Patents

Literature

138results about How to "Less coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

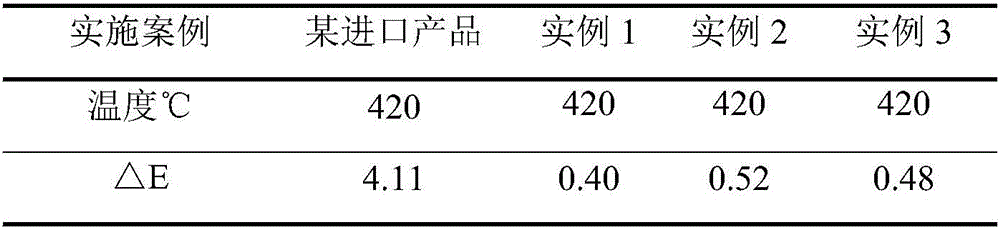

Preparation method of high-whiteness high-temperature-resistance color masterbatch level titanium dioxide

ActiveCN106118140AControl granularityHigh whitenessPigment treatment with organosilicon compoundsPigment physical treatmentTitaniumMoisture absorption

The invention discloses a preparation method of high-whiteness high-temperature-resistance color masterbatch level titanium dioxide. Based on a sulfuric acid process production technology, rutile type color masterbatch special titanium dioxide is prepared through the following steps of performing sufficient rinsing, performing washing with water, performing salting, and then performing calcining so as to prepare a rutile base material free from surface treatment, wherein the rutile base material has favorable whiteness and favorable particle fineness; and performing sufficient crushing through wet grinding and sand grinding, then performing inorganic enveloping, and performing flash evaporation and drying, wherein during crushing by gas streams, organic enveloping treatment is performed, so that the high-whiteness high-temperature-resistance color masterbatch level titanium dioxide with low moisture absorption and fine particle size is prepared. The color masterbatch level titanium dioxide prepared by the preparation method disclosed by the invention can notably improve the temperature resistance situations in down-stream enterprises and the application properties of resin, and has a wide market prospect that the color masterbatch level titanium dioxide can be used for different industrial uses and can be used for manufacturing different colorful plastic articles.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

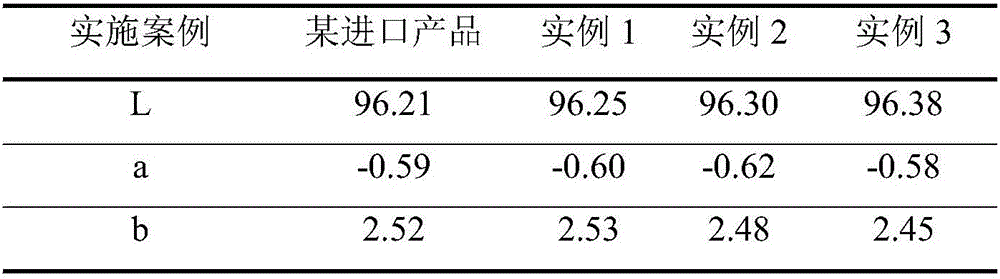

Insulator for low-temperature construction of asphalt pavement road roller and method for preparing same

ActiveCN102167939ANo pollution in the processNo chemical reactionClimate change adaptationCoatingsGreenhouseEngineering

The invention belongs to the technical field of preparation of insulators for the construction of asphalt pavement road rollers and relates to an insulator for the low-temperature construction of road rollers and a method for preparing the same. The insulator is mainly prepared by mixing silicone oil, compound emulsifier, glycerin, pH regulator, preserving agent and water. The insulator has the advantages of high chemical stability, high high-low temperature resistance, no corrosion to steel wheels, small amount of coating, lasting insulating effect, environment friendliness and the like. By using the insulator, the asphalt mixture pavement is guaranteed to be constructed at the ultralow temperature (15 DEG C below zero), so that the working season is greatly prolonged; and during normal-temperature construction, by using the insulator, the mixing temperature of the asphalt mixture is reduced to 15 to 20 DEG C under the condition of unchanging the compaction degree and the emitted greenhouse gases are reduced in the mixing process and the environment-friendly and energy saving requirements are met.

Owner:山西省交通科技研发有限公司

Method for fabricating obstruction coating film of modified polyvinyl alcohol and coating film produced thereby

InactiveCN1687264AReduce hydrogen bondingImprove water resistanceCoatingsPVA - Polyvinyl alcoholPolymer chemistry

The present invention provides a modified polyvinyl alcohol high-barrier coating film and its preparation method. Said method uses PVOH as raw material, and adopts the following steps: after the raw material is catalyzed, making modification, then adding adjuvant to make them into coating material, applying said coating material on the base film so as to form high-barrier coating film. After the PVOH molecular chain is partially catalyzed and condensed, the hydrogen bond action force in the molecular can be reduced, so that its water-proof property can be greatly raised.

