Patents

Literature

41results about How to "Assembly influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

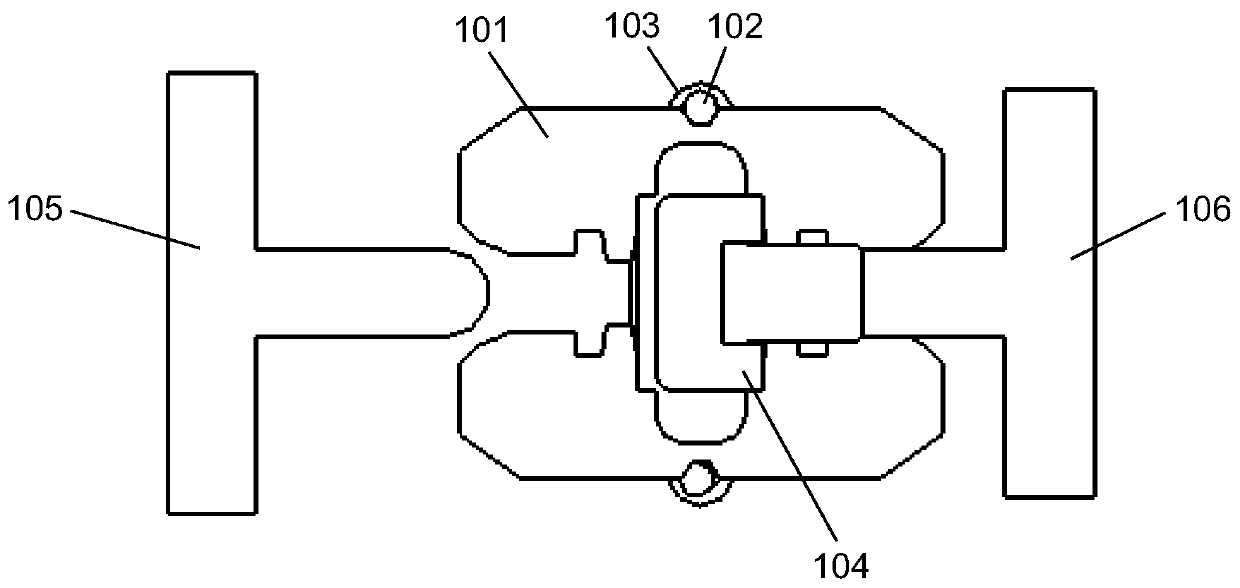

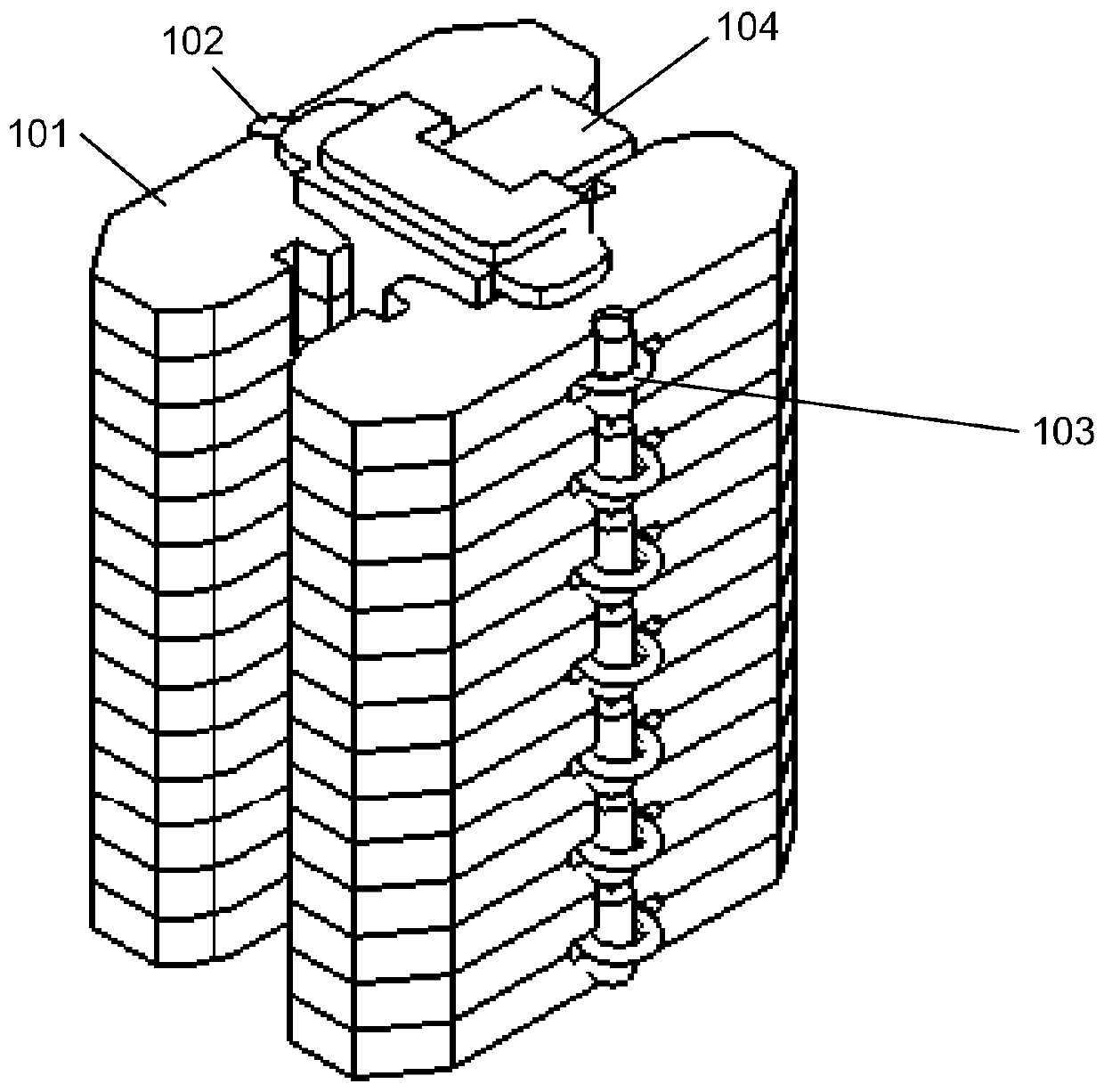

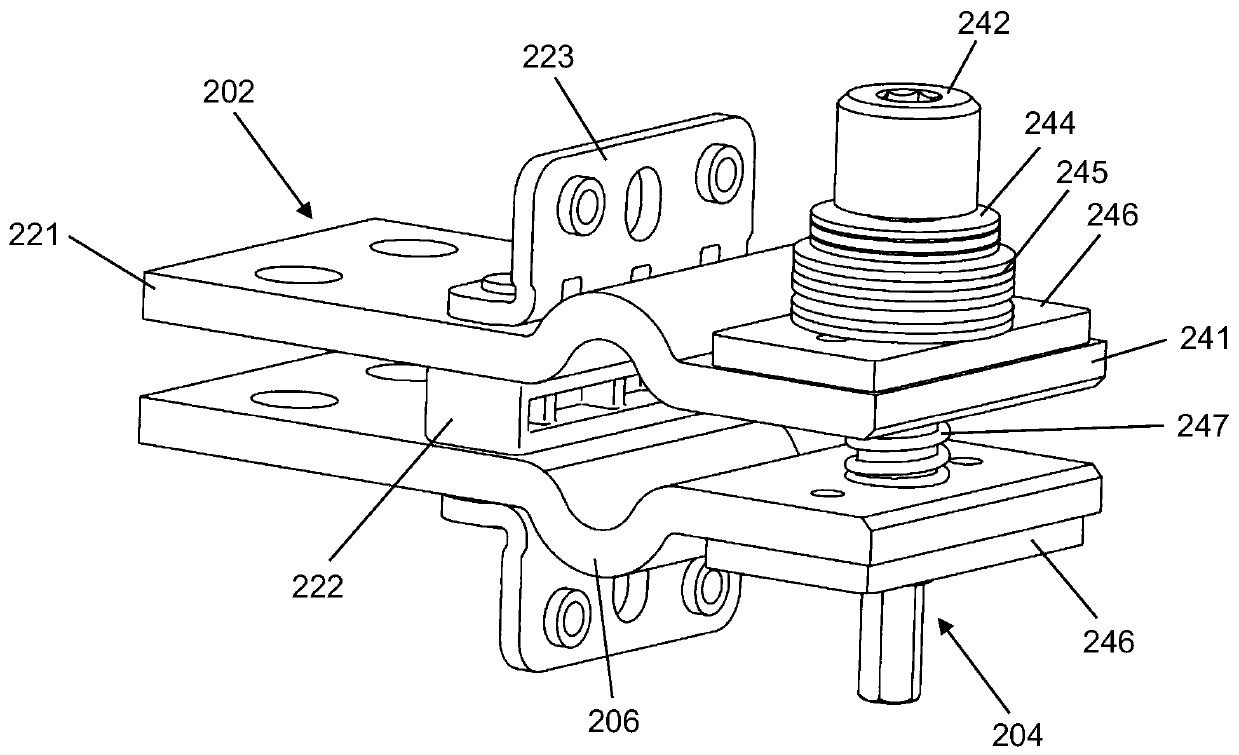

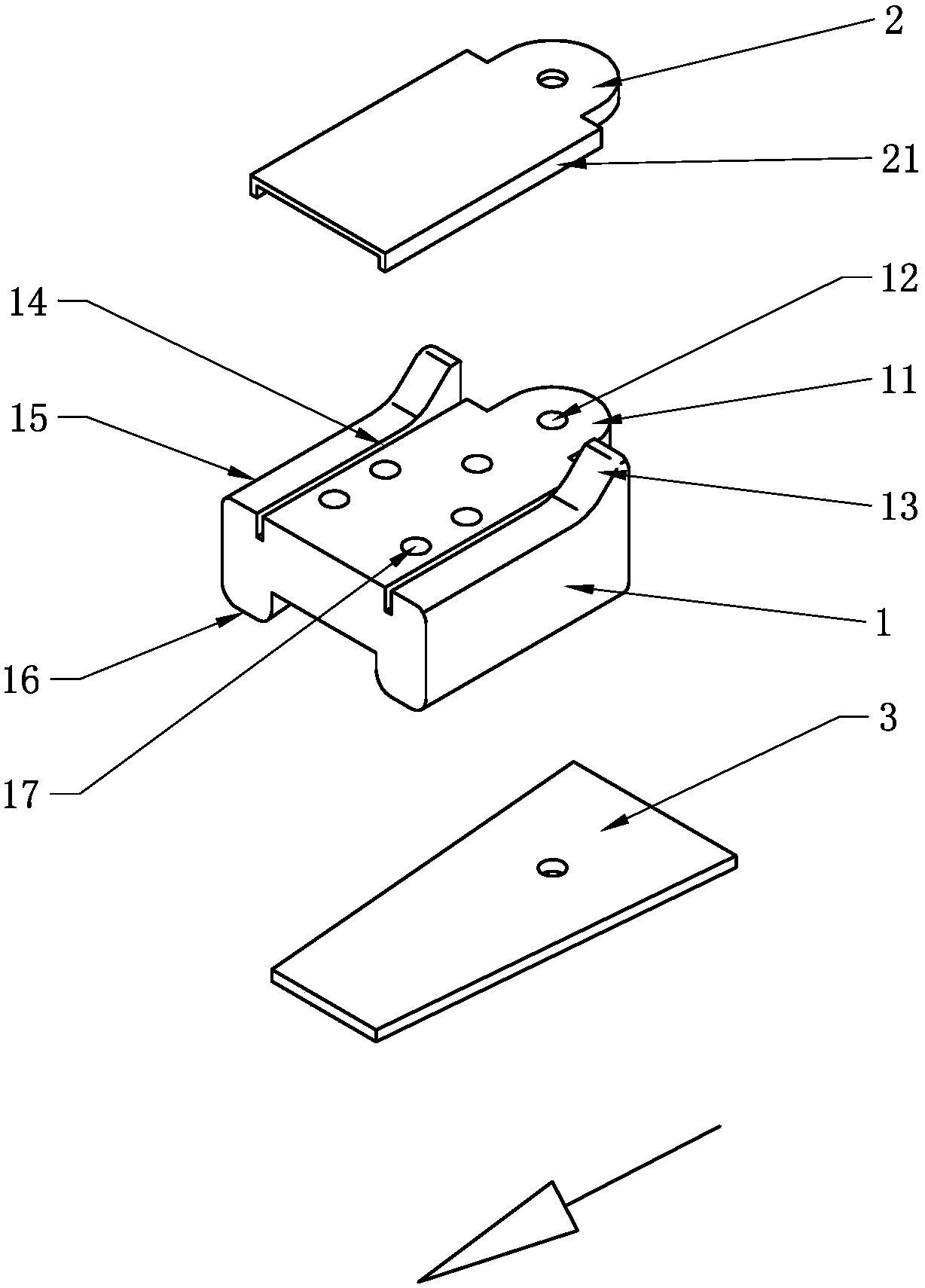

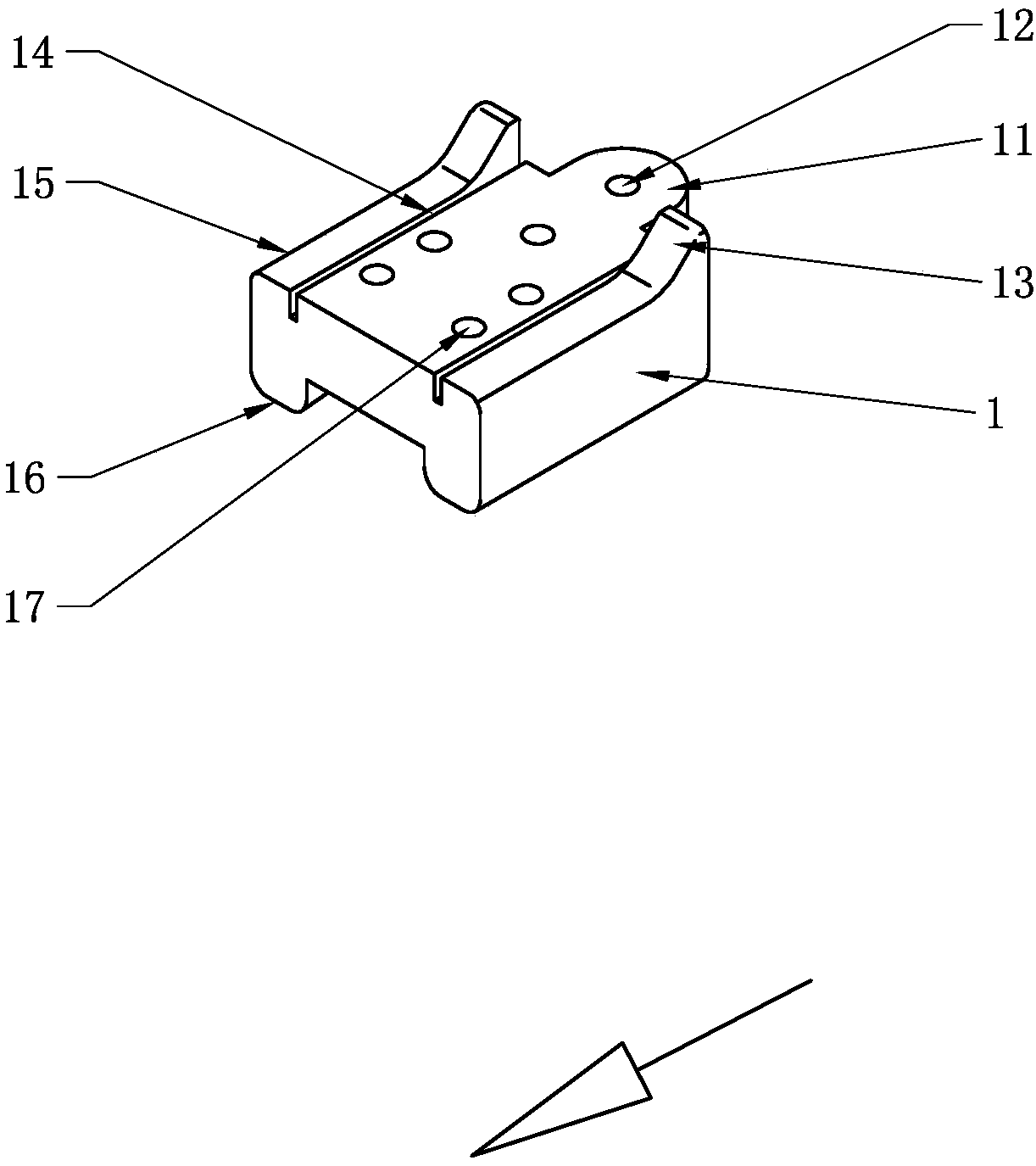

Electric appliance device and linkage electric connection assembly thereof

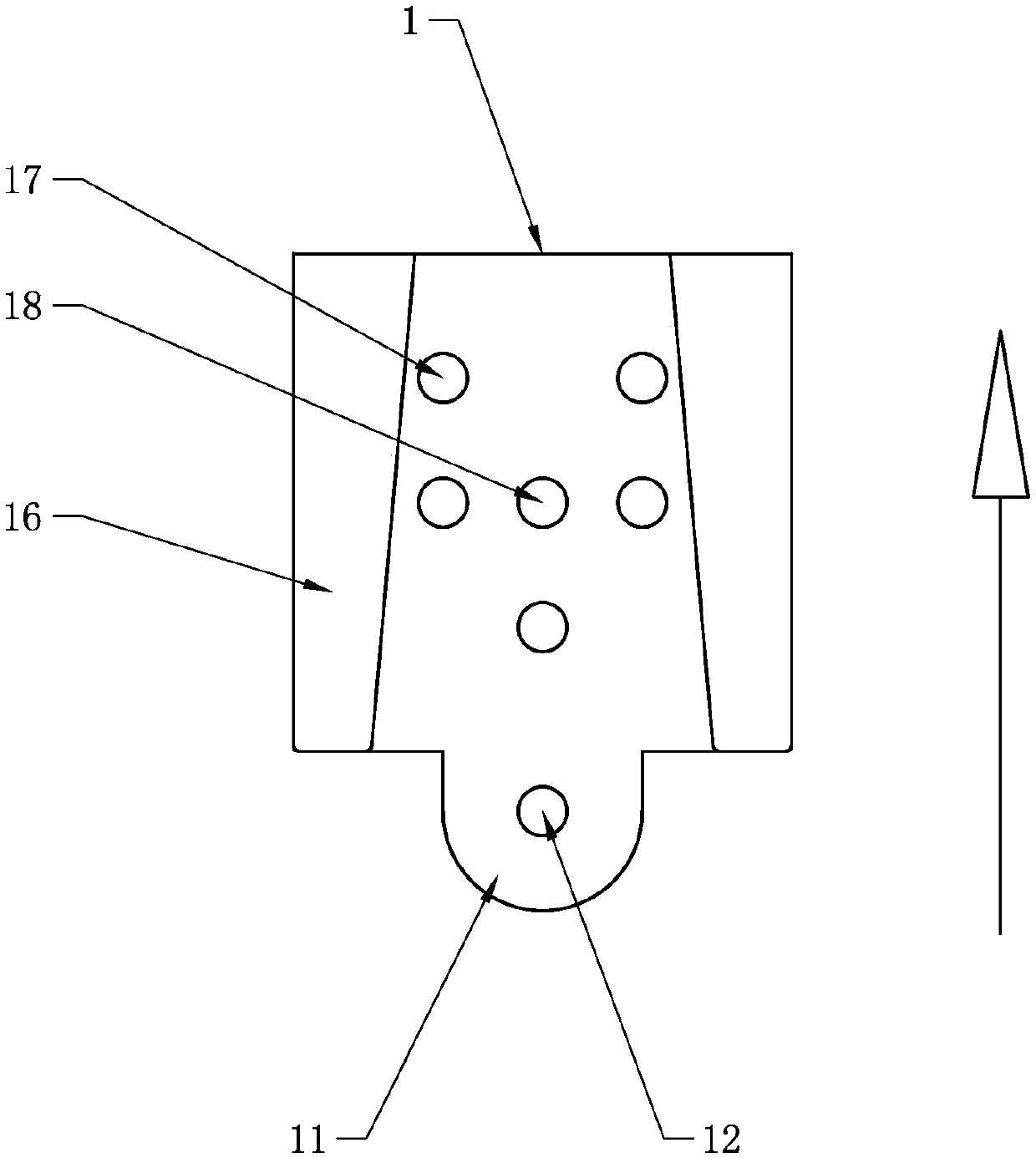

PendingCN111403938AAssembly influenceFully clingingSwitchgear with horizontal withdrawalSwitchgear detailsBusbarElectrical connection

