Patents

Literature

191results about How to "Increase firing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

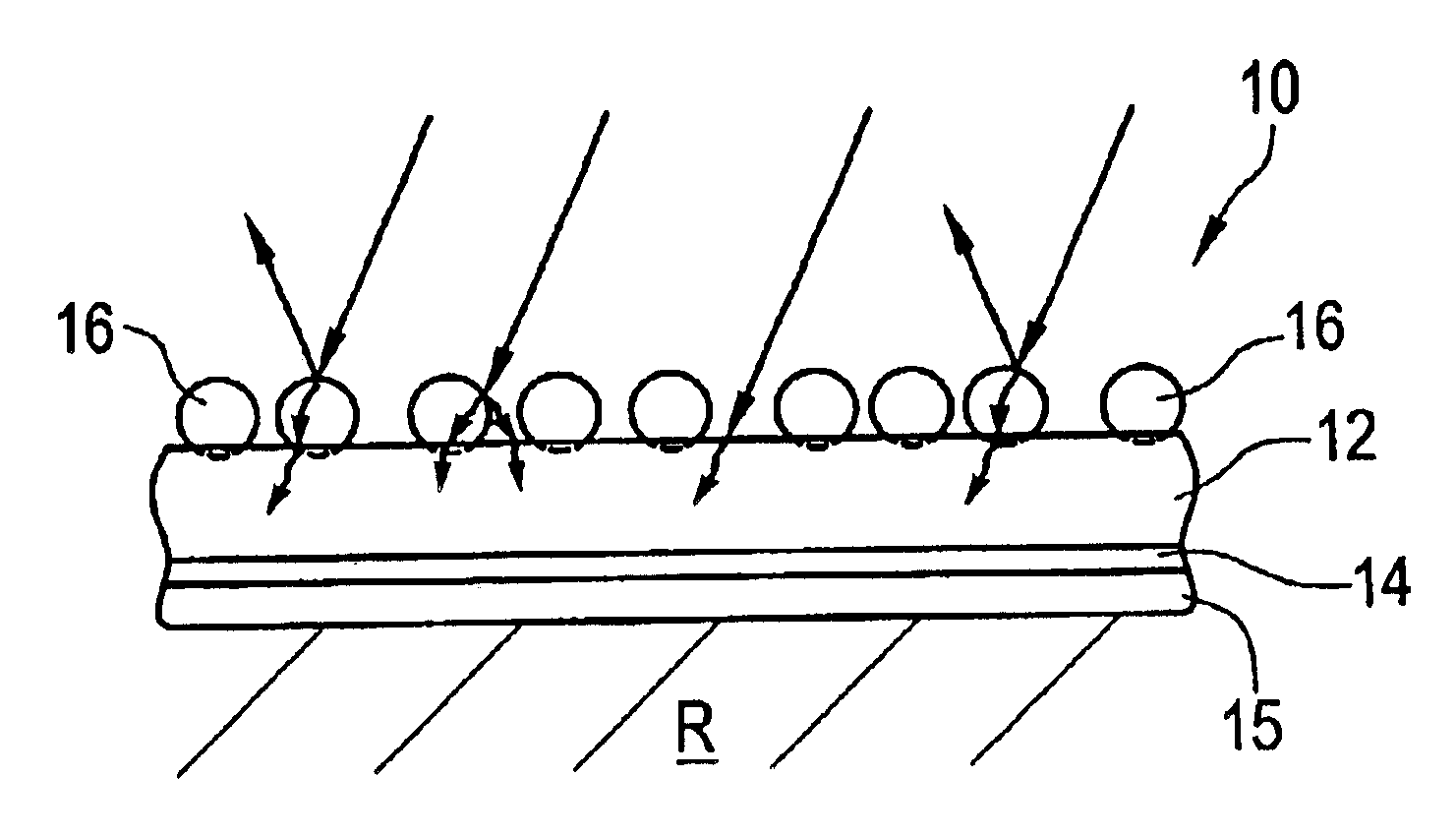

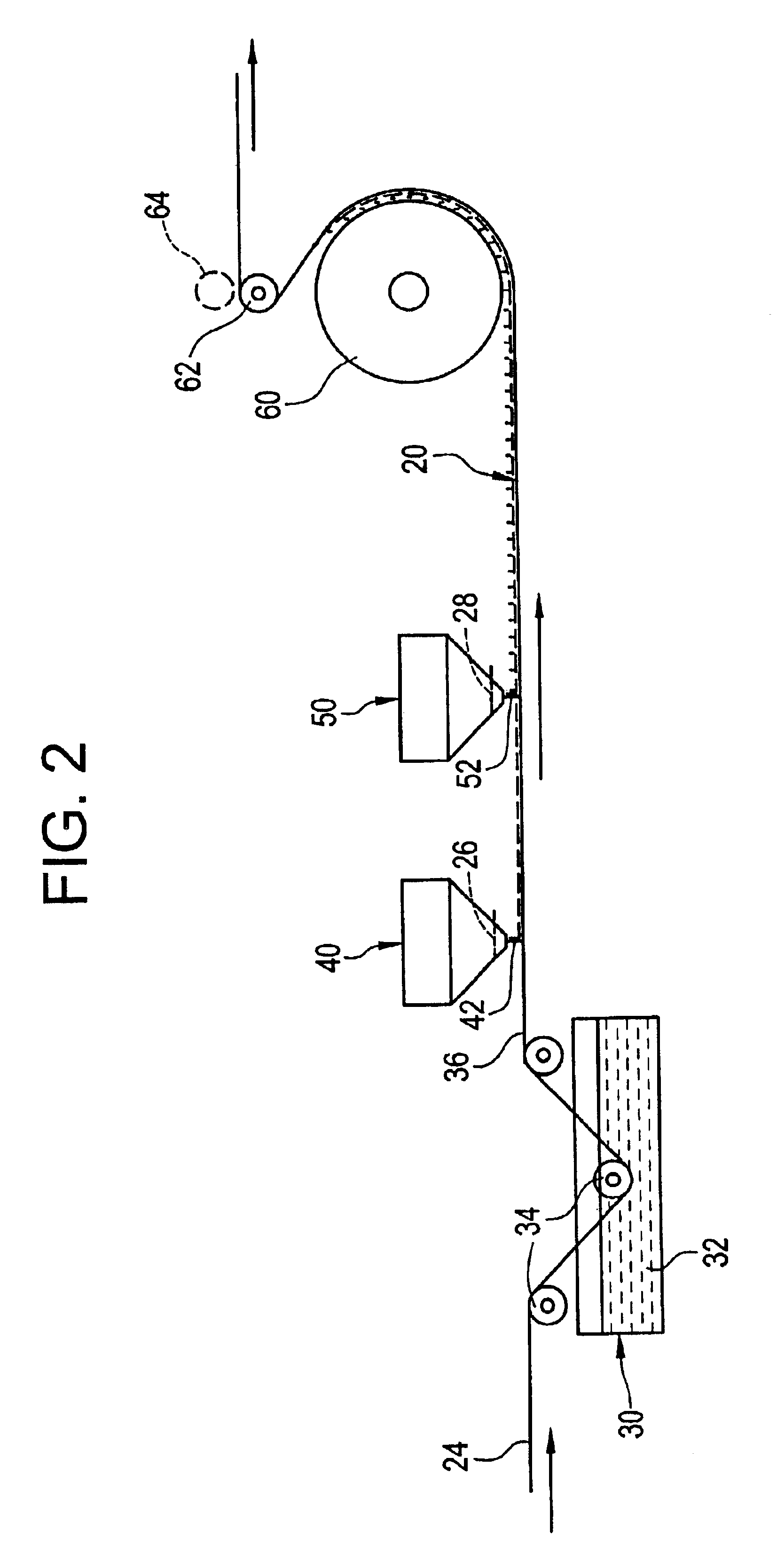

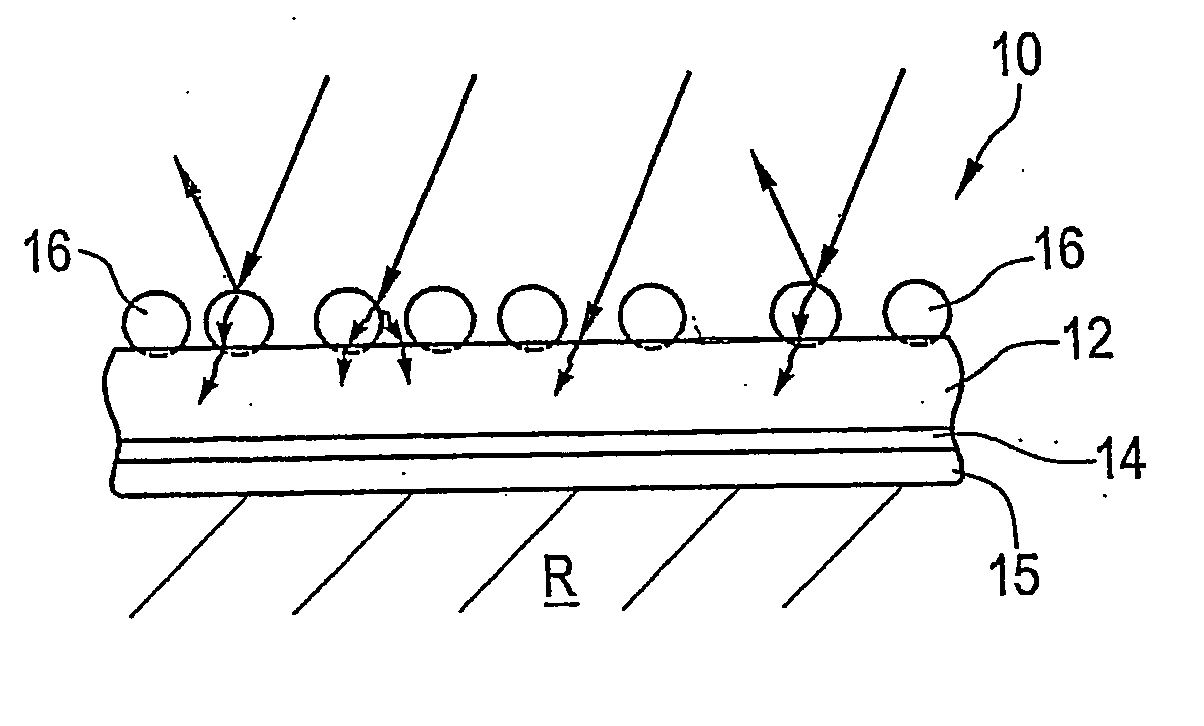

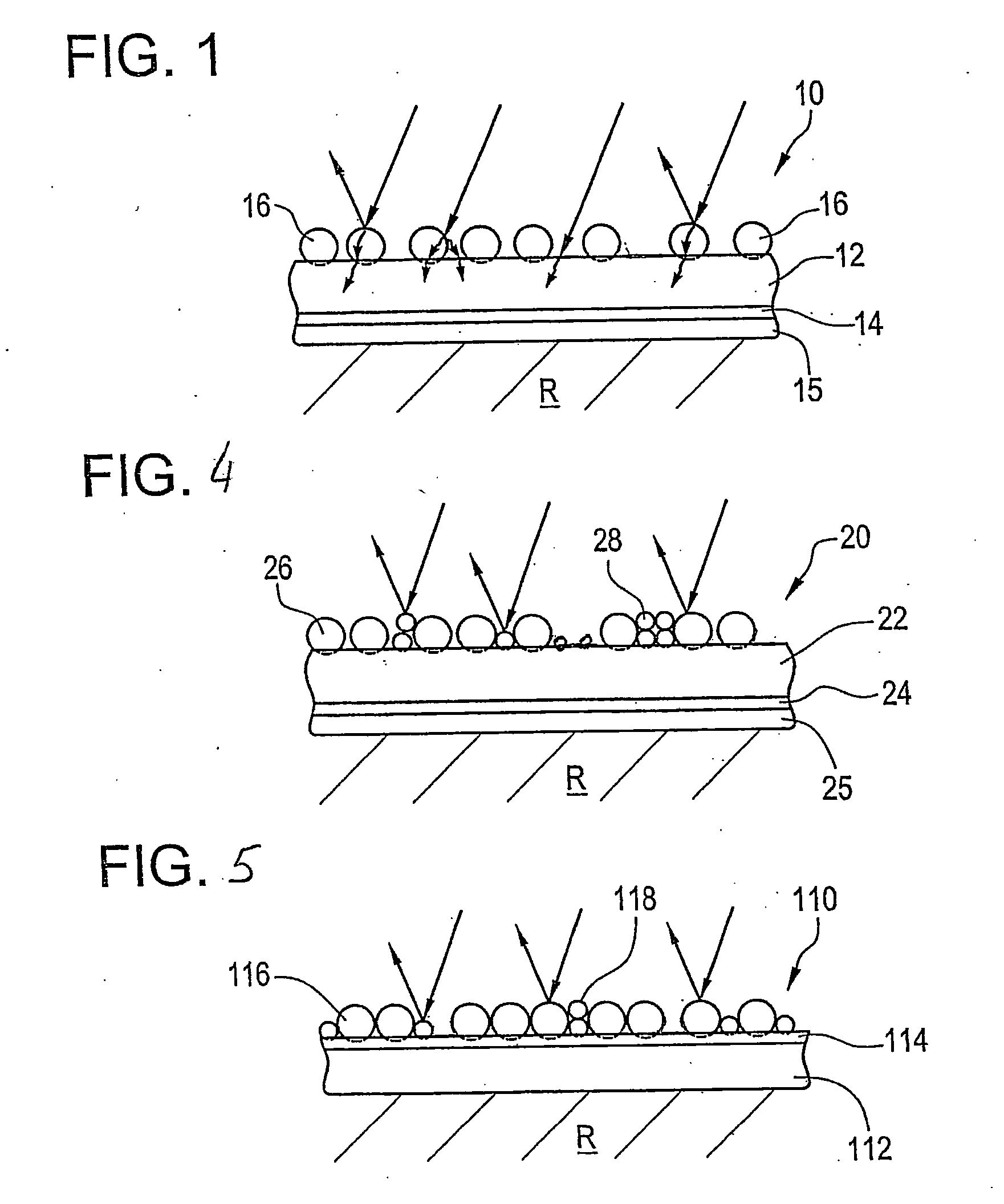

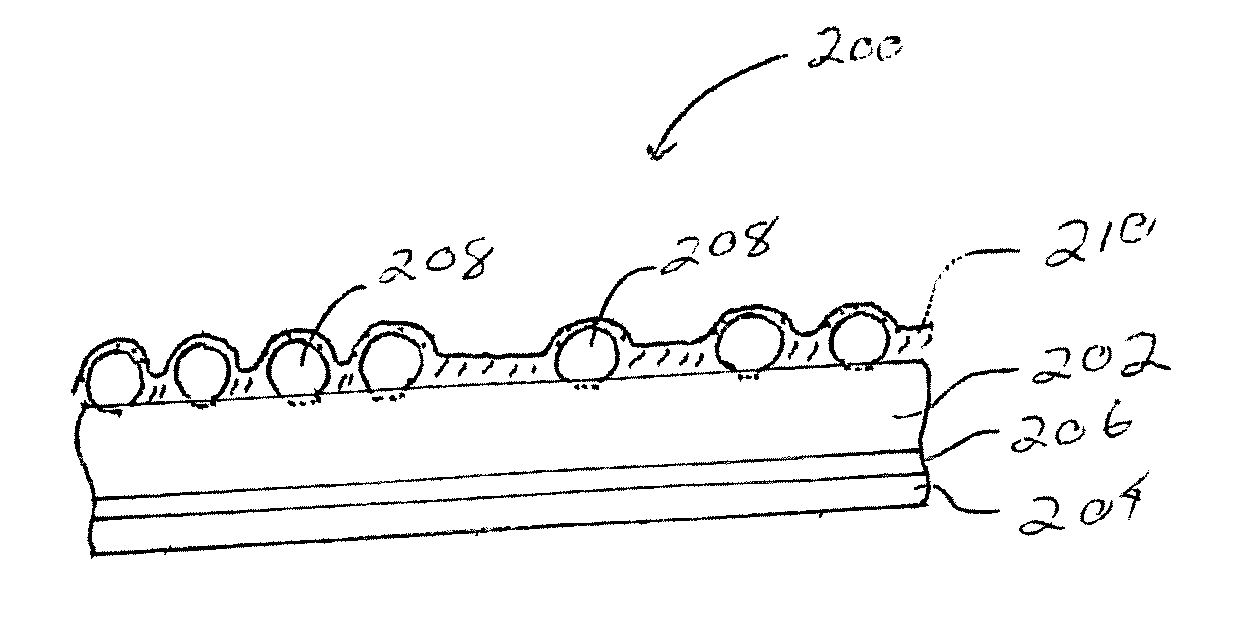

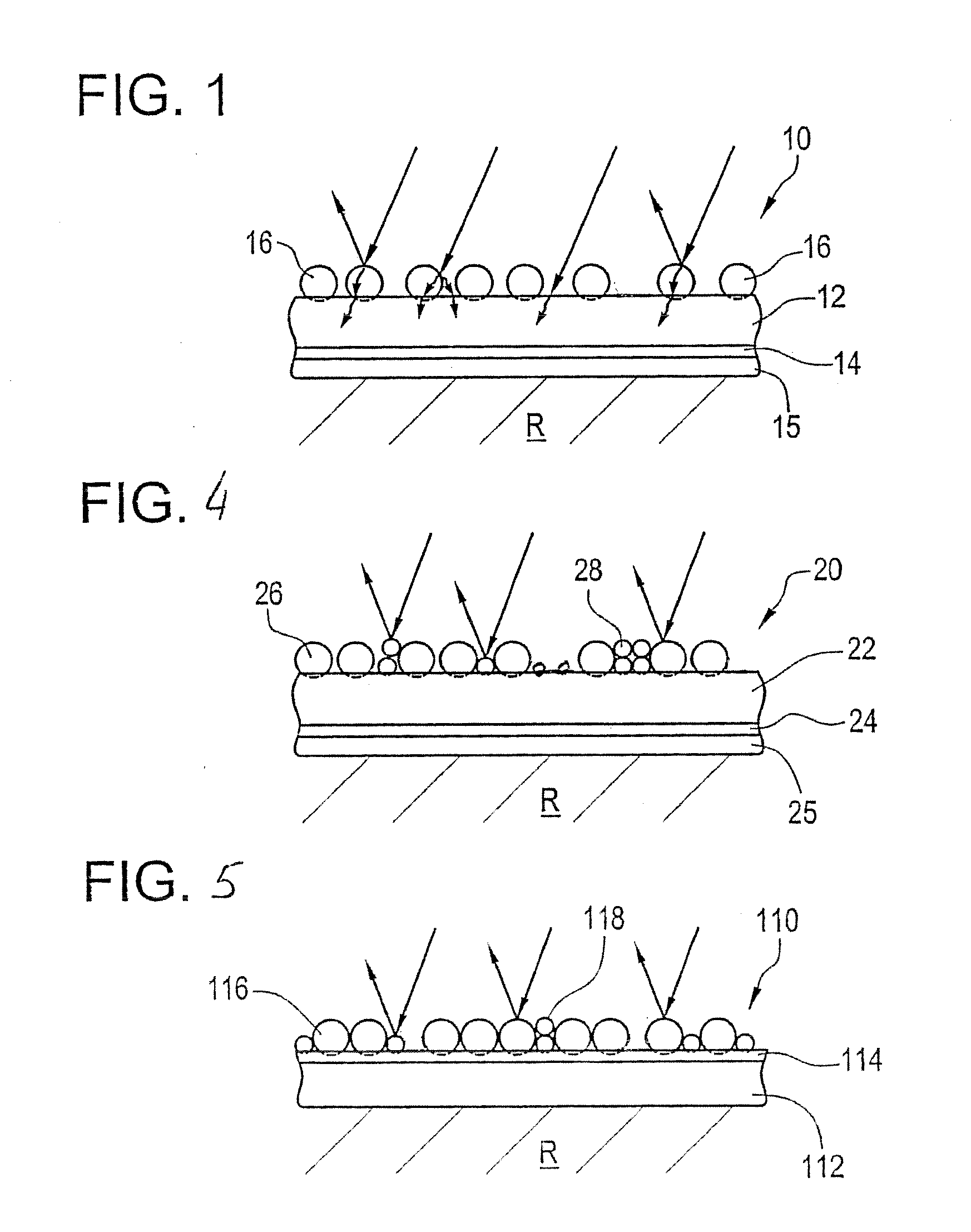

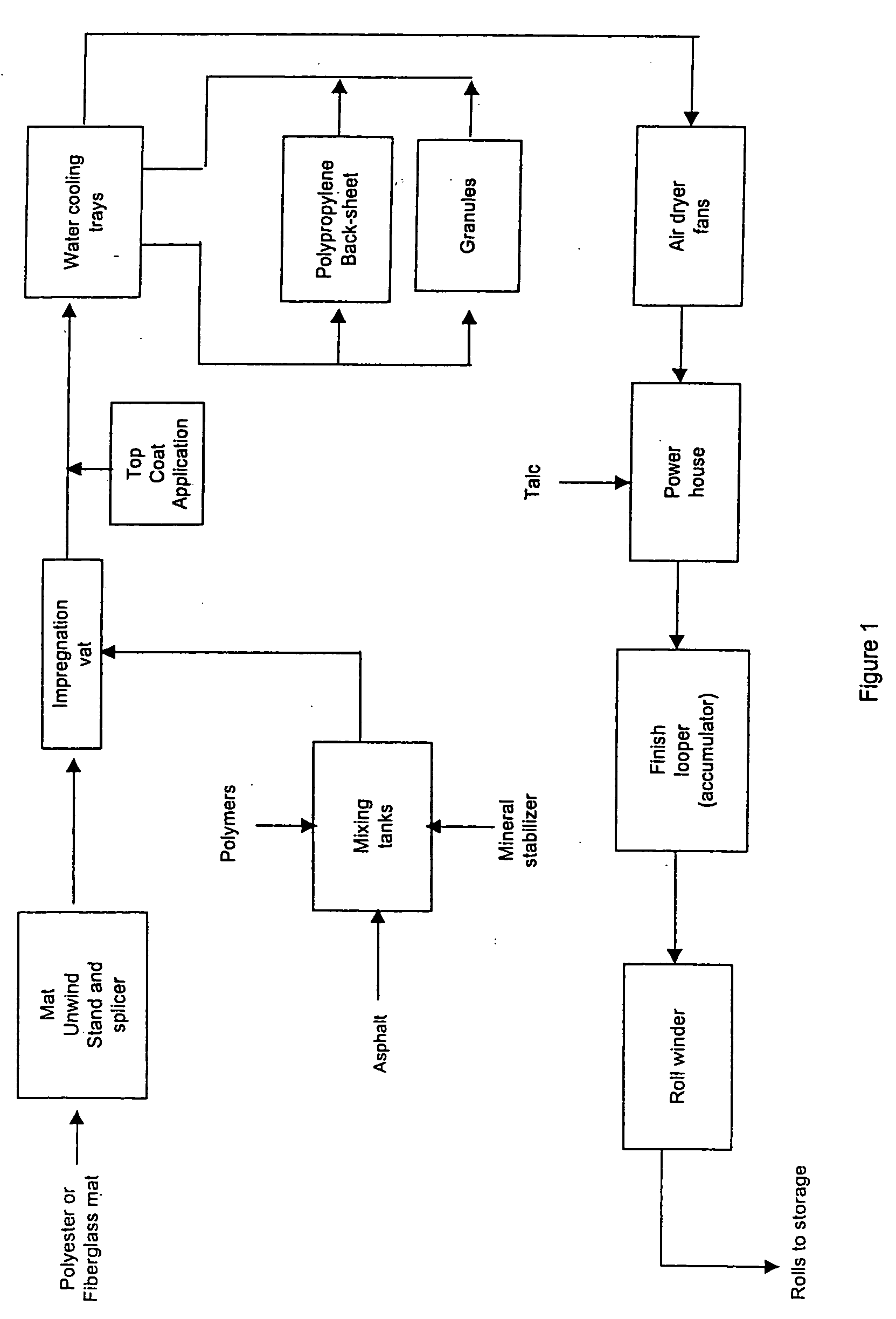

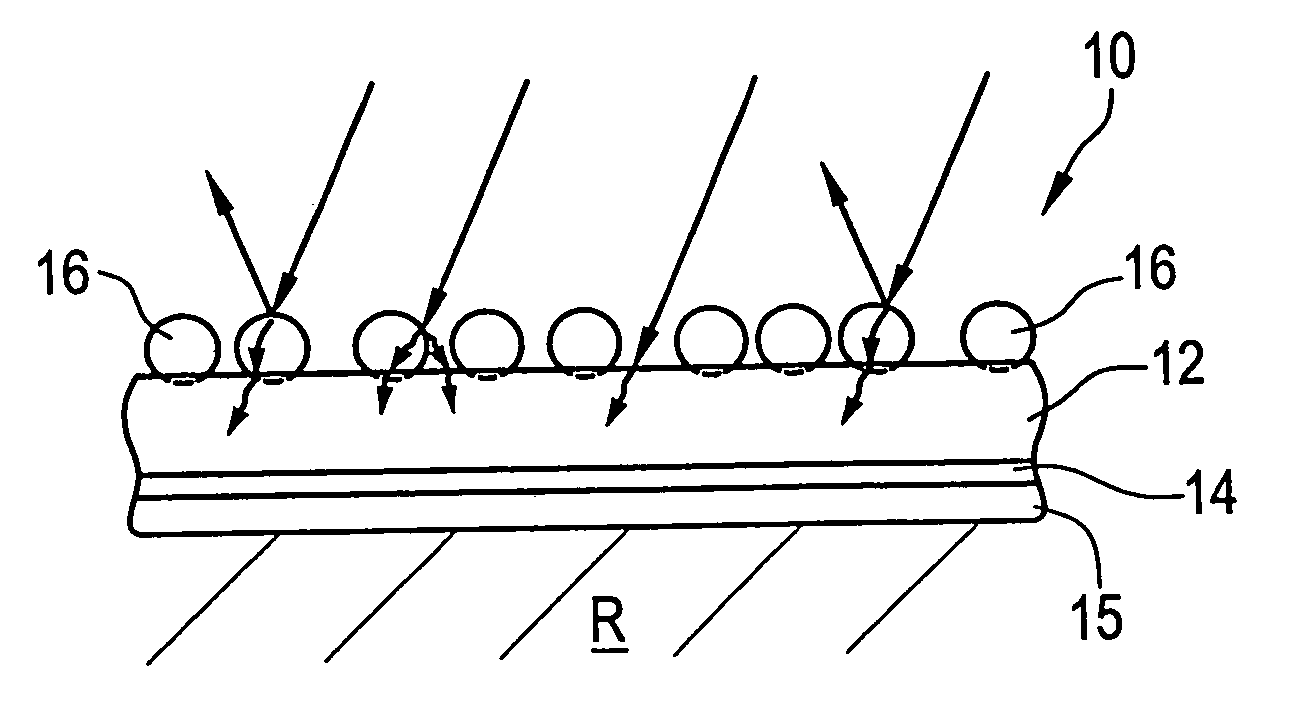

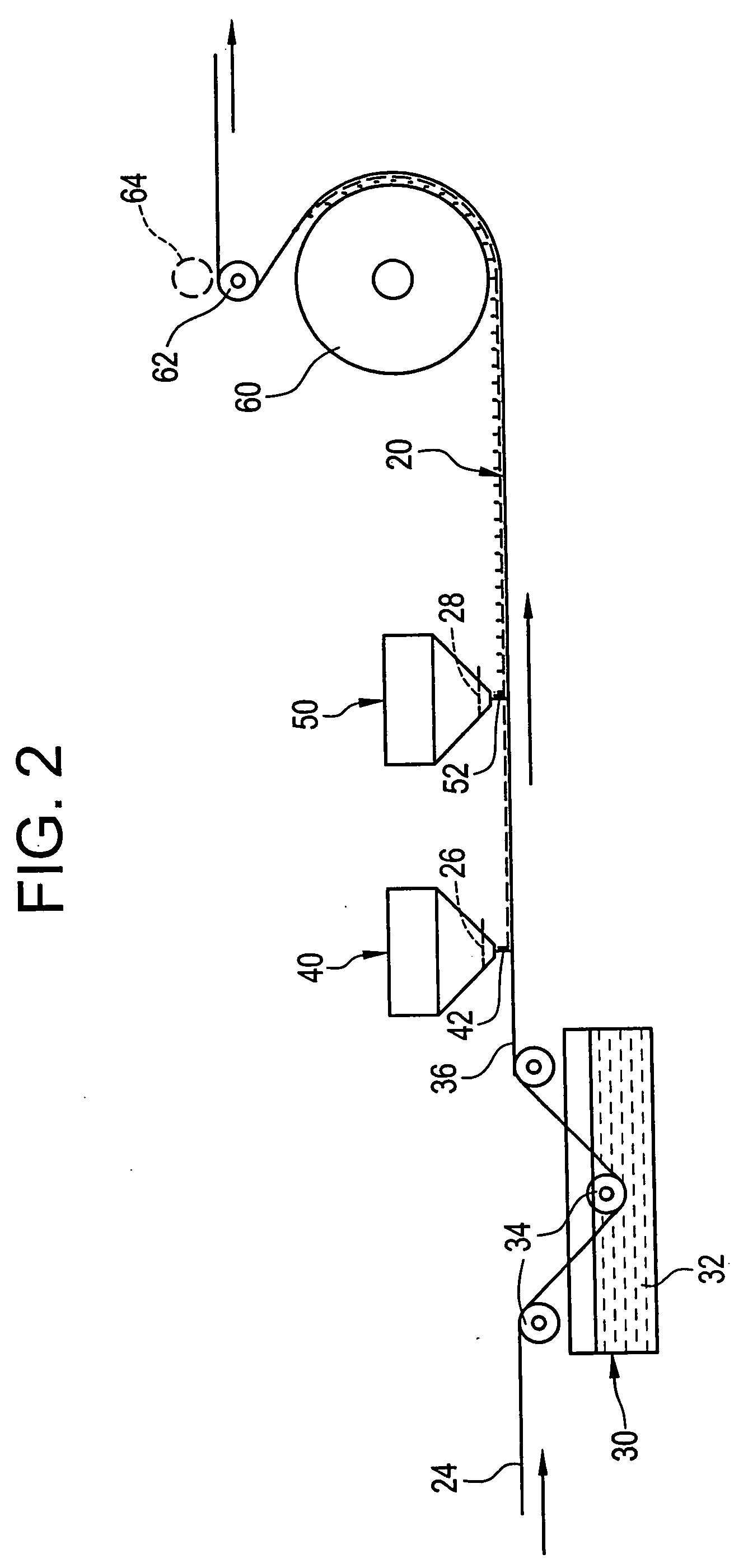

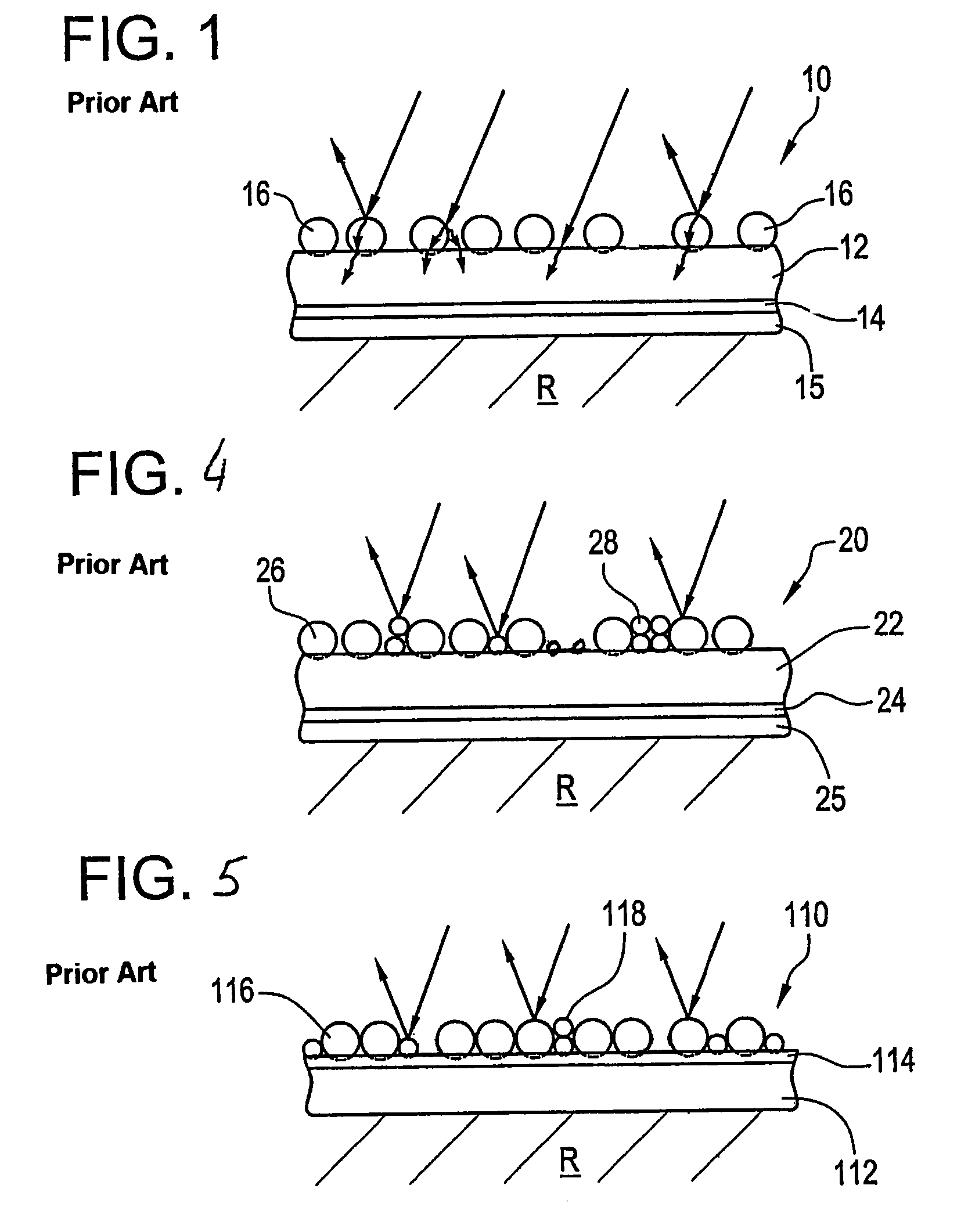

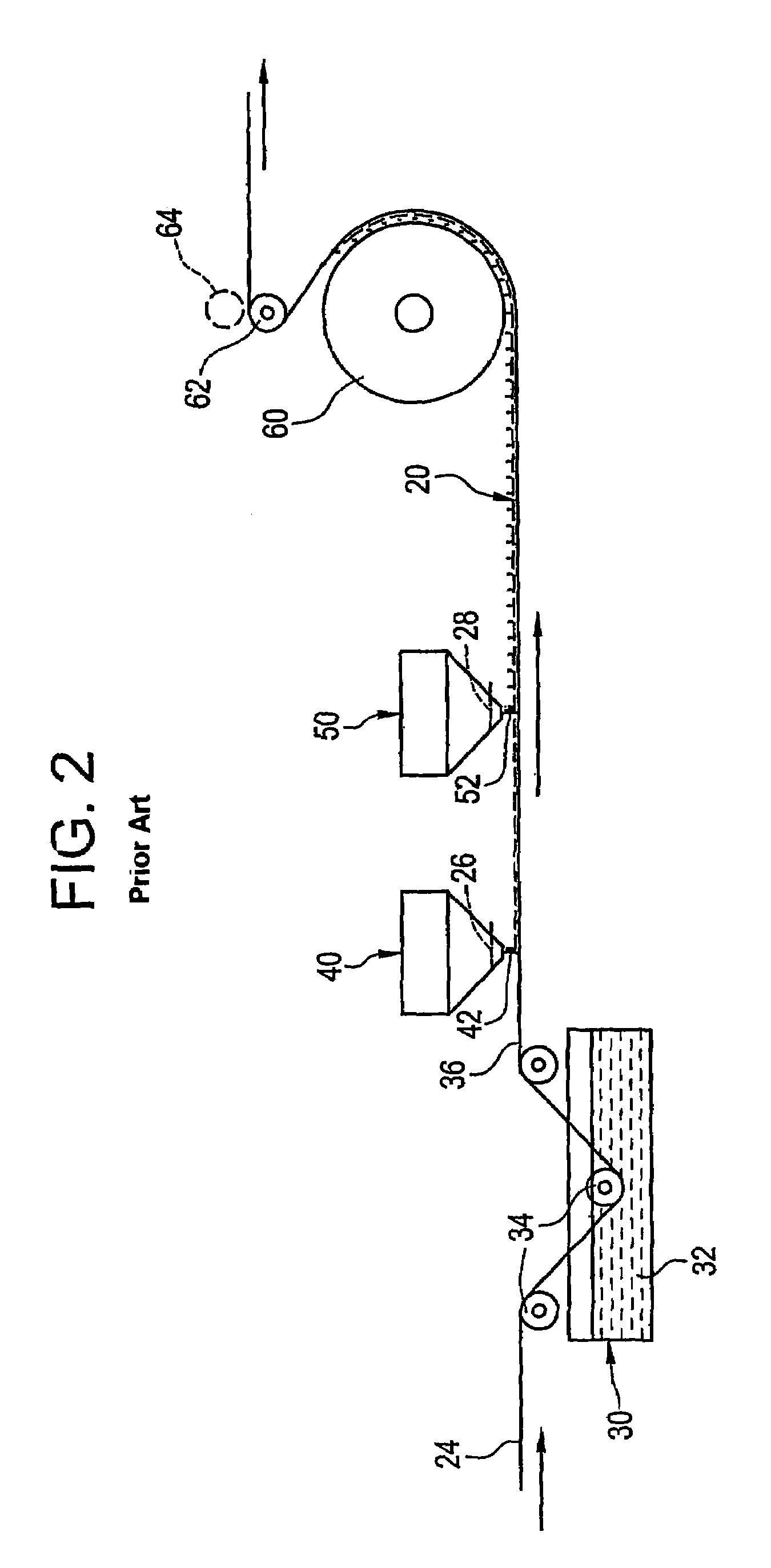

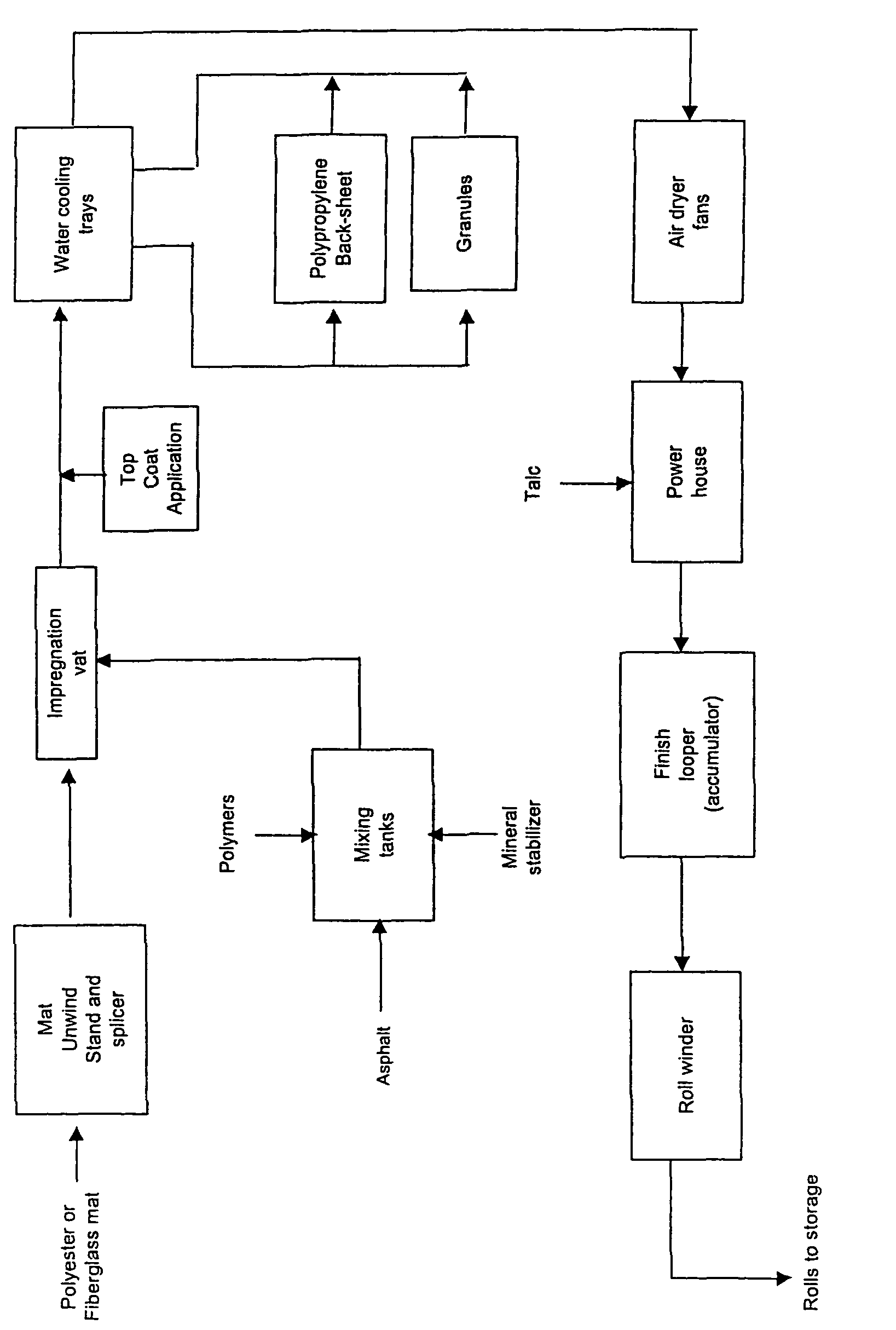

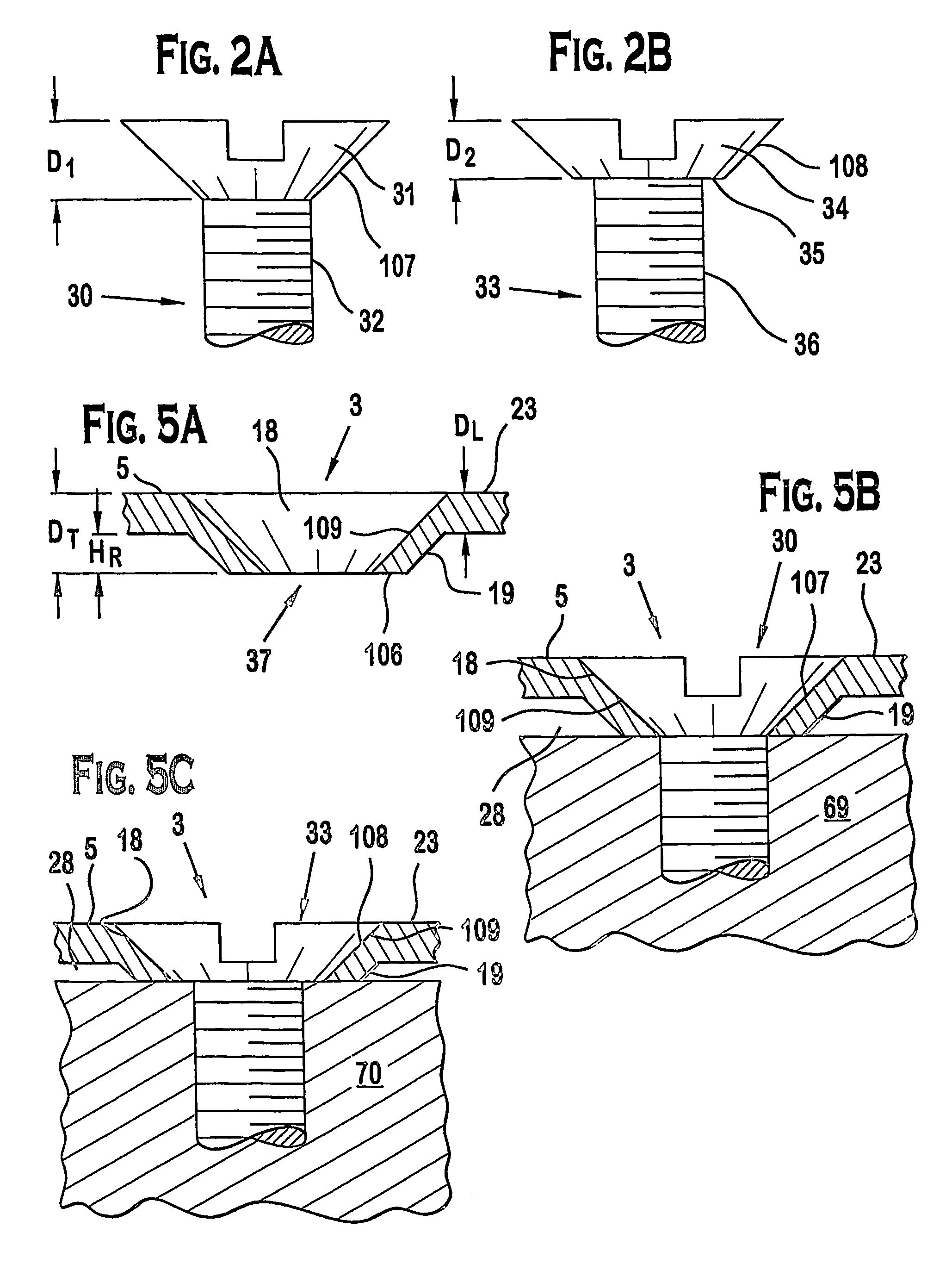

Method of forming an improved roofing material

InactiveUS6933007B2Improve reflectivityIncrease temperatureRoof covering using tiles/slatesCovering/liningsMaterials scienceReflectivity

A method of coating highly reflective granules on an adhering material of a roofing or siding material to form a roofing or siding material having an average resulting reflectivity on an upper surface of at least about 45%. The method includes the selecting of highly reflective granules and applying the highly reflective granules on an adhering material until over about 95% of a top surface of the adhering material is covered by the granules.

Owner:GARLAND INDS

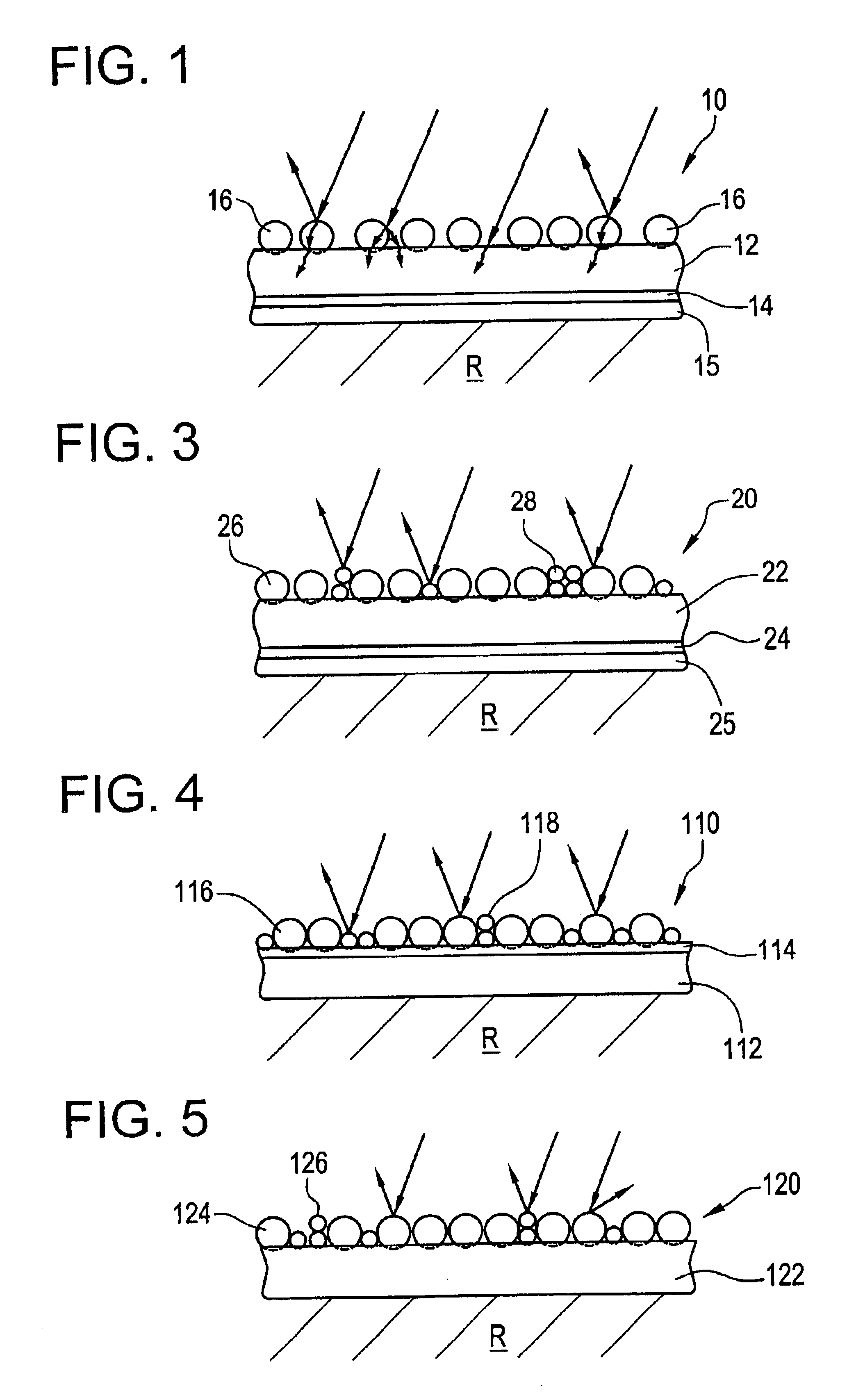

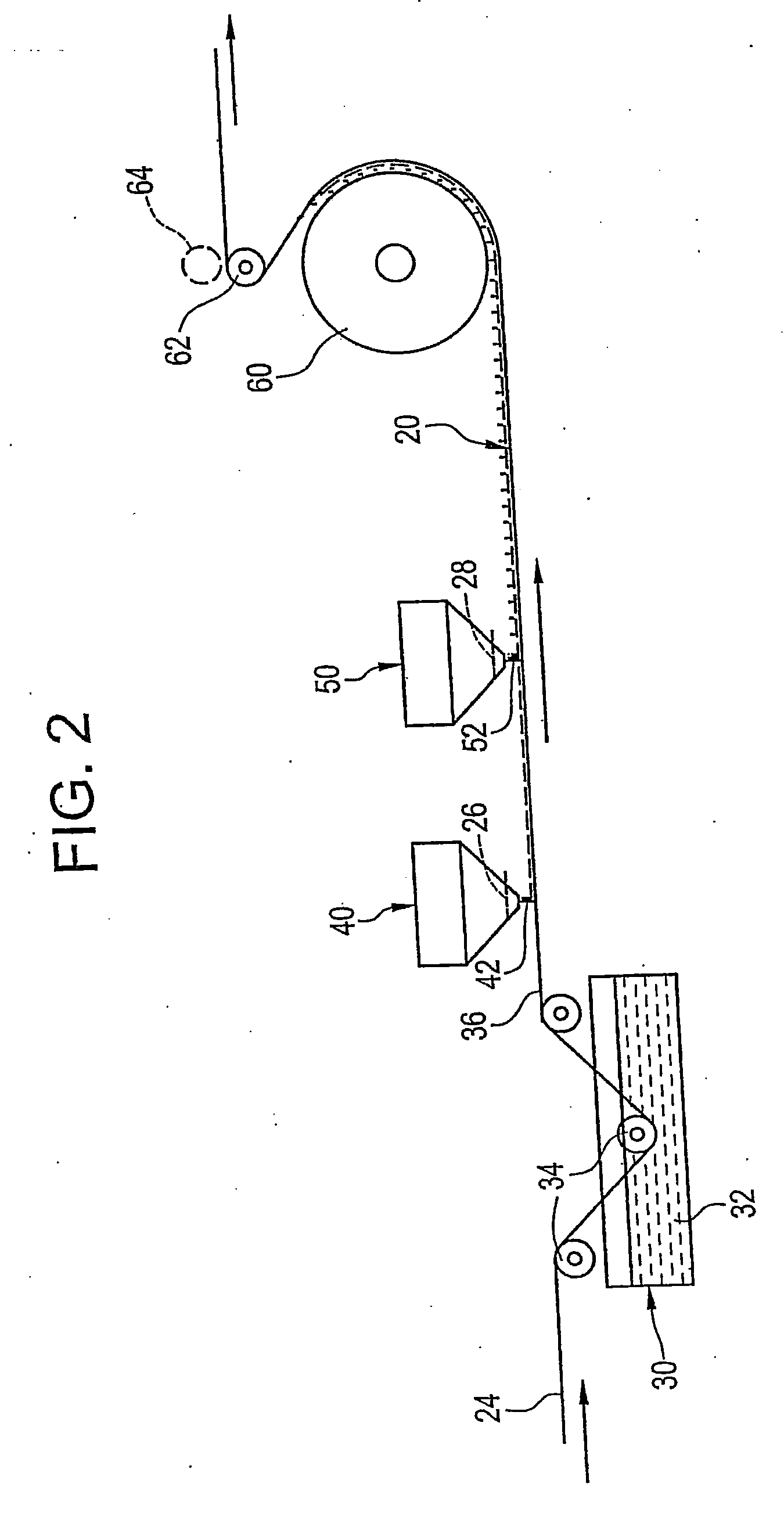

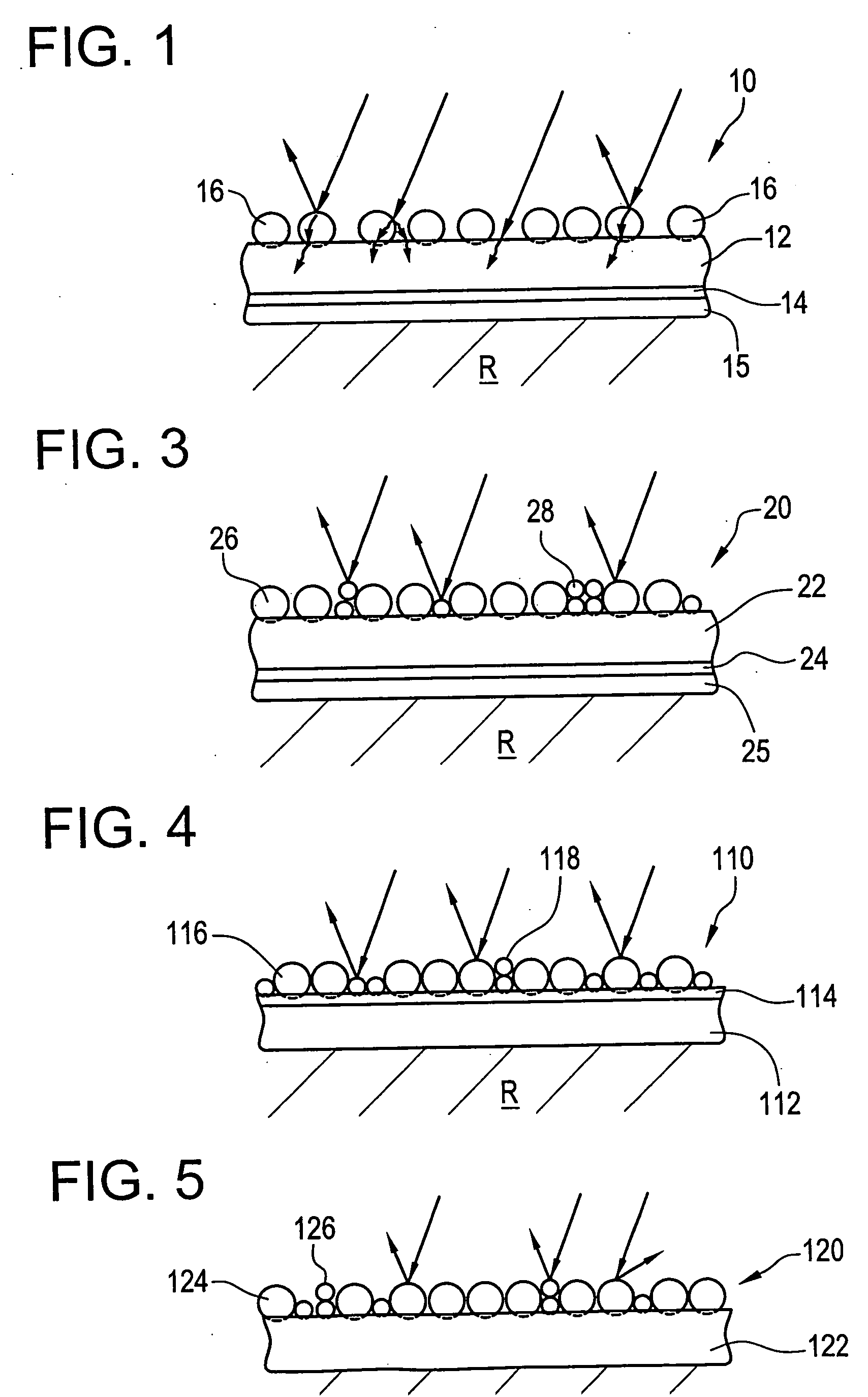

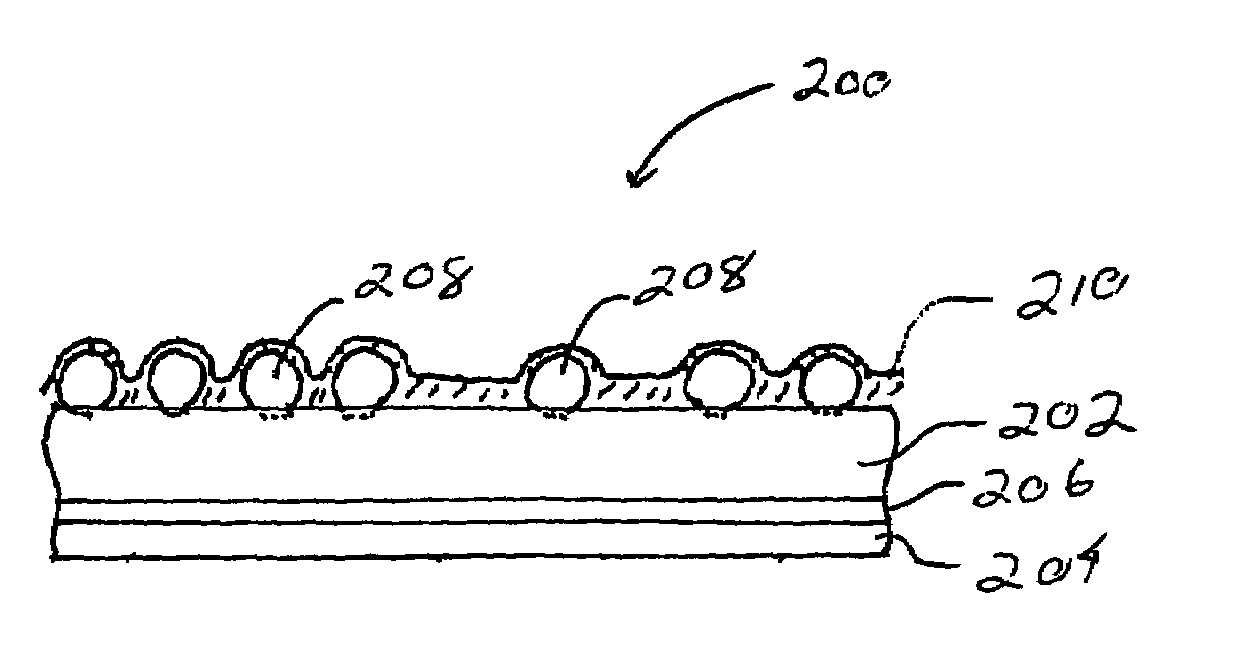

Highly reflective roofing materials

InactiveUS20070110961A1Reduce the amount requiredLow reflecting surfaceLiquid surface applicatorsRoof covering using flexible materialsReflectivityCivil engineering

A roofing or siding system having an improved average resulting reflectivity. The roofing and / or siding system is at least partially coated with a plurality of granules. At least one layer of paint is applied to the roofing and / or siding system to increase the resulting reflectivity of the roofing and / or siding system.

