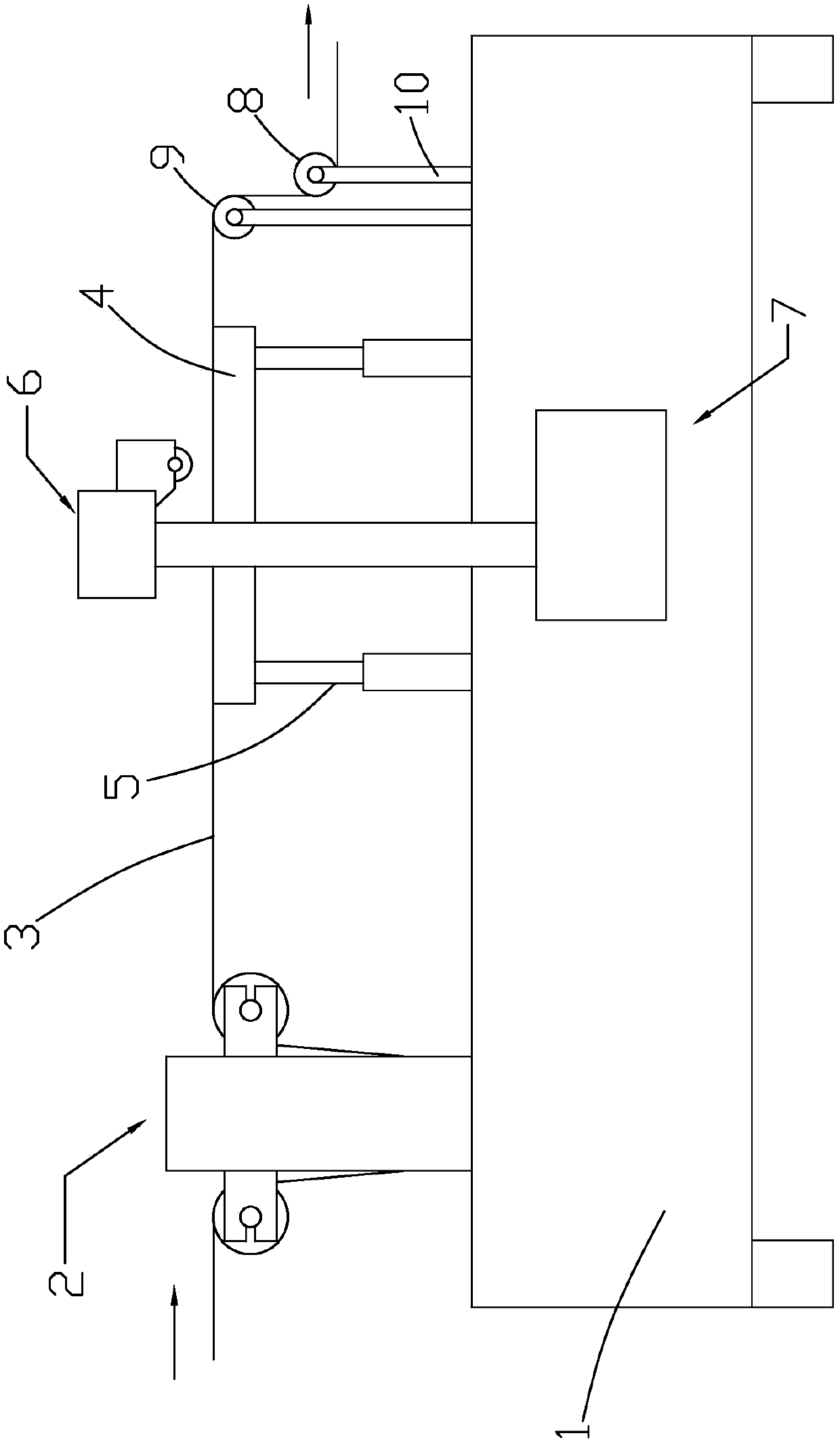

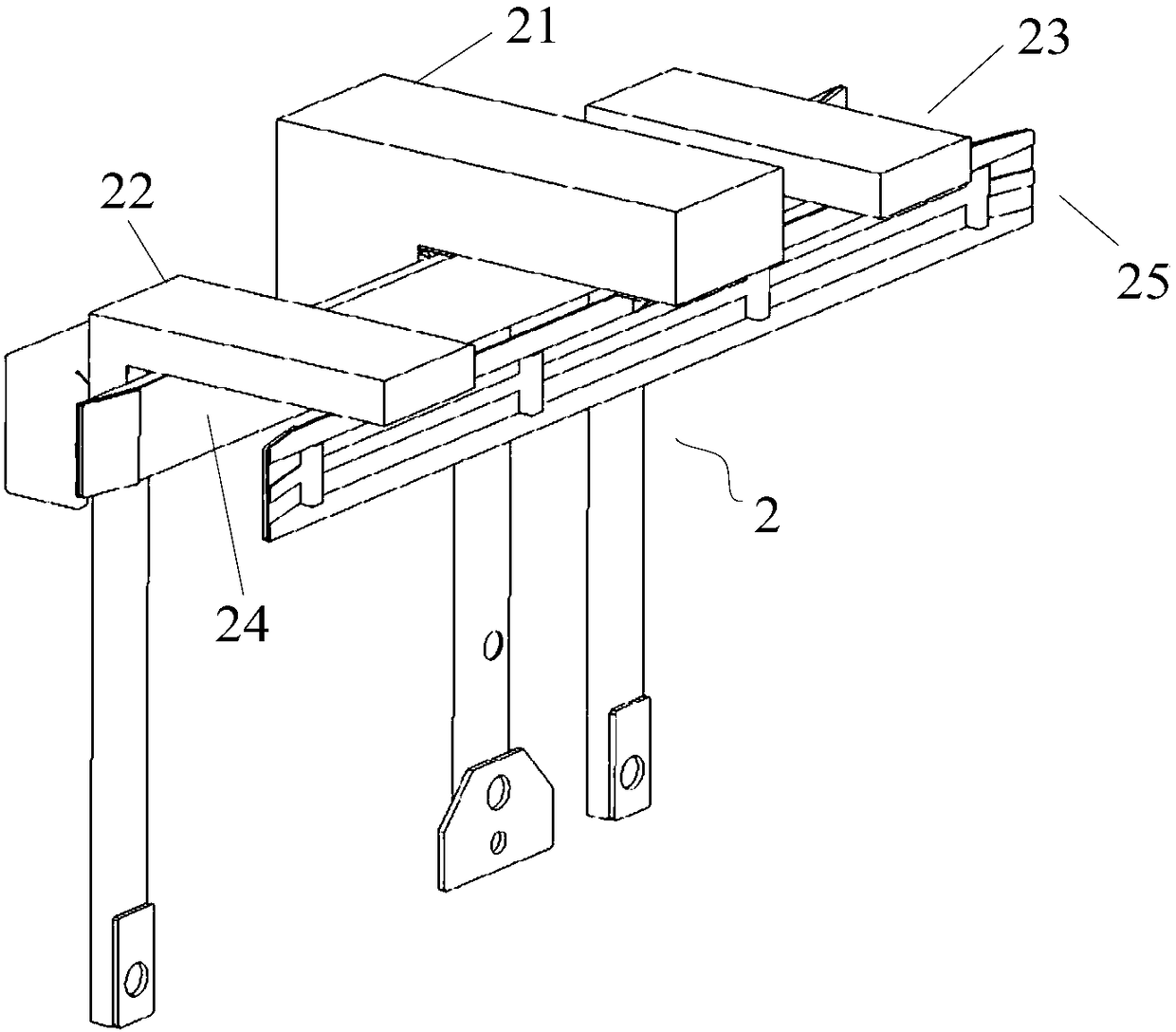

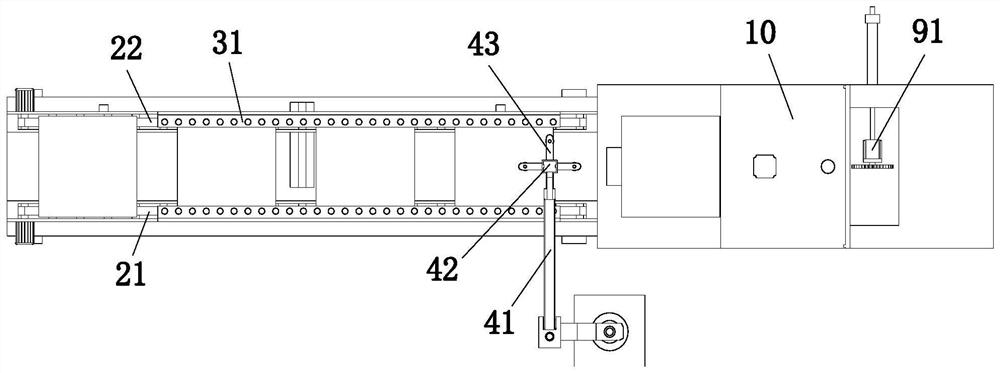

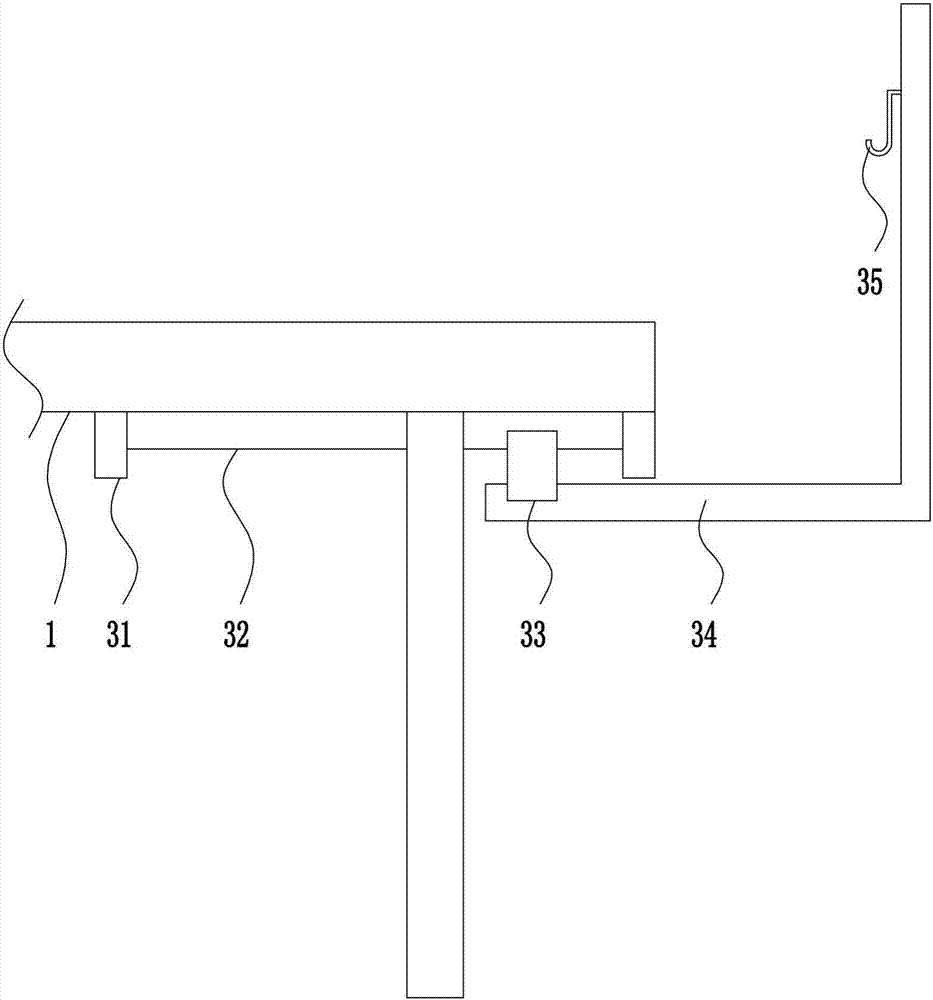

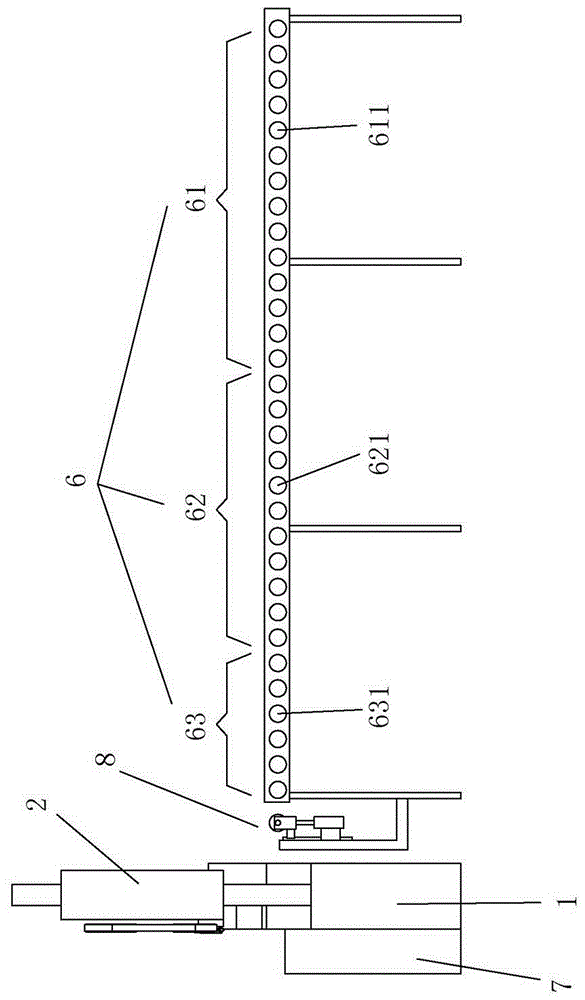

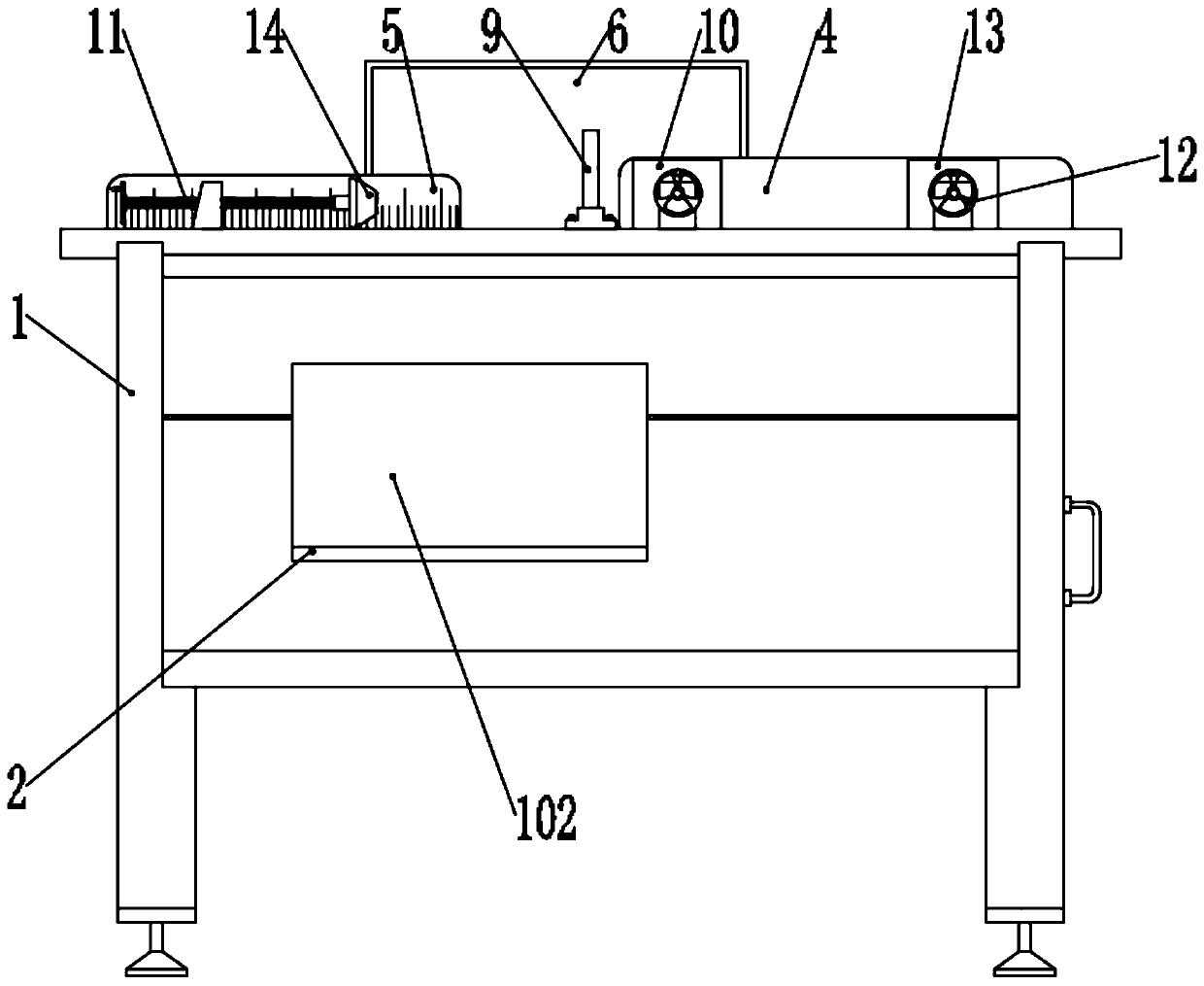

Guide correcting device of sponge cutting machine

ActiveCN102794787AAffect cutting accuracyShorten the lengthMetal working apparatusEngineeringMechanical engineering

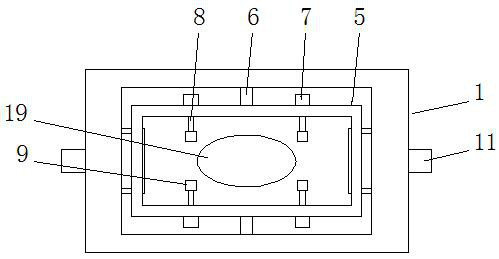

The invention relates to a guide correcting device of a sponge cutting machine. The guide correcting device is innovatively characterized by comprising a correcting conveying belt arranged on a conveying belt of a sponge cutting machine or a conveying belt extension section, and at least one correcting guide plate used for guiding and limiting sponges passing through the correcting conveying belt and arranged on one side or the two sides of the upper surface of the correcting conveying belt. The guide correcting device has the benefits as follows: the side surfaces of the sponges are limited by the correcting guide plates, so that the cutting precision of the sponges is prevented from being influenced due to positional deviation; and the correcting guide plates are arranged on a horizontal drive platform, and the positions of the correcting guide plates on the correcting conveying belt are changed by a horizontal adjustment mechanism so as to adapt to the sponges with different specifications.

