Synchronous construction method for chimney lining external concrete

A technology of synchronous construction and lining external concrete, which is applied in the direction of building types, buildings, towers, etc., can solve the problems of rising cost and long construction period, and achieve the effect of simple operation, good construction quality and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

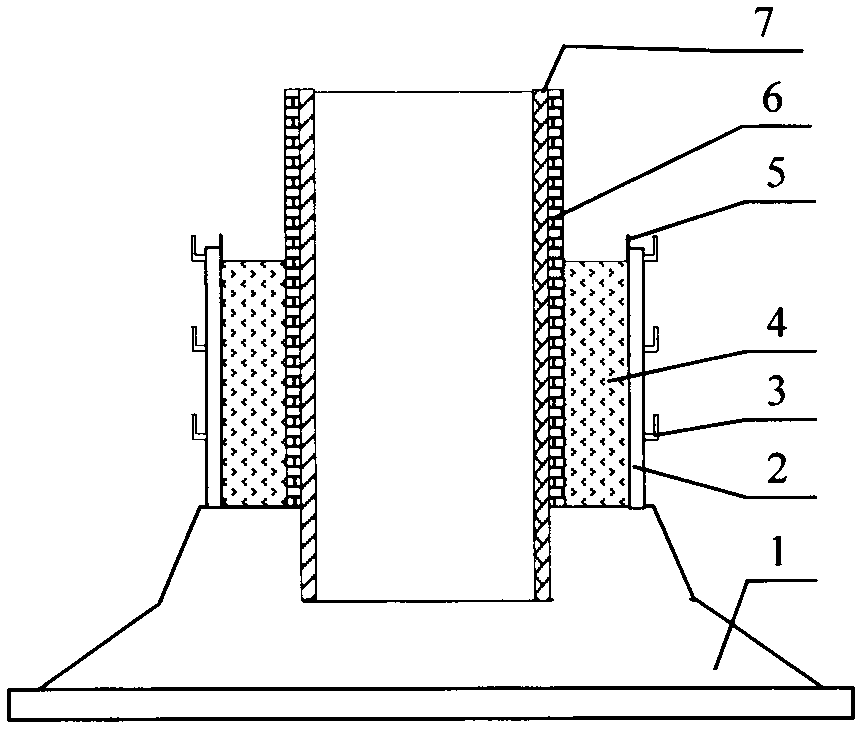

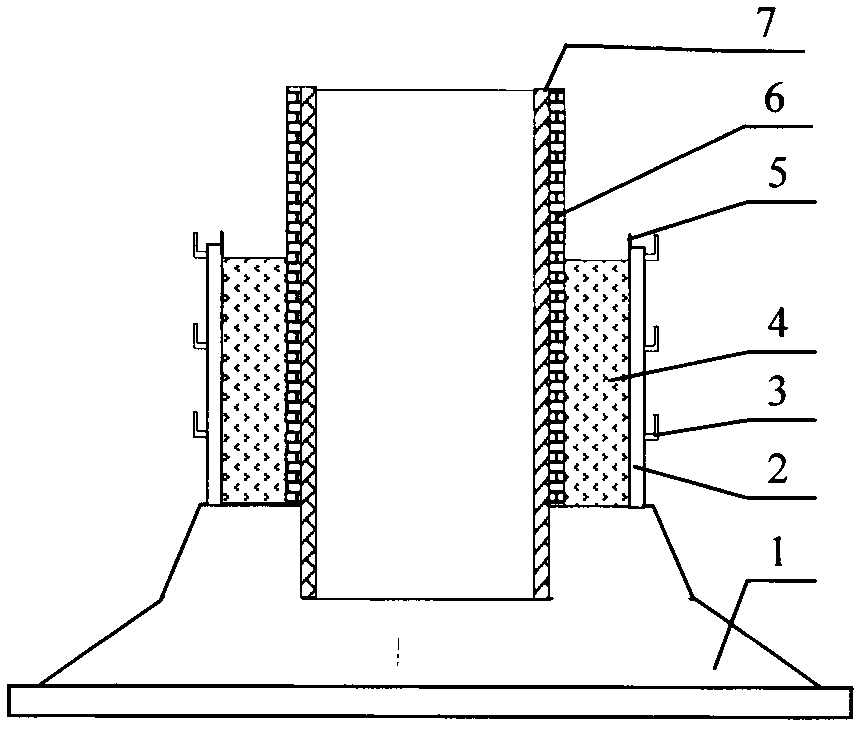

[0012] In the present invention, the construction process of the reinforced concrete chimney barrel includes: construction measurement, heat insulation layer 6, refractory brick lining 7 construction, concrete barrel body 4 steel bar binding, eversion mold 2 construction, and concrete barrel body 4 pouring.

[0013] The support structure of the eversion mold 2 is a vertical 25mm×25mm square steel and a 40mm×40mm flat steel welded and fixed in the circumferential direction, the distance between adjacent square steels is 100mm, and the fixed cold plate 5 on the support structure is a steel plate with a thickness of 1.8mm. 2 outer wall fixing hook 3.

[0014] The heat insulation layer 6 is made of aerated blocks.

[0015] Specific steps include:

[0016] 1) Engineering survey;

[0017] A. Measure and set reliable control piles in the chimney on the base 1, as the check point of the center point and coordinates of the chimney before the wall construction, the reference point dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com