Patents

Literature

148results about How to "Avoid resurgence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated hydrophilic polymers

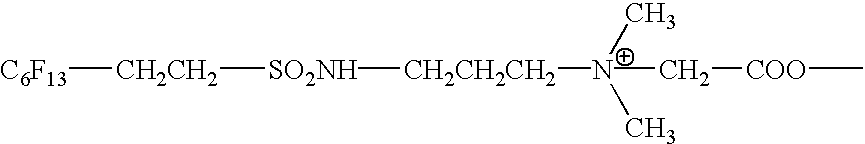

InactiveUS6521730B1Reduce surface tensionAvoid resurgenceFire extinguisherHydrophilic monomerHydrophilic polymers

1) Hydrophilic fluoropolymers obtained by radical polymerization, in a precipitating medium, of a mixture of monomers composed of at least one monomer with a perfluoroalkyl side chain, of one or more ionic or ionizable hydrophilic monomer(s) and optionally of one or more nonionic hydrophilic monomer(s).2) Use of these polymers as dispersants or thickeners and as additives in multipurpose fire-fighting emulsifiers.

Owner:EI DU PONT DE NEMOURS & CO

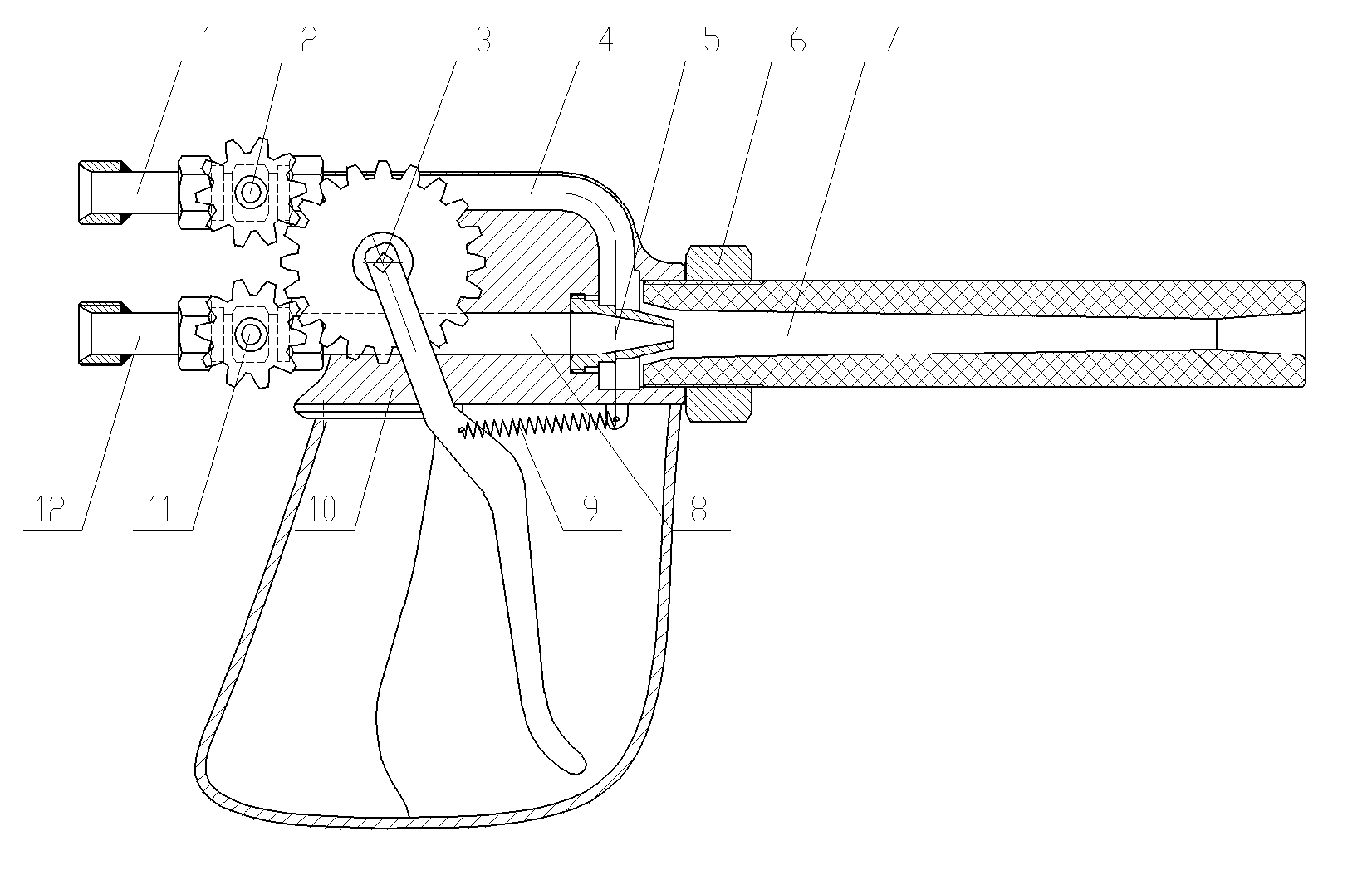

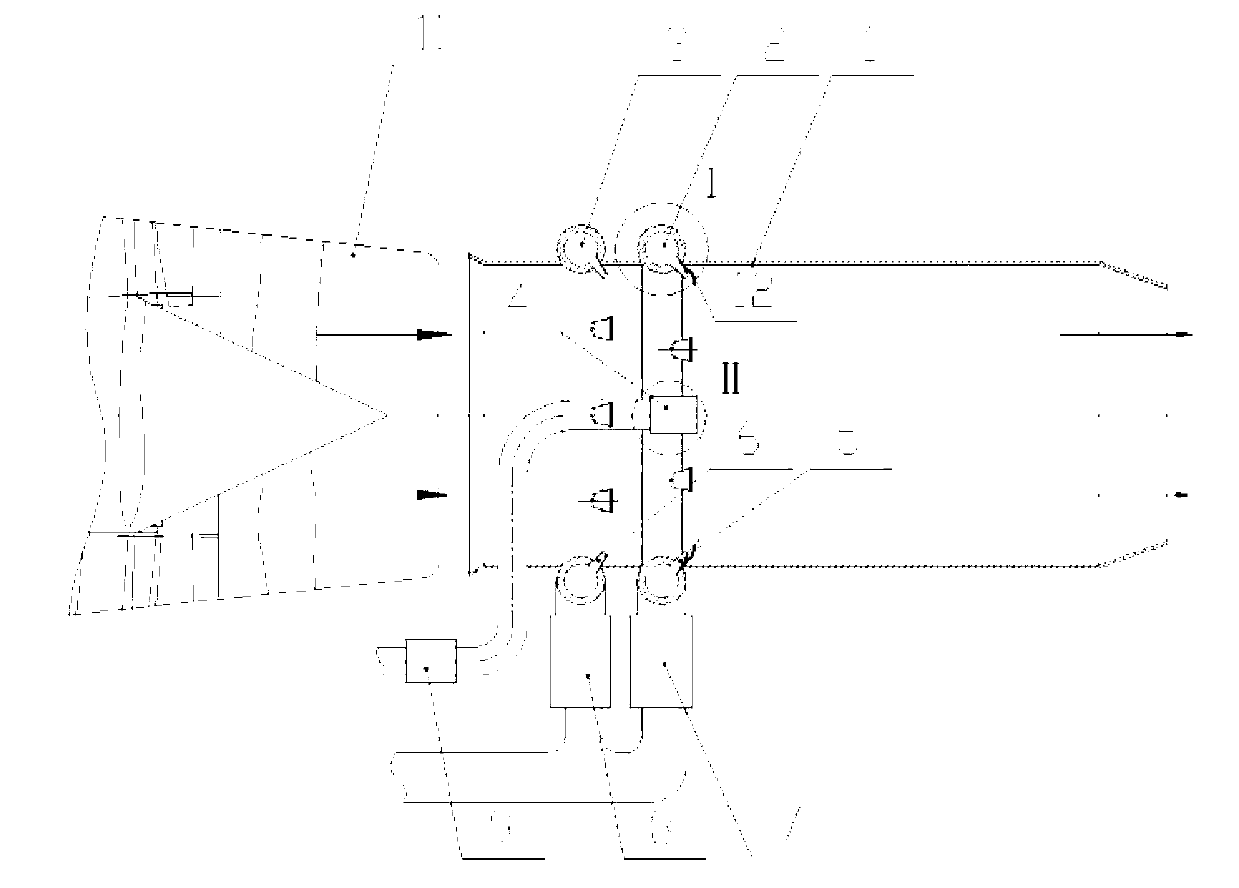

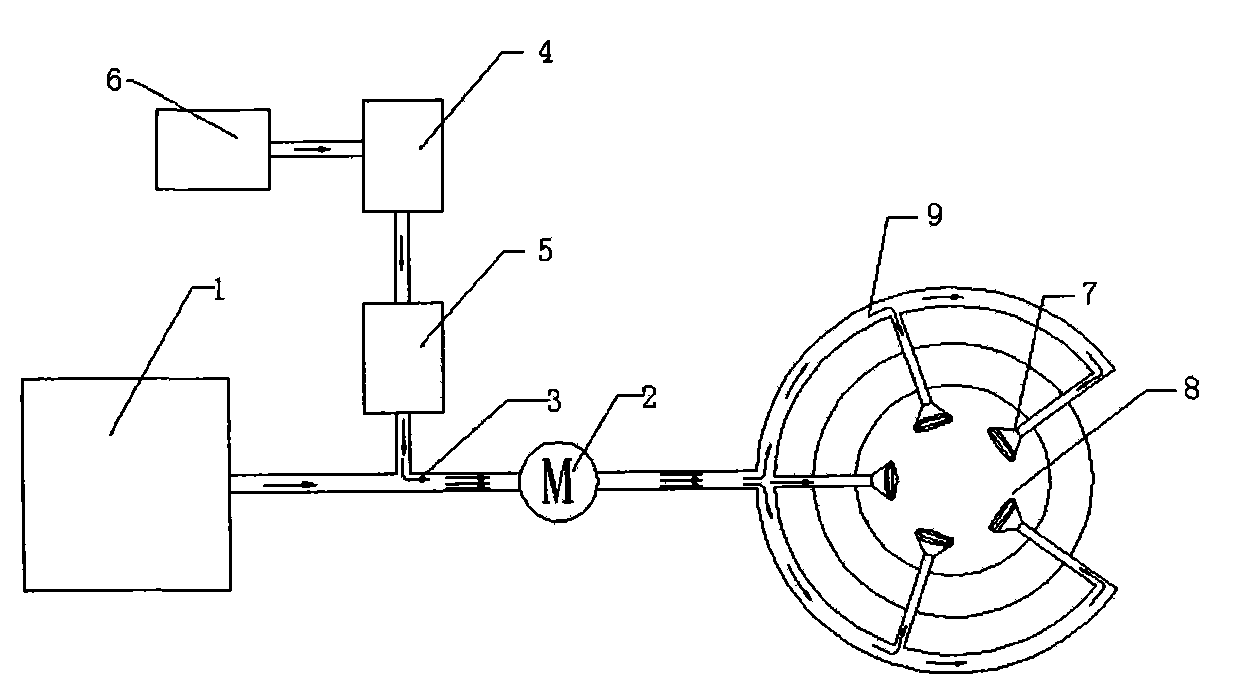

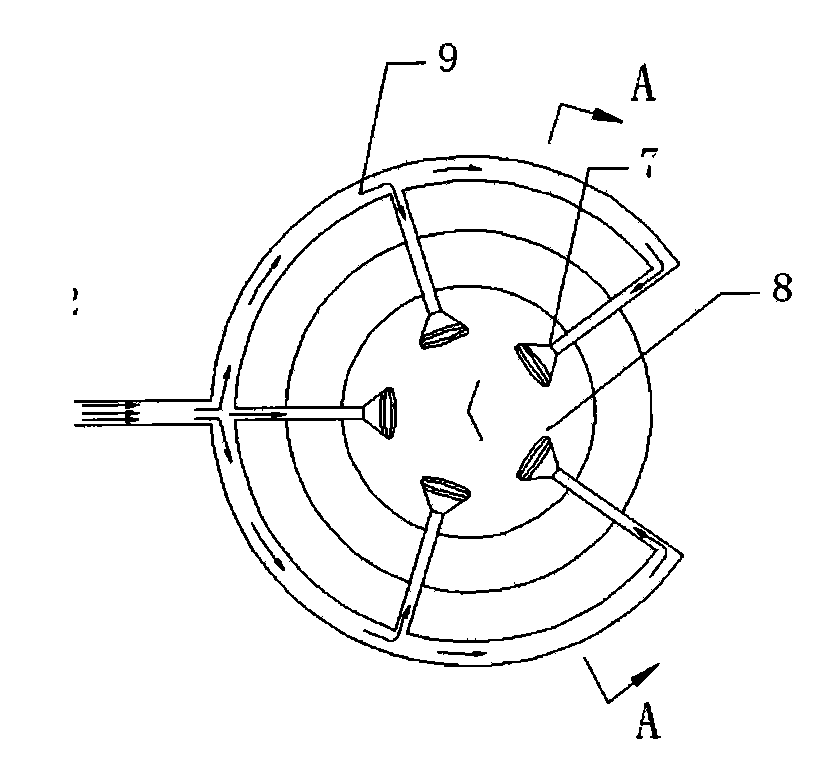

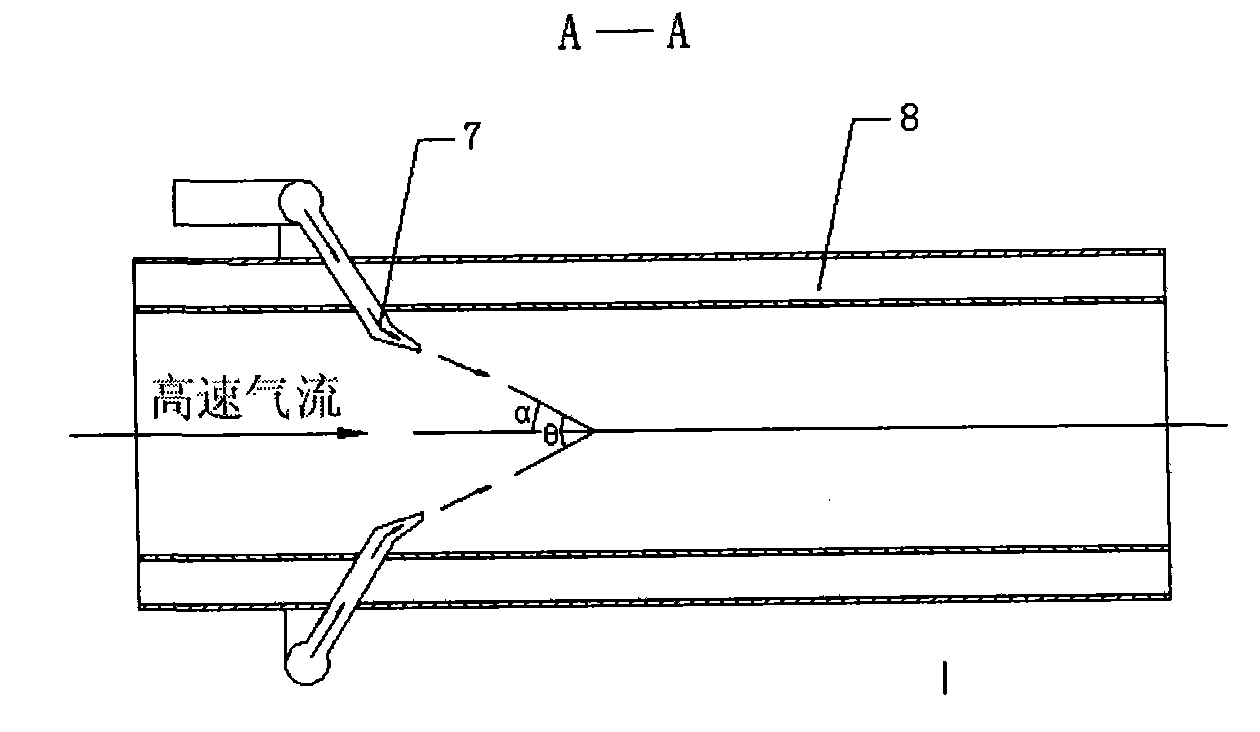

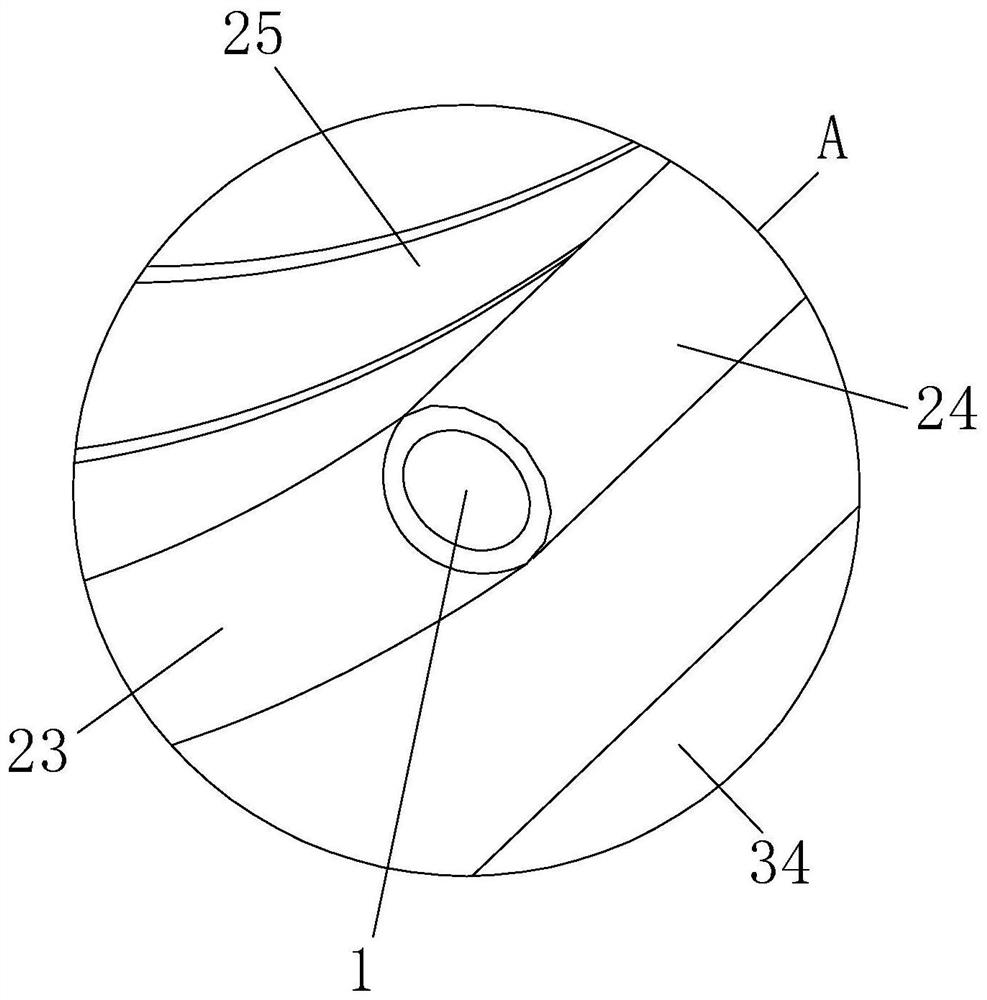

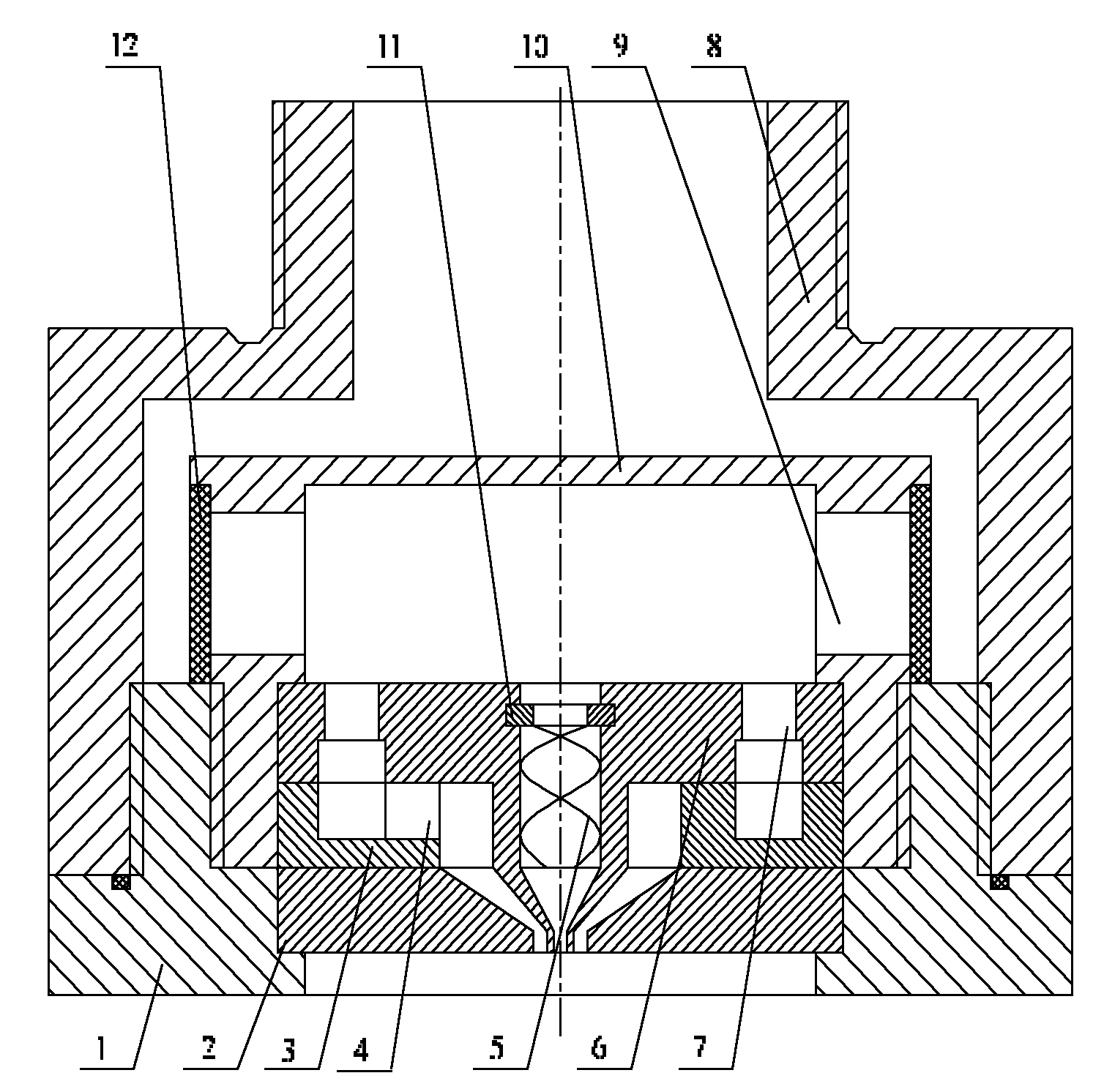

Compressed air foam extinguishing agent spraying gun and method thereof

The invention discloses a compressed air foam extinguishing agent spraying gun and a method thereof. Foam extinguishing agent liquid is sprayed out of an annular spraying channel which is positioned at an inlet of an extinguishing agent spraying gun pipe and is tightly attached to the wall surface to form a flowing liquid film attached to the wall; under impact and cutting of high-speed air flow injected by a convergence-shaped nozzle in the center of the inlet of the extinguishing agent spraying gun pipe, the liquid film is damaged; under the action of surface tension, the liquid film is contracted and wraps compressed air for cutting the liquid film, so that a plurality of air foam balls are generated, and foam extinguishing agent liquid becomes high-speed flowing compressed air foams; and the compressed air foams are accelerated in a 'laval nozzle' type gun pipe and then sprayed