Fast rope changing device of floor type multirope friction elerator

A friction hoist, floor-standing technology, applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of insufficient strength of the rope changing device, affecting the quality of rope changing, endangering mine safety, etc., achieving significant economic benefits and convenience The effect of using and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

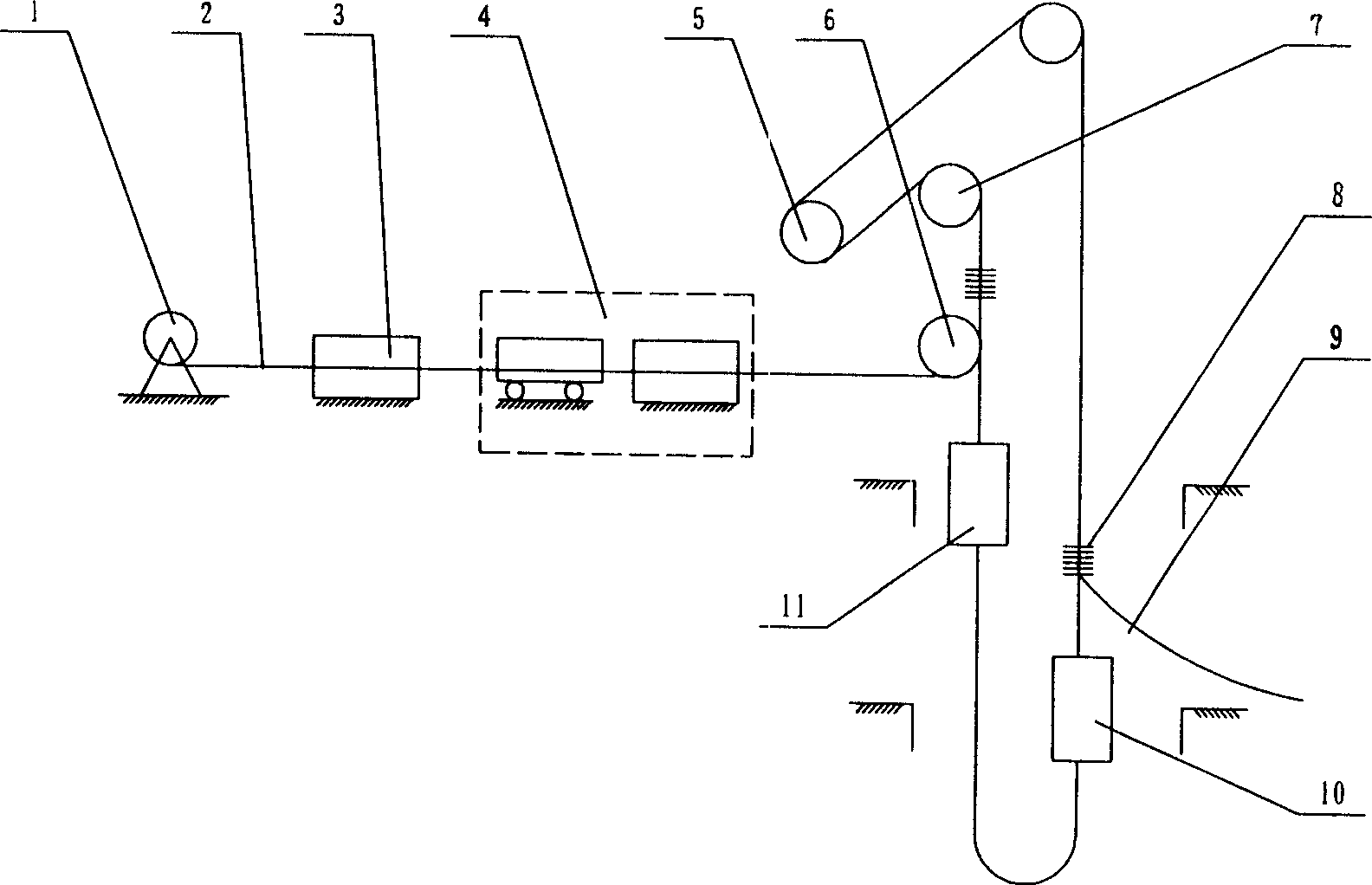

[0018] Take the five-rope friction hoist as an example.

