Electric pneumatic type machine for assembling U-shaped ribs of plate units

A pneumatic, single-component technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to apply other shapes of rib assembly, labor intensity of workers, long operation time, etc., to reduce labor costs and Uptime, smooth and reliable transmission, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

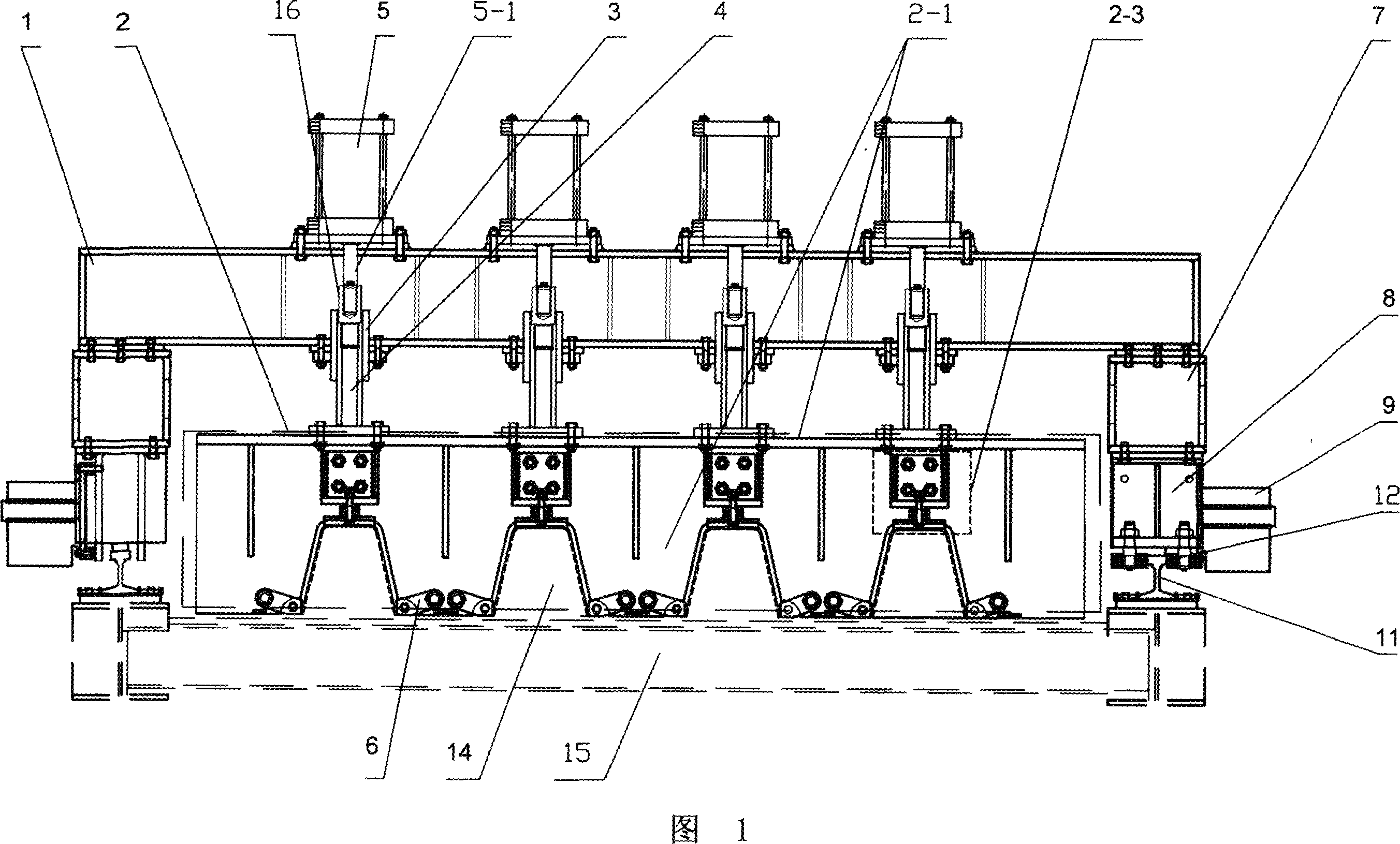

[0011] Specific Embodiment 1: This embodiment is an electro-pneumatic plate unit element U-shaped rib assembly machine, which includes a beam 1 and a formwork assembly 2 arranged below the beam 1. The formwork assembly 2 includes a formwork 2-1 and is arranged on the 2-1 The positioning block 6 at the lower end, there are at least two positioning blocks 6 and they are respectively arranged on both sides of the U-shaped rib to be assembled. The length of the positioning block 6 depends on the shape of the rib to be processed and the distance between the rib and the rib. Determined by the distance, the positioning block 6 is hinged to the template 2-1. A guide sleeve 3 is fixed on the crossbeam 1, and a guide rod 4 is arranged in the guide sleeve 3, and the lower end of the guide rod 4 is connected with the template assembly 2 by bolts. platform, the boss and the template 2-1 can be connected by bolts; the cylinder 5 is fixed on the beam 1, and the lower end of the piston rod 5-...

