Patents

Literature

134results about How to "Long spray distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

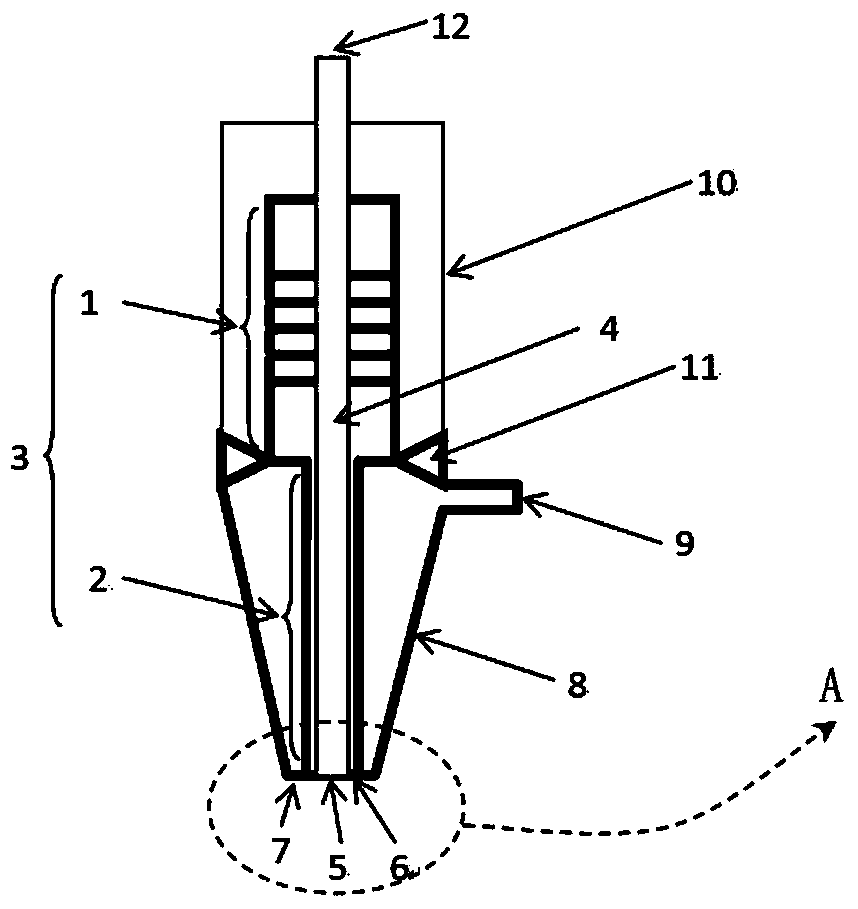

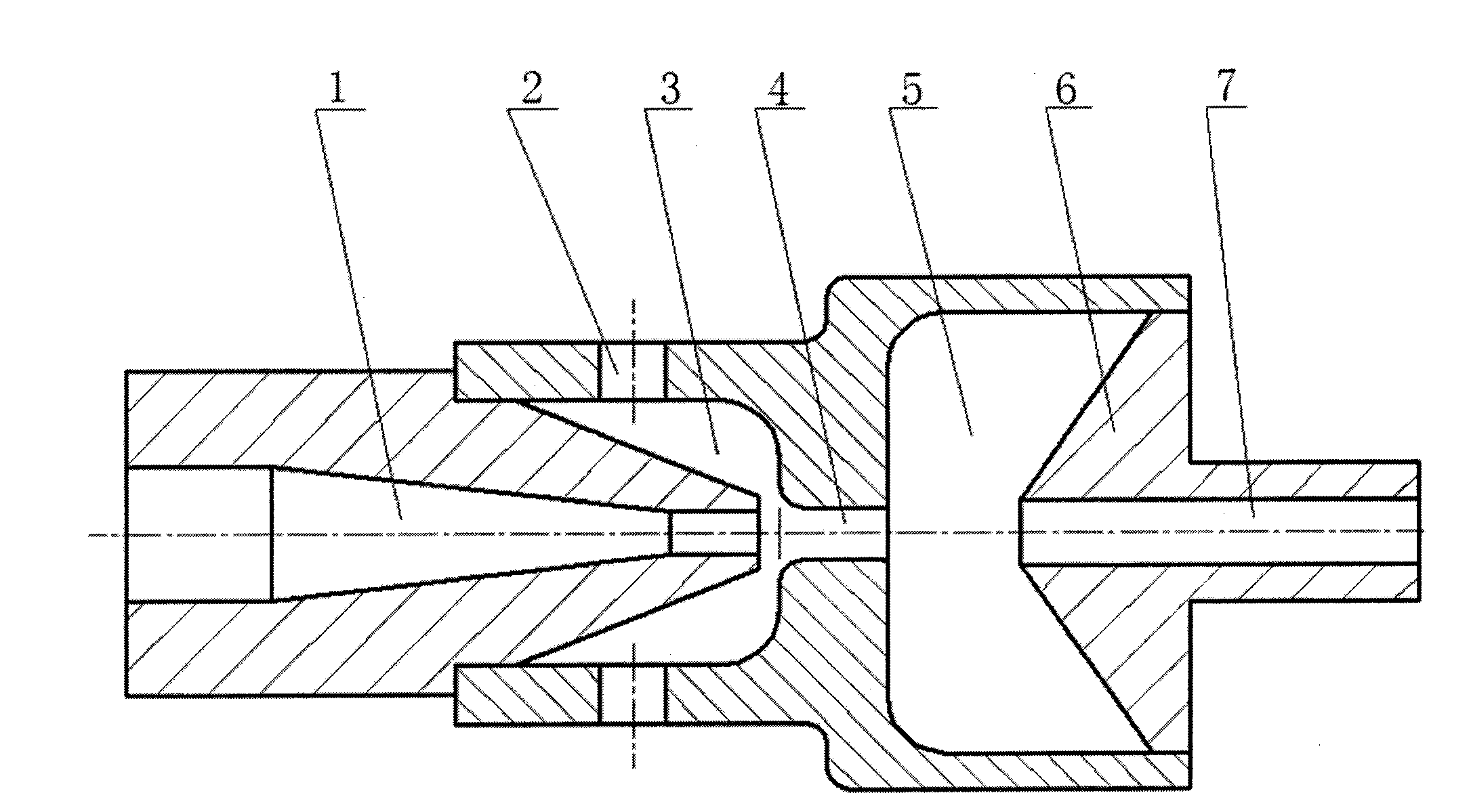

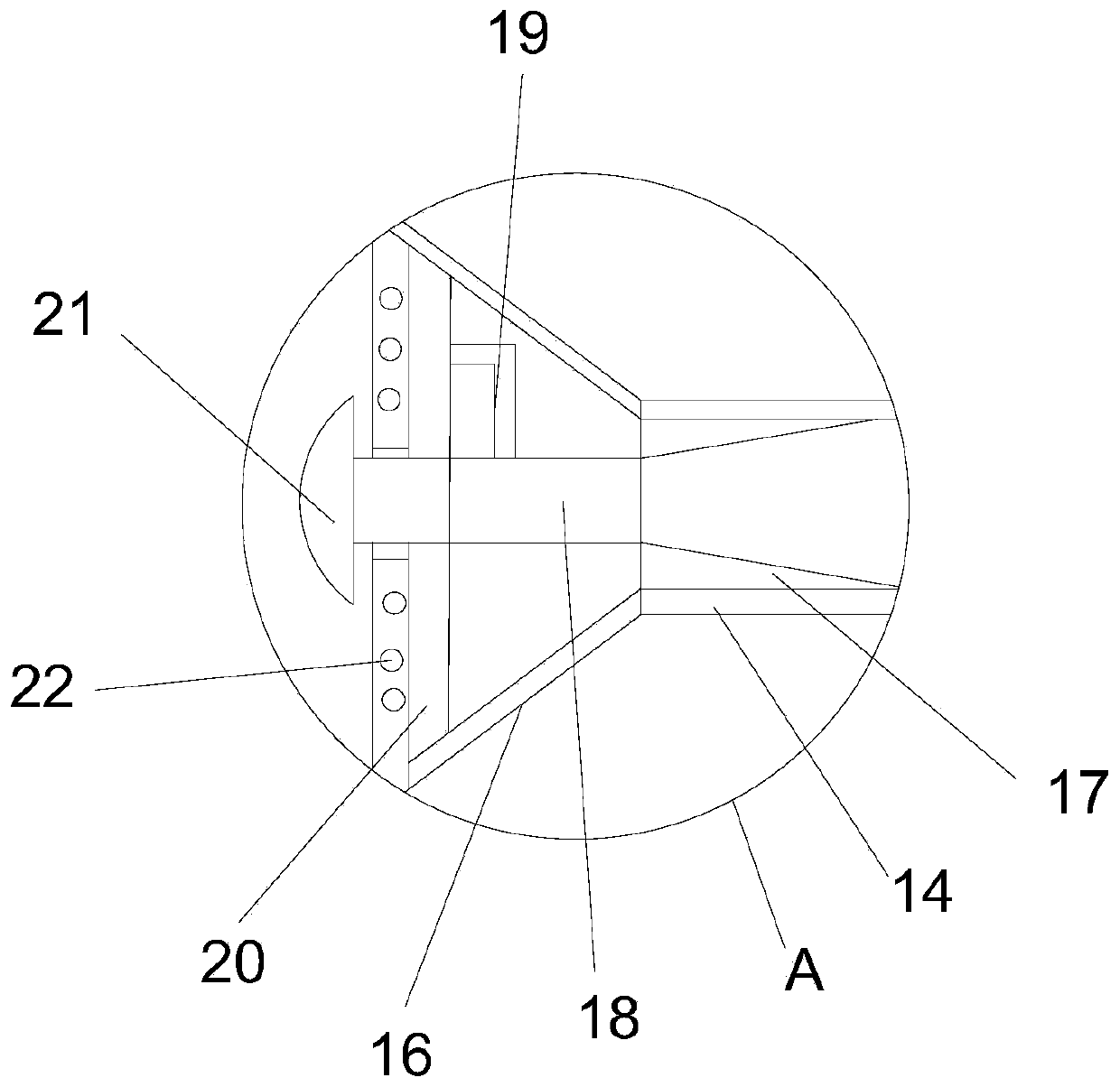

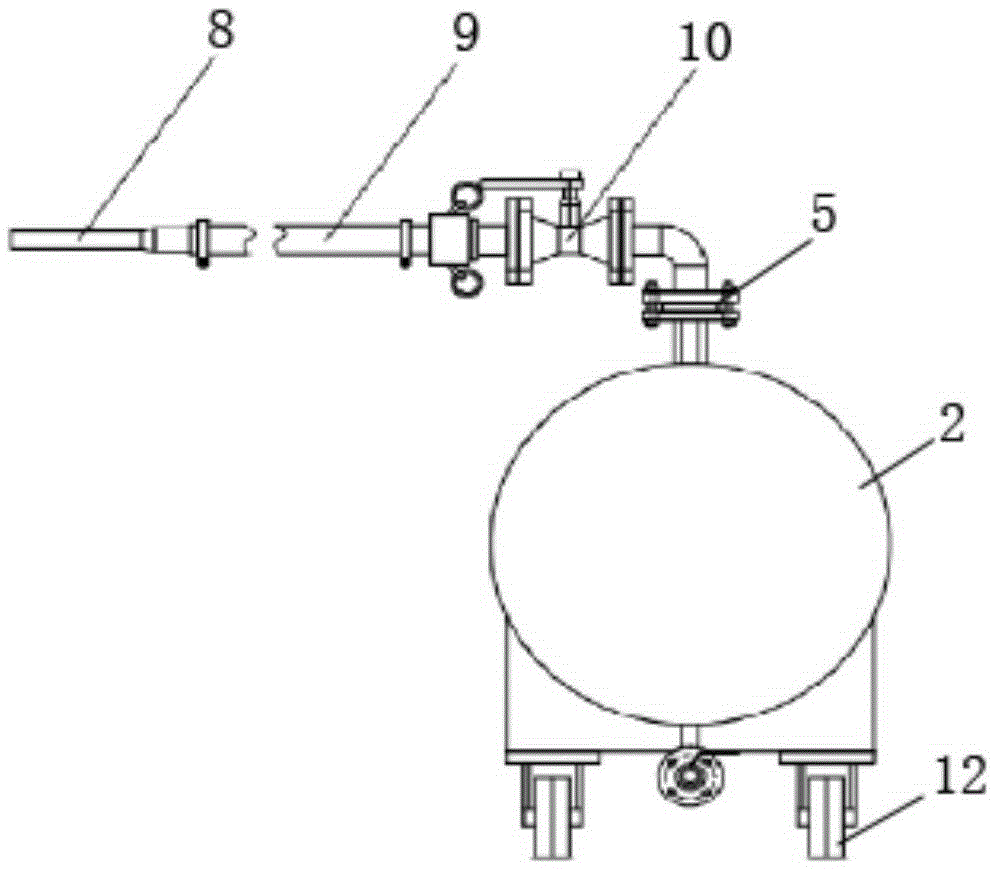

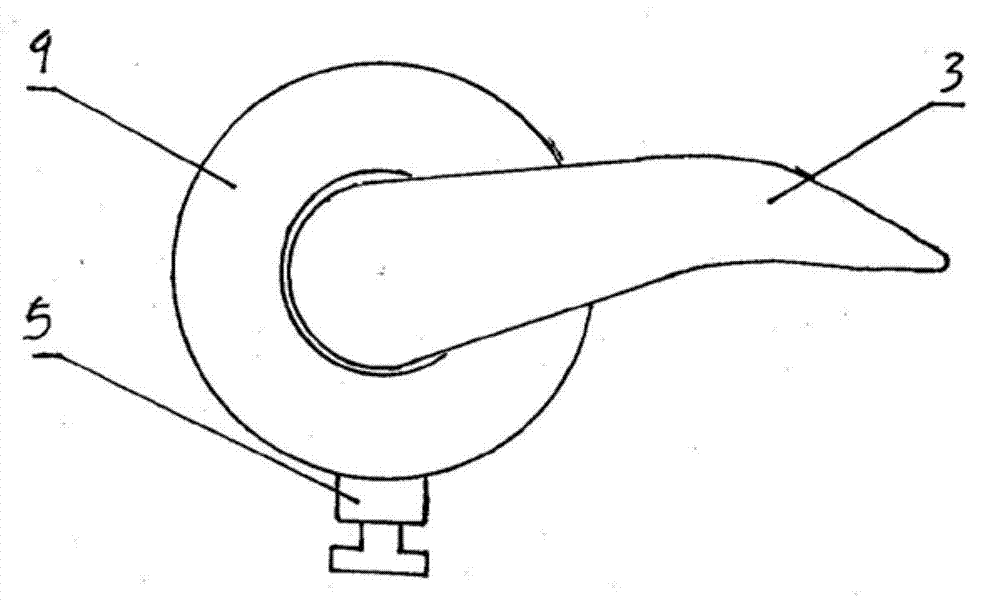

Gas-liquid mixing device

InactiveCN104147733ASimple structureLong spray distanceMixing methodsFire rescueProduct gasEngineering

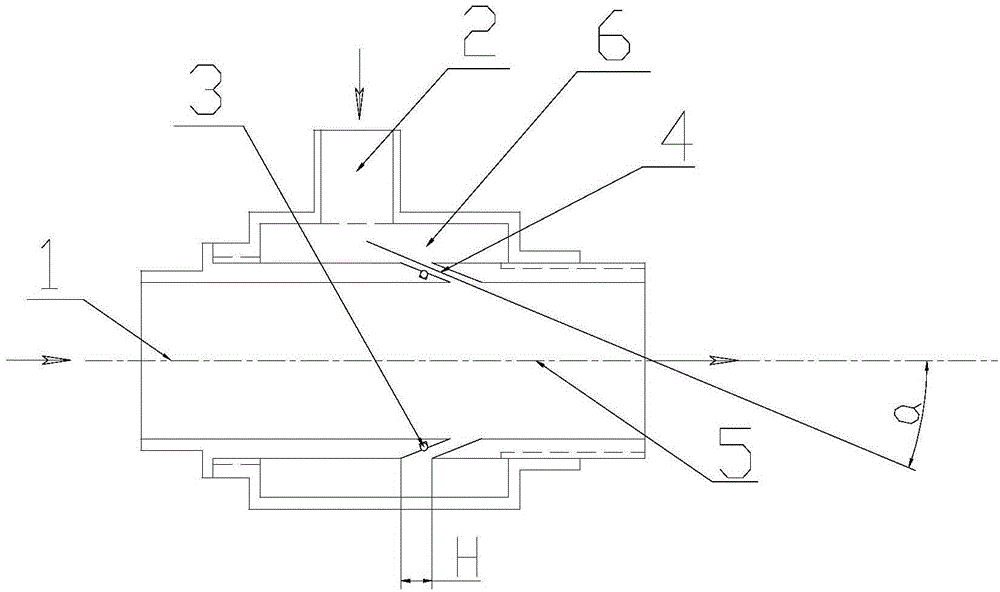

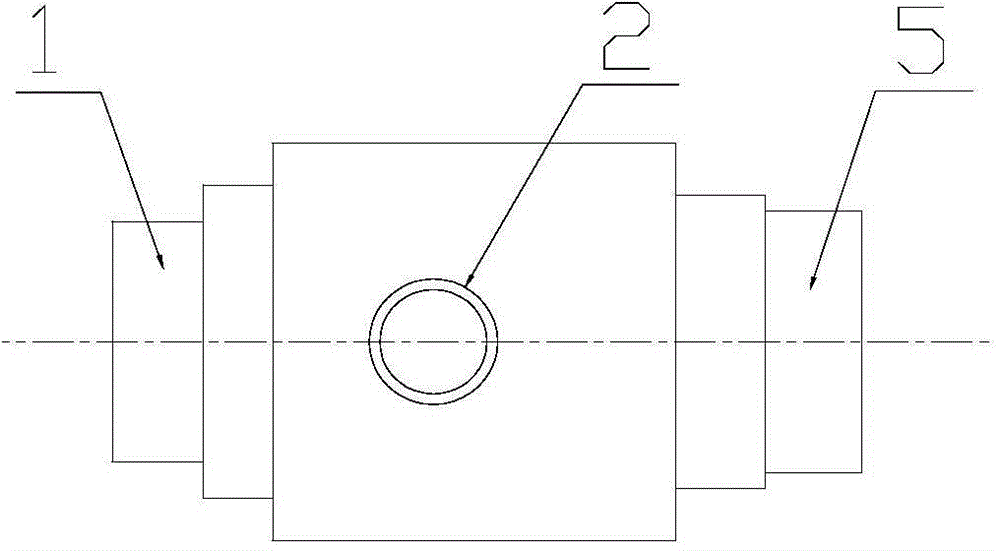

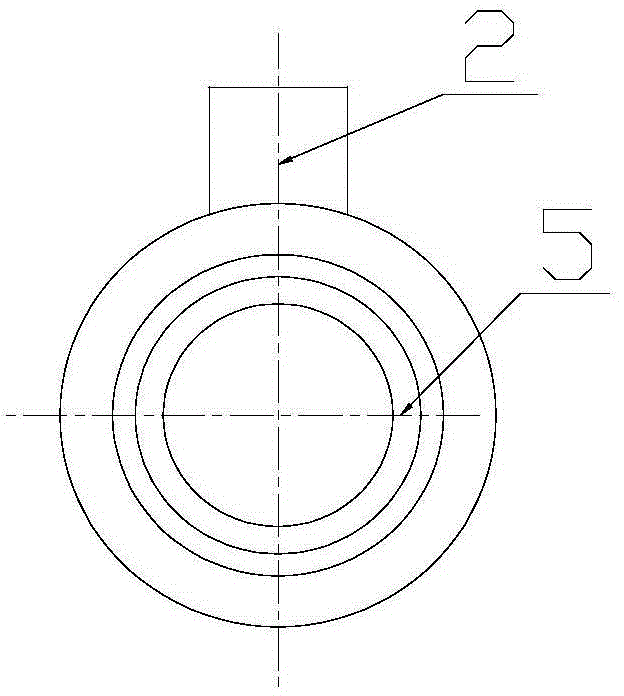

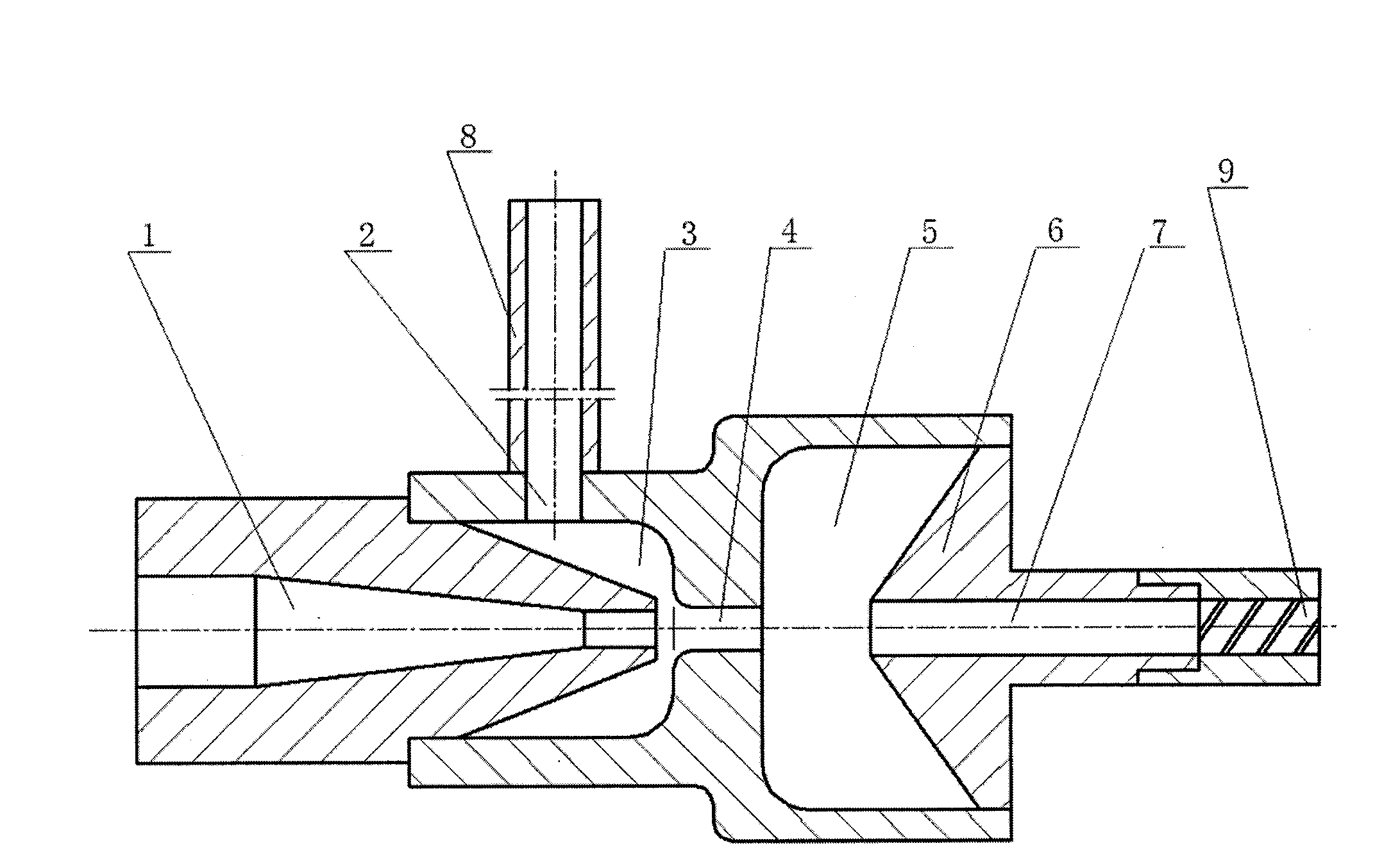

The invention discloses a gas-liquid mixing device. The gas -liquid mixing device comprises a gas inlet, a liquid inlet and a mixed solution outlet, wherein the gas inlet and the mixed solution outlet are formed in the same axial line, a combining part of the gas inlet and the mixed solution outlet is an annular nozzle, an included angle alpha formed by the annular nozzle is 45-80 degrees, an annular liquid cavity is arranged at the inlet end of the annular nozzle in a surrounding manner and is connected with the liquid inlet; the annular nozzle can be opened or closed, the width of the annular nozzle can be adjusted; the liquid inlet is formed along a radial direction or a tangent direction of the annular liquid cavity. The gas-liquid mixing device has the advantages that a conventional mixing structure is changed, the spraying is performed by adopting the annular nozzle with a certain slope as a liquid outlet, a negative pressure higher than that of a conventional nozzle can be generated, more gas is sucked, relatively high foam expansion ratio is generated, fluid flows without resistance, the device has no recoiling force, and is relatively long in spraying distance; the mixed solution outlet can be adjusted, and even closed, so that the liquid flow is adjusted; the gas-liquid mixing device is simple in structure, convenient to operate; the cost of system equipment is lowered.

