Patents

Literature

48results about How to "Guaranteed contact stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

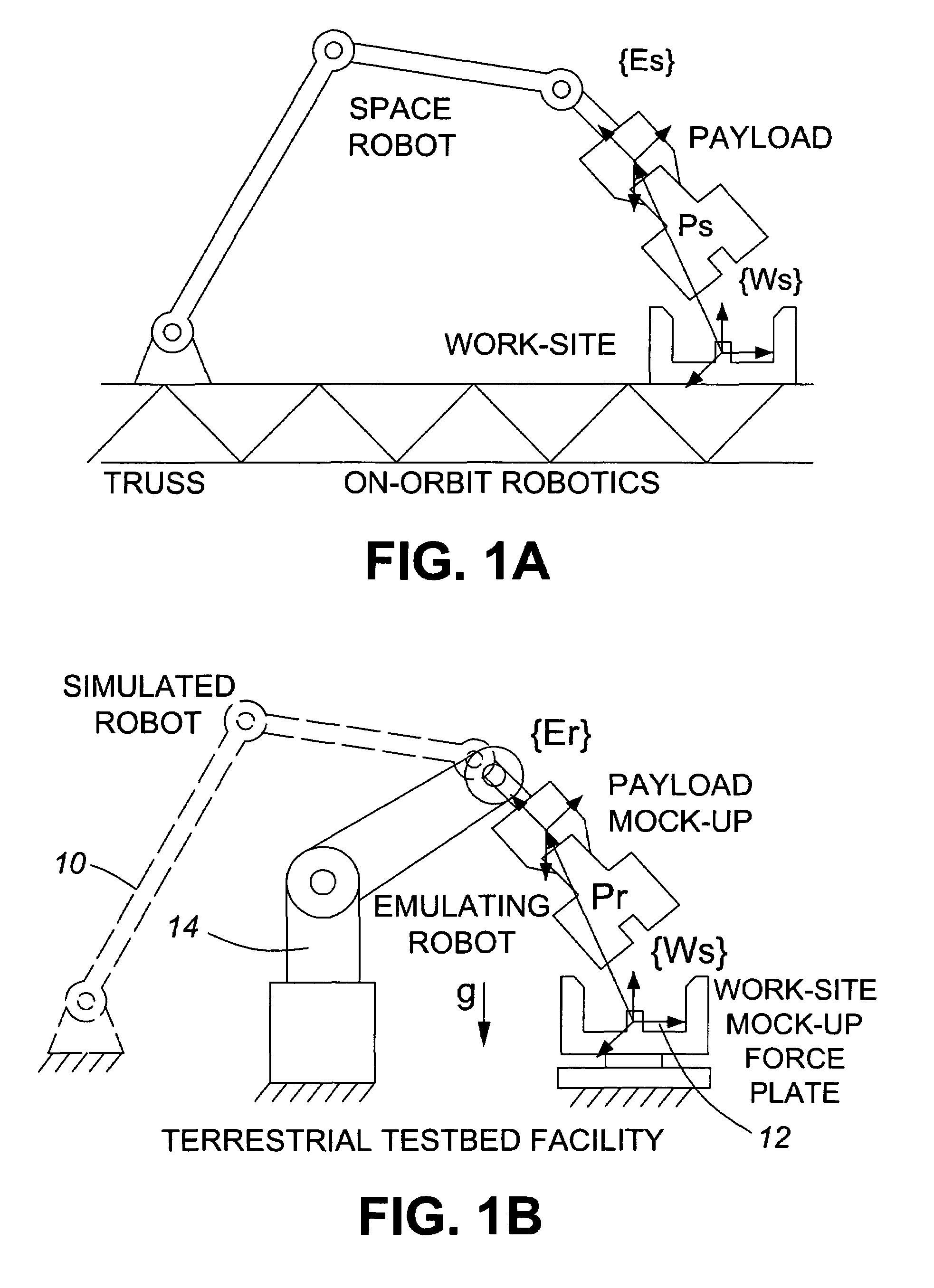

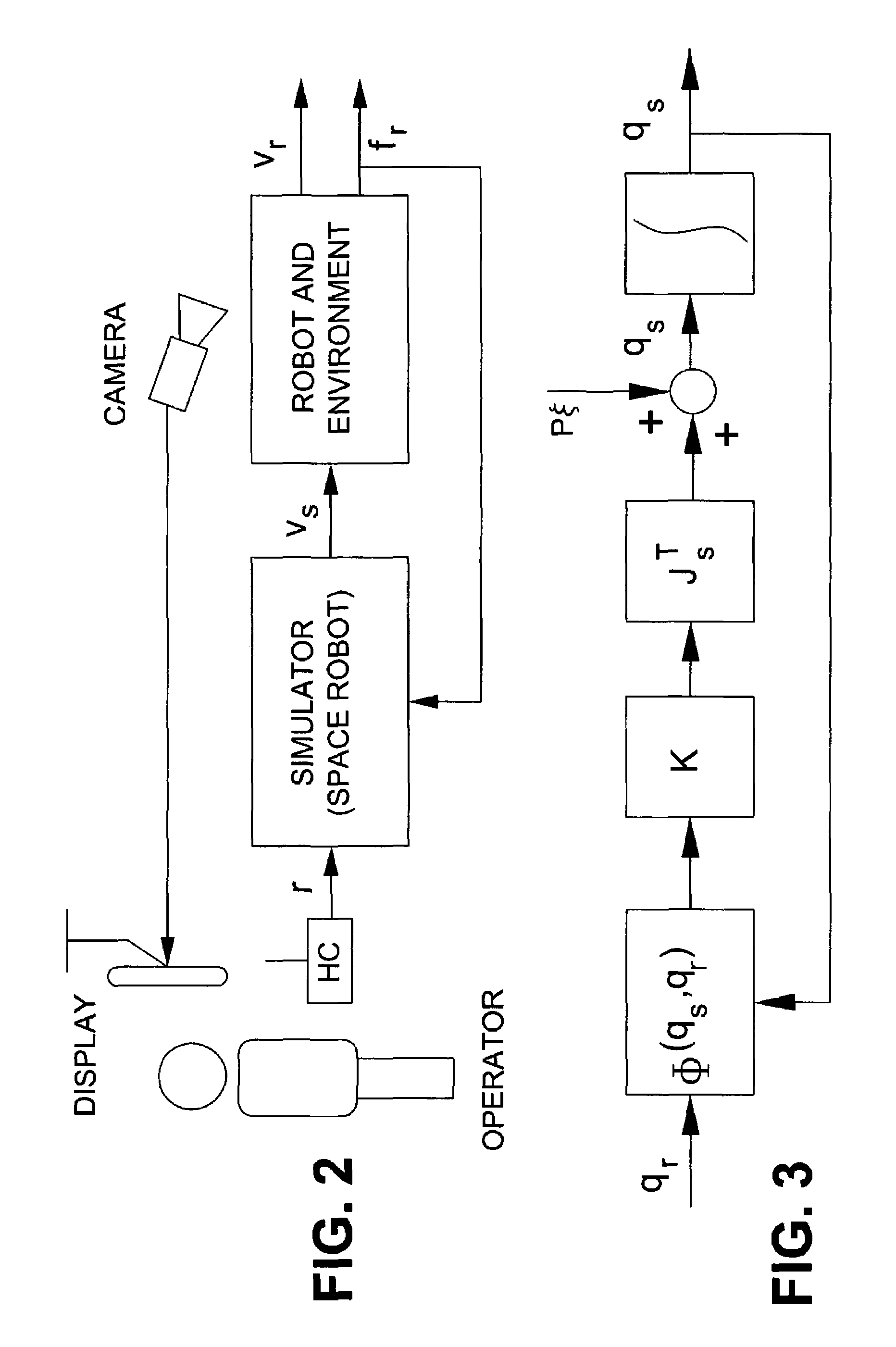

Robust impedance-matching of manipulators interacting with unknown environments

InactiveUS20070073442A1Minimizes disturbance sensitivityMore sensitivityProgramme-controlled manipulatorComputer controlMock upsSimulation

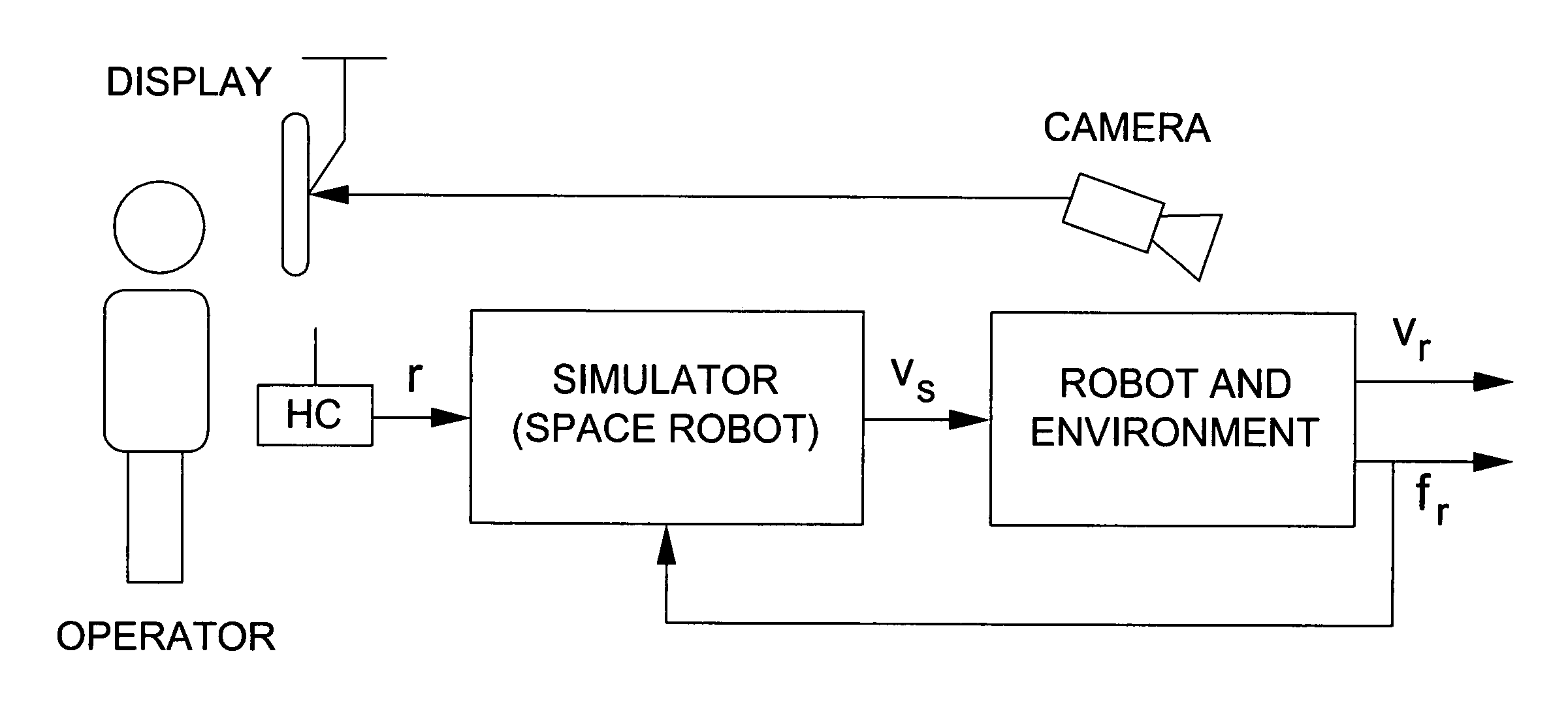

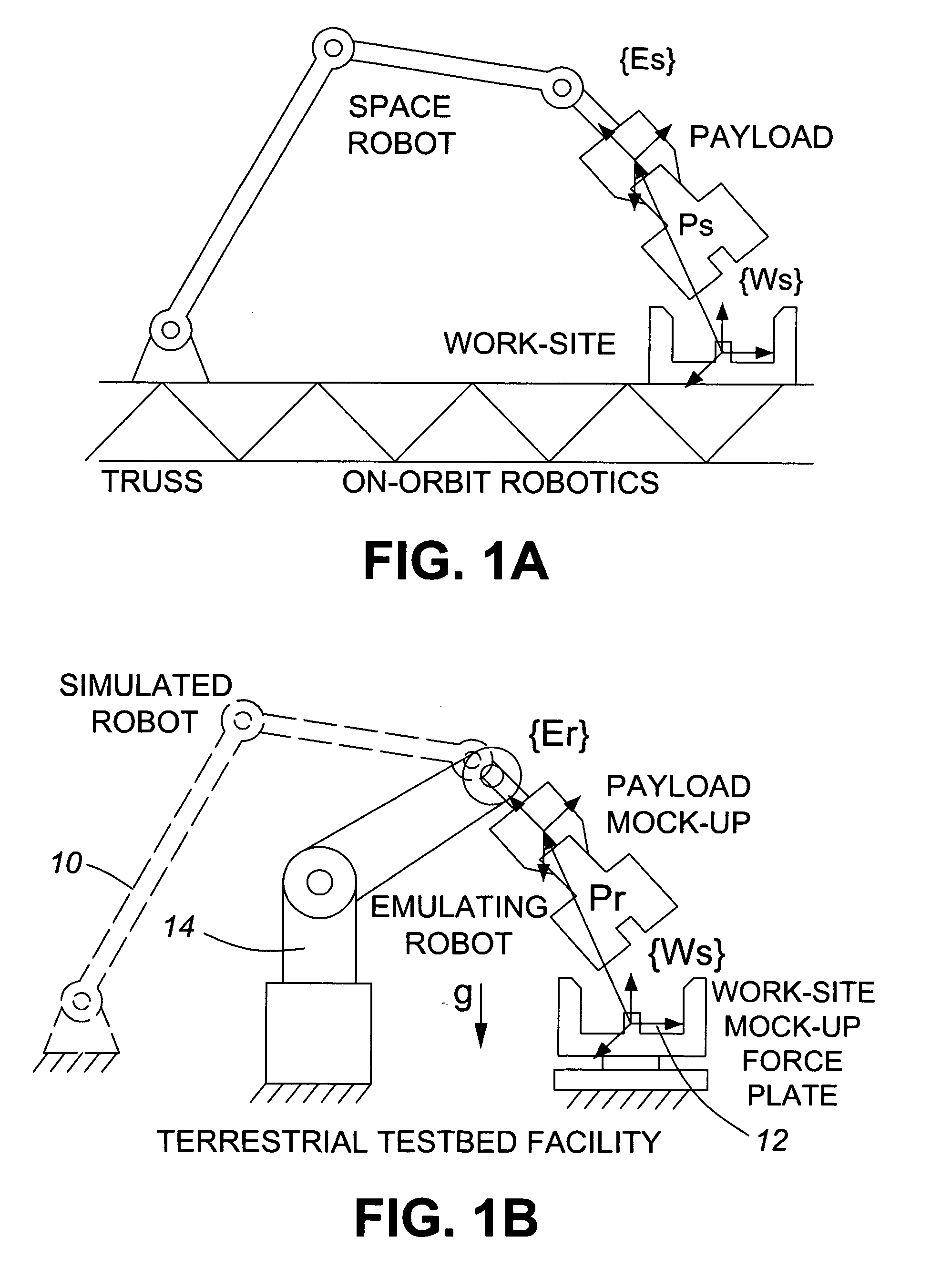

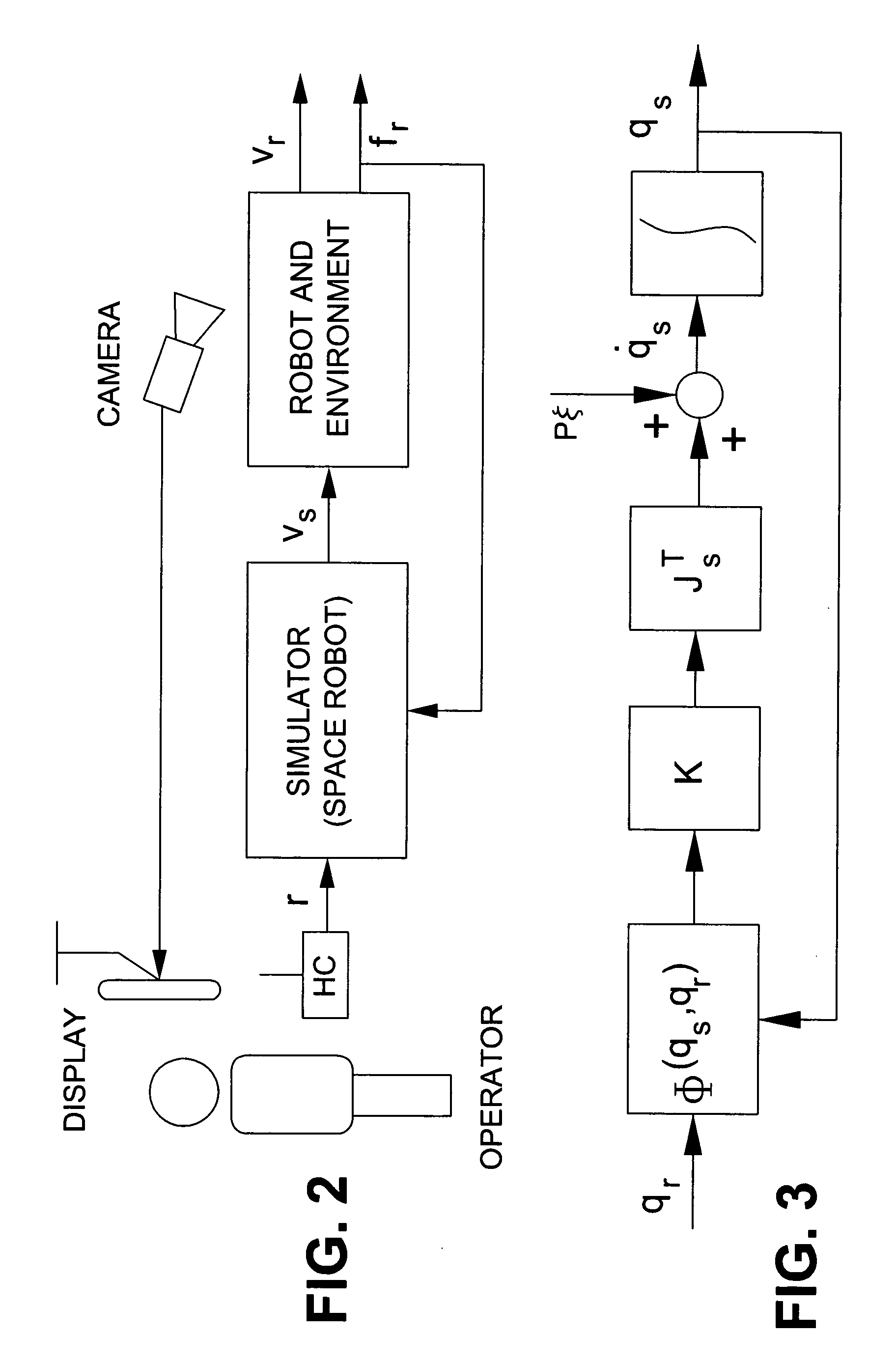

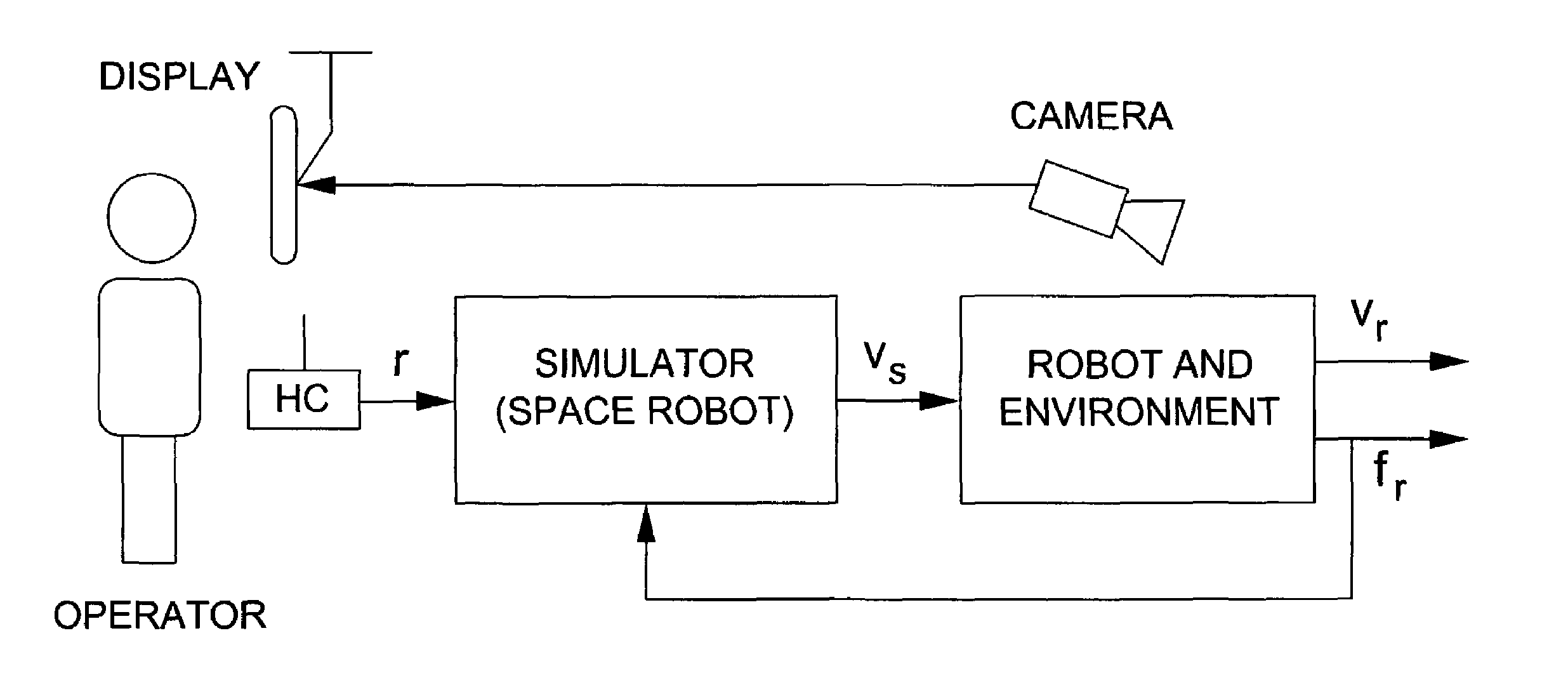

A system for replicating the behavior of a target robotic manipulator with respect to a payload and worksite, has a real-time simulator capturing the dynamics of the target robot manipulator; a mock-up of the payload and worksite; and an emulating robotic manipulator for interacting with said payload and worksite. The emulating robotic manipulator is controlled by the real-time simulator in a control loop to replicate the dynamical behavior of said target robotic manipulator in its environment by matching the impedance of the emulating robotic manipulator with that of the target robotic manipulator.

Owner:CANADIAN SPACE AGENCY

Robust impedance-matching of manipulators interacting with unknown environments

InactiveUS7688016B2Distance minimizationMinimizes noise sensitivityProgramme-controlled manipulatorComputer controlMock upsSimulation

