Patents

Literature

113results about How to "Reduce surface gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Low-luster polypropylene blending modified material and preparation method thereof

The present invention relates to the blending and modifying field of the polymer material, and discloses a polypropylene blend modified material with the lowered surface gloss. The polypropylene blend modified material of the present invention consists of the following components and weight percentages: 20 to 90 percent of polypropylene, 10 to 80 percent of polyethylene, 0 to 2 percent of peroxide cross-linking agent, 0 to 5 percent of antioxidant, 0 to 5 percent of processing aid, and 0 to 30 percent of filler. The preparation method is: the components are blended in the high-speed mixer for 5 to 15 minutes according to the proportion; the twin-screw extruder is used to melt and blend; the temperature of the extruder is set to be between 100 and 220 Celsius system, and the rotating speed of the screw to be 150 to 400 rounds per minute; after pelletizing and drying, the polypropylene blend modified material can be made. The polypropylene blend modified material of the present invention has the lowered surface gloss and the good extinction effects, and can be used in the fields such as the packaging, daily necessities and building materials, and so on.

Owner:广东波斯科技股份有限公司

Low-luster polypropylene composite material and preparation method thereof

The invention discloses a low-luster polypropylene composite material and a preparation method thereof, belonging to the field of polymer modifying and processing. The low-luster polypropylene composite material is prepared by the following raw materials with the weight percent in brackets: polypropylene (58 to 86%), wollastonite (13 to 30%), other inorganic padding (0 to 12%), flexibilizer POE (0 to 15%), antioxidant (0.1 to 2%), and other assistants (0 to 5%). The wollastonite (the inorganic padding) which can effectively lower the surface luster of a product is added to the basis formula of the polypropylene composite material, so as to prepare the low-luster polypropylene composite material with excellent performance.

Owner:SHANGHAI PRET COMPOSITES

Protective coating for painted or glossy surfaces

InactiveUS20070178239A1Improve water repellencyAccurate protectionPretreated surfacesOrganic dyesEmulsionFilm-forming agent

A glossy protective coating for painted or glossy surfaces is formed from a substantially silicone-free aqueous emulsion of film-forming agent, solvent, and a fluoropolymer that reduces soil adhesion and increases water repellency.

Owner:ZEP IP HLDG LLC

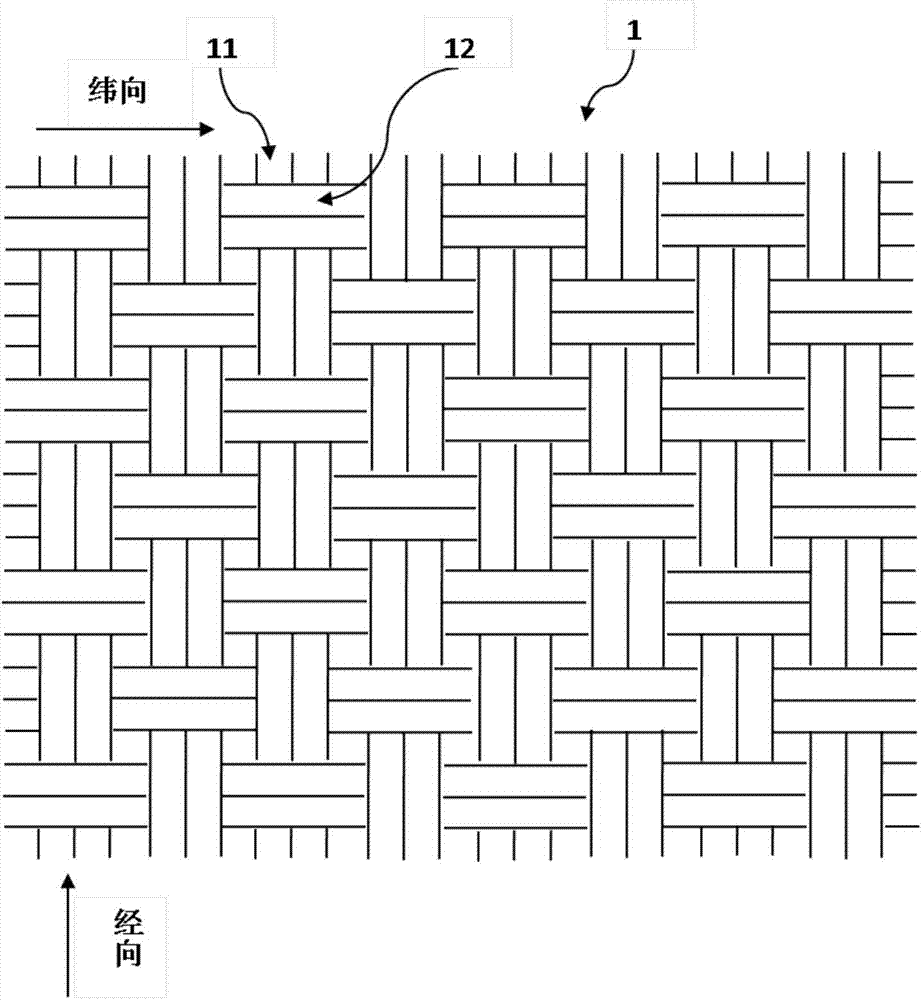

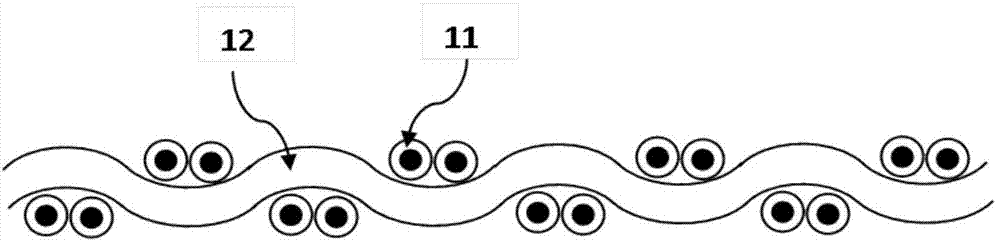

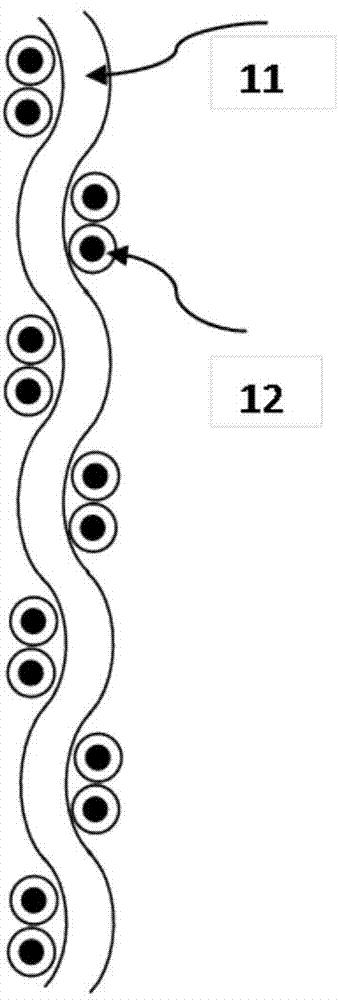

Sun-shading composite material with extinction and high flame-retardant effects

The invention discloses a sun-shading composite material with extinction and high flame-retardant effects. The composite material is a fabric comprising warps and wefts, wherein the fabric is woven by covering threads, rectangular or square gaps are left among the wefts, and the porosity of the composite material is 2-5%; the covering threads are made of a polyvinyl chloride composite material coating the surfaces of polyester fibers, the polyvinyl chloride composite material has the extinction and high flame-retardant effects and the covering threads are 0.3-0.5mm in diameter. The invention also provides a preparation method of the composite material. The sun-shading composite material has the characteristics of sunshading, ultraviolet ray resistance, inflaming retarding, high color fastness and the like of similar sun-shading composite materials, and also has the advantages of low glossiness, glare control, softness, comfort for eyes, fine and smooth handfeel and good breathability, and therefore, the sun-shading composite material can be well applied to the fields of leisure, fashion and individuation.

Owner:NINGBO XIANFENG NEW MATERIAL

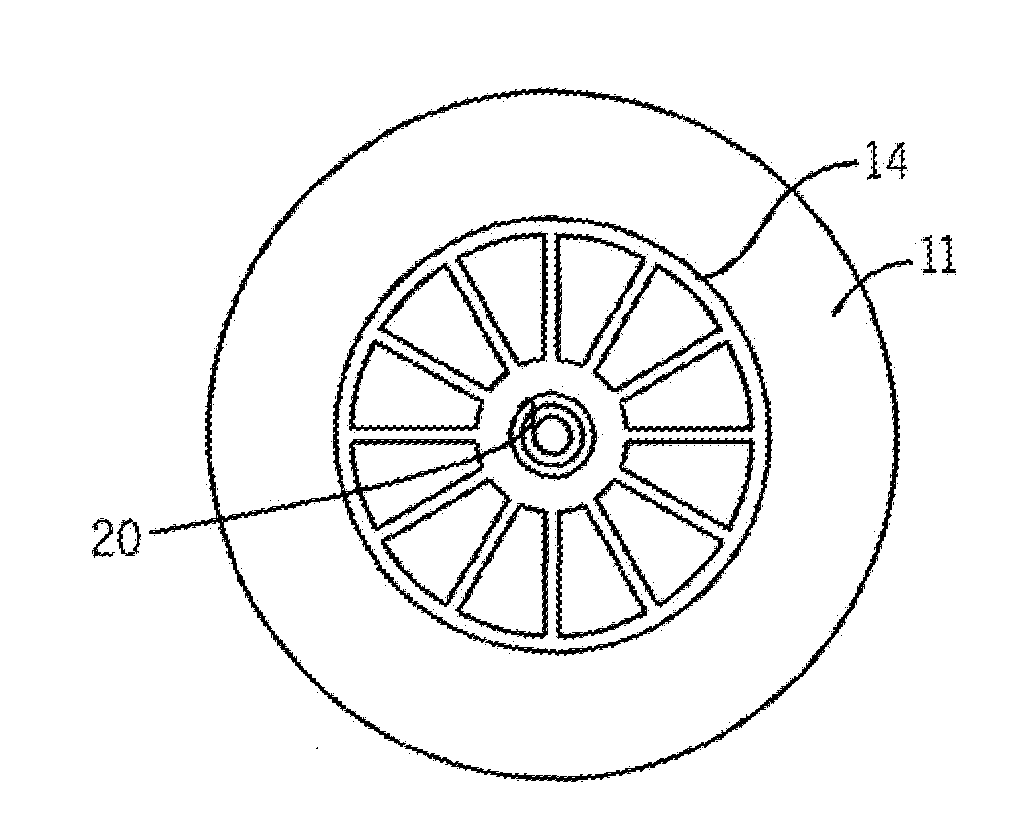

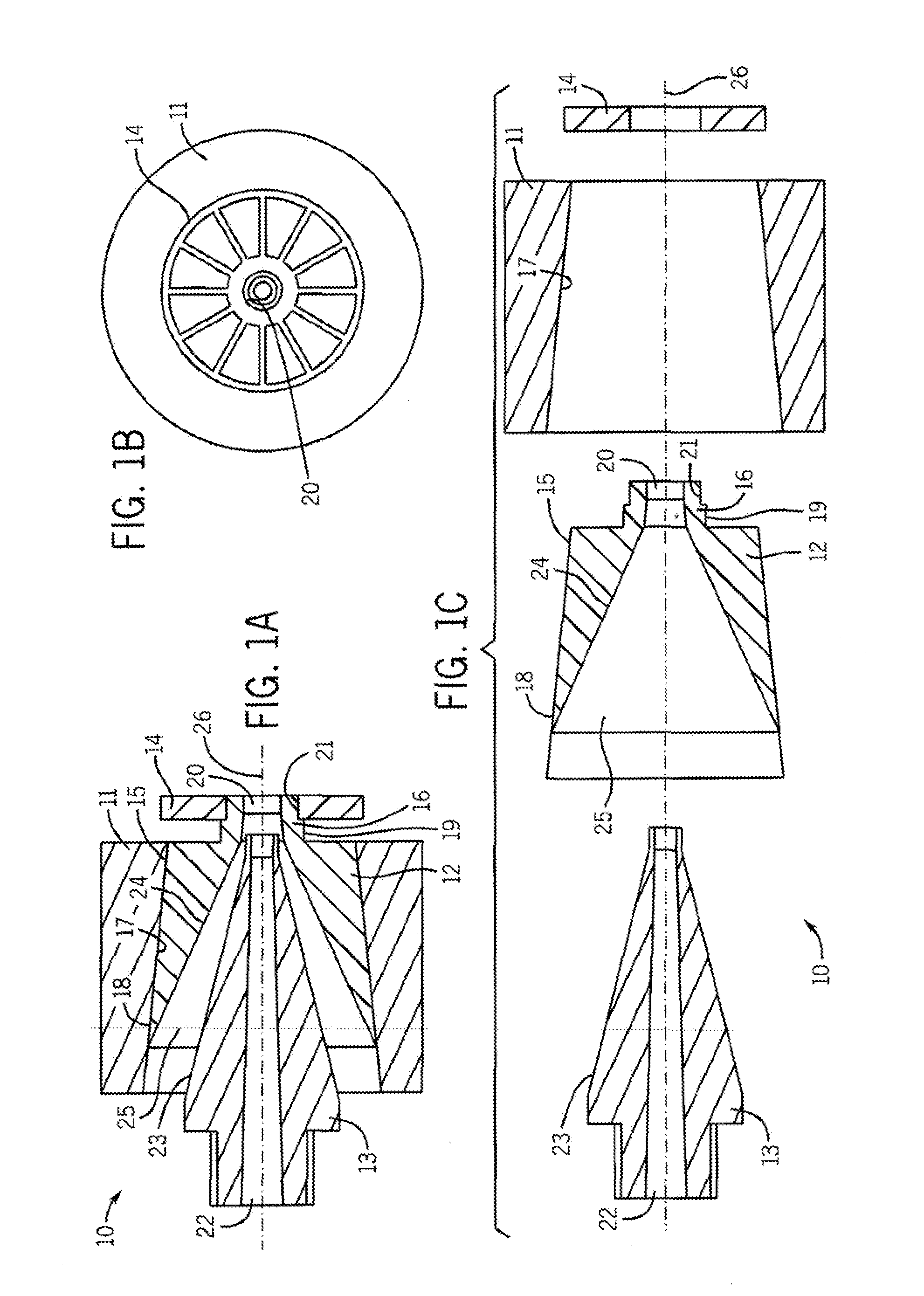

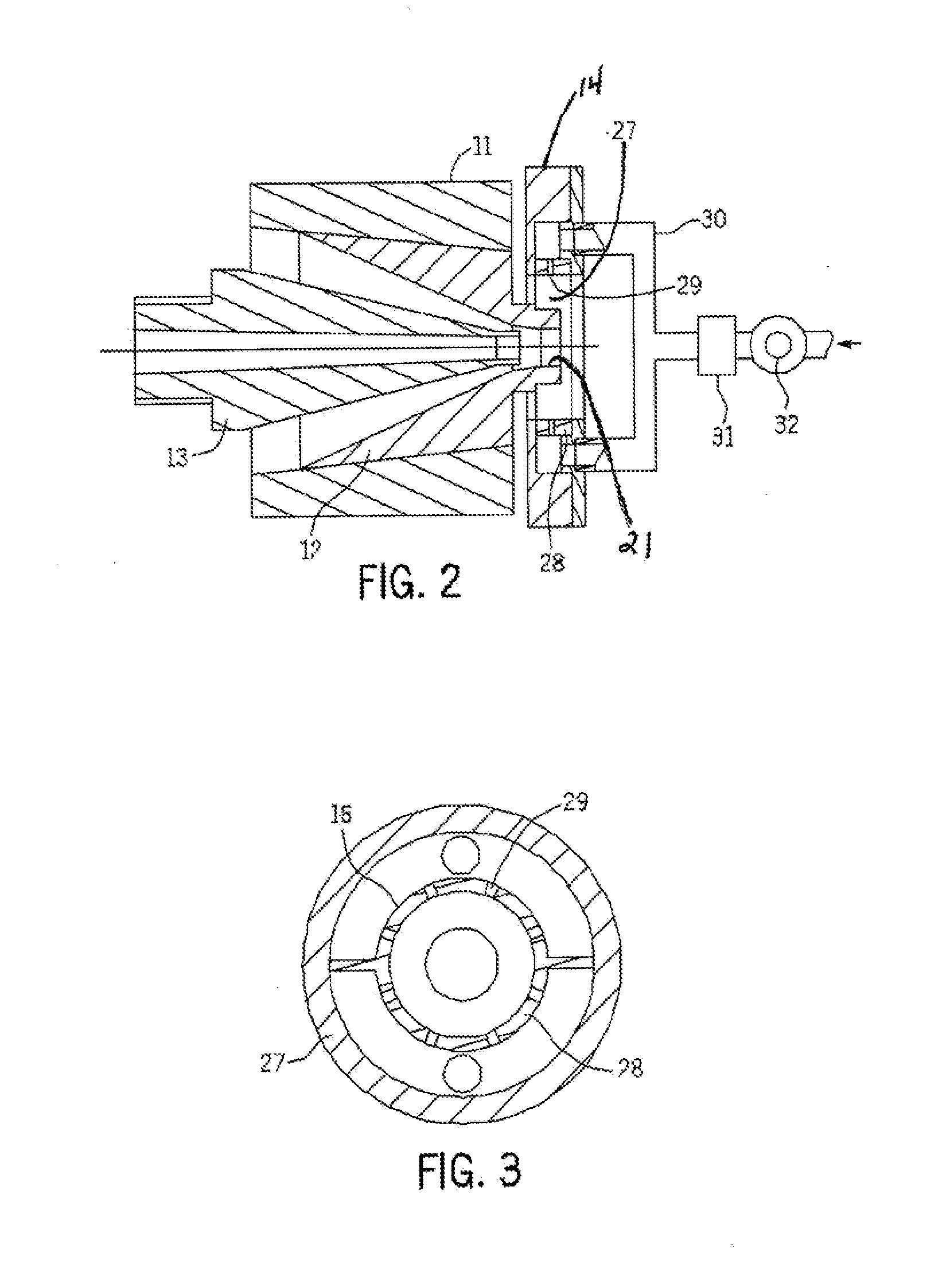

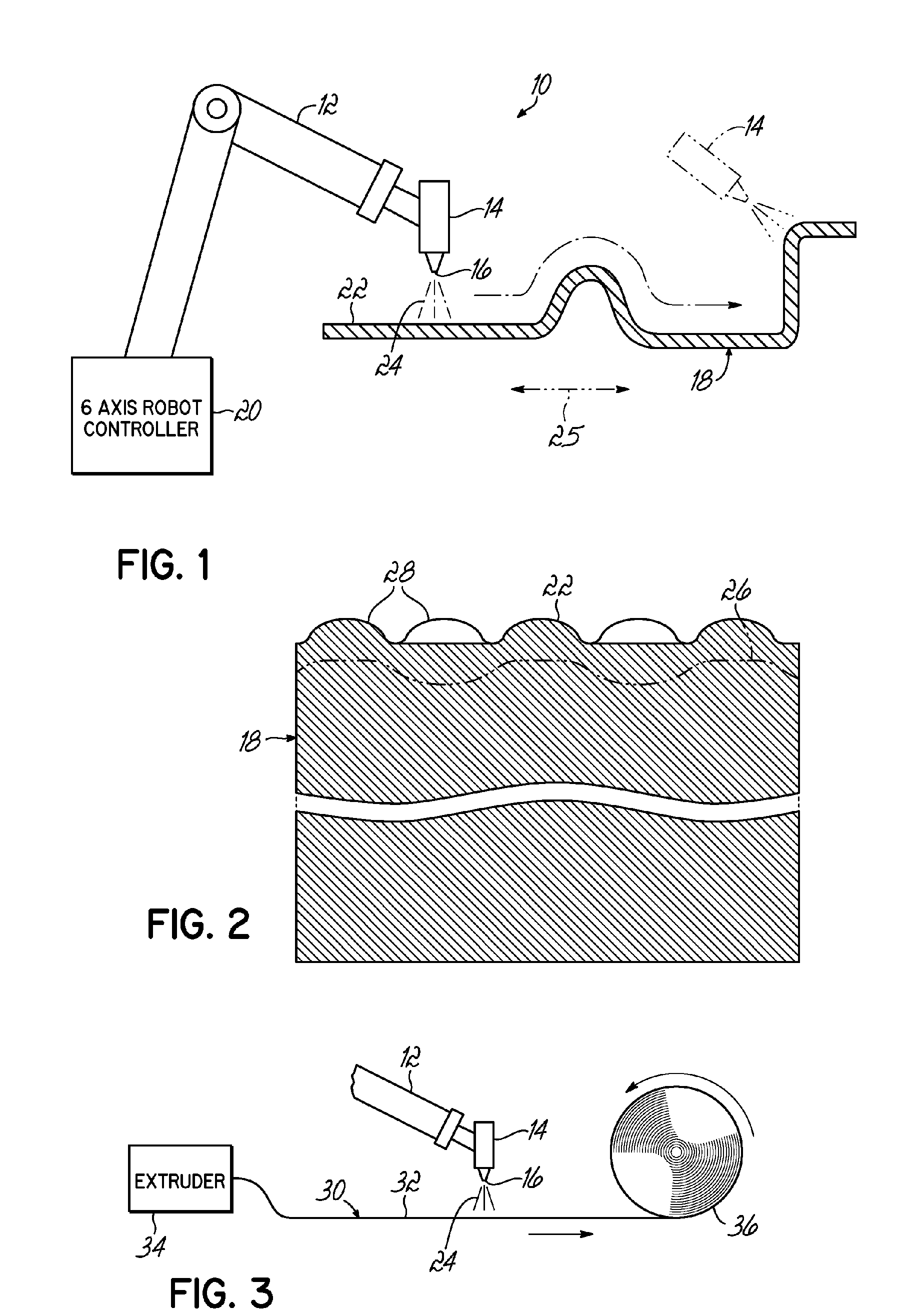

Die Assembly with Cooled Die Land

ActiveUS20130264092A1Excellent matte surface characteristicReduce surface glossPlastic/resin/waxes insulatorsInsulated cablesEngineeringMechanical engineering

