A high transparency and high fog anti-glare coating

An anti-glare and coating technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor light transmittance, low contrast, whitening of the anti-glare coating and anti-glare layer, and achieve high haze, high Transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

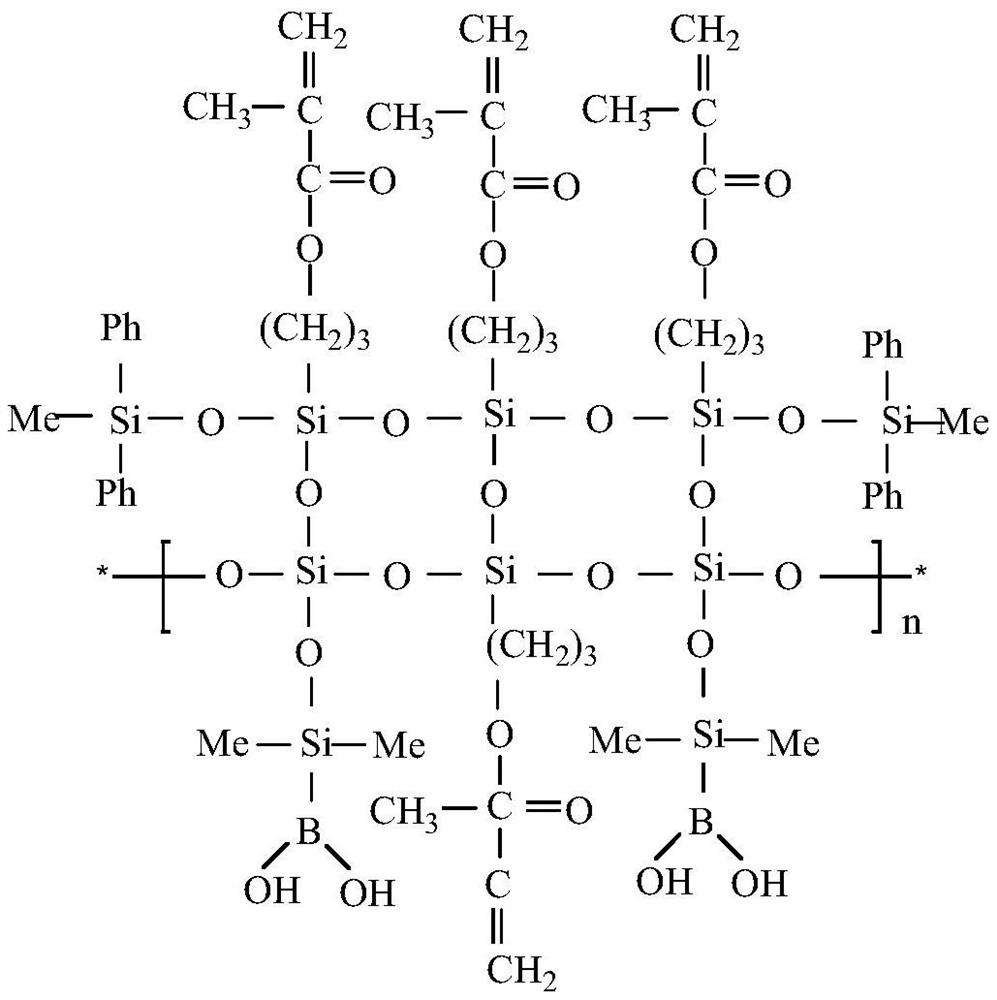

[0026] Embodiment 1 borosilicate resin

[0027] The borosilicate resin of the present invention is independently designed and synthesized. It is composed of silane coupling agent KH570, borosiloxane resin and tetraphenyldimethyldisilane. The degree of polymerization is 2-50, and each chain link contains 3 Acrylate and 2 boron molecules, the general reaction formula is:

[0028]