Owner:CANADIAN SPACE AGENCY

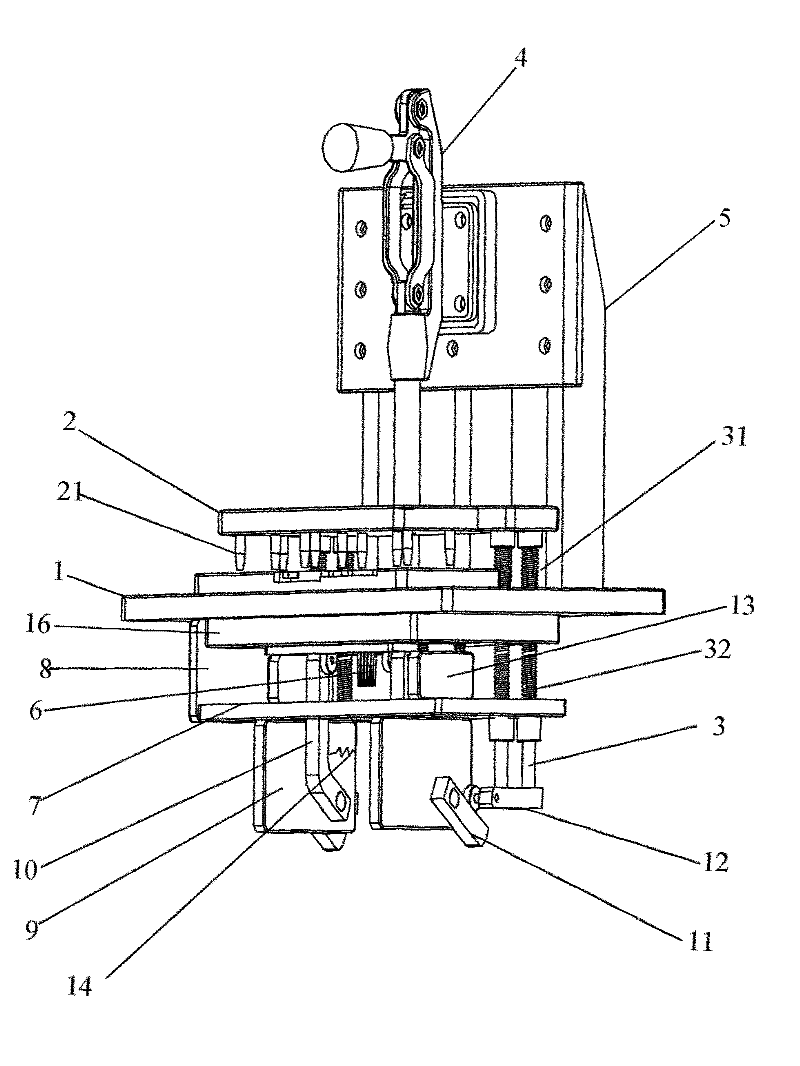

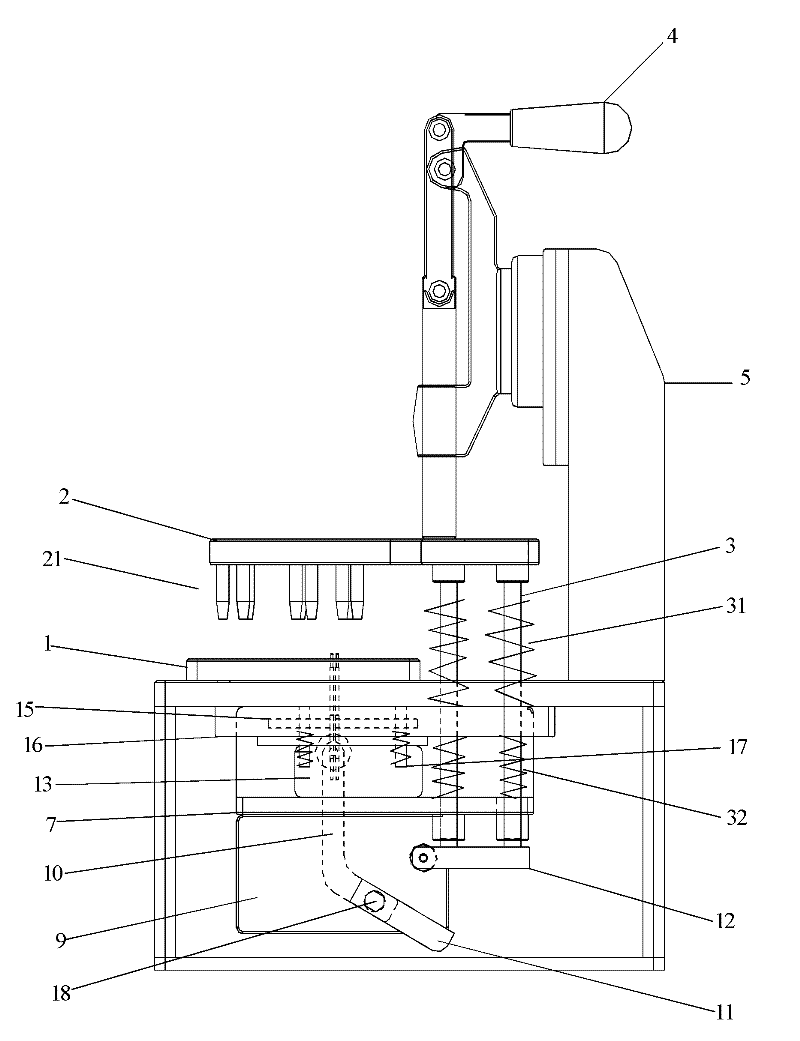

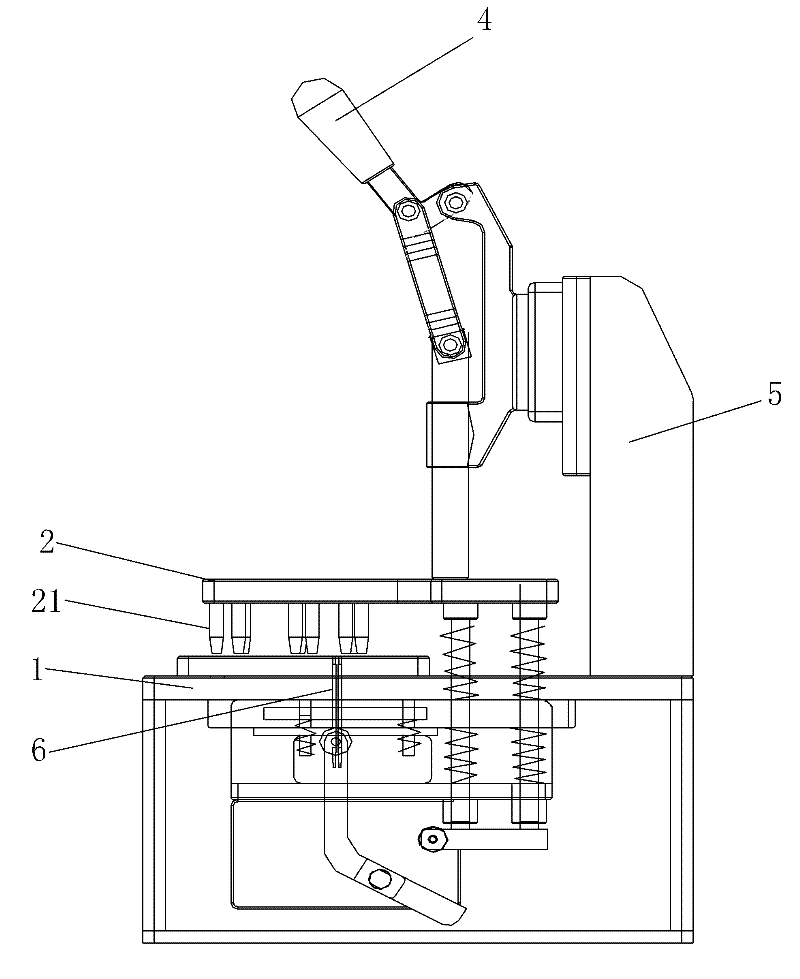

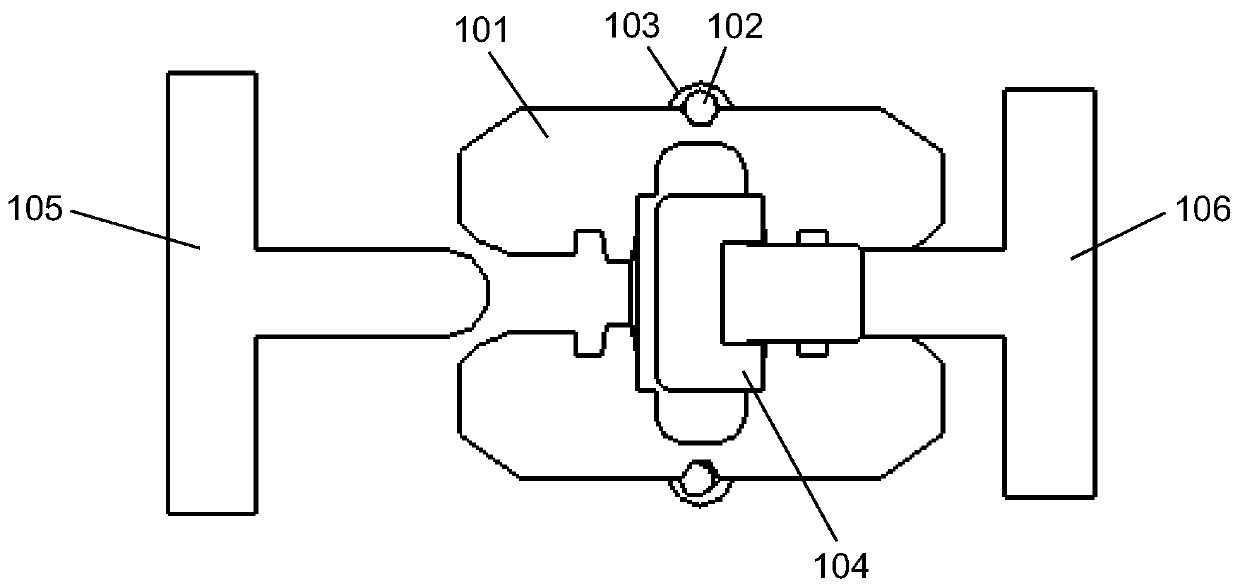

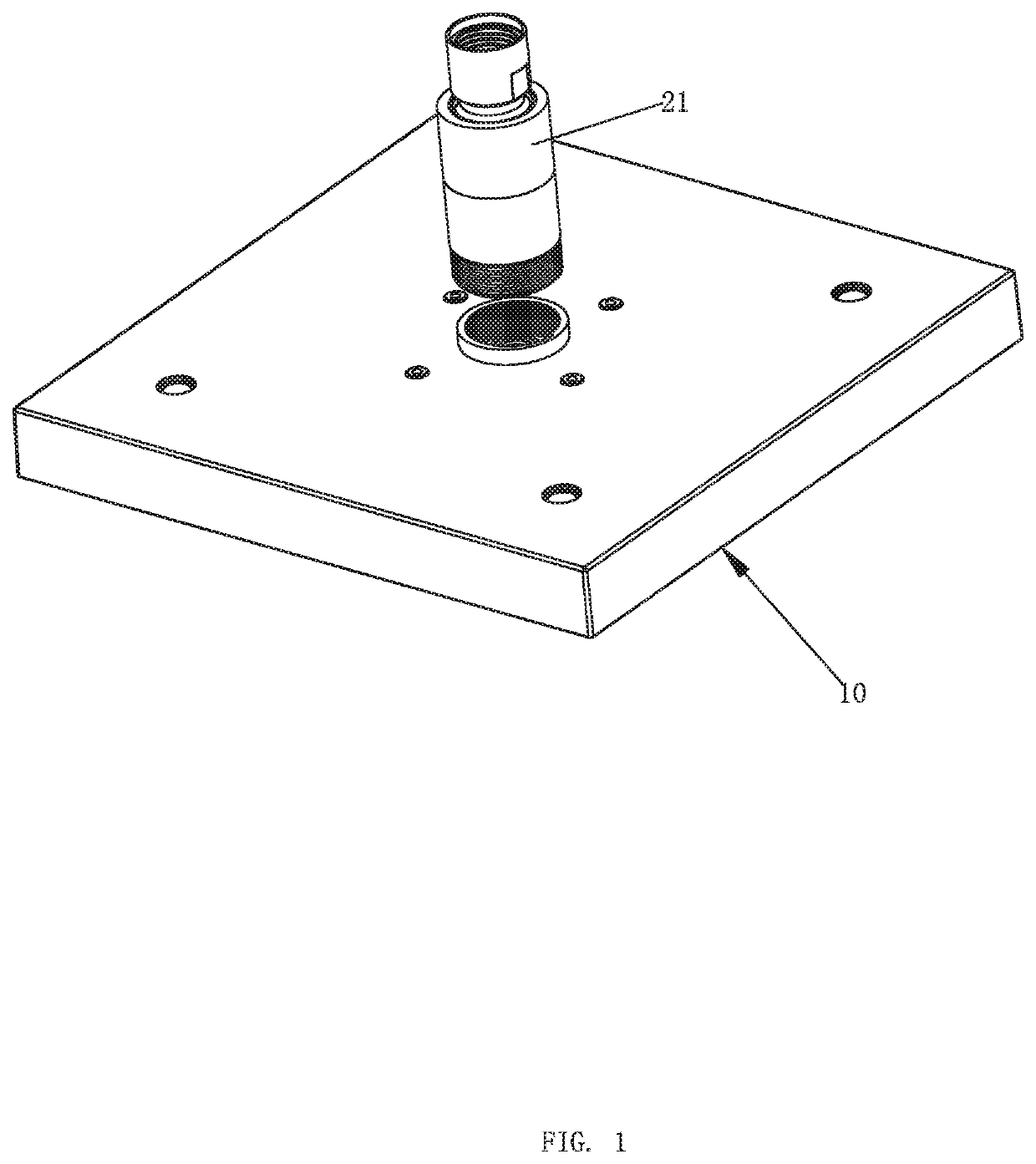

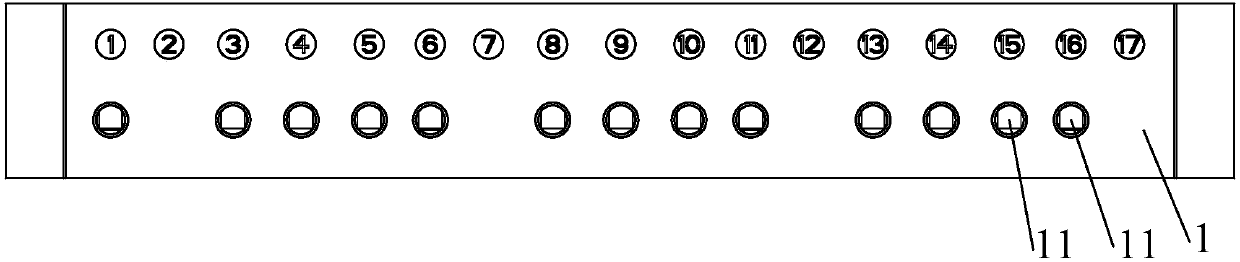

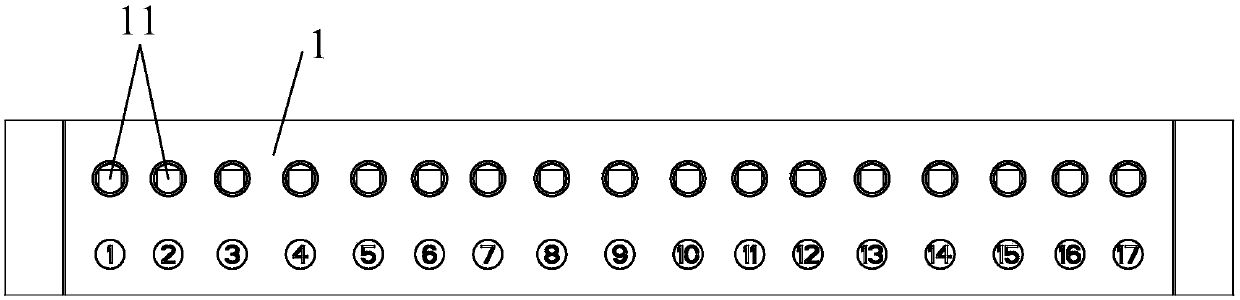

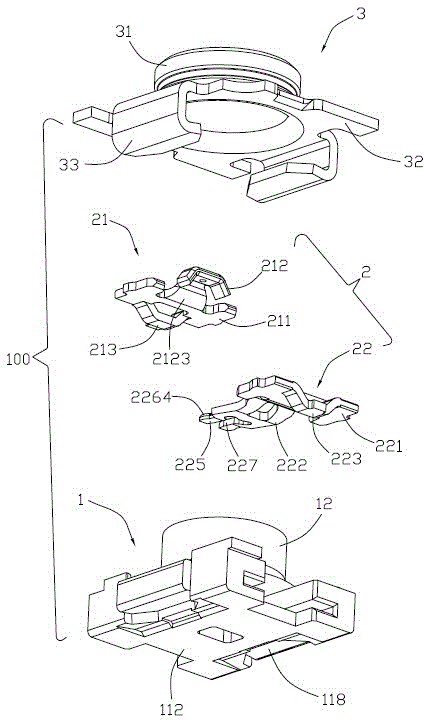

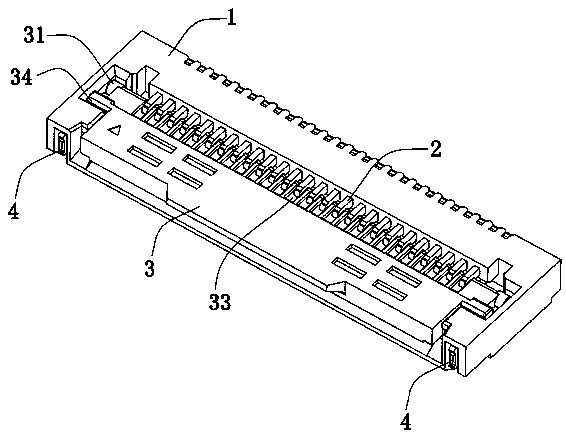

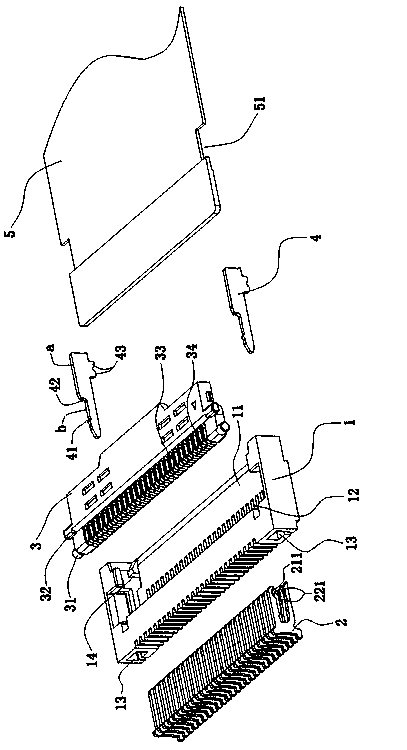

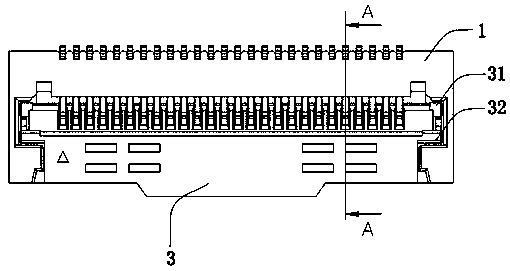

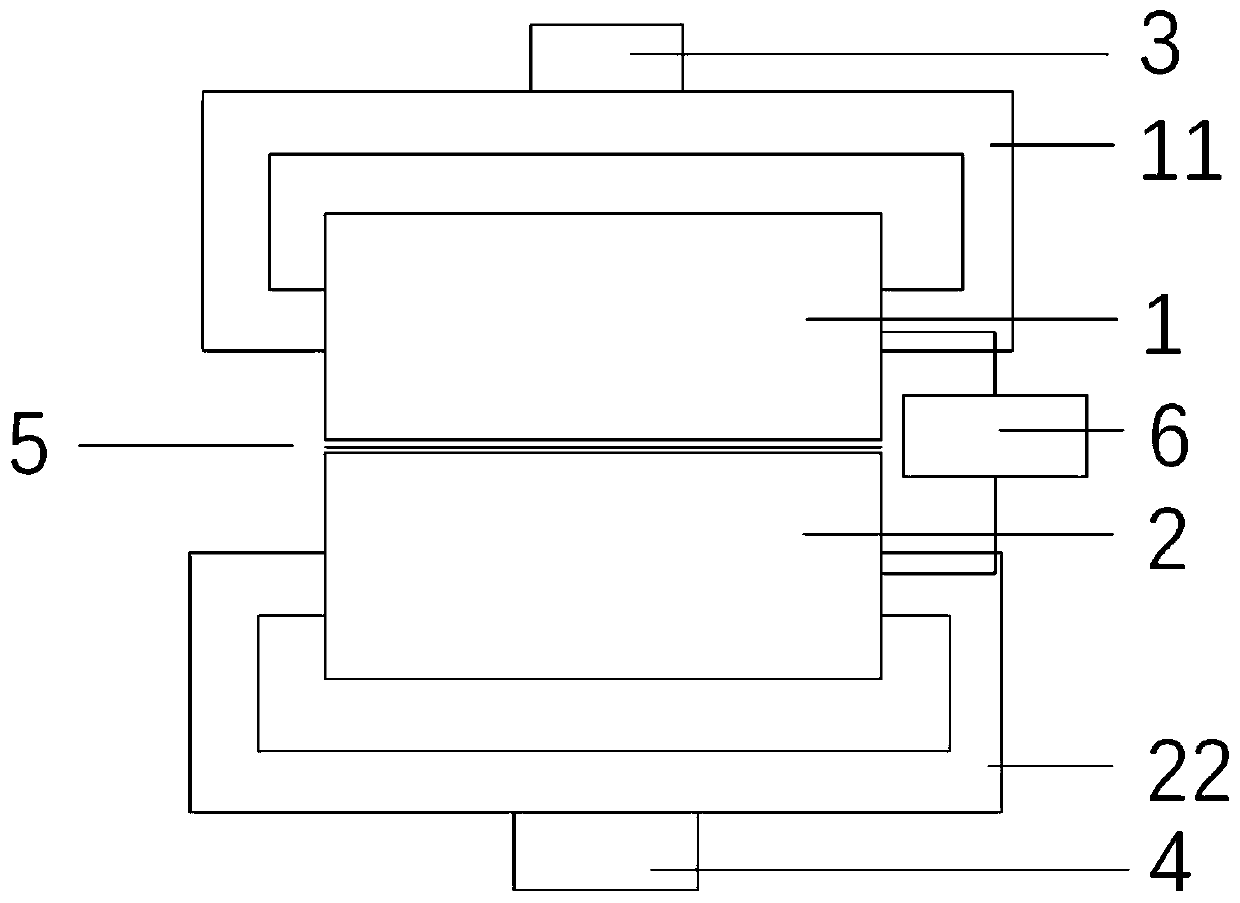

Test Fixture

ActiveCN102288792AGuaranteed contact stabilityReduce false positivesMeasurement instrument housingTest efficiencyNeedle position

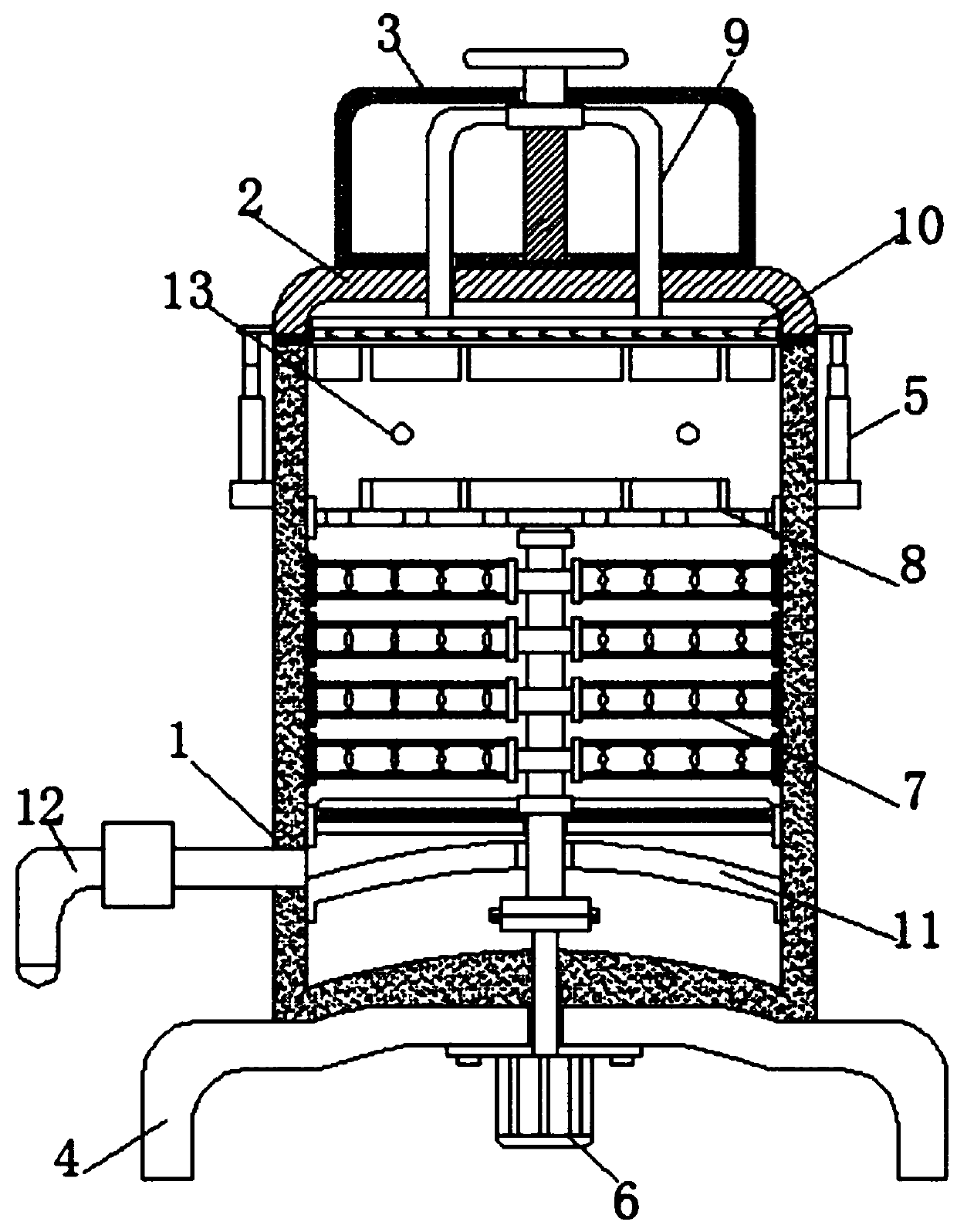

The embodiment of the invention discloses a test fixture, and relates to the technical field of testing of printed circuit boards. The test fixture reduces misdetection and improves the test efficiency in the process of testing a printed circuit board, and comprises a primary contact device, a carrier plate arranged under the primary contact device, a test needle positioned under the carrier plate and a secondary contact device; the primary contact device downwards presses a board to be tested on the carrier plate to contact the test needle; the secondary contact device is arranged under the carrier plate and connected with the primary contact device; and in the process of downwards pressing the primary contact device, after the board to be tested is contacted with the test needle, the secondary contact device drives the test needle to be separated from the board to be tested, and afterwards drives the test needle to be contacted with the board to be tested again.

Owner:HUAWEI DEVICE CO LTD

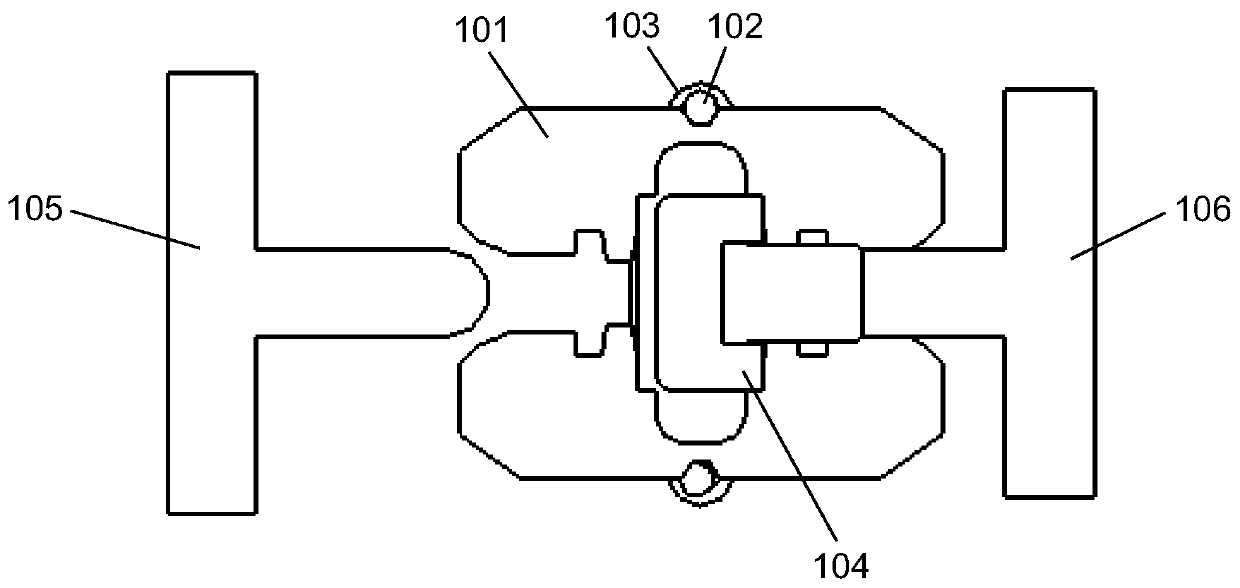

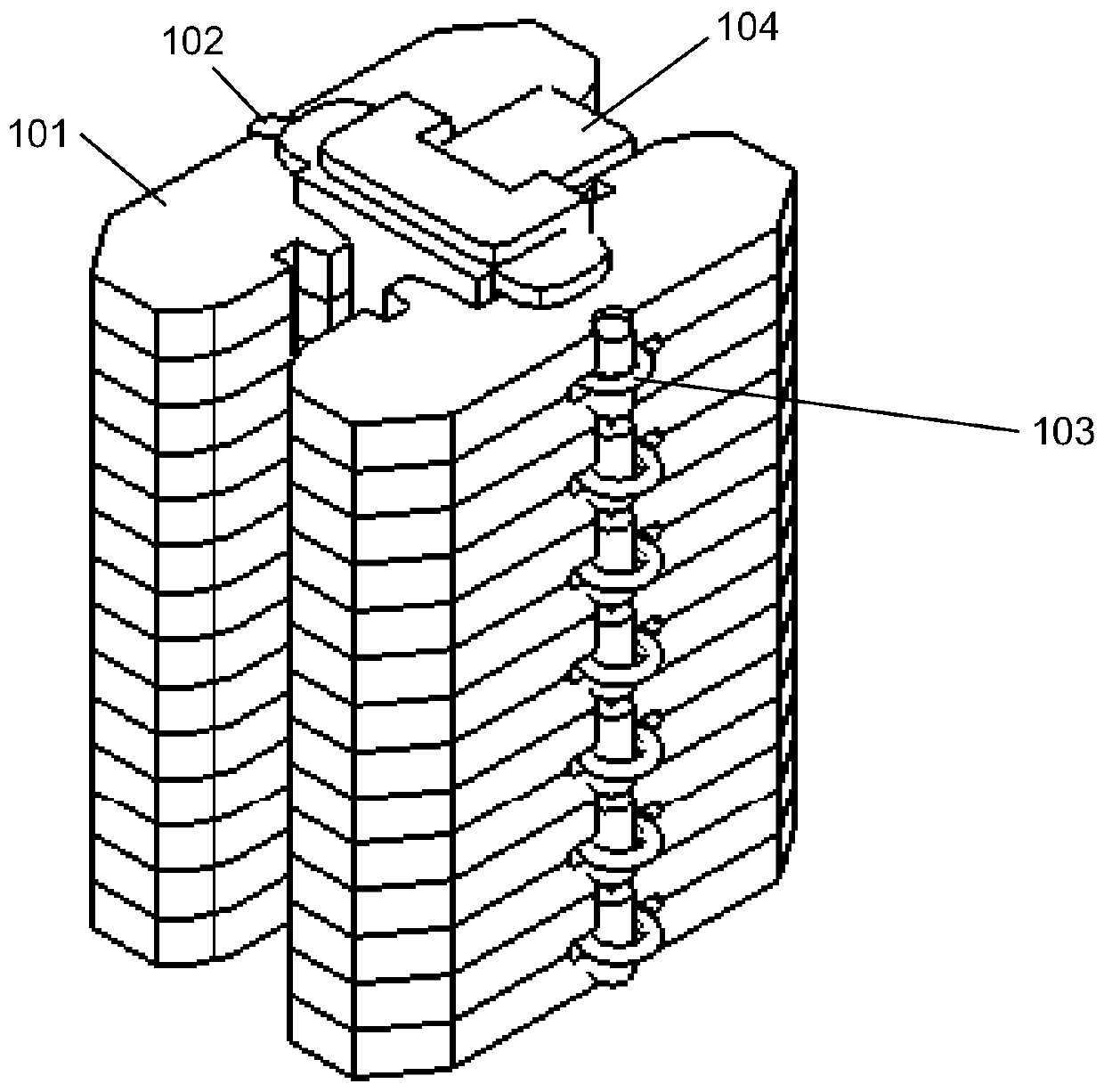

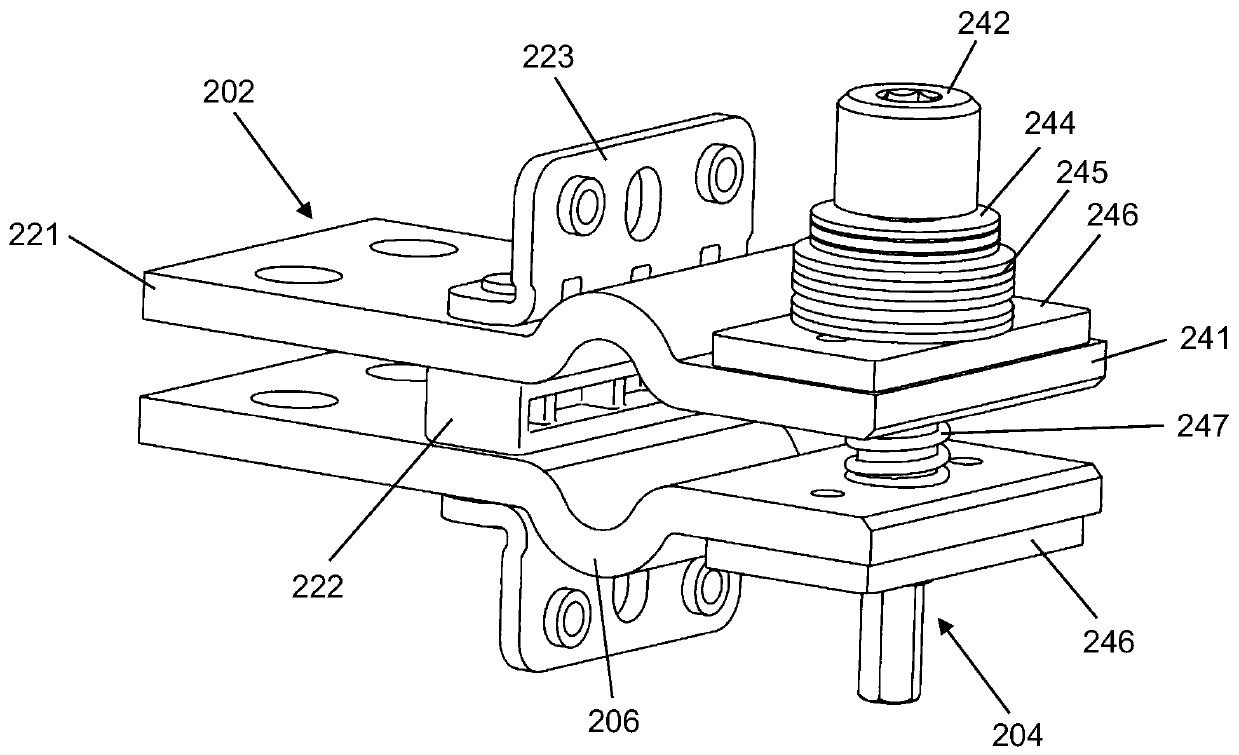

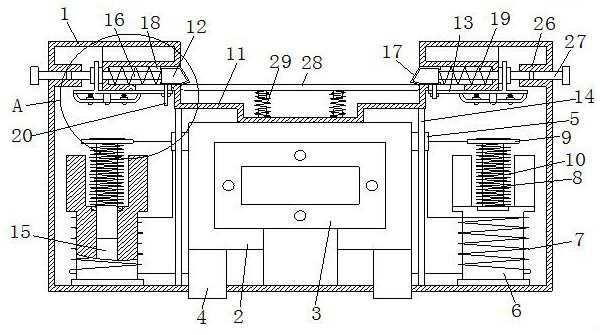

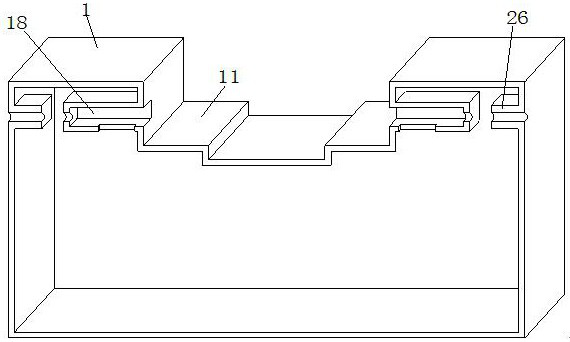

Electric appliance device and linkage electric connection assembly thereof

PendingCN111403938AAssembly influenceFully clingingSwitchgear with horizontal withdrawalSwitchgear detailsBusbarElectrical connection

Owner:SHANGHAI LEADING CONNECTION MECHATRONICS TECH CO LTD +1

Electric appliance device and electric connection device thereof

PendingCN111403939AAssembly influenceFully clingingSwitchgear with horizontal withdrawalSwitchgear detailsBusbarElectrical connection

The invention discloses an electric connection device, and the deviceis connected between a body of an electric appliance device with a draw-out structure and a draw-out device. The device comprises adraw-out device connection assembly, a body connection assembly and a flexible assembly. The draw-out device connection assembly is fixed on the draw-out device and is electrically connected with thewire inlet and outlet ends of the draw-out device. The body connection assembly comprises a contact piece with a clamping mechanism, and the clamping mechanism enables the contact piece to be tightlyattached to and clamp the body busbar. The flexible assembly is connected with the draw-out device connection assembly and the body connection assembly, and the body connection assembly, the flexibleassembly and the draw-out device connection assembly form a conductive path. The contact pieces of the body connection assembly are adapted to the position deviation of the body busbar to generate deviation, so the contact pieces are tightly attached to and clamp the body busbar, and the flexible assembly absorbs the deviation of the contact pieces through self deformation, so the deviation is not transmitted to the draw-out device connecting assembly.