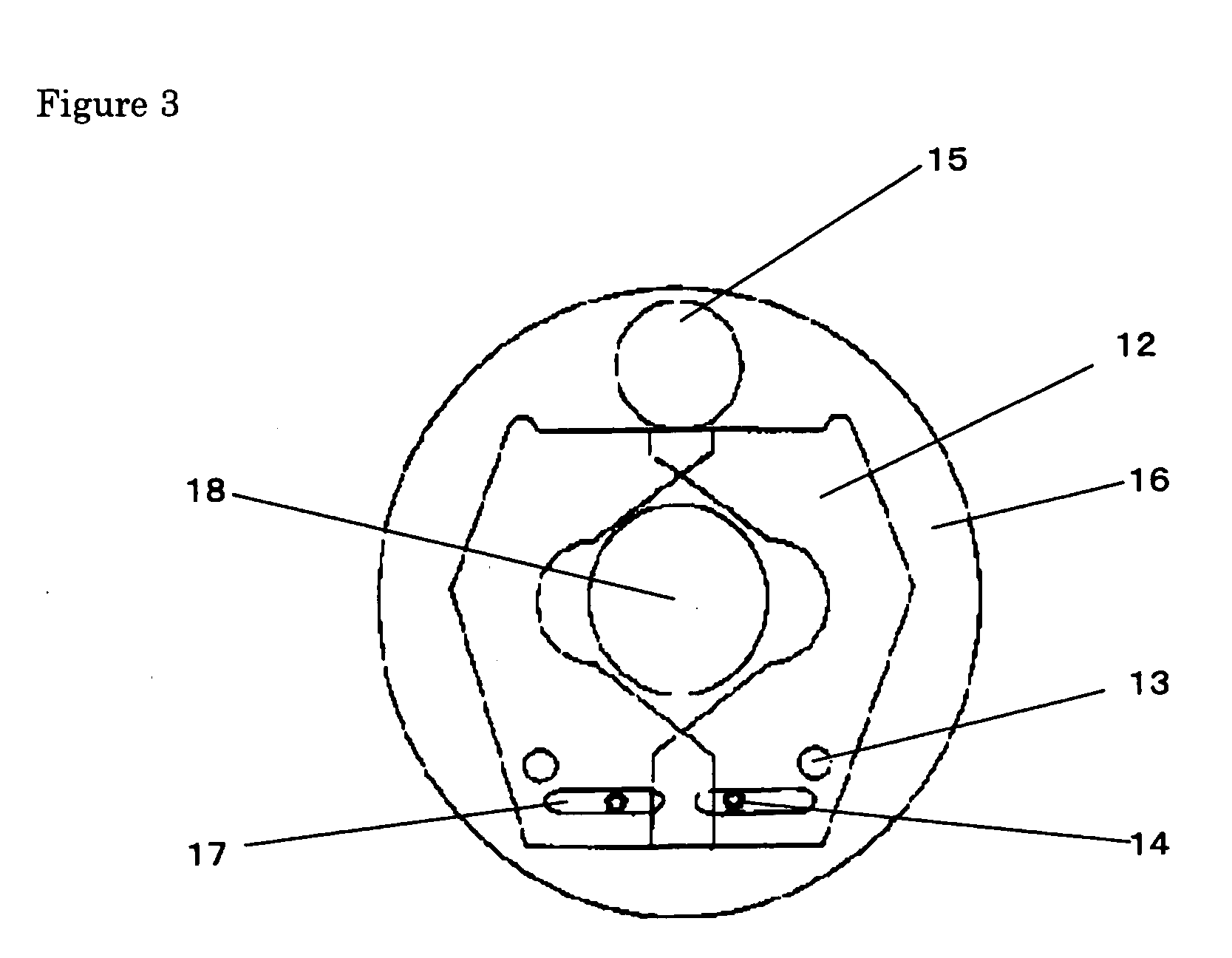

A die assembly (10) for extruding a polymeric coating onto a wire so as to impart a matte finish to the coating surface is provided. The die assembly (10) comprises: A) a die tip (13) comprising a tubular channel (22) through which a wire can pass, the channel (22) positioned along the central longitudinal axis (26) of the die assembly (10); B) a die body (12) comprising a trunk (15) and a head (16), the head (16) comprising a tubular channel (20), the head tubular channel (20) comprising a die land (21), the trunk (15) positioned about the die tip (13) so as to define an annular space (25) between the exterior surface (23) of the die tip (13) and the interior surface (24) of the trunk (15); C) a die holder (11) positioned about and in contact with the exterior surface (17) of the trunk (15); and D) a radiator (14) positioned about and in contact with the exterior surface (19) of the die land (21) of the die head (16).

Owner:DOW GLOBAL TECH LLC

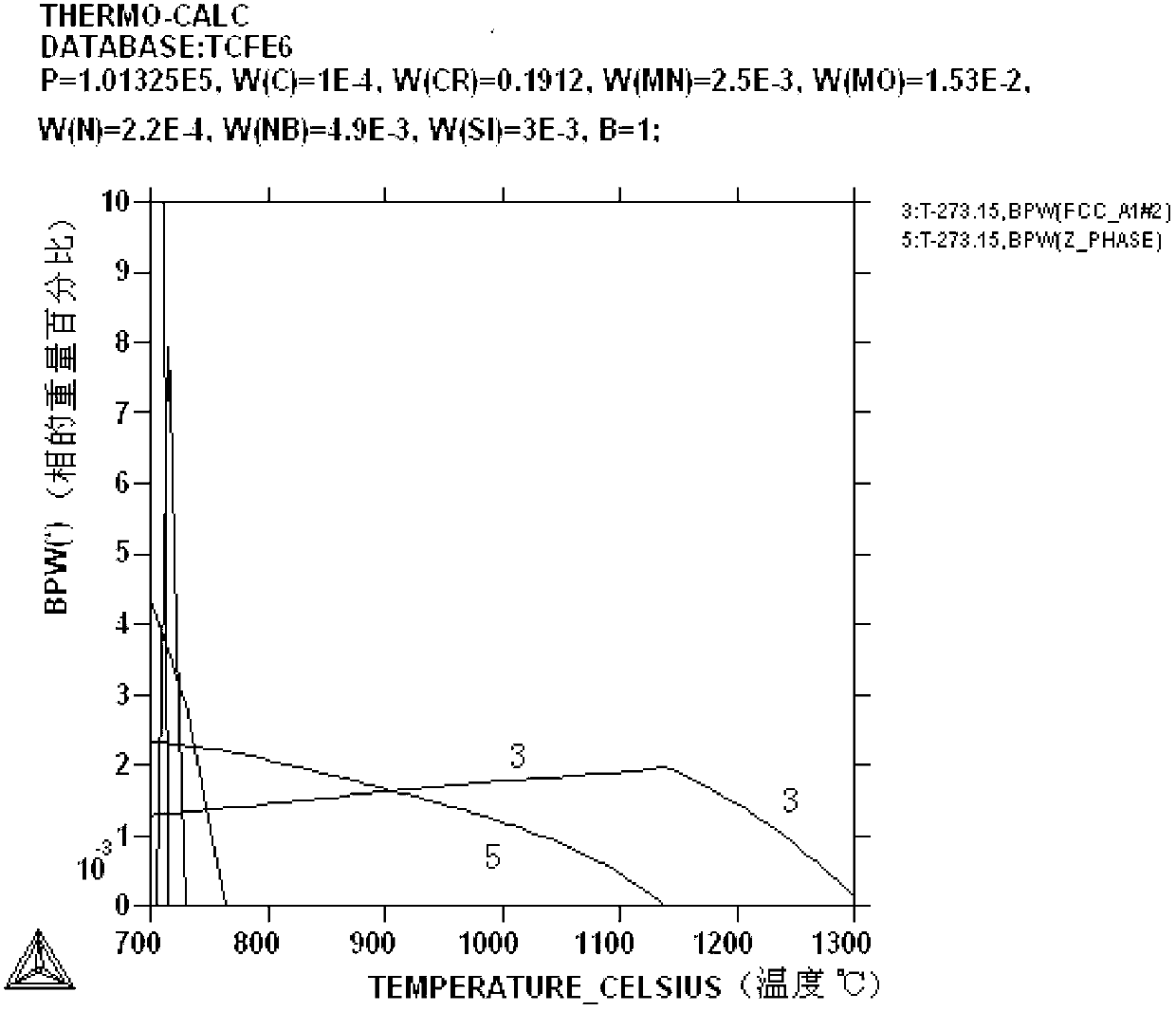

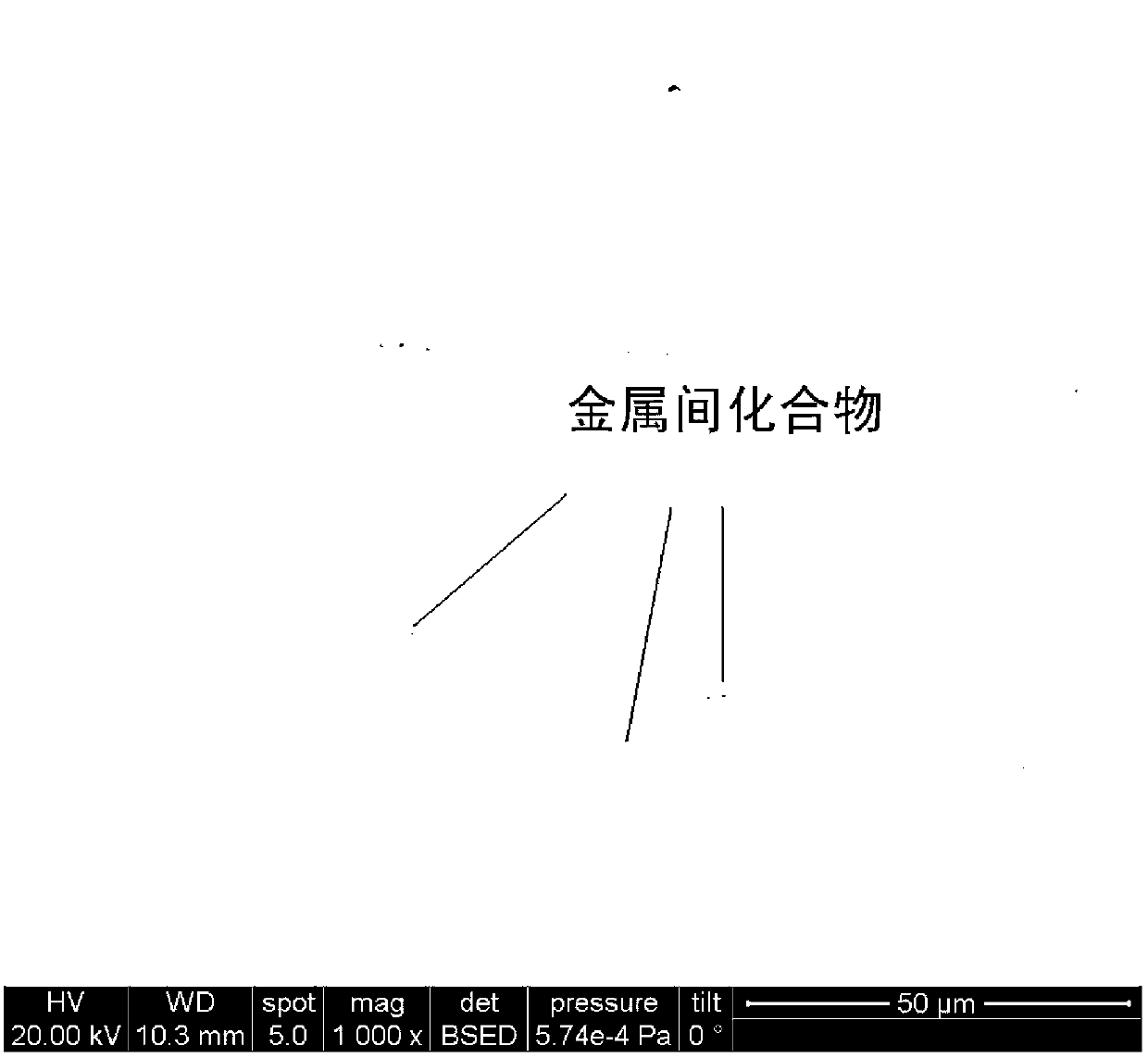

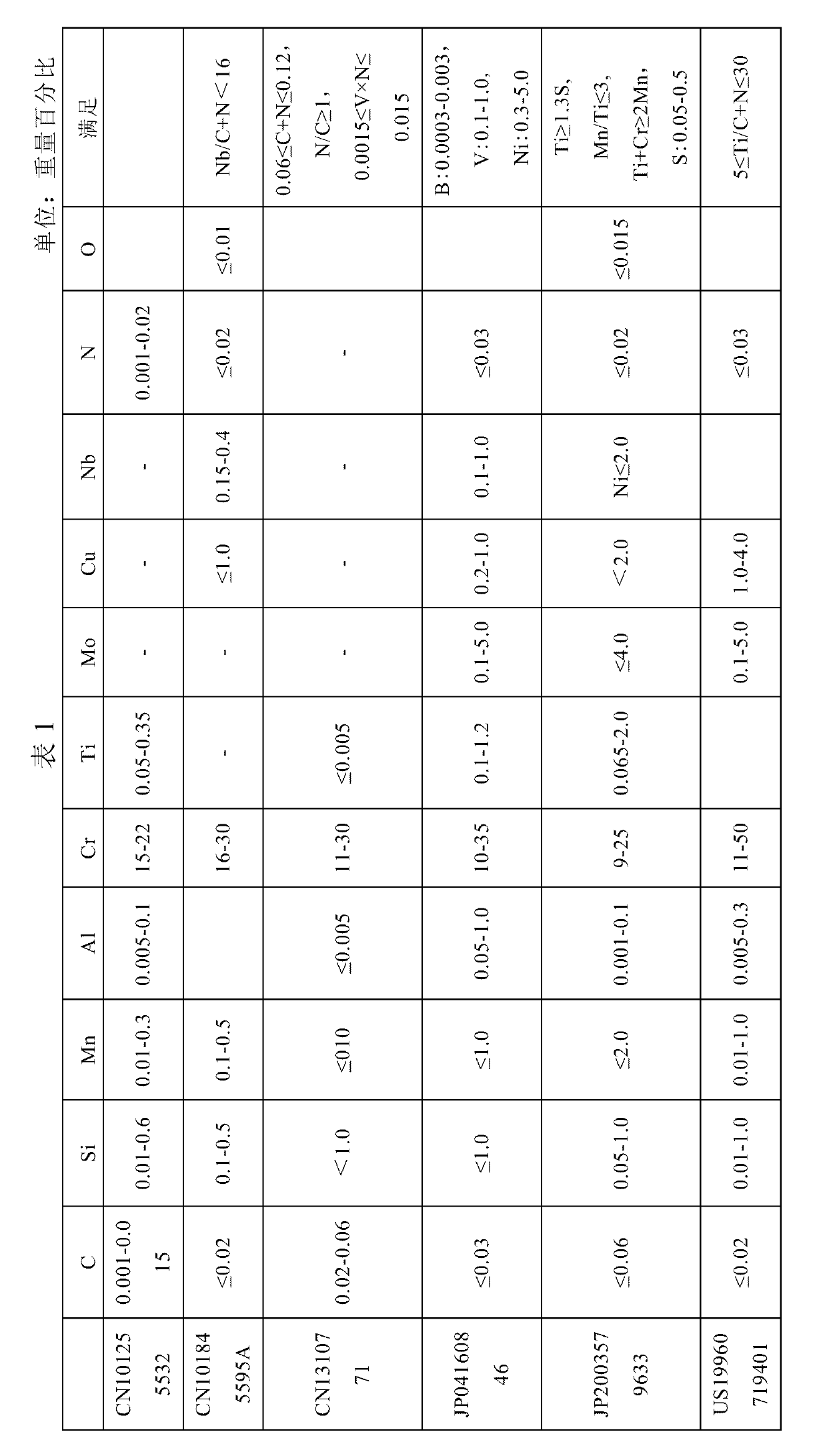

High-surface quality ferrite stainless steel plate and manufacturing method thereof

The invention discloses a high-surface quality ferrite stainless steel plate and a manufacturing method thereof. The high-surface quality ferrite stainless steel plate comprises, by weight, less than or equal to 0.03% of C, 0.20 to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.03% of P, less than or equal to 0.01% of S, 16 to 20% of Cr, 0.75 to 2.0% of Mo, 0.42 to 0.7% of Nb, less than or equal to 0.03% of N, less than or equal to 0.005% of Al, less than or equal to 0.005% of O and the balance Fe and unavoidable impurities, wherein based on Nb content, C content and N content respectively represented by Nb, C and N, Nb-20*C-7*N is greater than or equal to 0.15% and less than or equal to 0.7% and 1.2*C+N is less than or equal to 0.04%. Through smelting, hot rolling, two-rolling process cold rolling, bright annealing and flattening, the high-surface quality ferrite stainless steel plate which is a high-glossiness high-brightness low-roughness high-surface quality mirror material is obtained, has excellent corrosion resistance, cold deformation wrinkling resistance, high yield strength and high surface hardness and is suitable for automobile outer-decoration bright strips (pieces) and furniture decoration bright strips having high surface quality requirements.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

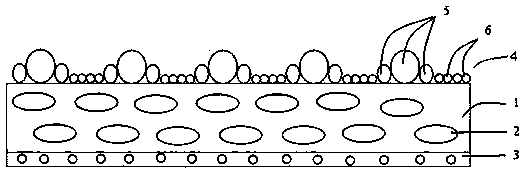

Efficient diffuse reflection film and preparing method thereof

ActiveCN103969723AGood diffuse reflectivityReduce surface glossMirrorsDiffusing elementsAcetic acidMicrobubbles

An efficient diffuse reflection film comprises a reflection film body, wherein microbubbles are distributed in the reflection film body provided with a diffuse reflection coating; the diffuse reflection coating is composed of, by mass, 20 parts of butanone, 12 parts of ethyl acetate, 10 parts of acrylate resin, 1 part of isocyanate, 1-5 parts of diffusion particles with the particle diameter ranging from 20 microns to 50 microns, and 0.5-5 parts of extinction powder. A preparing method comprises the steps: A, preparing master batches of the reflection film body; B, preparing master batches of an anti-adhesive layer; C, preparing a bidirectional tension film; and D, preparing the diffuse reflection coating and performing coating. The efficient diffuse reflection white film has extremely low surface gloss and excellent diffuse reflectivity, and therefore the reflection performance is extremely good.

