Closed discharge gap triggered by plasma jet and application thereof

A plasma and discharge gap technology, which is applied in the direction of plasma, spark gap overvoltage arresters, circuits, etc., can solve the problems of too small gap current, arc extinguishing, etc., achieve small leakage current, prevent gap current interruption, increase Effect of large working range and lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

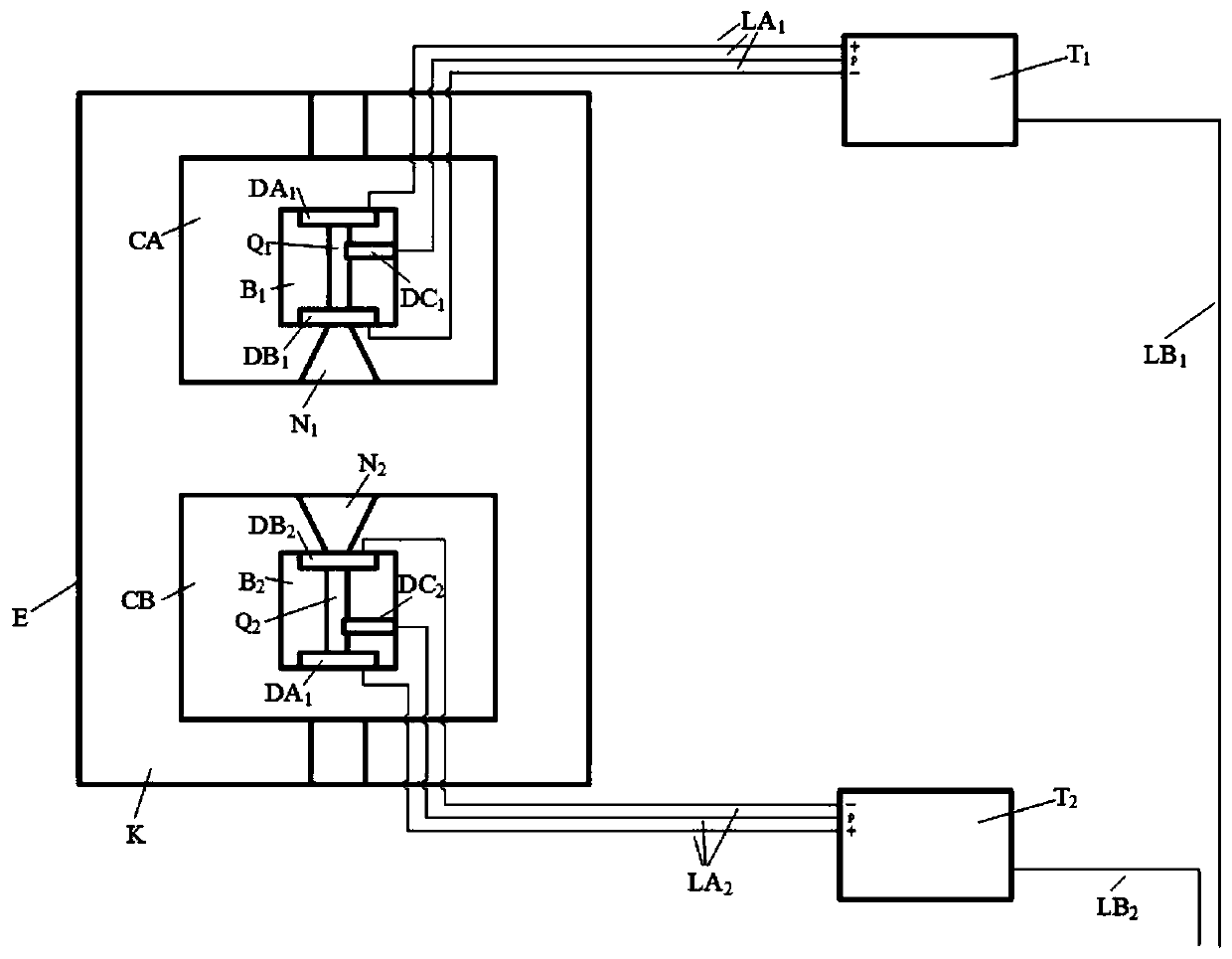

Embodiment 1

[0051] see figure 2 , the closed discharge gap triggered by the plasma jet is externally connected to the high-voltage isolated power supply P, the fixed part of the controllable arrester OA, the short-circuit part of the controllable arrester OB, the high-voltage bus M and the neutral line G; among them, the isolated power supply P i with plasma trigger T i Connected to the power supply terminal, P 1 The main insulation to the ground should have the same voltage level as the high-voltage bus M, P 2 Due to the possible overvoltage of the neutral line, the main insulation to the ground should also have the same voltage level as the high-voltage bus M; the high-voltage bus M is connected to the high-voltage end of the fixed part of the controllable arrester OA; the low-voltage end of the fixed part of the controllable arrester OA is connected to the The high-voltage end of the short-circuit part OB of the controllable arrester is connected with the high-voltage contact CA;

...