Owner:南通恒康数控机械股份有限公司

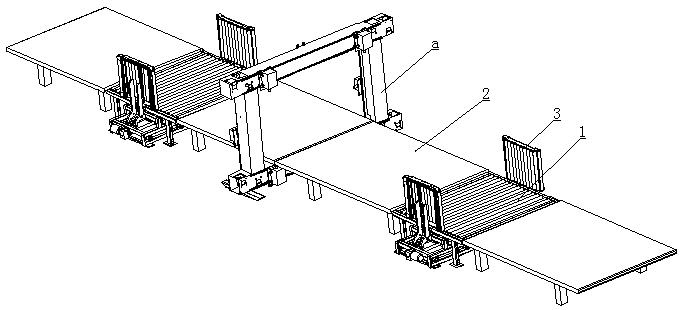

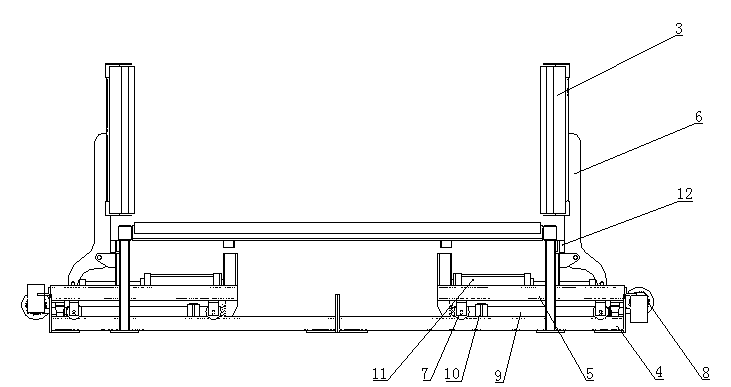

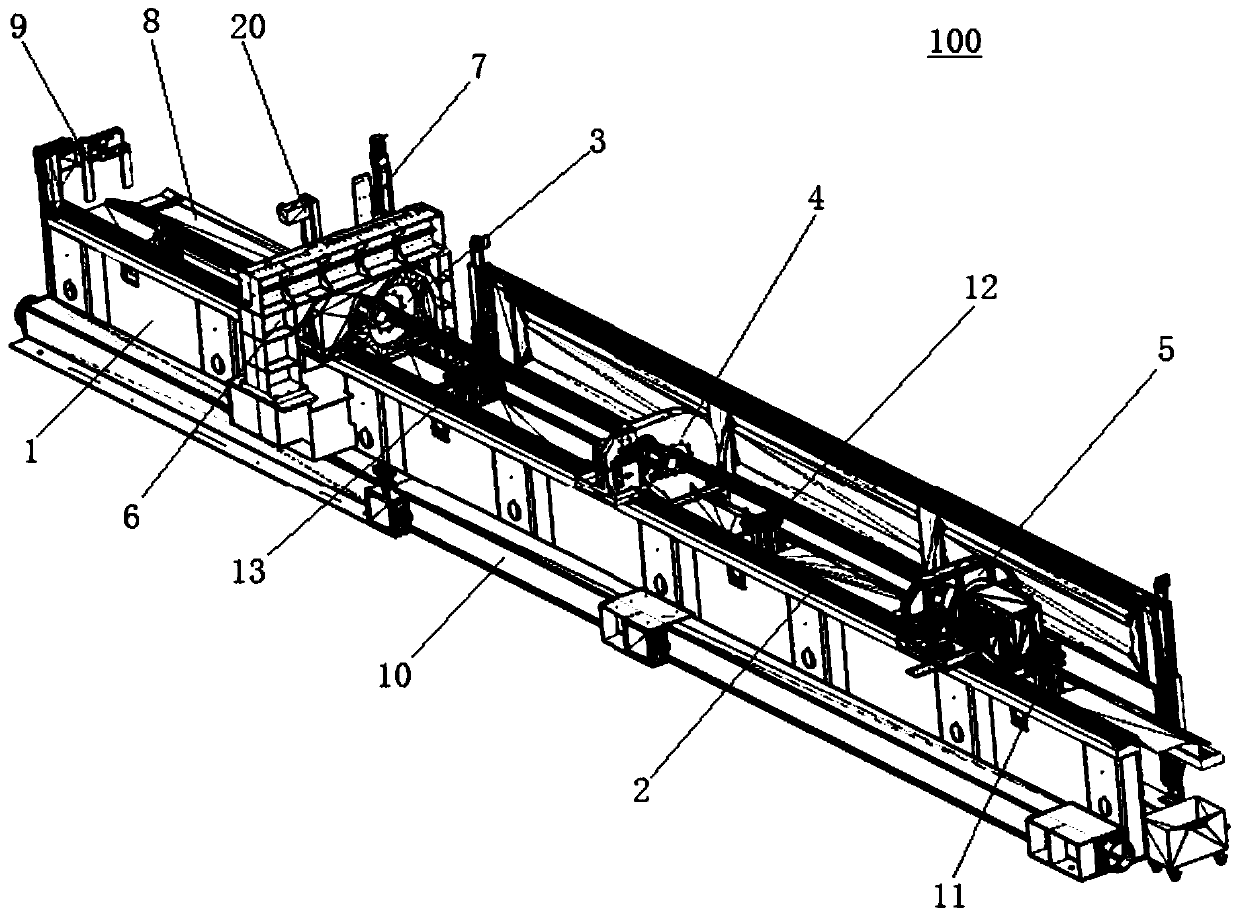

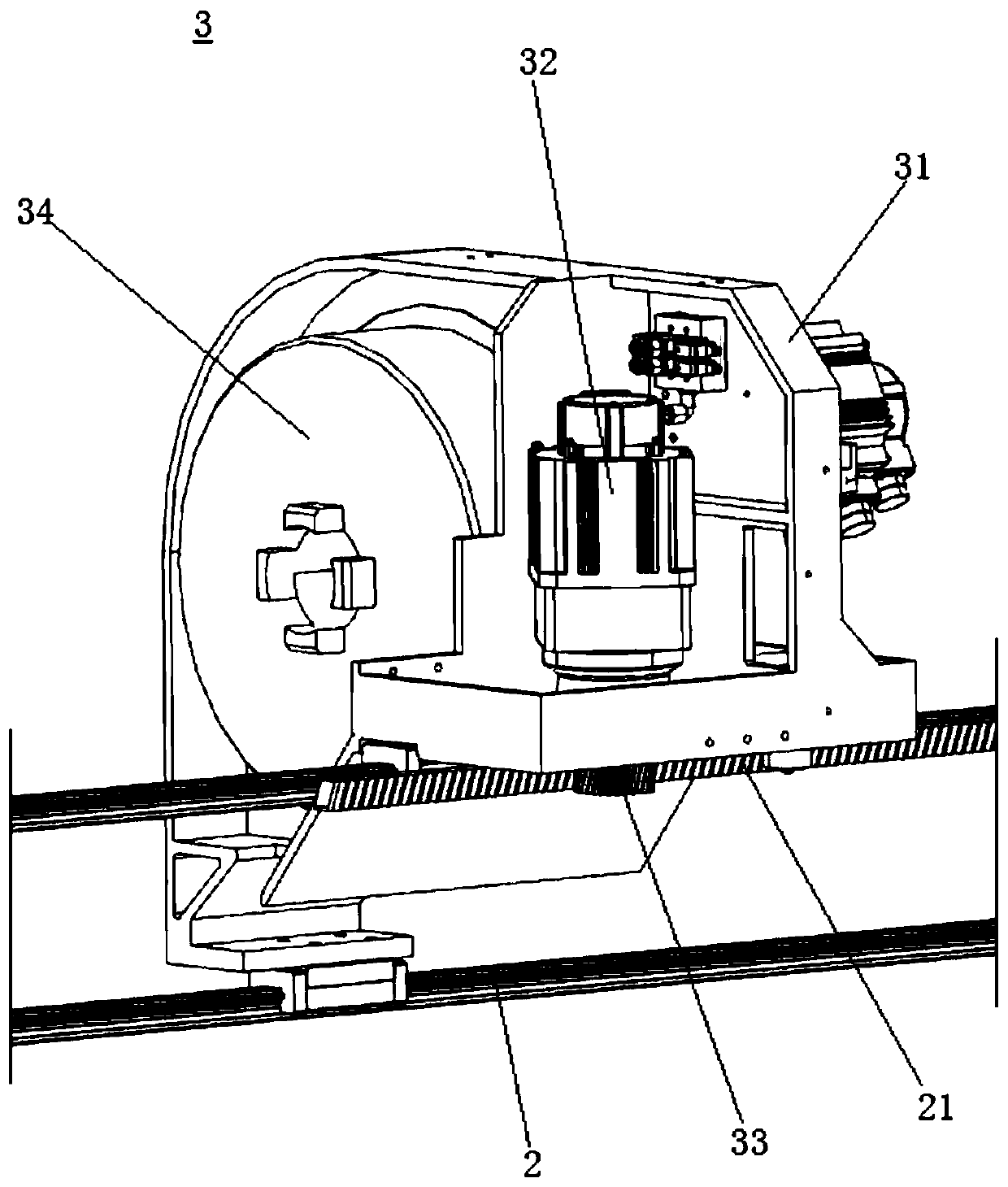

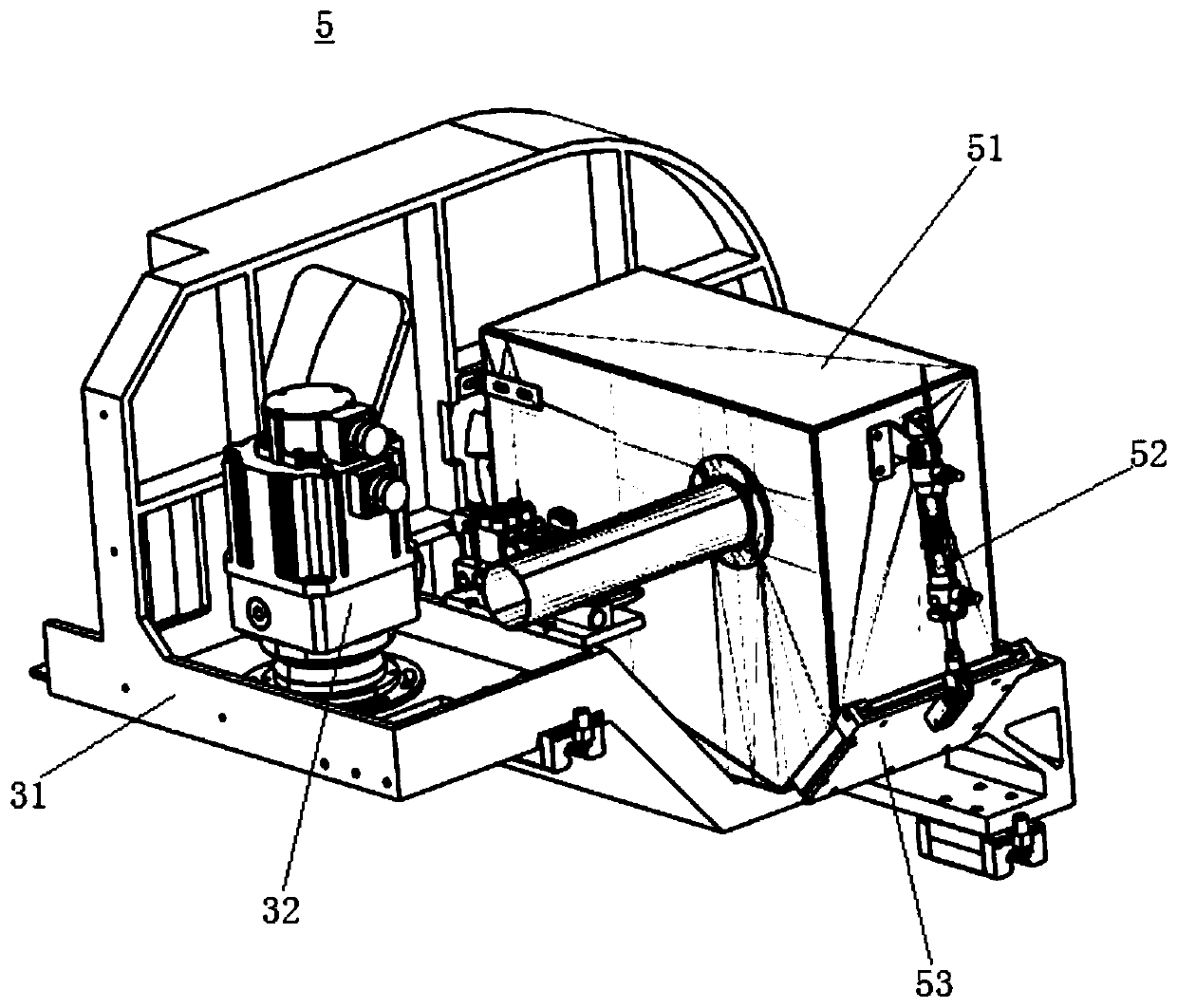

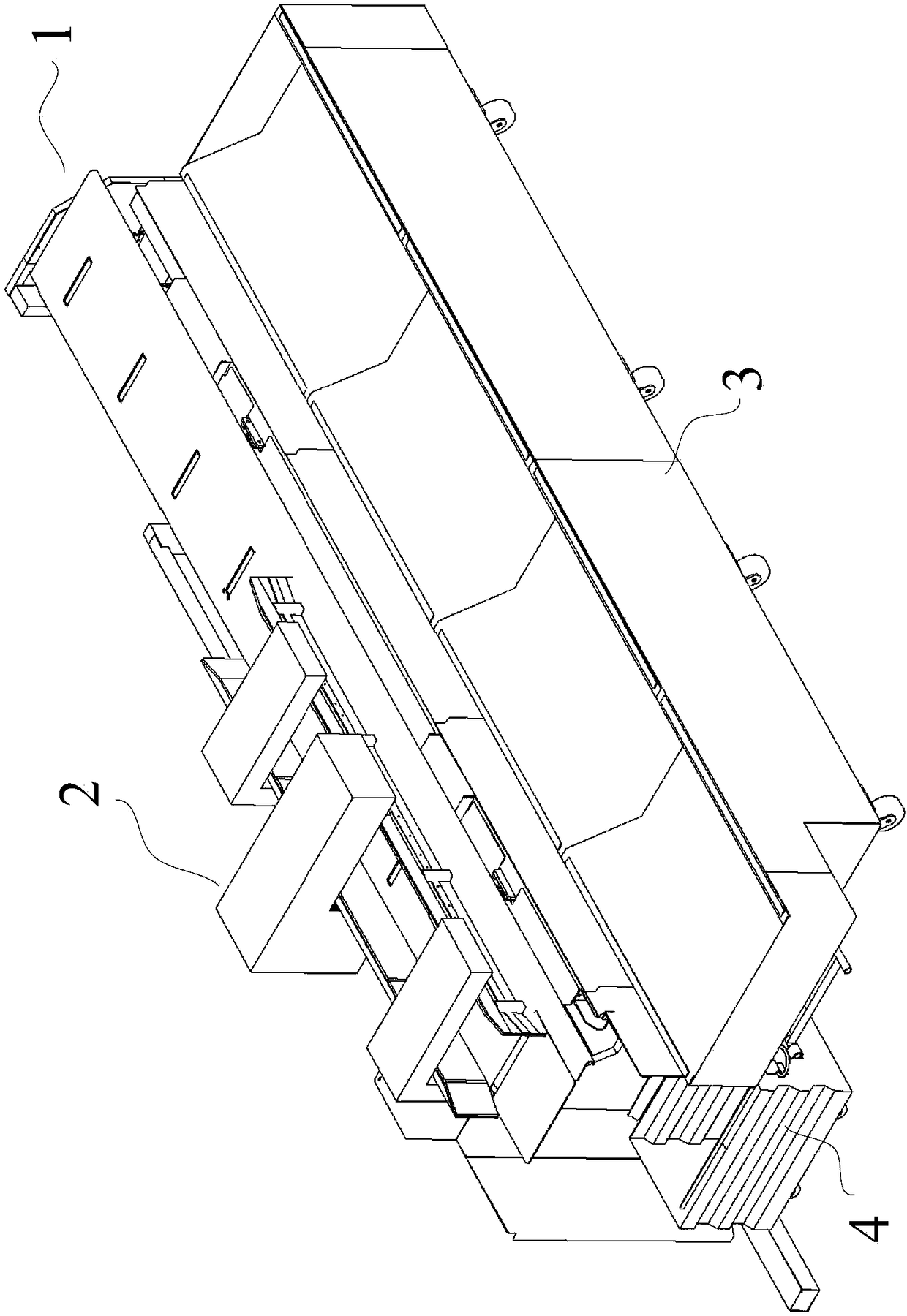

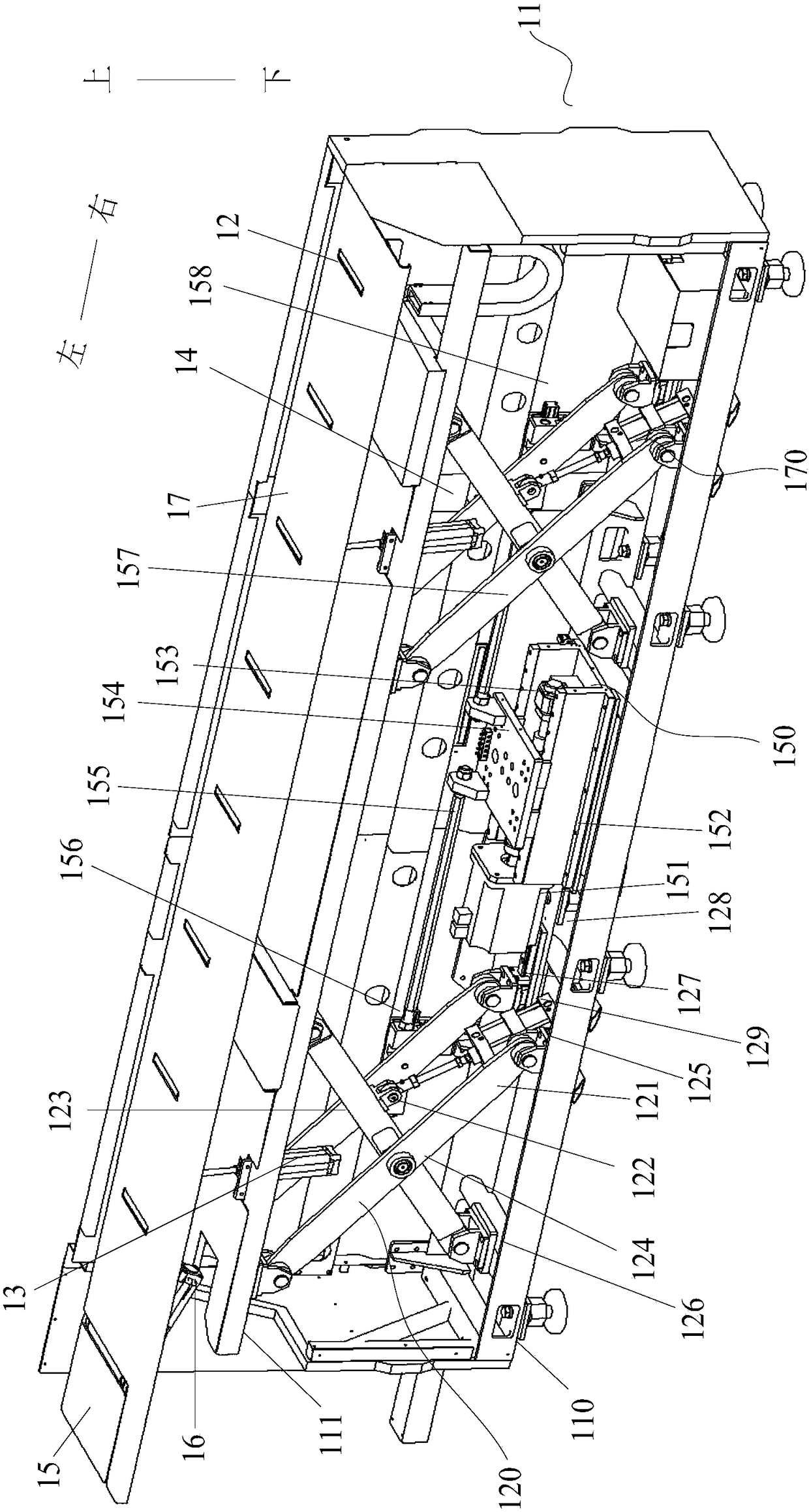

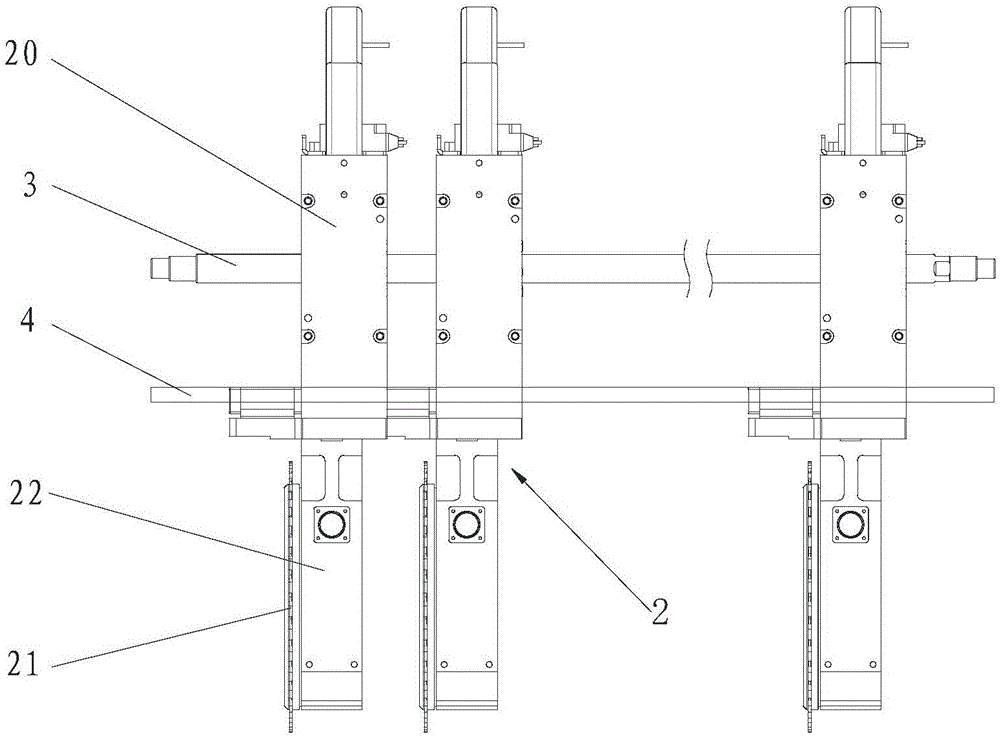

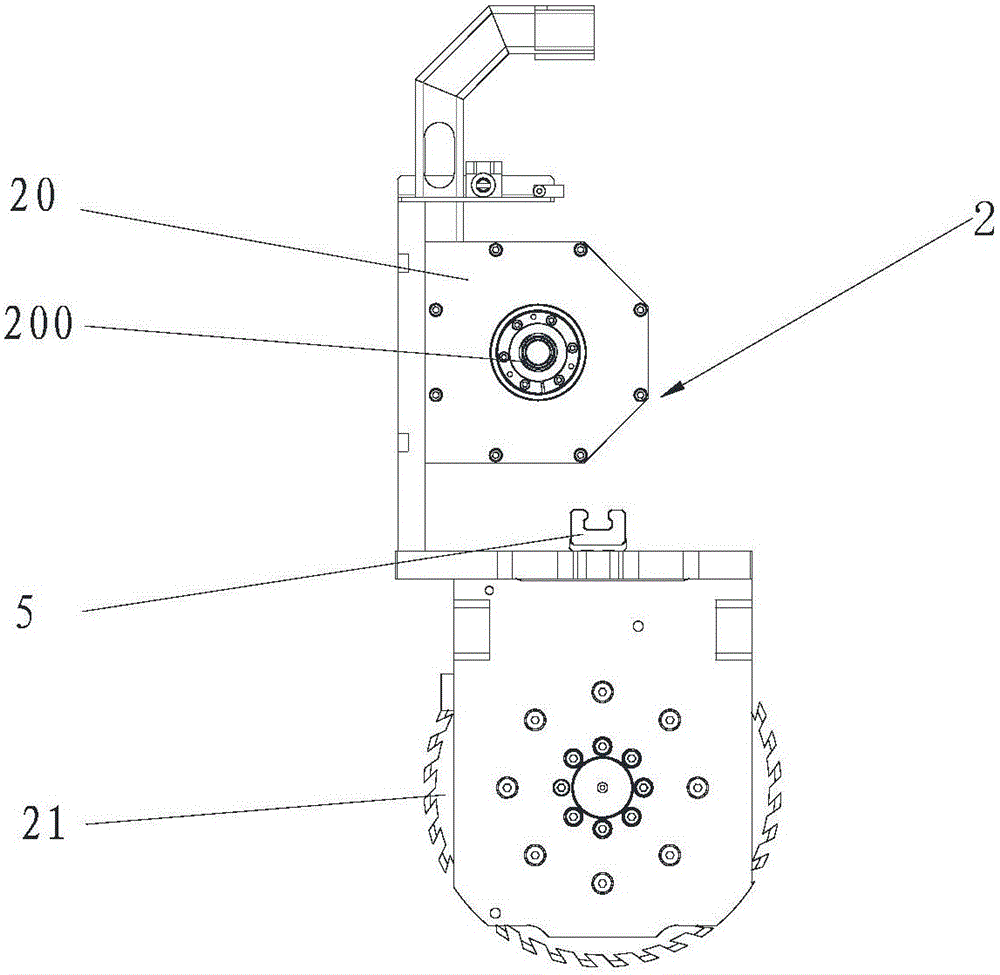

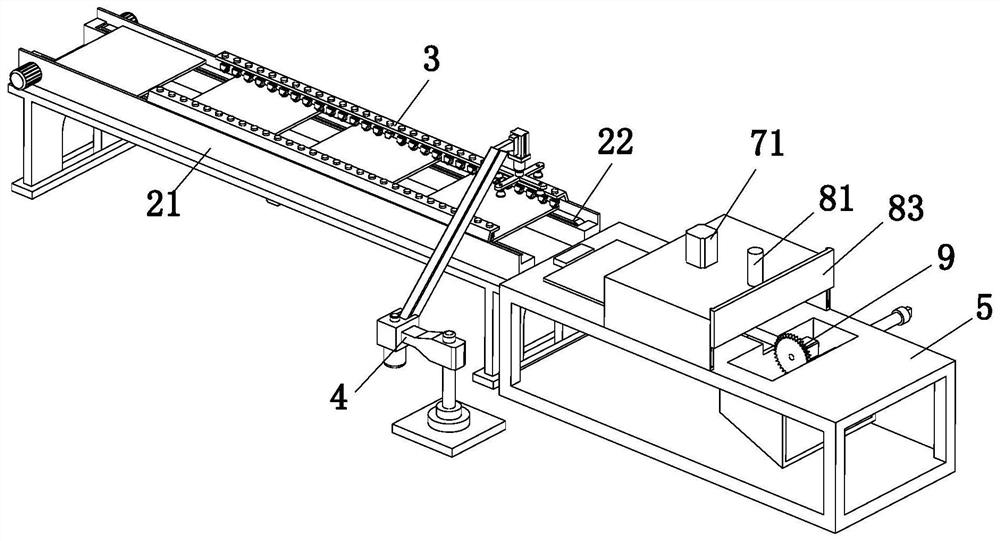

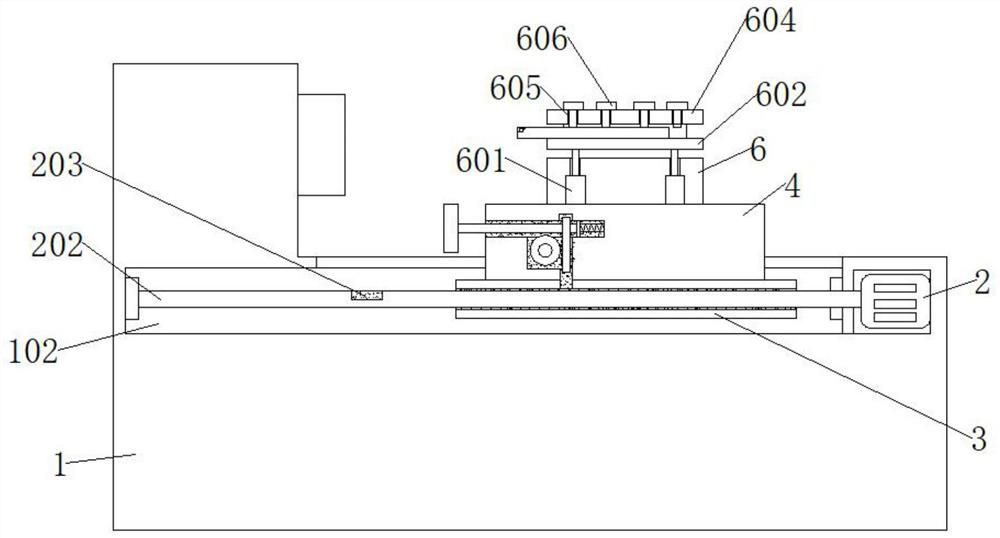

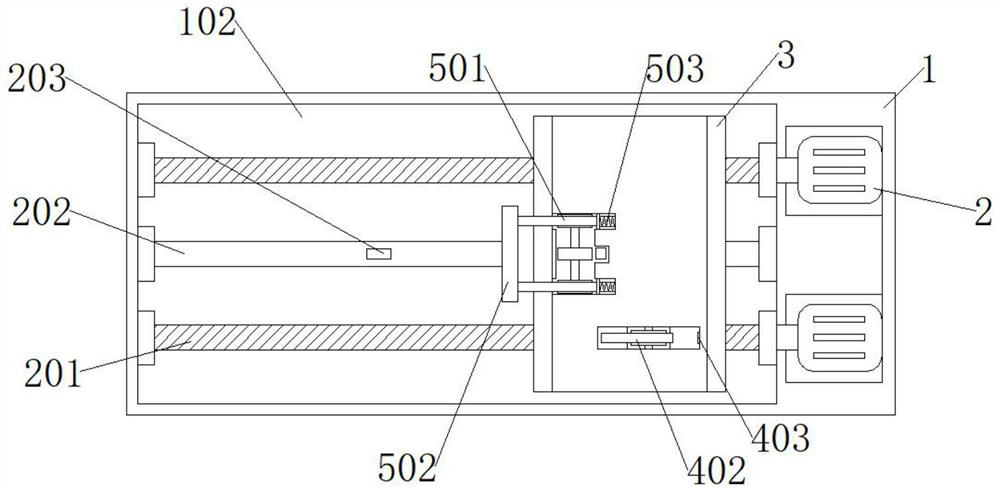

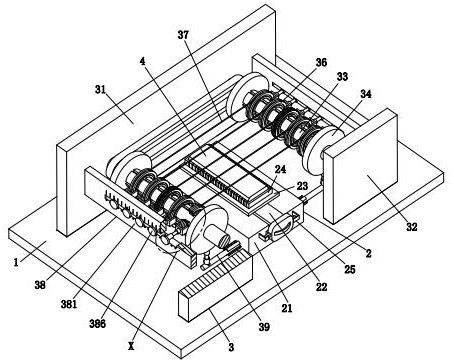

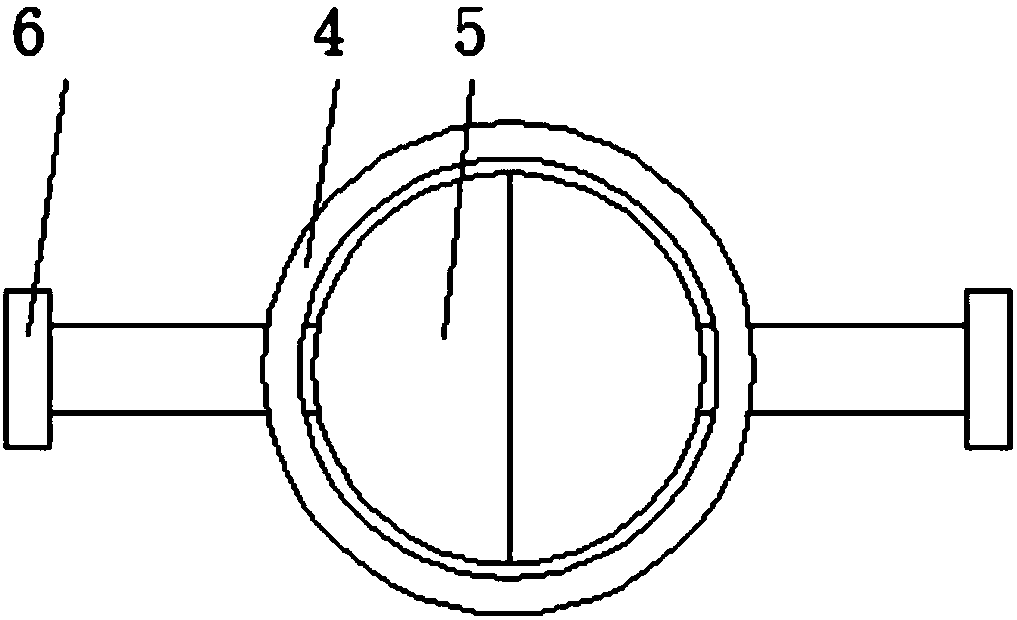

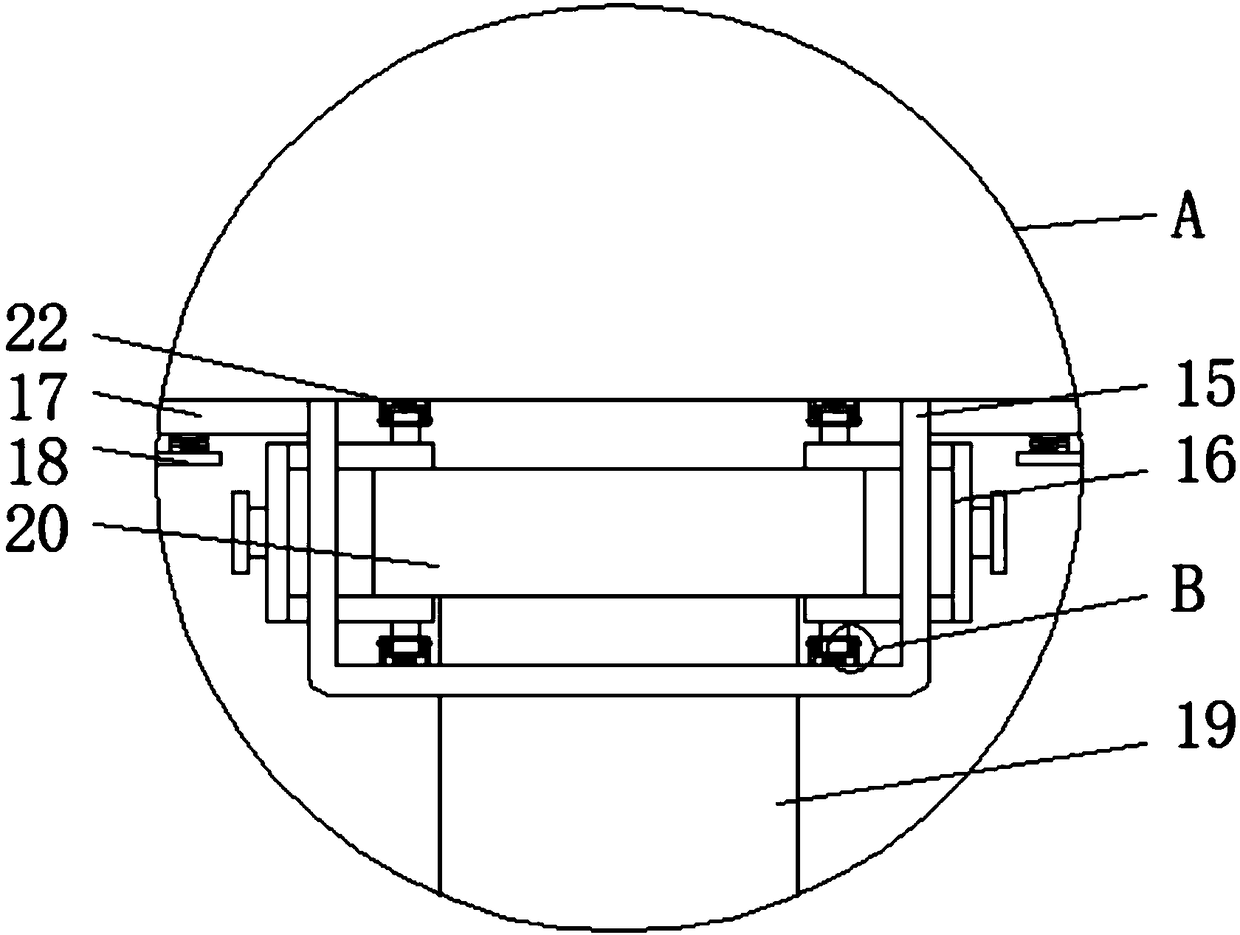

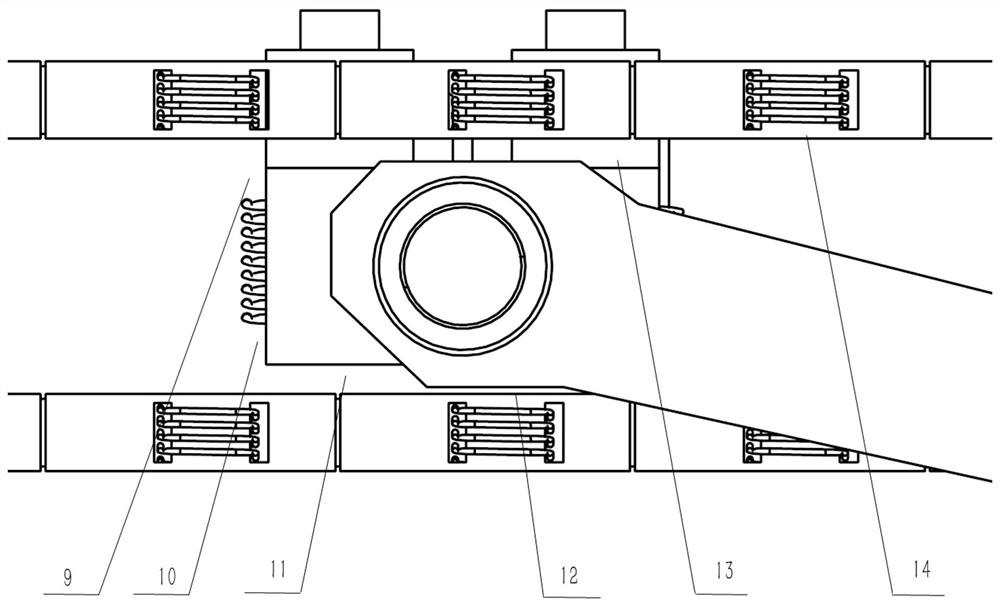

Three-chuck laser pipe cutter device

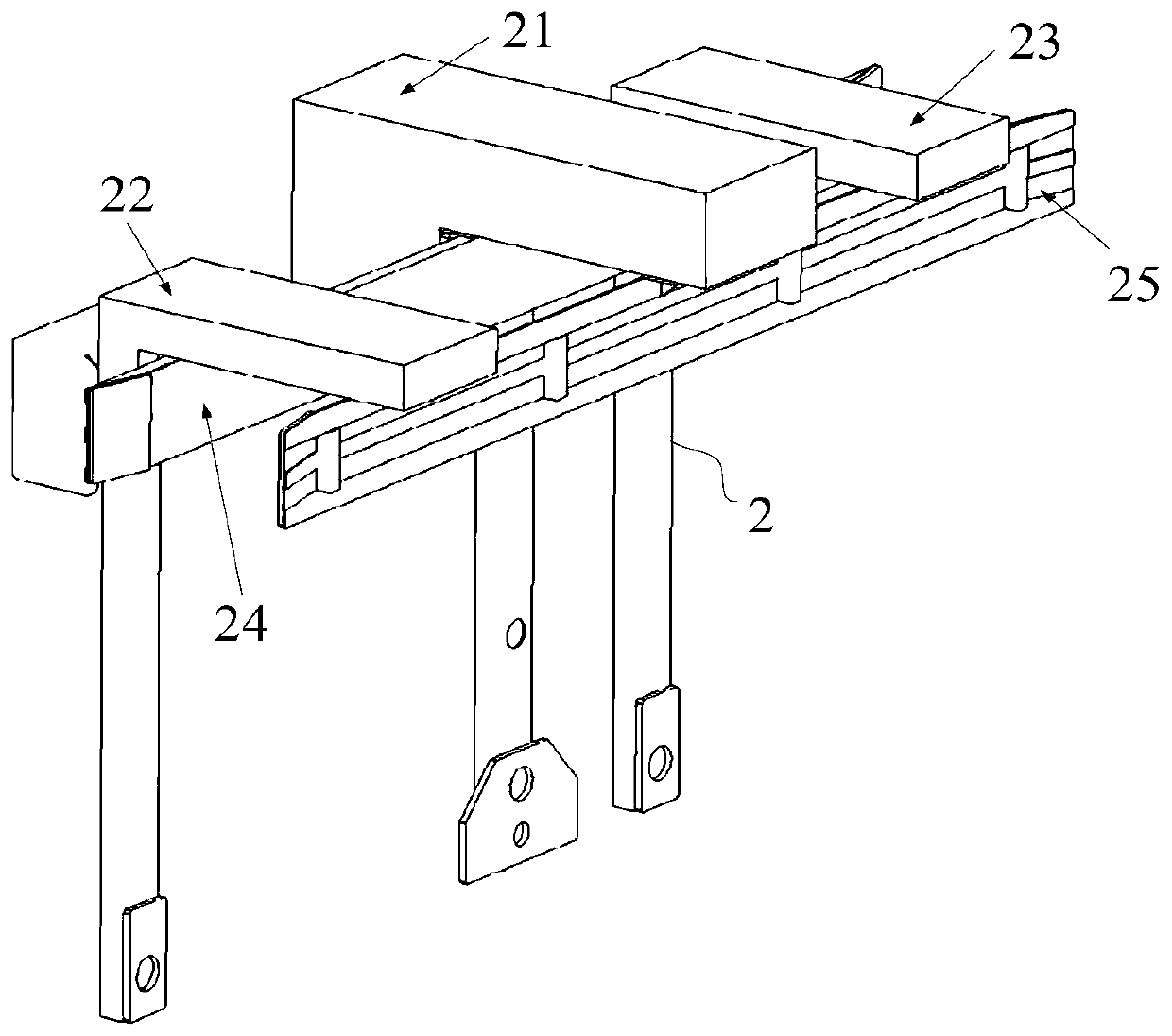

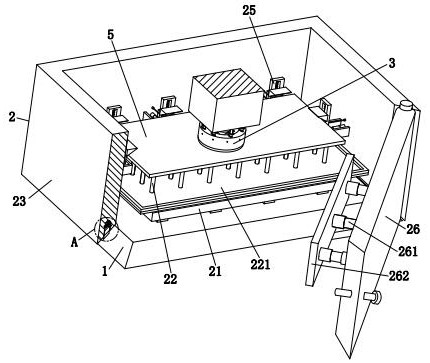

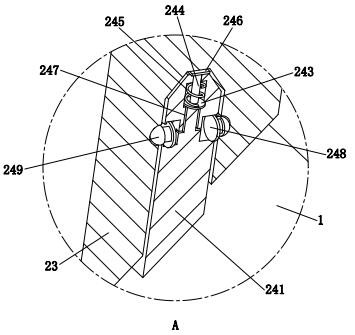

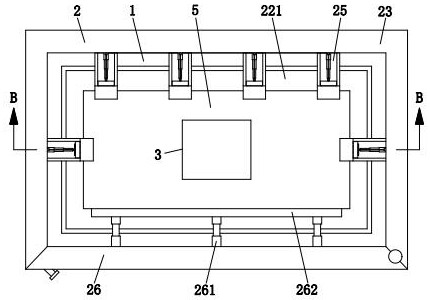

PendingCN110919206AGuaranteed cutting accuracySolve the problem of inertia swingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention discloses a three-chuck laser pipe cutter device. The three-chuck laser pipe cutter device comprises a machine tool, sliding rails, a front chuck unit, a middle chuck unit, a back chuckunit, a transverse beam support, a laser cutting head, a material-falling supporting plate unit, a discharging clamping unit and a plurality of supporting clamping units, wherein the sliding rails arearranged on the machine tool in parallel; the front chuck unit, the middle chuck unit and the back chuck unit can slide on the sliding rails; the transverse beam support is located above the machinetool; the laser cutting head is arranged on the transverse beam support; the material-falling supporting plate unit is located on the front side of the laser cutting head and can move up and down relative to the machine tool; the discharging clamping unit is located at the front end of the machine tool and assists in material falling; and the plurality of supporting clamping units are arranged atintervals along the sliding rails and can move up and down relative to the machine tool. By means of the three-chuck laser pipe cutter device, the pipe loading capacity and cutting efficiency are greatly improved, the problem that the residual tail material is long is solved, and the raw material cost is reduced.