Owner:SHANGHAI LEADING CONNECTION MECHATRONICS TECH CO LTD +1

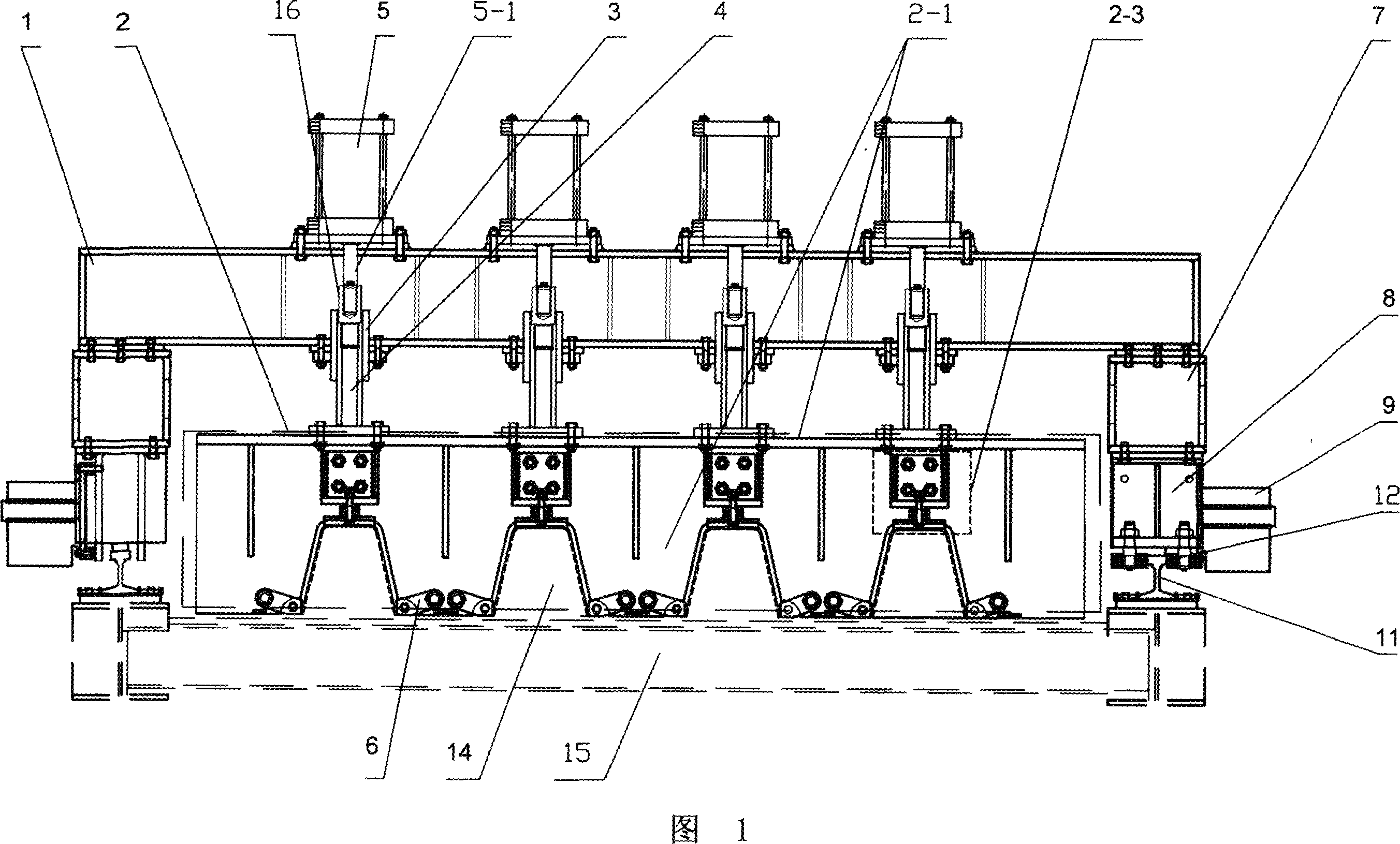

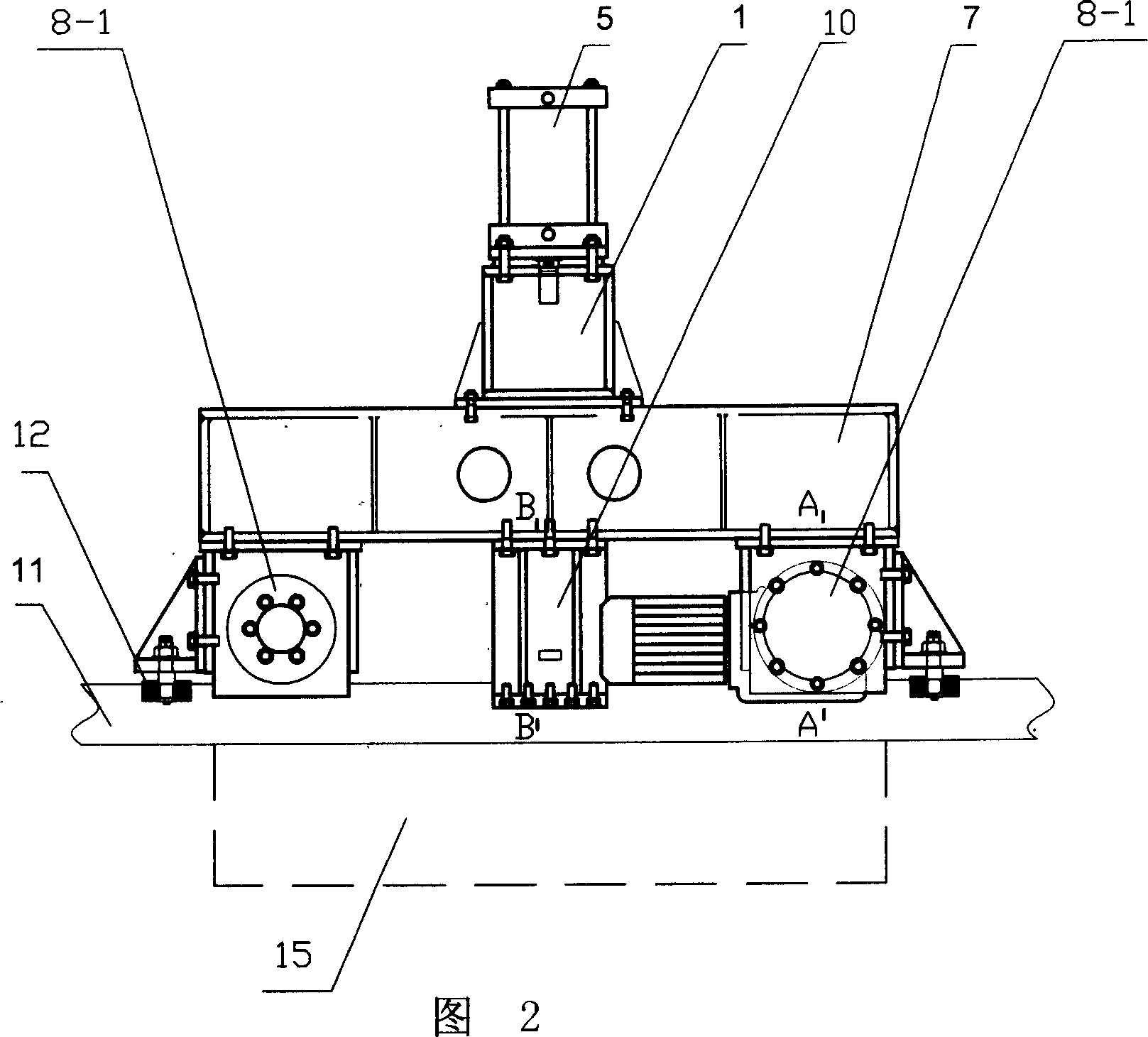

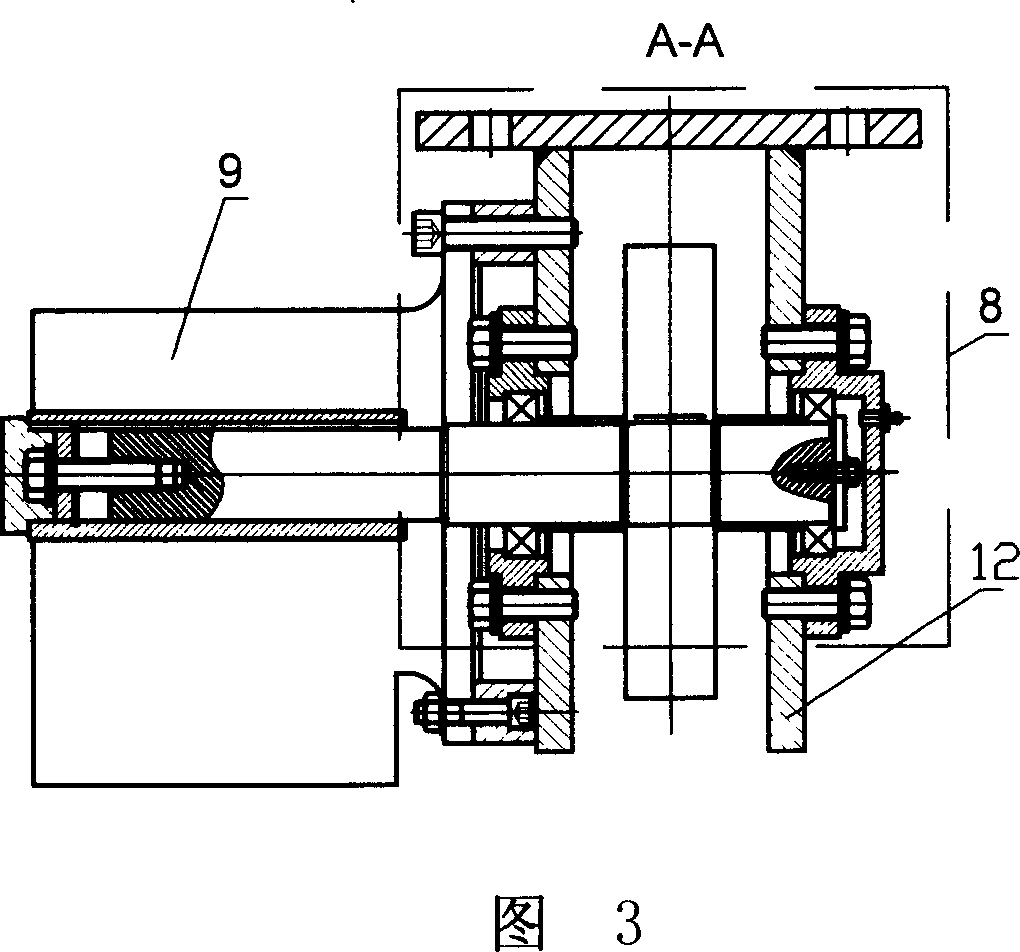

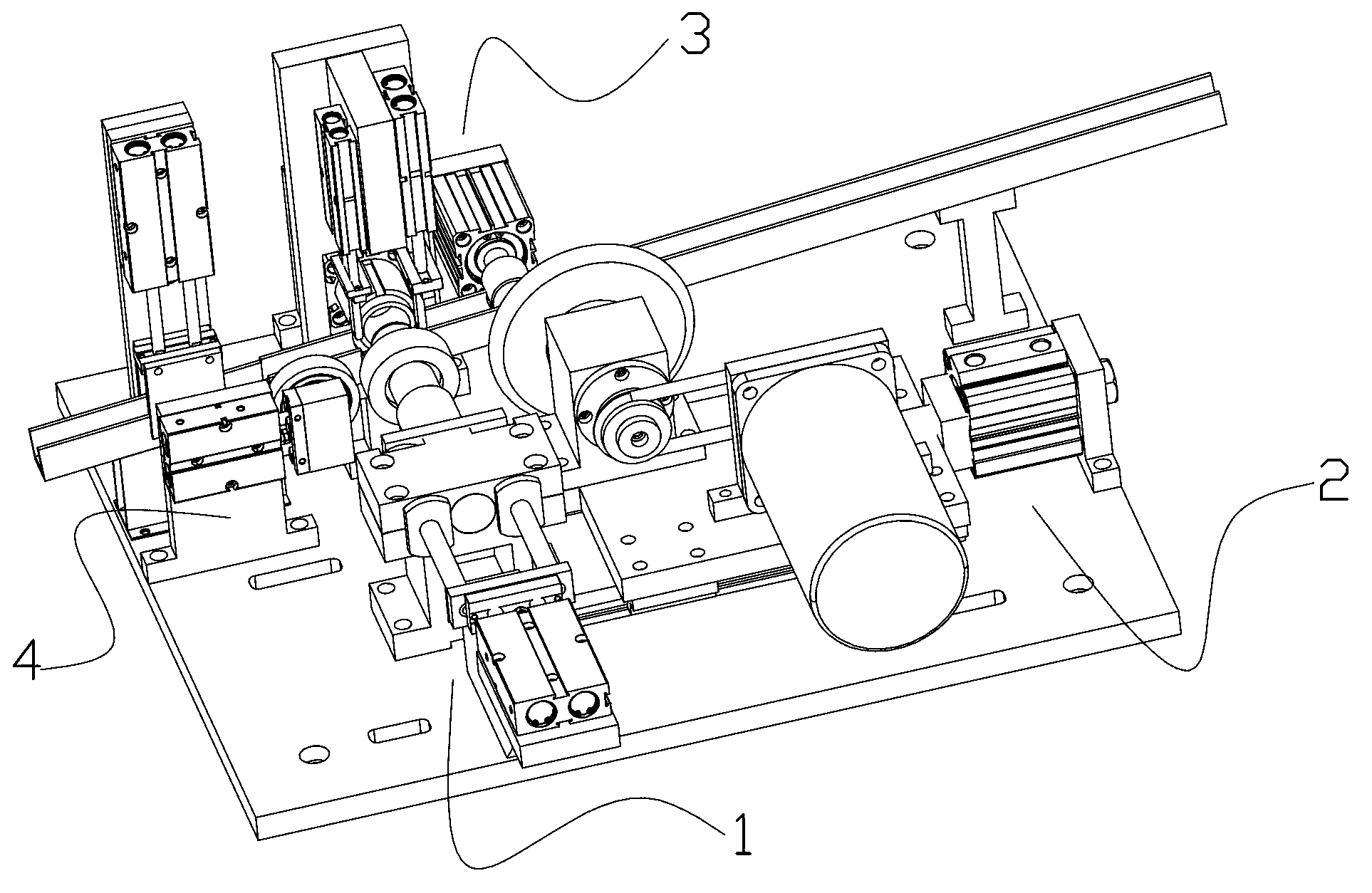

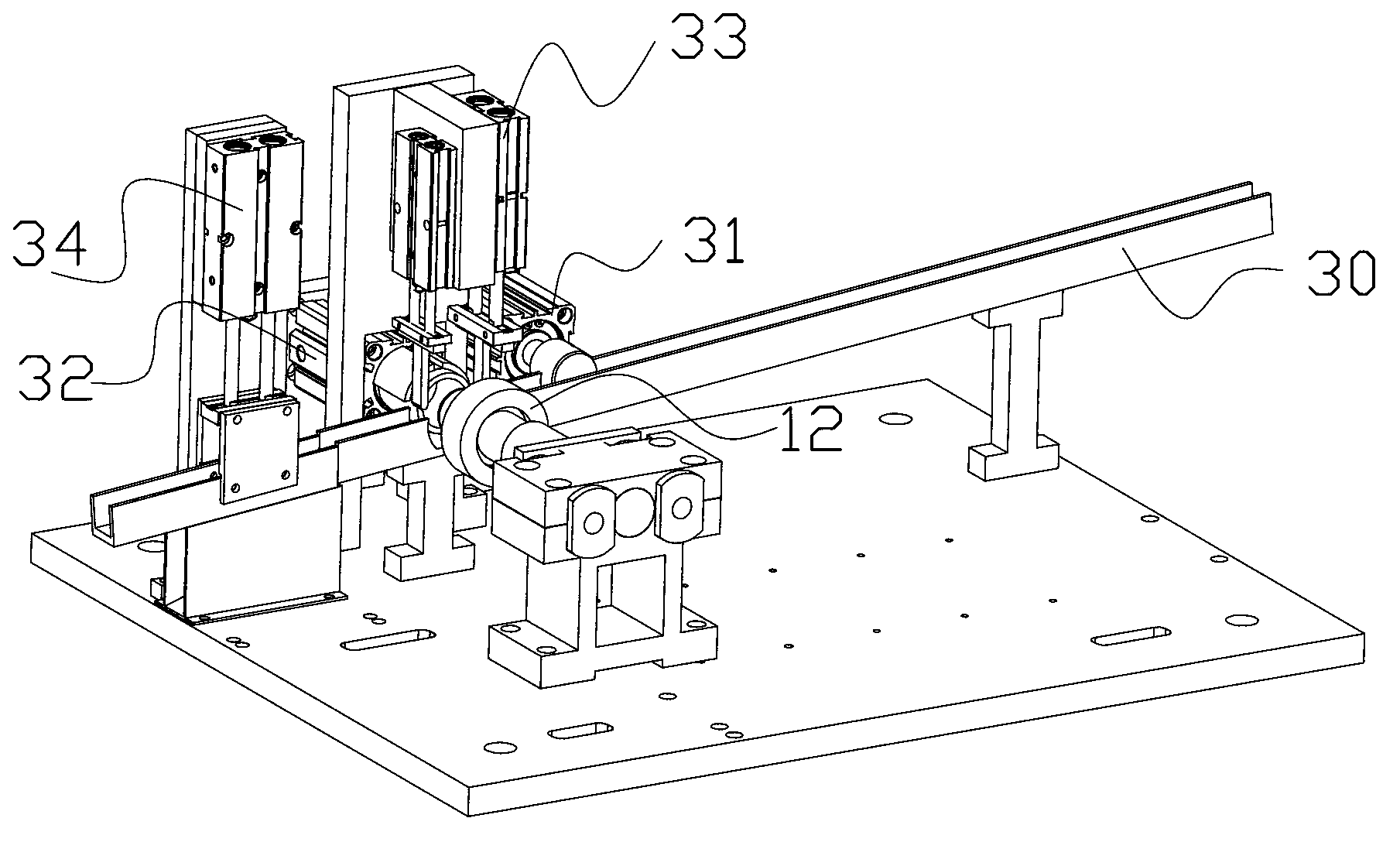

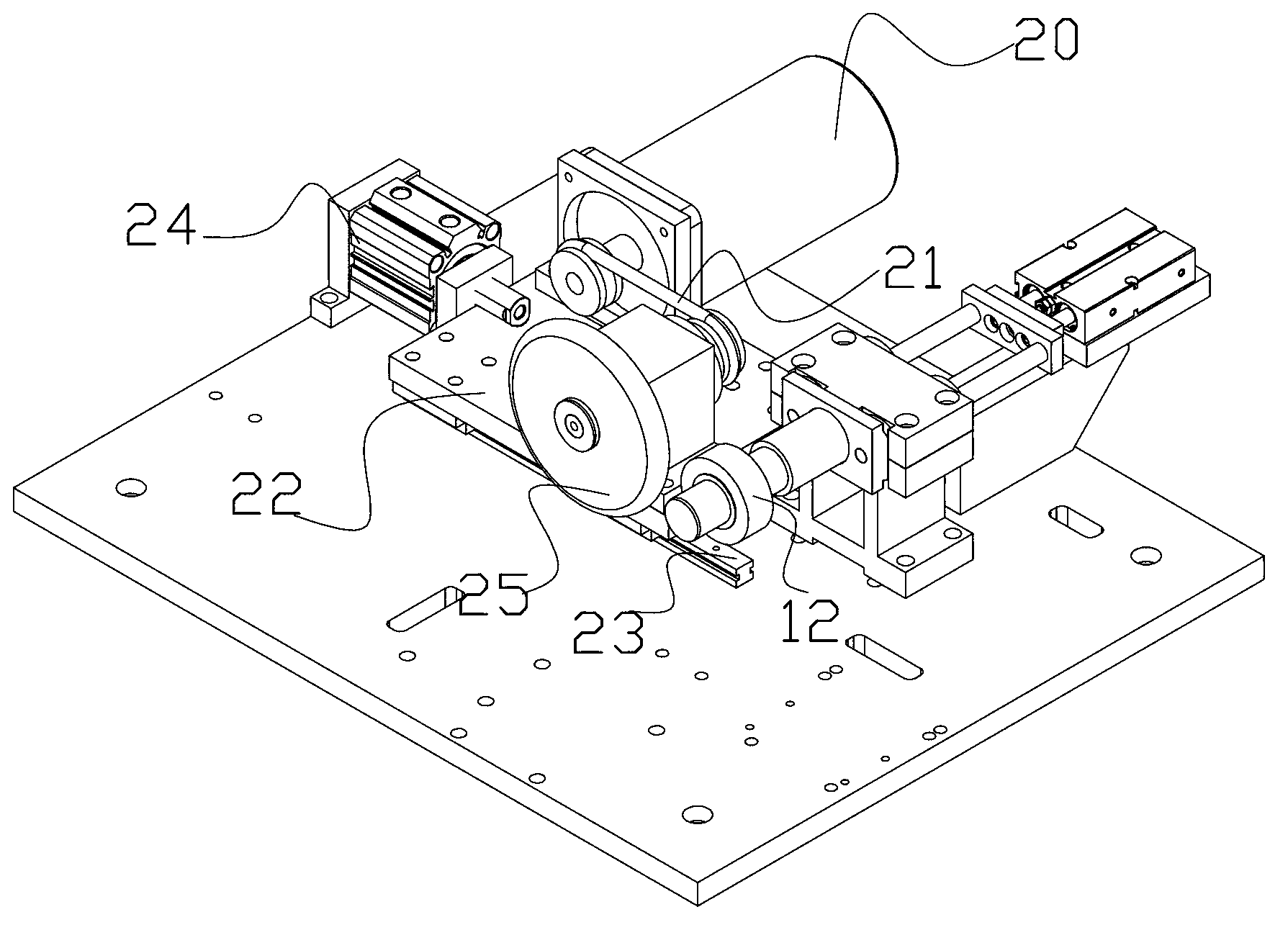

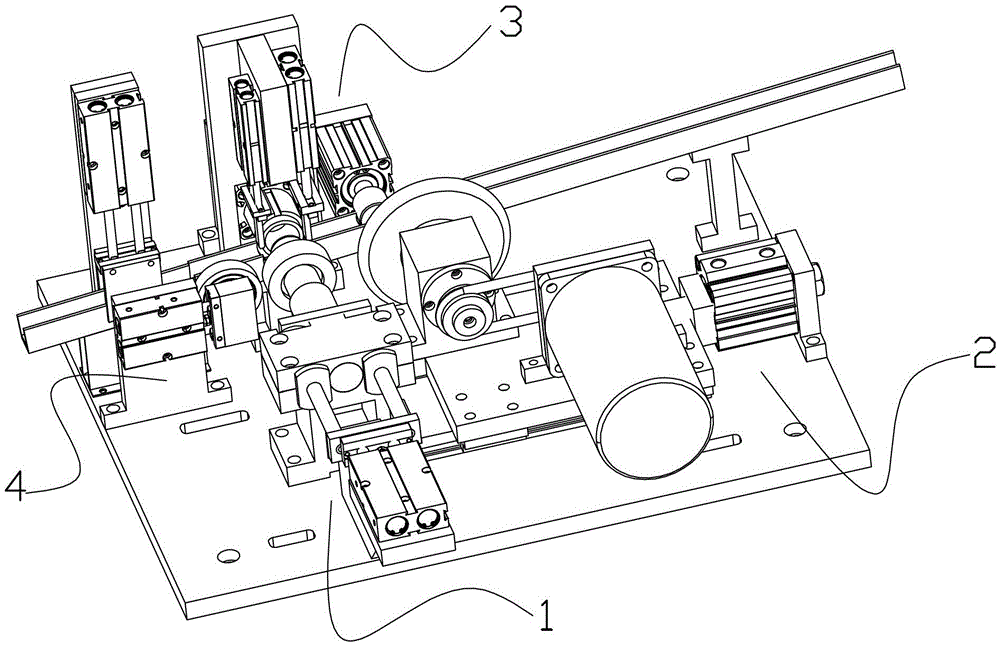

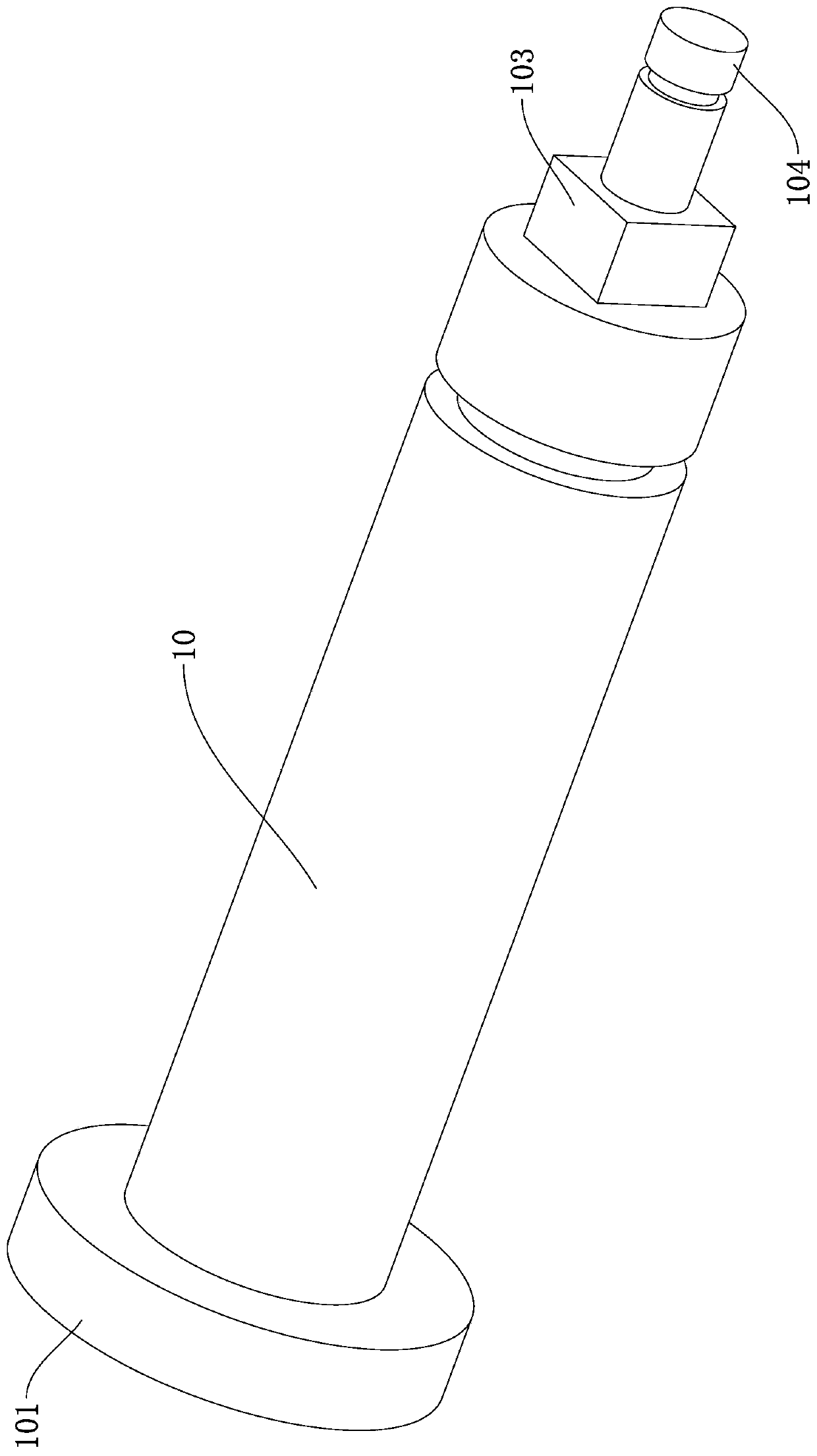

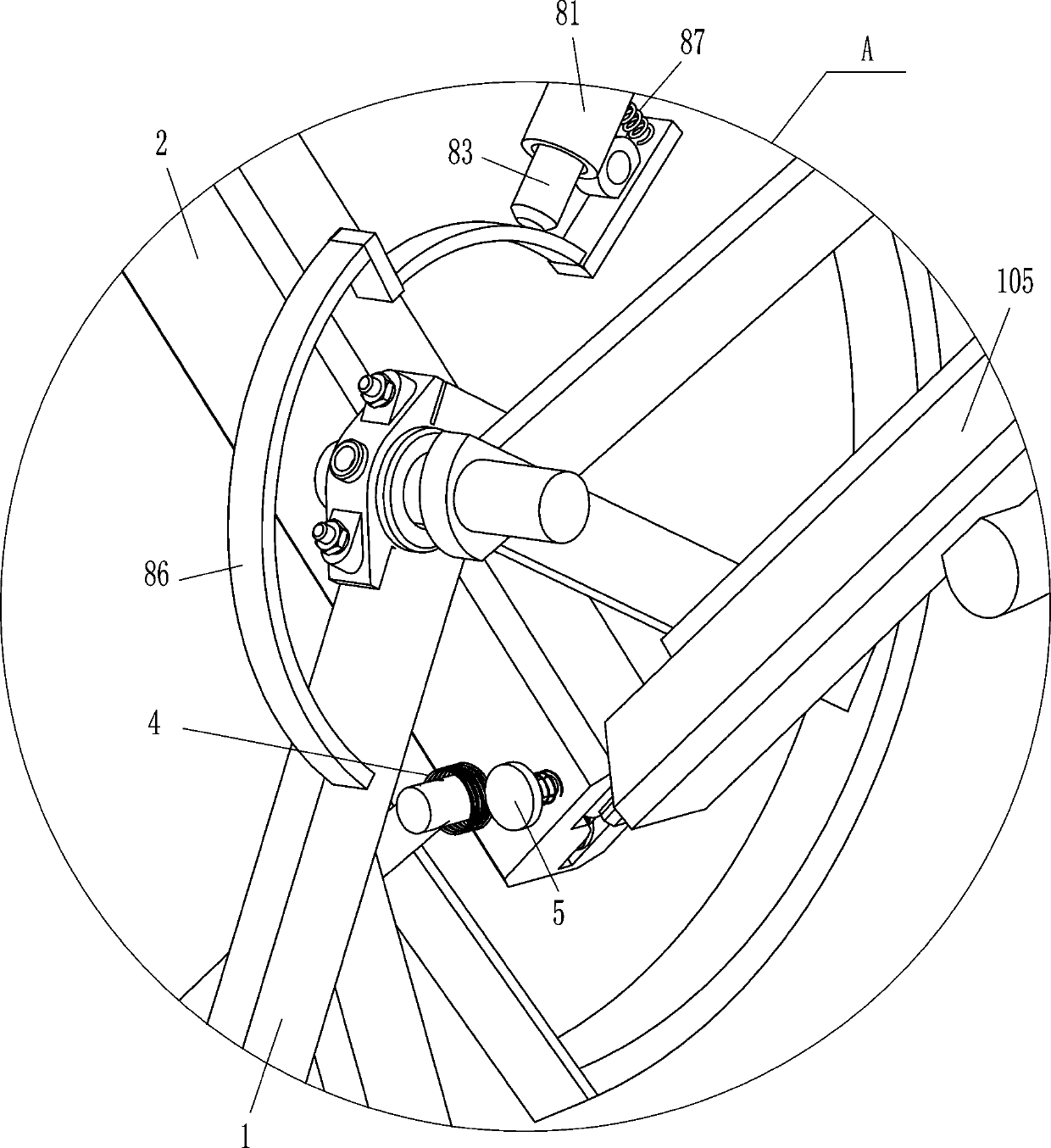

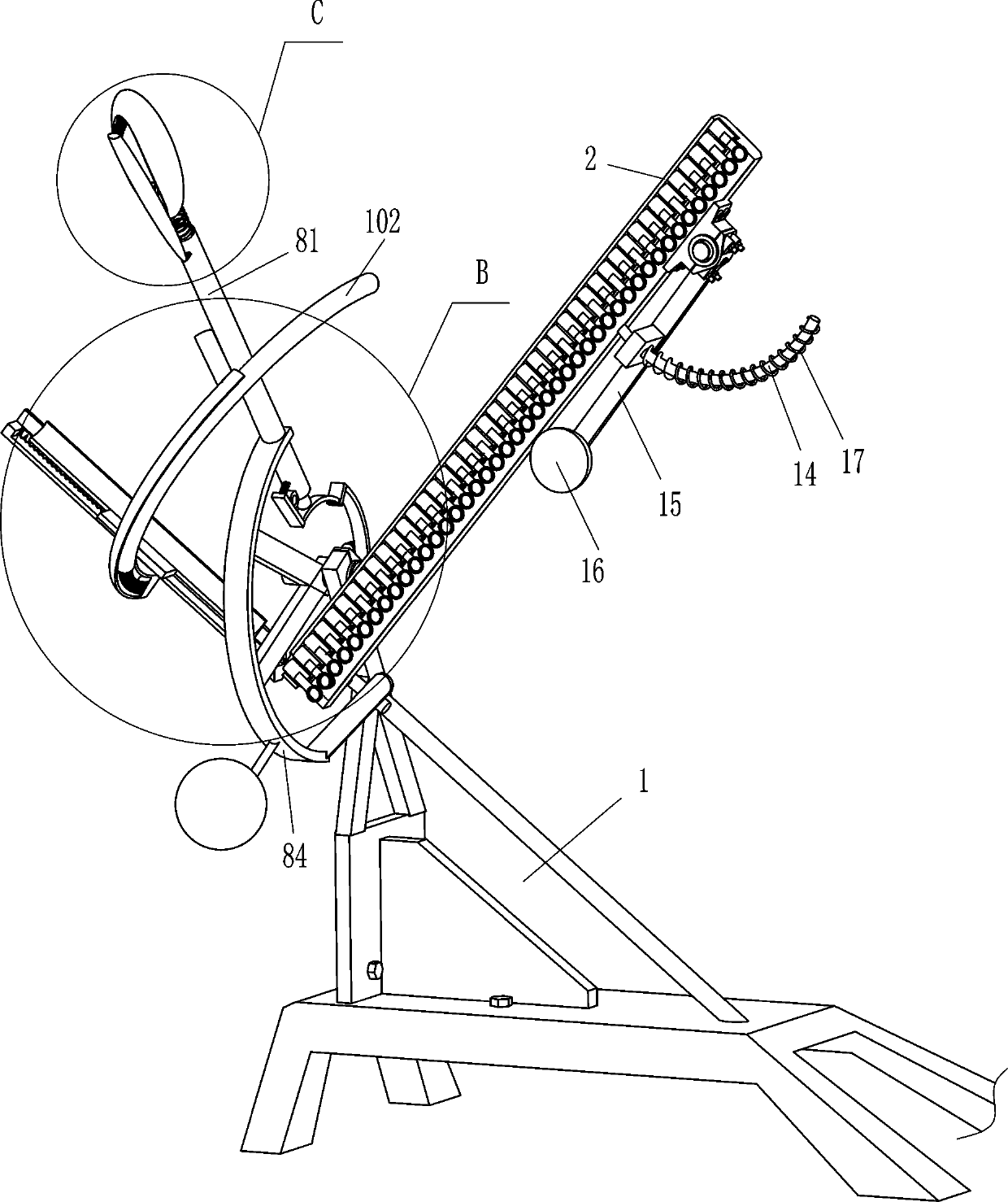

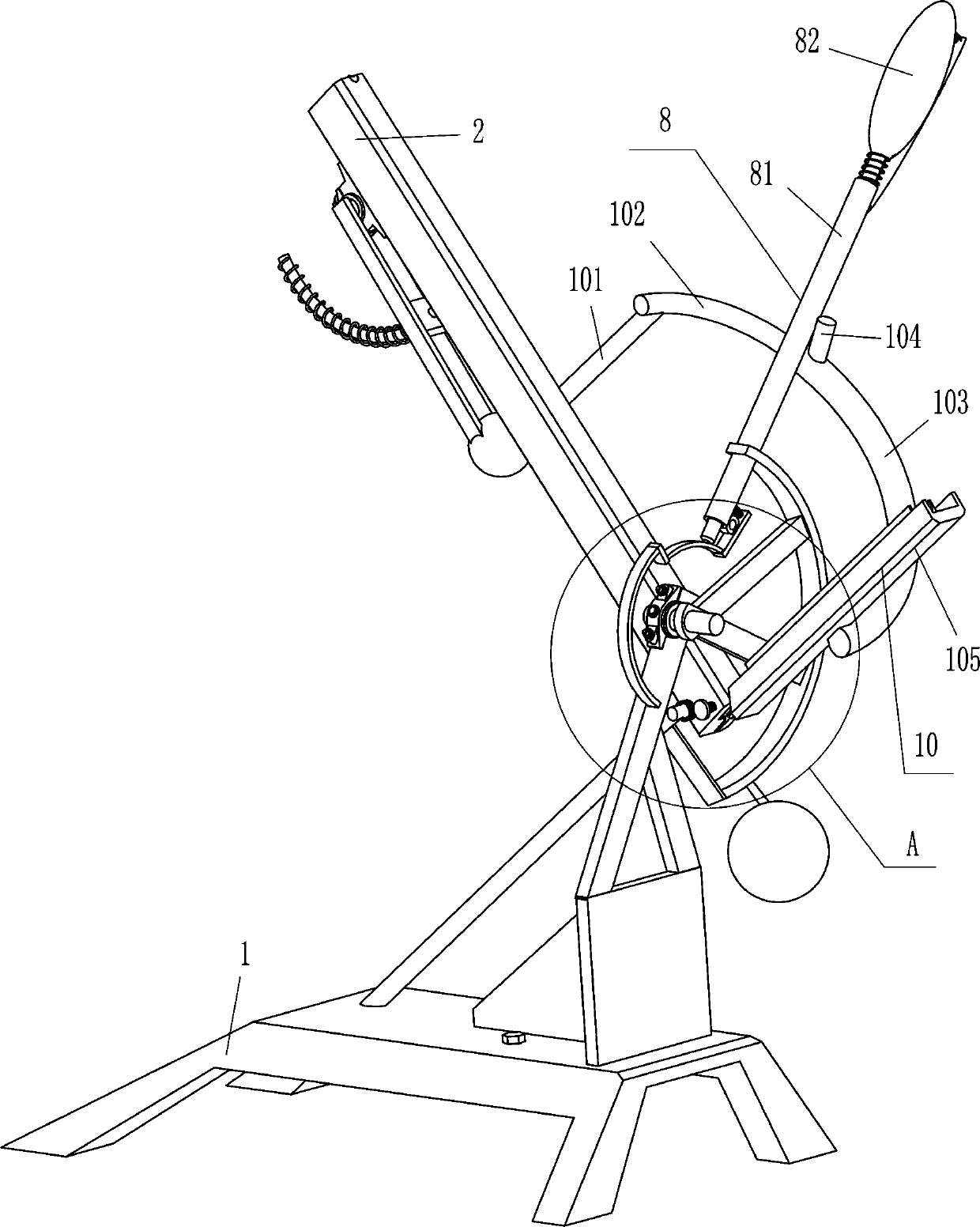

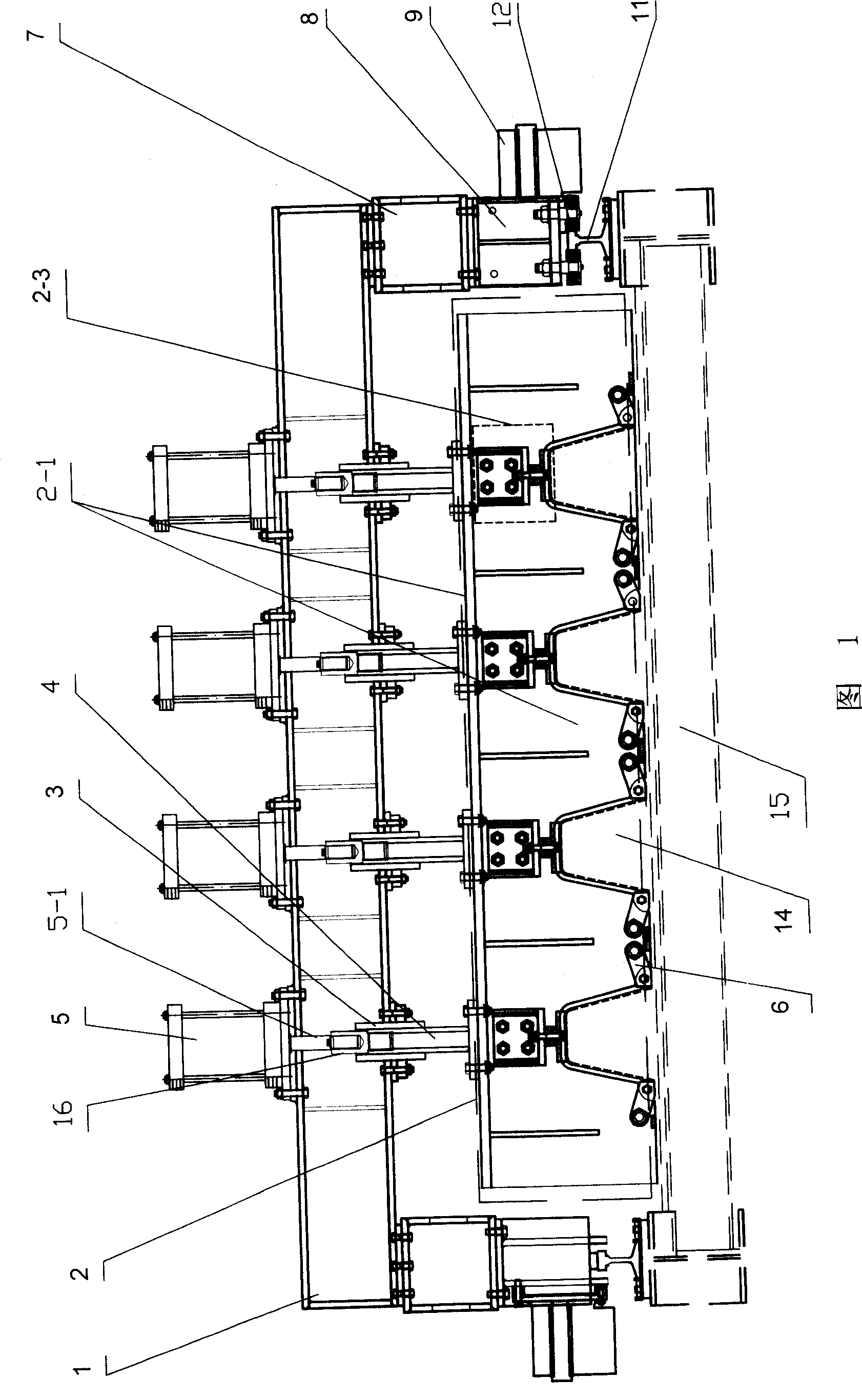

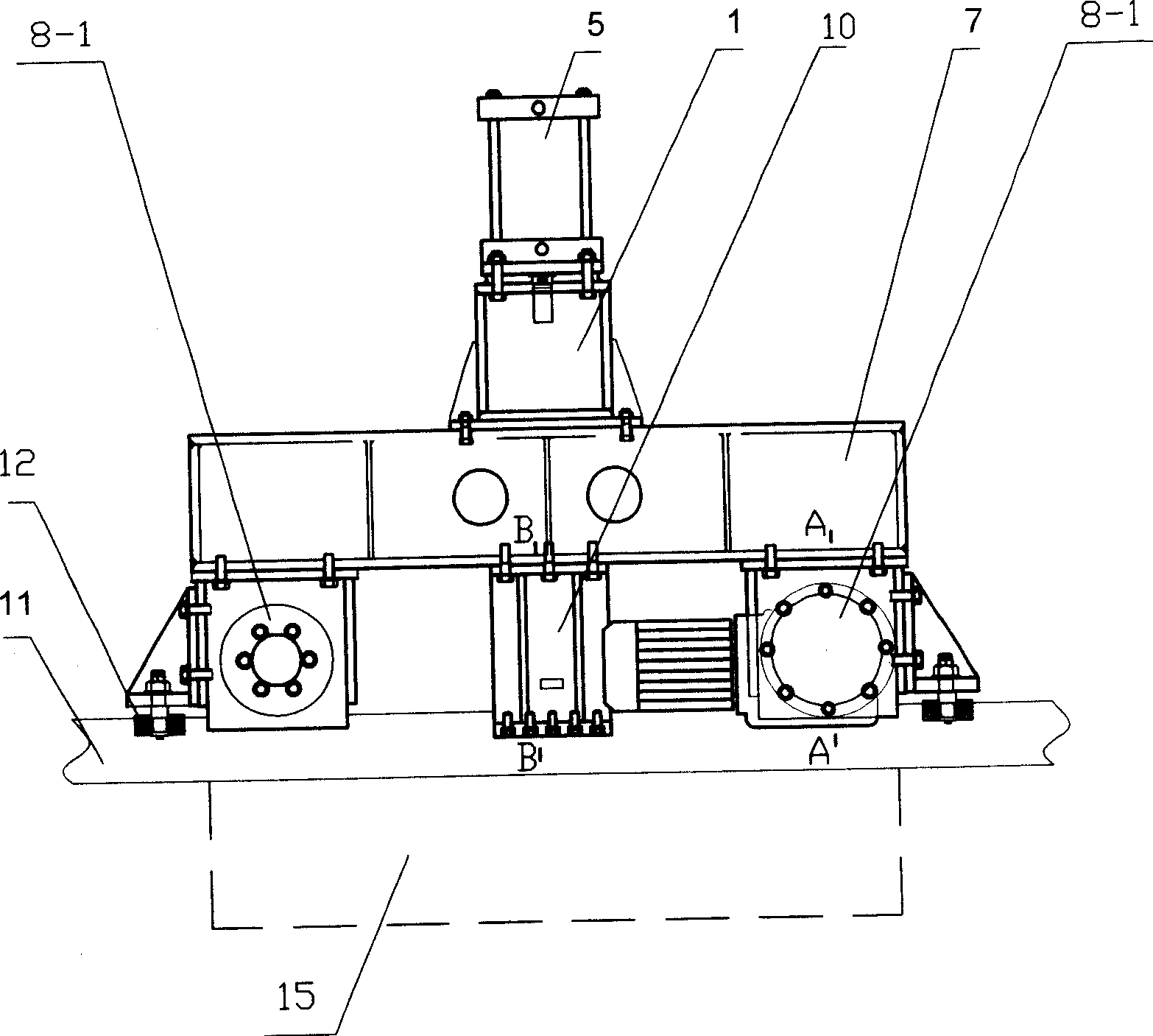

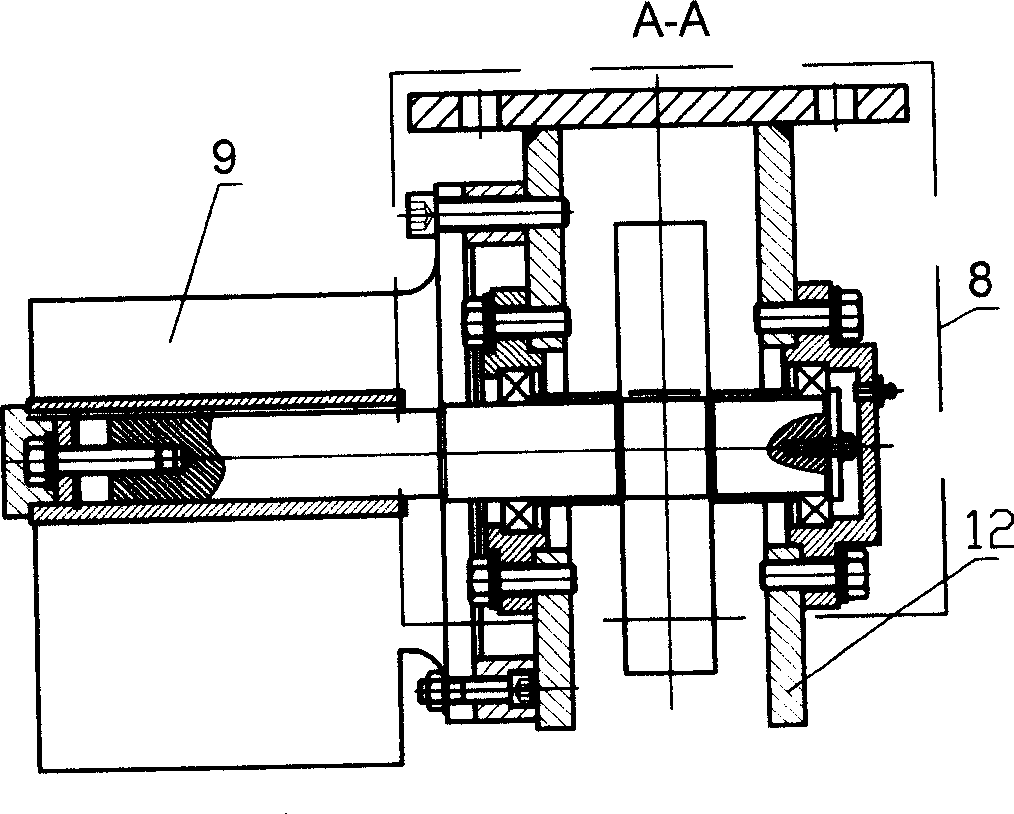

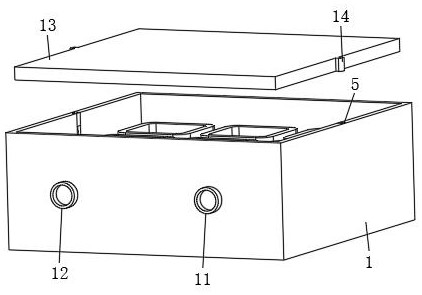

Electric pneumatic type machine for assembling U-shaped ribs of plate units

ActiveCN1947926AReduce or eliminate direct effectsExtended service lifeMetal working apparatusEngineeringPiston rod