Owner:HAINAN SHINER IND

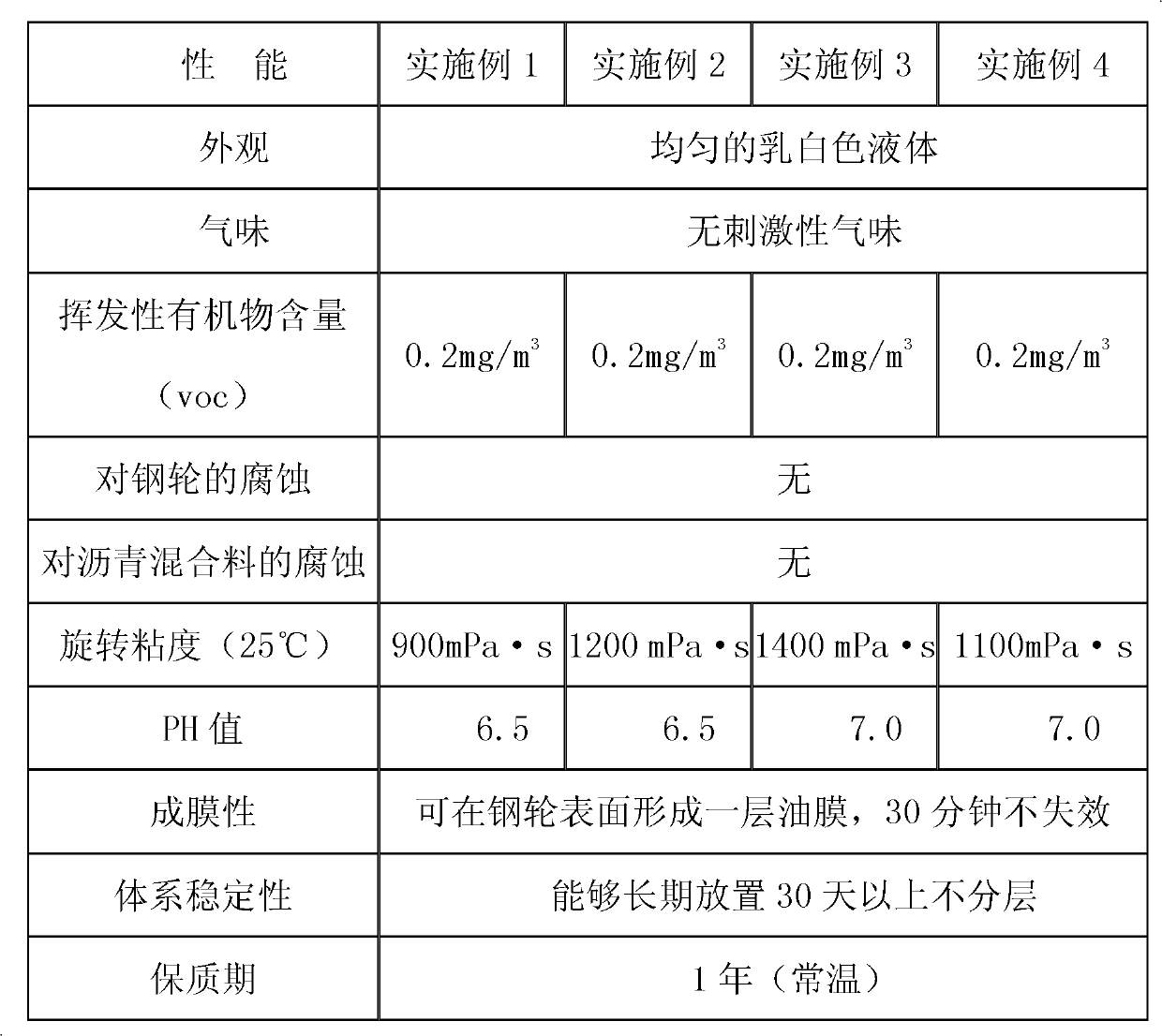

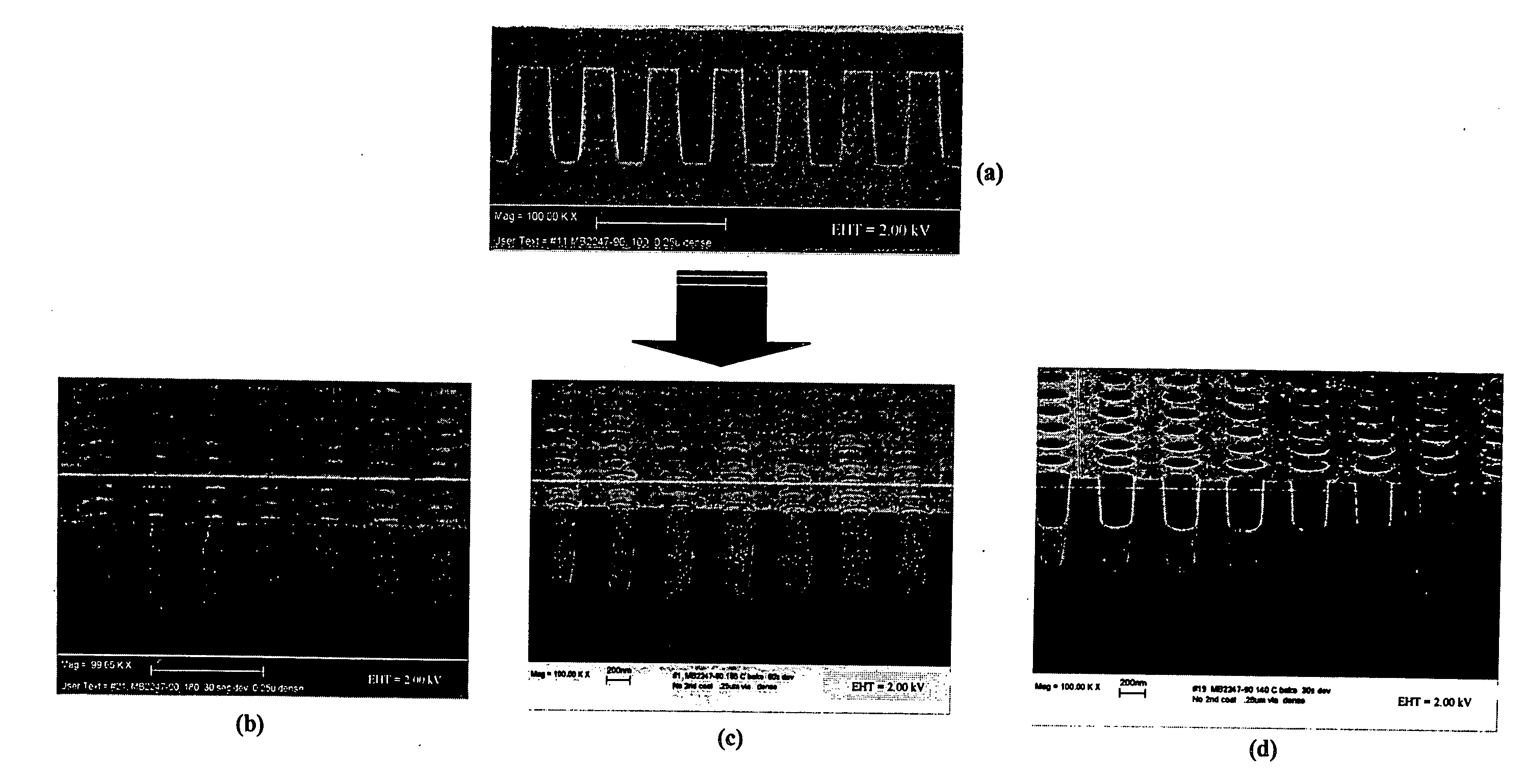

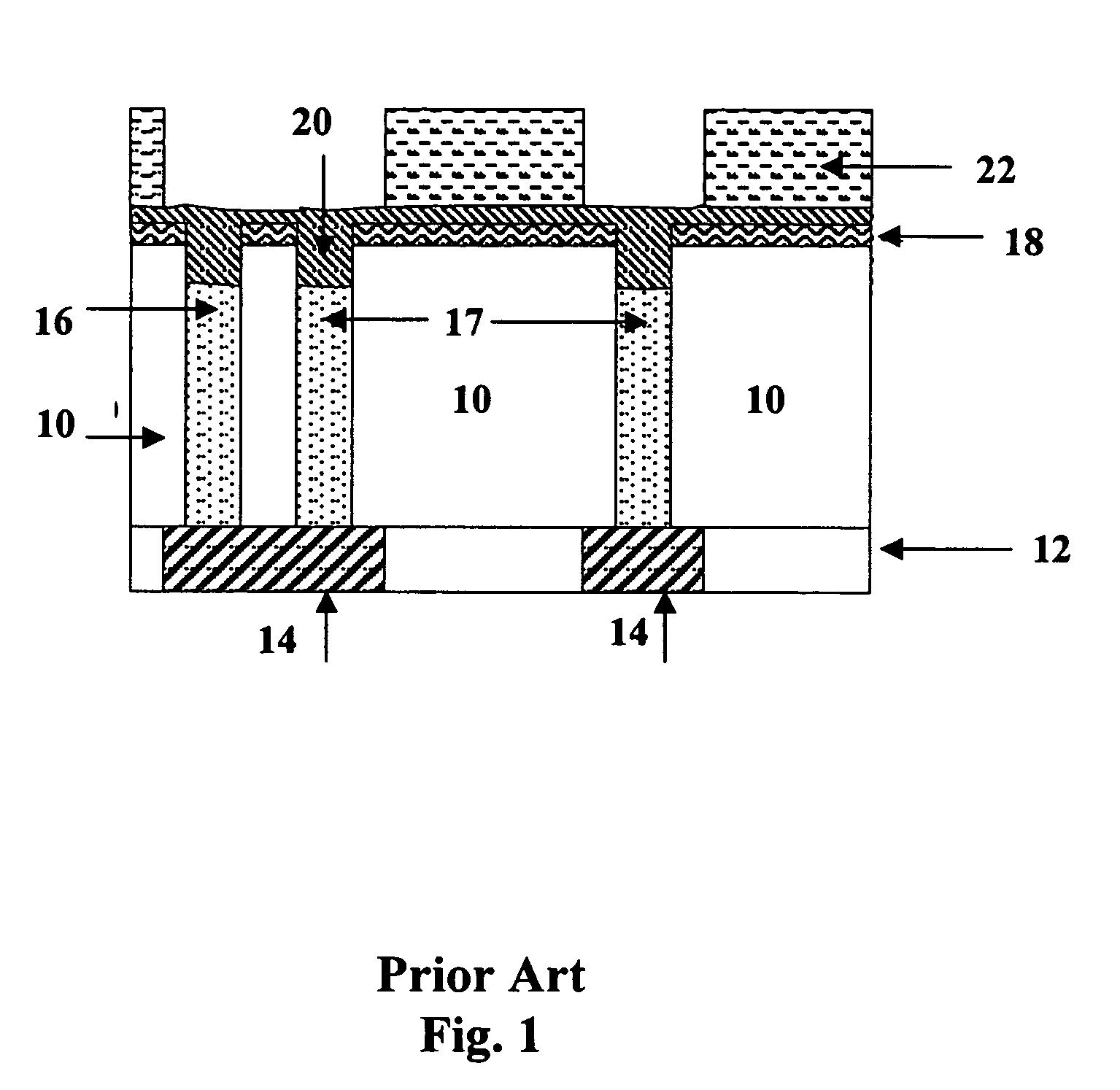

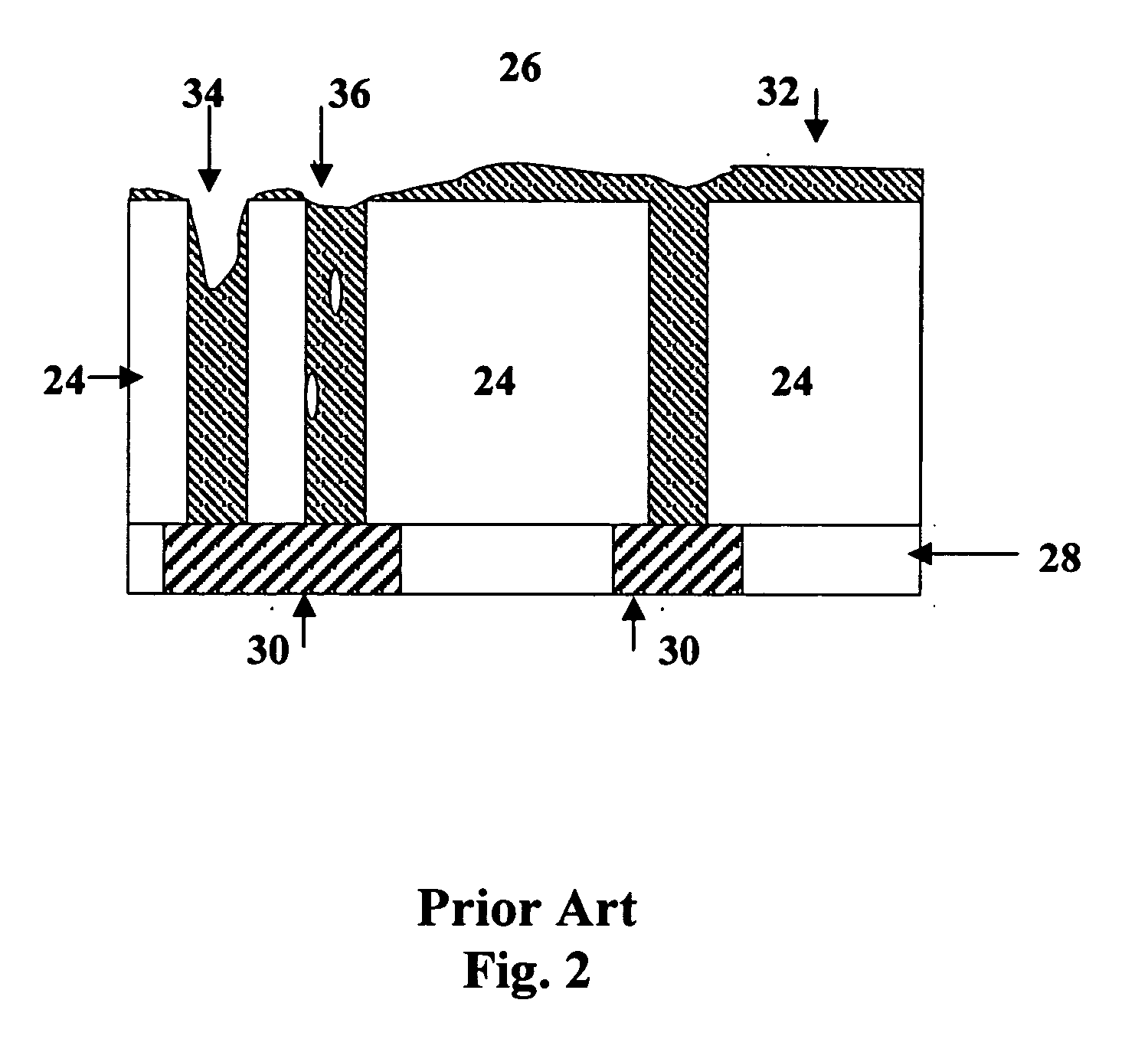

Developer-soluble materials and methods of using the same in via-first dual damascene applications

ActiveUS20050148170A1Reduced fencingReduced crown formationPhotosensitive materialsPhotomechanical apparatusThermal energyPolyester

Wet-recess (develop) gap-fill and bottom anti-reflective coatings based on a polyamic acid or polyester platform are provided. The polyamic acid platform allows imidization to form a polyimide when supplied with thermal energy. The gap-fill and bottom anti-reflective coatings are soluble in standard aqueous developers, and are useful for patterning via holes and trenches on semiconductor substrates in a dual damascene patterning scheme. In one embodiment, compositions composed of polyamic acids can be used as gap-filling (via-filling) materials having no anti-reflective function in a copper dual damascene process to improve iso-dense fill bias across different via arrays. In another embodiment, the same composition can be used for anti-reflective purposes, wherein the photoresist can be directly coated over the recessed surface, while it also acts as a fill material to planarize via holes on the substrate. The compositions described here are particularly suitable for use at exposure wavelengths of less than about 370 nm.

Owner:BREWER SCI

UV (ultraviolet) cured high-rigidity wear-resistant flame-retardant coating material and preparation method

InactiveCN102604459AImprove flame retardant performanceGood physical propertiesFireproof paintsWear resistantUltraviolet

The invention discloses a UV (ultraviolet) cured high-rigidity wear-resistant flame-retardant coating material and a preparation method thereof. The UV cured high-rigidity wear-resistant flame-retardant coating material comprises components including, by weight, 20-70% of UV curing resin, 20-50% of active diluent, 5-40% of functional sol, 3-5% of initiator and 0.1-0.6% of flatting agent, wherein the functional sol is sol containing flame-retardant element prepared by sol-gel method, functional filler is at least one of organically-modified talcum powder and montmorillonoid and particles with evident diameter gradient. Rigidity, wear resistance and flame retardant of the coating material can be improved greatly after the coating material is coated on base material. The UV cured high-rigidity wear-resistant flame-retardant coating material can be applied to the surfaces of furniture, wood floor and plastics.

Owner:SHANGHAI UNIV

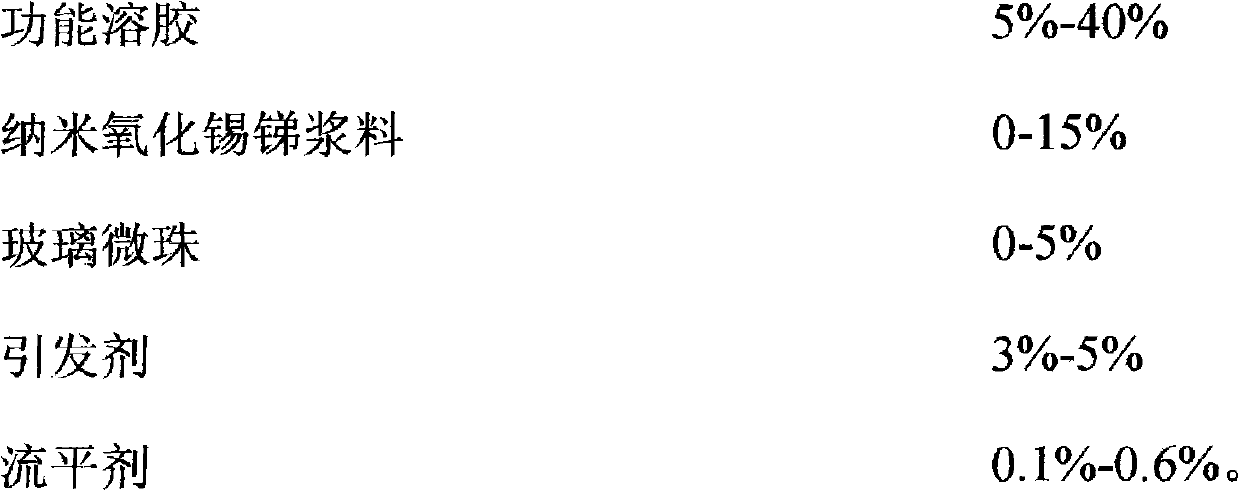

Method for preparing ultraviolet (UV) curing flame-retardant coating material and UV curing flame-retardant coating material

The invention discloses a method for preparing an ultraviolet (UV) curing flame-retardant coating material. The method comprises the following steps of: (1) preparing functional sol which is nano-sol modified by a silane coupling agent or sol generated by hydrolyzing alkoxide or the silane coupling agent; and (2) adding 20 to 70 mass percent of UV curing resin, 20 to 50 mass percent of reactive diluent, 5 to 40 mass percent of functional sol, 0 to 15 mass percent of nano antimony tin oxide slurry, 0 to 5 mass percent of glass microspheres, 3 to 5 mass percent of initiator and 0.1 to 6 mass percent of leveling agent into a dispersing kettle, and dispersing for 0.5 to 3 hours at the rotating speed of 1,000 to 2,000rpm to obtain the UV curing high-hardness wear-resistant flame-retardant coating material. The invention also discloses the UV curing flame-retardant coating material. The UV curing flame-retardant coating material can prevent heat transfer from the source, the surface temperature and internal environment temperature of the coating material are effectively reduced, and the aims of improving the working environment and reducing energy consumption are fulfilled.

Owner:上海大学浙江嘉兴新兴产业研究院

Ink jet recording sheet

Ink jet recording sheet has excellent coloring properties for dye ink as well as pigment ink, a high degree of brightness, and excellent preservability for white paper portions. The ink jet recording sheet includes: a paper supporting medium made by machining pulp; an undercoating layer including at least a pigment and an adhesive; and an ink receiving layer including at least a pigment and an adhesive, the undercoating layer and the ink receiving layer being disposed on at least one surface of the paper supporting medium, and the ink receiving layer being located outermost thereof, wherein the undercoating layer includes titanium dioxide as the pigment and at least one emulsion type adhesive selected from acryl polymers, ethylene-vinyl acetate copolymers, or vinyl acetate polymers; and the ink receiving layer includes silica having an average secondary particle size of 3 to 11 m as the pigment, and a cationic ink fixing agent.

Owner:SEIKO EPSON CORP

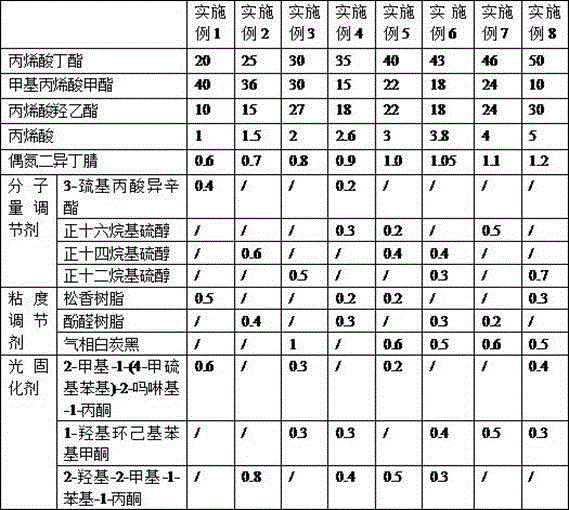

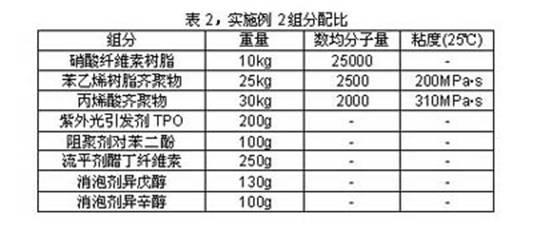

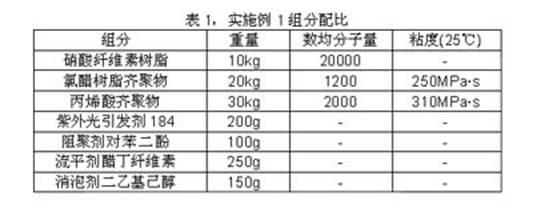

UV-cured acrylic pressure-sensitive adhesive and preparation method thereof

ActiveCN104592903ALess coatingLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventChemistry

The invention discloses a UV-cured acrylic pressure-sensitive adhesive. The pressure-sensitive adhesive has a viscosity of 5000-8500 CPS at a normal temperature and prepared by compounding the following raw materials in parts by weight: 20-50 parts of butyl acrylate, 10-40 parts of methyl methacrylate, 10-30 parts of hydroxyethyl acrylate, 1-5 parts of acrylic acid, 0.4-0.8 part of a molecular weight regulator, 0.6-1.2 parts of azodiisobutyronitrile, 0.1-1 part of a viscosity regulator and 0.1-1 part of a light curing agent. Compared with the prior art, the UV-cured acrylic pressure-sensitive adhesive provided by the invention has the advantages that the solid content is 100%, the performances of a common solvent-type pressure-sensitive adhesive can be achieved as long as the coating thickness is 30 microns, the coating amount is low, and the cost and the energy consumption are reduced; because the viscosity ranges from 6000 to 6500CPS, the UV-cured acrylic pressure-sensitive adhesive is suitable for a traditional scrape-coating process; a photoinitiator in the adhesive is synthesised onto the molecular chain of glue water, so that the stability is good, and the photocuring shrinkage rate is low.

