Patents

Literature

85 results about "High fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Fluoride Toothpaste. Description: Prescription strength or high fluoride toothpaste has a high concentration of sodium fluoride (NaF) and ranges from above 1,500 parts per million (ppm) to 5,000 ppm which is the maximum concentration available. The maximum concentration of fluoride in conventional OTC products is 1,500 ppm.

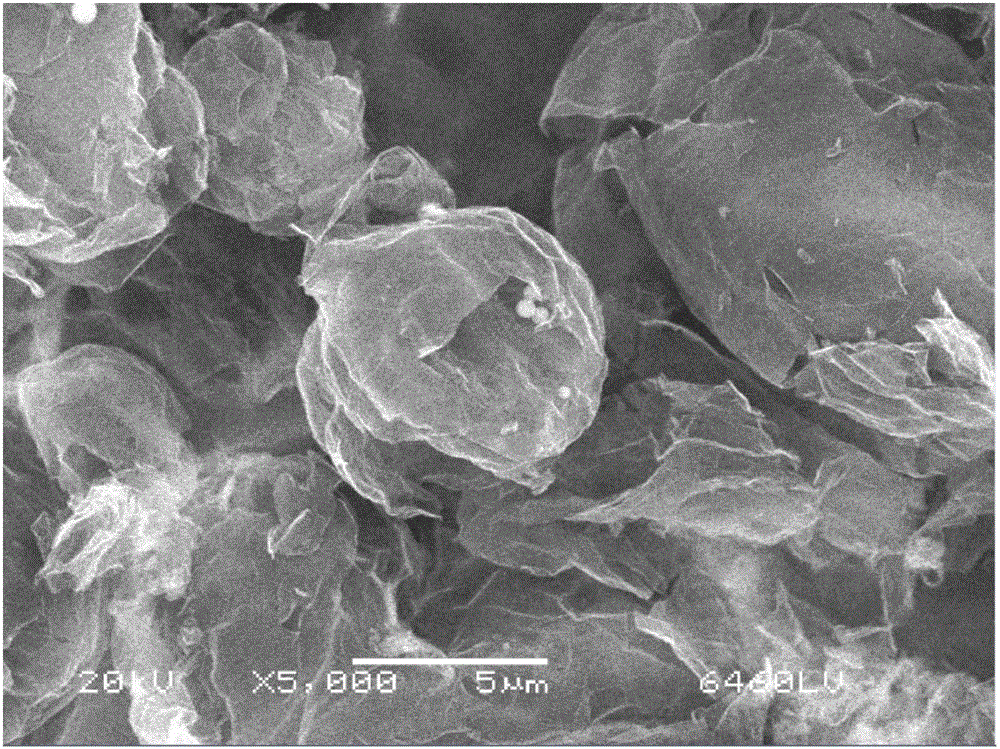

High-fluoride-content graphite fluoride and preparation method thereof

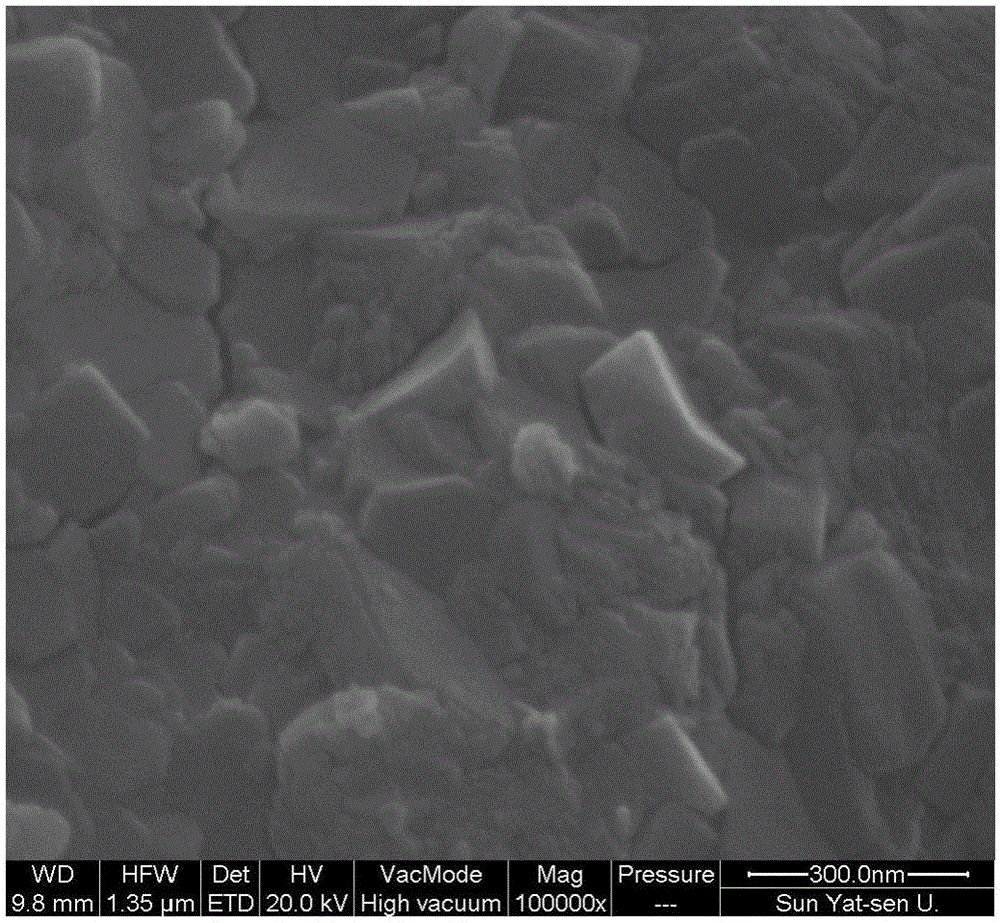

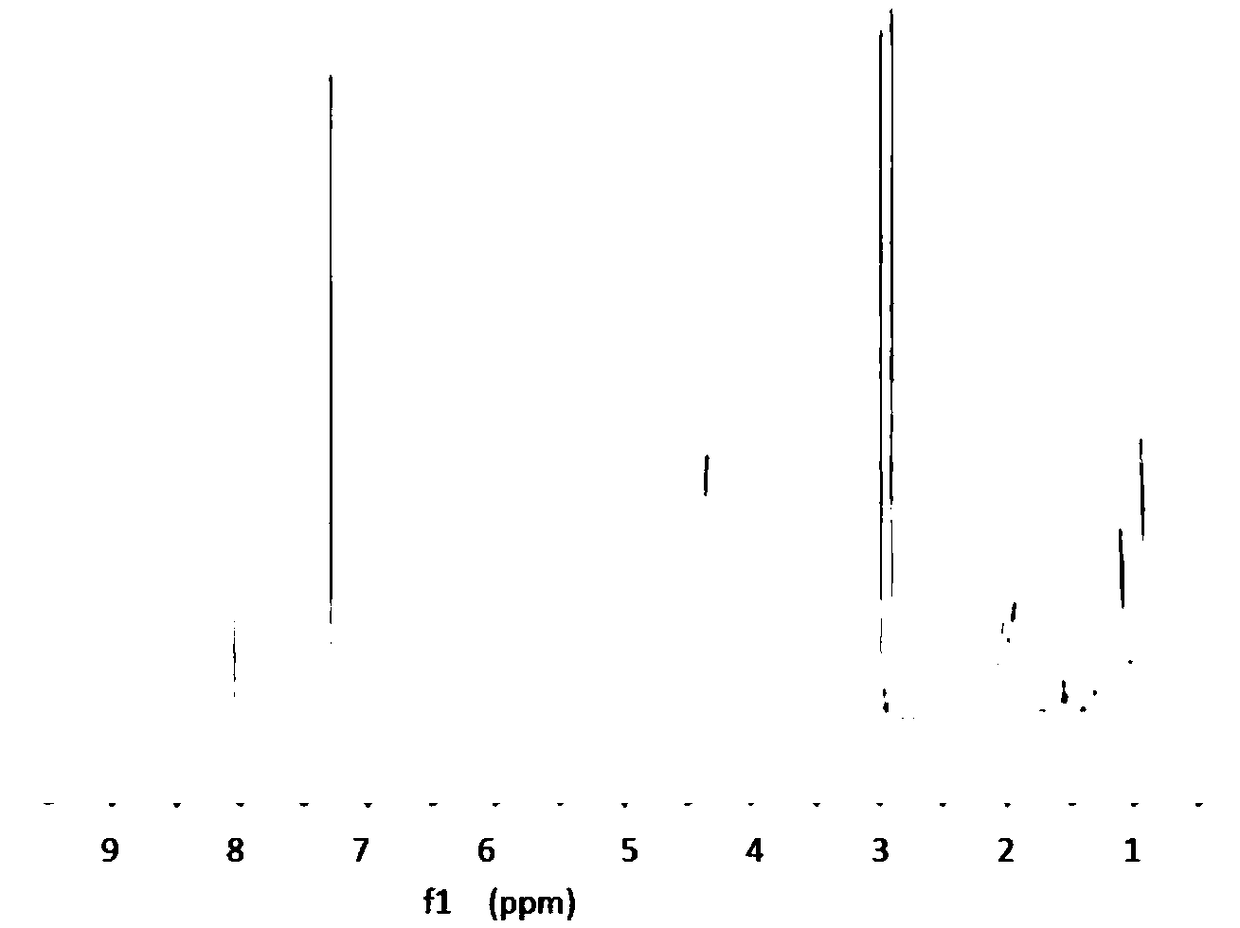

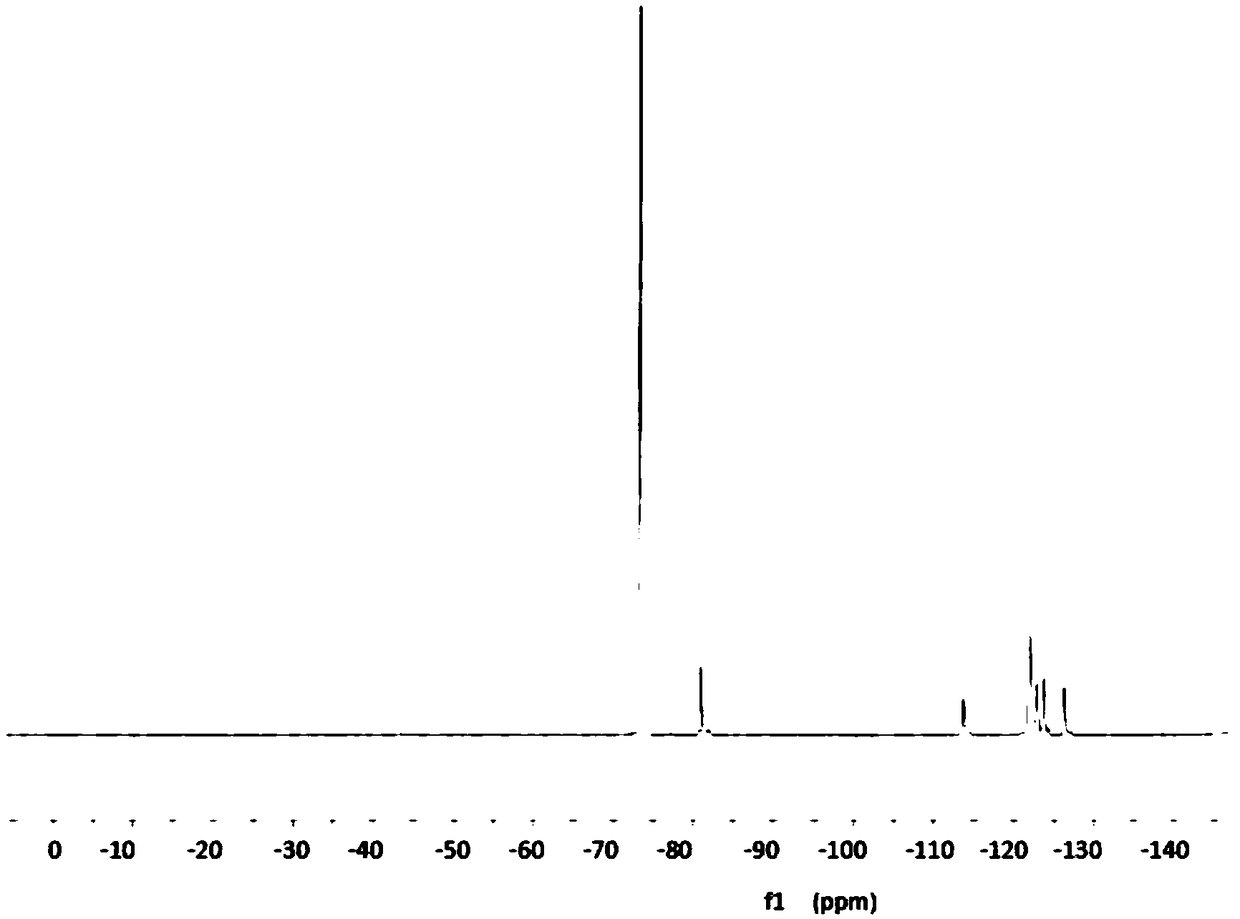

ActiveCN103420352AEasy to spreadFully contactedGrapheneCarbon fluoridesHigh fluorideReaction temperature

