Patents

Literature

237 results about "Contact protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact protection methods are designed to mitigate the wear and degradation occurring during the normal use of contacts within an electromechanical switch, relay or contactor and thus avoid an excessive increase in contact resistance or switch failure.

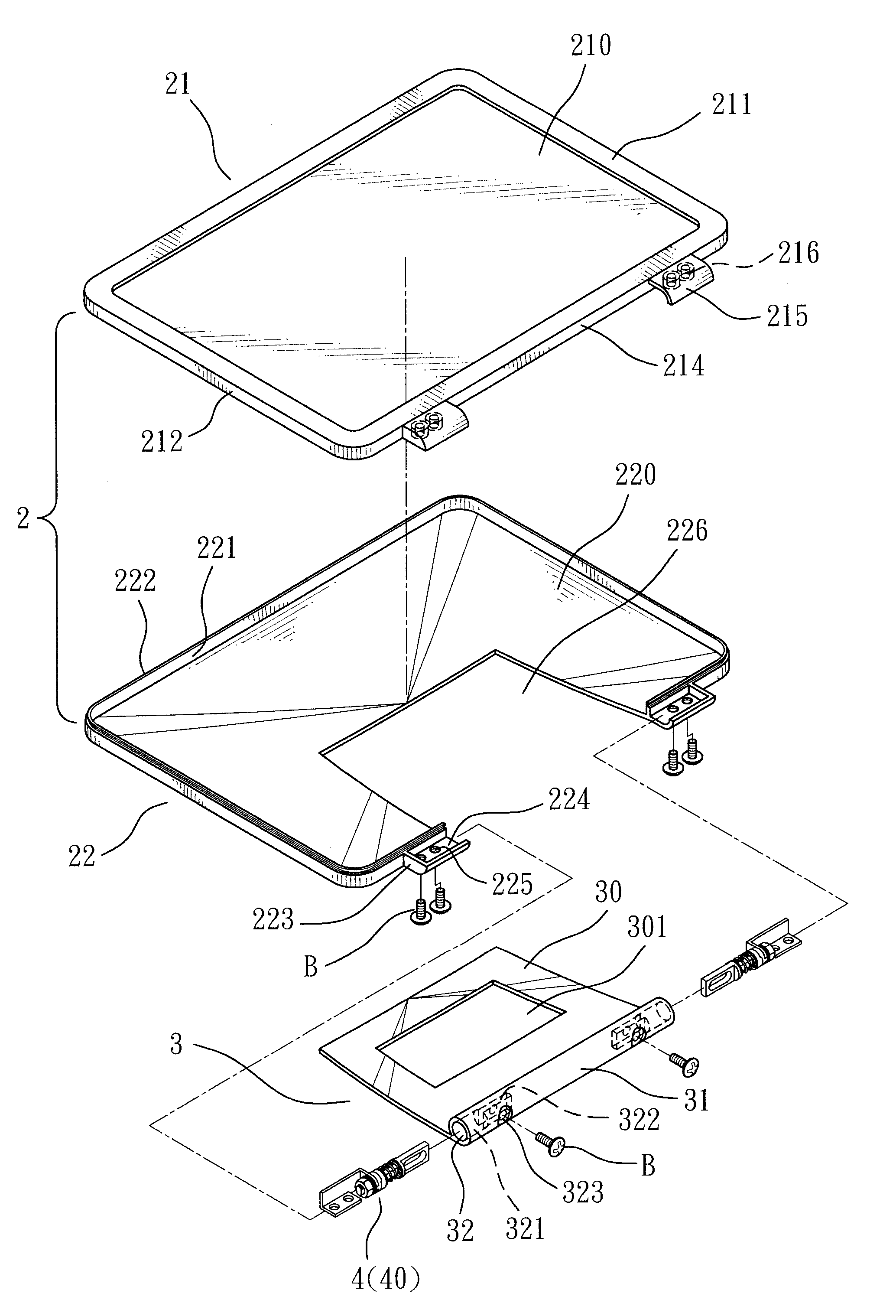

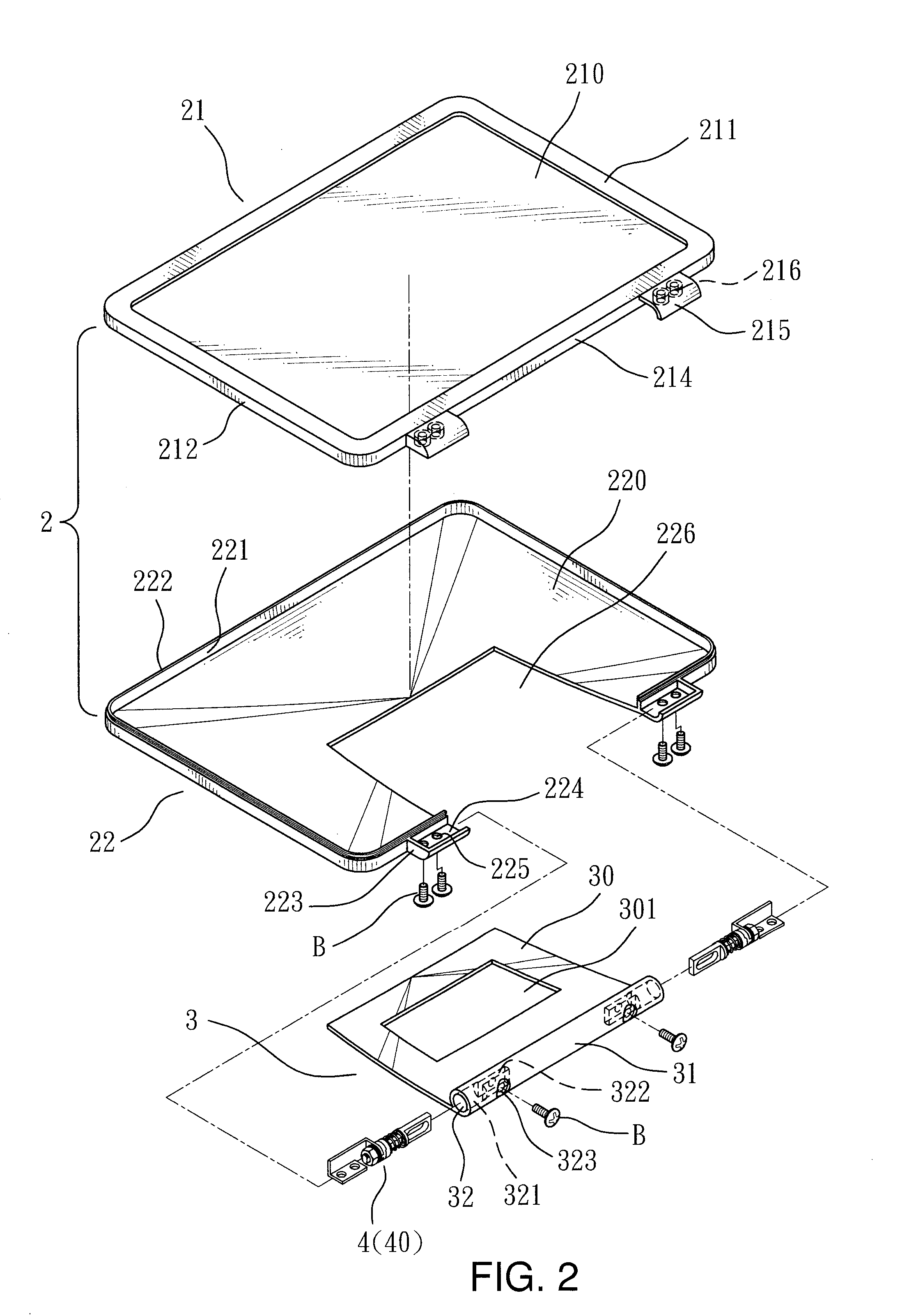

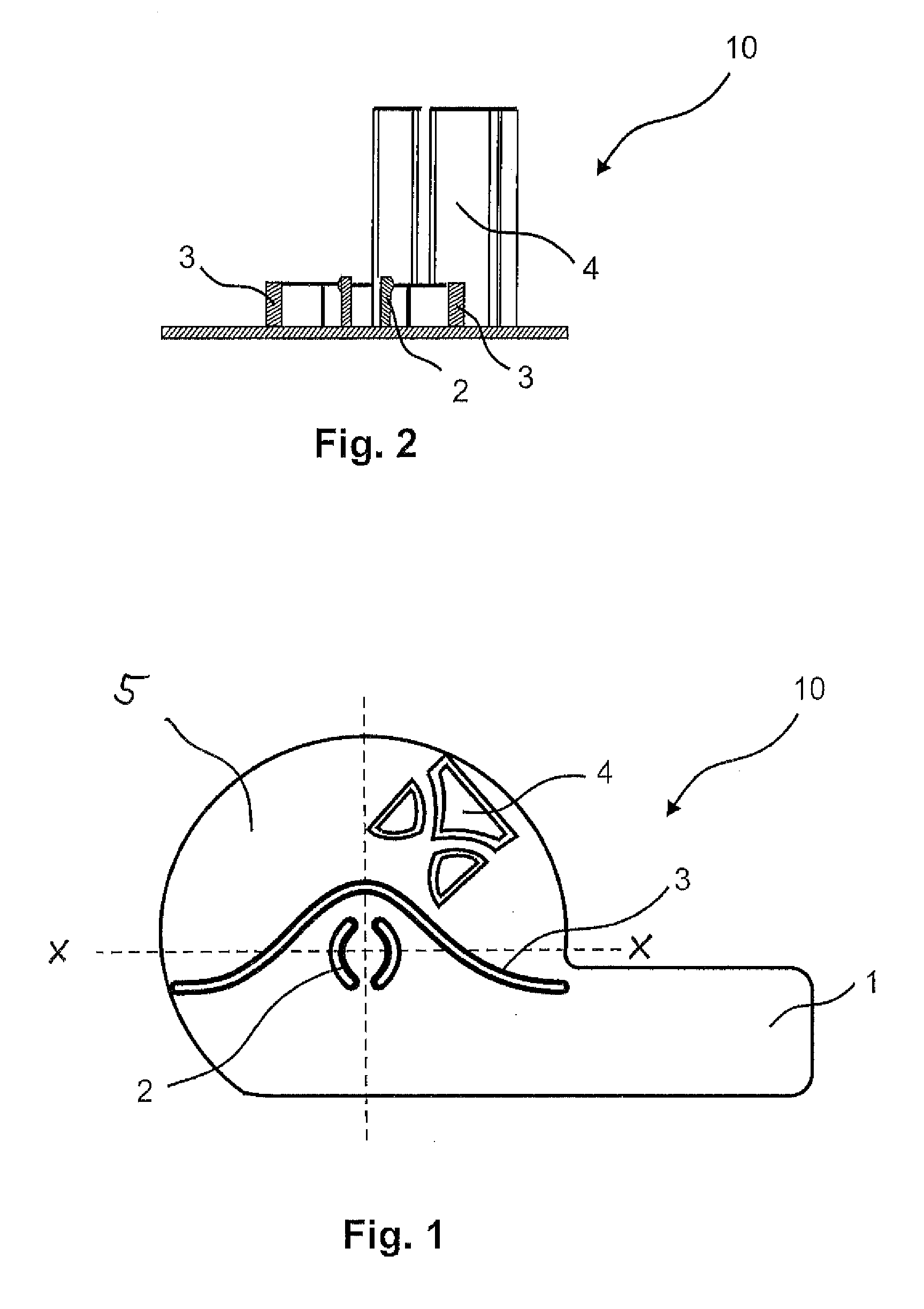

Protective cover support rack for portable electronic devices

InactiveUS8231099B2Easy to watchEasy to holdPicture framesDomestic mirrorsStanding PositionsEngineering

Owner:E LEAD ELECTRONICS

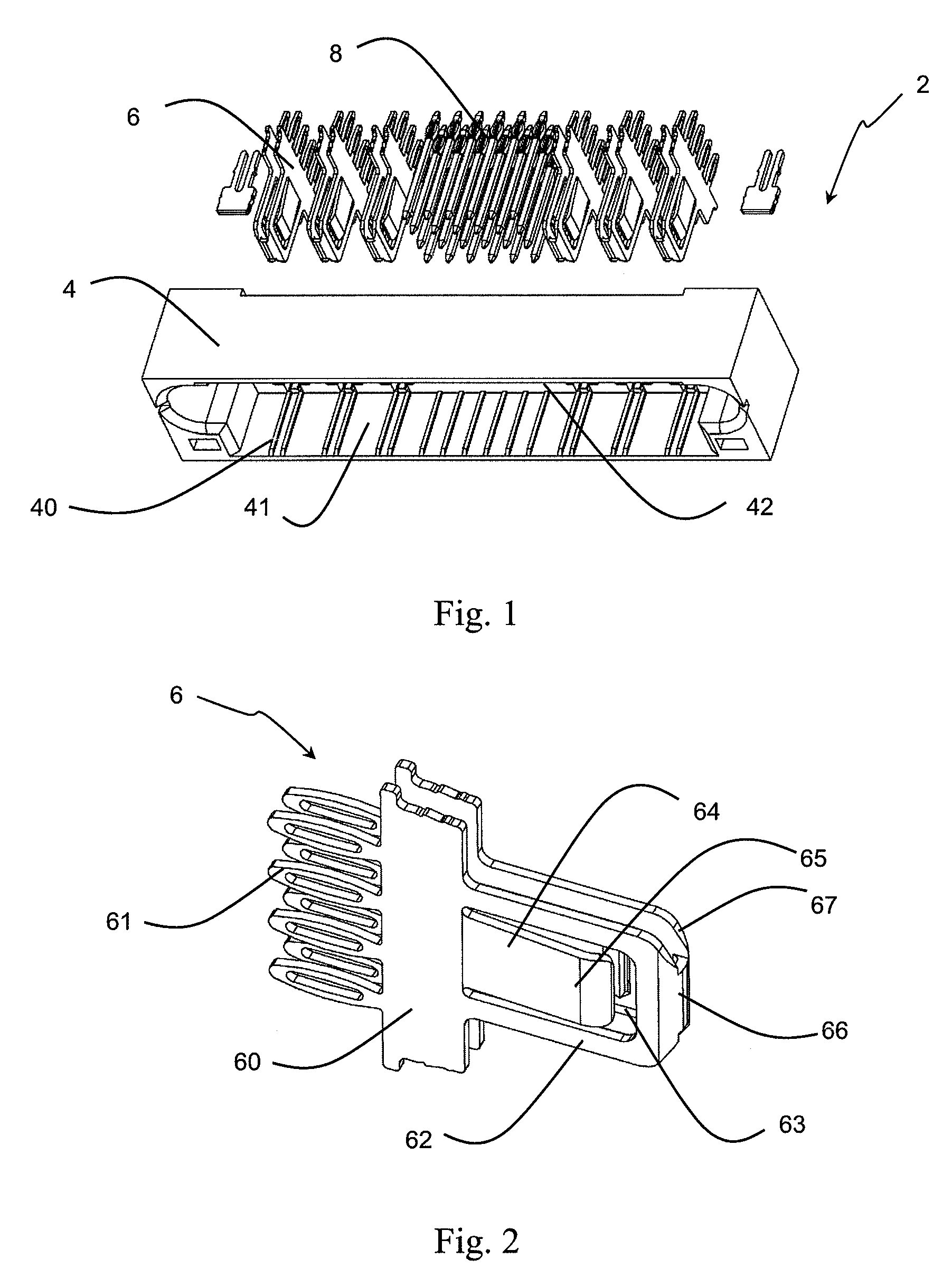

Contact protector for electrical connectors

ActiveUS20060046526A1Electrically conductive connectionsCoupling device detailsInterference fitElectrical connector

A protective housing removably attached to an electrical connector to prevent damage to contacts of the connector during, for example, shipping or handling of the electrical connector before the connector is connected with an electrical device such as a second electrical connector. The contact protector may include a pull portion of adhesive tape that abuts a housing of the electrical connector, creating an interference fit. The contact protector may include a handle integrated with the contact protector to facilitate removal of the contact protector from the electrical connector.

Owner:FCI AMERICAS TECH LLC

Contact protector for electrical connectors

ActiveUS7278856B2Electrically conductive connectionsTwo-part coupling devicesInterference fitElectrical devices

A protective housing removably attached to an electrical connector to prevent damage to contacts of the connector during, for example, shipping or handling of the electrical connector before the connector is connected with an electrical device such as a second electrical connector. The contact protector may include a pull portion of adhesive tape that abuts a housing of the electrical connector, creating an interference fit. The contact protector may include a handle integrated with the contact protector to facilitate removal of the contact protector from the electrical connector.