An electrically pneumatic assembling machine for assembling the U-shaped rib onto the unit plate used for the steel structure of bridge is composed of a transverse beam, a formwork module under said transverse beam, the guide sleeves fixed to said transverse beam, the guide rods in said guide sleeves and connected between formwork module and piston rod of cylinder, and the cylinders fixed to said transverse beam.

Owner:WUCHUAN HEAVY ENG

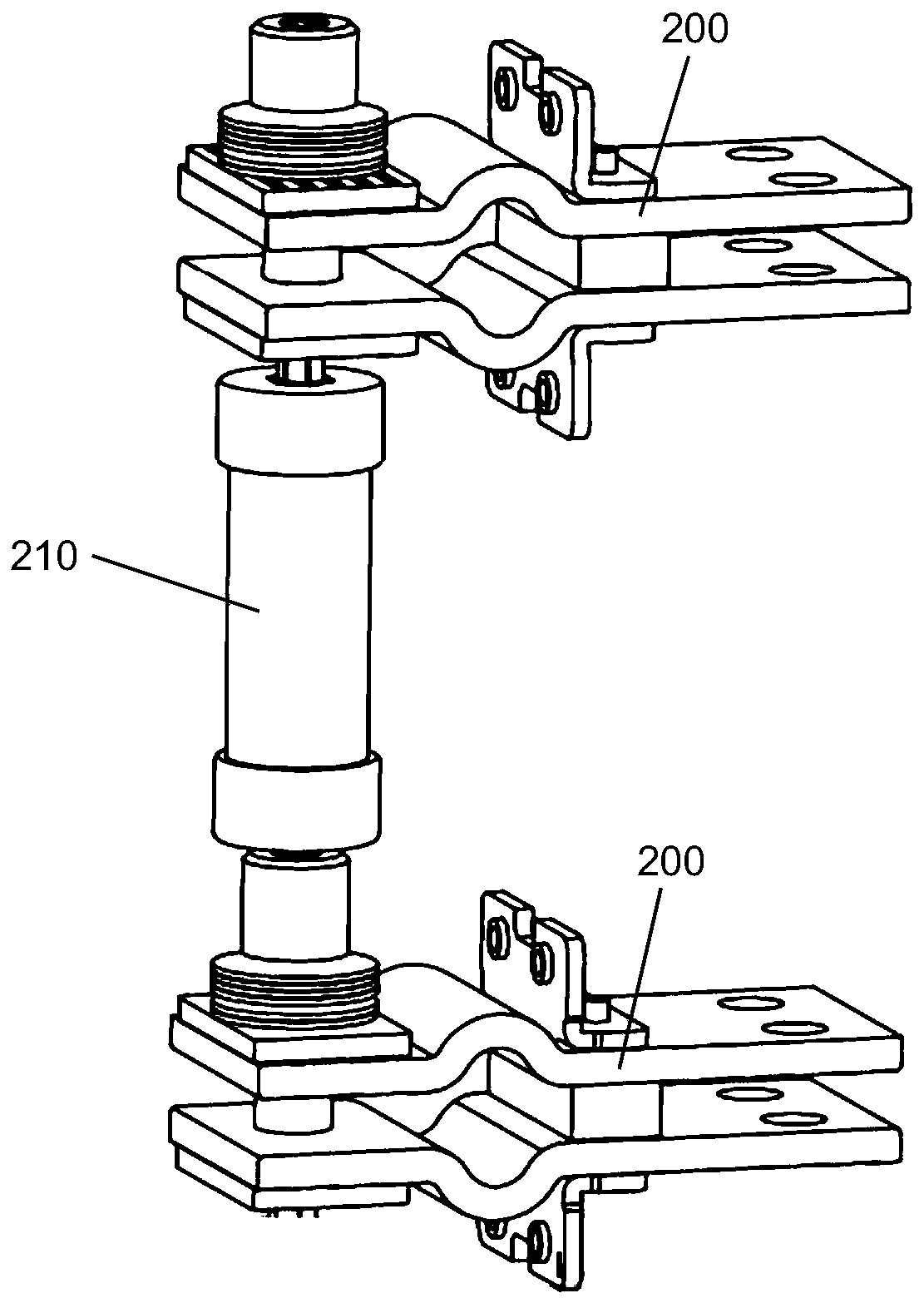

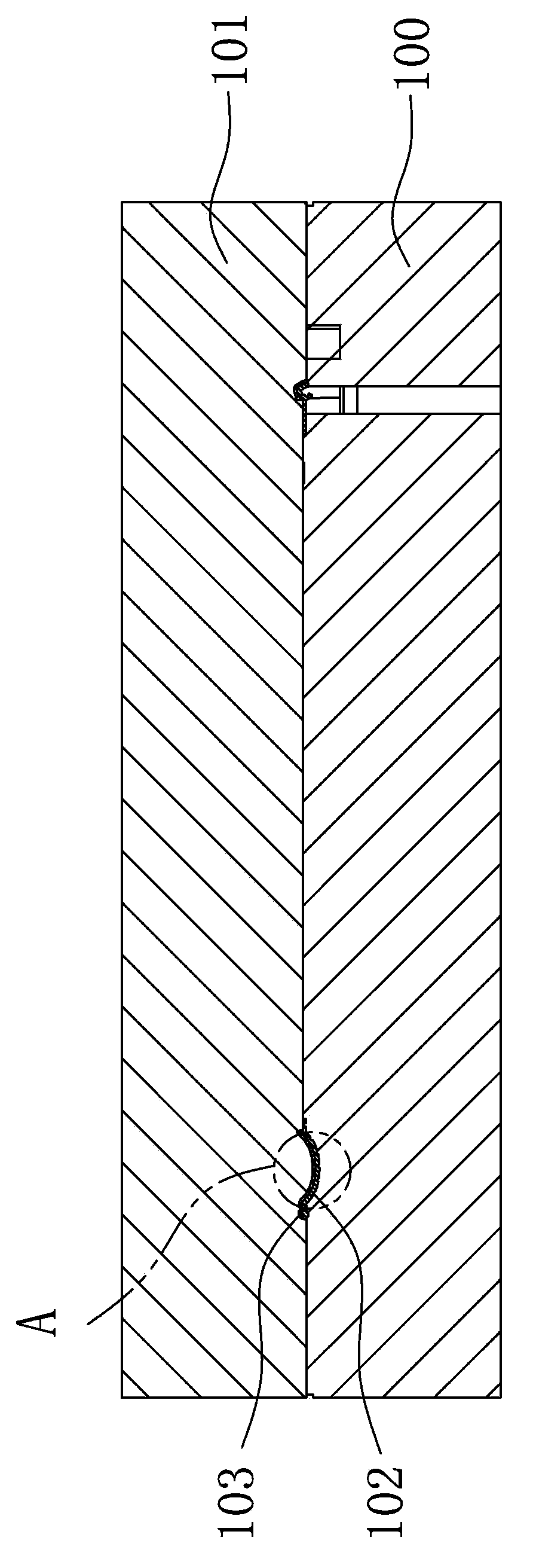

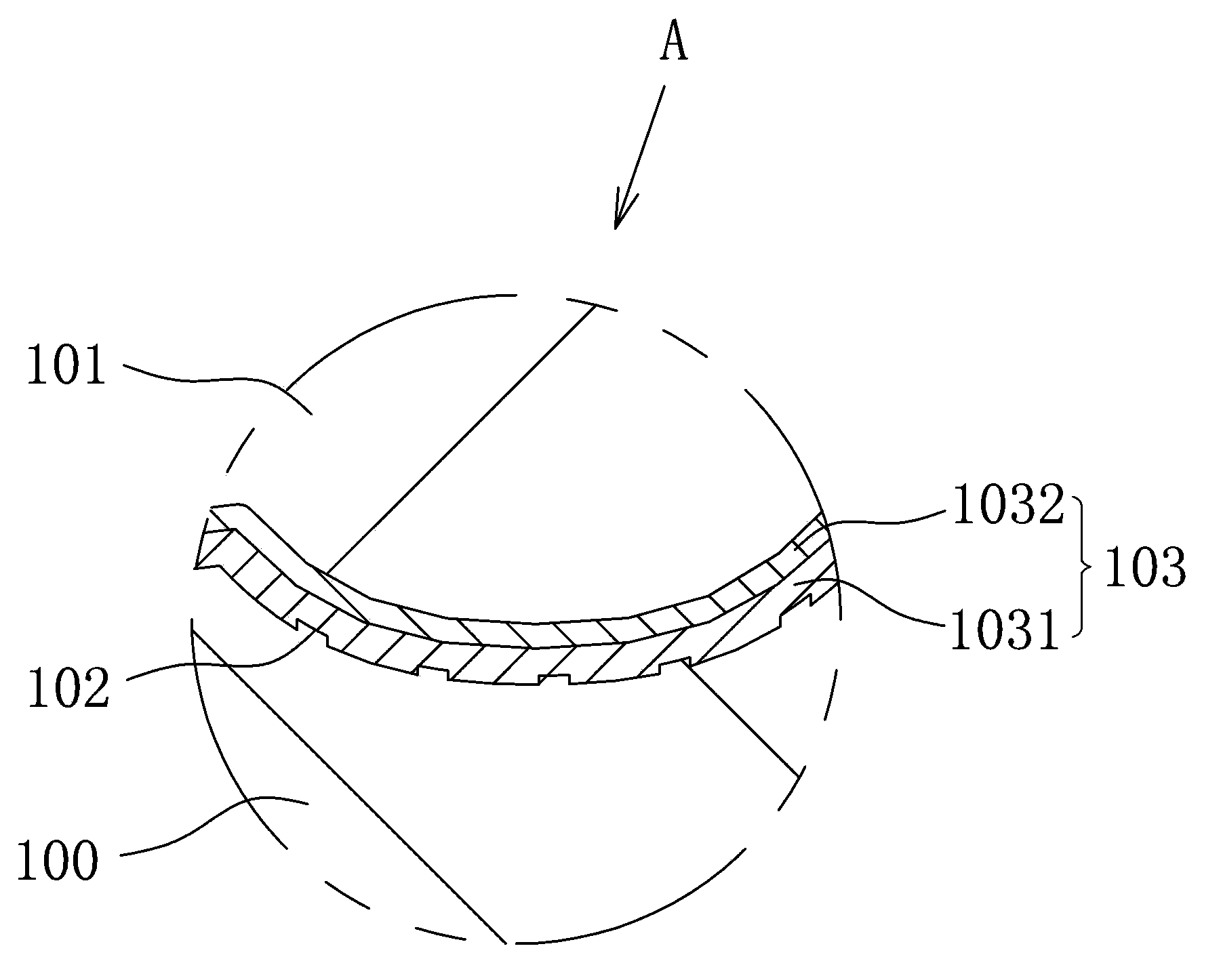

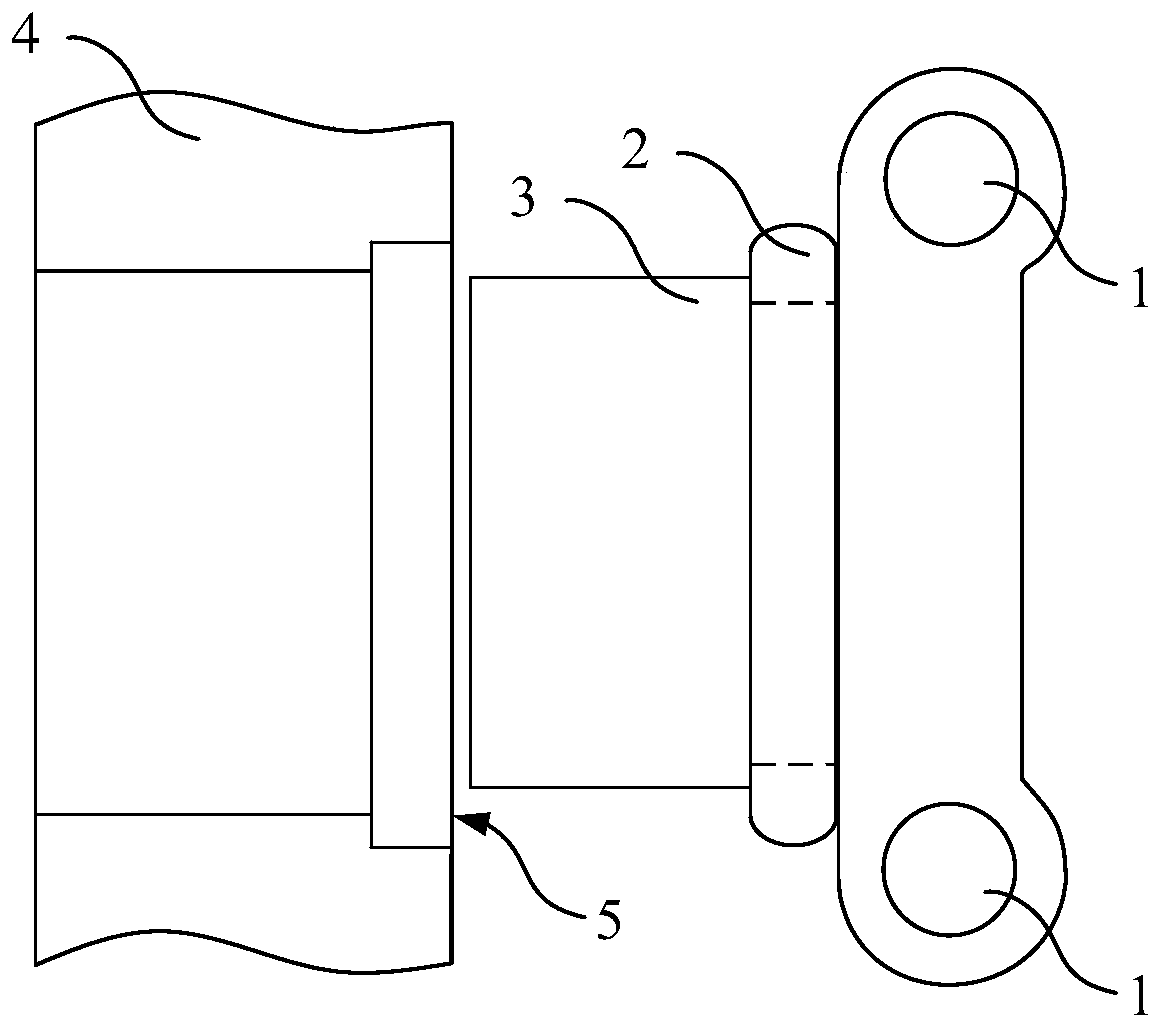

Electric appliance device and electric connection device thereof

PendingCN111403939AAssembly influenceFully clingingSwitchgear with horizontal withdrawalSwitchgear detailsBusbarElectrical connection

The invention discloses an electric connection device, and the deviceis connected between a body of an electric appliance device with a draw-out structure and a draw-out device. The device comprises adraw-out device connection assembly, a body connection assembly and a flexible assembly. The draw-out device connection assembly is fixed on the draw-out device and is electrically connected with thewire inlet and outlet ends of the draw-out device. The body connection assembly comprises a contact piece with a clamping mechanism, and the clamping mechanism enables the contact piece to be tightlyattached to and clamp the body busbar. The flexible assembly is connected with the draw-out device connection assembly and the body connection assembly, and the body connection assembly, the flexibleassembly and the draw-out device connection assembly form a conductive path. The contact pieces of the body connection assembly are adapted to the position deviation of the body busbar to generate deviation, so the contact pieces are tightly attached to and clamp the body busbar, and the flexible assembly absorbs the deviation of the contact pieces through self deformation, so the deviation is not transmitted to the draw-out device connecting assembly.

Owner:SHANGHAI LEADING CONNECTION MECHATRONICS TECH CO LTD +1

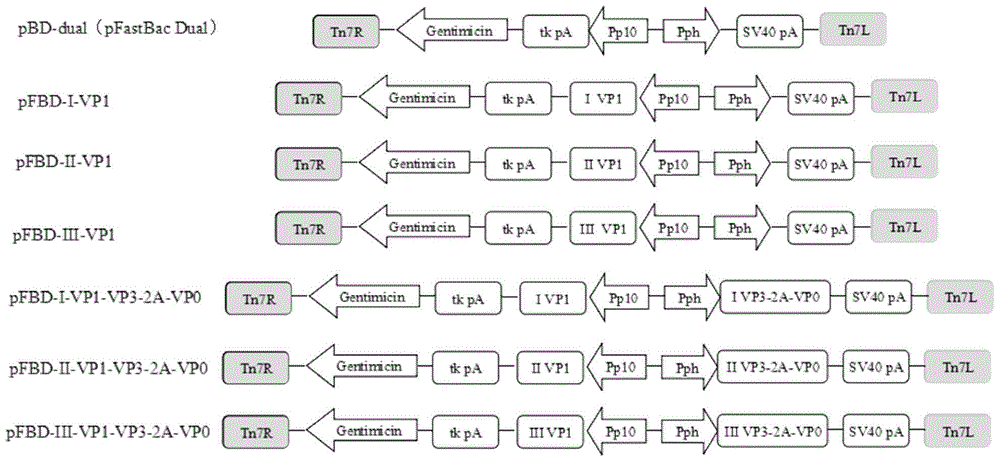

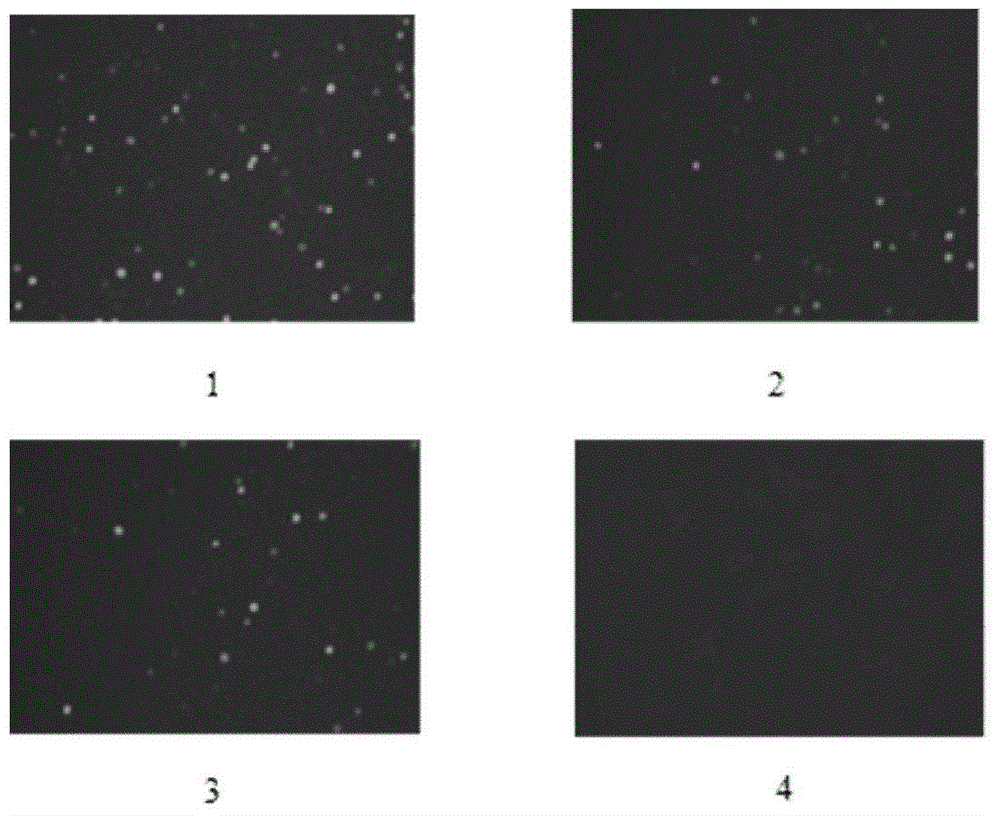

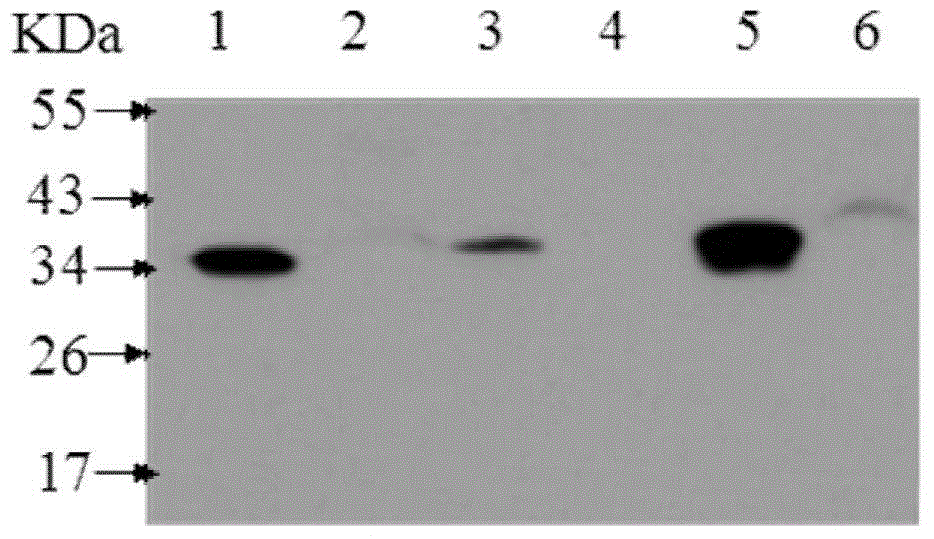

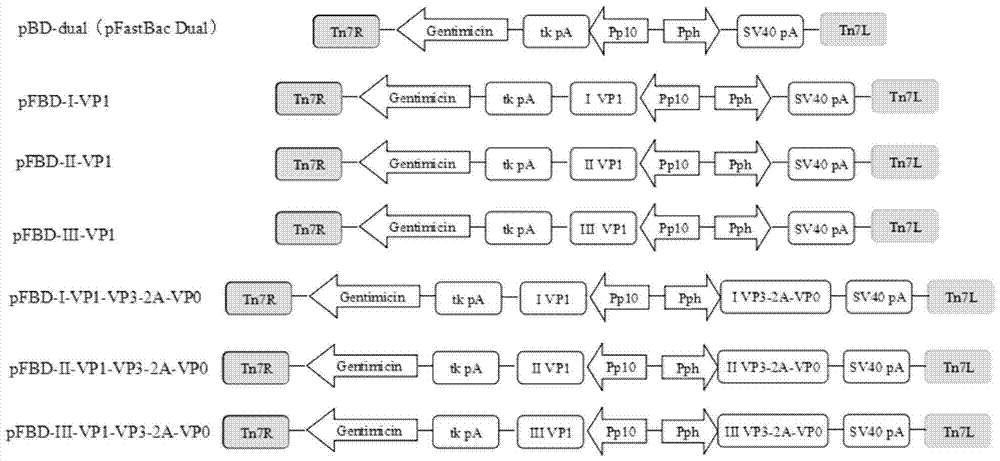

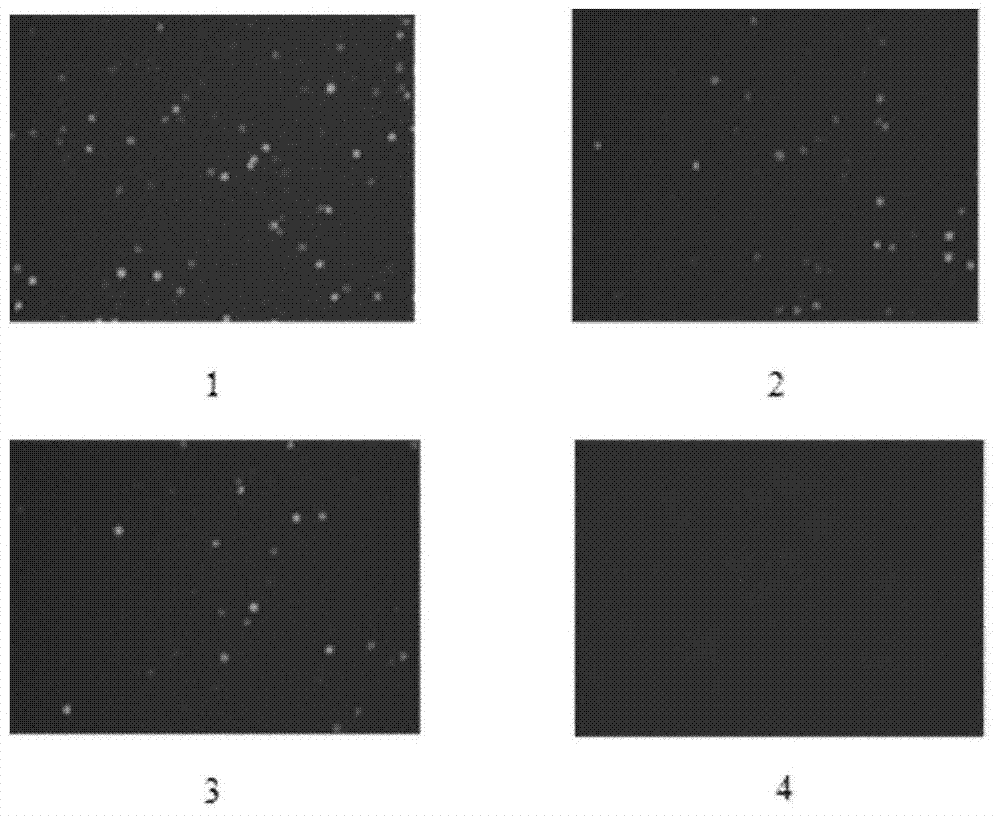

Vector for expressing protein of poliovirus sample particles and method for preparing poliovirus sample particles

ActiveCN104480143AAssembly influenceAffect expression imbalanceViral antigen ingredientsInactivation/attenuationDiseasePoliovirus

The invention discloses a vector for expressing protein of poliovirus sample particles and a method for preparing the poliovirus sample particles. The vector contains expression cassettes with the following structures: an arbitrary gene in poliovirus structural proteins VP0, VP1 and VP3 genes is located in the downstream of a promoter 1, and the other two genes are connected by virtue of a 2A sequence and are located in the downstream of a promoter 2, and directions of promoting expressions of the two promoters are opposite. The method for preparing the poliovirus sample particles comprises the following steps: transfecting the carrier to a corresponding host cell, culturing to obtain virus particles or recombinant baculovirus, and infecting the virus to the host cell if the recombinant baculovirus is obtained so as to obtain the virus sample particles. The poliovirus sample particles can be used for respectively inducing high-titer neutralization titer in a body, and can be used as a vaccine for preventing and treating poliovirus infected related diseases.

