Patents

Literature

64results about How to "Reduce visible light transmittance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

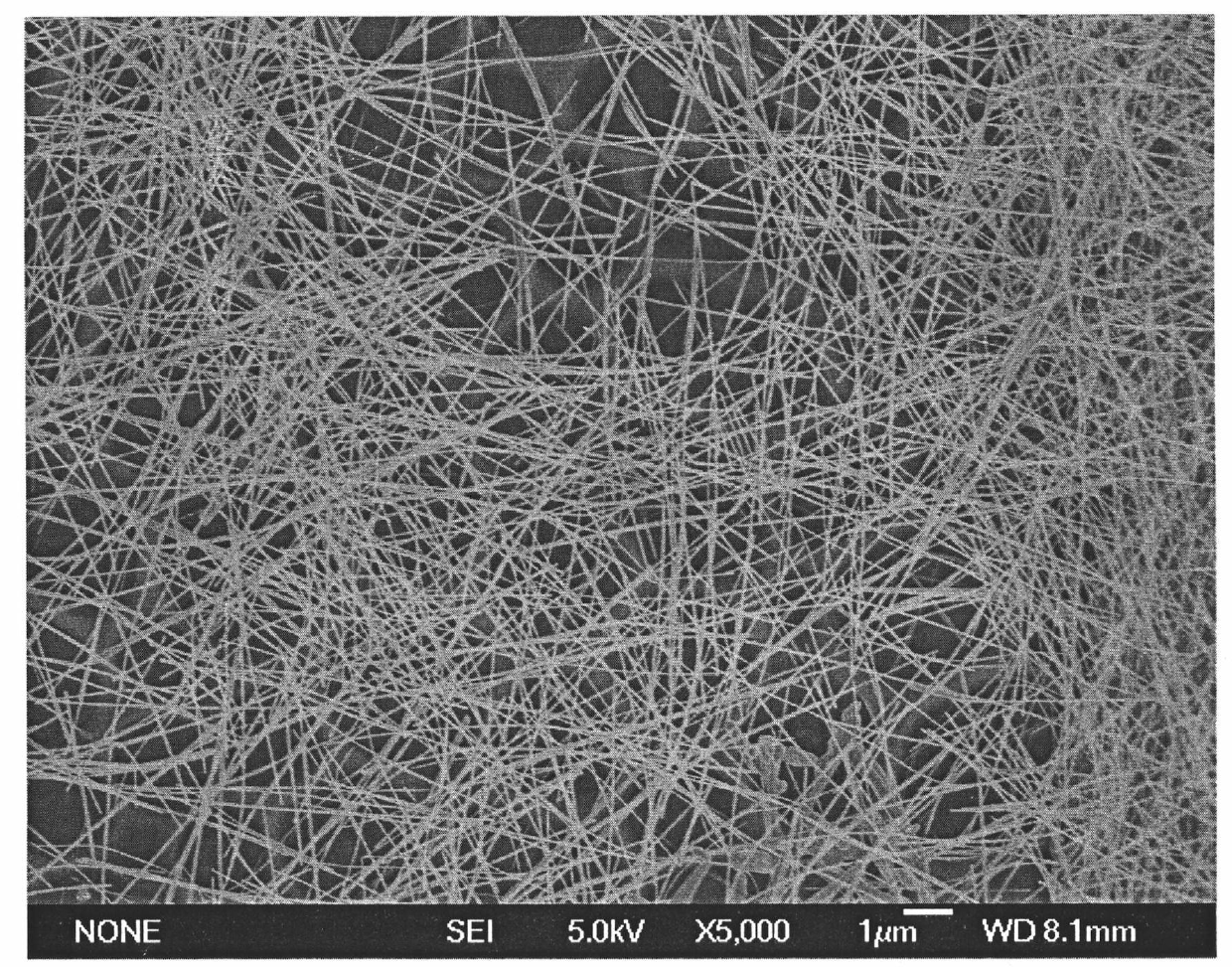

Flexible transparent conductive film based on organic polymers and silver nanowires and preparation method thereof

InactiveCN102087884AEnhanced light absorptionImprove conductivityConductive layers on insulating-supportsIndividual molecule manipulationElectrically conductiveNanometre

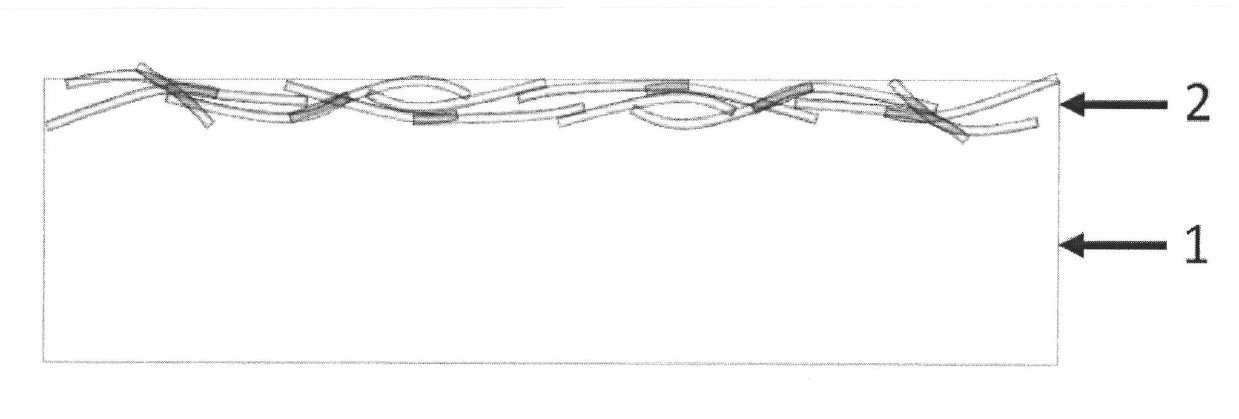

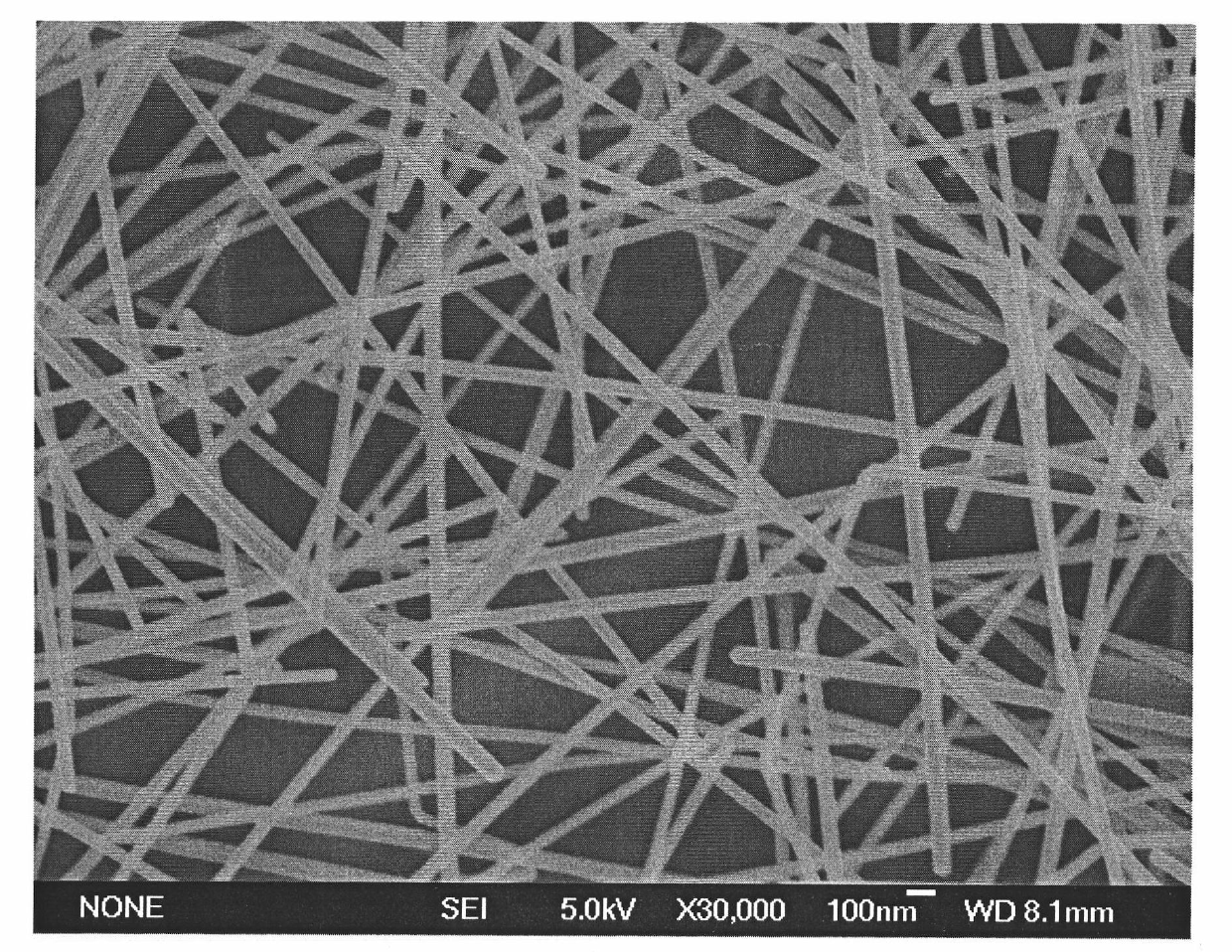

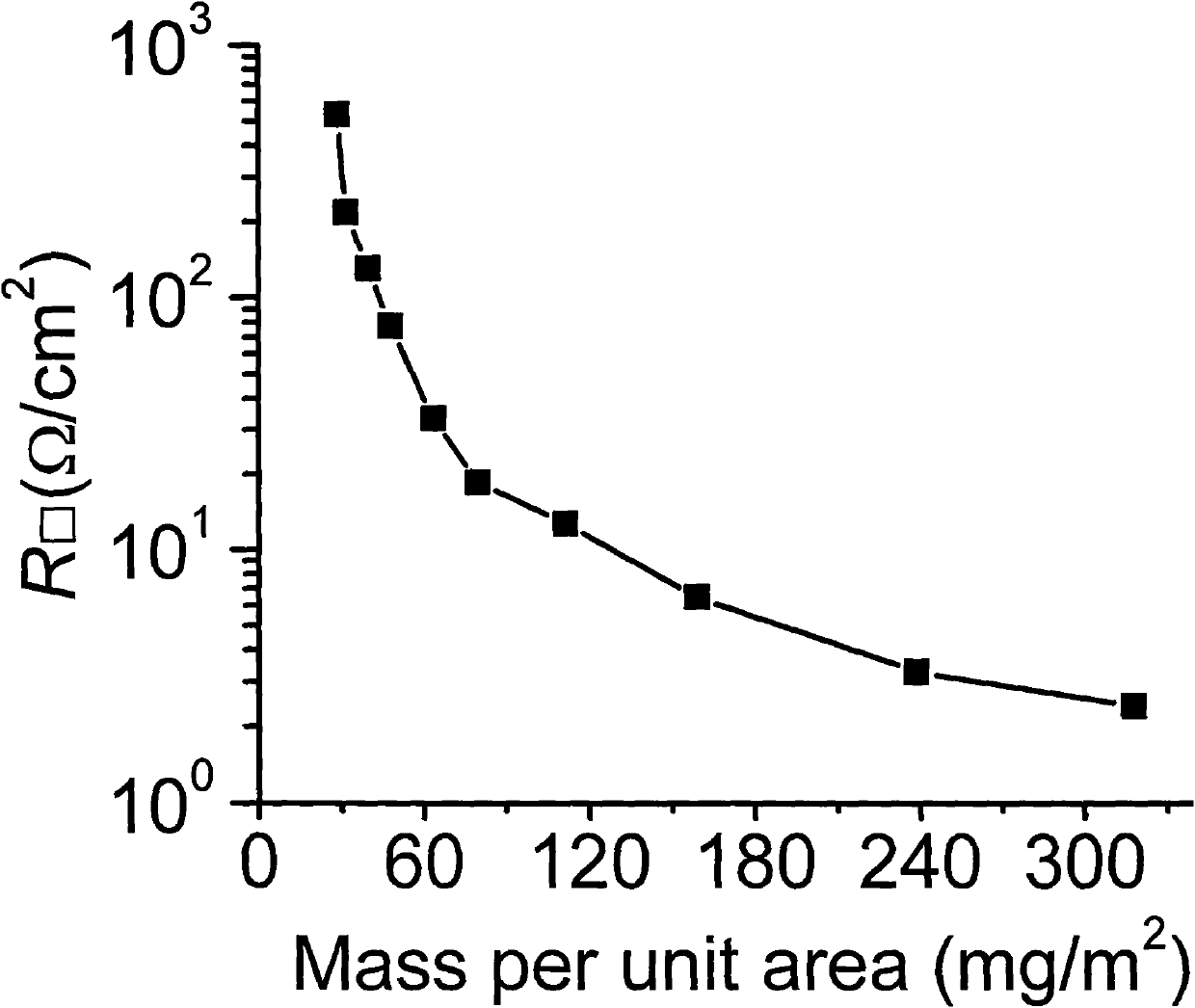

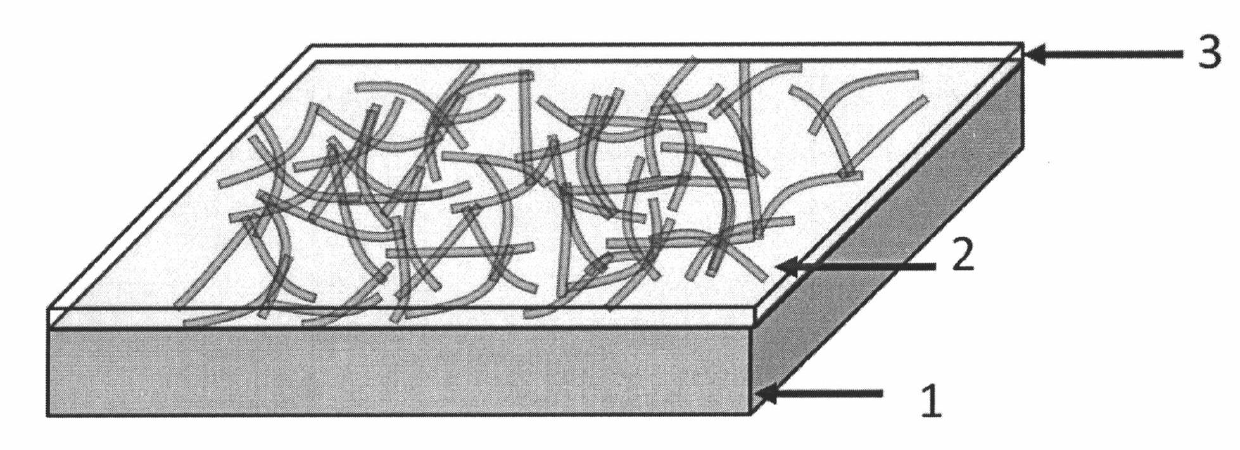

The invention provides a flexible transparent conductive film based on organic polymers and silver nanowires and a preparation method thereof. The flexible transparent conductive film based on organic polymers and silver nanowires is characterized in that a continuous conductive network formed by the silver nanowires is half-buried in the surface layer of the organic polymers, part of the surfaces of the silver nanowires is exposed on the surfaces of the organic polymers, and the conductive surface of the transparent conductive film is formed by the surfaces of the organic polymers and the surfaces of the silver nanowires. First, a conductive silver nanowire layer is prepared and uniformly distributed on a flat surface, and then a transparent organic polymer layer is distributed on the silver nanowire layer, thus the flexible transparent conductive film is formed. The flexible transparent conductive film has the advantages of high visible light transmittance, low square resistance, firm combination and flat surface.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