Owner:CHENGDU ZINENG FIRE EQUIP

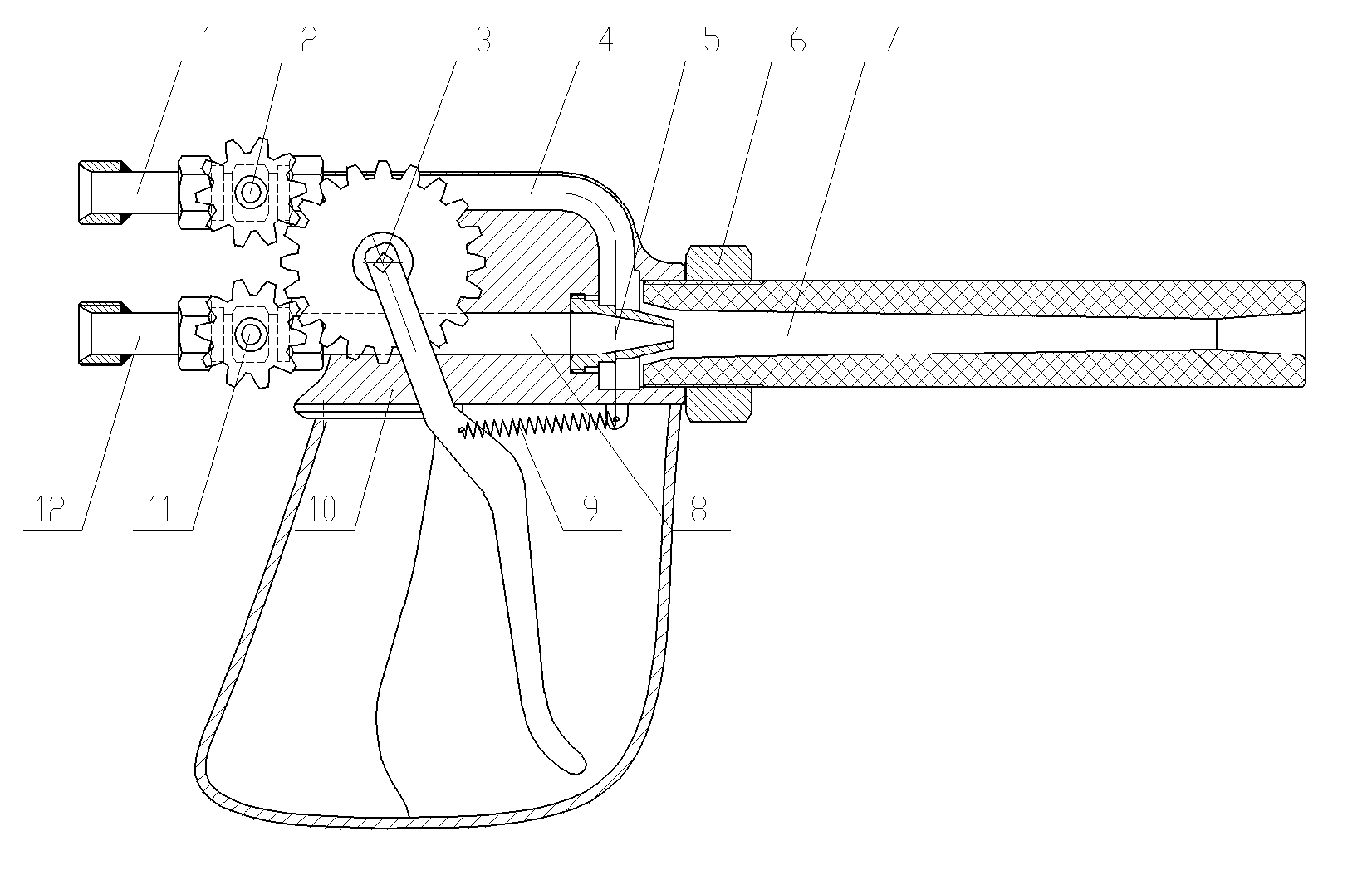

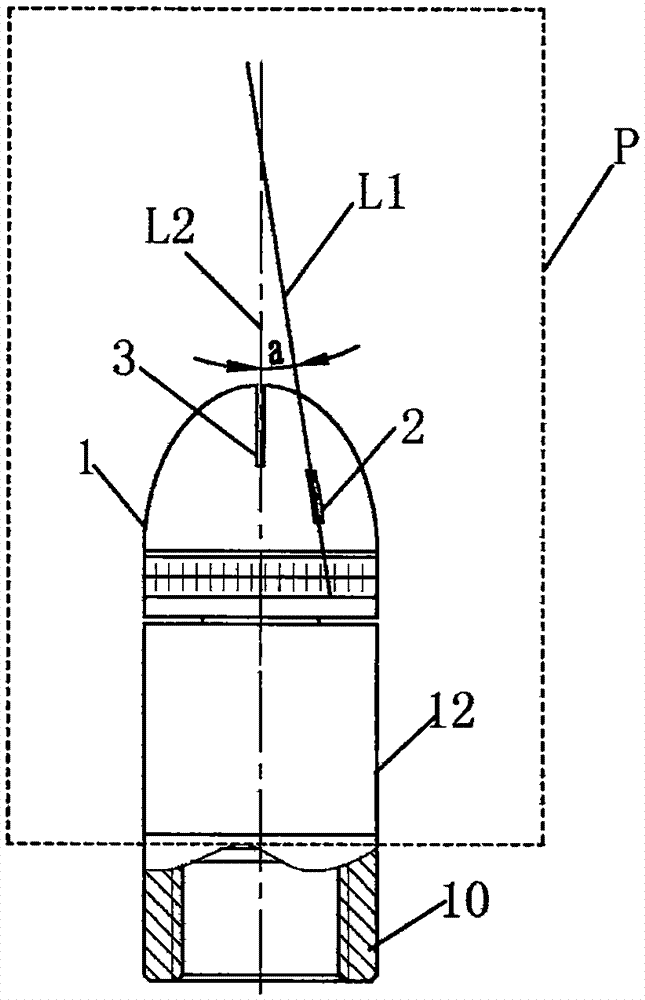

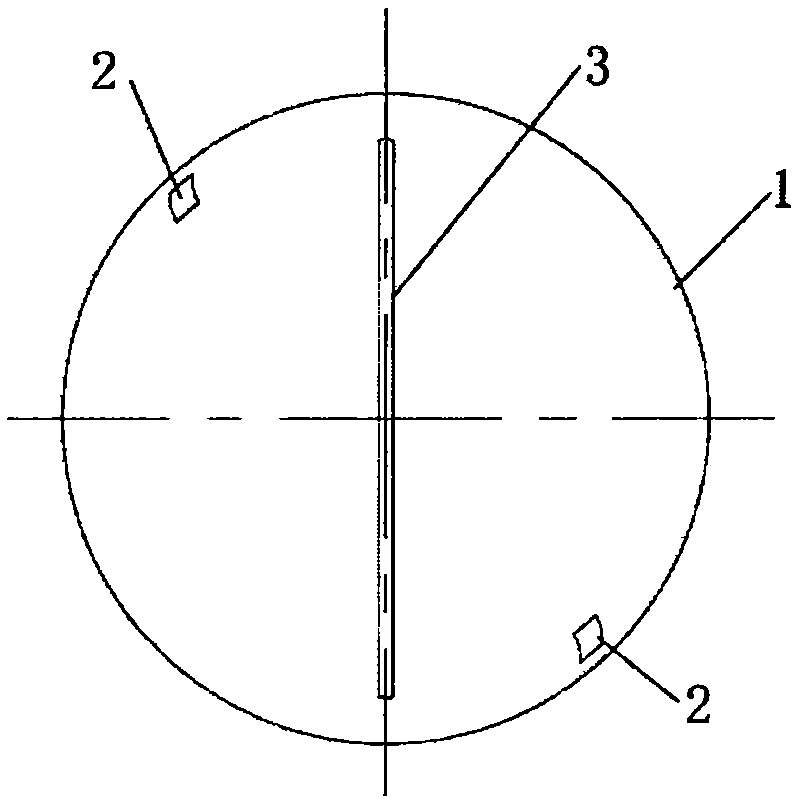

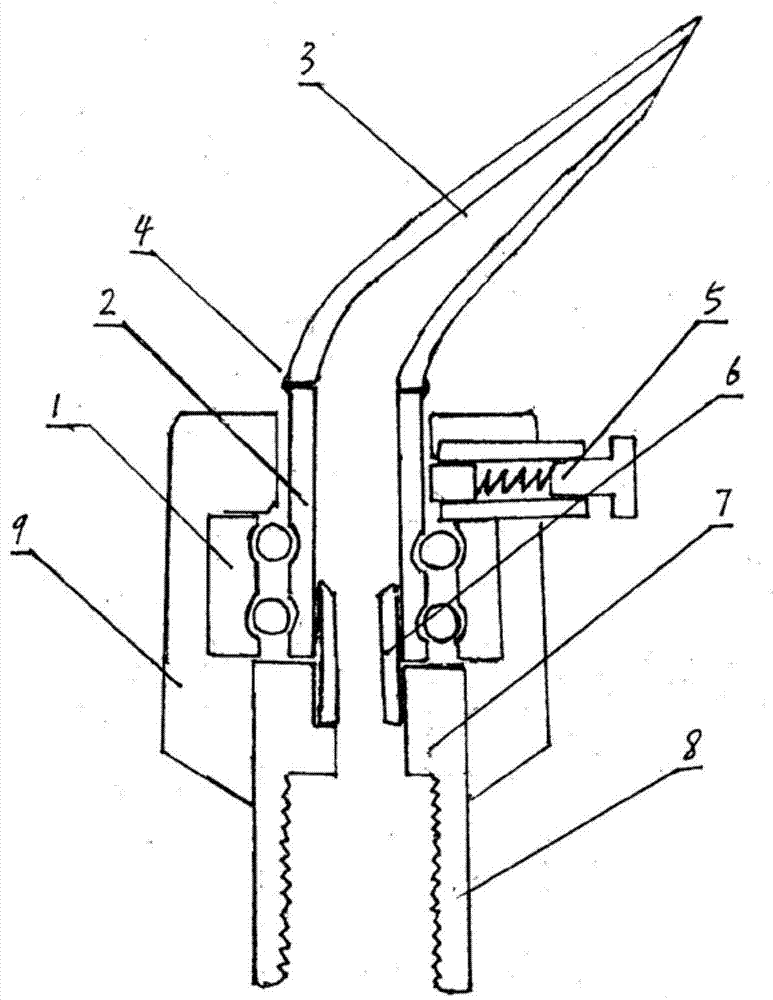

Compressed air foam extinguishing agent spraying gun and method thereof

The invention discloses a compressed air foam extinguishing agent spraying gun and a method thereof. Foam extinguishing agent liquid is sprayed out of an annular spraying channel which is positioned at an inlet of an extinguishing agent spraying gun pipe and is tightly attached to the wall surface to form a flowing liquid film attached to the wall; under impact and cutting of high-speed air flow injected by a convergence-shaped nozzle in the center of the inlet of the extinguishing agent spraying gun pipe, the liquid film is damaged; under the action of surface tension, the liquid film is contracted and wraps compressed air for cutting the liquid film, so that a plurality of air foam balls are generated, and foam extinguishing agent liquid becomes high-speed flowing compressed air foams; and the compressed air foams are accelerated in a 'laval nozzle' type gun pipe and then sprayed at high speed. By the compressed air foam extinguishing agent spraying gun and the method thereof, the compressed air and the foam extinguishing agent are mixed in a gun body to generate the compressed air foam which is sprayed at high speed; fuel fire can be quickly extinguished, and reignition is avoided; fire with the same intensity can be extinguished; and a large number of foam extinguishing agents can be saved.

Owner:中国人民解放军海军装备技术研究所

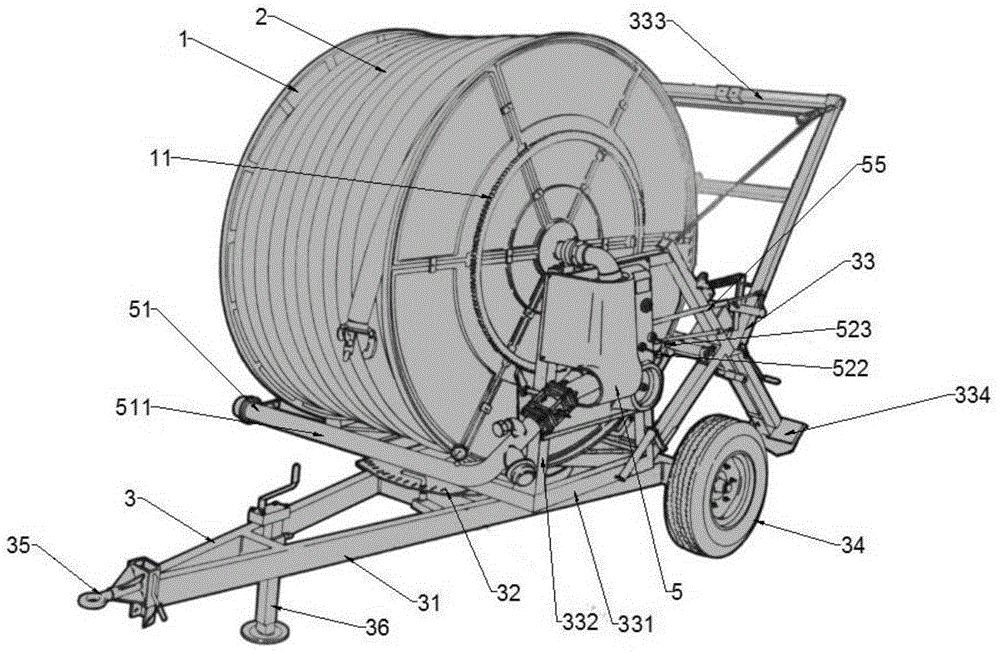

Natural focusing type ultrasonic atomization nozzle

ActiveCN104324839AReduce volumeEvenly distributedLiquid spraying apparatusPrintingTransformerEngineering

Owner:千藤(南京)环保科技有限公司

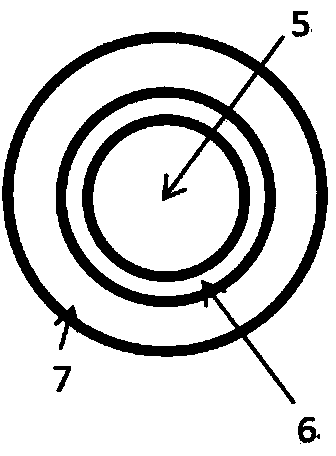

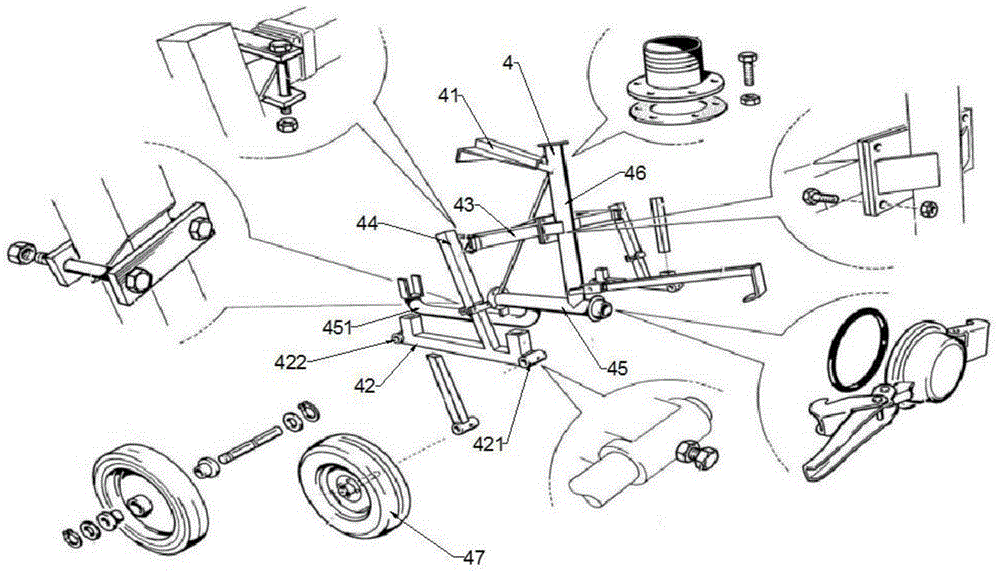

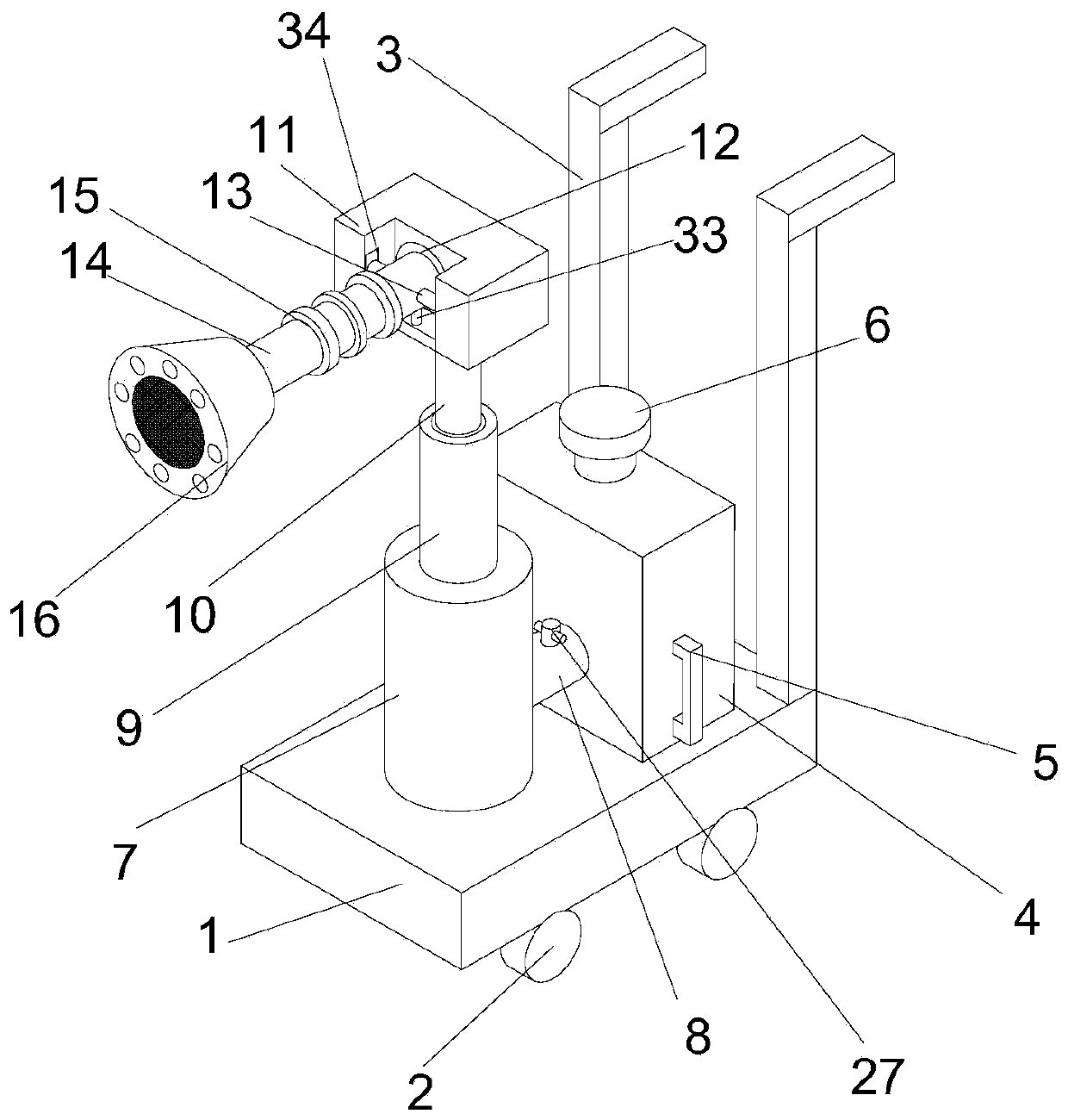

Reel sprinkling irrigation machine

ActiveCN105104115ASmall head lossLong spray distanceClimate change adaptationWatering devicesPipingAgricultural irrigation

The invention discloses a reel sprinkling irrigation machine and belongs to the technical field of agricultural irrigation machinery. The sprinkling irrigation machine disclosed by the invention is mainly composed of a reel, a water pipe, a rack, a biased spraying vehicle and a water flow control system, wherein the water flow control system comprises a pipeline, a water turbine, a speed changing box and a water flow adjusting valve. The water turbine and the speed changing box adopt a coaxial design. A power shaft of the water turbine is a power input shaft of the speed changing box. Meanwhile, the water flow adjusting valve capable of distributing flow is further arranged at the front end of the water turbine. According to the sprinkling irrigation machine disclosed by the invention, machine-entering pressure requirements on irrigation water are reduced; meanwhile, a spraying distance is provided, the spraying area is enlarged and the energy conversion efficiency is improved.

Owner:HARBIN KT TECH

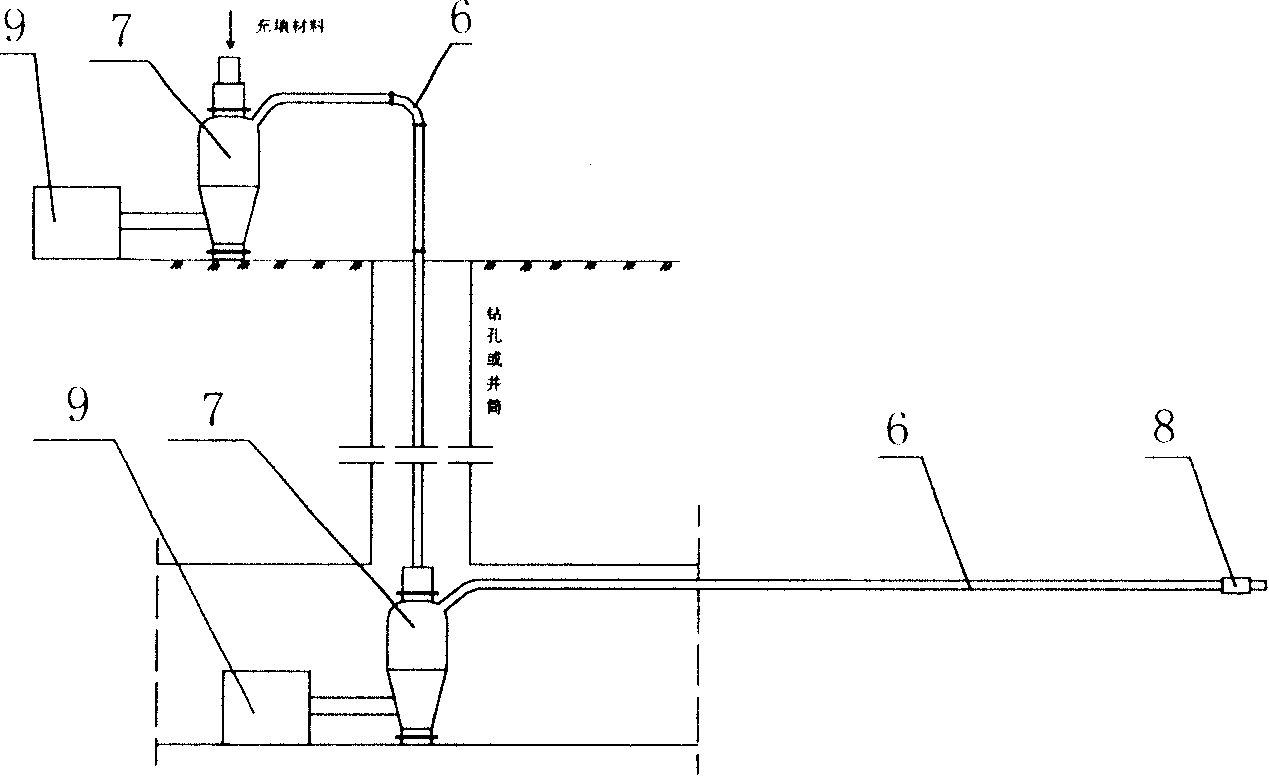

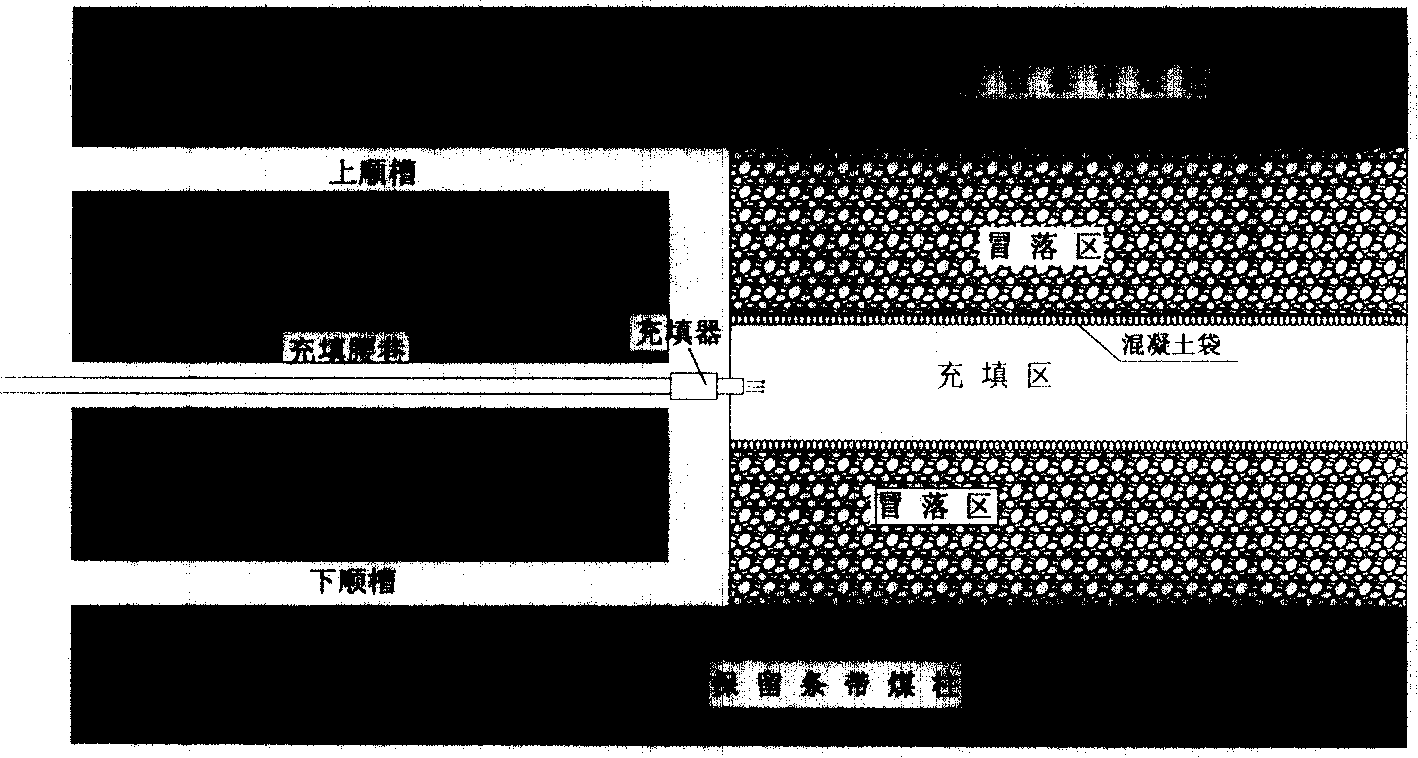

Filling device and method for filling down-hole goaf by same

The filling apparatus include one compressor, one storehouse pump, one ash conveying pipeline and one filling unit. After the compressor feeds compressed air to the storehouse pump, the filling material is conveyed through the ash conveying pipeline from the storehouse pump to the filling unit and jetted to the filled region. The filling unit includes one convergent pipe, one throat pipe, one diverging pipe, one rifling pipe and one water pipe. The filled region is first separated out from waste area in the mine and then filled with the filling material while mining coal in the working face. The present invention is simple, practical, low in cost and suitable for filling of various kinds of mine, especially coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Anti-crystallization compact type urea mixing device