Embodiment 2

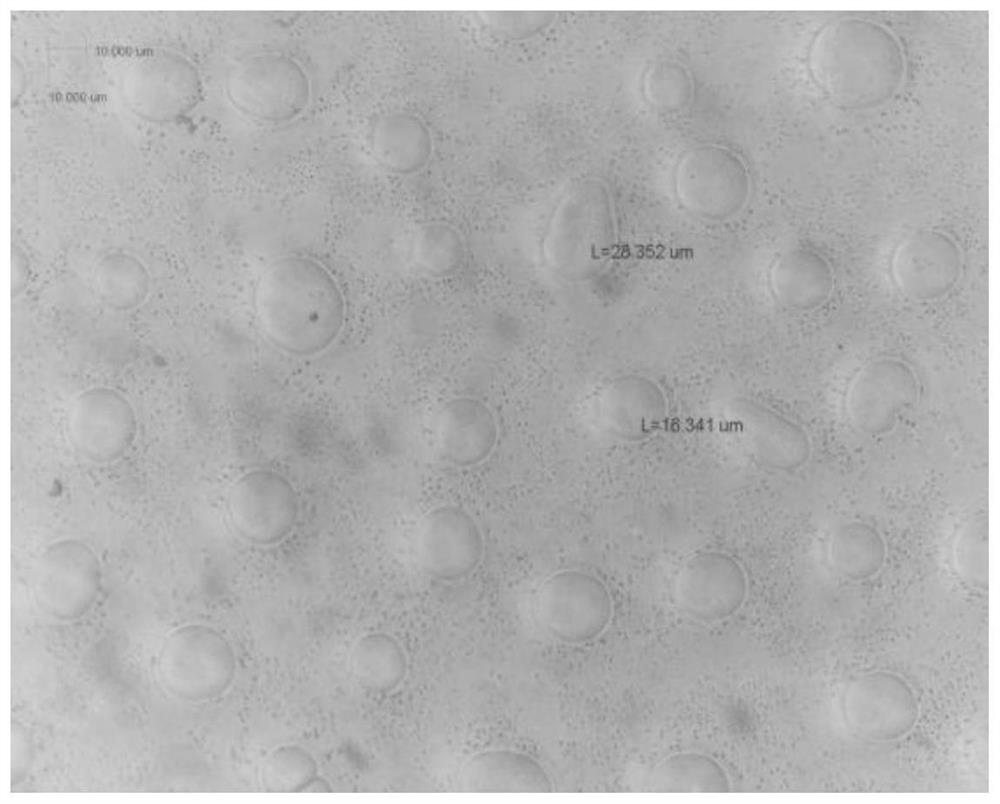

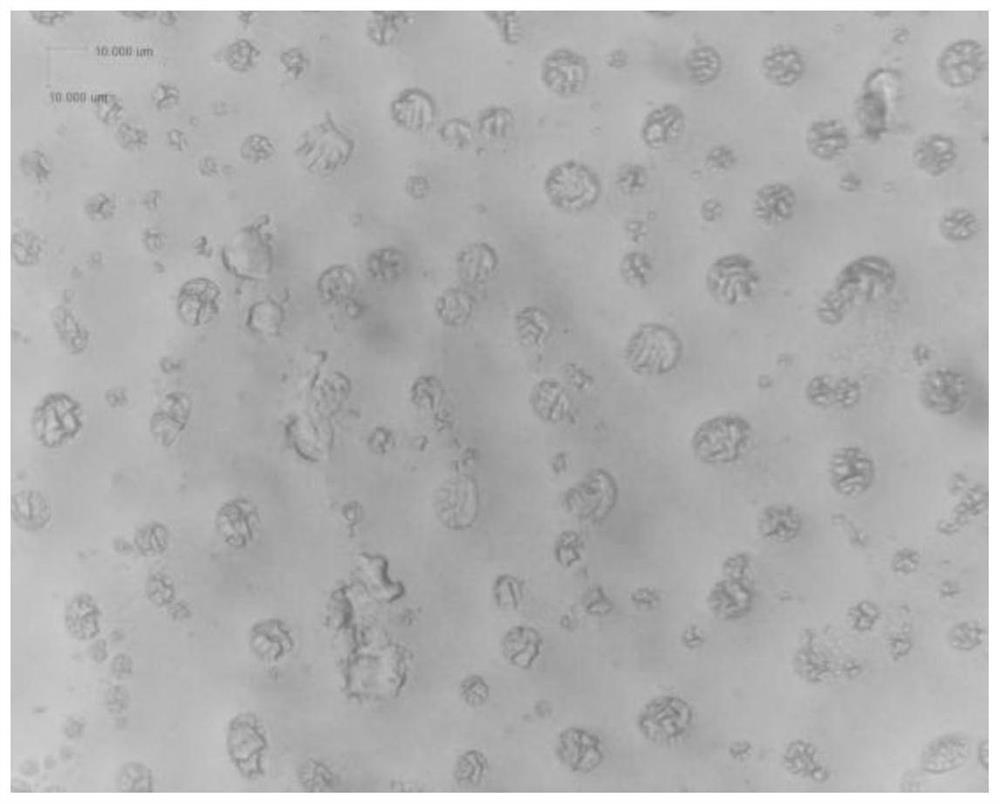

[0030] The preparation of the high-transmission and high-fog anti-glare film of this embodiment is carried out as follows: take B-MDT45wt%, photocurable resin 45wt%, photoinitiator and auxiliary agent 10wt%, B-MDT, photocurable resin, photoinitiator and Mix organic solvents, disperse at a high speed for 15 minutes, and disperse at a speed of 1000-2000rpm, then add additives, and continue to disperse at a high speed for 15 minutes to obtain a coating liquid; apply the coating liquid to optical surfaces by dimple coating or blade coating On the surface of PET film, the coating thickness is 1-20 microns, dried at 80-100°C for 5-10 minutes, and then enters the UV exposure machine for radiation curing, and the radiation dose is 400-2000mJ / cm 2 , the coating speed is 5-20 m / min, and a high-transparency, high-fog, anti-glare film is obtained.

[0031] Wherein, B-MDT is obtained by the method of Example 1; the photocurable resin is aliphatic polyurethane hexaacrylate resin, Sartomer, ...

Embodiment 3

[0034] The preparation of the high transparency and high fog anti-glare film of this example is carried out as follows: Take 20wt% of B-MDT, 20wt% of photocurable resin, 50wt% of reactive diluent, 10wt% of photoinitiator and auxiliary agent, and mix B-MDT, photocuring Mix resin, reactive diluent, photoinitiator and organic solvent, disperse at a high speed for 15 minutes at a speed of 1000-2000rpm, then add additives, continue to disperse at a high speed for 15 minutes, and obtain a coating solution; use dimple coating or blade coating Apply the coating solution on the surface of the optical PET film by cloth method, the coating thickness is 1-20 microns, dry at 80-100°C for 5-10 minutes, enter the UV exposure machine for radiation curing, and the radiation dose is 400-2000mJ / cm 2 , the coating speed is 5-20 m / min, and a high-transparency, high-fog, anti-glare film is obtained.

[0035] Wherein, B-MDT is obtained by the method of Example 1; the photocurable resin is aliphatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com