Owner:GARLAND INDS

Roofing and/or siding material and a method of forming thereof

ActiveUS20090317593A1Reduce the amount requiredLow reflecting surfaceLiquid surface applicatorsRoof covering using tiles/slatesReflectivityCivil engineering

A roofing and / or siding system having an improved average resulting reflectivity. The roofing and / or siding system is at least partially coated with a plurality of granules. At least one layer of paint is applied to the roofing and / or siding system to increase the resulting reflectivity of the roofing and / or siding system.

Owner:GARLAND INDS

White reflective coating for modified bitumen membrane

ActiveUS20050261407A1Small smellMinimal disruptionLiquid surface applicatorsReflecting/signal paintsEngineeringSteep slope

A coating composition useful for building materials products, especially roofing surfaces, is provided. The coating composition provides durable exterior protection to surfaces that it applied to, and it has reflective properties. The coating composition includes a mixture of a polymeric binder, a polymeric carrier and a pigment. The pigment is present in the coating composition in amount that is capable of providing a coating that has an initial energy efficiency rating greater than or equal to 0.65 for a low-sloped roof, or an initial energy efficiency greater than or equal to 0.25 for a steep-sloped roof.

Owner:BMIC LLC

Roofing materials

InactiveUS20050238848A1Improve reflectivityIncrease temperatureRoof covering using tiles/slatesCovering/liningsHardnessReflectivity

A roofing or siding system having an improved average resulting reflectivity. The roofing and / or siding system is at least partially coated with a plurality of granules. The granules have an average reflectivity of at least about 55% and an average hardness of over about 3 Moh's.