ActiveCN110410185APrevent crystallizationReduce the risk of hitting a wall prematurelyExhaust apparatusSilencing apparatusInjection portEngineering

The invention discloses an anti-crystallization compact type urea mixing device. The device comprises a first mixing device defined by a top plate, a bottom plate, and an annular side wall, wherein the annular side wall is formed by sequentially connecting a first arc-shaped plate, a first straight plate, a second arc-shaped plate and a second straight plate in an end-to-end mode, a through hole communicating with a DPF unit is formed in the position, close to the first arc-shaped plate, of the top plate, a urea injection port communicating with an inner cavity is formed in the first arc-shaped plate, the inner cavity is internally provided with a rotational flow mixer which is arranged near the second arc-shaped plate, an inclined plate which is connected with the outer wall of the rotational flow mixer and the middle of the first straight plate and a baffle plate, the baffle plate is in a C-shaped structure with an opening facing the second straight plate, the two ends of the baffleplate are connected with the first arc-shaped plate and the second straight plate correspondingly, a plurality of airflow inlets are uniformly formed in the side, far away from the baffle plate, of the outer wall of the rotational flow mixer, a plurality of airflow outlets are uniformly formed in the top of the rotational flow mixer, and an S-shaped flow channel is defined by the rotational flow mixer, the inclined plate, the baffle plate and the annular side wall. According to the device, urea is prevented from crystallizing, and the mixing effect is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

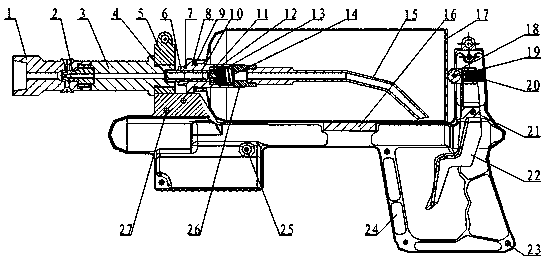

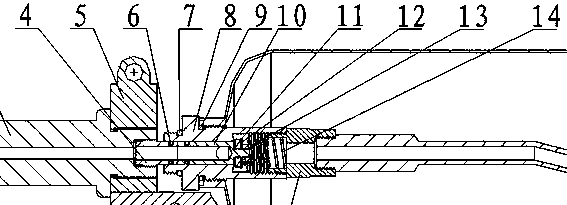

Handheld spraying disperser

The invention discloses a handheld spraying disperser which comprises a front spraying pipe (1), a rear spraying pipe (3), an ejector pin pipe (4), a gas powder bottle (17), a trigger (22) and a support assembly (24). The front end of the rear spraying pipe (3) is in threaded connection with the rear end of the front spraying pipe (1), the rear end of the rear spraying pipe (3) is connected with the front end of the ejector pin pipe (4), the rear end of the ejector pin pipe (4) is communicated with a mouth of the gas powder bottle (17) through a powder bottle valve (8), the rear spraying pipe (3) is fixed to the support assembly (24) through a spraying pipe connector (5), the gas powder bottle (17) is fixed to the support assembly (24) through a powder bottle tray (16), the trigger (22) is fixed to a handle (31) through a first screw (21), and one end of the trigger (22) abuts against the rear end of the gas powder bottle (17) in a pressing mode through a jacking wheel (18). The handheld spraying disperser is of a combined structure of the gas powder bottle, the spraying pipes and the support assembly, is simple in structure, convenient to carry, easy to operate and capable of spraying powder lachrymator and liquid lachrymator.

Owner:CHENGDU JINAN EQUIP

Self-suction pulse water jet ejection device

InactiveCN102989612AImproved erosion performanceLong spray distanceLiquid spraying apparatusWater jetAerospace engineering

The invention relates to an ejection device capable of ejecting water jet with good erosion effect under low water pressure situation, the self-suction pulse water jet ejection device can be used in the fields of washing, rinsing, spraying and the like. Under the condition of the prior art, the water ejected by the washing, rinsing, spraying and the like ejection device needs higher pressure; now a lot of washing, rinsing and spraying operation utilize tap water with low pressure from the tap water pipe network to direct eject, as the water pressure is limited by the pressure of the pipe network, the erosion effect of ejection distance of the water jet ejected through a nozzle is limited; if the water pressure of the ejection device is improved through adopting other pressure water equipment, the investment and other problems in use are increased. The self-suction pulse water jet ejection device does not need any other external power, the energy of the water jet flown in the ejecting device is utilized, the water jet entering the ejection device can perform self suction and self-excitation vibration, the low pressure continuous water jet is changed into aeration pulse water jet; the erosion capability of the aeration pulse water jet is improved under the condition that the water pressure is not improved, the ejection distance is farther, the performance of washing, rinsing, spraying equipment is improved, and the use range of the washing, rinsing and spraying equipment is enlarged.

Owner:李远明

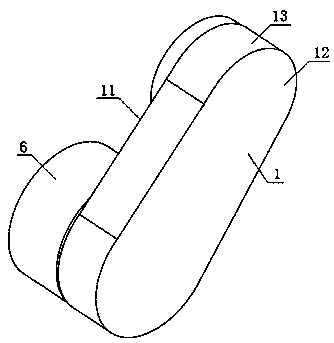

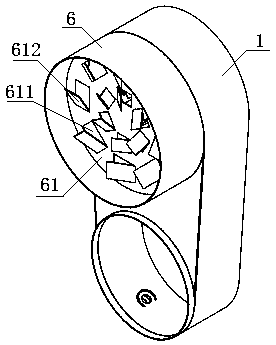

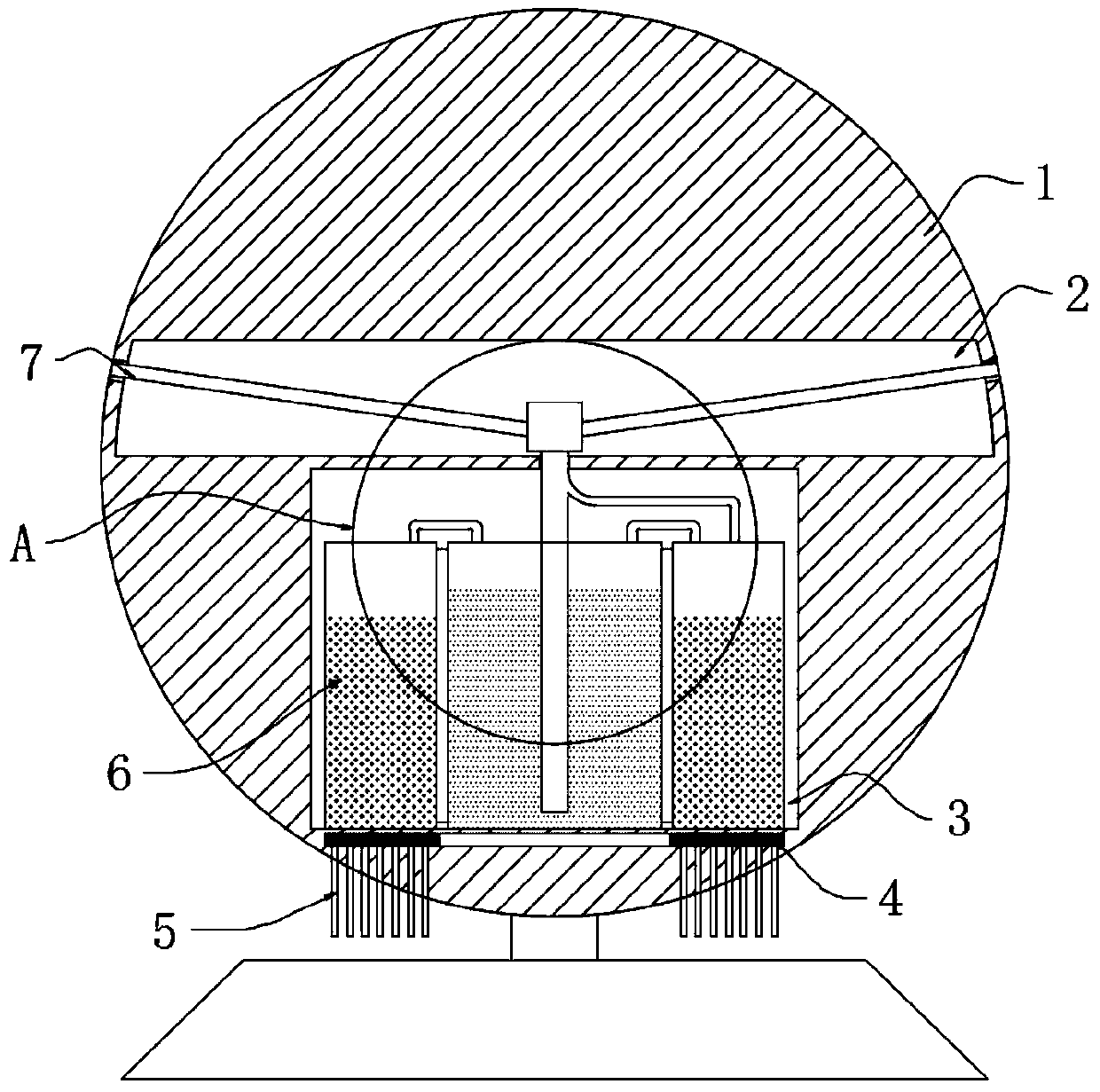

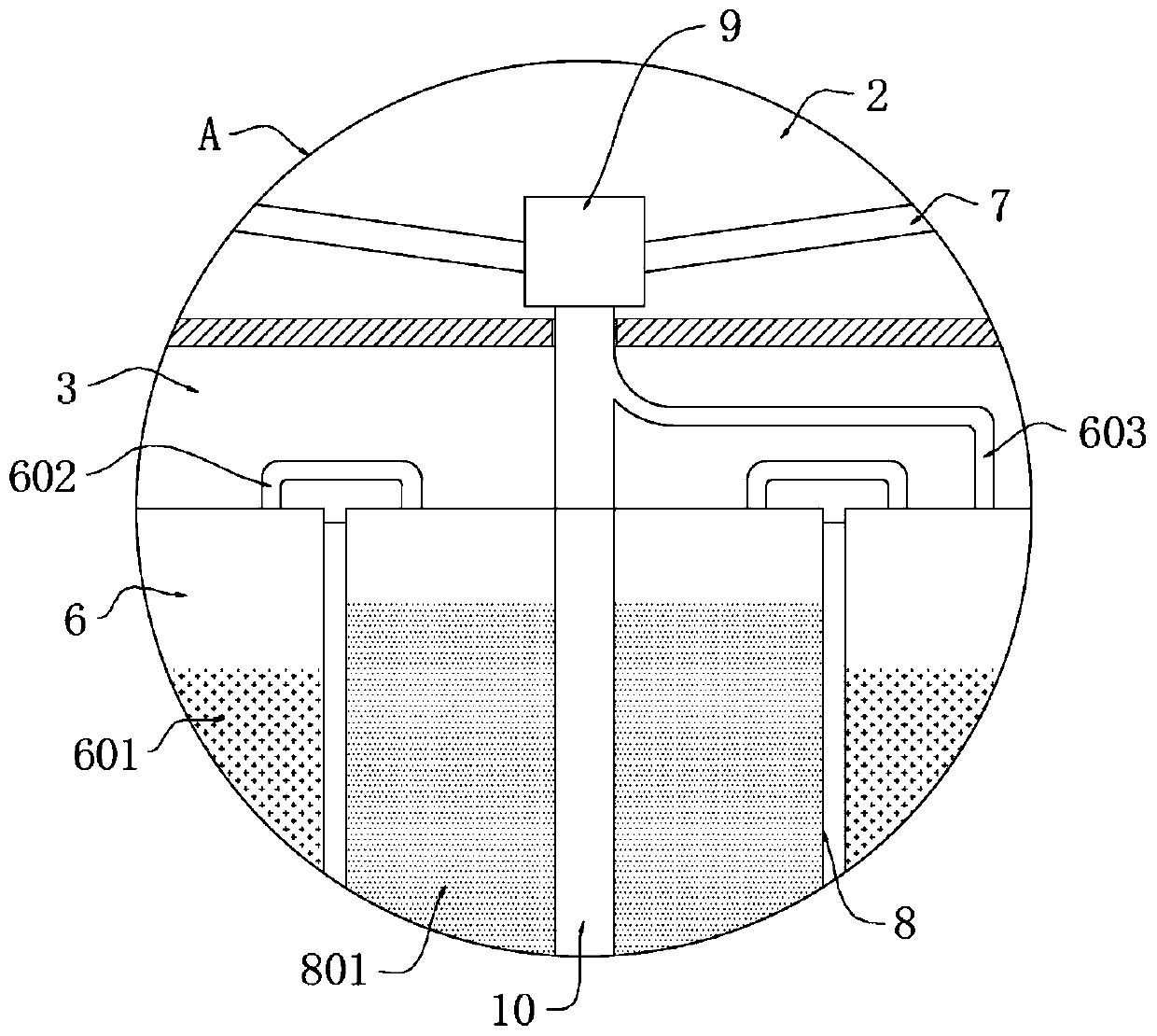

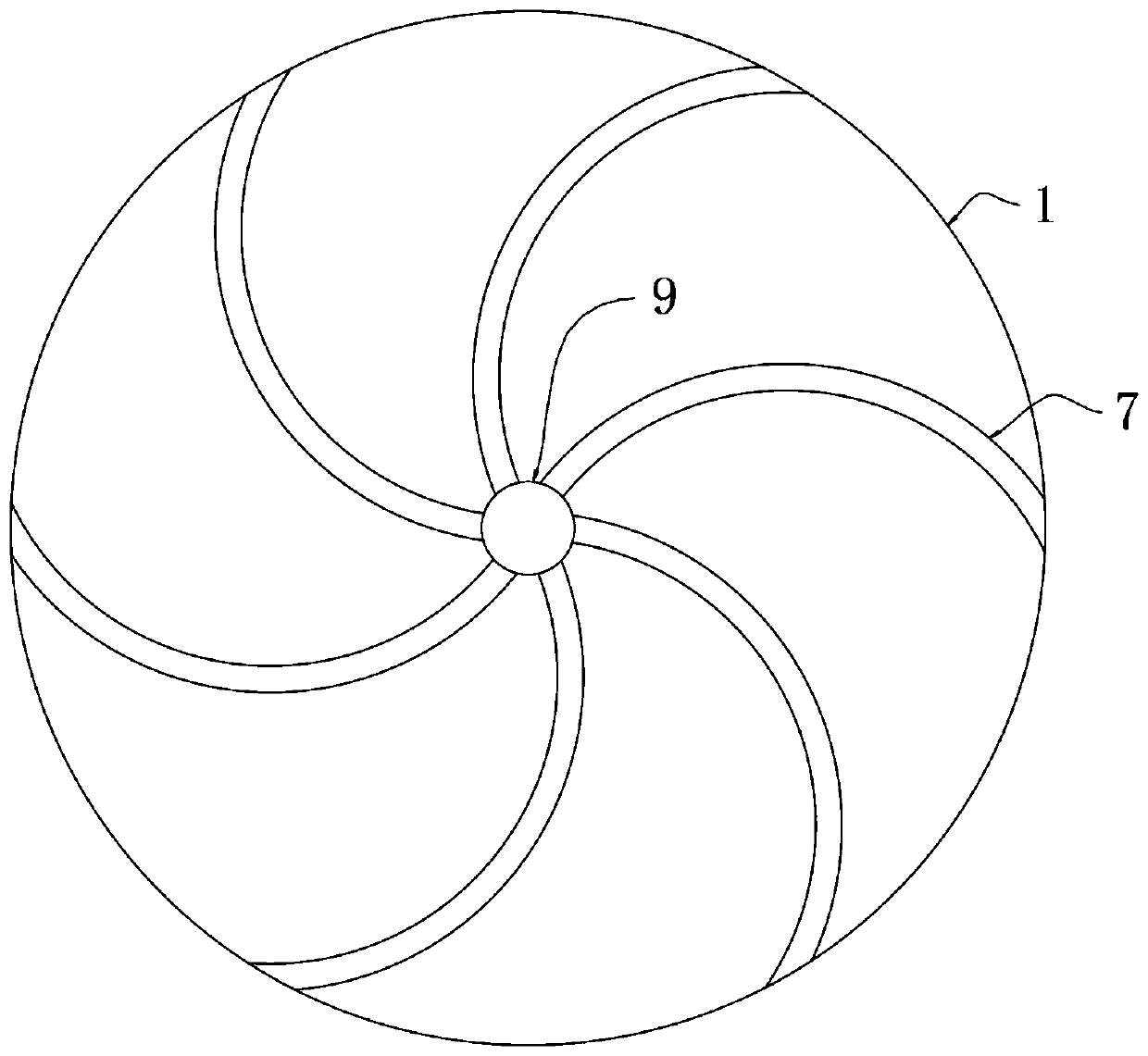

Ball type self-induction self-rotation fire extinguishing device

ActiveCN111202932AAchieve fire extinguishing effectAchieve securityFire rescueHeat conductingMetal powder

The invention discloses a ball type self-induction self-rotation fire extinguishing device. The ball type self-induction self-rotation fire extinguishing device comprises a ball body, and a pipe cavity and a storage cavity are separately formed in the ball body. An annular heat conducting plate is embedded at the bottom of the storage cavity, and an annular high-pressure tank is installed at the upper end of the annular heat conducting plate. A storage tank is installed in the center of the storage cavity, and the storage tank is located in the middle of the annular high-pressure tank. A plurality of pressure equalizing pipes are symmetrically arranged at the upper ends of the storage tank and the annular high-pressure tank together. The annular high-pressure tank is filled with evaporating liquid, and the storage tank is filled with metal powder. A powder discharge pipe is hermetically inserted into the storage tank, and the upper end of the powder discharge pipe extends into the pipecavity and is provided with a pressure valve. According to the ball type self-induction self-rotation fire extinguishing device, a fire can be automatically detected and extinguished through annularheat conducting sheets and the annular heat conducting plate; harmless and environmental-friendly fire extinguishing can be realized through copper powder; the ball body is made to rotate through an arc spray pipe, and the fire extinguishing range is enlarged; and fire extinguishing is more uniform through a guide cone, the fire extinguishing effect is enhanced, and reburning is prevented.