at high speed. By the compressed air foam extinguishing agent spraying gun and the method thereof, the compressed air and the foam extinguishing agent are mixed in a gun body to generate the compressed air foam which is sprayed at high speed; fuel fire can be quickly extinguished, and reignition is avoided; fire with the same intensity can be extinguished; and a large number of foam extinguishing agents can be saved.

Owner:中国人民解放军海军装备技术研究所

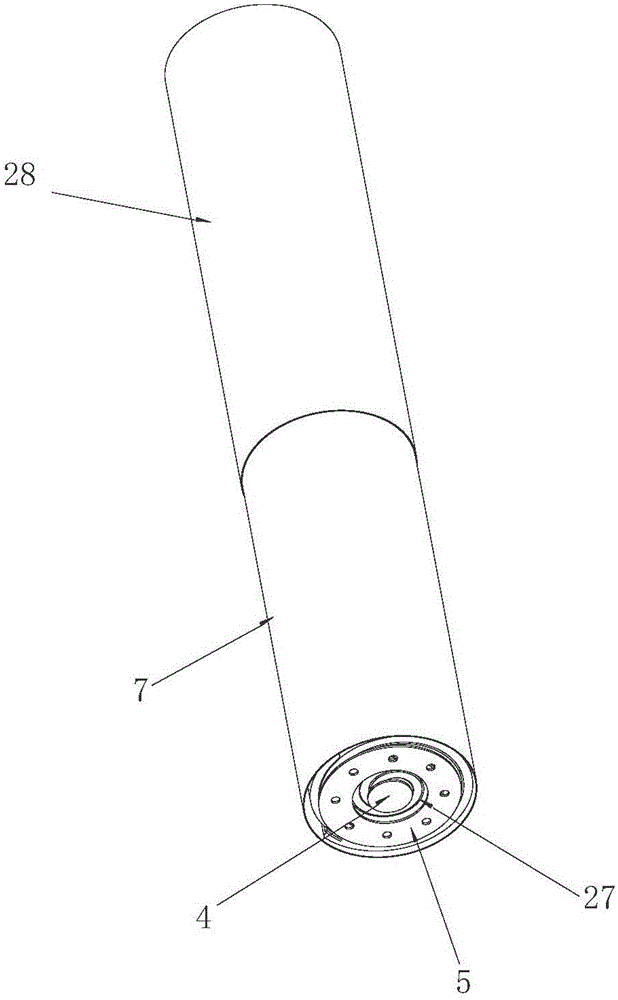

Smoke cartridge and low-temperature smoking set

The invention discloses a smoke cartridge and a low-temperature smoking set. The smoke cartridge comprises a first tobacco piece and a second tobacco piece, wherein a flexible heating element is clamped between the first tobacco piece and the second tobacco piece so as to form a combined piece; the combined piece is rolled to form a cylinder; two ends of the flexible heating element are respectively connected with a first electrode plate and a second electrode plate; the first electrode plate and the second electrode plate are attached to one bottom surface of the cylinder or a cylindrical side surface; a gap is formed between the first electrode plate and the second electrode plate. A heating wire of the smoke cartridge is fixed in the smoke cartridge, so cigarettes are heated inside the smoke cartridge, the heating speed is high, uniform heating is realized, and the utilization rate of heat energy is high. Because the heating element does not need to be fixed on the outer wall of the smoke cartridge, the outer wall of the smoke cartridge can be coated by tobacco paper, and the smoke cartridge is prevented from being wetted or mildewed and is conveniently carried and stored by a user; and moreover, according to the low-temperature smoking set disclosed by the invention, the smoke cartridge is easy to mount and detach, cigarette ash is convenient to clean, and the user has an experience of real cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

