Matte polyimide black film with low heat shrinkage rate, and preparation method thereof

A technology of polyimide and shrinkage rate, which is applied in the field of low thermal shrinkage matte polyimide black film and its preparation, can solve the problem of uneven dispersion of matting agent particle agglomeration, poor storage stability of slurry, low solid content, etc. problems, to achieve the effect of good dimensional stability, low visible light transmittance, and low surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

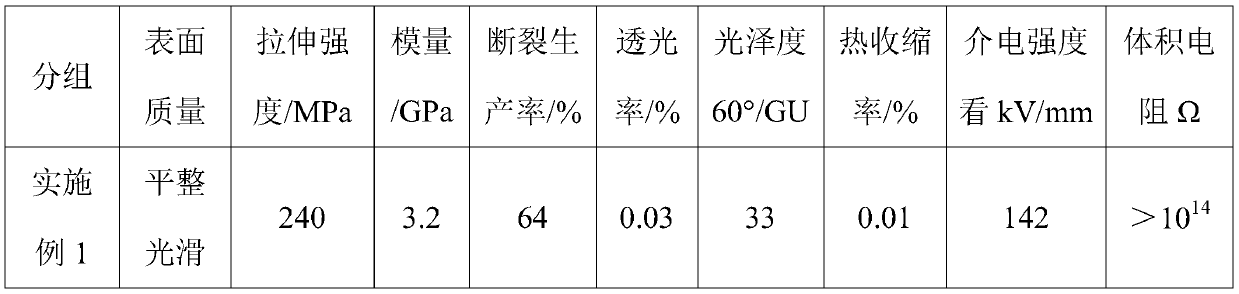

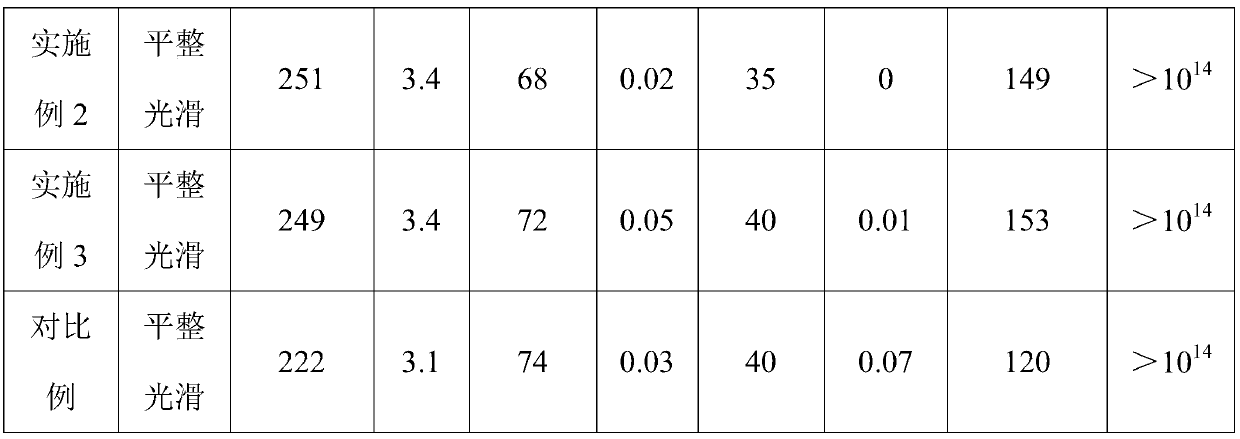

Examples

Embodiment 1

[0051] A kind of preparation method of low heat shrinkage matte polyimide black film, comprises the steps:

[0052] S1. Preparation of polyamic acid resin solution: In nitrogen atmosphere, add 2.47kg of 3,3-4,4-diaminodiphenyl ether and 0.82kg of p-phenylenediamine to 40kg of N,N'-dimethylacetamide Dissolved to obtain an aromatic diamine solution; add 0.56 kg of coupling agent-modified silica with an average particle size of 4 μm to the aromatic diamine solution and mix evenly, then add 3.78 kg of pyromellitic dianhydride at a uniform speed for 10 times, Stirring and reacting at 40° C. for 4 h to obtain a polyamic acid resin solution, wherein the solid content of the polyamic acid resin solution is 15 wt %;

[0053]S2. Preparation of black slurry: Dilute 1.44 kg of the polyamic acid resin solution obtained in S1 with N,N'-dimethylacetamide to a solid content of 5 wt% to obtain solution A, and add 0.09 kg of polyurethane under high-speed stirring Mix with similar dispersants, ...

Embodiment 2

[0057] A kind of preparation method of low thermal shrinkage matte polyimide black film, comprises the steps:

[0058] S1. Preparation of polyamic acid resin solution: In a nitrogen atmosphere, add 3.64kg of 3,3-4,4-diaminodiphenyl ether and 0.85kg of 2,5-dimethylacetamide to 45kg of N,N'-dimethylacetamide Dissolve aminotoluene to obtain an aromatic diamine solution; add 0.4 kg of coupling agent-modified aluminum oxide with an average particle size of 4 μm to the aromatic diamine solution, mix well, and then add 4.68 kg of pyromellitic acid at a uniform speed for 12 times Dianhydride, stirring and reacting at 45° C. for 6 hours to obtain a polyamic acid resin solution, wherein the solid content of the polyamic acid resin solution is 16.9 wt %;

[0059] S2. Preparation of black slurry: Dilute 1.28kg of the polyamic acid resin solution obtained in S1 with N,N'-dimethylacetamide to a solid content of 6wt% to obtain solution A, and add 0.14kg of polyurethane under high-speed stirr...

Embodiment 3

[0063] A kind of preparation method of low thermal shrinkage matte polyimide black film, comprises the steps:

[0064] S1. Preparation of polyamic acid resin solution: In a nitrogen atmosphere, add 3.77kg of 3,3-4, 4-diaminodiphenyl ether and 0.62kg of p-phenylenediamine are dissolved to obtain an aromatic diamine solution; adding 0.53kg of an average particle diameter to the aromatic diamine solution is a coupling agent modified silica of 6 μm and mixes evenly, and then Add 0.62kg of 3,3'-4,4'-biphenyltetracarboxylic dianhydride and 3.85kg of pyromellitic dianhydride in 12 times at a uniform speed (the 3,3'-4,4'-biphenyltetracarboxylic dianhydride is added first in order) acid dianhydride), stirred and reacted at 50°C for 5h to obtain a polyamic acid resin solution, wherein the solid content of the polyamic acid resin solution was 18wt%;

[0065] S2. Preparation of black slurry: Dilute 2.01 kg of the polyamic acid resin solution obtained in S1 with N,N'-dimethylformamide to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com