specific Embodiment approach 2

[0014] Embodiment 2: The formwork assembly 2 in this embodiment also includes an elastic platen device 2-3 fixed on the formwork 2-1, and the elastic platen device 2-3 includes a platen seat 2-3- 1. The rubber spring 2-3-2 and the pressure plate 2-3-3 are connected by bolts. The rubber spring 2-3-2 is set on the elastic platen device, which can compensate the U-shaped rib with height error without causing the U-shaped rib to be deformed under pressure, so that the assembly accuracy can be improved and the Damage to cylinders or other components due to inaccurate pressure control. The rubber spring in this embodiment can also be replaced by a metal spring, both of which can achieve the above purpose, and therefore all fall within the protection scope of the present invention.

specific Embodiment approach 3

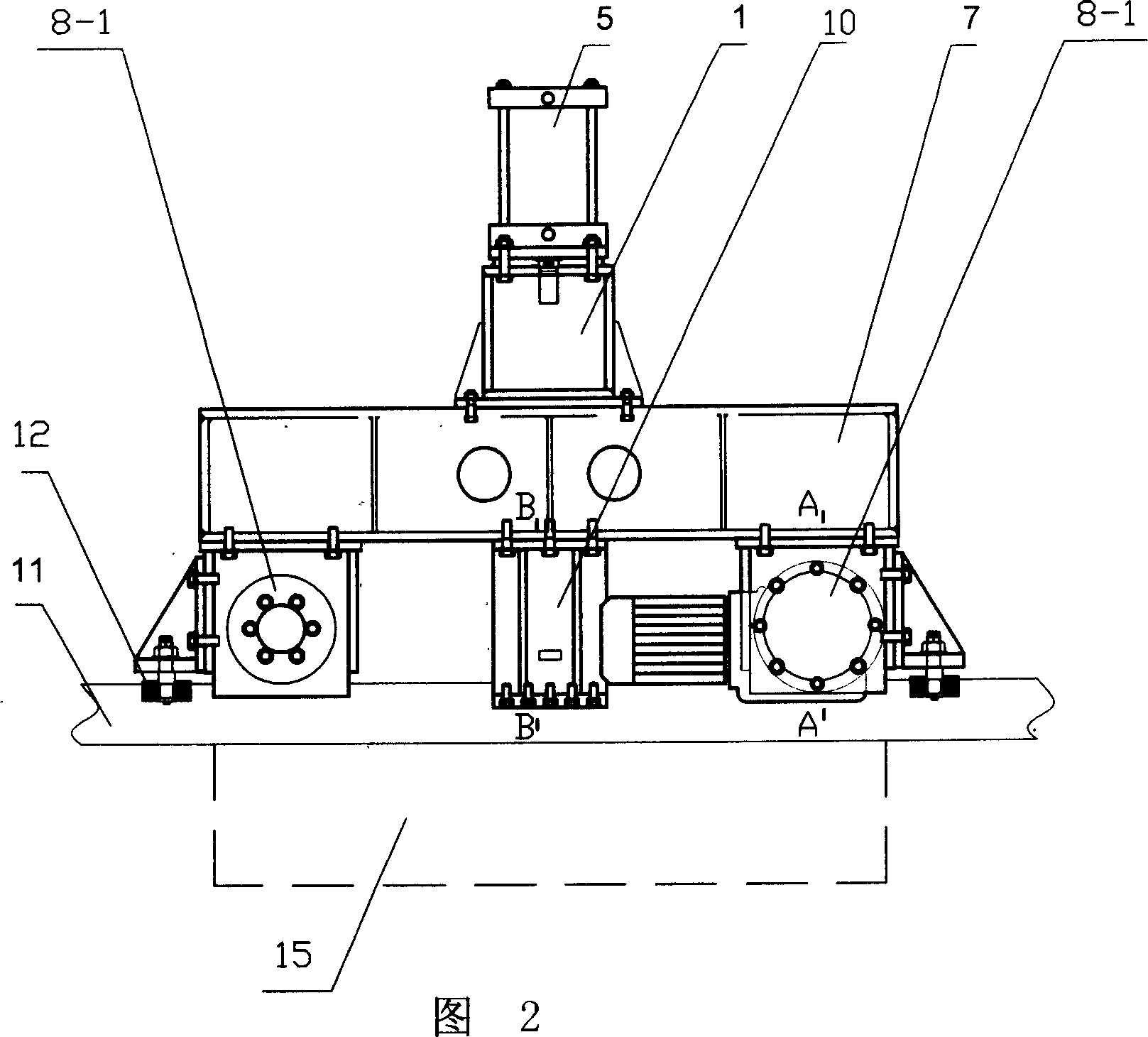