Owner:SOUTH CHINA UNITED VACCINE INST

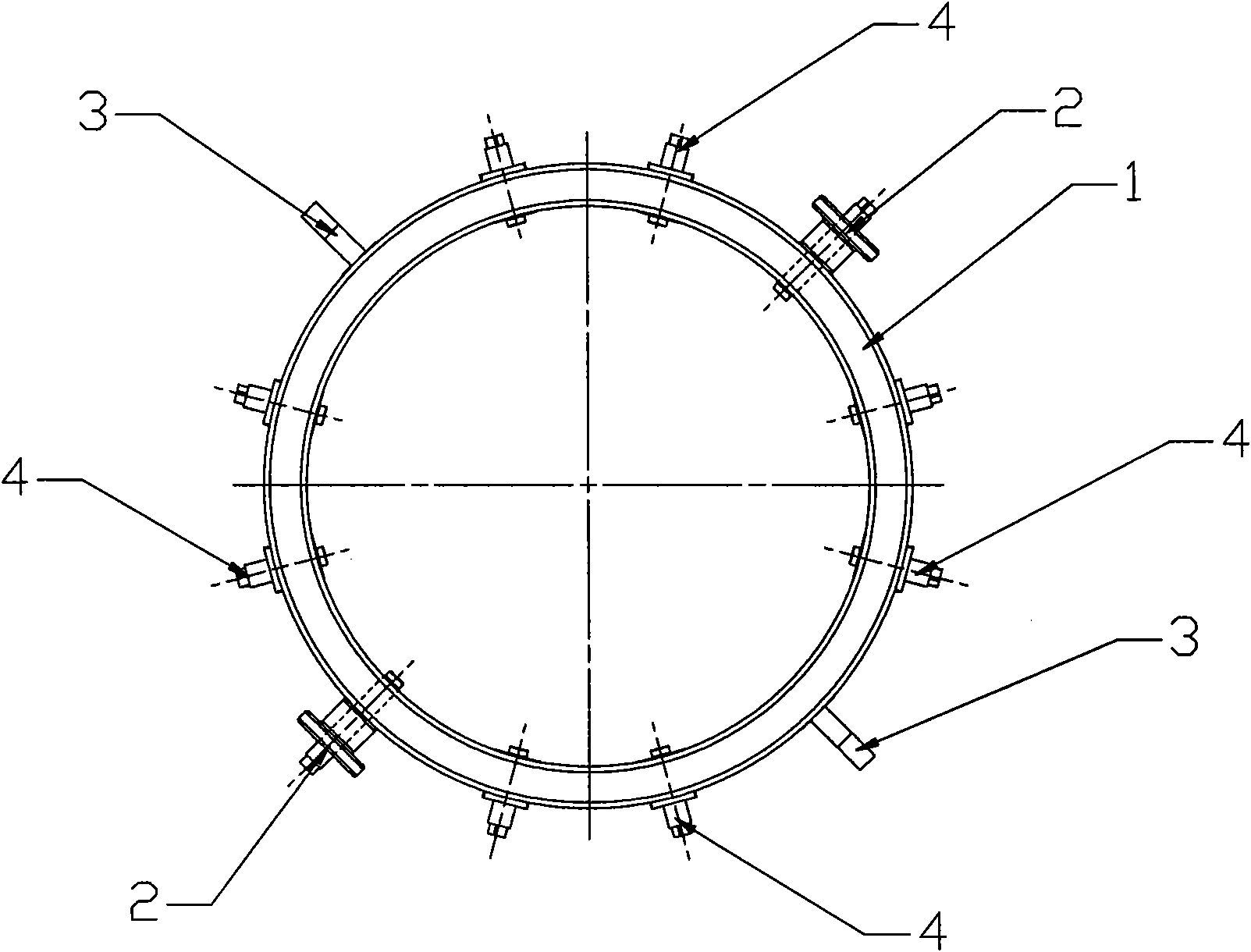

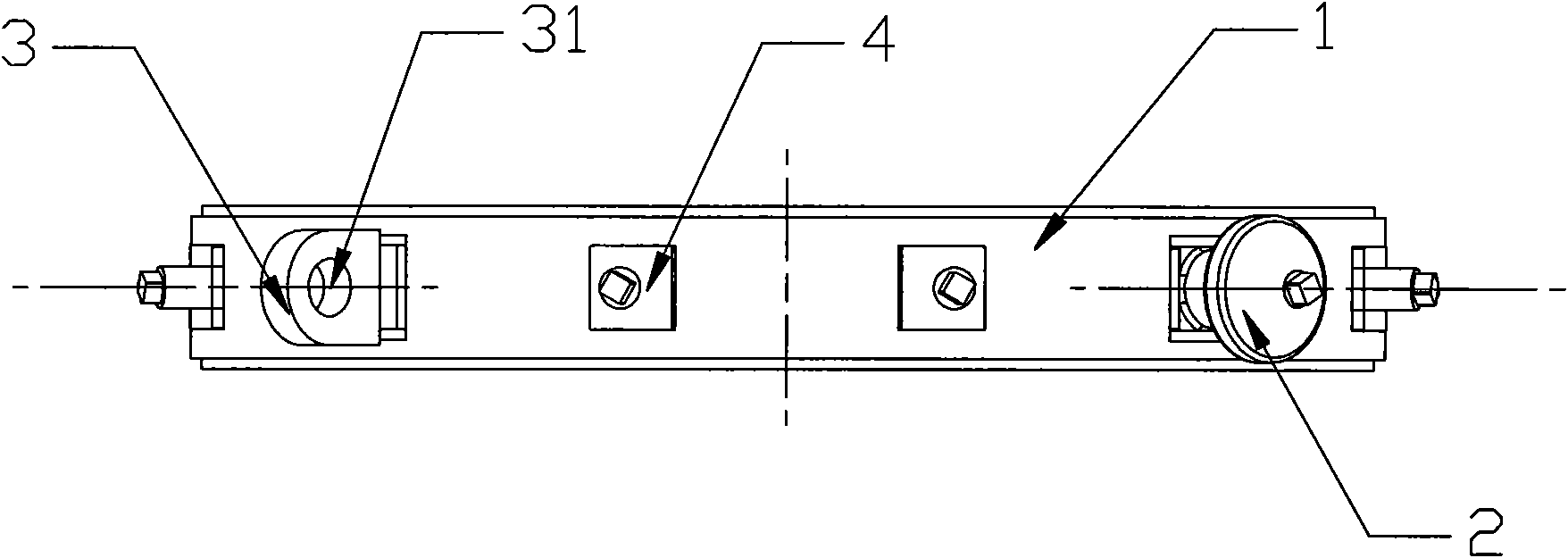

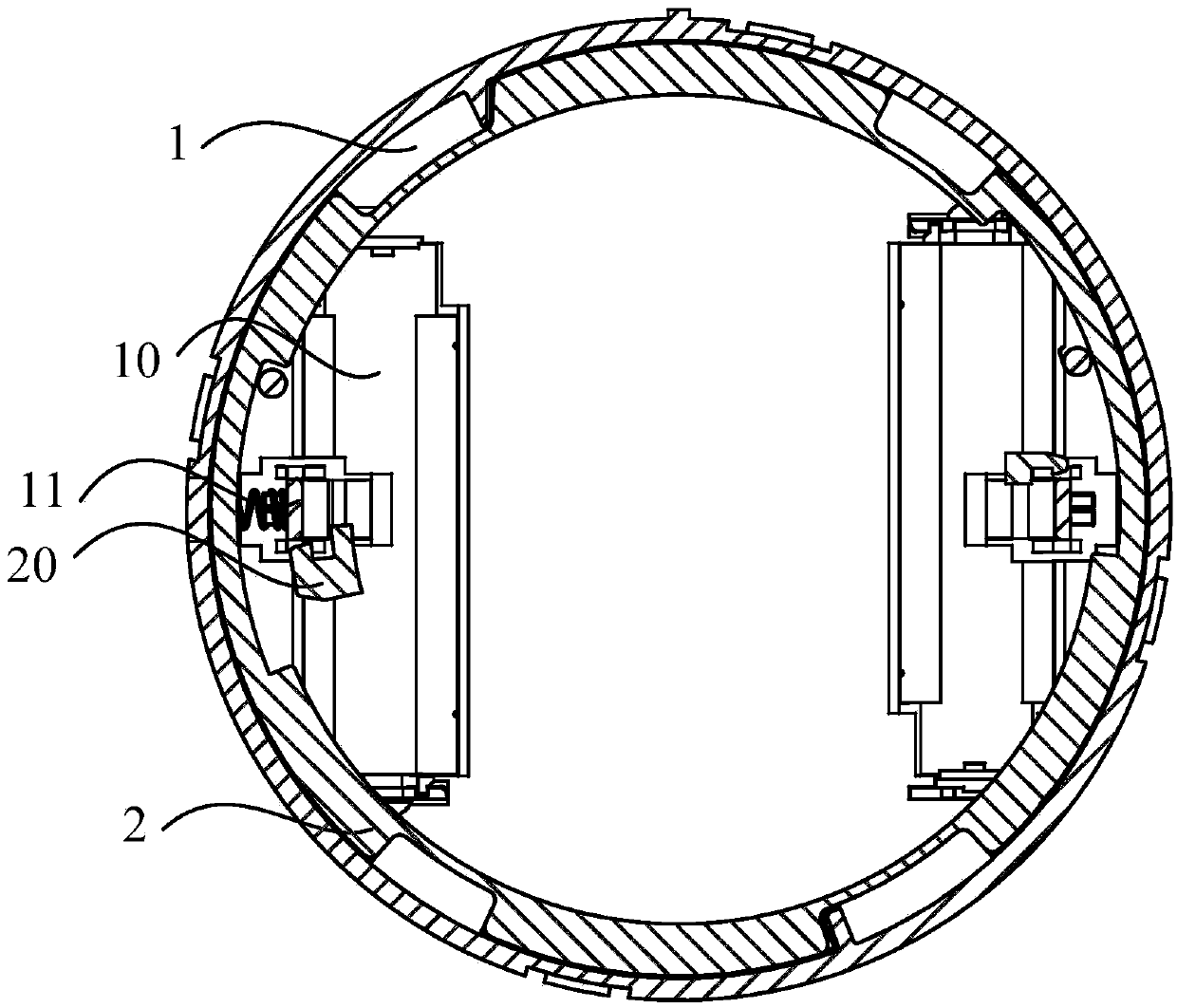

Hoist tool for round piece with groove on periphery surface

ActiveCN101920904AAssembly influenceSpeed up assembly and installationLoad-engaging elementsEngineeringScrew thread

The invention discloses a hoist tool for a round piece with a groove on a periphery surface, which comprises a ring with an inner diameter larger than the outer diameter of the round piece, wherein the periphery surface of the ring is provided with more than two radial thread through holes; and a bolt is arranged in the thread through hole. The hoist tool of the structure realizes the supporting of the round piece through extending the bolt into the peripheral groove of the round piece, thereby achieving the aim of horizontally slinging the round piece; the hoist tool can not contact to the lower surface of the round piece and can not cause influence on the assembly of the lower surface of the round piece and the coordinated surface of the round pieces, and quickens the speed of assembling and mounting machinery.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

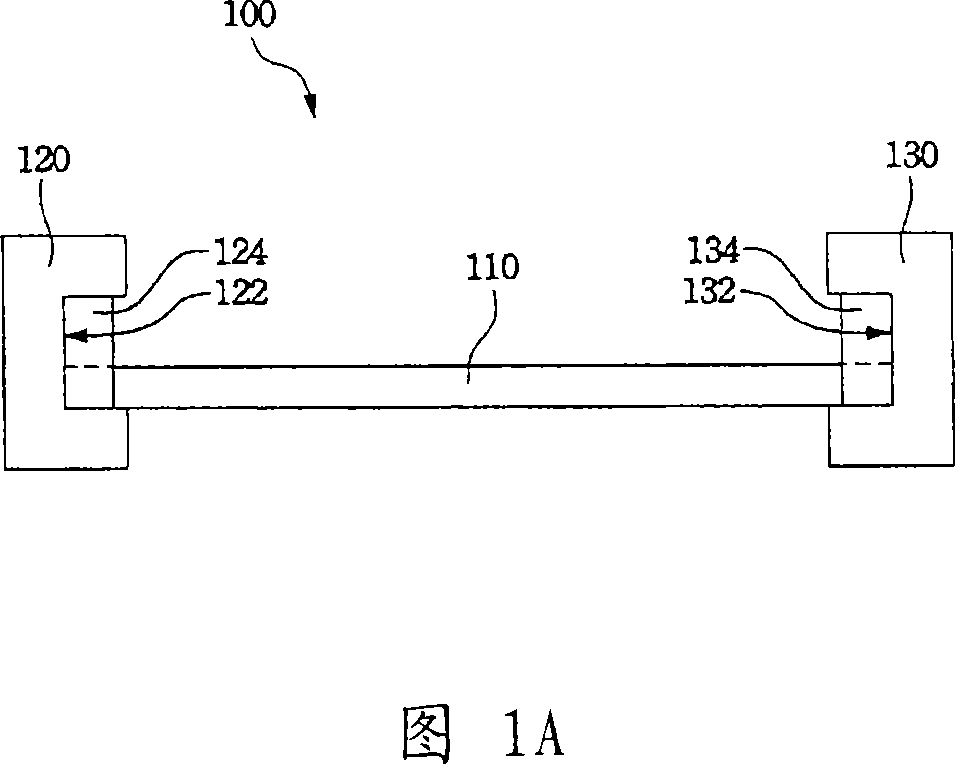

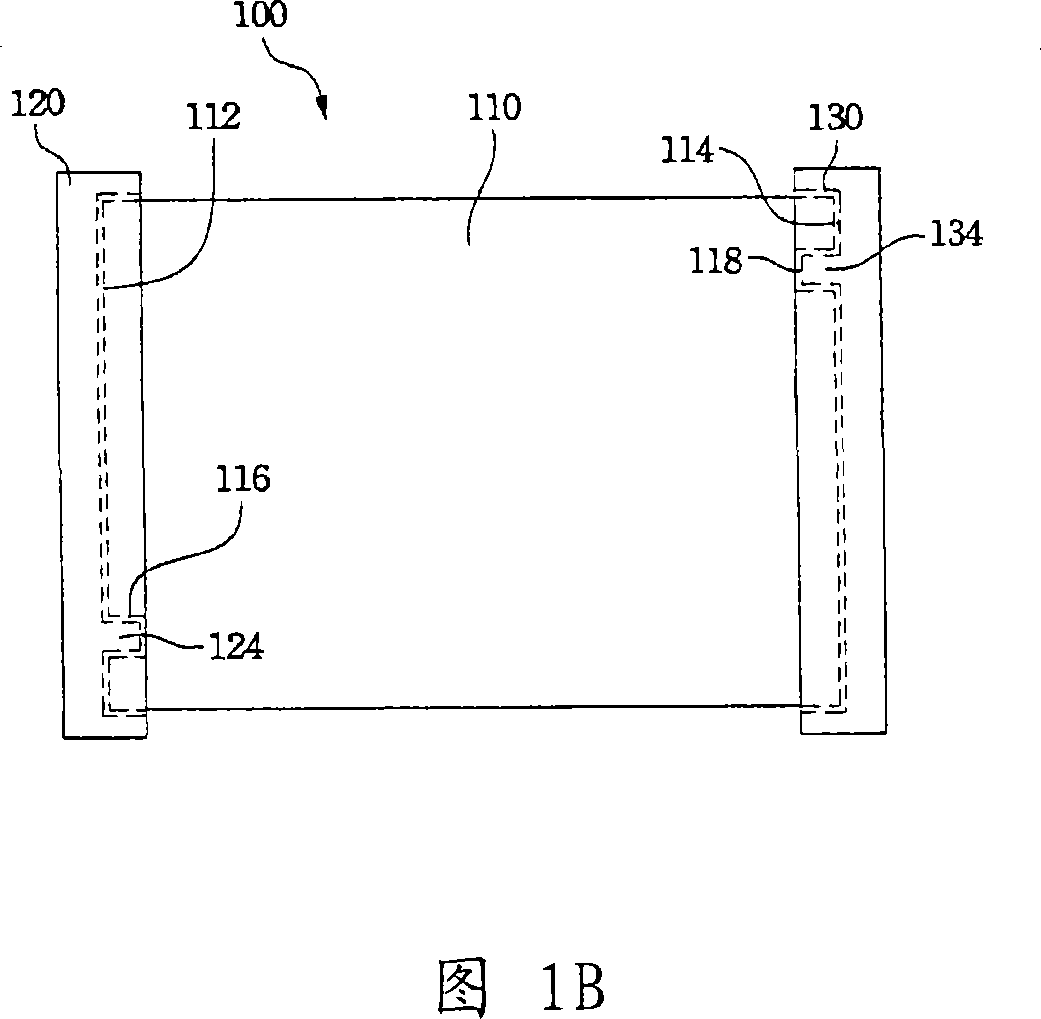

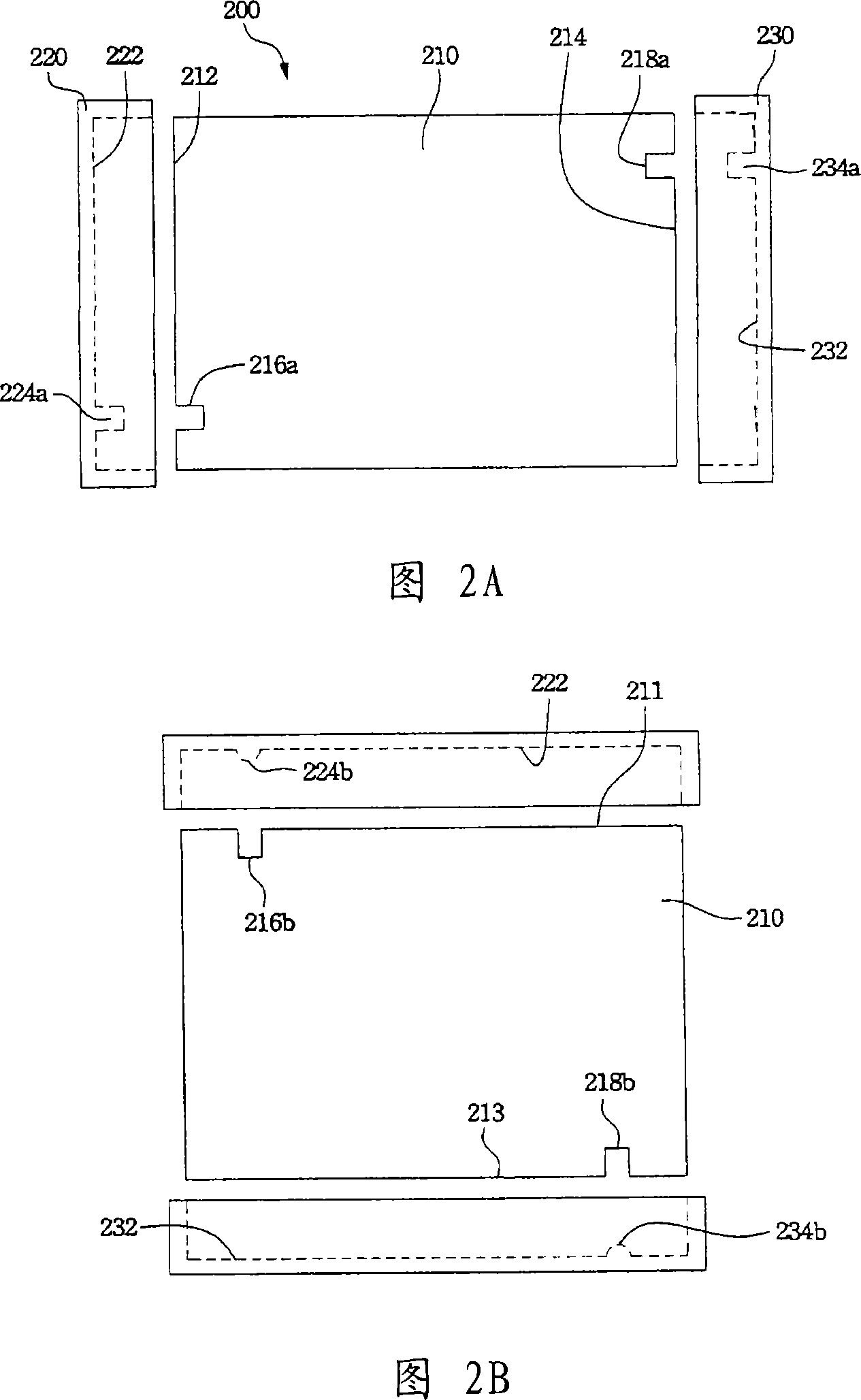

Backlight module

This invention discloses a sort of back-light module, and it consists of an optics film and an outline border. The optics has one side at least, and two gaps which are formed in the side and they locate in the different height apart. The outline border has a flute in order to contain the optics film in the flute. There have two projections which correspond the gap in the flute, and the projection locates in the gap when the optics film is packed in the outline border.

Owner:AU OPTRONICS (XIAMEN) CORP +1

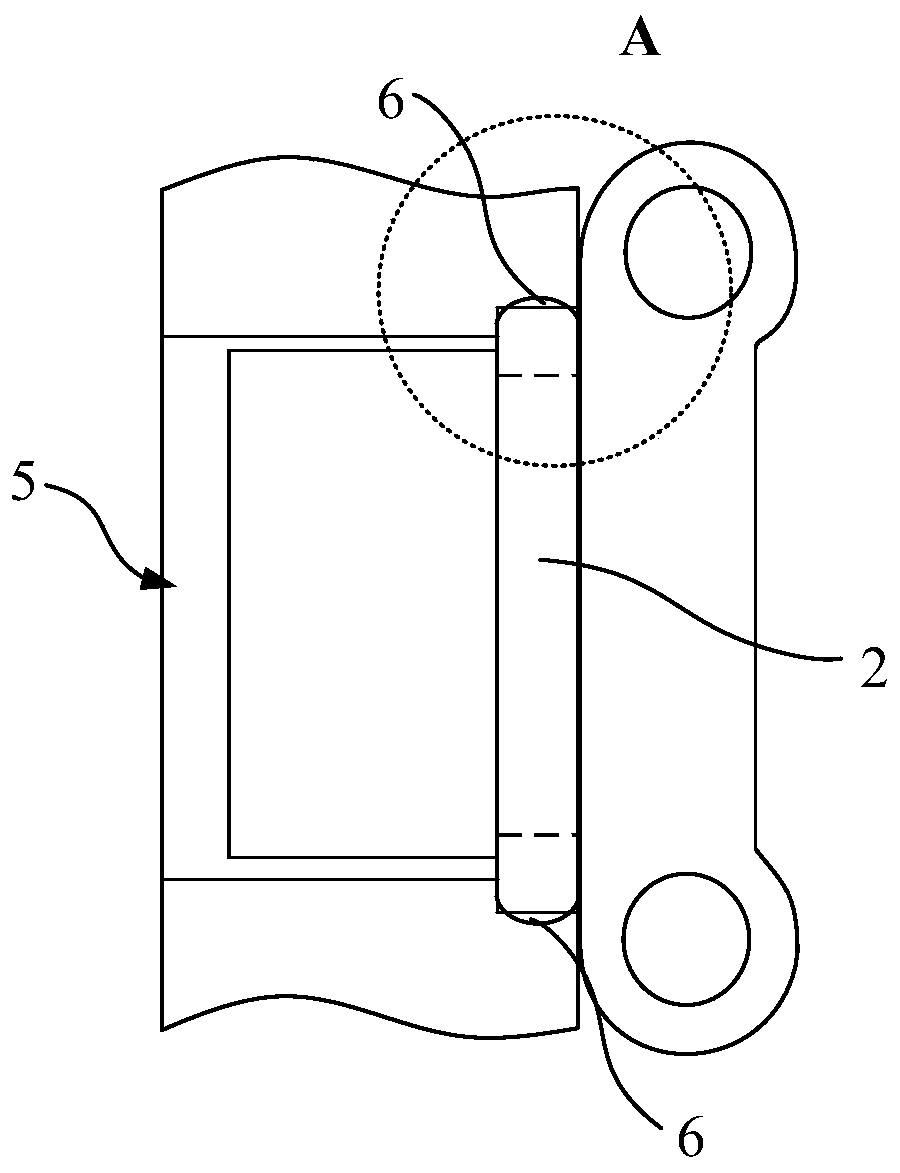

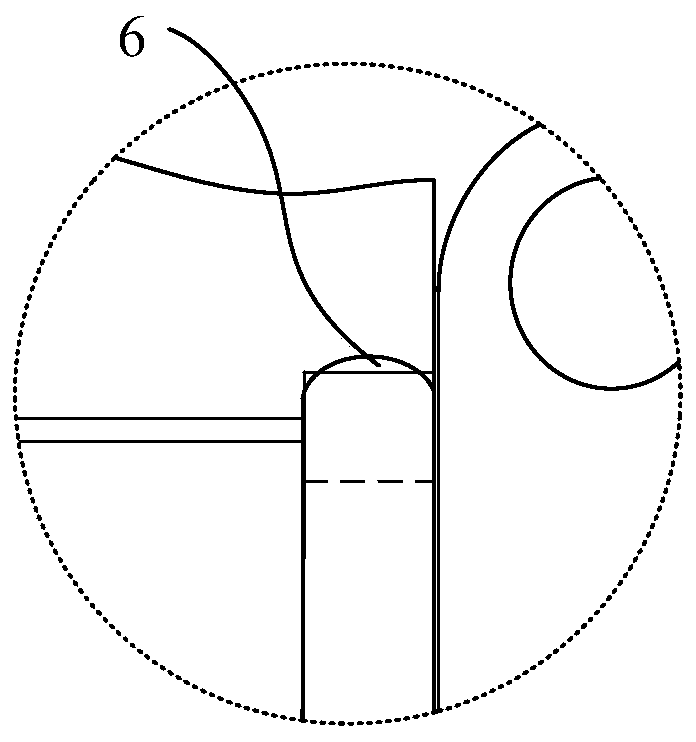

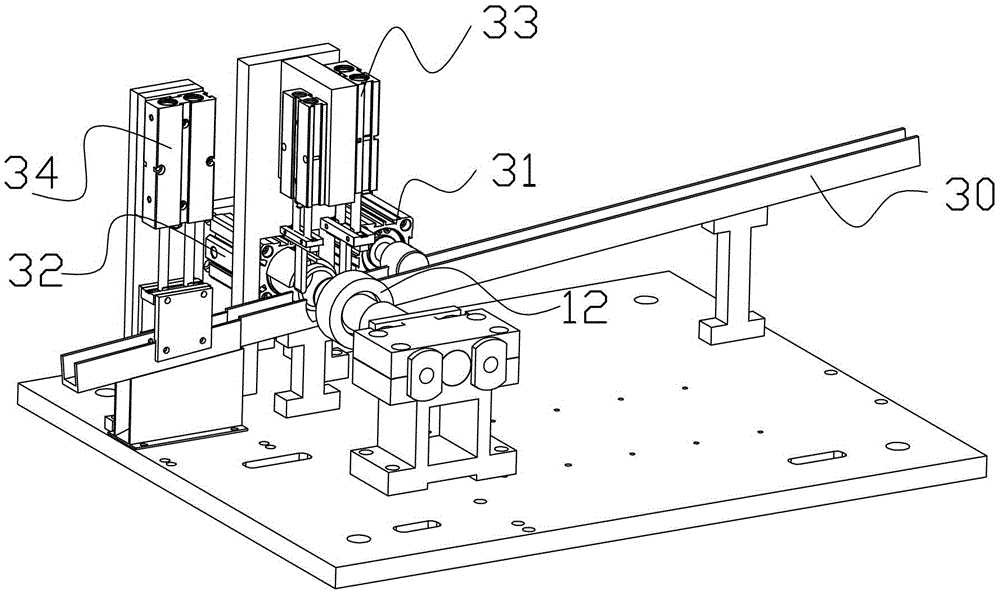

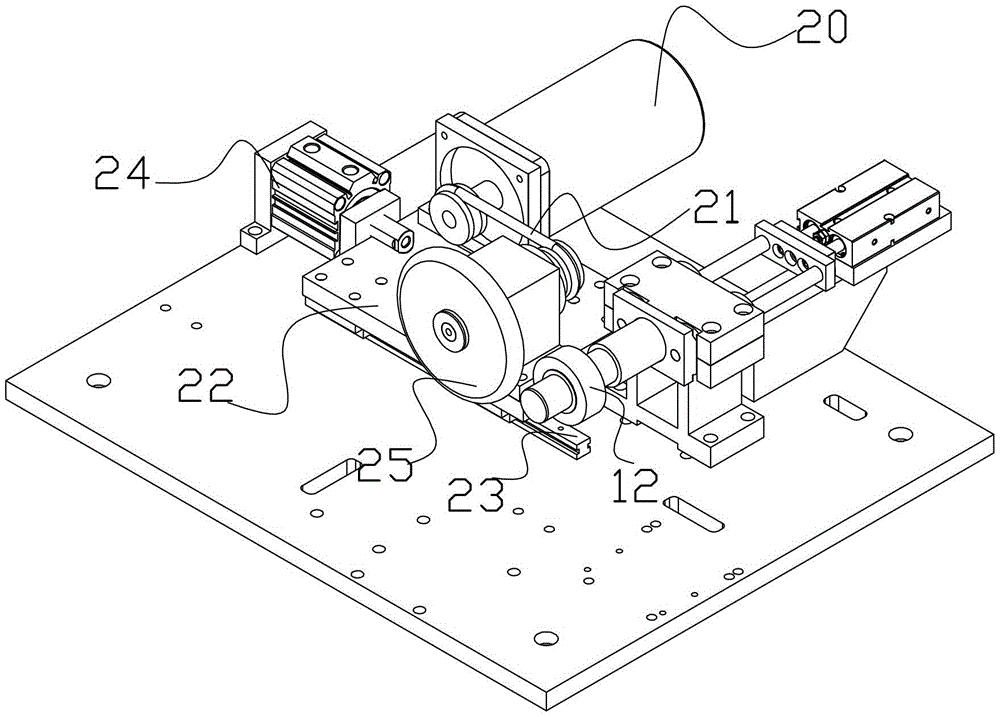

System for detecting performance of needle roller bearing of connecting rod big end

InactiveCN103076176AAssembly influenceAvoid inaccuraciesMachine bearings testingNeedle roller bearingData acquisition

The invention discloses a system for detecting the performance of a needle roller bearing of a connecting rod big end. The system comprises a bearing inlet and outlet mechanism assembled on a system rack, an inertia wheel driving mechanism, a bearing detection mechanism and a data acquisition processor, wherein the bearing detection mechanism comprises a detection mandrel fixedly arranged on the rack and a bearing detection sleeve suspended on the detection mandrel; and the bearing detection sleeve comprises the needle roller bearing to be detected and a detection inertia wheel sleeved with the needle roller bearing. The novel detection system is provided for an inner and outer circle-free needle roller bearing of the connecting rod big end and the shortcomings of a method for detecting the performance of the needle roller bearing in the prior art, detection results are more comprehensive and accurate, and the influence of the quality of the needle roller bearing on assembly and the performance of an engine is eliminated.