Owner:SHANGHAI LEADING CONNECTION MECHATRONICS TECH CO LTD +1

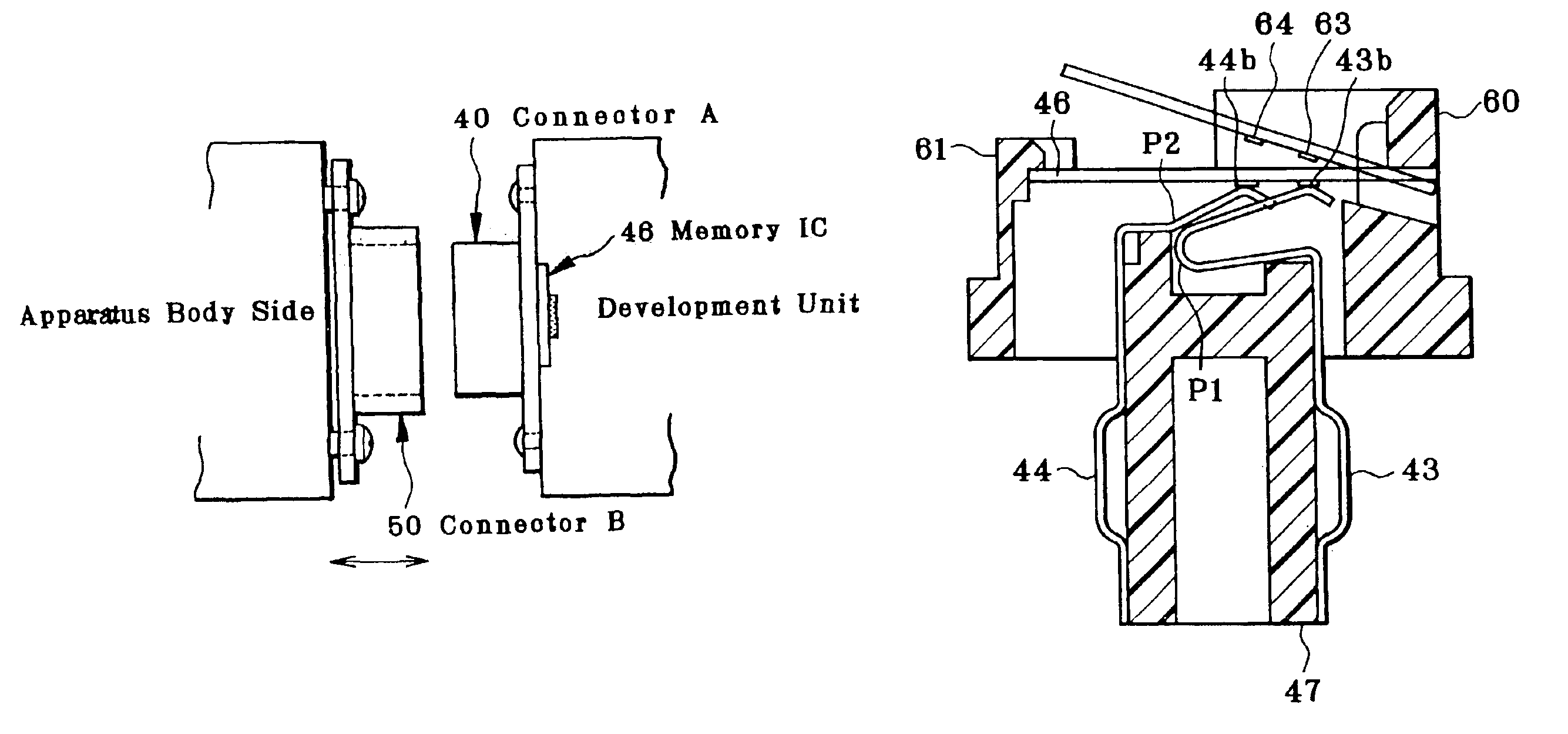

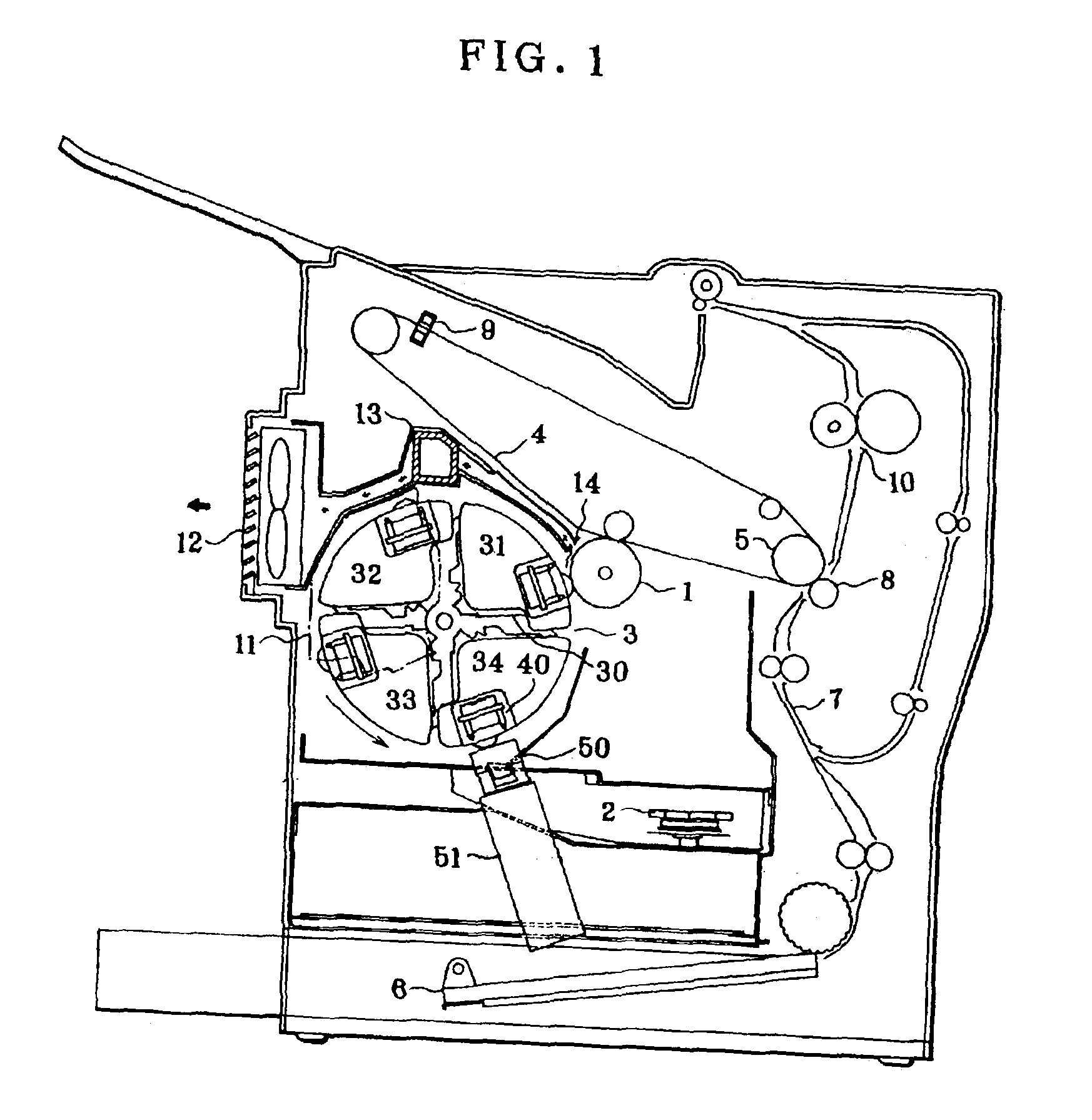

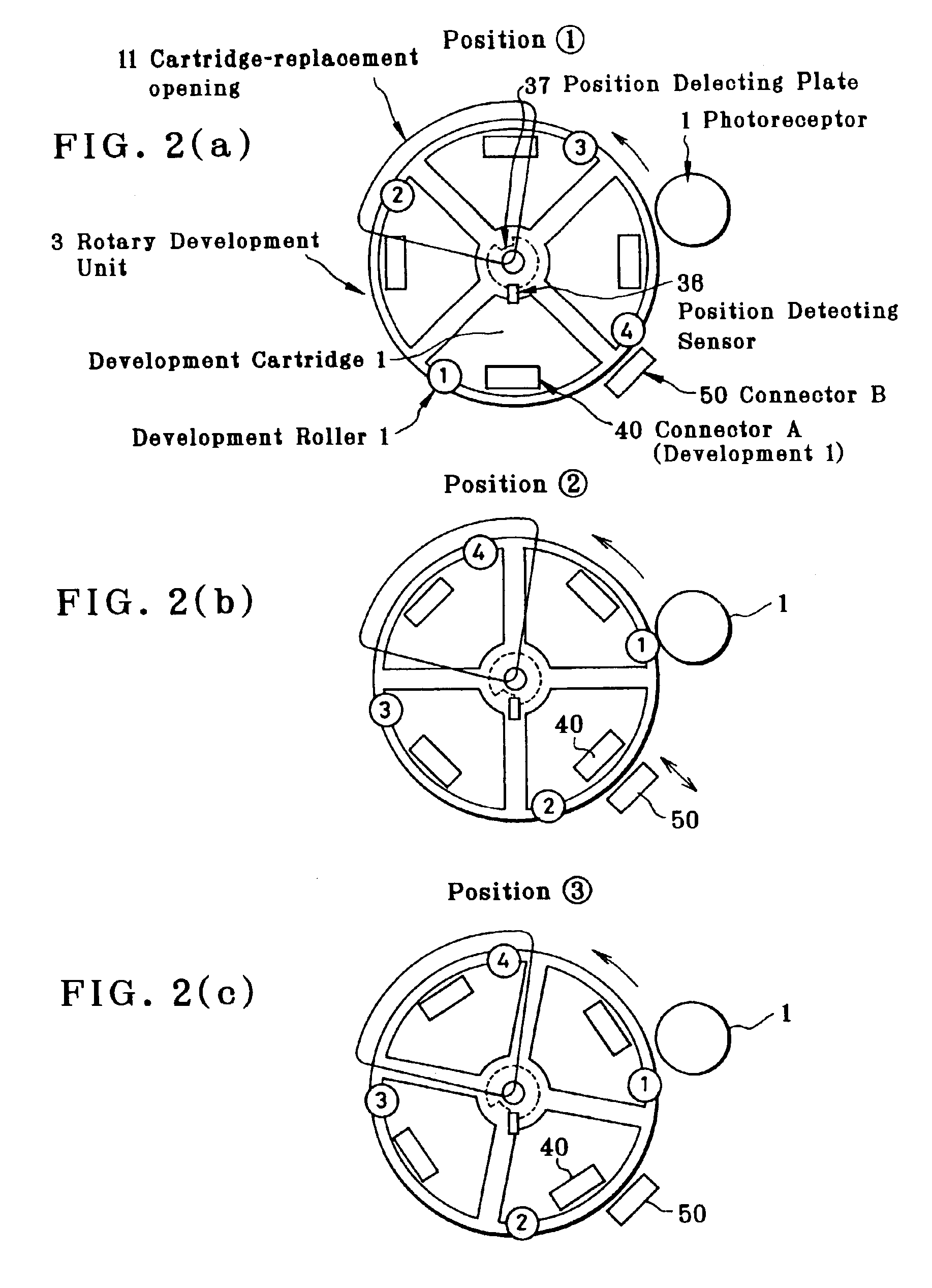

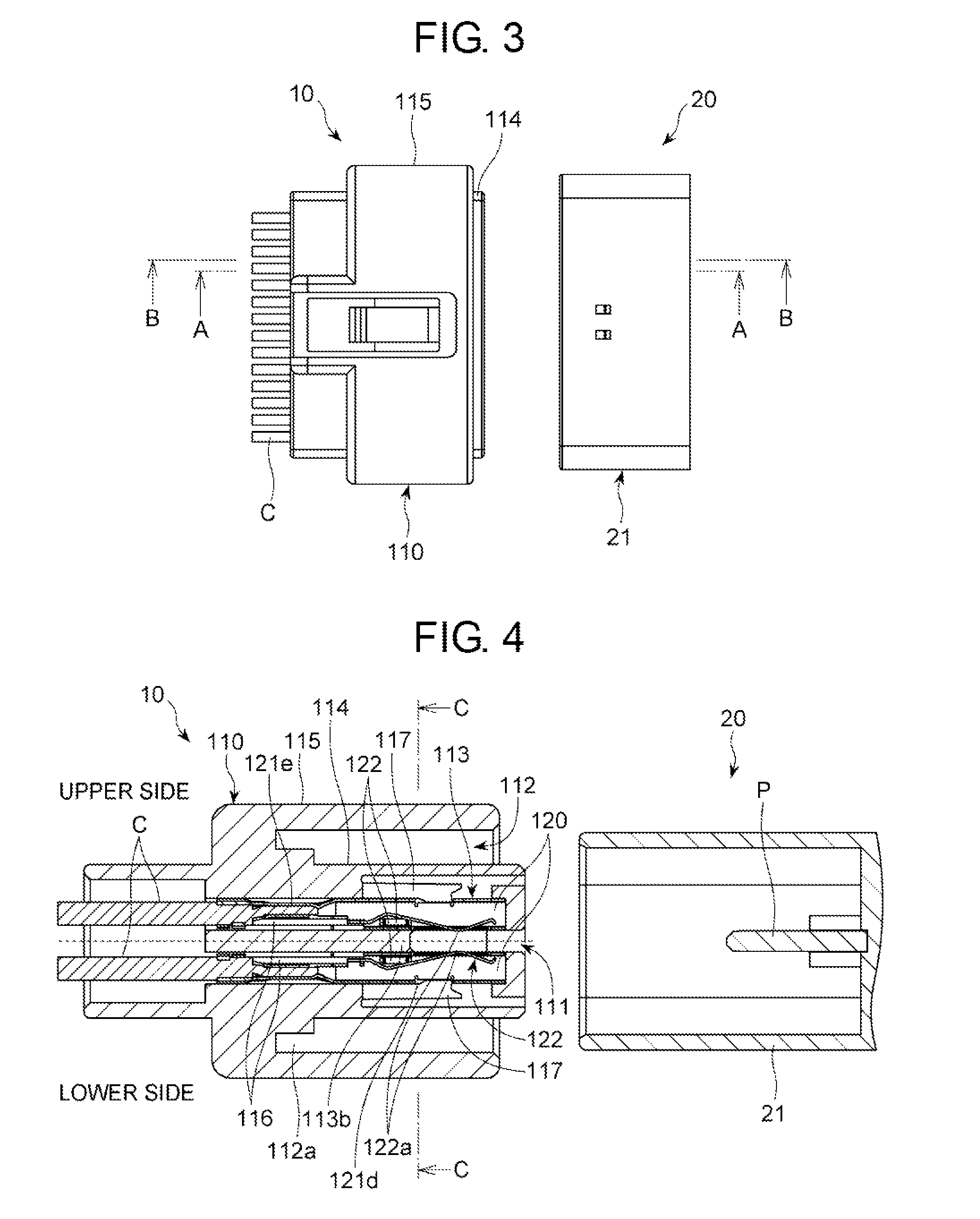

Connector having a built-in memory IC mounted on a development cartridge

InactiveUS6892039B2Guaranteed contact stabilityImprove reliabilityEngagement/disengagement of coupling partsTwo-part coupling devicesFuselageContact protection

A connector with a built-in memory IC which is mounted on a rotary development unit of a printer. The memory IC substrate is disposed within a contact protecting member and behind the rear side of an impact receiving member. A first electric contact is disposed on the front side of the impact receiving member and is connected to a second electric contact via a conductive member. The second electric contact spring contacts the memory IC substrate. The connector contains guide members to help stabilize the connection between the connector and the body side connector of the printer.

Owner:SEIKO EPSON CORP

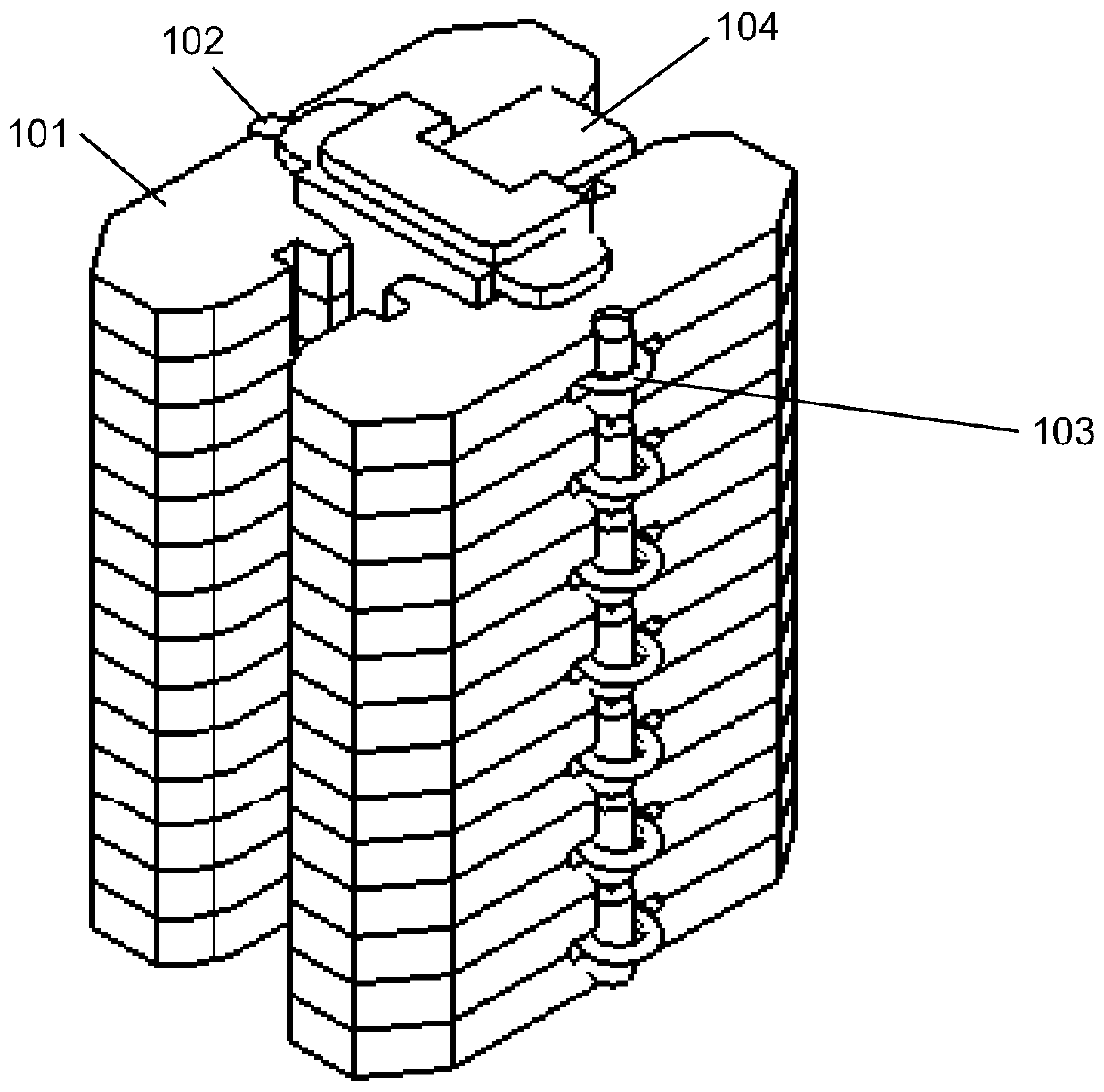

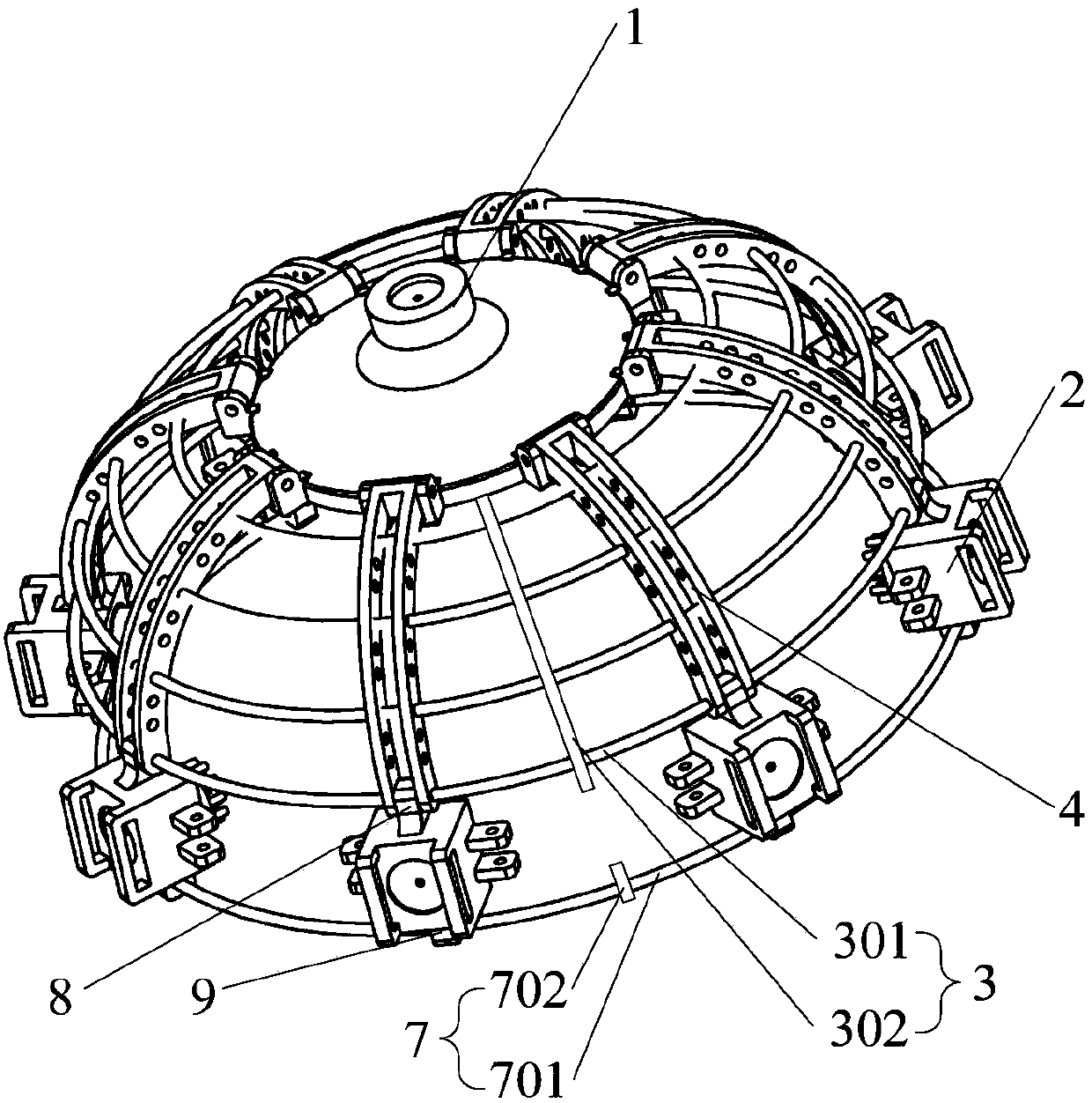

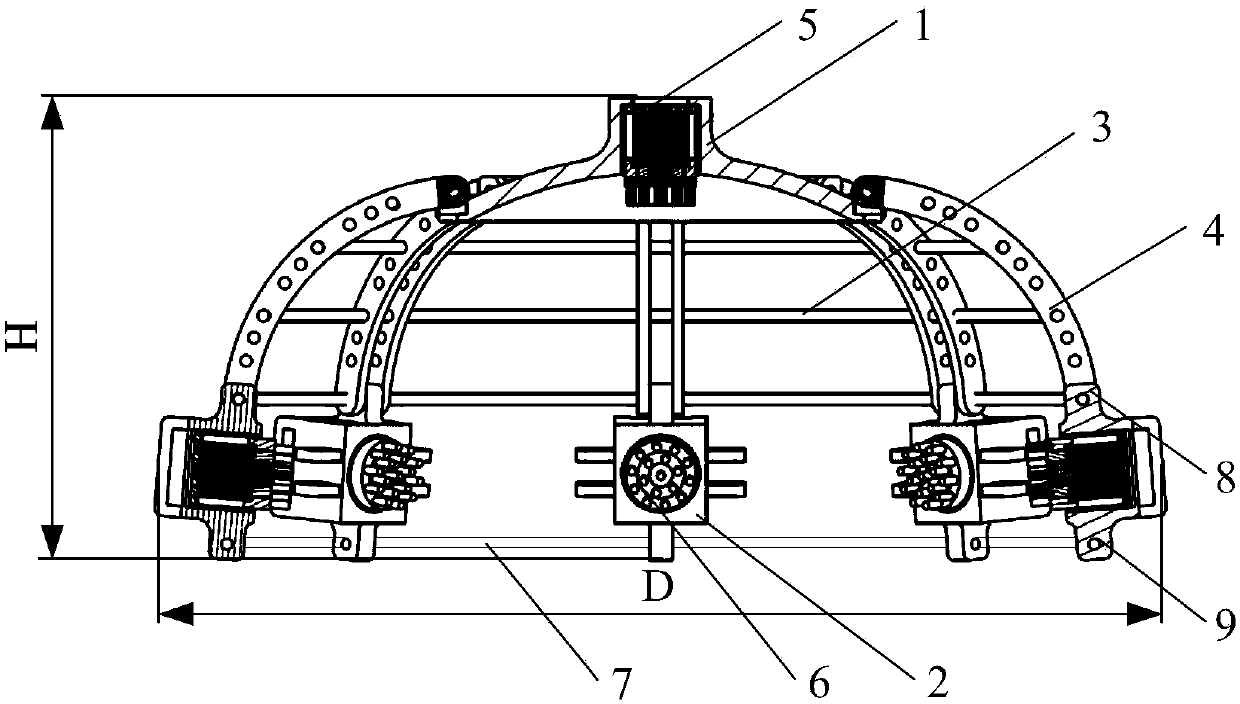

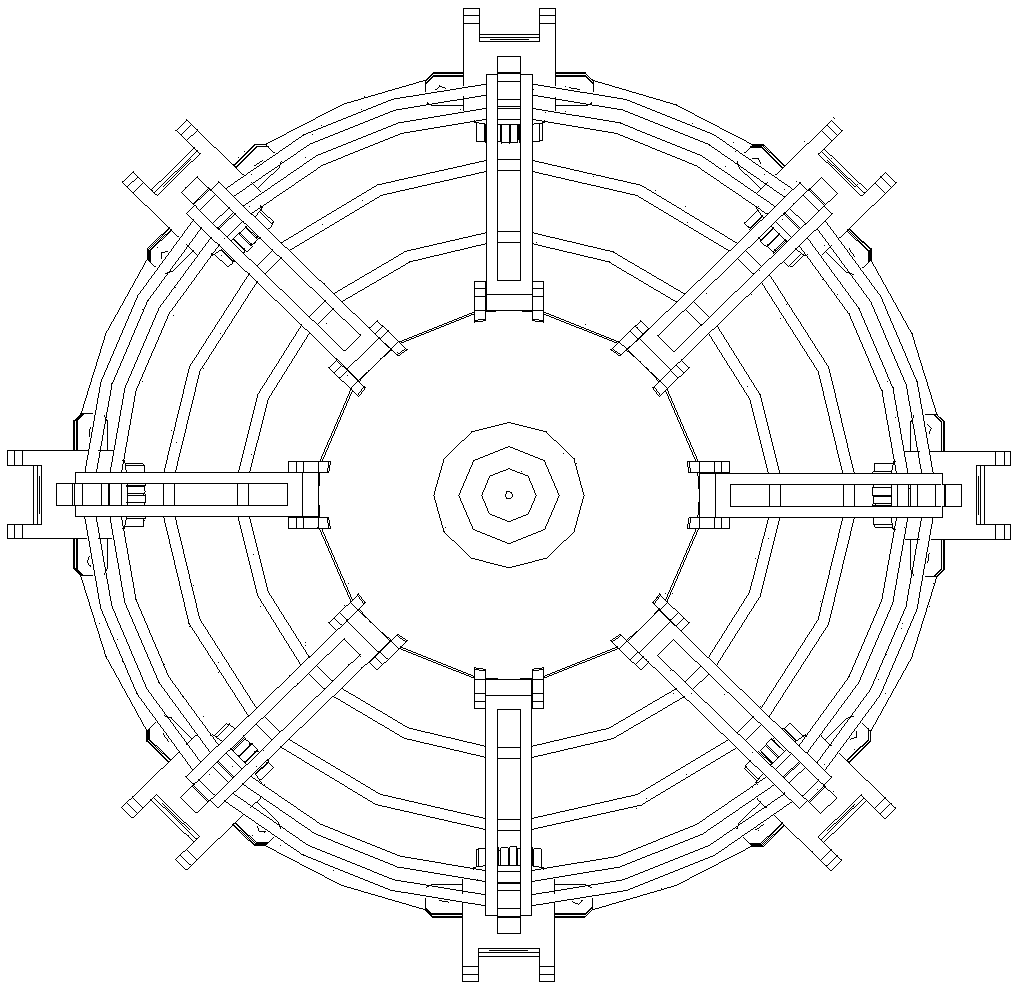

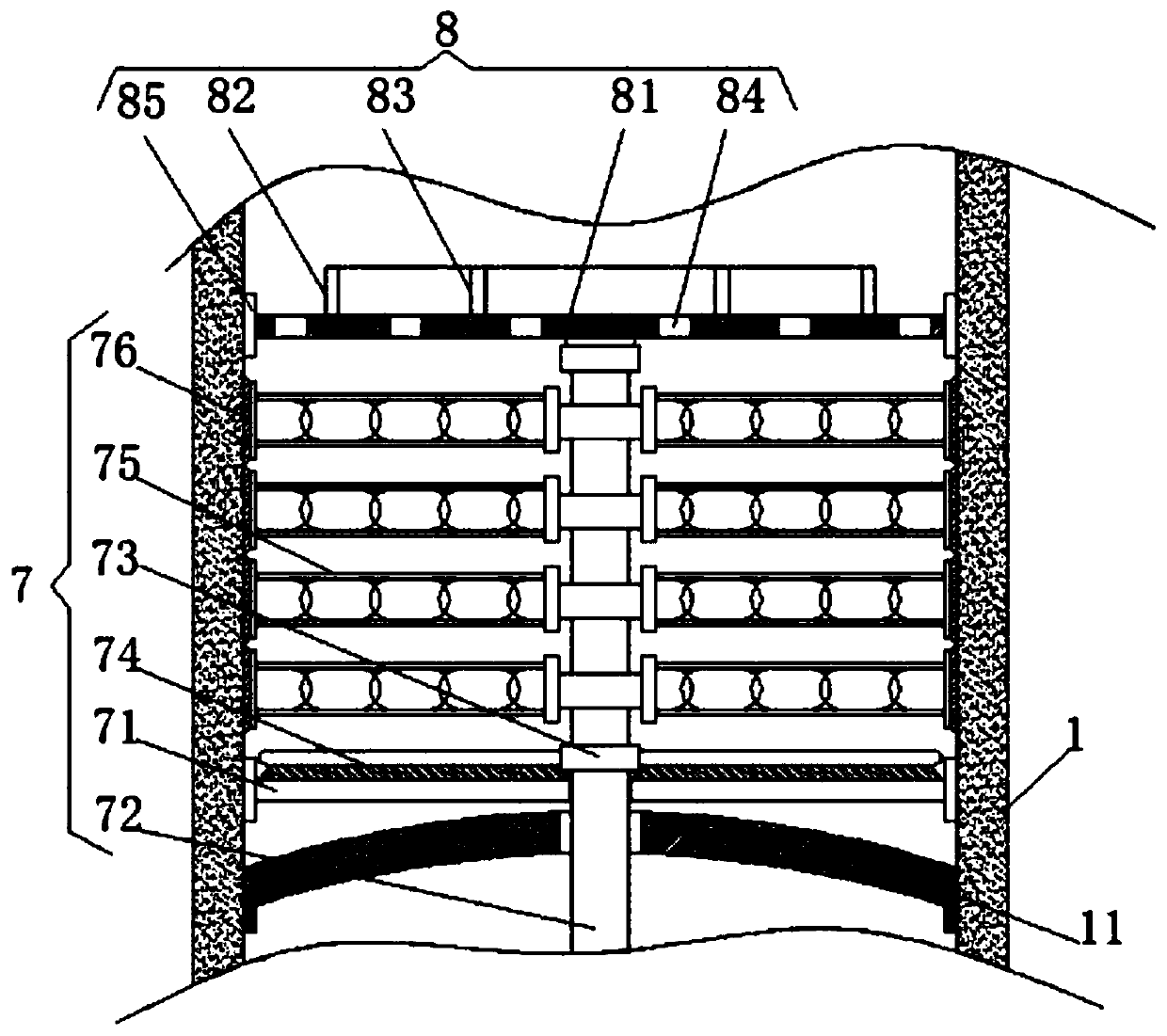

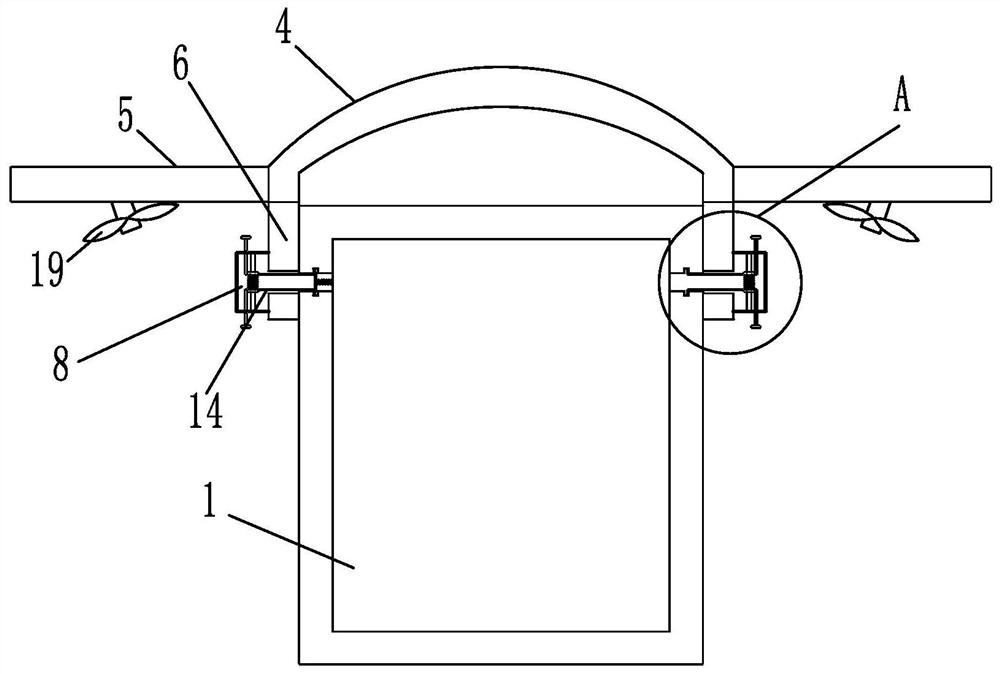

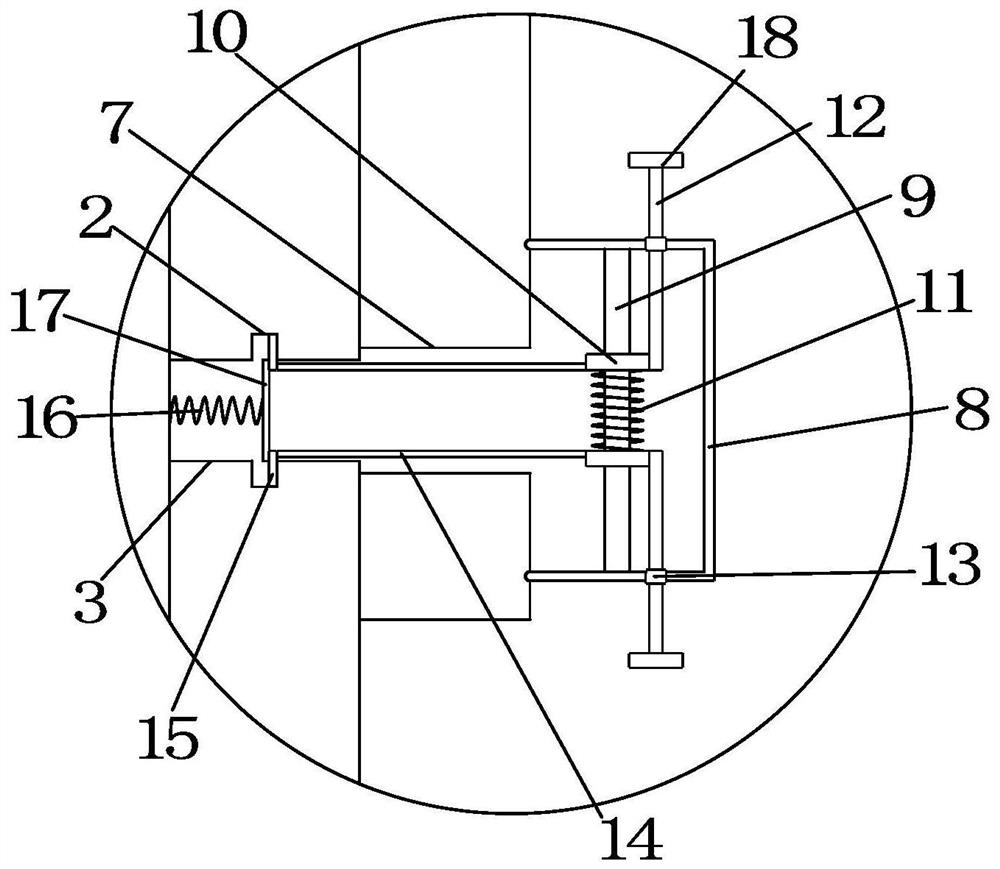

EEG acquisition support

ActiveCN107693013AGuaranteed contact stabilityImprove stabilityDiagnostic recording/measuringSensorsEngineeringEeg electrodes

The invention relates to an EEG acquisition support, and belongs to the technical field of dry-type EEG acquisition systems, which can solve the problem that the conventional EEG acquisition supportscannot ensure the stability of contact between EEG electrodes and a scalp in the prior art. The EEG acquisition support includes a pre-tensioning cover for holding a test part of an EEG test object, atop electrode base positioned on the top of the pre-tensioning cover, and circumferential electrode bases positioned on the periphery of the pre-tensioning cover; the pre-tensioning cover includes afirst elastic pre-tensioning ring and a plurality of suspension arms; the plurality of suspension arms are arranged in the radial direction of the pre-tensioning cover; the plurality of suspension rods are connected in series through the first elastic pre-tensioning ring; and one ends of the suspension rods are connected to an outer edge of the top electrode base, and the other ends of the suspension rods are connected to the circumferential electrode bases. The EEG acquisition support can be used for EEG acquisition.

