Coating material for anti-glare laminated glass and application method thereof

A technology of laminated glass and coating materials, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

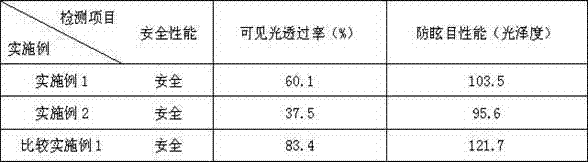

Examples

Embodiment 1

[0020] First weigh 3.0g of nano-ATO powder, Yb 2 o 3 Powder 1.2g, solvent is ethyl acetate 300ml, add polymethacrylic acid 5ml and ACR resin 8g therein, use ball mill to disperse 72h and make ATO slurry; Next, add above-mentioned ATO slurry 20ml to 80mlPVB resin, through High-speed mechanical dispersion for 30 minutes to prepare ATO glue; again, apply ATO glue on the glass surface, combine under normal pressure, and apply a load of 4.5kN / m 2 And raise the temperature to 100°C, keep the temperature for 1 hour, and then cool the furnace to room temperature to prepare ATO glass.

Embodiment 2

[0022] First weigh 3.0g of nano-ATO powder, Yb 2 o 3 Powder 1.2g, solvent is ethyl acetate 300ml, add polymethacrylic acid 5ml and ACR resin 8g therein, use ball mill ball mill to disperse 72h and make ATO slurry; Next, add above-mentioned ATO slurry 40ml to 60mlPVB resin, through High-speed mechanical dispersion for 30 minutes to prepare ATO glue; again, apply ATO glue on the glass surface, combine under normal pressure, and apply a load of 4.5kN / m 2 And raise the temperature to 90°C, keep the temperature for 1 hour, and then cool the furnace to room temperature to prepare ATO glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com