Owner:GARLAND INDS

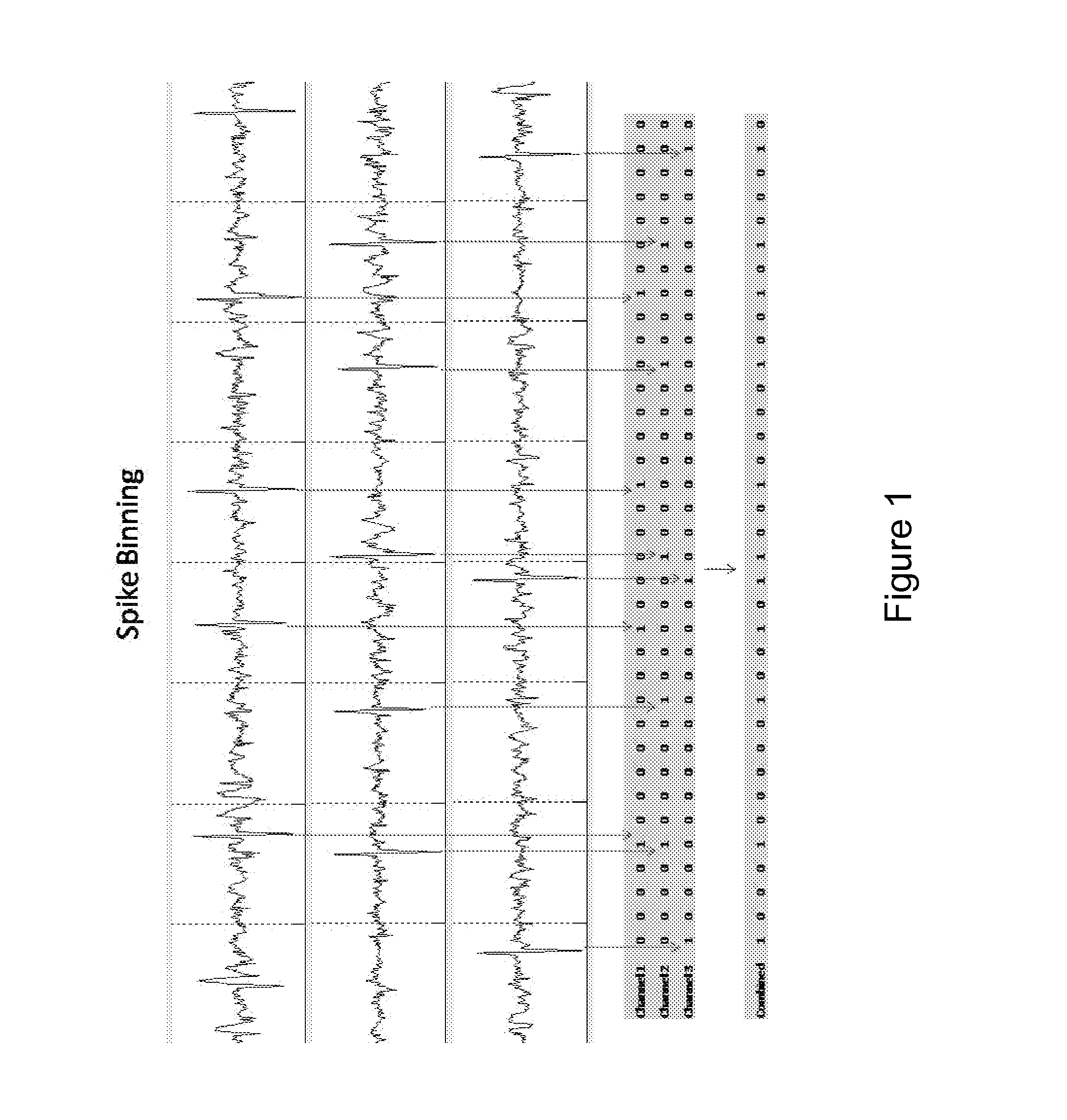

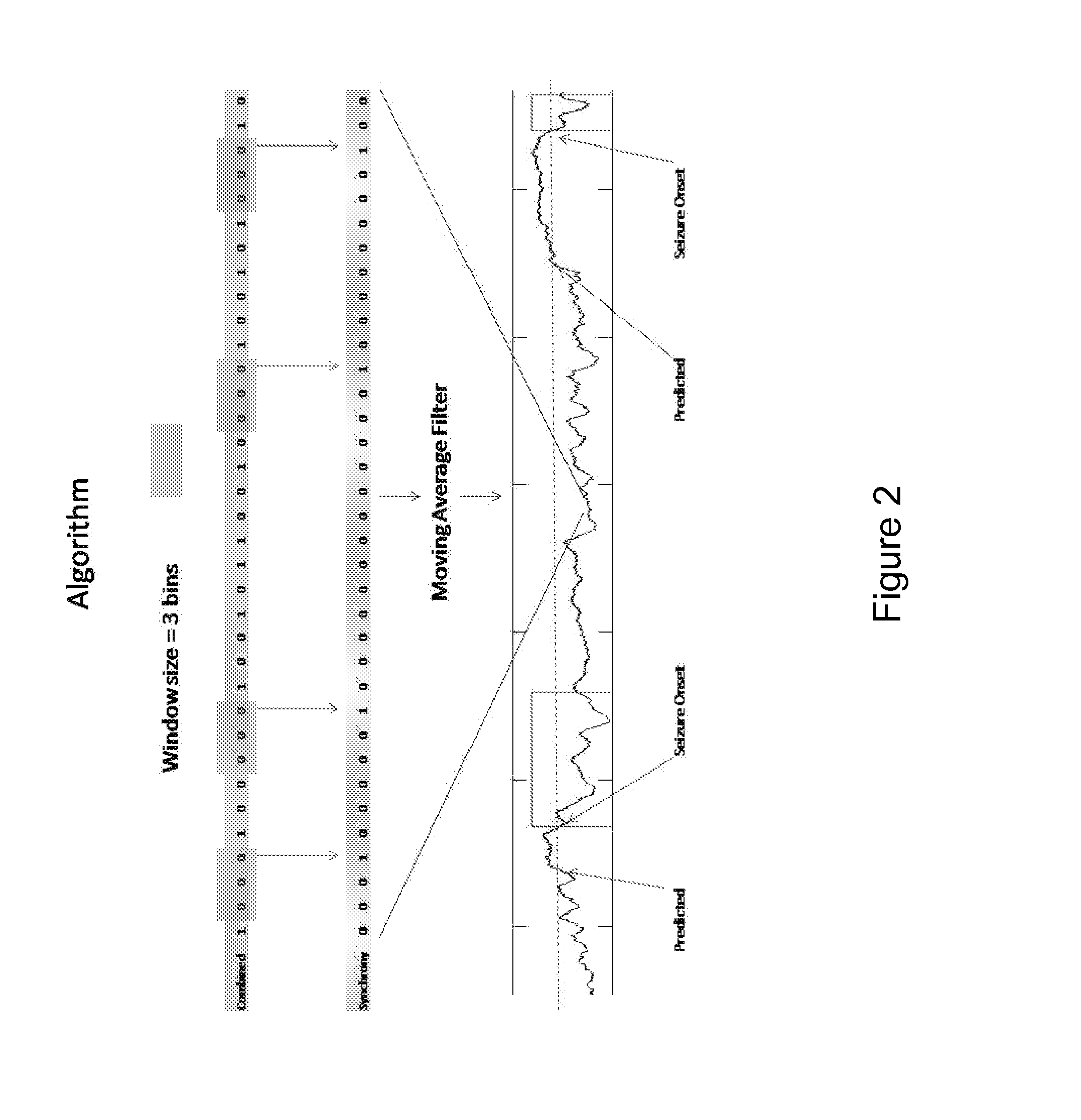

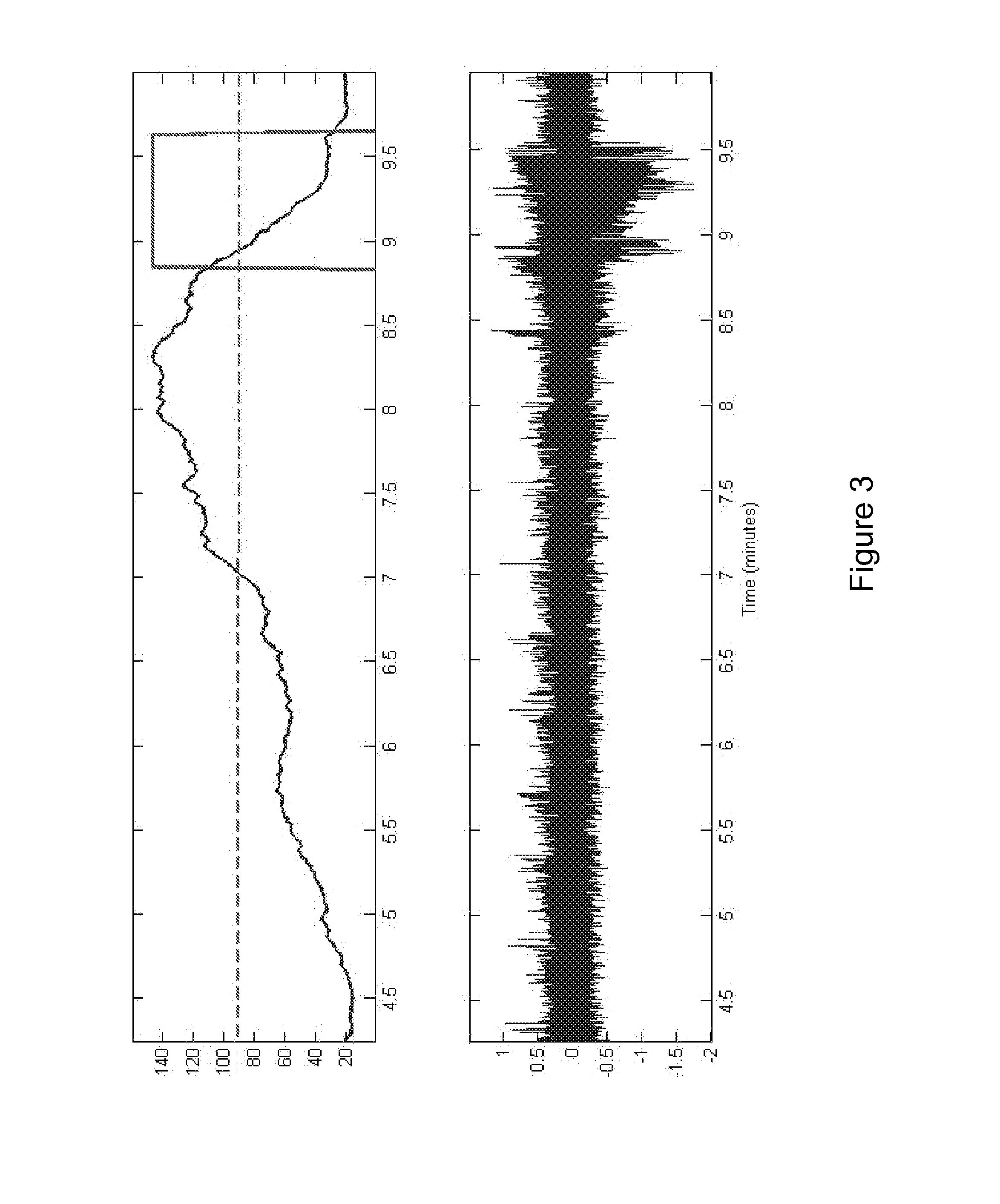

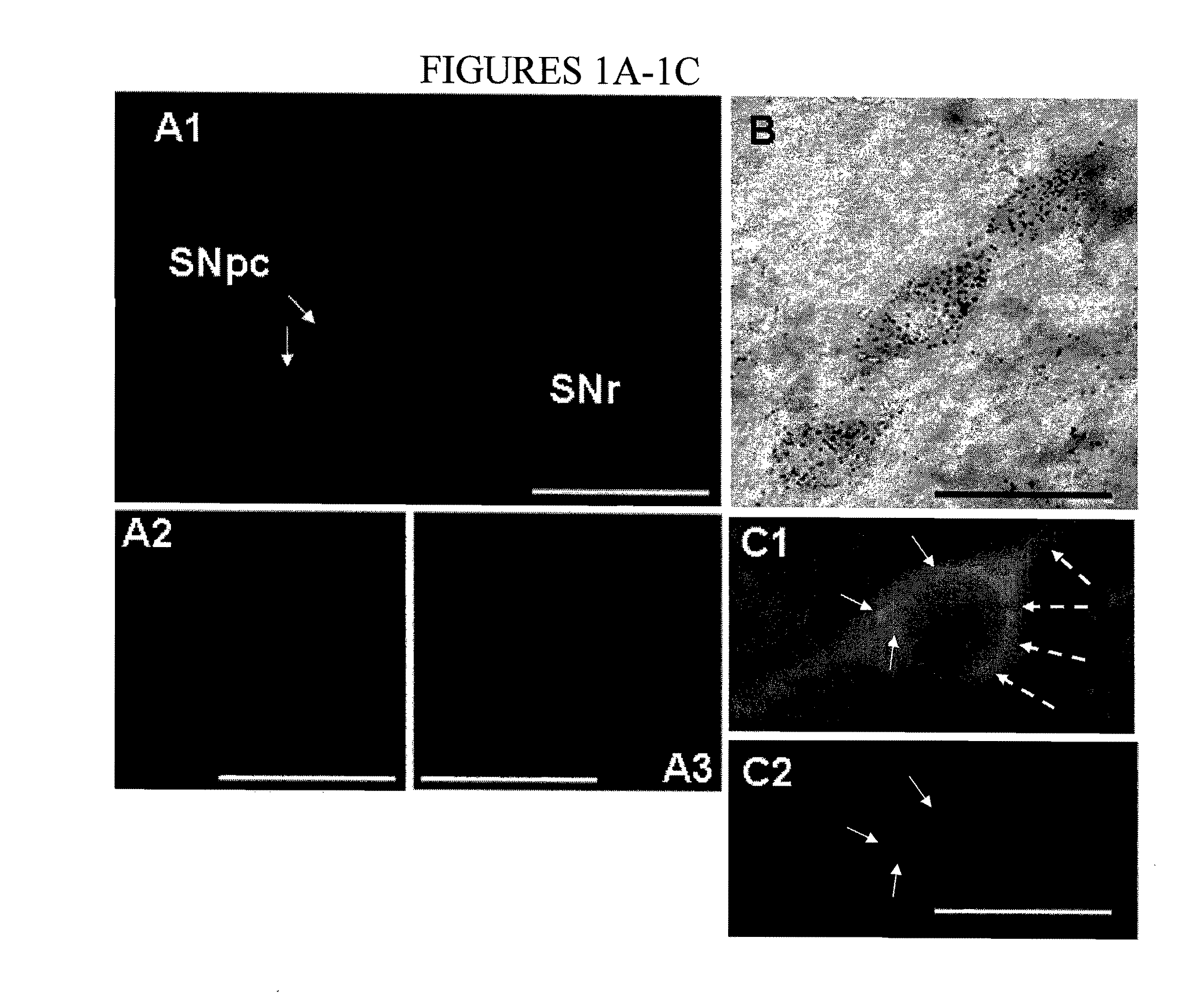

System and method of detecting and predicting seizures

InactiveUS20140257128A1Increase coherenceIncrease rate of fireImplantable neurostimulatorsSensorsAction potentialEpileptic seizure

The present invention describes systems and methods for predicting and detecting a seizure in a subject. The methods of the invention comprise measuring interneuron synchrony in terms of the coherence between interneuron action potentials and local field potential oscillations. In one embodiment, the detection of specific patterns of coherence, correlation and firing rate of interneurons predicts an upcoming seizures.

