Patents

Literature

33results about How to "With anti-glare effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

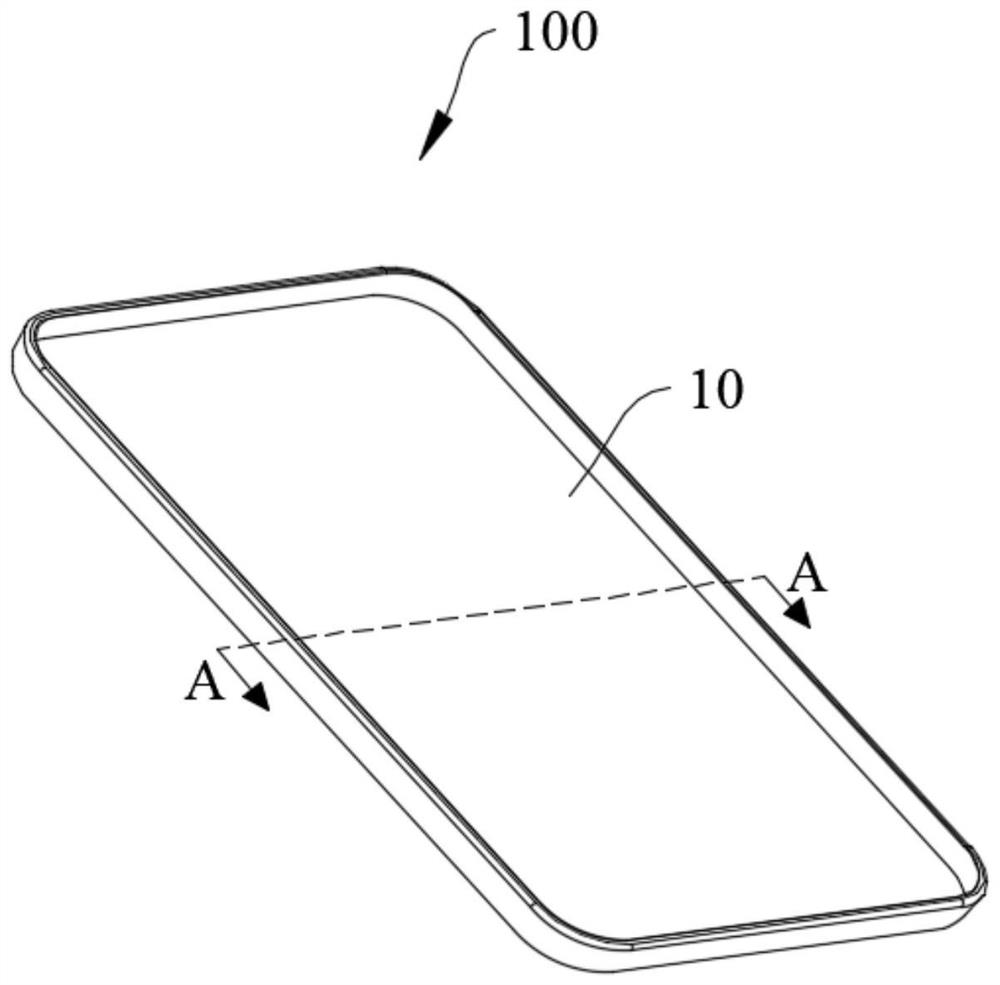

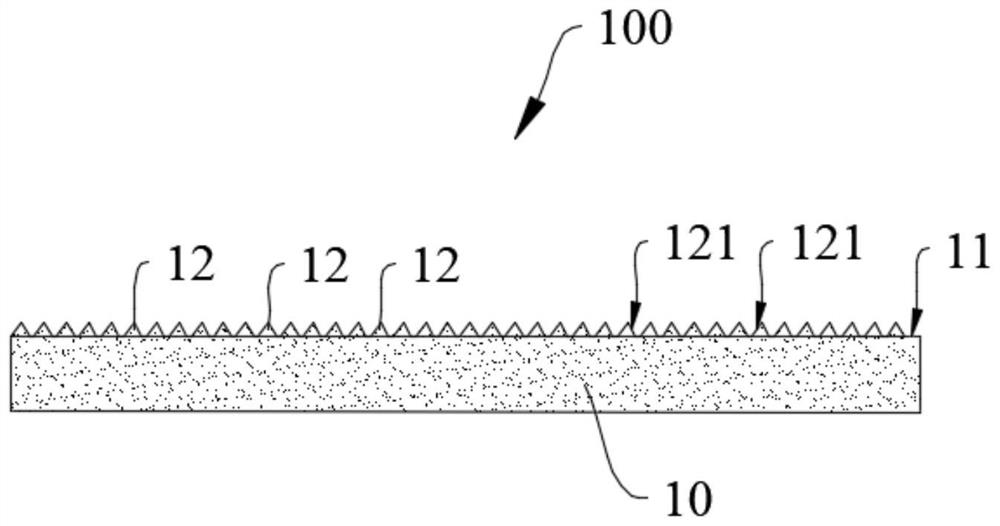

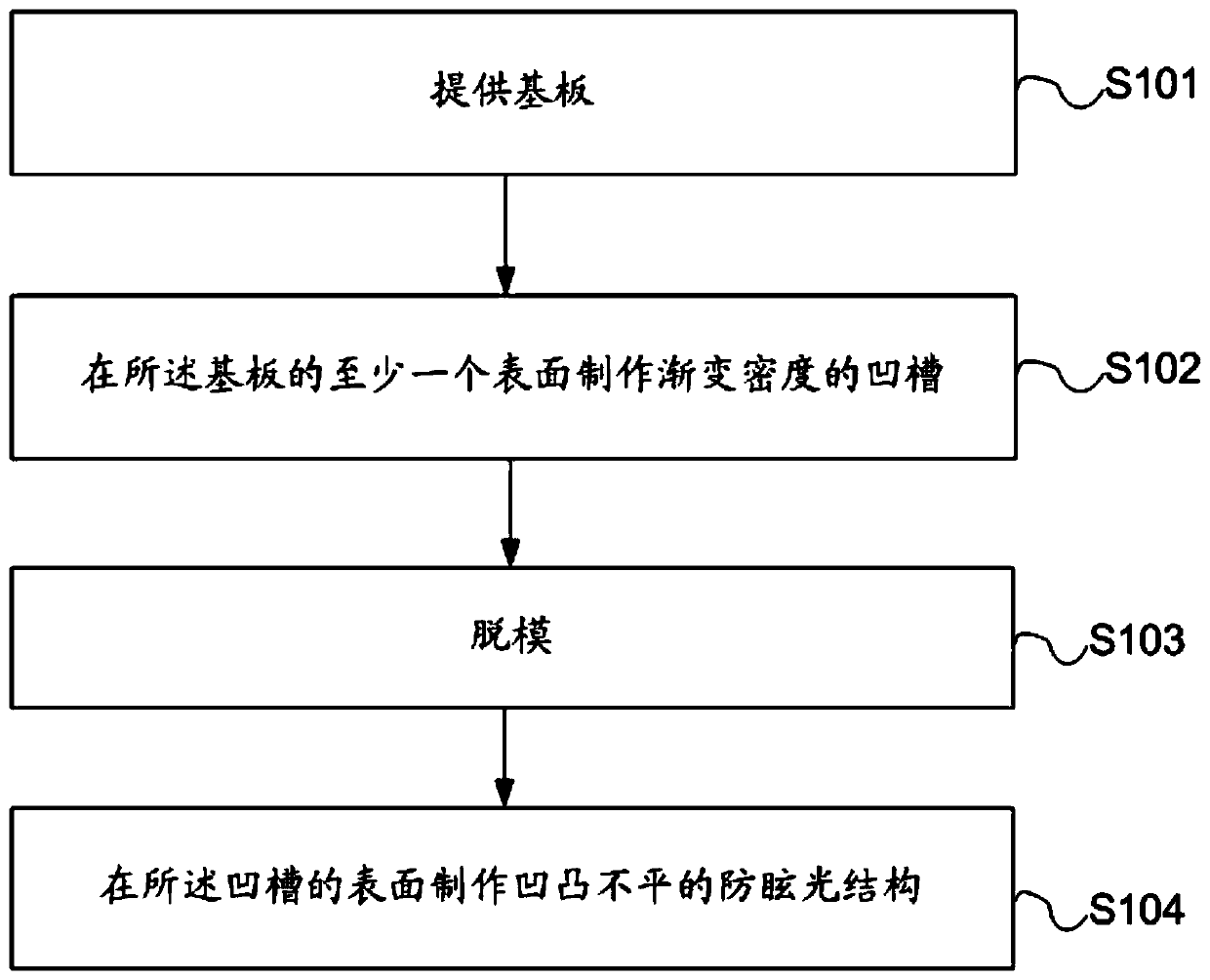

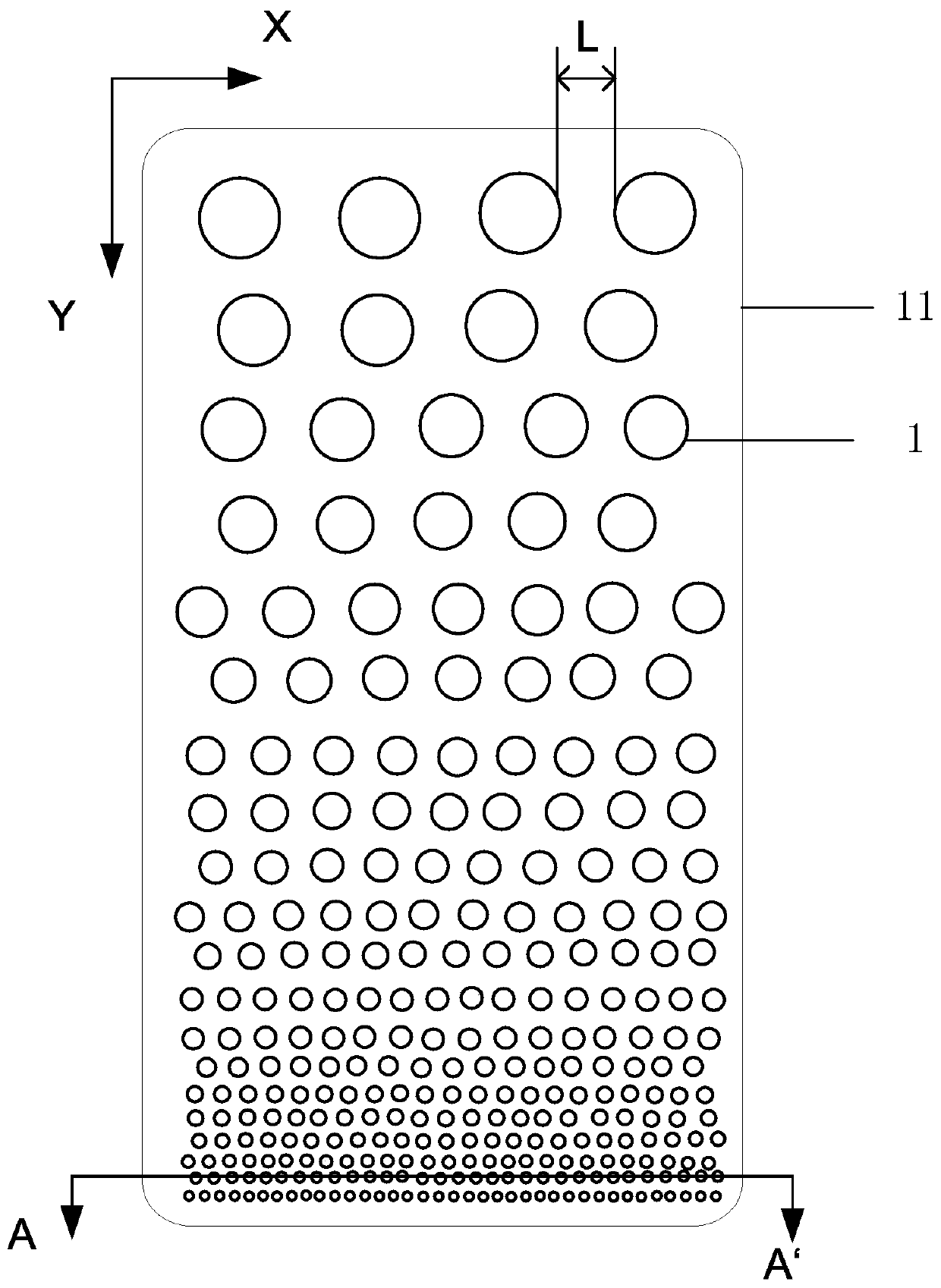

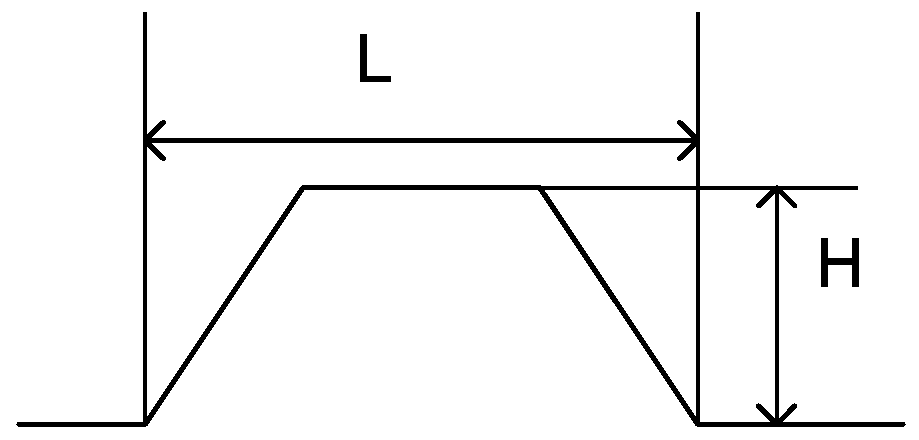

Gradient anti-glare cover plate and making method thereof as well as electronic equipment

ActiveCN107608013AAchieve natural gradientsTo achieve a gradient effectDiffusing elementsPhotomechanical apparatusDiffuse reflectionEngineering