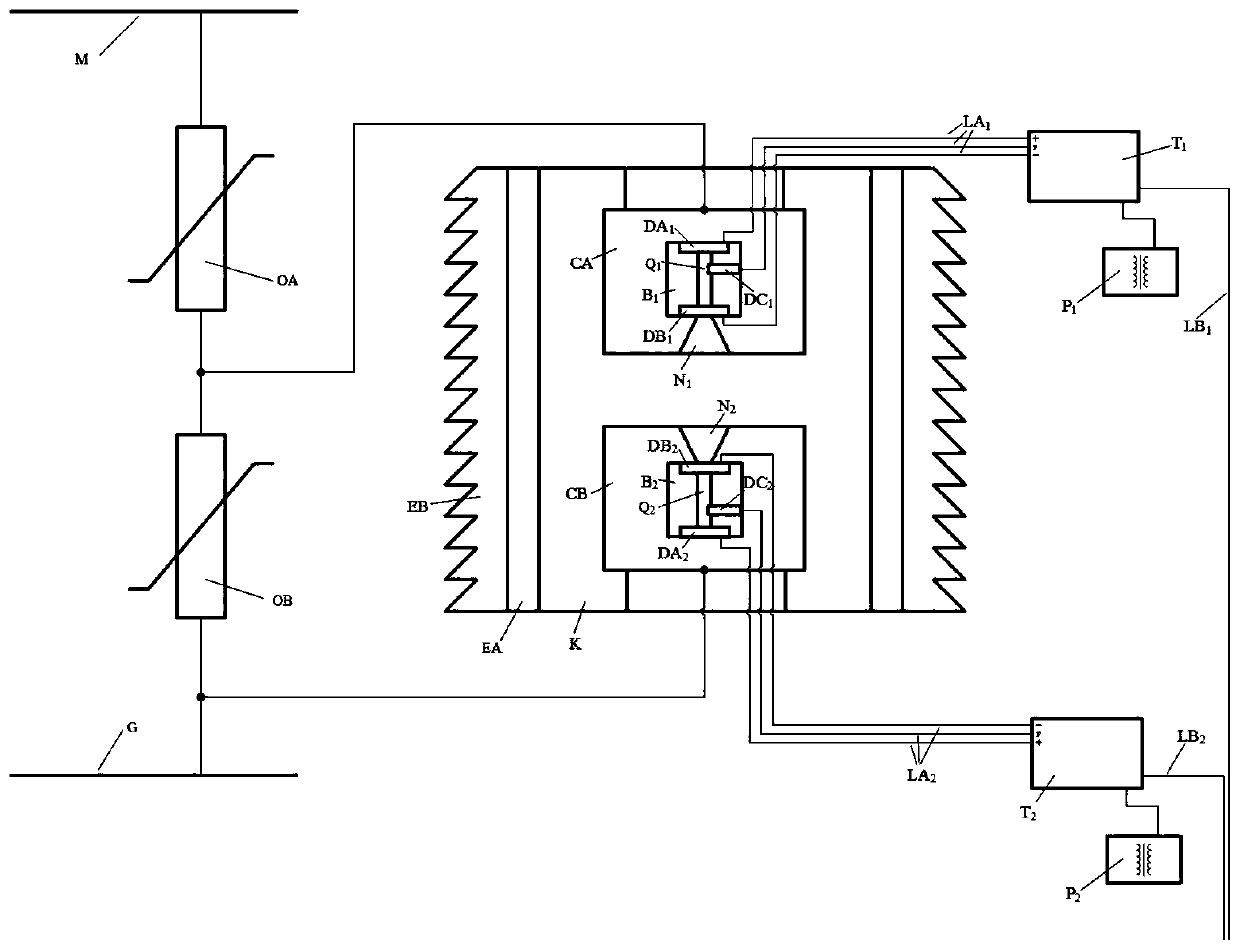

Embodiment 2

[0057] see image 3 The high-voltage contact CA and the low-voltage contact CB are made of copper-tungsten alloy, and two sets of independent plasma injection units are respectively installed; the high-voltage electrode DAi, the low-voltage electrode DBi and the pulse electrode DCi are made of copper-tungsten alloy; the erosion material Bi is made of high-density polymer. Ethylene; the pipe diameter of the erosion chamber Qi is 5mm, and the pipe length is 80mm; the nozzle Ni is an expanded cone angle, and the full angle of the cone angle is 8°; the plasma trigger Ti can output a pulse voltage of 100kV first, and then output a peak value of 20kA, pulse Pulse current with a width of 100us; plasma trigger T 1 and T 3 Connect in parallel to the isolated power supply P 1 , the plasma trigger T 2 and T 4 Connect in parallel to the isolated power supply P 2 , isolated power supply P i It has the same voltage level as the high-voltage busbar M; the fully enclosed shell E is comp...