Owner:FCI AMERICAS TECH LLC

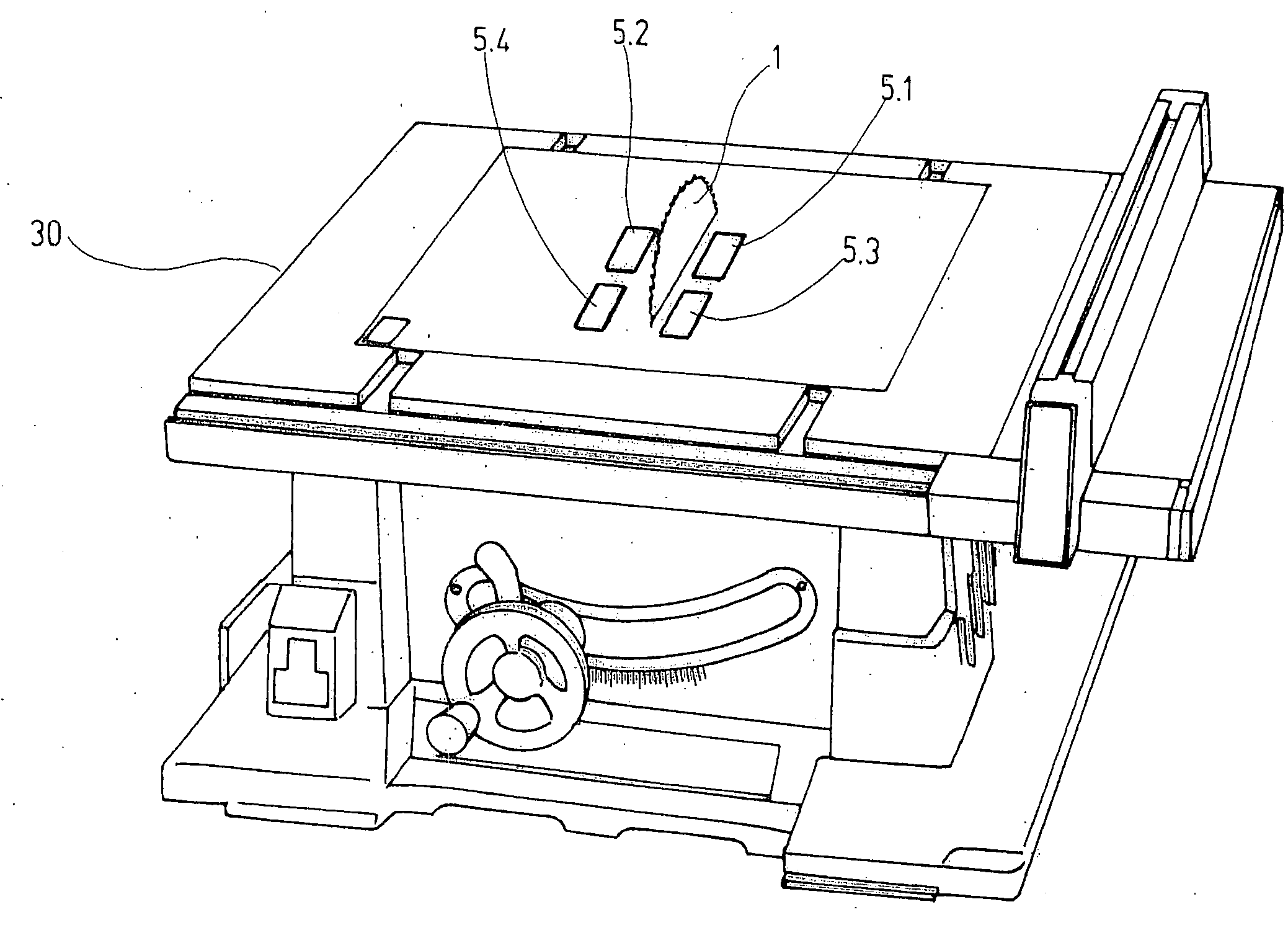

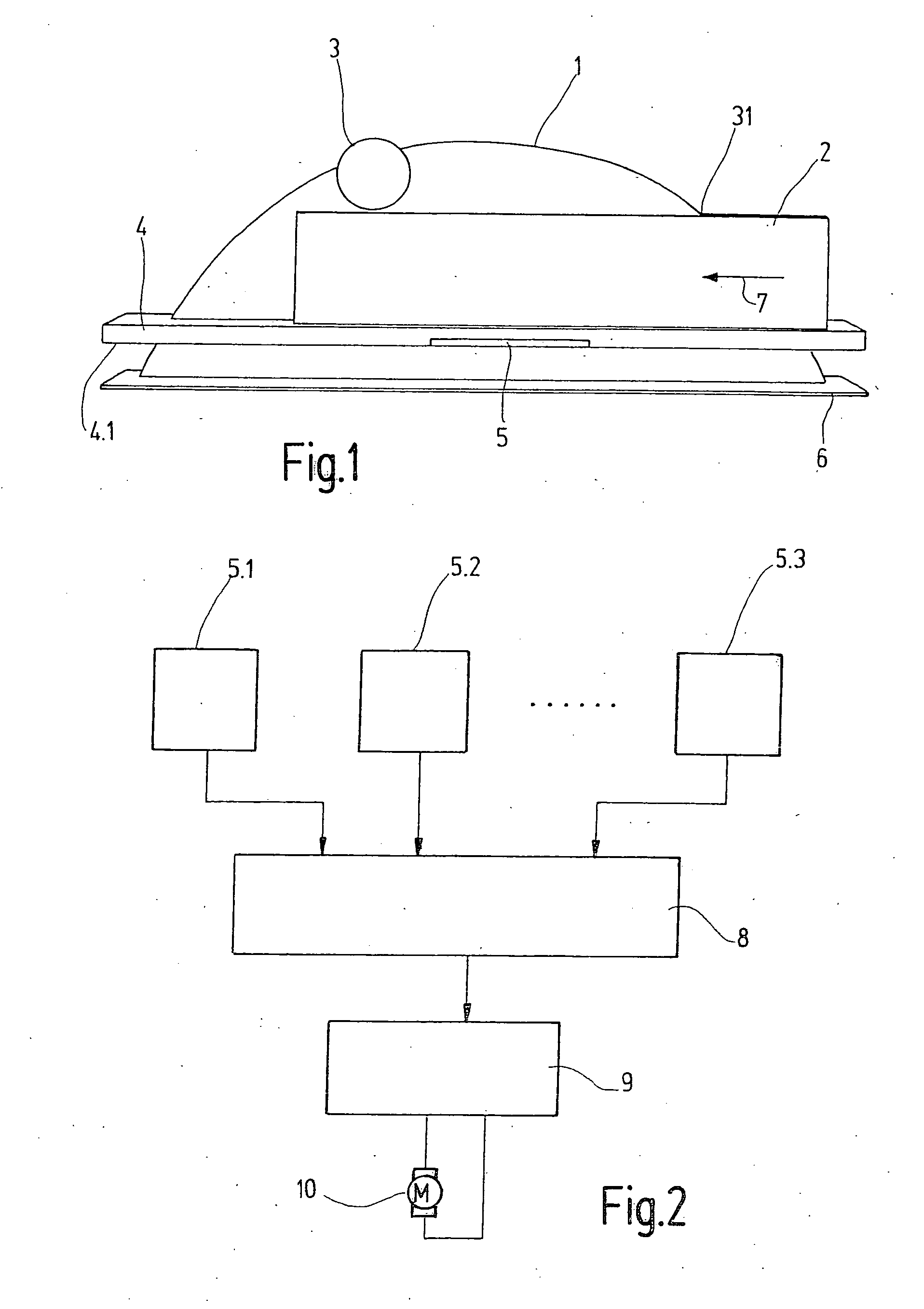

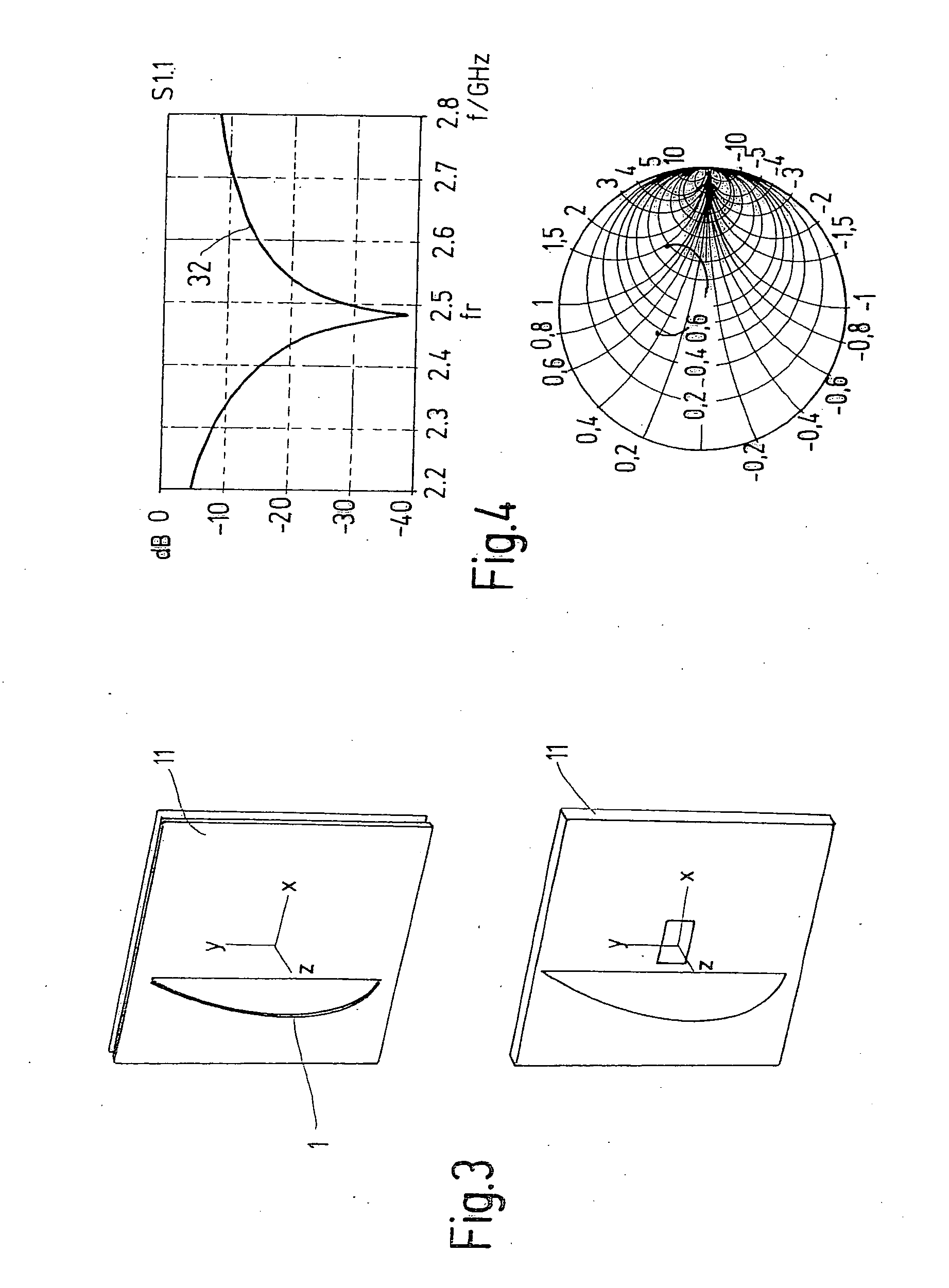

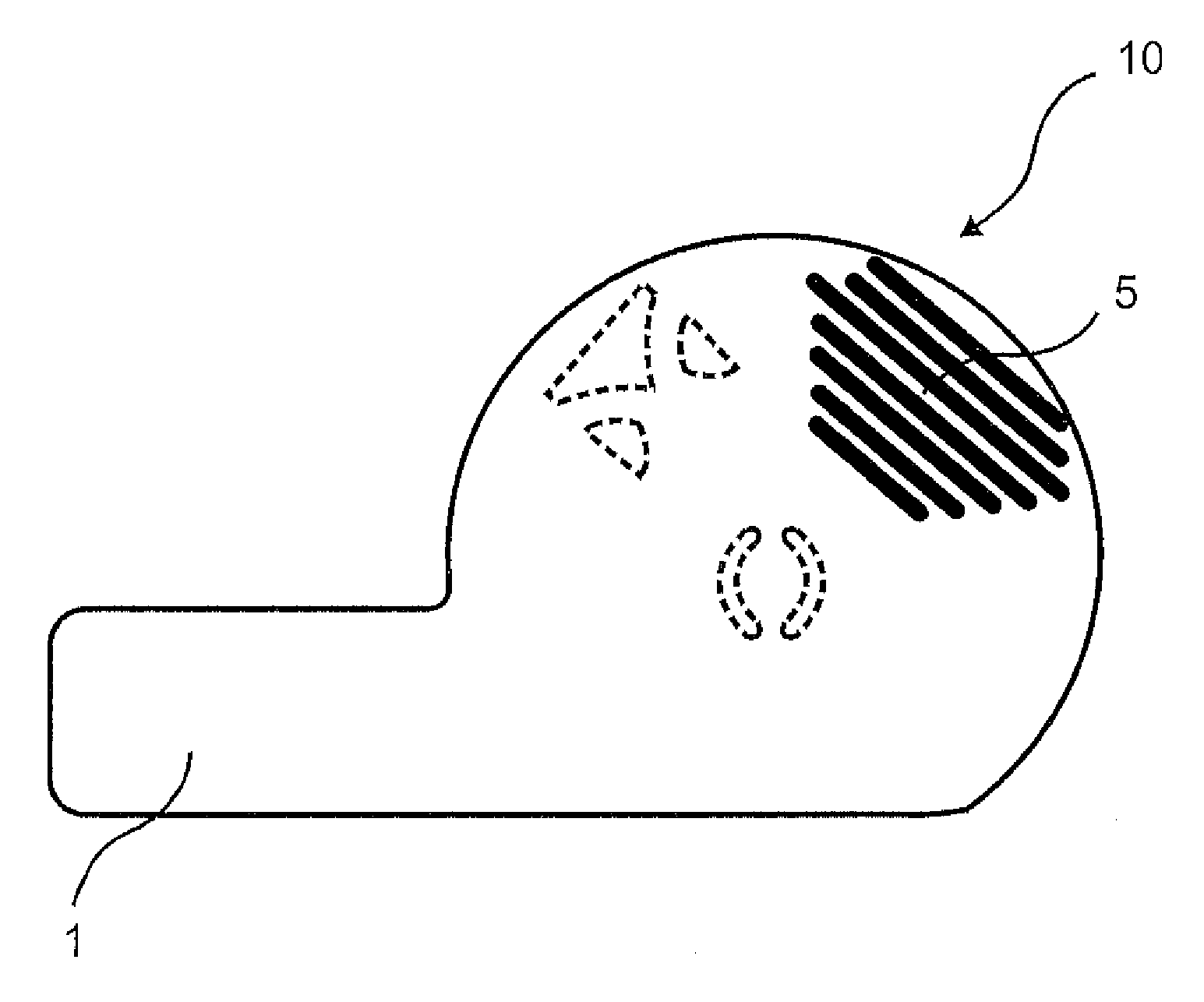

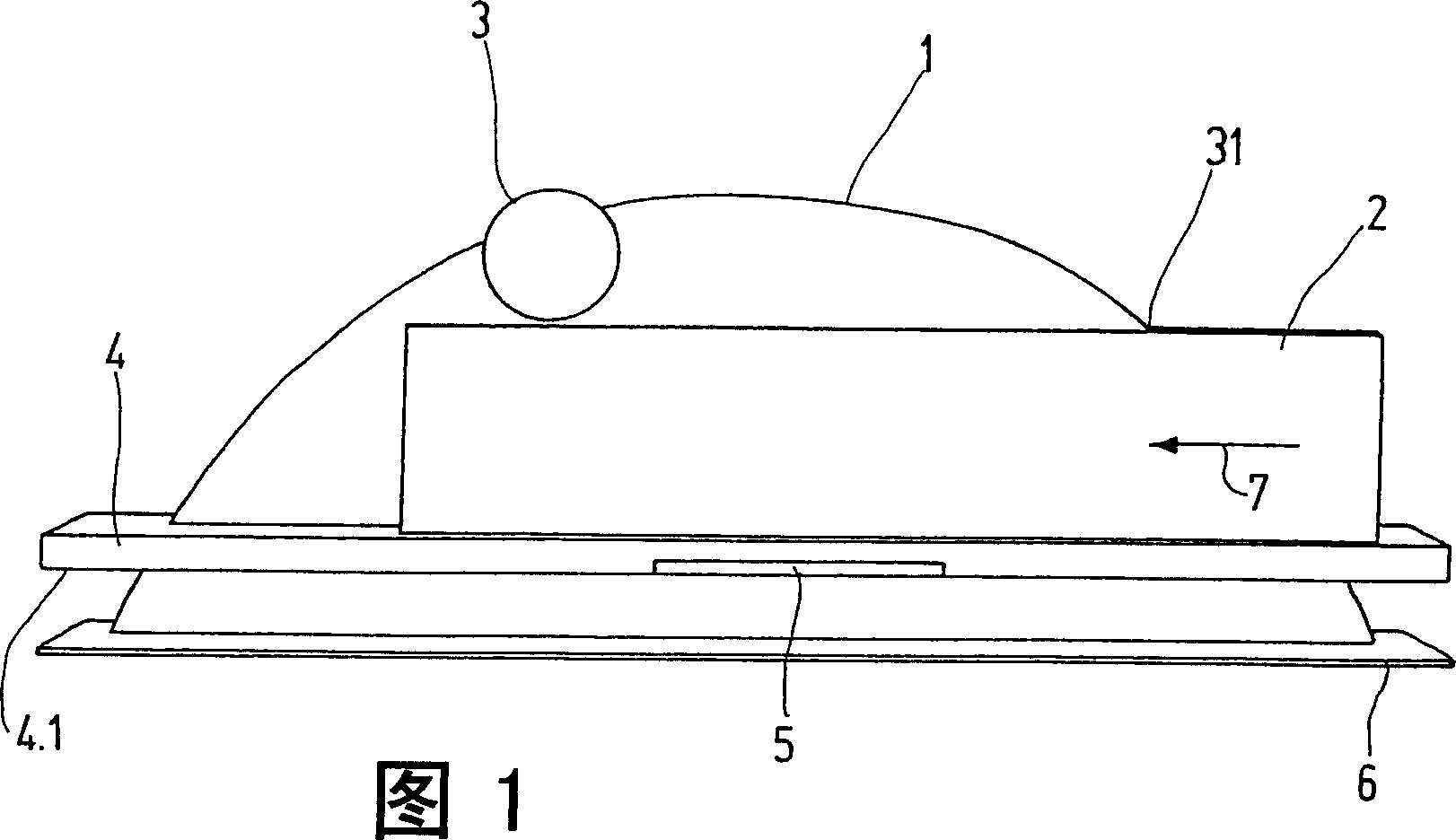

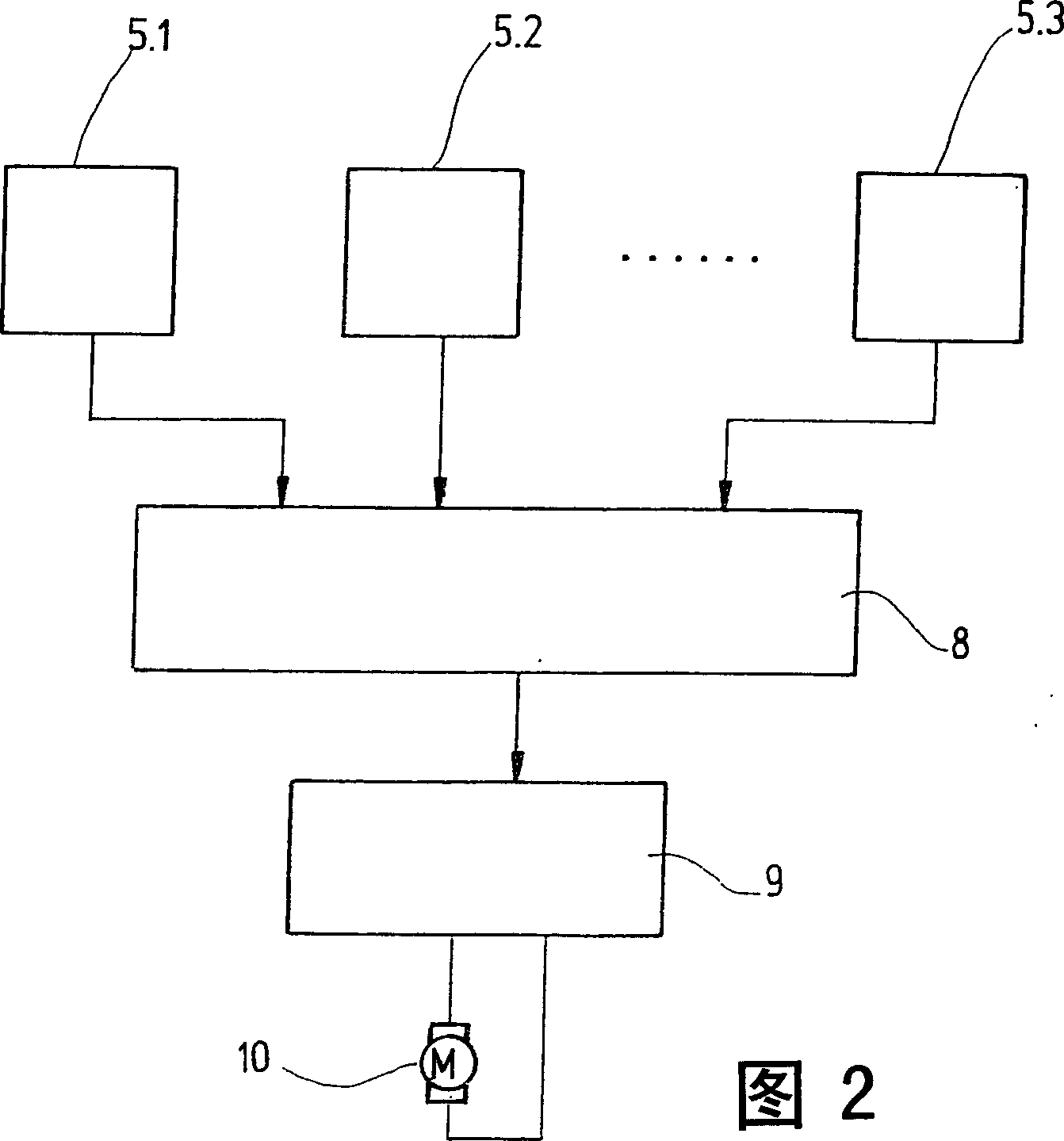

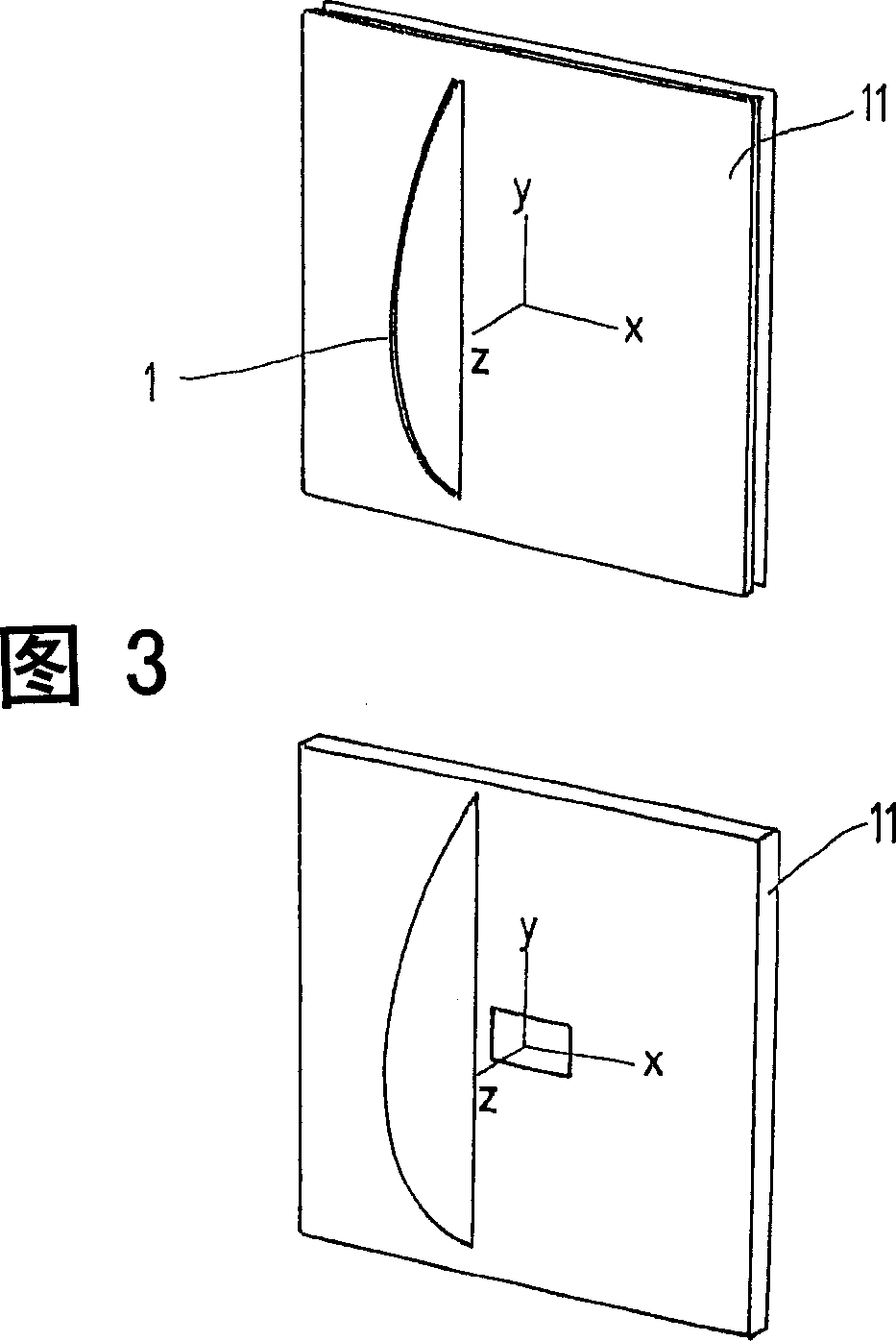

Device for protecting against accidental contact and method for protecting against accidental contact of a displaceable part

ActiveUS20050145080A1Sufficient degree of safetyNot to hinder workEmergency protective circuit arrangementsShearing machinesElectromagnetic fieldContact protection

The invention relates to a contact protection device. The device according to the invention has a sensor (5) for generating and detecting an electromagnetic field situated in the vicinity of a moving part (1) that should not be touched. The device according to the invention also has an evaluation unit (8) that is connected to the sensor (5) in order to evaluate sensor signals that can be generated by the sensor (5), wherein the evaluation unit (8) can generate an evaluation signal. Finally, a control unit (9) connected to the evaluation unit (8) is provided, which is designed and can be operated so as to control the movement of the part (1) as a function of the evaluation signal.

Owner:ROBERT BOSCH GMBH

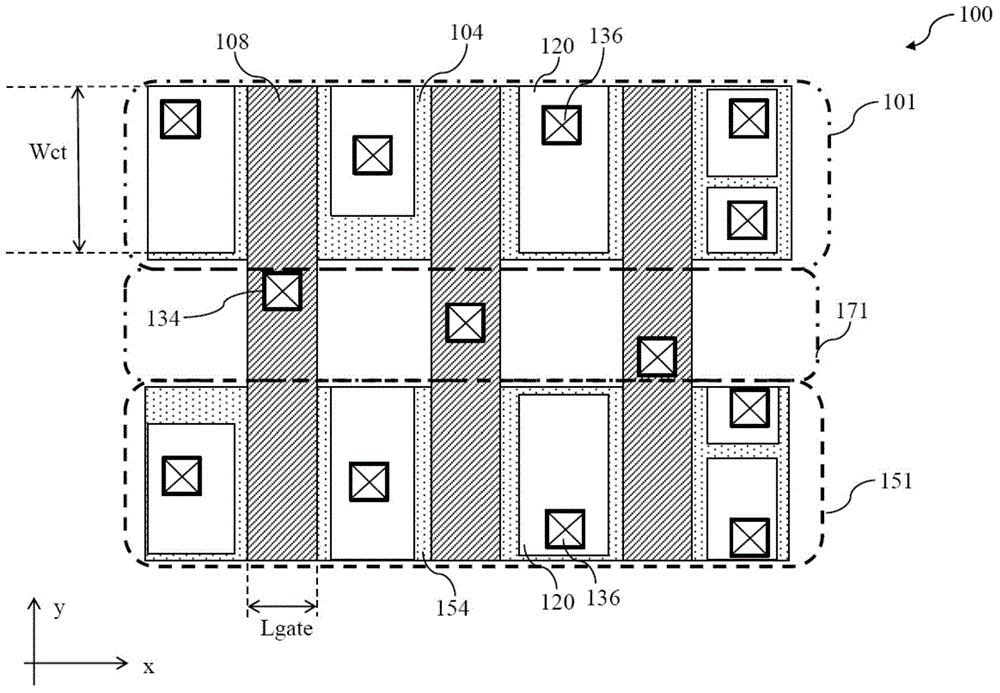

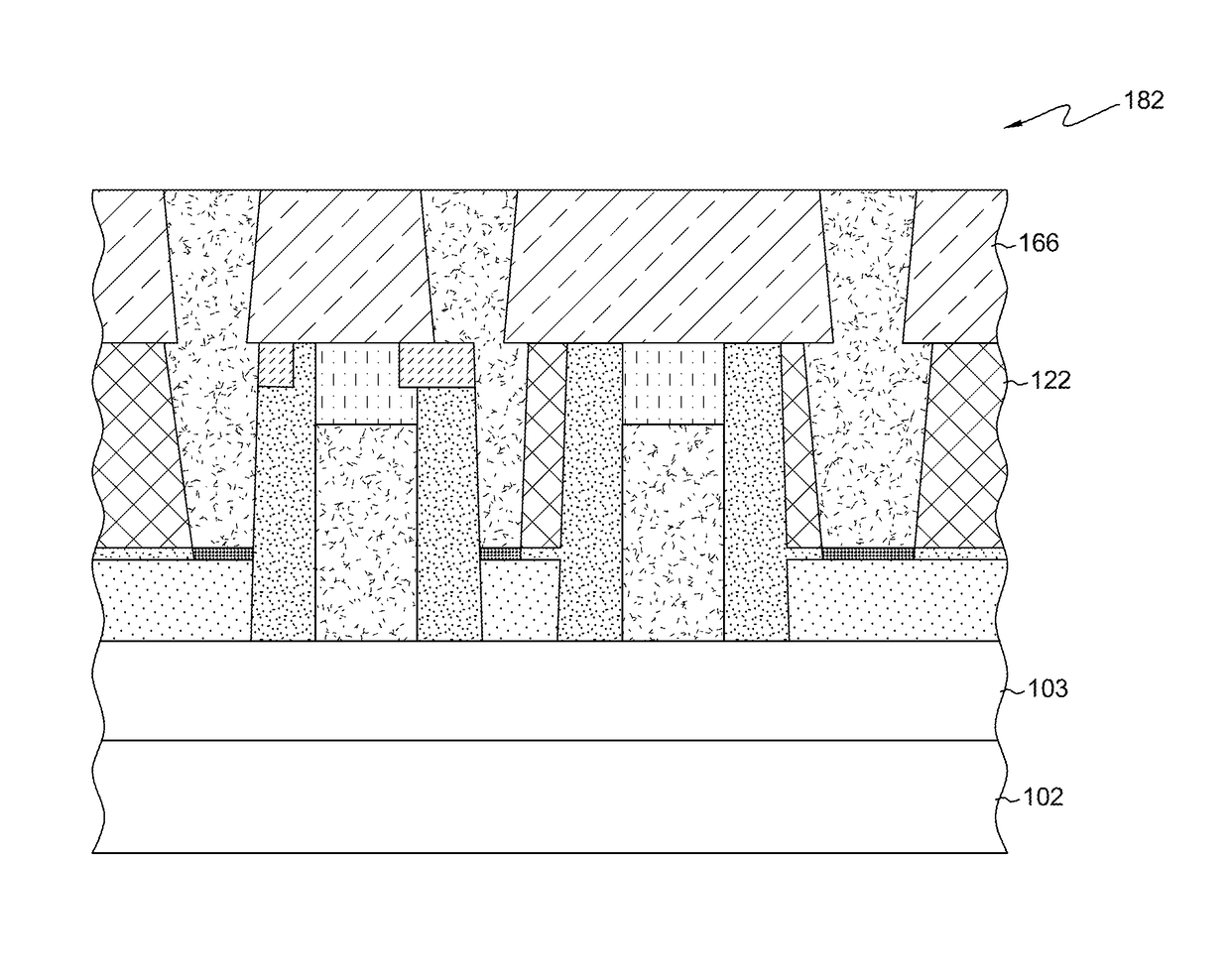

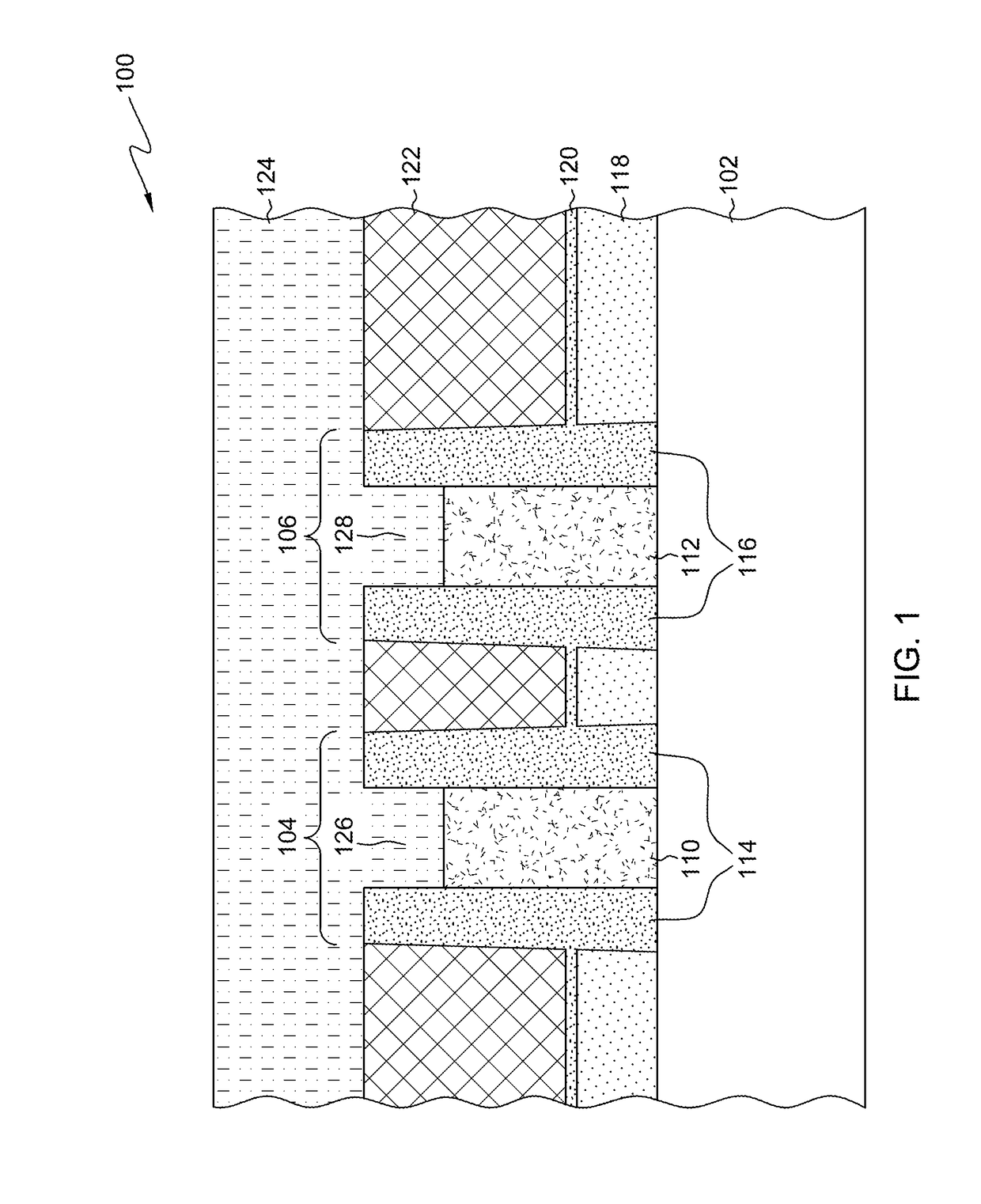

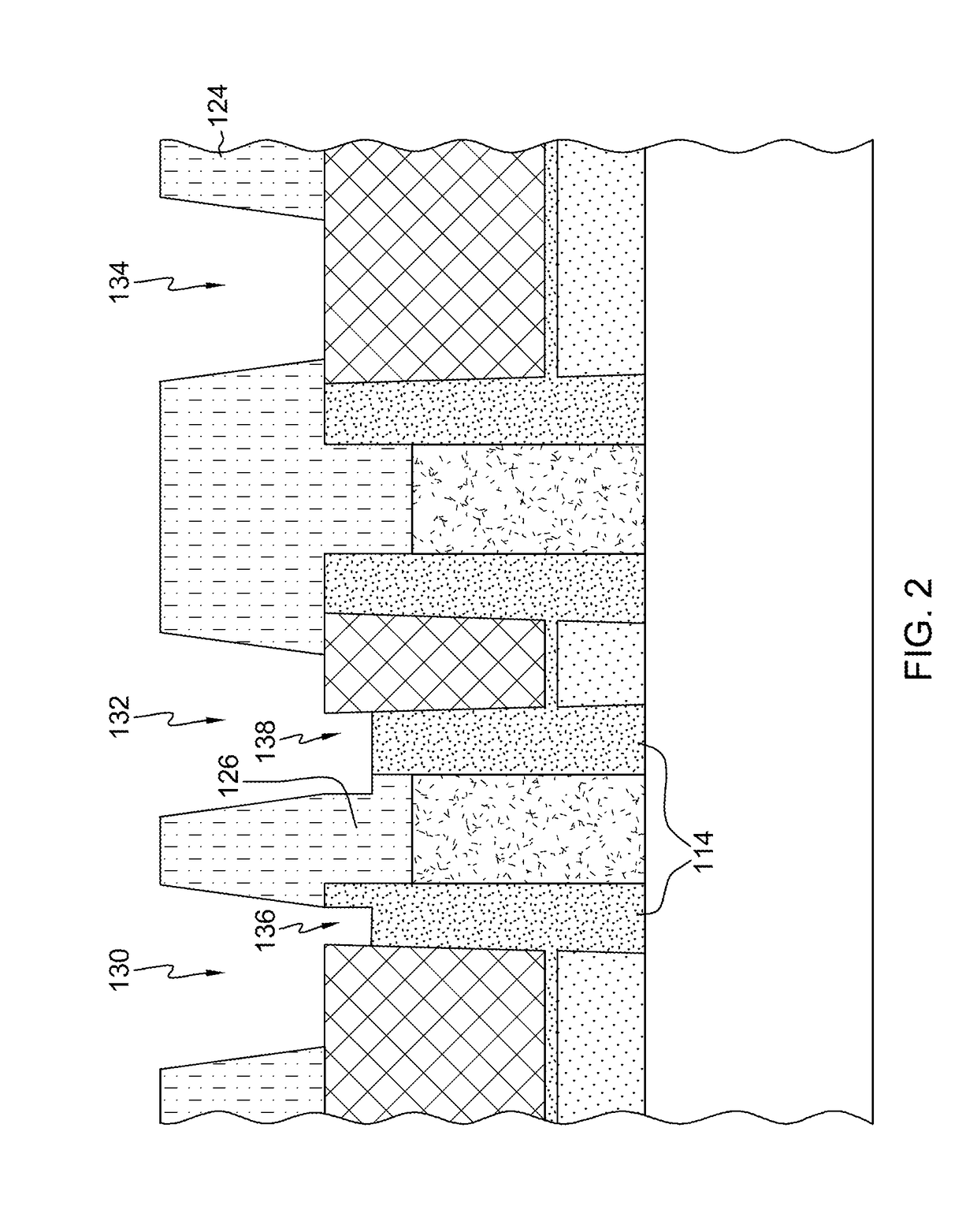

Structure and method for semiconductor device

InactiveCN105097470ASmall sizeProtection against accidental short circuitsTransistorSemiconductor/solid-state device detailsGate stackProtection layer

Provided is a semiconductor device and methods of forming the same. The semiconductor device includes a substrate having source / drain regions and a channel region between the source / drain regions; a gate structure over the substrate and adjacent to the channel region; source / drain contacts over the source / drain regions and electrically connecting to the source / drain regions; and a contact protection layer over the source / drain contacts. The gate structure includes a gate stack and a spacer. A top surface of the source / drain contacts is lower than a top surface of the spacer, which is substantially co-planar with a top surface of the contact protection layer. The contact protection layer prevents accidental shorts between the gate stack and the source / drain regions when gate vias are formed over the gate stack. Therefore, gate vias may be formed over any portion of the gate stack, even in areas that overlap the channel region from a top view.

Owner:TAIWAN SEMICON MFG CO LTD

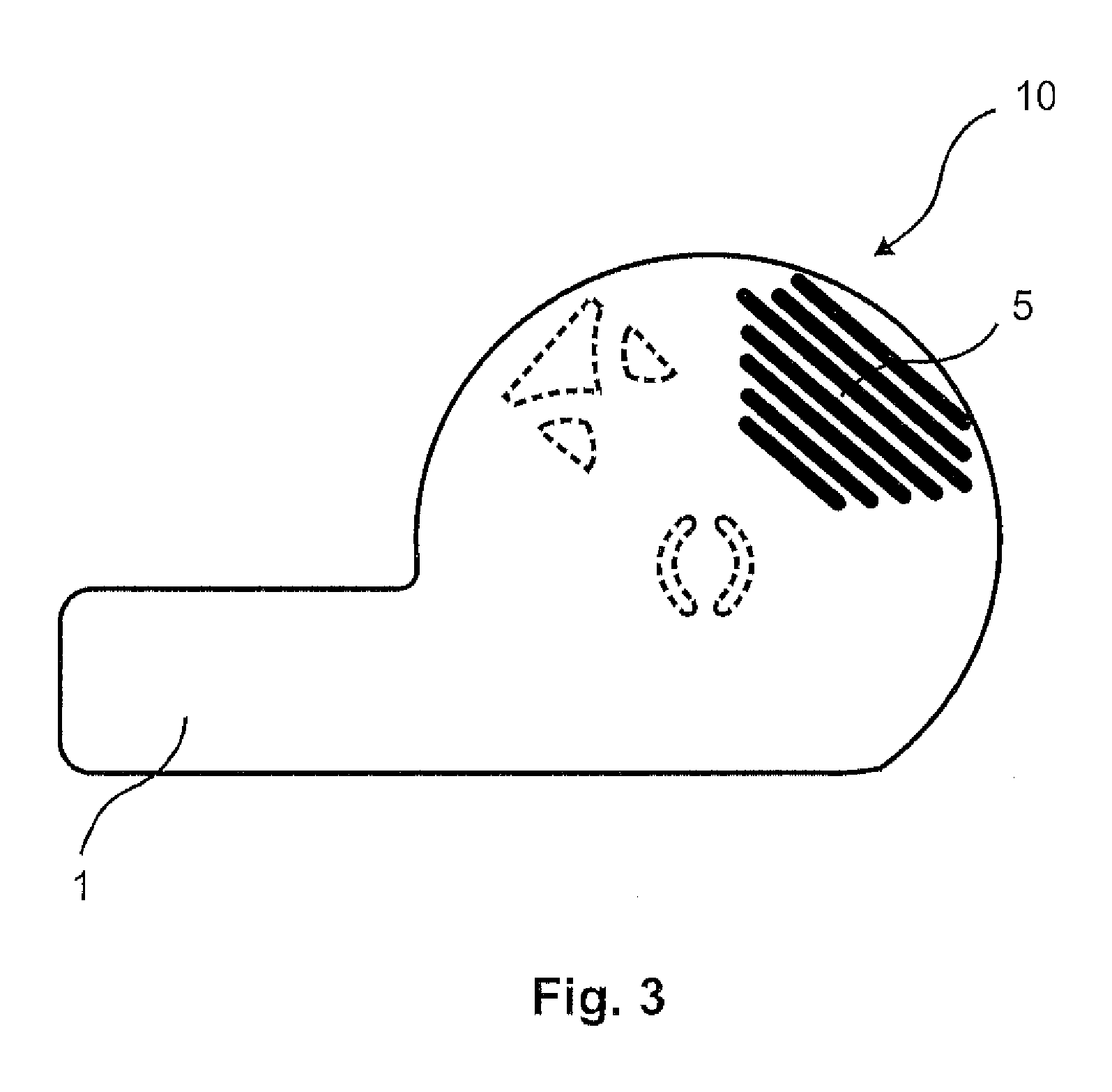

Contact protection apparatus for a medical fluid-conducting cassette and cassette

ActiveUS20130030404A1Firmly connectedPrevent movementDiagnosticsSurgeryBiomedical engineeringContact protection

The present invention relates to a contact protection apparatus for covering a connection point of a medical fluid-conducting cassette for a medical fluid treatment, having at least one covering device for covering the connection point before the use of the cassette, and having at least one connection section for detachably connecting or holding the contact protection apparatus on the cassette. The present invention further relates to a medical fluid-conducting cassette having at least one contact protection apparatus according to the present invention.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

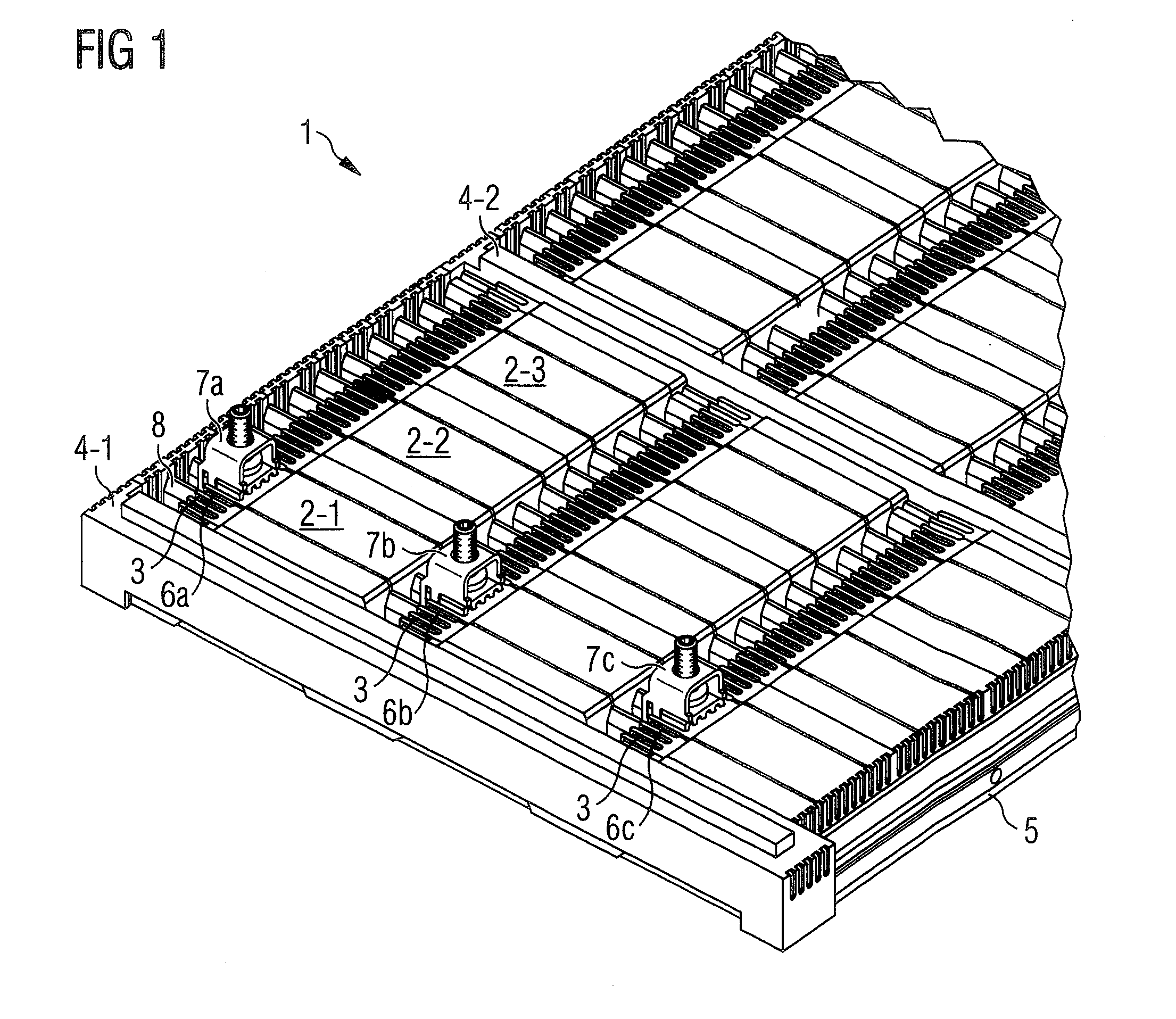

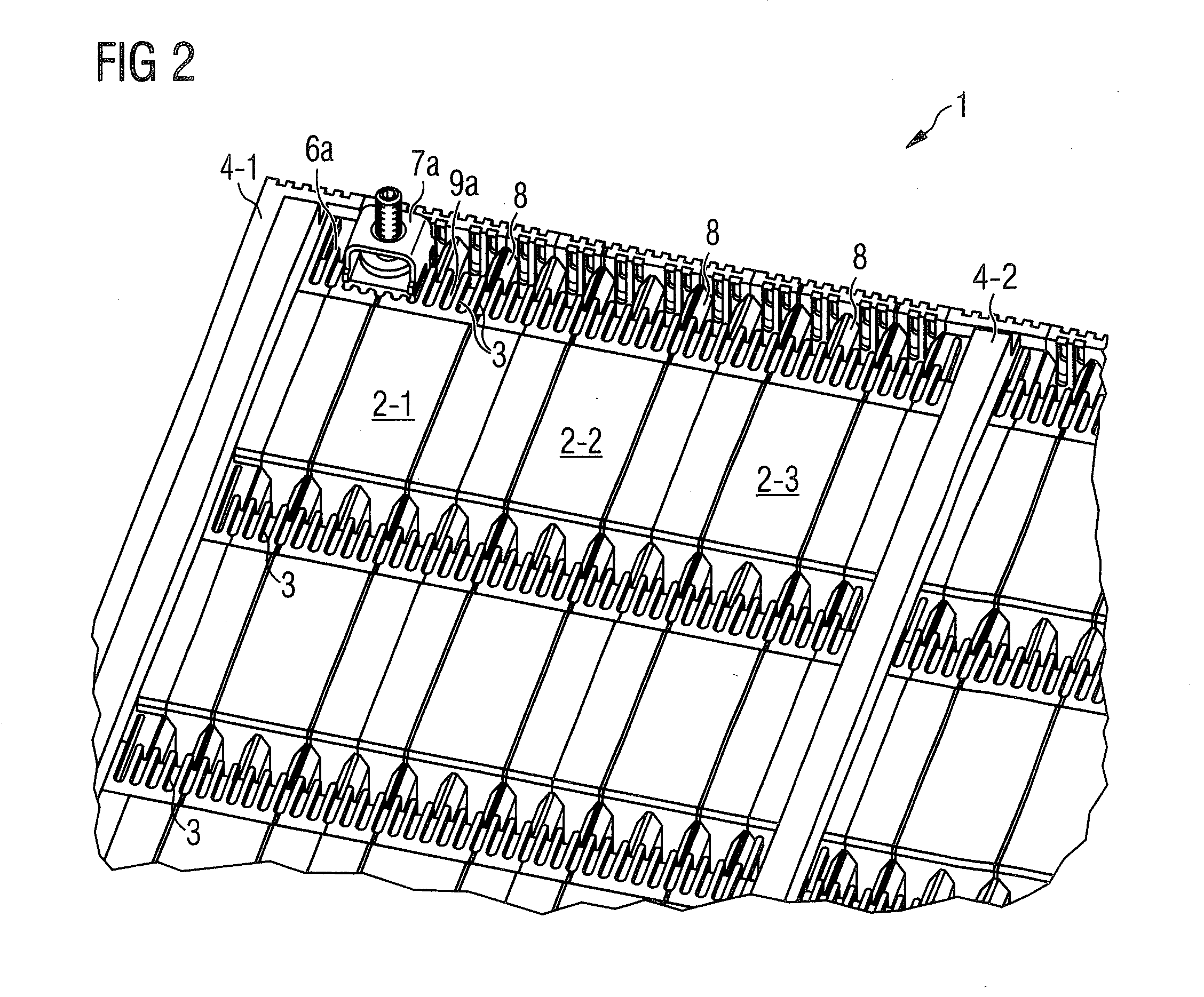

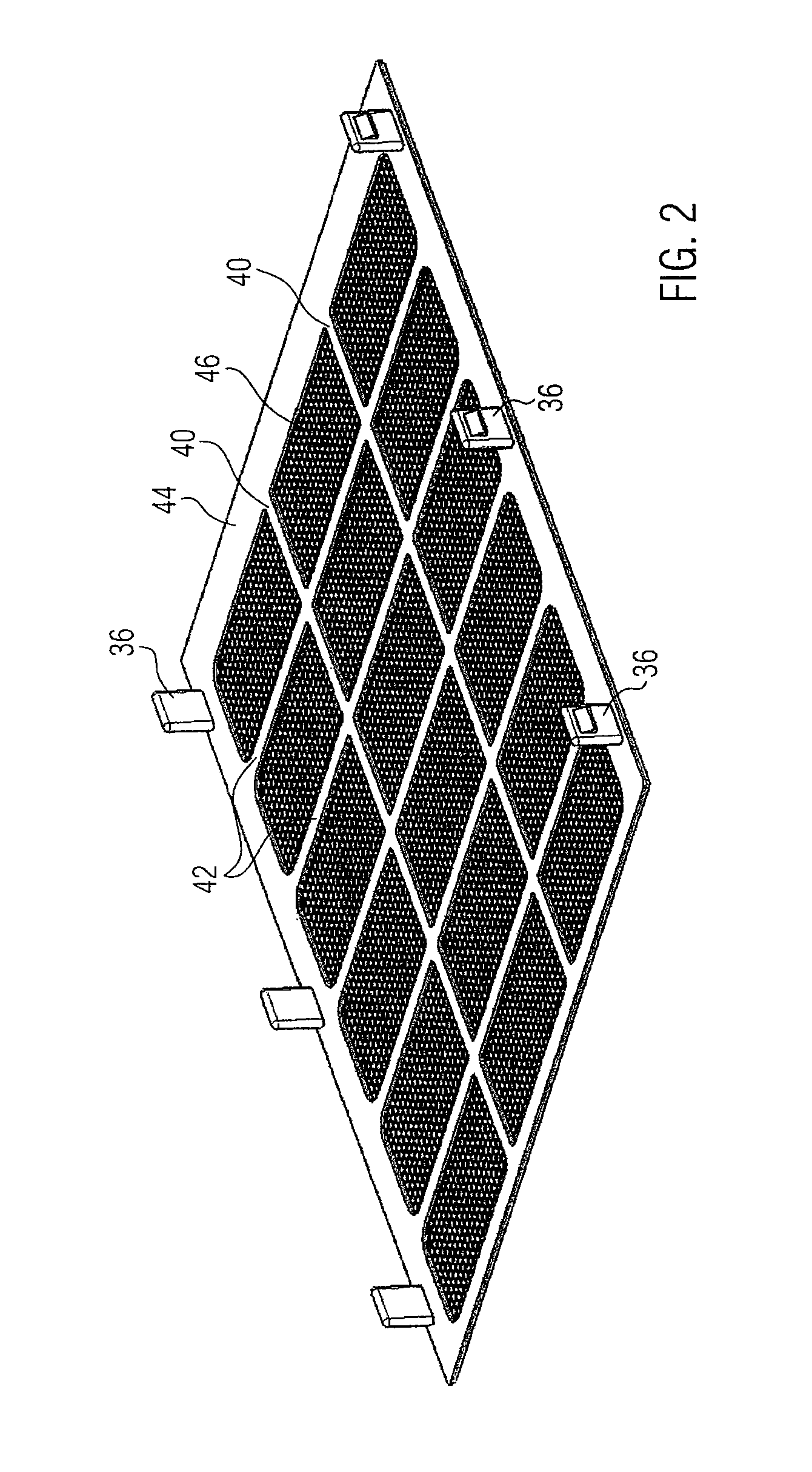

Contact protection system for power busbars

ActiveUS20150111426A1The method is simple and convenientAvoid disadvantagesBus-bar/wiring layoutsElectrically conductive connectionsElectricityBusbar

Contact protection system for power busbars having planar contact protection modules which each comprise holding feet for engaging behind the power busbars and latching elements for mutually latching with adjacent contact protection module, wherein the contact protection modules comprise for each power busbar a terminal-receiving region for receiving connecting terminals which are provided for electrically contacting the respective power busbar.

