Patents

Literature

278results about "Sawing components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

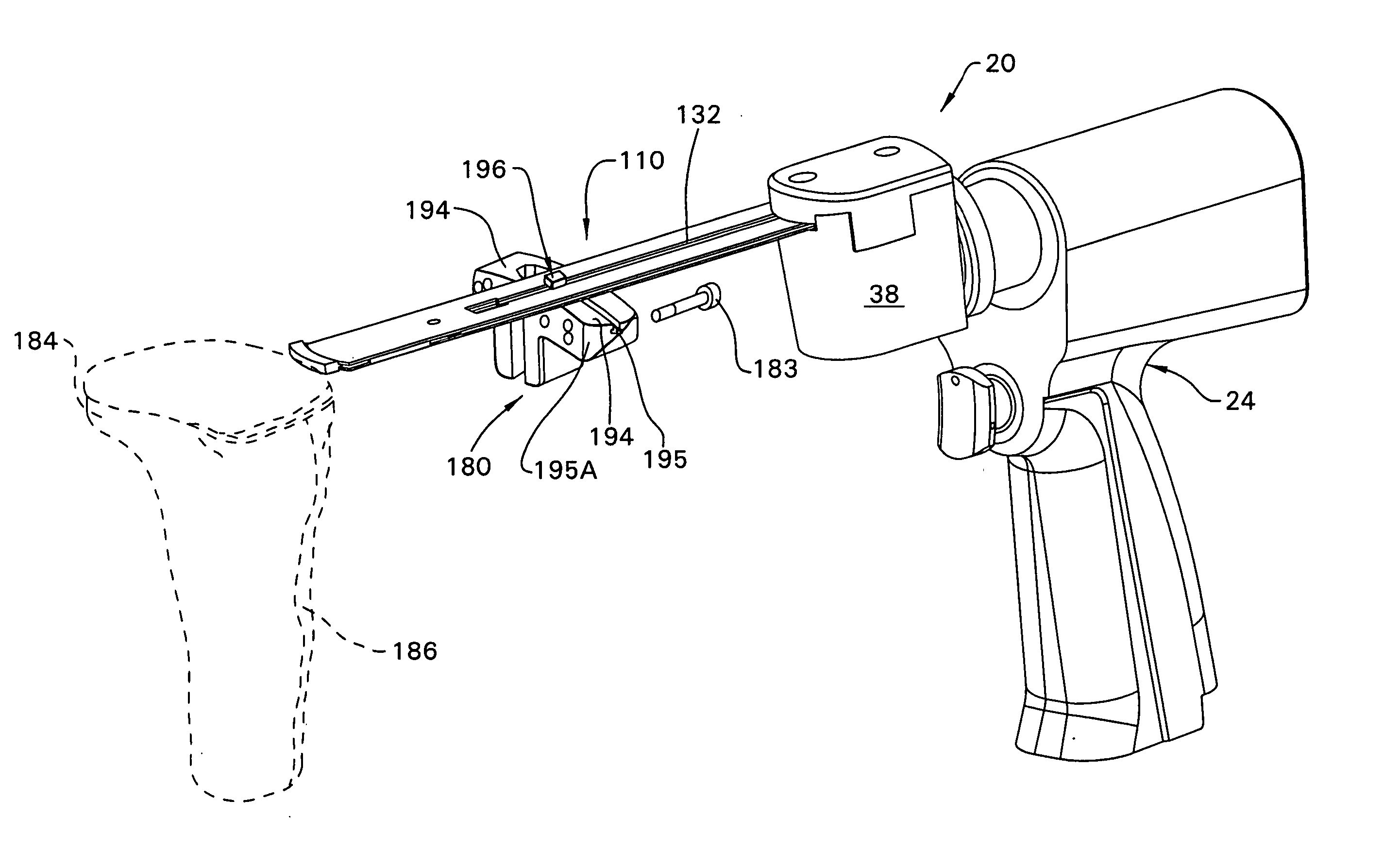

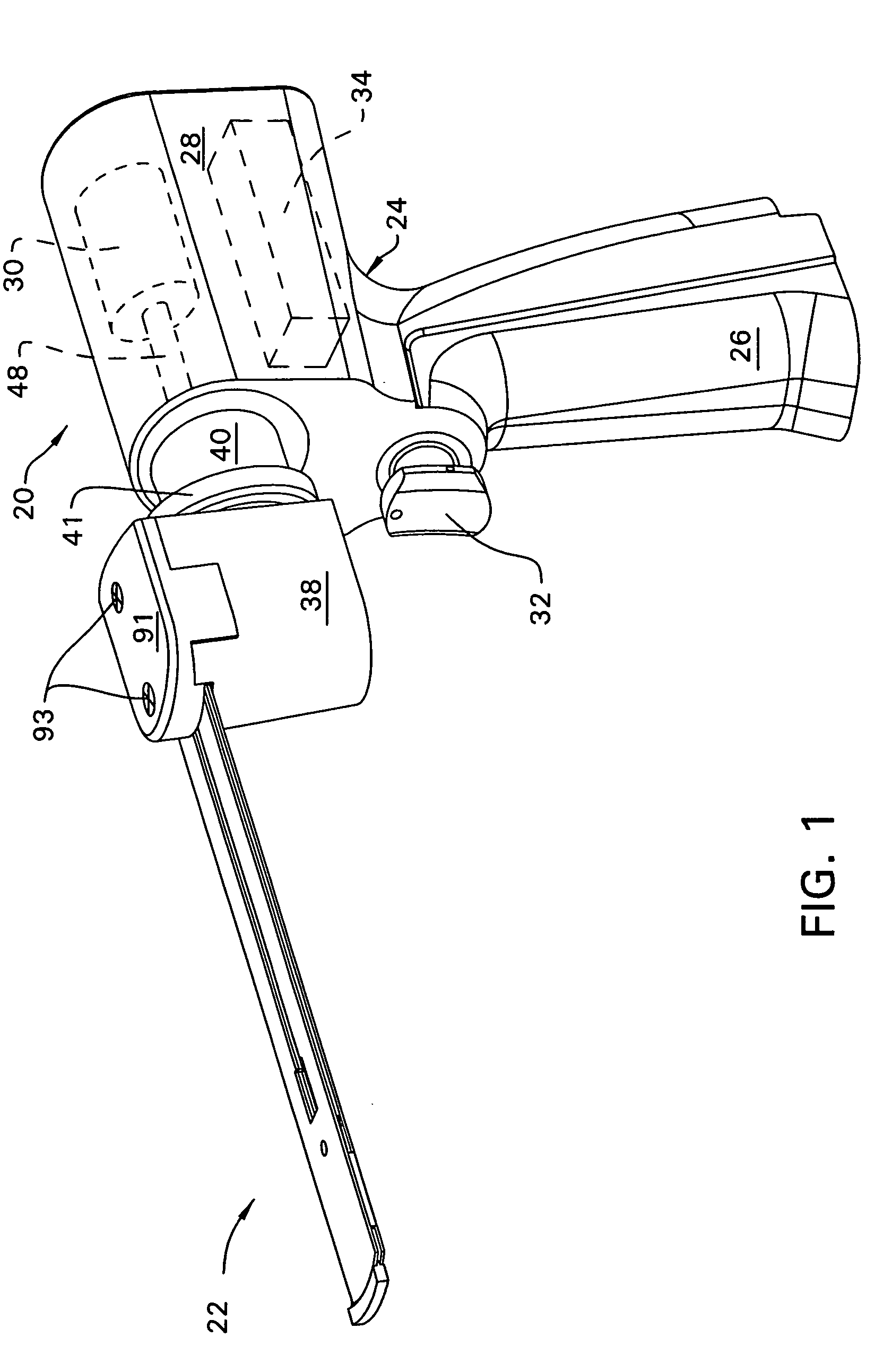

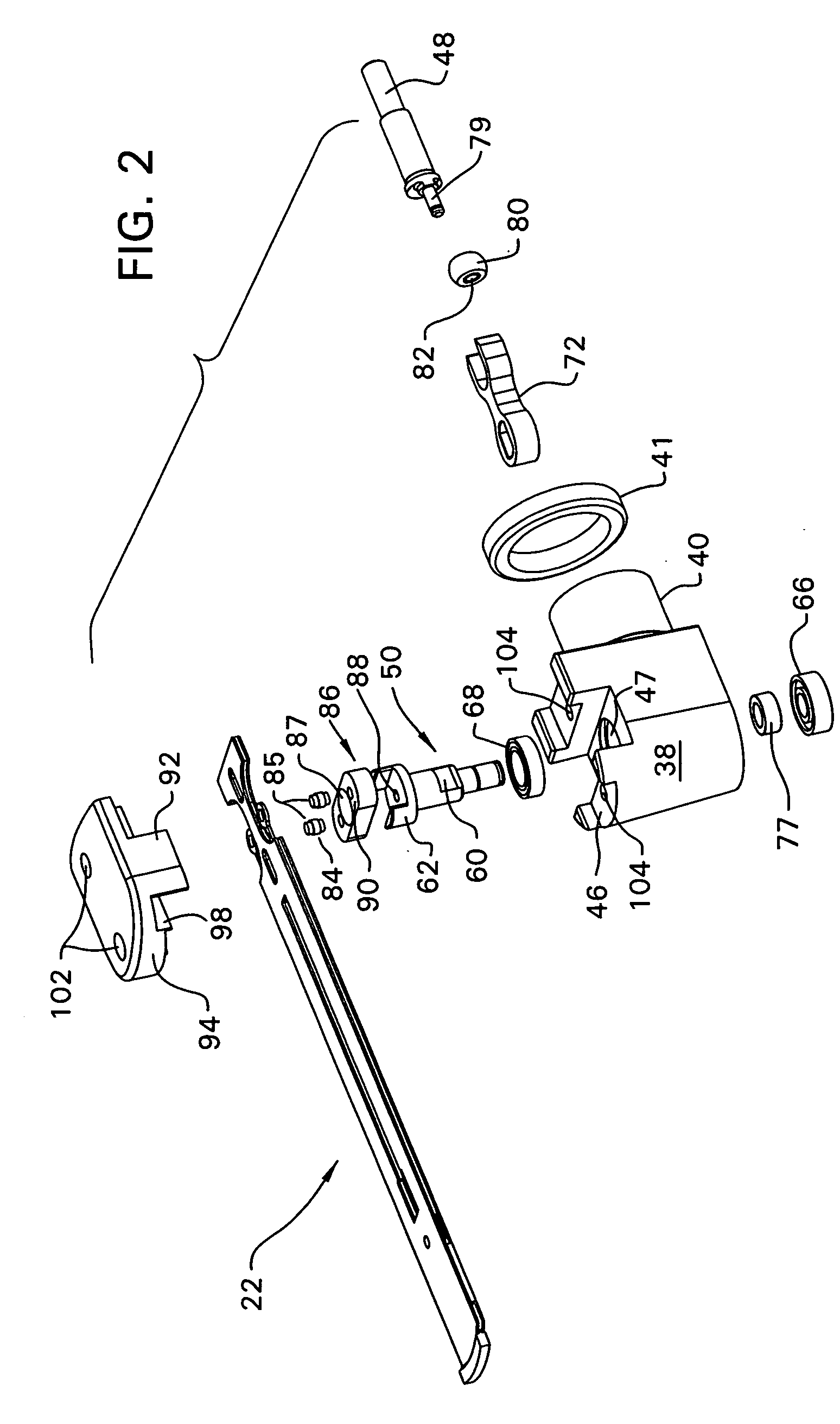

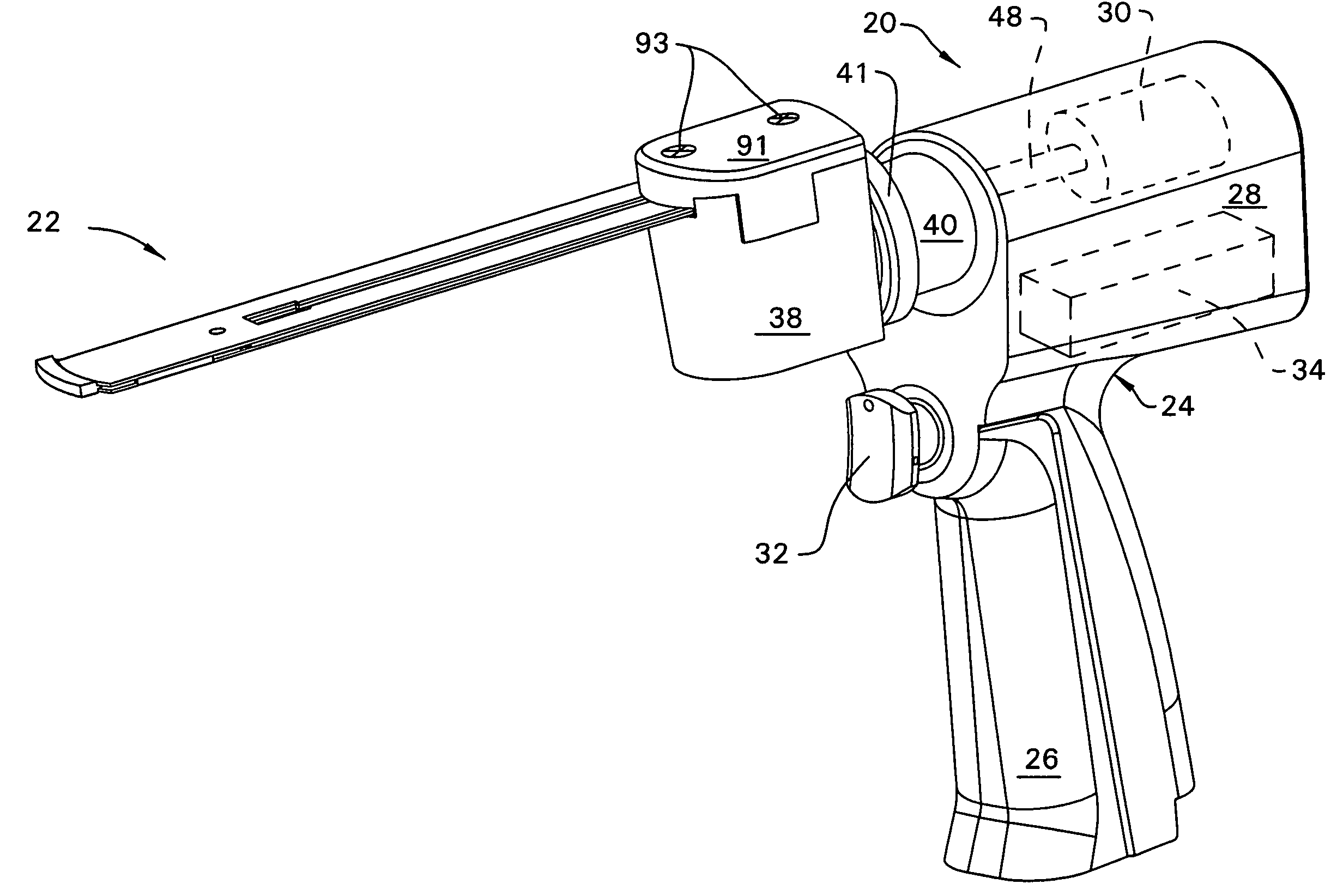

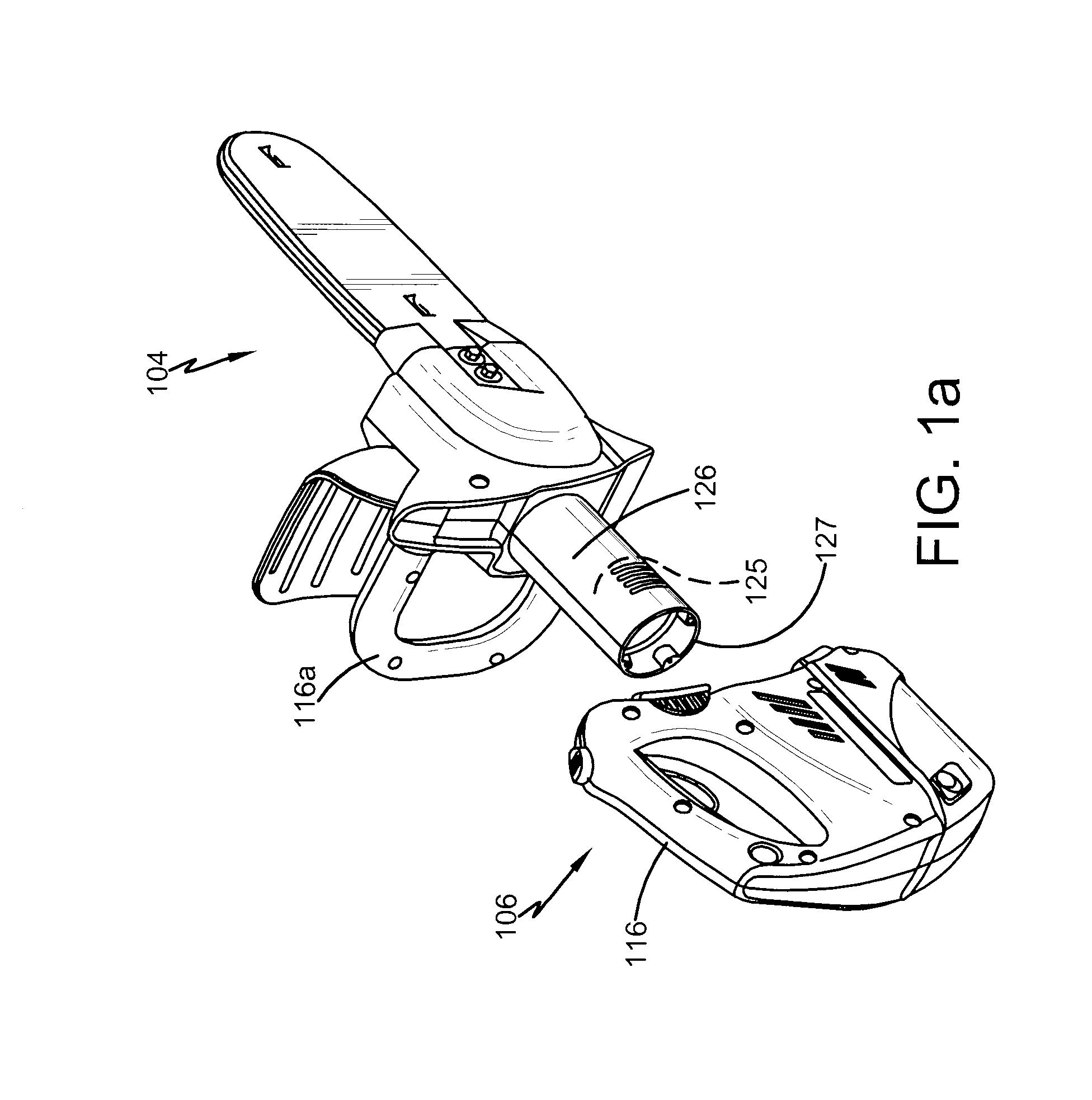

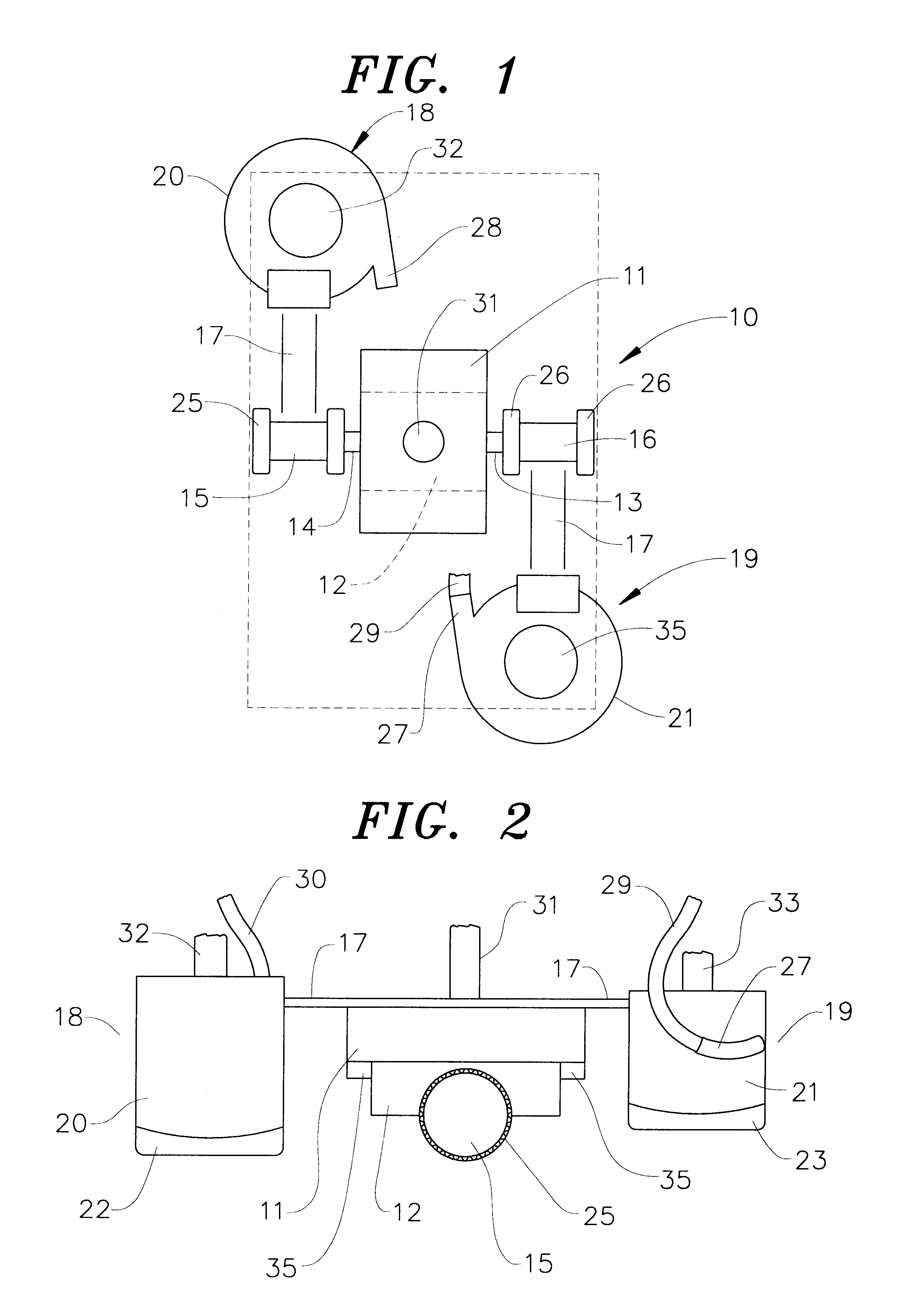

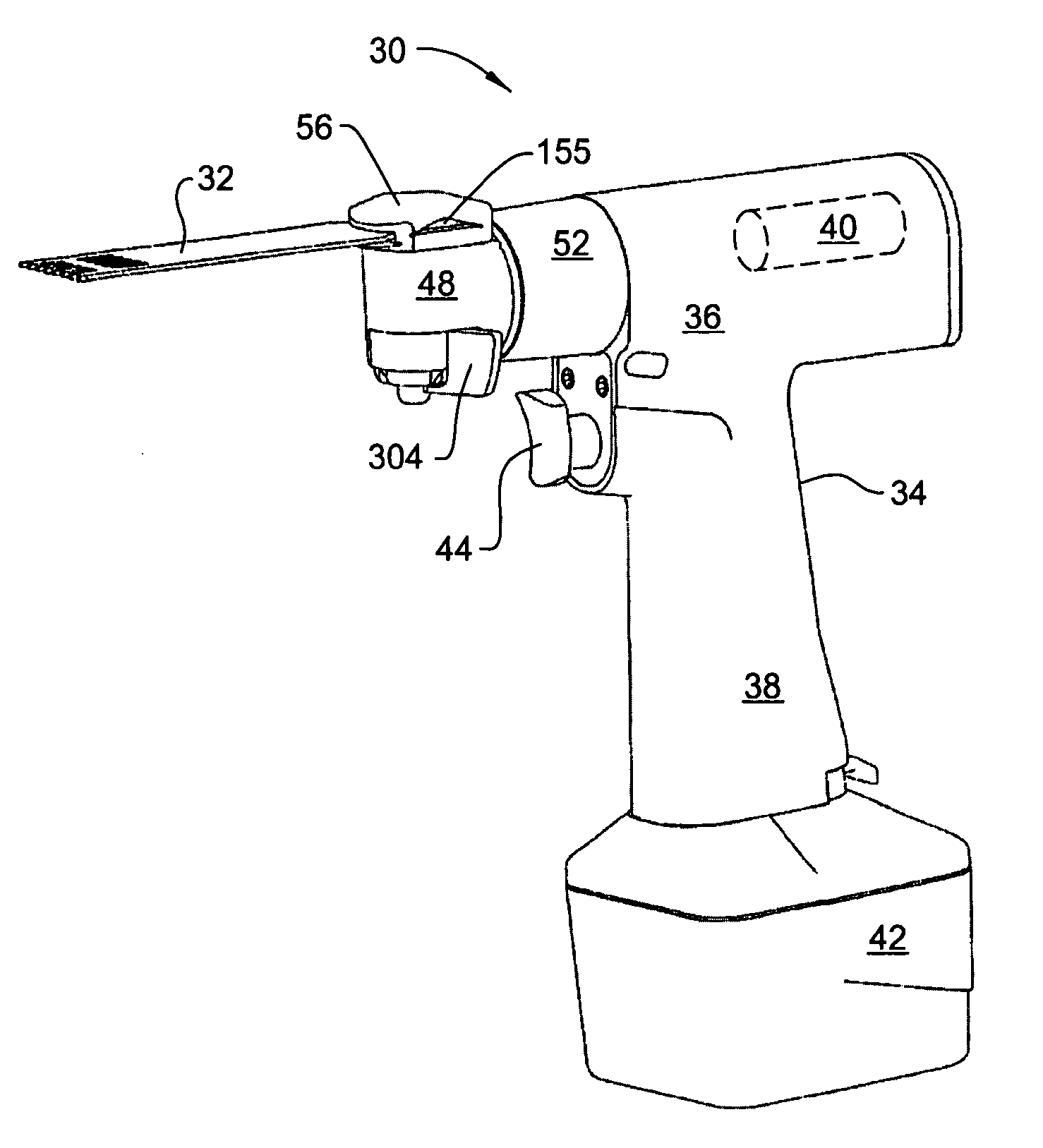

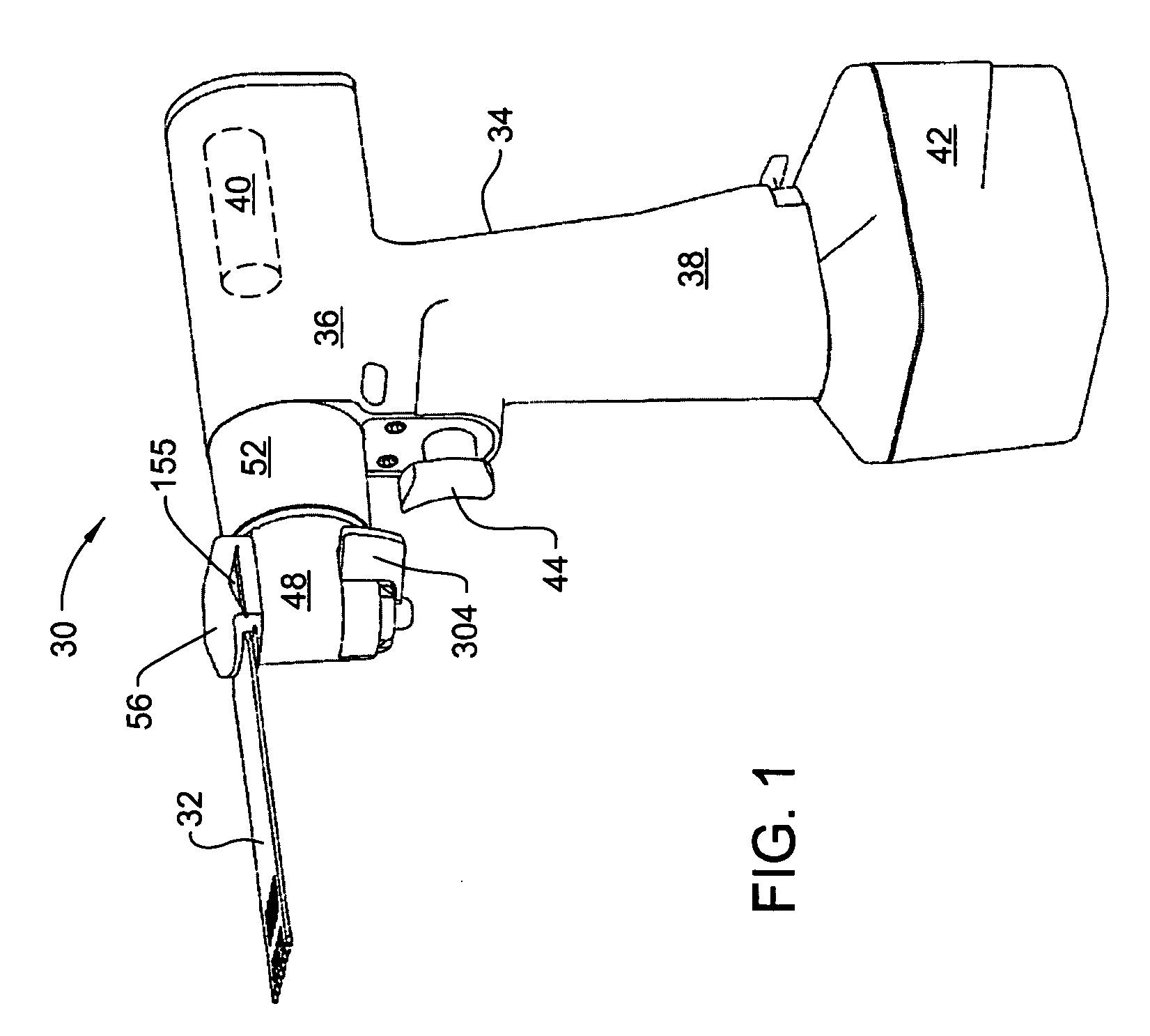

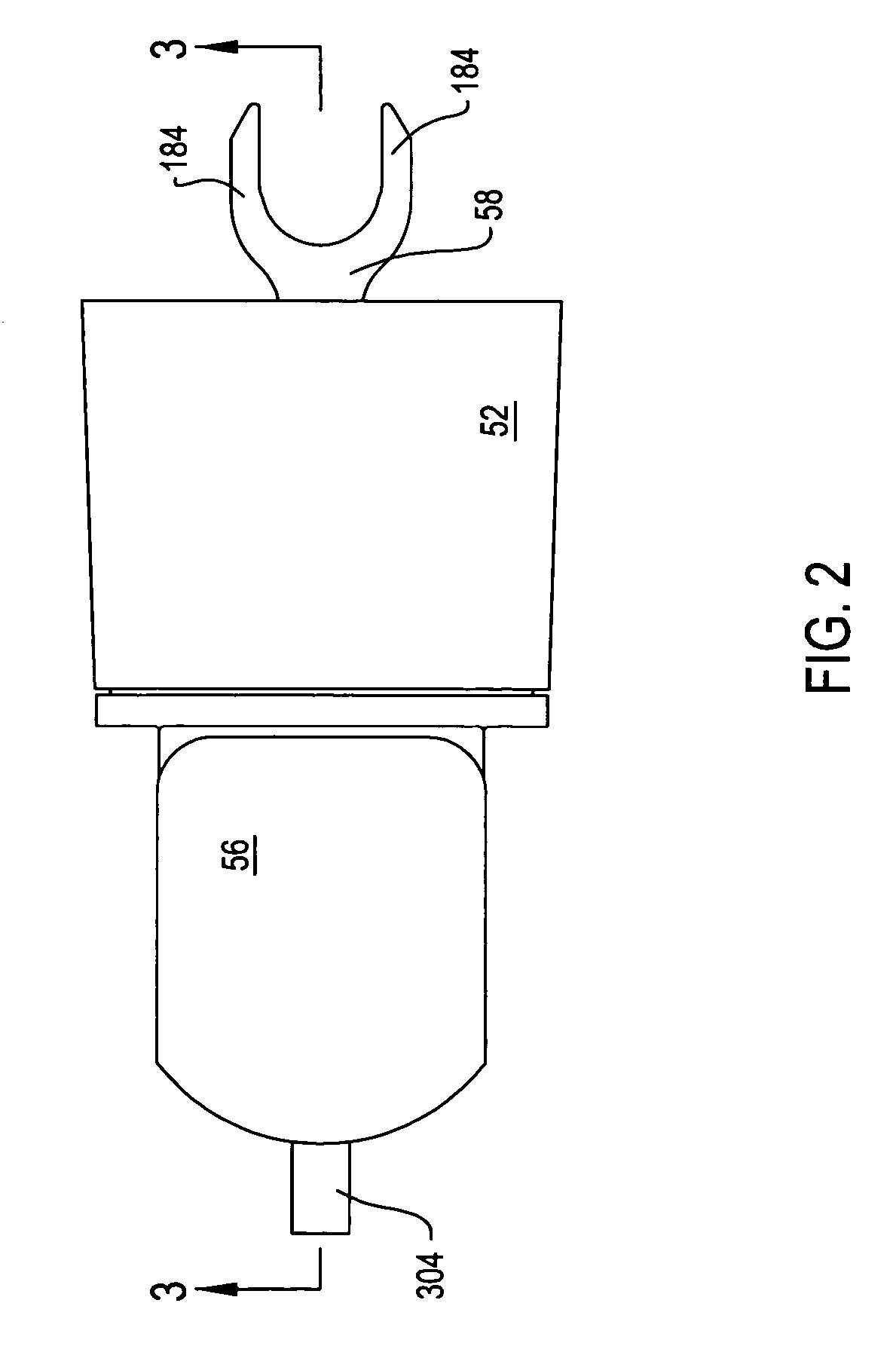

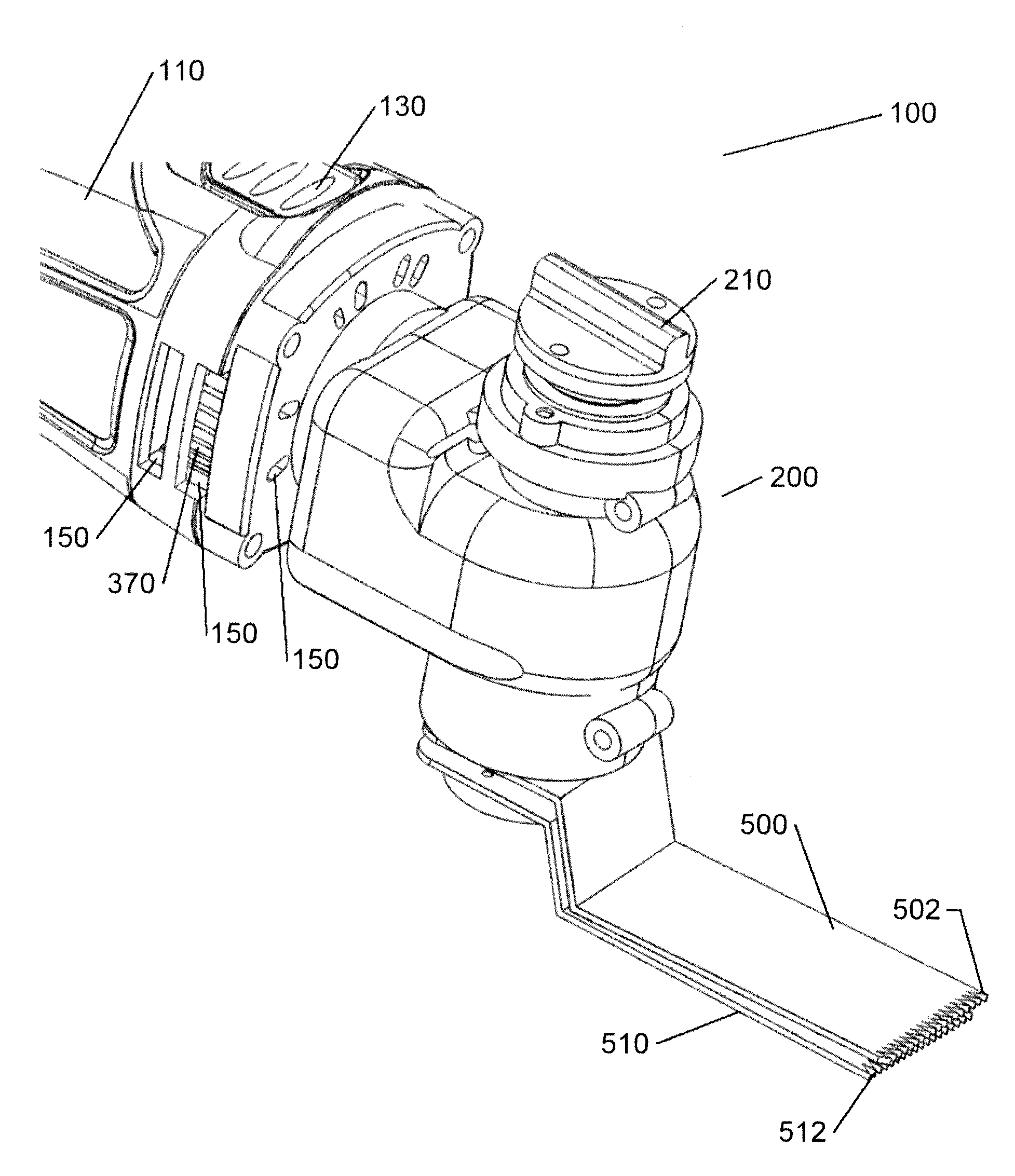

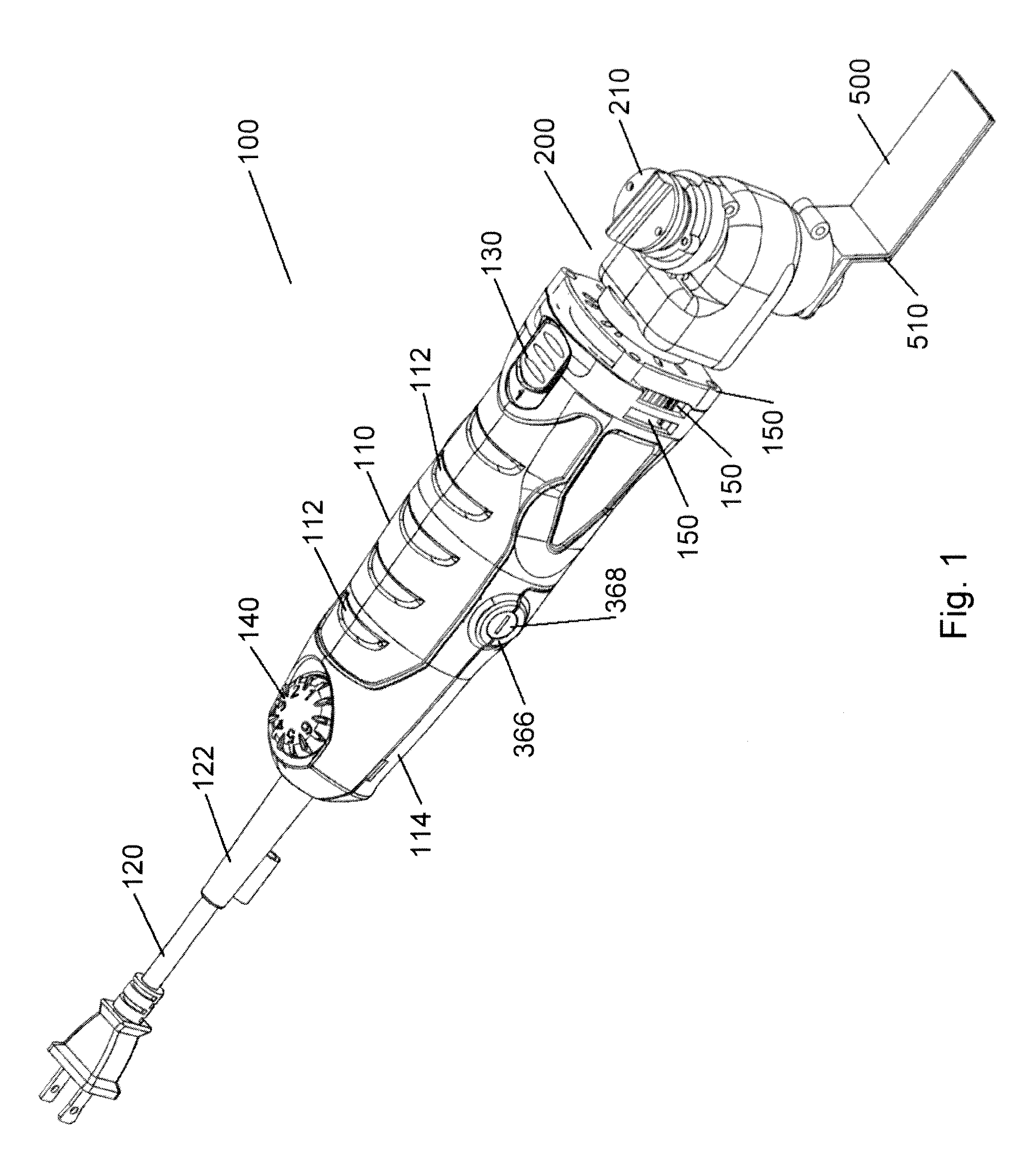

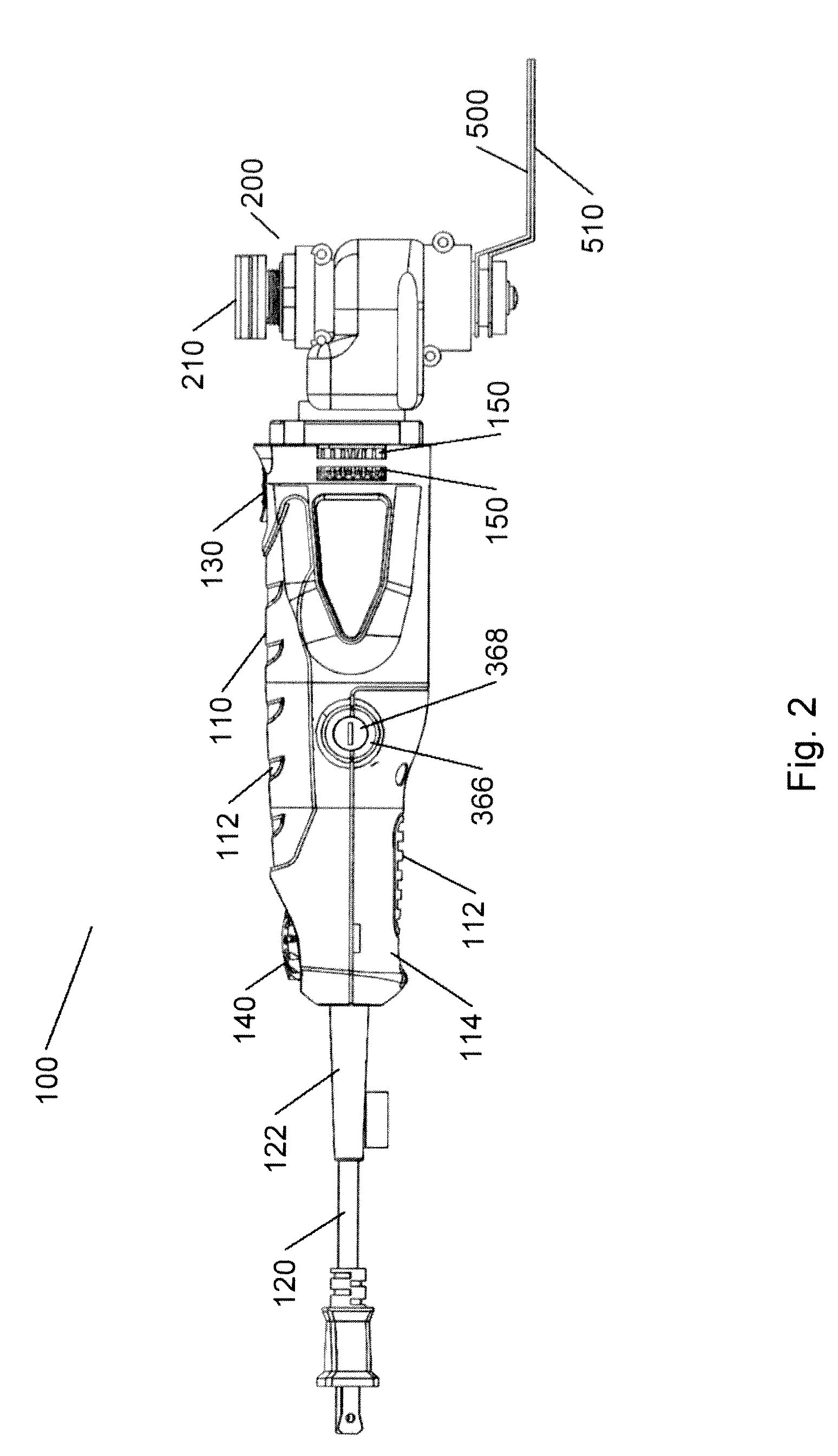

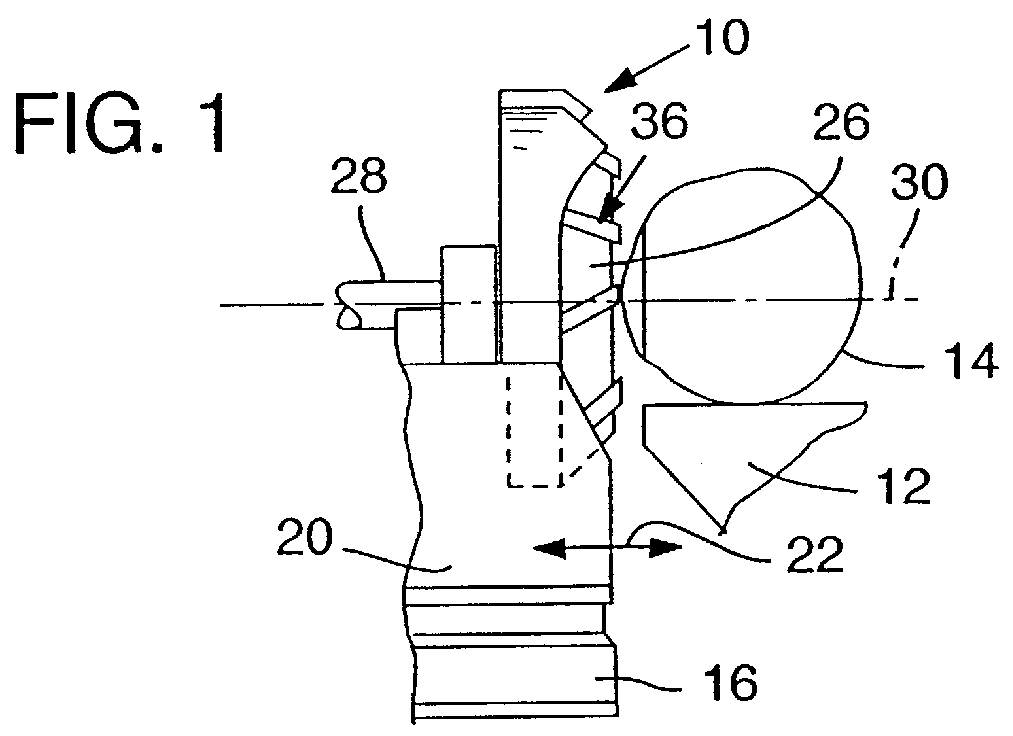

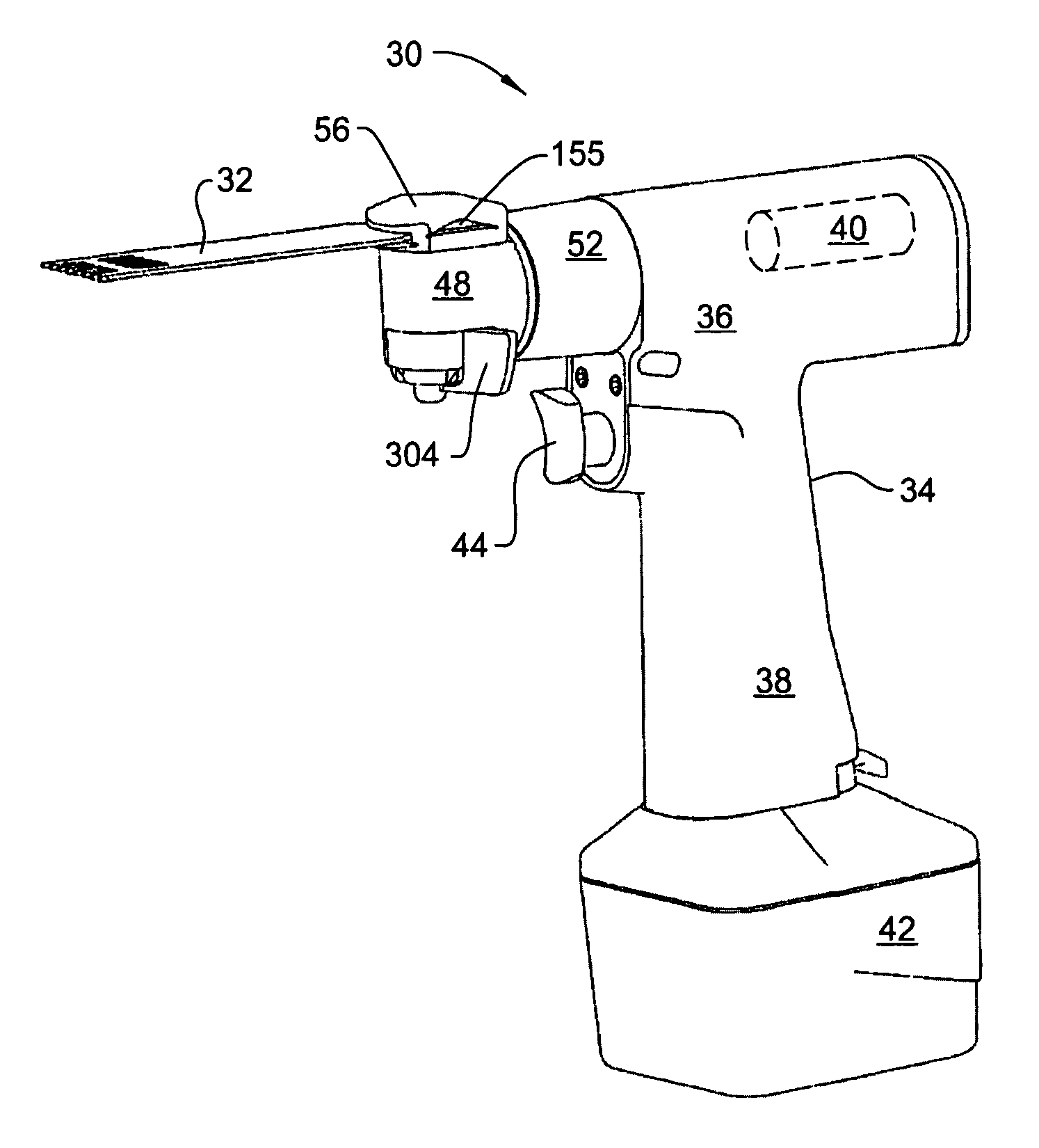

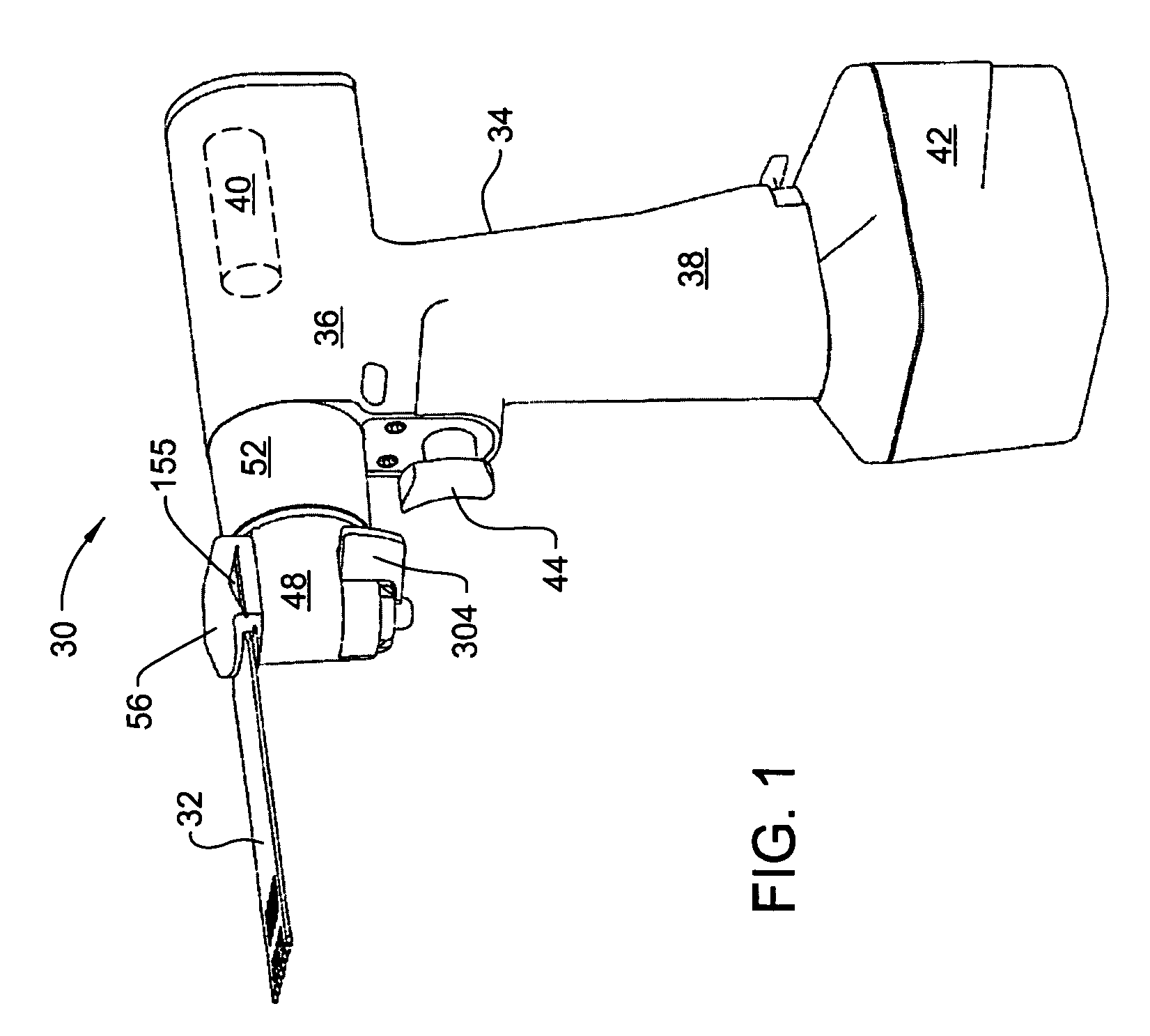

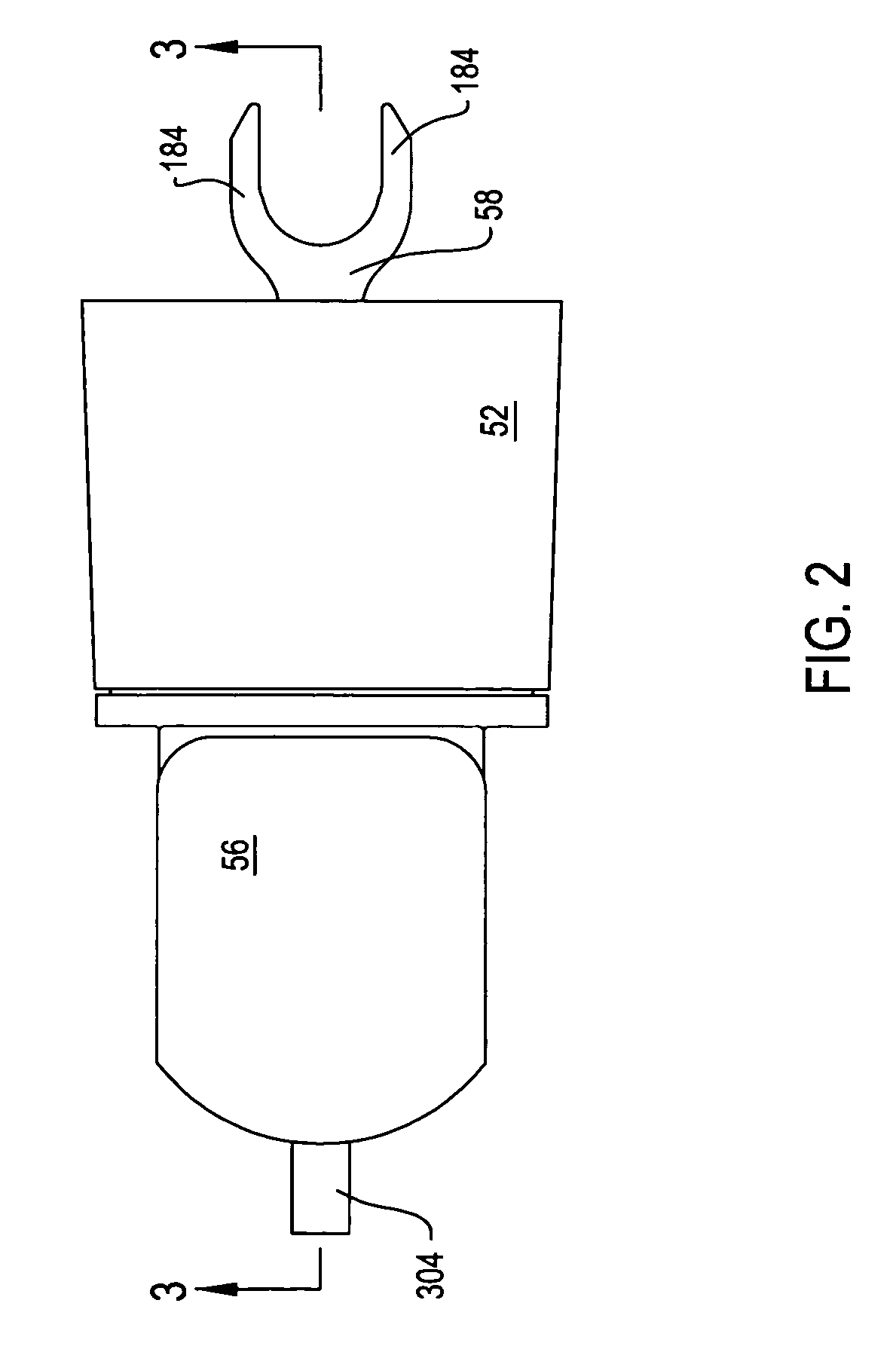

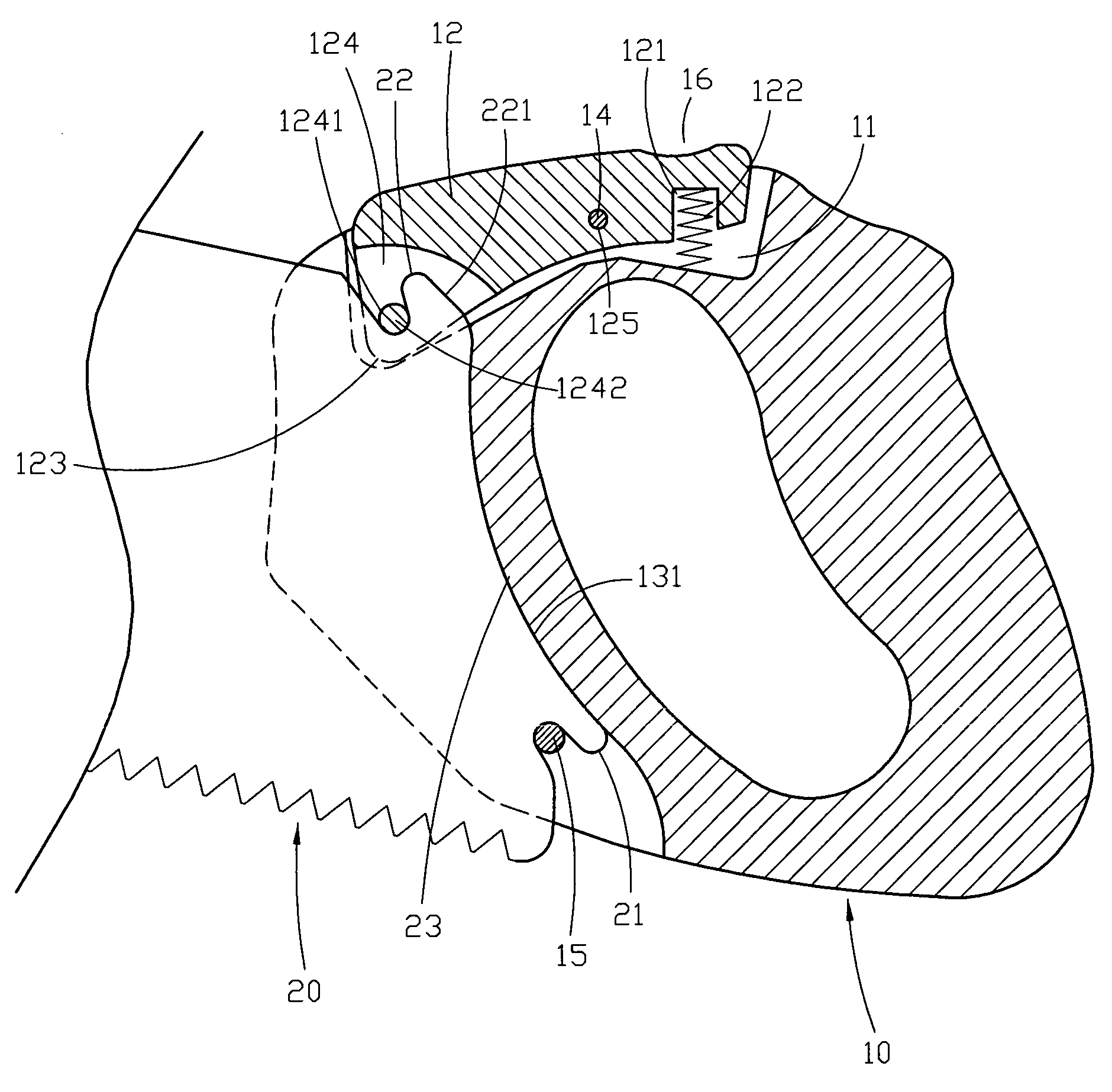

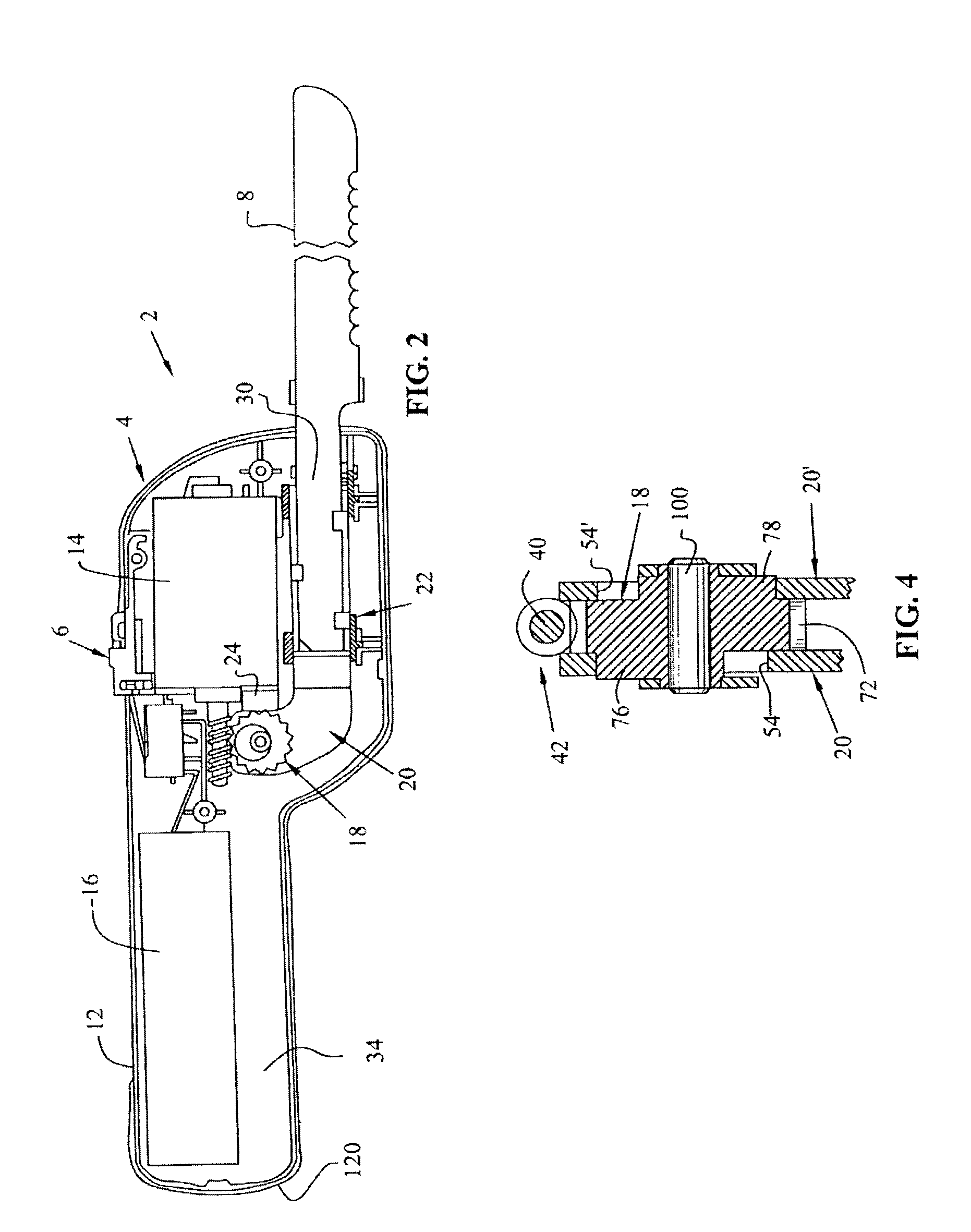

Surgical sagittal saw and method of using same

ActiveUS20060009796A1Small sizeGreat cutting site visibilityMetal sawing devicesNon-rotary toothed toolsReciprocating motionEngineering

A surgical sagittal saw including a handpiece from which a planar guide bar extends. A saw blade is mounted to the distal end of the guide bar to move across the guide bar. Drive rods connect the saw blade to a drive assembly in the handpiece, which drive assembly reciprocates the drive rods. The drive rods oscillate the saw blade across the distal end