Patents

Literature

86 results about "Body linings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

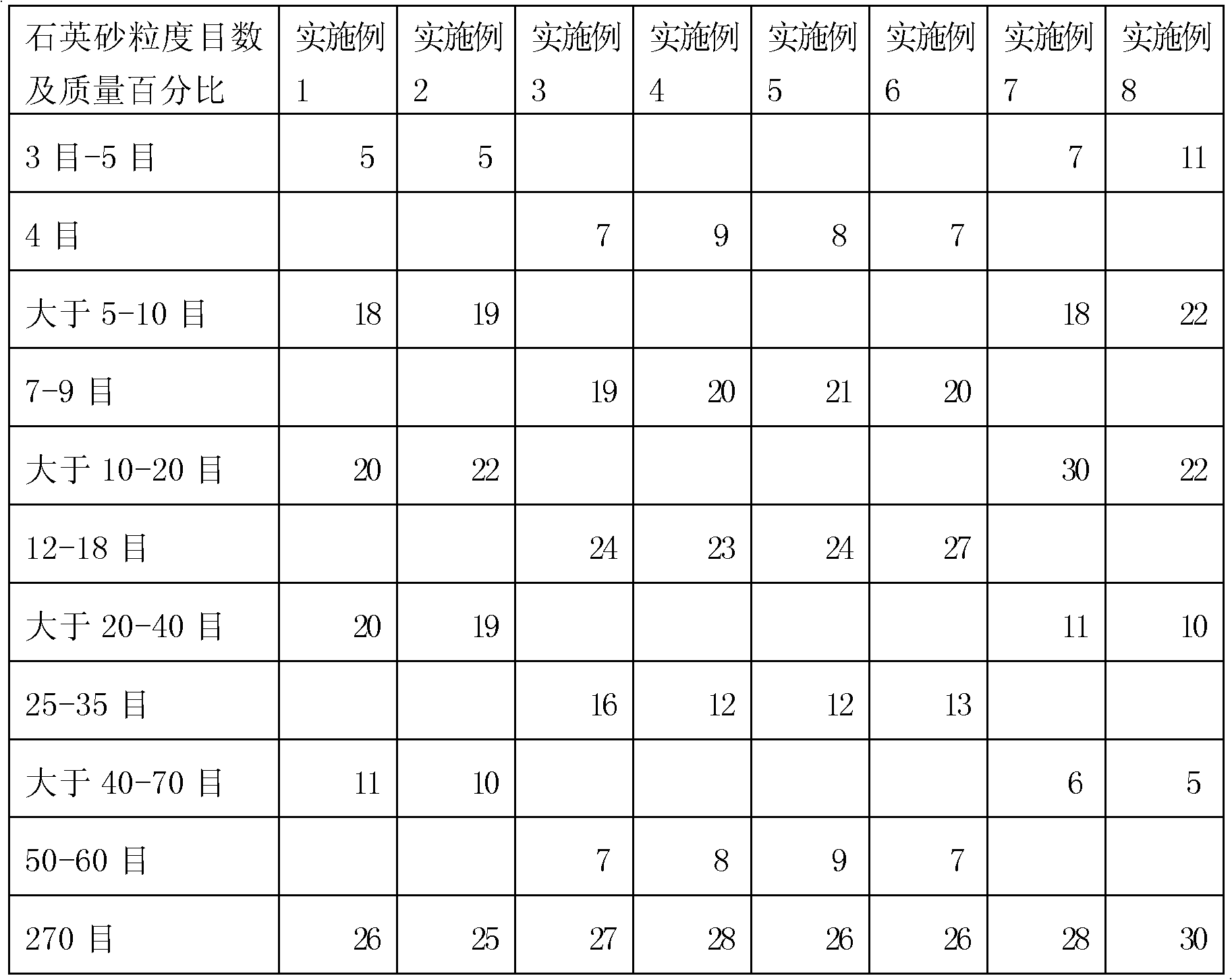

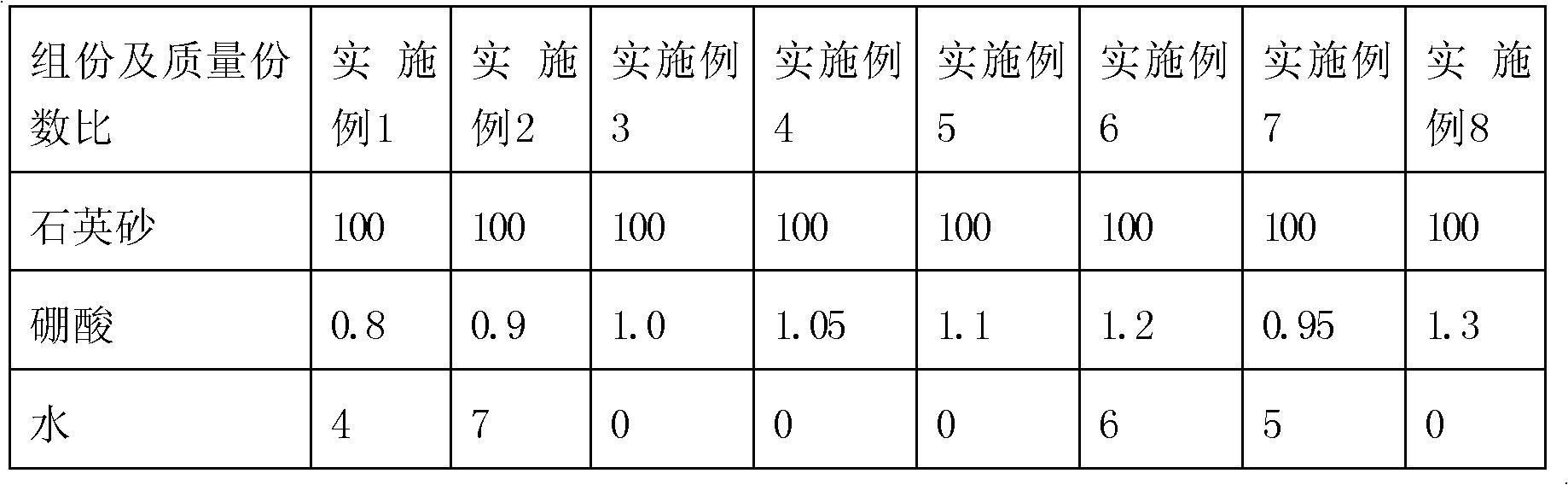

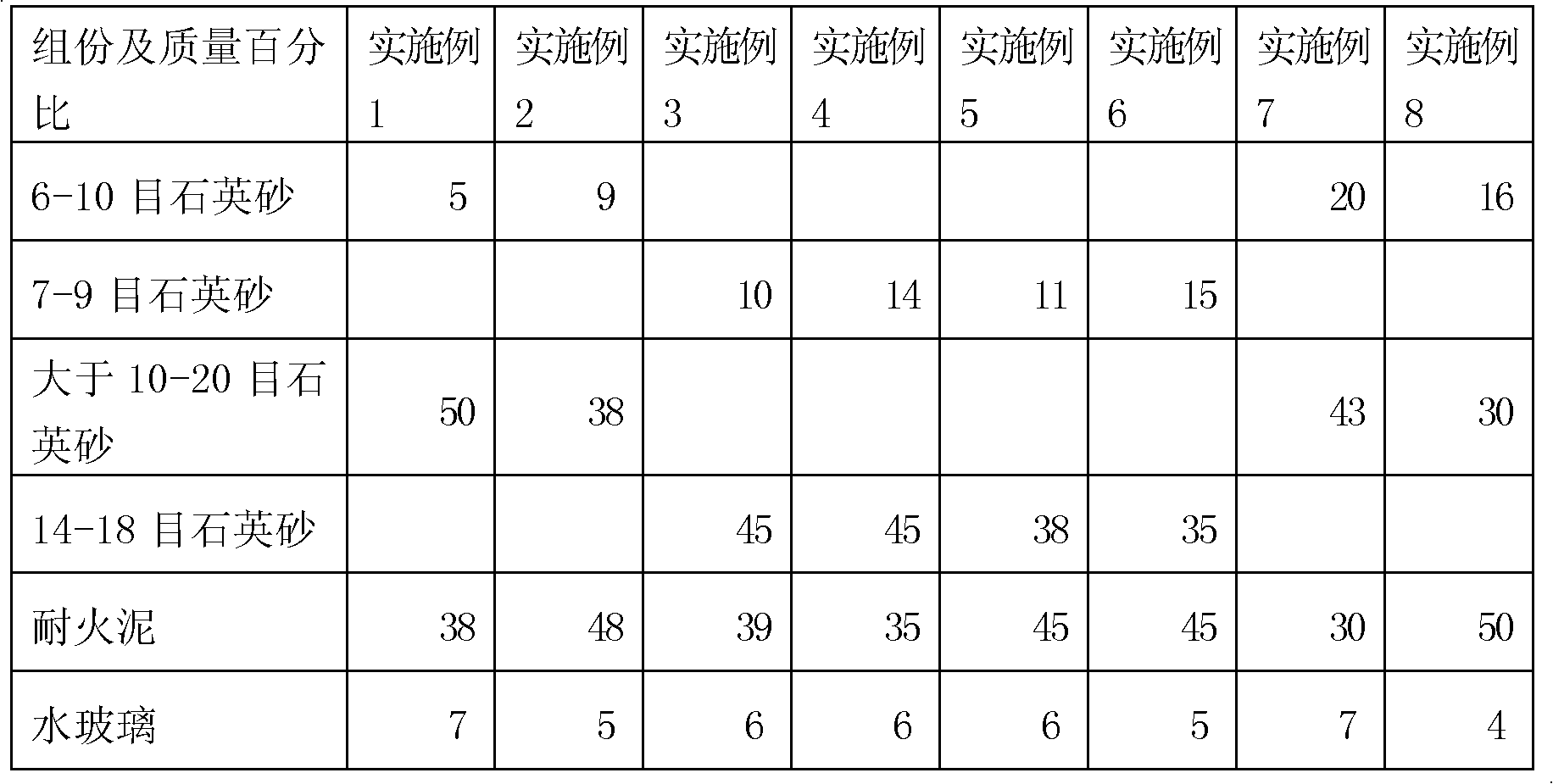

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

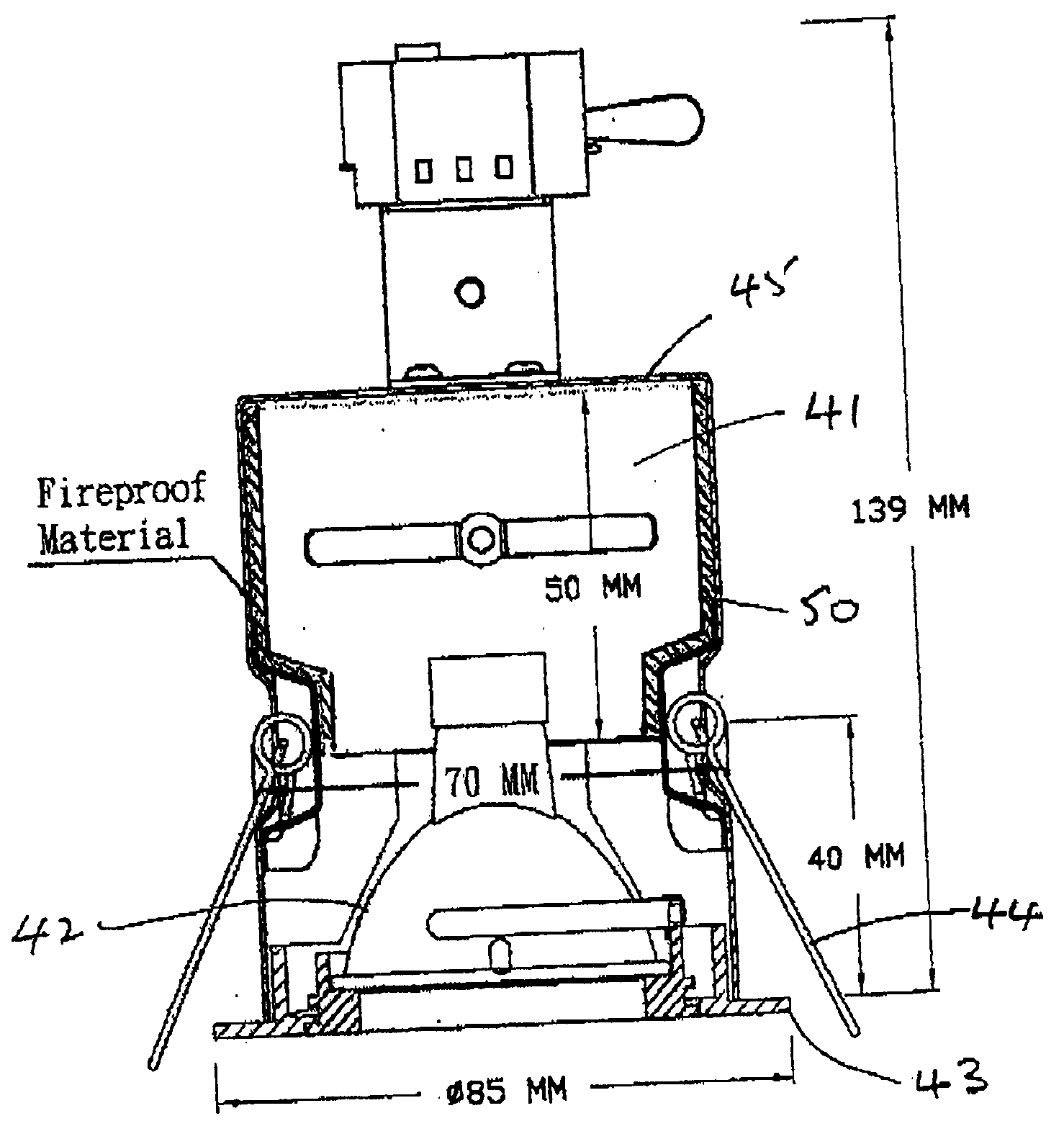

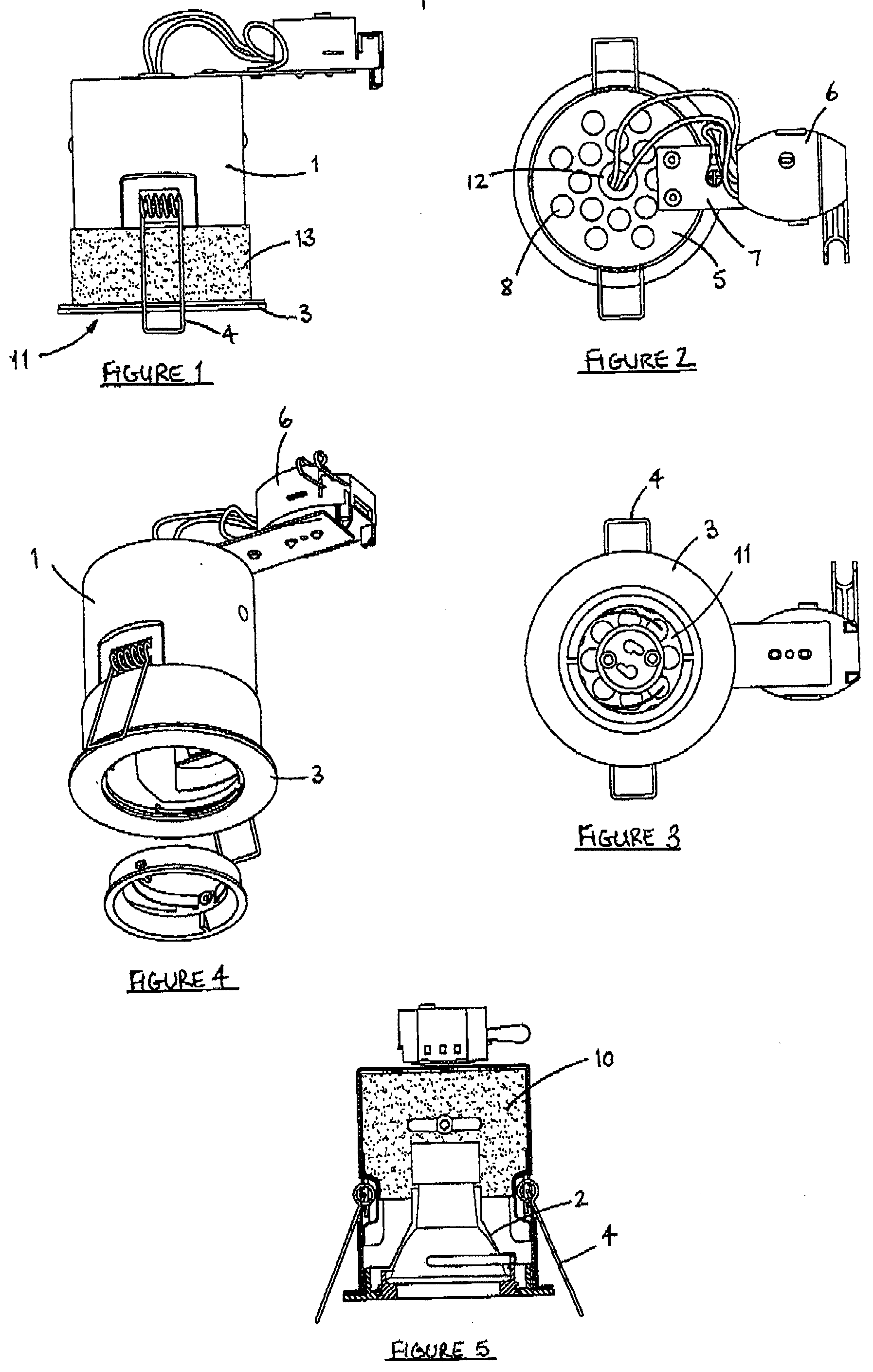

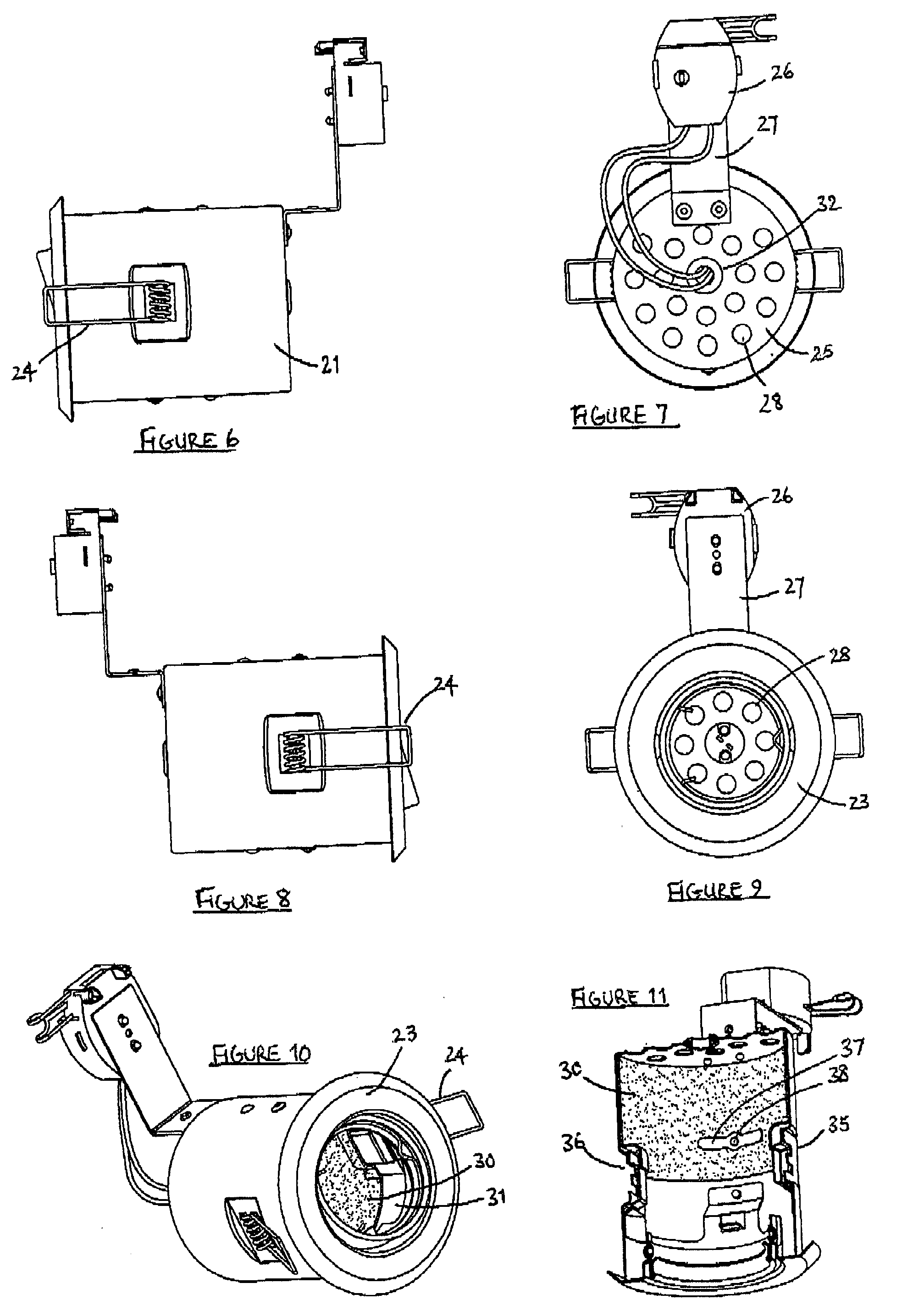

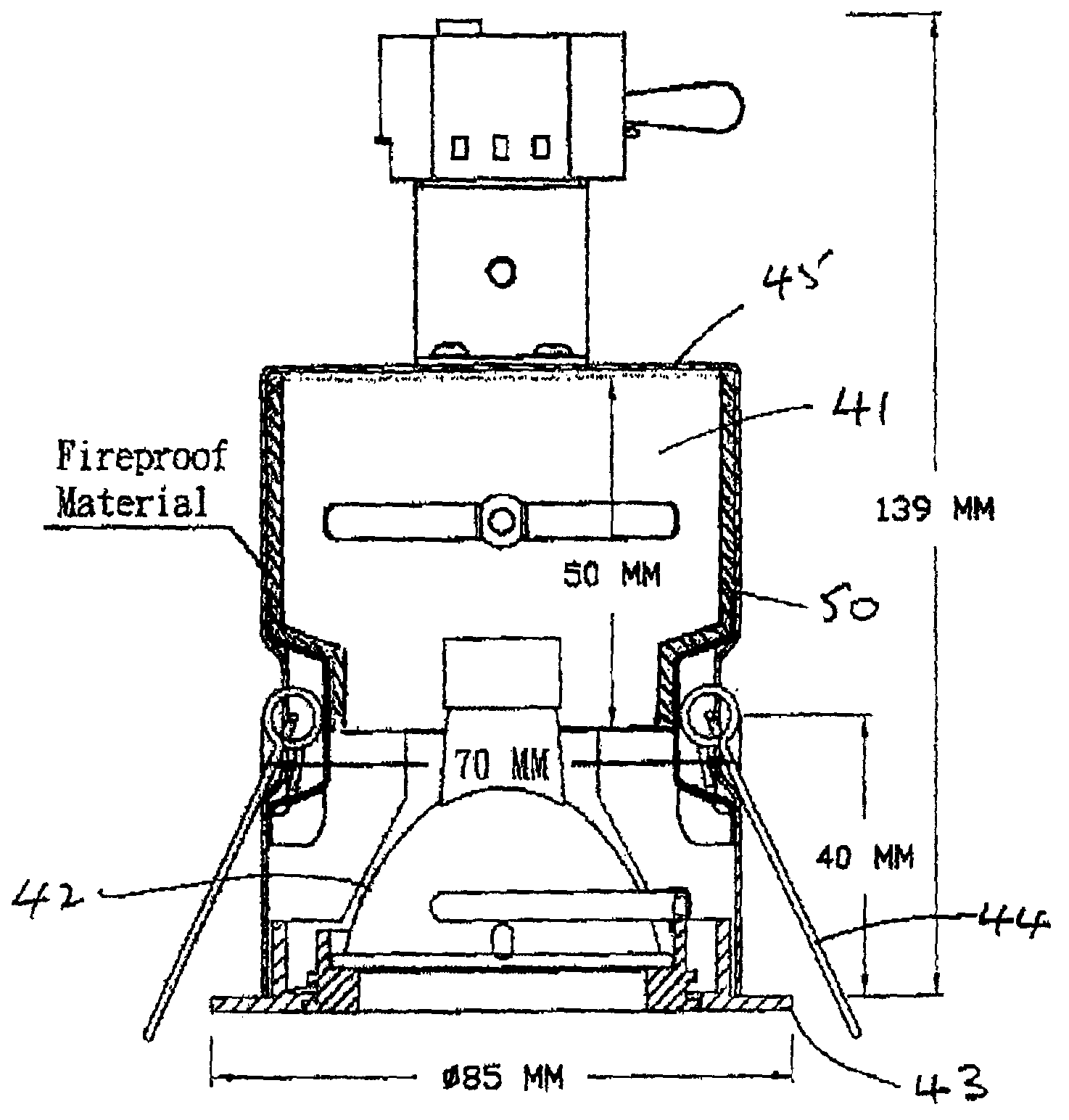

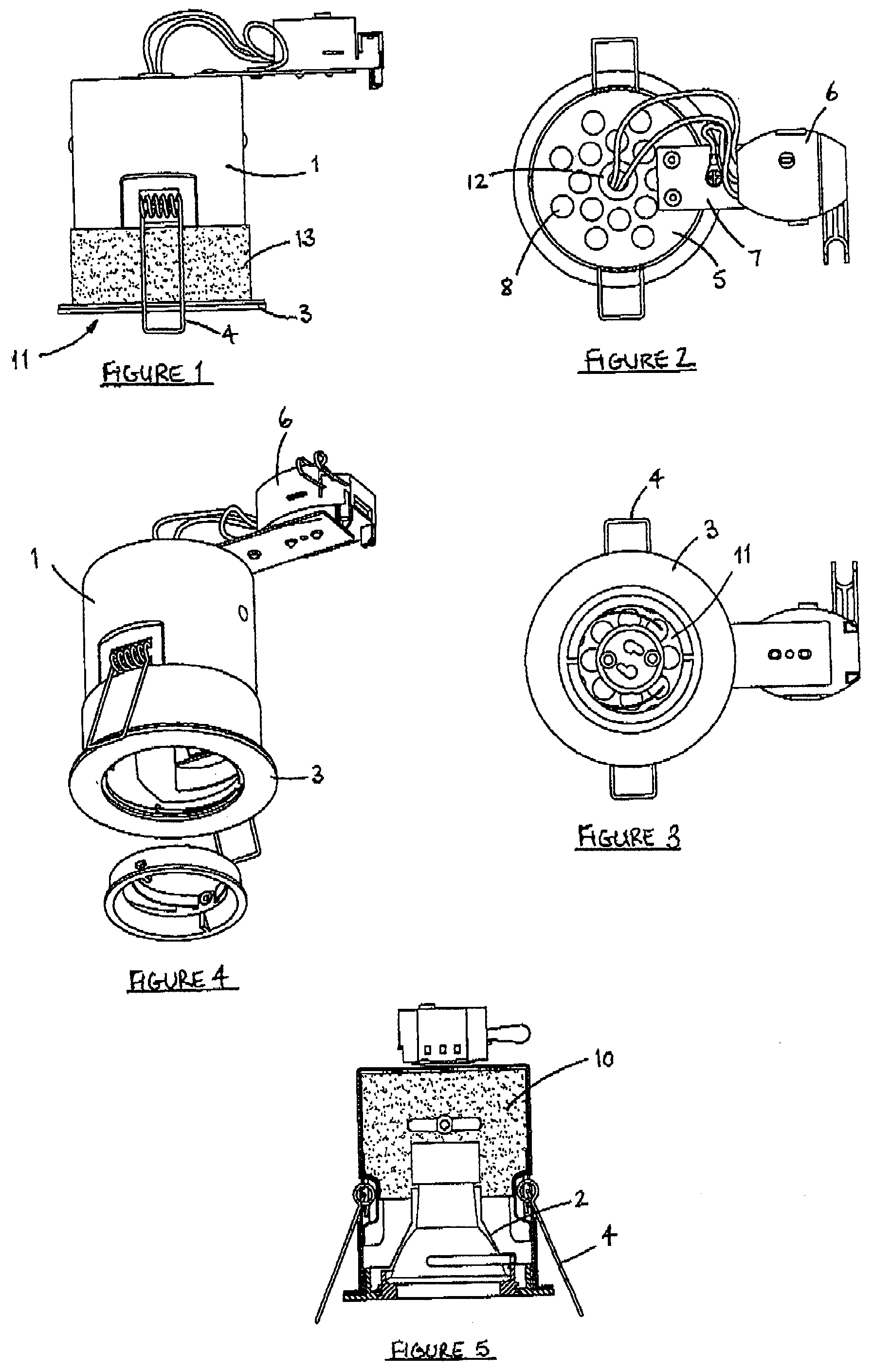

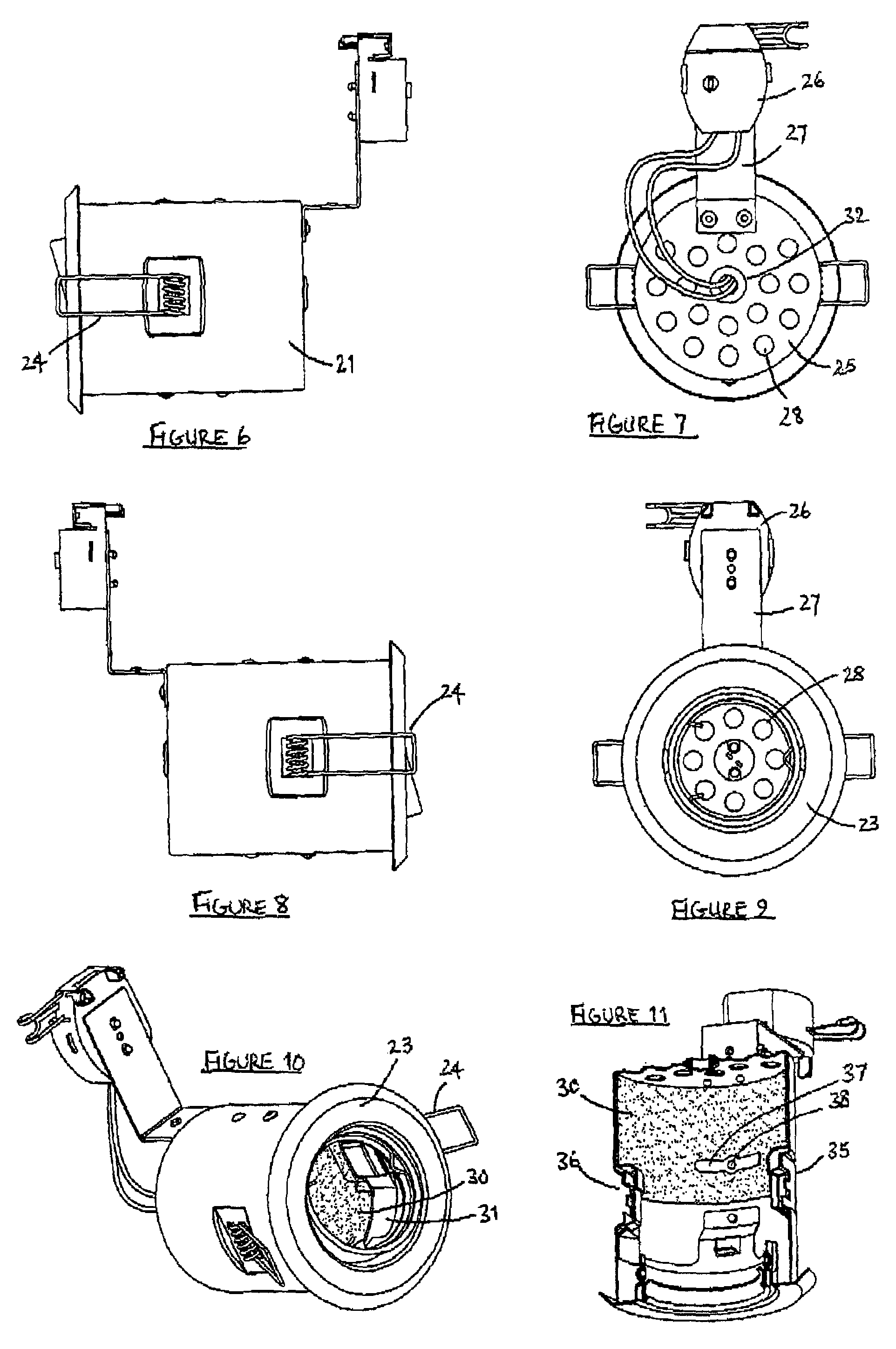

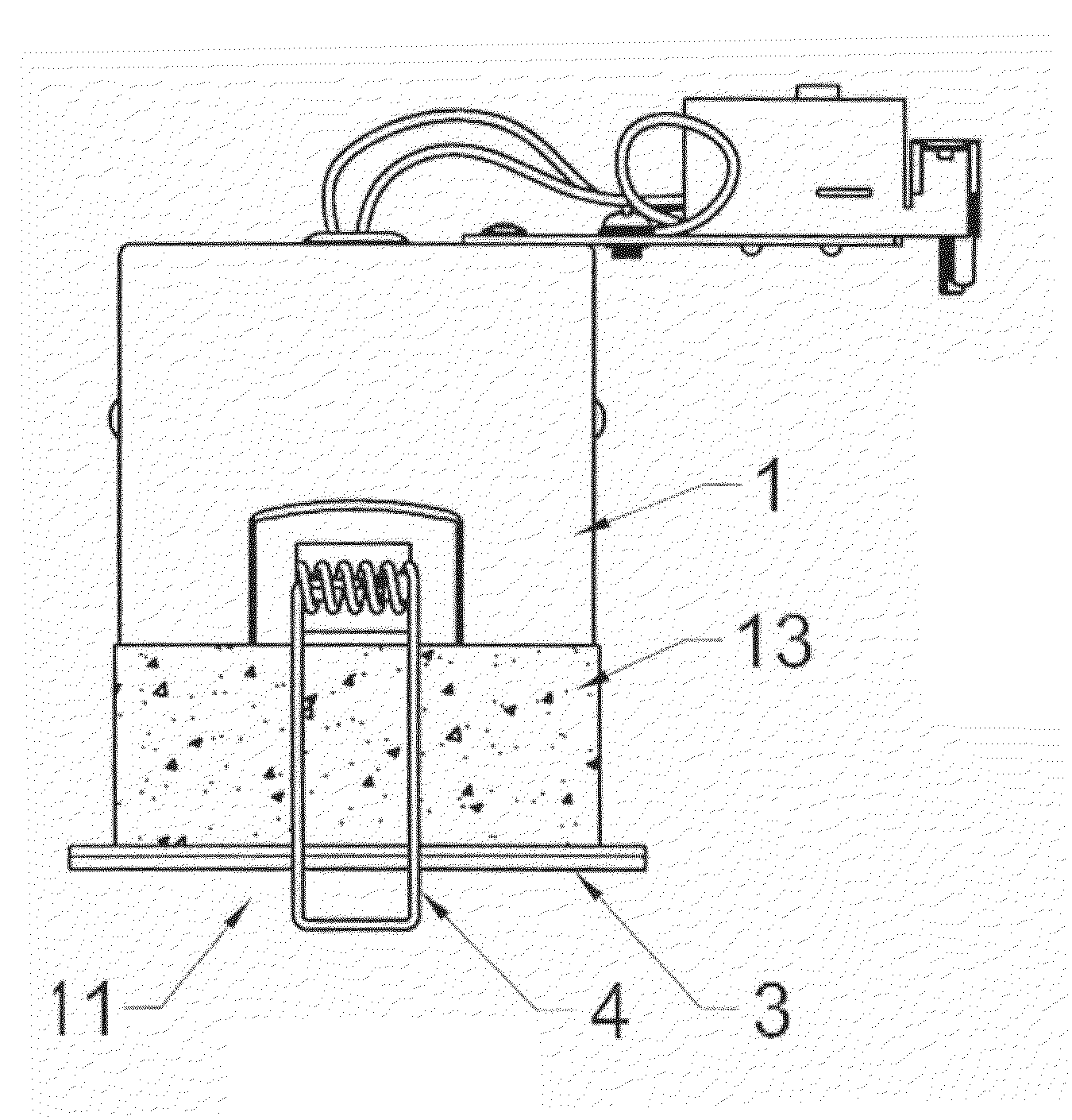

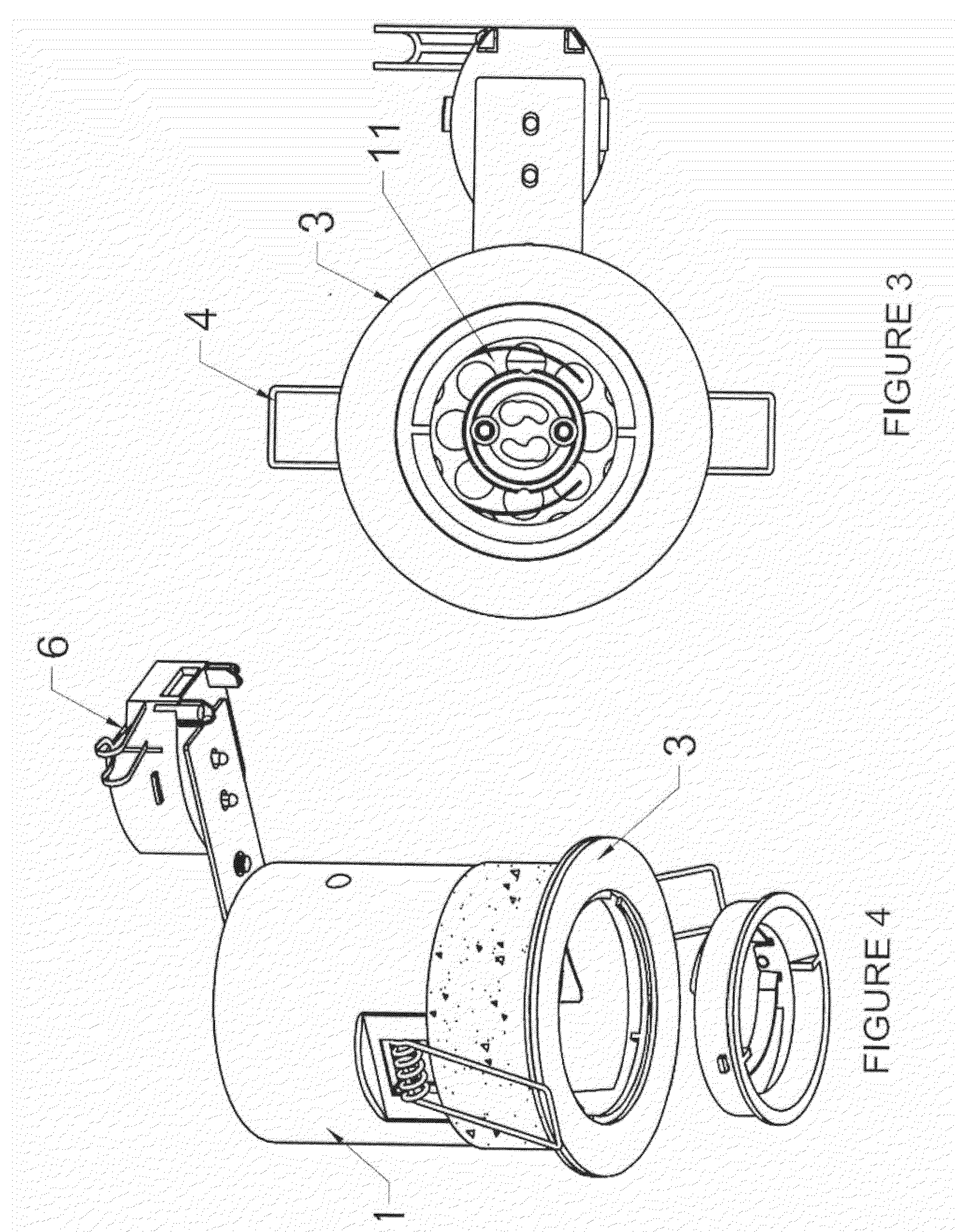

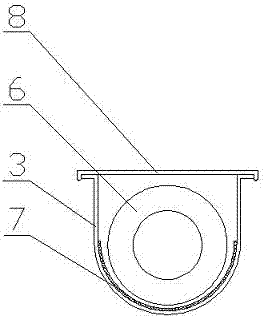

Improvements to fire rated downlights

ActiveUS20070109796A1Increase firing rateIncrease the gapLighting support devicesVehicle interior lightingBiomedical engineeringBody lines

A casing for a downlight having a tubular body from which the light of a lamp when installed in the body is emitted from the front of the body and having a rear end wall closing the body from the rear, wherein intumescent material is placed within the tubular body lining the tubular wall of the tubular body.

Owner:GIGAPHOTON

Fire rated downlights

ActiveUS7476010B2Increase firing rateIncrease the gapLighting support devicesLighting heating/cooling arrangementsEngineeringMechanical engineering

A casing for a downlight having a tubular body from which the light of a lamp when installed in the body is emitted from the front of the body and having a rear end wall closing the body from the rear, wherein intumescent material is placed within the tubular body lining the tubular wall of the tubular body.

Owner:GIGAPHOTON

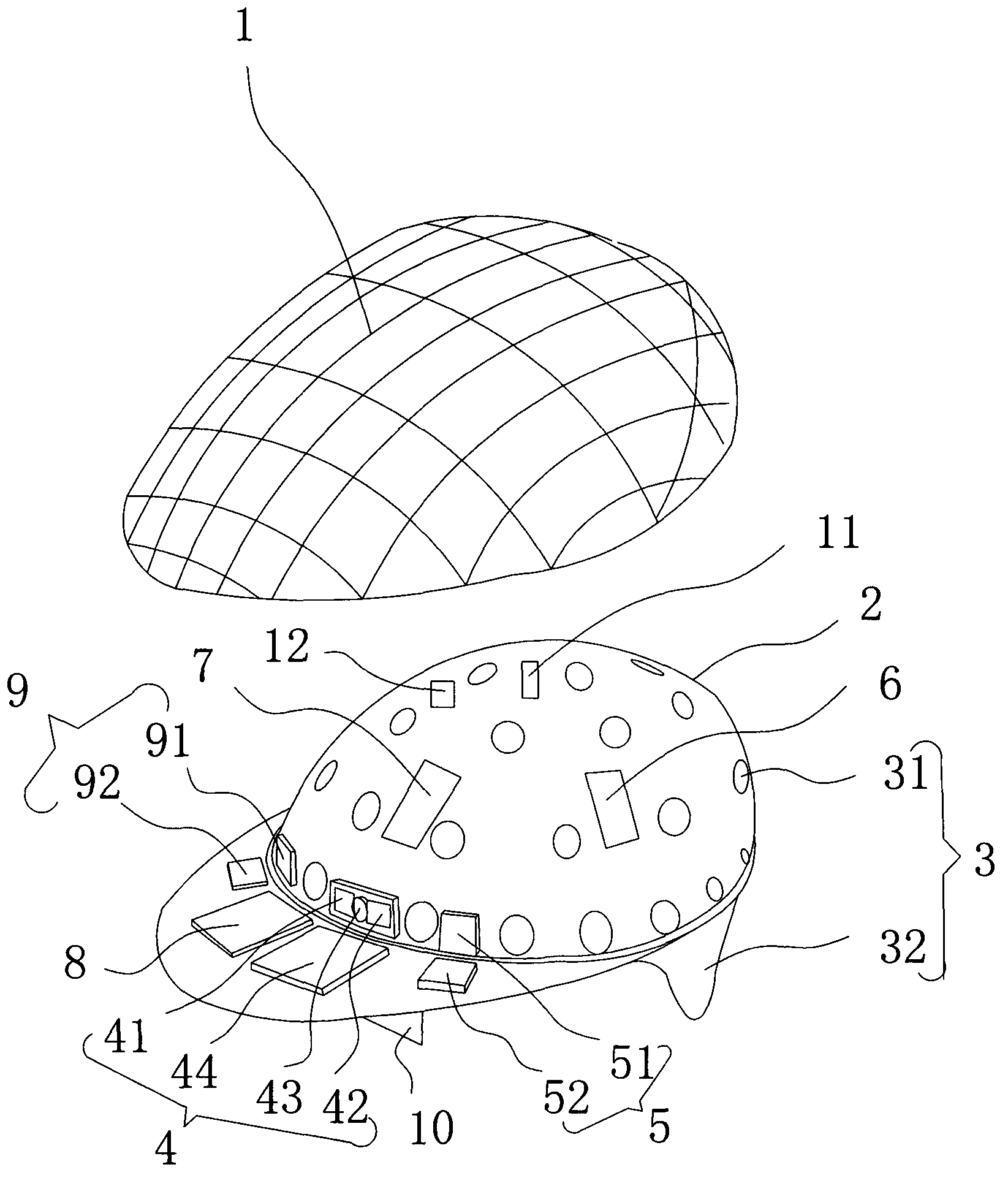

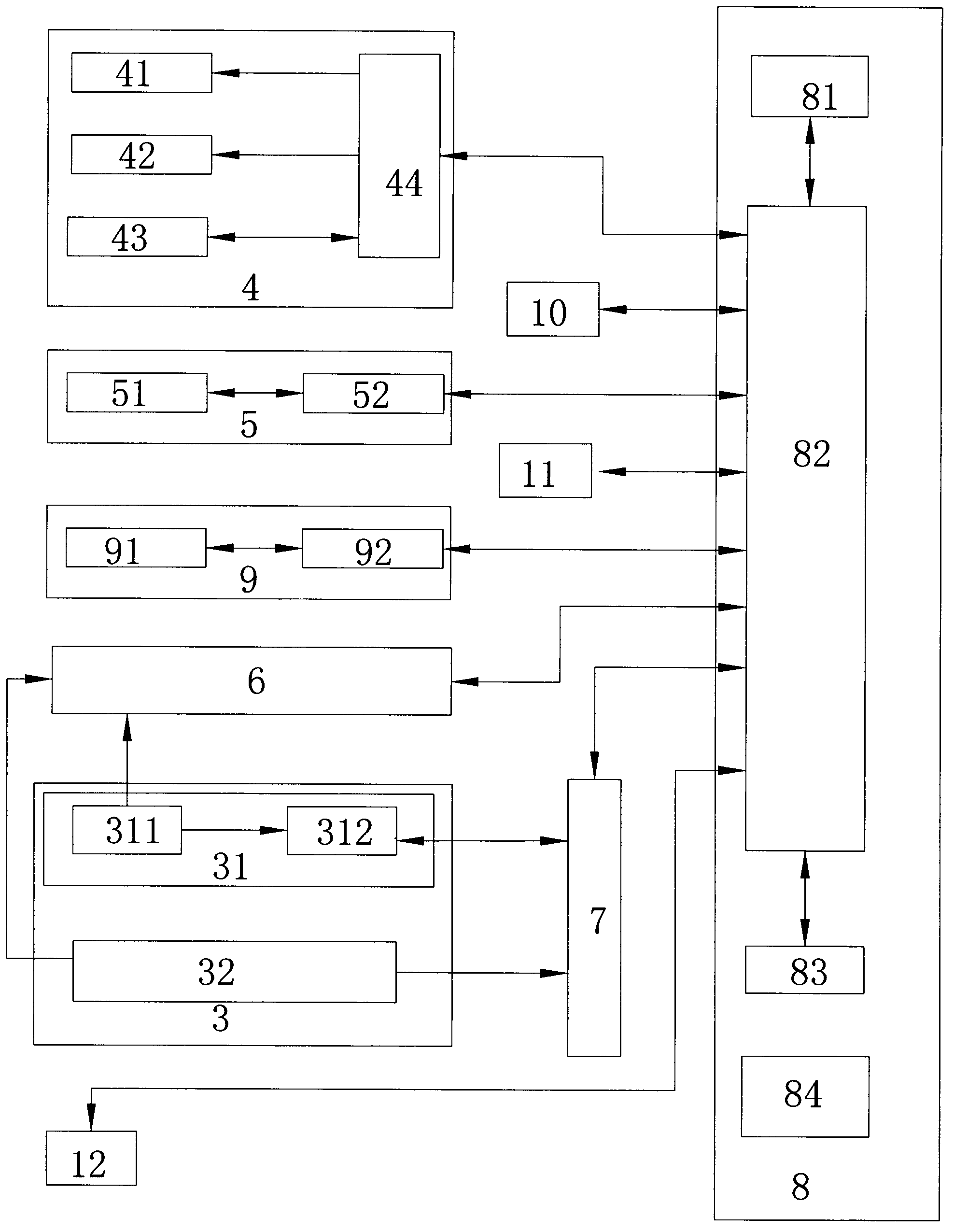

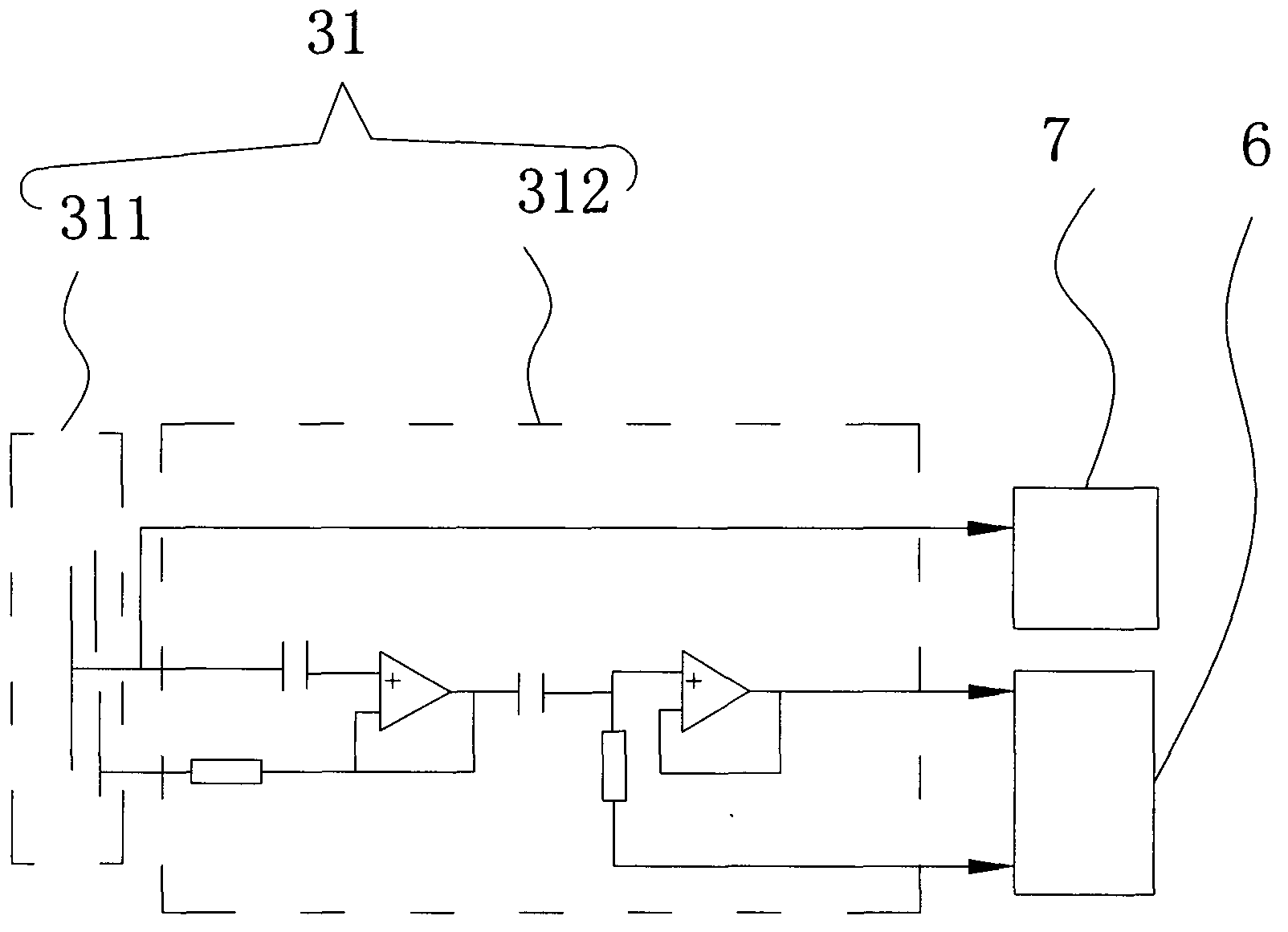

Cap with brain wave and physical sign collection functions

ActiveCN103300851AEfficient collectionImprove the accuracy of useDiagnostic recording/measuringSensorsHuman bodyBody temperature measurement

The invention discloses a cap with brain wave and physical sign collection functions. The cap comprises a cap top cover and a cap body lining, wherein a sensing electrode module, a blood oxygen module, a body temperature measurement module, a brain wave processing module, a transcranial direct current module, a head-mounted processing module and a body sweat electrolysis analyzer are arranged in the cap body lining; the sensing electrode module is arranged in the