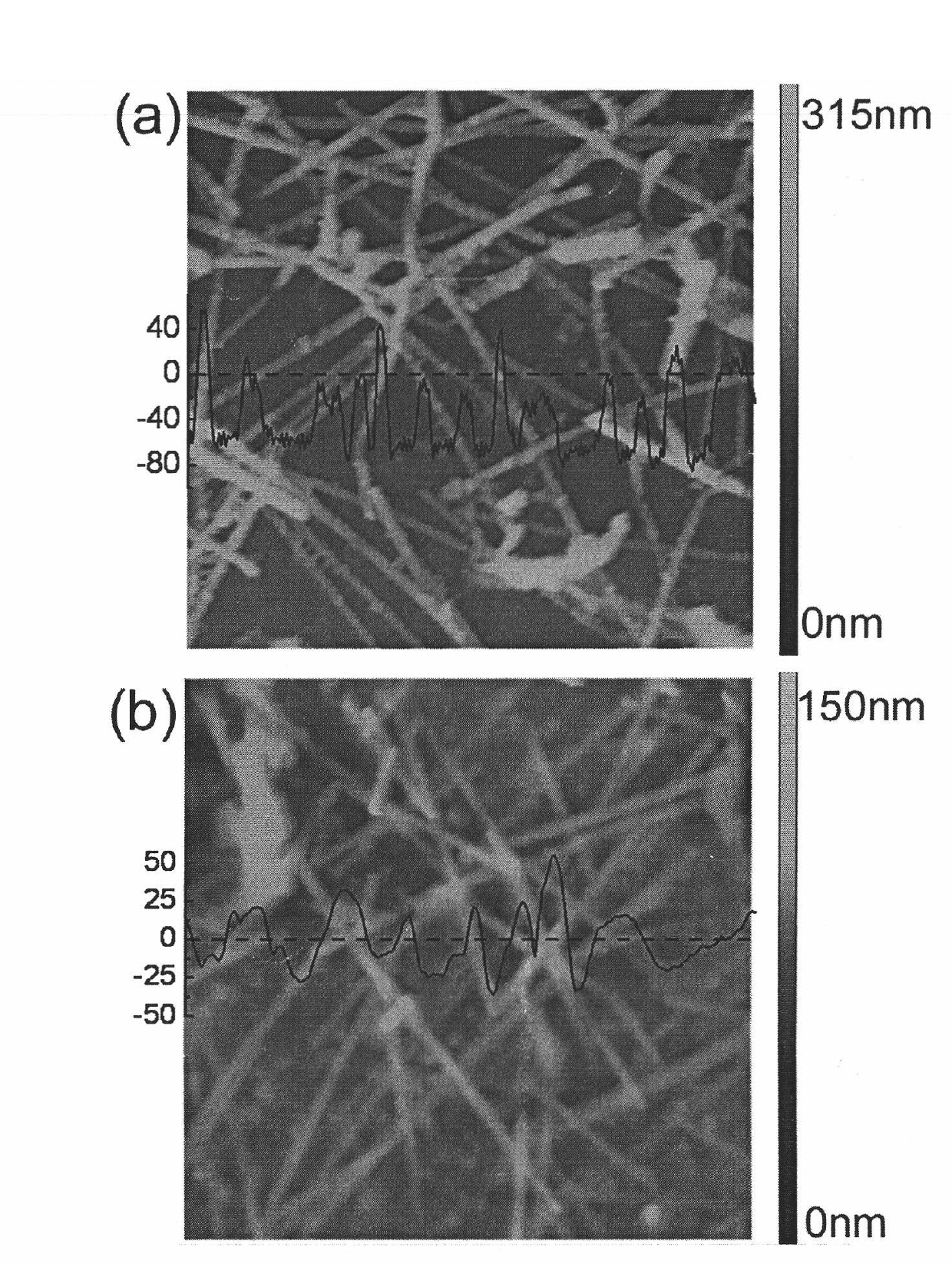

Planar silver nanowire transparent conductive thin film and preparation method thereof

InactiveCN102087885AImprove the firmness of the bondImprove bindingConductive layers on insulating-supportsIndividual molecule manipulationPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a planar silver nanowire transparent conductive thin film and a preparation method thereof. The transparent conductive thin film is characterized in that: a silver nanowire conductive layer which is arranged on a substrate is covered by a planar conductive polymer layer; the silver nanowire conductive layer realizes a conduction function; and the planar polymer layer fills holes in the silver nanowire conductive layer, so that the surface roughness is reduced and the firmness of the bonding of the silver nanowires and the substrate is improved. For example, the roughness of the silver nanowire transparent conductive thin film on the polyethylene terephthalate (PET) substrate is reduced to 25nm from 67nm when the conductive layer is not covered by using a poly(3,4-dioxy ethyl thiophene) / poly(styrene sulfonic acid) planar layer, the visible light transmittance reaches 77 percent when square resistance is 158, and good bonding force is guaranteed.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

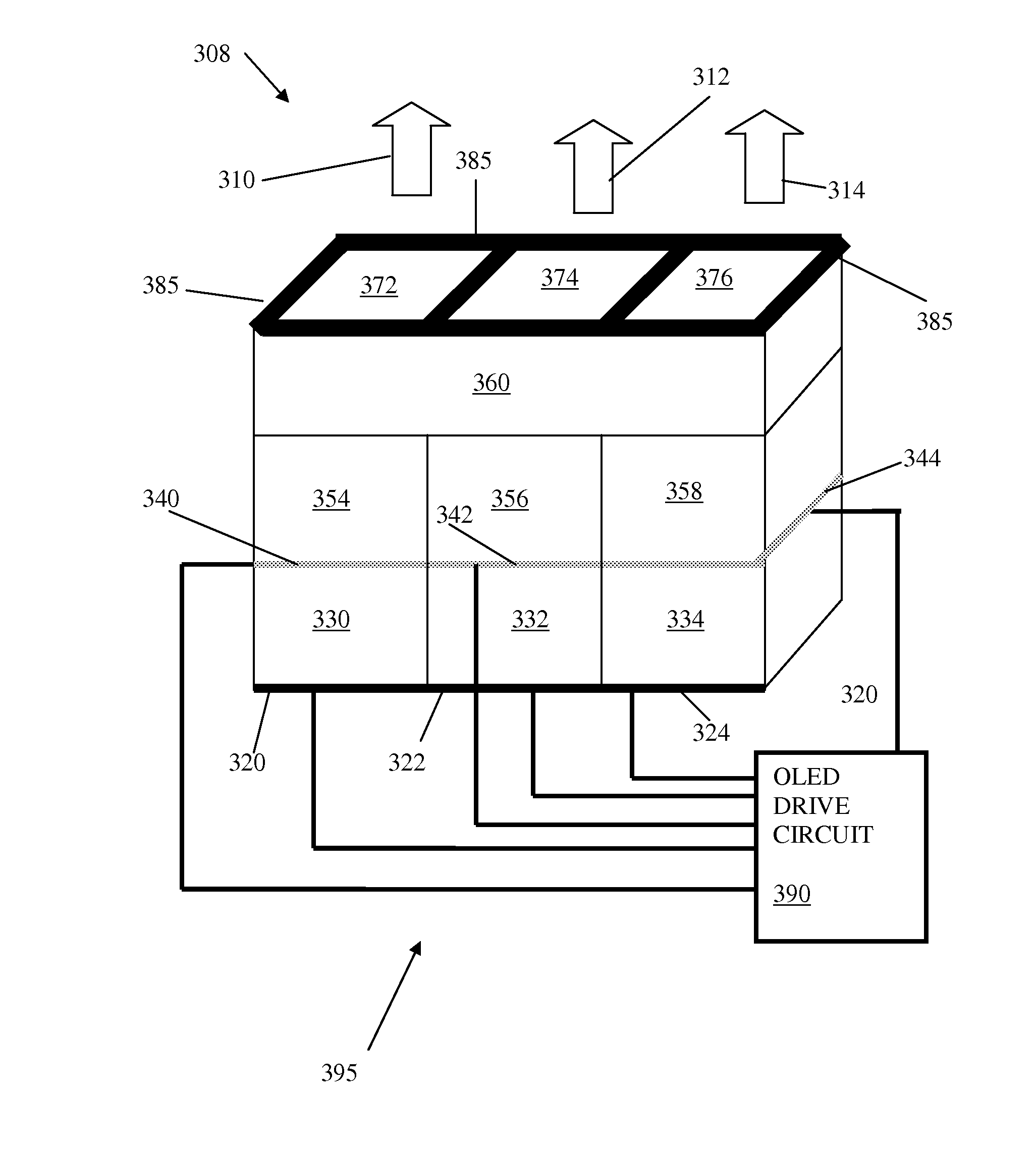

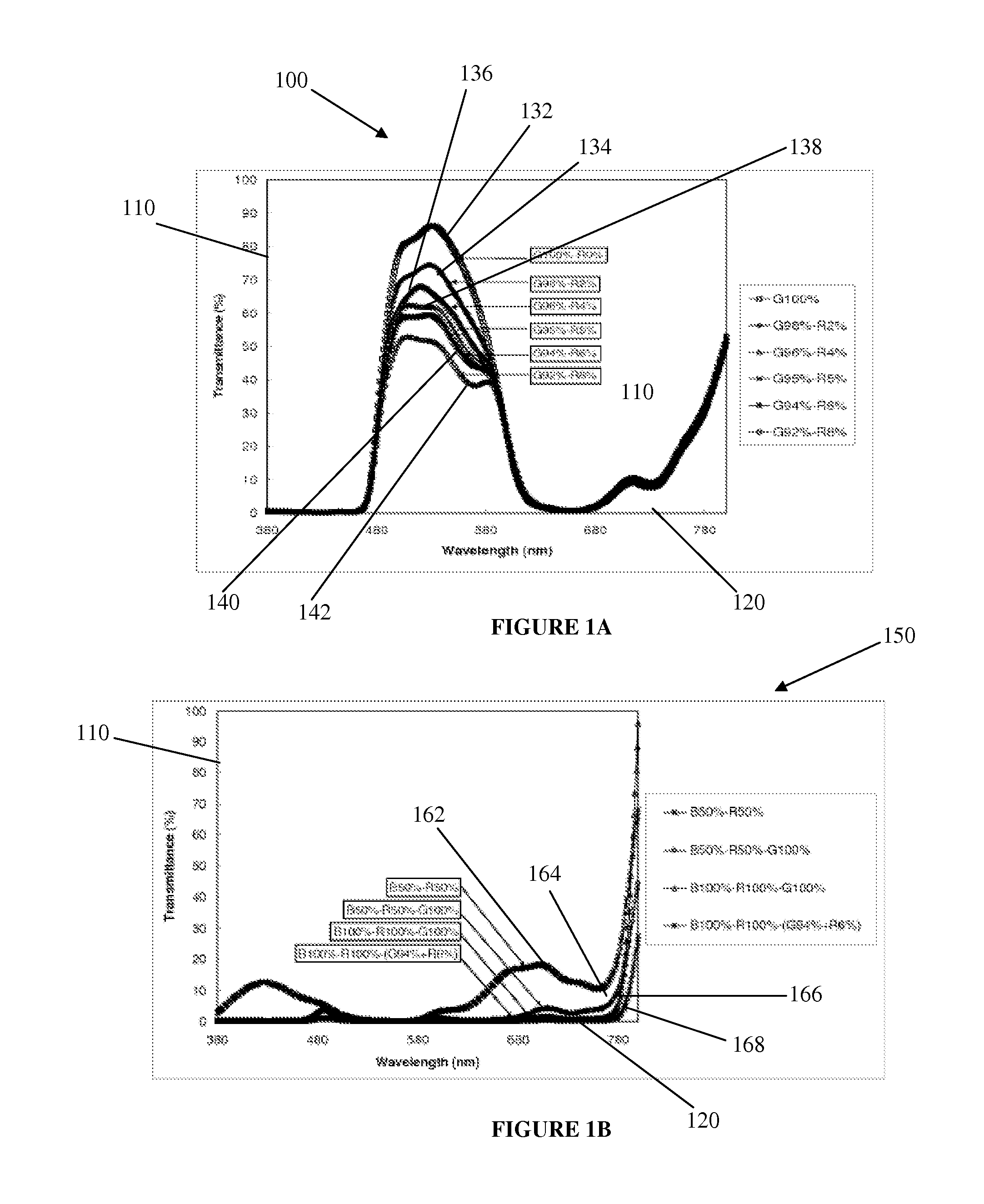

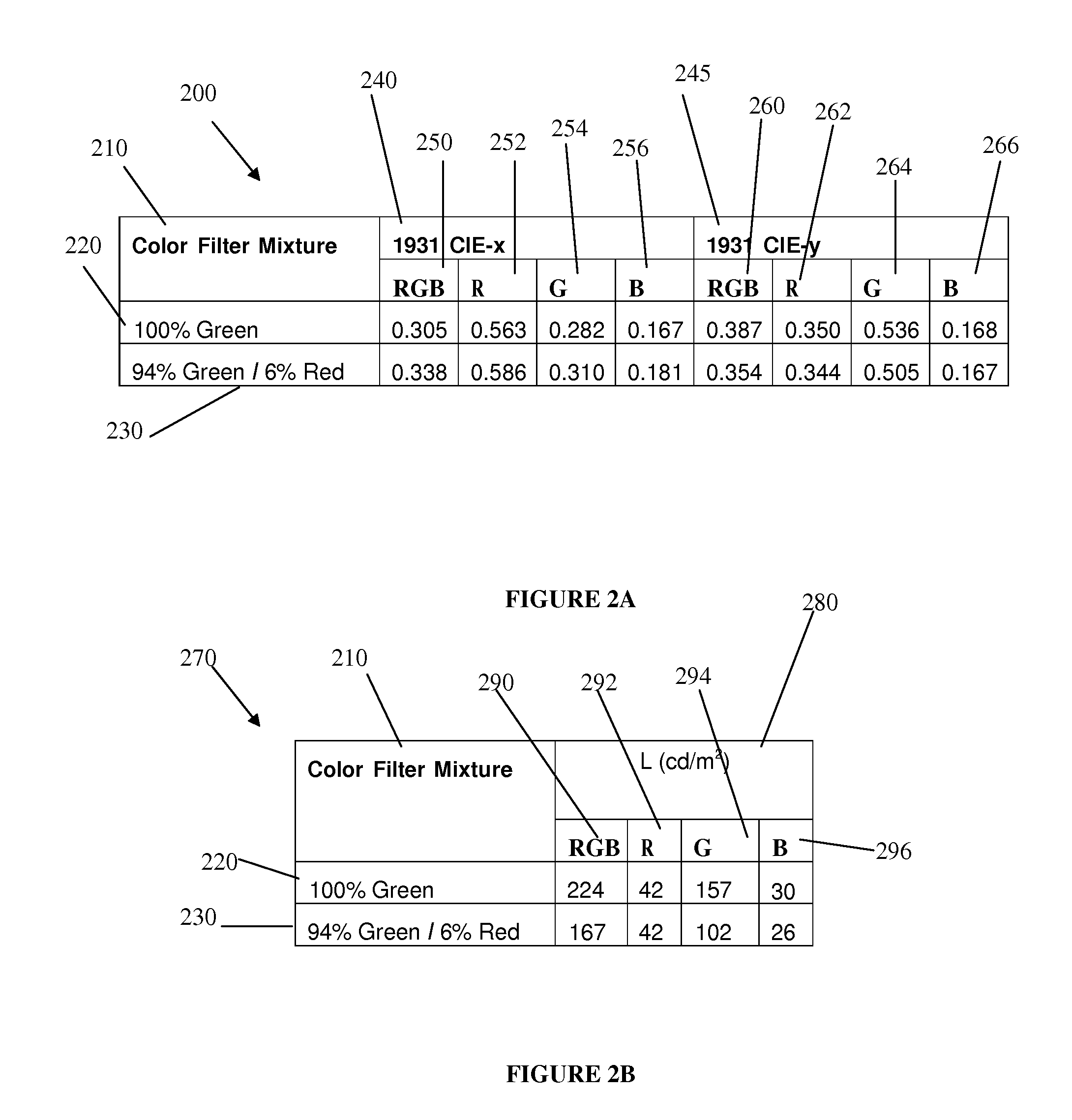

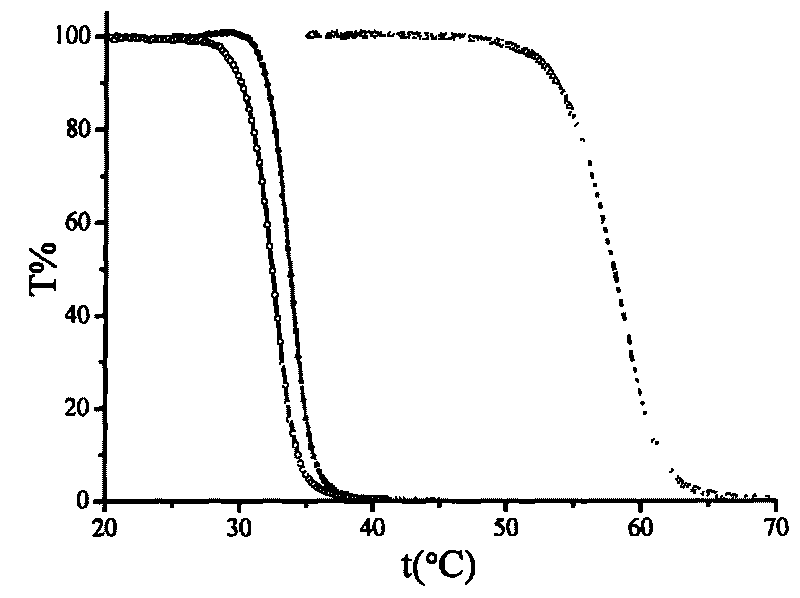

Method of tuning display chromaticity by mixing color filter materials and device having mixed color filter materials

ActiveUS20110316413A1Good white balanceReduce outputDischarge tube luminescnet screensLamp detailsDisplay deviceLight emitting device

A color display is provided that includes a light emitting sub-pixel and a filter layer including first and second color filter materials. The first color filter material is adapted to reduce transmittance of visible light outside a first transmittance spectrum corresponding to a first color, and the second color filter material is adapted to reduce transmittance of visible light outside a second transmittance spectrum corresponding to a second color. The second color is different than the first color. A color display having a white-balanced pixel is provided. A method of white-balancing a light emitting device is provided. A method of reducing unwanted light output due to electrical leakage is provided to fall below a pre-determined threshold. An opaque layer may be interposed between the sub-pixels and / or may frame illuminated areas of sub-pixels, and may be a combination of red, green, and / or a blue filter material.