Owner:SUZHOU QUICK LASER TECH

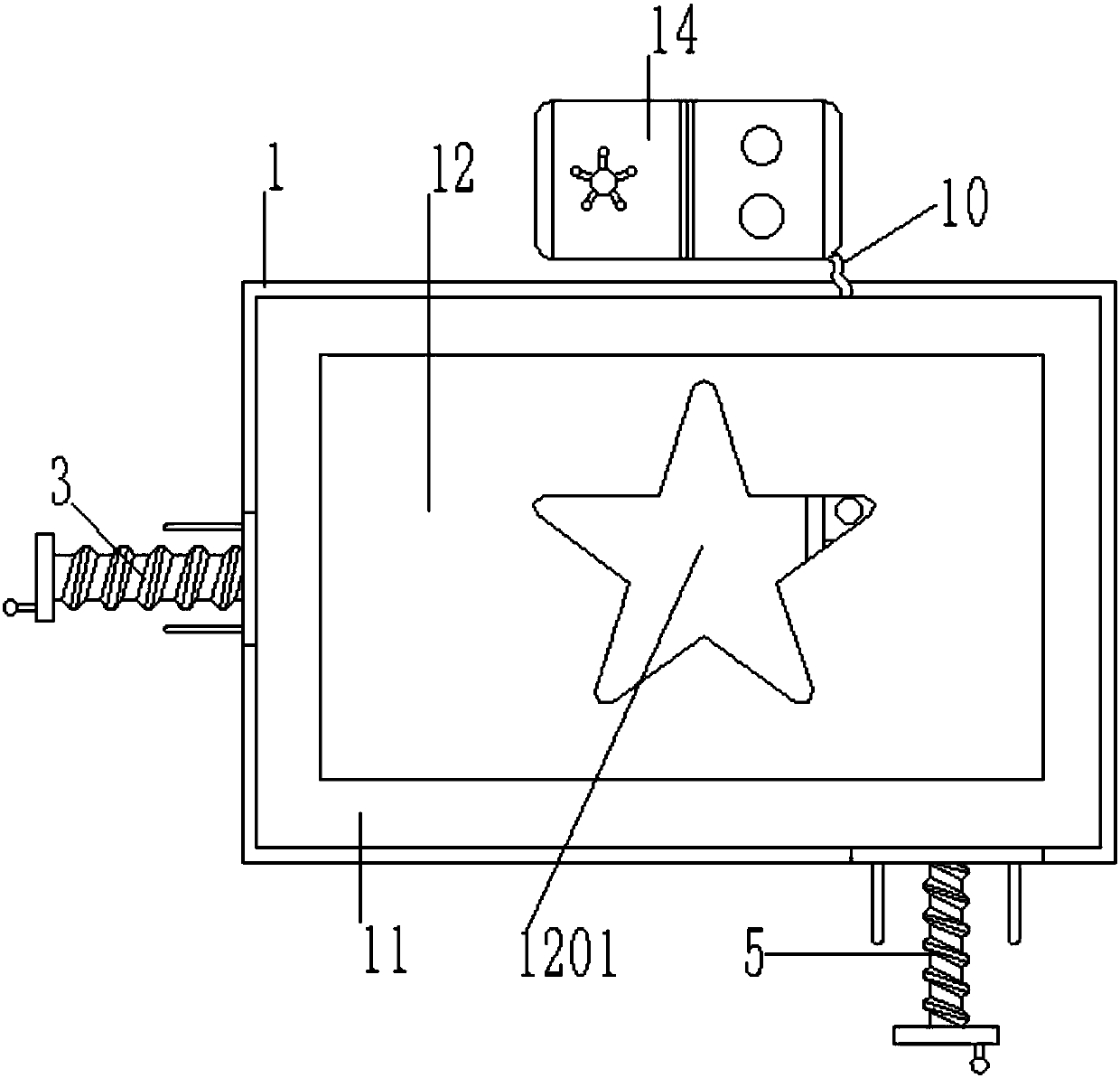

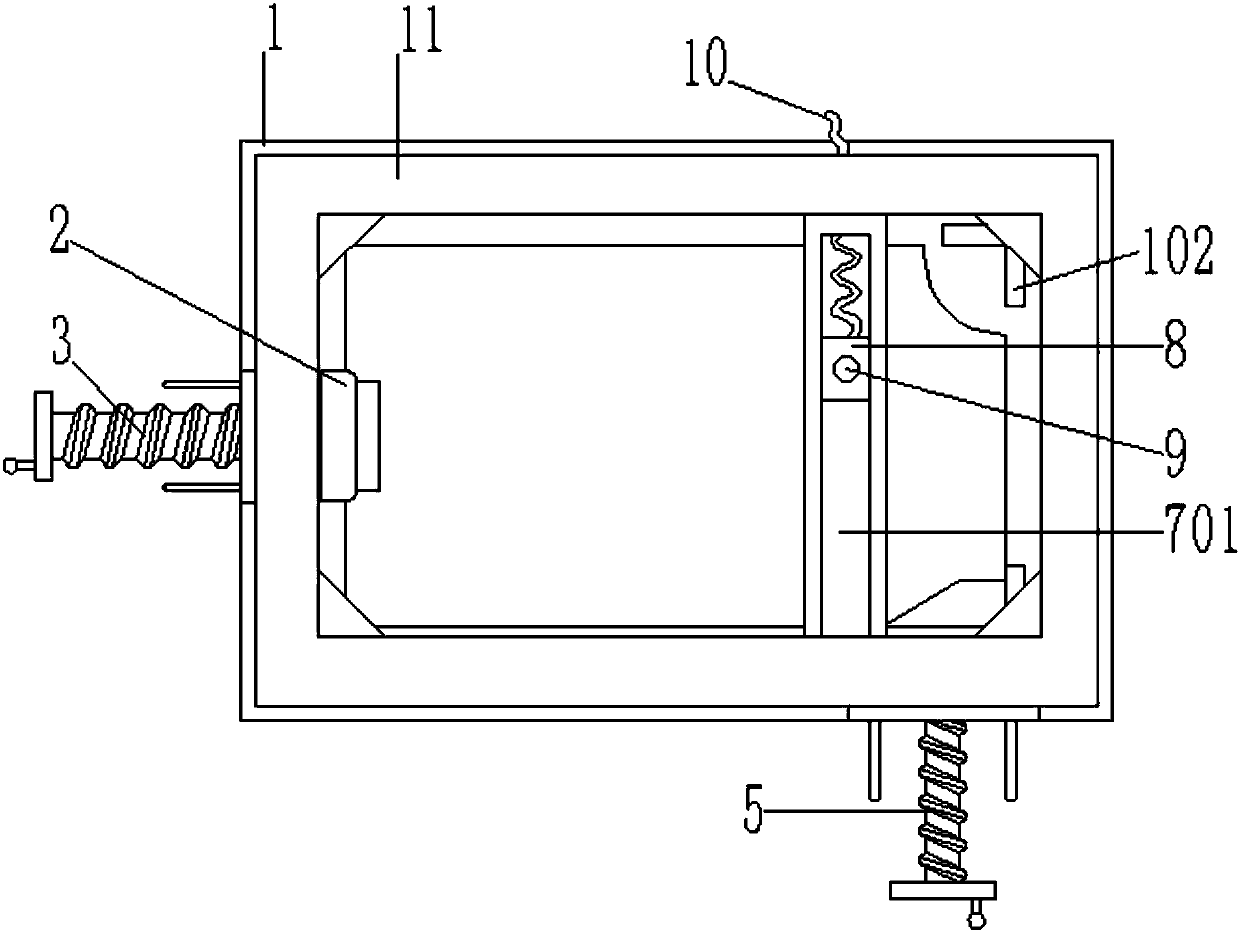

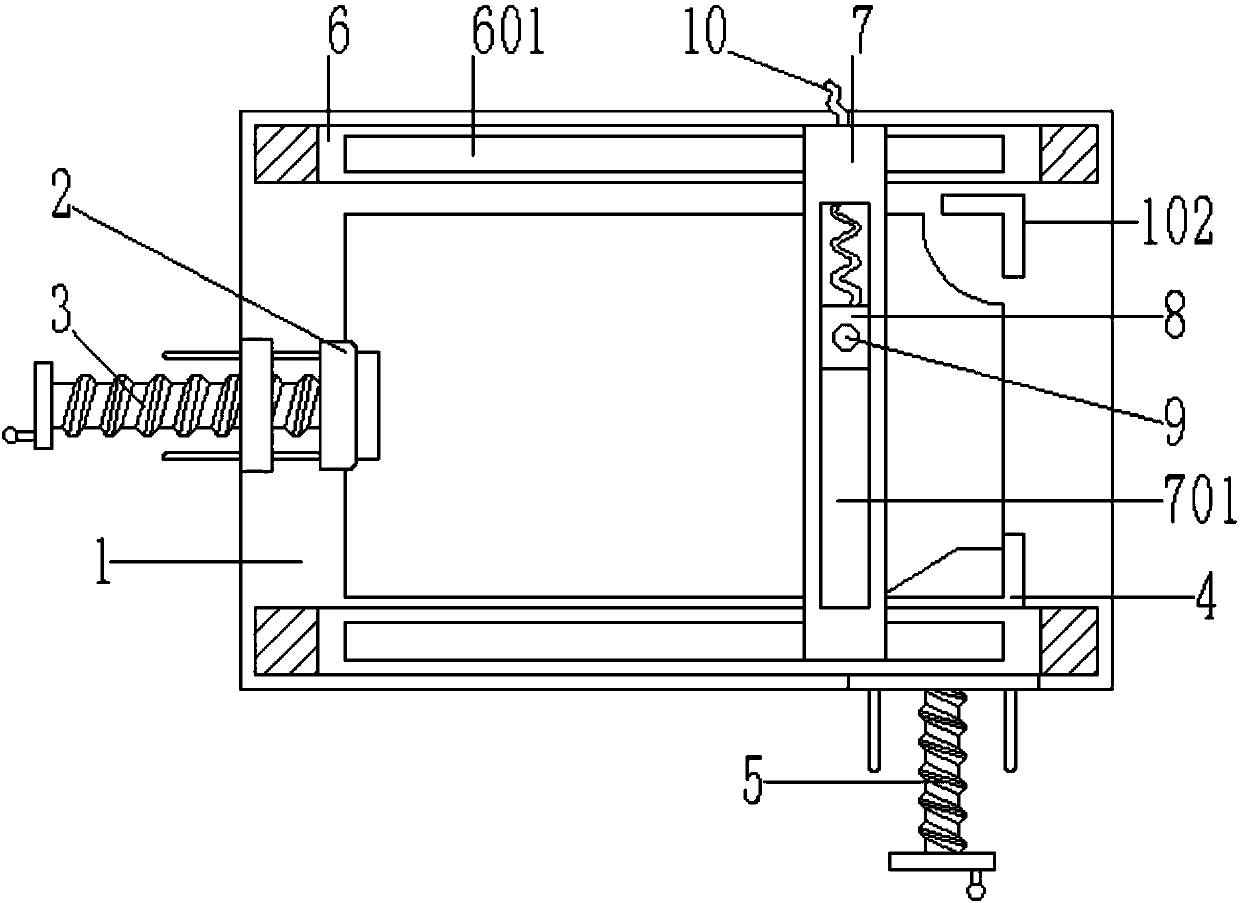

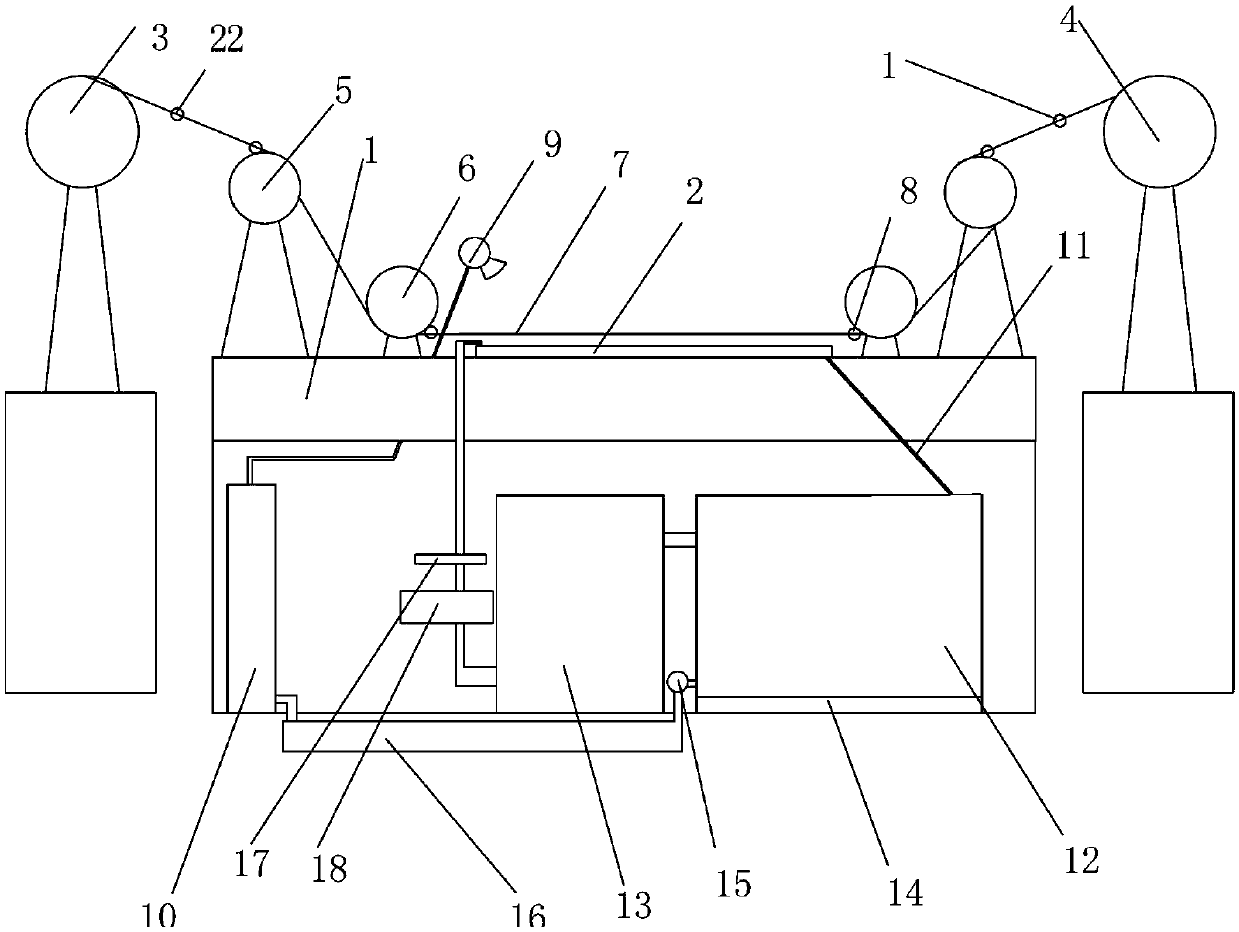

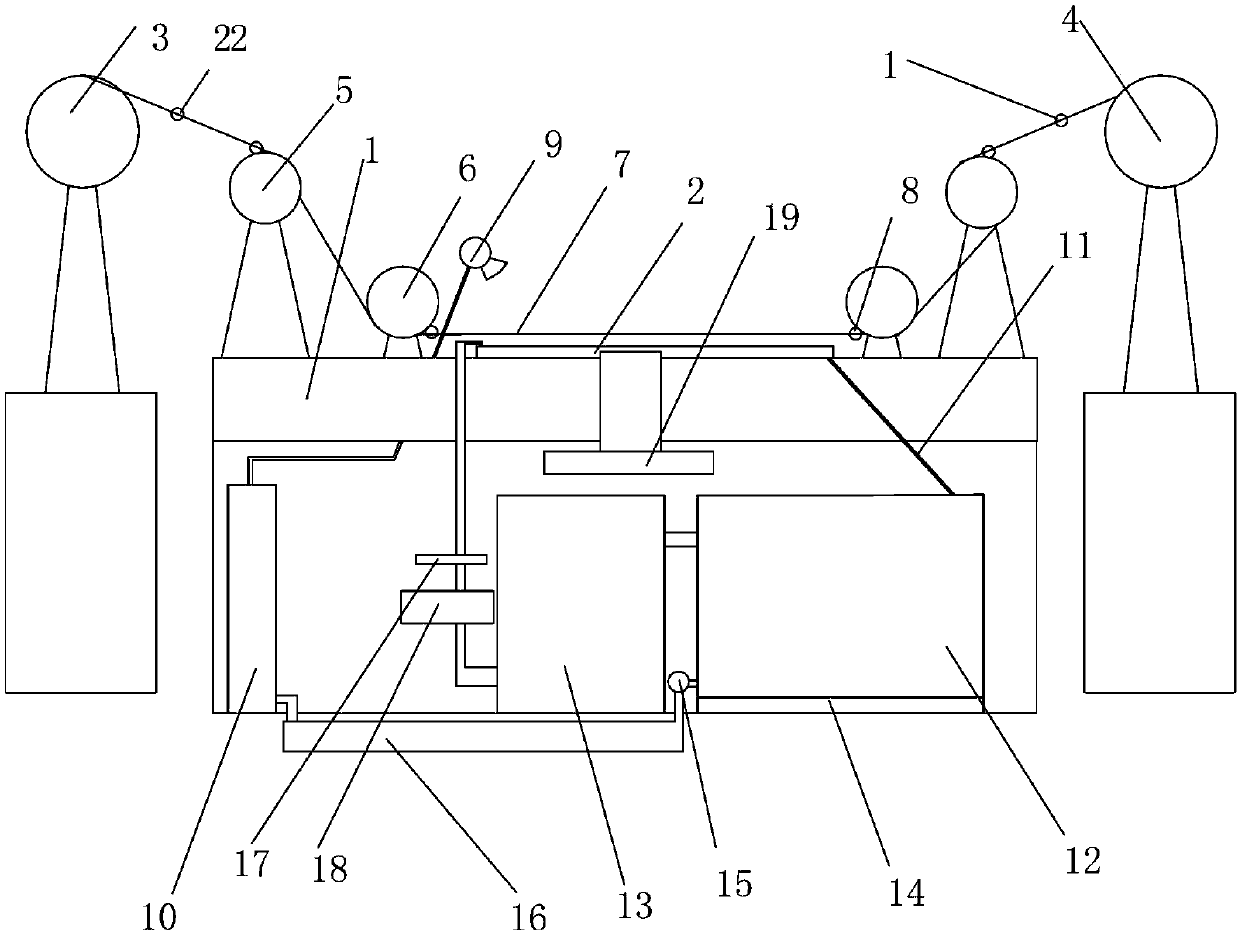

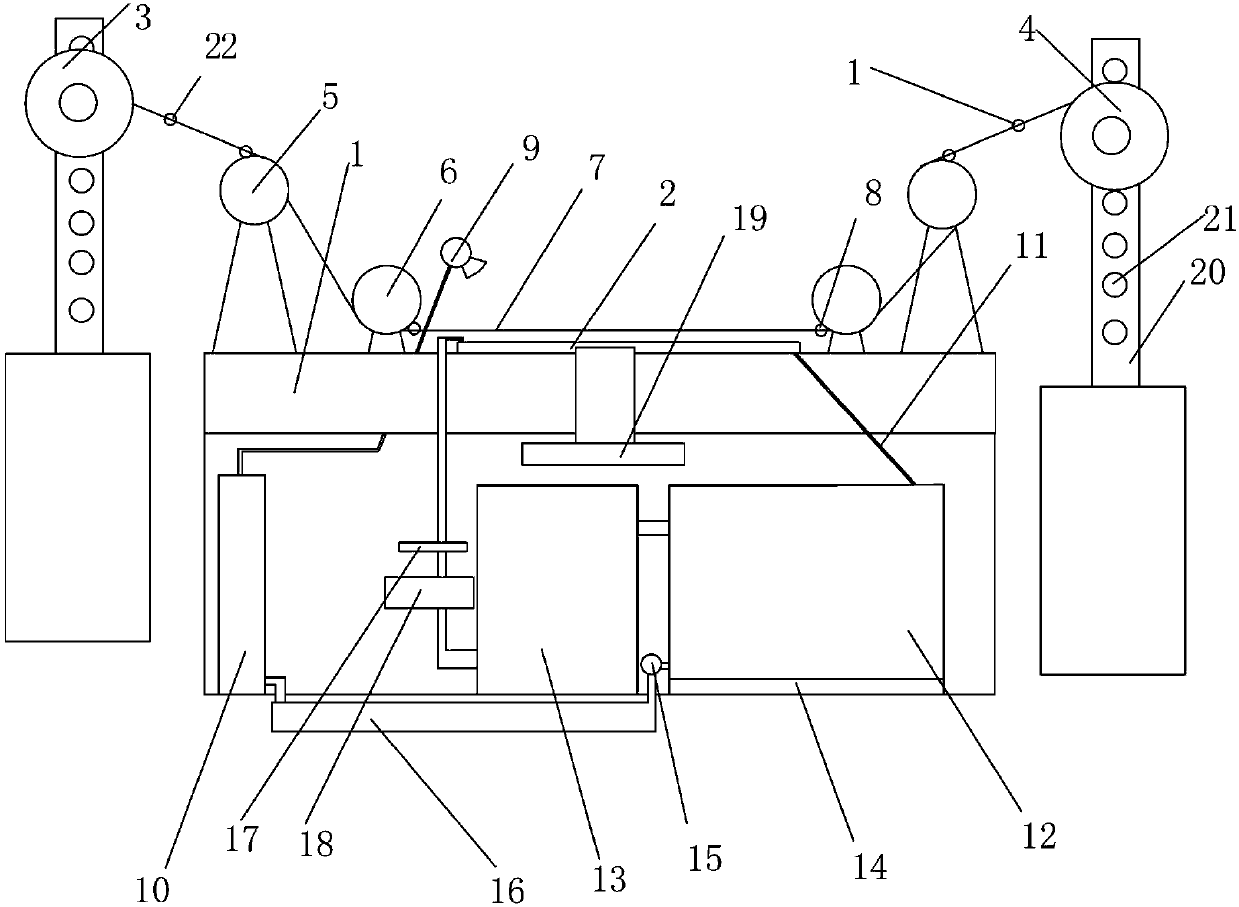

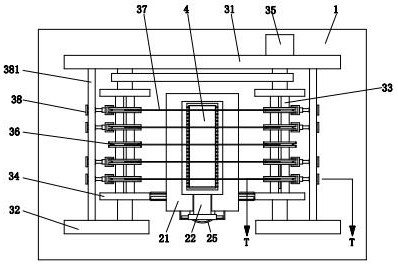

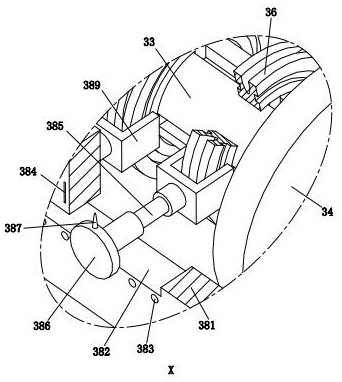

Stainless steel band production device with wide-range adjusting function and production method

ActiveCN107671347AHigh precisionHigh movement accuracyShearing machinesShearing machine accessoriesAssembly lineRejection rate

The invention discloses a stainless steel band production device with the wide-range adjusting function. The stainless steel band production device comprises a box body, a tensioning mechanism, a machining platform, a cutting mechanism and a height adjusting mechanism. The tensioning mechanism and the machining platform are both located above the box body. The tensioning mechanism is located at the left side of the machining platform. The machining platform is connected with the box body through a hydraulic lifting rod. The cutting mechanism is located above the machining platform and is further connected with the box body through the height adjusting mechanism. A driving roller and a driven roller are further arranged on the top face of the box body and are both located at the right sideof the machining platform. The driving roller and the driven roller are both connected with the box body through a supporting rod. Stainless steel bands penetrate in from the tensioning mechanism andfurther wind across the driven roller and the driving roller to be output after passing through the machining platform. By means of the stainless steel band production device with the wide-range adjusting function, the cutting machining requirements of the stainless steel bands of different widths can be met; and moreover, machining precision of the stainless steel bands is improved, and the rejection rate is lowered. The machining method is simple in technological step, the production demand of an assembly line can be met, manufacturing cost is reduced and the machining period is shortened.

Owner:ZHEJIANG JIANHENG IND

Unloading device

ActiveCN108789572AImprove cutting accuracyRealize automatic separationMetal working apparatusAgricultural engineeringWaste material

The embodiment of the invention discloses an unloading device, and relates to the technical field of mechanical automation. The unloading device comprises an unloading part and a limiting part. The unloading device comprises a shear-fork type lifting platform, a loading plate, a first air cylinder, a second air cylinder, a turnover plate and a third air cylinder. The shear-fork type lifting platform comprises a machine frame, a bracket, a first shear-fork type lifting mechanism, a travel control mechanism and a second shear-fork type lifting mechanism. The limiting part comprises a first limiting mechanism, a second limiting mechanism, a third limiting mechanism, a first striker plate and a second striker plate. The unloading device is helpful to improve the cutting accuracy of pipe product and realize the automatic separation of waste materials.

Owner:HANS LASER TECH IND GRP CO LTD +1

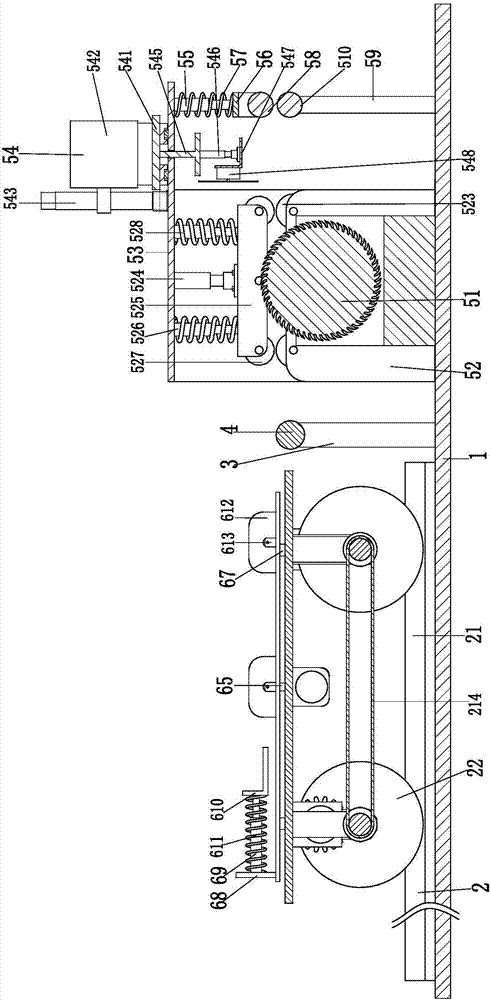

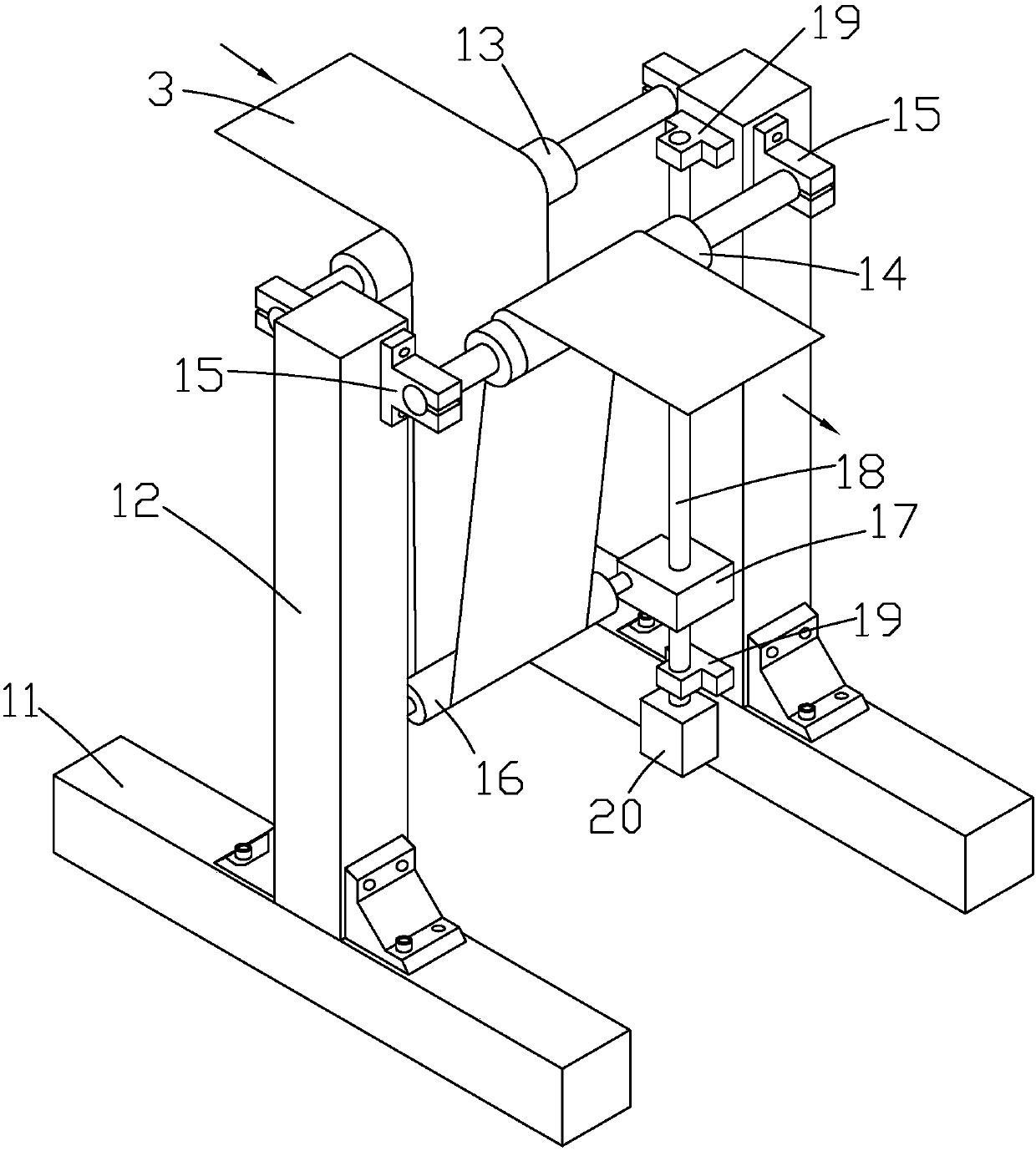

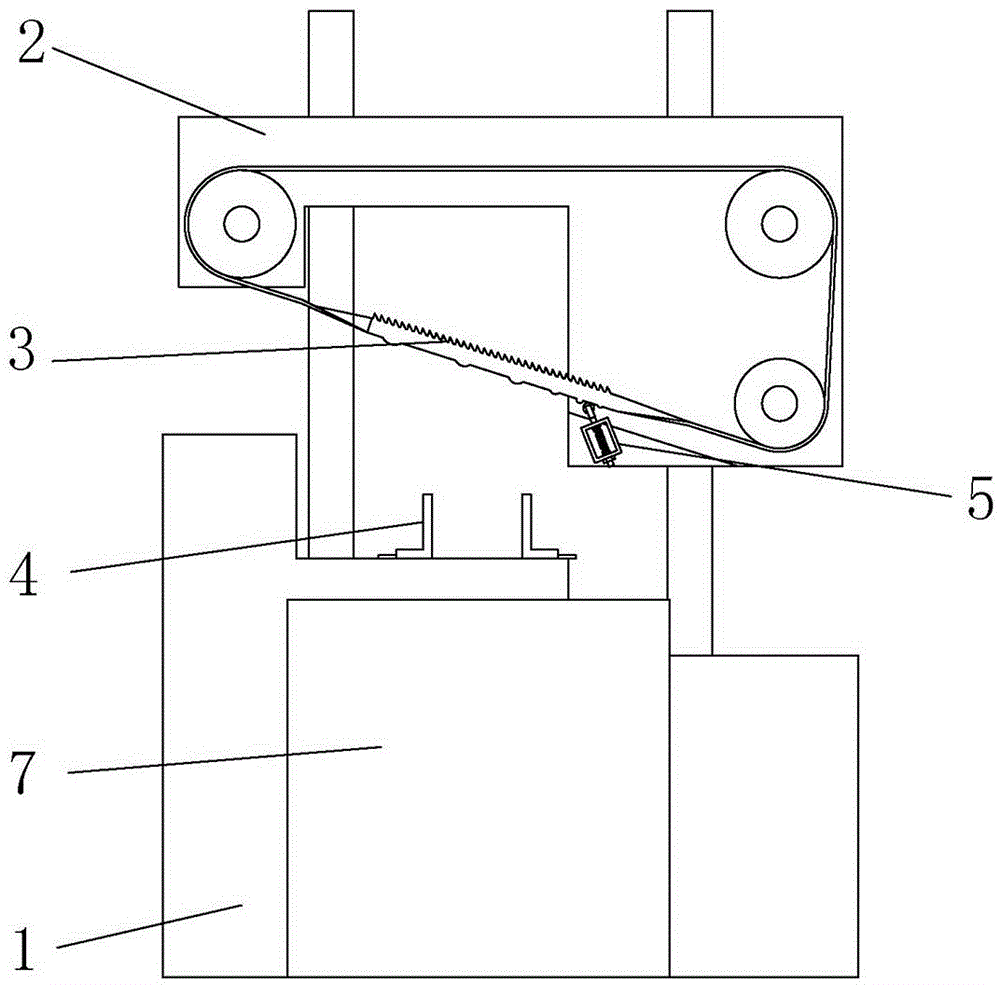

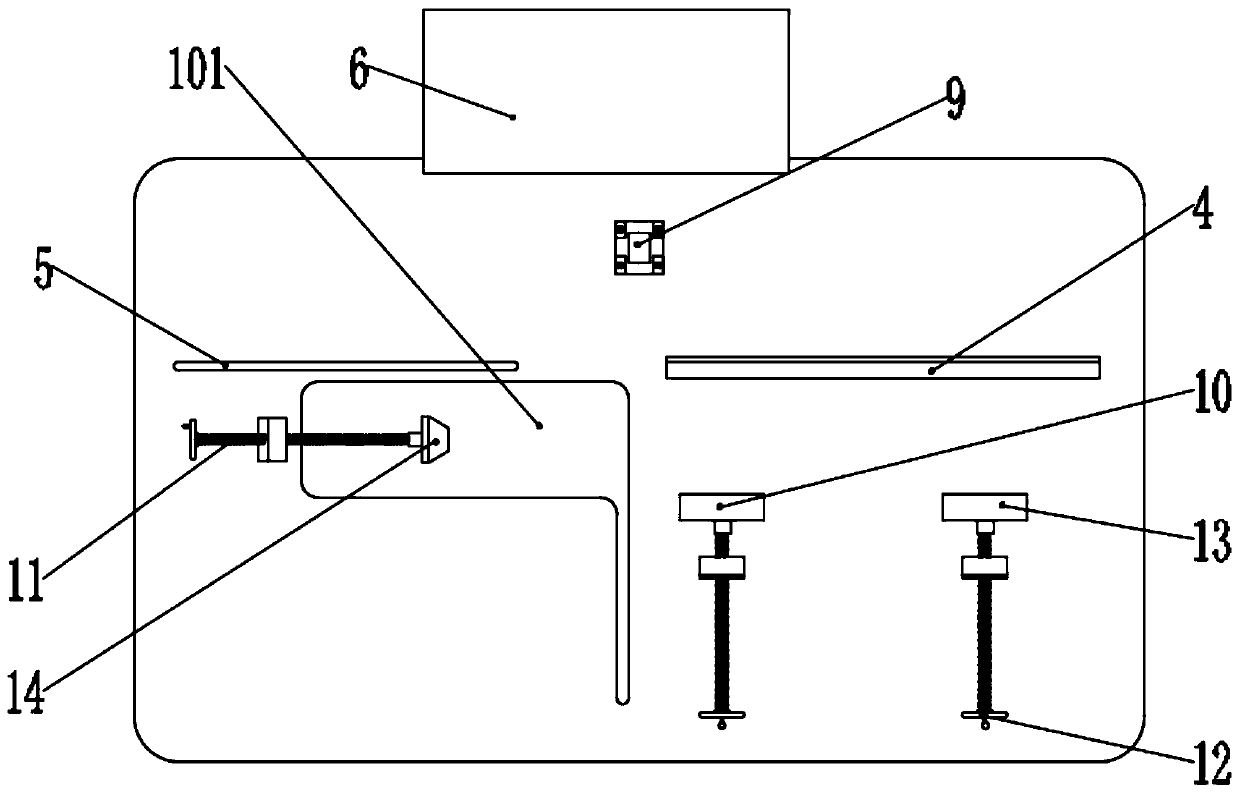

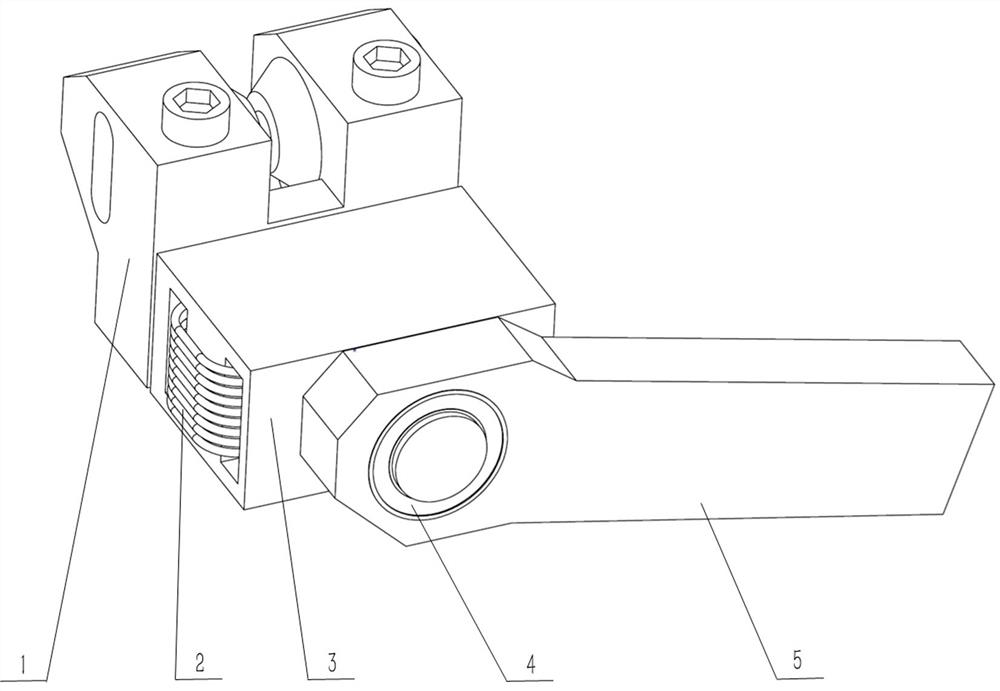

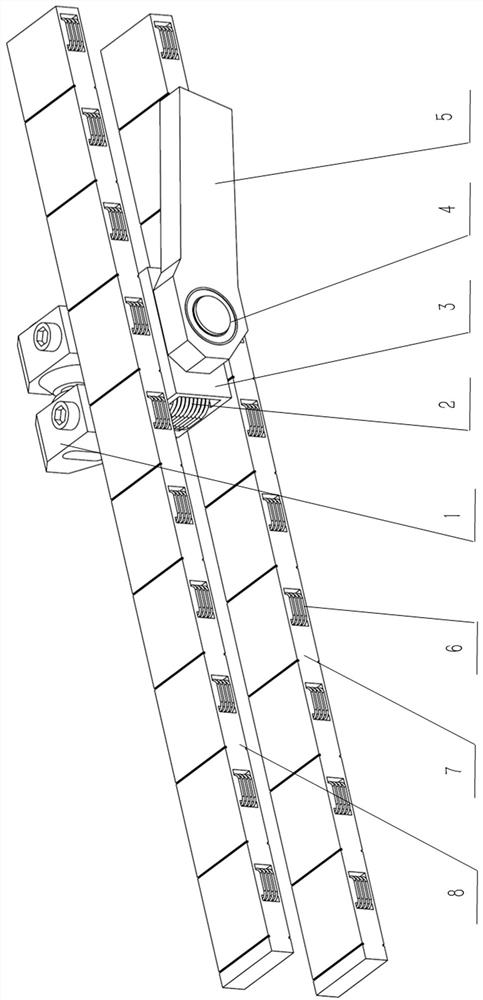

Adjusting method for positions of saw blades of floor dividing and cutting machine and floor dividing and cutting machine

InactiveCN105856333AAffect cutting accuracyEasy to adjustCircular sawsEngineeringMechanical engineering

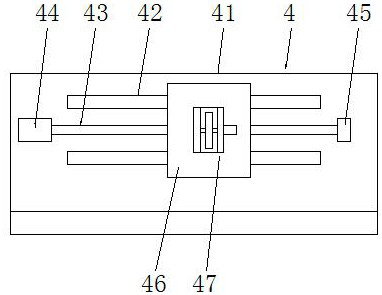

The invention discloses an adjusting method for positions of saw blades of a floor dividing and cutting machine. The adjusting method is characterized by comprising specific steps that firstly, each saw blade is mounted on an independent working motor to manufacture an independent cutting head, a stepping motor is arranged on each cutting head, and hollow rotating shafts of all the stepping motors are spirally and fixedly arranged on a lead screw of the dividing and cutting machine in a sleeving manner; and secondly, the fact that a single stepping motor is driven to move on the lead screw is used for achieving adjustment of the positions of the cutting heads. The invention further discloses the floor dividing and cutting machine. The floor dividing and cutting machine is characterized by comprising the fixedly-arranged lead screw and the cutting heads, each cutting head comprises the corresponding saw blade, the corresponding working motor for driving the saw blade to rotate and the corresponding stepping motor, the stepping motors are provided with the hollow rotating shafts, and the hollow rotating shafts are spirally arranged on the lead screw in the sleeving manner. Adjustment of the saw blade positions is convenient to operate, the saw blade positions are accurate in positioning, and the divided and cut materials are high in size precision.

