Plastic injection molding cutting platform facilitating material overturning

A cutting platform and plastic technology, applied in metal processing and other directions, can solve the problems of affecting cutting quality, inability to flip plastic, and greatly affecting cutting accuracy, so as to improve convenience, ensure convenience, and prevent pollution of the workshop environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

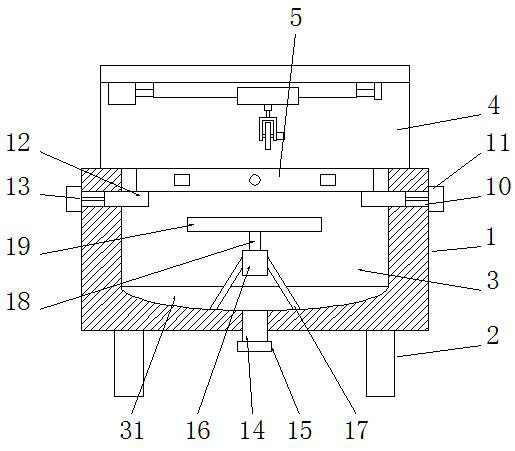

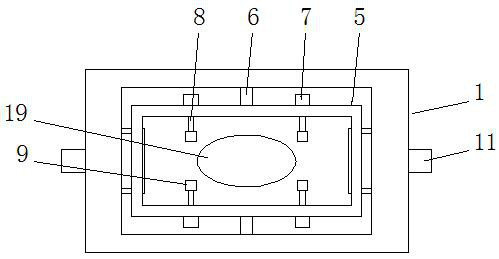

[0031] See Figure 1-2 , a plastic injection molding cutting platform that is convenient for turning over materials, including a machine platform 1, a cutting cavity 3 is embedded in the top end of the machine platform 1, and the bottom end of the cutting cavity 3 is connected to a diversion cavity 31, and the machine platform The edge of the bottom end of 1 is evenly provided with several supporting legs 2, and the inner cavity of the cutting chamber 3 is provided with an overturning frame 5, and the overturning frame 5 is a rectangular ring frame, and the front and rear ends of the overturning frame 5 are rotatably connected to the On the inner cavity wall of the cutting chamber 3, the top surface of the turning frame 5 is flush with the top surface of the machine table 1, and the front and rear ends of the turning frame 5 are uniformly provided with a plurality of first electric telescopic devices 7, and the first electric telescopic The movable end of the first telescopic ...

Embodiment 2

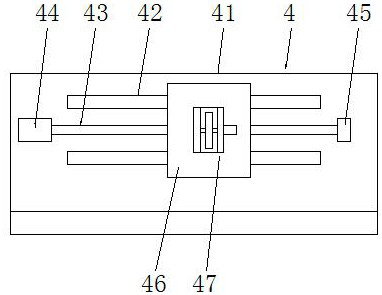

[0036] See Figure 3-4 The difference from Embodiment 1 is that the cutting mechanism 4 includes a vertical plate 41, the vertical plate 41 is an L-shaped structure, and the inner cavity top wall of the vertical plate 41 is symmetrically provided with guide rails 42 front and rear, and the guide rails 42 are T-shaped guide rail, a lead screw 43 is arranged between the two guide rails 42, and the relationship between the guide rail 42 and the lead screw 43 is parallel to each other. One end of the lead screw 43 is connected to the feed motor 44 in rotation, and the lead screw 43 The other end is rotatably connected to the vertical plate 41 through the bearing seat 45, the feed motor 44 is fixedly mounted on the vertical plate 41, the leading screw 43 is sleeved with a moving seat 46 matched with the guide rail 42, and the moving seat 46 The bottom end of the cutting tool assembly 47 is fixedly installed, and the feed motor 44 drives the lead screw 43 to rotate positively and ne...

Embodiment 3

[0039] See Figure 5 , and the difference from embodiment 2 is that: the inner cavity side wall of the vertical plate 41 is provided with a water spraying part 20 matched with the overturn frame 5, and the water spraying part 20 is evenly provided with a number of nozzles 21, so The top of the vertical plate 41 is fixedly connected to the water tank 23, and the water tank 23 is connected to the water spray member 20 through the water pipe 22. The water pump 27 is installed on the water pipe 22, and the water in the water tank 23 is extracted by the water pump 27, so that the water flows along the water pipe. 22 into the water spray member 20, and finally spray the water flow through the nozzle 21, and then use the water flow to spray on the turning frame 5, and use the water flow to clean the cutting disc knife 474, which can effectively prevent the cutting plastic chips from splashing, thereby ensuring the cutting of plastic products. environmental protection;

[0040] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com