Owner:EMAGIN CORP

Interlayer for Laminated Glass and Laminated Glass

ActiveUS20070231584A1Improve performanceReduce visible light transmittanceSynthetic resin layered productsGlass/slag layered productsPrivacy protectionEthylene-vinyl acetate

The present invention provides an interlayer for laminated glass which comprises at least one layer composed of an opaque ethylene-vinyl acetate copolymer resin composition or opaque polyvinyl acetal resin composition, and also provides the laminated glass using such interlayers. The interlayer for laminated glass and the laminated glass according to the present invention can offer excellent privacy protection.

Owner:SEKISUI CHEM CO LTD

Ultraviolet/infrared absorbent low transmittance glass

InactiveUS6287998B1Reduce transmittanceReduce visible light transmittanceWindowsWindscreensTransmittanceUltraviolet

An ultraviolet / infrared absorbent low transmittance glass is formed of a base glass and colorants. The base glass contains 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO wherein a total amount of MgO and CaO is between 5 and 15 wt. %; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O wherein a total amount of Na2O and K2O is in a range of 10 and 20 wt. %; and 0 to 5 wt. % B2O3. The colorants contains more than 1.2 wt. % and not more than 1.5 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; equal to or more than 0.003 wt. % and less than 0.015 wt. % CoO; 0.0009 to 0.005 wt. % Se; 0.0005 to 0.05 wt. % NiO; and 0 to 0.2 wt. % of TiO2, wherein FeO expressed as Fe2O3 is between 15 and 50 wt. % of T-Fe2O3. The ultraviolet / infrared absorbent low transmittance glass has a bronze or gray color shade, low visible light transmittance, low solar energy transmittance and low ultraviolet transmittance, so that it is useful for a privacy protecting glass in a rear window of a vehicle.

Owner:NIPPON SHEET GLASS CO LTD

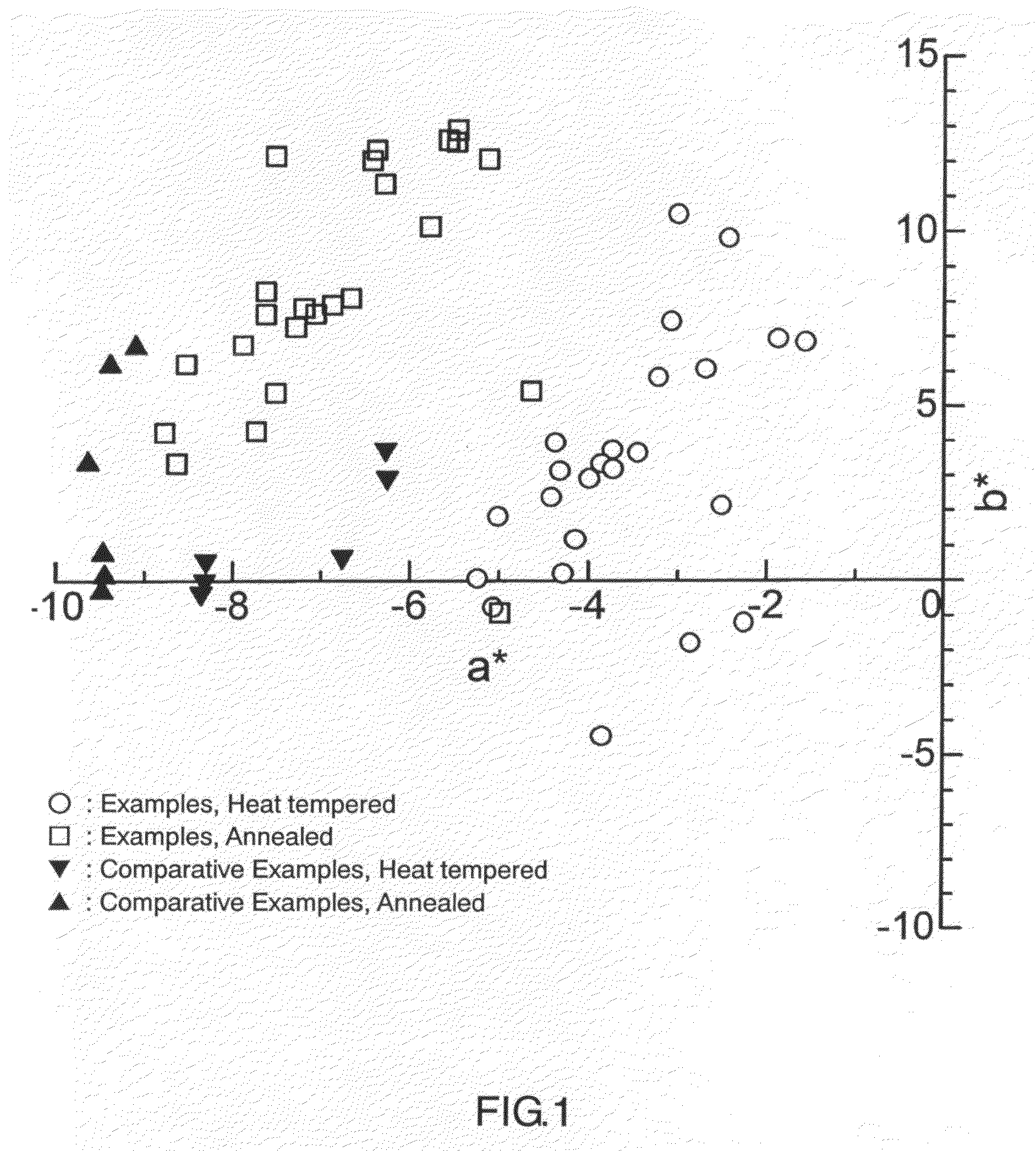

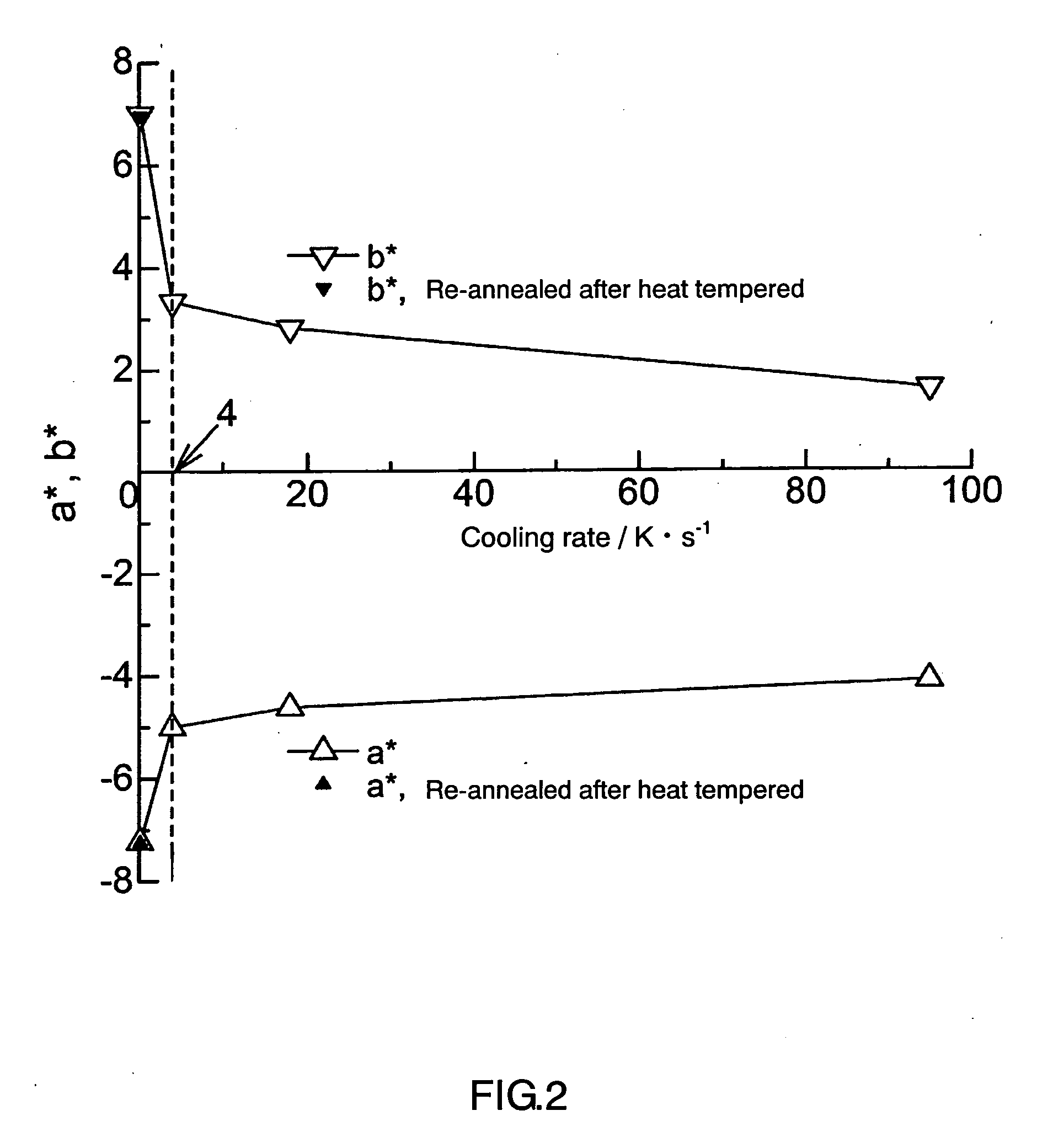

Glass substrate for flat panel display, process for producing the same, and display panel employing the same

InactiveUS20090253567A1Reduce visible light transmittanceImpaired balanceCathode ray tubes/electron beam tubesGas discharge vessels/containersSilver electrodeMetallurgy

The present invention provides a glass substrate for flat panel display in which yellowing occurring in a case of forming silver electrodes on glass substrate surface is inhibited.A glass substrate for flat panel display, which is formed by a float method, which has a composition consisting essentially of, in terms of oxide amount in mass %:SiO250 to 72%,Al2O30.15 to 15%,MgO + CaO + SrO + BaO4 to 30%,Na2Omore than 0% and at most 10%,K2O1 to 21%,Li2O0 to 1%,Na2O + K2O + Li2O6 to 25%,ZrO20 to 10%, andFe2O30.0725 to 0.15%; andwherein the average Fe2+ content in a surface layer of the glass substrate within a depth of 10 μm from the top surface is at most 0.0725% in terms of Fe2O3 amount.

Owner:ASAHI GLASS CO LTD

Ultraviolet/infrared absorbent low transmittance glass

The ultraviolet / infrared absorbent low transmittance glass has a grayish, almost neutral color shade, low visible light transmittance, low total solar energy transmittance, and low ultraviolet transmittance, and is suitable for a rear window of a vehicle and capable of protecting privacy. The glass consists of base glass including: 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO wherein a total amount of MgO and CaO is 5 to 15 wt. %; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O wherein a total amount of Na2O and K2O is 10 to 20 wt. %; and 0 to 5 wt. % B2O3, and colorants including: 1.0 to 1.6 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; more than 0.019 wt. % and equal to or less than 0.05 wt. % CoO; more than 0.0008 wt. % and equal to or less than 0.003 wt. % Se; and more than 0.05 wt. % and equal to or less than 0.1 wt. % NiO. The glass with any one of thicknesses between 1.8 mm and 5 mm has a visible light transmittance (YA) measured by the C.I.E. illuminant "A" in a range from 5 to 25%, a solar energy transmittance (TG) of 5 to 25%, and an ultraviolet transmittance (Tuv) specified by ISO of not greater than 15%.

Owner:NIPPON SHEET GLASS CO LTD

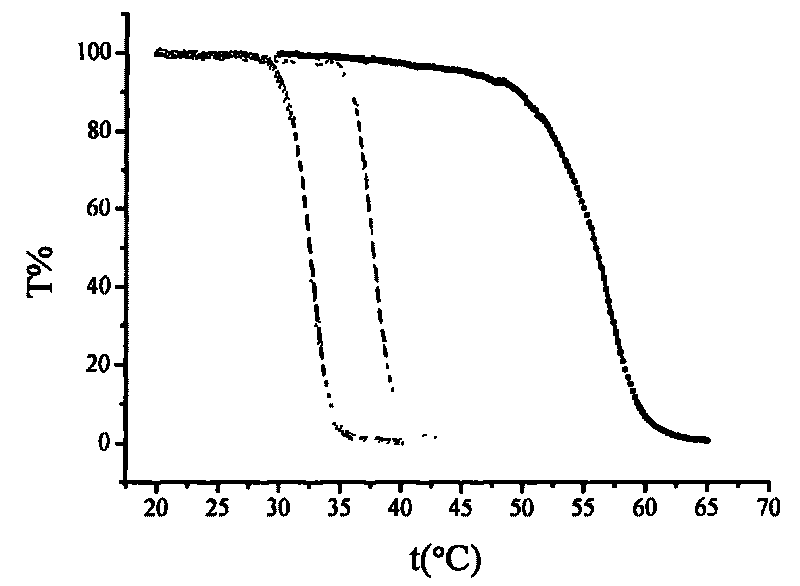

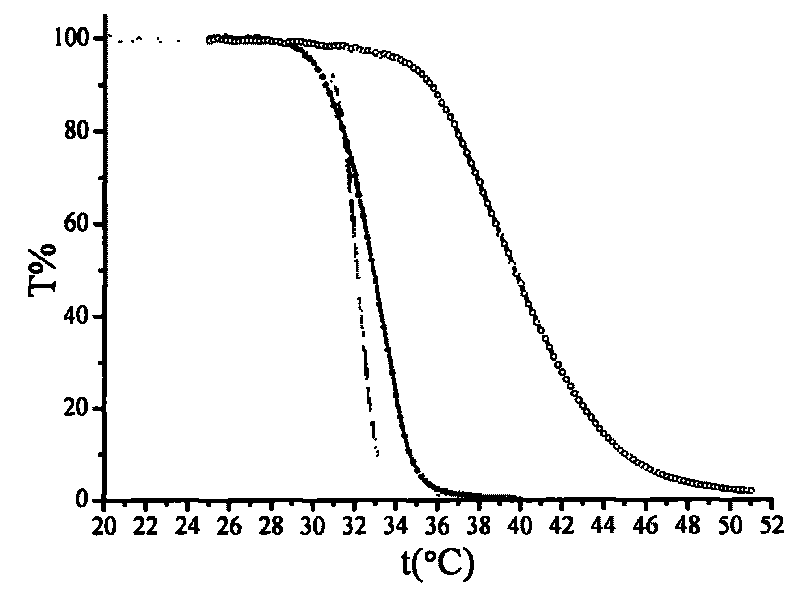

Degradable material having multiple sensitive properties, manufacturing method thereof and use thereof

InactiveCN101696272AReduce visible light transmittanceReduce transmittanceVector-based foreign material introductionIonTransmittance

The invention relates to a degradable material having multiple sensitive properties, a manufacturing method thereof and use thereof. The manufacturing method comprises: dissolving oligo(polyethyleneimine) and N,N'-bis(acryloyl)cystamine in an organic solvent to allow the oligo(polyethyleneimine) and N,N'-bis(acryloyl)cystamine to cross link under a heating condition to form a network polymer; dissolving the network polymer and N-isopropyl acrylamide in deionized water; and heating mixture for reaction to form a target product. The cross-linked network polymer prepared by the method has multiple environmental pH, temperature and oxidoreduction sensitive properties. The visible light transmittance of the aqueous solution of the cross-linked network polymer gradually reduces to zero from 100 percent with the rise of temperature and the minimum critical consolute temperature of the aqueous solution of the cross-linked network polymer decreases with the increase of thepH value of the solution. In a reductive environment, with the breakage of disulfide bonds, the cross-linked network polymer degrades quickly into small molecular weight compounds, and the transmittance of the solution under visible light keeps constant as the temperature rises. The material can carry positive charges and is a novel multi-sensitivity polycation genonic vector that has small cytotoxicity and a wide application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Glass With Low Solar Transmittance

ActiveUS20130105722A1Improve liveabilitySuperior ultravioletBuilding constructionsUltravioletSolar transmittance

Disclosed is a glass with low solar transmittance, which is characterized by that it has a basic composition of soda-lime-silica glass, that it contains as coloring components 0.70-1.70 mass % of Fe2O3 (total iron in terms of ferric iron), 0.15-0.45 mass % of FeO (ferrous iron), 0-0.8 mass % of TiO2, 100-350 ppm of CoO, 0-60 ppm of Se, 100-700 ppm of Cr2O3, and 3-150 ppm of MnO, that it has a ratio (Fe2+ / Fe3+) of ferrous iron to ferric iron of 0.20-0.80. This glass has superior ultraviolet absorbing performance and infrared absorbing performance (heat insulation performance) and an appropriate transparency.