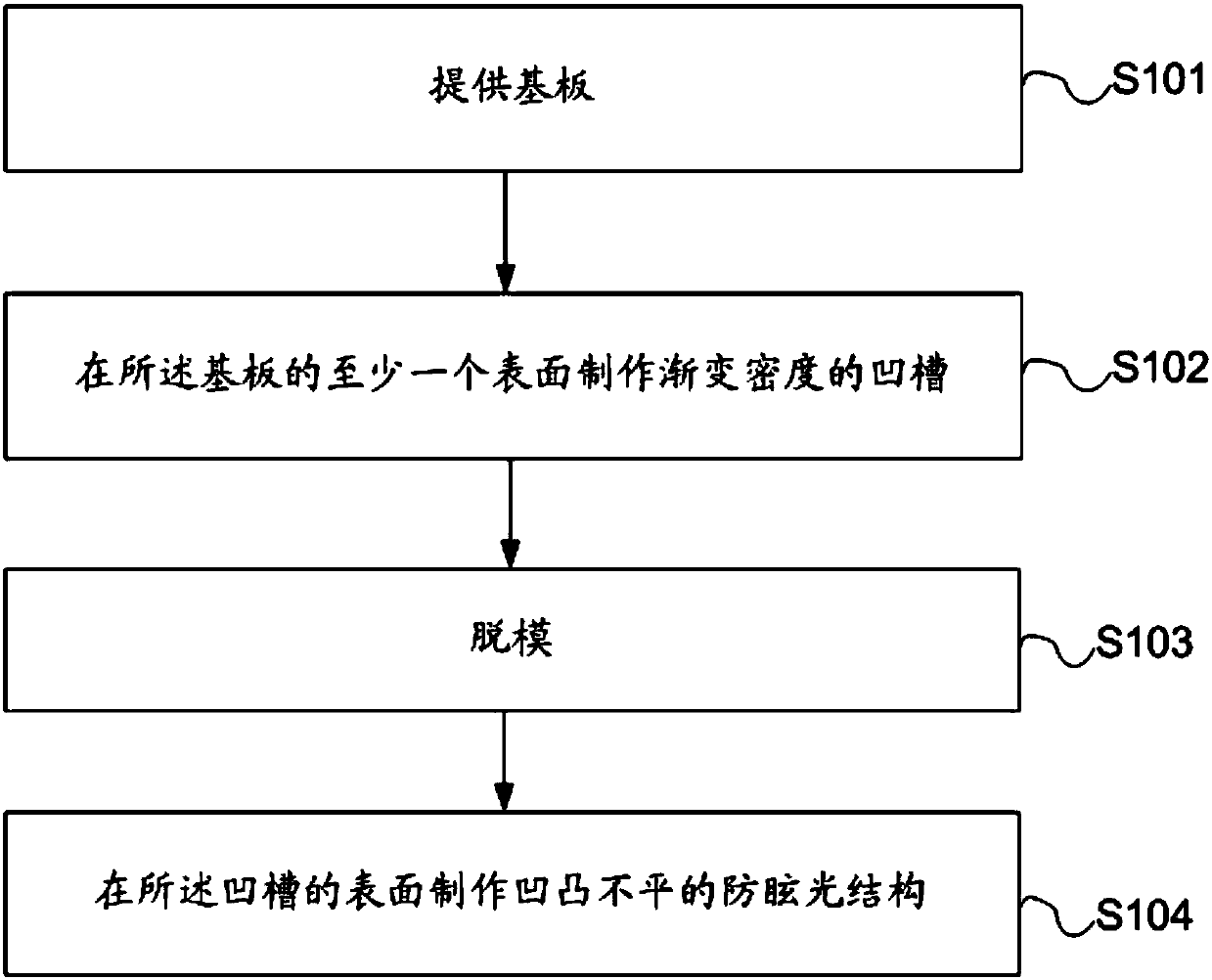

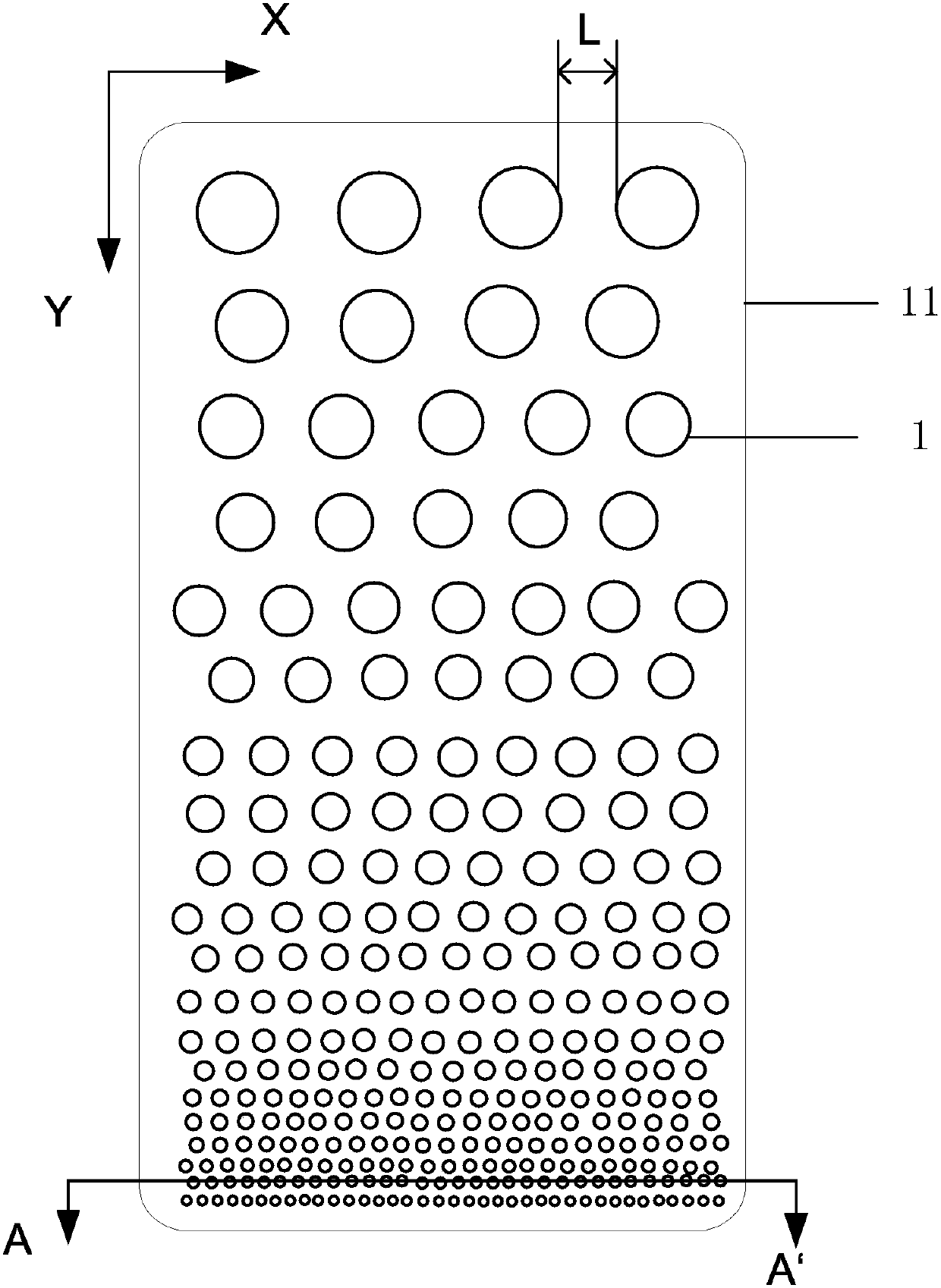

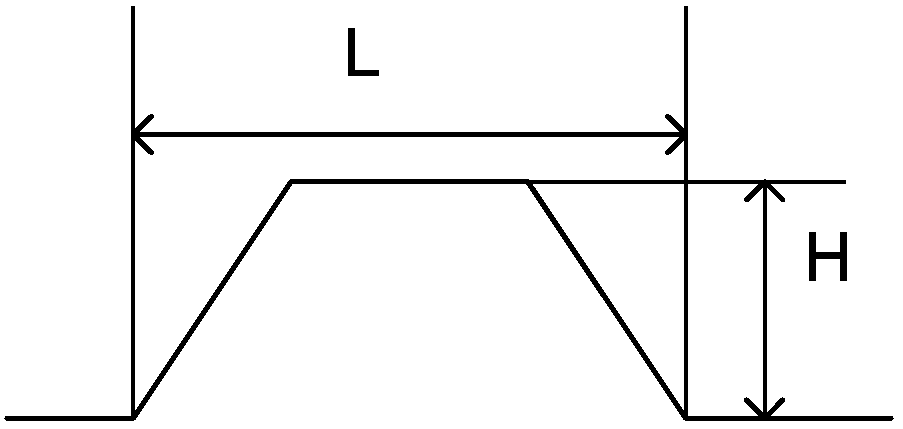

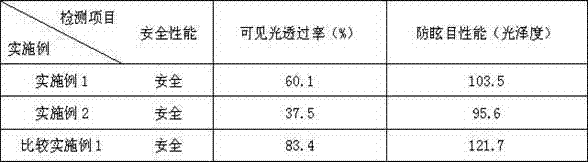

The application provides a gradient anti-glare cover plate and a making method thereof as well as electronic equipment. The making method comprises the following steps: providing a substrate; making graded-density grooves in at least one surface of the substrate, wherein the distance between the every two adjacent grooves is less than 5 microns; demoulding; making uneven anti-glare structures on the surfaces of the grooves. The graded-density grooves are firstly formed before anti-glare production, and the distance between the every two adjacent grooves is less than 5 microns, so that the natural gradual change of light can be realized, a gradual change effect is achieved, and the appearance of the gradient anti-glare cover plate is enabled to be more attractive; therefore, the gradient anti-glare cover plate is more greatly different from cover plates of other electronic products, and a homogenization phenomenon is further avoided. Furthermore, the anti-glare effect of the gradient anti-glare cover plate is realized mainly by means of irregular rugged small salient points directly formed in the grooves, and a diffuse reflection function is realized; the gradient and anti-glare effect is realized only by combining the two processes, so that the making technology is simple.

Owner:TRULY OPTO ELECTRONICS

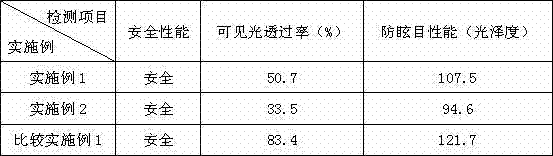

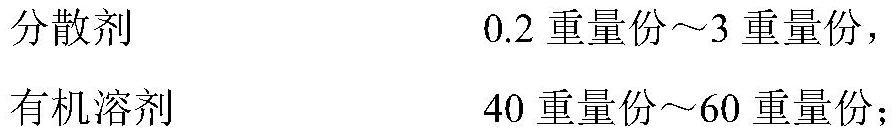

Coating material for anti-glare laminated glass and application method thereof

InactiveCN102653653AWith anti-glare effectReduce visible light transmittanceCoatingsAcrylic resinOrganosolv

The invention discloses a coating material for anti-glare laminated glass and an application method thereof. The coating material for anti-glare laminated glass is prepared through the steps of: based on nano ATO (antimony doped tin oxides) powder, through taking ethyl acetate as an organic solvent, adding materials such as ACR (acrylic resin), ball-milling mediums and the like into a mixture of the nano ATO powder and the ethyl acetate, and then carrying out ball milling dispersion on the obtained product so as to obtain ATO paste; through taking PVB (polyvinyl butyral) resin as a basic material, adding the ATO paste into the basic material, and carrying out high-speed mechanical dispersion on the obtained mixture so as to obtain an ATO sizing material; coating the ATO sizing material on the surface of glass; combining glass sheets together and pressurizing the combined glass sheets; and heating so as to obtain the coating material. The coating material disclosed by the invention integrates the safety performance of laminated glass and the anti-glare performance of ATO particles, therefore, the coating material can be widely used in the anti-glare fields of safety glass such as various construction safety glass and laminated glass for front windows of automobiles, and the like.

Owner:WUHU YAOHUA GLASS HORTICULTURE

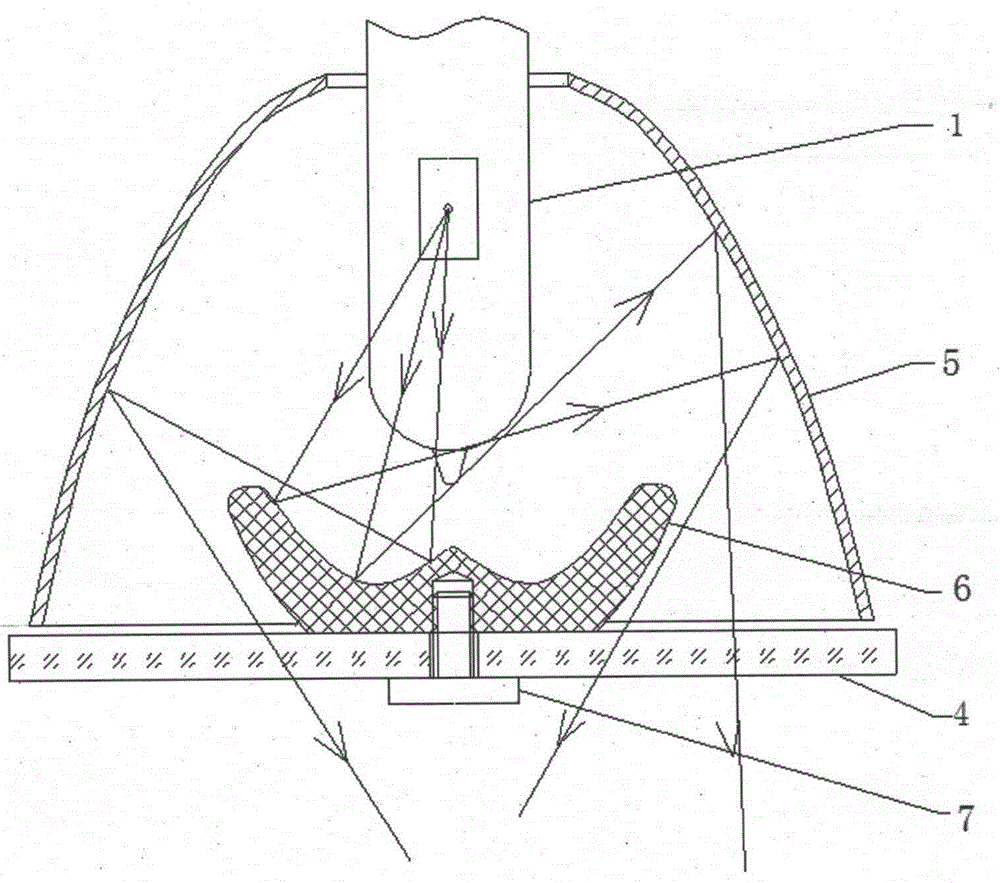

LED illumination device and illumination combination device thereof

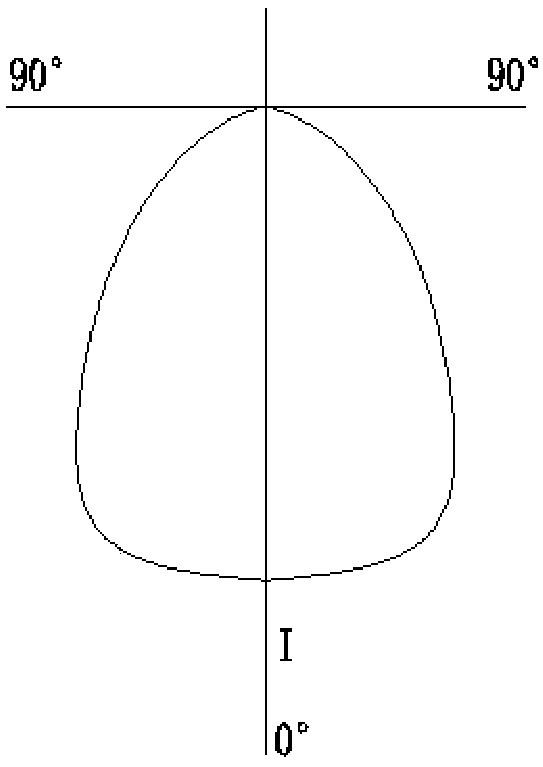

PendingCN109681817AEnhance the light intensity of the wingsImprove lighting uniformityMechanical apparatusOutdoor lightingLight sourceIlluminance

The invention discloses an LED illumination device and an illumination combination device thereof, belonging to the technical field of semiconductor illumination. The LED illumination device comprisesa lampshade and at least two LED light sources mounted in the lampshade, wherein a light-reflecting partition board is further arranged in the lampshade, and the side surface of the light-reflectingpartition board is a reflection surface; and the arranged LED light sources are separated through the light-reflecting partition board. According to the LED illumination device, uniform-luminance illumination function required by the grading design can be realized without a complex structural design and complex and machining and assembling processes, the dazzling can be effectively inhibited, thevisual perception can be improved, the visual fatigue can be relieved; and meanwhile, the LED illumination device is low in production cost and manufacturing cost, suitable for large-scale applicationand promotion and convenient for extension and large-scale use, one or more LED illumination device can be singly used or combined for use so as to meet the grading requirements of use occasions.

Owner:史杰

ATO (antimony doped tin oxides) coating material for laminated glass and application method thereof

InactiveCN102653654AWith anti-glare effectReduce visible light transmittanceCoatingsOrganic solventAcrylic resin

The invention discloses an ATO (antimony doped tin oxides) coating material for laminated glass and an application method thereof. The ATO coating material for laminated glass is prepared through the steps of: based on nano ATO powder, through taking ethyl acetate as an organic solvent, adding materials such as ACR (acrylic resin), ball-milling mediums and the like into a mixture of the nano ATO powder and the ethyl acetate, and then carrying out ball milling dispersion on the obtained product so as to obtain ATO paste; through taking PVB (polyvinyl butyral) resin as a basic material, adding the ATO paste into the basic material, and carrying out high-speed mechanical dispersion on the obtained mixture so as to obtain an ATO sizing material; coating the ATO sizing material on the surface of glass; combining glass sheets together and pressurizing the combined glass sheets; and heating so as to obtain the ATO coating material. The ATO coating material disclosed by the invention integrates the safety performance of laminated glass and the anti-glare performance of ATO particles, therefore, the ATO coating material can be widely used in the anti-glare fields of safety glass such as various construction safety glass and laminated glass for front windows of automobiles, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Shell and preparation method thereof, and electronic equipment

ActiveCN113966114AWith anti-glare effectFlash sand brightDecorative surface effectsCasings/cabinets/drawers detailsMechanical engineeringReflectivity

The invention provides a shell and a preparation method thereof, and electronic equipment. The shell comprises a shell body, wherein the shell body comprises a plurality of protruding structures, the protruding structures are located on the surface of the shell body, each protruding structure comprises a plurality of reflecting surfaces, the reflectivity of the shell body to visible light is larger than or equal to 60%, and the shell body is a glass body. The shell provided by an embodiment of the invention has a brighter and flatter granular flashing sand or pearlescent effect.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