Owner:WUYI UNIV

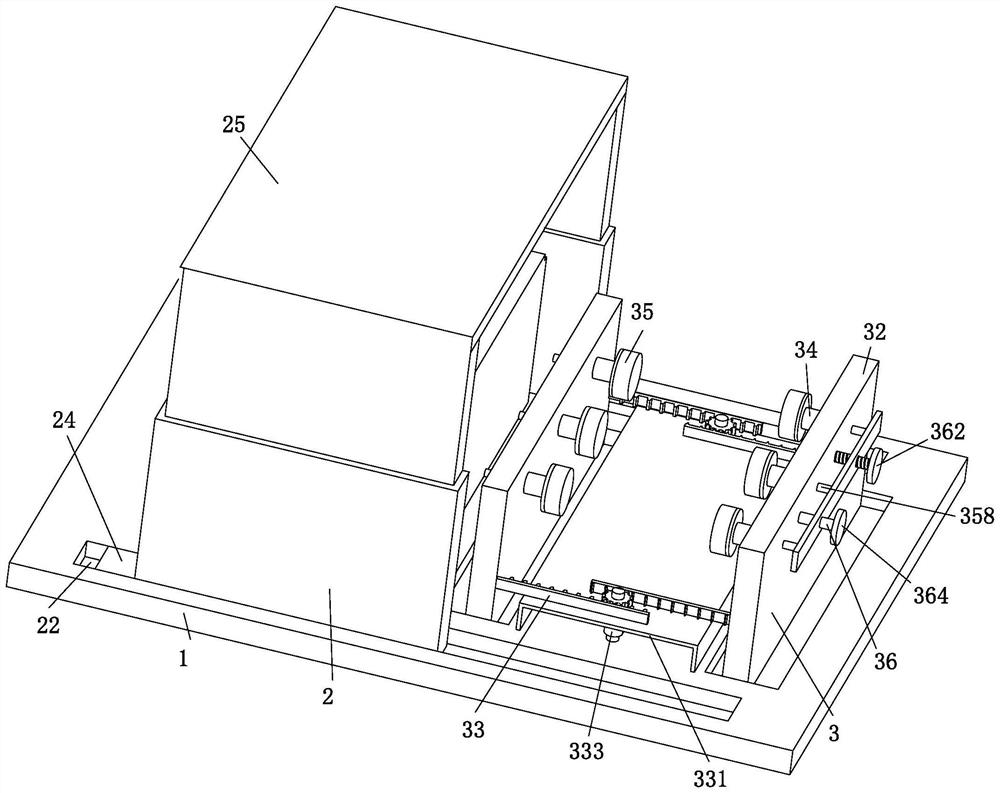

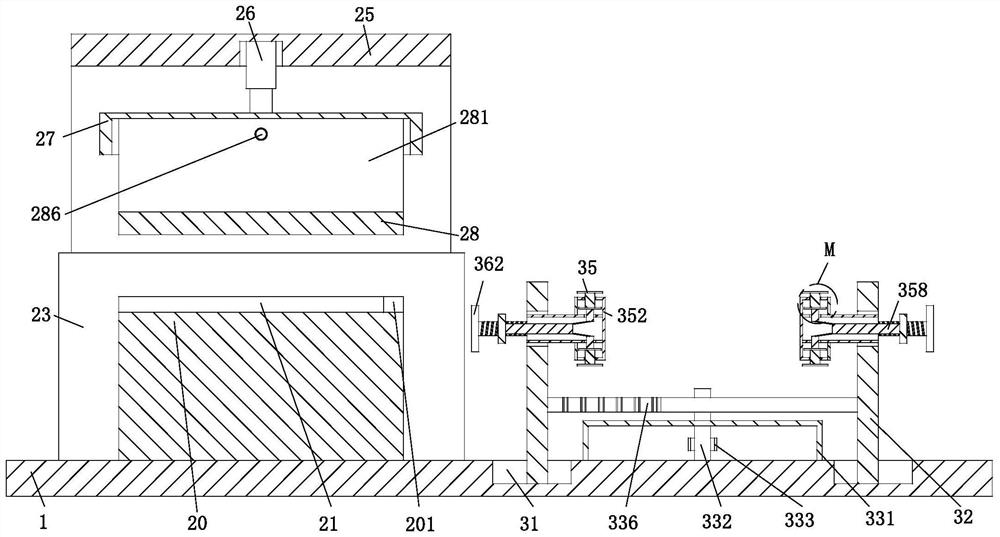

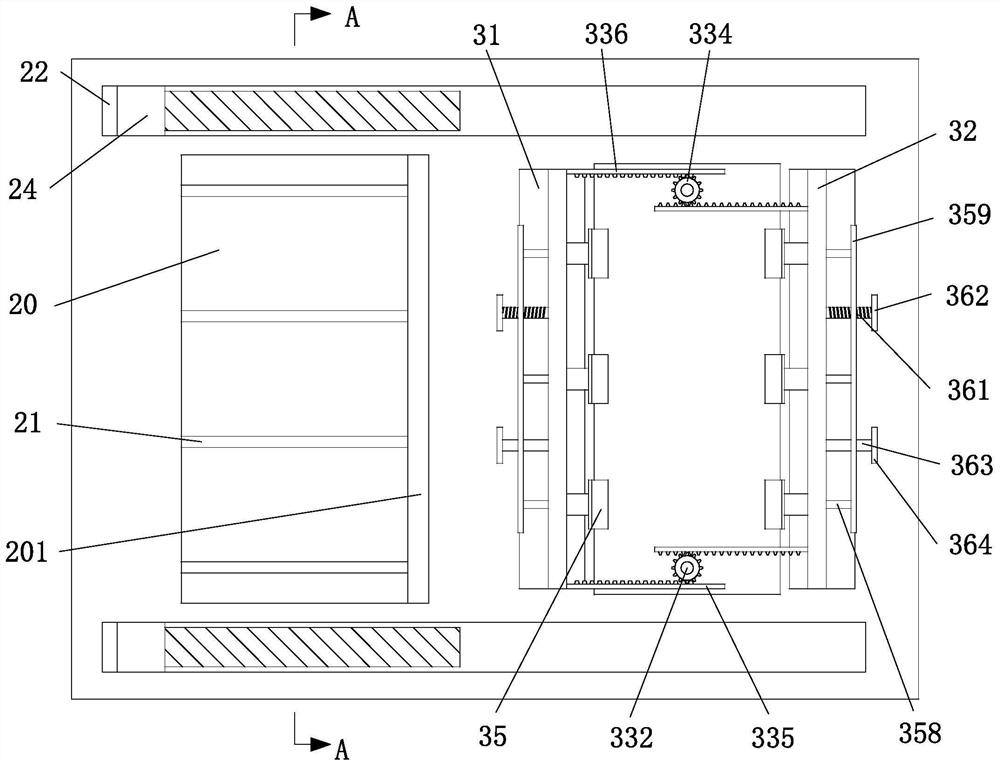

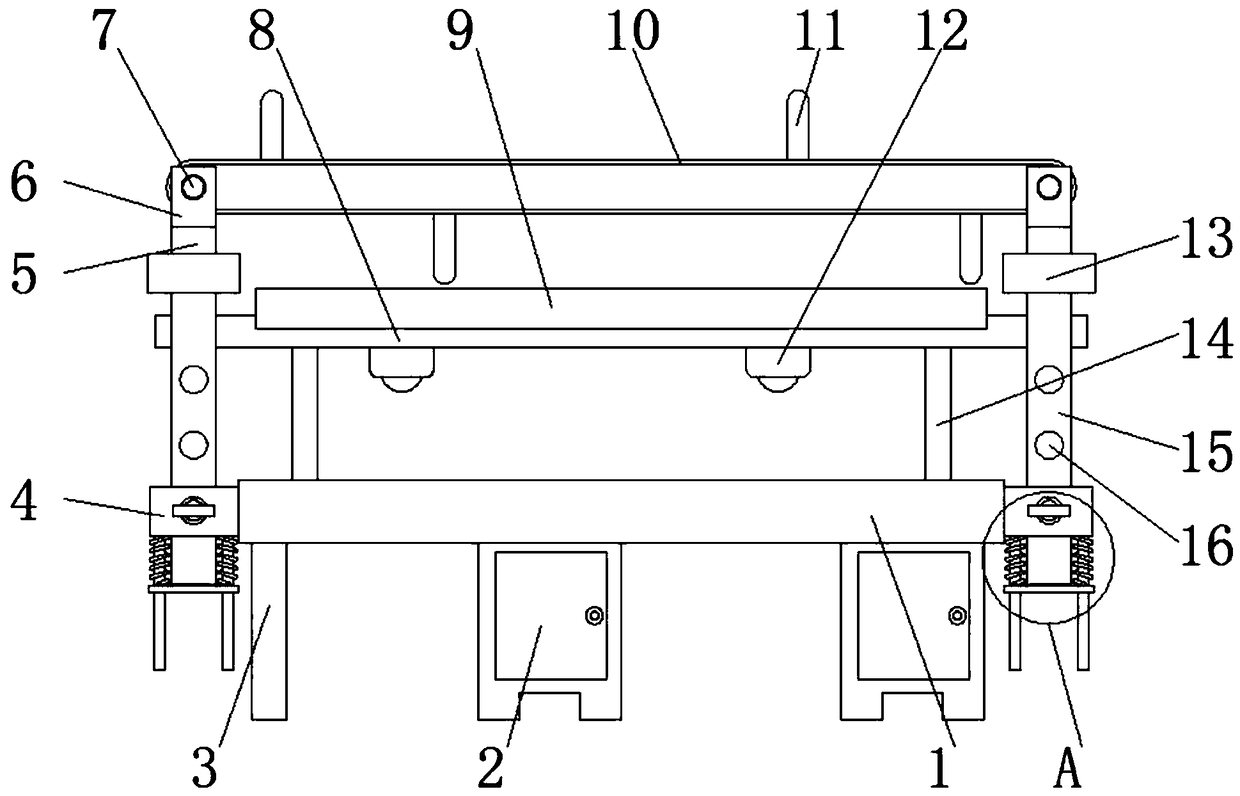

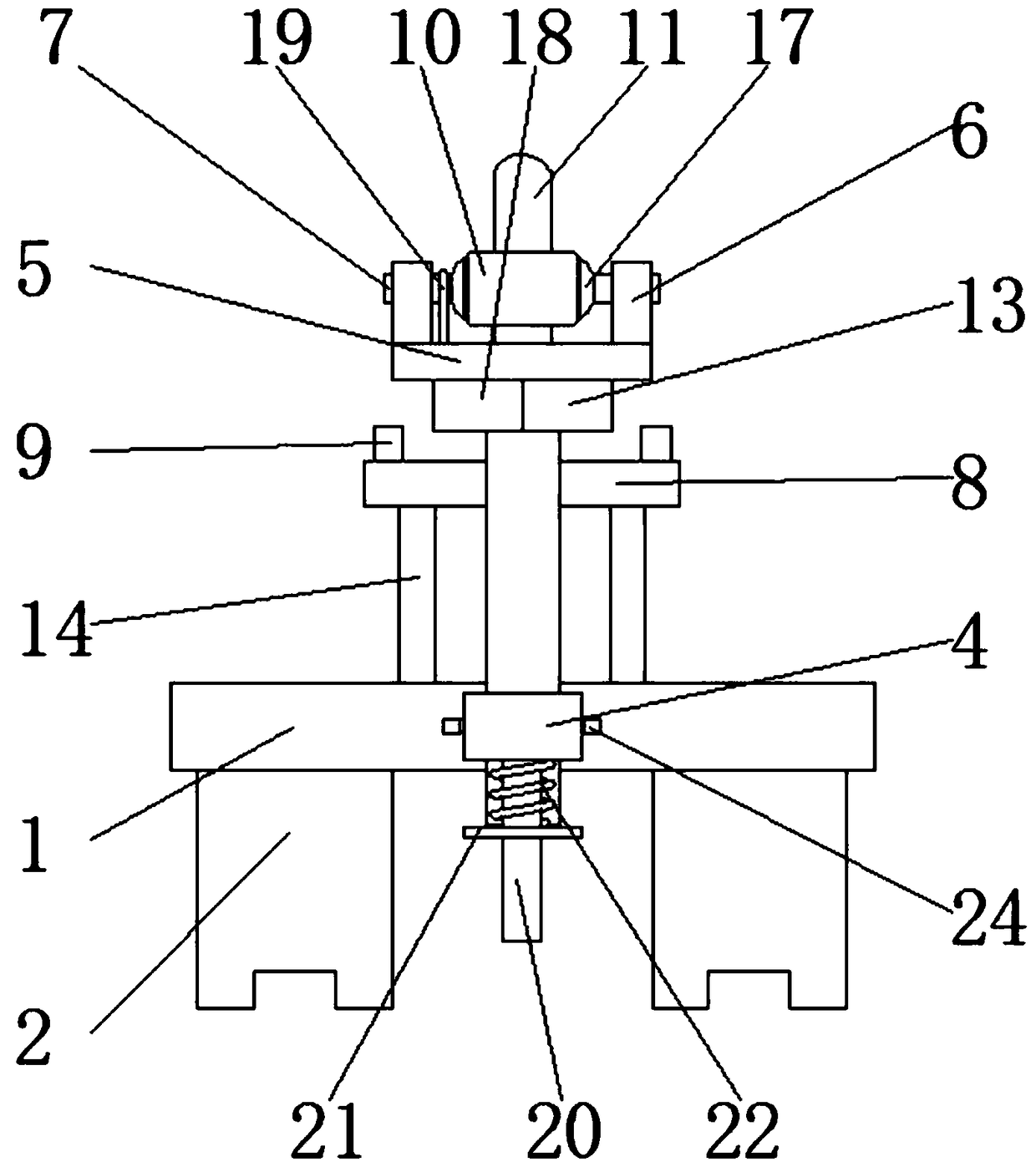

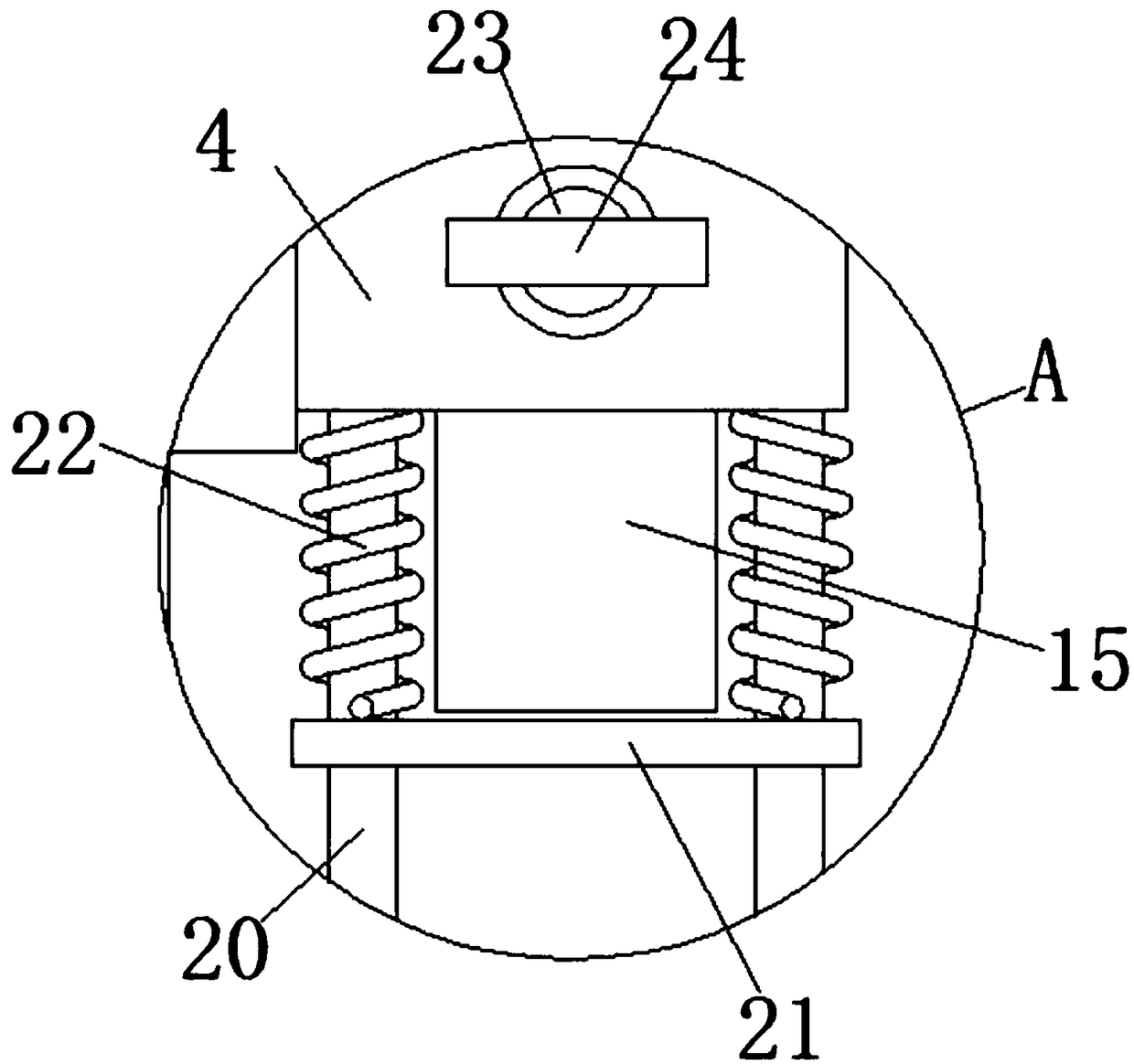

Gate valve producing, manufacturing and assembling equipment and assembling method

PendingCN114378758AAvoid difficultyGuaranteed accuracyWork holdersMetal-working hand toolsButt jointEngineering

The invention relates to gate valve producing, manufacturing and assembling equipment and an assembling method.The gate valve producing, manufacturing and assembling equipment comprises a workbench, a fixing device and a moving device.Through cooperation of the workbench, the fixing device and the moving device.Firstly, upper die bases of gate valves needing to be produced and assembled are placed on the fixing device in batches; an upper die base of a gate valve is clamped and fixed through the fixing device, at the moment, lower die bases, needing to be produced and assembled, of the gate valve are placed on the moving device in batches and are clamped and fixed through the moving device, and then the upper die base and the lower die base of the gate valve are in rapid butt joint through cooperation of the fixing device. The problem that the difficulty of workers is increased due to single butt joint is solved, and meanwhile the butt joint accuracy of the upper die base and the lower die base of the gate valve is guaranteed.

Owner:钟永广

Female mold anti-sticking structure

The invention discloses a female mold anti-sticking structure applied to double injection molds. The anti-sticking structure comprises a plurality of cylindrical bosses which are uprightly arranged on a male mold core respectively and protruding into a product, wherein the bosses and the male mold core are made from the same material. According to the anti-sticking structure, the contact area of the product and the male mold core is increased by virtue of the bosses on the male mold core, the area of the male mold core on which the product is located is larger than that of a female mold core and consequently the product is prevented from sticking to a female mold; by the female mold anti-sticking structure, the loss is reduced and the efficiency is enhanced, and the anti-sticking structure does not cause any influence on product assembly.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

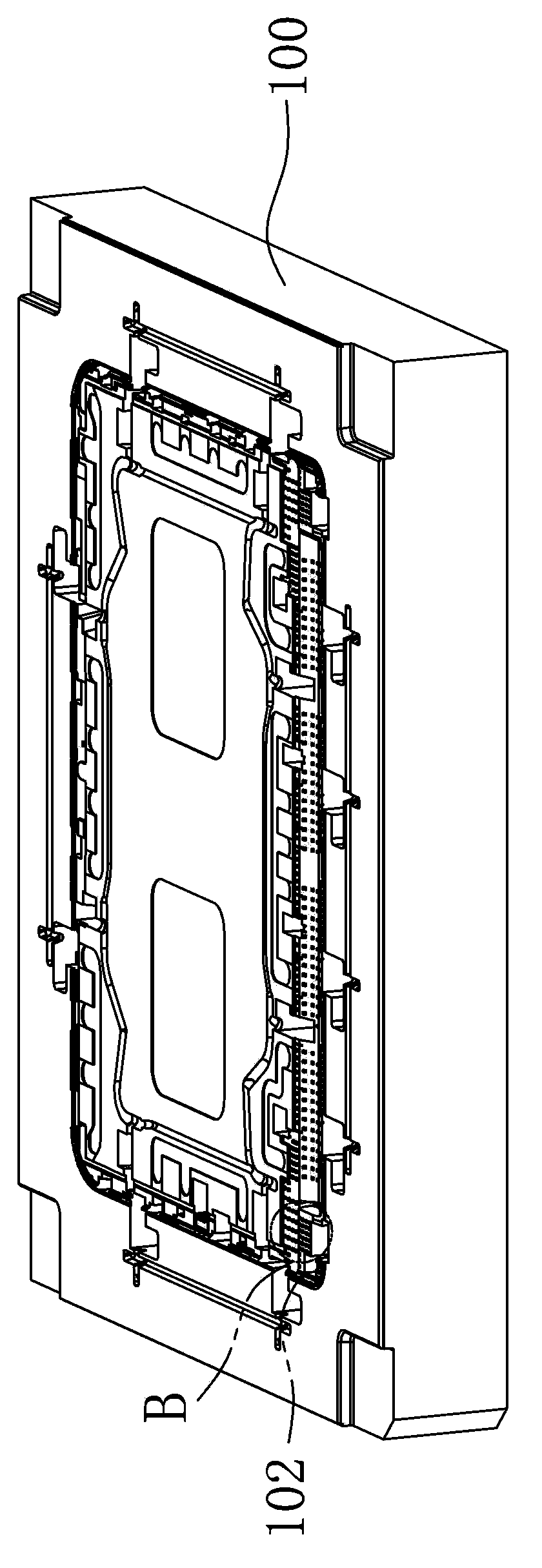

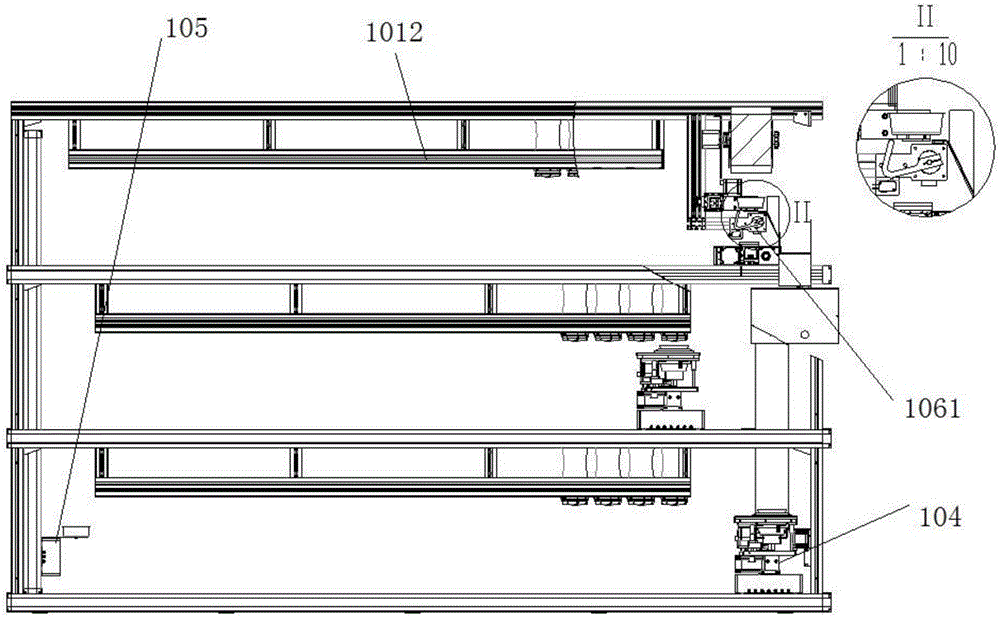

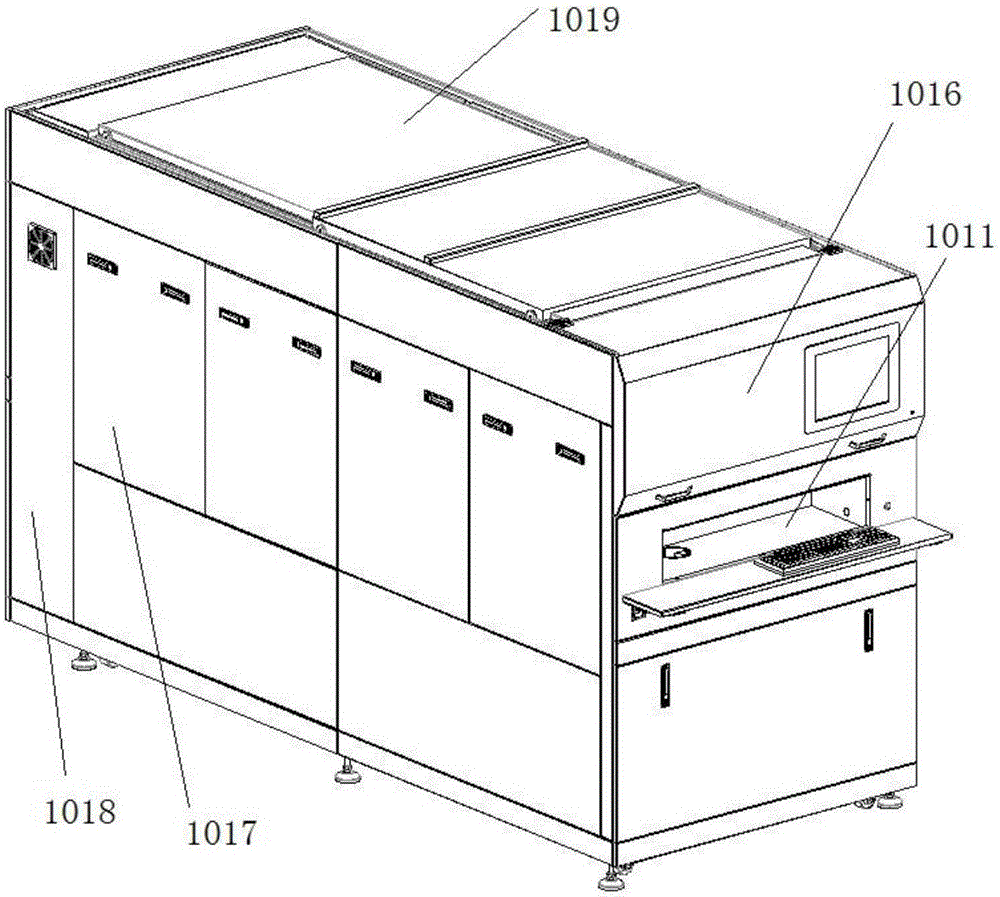

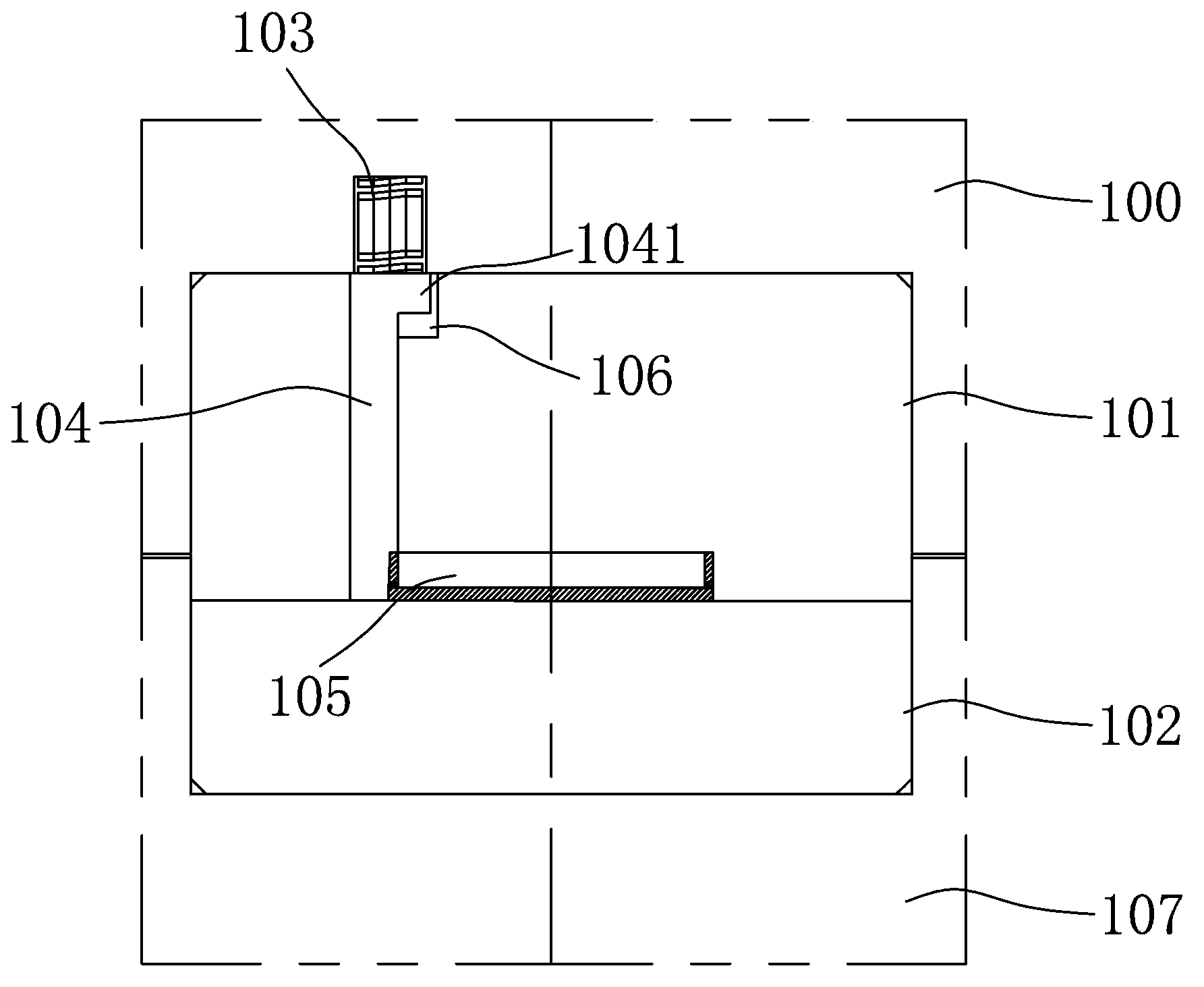

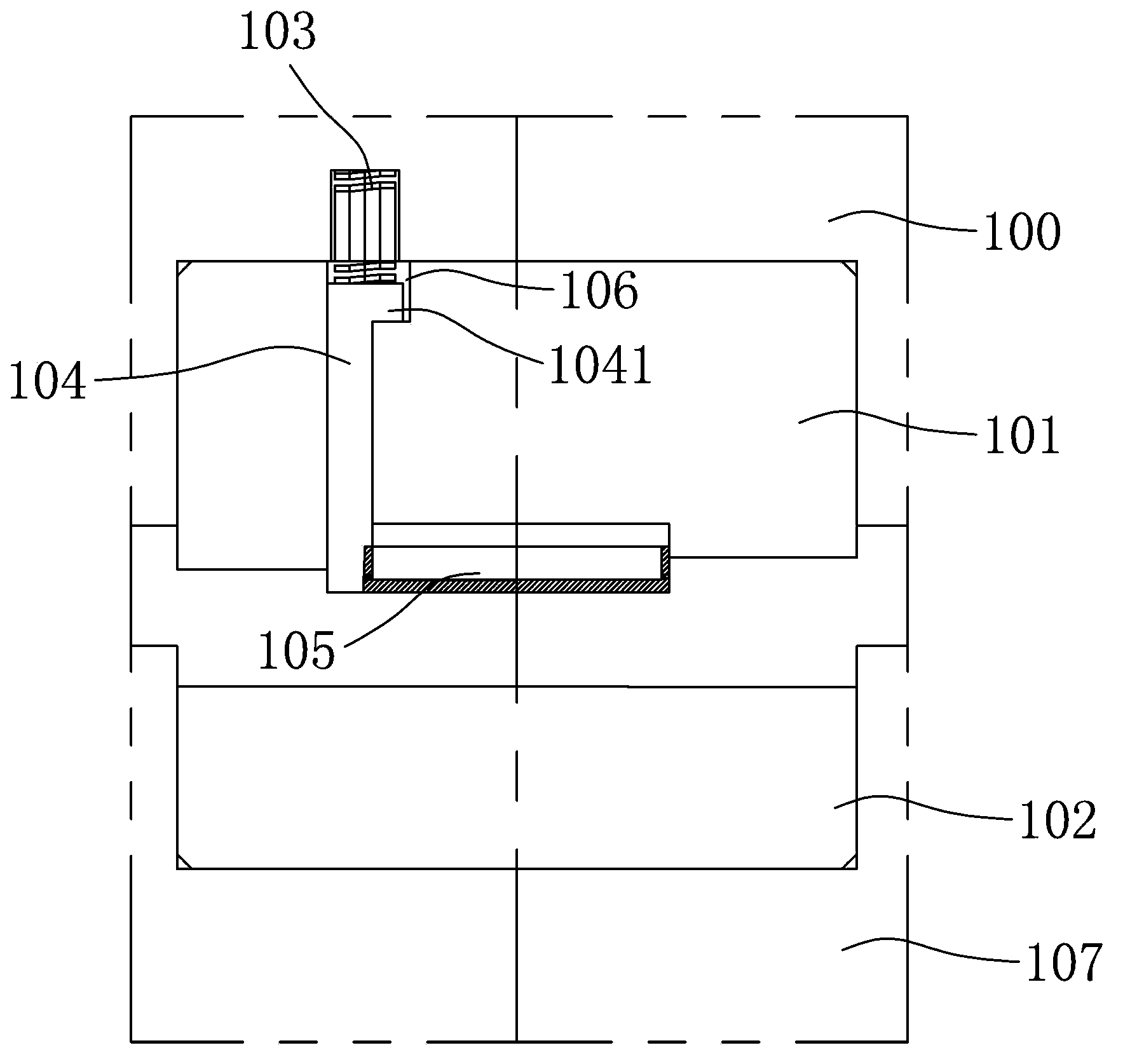

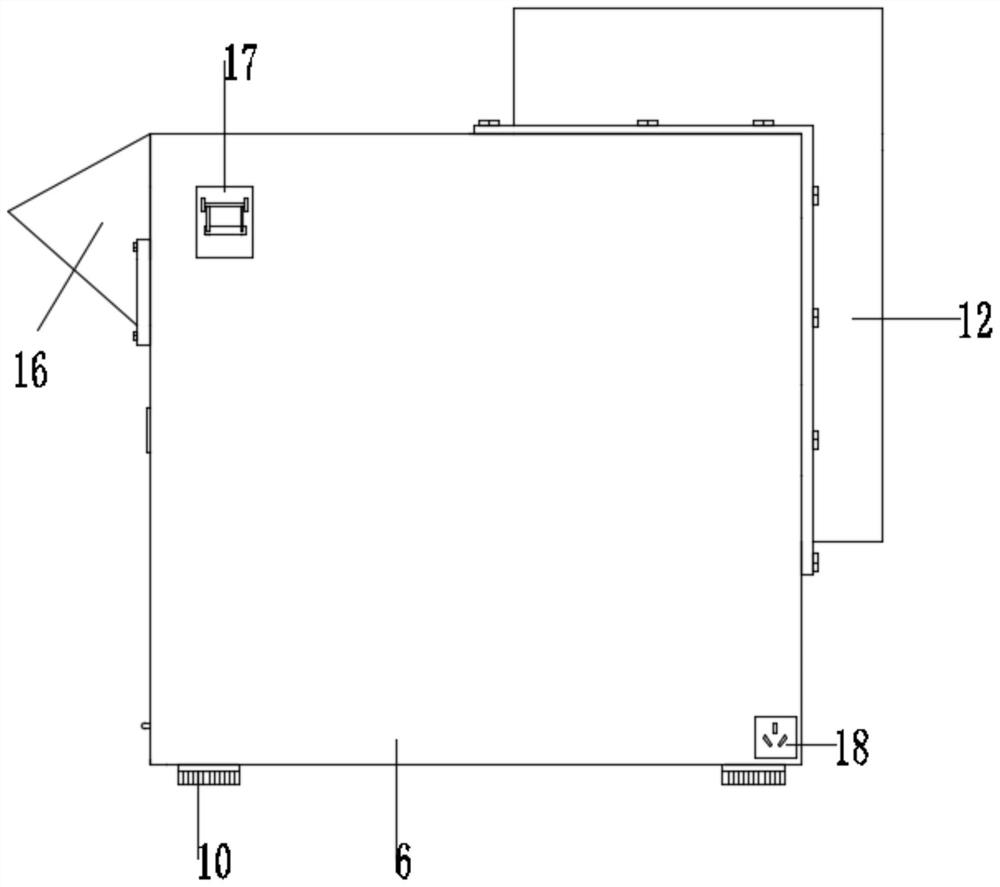

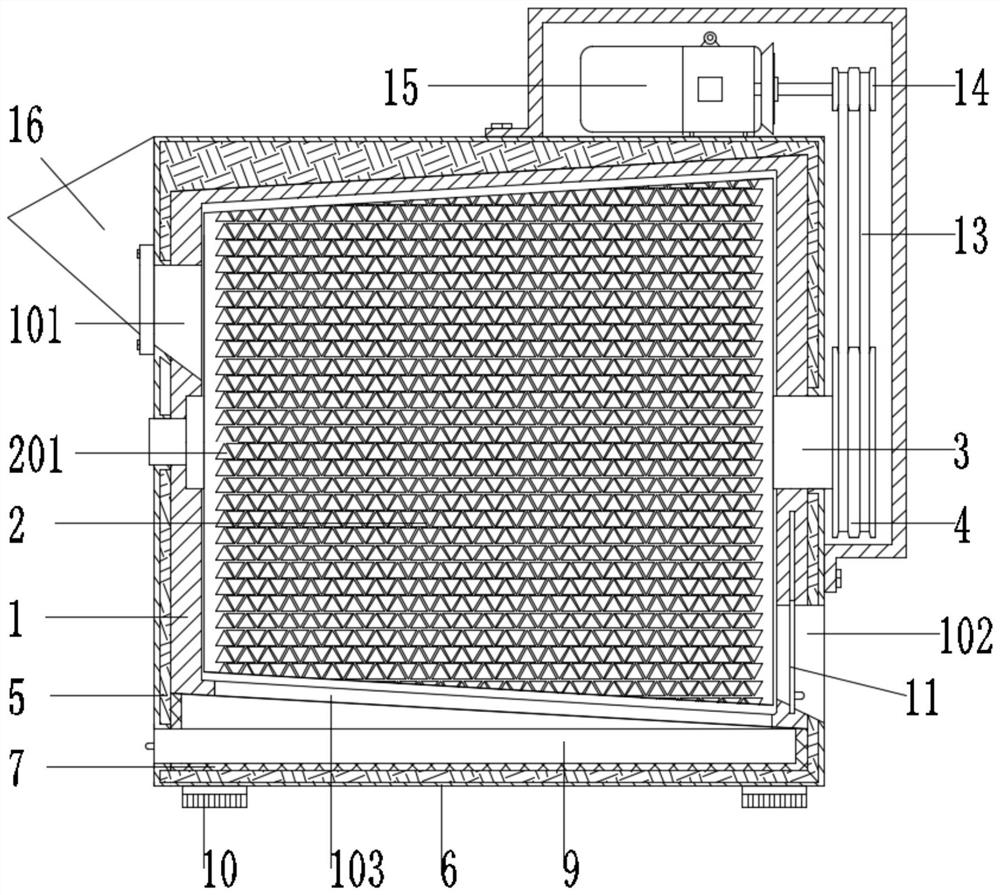

Multi-layer medicine dispensing machine

ActiveCN106697342AGuaranteed dockingGuaranteed disengagementSolid materialOperation roomBiomedical engineering

The invention discloses a multi-layer medicine dispensing machine. The multi-layer medicine dispensing machine comprises a machine frame body; a plurality of medicine bottle placing shelves are arranged in the machine frame body; a plurality of medicine bottle placing openings are formed in each medicine bottle placing shelf; a medicine dispensing mechanism is arranged below each medicine bottle placing shelf and is arranged on a left-right movement module, and the left-right movement module can do reciprocating rectilinear motion on installed machine frame guide rails; a front-back movement module is arranged between the medicine dispensing mechanism and the left-right movement module; the medicine dispensing mechanisms can run to any position of the plane where the medicine dispensing mechanism is located through the front-back movement module and the left-and-right movement module so as to carry out medicine dispensing; a picking and placing operation room is arranged on one side of the machine frame body; a medicine box placing inlet is formed in the position of the picking and placing operation room and is connected to a medicine box storage device; and a medicine box pushing mechanism is arranged at the bottom of the medicine box storage device. The multi-layer medicine dispensing machine has the advantages that the structure is ingenious, and multi-layer independent and synchronous medicine dispensing can be realized.

