Manufacturing technology of multi-layer composite color-change polarizing resin lens for interior of vehicle

A resin lens and multi-layer composite technology, applied in optics, lamination, application, etc., can solve problems such as danger, achieve the effect of reducing interference and damage, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

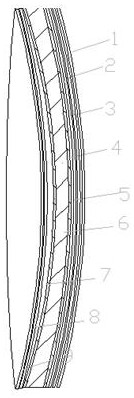

[0028] Such as figure 1 Middle: 1 is the anti-reflection coating layer on the front surface of the resin substrate, 2 is the hard coating layer on the front surface, 3 is the discoloration layer on the front surface, 4 is the polarizing layer, 5 is the UV adhesive layer, 6 is the resin substrate, 7 8 is the back surface color-changing layer, 8 is the hard coating layer on the back surface of the resin substrate, and 9 is the anti-reflection coating layer on the back surface.

[0029] Red: yellow: blue = 2:5:3 is adjusted to gray pigment, and then adsorbed on PVA to form a 30% transparent polarizing film. Then use protective film, release film, pressure-sensitive adhesive, double-layer TAC or PET to form and process into 4base finished color-changing polarizing film;

[0030] Clean and dry the 4base resin substrate, then spin-coat the front surface of the resin substrate with UV adhesive, and then paste a 4base polarizing film layer on the front surface of the lens, and mark t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com