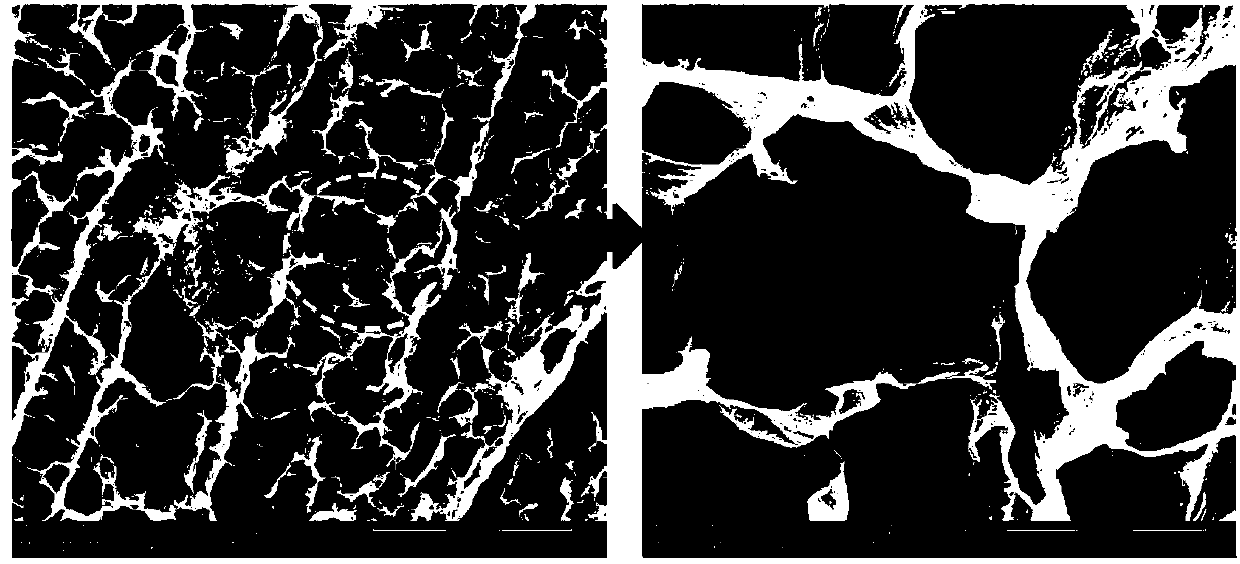

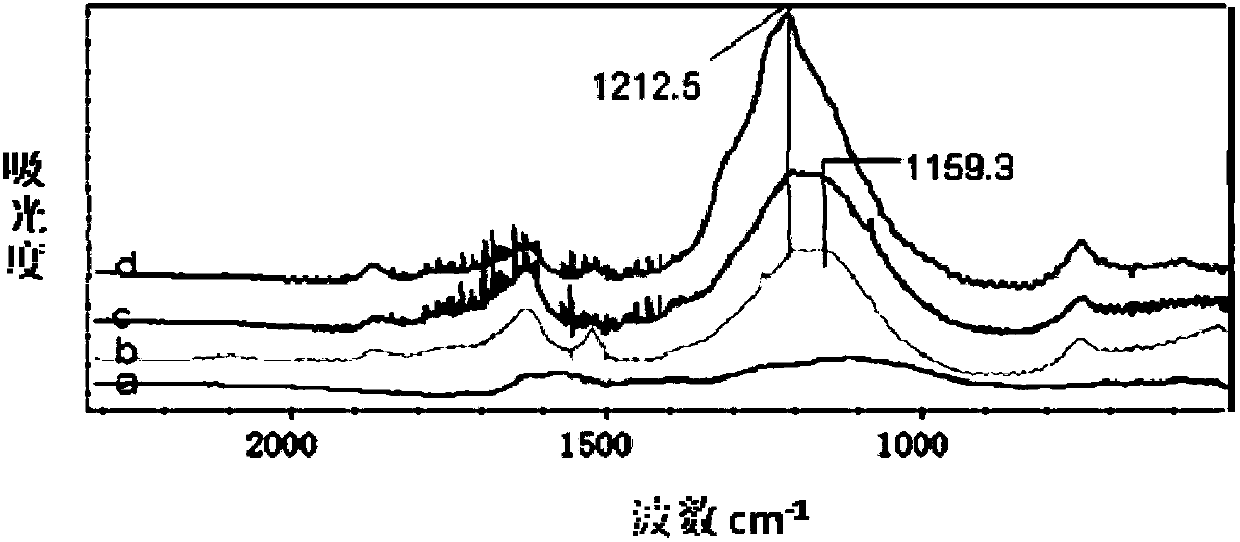

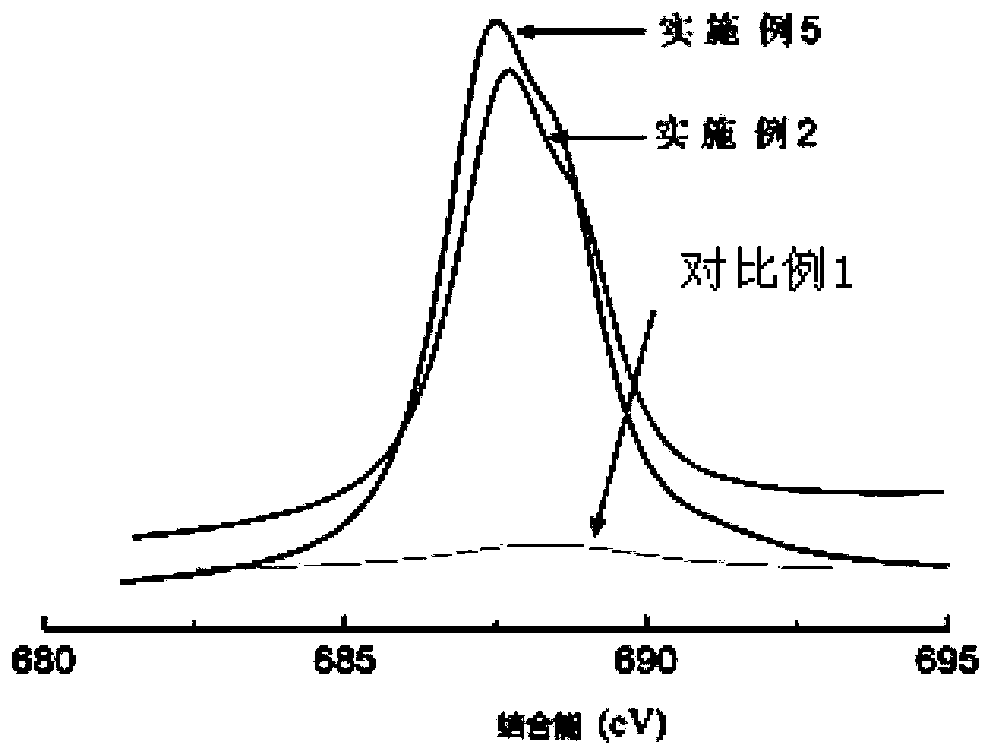

The invention discloses high-fluoride-content graphite fluoride and a preparation method thereof. The method comprises the following steps: preparing aqueous dispersion liquid of graphite oxide with a conventional improved Hummers method, then freezing the aqueous dispersion liquid of graphite oxide in liquid nitrogen to be completely frozen into solid, and freezing and drying to obtain cellular graphite oxide; under a mixed atmosphere of inert gas and fluoride, warming the cellular graphite oxide for fluoridation, and cooling to room temperature. The fluoride content of the prepared high-fluoride-content graphite fluoride is 55-70 percent, fluorine atoms are bonded with carbon atoms in a covalent bond mode, weightlessness peak temperature is larger than 470 DEG C, the heat stability is good, and the resistance is larger than 1012 omega. The prepared graphite fluoride has the advantages of high fluoride content, good heat resistance of fluorine-containing groups, low cost, simple process, lower reaction temperature, high safety and energy saving, is suitable for mass production, and has a better application prospect.

Owner:SICHUAN UNIV

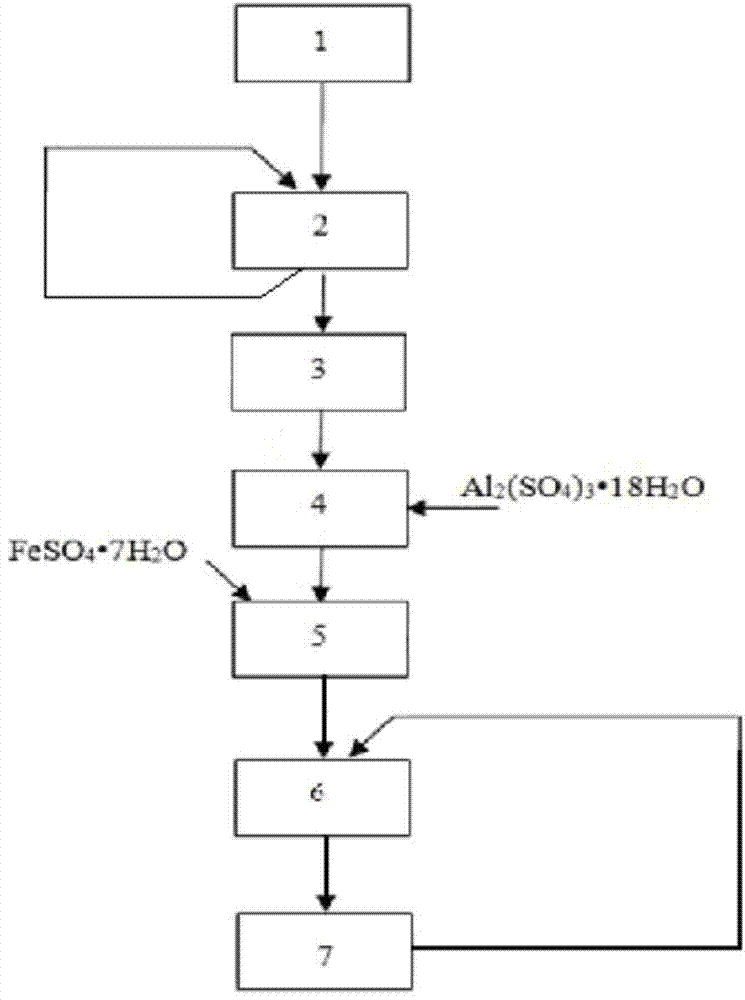

High-fluoride-containing wastewater treatment technology in fluorine chemical industry

ActiveCN105084591ANot easy to precipitateReduce fluorine contentWater contaminantsMultistage water/sewage treatmentChemical industryHigh fluoride

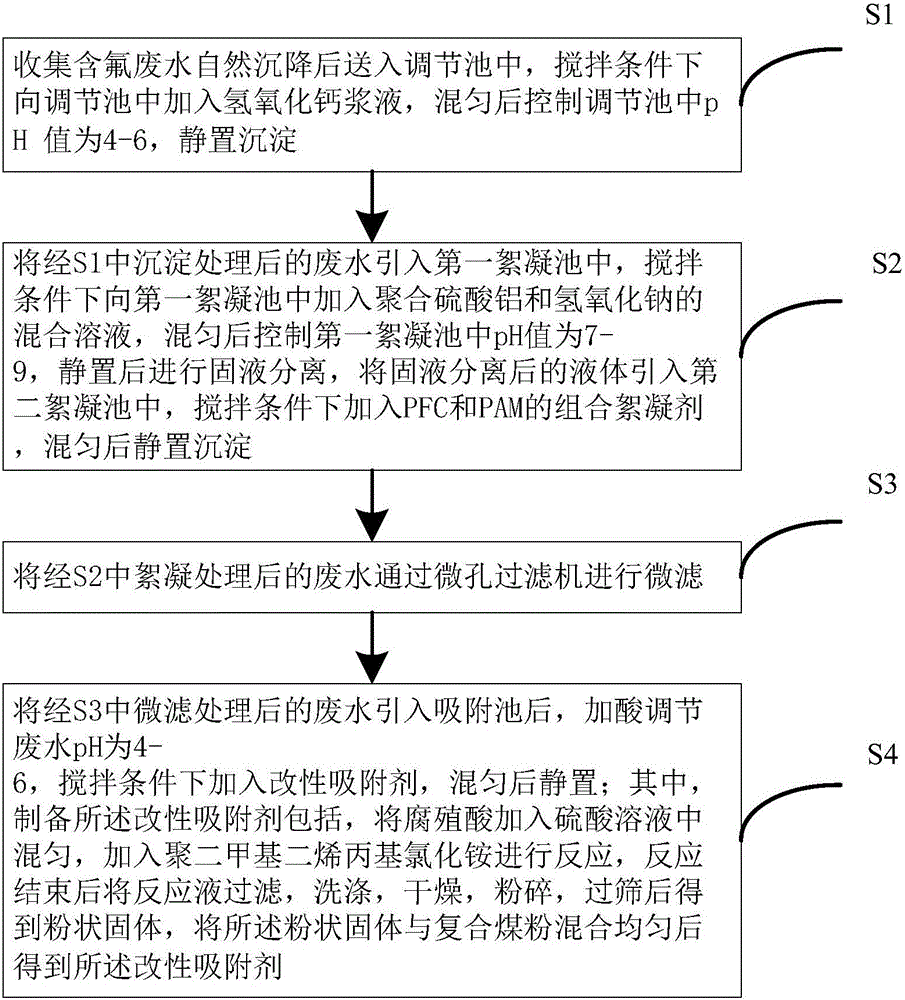

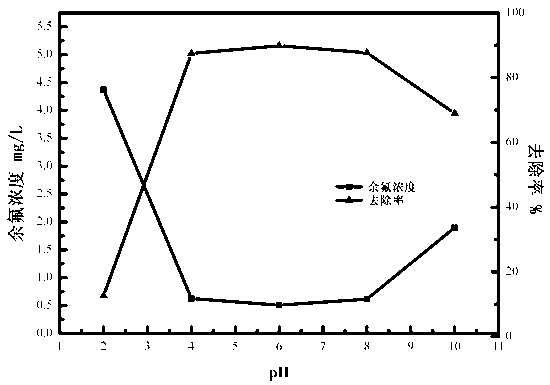

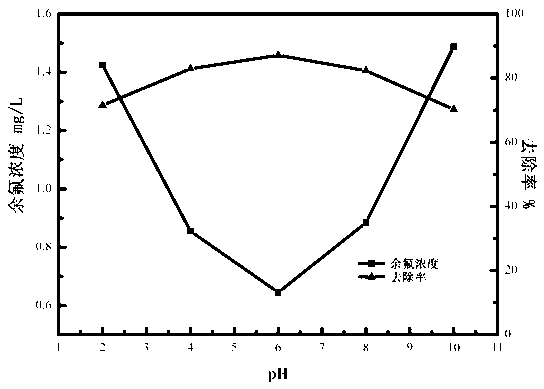

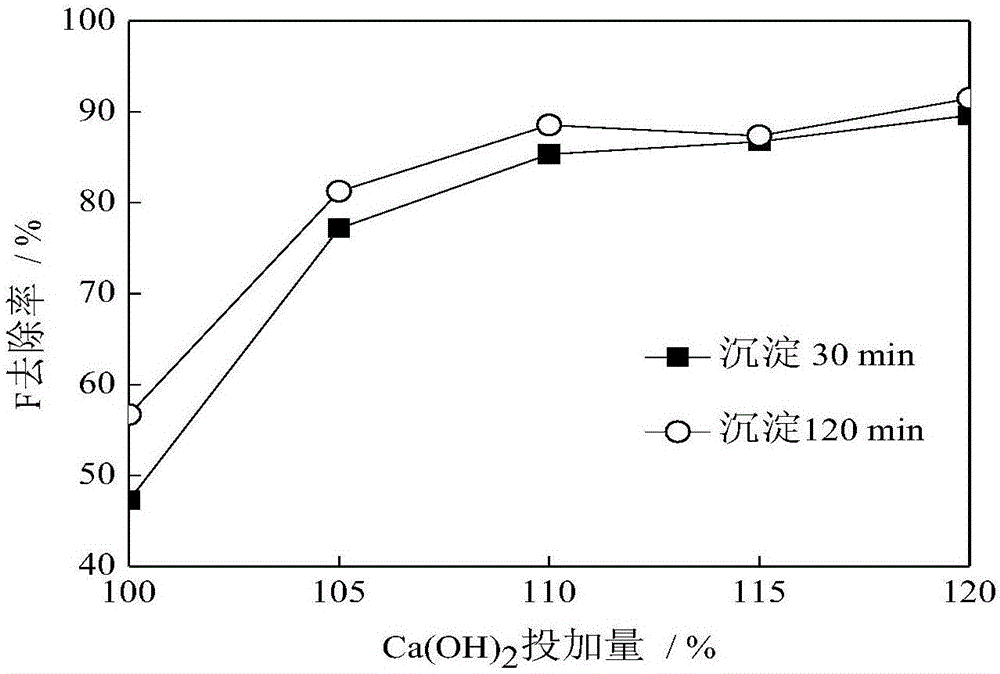

The invention discloses a high-fluoride-containing wastewater treatment technology in the fluorine chemical industry. The treatment technology comprises the steps that precipitation is conducted, fluoride-containing wastewater is collected and fed into an adjusting pool, calcium hydroxide slurry is added into the adjusting pool and evenly mixed, the pH value of the adjusting pool is controlled to range from 4 to 6, and standing precipitation is conducted; flocculation is conducted, the wastewater which is treated through the precipitation is introduced into a first flocculation pool, a mixed solution of polyaluminium sulfate and sodium hydroxide is added, the pH value of the first flocculation pool is controlled to range from 7 to 9, solid-liquid separation is conducted after standing is conducted, separated liquid is introduced into a second flocculation pool, a combined flocculating agent of PFC and PAM is added, and standing precipitation is conducted after even mixing is conducted; microfiltration is conducted, and microfiltration is conducted on the wastewater which is treated through the flocculation through a microporous filter; absorption is conducted, the wastewater which is treated through the microfiltration is introduced into an absorption pool, the pH of the wastewater is adjusted to range from 4 to 6, a modified absorbent is added, and standing is conducted after even mixing is conducted. By means of the treatment technology, the fluorine content of the wastewater reaches the effluent standard, and the whole treatment technology is simple, mature, practical, economic and reasonable.