Owner:BEIJING MECHANICAL EQUIP INST

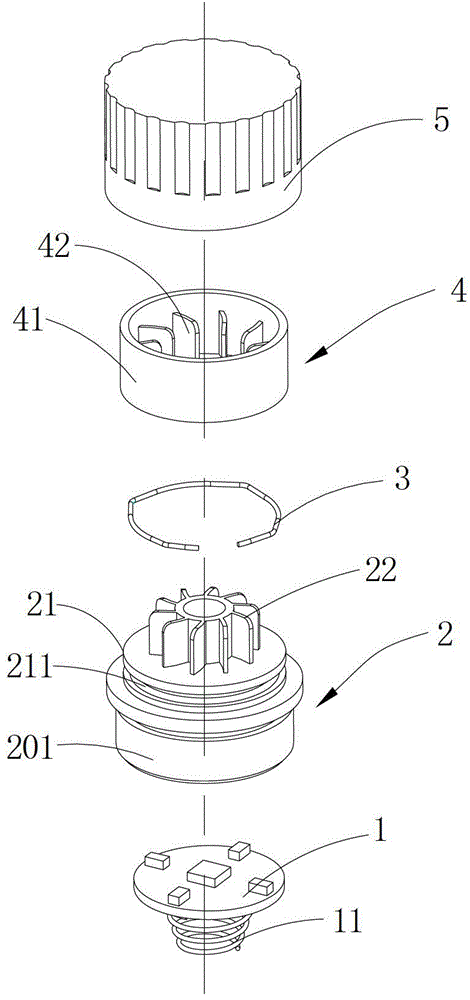

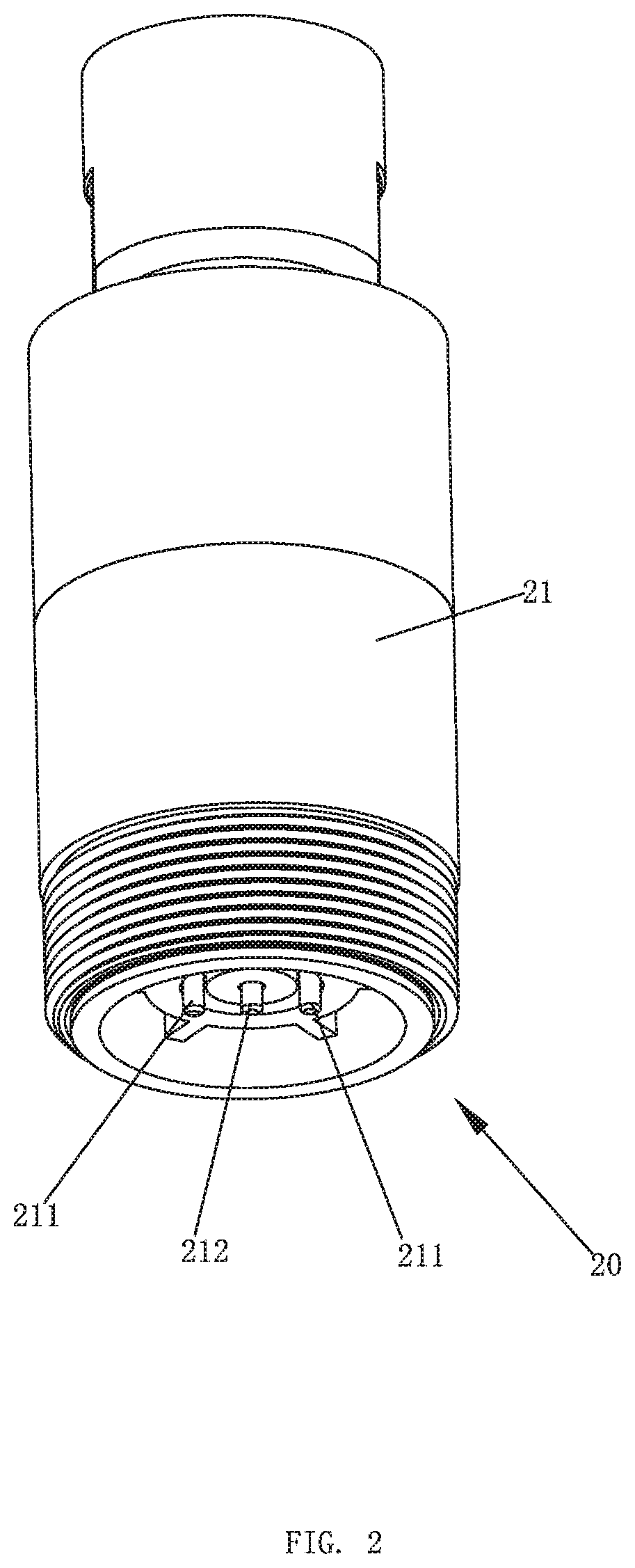

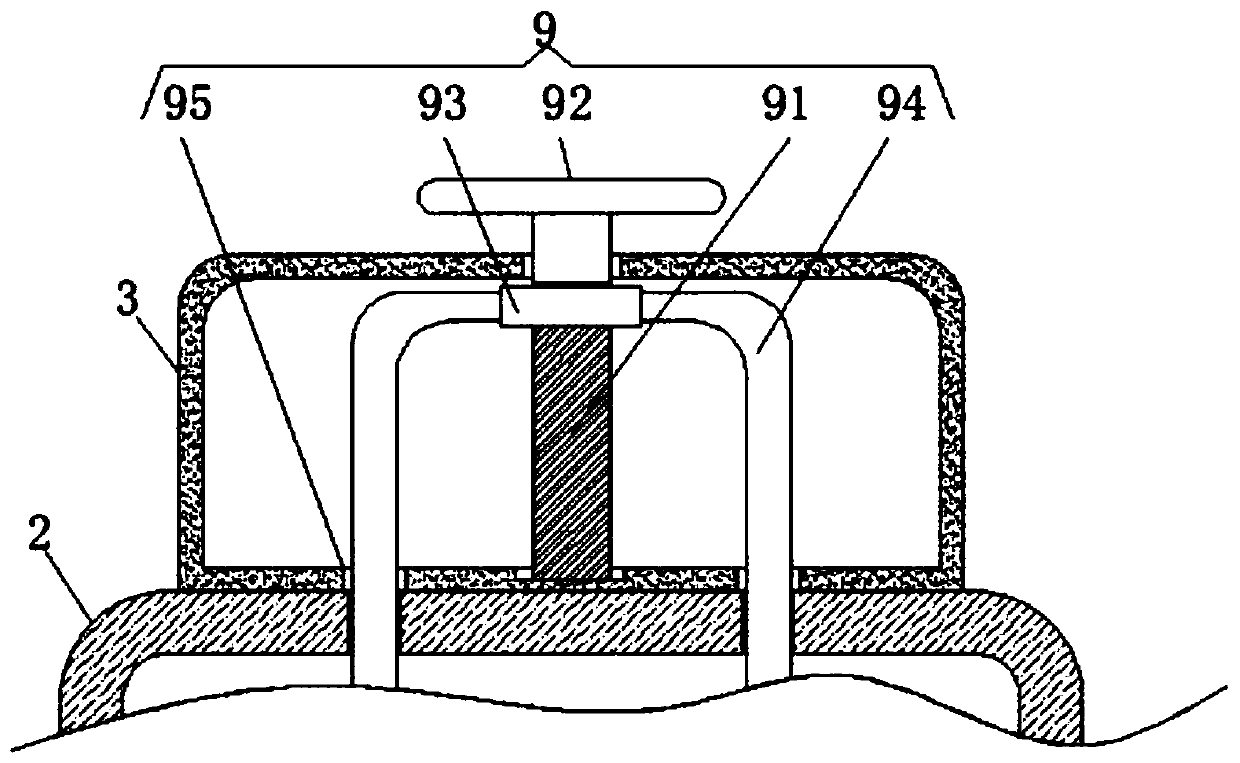

Flashlight and tail cover component thereof

ActiveCN104373903ASo as not to damageGuaranteed contact stabilityWith electric batteriesElectric lighting with batteriesEngineeringFlashlight

The invention discloses a flashlight and a tail cover component thereof. The flashlight tail cover component comprises a tail cover and a rotating cover, a thread used for being connected with a flashlight body is arranged on the tail cover, the outer side of the tail cover extends to be provided with a matched connecting end, a first gear is arranged on the matched connecting end, the rotating cover is rotatably connected to the matched connecting end of the tail cover in a covered manner, a second gear is arranged in the rotating cover, the first gear is an inner gear or an outer gear, the second gear is an outer gear or an inner gear matched with the first gear, a gear tooth engaging position of at least one of the first gear and the second gear is bent, engaging faces of the gears are outwards-protruding faces of gear teeth in a direction that the tail cover which is driven by rotating of the rotating cover rotates relative to the flashlight body, and the gear tooth end of at least one of the gears with the bent gear teeth can elastically deform towards a concave face to be disengaged with the gear teeth of the other gear. An over-tight slipping structure is arranged, so that protecting of the thread is facilitated.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Electric connector

InactiveUS20130217264A1Guaranteed contact stabilityReduce contact loadSecuring/insulating coupling contact membersTwo-part coupling devicesEngineeringElectrical connector

The electrical connector includes a connector housing having a slot into which a circuit board is to be inserted, and a plurality of connector terminals to be inserted into the connector housing, the connector housing including terminal spaces into which the connector terminals are inserted, and partition walls partitioning the terminal spaces from adjacent ones, the connector terminals each including a sheath to be inserted into one of the terminal spaces, and a resilient contact making electrical contact with the circuit board, the electrical connector including a convex and a concave for preventing the terminal spaces and the circuit board from falling apart from each other, the convex being formed on opposite sidewalls of the sheath, and the concave being formed at the partition walls.

Owner:DAIICHI SEIKO CO LTD

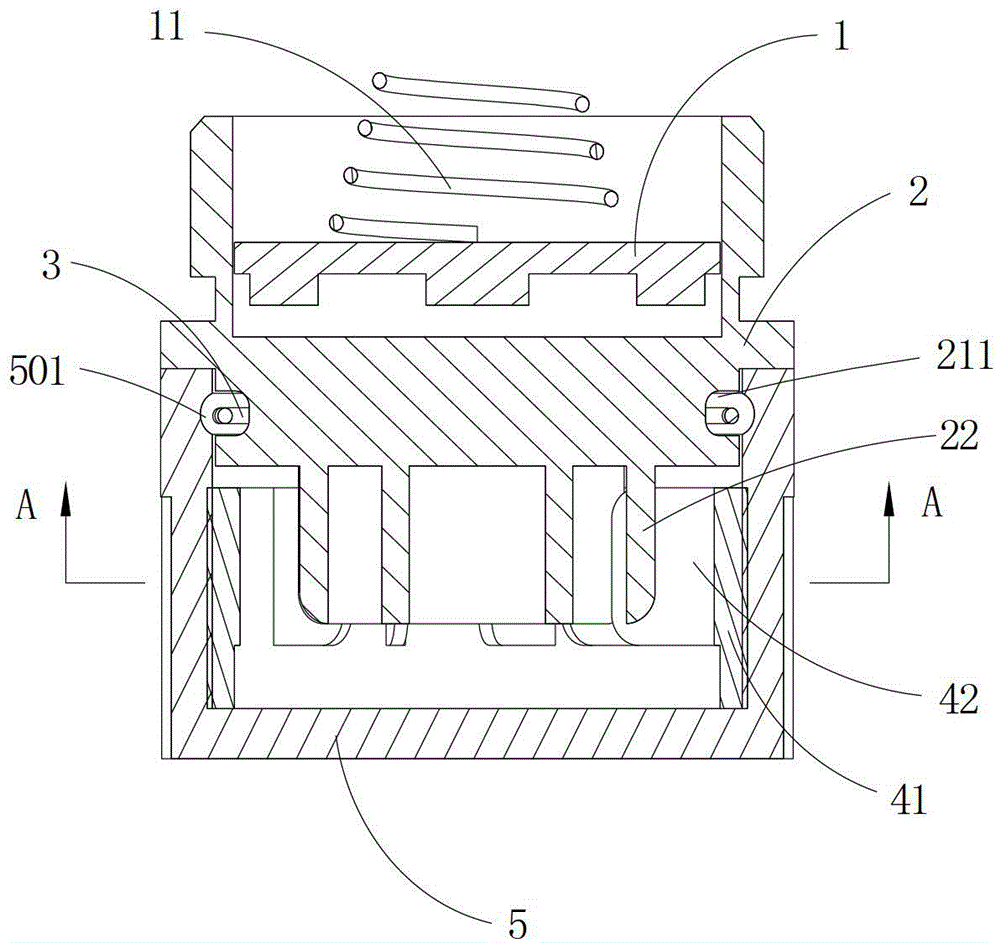

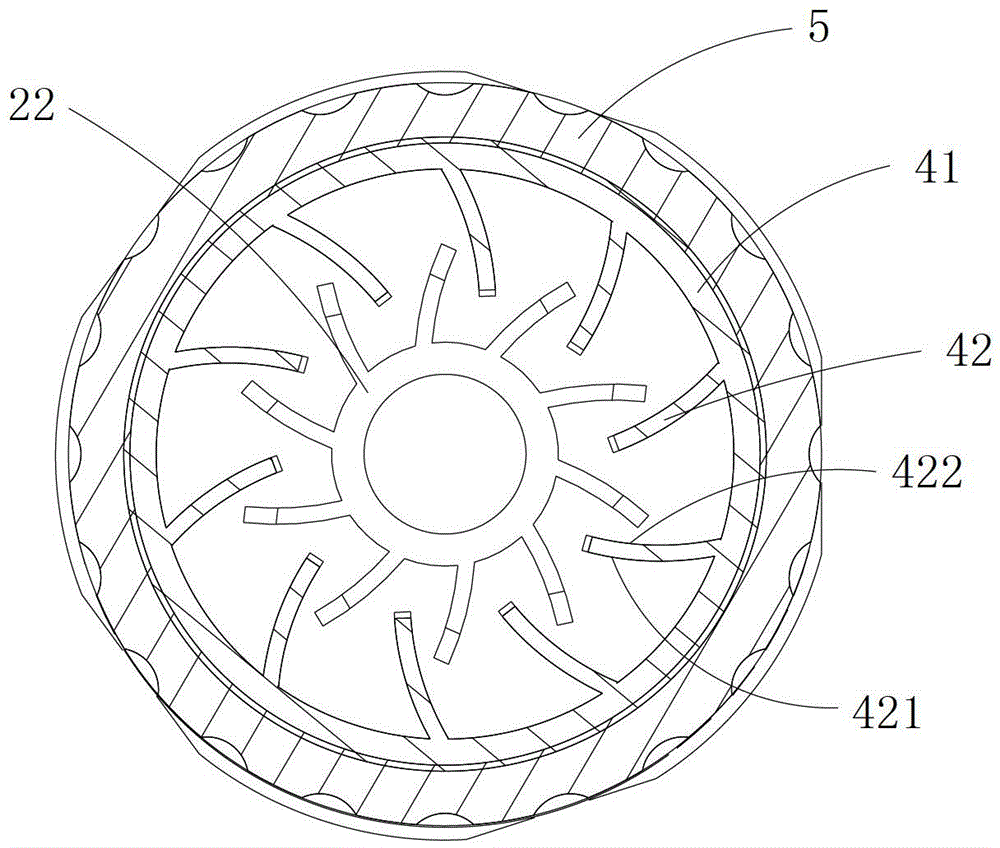

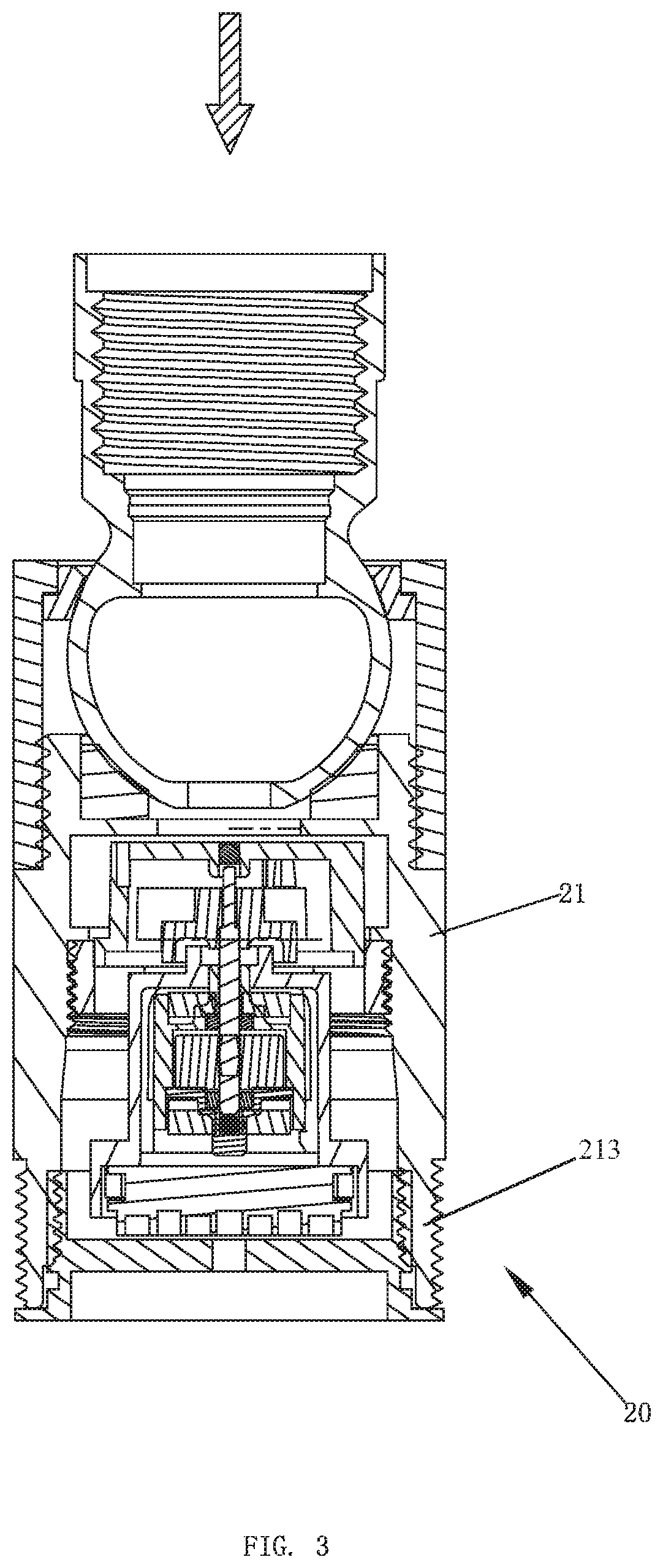

Self-power-generating water outflow device with a light

ActiveUS20210048160A1Reduce replacement costsGuaranteed contact stabilityLighting elementsSpray nozzlesEngineeringMaterials science

Disclosed is a self-power-generating water outflow device with a light. An LED light source and a driving circuit for driving the LED light source are disposed in a water outflow terminal, and a first positive electrode and a first negative electrode are electrically connected to the driving circuit. A connector is detachably connected to the water outflow terminal. The connector comprises a connection housing and a self-power-generating component. The self-power-generating component is disposed in the connection housing, and the connection housing comprises one or more second positive electrodes and one or more second negative electrodes electrically connected to the self-power-generating component. When the connector is connected to the water outflow terminal, the first positive electrode is in contact with the one or more second positive electrodes and the first negative electrode is in contact with the one or more second negative electrodes.

Owner:XIAMEN LOTA INT CO LTD

Electrical connector having means to prevent terminal spaces falling apart from a circuit board

InactiveUS8876561B2Guaranteed contact stabilityReduce contactSecuring/insulating coupling contact membersTwo-part coupling devicesElectricityEngineering

An electrical connector includes a connector housing having a slot into which a circuit board is to be inserted, and a plurality of connector terminals to be inserted into the connector housing. The connector housing includes terminal spaces into which the connector terminals are inserted, and partition walls partitioning the terminal spaces from each other. The connector terminals each include a sheath to be inserted into one of the terminal spaces, and a resilient contact making electrical contact with the circuit board. The electrical connector includes a convex portion and a concave portion for preventing the terminal spaces and the circuit board from falling apart from each other. The convex portions can be formed on opposite sidewalls of the sheath, and the concave portions can be formed at the partition walls.

Owner:DAIICHI SEIKO CO LTD

Board-to-board connector component

PendingCN110571555AGuaranteed multi-touchMulti-touchCoupling contact membersBoard-to-board connectorEngineering

The invention discloses a board-to-board connector component. The component comprises a socket connector provided with an annular accommodating space. The socket connector comprises an insulating body, a metal piece fixed with the insulating body, and a plurality of terminals. The insulating body comprises a bottom wall, a side wall, an end wall and an island portion. The plurality of terminals are correspondingly fixed on the side wall in two rows. The metal piece is fixed at two ends of the insulating body. The metal piece comprises an elastic arm portion extending into the annular accommodating space from a convex portion. The elastic arm portion comprises a pair of second elastic arms located near the island portion. Each second elastic arm comprises a second elastic arm body portion and a second elastic arm contact portion, wherein the second elastic arm contact portion is formed by bending an upper end position of the second elastic arm body portion and protruding into the annular containing space. A large-current transmission requirement can be realized.

