Coated priming composition-free nail-shooting ammunition pellet formula and preparation method thereof

A technology of percussion powder and ammunition tablets, which is applied in the field of nail-shooting ammunition, can solve problems such as low nitrocellulose dust content, easy moisture absorption during storage, and explosion accidents, so as to improve process safety, solve process safety problems, The effect of less dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

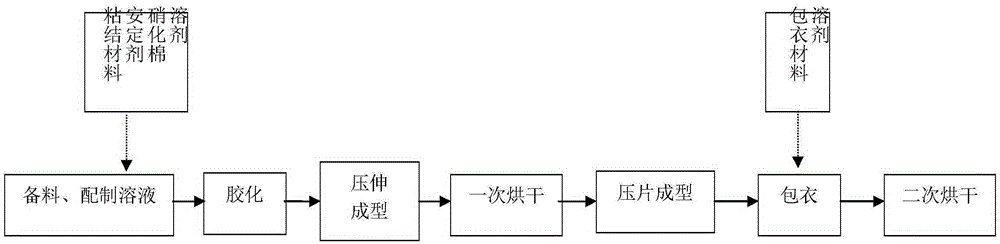

Method used

Image

Examples

Embodiment 1

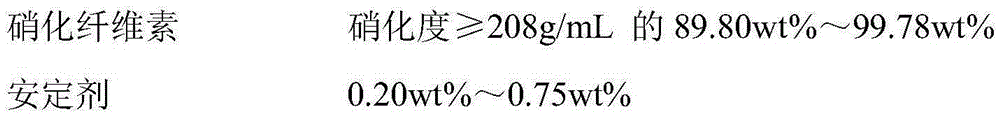

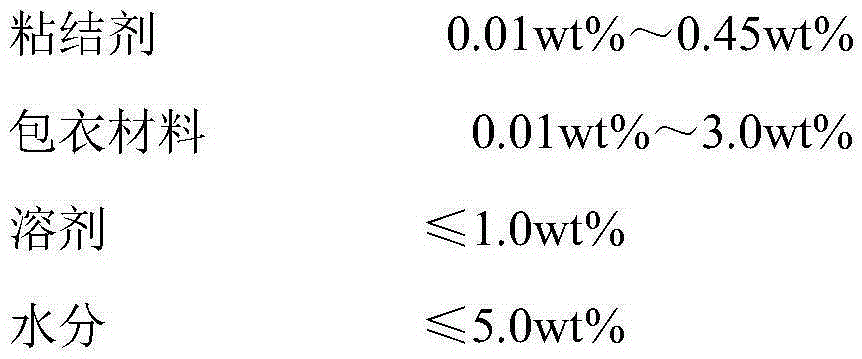

[0029] Formula 1: Calculated according to the total amount of each component content of the tablet,

[0030]

[0031] (1) Raw material preparation and solution preparation: the nitrocellulose containing water with a moisture content of 20 wt % to 40 wt % is calculated as the absolute dry weight, and 99.78 kg is weighed. Dissolve 0.20wt% of the stabilizer in a total amount of 100kg, and 0.01wt% of a binder in a total amount of 100kg in one or more solvents such as ethers, alcohols, esters, and ketones. The stabilizer-bonding agent-solution, based on the total amount of 100kg, the amount of solvent used is 20wt%-80wt%. The binder includes one or both of ethyl cellulose EC and cellulose glycolate butyrate CAB.

[0032] (2) Gelling: Put the weighed nitrocellulose containing water into the gelling machine (kneader), and add the prepared stabilizer-binder-solution binder solution into the gelling machine (kneader) Medium, gelling 30min ~ 60min. Stabilizers include one or more ...

Embodiment 2

[0046] Formula 2: Calculated according to the total amount of each component content of the tablet,

[0047]

[0048]

[0049] The preparation method of coated nail-shooting ammunition tablet without percussion agent, the steps are as follows:

[0050] (1) Raw material preparation and solution preparation: the nitrocellulose with a moisture content of 20wt%-40wt% was calculated as the absolute dry weight, and 95kg was weighed. Based on the total amount of 100kg, one or more of 0.60wt% of diphenylamine DPA, I neutralizing agent and II neutralizing agent are used as stabilizers, and 0.20wt% of ethyl cellulose One or two of EC and cellulose glycolate butyrate CAB are used as binders, and one or more of ethers, alcohols, esters, and ketones are used as solvents to prepare stabilizers-bonding Agent-solution, based on a total amount of 100kg, the amount of solvent used is 20wt% to 80wt%.

[0051] (2) Gelling: Put the weighed nitrocellulose containing water into the gelling m...

Embodiment 3

[0065] Formula 3: Calculated according to the total amount of each component content of the tablet,

[0066]

[0067] The preparation method of coated nail-shooting ammunition tablet without percussion agent, the steps are as follows:

[0068] (1) Raw material preparation and solution preparation: Calculate the nitrocellulose with a water content of 20wt% to 40wt% as the absolute dry weight, and weigh 89.8kg. One or more of 0.75wt% of diphenylamine DPA, I neutralizing agent, and II neutralizing agent are used as stabilizers based on a total amount of 100kg, and 0.45wt% of ethyl cellulose EC, One or two kinds of cellulose hydroxyacetate butyrate CAB are used as a binder; based on a total of 100kg, one or more of ethers, alcohols, esters, and ketones are used as solvents to prepare diazepam Agent-binder-solution, the amount of solvent used is 20wt%-80wt%.

[0069] (2) Gelling: Put the weighed nitrocellulose containing water into the gelling machine (kneader), and add the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com