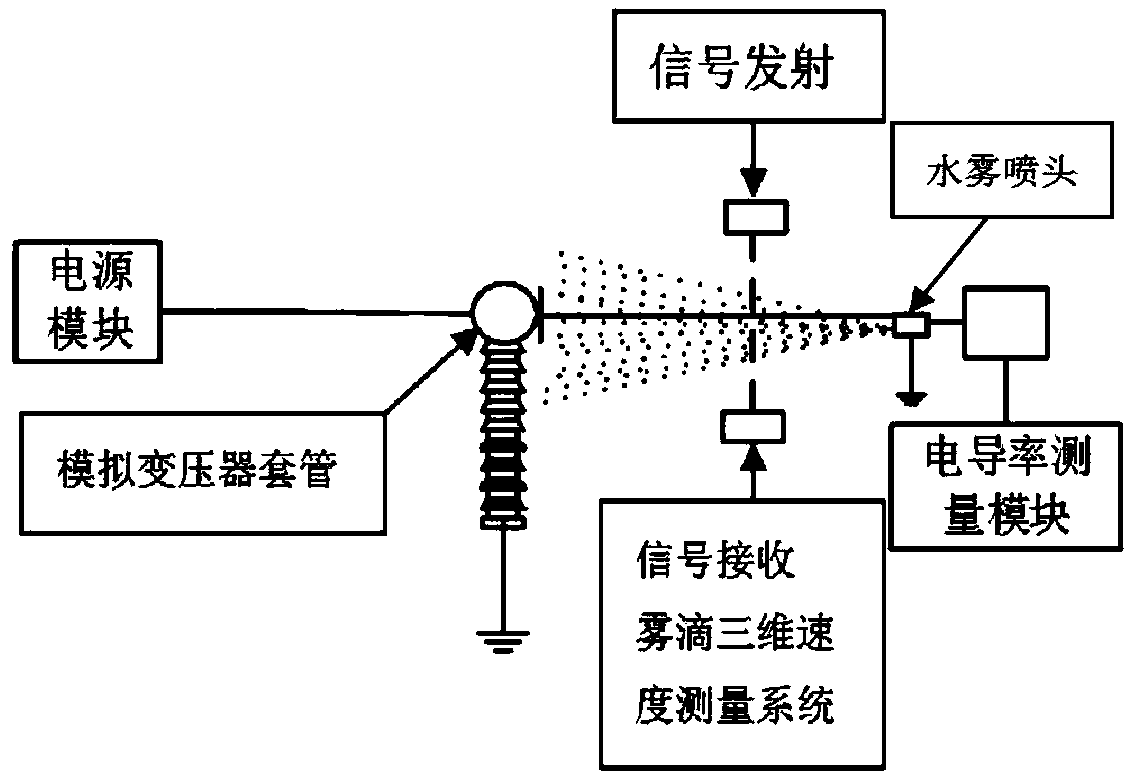

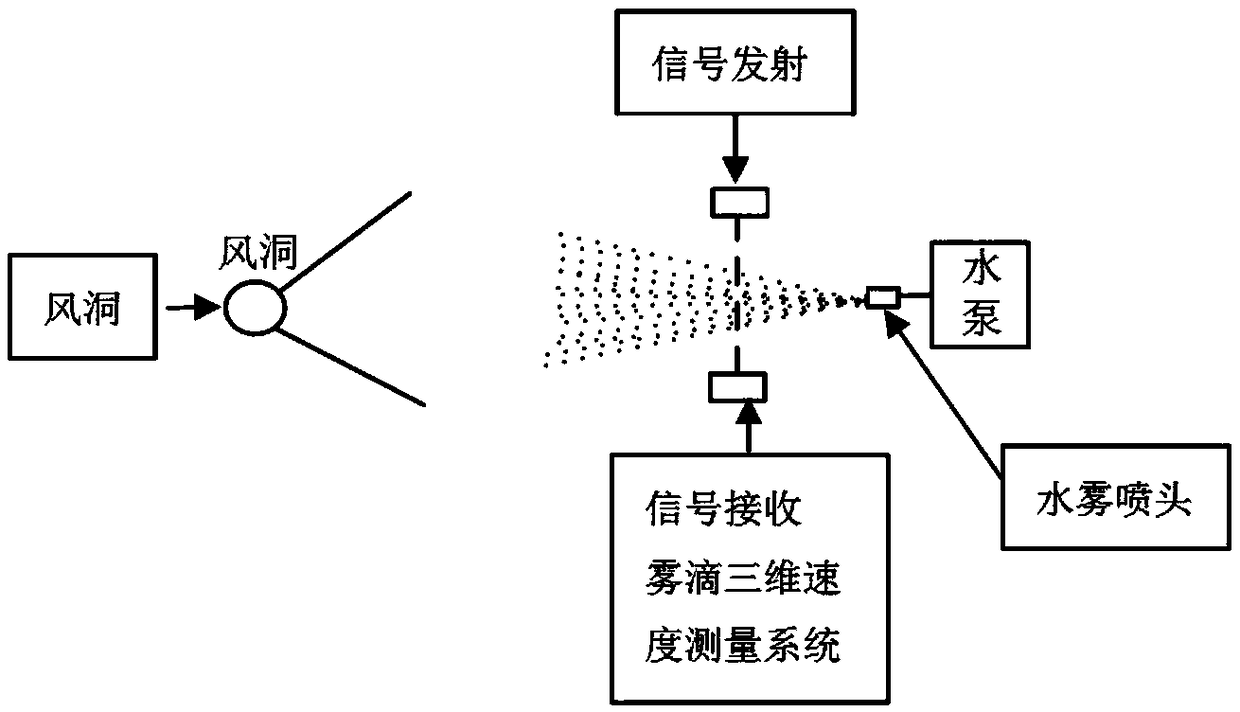

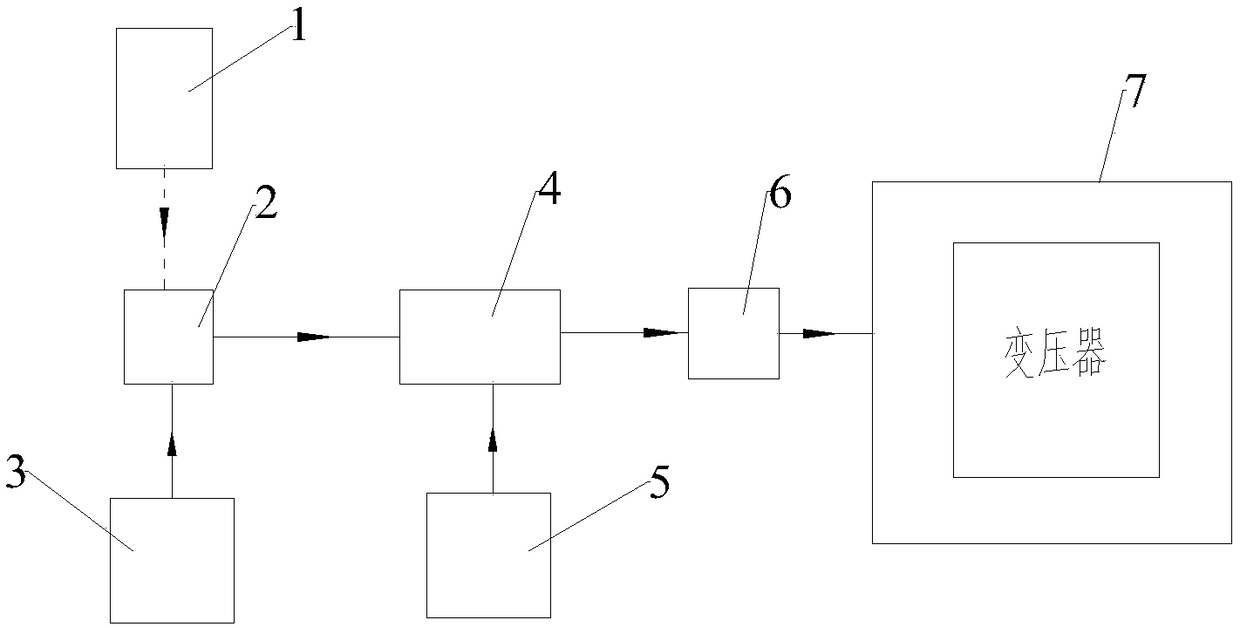

Transformer oil fire extinguishing agent and fire extinguishing system

The invention discloses a transformer oil fire extinguishing agent. The transformer oil fire extinguishing agent comprises, by weight, 20-30 parts of an oil-in-water type emulsifying agent, 5-20 partsof a turbidity point improving agent, 3-15 parts of a surface spreading agent, 1-5 parts of a negative combustion catalyst, 1-5 parts of a near-fire gelatinizing synergist, 0.1-3 parts of a corrosioninhibition auxiliary and 40-60 parts of water. The invention further provides a fire extinguishing system for a transformer, and the fire extinguishing system adopts the transformer oil fire extinguishing agent. The substances in the transformer oil fire extinguishing agent are low in electric conductivity and high in insulating property and achieve the synergistic effect, and therefore the finally-obtained composite fire extinguishing agent has the advantages that the insulating property is high, the fire extinguishing efficiency is high, and electrifying is safe and reliable. In addition, water mist sprayed by the fire extinguishing system for the transformer is high in insulating property, electrified fire extinguishing can be achieved, and the outdoor wind resistance is achieved.

Owner:STATE GRID HUNAN ELECTRIC POWER +3

Double-aerosol-extinguishant spraying device

ActiveCN103127641AImprove fire extinguishing efficiencyQuickly turn offFire rescueSpray nozzleAirflow

The invention discloses a double-aerosol-extinguishant spraying device which comprises a high-shooting-speed fan or an aero-gas turbine, an aerosol extinguishant spraying tube, a water supply ring, a foamite supply ring, a superfine dry powder extinguishing agent spraying gun, a superfine water mist spraying nozzle, a foamite spraying nozzle, a first solenoid valve, a second solenoid valve and a third solenoid valve. The double-aerosol-extinguishant spraying device achieves mass flow and high-shooting-speed spraying. Double-aerosol-extinguishant jet flow sprayed by the double-aerosol-extinguishant spraying device is sprayed into an internal space of a building on fire, aerosol extinguishants are rapidly dispersed to generate a 'totally flooding' state and enter the interior of flames under the action of entrainment airflow of the flames, and consequently a fire in the building can be rapidly put out, and the flames are prevented from reburning.

Owner:SHANDONG GUOTAI TECH

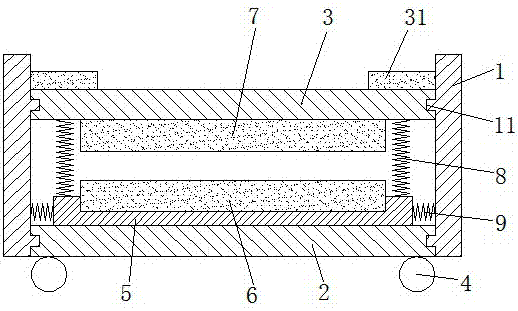

Damping base

InactiveCN107339552APrevent impactReduce vibrationPortable framesNon-rotating vibration suppressionEngineeringHorizontal and vertical

The invention provides a shock-absorbing base, which includes a bottom surface and a side wall. A lower support plate is provided on the upper end of the bottom surface, and the lower support plate and the side wall are connected by a plurality of transverse compression springs; the lower support plate A groove is arranged on the groove, and a lower magnet is arranged on the groove, and the lower support plate is connected with the upper support plate through a longitudinal compression spring, and the upper support plate is connected with the side wall; the lower part of the upper support plate An upper magnet is provided, a gap is provided between the upper magnet and the lower magnet, and the upper magnet and the lower magnet are arranged opposite to each other with the same magnetic poles. The invention can reduce the vibration from the horizontal and vertical directions, and reduce the noise when the equipment is running; it can bear heavy weight, is not easy to break, and has a simple and reasonable structure.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Preparation method for oxygen barrier composite layer grain packing bag

InactiveCN102514235AAvoid resurgenceTo meet the requirements of anti-mildewPaper-makingBox making operationsFiberWhole body

The invention relates to a preparation method for an oxygen barrier composite layer grain packing bag. The preparation method is characterized by comprising the following steps of: adopting anti-aging polypropylene materials as a protection layer; adopting a three-layer composite oxygen barrier film consisting of polypropylene / ethylene-vinyl acetate / polyethylene or polypropylene / partial chloroethylene / and polyethylene as an oxygen barrier layer; mixing linen with ES fiber according to different proportions; preparing two layers of fiber webs of a film sticking layer and a moisture absorption layer respectively by a nonwoven technology; combining the fiber webs into a whole body through a needling layer; overlapping a non-hydrophilic ES fabric web formed by the nonwoven technology on themoisture absorption layer; preparing a composite water locking layer by needling again, wherein the three layers of materials are the protection layer, the oxygen barrier layer and the composite water locking layer sequentially from top down; preparing a material of a bag body through thermal compound; and preparing the grain packing bag by cutting, suturing, hot pressing and sealing. According to the method, the conventional production equipment can be used, the process is simple, the production cost is low, the mold and toxin are prevented from being bred in grains in the bag by regulating the proportion of the materials of all the layers and in the layers, and various requirements of storage, transportation and mold resistance are met.

Owner:安吉振兴布业有限公司 +1

Glyphosate assistant and preparation method thereof

InactiveCN103109801AReduce manufacturing costImprove liquidityBiocideGroup 5/15 element organic compoundsSulfite saltGlyphosate

The invention discloses a glyphosate assistant and a preparation method thereof. The glyphosate assistant comprises the following raw materials in percentage by weight: 15-30% of anhydrous sodium sulfite, 10-15% of sulphamic acid or sodium borate, 40-60% of ammonium bicarbonate, 5-10% of catalyst and 4-15% of surfactant; the glyphosate assistant can convert glyphosate active compound into glyphosate soluble powder under the condition of normal temperature and normal pressure; the prepared soluble powder is dry, and the expanding or moisture absorption is avoided; the preparation method mainly comprises the steps of preparing surfactant, catalyst and product; and the preparation method is simple and practicable.

Owner:段凤羽

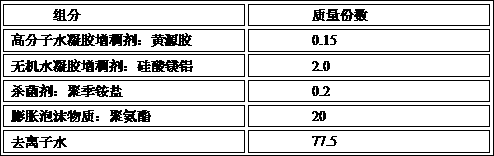

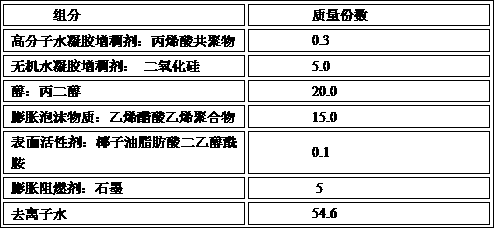

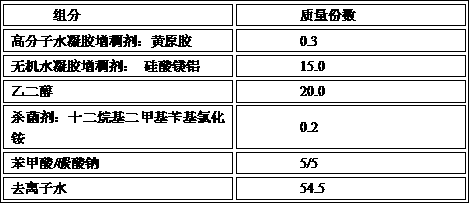

Fireproof cooling hydrogel and preparation method thereof

The invention relates to the fields of manufacturing and application of heat-resistant, heat-insulating, flame-retardant and high-temperature expansion materials, specifically to a hydrogel with fireproof and cooling functions and a preparation method thereof. The hydrogel comprises the following components in parts by mass: 0.05-20 parts of a hydrogel thickening agent, 5-35 parts of a freezing point depressant, 1-30 parts of an expanded foam material, 1-15 parts of an expanded flame retardant, 0.01-1 part of a foaming agent, 1-15 parts of a gas generating agent and 0.01-1 part of a bactericide. The hydrogel provided by the invention has the following innovations: when the hydrogel directly acts on the surface of a comburent, the hydrogel can be adhered to the surface of the comburent; meanwhile, foams can be generated on the surface of the comburent and contain water, so the water can be sealed in the foams to continuously exert cooling and fire extinguishing effects; after the wateris dried, an expansion flame-retardant layer can be formed to provide continuous heat-insulation and flame-retardant functions; and the functions of fire extinguishing, cooling, heat insulation and fire reburning prevention are achieved.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

Processing method of crispy fried ducks

The invention discloses a processing method of crispy fried ducks. The processing method of the crispy fried ducks is characterized by comprising the following steps: slaughtering ducks, removing feathers, internal organs and flippers, carrying out marinating, cooking the marinated ducks with water, sorting the cooked ducks, namely pressing the breastbones of the sorted cooked ducks to be flat, and removing exposed leg bones and residual feathers; stewing the cooked ducks with marinade, carrying out starching, namely weighing beta-cyclodextrin of which the weight is 0.1-0.2% of the weight of the to-be-starched ducks, adding water into the weighed beta-cyclodextrin so as to prepare thin paste, and coating inner and outer surfaces of the stewed ducks with the thin paste; carrying out oil-frying until the coated ducks are crispy, carrying out sealed packaging, and carrying out sterilizing. According to the processing method of the crispy fried ducks, the seasonings are adjusted, so that unique fresh and delicious flavor of the ducks is more obvious. Sodium nitrite and cyclodextrin are added so as to greatly prolong storage time of the crispy fried ducks; and tests have proven that the storage time of the crispy fried ducks is 12 months, so that food safety is ensured. By adding the beta-cyclodextrin, the processing method of the crispy fried ducks is capable of removing fishy smell of the ducks in a long time by utilizing unique 'cavity' structure of the cyclodextrin as well as effectively preventing the crispy fried ducks from dampening by the barrier layer formed by the cyclodextrin. The crispy fried ducks produced by the processing method are delicious in taste, crispy in the outsides, tender in the meat texture and long in storage lives.