Owner:KUNSHAN JIAHUA ELECTRONICS

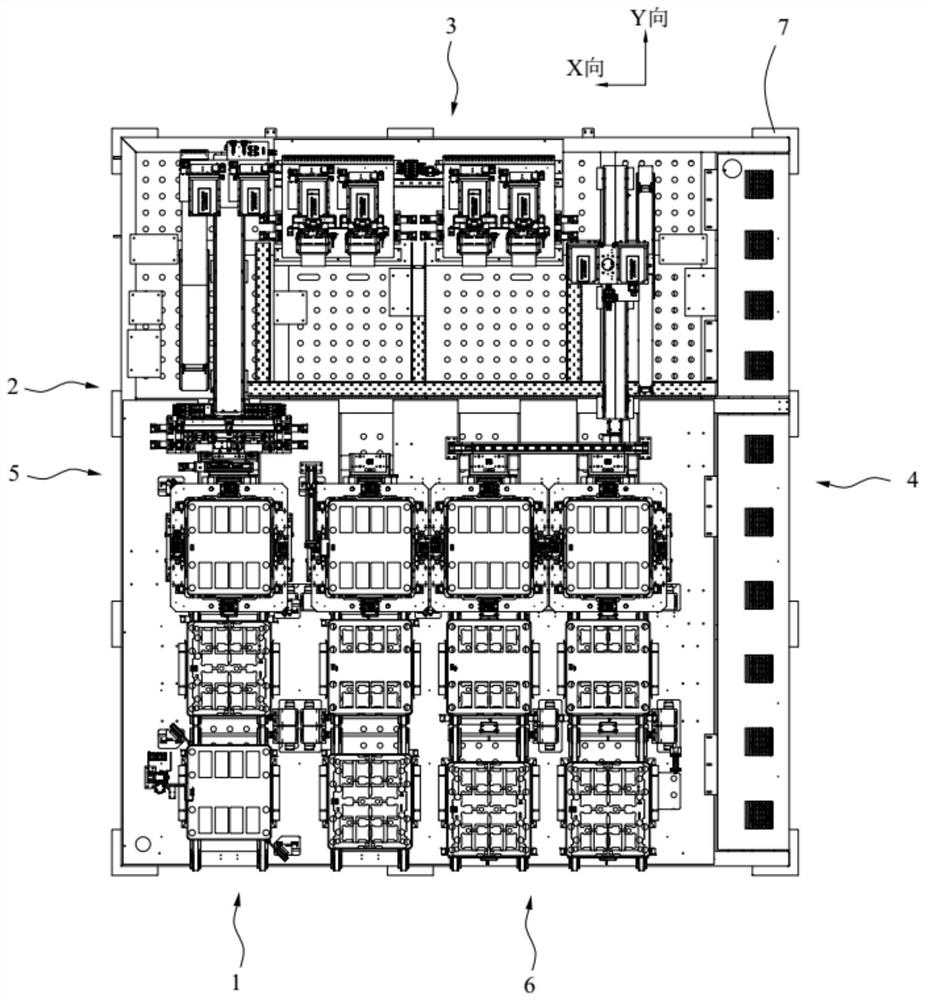

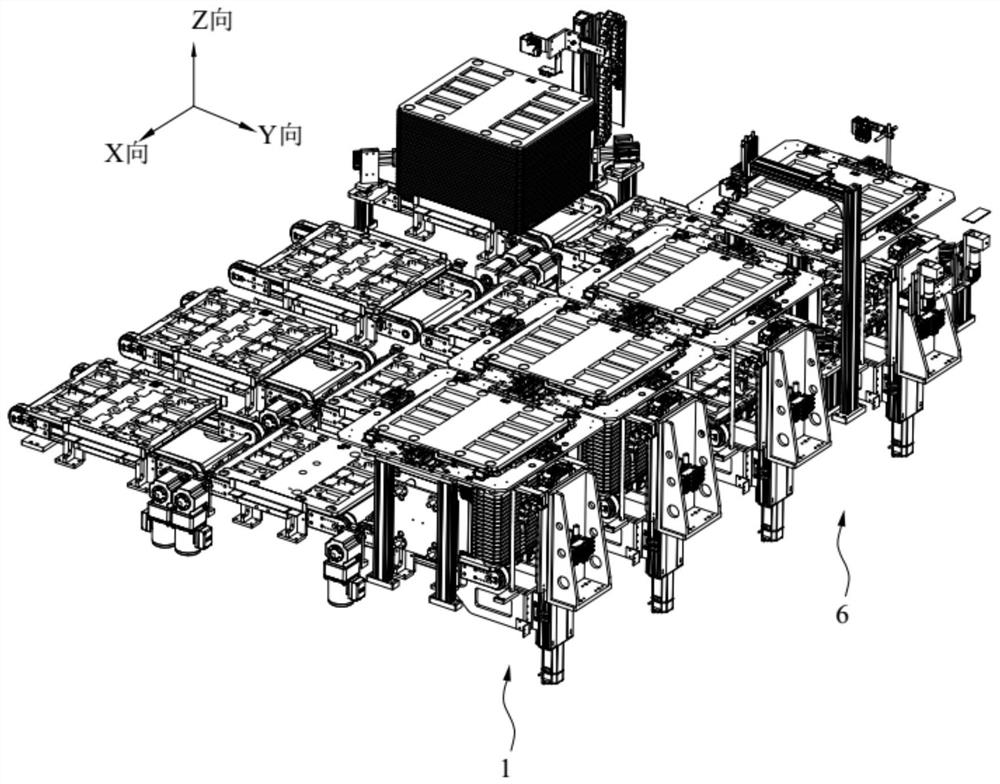

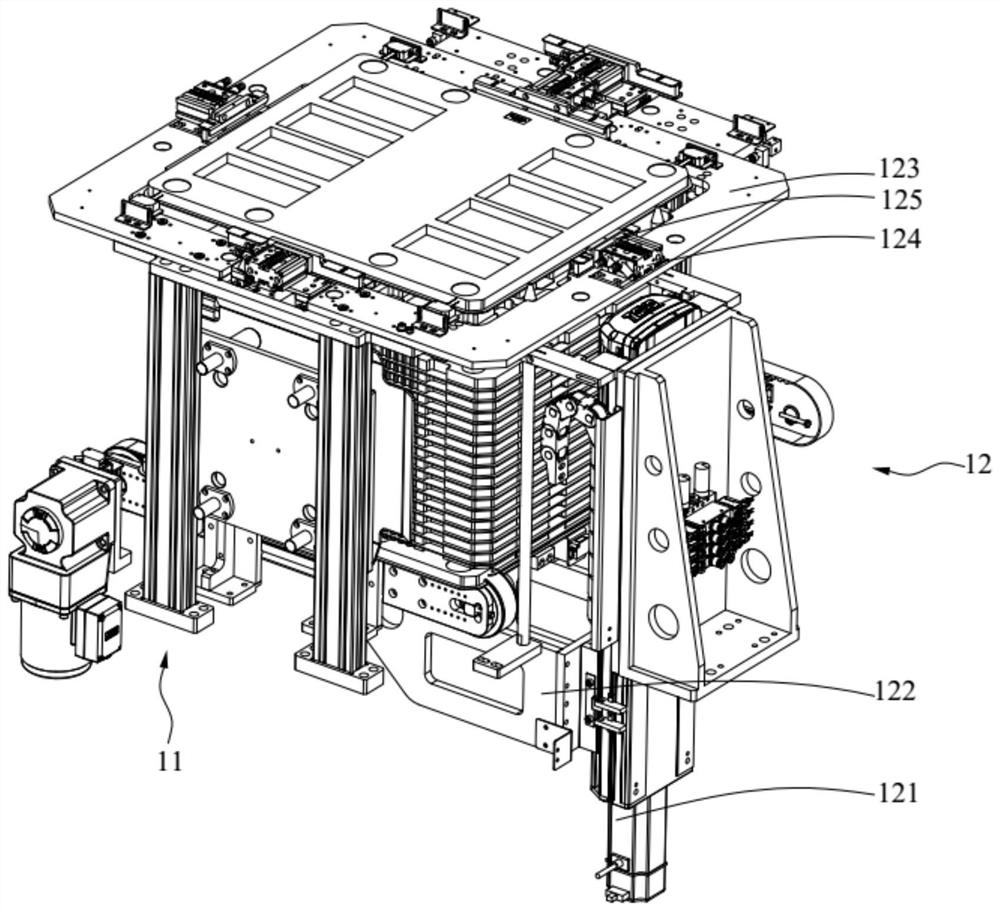

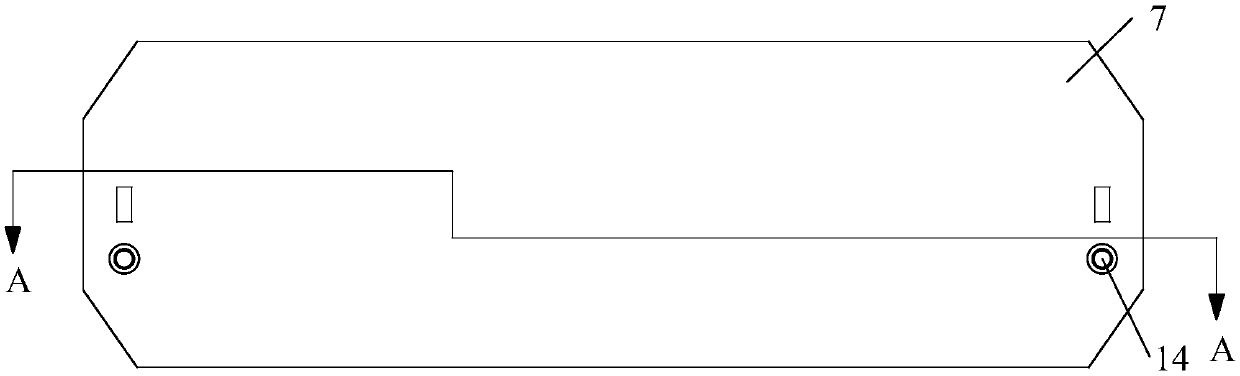

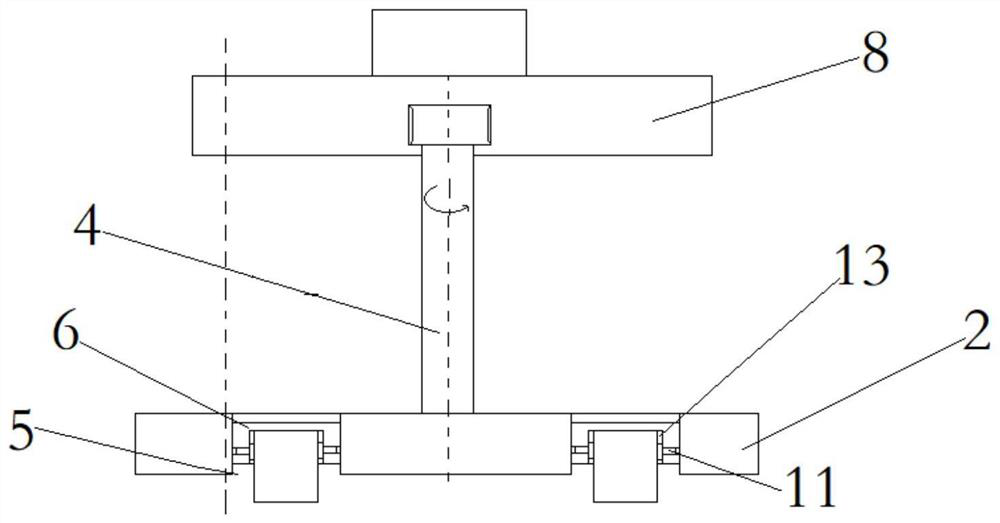

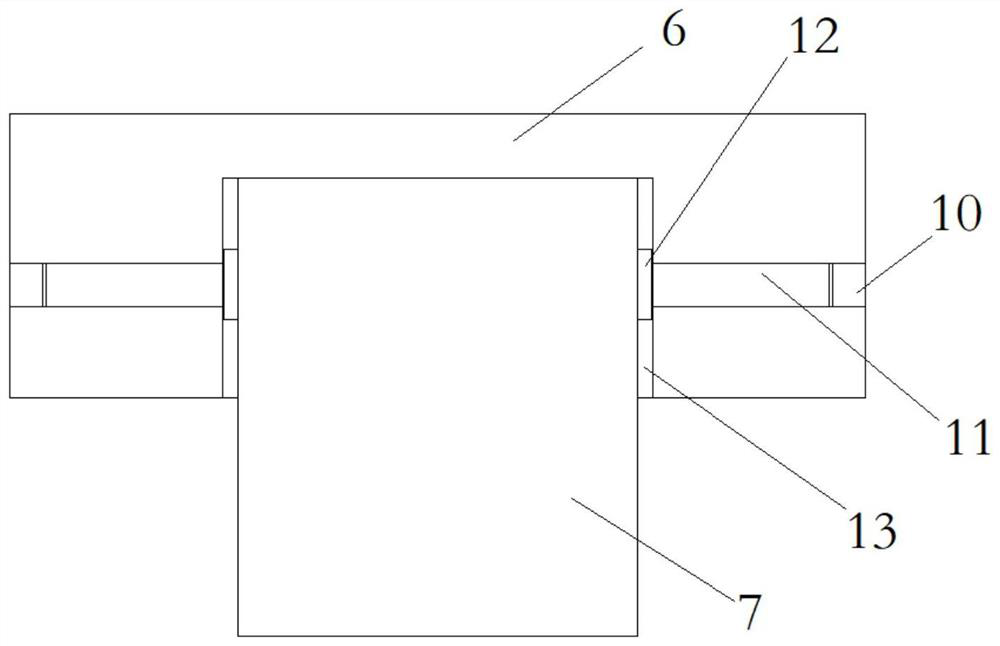

Detection device and production line

PendingCN112051449AQuality improvementGuaranteed contact stabilityResistance/reactance/impedenceStatic indicating devicesProduction lineEngineering

The invention belongs to the technical field of display panel production and manufacturing, and discloses a detection device and a production line. The detection device comprises a first adjusting mechanism capable of bearing a to-be-detected workpiece and performing pre-alignment processing on the to-be-detected workpiece, wherein a detection hole is formed in the to-be-detected workpiece; a second adjusting mechanism which comprises a transfer conveying mechanism, a fine adjusting mechanism and a crimping mechanism, wherein the transfer conveying mechanism is configured to grab the to-be-detected workpiece subjected to pre-alignment treatment and place the to-be-detected workpiece on the fine adjusting mechanism, and the fine adjusting mechanism can bear the to-be-detected workpiece andperform fine alignment treatment on the to-be-detected workpiece, so that a crimping mechanism can extend into a detection hole and is electrically connected with the detection hole to detect the impedance of the to-be-detected workpiece. According to the detection device, a mode of combining pre-alignment processing and fine alignment processing is adopted, so that the positioning accuracy is improved. The crimping mechanism can extend into the detection hole and is electrically connected with the detection hole, so that the measurement precision is improved, and the finished product qualityis improved.

Owner:SUZHOU JINGLAI OPTO CO LTD +1

Novel smart testing junction box

PendingCN108037479AGuaranteed contact stabilityStable jobElectrical measurementsPhotovoltaic energy generationElectrical conductorEngineering

The invention provides a novel smart testing junction box. The junction box comprises an insulating base and multiple groups of wiring terminals, wherein each group of wiring terminals comprise a wiring conductor arranged in the insulating base, a wiring jack formed in the end part of the wiring conductor, a plurality of crimping screws and a short contact tag which is detachably connected betweenthe two crimping screws; a wiring through hole which is used for connecting the end part of a conductor and exposed from the wiring jack is formed in the insulating base; the short contact tag is positioned outside the insulating base; the end parts of the crimping screws are in threaded connection with the wiring conductor and electrically conducted; each group of wiring terminal further comprises a connecting conductor arranged on the joint of the crimping screws and the short contact tag, the end, far from the wiring conductor, of the connecting conductor extends out from the insulating base, and is contacted with the short contact tag; the other end of the connecting conductor is contacted with the wiring conductor; and the connecting conductor and the short contact tag are locked bythe crimping screws to ensure the contact stability between the wiring conductor and the short contact tag, and the circuit break phenomenon between the wiring conductor and the short contact tag canbe effectively avoided.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

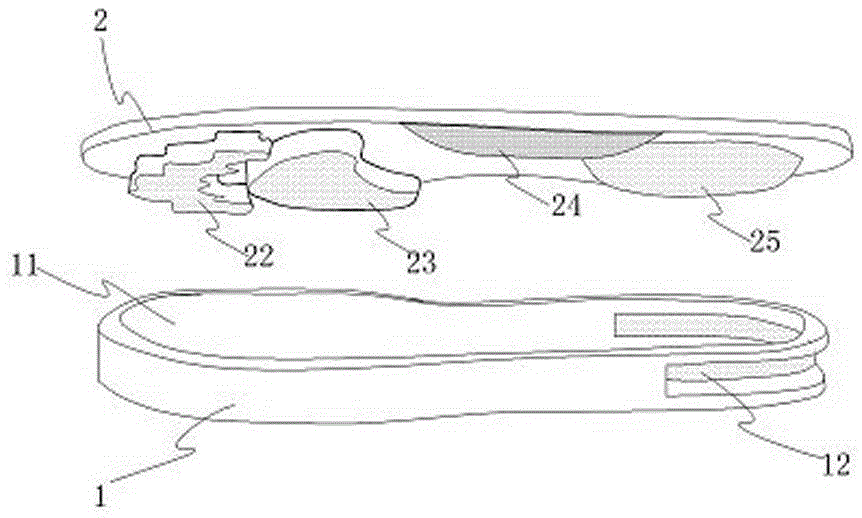

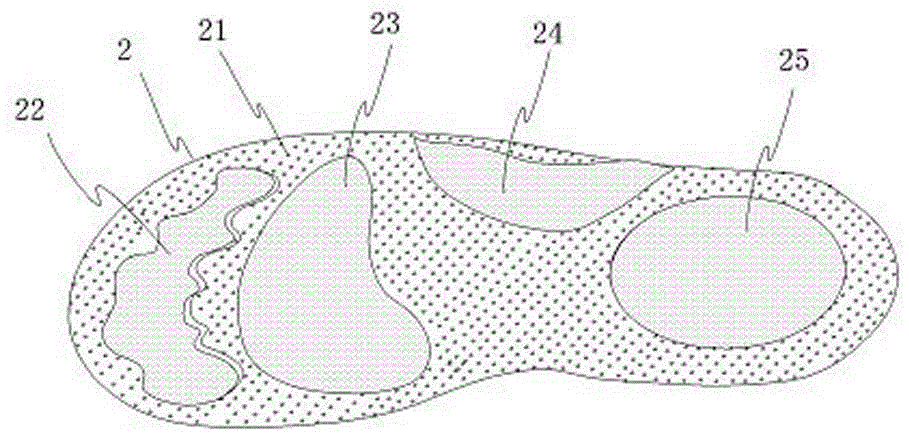

Running shoe sole

The invention relates to a shoe sole, and provides a running shoe sole which can effectively prevent the feet from being injured, has the excellent damping and boosting actions and is suitable for manufacture of exercise running shoes. The running shoe sole comprises a large sole body and a middle sole body arranged on the large sole body, and the lower surface of the middle sole body is provided with a toe air cushion, a phalanx air cushion and a heel air cushion which correspond to a toe area, a phalanx area and a heel area of the foot respectively; the upper surface of the large sole body is provided with a containing groove used for containing the middle sole body, the lower surface of the toe air cushion, the lower surface of the phalanx air cushion and the lower surface of the heel air cushion jointly form a contact face used for allowing the middle sole body to make contact with the groove bottom of the containing groove, and the bottom face of the middle sole body is far away from the groove bottom of the containing groove; the lower surface of the large sole body is provided with ground-gripping patterns.

Owner:QIERTE CO LTD

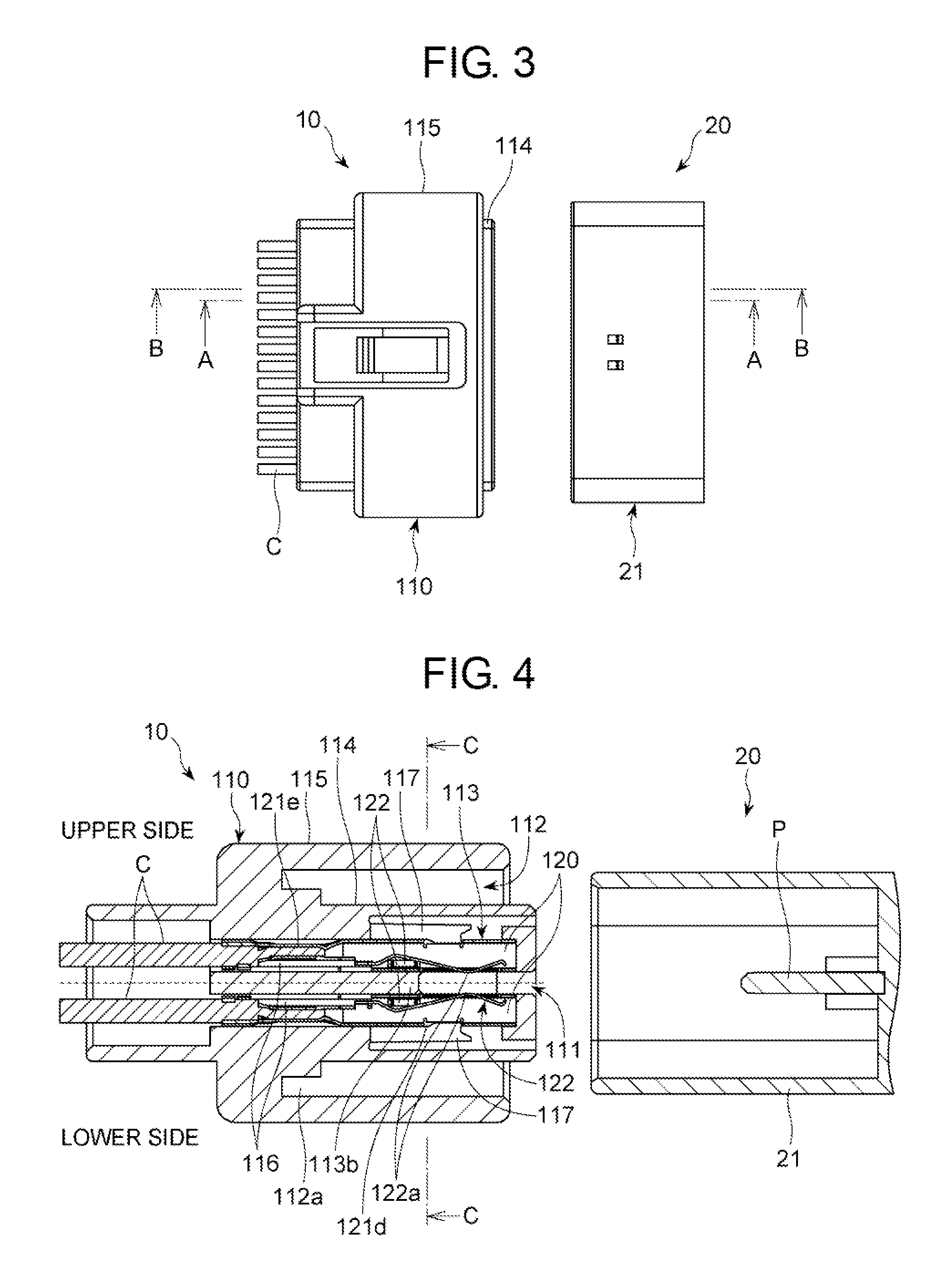

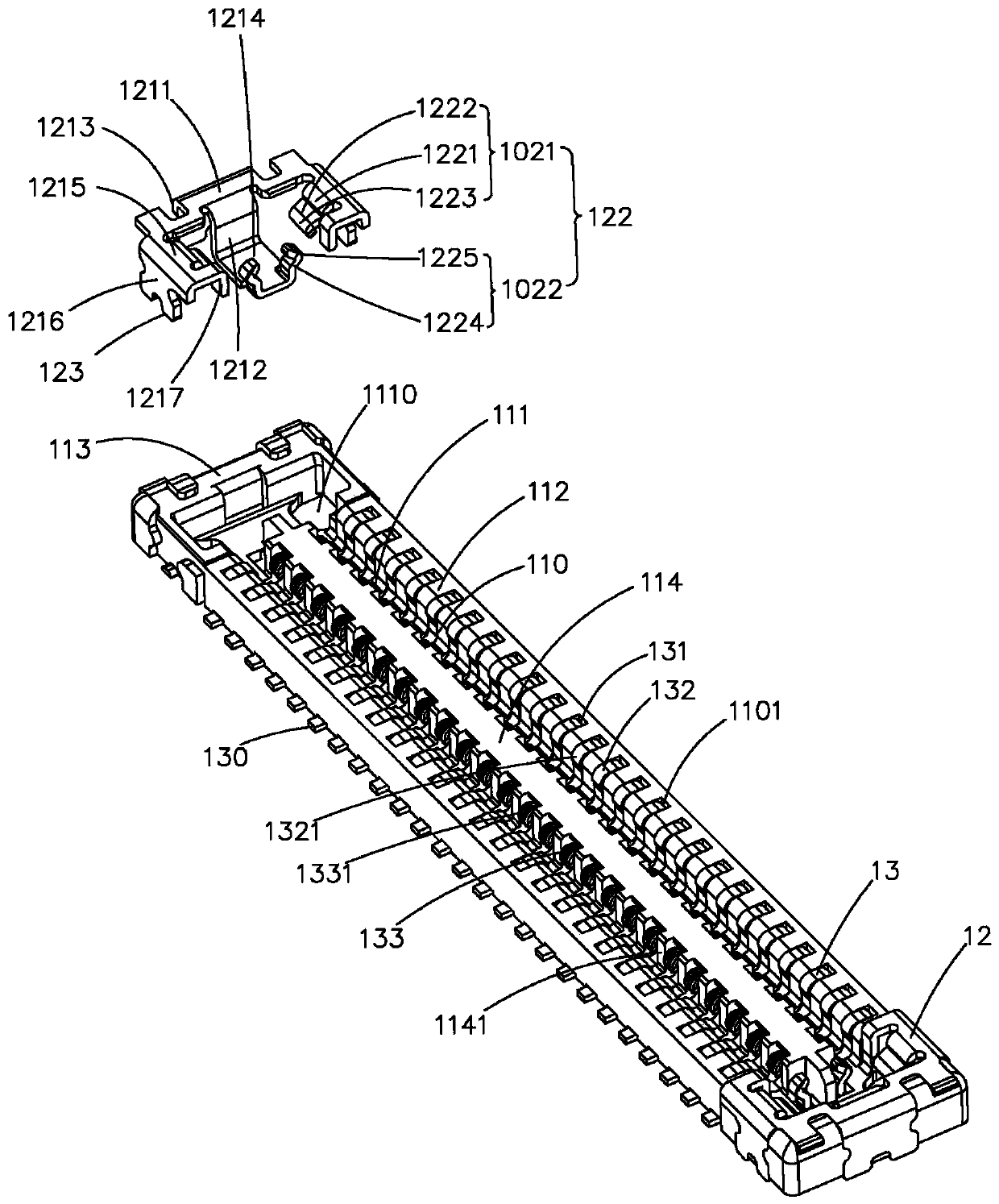

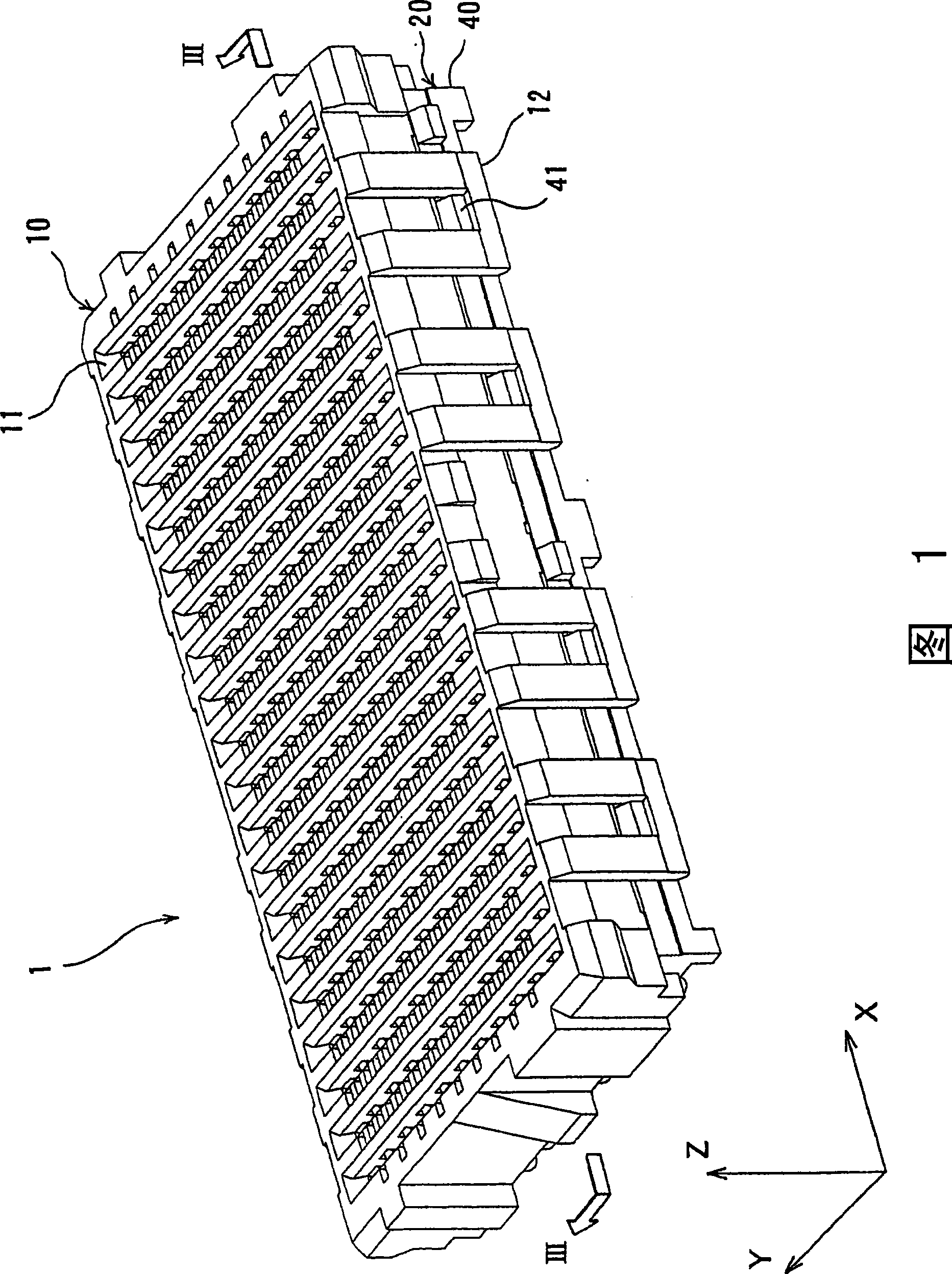

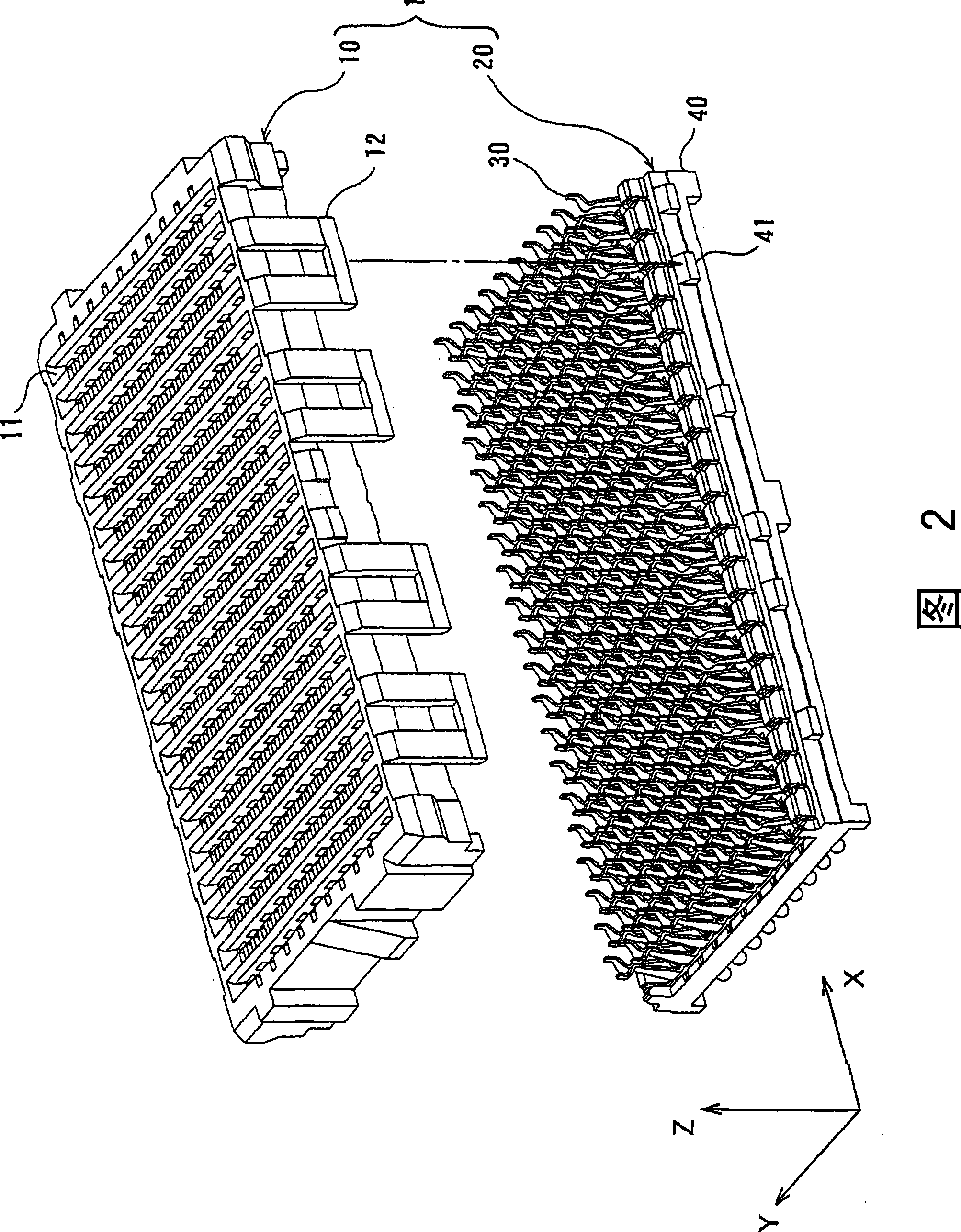

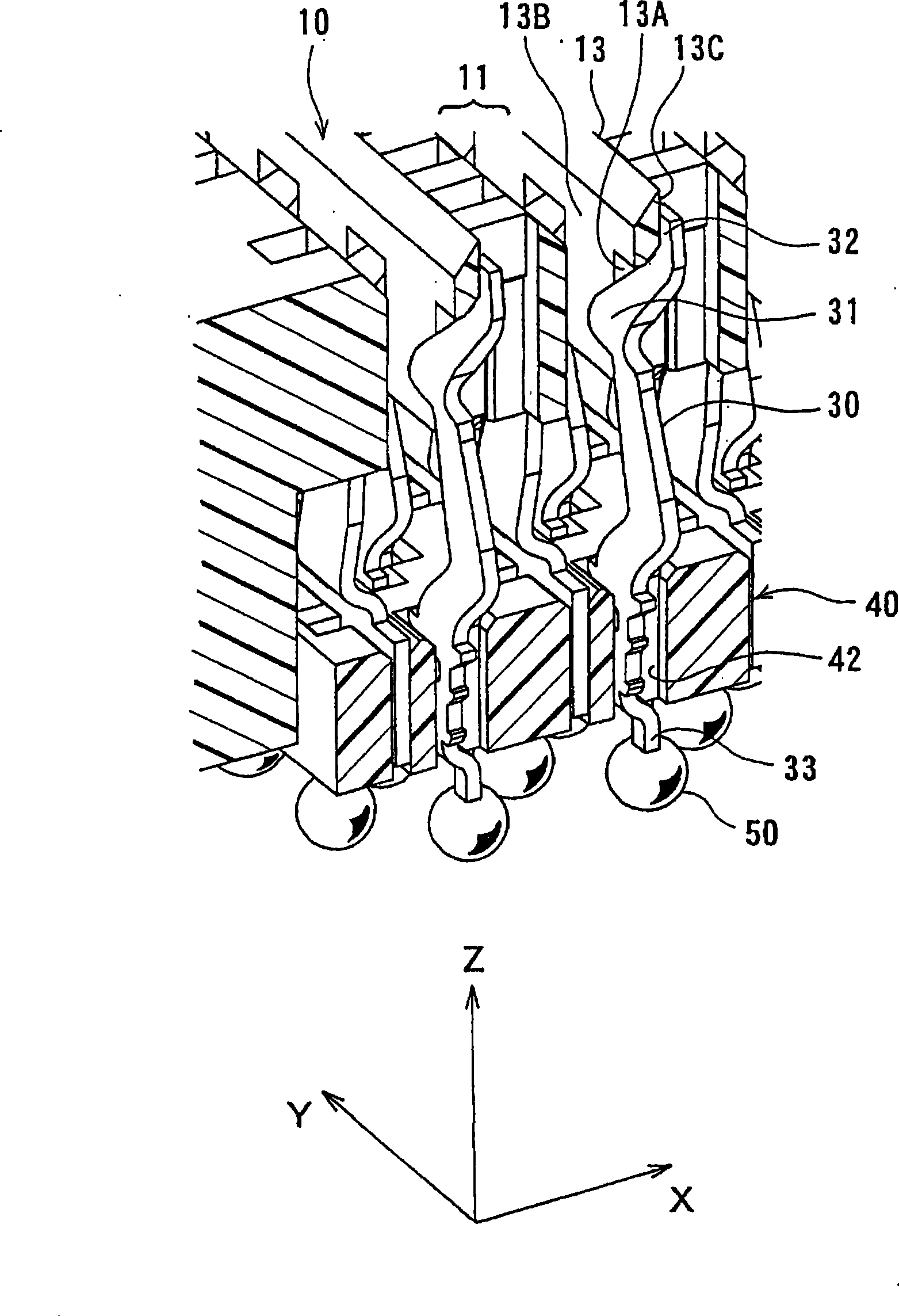

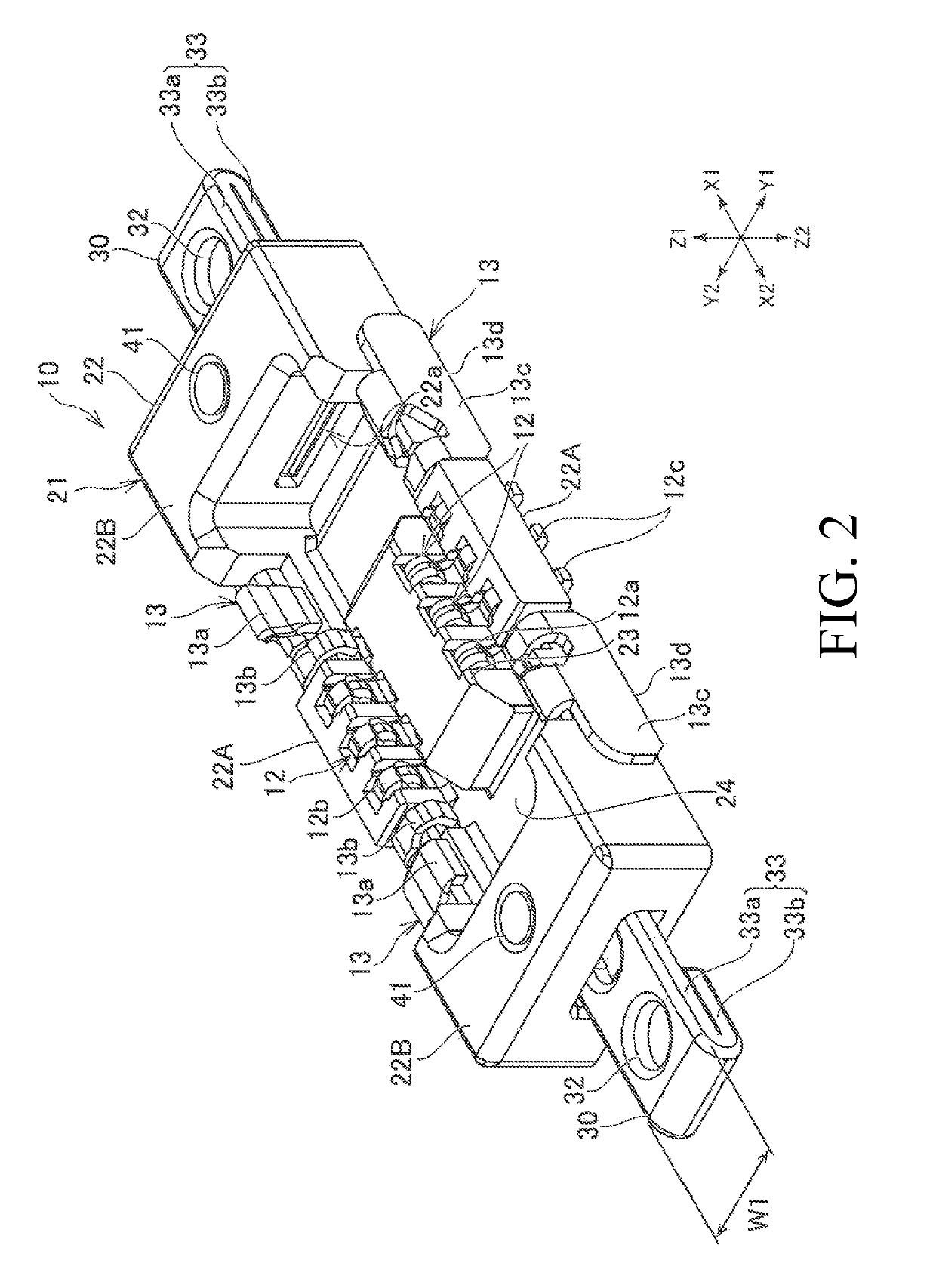

Electrical connector for circuit board

ActiveCN101388500AGuaranteed contact stabilitySecuring/insulating coupling contact membersTwo-part coupling devicesElectrical connectorRelay

The invention provides an electrical connector which ensures stability in contact with a relay part even if deviation is generated between parts. In the connector (1), a relay member receiving body (10) is assembled on a spreading surface of a plurality of rows of terminal groups of terminals (30, 30') relatively successfully kept on a terminal holder (40), namely on an assembly direction orthogonally of a terminal arrangement surface with the terminal holder (40), wherein a plurality of receiving grooves (11) of the relay member receiving body (10) and the receiving relay member (P) are respectively formed spreading along the assembly direction, a plurality of terminals (30, 30') are upright relative to the terminals, kept on one end side of the terminals (30, 30'). Contact parts (31, 31') contacted with the relay part (P) and deformed flexurally are arranged on the other end side of the terminals (30, 30') toward the inner side of the receiving grooves (11). A front end part of the other end side of the plurality of terminals (30, 30') are bunted with the relay member receiving body (10), subjected to precompression of the direction deviating from the relay part (P) on the flexural direction of the contact parts (31, 31').