Owner:DREXEL UNIV

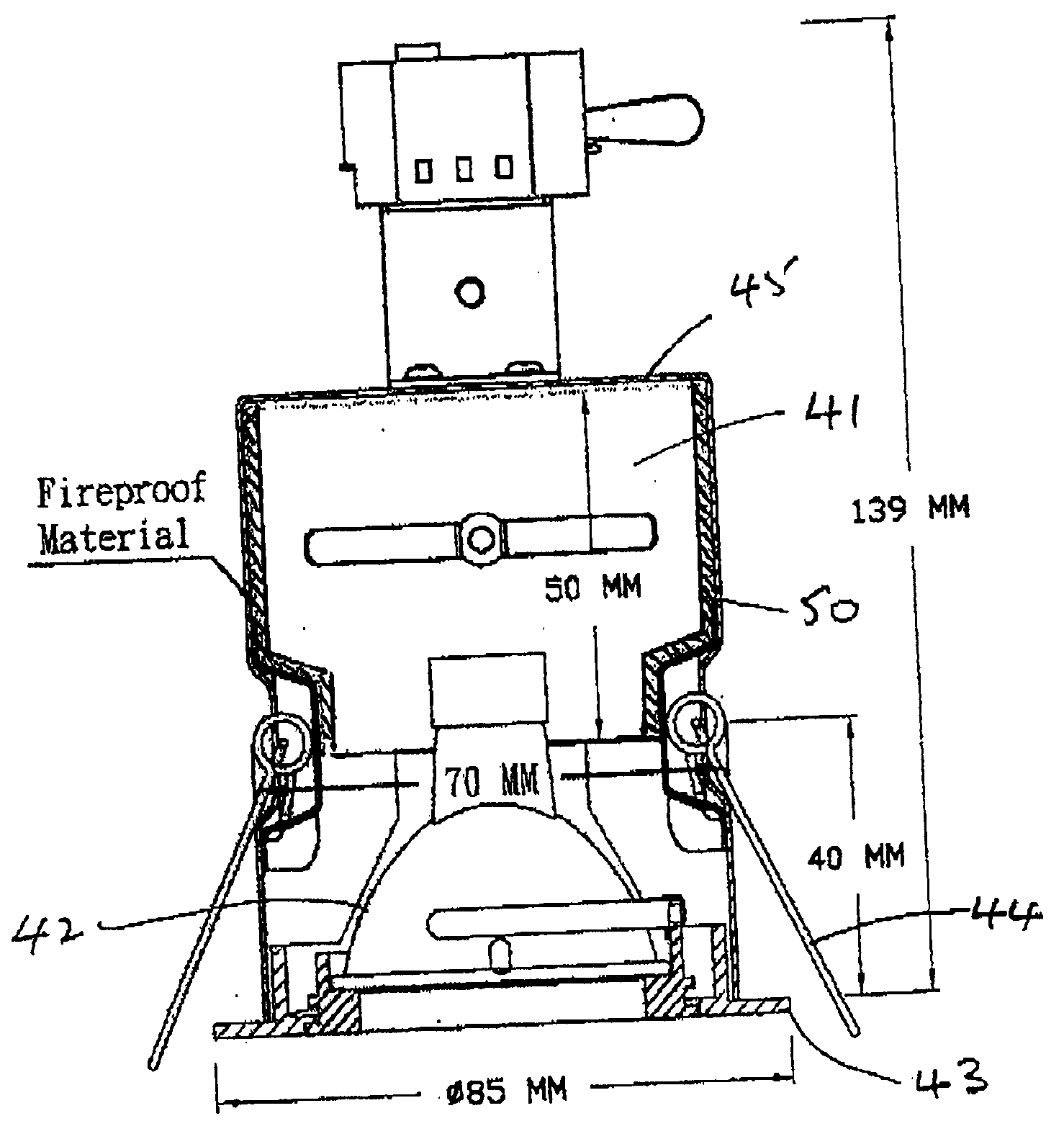

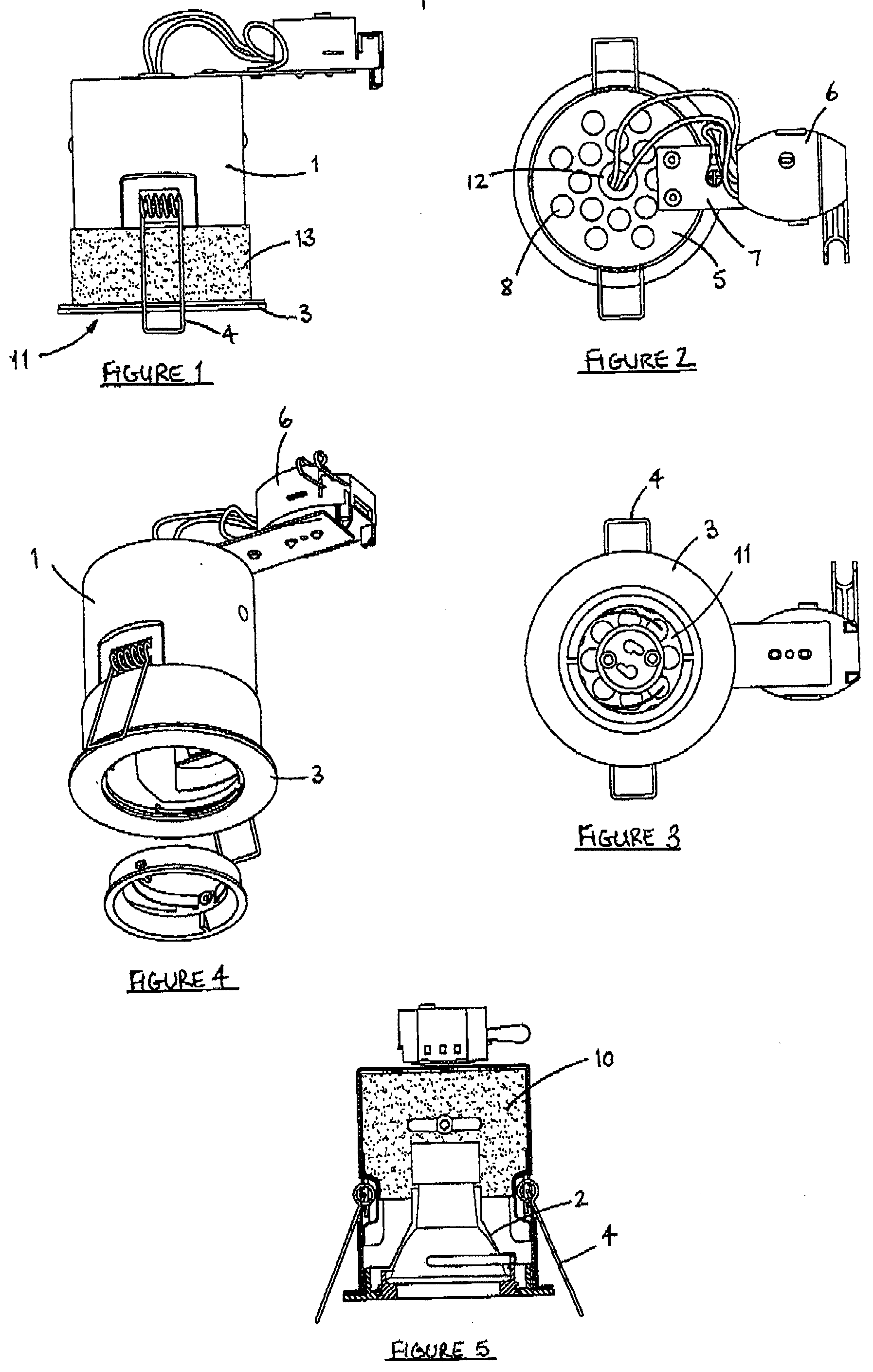

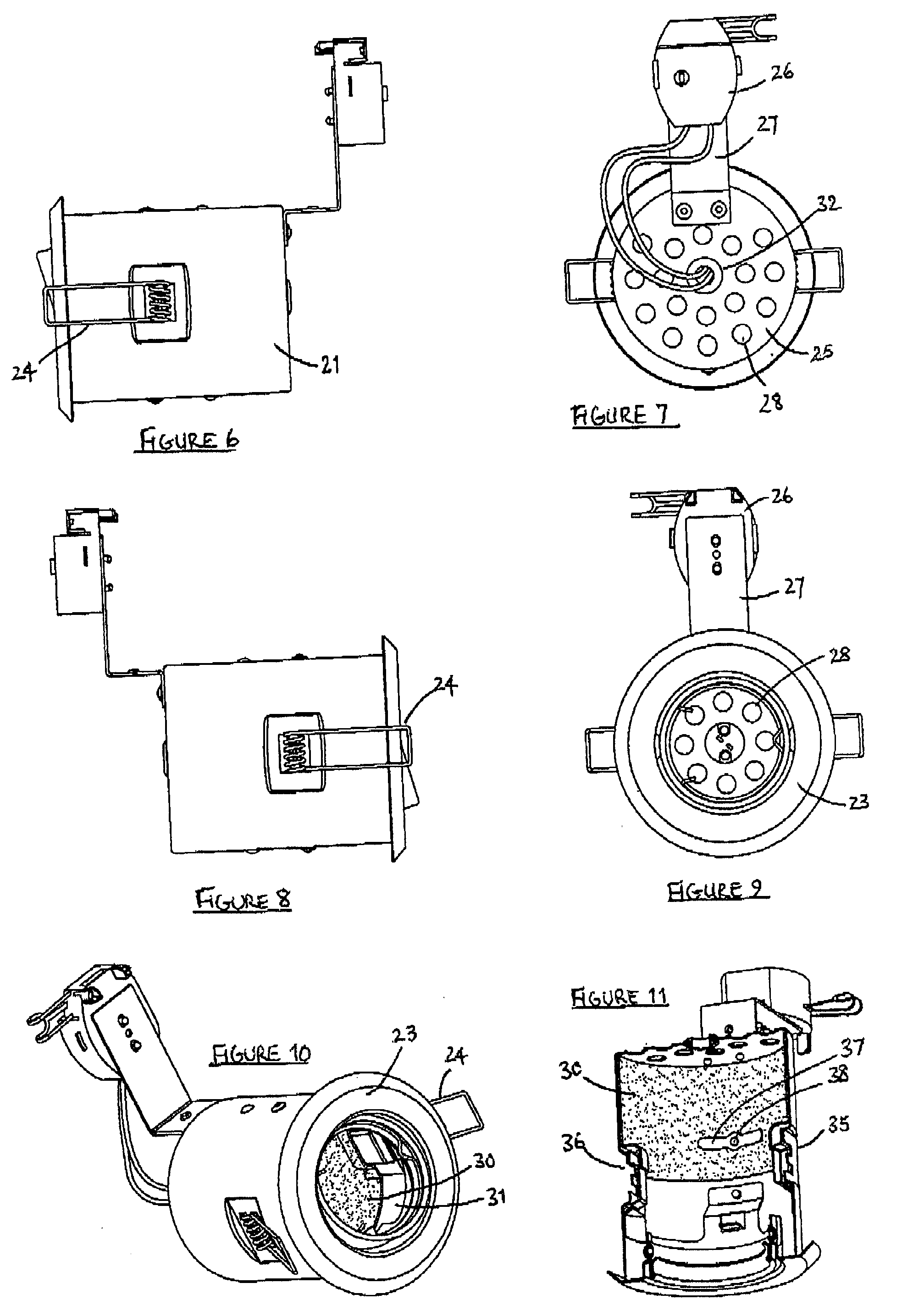

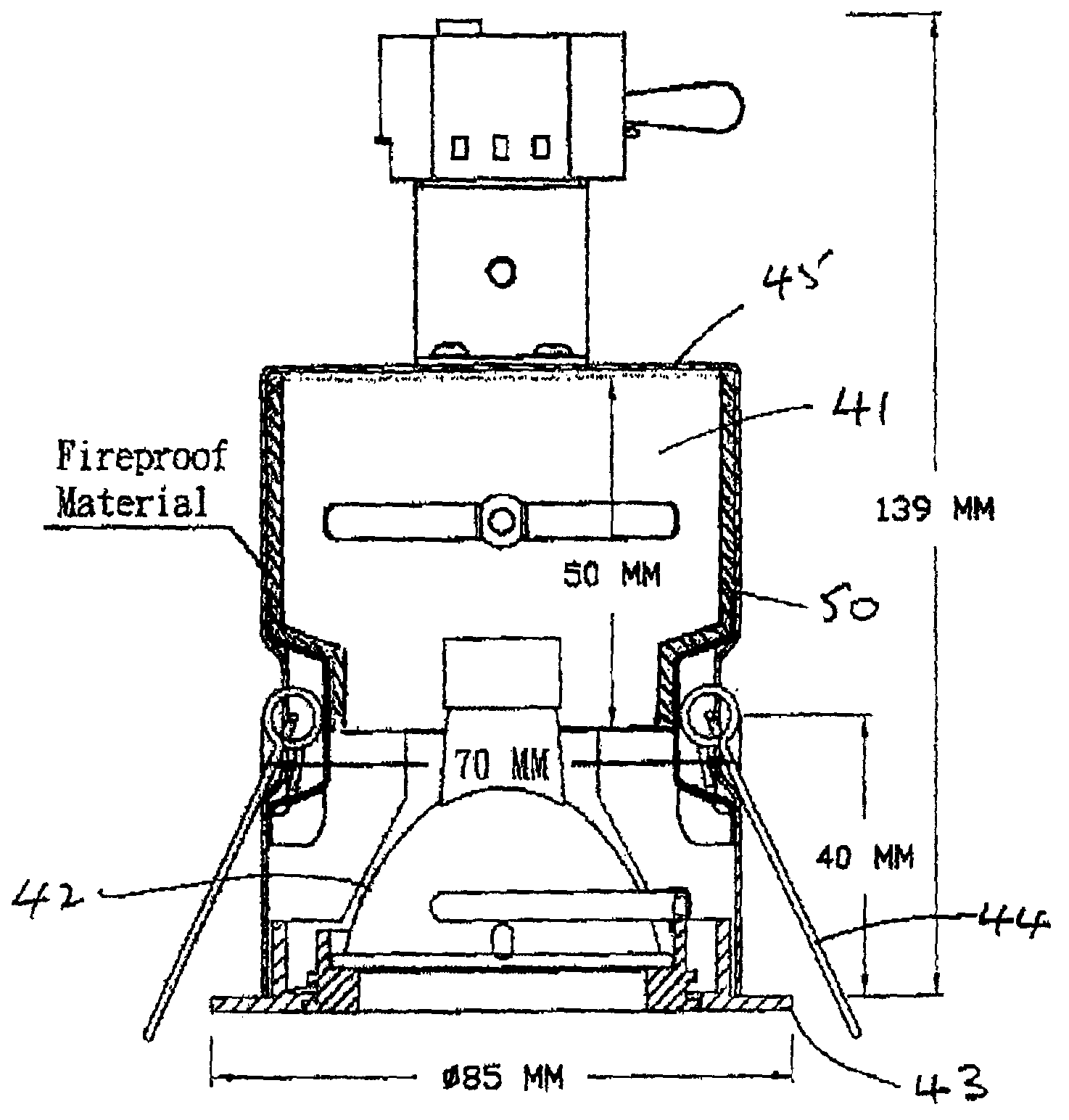

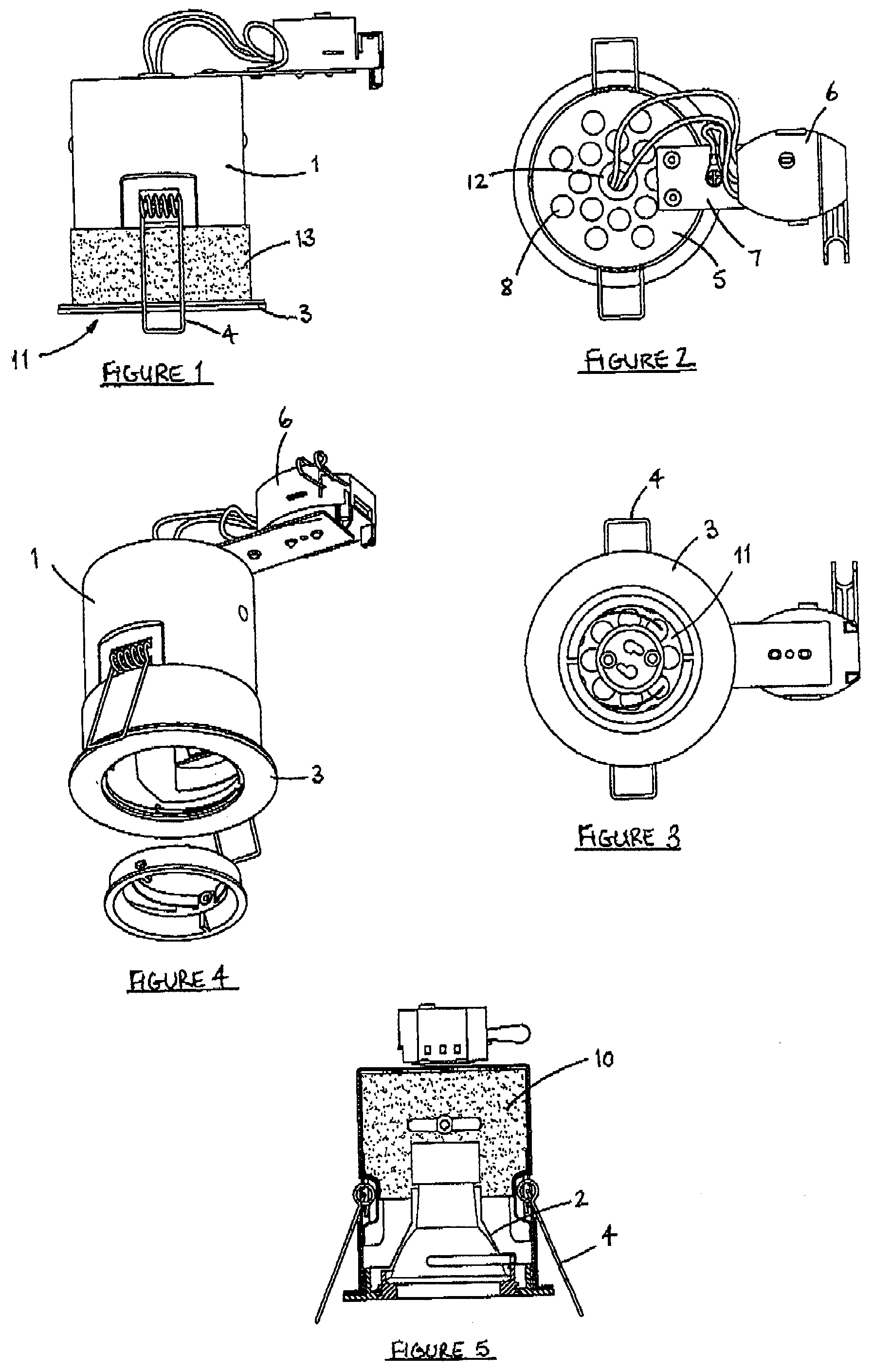

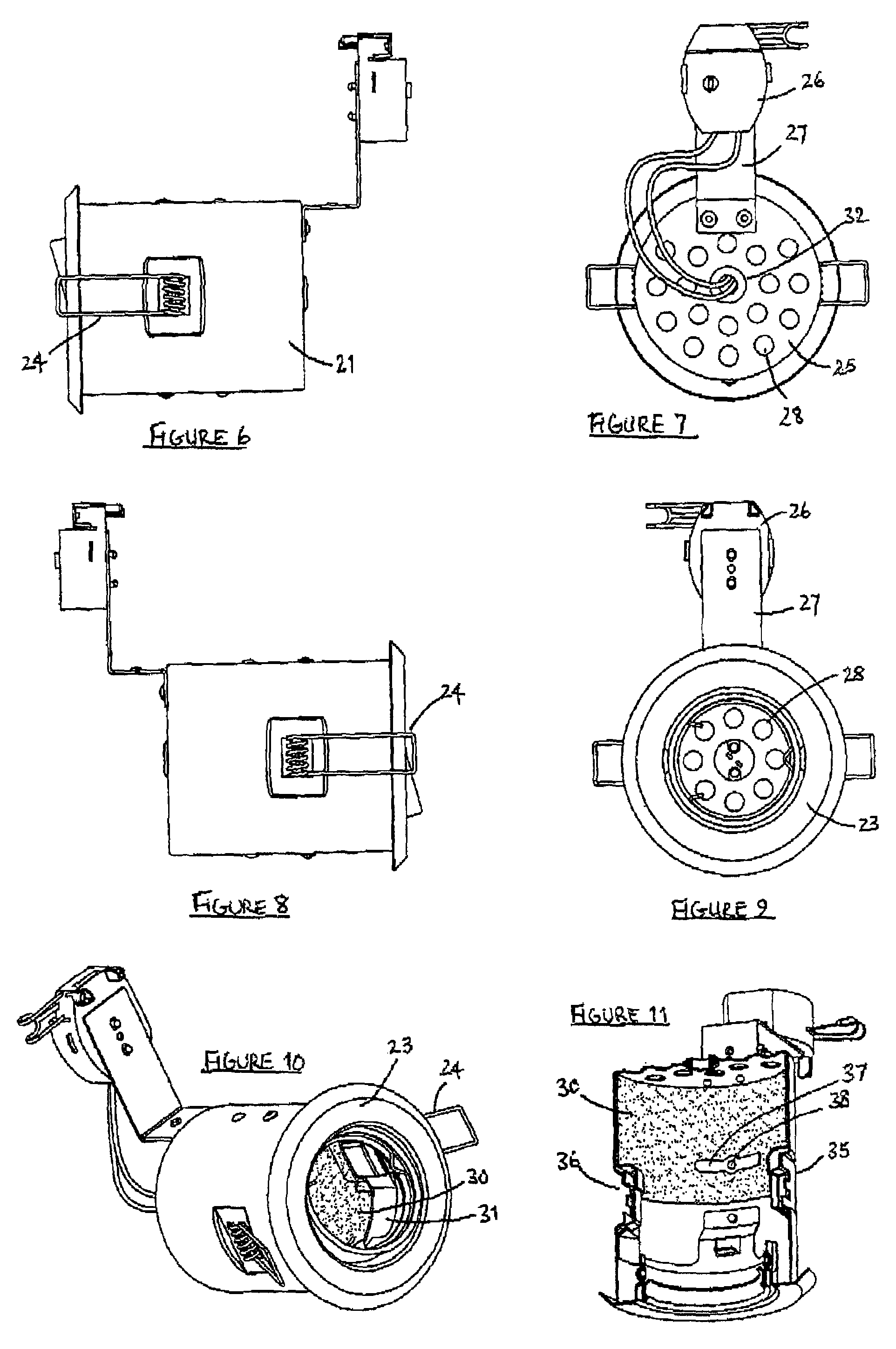

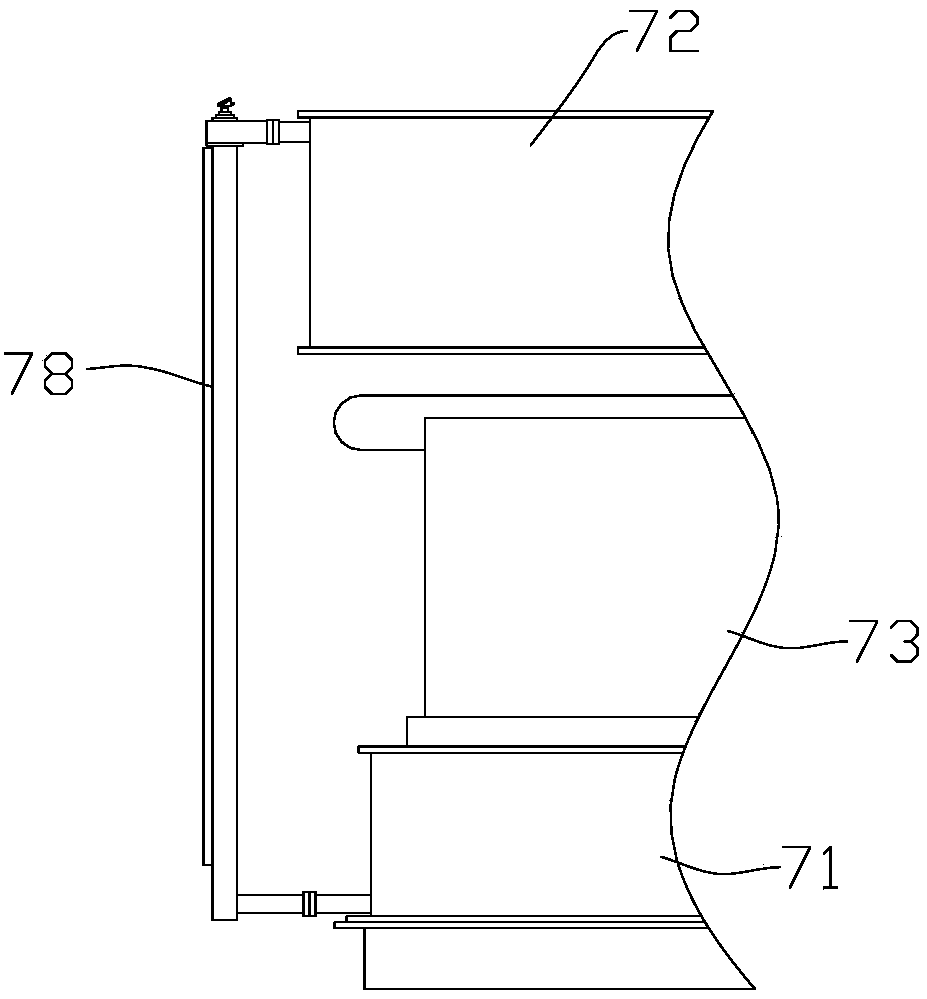

Improvements to fire rated downlights

ActiveUS20070109796A1Increase firing rateIncrease the gapLighting support devicesVehicle interior lightingBiomedical engineeringBody lines

A casing for a downlight having a tubular body from which the light of a lamp when installed in the body is emitted from the front of the body and having a rear end wall closing the body from the rear, wherein intumescent material is placed within the tubular body lining the tubular wall of the tubular body.

Owner:GIGAPHOTON

Fire rated downlights

ActiveUS7476010B2Increase firing rateIncrease the gapLighting support devicesLighting heating/cooling arrangementsEngineeringMechanical engineering

A casing for a downlight having a tubular body from which the light of a lamp when installed in the body is emitted from the front of the body and having a rear end wall closing the body from the rear, wherein intumescent material is placed within the tubular body lining the tubular wall of the tubular body.