Owner:NANCHONG GUOJIANGLONG FOOD

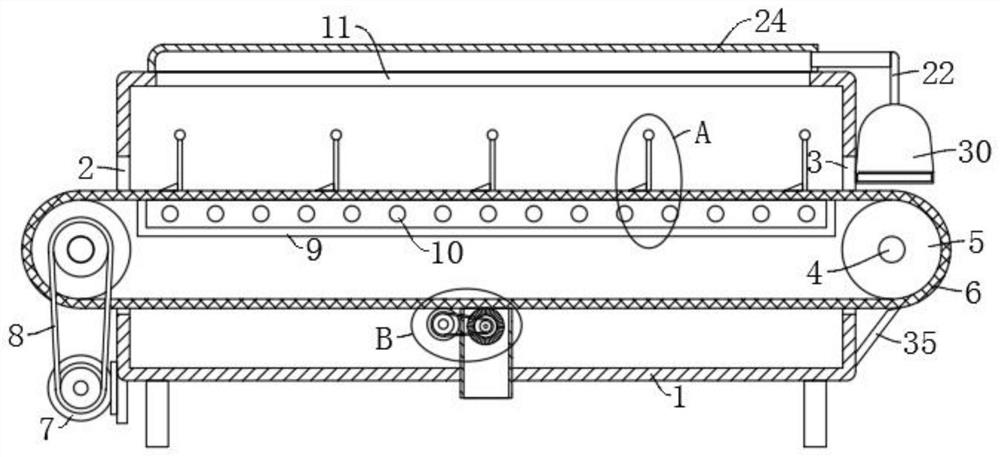

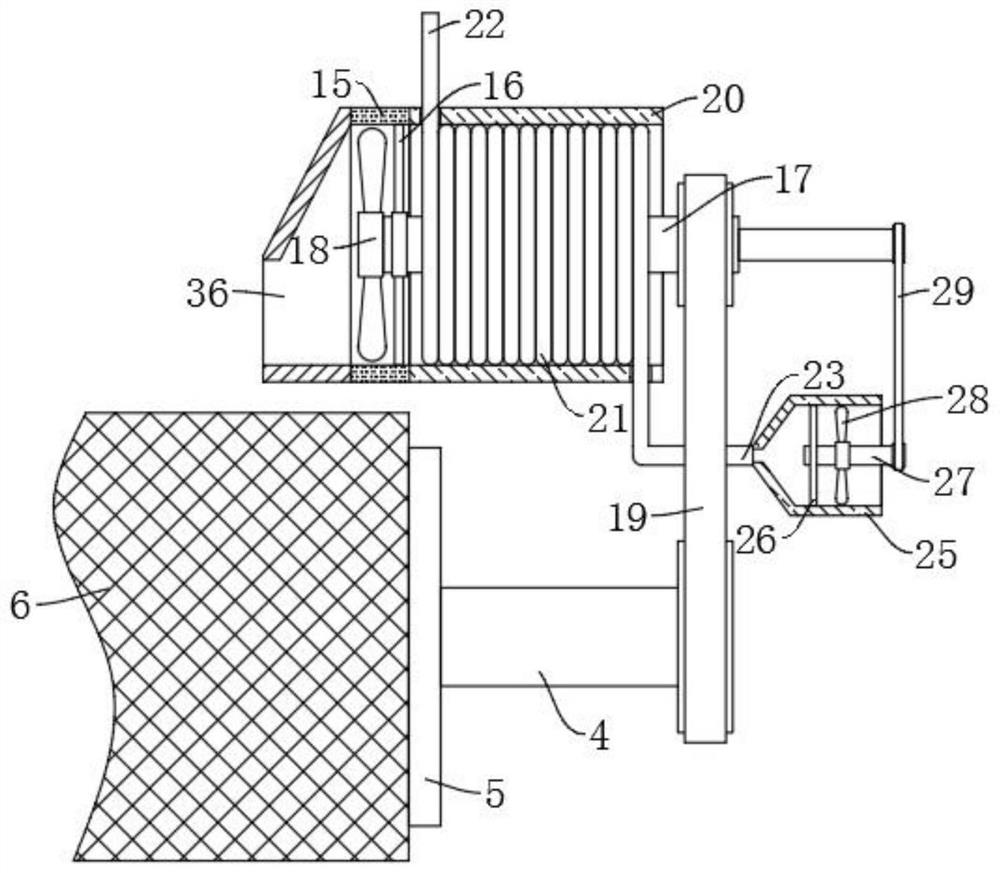

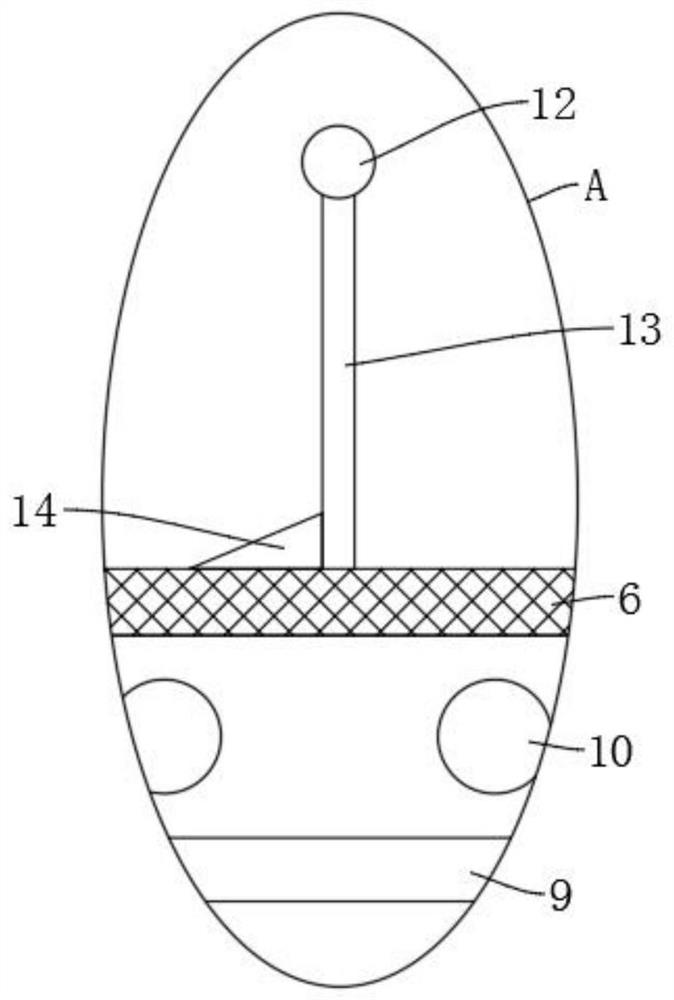

Roller type efficient mulberry leaf drying device

ActiveCN107990663AAffect nutritional valueAvoid uneven heatingDrying gas arrangementsDrying chambers/containersDrive shaftAgricultural engineering

The invention discloses a roller type efficient mulberry leaf drying device. The roller type efficient mulberry leaf drying device comprises a base, a roller, a transmission mechanism and an air heater; two stand plates are arranged on the left and right sides of the top of the base; a cross beam is connected to the tops of the stand plates on the two sides; the roller is arranged above the base;a left rotating shaft and a right rotating shaft are respectively connected to the centers of the end surfaces on the two sides of the roller; the right rotating shaft is an extension shaft with a hollow design; a transmission shaft for driving the left rotating shaft to rotate is arranged on the left side of the left rotating shaft; the transmission shaft is provided with a transmission mechanismfor driving the transmission shaft to rotate; the air heater is mounted on the right side of the base; a hot air pipe upwards extends to penetrate through the stand plate on the right side, and extends into the roller in the axis direction of the right rotating shaft; exhaust ports are densely formed in the hot air pipe; and an overturning rod is arranged at the outer periphery of a pipe body ofthe hot air pipe. The mulberry leaf drying device can effectively prevent nutrient loss of mulberry leaves to guarantee no influence on nutritional value of the mulberry leaves, and meanwhile, is uniform in heating of the mulberry leaves and excellent in drying effect to guarantee the quality grade of dried finished products.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH +1

Additive for water-mist fire suppression system

InactiveCN1634622ANo pollution in the processImprove fire extinguishing efficiencyFire extinguisherSodium lactateN dimethylformamide

The invention relates to a water mist fire extinguishing addictive. It characterizes in that 3.0%-6.0%(by weight) fluorine surfactant, 67.45%-80.25%(by weight) water, 0.25%-0.5%(by weight) triethanal amine ,4.0%-6.5%(by weight) urea, 1.0%-1.5%(by weight) sodium lactate, 1.5%-3.0%(by weight) alkylphenol polyoxyethylene are added to 10.0% to 15.0%(by weight) N-N-dimethylformamide, then PH of which be regulated between 7.5 to 8.5 by acetic acid or sodium hydroxide after it dissolved completely. Filtering the solution to get the concentrated solution of the water mist fire extinguishing addictive of the present invention. Water should be added to dilute the solution to lower the fluorine surfactant content down to 0.2% to 0.8% in use.