Owner:朱香芽

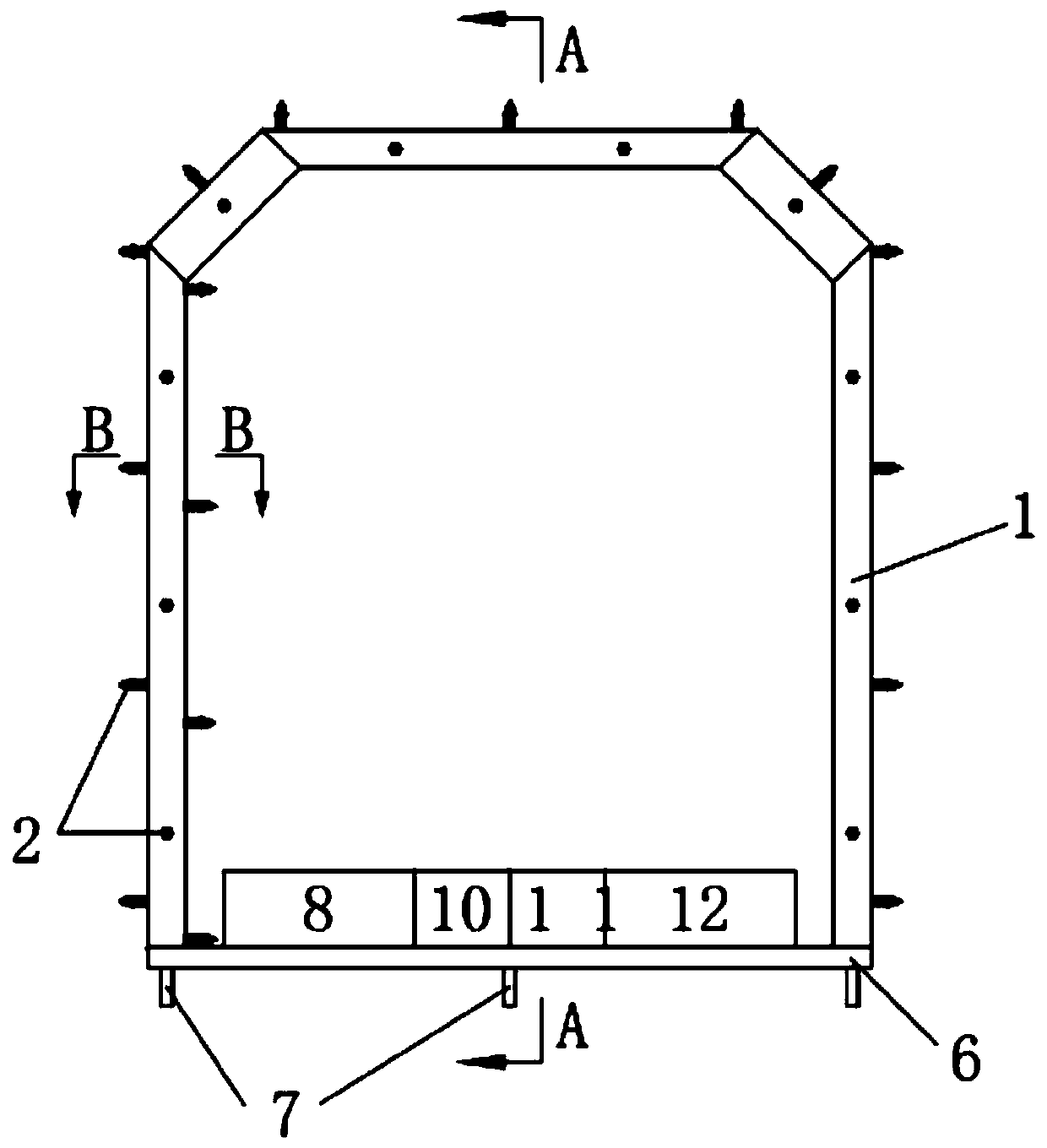

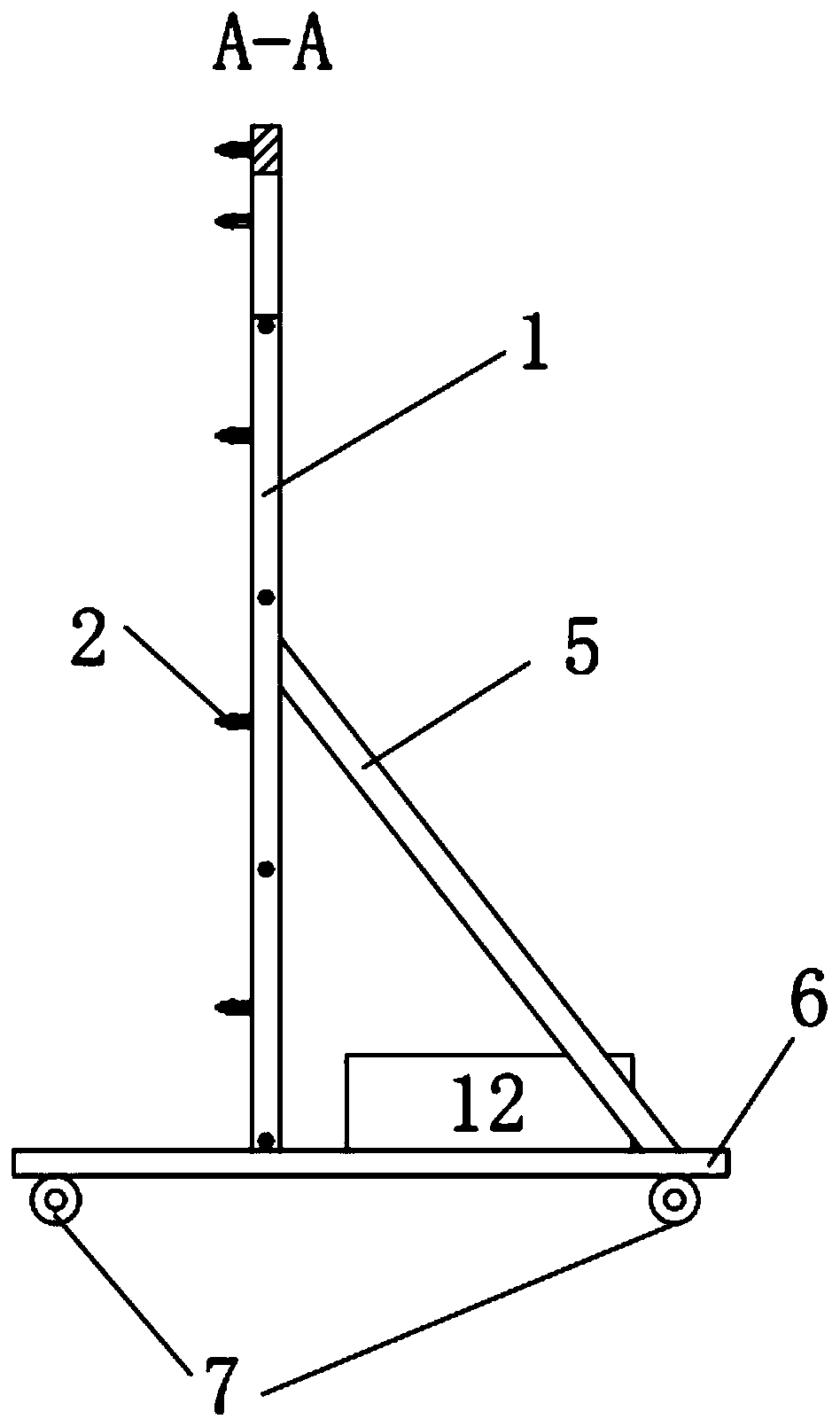

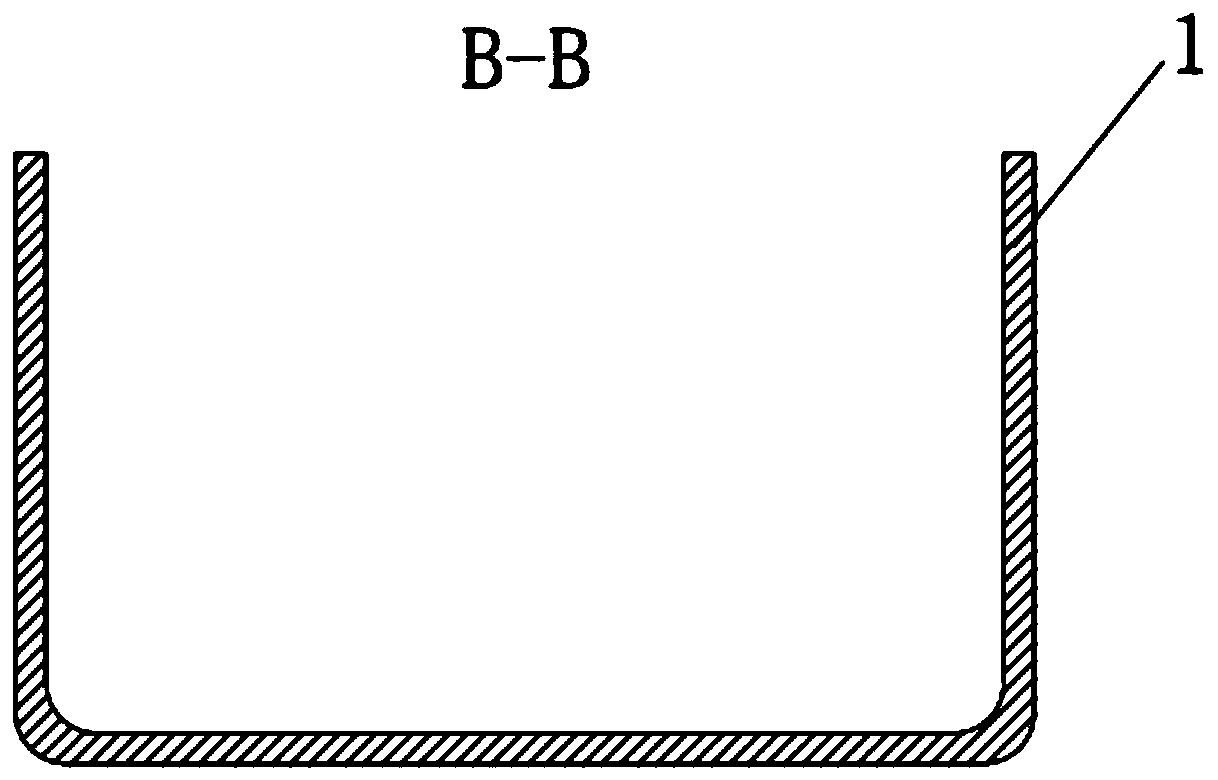

Cloud dust-removal device for metal mine roadway

InactiveCN109779674ASave waterLittle loss of calorific valueDust removalFire preventionDust particlesUltrasonic atomization

The invention discloses a cloud dust-removal device for a metal mine roadway, including a steel frame structure, ultrasonic atomization nozzles, an inclined strut, a steel bottom plate, a water drainage diverter arranged on the steel bottom plate, a precise water filtering device, an air pressure gauge and a regulating valve thereof, a water flowmeter and a regulating valve thereof, and an air exhaust diverter. The steel frame structure is fixedly connected to the steel bottom plate. One end of the inclined strut is fixedly connected with the steel frame structure, and the other end is fixedlyconnected with the steel bottom plate. The steel frame structure is a gantry frame and is made of U-shaped steel, the opening direction of the U-shaped steel is the same as the air flow direction, the ultrasonic atomization nozzles are fixed to the front side and the left side and the right side of the U-shaped steel, the spraying angle is 80 degrees, the ultrasonic atomization nozzles on the front side directly face the air flow direction for spraying, and the ultrasonic atomization nozzles on the left side and the right side are staggered. By arranging the ultrasonic atomization nozzles with the spraying angle of 80 degrees, the whole roadway section can be filled with dry fog, the contact area between the dry fog and dust particles is fully increased, the dust removal effect is good, and the service life is long.

Owner:NORTH CHINA INST OF SCI & TECH +1

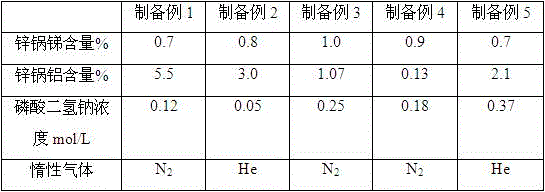

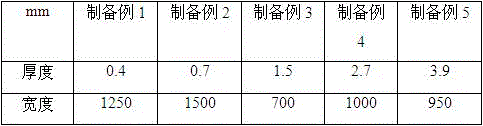

Preparation technology of galvanized steel sheet with continuous hot-dip spangles

ActiveCN106702101AGuaranteed mechanical propertiesImprove anti-corrosion performanceHot-dipping/immersion processesFurnace typesAir knifeMechanical property

The invention relates to the technical field of galvanizing of steel sheets, and discloses a preparation technology of a galvanized steel sheet with continuous hot-dip spangles. The preparation technology comprises the following steps of uncoiling, and cleaning; annealing: sending a steel sheet into an annealing furnace to reduce and calcine, wherein the annealing atmosphere is a H2 (hydrogen) and N2 (nitrogen) mixed gas, and the annealing temperature is 720 to 800 DEG C; hot-dip: cooling the steel sheet by air, cooling to 470 to 520 DEG C at the average temperature, sending into a zinc pot, and performing hot-dip, wherein the temperature of the zinc pot is 455 to 470 DEG C, and the content of antimony in the zinc pot is 0.7 to 1.0% (in percentage by mass); spraying: enabling an air knife to scrape the excessive hot-dip liquid on the steel sheet, spraying and cooling, wherein the temperature of spraying liquid is 55 to 60 DEG C, and the spraying liquid is a monosodium phosphate water solution; flattening, and passivating; coiling. The preparation technology has the advantages that the production cycle is short, the spangles are small and uniform, and the mechanical property and anticorrosive property of the prepared steel sheet are excellent.

Owner:重庆万达薄板有限公司

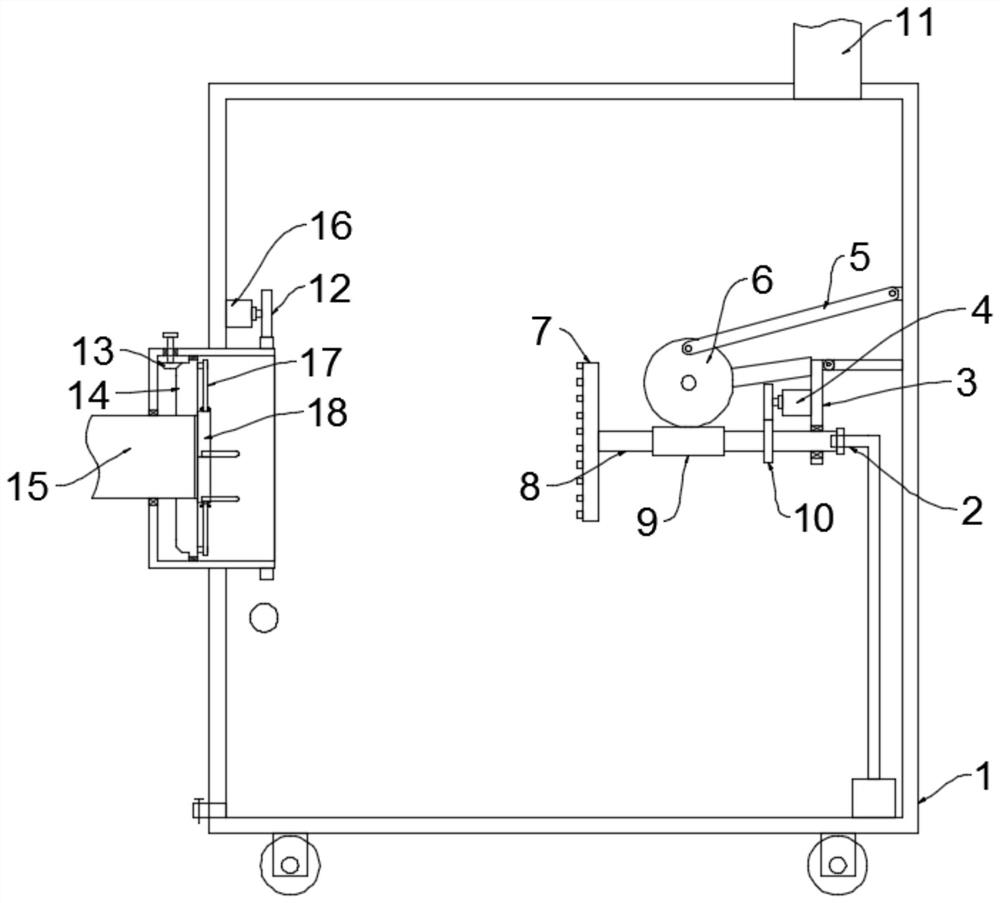

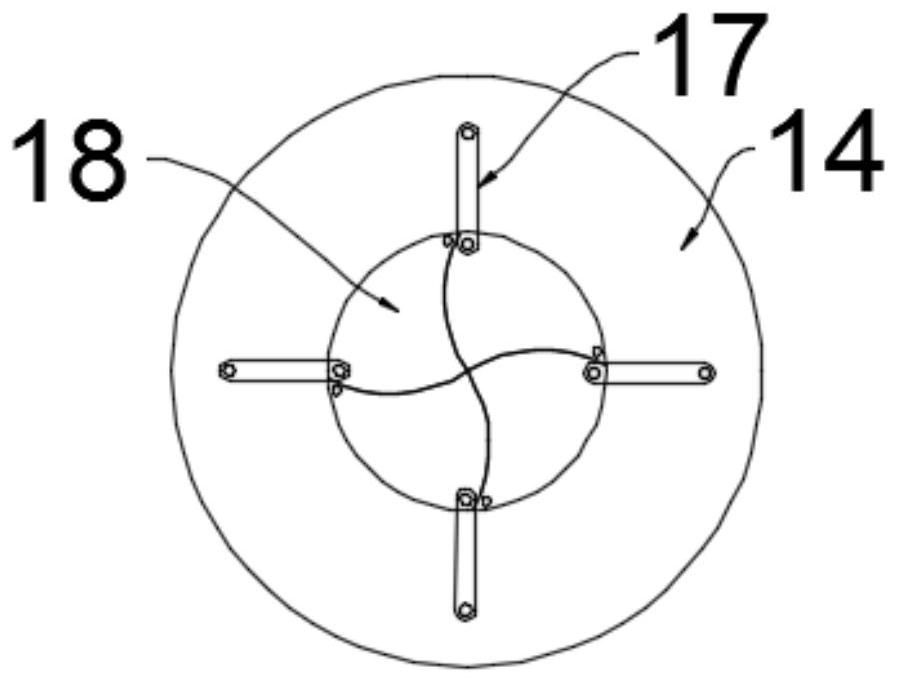

Full spraying device for environmental-friendly machine

InactiveCN111744689AFull sprayExpand the spraying rangeUsing liquid separation agentMovable spraying apparatusEnvironmental engineeringWaste gas

The invention discloses a full spraying device for an environmental-friendly machine, and relates to the technical field of environmental-friendly machines. The full spraying device is mainly used forsolving the problem of insufficient spraying of existing environmental-friendly mechanical waste gas. The full spraying device comprises a box body and a spraying unit arranged in the box body. The spraying unit is arranged in the position, opposite to a pipe opening of a gas inlet pipe, in the box body. The spraying unit comprises a spraying disc, a hollow rotating shaft, a first driving mechanism for driving the hollow rotating shaft to rotate, a worm, a worm wheel and a first connecting rod. An adjusting unit is arranged at the gas inlet pipe. The adjusting unit comprises a cylinder body,a second driving mechanism for driving the cylinder body to rotate and a valve assembly. The spraying unit is arranged for rotating type spraying, the spraying is sufficient and comprehensive, the spraying disc swings up and down, and the spraying range is enlarged; and the adjusting unit is arranged and used for adjusting the gas inlet amount, the phenomenon that spraying is insufficient due to too fast gas inlet is avoided, the cylinder body rotates, the cylinder body drives the valve assembly to rotate, the waste gas forms spiral cyclone, the spraying distance is longer, the waste gas is more fully contacted with spraying liquid, and the spraying efficiency is further improved.

Owner:李秀英

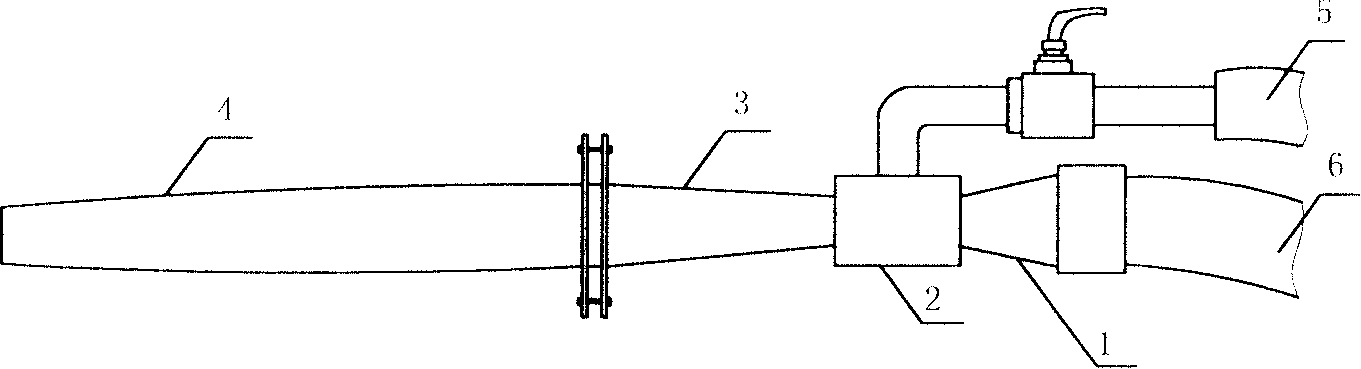

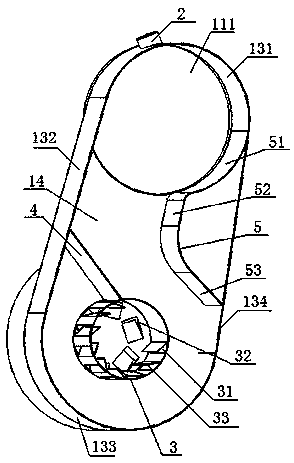

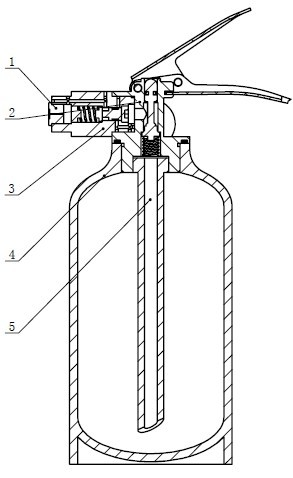

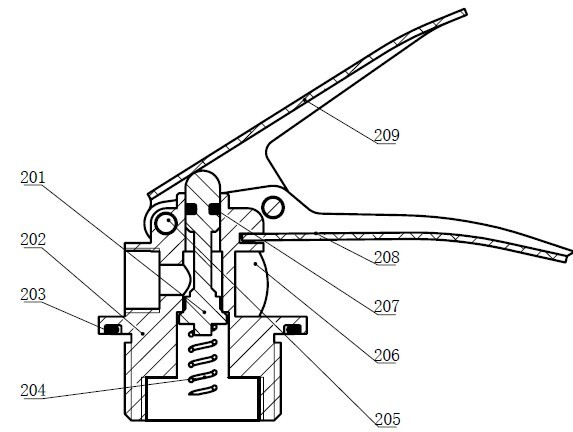

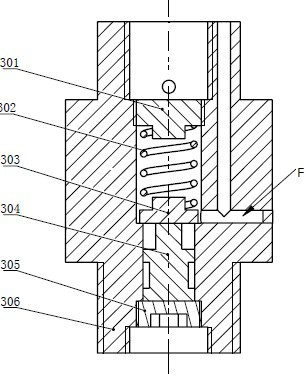

Portable water mist fire extinguisher

The invention discloses a portable water mist fire extinguisher, which comprises a nozzle (1), a switching valve (2), a pressure reducing valve (3), a shell (4) and a straw (5). The switching valve (2) is arranged at an opening on the upper part of the shell (4); the pressure reducing valve (3) is arranged on the switching valve (2); the nozzle (1) is connected with the pressure reducing valve (3); one end of the straw (5) is connected with the switching valve (2), and the other end of the straw (5) penetrates into the shell (4); and water in the shell (4) passes through the straw (5) and the switching valve (2) and enters the pressure reducing valve (3), and pressure water subjected to pressure reduction by the pressure reducing valve (3) flows out of the nozzle (1) to form water mist. The portable water mist fire extinguisher can effectively extinguish various types of fire, and has high environment compatibility, constant working pressure, high fire extinguishing efficiency, light weight and small volume.