Owner:GIGAPHOTON

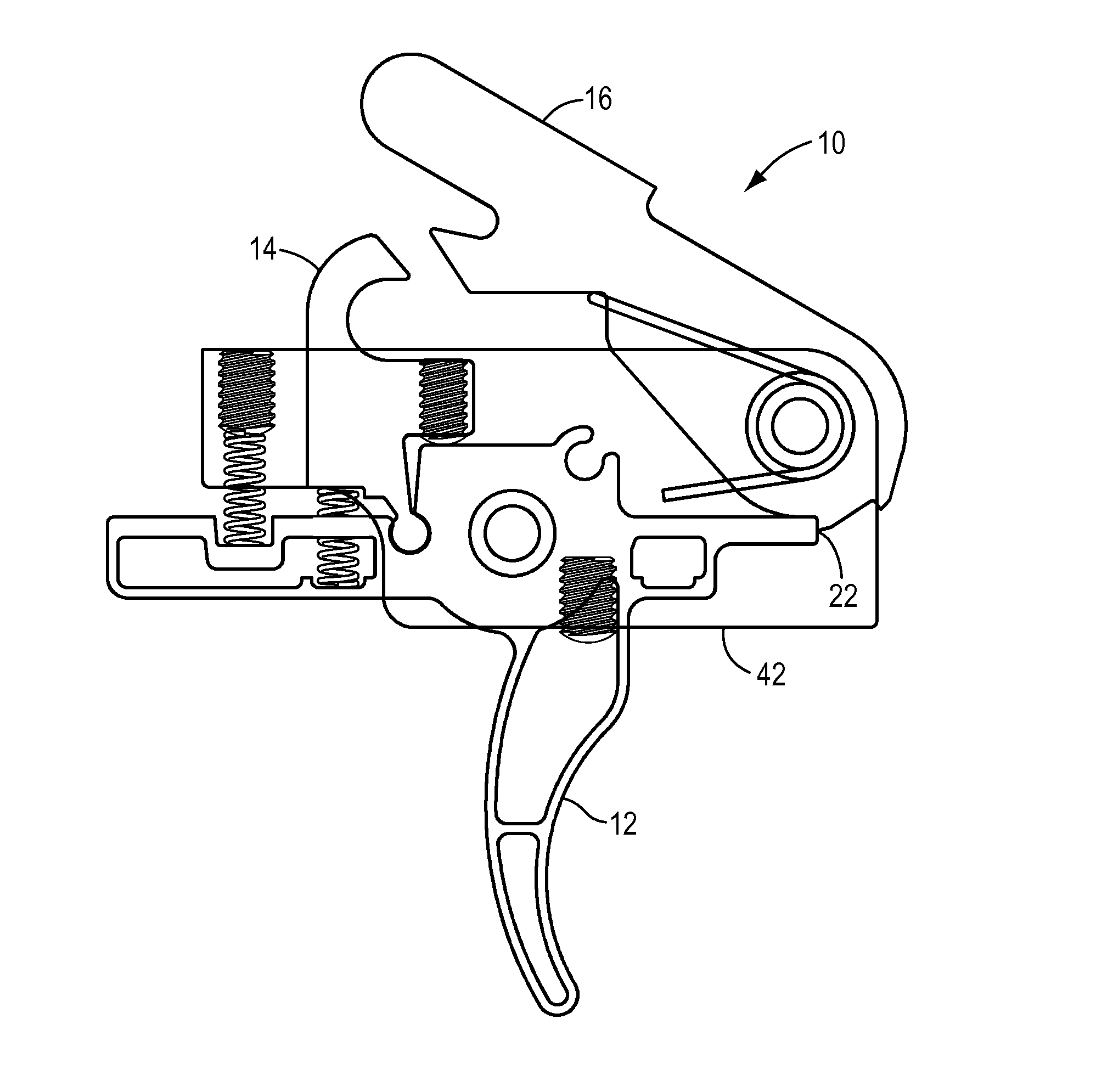

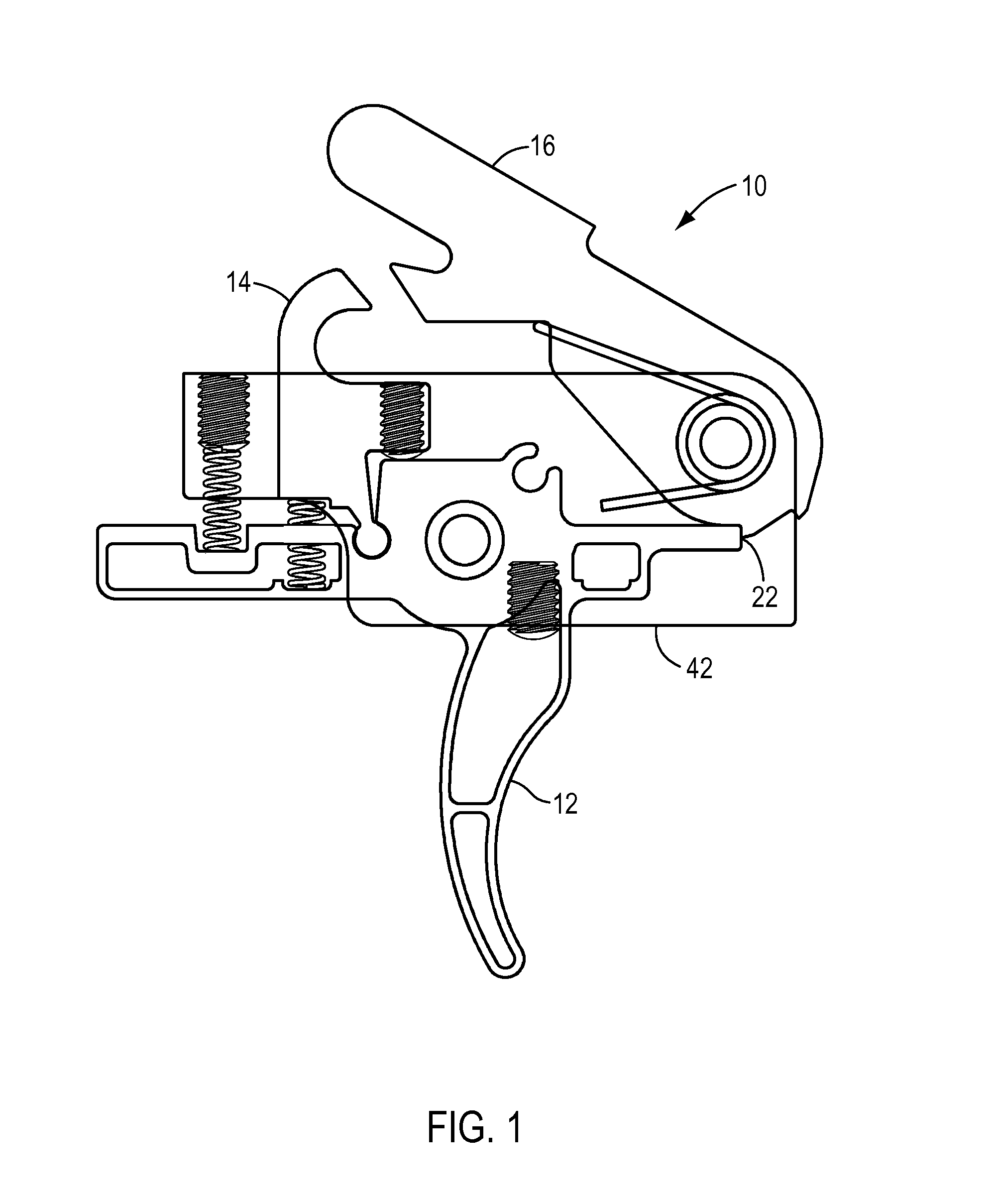

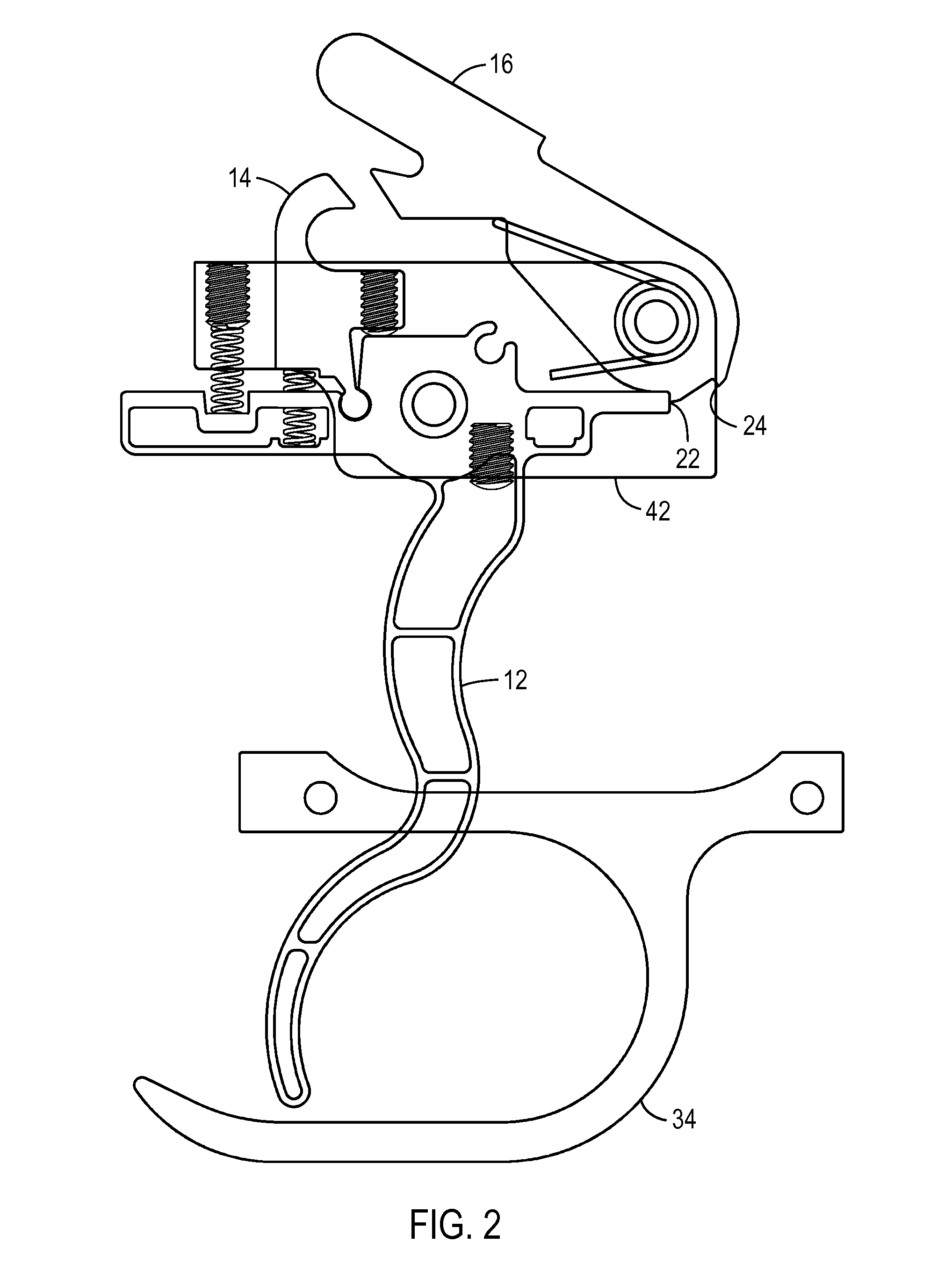

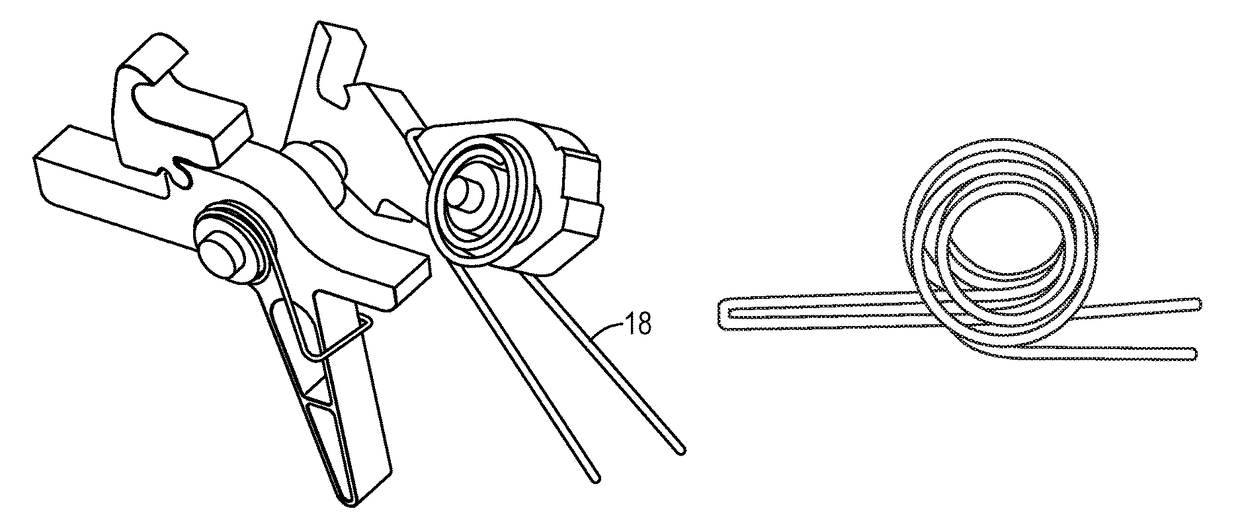

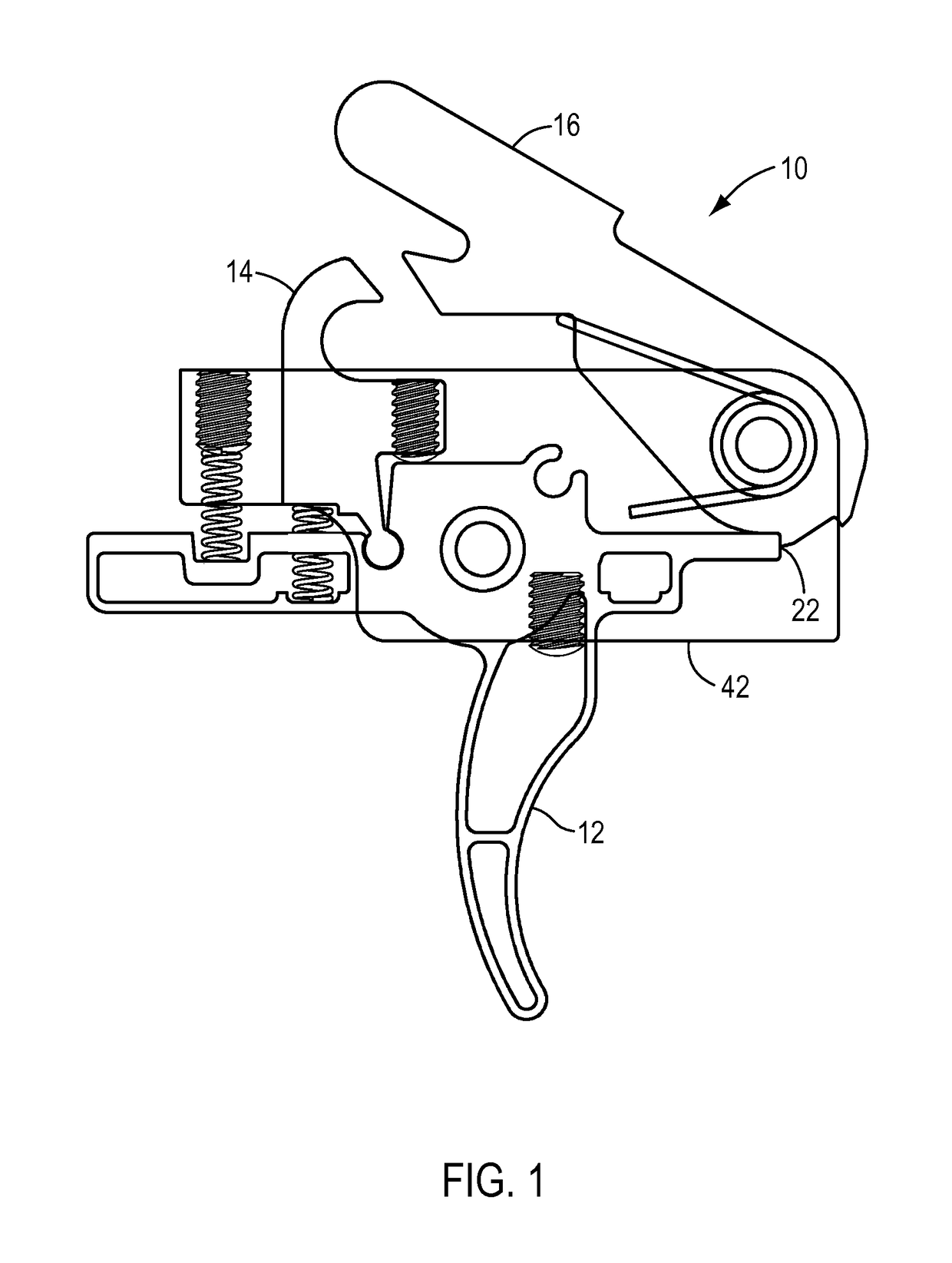

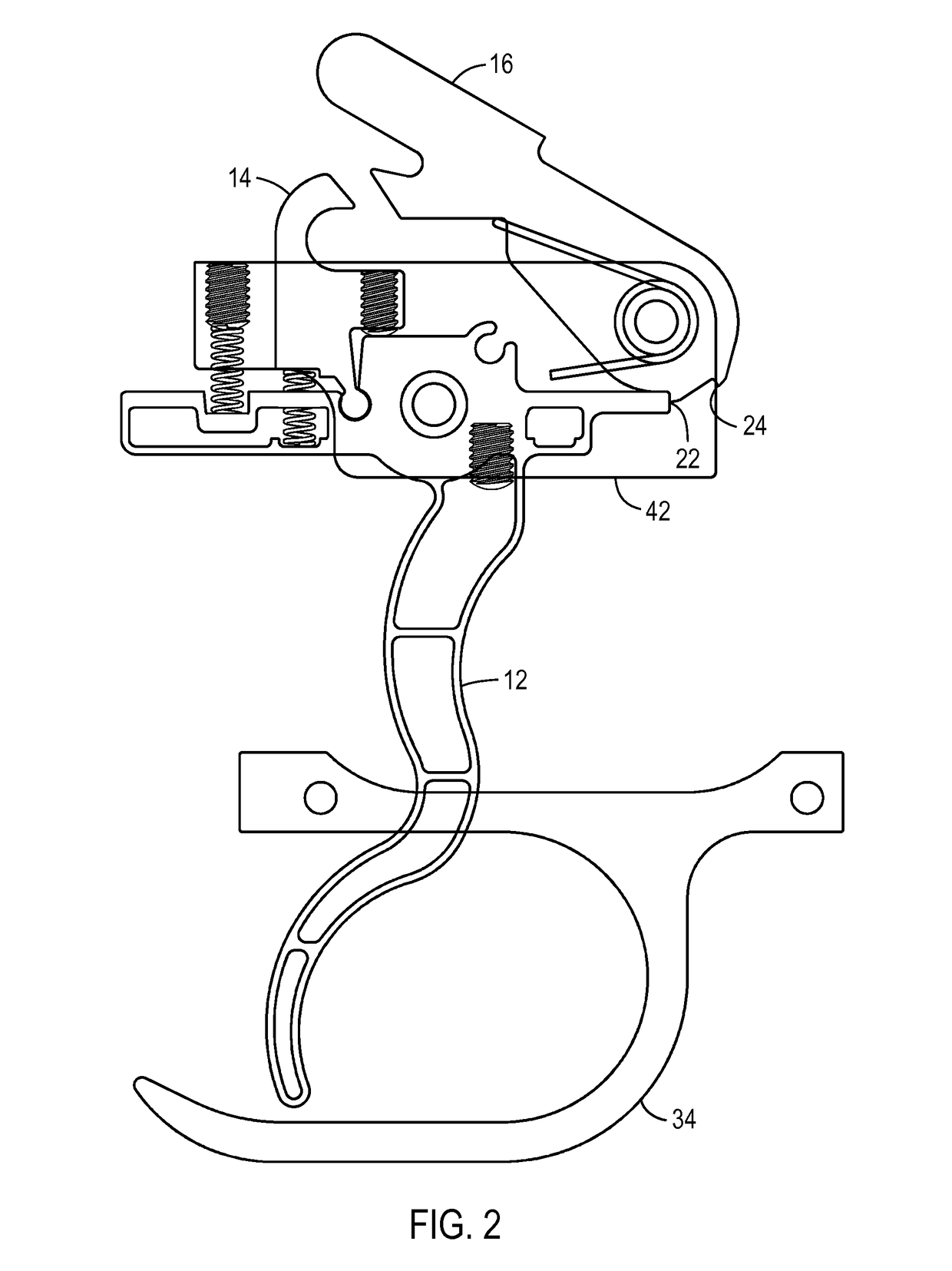

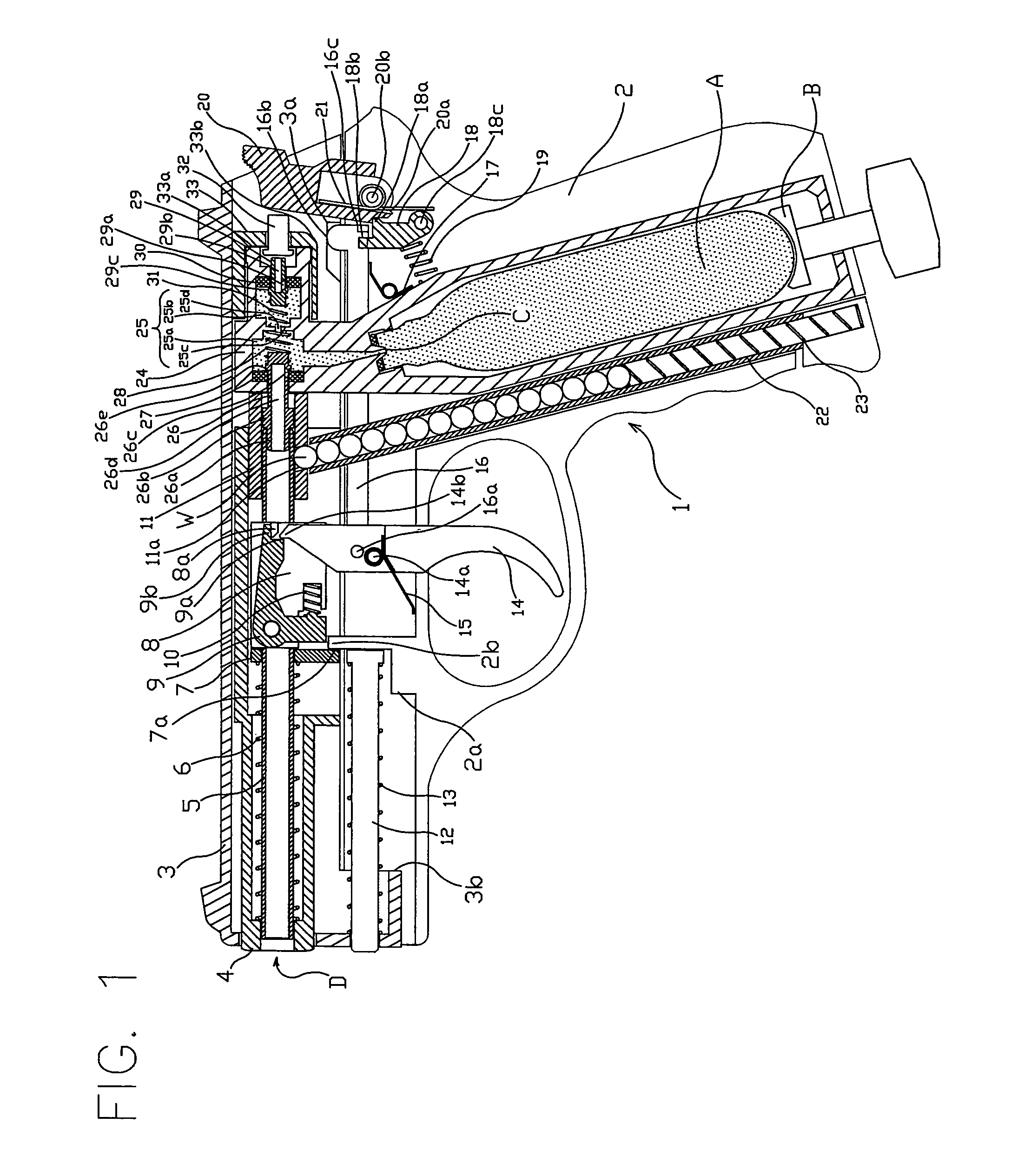

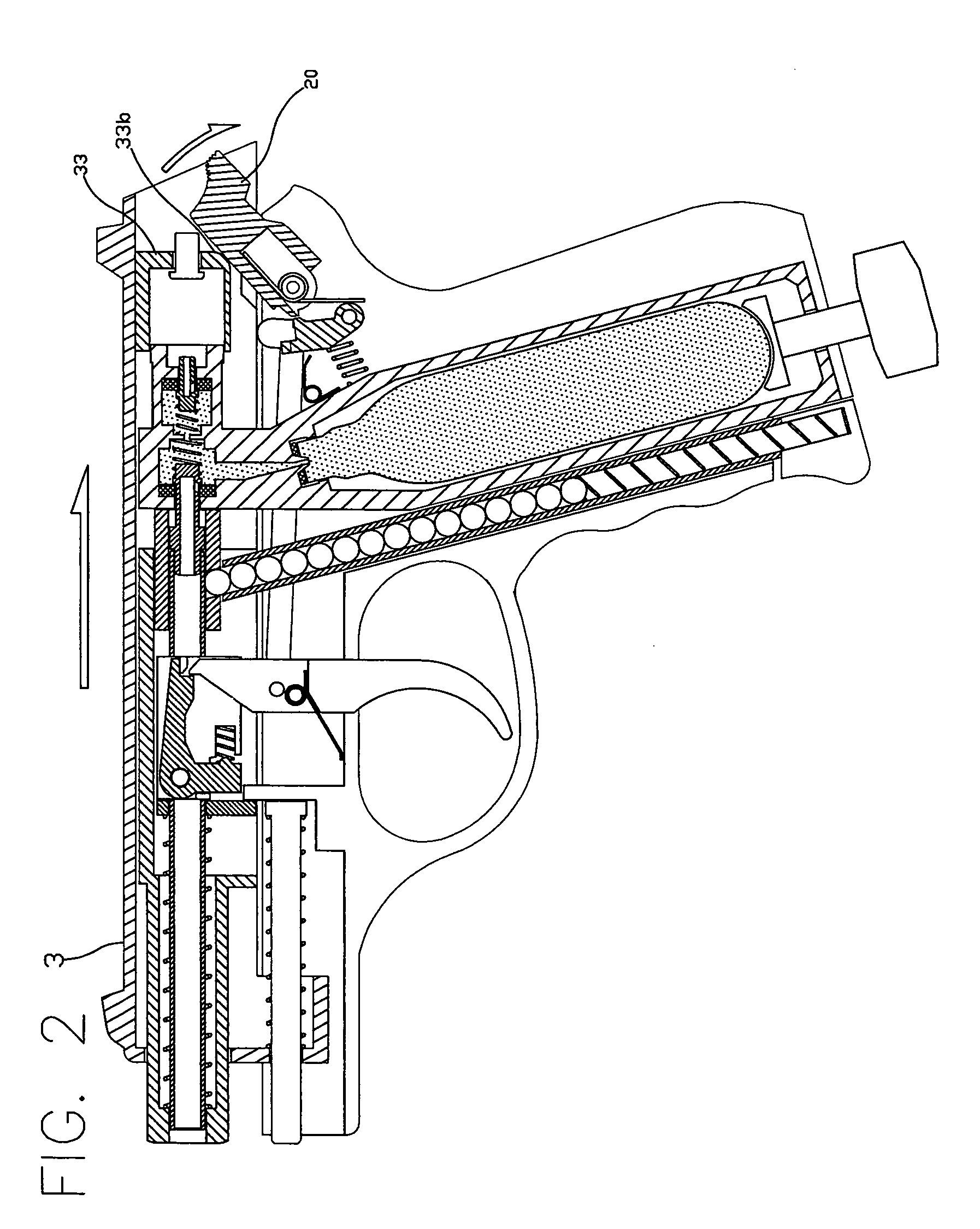

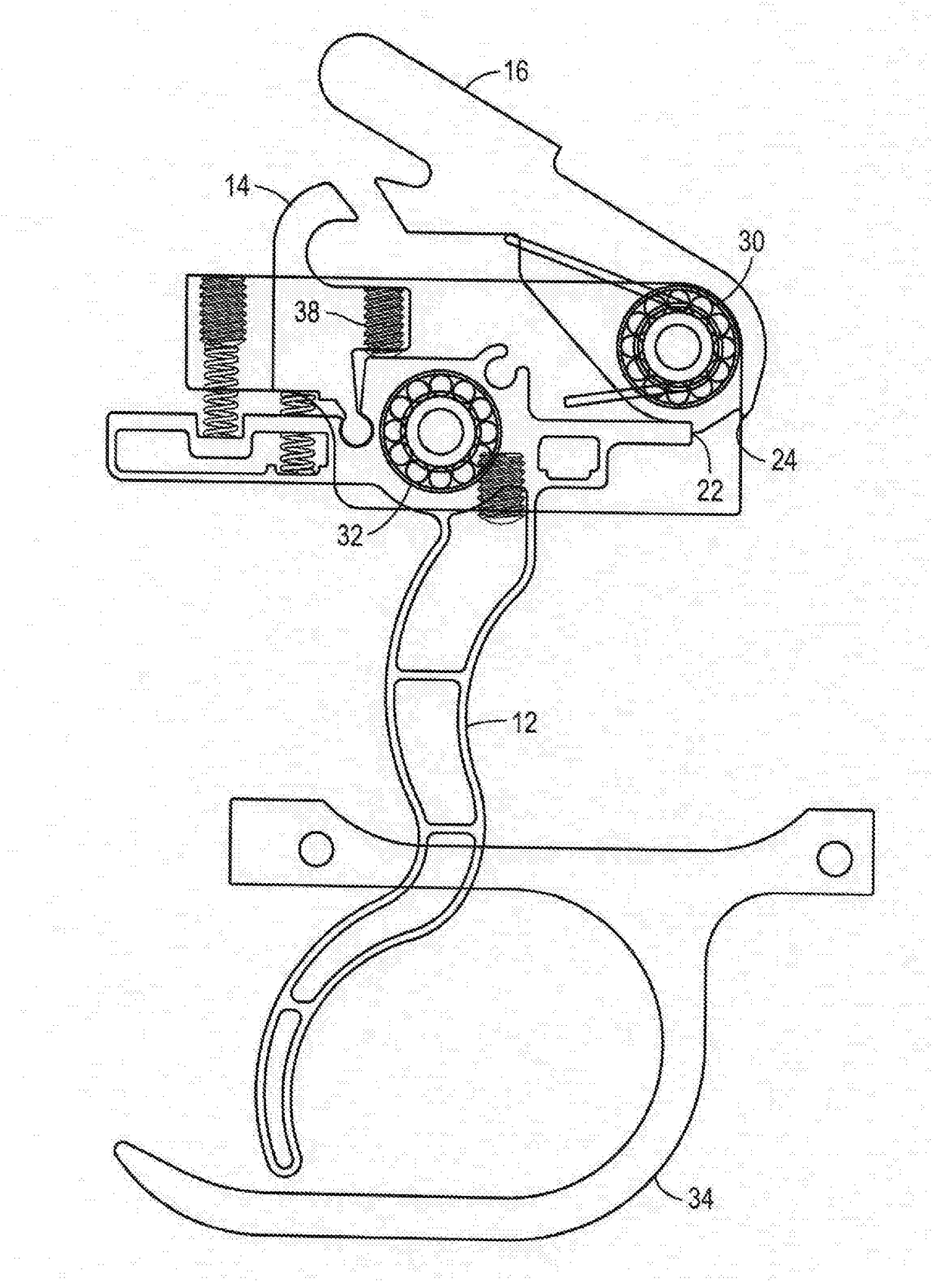

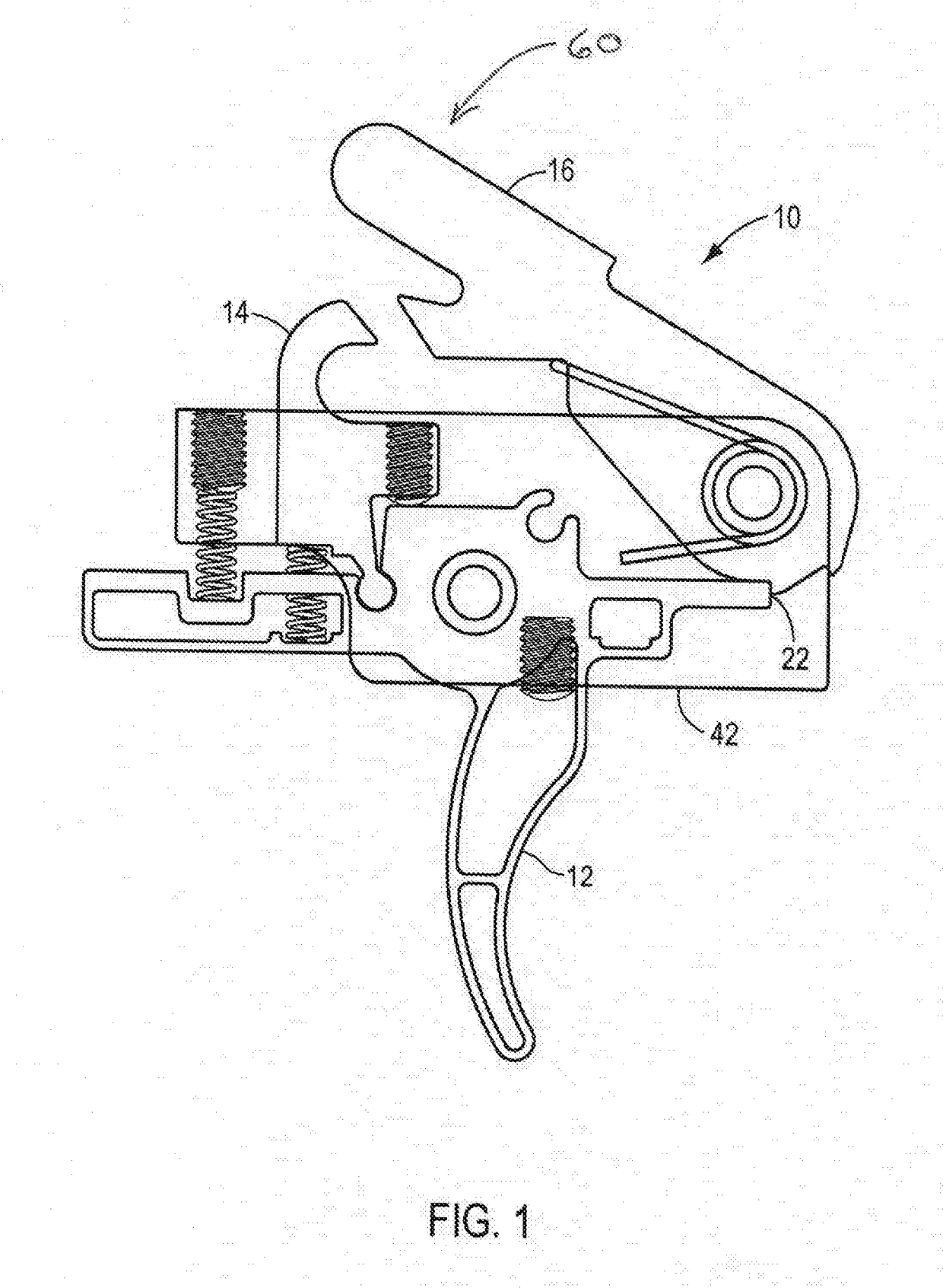

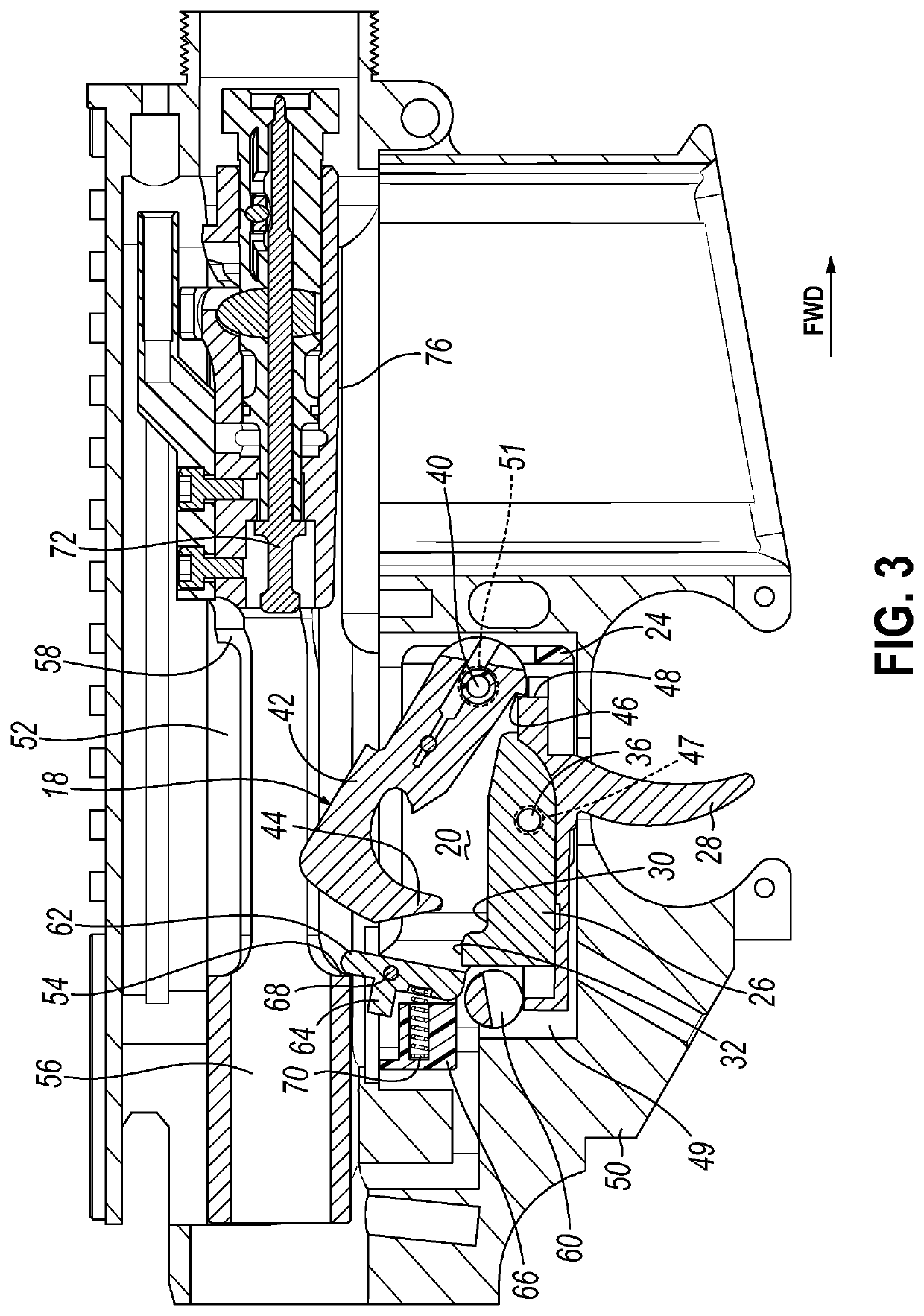

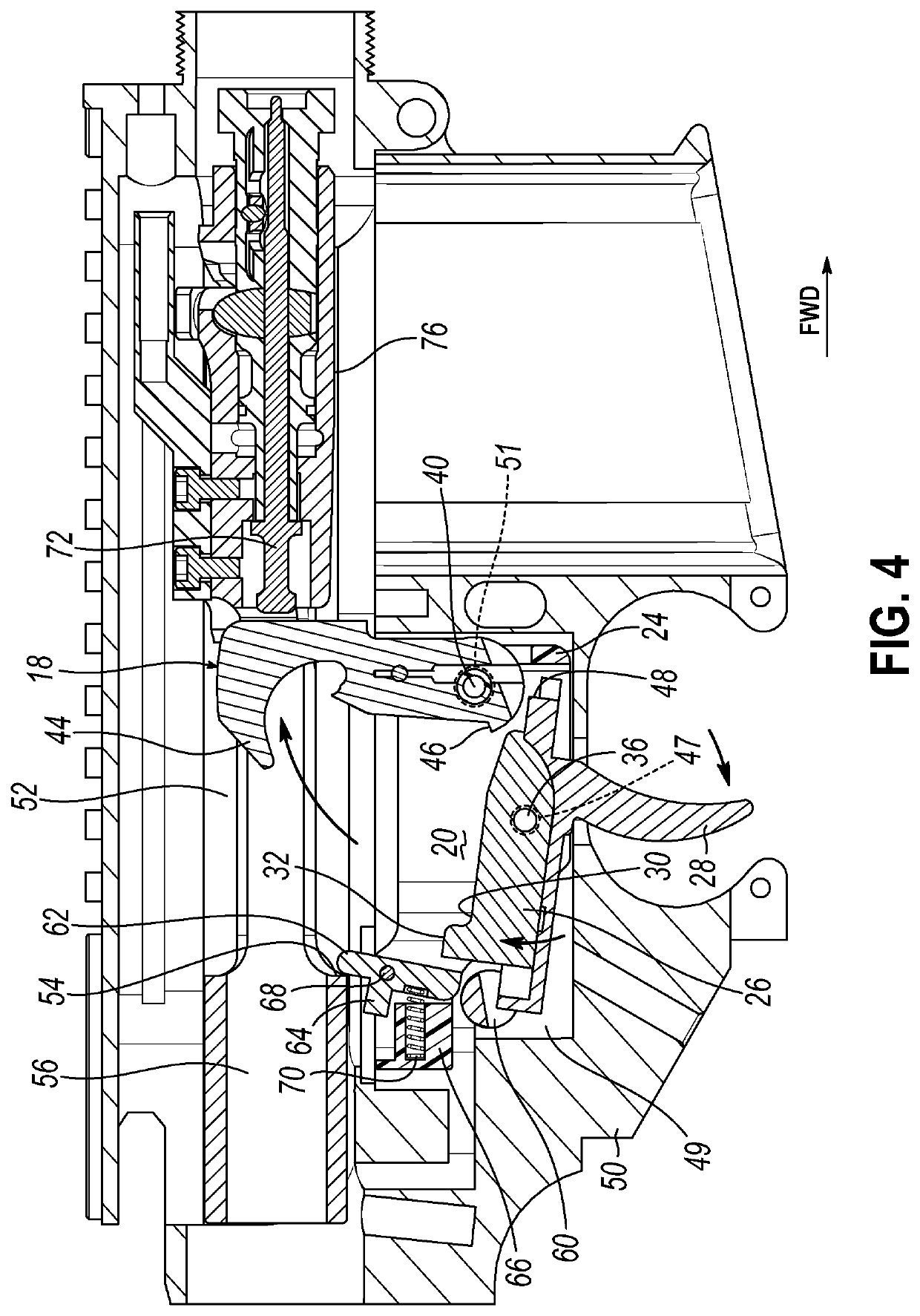

Drop In Trigger Assembly

ActiveUS20160363401A1Trigger pull effort rateDecreasing trigger weightFiring/trigger mechanismsEngineeringMechanical engineering

A modular trigger and hammer assembly having a hammer, a trigger, a disconnector and a hammer spring for use in a weapon including at least a lob including a firing notch, a safety notch; and a curved landing flat. Also including a trigger needle bearing and a hammer needle bearing.

Owner:ART IDEAS LLC

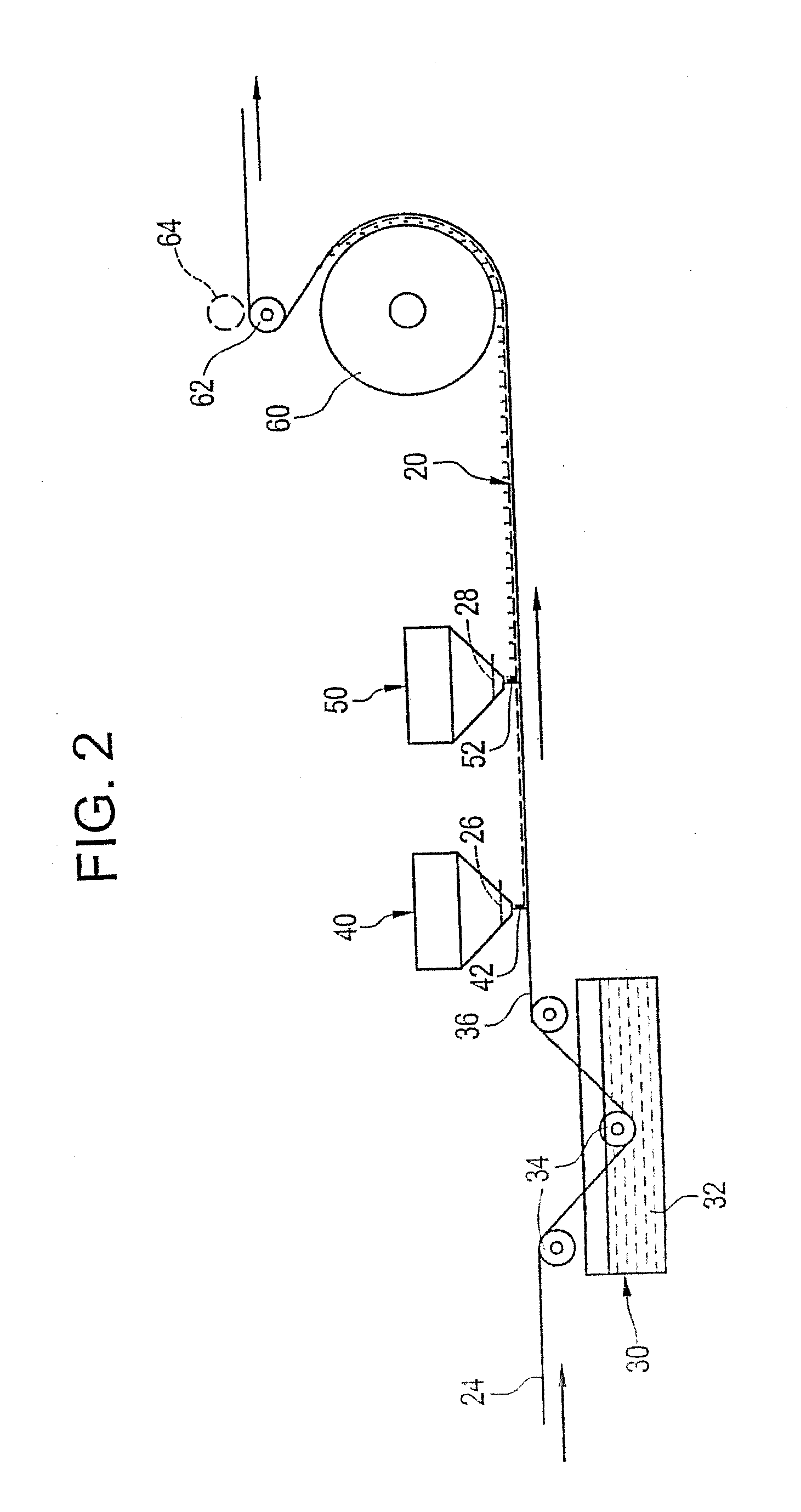

Method of forming a prefabricated roofing or siding material

ActiveUS7291358B1Increase temperatureProlong lifeRoof covering using flexible materialsLaminationReflectivityCivil engineering

A roofing or siding system having an improved average resulting reflectivity. The roofing and / or siding system is at least partially coated with a plurality of granules. At least one layer of paint is applied to the roofing and / or siding system to increase the resulting reflectivity of the roofing and / or siding system.