Owner:YANTAI DARBOND TECH

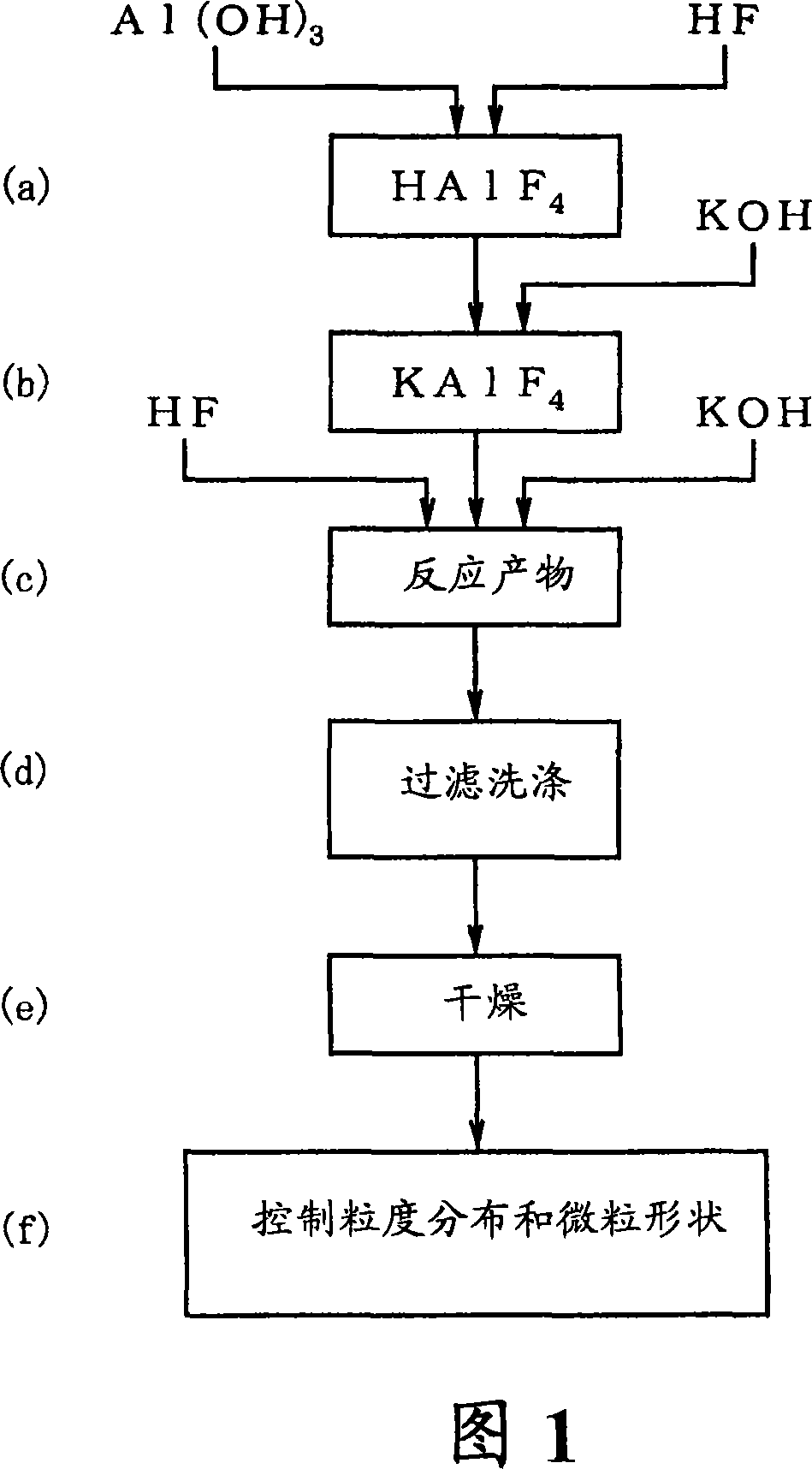

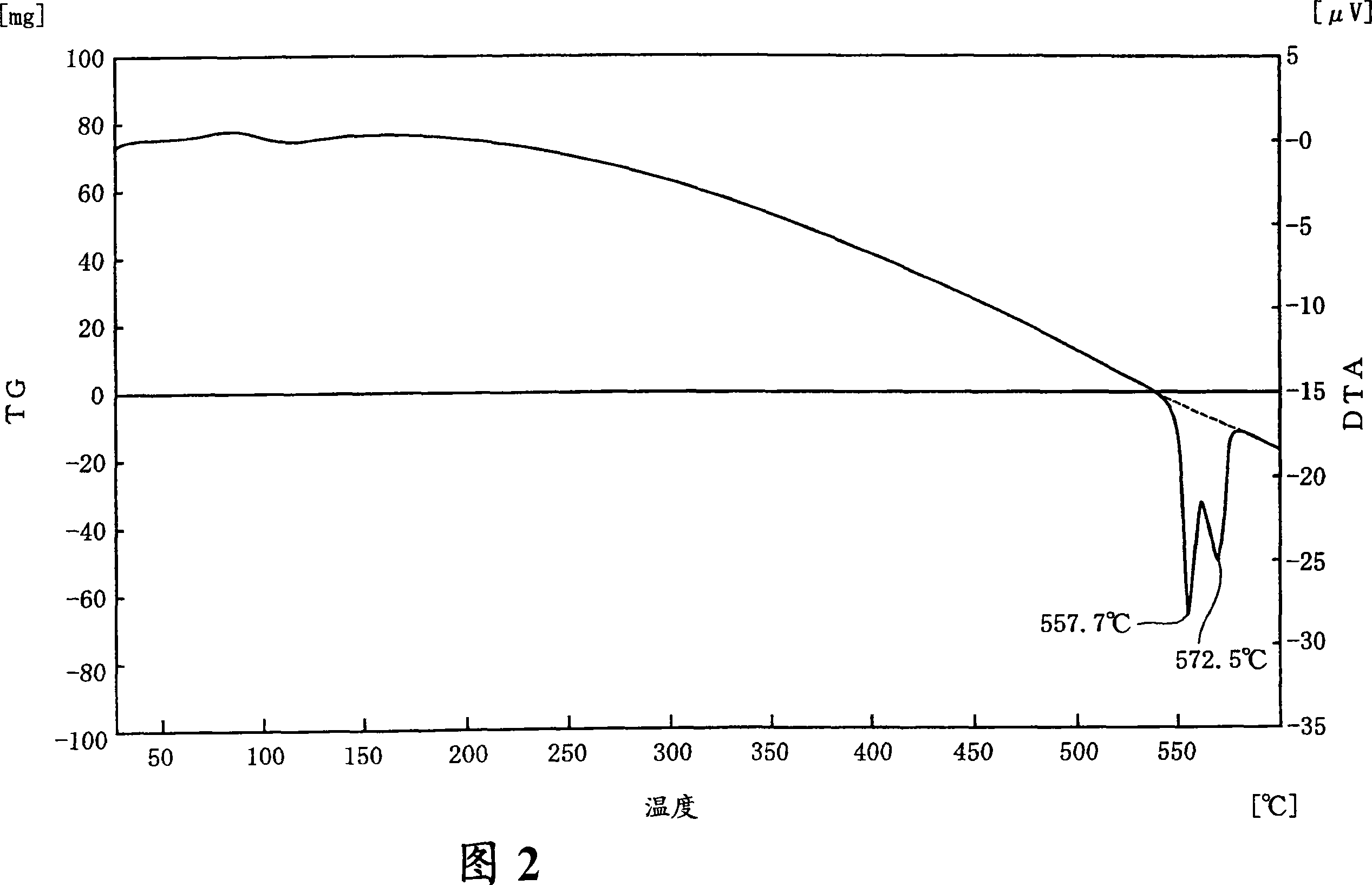

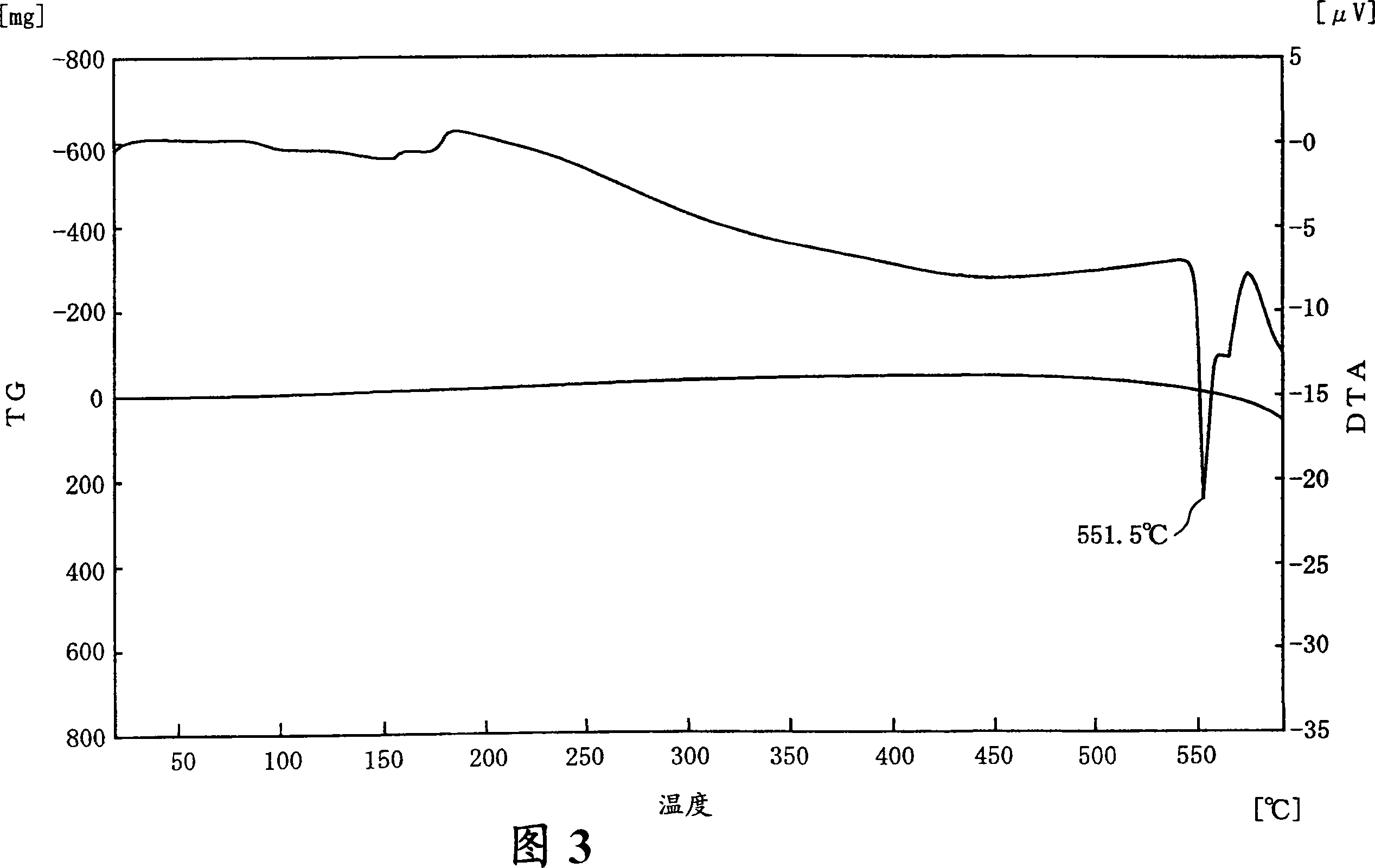

Flux powder for brazing aluminum material and process for producing the flux powder

InactiveCN101146645AImprove securityCost-effectiveWelding/cutting media/materialsSoldering mediaGeneral purposeMetallurgy

The present invention provides a flux powder, which has good expansibility when brazing Mg-containing aluminum-based materials, the flux powder is non-corrosive and has excellent safety, is inexpensive and economical, and can be widely used in General purpose. The present invention provides an improved flux powder, which contains KAlF4, K2AlF5 and K2AlF5·H2O, and is used for brazing aluminum-based materials with a Mg content of 0.1-1.0% by weight. The improved characteristic composition is that it has K / Al A composition with a molar ratio in the range of 1.00 to 1.20 and a F / Al molar ratio in the range of 3.80 to 4.10. The total content of K2AlF5 and K2AlF5·H2O is 6.0 to 40.0% by weight, and the balance is KAlF4. Part or all of the crystal structure of K2AlF5·H2O It is at least one of K-deficient, F-deficient, or K- and F-deficient crystal structures.

Owner:JEMCO INC +1

Method for reducing difference on two sides of paper-making reconstituted tobacco

The invention disclose a method for reducing difference on two sides of paper-making reconstituted tobacco, which adopts the moistening manner of quantitatively spraying atomized tap water on the back of a coated substrate through an atomizing nozzle to increase the liquidity of coating liquid on the back of a sheet, and prompt the coating liquid on the back to further permeate to the front, and the distribution difference of coating weight on the front and the back is reduced, and uniformly front and back coating weight of the sheet is achieved. The method has less input, simple control, and obvious effect. The vertical height between the atomizing nozzle and the sheet is 250 to 350 mm; the centre line of the nozzle is vertical to an oblique plane of the sheet; the mist granularity is not greater than 300 micrometers; and the spraying volume for the sheet is 150 to 250 g per square meter.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

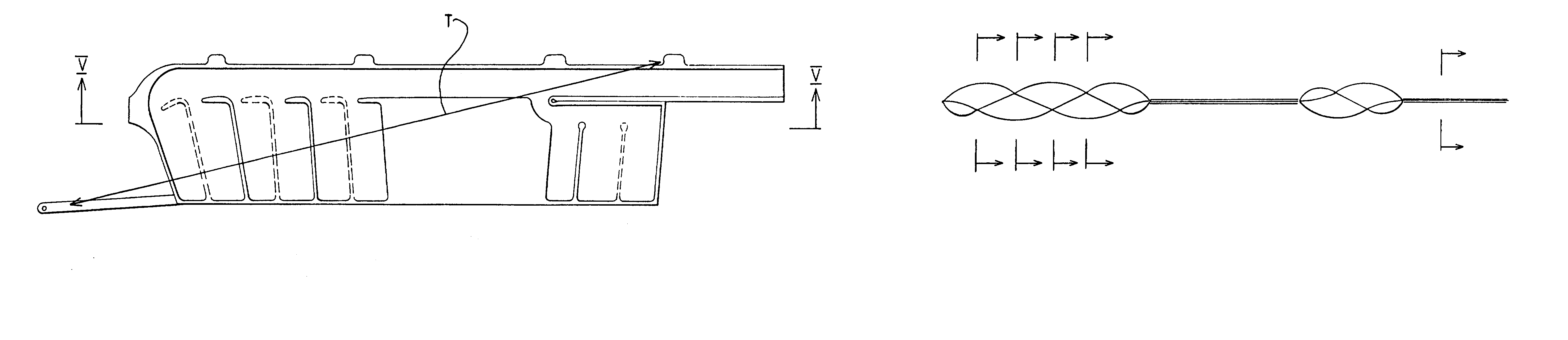

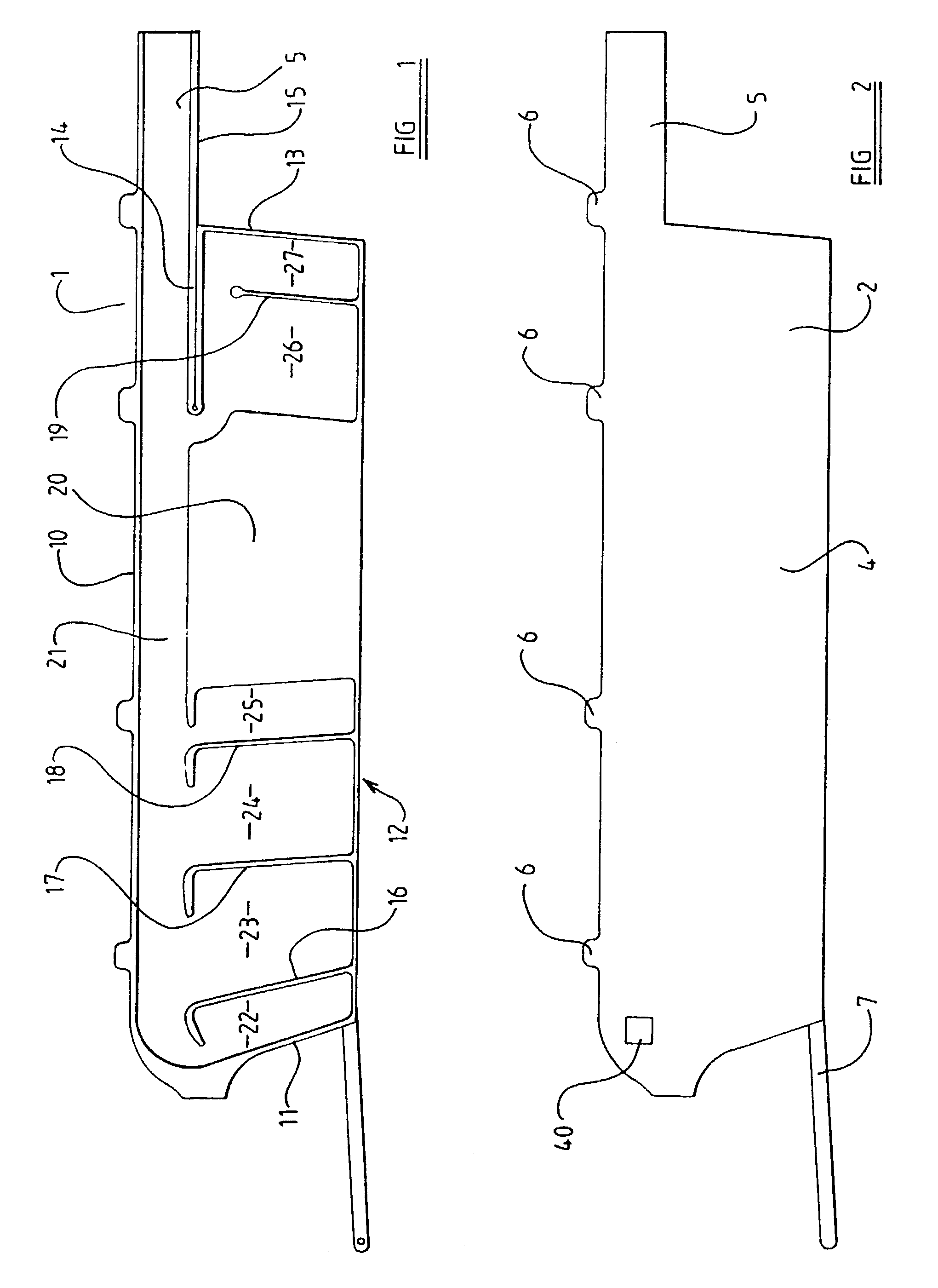

Air-bag arrangement and a method of inflating an air-bag

InactiveUS7025375B2Improve protectionLess coatingEnvelopes/bags making machineryPedestrian/occupant safety arrangementEngineeringAirbag