of the guide bar. The saw is used with a cutting guide that is in a fixed position relative to the bone or hard tissue to be cut. A capture element is disposed adjacent the guide surface and holds the guide bar to the guide surface so the cut is made along the desired cut plane.

Owner:STRYKER CORP

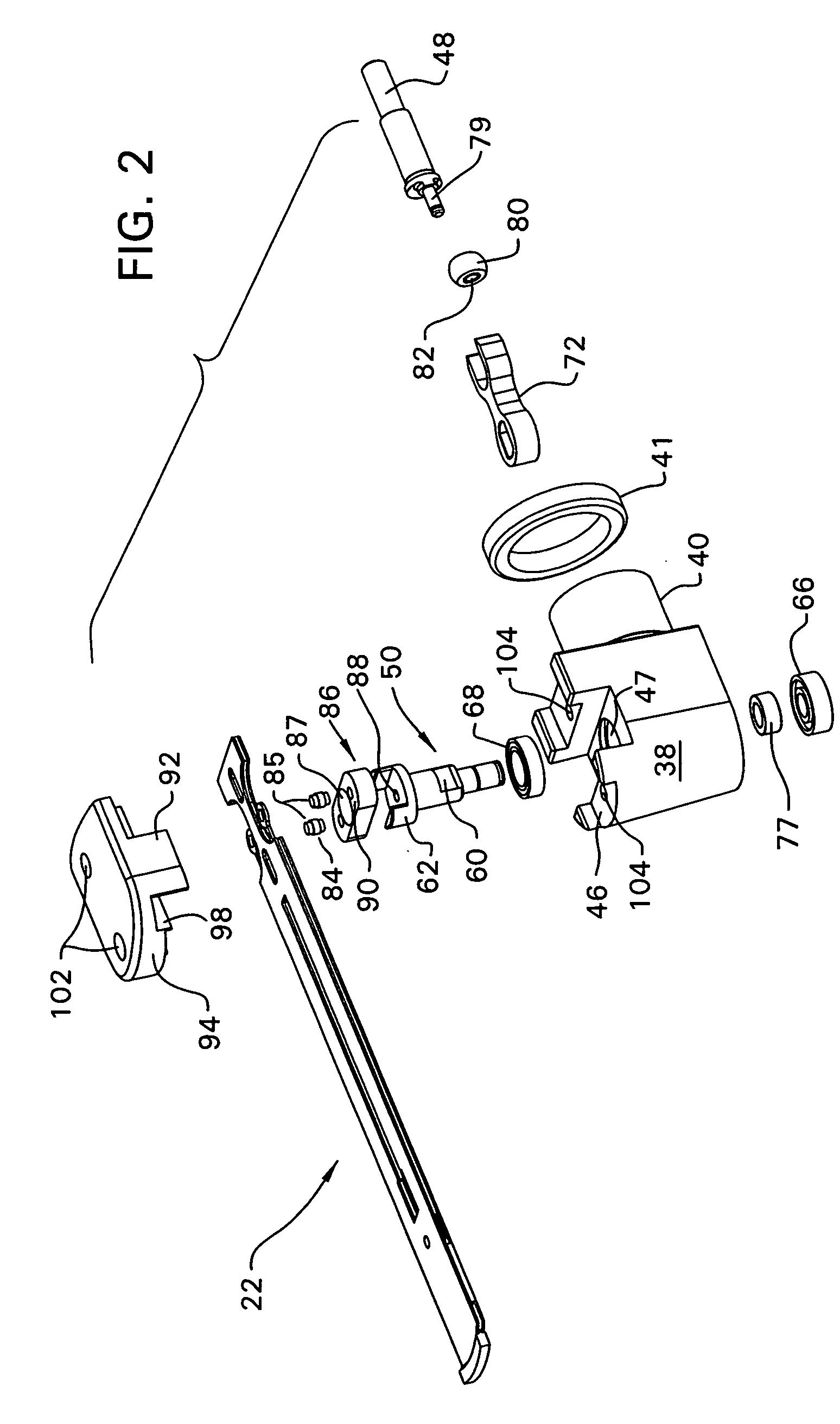

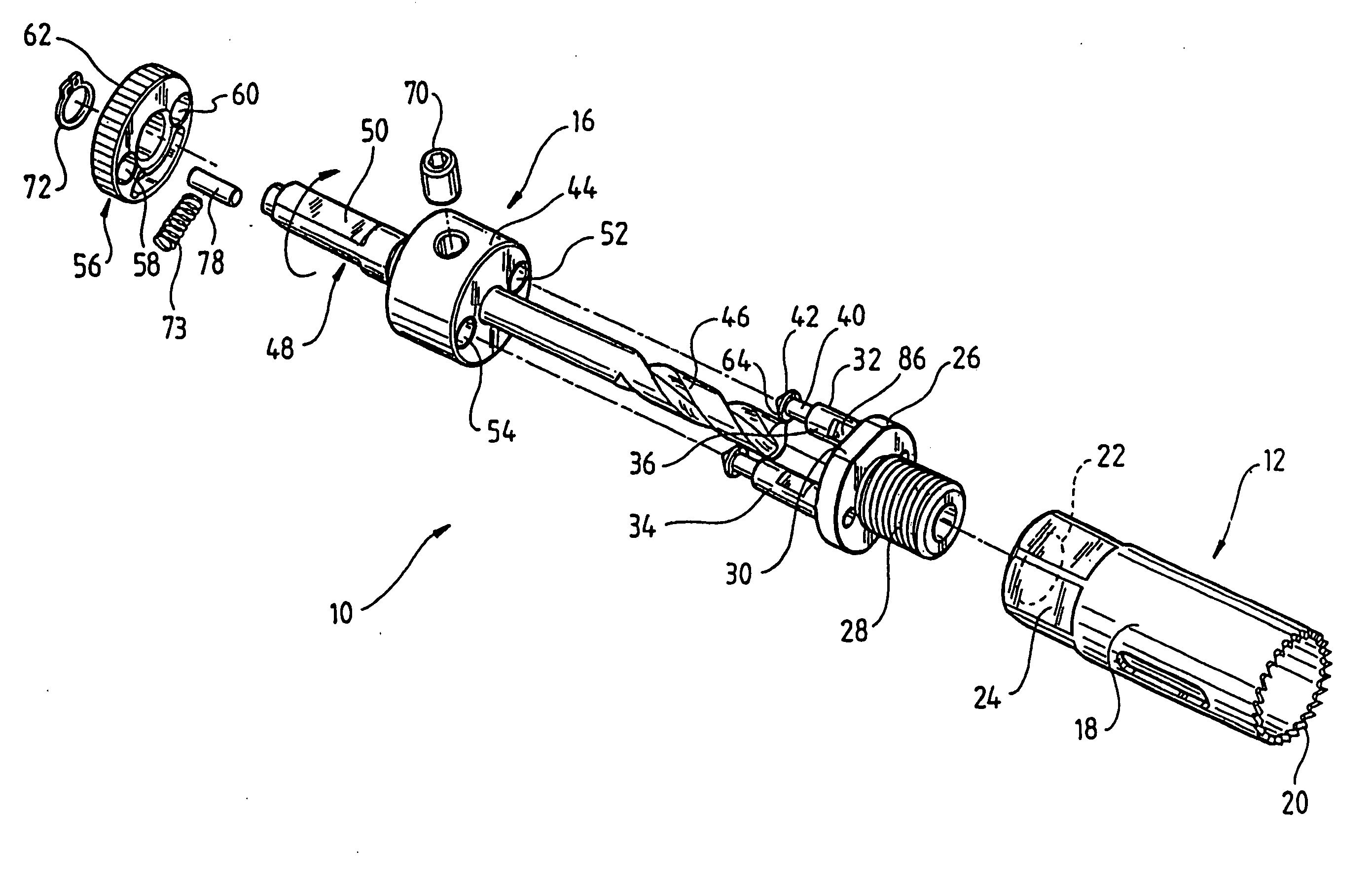

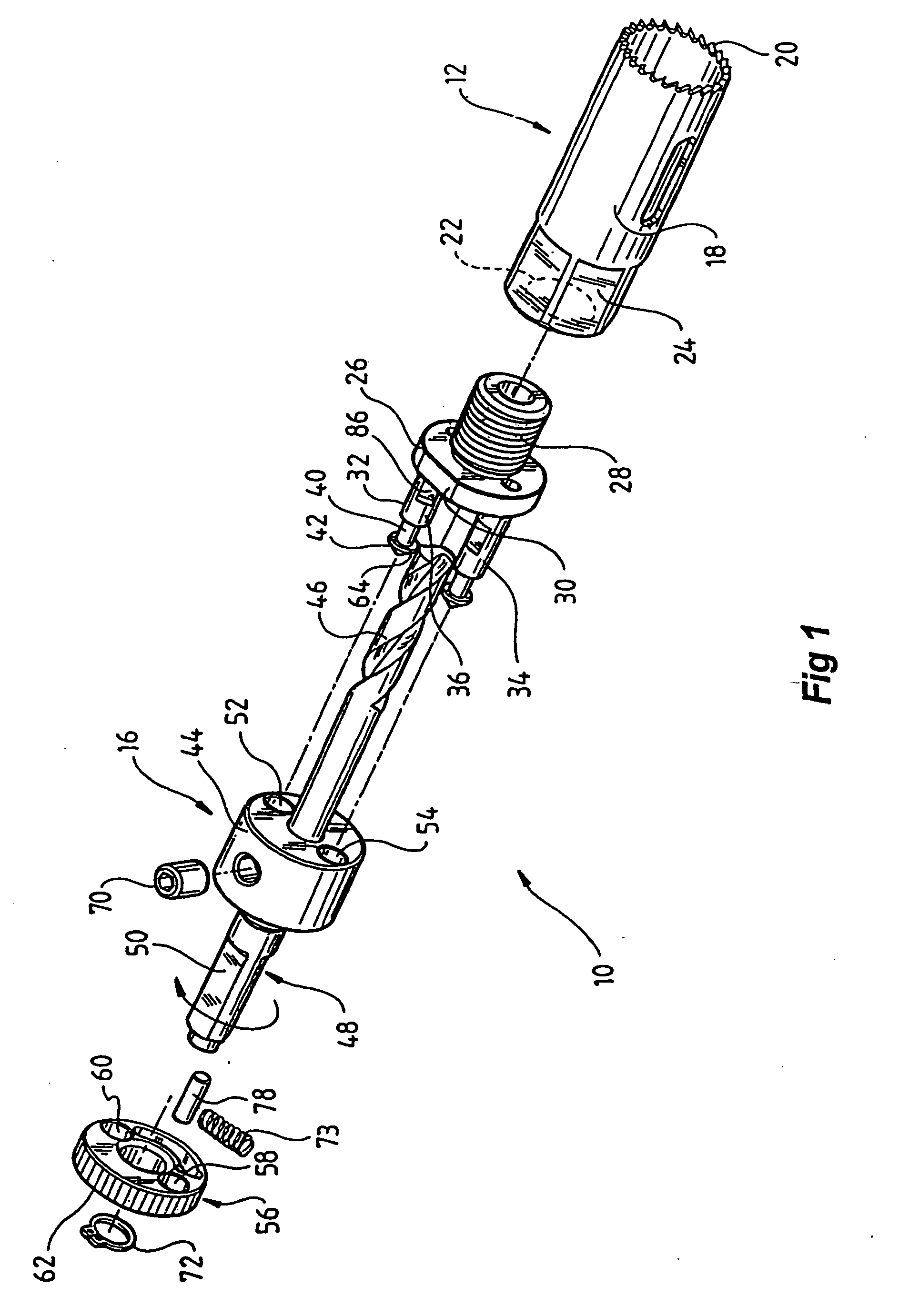

Surgical sagittal saw including a handpiece and a removable blade assembly, the blade assembly including a guide bar, a blade head capable of oscillatory movement and a drive rod for actuating the blade head

ActiveUS7497860B2Less vibratory motionAvoid excessive wearMetal sawing devicesNon-rotary toothed toolsReciprocating motionEngineering

A surgical sagittal saw including a handpiece from which a planar guide bar extends. A saw blade is mounted to the distal end of the guide bar to move across the guide bar. Drive rods connect the saw blade to a drive assembly in the handpiece, which drive assembly reciprocates the drive rods. The drive rods oscillate the saw blade across the distal end of the guide bar. The saw is used with a cutting guide that is in a fixed position relative to the bone or hard tissue to be cut. A capture element is disposed adjacent the guide surface and holds the guide bar to the guide surface so the cut is made along the desired cut plane.