Owner:江苏豪凯机械有限公司

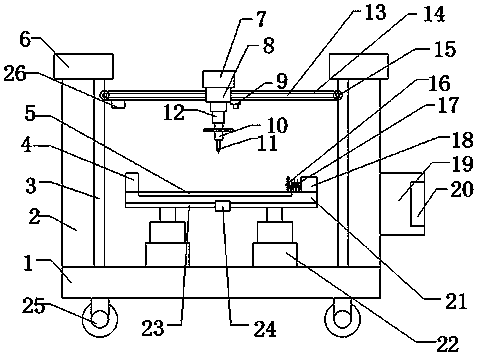

Ceramic-tile cutting machine

InactiveCN107584680AEasy to fixAffect cutting accuracyWorking accessoriesStone-like material working toolsWater flowEngineering

The invention provides a ceramic-tile cutting machine. The ceramic-tile cutting machine comprises a sliding column, a rectangular hole, a working block, a hand-control shaft, a high-pressure pipeline,a template storage frame, a template, a polygonal hole, a water-jet cutting head, a water cutting machine, a drawer, a blocking net, an elastic line, a filtering plate, a filtering net and a water flowing valve, wherein a cutting platform is of a hollow structure; a cutting hole is arranged at the top part of the cutting platform; a T-shaped fixed block is arranged on the end surface of the top part of the cutting platform. The ceramic-tile cutting machine provided by the invention has the beneficial effects that the benefit for improving the freedom degree of movement of the water-jet cutting head is achieved, and the water-jet cutting head can finish cutting work with different angles and different positions, so that the practicability of the cutting machine is greatly improved; specifically, in working, the hand-control shaft can move left and right or back and forth along the polygonal hole of the template, and then the water-jet cutting head arranged at the bottom part of the hand-control shaft can move freely at the cutting hole, so that a person can be convenient to cut out irregular cutting lines such as inclined arcs and the like on a ceramic tile and the handling capability of the cutting machine for irregular products is improved.

Owner:桐乡市瑞远纺织有限公司

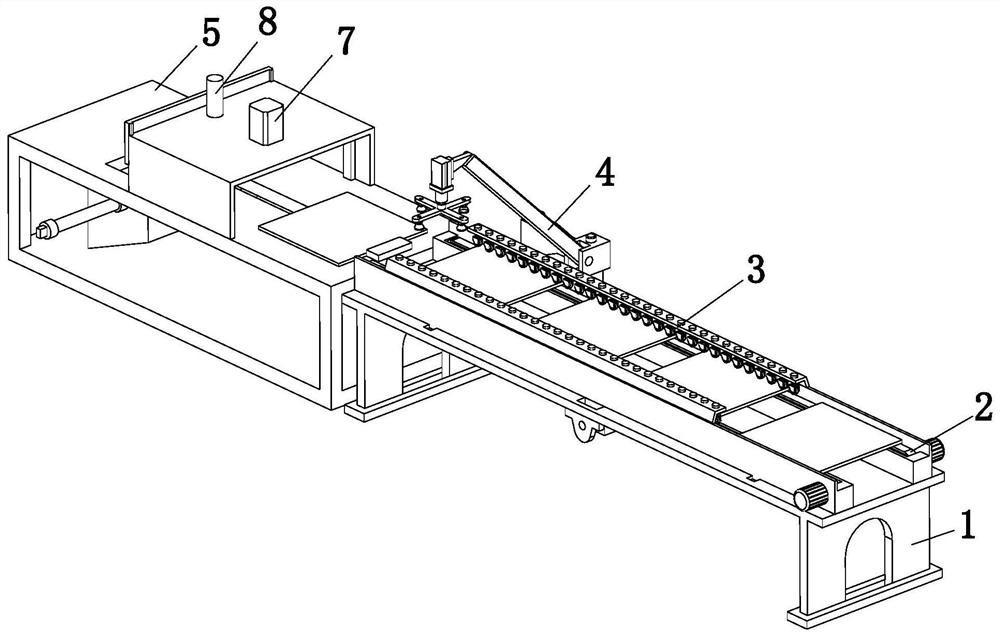

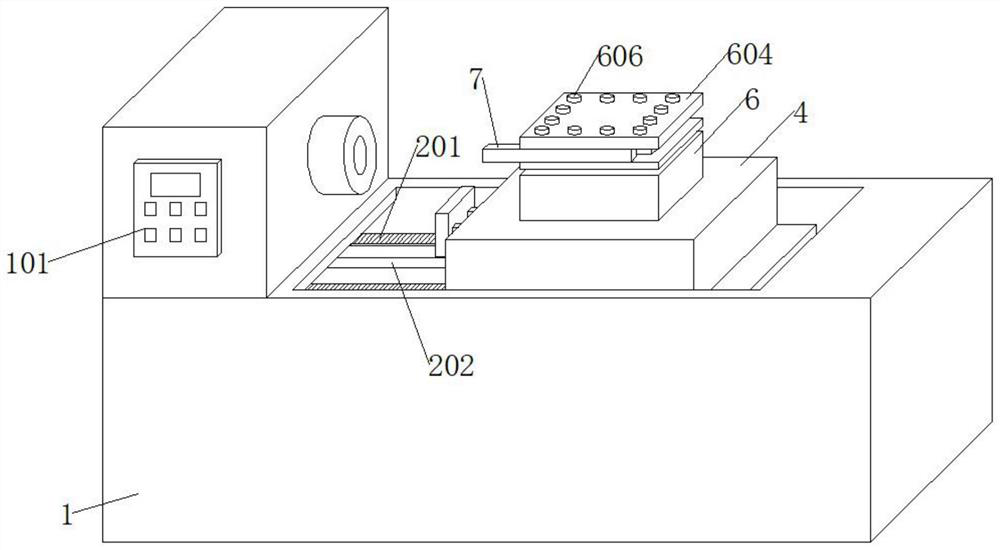

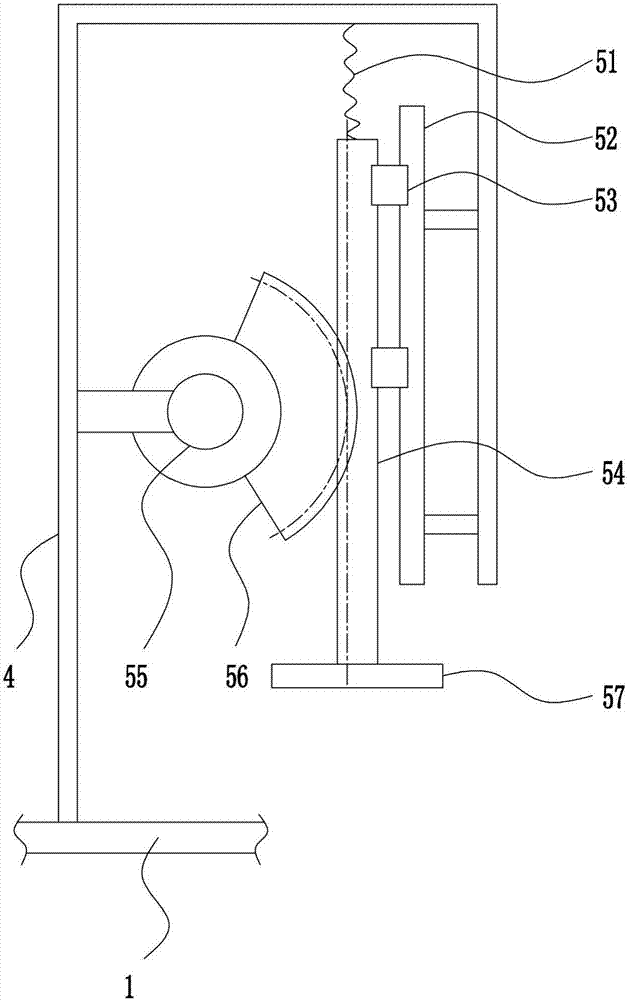

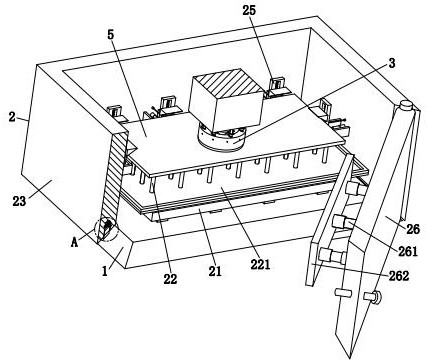

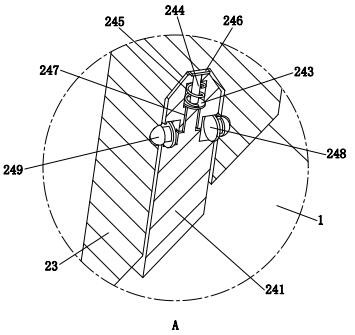

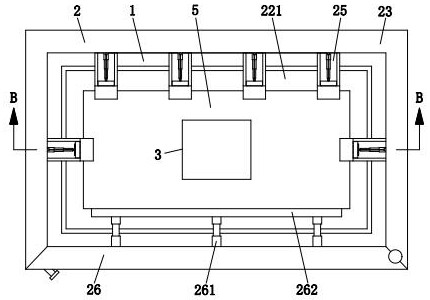

Cutting device for plate processing

InactiveCN113102831ARealize automatic loading stepsReduce manual laborMetal sawing devicesEngineeringTransfer mechanism

The invention discloses a cutting device for plate processing, and belongs to the field of plate processing equipment. The cutting device comprises a supporting frame, a conveying mechanism, two limiting mechanisms, a transferring mechanism, a machining table, a pushing mechanism, a clamping mechanism, a linkage mechanism and a cutting mechanism, the machining table is arranged beside one end of the supporting frame, and the conveying mechanism is arranged at the top of the supporting frame; and the two limiting mechanisms are symmetrically installed at the top of the conveying mechanism, the transferring mechanism is arranged beside one end of the machining table and one end of the supporting frame, a portal frame connected with the machining table is arranged at the top of the machining table, the clamping mechanism and the linkage mechanism are both installed on the portal frame, and the cutting mechanism is installed at the bottom of the machining table. The automatic feeding step of plates can be achieved, manual labor is reduced, the production efficiency is improved, the cutting efficiency and effect of the plates are improved, the reject ratio of the plates is greatly reduced, the production cost is reduced, and practicability is high.

Owner:蔡荣兴

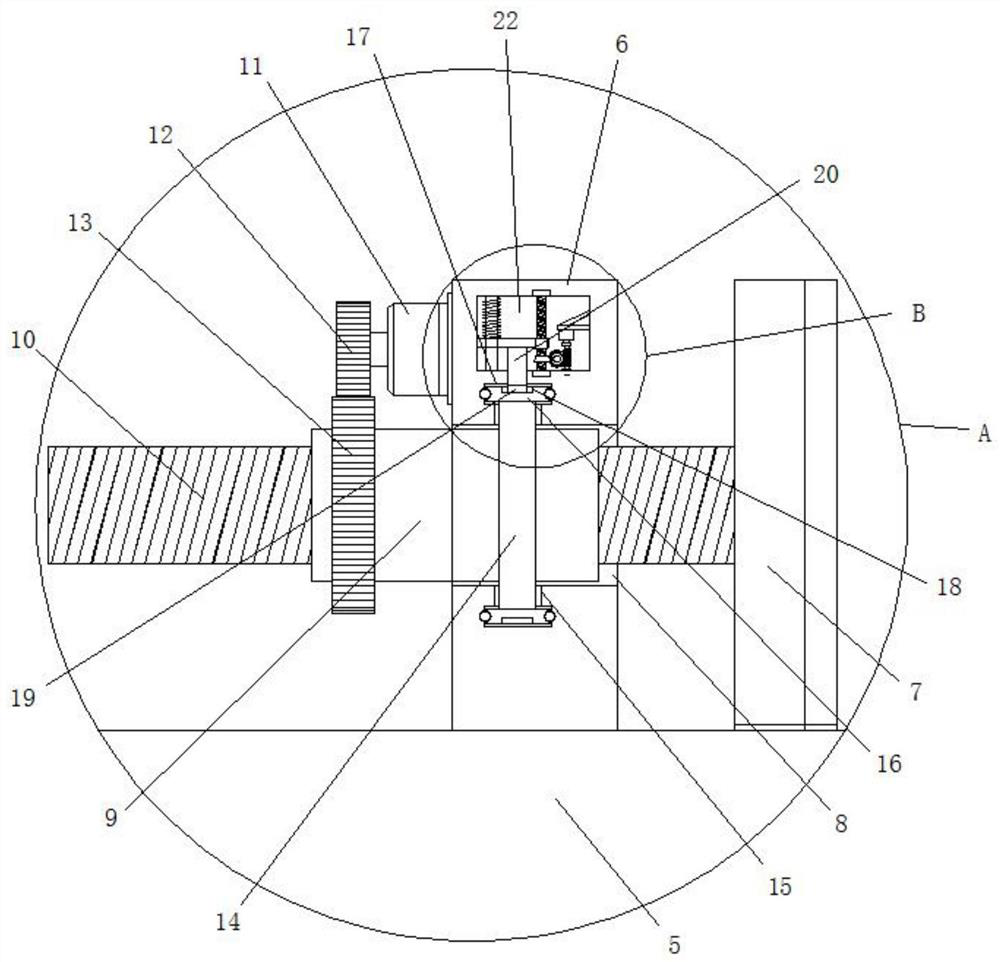

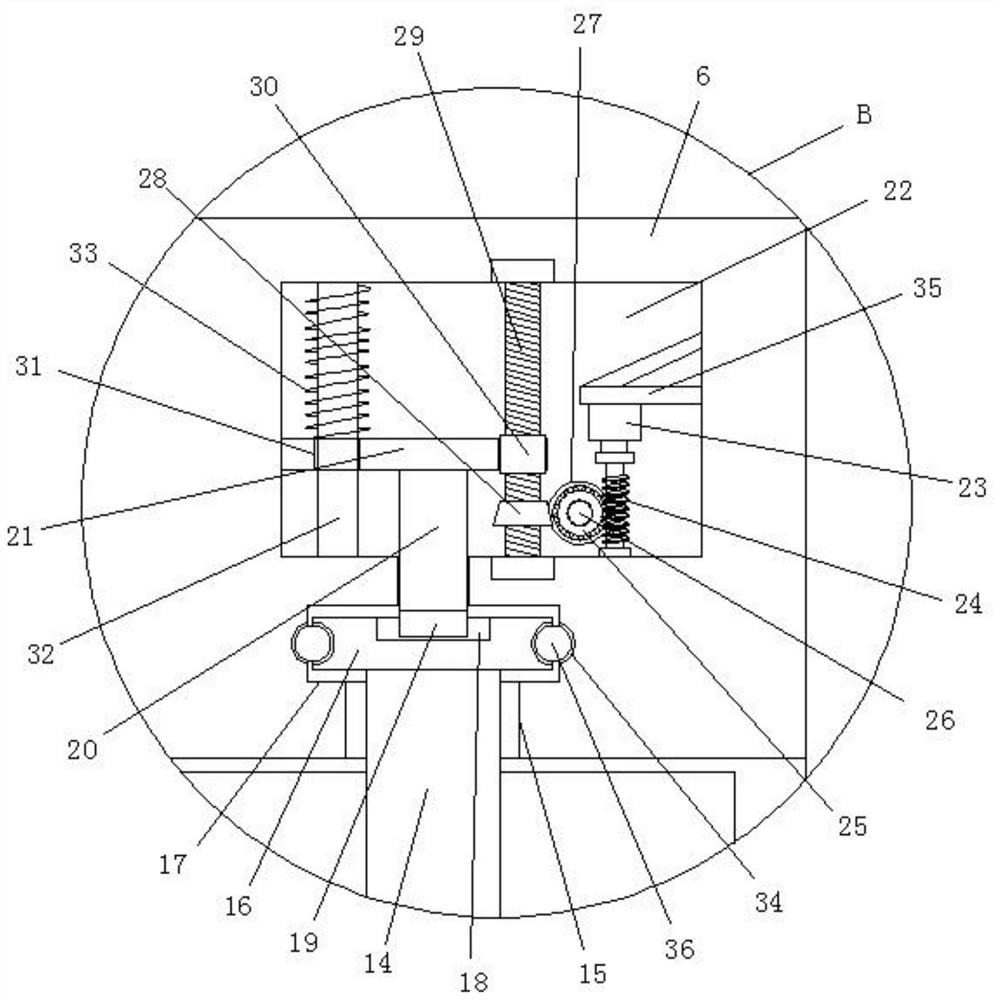

Knife collision prevention device used on knife rest of numerical control machine tool

PendingCN113770796APrevent movementAffect cutting accuracyFeeding apparatusMaintainance and safety accessoriesNumerical controlGear wheel

The invention provides a knife collision prevention device used on a knife rest of a numerical control machine tool, and relates to the technical field of numerical control machine tools. The knife collision prevention device comprises a machine tool body, a sliding plate, the knife rest and a clamping assembly, an equipment box is fixedly installed at the top of the machine tool body, an operation panel is fixedly installed on the front face of the equipment box, a moving cavity is formed in the machine tool body, a sliding rod is fixedly installed in the moving cavity, the sliding plate is arranged in the moving cavity, an equipment block is fixedly installed at the top of the sliding plate, the knife rest is fixedly connected to the top of the equipment block, and the clamping assembly is arranged between the sliding rod and the sliding plate and used for clamping and fixing the sliding plate. According to the device, through cooperative use of a threaded lead screw, a gear, a moving block and a travel switch, movement of a knife can be stopped before knife collision, and through cooperative use of electric push rods, a lifting plate and a knife groove, the height of the knife can be adjusted.

Owner:付晓倩

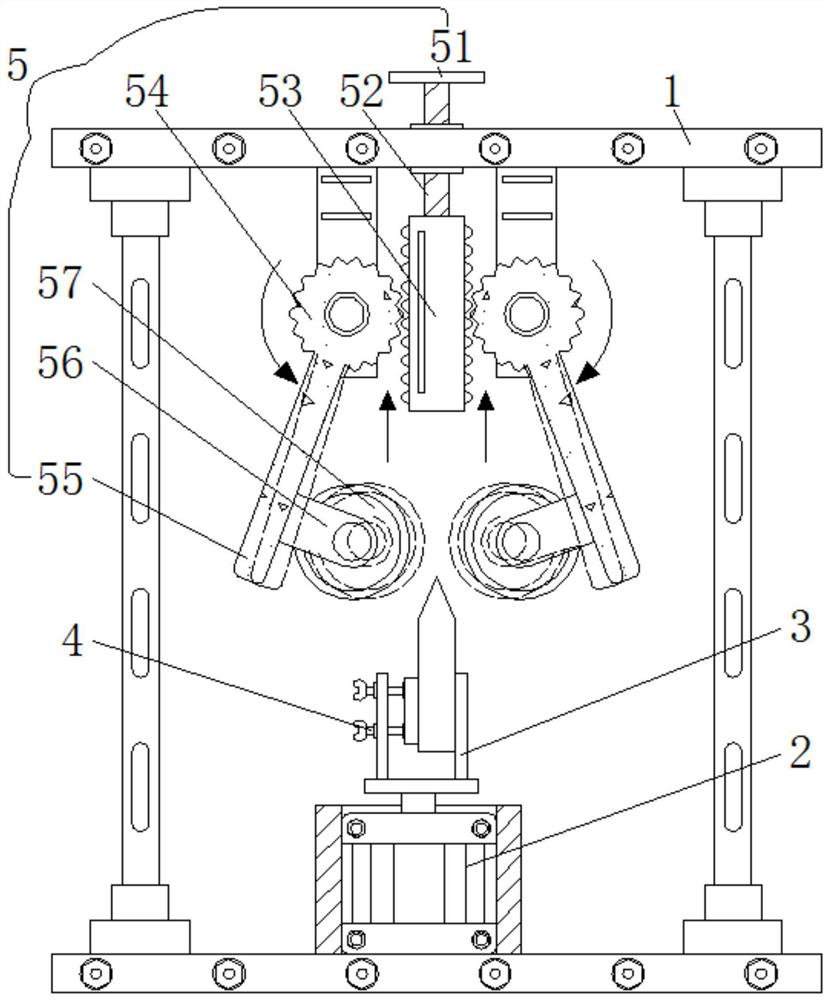

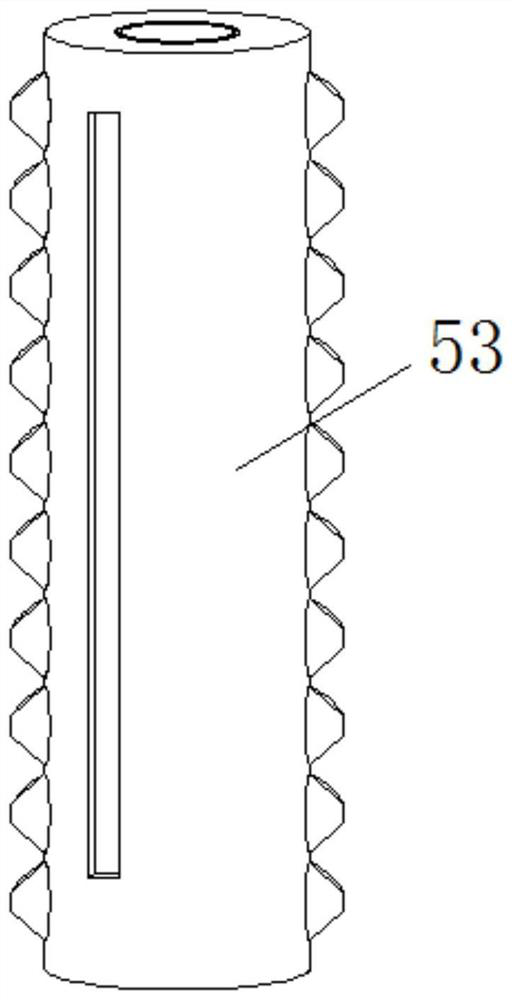

Silver-copper alloy rod cutting device

InactiveCN108274301AImprove accuracyConvenient electric fixationAutomatic control devicesMeasurement/indication equipmentsLaser transmitterGear wheel

The invention relates to a silver-copper alloy rod cutting device. The silver-copper alloy rod cutting device comprises a base and a working platform. Two vertical beams are fixedly installed on the upper surfaces of the two ends of the base, gear tracks are installed on the inner sides of the vertical beams in parallel, and the two gear tracks are connected with a transverse beam through rollinggears. A transverse guide rail is arranged on the upper surface of the transverse beam, a transverse moving block is arranged on the upper surface of the transverse guide rail, and a driving motor isarranged on the upper surface of the transverse moving block. A micro expansion device is arranged on the lower portion of the transverse moving block and connected with a motor through a connecting plate, the bottom of the motor is connected with a cutting head, and a laser transmitter is arranged on the lower right corner of the transverse moving block. By means of the laser calibration mode, the cutting accuracy rate of a silver-copper alloy rod is improved, the silver-copper alloy rod can be conveniently and electrically fixed by a worker, and the phenomenon that due to the fact that the silver-copper alloy rod is shaken in the cutting process, the cutting accuracy is affected is avoided.

Owner:成都市鼎立联兴科技有限公司

Plastic injection molding cutting platform facilitating material overturning

InactiveCN112045740AConvenience guaranteedGuaranteed stabilityMetal working apparatusPhysicsPlastic injection molding

The invention discloses a plastic injection molding cutting platform facilitating material overturning. The plastic injection molding cutting platform comprises a machine table, wherein a cutting cavity is embedded into the top end of the machine table; the bottom end of the cutting cavity is connected to a flow guide cavity in a penetrating mode; a plurality of supporting legs are uniformly arranged on the edge of the bottom end of the machine table; an overturning frame is arranged in an inner cavity of the cutting cavity; the front end and the rear end of the overturning frame are rotatablyconnected to the inner cavity wall of the cutting cavity through rotating shafts; a plurality of first electric telescopic devices are uniformly arranged at the front end and the rear end of the overturning frame; and the movable ends of first telescopic rods on the first electric telescopic devices penetrate through the side wall of the overturning frame and are fixedly connected to clamps. Whenthe plastic injection molding cutting platform is used, a to-be-cut plastic product is placed in the inner cavity of the overturning frame, the first electric telescopic devices are matched with thefirst telescopic rods to eject the clamp out, and the plastic product is clamped through the clamps; and the plastic product can be overturned by directly overturning the overturning frame, so that the convenience for overturning of the plastic product is greatly improved, and the influence of the clamping precision on the cutting precision of the plastic can be effectively avoided.

Owner:应嘉迪

Leather cutting device for leather manufacturing

InactiveCN106868231AEasy to collectSmall footprintLeather clicking/perforating/clickingEngineeringMechanical engineering

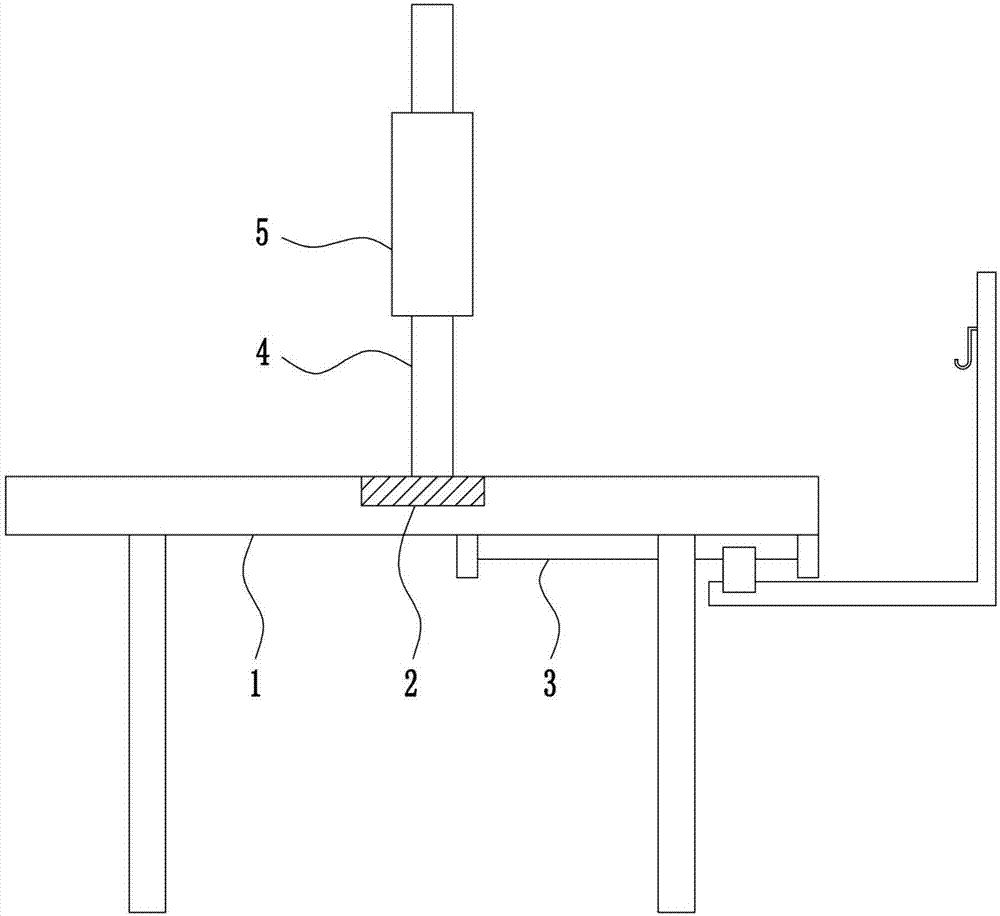

The invention relates to a cutting device, and in particular relates to a leather cutting device for leather manufacturing. The device comprises a worktable, a cutting plate, a collecting device, a bracket, a cutting device, etc., wherein the embedding plate is embedded into the middle part of the worktable; the collecting device is arranged at the right end of the bottom part of the worktable; the bracket on which the cutting device is mounted is arranged in the middle part of the rear sidewall of the worktable. The leather cutting device is high in cutting efficiency, high in cutting accuracy, convenient to collect leather, and convenient to operate; the worktable can be protected; the leather is cut after being cleaned, so that a cutter is protected.