position where the forehead and the scalp of a human body are contacted and is electrically connected with the skin of the human body in a dry type conduction manner; the blood oxygen module is arranged in the forehead position of the cap body lining; the body temperature measurement module is arranged in the upper part position of the forehead of the cap body lining; the body sweat electrolysis analyzer is arranged on the left side or the right side of the forehead of the cap body lining; the head-mounted processing module is arranged in the position of a visor of the cap body lining; and the brain wave processing module and the transcranial direct current module are arranged on two sides of the front end of the cap body lining. The cap is simple in structure, and can effectively collect brain wave and physical sign data of a user in different states, adjust the physiological cycle timely and improve the work and study efficiency.

Owner:TAPUYIHAI SHANGHAI INTELLIGENT TECH CO LTD

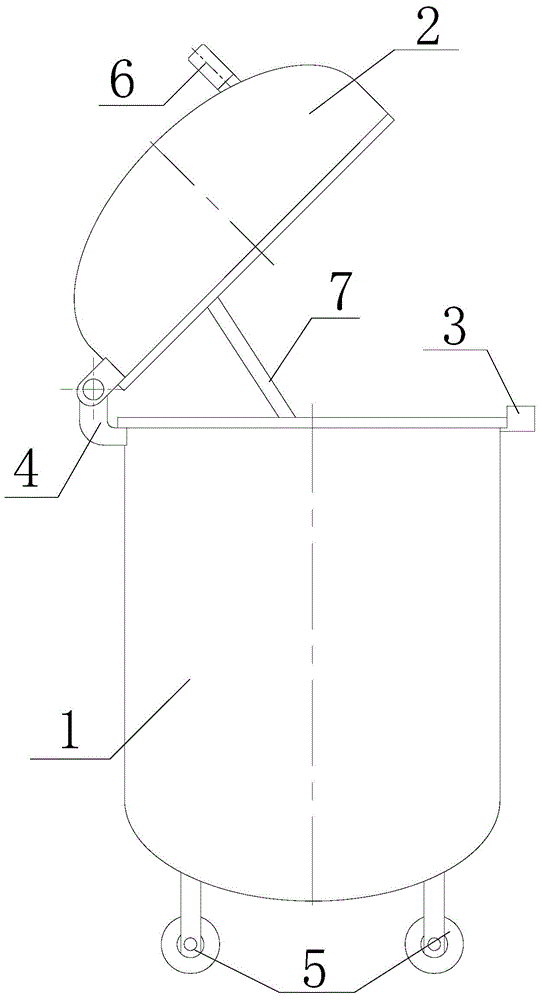

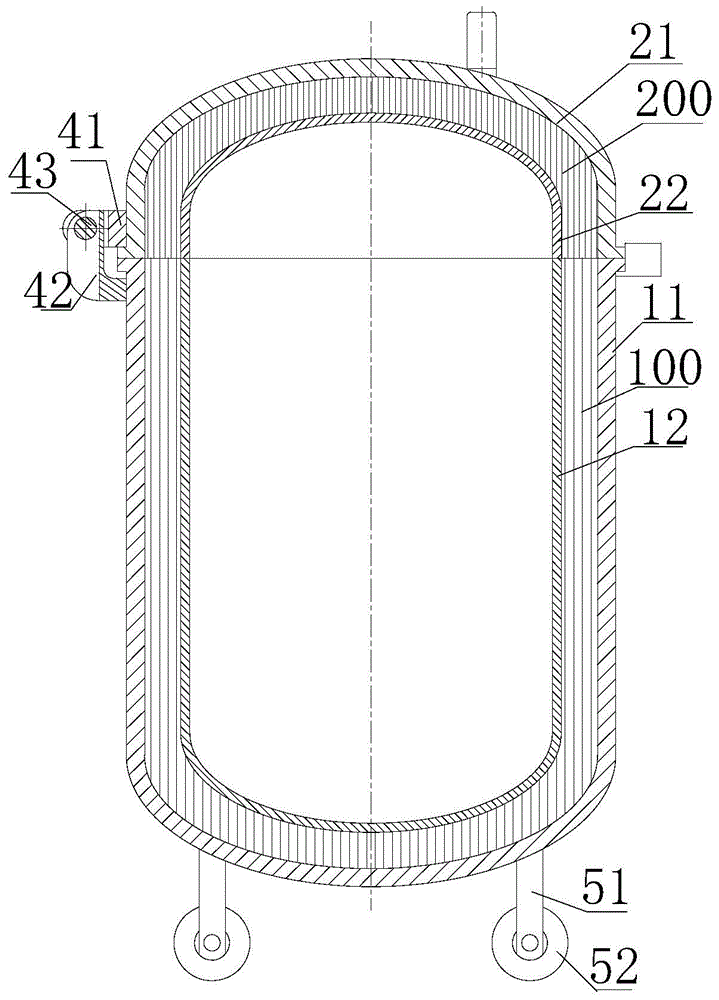

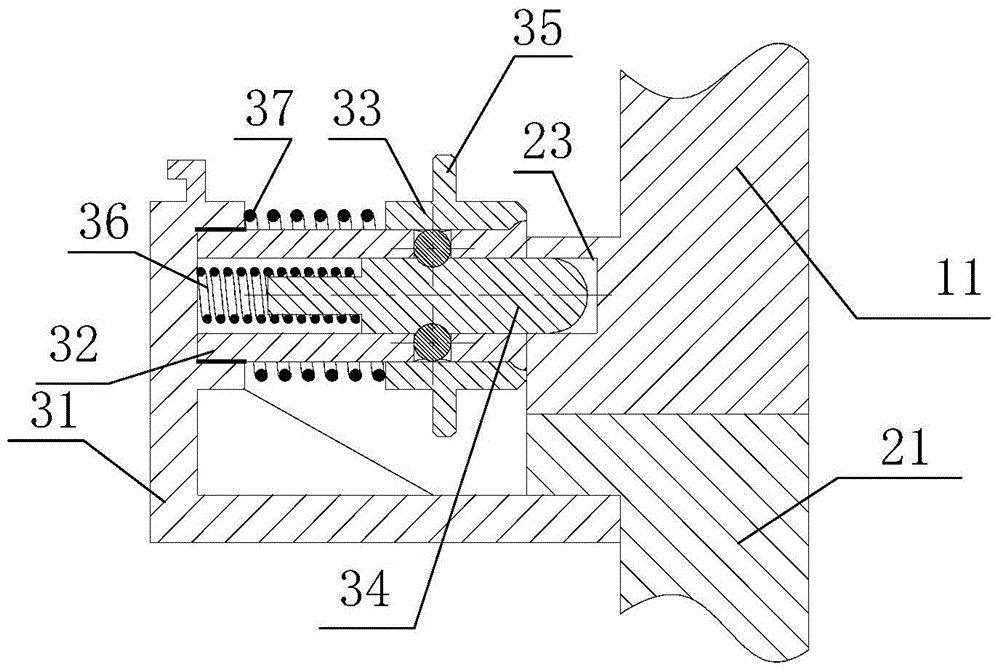

Portable and deformable energy adsorption anti-explosion pot

The invention discloses a portable and deformable energy adsorption anti-explosion pot, which comprises a pot body, a pot cover, a locking device, a hinge, universal wheels, a handle and a support rod, wherein the pot body and the pot cover are connected via the hinge, and can be quickly locked by the locking device, as a result, a closed inner cavity is formed; the pot body sequentially comprises an outer casing, a pot body lining interlayer and an inner casing from outside to inside; the pot cover comprises an outer cover, a pot cover lining interlayer and an inner cover from inside to outside in sequence. All of the outer casing, the inner casing, the outer cover and the inner cover are made of steel material with super plasticity; the pot body lining interlayer and the pot cover lining interlayer are made of aluminum or steel honeycomb. The whole anti-explosion pot can move via the universal wheels at the bottom. The anti-explosion pot, disclosed by the invention, can effectively lower or eliminate intimidation of explosion impact to protected bodies or personnel, is greatly lightened, is convenient to carry to reach a sudden and doubtful explosion event field or evacuates the field, and performs relative treatment.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