Owner:STRYKER CORP

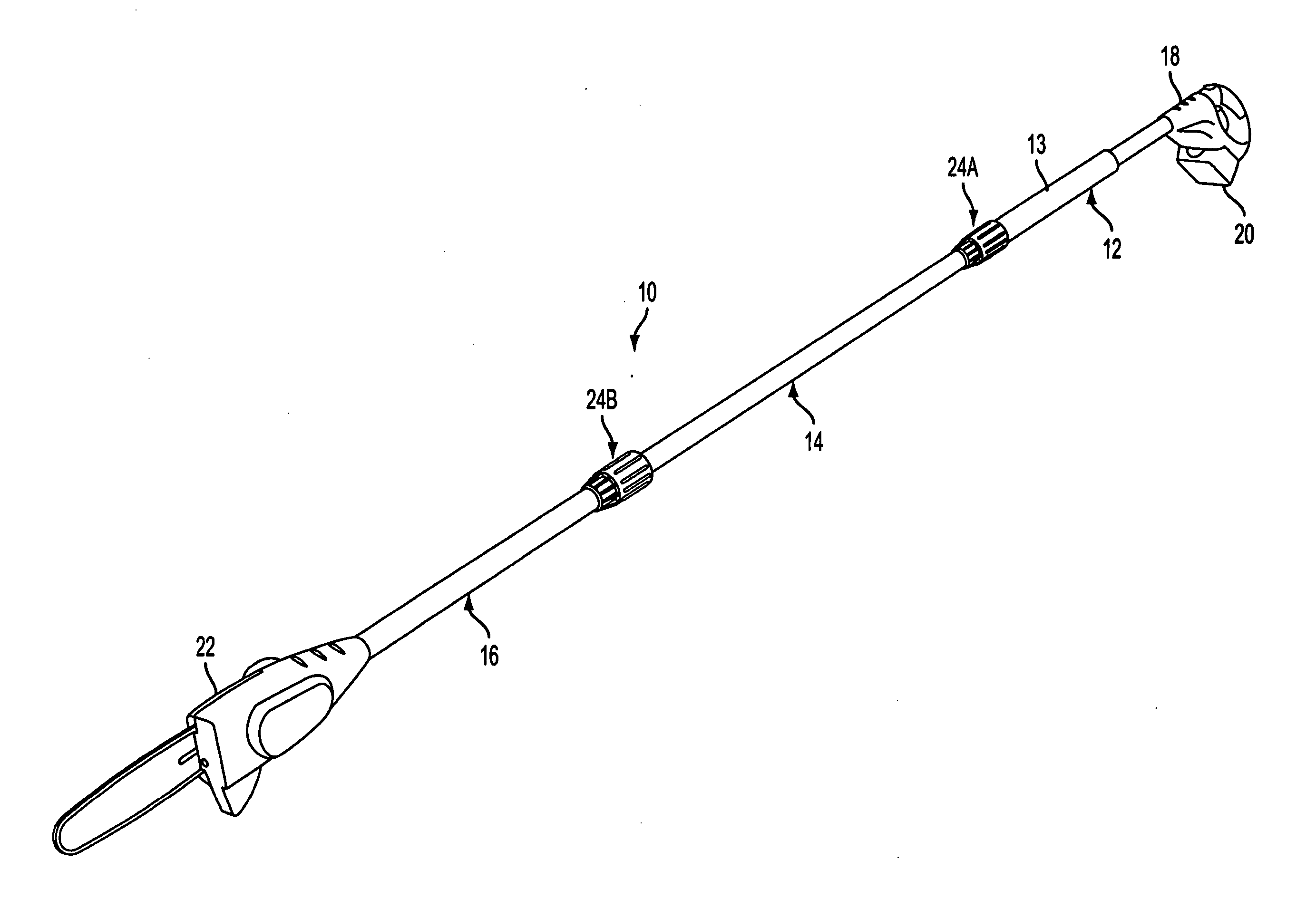

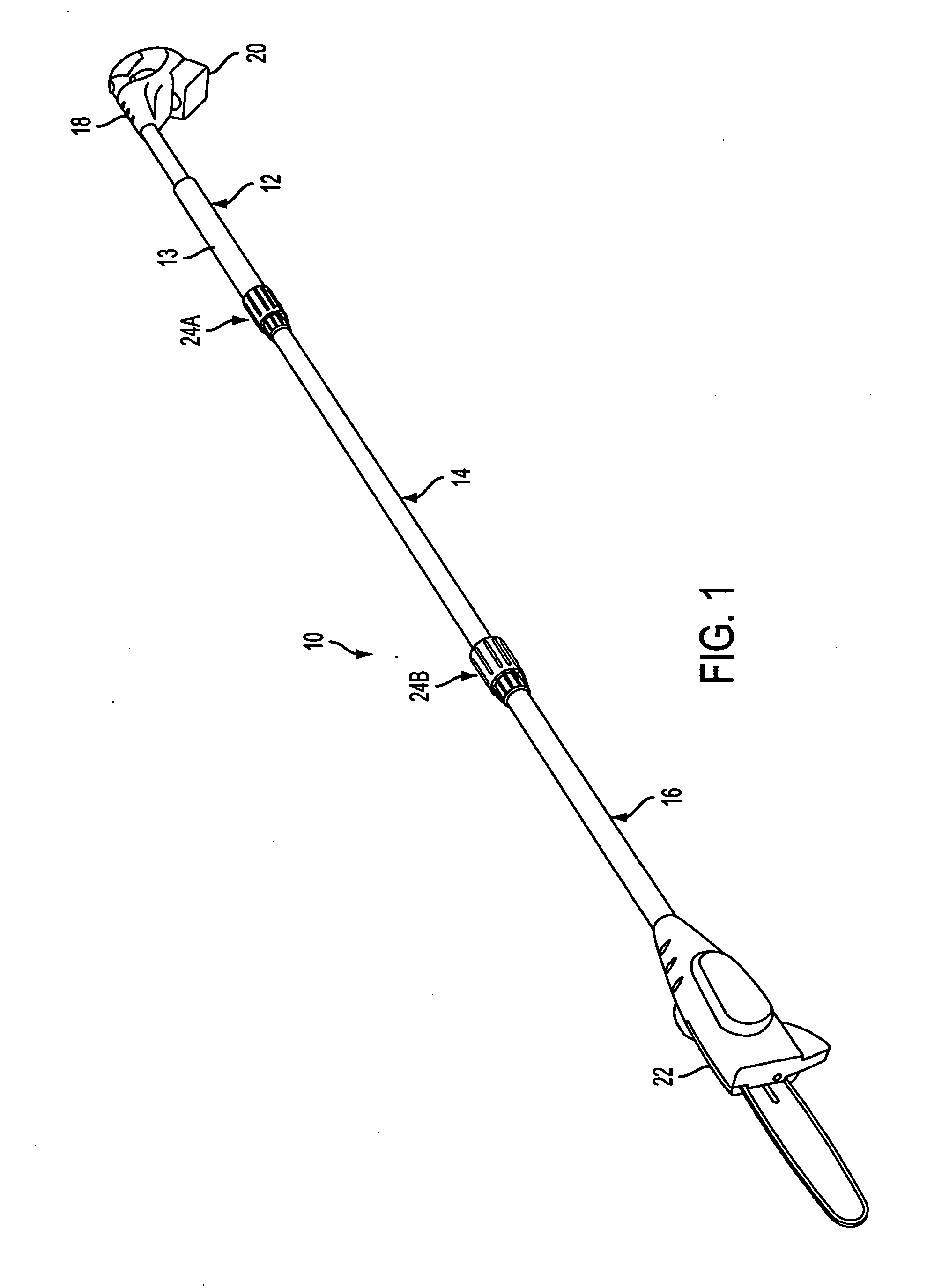

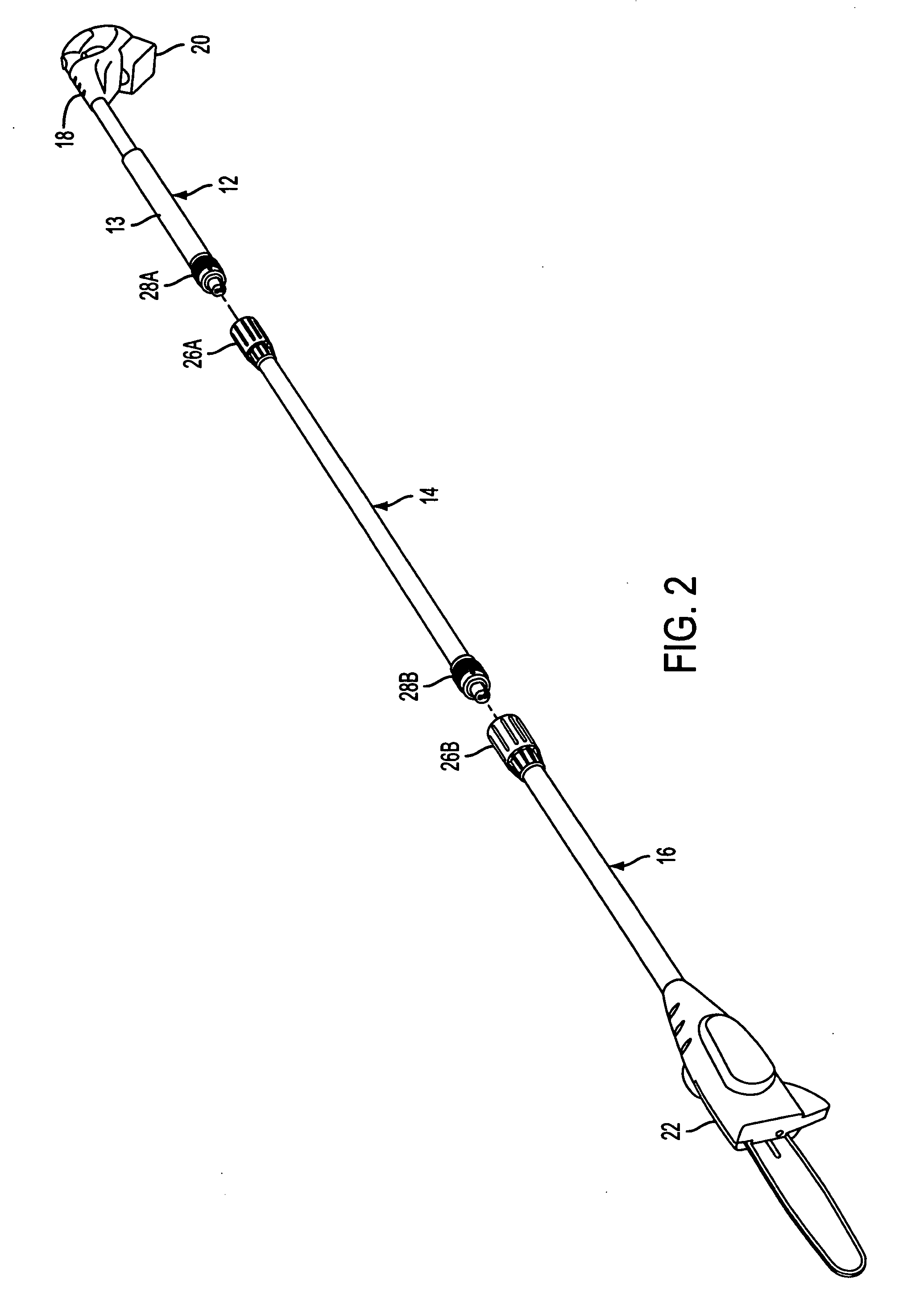

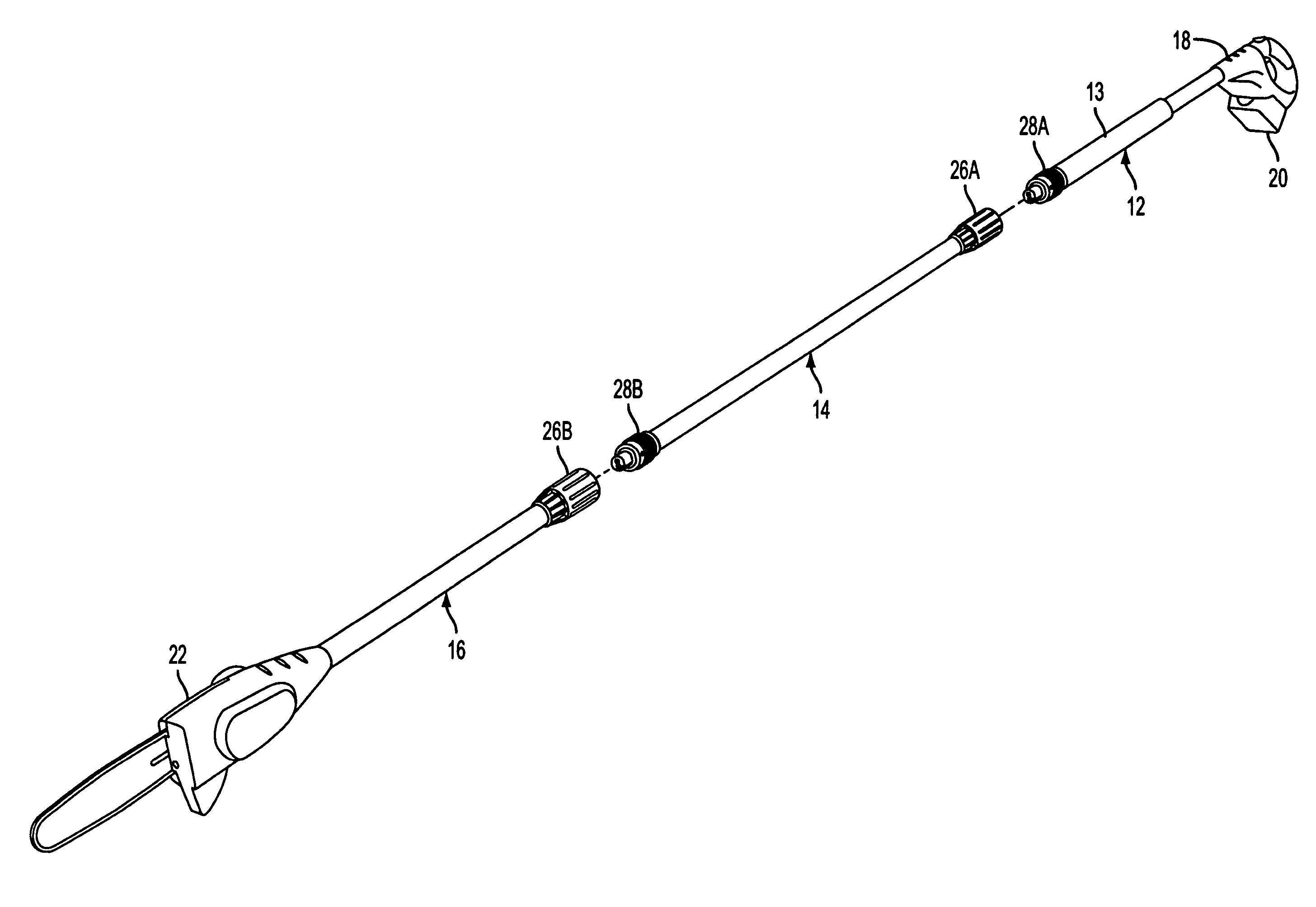

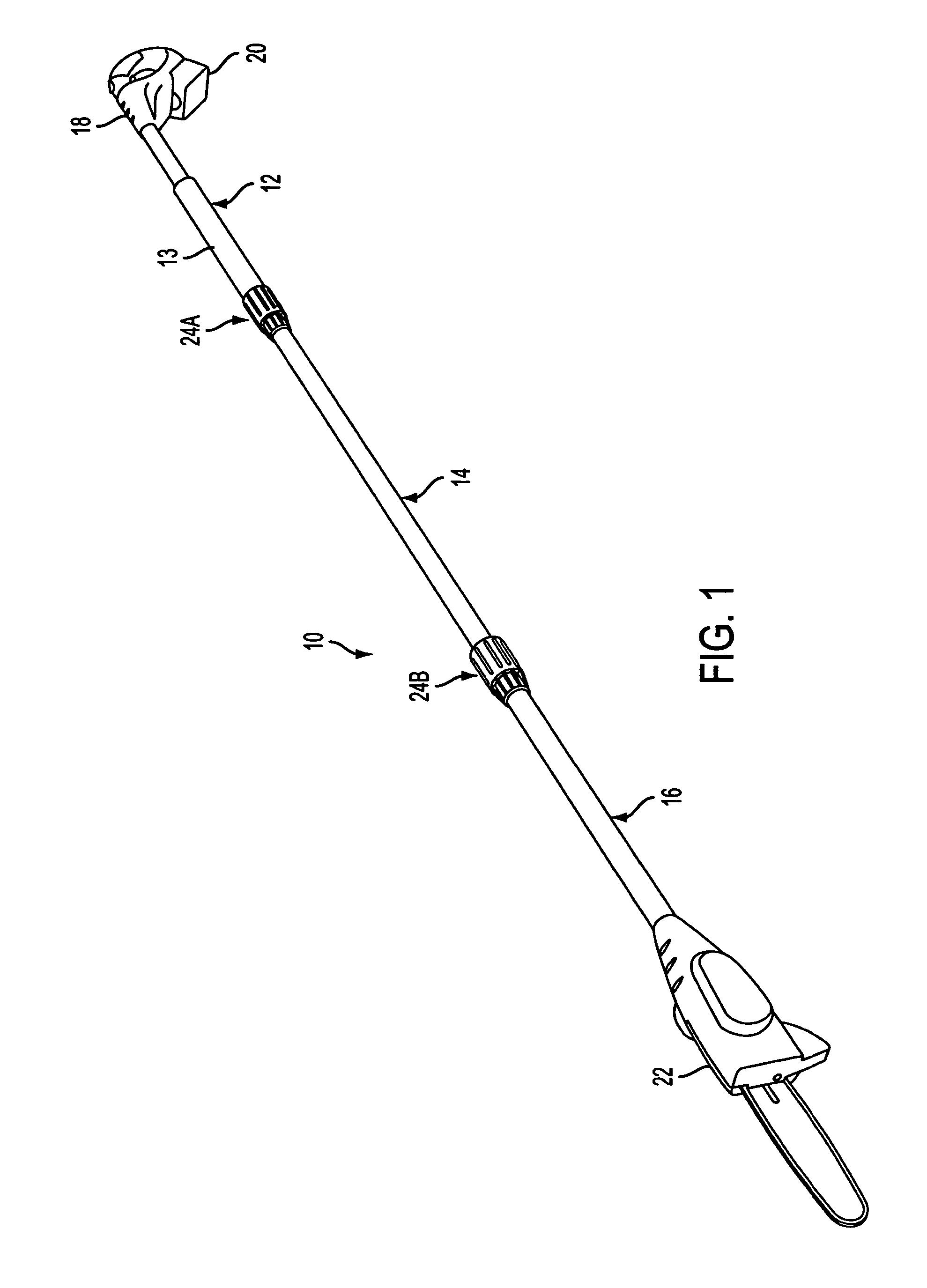

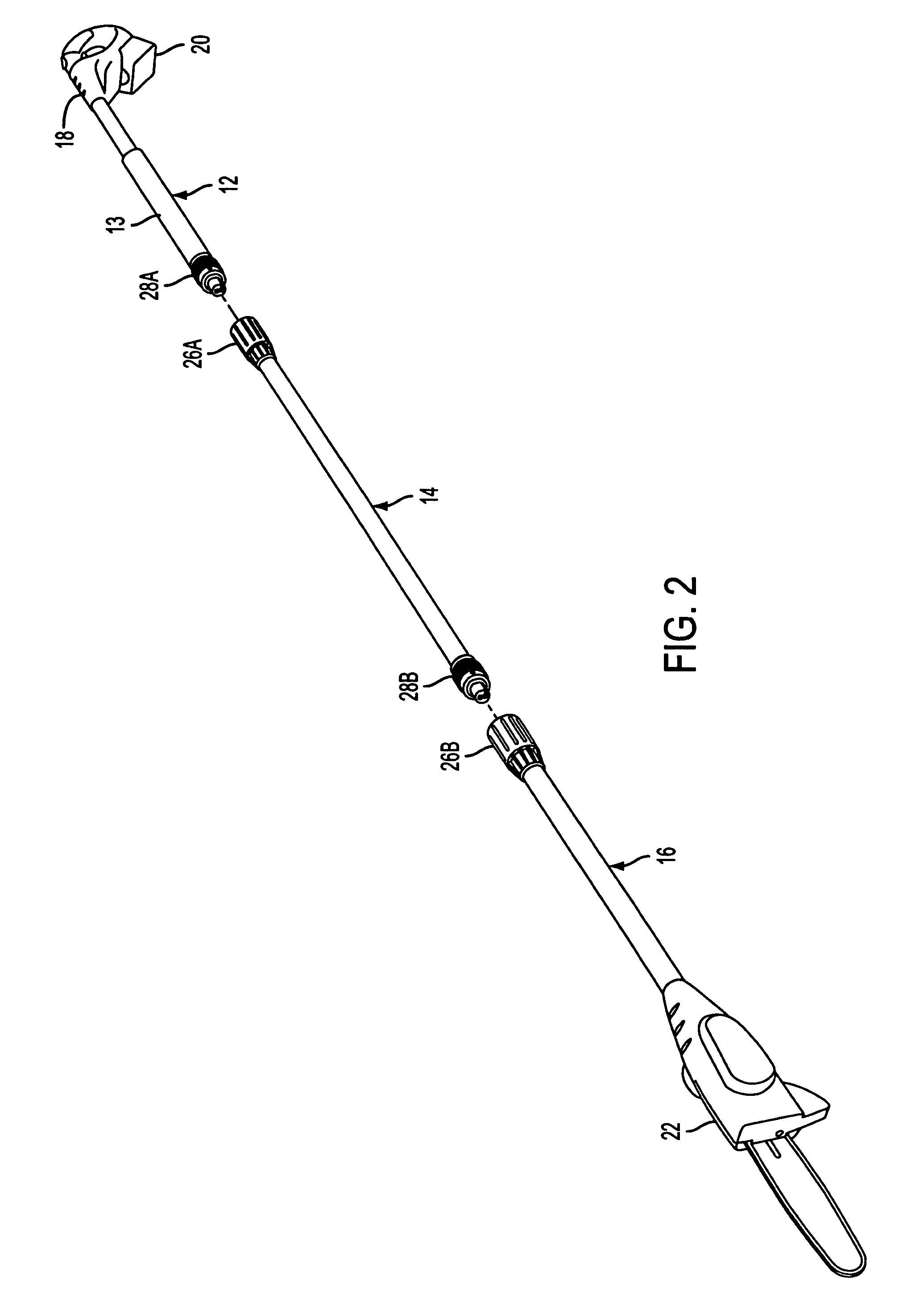

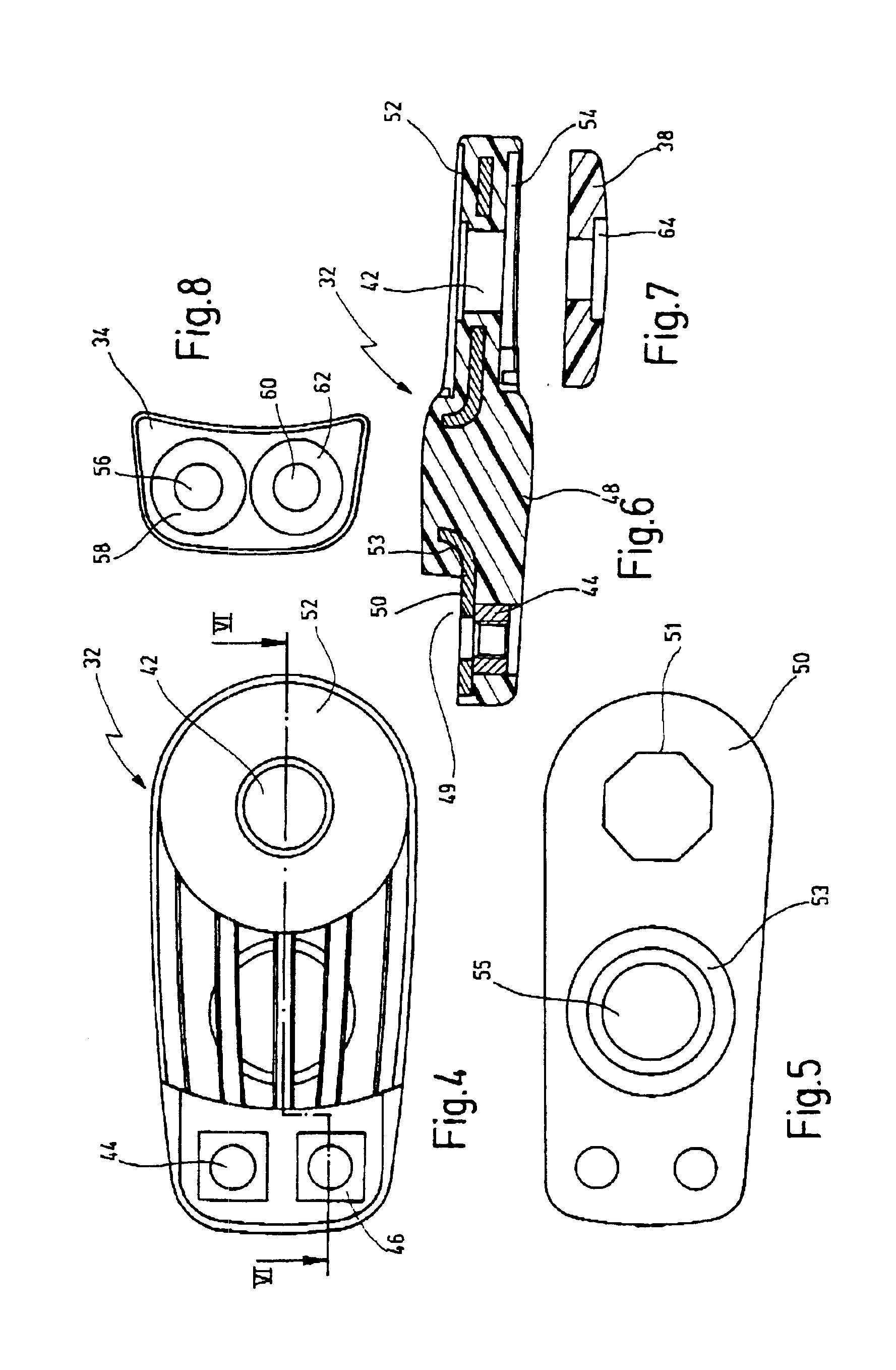

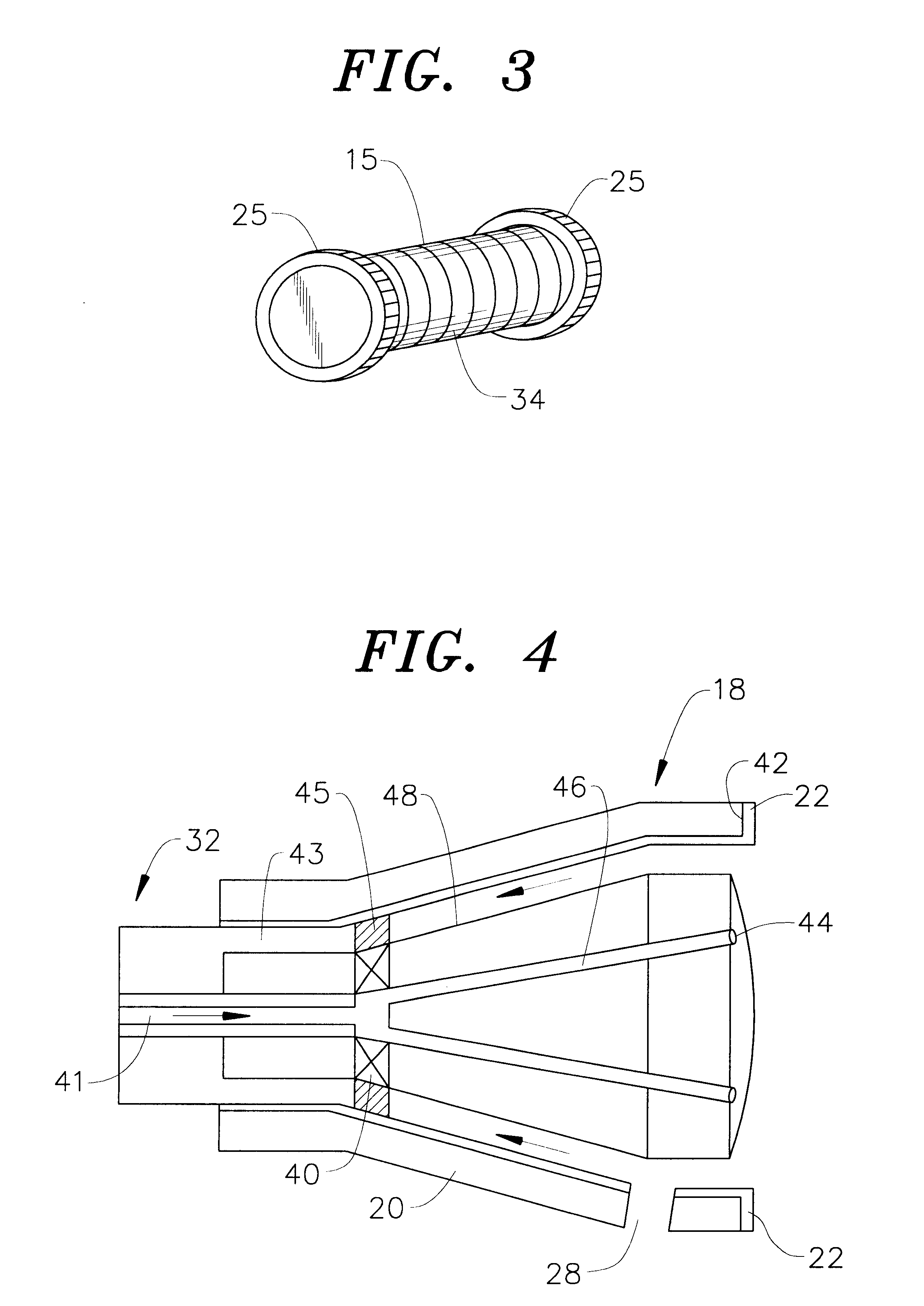

Extensible pole saw having separable sections

InactiveUS20060048397A1Power deliverMetal sawing devicesNon-rotary toothed toolsElectrical conductorEngineering

An elongated pole pruner for cutting and trimming trees, bushes and the like having three separable sections, that when assembled, form an extended length pruner. The pole pruner includes a first section containing a handle and battery pack, a second extension section, and a third section that contains the purner itself. Each of the sections contains an electrical conductor that is attached to corresponding conductor in an adjacent pole sections via a male plug and female receptacle. In this way, the battery pack in the first section of the pole is able to deliver power through the second section to the pruner in the third section.

Owner:BLACK & DECKER INC

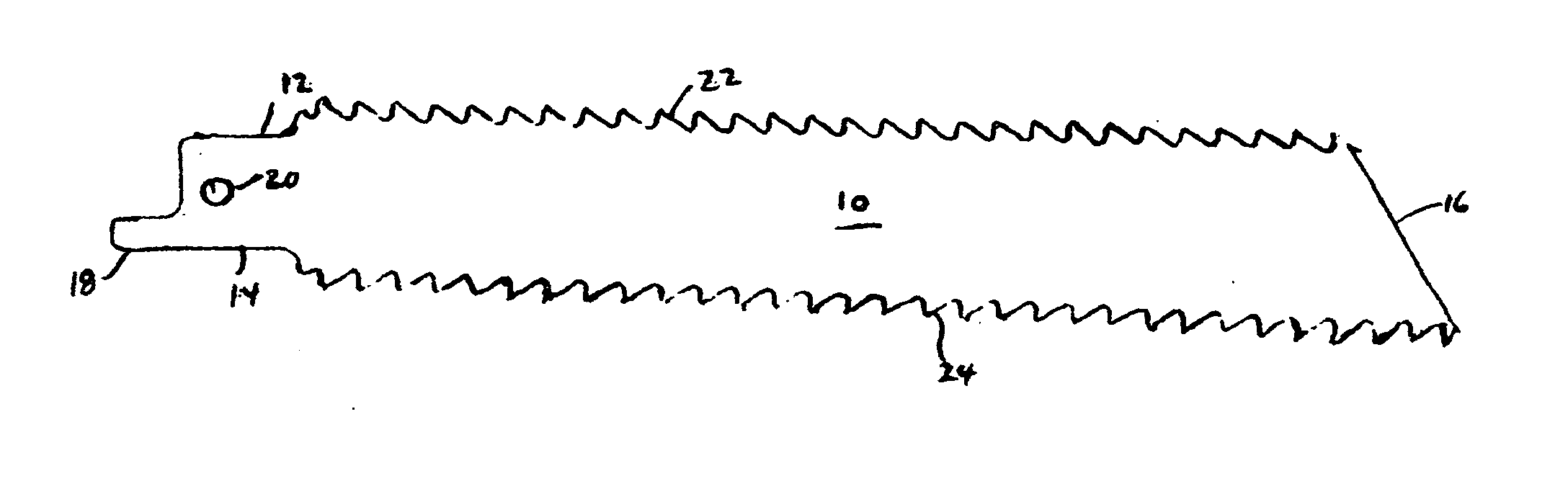

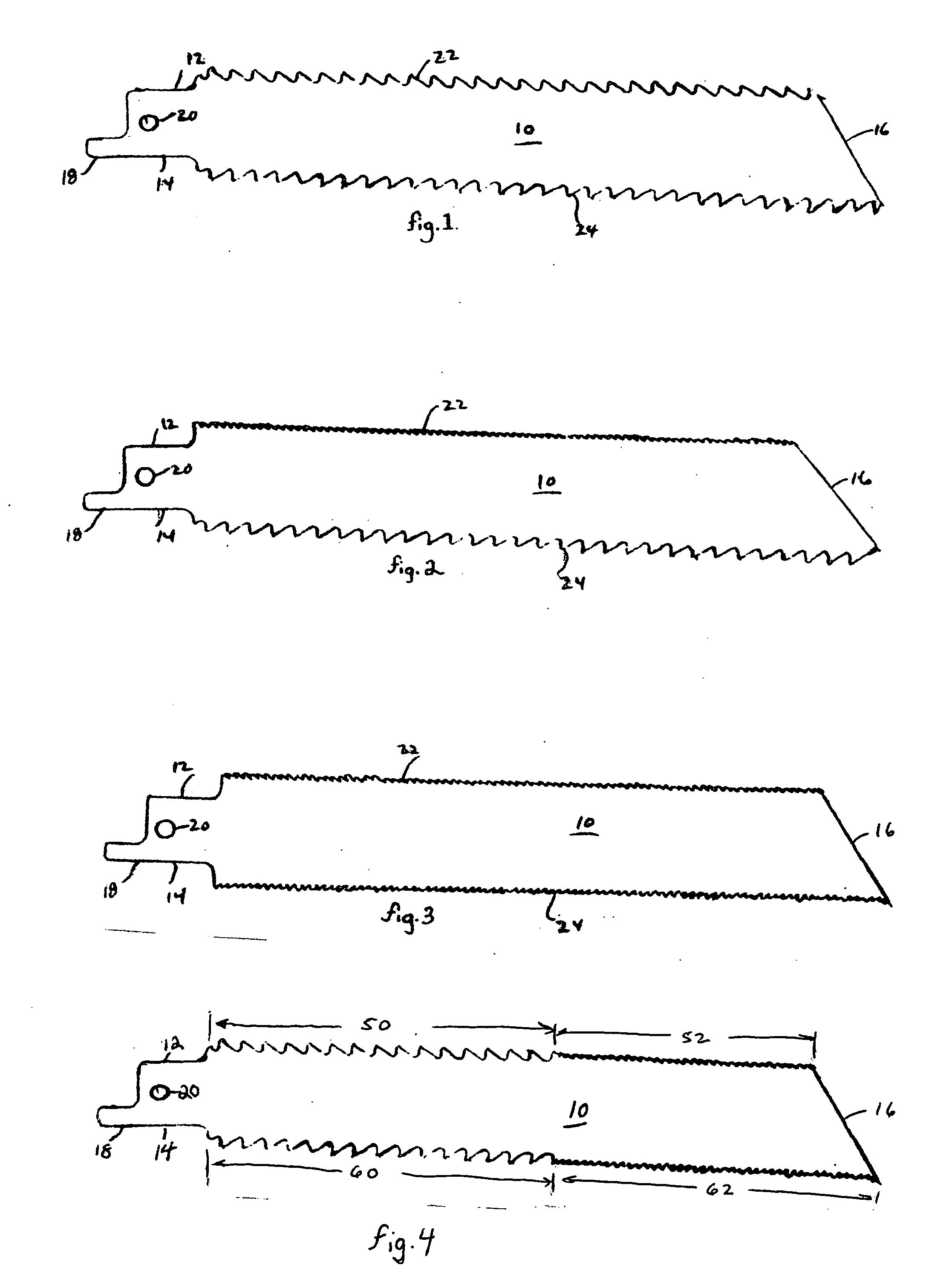

Construction saw blade

A construction saw blade having pluralities of cutting teeth along upper and lower edge surfaces thereof, an aperture transversely extending through the blade adjacent its rearwardly facing back end of a configuration and dimension to receive a fastener to removably secure the blade to a reciprocating saw for use, and wherein each plurality of cutting teeth include rake angles for cutting substantially only on a pull stroke of the reciprocating saw.