Owner:ANHUI JINYANG FLUORINE CHEM

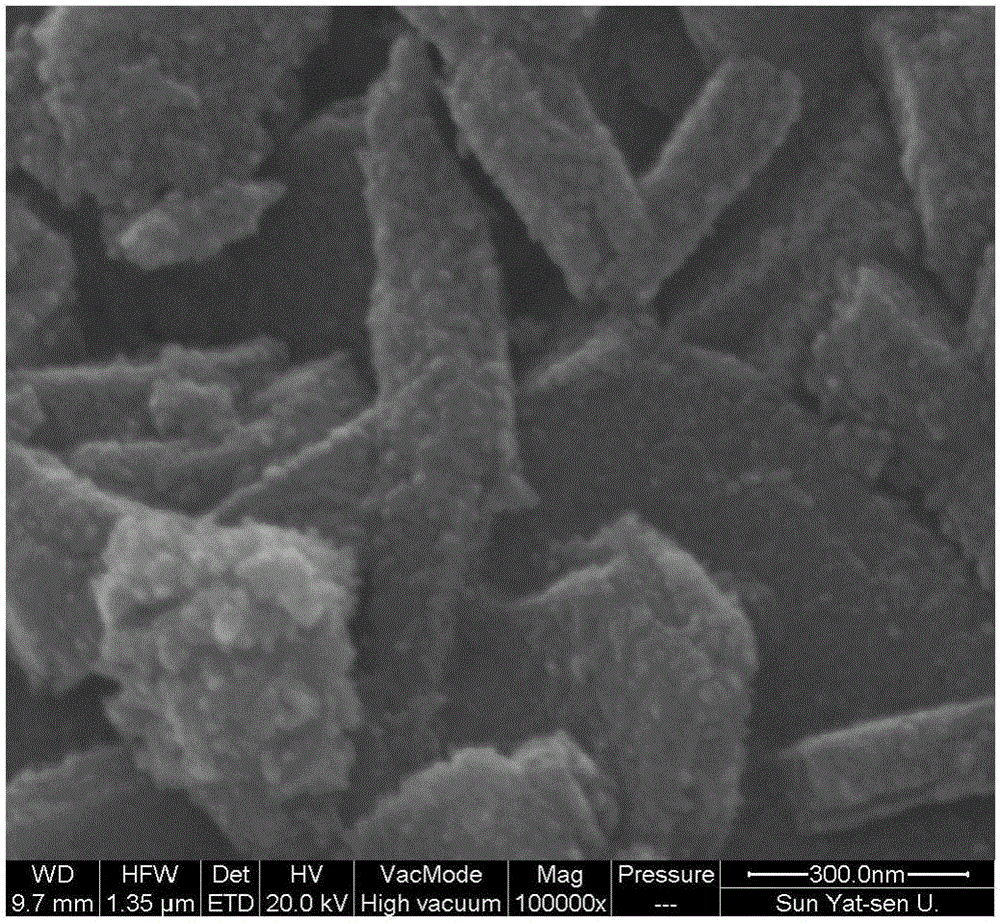

Fluorinated graphite and preparation method thereof

The invention relates to the technical field of new materials, in particular to a preparation method of fluorinated graphite. The preparation method of the fluorinated graphite includes the following steps that S1, graphene and a first fluorinating agent perform fluorinating reaction under inert gas protection to obtain a fluorinated graphite coarse product, wherein the reaction temperature is 150-550 DEG C, the reaction time is 2-20 hours, the graphene is graphene powder or a graphene film, and the first fluorinating agent contains fluorine gas; S2, the fluorinated graphite coarse product and a second fluorinating agent perform fluorinating reaction under inert gas protection to obtain fluorinated graphite, wherein the reaction temperature is 150-400 DEG C, the reaction time is 2-10 hours, and the second fluorinating agent is gas-phase fluoride. By the adoption of the method, the fluorinated graphite with high fluoride content can be prepared, the fluorine content is close to the theoretical level, and the defect density is low.

Owner:湖北高地石墨烯科技有限公司

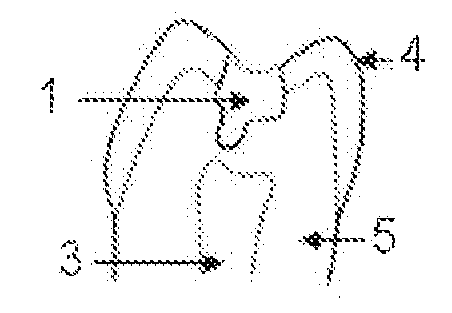

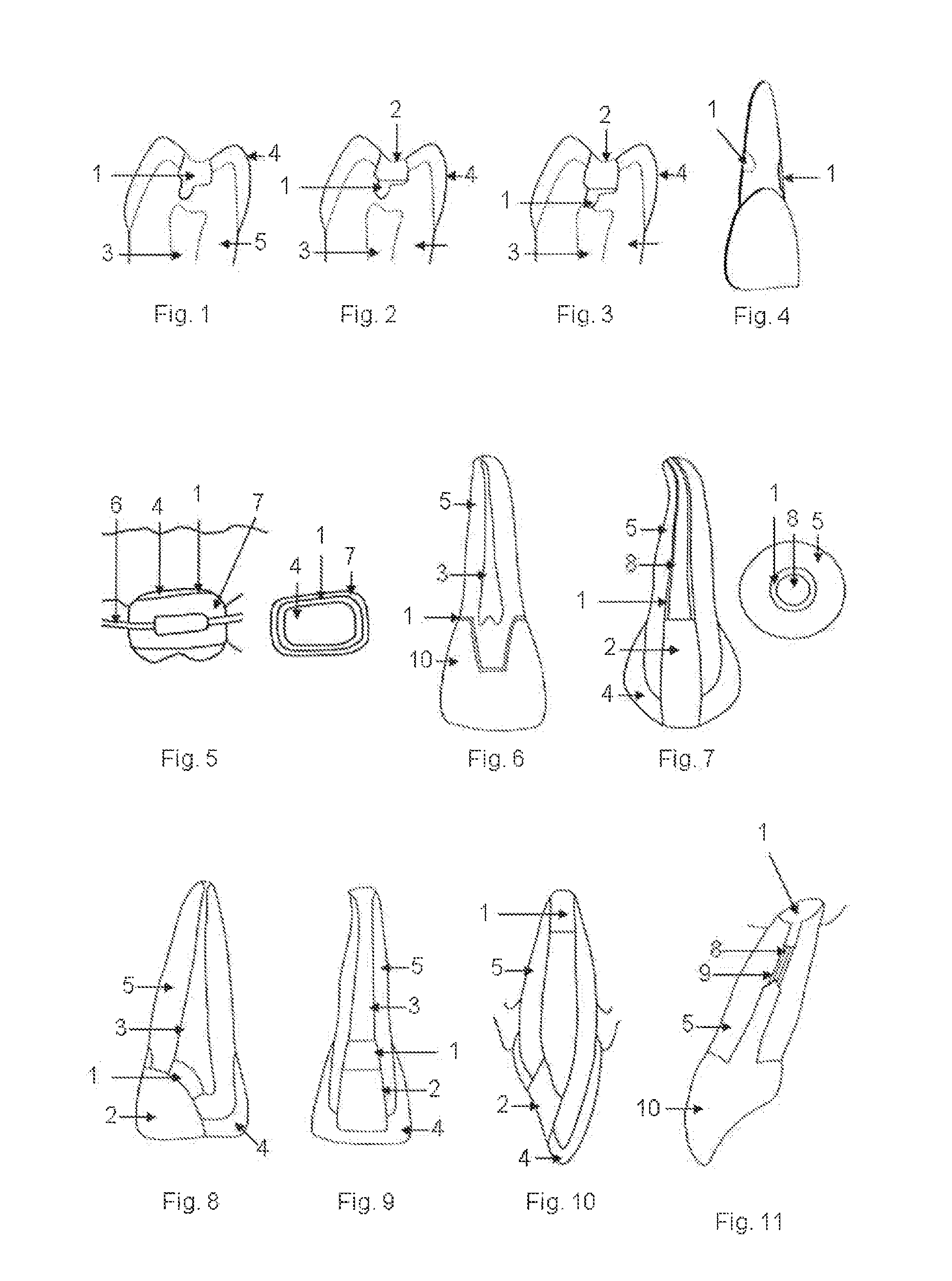

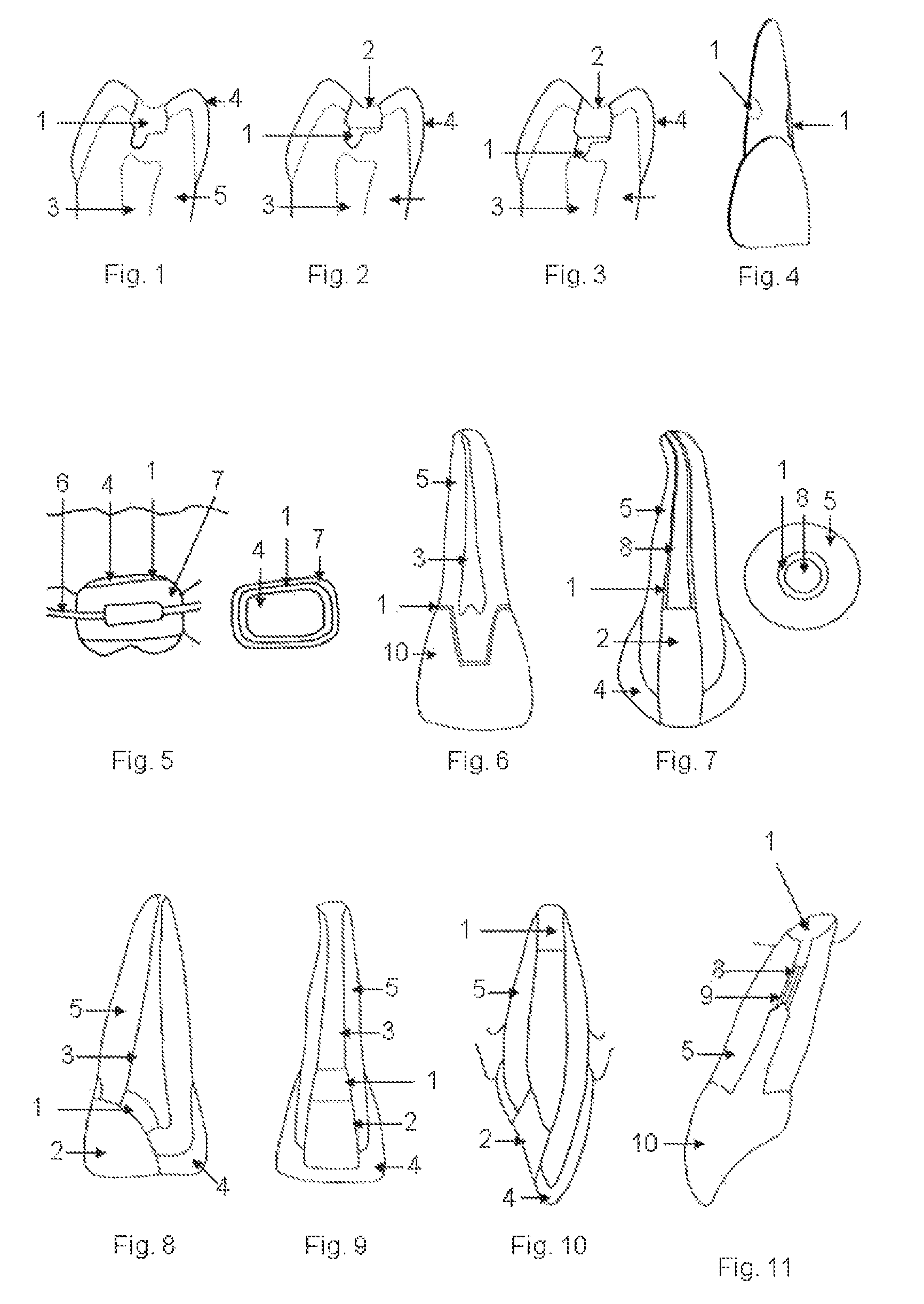

Mineral trioxide aggregate (MTA) composition and use

ActiveUS20120156308A1Good strength developmentFast setting timeHeavy metal active ingredientsBiocideDiseaseHigh fluoride

The present application discloses a fast-setting mineral trioxide aggregate (MTA) with fluoride release for practical treatment of diseases in teeth and bone, e.g. for caries treatment and / or prevention. The cariostatic MTA contain calcia-silica-alumina cement with moderately increased tricalcium aluminate content allowing high calcium hydroxide release. The MTA composition support remineralization and biomineralization, and it is suitable for stimulation of hard tissue regeneration. MTA embodiments contain superplasticizerand nanosilicate for improved mechanical properties. The MTA compositions include optional radiocontrast and nano-enriched leachable fluorine, nitrate, strontium, and phosphate. The fast-setting MTA paste exhibits flow-to-clay-like consistency, which allows new practical applications including cavity lining, temporary restoration, bonding, and cementations in one MTA embodiment. The high calcium hydroxide and high fluoride release are suitable for caries prevention and treatment, and per se inhibition of dental symptoms.

Owner:DENTOSOLVE APS

Fluoride-resistant ore leaching bacterium and application thereof in efficient leaching process of high-fluoride uranium ore

ActiveCN104745498AStrong fluorine resistanceAchieve protectionBacteriaMicroorganism based processesHigh fluorideUranium ore

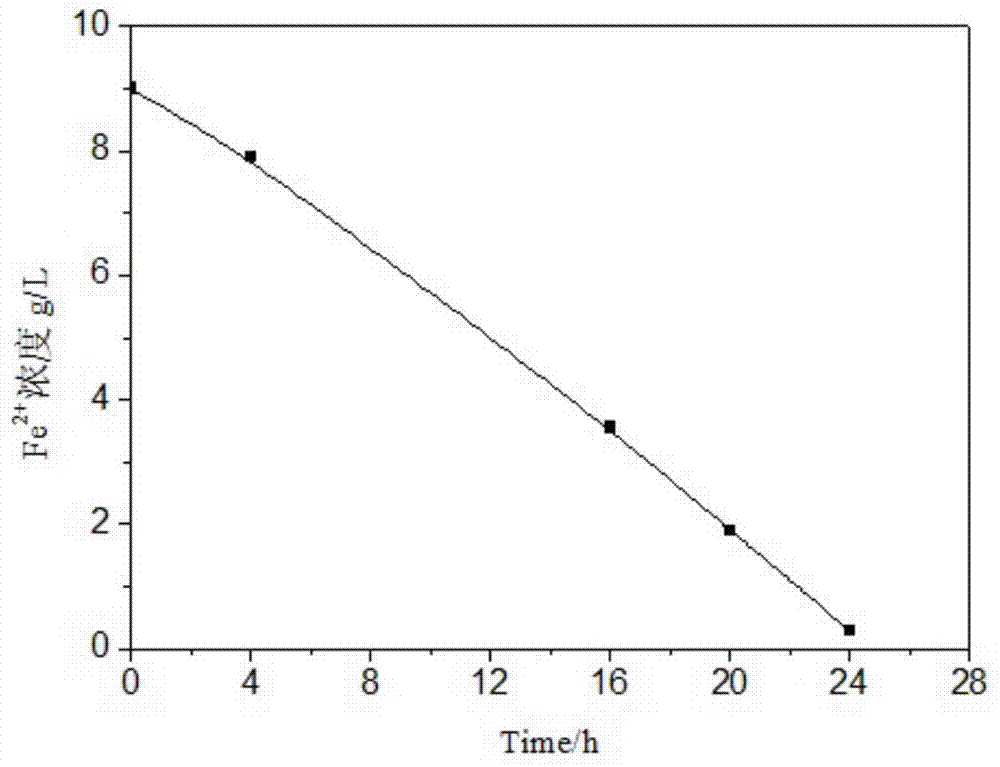

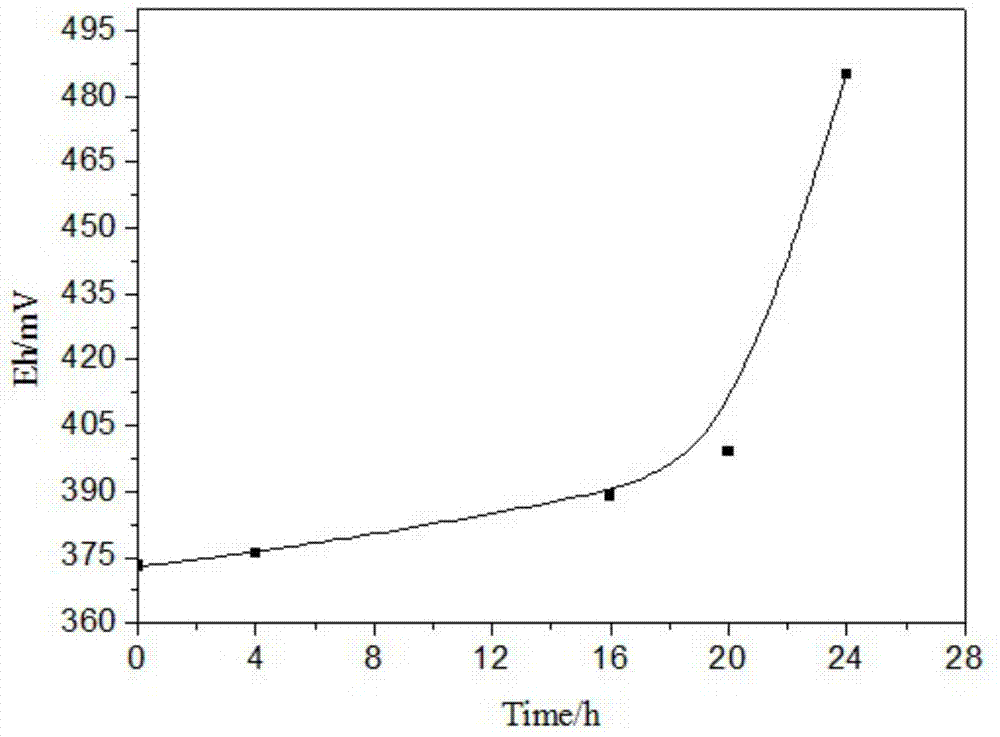

The invention relates to a fluoride-resistant ore leaching bacterium and application thereof in an efficient leaching process of high-fluoride uranium ore. The fluoride-resistant acidophilus Acidithiobacillus ferrooxidans is collected at China General Microbiological Culture Collection Center (CGMCC for short) on July 1, 2013 and has a collection number of CGMCC NO.7836. The strain can grow in a fluorine-containing solution under an acidic condition, has fluorine resistance of 3.0g / L or above and also has a relatively good capability of oxidizing Fe<2+> into Fe<3+>. When the fluoride-resistant strain (CGMCC NO.7836) is applied to simulated biological dump leaching process of fluorine-containing uranium ore, 55-day uranium leaching rate is improved by 3.70% as compared with that in an acid leaching method; the uranium leaching rate is improved obviously and production cost is reduced; moreover, since adsorption tail liquid during uranium leaching can be recycled, environment pollution can be reduced. Therefore, the strain can be widely applied to biological leaching.