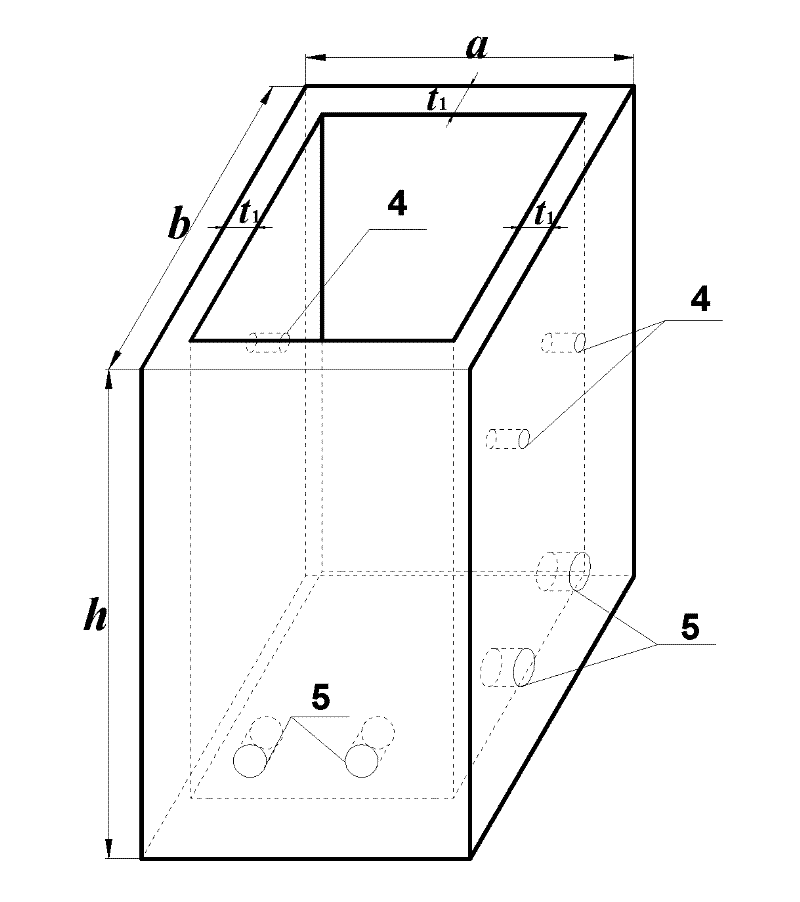

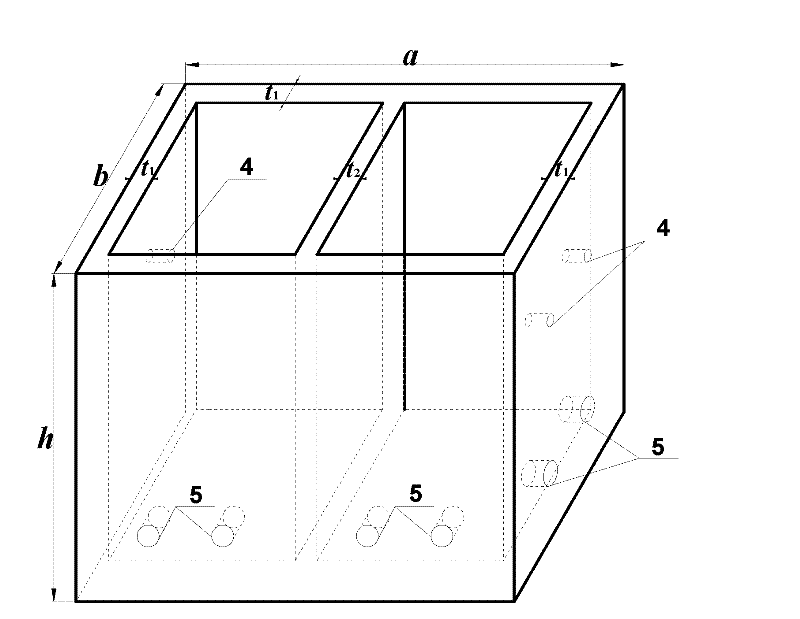

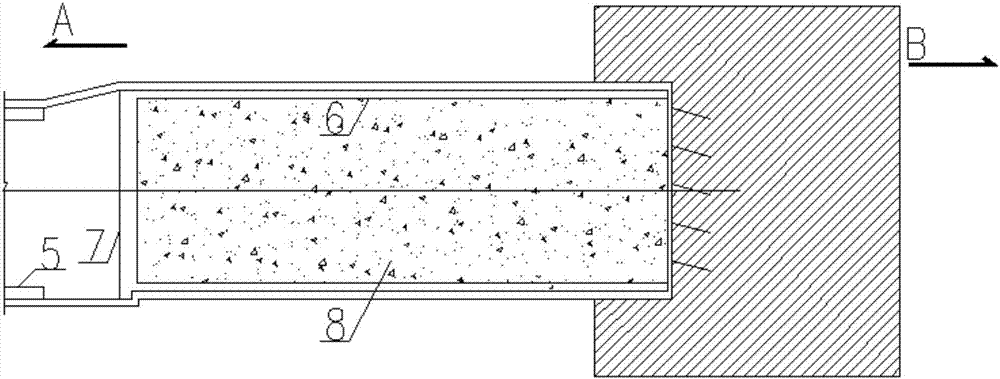

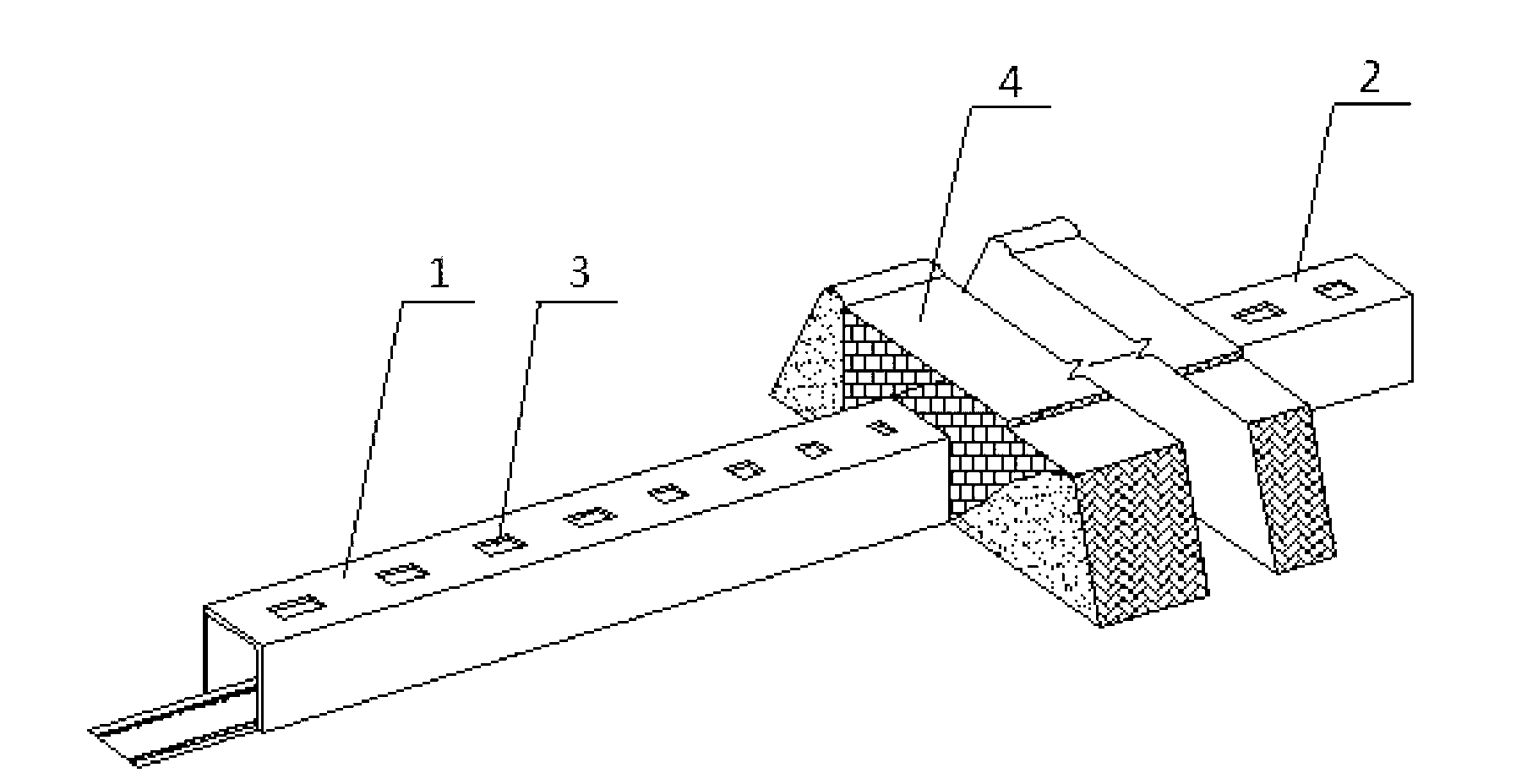

Box body lining type mudslide discharging and guiding groove and application and construction method thereof

ActiveCN102373692AControl flow rateImprove securityBarrages/weirsArtificial water canalsReinforced concreteEngineering

The invention discloses a box body lining type mudslide discharging and guiding groove suitable for mudslide with great longitudinal river slope of a gully bed, and an application and construction method thereof. The discharging and guiding groove comprises a groove bottom and side walls at two sides of the discharging and guiding groove, wherein the groove bottom comprises a transverse penetrating type ribbed threshold and a plurality of stages of baffle sills which are filled between an upstream ribbed threshold and a downstream ribbed threshold and are distributed in a stepped shape; each-stage baffle sill is formed by connecting a plurality of prefabricated reinforced concrete rectangular box bodies along the direction of the transversely penetrating the discharging and guiding groove; the top surface of each rectangular box body is opened; other five surfaces of each rectangular box body are closed; and each rectangular box body is filled with soil mass. Compared with the prior art, mutual action between the soil mass filled in the rectangular box bodies and the mudslide is used to consume the movement kinetic energy of part of the mudslide, regulate and control the flow speed of the mudslide and control the corrosion and the scouring of the mudslide to the groove bottom, so that the safety of the discharging and guiding groove is improved and the later-stage maintenance expense is reduced; compared with a full-lining type groove, the box body lining type mudslide discharging and guiding groove has the construction period shortened by 10-30 percent and the later-stage maintenance expense reduced by 50-80 percent; and compared with a soft-foundation energy dissipation type groove, the box body lining type mudslide discharging and guiding groove has the later-stage maintenance expense reduced by 30-50 percent.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

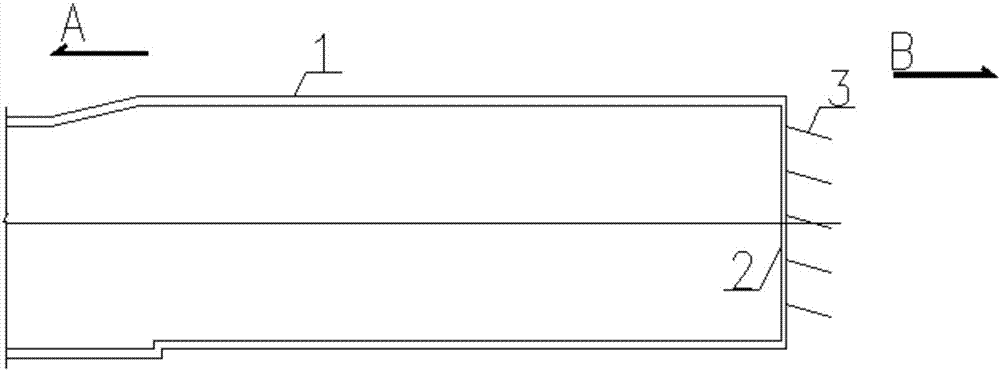

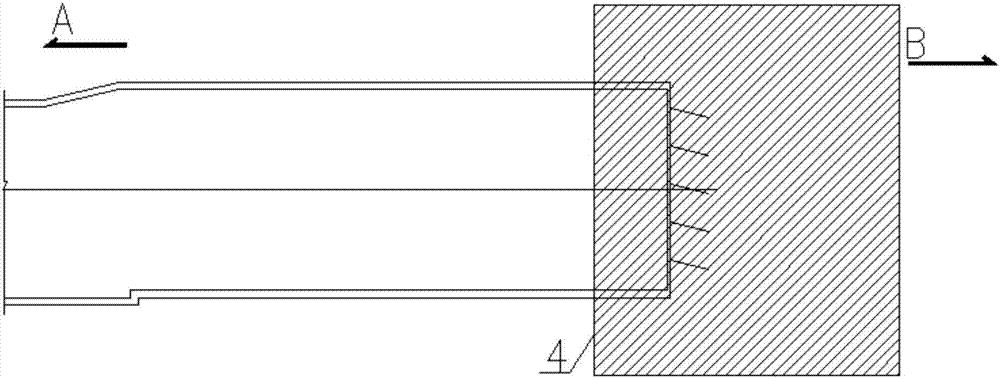

Water-bottom mine shield tunnel combination butt joint structural form and construction method thereof

InactiveCN106907164ARich organizationReceive construction safetyUnderground chambersTunnel liningEngineeringCement mortar

The invention provides a water-bottom mine shield tunnel combination butt joint structural form and a construction method thereof and relates to the technical field of urban rail transit construction. A bench cut method is adopted for excavation from a mine tunneling method tunnel section, receiving section tunnel primary support construction is conducted, and a bottom sub wall is closed when excavation is conducted to a butt joint point; the stratum in front of a butt joint section is subjected to grouting reinforcement; then a receiving section is poured to close a box body lining, and the box body lining is filled with cement mortar; then a shield machine conducts constant-speed tunneling and enters the box body lining after directly breaking the bottom sub wall and the filled cement mortar; a cutterhead of the shield machine is arranged to be detachable, then a hoisting point is arranged on a shield machine outer shell, all components of the shield machine are detached and conveyed out from the position, on the rear side, of a shield machine tunnel, and the steel shell of the shield machine is left in a hole; and finally, a secondary lining is constructed in the tunnel for connecting all the sections. The water-bottom mine shield tunnel combination butt joint structural form and the construction method thereof are suitable for butt joint construction, adopting a mining method and a shield method, of the underwater and subsea tunnel and an underground structure, structural stability and construction safety are good, and the organizational form of the shield construction method is enriched.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

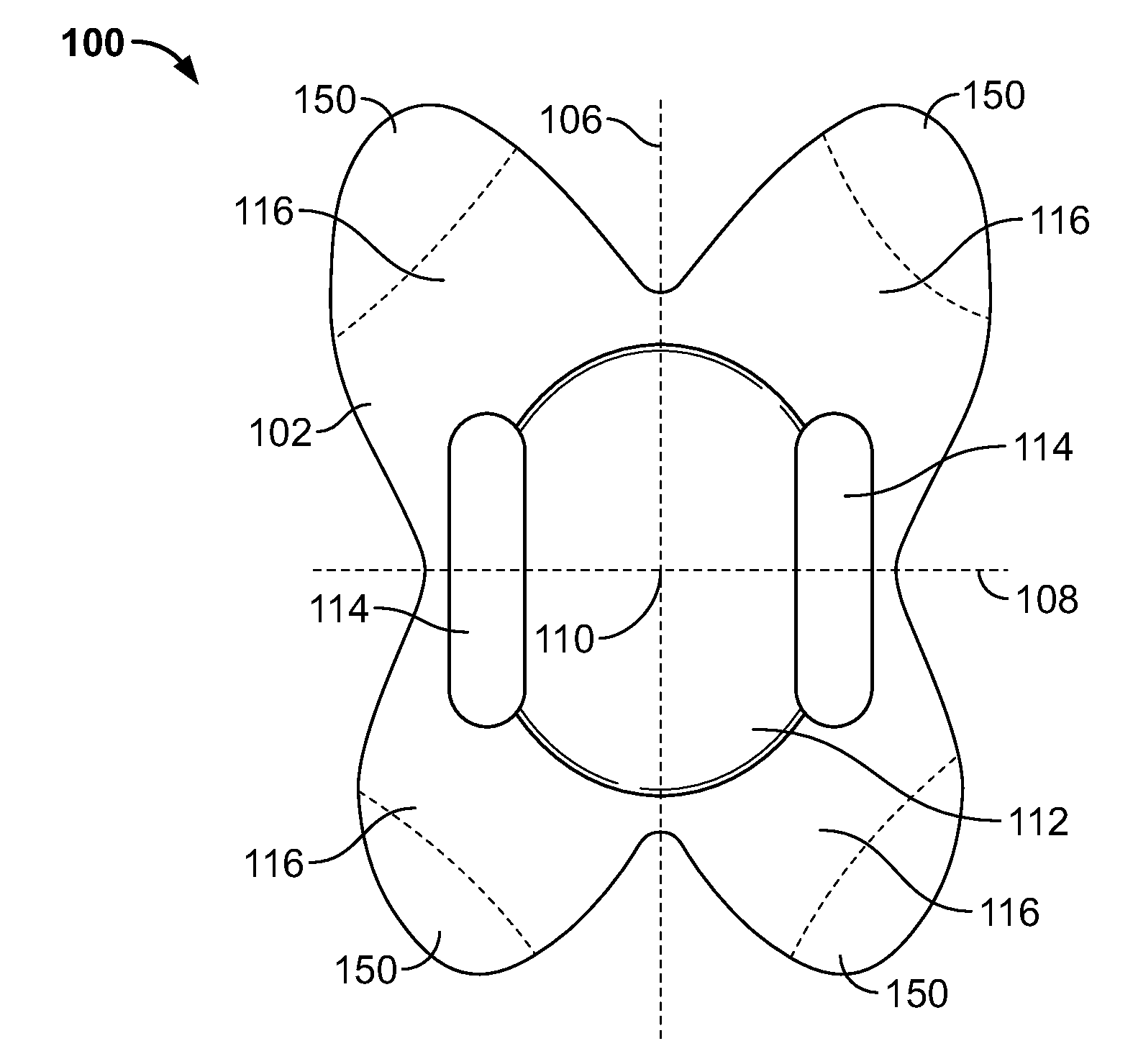

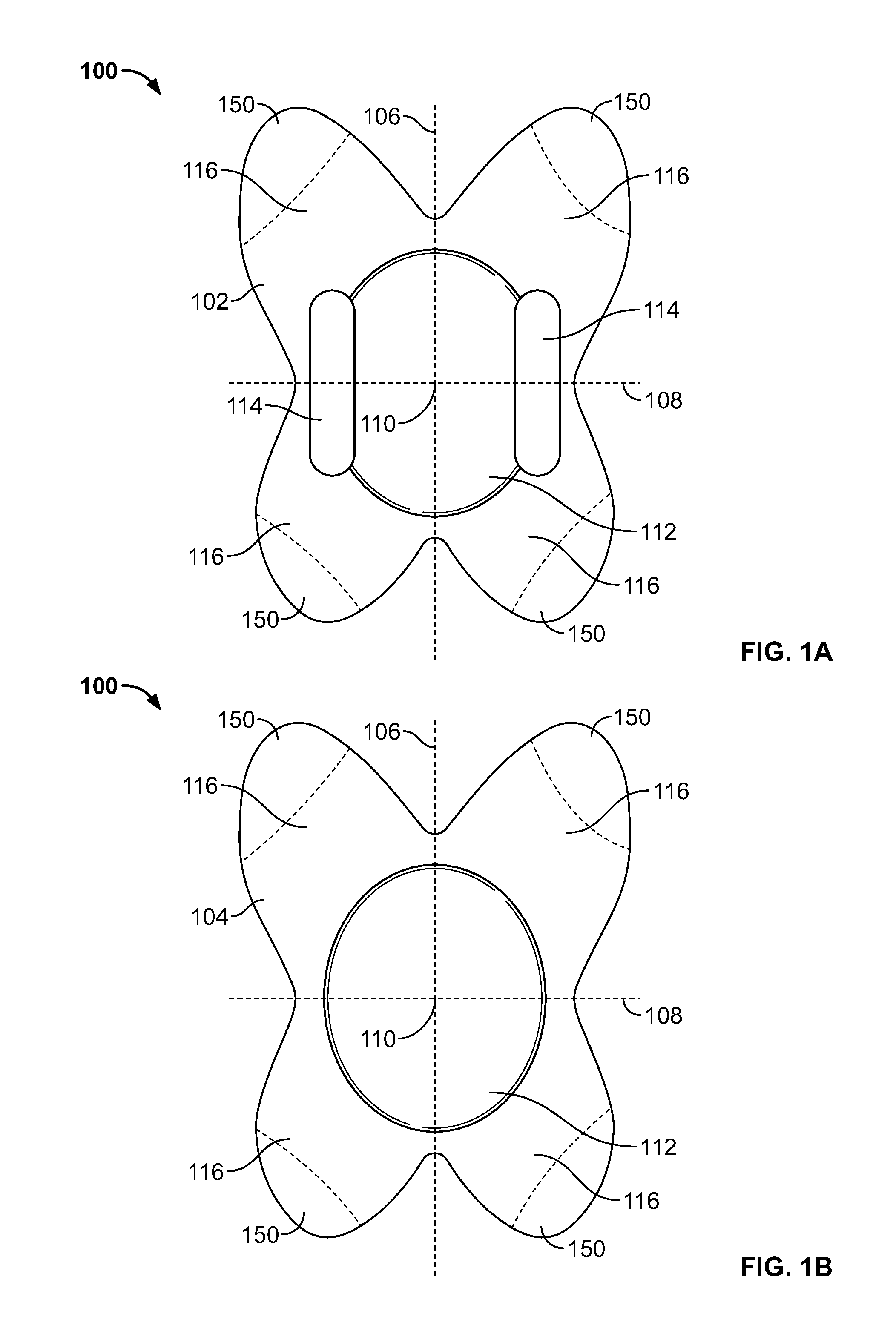

Devices and methods for treating accidental bowel leakage

Described here are body liners and methods for treating accidental bowel leakage using one or more body liners. The body liners may be formed from one or more liner layers and in some instances may comprise one or more adhesive regions to connect the body liners to the skin of a wearer. The body liners may be configured to absorb fluid, and may selectively distribute fluid relative to the body liner.

Owner:ATTENDS HEALTHCARE PRODS

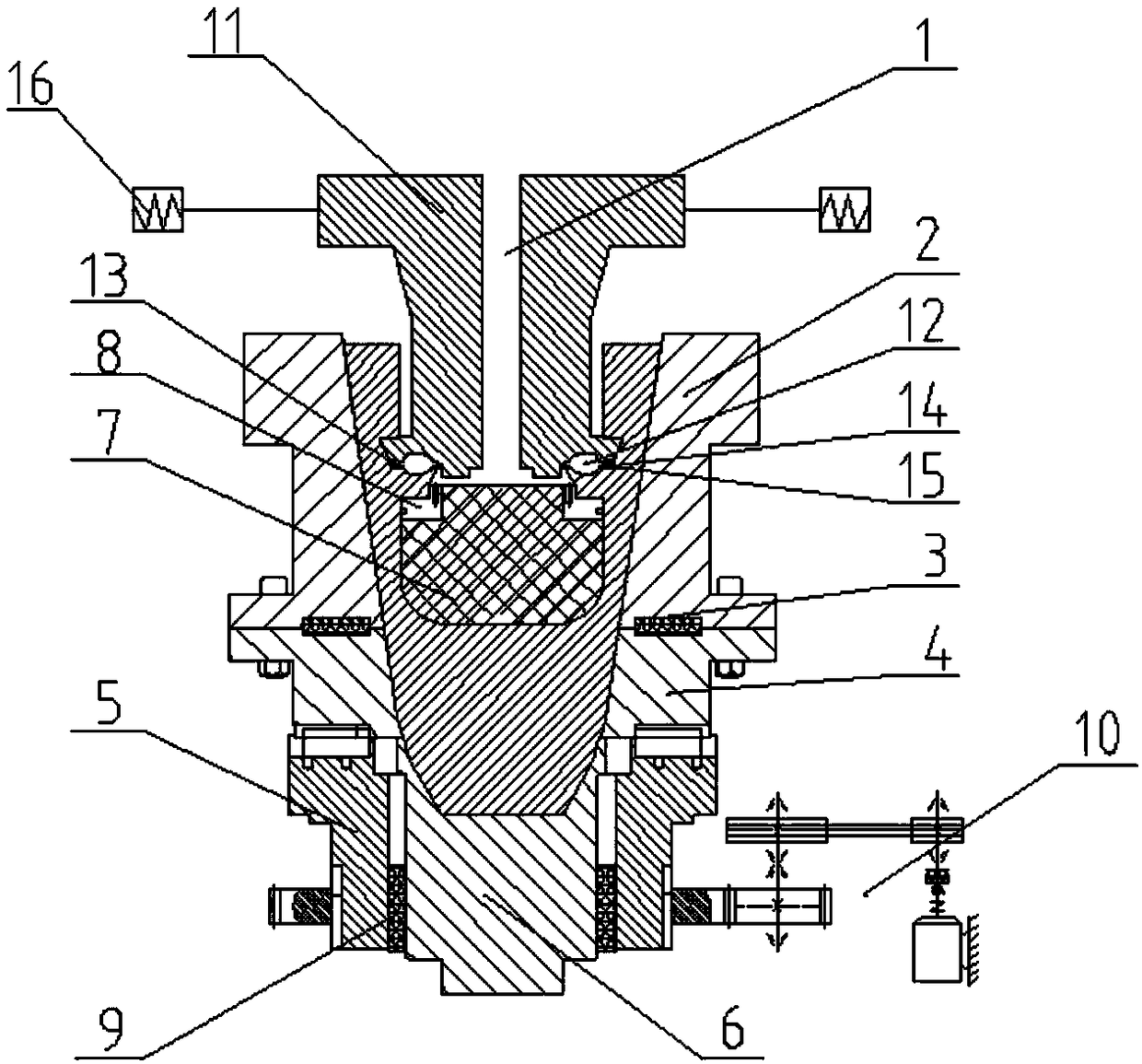

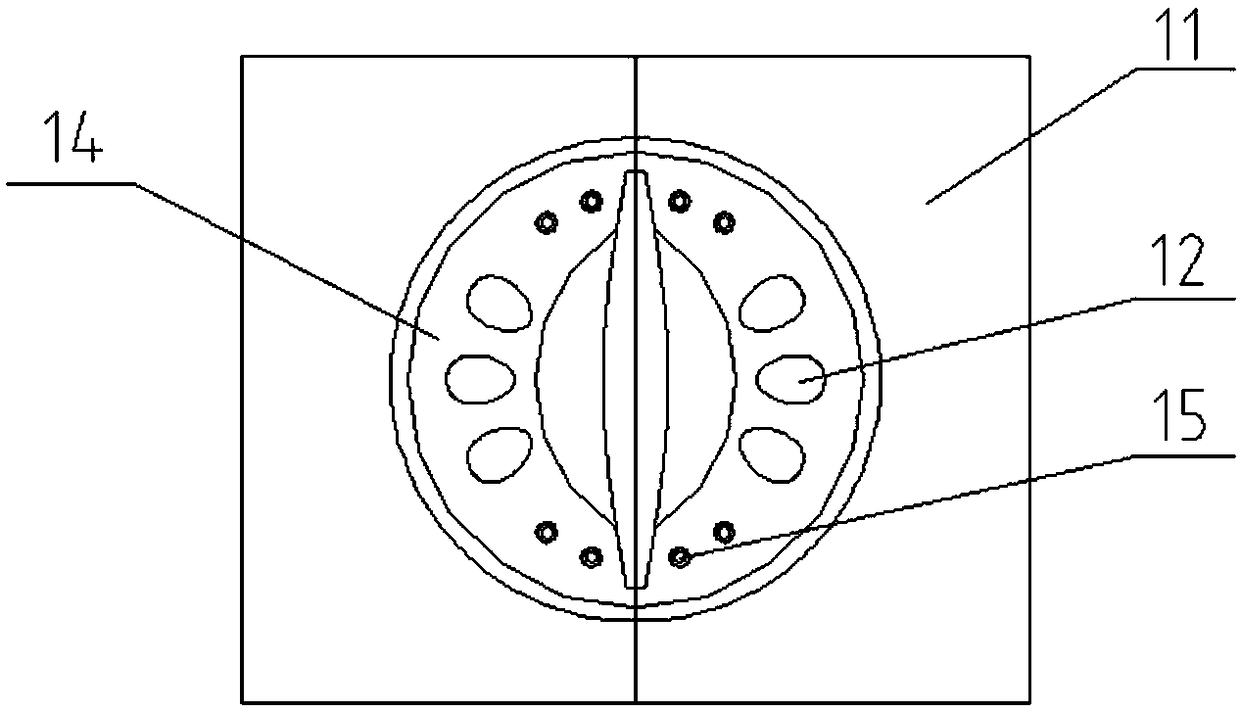

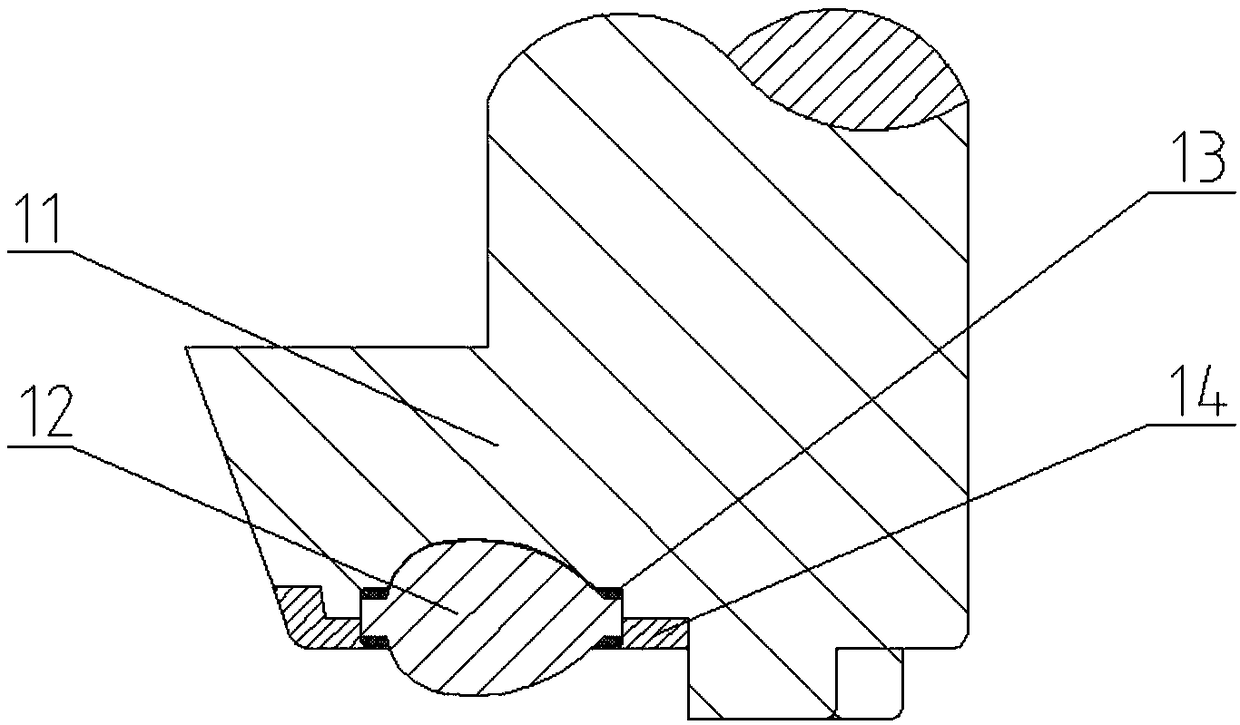

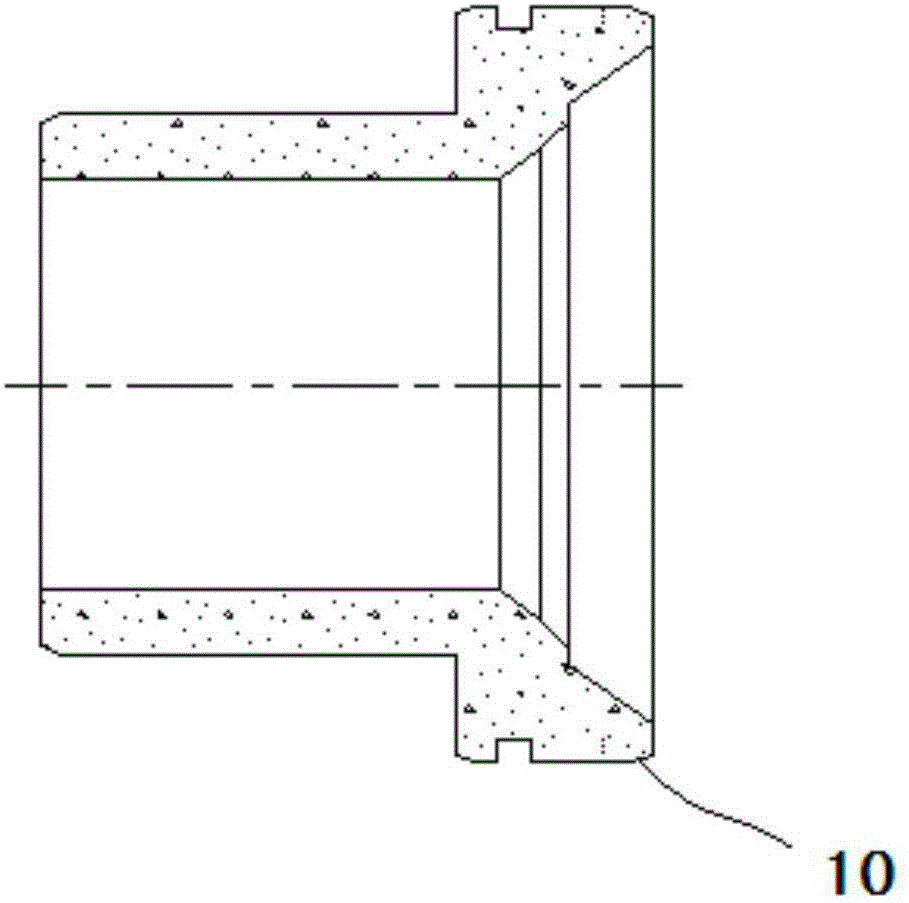

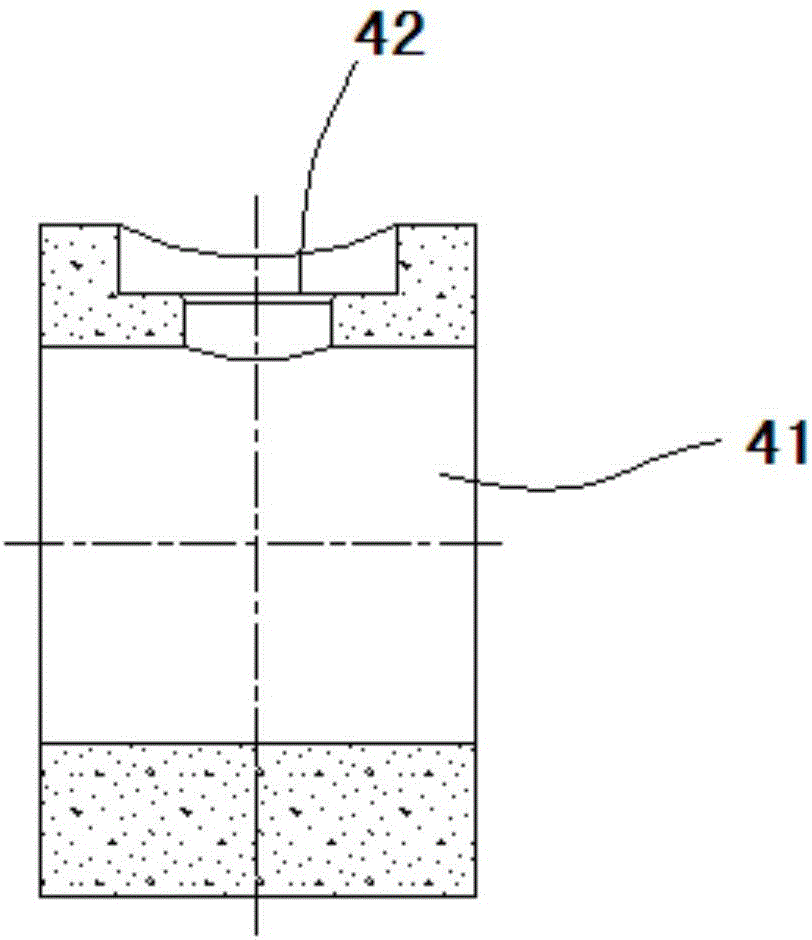

Die with roller inner rib rotating and extruding function and molding method thereof

ActiveCN109465308APrevent collapseDoes not affect normal useExtrusion diesMechanical engineeringBody linings

The invention relates to a die with a roller inner rib rotating and extruding function and a molding method thereof. According to the technical scheme, the die with the roller inner rib rotating and extruding function comprises a split male die, an upper female die, a key, a lower female die, a rotary plate, a tray, a sand core lining and a steel ring lining, The tray is arranged at the bottom ofthe lower female die and is connected with the rotary plate through a sliding key. The bottom surface of the lower female die is connected with the rotary plate. The upper female die is connected to the lower female die through bolts. The sand core lining is mounted in an inner cavity of an extruded conical barrel blank. The steel ring lining is arranged on the periphery of the upper end surface of the sand core lining. The split male die is mounted on an upper die base. The molding method comprises the steps that the die with the roller inner rib rotating and extruding function is mounted onan extruding rotating machine, thus the rotary plate is connected with an extruding rotating power system of the extruding rotating machine, then the conical barrel blank is put into an inner cavity of the upper female die and an inner cavity of the lower female die, the sand core lining and a steel body lining are sequentially placed in an inner cavity of the conical barrel blank, and the split male die is descended to a groove position of the inner wall of a barrel in a combined state, so that rotating and rolling forming is conducted.