Owner:WOHNER GMBH & CO KG ELEKTROTECHNISCHE SYST

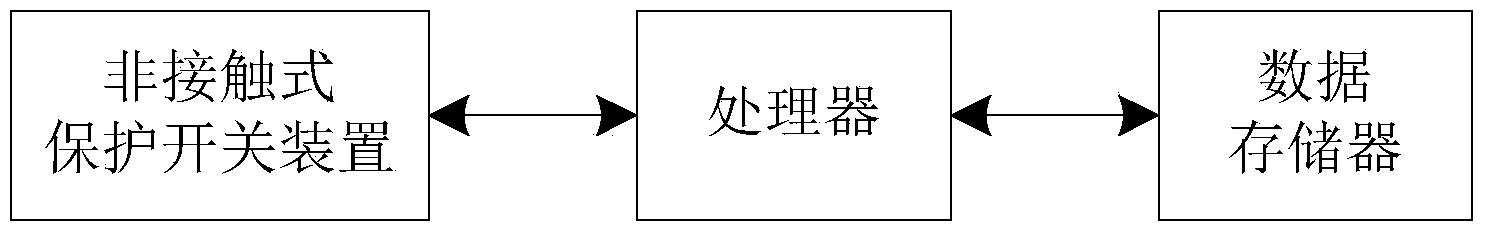

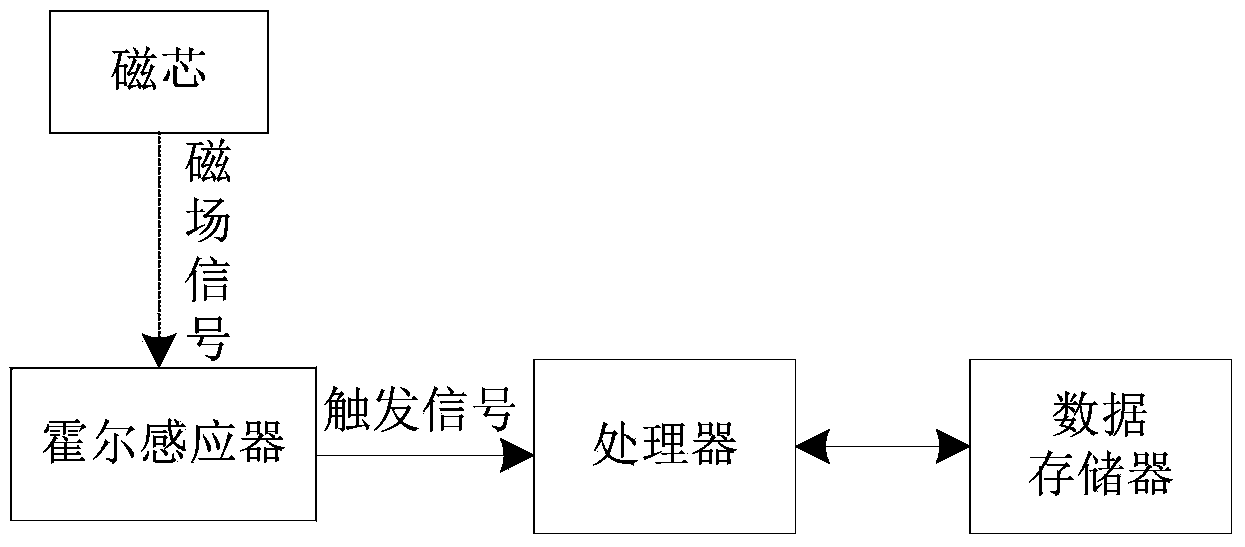

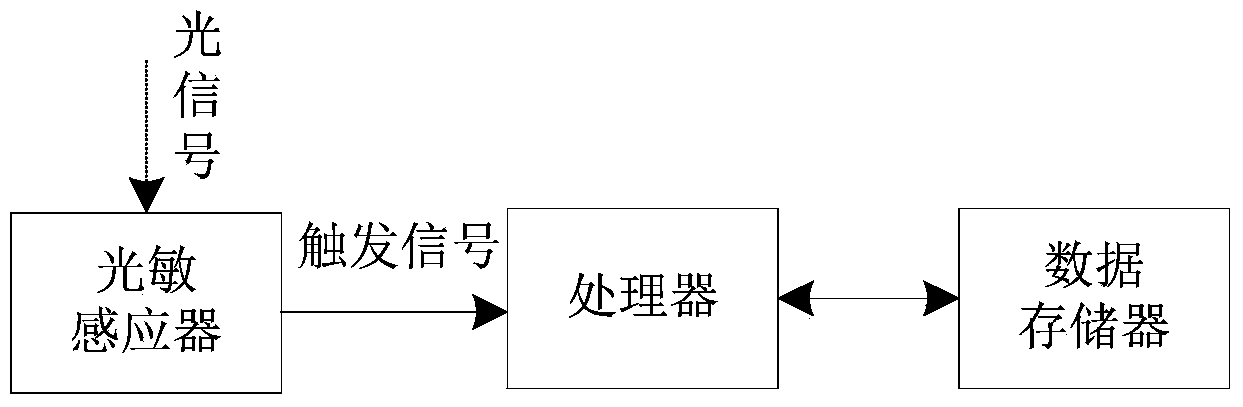

Casing with non-contact protection switch and POS machine

InactiveCN103456108AAchieve tamper protection effectOvercoming false triggersCash registersEngineeringLight signal

The invention discloses a casing with a non-contact protection switch and a POS machine with the casing. The casing with the non-contact protection switch comprises a casing body and a non-contact protection switch device arranged in the casing body and used for preventing the casing body from being disassembled. The casing body comprises a casing bottom and a casing cover. According to the casing with the non-contact protection switch and the POS machine, the non-contact protection switch device is used for replacing a traditional physical and mechanical switch device, the protection switch is triggered through the skillful utilization of changes of magnetic field signals or light signals, the casing anti-disassembly and protection effect is achieved, meanwhile, the defects that a casing anti-disassembly device in the prior art is prone to causing false triggering and poor in stability and reliability are overcome, and unnecessary losses caused by false triggering are avoided. The casing with the non-contact protection switch can be widely applied to various casings with protection circuits and POS machines.

Owner:SHENZHEN XINGUODU TECH

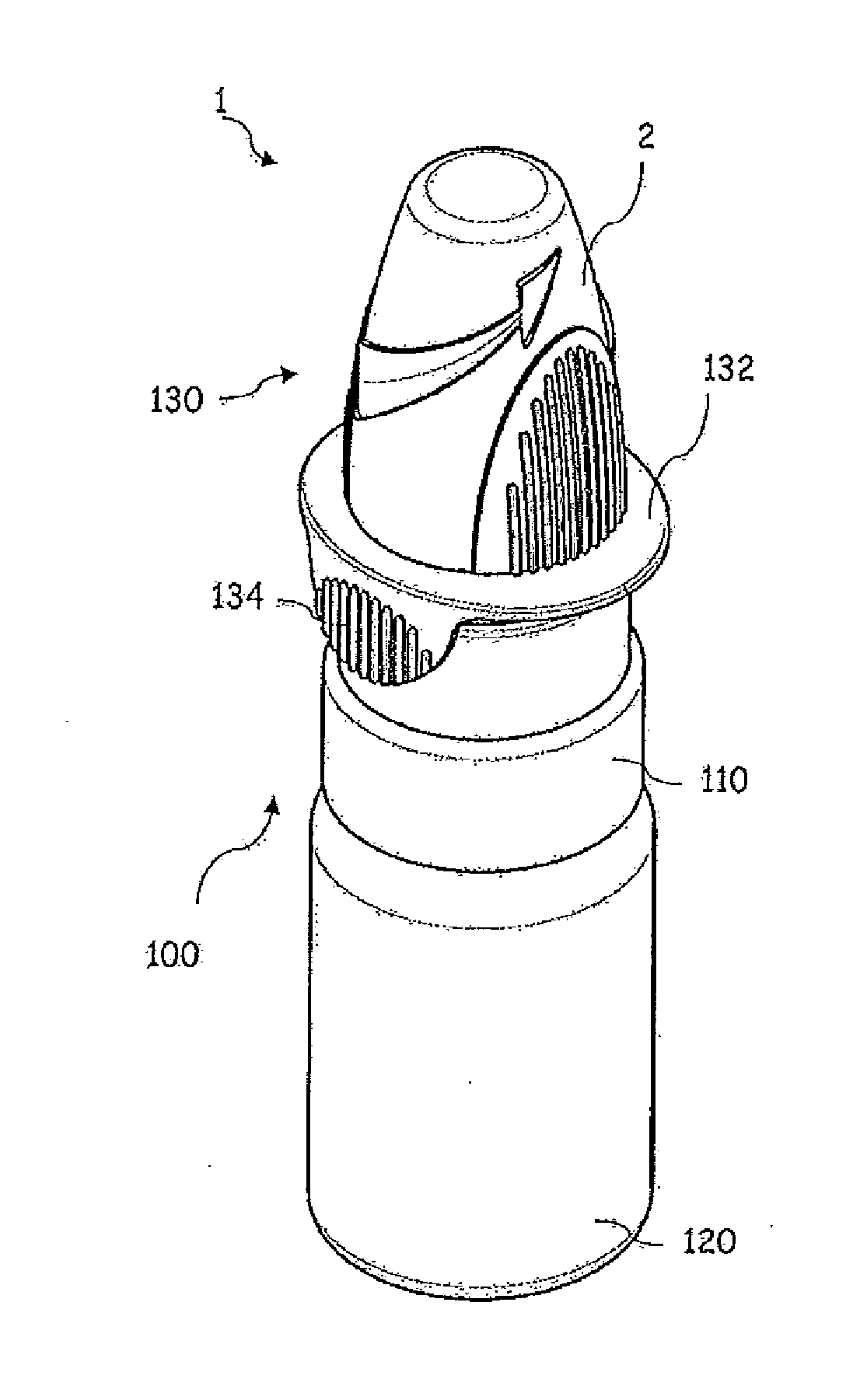

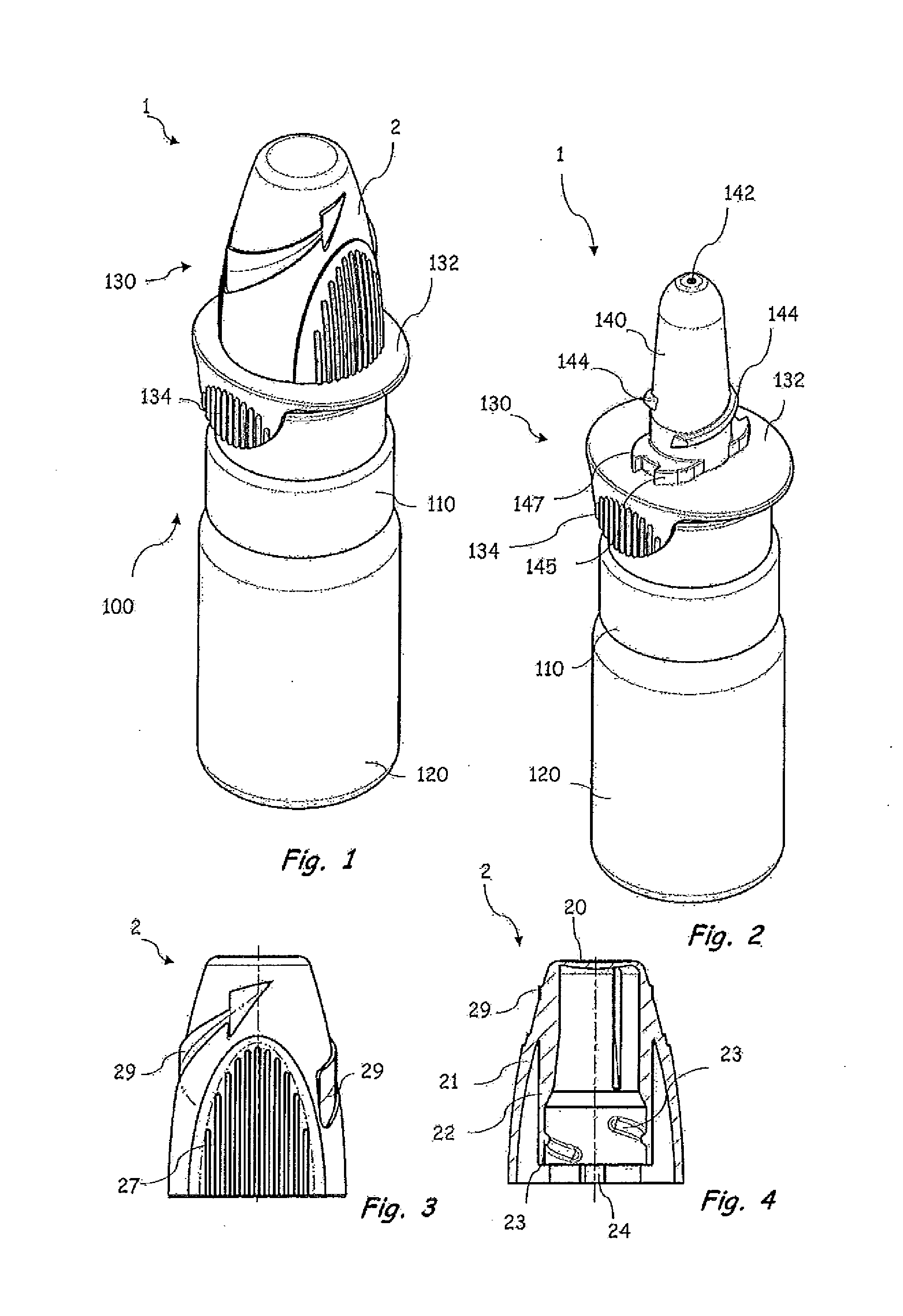

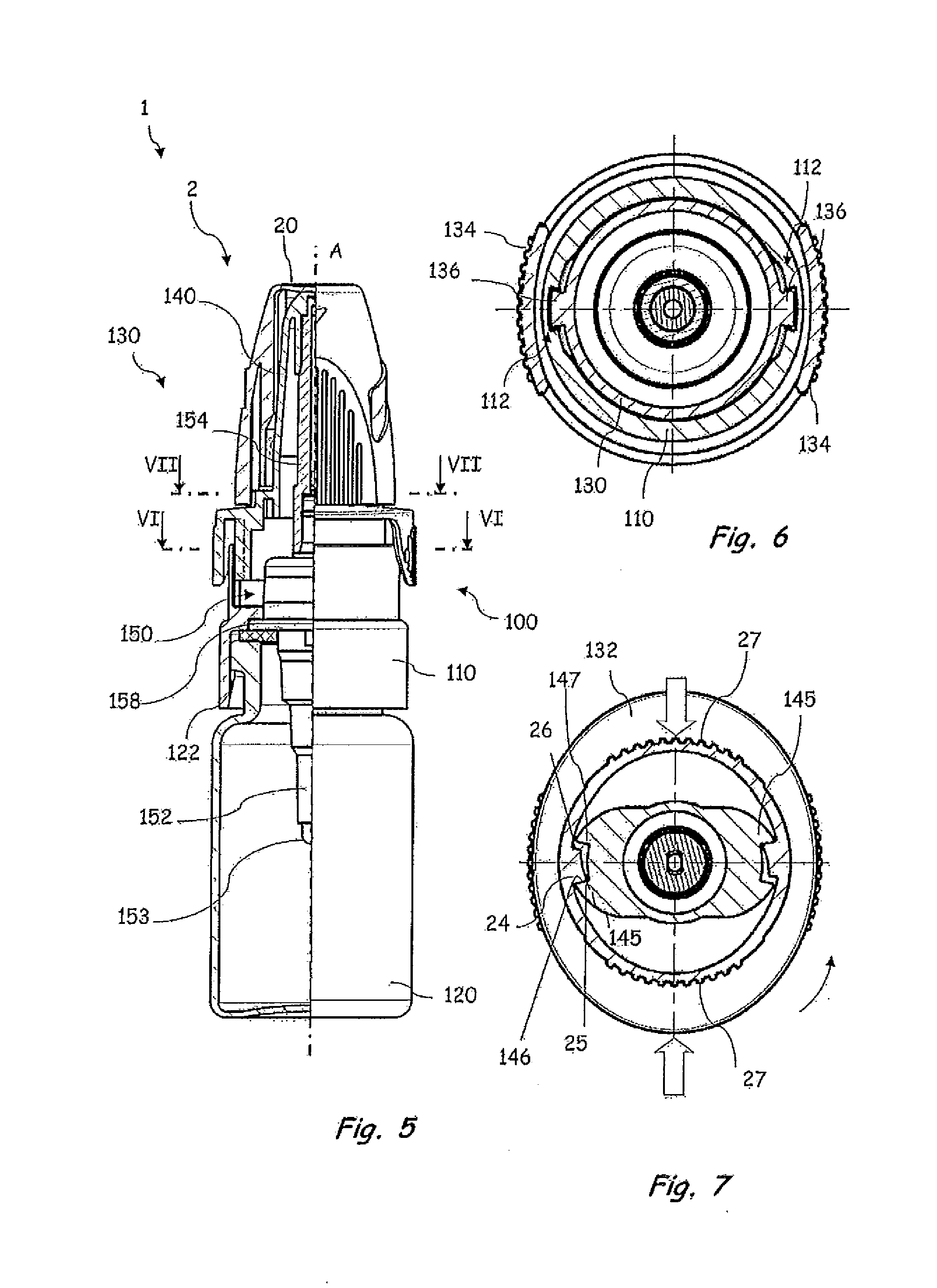

Childproof discharging device

ActiveUS20160243319A1Low structural expenditureEffective child lockClosuresMedical devicesEngineeringContact protection

A discharging device for a pharmaceutical liquid dispenser including a housing, an applicator tip with a discharge opening and a protective cap. A locking tooth is provided on the protective cap and a counter tooth is provided on the applicator tip. The locking tooth passes over the counter tooth when the protective cap is rotated relative to the applicator tip in a first direction, and the locking tooth and the counter tooth prevent rotation in a direction opposite the first direction. The protective cap and the applicator tip are adapted to each other such that the discharge opening contacts a lid region of the protective cap after the locking tooth has passed over the counter tooth, and the discharge opening can be closed in a sealed manner by the protective cap. The protective cap is deformable to disengage the locking tooth and the counter tooth.

Owner:APTAR RADOLFZELL

Device for protecting against accidental contact and method for protecting against accidental contact of a displaceable part

InactiveCN1717563AFavorable expansion structureSimple structureMetal sawing accessoriesEngineering safety devicesElectromagnetic fieldContact protection

The invention relates to a device for protecting against accidental contact. The inventive device comprises a sensor (5) for producing and detecting an electromagnetic field, which is arranged in close proximity to a non-contactable displaceable part (1). The inventive device also comprises an evaluation unit (8) which is connected to the sensor (5) in order to evaluate the sensor signal produced by the sensor (5). An evaluation signal can be produced by the evaluation unit (8). Said device further comprises a control unit (9) which is connected to the evaluation unit (8) and which is embodied and operated in such a manner that the movement of the part (1) can be controlled according to the evaluation signal.

Owner:ROBERT BOSCH GMBH

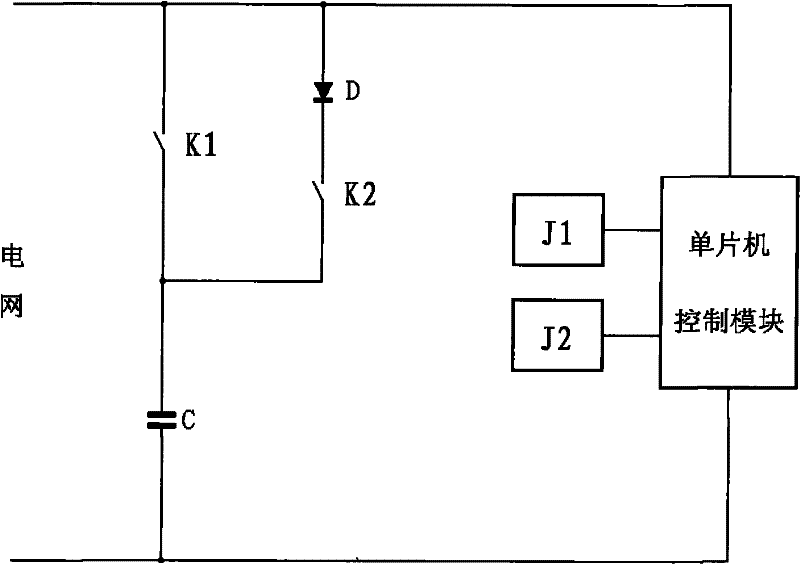

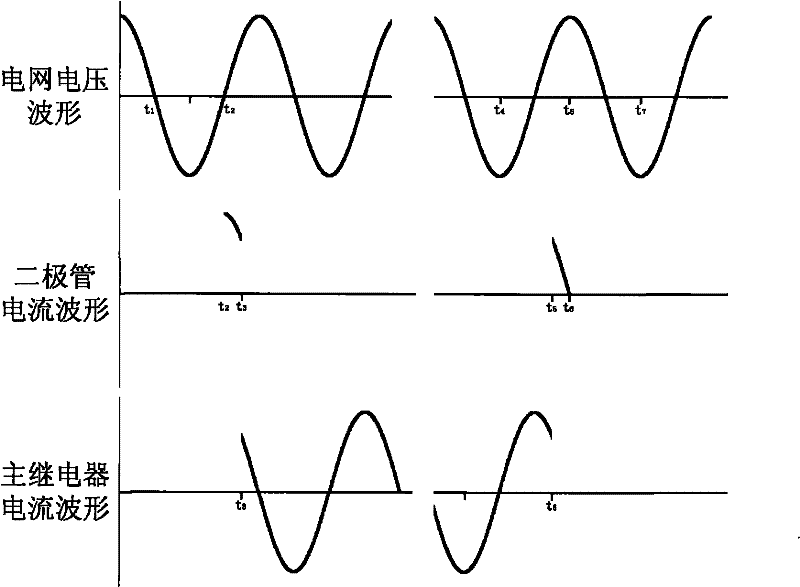

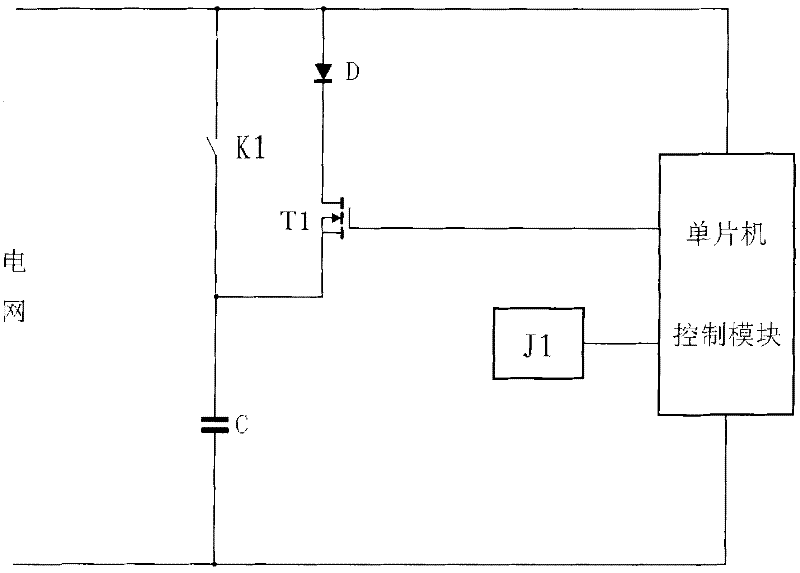

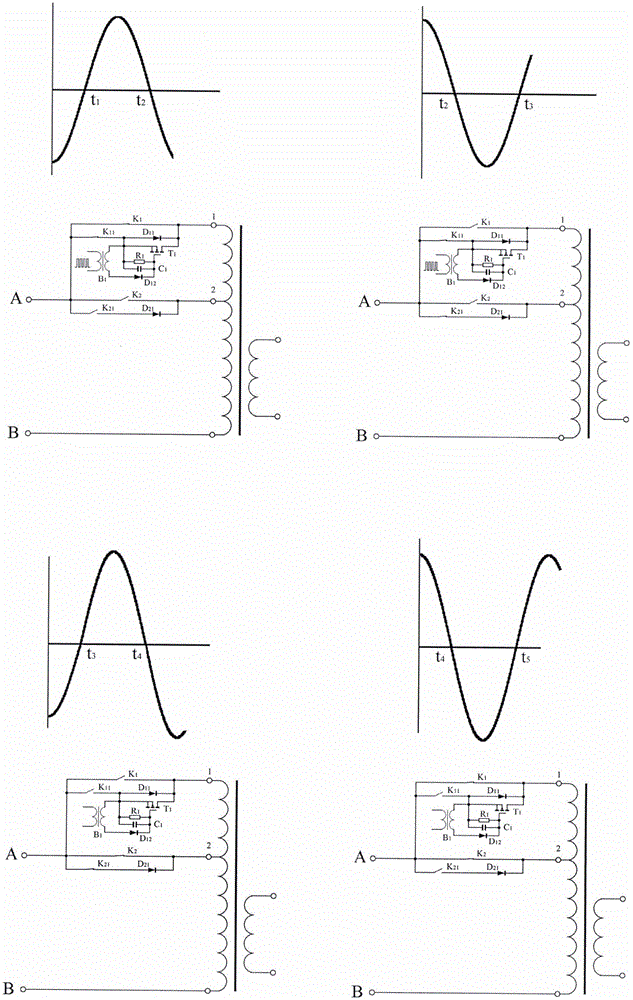

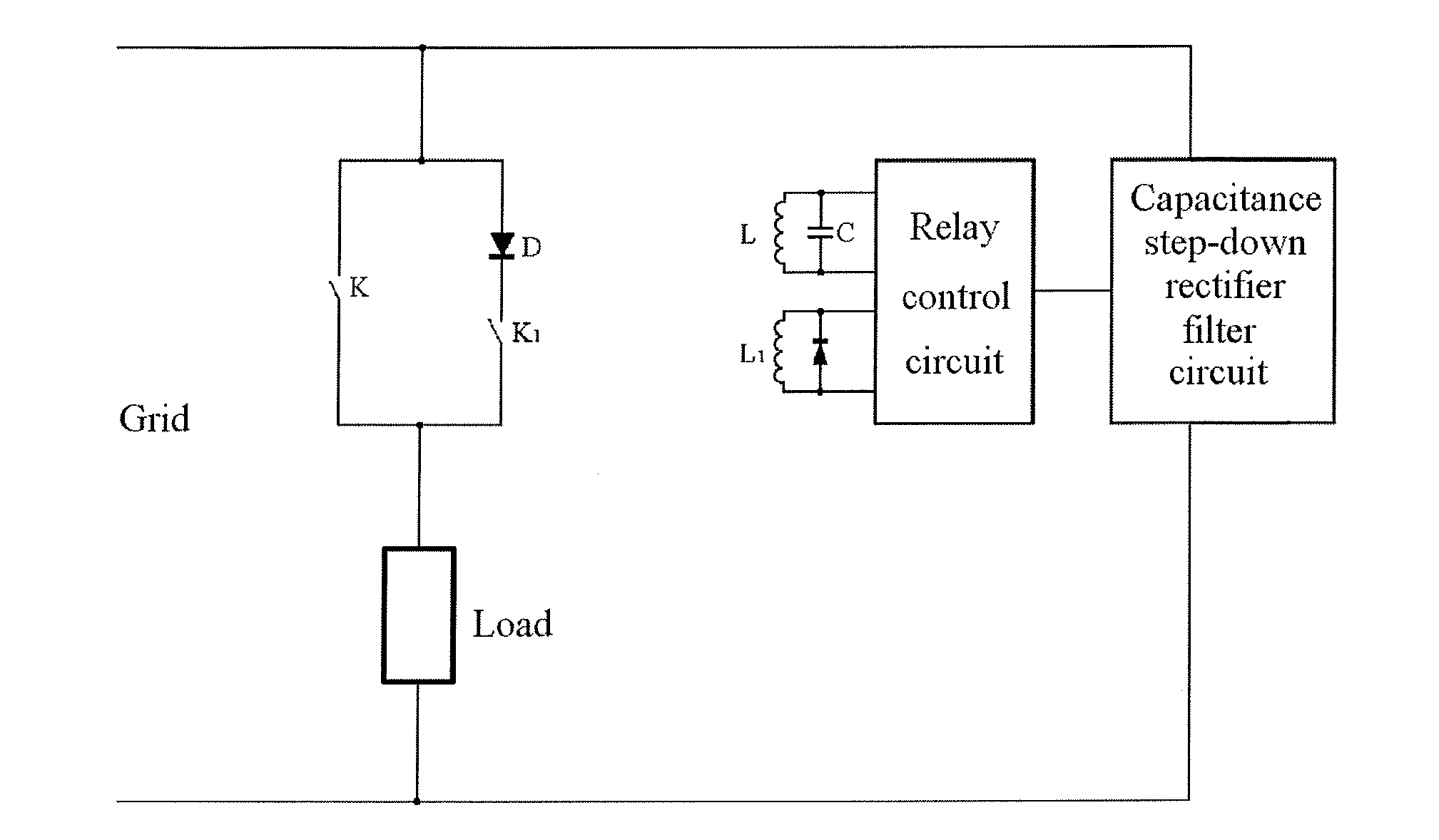

AC capacitor switching circuit

InactiveCN102299519ASimple structureLow costEmergency protective circuit arrangementsReactive power adjustment/elimination/compensationElectronic switchAlternating current

The invention proposes a switching method and switching circuit of an AC capacitor. A main relay contact protection circuit is formed by a diode and an auxiliary relay in parallel at both ends of the relay contacts, and the main relay contacts are closed or broken during the conduction period of the diode. Open, there is no surge current and no contact ignition when the contacts are in action. The withstand voltage of the switching switch when it is disconnected is equivalent to that of the relay switching switch, and the misleading phenomenon of the electronic switch will not be found, and the switching speed Equivalent to thyristor switching. It has the characteristics of simple circuit, reliable operation, low cost and fast switching speed.

Owner:王海

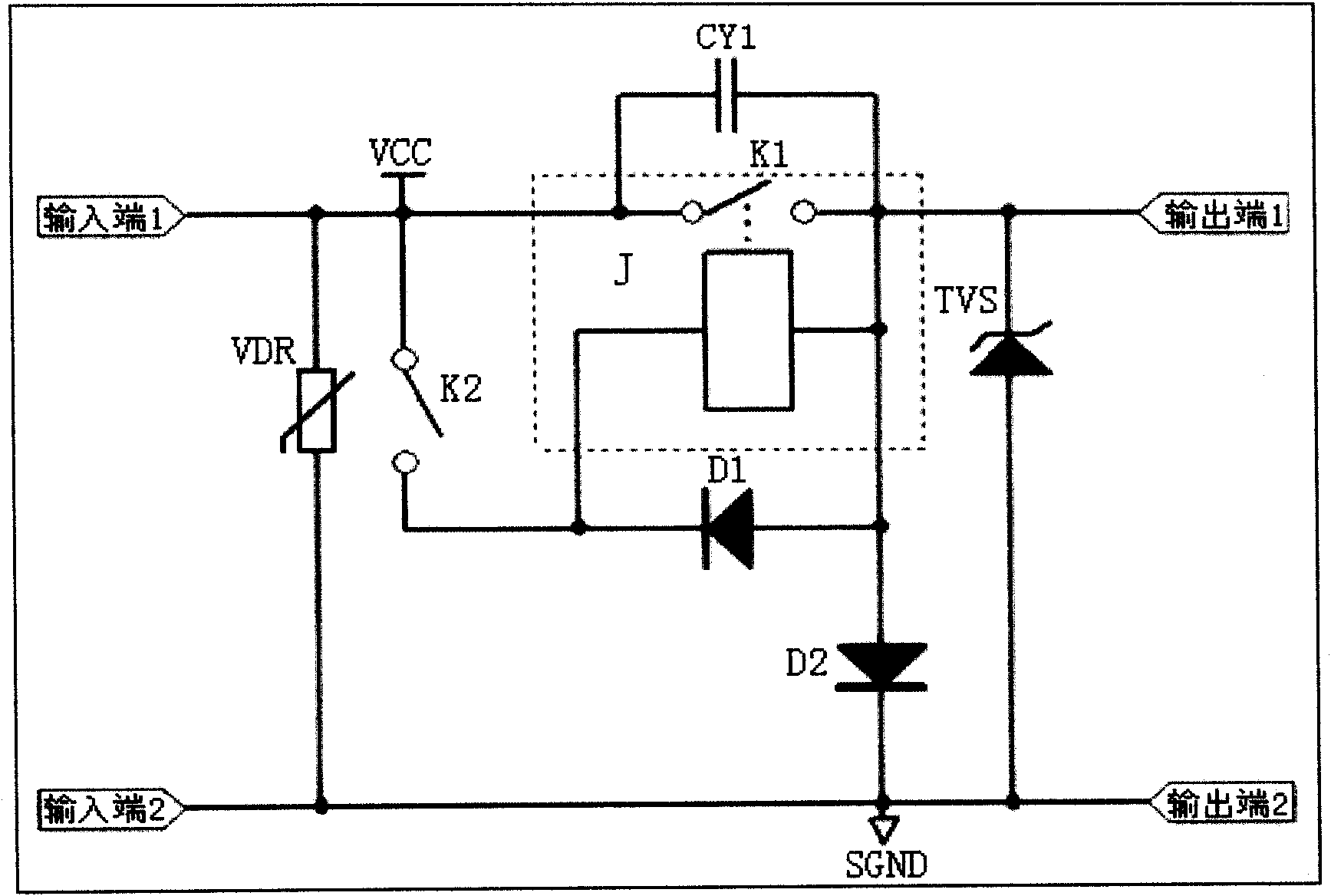

Circuit with reversed power polarity and inrush voltage protection

InactiveCN101615779AEffective protectionFree from damageEmergency protective arrangements for limiting excess voltage/currentArrangements responsive to excess voltageOvervoltageEngineering

The invention discloses a protection circuit which is used for preventing reversed polarity of power and inrush voltage, comprising an overvoltage protection circuit; the invention is characterized by further comprising a protection circuit against reversed polarity; the overvoltage protection circuit is composed of a voltage dependent resistor and a transient voltage suppresser; one end of the voltage dependent resistor is connected with an input end 1 and a power anode, and the other end is connected with an input end 2 and a grounding terminal; a positive end of the transient voltage suppresser is connected with an output end 2 and the grounding terminal, and a negative end of the transient voltage suppresser is connected with an output end 1; the protection circuit against reversed polarity comprises a relay contact protection circuit and a sub-circuit; the relay contact protection circuit is serially connected between the power anode and the output end 1; one end of the sub-circuit is connected with the power anode, and the other end is connected with the output end 2. The invention realizes a reversed polarity protection circuit with low current controlling big current, low power consumption and high reliability, to ensure correct polarity connection of the input power and effectively protect precise components in inner circuit, thus ensuring the normal and reliable running of power in the electronic circuit.

Owner:SHANGHAI BOOM FIBER SENSING TECH

Contact protection circuit and high voltage relay comprising the same

ActiveUS20120013200A1Extended service lifeTimely controlBoards/switchyards circuit arrangementsEmergency protective arrangements for automatic disconnectionHigh resistanceElectrical resistance and conductance

The invention provides a switching device having a contact protection circuit for arcing suppression. The switching device comprises a main relay for interrupting a load path and a dual coil auxiliary having a high resistance coil and a low resistance coil that operate the switching of an auxiliary contact. The auxiliary contact is connected in series with a PTC device and the low resistance coil of the auxiliary relay in a series arrangement. The series arrangement is connected in parallel to the main contact. When the main relay opens, the auxiliary contact is maintained closed during a given time interval due to the magnetic flux generated by the low resistance coil. The given time interval depends on the transition of the PTC device to trip state. In another configuration, the dual coil relay is substituted by two auxiliary relays.

