Cylinder body lining assembling tool

A technology for assembling tools and bushings, which is applied in the field of cylinder bushing assembling tools, can solve the problems of low installation efficiency, lack of limit devices, time-consuming and labor-consuming, etc., and achieve the advantages of not being easy to shake, ensuring installation accuracy and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

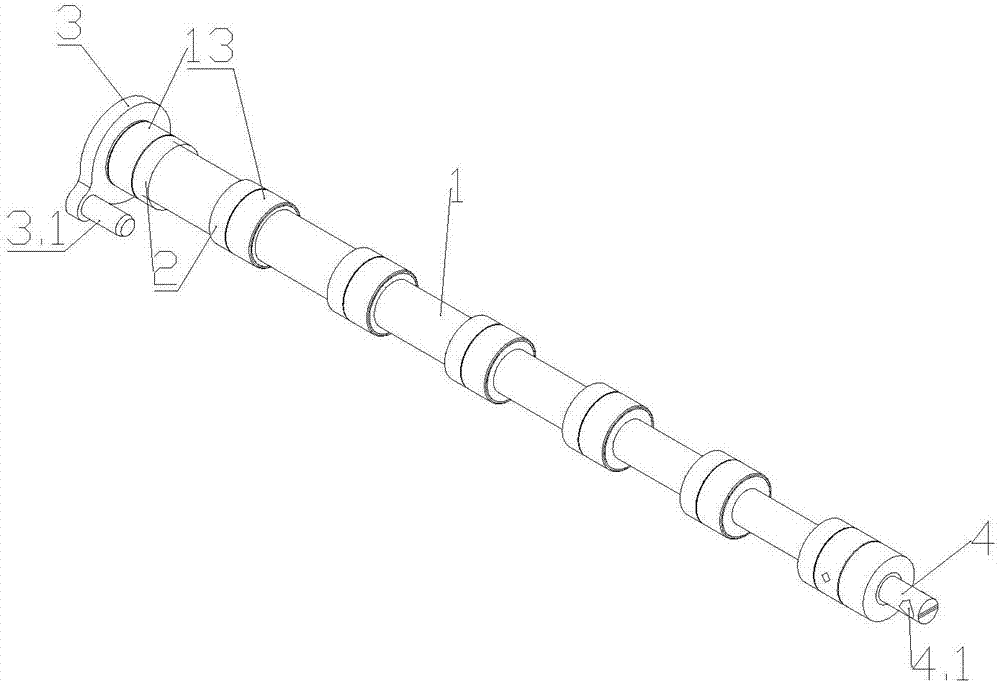

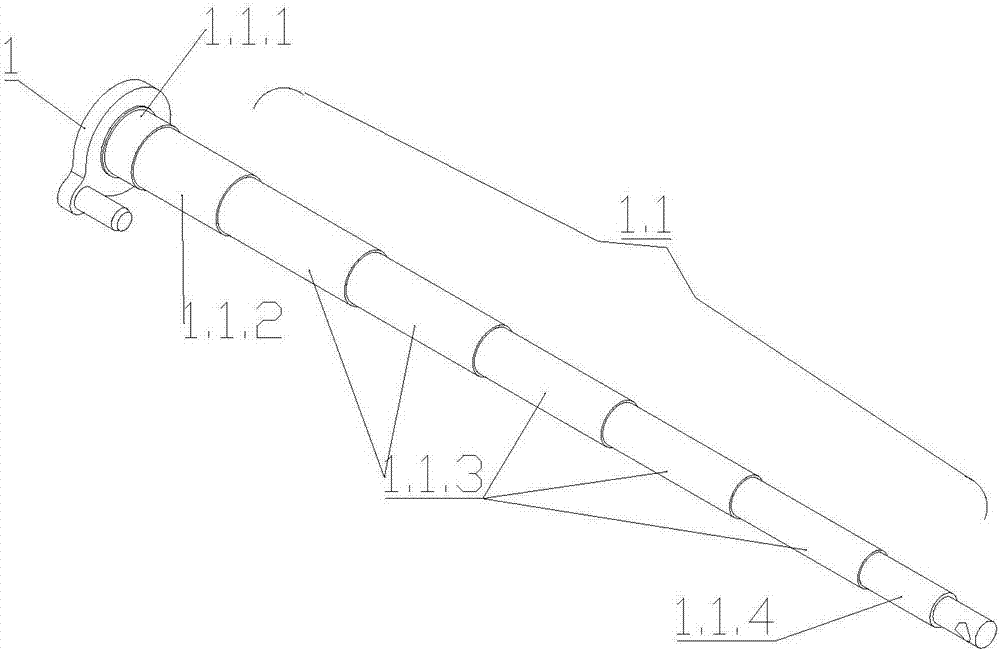

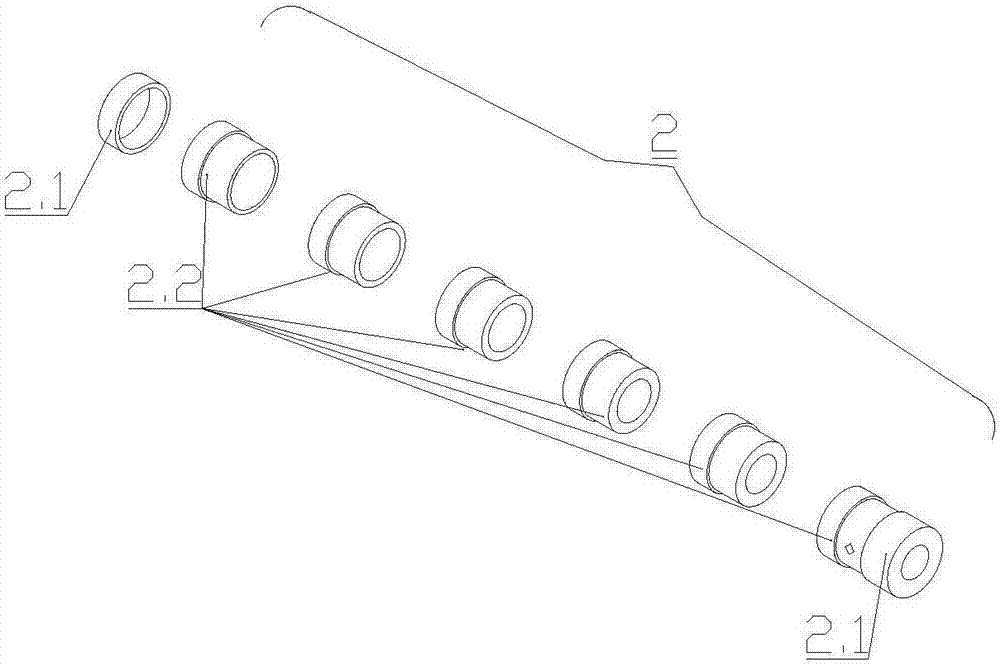

[0024] like Figure 1 to Figure 8 As shown, a cylinder bushing assembly tool includes an assembly pull rod, and the assembly pull rod includes a stepped shaft 1 and 8 spacer sleeves 2; the stepped shaft 1 includes 8 shaft bodies 1.1 with decreasing diameters in turn, The axes of body 1.1 are located on the same straight line, and the diameter difference between adjacent shaft bodies 1.1 is 4 mm; shaft body 1.1 includes positioning shaft body 1.1.1, top shaft body 1.1.2, tail shaft body 1.1.4 and top shaft body 5 middle shaft bodies 1.1.3 between the body 1.1.2 and the tail shaft body 1.1.4; the axial lengths of the top shaft body 1.1.2, the tail shaft body 1.1.4 and each middle shaft body 1.1.3 and the corresponding The distance between each limit baffle plate 12 of the cylinder block 10 camshaft hole 11 matches; the axial width of the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com