An air-bag arrangement provides protection for the occupant of a motor vehicle. The air-bag arrangement incorporates an airbag (50) formed by two layers (51, 52) interconnected to form a first set of chambers (53, 54, 55, 56, 57, 58), having a plurality of elongated substantially parallel chambers. A further fabric layer (61) is connected to one of the two layers (52) forming the main part of the inflatable element to define a second chamber set including two chambers (62, 63). The chambers are off-set from the adjacent chambers (54, 55, 56) defined by the first two layers (51, 52). Apertures (59, 60) provided in the layer (52) allow for the inflation of the second set of chambers (62, 63).

Owner:AUTOLIV DEV AB

Acrylic acid coating film and its manufacturing method

ActiveCN1686712AGood low temperature heat sealabilityHigh heat sealing strengthLayered productsEmulsionSoftened water

An acrylic acid coated film is composed of a substrate layer, a coated acrylic paint layer and a sandwich layer between the first two layers. Its preparing process includes such steps as preparing acrylic paint from acrylic emulsion, softened water, smoothing agent and detackifier, coating it on the substrate and baking.

Owner:HAINAN SHINER IND

Biaxially oriented polypropylene lamination film base material as well as preparation method and application thereof

ActiveCN105479884ASimple manufacturing processImprove bindingLamination ancillary operationsSynthetic resin layered productsPolymer scienceCarvacryl acetate

The invention relates to a biaxially oriented polypropylene lamination film base material as well as a preparation method and an application thereof. The biaxially oriented polypropylene lamination film base material comprises a polypropylene surface layer, a polypropylene core layer and an ethylene-vinyl acetate layer, and is prepared by coextrusion and bidirectional stretching of surface-layer polypropylene resin, core-layer polypropylene resin and ethylene-vinyl acetate resin. The biaxially oriented polypropylene lamination film base material can be directly coated with EVA hot melt adhesive without coating a bottom sizing agent, thus simplifying a preparation process of a lamination film, avoiding potential safety hazard caused by organic solvents in the bottom sizing agent, being capable of improving production efficiency and reducing energy consumption, and avoiding the problem of color change in the storage period of a film base material caused by a conventional bottom coating method. The EVA priming coat has good binding force with EVA hot melt adhesive in the prior art and can also improve the stripping strength of the EVA hot melt adhesive coating.

Owner:GUANGDONG DECRO FILM NEW MATERIALS +1

Scratch-resistant and anti-fouling TPU vehicle body protection film and production process thereof

InactiveCN109837036AImprove scratch resistanceExcellent anti-scratch and anti-fouling performanceAntifouling/underwater paintsFilm/foil adhesive primer layersPolyesterMicro nano

The invention discloses a scratch-resistant and anti-fouling TPU vehicle body protection film, which comprises a base material layer and a glue layer arranged on the lower portion of the base materiallayer, the base material layer is a TPU film, the upper surface of the TPU film is provided with an scratch-resistant and anti-fouling coating, the scratch-resistant and anti-fouling coating comprises, by mass, 50-85 parts of a main body resin, 0.01-5 parts of an initiator or / and cross-linking agent, 5-50 parts of a filler, 0-20 parts of an auxiliary agent, and 0-30 parts of a solvent, the fillercomprises nanometer polymer micro-beads self-assembled into micro-nano clusters, and the main body resin is a composition of polyester type polyurethane or / and acrylic resin. According to the presentinvention, the novel scratch-resistant and anti-fouling TPU vehicle body protection film is formed by improving the formula of the scratch-resistant and anti-fouling coating, such that the TPU vehicle body protection film can integrate the effects of scratch resistance and stain resistance through the scratch-resistant and anti-fouling coating compared with the existing protection film.

Owner:SHANGHAI NAR INDAL +1

Radiation-sensitive composition, multilayer body and method for producing same, and electronic component

ActiveCN1957299AGood dissolution stabilityEfficient coatingSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusEtherSolvent

Disclosed is a very safe radiation-sensitive composition having excellent electrical characteristics and good solution stability which is able to form a coating free from unevenness. Also disclosed are a multilayer body wherein a resin film is formed on a substrate by using this radiation-sensitive composition, and a method for producing such a multilayer body. A radiation-sensitive composition containing a cyclic olefin polymer having a polar protic group, a radiation-sensitive compound, a crosslinking agent and a solvent is characterized in that the solvent contains a dialkylene glycol dialkyl ether having two different alkyl groups in one molecule. A multilayer body comprises a substrate and a resin film formed on the substrate using the above-described radiation-sensitive composition.

Owner:ZEON CORP

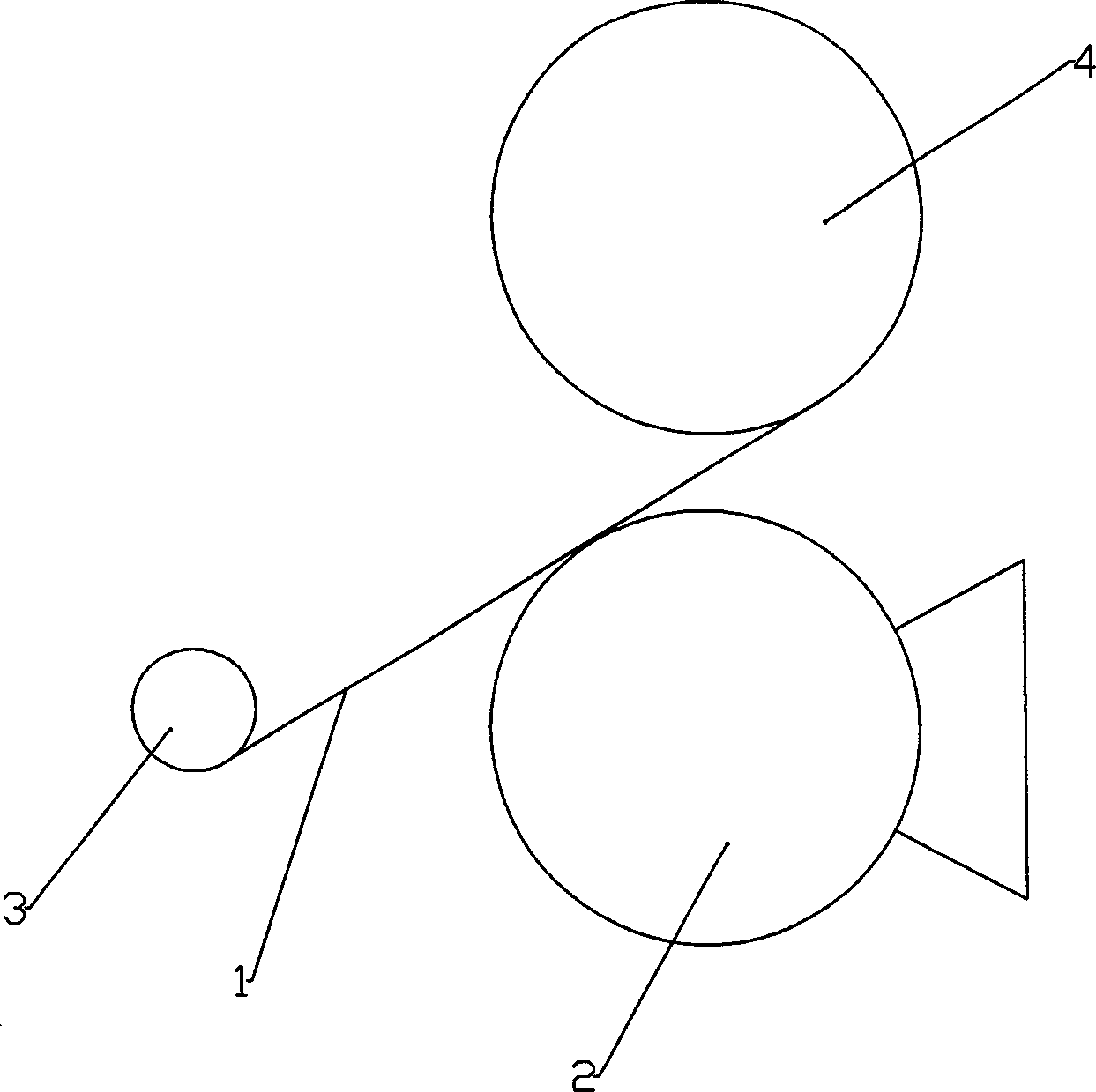

Roofing Material And Method Of Making The Same

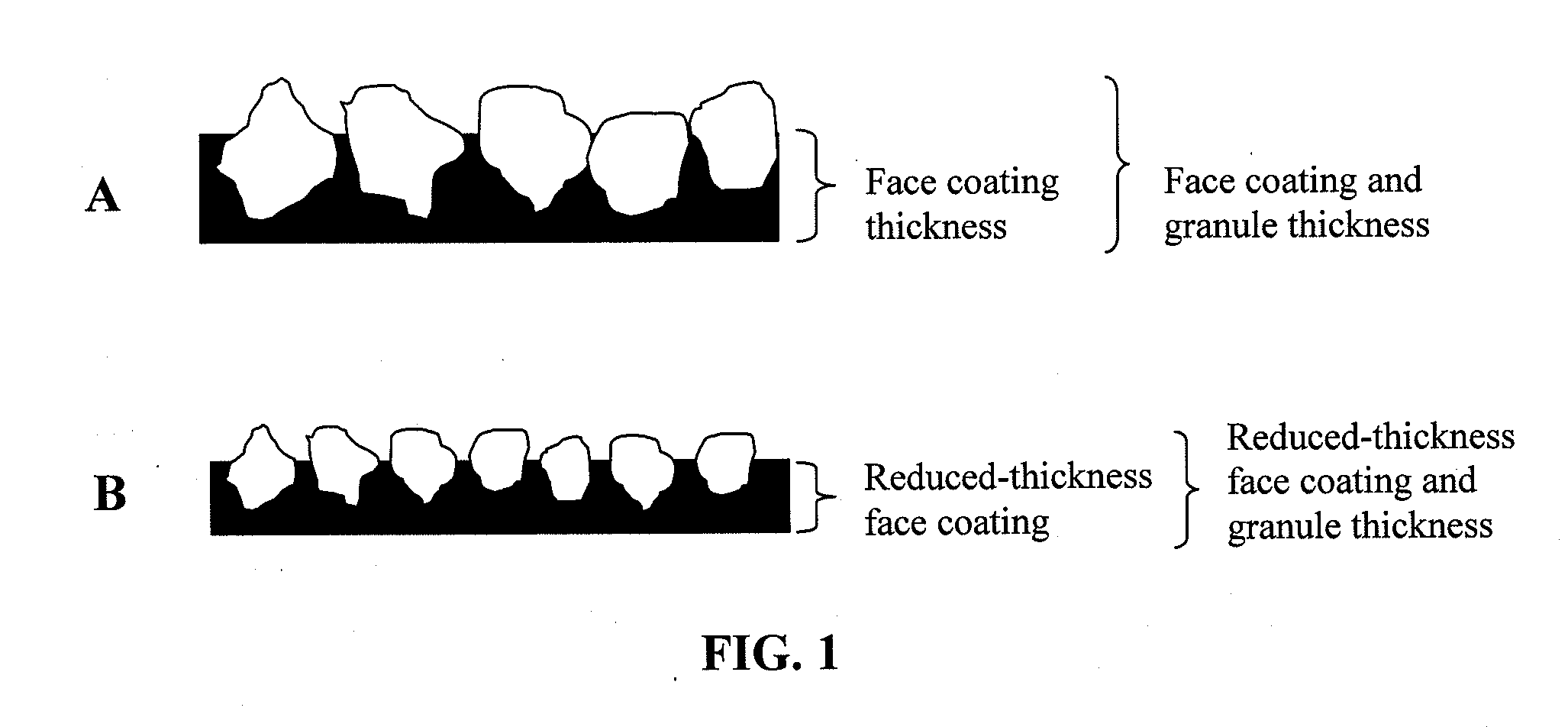

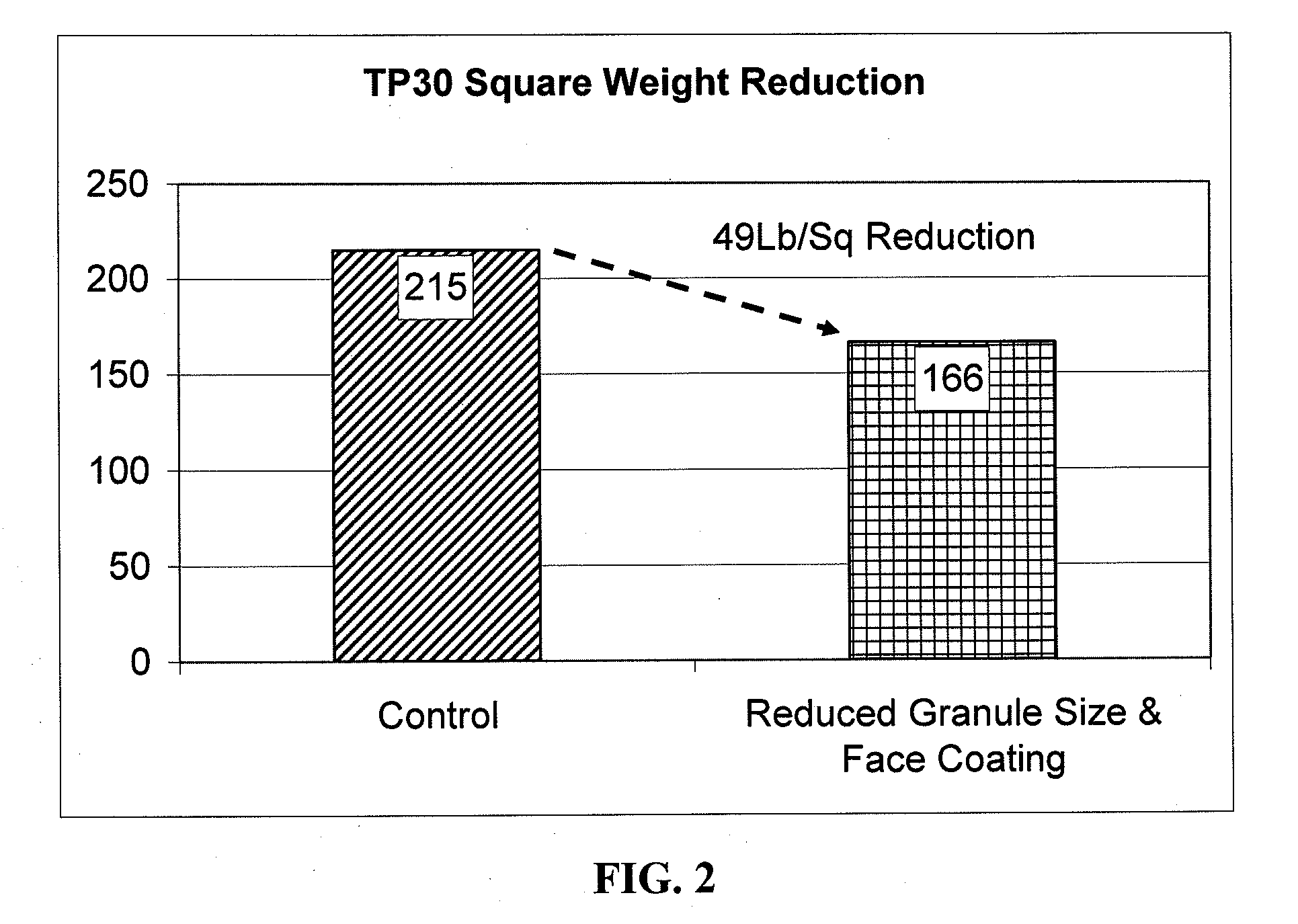

ActiveUS20110189433A1Good illusionImprove visual appearanceRoof covering using slabs/sheetsRoof covering using tiles/slatesFilling materialsMedicine

