Three-chuck laser pipe cutter device

A technology of laser cutting and laser cutting head, which is applied in the direction of auxiliary devices, laser welding equipment, tubular objects, etc., can solve the problem of the length of remaining tailings, etc., and achieve the effect of ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

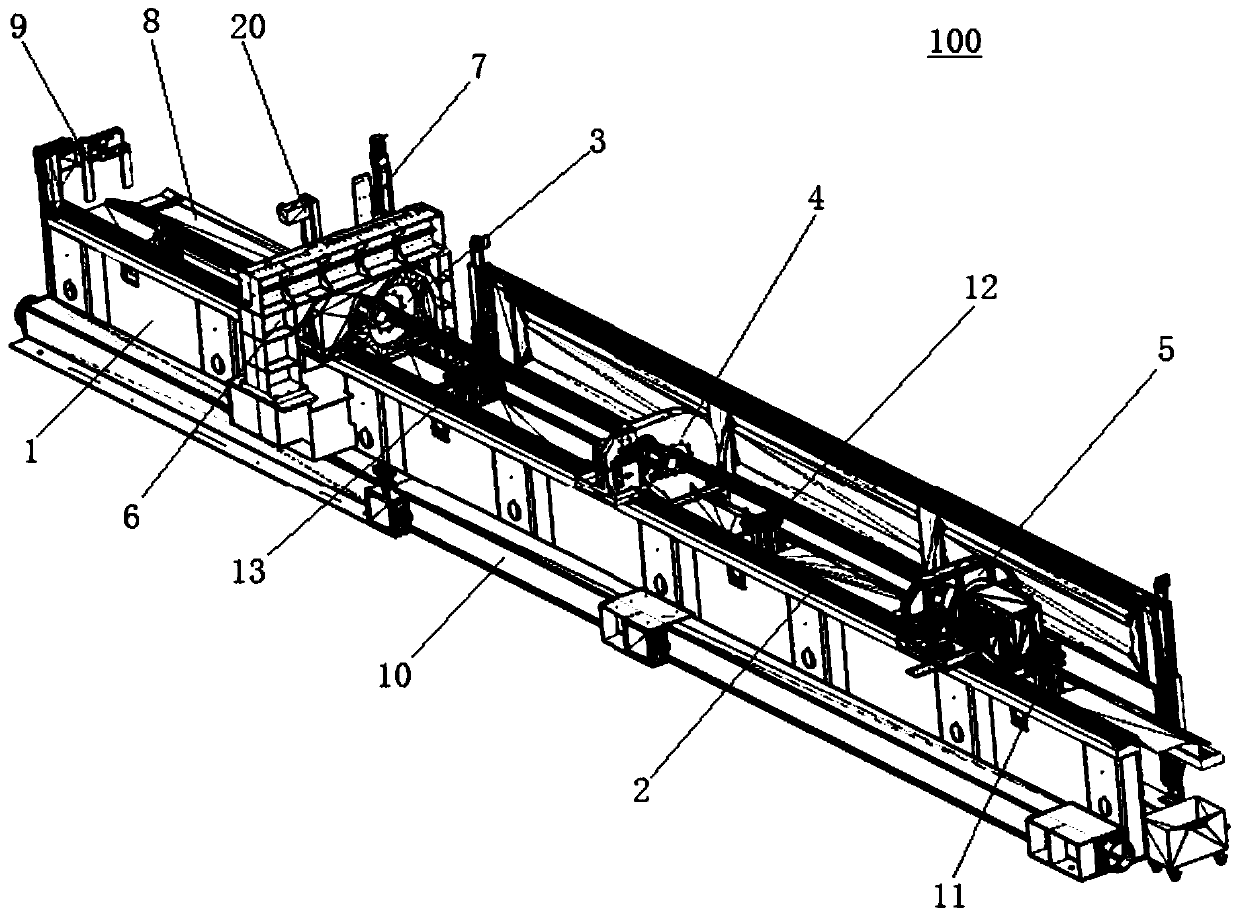

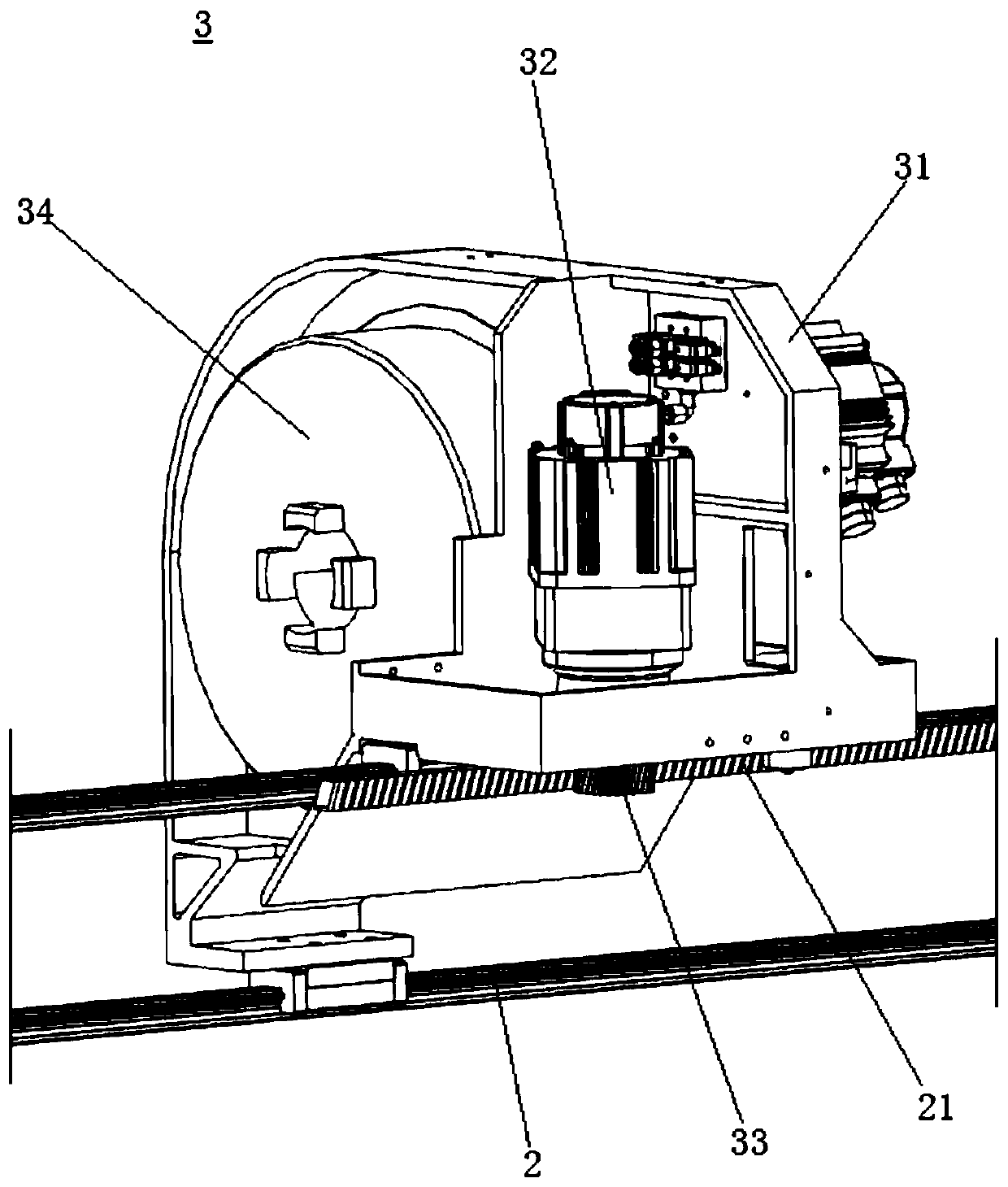

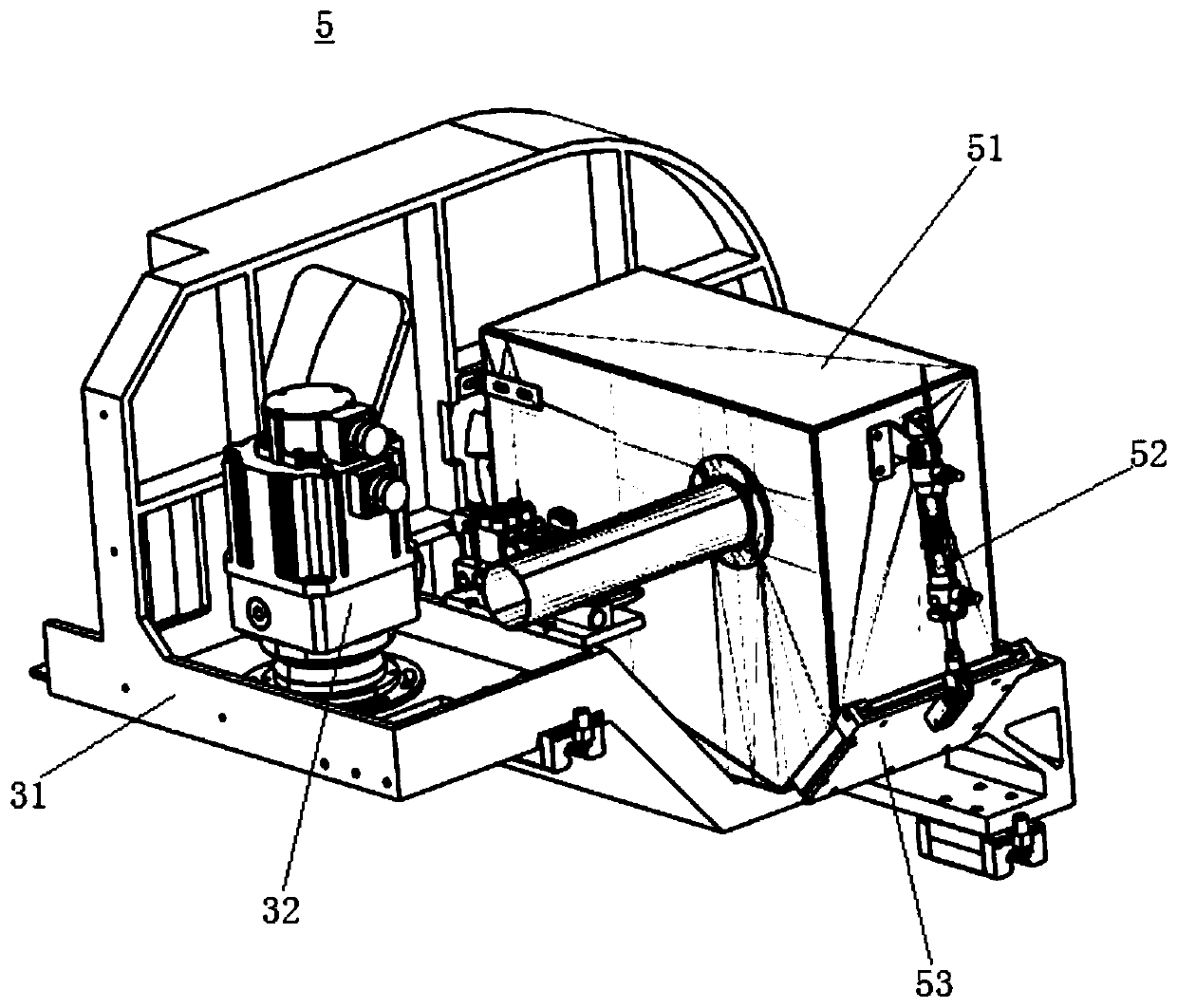

[0033] Please refer to Figure 1-Figure 11 , the present embodiment is a three-chuck laser pipe cutting machine device 100, which includes a machine tool 1, a slide rail 2 arranged in parallel on the machine tool 1, a front chuck unit 3 that can slide on the slide rail 2, and a middle chuck unit 4 With the rear chuck unit 5, the beam support 6 on the machine tool 1, the laser cutting head 7 arranged on the beam support 6, the blanking pallet unit 8 which is located on the front side of the laser cutting head 7 and can move up and down relative to the machine tool 1 , a blanking and clamping unit 9 located at the front end of the machine tool 1 to assist blanking, and several supporting clamping units arranged at intervals along the slide rail 2 and capable of moving up and down relative to the machine tool 1 .

[0034] A rack 21 is provided on the machine tool 1 along the direction of the slide rail 2 .

[0035] The front chuck unit 3, the middle chuck unit 4 and the rear chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com