Owner:TYCO ELECTRONICS FRANCE +1

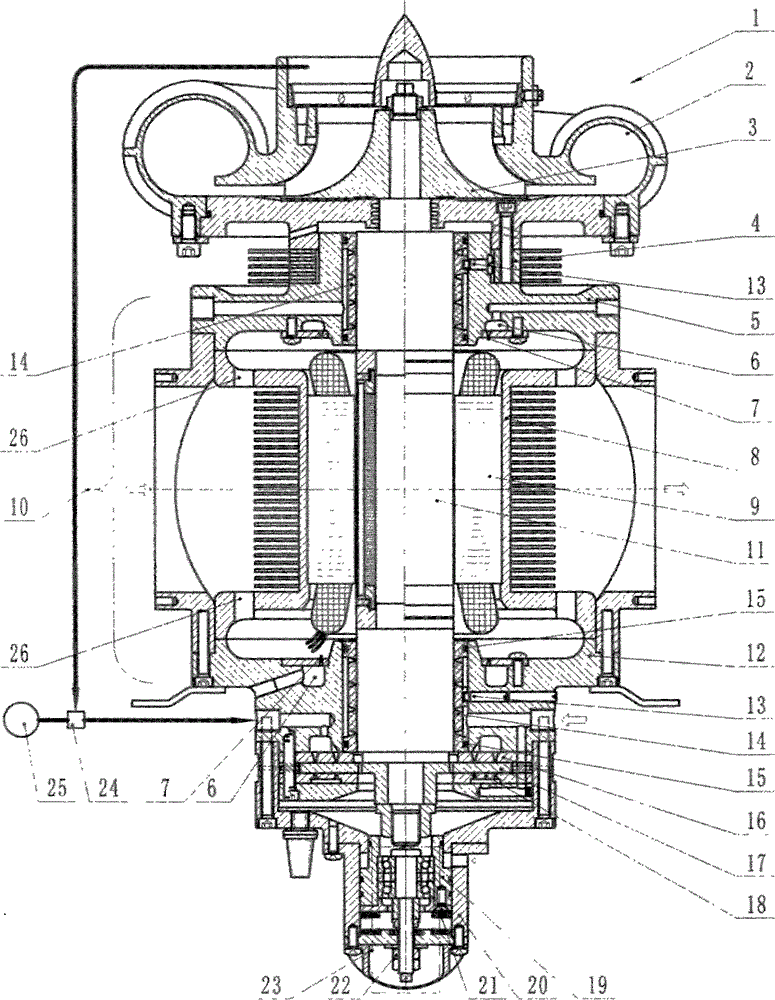

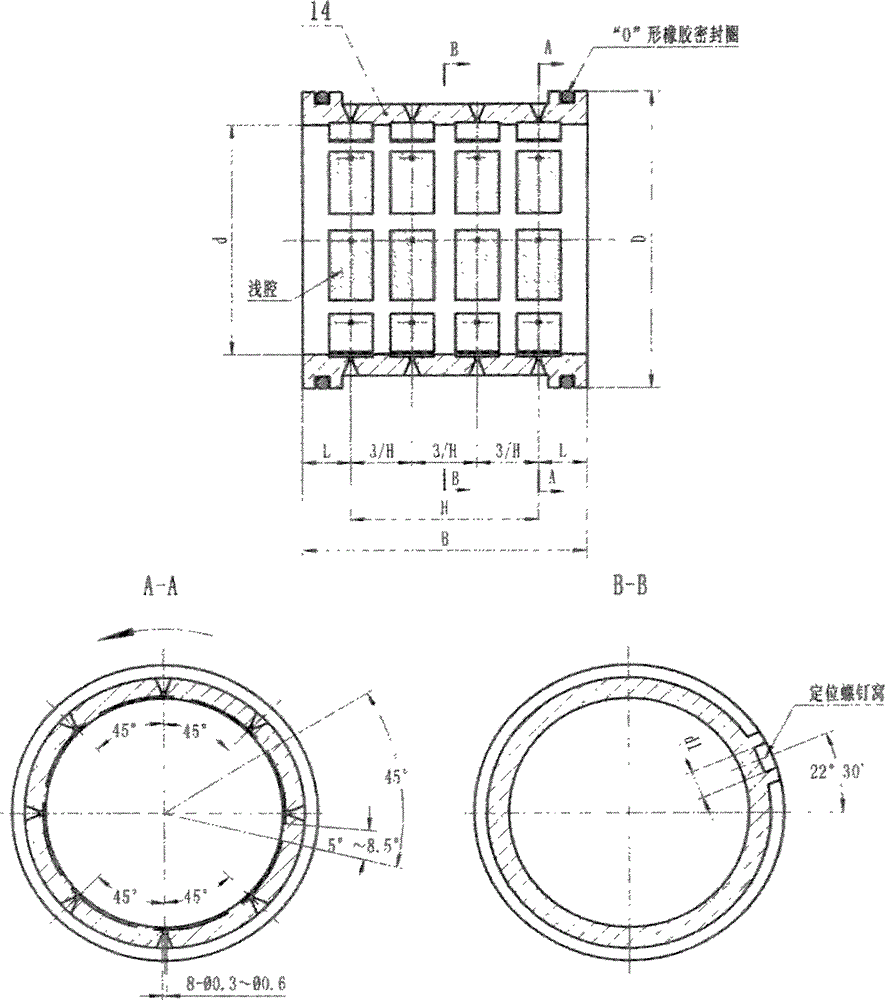

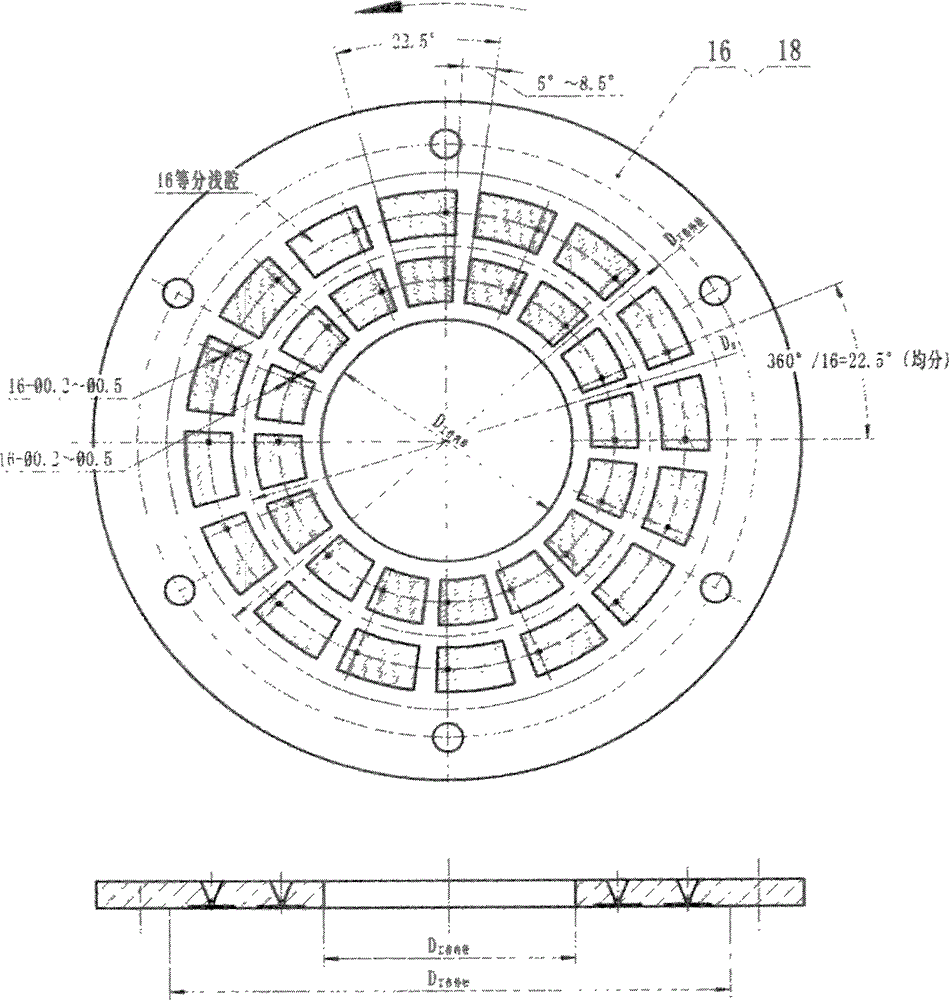

Gas dynamic-static pressure mixing bearing system for high-speed motor and electric rotating machinery

InactiveCN104019131AGuaranteed uptimeBearingsSupports/enclosures/casingsRolling-element bearingEngineering

The invention relates to a gas dynamic-static pressure mixing bearing system for a high-speed motor. The gas dynamic-static pressure mixing bearing system is used for vertically supporting high-speed electric rotating machinery. One radial dynamic-static pressure mixing bearing is mounted on each of shaft necks of the upper end and the lower end of a motor rotor, and an axial dynamic-static pressure mixing bearing is closely mounted on the lower side of the radial dynamic-and-static pressure mixing bearing at the lower end; a rolling bearing axial support for carrying out non-contact protection on the axial bearing of the motor rotor is arranged at the bottom of the motor rotor, and finally the whole forms the gas dynamic-static pressure mixing bearing system for a high-speed motor rotor support. The high-speed electric rotating machinery of the gas dynamic-and-static pressure mixing bearing system is adopted, so that the motor rotor can realize the stable and high-speed rotation, and the effect is significant.

