LED projection lamp

A technology of LED floodlights and LED light sources, applied in the field of floodlights, can solve problems such as high voltage of integrated LED lamp beads, unsuitability for mass production, general heat conduction and heat dissipation effects, etc., to avoid glare and glare, assembly High efficiency and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

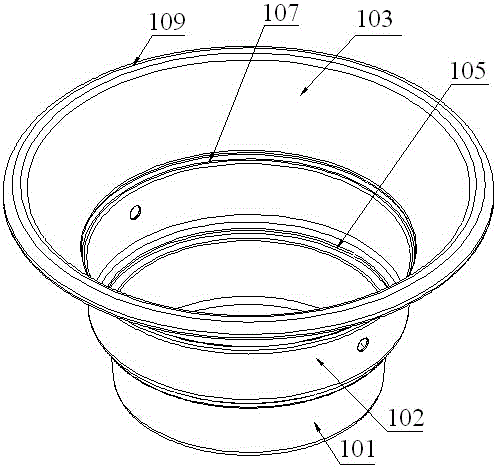

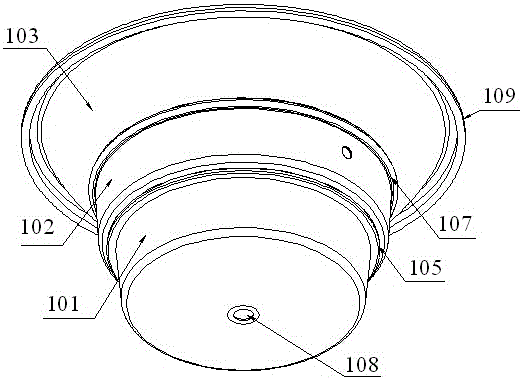

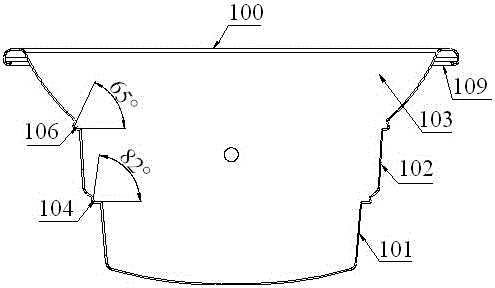

[0018] refer to Figure 1 to Figure 3 , an embodiment of an LED flood light of the present invention is proposed, including a lamp housing 100 formed by spinning an aluminum plate by a drilling machine, an LED light source structure fixed in the lamp housing 100, and a lamp housing 100 And cover the transparent cover on the LED light source structure, and the driving device connected with the LED light source structure.

[0019] Wherein, the light-transmitting cover is made of milky white light-transmitting material, and the white light-transmitting cover makes the light even and soft, and has anti-glare effect.

[0020] Existing lamp housings are generally made of die-cast aluminum, which is relatively heavy, heavy, low flexibility, inconvenient to form, high defective rate in the production process, and general hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com