Owner:CENT GLASS CO LTD

Dark Neutral Green Gray Soda-Lime Glass Composition

ActiveUS20120058879A1Reduce visible light transmittanceImprove melting qualitySoda-lime glassSolar transmittance

The present invention relates to a dark neutral green gray soda-lime glass composition comprising, as a colorant ingredient per 100 weight parts of a base glass composition, 1.4 to 2.5 weight parts of total Fe2O3, 0.02 to 0.04 weight parts of CoO, 0.0001 to 0.004 weight parts of Se, 0.005 to 0.5 weight parts of MnO2, and 0.05 to 1 weight parts of CeO2. The glass composition of the present invention has a visible light transmittance (LTA) of 15% or less, an ultraviolet ray transmittance (Tuv) of 0 to 1%, and a solar transmittance (Tsol) of 15% or less, measured for a reference thickness of 4 mm. As described above, the glass composition of the present invention is excellent in absorbing ultraviolet rays and solar heat, and therefore can be valuably used in privacy glass or a sunroof of a motor vehicle, or in glass used for construction.

Owner:KCC GLASS CORP

Glass Article and Method of Producing the Same

InactiveUS20090181843A1Reduce the impactReduce visible light transmittanceGlass furnace apparatusGlass/slag layered productsTransmittanceMaterials science

The present invention provides a glass article using a glass composition including a base glass composition and colorants. The base glass composition includes, expressed in mass %: 65 to 80% of SiO2; 0 to 5% of Al2O3; 0 to 10% of MgO; 0 to 15% of CaO; 5 to 15% of MgO+CaO; 10 to 18% of Na2O; 0 to 5% of K2O; 10 to 20% of Na2O+K2O; and 0 to 5% of B2O3, and the colorants consist essentially of, expressed in mass %: 0.6% to 1.0% of T-Fe2O3; 0.026 to 0.8% of TiO2; 0 to 2.0% of CeO2; 0.01 to 0.03% of CoO; 0 to 0.0008% of Se; and 0.06 to 0.20% of NiO. The glass article has a grayish color tone, and has a visible light transmittance in a range of 15% to 40%, which is measured with the illuminant A at a thickness of 3.1 mm.

Owner:NIPPON SHEET GLASS CO LTD

Ultraviolet/infrared absorbent low transmittance glass

InactiveUS20010025004A1Improving ultraviolet absorptivityImprove ultraviolet absorptivityTO-18Transmittance

The ultraviolet / infrared absorbent low transmittance glass has a grayish green color shade, low visible light transmittance, low total solar energy transmittance, and low ultraviolet transmittance, and is suitable for a rear window of a vehicle and capable of protecting privacy. The glass consists of base glass including: 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO wherein a total amount of MgO and CaO is between 5 and 15 wt. %; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O wherein a total amount of Na2O and K2O is between 10 and 20 wt. %; and 0 to 5 wt. % B2O3, and colorants including: more than 0.95 wt. % and 1.2 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; 0.001 to 0.0180 wt. % CoO; 0.0001 to 0.0008 wt. % Se; and 0.003 to 0.2 wt. % NiO.

Owner:NIPPON SHEET GLASS CO LTD

Ultraviolet/infrared absorbent low transmittance glass

The ultraviolet / infrared absorbent low transmittance glass has a grayish, almost neutral color shade, low visible light transmittance, low total solar energy transmittance, and low ultraviolet transmittance, and is suitable for a rear window of a vehicle and capable of protecting privacy. The glass consists of base glass including: 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO wherein a total amount of MgO and CaO is 5 to 15 wt. %; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O wherein a total amount of Na2O and K2O is 10 to 20 wt. %; and 0 to 5 wt. % B2O3, and colorants including: 1.0 to 1.6 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; more than 0.019 wt. % and equal to or less than 0.05 wt. % CoO; more than 0.0008 wt. % and equal to or less than 0.003 wt. % Se; and more than 0.05 wt. % and equal to or less than 0.1 wt. % NiO. The glass with any one of thicknesses between 1.8 mm and 5 mm has a visible light transmittance (YA) measured by the C.I.E. illuminant "A" in a range from 5 to 25%, a solar energy transmittance (TG) of 5 to 25%, and an ultraviolet transmittance (Tuv) specified by ISO of not greater than 15%.

Owner:NIPPON SHEET GLASS CO LTD

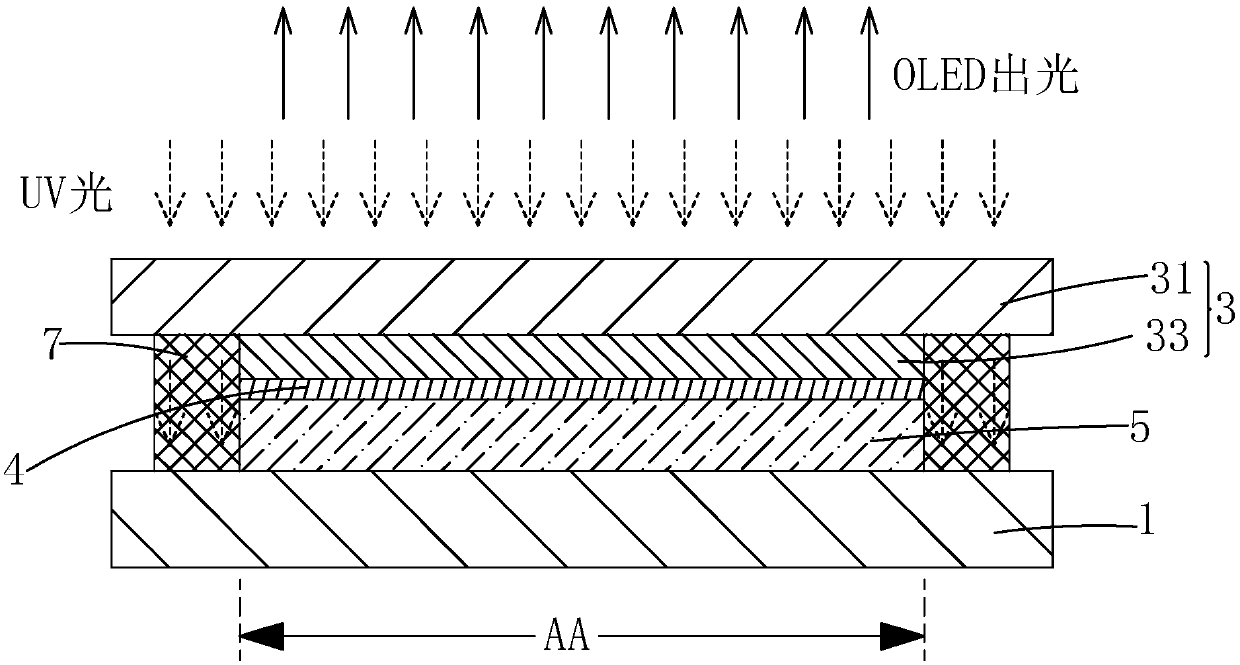

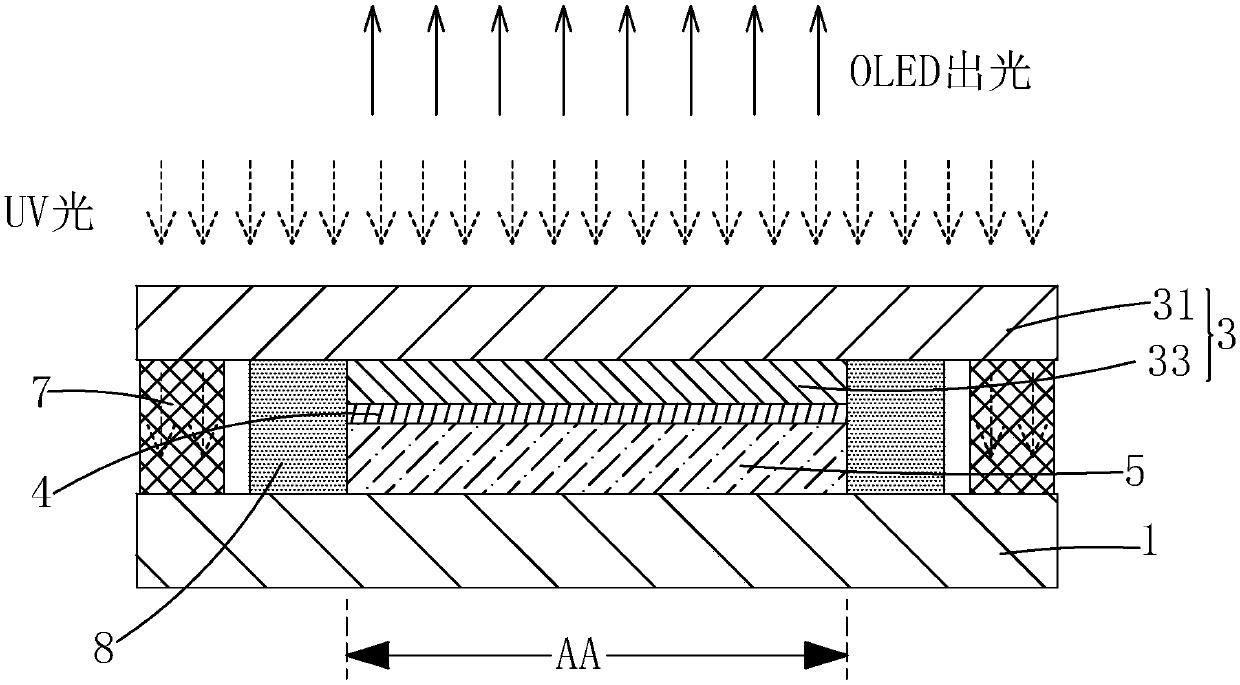

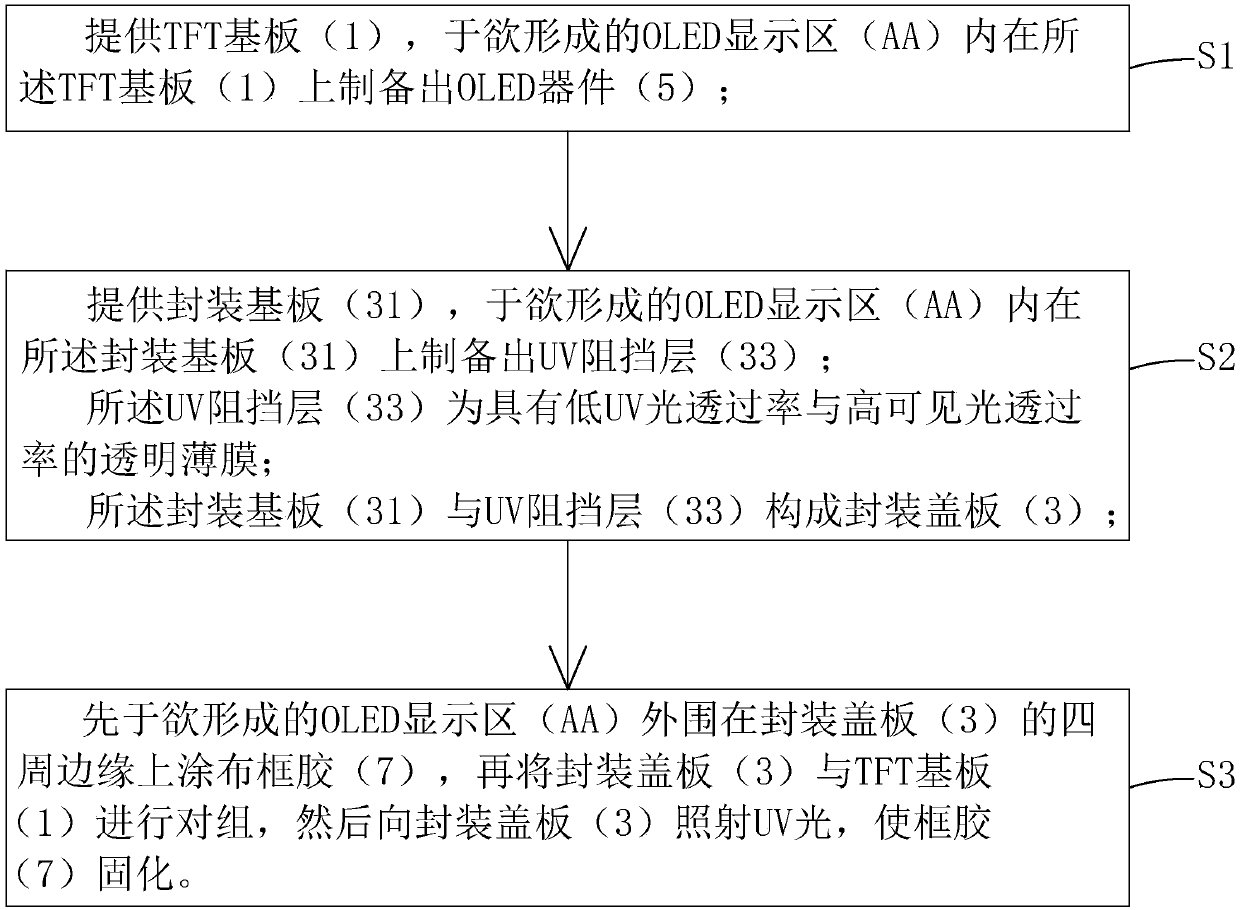

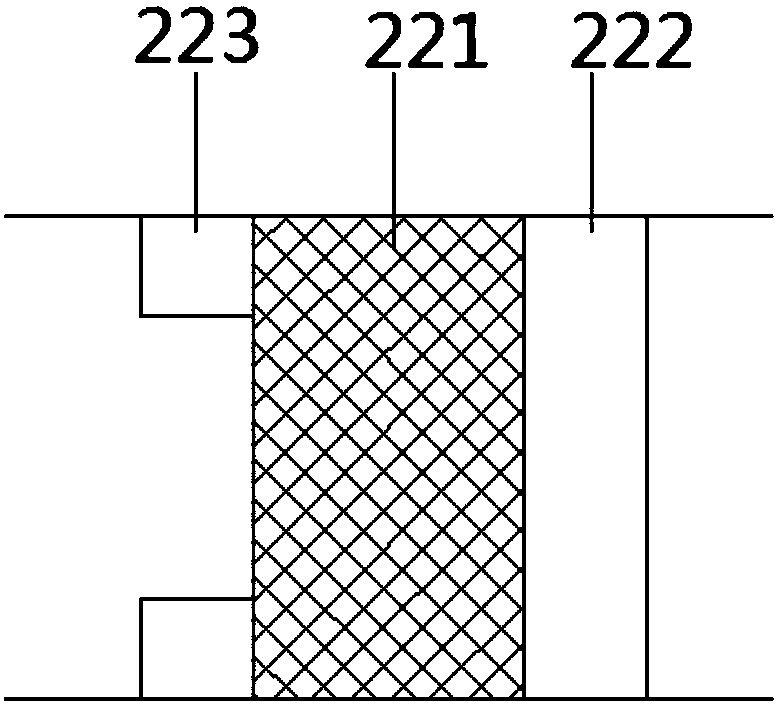

OLED packaging structure and OLED packaging method

InactiveCN107706313ALow UV light transmittanceReduce visible light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveWater vapor