Owner:GARLAND INDS

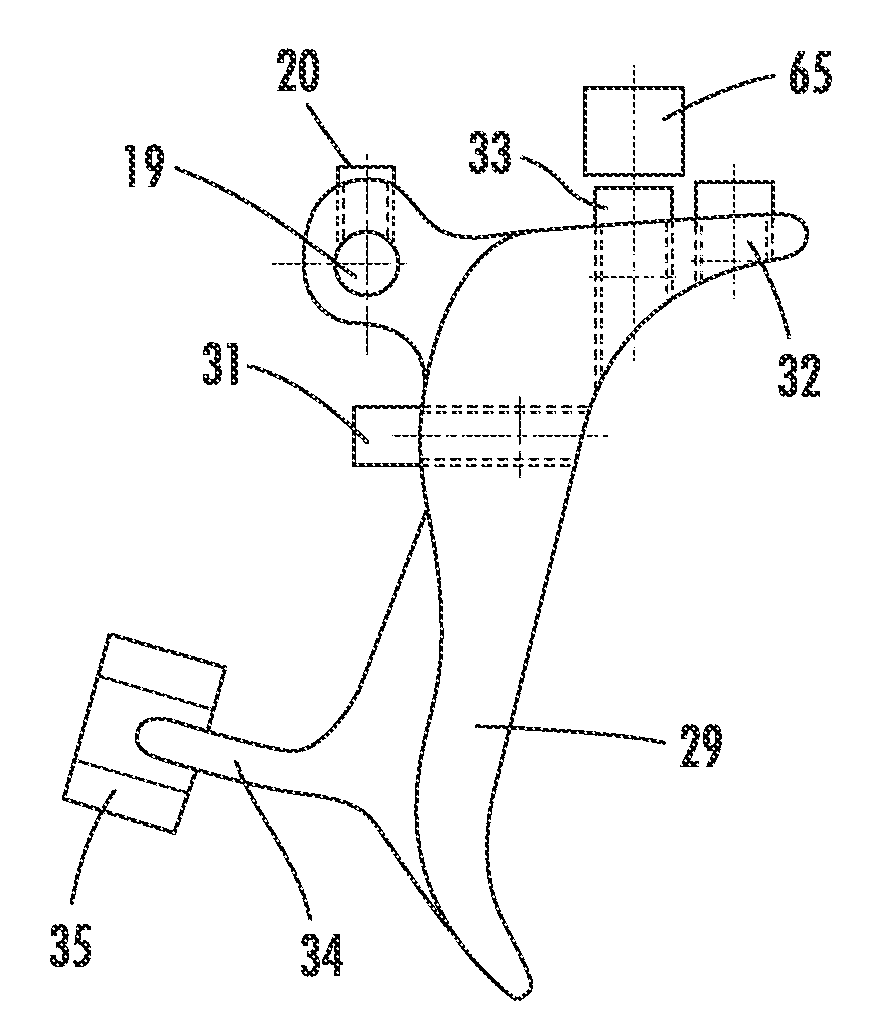

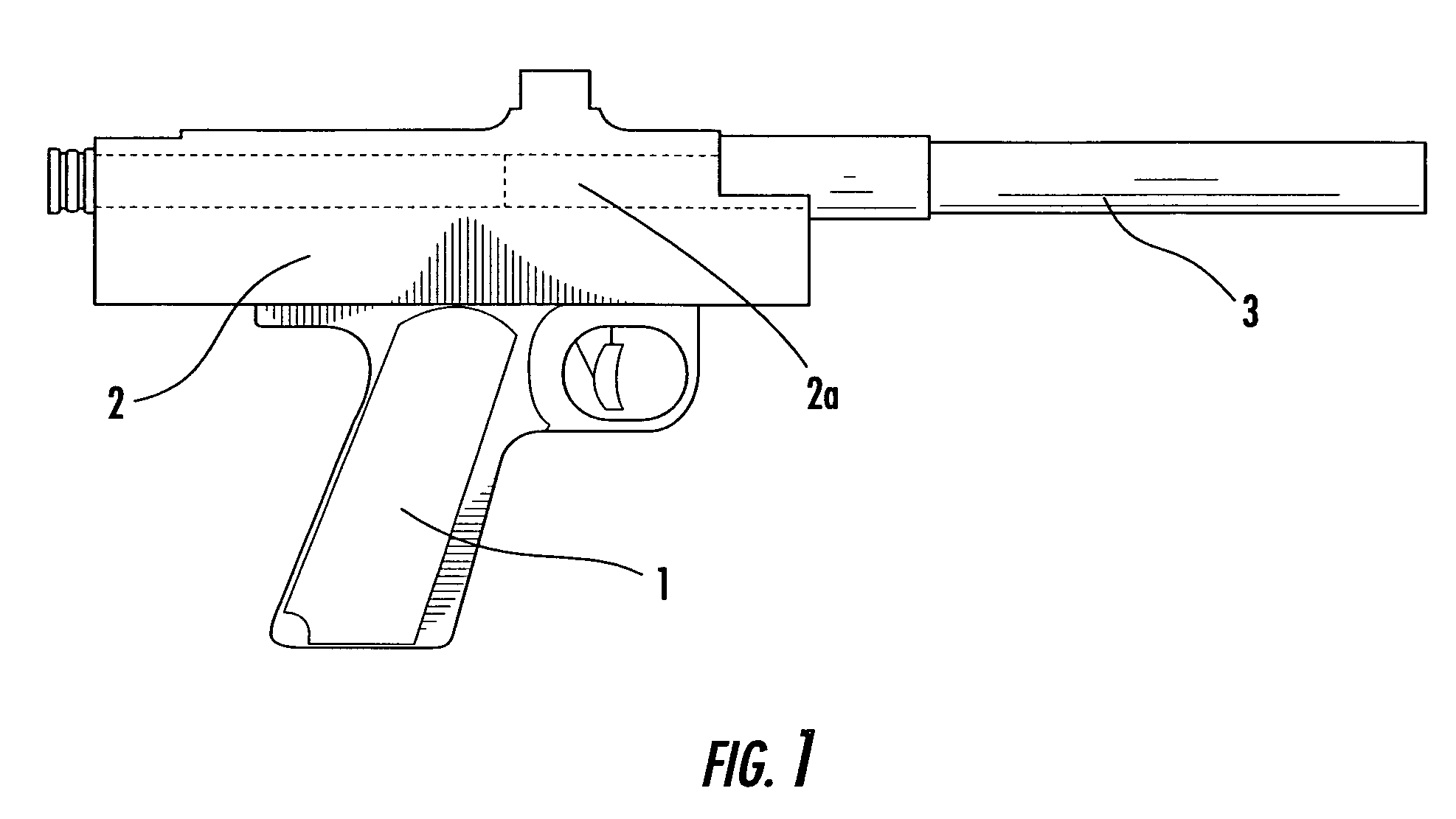

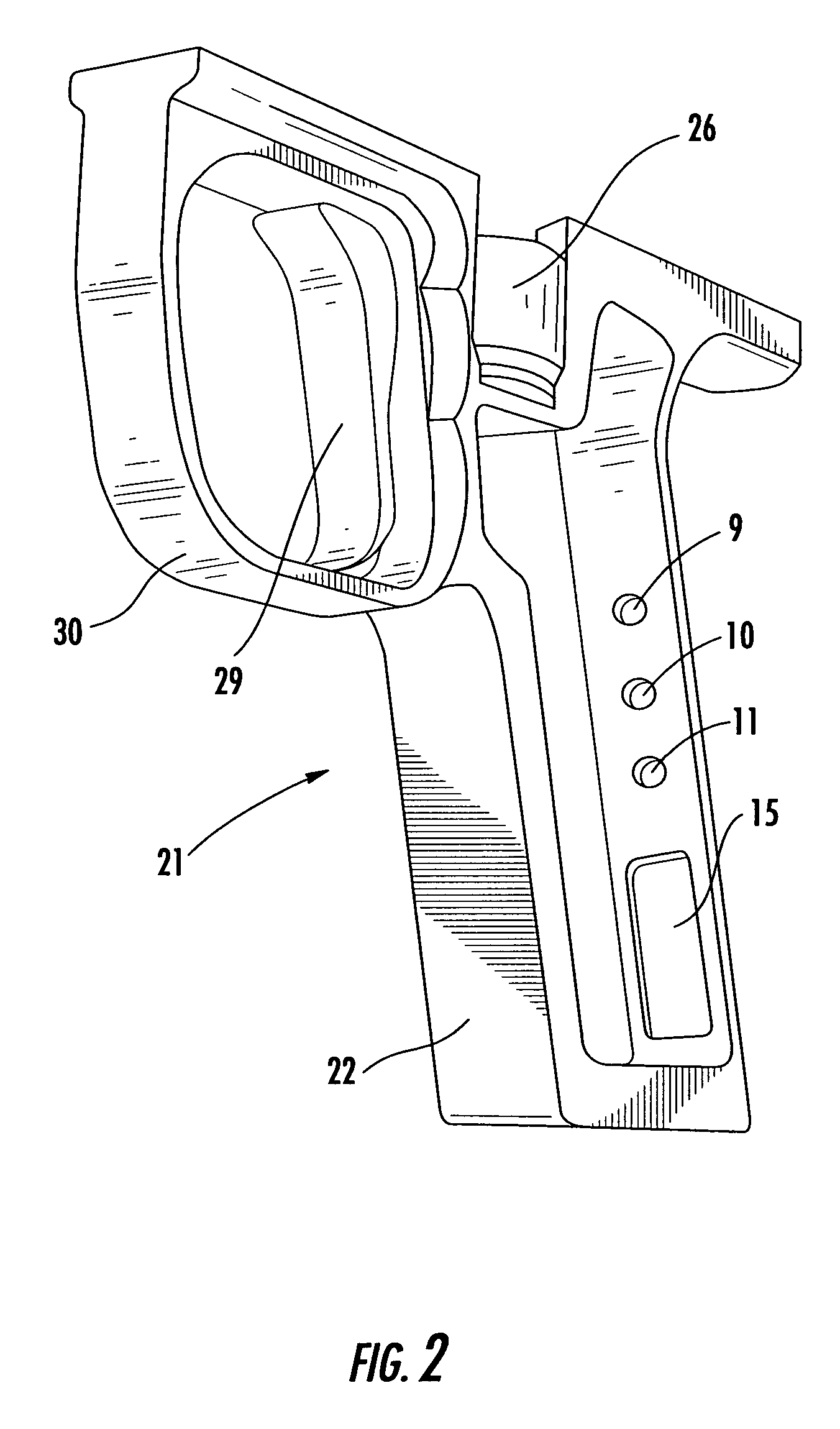

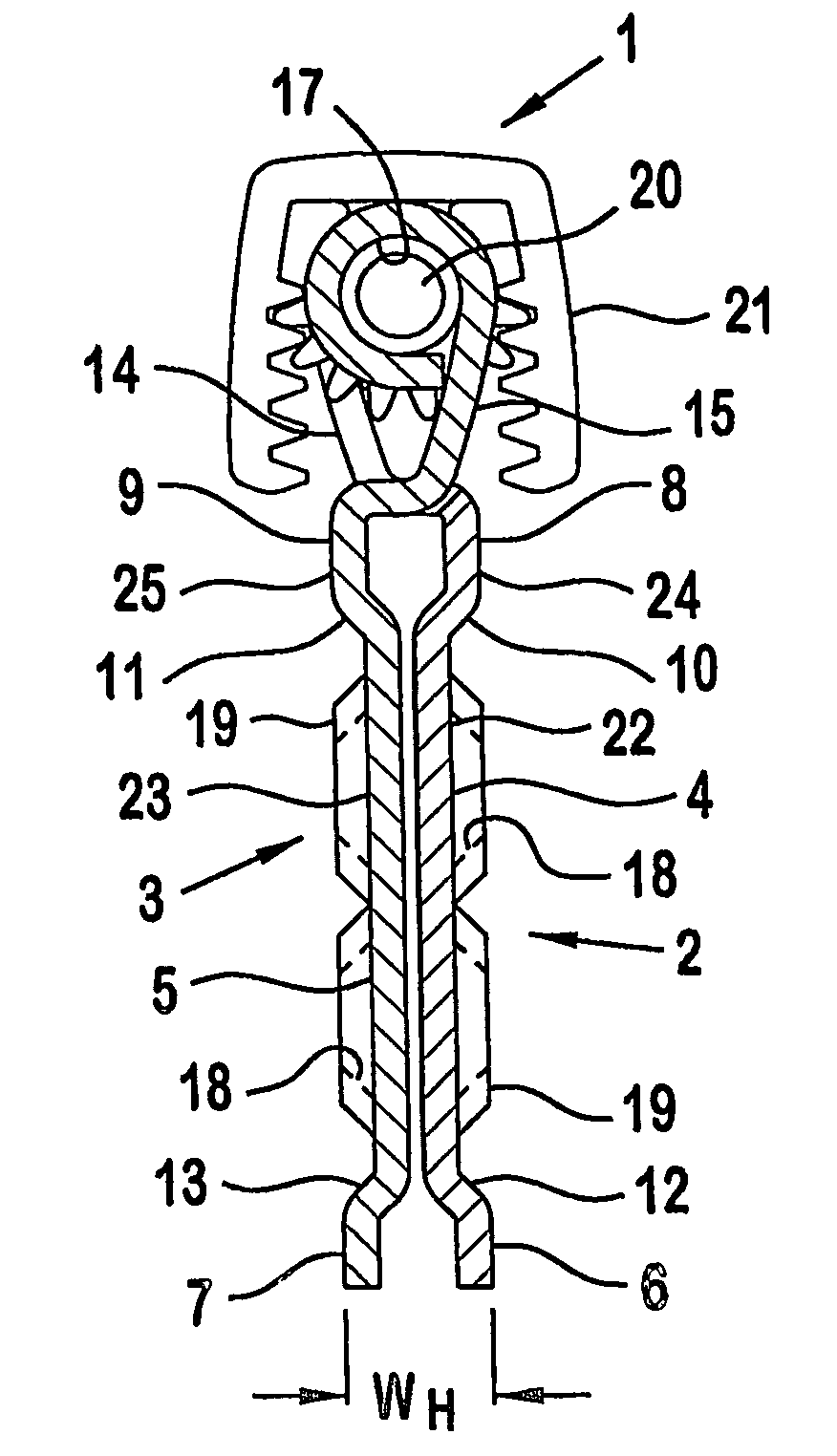

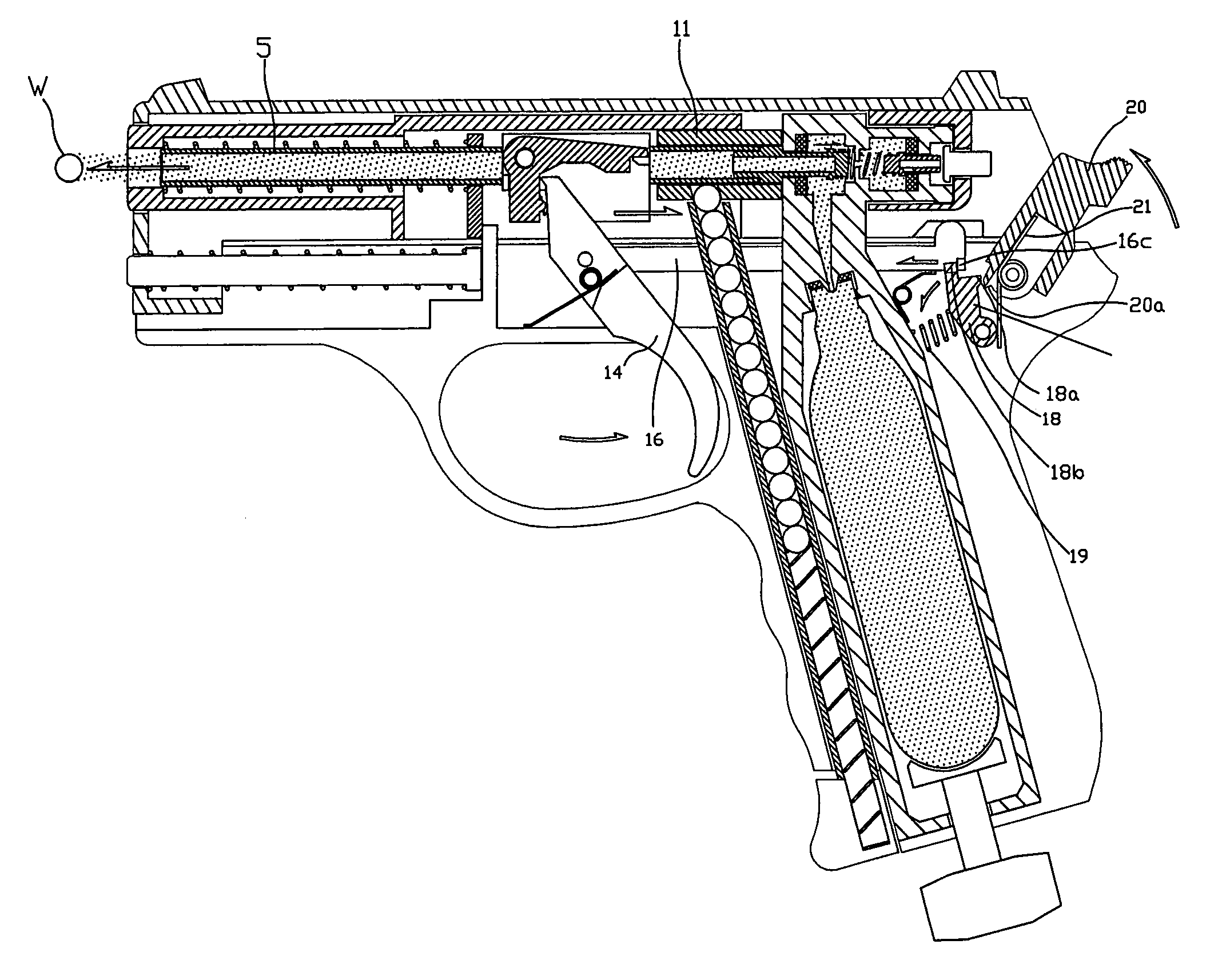

Method of firing a paintball marker

InactiveUS7073284B2High fire ratingIncrease firing rateFiring/trigger mechanismsCompressed gas gunsDisplay deviceEngineering

The method of firing a paintball marker uses a grip frame 21 replaces an existing grip frame 1 on a paintball marker in order to convert said paintball marker from a mechanically operated paintball marker into an electro-pneumatic paintball marker. The electronic grip frame 21 utilises an optical sensor in order to detect the operation of a trigger 29 and a second optical sensor to detect the presence of objects within the breech of the paintball marker. Electrical signals from these sensors are taken to an electronic circuit board 24, which controls the operation of two solenoids (one shown 26) in order to fire and re-cock the paintball marker. A user interface comprising pushbuttons 12, 13, 14 and a multi-character display 16, allows the user to define how the grip frame 21 functions.

Owner:PLANET ECLIPSE

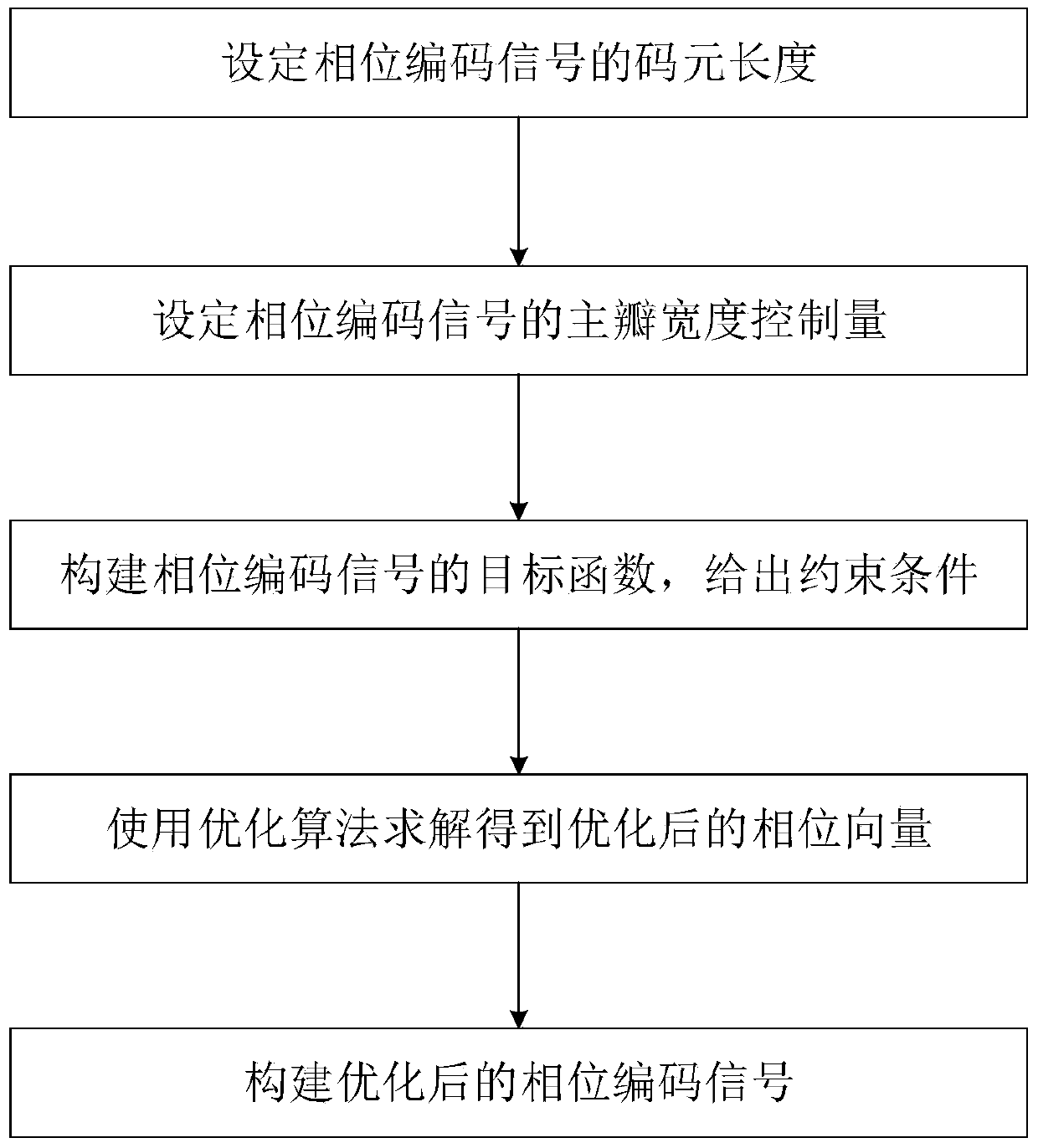

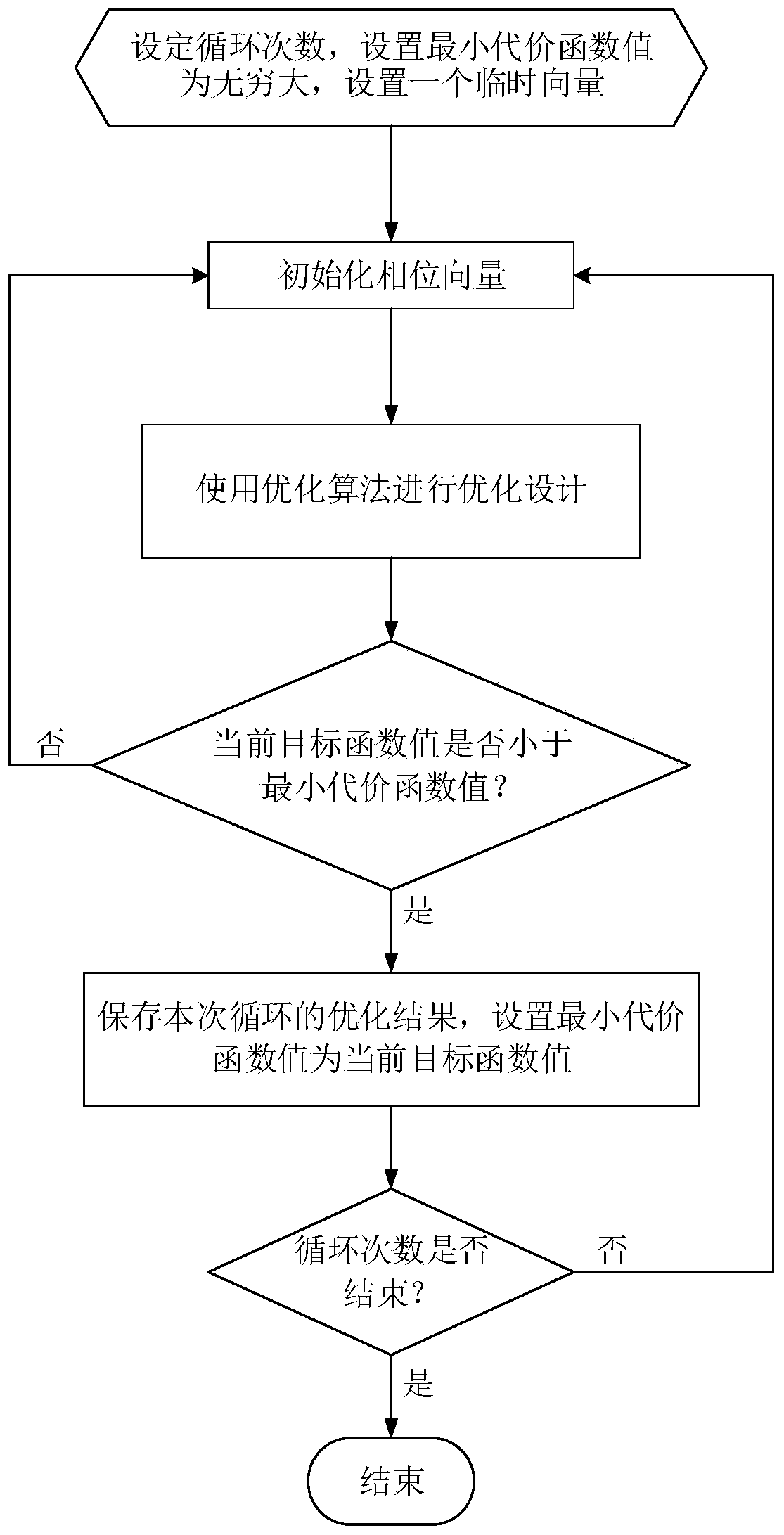

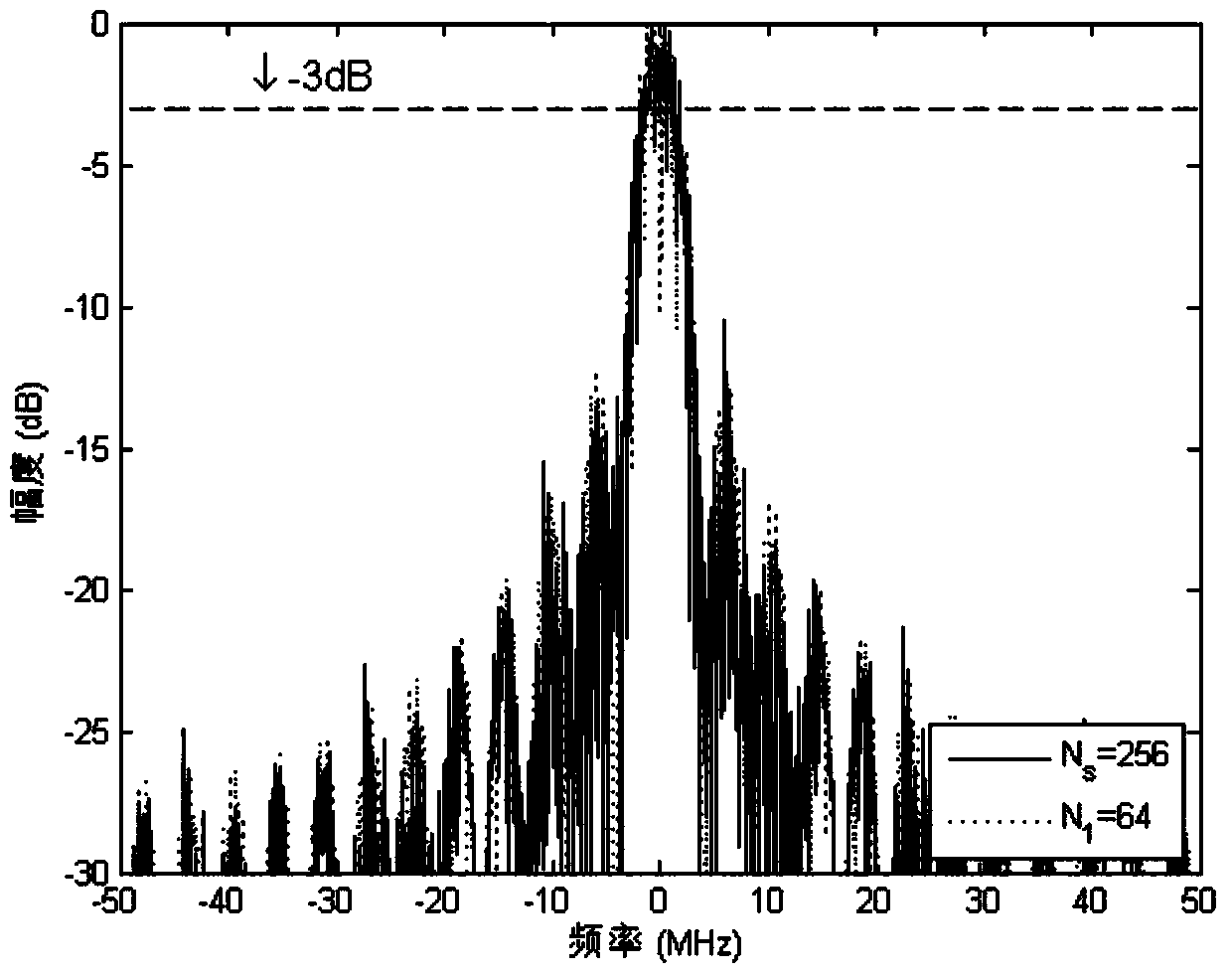

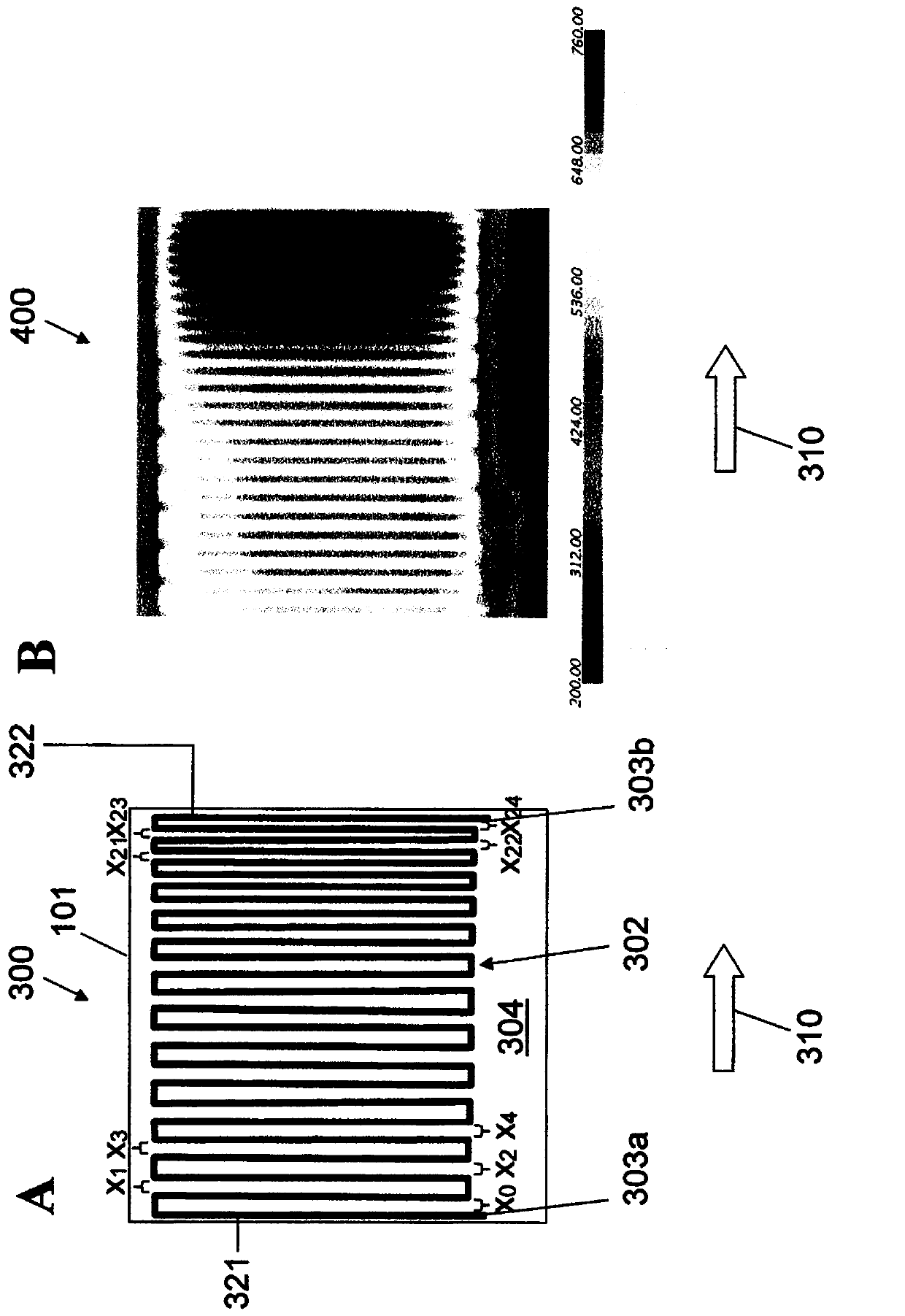

High bit rate and low range resolution of low sidelobe phase coded signal design method

ActiveCN104198996AIncrease firing rateIncrease code lengthRadio wave reradiation/reflectionImage resolutionPhase Code

The invention discloses a high bit rate and low range resolution of low sidelobe phase coded signal design method which mainly aims at solving the problems that the range sidelobe of a phase coded signal cannot be further reduced by the existing method and the existing phase coded signal is easy to identify. The implementation process of the high bit rate and low range resolution of low sidelobe phase coded signal design method comprises step 1, setting the code element length of a phase coded signal; step 2, setting a value of the main lobe width control quantity of the phase coded signal; step 3, building an objective function of the phase coded signal according to the code element length and the main lobe width control quantity of the phase coded signal; step 4, building constraint conditions of the phase coded signal; step 5, solving the objective function by an optimization algorithm under the constraint conditions to obtain an optimized phase coded signal. According to the high bit rate and low range resolution of low sidelobe phase coded signal design method, the range sidelobe of the phase coded signal can be further reduced, the identified difficulty of the phase coded signal can be increased, and the high bit rate and low range resolution of low sidelobe phase coded signal design method can be applied to the design of the phase coded signal.