A roofing material comprising an upper surface and a lower surface, wherein the upper surface includes reduced-particle size granules and may further include a reduced-thickness face coating. The thickness of the upper surface is related to the particle size of the granules deposed on the face coating. A smaller particle size granule than those used in traditional roofing shingles is utilized in the upper surface which may allow for a reduced-thickness face coating while not sacrificing the retention of the granules on the surface of the roofing material or desired physical characteristics. The face coating may include a reduced amount of filler material, such as mineral fillers, than face coatings of traditional roofing materials.

Owner:BMIC LLC

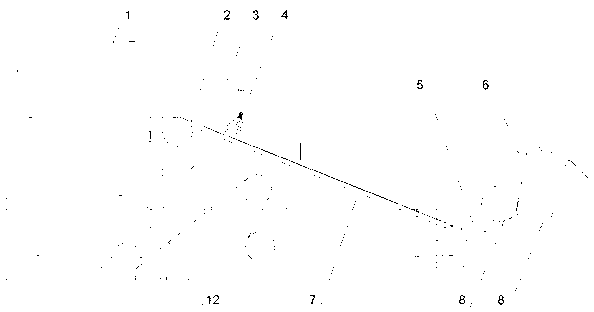

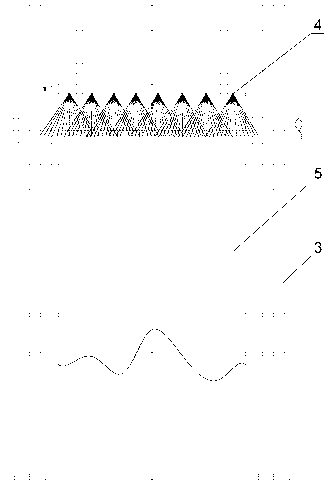

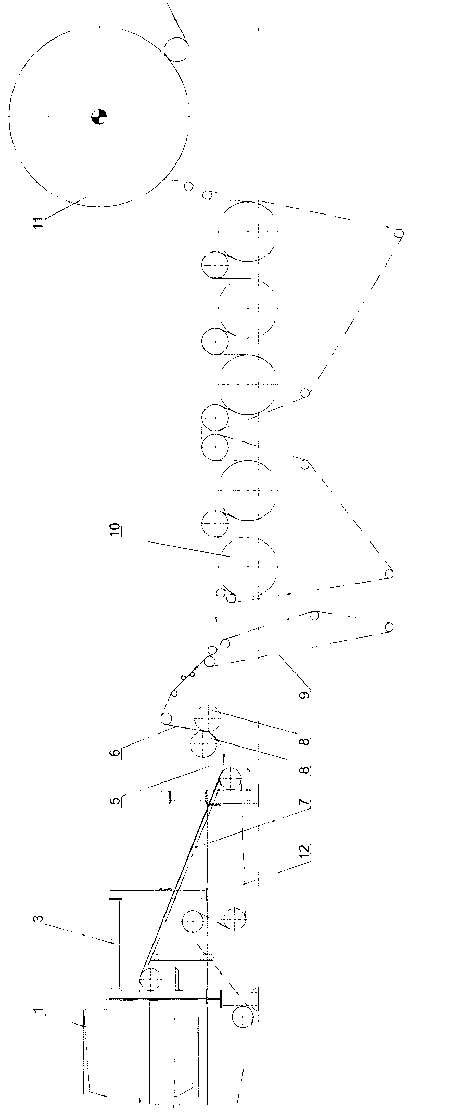

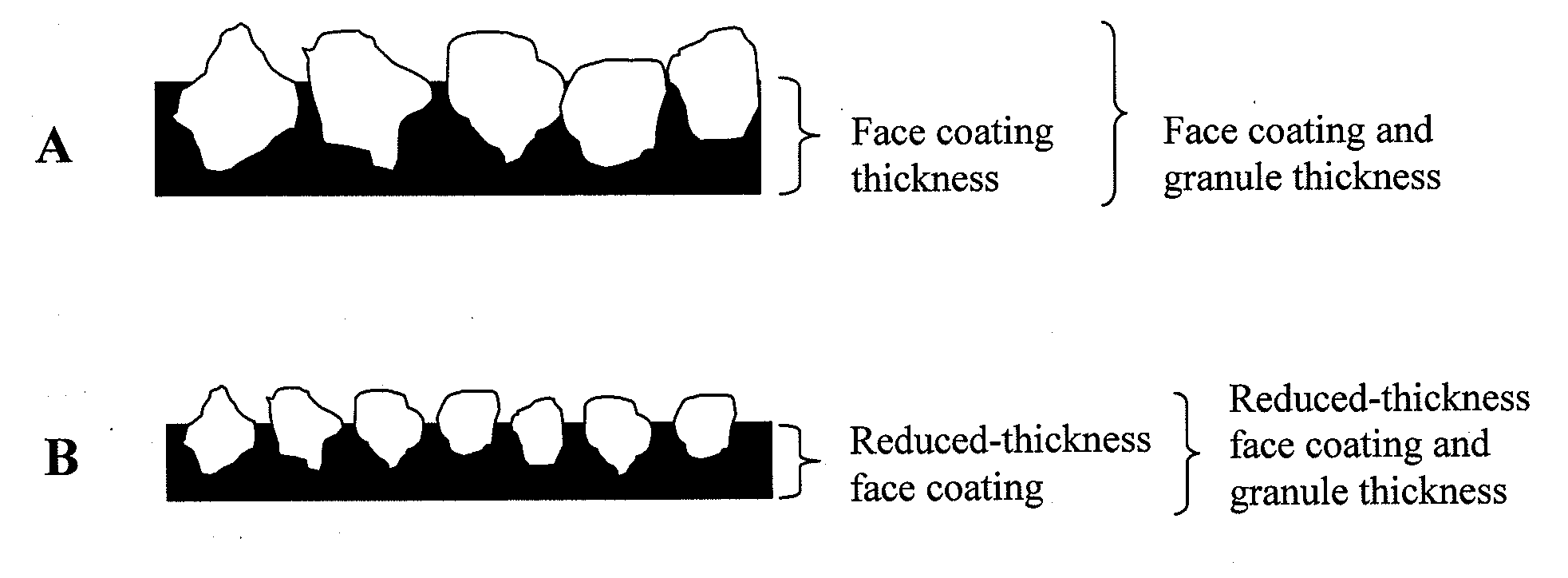

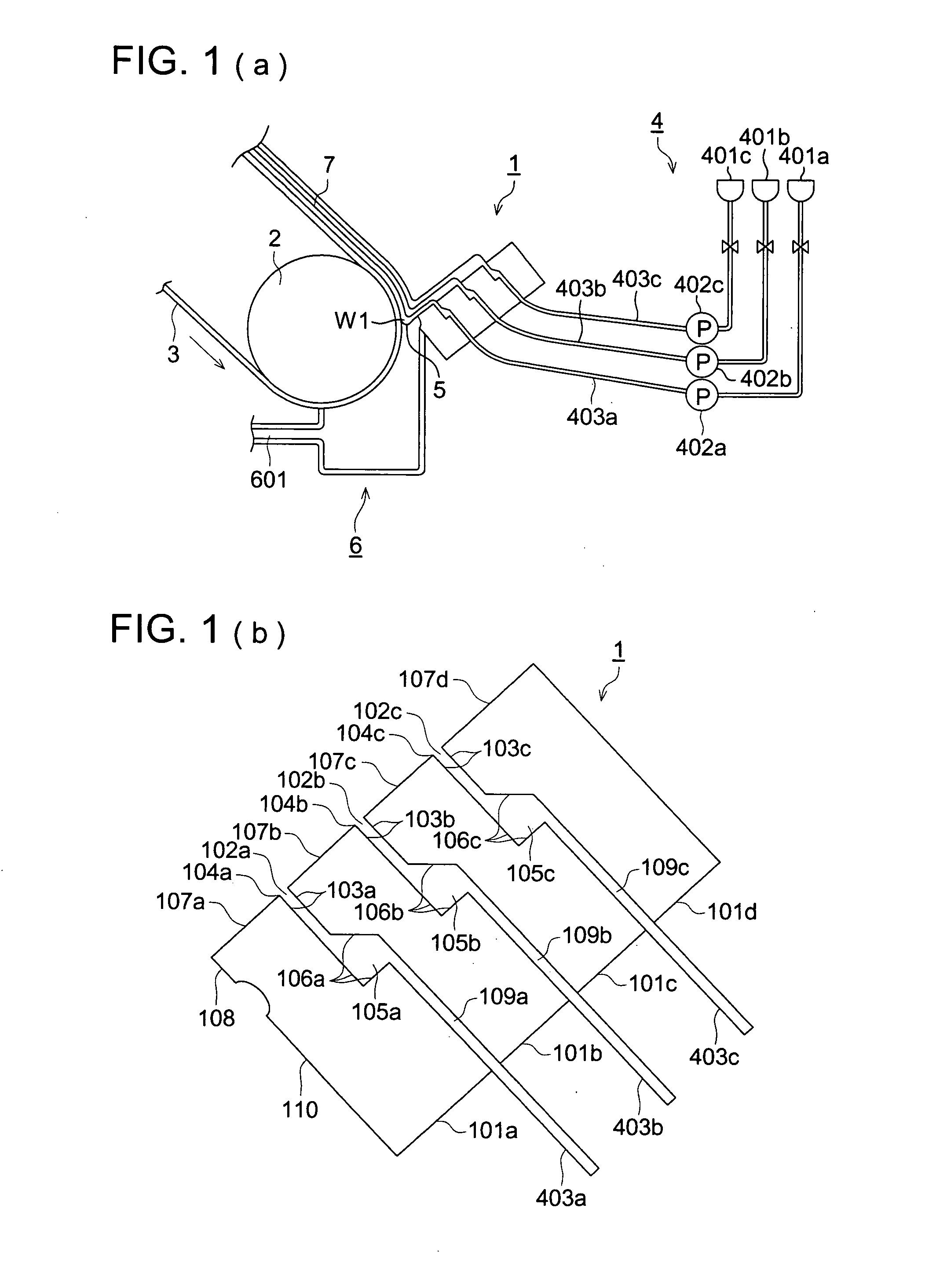

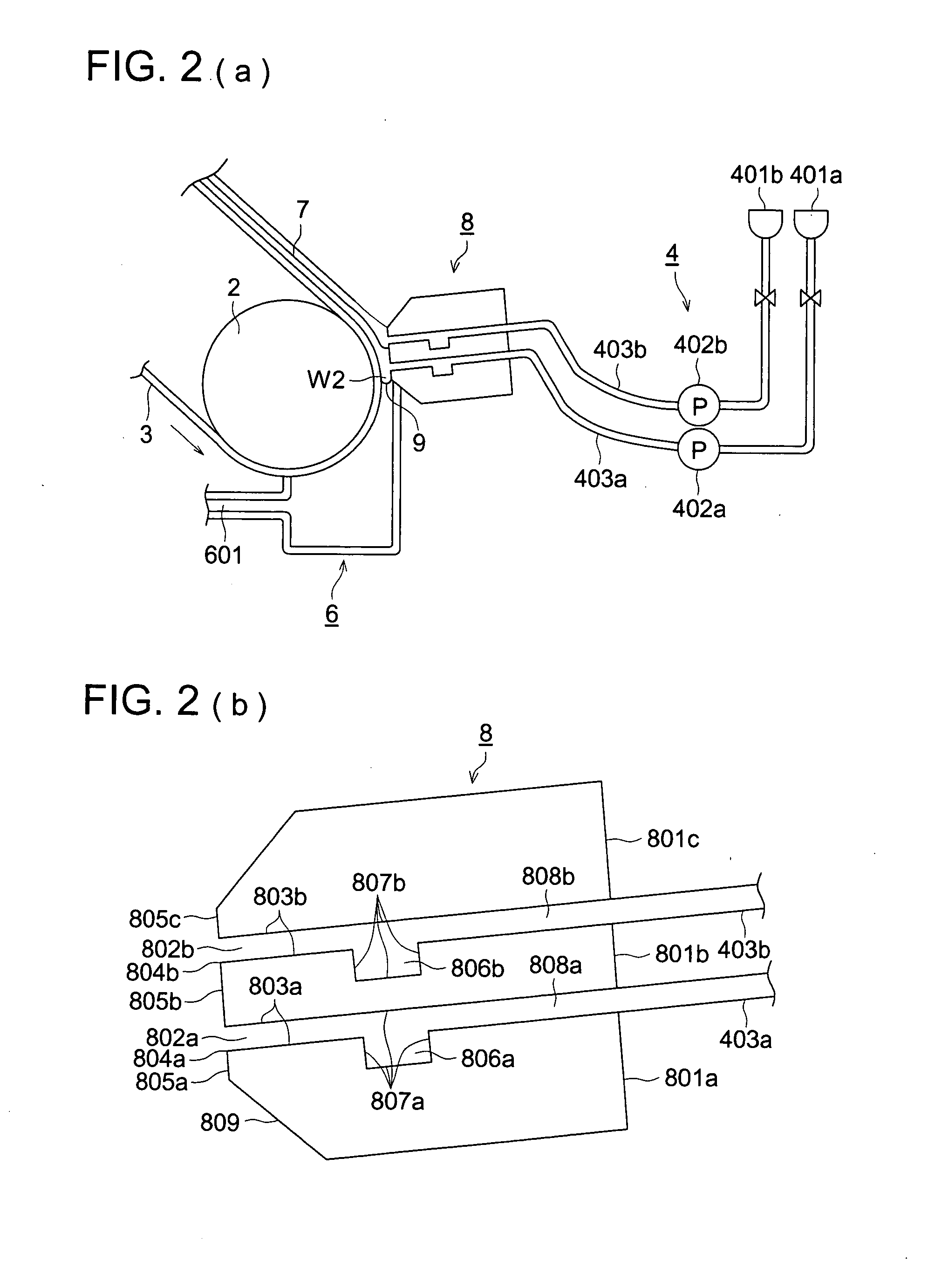

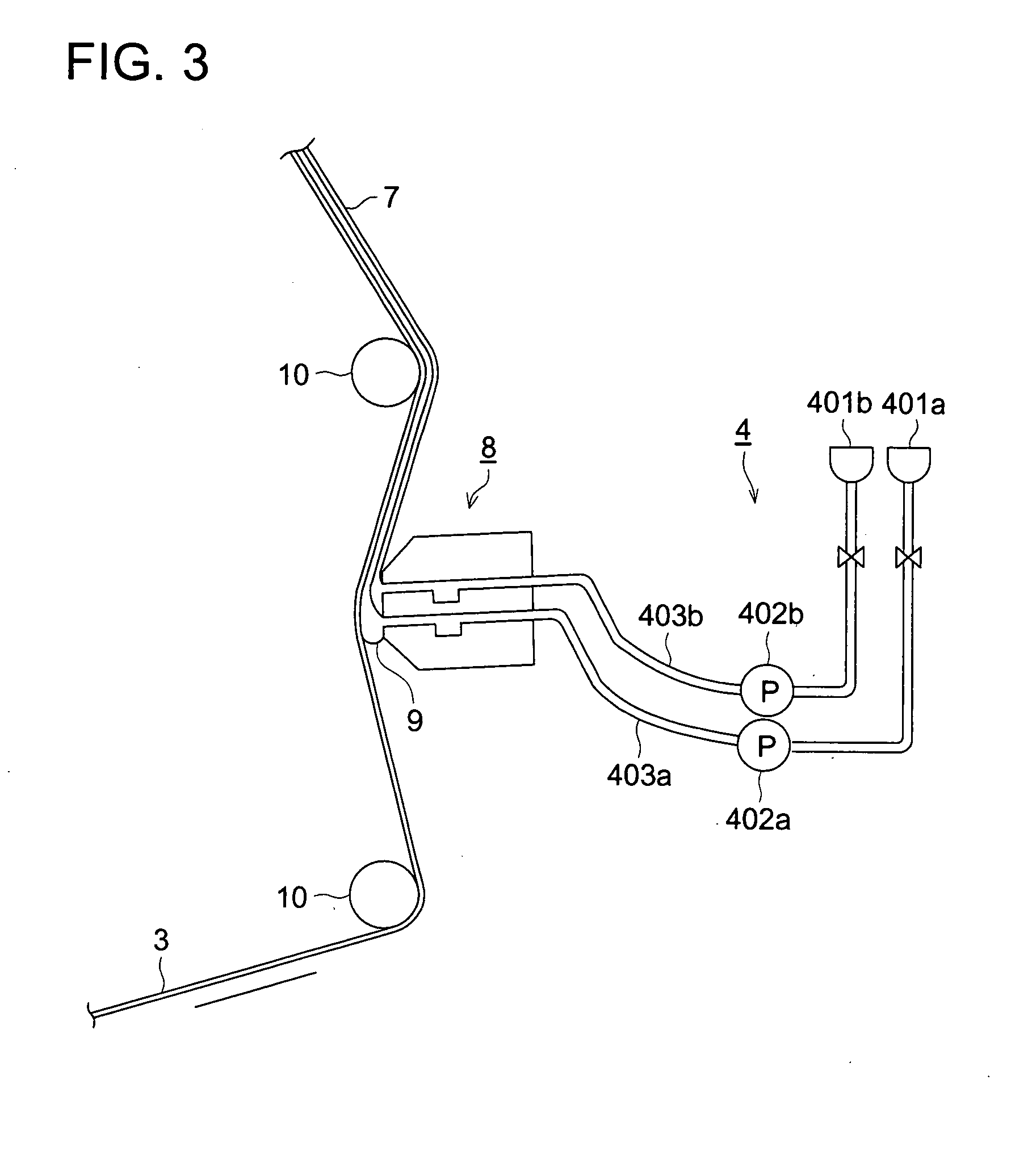

Producing method for die coater and coating apparatus

InactiveUS20050074555A1Less coatingHigh strengthPretreated surfacesCoatingsCooking & bakingEngineering

A method of producing a die coater structured with at least two bars so as to form a pocket section to extend a coating liquid in a coating width direction, a coating liquid supply port to supply a coating liquid to the pocket section, and a slit section to discharge a coating liquid from the pocket section to a material to be coated, wherein at least a part of a surface of the two bars coming in contact with a coating liquid is covered with a fluorine-based resin, the method comprises a covering process of covering a part of a surface of a bar coming in contact with a coating liquid with a fluorine-based resin; and a baking process of baking the fluorine-based resin covering the part of the surface of the bar at a temperature of 100 to 380° C.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Coating kraft liner board paper

ActiveCN101397765ACover evenly and fullyLess coatingCoatings with pigmentsCoatingsAdhesive cementPaperboard