Owner:吴宏 +1

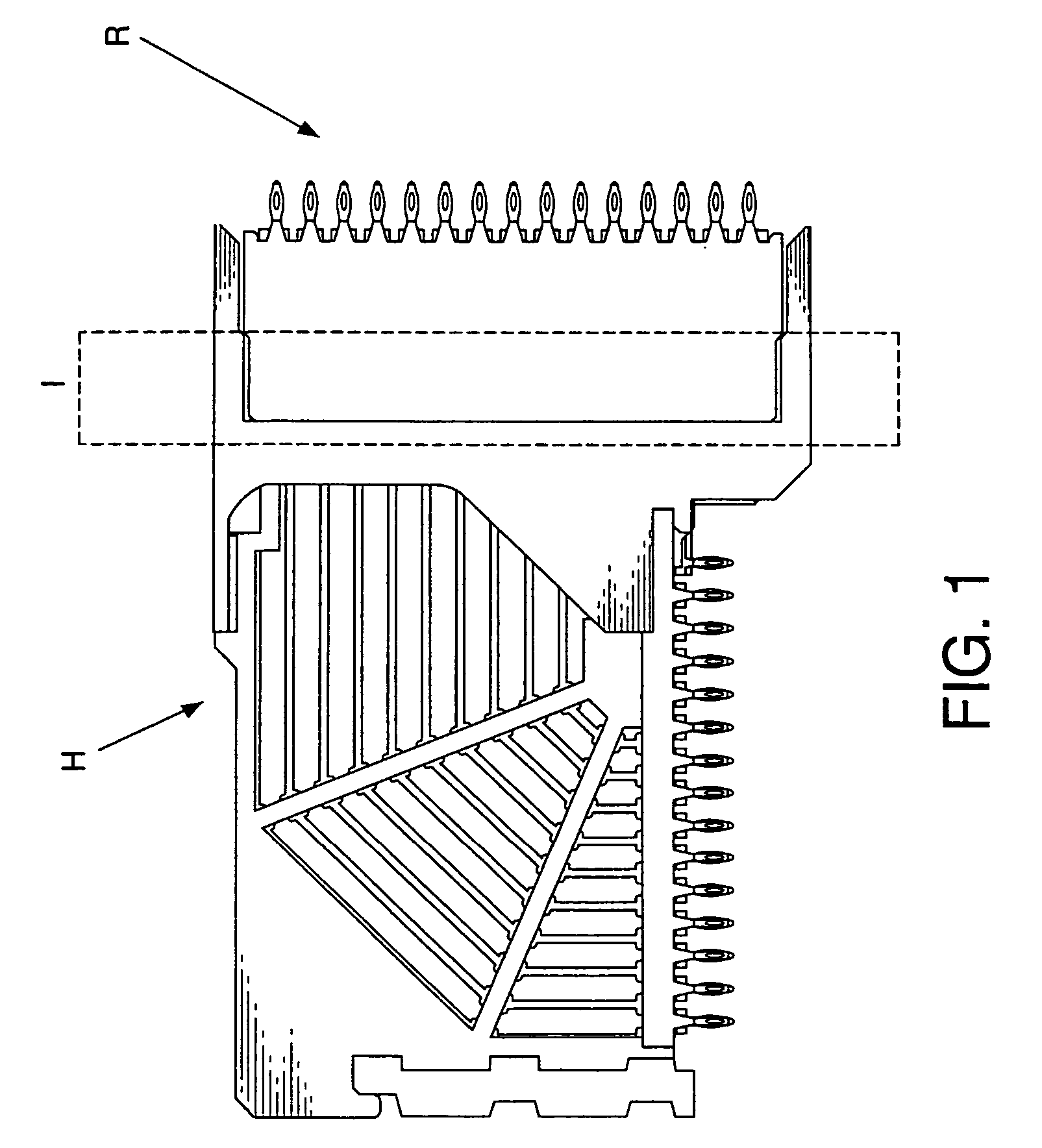

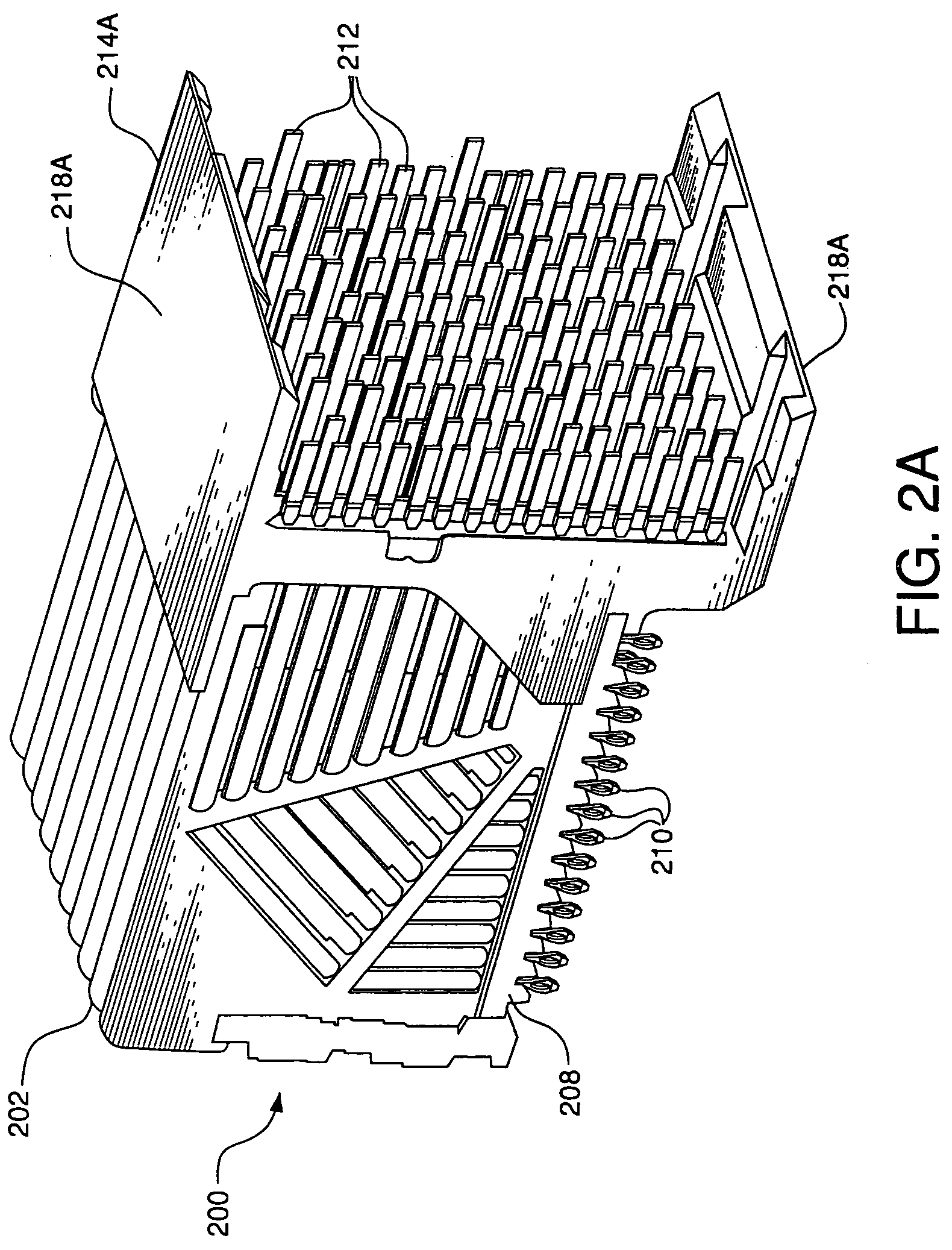

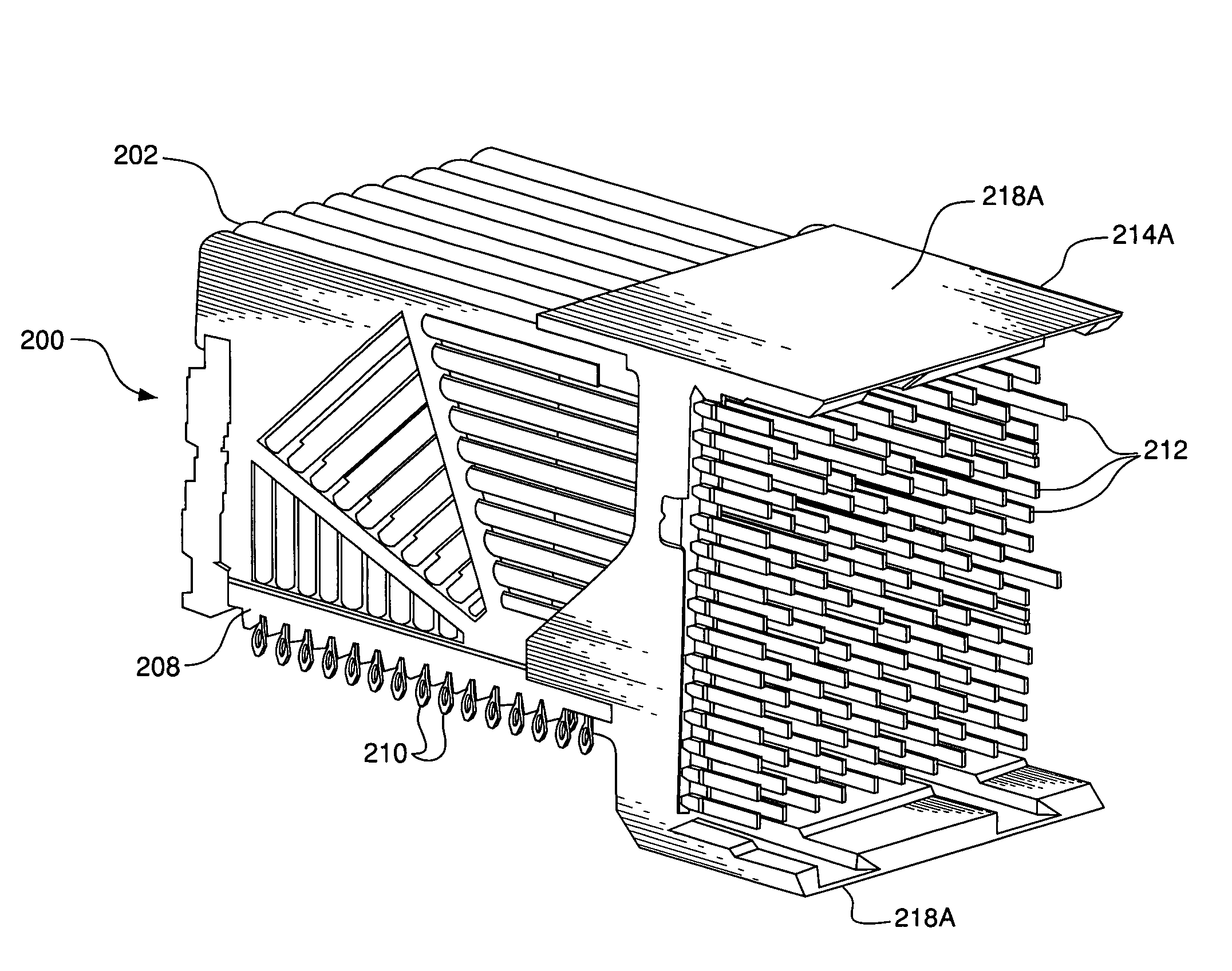

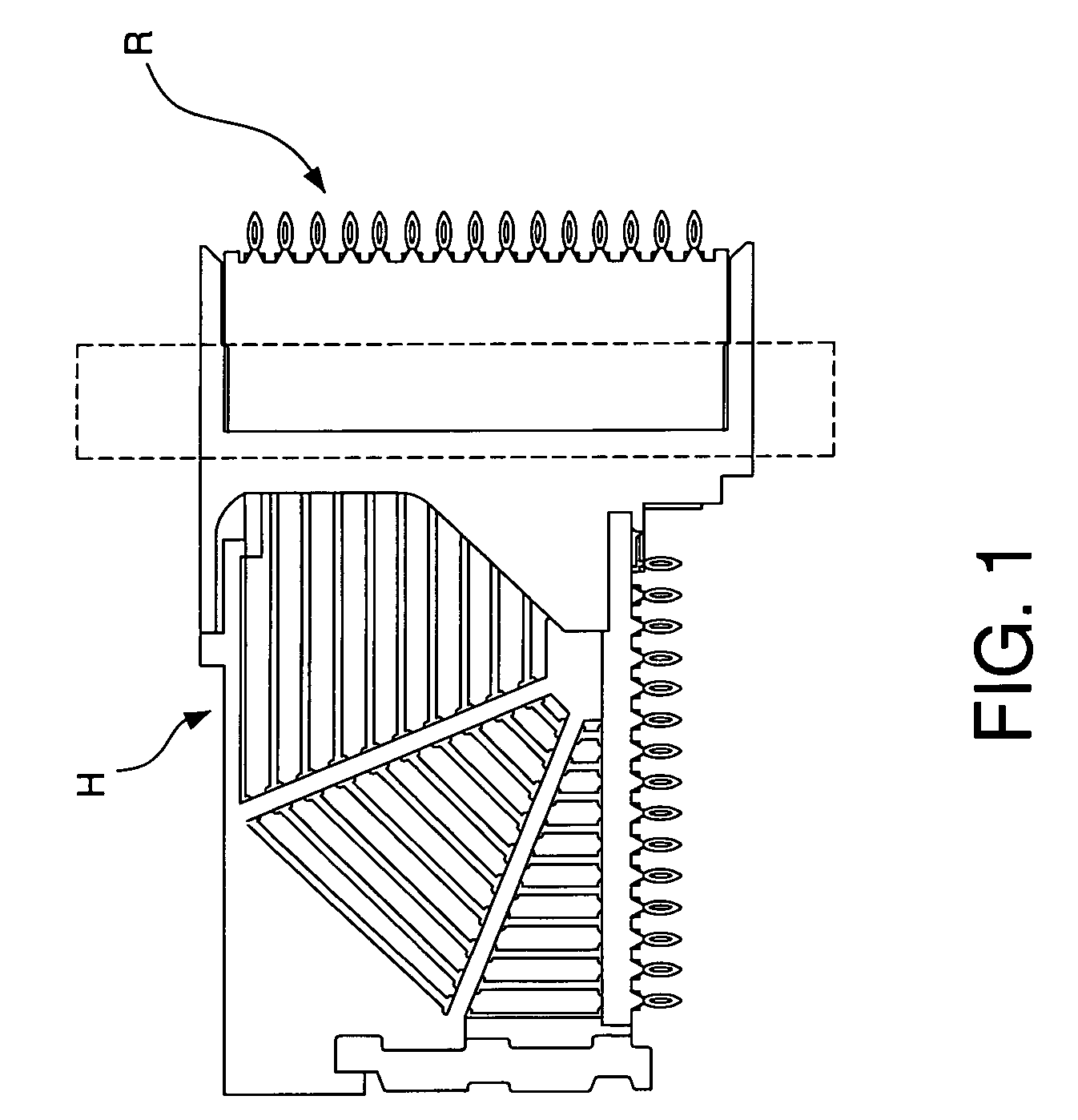

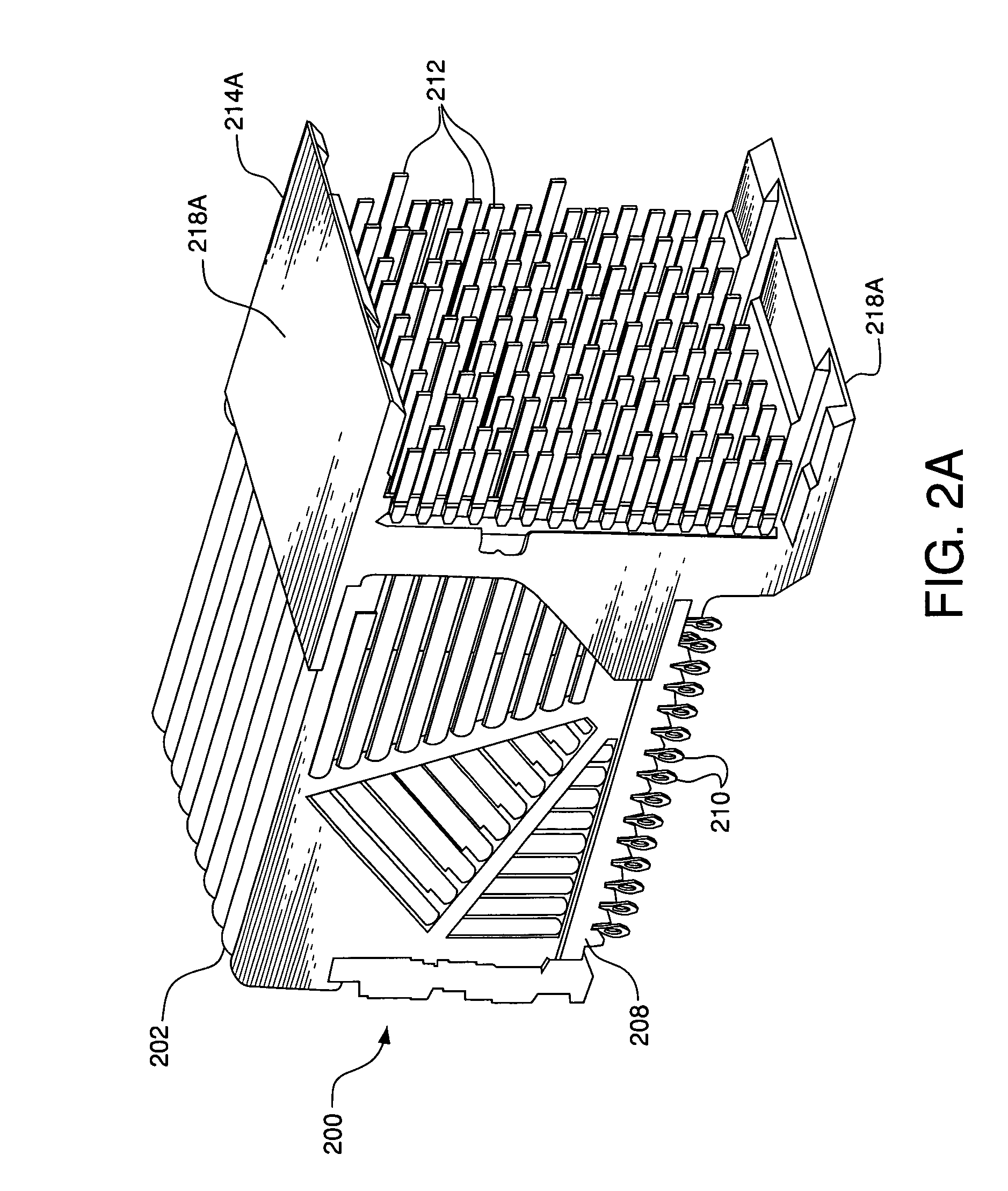

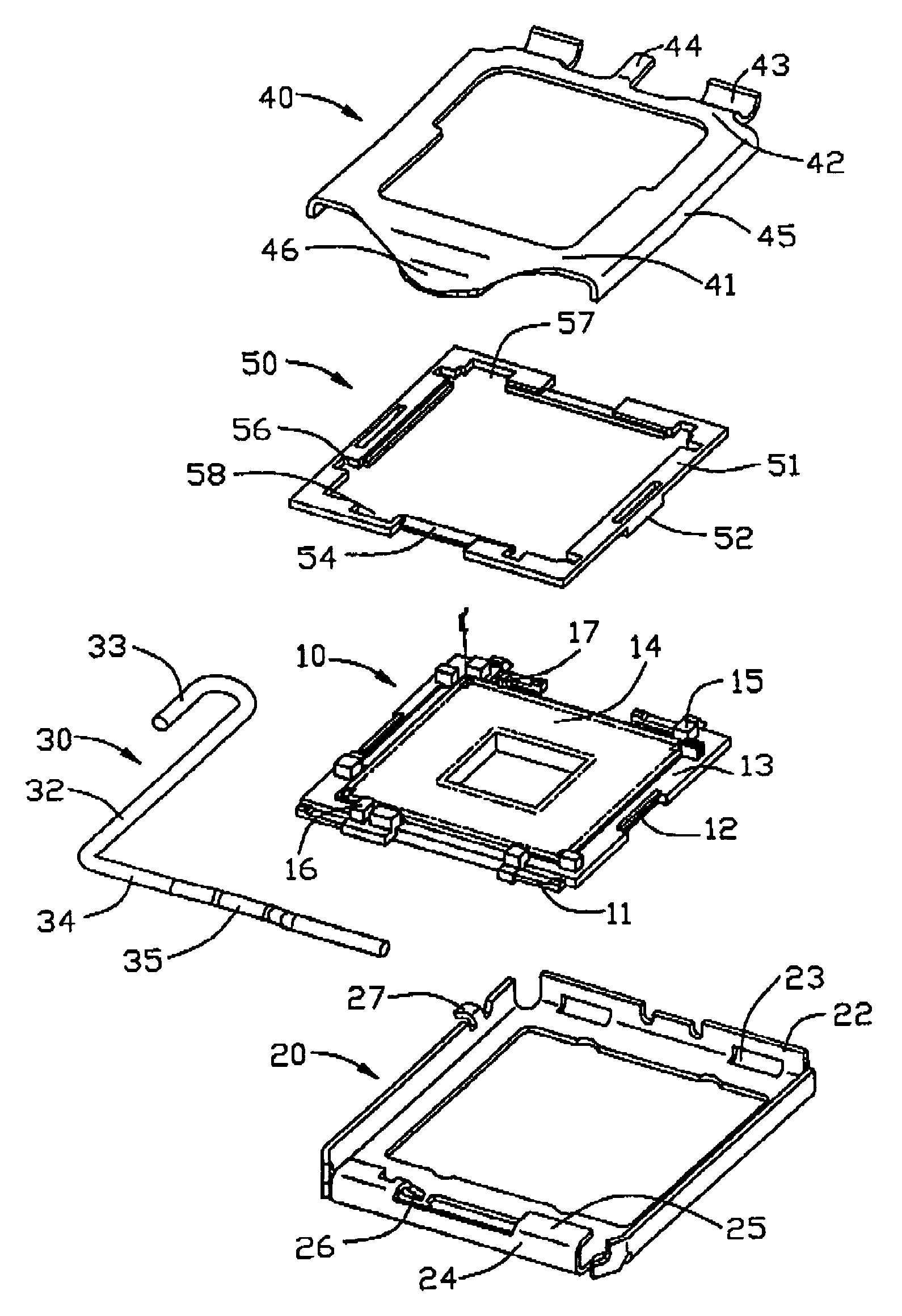

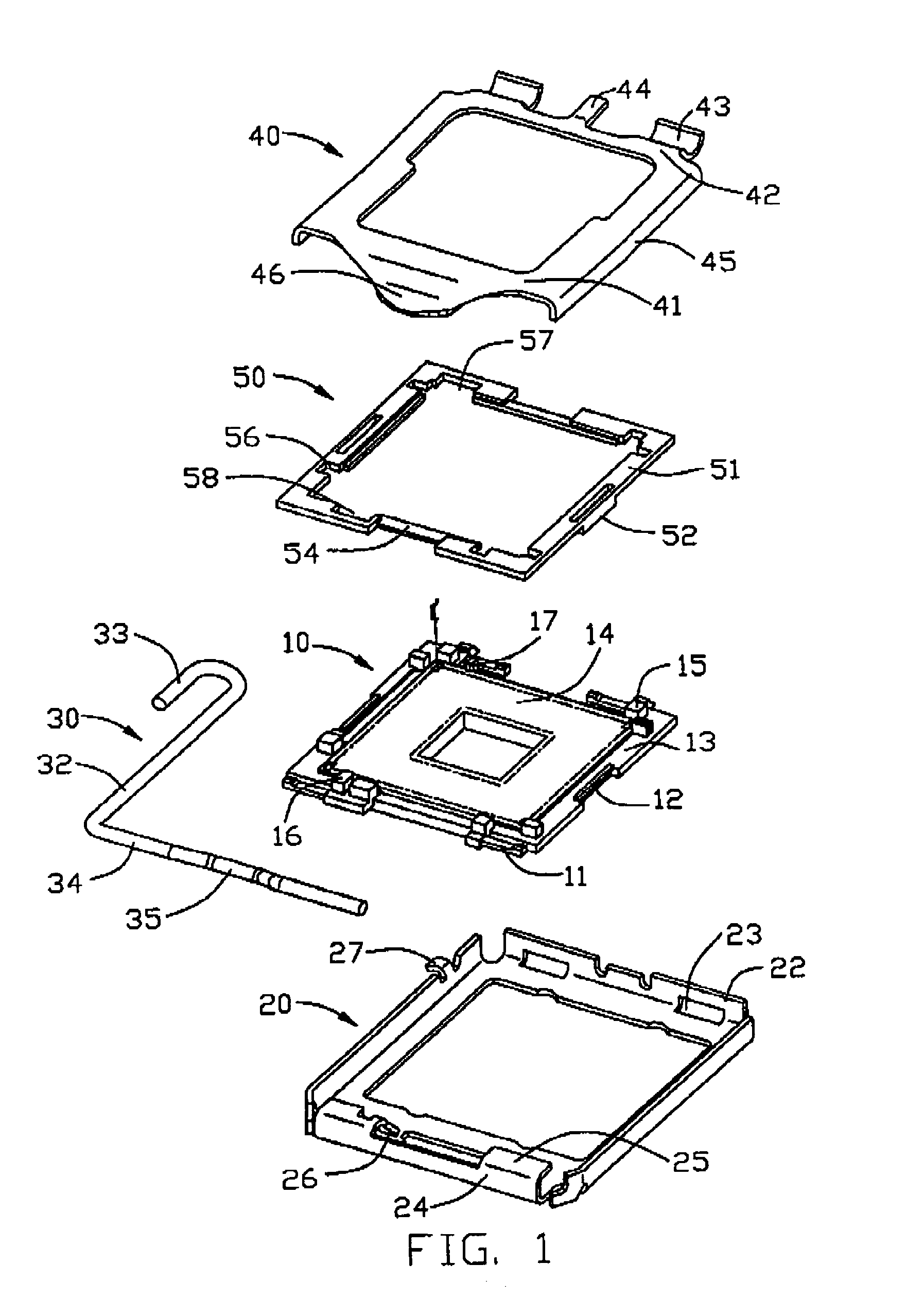

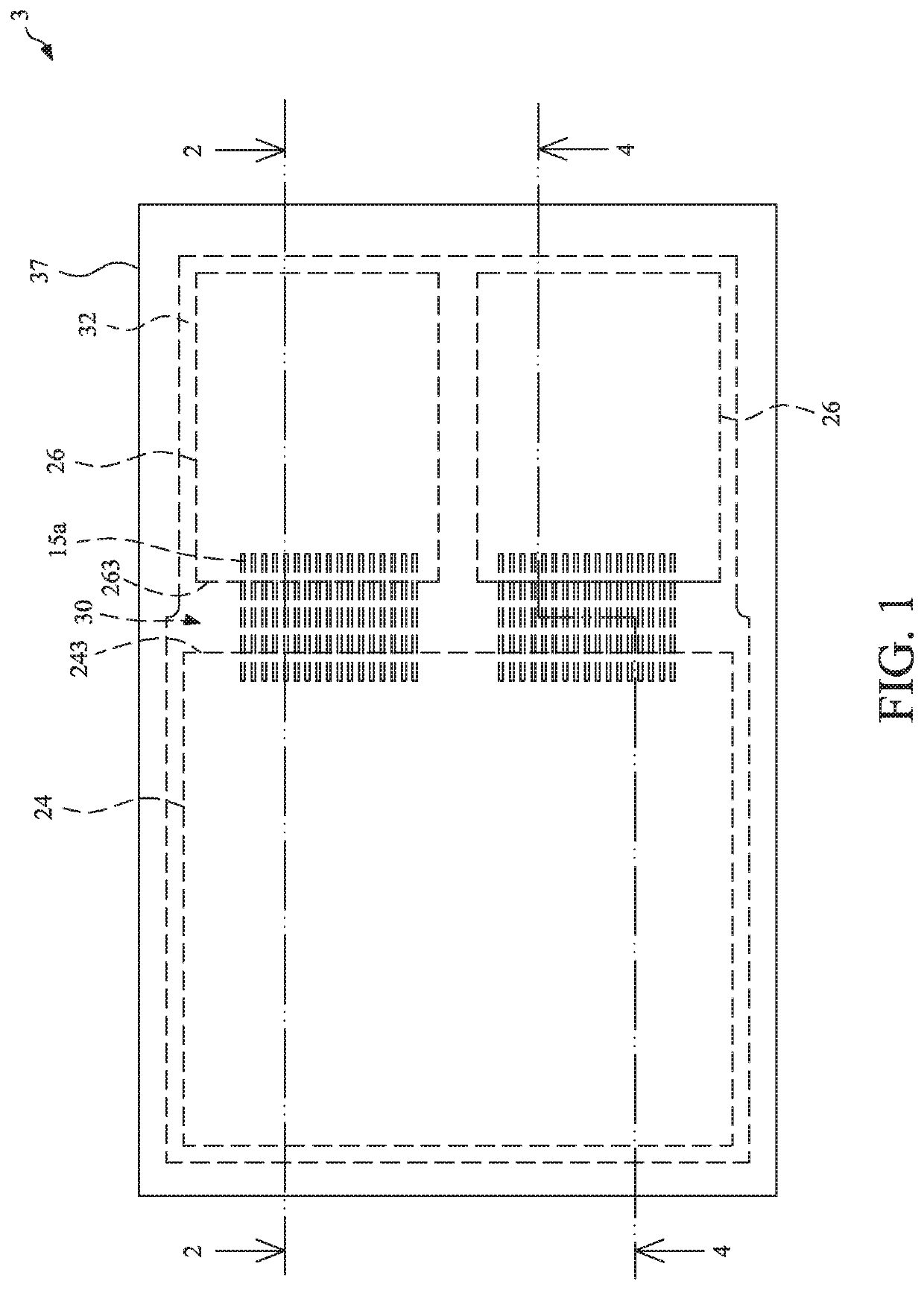

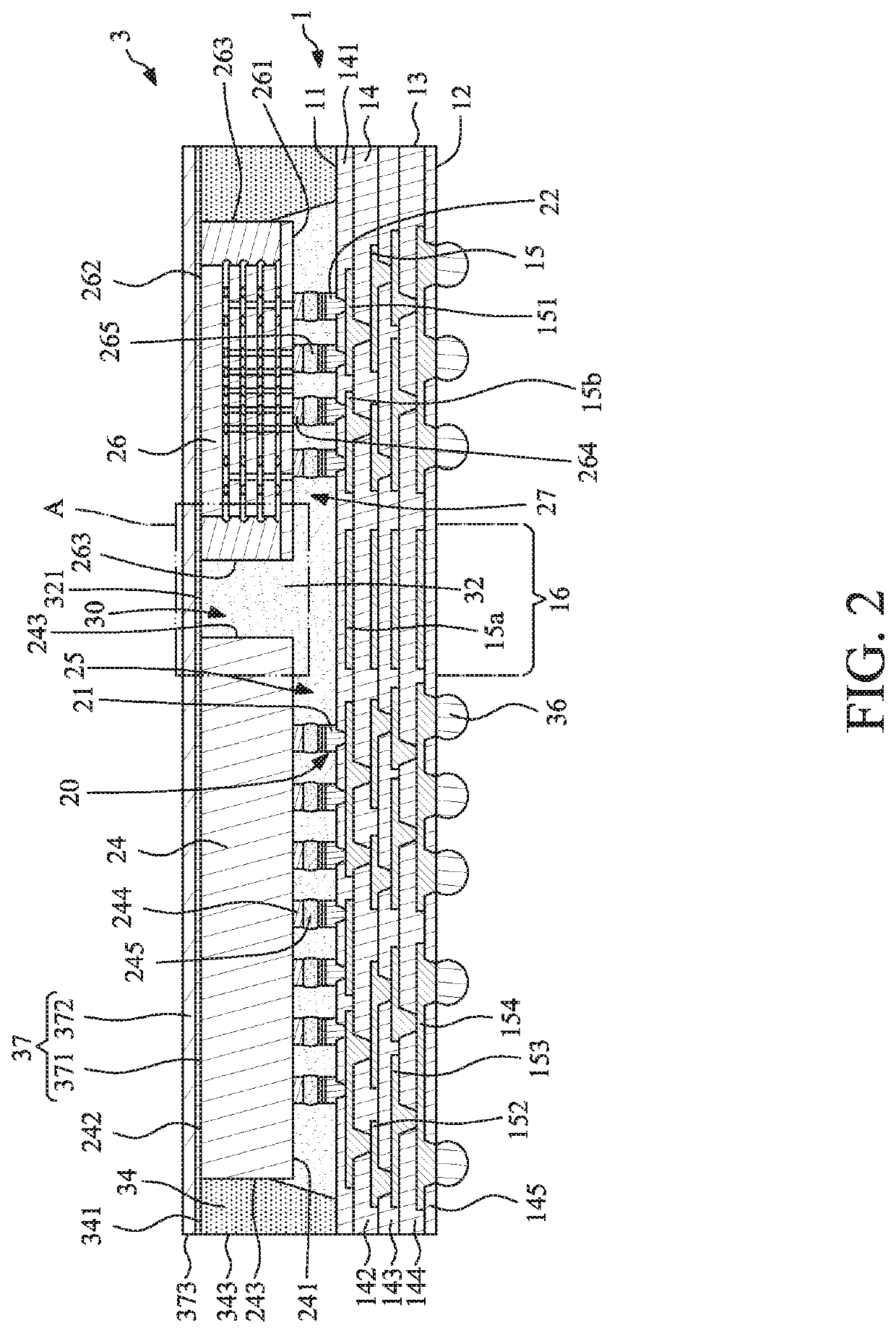

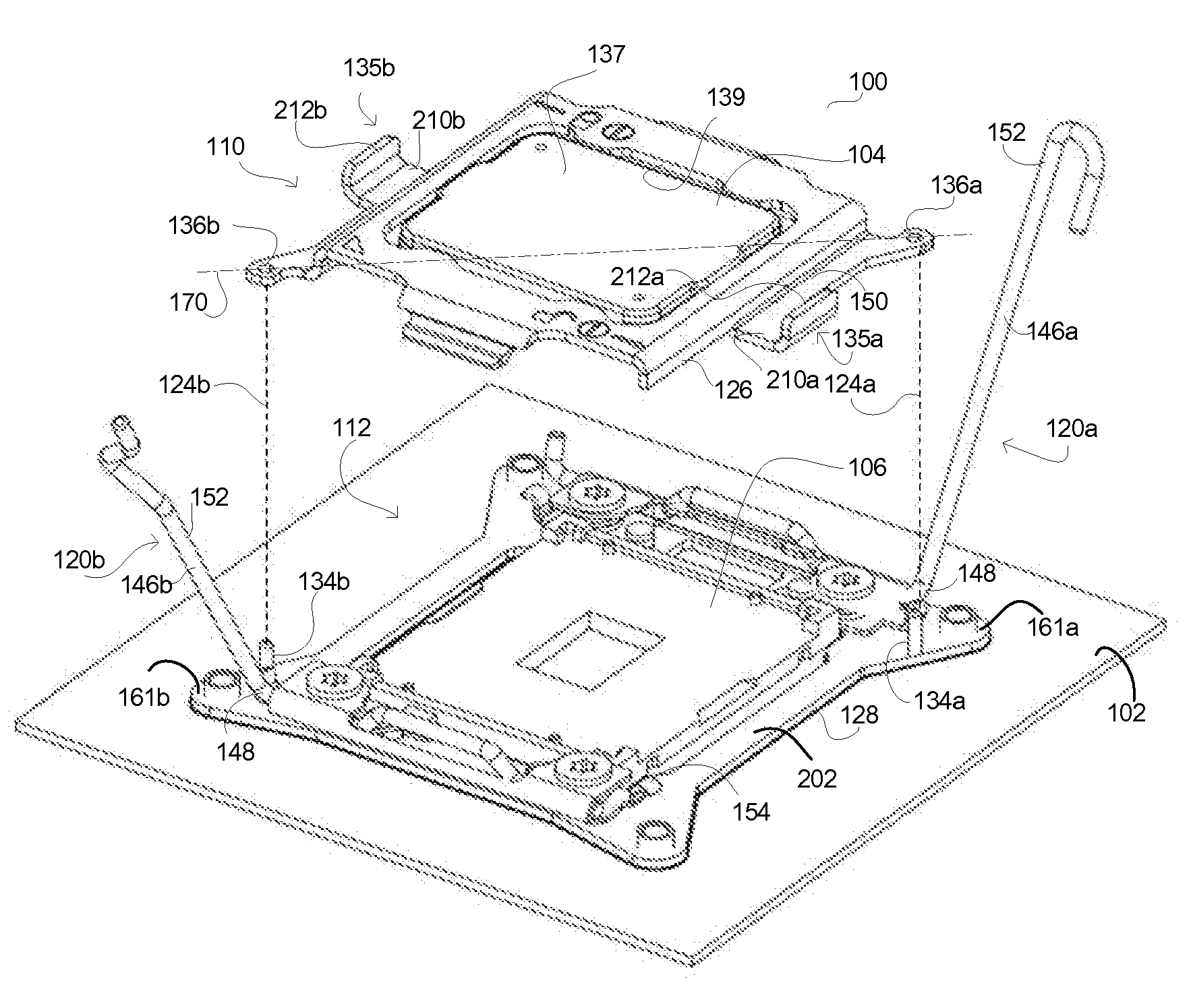

Land grid array socket having contact-protecting mechanism

ActiveUS7112068B2Avoid damageReliable electrical interconnectionEngagement/disengagement of coupling partsLive contact access preventionFree stateElectrical connection

An LGA socket includes a socket body (10), a number of contacts planted in the socket body, a hollowed floating frame (50) floating on a number of push fingers (11) formed on the socket body, a stiffener (20) disposed right round the socket body and the floating frame, and a socket plate (40) and a load lever (30) respectively mounted to opposite ends of the stiffener. The floating frame is provided with a number of receiving sections (54) to hold an LGA package (60). The floating frame with the LGA package held thereon is vertically movable between a free state in which the conductive pads of the LGA package do not engage with the contacts, and a compressed state in which the conductive pads of the LGA package resiliently register with corresponding contacts. Thus, damage to the contacts during installation is avoided and reliable electrical connection is ensured.

Owner:HON HAI PRECISION IND CO LTD

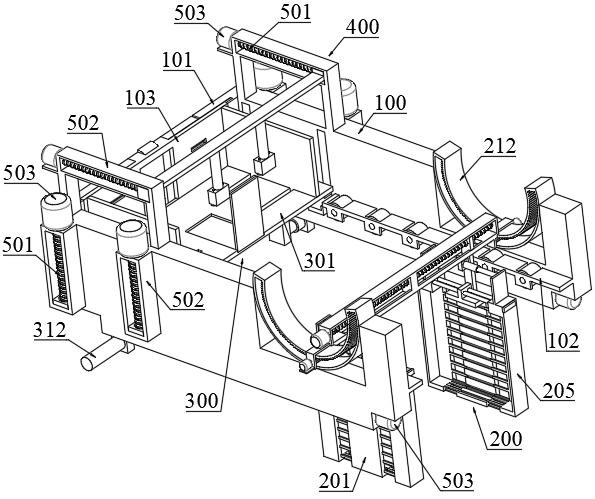

Soaked circuit board transfer device

ActiveCN114538065AHigh degree of automationAvoid contactPrinted circuit manufactureDe-stacking articlesProduction lineEngineering

A soaked circuit board transfer device comprises two supporting frames, a clamping mechanism, a transfer mechanism and a pushing mechanism. The supporting frame is located at one end of the conveying belt, a transverse plate is arranged at the end, close to the conveying belt, of the supporting frame, and supporting plates are arranged on the inner side of the supporting frame. The clamping mechanism is arranged at the other end of the supporting frame and comprises two arc-shaped rails, a linear mechanism is arranged between the two arc-shaped rails, and two clamping assemblies are arranged at the moving end of the linear mechanism and used for clamping a circuit board; the transfer mechanism comprises a bearing plate arranged on the rollers and two vertical moving mechanisms, the bearing plate is used for bearing the circuit board clamped by the clamping mechanism, and the vertical moving mechanisms are arranged on the outer side of the supporting frame and used for lifting or lowering the bearing plate; the pushing mechanism is arranged above the supporting frame and is used for pushing out the circuit board on the bearing plate; the circuit boards in the transfer trolley can be automatically transferred and conveyed to the conveying belt, the automation degree of the production line is improved, workers are prevented from making direct contact with the circuit boards soaked in water, and the health of the workers is protected.

Owner:四川英创力电子科技股份有限公司

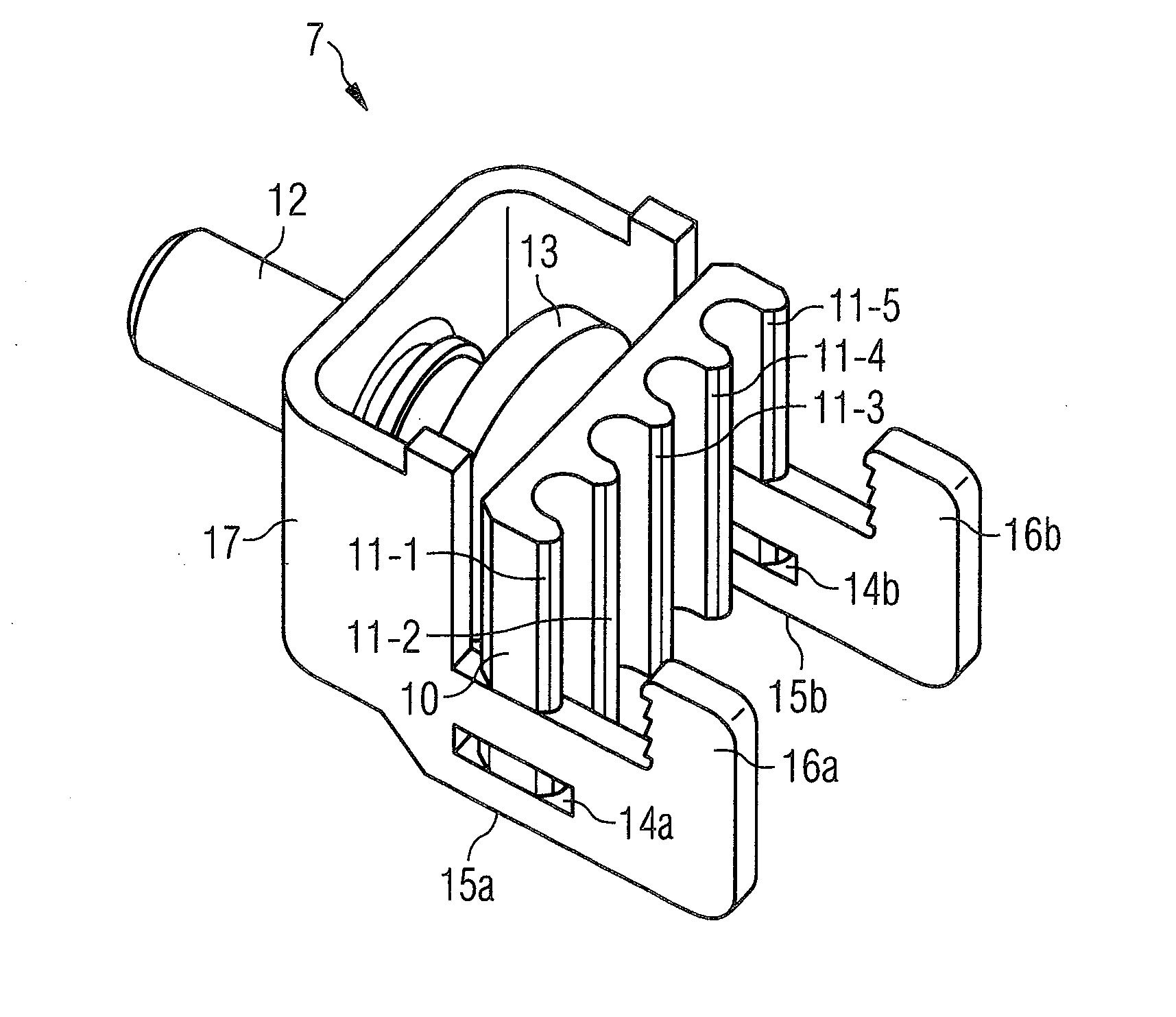

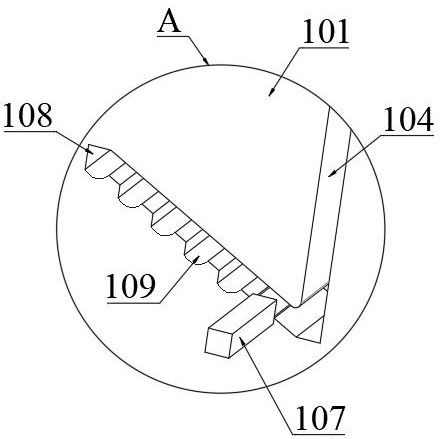

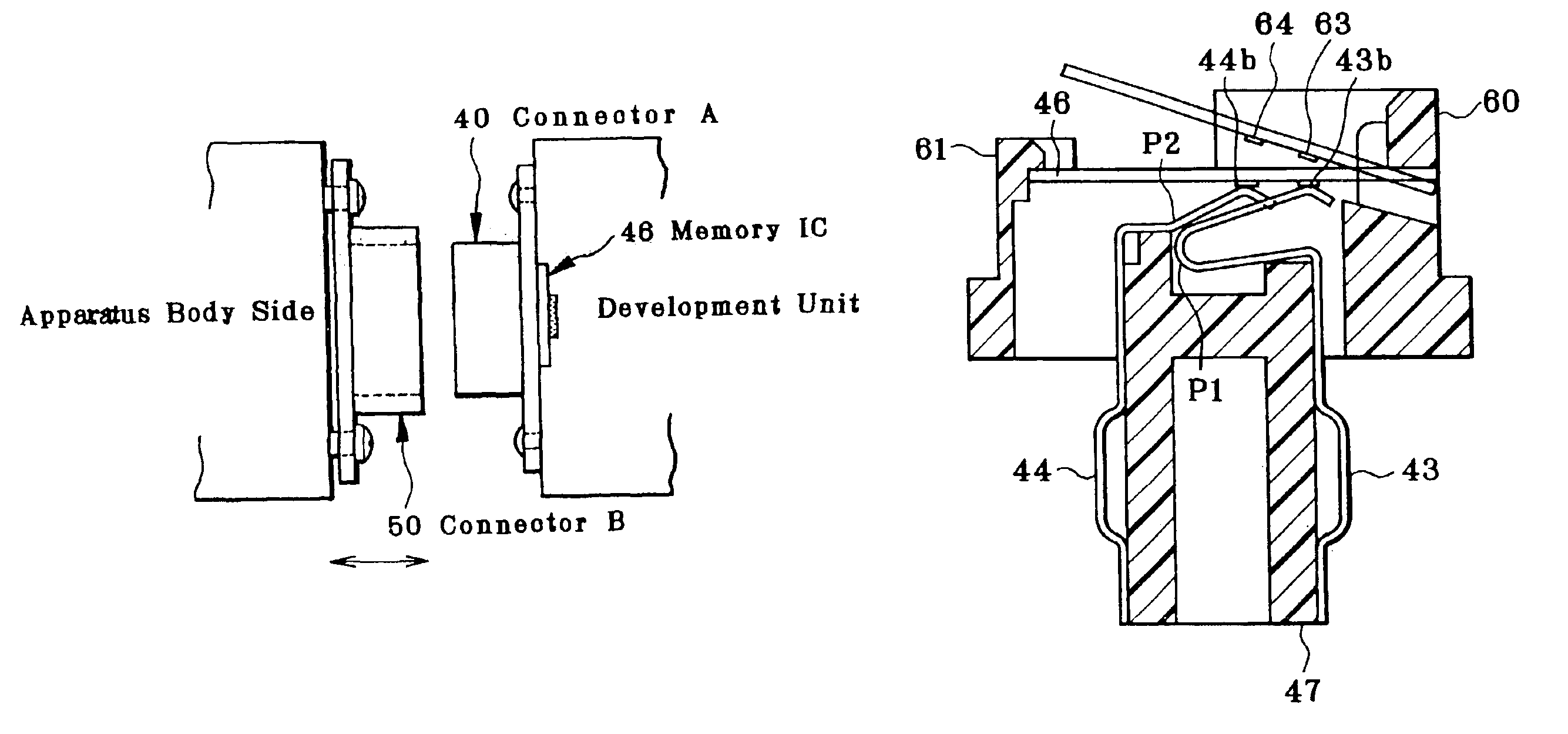

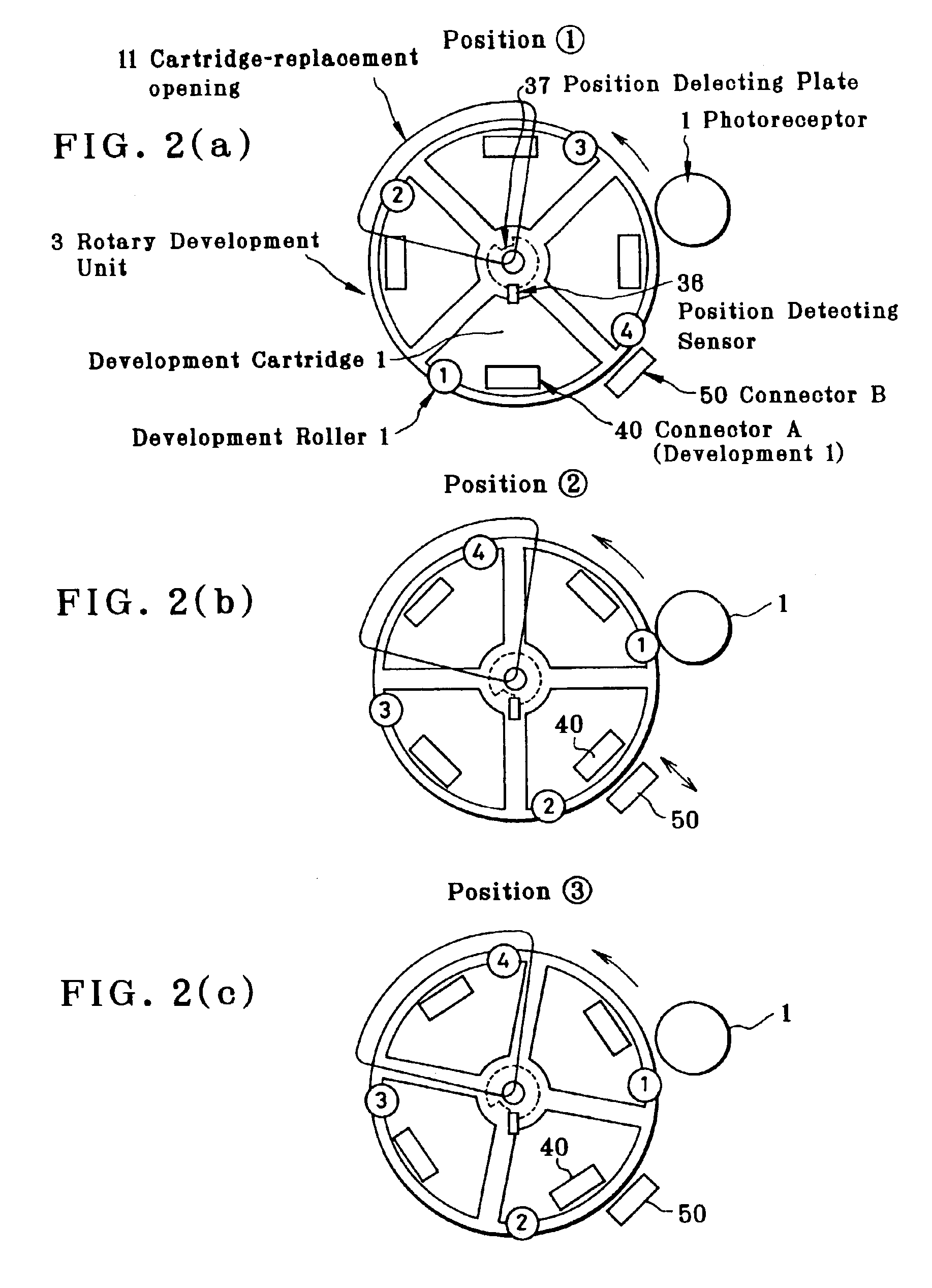

Connector having a built-in memory IC mounted on a development cartridge

InactiveUS6892039B2Guaranteed contact stabilityImprove reliabilityEngagement/disengagement of coupling partsTwo-part coupling devicesFuselageContact protection

A connector with a built-in memory IC which is mounted on a rotary development unit of a printer. The memory IC substrate is disposed within a contact protecting member and behind the rear side of an impact receiving member. A first electric contact is disposed on the front side of the impact receiving member and is connected to a second electric contact via a conductive member. The second electric contact spring contacts the memory IC substrate. The connector contains guide members to help stabilize the connection between the connector and the body side connector of the printer.

Owner:SEIKO EPSON CORP

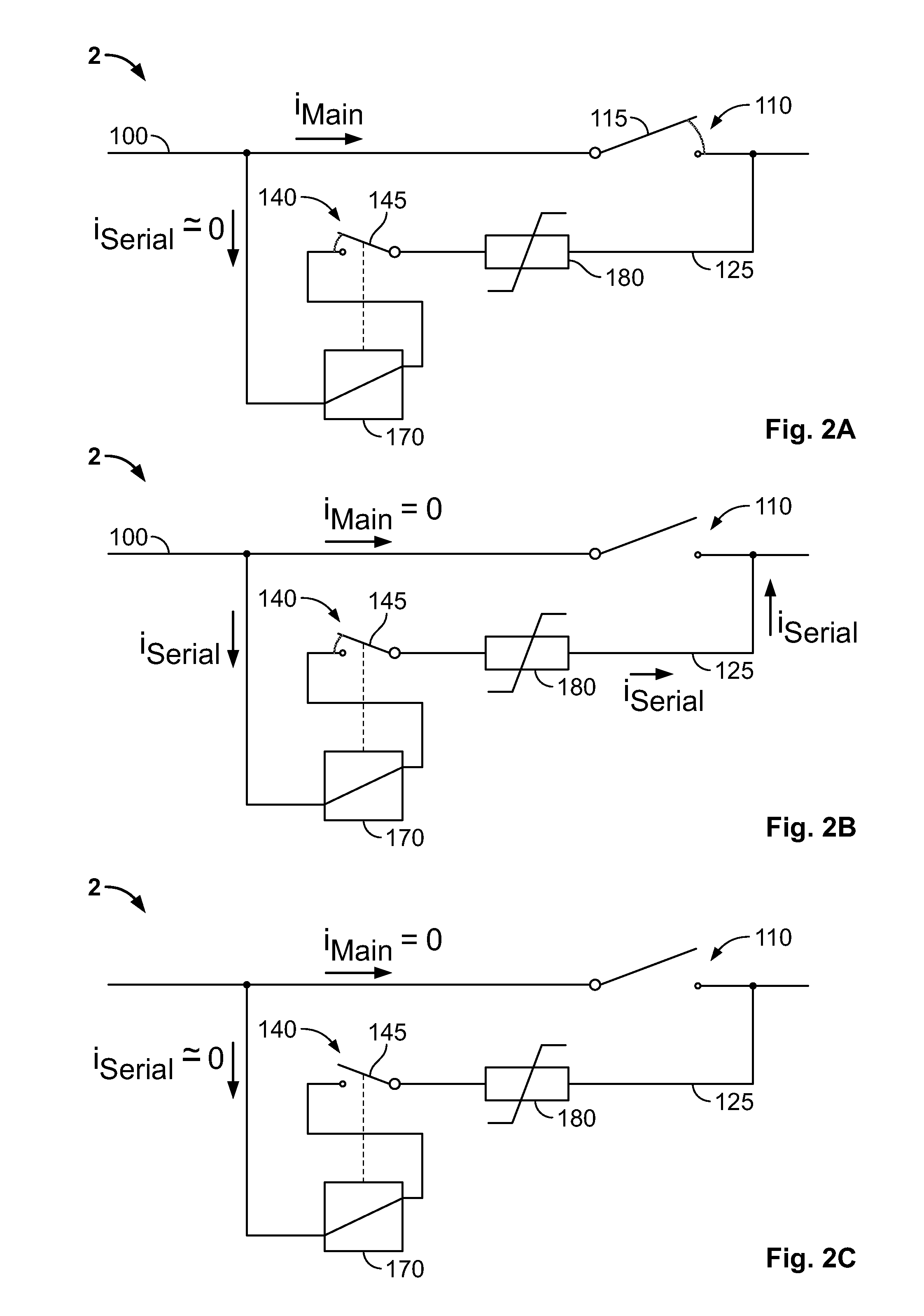

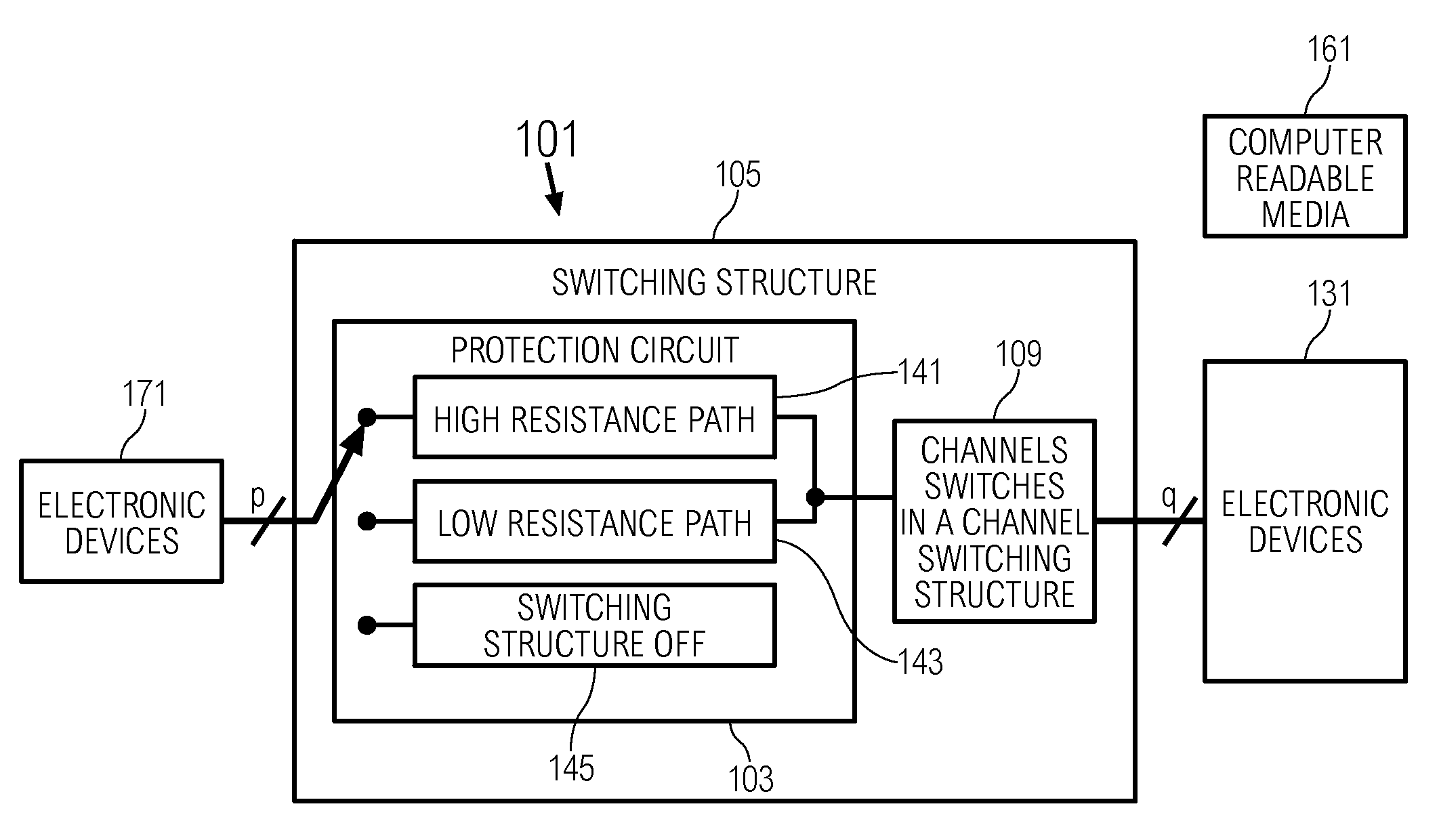

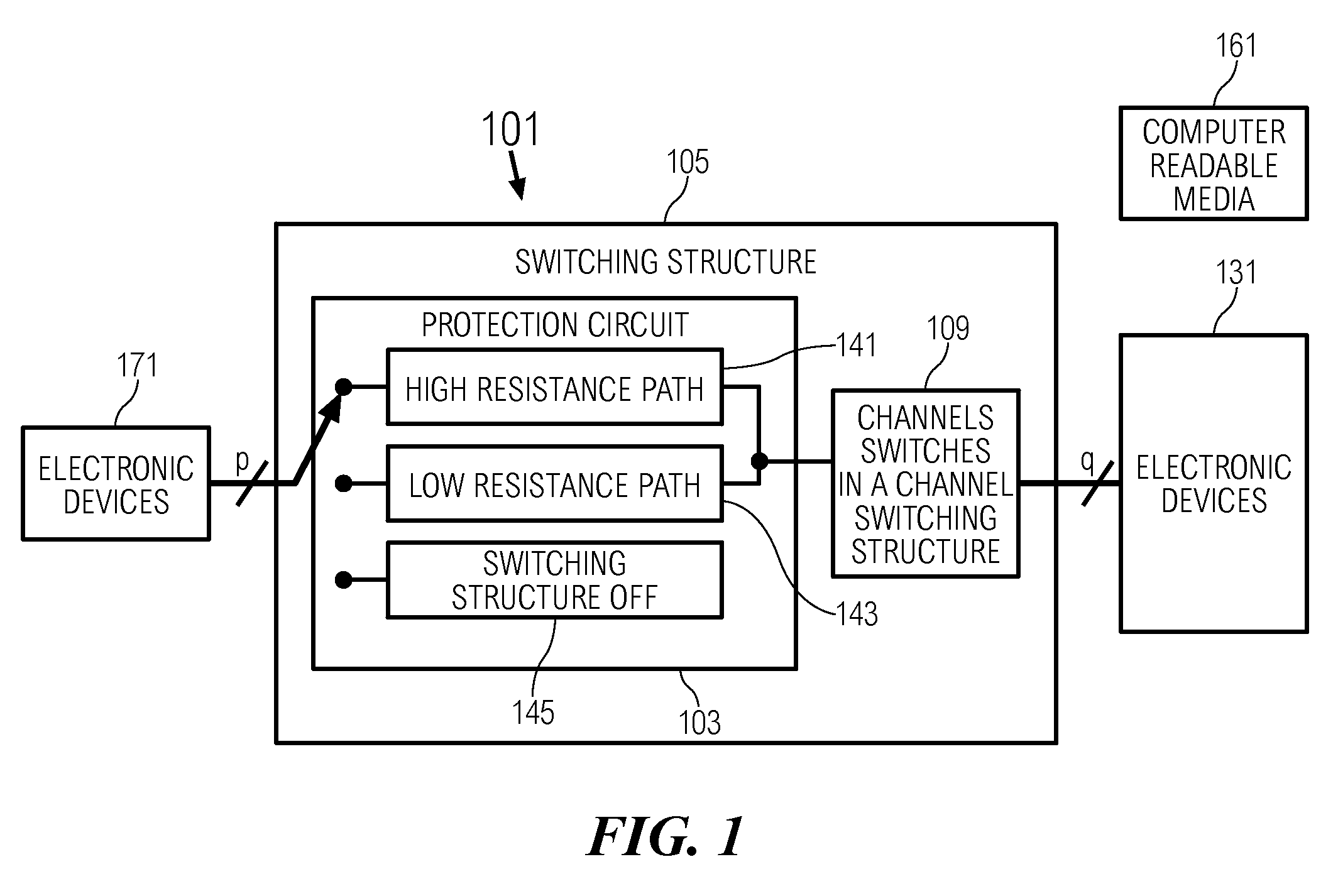

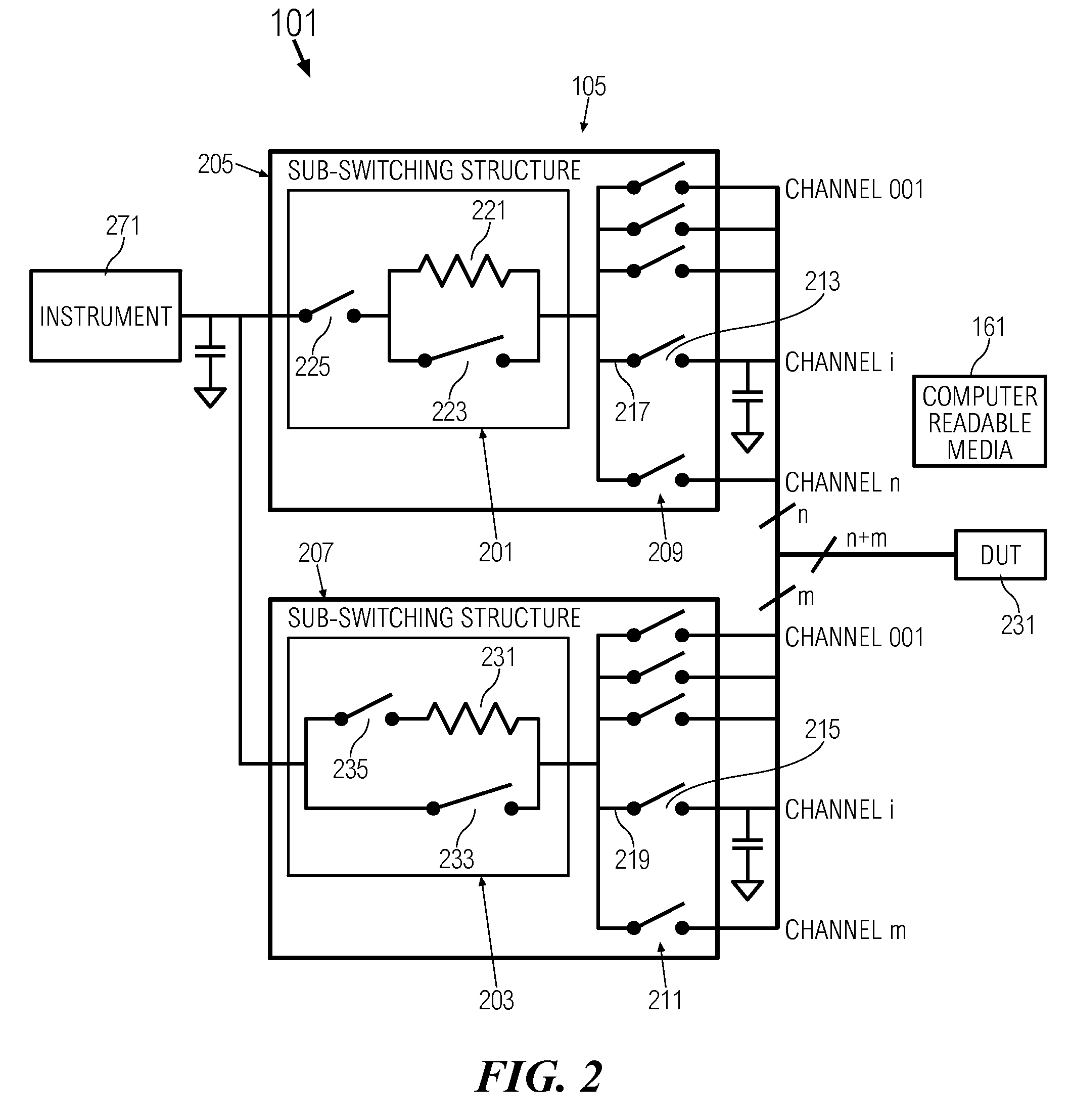

Dynamic Switch Contact Protection

A dynamic switch contact protection circuit and technique to protect a channel switch within an electrical system by limiting transients when the switch is turned on or turned off. The protection circuit comprises switching between a high resistance path and a low resistance path. The high resistance path comprises a resistor. A bypass switch is connected in parallel to the resistor to affect the low resistance path. The protection circuit can connect or disconnect switch cards to the electrical system enabling the creation of a larger switching structure. Disconnected switch cards within a switching structure preserves system bandwidth by limiting capacitive loading. Electing which switch to close last or open first can prolong the length of usage of the switches.