Owner:NINGBO DXC NEW MATERIAL TECH

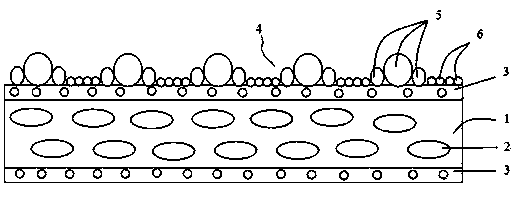

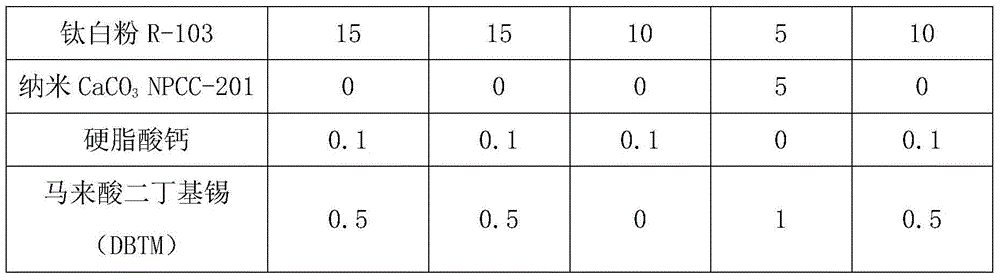

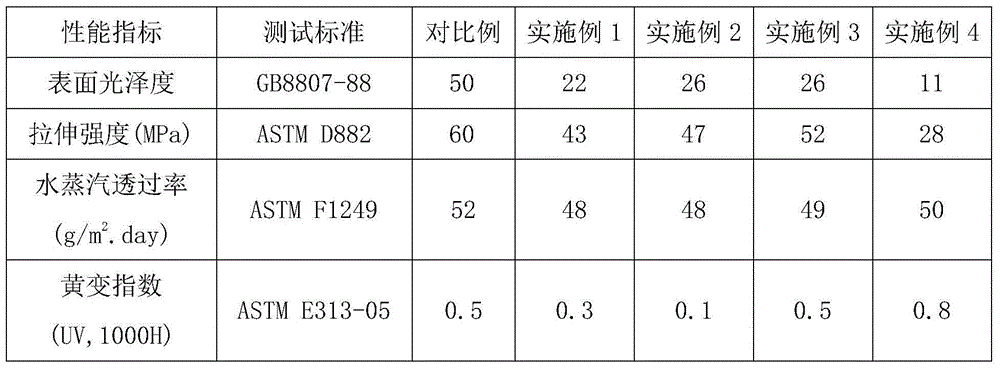

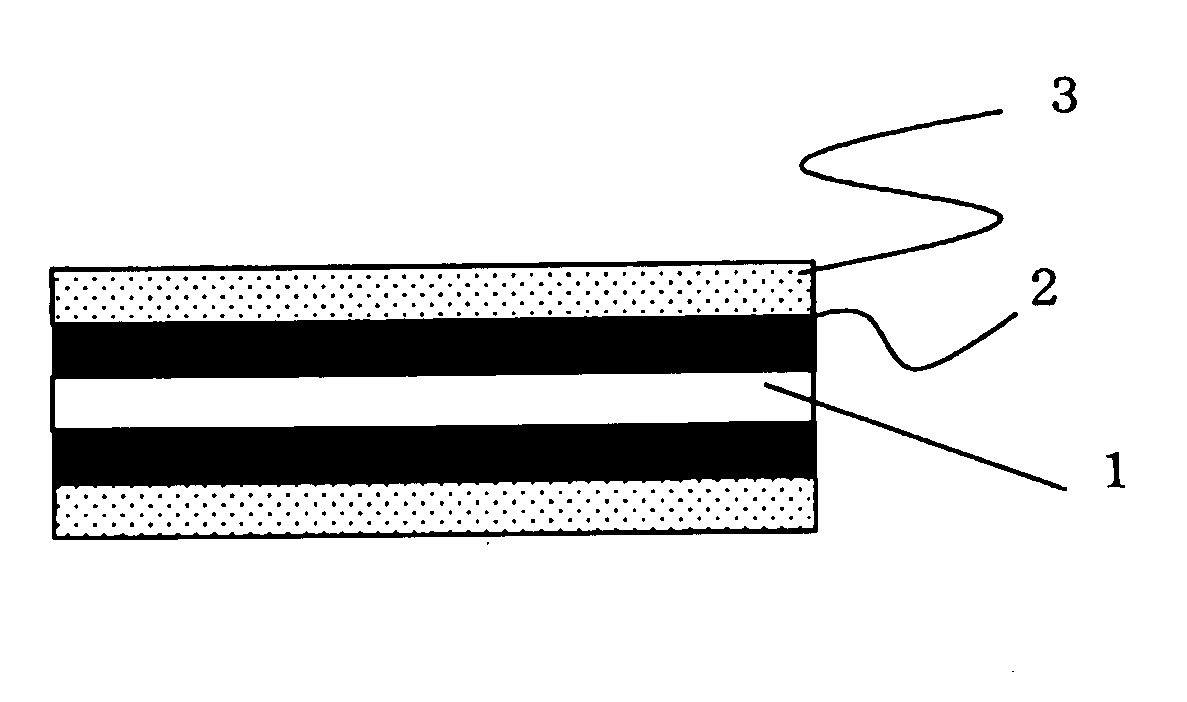

Low surface gloss polyvinylidene fluoride film and preparation method thereof

The present invention relates to a low surface gloss polyvinylidene fluoride film and a preparation method thereof, and belongs to the field of solar photovoltaic cell applications. According to the present invention, 59.9-69.4 parts by weight of polyvinylidene fluoride, 1-10 parts by weight of a delusterant, 0.5-5 parts by weight of a processing aid, 0-5 parts by weight of an inorganic filler, and 10-20 parts by weight of a toughening modifier are mixed and then subjected to slobbering or film blowing to obtain the low surface gloss polyvinylidene fluoride film, wherein the surface gloss of the film is reduced through the delusterant in the formula so as to make the surface gloss of the prepared film be less than 30, the fluidity of the polyvinylidene fluoride is improved through the processing aid so as to easily carry out melt extrusion and film forming, and the film can easily maintain the good toughness through the toughening modifier; and the prepared polyvinylidene fluoride film has advantages of excellent mechanical property, low surface gloss, high weathering resistance, high water barrier property, high vapor barrier property, and the like.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

Heat-resistant, light-shielding film, production thereof, and aperture and light intensity adjusting device using the same

InactiveUS20080213555A1Improve surface wear resistanceImprove friction resistanceSynthetic resin layered productsVacuum evaporation coatingDigital videoShutter

A heat-resistant, light-shielding film having high light shielding capacity, high heat resistance, high sliding characteristics, low surface gloss and high electroconductivity, and useful for optical device parts, e.g., shutter or aperture blades for digital cameras and digital video cameras, and aperture blades for adjusting light intensity for projectors; method for producing the film; and aperture and light intensity adjusting device using the film.The heat-resistant, light-shielding film comprising a heat-resistant resin film base (A) resistant to 200° C. or higher, coated, on one or both sides, with an Ni-base metallic film (B) having a thickness of 50 nm or more by sputtering and then with a low-reflectivity film (C) of Ni-base oxide also by sputtering, and having a surface roughness (arithmetic average height Ra) of 0.1 to 0.7 μm.

Owner:SUMITOMO METAL MINING CO LTD

Matting resin modified polyvinyl chloride (PVC) matt film

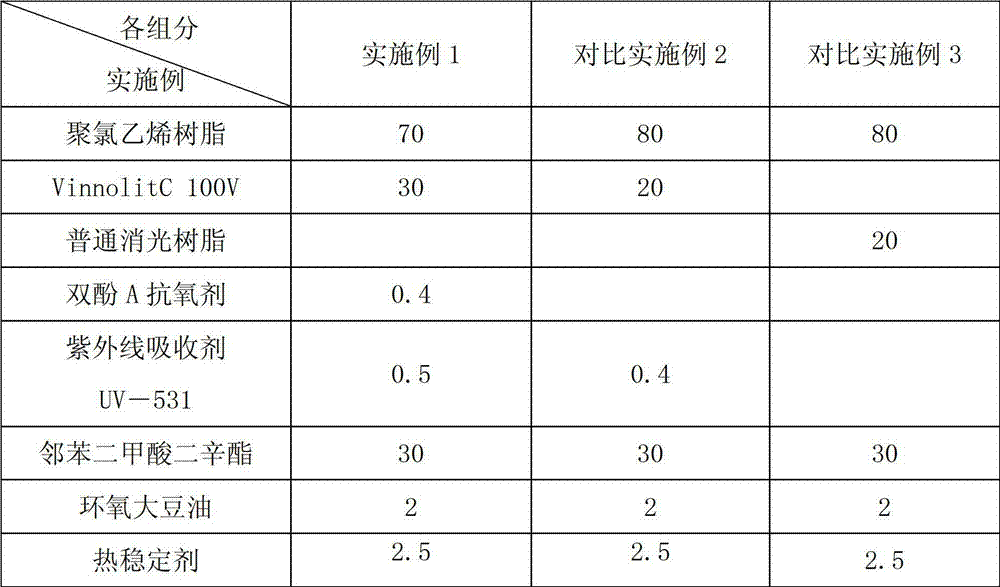

The invention relates to a matting resin modified polyvinyl chloride (PVC) matt film, belonging to the technical field of PVC matt films. The matting resin modified PVC matt film comprises the following components: 60 to 90 weight parts of polyvinyl chloride resin, 10 to 40 weight parts of matting resin (VinnolitC 100V), 20 to 50PHR of dioctyl phthalate, 2 to 10PHR of epoxy soybean oil, 2 to 5PHR of a thermal stabilizer, 0.3 to 0.5PHR of an antioxidant, and 0.1 to 1.0PHR of an ultraviolet absorbent. The modified matt film can achieve surface effects of anti-sticking, matting, grain forming and the like, has a good surface matting effect, has high adaptability to processing conditions, and has the advantages of good matting effect and the like in a broad plasticizing temperature range.

Owner:TIANJIN TIANSU SCI & TECH GROUP

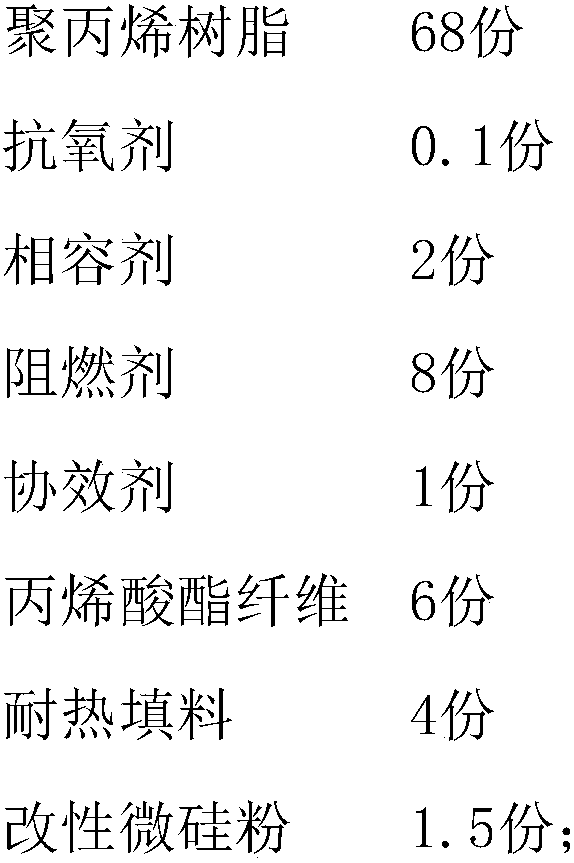

High-flame-retardancy high-heat-resistance MPP pipe and preparation method thereof

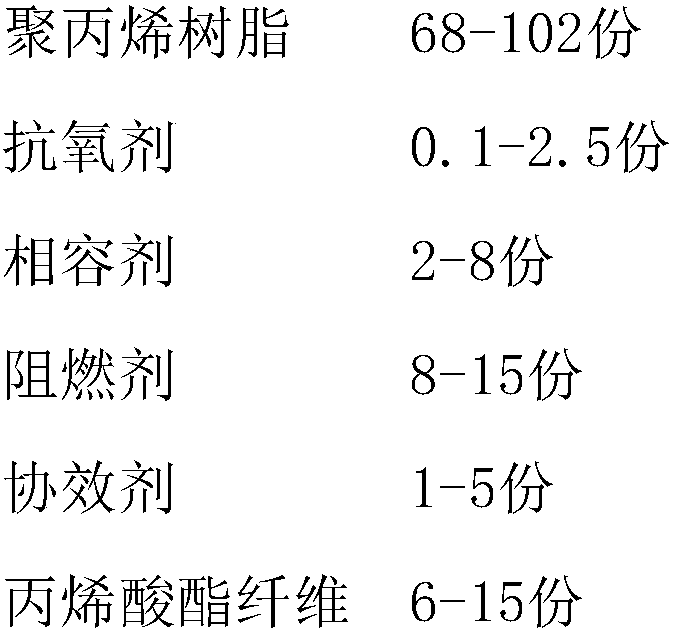

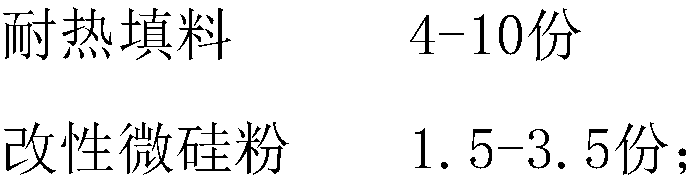

The invention relates to the technical field of high polymer materials, and in particular relates to a high-flame-retardancy high-heat-resistance MPP pipe and a preparation method thereof. The MPP pipe comprises the following raw materials in parts by weight: 68-102 parts of polypropylene resin, 0.1-2.5 parts of an antioxidant, 2-8 parts of a compatilizer, 8-15 parts of a flame retardant, 1-5 parts of a synergistic agent, 6-15 parts of an acrylate fiber, 4-10 parts of a heat-resistant filler and 1-5 parts of modified micro-silicon powder, wherein the heat-resistant filler is the mixture composed of calcium carbonate, lignocelluloses and magnesium silicide according to the weight ratio of 3-12:3-8:1-2. The MPP pipe disclosed by the invention has better flame retardancy, heat resistance, smoke inhibition performance, stability, oxidation aging resistance and the like, the strength is high, and the heat-resistant filler is adopted, the heat resistance and the processing flowing property of the MPP pipe can be effectively improved, the surface glossiness is reduced, the forming performance is good, the processing performance is good, and the use value is high.

