High temperature high pressure ceramic valve

A high-temperature, high-pressure, ceramic valve technology, applied in the field of ceramic valves, can solve the problems of not being able to adapt to high wear, strong corrosion, affecting system operation stability, and short service life, so as to achieve extended life, good sealing effect, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

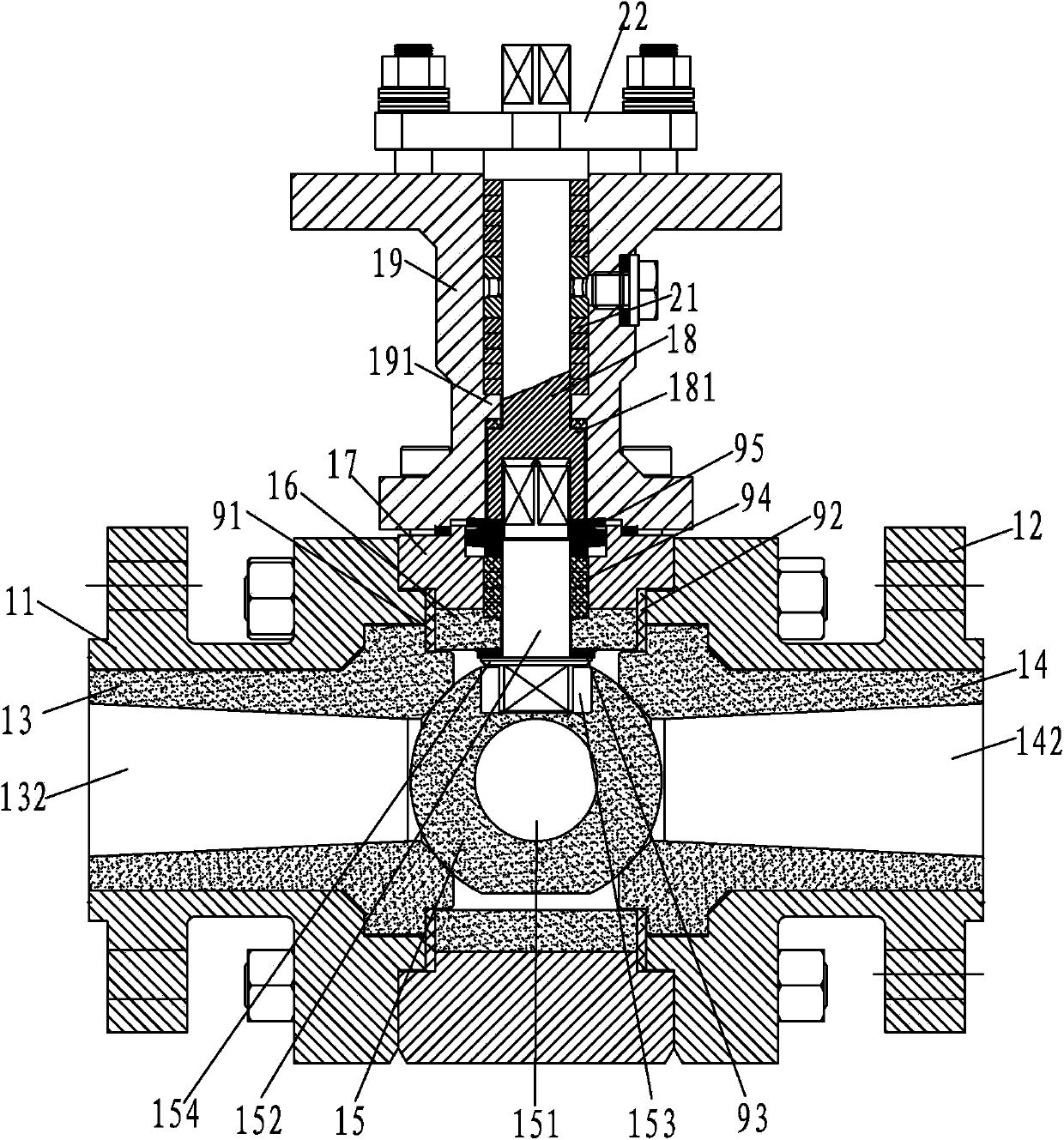

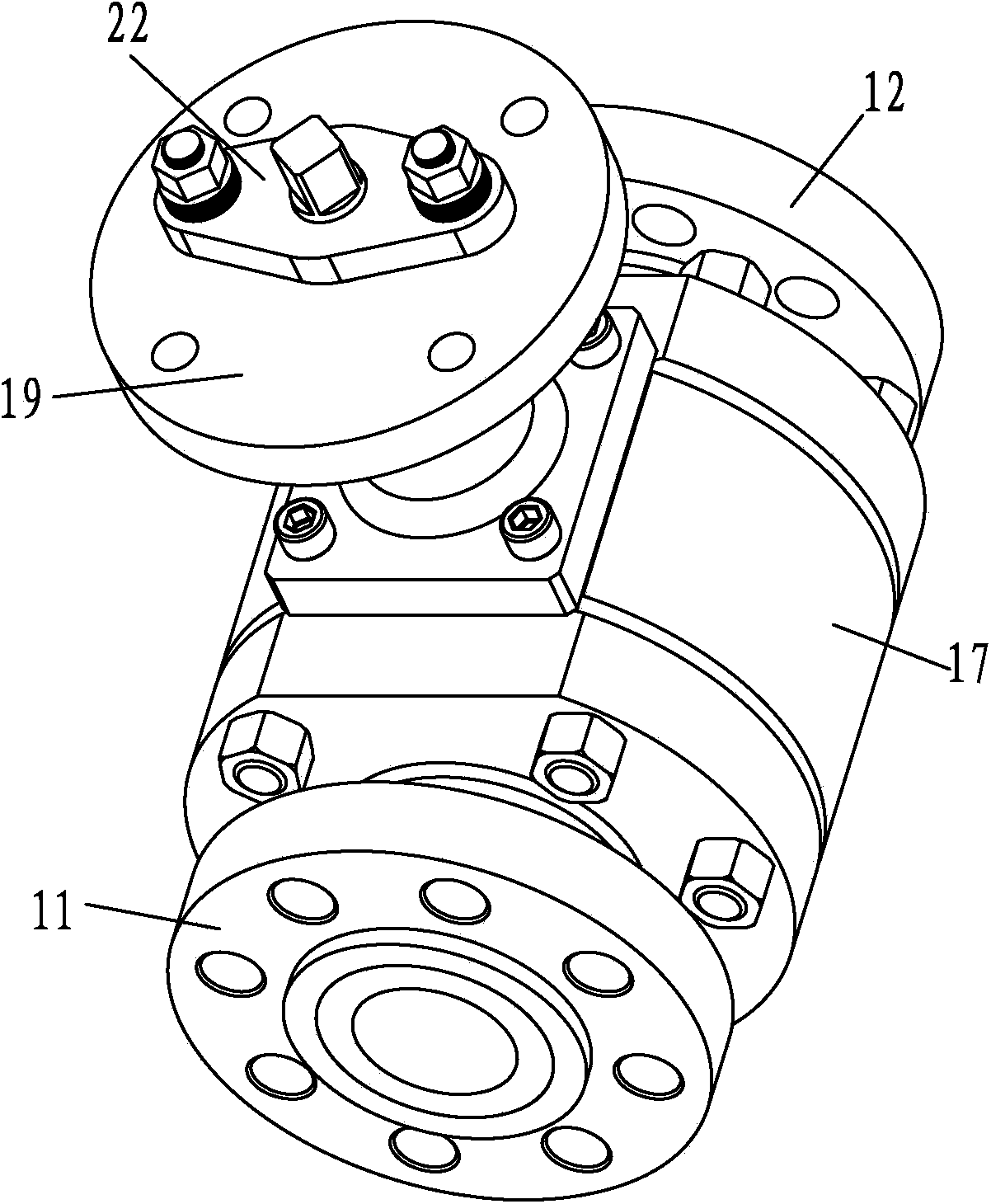

[0026] Such as figure 1 , 2 As shown, a high-temperature and high-pressure ceramic valve includes left and right flanges 11, 12, left and right valve seats 13, 14, a ball 15, a valve inner lining 16, a valve body 17, left and right flanges 11, 12 Set respectively outside the left and right valve seats 13 and 14, between the left valve seat 13 and the left flange 11, between the right valve seat 14 and the right flange 12 are all interference fits, and the centers of the left and right valve seats are all set Runner 132,142 is arranged, and spheroid 15 is arranged between left and right valve seat 13,14, and the axis of left and right valve seat 13,14 all passes through the center of spheroid 15, and spheroid 15 center is provided with through hole 151, and spheroid 15 is provided with a stem hole 153, the stem hole is a blind hole, the stem 152 is installed in the stem hole 153, the valve body 17 is clamped between the left and right flanges 11, 12, the valve body lining 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com