Owner:HUAZHONG UNIV OF SCI & TECH

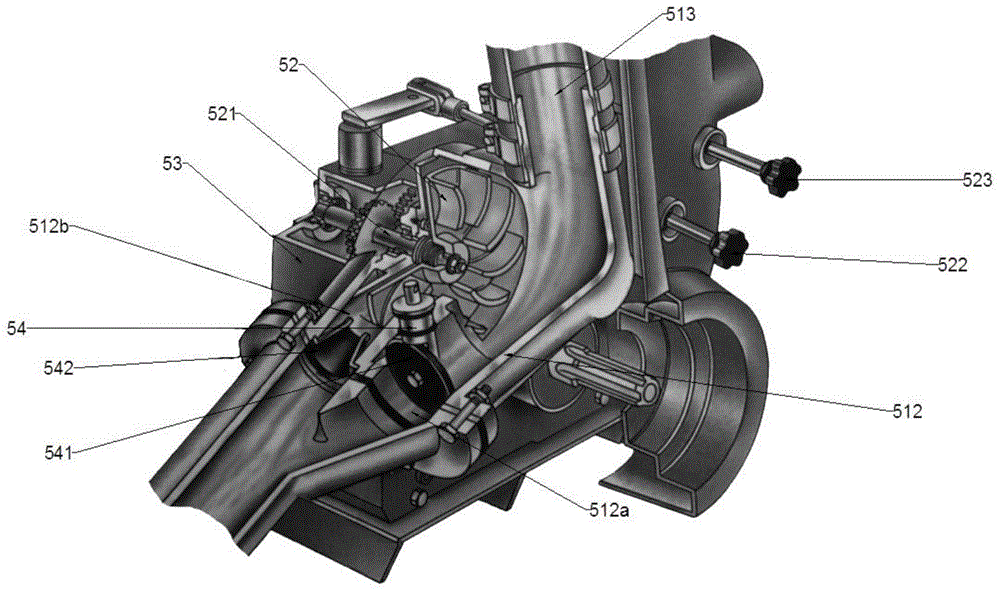

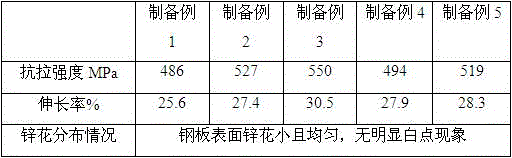

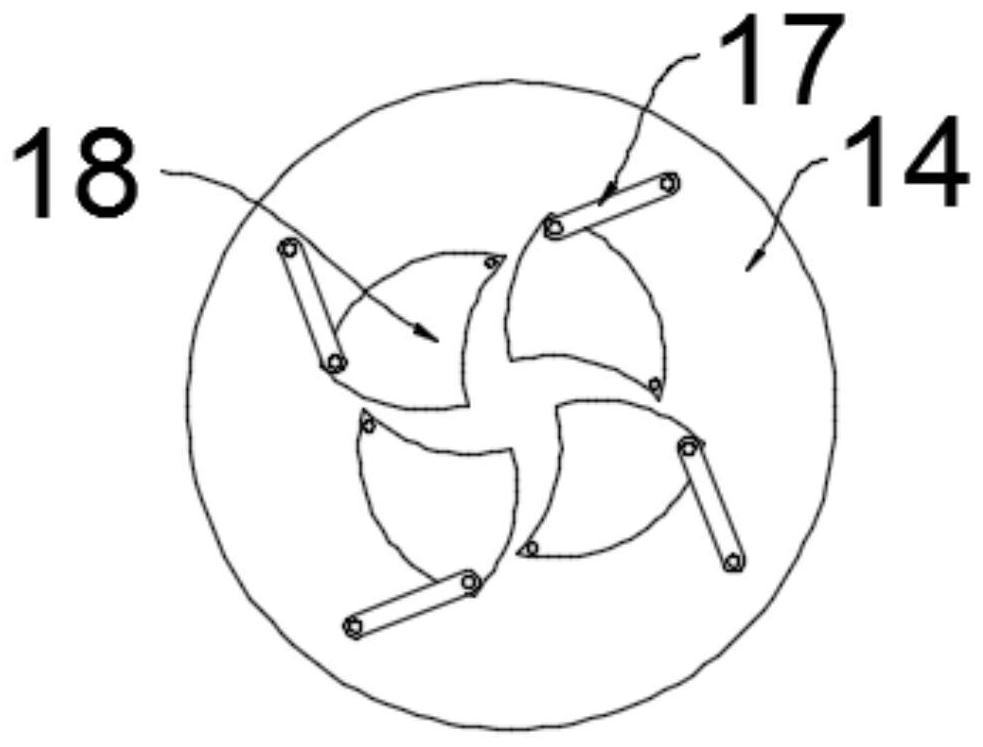

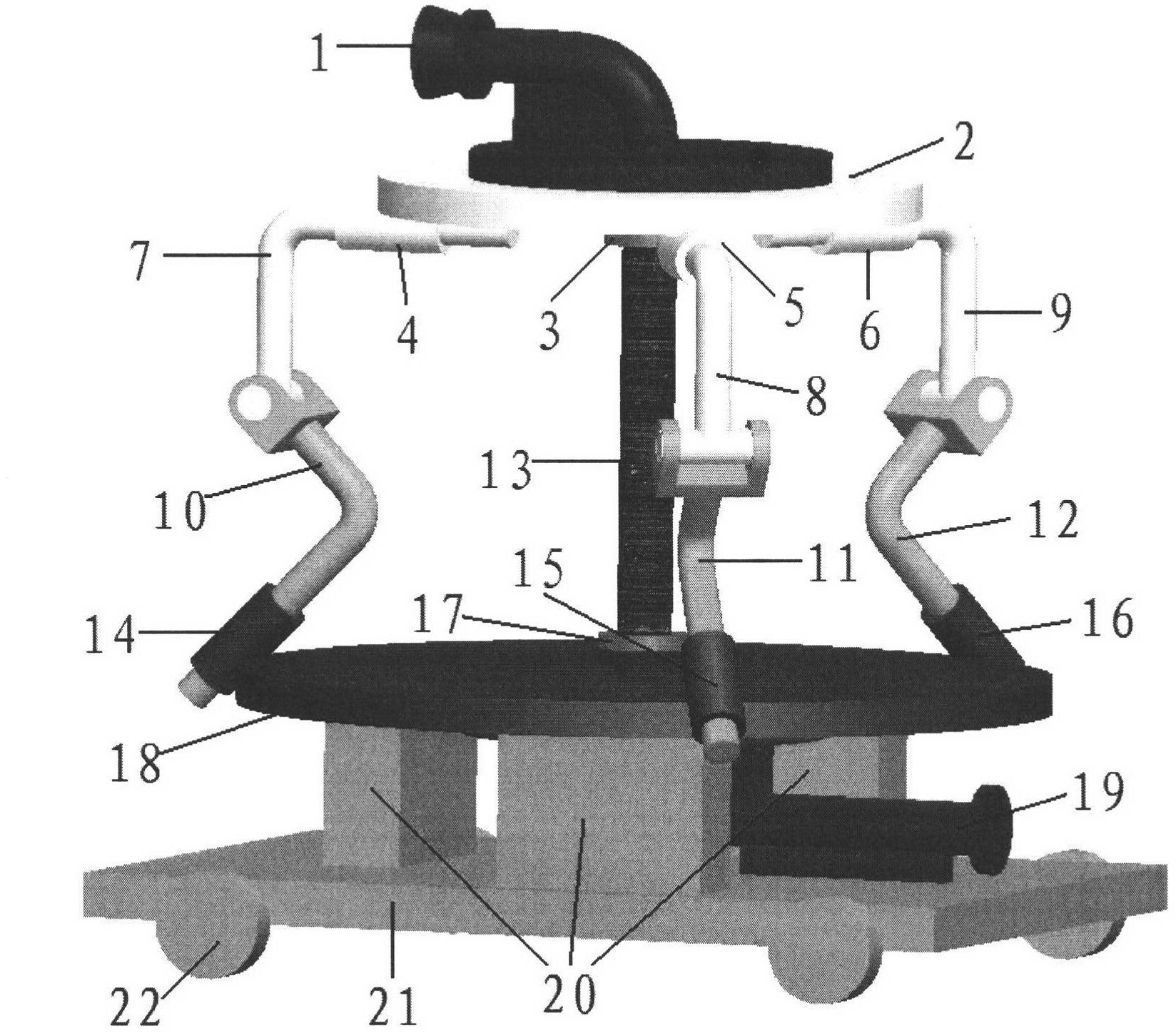

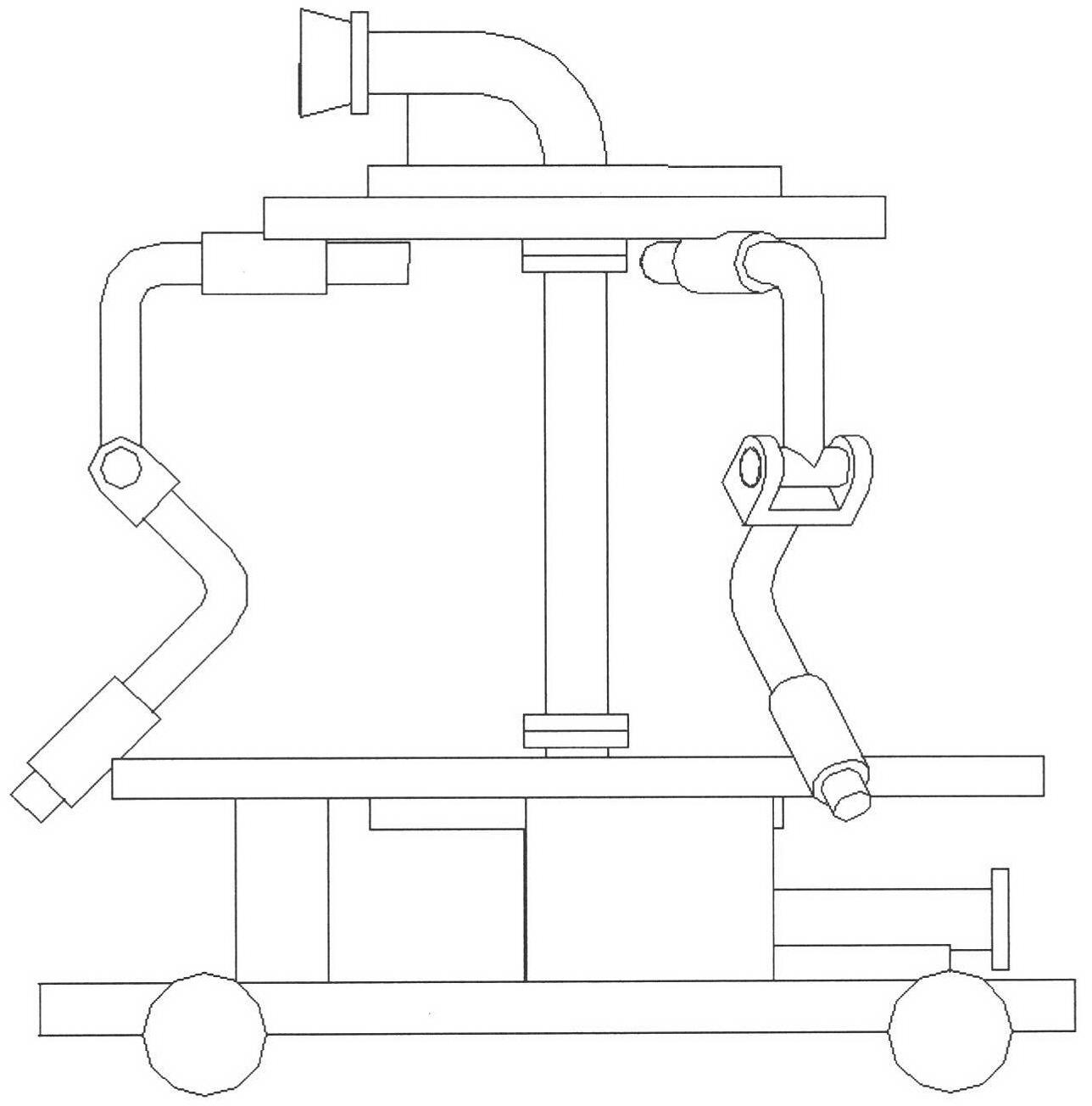

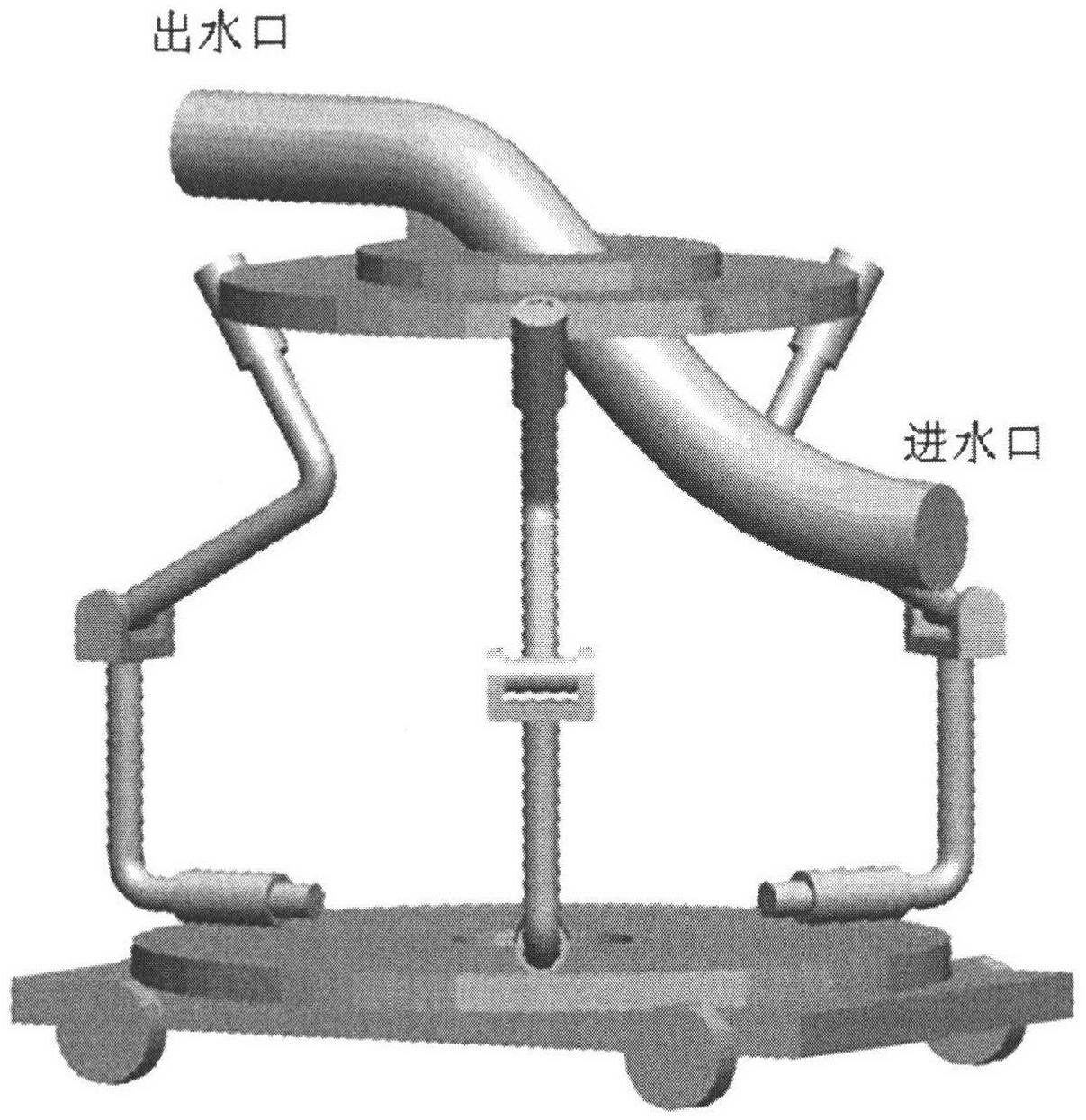

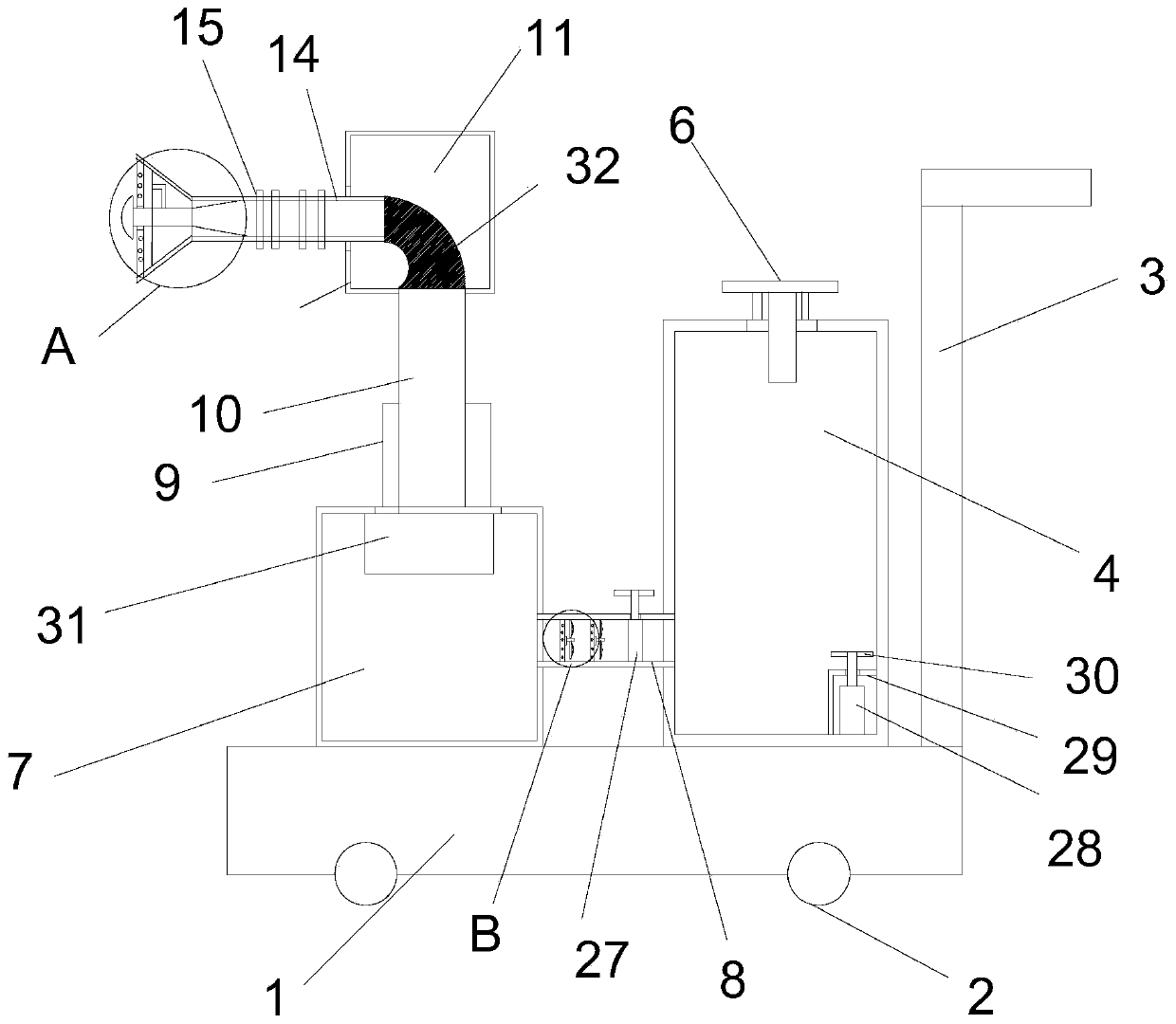

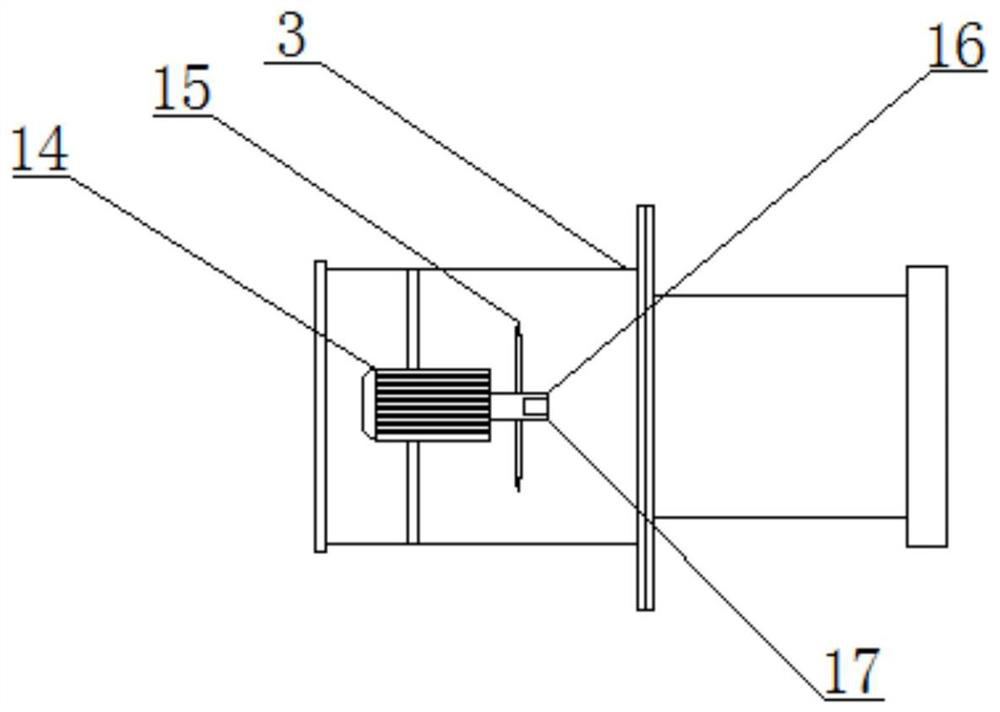

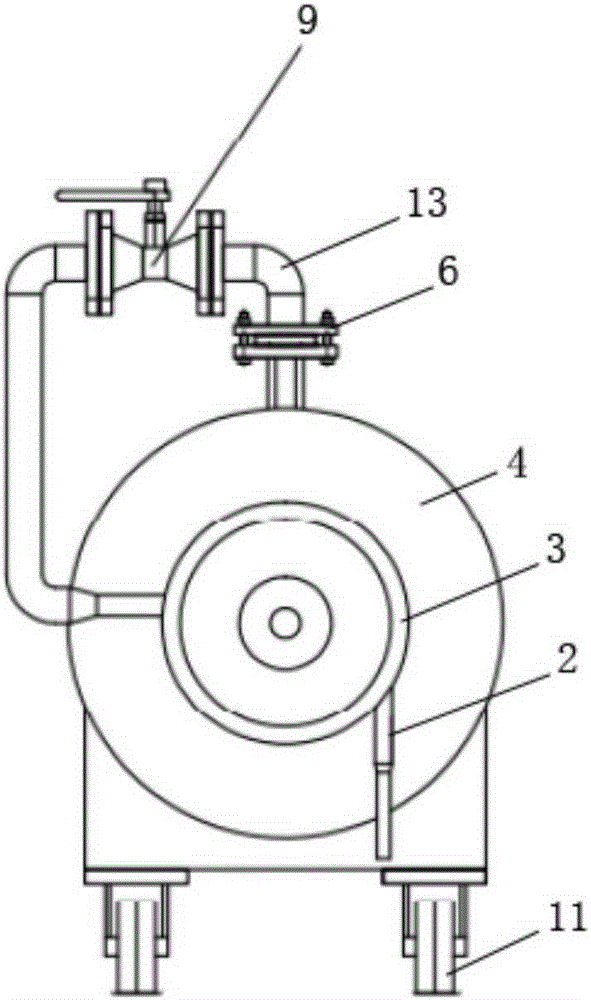

3CRC parallel mechanism fire monitor

The invention replaces a pipeline structure in a current fire monitor system by a 3CRC parallel mechanism, provides a parallel mechanism fire monitor device, thus reduces pressure loss generated by flowing through a bend, increases the fire-extinguishing fluid jet distance and height at a same inlet pressure, reduces energy consumption, and improves benefits. The invention comprises a 3CRC parallel mechanism, a water flow pipeline system, and a mobile pedestal. The main part of the 3CRC parallel mechanism comprises a parallel mechanism mobile platform [2] and a parallel mechanism fixed platform [18] which are connected by 3 side chains. The structure of each side chain is completely the same; taking one side chain for example, the side chain is started from the parallel mechanism mobile platform [2], and a cylindrical pair one [4], a connecting rod one [7], a lower connecting rod one [10], a lower cylindrical pair one [14], and the parallel mechanism fixed platform [18] are connected together; by the driving of a servo motor, relative rotation between the connecting rod one [7] and the lower connecting rod one [10] is realized; the other two side chains can realize similar motion,and the combined motion of the 3 side chains can realize the motion output function of the whole device. During application, the fire monitor mobile pedestal is moved to a proper position; a high pressure water inlet [19] is connected to a high pressure water pipe outlet of a hydrant; and a switch of the hydrant is turned on to perform fire-fighting work of the fire monitor.

Owner:EAST CHINA JIAOTONG UNIVERSITY

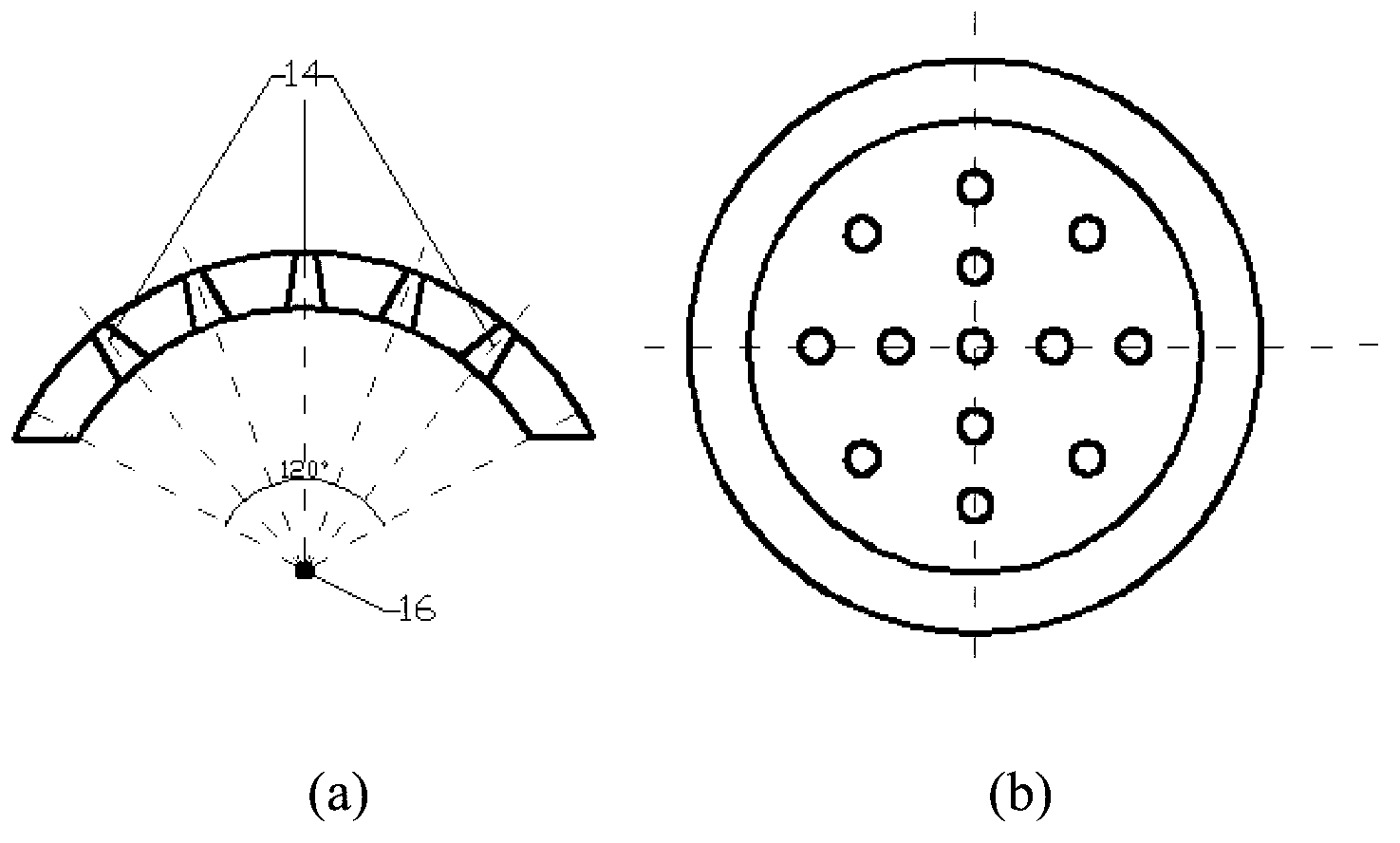

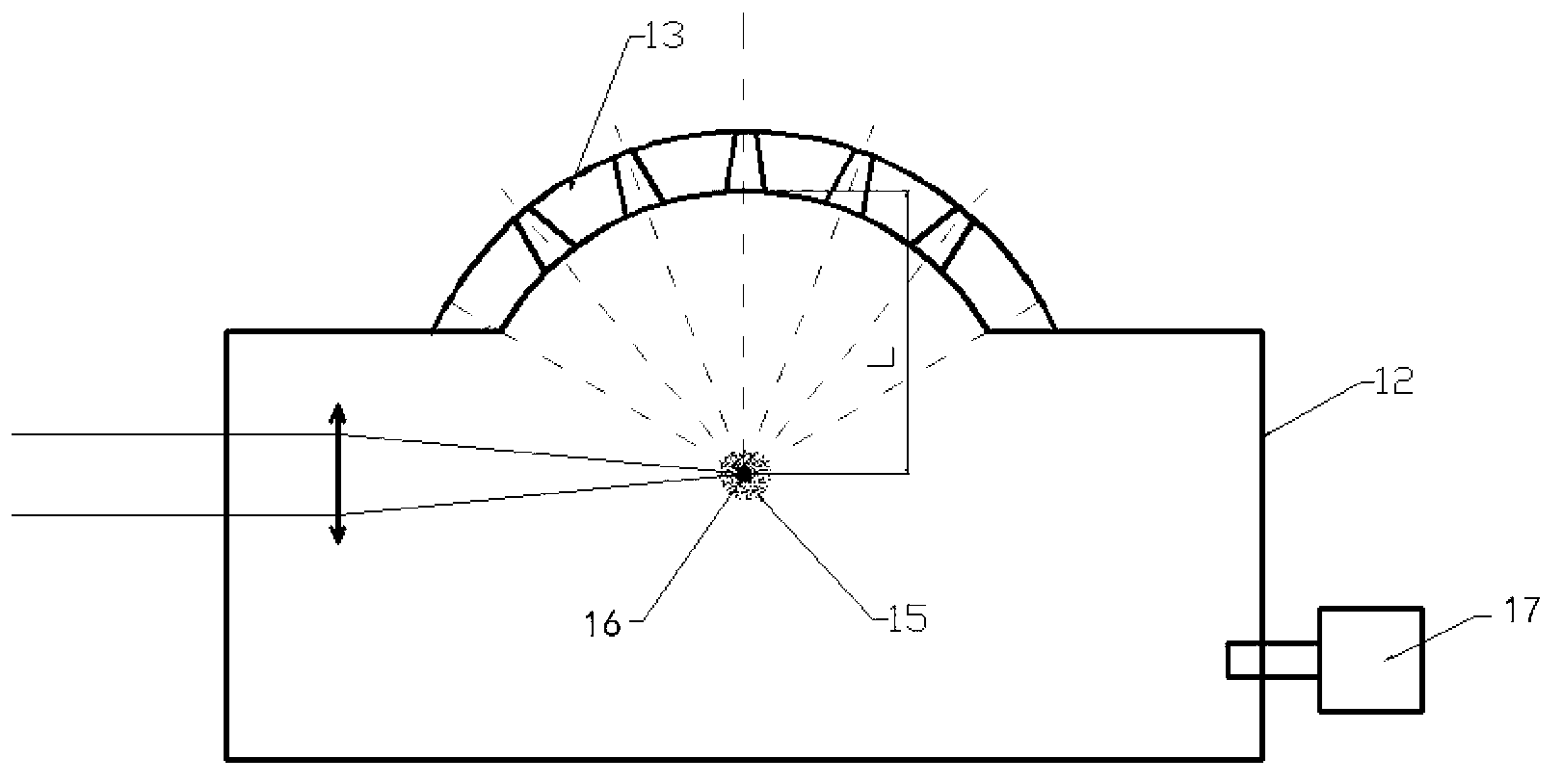

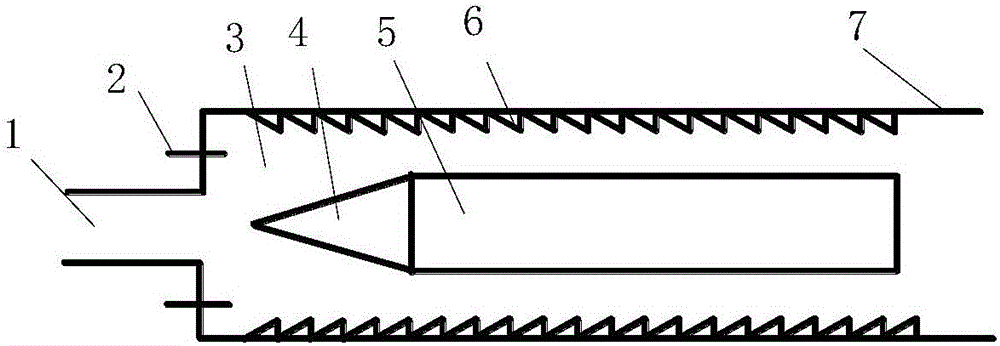

Liquid tin target generator for laser plasma extreme ultraviolet light source

InactiveCN103217869ALong spray distanceImprove conversion efficiencyPhotomechanical exposure apparatusX-ray tube with very high currentHigh pressureExtreme ultraviolet

