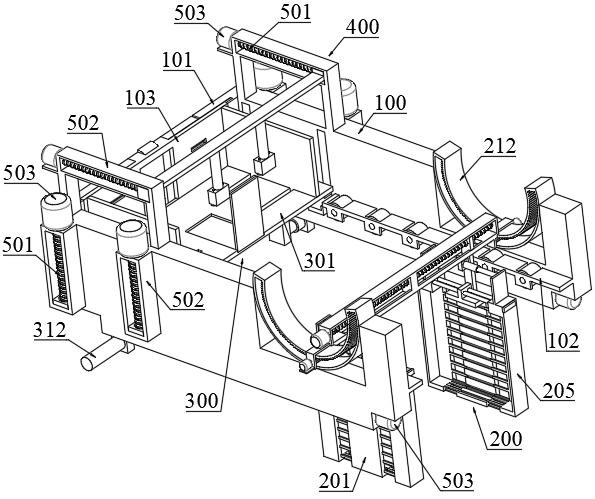

Soaked circuit board transfer device

A technology for transferring devices and circuit boards, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of low degree of automation in the production line, affect workers' health, and many manpower, so as to prevent falling, protect health, and enhance The effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

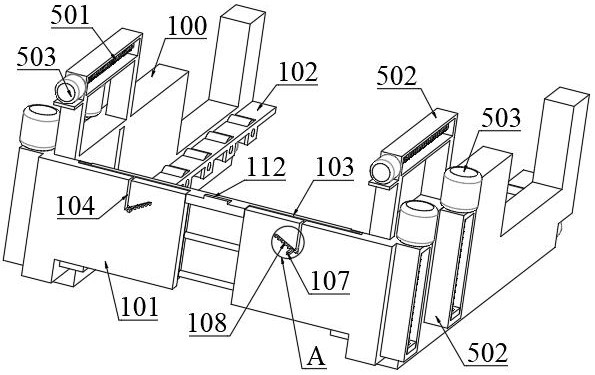

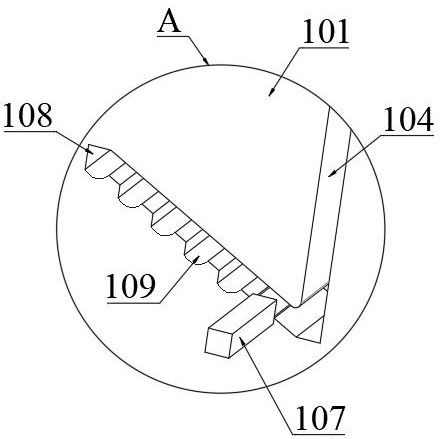

[0044] The specific implementation is described as follows:

[0045] First, transfer the transfer car with the circuit board to the bottom of the clamping mechanism 200 . At this time, the cross bar 211 is located at one end of the arc track 212 and the clamping assembly is in a horizontal state. Then the second motor 218 is activated to drive the sleeve to the rotating shaft 215 The upper gear 216 rotates. Under the cooperation of the gear 216 and the ring gear 217, the crossbar 211 starts to rotate, and drives the clamping assembly to rotate until the crossbar 211 is at the lowest point of the arc track 212. At this time, the clamping assembly is in a vertical position. The circuit board is in the straight state, and the circuit board is between the two clamping assemblies, and then the first motor 213 is activated to drive the first screw rod 210 to rotate. Since the two threads of the first screw rod 210 have opposite directions of rotation, the two clamping The components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com