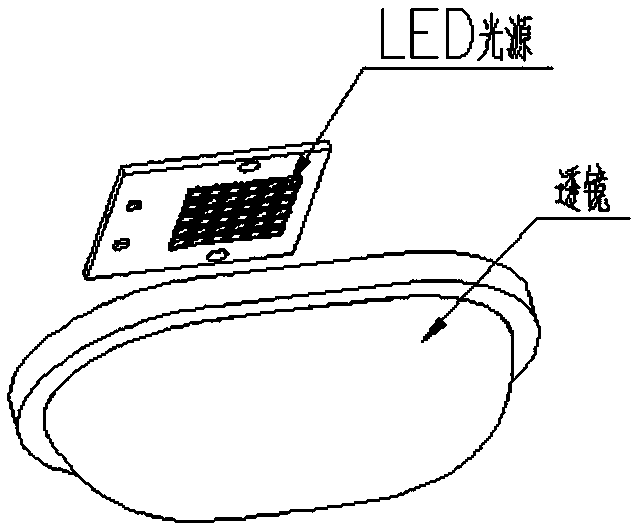

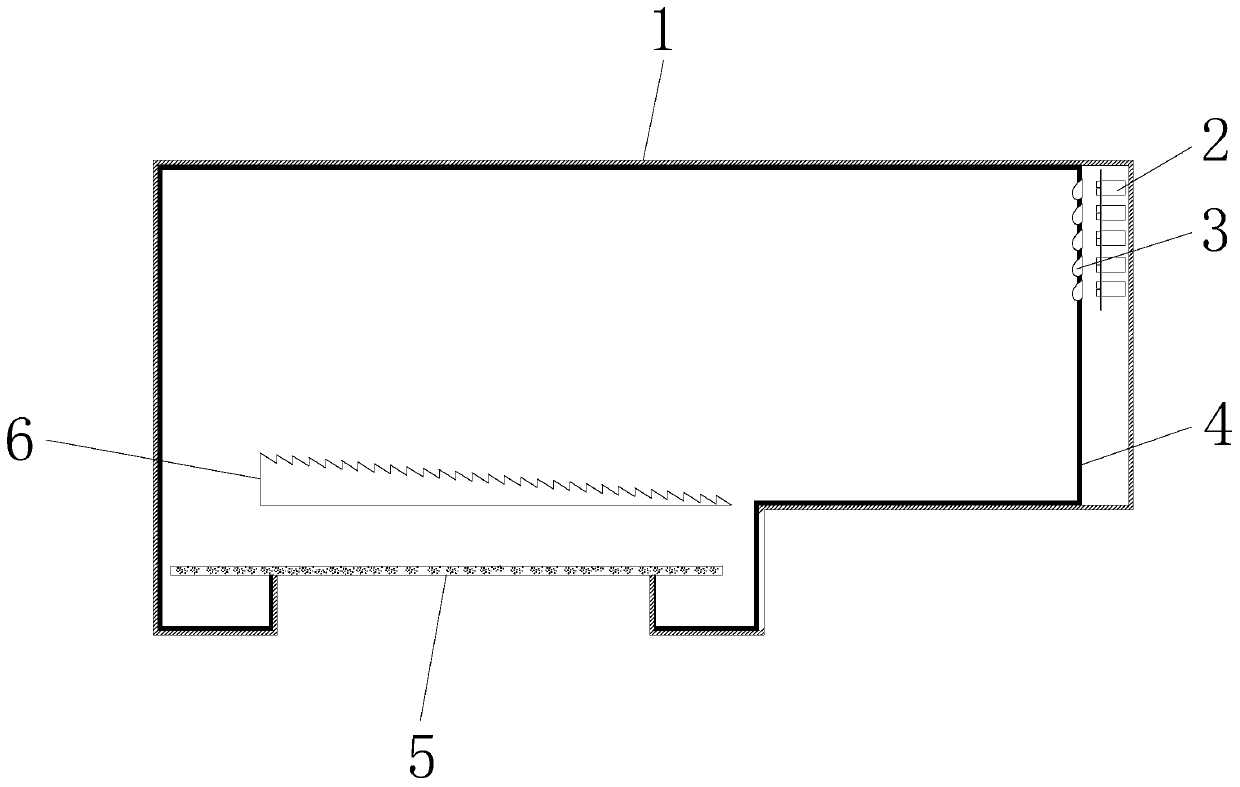

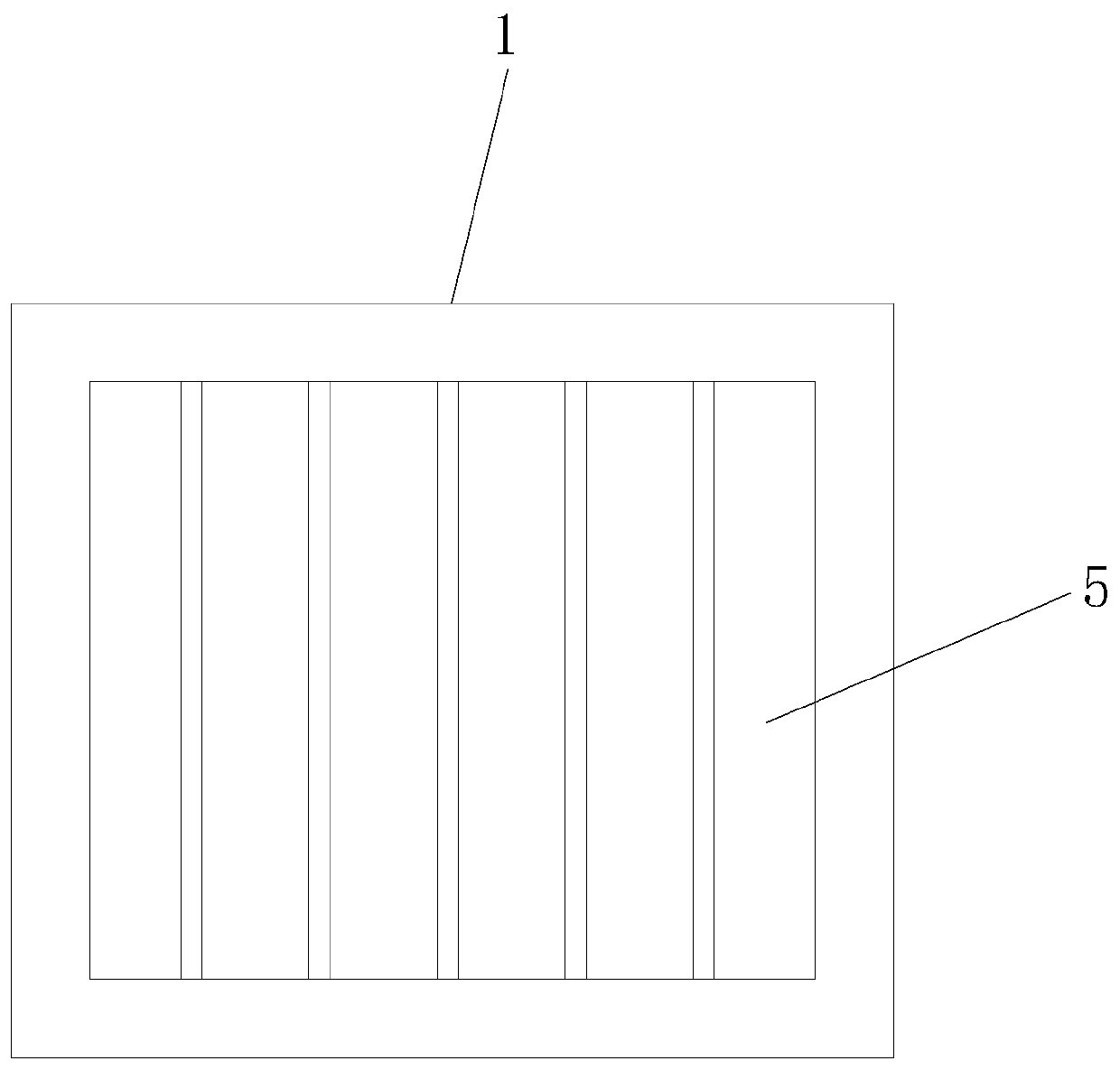

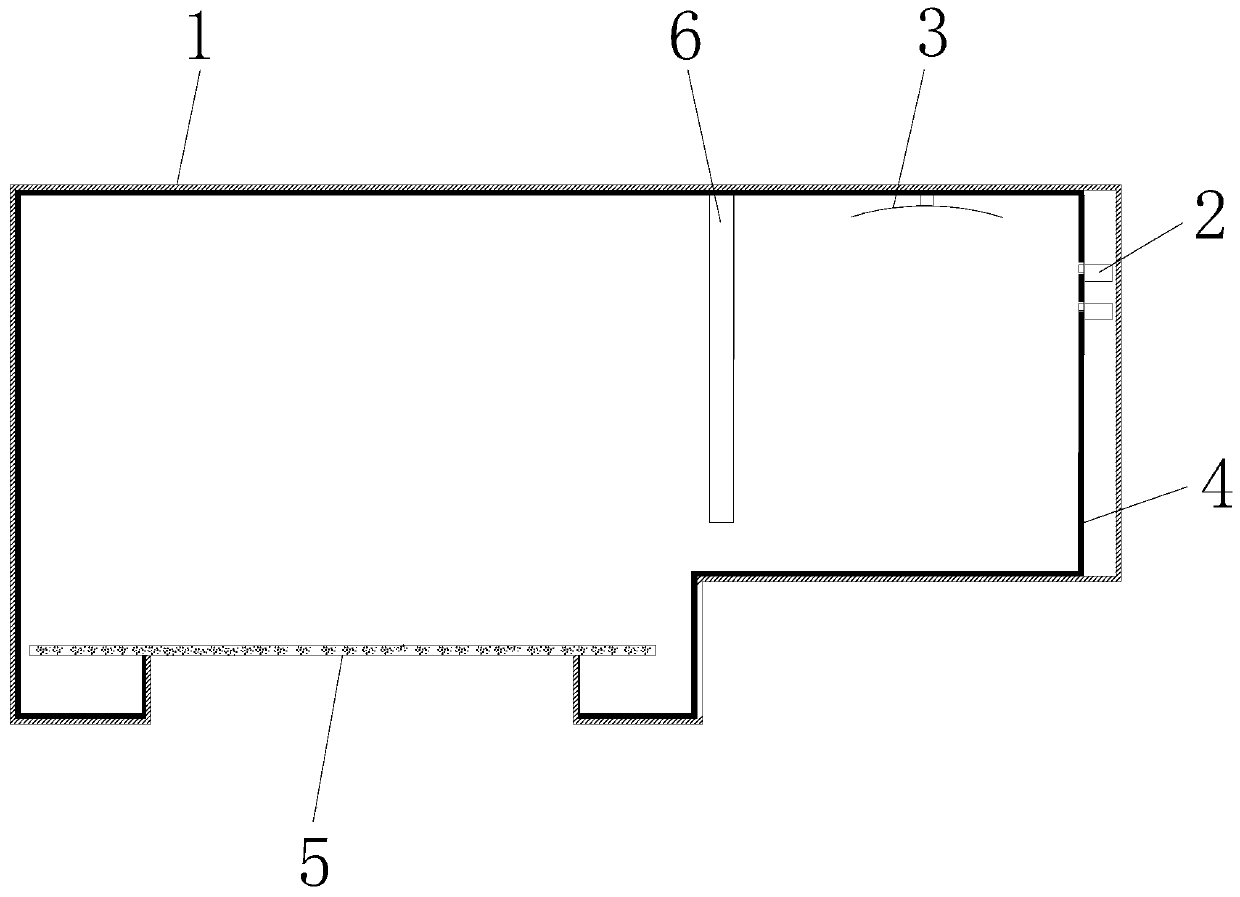

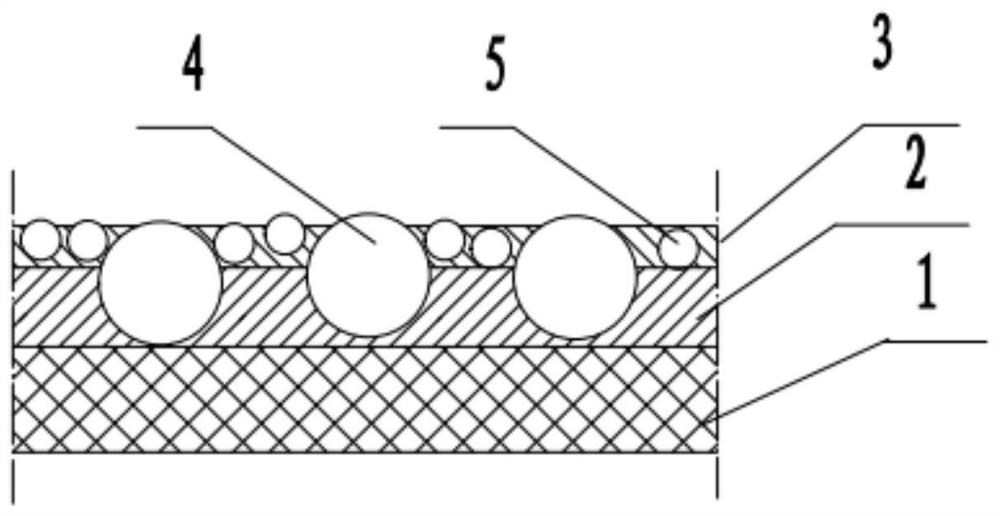

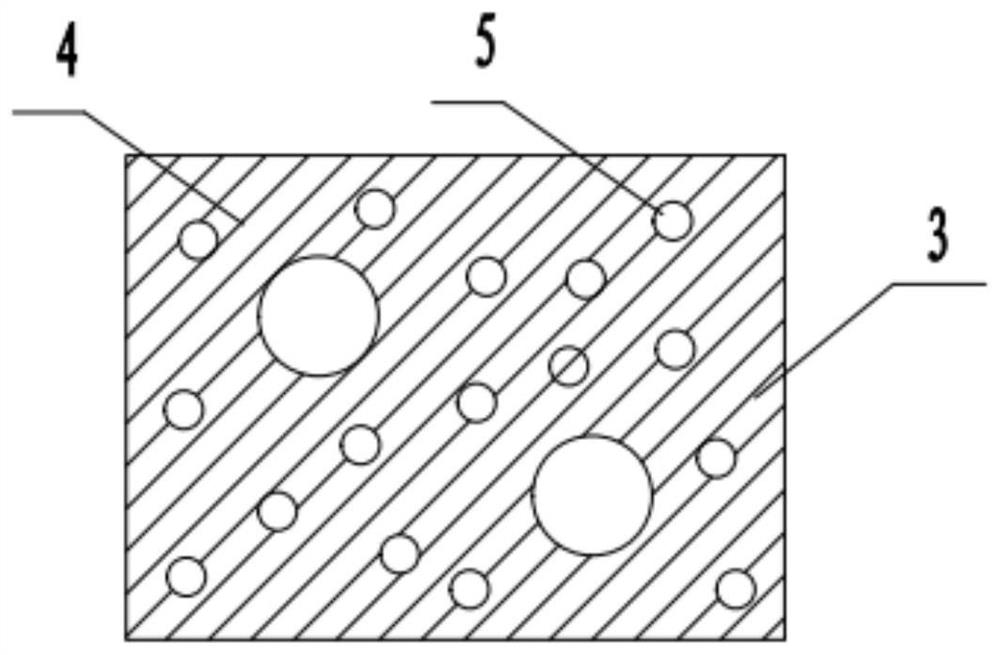

Panel lamp with skylight effect and implementation method thereof

PendingCN110822326AEnhance the blue effectWith anti-glare effectSpectral modifiersRefractorsFirst lightEngineering

The invention discloses a panel lamp with a skylight effect. The panel lamp comprises an outer shell, a plurality of light-transmitting plates are connected to the lower portion of the outer shell, aplurality of light-emitting light sources are connected to one side of the upper end in the outer shell, a shaping lens corresponding to each light-emitting light ource is arranged on one side of thelight-emitting light source, and each light-emitting light source comprises a first light source and a second light source, wherein each first light source is arranged above the corresponding second light source. The invention further discloses an implementation method of the panel lamp with the skylight effect. Titanium dioxide particles are uniformly packed in the light-transmitting plate, so that when white light emitted by the first light sources passes through the light-transmitting plates, blue light is scattered, and the light-transmitting plates are enabled to have a blue visual effect; and when the blue light emitted by the second light sources passes through the light-transmitting plates, the blue light is scattered, and the blue effect of the light-transmitting plates is enhanced, so that the blue sky effect is simulated.

Owner:HENGDIAN GRP TOSPO LIGHTING

Silica sol doped anti-dazzle anti-reflection coating solution as well as preparation method and application of silica sol doped anti-dazzle anti-reflection coating solution

The invention discloses a silica sol doped anti-dazzle anti-reflection coating solution as well as a preparation method and application thereof, and relates to the technical field of solar glass. The silica sol-doped anti-dazzle anti-reflection coating solution provided by the invention contains the modified large-size silica sol, the pore forming agent, the silane coupling agent and the diluent, and after the glass surface is coated into a film through a roller coating coating process, particles in the modified large-size silica sol can form a micro-convex structure in a film layer Therefore, the film layer and the glass have an anti-dazzle effect. The film coating solution is prepared by adopting a chemical synthesis method, is suitable for a roll coating process with the highest film coating efficiency, is simple to process and does not need to adopt an atomization spraying mode; And multiple layers of films do not need to be additionally plated, so that the production efficiency can be improved and the production cost can be reduced.

Owner:DONGGUAN CSG SOLAR GLASS +1

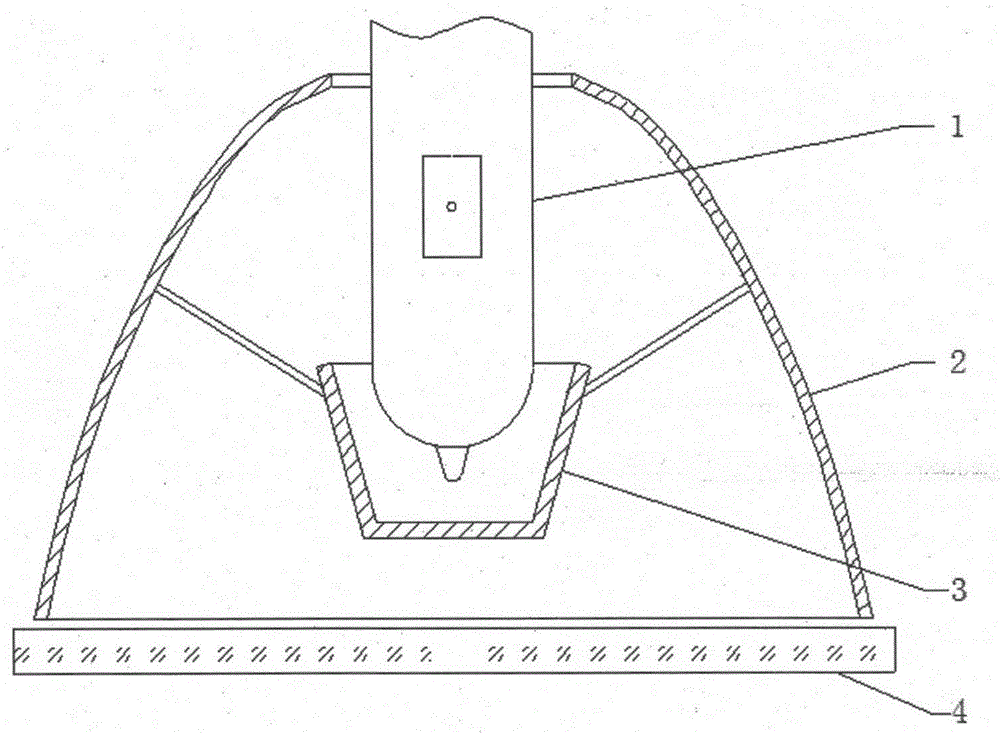

Manufacture process of anti-glare lamp with light efficiency improvement function

InactiveCN103557495AHigh light efficiencyEasy to installLight fasteningsReflectorsIlluminanceOptoelectronics

The invention relates to a manufacture process of an anti-glare lamp with a light efficiency improvement function. The manufacture process is characterized by comprising the following steps: an optical glare cover is made; a first reflective surface is formed on the upper surface of the optical glare cover; a chrome plated decorative bolt is used for fastening the optical glare cover on toughened glass; the toughened glass is mounted on a reflecting shade equipped with a light source, wherein the inner surface of the reflecting shade is a second reflective surface; and incident light emitted by the light source irradiates on the first reflective surface from different angles, is reflected onto the second reflective surface from different angles after the reflection by the first reflective surface, and then is reflected out by the second reflective surface from different angles, so that a complete set of optical system is formed. The anti-glare lamp with the light efficiency improvement function is simple and convenient to mount manually without a special tool; the optical glare cover has an anti-glare effect and can also serve as an auxiliary reflecting shade, therefore, the light efficiency of a lamp is improved, the illumination intensity can be improved by 20% compared with a lamp with a conventional glare cover, and energy conservation and emission reduction effects are achieved.

Owner:郝乐(上海)电子有限公司

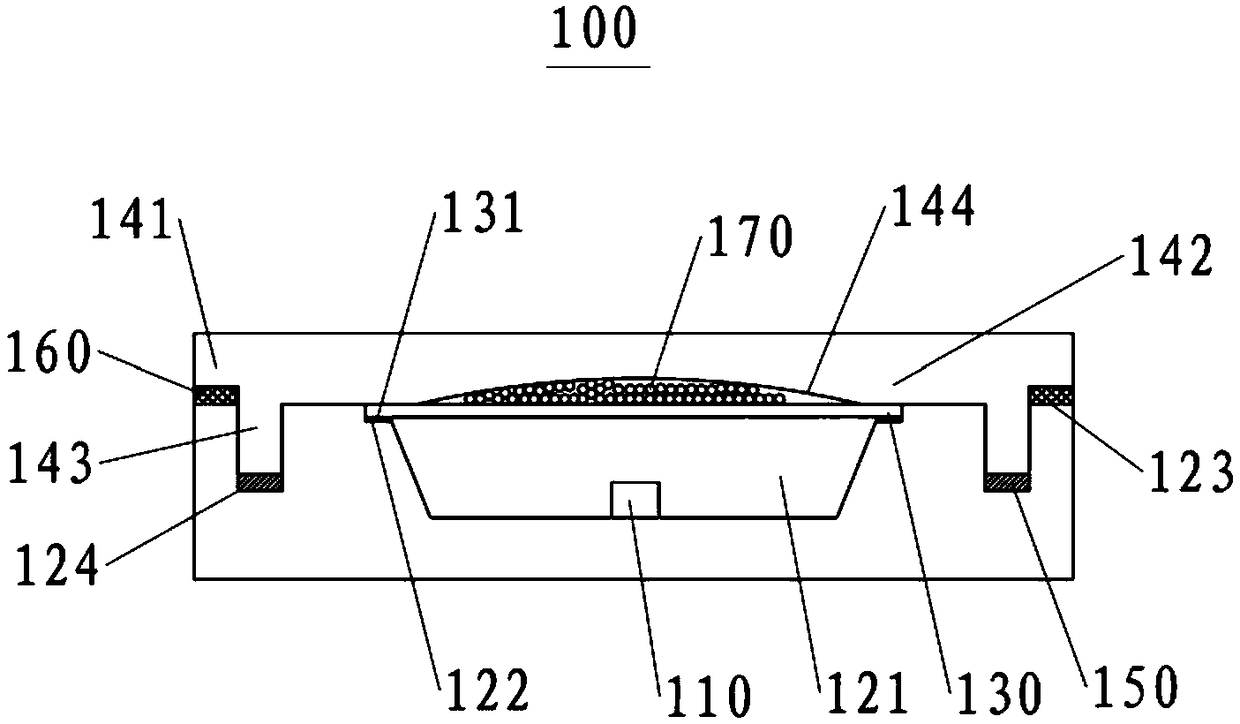

LED packaging structure and LED light source device

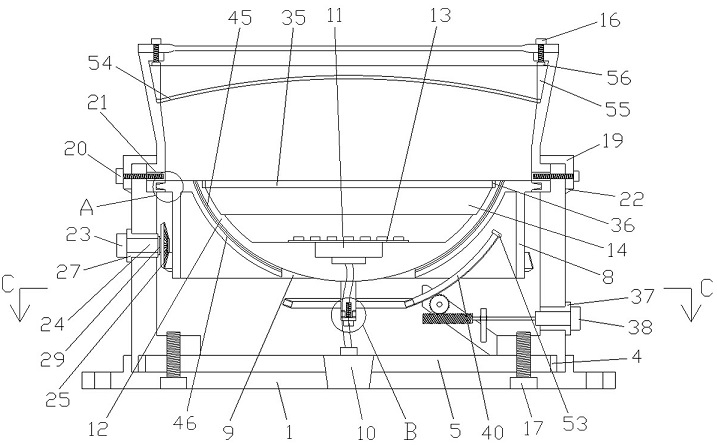

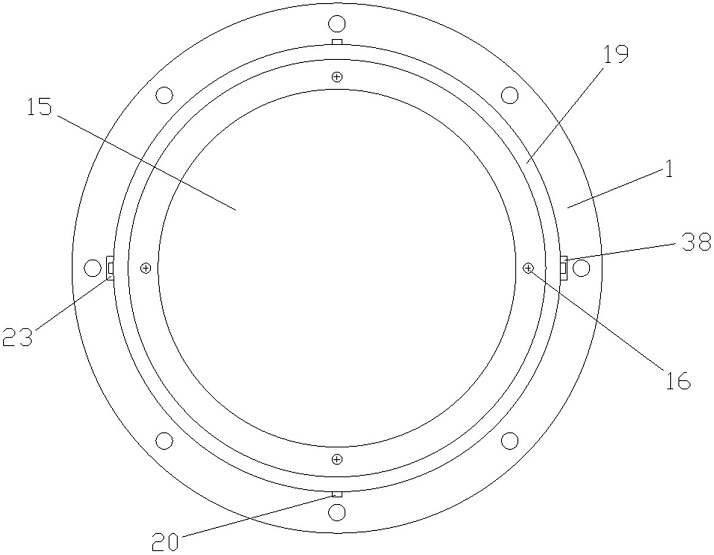

ActiveCN113217831AWith stableEliminate internal stressProtective devices for lightingGas-tight/water-tight arrangementsRubber ringLight irradiation

