Manufacture process of anti-glare lamp with light efficiency improvement function

A production process and anti-glare technology, which is applied in the fixing of light sources, components of lighting devices, lighting devices, etc., can solve the problems of utilization of lost light, failure to achieve energy conservation and emission reduction, and reduction of lamp efficiency, etc., to achieve easy installation, Improve the lighting effect of lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

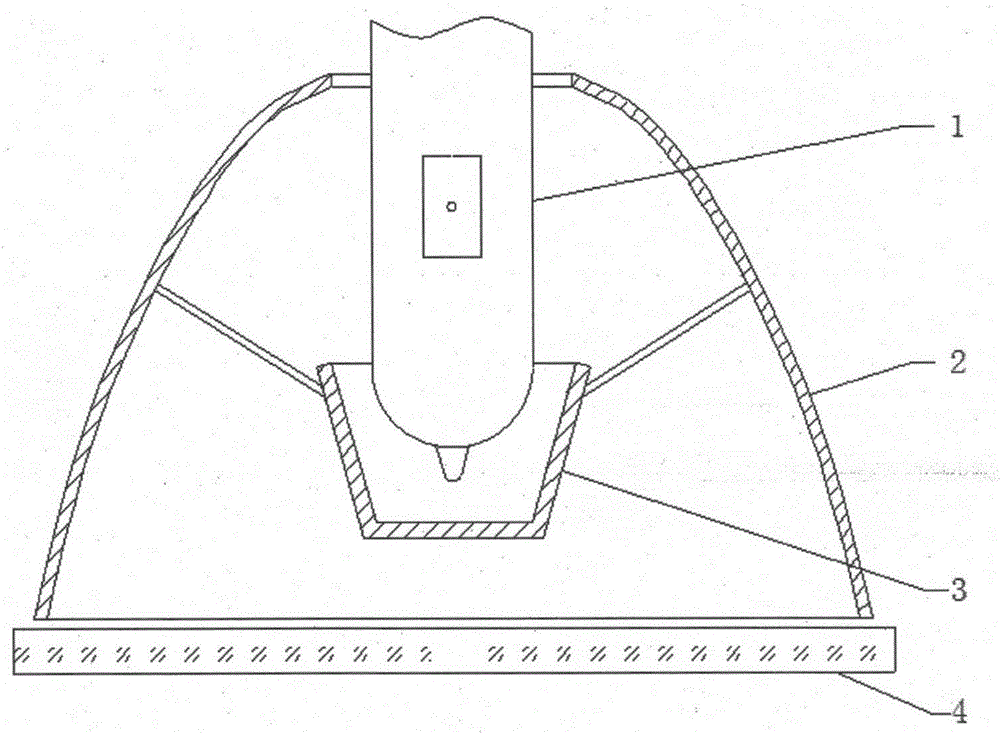

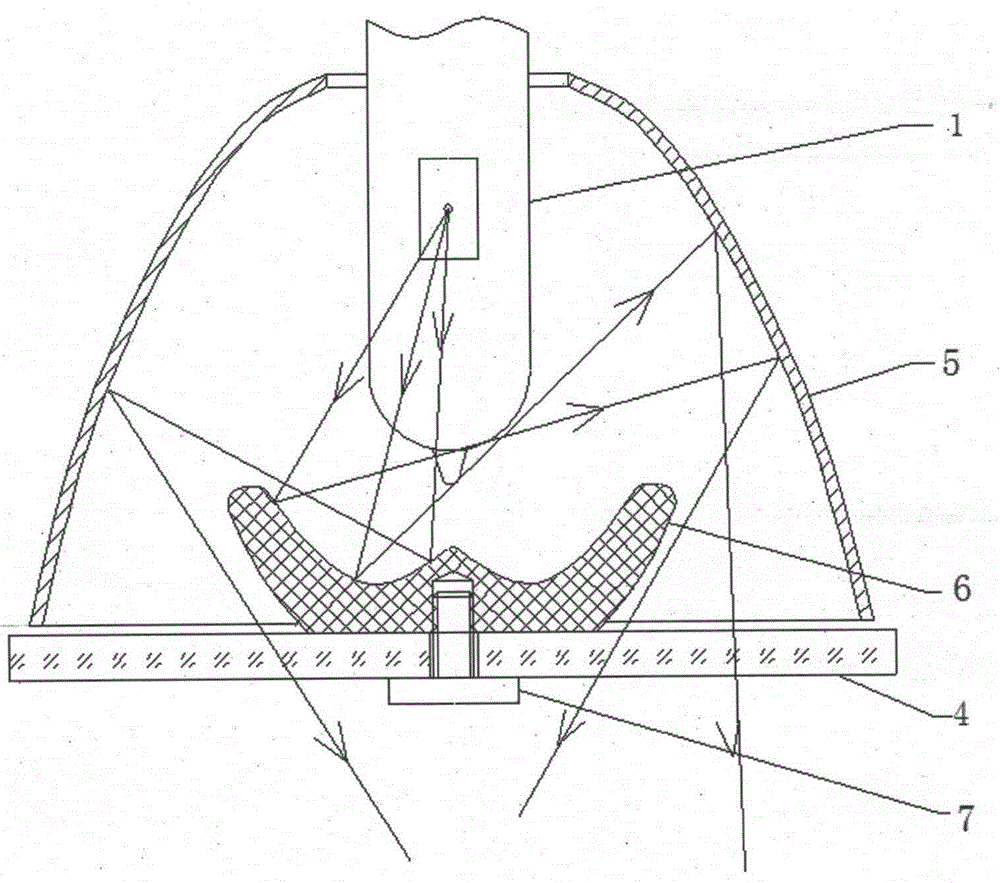

[0013] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0014] Such as figure 2 As shown, an anti-glare lamp with improved light efficiency provided by the present invention includes a light source 1 extending into the reflector 5, a tempered glass 4 is provided under the reflector 5, and a tempered glass 4 is fixed under the light source 1. The optical glare cover 6 on the glass 4, the upper surface of the optical glare cover 6 is the first reflective surface, the inner surface of the reflector 5 is the second reflective surface, the incident light emitted by the light source 1 is irradiated on the first reflective surface from different angles After being reflected by the first reflective surface, it is reflected on the second reflective surface from different angles, and then reflected by the second reflective surface from different angles.

[0015] The manufacturing process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com