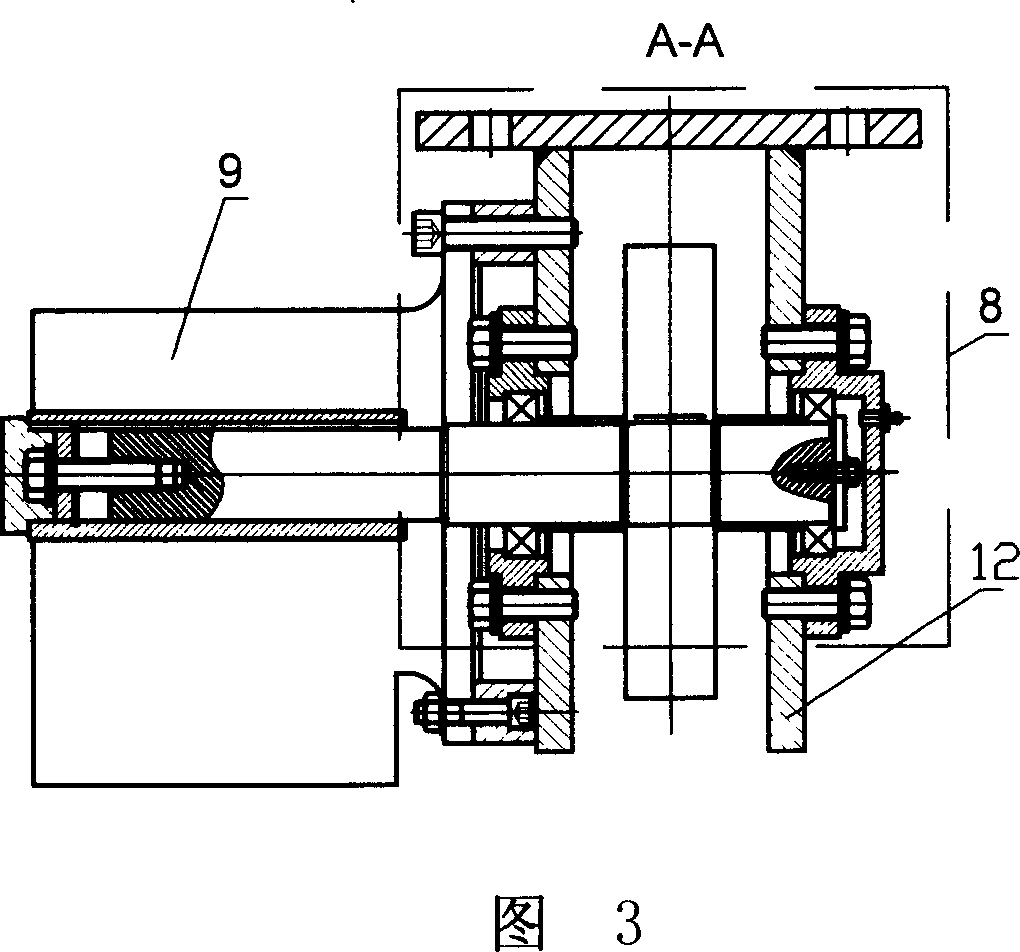

[0015] Specific embodiment three: the beam 1 in this embodiment is fixed on the longitudinal beam 7, and the lower end of the longitudinal beam 7 is fixed on the wheel assembly 8, and the wheel 8-1 on the wheel assembly 8 is arranged on the track 11, and it also It includes a driving device 9, which is a combination of a reducer and a motor, and the output shaft of the motor is connected to the central shaft of the wheel 8-1 through a bevel gear reducer. The assembly machine is set on the track through the wheels, and the wheels are driven by the motor to walk freely, which can solve the trouble of manual carts and reduce the labor expenditure and running time of workers; the bevel gear transmission connection can ensure stable and reliable transmission. Reduce noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com