Owner:HIROSE ELECTRIC GROUP

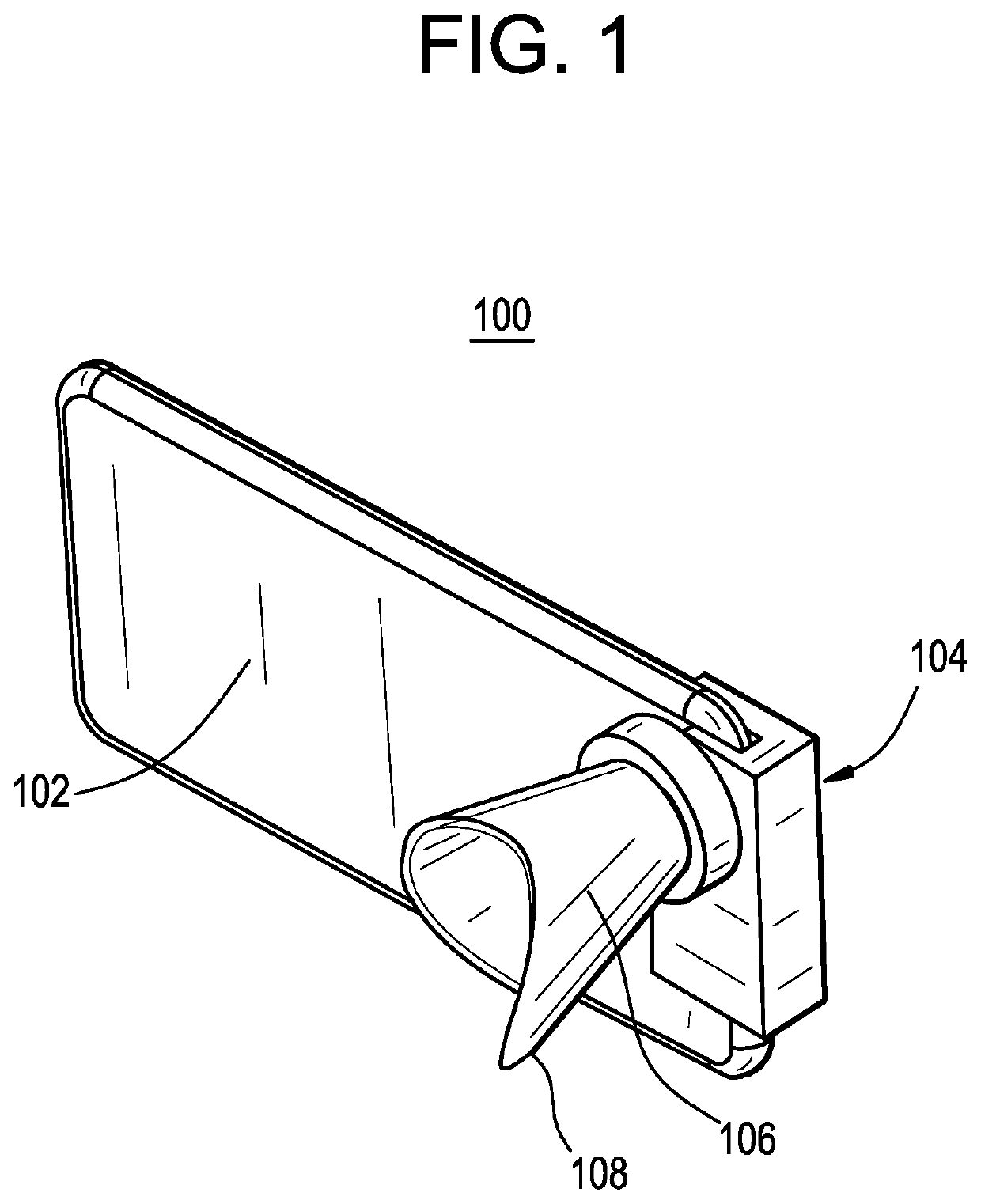

Method and means for evaluating toric contact lens rotational stability

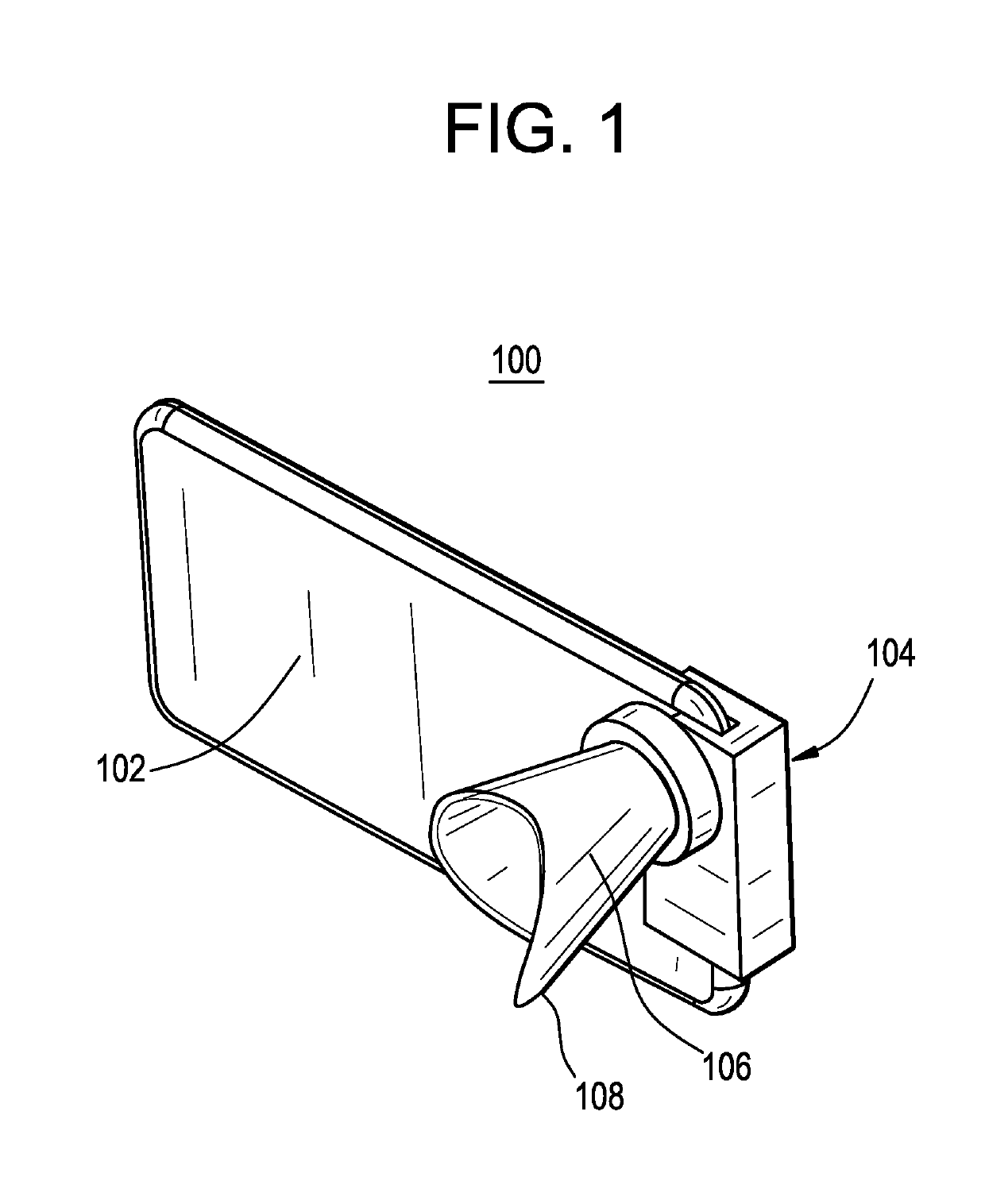

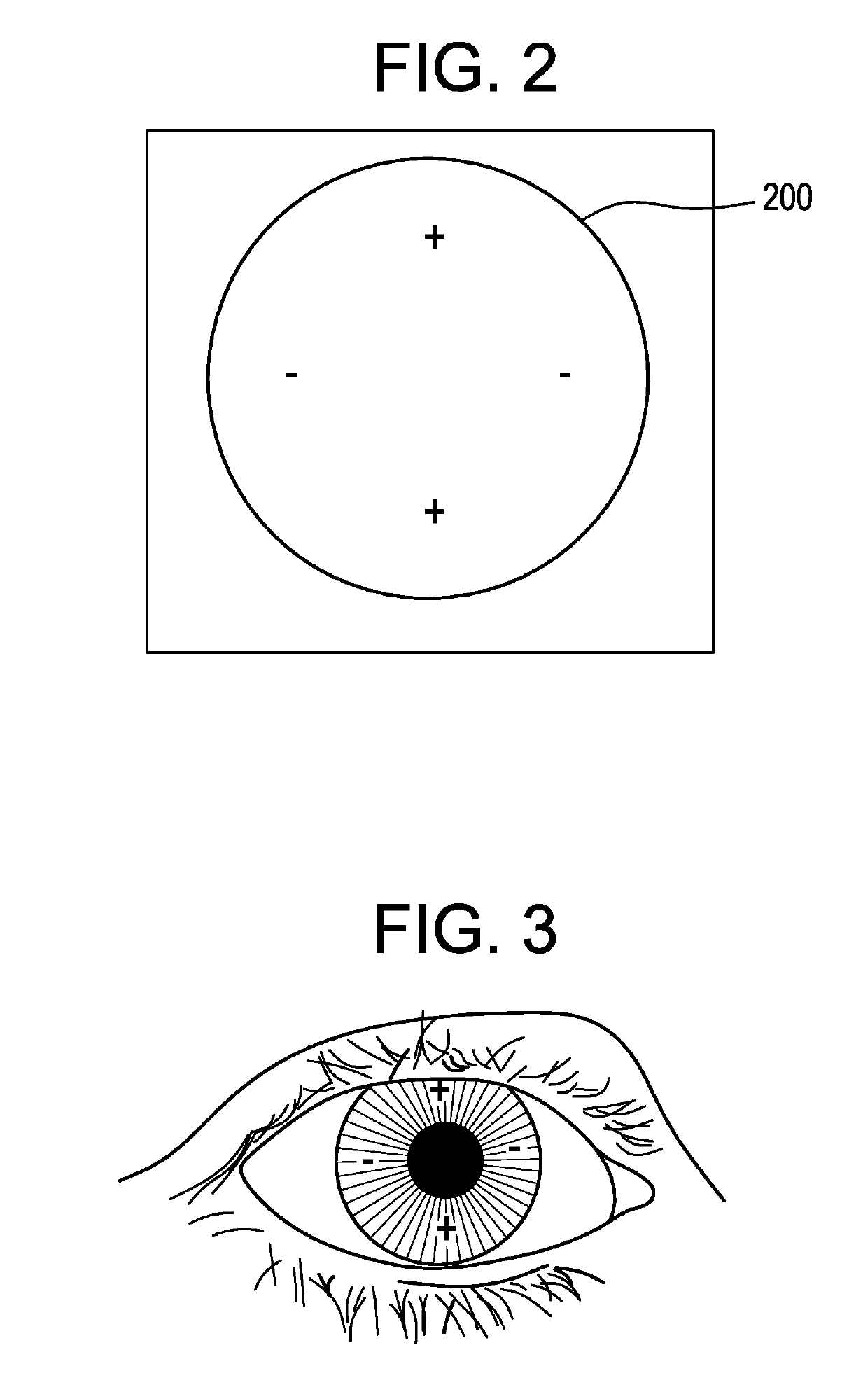

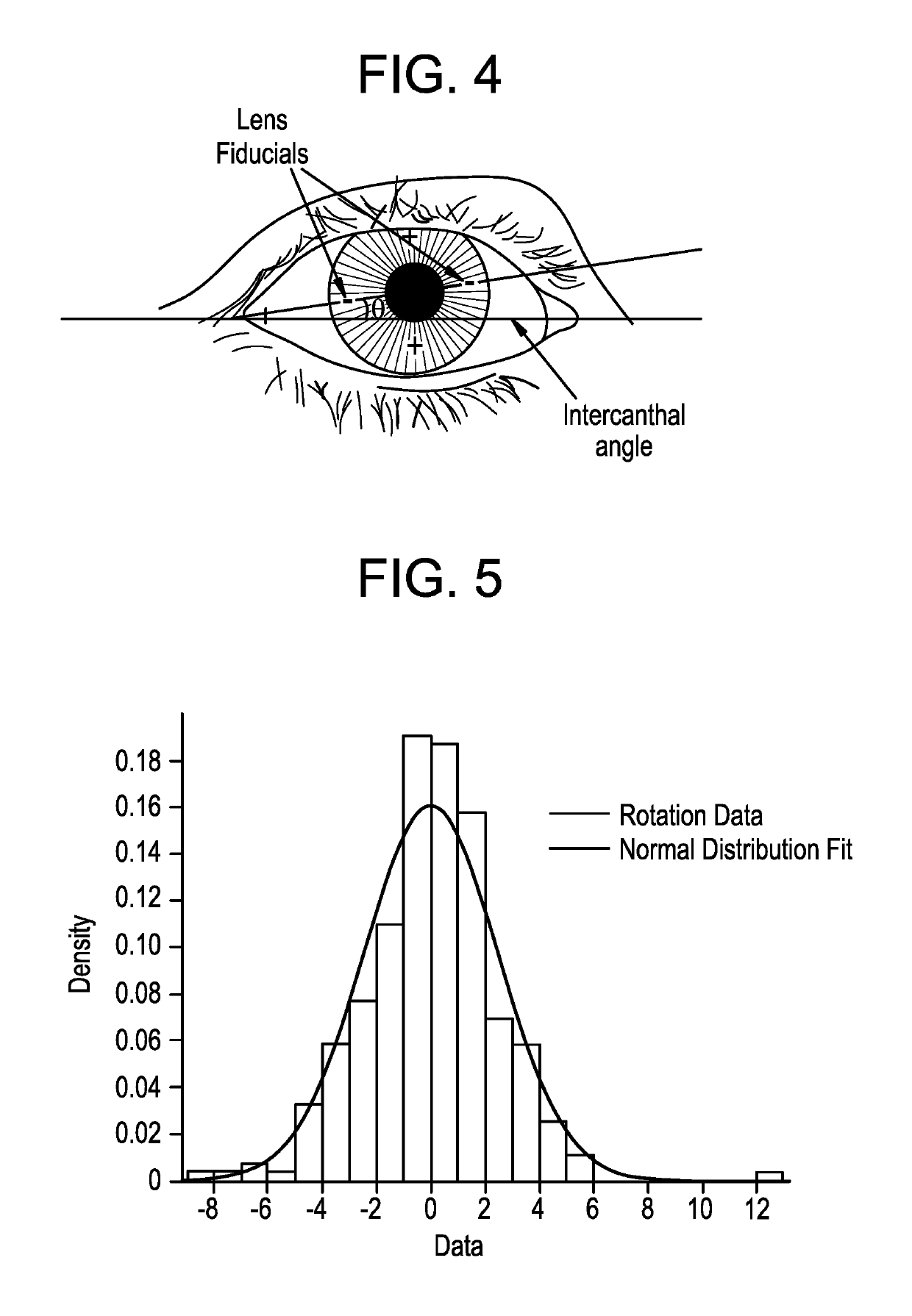

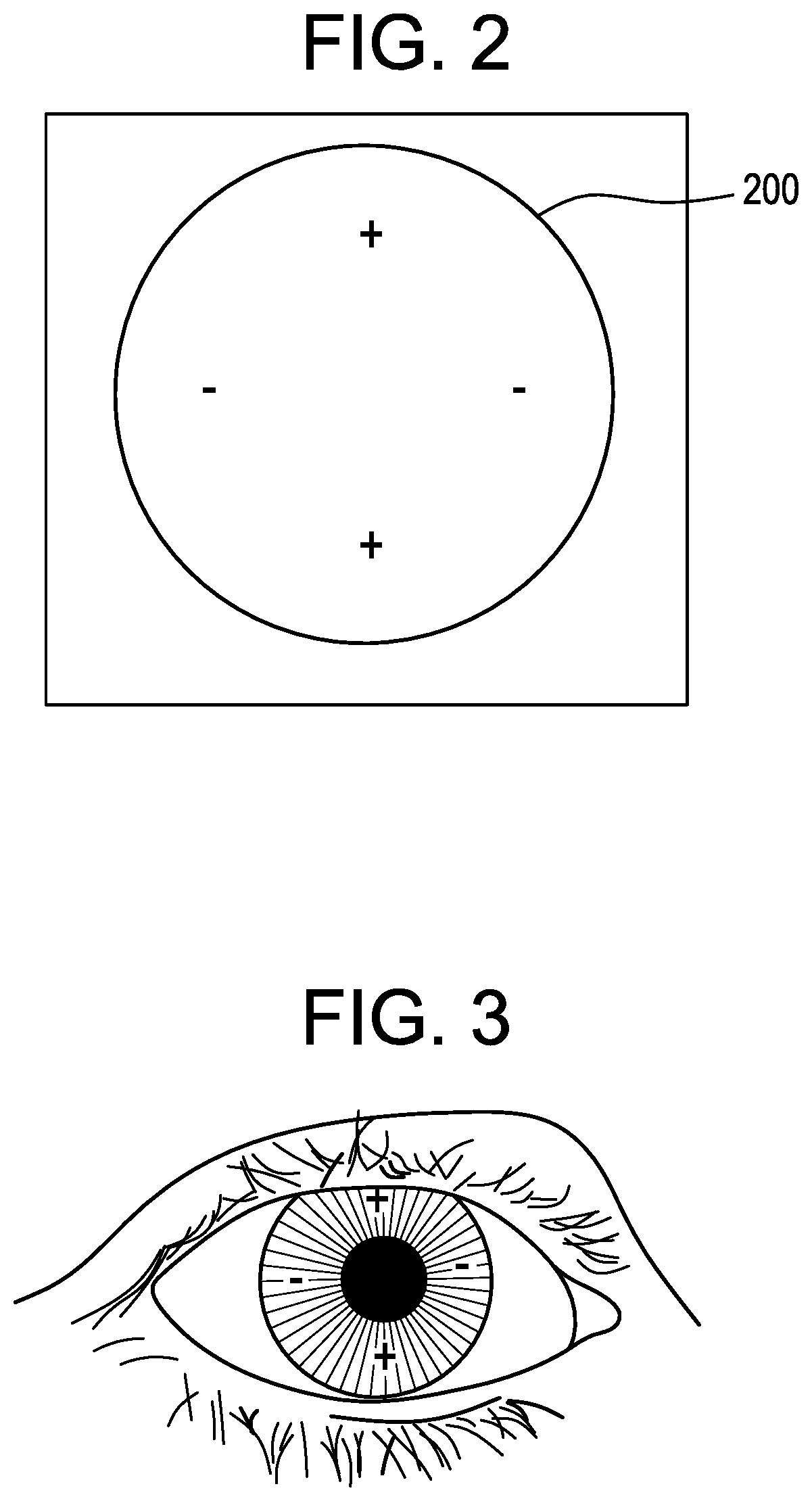

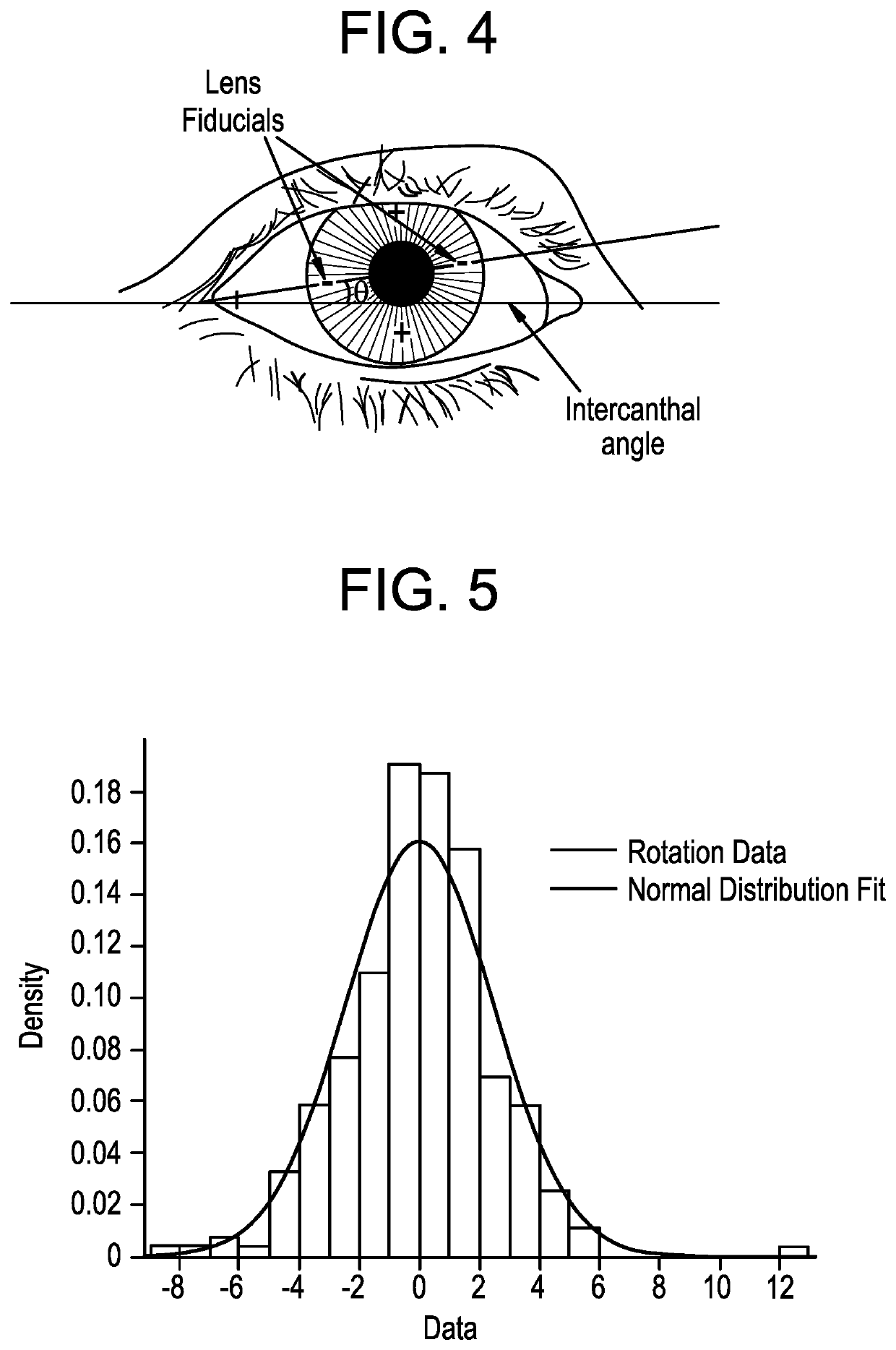

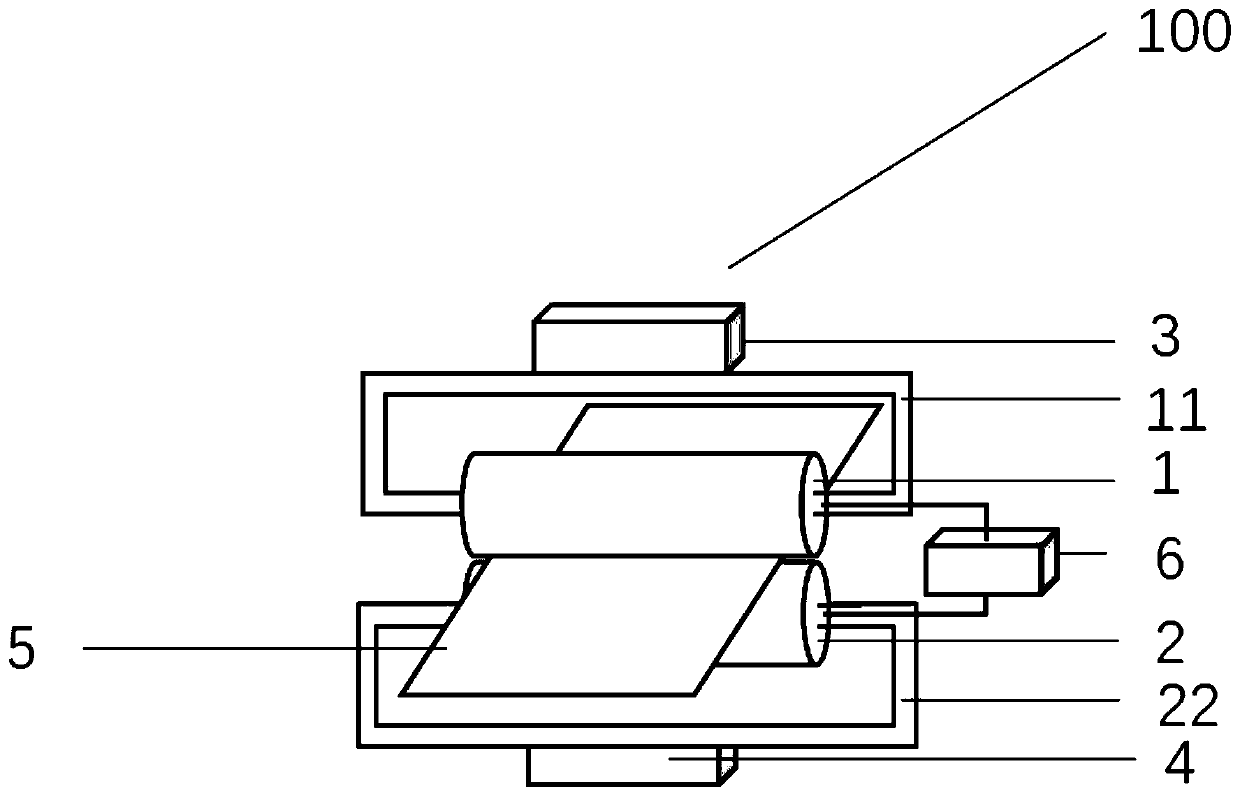

ActiveUS20190104210A1Avoid stray lightEasy to inexpensiveEye diagnosticsMountingsCamera lensRotational stability

The present invention is directed to a method and means for enabling contact lens wearers to photograph their own eyes using an electronic device with a camera such as an iPhone with a macro lens, for example, Olloclip® Macro Pro Lens Set 7× lens, and a custom three-dimensional printed eyecup attachment. The eyecup attachment is designed to position the camera at a suitable and reproducible distance from the eye to ensure that the system can focus appropriately on the lens details. The eyecup attachment also serves to block stray light and diffuse the ambient lighting. In addition, the eyecup attachment ensures that the camera is held in the correct orientation while photos are being captured. The capture images are analyzed using image processing software to determine the angel of rotation of the contact lens.