The invention discloses an LED packaging structure. The LED packaging structure comprises a base, wherein a shell is arranged on the surface, located on the inner side of a limiting edge, of the base; a heat dissipation substrate is arranged on the surface, located on the inner side of a first expansion rubber ring, of the base; a lampshade is arranged above a gasket block; a rotary fixing base is arranged in a third matching groove in a matched mode; a rotation control mechanism is arranged on the rotary fixing base and one side wall face of the shell; reflection cups are arranged in the fourth matching groove in a matched mode; an LED chip installation plate is arranged on the reflection cup located at the bottom of the groove; a combined lens is arranged on the reflection cup located above the LED chip installation plate; angle adjusting mechanisms are arranged at the bottom ends of the reflection cups and one side wall face of the shell; and an anti-dazzle net is arranged on the top surface of the lampshade. According to the LED packaging structure, mounting and fixing effects among the base, the shell, the lampshade and the anti-dazzle net are good, and light irradiation angles can be adjusted through the rotation control mechanism and the angle adjusting mechanisms. The invention further provides an LED light source device with sealing performance and light irradiation effect.

Owner:佛山市其利照明电器有限公司

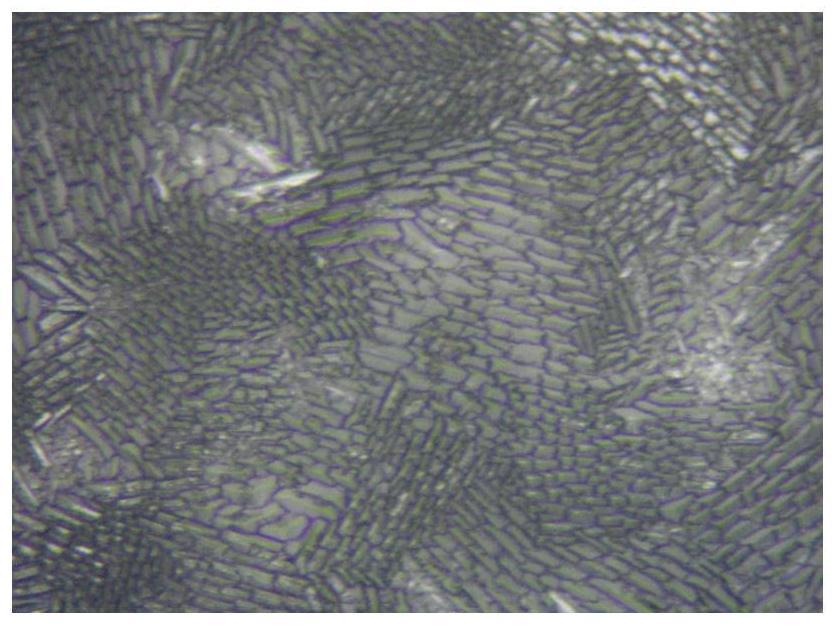

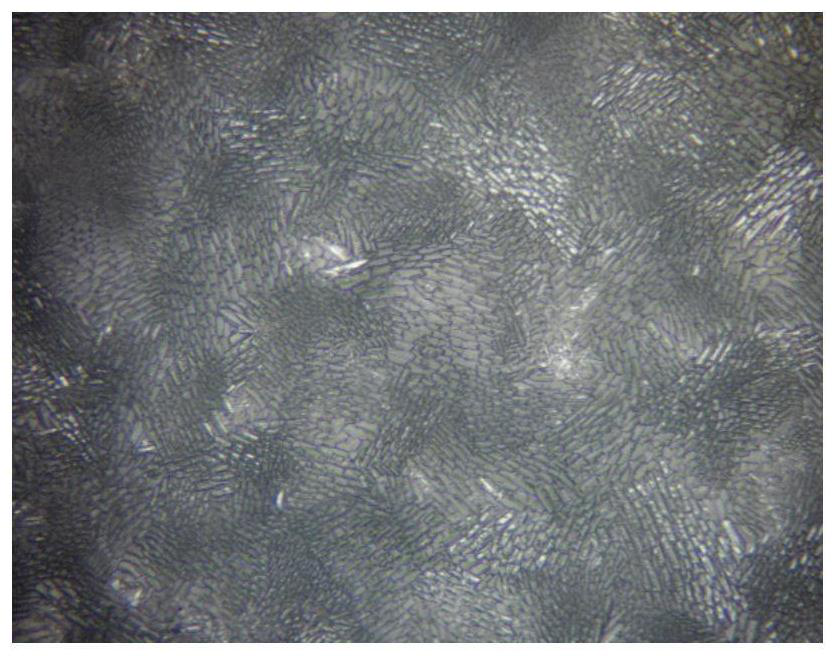

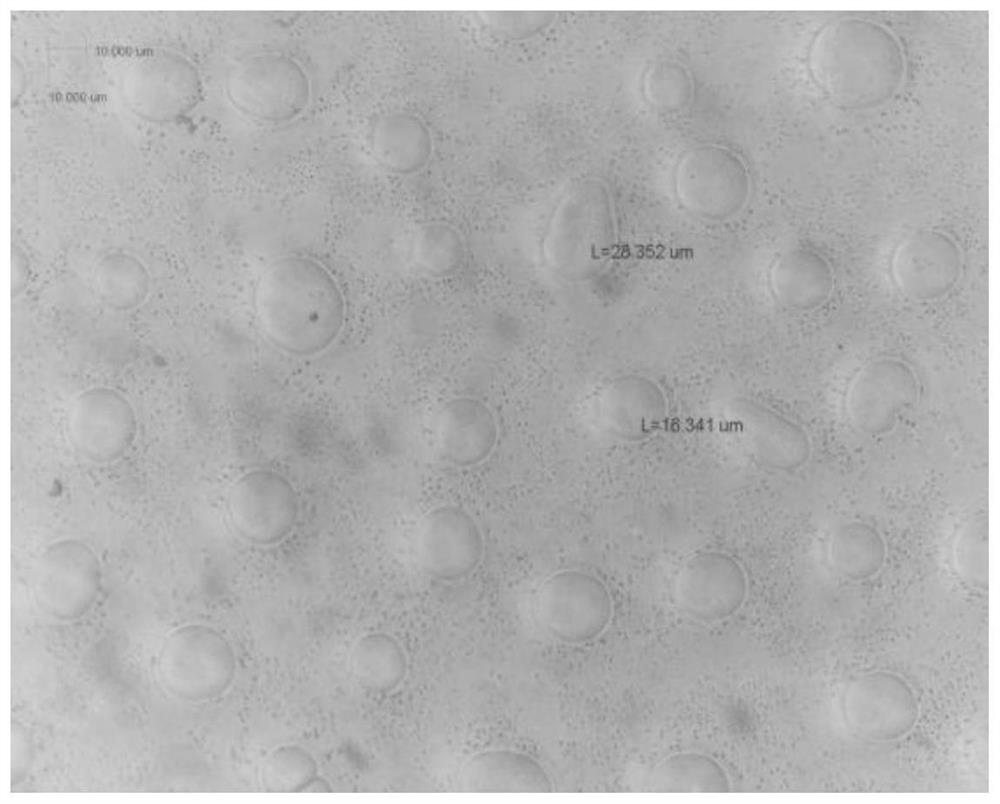

Frosting liquid medicine and process for directionally arranging crystal lattices on etched surface of high-alumina-silica glass

The invention provides frosting and a process for directionally arranging crystal lattices on an etched surface of high-alumina-silica glass. A formula of frosting liquid medicine comprises water, ammonium bifluoride, potassium fluoride, sodium fluoride, ammonium fluosilicate, ammonium sulfate, potassium nitrate, nitric acid, citric acid, cellulose and an ion dispersing agent. The frosting process comprises the following steps: (1) preparing frosting liquid medicine; (2) performing ink protection on the non-processed surface of the high-alumina-silica glass; (3) soaking the high-alumina-silica glass with hydrofluoric acid to obtain glass to be processed; (4) clamping the to-be-processed glass by using mechanical equipment, and setting a movement track of the to-be-processed glass; (5) soaking the to-be-processed glass into the frosting liquid medicine, and performing soaking treatment; and (6) after soaking, taking out the glass, cleaning with neutral deionized water, and drying. The high-alumina-silica glass obtained by the invention not only has the hazy and anti-dazzle effects of traditional frosting, but also can present a flickering effect as lakesling in the sun, and is higher in aesthetic degree.

Owner:惠州市百时达化工有限公司

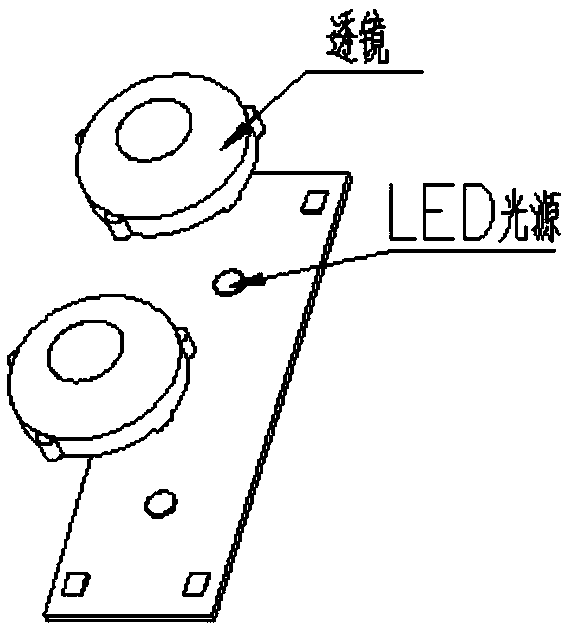

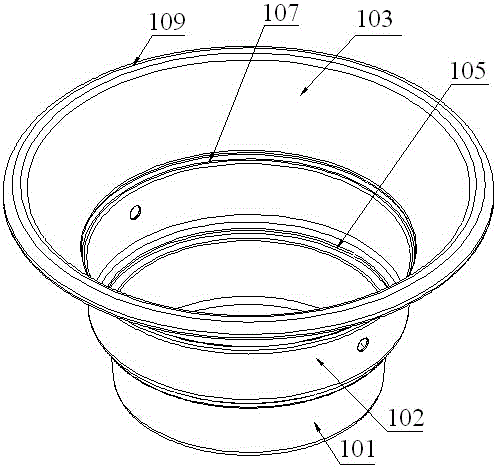

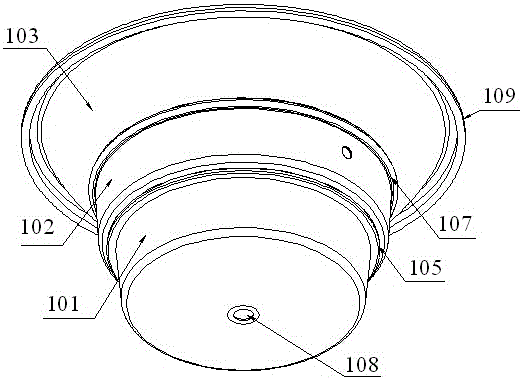

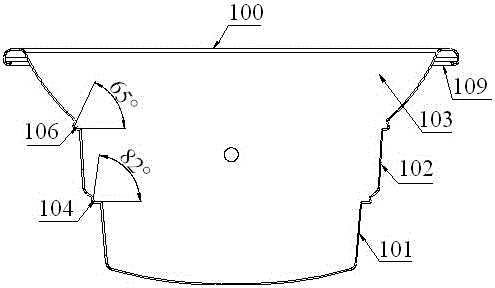

LED projection lamp

InactiveCN105042422AUniform and soft glowGood flexibilityPoint-like light sourceLighting heating/cooling arrangementsHollow cylinderEngineering

The invention discloses an LED projection lamp. The LED projection lamp comprises a lamp housing formed by spinning of an aluminum plate through a drilling machine, an LED light source structure clamped in the lamp housing, a light-pervious cover which is clamped in the lamp housing and covers the LED light source structure, and a driving device. The LED light source structure comprises a substrate and SMD LED lamp beads arranged on the substrate. A hollow-cylinder-shaped bottom cavity provided with accommodating space, a middle cavity, and an inverted-circular-truncated-cone-shaped light guiding arc-shaped curved surface formed after an opening in the upper end of the middle cavity inclines and extends outwards, wherein the diameter of the middle cavity is larger than that of the bottom cavity. A first annular clamping groove into which the substrate can be clamped and pressed is formed in the position where the bottom cavity is connected with the inner wall of the middle cavity, and a first included angle is formed on the section of the first annular clamping groove. A second annular clamping groove into which the light-pervious cover can be clamped and pressed is formed in the position where the middle cavity is connected with the inner wall of the light guiding arc-shaped curved surface, and a second included angle is formed on the section of the second annular clamping groove. A wire passing hole is formed in the bottom of the lamp housing, and the lamp housing is integrally formed.

Owner:姚耀安

Panel lamp capable of presenting sky effect and implementation method thereof

PendingCN110848598AFacilitated DiffusionIncrease scatteringSpectral modifiersRefractorsEngineeringMaterials science

The invention discloses a panel lamp capable of presenting a sky effect; and the panel lamp comprises an outer shell, a plurality of diffusion plates are connected below the outer shell, a plurality of light emitting sources are connected to one side of the upper end of the interior of the outer shell, a uniform light plate perpendicular to the diffusion plates is arranged on one side of each light emitting source, and a light reflecting plate is arranged at the top end of the interior of the outer shell and located between the uniform light plate and the light emitting sources. The inventionfurther discloses an implementation method of the panel lamp capable of presenting the sky effect. The interiors of the diffusion plates are uniformly filled with titanium dioxide particles, so that when white light emitted by the light emitting sources passes through the diffusion plates, blue light is scattered, and the diffusion plates exhibit a blue visual effect; and the blue light is scattered when the blue light between 450 nm and 650 nm passes through the diffusion plates, and the blue effect of the diffusion plates is enhanced, so that the blue-sky effect is simulated.