The invention discloses a coating kraft paperboard which utilizes unbleached kraft paperboard as a coating base paper, wherein, a pigment coating containing an adhesive is formed on the unbleached kraft paperboard while the pigment coating comprises a base coating pigment coating, a floating coating pigment coating and a top coating pigment coating. Each pigment coating contains complex titanium pigment as a pigment component. The invention has the advantages of comparatively low relative cost, low coating consumption, even and full coating covering, no striation, no crack, no delamination and good adaptability for printing, thereby being capable of meeting the requirements of box making and printing.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Environmentally aluminium-plating film transfer coating

The invention relates to a kind of beaded paint used in packing and printing industry, especially, it is a type of environmental abstracting al-film. the percentage by weight of the beaded paint 3%-8% acetate, 10%-15% acrylic resin, 40%-50% acetic acid second ester, 5%-10% alc and 30%-40% alkone. The advantage of the invention is that first, it can be peeled off cleanly and surface of aluminizing can be displaced sufficiencily. Second, every sq.m 1-2 gram is enough, third, it is environmental, so can be used again and again, thus, the cost of manufacture is very low.

Owner:SHANGHAI WEIKAI CHEM

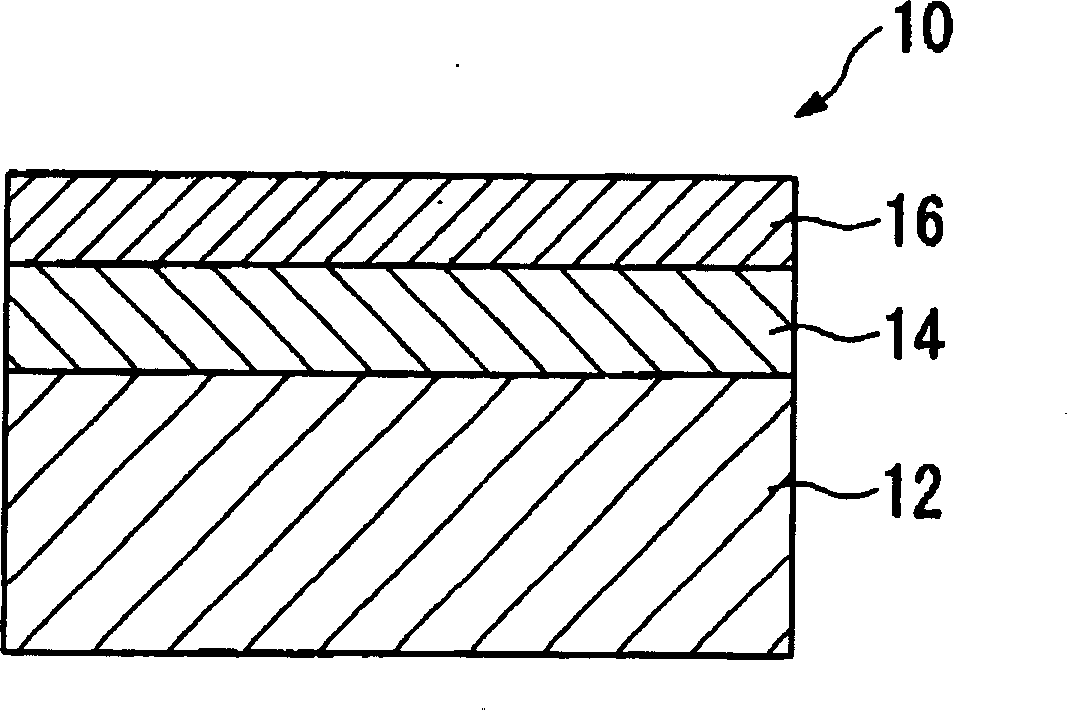

Laminated polyester film and manufacturing process thereof

ActiveUS20070184262A1High transparencyGood slipperinessLiquid surface applicatorsFilm/foil adhesivesPolyesterPolymer science

A laminated polyester film comprising a coating layer formed on at least one side of a polyester film, this coating layer comprising a polymer binder and inorganic-organic composite particles having an average particle diameter of 200 to 2,000 nm. This film has excellent scratch resistance, adhesion, transparency and slipperiness and is useful as an adhesive film for optical use.

Owner:TEIJIN DUPONT FILMS JAPAN

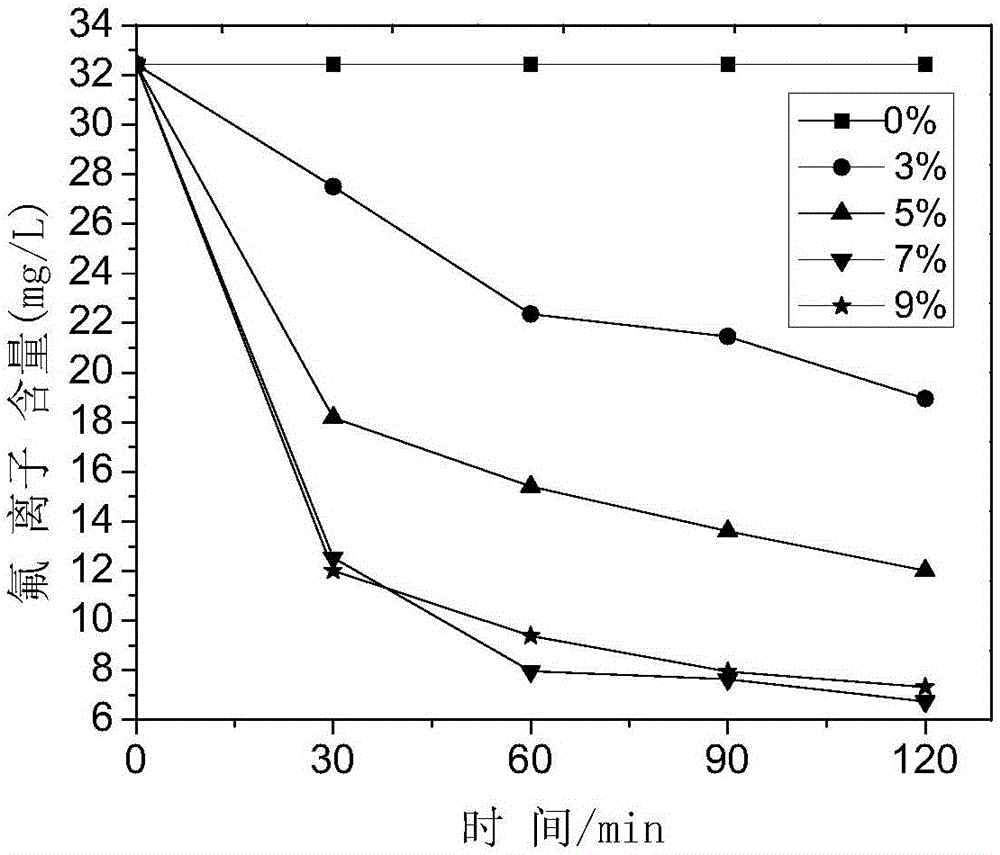

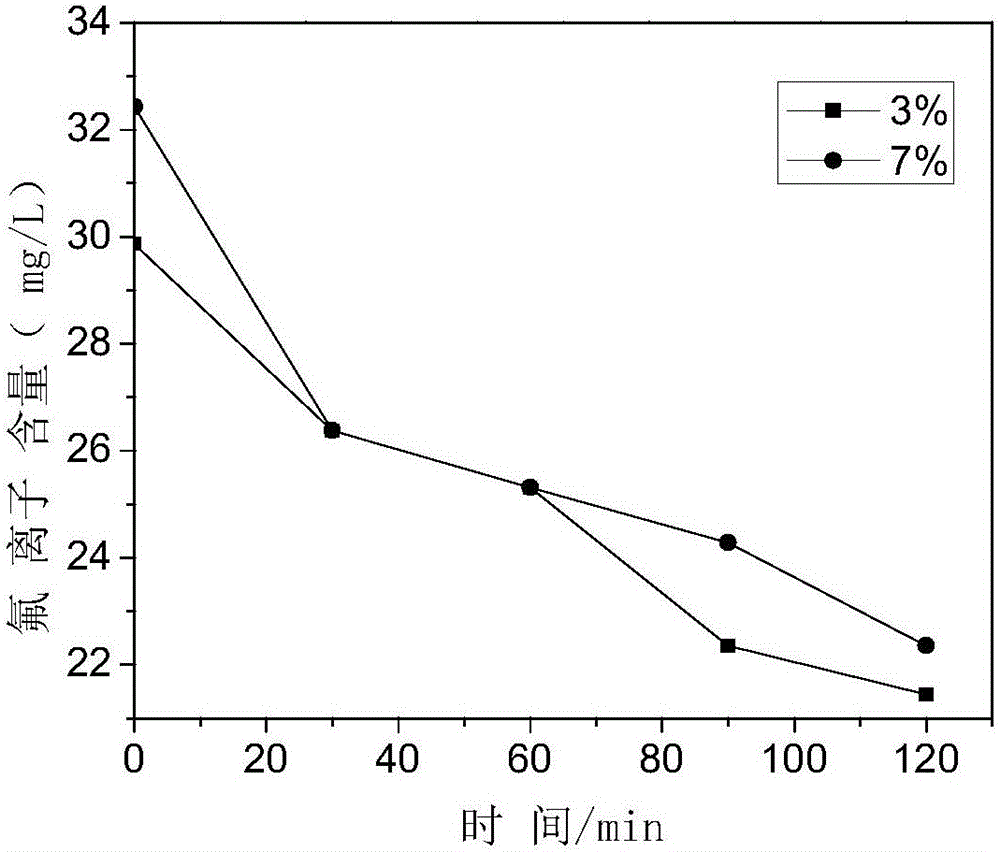

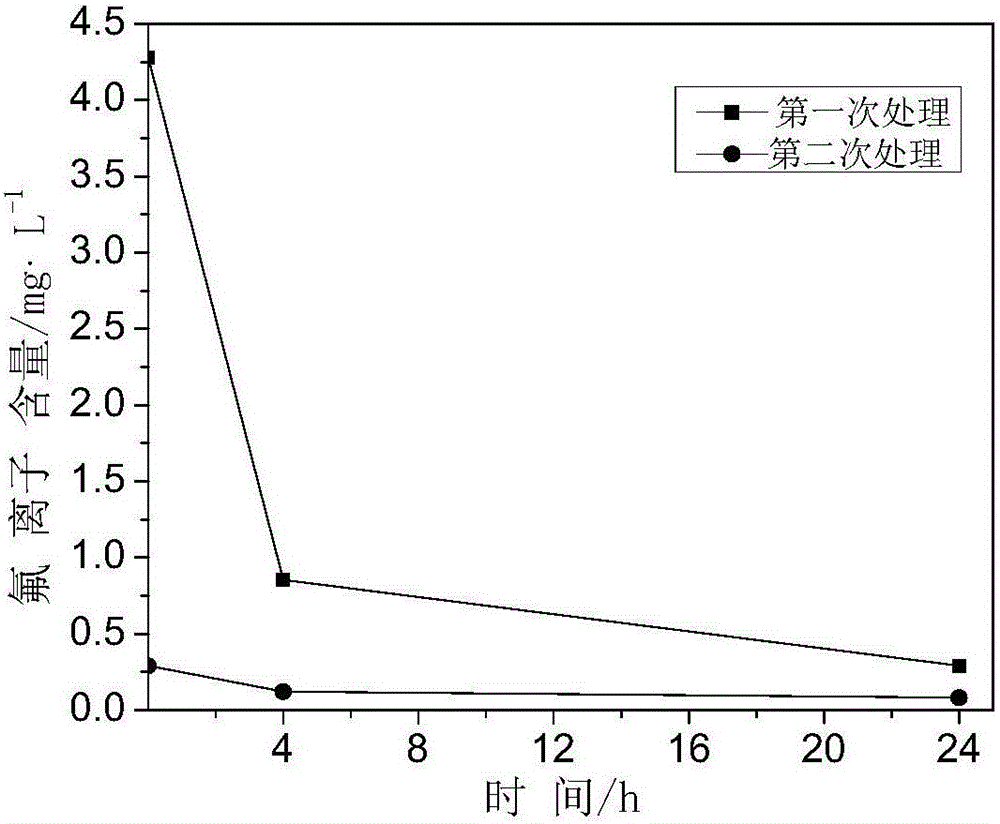

Preparation method of porous composite material for removal of fluorine ions from water