Owner:ZHONGBEI UNIV

Maintaining method for blast furnace

InactiveCN101250598AImprove cooling effectStable at workBlast furnace componentsBlast furnace detailsRepair timeCooling effect

The invention provides a protection process of a blast furnace, which is a process which combines the furnace body grouting for the positions where furnace shell has high temperature, the installation of copper cooling sticks on cooling wall damaging positions, and the spraying lining for furnace body lining, wherein grouting adopts the way of indentation grouting, high aluminum fire-proof material is pressed into the furnace shell through a grouter, and furnace body damaging positions are sprayed after spraying lining and descending stock-line through damping down. Through the process of the invention, the copper cooling sticks are installed on burned-out cooling walls through damping out after the cooling wall is burned out, and thereby reaching the same cooling effect with the cooling walls, simultaneously cooling wall acid cleaning technology is adopted to conduct treatment, thereby increasing cooling effect. The process can significantly increase the cooling effect of the blast furnace cooling walls, thereby making the blast furnace working type basically stable, significantly delaying the damage of cooling walls and reducing blowing-out medium repair time, and obtaining excellent economical benefits.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

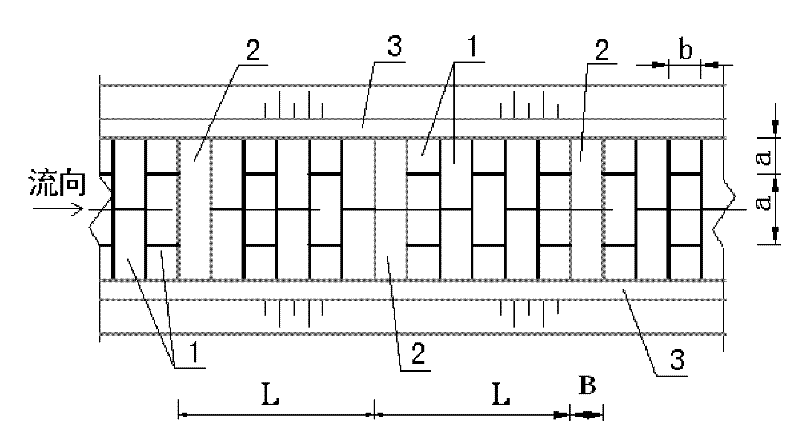

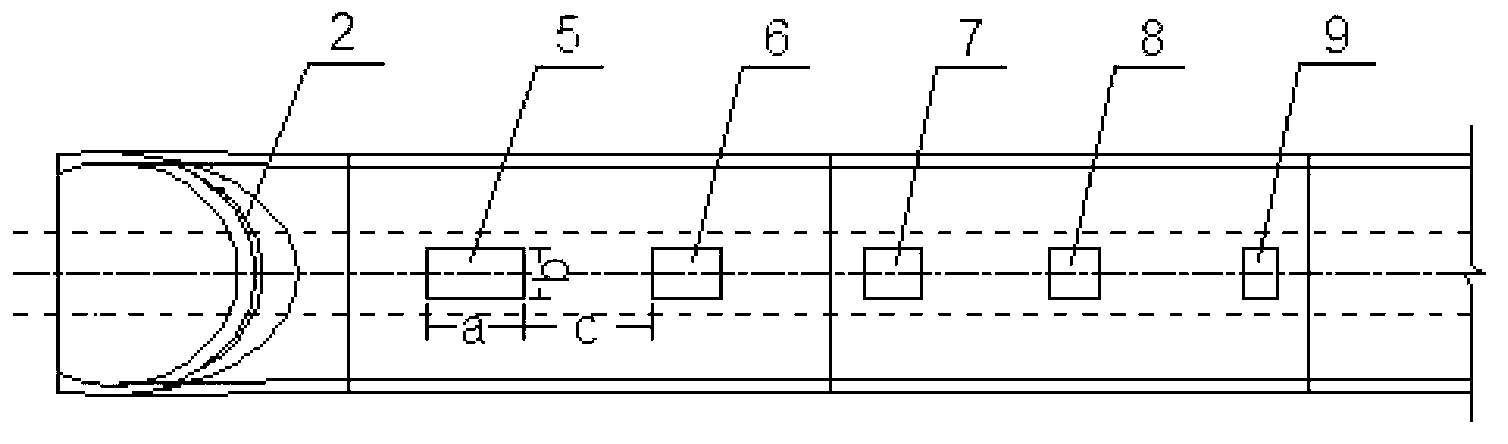

Buffer structure of double-track tunnel portal of high-speed rail

InactiveCN103016025AMitigate micro pressure wave effectAlleviate micro-pressure wave phenomenonTunnelsTerrainEconomic benefits

The invention provides a buffer structure of a double-track tunnel portal of a high-speed rail. The buffer structure is characterized in that the buffer structure is used for the double-track tunnel of the high-speed rail and is a rectangular hole body lining and butting with the tunnel portal, the rectangular hole body is positioned at the outer side of the tunnel portal, and the cross section of the rectangular hole body is rectangular; one to five openings are arranged at the top part of the rectangular hole body in the length direction of the rectangular hole body, and the area ratio of the total area of the openings and the area of the hollow cross section of a portal lining is 30-90 percent; and the area of the openings arranged in the length direction of the rectangular hole body is gradually reduced to the tunnel portal direction according to 50-90 percent. The buffer structure can effectively relieve the micro-pressure wave phenomenon of the tunnel portal of the high-speed rail and prevents the sonic boom generated by the tunnel portal from generating bad influence on surroundings, and the social effect is significant. As the buffer structure has the advantages of simple structure, strong integrity, strong applicability to terrain and geological conditions and convenience in construction, the production cost caused by the buffer structure arranged at the portal can be effectively reduced, and the economic benefit is significant.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Fire rated downlights

InactiveUS20090161370A1Increase firing rateIncrease the gapLighting support devicesVehicle interior lightingMechanical engineeringBody lines

A casing for a downlight having a tubular body from which the light of a lamp when installed in the body is emitted from the front of the body and having a rear end wall closing the body from the rear, wherein intumescent material is placed within the tubular body lining the tubular wall of the tubular body.

Owner:GIGAPHOTON

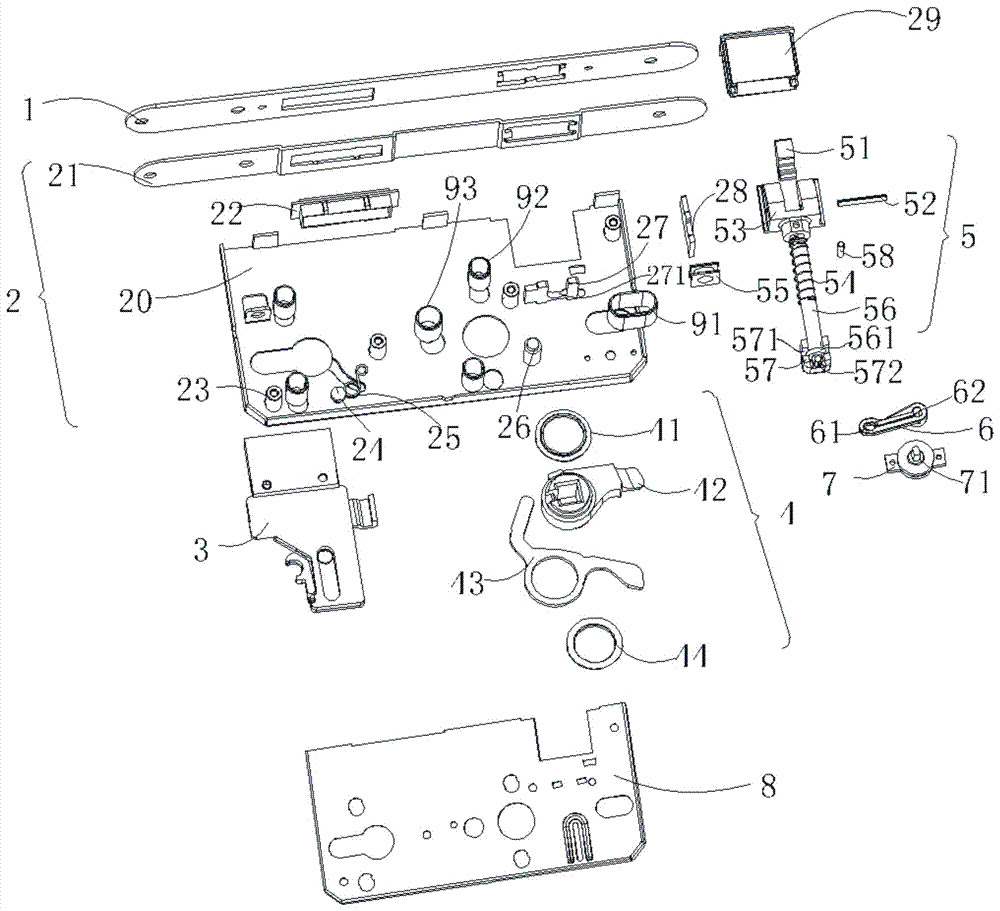

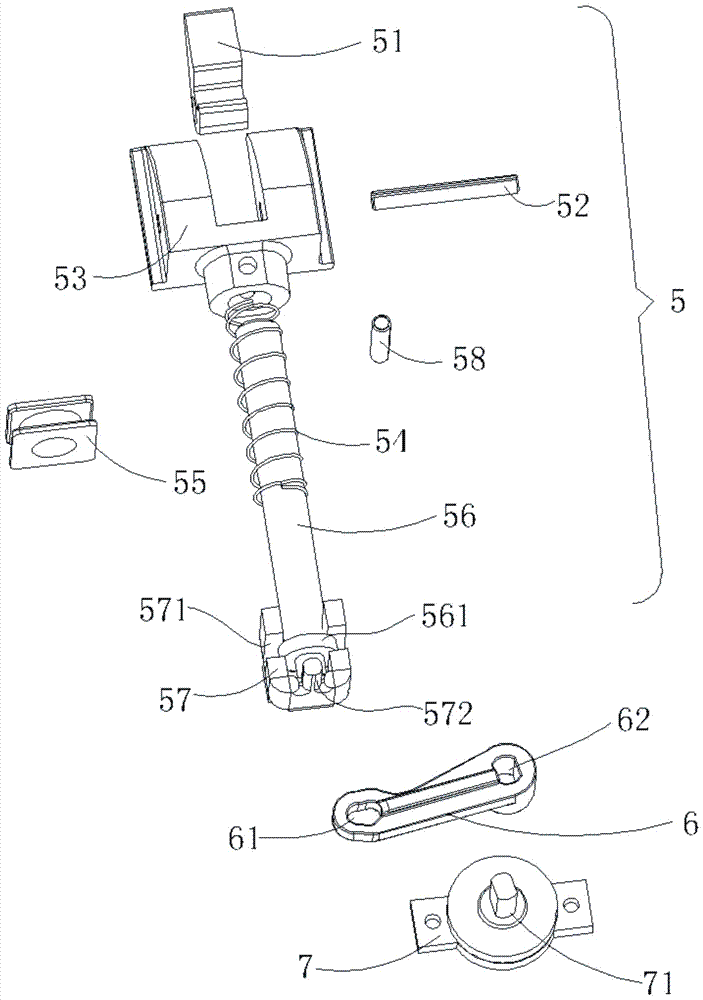

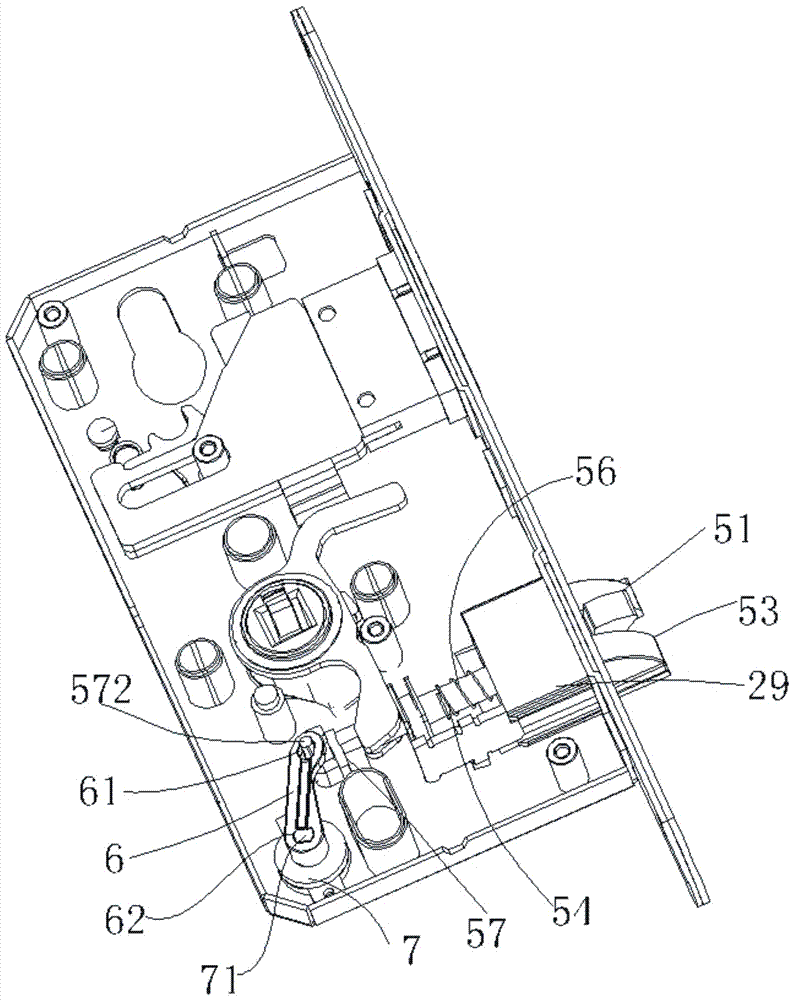

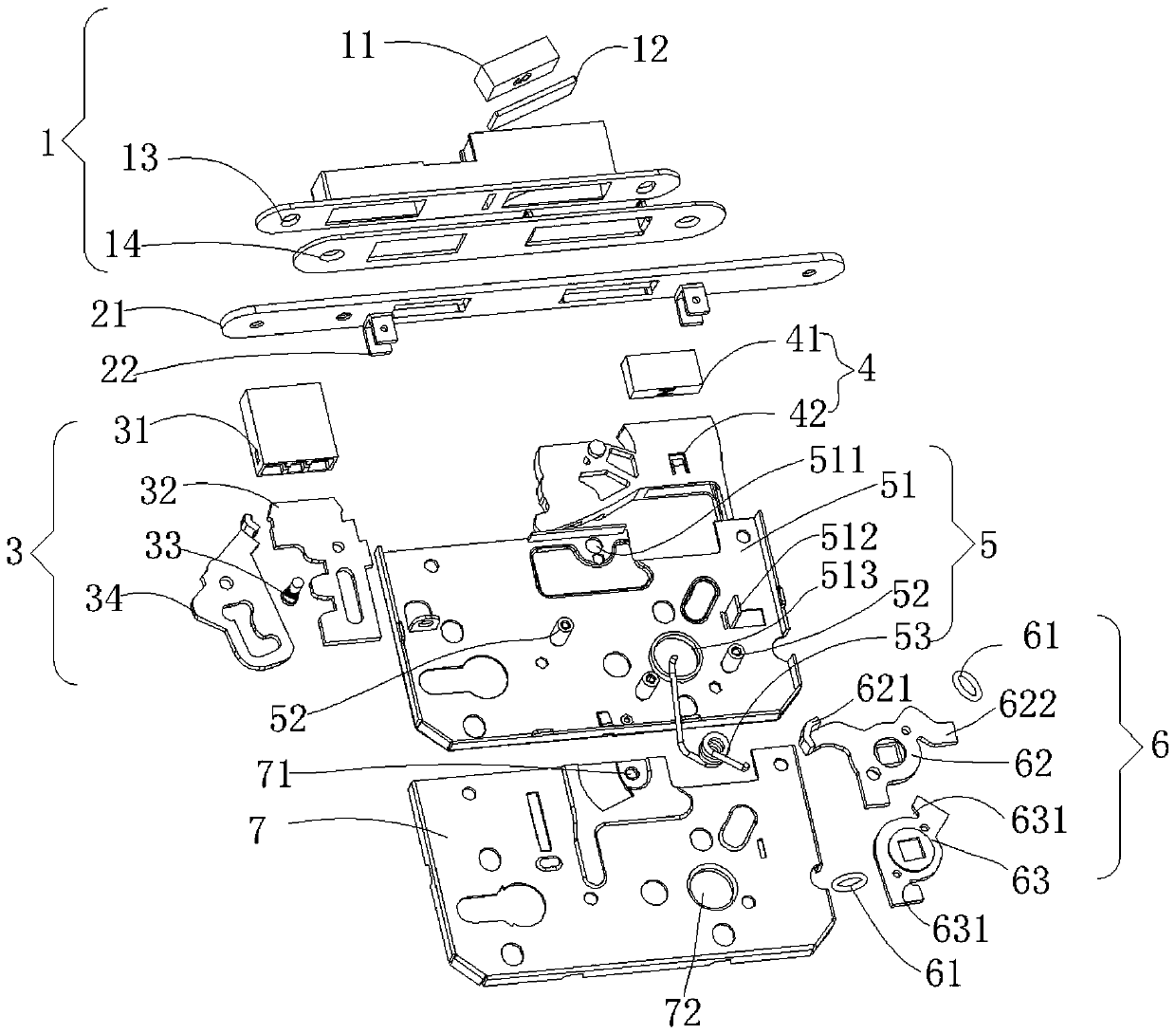

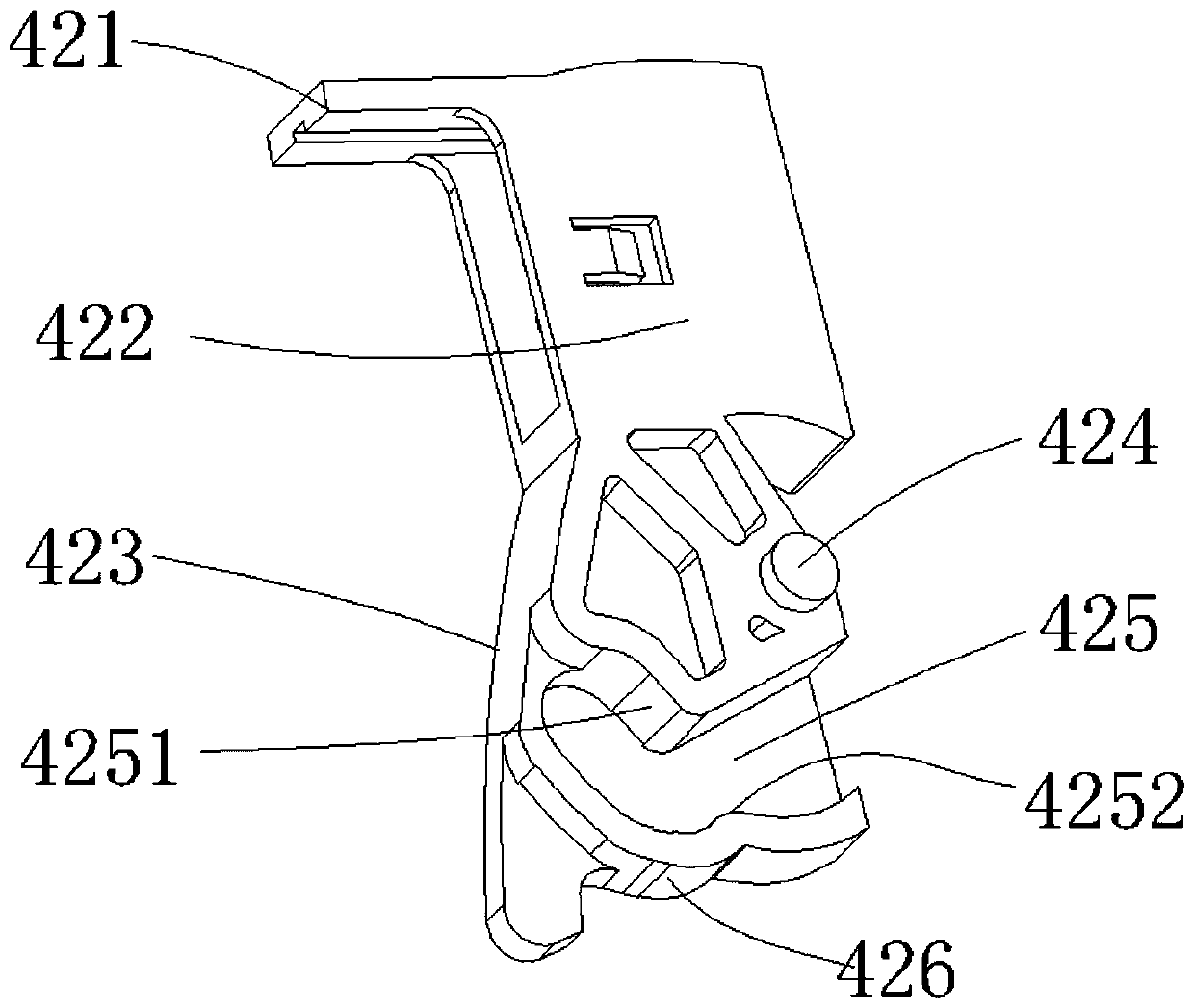

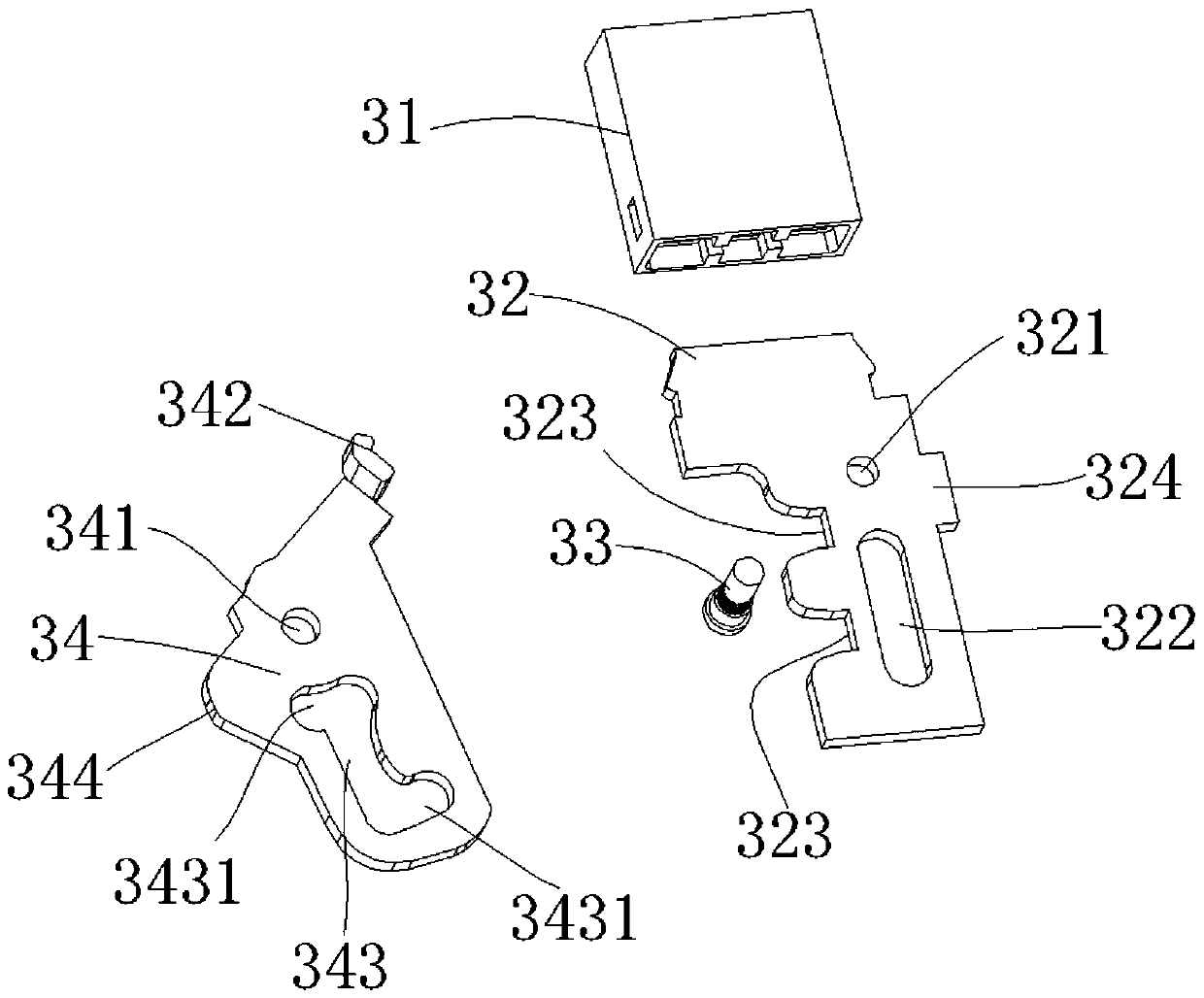

Lock body inclined tongue buffer structure

PendingCN107288421AReduced impact sound issuesImprove securityBuilding locksPlastic materialsEngineering

The invention provides a lock body inclined tongue buffer structure. The structure comprises a lock body outer lining plate, an inclined tongue module, a damper, a connecting rod, an inclined tongue shifting module, a transmission piece, a square tongue mechanism, a box cover and a lock body box bottom module; the inclined tongue module comprises an inclined tongue, a friction tongue, a pull rod, a spring, a limiting silent ring and a slide block; and the lock body box bottom module comprises a lock body lining plate, a square tongue silent block, an inclined tongue silent block, a box bottom, a stud, a guide column, a positioning plate, a spring, a fastening nail and a damper. The structure adopts one or more of silent plastic materials such as nylon, TPE elastic plastic and ABS for manufacturing the parts so as to replace metal parts, or adopts a method of separating the metal parts by silent plastic materials to reduce the noise generated by friction. Meanwhile, the buffer function of the damper is matched to reduce the noise generated by mutual collision among all parts in working of a lock body.

Owner:GUANGDONG MINGMEN LOCKS IND

Method for preventing lining plate of ball grinder from cracking

InactiveCN101623746AReduce downtimeIncrease effective volumeFoundry mouldsFurnace typesEngineeringLost-foam casting

The invention relates to a method for preventing a lining plate of a ball grinder from cracking, which is suitable for improving the lining plate of the prior ball grinder and aims to enhance the yield limit of the lining plate of the ball grinder. The method adopts high manganese steel materials, such as ZGMn13Cr2Mo and ZG32Mn9SiCr2MoRe or ZGMn9Cr2ReSi, containing metallic elements, i.e. Cr, Mo, and the like to manufacture an end lining plate, a cylinder body lining plate and a grid lining plate of the ball grinder by a lost foam casting method and needs to carry out heat processing for cast and formed lining plates before the lining plates are installed to be used. The method comprises the following steps: firstly, placing the lining plates into a furnace to be heated to 200 DEG C-300 DEG C, and preserving the temperature of the lining plates for 1-2 hours; then heating the lining plates to 650 DEG C-680 DEG C according to the speed of 40 DEG C-50 DEG C / hour, and preserving the temperature of the lining plates for 4.5-5 hours; then heating the lining plates to 1060 DEG C-1090 DEG C according to the speed of 60 DEG C-70 DEG C / hour, and preserving the temperature of the lining plates for 3.0-4.0 hours; taking the lining plates out of the furnace, placing the lining plates into water to subject to water toughening processing, then placing the lining places into a tempering furnace to be heated to 300 DEG C-350 DEG C according to the speed of 40 DEG C-50 DEG C / hour, and preserving the temperature of the lining plates for 6-8 hours; then cooling the lining plates at the speed of 1.5-2.5 min / mm; tempering the lining plates into the furnace, and controlling the temperature of the lining plates below 150 DEG C.