Owner:XIDIAN UNIV

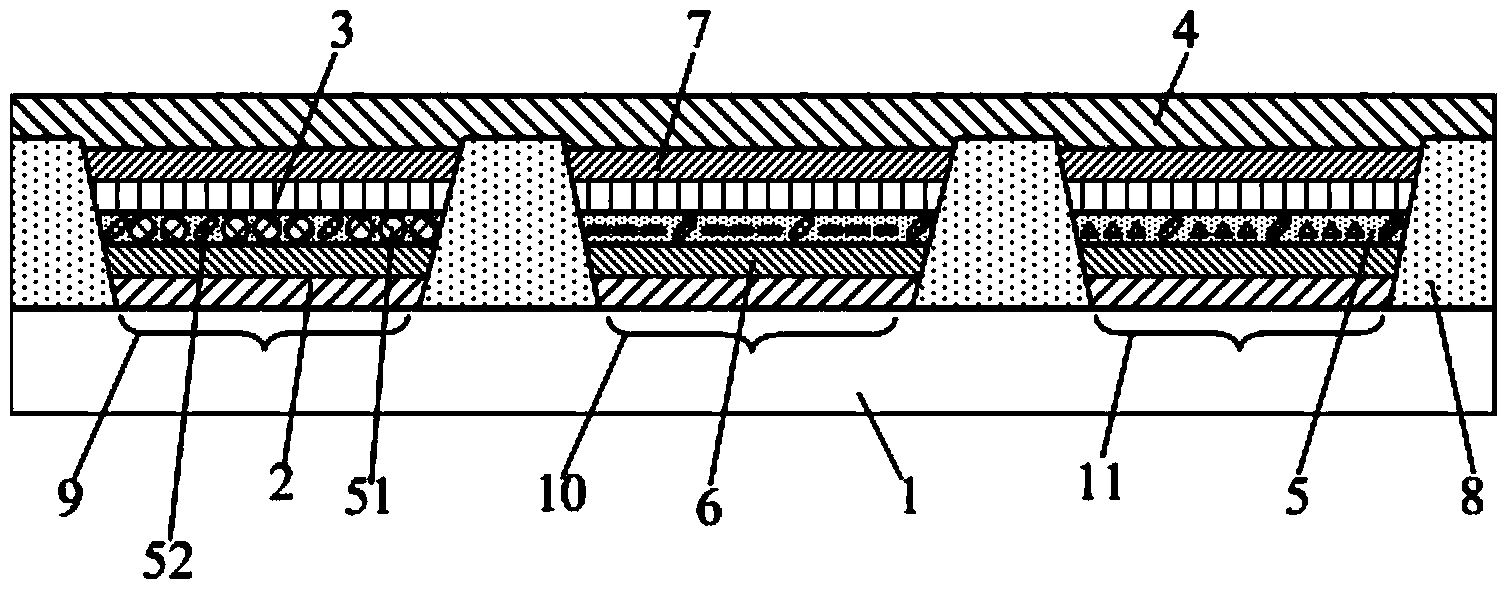

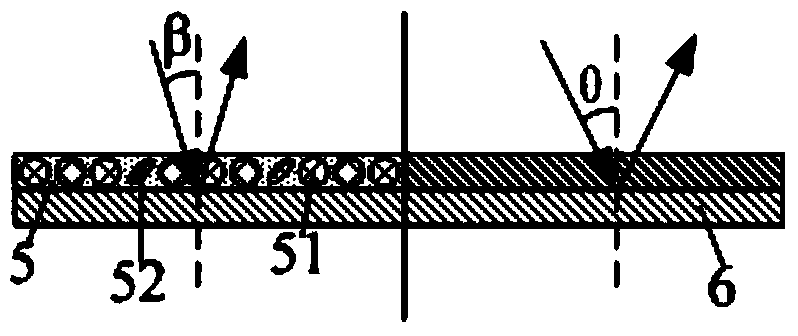

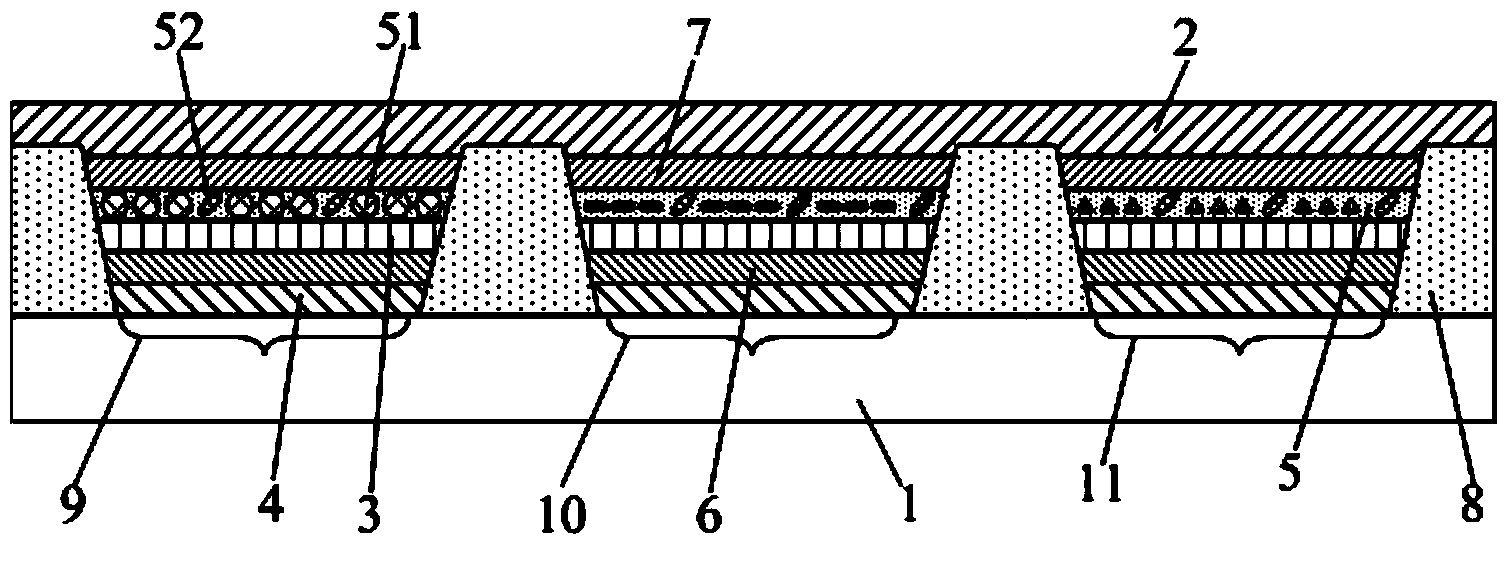

Organic electroluminescent device and display device

ActiveCN103872261AImprove external quantum efficiencyImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescencePhysics

The invention provides an organic electroluminescent device and a display device. The organic electroluminescent device comprises a substrate, an opaque electrode, a luminescent layer and a transparent electrode, wherein the opaque electrode, the luminescent layer and the transparent electrode are arranged above the substrate, the luminescent layer is arranged between the opaque electrode and the transparent electrode, a diffusion layer is also arranged between the luminescent layer and the opaque electrode, and the light, facing one side of the diffusion layer, emitted from the luminescent layer can be fully reflected by the diffusion layer. The organic electroluminescent device has the advantage that by arranging the diffusion layer between the luminescent layer and the opaque electrode, the external quatum efficiency is improved, and the internal quatum efficiency is also improved, so the efficiency is improved. The display device of the organic electroluminescent device can improve the efficiency and display effect.

Owner:BOE TECH GRP CO LTD

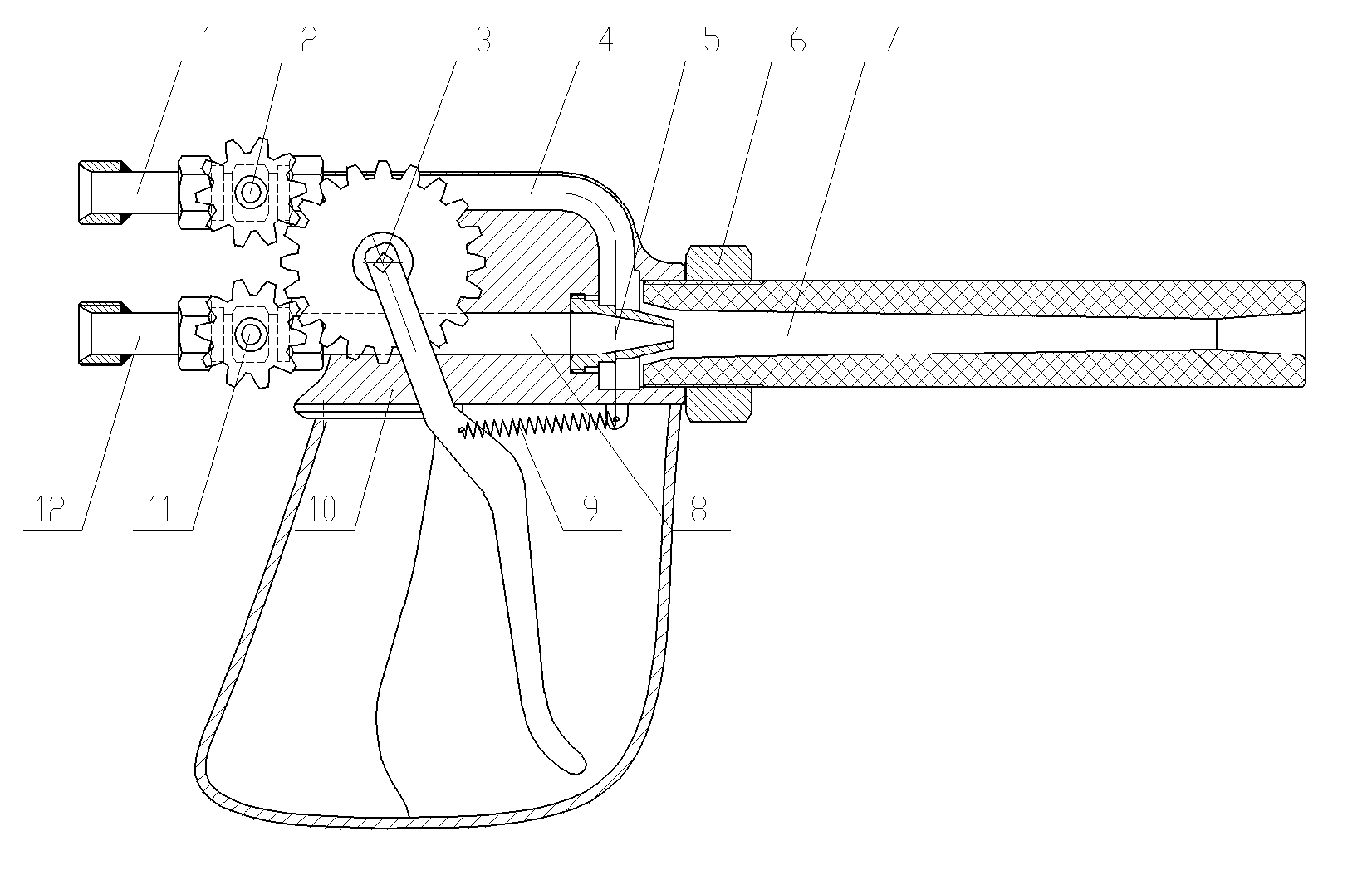

Compressed air foam extinguishing agent spraying gun and method thereof

The invention discloses a compressed air foam extinguishing agent spraying gun and a method thereof. Foam extinguishing agent liquid is sprayed out of an annular spraying channel which is positioned at an inlet of an extinguishing agent spraying gun pipe and is tightly attached to the wall surface to form a flowing liquid film attached to the wall; under impact and cutting of high-speed air flow injected by a convergence-shaped nozzle in the center of the inlet of the extinguishing agent spraying gun pipe, the liquid film is damaged; under the action of surface tension, the liquid film is contracted and wraps compressed air for cutting the liquid film, so that a plurality of air foam balls are generated, and foam extinguishing agent liquid becomes high-speed flowing compressed air foams; and the compressed air foams are accelerated in a 'laval nozzle' type gun pipe and then sprayed at high speed. By the compressed air foam extinguishing agent spraying gun and the method thereof, the compressed air and the foam extinguishing agent are mixed in a gun body to generate the compressed air foam which is sprayed at high speed; fuel fire can be quickly extinguished, and reignition is avoided; fire with the same intensity can be extinguished; and a large number of foam extinguishing agents can be saved.

Owner:中国人民解放军海军装备技术研究所

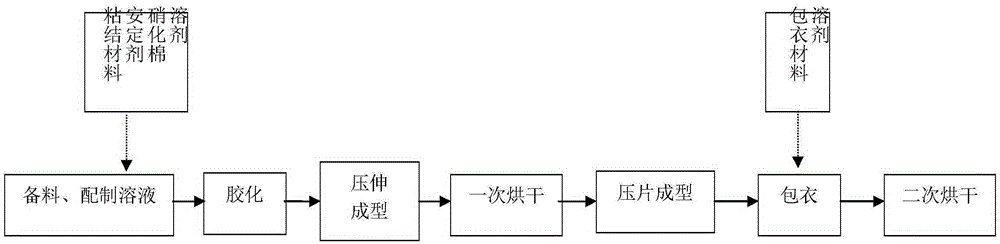

Coated priming composition-free nail-shooting ammunition pellet formula and preparation method thereof

InactiveCN105330495AImprove moisture resistanceUniform sizeNitrated explosive compositionsCombustionNitrocellulose

The invention relates to a coated priming composition-free nail-shooting ammunition pellet formula and preparation method thereof. The coated priming composition-free nail-shooting ammunition pellet formula comprises, by weight, 89.80 to 99.78% of nitrocellulose, 0.20 to 0.75% of a stabilizing agent, 0.01 to 0.45% of a binder, 0.01 to 3.0% of a coating material, a solvent with an amount<=1.0%, and water with an amount <=5.0%. According to the preparation method, nitrocellulose containing water is taken as a base material; the nitrocellulose containing water, the solvent, the stabilizing agent, and the binder are delivered into a gelling kneading machine for gelling after a certain time of mixing; an obtained mixture is pressed into particles, the particles are dried and are subjected to moulding using a tablet machine so as to obtain pellets; and the pellets are coated with the coating material in a coating kettle, and are subjected to secondary drying. The obtained coated priming composition-free nail-shooting ammunition pellets possess excellent humidity resistance, and problems of the prior art, that drying efficiency is low, energy consumption is high, a large amount of dust is generated, combustion explosion is easily caused, and technology safety is poor, are solved.

Owner:LUZHOU NORTH CHEM IND

White reflective coating for modified bitumen membrane

ActiveUS8277881B2Energy efficacyIncreased durabilityPretreated surfacesReflecting/signal paintsSteep slopePolymer

A coating composition useful for building materials products, especially roofing surfaces, is provided. The coating composition provides durable exterior protection to surfaces that it applied to, and it has reflective properties. The coating composition includes a mixture of a polymeric binder, a polymeric carrier and a pigment. The pigment is present in the coating composition in amount that is capable of providing a coating that has an initial energy efficiency rating greater than or equal to 0.65 for a low-sloped roof, or an initial energy efficiency greater than or equal to 0.25 for a steep-sloped roof.

Owner:BMIC LLC

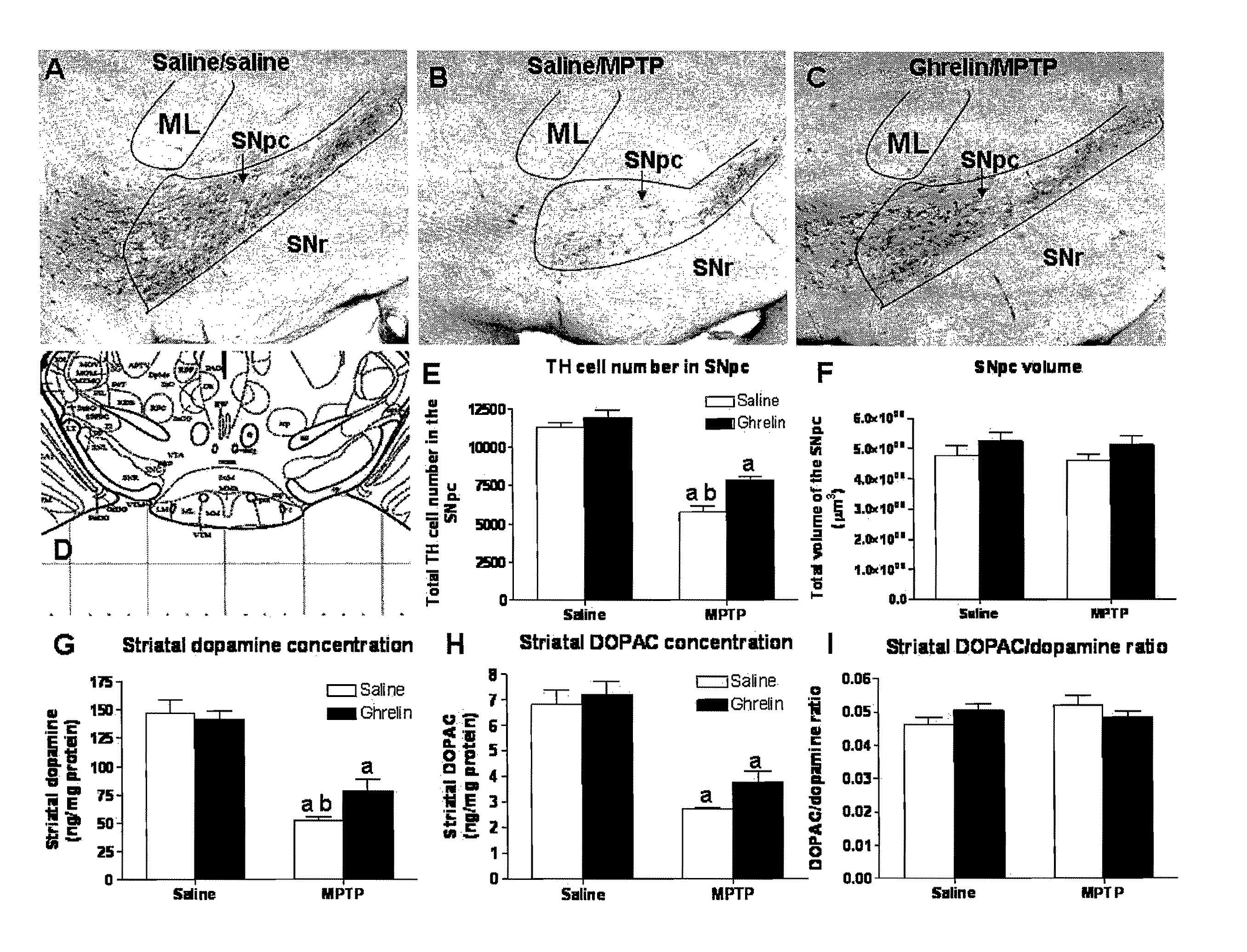

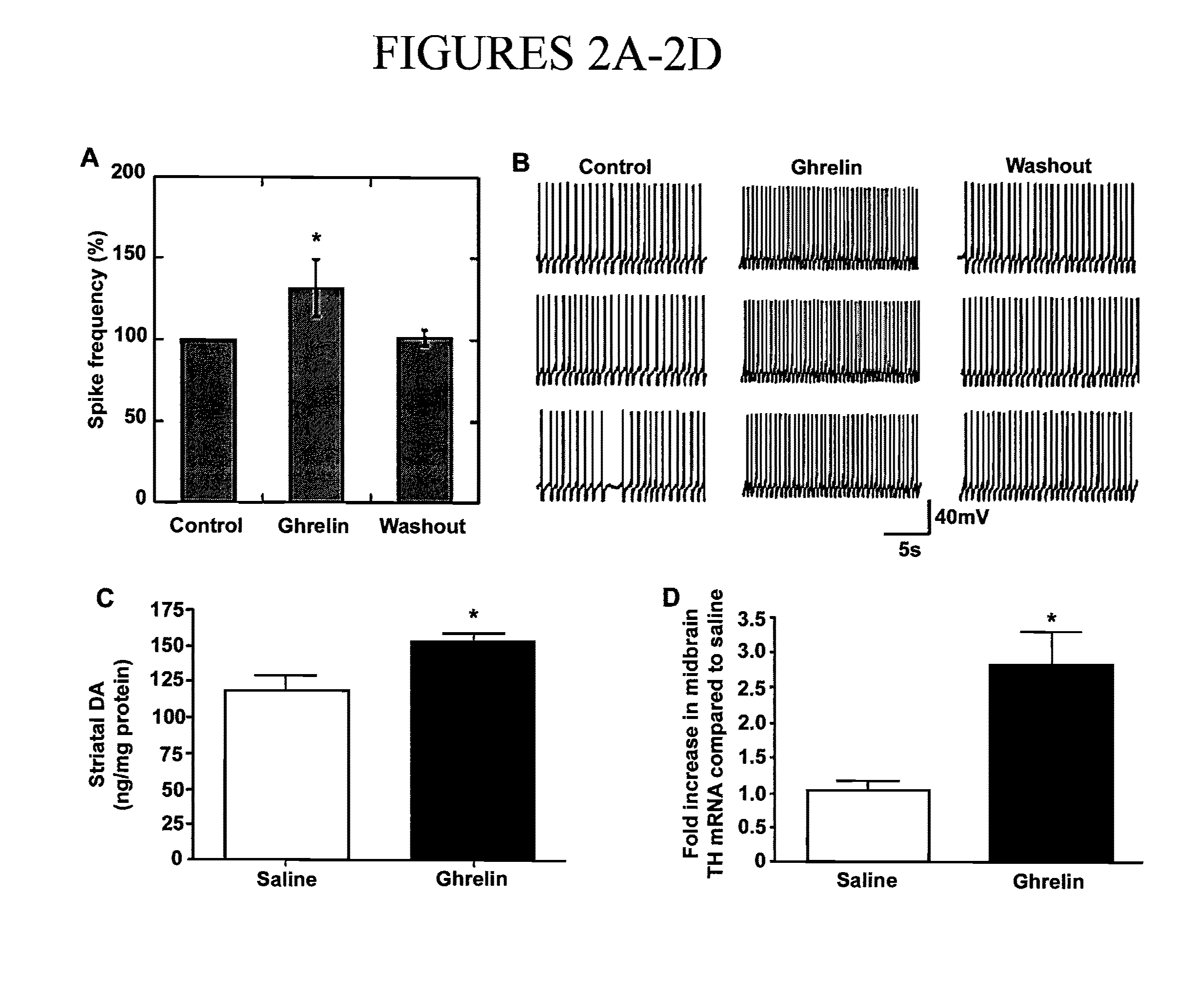

Ghrelin Protects Substantia Nigra Dopamine Neurons

A method of treating neurodegeneration of substantia nigra pars compacta (SNpc) dopamine neurons and compositions therefor are provided.

Owner:YALE UNIV

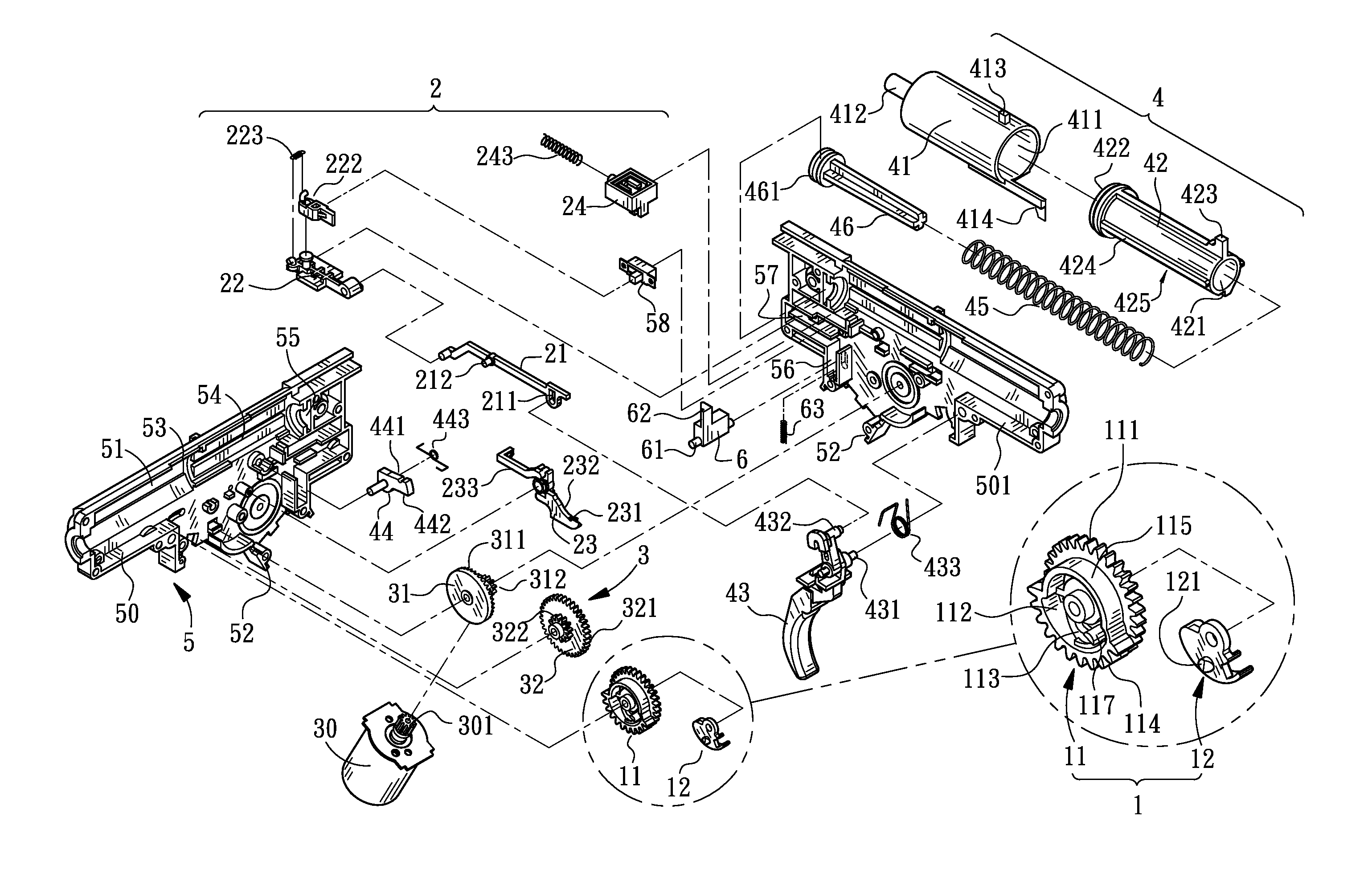

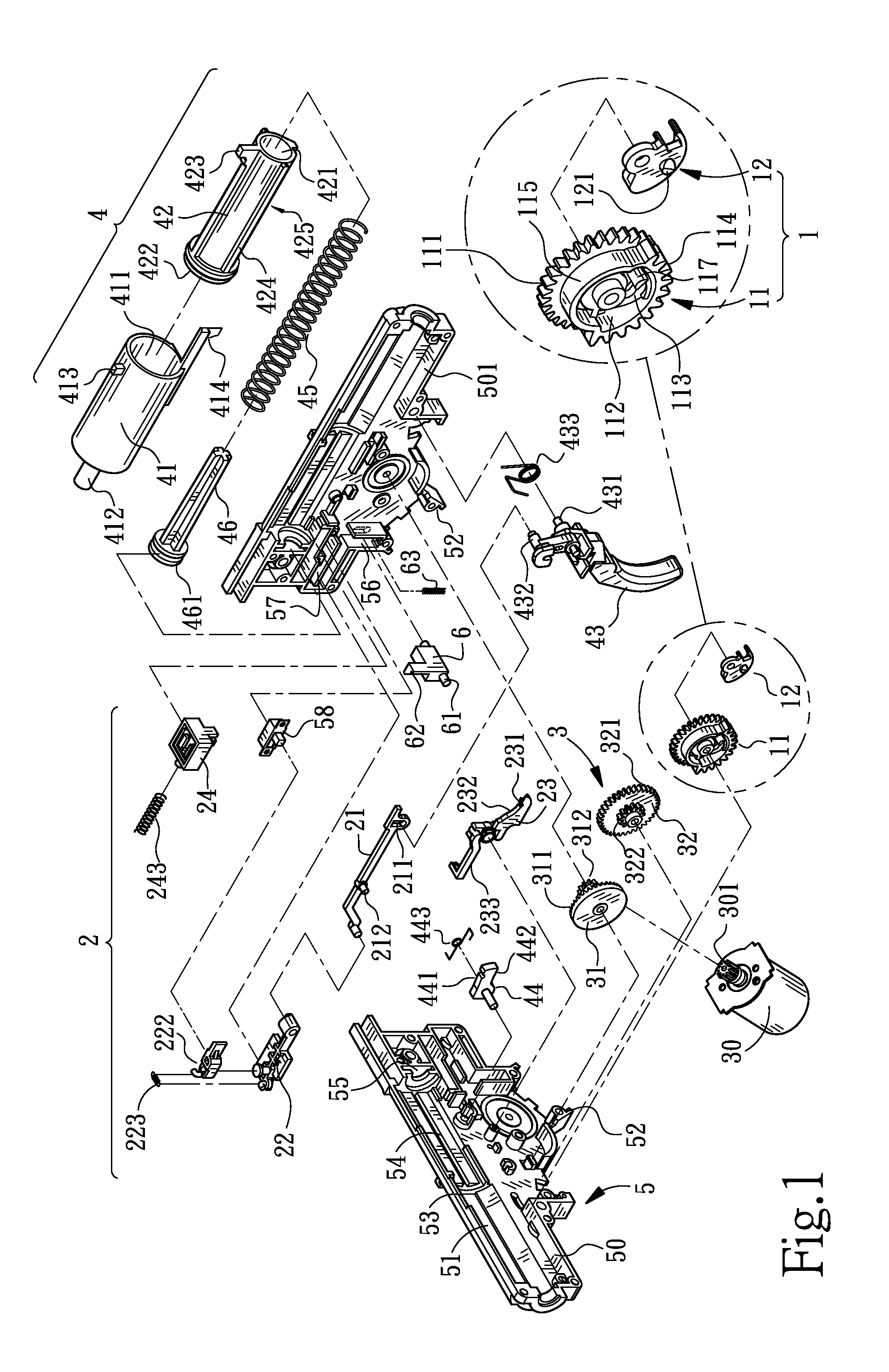

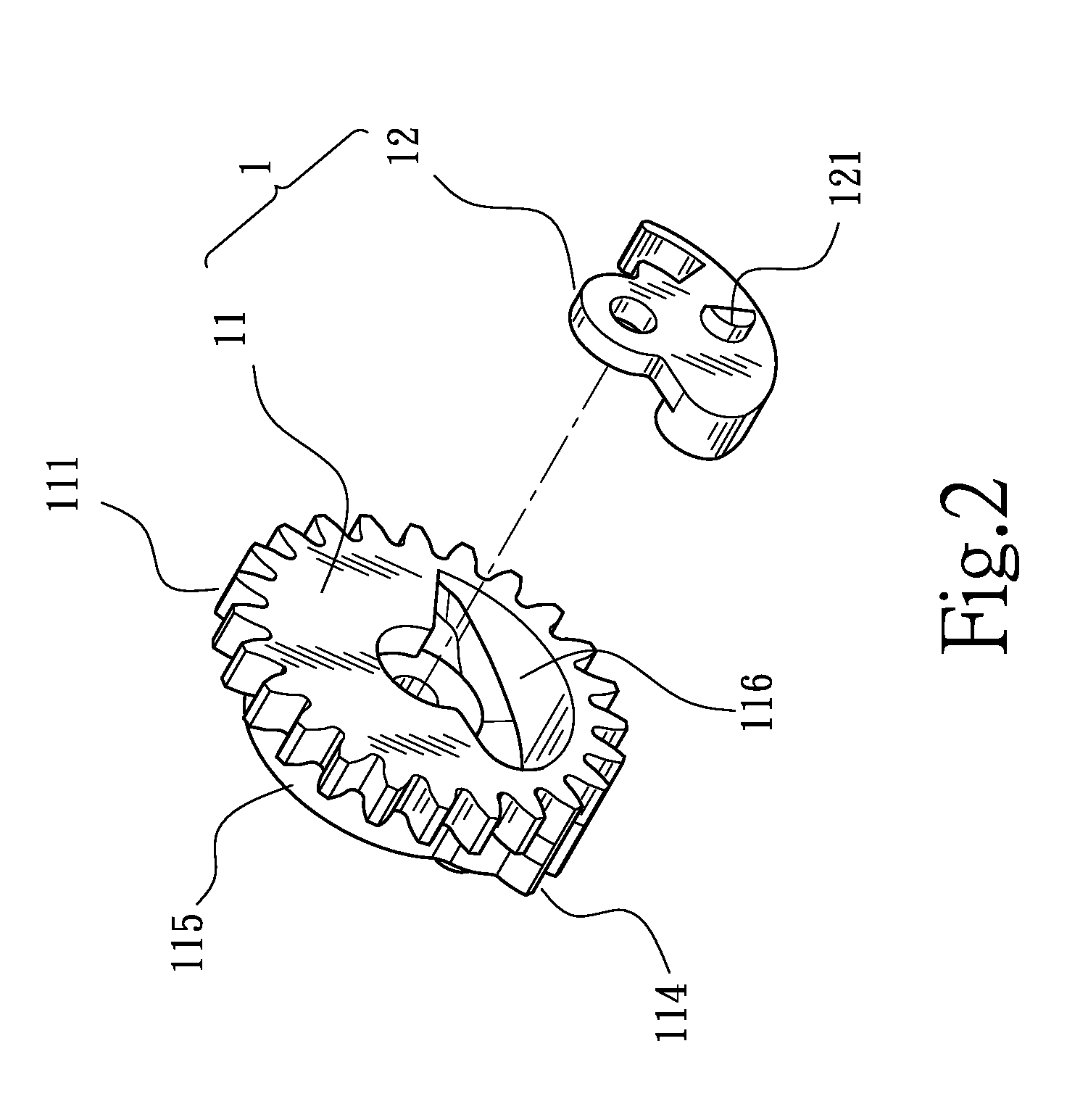

High shooting speed dual-power gear structure of toy gun

InactiveUS20150059724A1Avoid it happening againImprove the quality of operationCompressed gas gunsEngineeringGear tooth

A high shooting speed dual-power gear structure of toy gun disclosed mainly includes a compound gear and an interlocking member. The compound gear has fine gear uniformly distributed on one side and at the circumference thereof, and coarse gear partially and uniformly distributed on the other side and at the circumference thereof with an indentation formed at the portion without gear teeth. The fine gear being driven by a electromotor through a transmission component is capable of driving a piston to compress a piston spring during the rotating process. A gun bolt core tube having an L-shaped hook part is furnished at the outer circumference of the piston. Moreover, a second interlocking projecting pin capable of controlling the power source of the electromotor is furnished on a side of the compound gear. The interlocking member being attached to a side opposite to the second interlocking projecting pin of the compound gear has a first interlocking projecting pin that contacts the L-shaped hook part to drive the gun bolt core tube into the action of bullet loading. By having the first interlocking projecting pin and the second interlocking projecting pin be furnished on opposite sides of the compound gear, the action process and period between their contacting control can be enhanced to absorb the inertia rotation after the electromotor is powered off to avoid the occurrence of repeated bullet loading.