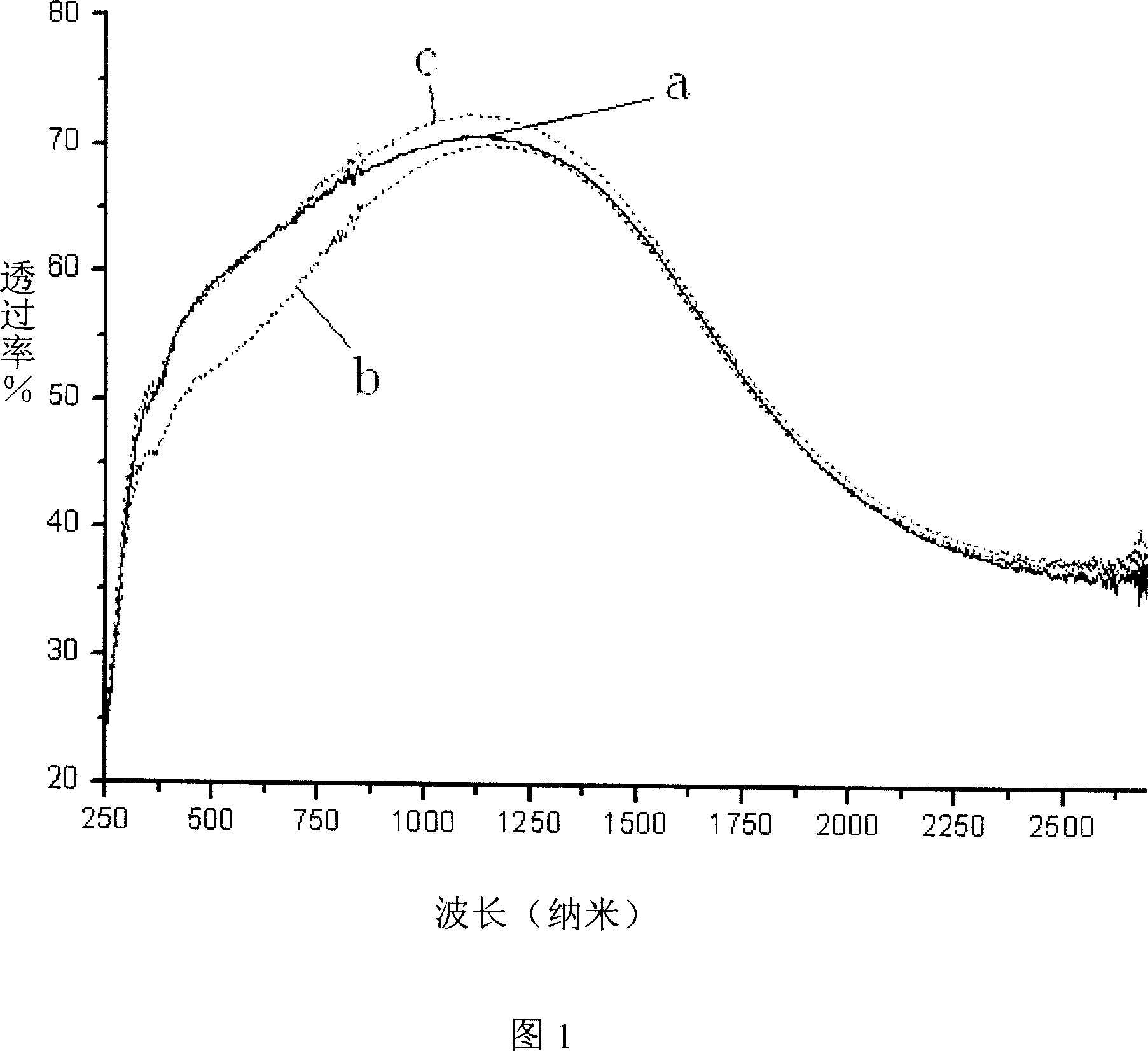

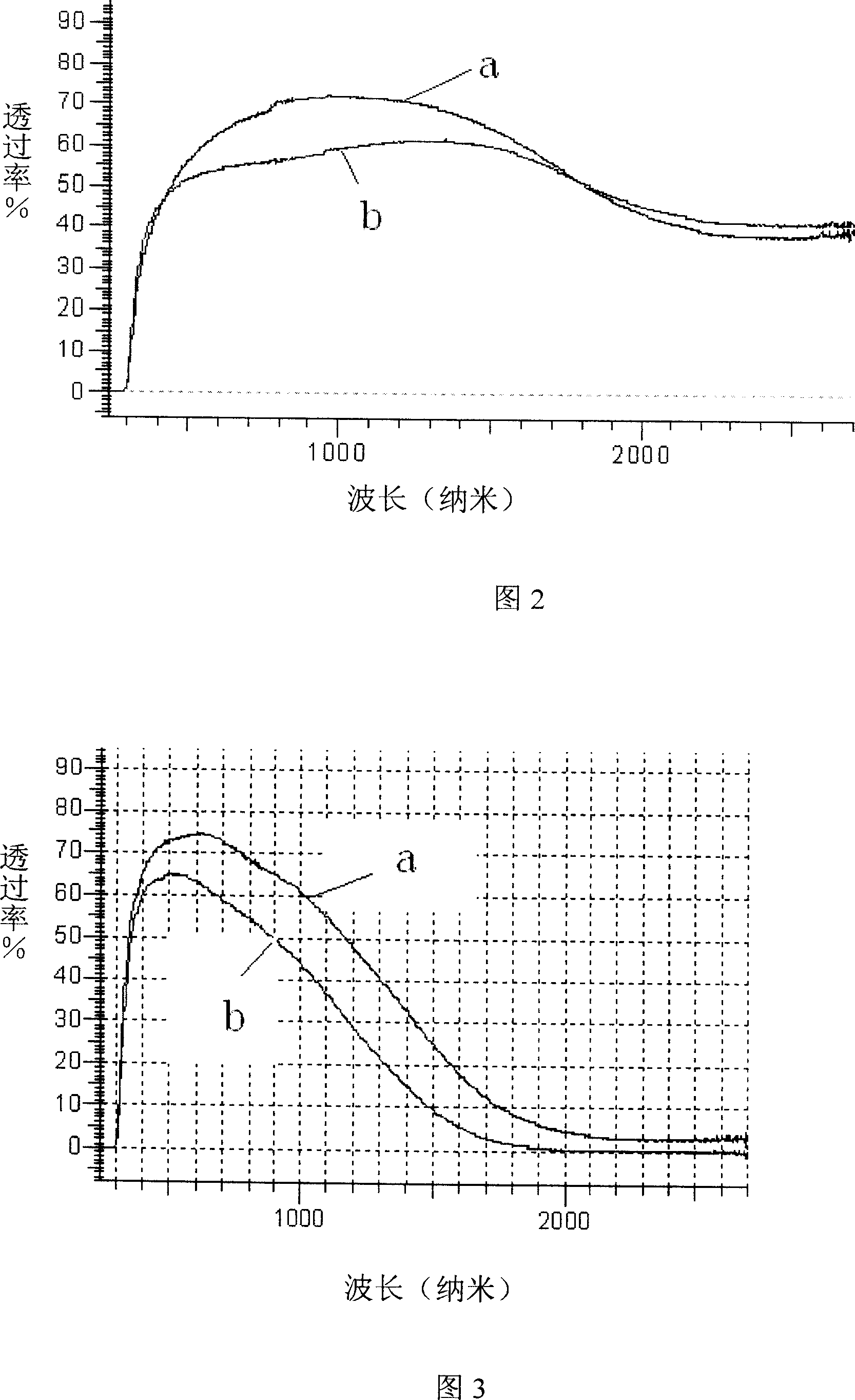

The invention provides an OLED packaging structure and an OLED packaging method. The OLED packaging structure comprises a TFT substrate (1), a packaging cover plate (3), an OLED device (5), and frameadhesive (7), wherein the packaging cover plate (3) is arranged opposite to the TFT substrate (1); the OLED device (5) is arranged in an effective display region (AA) of the OLED and on one side, close to the packaging cover plate (3), of the TFT substrate (1); the frame adhesive (7) is arranged on the periphery of the effective display region (AA) of the OLED and between the TFT substrate (1) andthe packaging cover plate (3); the packaging cover plate (3) comprises a packaging substrate (31) and an UV barrier layer (33) which is arranged on one side, close to the TFT substrate (1), of the packaging substrate (31) and corresponding to the effective display region (AA) of the OLED; and the UV barrier layer (33) is a transparent thin film with low UV light transmittance and high visible light transmittance, so that influence to the electrical performance and stability of the TFT in frame adhesive (7) curing process by UV light can be lowered, water vapor and oxygen are further isolated,and the service life of the OLED device (5) is prolonged.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Nano coating with photochromic and sunlight control characteristics, its preparing method and use

InactiveCN101024742ALow toxicityEnvironmentally friendlyPolyurea/polyurethane coatingsSpecial surfacesAqueous solutionNanometre

The invention relates to nanometer coating material that has photochromism and sunshine controlled capability, and the manufacturing method and the application. It includes the following steps: adding aqueous solution of adulterated stannic oxide tin oxide nanometer to container, whisking and adding the solution of IB series transition metal nanometer partical and / or adding the compound of IB series metal to gain the aqueous solution nanometer coating with photochromism and sunshine controlled capability. The mol ratio of doped chemical in stannic oxide and the tin is 0.1-20:100. The mol ratio of stannic oxide and the IB series metal element is 200:1-5:1. The invention could be coated onto surface of glass or organic material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Interlayer for laminated glass and laminated glass

ActiveUS8012612B2Improve performanceReduce transmittanceSynthetic resin layered productsGlass/slag layered productsPolyvinyl alcoholPrivacy protection

The present invention provides an interlayer for laminated glass which comprises at least one layer composed of an opaque ethylene-vinyl acetate copolymer resin composition or opaque polyvinyl acetal resin composition, and also provides the laminated glass using such interlayers. The interlayer for laminated glass and the laminated glass according to the present invention can offer excellent privacy protection.

Owner:SEKISUI CHEM CO LTD

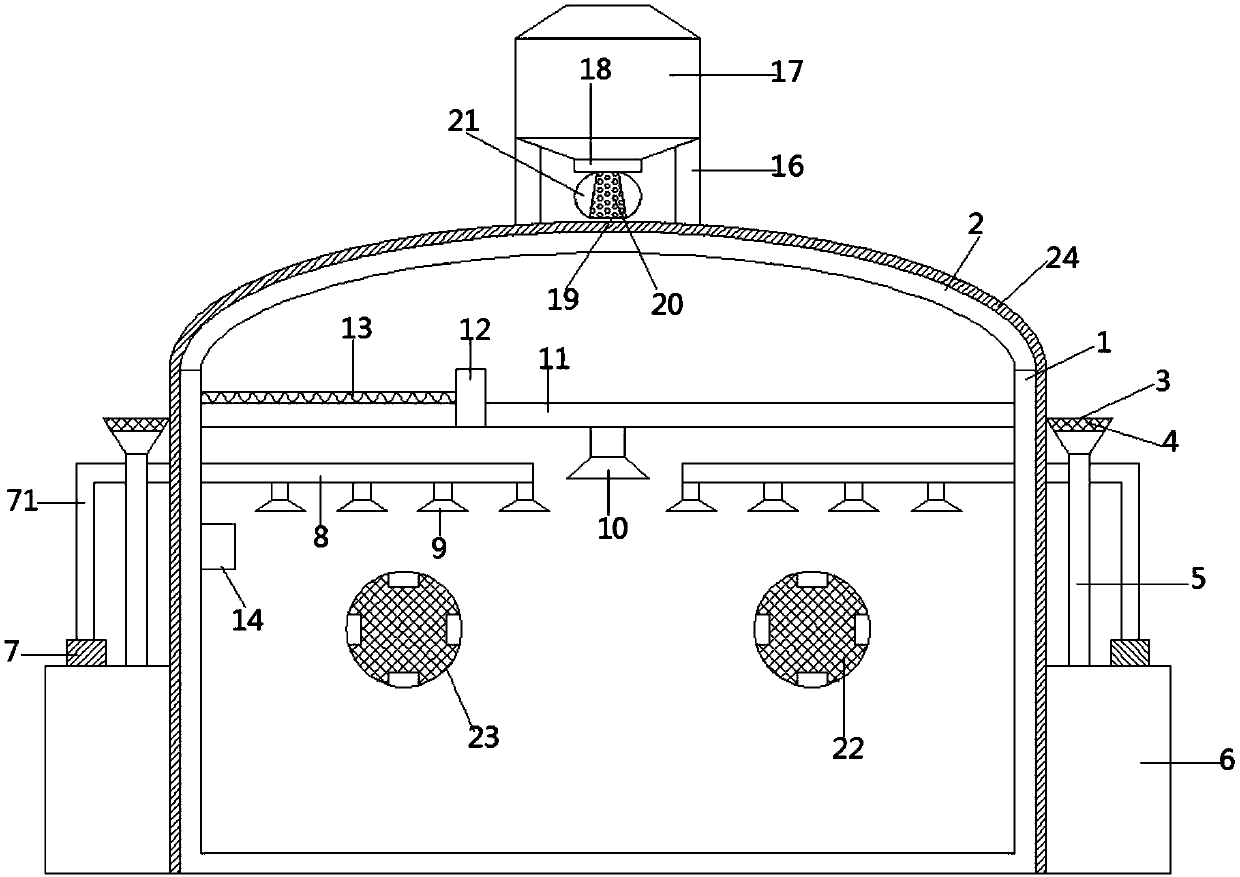

Efficient planting device for agricultural planting

InactiveCN107616031AReduce use costGuaranteed normal growthGeneral water supply conservationSnow trapsWater sourceGreenhouse

The invention discloses an efficient planting device for agricultural planting. The device comprises a greenhouse body and a greenhouse ceiling, water collection tanks are arranged at the tops of theouter sides of both the left side and the right side of the greenhouse body, filtering nets are arranged at the tops of the water collection tanks, the bottoms of the water collection tanks are both connected with water accumulation boxes through lower water pipes, the water accumulation boxes at the left side and the right side are both connected with spraying pipes located at the upper sides inside the greenhouse body through connection water pipes, and water pumping pumps are connected to the bottoms of the connection water pipes. According to the efficient planting device for agriculturalplanting, rainwater can be effectively collected and utilized to conduct irrigation, the using cost of the greenhouse is lowered, the effects of conducting ventilation and maintaining the indoor temperature and humidity to be stable can be achieved, the planting effect is improved, a fan is arranged in the channel, through a controller, a walking mechanism is controlled to move, a sunshade screenis driven to be unfolded, the temperature inside the greenhouse is lowered, and the greenhouse does not need to be manually covered with the sunshade screen, besides, salt for melting snow can be uniformly sprayed to the greenhouse ceiling in the circumferential direction, the spraying effect is good, the coverage area is large, and the snow melting effect is good.