Owner:JOHNSON & JOHNSON VISION CARE INC

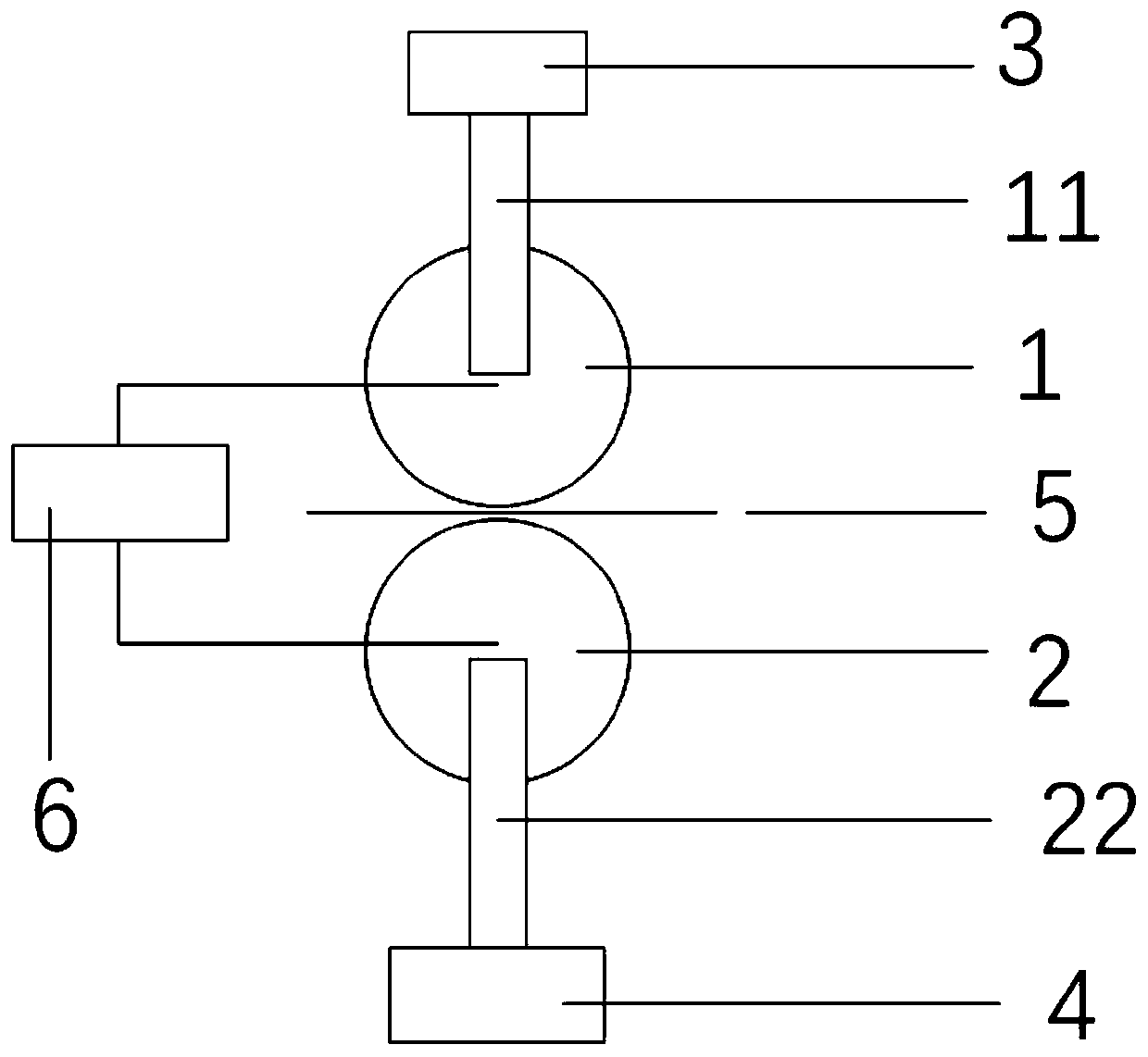

Household noodle soup raw material making device and method based on torque friction effect

InactiveCN111493694ASolve the problem of inconvenient crushing and increased labor intensityStir wellKitchen equipmentTorque transmissionElectric machinery

Owner:向开秀

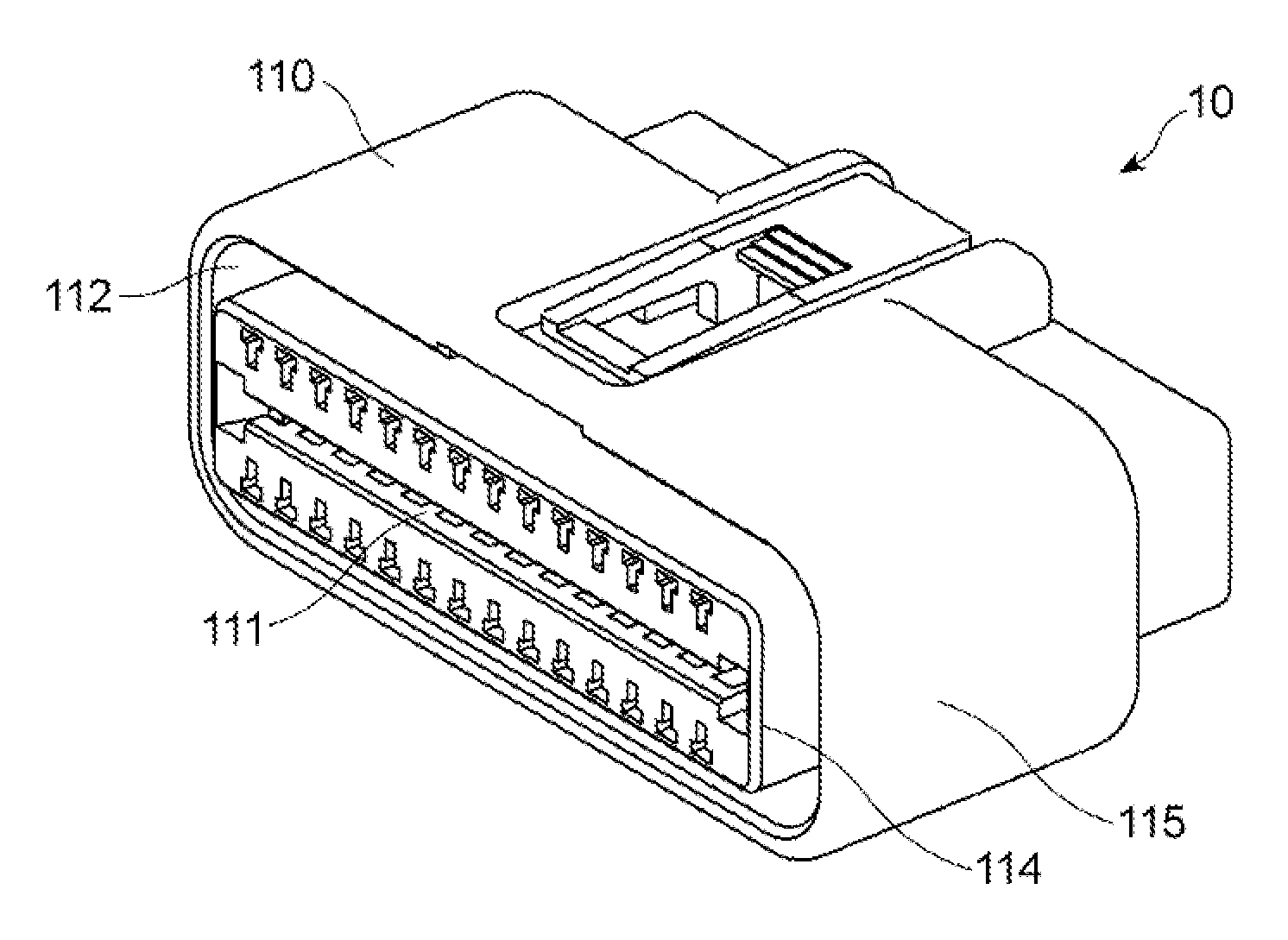

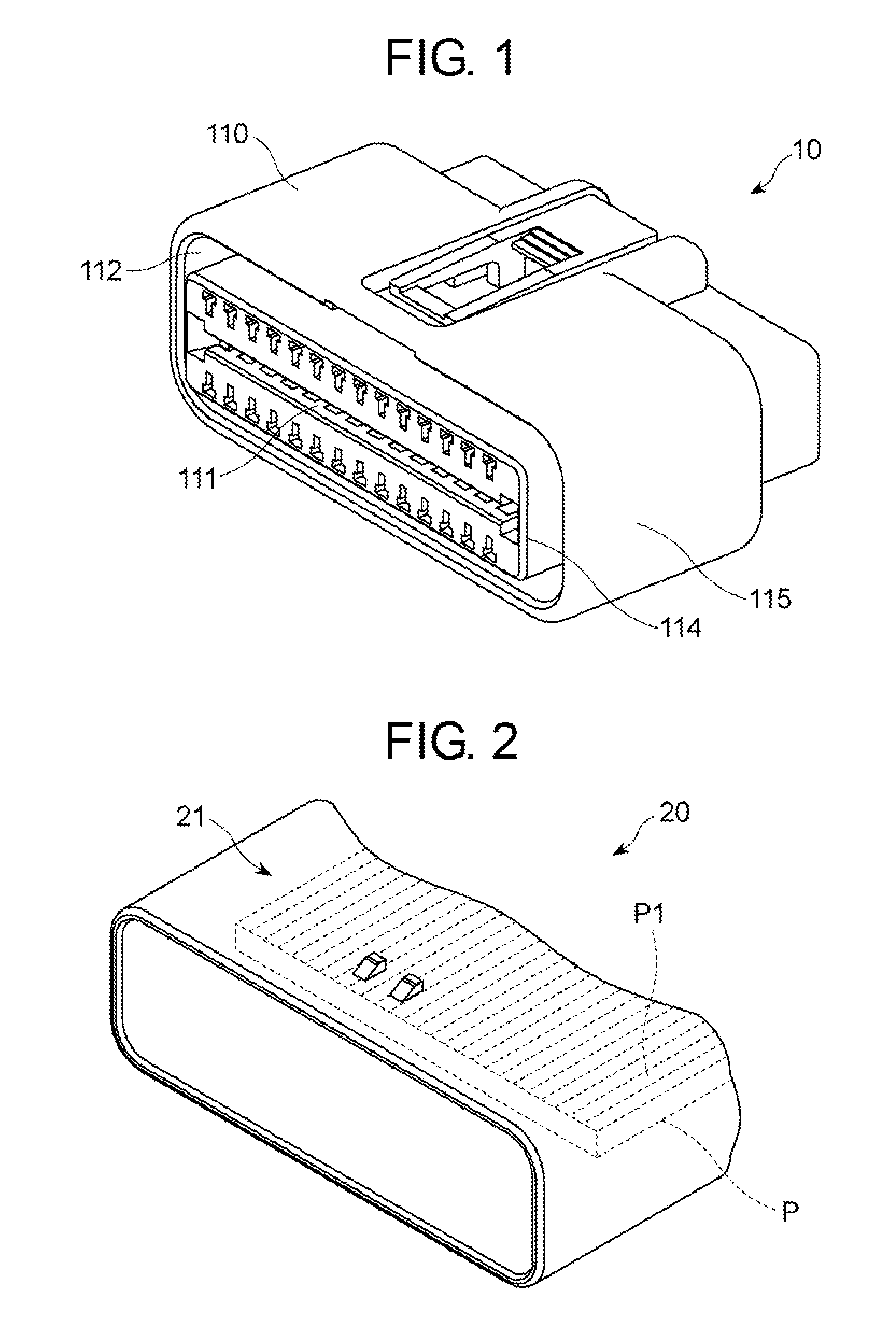

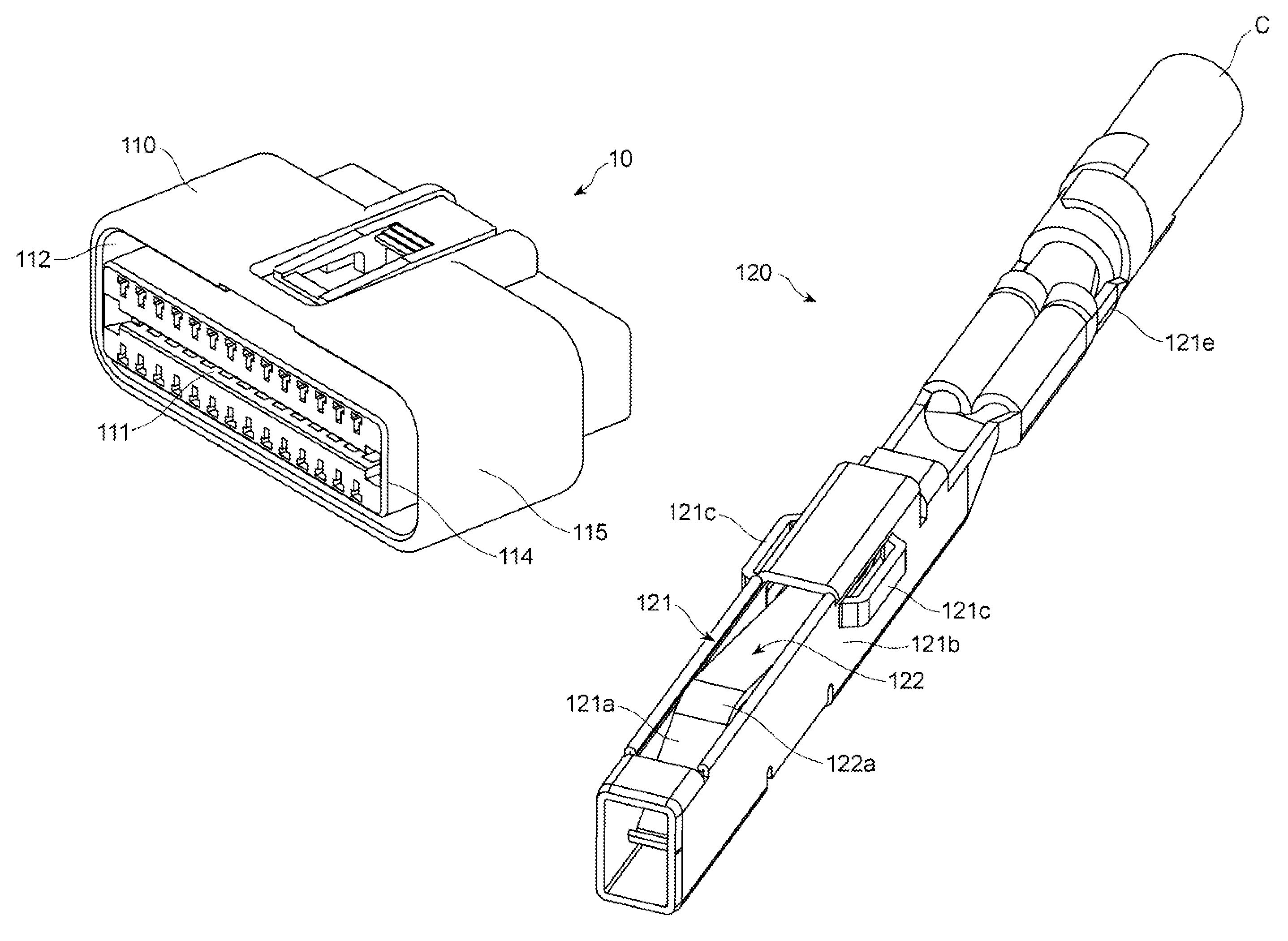

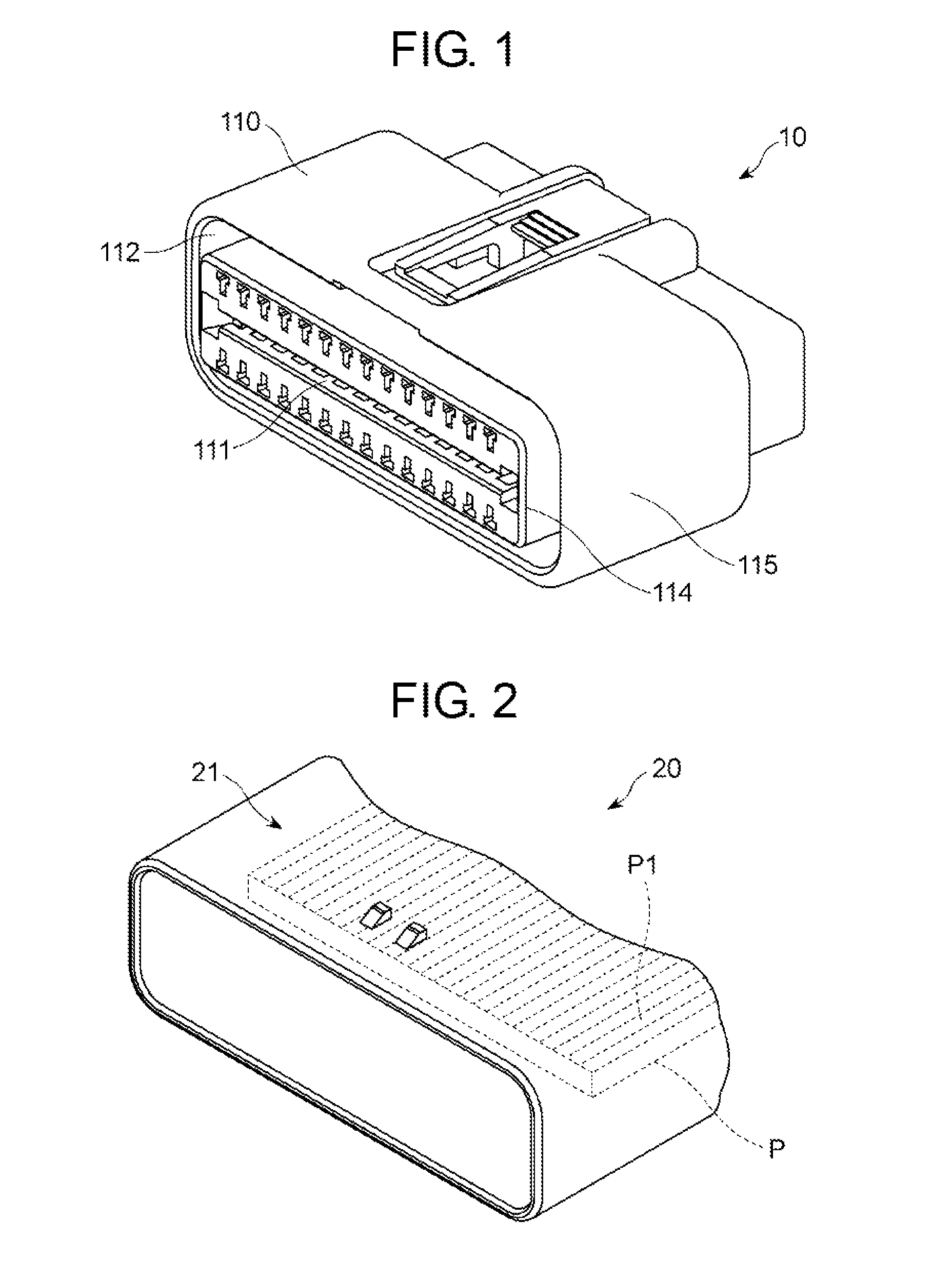

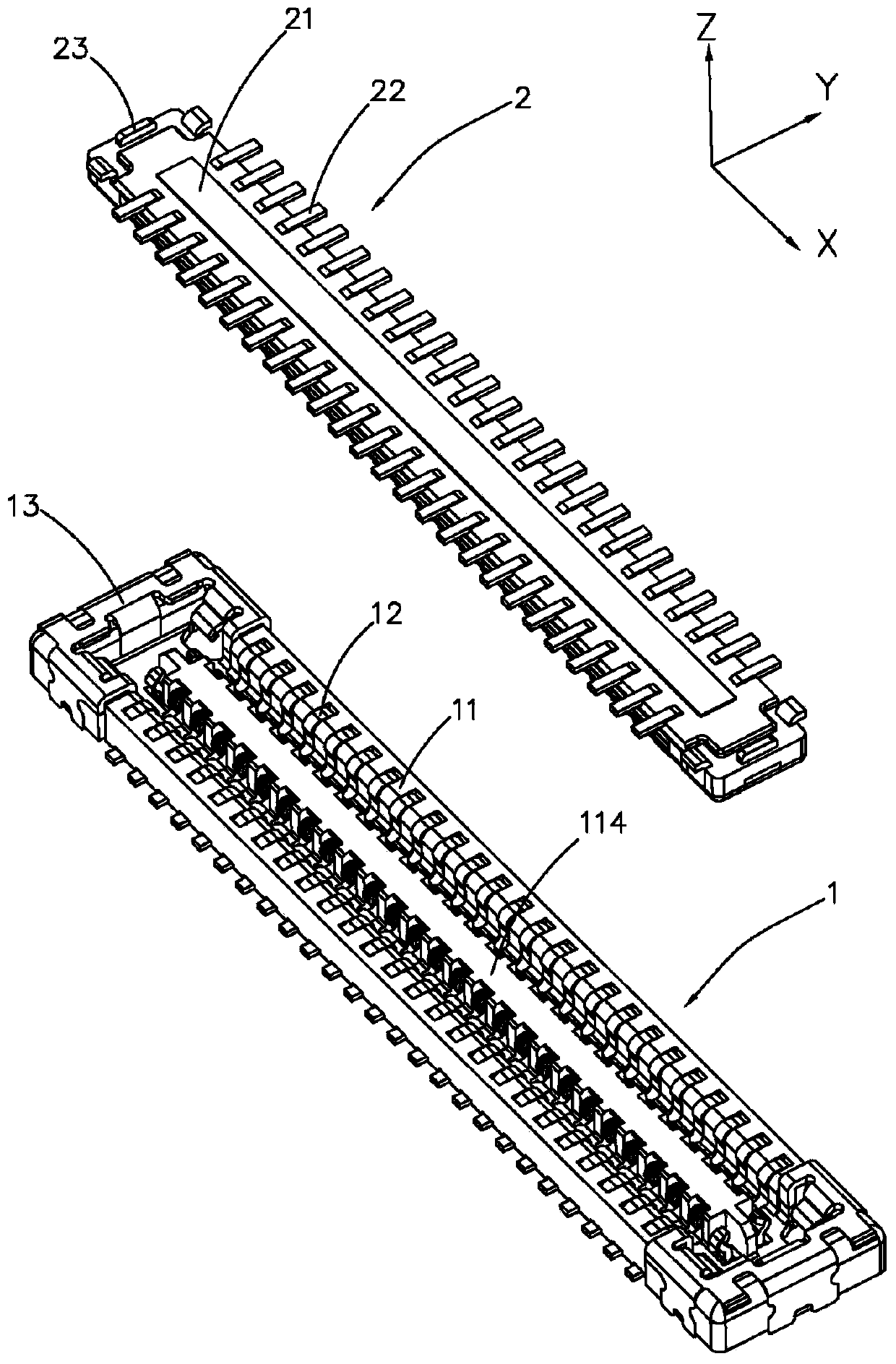

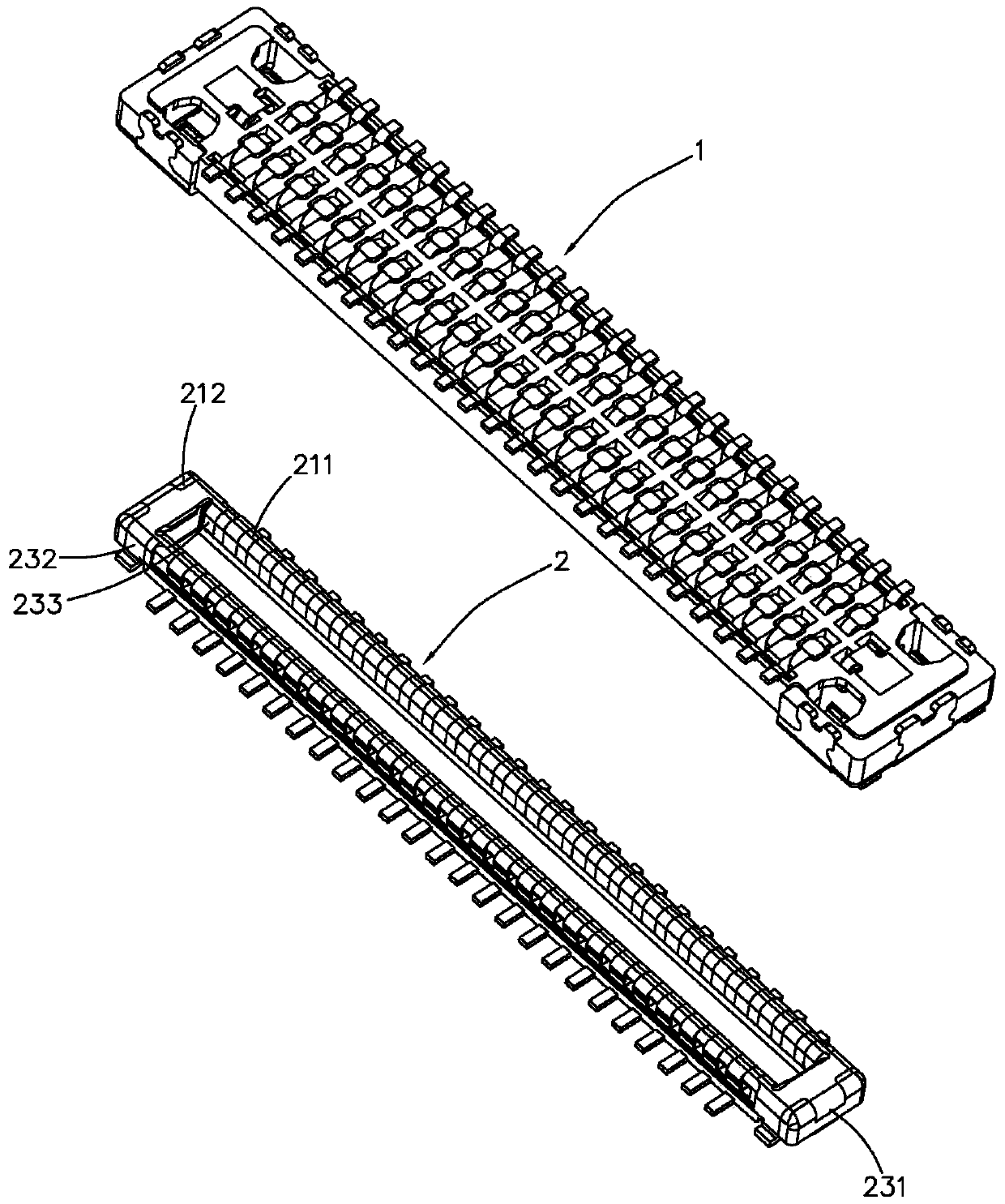

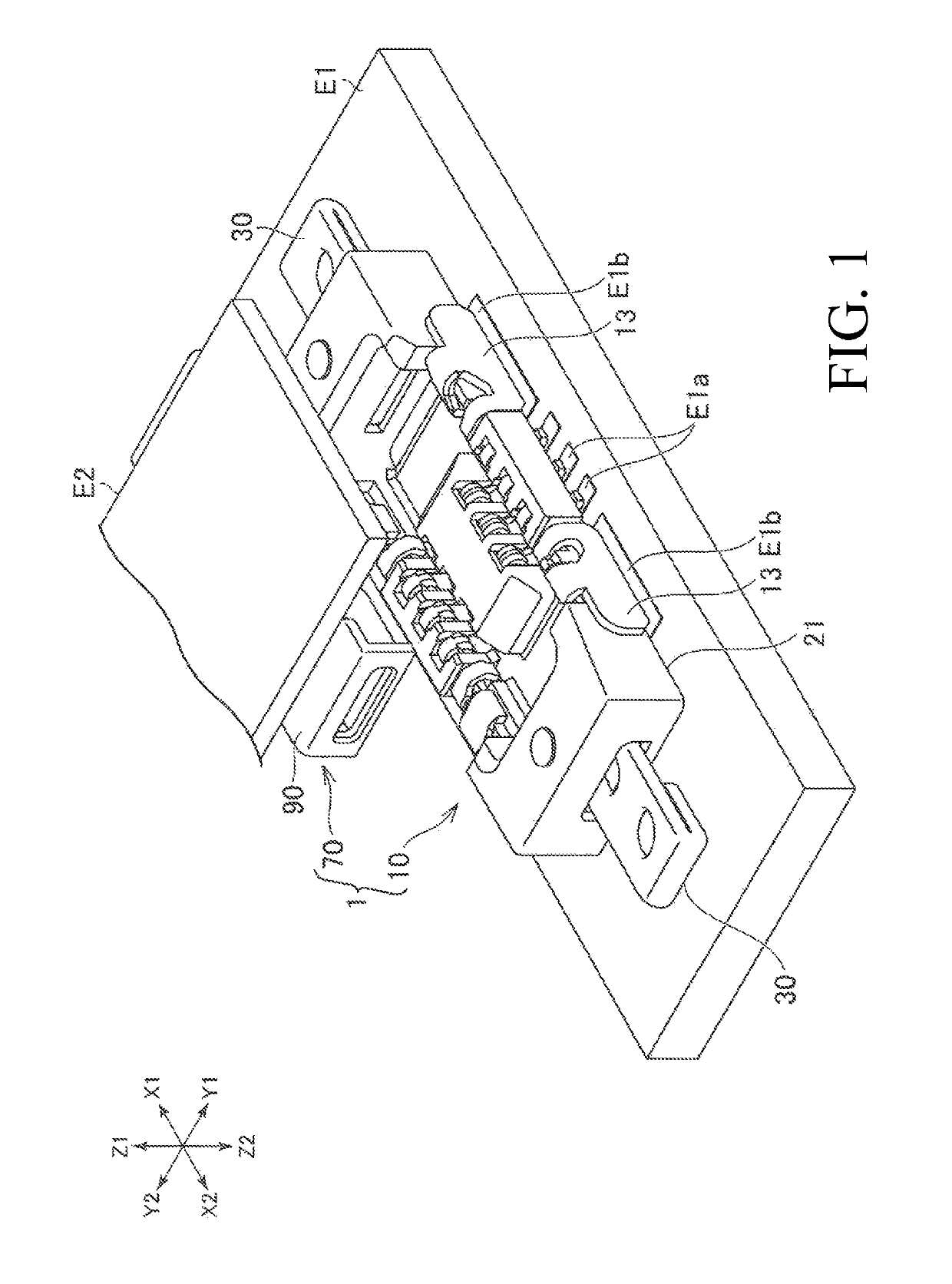

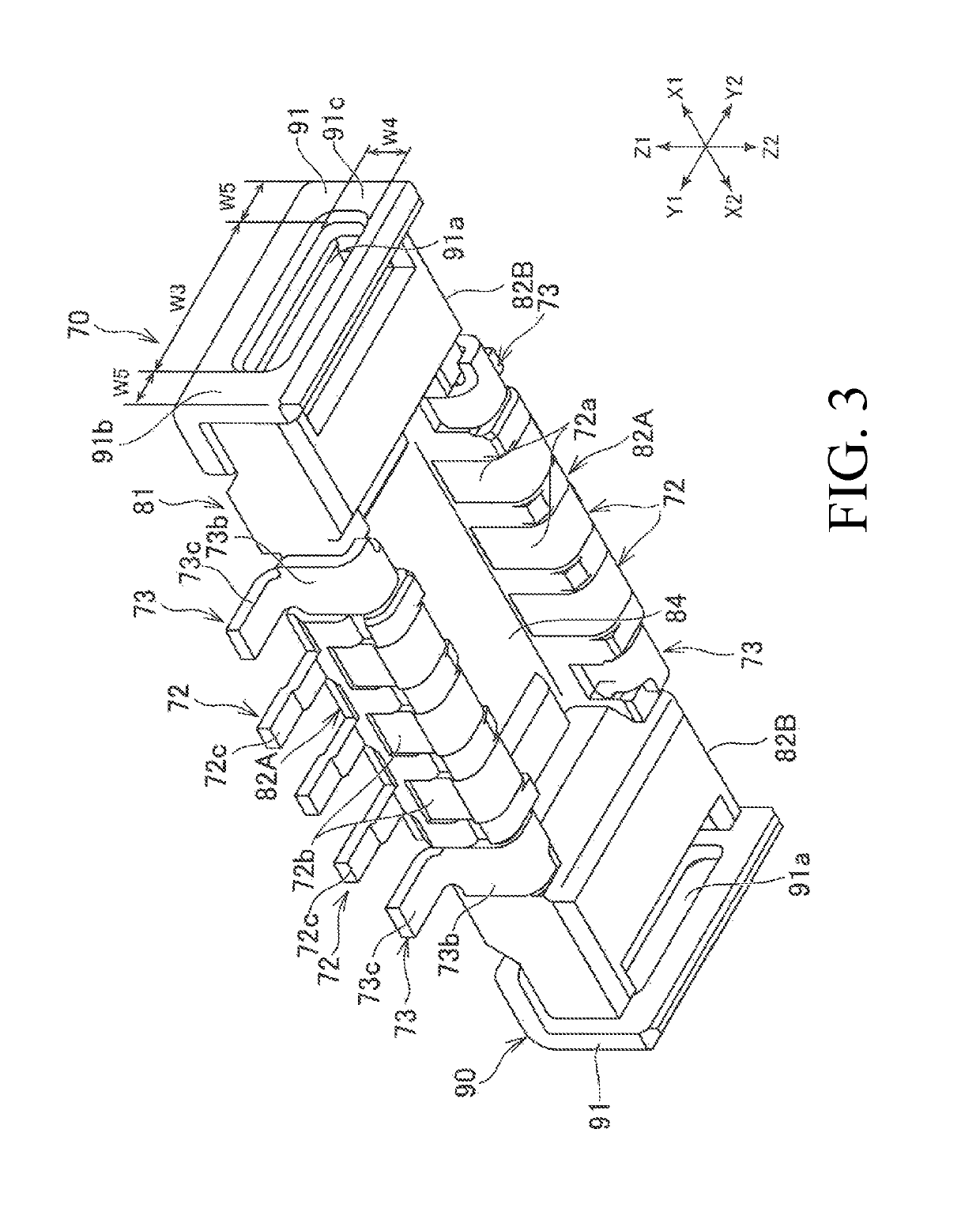

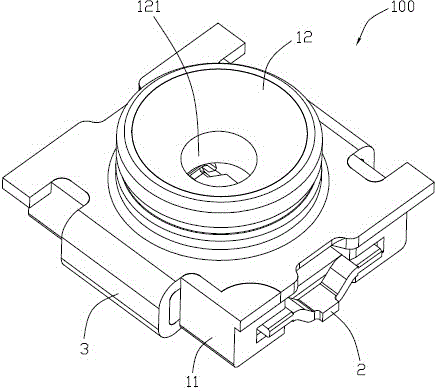

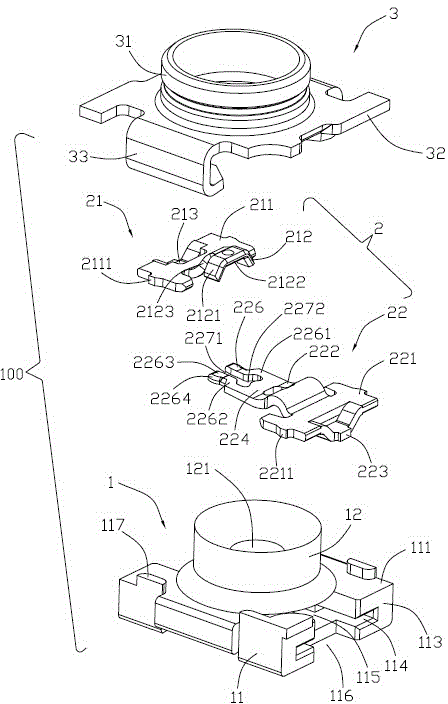

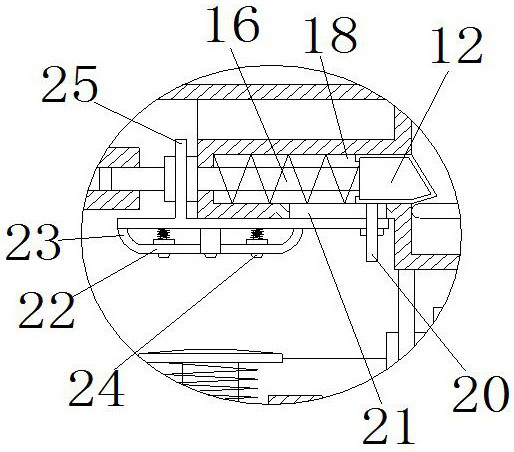

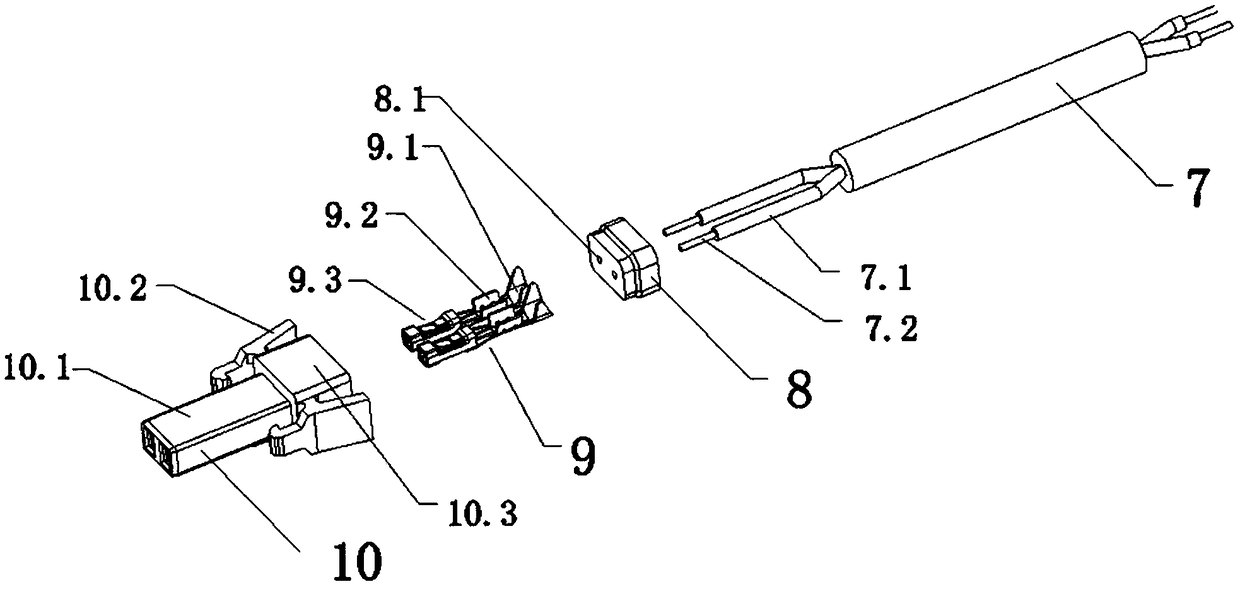

Connector and connector assembly

ActiveUS10361513B2Guaranteed contact stabilityReduce the overall heightEngagement/disengagement of coupling partsMechanical engineering

Owner:MOLEX INC

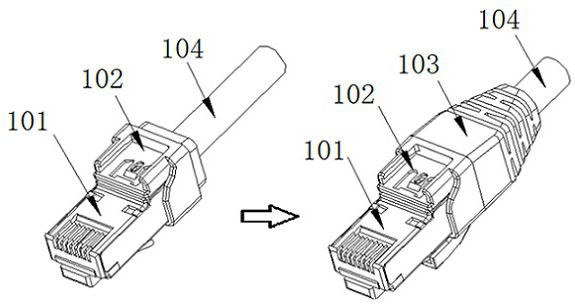

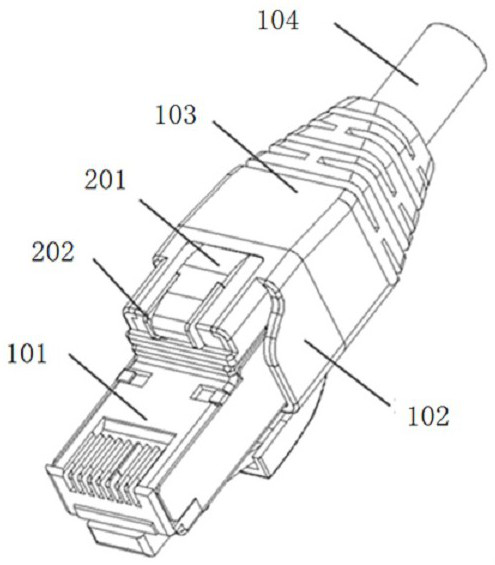

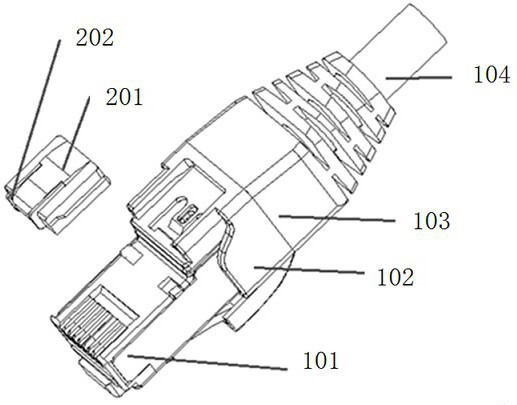

RJ45 interface connector with intelligent chip management function

ActiveCN111653904AImprove development efficiencyEase of mass productionCoupling device detailsTwo-part coupling devicesDistribution frameHemt circuits

The invention relates to an RJ45 interface connector with an intelligent chip management function. The connector comprises three parts, the first part is an RJ45 connector with the main size meeting the known standard, and the RJ45 connector is used for communication cable connection; the second part is a chip arrangement; and the third part is a tail sleeve. When the first part is inserted into the communication port of the distribution terminal, the contact of the second part is connected with the detection circuit of the distribution frame, and the distribution frame can read the identification code of the intelligent chip in the second part of the connector so as to carry out intelligent management. The RJ45 interface connector has the advantages that the standard RJ45 connector is fully utilized, and the development efficiency and the reliability and stability of batch products are greatly improved.