Owner:UNIV OF SCI & TECH OF CHINA

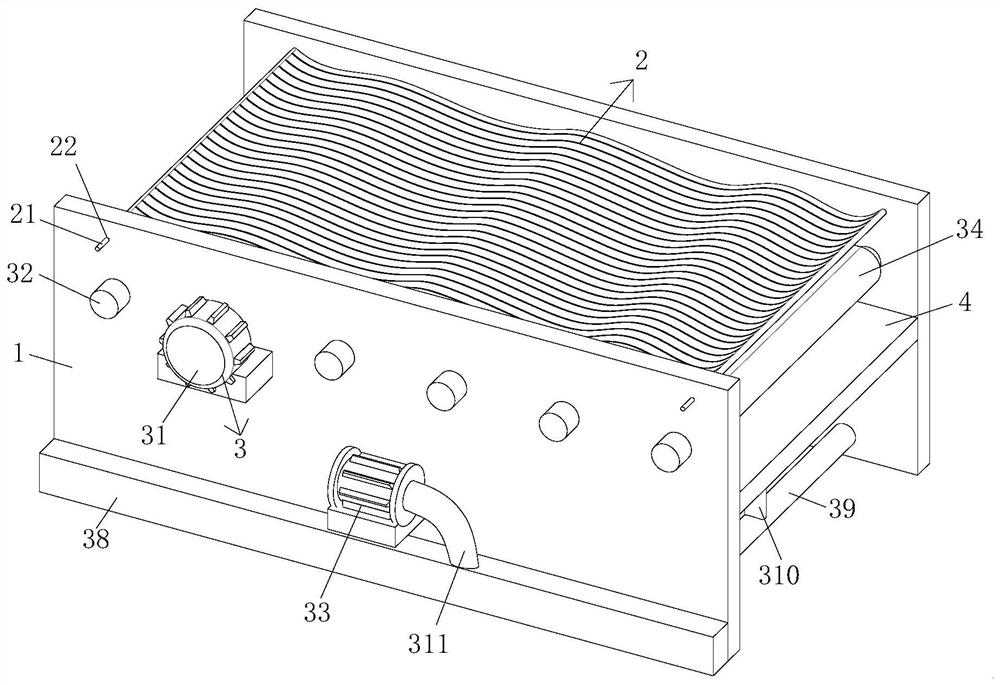

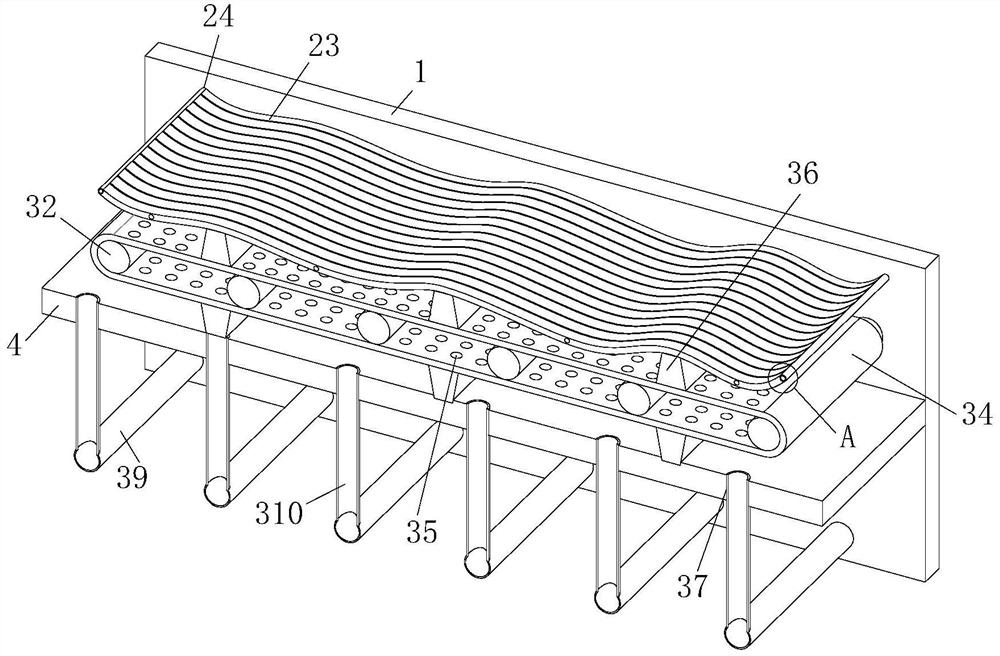

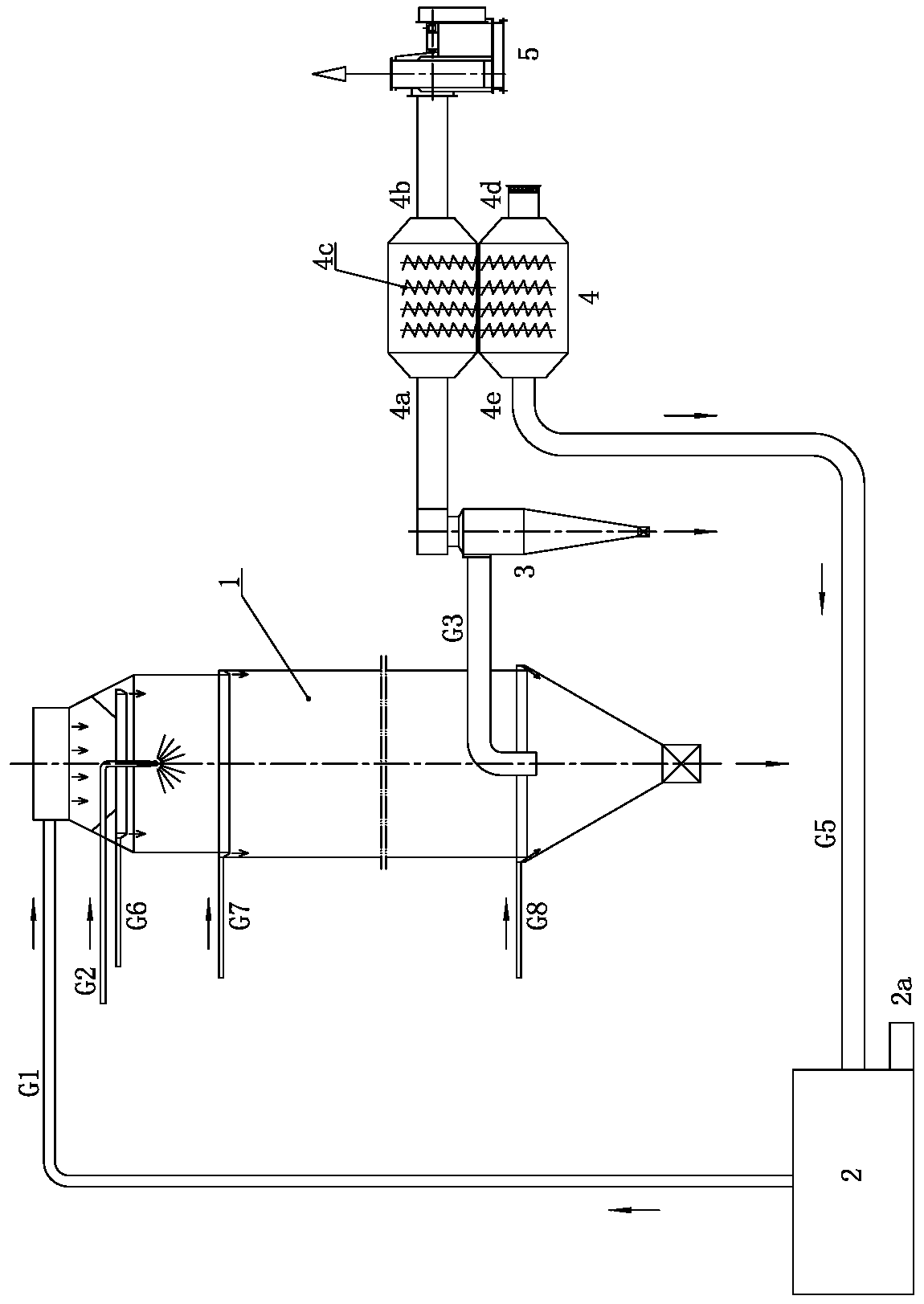

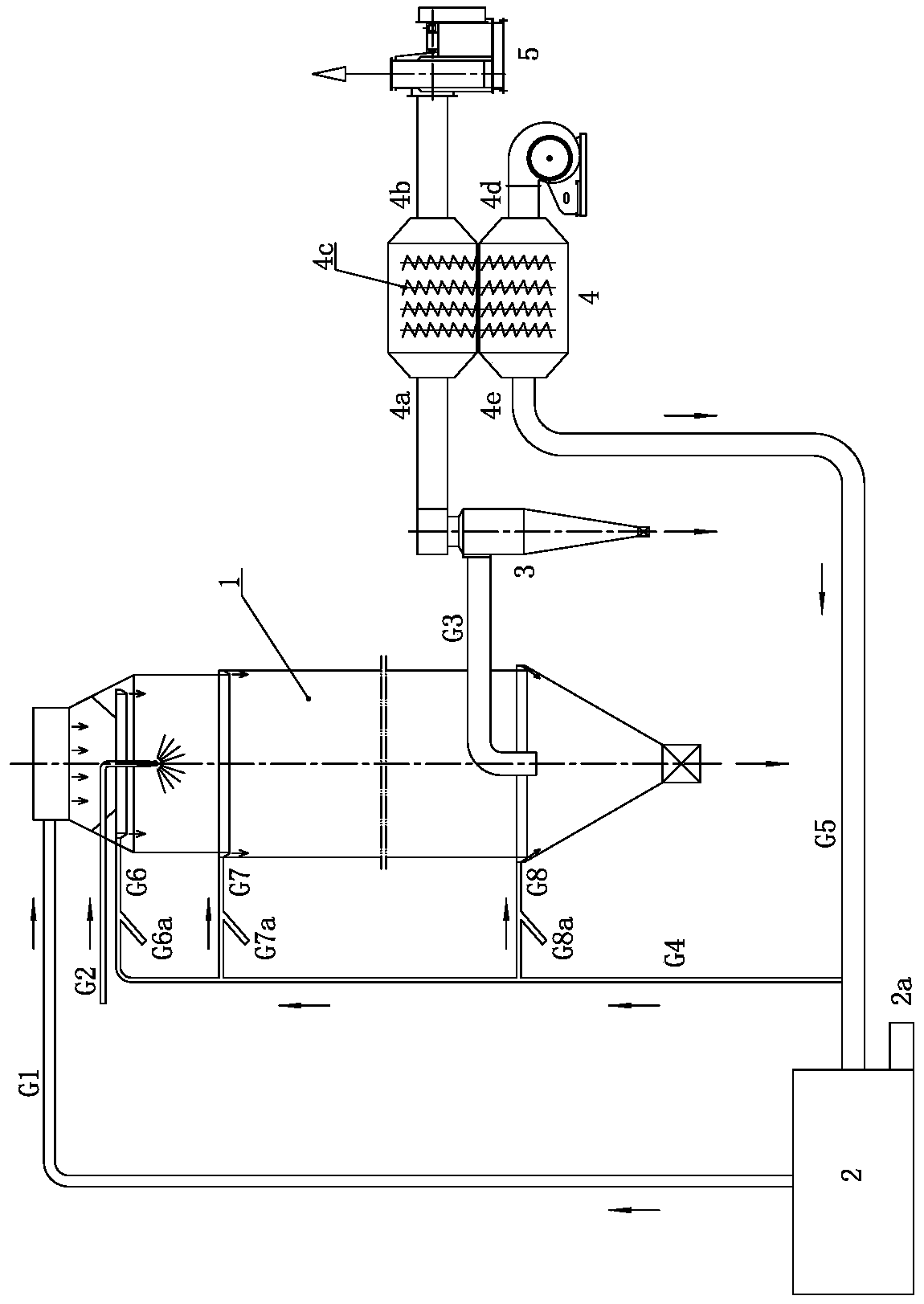

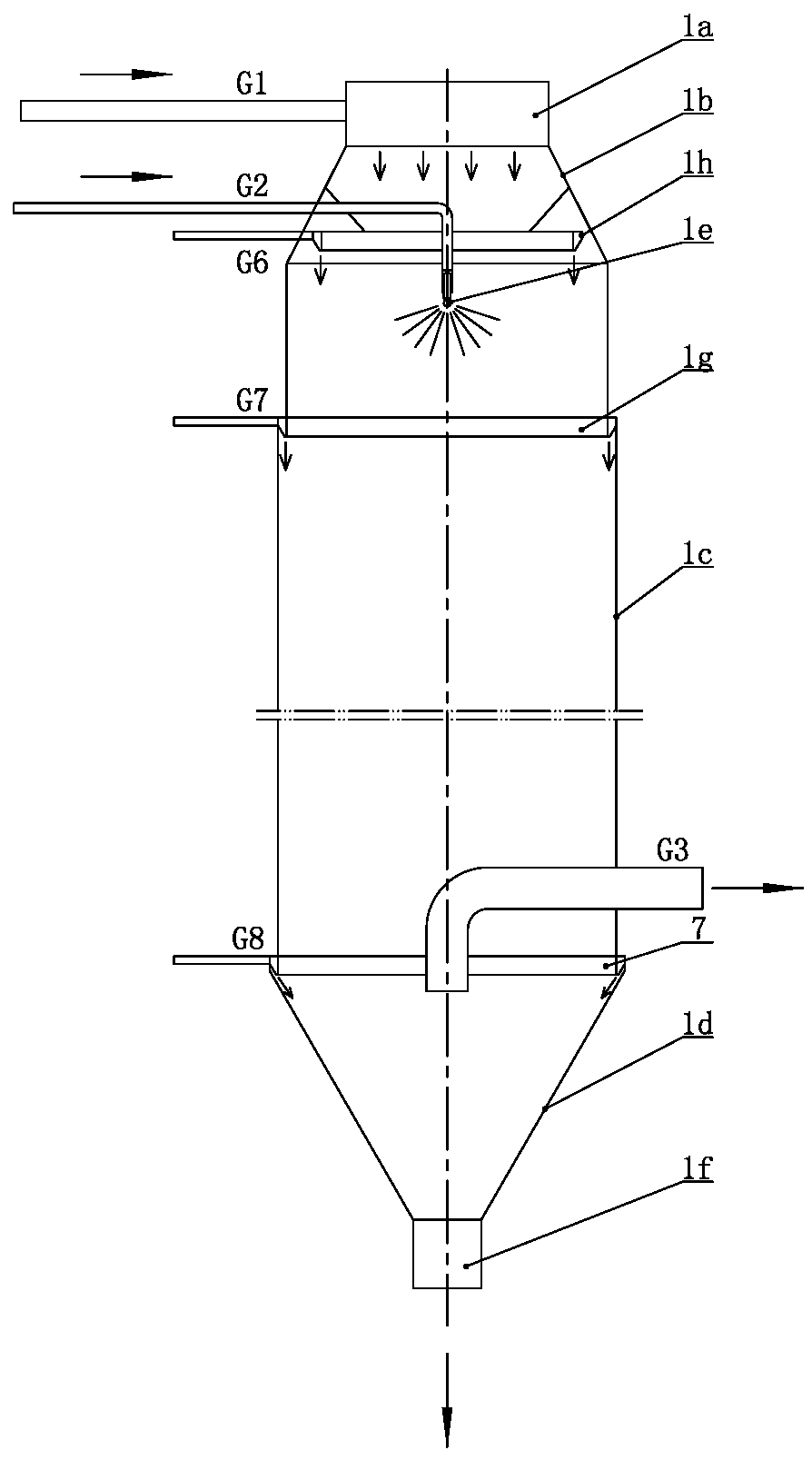

Method and device for generating foam in high-speed gas jet

ActiveCN102029030AImprove fire extinguishing efficiencyHigh foaming rateFire rescueLiquid waterTruck

The invention discloses a method and a device for generating foam in high-speed gas jet. The method comprises the following steps of: jetting foam extinguishing fluid to form liquid film jet, impacting a liquid film by using high-speed airflow to tear the liquid film, mixing the torn liquid film and gas to generate foam beads so as to form foam jet which does not contain flowable liquid water. A turbojet fire fighting truck has the function of jetting a foam extinguishing agent, and extinguishing efficiency is greatly improved; when a foam jetting button is not pressed, the turbojet fire fighting truck jets gas-water mist jet to disperse toxic fume in a fire scene, control fire, cool the fire scene and rescue people in the fire scene; and when the foam jetting button is pressed, the turbojet fire fighting truck jets gas-foam jet to quickly extinguish large oil gas fire and prevent oil gas from reburing, so that the turbojet fire fighting truck with the jet power of thousands of kilowatts becomes truly large fire fighting equipment.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

Method for preparing mildew-proof grain packing bag with water locking layer

The invention relates to a method for preparing a mildew-proof grain packing bag with a water locking layer. The method comprises the following steps of: preparing a protective layer by adopting an anti-aging polypropylene material; preparing an oxygen isolating layer by adopting a three-layer composite oxygen isolating film consisting of polypropylene / ethylene-vinyl acetate / polyethylene or polypropylene / vinylidene chloride / polyethylene; blending super absorbent fibers (SAF) and ethylene-propylene side by side (ES) fibers, and preparing the water locking layer by a non-woven processing method; preparing a non-hydrophilic layer by adopting non-hydrophilic polypropylene spun-bond nonwoven cloth or non-hydrophilic polypropylene / polyethylene double-component fiber hot-rolled nonwoven cloth; thermally compounding the protective layer, the oxygen isolating layer, the water locking layer and the non-hydrophilic layer from top to bottom to obtain a bag material; and cutting, sewing, performing hot pressing, sealing the edges, and thus obtaining the mildew-proof grain packing bag with the water locking layer and with high strength. The conventional production equipment can be used in the method, so the method is simple and low in production cost; and by adjusting the proportion of the materials of all layers or the materials in each layer, mildew and toxin are prevented from beingpropagated in the grains in the bag, and the storage, transportation and mildew-proof requirements of various grains are met.

Owner:DONGHUA UNIV +1

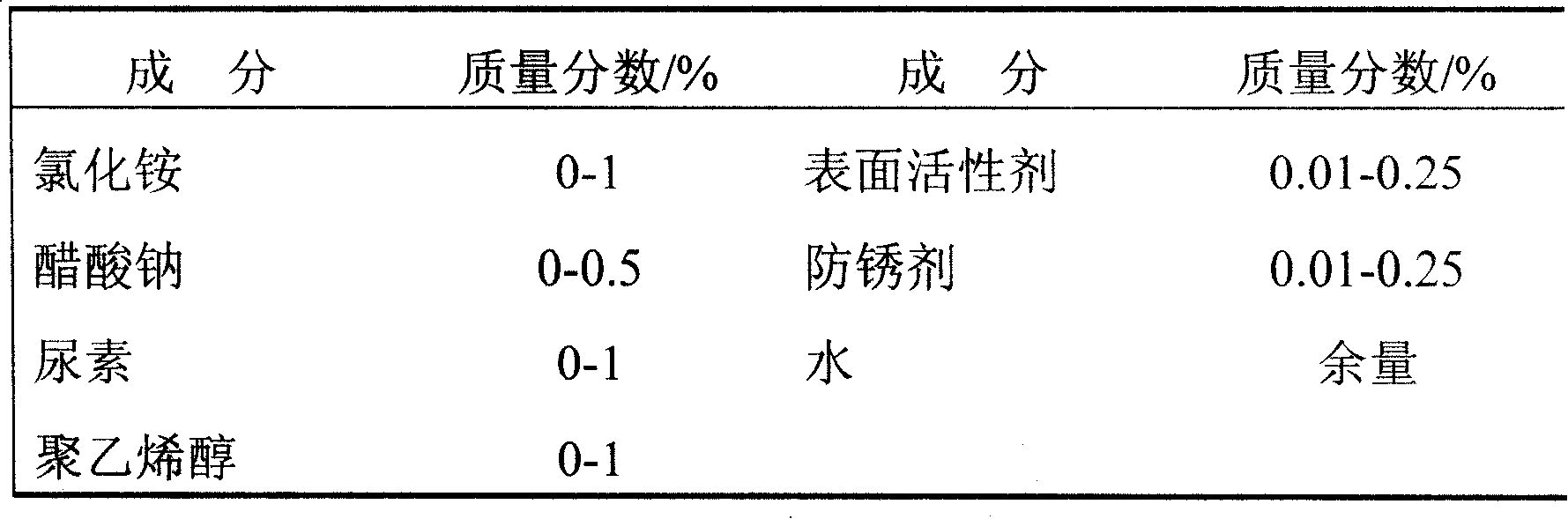

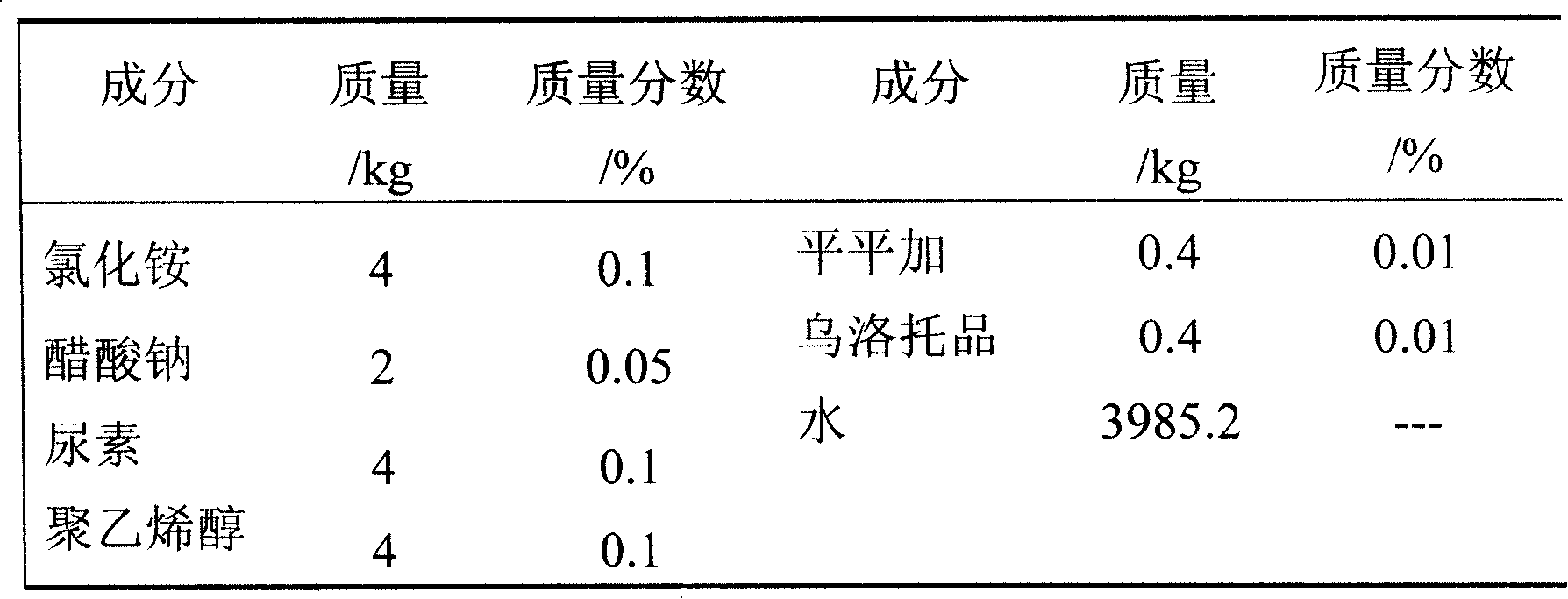

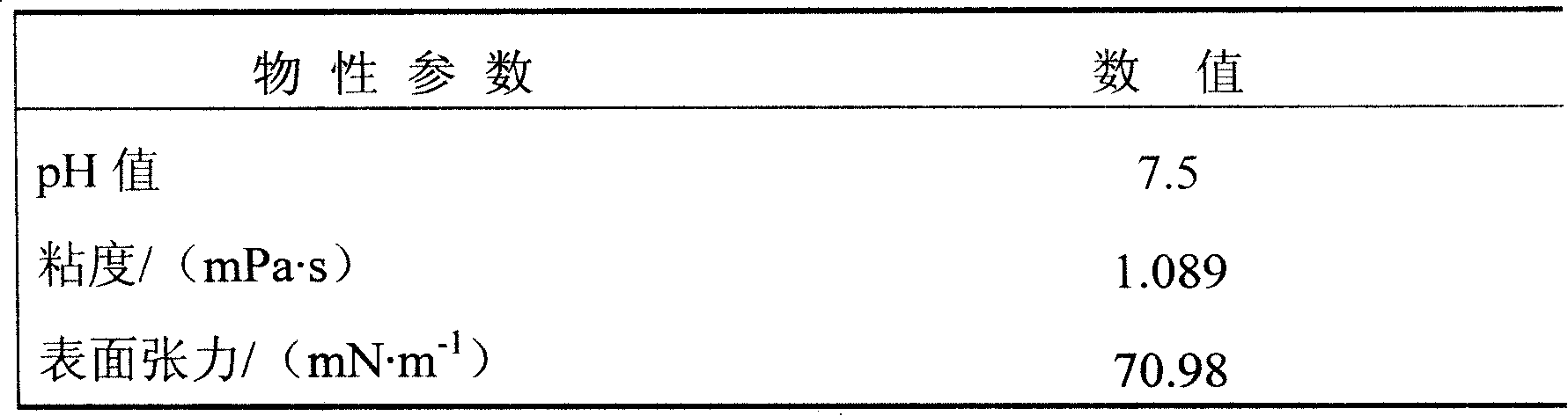

Water solution containing fine spray extinguishment additive agent and preparation and application