Owner:尚许静

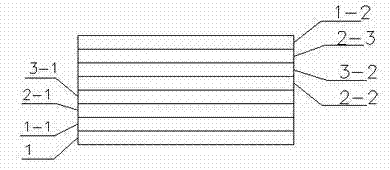

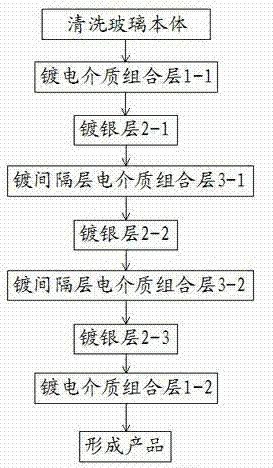

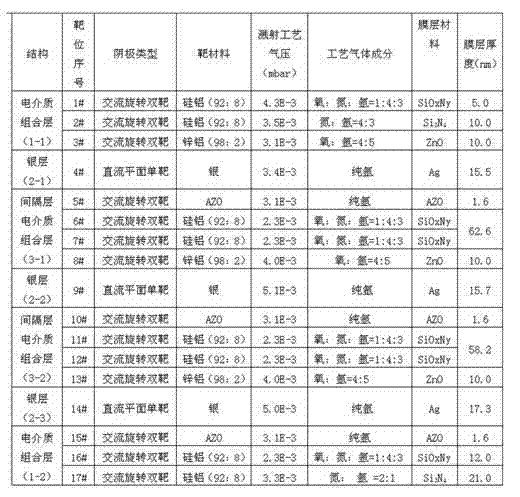

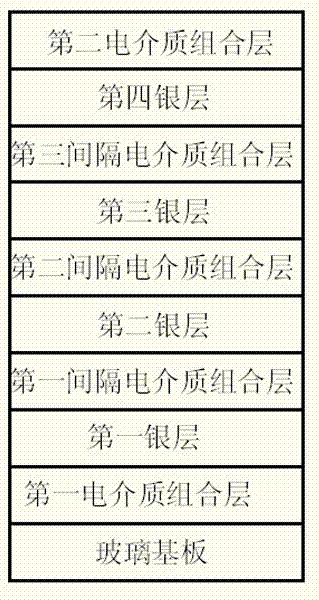

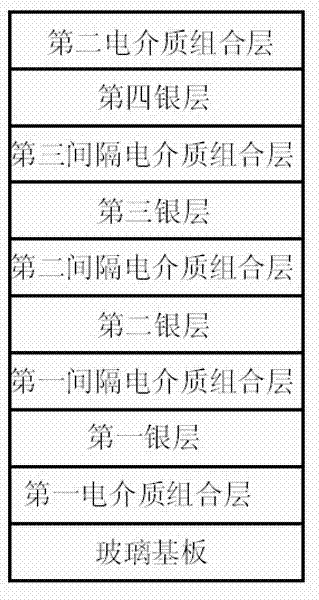

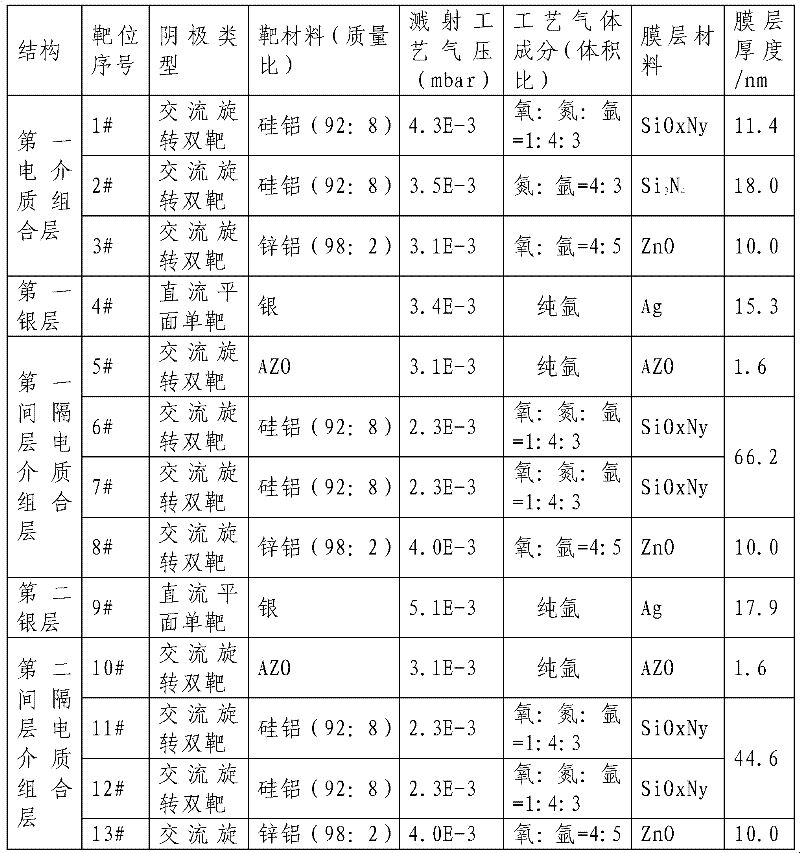

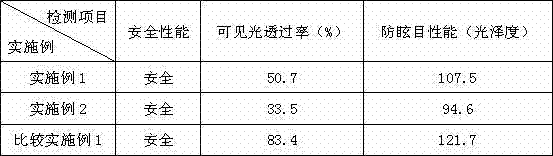

Triple-silver low-emissivity coated glass and preparation method thereof

The invention relates to a triple-silver low-emissivity coated glass, which comprises a glass body and a coating film coated on the glass body. The coating film comprises two dielectric combination layers, three silver layers and two spacing layer dielectric combination layers. The two dielectric combination layers are respectively arranged at the upper layer and the lower layer of a coating layer. The three silver layers and the two spacing layer dielectric combination layers are alternately arranged between the two dielectric combination layers in order. The dielectric combination layers and the spacing layer dielectric combination layers are all composed of one or more film layers of SSTOx, CrNx, CdO, MnO2, InSbOx, TxO, SnO2, ZnO, ZnSnOx, ZnSnPbOx, ZrO2, AZO, Si3N4, SiO2, SiOxNy, BiO2, Al2O3, Nb2O5, Ta2O5, In2O3 and MoO3. The triple-silver low-emissivity coated glass disclosed in the invention abolishes a metal barrier layer in a traditional film layer structure, and employs novel material dielectric combination layers to conduct silver layer protection, so that the influence of film layers on visible light transmittance can be effectively reduced, and consequently, high visible light transmittance, low emissivity, and a good photothermal ratio can be obtained. Besides, with diverse color options, the triple-silver low-emissivity coated glass has a wide range of application.

Owner:林嘉宏

Ultraviolet-infrared absorbent low transmittance glass

InactiveUS6524713B2Reduce transmittanceReduce visible light transmittanceGlass/slag layered productsUltravioletTransmittance

Owner:NIPPON SHEET GLASS CO LTD

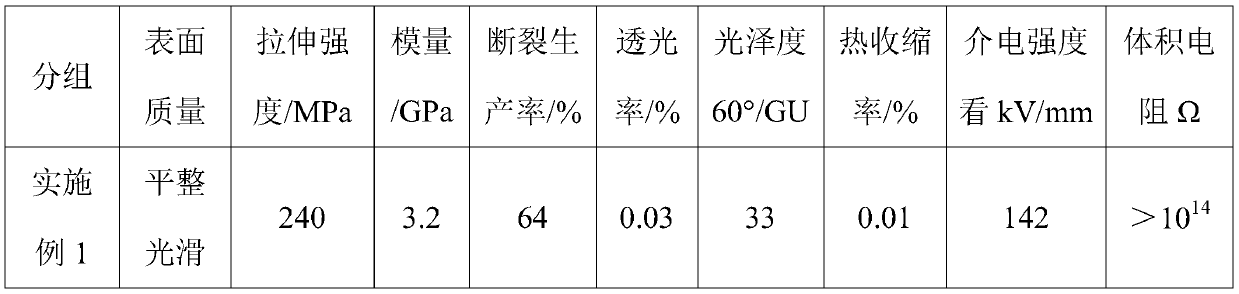

Matte polyimide black film with low heat shrinkage rate, and preparation method thereof

The invention discloses a preparation method of a matte polyimide black film with a low heat shrinkage rate. The method comprises the following steps: S1, preparing a polyamide acid resin solution: adding a matting agent into an aromatic diamine solution in an inert gas atmosphere, mixing until uniformity, adding aromatic dianhydride, and carrying out a stirring reaction to obtain the polyamide acid resin solution, wherein the aromatic diamine contains rigid aromatic diamine, and the rigid aromatic diamine is at least one of p-phenylenediamine, 2,5-diaminotoluene, 1,5-naphthalenediamine, 2,5-naphthalenediamine and 2,6-naphthalenediamine; S2, preparing a black slurry; and S3, preparing the matte polyimide black film with the low heat shrinkage rate. The invention further discloses the mattepolyimide black film with the low heat shrinkage rate. The matte polyimide black film with the low heat shrinkage rate is prepared through the preparation method of the matte polyimide black film with the low heat shrinkage rate. The matte polyimide black film with the low heat shrinkage rate has the advantages of low shrinkage rate, matt effect, maintenance of mechanical properties and electrical properties, good dimensional stability, low visible light transmittance and low surface gloss.

Owner:ANHUI GUOFENG PLASTIC

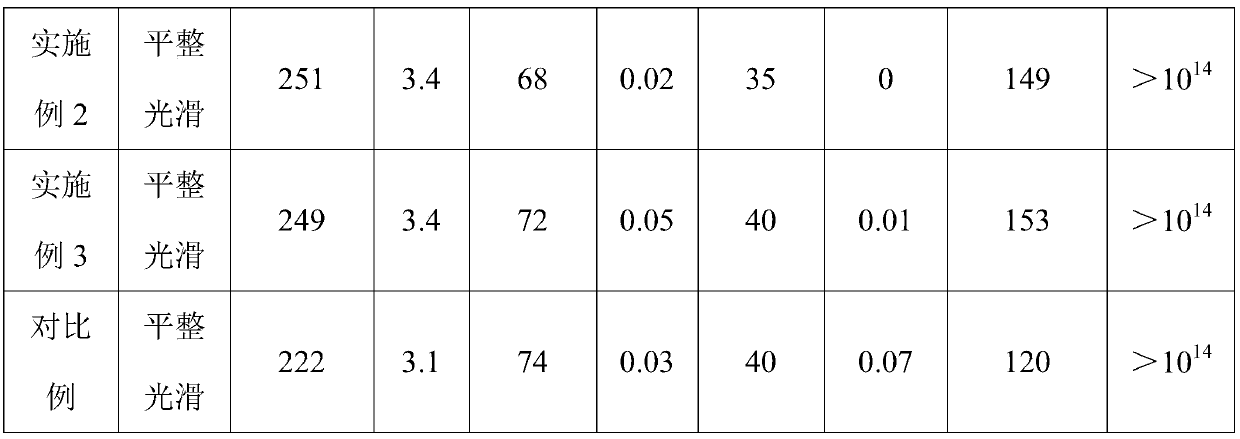

Coating material for anti-glare laminated glass and application method thereof

InactiveCN102653653AWith anti-glare effectReduce visible light transmittanceCoatingsAcrylic resinOrganosolv

The invention discloses a coating material for anti-glare laminated glass and an application method thereof. The coating material for anti-glare laminated glass is prepared through the steps of: based on nano ATO (antimony doped tin oxides) powder, through taking ethyl acetate as an organic solvent, adding materials such as ACR (acrylic resin), ball-milling mediums and the like into a mixture of the nano ATO powder and the ethyl acetate, and then carrying out ball milling dispersion on the obtained product so as to obtain ATO paste; through taking PVB (polyvinyl butyral) resin as a basic material, adding the ATO paste into the basic material, and carrying out high-speed mechanical dispersion on the obtained mixture so as to obtain an ATO sizing material; coating the ATO sizing material on the surface of glass; combining glass sheets together and pressurizing the combined glass sheets; and heating so as to obtain the coating material. The coating material disclosed by the invention integrates the safety performance of laminated glass and the anti-glare performance of ATO particles, therefore, the coating material can be widely used in the anti-glare fields of safety glass such as various construction safety glass and laminated glass for front windows of automobiles, and the like.

Owner:WUHU YAOHUA GLASS HORTICULTURE

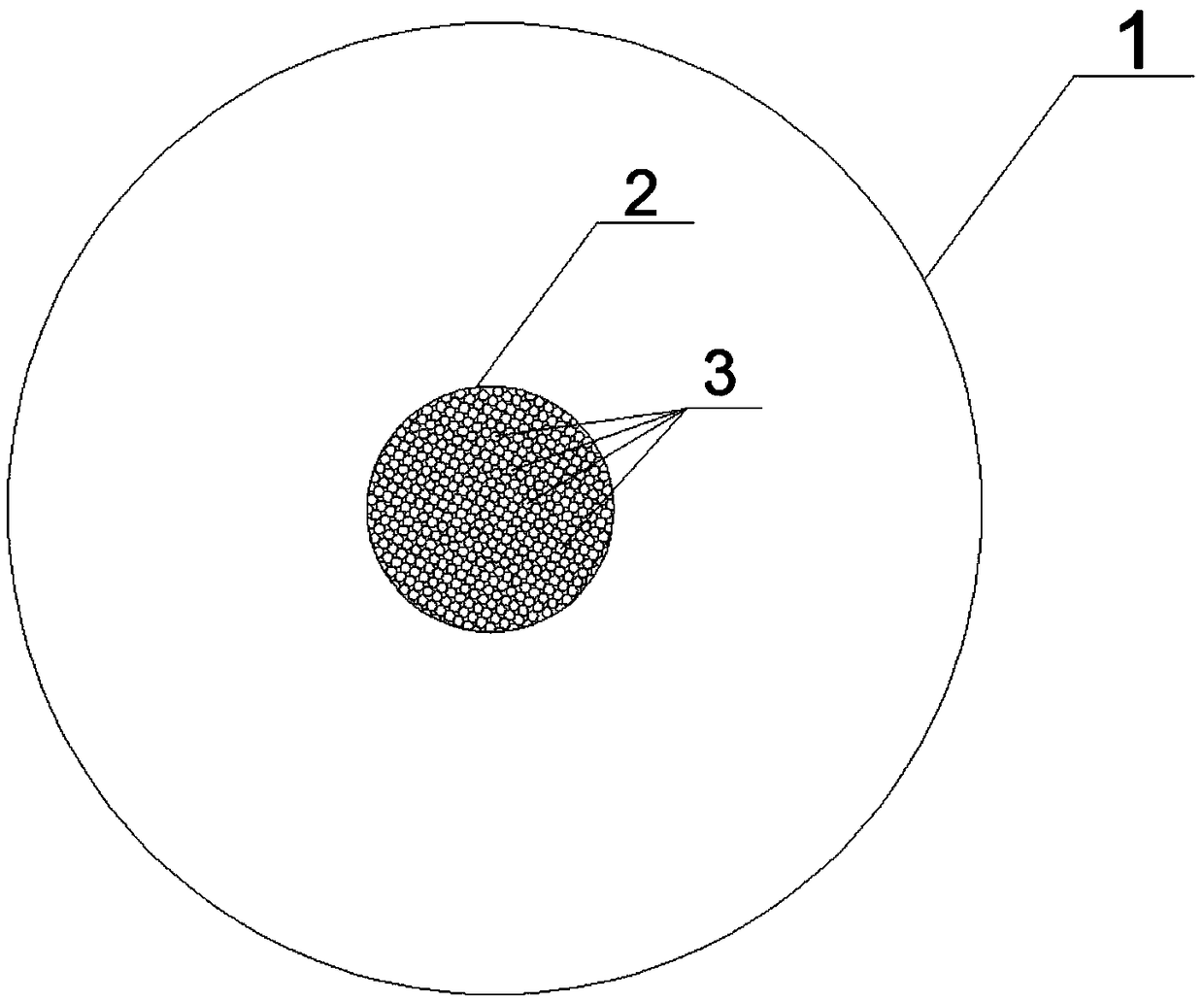

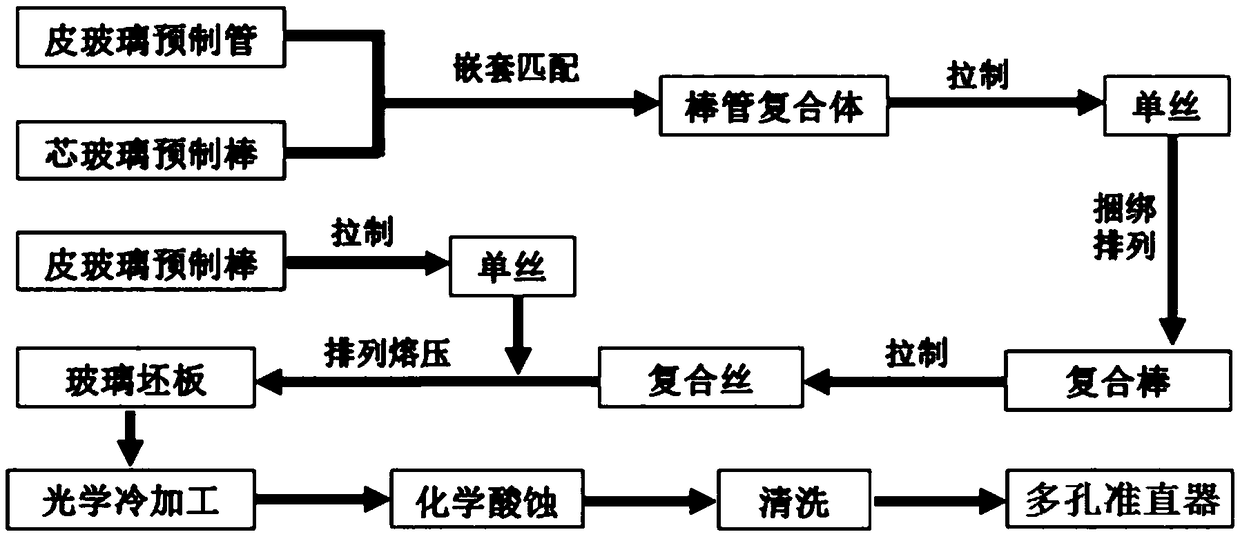

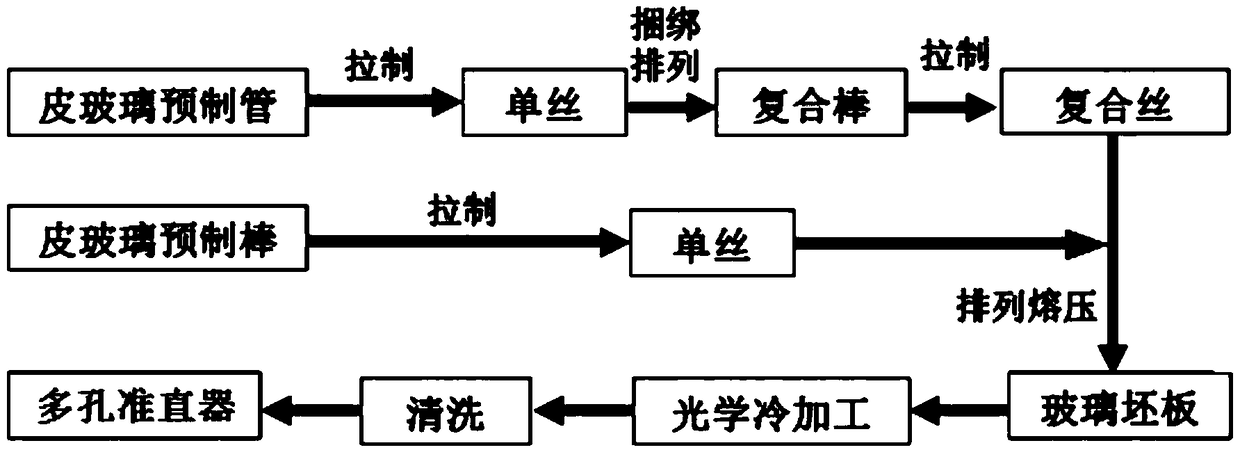

Collimator and manufacturing method

ActiveCN108922646ASolve Dimensional Accuracy IssuesUniform sizeGlass making apparatusHandling using diaphragms/collimetersAcid etchingFilling materials

The invention relates to a collimator and a manufacturing method. The collimator includes a base body of a flat plate shape, wherein the upper surface and lower surface of the base body are parallel to each other, at least a through hole which penetrates through the upper surface and the lower surface and has a pore diameter of 1-100 [mu]m is formed in the base body, and the base body is made of glass. A glass blank plate is prepared by using a glass rod tube nested drawing method, optical cold processing is conducted, and then chemical etching is performed so as to obtain the collimator. After the glass of the collimator is determined, core glass matched with the determined glass is designed, and the core glass is removed through acid etching, wherein the core glass is mainly used as a filling material of micropores during manufacture so as to ensure the roundness of the micropores. Through the collimator, the collimation efficiency of particles and stability of particle movement canbe improved effectively, the scattering angle of the particles is reduced, and conditions for high stability, high reliability and miniaturization of atomic clocks, ray cameras and other precision equipment are created.