InactiveCN105126738ASimple methodEasy to operateOther chemical processesWater contaminantsRare-earth elementFluidized bed

The invention relates to a material for removal of fluorine ions from drinking water, or deep defluorination of fluorine-containing wastewater. The material is prepared by coating the surface of porous foam glass with a layer of rare earth element lanthanum's oxide. The material can be used as the filler of a water treatment tower and can effectively reduce the concentration of fluorine ions in water. By using a tower type fluidized bed, the fluorine ion concentration can be reduced to 0.1ppm. The treatment can be used for regeneration and recycling.

Owner:CHANGZHOU UNIV

Low ignition propensity cigarette paper

InactiveUS20090025742A1Reduce propensityLess coatingNon-fibrous pulp additionNatural cellulose pulp/paperAqueous solutionBiomedical engineering

Owner:JAPAN TOBACCO INC

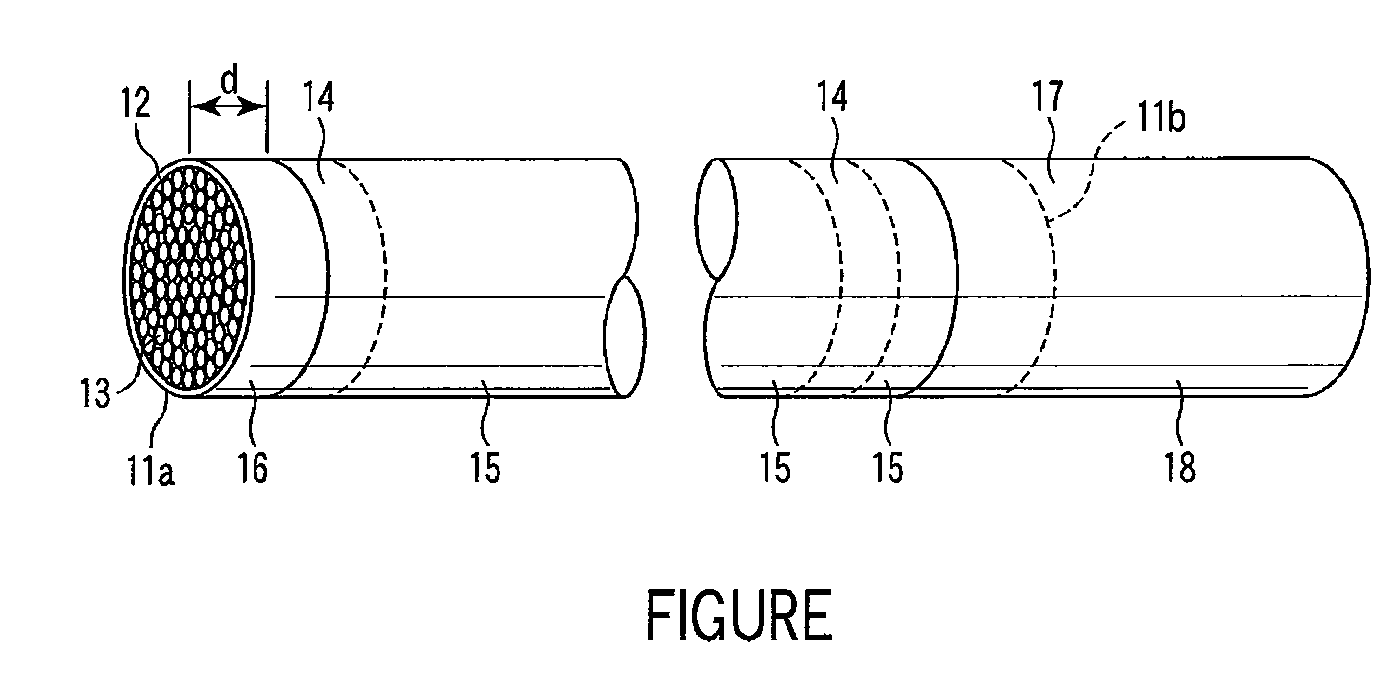

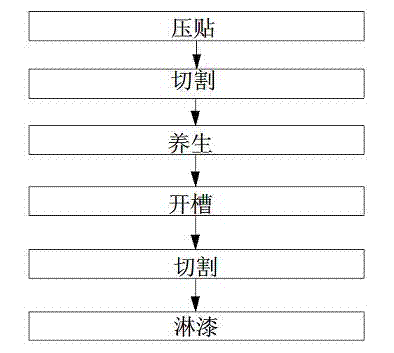

Laminated wooden floor with paint facing layer and production process

ActiveCN102852313AHigh saturationImprove surface brightnessWood working apparatusFlooringFiberAdhesion force

The invention provides a laminated wooden floor with a paint facing layer. The laminated wooden floor comprises a UV (Ultra Violet) paint wear resistance layer, a decoration layer, a base material layer and a balance layer, which are sequentially arranged from top to bottom. The base material layer is a high-density fiber board; a decoration layer is adhered to the base material layer; a UV paint wear resistant layer is coated on the decoration layer; the decoration layer is a pitted surface board with a pitted surface; and the moisture-proof balance layer is adhered below the substrate layer. A production process of the laminated wooden floor comprises the following steps of pressing, cutting, preserving, grooving, and packaging to be in stock after coating in a qualified manner. The laminated wooden floor provided by the invention has the advantages of better waterproof property, and thick and comfortable foot sense. The laminated wooden floor is coated after the preservation time of 5-10 days and has the better film adhesion force; the four edges of a notch are sealed with wax, so that the product waterproof property is improved, and the release of mail compound VOC (Volatile Organic Compounds) is reduced. The wear-resistant component of aluminum trioxide is added on finish paint, so that not only can the adhesion force of the film be increased, but also the wear resistance of the surface can be effectively increased.

Owner:JIANGSU KENTIER WOOD

Acrylic esters oiliness pressure-sensitive glue with 60 solid content and preparation method thereof

InactiveCN101358116ALess coatingHigh solid contentEster polymer adhesivesIsooctyl acrylatePolymer science

The present invention provides a 60-solid-content acrylic unctuous pressure-sensitive adhesive, the solid content of which is equal to or more than 60 percent, preferably 60 percent to 62 percent, and the viscosity of which is between 1000CPS and 3500CPS, preferably between 1500CPS and 2500CPS. The material formula of the 60-solid-content acrylic unctuous pressure-sensitive adhesive contains 2-ethylhexyl acrylate, butyl acrylate, winyl acetic ester, acrylic acid, molecular weight regulator, azodiisobutyronitrile, ethyl acetate, ethanol, curing agent and viscosity regulator. The present invention also provides processing steps and conditions for preparing the 60-solid-content acrylic unctuous pressure-sensitive adhesive. Since the solid content is increased, when the same dry adhesive film is coated with the 60-solid-content acrylic unctuous pressure-sensitive adhesive, the amount of the coated wet adhesive can be reduced, and cost and energy consumption are reduced. Moreover, since the viscosity of the 60-solid-content acrylic unctuous pressure-sensitive adhesive is between 1000CPS and 3500CPS, an ordinary curved scraper can be adapted to the 60-solid-content acrylic unctuous pressure-sensitive adhesive.