Owner:有研资源环境技术研究院(北京)有限公司

Preparation method of bone char fluoride removal agent loaded with aluminium ions

InactiveCN101596446AImprove adsorption capacityAnti-interferenceOther chemical processesWater/sewage treatment by sorptionHigh fluorideRoom temperature

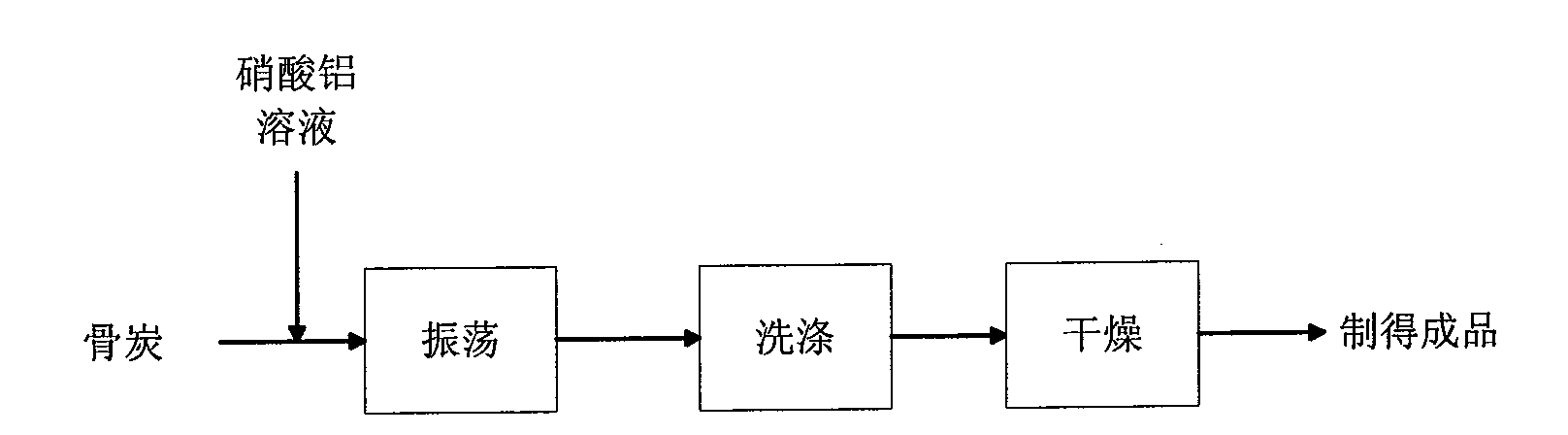

The invention relates to a preparation method of a bone char fluoride removal agent loaded with aluminium ions, belonging to the field of drinking water fluoride removal treatment. In the method, bone char of certain mass is put into an aluminium salt solution of certain volume; the mixture of the bone char and the aluminium salt solution is oscillated for certain time under certain condition; the bone char is taken out, washed by clear water and dried under room temperature. The mass ratio between the bone char and the aluminium salt solution is 1:8-1:12. The condition of the oscillation is as follows: the bone char and the aluminium salt solution is fully mixed in the process of oscillation, the time of oscillation is not less than 24h, the temperature of the mixture is kept at 20-40 DEG C during oscillation. Batch adsorption tests show that the adsorption capacity of the aluminium-loaded bone char fluoride removal agent is 60% higher than that of ordinary bone char fluoride removal agents. Used in the areas taking high-fluoride ground water as drinking water resource, the fluoride removal agent can effectively ensure the residents with drinking water safety, reduce the cost for producing water and the workload of daily maintenance of water supply engineering simultaneously.

Owner:TSINGHUA UNIV

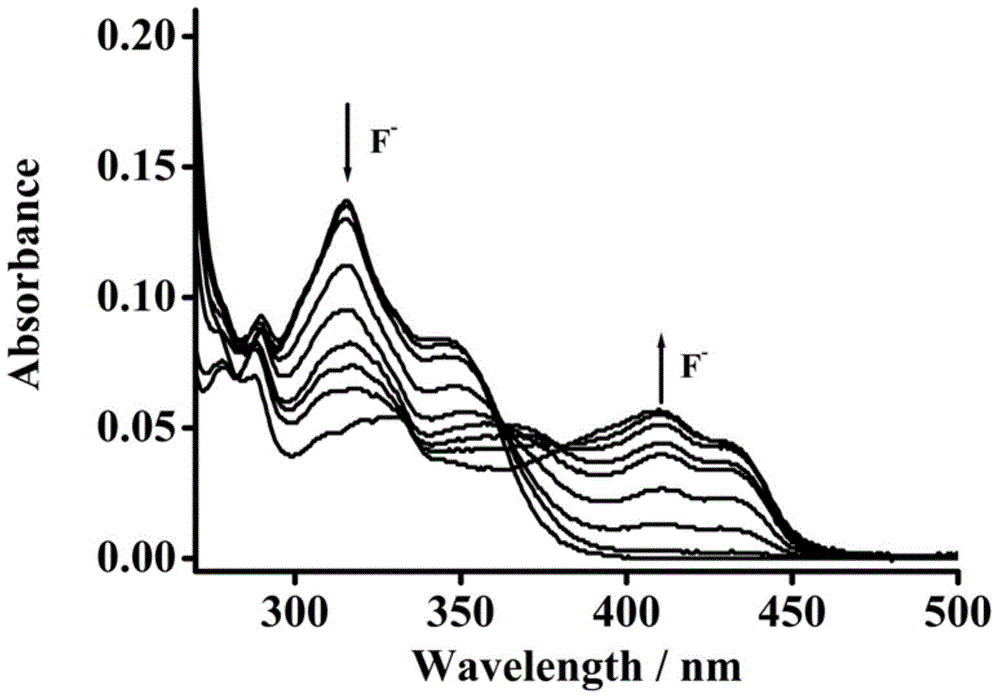

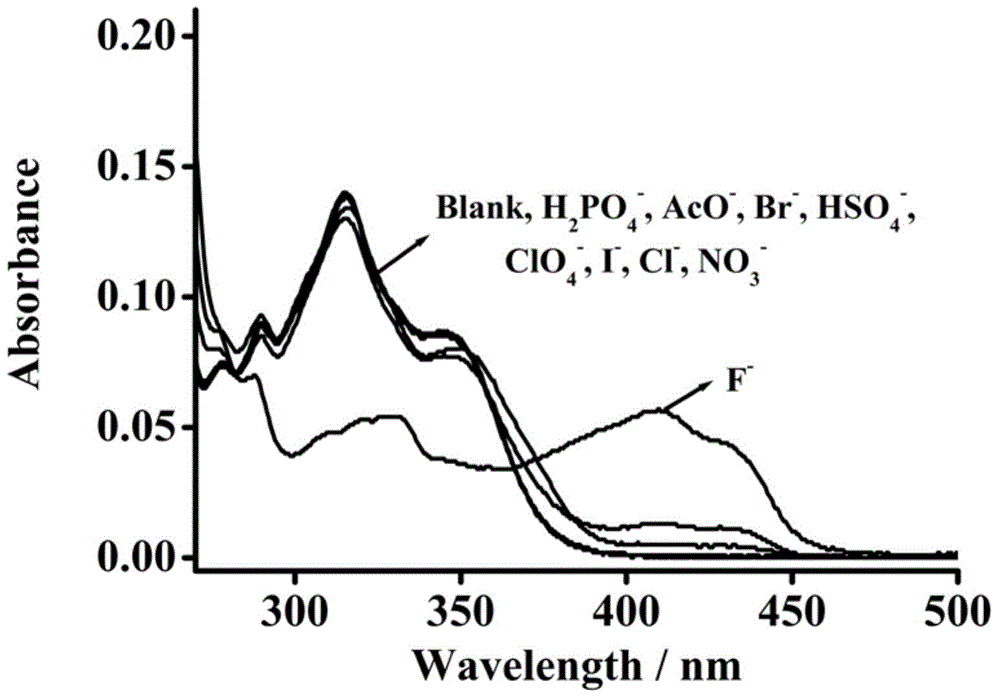

Fluorescent molecular probe for detecting fluoride ions as well as synthesis method and application thereof

InactiveCN104418875AHigh sensitivityStable fluorescenceGroup 4/14 element organic compoundsMaterial analysis by observing effect on chemical indicatorHigh fluoridePhosphate

The invention relates to a preparation method of a fluorescent molecular probe for detecting fluoride ions through colorimetric detection and fluorescence enhancement and an application of the fluorescent molecular probe to detecting fluoride ions. The fluorescent molecular probe is prepared by protecting 2-hydroxyl-1-naphthaldehyde taken as a raw material with silane and then condensing the raw material and malononitrile. The fluorescent molecular probe is simple and convenient to synthesize, and reaction conditions are mild. The fluorescent molecular probe has the specific characteristics that the probe molecule has stable optical properties and higher synthetic yield; the probe molecule has high fluoride ion detection sensitivity and low lower limit of detection, and the limit of detection is 0.52mu M; the response range is 0-100mu M and the detection range is wide; the probe molecule has good selectivity and has no responses to anions, such as dihydrogen phosphate radicals, acetate radicals, bromide ions, hydrosulfate radicals, chlorate radicals, iodide ions, chloride ions and nitrate radicals; the probe molecule is suitable for colorimetric detection; the fluorescent molecular probe has practical application values in the fields of biochemistry, environmental sciences and the like.

Owner:SUZHOU ROWLAND BIOTECH

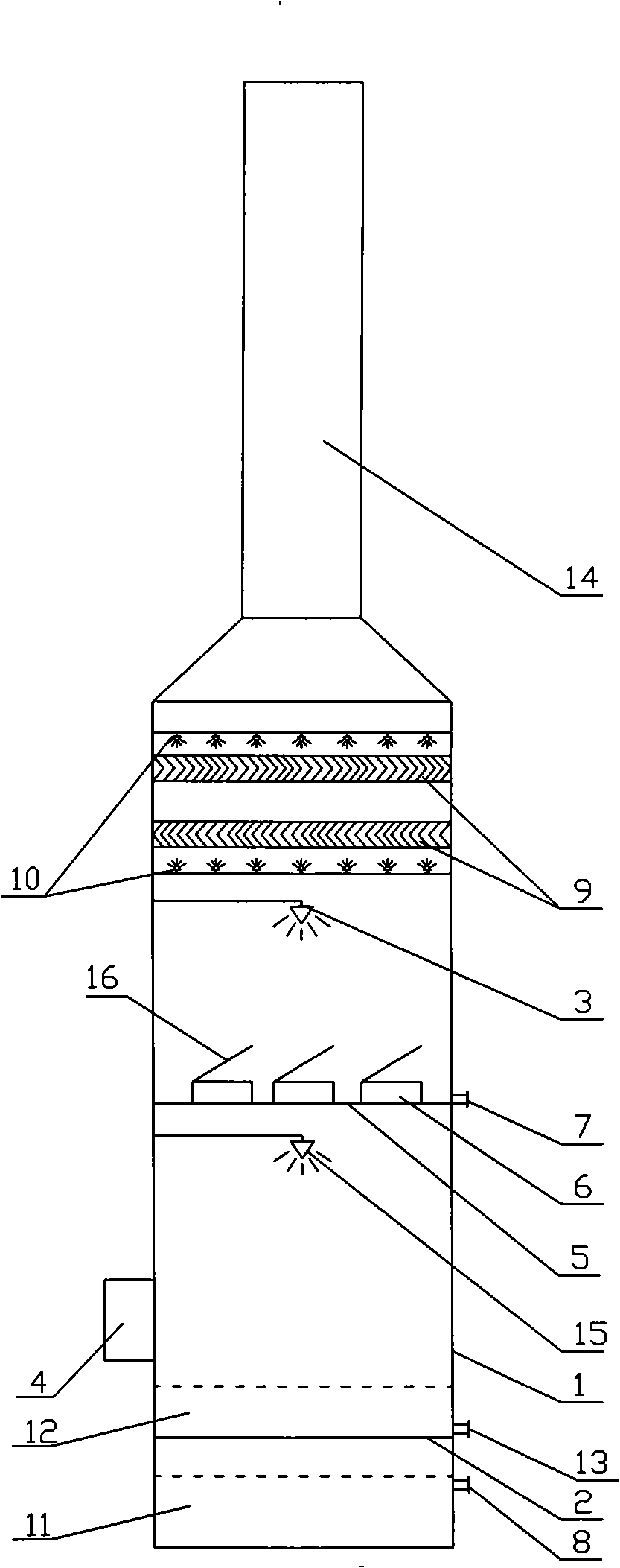

Double return route absorption tower and method for treating fluorine contained tail gas using double return route absorption tower

InactiveCN101279196AImprove absorption rateLess investmentDispersed particle separationHigh absorptionAtmospheric air

The invention relates to a double circuit absorption tower and a method for treating tail gas with fluoride via the double circuit absorption tower. The smoke with fluoride enters a first absorption zone of the absorption tower, then enters a secondary absorption zone for a second time purification via a gas cylinder after being cooled and purified and is discharged into the atmosphere via a chimney arranged at the top of the absorption tower after the mist is removed. The lower section of the tower body is a secondary serum recirculating tank; the middle section is the first absorption zone; the lower part of the middle section is a first-level serum recirculating tank; a spraying device is arranged at the upper part of the first absorption zone; a baffle with the gas cylinder is a secondary absorption zone at the upper section of the tower body; the upper part is provided with the spraying device, a demister and a cleaning device; the chimney is arranged at the top of the absorption tower. The tower combines the original two towers into an absorption tower through arranging an upper and a lower baffle, which similarly realizes the high absorption rate of the two towers; the slaking process of limestone or lime is realized in the serum recirculating tank at the bottom of the tower, which reduces the equipment and saves the investment; at the same time, through controlling the pH value of an absorption serum, the absorption rate of the fluoride is raised on the basis of saving the limestone or the lime.

Owner:湖北三新磷钙有限公司

High Fluoride Ion Oral Care Composition and Method for Maintaining Anticaries Activity

An oral care composition and method of maintaining anticaries activity of fluoride ion in an oral care composition are described. An oral care composition comprises a fluoride ion source sufficient to maintain a high fluoride content in the composition, an effective amount of a desensitizing agent and water. A method of maintaining anti caries activity of fluoride km in an oral care composition comprises providing an oral care composition comprising fluoride ions, an effective amount of a desensitizing agent and water.