Owner:HENGDIAN GRP TOSPO LIGHTING

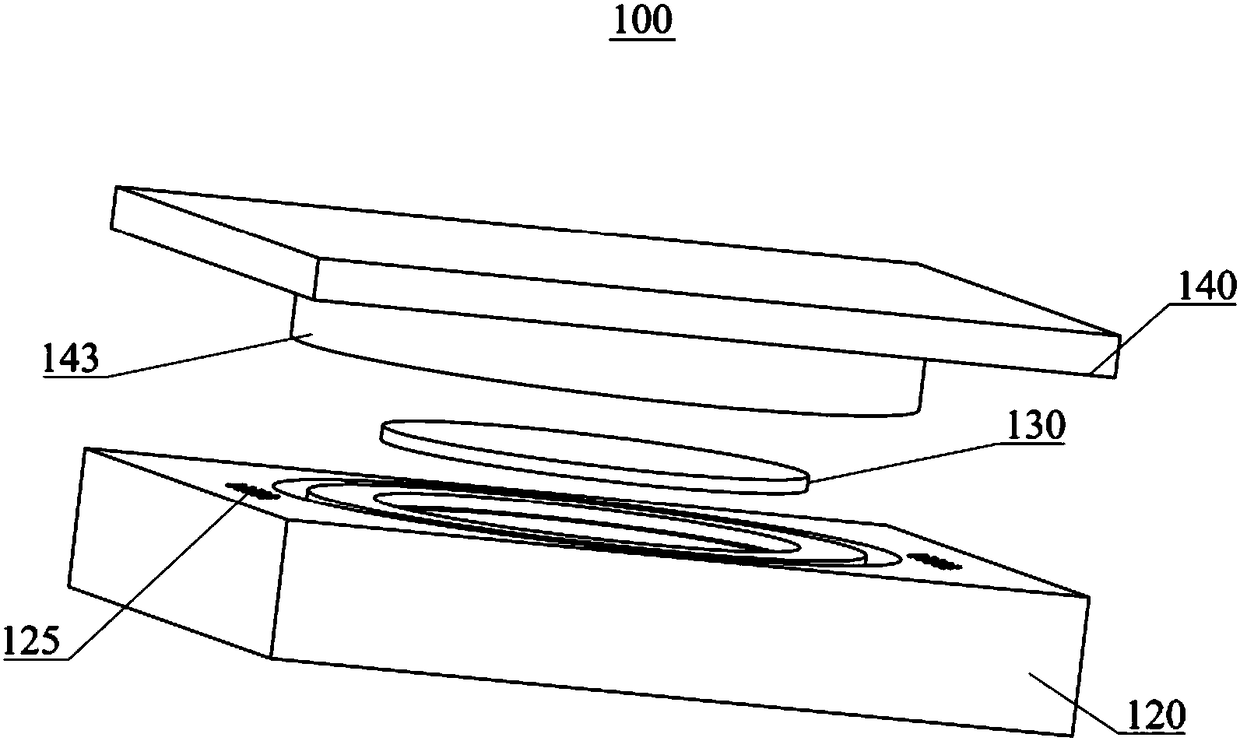

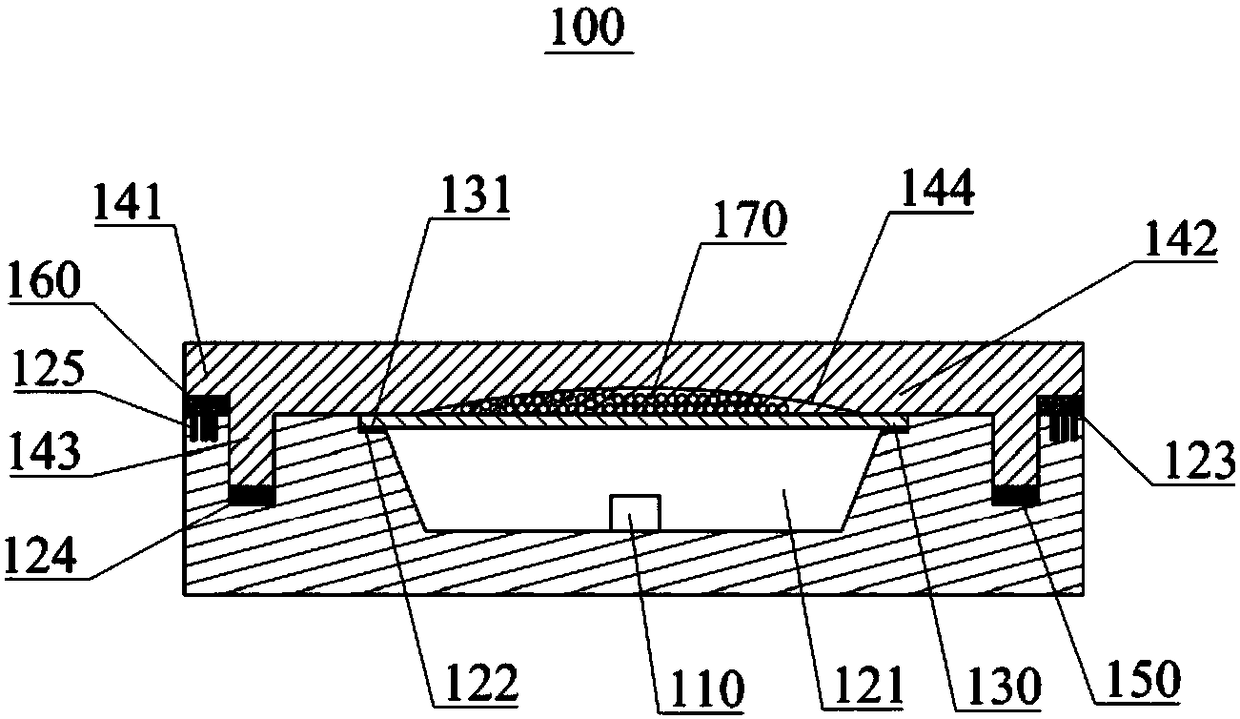

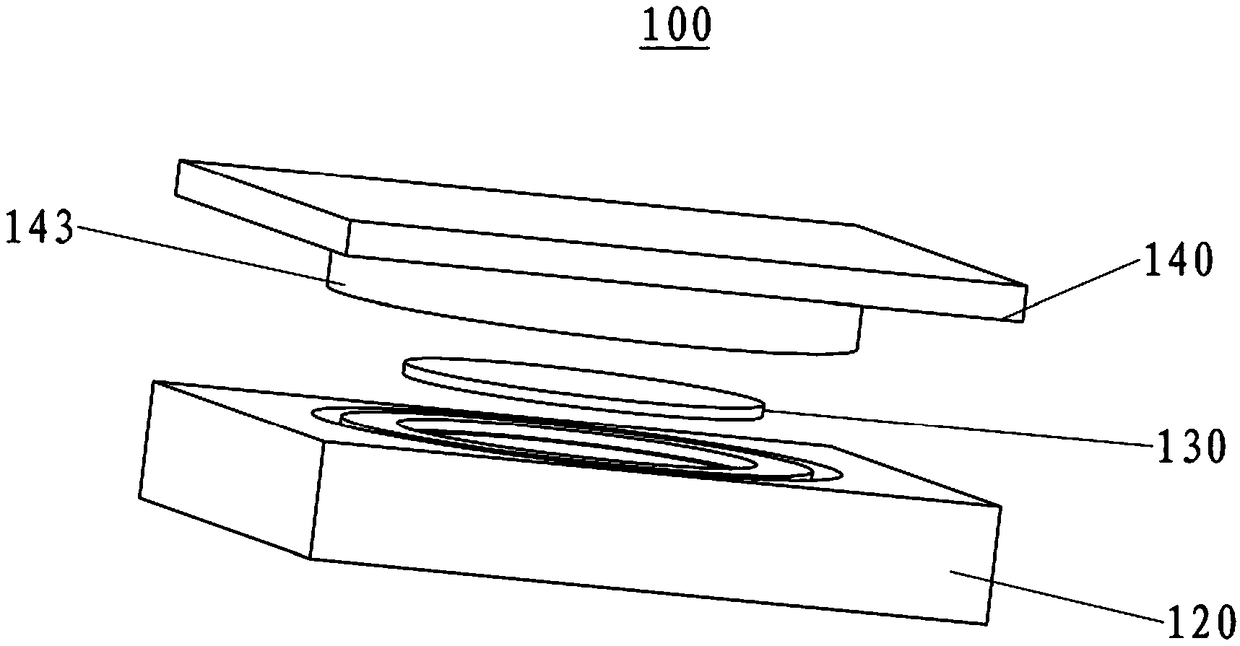

LED (Light Emitting Diode) device and LED lamp

The invention discloses an LED (Light Emitting Diode) device and an LED lamp. The LED device comprises a substrate, a first light transmission plate and a second light transmission plate. A cavity isformed in the substrate, an LED chip is arranged in the cavity, a stepped face is formed at an open end of the cavity, and a seal groove is formed in the peripheral face of the cavity. The first lighttransmission plate is arranged on the stepped face. The second light transmission plate comprises a peripheral part and an intermediate part, an annular lug matched with the seal groove is arranged between the peripheral part and the intermediate part, a desiccant is used for filling between the peripheral part and the intermediate part, the thickness of the peripheral part is smaller than that of the intermediate part, the intermediate part is opposite to the cavity and presses the first light transmission plate, a microporous layer opposite to the peripheral part is arranged on the peripheral face, a bonding adhesive is used for filling between the peripheral part and the substrate and infiltrates into the microporous layer, a concave spherical face with an opening facing to the first light transmission plate is formed in the intermediate part, and a plurality of glass micro-beads are arranged in the intermediate part. According to the LED device and the LED lamp, outside corrosivesubstances are subjected to dual isolation, the failure rate of the LED device can be effectively improved, and the LED device has an anti-dazzle effect.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

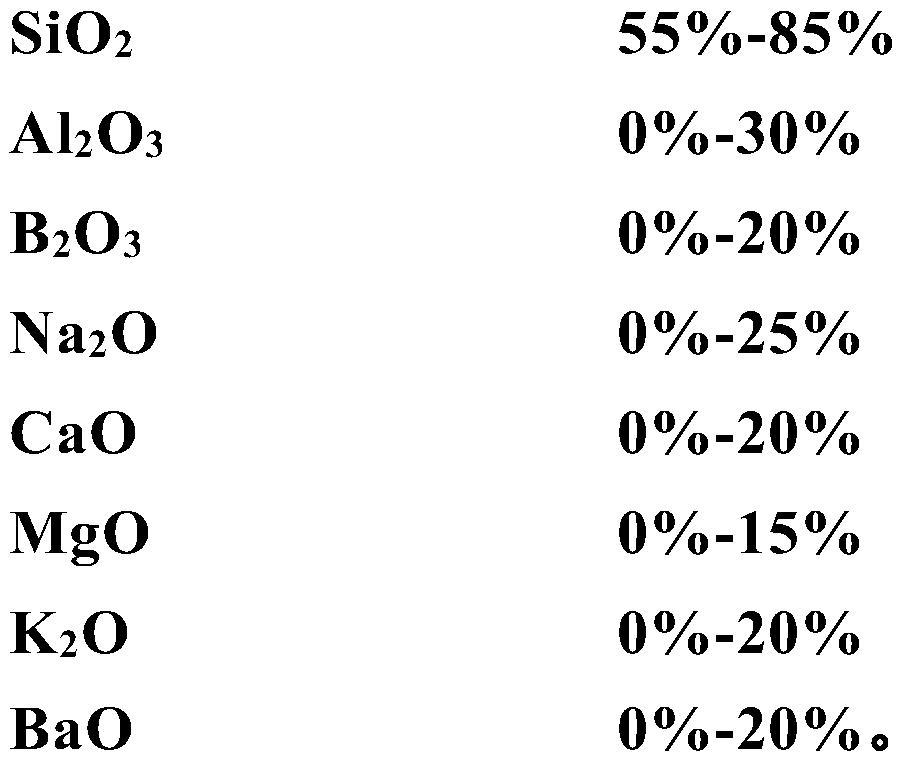

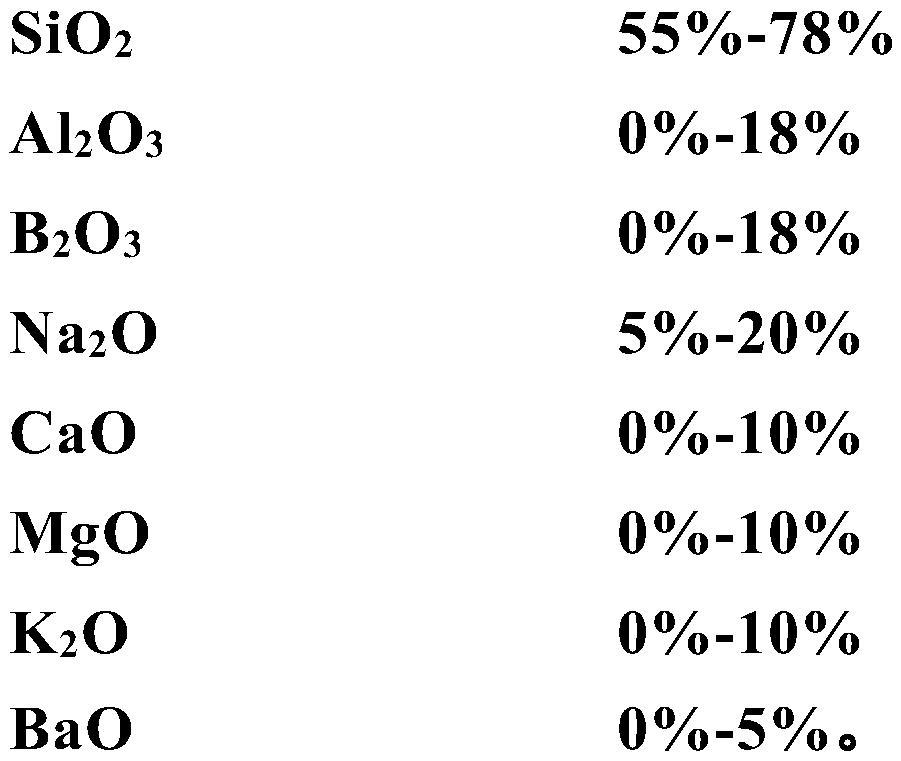

Anti-glare glass sheet

Owner:AGC GLASS EUROPE SA +3

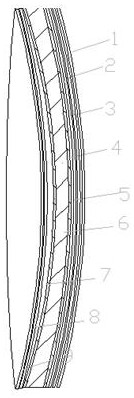

Manufacturing technology of multi-layer composite color-change polarizing resin lens for interior of vehicle

InactiveCN111633893AWith anti-glare effectImprove practicalityLaminationOptical articlesManufacturing technologyAssembly line

The invention discloses a manufacturing technology of a multi-layer composite color-change polarizing resin lens for the interior of a vehicle. The technology mainly comprises special treatment for aresin polarizing film and a pasting process. The polarizing film with the same curvature is pasted to the surface of the resin hardened lens, the polarizing resin lens is marked according to a polarizing assembly line, an automatic hardening machine is used for dip-coating a color-change layer on the front surface of the lens, a surface hardened layer is added, then curing is performed, and the cured lens is placed in a vacuum film coating machine for film coating. The lens produced through the technology is fashionable and practicable.

Owner:ZENNI OPTICAL

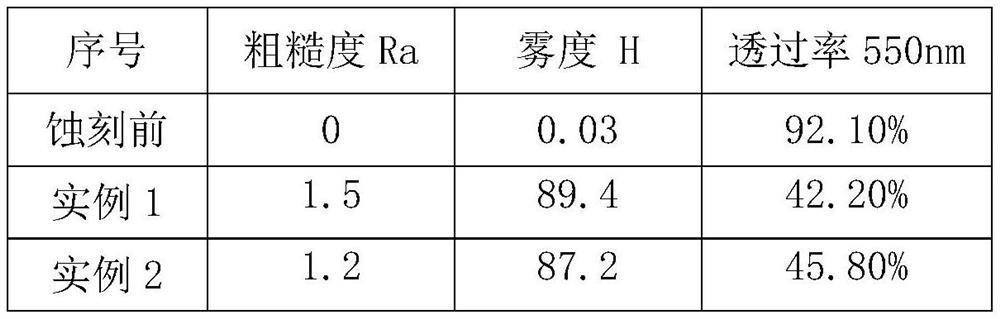

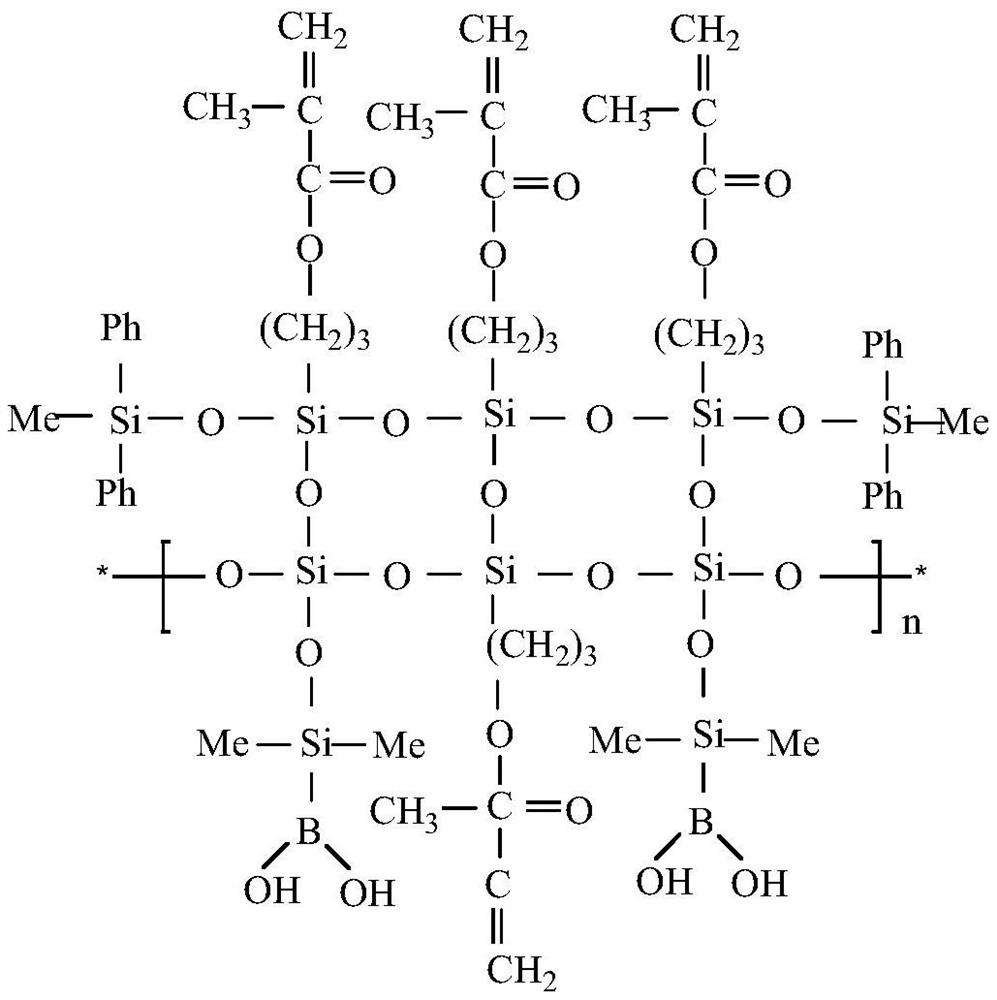

A high transparency and high fog anti-glare coating

ActiveCN113402976BWith anti-glare effectHigh light transmittancePolyurea/polyurethane coatingsAcrylic resinThin membrane

The invention discloses a high-transparency and high-fog anti-glare coating, which comprises a UV-curable borosilicate resin (B-MDT), a UV-curable acrylic resin, a reactive diluent, a photoinitiator and an auxiliary agent, according to weight percentage It is: 10-70% of boron-containing silicone resin, 10-50% of acrylic resin, 10-70% of reactive diluent, 1-5% of photoinitiator, and 5-9% of auxiliary agent. On the basis of ensuring that the product has an anti-glare effect, the coating of the present invention ensures high light transmittance and high haze, and the light transmittance when coated on the film can reach more than 90%, and the haze is 60% to 85%. It is difficult to achieve a haze of more than 75% when the light transmittance of the film is kept above 90%.

Owner:佛山市菲锐表面科技有限公司

Using method for nano ATO coating material of laminated glass

InactiveCN109370331AReduce visible light transmittanceReduce transmittanceCoatingsPolyvinyl butyralOrganic solvent

The invention discloses a using method for a nano ATO coating material of laminated glass. The method comprises the following steps: taking nano ATO powder as basis, taking ethyl acetate as an organicsolvent, adding polyacrylamide, Yb2O3 powder, an ACR resin and a ball milling medium, and performing ball-milling dispersion to prepare ATO slurry; taking a PVB (Polyvinyl Butyral) resin as base stock, adding the prepared ATO slurry, and performing high-speed mechanical dispersion to prepare ATO rubber; coating the ATO rubber onto the glass surface, laminating under a normal pressure, applying aload of 5kN / m<2>, heating to 95-180 DEG C, holding the temperature for 2-8 hours, and performing furnace cooling to a room temperature, thereby obtaining the product. The using method disclosed by theinvention can be widely applied to the fields of dazzling prevention of safety glass such as safety glass of various buildings, windshield laminated glass and the like, and the problems that the ATOparticles cannot be dispersed and the ATO laminated glass prepared by drying after coating and film forming is low in safety, transparency and anti-dazzling property and the like can be effectively solved.