Owner:CHENGDU YH INTELLIGENT EQUIP TECH CO LTD

Female mold anti-sticking mechanism

A female mold anti-sticking mechanism is used in a mold. The female mold anti-sticking mechanism comprises an insert core and an elastic component. The insert core is arranged in a female mold core. One end of the insert core abuts against a male mold core, and the end, abutting against the male mold core, of the insert core is used for forming a product. The other end of the insert core is provided with a hanging platform. When the mold is opened, the insert core is prevented from moving by the hanging platform. The elastic component is arranged in a female mold plate, and one end of the elastic component contacts the insert core. According to the female mold anti-sticking mechanism, when the mold is closed, the elastic component is in a compressive state, after the mold is opened, the insert core starts to move due to elastic force received from the elastic component, and the product is firstly separated from the female mold core under movement of the insert core, so that the phenomenon that the product is stuck to the female mold core is prevented. The female mold anti-sticking mechanism reduces cost, improves efficiency and is free of influence on assembly of the product.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

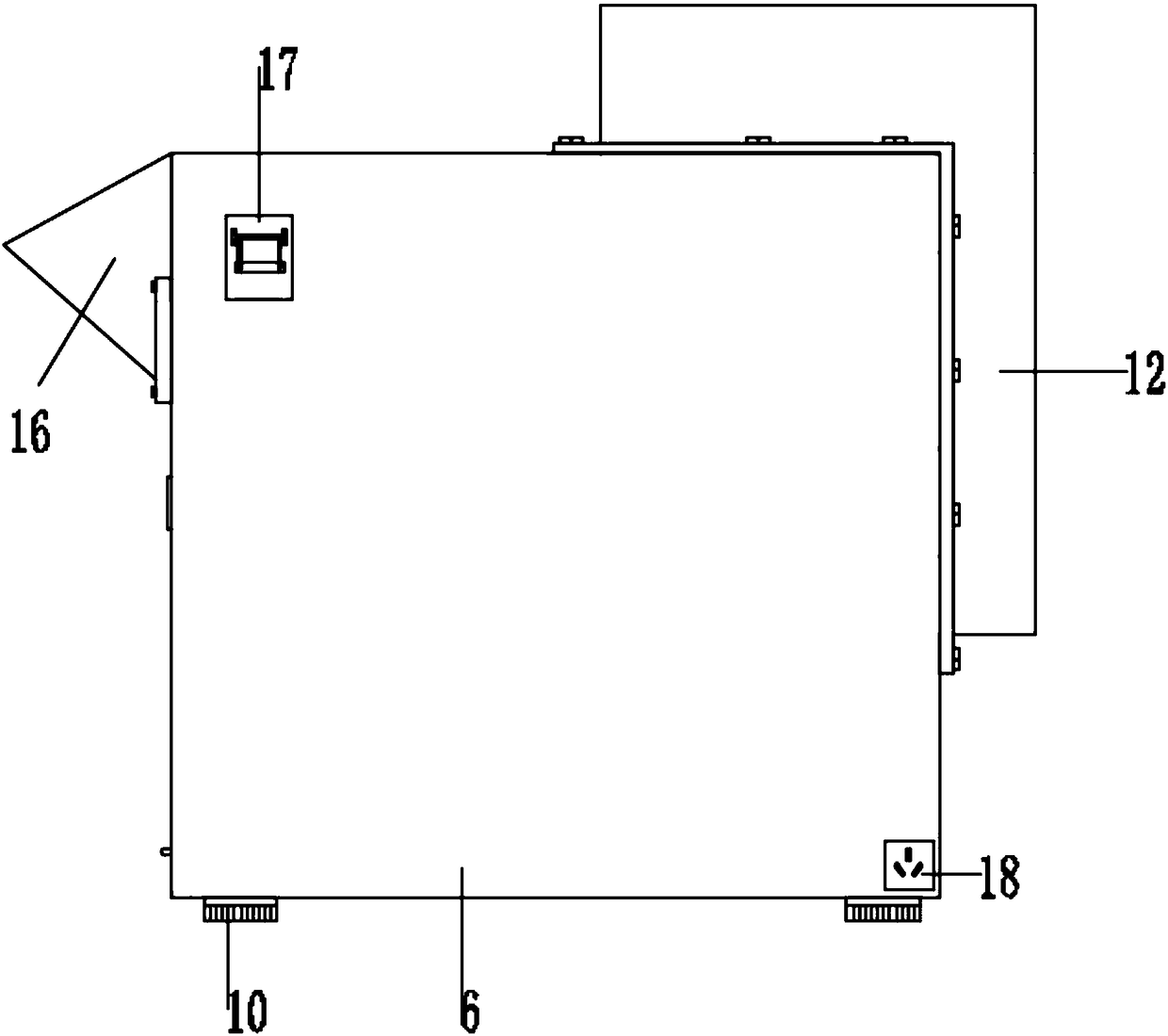

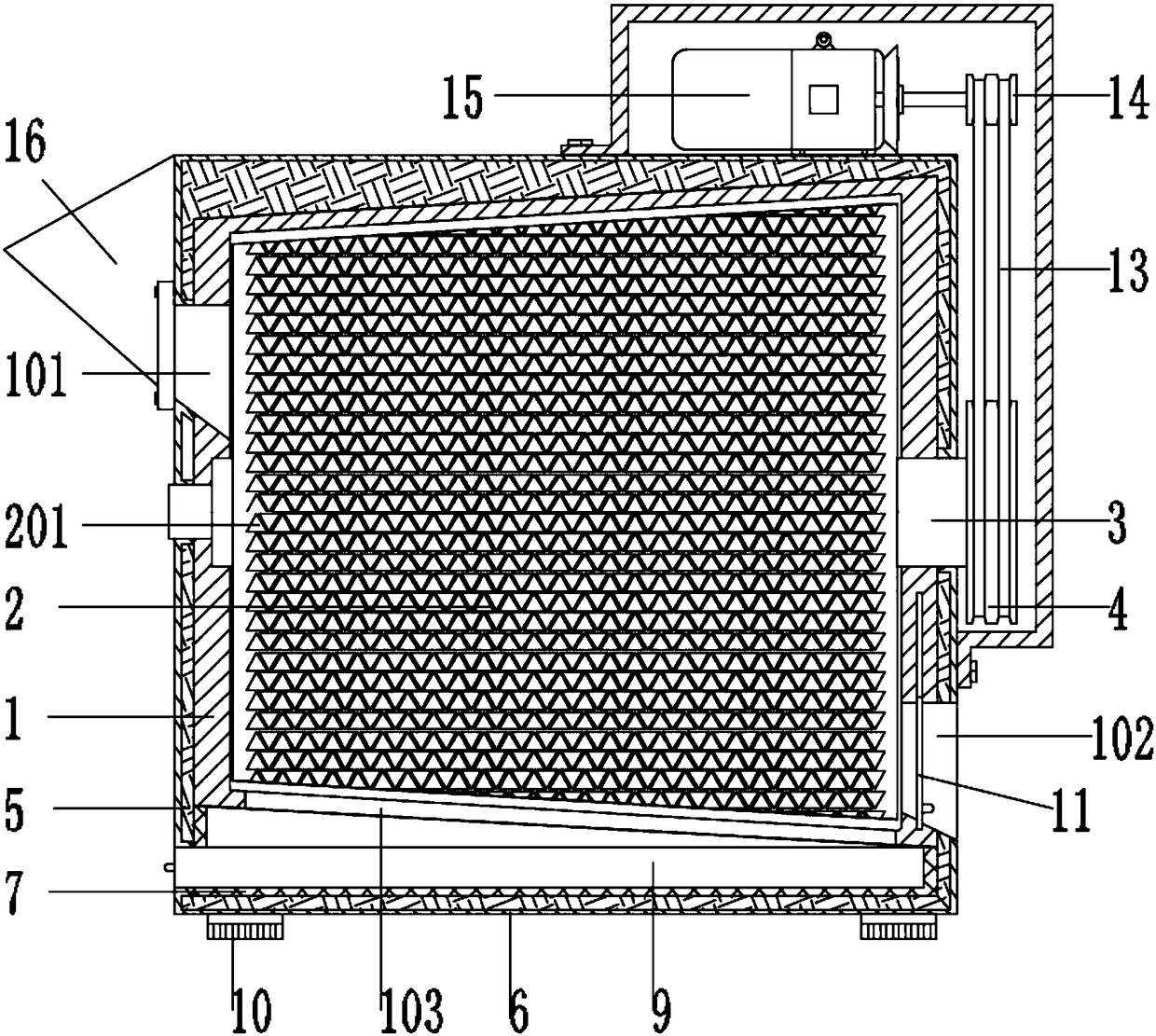

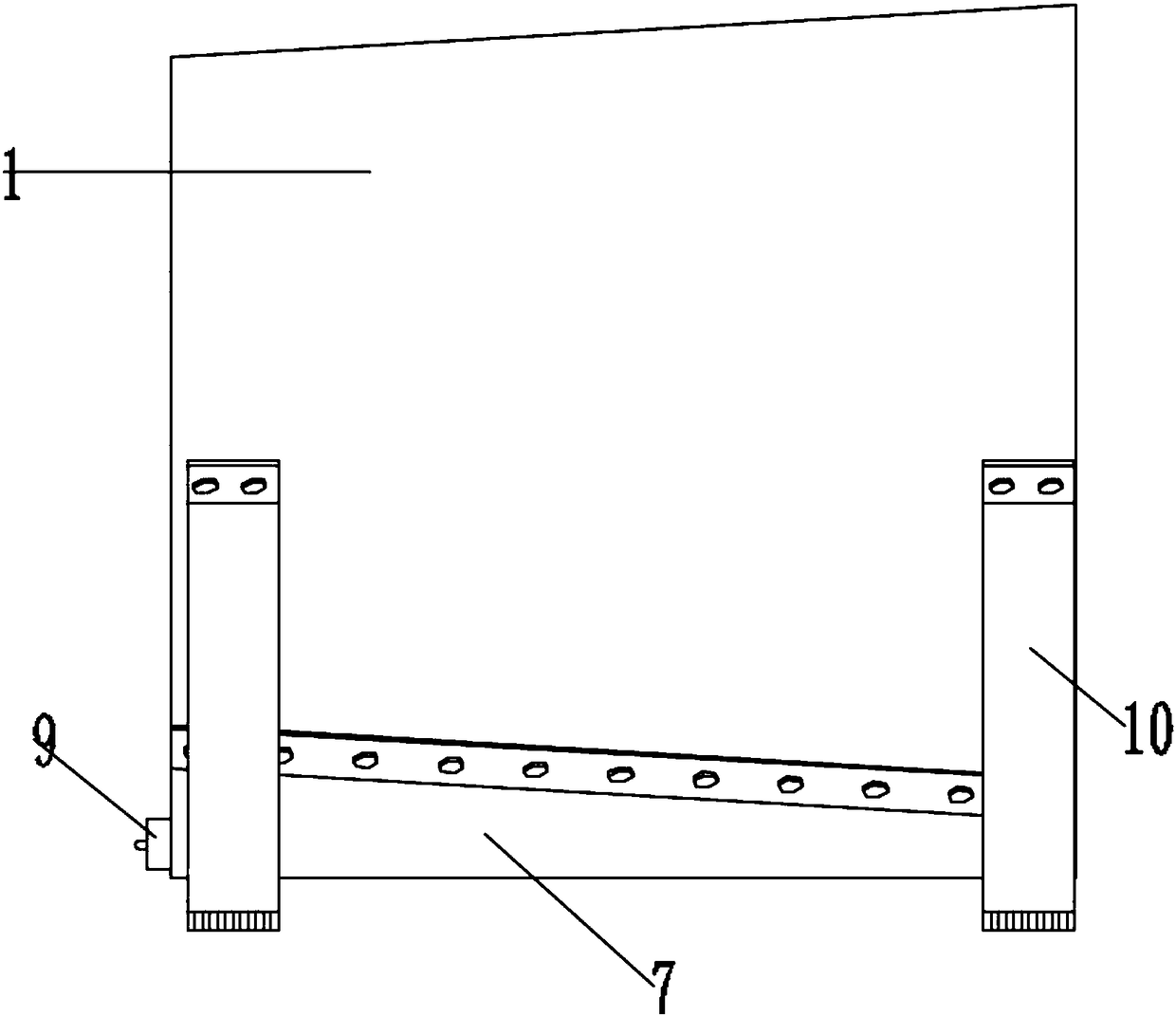

Rust removing equipment for machining

ActiveCN108527137AEasy to assemble and useReduce physical laborEdge grinding machinesPolishing machinesEngineeringControl switch

The invention provides rust removing equipment for machining. The rust removing equipment comprises a master control switch and a power plug. Four supporting columns are mounted on the outer wall of arust removing inner cylinder, and a feeding hole is formed in the top of the left side end face of the rust removing inner cylinder and communicates with the bottom of a feeding funnel; a discharginghole is formed in the bottom of the right side end face of the rust removing inner cylinder, a gate plate is mounted at the discharging hole, and one end of the gate plate is slidablyconnected with the interior of the rust removing inner cylinder; and a rust leaking hole is formed in the bottom of the rust removing inner cylinder and located in the top of a rust residue collecting drawer. Grinding balls and the outer walls of mechanical parts makes mutual friction advantageouslythrough rotating of a rust removing rotating cylinder, and rust contained in the exteriors of the mechanical parts is removed, so that the exteriors of the mechanical parts are smoother and cleaner, and the mechanical parts can conveniently assembled and used by people; the rust removing rotating cylinder is arranged obliquely so thatpeople can discharge the mechanical parts convenientlythrough rotating of the rust removing rotating cylinder, physical labor of people is reduced, and the working efficiency is promoted.

Owner:扬州君杰金属制品有限公司

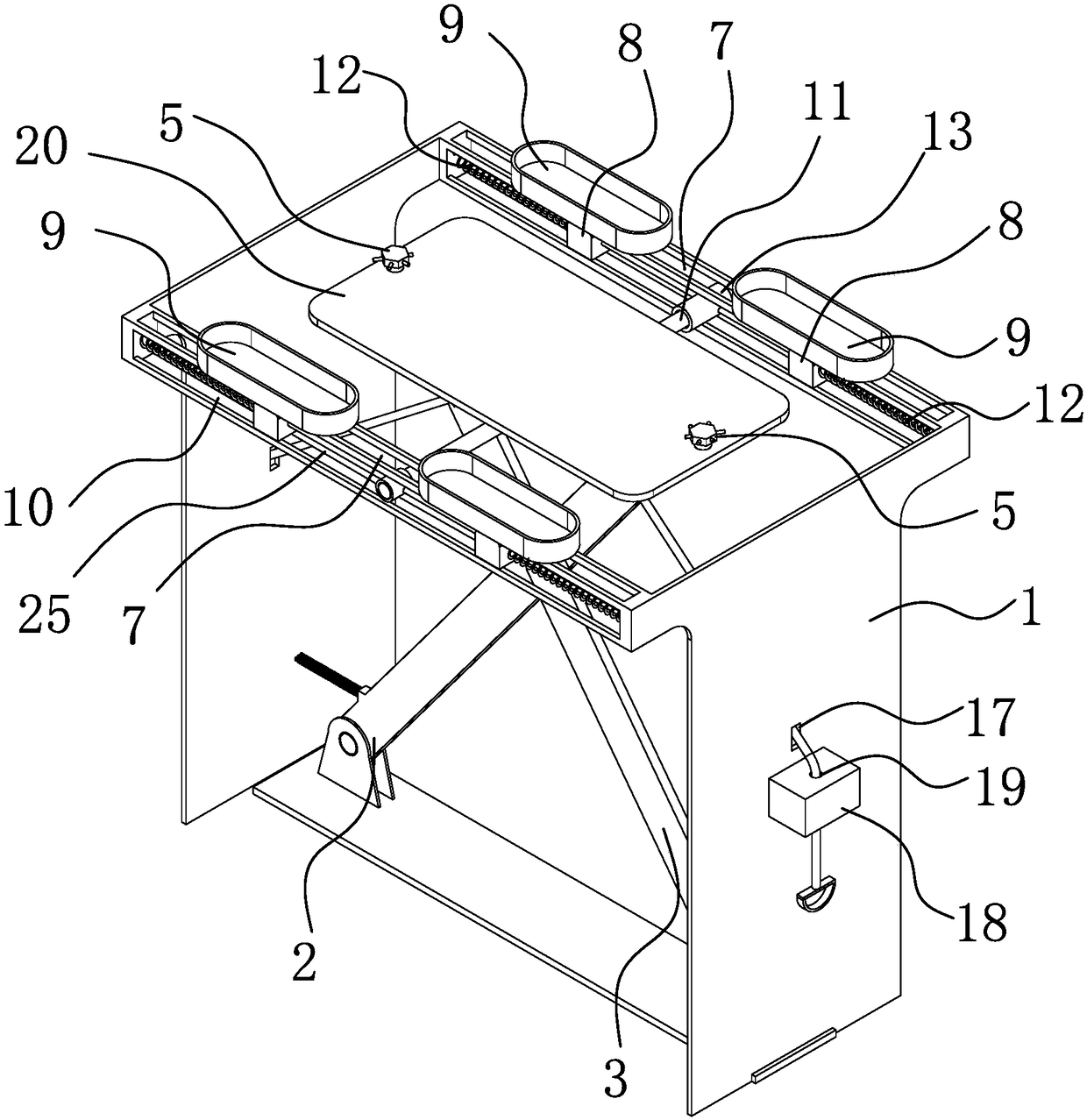

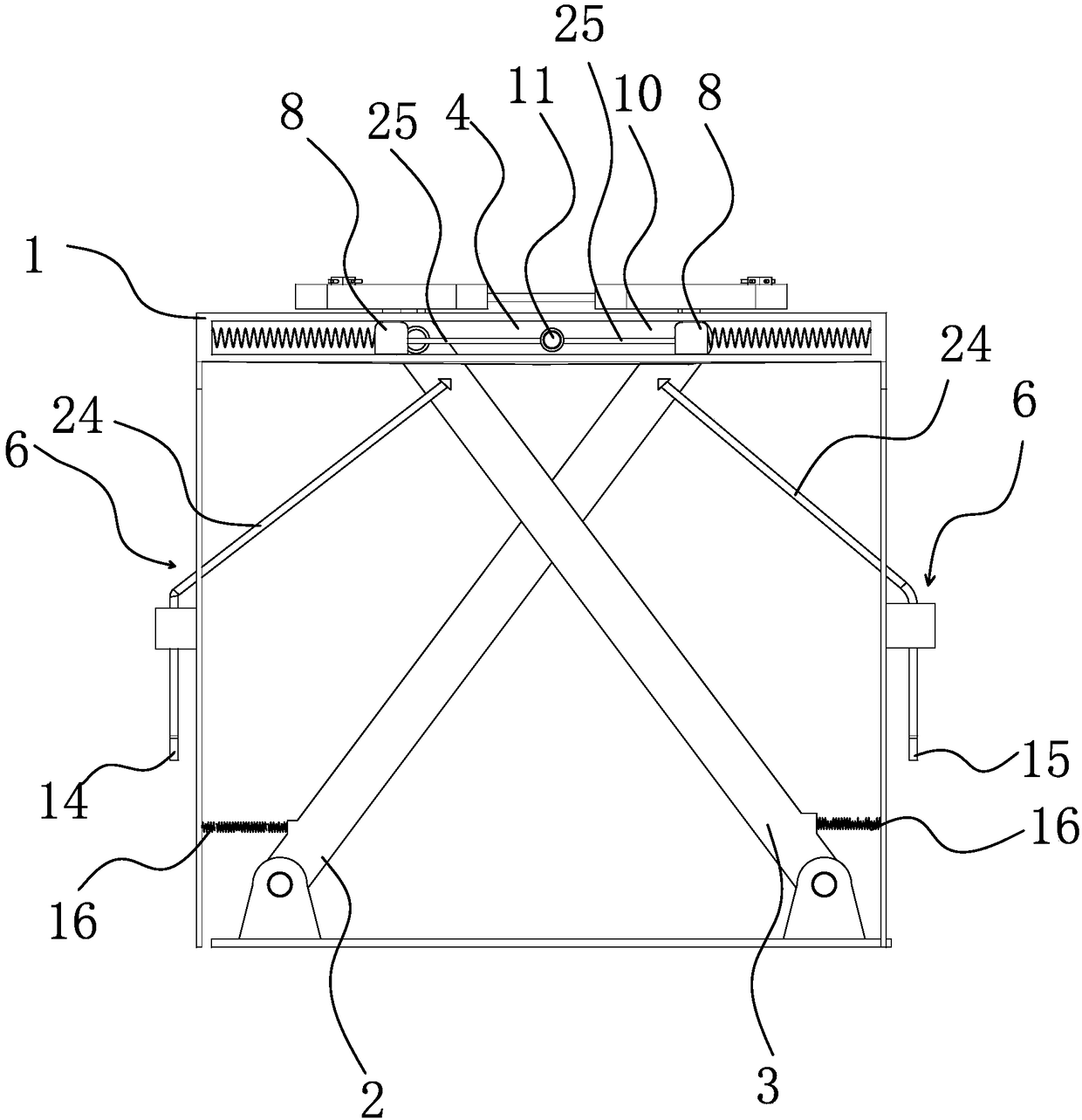

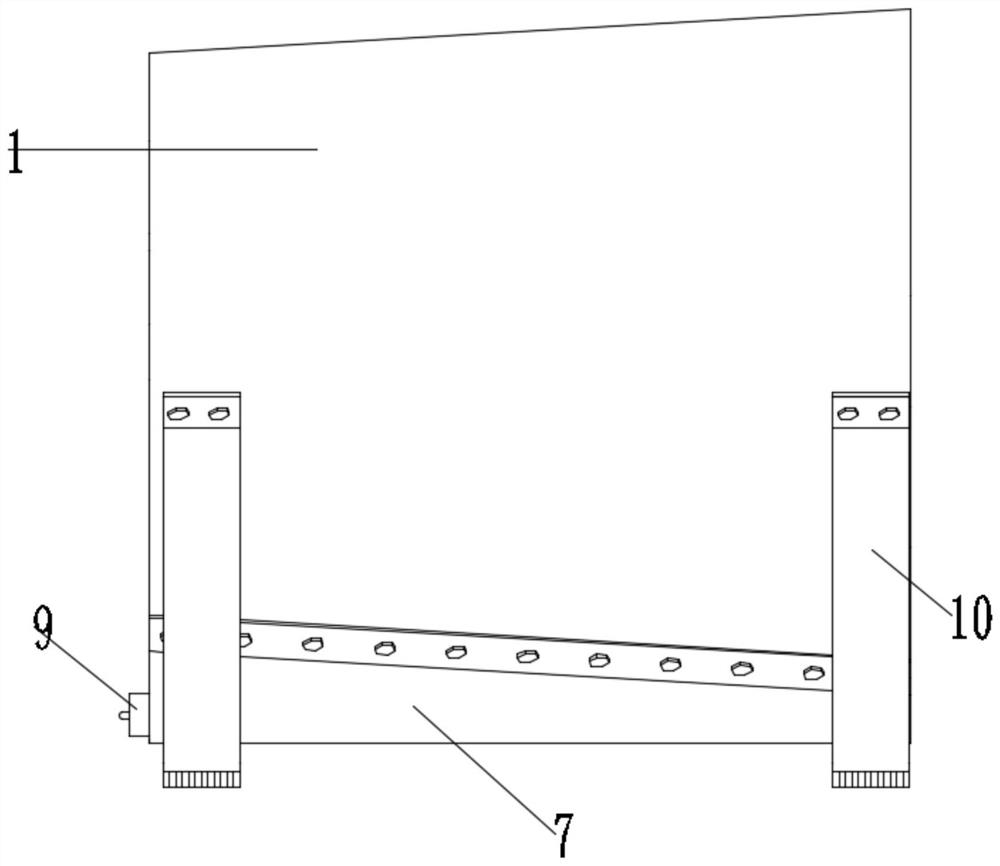

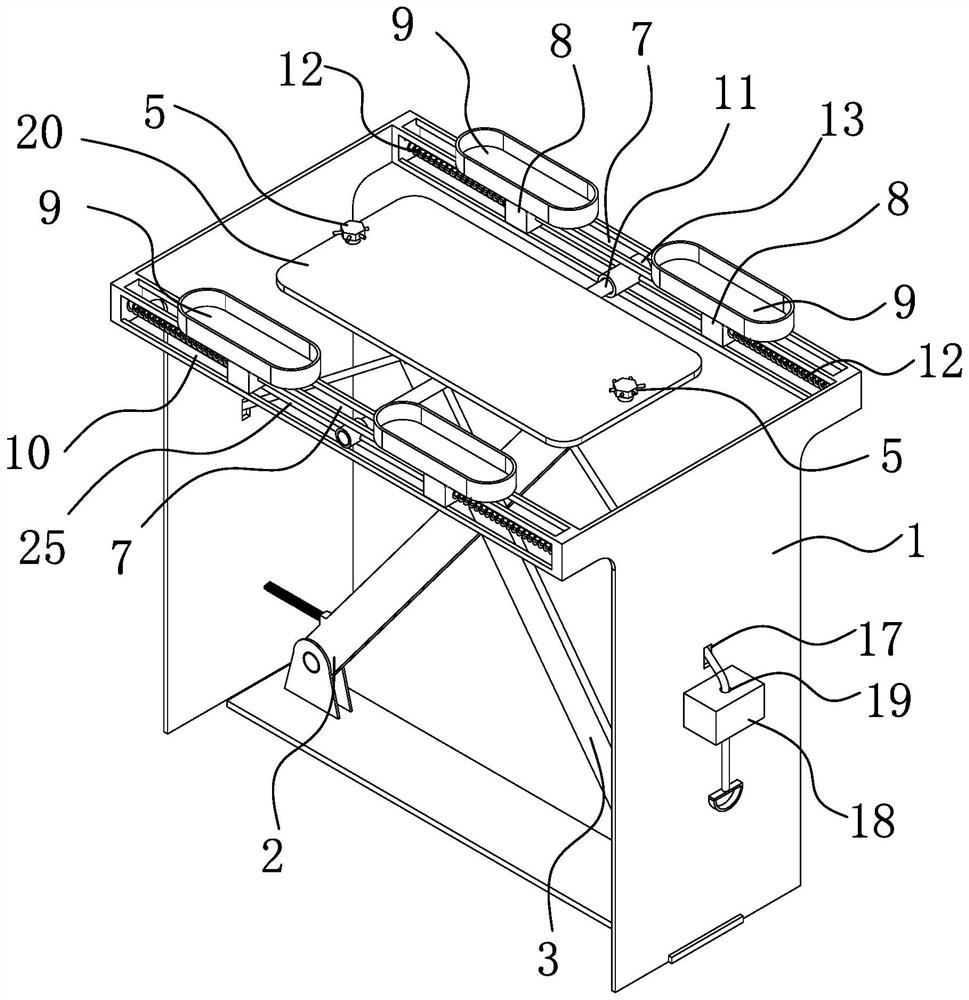

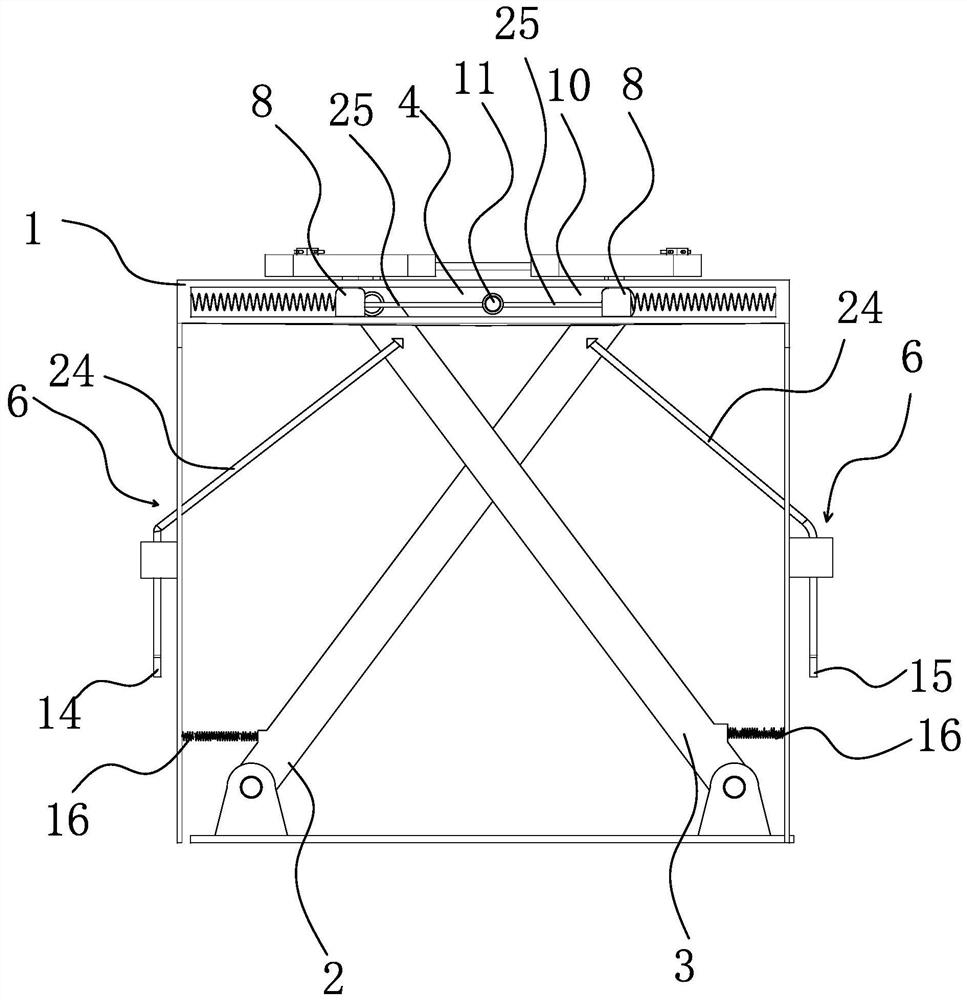

Double-person worktable

The invention belongs to the technical field of machinery, relates to a double-person worktable, and solves such technical problems as low working efficiency in assembly of the same product by two persons in the prior art. The double-person worktable comprises a bracket; the bracket is provided with space for mounting a connecting rod mechanism in self length direction; the connecting rod mechanism comprises a first connecting rod, a second connecting rod and a cross bar; the lengths of the first connecting rod and the second connecting rod are both 25 unit lengths; the lower end of the firstconnecting rod and the lower end of the second connecting rod are both hinged to the bracket; the distance from the lower hinge point of the first connecting rod to the lower hinge point of the secondconnecting rod is 20 unit lengths; the upper end of the first connecting rod and the upper end of the second connecting rod are hinged with the two ends of the cross bar; the length of the cross baris 10 unit lengths; a positioning device for fixing workpieces to be assembled is arranged on the upper surface of the cross bar; and the bracket is provided with a driving device capable of driving the first connecting rod and / or the second connecting rod to swing. The double-person worktable can effectively improve the assembly efficiency.