The invention discloses a liquid tin target generator for a laser plasma extreme ultraviolet light source. The liquid tin target generator comprises a container, a vibrating rod, a nozzle, a heating system, a pressurizing system and a cooling mechanism, wherein micropores which are in central symmetry by using the center of the nozzle as a symmetric point and are uniformly distributed are formed in the nozzle, the diameter of the outlet end of each micropore is more than that of the inlet end of the micropore, and all micropores are pointed to a laser acting point from different angles. The heating system is used for melting a tin material which is in a solid state at a normal temperature into a molten tin material; the molten tin material is fragmented into liquid drops from a continuous liquid flow due to the vibration of the vibrating rod; the pressurizing system is used for applying a high pressure to the container to ensure that the molten tin material are sprayed out from the tiny micropores of the nozzle and form thick mist; a laser beam focuses on the converged liquid mist through a lens to generate EUV (Extreme Ultraviolet) radiation; and the vacuum system is used for vacuumizing a target chamber through a mechanical pump. The liquid tin generator has the advantages that the spraying distance of the target material is far, the influence on optical elements such as the nozzle and a converging lens is little, the laser absorption efficiency and the EUV conversion efficiency are high, and the system stability is good; and the liquid tin target generator is suitable for industrial large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

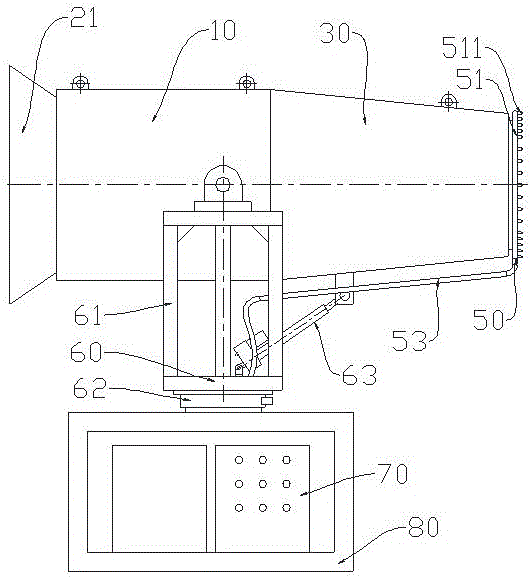

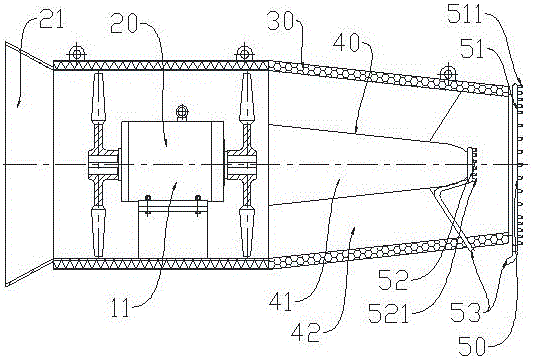

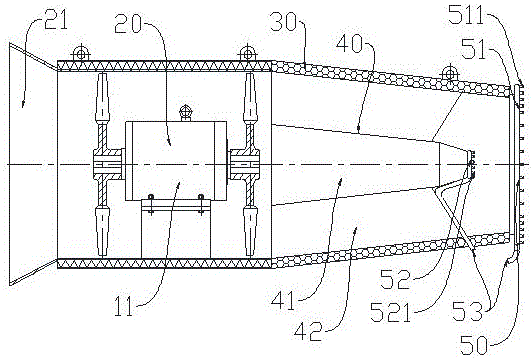

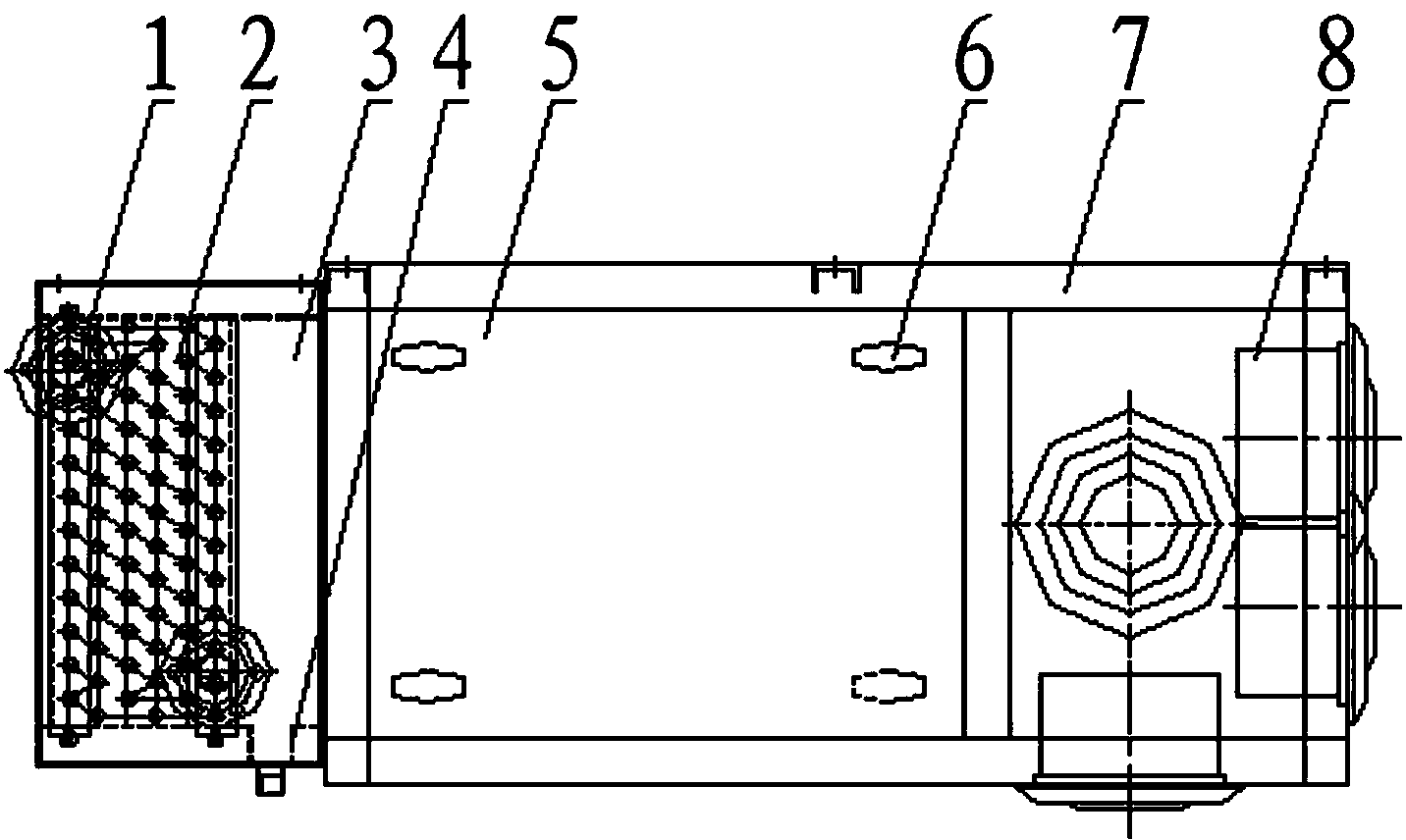

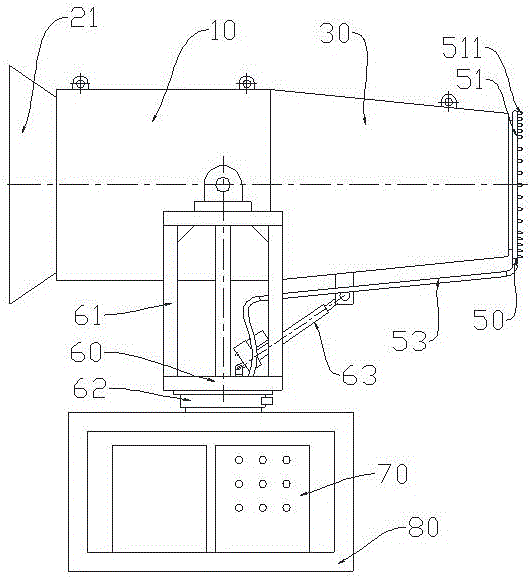

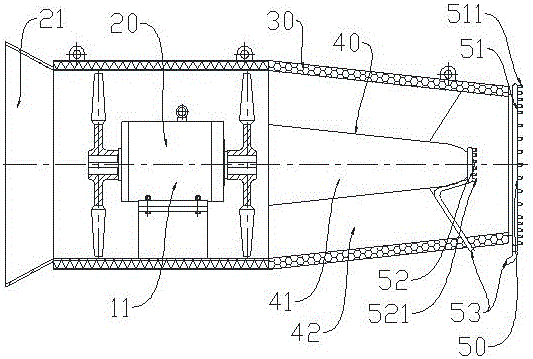

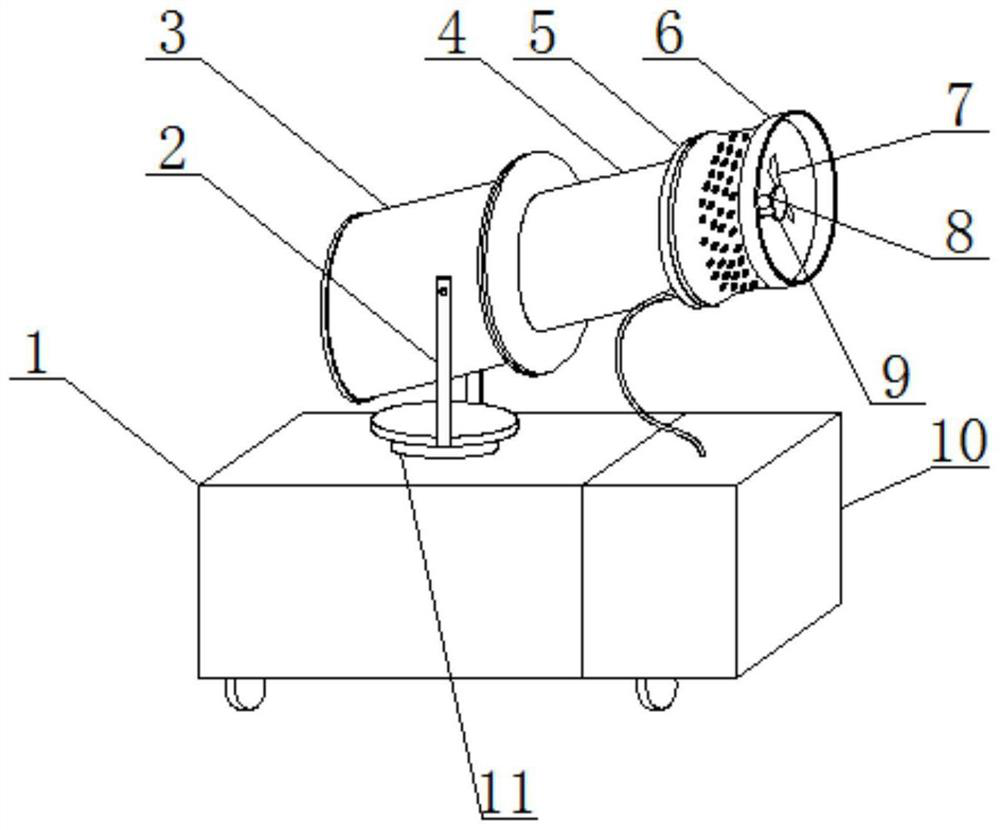

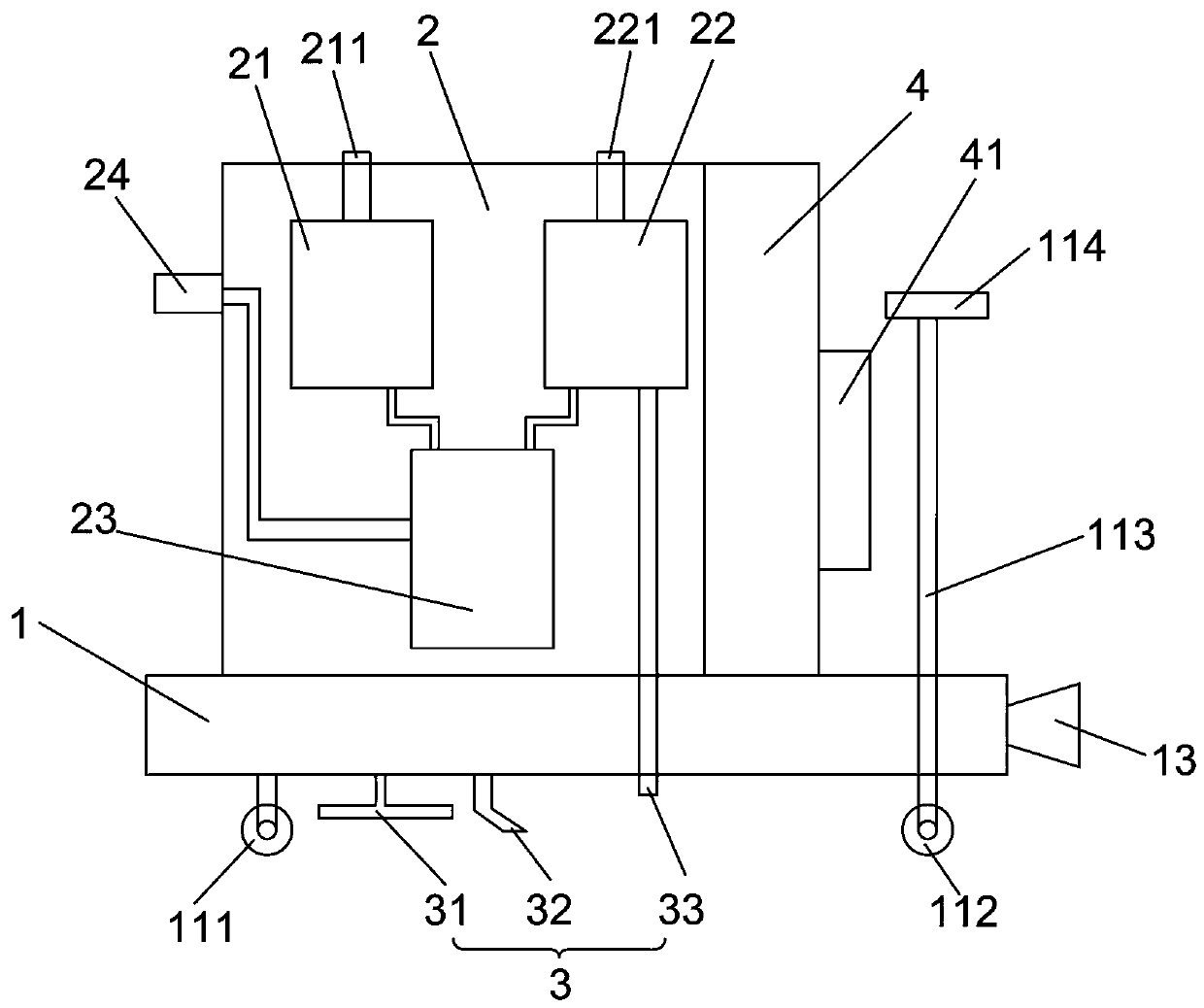

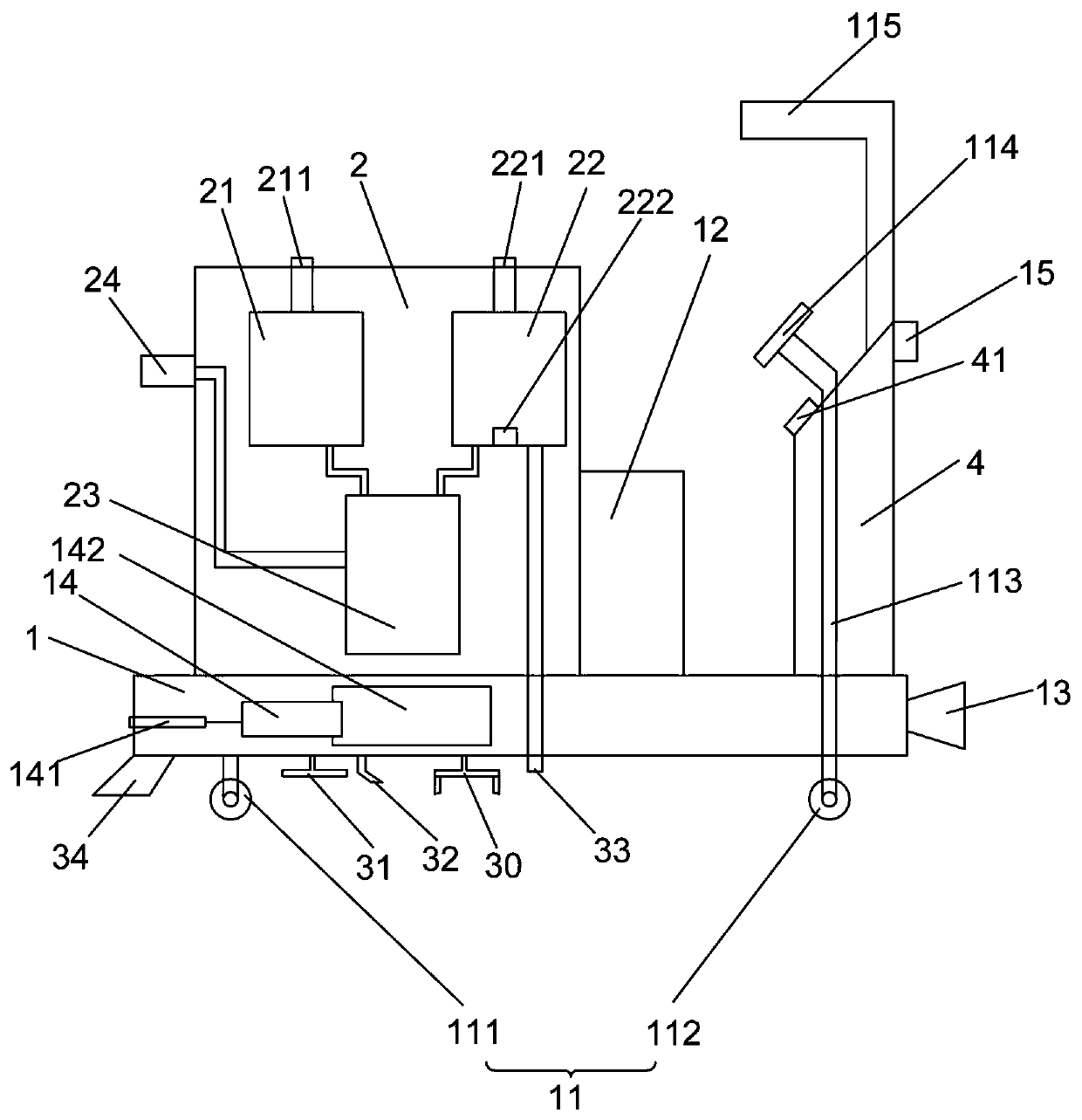

Very-long-range spraying dedusting equipment, spraying dedusting vehicle, and spraying device and spraying method of very-long-range spraying dedusting equipment and spraying dedusting vehicle

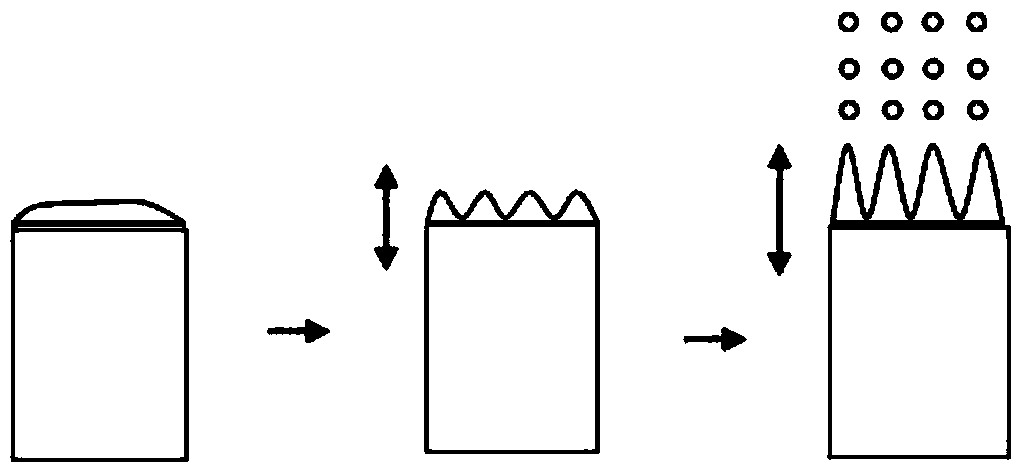

ActiveCN106694273AReduce lossLess atomized water dropletsUsing liquid separation agentLiquid spraying apparatusRing typeSpray method

The invention discloses a spraying device which comprises an axial flow fan, a spraying cylinder, a protective cover, a flow guide assembly and a spraying assembly; the spraying cylinder is connected with an air outlet of the axial flow fan; the protective cover is arranged at an air inlet of the axial flow fan; the flow guide assembly comprises a flow guide core body and a flow guide plate; the flow guide core body is fixedly arranged in the center of the spraying cylinder through the flow guide plate, and is arranged in the wind direction in the spraying cylinder; the spraying assembly comprises an outer spraying component arranged at an air outlet of the spraying cylinder and an inner spraying component arranged at the tail part of the flow guide core body; the outer spraying component is a single-ring type spraying component, a dual-ring type spraying component or a multi-ring type spraying component; and the inner spraying component adopts a single nozzle, double nozzles or a plurality of nozzles. The spraying device has the technical advantages of long spraying range and high dedusting efficiency. In addition, the invention further provides a spraying method for the spraying device, and a spraying dedusting vehicle and very-long-range spraying dedusting equipment which use the spraying device or the spraying method.

Owner:长沙贤正益祥机械科技有限公司

Pneumatic sprayer for fruit tree planting

InactiveCN111011334AAccelerate precipitation dissolutionEasy and quick passTransportation and packagingMixer accessoriesFruit treeWater storage tank

The invention relates to the technical field of fruit tree irrigation, and discloses a pneumatic sprayer for fruit tree planting. The pneumatic sprayer includes a rectangular plate, the rectangular plate has a rectangular structure, four vehicle wheels are arranged below the rectangular plate, and the vehicle wheels are fixedly connected to the lower part of the rectangular plate and are symmetrically installed around the rectangular plate; push rods are symmetrically arranged front and back on the rectangular plate, each push rod is an L-shaped rectangular rod, and the lower end of each pushrod is fixedly connected to the upper wall surface of the rectangular plate; and a water storage tank is arranged on the rectangular plate. According to the pneumatic sprayer, moving columns are arranged, each moving column is clamped in one corresponding control groove, the two moving columns are fixed symmetrically left and right on the outer wall surface of a mist spray pipe, a control rod is arranged in a groove, the control rod can control the mist spray pipe to move up and down through stretching, the mist spray pipe moves up and down to drive the two moving columns on an outer cylinderof the mist spray pipe to move up and down in the corresponding control grooves, a rotating column is arranged, a telescopic column can rotate in the rotating column, so that the effect of steering and adjusting the sprayer up and down, left and right in all directions is achieved.

Owner:重庆康调农业科技有限公司

Marine jet flow induced draught cooling device

InactiveCN104165424AReduce power consumptionReduce noiseDucting arrangementsLighting and heating apparatusNozzle

The invention relates to a marine jet flow induced draught cooling device which comprises a box body, wherein a diagonal fan is arranged in the middle of the box body, a cooling device is arranged at the position of an air inlet of the diagonal fan, and jet flow nozzles are arranged on the front side, the left side, the right side and the lower side of the portion, in front of the air outlet portion of the diagonal fan, of the box body. Due to the fact that the jet flow nozzles are arranged on the left side, the right side and the lower side of the box body, the angle can be adjusted to enable air to be fed in all directions, and the air feeding range is wide.