Owner:SHANGHAI ZEAFEE DIGITAL INKJET COMPOSITE MATERIALCO

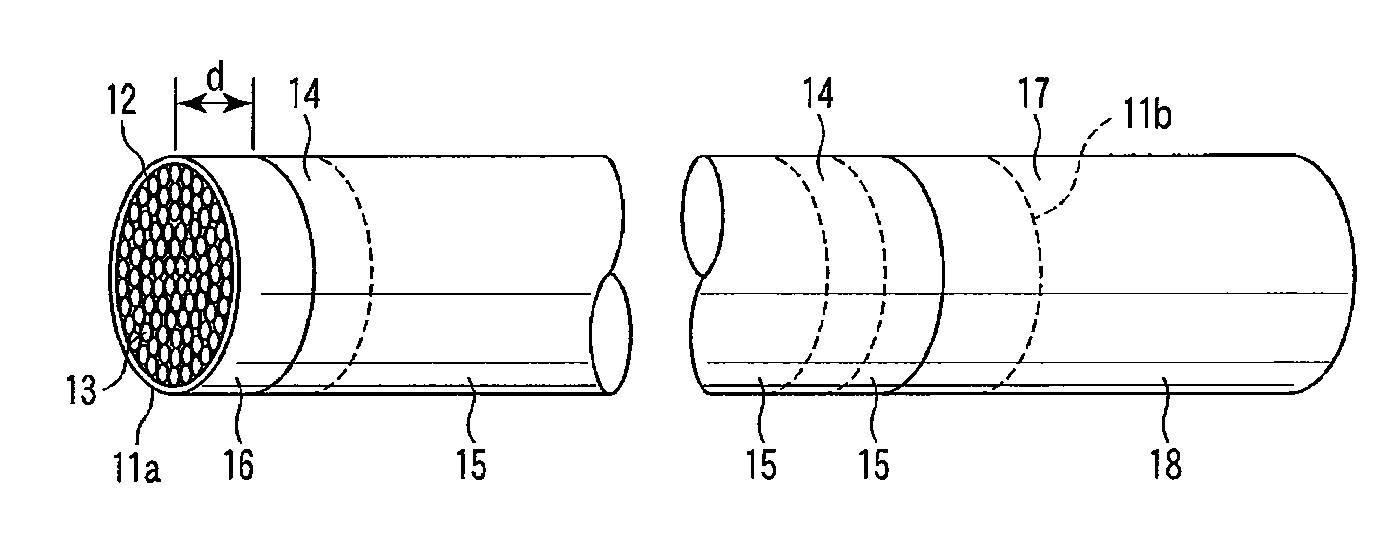

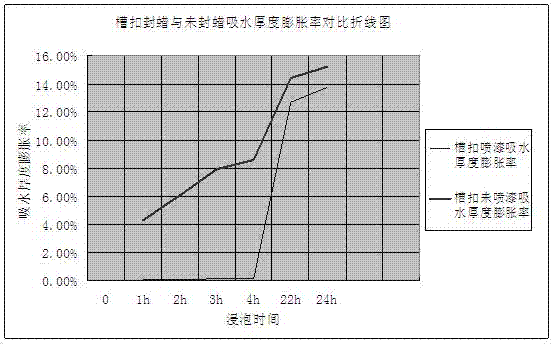

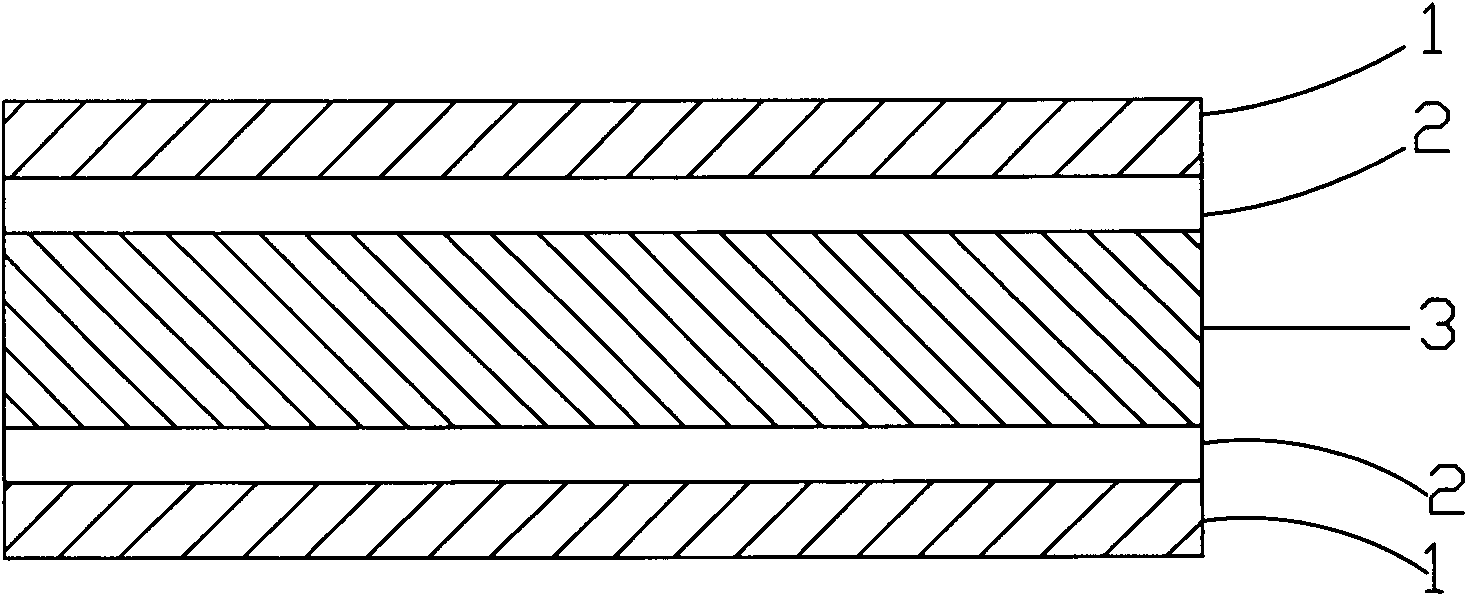

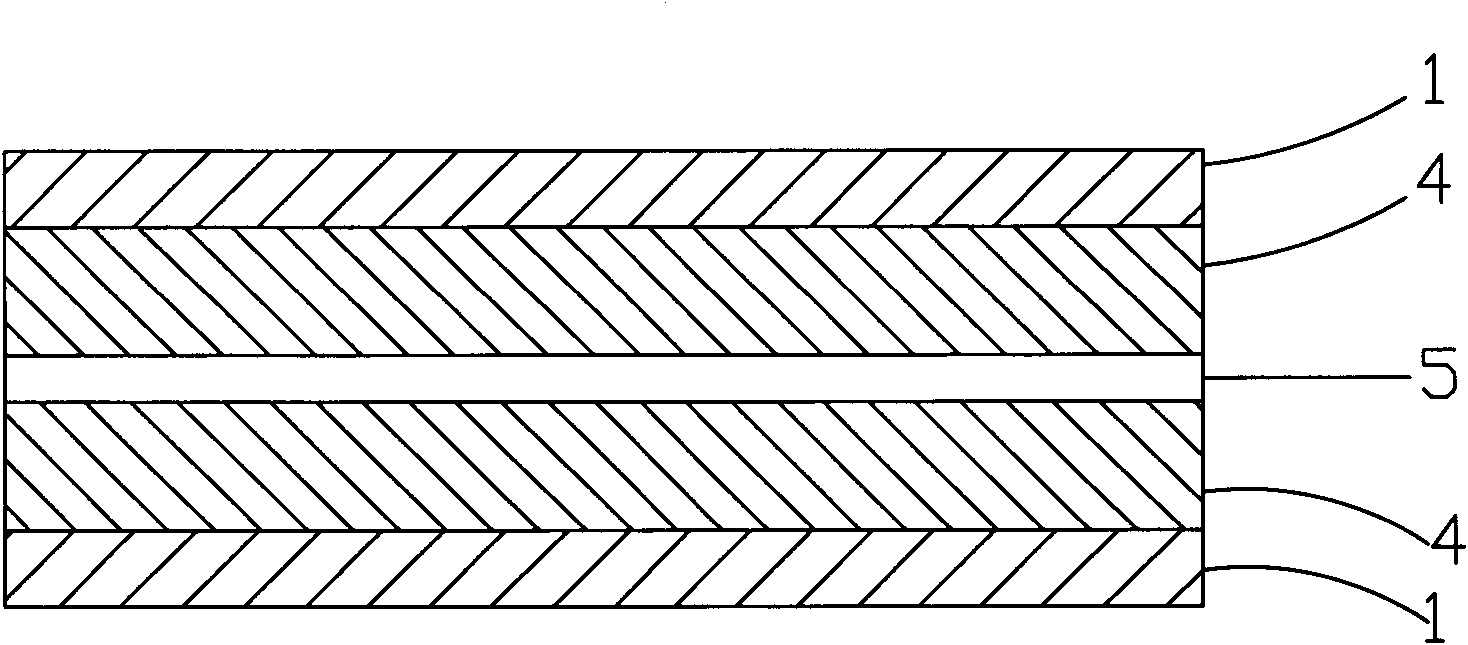

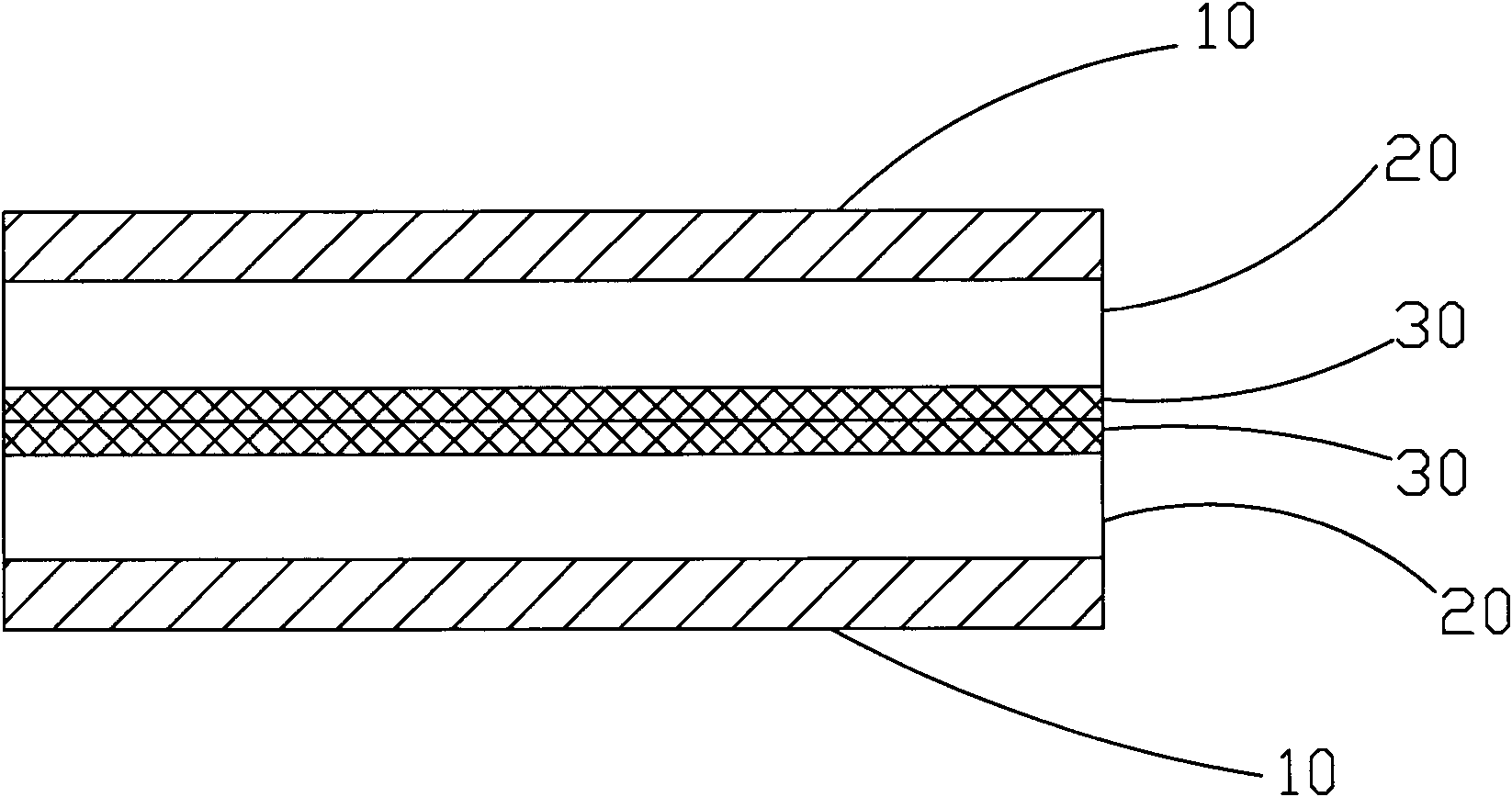

Double-surface flexible copper-clad plate and manufacturing method thereof

InactiveCN102009506AImprove heat resistanceLow water absorptionSynthetic resin layered productsMetal layered productsHeat resistanceEngineering

The invention relates to a double-surface flexible copper-clad plate and a manufacturing method thereof. The double-faced flexible copper-clad plate comprises two single-surface copper-clad plates which are arranged in a mirror symmetry way, each single-surface copper-clad plate comprises a copper foil, a thermosetting polyimide layer and a padding-filled thermoplastic polyimide layer, wherein the thermosetting polyimide layer and the padding-filled thermoplastic polyimide layer are sequentially coated on the copper foil; and the two single-surface copper-clad plates are mutually laminated and arranged in the mirror symmetry way along the padding-filled thermoplastic polyimide layer. With respect to the double-surface flexible copper-clad plate, the heat resistance of the copper-clad plates is enhanced and the water absorption rate and the cost of the copper-clad plates are reduced while the good flexibility resistance and bending resistance of the copper-clad plates are kept through the matching action of the thermoplastic polyimide layers with resins filled with padding and a thermosetting polyimide layer without being filled with the padding; and in addition, the double-surface flexible copper-clad plate has simple manufacturing process and is coated only twice so that the coating amount is greatly reduced, the production efficiency is enhanced, and the cost is reduced, and the double-surface flexible copper-clad plate is suitable for manufacturing flexible printed-circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

UV (Ultra Voilet) light curing transfer printing coating sizing agent and transfer printing coating

The invention relates to a UV (Ultra Voilet) light curing transfer printing coating sizing agent and a coating prepared from the sizing agent. A photoinitiator is used to initiate polymerization under the irradiation of ultraviolet light so as to realize curing. The curing speed is high. The yield is high. The product has high heat resistance, good mechanical strength and good stripping performance.

Owner:SHANGHAI CHIVA NEW MATERIAL TECH

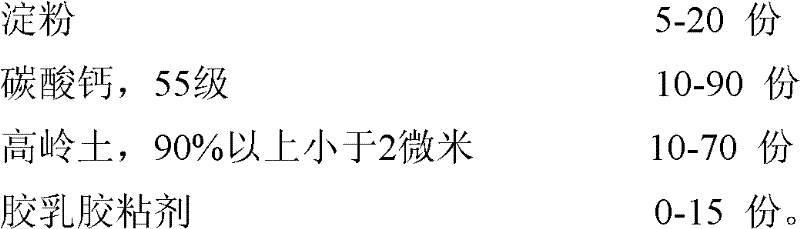

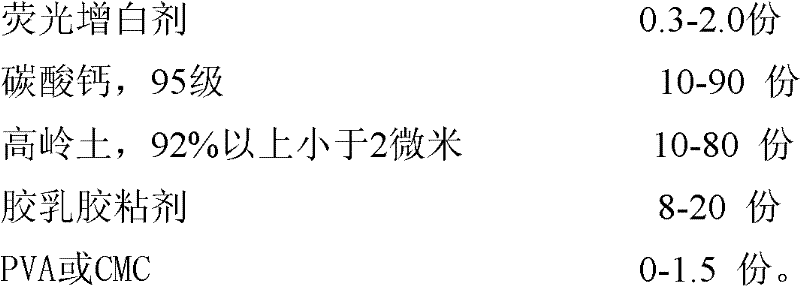

A method for producing coated linerboard or coated kraftboard at low cost and the coated linerboard or coated kraftboard produced by the method

InactiveCN102286897AImprove whitening functionReduce inhibitionPaper coatingLuminescent/fluorescent substance additionOptical brightenerCardboard box

The invention relates to a coated box board or coated kraft liner, in particular to a coated box board / kraft liner and a method for producing the same at low cost. The method comprises the steps of coating prime coat on the box board or unbleached kraft liner and coating top coat on the box board or unbleached kraft liner, wherein the primer coat comprises starch; and the top coat comprises an optical brightening agent. The coated box board or coated kraft liner and the method have the following beneficial effects: the prime coat and the top coat do not have mandatory requirements for the rawmaterials and different quality of pigments can be used in the coat of different coatings, thus further saving the production cost, and the coating weight each time is lower, thus not only being beneficial to drying but also being beneficial to improvement of the production efficiency.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-viscosity emulsion type pressure sensitive adhesive and preparation method thereof

InactiveCN107936878AEasy to manufactureReduce the number of operationsEster polymer adhesivesRosin adhesivesEmulsionDouble bond

The invention provides a high-viscosity emulsion type pressure sensitive adhesive. The high-viscosity emulsion type pressure sensitive adhesive is prepared by polymerizing the following components inparts by weight: 38 to 40 parts of water, 0.3 to 0.4 part of ammonium persulfate, 0.3 to 0.4 part of emulsifier, 50 to 55 parts of acrylate monomer mixed materials and double-bond-polymerizable tackifying resin, wherein the double-bond-polymerizable tackifying resin is prepared from 1 to 6 parts of polymerized rosin resin and 1 to 6 parts of terpene-phenolic resin. Meanwhile, the invention provides a preparation method of the high-viscosity emulsion type pressure sensitive adhesive. The preparation method comprises the following steps: adding 14 parts of the water and 0.4 part of the emulsifier into an emulsification tank, opening a stirrer for stirring, and adding quantitative acrylate monomer mixed materials required by a formula for sufficient emulsifying to form pre-emulsion; adding the water, heating to 80 to 90 DEG C and then adding NaHCO3 and the ammonium persulfate; controlling the temperature of a reaction still at 80 to 90 DEG C, and dropwise adding the pre-emulsion and the ammonium persulfate to obtain emulsion; keeping the temperature of the reaction still at 80 to 90 DEG C, and dropwise adding polymerized rosin resin emulsion and terpene-phenolic resin emulsion; cooling after the dropwise adding is ended, carrying out heat preservation at 45 to 50 DEG C, adding ammonia water and adjusting a pH value to 8.

Owner:ZHONGSHAN FUZHOU ADHESIVE PROD CO LTD

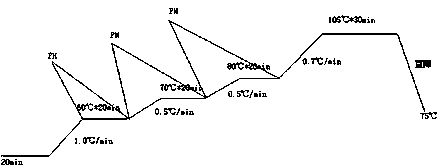

Process for producing texture feeling nylon fabric

ActiveCN108729268AImprove liquidityLess coatingLiquid/gas/vapor removalHeating/cooling textile fabricsWrinkle skinEngineering

The invention discloses a process for producing a texture feeling nylon fabric. The process comprises the following steps: collecting cloth, performing cold padding, desizing, dyeing, dewatering and scotching, drying, setting, coating and fixing. The dyeing process comprises the following sub-steps: adopting a rope dyeing manner of an overflow dyeing machine, raising the temperature to the highestdyeing temperature according to the dyeing process, maintaining the temperature, reducing to a set temperature according to a cooling rate of 2.5-5.0 DEG C per minute, enabling the cloth surface to wrinkle, and forming warp wrinkles; the setting process comprises the following sub-steps: performing advanced weft feed in front of a fabric top board under the necking condition, and enabling the fabric to have upwards weft wave wrinkles before entering a drying oven; and the coating process comprises the following sub-steps: adopting a polyacrylate coating, and coating a coating for shaping andhighlighting texture on one side of the fabric. The texture feeling nylon fabric produced by the process for producing the texture feeling nylon fabric disclosed by the invention has three-dimensionaltexture, full hand feel as well as waterproof and windproof ventilation functions.

Owner:台华高新染整(嘉兴)有限公司

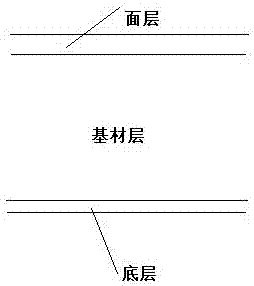

Formaldehyde-free solid wood composite floor and manufacturing method thereof

InactiveCN107310006AImprove filling abilityDoes not see throughLaminationLamination apparatusSolid woodSurface layer

The invention discloses a formaldehyde-free solid wood composite floor and a manufacturing method thereof. The formaldehyde-free solid wood composite floor comprises a surface layer, a base material layer and a bottom layer which are arranged from top to bottom. The base material layer is formed by sequentially bonding an upper layer body, a middle layer body and a lower layer body from top to bottom. The upper layer body and the lower layer body are both a two-layer board, and the middle layer body is a three-layer board. The two-layer board is composed of two layers of veneers with perpendicular texture, and the three-layer board is composed of three layers of veneers with perpendicular texture from top to bottom. All the veneers are bonded through YSD851 glue. The invention further provides the manufacturing method of the formaldehyde-free solid wood composite floor. The composite floor is free of formaldehyde and has no harm to human health; the glue is good in filling property, few in applied quantity, high in production efficiency and low in requirement for the hot-press time, temperature and pressure compared with other glue and saves cost; and the glue is long in active period and capable of being used for a long time.

Owner:兰州科天水性科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com