Multi-coil thermocompression assembly method and thermocompression assembly device

A technology of assembly device and assembly method, which is applied in the direction of coil manufacturing, transportation and packaging, charging stations, etc., can solve the problems of increased thickness and low assembly efficiency, and achieve the effect of high assembly efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

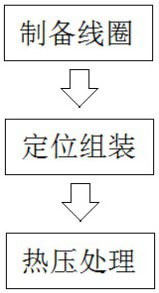

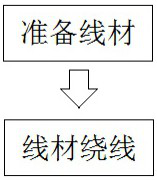

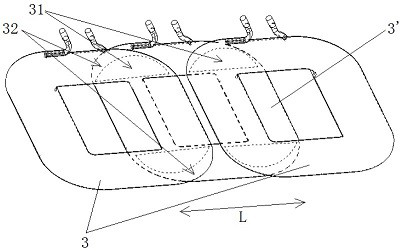

[0033] Such as figure 1 with image 3 As shown, the present invention provides a multi-coil hot-press assembly method, which includes the following steps: Coil preparation: making the wire into a coil, and forming a hot-melt adhesive layer on the surface of the coil; positioning assembly: according to the assembly of at least two coils form, positioning and placing at least two coils; hot-pressing treatment: hot-pressing at least two coils to melt the designated part 31 of the hot-melt adhesive layer, thereby bonding at least two coils to each other.

[0034] In the hot-press assembly method for multi-coils of the present invention, a hot-melt adhesive layer is formed on the surface of the coils during the process of preparing the coils, and then at least two coils are positioned and placed, and at least two coils are hot-pressed, The specified part 31 of the hot melt adhesive layer is melted, so that at least two coils are bonded to each other, and the assembly of multiple c...

Embodiment approach 2

[0044] Such as Figure 7 As shown, the present invention also provides a multi-coil thermocompression assembly device. The above thermocompression assembly method is used to assemble at least two coils. The thermocompression assembly device includes: a positioning jig 2, at least two coils are positioned and placed on the positioning jig 2; the device main body 1 is provided with a heat-pressing mechanism 12, which is used for heat-pressing at least two coils in the positioning fixture 2. The working principle and beneficial effects of the hot-press assembly device are the same as those of the hot-press assembly method in Embodiment 1, and will not be repeated here.

[0045] Such as Figure 7 As shown, specifically, the device main body 1 includes an equipment rack 11, a control cabinet 111 is installed on the lower part of the equipment rack 11, and a control module is built in the control cabinet 111. The hot pressing mechanism 12 is installed on the equipment rack 11 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com