Owner:JIANGSU JOSUN AIR CONDITIONER

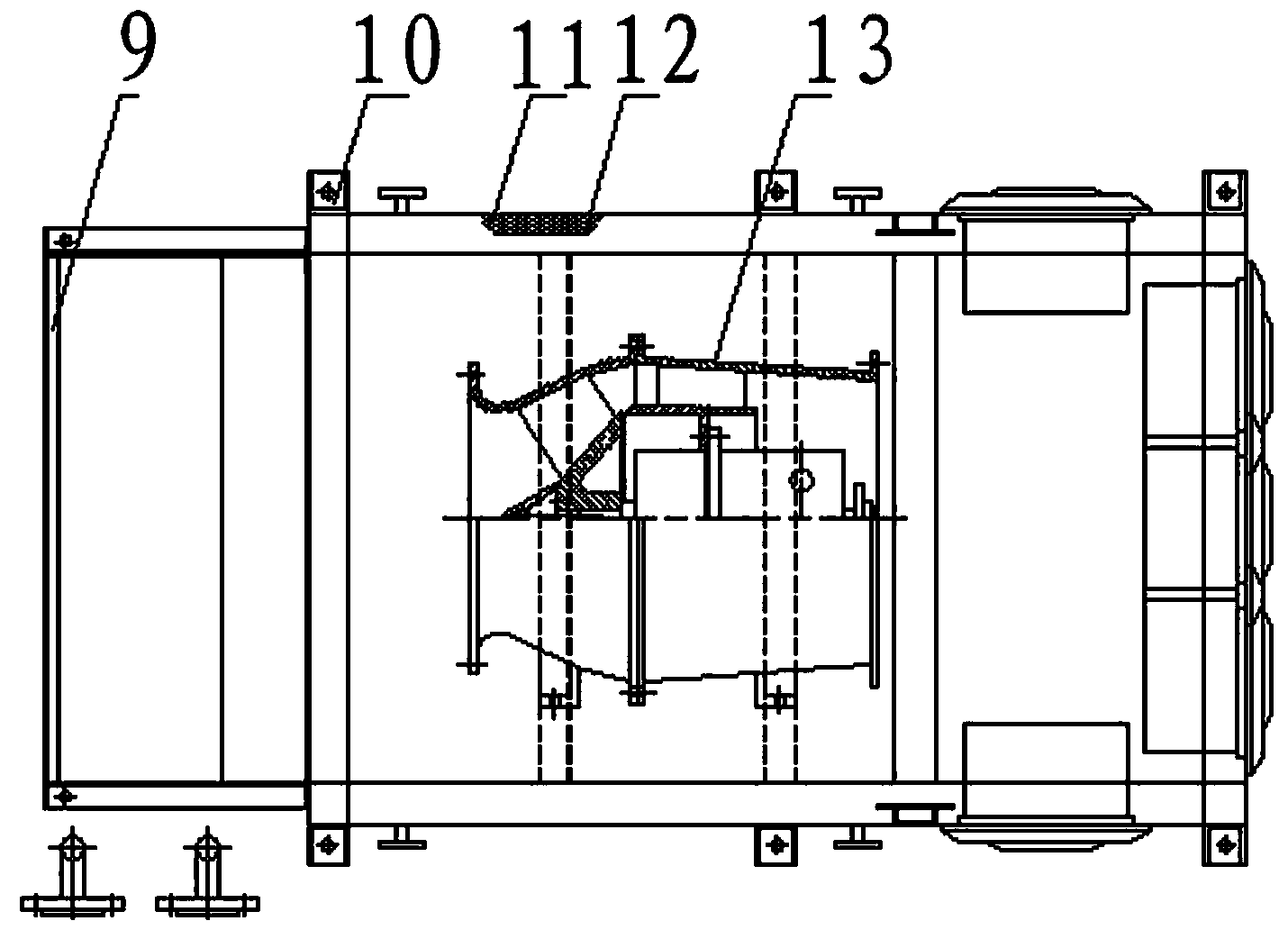

Atomization sterilization machine

The invention relates to an atomization sterilization machine. The atomization sterilization machine includes a spray mechanism, a liquid replenishment tank, a fan and atomizers; and the atomization sterilization machine is characterized in that the spray mechanism includes a liquid storage part, an atomization chamber and a spray head communicating with one another, the spray head includes at least one azimuth mist outlet, the opening of the azimuth mist outlet is inclined upwards, the liquid supplement tank is connected to the liquid storage part through a liquid supplement pipeline, the fanis fixedly connected to an air inlet of the atomization chamber, a mist blocking plate extends from the lower end of the air inlet towards the interior of the atomization chamber, the mist blocking plate is inclined upward, and the atomizers are uniformly distributed at the bottom of the liquid storage part. According to the atomization sterilization machine, the wind direction is changed by themist blocking plate, and power is preferentially provided for small particles located in the upper region of the atomization chamber to obtain a longer spray distance; heights of the mist blocking plate and an atomization peak are matched, so that the atomized particles are screened, and a better mist dispersion effect is obtained; and the design of the 45 degrees elevation angle opening of the azimuth mist outlet is conducive to increasing the spray distance of the disinfection machine.

Owner:湖南省谛源光学科技有限公司

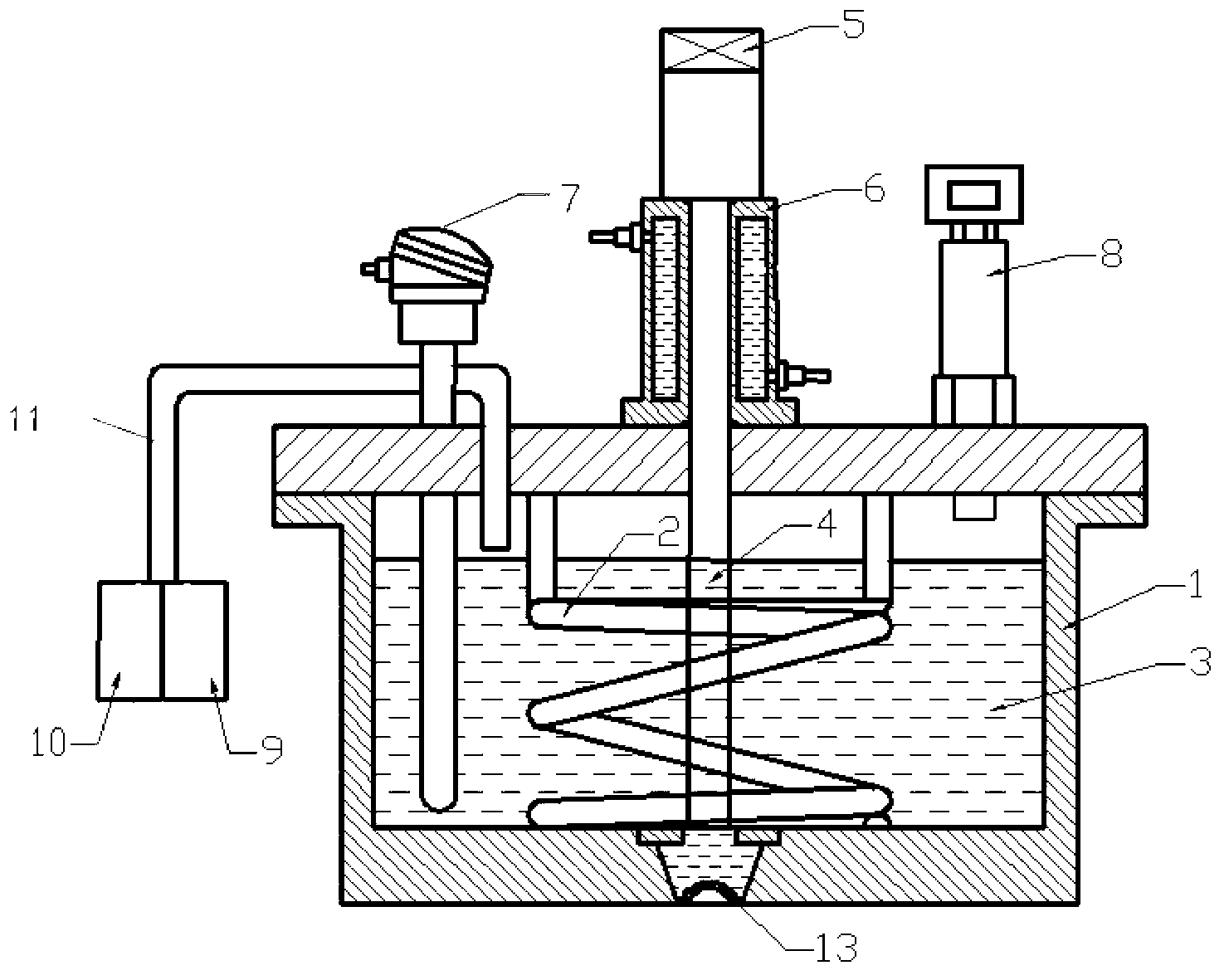

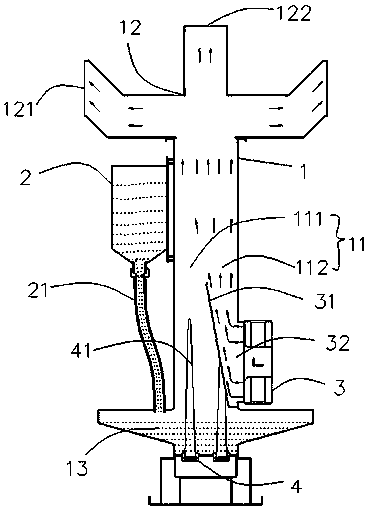

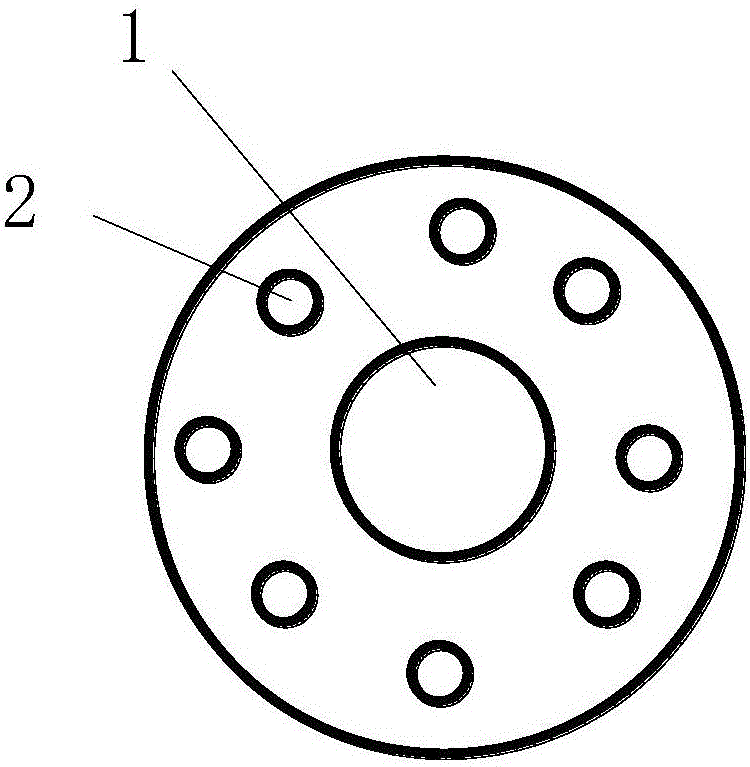

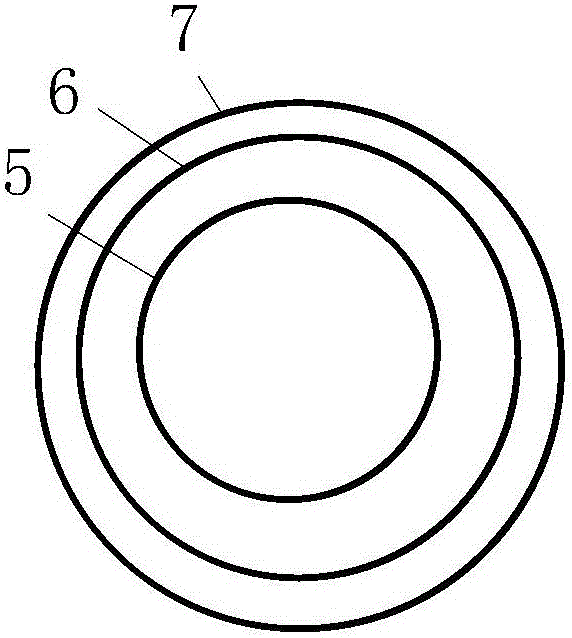

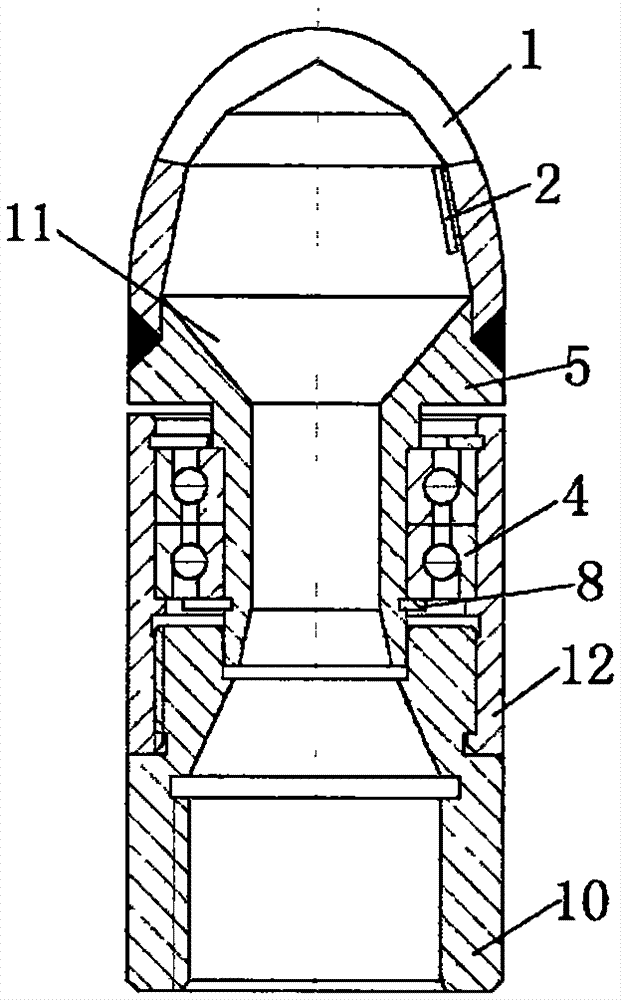

Large-flow compressed air and foam mixing device

ActiveCN105126277ALong spray distanceIncrease kinetic energyFire rescueSpray nozzleAerospace engineering

The invention discloses a large-flow compressed air and foam mixing device and relates to the technical field of compressed air and foam mixing devices. The large-flow compressed air and foam mixing device solves the problem that because existing air-liquid mixing devices are simple in structure and air and liquid cannot be fully mixed when the flow of foam-mixed liquid is increased, the foaming quality is influenced. The large-flow compressed air and foam mixing device comprises a foam-mixed liquid nozzle. The foam-mixed liquid nozzle is connected with a mixing cavity, a conical turbulence device is arranged in the mixing cavity, the tail end of the conical turbulence device is connected with a secondary turbulence device, inner wall surface bosses are arranged on the inner side of the pipe wall of the mixing cavity, the arrangement length of the inner wall surface bosses on the inner wall surface of the mixing cavity is equal to the total length of the conical turbulence device and the secondary turbulence device, and air inlet pipes are uniformly arranged on the end surface, connected with the foam-mixed liquid nozzle, of the mixing cavity.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

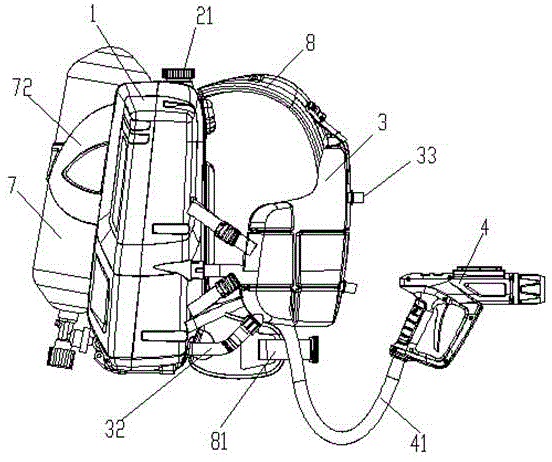

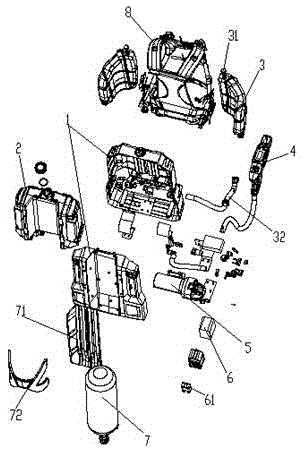

Backpack type electric water fire extinguishing plant

The invention discloses a backpack type electric water fire extinguishing plant which comprises a backpack housing, a double-shoulder-strap assembly, an intelligent water gun and a main liquid storage tank. A water pump connected with a bottom outlet of the main liquid storage tank is arranged in the backpack housing, and the water pump and the intelligent water gun are connected through a water outlet pipeline. Two auxiliary liquid storage tanks are symmetrically arranged on the double-shoulder-strap assembly, and the bottoms of the two auxiliary liquid storage tanks are connected with the bottom of the main liquid storage tank through water feeding pipelines. Through the mode, the backpack type electric water fire extinguishing plant is particularly provided with the auxiliary liquid storage tank and the main liquid storage tank so that more fire extinguishing liquid can be carried; front and back balance weights are more reasonable, so that the operation stability and comfort of firefighters are improved; the intelligent water gun is in an electric liquid spraying design so as to be free of accumulated pressure, safer, easy to operate, far in spraying distance, efficient in fire extinguishing, rich in information display and beneficial to on-site liquid storage and continuous operation.

Owner:ZHONG DA YUAN MECHANICAL & ELECTRICAL TECH SUZHOU CO LTD

Travelling-type wind-and-water-linkage spraying and dust falling device for mines and application method of device

The invention relates to a travelling-type wind-and-water-linkage spraying and dust falling device for mines and an application method of the device and belongs to the technical field of mine intelligent equipment. A water tank is full of water, the device moves in a mineral drive by means of the method that rear wheels are driven by a motor, when a dust concentration inductor on a purification tower detects that the dust concentration is overhigh, a controller can drive a high-pressure pump to convey water in the water tank to an atomization device, and the water is atomized by the atomization device and conveyed to a spraying device through a spraying pipeline; meanwhile, a fan works, air is sucked through a fan pipeline, dust in the air is filtered through a filter net, wind is conveyedto a filtering liquid storage device through the fan, mist in the air is concentrated into water in the filtering liquid storage device, and then the water is conveyed and returned to the water tankthrough a booster pump; and the filtered high-pressure air is conveyed to the spraying device through a high-pressure air pipeline to be mixed with the mist, and then the air and mist are sprayed outthrough a spray head, so that dust falling inside the mineral drive is completed.

Owner:常州市绿意管道有限公司

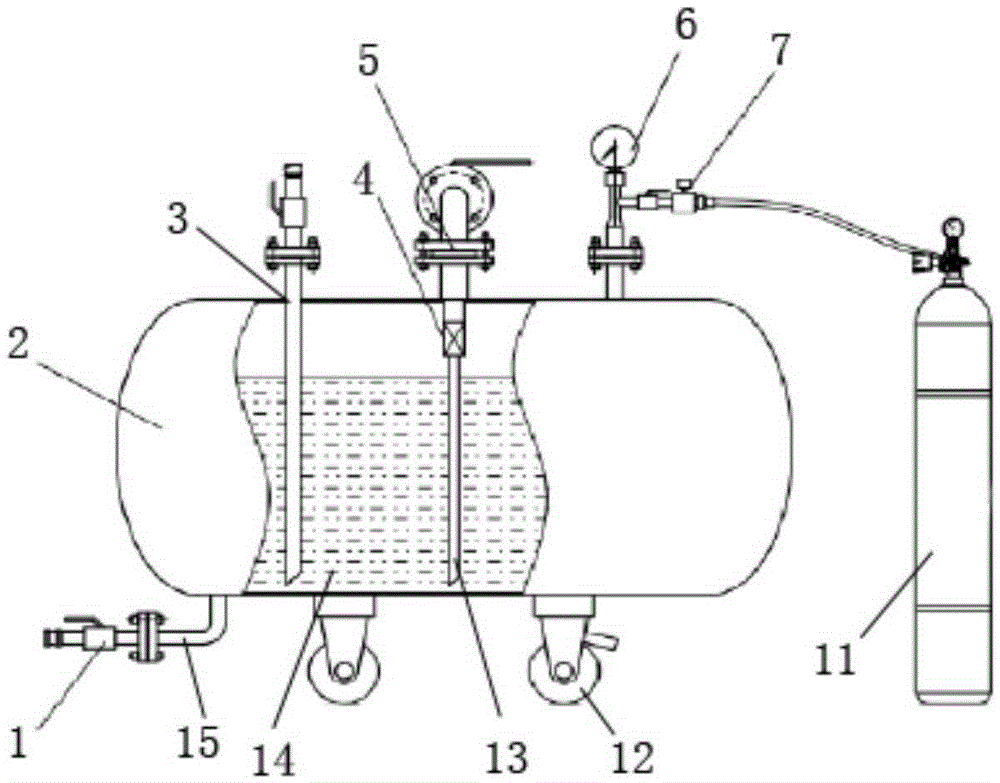

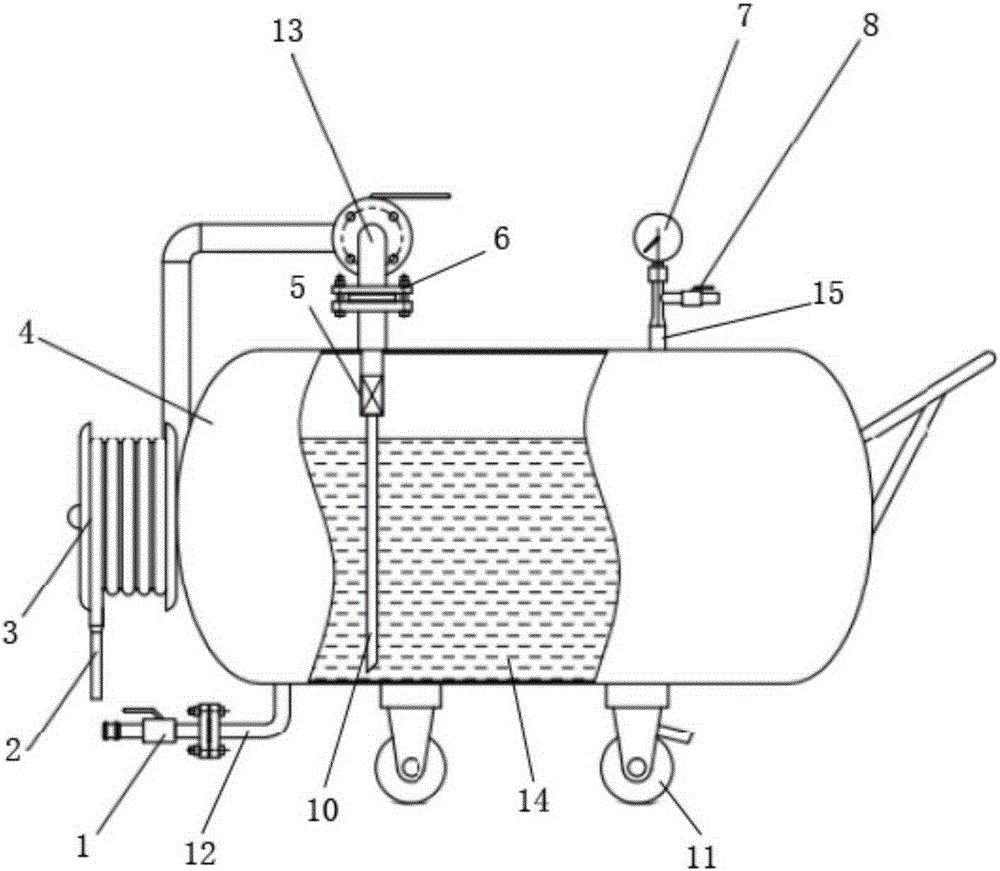

Energy storage type compressed gas foam fire extinguishing device

InactiveCN105327475AImprove the mixing effectIncrease kinetic energyFire rescueBoiling pointNitrogen

The invention discloses an energy storage type compressed gas foam fire extinguishing device. The device comprises a pressure liquid storage tank, a foam generator and a pressure steel cylinder, wherein the pressure liquid storage tank is filled with foam fire extinguishing agent mixed liquid; a liquid inlet pipe for filling the foam fire extinguishing agent mixed liquid is arranged on the pressure liquid storage tank; compressed nitrogen or air is filled in the pressure steel cylinder; the pressure steel cylinder is connected with the pressure liquid storage tank through a gas conveying pipeline; the foam generator is arranged in the pressure liquid storage tank, and is positioned above the foam fire extinguishing agent mixed liquid; and a liquid nozzle, a gas inlet and a spoiler are arranged on the foam generator. The energy storage type compressed gas foam fire extinguishing device can greatly improve the mixing capacity of foam liquid and high-pressure gas, so that jetted foams are high in kinetic energy, the foam stability and the foam jetting strength are enhanced, and the penetrability of such low-boiling-point materials as epoxypropane to the foams in burning is effectively stopped.

