Compressed air foam extinguishing agent spraying gun and method thereof

A technology of compressed air foam and foam fire extinguishing agent, which is applied in fire rescue and other fields, can solve problems such as difficult to realize, foam fire extinguishing device and cart-type foam fire extinguisher, etc. high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

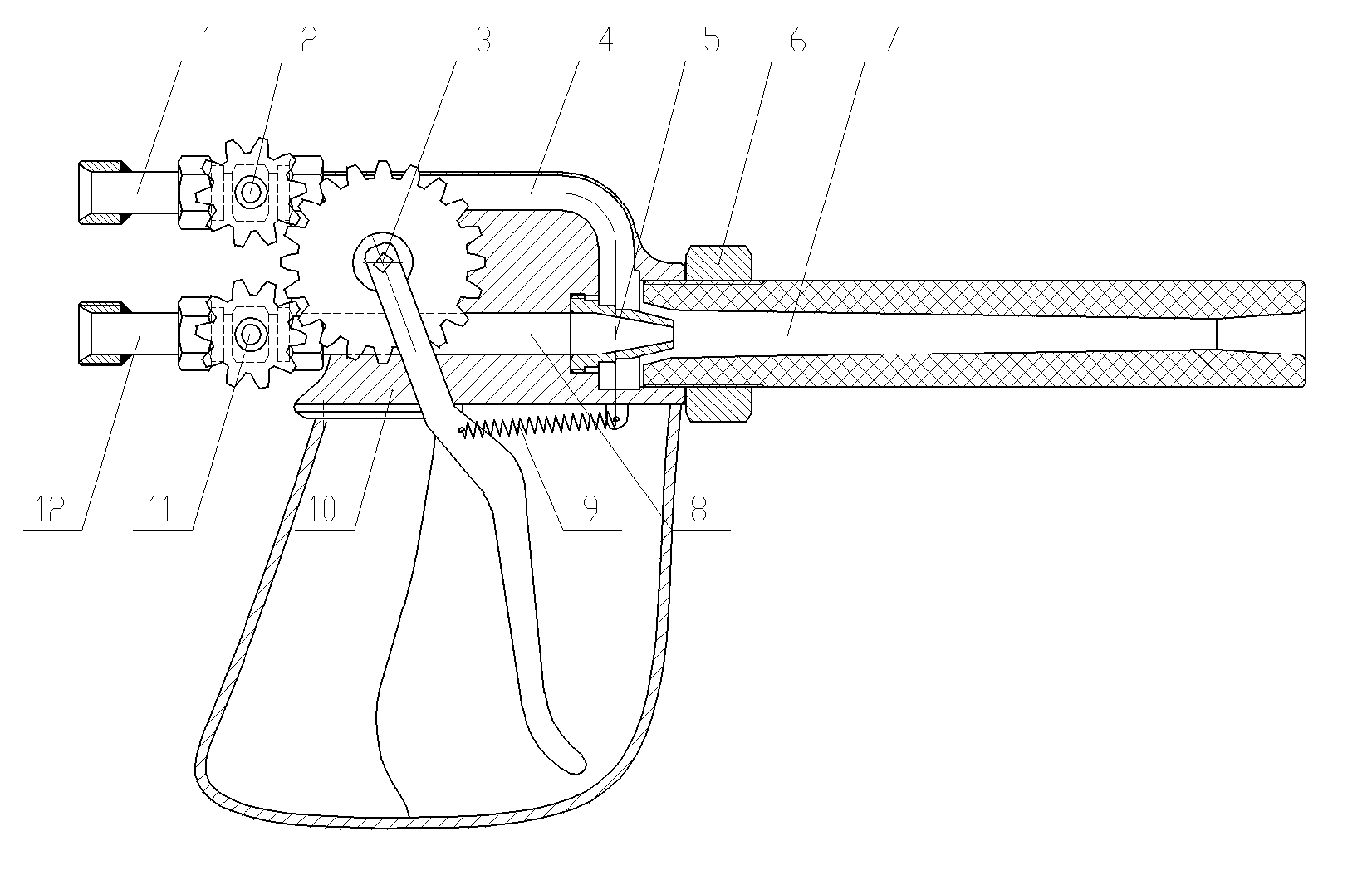

Embodiment 1

[0027] When the compressed air foam fire extinguishing agent spray gun of the present invention is used on a trolley-type non-pressurized water film-forming foam fire extinguisher, the hose for outputting the foam extinguishing agent on the fire extinguisher tank is connected to the foam extinguishing agent input connector 1 of the spray gun. The output hose of the air tank is connected with the air inlet connector 12 after being decompressed by the pressure reducer. Turn on the trigger 3 with the transmission gear. After the high-pressure air from the compressed gas cylinder is reduced to 0.8-1.0 MPa by the pressure reducer, a route air inlet connector 12 enters the ball valve 11 with the transmission gear and the air pipeline 8 and flows When passing the convergent nozzle 5, the rate of fire is increased, but the outlet diameter of the convergent nozzle 5 is small, which limits the gas flow to 15-20 liters / sec. Another compressed air is input into the foam fire extinguisher ta...

Embodiment 2

[0029] The compressed air foam fire extinguishing agent spray gun of the present invention, when used as a hand-held fire extinguishing agent spray gun for firefighters, supplies compressed air with a pressure of 0.8 to 1.0 MPa from a vehicle-mounted or ship-borne air compressor and enters it into the air inlet connector 12; The diluted aqueous film-forming foam fire extinguishing agent with a pressure of 0.8-1.0 MPa is input into the foam fire-extinguishing agent connector 1, and the trigger 3 with the transmission gear is turned on. The diluted aqueous film-forming foam fire extinguishing agent flows through the "Laval tube" The gap of the spray channel formed between the barrel 7 and the convergent nozzle 5, when the gap of the spray channel is 4.5 mm, the flow rate of the aqueous film-forming foam fire extinguishing liquid is maintained at about 2.0 kg / sec; the convergent nozzle 5 compresses The air flow rate is maintained at 60 to 70 liters per second, and the spray distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com