Owner:CHINA BUILDING MATERIALS ACAD

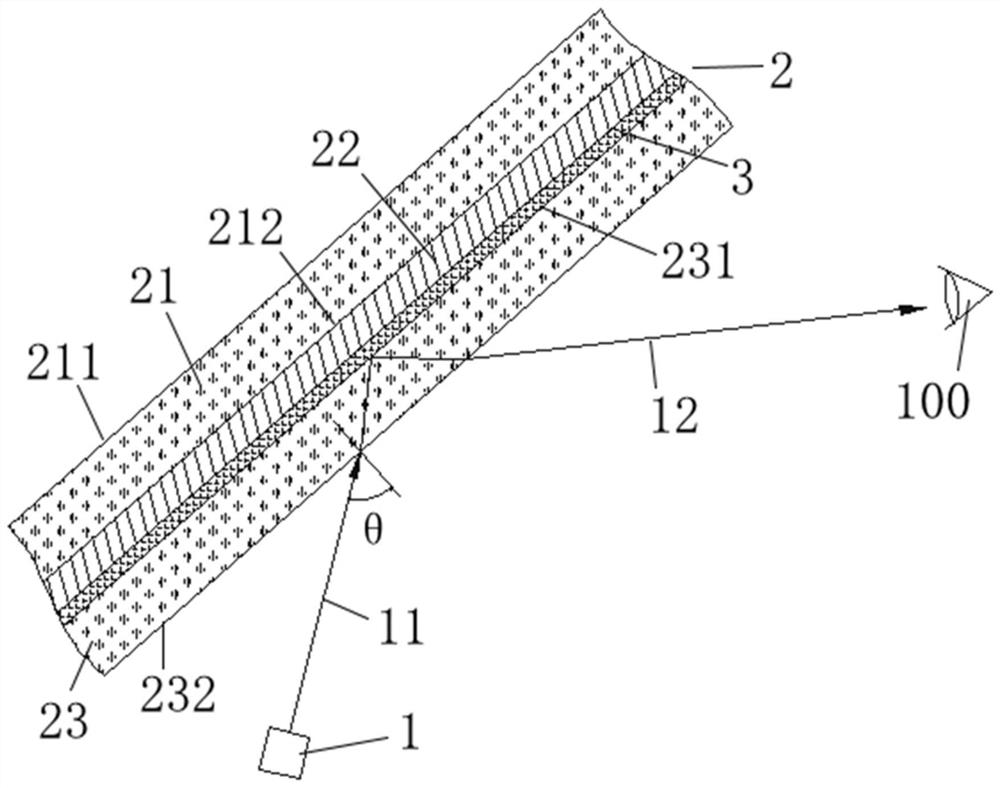

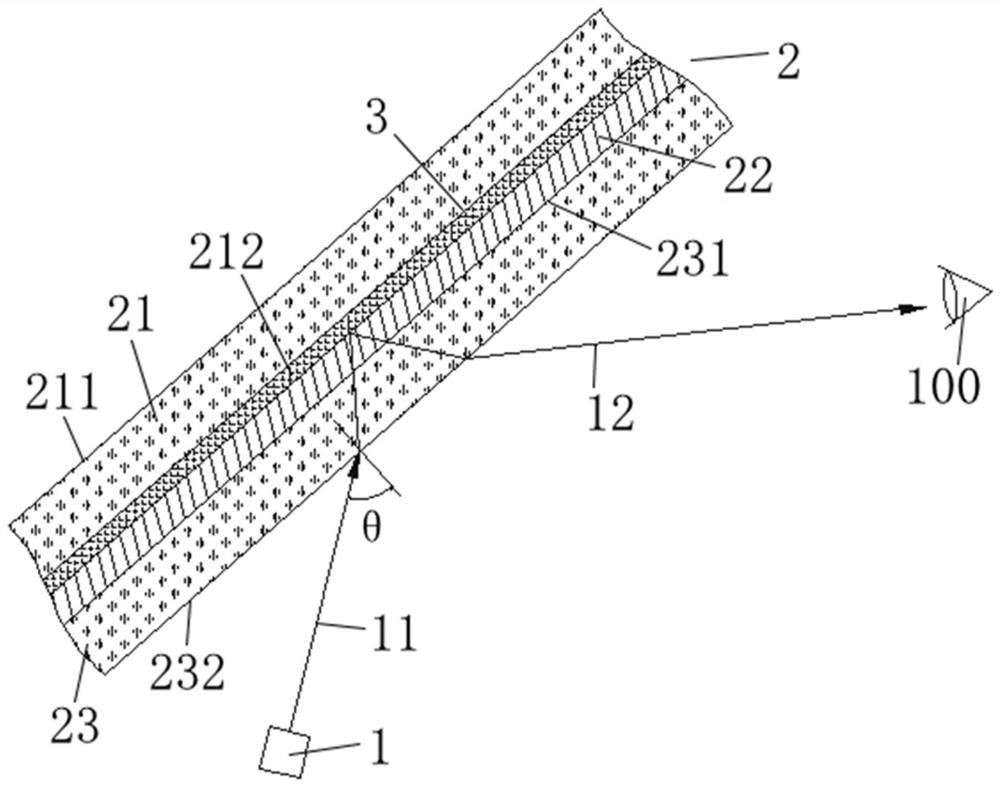

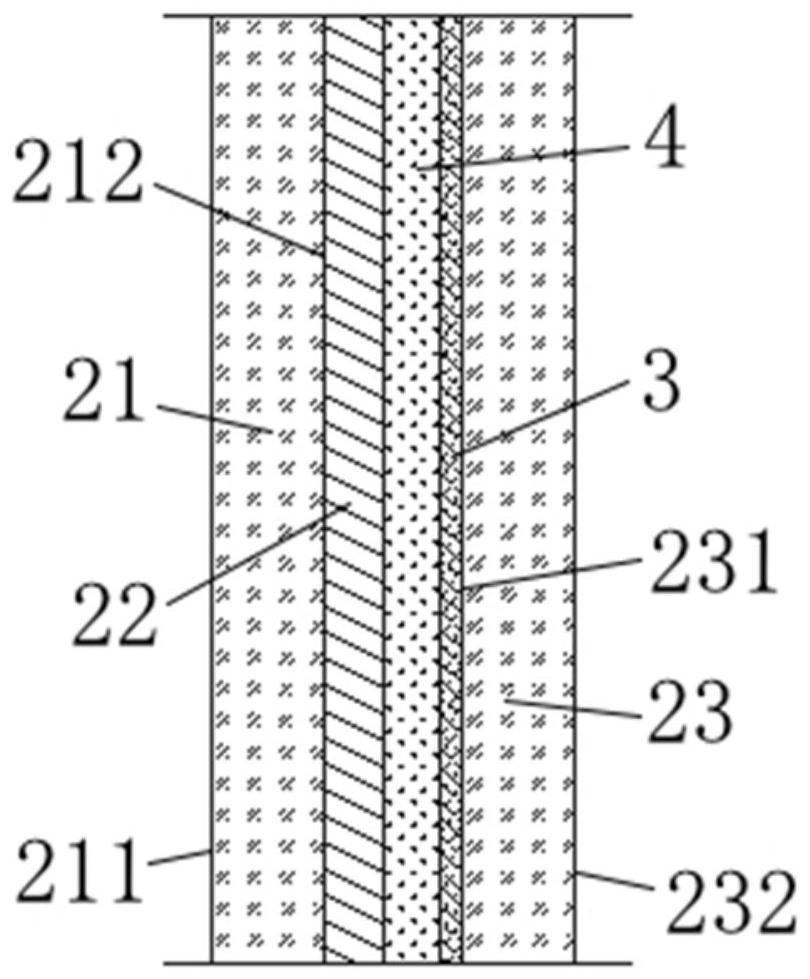

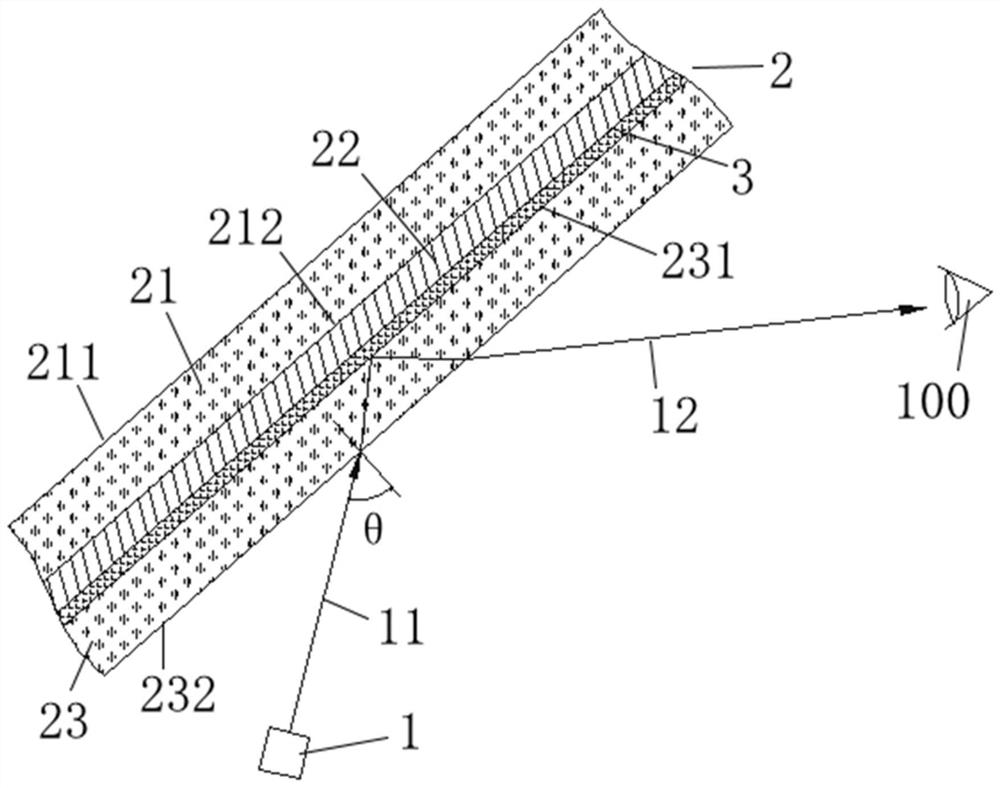

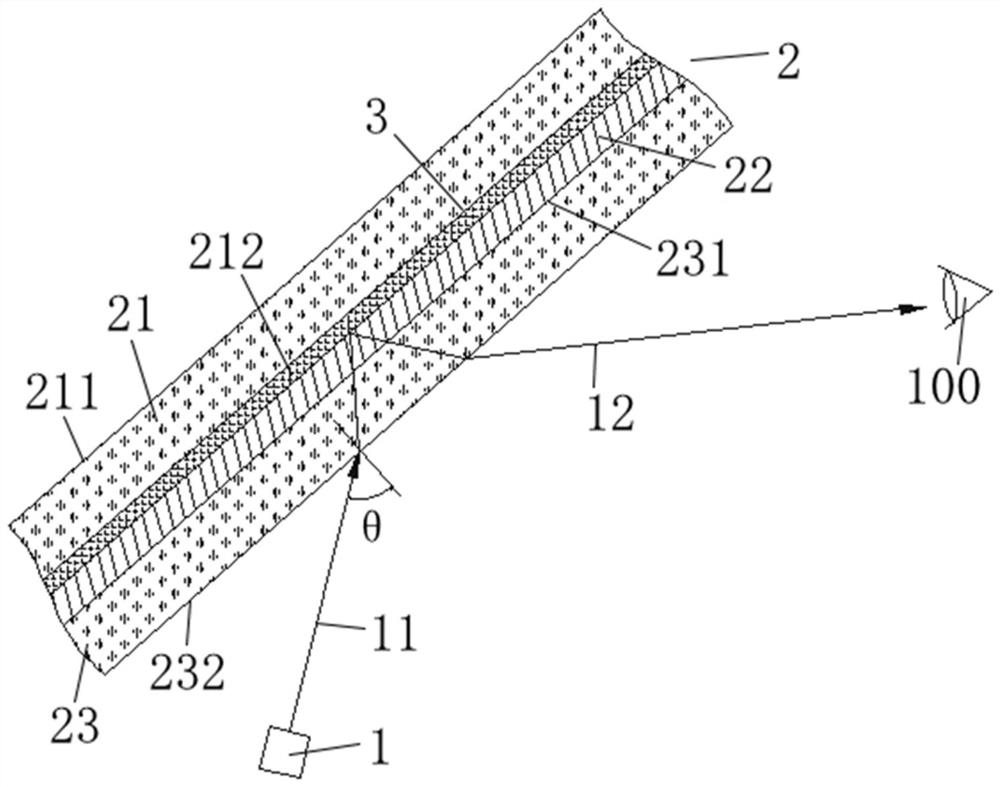

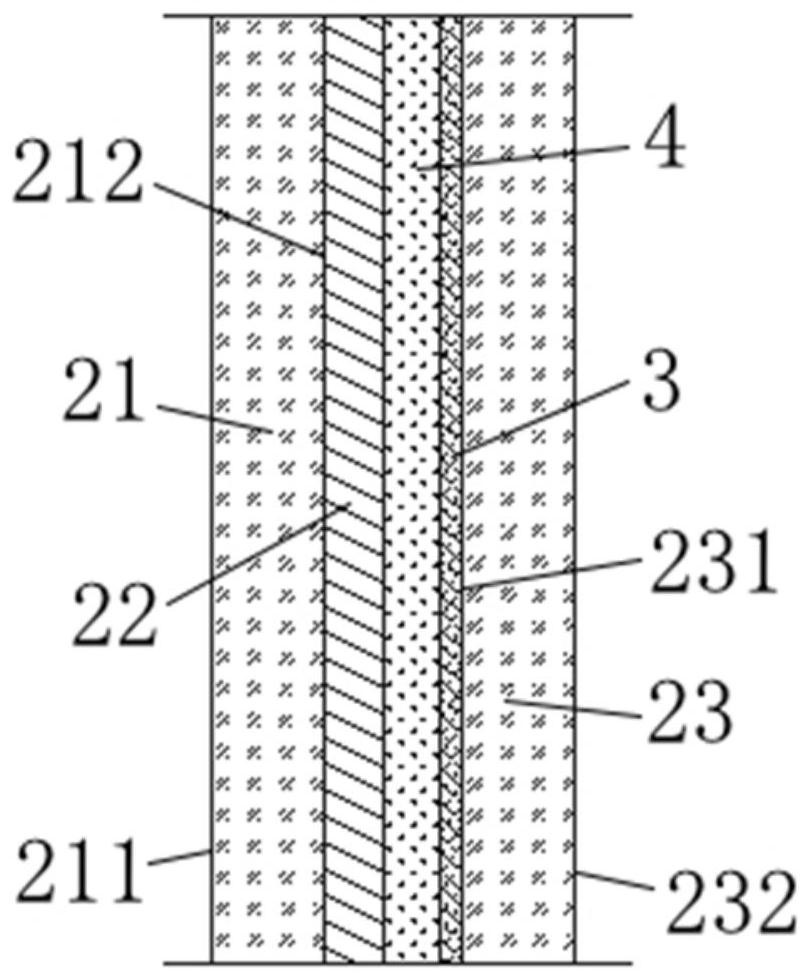

Head-up display system

ActiveCN113238378ARich in colorHigh visible light transmittanceLayered productsOptical elementsAngle of incidenceThin glass

The invention relates to the technical field of head-up display, in particular to a head-up display system utilizing a transparent nano-film for imaging display, and particularly provides a head-up display system comprising ultra-thin glass. The head-up display system comprises a projection light source, laminated glass and a transparent nano film, wherein the transparent nano film comprises at least two metal layers; the projection light source is used for generating P polarized light, the laminated glass provided with the transparent nano film has the maximum reflectivity Rmax and the minimum reflectivity Rmin for the P polarized light within the incident angle of 45-72 degrees, and Rmax / Rmin is equal to 1.0-2.0. A clear head-up display image without visual ghosting can be generated, the requirements of high P polarized light reflectivity, high visible light transmittance and low fourth surface visible light reflectivity are met, the head-up display image presents a neutral color, and the color of the head-up display image is richer so as to realize full-color display.