Owner:KEYSIGHT TECH

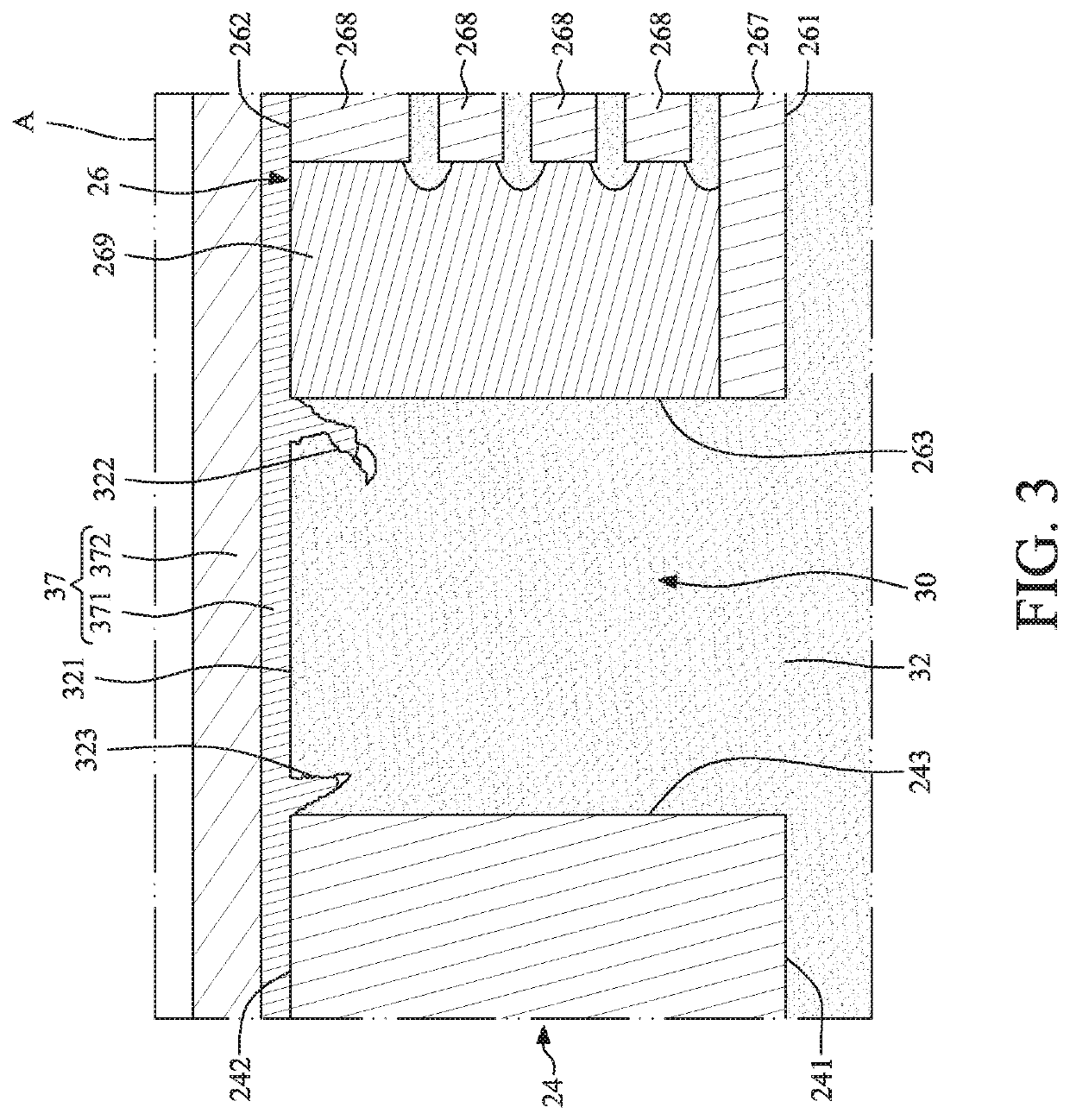

Package structure and method for manufacturing the same

InactiveUS20210159188A1Semiconductor/solid-state device detailsSolid-state devicesElectrical connectionElectronic component

A package structure includes a wiring structure, a first electronic device, a second electronic device, a protection material and a reinforcement structure. The first electronic device and the second electronic device are electrically connected to the wiring structure. The protection material is disposed between the first electronic device and the wiring structure and between the second electronic device and the wiring structure. The reinforcement structure is disposed on and contacts the first electronic device and the second electronic device. The reinforcement structure contacts the protection material.

Owner:ADVANCED SEMICON ENG INC

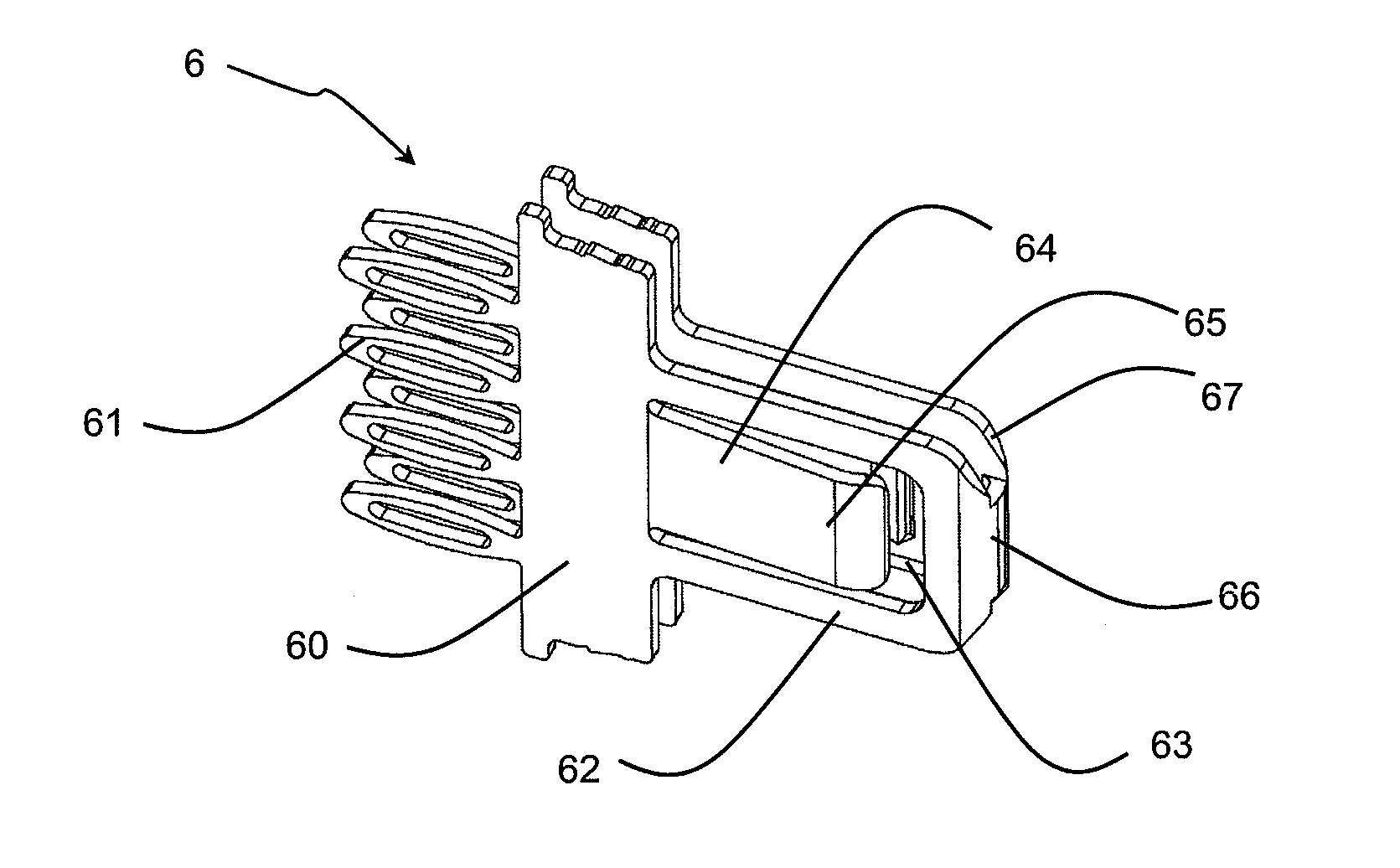

Power connector and power connector assembly with contact protection mechanism

InactiveUS7766664B2Increase powerImprove reliabilityElectric discharge tubesCoupling contact membersEngineeringContact protection

The present invention relates to a power connector. The power connector includes a housing and a number of contacts received in the housing. At least one of the contacts includes a pair of opposite walls spaced apart at a predetermined distance. The walls have a front end respectively. The contact may further include a contact protection mechanism for protecting the contacts, wherein the contact protection mechanism bridges the front ends of the walls. The present invention also relates to a power connector assembly.

Owner:ALLTOP ELECTRONICS SU ZHOU

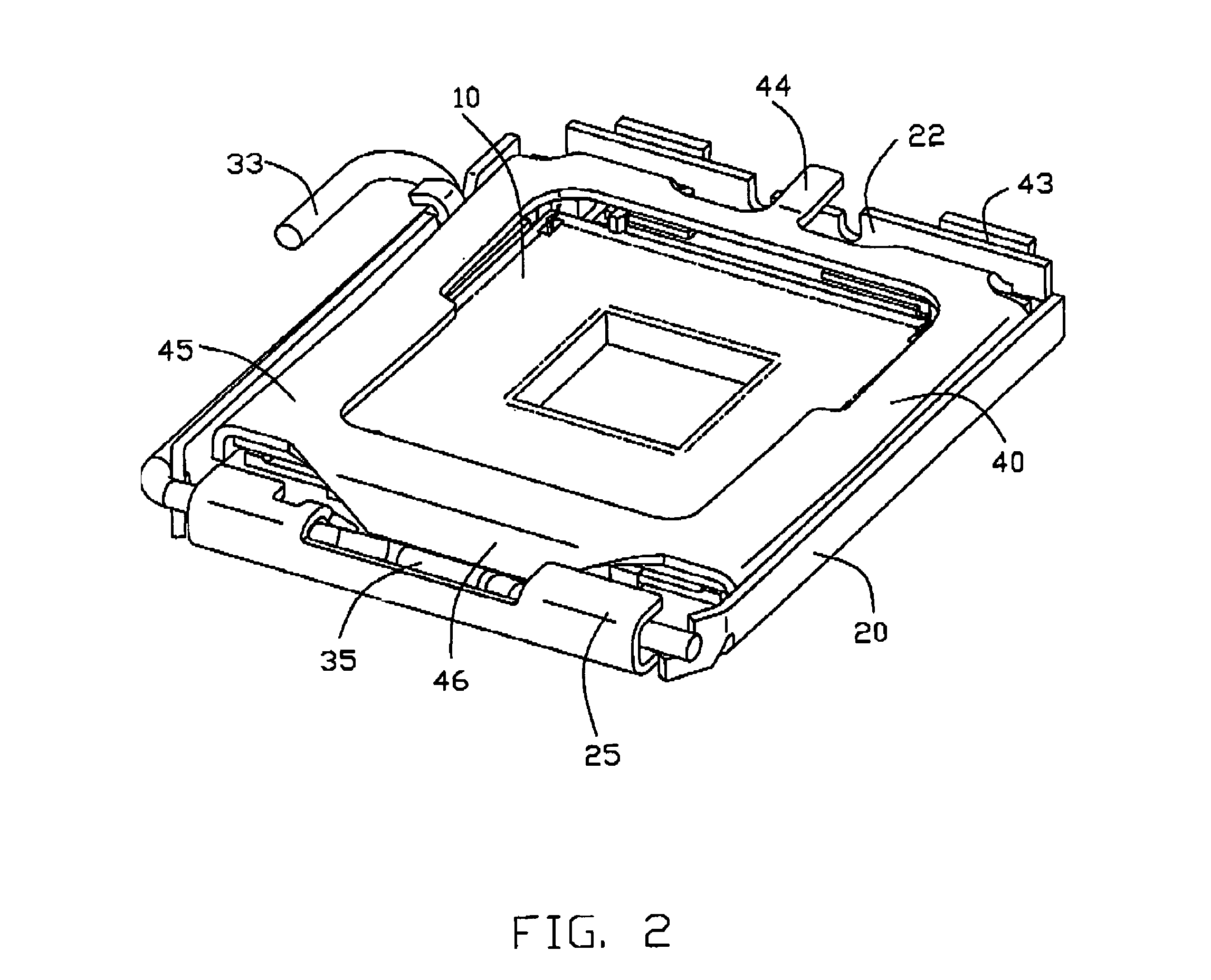

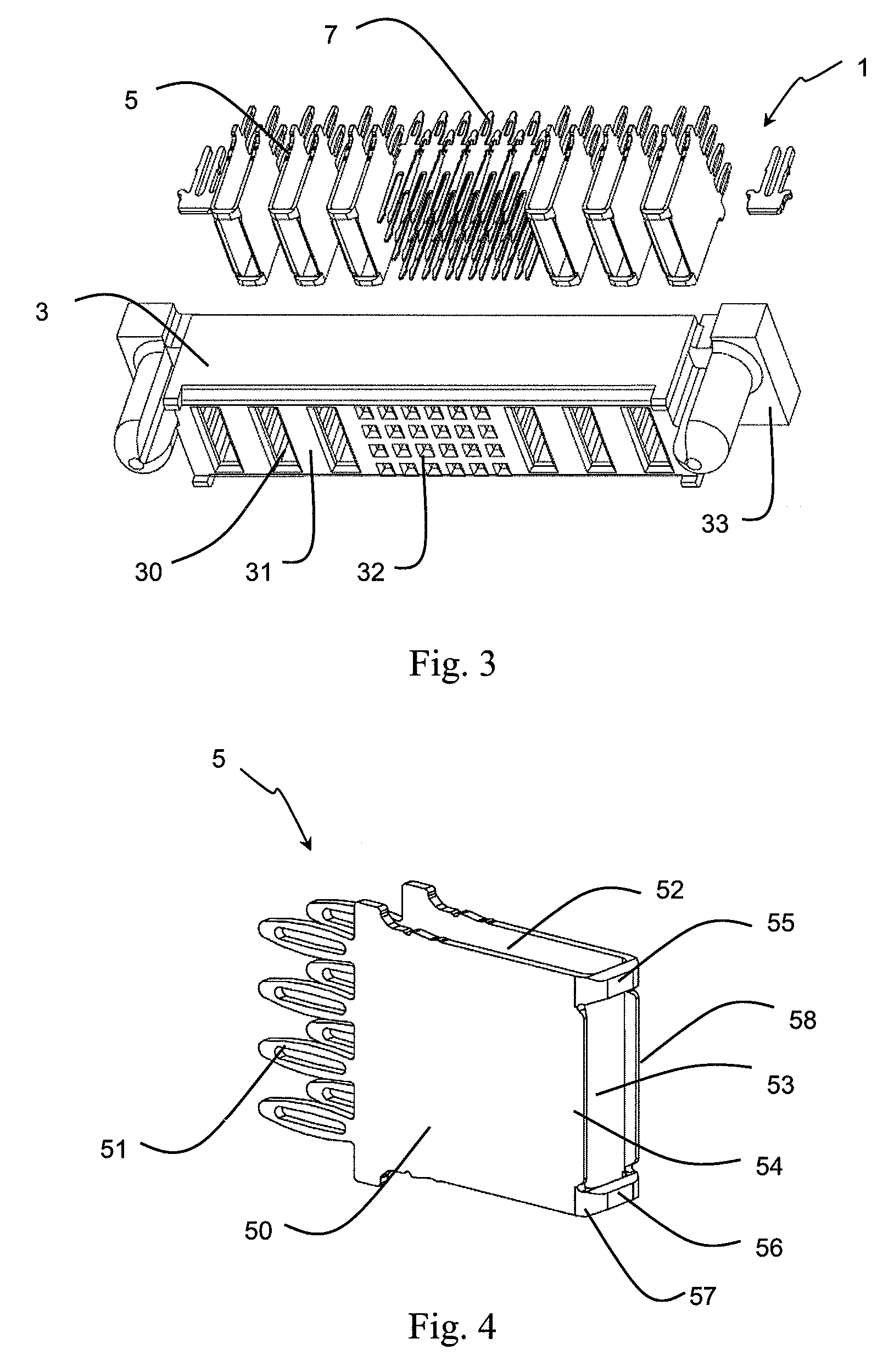

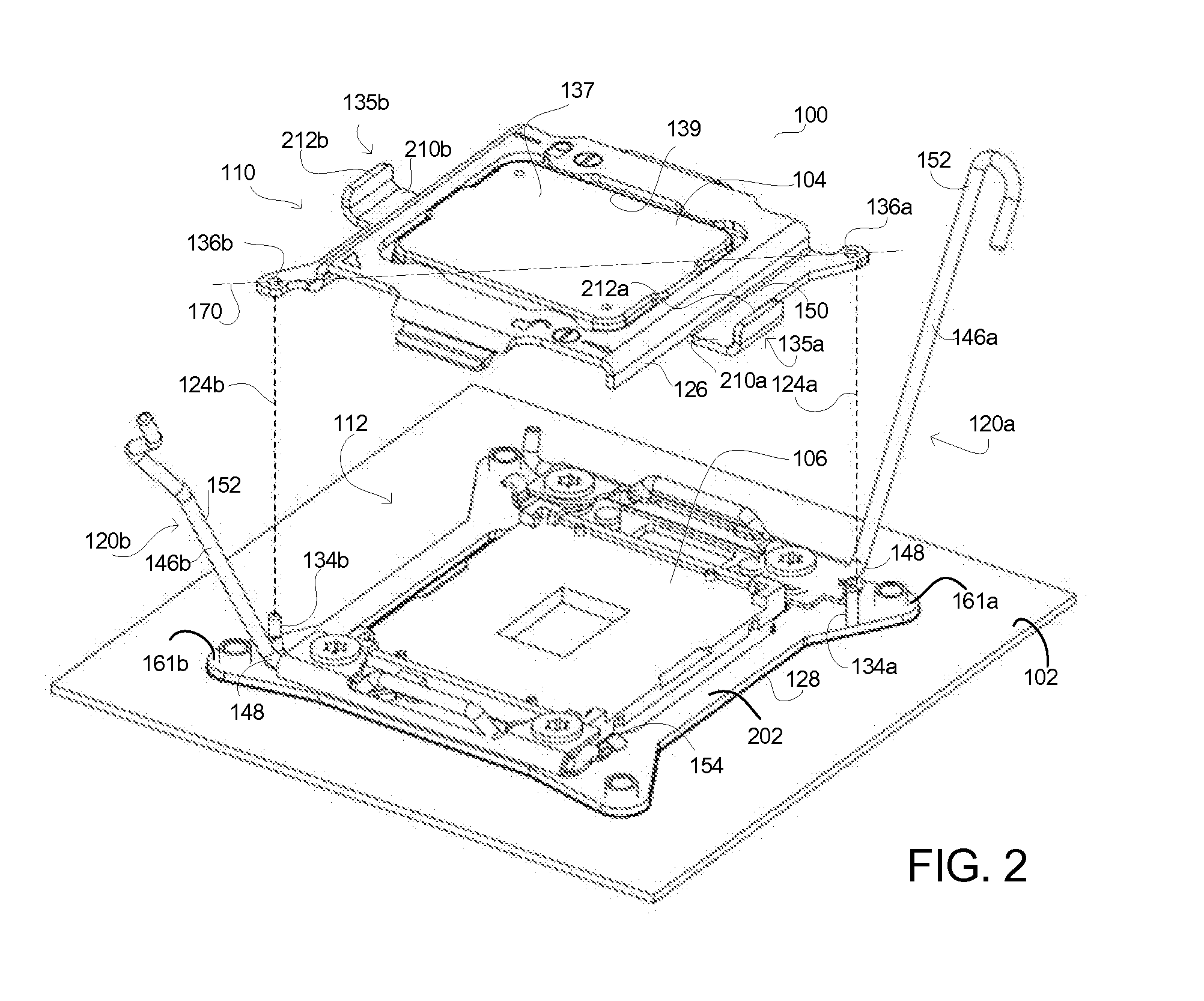

Contact protection for integrated circuit device loading

ActiveUS20140092573A1Electrically conductive connectionsSemiconductor/solid-state device detailsEngineeringContact protection

In one embodiment, a load frame and an integrated circuit device are aligned, with a base frame carried on a substrate, along a first alignment axis defined by a first alignment post extending from the base frame to the load frame, in a direction transverse to the substrate, and a first biasing device carried on the base frame is actuated to engage and bias the load frame toward the base frame aligned with the load frame, and to bias the integrated circuit toward the substrate. A latch latches the load and base frames together, aligned with and biased towards each other with the integrated circuit device and the substrate aligned with, and biased toward each other. Other aspects and features are also described.

Owner:INTEL CORP

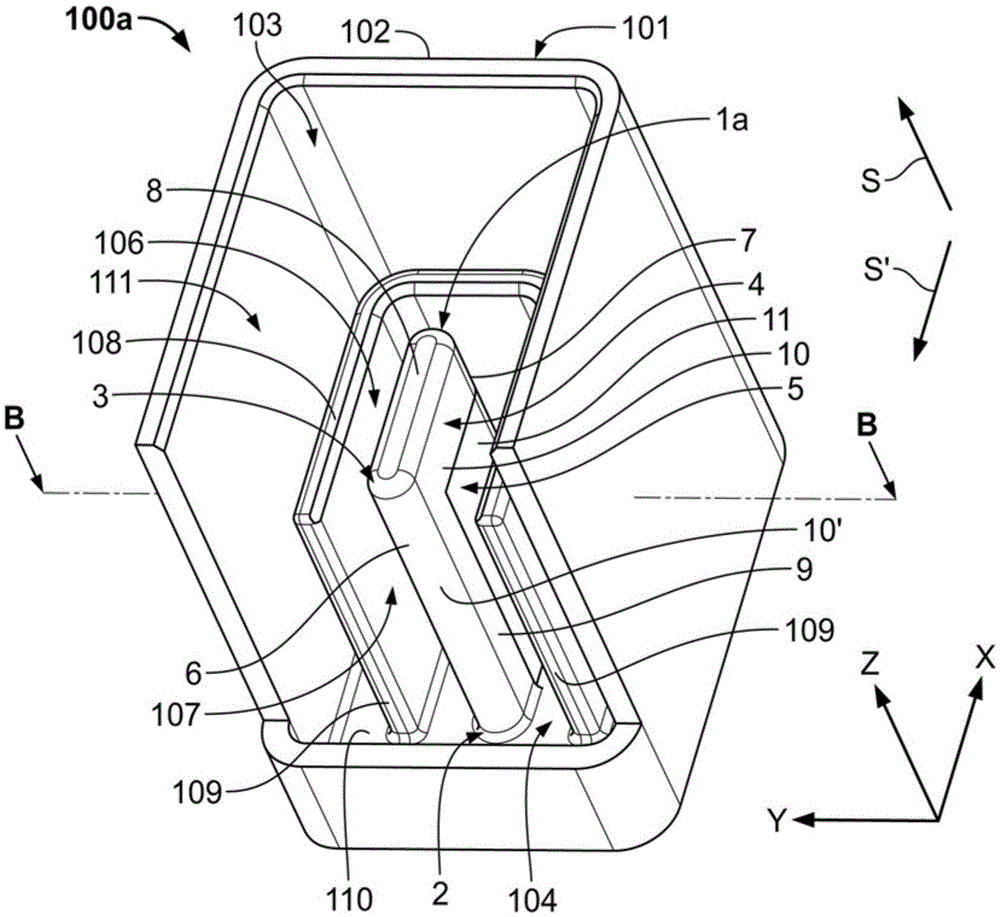

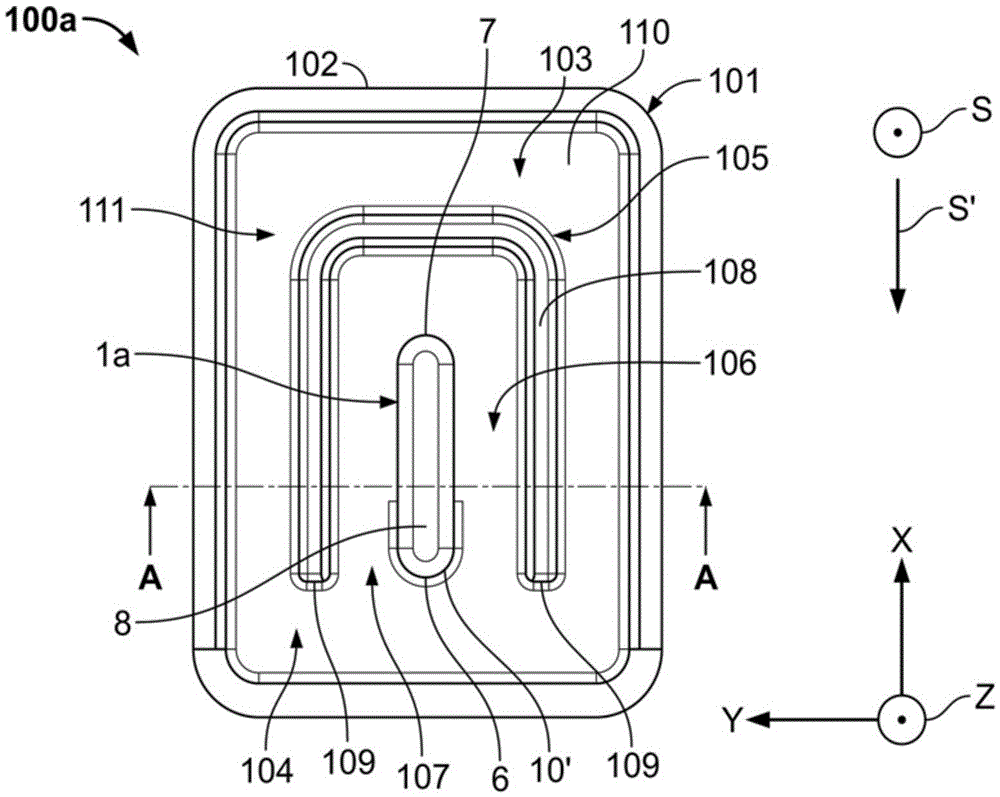

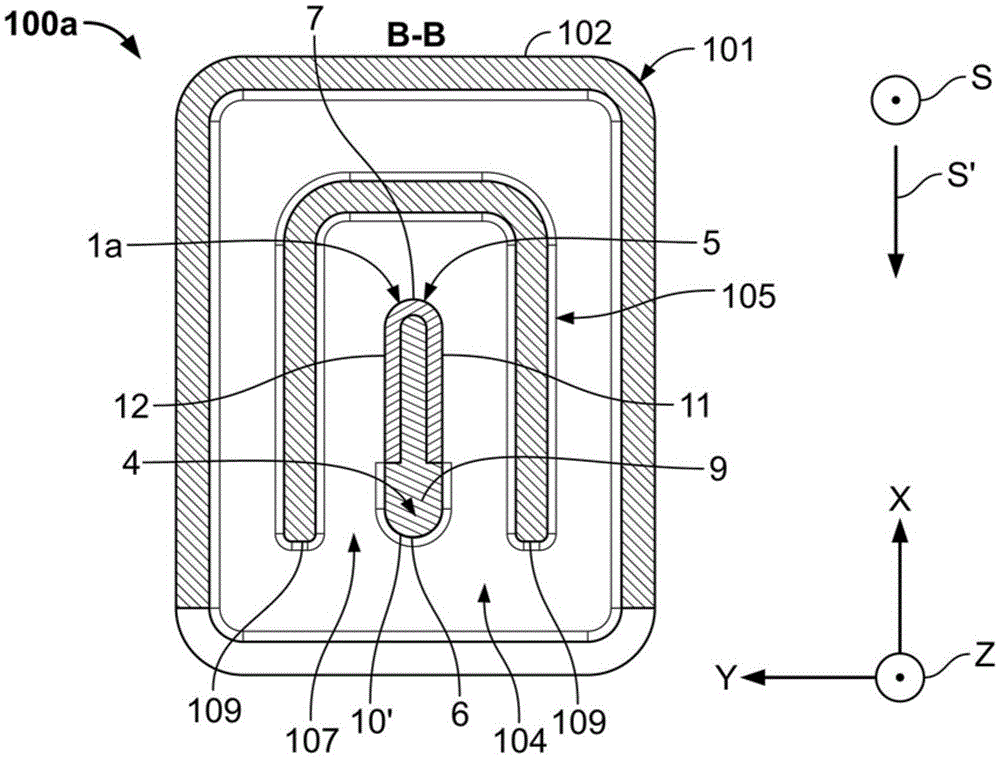

High-voltage finger protection

ActiveCN105493352ANo agingThe non-existent wear and tear problemVehicle connectorsCoupling contact membersEngineeringContact element

The present invention relates to an electrical pin contact element (1a to 1g) for a high-current and / or high-voltage plug type connector in motor vehicle technology, having a free end (3) and having a base (2) which is spaced apart from the free end (3) for fixing the pin contact element (1a to 1g) in the plug type connector. The invention further relates to a connector element (100a to 100g) for a high-current and / or high-voltage plug type connector in motor vehicle technology. Finally, the invention relates to a method for producing an electrical pin contact element (1a to 1g) for a high-current and / or high-voltage plug type connector in motor vehicle technology, wherein there are formed a free end (3) and a base (2) of the pin contact element (1a to 1g), which base is spaced apart from the free end (3). In order to ensure contact protection which is as simple, robust and cost- effective as possible, it is provided according to the invention that an electrically insulating contact protection member (4) extends from the base (2) as far as the free end (3) so as to form an outer face (10') of a contact protection portion (9, 9'), that the connector element (100a to 100g) has at least one pin contact element (1a to 1g) according to the invention and that the pin contact element (la to lg) is provided externally with an electrically insulating contact protection member (4) from the base (2) as far as the free end (3).

Owner:TE CONNECTIVITY GERMANY GMBH

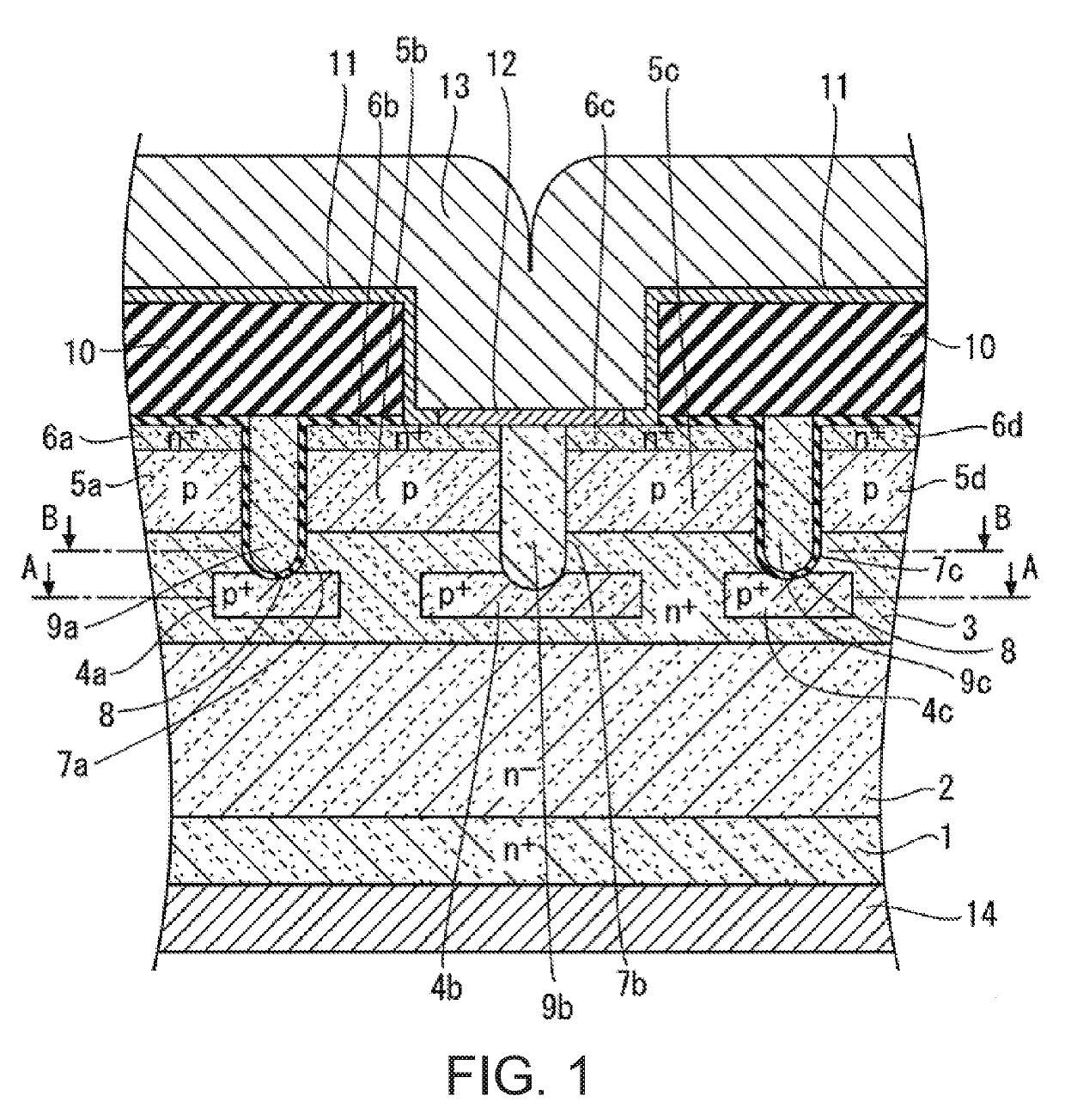

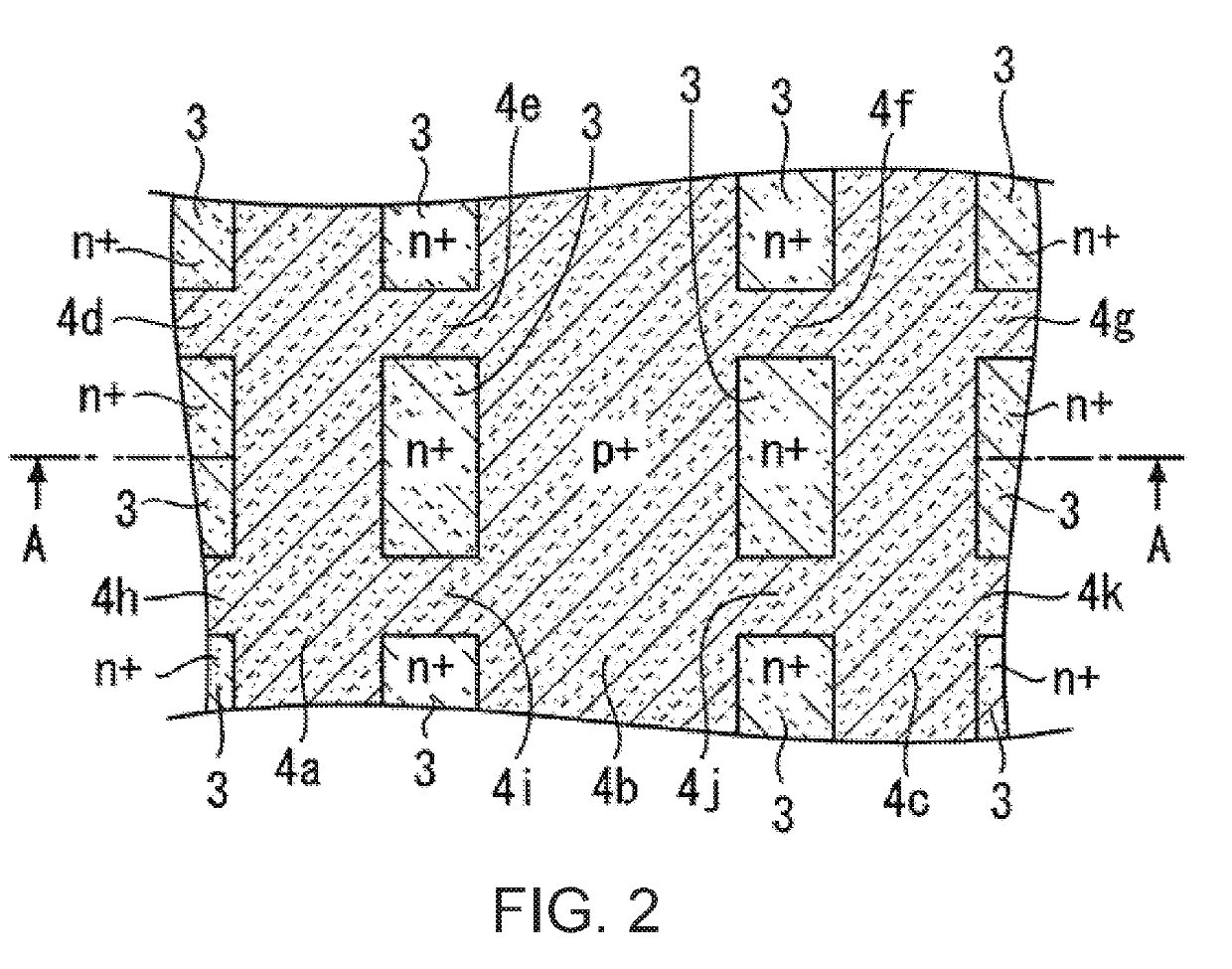

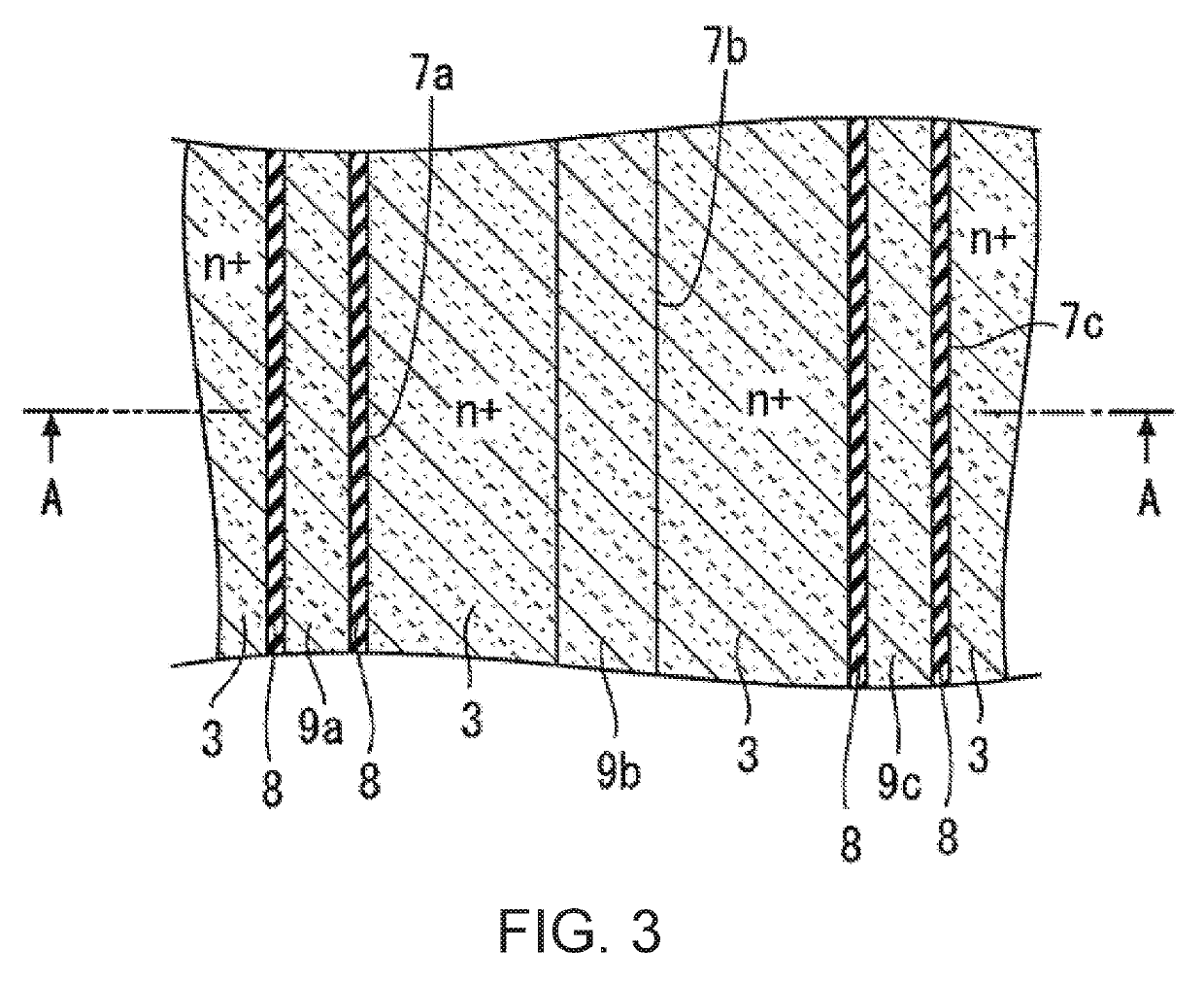

Insulated gate semiconductor device and method of manufacturing same

ActiveUS20190288104A1Reduce stepsLower resistanceThyristorDiodePower semiconductor deviceSemiconductor materials