Owner:COLGATE PALMOLIVE CO

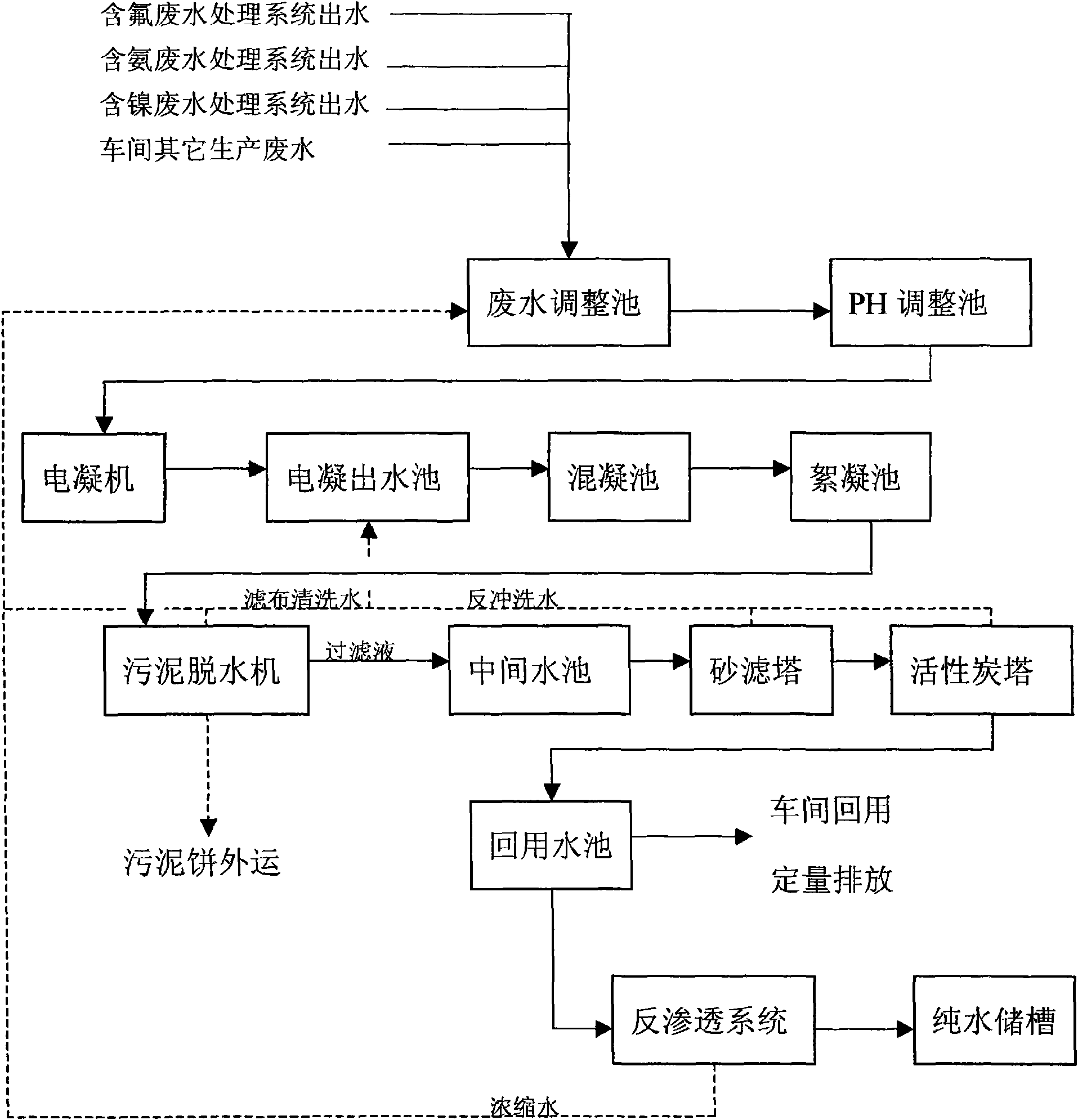

Treatment and reuse technology for aluminum surface treatment wastewater

ActiveCN101565255AEfficient removalImprove reuse rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh fluorideFiltration

The invention relates to treatment and reuse technology for aluminum surface treatment wastewater, which is characterized in that the technology mainly comprises working procedures of pretreatment, electric coagulation treatment, chemical precipitation and adsorption, filtration and reverse osmosis; pretreating high fluoride-containing wastewater, ammonia-containing wastewater and nickel-containing wastewater respectively, centralizedly draining the wastewater to a wastewater disposal basin, conveying the wastewater to a pH adjustment tank, conveying the wastewater to an electric coagulation machine for electric coagulation treatment after the pH value is adjusted to be between 4 and 6 in the pH adjustment tank, and making the wastewater after the electric coagulation treatment enter an electric coagulation discharge bay; and conveying the wastewater in the electric coagulation discharge bay to a coagulating basin, conveying the wastewater to a flocculation basin, adding a flocculating agent into the flocculation basin to ensure that the wastewater performs a coagulation-flocculation reaction, and finally adding activated carbon from the position, which is close to a water outlet, of the flocculation basin to adsorb small granular substances and colors in the wastewater. The technology can effectively remove heavy metals and salts in the wastewater, ensure that the COD in the treated wastewater is less than or equal to 25 mg / L, and has high reuse rate of reclaimed water.

Owner:江阴新苏铝科技有限公司

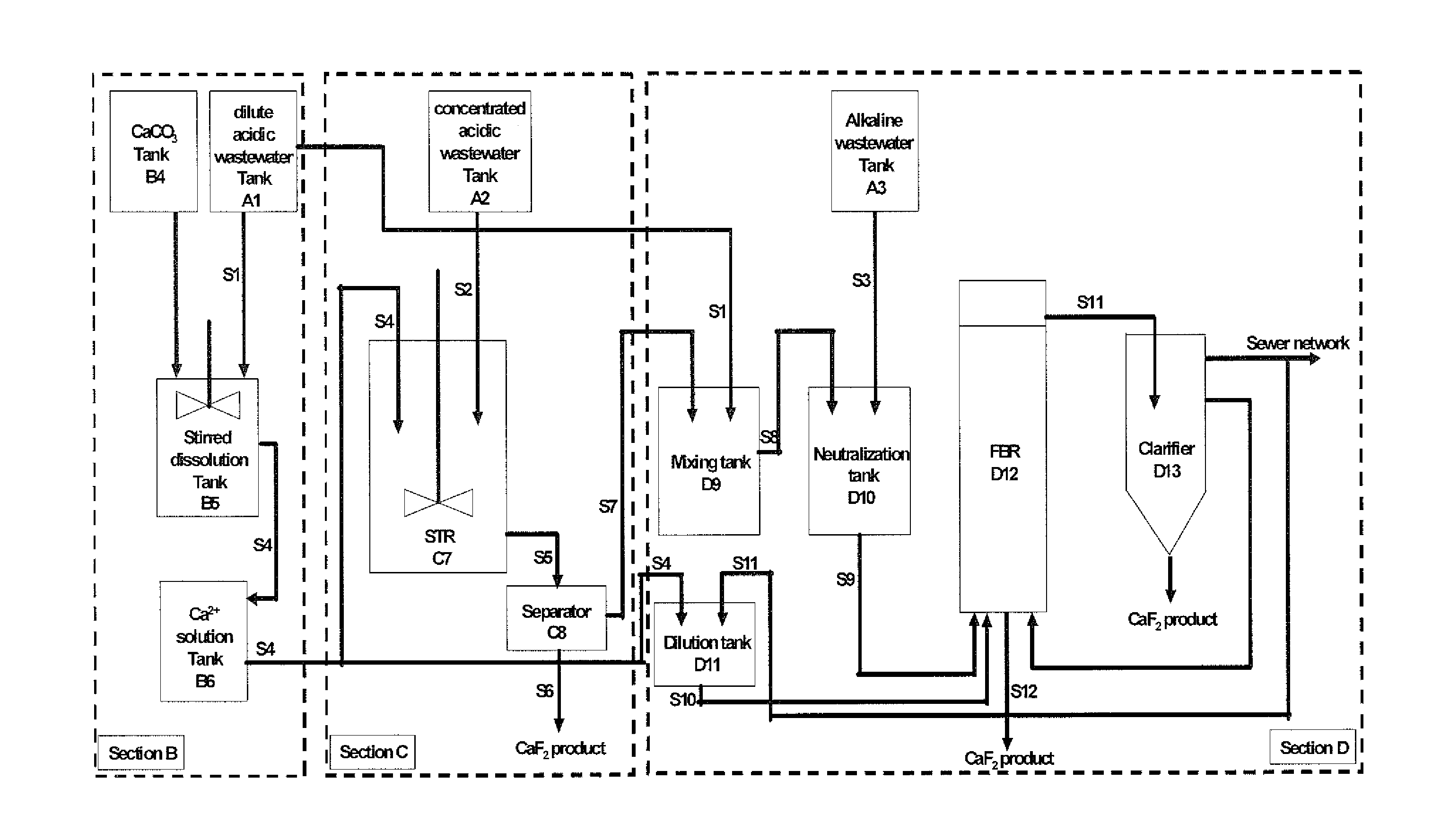

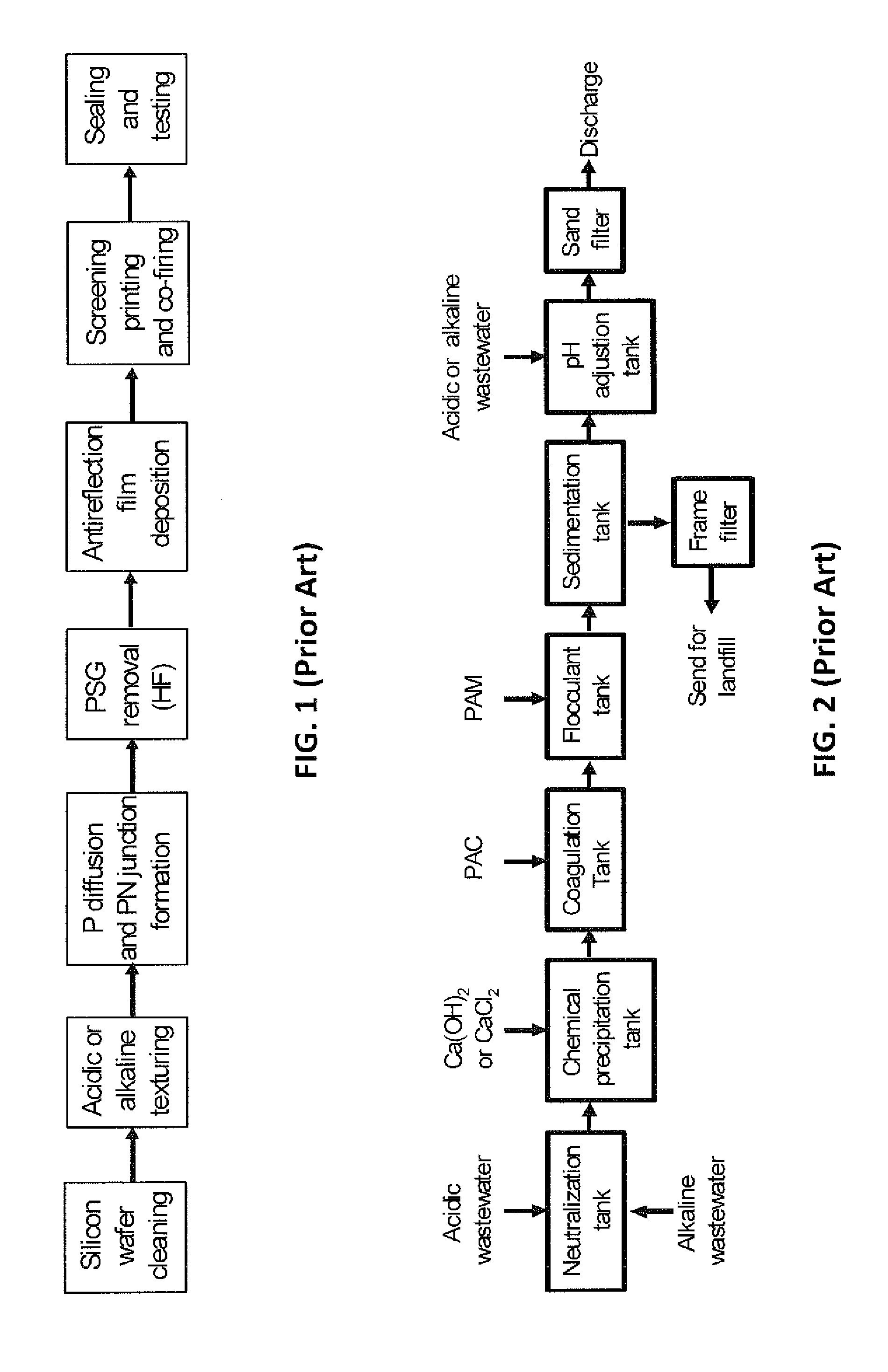

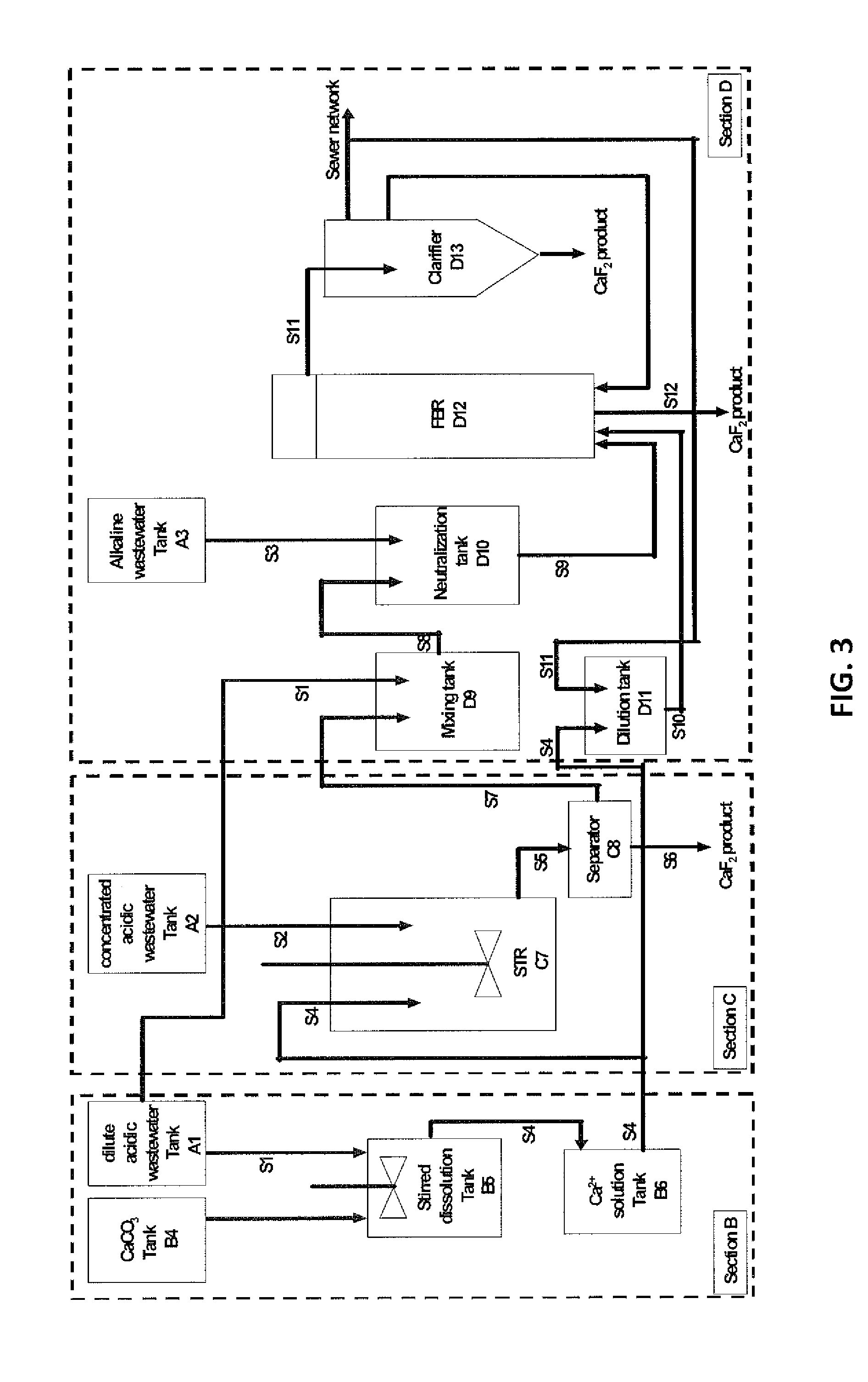

Process for recovery of fluoride from wastewater produced in crystalline silicon solar cell manufacturing