Owner:湖北汉耐尔新材料科技有限公司

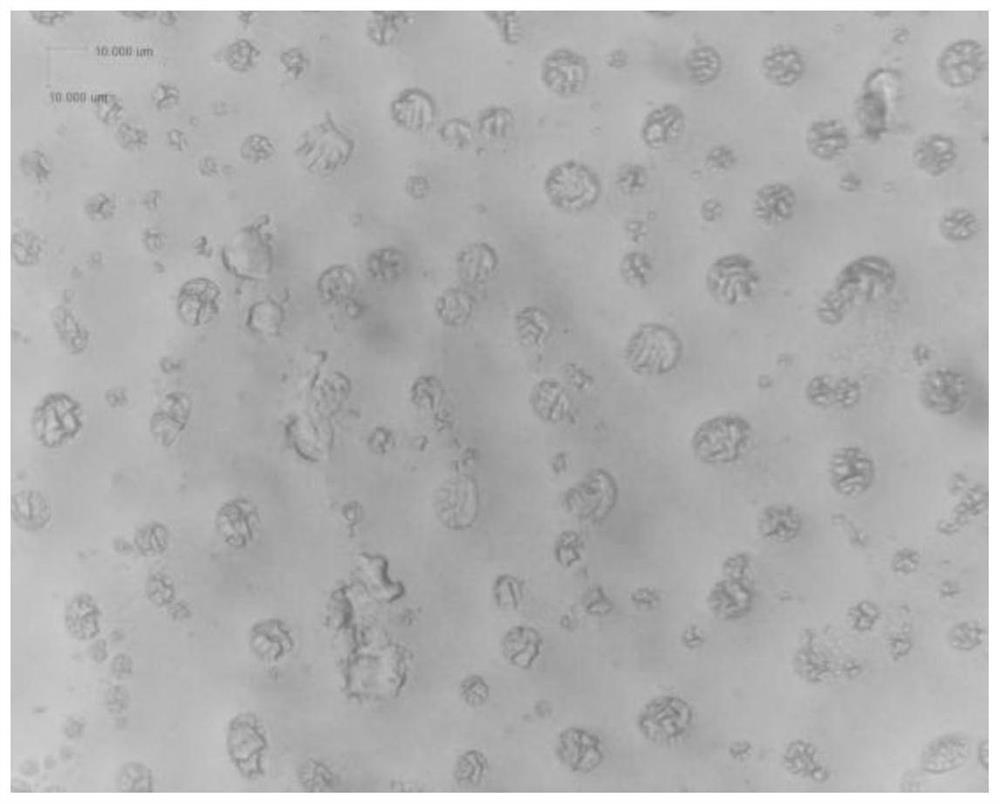

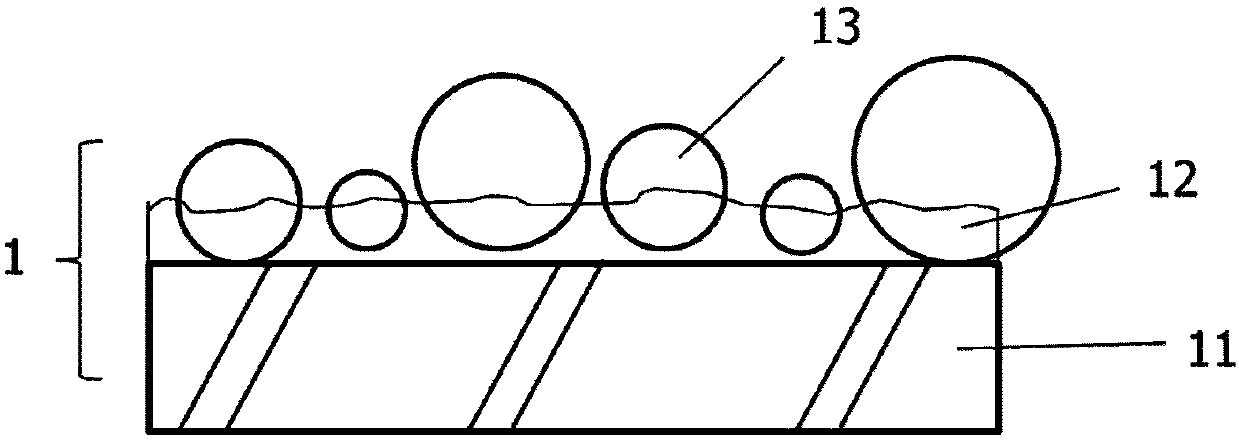

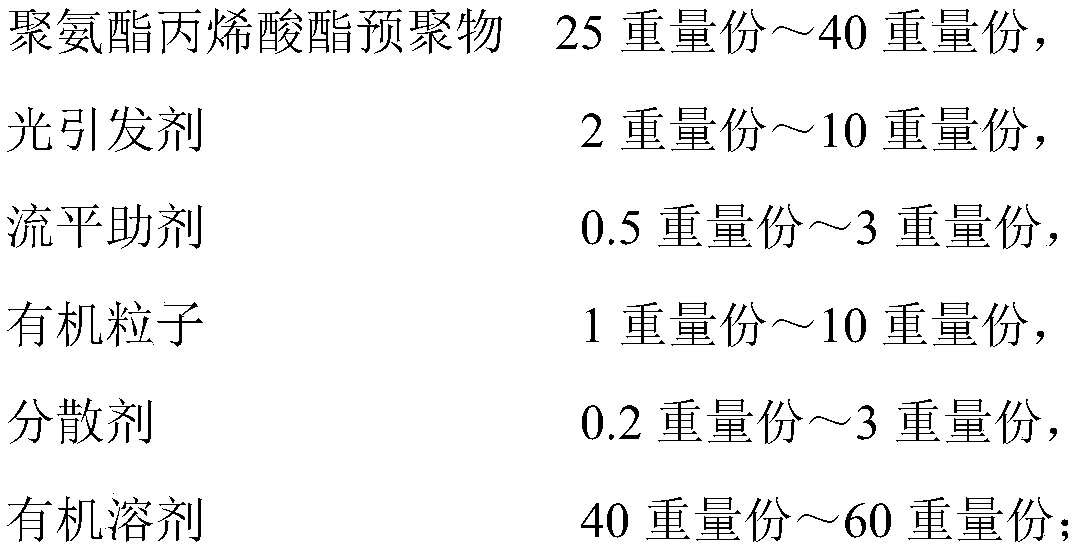

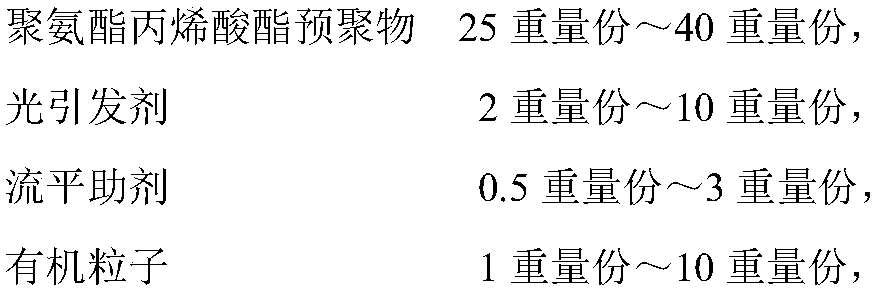

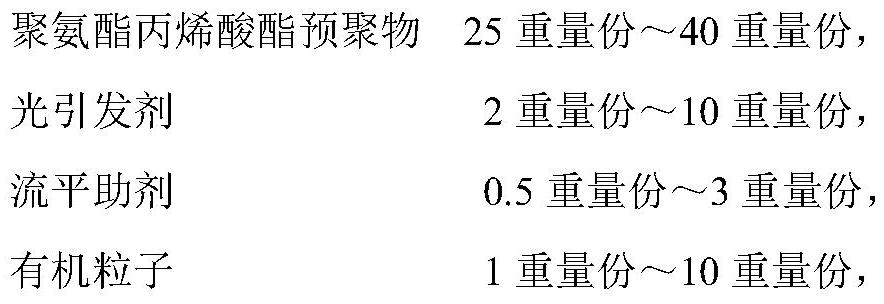

Release type hardening membrane

ActiveCN107828073AReduce release forceHigh hardnessPolyurea/polyurethane coatingsOrganic solventUrethane acrylate

A release type hardening membrane comprises a supporter and a matt hard coating layer coated on the surface of the supporter, wherein the matt hard coating layer is prepared by curing a coating solution which is prepared from the following components in parts by weight: 25 to 40 parts of polyurethane acrylate prepolymer, 2 to 10 parts of a light initiator, 0.5 to 3 parts of a leveling agent, 1 to10 parts of organic particles, 0.2 to 3 parts of a dispersing agent and 40 to 60 parts of an organic solvent. The release type hardening membrane provided by the invention has a lower release force and is capable of preventing sticking of advertising stickers and adhesive tapes; meanwhile, the coating layer has scratch-resistant and anti-dazzle functions, so that the release type hardening membrane can be used for surface protection of solar cell panels of shared bicycles.

