Full-automatic plate bidirectional sawing device and sawing method thereof

A sawing device, fully automatic technology, applied in the direction of sawing components, sawing equipment, circular saws, etc., can solve the problems of occupying workshop space, cost and instability increase, and achieve resource saving, large market space and economy benefit and solve the effect of low degree of numerical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained by following the detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

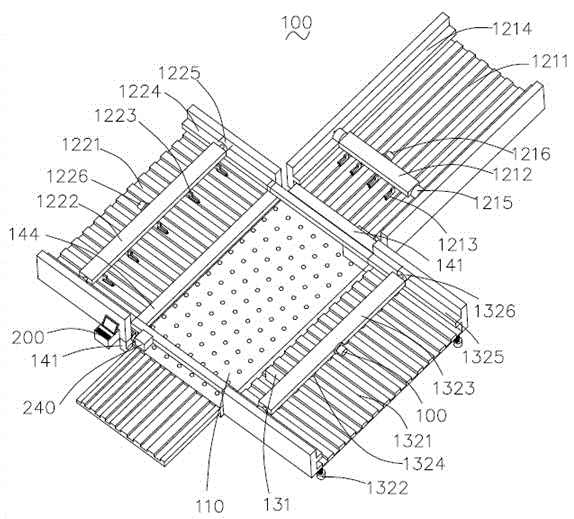

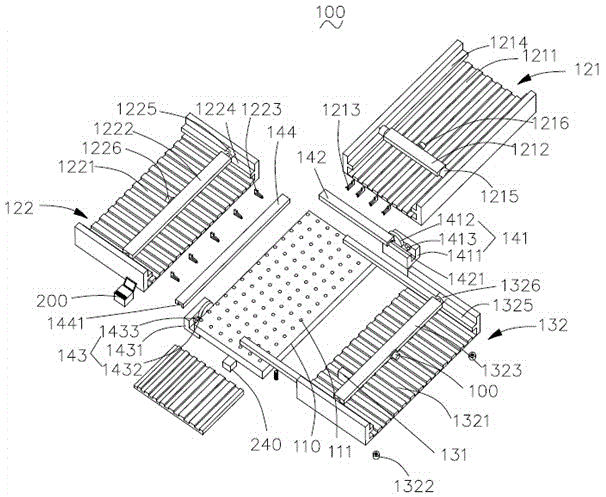

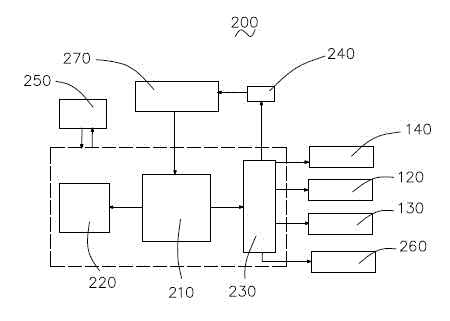

[0054] A full-automatic bidirectional sawing device for sheet metal includes a machine main body 100 and a control unit 200 arranged on the machine main body 100, and the control unit 200 controls the operation of the machine main body 100. The machine body 100 includes a reversing table 110, a pinching mechanism 120, a pushing mechanism 130 and a sawing mechanism 140. The pinching mechanism 120 includes a first pinching mechanism 121 and a second pinching mechanism 122, and the first pinching mechanism 121 and the second pinching mechanism 122 are respectively arranged on two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com