Owner:SHENZHEN ANPOWER ELECTRIC

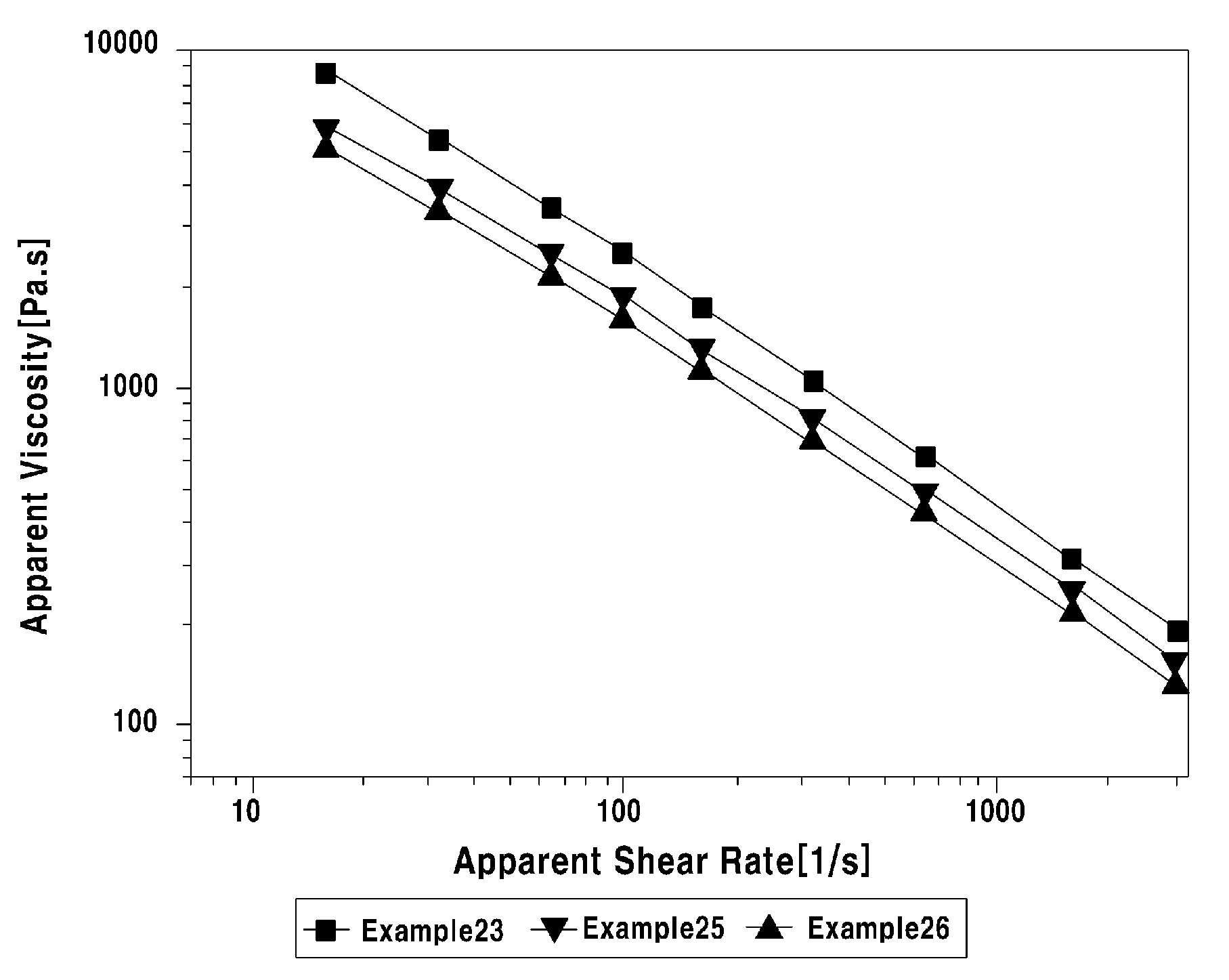

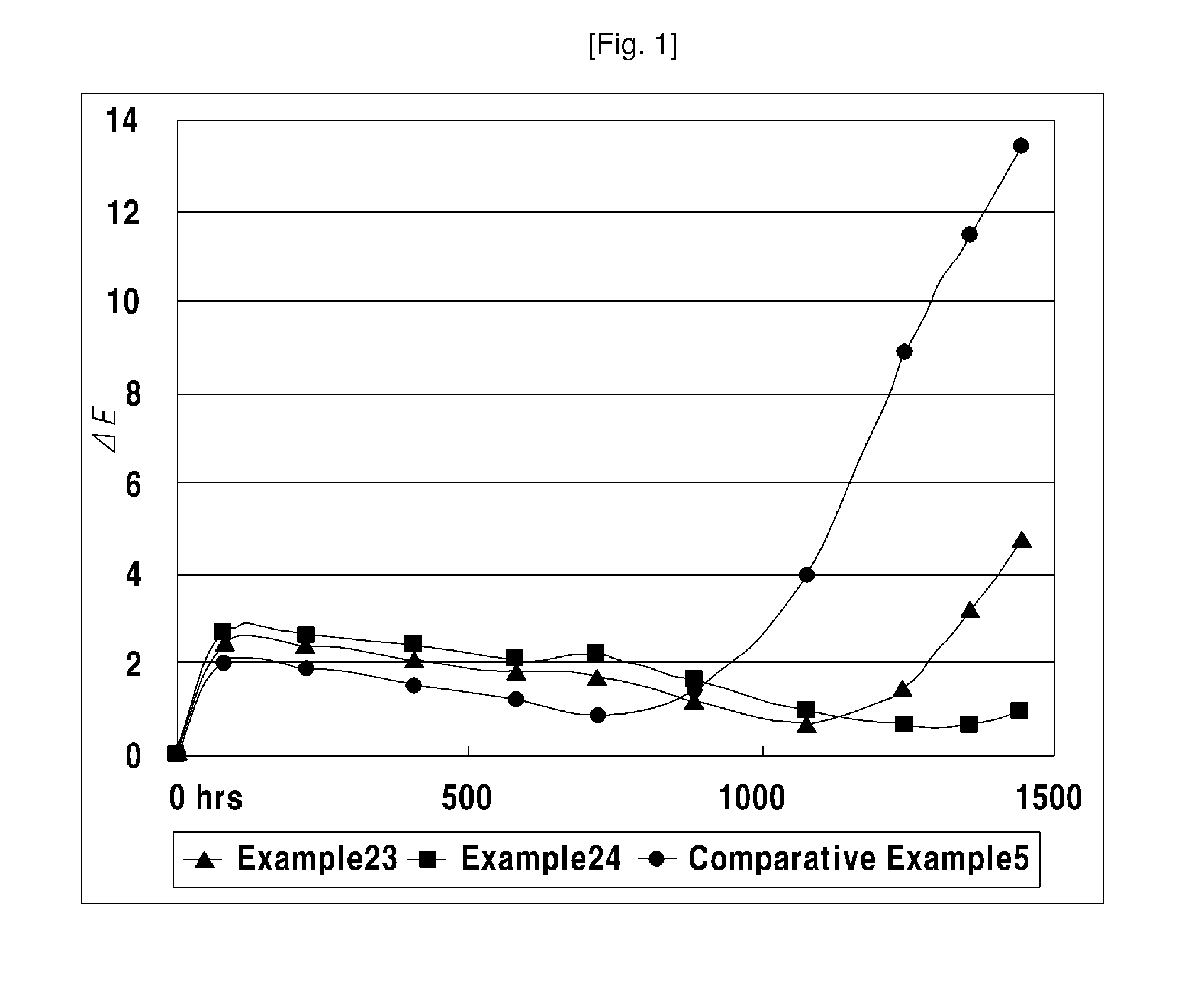

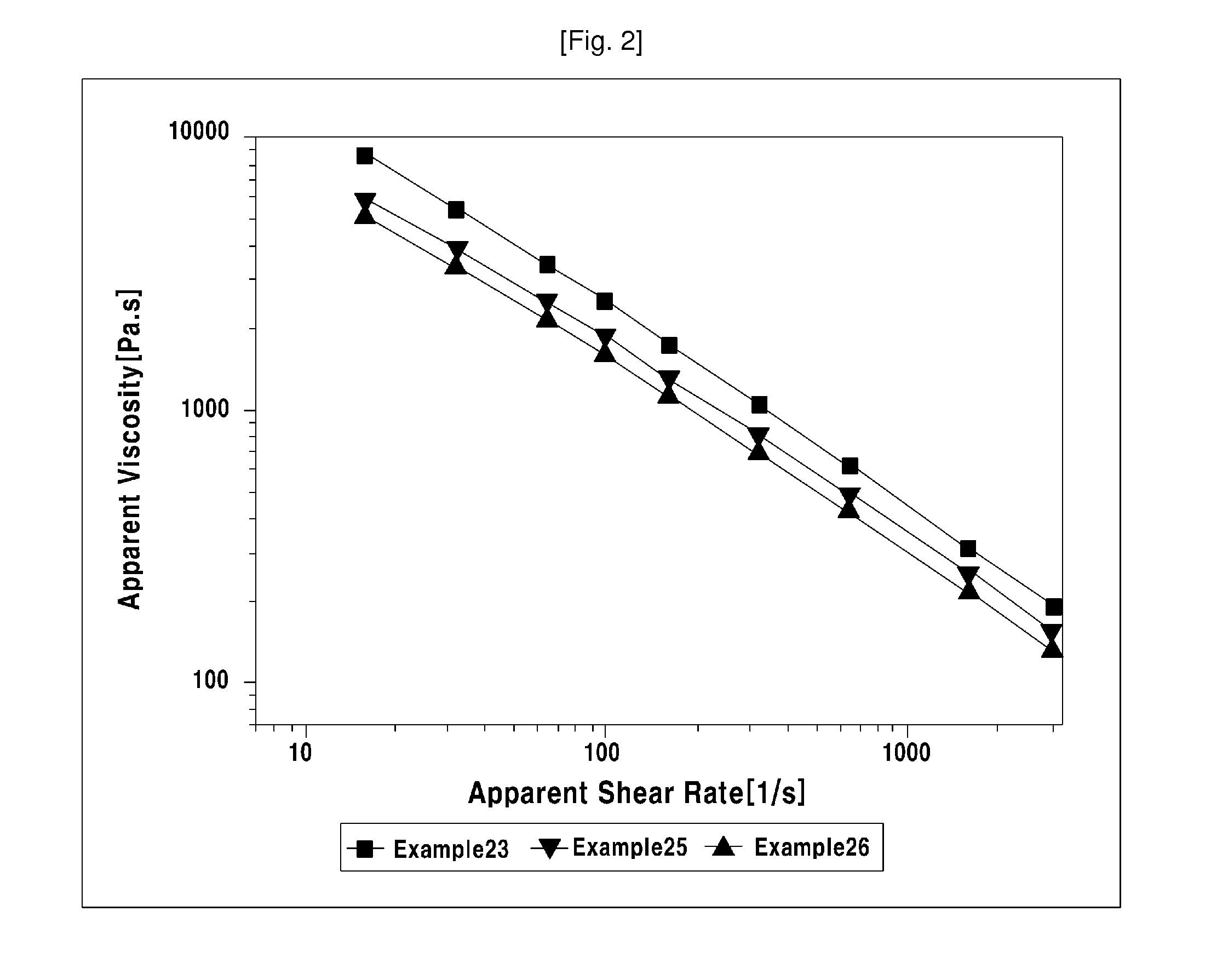

Low surface gloss styrene resin composition, and low surface gloss sheet and composite article therefrom

ActiveUS20100075165A1Good weather resistanceReduce surface glossOther chemical processesSynthetic resin layered productsPlasticizerPolystyrene

The present invention relates to a low surface gloss styrene resin composition. The composition of the present invention is composed of (A) 80-99.9 weight % of the basic resin comprising rubber-modified styrene resin and (B) 0.1-20 weight % of syndiotactic polystyrene, the matting agent. The composition also includes (C) hydrogenated styrene block copolymer comprising styrene block and butadiene rubber block as a compatibilizer by 0.1-20 weight % for the total weight of the low surface gloss styrene resin composed of (A) the basic resin and (B) the matting agent and additionally includes (D) a plasticizer by 0.1-30 weight %. The composition of the present invention has excellent weatherability and impact-resistance in addition to the low surface gloss properties, so that it can be applied in various products, particularly exterior products for structures such as sidings and window frames, etc.

Owner:LG CHEM LTD

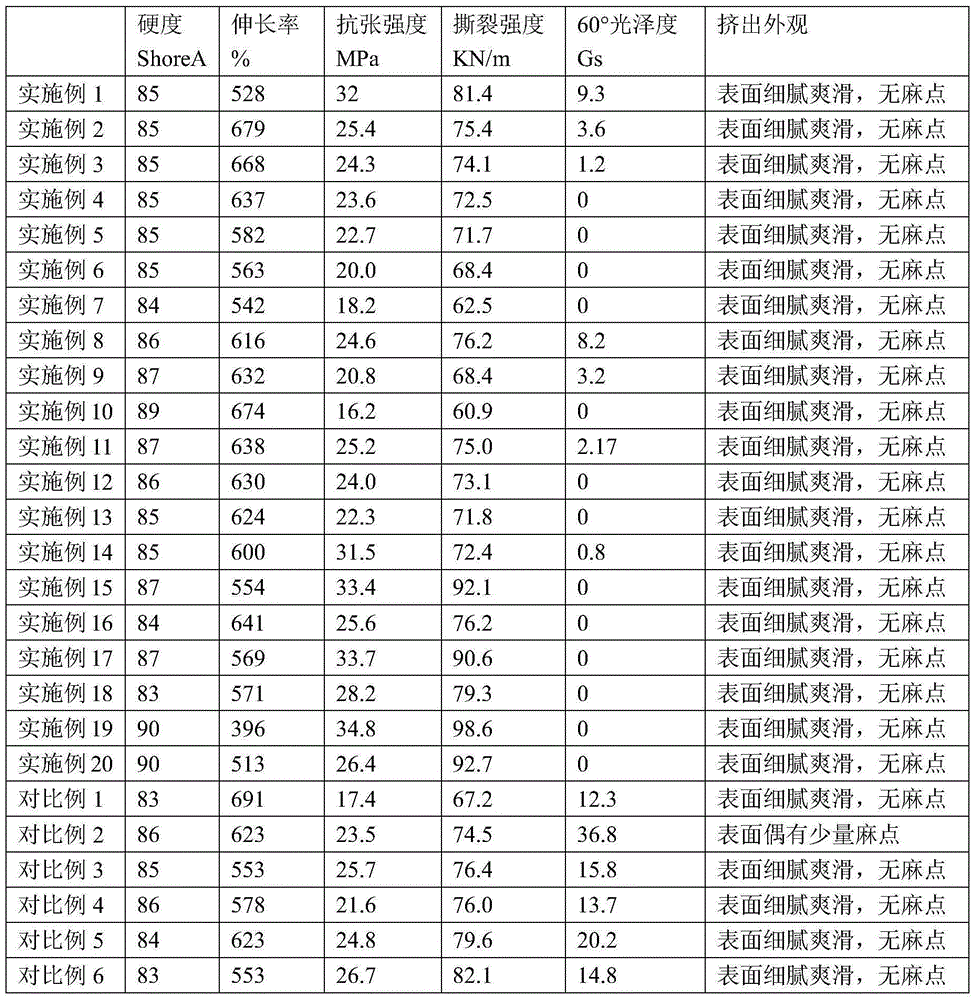

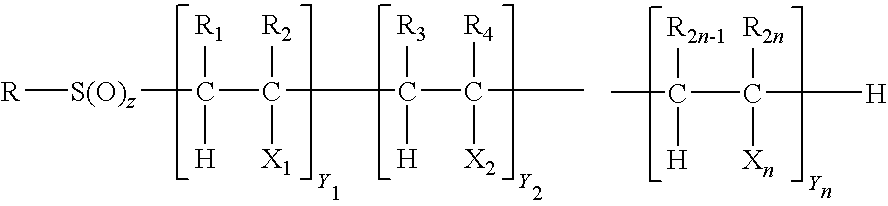

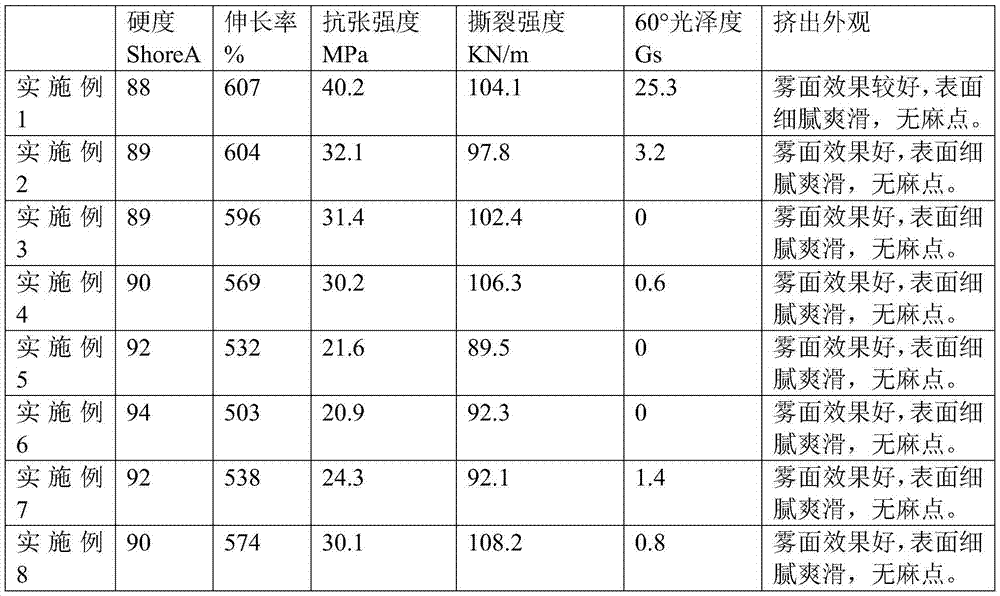

Thermoplastic polyurethane composition and preparation method thereof

The invention relates to a thermoplastic polyurethane composition and a preparation method thereof. The composition comprises the following substances by the mass percentage: (a) 55-90% of a thermoplastic polyurethane elastomer, (b) 7-40% of a copolymer, and (c) 2-8% of a compatilizer. The copolymer is selected from one or more of the following polymers: SBS, SEBS, SIS and SEPS with the number-average molecular weight of 50 thousand-100 thousand. In addition, EPDM with the weight-average molecular weight of 100 thousand-400 thousand can be added and can cooperate with the copolymer, and in the premise of relatively low copolymer amount, better extinction effect is achieved. According to the ASTM D523 standard, the surface glossiness of the angle of 60 degrees is tested to be less than 10 Gs, and the lowest reaches 0; and the material has good mechanical properties and processing performance, and is suitable for preparation of wire cables, pipes, belts and thin film products.

Owner:WANHUA CHEM GRP CO LTD

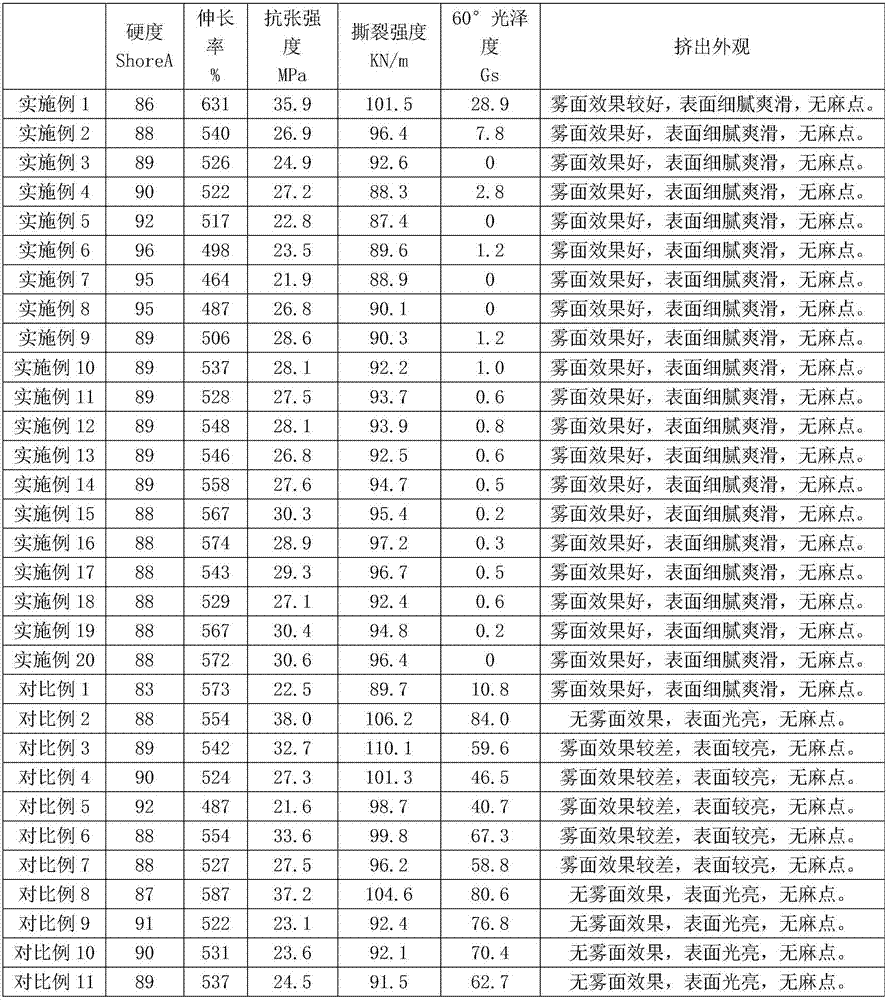

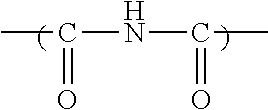

Low-glossiness thermoplastic polyurethane composition and preparation method and application thereof

The invention relates to a low-glossiness thermoplastic polyurethane composition and a preparation method and application thereof. The composition comprises, by weight, (A) 50%-95% of thermoplastic polyurethane elastomer, (B) 3%-45% of thermoplastic polyamide polymer or commixture of thermoplastic polyamide and thermoplastic polyamide polymer; (C) 1%-20% of a third component, wherein the third component is selected from one or more of inorganic filler, polycarbonate powder, PTFE (polytetrafluoroethylene) powder and organic (hypophosphite)phosphate. According to standard ASTM D523 tests, 60-degree surface glossiness is lower than 30Gs, and the composition is great in mechanical property and processability, uniform and delicate in surface matting effect, smooth in handfeel and suitable for preparation of cables, pipes, belts and film products.