InactiveCN101214411AReduce the temperatureStrong penetrating powerFire rescueFire extinguisherSodium acetateCombustion

The invention relates to aqueous solution with fine water mist fire extinguishment additive, with the quality percentage of all components as below: ammonium chloride 0 percent to 1 percent, polyvinyl alcohol 0 percent to 1 percent, sodium acetate 0 percent to 0.5 percent, surface active agent 0.01 percent to 0.25 percent, urea 0 percent to 1 percent, rust preventive 0.01 percent to 0.25 percent, and the rest is water. The aqueous solution can improve the fire extinguishing efficiency of the fine water mist and effectively prevent after-combustion of inflamers; has little corrosion to equipments and instruments; basically has no pollution to fire scenes; is high-efficiency, stable and clean; the raw materials of all components are easy to be obtained; has stable performance; is basically nontoxic and low in cost; and has low consumption.

Owner:HENAN POLYTECHNIC UNIV

Concentrated high-efficient fire extinguishing agent and preparation method thereof

The invention belongs to the field of chemical materials, and particularly relates to a concentrated high-efficient fire extinguishing agent and a preparation method thereof. The concentrated high-efficient fire extinguishing agent is prepared from the following raw materials: urea, ammonium chloride, ammonium sulfate, sodium bicarbonate, potassium carbonate, a sodium silicate gel solution, ethylene glycol, ammonium polyphosphate, a surfactant, a foaming agent and water. The fire extinguishing agent is fewer in raw materials, low in cost, high in fire extinguishing grade, wide in application range and good in anti-reflash performance; the fire extinguishing agent is low in freezing point, so that the freezing point is applicable to the low-temperature environment of the northeast area; the fire extinguishing agent is concentrated, and before use, the fire extinguishing agent is mixed with water according to a ratio of 1:16 and can extinguish fires of 2A and 89B, so that the fire extinguishing agent occupies small space when being stored conventionally; and the fire extinguishing agent is soluble in water, so that a uniform solution state can be reached immediately after the fire extinguishing agent is mixed with water.

Owner:沈阳仁辉消防科技有限公司

Composite dry powder extinguishing agent and preparation method therefor

InactiveCN103877693AAvoid resurgenceHas natural moisture resistanceFire extinguisherMagnesium ionEthanol

The invention discloses a gas-solid composite dry powder extinguishing agent and a preparation method therefor. The method is characterized by the steps as follows: dissolving urea in an ethanol-water mixed solution with a volume ratio of ethanol to water being 1:2-5, the concentration of magnesium ion being 0.2-1.2 mol / L and the molar ratio of the urea to the magnesium ion being 2-6:1; heating the mixed solution at 90-120 DEG C for 8-12 hours to obtain a white precipitate of magnesium hydroxide; filtering the solution; washing the white precipitate; drying the white precipitate at 120 DEG C for 6-12 hours; placing the dried magnesium hydroxide precipitate into a pressure-resistant container; vacuumizing the container; filling the pressure-resistant container with 2-bromo-3,3,3-trifluoropropene (BTP) liquid, wherein the mass of the 2-bromo-3,3,3-trifluoropropene accounts for 5.0-16% of the mass of the system; allowing the system to stand at 35-50 DEG C for 12-24 hours; cooling the system to room temperature; adding talcum powder to the container with the mass of the talcum powder accounting for 1.0-4.0% of the mass of the system; mixing the powder uniformly to obtain the gas-solid composite dry powder extinguishing agent. The extinguishing agent is low in corrosivity and good in anti-reburn performance. The raw materials of the extinguishing agent are cheap and easy to obtain and the preparation process is simple. The extinguishing agent is suitable for various fire hazards such as solid fires, combustible gas fires and liquid fires or the like.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

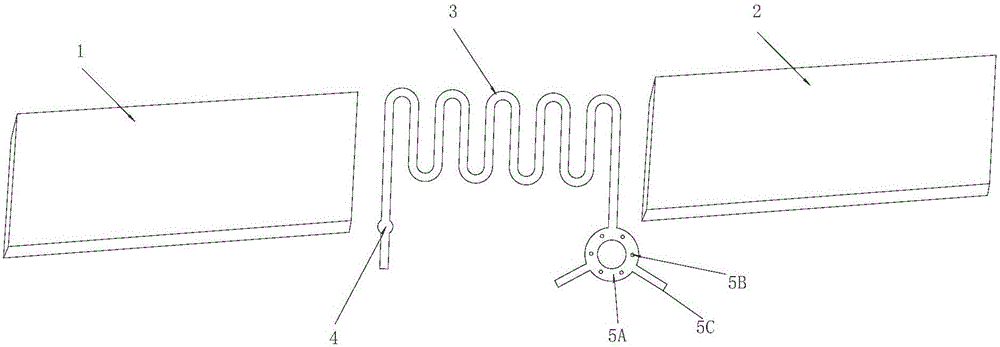

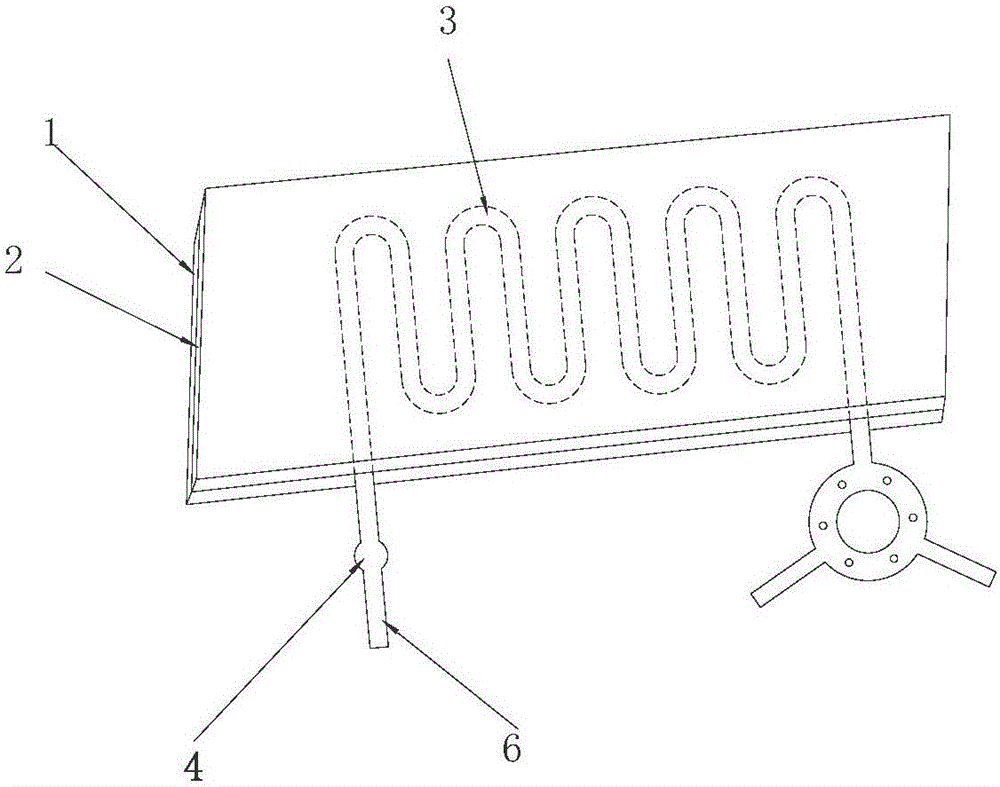

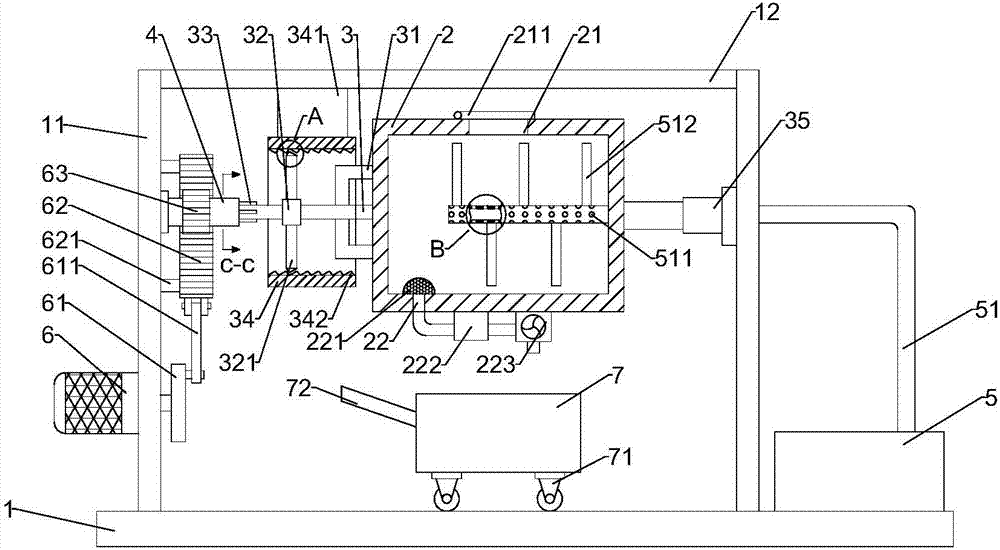

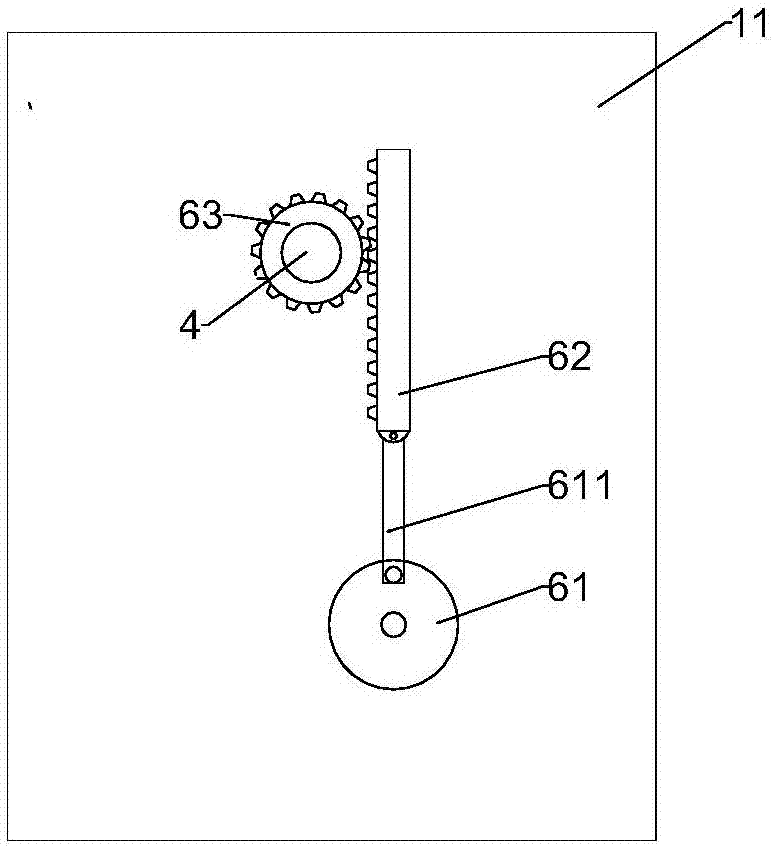

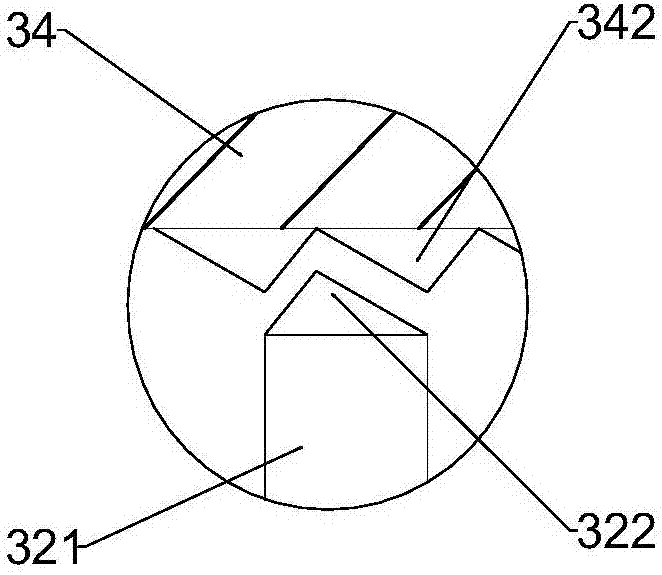

Outdoor airing use airing device for sliced earthworm processing

ActiveCN111964404AAvoid resurgenceQuick foldDrying gas arrangementsDrying machines with non-progressive movementsMedicinal herbsAgricultural science

The invention provides an outdoor airing use airing device for sliced earthworm processing and relates to the field of medicinal material processing. Two side plates used for supporting equipment, a sliced earthworm airing mechanism used for laying the earthworms and performing airing treatment on the earthworms, and a wind power guiding mechanism used for guiding the earthworms and performing wind power accelerating airing on the earthworms are included. The sliced earthworm airing mechanism and the wind power guiding mechanism are both arranged on the side plates. According to the outdoor airing use airing device for sliced earthworm processing, according to the problems of energy consumption, airing, damage and the like existing in the airing process of the earthworms, an ingenious andspecial airing device is designed, heat energy and wind power are concentrated for airing, influences by various factors such as weather on the finished product quality can be overcome, and thereforethe problems that generally cut earthworms cannot be easily overturned during airing and drying, airing is prone to be nonuniform, adhesion to the ground is easily caused during airing or drying, longtime is needed for airing and drying, and the processing efficiency is affected to a certain degree are effectively solved.