Owner:HAWTHORN JOHN E

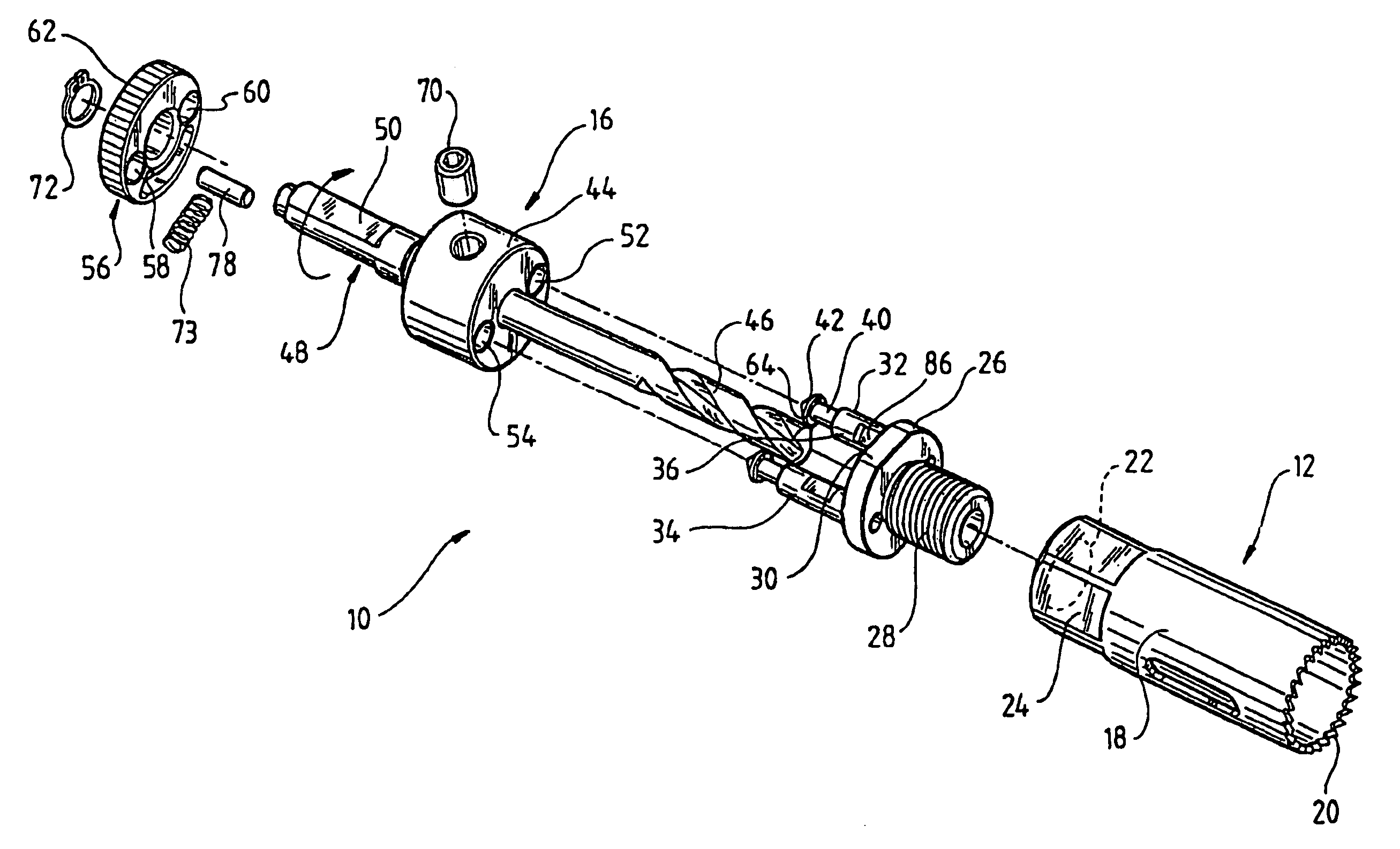

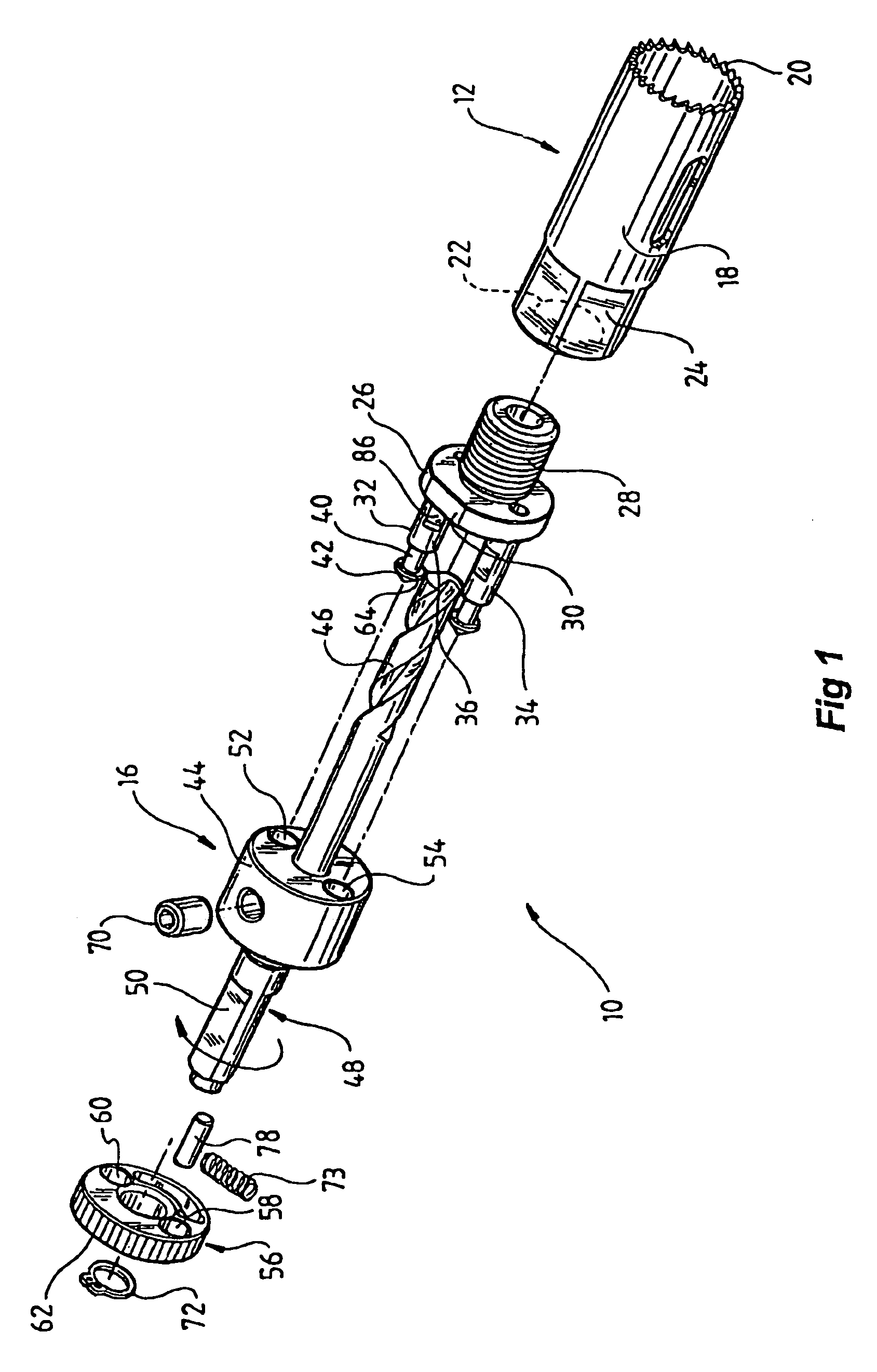

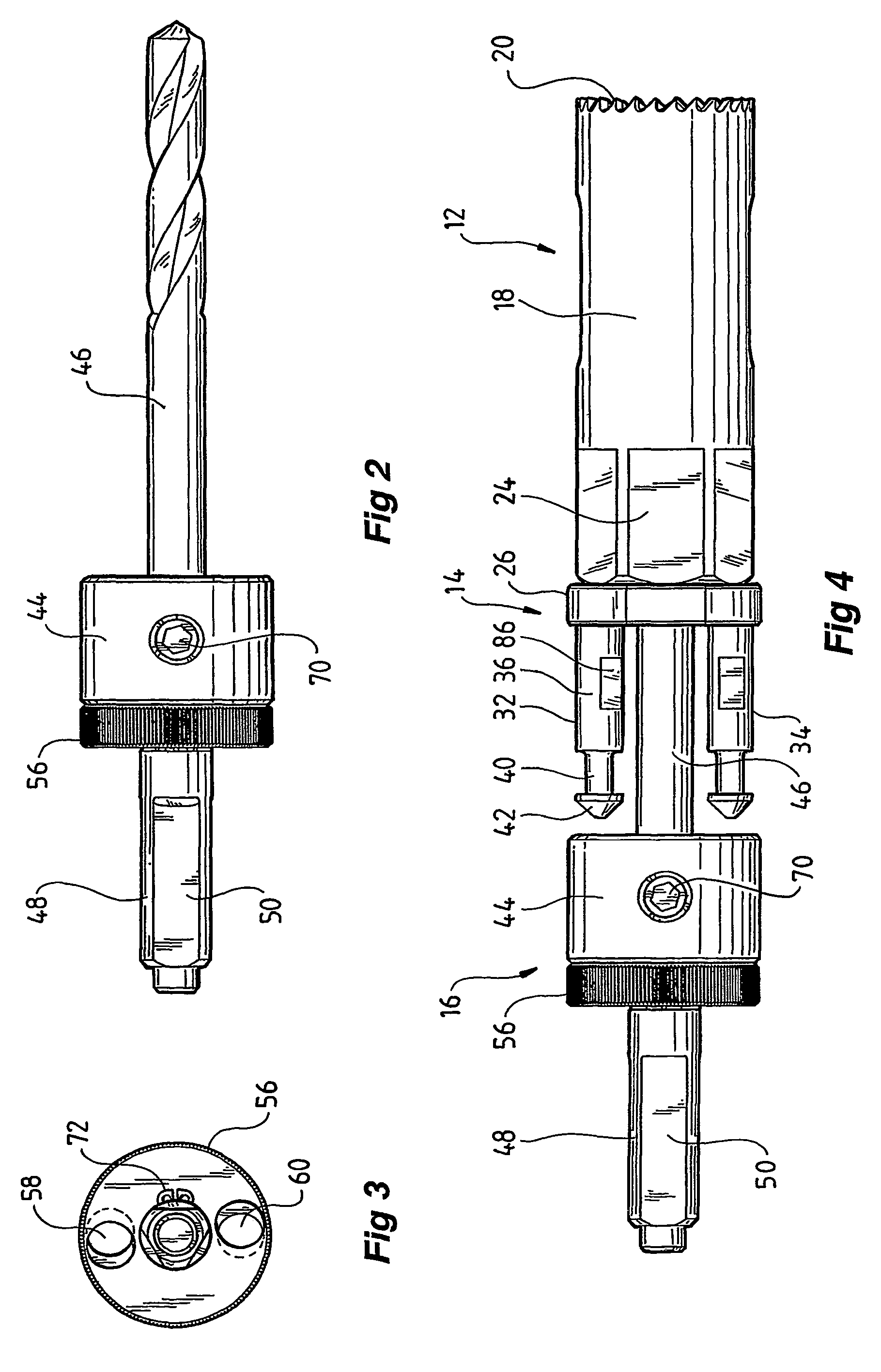

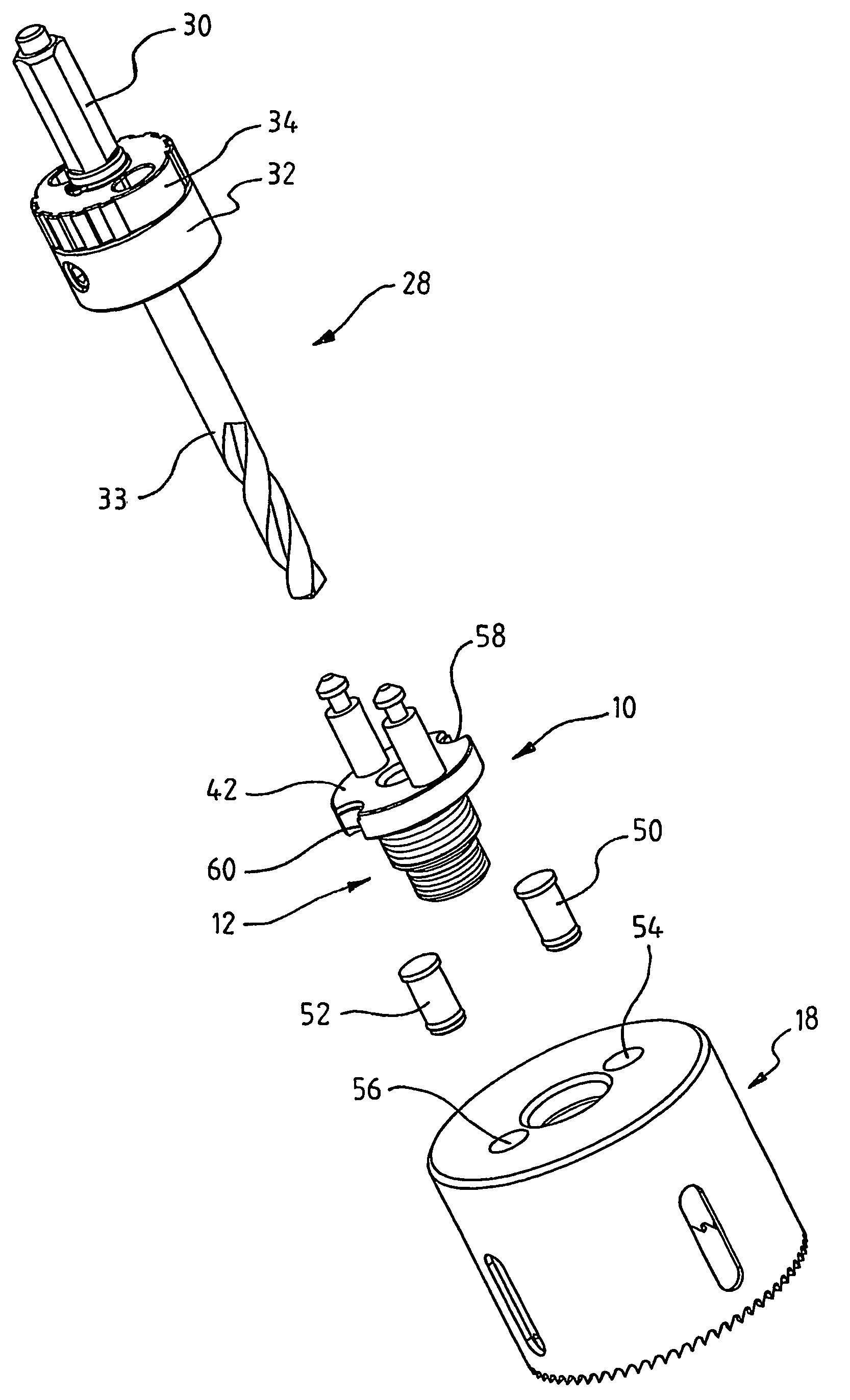

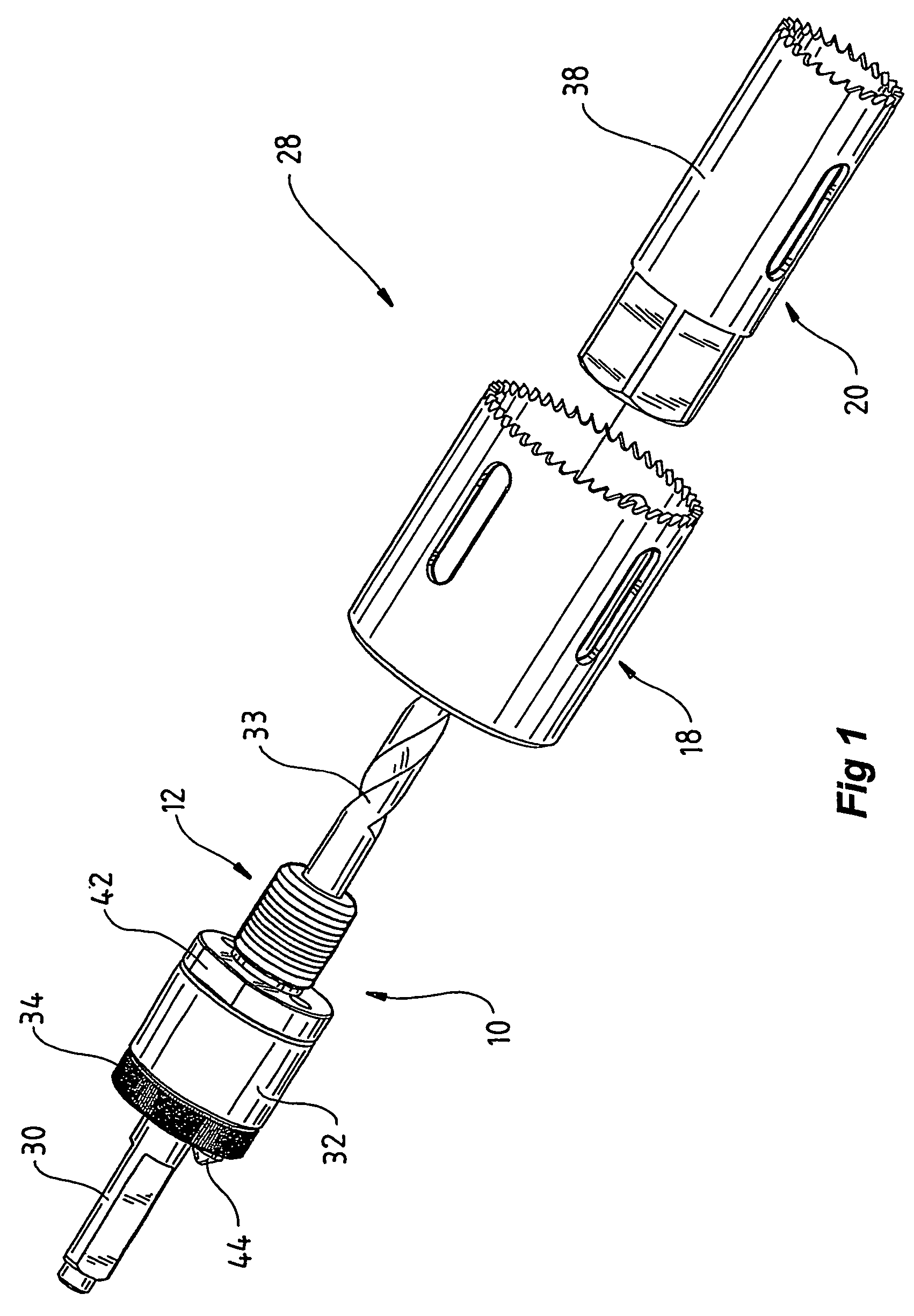

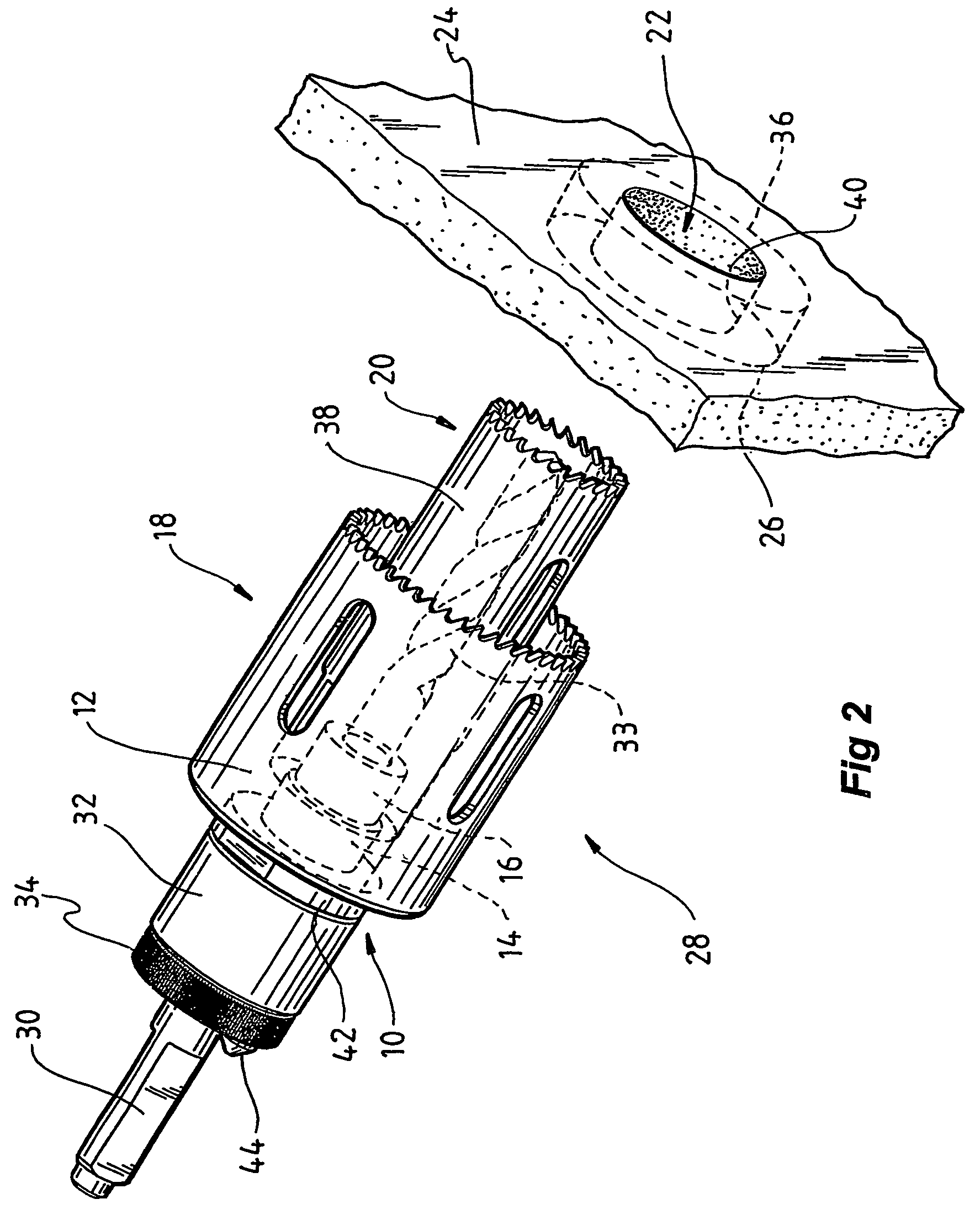

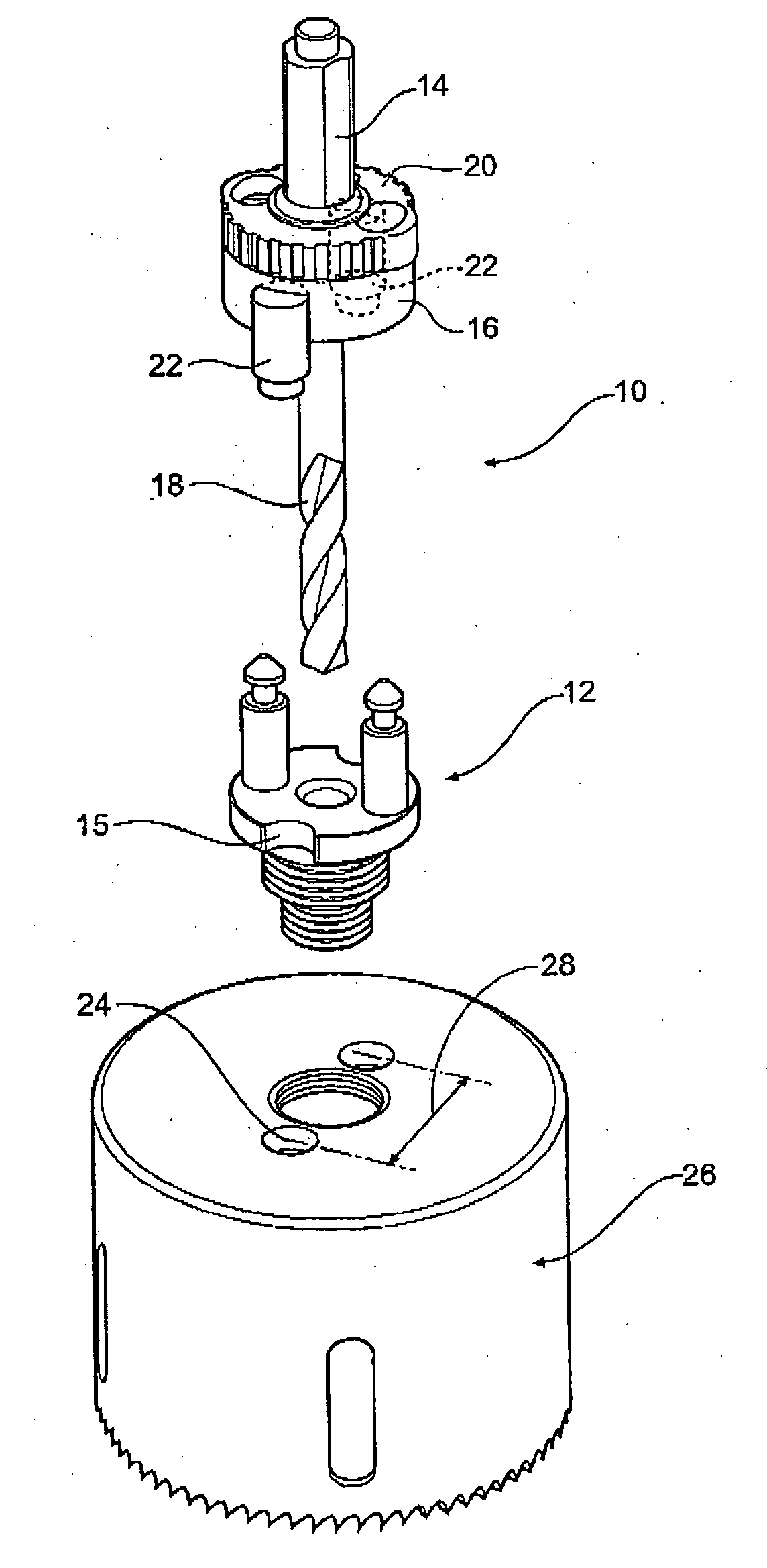

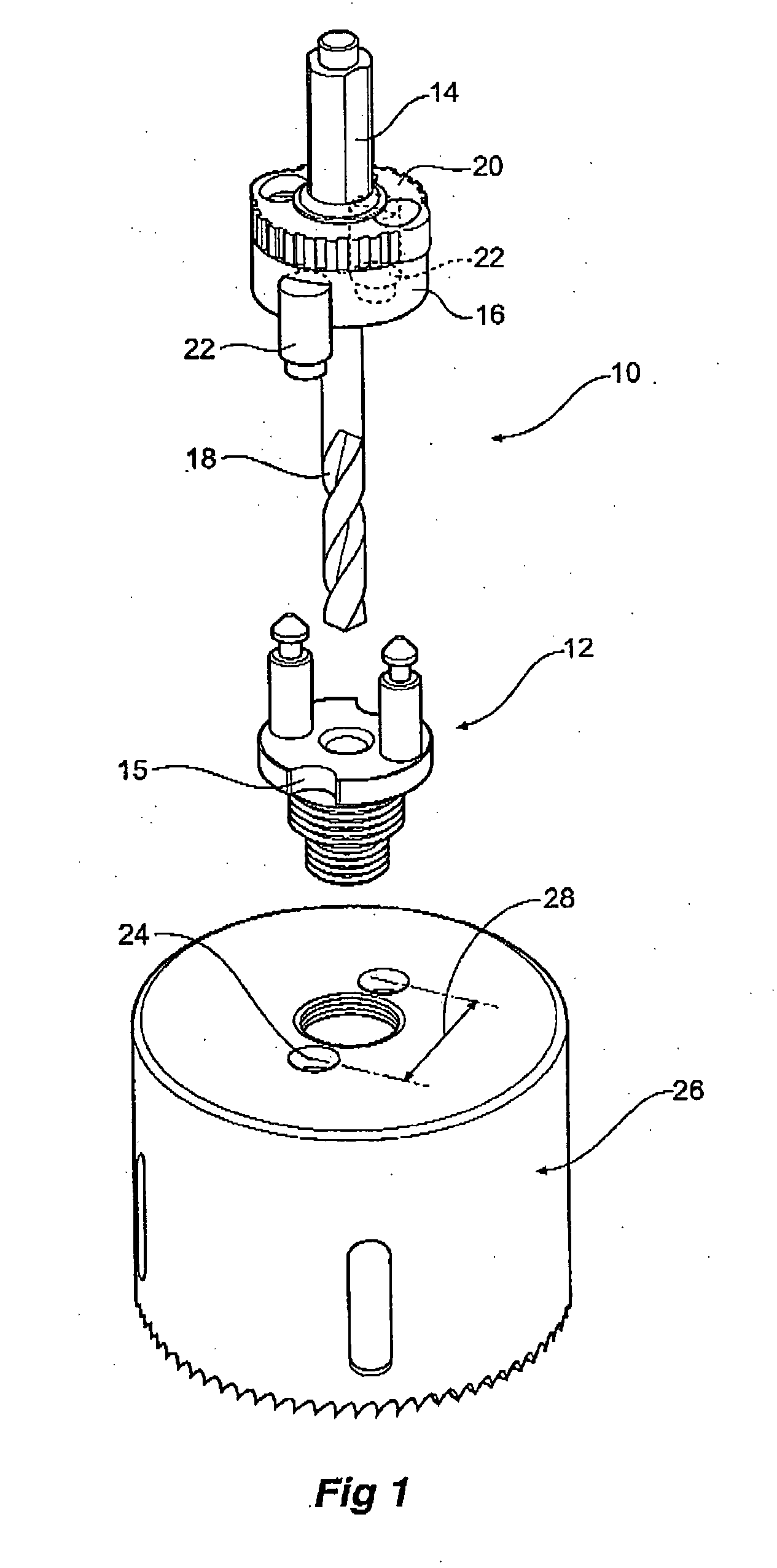

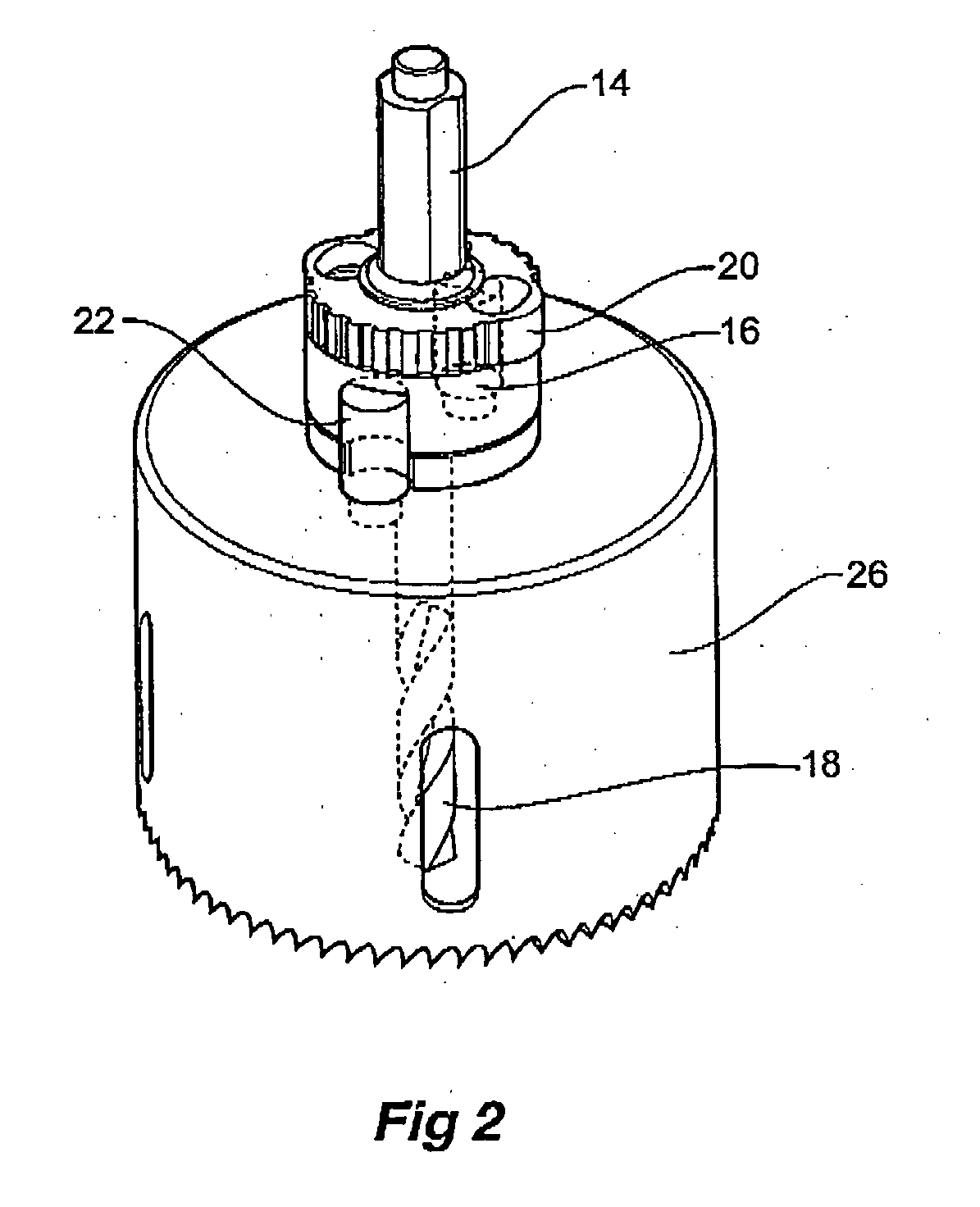

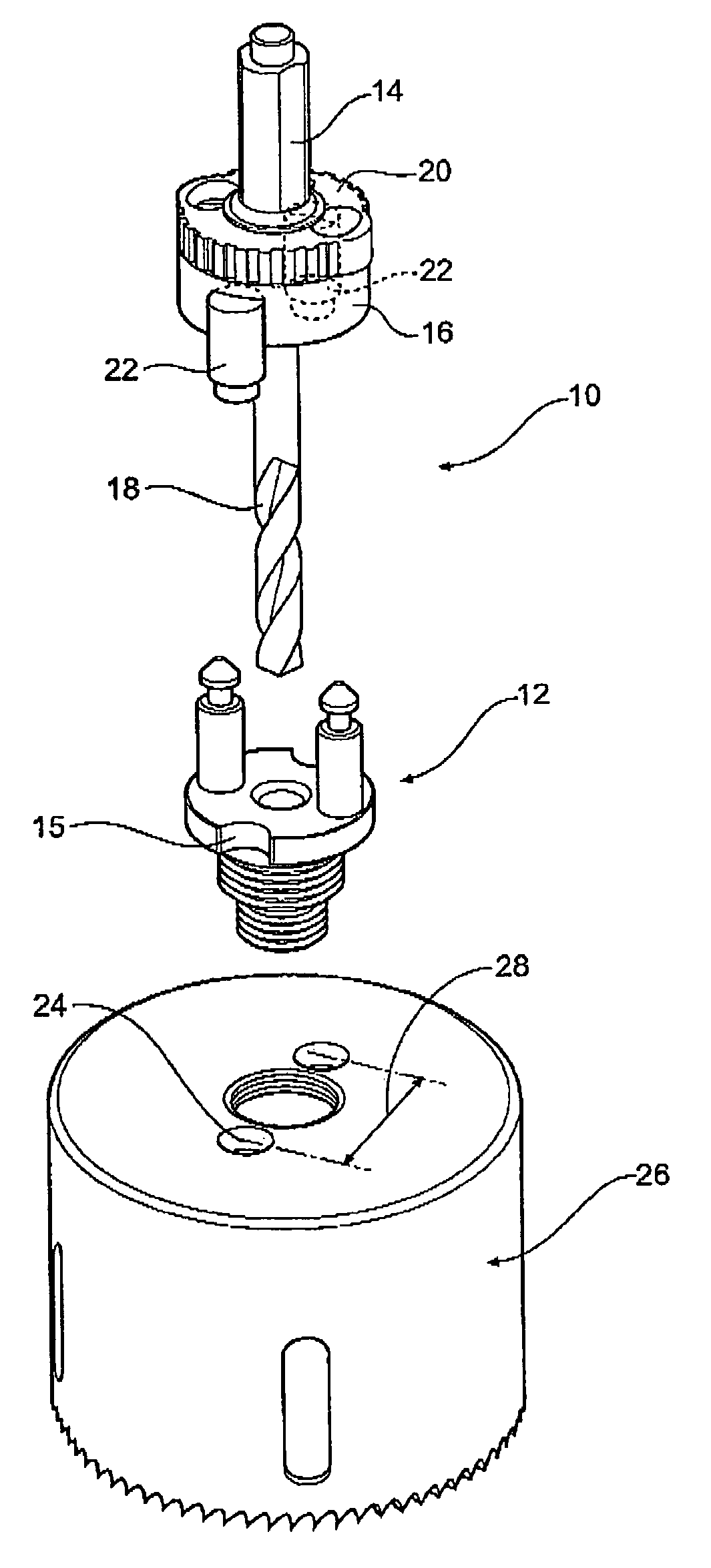

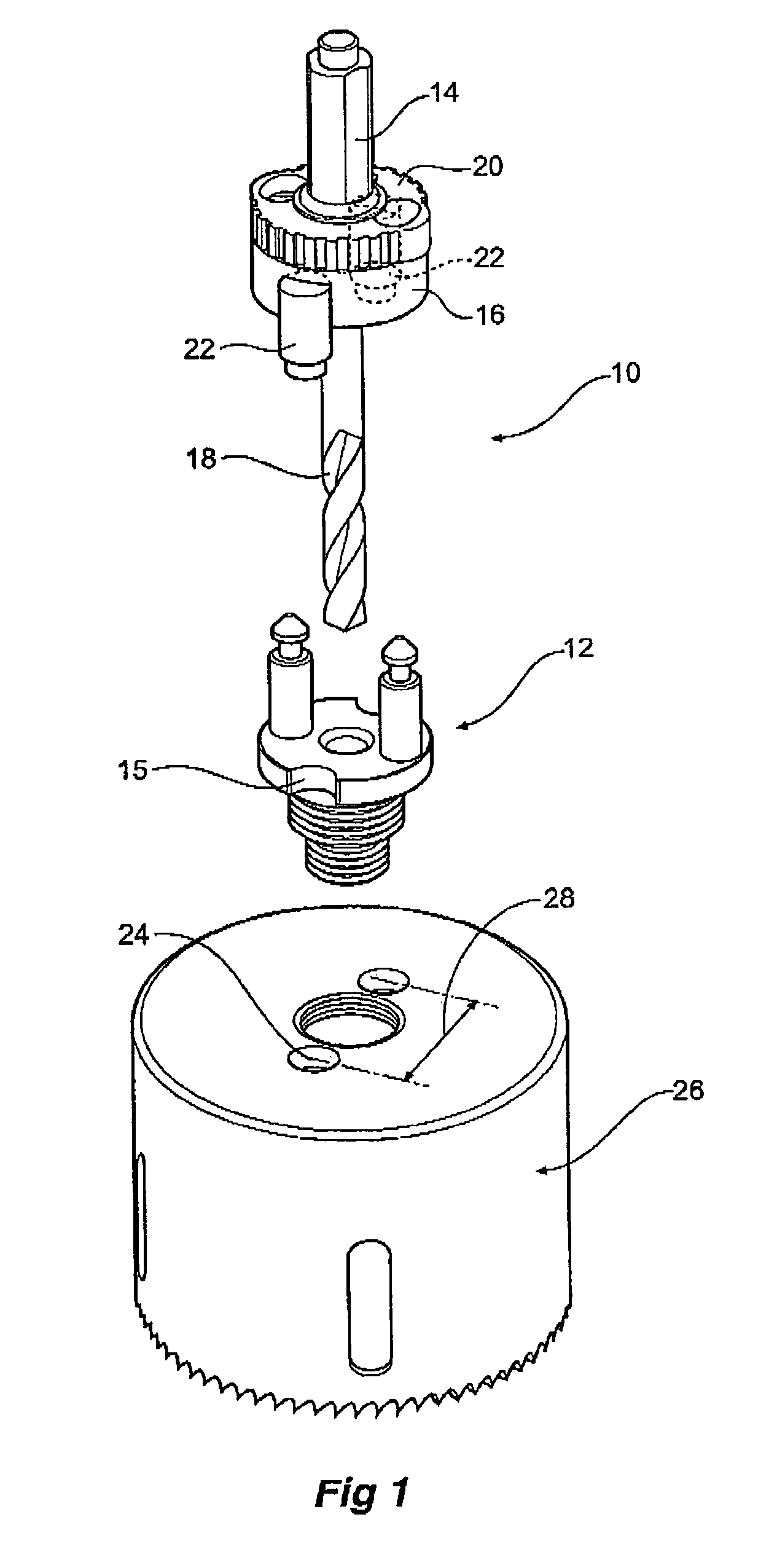

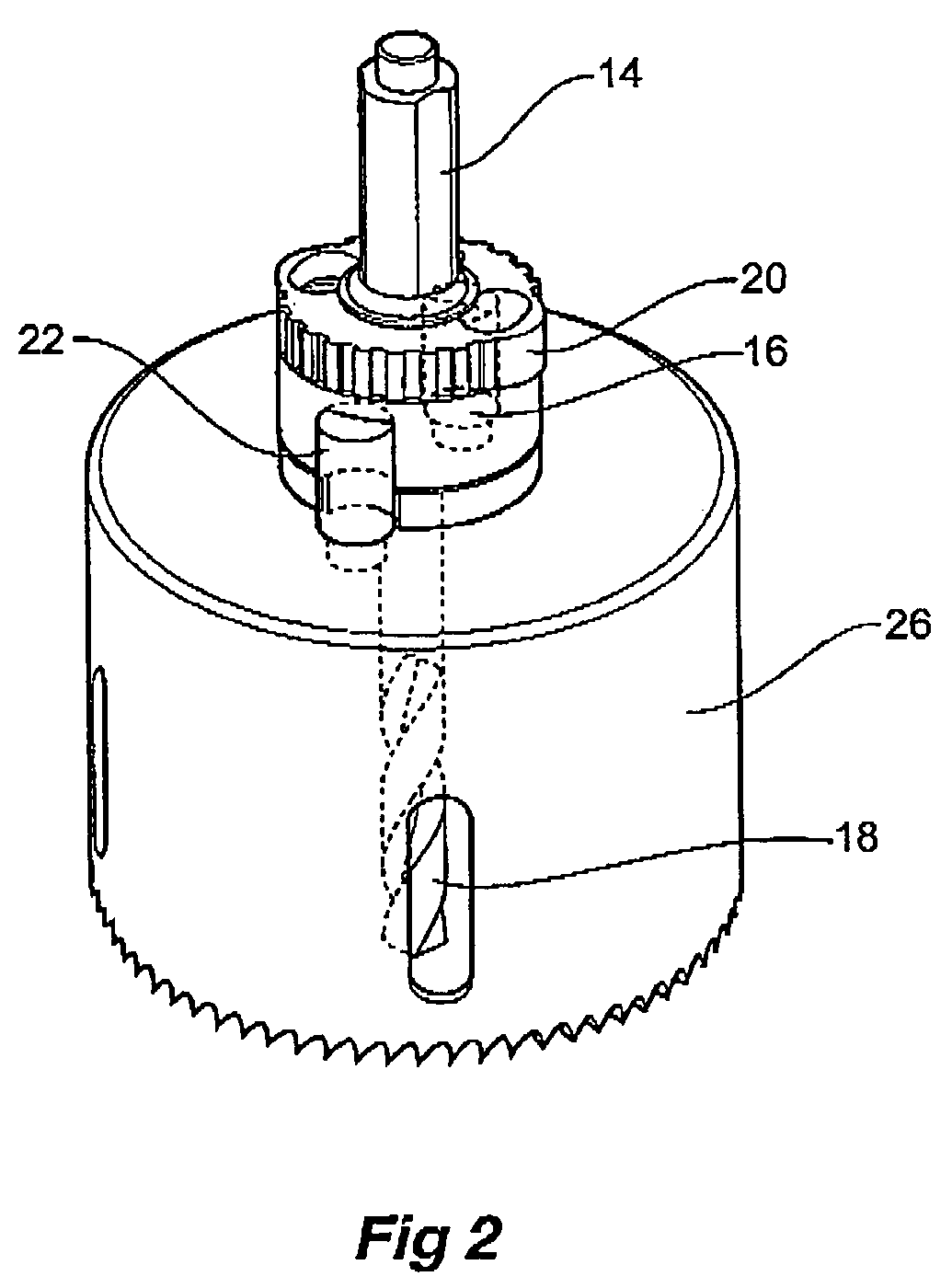

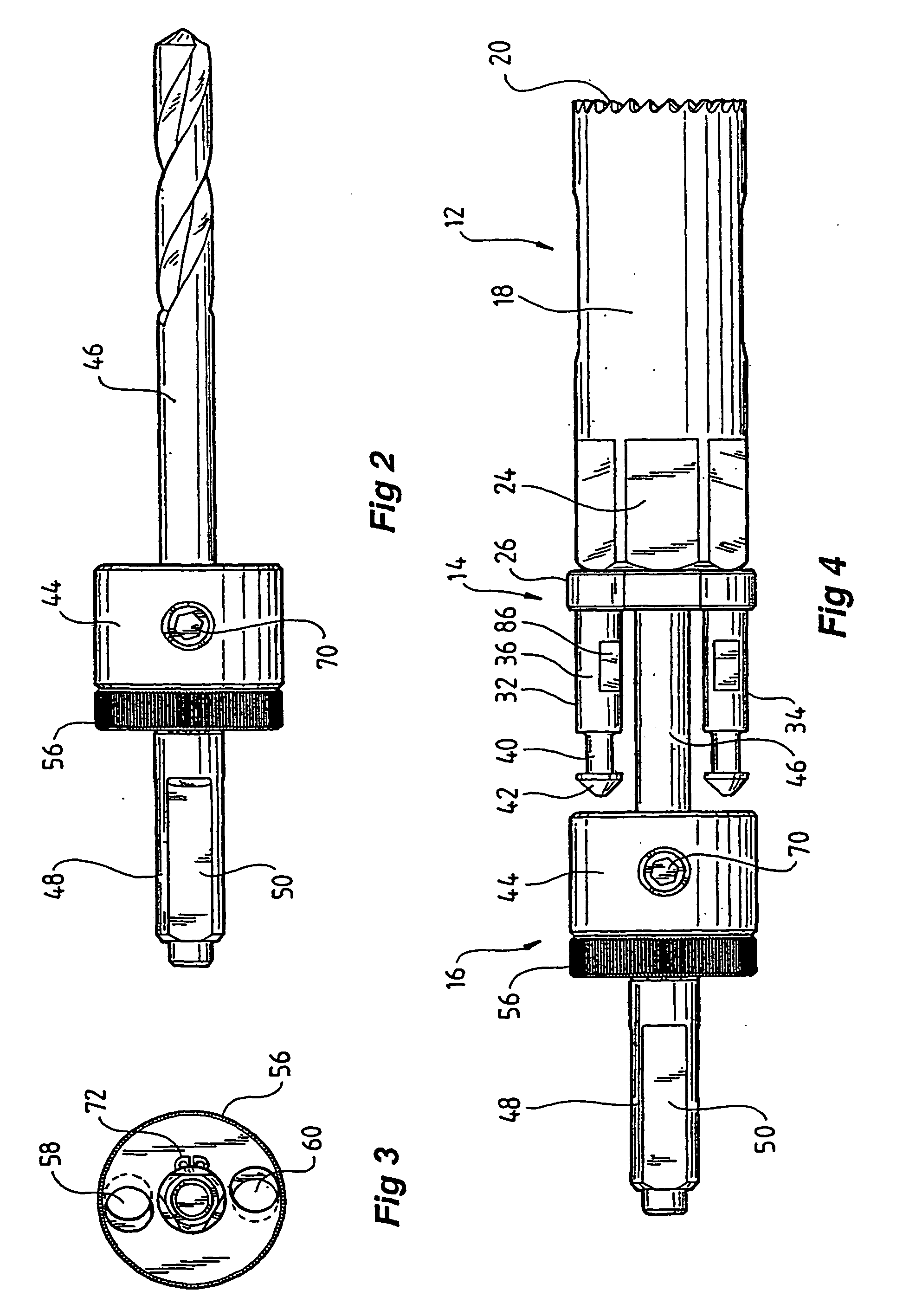

Hole saw assembly

InactiveUS7101124B2Quick deleteThread cutting machinesTransportation and packagingHole sawEngineering

A hole-saw assembly including a hole-saw having at one end a plurality of cutting teeth and at the other end two shafts. The assembly includes a mandrel coaxially aligned with said hole-saw and including a body having two bores therethrough coaxially aligned with said shafts. An annulus located on top of the body is coaxially aligned with said mandrel and hole saw and includes two holes, the annulus rotatable around its longitudinal axis from a first to a second position. In the first position the annulus holes are aligned with the bores and shafts allowing the shafts to be freely insertable and removable and in the second position the holes are misaligned to lock the shafts to the annulus. Such an arrangement allows the hole-saw and the mandrel to be easily and quickly mountable and demountable.