InactiveUS20140161714A1Improve efficiencyReduce the amount requiredMagnesium fluoridesCalcium/strontium/barium fluoridesHigh fluorideFluidized bed

A method for processing fluoride-containing wastewaters from a factory, which includes the following steps: Step 1: collecting the fluoride-containing wastewaters into three pools: an acidic high-fluoride wastewater, an acidic low-fluoride wastewater, and an alkaline wastewater; Step 2: adding a calcium compound to the acidic low-fluoride wastewater to produce a calcium-containing solution; Step 3: reacting a portion of the calcium-containing solution with the acidic high-fluoride wastewater at a calcium-to-fluoride molar ratio of from about 0.5:1 to about 1.5:1 to produce a mixture comprising calcium fluoride particles suspended in a mother liquor; Step 4: separately collecting the calcium fluoride particles and the mother liquor; Step 5: diluting the mother liquor with a diluent to produce a mixed solution; and Step 6: introducing the mixed solution, the calcium-containing solution, and the alkaline wastewater into a fluidized bed reactor, which contains a calcium fluoride crystallization seed material, to form calcium fluoride crystals.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Method for preparing lanthanum or cerium pillared montmorillonite fluorine removal agent

InactiveCN103071452ASimple preparation processShorten the production cycleOther chemical processesWater/sewage treatment by sorptionHigh fluorideCerium

The invention discloses a method for preparing a lanthanum or cerium pillared montmorillonite fluorine removal adsorbent agent. The method comprises the processes of: preparation of pillared liquid, sodium treatment of montmorillonite, aging of pillars, centrifugal washing, calcination, crushing, screening and the like. The method comprises the following concrete steps of: adding a certain proportion of alkali into a soluble trivalent lanthanum or cerium salt solution to prepare the pillared liquid; then adding into montmorillonite turbid liquid subjected to sodium treatment, and carrying out pillar aging; centrifugally washing the turbid liquid for multiple times, and drying; calcining in a muffle furnace; and crushing and screening to obtain particles, i.e. the fluorine removal agent. The lanthanum or cerium pillared montmorillonite fluorine removal agent prepared by the method provided by the invention has high adsorption capacity on fluorine, cannot cause secondary pollution, has a wide applicable pH range, and is used for treating high-fluoride drinking water; and the fluoride concentration in the treated water can reach the national drinking water standard.

Owner:HEFEI UNIV OF TECH

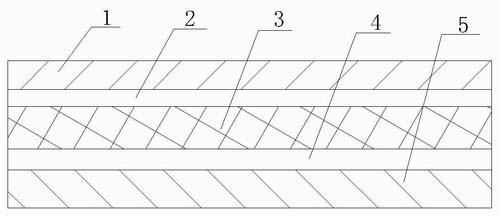

Fluoride thin film backplane with light reflection function

InactiveCN102632669AImprove waterproof rateGood energy saving effectSynthetic resin layered productsPhotovoltaic energy generationHigh fluorideFire resistance

The invention discloses a fluoride thin film backplane with light reflection function, belonging to the technical field of a backplane. The backplane is provided with a PU (Polyurethane) pouring layer, a light reflection layer, a PET (polyethylene terephthalate) layer, an adhesive layer and a high-fluoride combined crystal thin film layer from top to bottom in sequence; the PET layer is connected with the PU pouring layer through the light reflection layer; the PET layer is connected with the high-fluoride combined crystal thin film layer by thermal fusion of the adhesive layer; and the fluoride content in the high-fluoride combined crystal thin film layer is 76%. According to the fluoride thin film backplane with the light reflection function, the backplane is composed of the PU pouring layer, the light reflection layer, the PET layer, the adhesive layer and the high-fluoride combined crystal thin film layer; wherein the backplane is strong in adhesive firmness, good in light reflection performance and short in time for preparation technology; in addition, the fire resistance, the weather resistance, the reliability and waterproofness of the backplane are improved; the energy consumption is reduced; the electricity generating efficiency of photovoltaic modules is improved by more than 1%; the fire resistance is improved from HB level to be V2 level; and the peel strength is improved from 40 N / cm to be 60-110 N / cm.

Owner:杭州联合新材科技股份有限公司

Treatment method of fluoride-containing wastewater and application

ActiveCN106745626AAchieve separationCompliance with emission standardsWater contaminantsWater/sewage treatmentHigh fluorideEmission standard

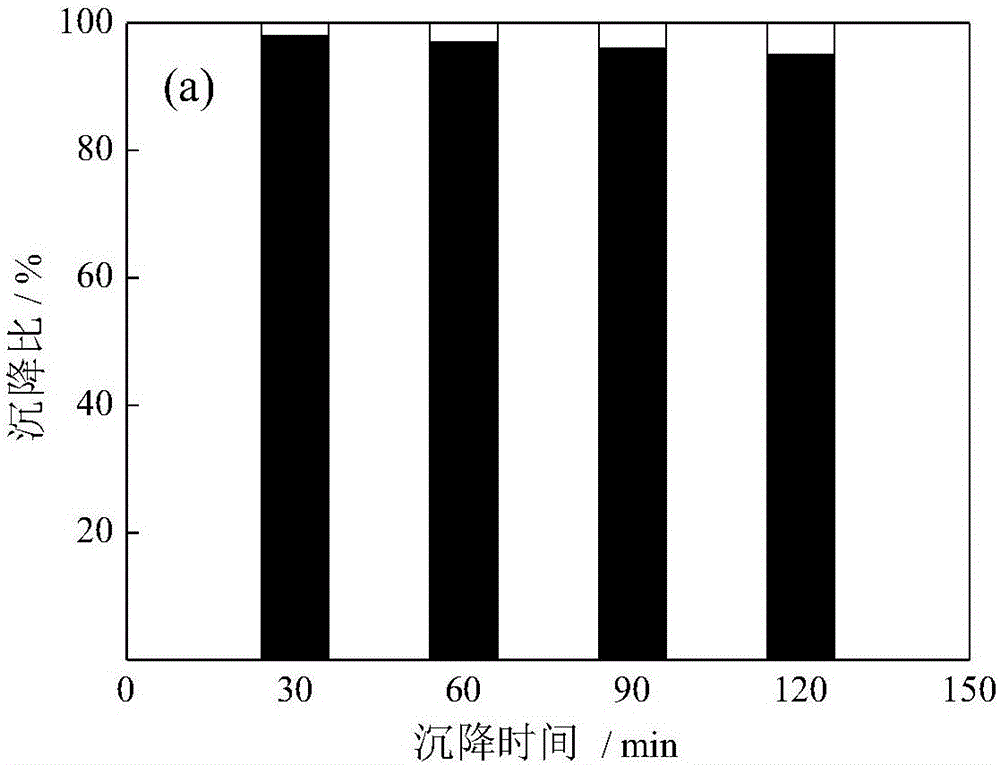

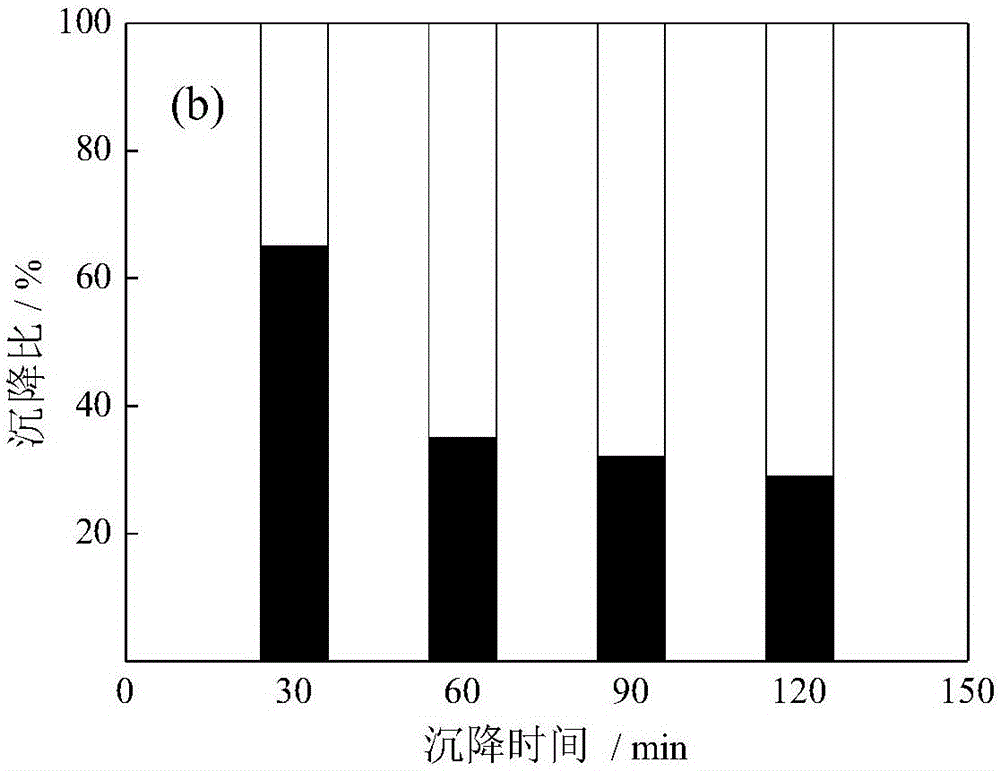

The invention discloses a method for treating fluoride-containing wastewater. The method comprises the following steps: adding Xmol Ca(OH2) to the fluoride-containing wastewater with pH of 7-9 under the temperature of 40-70 DEG C; stirring to react for at least 20 minutes; then continuously adding Ymol CaCl2; stirring to react for at least 20min. According to the method for treating the fluoride-containing wastewater, after the reaction is finished, supernate accounts for 70% of the volume of the fluoride-containing wastewater while standing for 120 minutes, so that the mud-water separation of the mixed liquid can be realized. The invention further discloses a treatment method of high-fluoride-containing wastewater. When the treatment method is used for treating the high-fluoride-containing wastewater of which the F concentration is not lower than 5000mg / L, the F concentration of the supernate can be reduced to be 10mg / L or lower after the reaction is finished and the standing still is carried out for 30 minutes. Therefore, the emission standard is met.

Owner:郑州亦森环保科技有限公司

Marine antifouling paint with low surface energy and preparation method thereof

InactiveCN102533081ALow toxicityLow costAntifouling/underwater paintsPaints with biocidesHigh fluoridePhenyl Ethers

The invention relates to a marine antifouling paint with low surface energy and a preparation method thereof. The marine antifouling paint is prepared according to the following steps and process parameters: (1) dissolving polytetrafluoroethylene into dimethylbenzene to prepare solution A; (2) dispersing nano SiO2, 800-mesh TiO2 and dispersing agents into dimethylbenzene uniformly to prepare dispersion solution B; and (3) adding the solution A and the solution B into a diluent and then into fluorocarbon resin, adding a liquid paraffin, hydrophobic additive, defoamer, polyethylene glycol octyl phenyl ether and leveling agent, mixing well, dispersing uniformly through a sand mill, adding poly isocyanurate ester hardener, stirring, and coating the paint with the hardener into a film. The toxicity of the traditional cuprous marine antifouling paint can be reduced, the cost of the traditional coating with high fluoride content can be decreased, the design is environmentally friendly, and the cost of the marine antifouling paint is low.

Owner:中油新星纳米工程技术有限公司

Modified activated aluminum oxide with high fluoride ion adsorption capability, and preparation method thereof

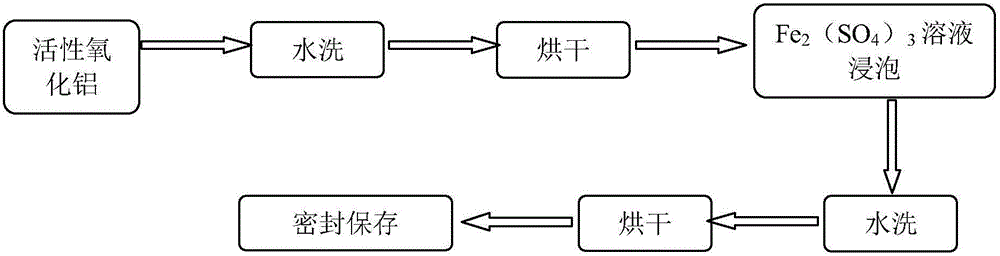

InactiveCN106000281AEasy to prepareIncreased fluoride removalOther chemical processesWater/sewage treatment by sorptionHigh fluorideSulfate

The invention discloses a preparation method of modified activated alumina with high adsorption capacity for fluoride ions, which comprises the following steps: (1) select activated alumina, wash and dry for standby; (2) select ferric sulfate, use After ionized water dissolves, ferric sulfate solution is obtained; (3) select activated alumina for subsequent use in step (1), place in the ferric sulfate solution of step (2), discard redundant ferric sulfate solution after soaking, wash, Drying can produce modified activated alumina with high adsorption capacity. The preparation method has simple operation modification process and is suitable for practical application. The present invention also discloses the modified activated alumina prepared by the above-mentioned preparation method of the modified activated alumina with high adsorption capacity for fluorine ions. Significantly improved, and can effectively reduce the cost of drinking water treatment.

Owner:李明宇

Dentifrice compositions with improved fluoride uptake

ActiveUS10226410B2Lower Level RequirementsPromote resultsCosmetic preparationsToilet preparationsHigh fluorideNuclear chemistry

Certain alkaline dentifrice compositions with relatively high level of water and calcium-containing abrasive, a basic amino acid, and a relatively low level of humectant, have a surprisingly high fluoride uptake.

Owner:THE PROCTER & GAMBLE COMPANY

Technology for recycling indium from zinc oxide material with high fluoride and chlorine contents and removing fluorine, chlorine and arsenic from raffinate

ActiveCN103540766AImprove use valueEliminate pollutionProcess efficiency improvementHigh fluorideIndium

The invention relates to a technology for recycling indium from a zinc oxide material with high fluoride and chlorine contents and removing fluorine, chlorine and arsenic from a raffinate. The technology comprises the steps that a by-product, namely an indium-containing zinc oxide material which is produced after smelting is added with water to pulpify, added with sulfuric acid for leaching and filter pressing, a primary filtrate is extracted and back-extracted through utilizing an organic phase, and indium in the filtrate enters an organic phase liquid; copper slag and copper sulfate are added into the raffinate, and a dechlorinated liquid is obtained after heating and stirring; lime is added into the dechlorinated liquid, and when the pH value of the liquid is controlled between 4-5 under the stirring condition, a liquid which is removed with the fluorine and arsenic is obtained. The technology can be utilized to remove the fluorine, the chlorine and the arsenic in a wet method, and valuable metals such as the indium and zinc in the smelting by-product, namely the indium-containing zinc oxide material is reasonably recycled through utilizing the technology, so that the pollution of the zinc smelting by-products to water, air and soil is eliminated, the use value of a zinc oxide material is increased, the production cost is saved, the production environment is improved, and the environmental pollution is reduced.

Owner:SHAANXI ZINC IND

Fluoroacrylate copolymer-containing coating material with high fluoride content and preparation method of coating material

ActiveCN108359051AIncrease contentExcellent superhydrophobicityCoatingsMaterials preparationHigh fluoride

The invention discloses a fluoroacrylate copolymer-containing coating material with high fluoride content and a preparation method of the coating material, and belongs to the field of material preparation. The structural formula of the fluoroacrylate copolymer-containing coating material with high fluoride content is shown in the description, wherein m is equal to 2, 4 or 6; n is equal to 1 or 2;R is H or CH3. Gloss of a coating can be improved while weather fastness and corrosion resistance of the fluoride-containing coating are improved by regulating monomer components and proportion, and application range of the fluoride-containing coating is enlarged.