Provided are: injection control regions of a second conductivity type provided on a charge transport region of a first conductivity type; main electrode regions of the first conductivity type provided on the injection control regions; insulated gate electrode structures going through the main electrode region and the injection control regions in the depth direction; an injection suppression region going through the main electrode regions and the injection control regions in the depth direction so as to form a pn junction in a path leading to the charge transport region, the injection suppression region including a semiconductor material with a narrower bandgap than a material of the charge transport region; and a contact protection region of the second conductivity type contacting the bottom surface of the injection suppression region.

Owner:FUJI ELECTRIC CO LTD

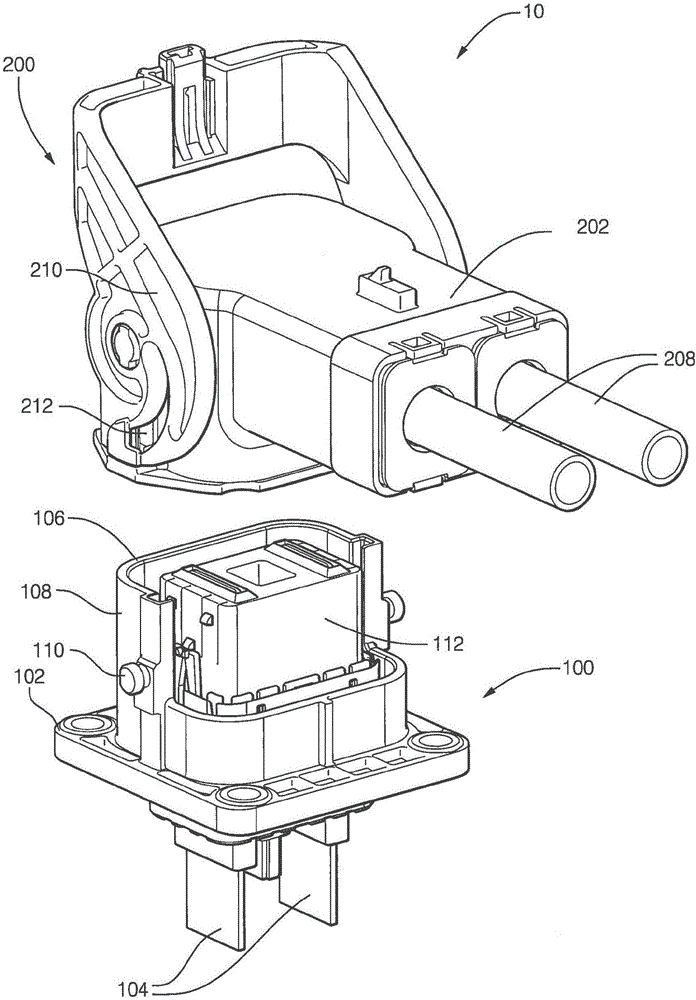

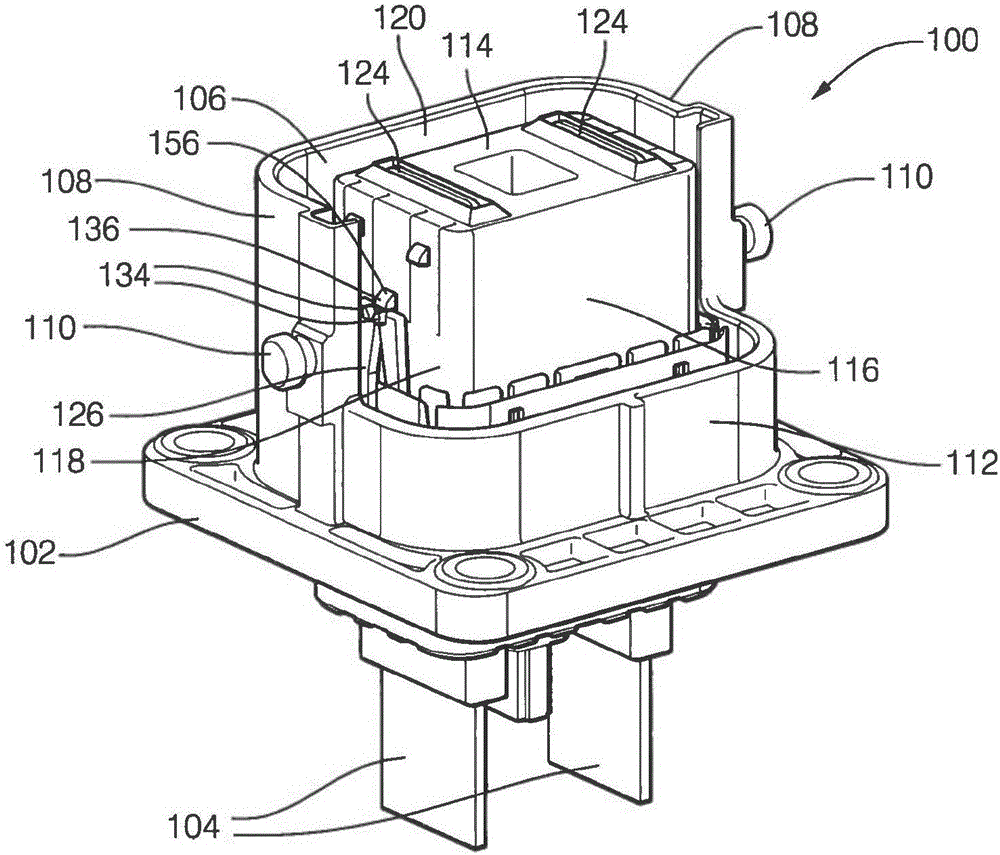

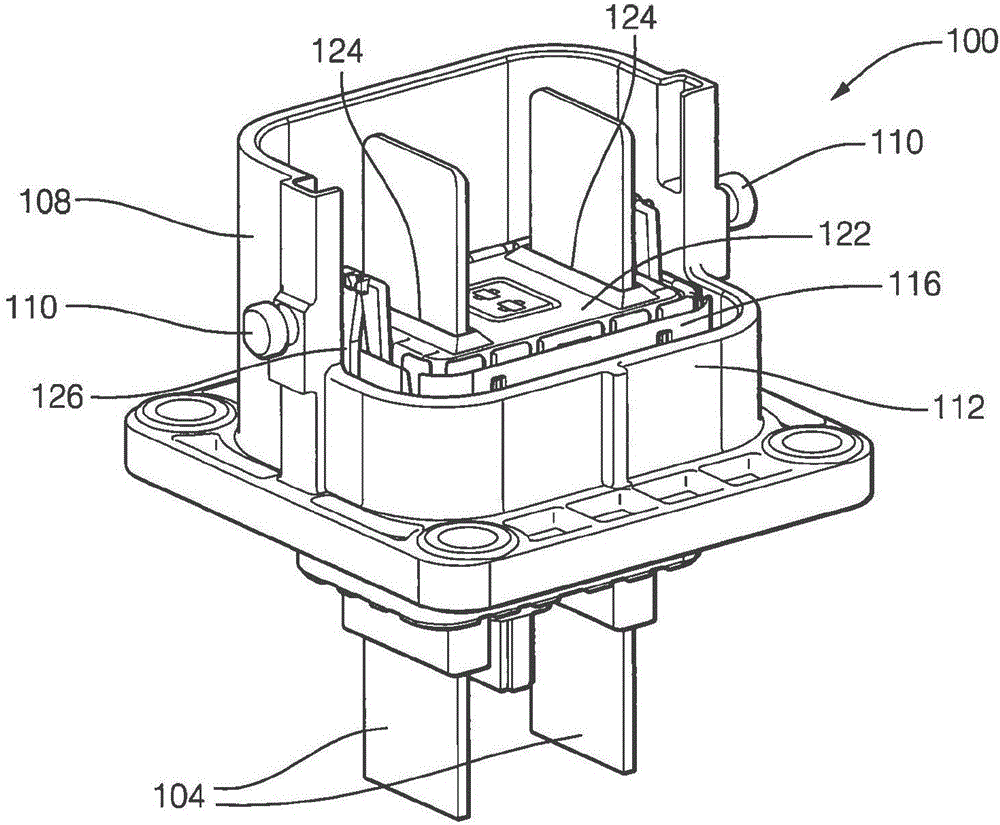

Right angle connector with terminal contact protection

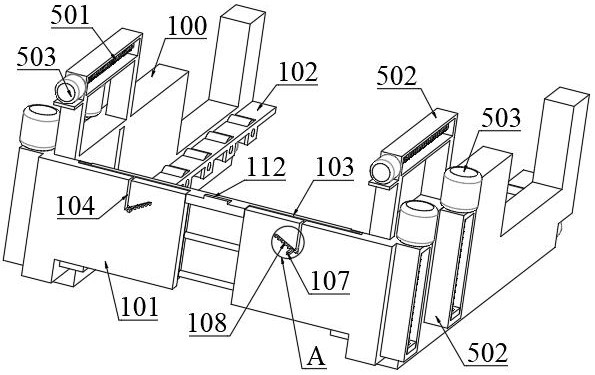

ActiveCN106532332AEngagement/disengagement of coupling partsVehicle connectorsEngineeringElectrical connector

A connector assembly (10), such as a high voltage electrical connector assembly, includes a first connector (100) having a first housing (102) and an intermediate housing (112) attached to the first housing (102). The intermediate housing (112) is moveable from a first position (120) to a second position (122). A flexible retaining arm is configured to hold the intermediate housing (112) in the first position (120). The connector assembly (10) further includes a second connector (200) having a second housing (202). The second housing (202) defines a release wedge (214) that engages and flexes the retaining arm, thereby releasing the intermediate housing (112) from engagement with the retaining arm and allowing the intermediate housing (112) to move from the first position (120) to the second position (122) as the first connector (100) is connected to the second connector (200). A terminal in the first housing (102) is enclosed within the intermediate housing (112) in the first position (120), and protrudes from an aperture in a surface of the intermediate housing (112) in the second position (122).

Owner:APTIV TECH LTD

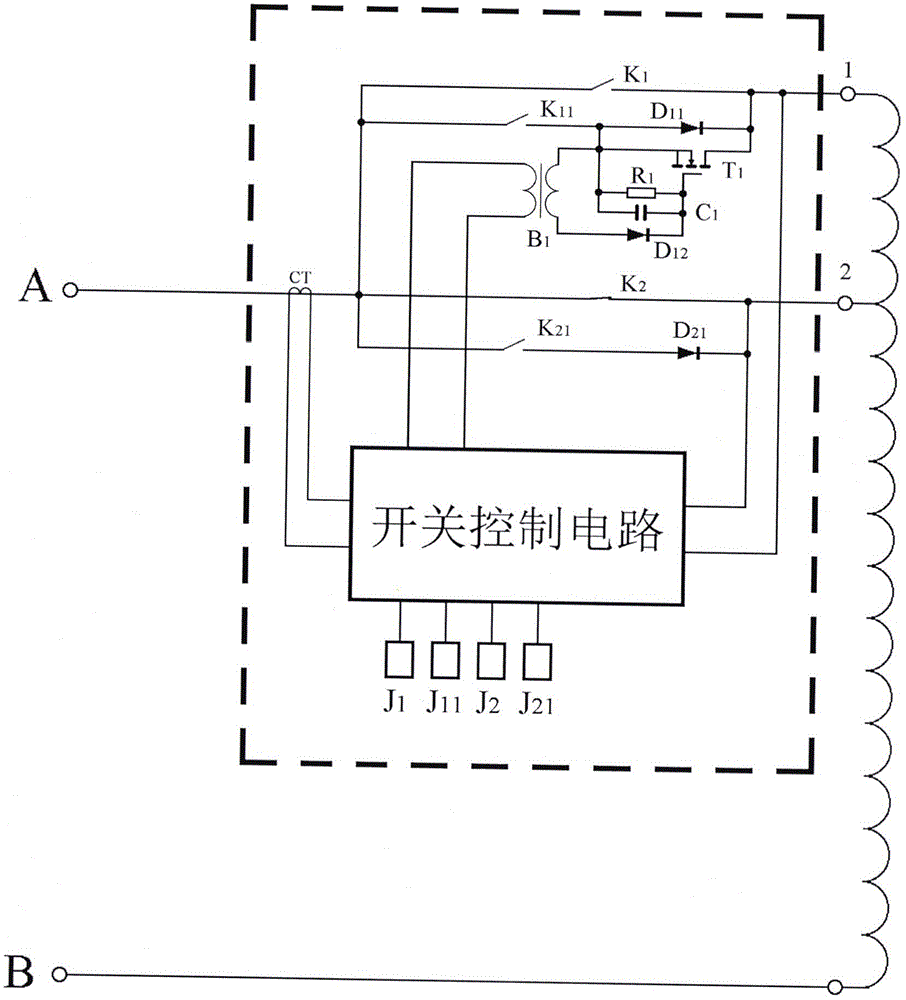

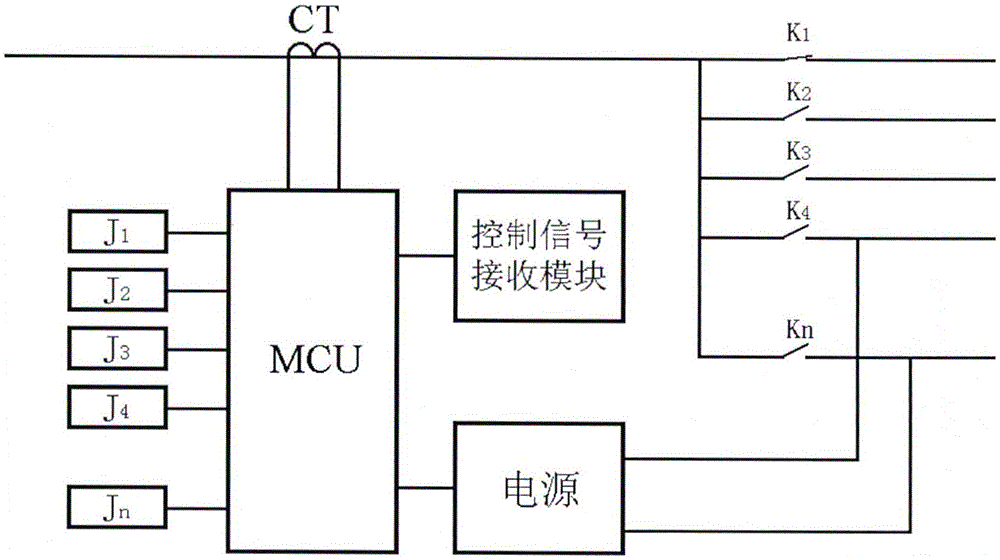

On-load tap-changer of transformer and on-load tap changing transformer

ActiveCN105632727AWill not cause short circuitFast switching speedEmergency protective circuit arrangementsConversion without intermediate conversion to dcTap changerControl circuit

The invention relates to an on-load tap-changer of a transformer. The on-load tap-changer of the transformer comprises a plurality of tap-changer units and a switch control circuit, wherein each tap-changer unit comprises two relay switch contacts and corresponding contact protection circuits; one end of each of two switch contacts is connected with a corresponding transformer winding tap and the other end is connected with a power supply after being connected in parallel; two switch contact protection braches are a series circuit of an MOS tube and an auxiliary relay contact and the other series circuit of a diode and the other auxiliary relay contact respectively; two series circuits are connected with two ends of the corresponding switch contacts in parallel respectively; the plurality of tap-changer units are connected with one another in parallel to form a multi-winding branch tap-changer; and the switch control circuit controls all main switches, auxiliary switches and MOS tubes to act according to a certain time order, so that switching of transformer windings is achieved. Compared with an existing on-load tap-changer, the on-load tap-changer of the transformer provided by the invention has the advantages of being high in tapping speed, free of an inrush current in a tapping process, continuous in current, simple to operate, high in reliability, small in volume, light in weight, low in cost and the like.

Owner:GYRK INT TECH

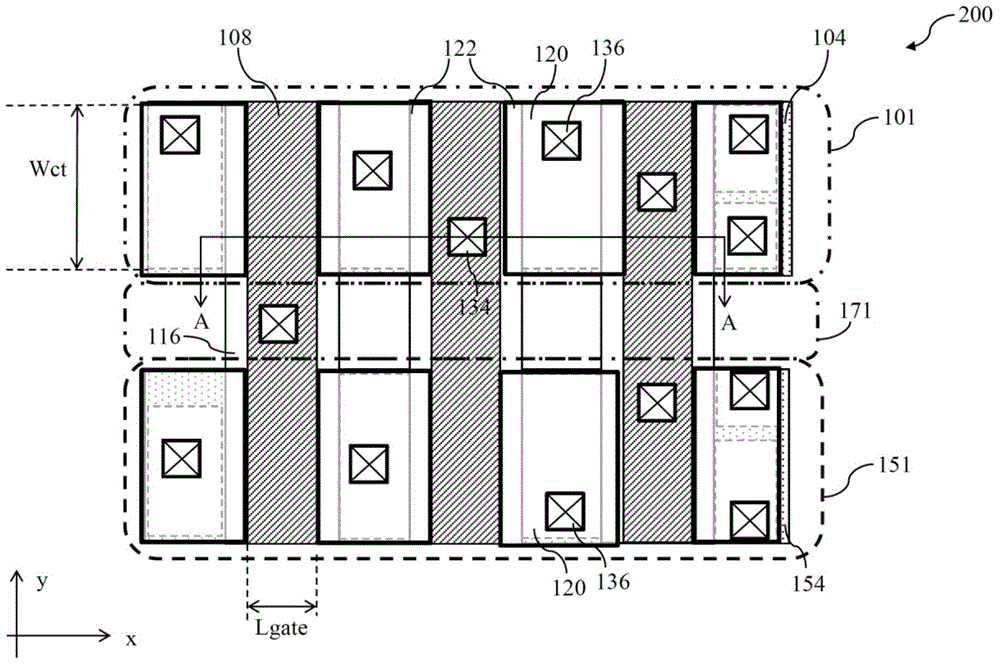

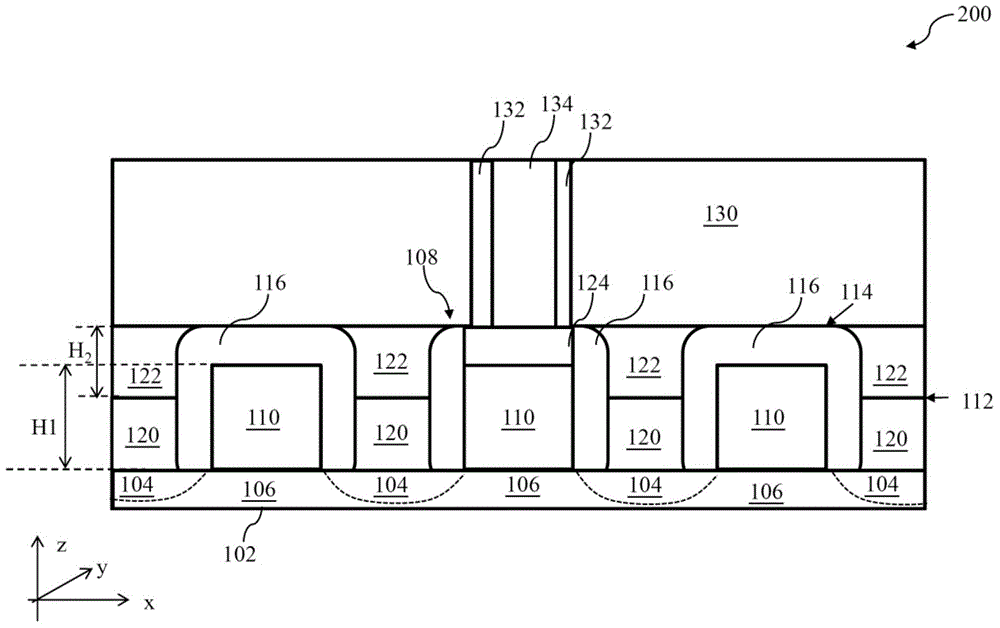

Self-aligned contact protection using reinforced gate cap and spacer portions

ActiveUS20180130889A1Reduce or eliminate gate cap and/or spacer lossReducing or eliminating gate cap and spacer lossTransistorSolid-state devicesSemiconductor structureEngineering

A method includes providing a starting structure, the starting structure including a semiconductor substrate, sources and drains, a hard mask liner layer over the sources and drains, a bottom dielectric layer over the hard mask liner layer, metal gates between the sources and drains, the metal gates defined by spacers, gate cap openings between corresponding spacers and above the metal gates, and a top dielectric layer above the bottom dielectric layer and in the gate cap openings, resulting in gate caps. The method further includes removing portions of the top dielectric layer, the removing resulting in contact openings and divot(s) at a top portion of the spacers and / or gate caps, and filling the divot(s) with etch-stop material, the etch-stop material having an etch-stop ability better than a material of the spacers and gate cap. A resulting semiconductor structure is also disclosed.