Owner:KEIGHTLEY KYM JOHN

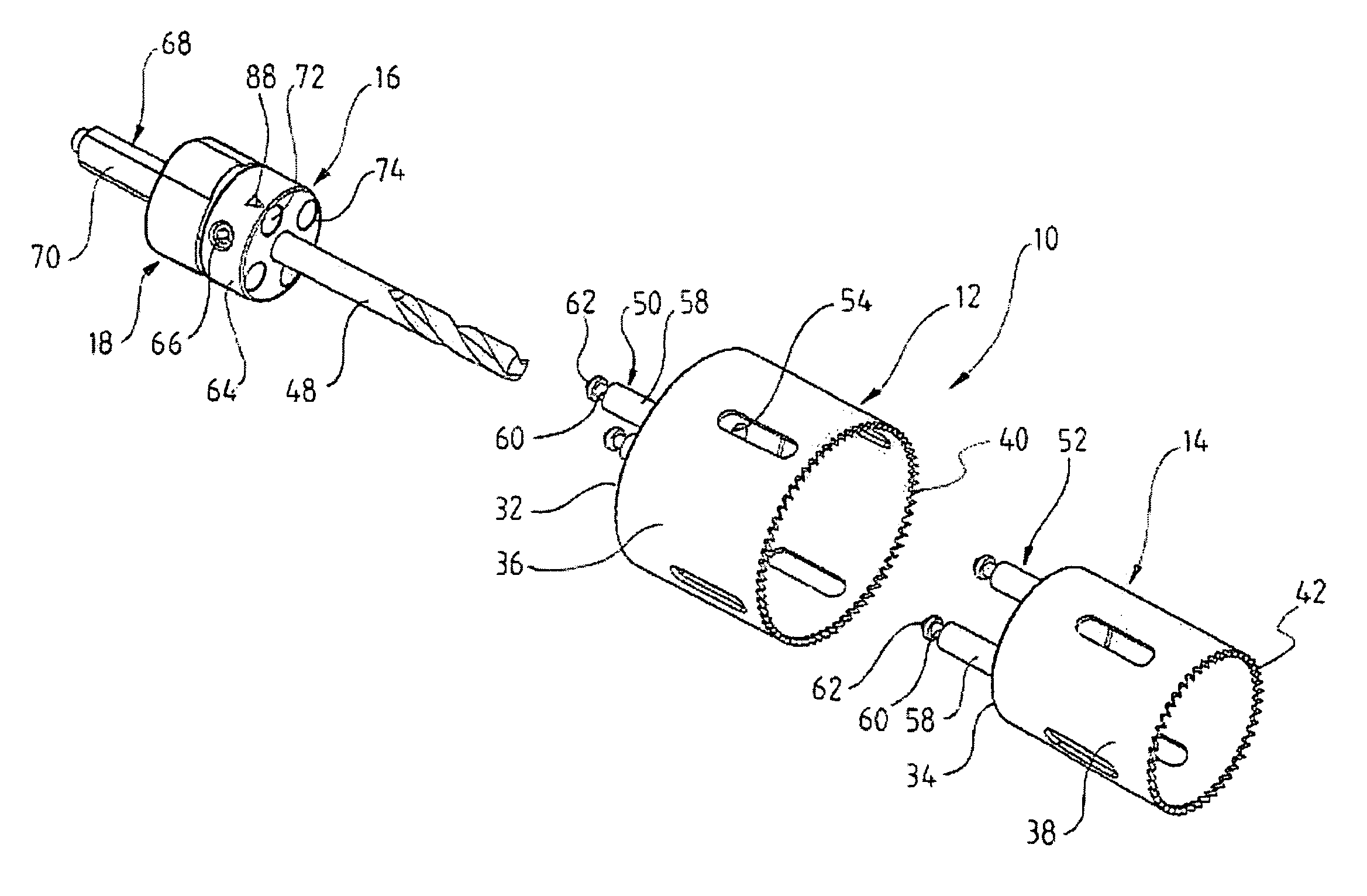

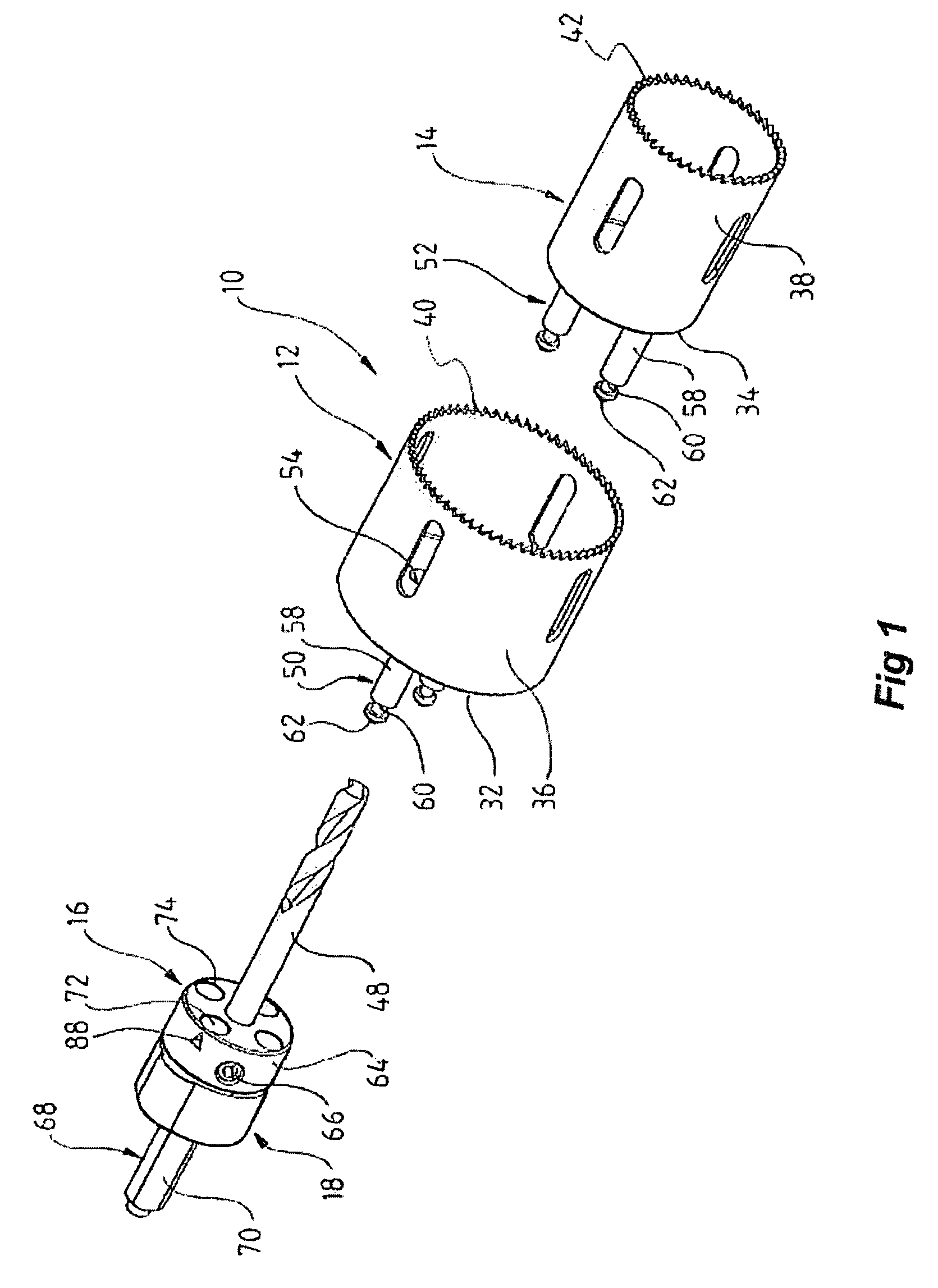

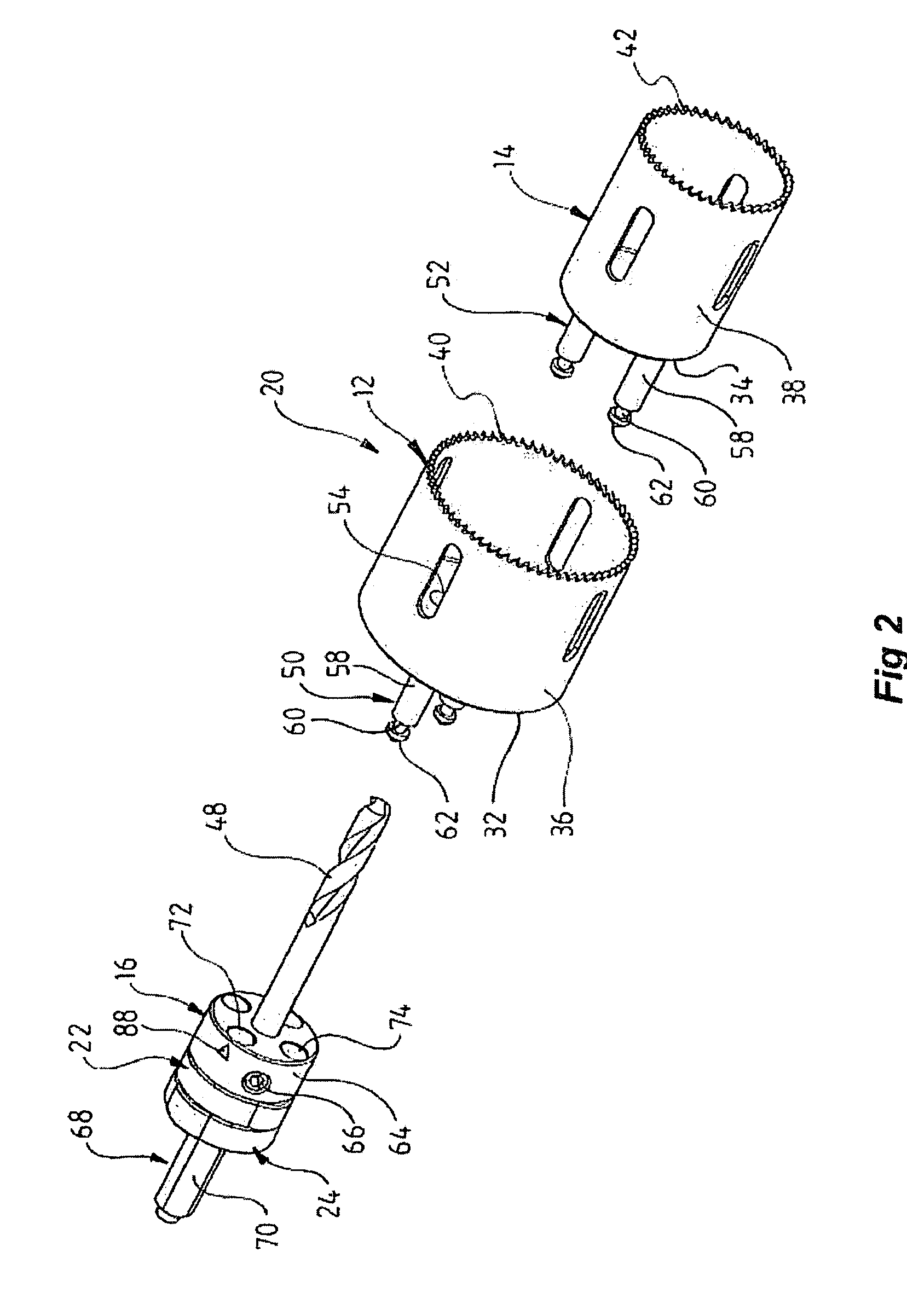

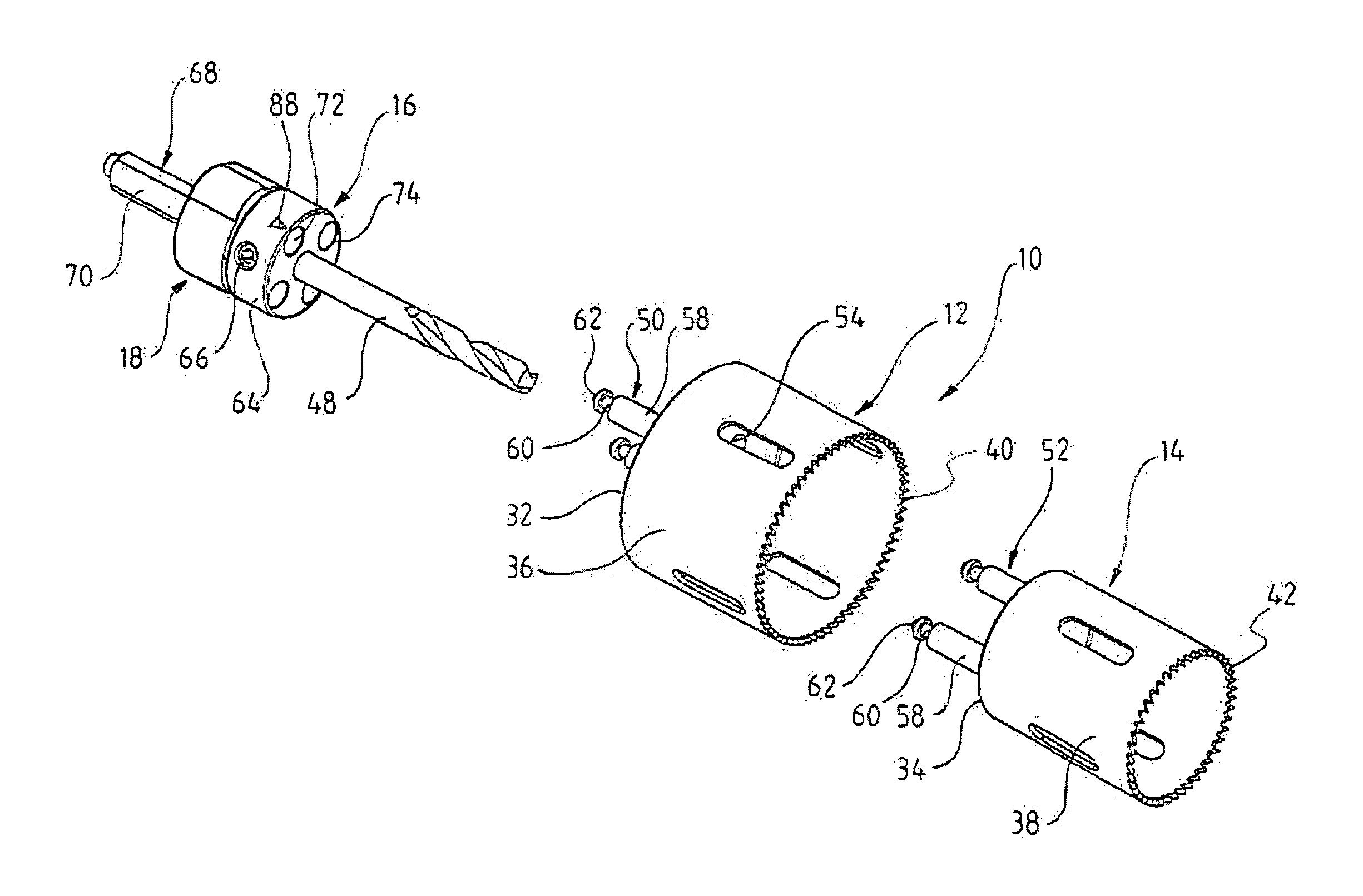

Hole-saw assembly including two hole-saws

The present invention relates to an improved hole-saw assembly and in particular, to a mandrel engageable by a drill and including at least one locking ring or annulus that allows for the base of two hole-saws of different diameter to be quickly and easily mountable and demountable from the mandrel. The hole-saw assembly includes a first hole-saw having a base that includes a pair of drive-pins extending outwardly therefrom and a pair of apertures for insertion therethrough of the drive pins of a second hole-saw. The drive pin pairs are then inserted through corresponding apertures in the mandrel to engage an annulus coupled to the mandrel. The present invention provides for each drive pin to be engaged by the annulus despite the difference in longitudinal length of the drive pins beyond the base of the first hole-saw. The hole-saws are snap-fit within the annulus and may be disengaged by simply rotating the annulus to a second position. A further embodiment of the present invention further allows one to insert the hole-saws into any one of the mandrel insertion points without being concerned about whether it contains the correct engaging means or not. A still further embodiment of the invention prevents slight longitudinal movement which is known to occur when the hole-saws are coupled to the mandrel.

Owner:KEIGHTLEY KYM JOHN

Extensible pole saw having separable sections

An elongated pole pruner for cutting and trimming trees, bushes and the like having three separable sections, that when assembled, form an extended length pruner. The pole pruner includes a first section containing a handle and battery pack, a second extension section, and a third section that contains the purner itself. Each of the sections contains an electrical conductor that is attached to corresponding conductor in an adjacent pole sections via a male plug and female receptacle. In this way, the battery pack in the first section of the pole is able to deliver power through the second section to the pruner in the third section.

Owner:BLACK & DECKER INC

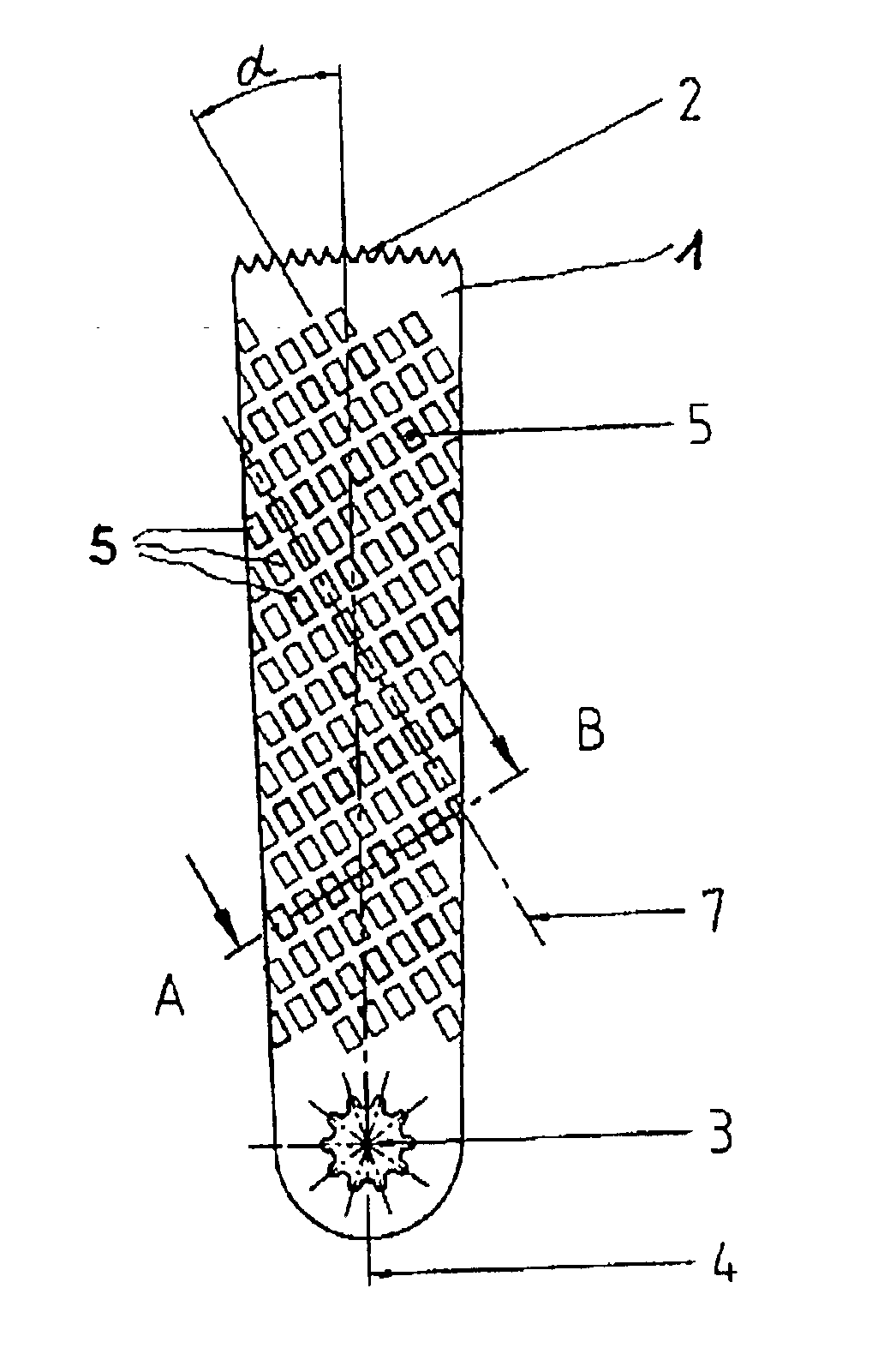

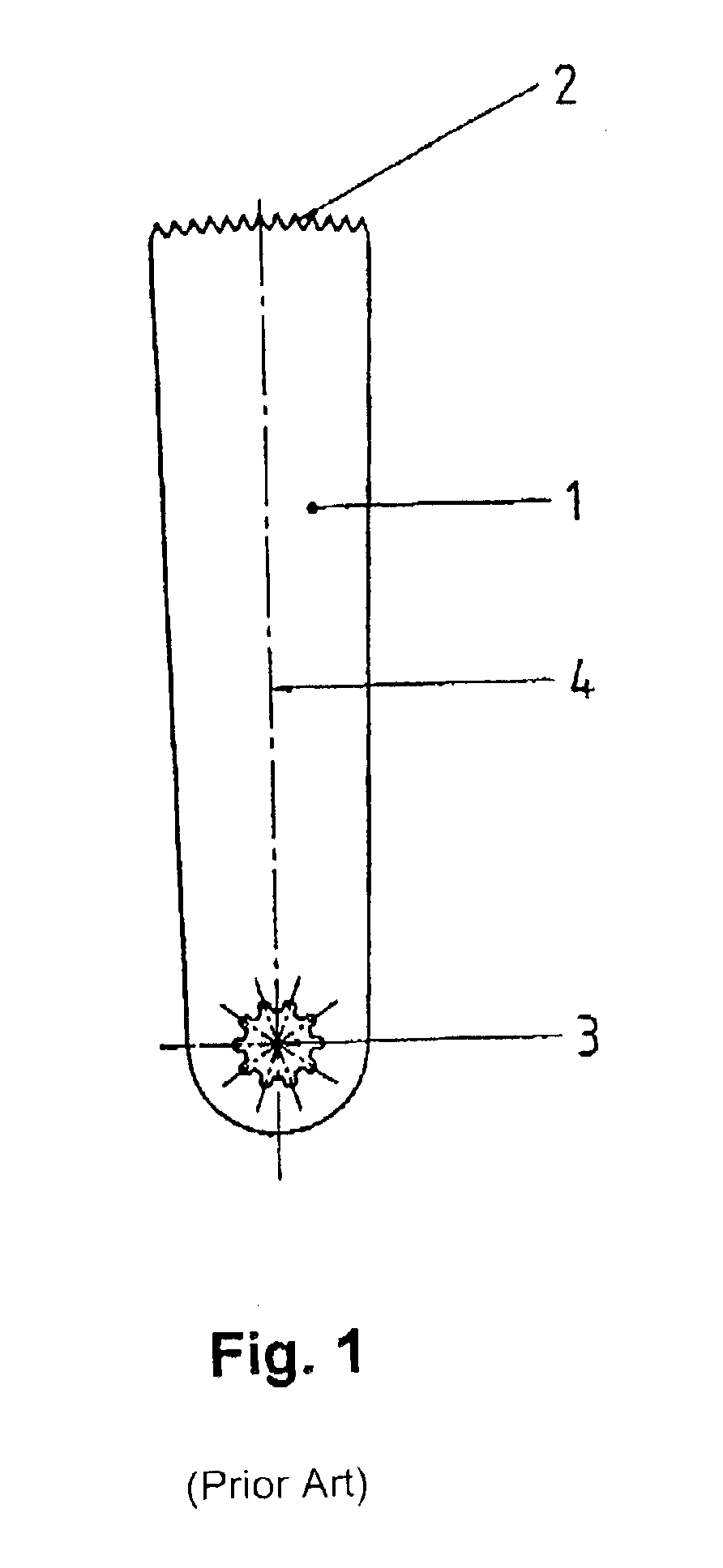

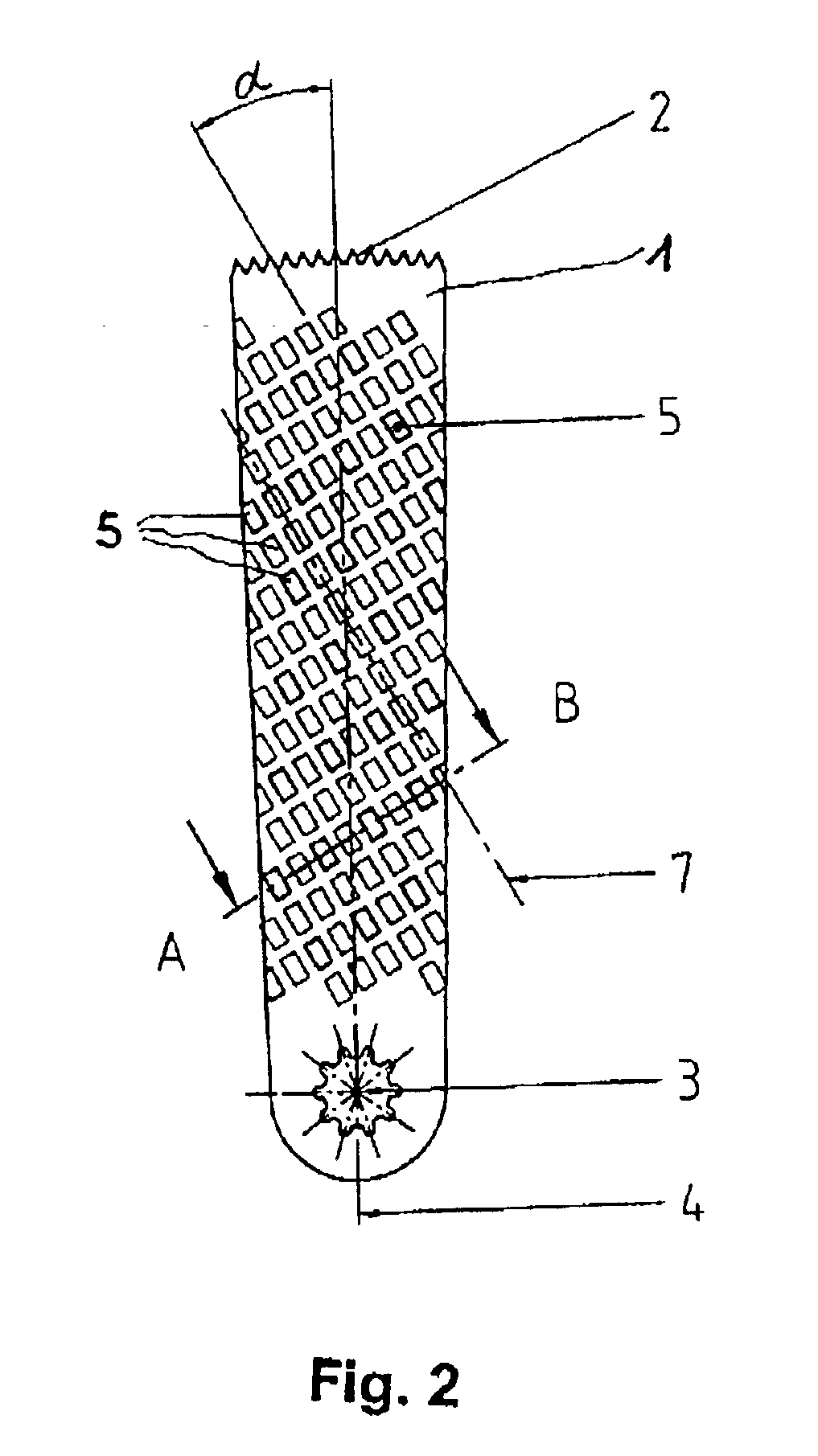

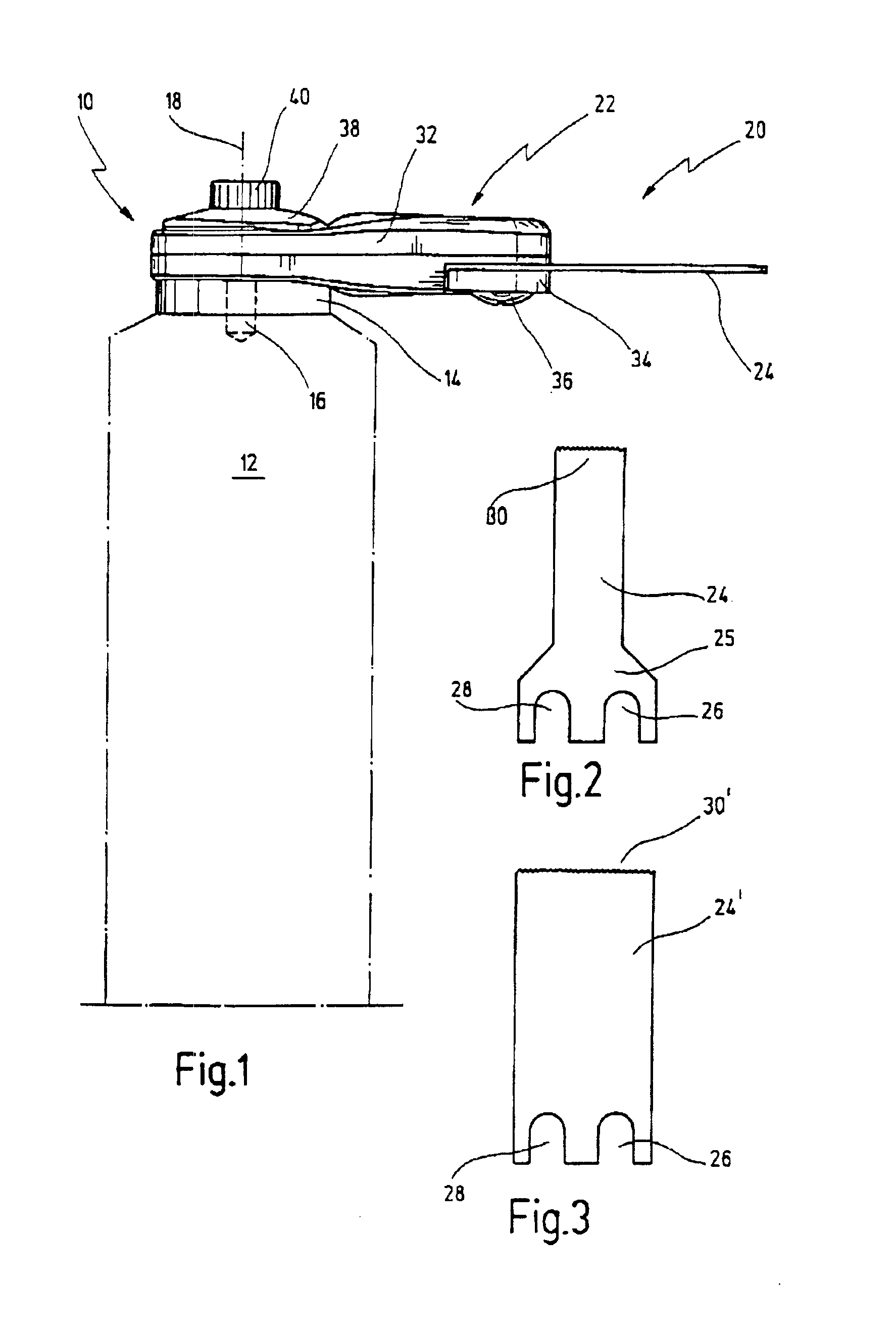

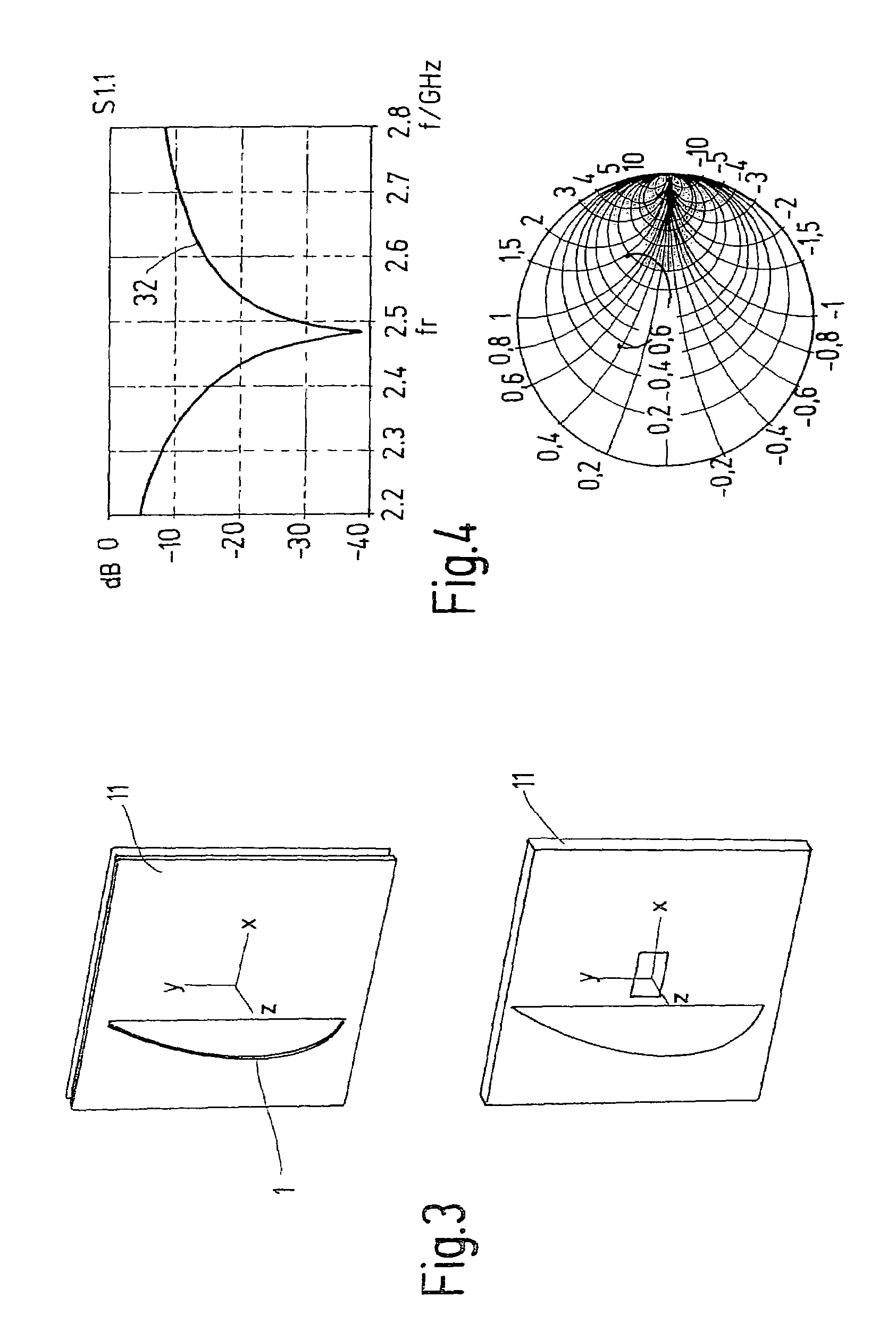

Saw blade for medical applications

InactiveUS7001403B2Precise cuttingDamped reliablyMetal sawing devicesNon-rotary toothed toolsMechanical engineeringMedical treatment

Owner:HAUSMANN THOMAS +1

Tool having a holder for mounting on a drive shaft

InactiveUS6865813B2Low costEasy to produceMetal sawing devicesDrilling/boring measurement devicesDrive shaft

A tool is disclosed having a holder provided with a mounting opening for mounting on a drive shaft, which may be driven in oscillating fashion, and having further a fixture for mounting a working element. The working element comprises at least two holding sections, spaced one from the other in tangential direction to the mounting opening, and wherein a mounting plate is provided which is engaged by releasable securing elements that coact with the holding sections for clamping the working element against the holder.

Owner:C & E FEIN

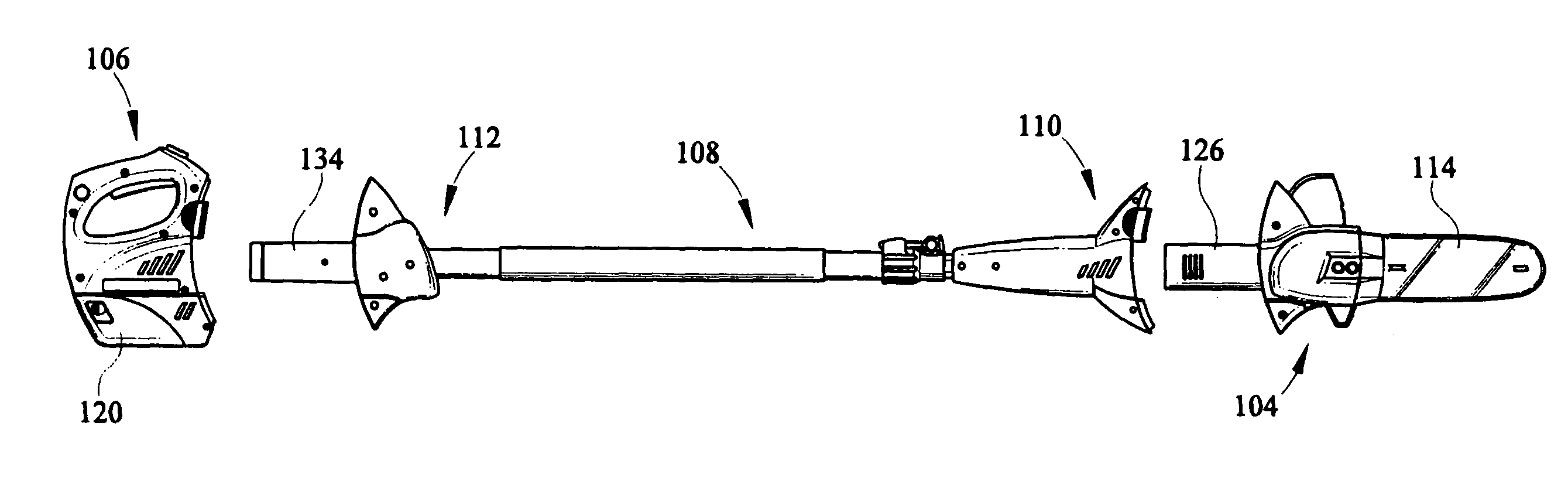

Split power tool with extension

An extendable hedge trimmer includes a housing having a handle end and a tool end. The handle end includes a battery and an electrical connector. The tool end includes a hedge trimming implement, a motor, and an electrical connector. The electrical connector of the tool end is electrically connected with the motor. Wiring is included within the handle end for electrically connecting the battery and the electrical connector of the handle end. The trimmer also includes a pole which is releasably connectable between the tool end and the handle end. The pole is configured for electrically connecting the handle end with the tool end. The trimmer also includes a latch mechanism for releasably attaching the pole between tool end and handle end. The trimmer also includes an input for receiving AC line power via a power cord, the trimmer configured for being powered by AC line power and / or battery power.