Owner:HEFEI LUCKY SCI & TECH IND

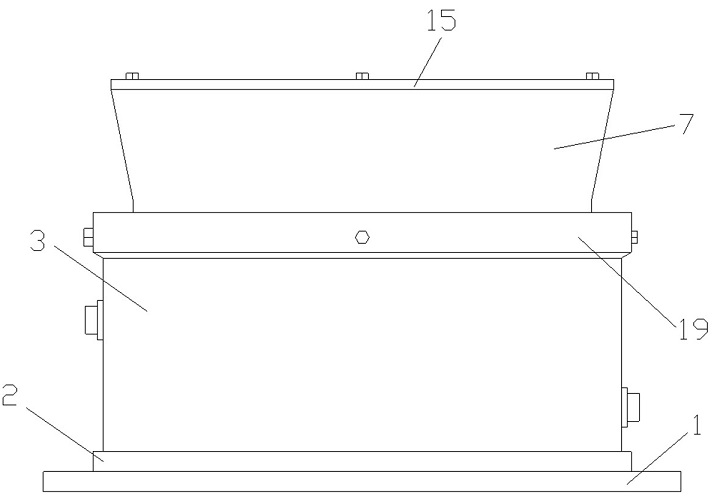

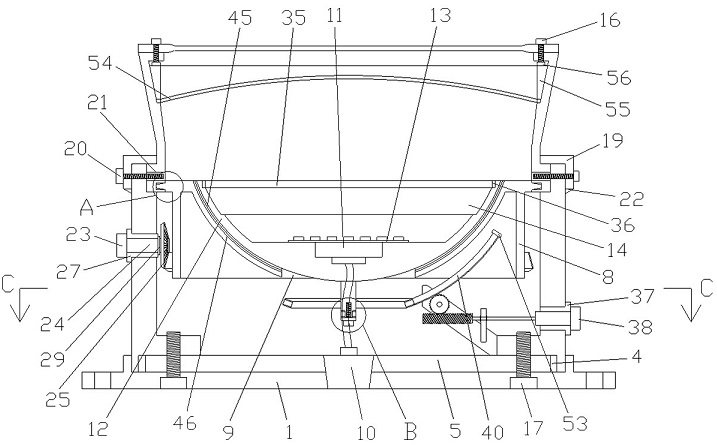

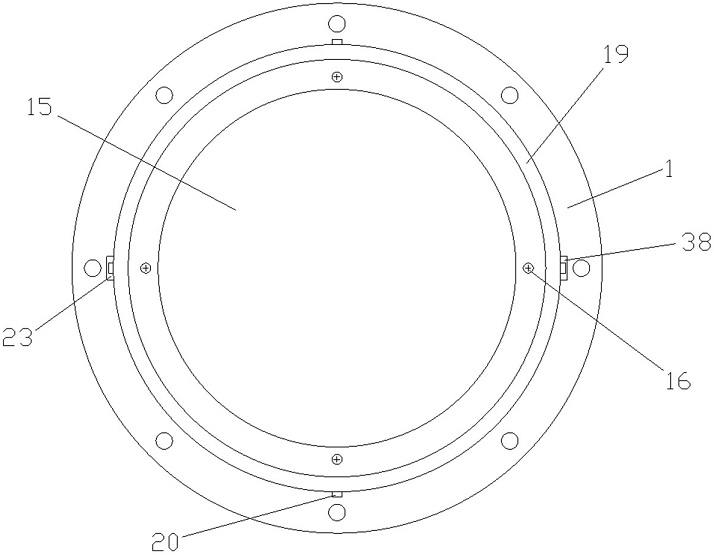

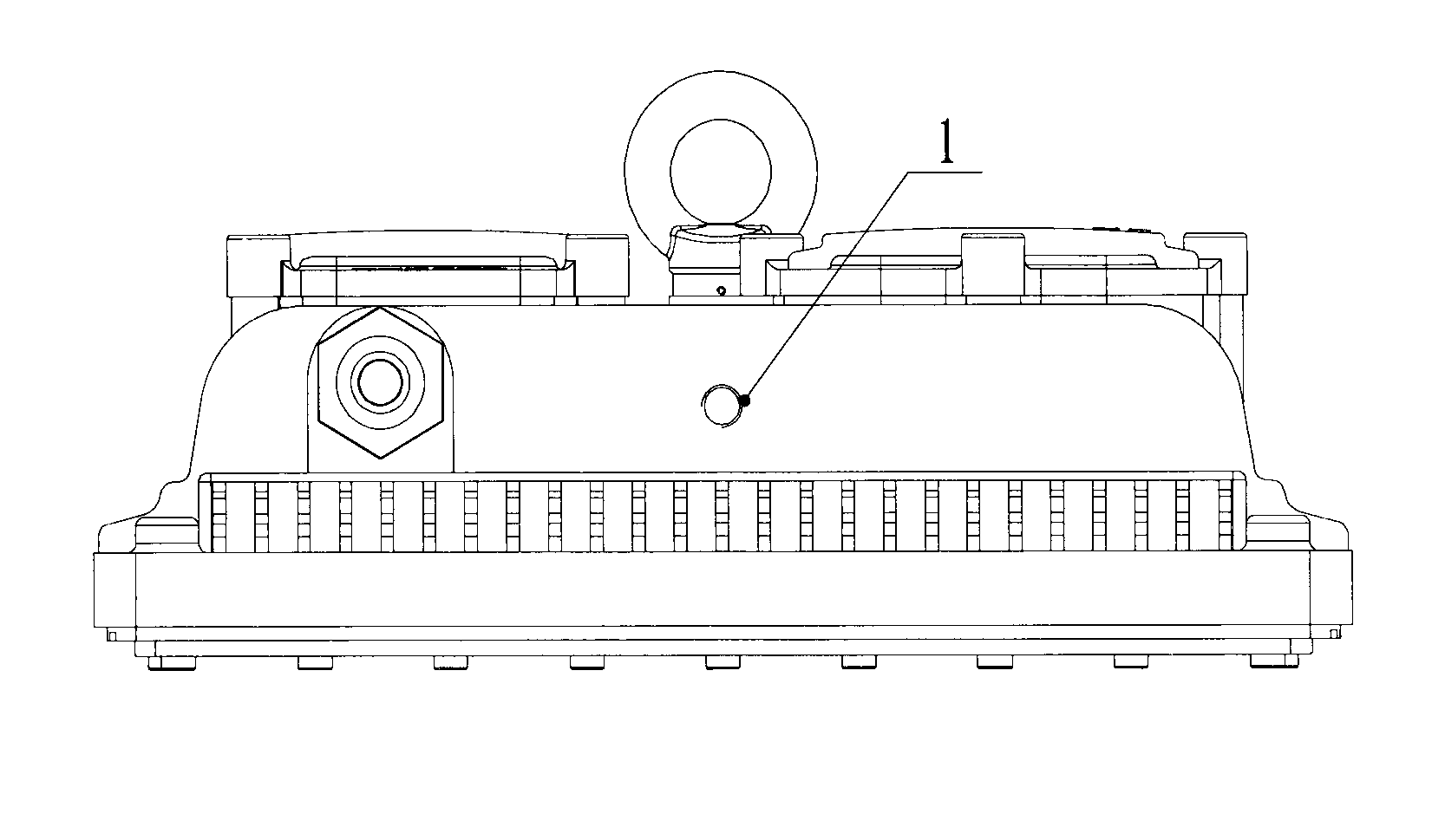

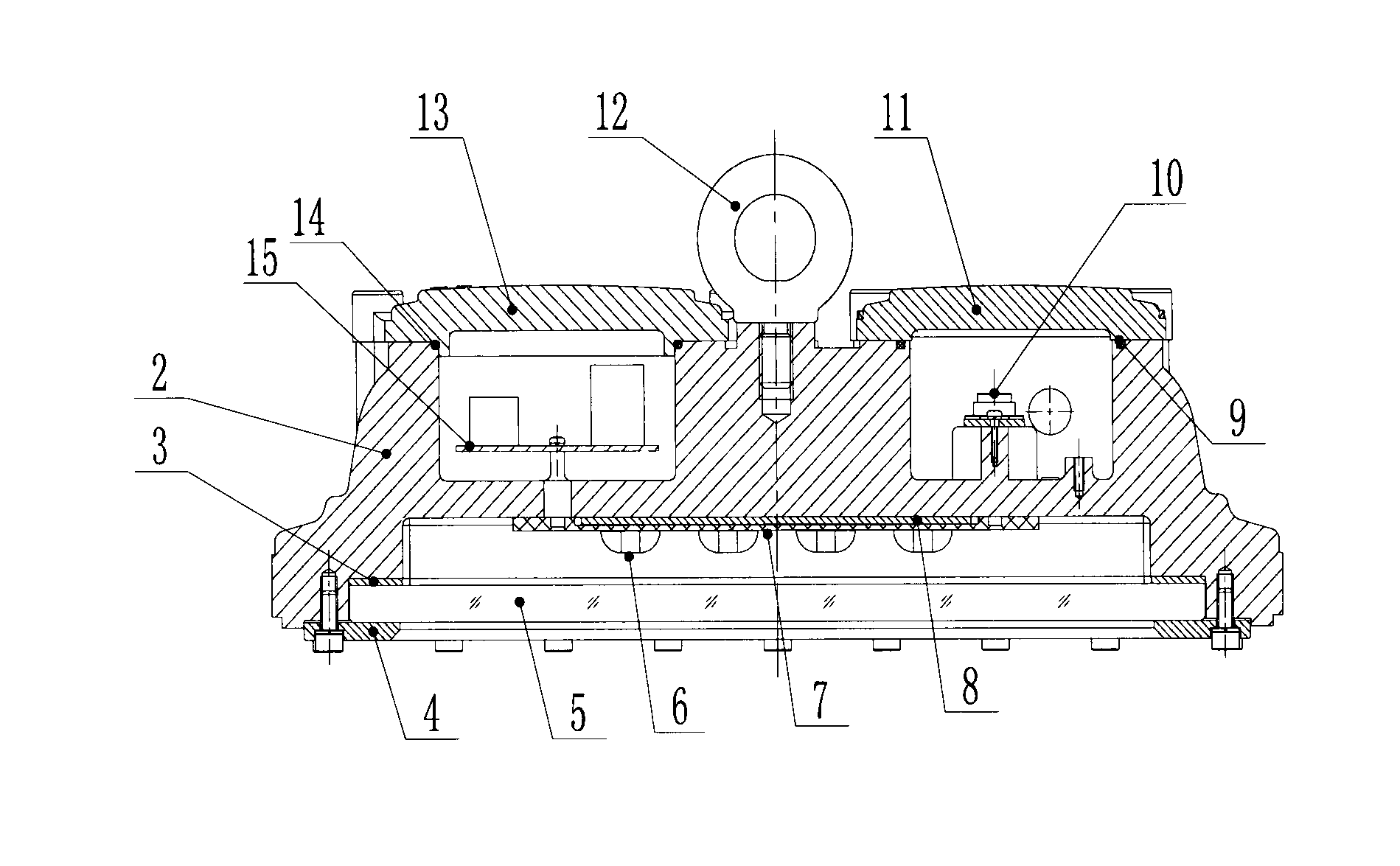

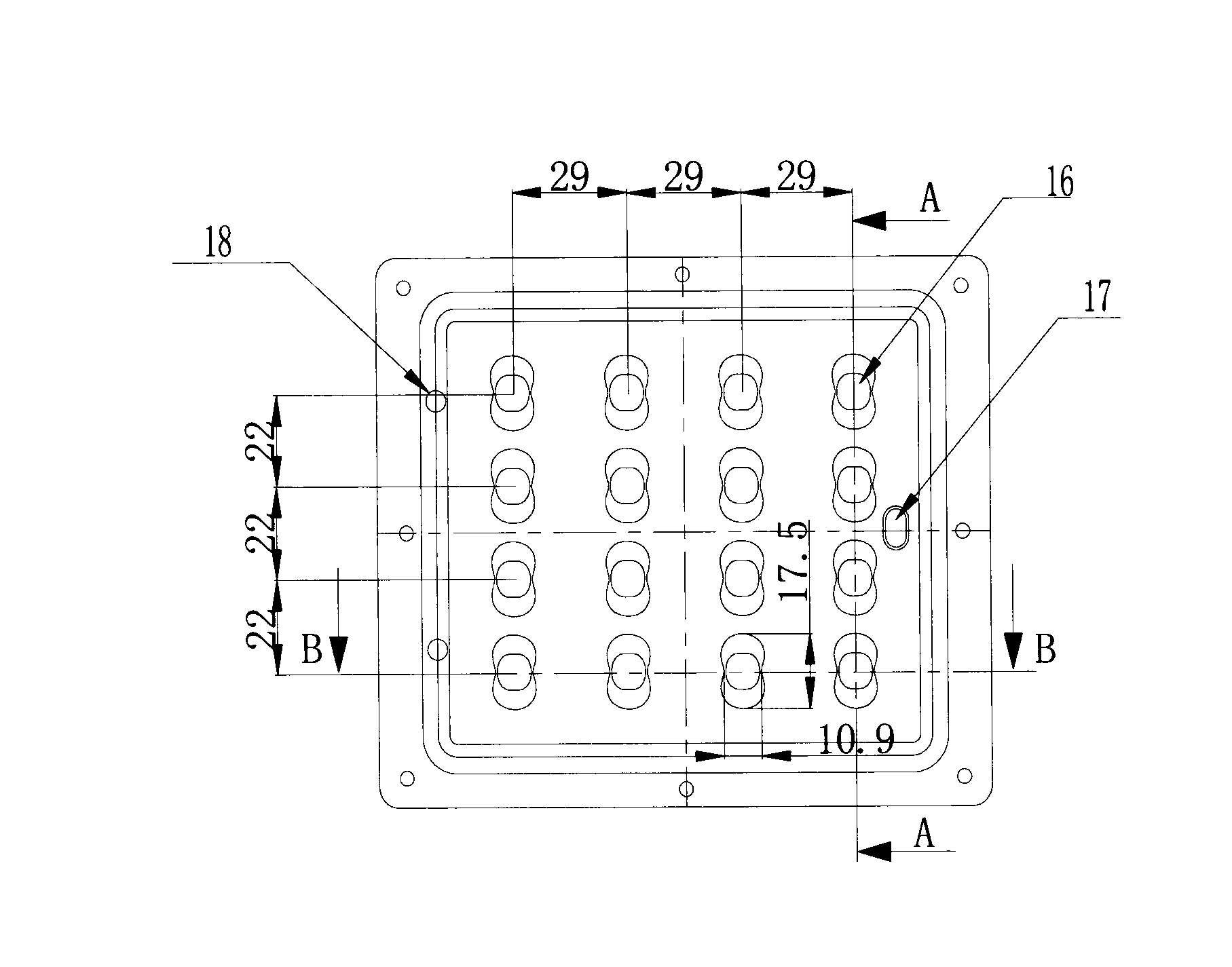

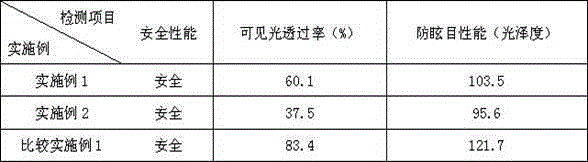

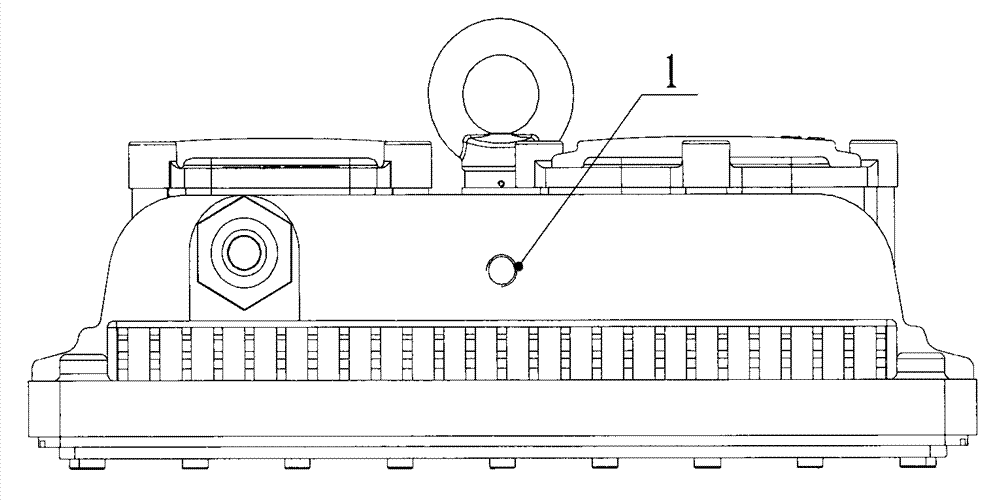

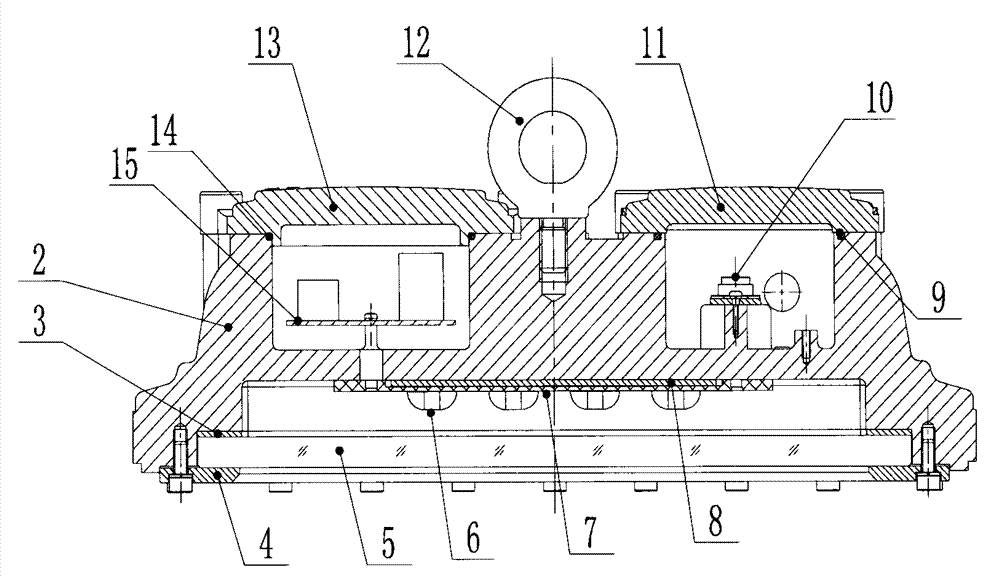

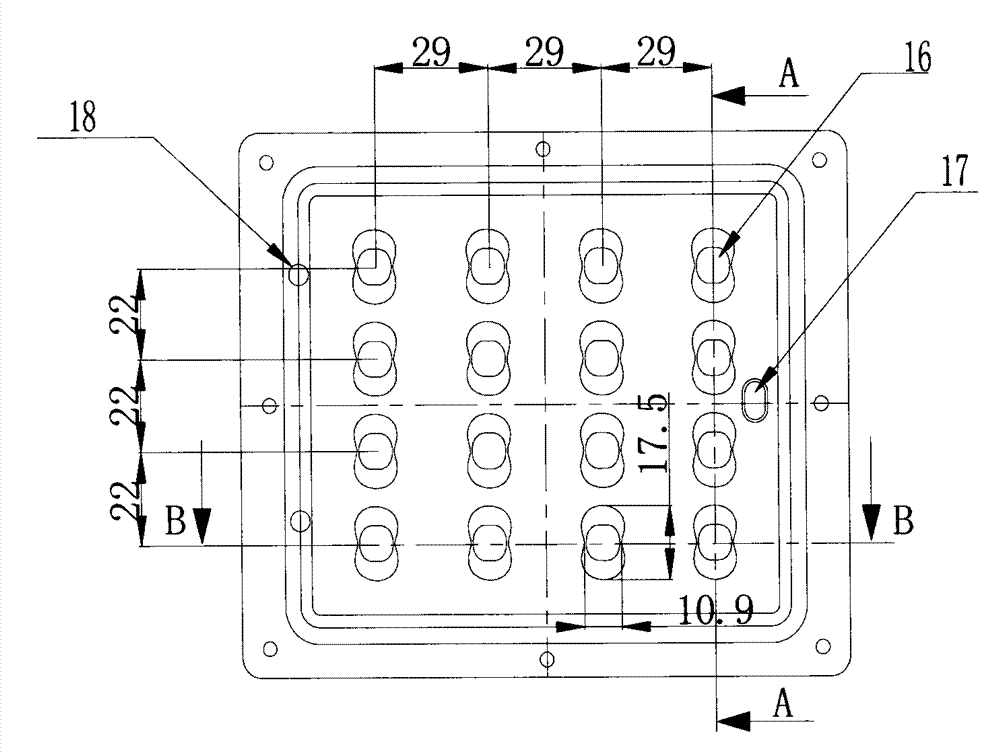

Flameproof LED roadway lamp for mines

ActiveCN102798057AIncrease profitIncrease the installation distanceLighting applicationsPoint-like light sourceIlluminanceRectangular aperture

The invention relates to a flameproof LED roadway lamp for mines, which comprises a lamp shell (2), a copper cushion plate (3) and a transparent part (5) installed on the front face of the lamp shell and a pressing device pressing plate (4). The flameproof LED roadway lamp for mines comprises an electrical appliance assembly LED driving plate (15) and an insulating screw (10) installed in a wiring cavity. The flameproof LED roadway lamp for mines comprises a rear cover (11) and a rear cover (13) installed at the back face of the lamp shell, and the rear cover (13) and the rear cover (11) are connected in parallel to form an independent cavity. The flameproof LED roadway lamp for mines comprises a light-emitting assembly LED light source (6), an LD aluminum base plate (8) and an LED lens (7). The light emitting angle of the lens is 95*130 DEG, 4 rows of 16 flameproof LED roadway lamps for mines are arranged in parallel, light distribution is rectangular aperture, the installation distance of adjacent lamps is extended, the use quantity of the lamps is reduced, the lens concentrates all discrete light in the space on a working face, and the illuminance of the working face is increased. The LED lamp bead is arranged in the center of the bottom face of each lens, the effective light distribution of 120-180 DEG discrete light emitted by LED is ensured, the utilization rate of light is increased, and the flameproof LED roadway lamp for mines also has the effect of preventing glare.