Owner:WANHUA CHEM GRP CO LTD

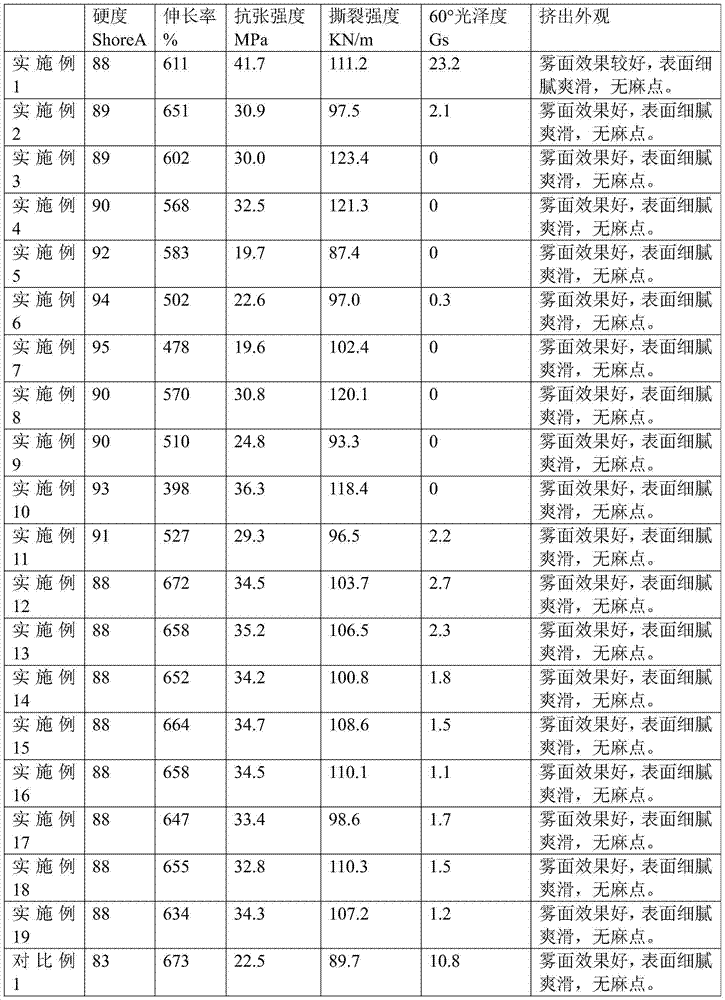

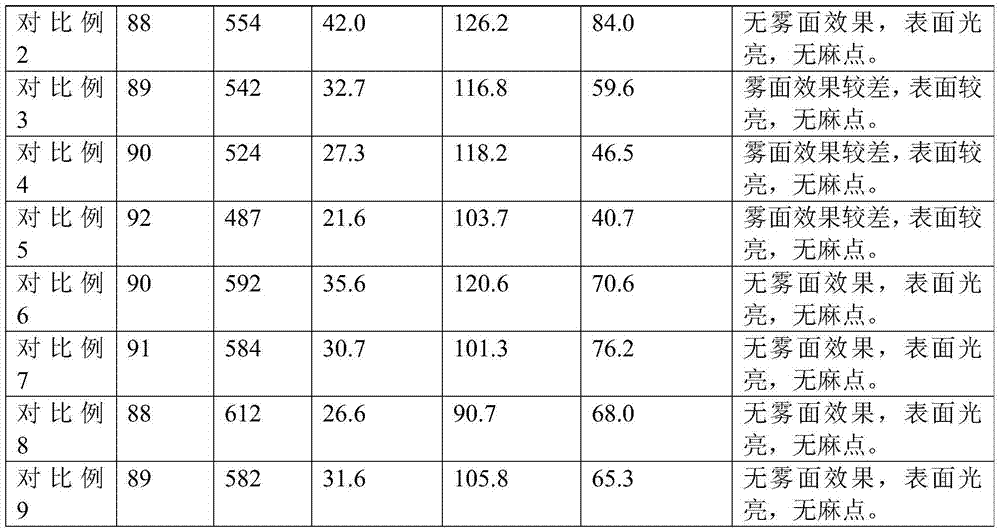

Low-glossiness thermoplastic polyurethane composition and preparation method and application thereof

ActiveCN106928693AGood compatibilityImprove mechanical propertiesPolyesterThermoplastic polyurethane

The invention relates to a low-glossiness thermoplastic polyurethane composition and a preparation method and application thereof. The low-glossiness thermoplastic polyurethane composition comprises, by mass percentage, 50-95% preferably 70-85% of thermoplastic polyurethane elastomer, 3-45% preferably 10-20% of thermoplastic polyester polymer and 1-20% preferably 5-10% of inorganic filler. The preparation method includes: melting and blending the components according to a certain proportion to obtain composition granules, and using melt extrusion equipment to extrude sheets of about 1mm. The low-glossiness thermoplastic polyurethane composition has the advantages that standard ASTM D523 tests show that the 60-degree-angle surface glossiness of the composition is lower than 30Gs, and the composition is good in mechanical performance and machining performance, even and fine and smooth in surface dulling effect, smooth in touch and suitable for being used for producing cables, pipes, belts and thin film products.

Owner:WANHUA CHEM GRP CO LTD

Protection film used for surface of NFC and preparation method of protection film

ActiveCN105482731AReduce surface glossSolvent resistantFilm/foil adhesivesInksTectorial membraneEngineering

The invention relates to a protection film used for the surface of NFC. The protection film comprises a PET base material layer, an adhesive layer arranged on one side of the PET base material layer and a release film layer attached to the adhesive layer. A black ink layer is arranged on the other side of the PET base material layer, the black ink layer is coated with a matte oil layer which is formed by film formation of an organic delustering agent, the black ink layer contains 0.5%-0.8% of aluminum compound, and the mean grain size of the aluminum compound ranges from 0.2 mm to 0.5 mm. The invention further relates to a preparation method of the protection film. The matte oil layer prevents fingerprints and scratches, meanwhile, the protection film has the functions of resisting solvents, achieving heat radiation and the like, and the service life of an NFC chip can be effectively prolonged. In addition, the aluminum compound is added to the black ink layer, waves, interfering with communication message receiving of a mobile phone, sent by the NFC chip can be shielded, it is guaranteed that the adhesive force of the adhesive layer of the protection film is moderate, the protection film can be completely attached to the surface of NFC, and adhesive residues or other pollution cannot be caused to the surface of NFC after the protection film is removed.

Owner:NINGBO SOKEN CHEM

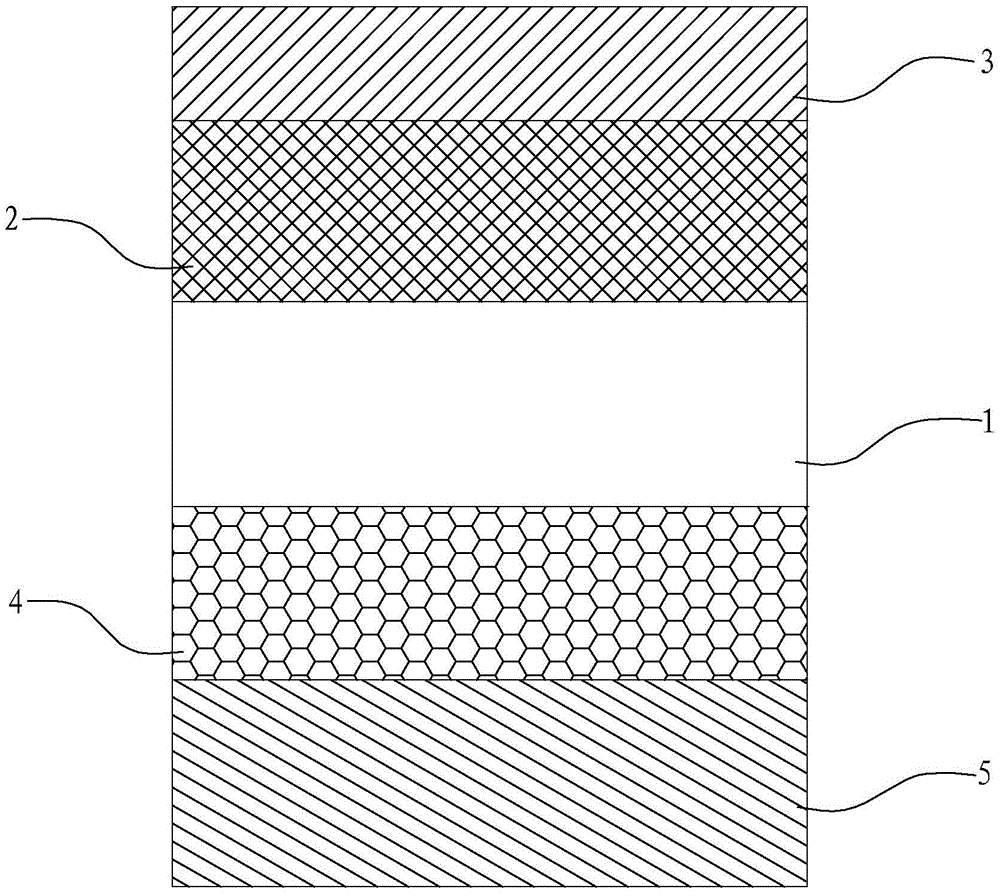

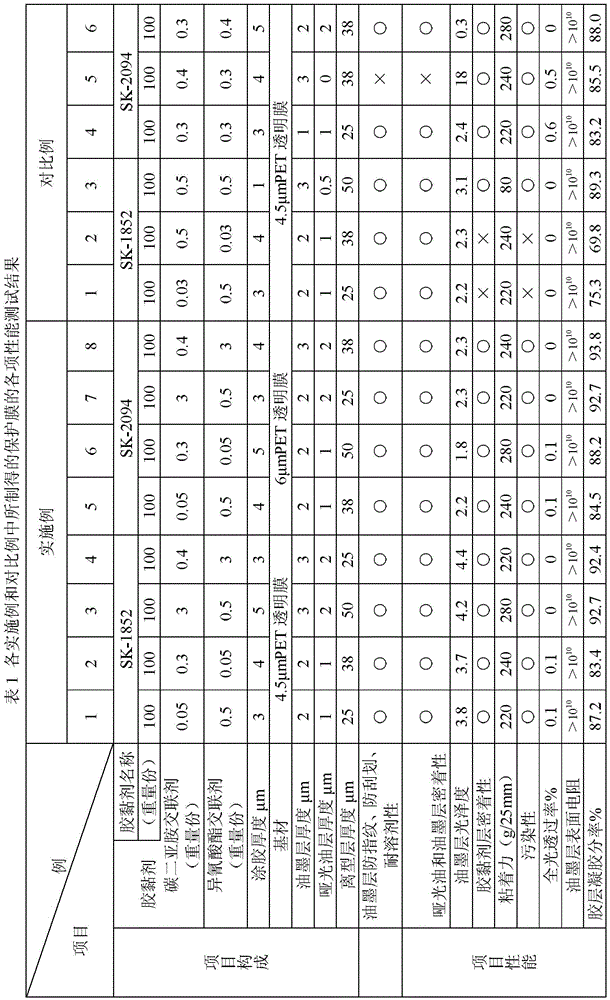

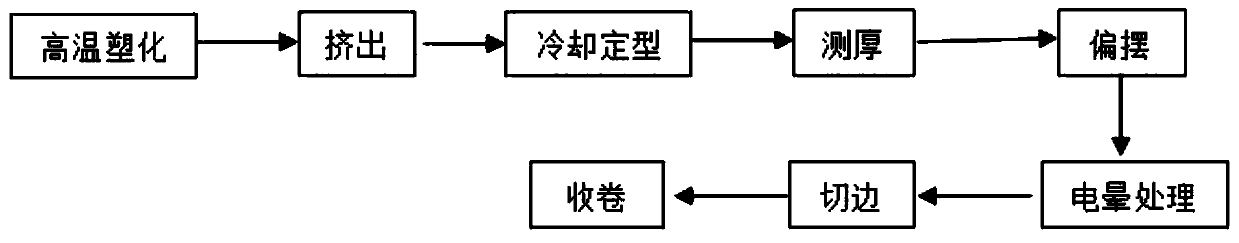

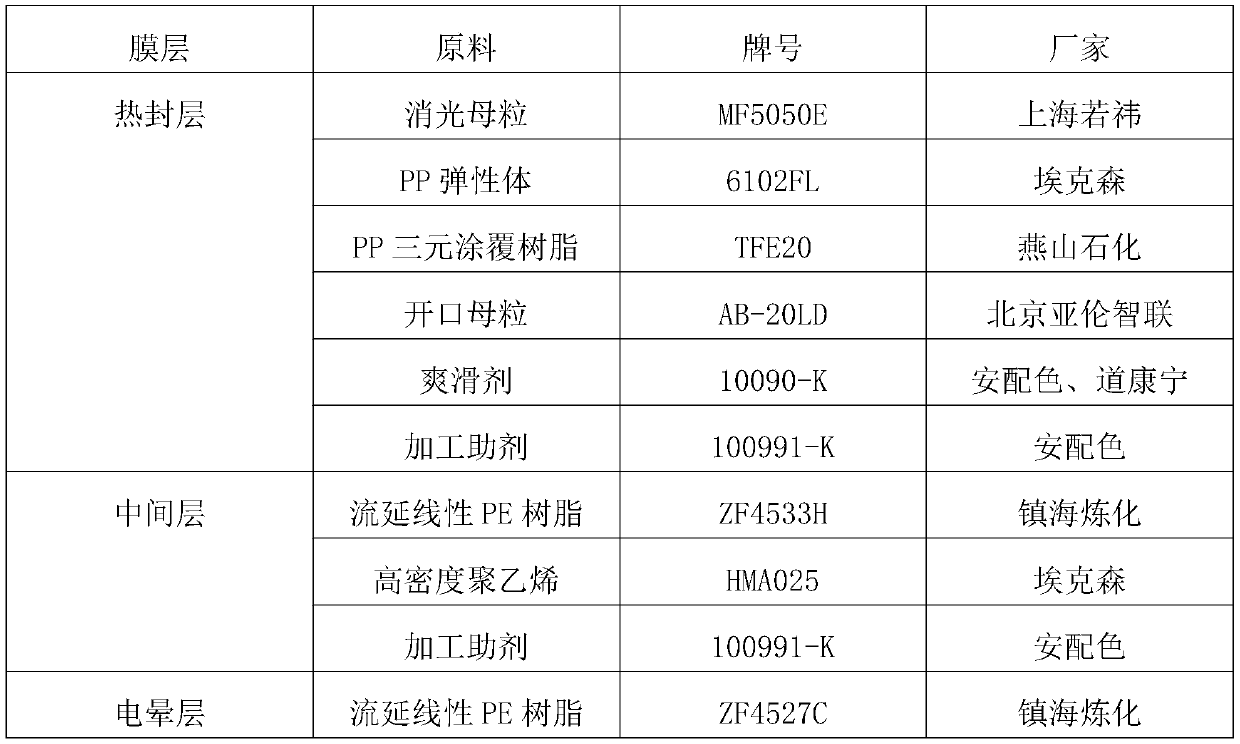

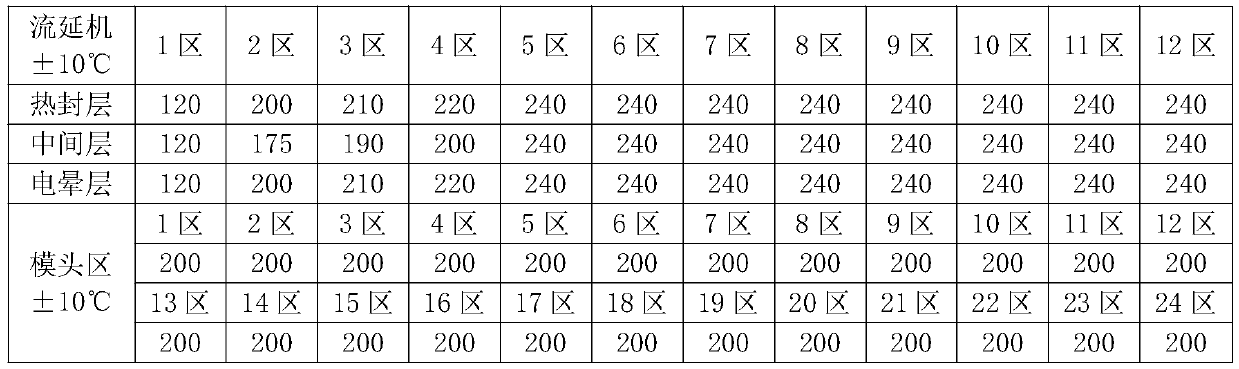

Extinction casting PE film and production process thereof

ActiveCN110305402ASpecular Scatter ScaleGood heat sealing performanceSynthetic resin layered productsFlat articlesMasterbatchElastomer

The invention relates to an extinction casting PE film and a production process thereof. The extinction casting PE film comprises a heat sealing layer, an intermediate layer and a corona layer, wherein the heat sealing layer comprises extinction masterbatch, a PP elastomer, PP ternary coating resin, opening masterbatch, a slipping agent and a processing aid; the intermediate layer comprises cast linear PE resin, high density polyethylene and a processing aid; and the corona layer comprises cast linear PE resin. The extinction cast PE film prepared by the composition is suitable for the requirements of printing equipment: excellent thickness uniformity, stable friction coefficient, 10% high tensile strength, high tensile breaking force, low surface gloss of extinction surface, high overallhaze of the film, fine appearance of the film surface, suitability for high-speed printing of intaglio and flexographic plates, accurate color coating and no deviation during intaglio multi-color printing.

Owner:HUANGSHAN NOVEL

Release Sheet And Formed Article Obtained By Using Such Release Sheet

ActiveUS20070202301A1Improve heat resistanceHigh mechanical strengthNon-fibrous pulp additionCoatings with pigmentsHeat resistanceEngineering

The present invention relates to a release sheet which comprises a mat making layer forming a refined uneven of mat style on a surface, the mat making layer being provided on at least one surface of a substrate sheet, and a release layer formed with a coating film layer of releasable resin containing ultra micro particles having an average particle size of 0.01 to 0.3 μm, the release sheet being provided on a surface of the mat making layer. The release sheet of the present invention has superior heat resistance and mechanical strength for a long time, and can prevent change of mat style having low gloss of the surface or of gloss, even if repeat uses are conducted. By using the release sheet of the present invention, a formed article such as synthetic leathers and decorative laminated plates having uniformity quality, can be provided.

Owner:LINTEC CORP

Polyacetal resin compostition

InactiveUS20100022691A1Good weather resistanceSuppressed surface glossLayered productsPaints for electrolytic applicationsWeather resistanceCore shell

The present invention provides a polyacetal resin composition having excellent weather resistance and suppressed surface gloss, and having extremely reduced generation of formaldehyde. Particularly, to 100 parts by weight of (A) a polyacetal resin are blended 0.01 to 5 parts by weight of (B) a weathering (light) stabilizer, 1 to 50 parts by weight of (C) a core-shell polymer having a core of a rubbery polymer and a shell of a glassy polymer composed of a vinyl-based copolymer; and 0.01 to 5 parts by weight of (D) a compound selected from an isocyanate compound, an isothiocyanate compound, and a modified compound thereof.