Owner:MTD PRODUCTS

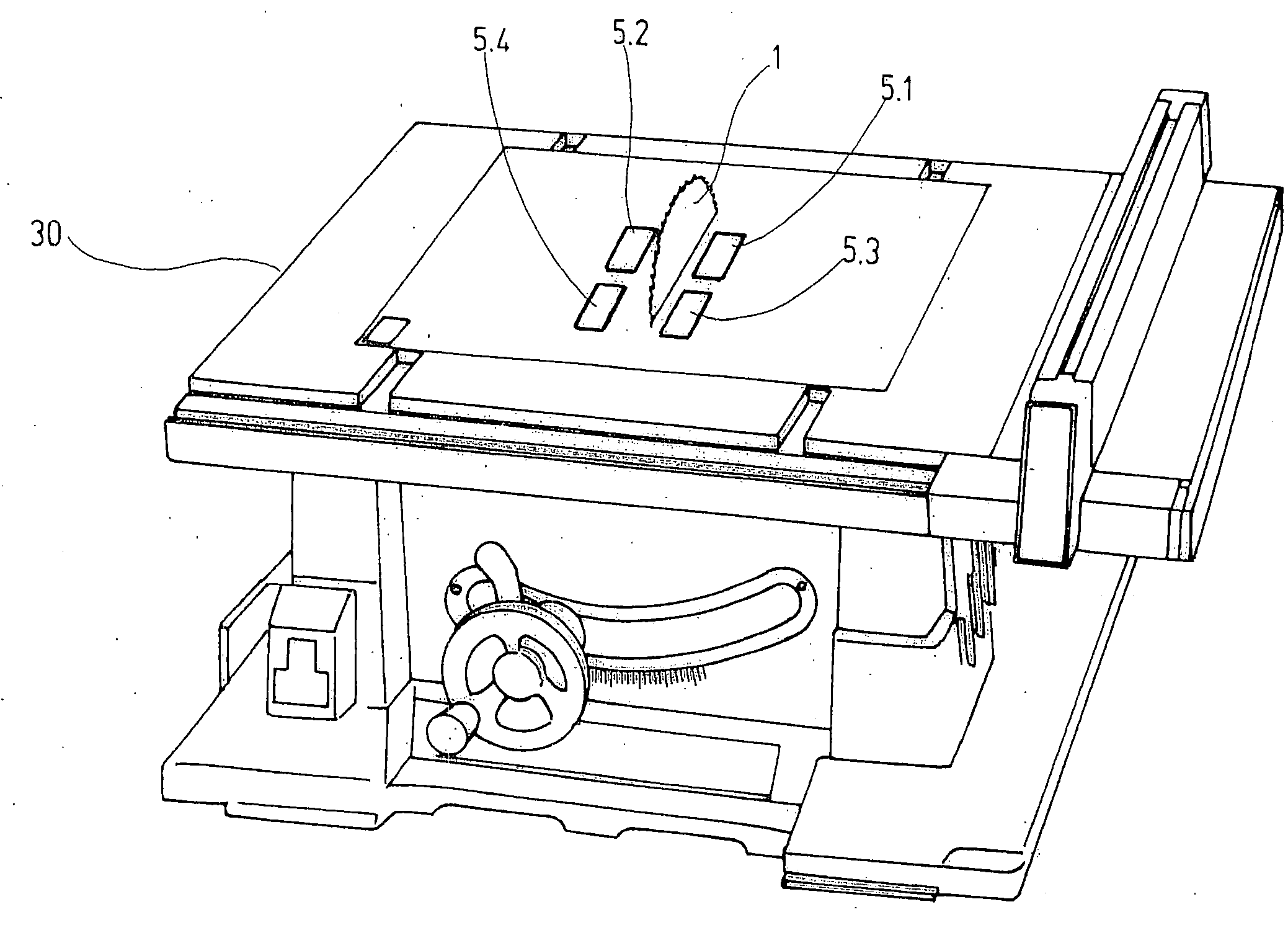

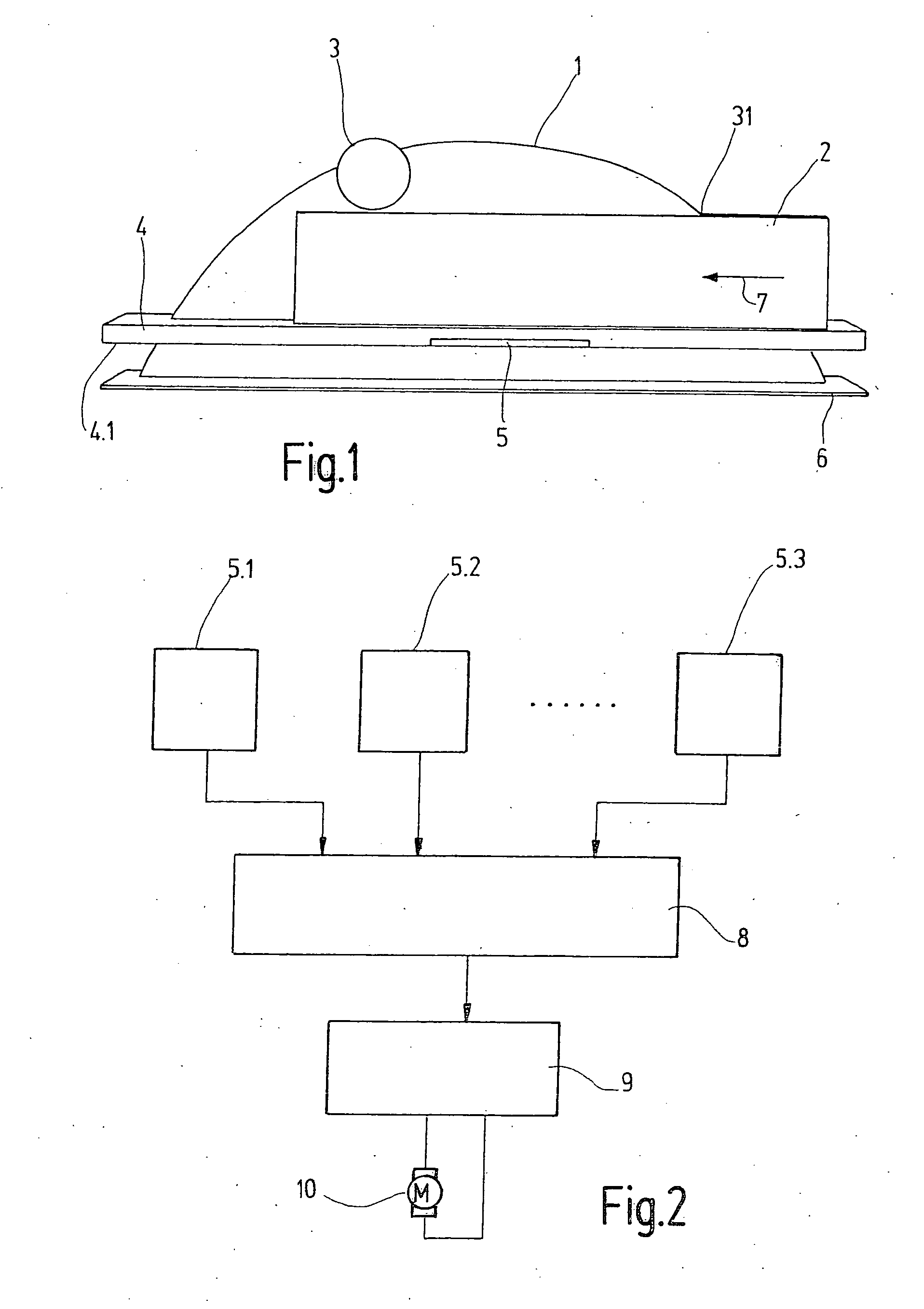

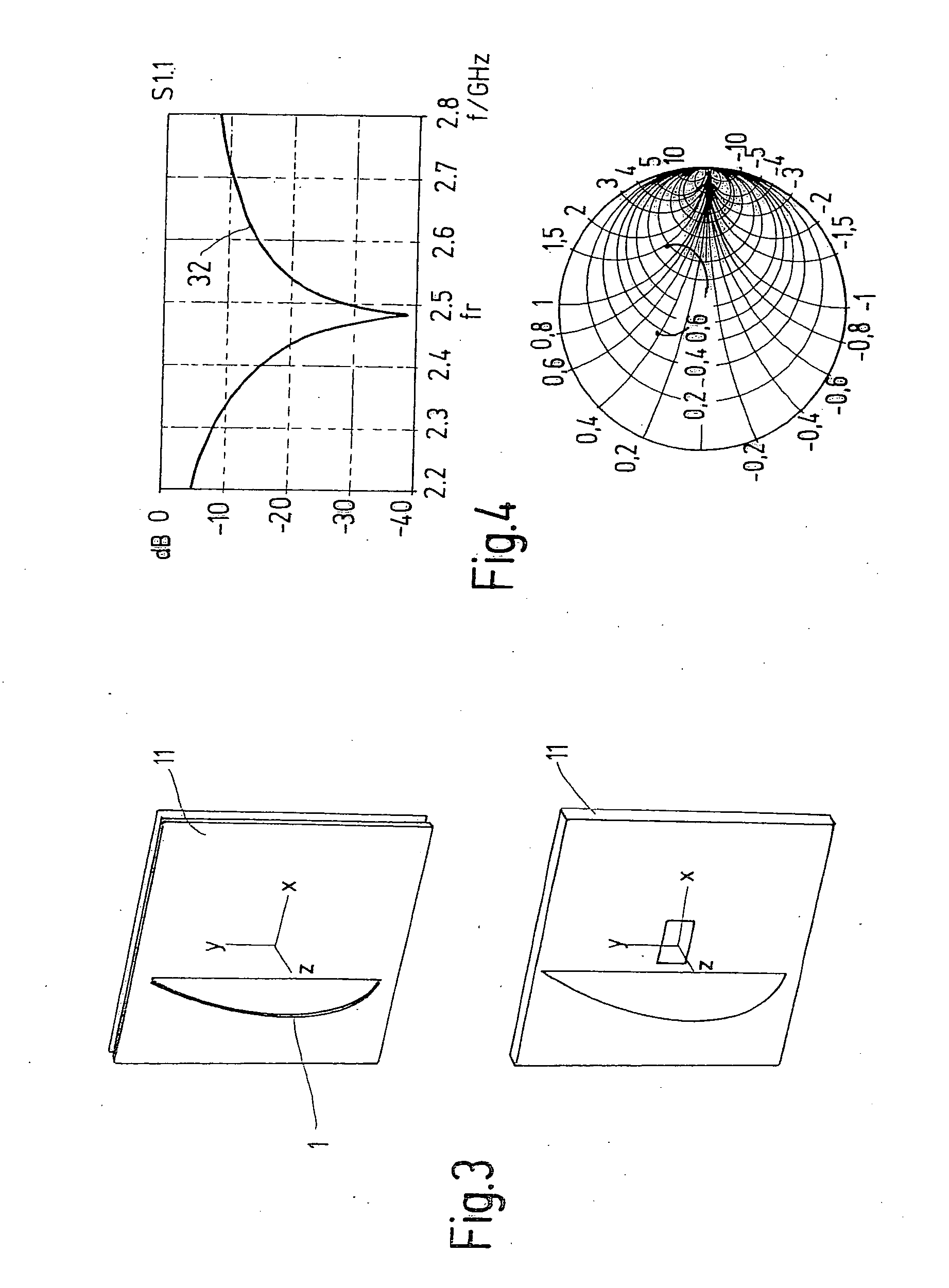

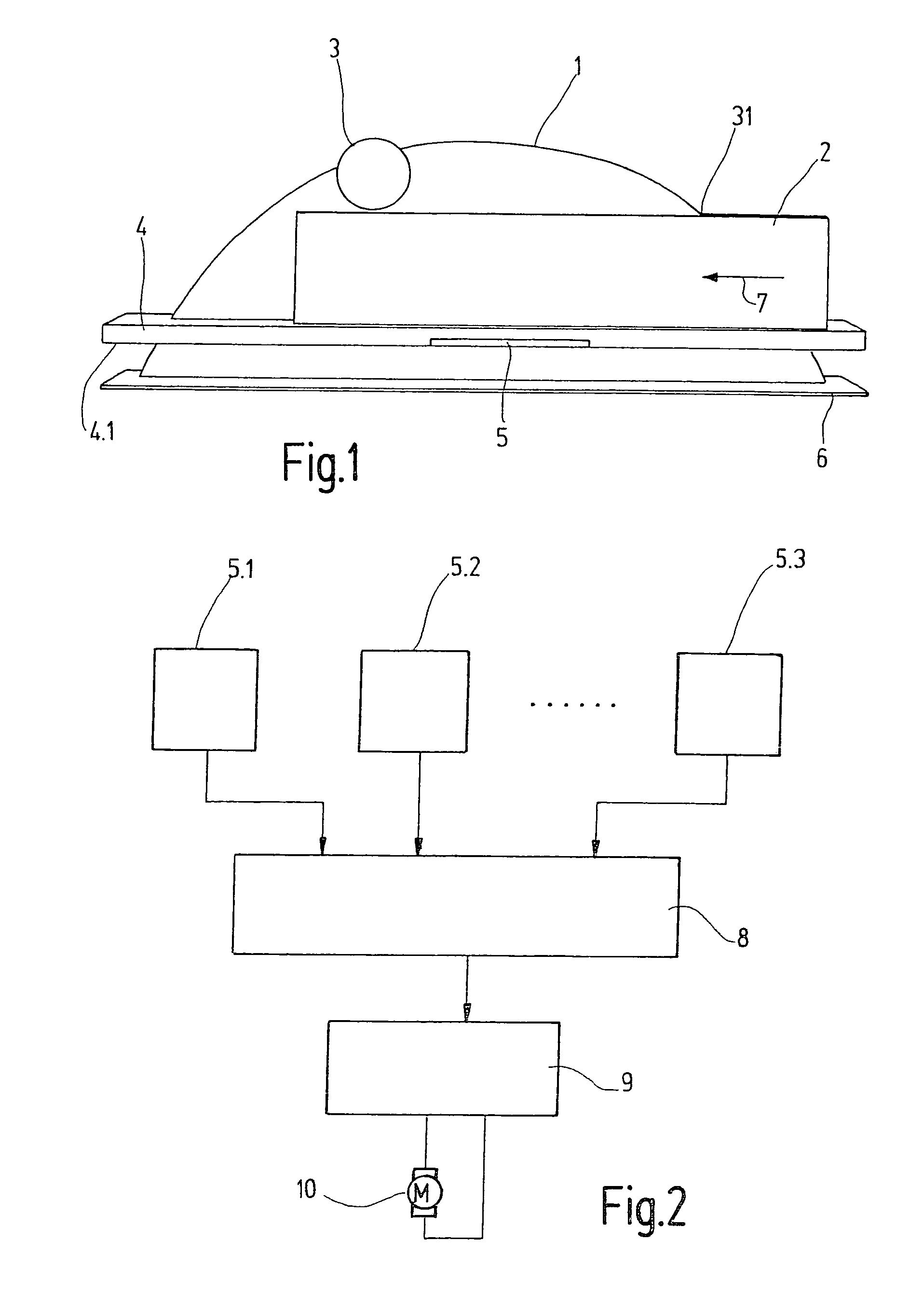

Device for protecting against accidental contact and method for protecting against accidental contact of a displaceable part

ActiveUS20050145080A1Sufficient degree of safetyNot to hinder workEmergency protective circuit arrangementsShearing machinesElectromagnetic fieldContact protection

The invention relates to a contact protection device. The device according to the invention has a sensor (5) for generating and detecting an electromagnetic field situated in the vicinity of a moving part (1) that should not be touched. The device according to the invention also has an evaluation unit (8) that is connected to the sensor (5) in order to evaluate sensor signals that can be generated by the sensor (5), wherein the evaluation unit (8) can generate an evaluation signal. Finally, a control unit (9) connected to the evaluation unit (8) is provided, which is designed and can be operated so as to control the movement of the part (1) as a function of the evaluation signal.

Owner:ROBERT BOSCH GMBH

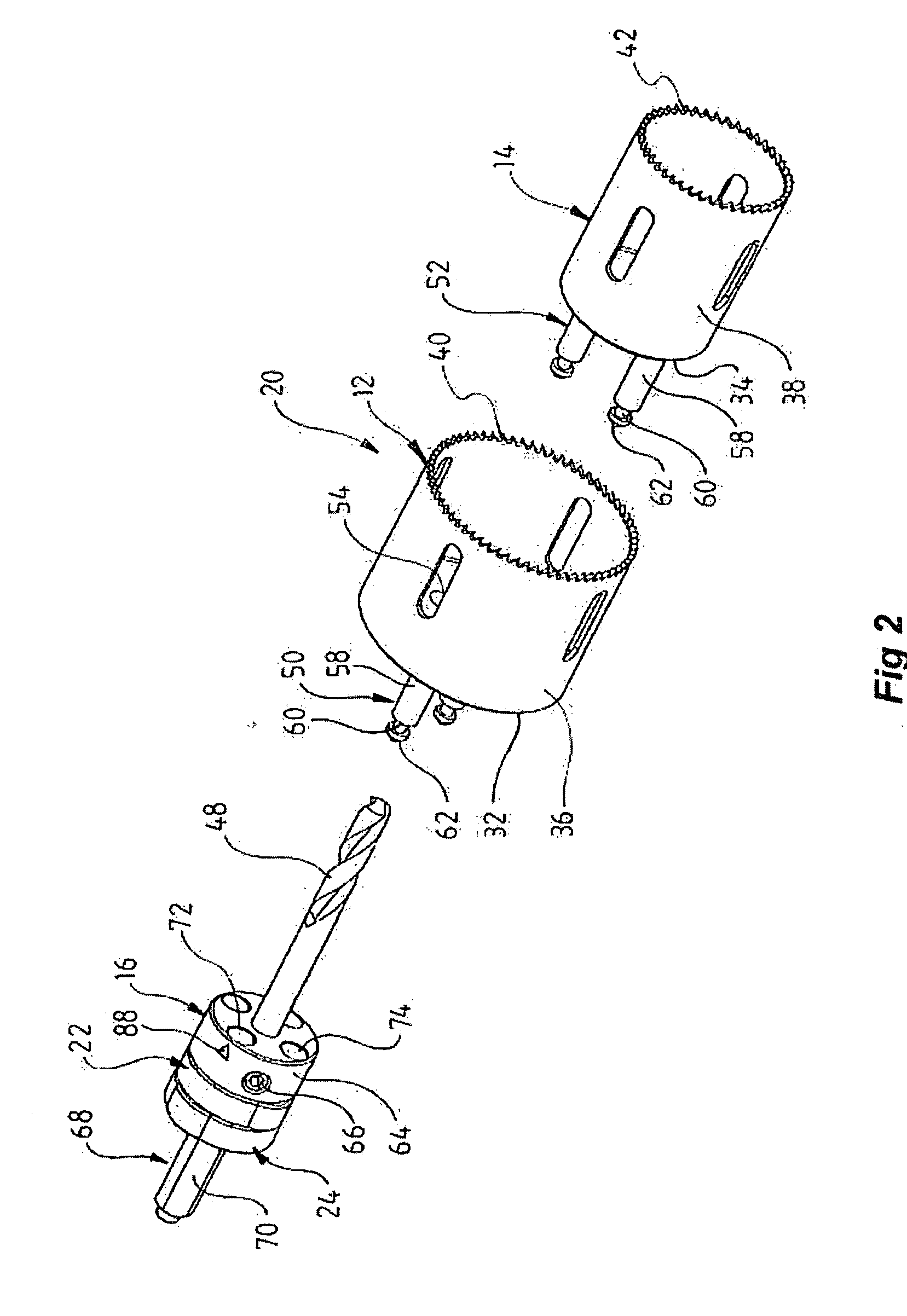

Hole saw boss

InactiveUS7850405B2Avoid over-tighteningThread cutting machinesTransportation and packagingLocking mechanismHole saw

The present invention relates to an improved hole saw boss (10) and in particular, to a boss including a threaded member (12) adapted to accommodate two hole saws of the same or different bore thread diameters. The present invention allows for a pre-existing aperture (22) in a work piece to be simply enlarged. This is useful if a new lock mechanism is being installed in a door with a pre-existing aperture where the lock mechanism requires a larger aperture than that which was in existence. Currently the aperture has to be enlarged by manual handwork since there is no centre-point to which a pilot drill may be enlarged. The threaded bore diameters of the present invention correspond with the commonly available hole saw threaded bore diameters. The present invention therefore provides the public with device for enlarging apertures which is simply, cost effective and can be used with currently available hole saws.

Owner:KEIGHTLEY KYM JOHN

Device for protecting against accidental contact and method for protecting against accidental contact of a displaceable part

ActiveUS7173537B2Sufficient degree of safetyAvoid normal workEmergency protective circuit arrangementsShearing machinesEngineeringElectromagnetic field

The device according to the invention has a sensor (5) for generating and detecting an electromagnetic field situated in the vicinity of a moving part (1) that should not be touched. The device according to the invention also has an evaluation unit (8) that is connected to the sensor (5) in order to evaluate sensor signals that can be generated by the sensor (5), wherein the evaluation unit (8) can generate an evaluation signal. Finally, a control unit (9) connected to the evaluation unit (8) is provided, which is designed and can be operated so as to control the movement of the part (1) as a function of the evaluation signal.

Owner:ROBERT BOSCH GMBH

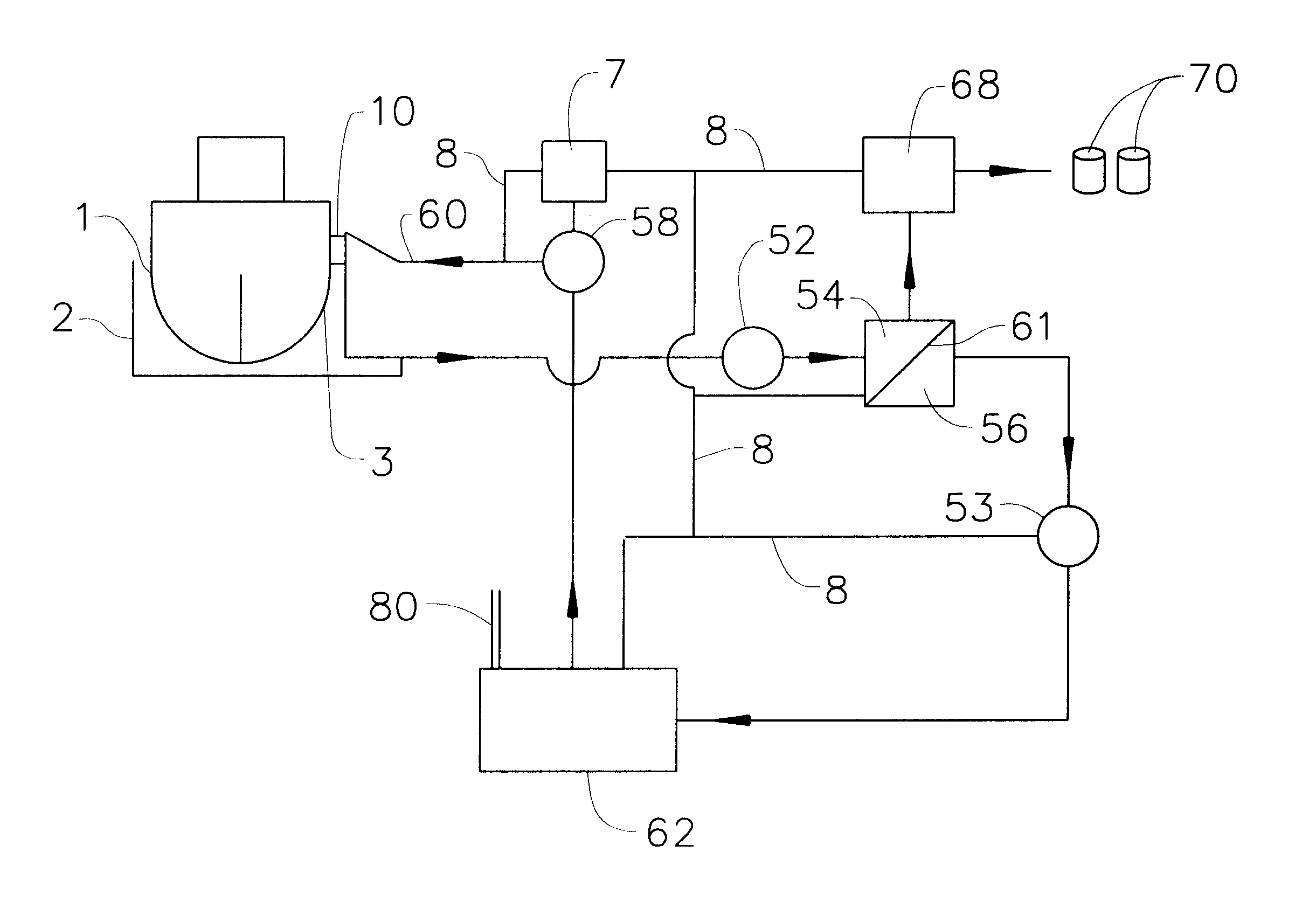

Air gap magnetic mobile robot

A mobile robot for cleaning, stripping, reconditioning or refurbishing a coating on a metal work piece has a remote controlled power module for locomotion and a working head for removing the coating. The robot is held on the metal work piece by magnets mounted on the robot but spaced from the work piece.

Owner:DCP WATERJET HLDG INC

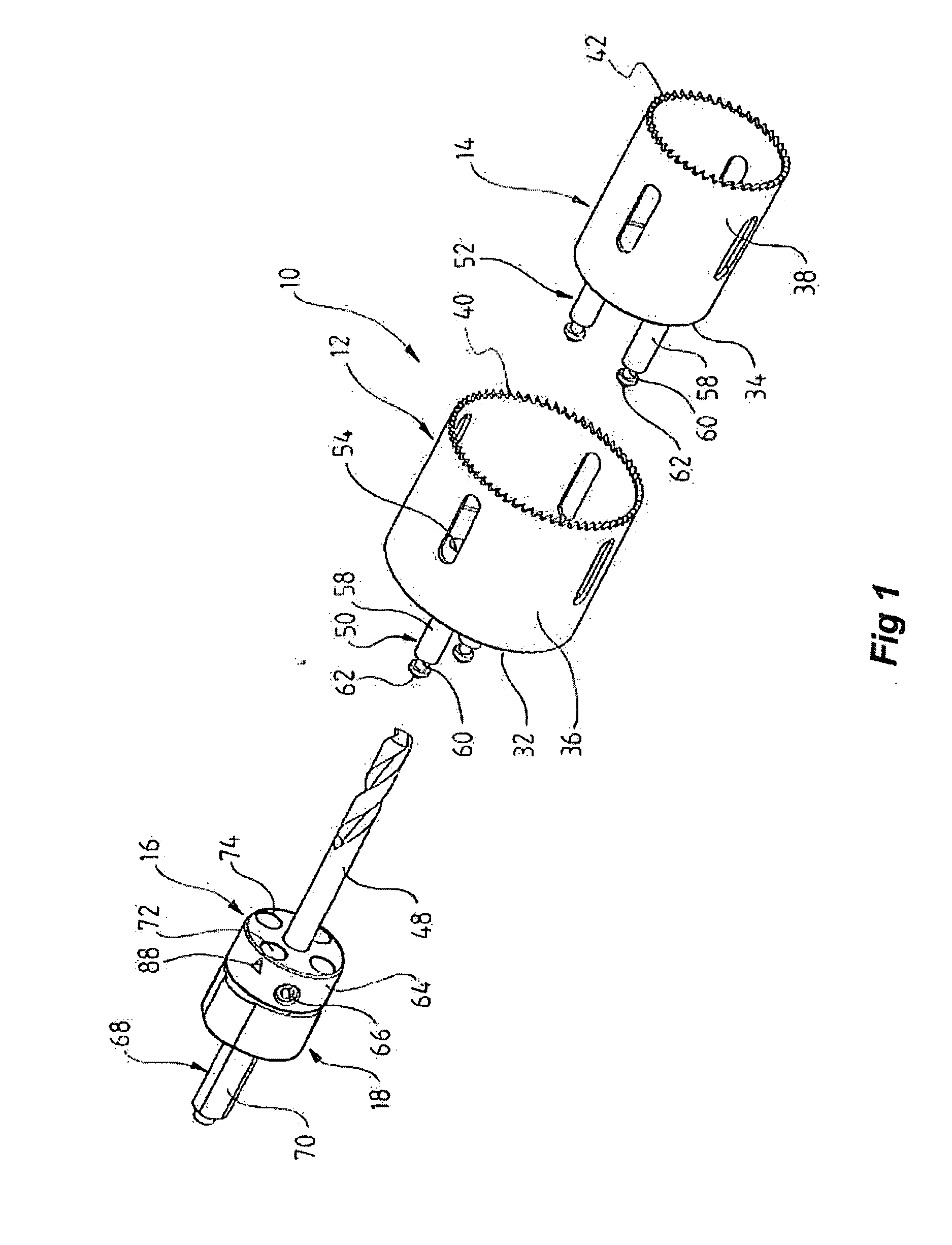

Hole Saw Assembly

The present invention relates to a hole-saw assembly (10) including a hole saw (26) having at one end a plurality of cutting teeth and at the other end two shafts. The assembly includes a mandrel (16) coaxially aligned with said hole-saw and including a body having two bores there through coaxially aligned with said shafts. An annulus (20) located on top of the body is coaxially aligned with said mandrel and hole saw and includes two holes, the annulus rotatable around its longitudinal axis from a first to a second position. In the first position the annulus holes are aligned with the bores and shafts allowing the shafts to be freely insertable and removable and in the second position the holes are misaligned to lock the shafts to the annulus. The mandrel further includes a pair of driving pins (22) adapted to engage driving apertures (24) found in hole saws especially larger ones. Typically the driving pins may biased to enable the assembly to be used even with those hole saws that do not include driving apertures and that also enables easier assembly of the device. A compressible O-ring (42) may further facilitate the operation of the assembly. This device avoids the problem of thread stripping.

Owner:KEIGHTLEY KYM JOHN

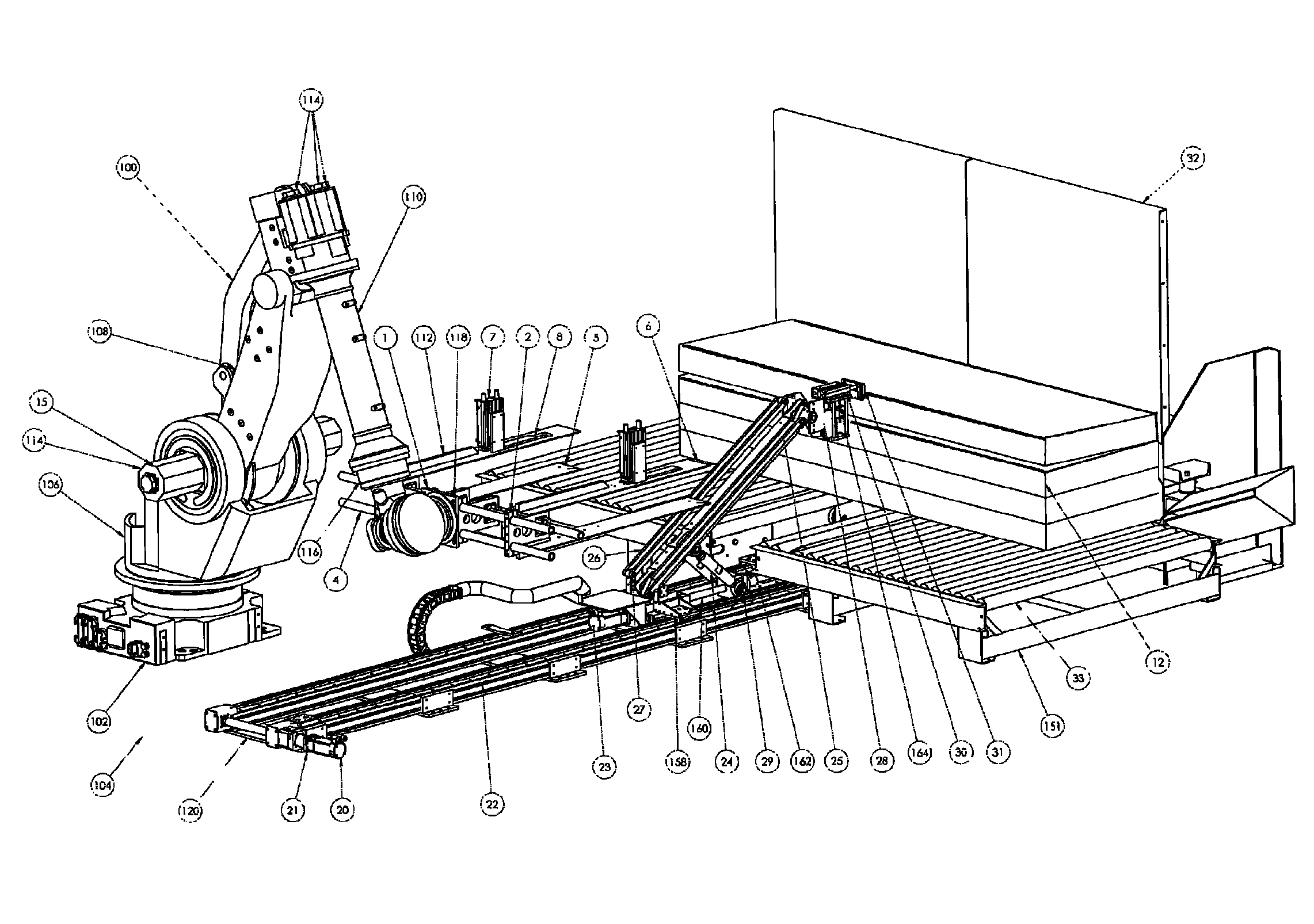

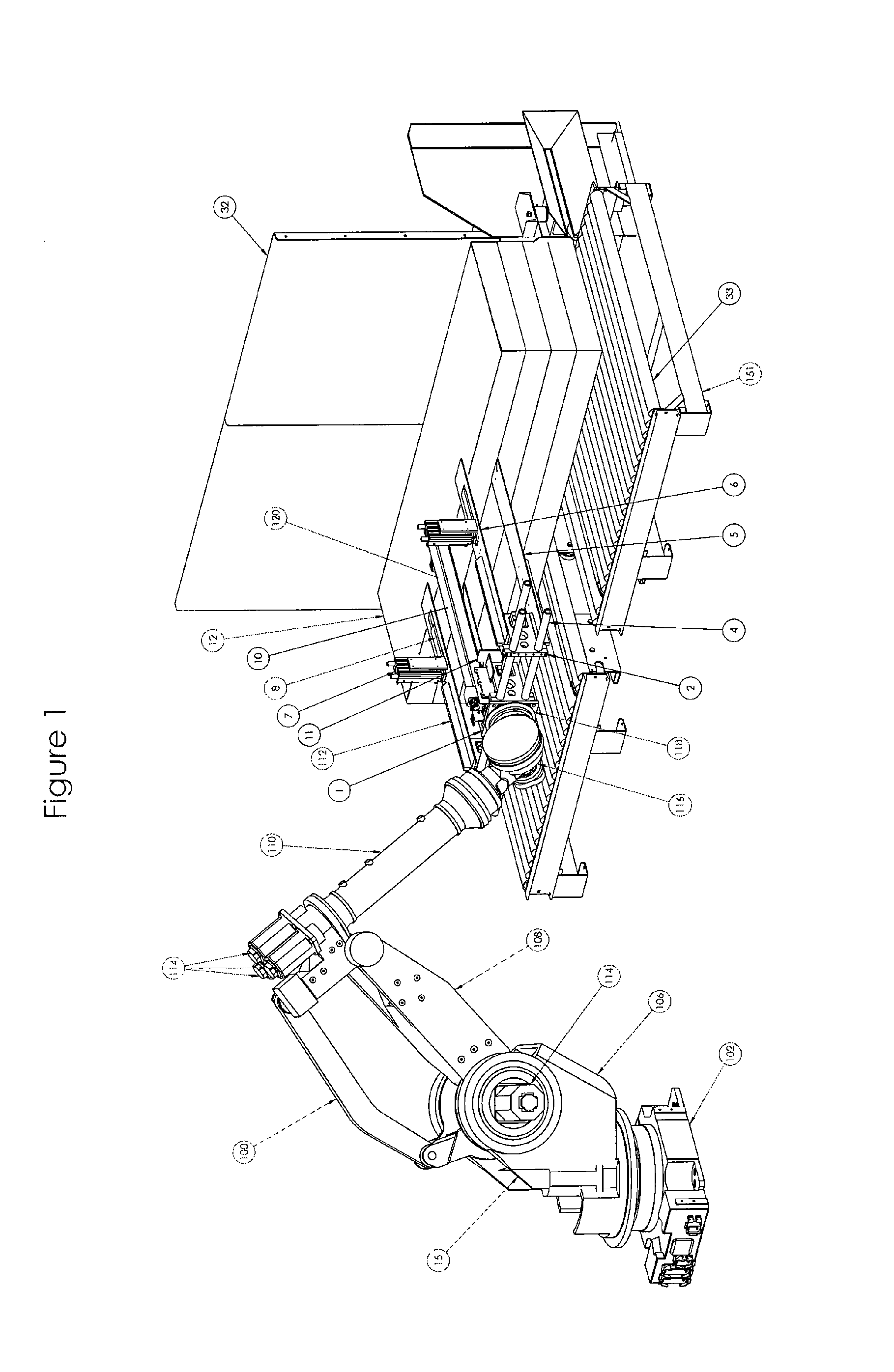

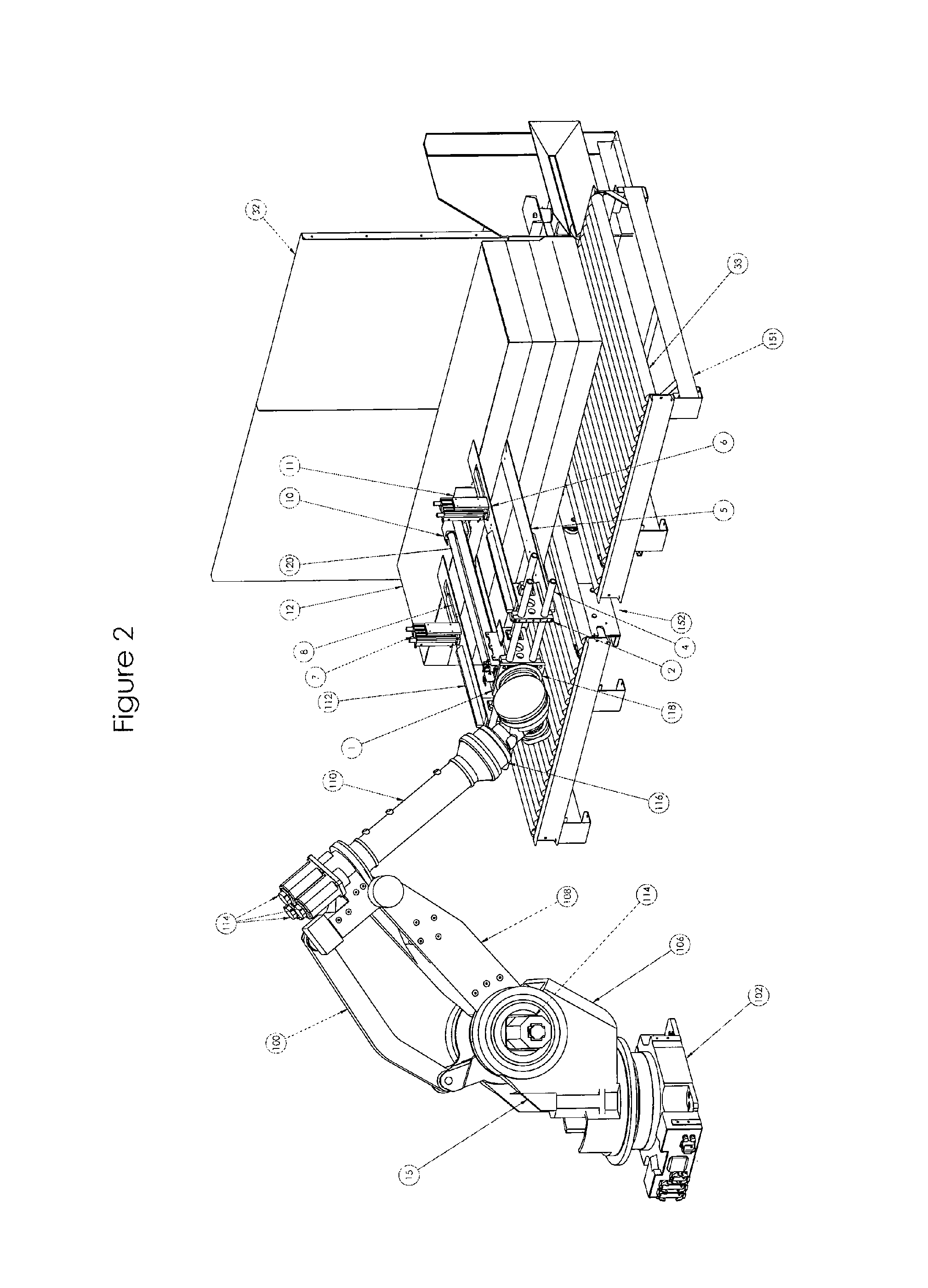

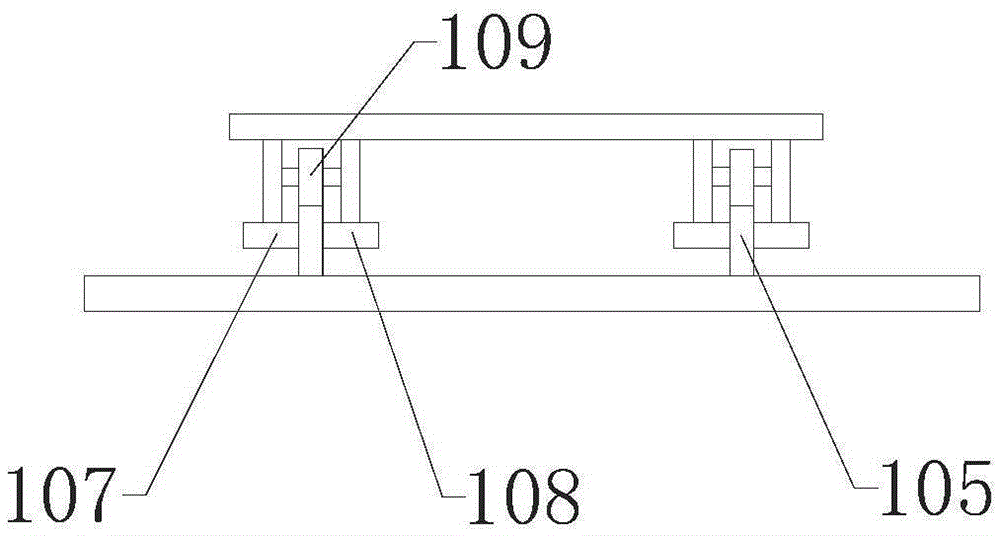

Robotic lifting apparatus

InactiveUS8777551B1Efficient separationEfficient removalGripping headsSawing componentsRobotic armEngineering

An apparatus for separating and moving a selected number of items, such as a sheets, boards or blanks is provided in which a robotic arm is constructed with forks capable of securely compressing a desired number of items therebetween for displacement from a stack of the items. The items to be grasped by the arm are initially separated from the remainder of the stack by a separation mechanism that can be mounted directly to the arm or to a support structure for the stack of items. The separation mechanism engages and lifts the desired number of items from the stack to enable the forks on the arm to engage each side of the items. The apparatus can be quickly reconfigured to engage and remove any desired number of items from the stack and / or to accommodate changes I the shape, size and / or thickness of the items.