Owner:CHINA PETROLEUM & CHEM CORP +1

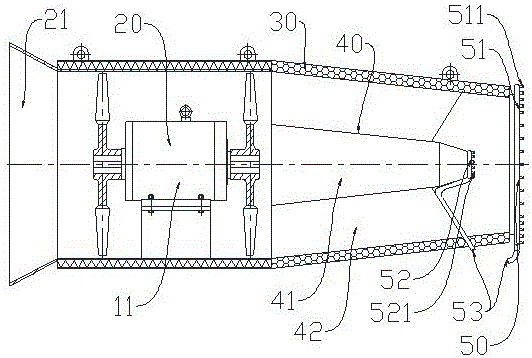

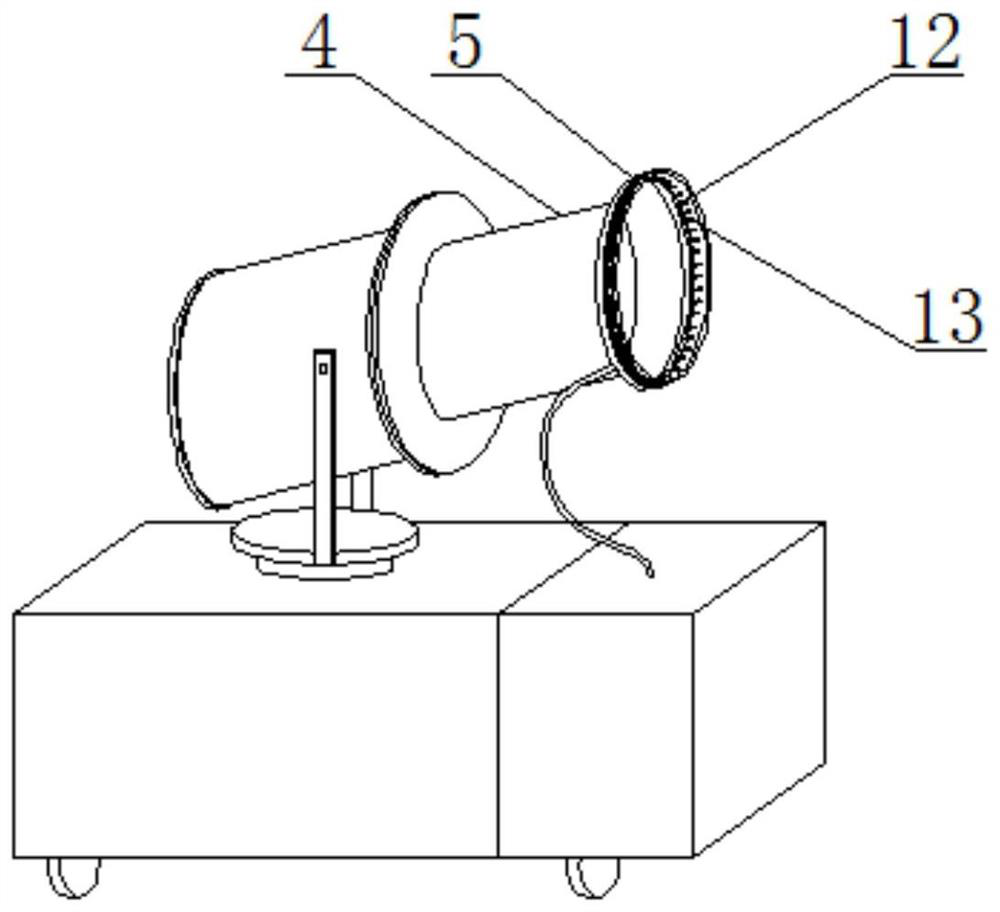

Spraying device, spraying method and dust suppression vehicle

ActiveCN106733284AReduce lossLess atomized water dropletsUsing liquid separation agentLiquid spraying apparatusEngineeringWind direction

The invention discloses a spraying device which comprises an axial flow fan, a spraying barrel connected with an air outlet of the axial flow fan, a protection cover arranged on an air inlet of the axial flow fan, a flow guide assembly comprising a flow guide core and a flow guide plate and an internal spraying assembly arranged at the tail end of the flow guide core. The flow guide core is fixedly arranged in the center of the spraying barrel through the flow guide plate, the flow guide core is distributed in the spraying barrel in the air direction, and the internal spraying assembly adopts a single spraying nozzle or double spraying nozzles or multiple spraying nozzles; and in addition, the spraying assembly is not arranged in the circumferential direction of the air outlet of the spraying barrel. The spraying device has the beneficial effects that the jetting distance is long, turbulent flow at a jetting final point is reasonable, the dust collection efficiency of the jetting final point position can be effectively improved, and the dust collection efficiency is improved. In addition, the invention further provides a spraying method used by the spraying device and a dust suppression vehicle comprising the above the spraying device or using the above spraying method.

Owner:HUBEI RUNLI SPECIAL AUTOMOBILE

Dust-falling spraying device for building construction

InactiveCN111957140ALong distanceLong spray distanceUsing liquid separation agentElectric machineryFan blade

The invention discloses a dust-falling spraying device for building construction. The device comprises a base and a water tank, the water tank is mounted on the outer wall of the front end of the base; a rotating seat extending upwards is arranged in the outer wall of the upper end of the base; a rear cylinder is arranged on the upper side of the rotating seat; the rear fan blades on the crankshaft are driven by a working motor in the rear cylinder to rotate quickly; meanwhile, a mounting shaft and the front fan blades are driven to rotate; then, a water pump can be used for pressurizing the water and conveying the water into an annular pipe; finally, water mist is sprayed forwards through a spray head; the front fan blades can blow the water mist farther; meanwhile, a large spraying rangeis formed through the round holes in a diffusion cylinder, sprayed water mist and dust particles in the air are combined and agglomerated, and finally fall to the ground under the action of gravity,so that the purpose of dust removal is achieved, and by additionally arranging the diffusion cylinder and the front fan blades, the range of the sprayed water mist is wider, and the distance is longer.

Owner:江苏金鼎建设集团有限公司

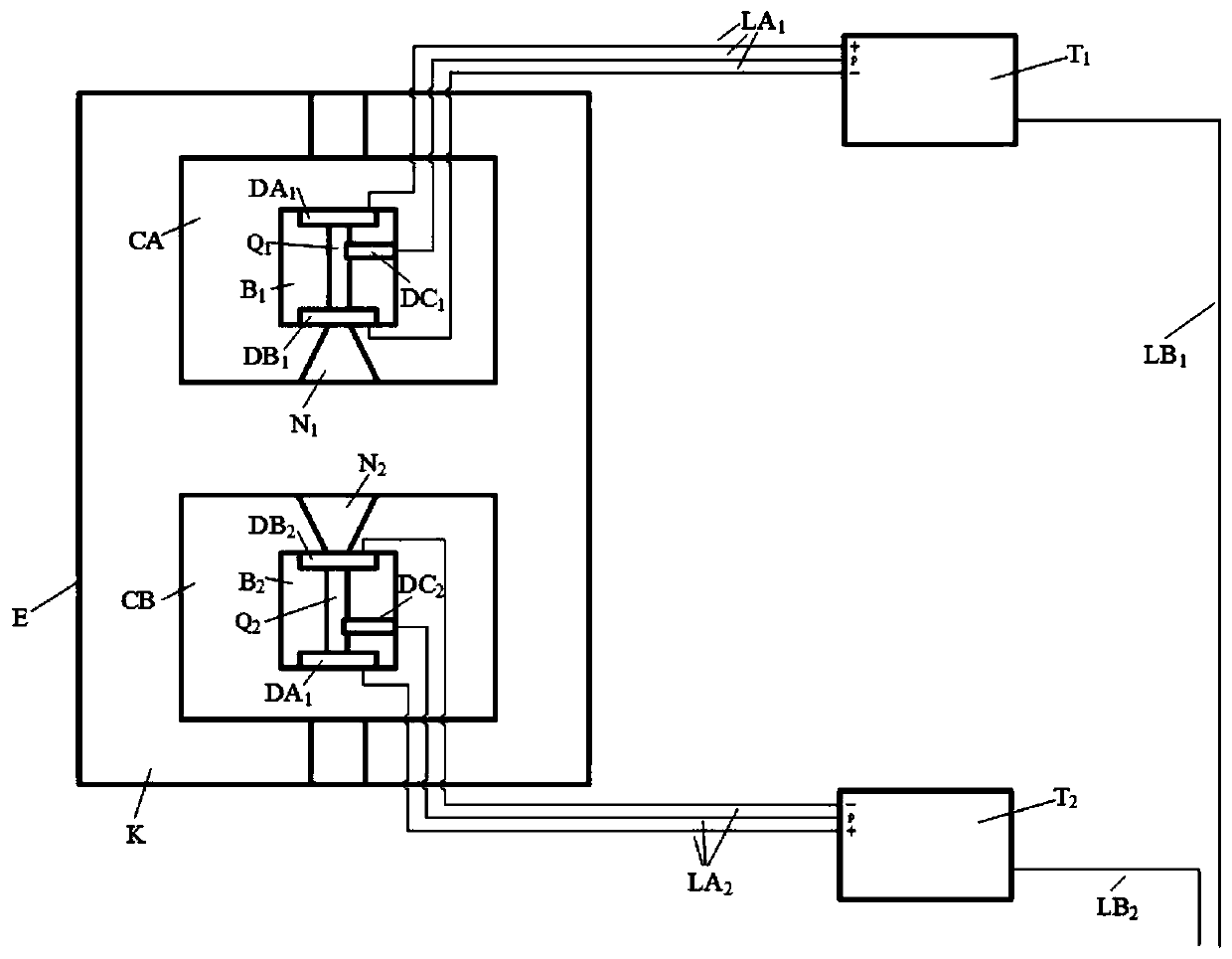

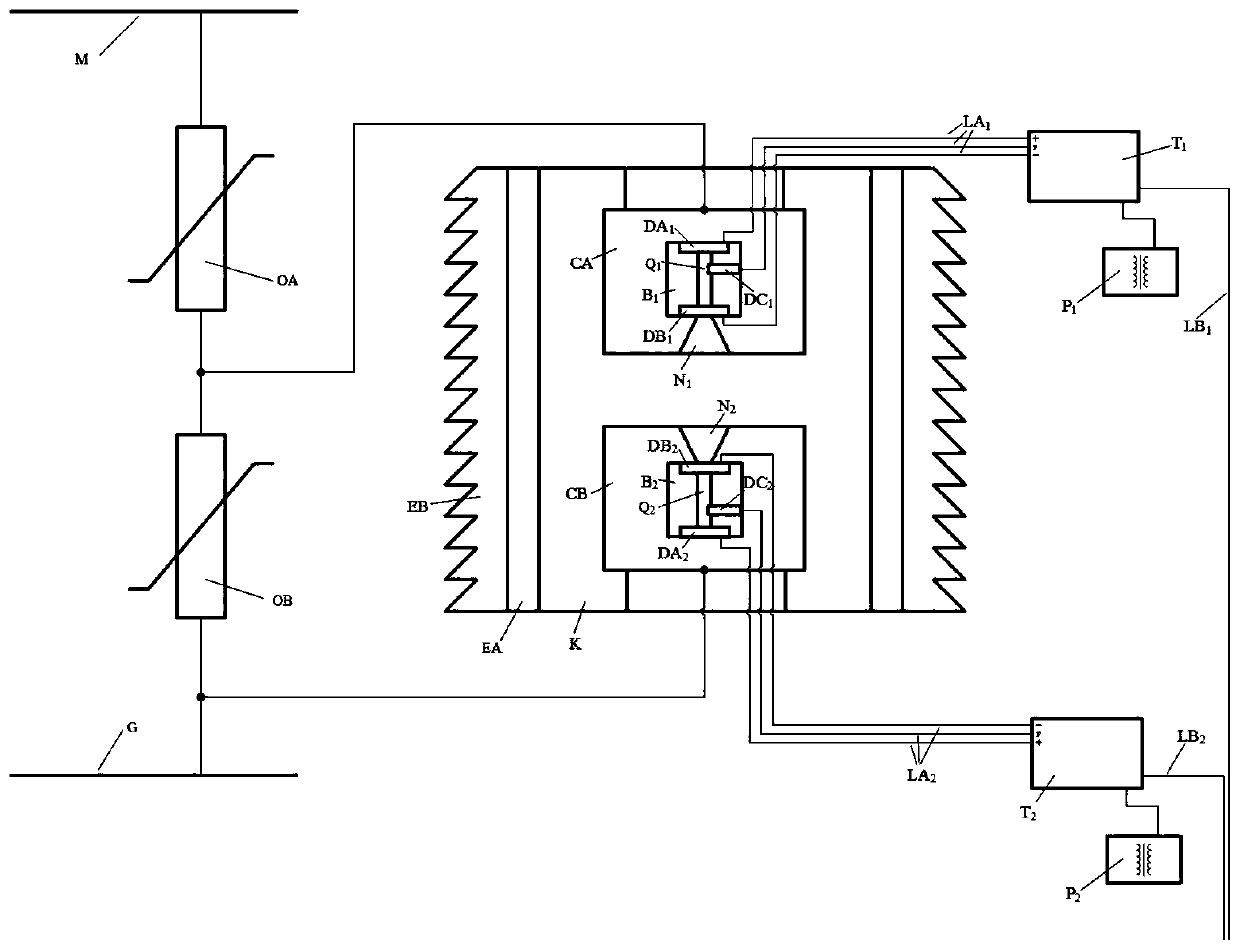

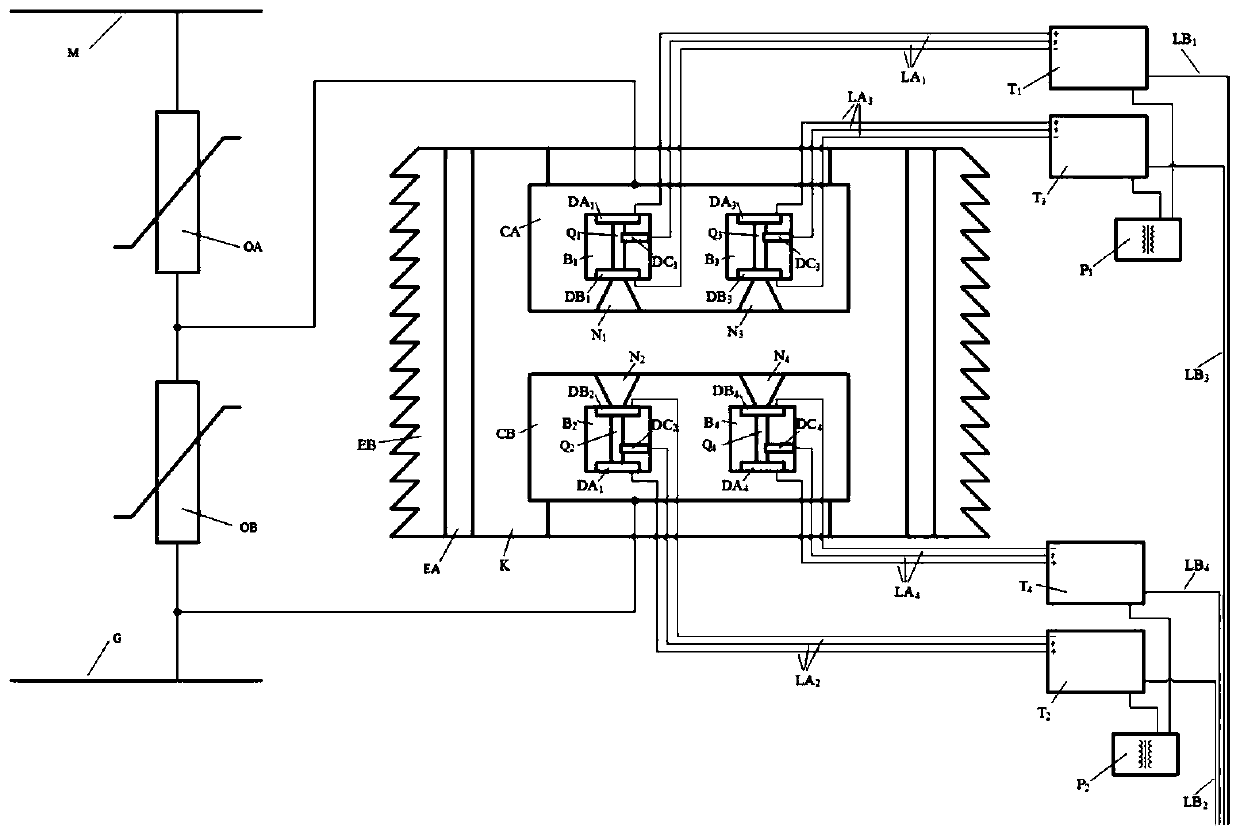

Closed discharge gap triggered by plasma jet and application thereof

PendingCN110430655AReliable actionImprove controlSpark gap detailsPlasma techniquePlasma jetHigh pressure

The invention discloses a closed discharge gap triggered by a plasma jet and an application thereof. The closed discharge gap comprises a plasma spraying unit comprising an injection device and a plasma trigger T, wherein the injection device is arranged in a contact unit, generates plasmas and ablate the ablation materials through pulse voltages and currents and generates a plasma jet by adoptinga capillary action of an elongated cavity, the injection device is connected with a plasma trigger T through the high voltage wire LA, the contact unit is arranged in the cavity unit for tolerance ofarc ablation, the cavity unit is used for providing a closed high-pressure gaseous medium environment. The closed discharge gap can ensure the reliable operation in the low work parameters, improvesthe control performances of the discharge gap, increases the work range and service life of the discharge gap, solves the problems that the arc is extinguished due to the small gap current, avoids thegap breaking, and replaces the complex and high-cost energy storage and freewheeling device.

Owner:西安西交瑞力电气研究院有限公司

Automatic rotating sprayer

ActiveCN106984456AImprove atomization effectReduce manufacturing costMovable spraying apparatusSprayerEngineering

The invention discloses an automatic rotating sprayer which comprises a stator, a rotating head rotationally connected to the stator, and at least one power slit. The rotating head is provided with a fluid cavity, at least one fluid inlet and multiple fluid outlets, wherein the fluid inlet and the fluid outlets communicate with the fluid cavity. The power slits are arranged on the rotating head and communicate with the fluid cavity, the projection line, on the longitudinal projection face, of the axis of the power slit does not coincide with the projection line, on the longitudinal projection face, of the axis in the height direction of the rotating head, so that when a solution in the fluid cavity is sprayed out from the power slit, impact force is generated on the rotating head and is then converted into torque driving the rotating head to rotate, the solution is in the shape of fog curtains when sprayed out from the power slit, the fog curtains can be better atomized under the rotation of the rotating head, and therefore the atomization effect of the sprayer is improved, and the weight of the sprayer is reduced; and meanwhile, the resistance exerted on the solution is low when the solution is sprayed out of the power slit, relatively small kinetic energy is lost, and the injection range of the atomized solution is longer.

Owner:BEIJING CHINA SCI PURIFICATION ECO TECH

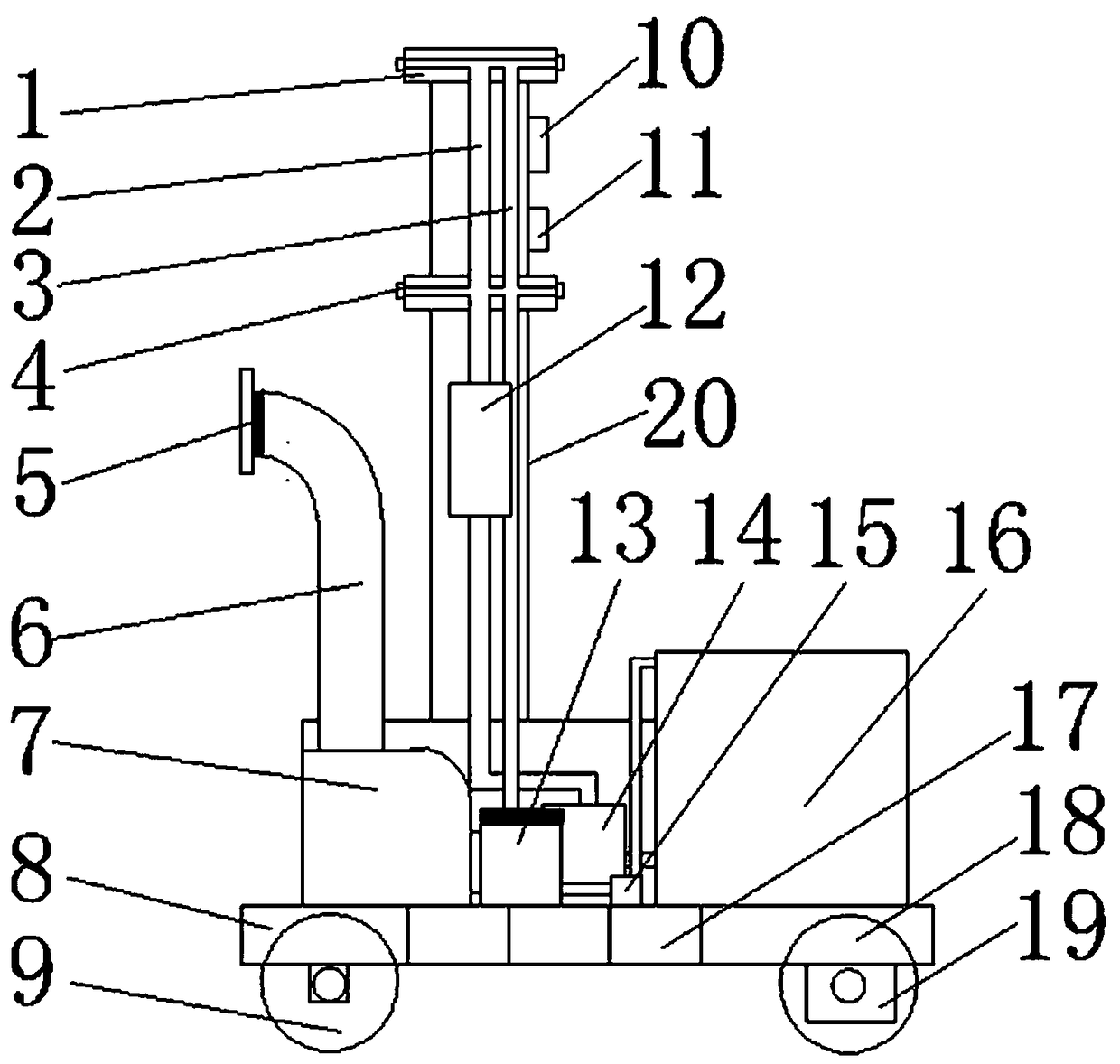

Electric high-pressure fire extinguishing device with sweeping function

ActiveCN110523038ASimple structureEasy to useSuction cleanersFire rescueElectricityCarrying capacity

The invention provides an electric high-pressure fire extinguishing device with a cleaning function, and relates to the technical field of fire-fighting equipment. The device comprises a movable frame, a fire extinguishing part, a cleaning part and a control part, wherein the fire extinguishing part and the cleaning part are both arranged on the movable frame, the fire extinguishing part comprisesa medicament cavity, a water cavity, a mixing cavity and a spray head, and a mixing pump electrically connected with the control part is arranged in the mixing cavity; the cleaning part comprises a rotating mop, a dust collector and a fine nozzle connected with the water cavity, and a rotating wheel is arranged under the movable frame. The electric high-pressure fire extinguishing device with thecleaning function is simple in structure, is convenient to use, can be flexibly moved to a fire extinguishing point, is large in water carrying capacity, long in fire extinguishing agent storage time, effective spraying distance and spraying time and good in fire extinguishing effect, is not influenced by the temperature, and can clean and water daily.

Owner:广德君安达消防科技有限公司

Agricultural rotary water spray nozzle

ActiveCN103495513AConserve waterTo achieve the purpose of rotation without leakageMovable spraying apparatusRubber ringBall bearing

An agricultural rotary water spray nozzle mainly comprises a water inlet pipe, a double-circle ball bearing, a water outlet spray pipe, a rotation speed adjusting device and the like. The water inlet pipe, a bearing middle cylinder inside the double-circle ball bearing and the water outlet spray pipe are sequentially connected, wherein the water outlet spray pipe is directly welded with the bearing middle cylinder, the water inlet pipe is connected with the bearing middle cylinder through a rubber ring so as to achieve the purpose of rotation without seepage, and the water outlet spray pipe stretches out obliquely and is slightly bent spatially so as to enable reaction thrust generated by water spraying to serve as power for rotation. The agricultural rotary water spray nozzle can spray water obliquely and can rotate automatically, is wide in spraying range, large in spraying area and even in wetting, and is a best drought resisting device.

Owner:河北鼎晨农业集团有限公司

Pressure storage type compressed gas foam extinguishing system

The invention discloses a pressure storage type compressed gas foam extinguishing system which comprises a pressure liquid storage tank and a foam generator. The pressure liquid storage tank is filled with foam extinguishing agent mixed liquid and compressed gas. The foam generator is arranged in the pressure liquid storage tank and the foam generator is located above the foam extinguishing agent mixed liquid. A gas inflow hole, a liquid inlet and a turbulator are arranged on the foam generator. The liquid inlet is communicated with a liquid suction pipe arranged at the lower end of the foam generator. The bottom of the liquid suction pipe is located on the lower portion of the pressure liquid storage tank. A foam outlet pipe connected with the foam generator is arranged at the top end of the pressure liquid storage tank. A foam delivery pipe is arranged on one side of the pressure liquid storage tank and communicated with the foam outlet pipe. A foam gun is arranged at the tail end of the foam delivery pipe. The pressure storage type compressed gas foam extinguishing system can generate even, exquisite and stable kinetic energy foam without sucking air from the outside and is high in extinguishing speed, wide in covering range and large in jet distance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com