Owner:POLYPLASTICS CO LTD

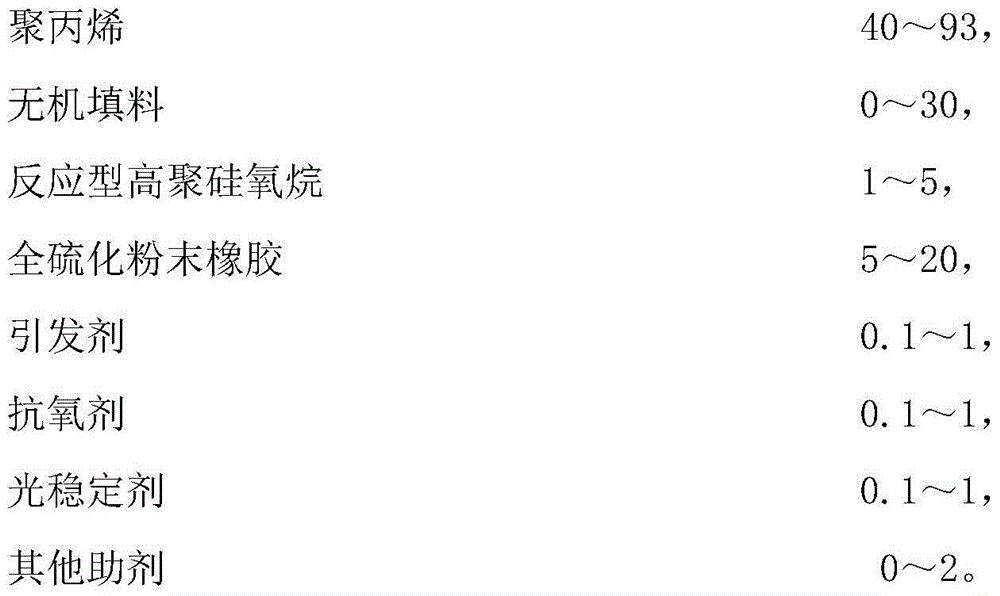

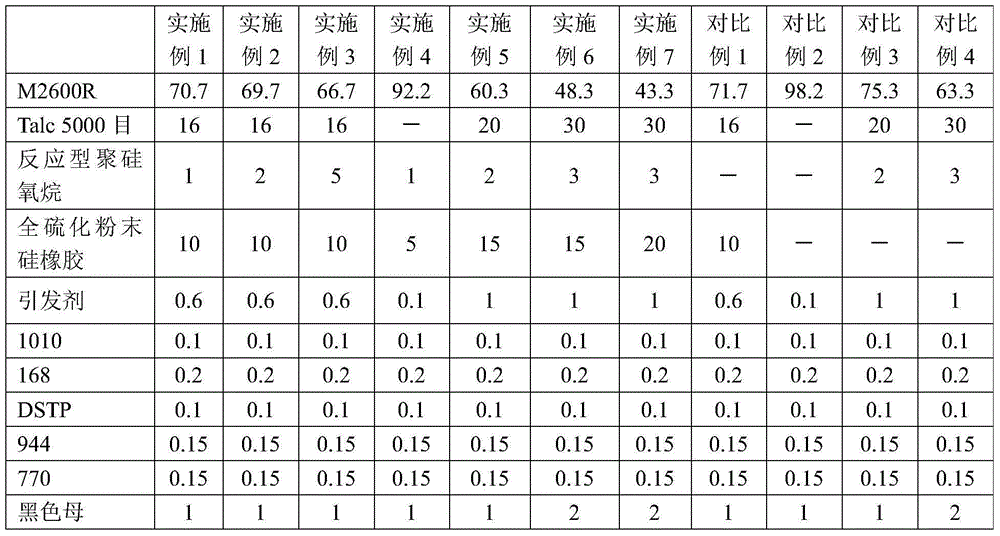

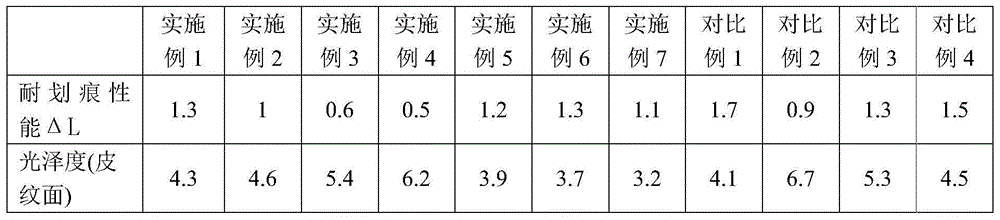

Scratching-resistant low-gloss polypropylene composite material and preparation method thereof

InactiveCN104558837AImprove scratch resistanceReduce surface glossPolypropylene compositesPolymer science

The invention discloses a scratching-resistant low-gloss polypropylene composite material and a preparation method thereof. The scratching-resistant low-gloss polypropylene composite material is prepared from the following raw materials in percentage by weight: 40-93% of polypropylene, 0-30% of an inorganic filler, 1-5% of reaction type high polysiloxane, 5-20% of fully vulcanizated powdered rubber, 0.1-1% of an initiator, 0.1-1% of an antioxidant, 0.1-1% of a light stabilizer, and 0-2% of other auxiliaries. According to the preparation method disclosed by the invention, the reaction type high polysiloxane and the fully vulcanizated powdered rubber are added to the basic formula, so that when the scratching resistance of the polypropylene material is improved, the high gloss problem of the product caused by addition of polysiloxane can be solved; the obtained polypropylene composite material is low in surface gloss, good in light extinction effect, and suitable for automobiles, household appliances and other fields.

Owner:SHANGHAI PRET COMPOSITES +2

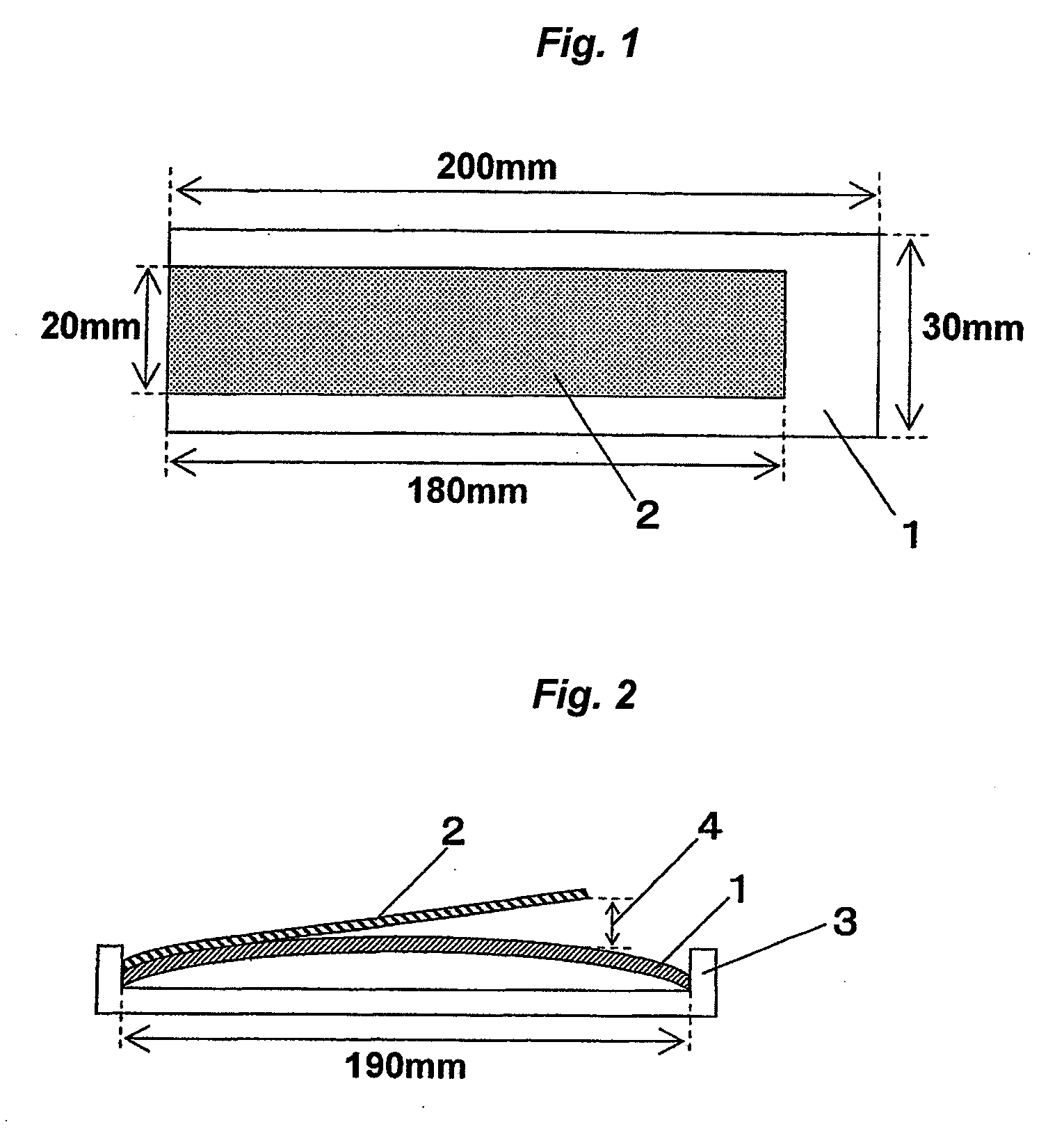

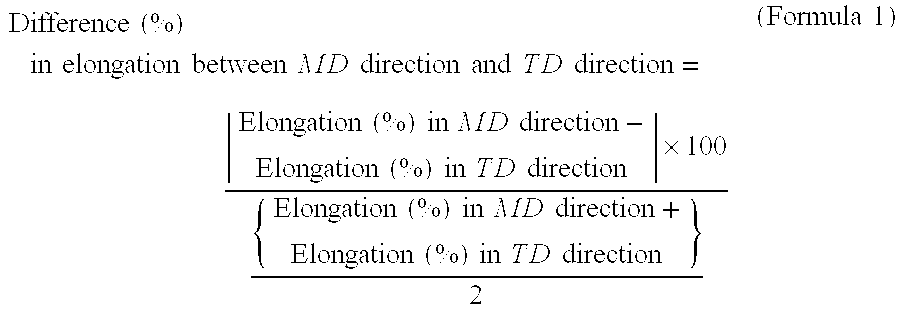

Double-sided adhesive tape for fixing decorative sheet for speaker and method for attaching decorative sheet for speaker to housing

InactiveUS20090272491A1Improve adhesionStable separationAdhesive processesSynthetic resin layered productsEngineeringNonwoven fabric

The present invention provides a double-sided adhesive tape for fixing a decorative sheet for speaker, which includes a nonwoven fabric substrate, an acrylic pressure-sensitive adhesive layer A disposed on one side of the nonwoven fabric substrate and an acrylic pressure-sensitive adhesive layer B disposed on the other side of the nonwoven fabric substrate, in which the adhesive tape has a tensile strength in the tape flow (MD) direction of 8 N / 10 mm or more and a tensile length in the width (TD) direction of 8 N / 10 mm or more. The double-sided adhesive tape is excellent in the adhesion performance to a housing and a decorative sheet for speaker and at the same time, has excellent releasability ensuring that when separating the decorative sheet portion, smooth separation can be attained without leaving a residue of tape or pressure-sensitive adhesive on the housing portion.

Owner:NITTO DENKO CORP

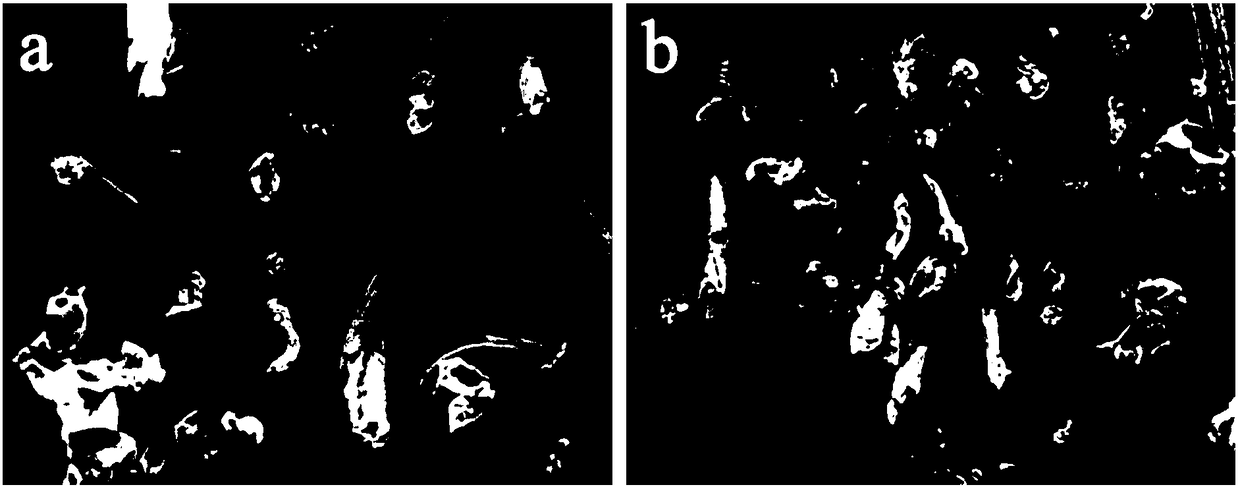

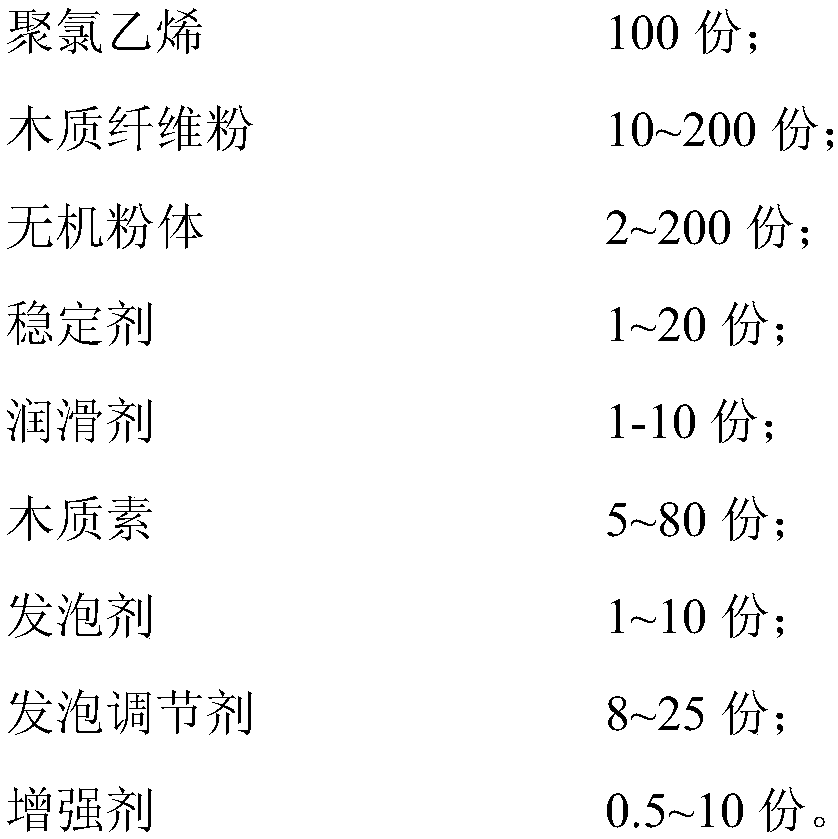

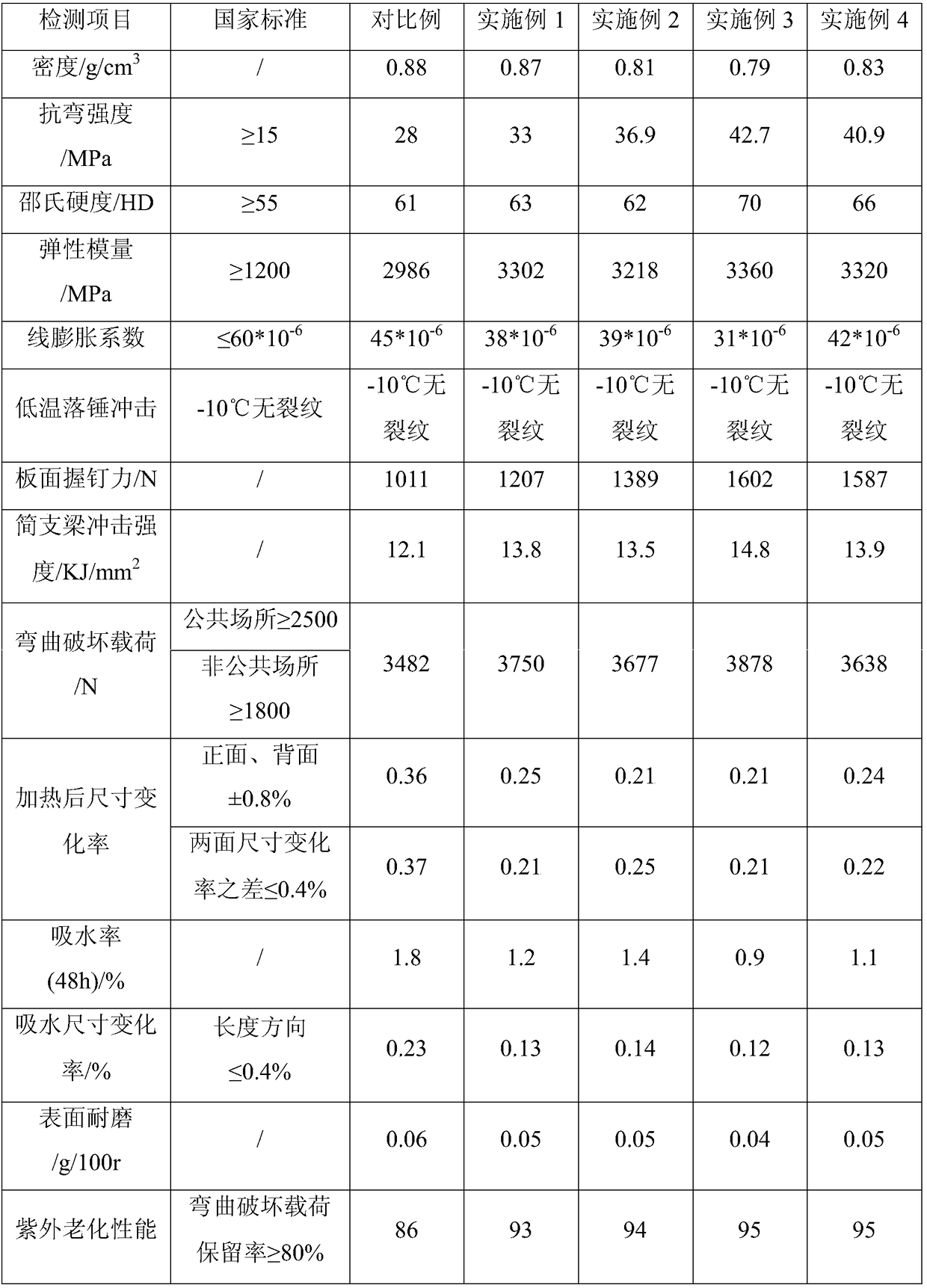

Lignin enhanced polyvinyl chloride wood plastic foam composite material, and preparation method thereof

The invention discloses a lignin enhanced polyvinyl chloride wood plastic foam composite material, and a preparation method thereof. The lignin enhanced polyvinyl chloride wood plastic foam compositematerial is composed of, by weight, 100 parts of polyvinyl chloride, 10 to 200 parts of wood fiber powder, 2 to 200 parts of an inorganic powder, 1 to 20 parts of a stabilizing agent, 1 to 10 parts ofa lubricant, 5 to 80 parts of lignin, 1 to 8 parts of a compatilizer, 1 to 10 parts of a foaming agent, 8 to 25 parts of a foaming conditioning agent, and 0.5 to 10 parts of a reinforcing agent. Compared with the prior art, the preparation method comprises following advantages: lignin enhancing technology is combined with micropore foaming technology, so that material lightweighting is ensured, and the plasticizing performance, the flame resistance, the ultraviolet resistance, the aging resistance, the biological resistance, the radiation resistance, and rheological performance, the screw extrusion performance, and the heat resistance of the lignin enhanced polyvinyl chloride wood plastic foam composite material are improved obviously, product surface gloss is improved, product water absorption performance is reduced, and the high performance lignin enhanced polyvinyl chloride wood plastic foam composite material with lightweighting characteristics is obtained.

