Preparation method of porous composite material for removal of fluorine ions from water

A porous composite material, fluoride ion technology, applied in chemical instruments and methods, water pollutants, silicon compounds, etc., can solve the problems of large specific surface area, less research on performance, etc., achieving less coating amount and easy operation of the process flow , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A specific embodiment of the preparation of a porous composite material for removing fluoride ions in water is as follows:

[0019] (1) Preparation method 1: dissolving lanthanum nitrate hexahydrate (or lanthanum triacetate, or lanthanum trichloride) in distilled water to make a solution, the concentration of lanthanum is 0.5-6mol L -1 . The foam glass (average pore diameter 0.5 ~ 2mm, porosity 40 ~ 80%) with a particle diameter of 10 ~ 20mm is dropped into the solution according to the ratio of mass ratio lanthanum trioxide / foam glass = 0.005 ~ 0.09 / 1, Use ammonia water to adjust the pH, so that the pH value of the system is between 8 and 9; (or use a concentration greater than 2mol L -1 After the foam glass is impregnated with lanthanum nitrate hexahydrate solution, it is fumigated to alkaline with ammonia water, and this method is suitable for industrialized mass production). Dry the foam glass together with the solution in an oven (in the immersion fumigation meth...

Embodiment 1

[0028] Embodiment 1: The content of lanthanum oxide is 3~9% the preparation method of porous composite material, and specific implementation method is as follows:

[0029] Raw material: Foam glass 10~20mm

[0030] Lanthanum nitrate hexahydrate, ammonia water

[0031] Instrument: Fluoride ion selective electrode

[0032] The lanthanum oxide loading rate of table 1 cellular glass

[0033]

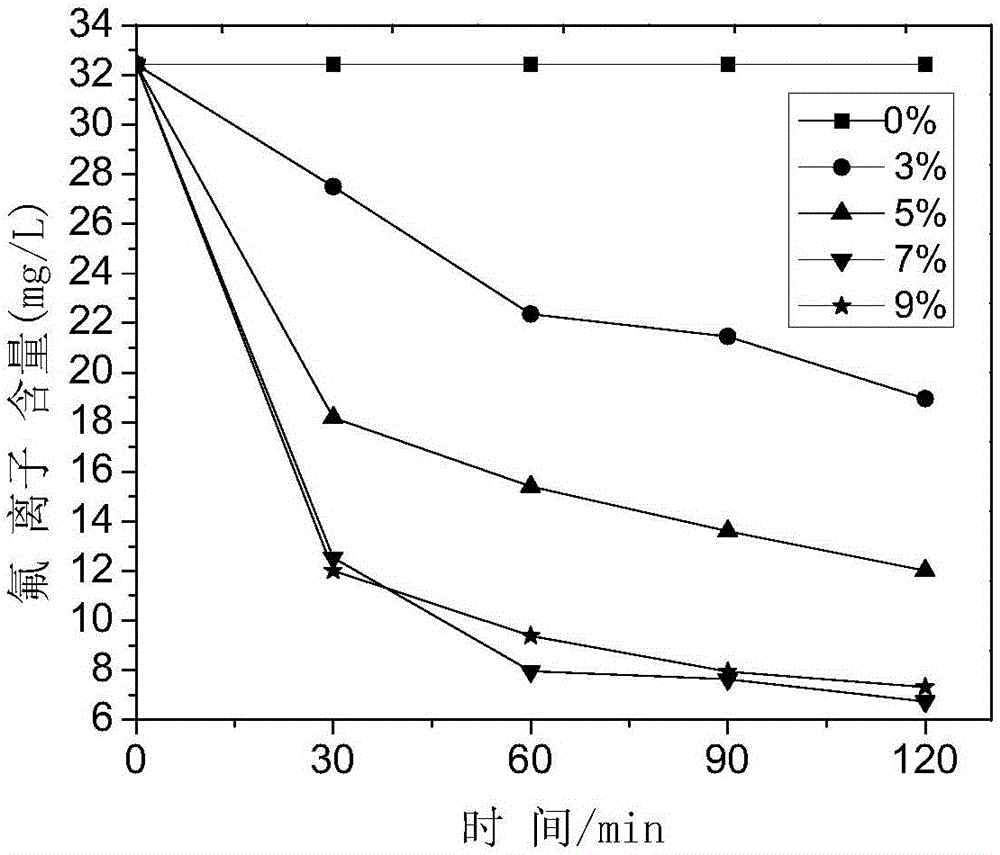

[0034] The sintering temperature of the foam glass loaded with lanthanum is 580°C and the holding time is 60 minutes, and 600mL of high fluorine-containing water is treated, and the fluorine content is 32mg L -1 . The treatment time is 2 hours, and the fluoride ion content is measured every half hour. The result is as figure 1 As shown, the best fluorine effect is that the content of lanthanum oxide is 7%, and the foam glass without lanthanum oxide has no effect on the removal of fluoride ions. Depend on Figure 5 It can be seen from the scanning electron microscope pictures of the ...