Owner:NANJING PUTIAN TELEGE INTELLIGENT BUILDING

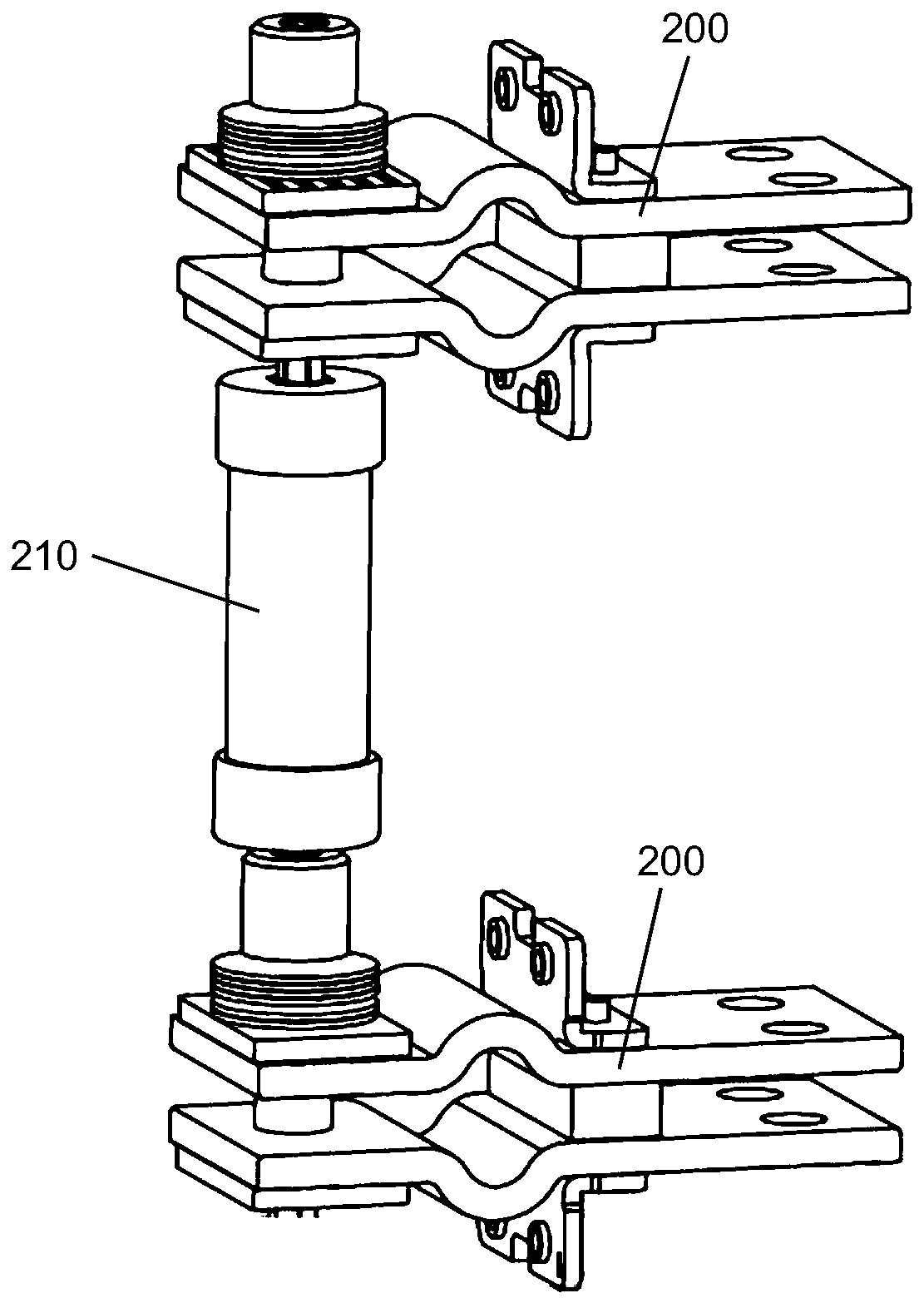

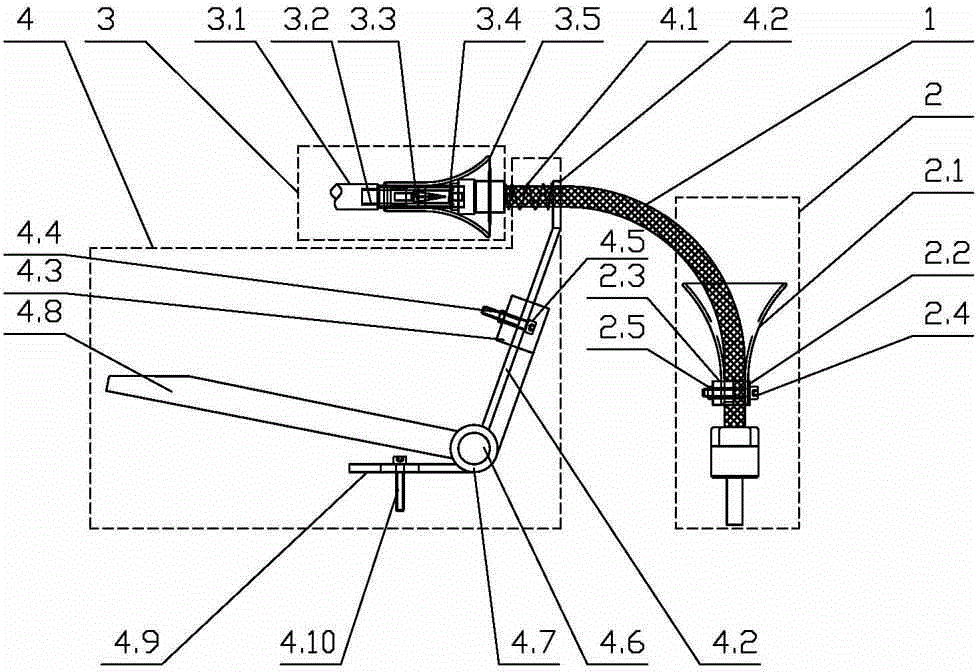

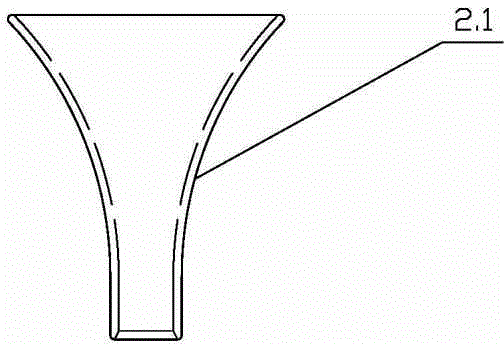

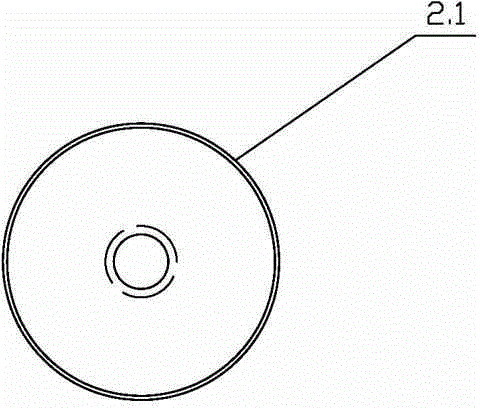

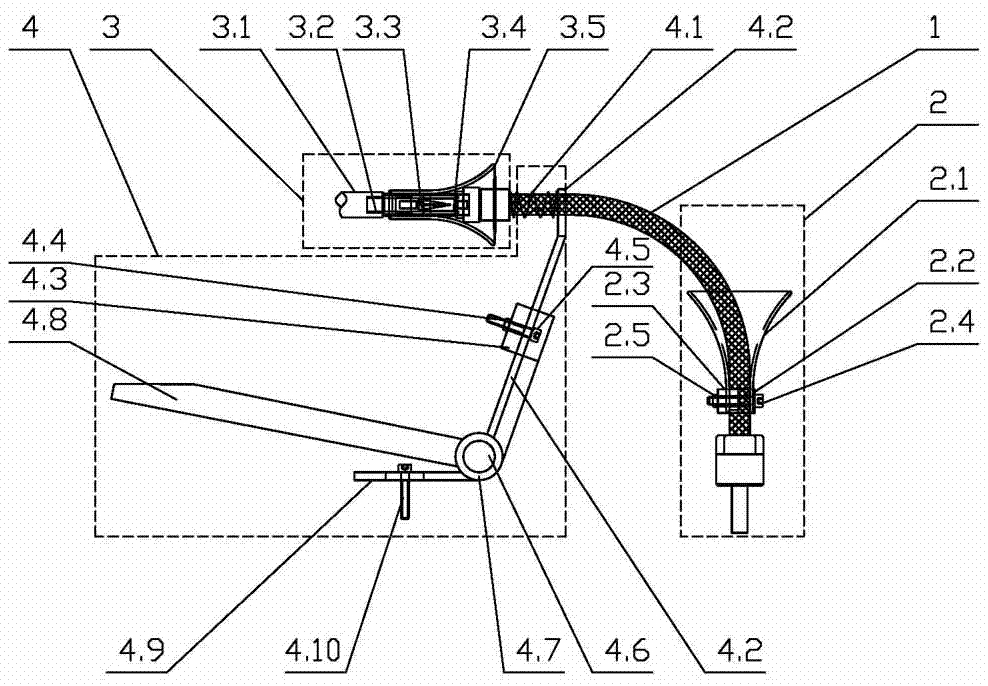

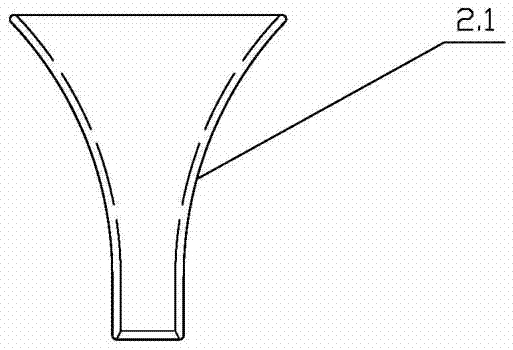

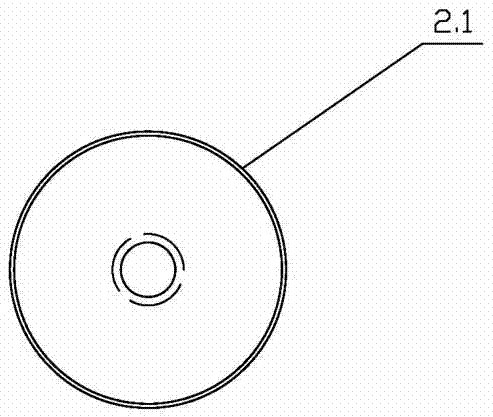

Automatic self-positioning compress electricity inlet component device and installing method thereof

ActiveCN104947077AAvoid stress concentrationPrevent water from entering the electrodeChemical vapor deposition coatingElectricityEngineering

The invention relates to an automatic self-positioning compress electricity inlet component device and an installing method thereof. The automatic self-positioning compress electricity inlet component device comprises an electricity inlet component protection mechanism and an automatic compressing electricity inlet component mechanism; the electricity inlet component protection mechanism comprises a horn mouth clamped groove which sleeves an electricity inlet component, is fixed to the electricity inlet component, and can completely eradicate stress concentration to conduct 360-degree protection in the working process of the electricity inlet component; the horn mouth clamped groove comprises a taper-shaped hexagonal fastening electrode tip, a taper-shaped electrode female head, a shielding tube and a positioning horn mouth lock bracket, wherein the shielding tube is installed on an electrode stem, the positioning horn mouth lock bracket sleeves the shielding tube and can promote an electricity inlet component to position automatically, the situation of the taper-shaped hexagonal fastening electrode tip can be observed conveniently at the same time, and the taper-shaped electrode female head is automatically positioned and connected with the taper-shaped hexagonal fastening electrode tip through a taper-shaped face; the automatic compressing electricity inlet component mechanism is a lever automatic compressing mechanism which promotes the electricity inlet component automatically to be compressed in a PECVD working procedure when a workpiece frame enters a depositing furnace and moves to a location and promotes electricity inlet component to loosen automatically at the same time when the technology is finished and discharging is conducted and the workpiece frame leaves limitation of the depositing furnace.

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

A device for self-positioning and automatically pressing power-in components and its installation method

ActiveCN104947077BExtended service lifeDesign scienceChemical vapor deposition coatingElectricityStress concentration

The invention relates to an automatic self-positioning compress electricity inlet component device and an installing method thereof. The automatic self-positioning compress electricity inlet component device comprises an electricity inlet component protection mechanism and an automatic compressing electricity inlet component mechanism; the electricity inlet component protection mechanism comprises a horn mouth clamped groove which sleeves an electricity inlet component, is fixed to the electricity inlet component, and can completely eradicate stress concentration to conduct 360-degree protection in the working process of the electricity inlet component; the horn mouth clamped groove comprises a taper-shaped hexagonal fastening electrode tip, a taper-shaped electrode female head, a shielding tube and a positioning horn mouth lock bracket, wherein the shielding tube is installed on an electrode stem, the positioning horn mouth lock bracket sleeves the shielding tube and can promote an electricity inlet component to position automatically, the situation of the taper-shaped hexagonal fastening electrode tip can be observed conveniently at the same time, and the taper-shaped electrode female head is automatically positioned and connected with the taper-shaped hexagonal fastening electrode tip through a taper-shaped face; the automatic compressing electricity inlet component mechanism is a lever automatic compressing mechanism which promotes the electricity inlet component automatically to be compressed in a PECVD working procedure when a workpiece frame enters a depositing furnace and moves to a location and promotes electricity inlet component to loosen automatically at the same time when the technology is finished and discharging is conducted and the workpiece frame leaves limitation of the depositing furnace.

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

coaxial connector

ActiveCN103269001BGuaranteed contact stabilityEfficient scrapingCoupling contact membersTwo-part coupling devicesEngineeringContact position

The invention provides a coaxial connector, which comprises an insulation body, a fixed terminal and a movable terminal, wherein the fixed terminal and the movable terminal are fixedly arranged on the insulation body; the insulation body is provided with a containing hole; the fixed terminal is provided with a first fixed part and a first contact part connected with the first fixed part; the movable terminal is provided with a second fixed part and an elastic part extending from the second fixed part; the elastic part is provided with an abutting part and a second contact part, wherein the abutting part is upwards exposed in the containing hole, and the second contact part extends from the abutting part; one of the first contact part and the second contact part comprises inclination parts which are positioned on two sides and aslant extend to the other one; the other one of the first contact part and the second contact part comprises two parallel contact arms and a movable gap formed between the two contact arms for the two contact arms to retract and move oppositely; and the two contact arms are scraped and moved with the inclination parts in the contact and separation process of the fixed terminal and the movable terminal to scrap sundries between the contact positions.

Owner:KUNSHAN JIAHUA ELECTRONICS

Switch type surge protector

ActiveCN112510662AReliable groundingHigh compressive strengthEmergency protective arrangements for limiting excess voltage/currentConnection contact member materialElectrical resistance and conductanceElectrical connection

The invention discloses a switch type surge protector, which comprises a protector shell, wherein a hot melting action assembly, a piezoresistor (2) and a resistor bracket (3) for fixing the piezoresistor (2) are arranged in the protector shell, the piezoresistor (2) is fixed in the protector shell through the resistor bracket (3), the lower end of the piezoresistor (2) is provided with two protector terminals (4), two sides of the piezoresistor (2) are respectively provided with a conducting sheet (5), the hot melting action assembly comprises a fixed iron core (6) and a coil winding (7), thefixed iron core (6) is fixed on the inner wall of the protector shell, the coil winding (7) is wound outside the fixed iron core (6), and one end of the coil winding (7) is electrically connected with one protector terminal (4) of the piezoresistor (2). According to the invention, the grounding reliability of the surge protector is guaranteed, and the connection between the grounding wire and thewiring end of the surge protector is prevented from loosening after being pulled.

Owner:扬州浪涌电气有限公司

an ffc connector

ActiveCN108376848BAvoid the phenomenon of "getting down"Increase contact forceCoupling device connectionsRotational axisEngineering

The invention discloses a FFC connector comprising the following parts: an insulation housing with a FFC flat cable insert port arranged on one side, and the other side is provided with a plurality ofconnecting terminal mount holes arranged at intervals; the FFC flat cable inserted in the FFC flat cable insert port; connecting terminals inserted in the connecting terminal mount holes; an insulation gland with two ends respectively having a rotary shaft, the insulation gland is arranged on the insulation housing in an overturn manner, and can be folded to cover the FFC flat cable; two positioning pieces respectively inserting into plug holes arranged on two ends of the insulation housing, the positioning piece is provided with a rotary groove matched with the rotary shaft, and provided with a limit portion that stops the insulation gland from continuously rotating downwards when the insulation gland rotates to the horizontal level. The FFC connector is provided; the positioning piece is provided with the limit portion that stops the insulation gland from continuously rotating downwards when the insulation gland rotates to the horizontal level, thus preventing the insulation gland from having a bending phenomenon caused by excessive rotations.

Owner:乐清市华宝电子有限公司

Method and means for evaluating toric contact lens rotational stability

ActiveUS11509755B2Easy to inexpensiveEasy to utilizeEye diagnosticsMountingsAmbient lightingOphthalmology

The present invention is directed to a method and means for enabling contact lens wearers to photograph their own eyes using an electronic device with a camera such as an iPhone with a macro lens, for example, Olloclip® Macro Pro Lens Set 7× lens, and a custom three-dimensional printed eyecup attachment. The eyecup attachment is designed to position the camera at a suitable and reproducible distance from the eye to ensure that the system can focus appropriately on the lens details. The eyecup attachment also serves to block stray light and diffuse the ambient lighting. In addition, the eyecup attachment ensures that the camera is held in the correct orientation while photos are being captured. The capture images are analyzed using image processing software to determine the angel of rotation of the contact lens.

Owner:JOHNSON & JOHNSON VISION CARE INC

Resistance testing equipment

PendingCN109870612AImprove reliabilityIncrease credibilityResistance/reactance/impedenceMeasurement instrument housingElectrical resistance and conductanceEngineering

The invention discloses resistance testing equipment. The equipment comprises a first pressure part, a first supporting part, a pressure control device, a pressure sensor and a testing module, whereinthe first pressure part is positioned above the first supporting part and opposite to the first supporting part; a contact interface when the first pressure part is in contact with the first supporting part is a line-line interface, a point-point interface or a point-line interface; the pressure control device is connected with the first pressure part and / or the first supporting part; the pressure sensor is connected with the first pressure part and / or the first supporting part; the testing module is a resistance testing module, or a voltage testing module and / or a current testing module; andthe first pressure part and the first supporting part are connected with the resistance testing module, or the voltage testing module and / or the current testing module. The equipment is used for performing intermittent testing or real-time testing on all areas or designated areas of a test object.

Owner:川源科技(苏州)有限公司

A protective cover structure for an electric vehicle vertical charging pile

ActiveCN108538338BPrevent static electricityAvoid feverInstrument housingStructural engineeringElectric vehicle

The invention provides a protection cover structure for a vertical charging pile for electric vehicles. The structure comprises a charging pile body; the side wall of the charging pile body is provided with installing grooves; the side, facing the outside of the charging pile body, of each installing groove is provided with a stop groove; the top of the charging pile body is sleeved with a protection cap; the side surface of the protection cap is provided with a baffle plate; an installing plate is arranged under the protection cap; the installing plate is provided with installing holes corresponding to the installing grooves in position; two parallel clamping rods with the relative distance being elastically adjustable are arranged in the installing holes and the installing grooves; the ends, in the installing grooves, of the clamping rods are provided with stop blocks which can be clamped into the installing grooves from the stop grooves. The protection cap can shield a charging pileagainst wind, water and sunlight, so that the service life of the charging pile is increased; the clamping rod can be used for the installation of the charging pile, and the protection cap is convenient to install; the clamping rods can buffer and absorb shock, so that the service life of the charging pile is prolonged, the contact stability of the charging pile and an electric vehicle is improved, the charging efficiency is increased and the safety of a power source in the electric vehicle can be protected.

Owner:KERUN ELECTRIC POWER TECH CO LTD

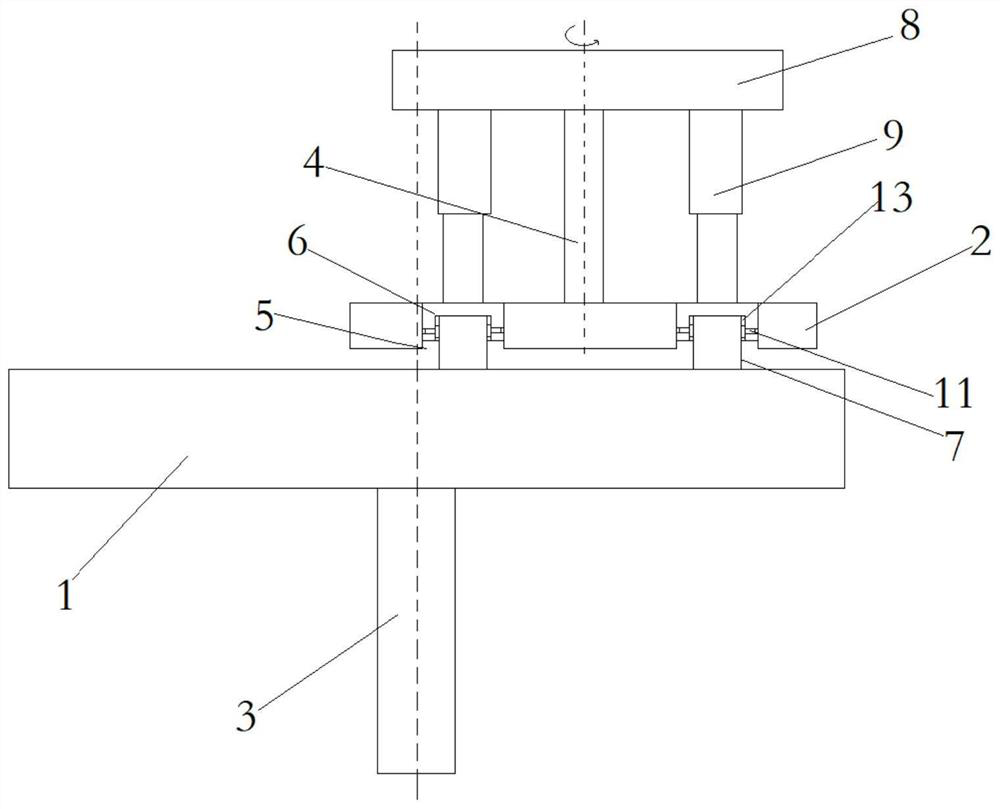

A planetary grinding device and grinding method for a plane optical element

ActiveCN111702653BGrinding speed is fastGuaranteed flatnessOptical surface grinding machinesLapping machinesPhysicsGrinding process

The invention discloses a planetary grinding device and a grinding method for a plane optical element. By arranging the lower end surface of the workpiece disk parallel to the upper end surface of the grinding table, the grinding table and the workpiece disk can rotate differently from each other. A plurality of fixture positioning holes, a plurality of fixture positioning holes are arrayed around the axis of the drive shaft of the workpiece disc, and the optical element to be processed is clamped by the fixture, and the end surface to be polished of the optical element to be processed is aligned with the grinding surface after being limited by the workpiece disc. End surface contact, and finally adjust the pressure between the optical element to be processed and the grinding table through the pressure device to ensure the contact stability between the optical element to be processed and the grinding table. The structure of this device is simple. The movement mode rotates with each other, which greatly improves the grinding speed of the planar optical element. During the grinding process, the same pressure is maintained in real time by the pressure device, which ensures the flatness of the workpiece processing and improves the processing efficiency of the entire processing process.

Owner:XI AN JIAOTONG UNIV

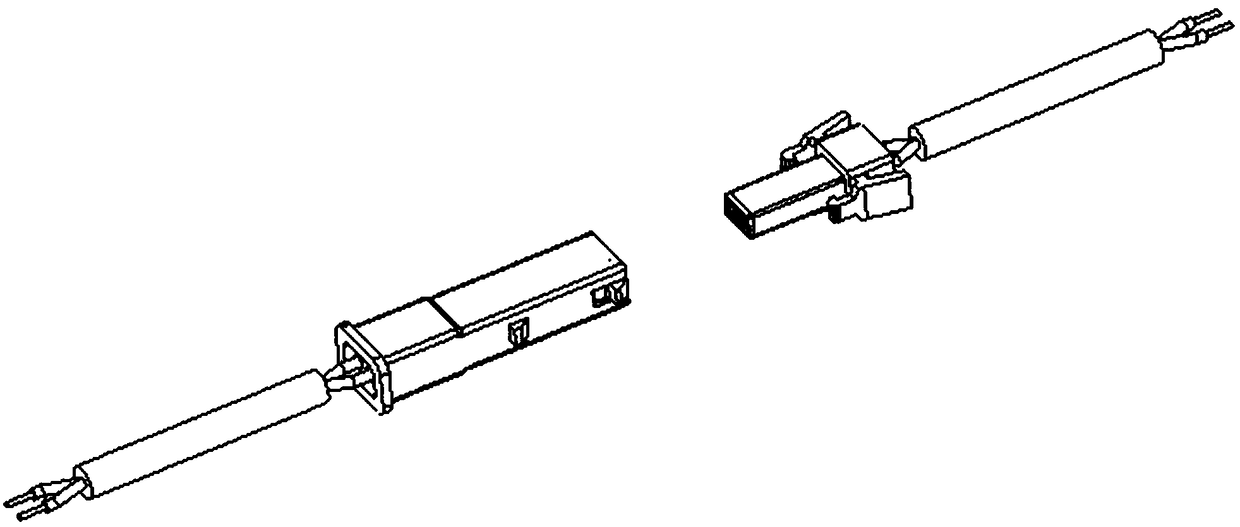

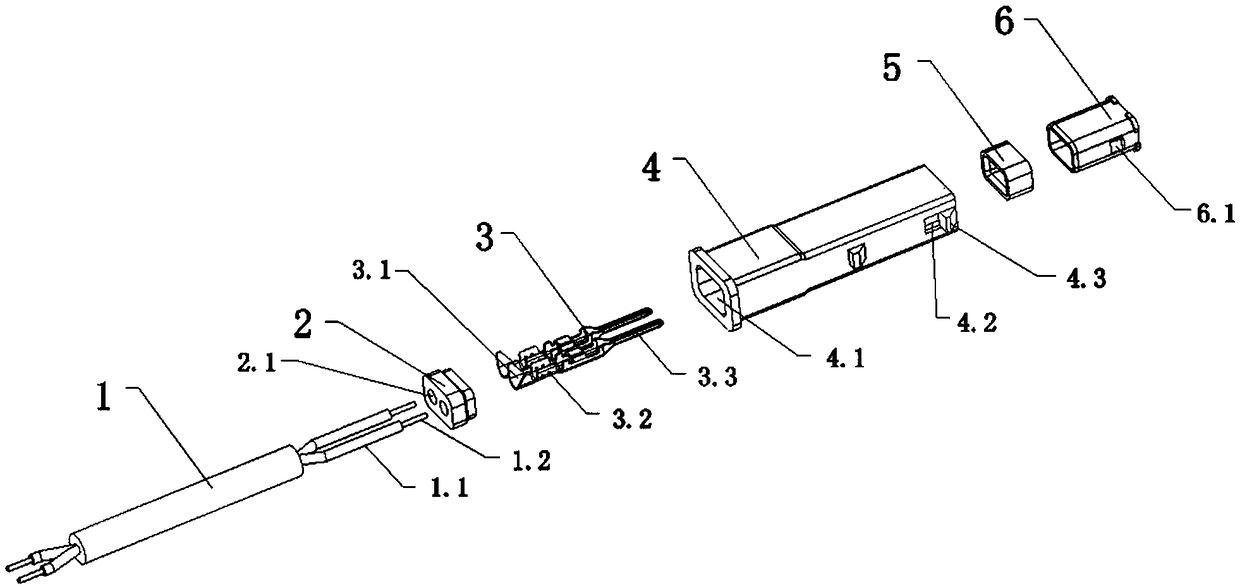

A waterproof connector

ActiveCN106785655BWith waterproof functionWith foolproof functionCouplings bases/casesTwo-part coupling devicesMechanical engineeringEngineering

Owner:NINGBO CONNFLY ELECTRONIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com