Owner:南京道图信息技术有限公司

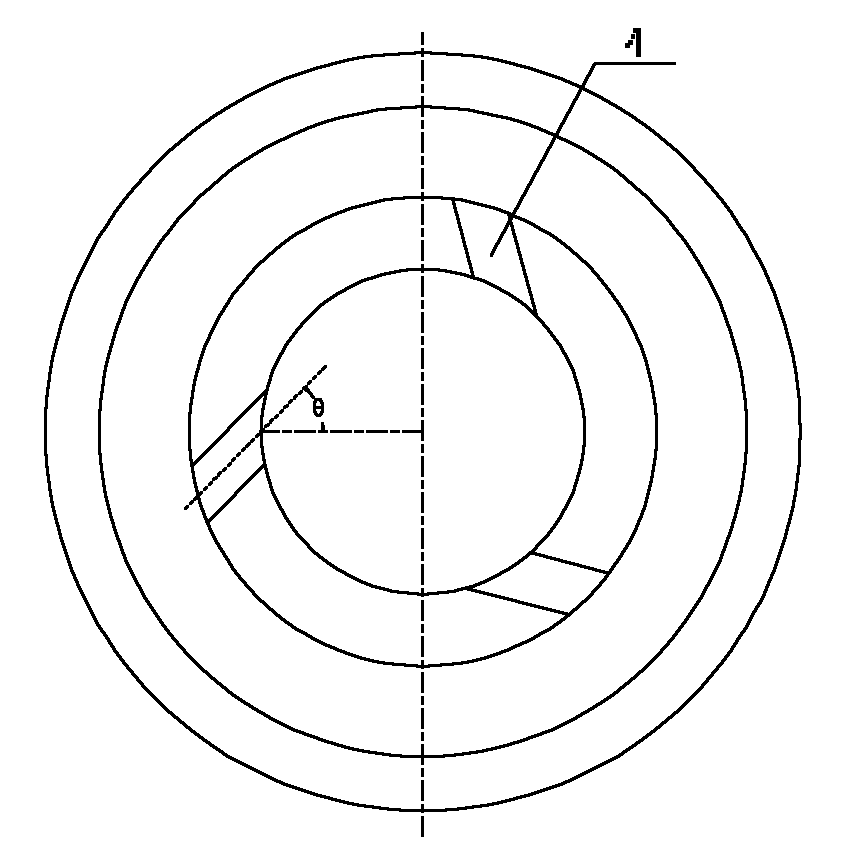

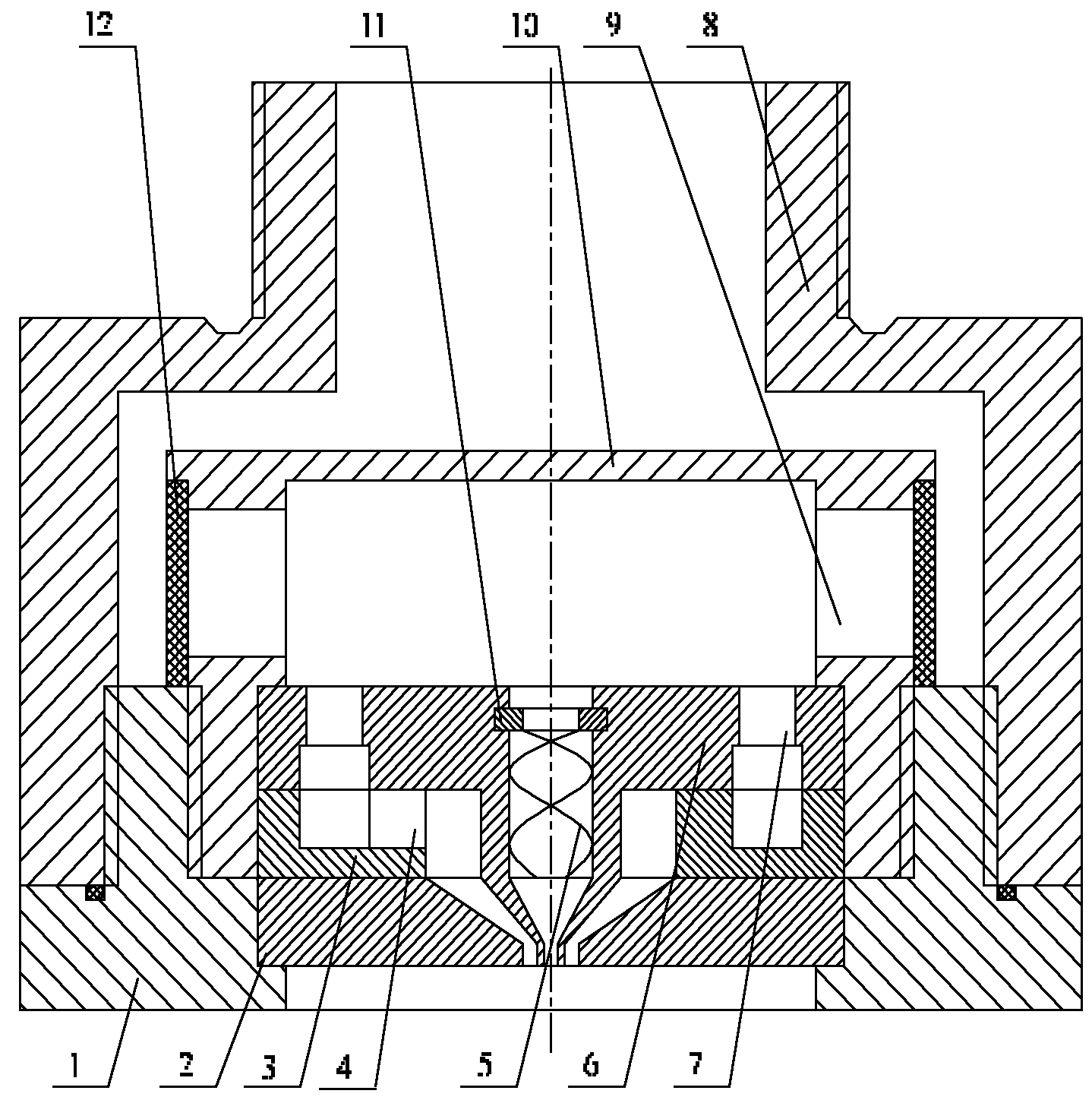

High-pressure direct injection type double-layer fine mist spray head

InactiveCN101972532AIncreased turbulence intensityEvenly distributedFire rescueAgricultural pesticidesWater flow

The invention discloses a high-pressure direct injection type double-layer fine mist spray head. The spray head comprises a spray head cap (1), an atomization plate (2), a whirl plate (3), a guide post (5), a shunt plate (6), a spray head seat (8), a filter cylinder (10), a clamping ring (11) and a filter screen (12). High-pressure water current rotates regularly at a high speed along a circular whirl cavity formed by the whirl plate and the conical part of the shunt plate under the guide of a flow guide slot of the whirl plate so that the water mist sprayed from an outer nozzle has the characteristics of high speed, uniform distribution and the like; a double-layer fire extinguishing nozzle greatly increases the atomization angle of the spray head and improves the atomization range, and the water current still has high axial motion quantity so that the mist drops can penetrate the fire field space to realize deep fire extinguishment; and circular water films are unstably broken more easily under the action of the air through the circular outer nozzle so that good atomization effect is achieved. The spray head also can be applied in the fields of agricultural pesticide spraying, food processing, medicinal treatment and the like besides the fire fighting field.

Owner:九江中船消防设备有限公司

Cosmetic production raw material drying device

InactiveCN111947437AEffective automatic flangingImprove drying efficiencyDrying solid materials with heatCleaningElectric machineryProcess engineering

The invention discloses a cosmetic production raw material drying device, and belongs to the field of cosmetics. The cosmetic production raw material drying device comprises a drying box, wherein rollers are rotatably connected into an inlet and an outlet through rotating shafts, the outer walls of the two rollers are sleeved with a conveying belt, a motor is fixedly installed on the side wall ofthe drying box, and an output shaft of the motor is in transmission connection with one of the rollers through a first chain. A plurality of evenly-distributed transverse rods are fixedly connected between the inner walls of the drying box, triangular blocks attached to the upper end face of the conveying belt are fixedly connected to the lower ends of the transverse rods through supporting rods,an exhaust groove is formed in the upper end of the drying box, and an air blowing device connected with the rotating shaft is arranged at the upper end of the outlet. A cleaning device matched with the conveying belt is arranged at the lower end of the drying box; The cosmetic production raw material drying device dries cosmetic raw materials while the cosmetic raw materials are turned over and and blow-dried, moisture regaining caused by steam after drying of the raw materials is prevented, and the drying effect is greatly improved.

Owner:陈晓明

Air-purification, humidifying, self-cleaning, antimicrobial and healthy shell powder biomass dry powder coating

The invention relates to the field of a multifunctional biomass coating, particularly to an air-purification, humidifying, self-cleaning, antimicrobial and healthy shell powder biomass dry powder coating. The dry powder coating comprises, according to a weight part ratio, 25-40 parts of shell powder, 0.5-2.0 parts of nanometer yiwangshi negative ion powder, 10-20 parts of titanium dioxide, 0.8-2.5parts of a solid antifoaming agent, 0.5-10 parts of pigments and fillers, 7-13 parts of an adhesive, 0.5-5.0 parts of cellulose ether, 0.5-1.5 parts of a wetting dispersant, 1.5-2.0 parts of a dry film mildew inhibitor, and 0.5-1.5 parts of an auxiliary agent. The air-purification, humidifying, self-cleaning, antimicrobial and healthy shell powder biomass dry powder coating takes shell powder asa main raw material, doesn't emit harmful gases including formaldehyde, benzene, ammonia gas, and TVOC (volatile organic compounds), and has the function of formaldehyde and VOC adsorption, breathability and humidity controlling, and wall self-cleaning, is easy to repair, is antimicrobial, and can remove ticks and peculiar smell.

Owner:上海雁阵生物科技发展有限公司

Flow-control and variable-temperature spray drying system

PendingCN109045733AImprove cleanlinessAvoid wall stickingEvaporator accessoriesEvaporation by sprayingTemperature controlPulp and paper industry

The invention relates to a flow-control and variable-temperature spray drying system which comprises a heating device, a spray drying tower and an induced draft fan, wherein the spray drying tower comprises an uniform-air section, a tower upper cone, a barrel and a lower cone body from top to bottom; the side wall of the uniform-air section is connected with a tower body hot-blast main pipe; the side wall of the tower upper cone is connected with a feed liquid pipe; the inner end of the feed liquid pipe is connected with a feed liquid atomizing device; the feed liquid atomizing device is positioned on the axis of the barrel; the lower end of the barrel is connected with a tower body exhaust pipe; a finished product discharge valve is mounted at a lower port of the lower cone body; an air outlet of the heating device is connected with the tower body hot-blast main pipe; at least one barrel rectifying ring capable of forming an annular downward air flow on the inner wall of the barrel ismounted on the circumference of the barrel of the spray drying tower; the barrel rectifying ring is coaxial with the barrel; the outer side wall of the barrel rectifying ring is connected with a barrel rectifying ring blast pipe; a plurality of temperature gradients are formed in the tower body from top to bottom. The spray drying system can avoid wall sticking and realize online variable-temperature control, and the product has the advantages of high yield and good quality.

Owner:吴际

Mooncake coated with mixed sugar

ActiveCN101984833APrevent expansion and deformationAvoid resurgenceBakery productsSugarFilling ratio

The invention relates to a mooncake coated with mixed sugar, belonging to the technical field of food production. The invention aims at the technical problems of the traditional production process of the mooncake that the mooncake is easy to expand and deform, the patterns on the mooncake are not clear and are easy to rewet, and the mooncake skin is fogged and has bad mouth feeling. The mooncake skin of the mooncake coated with mixed sugar is prepared from the following raw materials in parts by weight: 40-50 parts of flour, 15-30 parts of sugar, 14-18 parts of oil, 2-5 parts of honey and 16-18 parts of water. The specific preparation method comprises the following steps: wraping filling with the skin according to a skin-filling ratio of 2:3, filling the mooncake in a mould of which bottom is carved with patterns to compact, taking out the formed mooncake, coating a layer of flour paste accounting for 3-5wt% of the skin on the surface, drilling at least one hole in the mooncake, baking the mooncake in an oven, taking out the baked mooncake from the oven, and cooling to obtain the finished product. The mooncake coated with mixed sugar has the following advantages: the mooncake can not expand and deform, the patterns on the mooncake are clear and can not rewet, and the mooncake skin is not fogged and has good mouth feeling.

Owner:太原双合成文化传播有限公司

Paper mulberry bark dyeing method capable of preventing color fading

InactiveCN107139292ANot easy to fadeUniform colorRadiation/waves wood treatmentWood treatment detailsMicrowaveEngineering

The invention belongs to the technical field of bark processing, in particular to a method for dyeing bark bark to prevent fading. First, the bark bark is soaked in soaking liquid, steamed and dried, which not only can effectively kill harmful bacteria carried by the bark, but also Enlarging the pores between the bark cell structures is conducive to dyeing, and can effectively improve the stability of the bark fibers, making them more flexible and elastic, and effectively inhibiting the cracking of bark handicrafts; then soaking in dyeing agents, microwave and heat The pressure drying treatment can not only make the bark of the tree evenly colored, bright in color, enhance its anti-sun ability, avoid decay and fading after exposure to the sun, but also effectively prevent moisture resurgence. The smell is fragrant, non-irritating, and will not cause any damage to the human body.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