Owner:TAIYUAN IRON & STEEL GROUP

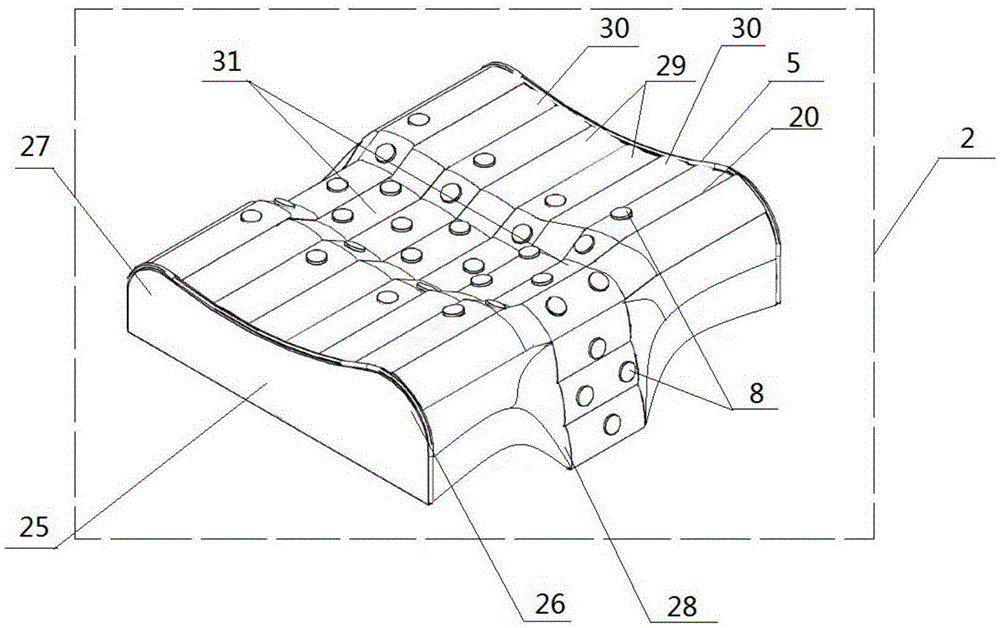

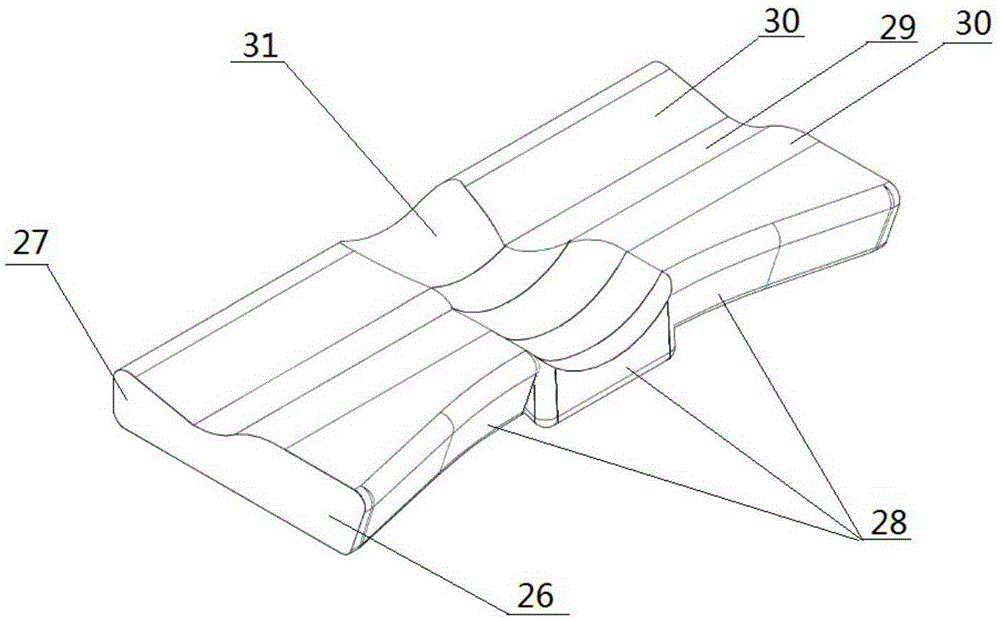

Multifunctional cervical vertebra maintenance pillow

The invention provides a multifunctional cervical vertebra maintenance pillow. The multifunctional cervical vertebra maintenance pillow comprises a pillow case and a pillow, wherein the pillow case is formed by sewing edges of an upper anti-mite sanitary finish high-count cotton fabric, a lower anti-mite sanitary finish high-count cotton fabric and a middle Evolon anti-mite fabric; the pillow comprises a cover body and an inner core, and the cover body comprises a reticulated cloth layer, stone needles, a cotton lining cloth layer, magnetite, a coffee carbon non-woven fabric layer, tartary buckwheat shells, an anion far infrared sintering particle inner core layer, a pure polyester lining cloth layer, a first cotton fabric layer, a carbon fiber heat emitting layer, a core body lining cloth layer, a knitted core body lining cloth layer and a second cotton fabric layer. The multifunctional cervical vertebra maintenance pillow has the beneficial effects that due to a unique structure and setting of health functions such as anti-mite technology, stone needle therapy, biological magnetic energy, far infrared health care, anion health care and ecological simulated heat energy, a health function on the brain of a human body is fully realized, and certain protection and adjustment can be given to a physiological curve of cervical vertebrate of a human body.

Owner:TIANJIN JIANLONG TECH

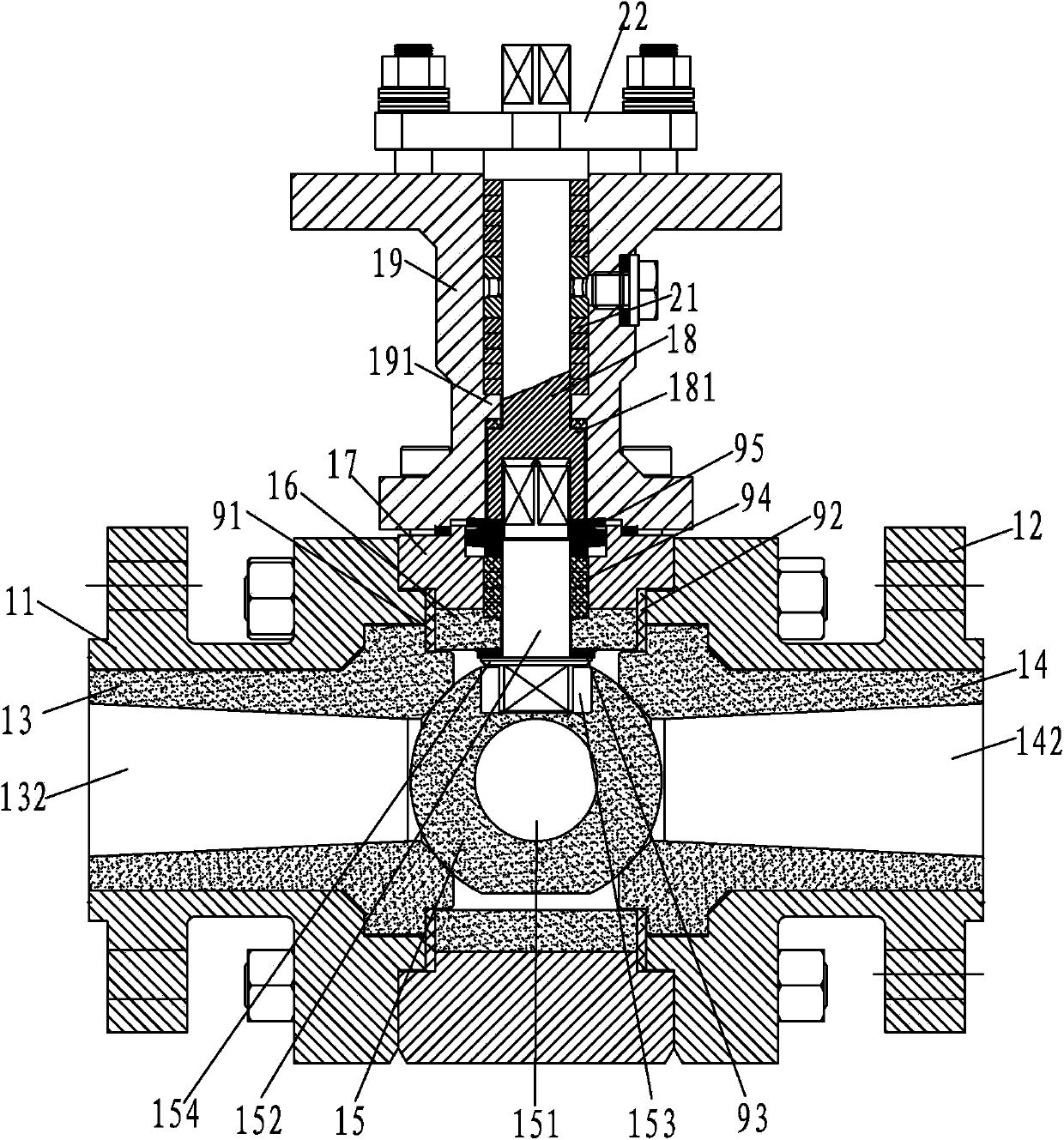

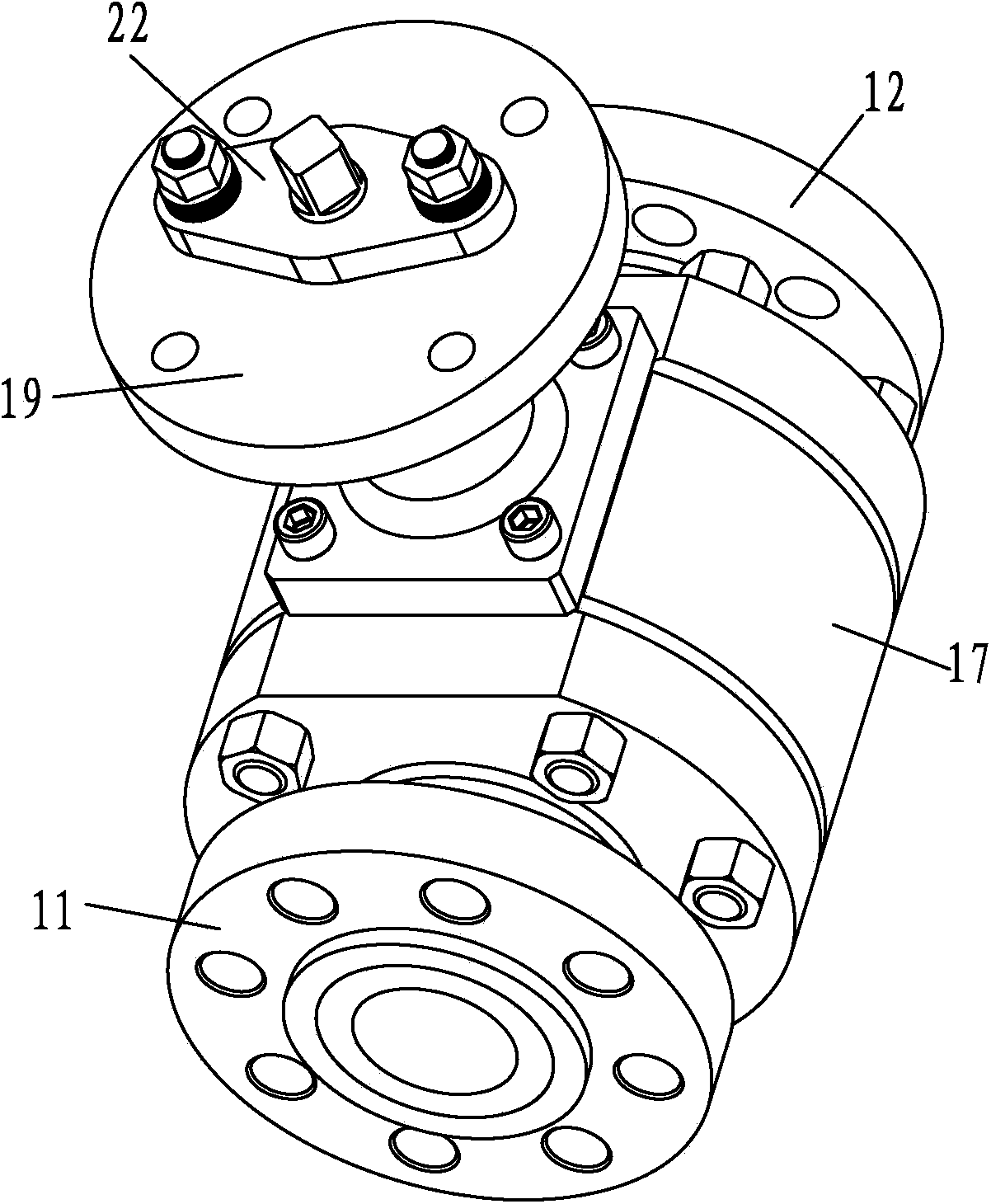

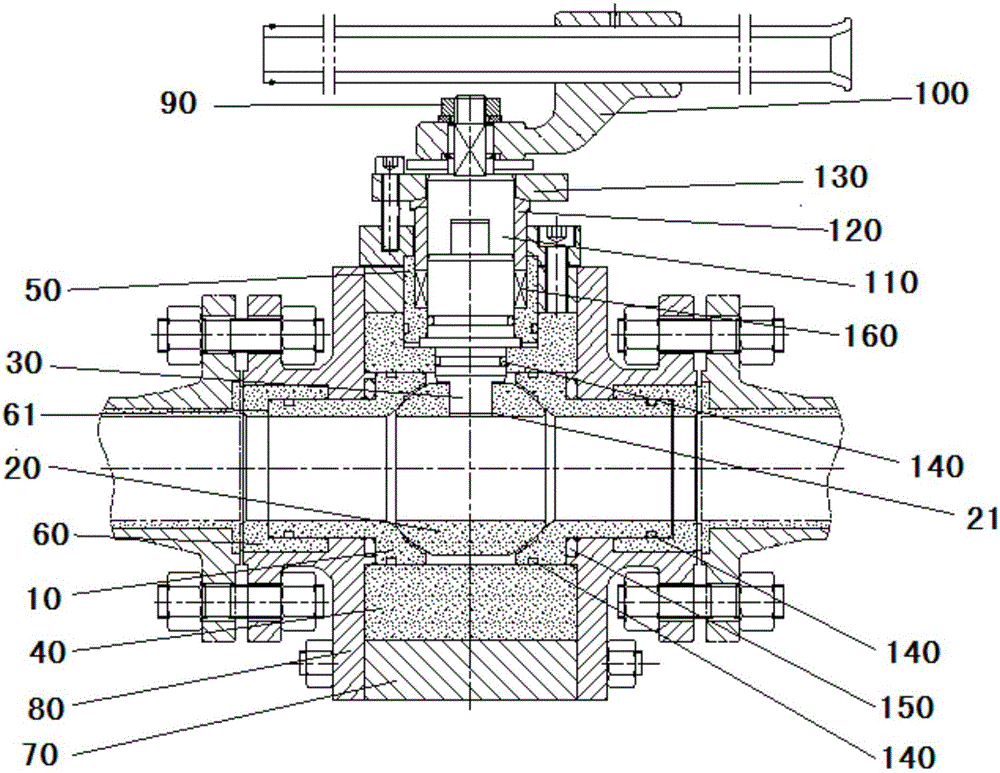

High temperature high pressure ceramic valve

ActiveCN103470800AImprove high temperature resistanceImprove corrosion resistancePlug valvesValve housingsEngineeringHigh pressure

A high temperature high pressure ceramic valve comprises a left flange, a right flange, a left valve seat, a right valve seat, a sphere, a valve body lining and a valve body; the left flange and the right flange are sleeved outside the left valve seat and the right valve seat; centers of the left valve seat and the right valve seat are provided with flow channels; the sphere is arranged between the left valve seat and the right valve seat; a through hole is formed in the center of the sphere; a valve rod is connected to the upper end of the sphere; the valve body is clamped between the left flange and the right flange; the valve body lining is clamped between the left valve seat and the right valve seat; the valve body is sleeved outside the valve body lining; the left flange, the right flange and the valve body are mutually fixed; through holes are formed in the valve body lining and the valve body; the valve rod extends out from the through hole which is formed in the valve body; the left valve seat, the right valve seat, the sphere and the valve body lining are made of ceramic materials. The high temperature high pressure ceramic valve has the advantages of being high temperature resistant and corrosion resistant, enabling the high temperature resistant performance to be greatly improved and enabling the service life under poor working conditions to be prolonged.

Owner:YANTAI KINGWAY SCI & TECH

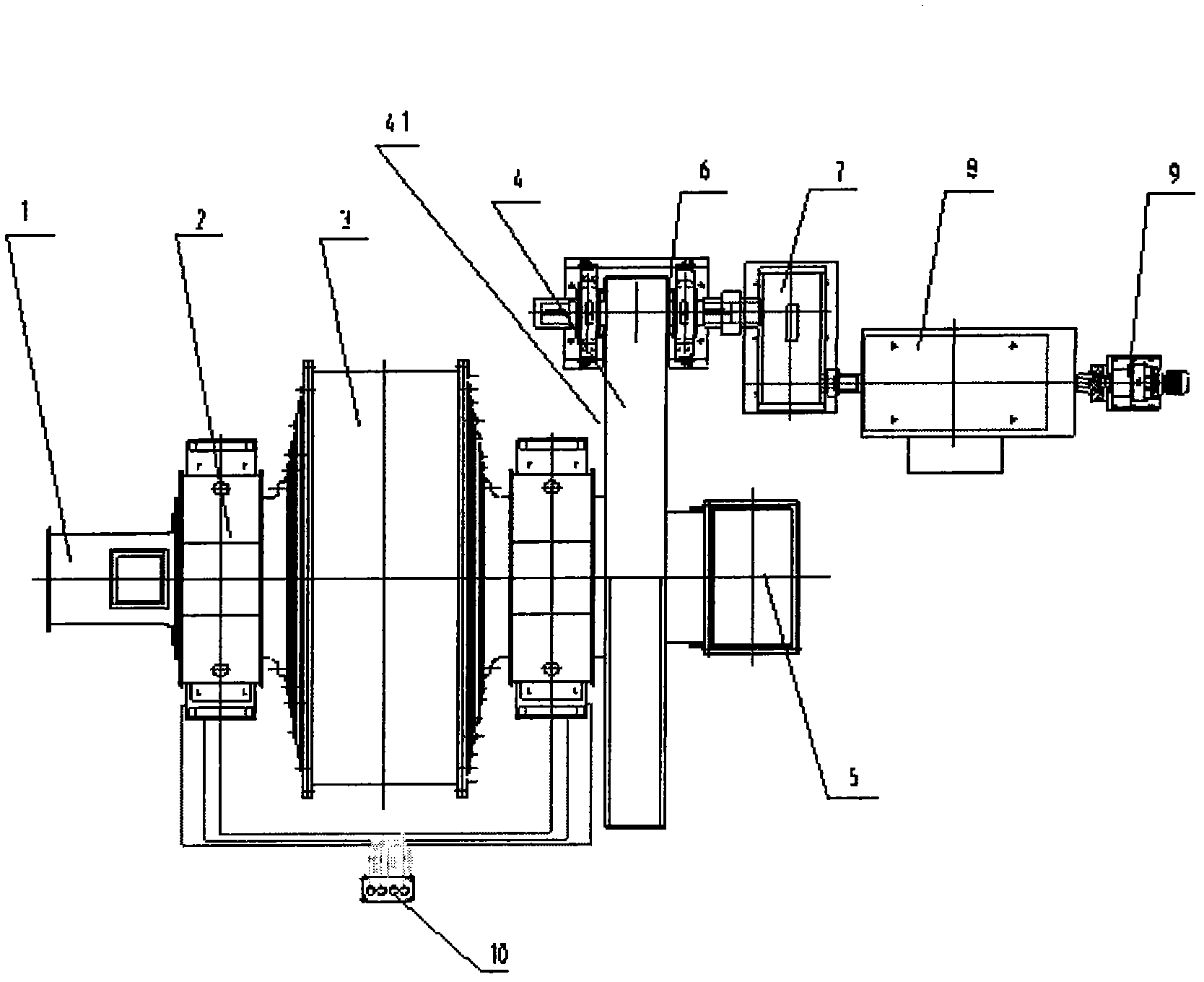

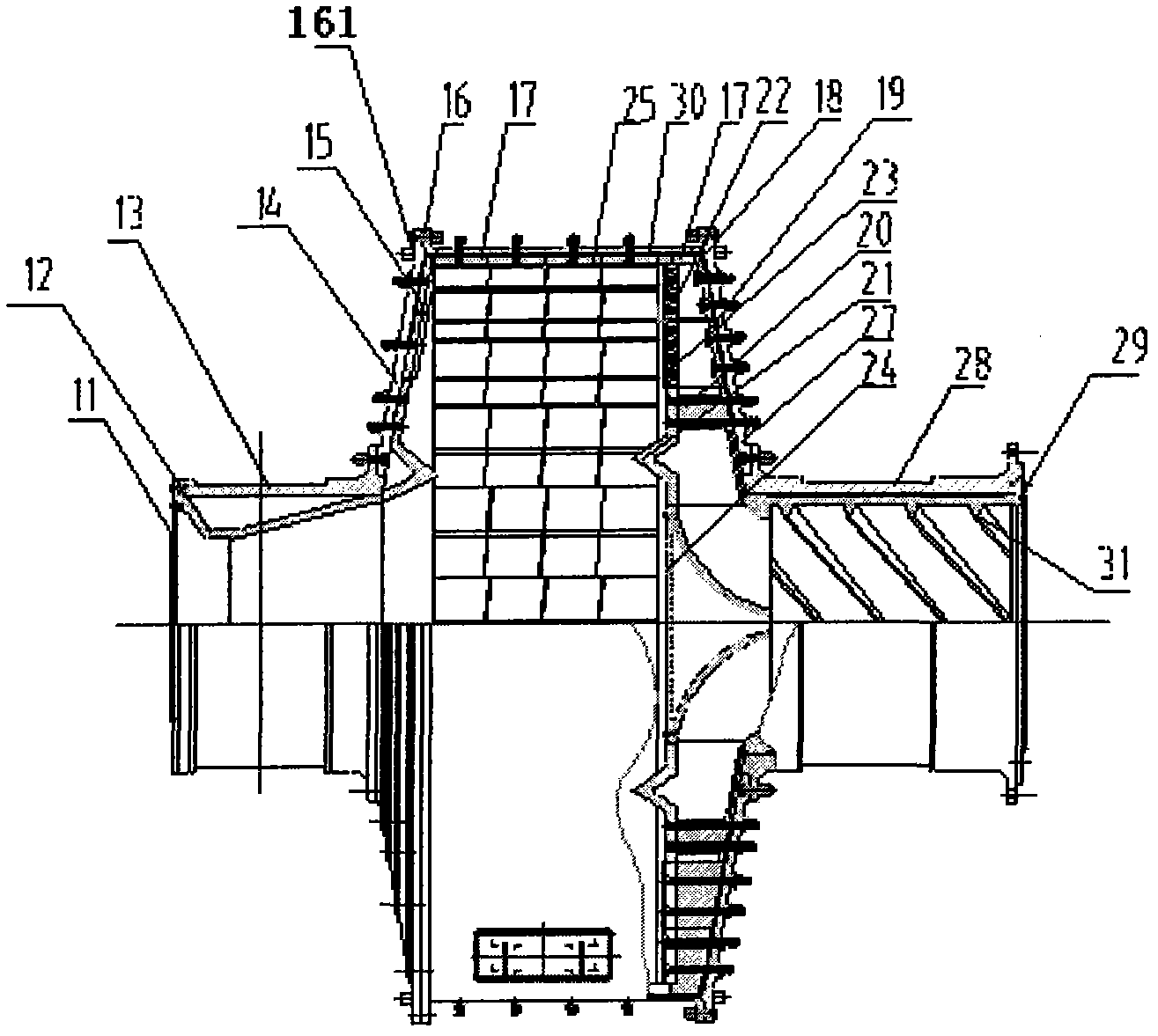

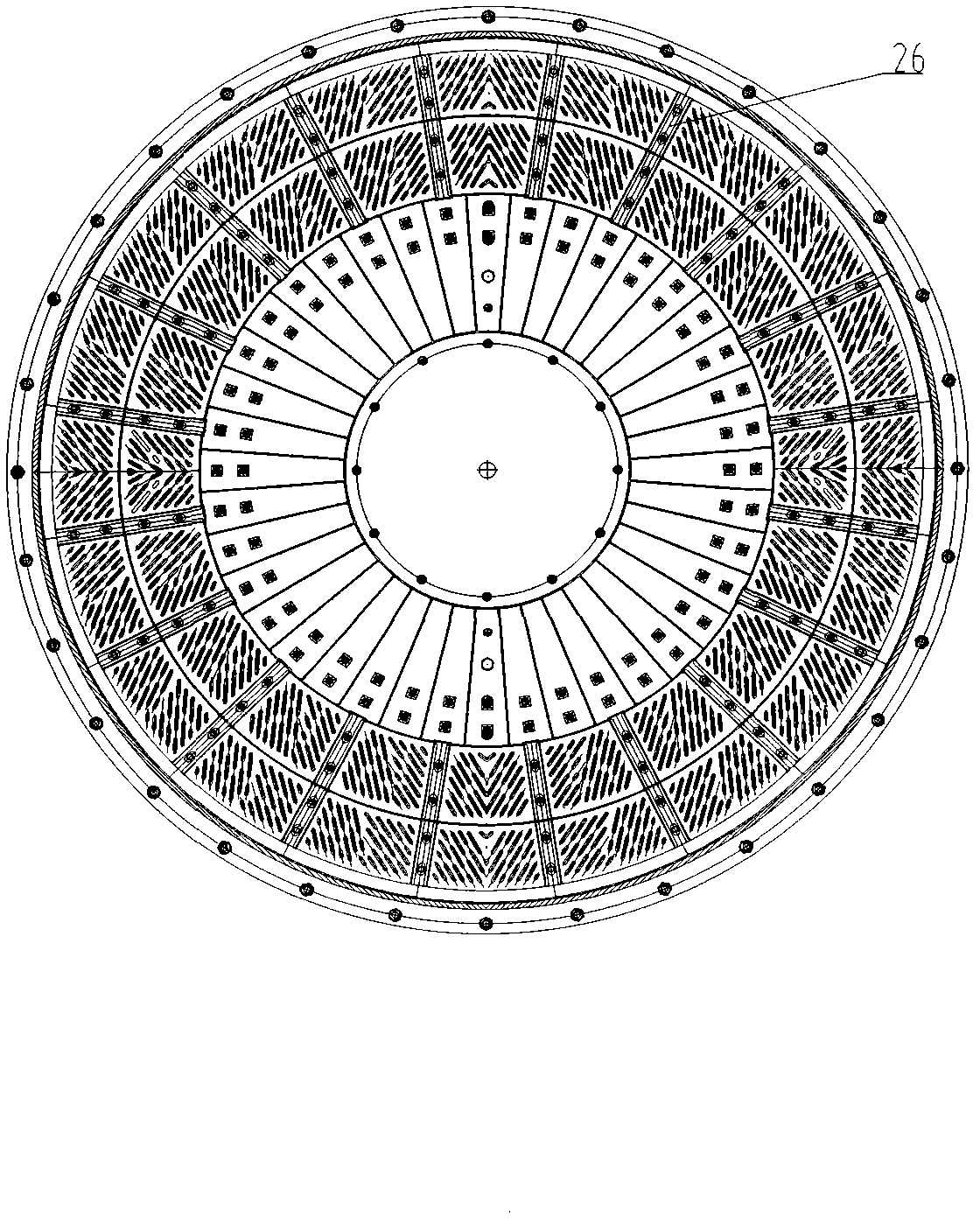

Large type crushing and grinding machine for crushing and grinding alumina crusting blocks

Provided is a large type crushing and grinding machine for crushing and grinding alumina crusting blocks. The large type crushing and grinding machine for crushing and grinding the alumina crusting blocks comprises a feeding part, a main bearing, a rotation part, a driven gear, a discharge part, a driving gear, a speed reducer, a main motor, a low-speed driving device and a lubricating device. One end of the feeding part stretches inside the rotation part of the crushing and grinding machine, the rotation part penetrates through the main bearing, the main bearing supports the rotation part as a supporting device, the rotation part is connected with the driven gear through bolts, the driving gear is meshed with the driven gear and drives the driven gear to rotate, the driving gear is connected with the speed reducer, the speed reducer is connected with the main motor through a coupler, the other end of the main motor is connected with the low-speed driving device through a clutch, and the lubricating device is arranged on the main bearing. The rotation part further comprises a feeding end cover plate, a feeding port, a feeding hollow journal, a feeding cone end cover, an end lining plate, a barrel body, a groove plate, a corrugated plate, an upper shifting plate, a lower shifting plate, a barrel body lining plate, a pressing bar, a discharge cone end cover, a discharge hollow journal and a discharge spiral. The large type crushing and grinding machine for crushing and grinding the alumina crusting blocks aims at achieving large energy generation under small wind action.