Owner:山东金丰新材料科技有限公司

Mineral trioxide aggregate (MTA) composition and use

ActiveUS8722100B2Good effectImprove mechanical propertiesHeavy metal active ingredientsBiocideHigh fluoridePhosphate

The present application discloses a fast-setting mineral trioxide aggregate (MTA) with fluoride release for practical treatment of diseases in teeth and bone, e.g. for caries treatment and / or prevention. The cariostatic MTA contain calcia-silica-alumina cement with moderately increased tricalcium aluminate content allowing high calcium hydroxide release. The MTA composition support remineralization and biomineralization, and it is suitable for stimulation of hard tissue regeneration. MTA embodiments contain superplasticizer and nanosilicate for improved mechanical properties. The MTA compositions include optional radiocontrast and nano-enriched leachable fluorine, nitrate, strontium, and phosphate. The fast-setting MTA paste exhibits flow-to-clay-like consistency, which allows new practical applications including cavity lining, temporary restoration, bonding, and cementations in one MTA embodiment. The high calcium hydroxide and high fluoride release are suitable for caries prevention and treatment, and per se inhibition of dental symptoms.

Owner:DENTOSOLVE APS

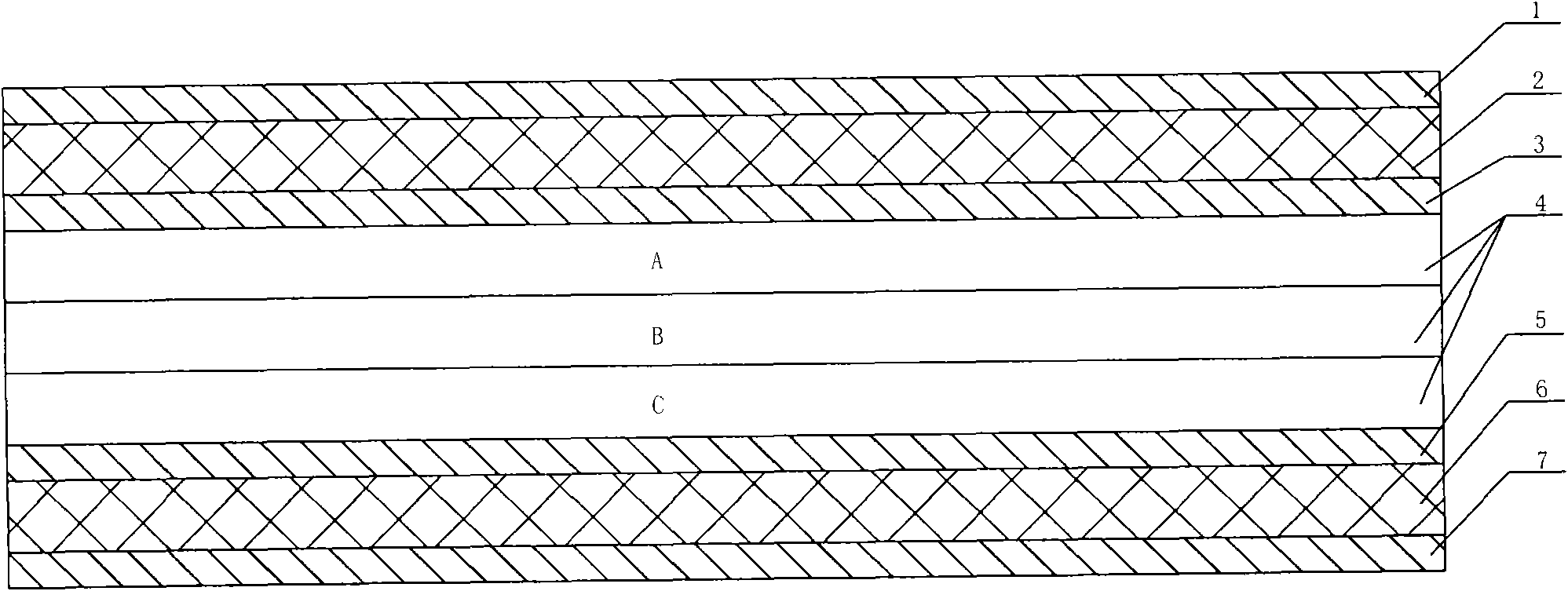

High-fluoride mixcrystal coating solar-energy photovoltaic cell back film and manufacturing method thereof

InactiveCN101783369AIncreased durabilityMeet performance requirementsFinal product manufacturePhotovoltaic energy generationHigh fluorideAdhesive

The invention relates to a high-fluoride mixcrystal coating solar-energy photovoltaic cell back film and a manufacturing method thereof, which belong to the technical field of solar-energy cell panel back films. The high-fluoride mixcrystal coating solar-energy photovoltaic cell back film comprises seven layers of structures which are sequentially arranged from top to bottom, wherein a first high-fluoride mixcrystal coating is coated between the lower surface of a first basic layer and the upper surface of a second basic layer, a second high-fluoride mixcrystal coating is coated between the lower surface of a third basic layer and the upper surface of a fourth basic layer, and a PET (polyethylene terephthalate) layer is coated between the lower surface of the second basic layer and the upper surface of the third basic layer. In the manufacturing method, the solar-energy photo-voltaic cell back film with seven layers of structures is manufactured by adopting an advanced high-fluoride mixcrtstal interconnection and penetration integration technology, a plasma titanium silicide nano-processing technology and a high-precision unrippled coating technology, the integral vacuum thermoforming of the solar-energy photo-voltaic cell back film, an EVA (ethylene vinyl acetate) sealing adhesive, a solar cell sheet and high-transmittance iron-free glass is carried out for 15 minutes, and the forming temperature is 135 DEG C. A formed assembly conforms to the performance requirement of a photovoltaic power generation device, and the service life can be more than 25 years.