Owner:SHENZHEN PURPLE LIGHTING TECH

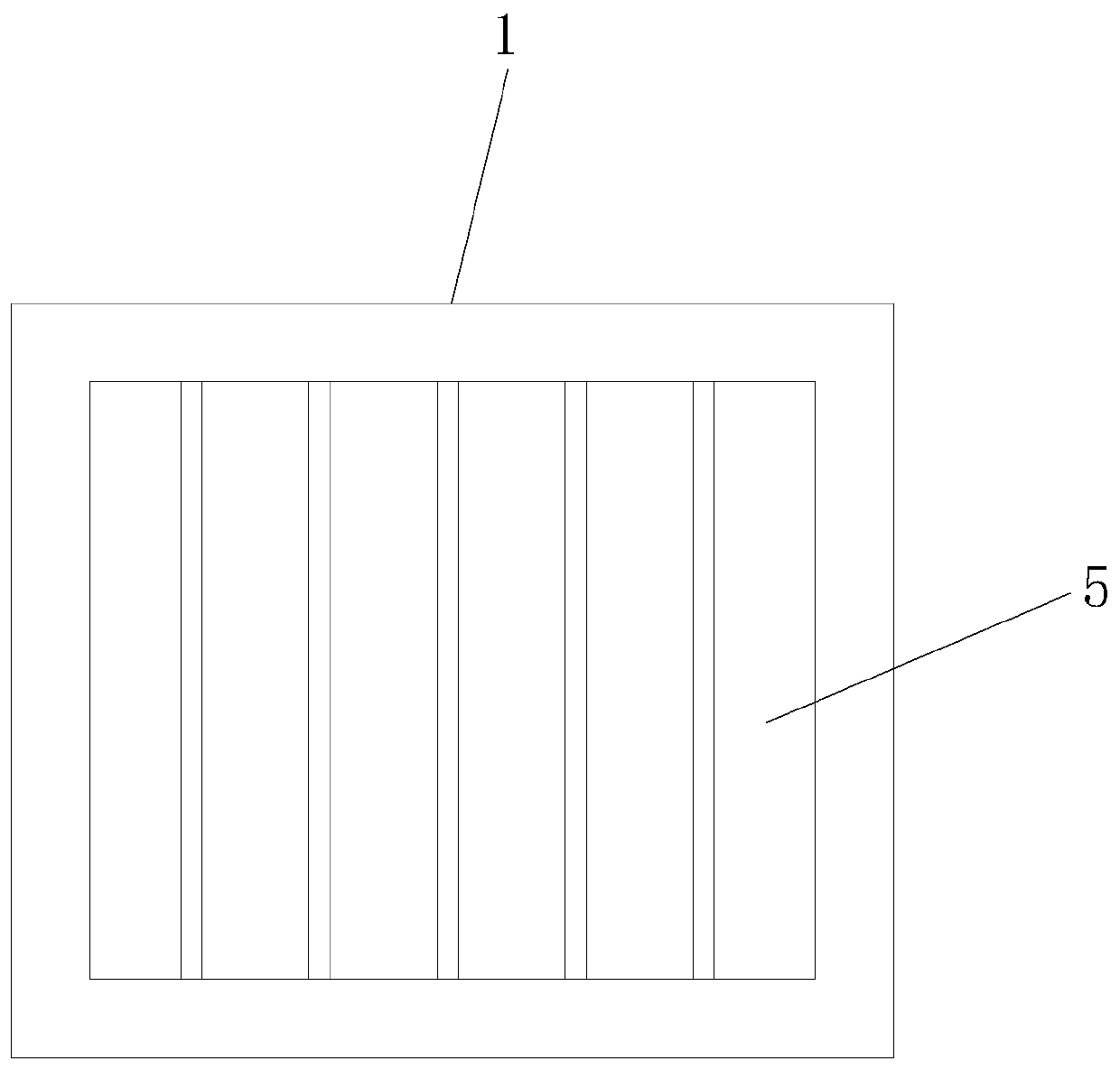

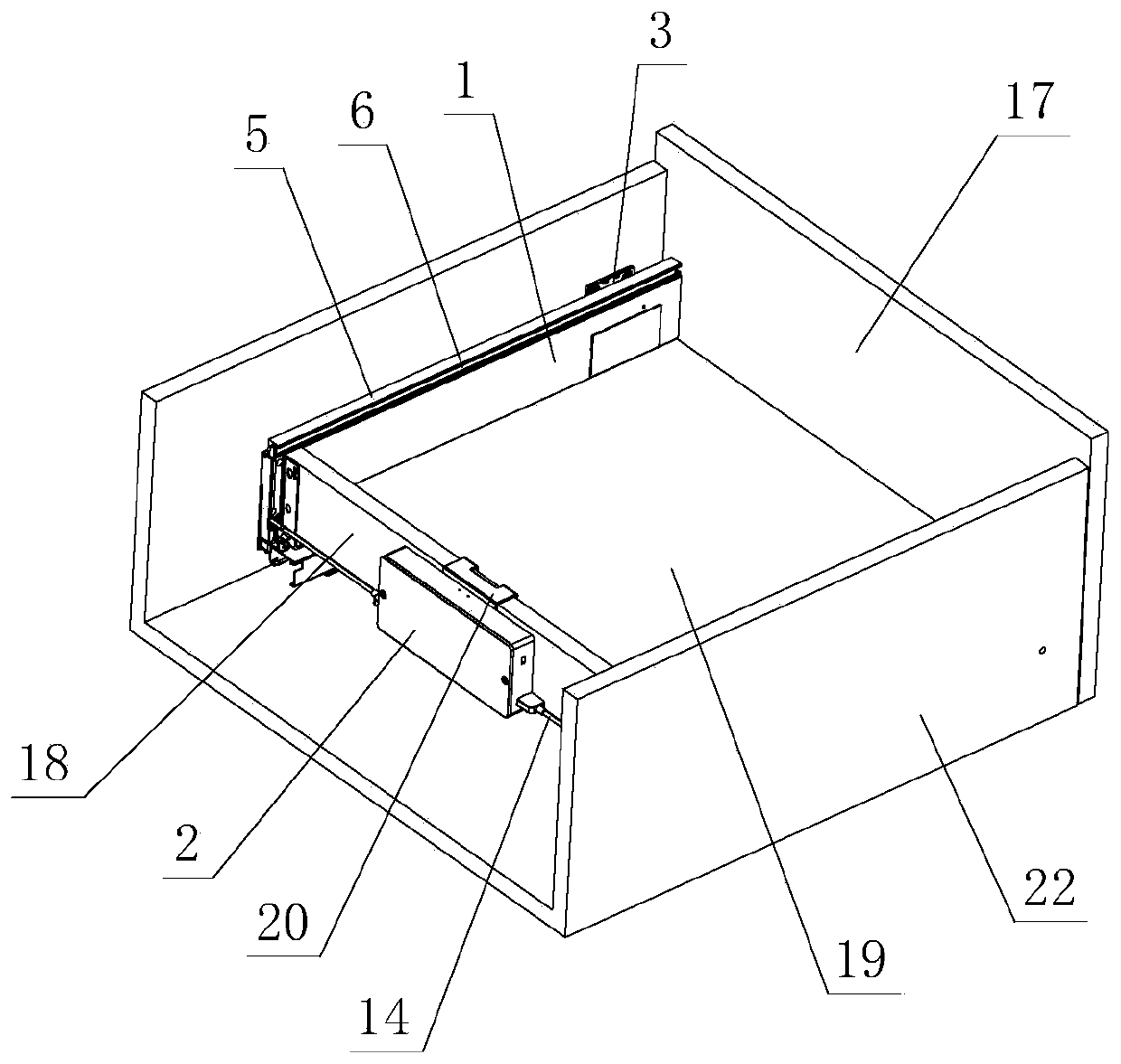

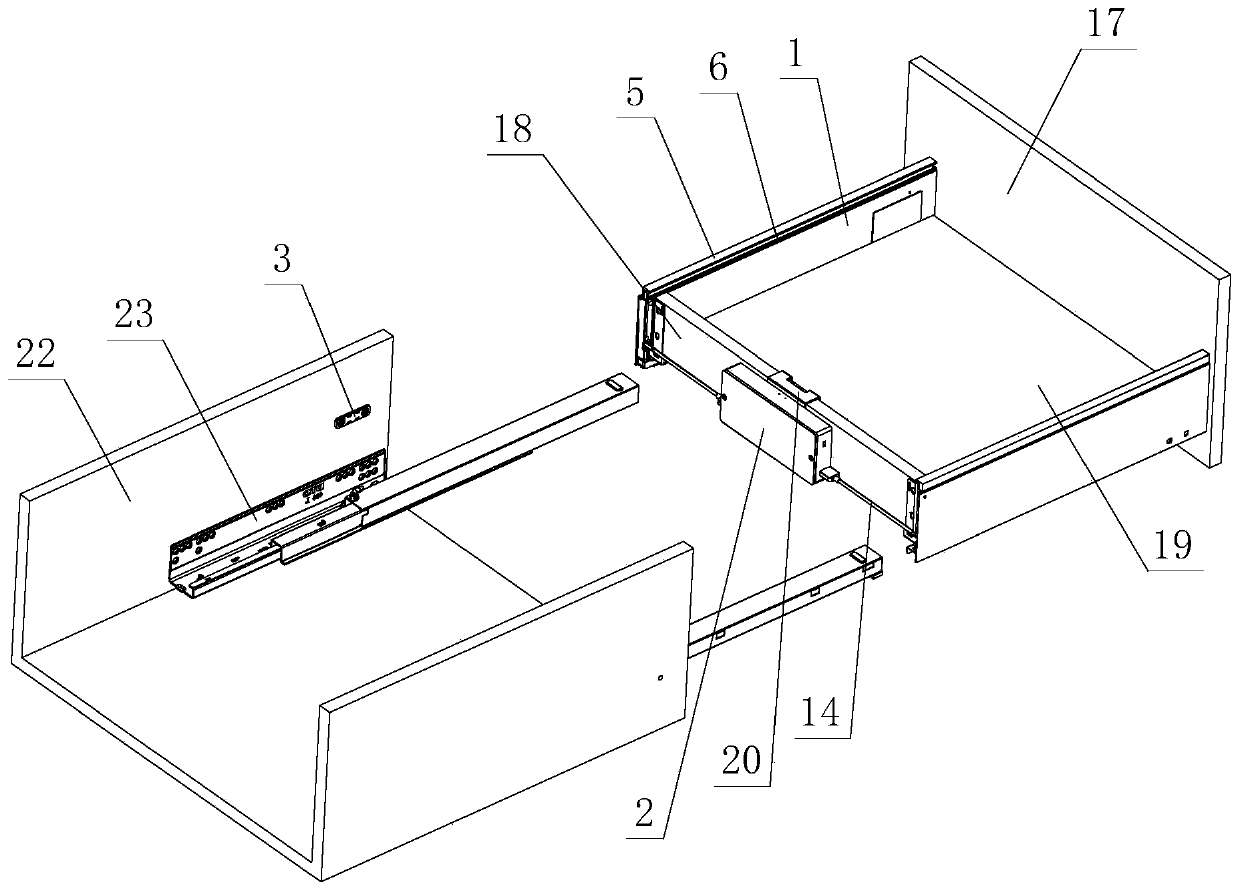

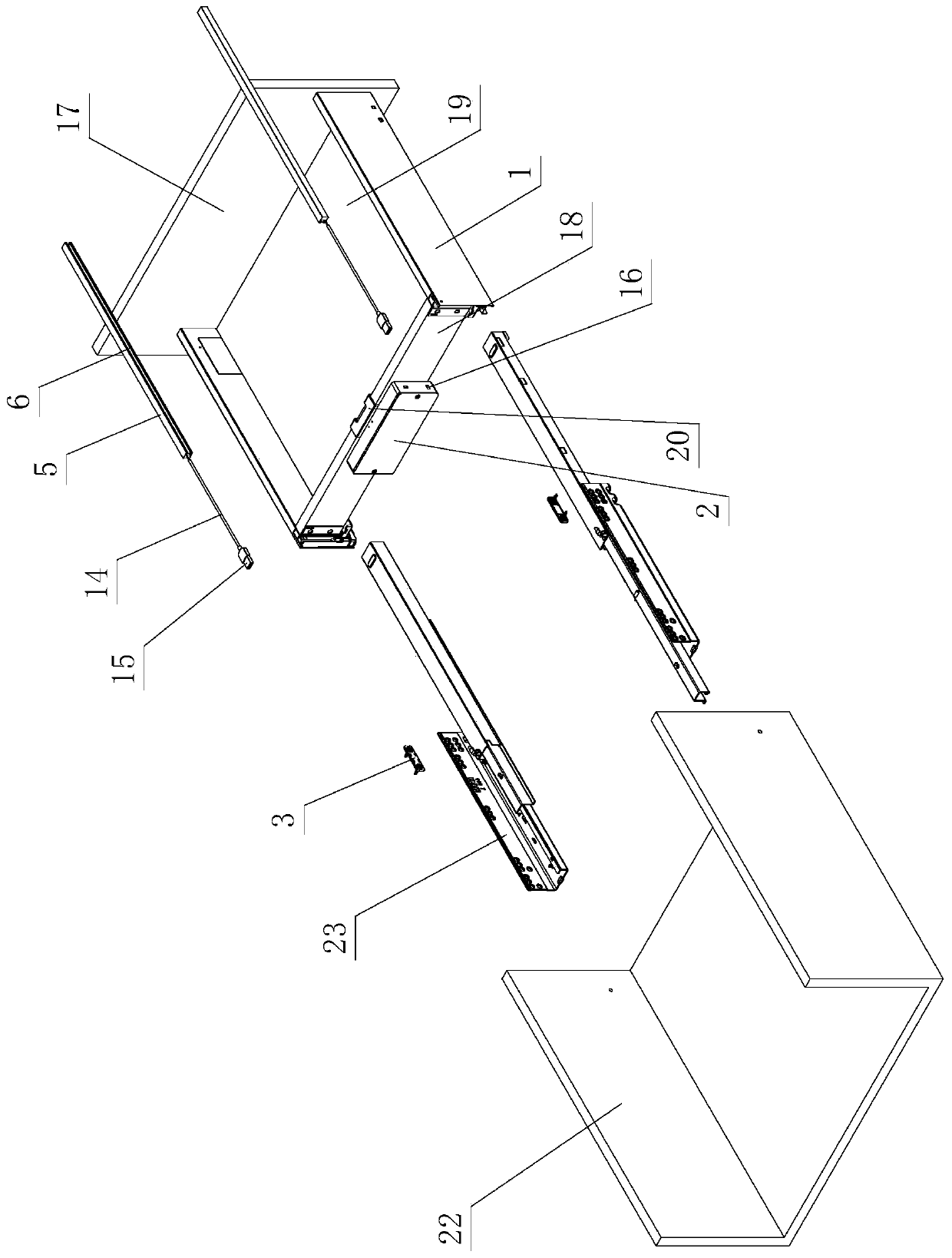

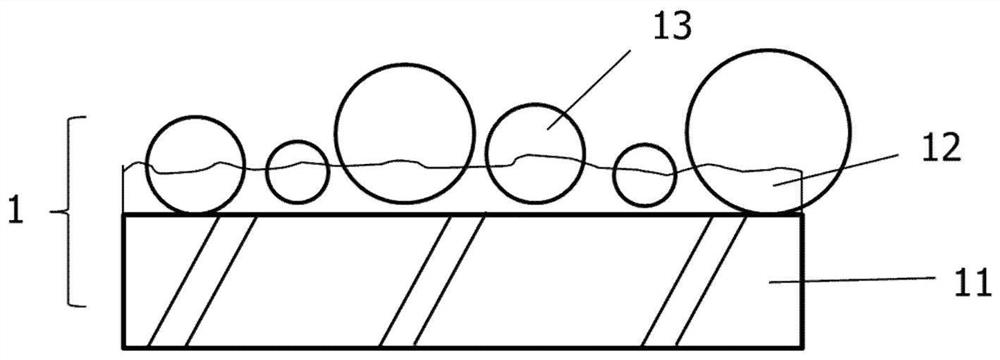

Anti-glare mechanism for interior illumination of furniture

PendingCN110792971AReduce use costEasy to installMechanical apparatusDomestic lightingEngineeringMechanical engineering

The invention relates to an anti-glare mechanism for interior illumination of furniture; the anti-glare mechanism comprises a power supply device, a furniture movable component and a furniture immovable component, wherein the furniture movable component and the furniture immovable component are in sliding fit with each other, and the furniture movable component at least comprises side plates; a magnet element is arranged on the furniture immovable component, the side plates are integrally formed, a lamp strip assembly is arranged at the tops or the side parts of the side plates in a pasting mode, in a clamping mode or through a fastening member, the lamp strip assembly is electrically connected with the power supply device, and an electromagnetic inductor is arranged on the lamp strip assembly; and when the furniture movable component is slidably opened and closed relative to the furniture immovable component, electromagnetic induction is carried out through the electromagnetic inductor and the magnet element, so that the lamp strip assembly is controlled to emit light or extinguish in the inner side directions of the side plates. Through the improvement of the structure, the anti-glare mechanism has the advantages of being simple and reasonable in structure, excellent in performance, convenient to use, low in manufacturing cost, easy to produce, easy to implement, multifunctional, energy-saving, environment-friendly, attractive in appearance, high in grade, soft in light and the like, and practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

A release hardened film

ActiveCN107828073BReduce release forceHigh hardnessPolyurea/polyurethane coatingsPolymer scienceOrganic solvent

Owner:HEFEI LUCKY SCI & TECH IND

Coating material for anti-glare laminated glass and application method thereof

InactiveCN102653653BWith anti-glare effectReduce visible light transmittanceCoatingsAcrylic resinOrganosolv

The invention discloses a coating material for anti-glare laminated glass and an application method thereof. The coating material for anti-glare laminated glass is prepared through the steps of: based on nano ATO (antimony doped tin oxides) powder, through taking ethyl acetate as an organic solvent, adding materials such as ACR (acrylic resin), ball-milling mediums and the like into a mixture of the nano ATO powder and the ethyl acetate, and then carrying out ball milling dispersion on the obtained product so as to obtain ATO paste; through taking PVB (polyvinyl butyral) resin as a basic material, adding the ATO paste into the basic material, and carrying out high-speed mechanical dispersion on the obtained mixture so as to obtain an ATO sizing material; coating the ATO sizing material on the surface of glass; combining glass sheets together and pressurizing the combined glass sheets; and heating so as to obtain the coating material. The coating material disclosed by the invention integrates the safety performance of laminated glass and the anti-glare performance of ATO particles, therefore, the coating material can be widely used in the anti-glare fields of safety glass such as various construction safety glass and laminated glass for front windows of automobiles, and the like.

Owner:WUHU YAOHUA GLASS HORTICULTURE

A kind of LED package structure and LED light source device

ActiveCN113217831BWith stableEliminate internal stressProtective devices for lightingGas-tight/water-tight arrangementsRubber ringEngineering

The invention discloses an LED packaging structure, which comprises a base, a shell is arranged on the surface of the base inside the limiting edge, a heat dissipation substrate is arranged on the surface of the base inside a first expansion rubber ring, a lampshade is arranged above the gasket block, and a third A rotating fixing seat is fitted in the matching groove, a rotating control mechanism is arranged on the rotating fixing seat and one side wall of the casing, a reflector is matched in the fourth matching groove, and an LED chip mounting plate is arranged on the reflector at the bottom of the groove. A combined lens is arranged on the reflective cup above the LED chip mounting plate, an angle adjustment mechanism is arranged on the bottom end of the reflective cup and one side wall of the casing, and an anti-glare net is arranged on the top surface of the lampshade. The invention provides a middle base , The installation and fixation effect between the shell, the lampshade and the anti-glare net is better, and the LED packaging structure can adjust the light irradiation angle through the rotation control mechanism and the angle adjustment mechanism, and the invention also provides a sealing and light irradiation effect. LED light source device.

Owner:佛山市其利照明电器有限公司

A kind of preparation method of anti-glare hardened film for polarizer

Owner:HEFEI LUCKY SCI & TECH IND

Flameproof LED roadway lamp for mines

ActiveCN102798057BIncrease profitIncrease the installation distanceLighting applicationsPoint-like light sourceIlluminanceRectangular aperture

The invention relates to a flameproof LED roadway lamp for mines, which comprises a lamp shell (2), a copper cushion plate (3) and a transparent part (5) installed on the front face of the lamp shell and a pressing device pressing plate (4). The flameproof LED roadway lamp for mines comprises an electrical appliance assembly LED driving plate (15) and an insulating screw (10) installed in a wiring cavity. The flameproof LED roadway lamp for mines comprises a rear cover (11) and a rear cover (13) installed at the back face of the lamp shell, and the rear cover (13) and the rear cover (11) are connected in parallel to form an independent cavity. The flameproof LED roadway lamp for mines comprises a light-emitting assembly LED light source (6), an LD aluminum base plate (8) and an LED lens (7). The light emitting angle of the lens is 95*130 DEG, 4 rows of 16 flameproof LED roadway lamps for mines are arranged in parallel, light distribution is rectangular aperture, the installation distance of adjacent lamps is extended, the use quantity of the lamps is reduced, the lens concentrates all discrete light in the space on a working face, and the illuminance of the working face is increased. The LED lamp bead is arranged in the center of the bottom face of each lens, the effective light distribution of 120-180 DEG discrete light emitted by LED is ensured, the utilization rate of light is increased, and the flameproof LED roadway lamp for mines also has the effect of preventing glare.

Owner:SHENZHEN PURPLE LIGHTING TECH

A small-scale perspective anti-glare glass panel manufacturing method

InactiveCN107651859BWith anti-glare effectLimit the scope of actionDomestic cooling apparatusLighting and heating apparatusThick plateUltrasonic welding

Owner:DONGGUAN TAISHENG GLASS CO LTD

LED device and LED lamp

InactiveCN108666402AAvoid quality defectsAvoid failureSemiconductor/solid-state device detailsSolid-state devicesAdhesive glueCorrosive substance

The invention discloses an LED device and an LED lamp. The LED device comprises a substrate, a first light-transmitting plate and a second light-transmitting plate, wherein a cavity is formed in the substrate, an opening is formed in one end of the cavity, the opening end of the cavity extends along the radial direction of the cavity to form a step surface, and a sealing groove is formed in the peripheral surface of the cavity; the first light-transmitting plate is arranged on the step surface, and a seal ring is arranged between the first light-transmitting plate and the step surface; the second light-transmitting plate comprises a periphery part and a middle part, an annular bulge is arranged between the periphery part and the middle part, the thickness of the periphery part is smaller than that of the middle part, the middle part and the cavity are oppositely arranged, the middle part is laminated onto the first light-transmitting plate, the annular bulge is tightly matched with theseal groove, a drying agent is filled between the annular bulge and the seal groove, a sealing adhesive glue is arranged between the periphery part and the substrate, a concave spherical surface is formed on the middle part, an opening of the concave spherical surface faces the light-transmitting plate, and the concave spherical surface is internally provided with a plurality of glass beads. Through the technical scheme, double-isolation external corrosive substances are adopted, the failure rate of the LED device can be improved effectively, and the LED device has an anti-glare effect.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

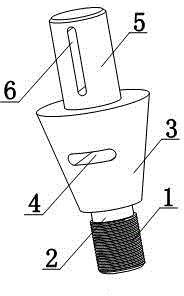

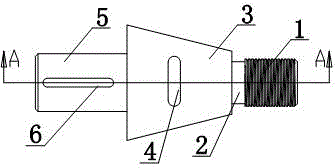

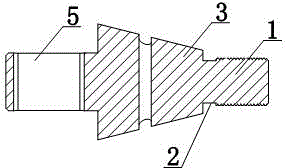

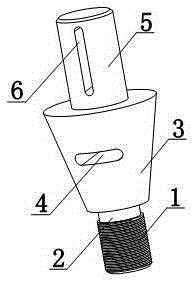

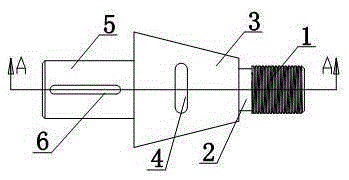

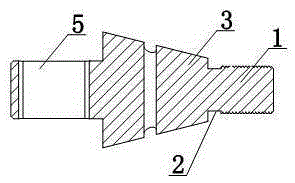

Lamp column capable of achieving gap light emission

The invention discloses a lamp column capable of achieving gap light emission. The lamp column comprises a threaded column made of aluminum alloy materials. External threads are arranged on the outer surface of the threaded column. A lampshade is arranged on the threaded column. The lampshade and the threaded column are of an integral structure. The lampshade is of a cavity structure. The two sides of the lampshade are provided with first light through grooves. The first light through grooves are communicated with the cavity structure of the lampshade. A column body is arranged on the lampshade. The column body and the lampshade are of an integral structure. The column body is of a cavity structure. The two sides of the column body are provided with second light through grooves. The second light through grooves are communicated with the cavity structure of the column body. The first light through grooves and the second light through grooves are spatially perpendicular to each other. According to the lamp column, vertical linear light and horizontal linear light can be emitted, the light does not dazzle persons when emitted at night, and the dazzling prevention effect is achieved.

Owner:伊莱灯饰电器(江门)有限公司

A slit glowing lamp post

The invention discloses a lamp column capable of achieving gap light emission. The lamp column comprises a threaded column made of aluminum alloy materials. External threads are arranged on the outer surface of the threaded column. A lampshade is arranged on the threaded column. The lampshade and the threaded column are of an integral structure. The lampshade is of a cavity structure. The two sides of the lampshade are provided with first light through grooves. The first light through grooves are communicated with the cavity structure of the lampshade. A column body is arranged on the lampshade. The column body and the lampshade are of an integral structure. The column body is of a cavity structure. The two sides of the column body are provided with second light through grooves. The second light through grooves are communicated with the cavity structure of the column body. The first light through grooves and the second light through grooves are spatially perpendicular to each other. According to the lamp column, vertical linear light and horizontal linear light can be emitted, the light does not dazzle persons when emitted at night, and the dazzling prevention effect is achieved.

Owner:伊莱灯饰电器(江门)有限公司

Gradient anti-glare cover plate, manufacturing method thereof, and electronic device

ActiveCN107608013BAchieve natural gradientsTo achieve a gradient effectDiffusing elementsPhotomechanical apparatusEngineeringDiffuse reflection

The application provides a gradient anti-glare cover plate and a making method thereof as well as electronic equipment. The making method comprises the following steps: providing a substrate; making graded-density grooves in at least one surface of the substrate, wherein the distance between the every two adjacent grooves is less than 5 microns; demoulding; making uneven anti-glare structures on the surfaces of the grooves. The graded-density grooves are firstly formed before anti-glare production, and the distance between the every two adjacent grooves is less than 5 microns, so that the natural gradual change of light can be realized, a gradual change effect is achieved, and the appearance of the gradient anti-glare cover plate is enabled to be more attractive; therefore, the gradient anti-glare cover plate is more greatly different from cover plates of other electronic products, and a homogenization phenomenon is further avoided. Furthermore, the anti-glare effect of the gradient anti-glare cover plate is realized mainly by means of irregular rugged small salient points directly formed in the grooves, and a diffuse reflection function is realized; the gradient and anti-glare effect is realized only by combining the two processes, so that the making technology is simple.

Owner:TRULY OPTO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com