Owner:洛阳宇航重工科技股份有限公司

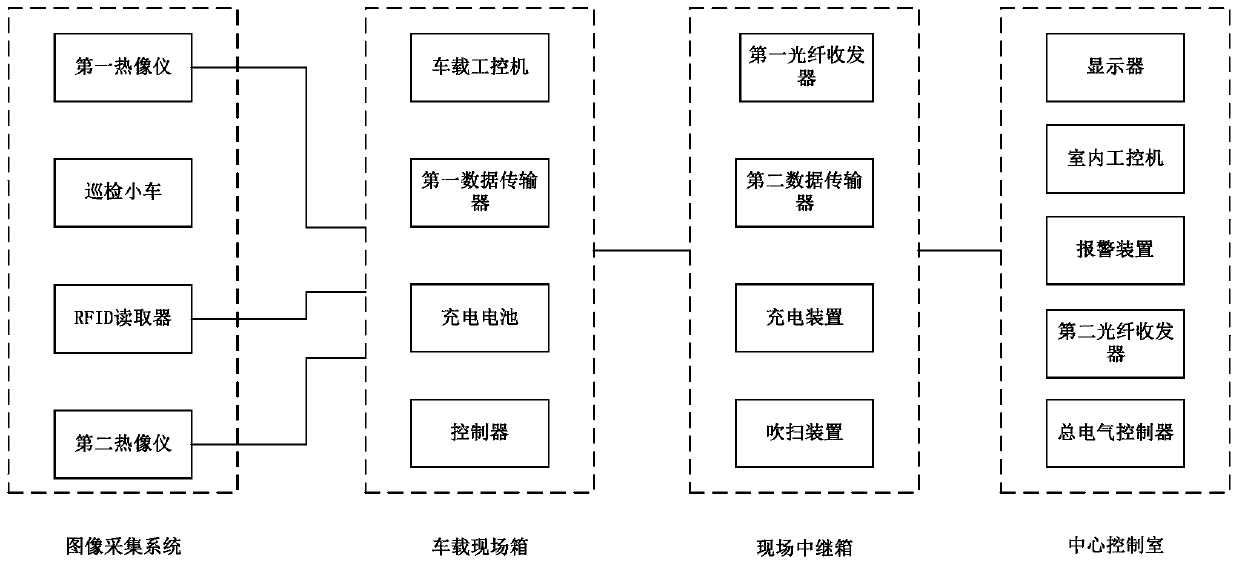

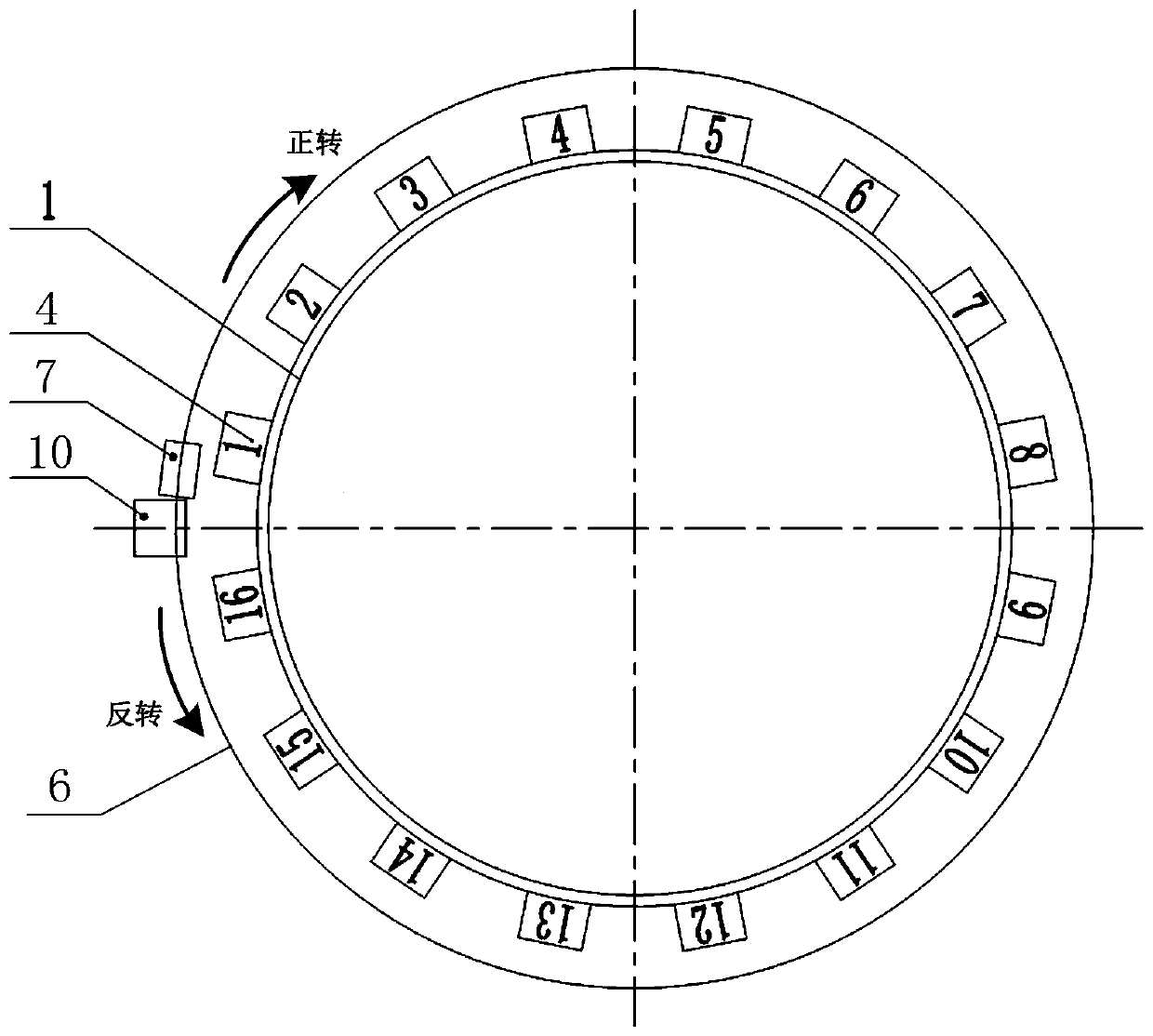

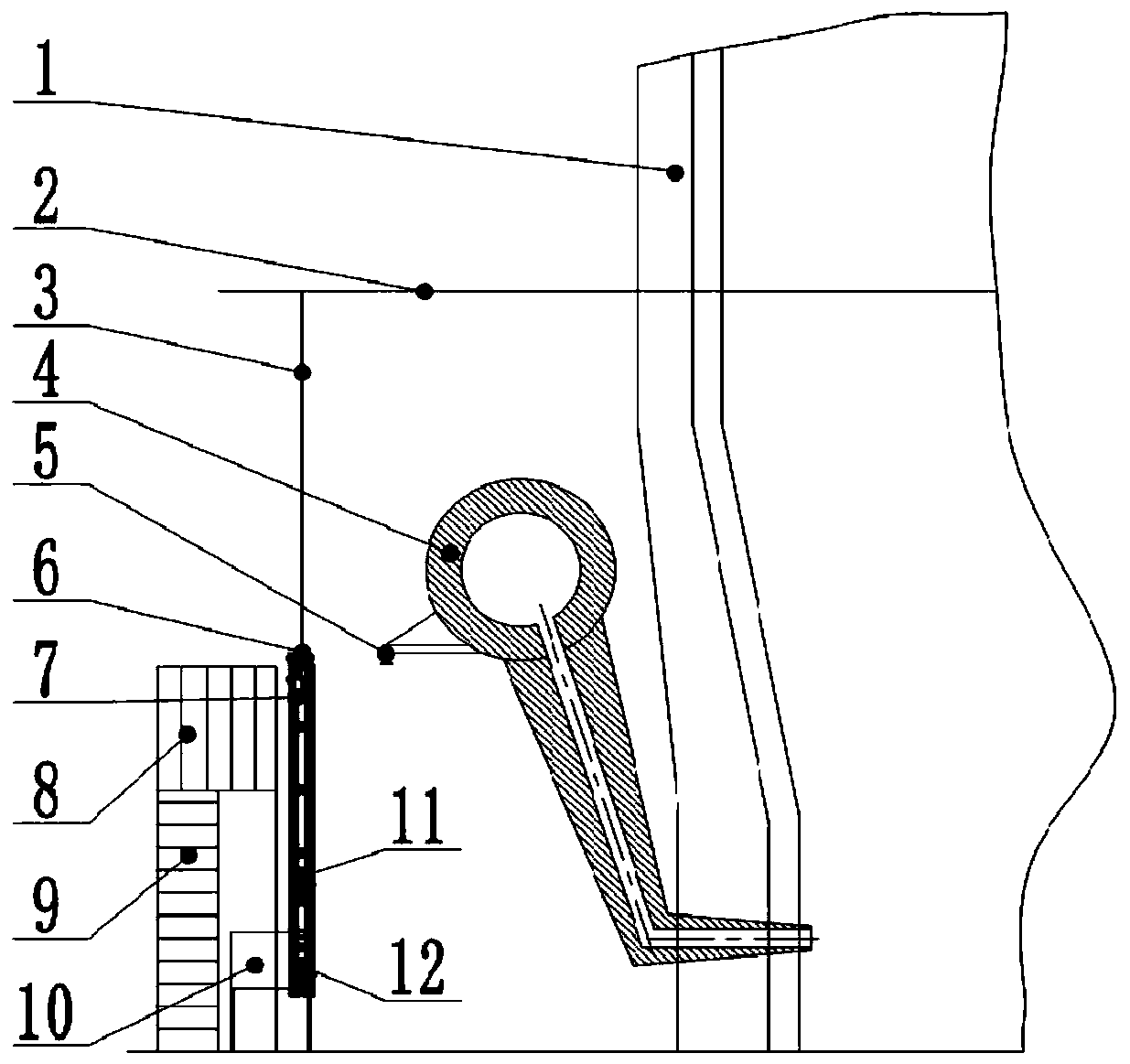

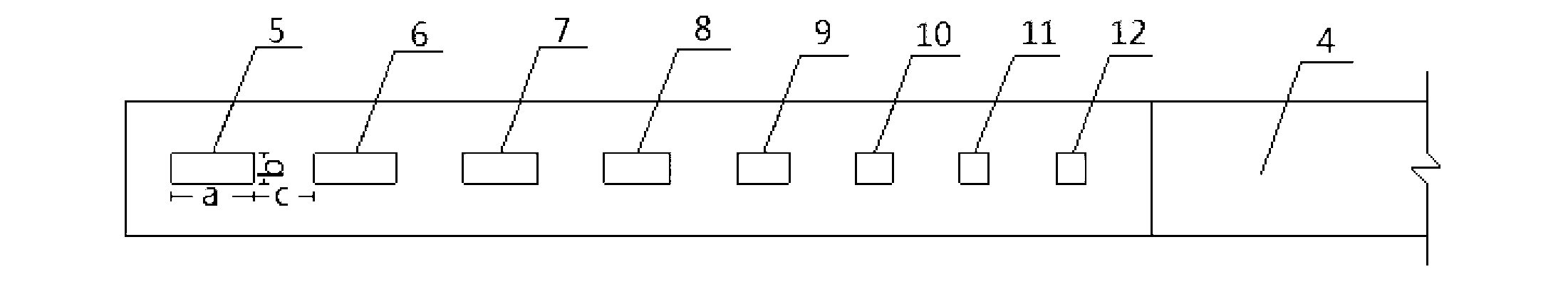

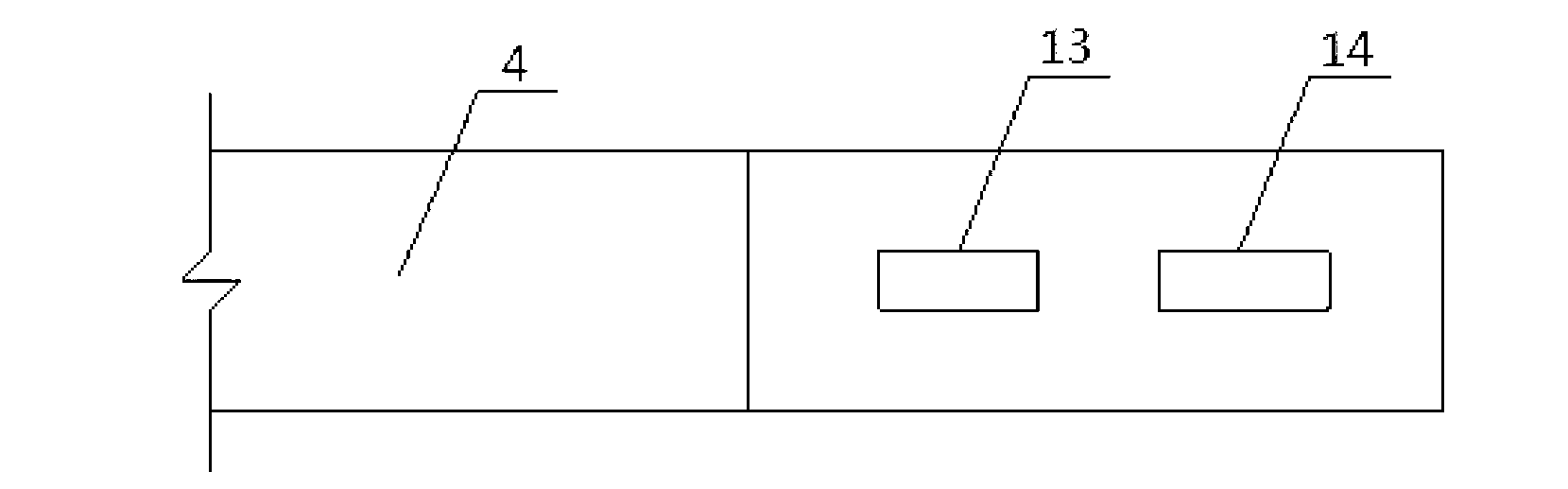

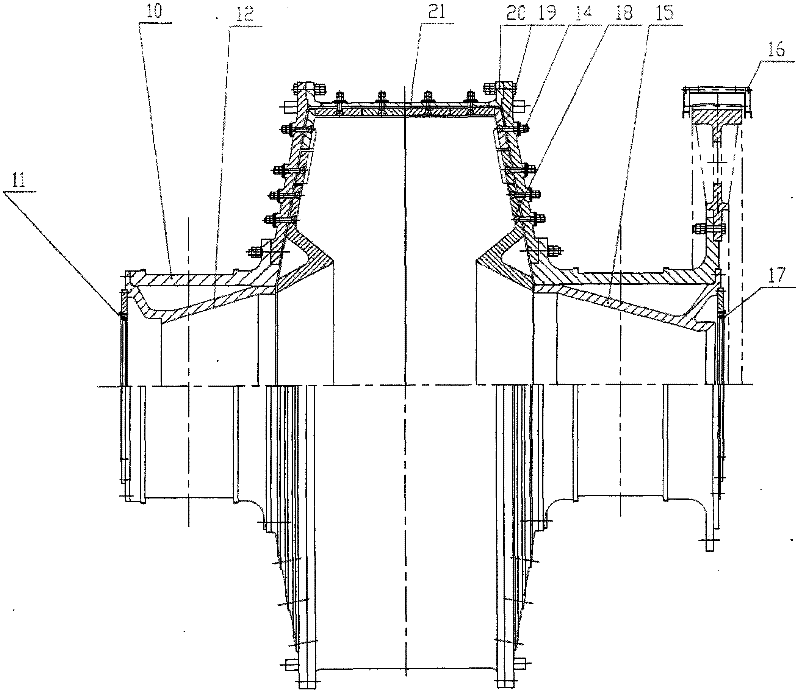

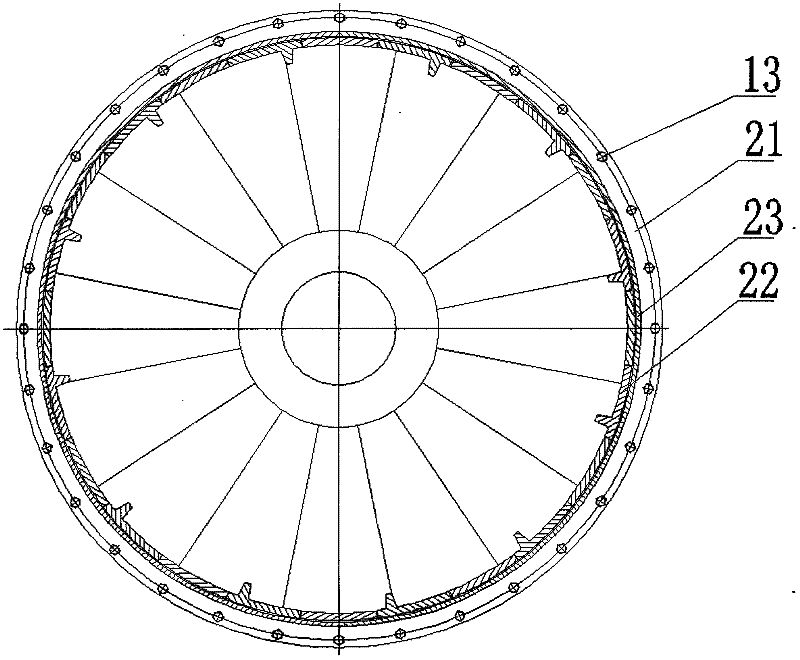

Blast furnace tuyere equipment and periphery furnace body lining corrosion state patrol system and method thereof

PendingCN109913602AAccurately locate damaged partsAccurate localization of severityChecking devicesImaging processingCorrosion

The invention discloses blast furnace tuyere equipment and a periphery furnace body lining corrosion state patrol system and method thereof. The system comprises a thermal imager, a patrol trolley, aring-shaped track and an image processing system. The ring-shaped track is arranged on the periphery of the blast furnace body in the circumferential direction of the blast furnace body. The patrol trolley is arranged on the ring-shaped track. The thermal imager is installed on the patrol trolley to collect thermal images of the blast furnace tuyere equipment and the periphery furnace body thereofin real time. The image processing system is connected with the thermal imager. The obtained infrared thermal images are processed to obtain the highest temperature value of different detection areasof the furnace body within the infrared thermal image collecting range, so that whether abnormal temperature occurs or not is judged and the corrosion state of a furnace body lining is detected. According to the patrol system and method, by means of monitoring over abnormity of the surface temperature of the blast furnace body, the purpose of detecting the damage situation of the blast furnace tuyere equipment and a periphery furnace body lining material thereof is achieved, and the equipment can be pre-detected and pre-repaired reasonably and beneficially in advance.

Owner:天津市三特电子有限公司

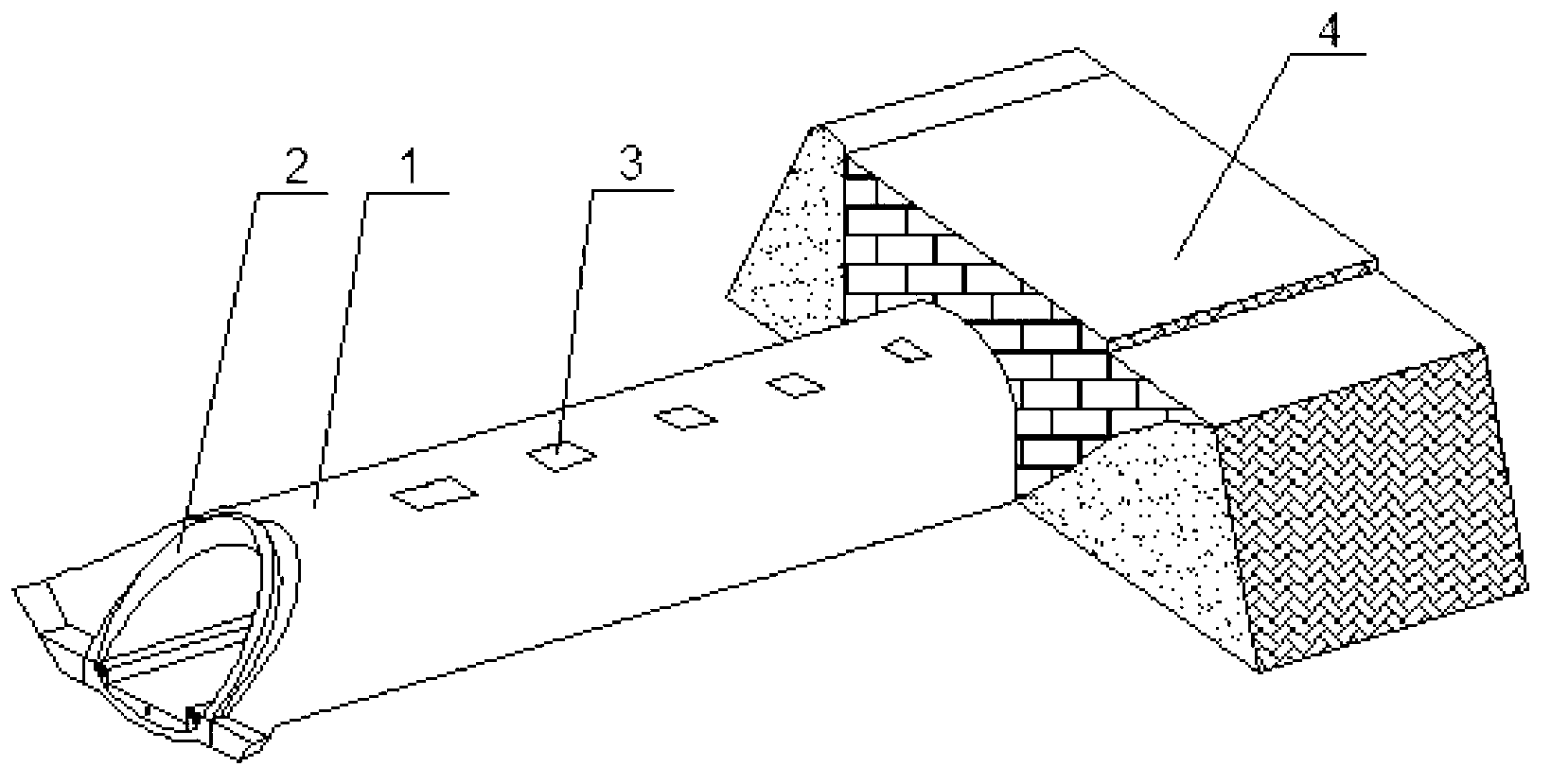

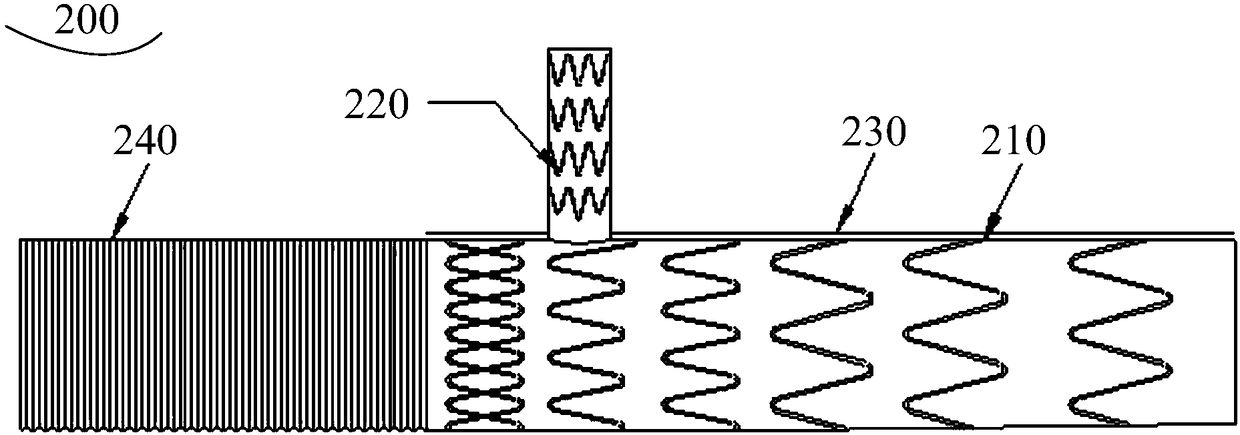

Buffer structure of single-track tunnel portal of high-speed rail

The invention provides a buffer structure of a single-track tunnel portal of a high-speed rail. The buffer structure is characterized in that the buffer structure is used for the single-track tunnel of the high-speed rail and is a rectangular hole body lining and butting with the tunnel portal, the rectangular hole body is positioned at the outer side of the tunnel portal, and the cross section of the rectangular hole body is rectangular; one to eight openings are arranged at the top part of the rectangular hole body in the length direction of the rectangular hole body, and the area ratio of the total area of the openings and the area of the hollow cross section of a portal lining is 0.75-2; and the area of the openings arranged in the length direction of the rectangular hole body is gradually reduced to the tunnel portal direction according to 50-90 percent. The buffer structure can effectively relieve the micro-pressure wave phenomenon of the tunnel portal of the high-speed rail and prevents the sonic boom generated by the tunnel portal from generating bad influence on surroundings, and the social effect is significant. As the buffer structure has the advantages of simple structure, strong integrity, strong applicability to terrain and geological conditions and convenience in construction, the production cost caused by the buffer structure arranged at the portal can be effectively reduced, and the economic benefit is significant.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