Owner:NANJING UNIV OF TECH

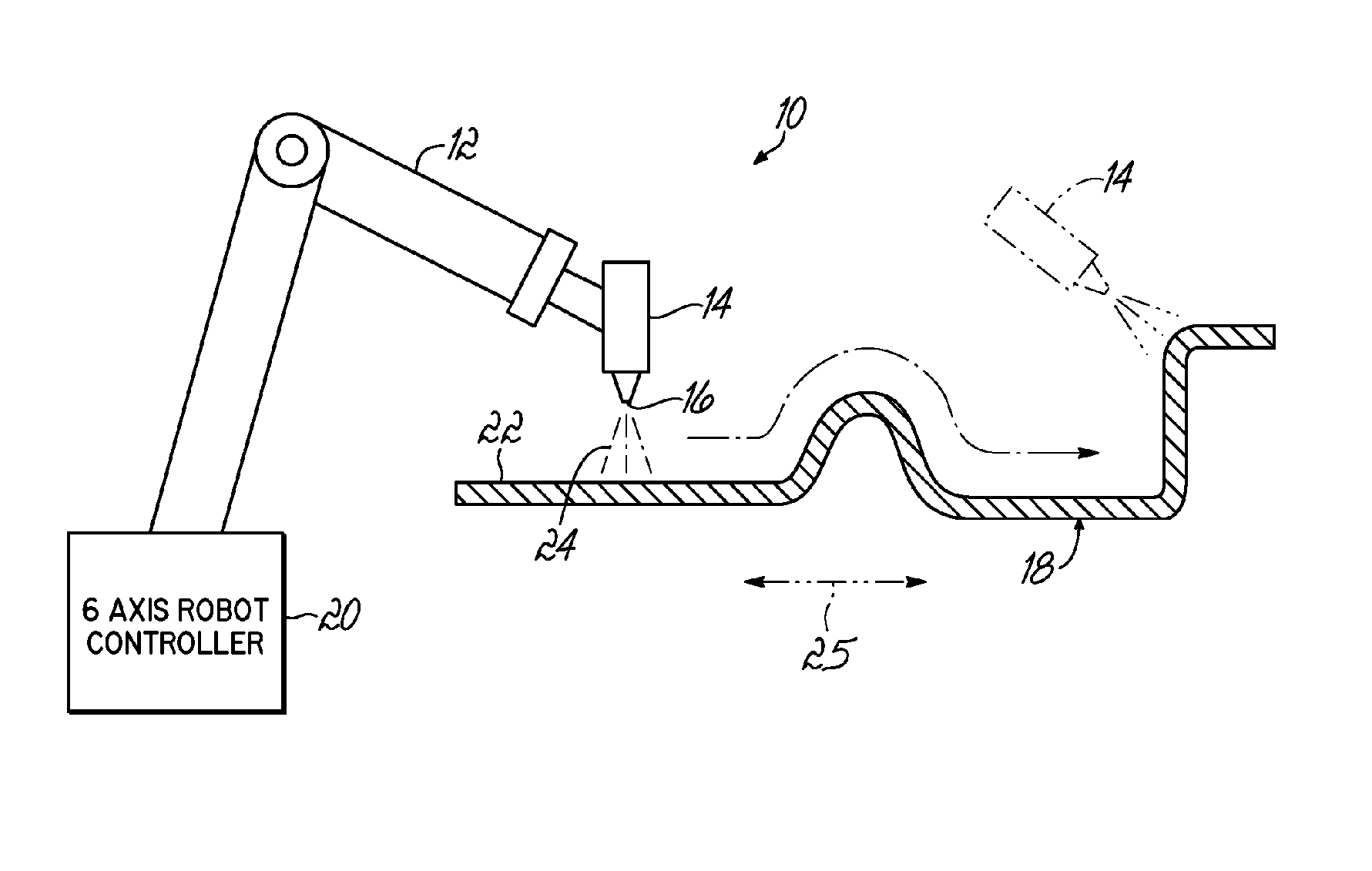

Process for creating a low gloss surface finish on a vehicle trim component

InactiveUS20060076715A1Reduce surface glossReduce glossDomestic articlesPlasma techniqueCorona dischargeGas plasma

Methods for reducing surface gloss of a vehicle interior trim component, such as non-carpeted floor coverings. Gloss is reduced by treating a surface of the interior trim component with an energy beam, such as a gas plasma, a flame plasma, or a corona discharge, emitted from a treatment device. A positioning device supports the treatment device in a spaced relationship to the surface. The positioning device causes the treatment device and the interior trim component to be moved relative to each other during the course of the gloss reduction treatment.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

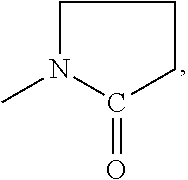

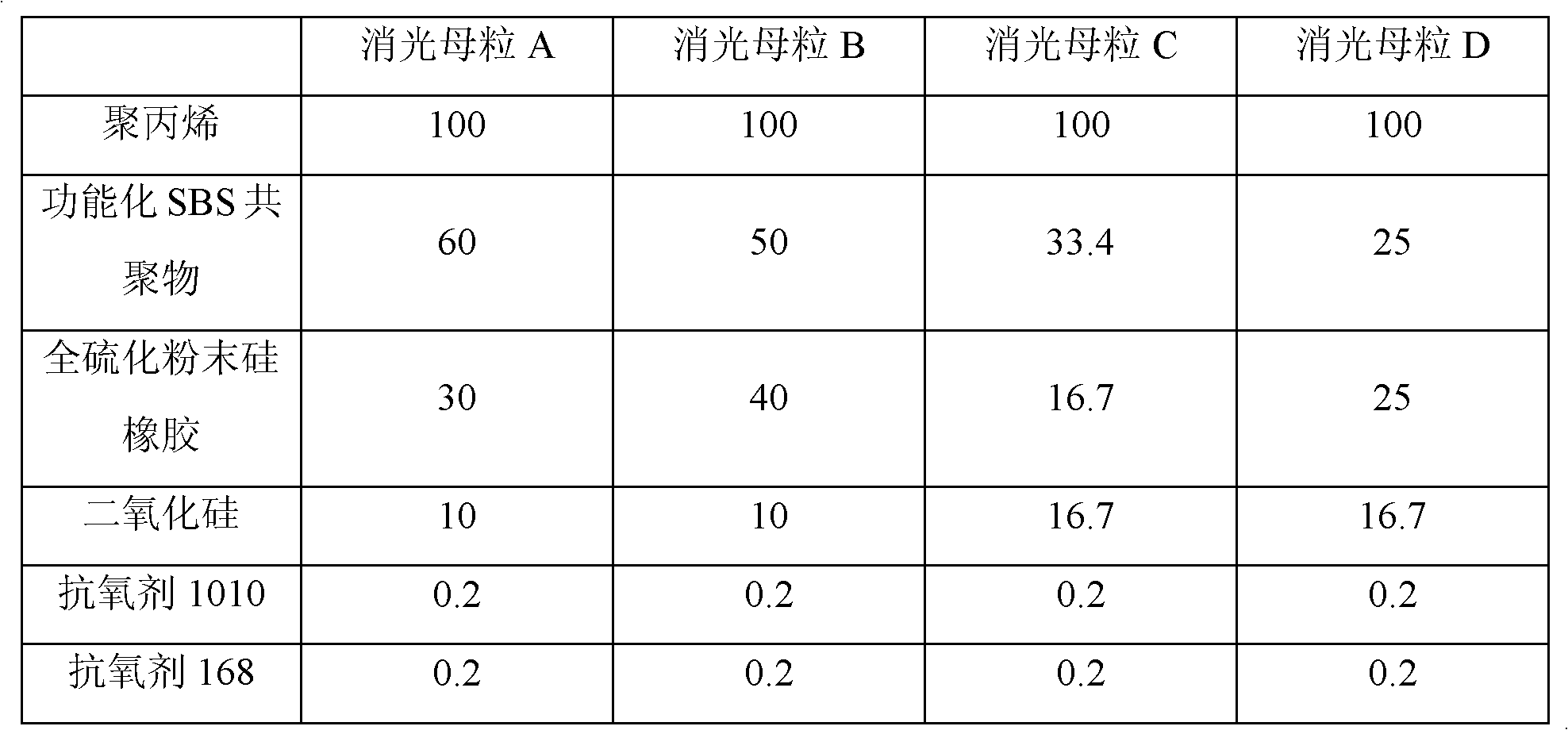

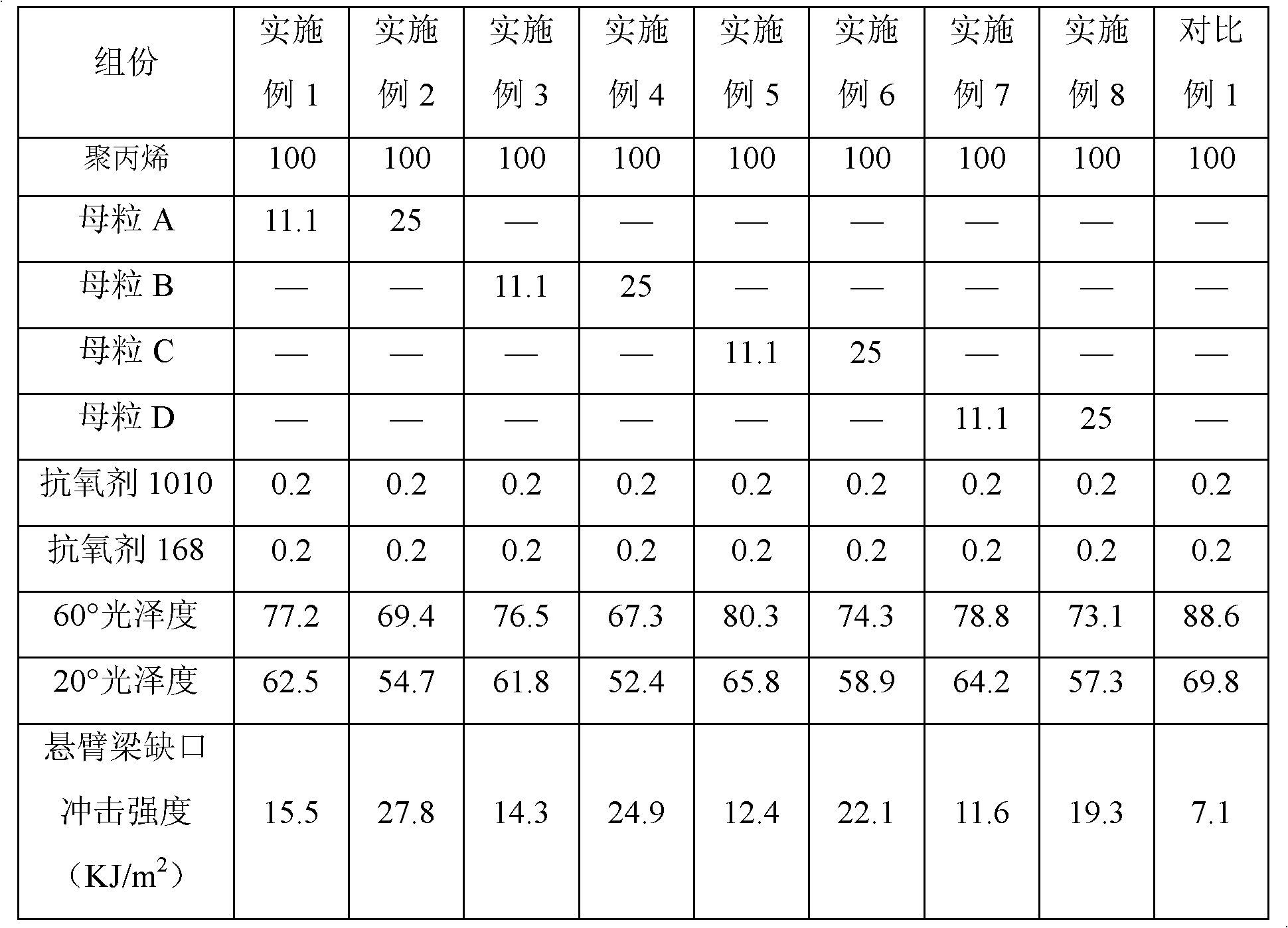

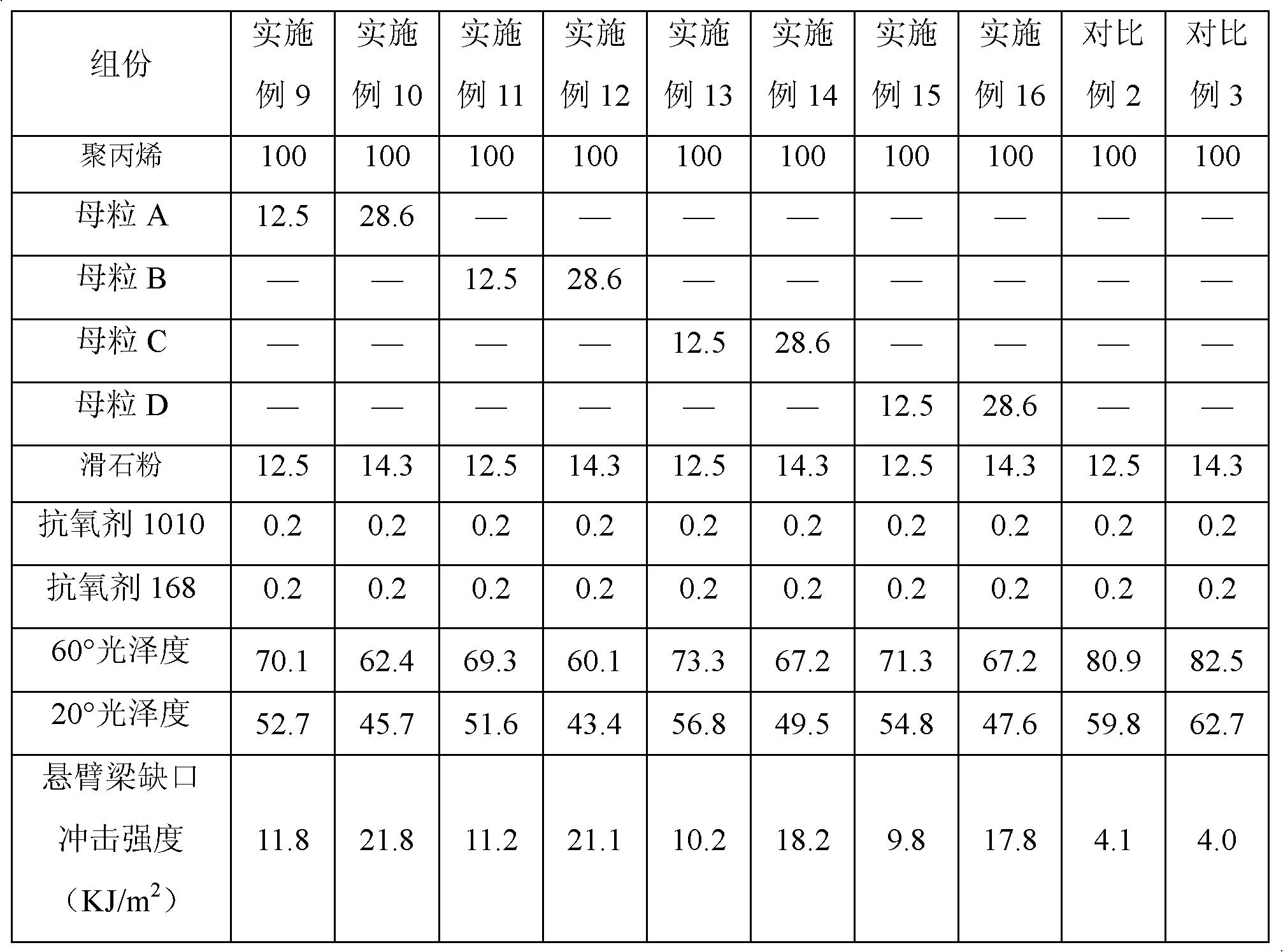

Polypropylene-use matting agent masterbatch, and preparation method and application thereof

The invention provides a polypropylene-use matting agent masterbatch, and a preparation method and an application thereof. The invention relates to the field of plastic modification. The masterbatch comprises the blended materials of, by weight: 100 parts of polypropylene, 20-70 parts of functionalized SBS copolymer, 10-50 parts of fully vulcanized powder silicone rubber, and 5-20 parts of silica. The fully vulcanized powder silicone rubber has an average particle size of 0.05-1mum and a gel content of 60wt% or higher. The average particle size of silica is 1-10mum. With the matting agent masterbatch provided in the invention, polypropylene modified material surface gloss can be substantially reduced. During an application process, matting agent masterbatch dose can be flexibly controlled according to different requirements on gloss. The application method is simple and reliable. The masterbatch can be widely applied in fields such as high-end automotive interior parts.