Owner:湖州娇斯登鞋业有限公司

Woodworking band-sawing machine

The invention relates to technical field of cutting equipment, specifically to a woodworking band-sawing machine which comprises a base, a cutting base, a drive wheel, a driven wheel and a band saw. A conveying device and a fixing device are arranged on the base; a cutting direction of the band saw and the horizontal direction form an included angle of 20-40 degrees; the sand saw comprises a band saw body, saw-teeth and arc-shaped convex teeth, and a roller which abuts against the arc-shaped convex teeth is arranged below the band saw; and in the cutting direction of the band saw, a gap between the front group of two adjacent arc-shaped convex teeth is smaller than that of a next group of two adjacent arc-shaped convex teeth. The woodworking band-sawing machine has a good saw dust removal effect, is low in heat emission quantity and has good cutting performance; the band saw is used for cutting from bottom to top, so that saw dust is conveniently discharged, and the saw dust is discharged through gaps among the sawteeth under action of gravity; and arc-shaped bulges are arranged, so that the band saw can vibrate periodically, thus saw dust in saw kurfs can be effectively discharged, saw dust among the sawteeth drops, and a saw blade is kept clean.

Owner:佛山市凯名洋锯业有限公司

Cutting machine for cutting anti-collision materials

PendingCN108466297AImprove efficiencyImprove pass rateMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of anti-collision material cutting and relates to a cutting machine for cutting anti-collision materials. The cutting machine for cutting the anti-collision materials comprises a rack. The rack is provided with a working table and the working table is providedwith a feeding device. A cutting device is arranged on the rack and is positioned in the transfer direction of the feeding device. The cutting device comprises a corner cutting assembly and a strip cutting assembly. The corner cutting assembly comprises a first mounting seat, a first cutting disk, a second cutting disk, a first motor and a second motor. The first cutting disk and the second cutting disk are correspondingly driven by the first motor and the second motorto rotate. The strip cutting assembly comprises a second mounting seat, a third cutting disk and a third motor. The third cutting disk is driven by the third motor to rotate. The first mounting seatand the second mountingseat are both movably arranged on the rack. The cutting machine for cutting the anti-collision materials is provided with the corner cutting assembly and the strip cutting assembly, anti-collision corners and anti-collision strips can be cut, and mechanical operation has higher efficiency compared with manual cutting in the prior art.

Owner:浙江佳诚婴童用品有限公司

Automatic laser cutting equipment for mechanical sheet metal machining

ActiveCN114227022AGuaranteed stabilityImprove cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesMetal machiningEngineering

The invention relates to the technical field of sheet metal machining, in particular to automatic laser cutting equipment for mechanical sheet metal machining, which comprises a worktable, a supporting unit and a cutting unit, the supporting unit is mounted at the upper end of the worktable, and the cutting unit is arranged on an external machine tool host; an existing laser cutting machine has the following problems that a common laser cutting machine cannot fix a workpiece, so that the workpiece is prone to deviation, and the cutting precision of the workpiece is affected; smudginess and sundries left on the surface of the workpiece which is not cleaned are easy to achieve the cutting effect of the laser cutting machine on the workpiece; according to the invention, a workpiece can be fixed in all directions, and the stability of the workpiece during cutting can be ensured, so that the cutting precision of the workpiece can be enhanced; the upper end face of a workpiece can be cleaned, so that the stability of the workpiece during cutting is guaranteed, and the cutting effect of the workpiece is enhanced.

Owner:江苏博朗智能装备有限公司

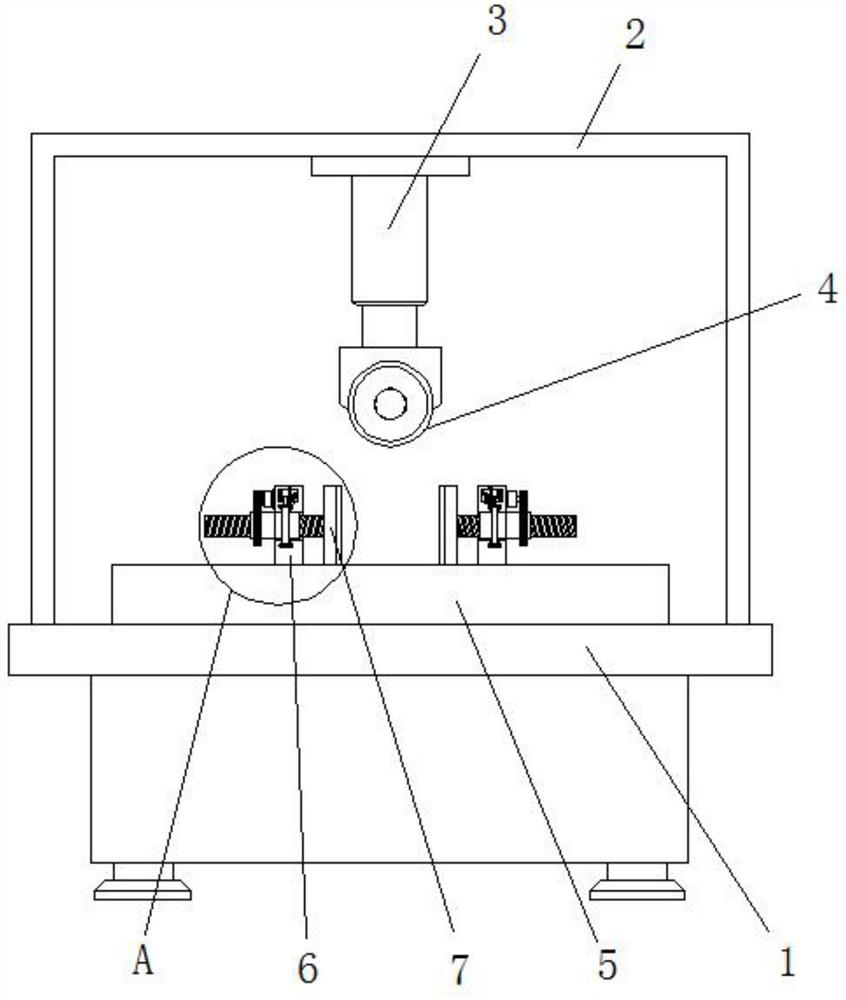

Machining cutting device for machine manufacturing

ActiveCN112170929APrevent the phenomenon of rotationOcclusal positioning is firmShearing machinesShearing machine accessoriesThreaded pipeMachine building

The invention discloses a machining cutting device for machine manufacturing. The machining cutting device comprises a machine table and a portal frame fixedly arranged on the machine table, a liftingmotor is arranged on an inner wall of the top of the portal frame, a cutting device body is arranged at an output end of the lifting motor, a cutting table is arranged below the cutting device body,a positioning and fixing mechanism is arranged on the cutting table and comprises two fixing frames fixedly arranged at the top of the cutting table, positioning blocks are movably arranged at the sides, close to each other, of the two fixing frames, and threaded rods are fixedly connected to the sides, away from each other, of the two positioning blocks. According to the machining cutting device,a threaded pipe and the threaded rods can be prevented from rotating in a threaded mode, it is guaranteed that threaded engagement positioning between the threaded pipe and the threaded rods is firmer, it can be guaranteed that the positioning block clamp and fix workpieces more stably, the situation that the cutting precision of the workpieces is affected due to deviation and displacement in theworkpiece cutting process is avoided, the cutting quality is guaranteed, and the usage requirement of people can be met.

Owner:WEIHAI VOCATIONAL COLLEGE

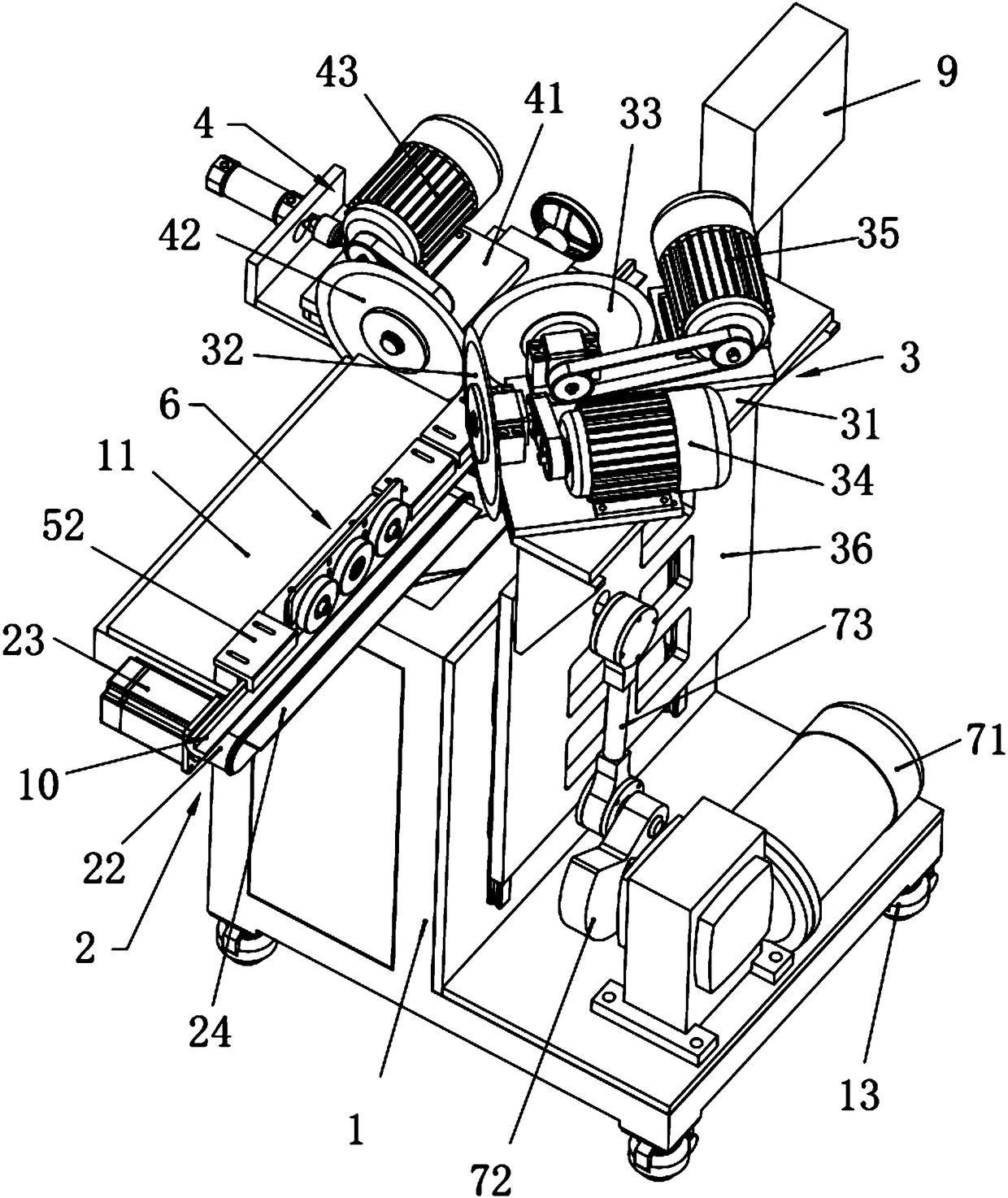

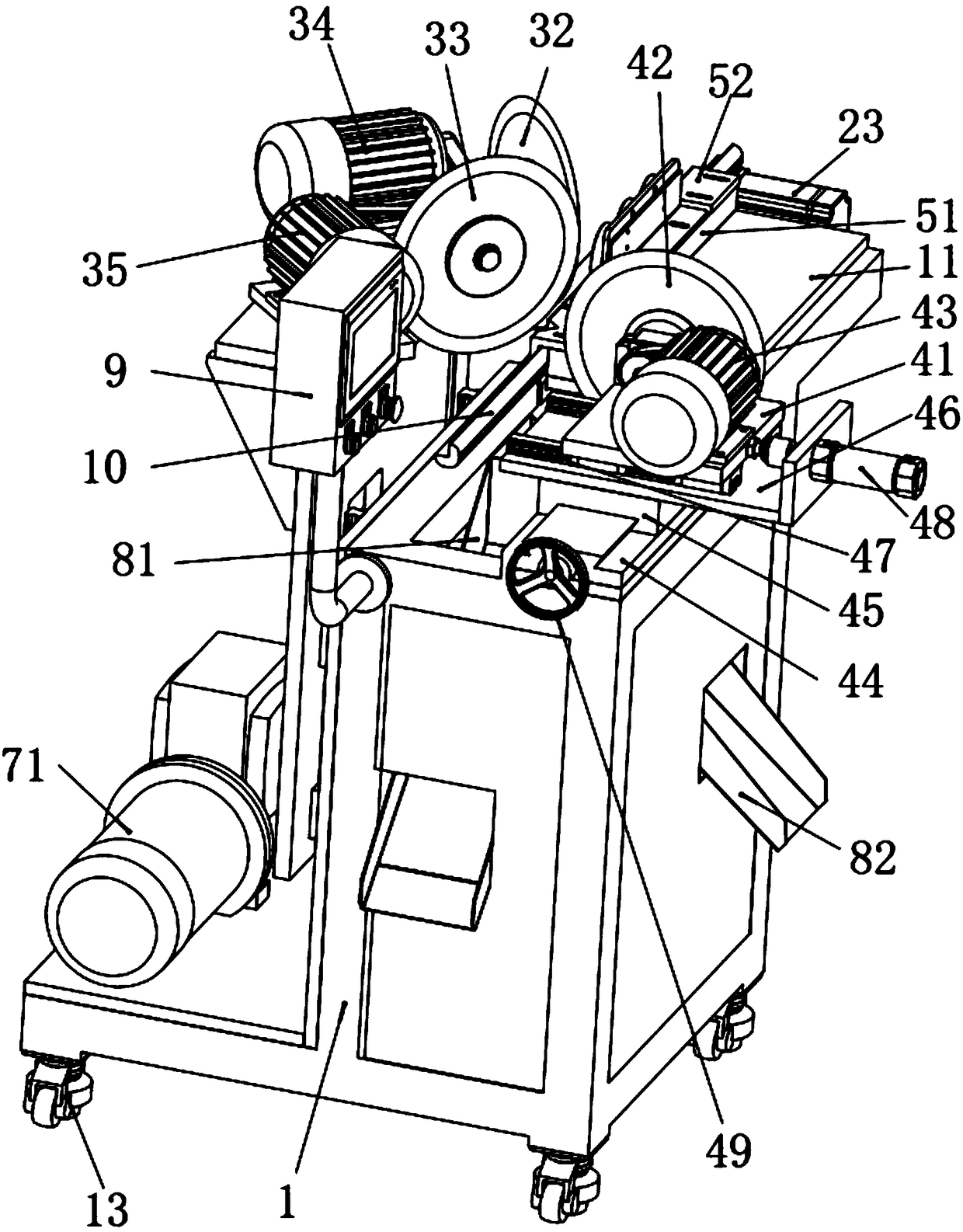

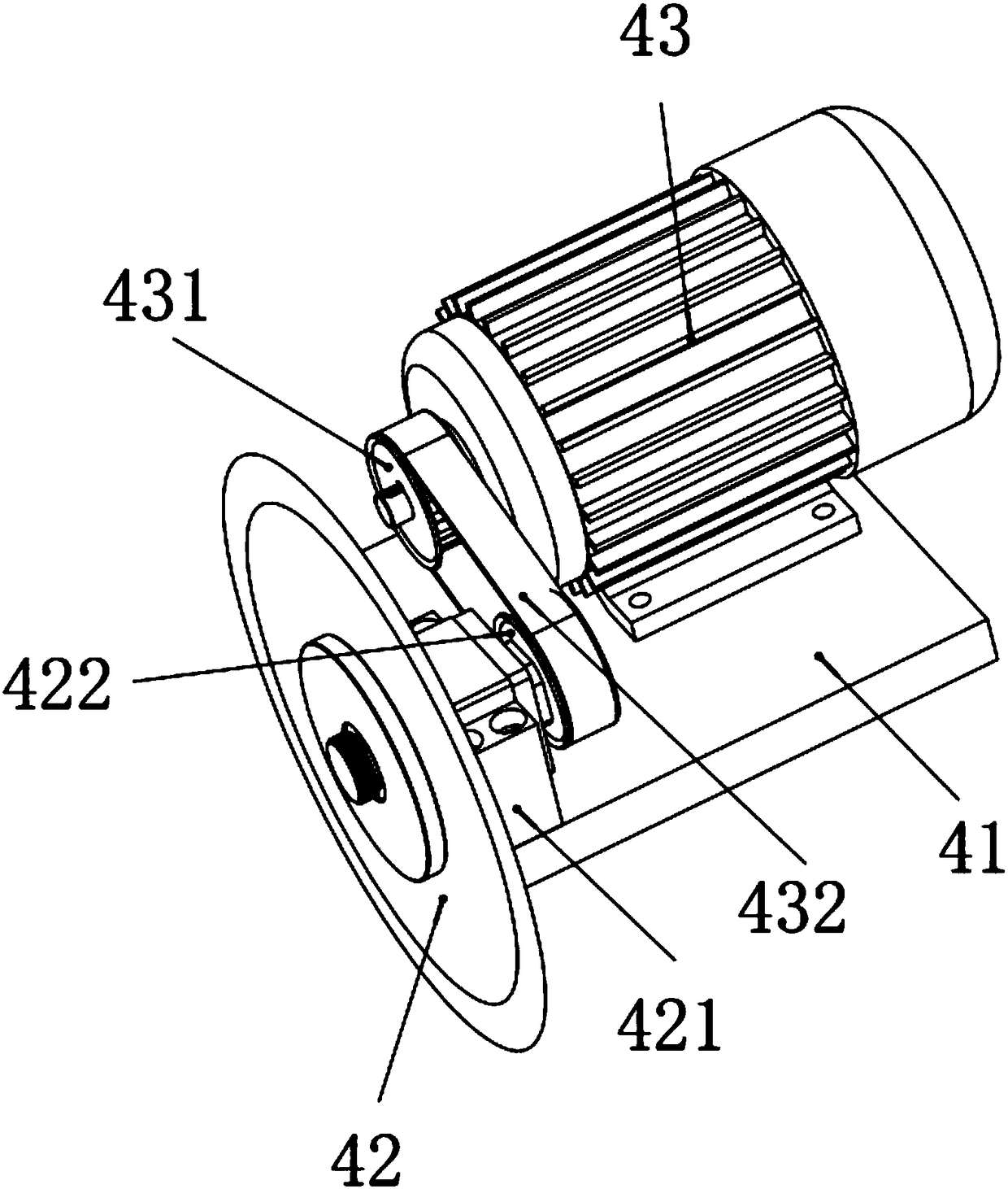

Cutter grinding device capable of preventing cutting precision from being affected by uneven cutting edge

InactiveCN113579864AEasy to adjust the grinding speedSave time at workGrinding drivesGrinding feed controlGrindingManufacturing engineering

The invention provides a cutter grinding device capable of preventing cutting precision from being affected by an uneven cutter edge, and relates to the technical field of cutters. The cutter grinding device capable of preventing the cutting precision from being affected by the uneven cutter edge comprises a grinding assembly, a rotating rod is arranged in the grinding assembly, a first lead screw is welded to the bottom of the rotating rod, and the outer wall of the bottom of the first lead screw is in threaded connection with a rack. According to the cutter grinding device capable of preventing the cutting precision from being affected by the uneven cutter edge, the rotating rod is rotated, at the moment, two grinding rollers can be tightly attached to the left side and the right side of the cutter edge of a cutter on the top of a fixing plate, and therefore the effect that the cutter cutting precision is reduced due to the fact that the grinding degrees of the two sides of the cutter edge are different is avoided. A butterfly-shaped rotary knob is rotated, the transmission ratio between a second conical shaft and a first conical shaft can be changed at the moment, the rotating speed of the grinding rollers is further changed, and therefore the effects that the grinding speed is conveniently adjusted according to cutters made of different materials, the working time is saved, and the working efficiency is improved are achieved.

Owner:深圳鹏锐实业有限公司

Wire cutting machine

InactiveCN107790832ASimple structureEasy to operateMeasurement/indication equipmentsLarge fixed membersWire cuttingEngineering

The invention discloses a wire cutting machine which comprises a nut and a lead screw. The nut comprises an outer nut body and an inner nut body. The outer nut body is arranged on the inner nut body in a sleeving manner. The inner nut body is arranged on the outer portion of the lead screw in a sleeving manner and can move on the lead screw. A spiral groove is formed in the inner nut body. An inclined cutting portion is arranged at the end of one side of the lead screw. An elastic locating part embedded in the cutting portion is arranged on the cutting portion. An arc groove carrying out pathguiding on the elastic locating part is formed in the outer nut body. A locating groove with the depth larger than that of the arc groove is formed in one end of the arc groove. A locating bearing isarranged on the contact face of the inner nut body and the outer nut body. The wire cutting machine is simple in structure, convenient to operate, low in price, reliable in performance and capable ofachieving the function of automatic limiting protection.

Owner:南通冒氏智能装备有限公司

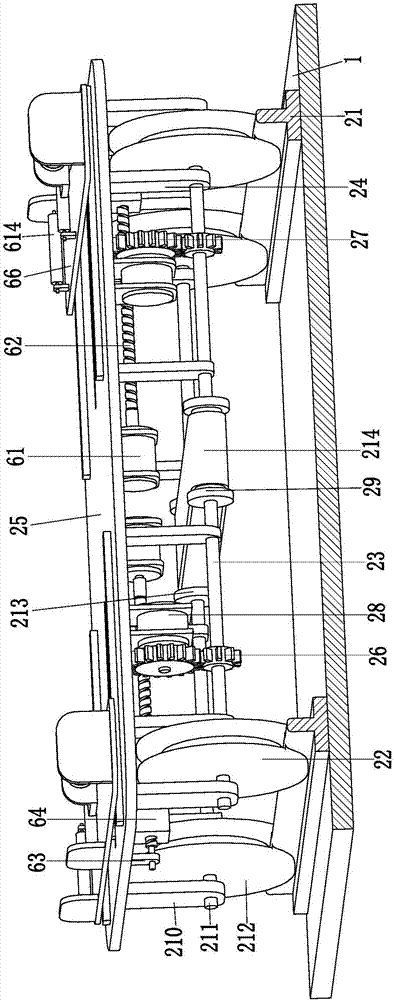

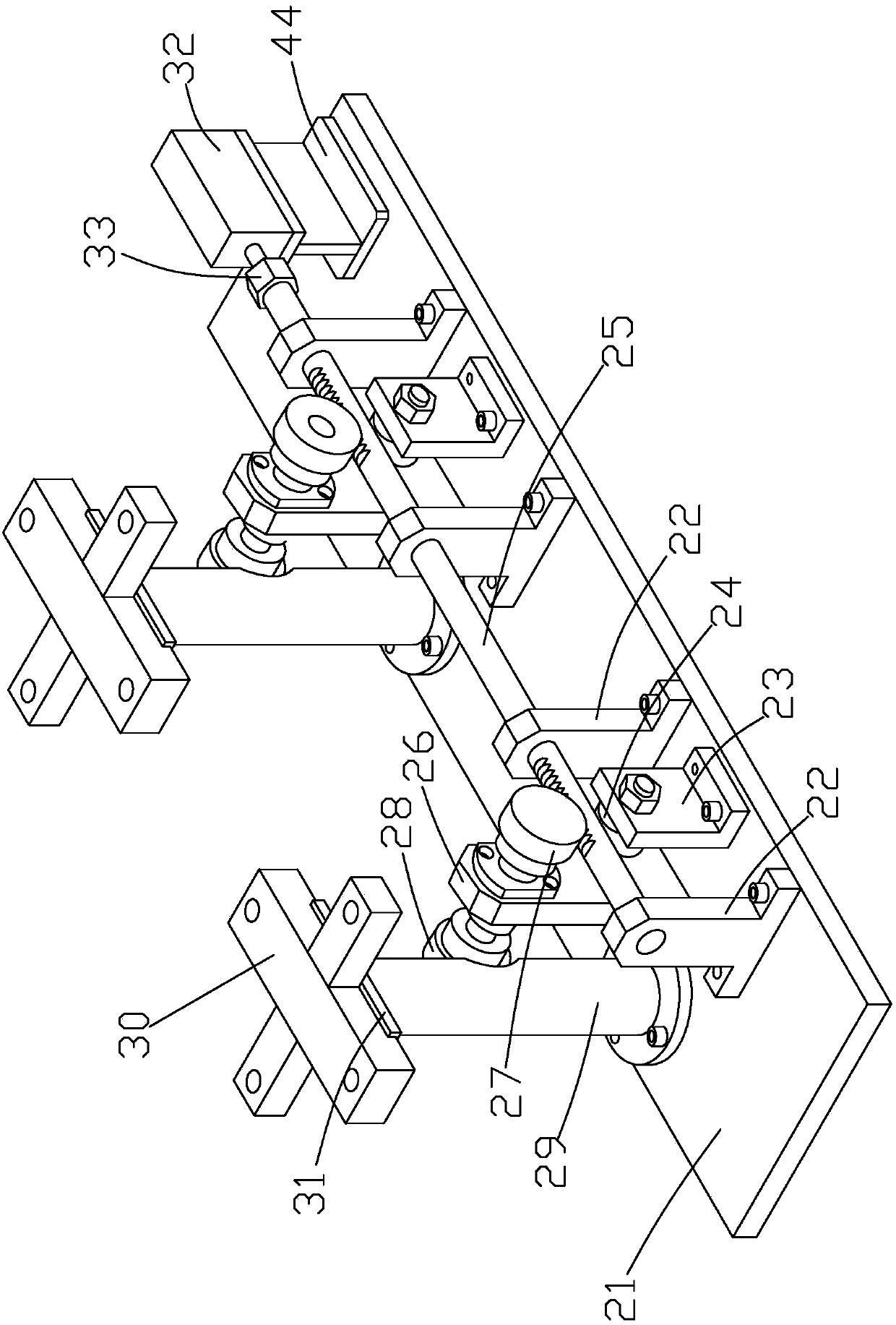

A vertical platen cowhide cutting machine

InactiveCN106881737BPrevent movementDimensionally stableFur cuttingMetal working apparatusEngineeringMechanical engineering

The utility model relates to a vertical platen type cowhide cutting machine, which belongs to the technical field of cowhide cutting equipment. It is characterized in that: it includes a cutting platform (7), a transverse cutting mechanism and a longitudinal cutting mechanism, a longitudinal pressing mechanism and a transverse pressing mechanism are arranged above the cutting platform (7), and the transverse pressing mechanism and the longitudinal pressing mechanism alternate with the cutting The platform (7) cooperates to compress the cowhide to be cut, the horizontal pressing mechanism cooperates with the horizontal cutting mechanism to cut the cowhide, and the longitudinal pressing mechanism cooperates with the longitudinal cutting mechanism to cut the cowhide, thereby cutting the cowhide into blocks. The longitudinal pressing mechanism and the horizontal pressing mechanism of the vertical platen cowhide cutting machine can respectively cooperate with the cutting platform to press the cowhide tightly, avoiding the movement of the cowhide during cutting, so that the cutting accuracy of the longitudinal cutting mechanism and the horizontal cutting mechanism is greatly improved. , to ensure the dimensional stability of the cut cowhide, thereby simplifying the subsequent processing technology and improving the quality of the product.