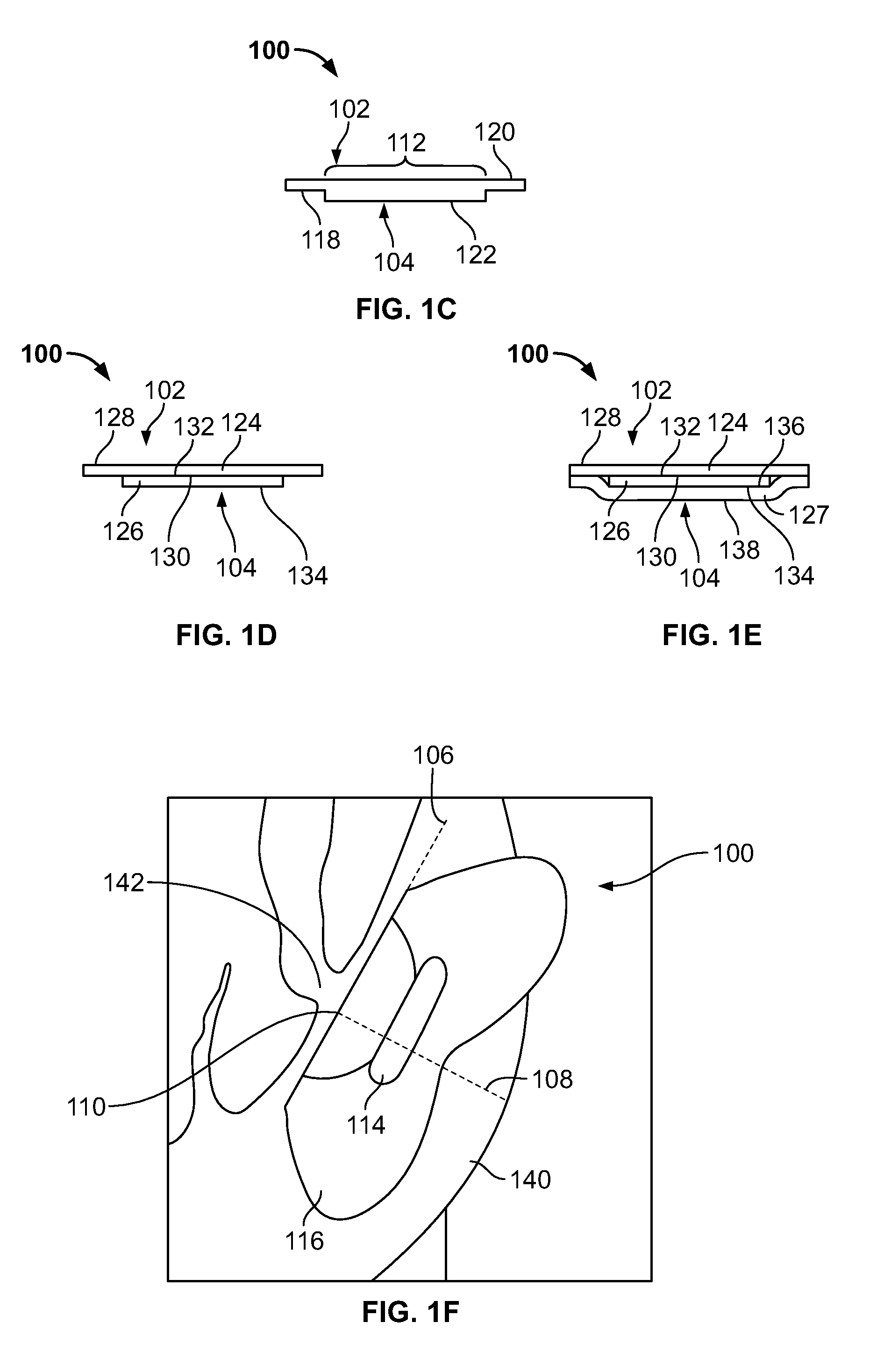

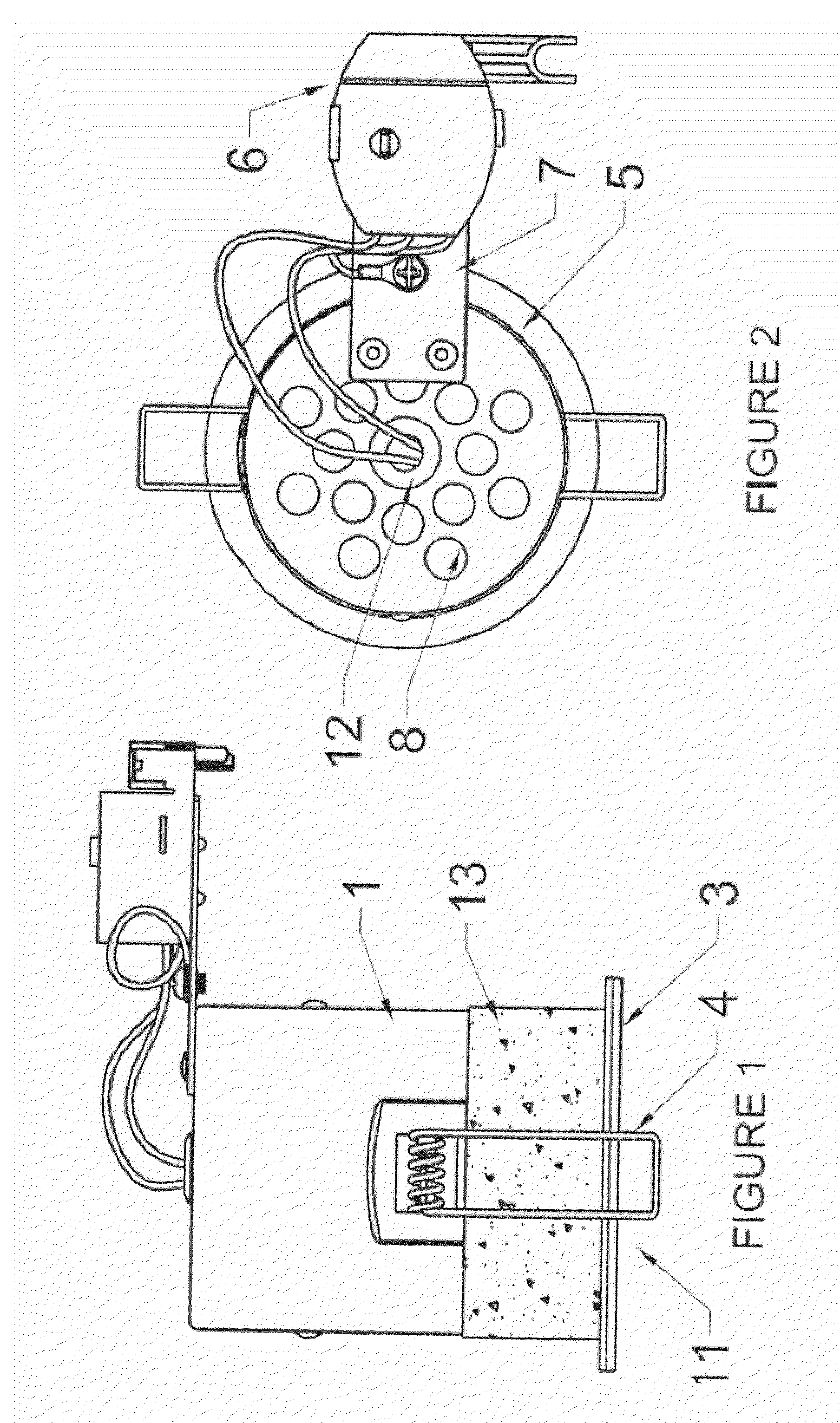

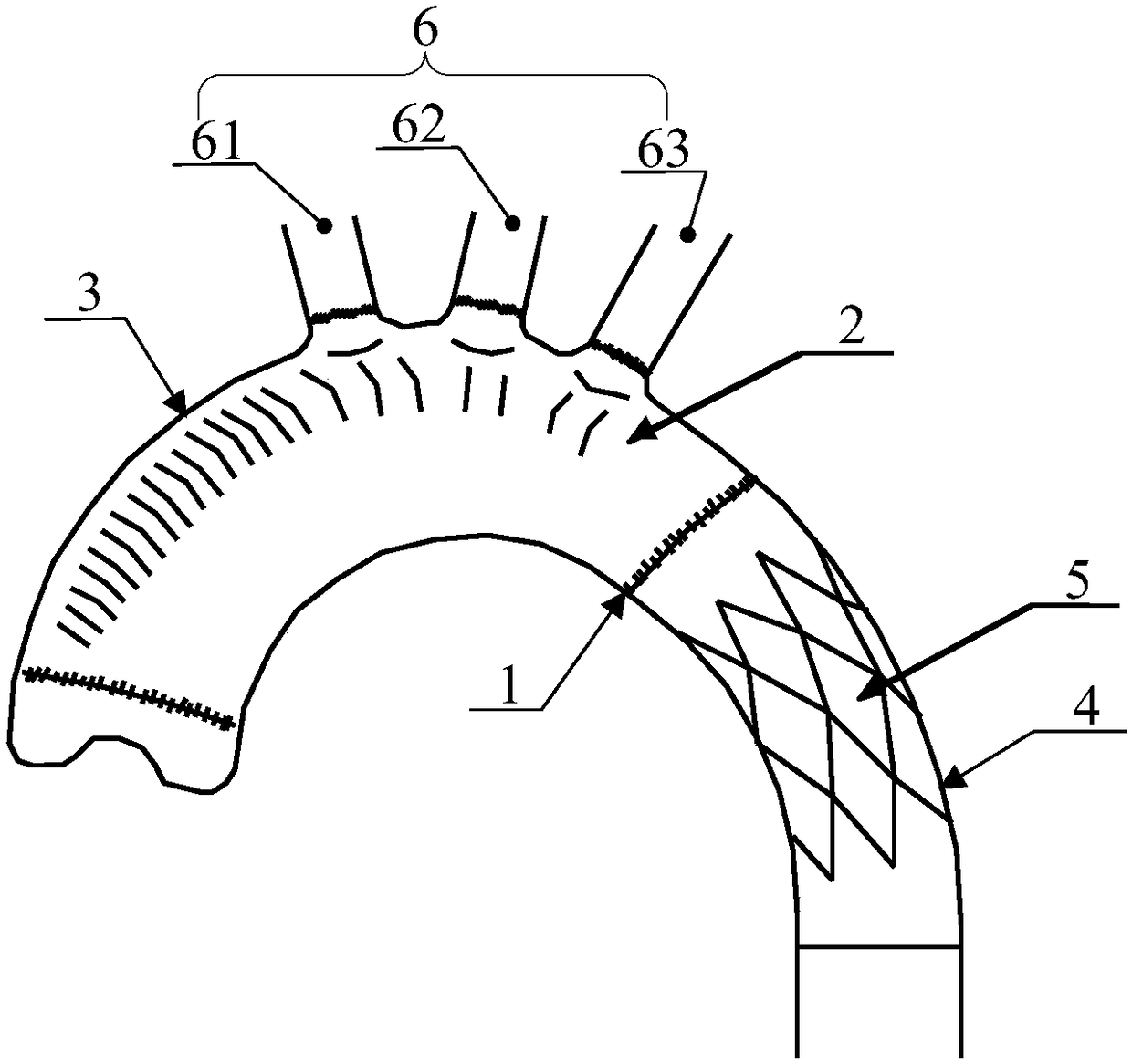

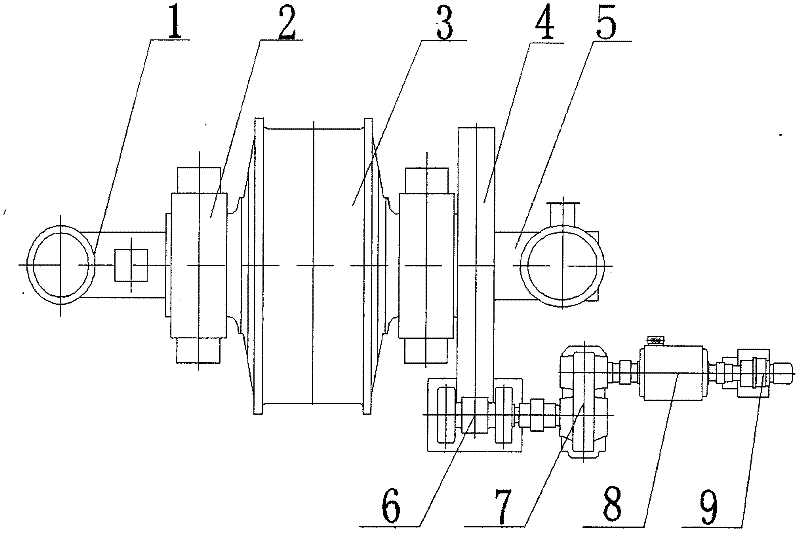

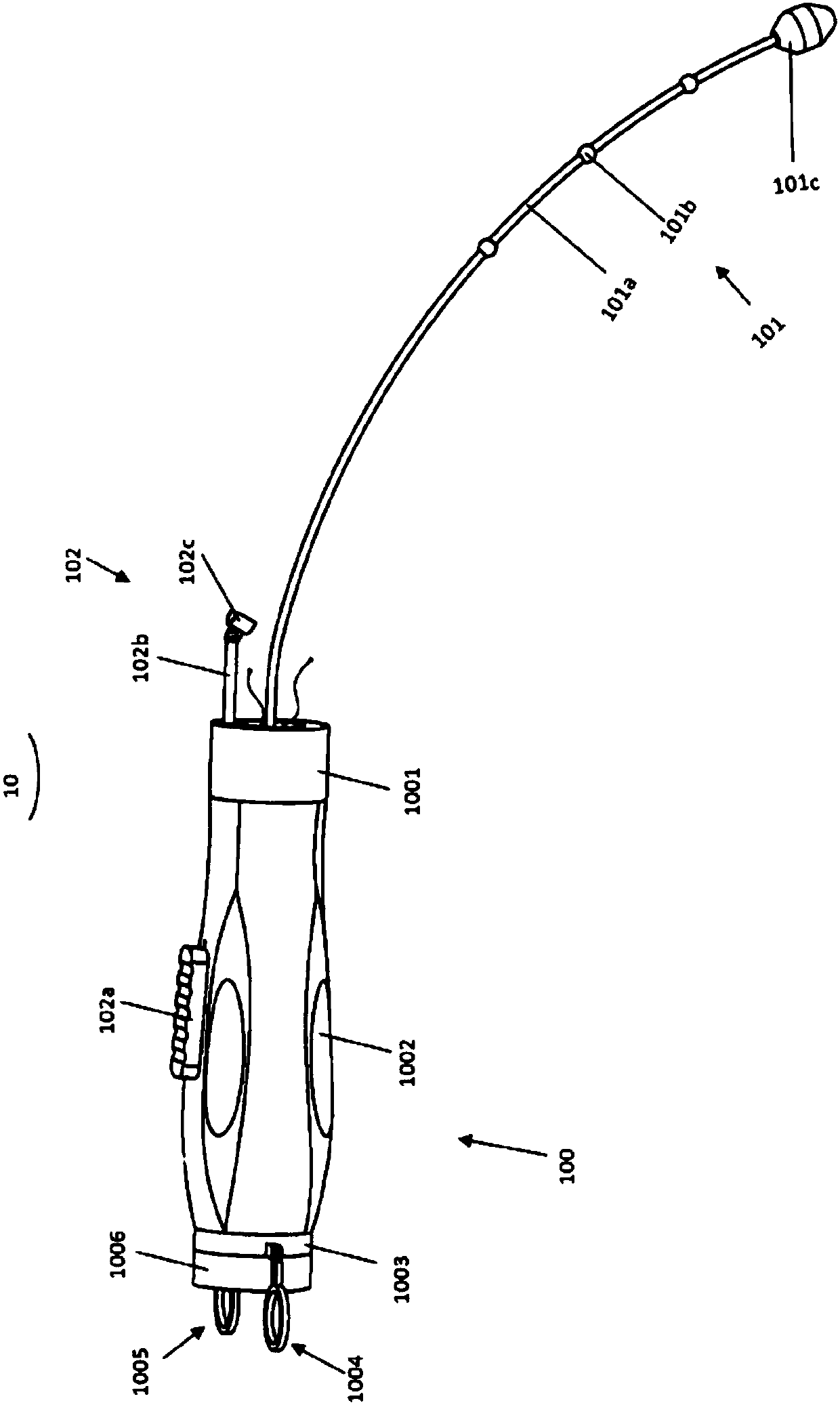

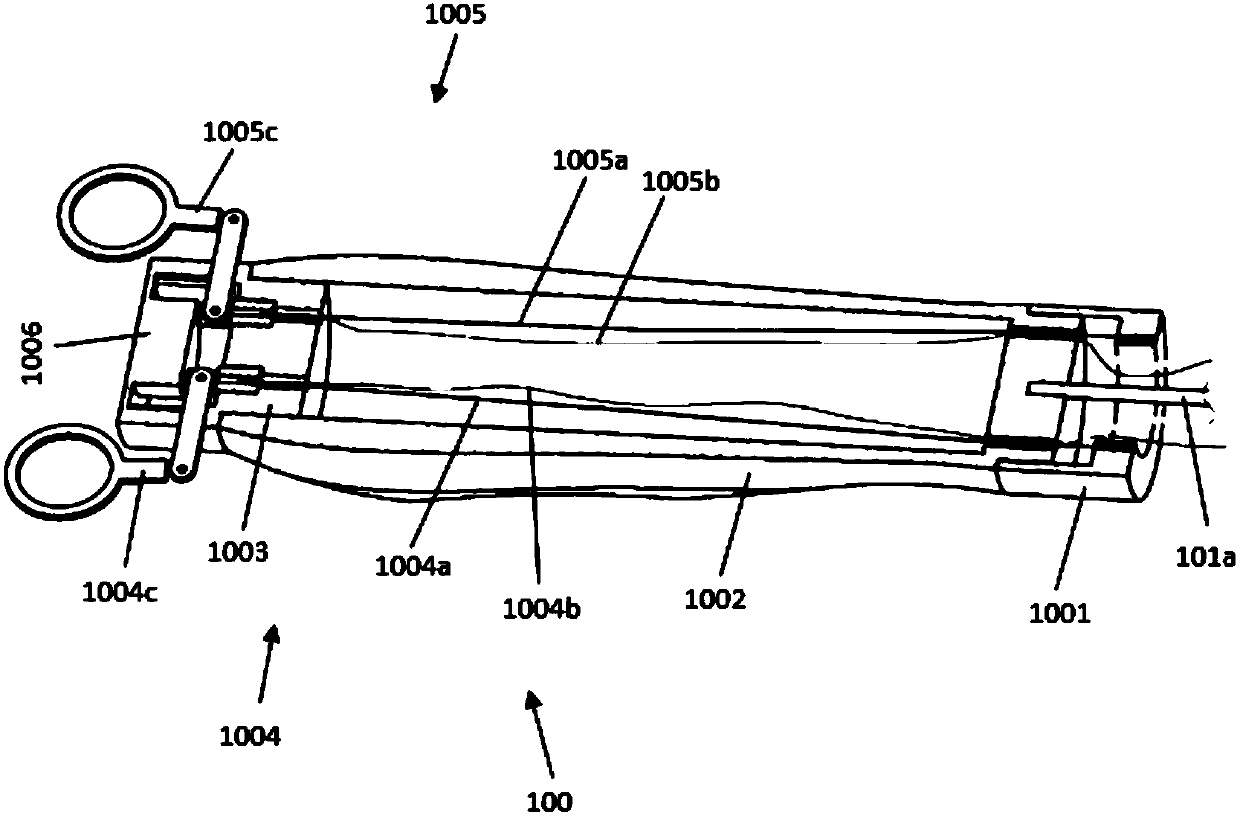

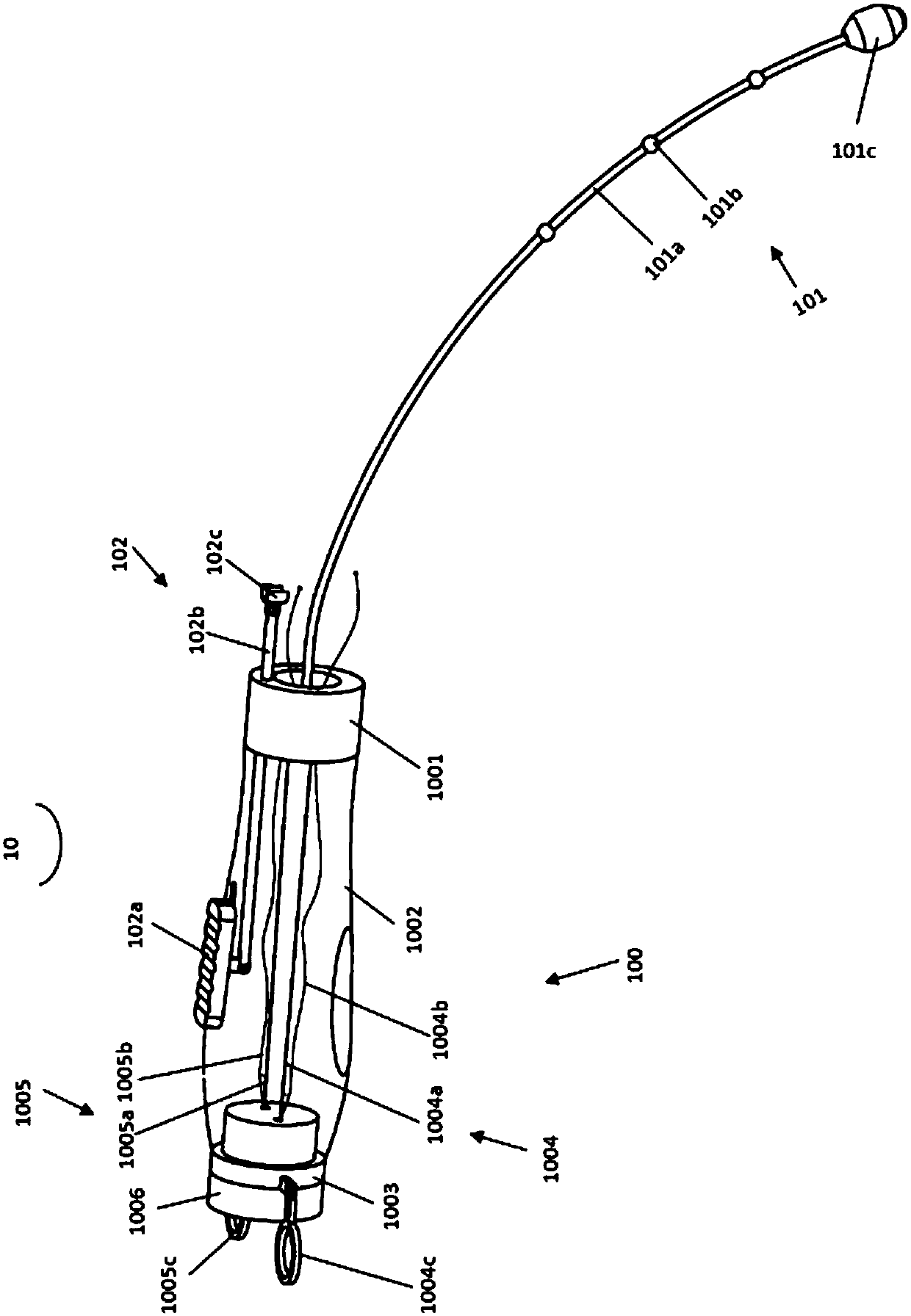

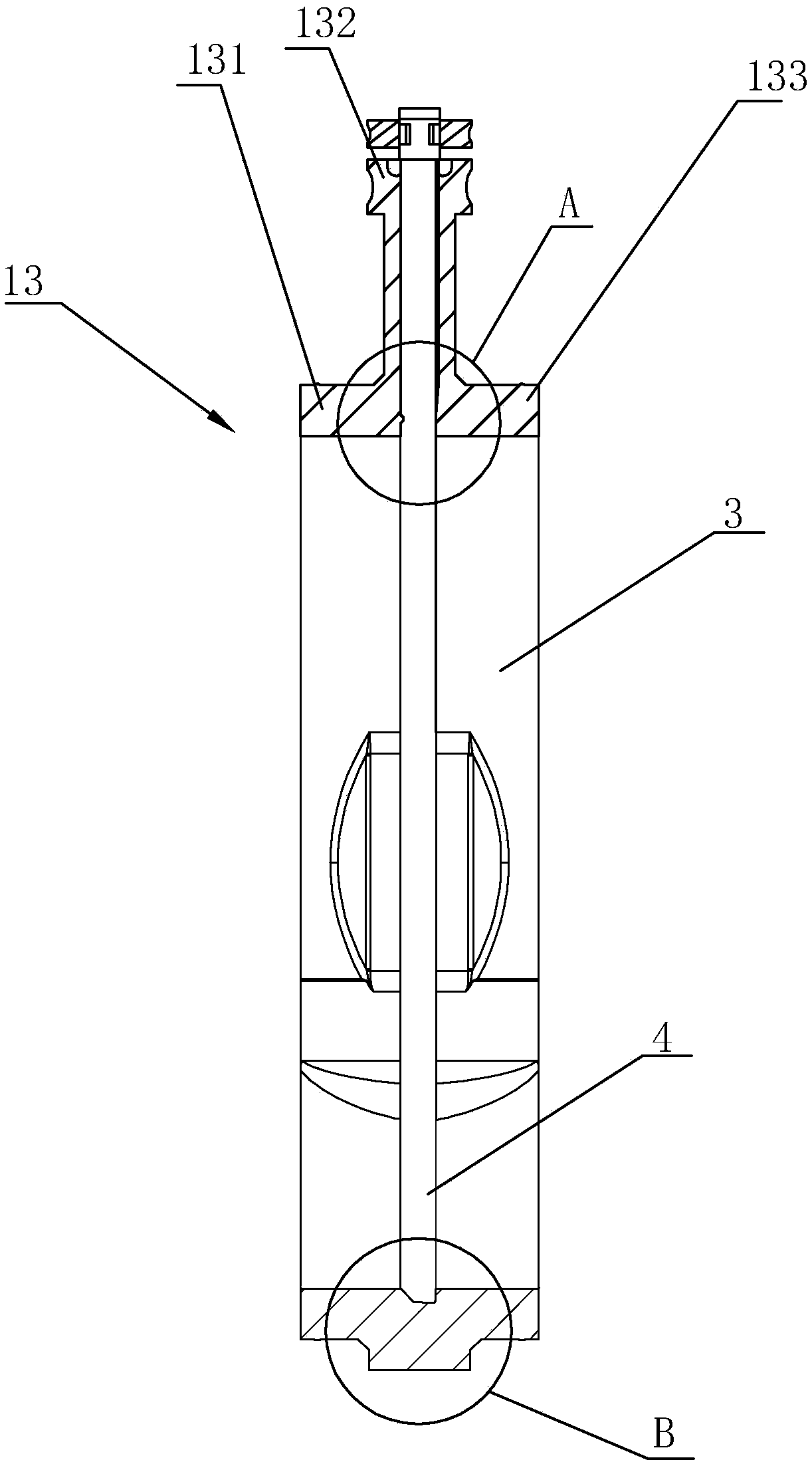

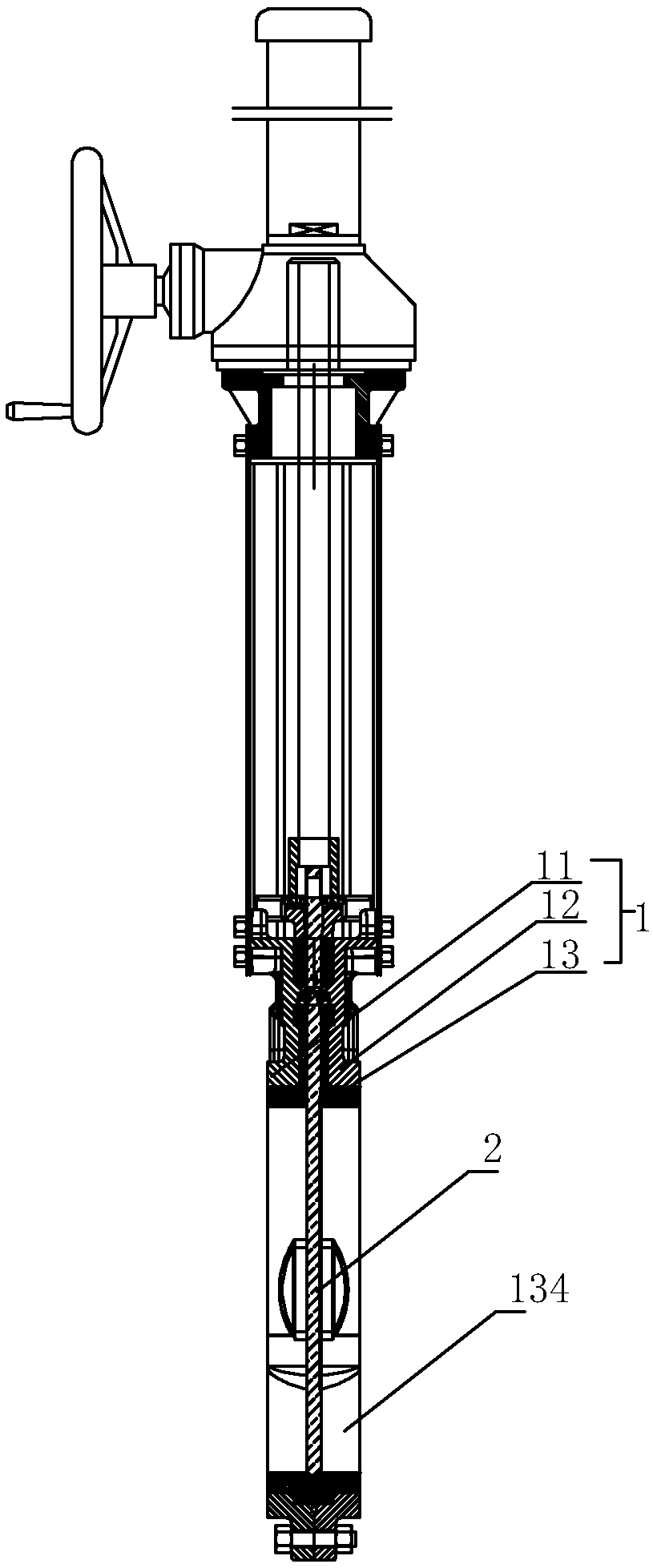

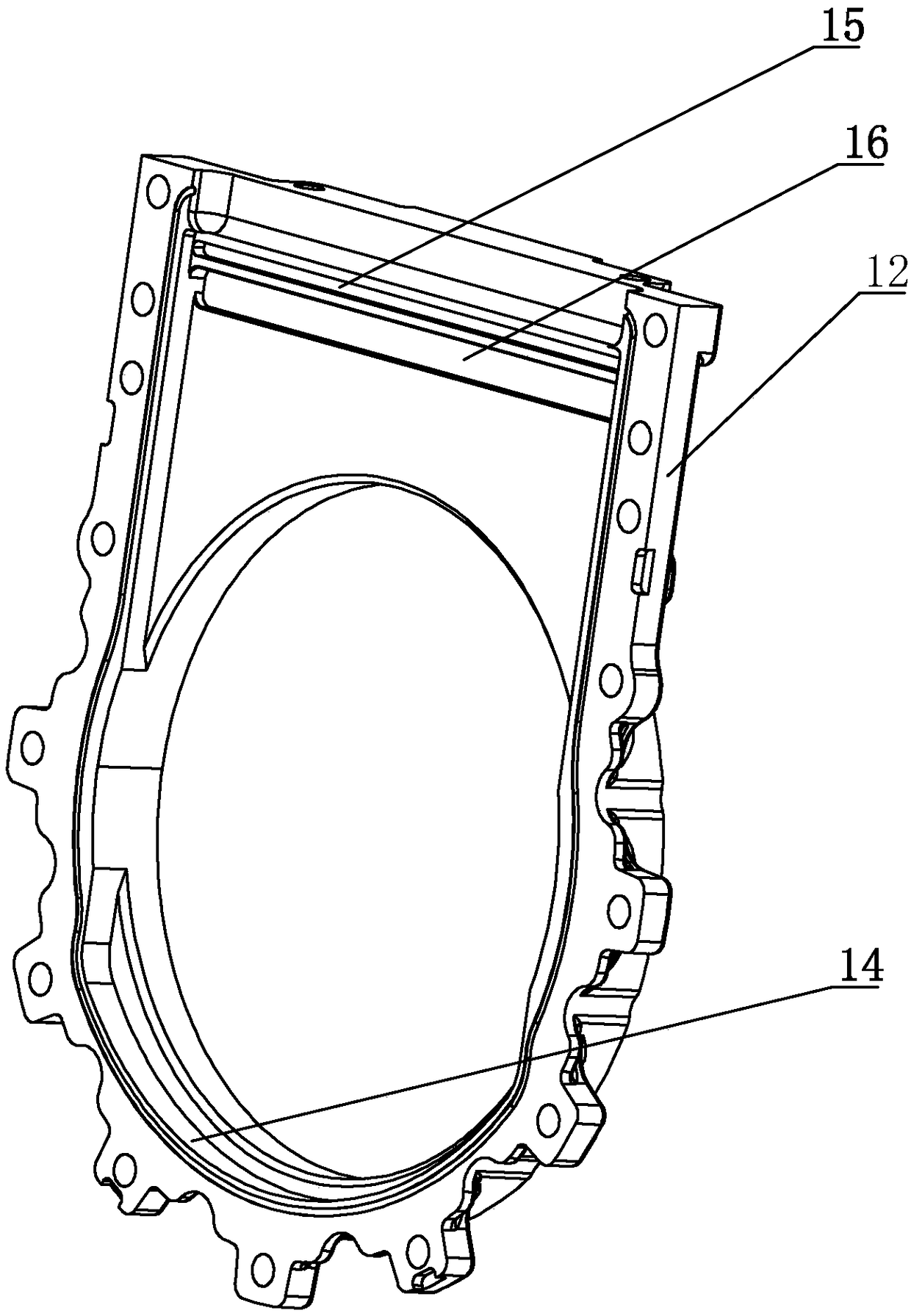

Intraoperative stent delivery system and intraoperative stent system

ActiveCN106618822BEasy to adjustEasy alignmentStentsBlood vesselsSurgical operationPostoperative complication

The present invention provides an intraoperative stent delivery system and an intraoperative stent system. The intraoperative stent includes a main body stent and a side branch stent arranged on the main body stent and extending outward. The intraoperative stent delivery system includes a main body an inner lining and a side branch inner lining arranged on the main body inner lining, the side branch bracket is configured to be sleeved on the side branch inner lining, the main body bracket is configured to be sleeved on the main body inner lining, and the side branch The inner liner is oscillatingly arranged on the main body inner liner to synchronously drive the side support bracket to swing relative to the main body support. In the present invention, by setting the side branch lining that can swing relative to the main body lining, the side branch stent can be swayed synchronously relative to the main body stent, which facilitates alignment and easy implantation of the side branch stent and the left subclavian artery during operation, and avoids thoracotomy The time of freeing and suturing the left subclavian artery in the operation is too long, which increases postoperative complications, reduces the difficulty of operation, shortens operation time, and expands the scope of surgical indications.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

High-performance ceramic ball valve

The invention discloses a high-performance ceramic ball valve. The ceramic ball valve comprises a valve seat, a ball body, a valve rod, a valve body lining, a packing box and a valve seat lining which are made of ceramic and a valve body, a valve deck, a fastening piece, a handle seat, a driving shaft, a packing pressing sleeve and a packing pressing plate which are made of metal materials; the valve seat lining is provided with a stepped inner hole, the outer diameter of the stepped inner hole is connected with an inner hole of the valve deck in a matched mode, the inner diameter of the stepped inner hole is connected with an outer circle located at the tail of the valve seat, and the joint of the stepped inner hole and the valve seat is provided with multiple elastic sealing rings. According to the high-performance ceramic ball valve, the structure is simple, multiple sealing structures are adopted, it is guaranteed that corrosive media cannot make contact with metal, and therefore serious potential safety hazards due to the fact that the metal materials are corroded by the media can be avoided.