Owner:CHINA PETROLEUM & CHEM CORP +1

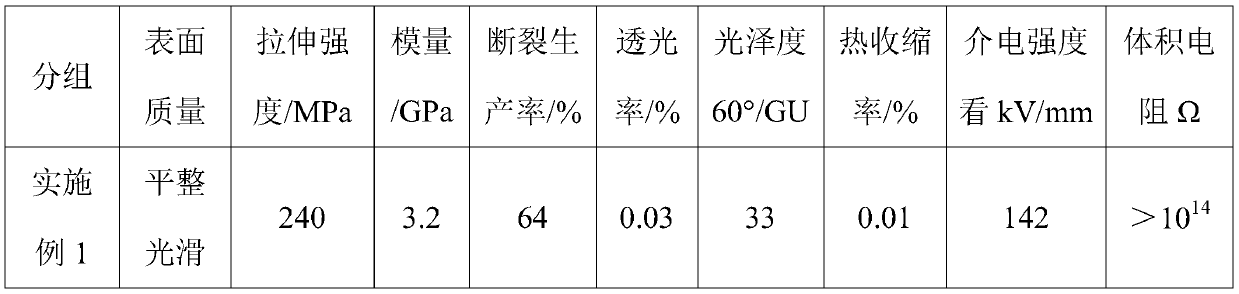

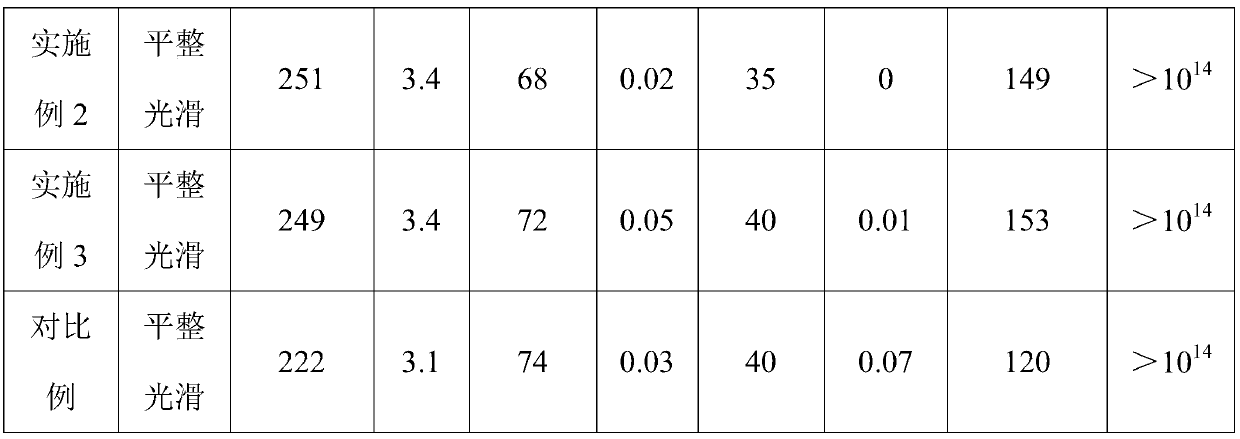

Matte polyimide black film with low heat shrinkage rate, and preparation method thereof

The invention discloses a preparation method of a matte polyimide black film with a low heat shrinkage rate. The method comprises the following steps: S1, preparing a polyamide acid resin solution: adding a matting agent into an aromatic diamine solution in an inert gas atmosphere, mixing until uniformity, adding aromatic dianhydride, and carrying out a stirring reaction to obtain the polyamide acid resin solution, wherein the aromatic diamine contains rigid aromatic diamine, and the rigid aromatic diamine is at least one of p-phenylenediamine, 2,5-diaminotoluene, 1,5-naphthalenediamine, 2,5-naphthalenediamine and 2,6-naphthalenediamine; S2, preparing a black slurry; and S3, preparing the matte polyimide black film with the low heat shrinkage rate. The invention further discloses the mattepolyimide black film with the low heat shrinkage rate. The matte polyimide black film with the low heat shrinkage rate is prepared through the preparation method of the matte polyimide black film with the low heat shrinkage rate. The matte polyimide black film with the low heat shrinkage rate has the advantages of low shrinkage rate, matt effect, maintenance of mechanical properties and electrical properties, good dimensional stability, low visible light transmittance and low surface gloss.

Owner:ANHUI GUOFENG PLASTIC

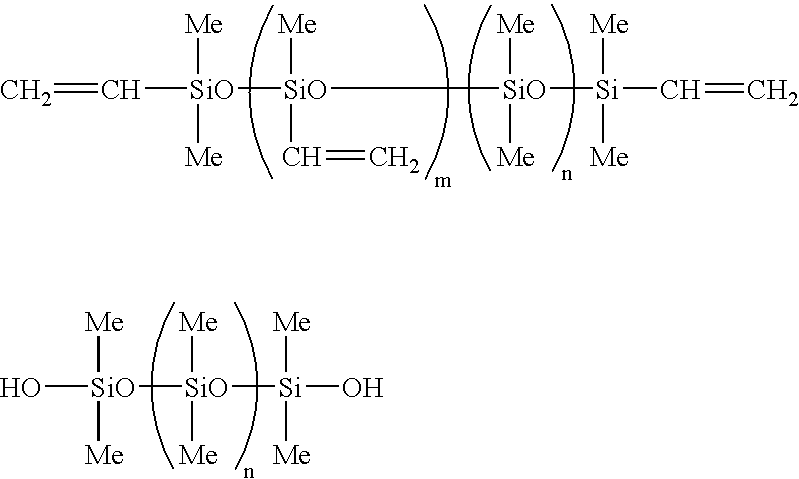

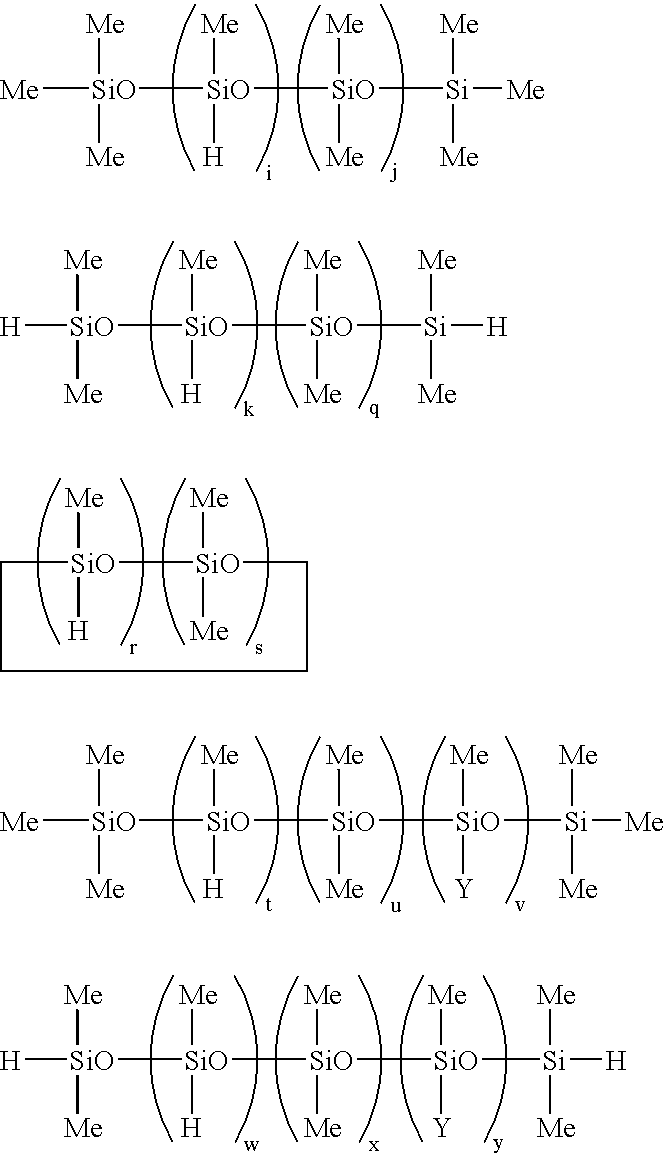

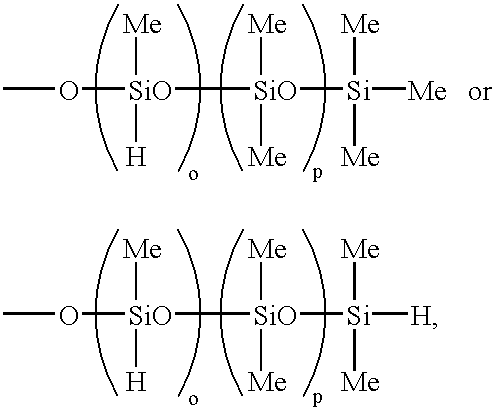

Silicone coating composition and release sheet

InactiveUS20040127636A1Easy to manufactureReduce surface glossSynthetic resin layered productsCellulosic plastic layered productsSilicone coatingSynthetic resin

The addition of silicone rubber fine particles to a composition comprising an organopolysiloxane having at least two alkenyl groups, an organohydrogenpolysiloxane having at least three SiH groups and a catalyst yields a composition which when coated onto any substrate, forms a coating whose surface is extremely reduced in gloss and highly uniform. Using the coating of the composition as a release sheet, synthetic resin sheets having matte surfaces can be readily manufactured.

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing shockproof composition of styrene resin in high tensile strength and low lustre

A styrene resin composition with high impact resistance and tension strength and low lustre is prepared through respectively preparing graft copolymer, copolymer, rubber elastomer, and the copolymer of polybutanediene and rubber elastomer, proportional mixing, adding additive and assistant, and pugging.

Owner:太仓中化环保化工有限公司

Low-glossiness thermoplastic polyurethane composition and preparation method and application thereof

The invention relates to a low-glossiness thermoplastic polyurethane composition and a preparation method and application thereof. The low-glossiness thermoplastic polyurethane composition comprises, by mass percentage, 55-95% preferably 75-85% of thermoplastic polyurethane elastomer, 3-40% preferably 10-20% of thermoplastic polyester polymer and 0.5-10% preferably 2-5% of third component, wherein the third component is selected from one or more of organic acid salt, PTFE powder and ionomer. The preparation method includes: melting and blending the components according to a certain proportion to obtain composition granules, and using melt extrusion equipment to extrude sheets of about 1mm. The low-glossiness thermoplastic polyurethane composition has the advantages that standard ASTM D523 tests show that the 60-degree-angle surface glossiness of the composition is lower than 30Gs, and the composition is good in mechanical performance and machining performance, even and fine and smooth in surface dulling effect, smooth in touch and suitable for being used for producing cables, pipes, belts and thin film products.

Owner:WANHUA CHEM GRP CO LTD

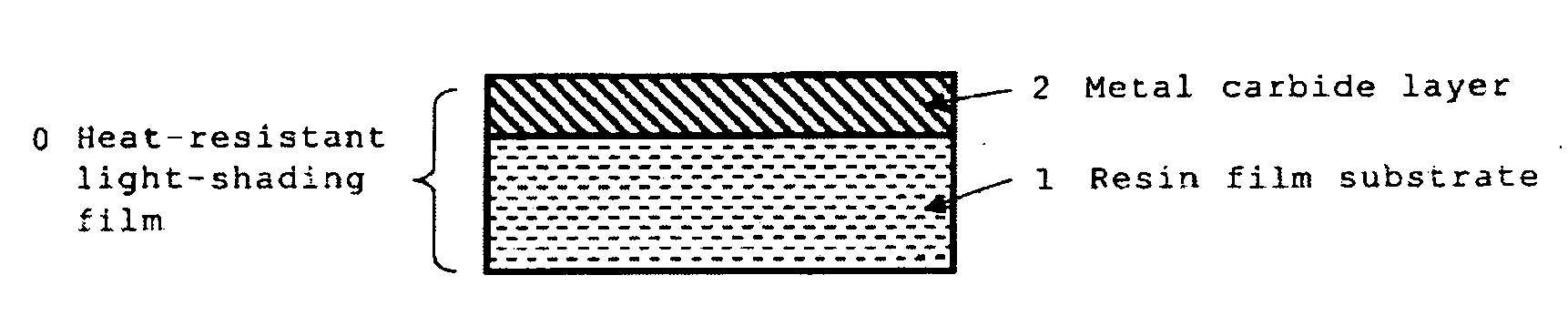

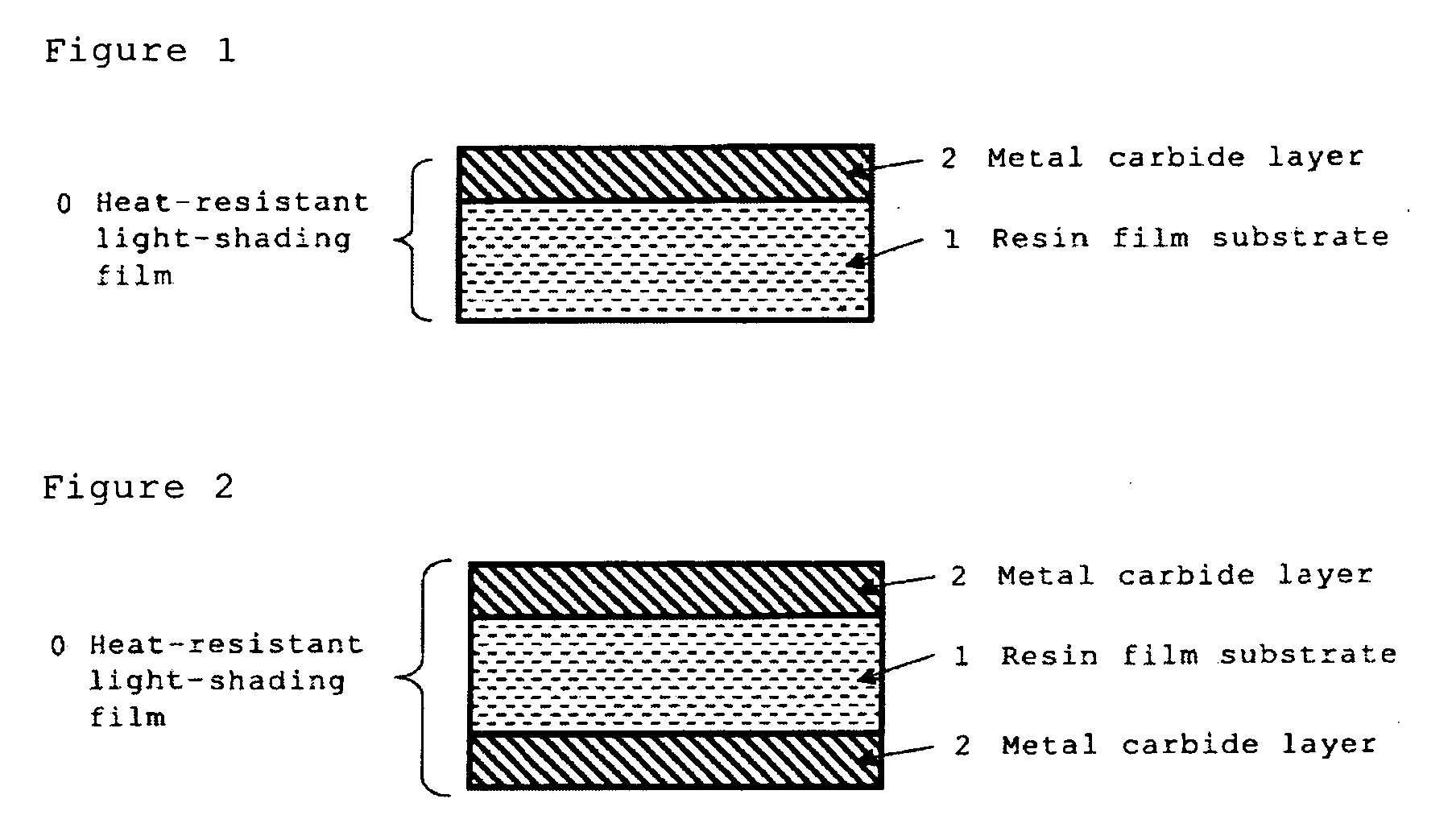

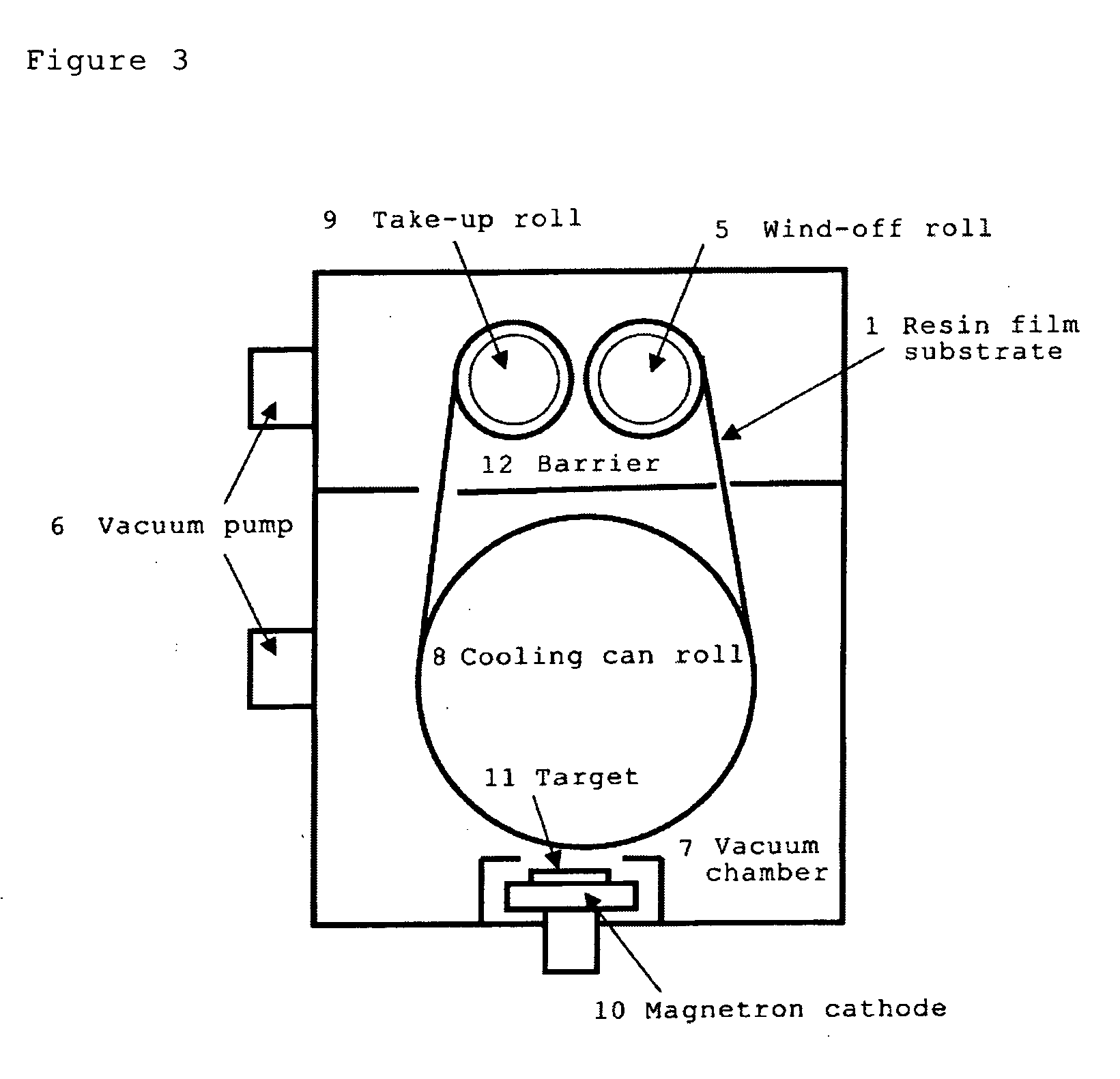

Heat-resistant light-shading film and production method thereof, and diaphragm or light intensity adjusting device using the same

InactiveUS20080254256A1Little deteriorationImprove conductivityVacuum evaporation coatingSputtering coatingDigital videoOptoelectronics

A heat-resistant light-shading film having high light shading capacity, high heat resistance, high sliding characteristics, low surface gloss and high electroconductivity, and useful for optical device parts such as shutter blades or diaphragm blades for diaphragm blades of lens shutter and the like for digital cameras and digital video cameras and diaphragm blades of light intensity adjusting device for projectors, and a method for producing the same.The heat-resistant light-shading film is a film comprising a resin film substrate (A) having a heat resistance of 155° C. or higher and a light-shading layer (B) of crystalline metal carbide film (MeC) formed on one side or both sides of the resin film substrate (A), characterized in that the light-shading layer (B) has a thickness of 100 nm or more and a surface roughness of 0.1 to 2.1 μm (arithmetic average height Ra), and content of carbon element (C) in the metal carbide film (MeC) is 0.3 or more in atomic number ratio to the total metal elements (Me).

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com