Owner:SHANDONG UNIV OF TECH

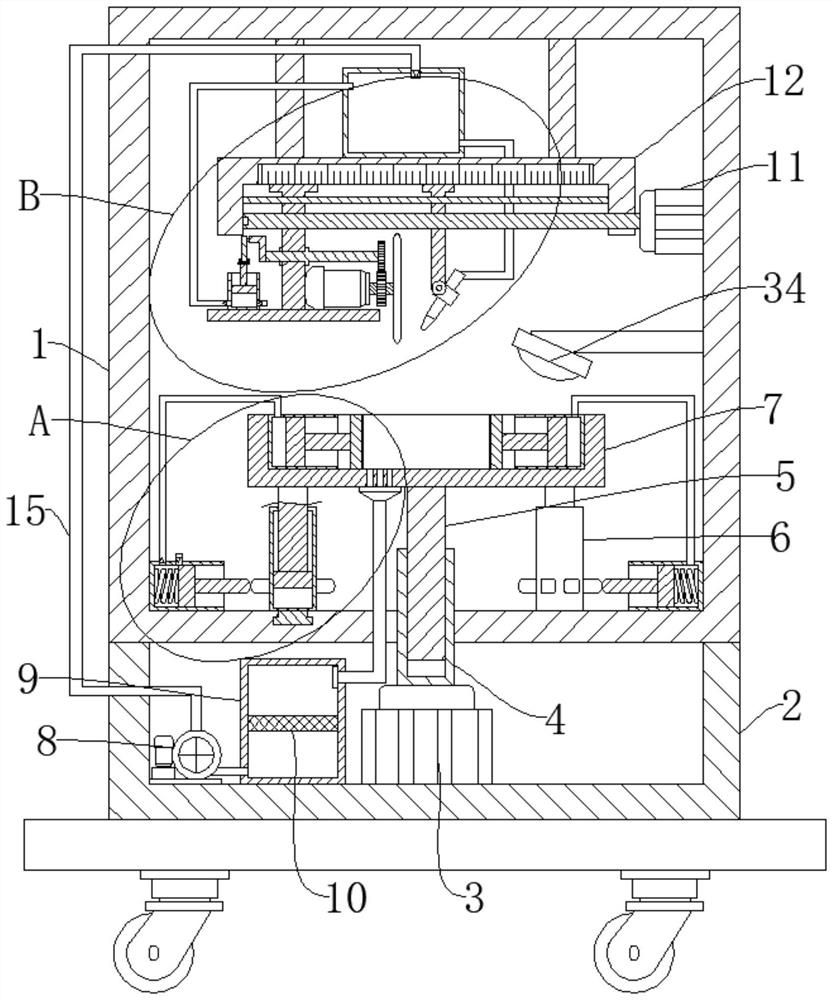

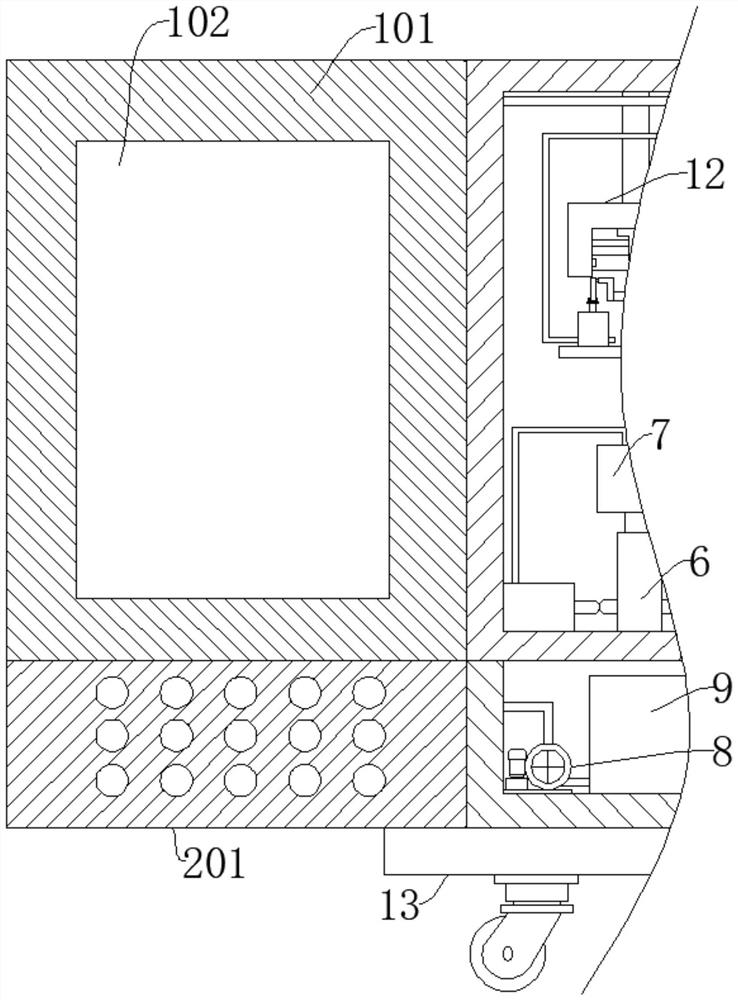

Cutting machining equipment for crystalline silicon cells of solar cell panel assembly

InactiveCN113733378AImprove stabilityGuaranteed cutting accuracyFinal product manufactureFine working devicesCrystallographyPhysical chemistry

The invention relates to the technical field of solar cell panel machining, in particular to cutting machining equipment for crystalline silicon cells of a solar cell panel assembly. The cutting machining equipment comprises a base, a mounting unit and a cutting unit, wherein the mounting unit is arranged in the middle of the upper end of the base, and the cutting unit is mounted at the upper end of the base and located on the outer side of the mounting unit. Existing laser cutting equipment is likely to cause a hot melting influence on notches of crystalline silicon cells, the cutting effect on the crystalline silicon cells is affected, and the operation is tedious; and the equipment cannot limit the crystalline silicon cells, the crystalline silicon cells lack stability, and the cutting precision on the crystalline silicon cells cannot be ensured. The cutting machining equipment can limit and fix the crystalline silicon cells, the stability of the crystalline silicon cells during cutting can be enhanced, and then the cutting precision of the cutting machining equipment on the crystalline silicon cells can be ensured. According to the cutting machining equipment, laser cutting can be replaced with a linear cutting machining mode, the operation is easy, and the machining cost of the crystalline silicon cells can be reduced.

Owner:江苏晟大光电科技有限公司

Plastic mold cutting device

InactiveCN114147883AAffect cutting accuracyAffect stabilityUsing liquid separation agentPositioning apparatusElectric machineEngineering

The invention discloses a plastic mold cutting device, and belongs to the technical field of mold production equipment. A plastic mold cutting device comprises a working box, an equipment box and a base, a first motor is fixedly connected into the equipment box, the output end of the first motor is fixedly connected with a cylinder, a threaded rod is rotationally connected into the cylinder through threads, and the upper end of the threaded rod penetrates through the working box and is fixedly connected with a containing table; according to the die cutting device, through the arrangement of the air inflation mechanism and the clamping mechanism, a die can be fixed, the situation that when the die is cut, the die shakes, and the cutting precision of the die is affected is prevented, through the arrangement of the pressurizing mechanism, the die cutting precision is improved, and the die cutting efficiency is improved. And the pressurizing mechanism can pressurize water in the water tank, a spray head sprays the water to the cutting position of the mold, dust generated during cutting is prevented from drifting around, and the practicability of the device during use is improved.

Owner:刘琪

Guide correcting device of sponge cutting machine

ActiveCN102794787BAffect cutting accuracyReduce width dimensionMetal working apparatusEngineeringMechanical engineering

Owner:南通恒康数控机械股份有限公司

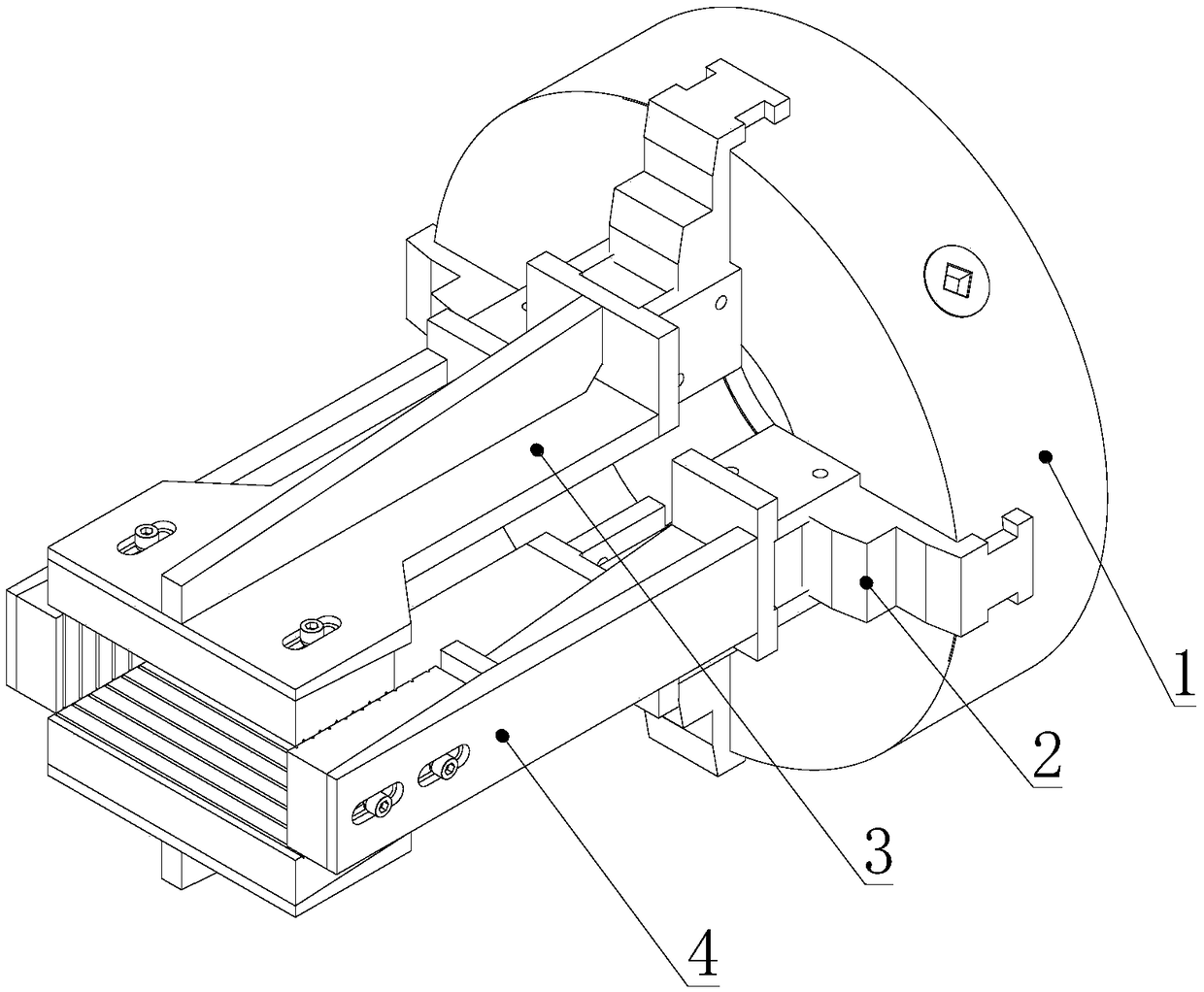

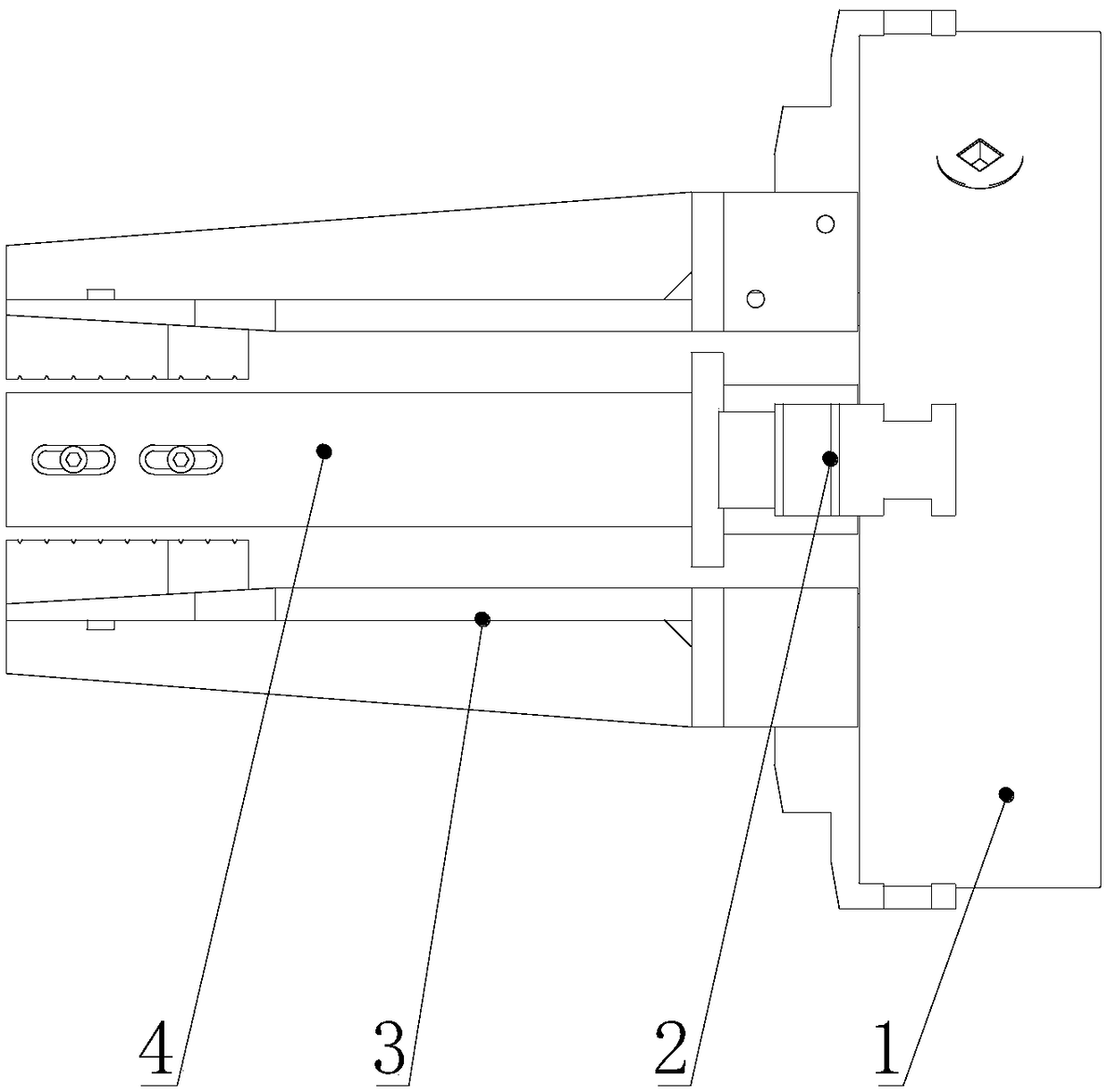

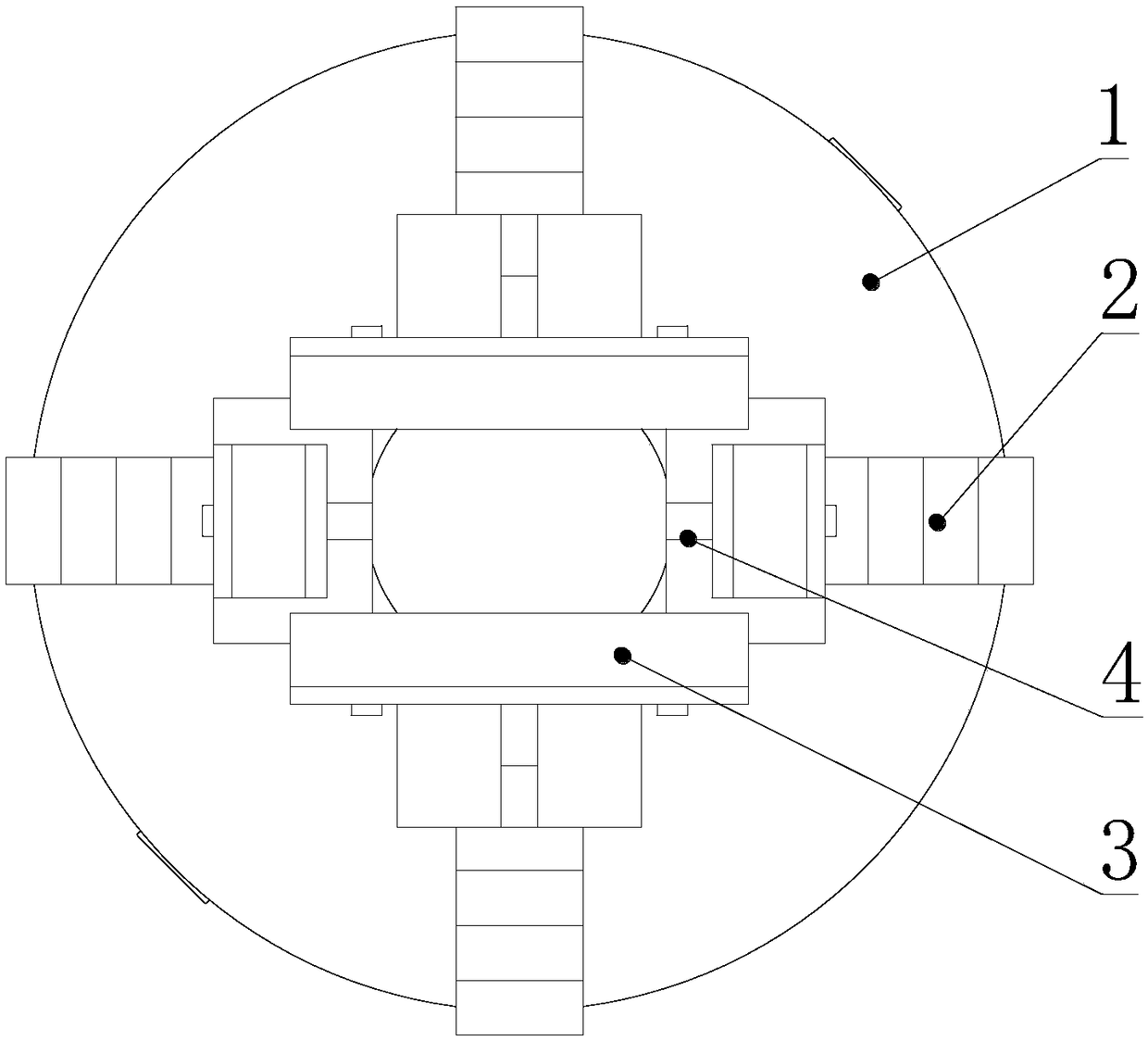

Tool used for clamping irregular workpieces

ActiveCN109366081AAchieve clampingAchieve fixationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine tool

A tool used for clamping irregular workpieces comprises a chuck, clamping claws, a first clamping unit and a second clamping unit; one end of the chuck is fixed to a rotating shaft of a machine tool;the other end of the chuck is provided with the clamping claws; the clamping claws are arranged into two groups; the two groups of clamping claws are perpendicularly arranged; two clamping claws are arranged in each group; one group of clamping claws are provided with the first clamping unit; and the other group of clamping claws are provided with the second clamping unit. The first clamping unitand the second clamping unit are correspondingly arranged, and are perpendicularly arranged to achieve fixing of a workpiece on two freedom degrees; and clamping on rectangular pipes, channel steel, I-shaped steel, U-shaped steel and other workpieces in irregular shapes is achieved, it is guaranteed that fixing is firm during cutting, and the cutting quality is guaranteed.

Owner:SHANDONG LEIMING CNC LASER EQUIP CO LTD

A protective treatment process for cutting and rolling of protective film

ActiveCN110919765BWill not deformEasy to useMetal working apparatusStructural engineeringKnife blades

The invention discloses a protection treatment process for protective film cutting and rolling, and specifically relates to the technical field of protective film cutting and rolling, which includes the following processing steps: Step 1, firstly collect the waste materials produced by the protective film processing, clean them up and arrange them for standby; step 2. Before cutting the processed and rolled protective film, determine the position of the cutting knife, and then wrap the protective film waste sorted in step 1 outside the protective film to be cut, and correspond to the position of the lower knife ;Step 3: After the lower knife position of the protective film is wrapped and thickened by the waste protective film, the roll cutting machine is turned on, and a circular blade is used on the roll cutting machine to carry out the roll cutting work. Thick protective film waste, after the waste is removed, the protective film wrapped by the waste is intact. The invention adopts the process of wrapping the protective film with the protective film waste and then cutting it into rolls. The protective film can be cut into rolls directly by using a round knife. It is simple and easy to operate during use, and the cut rolls of the protective film do not warp.

