Buffer structure of single-track tunnel portal of high-speed rail

A technology for high-speed railways and buffer structures, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as the inability to meet the pressure peak control standards of micro-pressure waves, and achieve the purpose of alleviating micro-pressure waves, mitigating micro-pressure waves, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

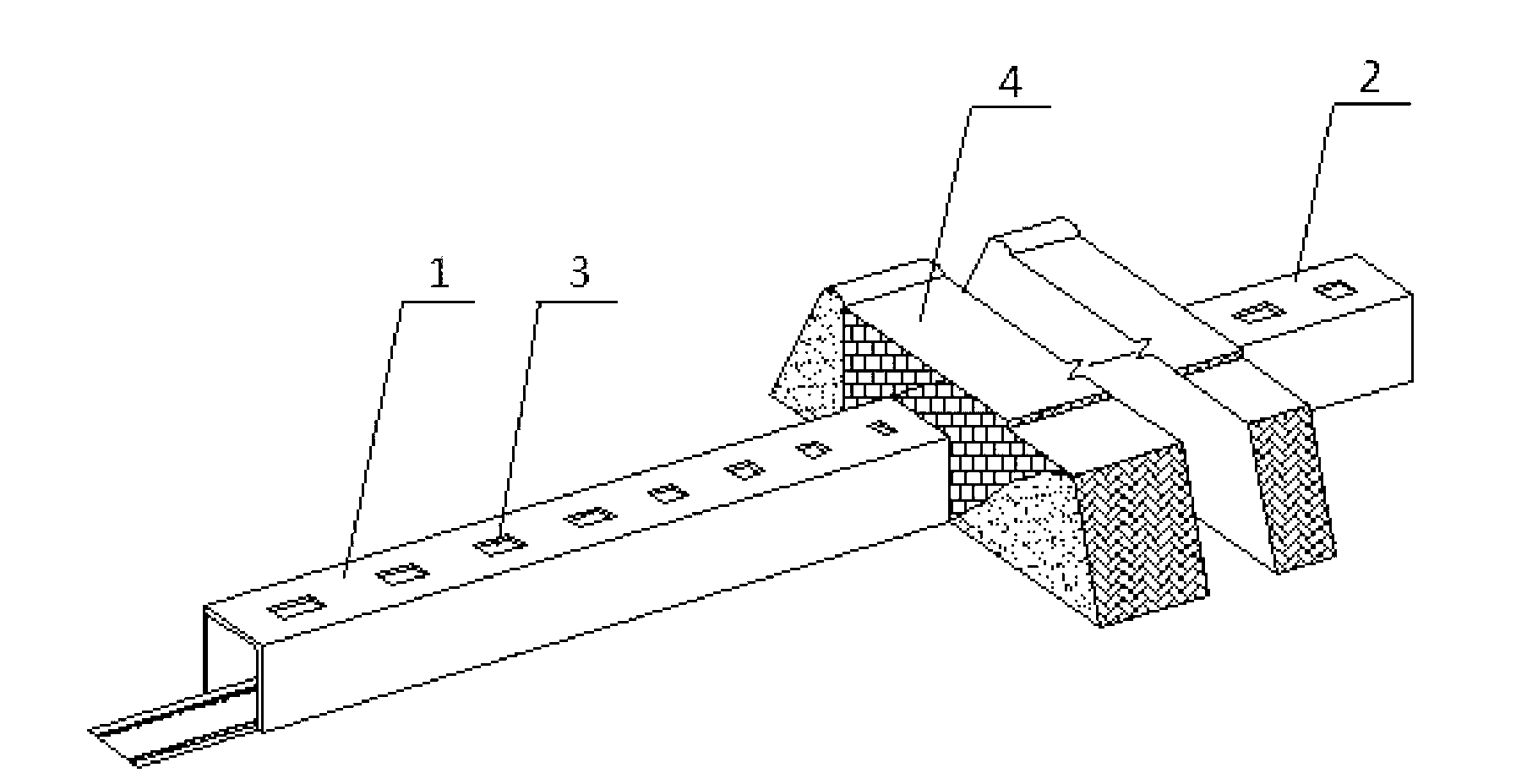

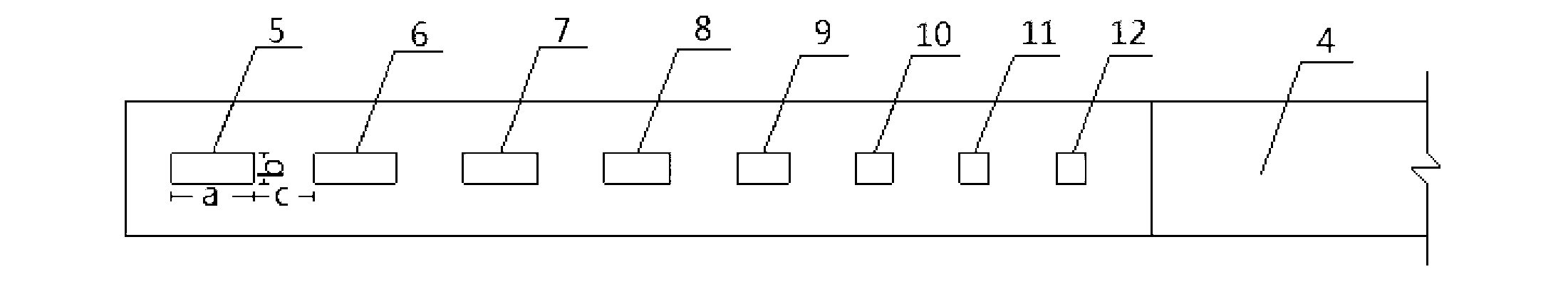

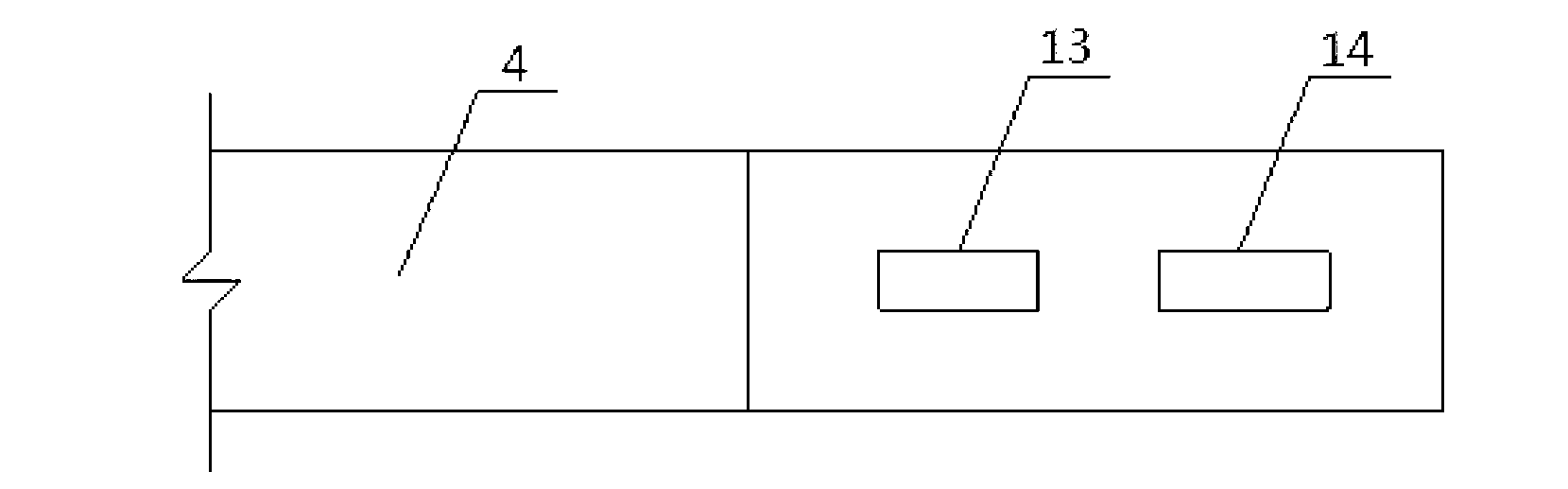

[0015] Further illustrate the present invention below in conjunction with accompanying drawing:

[0016] Such as Figure 1-3 As shown, the high-speed railway single-track tunnel entrance buffer structure of the present invention is a rectangular cavity 1 with a rectangular cross-section that is docked with the tunnel entrance lining 4 and positioned outside the tunnel entrance. Eight openings 3 are set in the direction of the first opening 5 to the eighth opening 12, and two openings 3, namely the ninth opening 13 and the tenth opening 14, are set on the top of the rectangular hole 2 at the exit of the tunnel along the length direction of the tunnel centerline. The area ratio of the total opening area to the hollow cross-sectional area of the opening lining is 0.75-2, and the area of each opening 3 arranged along the length direction of the rectangular cavity gradually decreases by 50-90% toward the tunnel entrance.

[0017] Preferably, the length of the rectangular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com