Owner:GLOBALFOUNDRIES US INC

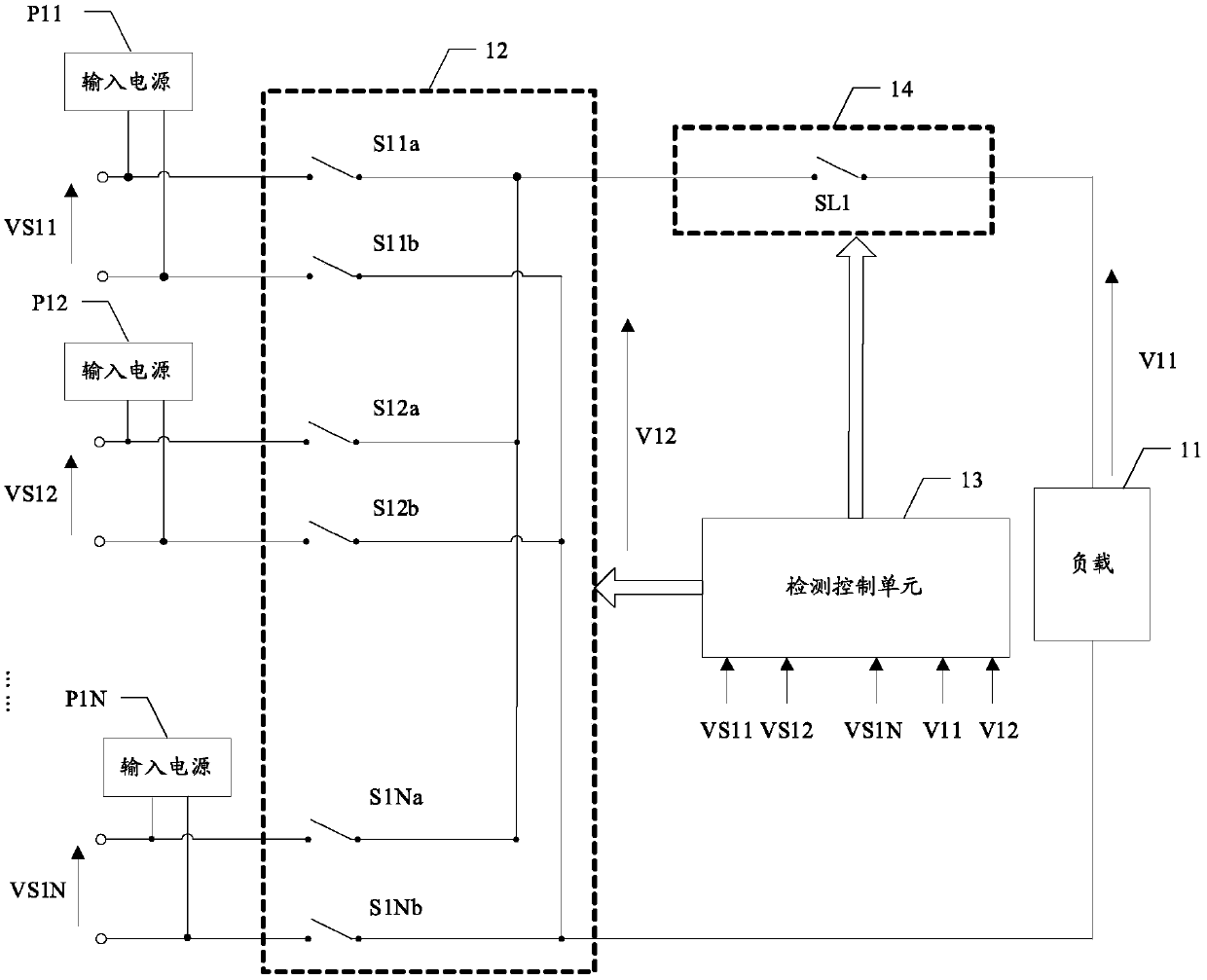

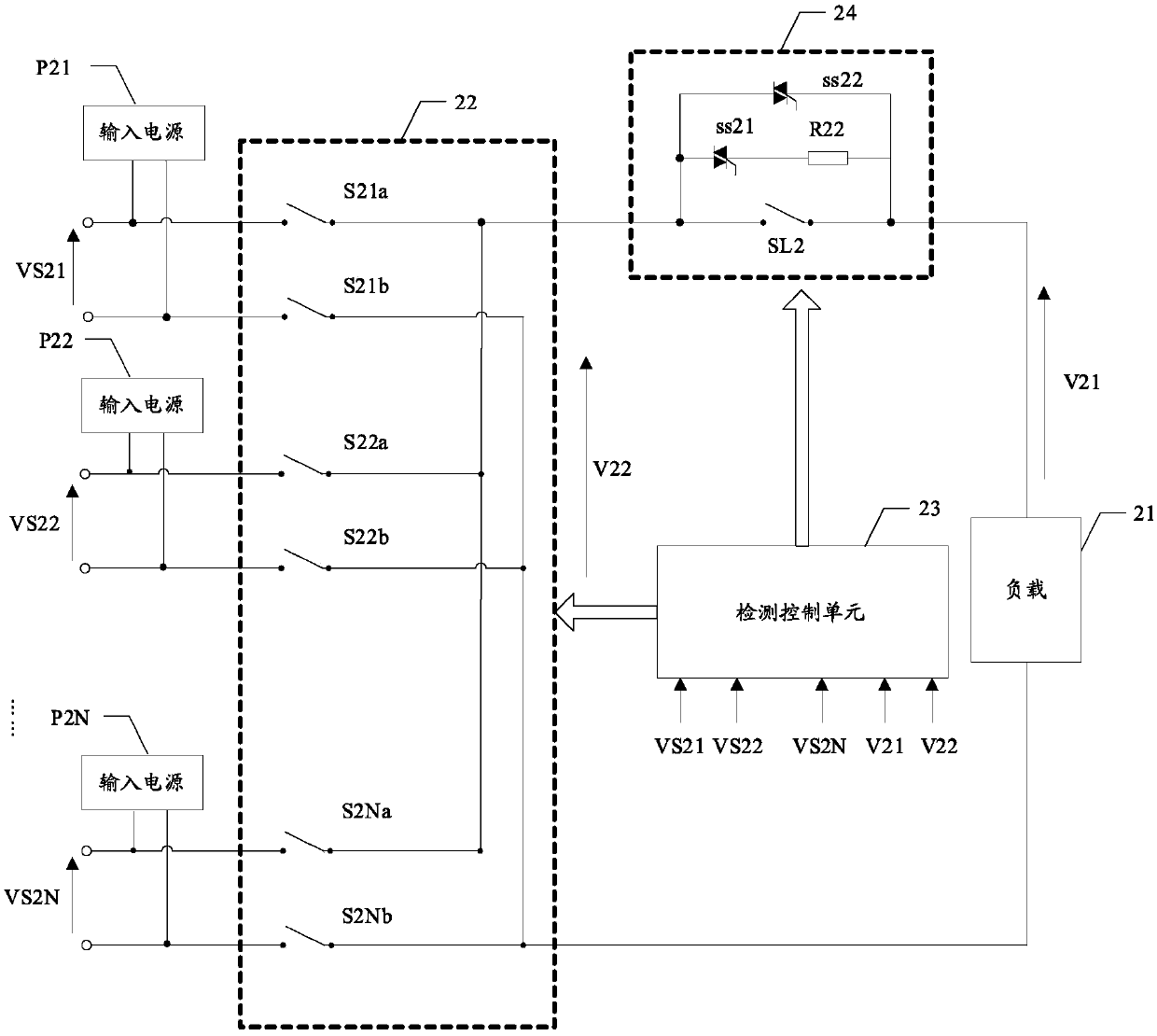

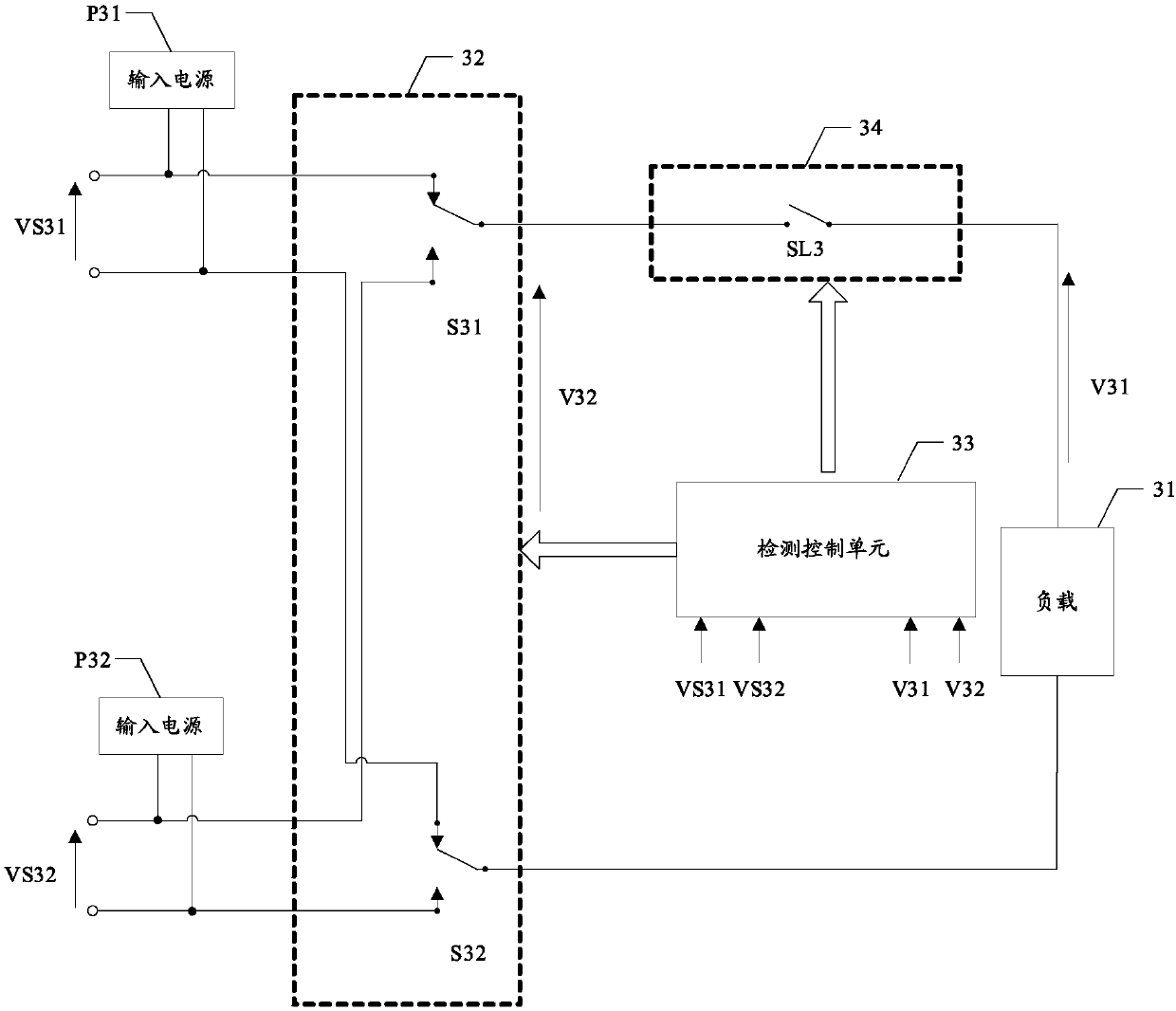

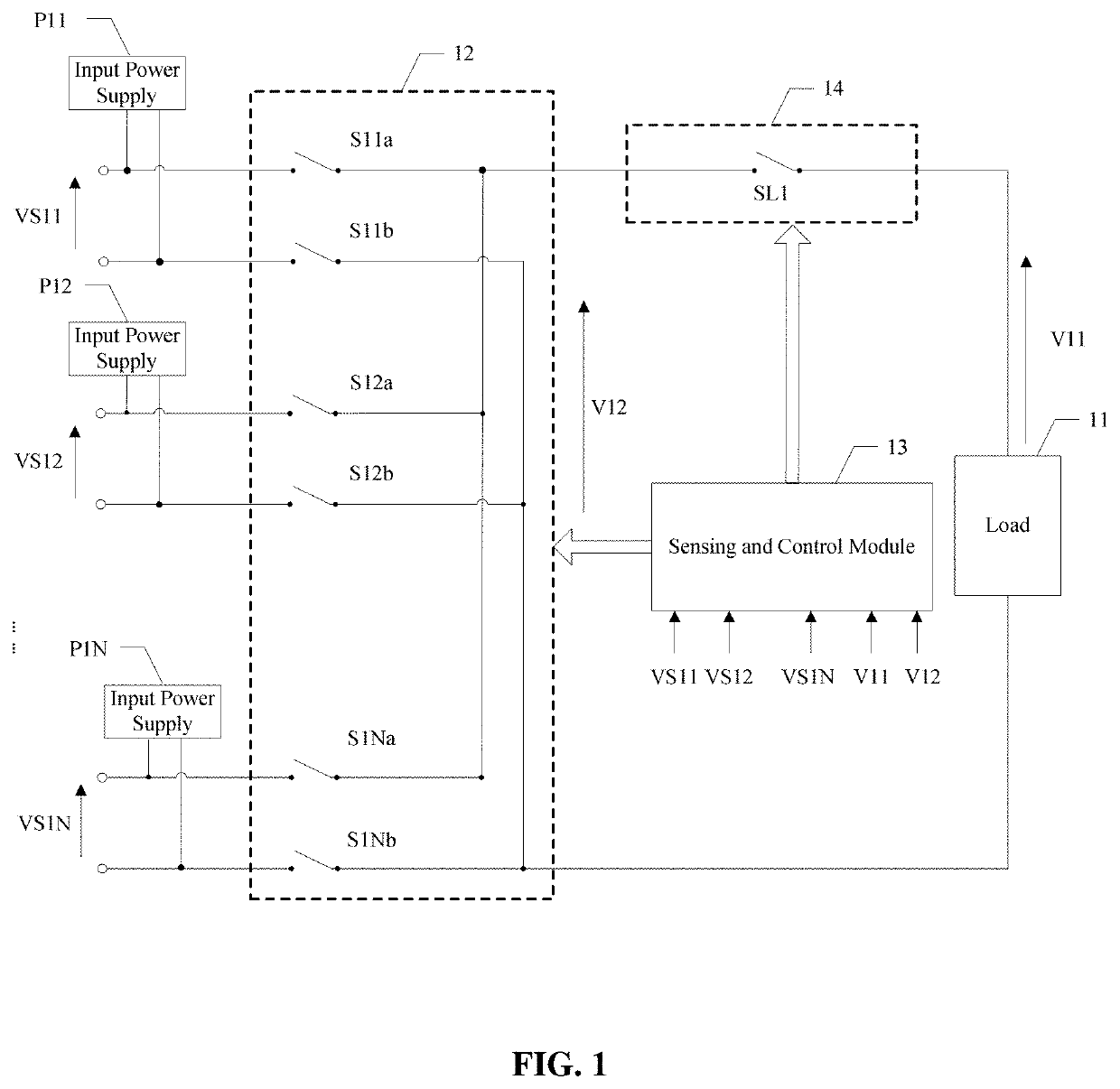

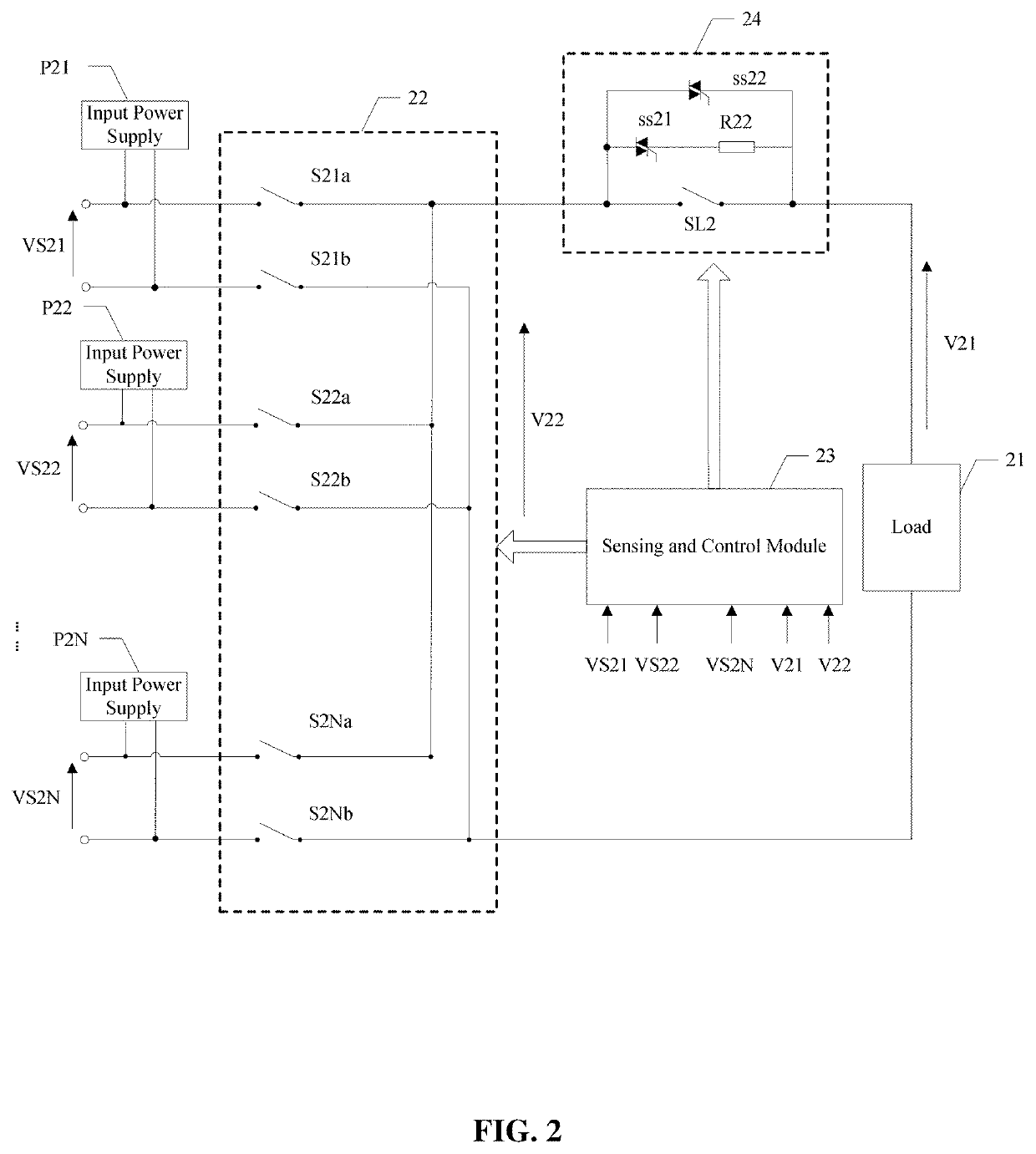

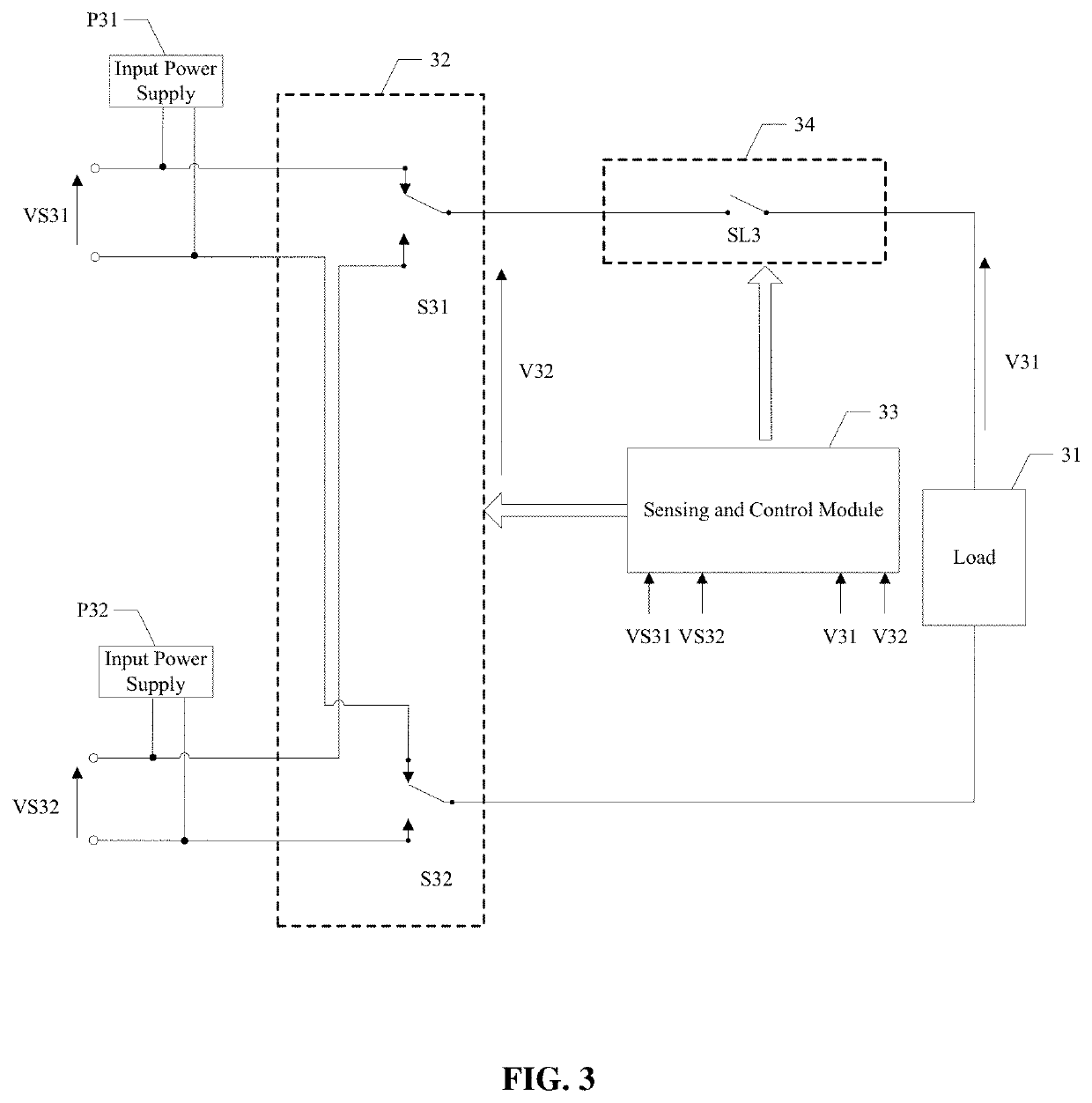

Input power supply selection circuit

ActiveCN110690694AReduce switching capacity requirementsSimple designSelective ac load connection arrangementsDc-dc conversionTerminal voltageControl cell

The invention provides an input power supply selection circuit. The circuit comprises a load, at least one input power supply which can provide a work power supply for the load, and an input selectioncircuit suitable for selecting one input power supply as the work power supply of the load among at least one input power supply, wherein the work power supply is a direct current power supply or analternating current power supply. The circuit further comprises a detection control unit which controls the input selection circuit to switch the work power supply of the load according to the voltageof at least one input power supply, the output end voltage of the input selection circuit, and the voltage of the load, and a load switch branch. One end the load switch branch is connected with theload, and the other end is connected with the output end of the input selection circuit. The load switch branch is suitable for controlling the closing and opening of the circuit where the load is located. The detection control unit is further suitable for controlling the closing and opening of the load switch branch. According to the invention, the design of the contact protection of the input selection switch is simplified, and the switching capacity requirement of the load switch branch is reduced.

Owner:MURATA MFG CO LTD

Input power supply selection circuit

ActiveUS20200014239A1Simple designReducing switching capacity requirementSelective ac load connection arrangementsDc-dc conversionControl engineeringControl theory

An input power supply selection circuit includes a load, at least one input power supply to provide an operation power supply for the load, an input selection circuit to select the at least one input power supply as the operation power supply for the load, a sensing and control module to control the input selection circuit to switch the operation power supply for the load, and a load switch branch to control the load to be connected or disconnected. The sensing and control module controls the load switch branch to be connected or disconnected, and when the load switch branch is disconnected, the load and the at least one input power supply are not electrically coupled. Therefore, a contact protection design is simplified and a switching capacity requirement of the load switch branch is lowered.

Owner:MURATA MFG CO LTD

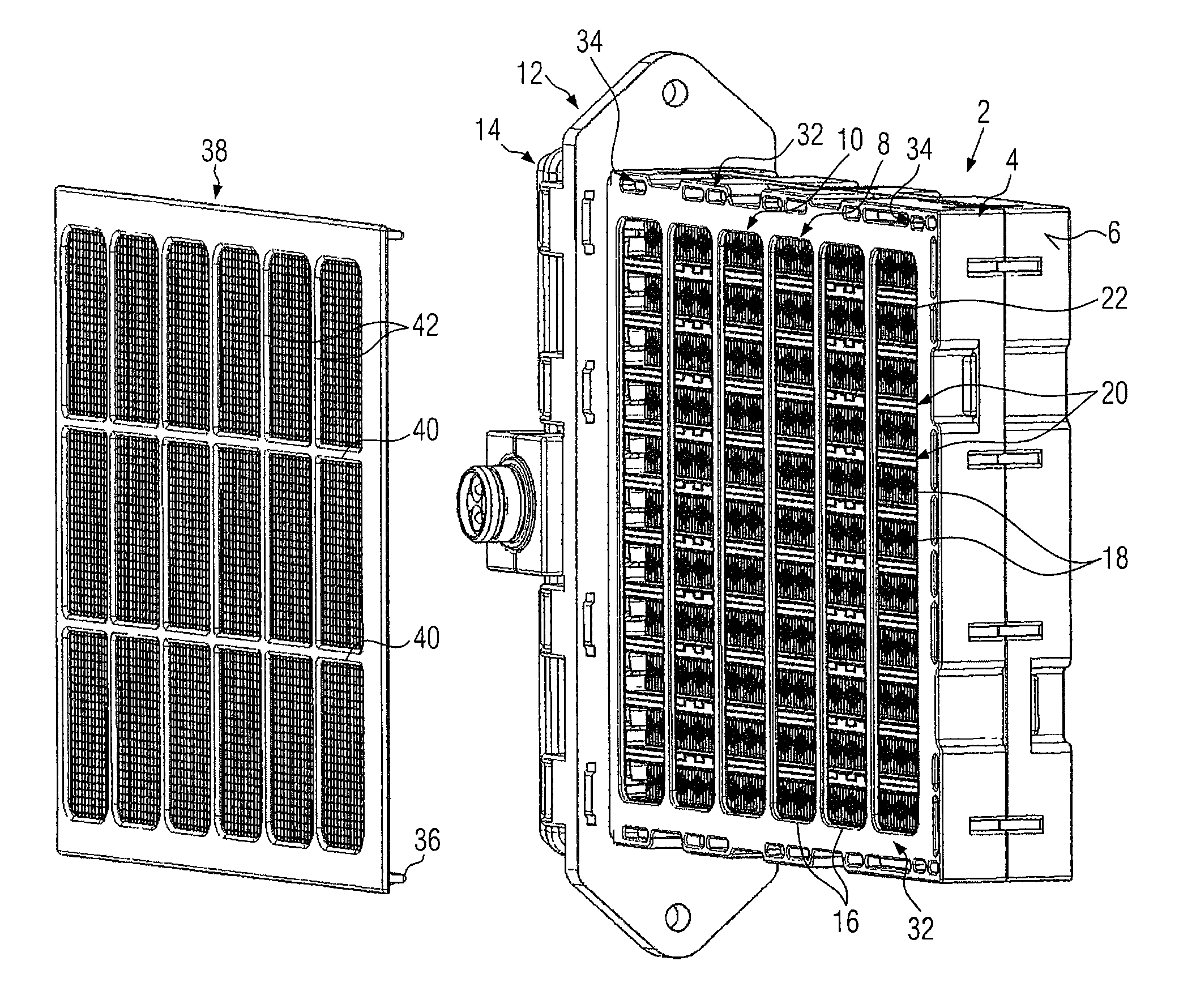

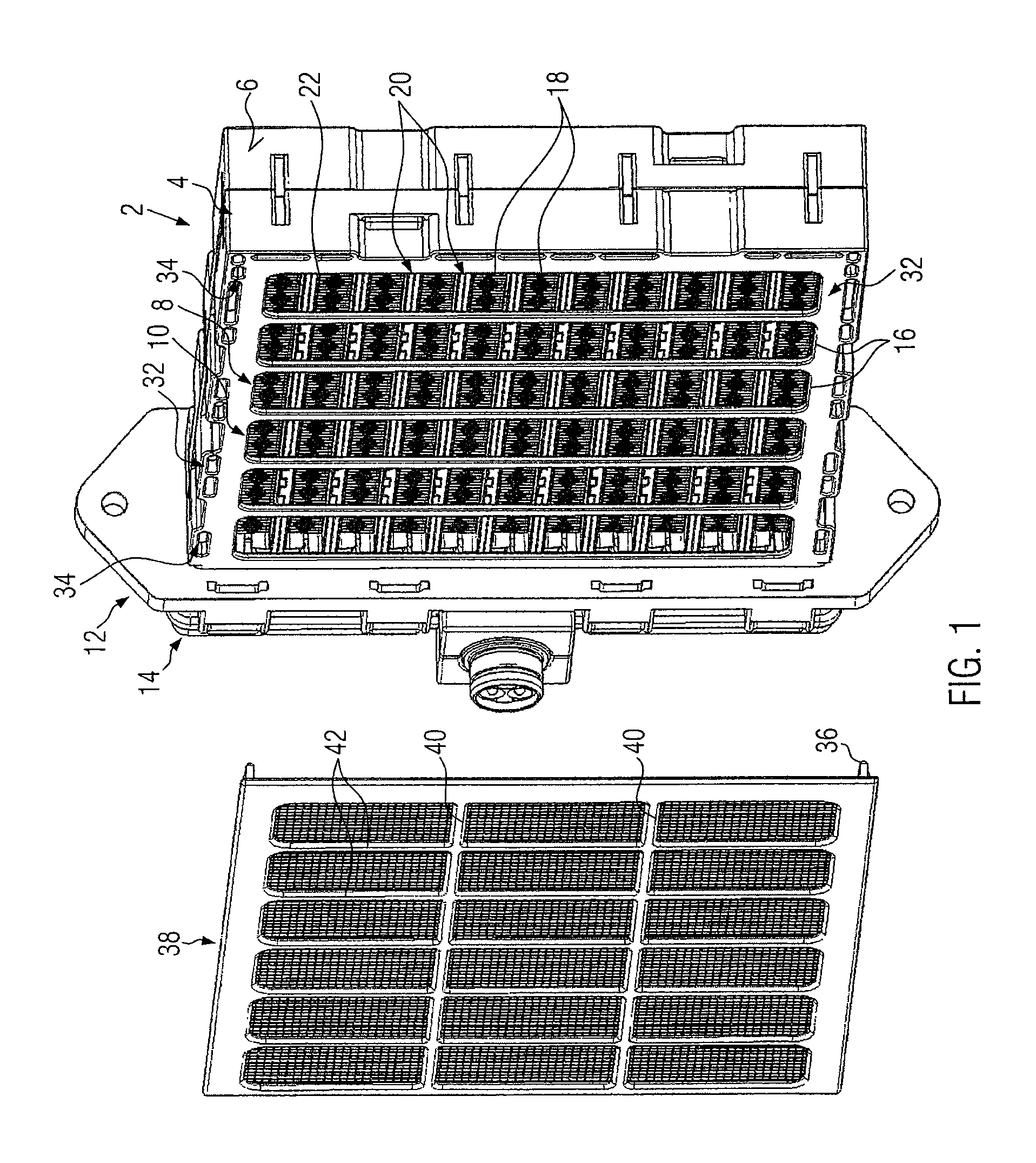

Electrical heating device

InactiveUS20120152931A1Operational securityImprove heating efficiencyHeater elementsAir heatersThermodynamicsEngineering

An auxiliary electrical heating device for a motor vehicle includes a heating block that includes parallel layers of at least one heat emitting element and at least one heat generating element. The heating block is held in a housing having oppositely situated housing openings. In order to permit the electrical heating device to be operated safely even at high operating voltages, a contact protection of an insulating material covers the respective housing openings.

Owner:EBERSPACHER CATEM

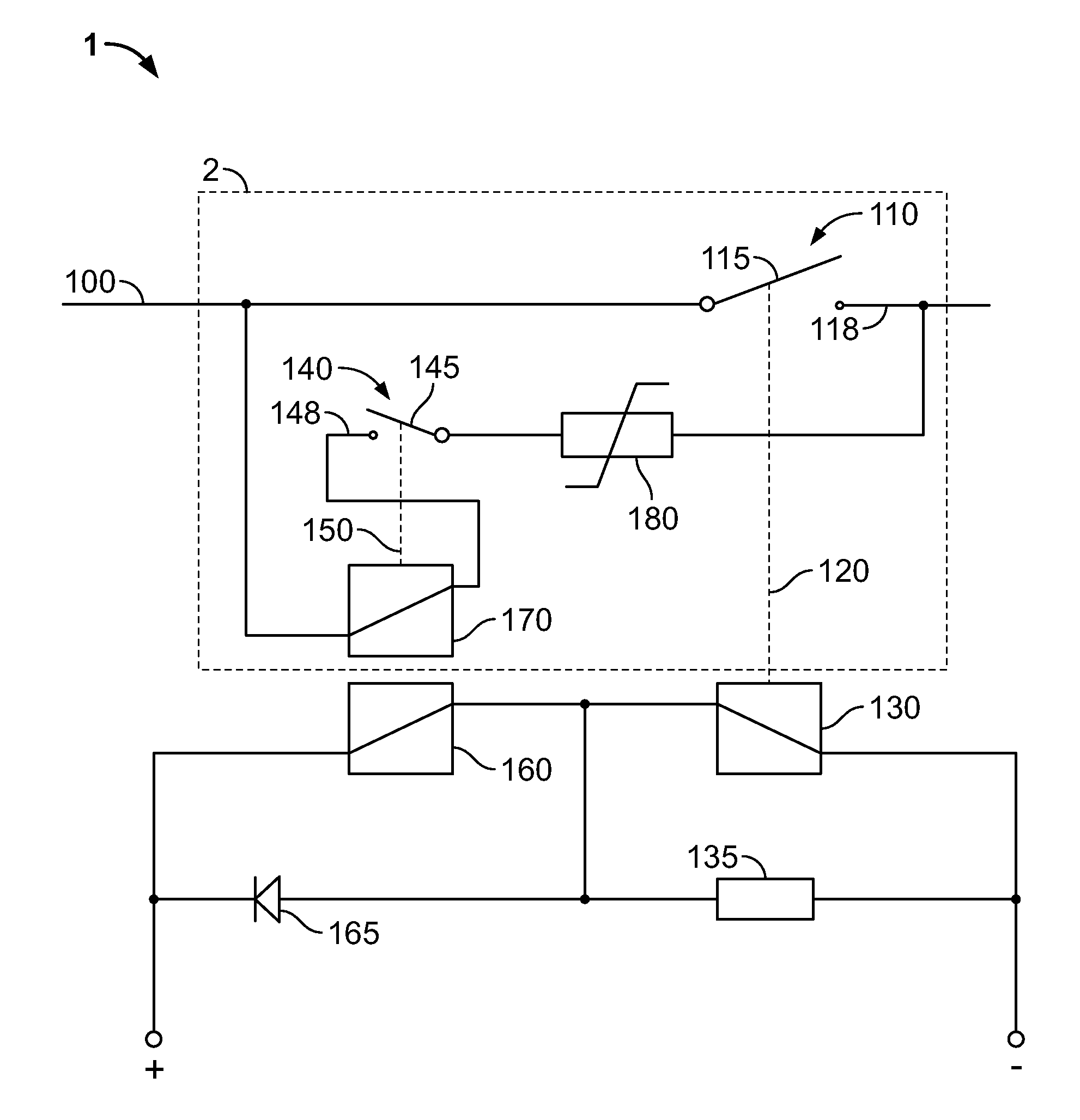

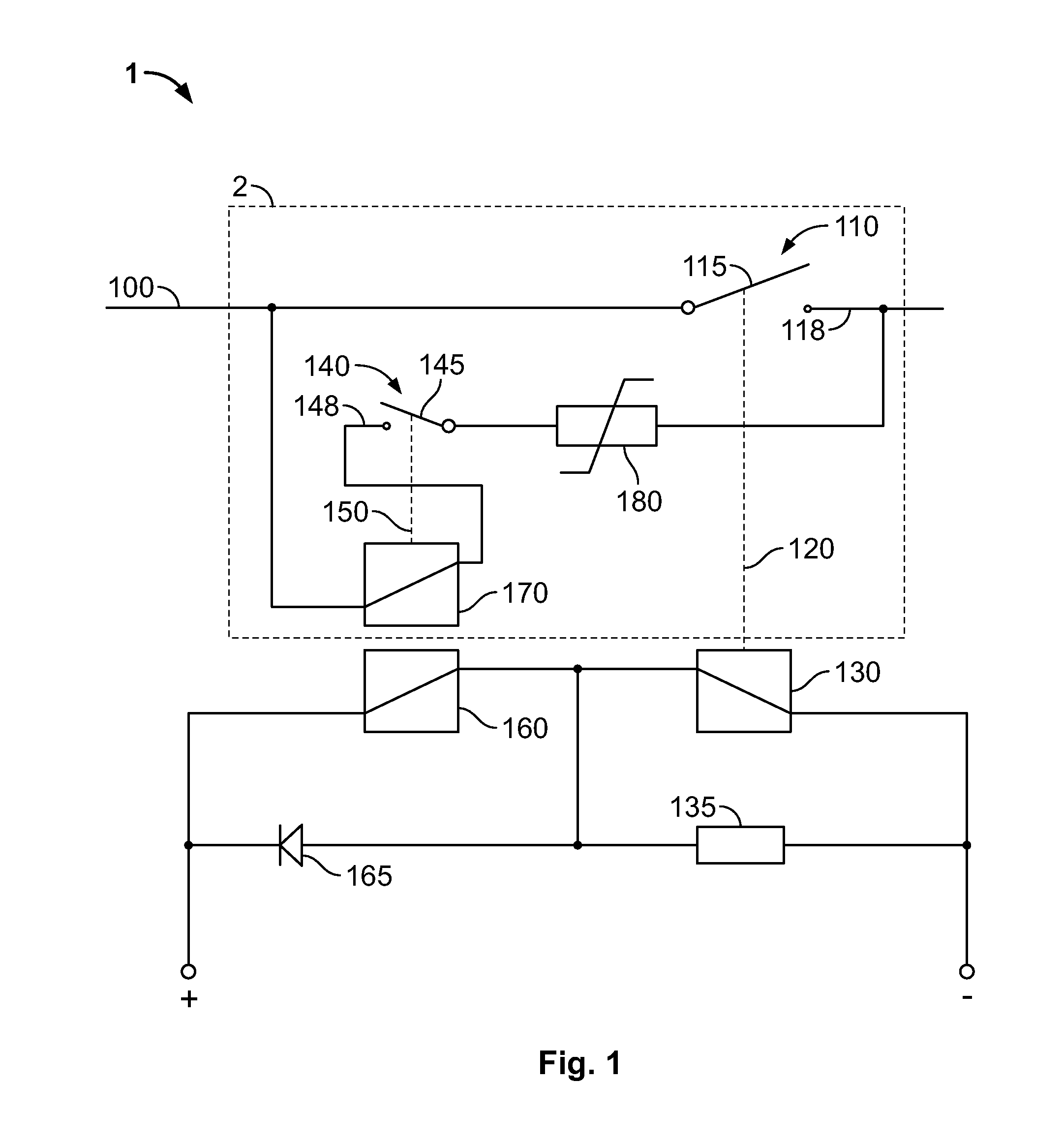

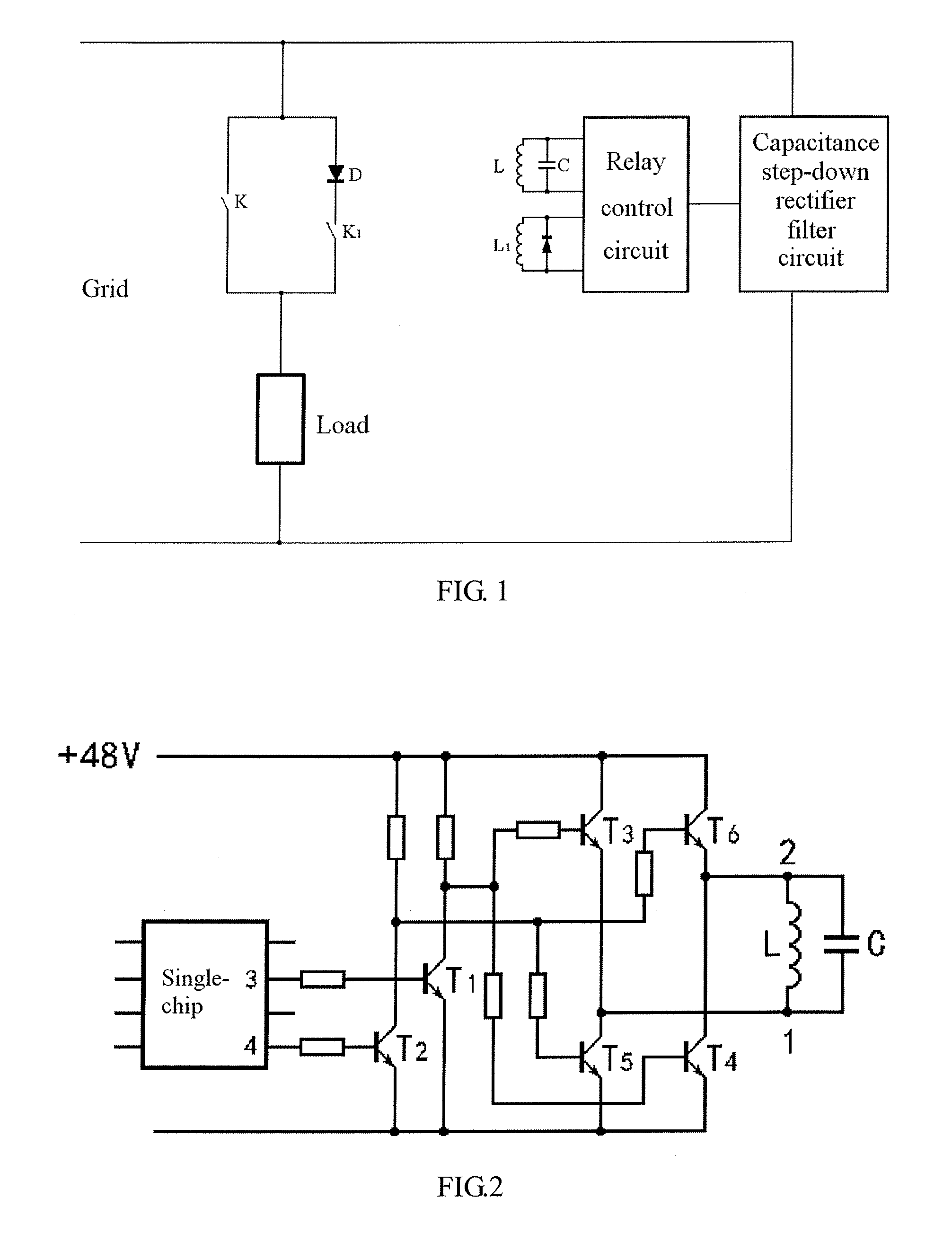

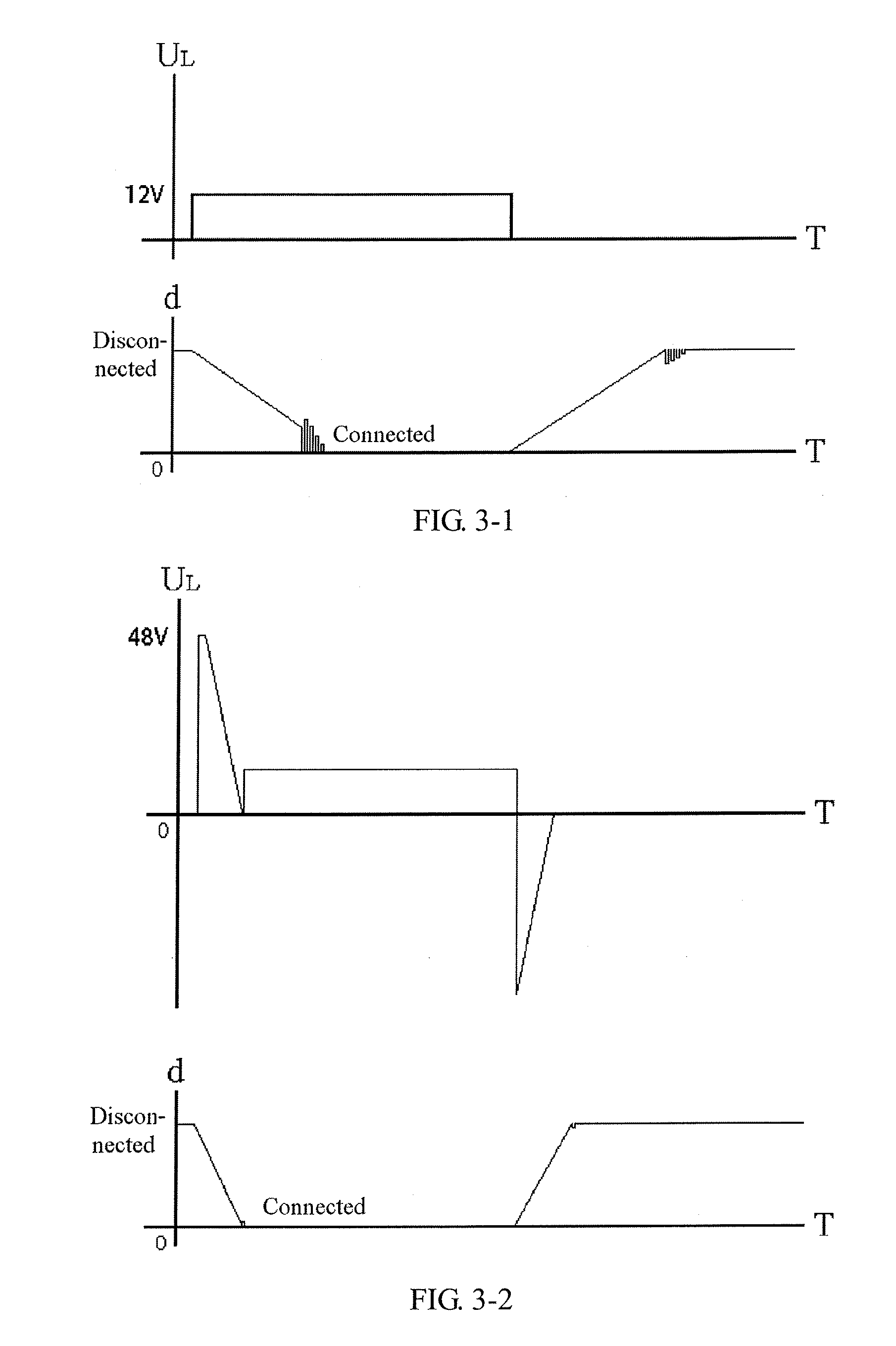

Control circuit of diode contact protection combination switch and relay control method

ActiveUS20160148768A1Shorten the timeExtended service lifeElectric switchesRelaysDriving currentMicrocomputer

A diode contact protection combination switch and a specific implementation method. The combination switch comprises a primary contact protection circuit formed by a primary switch contact of a primary relay, diodes parallel connected at two ends of the primary switch contact, and a contact of a secondary relay. A current capacity of the secondary relay is 1 / 10 to 1 / 1000 of a current capacity of a contact of the primary relay. A drive current of the primary relay changes according to a certain rule, so as to shorten travel time of the relay. The implementation method is a control method of shortening travel time of a relay, in which a current flowing through a relay is controlled by a PWM wave output by a single chip microcomputer of a relay control circuit. The diode contact protection combination switch is an on / off switch in the case of current zero crossing, which can easily implement over-current and over-voltage protection and remote manipulation functions. By means of the relay control method, travel time when a relay is closed / opened can be greatly shortened on the premise that the service life of the relay is ensured.

Owner:GYRK INT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com