Owner:FUYAO GLASS IND GROUP CO LTD

Four-silver coated glass with low radiation and manufacturing technique thereof

InactiveCN102514279AReduce visible light transmittanceReduce transmittanceGlass/slag layered productsMetal layered productsWeather resistanceInterference color

The invention discloses four-silver coated glass with low radiation and a manufacturing technique thereof, the four-silver coated glass with low radiation is provided with a coating film on a glass substrate; the four-silver coated glass with low radiation is characterized in that the film layer structure of the coating film from the glass substrate to the outside is sequentially as follows: a first dielectric combination layer, a first silver layer, a first isolation dielectric combination layer, a second silver layer, a second isolation dielectric combination layer, a third silver layer, a third isolation dielectric combination layer, a fourth silver layer and a second dielectric combination layer. According to the invention, the unique film layer structure and the manufacturing technique are utilized, and the dielectric layer made of a novel material is further used for replacing the traditional metal blocking layer to greatly improve the visible light transmissivity of the glass, reduce the interference color, increase the color selection range, guarantee high visible light transmissivity, low radiation rate, good photo-thermal ratio, optical stability and weather resistance for the improved products, and to obtain good thermal insulation and heat preservation effects.

Owner:林嘉宏

Ultraviolet/infrared absorbent low transmittance glass

InactiveUS20010056030A1Reduce transmittanceReduce visible light transmittanceGlass/slag layered productsUltravioletTransmittance

The ultraviolet / infrared absorbent low transmittance glass has an almost neutral color such as greenish gray, low visible light transmittance, low total solar energy transmittance, and low ultraviolet transmittance, and is suitable for a rear window of a vehicle and capable of protecting privacy. The glass consists of base glass including: 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO wherein a total amount of MgO and CaO is between 5 and 15 wt. %; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O wherein a total amount of Na2O and K2O is between 10 and 20 wt. %; and 0 to 5 wt. % B2O3, and colorants including: 1.25 to 1.5 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; 0.01 to 0.019 wt. % CoO; more than 0.0008 wt. % and equal to or less than 0.003 wt. % Se; and 0.055 to 0.1 wt. % NiO. The glass with a thickness between 2 and 5 mm has a visible light transmittance (YA) in a range from 10% to 25% using illuminant "A", a solar energy transmittance in a range from 5% to 20% and an ultraviolet transmittance (Tuv) of not more than 15%.

Owner:NIPPON SHEET GLASS CO LTD

ATO (antimony doped tin oxides) coating material for laminated glass and application method thereof

InactiveCN102653654AWith anti-glare effectReduce visible light transmittanceCoatingsOrganic solventAcrylic resin

The invention discloses an ATO (antimony doped tin oxides) coating material for laminated glass and an application method thereof. The ATO coating material for laminated glass is prepared through the steps of: based on nano ATO powder, through taking ethyl acetate as an organic solvent, adding materials such as ACR (acrylic resin), ball-milling mediums and the like into a mixture of the nano ATO powder and the ethyl acetate, and then carrying out ball milling dispersion on the obtained product so as to obtain ATO paste; through taking PVB (polyvinyl butyral) resin as a basic material, adding the ATO paste into the basic material, and carrying out high-speed mechanical dispersion on the obtained mixture so as to obtain an ATO sizing material; coating the ATO sizing material on the surface of glass; combining glass sheets together and pressurizing the combined glass sheets; and heating so as to obtain the ATO coating material. The ATO coating material disclosed by the invention integrates the safety performance of laminated glass and the anti-glare performance of ATO particles, therefore, the ATO coating material can be widely used in the anti-glare fields of safety glass such as various construction safety glass and laminated glass for front windows of automobiles, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

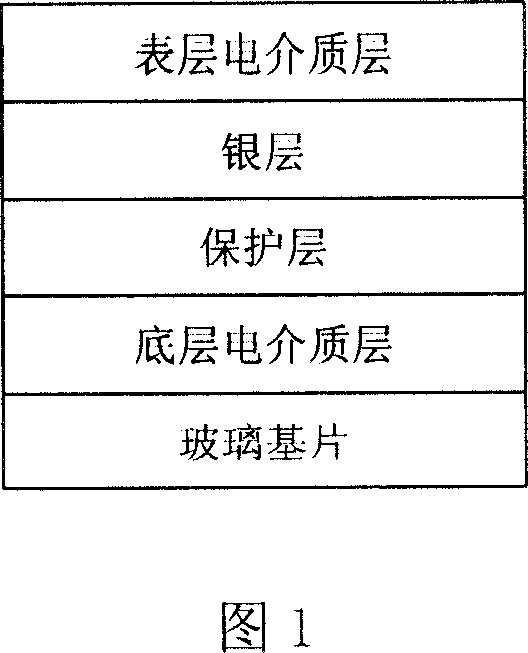

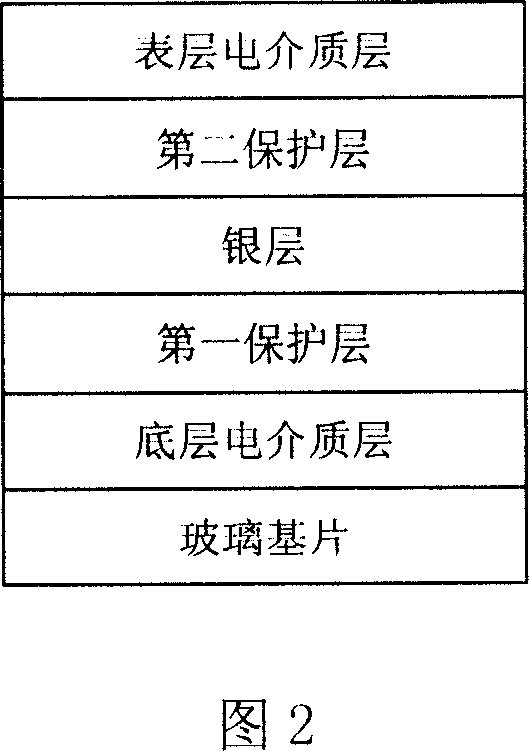

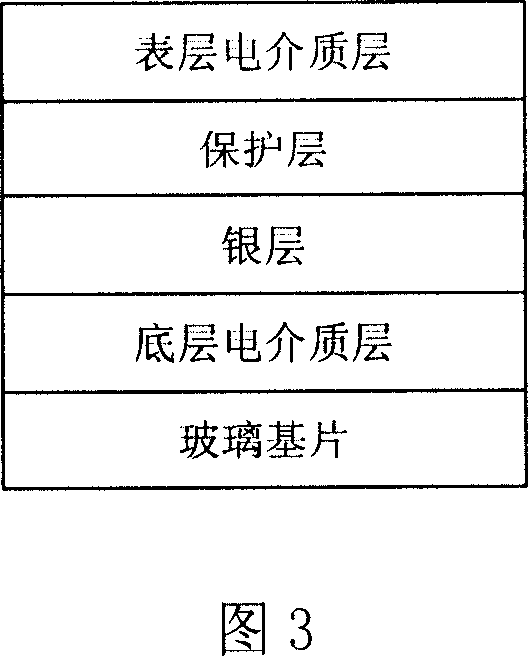

Thermostable low radiation composite film glass and its production technology

InactiveCN1948201AEnhanced high temperature thermal stabilityImprove thermal stabilityAluminium chlorideComposite film

The present invention discloses a thermal stable low-radiation compound film glass and its production process. It is characterized by that the upper surface of glass base is covered with a compound film formed from bottom layer electrolyte layer, first protection layer, silver layer, second protection layer and surface layer electrolyte layer. The described bottom layer electrolyte layer is aluminium chloride, its thickness is 40-55 nm, the described two protection layers are stainless steel, nichrome alloy or their partial oxide or nitride, its thickness is 1-10 nm, the thickness of the described silver layer is 10-18 nm, and the described surface layer electrolyte layer is aluminium nitride or aluminium oxide, and its thickness is 40-65 nm.

Owner:SHANDONG WENPING ENERGY SAVING GLASS

Method for preparing titanium-doped zinc oxide transparent conductive film on polyethylene terephthalate (PET) flexible substrate

InactiveCN102352484ALow resistivityWon't breakVacuum evaporation coatingSputtering coatingPolyethylene terephthalate glycolMaterials science

The invention discloses a method for preparing a titanium-doped zinc oxide transparent conductive film on a polyethylene terephthalate (PET) flexible substrate. The method comprises the following steps of: a) cleaning the PET flexible substrate; b) flushing and drying the substrate, and filling the substrate into a sputtering chamber; d) regulating the target-substrate distance to 52 millimeters, regulating the sputtering power to 60W, regulating the sputtering pressure intensity to 5Pa and regulating the flow to 30SCCM; e) sputtering for 5 minutes and stopping for 5 minutes; and f) sputtering for 20 minutes, and thus forming the titanium-doped zinc oxide transparent conductive film on the PET flexible substrate. The method has the advantages that: the optimal film forming temperature of the titanium-doped zinc oxide is low (about 100 DEG C); a homogeneous buffer layer is first deposited on the substrate, so that the blocking property of the substrate is improved, and the substrate is favorable for nucleation and growth of the conductive film; and the substrate is cleaned ultrasonically by an acetone solution, soaked by absolute ethanol and flushed by deionized water, so that the adhesion of the substrate is improved. The transparent conductive film prepared by the method has low resistivity, excellent conductive performance and good light transmission.

Owner:SHANDONG UNIV OF TECH

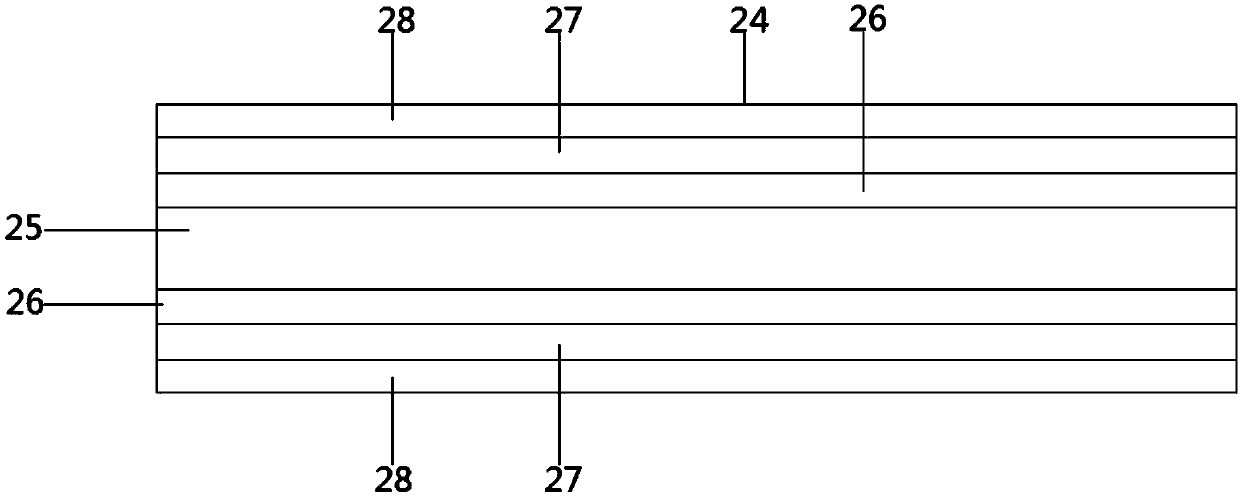

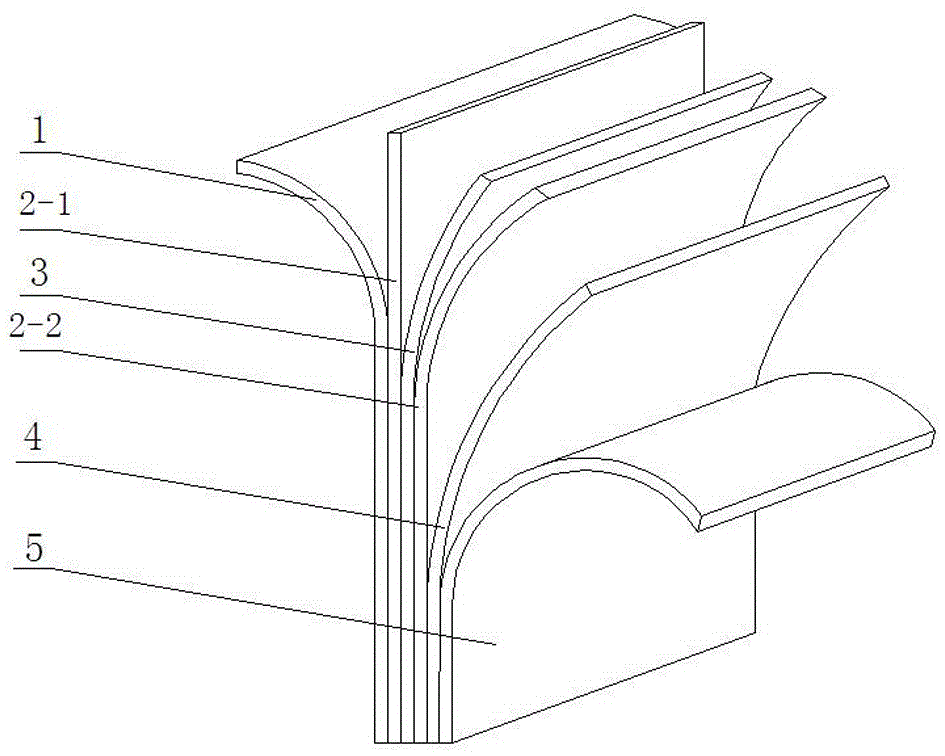

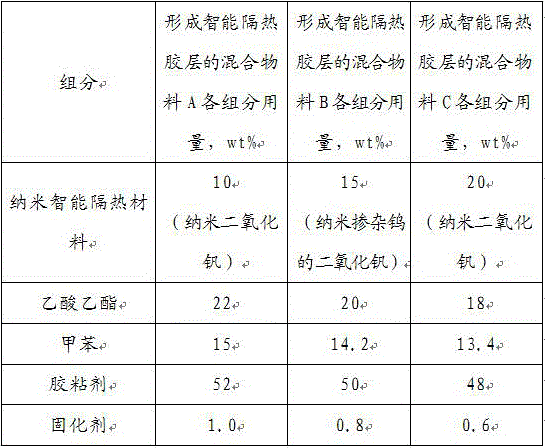

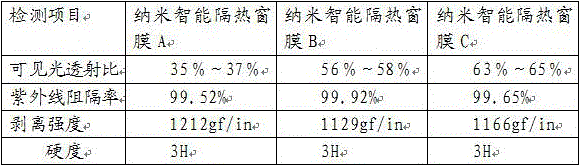

Nanometer intelligent thermal insulating window film

ActiveCN106183271AEasy to prepareEasy to operateSynthetic resin layered productsCoatingsPolyesterMetal coating

The invention relates to a nanometer intelligent thermal insulating window film which is composed of an anti-scratch layer (1), a polyester film or polycarbonate film base material (2-1), an intelligent thermal insulating glue layer (3), a polyester film or polycarbonate film base material (2-2) with a metal coating, an ultraviolet blocking pressure-sensitive glue layer (4) and a release film (5). The anti-scratch layer (1) is combined with one surface of the polyester film or polycarbonate film base material (2-1), the intelligent thermal insulating glue layer (3) is combined with the other surface of the polyester film or polycarbonate film base material (2-1), the surface of the metal coating of the polyester film or polycarbonate film base material (2-2) with the metal coating is located on the outer surface of the intelligent thermal insulating glue layer (3), the ultraviolet blocking pressure-sensitive glue layer (4) is combined with the other surface of the polyester film or polycarbonate film base material (2-2) with the metal coating, and the release film (5) is located on the outer surface of the ultraviolet blocking pressure-sensitive glue layer (4). The nanometer intelligent thermal insulating window film has a low radiation rate and high visible light transmittance.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Head-up display system

ActiveCN113238377AHigh reflectivity of P polarized lightHigh visible light transmittanceOptical elementsPhysicsReflectivity

The invention relates to the technical field of head-up display, in particular to a head-up display system utilizing a transparent nano-film for imaging display, and particularly provides a head-up display system comprising ultra-thin glass. The head-up display system comprises a projection light source, laminated glass and a transparent nano film, wherein the transparent nano film comprises at least two metal layers, the projection light source is used for generating P polarized light, the distance between the transparent nanometer film and the fourth surface is smaller than or equal to 1.86 mm, and the refractive index of the outer glass plate and / or the inner glass plate is 1.35-1.49. A clear head-up display image without visual ghosting can be generated, the requirements of high P polarized light reflectivity, high visible light transmittance and low fourth surface visible light reflectivity are met, and the defects of reddish color, yellow color and the like of the head-up display image can be eliminated, so that the head-up display image presents a neutral color; and the color of the head-up display image is richer so as to realize full-color display.

Owner:FUYAO GLASS IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com