3CRC parallel mechanism fire monitor

A fire monitor and mechanism-type technology, which is applied in fire rescue and other fields, can solve problems such as fire safety hazards, increased costs, and firefighter casualties, and achieves the effects of long spraying distance and height, easy assembly and control, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

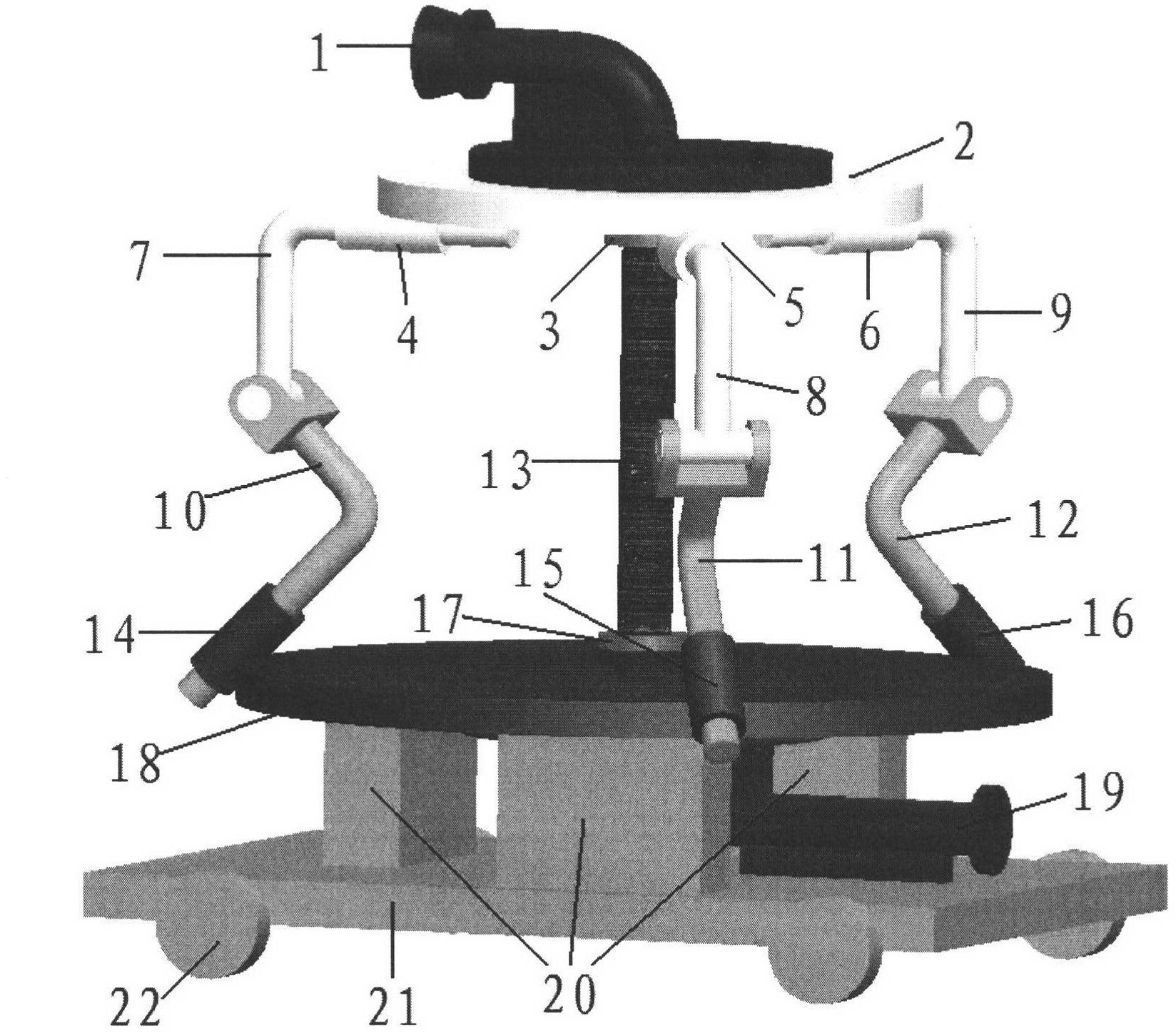

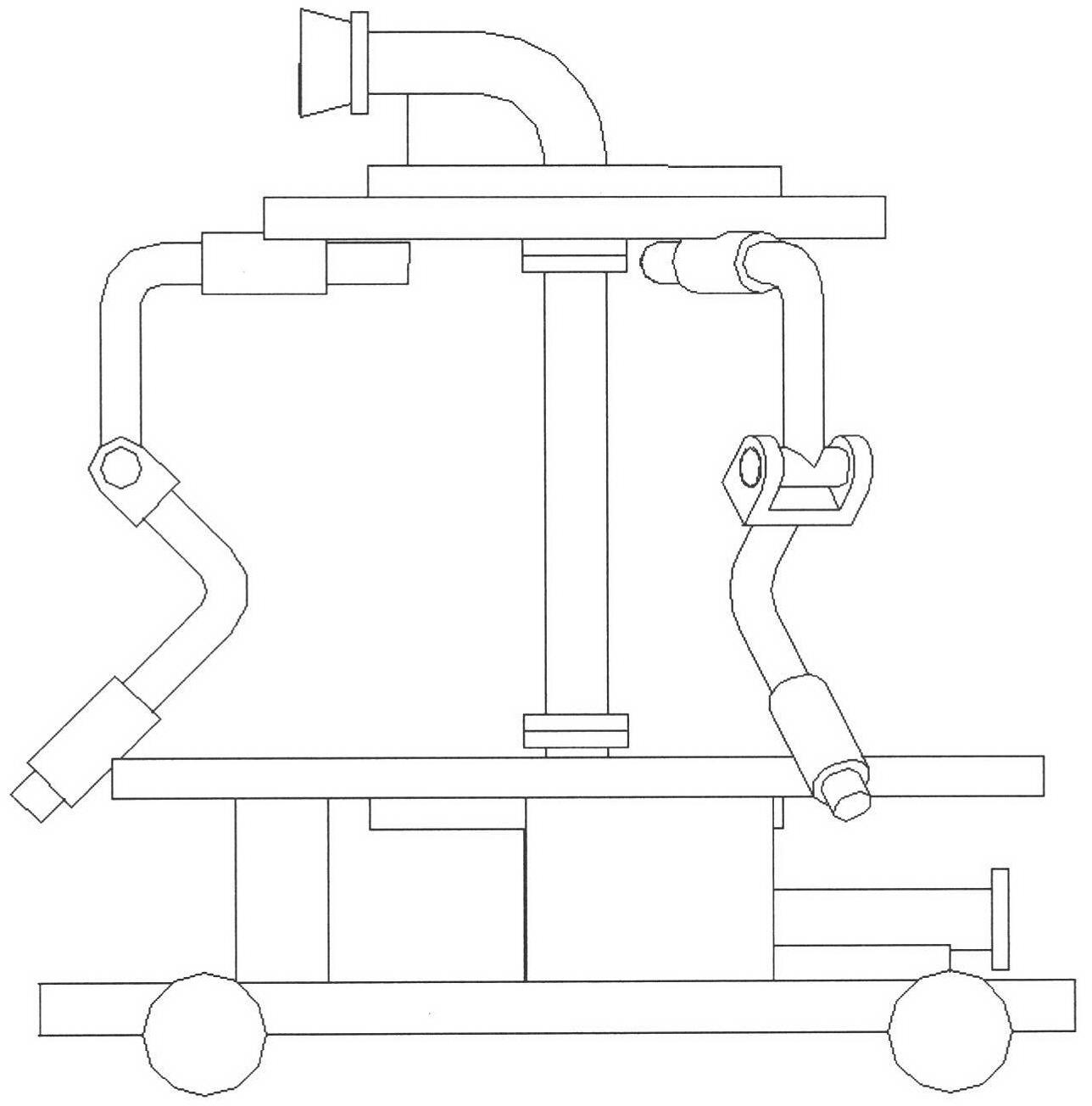

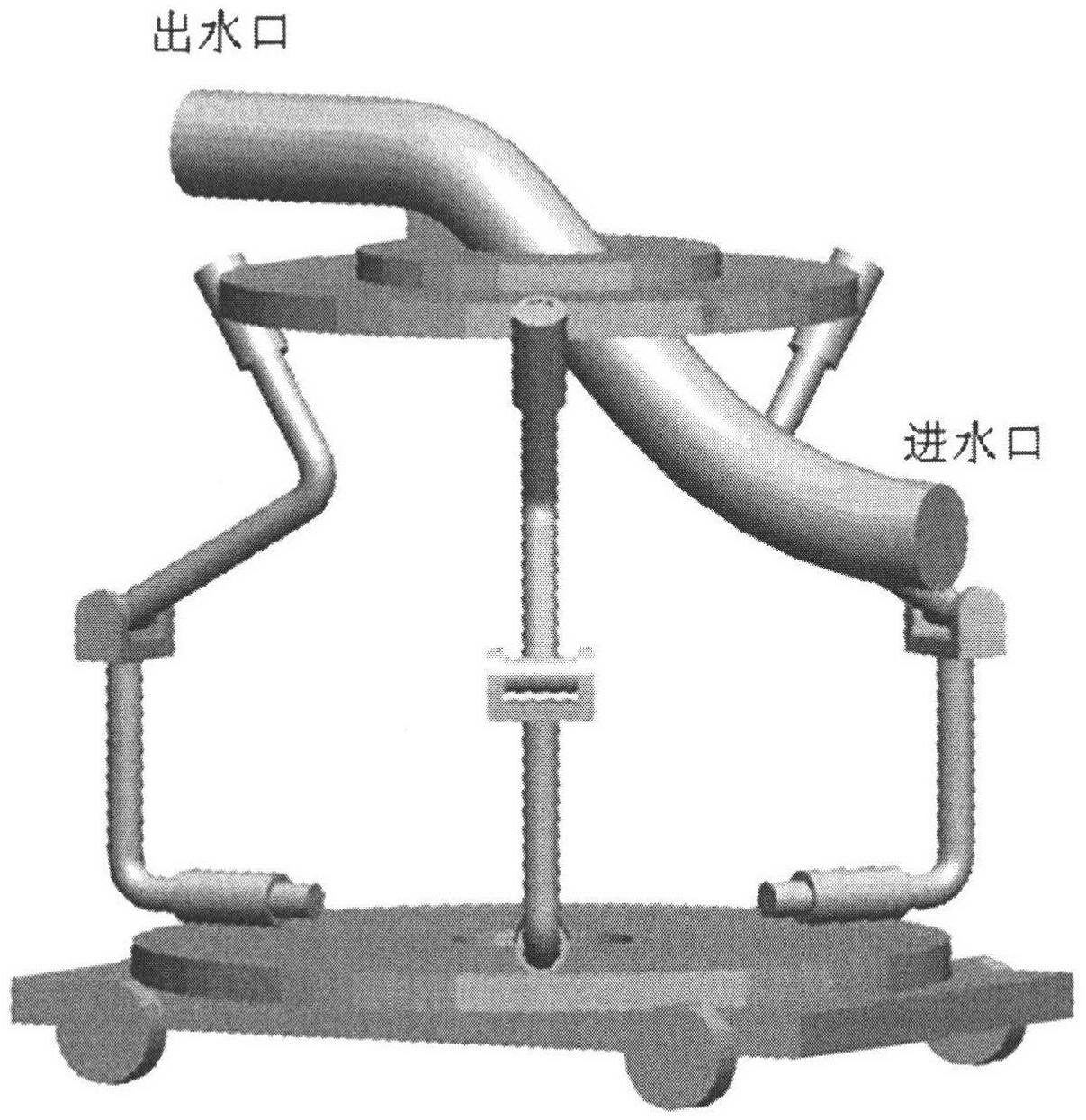

[0021] The present invention will be further described in conjunction with the drawings and embodiments.

[0022] The invention utilizes the multi-degree-of-freedom motion characteristics of the parallel mechanism to solve the problem of large fluid pressure drop in the pipes of conventional serial fire monitor products. The parallel mechanism type fire monitor can not only replace the existing fire monitor products, but also can be used in fire safety standards For higher occasions, the device can realize independent motion output of swing and pitch, and its drive is mainly realized by 3 sets of servo motors.

[0023] The components connecting the moving platform [2] of the parallel mechanism and the fixed platform [18] of the parallel mechanism are all entities with certain physical dimensions, so there may be collisions between components during the movement of the mechanism. Therefore, when considering the movement space of the mechanism, a certain space should be reserved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com