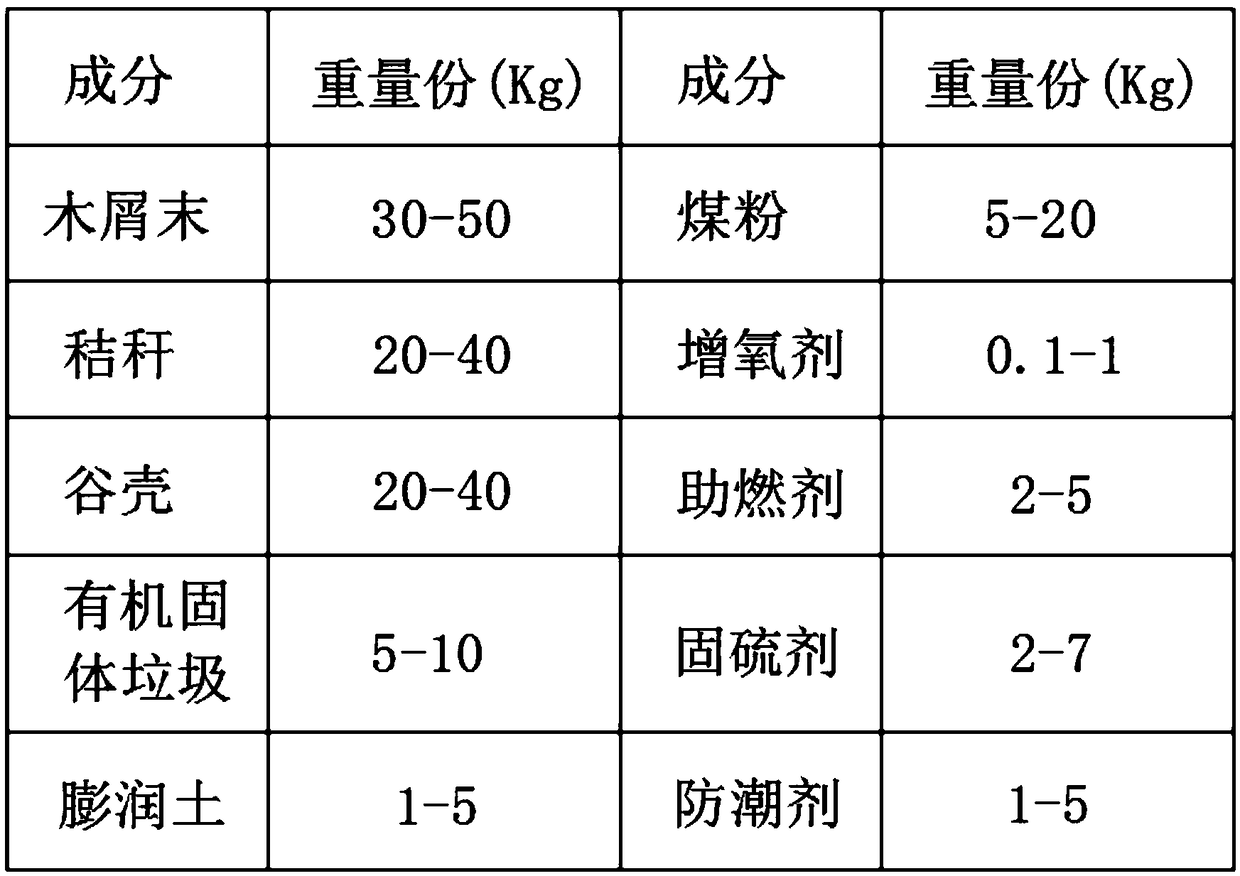

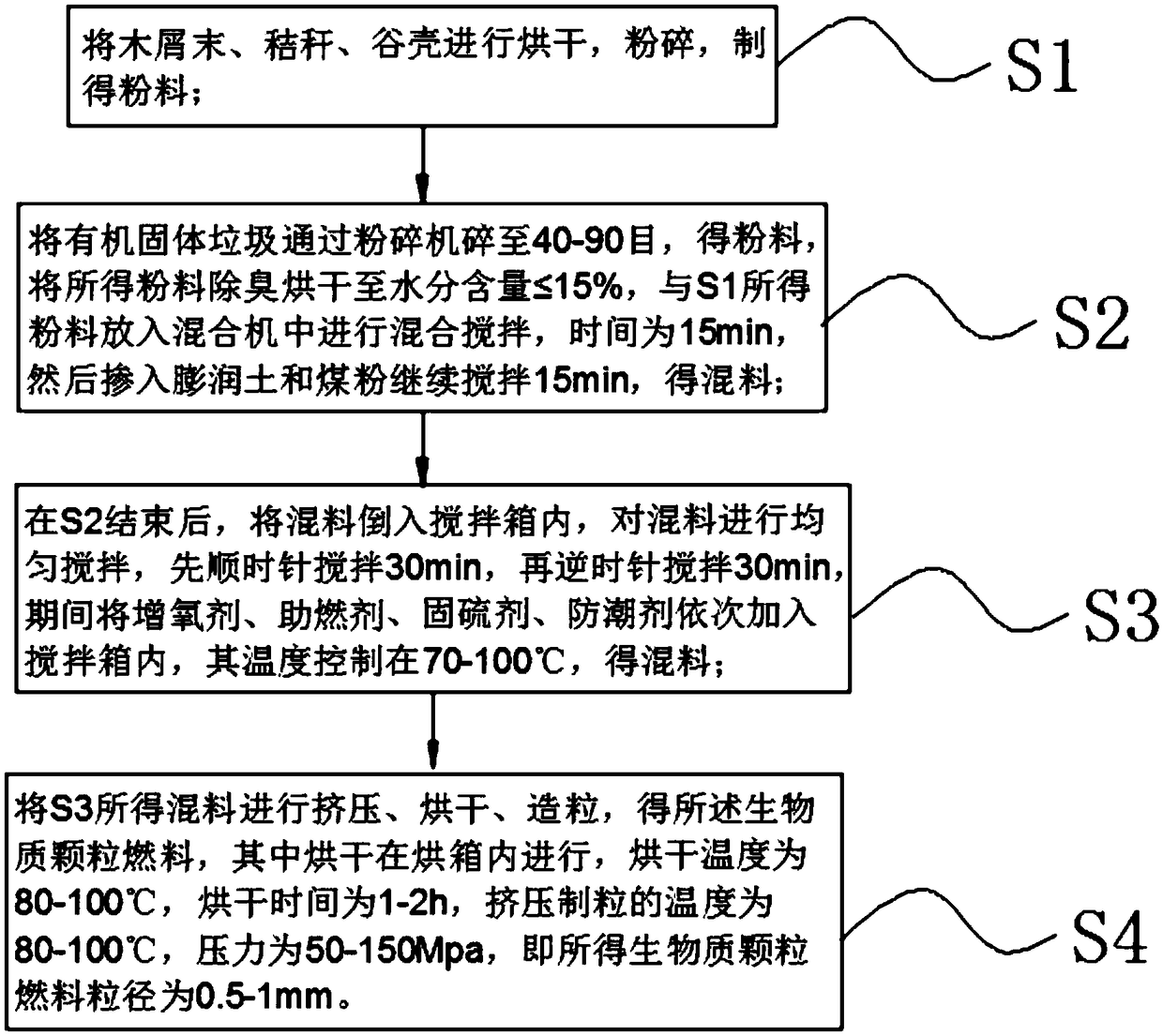

Biomass particle fuel with high calorific value and preparation method

InactiveCN109468151AIncrease heat valueImprove combustion efficiencyBiofuelsSolid fuelsOxygenateProcess engineering

The invention discloses a biomass particle fuel with a high calorific value and a preparation method. The biomass particle fuel comprises the following components in parts by weight: 30 to 50 parts ofsawdust powder, 20 to 40 parts of straw, 20 to 40 parts of rice husk, 5 to 10 parts of organic solid waste, 1 to 5 parts of bentonite, 5 to 20 parts of pulverized coal, 0.1 to 1 part of an oxygenate,2 to 5 parts of a combustion improver, 2 to 7 parts of a sulfur fixing agent and 1 to 5 parts of a moistureproof agent. According to the biomass particle fuel with the high calorific value provided by the invention, when the biomass particle fuel is actually used, biomass energy and organic solid waste are organically combined for use, the produced biomass particle fuel is high in caking ability,high in calorific value, high in combustion efficiency and less in combustion pollution and facilitates the construction of a biological environment, some pulverized coal is appropriately added, thecombustion effect can be strengthened, the calorific value of combustion can be improved, and the moistureproof agent is added inside the fuel, the storage of the fuel can be facilitated, the fuel isavoided from being affected by damp and moisture, and then the combustion quality of the fuel is improved, and simultaneously, the problem that the calorific value of combustion is low caused by the fact that the fuel is affected by damp is avoided.

Owner:江苏长鑫谊和生物质燃料有限公司

Wood softening and mouldproof method

InactiveCN107297803ASimple methodEasy to operateWood treatment detailsThermal wood treatmentEconomic IncomeChemistry

The invention mainly relates to the technical field of wooden product processing, and discloses a wood softening and mouldproof method. The method comprises the following steps: arranging wood; soaking the wood in acid; washing the wood with alkaline; blanching the wood; and softening the wood. The method is simple, and convenient to operate; mass treatment can be carried out; the pliability of the wood can be improved; breaking and cracking phenomena occurring during use can be reduced, the breaking rate is decreased to be 2.7%, and the cracking rate is decreased to be 4.9%; the mouldproof time is prolonged, so that the use performance of the wood is obviously improved, and as a result, the economic income is increased by 9.6%; after being cut, the wood is soaked in an acetate solution which contains high-concentration white granulated sugar, so that water entering the wood fibers can be accelerated to decrease the pH of the wood, and as a result, the wood fibers can be quickly softened; then angel wine active dry yeast is added for fermentation, and the generated ethyl acohol and bioactive constituents can permeate the wood fibers; after drying, pore structures among the fibers can be increased, thus the pliability of the wood can be improved; the color of the wood can be prevented from being deepened; and treatment traces are reduced.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

Softening method for bark

InactiveCN107127854ASimple methodEasy to operateWood treatment detailsCoating impregnationEconomic IncomeEcology

The invention relates to the technical field of wood product processing, and discloses a softening method for bark. The softening method for the bark comprises bark arrangement, bark alkali immersing, bark acid pickling, bark blanching, bark drying and bark softening. The method is simple, the operation is convenient, and a large batch of bark processing can be conducted. The flexibility of the processed bark is increased by 27.3%, cracking rate is decreased to 4.6%, the bark usage rate is obviously improved, and economic income is increased by 15.2%; the bark is made into a bark blank according to the requirement, processing is facilitated, the bark crushing rate is reduced, the infiltration of the treatment solution is facilitated, and the processing efficiency is improved; the bark blank is placed into a hot edible alkaline solution, gaps between cells are increased, the pH of the bark is increased, and the bark fiber is softened; and an acetic acid solution is sprayed onto the alkali immersed bark, and freezing and unfreezing are conducted after spraying, so that the acetic acid solution quickly penetrates into the bark, residual edible alkali in the bark can be neutralized, after an acid-base neutralization reaction, cell gaps can be increased, and a fibrous structure can be rapidly softened.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

Bacteriostatic deodorant fabric

InactiveCN107447335AStrengthen antibacterial and deodorizing effectGood sweat absorptionWeft knittingWarp knittingPolyesterDeodorant

The invention discloses bacteriostatic deodorant fabric which is prepared from, by weight, 40-45% of polyester fiber, 40-45% of cotton, 10-15% of polypropylene fiber and 3-5% of spandex. The bacteriostatic deodorant fabric has functional characteristics of being healthy, bacteriostatic, deodorant, capable of inhibiting odor and realizing one-way moisture guiding, quick in moisture adsorption and comfortable to wear and can bring more comfortable and decent wearing experience to users.

Owner:北京米特维斯科技有限责任公司

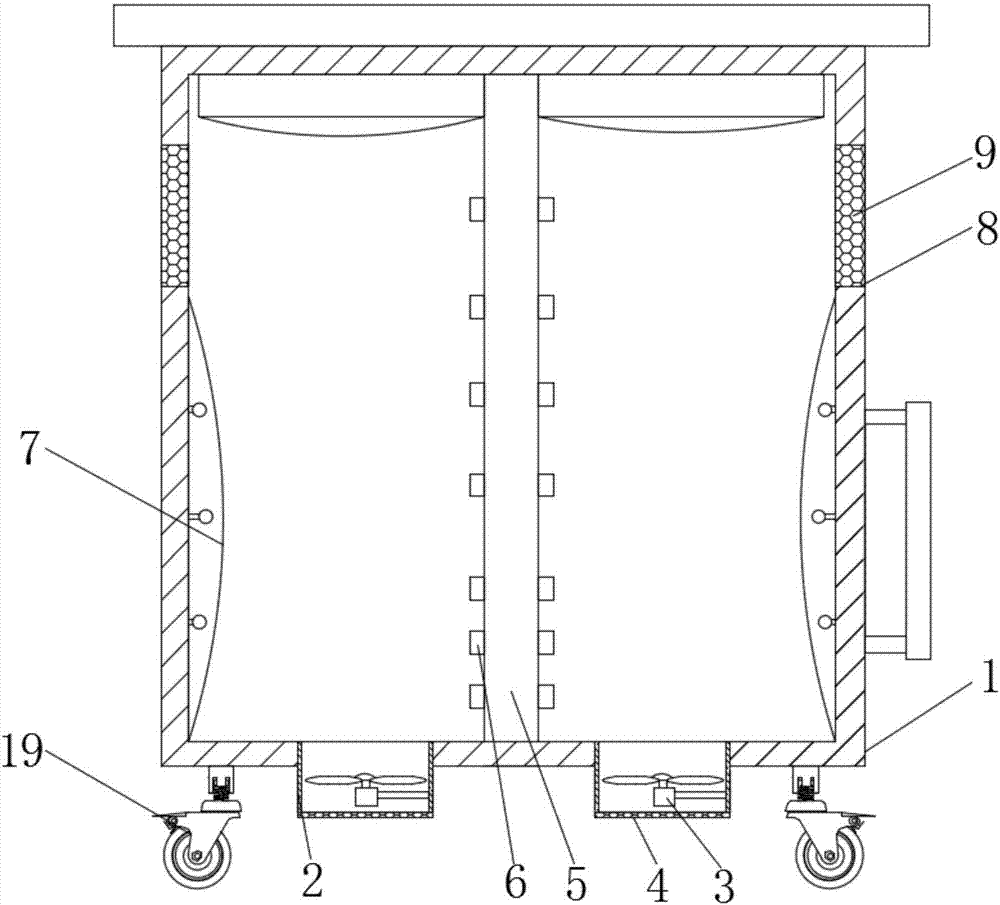

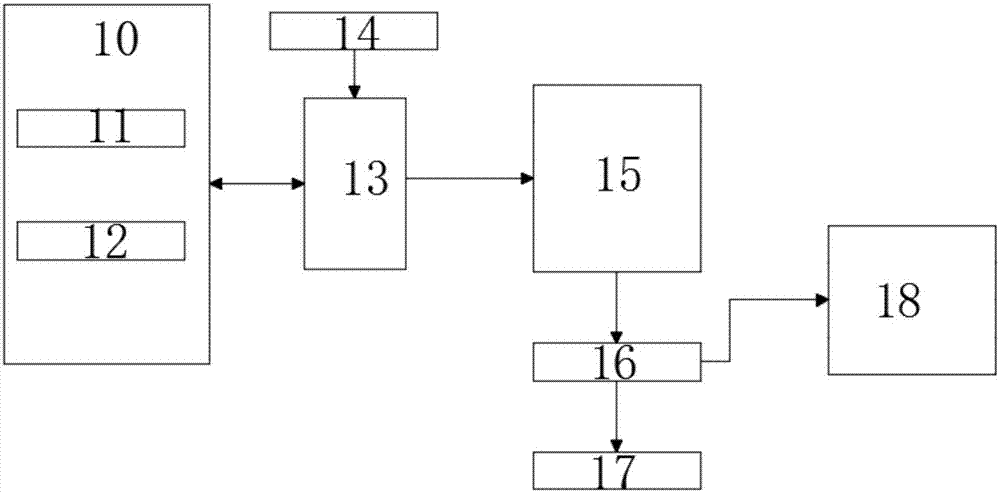

Textile storage cabinet

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

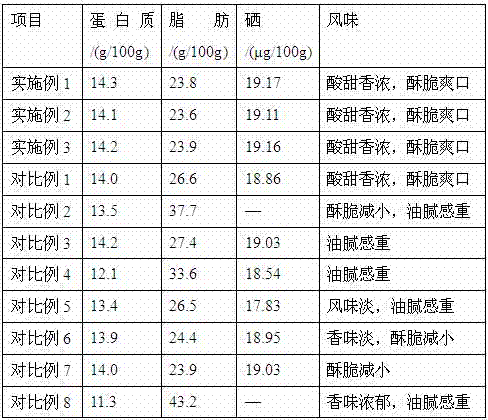

Preparation method of fermented walnut

InactiveCN107373573ASweet and sour tasteCrispy tasteFood freezingYeast food ingredientsSweetnessFat content

The invention mainly relates to the technical field of food processing, and discloses a preparation method of a fermented walnut. The preparation method of the fermented walnut comprises the steps of soaking, carrying out enzymolysis, fermenting, freezing, drying and packaging. The obtained fermented walnut is sweet and sour in taste, moderate in saltness and sweetness, and crisp in taste, has the selenium content being 19.17mug / 100g and the fat content being 23.6 percent, does not contain any additive, and is safe and healthy; a walnut kernel is boiled in hot water, so that a little fat in the walnut kernel can be leached; meanwhile, the walnut kernel is cured, so that the fragrance of the walnut is increased; the walnut is soaked and then added into a selenium yeast solution so as to be subjected to lipase enzymolysis, so that the organic selenium content in the walnut is increased, the fat in the walnut is reduced, a health care function of the walnut is improved, the walnut is prevented from being oxidized, and the shelf life is prolonged.

Owner:FUYANG SIJIWANG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com