Owner:张 丽英

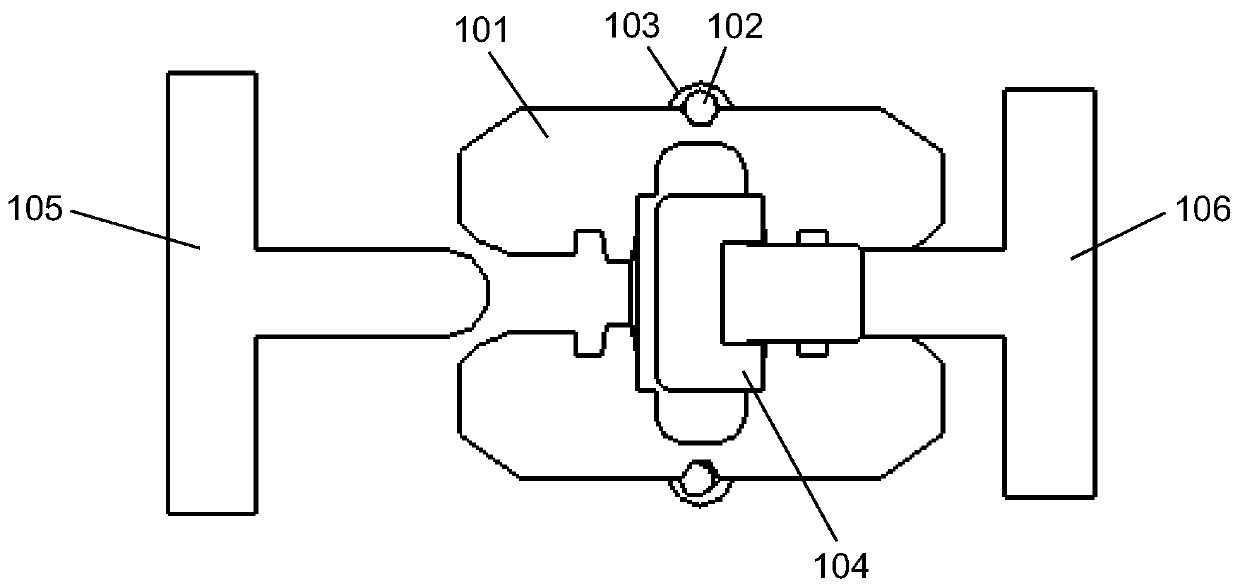

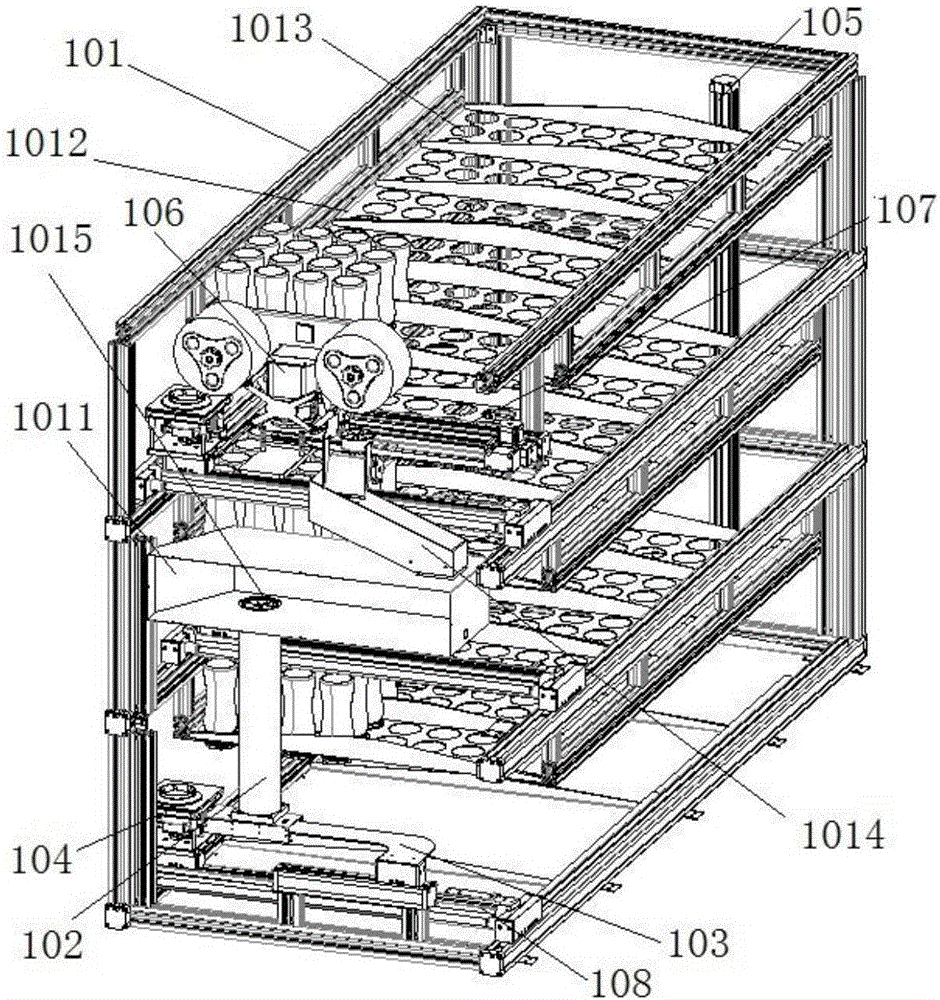

Moving device

InactiveCN111107186AAssembly influenceTelephone set constructionsStructural engineeringElectrical and Electronics engineering

The invention discloses a moving device, and relates to the technical field of battery assembly. The battery comprises a battery rear shell and a battery cover, a battery groove with an opening facingthe battery cover and a blocking arm matched with the battery groove are formed in the bottom face of the battery rear shell, and the blocking arm is provided with a first station and a second station. A limiting protrusion is arranged on the inner surface, facing the battery rear shell, of the battery cover, and when the battery cover is installed, the battery rear shell is provided with an installation path opposite to the moving track of the limiting protrusion. When the battery is not installed in the battery groove of the battery rear shell, the blocking arm is located at the first station, and the blocking arm is located on the installation path to interfere with the limiting protrusion. When the battery is installed in the battery groove of the battery rear shell, the blocking armis driven by the battery to move to the second station, and when the blocking arm is located at the second station, the blocking arm is located outside the installation path, and interference betweenthe blocking arm and the limiting protrusion is relieved. The battery rear shell and the battery cover are improved, the state of the battery groove is changed before and after the battery is mounted,and neglected mounting of the battery is reduced.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

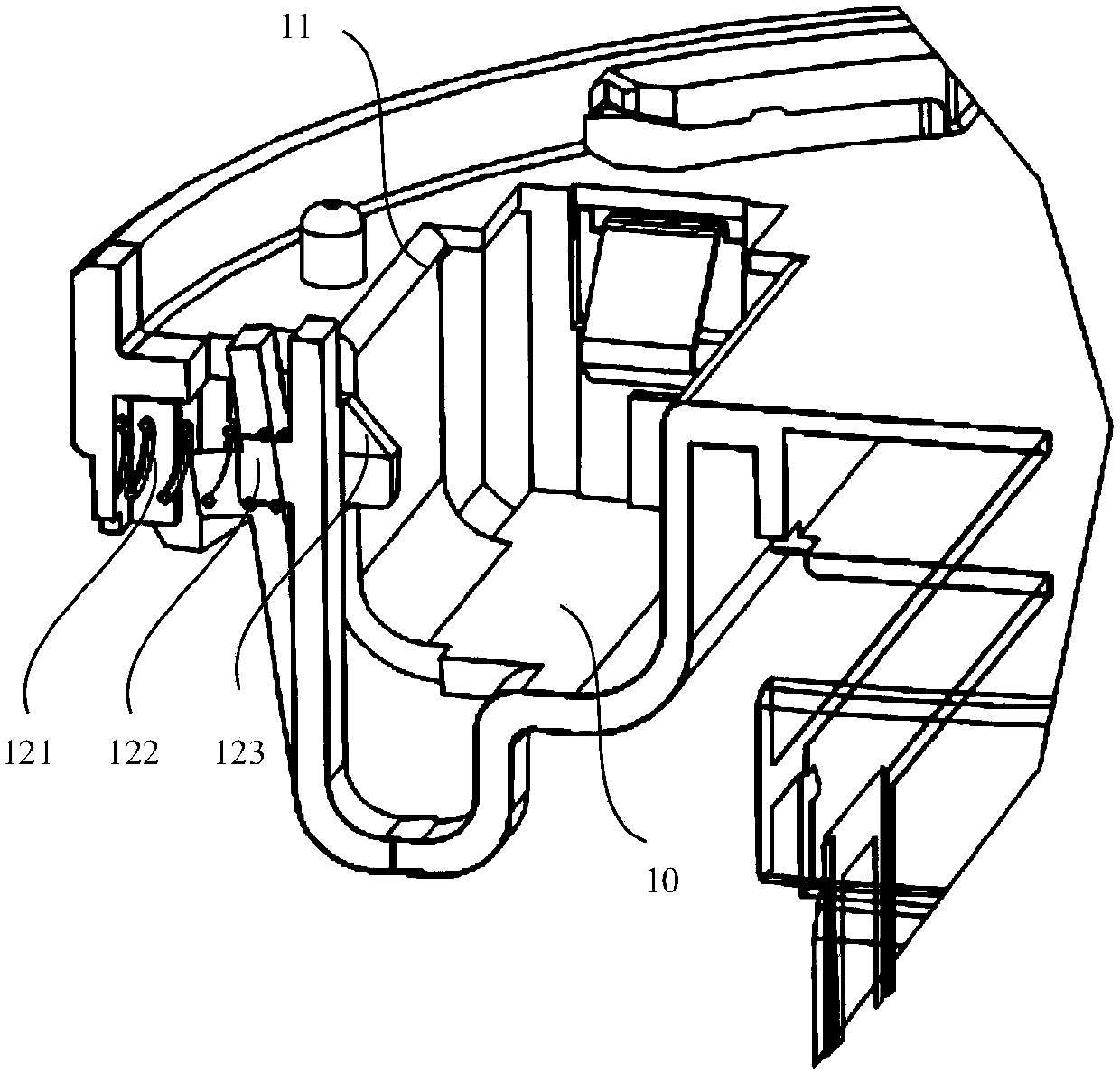

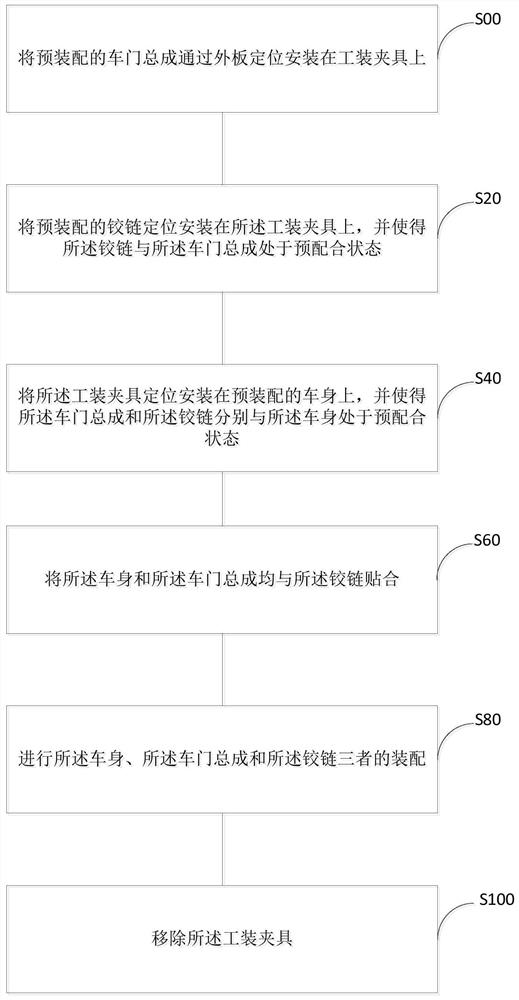

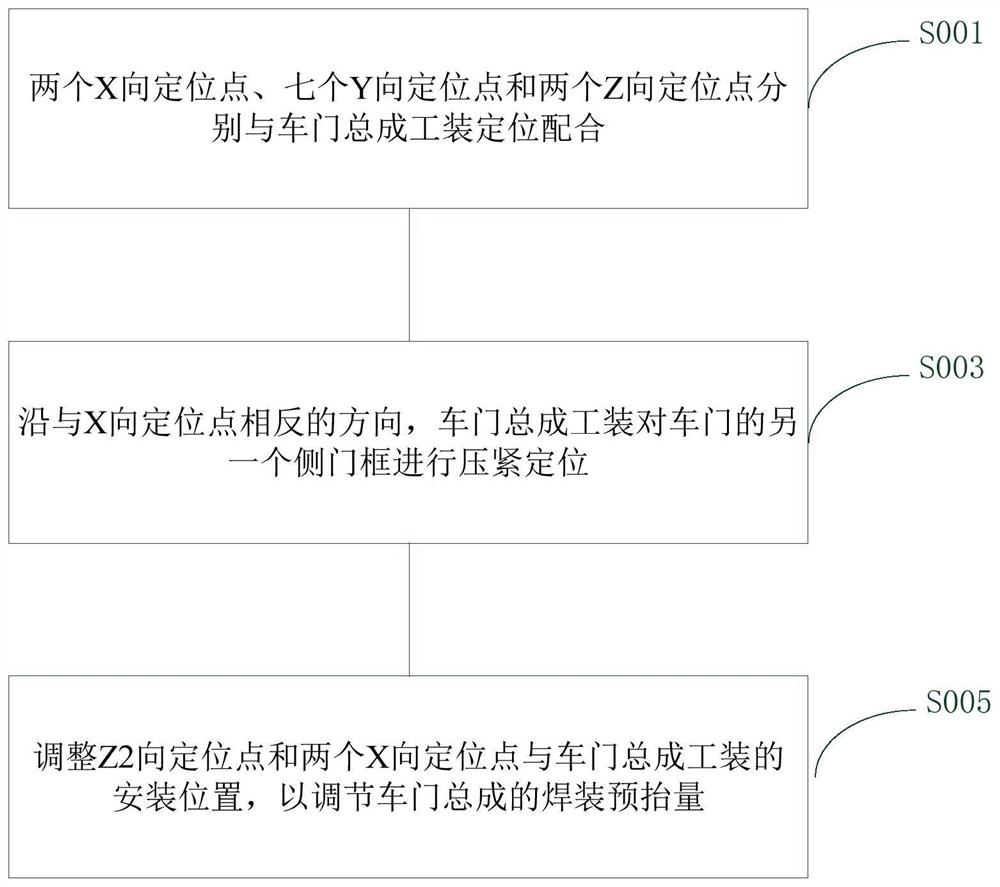

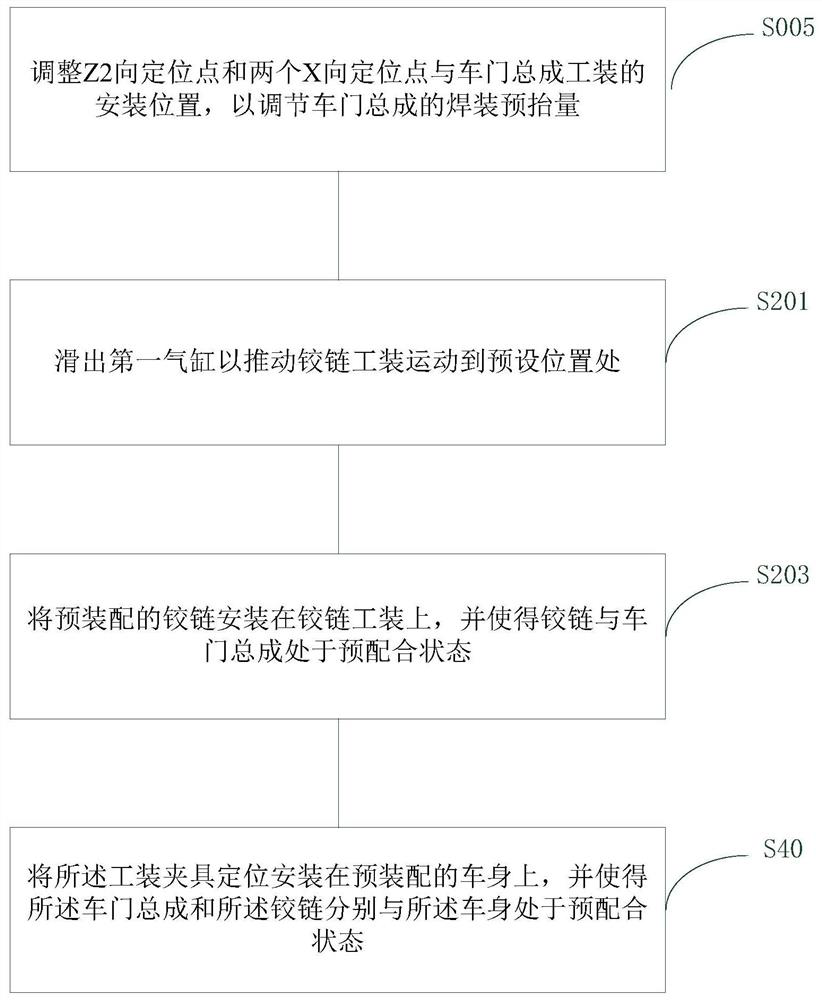

Automobile door assembly method and automobile door assembly device

The invention relates to the technical field of automobiles, in particular to an automobile door assembling method and an automobile door assembling device. The assembling method of the automobile door comprises the steps that a pre-assembled automobile door assembly is positioned and installed on a tool clamp through an outer plate; positioning and installing a pre-assembled hinge on the tool clamp, enabling the hinge and the door assembly to be in a pre-matched state; positioning and installing the tool clamp on a pre-assembled vehicle body, and the vehicle door assembly and the hinge are respectively in a pre-matched state with the automobile body; the automobile body and the automobile door assembly are attached to the hinge; assembling of the automobile body, the vehicle door assembly and the hinge is carried out, and the tool clamp is removed. According to the automobile door assembling method and the automobile door assembling device, the gap and surface difference between the automobile door assembly and the automobile body can meet the requirements, so that the assembling quality between the automobile door assembly and the automobile body is improved, and the assembling process is simple.

Owner:CHONGQING JINKANG NEW ENERGY VEHICLE CO LTD

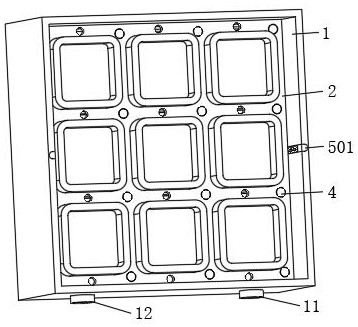

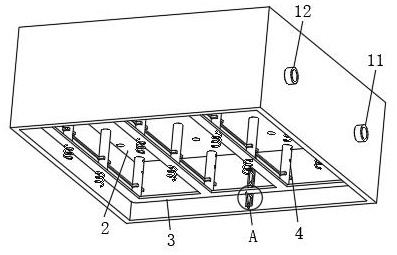

Workbench for assembling electronic component

InactiveCN109249356AAssembly influencePrevent fallingWork benchesMetal working apparatusMotor driveEngineering

The invention relates to the technical field of the electronic component assembly, and discloses a workbench for assembling an electronic component. The workbench for assembling the electronic component comprises an assembling workbench. The bottom of the assembling workbench is fixedly provided with storage boxes. There are four storage boxes, and the every two storage boxes are sorted as one group. The bottom of the assembling workbench is fixedly provided with support legs. Through assembling the electronic component at the top of the assembling workbench, the assembled electronic componentis placed at the top of a smooth placing plate. Cooperated with the action of a timing machine case, a motor in a motor box is rotated periodically. Through the transmission effect of a transmissionbelt, the output end of the motor drives a connection rotating rod to be rotated, and a conveying belt at the outer side face of a rotating cylinder is driven. Cooperated with a driving rod fixedly connected to the outer side face of the conveying belt, the electronic component at the top of the smooth placing plate is conveyed. The assembled electronic component is avoided from being stacked at the top of the assembling workbench, so that the assembly of the electronic component is affected.

Owner:绍兴市柯桥区蓝天软件有限公司

USB socket and electronic equipment

InactiveCN110534965AAssembly influenceGuaranteed tightnessCouplings bases/casesCoupling parts mountingInterference fitCPU socket

The invention provides a USB socket for electronic equipment and the electronic equipment. The USB socket comprises a body and a sealing ring, the body is sleeved with the sealing ring, the sealing ring comprises a main body part and a sealing part, and the sealing part is arranged on the surface of the side, away from the body, of the main body part. When the USB socket is inserted into a jack ina middle frame of the electronic equipment, the sealing part deforms to enable the sealing ring to be in interference fit with the inner wall of the jack of the middle frame to achieve sealing and waterproofing, the sealing ring and the inner wall of the jack of the middle frame define containing space, and the containing space is used for containing deformation of the sealing part. The USB socket provided by the invention is good in sealing and waterproof effects, and is beneficial to assembly.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Rubber mat for motorcycle oil tank

ActiveCN107628162AIncreasing the thicknessImprove shock absorptionInternal combustion piston enginesFuel tanksFuel tankPetroleum engineering

The invention discloses a rubber mat for a motorcycle oil tank. The rubber mat comprises a blocky body. The side, facing the rear side of a motorcycle, of the body is provided with a first extending part. The top of the first extending part is provided with a first through hole for an installation bolt to pass through. The radial outer surface of the first extending part can be attached to the inner surface of an installation lug. The side, close to the first extending part, of the top of the body is provided with a first protrusion. The side, facing the front side of the motorcycle, of the first protrusion can abut against the oil tank. The rubber mat and the installation lug of the motorcycle oil tank can be accurately positioned, and the assembling of the motorcycle oil tank is facilitated.

Owner:JIANGMEN HUARI GRP

A performance testing system for connecting rod big-end needle roller bearings

InactiveCN103076176BAssembly influenceAvoid inaccuraciesMachine bearings testingNeedle roller bearingData acquisition

Owner:WUYI UNIV

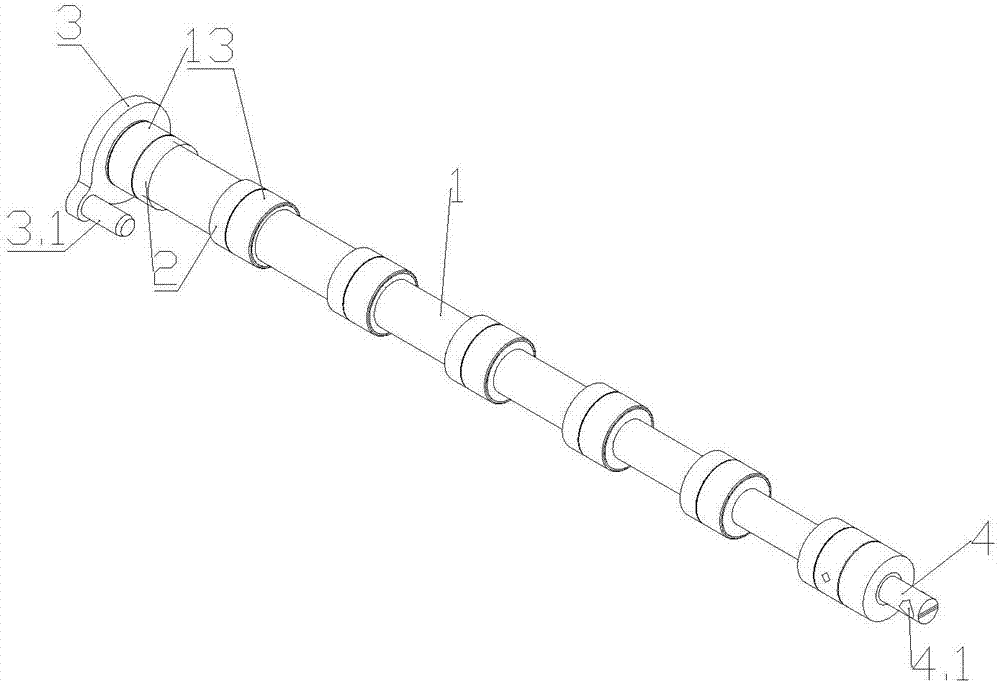

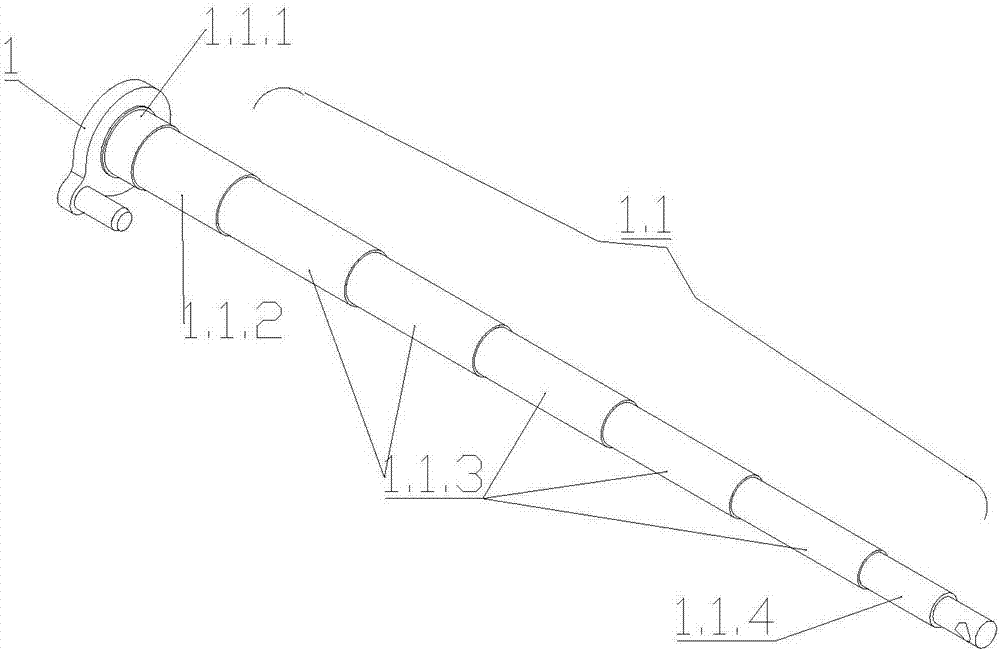

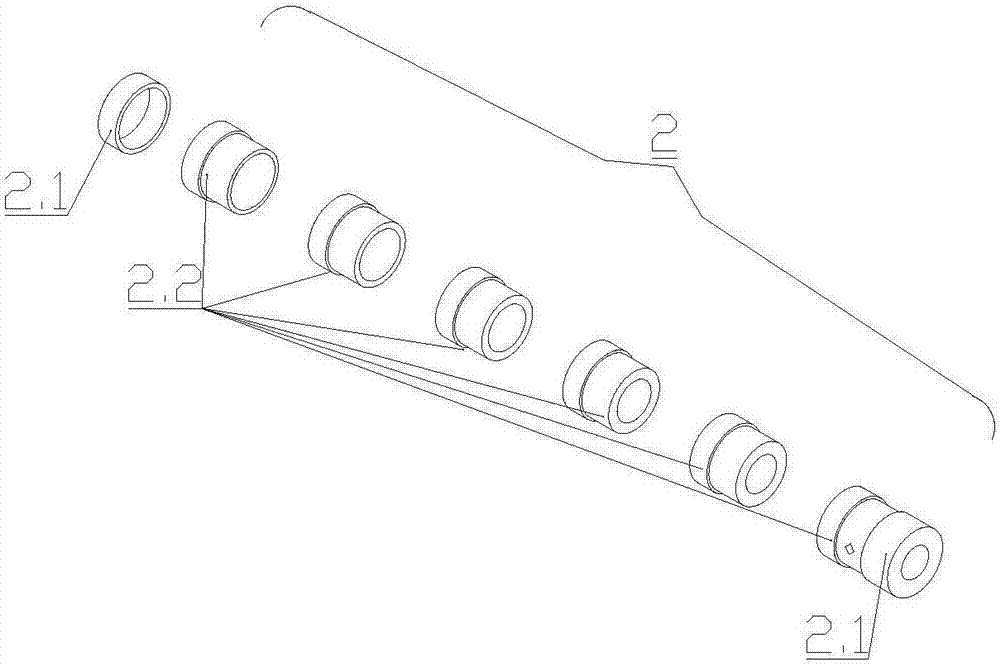

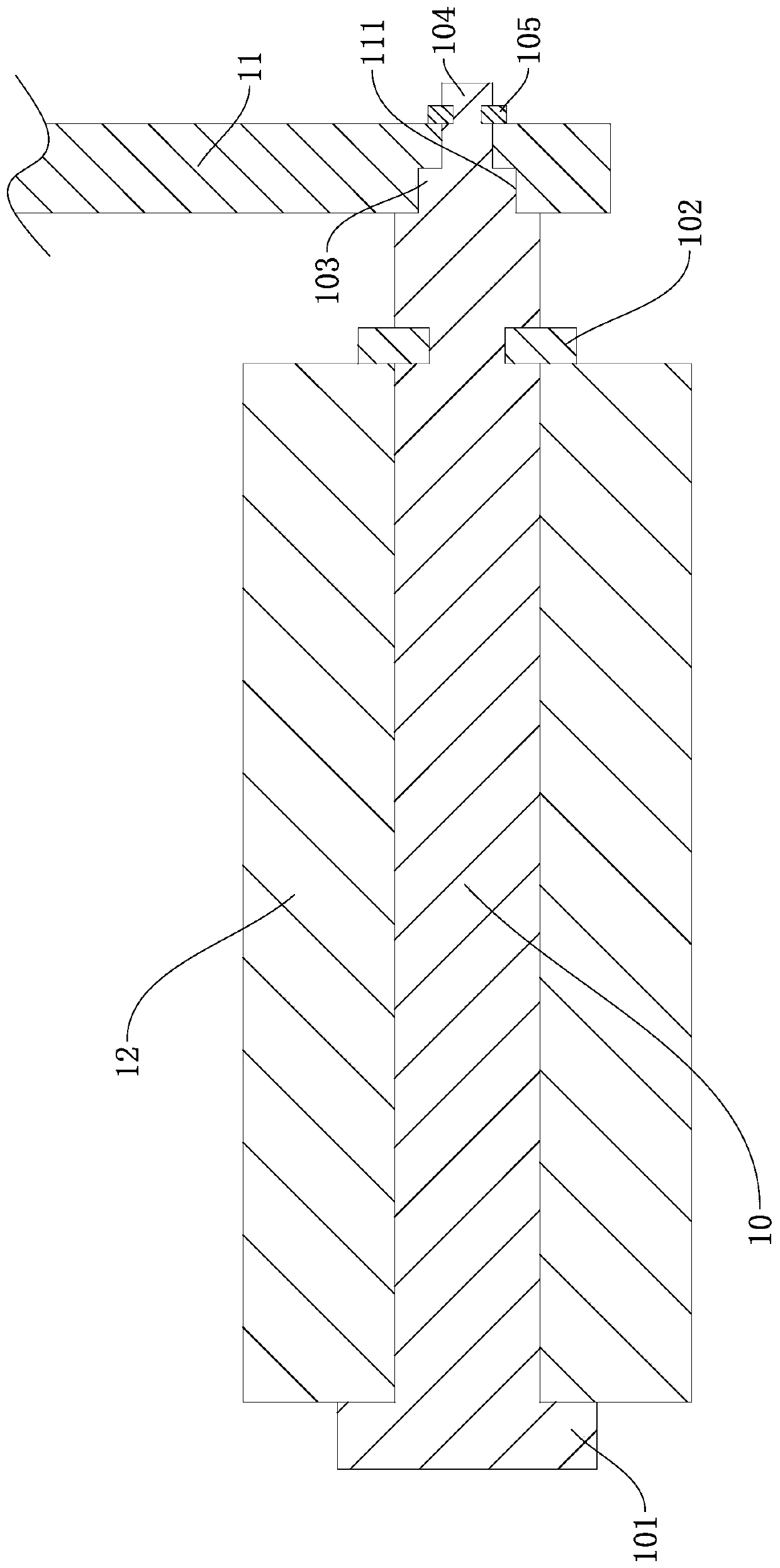

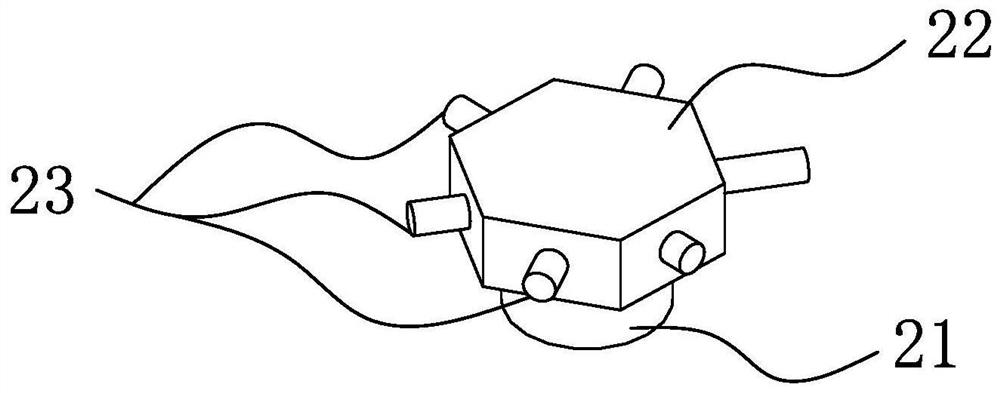

Cylinder body lining assembling tool

InactiveCN107139129AAssembly influencePrevent rotationMetal working apparatusMetal-working hand toolsEngineeringHydraulic equipment

The invention discloses a cylinder body lining assembling tool which comprises an assembling pull rod. The assembling pull rod comprises a stepped shaft and a plurality of limiting sleeves. The stepped shaft comprises a plurality of shaft bodies with the diameters gradually decreased. The axial lengths of the shaft bodies are matched with the distance between limiting baffles of a corresponding cylinder body cam shaft hole. The diameter difference value of every two adjacent shaft bodies is 2-6 mm. The limiting sleeves are located on the corresponding shaft bodies. The top of the stepped shaft is provided with a positioning end face. The positioning end face is provided with a positioning pin. The tail end of the stepped shaft is provided with a connection rod with a pin hole. According to the assembling tool, the stepped shaft and the limiting sleeves matched with the shaft bodies of the stepped shaft are adopted, hydraulic equipment is utilized for completing installation of all linings in one cam shaft hole at a time, operation is efficient, and the precision is high.