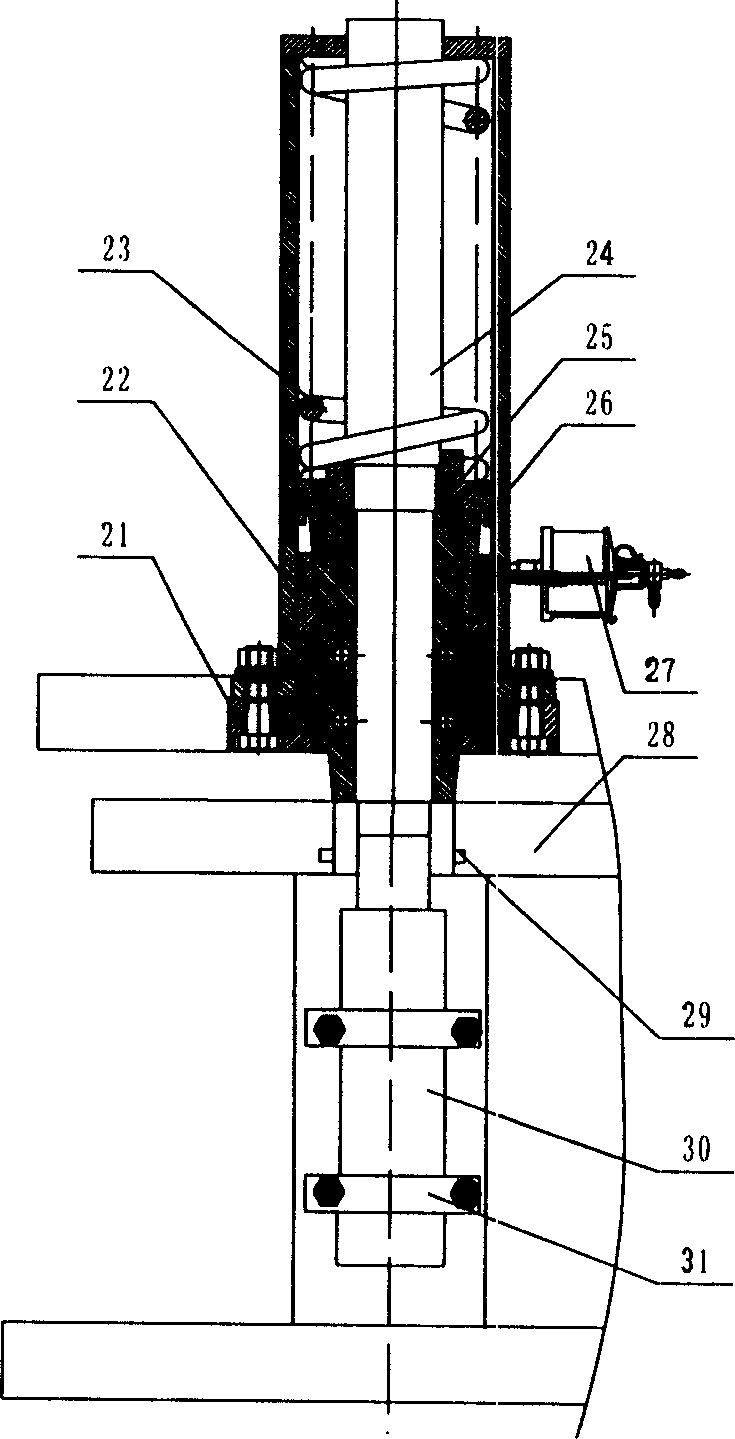

[0019] Put the spring 23, the spring seat 24, and the wedge block 26 into the sleeve 22, connect the sleeve 22 with the gland 21 with bolts, and install the needle valve type oil cup 27 on the sleeve 22 to form the anti-running rope Institution 3. Five sets of anti-running rope mechanisms are installed on the mounting frame 28, the hydraulic cylinder 30 is connected with a channel steel 31 by the pin 29, and the U-shaped card 32 fixes the hydraulic cylinder 30 on the mounting frame 28. The channel steel 31 is close to the wedge block 26, and when the piston rod stretches out, the channel steel 31 is driven to move, and the wedge block 26 also moves thereupon, compressing the spring 23. When the hydraulic cylinder 30 moved to the maximum stroke, the new steel wire rope 2 could be passed through five sets of anti-running rope mechanisms respectively. Channel steel 31 adopts 8# channel steel.

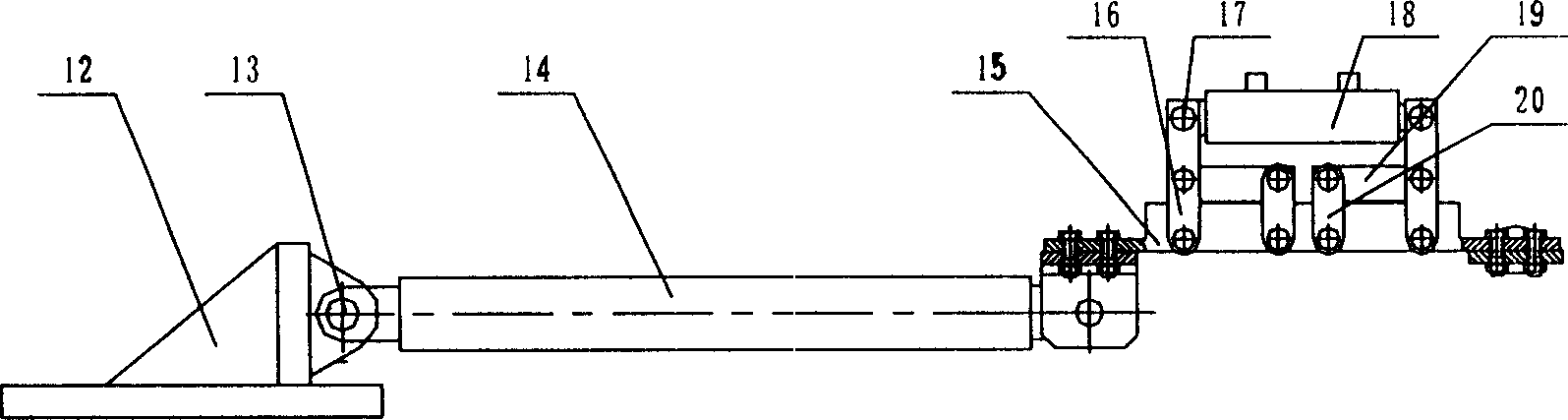

[0020] One end of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com