Owner:昆山云松电子材料有限公司

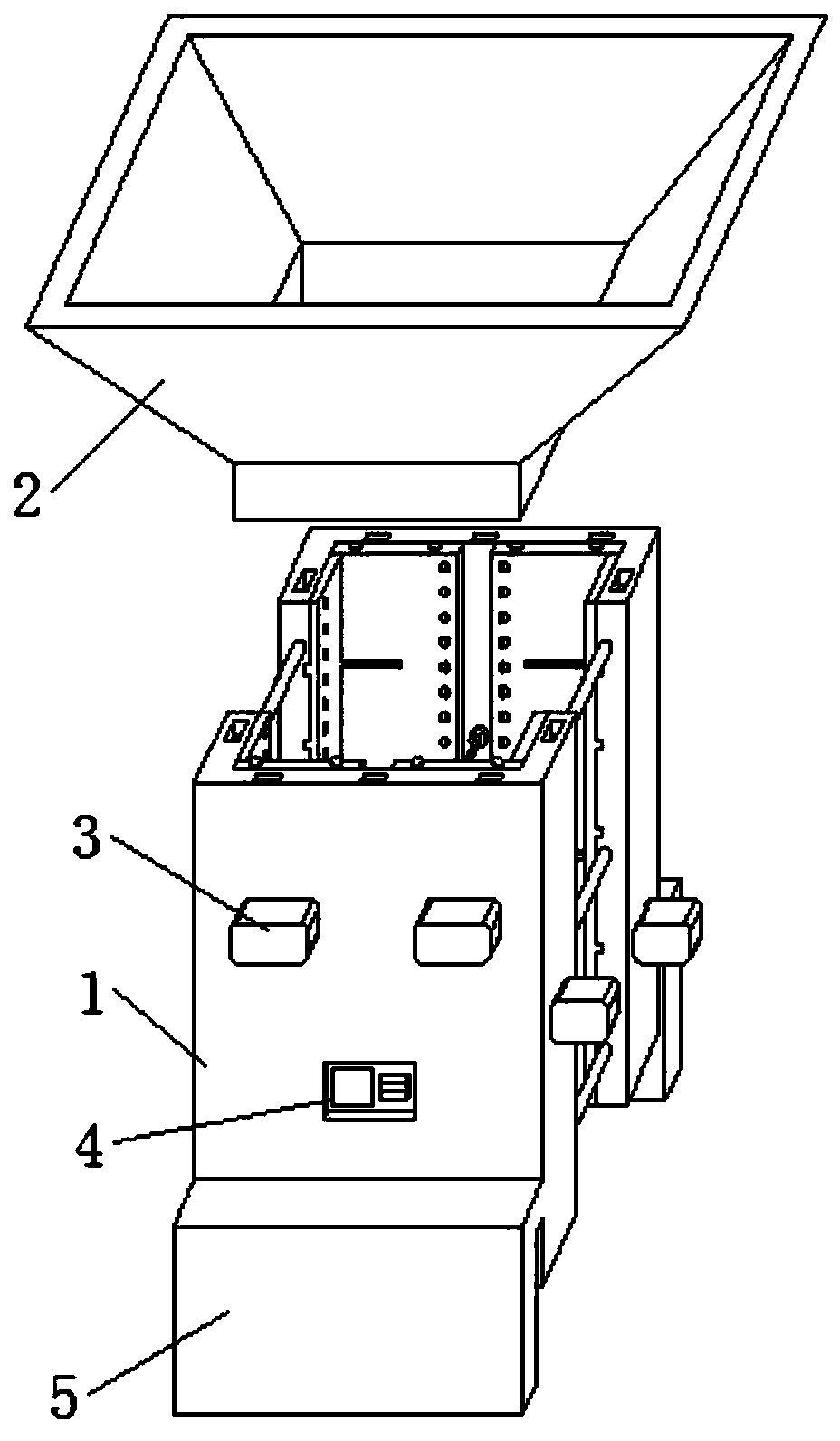

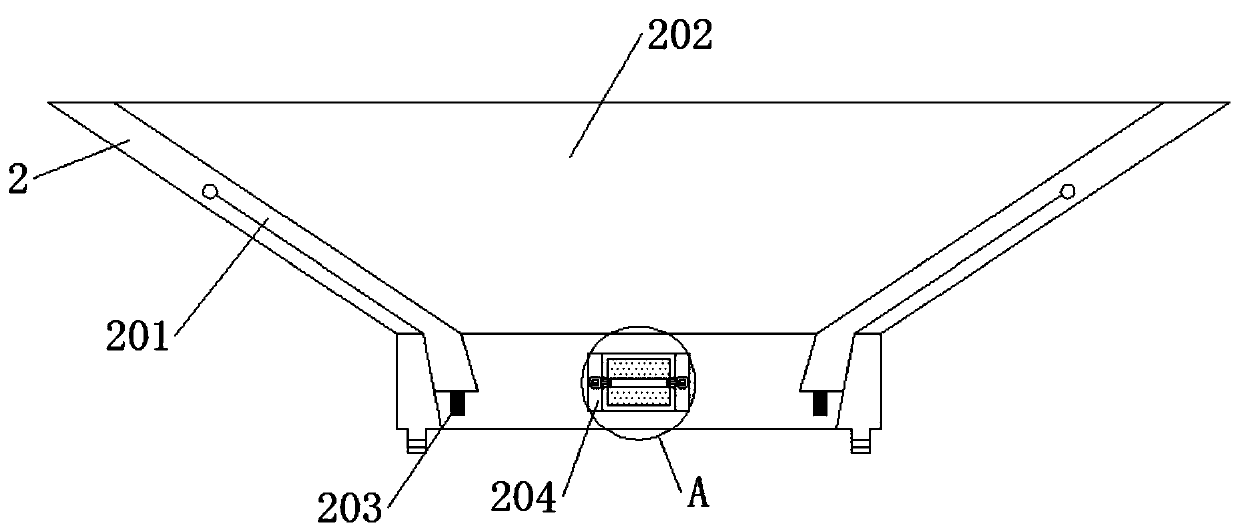

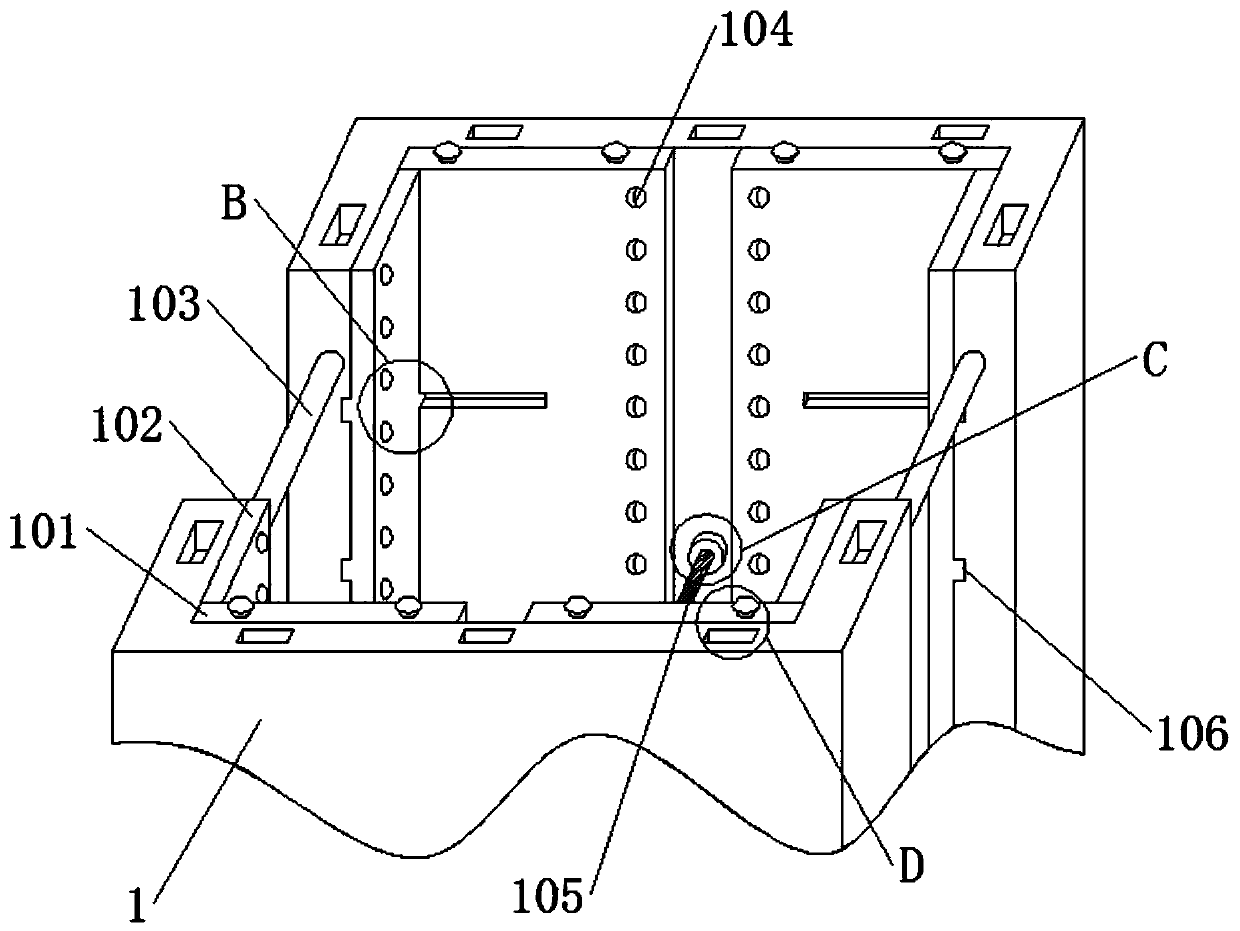

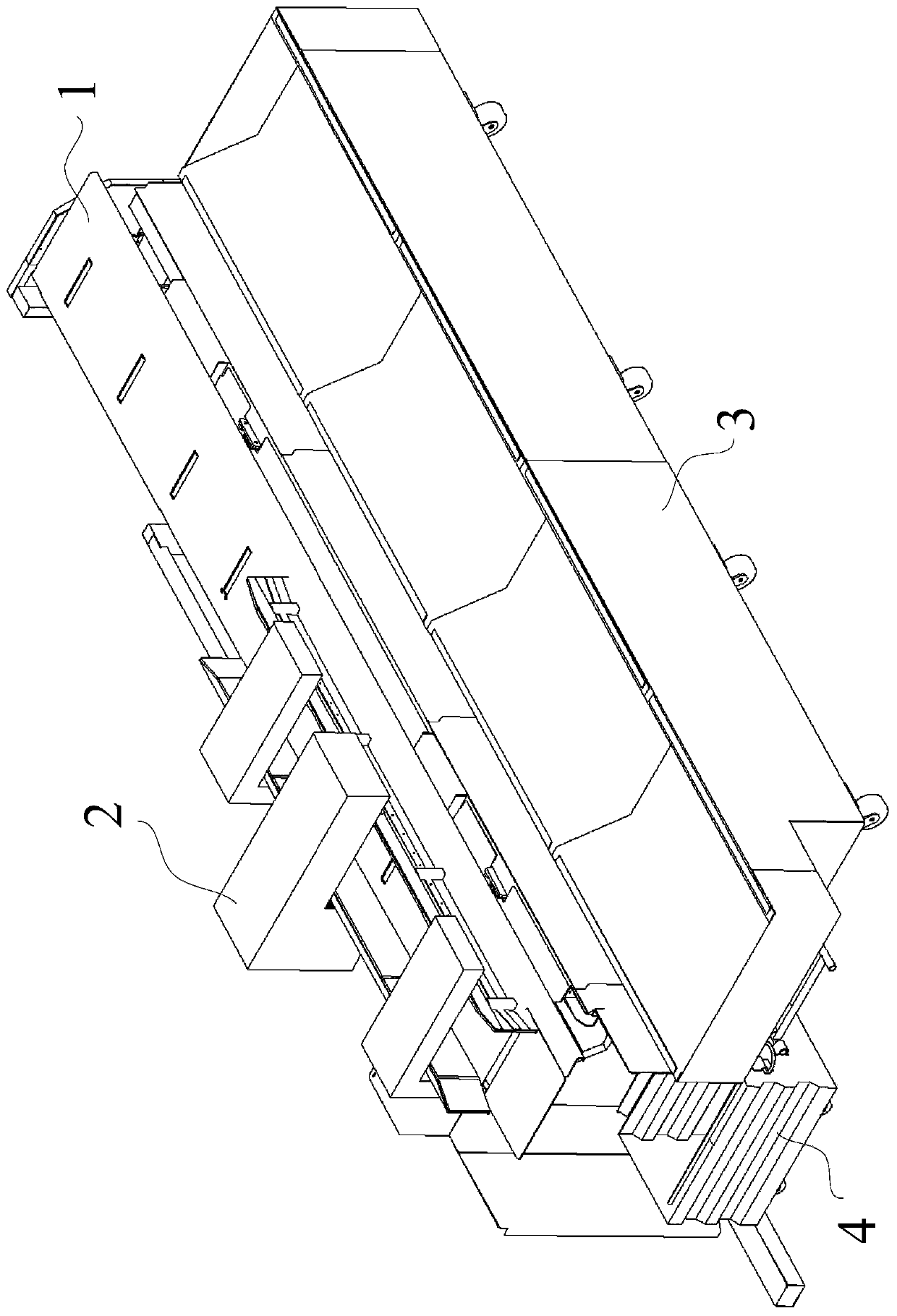

Foam cutting machine

ActiveCN110181603AAvoid shakingAffect cutting accuracyMetal working apparatusHydraulic pumpEngineering

The invention provides a foam cutting machine. The foam cutting machine comprises a shell, a funnel, a hydraulic pump and a controller, wherein the top end of the shell is fixedly connected with a funnel through a sleeving groove, and hydraulic pumps are separately fixedly connected to the middle parts of the front end and the rear end of the shell; the controller is embedded in the middle of thefront end of the shell; supporting plates are integrally arranged at the bottoms of the front end and the rear end of the shell; and a movable inner plate is integrally arranged on the inner wall of the funnel; an elastic traction rope is fixedly connected to the bottom end of the movable inner plate; a top groove is embedded in the middle of the top end of the funnel; correcting wheels are fixedly connected to the front side and the rear side of the bottom end of the inner wall of the funnel; small motors are embedded in the middles of the left end and the right end of the funnel respectively; a rotating shaft is movably connected to the middle of the inner wall of the correcting wheels; a friction wheel body is fixedly connected to the outer wall of the rotating shaft; transverse limiting plates are movably connected to the front end and the rear end of the inner wall of the outer shell separately; and a connecting button is connected to the top end of each transverse limiting platein a threaded mode. The whole device is stable in structure and convenient to use and operate; the cutting efficiency of a foam plate is high; the cutting precision is high; and the time and labor aresaved during cutting.

Owner:湖北世丰新材料有限公司

Unloading device

ActiveCN108789572BAffect cutting accuracyImprove cutting accuracyMetal working apparatusStructural engineeringMachine

The embodiment of the invention discloses an unloading device, and relates to the technical field of mechanical automation. The unloading device comprises an unloading part and a limiting part. The unloading device comprises a shear-fork type lifting platform, a loading plate, a first air cylinder, a second air cylinder, a turnover plate and a third air cylinder. The shear-fork type lifting platform comprises a machine frame, a bracket, a first shear-fork type lifting mechanism, a travel control mechanism and a second shear-fork type lifting mechanism. The limiting part comprises a first limiting mechanism, a second limiting mechanism, a third limiting mechanism, a first striker plate and a second striker plate. The unloading device is helpful to improve the cutting accuracy of pipe product and realize the automatic separation of waste materials.

Owner:HANS LASER TECH IND GRP CO LTD +1

An automatic laser cutting equipment for mechanical sheet metal processing

ActiveCN114227022BGuaranteed stabilityImprove cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention relates to the technical field of sheet metal processing, in particular to an automatic laser cutting device for mechanical sheet metal processing, which includes a workbench, a support unit and a cutting unit, the support unit is installed on the upper end of the workbench, and the cutting unit is arranged outside the machine On the main machine; the current laser cutting machine has the following problems: the common laser cutting machine cannot fix the workpiece, so the workpiece is prone to offset and affect the cutting accuracy of the workpiece; the dirt and impurities left on the surface of the workpiece without cleaning The cutting effect of the laser cutting machine on the workpiece is easy; the invention can fix the workpiece in all directions, which can ensure the stability of the workpiece during cutting, thereby enhancing the cutting accuracy of the workpiece; the invention can clean the upper surface of the workpiece , to ensure the stability of the workpiece during cutting, thereby enhancing the cutting effect of the workpiece.

Owner:江苏博朗智能装备有限公司

A cutting workbench equipped with a workpiece fastening mechanism for mechanical manufacturing

ActiveCN108817505BFor precise cuttingAffect the use effectMetal-working feeding devicesMeasurement/indication equipmentsMachine buildingSlag

The invention provides a cutting workbench provided with workpiece fastening device for machine manufacturing. The cutting workbench comprises a fixing chuck and a pressing block. A blanking cavity isformed in the left end of the cutting workbench, and an outlet of the blanking cavity is located on the front end face of the cutting workbench. A tool supporting frame is installed on the middle portion of the top end face of the cutting workbench through screws, a cutting tool is rotatably connected to the tool supporting frame, and the bottom of the cutting tool is located in a blanking opening. A fixing strip is installed on the right end of the top end face of the cutting workbench, and a fixing narrow scale is installed on the left end of the top end face of the cutting workbench. The centralized collection of high-speed high-temperature metal particles cut off by the cutting workbench is facilitated, and high-temperature powder is prevented from bursting against the surrounding personnel to cause harm to the personnel. Cooling liquid in a slag collection box is arranged, the high-temperature powder collected in the slag collection box cam be cooled, and high temperature metal particles are prevented from igniting the surrounding combustible to cause potential safety hazards.

Owner:徐州富能机械有限公司

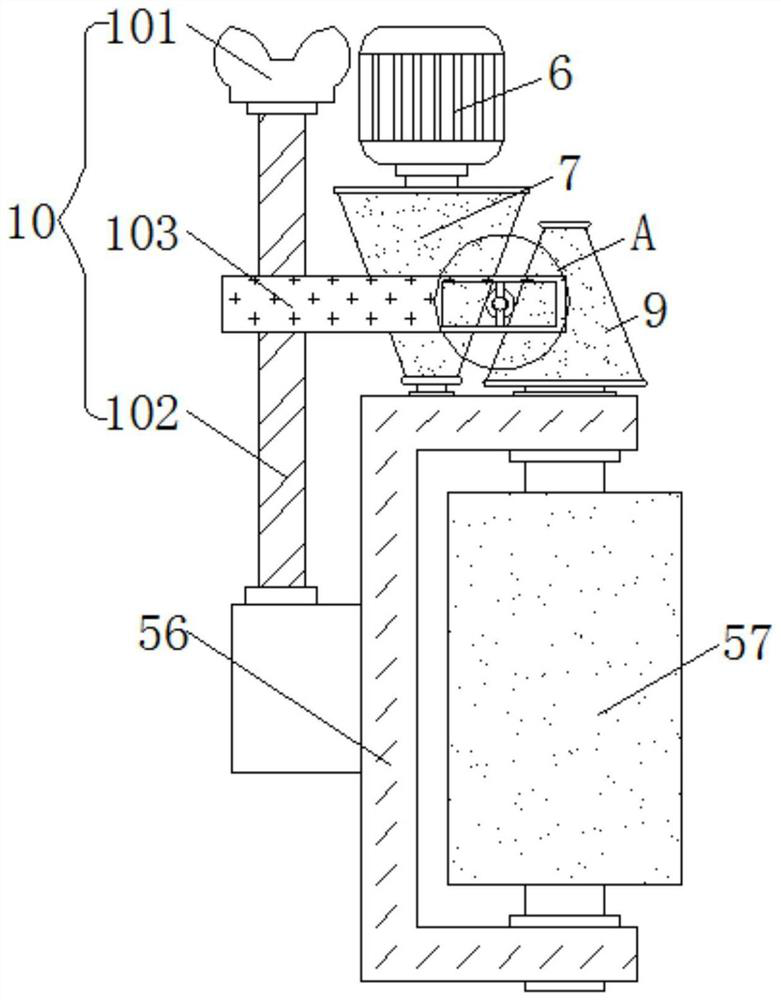

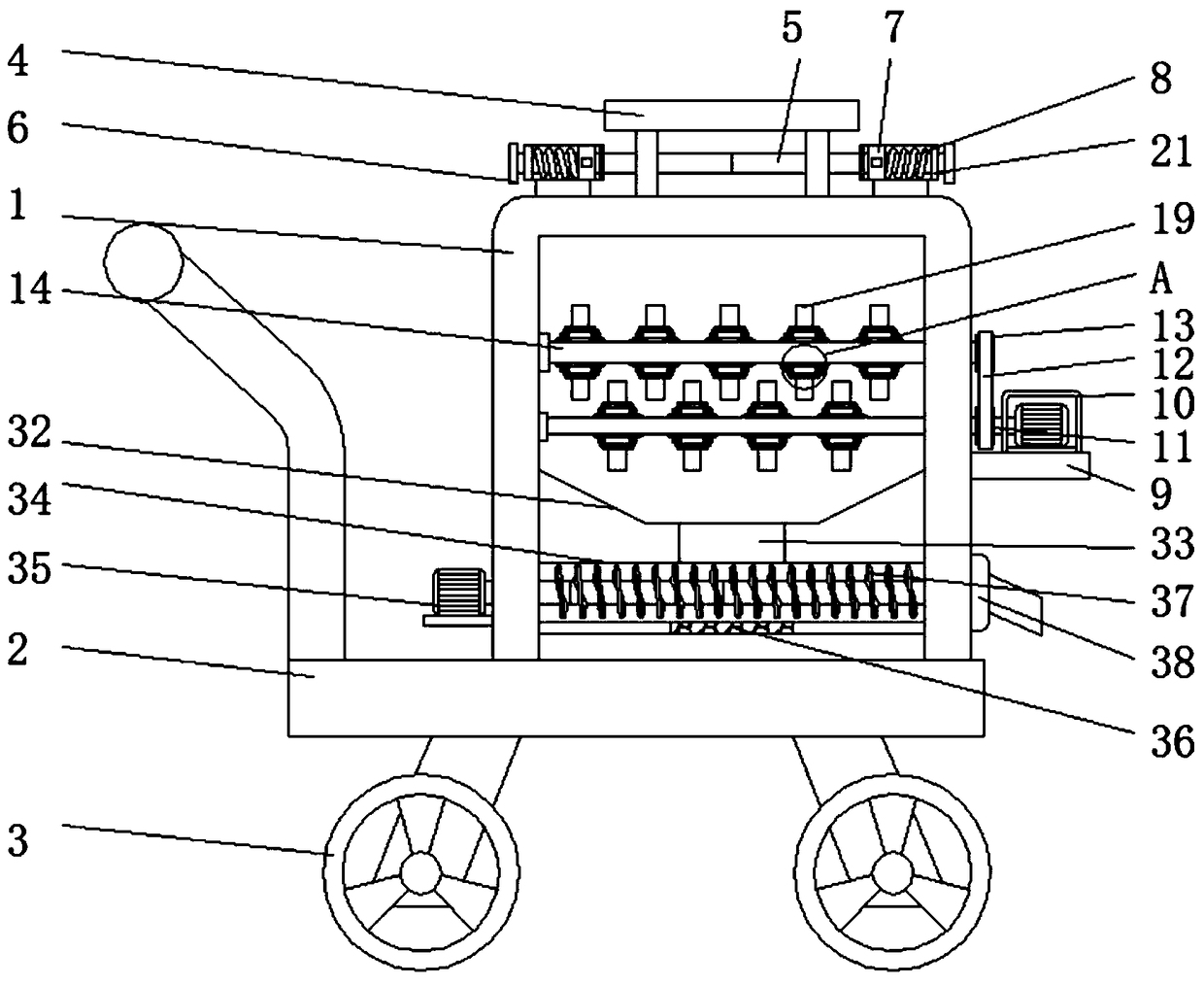

High-efficiency hay cutter for animal husbandry

The invention relates to the technical field of animal husbandry, and discloses a high-efficiency hay cutter for animal husbandry which comprises a cutting device. A supporting plate is fixedly mounted at the bottom of the cutting device, a universal wheel is fixedly mounted at the bottom of the supporting plate, the top of the cutting device is fixedly communicated with a feeding pipe, a quantitycontrol plate is movably mounted in the feeding pipe, and one end of the quantity control plate passes through and extends to the outside of the feeding pipe. Through the cooperation between a connecting plate and a fixed bolt, a cutting knife can move to different positions, so that the feed cutting length can be controlled, and the excessive crushing of the feed which affects poultry feeding isavoided. By utilizing the cooperation of a positioning block and a fixed plate, the cutting knife is prevented from falling from a movable rod during the use; by utilizing the cooperation of a sliding block and a connecting block, a sliding rod is prevented from shaking back and forth during movement; and by utilizing the cooperation of an extension rod and a buffer spring, the sliding rod is prevented from bouncing off from a buffer plate.

Owner:朱利松

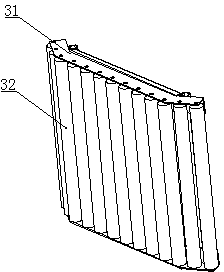

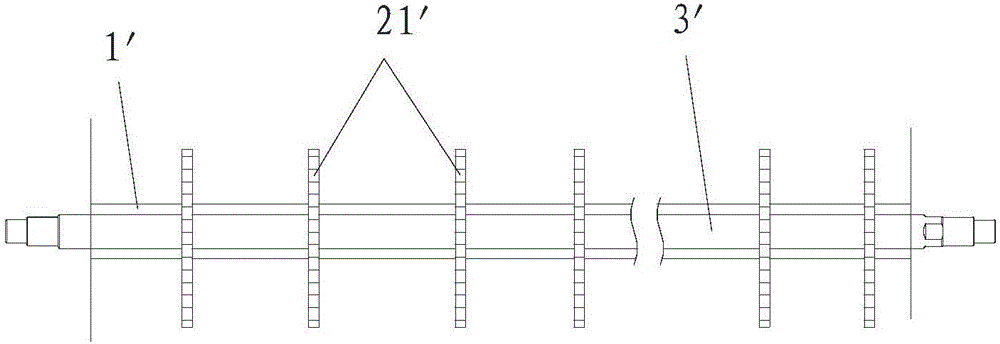

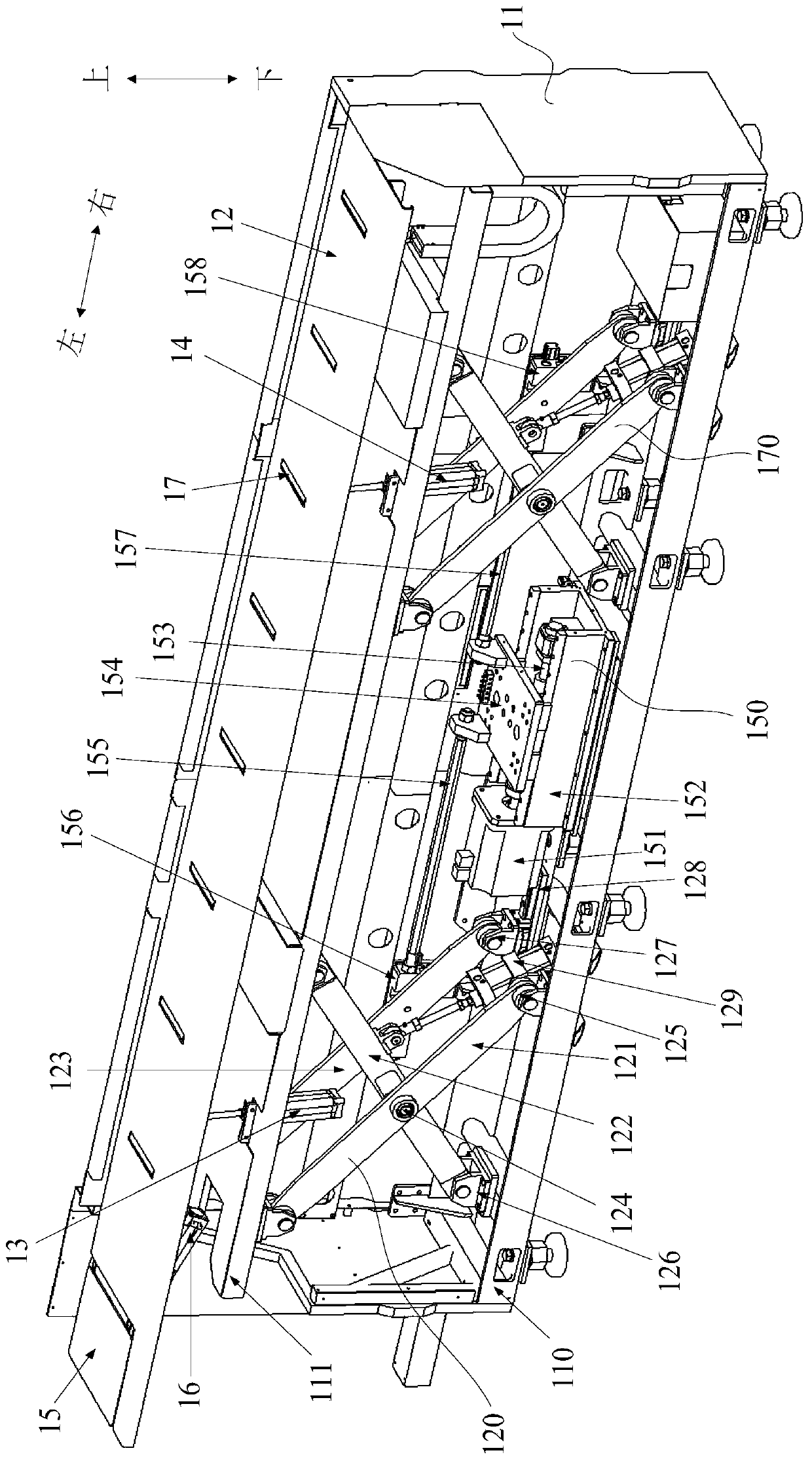

A magnetic levitation support structure and adjustment method for the bell mouth of a cigarette machine

ActiveCN110236220BAvoid problems such as fatigue fractureSimple structureCigarette manufactureFiberCarbon fibers

The invention discloses a magnetic levitation support structure and an adjustment method for the bell mouth of a cigarette machine. The support structure includes a bell mouth seat, a support and a connecting rod. One end of the rod is rotatably connected to the support, and the other end of the connecting rod is connected to the crank drive mechanism. A guide plate is provided at the position above and below the support, which are respectively an upper guide plate and a lower guide plate; several electromagnetic devices are evenly arranged in the guide plate; There is an installation cavity in the support, the left and right sides of the installation cavity are set as open, the upper and lower sides and the front and rear sides of the installation cavity are all set to be blocked, and an electromagnetic device is also installed in the installation cavity; the two guide plates are connected with the support The electromagnetic devices on the top are mutually exclusive, so that the support is suspended between the two guide plates. The invention adopts the magnetic levitation method to support the bell mouth and the connecting rod, cancels the structure of the carbon fiber support rod, thereby effectively avoiding the problems such as the fatigue fracture of the existing carbon fiber support rod device, and can meet the needs of high-speed dynamic follow-up cutting.

Owner:CHINA TOBACCO HENAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com