Owner:AUTOMATAN LLC

Hole saw assembly

The present invention relates to a hole-saw assembly (10) including a hole saw (26) having at one end a plurality of cutting teeth and at the other end two shafts. The assembly includes a mandrel (16) coaxially aligned with said hole-saw and including a body having two bores there through coaxially aligned with said shafts. An annulus (20) located on top of the body is coaxially aligned with said mandrel and hole saw and includes two holes, the annulus rotatable around its longitudinal axis from a first to a second position. In the first position the annulus holes are aligned with the bores and shafts allowing the shafts to be freely insertable and removable and in the second position the holes are misaligned to lock the shafts to the annulus. The mandrel further includes a pair of driving pins (22) adapted to engage driving apertures (24) found in hole saws especially larger ones. Typically the driving pins may biased to enable the assembly to be used even with those hole saws that do not include driving apertures and that also enables easier assembly of the device. A compressible O-ring (42) may further facilitate the operation of the assembly. This device avoids the problem of thread stripping.

Owner:KEIGHTLEY KYM JOHN

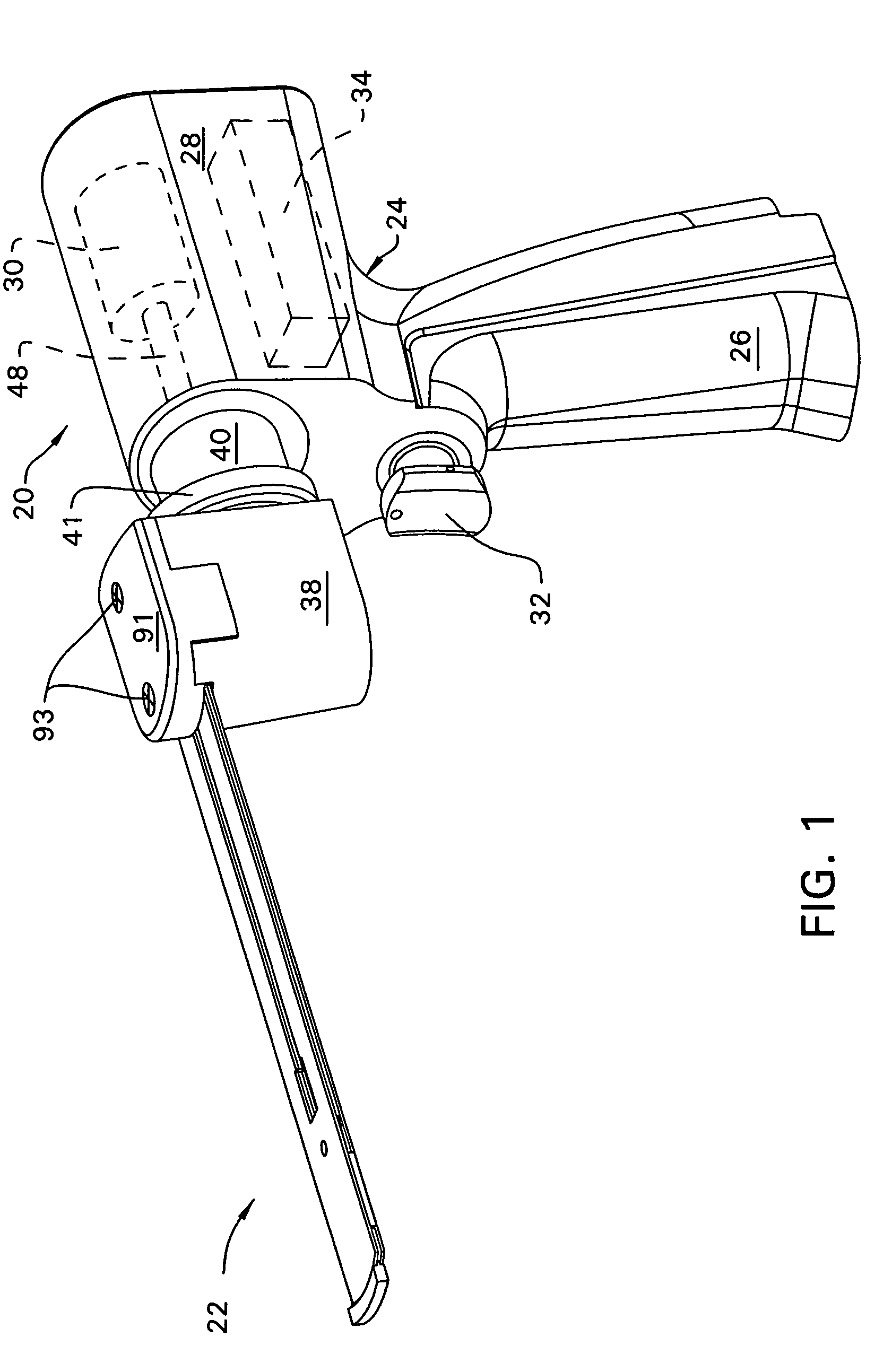

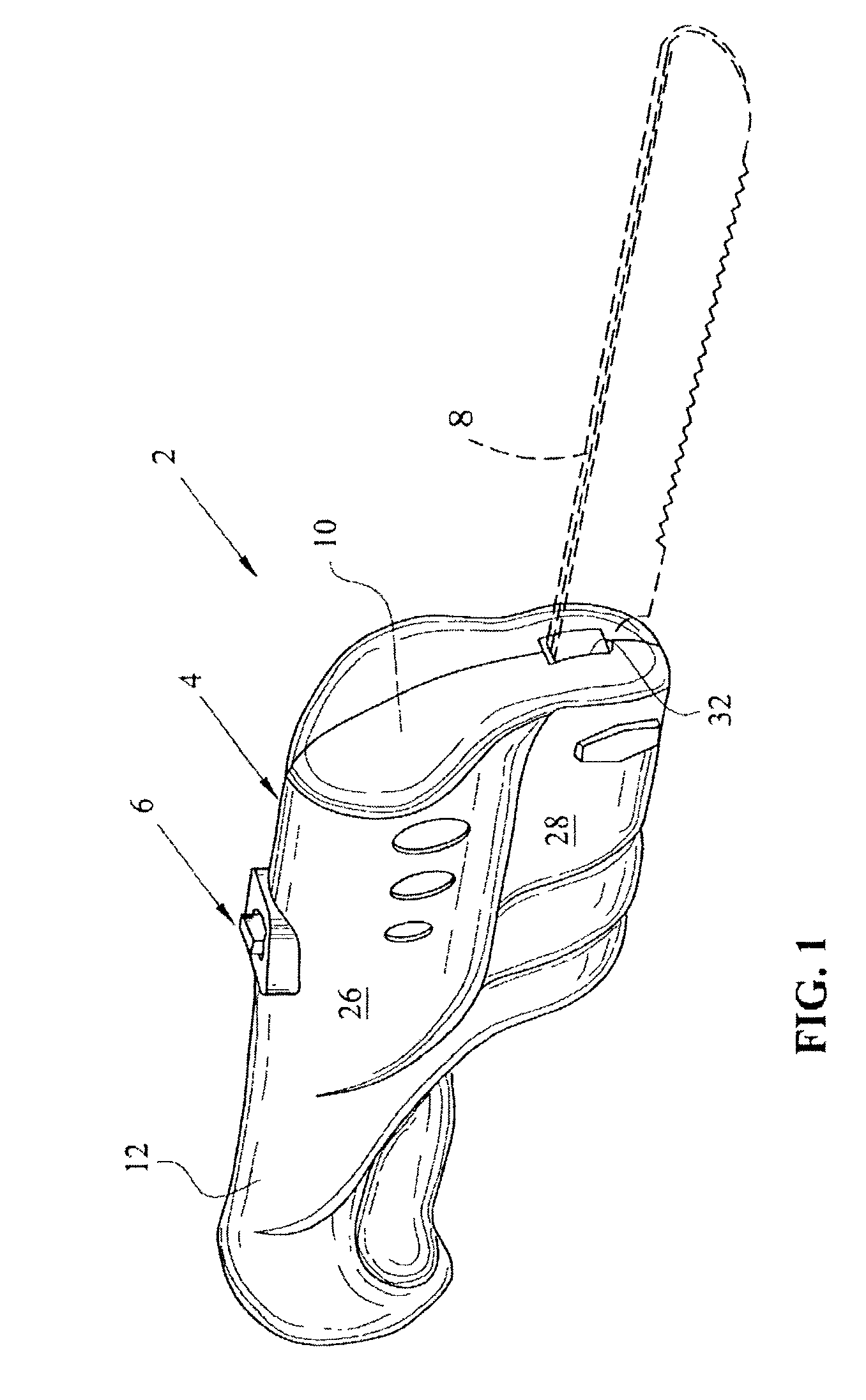

Surgical sagittal saw with quick release indexing head and low blade-slap coupling assembly

ActiveUS20070016238A1Smooth rotationMetal sawing devicesNon-rotary toothed toolsCouplingLocking mechanism

A surgical sagittal saw with a head that is able to index, rotate, relative to the longitudinal axis of the saw housing. The head has a neck that extends into an open distal end of the housing. A biasing assembly holds the head and neck sub-assembly in the open distal end of the housing. The biasing assembly is rotatable relative to the housing. A separate lock mechanism selectively holds the head in a fixed orientation around the saw housing longitudinal axis.

Owner:STRYKER CORP

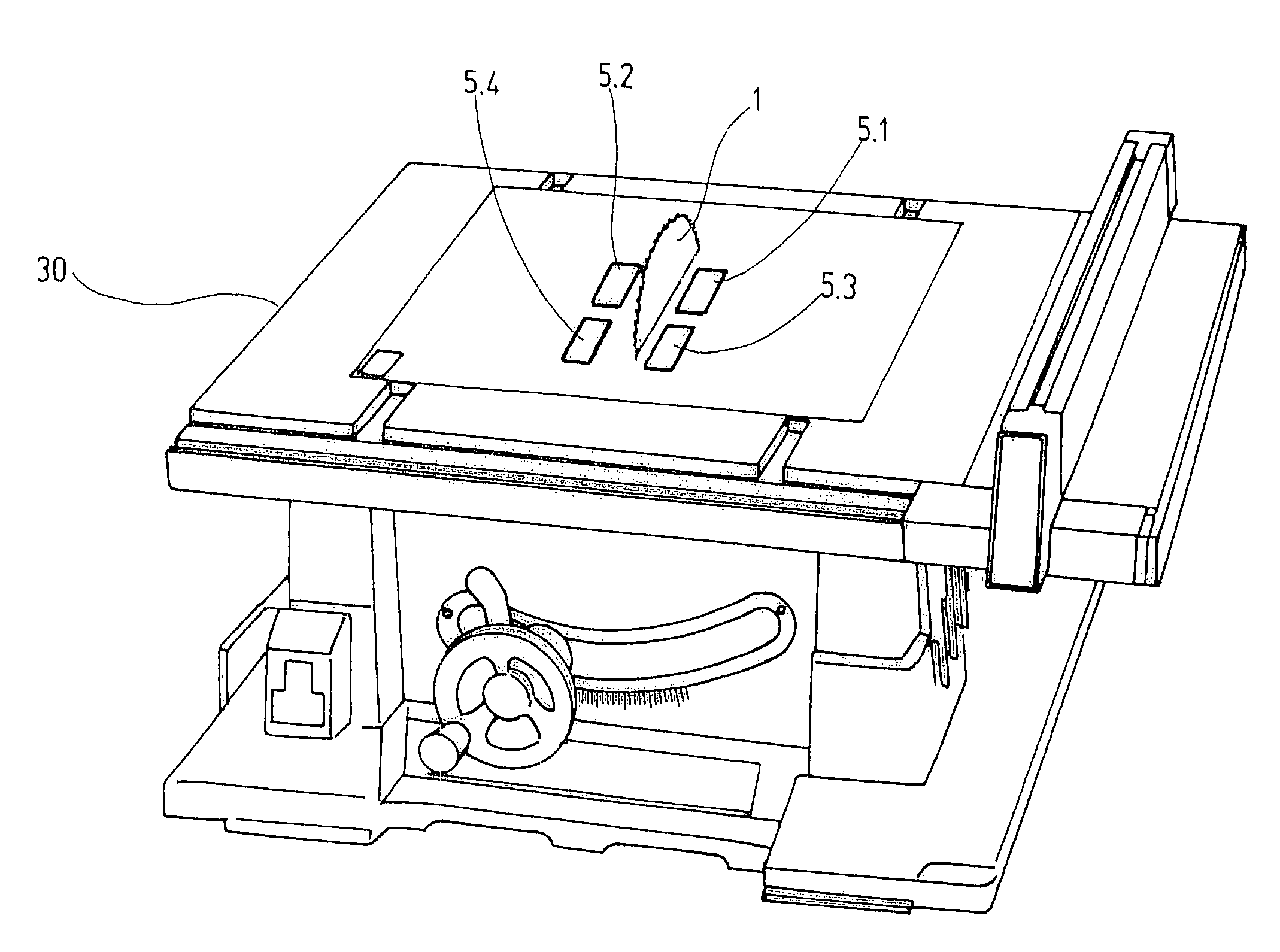

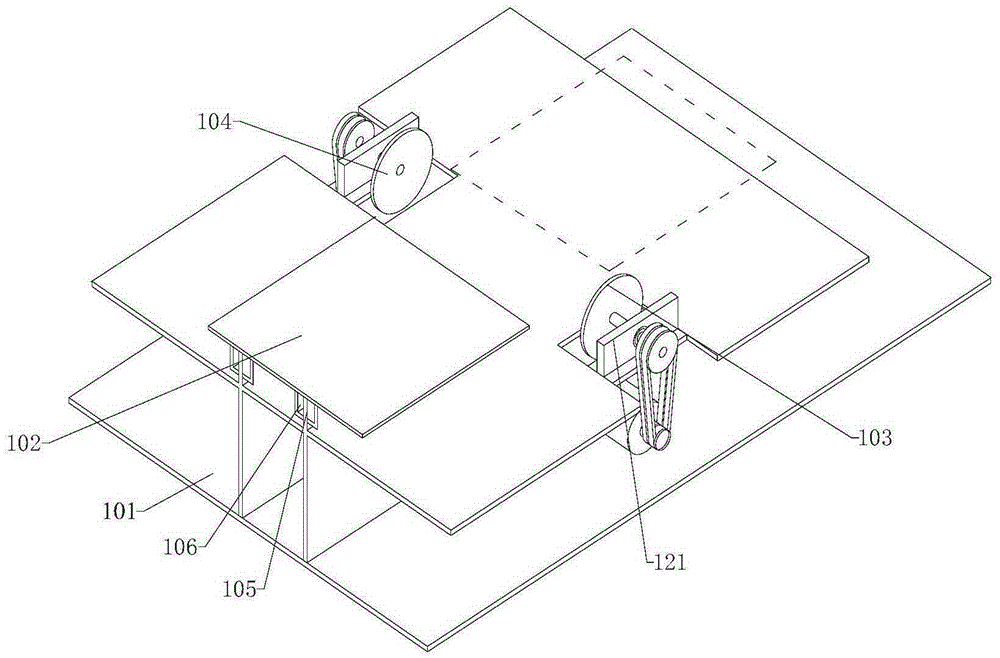

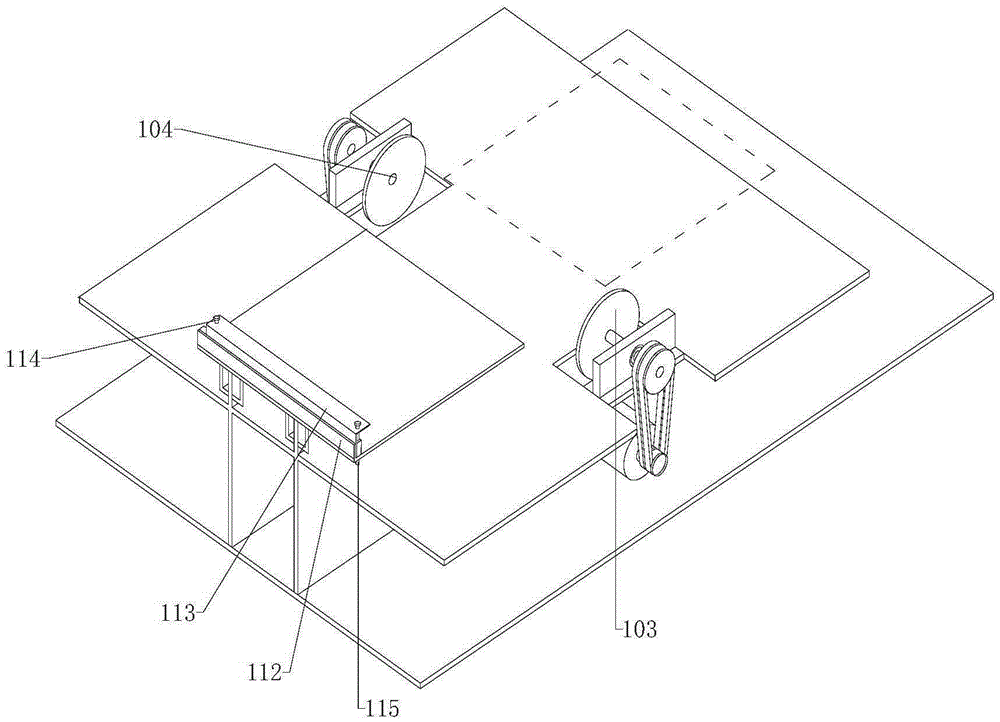

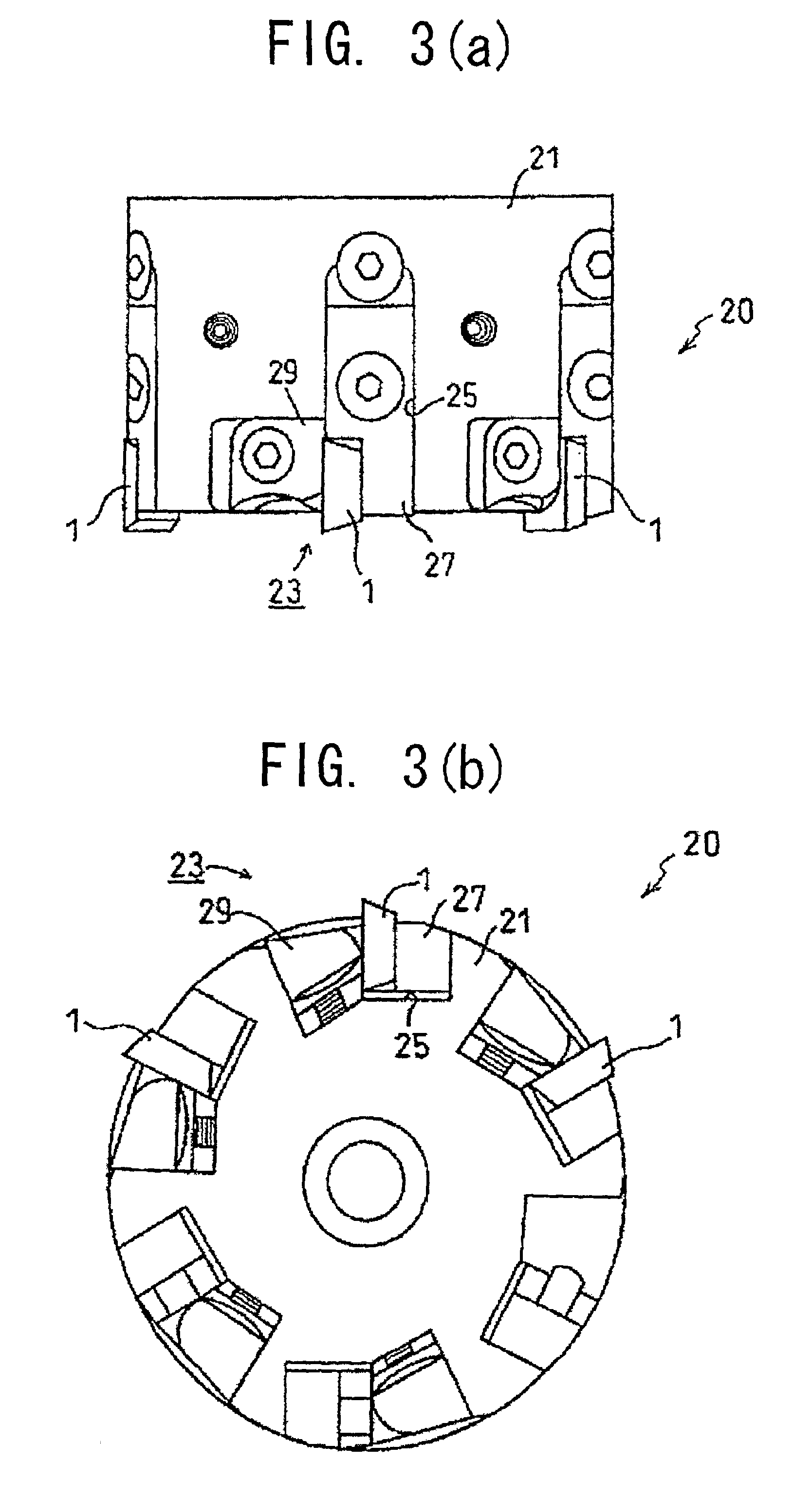

Cutting machine

InactiveCN105291198AReduce frictionReduce wearEdge grinding machinesSawing componentsEngineeringWood plank

The invention provides a cutting machine and belongs to the field of mechanical devices. The cutting machine comprises a rack body, a workbench, a drive device and a cutting part, wherein the rack body is provided with a first guide rail; the workbench is in sliding connection with the first guide rail; the drive device is connected with the workbench and the cutting part; the cutting part comprise a first longitudinal cutting part body and a second longitudinal cutting part body which are arranged symmetrically; the first longitudinal cutting part body and the second longitudinal cutting part body are connected with the rack body; the first longitudinal cutting part body is located on one side of the workbench in the direction of the first guide rail; the second longitudinal cutting part body is located on the side, away from the first longitudinal cutting part body, of the workbench. According to the cutting machine, the drive device drives the workbench to slide along the first guide rail, so that cutting machining of planks is automatic, the cutting precision of the planks can be ensured without experienced operators, work intensity of the operators is also relieved, and the plank machining efficiency is improved.

Owner:CHONGQING AIBUTE FURNITURE

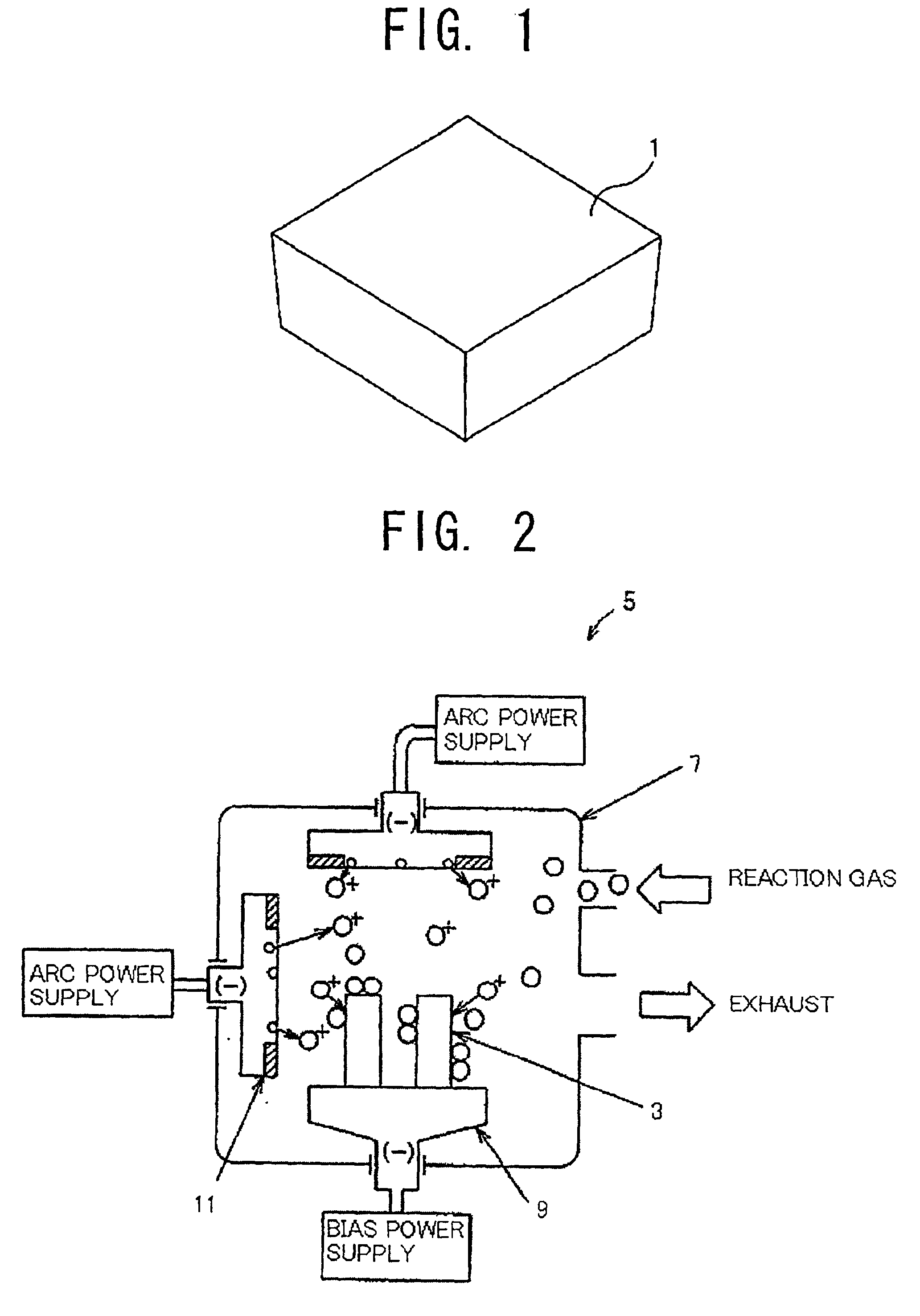

Cutting tool and tool with holder

InactiveUS6838151B2Improve performanceMaintain performanceTurning machine accessoriesMilling cuttersSurface roughnessCemented carbide

A cutting tool 1 includes a hard coating formed on the surface of a substrate formed of, for example, a hard material of cemented carbide (WC-Co-type cemented carbide) equivalent to JIS K10 and polished into the shape of ISO SPGN120312. The cutting tool 1 has a plate-shape with a rake face (the main surface side) that is wider than the opposite face. The hard coating has a thickness in the range of from 1 μm to 5 μm, is formed of a TiAlN material, and has a Ti / Al ratio of 1. Coarse grains present in the hard coating and having a size not less than coating thickness occupy an area percentage not greater than 5% by area. The hard coating has a surface roughness Ra of not greater than 0.1 μm and a surface roughness Rz of not greater than 1 μm.

Owner:NGK SPARK PLUG CO LTD

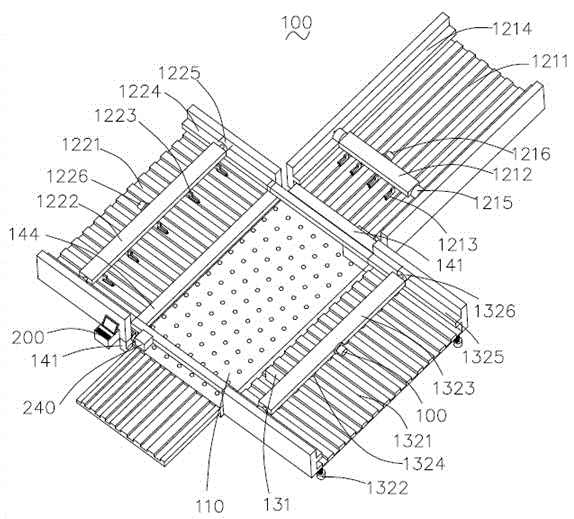

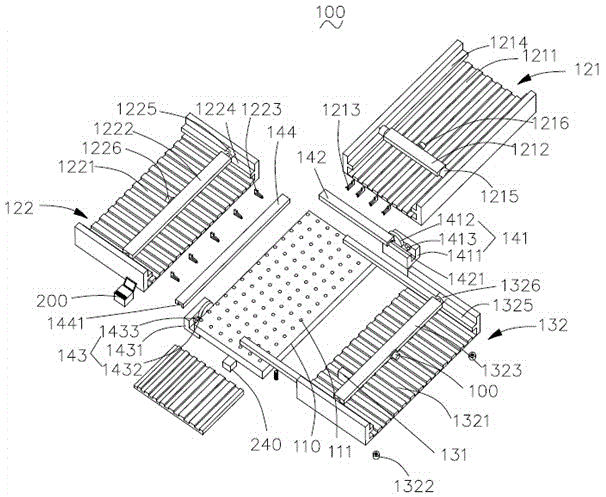

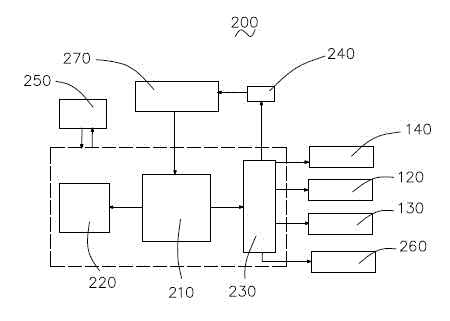

Full-automatic plate bidirectional sawing device and sawing method thereof

InactiveCN102873718AIncrease the level of automationIncrease productivitySawing componentsCircular sawsInformatizationEngineering

The invention discloses a full-automatic plate bidirectional sawing device and a sawing method of the full-automatic plate bidirectional sawing device. The full-automatic plate bidirectional sawing device comprises a platform body and a control unit, wherein the platform body comprises a reversing platform, a clamping mechanism, a pushing mechanism and a sawing mechanism; the clamping mechanism, the pushing mechanism and the sawing mechanism are arranged at the side of the reversing platform and integrally arranged in a T shape; the control unit comprises a computer host system and a display screen; the computer host system comprises a layout optimization module, a database module and a motion control module; the layout optimization module is used for optimizing cutting and layout to form an optimized layout drawing; the motion control module is used for controlling the platform body to work; and the database module is used for storing product data in real time. The full-automatic plate bidirectional sawing device is simple and reasonable in structural design, full-automatic in control, convenient to operate, good in safety, high in outturn percentage and novel in cutting method, so that the full-automatic sawing of batched plates via single equipment is realized; and the intelligent layout and an automatic labeling mechanism are combined, so that the informatization and the intellectualization of the production process are realized.

Owner:王石 +1

Hole saw assembly

A hole-saw assembly including a hole-saw having at one end a plurality of cutting teeth and at the other end two shafts. The assembly includes a mandrel coaxially aligned with said hole-saw and including a body having two bores therethrough coaxially aligned with said shafts. An annulus located on top of the body is coaxially aligned with said mandrel and hole-saw and includes two holes, the annulus rotatable around its longitudinal axis from a first to a second position. In the first position, the annulus holes are aligned with the bores and shafts allowing the shafts to be freely insertable and removable and in the second position the holes are misaligned to lock the shafts to the annulus. Such an arrangement allows the hole-saw and the mandrel to be easily and quickly mountable and demountable.

Owner:KEIGHTLEY KYM JOHN

Hole-saw assembly including two hole-saws

The present invention relates to an improved hole-saw assembly and in particular, to a mandrel engageable by a drill and including at least one locking ring or annulus that allows for the base of two hole-saws of different diameter to be quickly and easily mountable and demountable from the mandrel. The hole-saw assembly includes a first hole-saw having a base that includes a pair of drive-pins extending outwardly therefrom and a pair of apertures for insertion therethrough of the drive pins of a second hole-saw. The drive pin pairs are then inserted through corresponding apertures in the mandrel to engage an annulus coupled to the mandrel. The present invention provides for each drive pin to be engaged by the annulus despite the difference in longitudinal length of the drive pins beyond the base of the first hole-saw. The hole-saws are snap-fit within the annulus and may be disengaged by simply rotating the annulus to a second position. A further embodiment of the present invention further allows one to insert the hole-saws into any one of the mandrel insertion points without being concerned about whether it contains the correct engaging means or not. A still further embodiment of the invention prevents slight longitudinal movement which is known to occur when the hole-saws are coupled to the mandrel.

Owner:KEIGHTLEY KYM JOHN

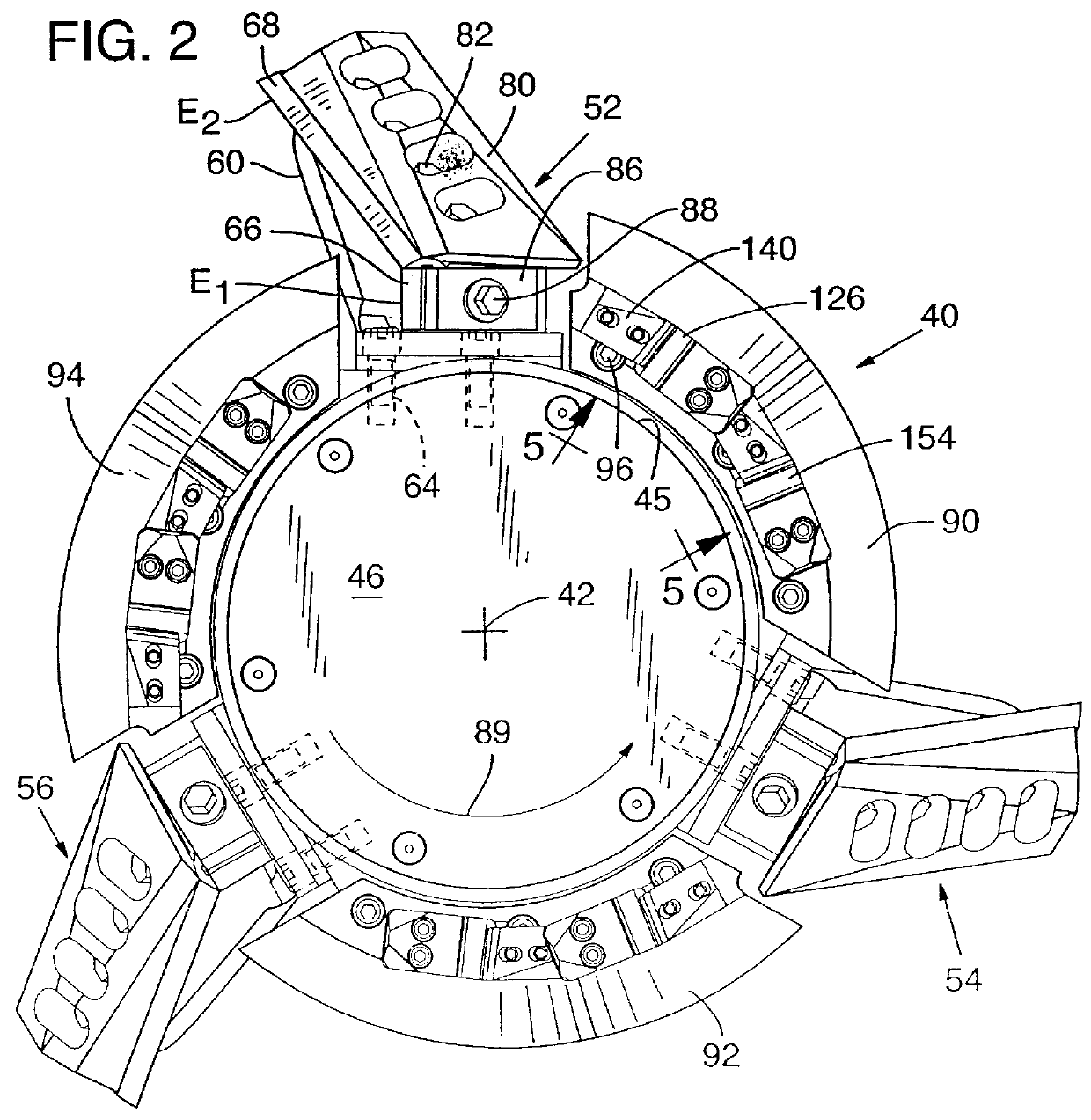

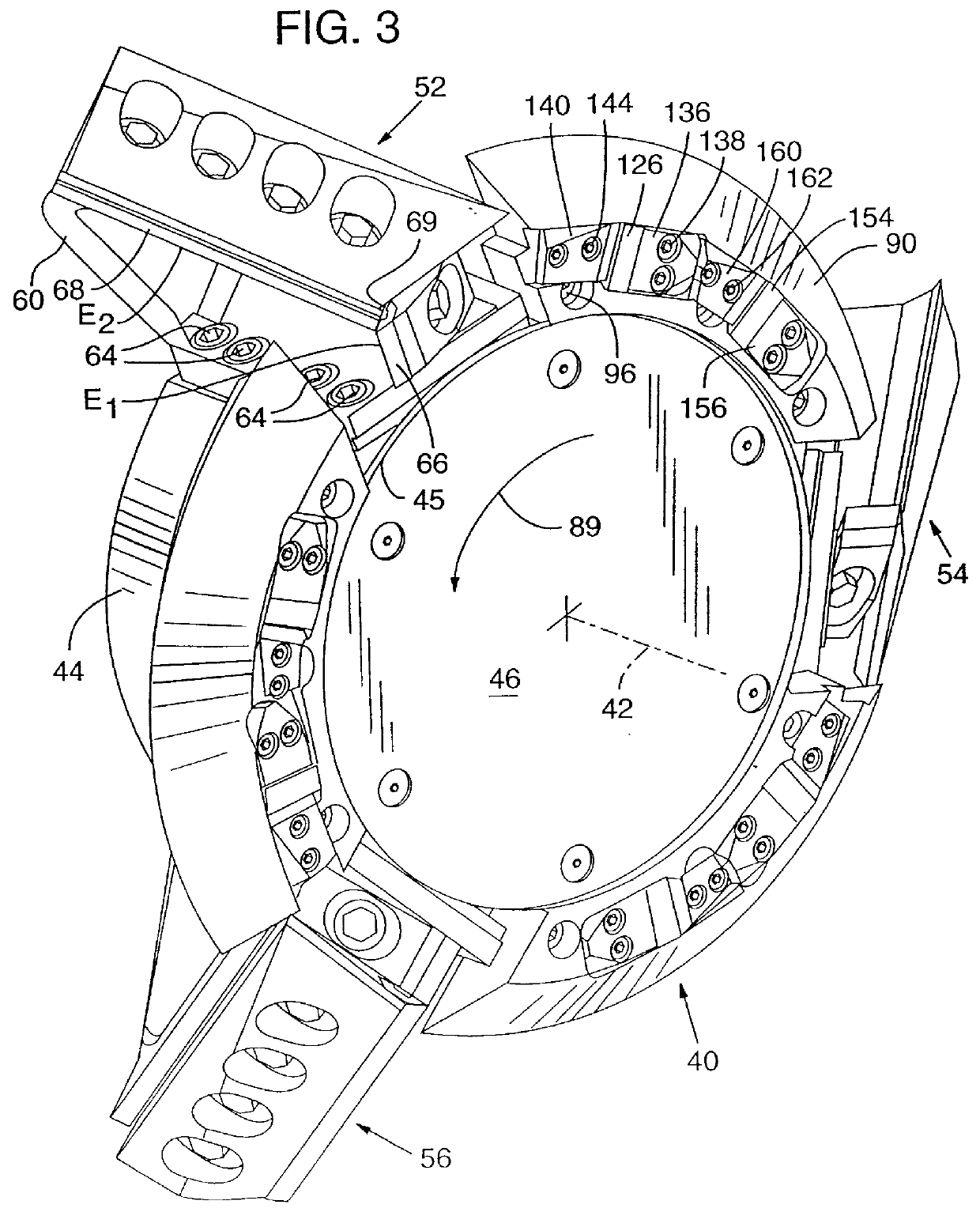

Dual oscillating multi-tool saw

InactiveUS20140068952A1Reduce vibrationReduce fatigueDrilling rodsConstructionsGear wheelEngineering

An oscillating multi-tool for cutting, scraping, sanding, or grinding of material. The oscillating multi-tool includes a body, a drive system and a gear arrangement. The drive system and the gear arrangement are designed to cause first and second tool attachments to partially or fully oscillate in opposite directions. The gear arrangement is connected or interconnected to first and second tool connectors. The first tool attachment is connected to the first tool connector and the second tool attachment is connected to the second tool connector. The gear arrangement causes the first and second tool connectors to move when the drive system is activated to thereby cause the first and second tool attachments to partially or fully oscillate in opposite directions relative to one another.

