A release hardened film

A hardened film and release technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the failure of shared bicycle smart locks and GPS positioning functions, affect solar panels receiving "sunlight", and affect shared bicycle power generation systems, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

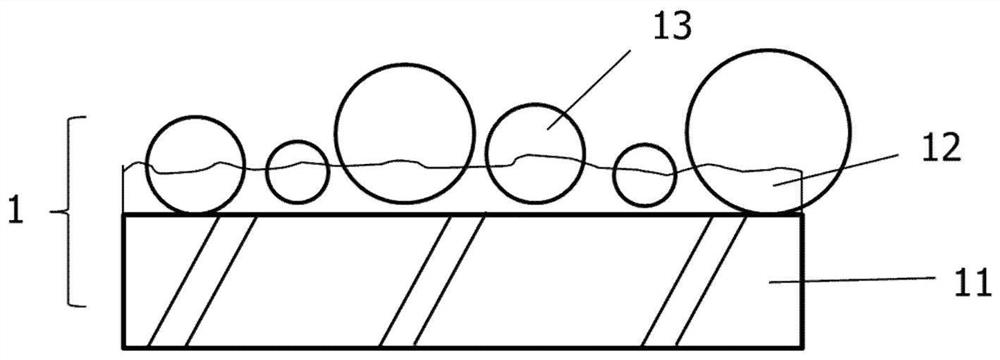

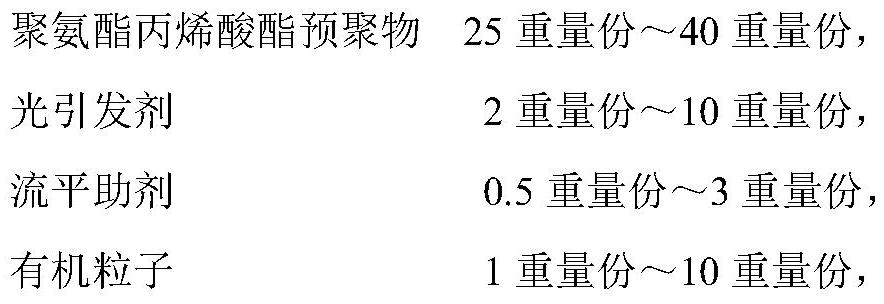

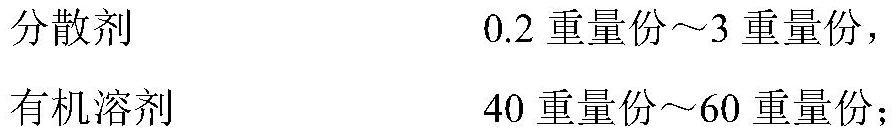

[0035] With 25.0g hexafunctional aromatic urethane acrylate prepolymer (Sinlimei Technology Co., Ltd., trade name: 670A2, functionality: 6), 10.0g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 184 ), 3.0g of leveling aid (BYK-UV3570, the molecular weight of the siloxane structure accounts for 80% of the molecular weight of the leveling aid), 10.0g of organic particles (polystyrene PS, particle size D1 is 15μm), 3.0 g of dispersant (BYK-111) and 49.0 g of ethanol were placed in a stirring pot, and stirred evenly to obtain a coating material.

[0036] The coating solution is coated on one side of a polycarbonate film with a thickness of 250 μm, and after drying for 3 minutes at an oven temperature of 120° C. 2 The coating was cured by UV light to obtain a matte hard coating with a coating thickness D2 of 3 μm. The evaluation results are listed in Table 1.

Embodiment 2

[0038]With 40.0g hexafunctionality aliphatic urethane acrylate prepolymer (Xinlimei Technology Co., Ltd., trade name: 230A2, functionality: 6), 2.0g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: TPO ), 0.5g of leveling aid (BYK-371, the molecular weight of the siloxane structure accounts for 70% of the molecular weight of the leveling aid), 1.0g of organic particles (polymethyl methacrylate PMMA, particle size D1 is 16 μm), 0.2 g of dispersant (BYK-2008) and 56.3 g of methyl ethyl ketone were placed in a stirring pot, and stirred evenly to obtain a coating material.

[0039] Apply the coating solution to one side of a polyethylene terephthalate film with a thickness of 188 μm, dry it for 3 minutes at an oven temperature of 120° C. 2 The coating was cured by UV light to obtain a matte hard coating with a coating thickness D2 of 6 μm. The evaluation results are listed in Table 1.

Embodiment 3

[0041] 31.0g nine-functionality aliphatic urethane acrylate prepolymer (Sartomer, trade name: CN9013NS, functionality: 9), 5.0g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 1173), 2.0 g of leveling aid (BYK-3710, the molecular weight of the siloxane structure accounts for 90% of the molecular weight of the leveling aid), 1.5g of organic particles (polybutyl methacrylate PBMA, particle size D1 is 17.5 μm) , 0.5 g of dispersant (BYK-2000) and 60.0 g of ethyl acetate were placed in a stirring pot, and stirred evenly to obtain a coating material.

[0042] Apply the coating liquid on one side of a polymethyl methacrylate film with a thickness of 500 μm, dry it for 3 minutes at an oven temperature of 120° C. 2 The coating was cured by UV light to obtain a matte hard coating with a coating thickness D2 of 3.5 μm. The evaluation results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com