Preparation technology of galvanized steel sheet with continuous hot-dip spangles

A galvanized steel sheet and preparation technology, which is applied in the field of galvanized steel sheet, can solve the problems of poor surface flatness, complex hot-dip process, and uneven spangles, and achieve smooth surface, low surface gloss, and uniform spangles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

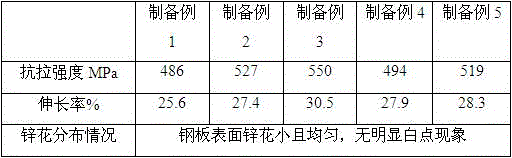

Examples

Embodiment Construction

[0028] Preparation Example

[0029] The preparation technology of continuous hot-dip galvanized steel sheet of the present invention comprises the following steps:

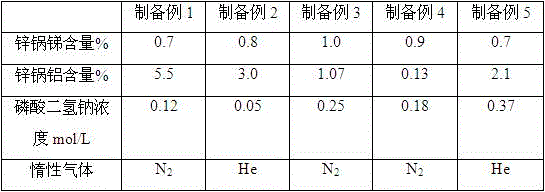

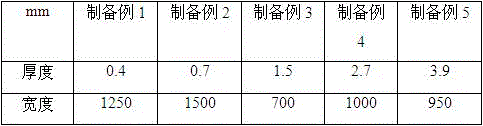

[0030] Step 1. Uncoiling and cleaning: the cold-rolled coil is uncoiled, the steel plate is sent to the welding machine and the inlet looper, and the surface of the steel plate is cleaned after chemical degreasing; chemical degreasing includes the following steps: spray cleaning with lye, and at the same time clean the surface of the steel plate After being squeezed dry, carry out secondary spray cleaning with clean water, and dry after squeezing dry; wherein, the thickness and width of the raw material steel plate are as shown in Table 1. Therefore, the carbon content of the steel plate is less than 0.12%;

[0031] Step 2, annealing: the steel plate enters the annealing furnace for reduction and calcination, and the annealing atmosphere is H 2 and N 2 The mixed gas, the annealing temperature is specifically sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com