Owner:MIG7 INFUSION +1

Chipper with detachable facing knives

InactiveUSRE36659E1Improve smoothnessUse of materialMulti-purpose machinesProfiling/shaping machinesEngineeringMechanical engineering

A rotary chipping head with multiple knife structures distributed about its periphery. Each knife structure includes an end-located chipping knife with a cutting edge movable in a plane disposed perpendicular to the axis of rotation of the chipping head. End-located facing knives are interspersed with the knife structures for producing a smooth face in the work being processed. Anvils preceding the facing knives produce compression in the work being processed. Detachable facing elements mount the facing knives and the anvils.

Owner:KEY KNIFE

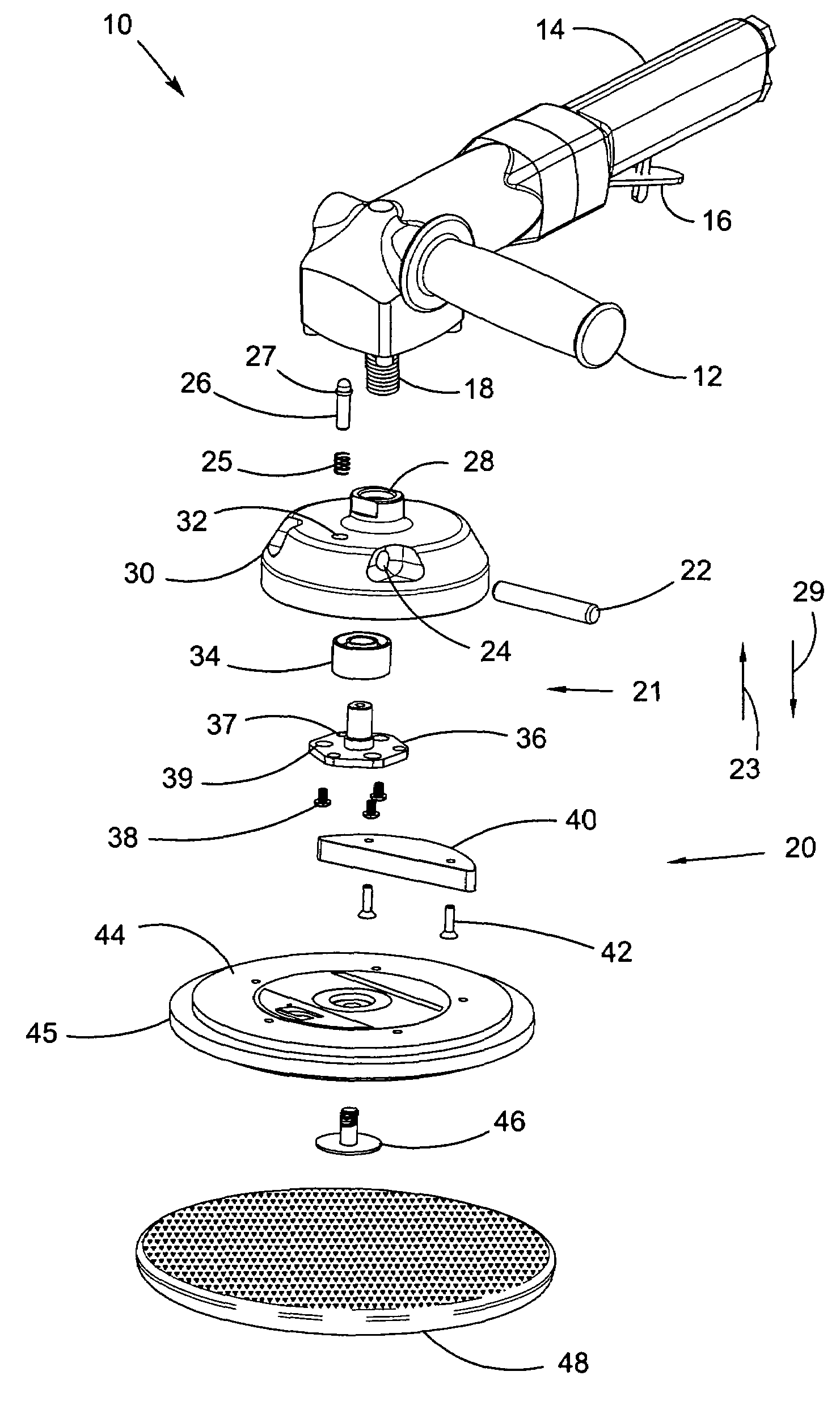

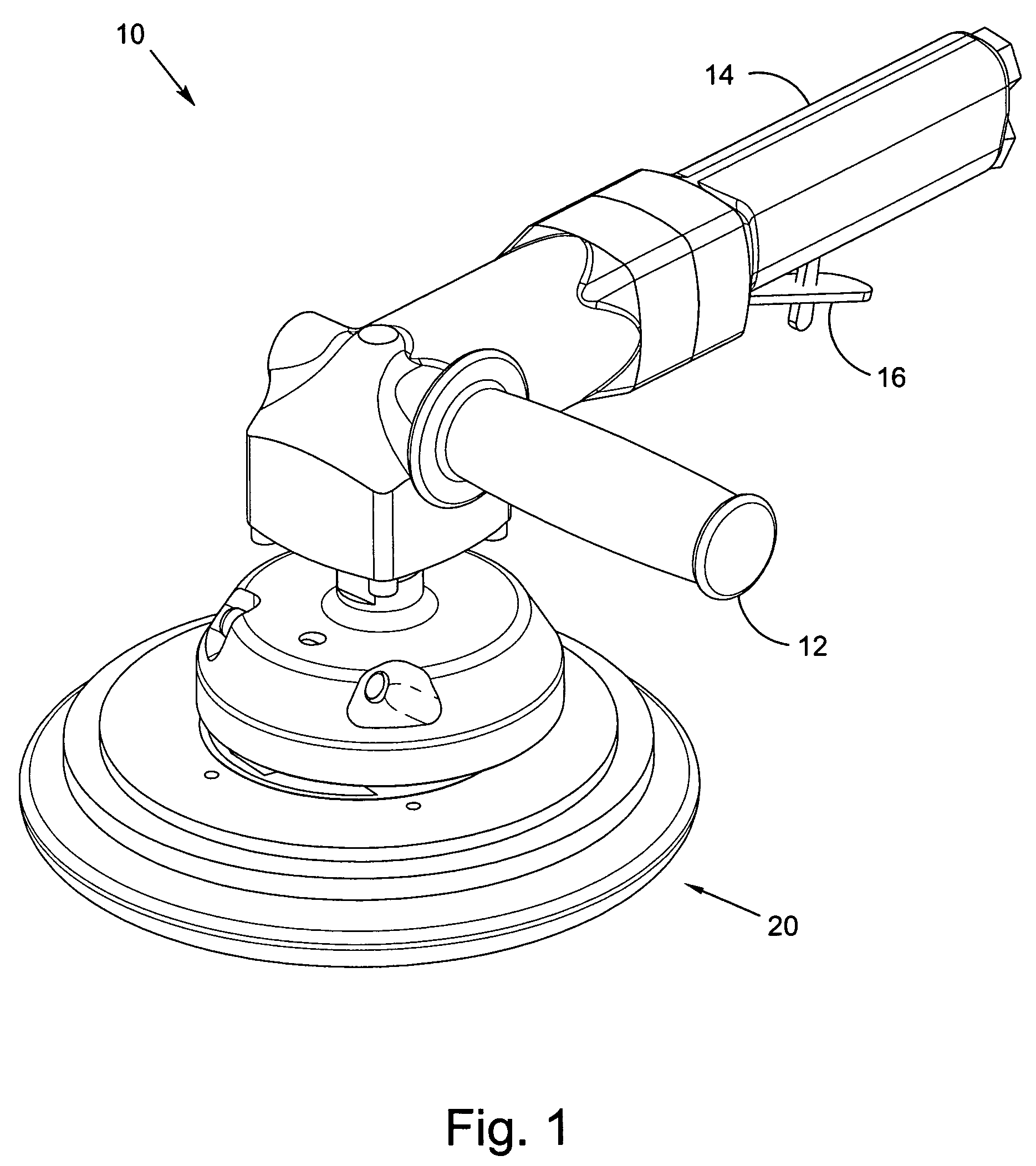

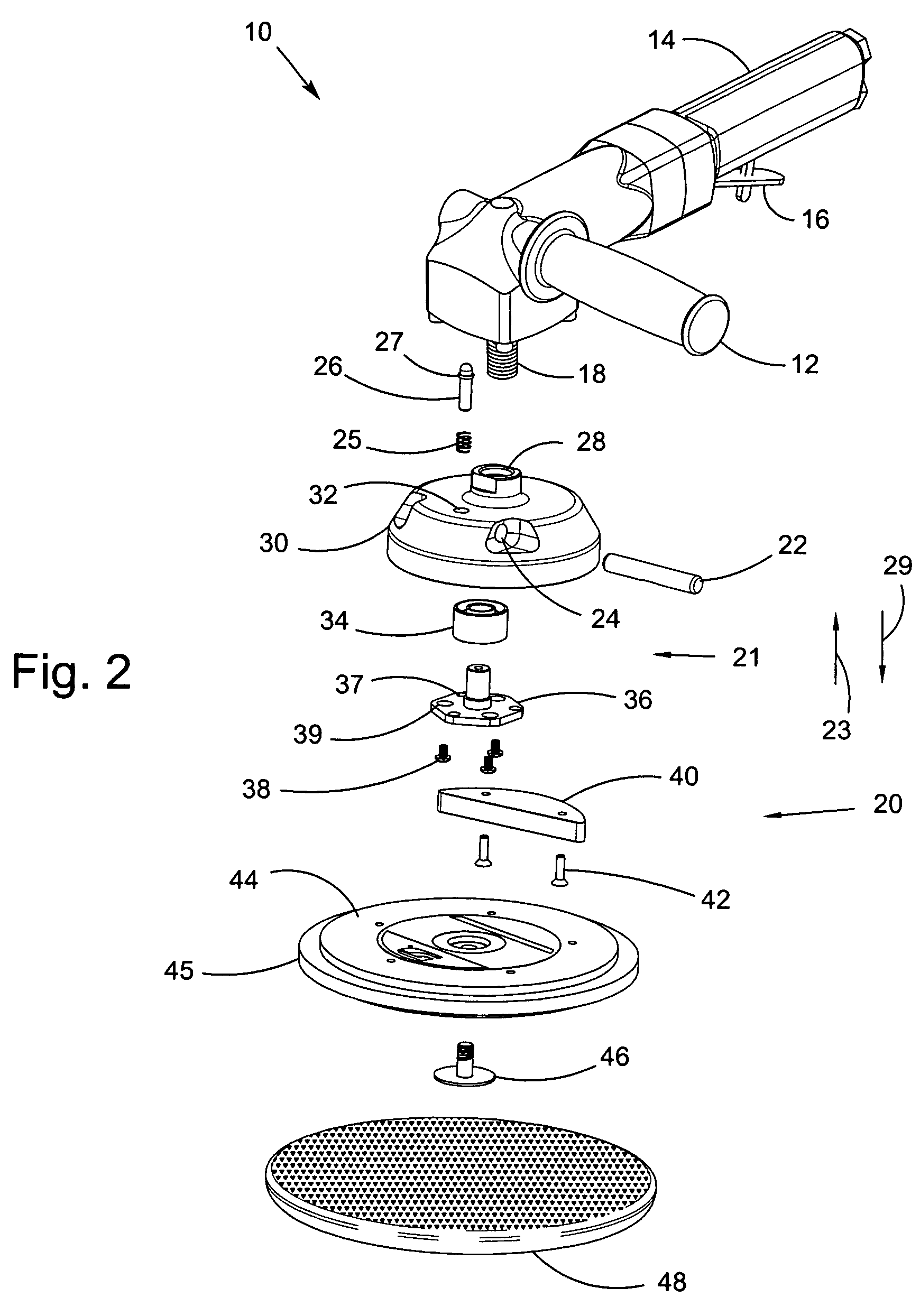

Locking random orbital dual-action head assembly

Owner:DYNABRADE

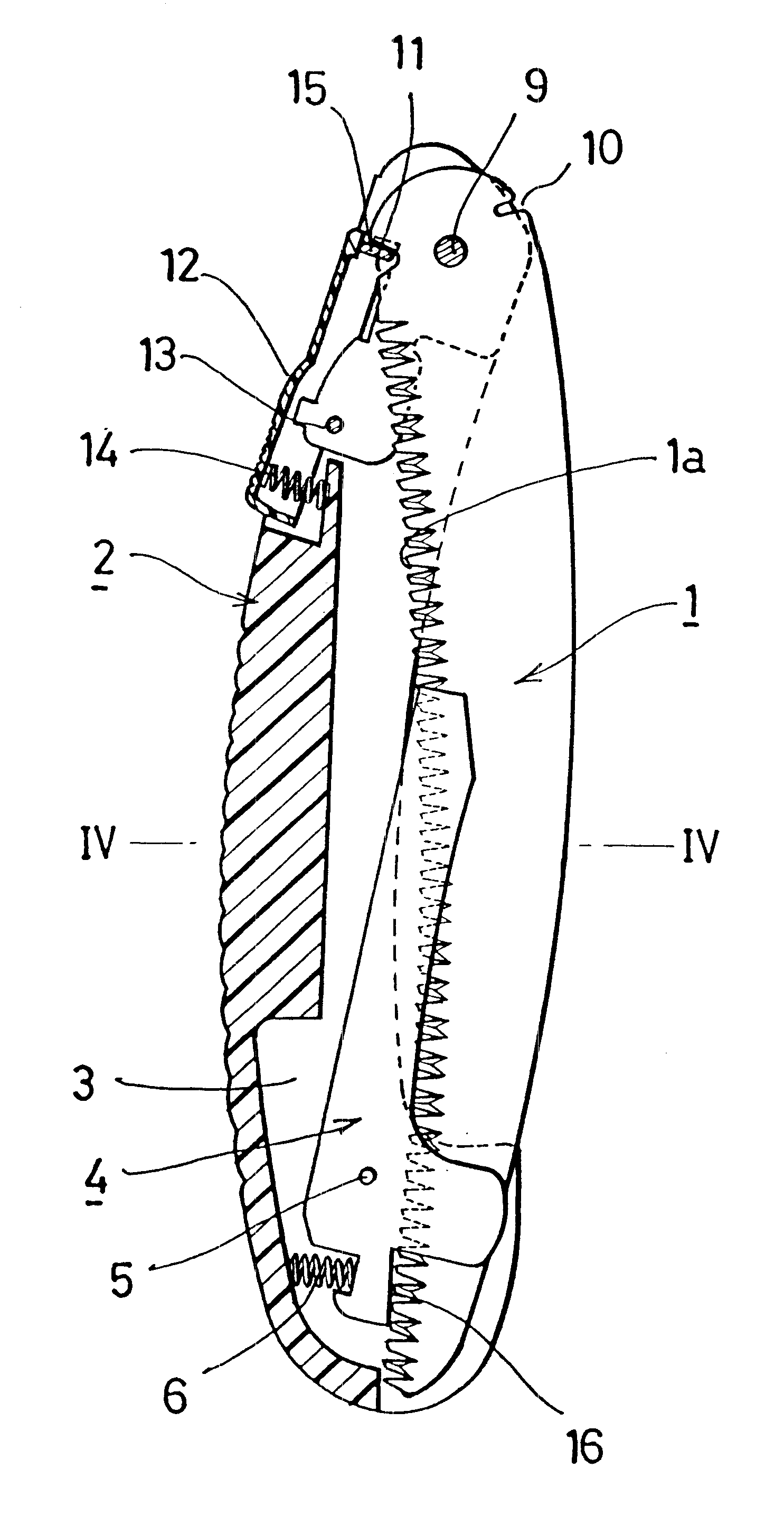

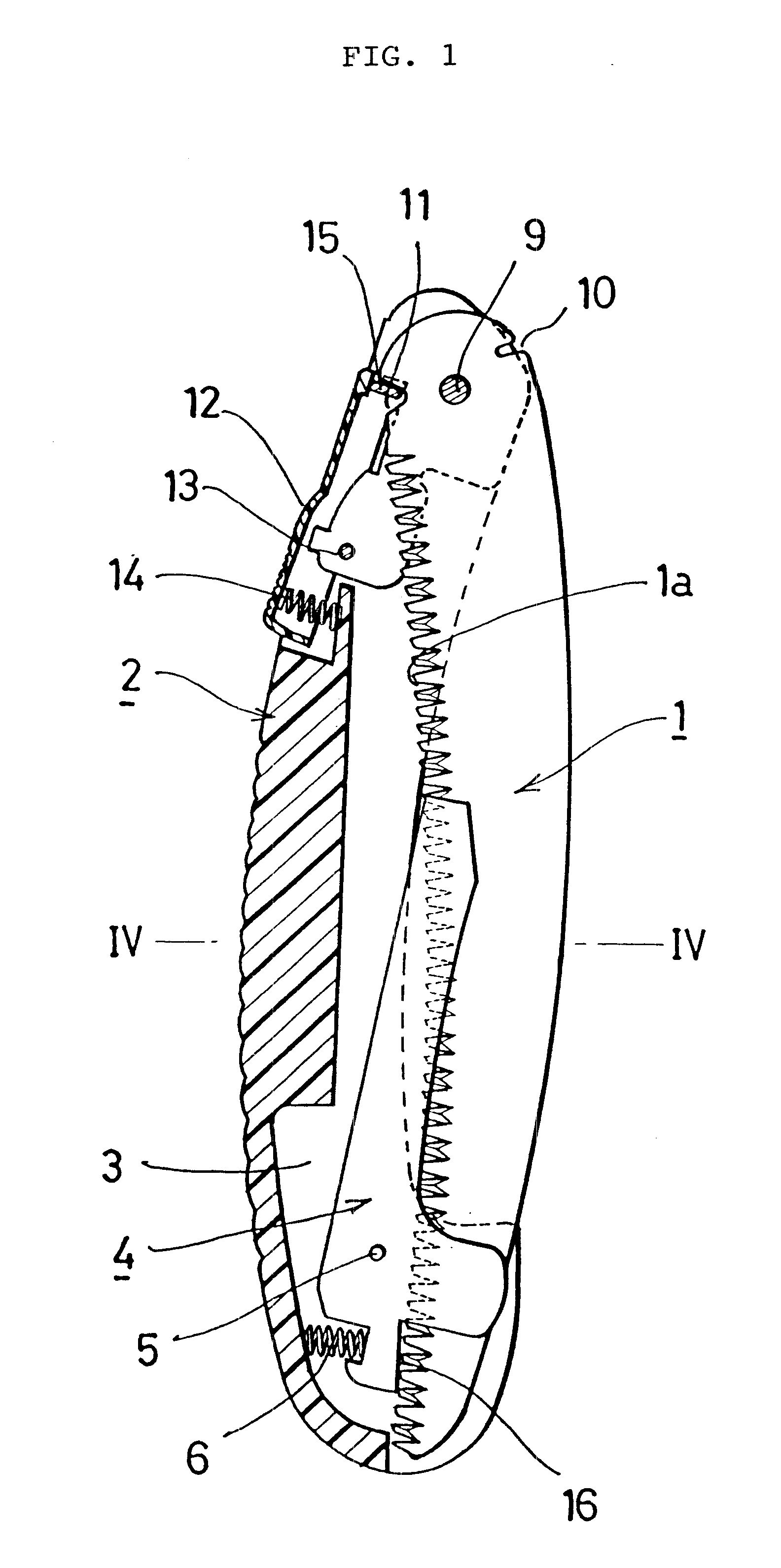

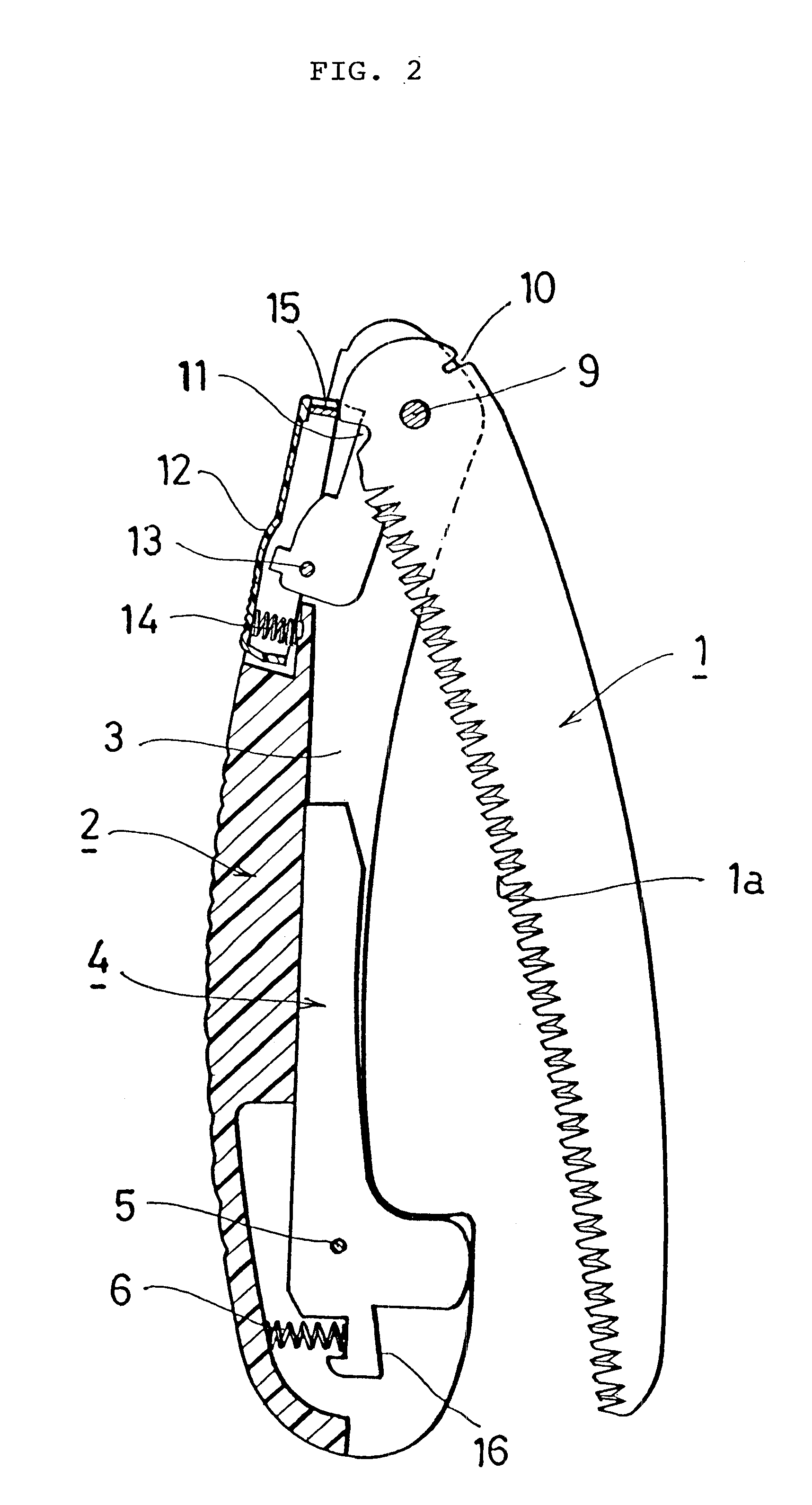

Folding saw

InactiveUS6463663B1Protective coverOvercome these defectsMetal sawing devicesPad sawsEngineeringMechanical engineering

A folding saw in which either the edge of the blade, the handle or both are curved, to prevent the edge of the blade from being exposed when blade is folded so that the saw can be handled safely. The protective cover in which the edge of the blade can be nestled is placed inside the housing groove of the handle having a semi-U-shaped cross section for housing the blade. The protective cover is retractable with respect to the housing groove, and when the blade is folded, projects out of the housing groove and covers the edge, which may be exposed. The protective cover is preferably energized by a spring so that it covers the edge whenever the blade is folded.

Owner:KANZAWA SEIKO

Surgical sagittal saw with quick release indexing head and low blade-slap coupling assembly

ActiveUS8100912B2Smooth rotationMetal sawing devicesNon-rotary toothed toolsLocking mechanismCoupling

Owner:STRYKER CORP

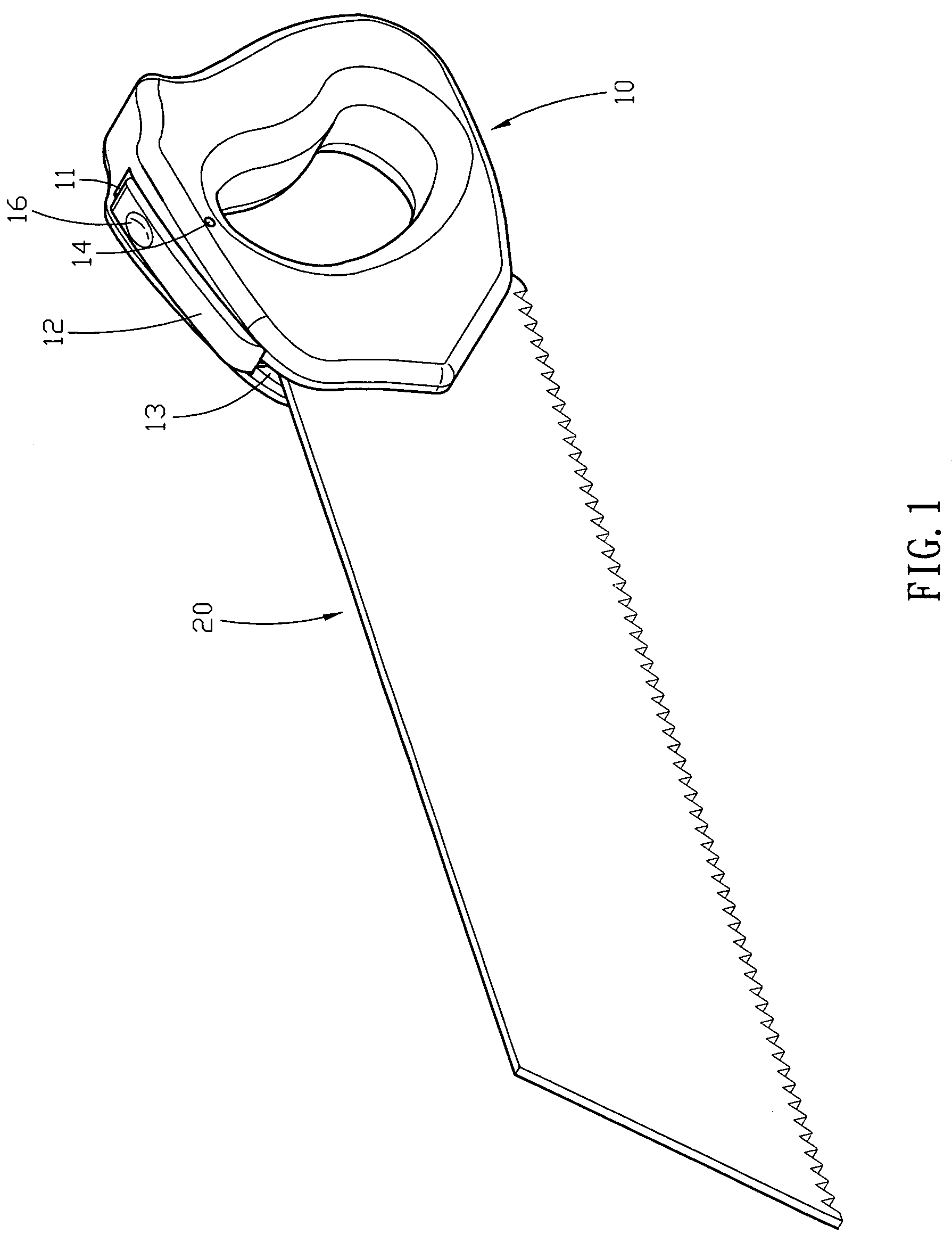

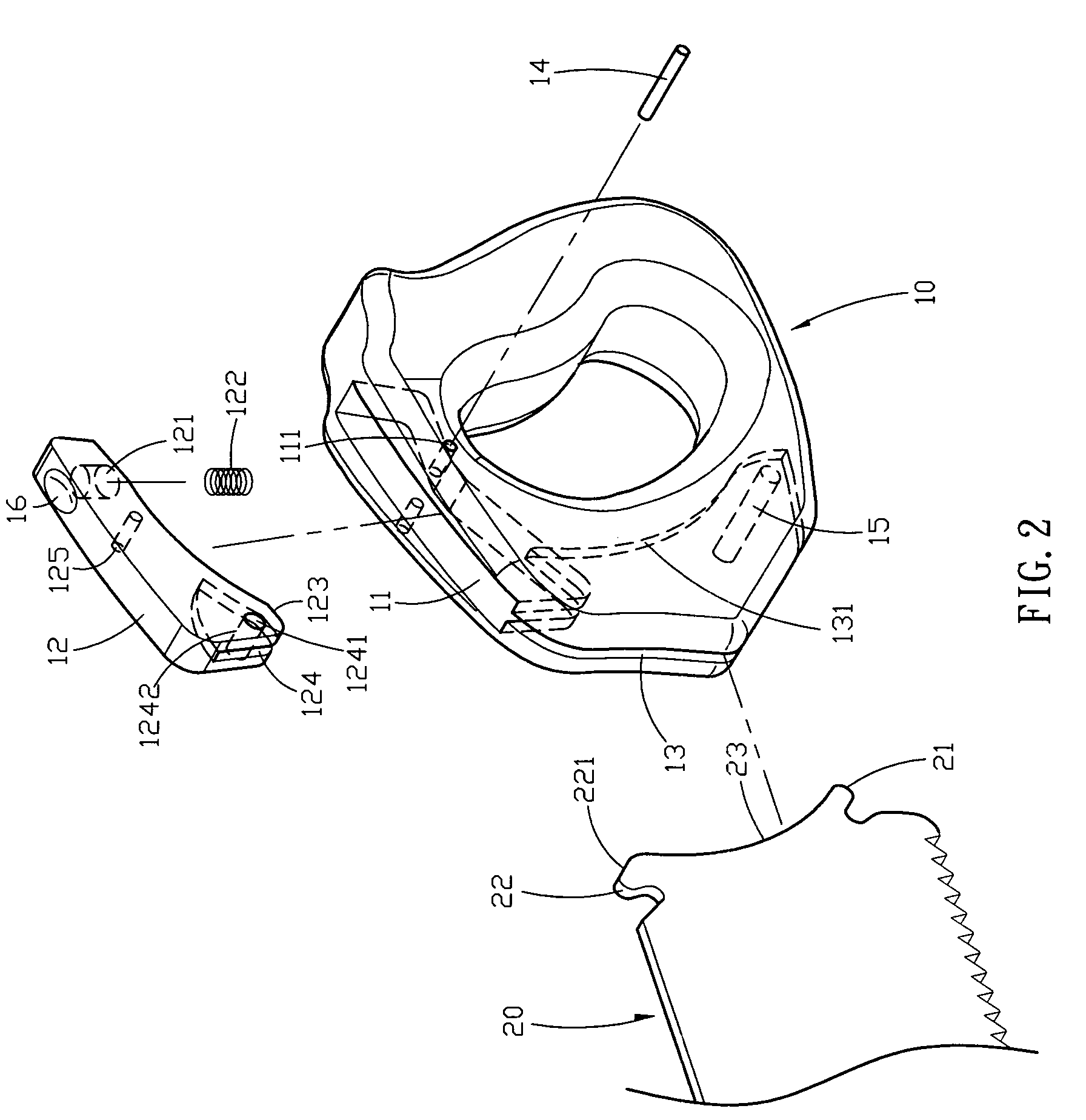

Handsaw having replaceable blade

InactiveUS7325314B1Simple and convenient replacement processEasy to replaceMetal sawing devicesPad sawsEngineeringMechanical engineering

A handsaw includes a handle, a blade removably mounted on the handle, and a press button pivotally mounted on the handle and detachably engaged with the blade to lock the blade on the handle and unlock the blade from the handle. Thus, the blade can be detached from the handle easily and rapidly by pressing the pressing portion of the press button, thereby facilitating the user replacing the blade. In addition, the concave face of the blade is rested on the convex face of the handle, so that the blade is supported by the handle rigidly and stably, thereby facilitating a user operating the handsaw.

Owner:KING JAWS METAL

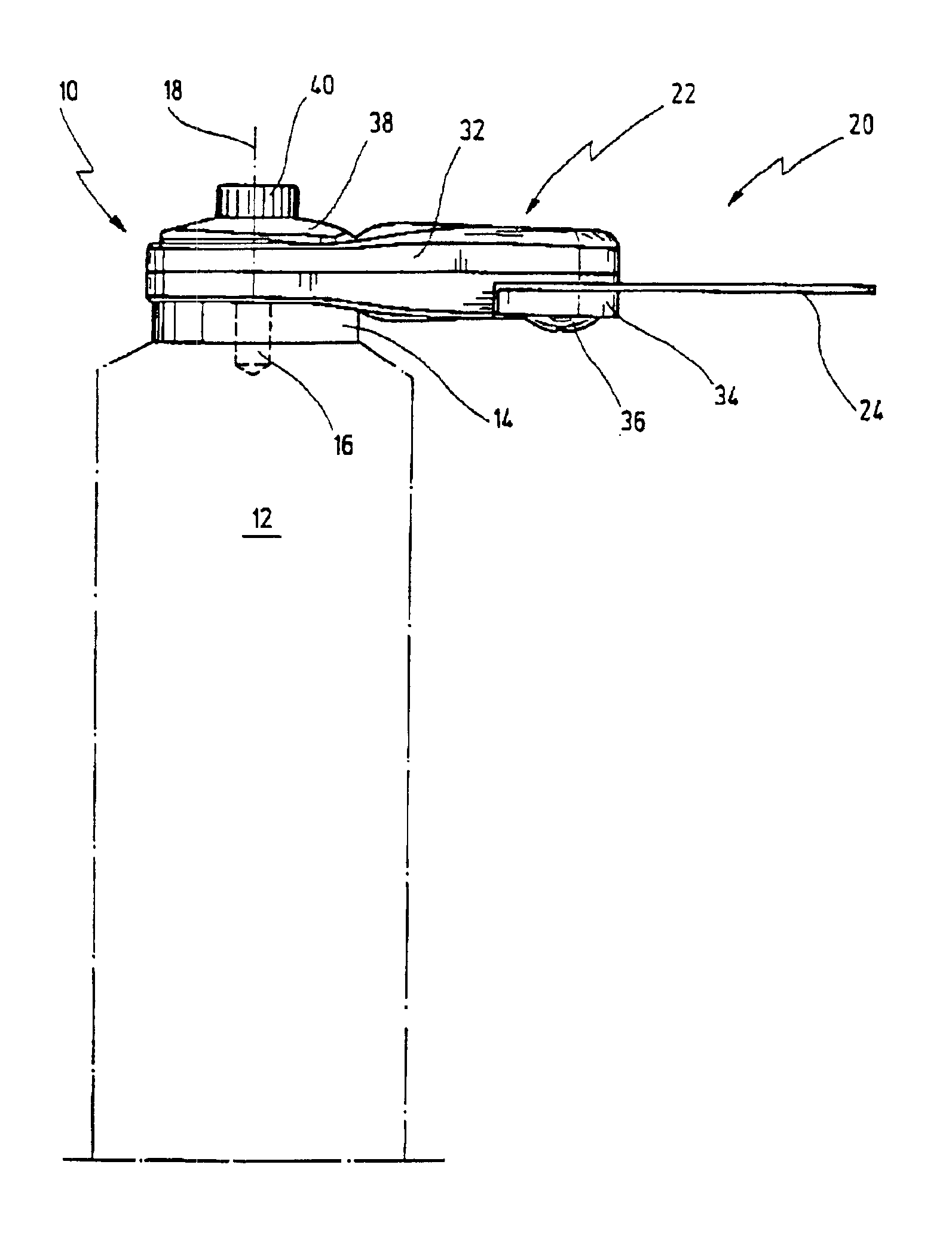

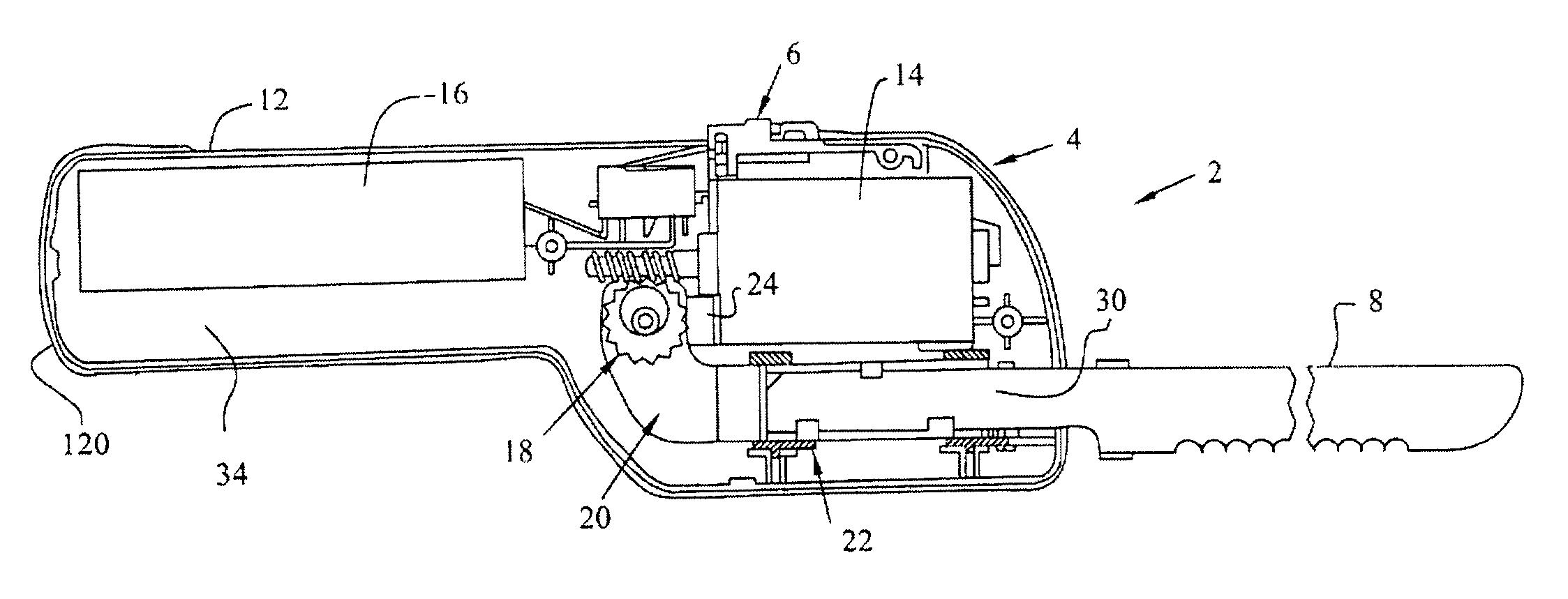

Battery-powered carving knife having a rechargeable battery pack

A battery-powered carving knife is shown having a housing and a switch, which connects and disconnects a battery to a motor. A drive mechanism including a worm gear together with a cam member causes reciprocation of reciprocating blade mounts to reciprocate back and forth in an out of phase fashion. The motor is positioned forward within the housing in motor receiving section, with the drive shaft of the motor facing rearwardly. The blade mounts are driven by the motor, and reciprocate in a position below the motor. The motor and blade mounts are positioned in front of a handgrip section, thereby improving the ergonomics of the device. Alternatively, the drive shaft can be positioned facing forward.

Owner:KDW COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com