Owner:INCORN HOBBY

Drop in trigger assembly

ActiveUS9863730B2Easy to installIncrease firing rateFiring/trigger mechanismsEngineeringMechanical engineering

A modular trigger and hammer assembly having a hammer, a trigger, a disconnector and a hammer spring for use in a weapon including at least a lob including a firing notch, a safety notch; and a curved landing flat. Also including a trigger needle bearing and a hammer needle bearing.

Owner:ART IDEAS LLC

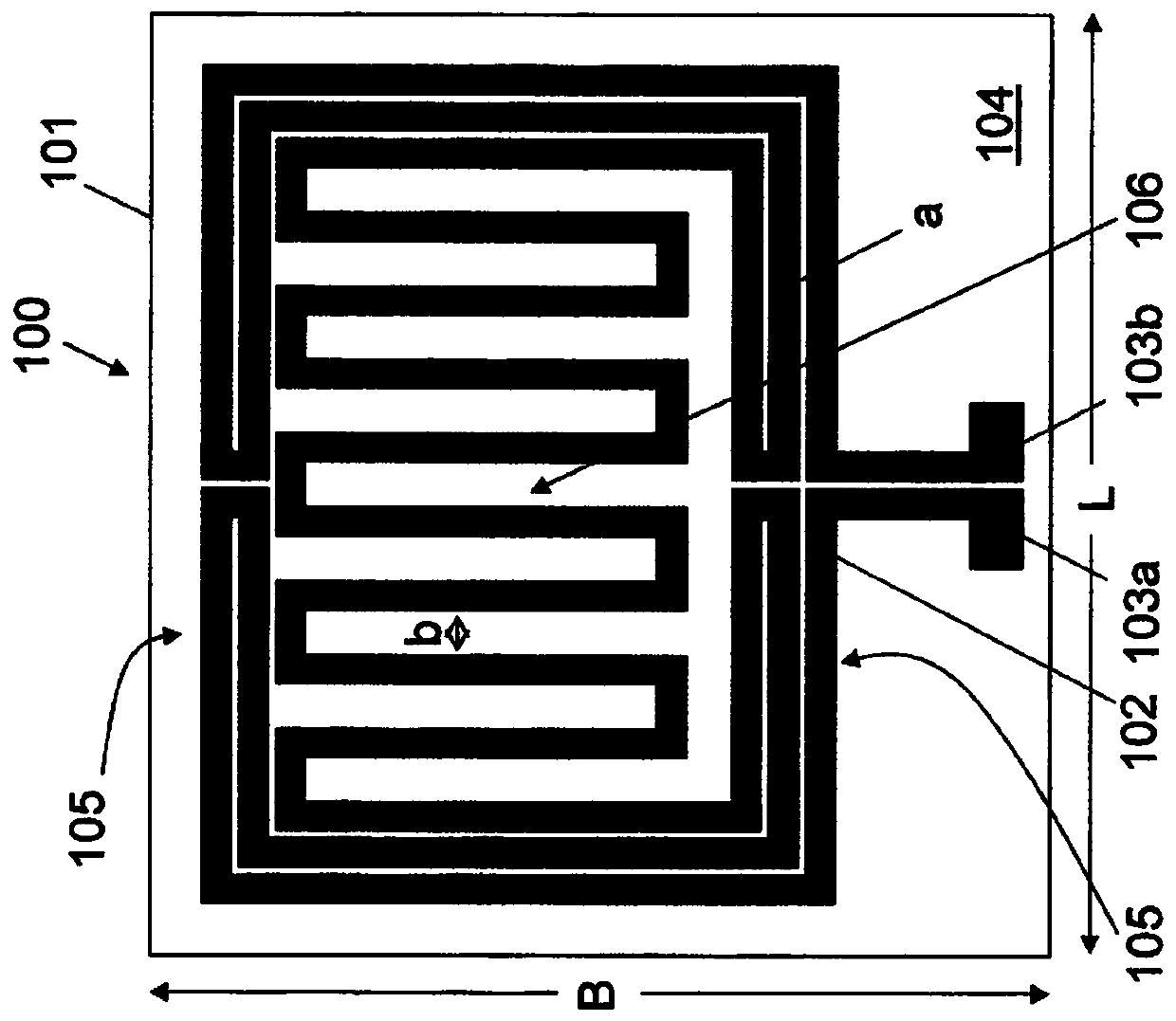

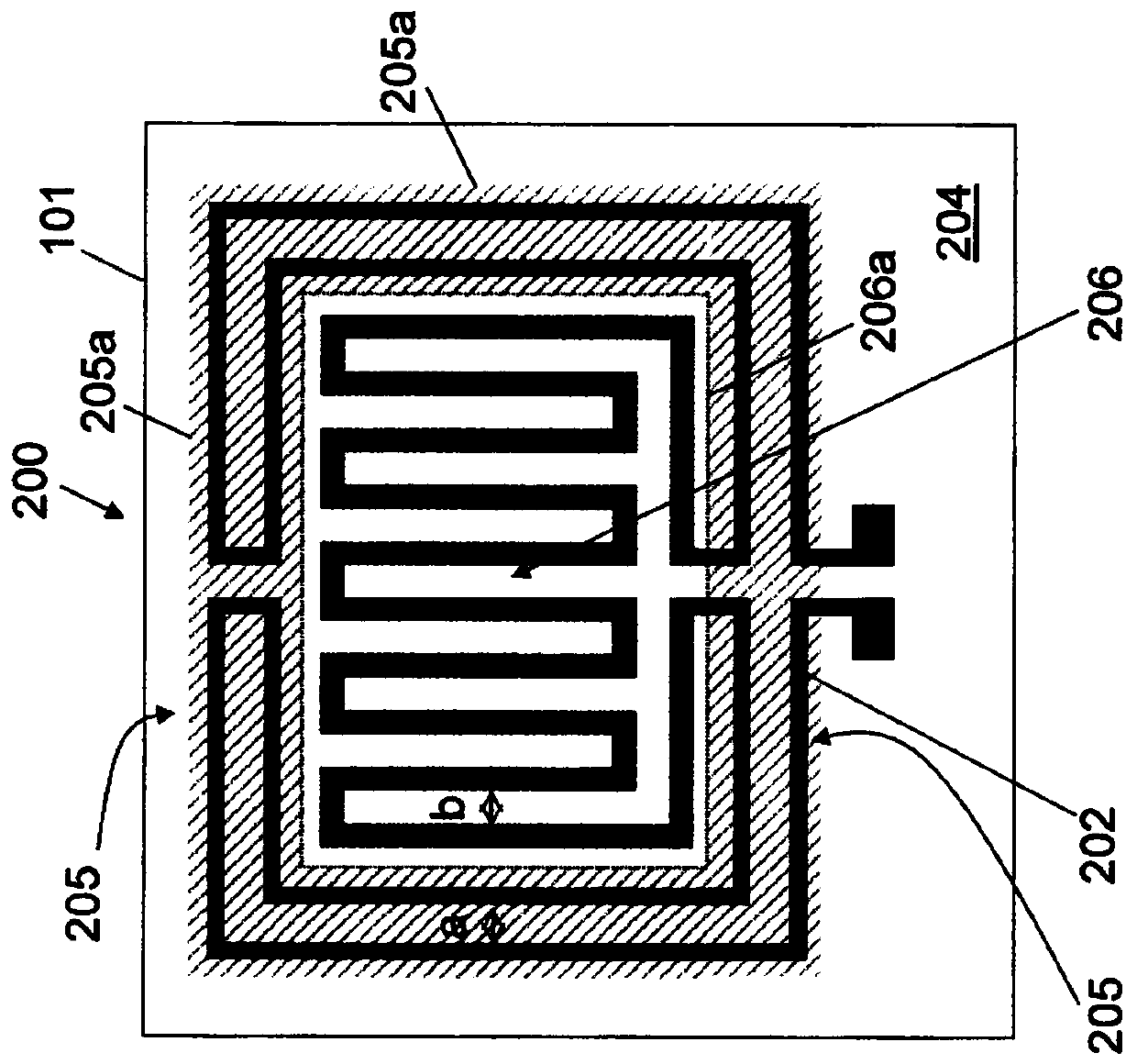

Infrared surface emitter

InactiveCN109716858AUniform irradiation intensityUniform heat treatmentSemiconductor/solid-state device manufacturingOhmic-resistance heatingEngineeringElectrical conductor

Known infrared surface emitters comprise a carrier with a heating surface and with a conductor track applied to a conductor track covering surface of the carrier and consisting of an electroconductiveresistive material that generates heat as a current flows through, the conductor track comprising a first conductor track section for producing a first surface output and a second conductor track section for producing a second surface output different from the first surface output. The aim of the invention is to provide an infrared surface emitter with a high level of irradiation, designed to emit radiation with an irradiation strength that is as homogeneous as possible. To this end, the carrier contains a composite material comprising an amorphous matrix component and an additional componentin the form of a semiconductor material, and the first conductor track section and the second conductor track section are connected in series and differ from each other in terms of the covering density thereof and / or the conductor cross-section thereof.

Owner:HERAEUS NOBLELIGHT LTD

Firing process of Nixing pottery products

The invention discloses a firing process of Nixing pottery products. The process comprises the steps that: (1) blank moisture eliminating is carried out, wherein blanks processed through a drying treatment are placed in a kiln, a temperature is gradually increased to 40-60 DEG C with a heating speed of 20-30 DEG C per hour, and continuous firing is carried out for 10-12h under the temperature; (2) after the moisture eliminating treatment, the temperature is increased to 1050-1100 DEG C with a heating speed of 50-100 DEG C per hour; and (3) heating is stopped, and the blanks are fetched from the kiln after cooling, such that blank firing is finished. According to the invention, moisture eliminating is carried out upon the blanks first, water content in the blanks are slowly discharged by firing under a low-temperature environment. Blank moisture eliminating is uniform, and blank cracking due to breakage caused by large amounts of bubbles produced in the blanks is avoided. With the process, a firing success rate is higher than 95%. Also, during the subsequent high-temperature firing process, blank shrinkage is reduced, and blank cracking rate is reduced, such that firing success rate is further improved.

Owner:钦州市奇圣古坭斋坭兴陶有限公司

Method for increasing sintering rate of Nixing pottery large utensil

The invention provides a method for increasing sintering rate of a Nixing pottery large utensil. The method includes the following steps: 1), preparing a blank material, namely making, by weight, 20-25 parts of east mud, 40-60 parts of west mud, 20-40 parts of golden yellow mud and 1-2 parts of NaCl to be the blank material; 2), forming a blank, namely making the blank material to be large utensils of various types; 3), drying the blank; 4), sintering the blank, namely feeding a large utensil blank which is dried into a kiln, increasing temperature gradually, increasing temperature by 500-600 DEG C from85-100 DEG C per hour, increasing temperature by 1000-1050 DEG C from 120-150 DEG C per hour, maintaining the temperature for sintering for 0.5-1h, naturally cooling, enabling the blank to be out of the kiln to obtain a Nixing pottery large utensil finished product. The golden yellow mud is adopted to replace part of the east mud, and a small amount of NaCl is added, so that sintering rate of the Nixing pottery large utensil is increased greatly.

Owner:钦州狮岩斋文化科技有限公司

Agate glaze for Ru porcelain, preparation method and application thereof of agate glaze in Ru porcelain

The invention belongs to the technical field of ceramics, and particularly discloses an agate glaze for Ru porcelain, a preparation method and an application thereof in Ru porcelain. By metering by volume percent, the agate glaze for Ru porcelain is prepared from the following components in parts by weight: 5 to 11 parts of kaolin, 4 to 8 parts of wind cave soil, 2 to 8 parts of half-slope soil, 3to 7 parts of Tang ditch soil, 10 to 20 parts of black stone, 8 to 16 parts of quartz, 1 to 3 parts of bovine bone, 0.5 to 3.0 parts of agate, 5 to 15 parts of calcite, 10 to 26 parts of melilite and2 to 8 parts of talc. According to the agate glaze for the Ru porcelain, through scientific and reasonable blending, the obtained glaze color is jade-like, bright, soft, mild, bright and smooth, theglaze is fat-piled, quiet and elegant, the color is moist, the internal quality, the appearance quality and the mechanical strength resistance of the Ru porcelain are improved, and the firing rate ofa product is greatly increased.

Owner:张斌洋

Hinge with stiffened leaf

A hinge including a stiffened leaf. The hinge may generally comprise a first longitudinally-extending leaf having a base portion and a mounting portion offset and preferably parallel to the base portion that defines a cavity. The mounting portion may contain at least one hole for attaching the leaf to a hinged object with a fastener. In one embodiment, the hole further includes an annular reinforcement disposed in the cavity proximate to the hole. The hole may be conical in shape and may extend into the reinforcement to receive and support a conically-shaped fastener head. The hinge is suitable for thin leaf construction and continuous full-length hinge applications.

Owner:VON DUPRIN

Air gun

ActiveUS7856969B2Reduce opening timeDegree of distributing gas pressure of gas is simplifiedCompressed gas gunsAir chamberAerospace engineering

Owner:MARUZEN

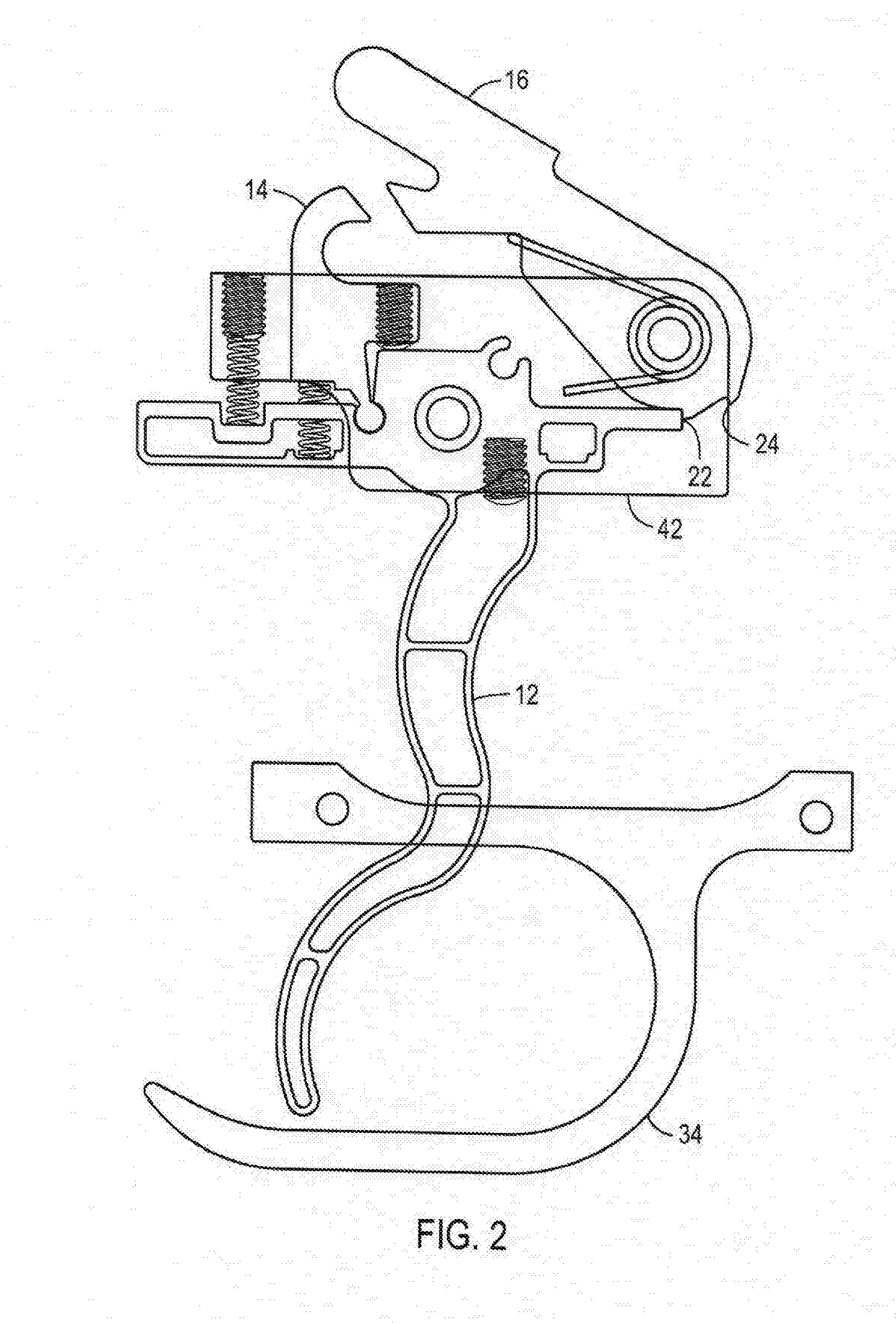

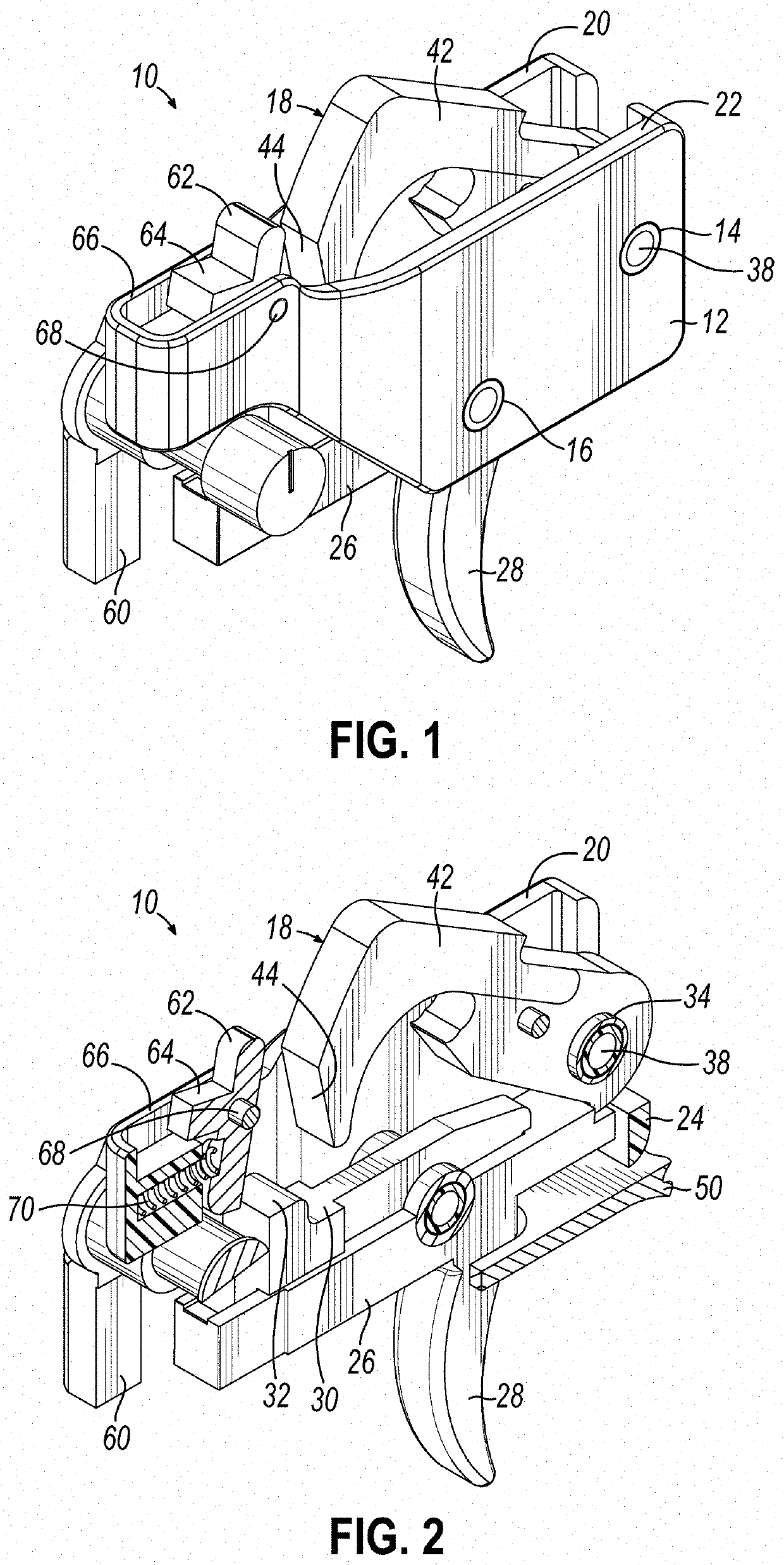

Trigger Assembly with Modifications

InactiveUS20180202740A1Trigger pull effort rateDecreasing trigger weightFiring/trigger mechanismsEngineeringMechanical engineering

Trigger assembly for use in a weapon. Components of the trigger assembly include a spring, a hammer, a disconnector, a trigger and other components related to a trigger assembly.

Owner:ELFTMANN JR ARTHUR J

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

Firearm trigger mechanism

ActiveUS10514223B1Increase firing rateSafety arrangementFiring/trigger mechanismsFire controlEngineering

A trigger mechanism for use in a firearm having a receiver with a fire control mechanism pocket, transversely aligned pairs of hammer and trigger pin openings in the pocket, and a bolt carrier that reciprocates and pivotally displaces a hammer when cycled. The trigger mechanism includes a hammer, a trigger member, and a locking bar. The hammer has a sear notch and is mounted in the fire control mechanism pocket to pivot on a transverse hammer pin between set and released positions. The trigger member has a sear and is mounted in the fire control mechanism pocket to pivot on a transverse trigger pin between set and released positions. The trigger member has a surface positioned to be contacted by hammer when the hammer is displaced by cycling of the bolt carrier, the contact causing the trigger member to be forced to the set position. The locking bar is pivotally mounted in a frame and spring biased toward a first position in which it mechanically blocks the trigger member from moving to the release position, and is movable against the spring bias to a second position when contacted by the bolt carrier reaching a substantially in-battery position, allowing the trigger member to be moved by an external force to the released position.

Owner:RARE BREED TRIGGERS LLC

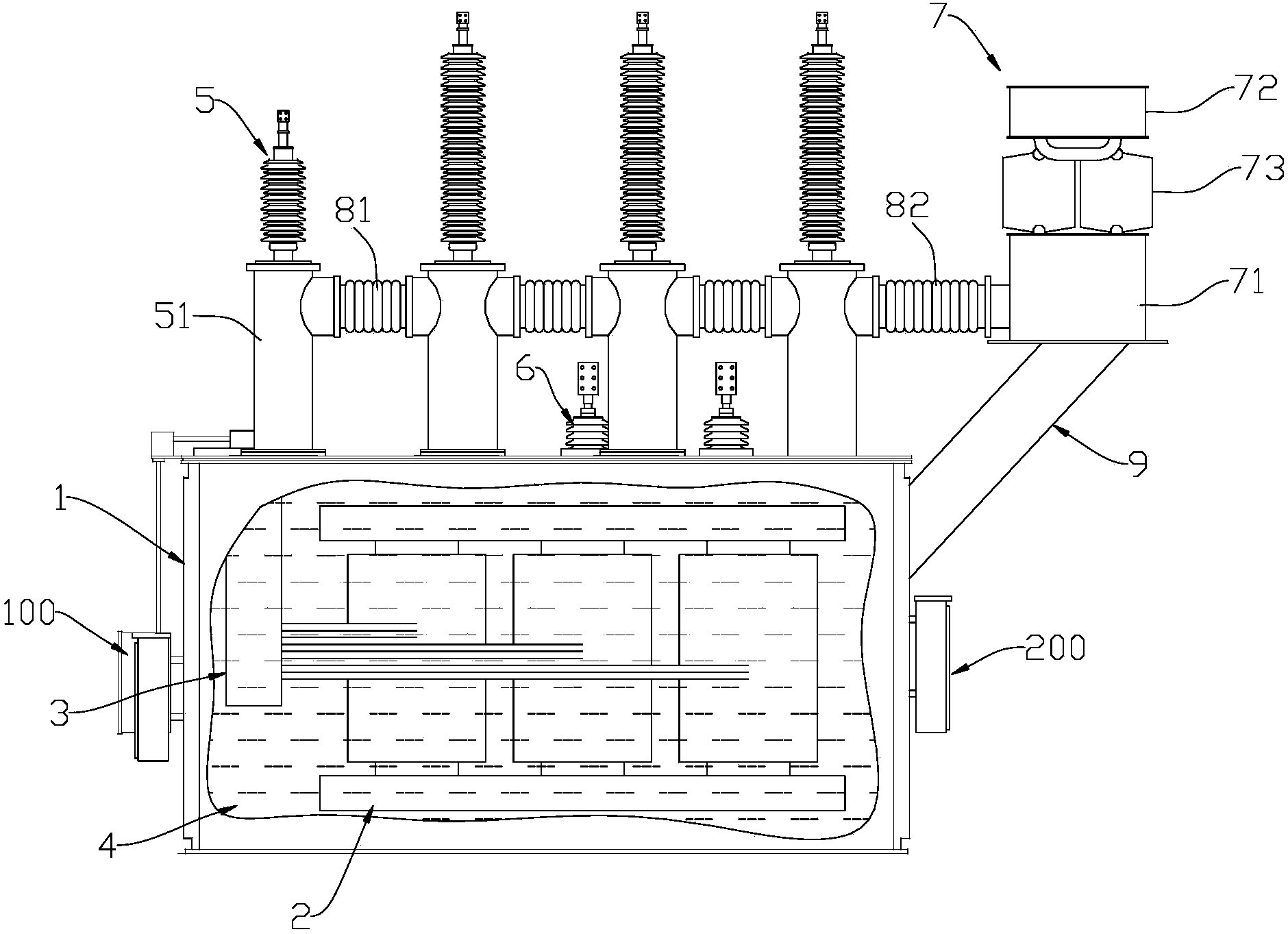

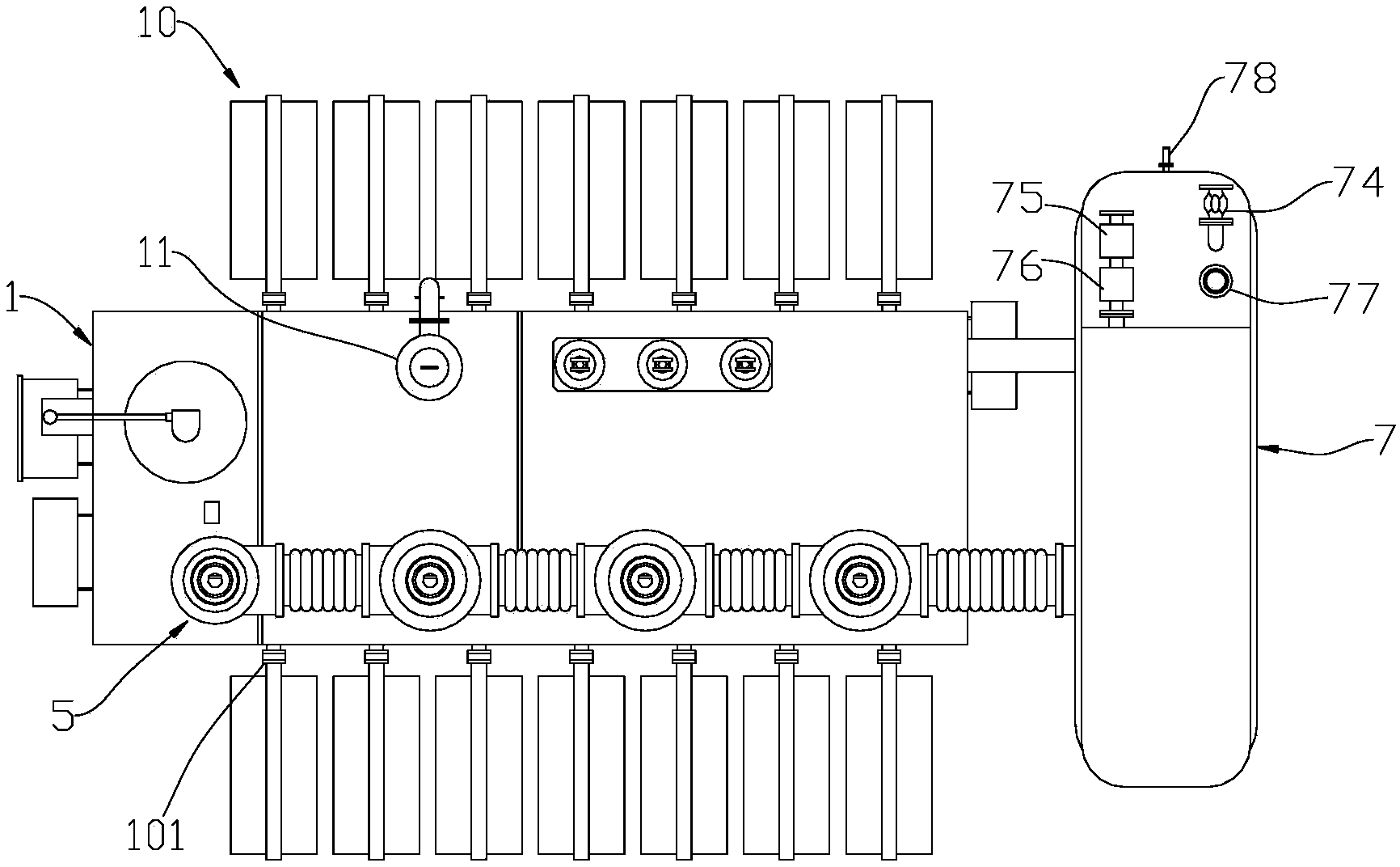

Evaporative cooling power transformer

ActiveCN104240908AGuaranteed normal operationIncrease firing rateTransformers/inductances coolingSteam pressureEngineering

The invention relates to an evaporative cooling power transformer. The evaporative cooling power transformer comprises a closed box body, a transformer body and an on-load tap changer arranged in the box body, an evaporative cooling insulating medium contained in the box body, and multiple high-pressure sleeves and multiple low-pressure sleeves arranged on the box body, wherein the transformer body and the on-load tap changer are submerged in the evaporative cooling insulating medium; the transformer further comprises a constant pressure box which is used for controlling the steam pressure in the box body; the constant pressure box is arranged above the box body; the constant pressure box is communicated with the high-pressure sleeves through corrugated pipes, and the multiple high-pressure sleeves are communicated with one another through corrugated pipes. Through additionally arranging the constant pressure box to match the evaporative cooling insulating medium, the steam pressure in the box body of the transformer is controlled, and the normal running of the transformer is guaranteed.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Inlaying process of Nixing pottery

The invention discloses an inlaying process of Nixing pottery. The inlaying process comprises the following steps: (1) preparing a preform body; (2) preparing a color clay material; (3) preparing mixed slurry: mixing the color clay material and the preform body to obtain a mixture, and charging water in the mixture to obtain the mixed slurry; (4) forming a green body; (5) engraving and inlaying, namely drawing a picture on the green body, wrapping an opening and a part, which is not engraved currently, of the green body with a plastic film, carving out grooves on two side edges along ink marks for the engraving part, smearing a layer of mixed slurry into the grooves, inlaying the color clay material into the grooves, leveling the color clay material, slightly drying the color clay material until the color clay material is concaved, smearing the mixed slurry into the grooves again, then inlaying the color clay material, leveling the color clay material, repeating for 3 to 6 times until the grooves are completely leveled by the color clay material; then tearing off partial plastic film, engraving and inlaying further in the above method until all engraving and inlaying work is completed; and (6) burning the green body. By adopting the inlaying process of Nixing pottery, the mutual absorption of the color clay material and the green body can be realized, the color clay material and the green body are unlikely to drop and crack in the burning process, and the burning success rate is high.

Owner:广西钦州大民坭兴陶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com