Wedge-shaped light guide plate with diffusion function and panel lamp with wedge-shaped light guide plate

A technology of light guide plate and flat panel lamp, which is applied in the direction of light guide of lighting system, semiconductor device of light-emitting element, optics, etc., which can solve the problems of high overall cost and high cost, and achieve the effect of not easy to wear, prolong service life, and uniform and soft light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

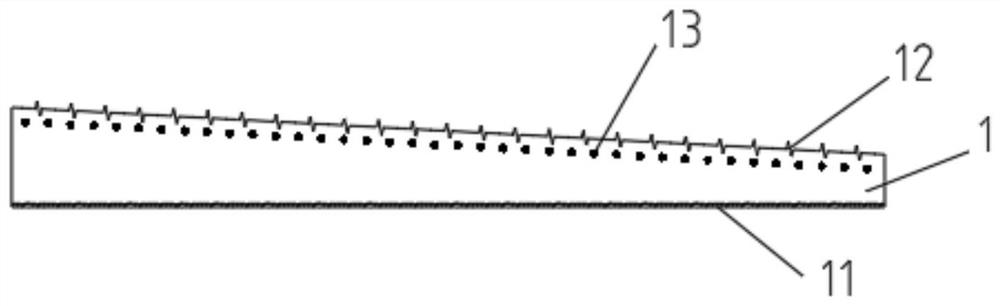

[0037] Embodiment 1: A wedge-shaped light guide plate with a diffusion function, including a substrate 1, the substrate has two opposite surfaces and are respectively a front 11 and a back 12, and the front is defined as a light-emitting surface, and the front is a plane and The back is a slope; at least one of the front and the back is a concave-convex surface with a function of diffusing light, and the concave-convex surface is an uneven rough surface formed by concave parts and convex parts;

[0038] There are several light guide points 13 inside the substrate.

[0039] The wedge-shaped light guide plate refers to a light guide plate with a right-angled trapezoidal section.

[0040] Such as figure 1 As shown, in this embodiment, it is also a better solution that means: the back is a concave-convex surface, and the front is a hard-treated smooth surface.

[0041] The concave-convex surface is a frosted surface or a prism surface (including a polygonal prism surface and a s...

Embodiment 2

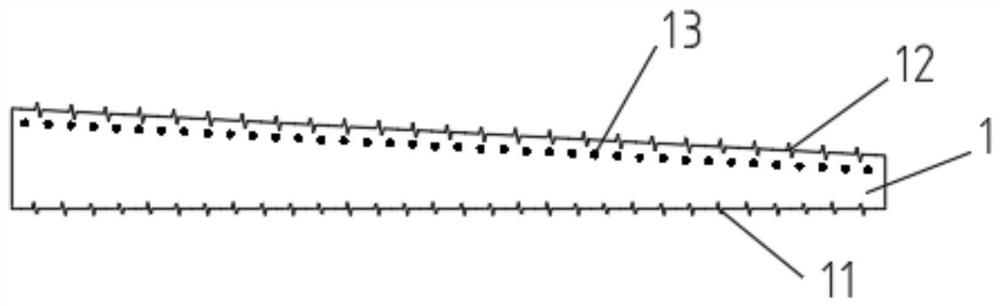

[0051] Embodiment 2: A wedge-shaped light guide plate with a diffusion function, the structure is similar to that of Embodiment 1, the difference is that: figure 2 As shown, the back and front are concave and convex.

Embodiment 3

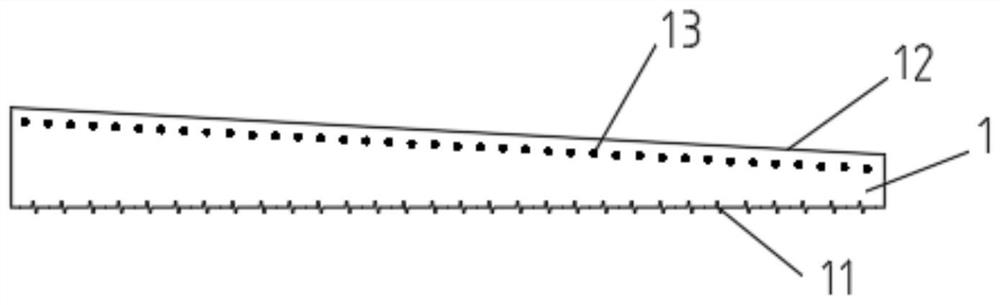

[0052] Embodiment 3: A wedge-shaped light guide plate with a diffusion function, the structure is similar to that of Embodiment 1, the difference is that: image 3 As shown, the back side is smooth, and the front side is concave-convex. The front side can be hardened or not.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com