Owner:SANBORA VALVE

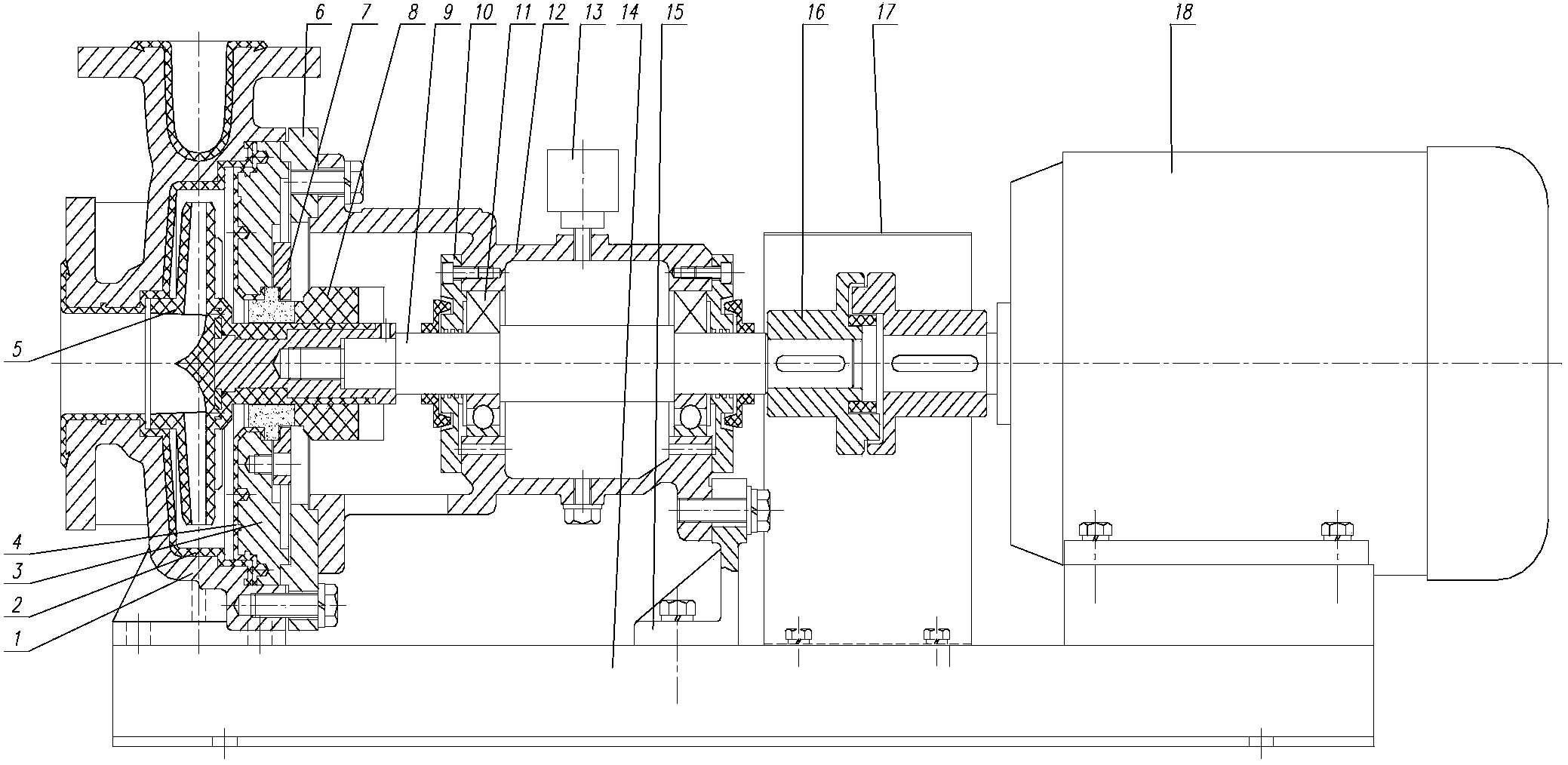

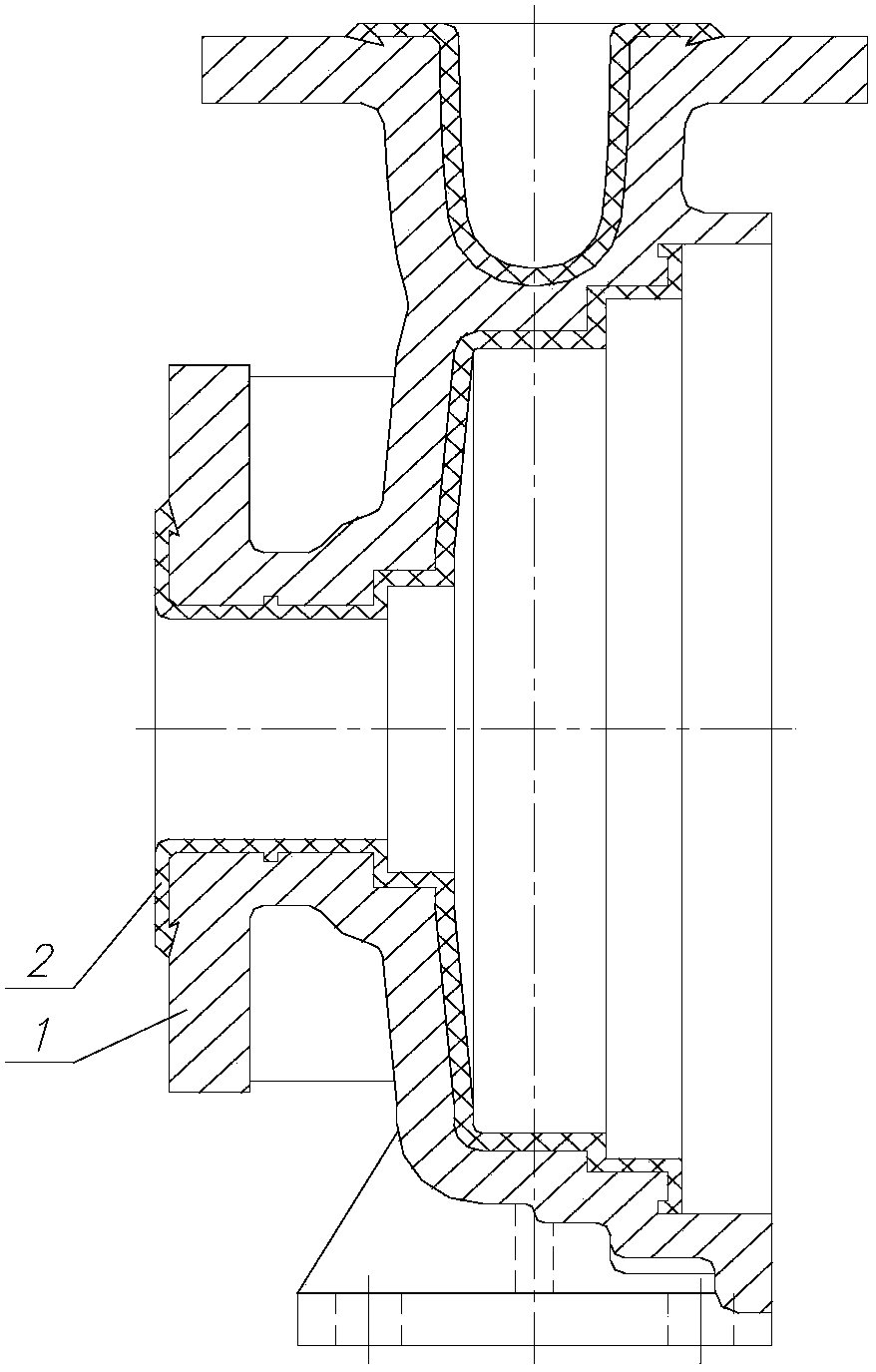

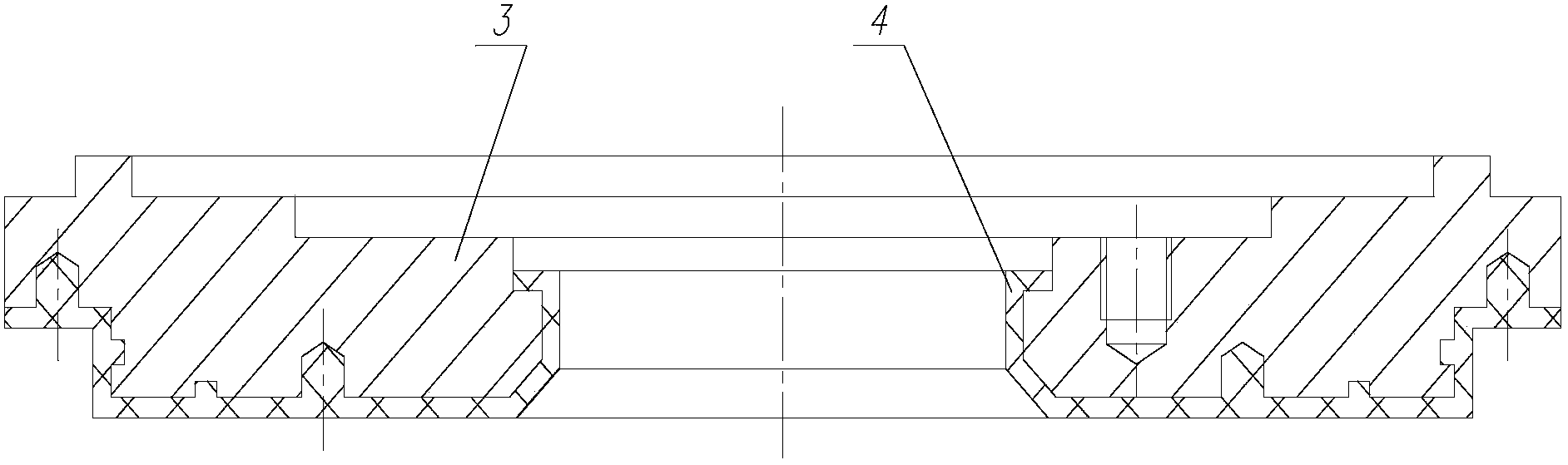

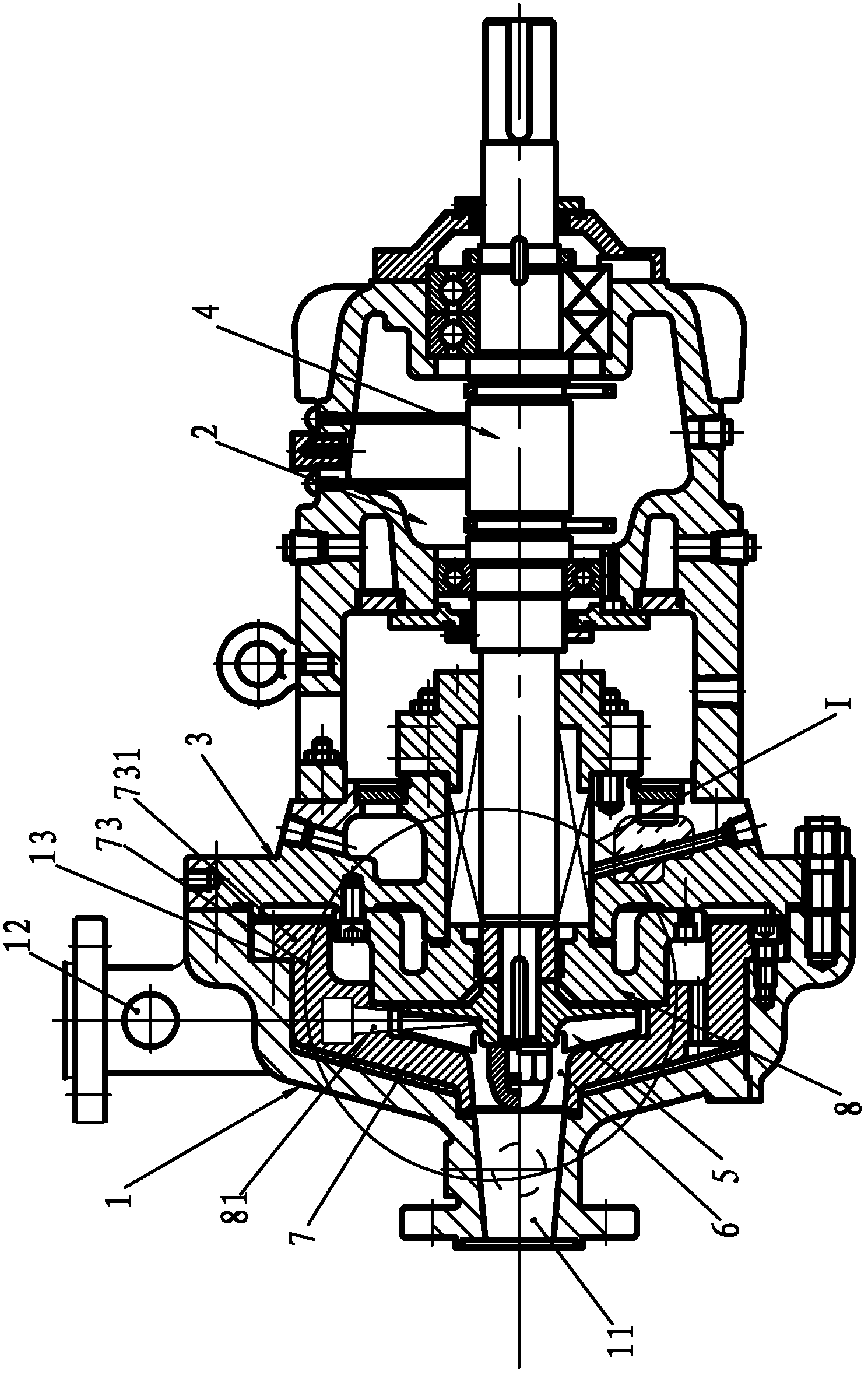

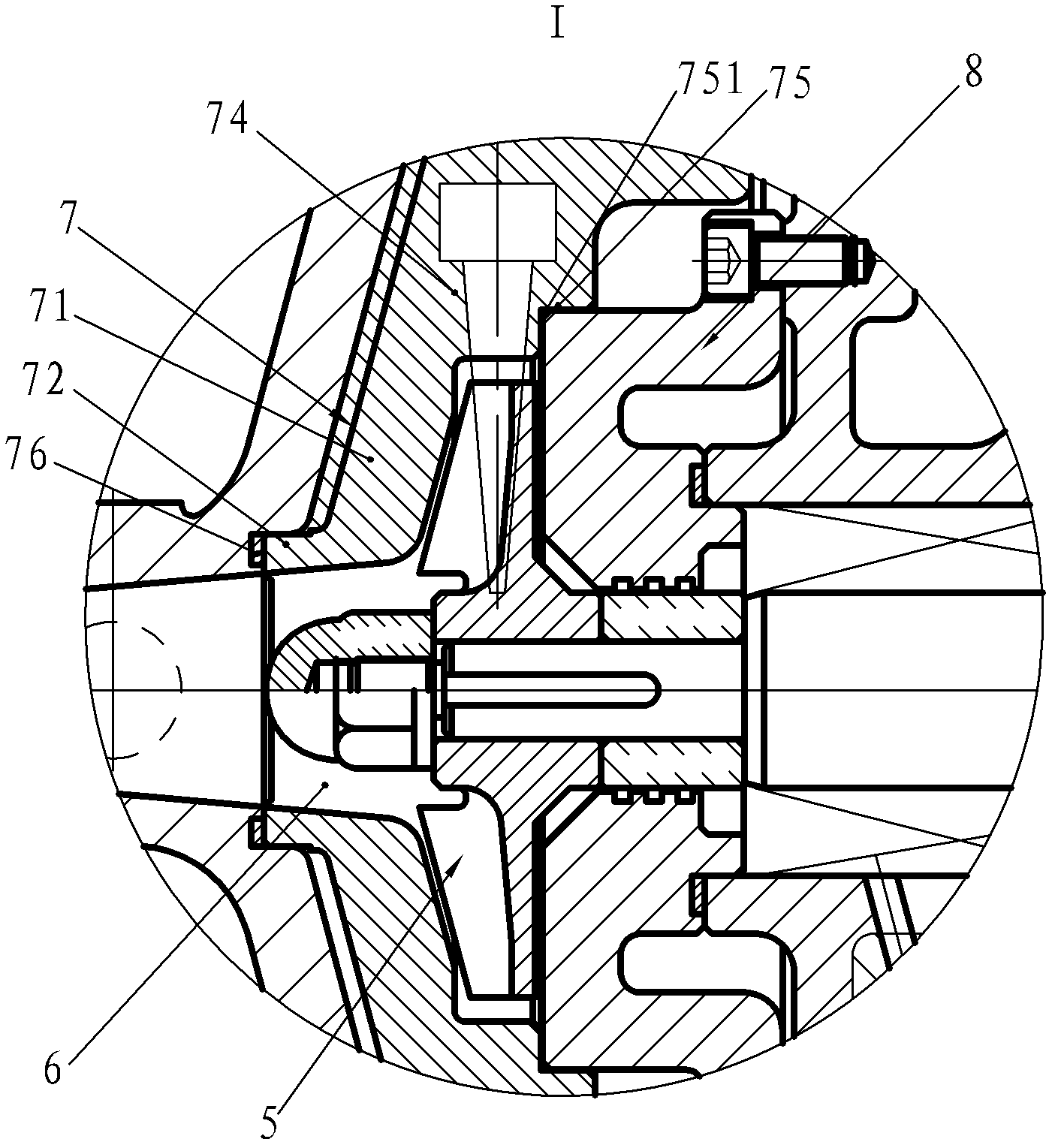

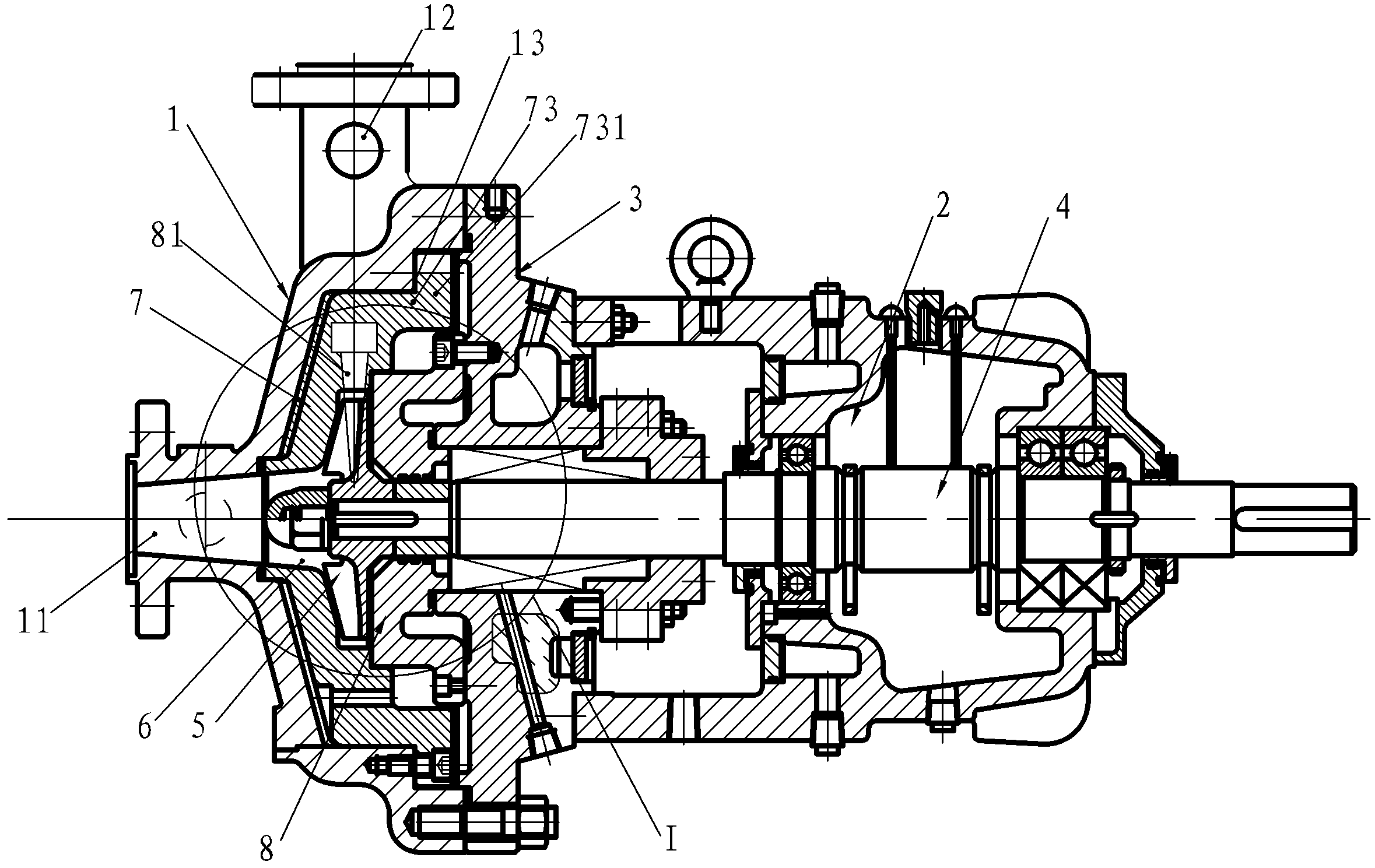

PTFE-lined chemical pump

A PTFE-lined chemical pump comprises a base, a pump body, an impeller, a pump cover, a pump shaft, a suspension and a motor. The pump shaft is fixed on the suspension through two bearings. A link plate is disposed between the suspension and the pump body. The other end of the suspension is supported on the base through a suspension support. A pump body lining is disposed in the pump body. A pump cover lining is disposed in the pump cover. The pump body lining, the impeller and the pump cover lining are all integrally-formed structural parts of F46 material. The parts of the PTFE-lined chemical pump are highly universal and interchangeable. The PTFE-lined chemical pump is high in hardness, wear resistance and corrosion resistance and can be used for delivering chemical liquids high in purity and corrosiveness.

Owner:上海佰诺泵阀有限公司

Autogenous tumbling mill for crushing aluminum oxide crusting block

The invention discloses an autogenous tumbling mill for crushing an aluminum oxide crusting block. By the autogenous tumbling mill, media are not required to be ground, so that the purity of a product is improved; a block of which the diameter is less than or equal to 300mm can be changed into particles of which the particle size is less than 0.075mm after being ground at a time, so that a material crushing process is simplified, and working efficiency is improved; and the abrasion resistance of a lining plate is improved, the service life of barrel bodies is effectively prolonged, and the maintenance cost of equipment is reduced. The autogenous tumbling mill consists of a feeding part, a main bearing part, a rotary part, a driven gear, a discharging part, a driving gear, a speed reducer, an active motor, a slow speed driving device, a hollow shaft neck, a feeding end gland, a feeding end hollow shaft neck, a bolt, a lining plate connecting bolt, a discharging end hollow shaft neck, a gear cover, a discharging end gland, an end cover lining plate, a cone end cover, a barrel body flange, a barrel body, a barrel body lining plate and a rubber pad. The autogenous tumbling mill has a simple structure, is convenient to use, is safely operated, is wear resistant and durable and saves occupied space and consumable materials of equipment.

Owner:洛阳宇航重工科技股份有限公司

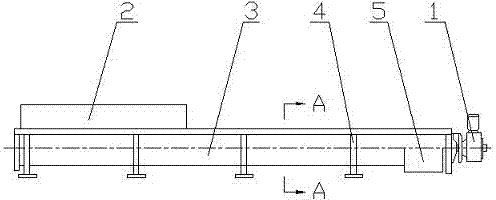

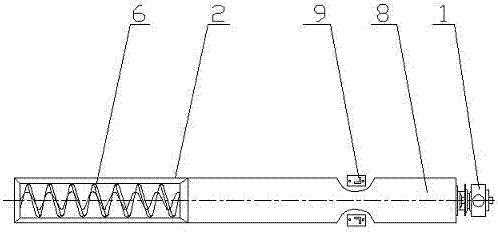

Shaftless screw conveyor

The invention discloses a shaftless screw conveyor. The shaftless screw conveyor comprises a driving device, a head assembly, an enclosure, a shaftless screw body, a trough body lining plate, a feeding port, a discharging port, a machine cover and a base, wherein the driving device is arranged at the discharging port end and comprises a motor and a speed reducer, the motor is connected with the speed reducer, the speed reducer is connected with the head end of the shaftless screw body, the head assembly is provided with a thrust bearing, the trough body lining plate is a wear-resistant plastic plate, a rubber plate or a glass-ceramic plate, the enclosure is U-shaped or O-shaped and is made of stainless steel, carbon steel or glass fiber reinforced plastic, the upper part of the enclosure is provided with the machine cover, the shaftless screw body is made of stainless steel or carbon steel, the feeding port and the discharging port are square or circular, and the base is connected with the enclosure through a support. The shaftless screw conveyor is compact in structure, reasonable in stress, smooth in material conveying without a bearing in a trough, and simple and convenient in maintenance; and except for the open feeding port and the discharging port, rest parts can all be closed by additionally arranging covers, so that materials cannot overflow and the pollution is reduced.

Owner:ANHUI YITONG MACHINERY

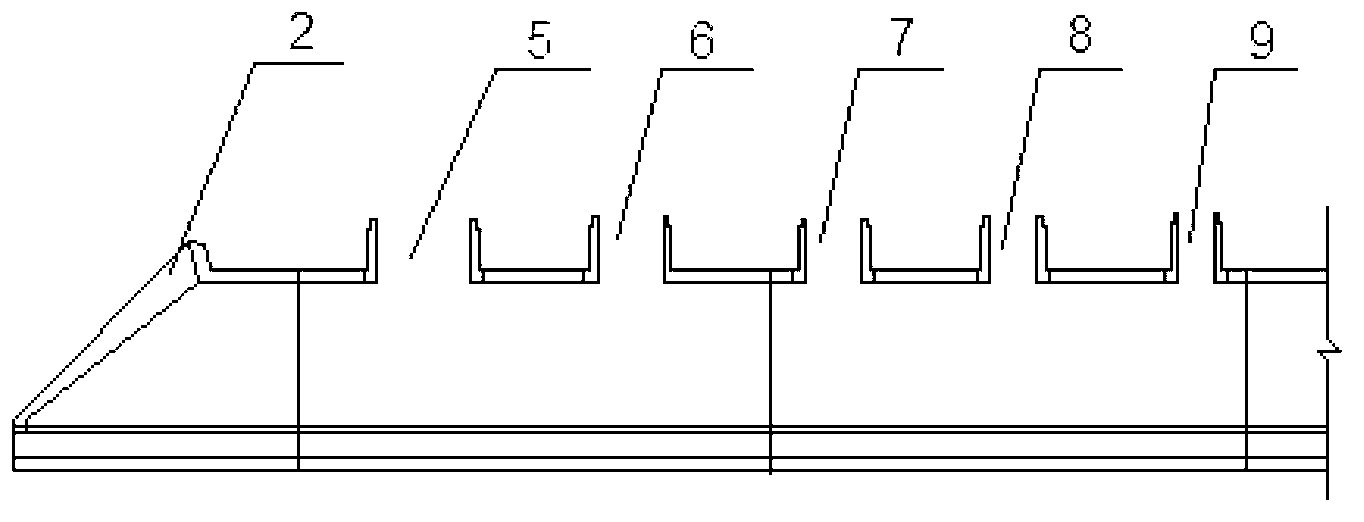

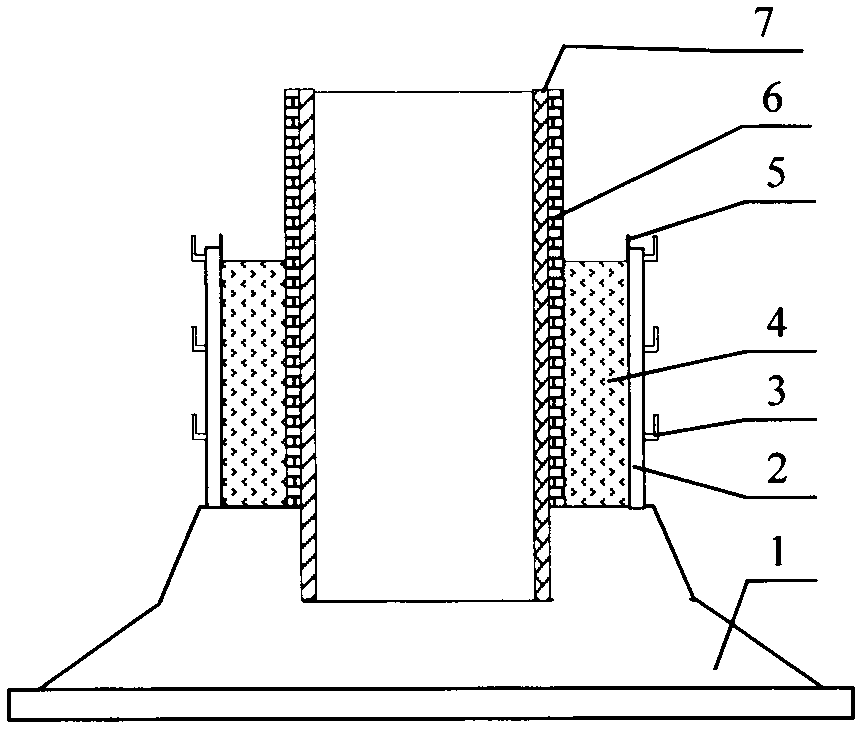

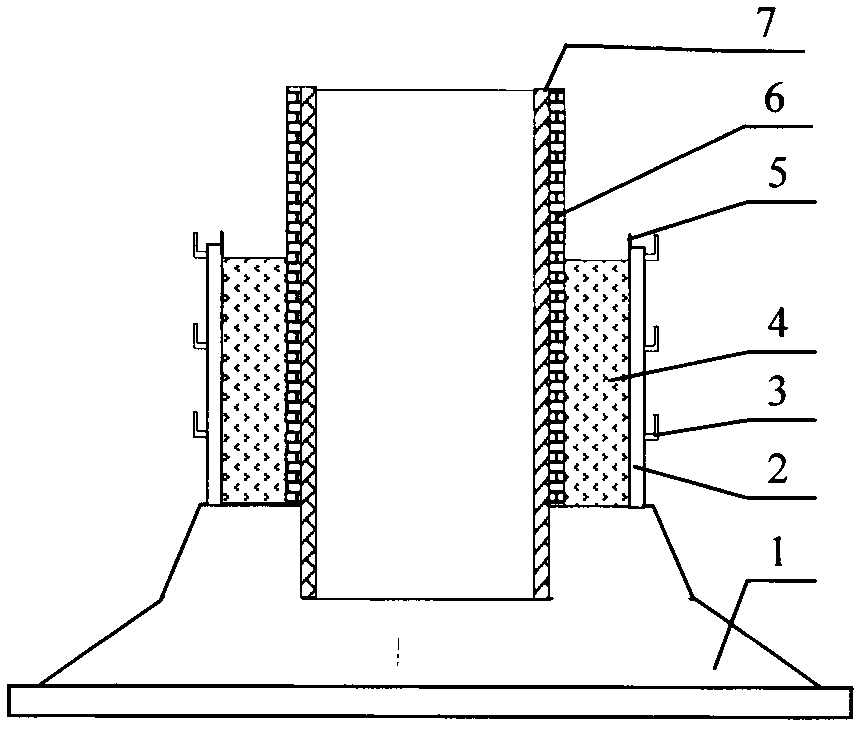

Synchronous construction method for chimney lining external concrete

The invention discloses a synchronous construction method for chimney lining external concrete. A working procedure for constructing a steel bar concrete chimney cylinder body comprises the following steps of: carrying out construction surveying; constructing a heat isolation layer (6) and a fireproof brick lining (7); binding steel bars on a concrete cylinder body (4); constructing an external folding die (2); and pouring the concrete cylinder body (4). By a synchronous construction process, concrete is poured among the heat isolation layer, the fireproof brick lining and an external template, so that the construction quality is high, the construction speed is high, and the construction safety is realized; the synchronous construction method is economic, practical and simple and convenient to operate; and the construction expense can be saved, and the construction cost can be reduced. For the same chimney, compared with the construction period of a sliding die, the construction period of the folding die is shortened by about 30 percent, so that the project construction cost is saved by about 20 percent; the synchronous construction method is remarkable in comprehensive technological economy and social benefit and suitable for construction of steel bar concrete chimney cylinder body linings with the diameter ranging from 30m to 80m and external folding dies.

Owner:YONGSHENG CONSTR GRP

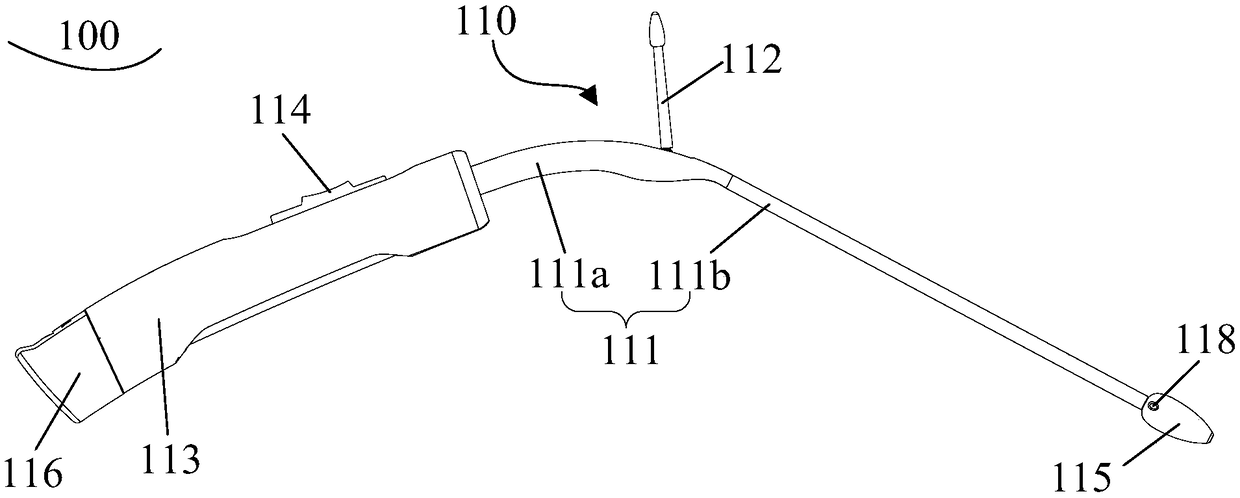

Intraoperative stent delivery system and use method thereof

The invention provides an intraoperative stent delivery system and an use method thereof. The intraoperative stent delivery system is used for loading and delivering the intraoperative stent. The intraoperative stent delivery system comprises a main body operating handle, a main body lining bar and a branch swing mechanism; the main body lining bar is arranged at the front end of the main body operating handle; the branch swing mechanism is also arranged at the front end of the main body operating handle; the main body operating handle comprises a front end cover, a middle handle, a rear end cover, a main body stent release portion, a branch support release portion and a lock cover; the main body lining bar comprises a bending bar, a limit ball and a guide head; and the branch swing mechanism comprises a sliding block , a transmission bar and a U-shaped ring. The invention also includes a method by using the system to deliver the intraoperative stent. The system can be used for delivering and releasing the single branch intraoperative stent so that the single branch intraoperative stent can solve the problem that the intraoperative stent is difficult to be matched with branch vessels, especially for the anastomosis with the left subclavian artery, accordingly the dissociation, the blocking and the anastomosis of the super-aortic branch vessels can be reduced or avoided so as toreduce the difficulty of surgery as well as the trauma of the surgery.

Owner:北京有卓正联医疗科技有限公司

Mute magnetic lock body

PendingCN107724802AIngenious ideaCompact structureNon-mechanical controlsHandle fastenersEngineeringMagnet

The invention provides a mute magnetic lock body which comprises a lock body lining plate assembly, a magnetic tongue assembly, a square tongue assembly, a square core shifting assembly, a torsional spring, a buckle box assembly, a lock body box bottom assembly and a box cover. The magnetic tongue assembly is internally provided with a magnetic tongue magnet, and the box bottom inside the box bottom assembly and the square core shifting assembly are each made of an easily-magnetized material; when external force acting does not exist, the magnet generates attractive force, so that a magnetic tongue keeps in a withdrawing state all the time; the magnetic lock body buckle box assembly is provided with a buckle box magnet, and when the buckle box magnet makes contact with the magnetic tonguemagnet in the magnetic tongue assembly during door closing, N and S poles are opposite, so that a door can be locked; and after door opening, attractive force between the magnetic tongue magnet and the box bottom as well as between the magnetic tongue magnet and the square core shifting assembly enables the magnetic tongue to be withdrawn and then keep flush with a lining plate. Through cooperation of the square tongue assembly and the magnetic tongue, when the magnetic tongue stretches out, a square tongue can be shifted, after the square tongue stretches out, the magnetic tongue is locked, and a handle idles; and the mute magnetic lock body is ingenious in conception, compact in structure and reliable in function.

Owner:GUANGDONG MINGMEN LOCKS IND

Sluice valve and manufacturing process of valve body lining part

ActiveCN109210218AImprove sealingCorrosion resistanceSlide valveValve housingsRubber materialEngineering

The invention discloses a sluice valve. A valve body comprises a left valve body, a right valve body and a valve body lining part, the valve body lining part is integrally formed by rubber materials,the left valve body and the right valve body are located on the left side and the right side of the valve body lining part respectively, the left valve body and the right valve body are used for tightly pressing the valve body lining part through screws, a through hole matched with the valve hole and a gate plate lifting groove communicating with the through hole are formed in the valve body lining part, and a side sealing groove and a bottom sealing groove are formed in the gate plate lifting groove; and when the gate plate moves downwards to seal the valve hole through the gate plate liftinggroove, the side edge of the gate plate is arranged in the side face sealing groove, and the U-shaped top end face of the gate plate is tightly pressed in the bottom sealing groove. The sluice valvehas a double-sealing-form effect simultaneously, so that the sealing of the gate valve can be effectively improved; and when the valve is opened, the gate plate is moved upwards, so that the inner side wall of the valve hole is bounced, and sundries are prevented from being deposited.

Owner:WENZHOU CHISUN VALVE MFG CO LTD

Dual-shell small-flow centrifugal pump

InactiveCN102425551AExtended service lifeMachining accuracy is easy to guaranteeSpecific fluid pumpsPump componentsStreamflowLinkage concept

The invention relates to a pump, in particular to a dual-shell small-flow centrifugal pump. The technical scheme provided by the invention is that: the dual-shell small-flow centrifugal pump comprises a pump body, a shaft seal device, a pump cover, a revolving shaft and an impeller, wherein the pump cover is arranged between the pump body and the shaft seal device; a flow channel is formed between the pump body and the pump cover; the pump body is provided with a medium inlet and a medium outlet which are communicated with each other through the flow channel; the impeller is in linkage connection with the revolving shaft and extends into the flow channel; the impeller is an open impeller; a pump body lining and a pump cover lining are arranged in the flow channel; the medium outlet is communicated with the flow channel through a diffusion hole formed on the pump body lining; the diffusion hole is conical; one end which is connected with the medium outlet is a large end, and one end which is connected with the flow channel is a small end; the flow channel is matched with the profile of the impeller; and the cross section of the flow channel is cylindrical. Due to the adoption of the technical scheme, a dual-shell small-flow centrifugal pump which has long service life and a simple structure, and is suitable for conveying particle mediums is provided.

Owner:EBARA GREAT PUMPS

Construction method for glass reinforced plastic scrubbing tower

InactiveCN102847427AImprove corrosion resistanceExcellent washing separation effectDispersed particle separationLiquid wasteWhole body

The invention discloses a construction method for a glass reinforced plastic scrubbing tower. The construction method is characterized in that an upper end cap, a lower flat-bottom end cap and a barrel body lining are sequentially fabricated by a manual pasting process and are connected with one another to form a whole body, a barrel body structure layer is fabricated by a winding process, and an anti-aging layer is fabricated by an injection process; the top of the upper end cap is provided with an exhaust pipe, and a barrel body is provided with an admission pipe and a content gauge pipe; the lower flat-bottom end cap is provided with a well-shaped support for supporting two outer-penetration cross beams; grids are placed on the outer-penetration cross beams; filler is laid on the grids; an internal cross beam is arranged above the filler and is sequentially provided with a water distribution pipe, a branch pipe and a main water pipe upwards; the main water pipe is communicated with a water supply pipe; a lower oblique-bottom end cap is further arranged in the tower, and the lower edge of the lower oblique-bottom end cap is provided with a discharge pipe; and the scrubbing power can also be provided with other accessories. According to the fabrication method disclosed by the invention, the scrubbing tower is convenient to produce and manufacture, is high in strength, good in appearance quality, light in mass, good in anti-corrosion performance, free from creep deformation and rusting, more uniform in spray cooling, easy to transport and arrange, has a good cooling effect, and ensures that tail gas can be completely scrubbed and separated, and no waste liquid remains at the bottom in the tower.

Owner:宜兴市瑞诚科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com