Owner:襄阳钛虎动力工程有限公司

Rust removal equipment for machining

ActiveCN108527137BEasy to assemble and useReduce physical laborEdge grinding machinesPolishing machinesMechanical componentsEngineering

The invention provides rust removing equipment for machining. The rust removing equipment comprises a master control switch and a power plug. Four supporting columns are mounted on the outer wall of arust removing inner cylinder, and a feeding hole is formed in the top of the left side end face of the rust removing inner cylinder and communicates with the bottom of a feeding funnel; a discharginghole is formed in the bottom of the right side end face of the rust removing inner cylinder, a gate plate is mounted at the discharging hole, and one end of the gate plate is slidablyconnected with the interior of the rust removing inner cylinder; and a rust leaking hole is formed in the bottom of the rust removing inner cylinder and located in the top of a rust residue collecting drawer. Grinding balls and the outer walls of mechanical parts makes mutual friction advantageouslythrough rotating of a rust removing rotating cylinder, and rust contained in the exteriors of the mechanical parts is removed, so that the exteriors of the mechanical parts are smoother and cleaner, and the mechanical parts can conveniently assembled and used by people; the rust removing rotating cylinder is arranged obliquely so thatpeople can discharge the mechanical parts convenientlythrough rotating of the rust removing rotating cylinder, physical labor of people is reduced, and the working efficiency is promoted.

Owner:扬州君杰金属制品有限公司

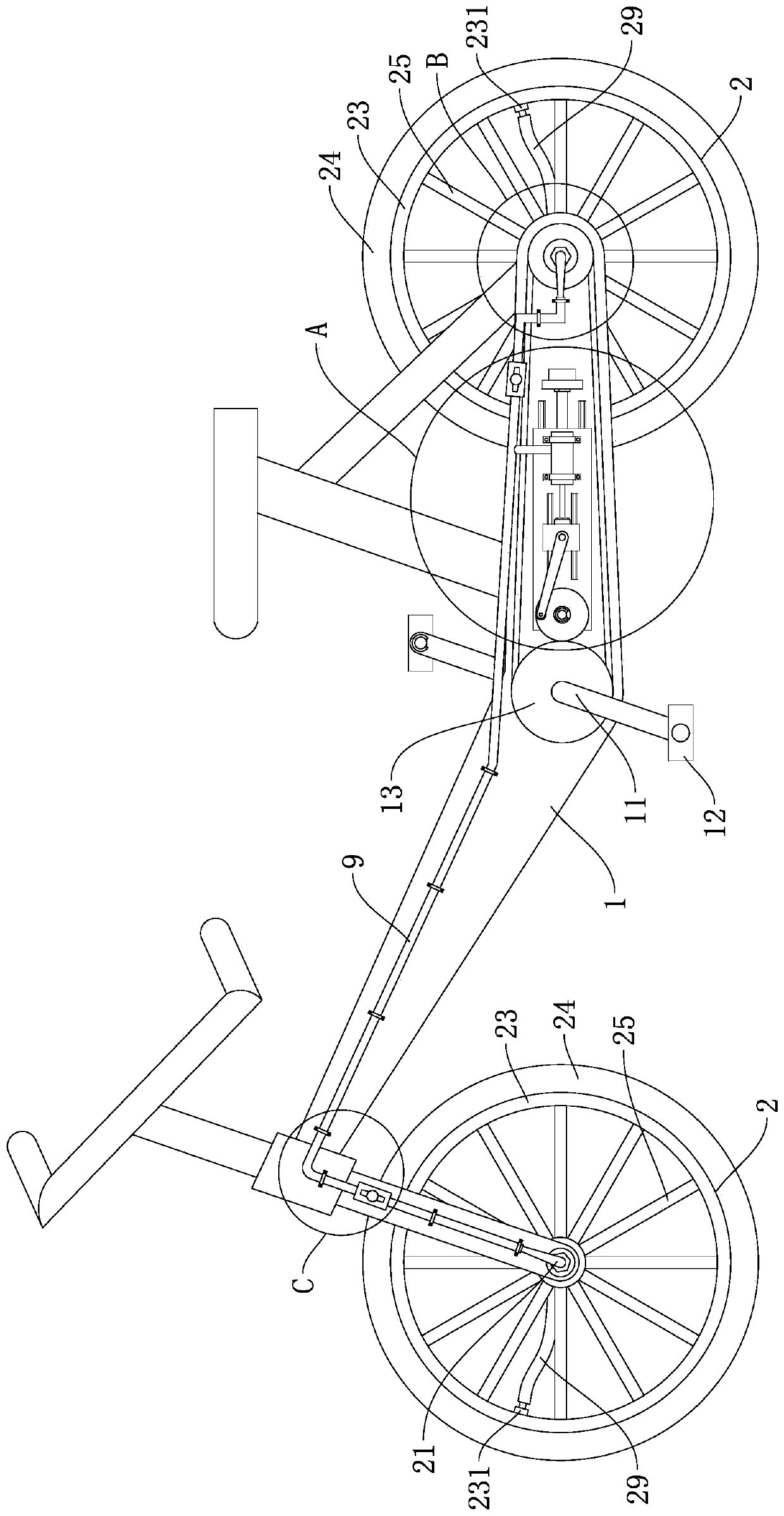

Bicycle with pedals convenient to install

The invention discloses a bicycle with pedals convenient to install. The bicycle comprises a bicycle frame, a crank is rotationally connected to the middle of the bicycle frame, pedals are installed at the two ends of the crank respectively, a supporting shaft penetrates through each pedal, the pedals are rotationally connected with the supporting shafts, the outer end of each supporting shaft isprovided with an end with the outer diameter larger than that of the corresponding supporting shaft, and the inner end of each supporting shaft penetrates through the corresponding pedal and then is clamped with a first clamping spring in a matched mode; a square inserting part is integrally formed in the middle of the inner end of the supporting shaft, the inserting part is inserted into a squareinserting groove in the outer side face of the crank, a plug pin coaxial with the supporting shaft is integrally formed in the middle of the inner end of the inserting part, and the plug pin movablypenetrates through the crank, then stretches out of the crank and is clamped with a second clamping spring in a matched mode; the supporting shaft arranged in the pedal in the penetrating mode is assembled with the crank in a matched and clamped mode, in this way, when the pedal and the crank are assembled, tools such as a wrench do not need to be used, and therefore convenience can be brought toinstallation of the pedal.

Owner:沈国荣

A double workbench

ActiveCN108297042BImprove assembly efficiencyEasy to assembleWork benchesStructural engineeringWorkbench

The invention belongs to the technical field of machinery and relates to a double-person workbench, which solves the technical problems of low work efficiency when two people simultaneously assemble and process the same product in the prior art. The two-person workbench includes a bracket. The bracket has a space for installing the link mechanism along its own length. The link mechanism includes the first link, the second link and the cross bar. The length of the first link and the second link is 25 pieces. Unit length, the lower end of connecting rod 1 and the lower end of connecting rod 2 are both hinged on the bracket, and the distance between the lower hinge point of connecting rod 1 and the lower hinge point of connecting rod 2 is 20 unit lengths, the The upper end and the upper end of the connecting rod 2 are respectively hinged with the two ends of the cross bar. The length of the cross bar is 10 unit lengths. The upper surface of the cross bar is provided with a positioning device for fixing the workpiece to be assembled. A driving device for swinging of rod one and / or connecting rod two. The two-person workbench can effectively improve assembly efficiency.

Owner:张 丽英

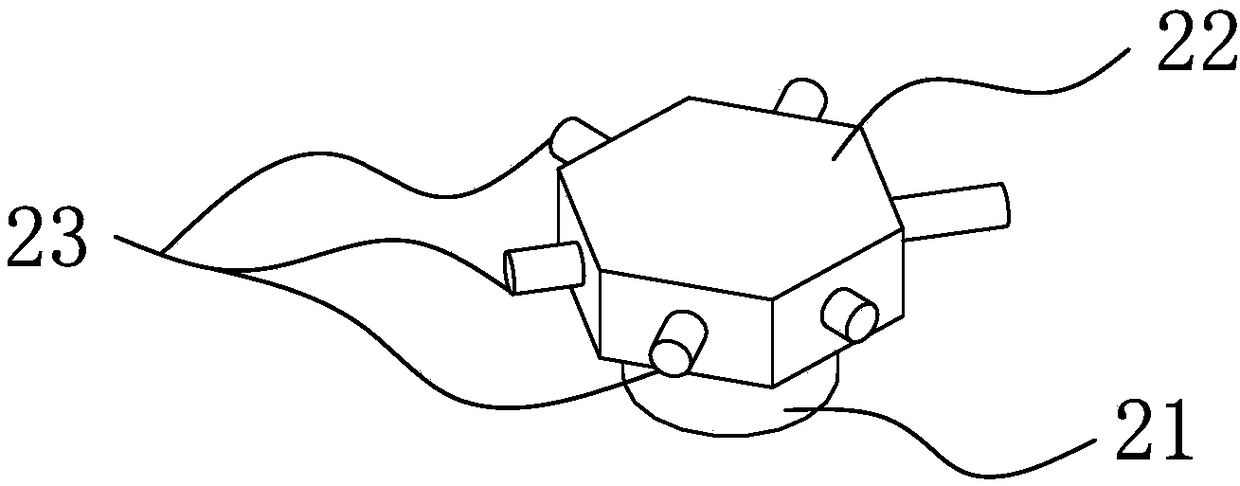

Terminal batch assembler for wire harness

ActiveCN111082281ASimple and efficient operationImprove work efficiencyLine/current collector detailsEngineeringElectrical and Electronics engineering

The invention relates to an assembler, in particular to a terminal batch assembler for wiring harnesses. The technical problem is how to design the terminal batch assembler for the wire harness, whichcan assemble terminals on the wire harness, is simple and convenient to operate, saves labor and is high in working efficiency. The invention discloses the terminal batch assembler for the wire harness. The terminal batch assembler comprises a bracket, a placing frame, an L-shaped clamping rod, a first spring, a contact rod, a rolling head and the like, wherein an upper part of a rear side of thebracket is fixedly connected with the placing frame for placing terminals, a bottom end of the placing frame is provided with a blocking mechanism for blocking the terminals, and a lower part of a front side of the placing frame is slidably provided with the L-shaped clamping rod for fixing the terminals. A proper amount of terminals are placed in the placing frame, one end of the wire harness isinserted into the terminals, a holding rod is pulled to rotate reversely to enable the rolling head to move backwards to press the terminals on the wire harness for assembly, a person does not need to hold the wire harness with one hand and sleeve the terminal on an end of the wire harness with the other hand to press and assemble with a tool, the operation is easy and convenient, the labor is saved, and the work efficiency is high.

Owner:赣州市领沃电子科技有限公司

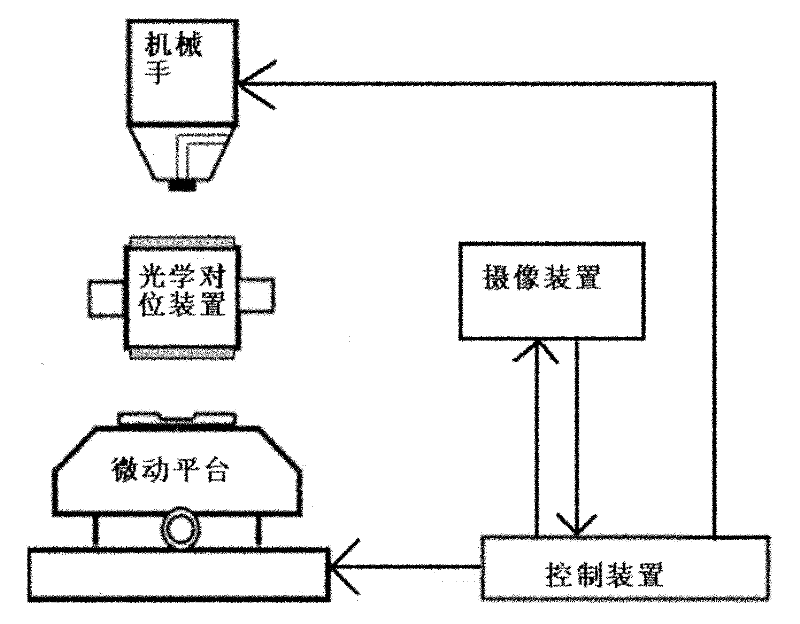

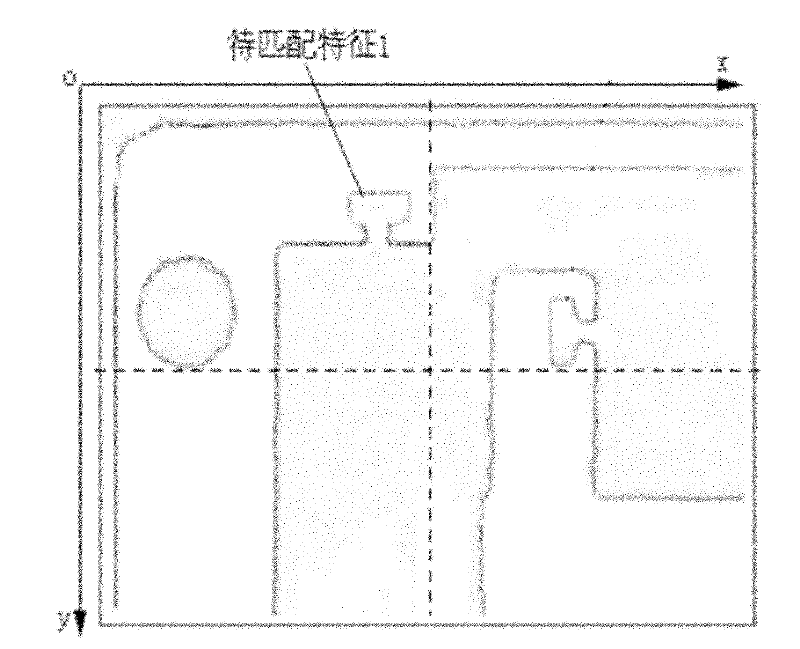

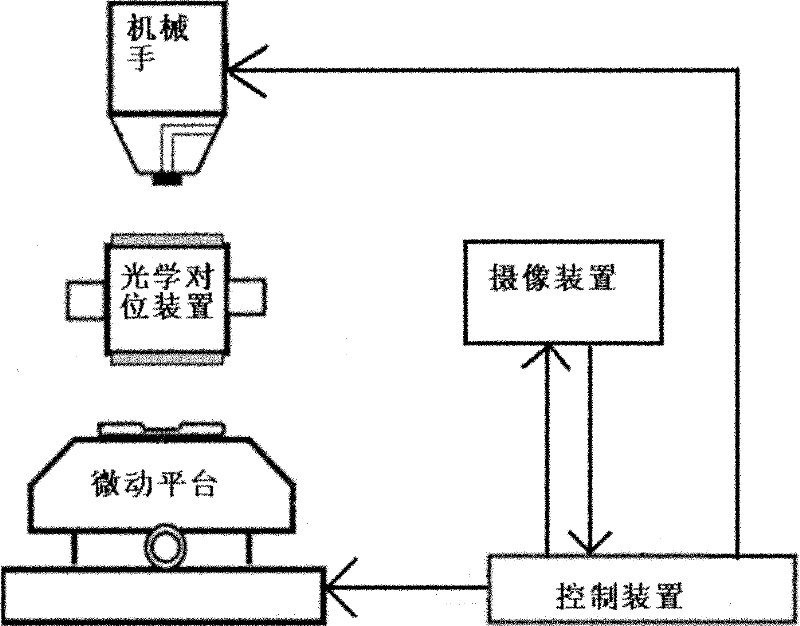

High-accuracy visual coaxial optical alignment assembly system for miniature structural member

ActiveCN102073148BSmall amount of calculationHigh speedOptical elementsTemplate matchingControl signal

The invention provides a high-accuracy visual coaxial optical alignment assembly system for a miniature structural member. The system comprises a manipulator, a light source, an optical alignment device, a micro-positioning platform, an image pick-up device and a control device, wherein the image pick-up device and the optical alignment device are positioned on the same horizontal line; and the manipulator and the micro-positioning platform are positioned above and below the optical alignment device respectively. A local template is used, images of both a base member and a member to be arranged are binary images, and a binary edge only exists in the template matching process, so the calculated amount is greatly reduced and the speed is improved during matching, and the requirement on a positioning real-time property is met. The local template is used for searching an accurate alignment pixel coordinate and a directional line included angle of the base member and the member to be arranged, and the micro-positioning platform is adjusted under control of a control signal generated by the system, so that the system has higher alignment accuracy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

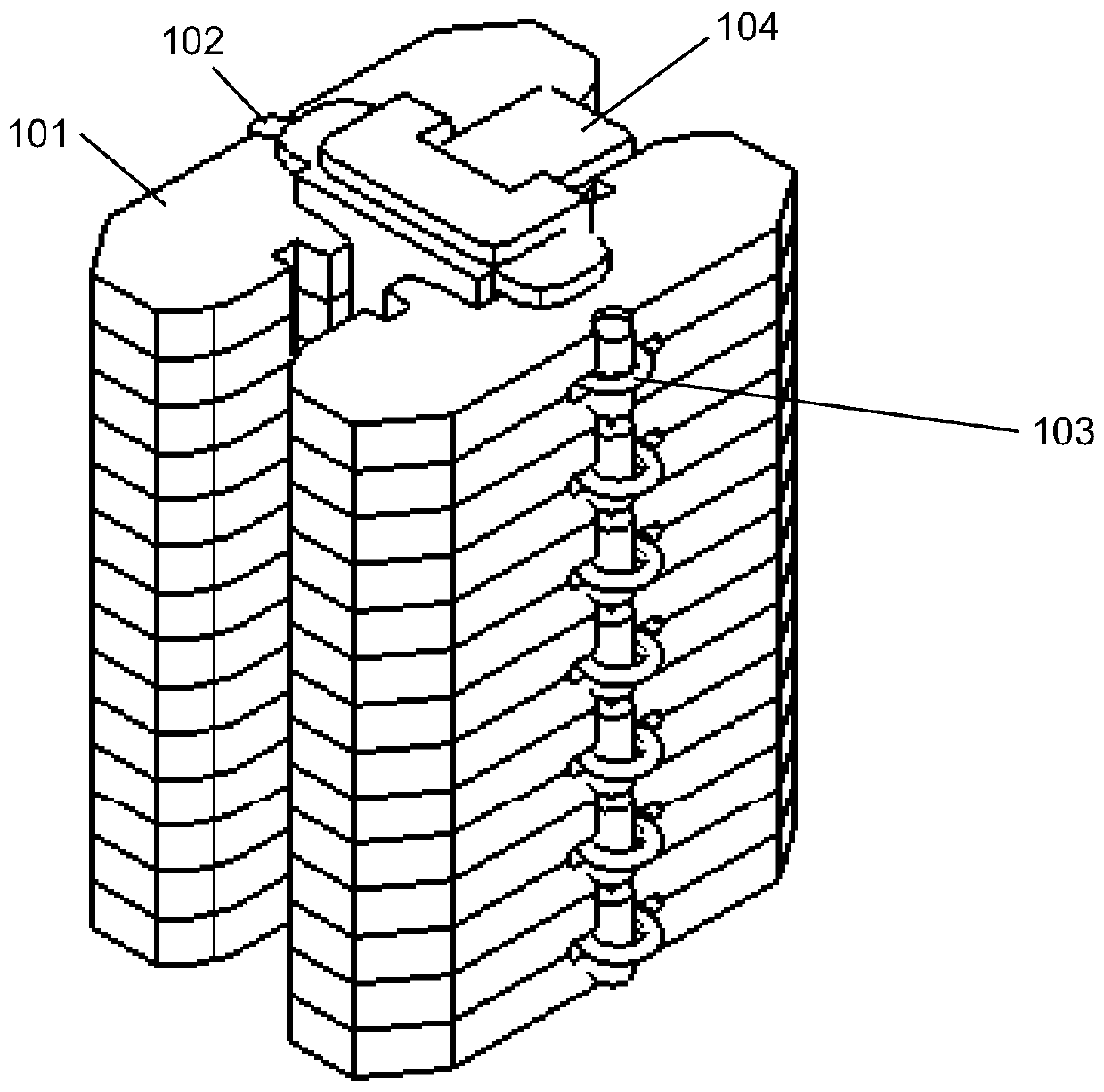

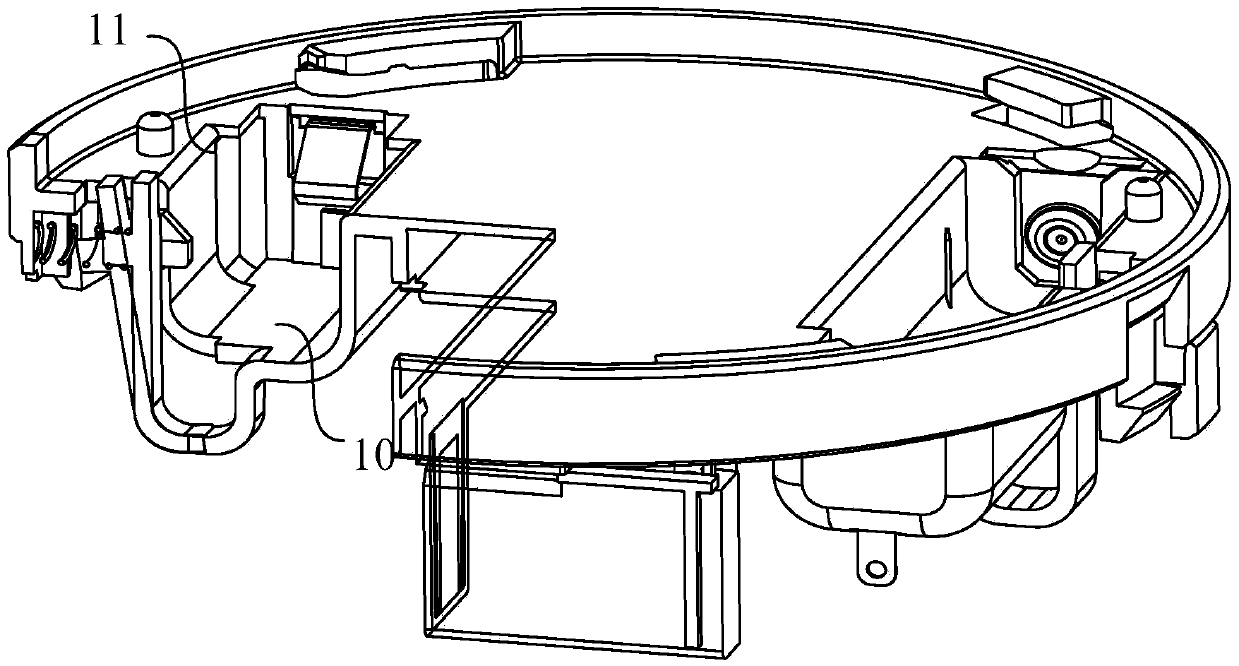

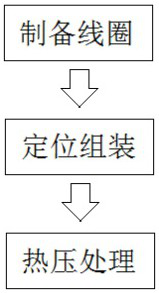

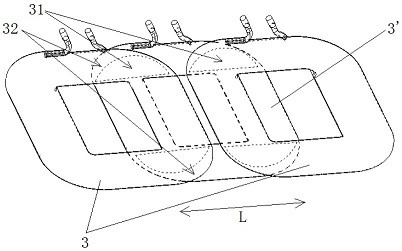

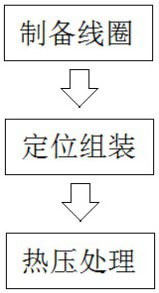

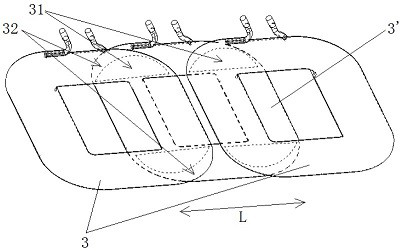

Hot-pressing assembly method and hot-pressing assembly device for multiple coils

ActiveCN113990651AAssembly influenceEasy to operateCharging stationsElectric vehicle charging technologyWire rodAdhesive glue

The invention belongs to the technical field of assembly of wireless charging modules, and discloses a hot-pressing assembly method and hot-pressing assembly device for multiple coils. The method comprises the following steps of: coil preparation, specifically, making wires into the coils, and forming hot melt adhesive layers on the surfaces of the coils; positioning and assembling, specifically, positioning and placing the at least two coils according to the assembling form of the at least two coils; and hot-pressing treatment, specifically, carrying out hot-pressing on the at least two coils to melt the specified parts of the hot melt adhesive layers so as to bond the at least two coils to each other. In the process of preparing the coils, the hot melt adhesive layers are formed on the surfaces of the coils, the at least two coils are positioned and placed, and then the specified parts of the hot melt adhesive layers are melted through hot pressing, so that the at least two coils are bonded with each other, the assembly of the multiple coils is completed, the operation is simple, the assembly efficiency is high; and glue does not need to be additionally adhered among the plurality of coils, so that the influence on the assembly of a wireless charging module due to the increase of the thickness of a coil module caused by the additionally adhered glue is avoided.

Owner:STEWARD FOSHAN MAGNETICS CO LTD

Multi-coil thermocompression assembly method and thermocompression assembly device

ActiveCN113990651BAssembly influenceEasy to operateCharging stationsElectric vehicle charging technologyWire rodAdhesive glue

The invention relates to the technical field of assembly of wireless charging modules, and discloses a multi-coil hot-press assembly method and a hot-press assembly device, including the following steps: preparing a coil: making a wire into a coil, and forming a hot melt on the surface of the coil Adhesive layer; positioning and assembly: according to the assembly form of at least two coils, position and place at least two coils; hot pressing treatment: heat and press at least two coils to melt the designated parts of the hot melt adhesive layer, so that at least two The coils are bonded to each other. In the present invention, a hot-melt adhesive layer is formed on the surface of the coil during the process of preparing the coil, and at least two coils are positioned and placed, and the designated part of the hot-melt adhesive layer is melted by hot pressing, so that at least two coils Adhere to each other to complete the assembly of multiple coils, the operation is simple, the assembly efficiency is high, and there is no need to attach additional glue between multiple coils, avoiding the additional glue that causes the thickness of the coil module to increase and affect the wireless charging module. Assemble.

Owner:STEWARD FOSHAN MAGNETICS CO LTD

Electric pneumatic type machine for assembling U-shaped ribs of plate units

ActiveCN100467202CReduce or eliminate direct effectsExtended service lifeMetal working apparatusEngineeringPiston rod

An electrically pneumatic assembling machine for assembling the U-shaped rib onto the unit plate used for the steel structure of bridge is composed of a transverse beam, a formwork module under said transverse beam, the guide sleeves fixed to said transverse beam, the guide rods in said guide sleeves and connected between formwork module and piston rod of cylinder, and the cylinders fixed to said transverse beam.

Owner:WUCHUAN HEAVY ENG

A new energy vehicle battery management cooling device

ActiveCN114639896BAssembly influenceGuaranteed temperatureSecondary cellsCell component detailsAutomotive batteryNew energy

The invention relates to the field of battery heat dissipation, and discloses a heat dissipation device for battery management of new energy vehicles. Several fixed seats arranged in a rectangular array and used for placing batteries are installed. The interior of the box is provided with a guide assembly connected with the air inlet, and the guide assembly includes a connected guide plate and a round pipe. The air outlet assembly is fixedly installed on the surface of the deflector. The present invention can further separate and fix the batteries through the cooperation between the guide components, the air outlet components, the moving components, the bumps, etc., and the spacing can avoid concentrated heat generation, facilitate heat dispersion and reduce the overall temperature of the battery pack; When ventilating, it will wait until the first connecting pipe farthest from the air inlet is ventilated before starting the overall synchronous air outlet, and start synchronously blowing air to dissipate heat to several batteries and the holder, so that each battery is subjected to the same blowing.

Owner:NANTONG WANHENG NEW ENERGY TECH CO LTD

A vector for expressing poliovirus-like particle protein and preparation method of poliovirus-like particle

ActiveCN104480143BAssembly influenceAffect expression imbalanceViral antigen ingredientsInactivation/attenuationVirus-like particleStructural protein

Disclosed are a vector expressing poliomyelitis virus-like granule proteins and a method for preparing poliomyelitis virus-like granules. The vector contains expression cassettes of the following structure: any one of three genes of poliomyelitis virus structural proteins i.e. VP0, VP1, VP3, is located in the downstream of promoter 1, and the other two are connected to the downstream of promoter 2 by a 2A sequence. The promoting expressions directions of the two promoters are opposite. The method for preparing poliomyelitis virus-like granules is that the corresponding host cells are transfected with the vector. After cultivation, virus-like granules and recombinant baculoviruses can be obtained. If what are obtained are the recombinant baculoviruses, then the host cells are infected with the viruses, and virus-like granules can be obtained.

Owner:SOUTH CHINA UNITED VACCINE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com