Embodiment 2

[0035] Example 2: Porous Composite Material Circulating Treatment of Highly Fluorinated Water

[0036] Raw material: Foam glass 10~20mm

[0037] Lanthanum nitrate hexahydrate, ammonia water

[0038] Instrument: Fluoride ion selective electrode

[0039] Lanthanum oxide load rate of table 2 cellular glass

[0040]

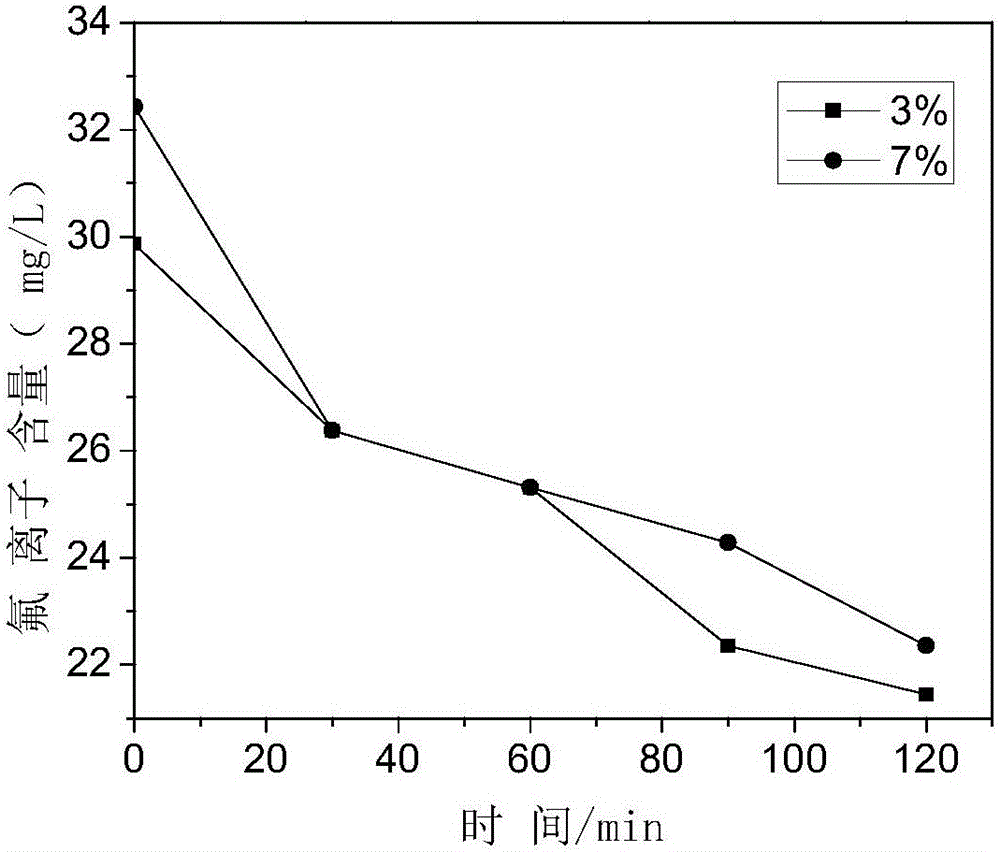

[0041] The sintering temperature of the foam glass loaded with lanthanum is 580°C and the holding time is 60 minutes. The 3% and 7% porous composite materials are respectively treated with 600mL high fluoride water for 2 hours, and the fluoride ion content is measured every half hour. The foam glass is washed with distilled water and then baked. After drying, treat 600mL high fluoride water respectively for 2 hours, and measure the fluoride ion content in half an hour. The result is as figure 2 Shown: The fluoride removal efficiency is greatly reduced within 2 hours, but the fluoride ion content is 18mg / L and 5mg / L after being placed for one day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com