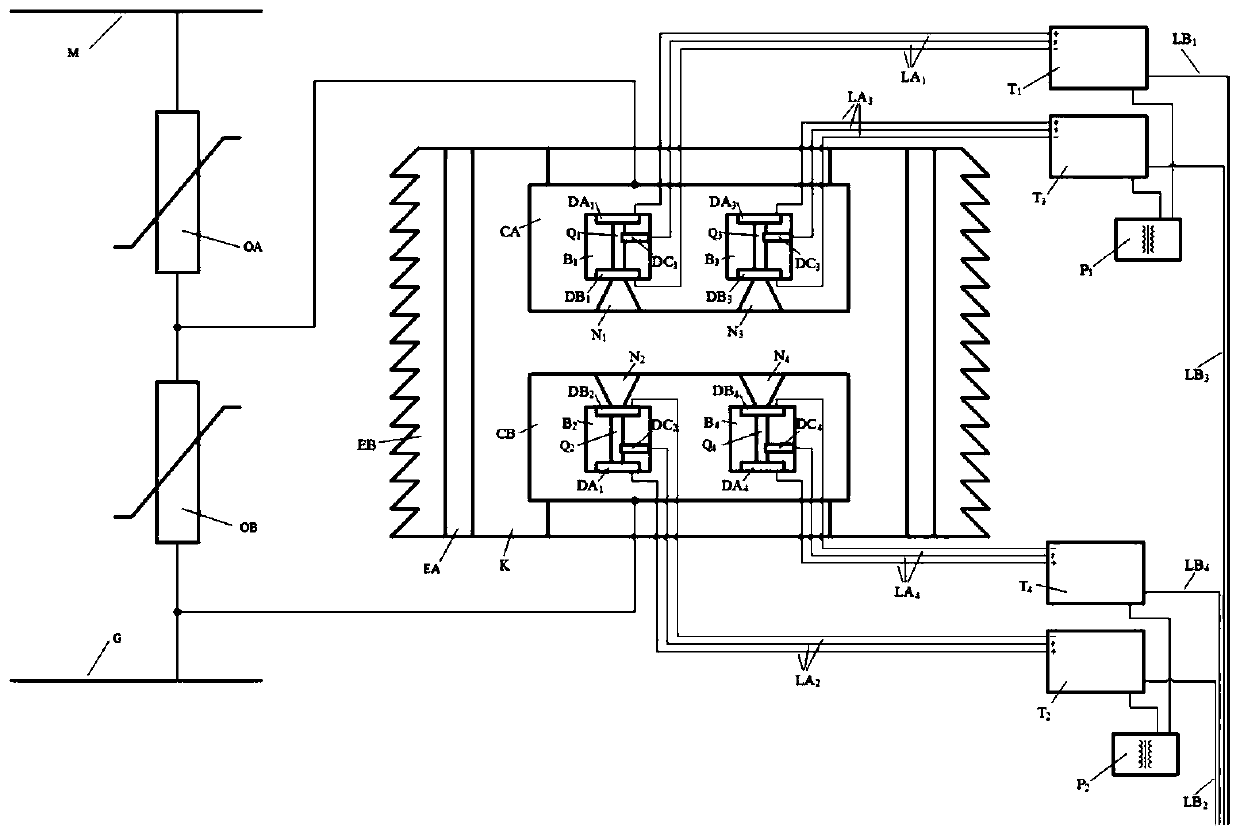

Embodiment 3

[0061] see Figure 4 , the high-voltage contact CA and the low-voltage contact CB are made of copper-tungsten alloy, the low-voltage contact CB is equipped with 4 sets of independent plasma injection units, and the high-voltage contact CA is not installed. The advantage of this is that only one isolated power supply P is needed in total. The high-voltage electrode DAi, the low-voltage electrode DBi and the pulse electrode DCi are made of copper-tungsten alloy; the erosion material Bi is made of polycarbonate; the diameter of the erosion chamber Qi is 3mm, and the length of the pipe is 50mm; The full angle is 15°; the plasma trigger Ti can output a pulse voltage of 50kV first, and then output a pulse current with a peak value of 10kA and a pulse width of 50us; the plasma trigger T i Parallel connection to the isolated power supply P, the isolated power supply P has the same voltage level as the high-voltage bus M; the fully enclosed shell E is composed of a metal shell EG and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com