Owner:杭州联合新材科技股份有限公司

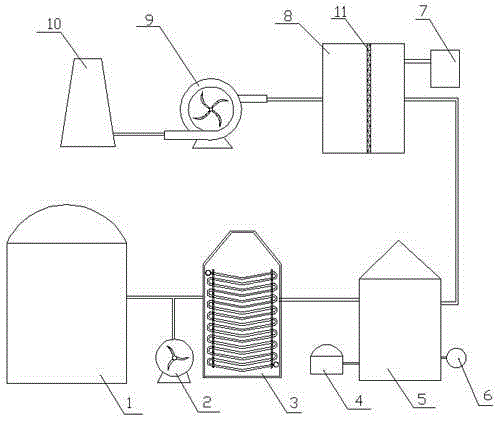

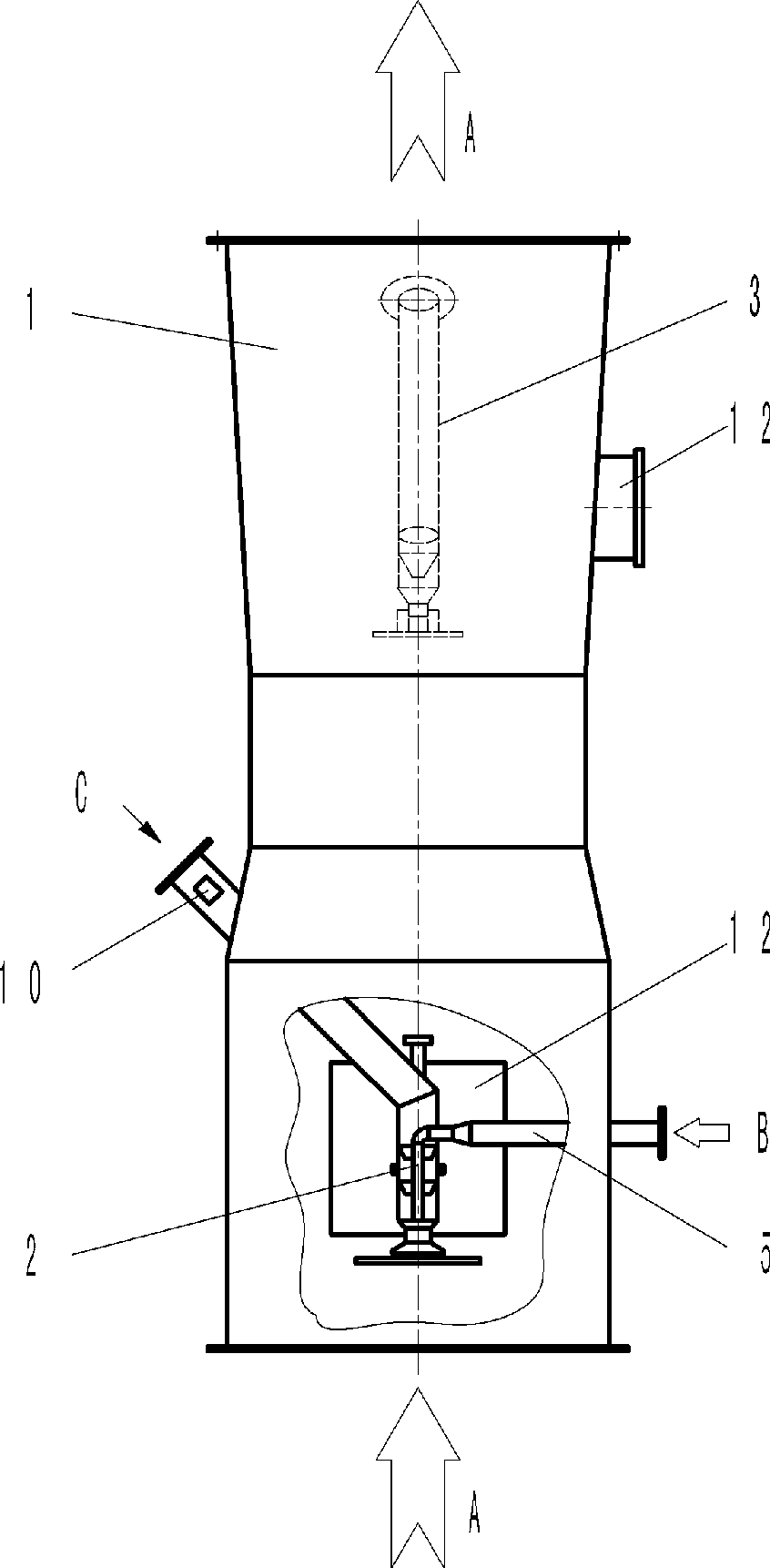

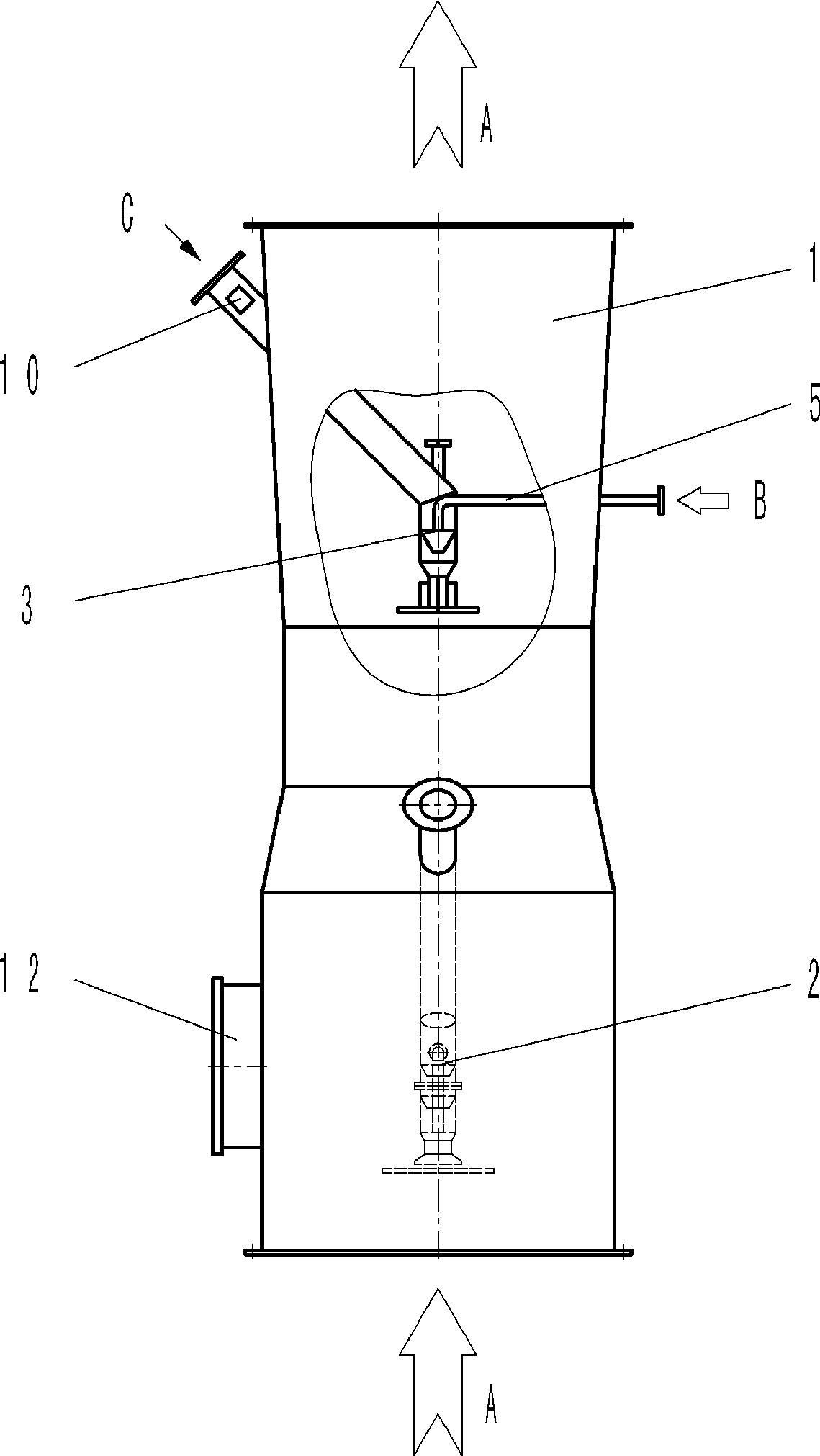

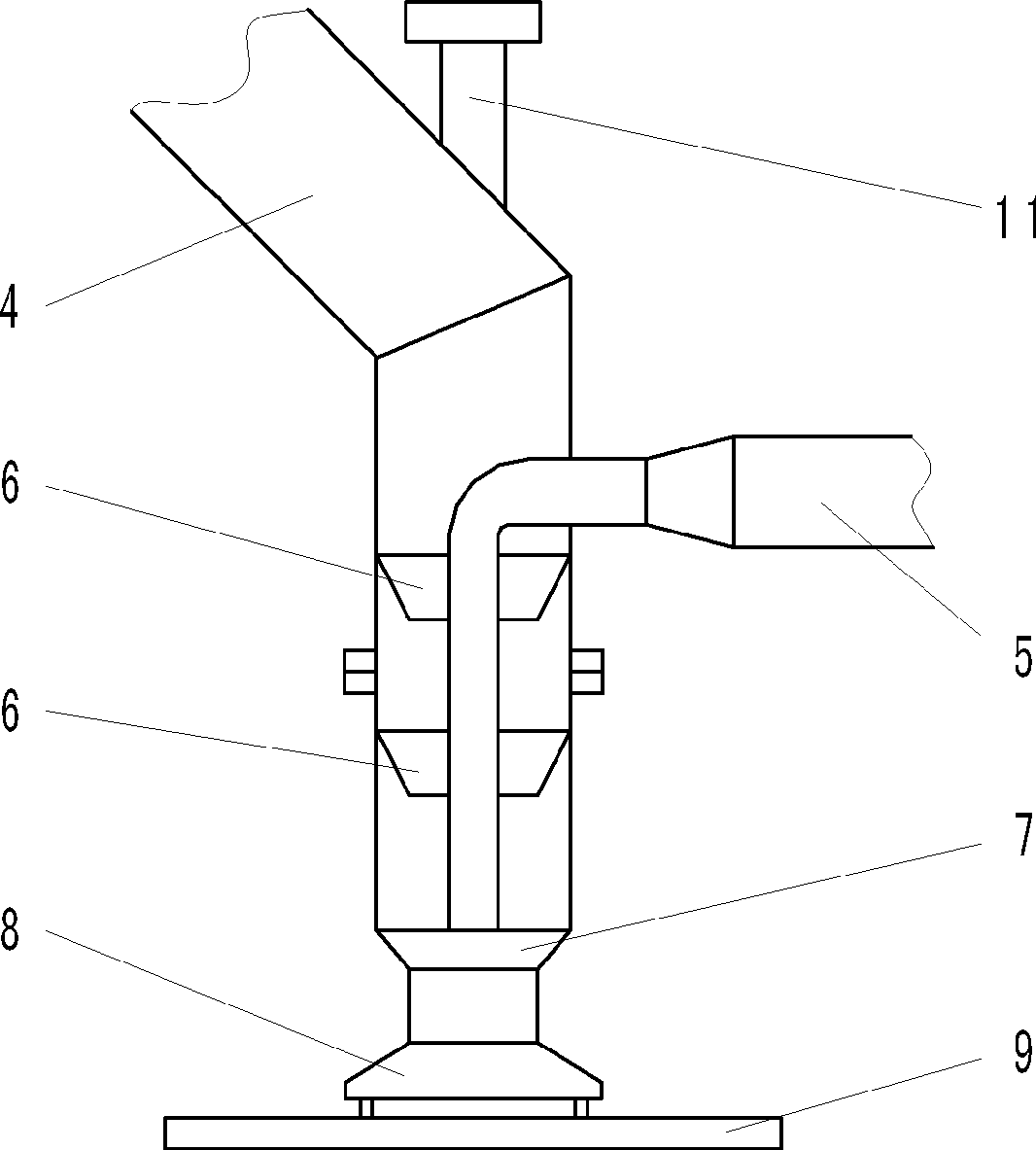

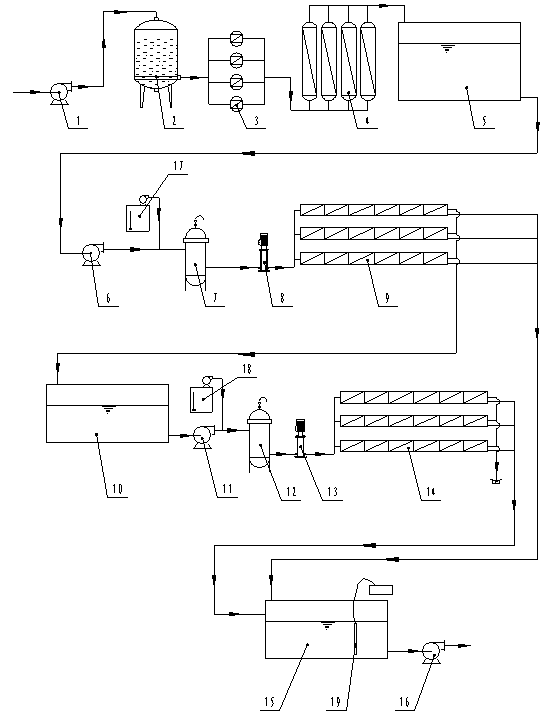

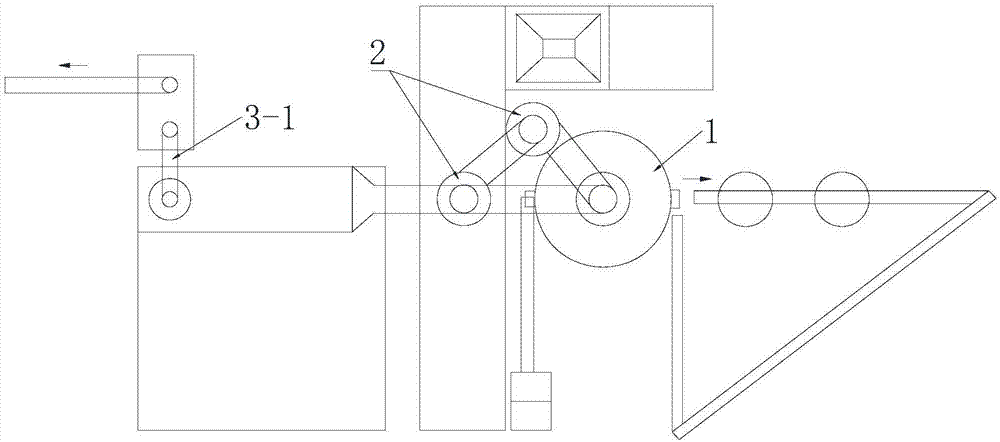

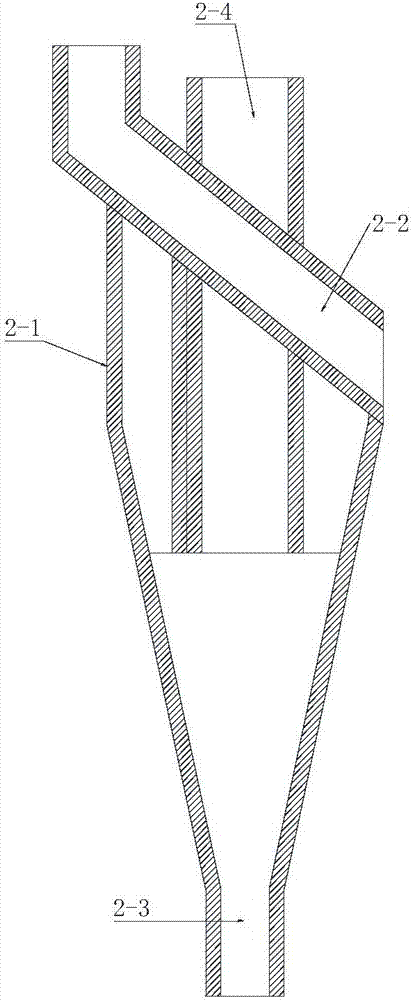

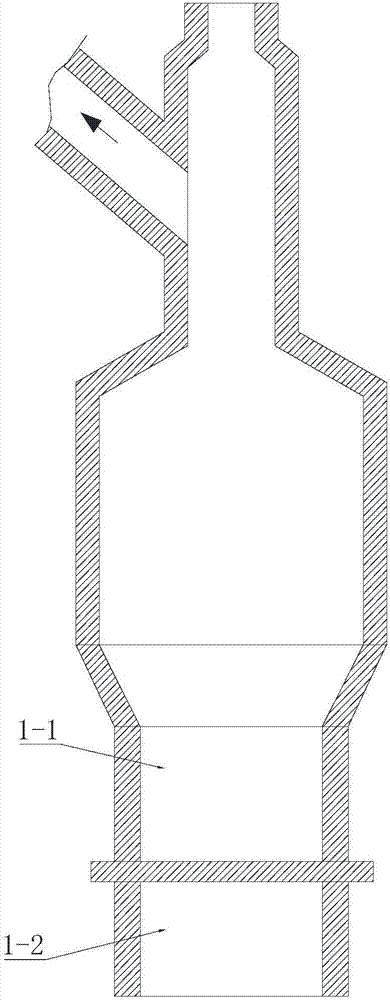

Treatment apparatus and method of high-boron high-fluoride flue gas for glass melting furnaces

InactiveCN104634126AReduce the temperatureImprove use valueIncreasing energy efficiencyWaste heat treatmentBorideHigh fluoride

The invention discloses a treatment apparatus and method of high-boron high-fluoride flue gas for glass melting furnaces. The apparatus comprises the glass melting furnace communicated with a waste heat boiler, an air cooler and the waste heat boiler. The air outlet of the waste heat boiler is communicated with an air inlet of a reaction column. The side of the reaction column is provided with a bin used for adding calcium powder. An atomizer atomizes water and feeds the water into the reaction column for reaction between the flue gas and the calcium powder; the reaction column is connected with a dust collector; the dust collector is communicated with an ash chamber used for discharging waste ash; an air outlet of the dust collector is connected with a fan; the fan provides power to convey the dedusted flue gas from the dust collector to a chimney. The combined process of waste heat boiler cooling, dry boron-removing and fluoride-removing reaction columns and bag dust collectors is utilized, waste heat of the glue gas from the glass melting furnace is make effective use, the temperature of the flue gas is decreased to a range required by a following treatment system, boride and fluoride in the flue gas are efficiently removed, the concentration of pollutants in emitted waste gas meets the emission standard, and environment friendliness is enhanced.

Owner:LUOYANG INST OF SCI & TECH

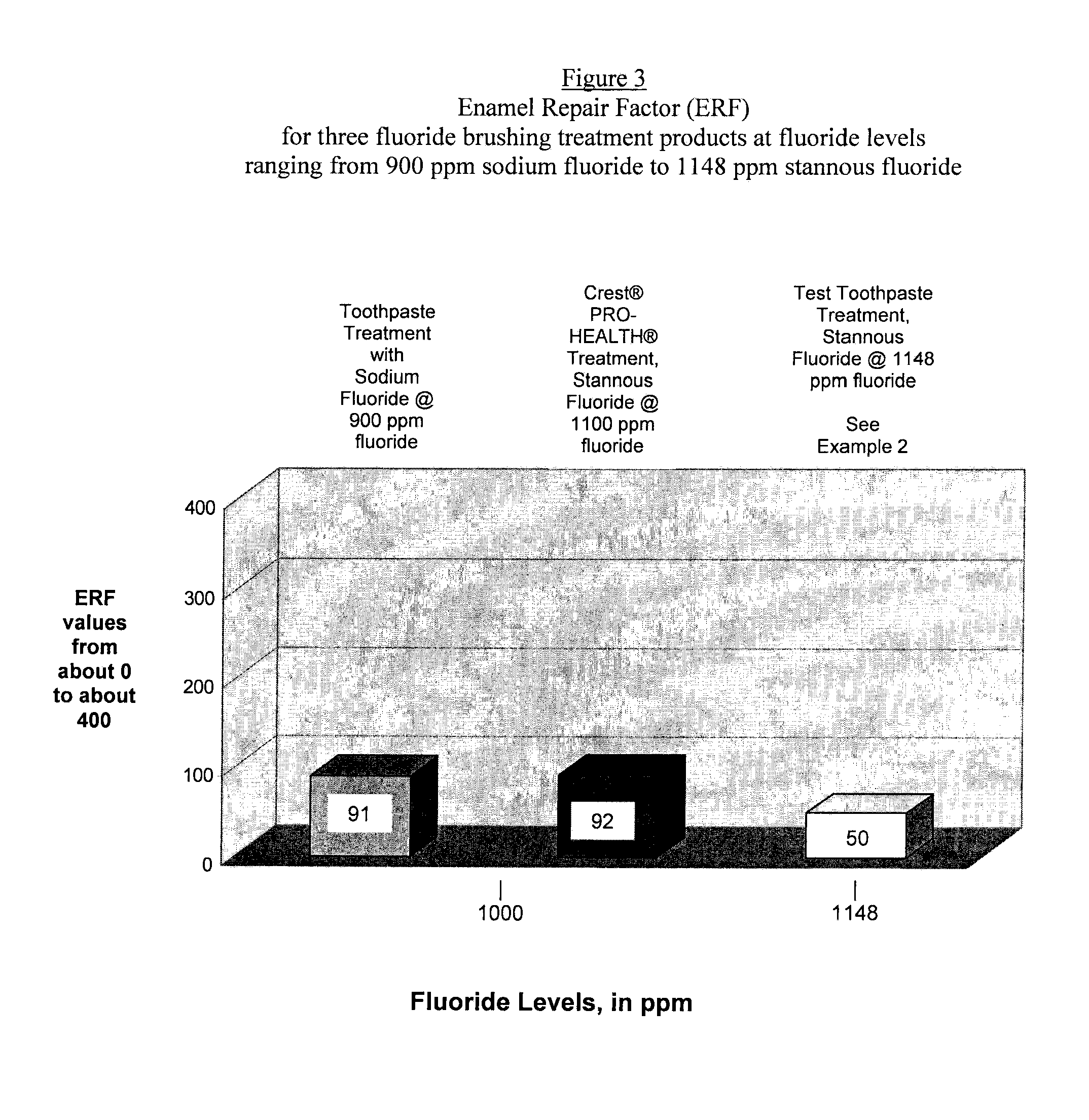

Enamel protectant and Repair Toothpaste Treatments

ActiveUS20140294741A1Reduce fluoride contentIncrease valueCosmetic preparationsToilet preparationsBiofilmHigh fluoride

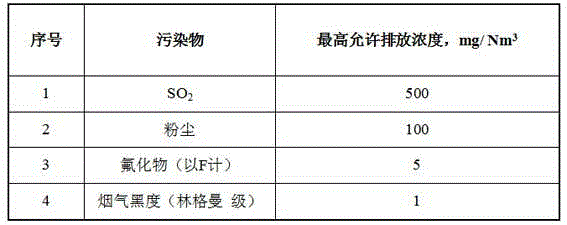

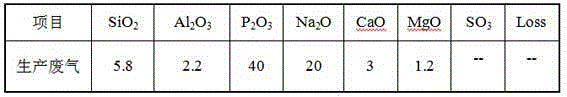

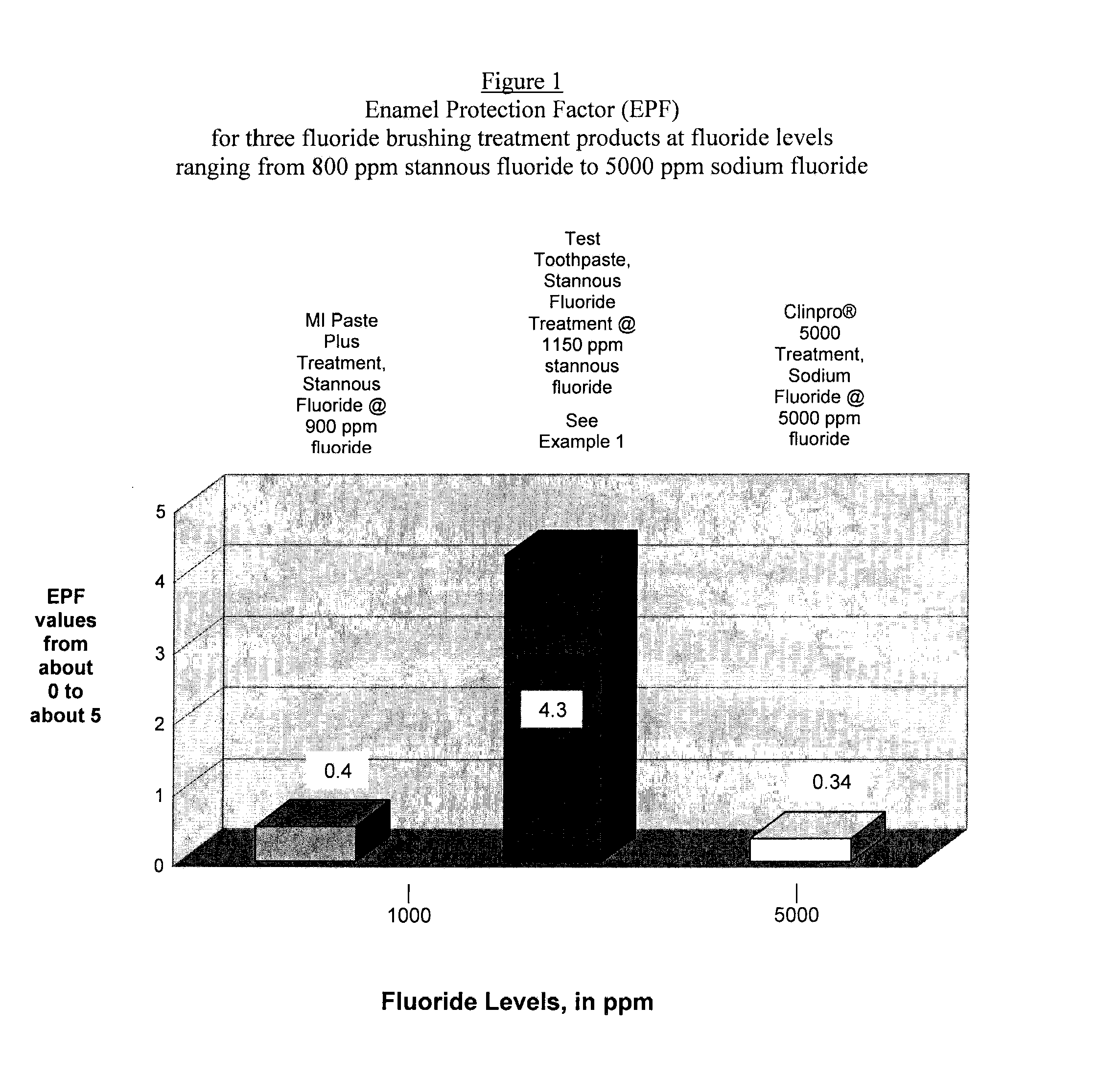

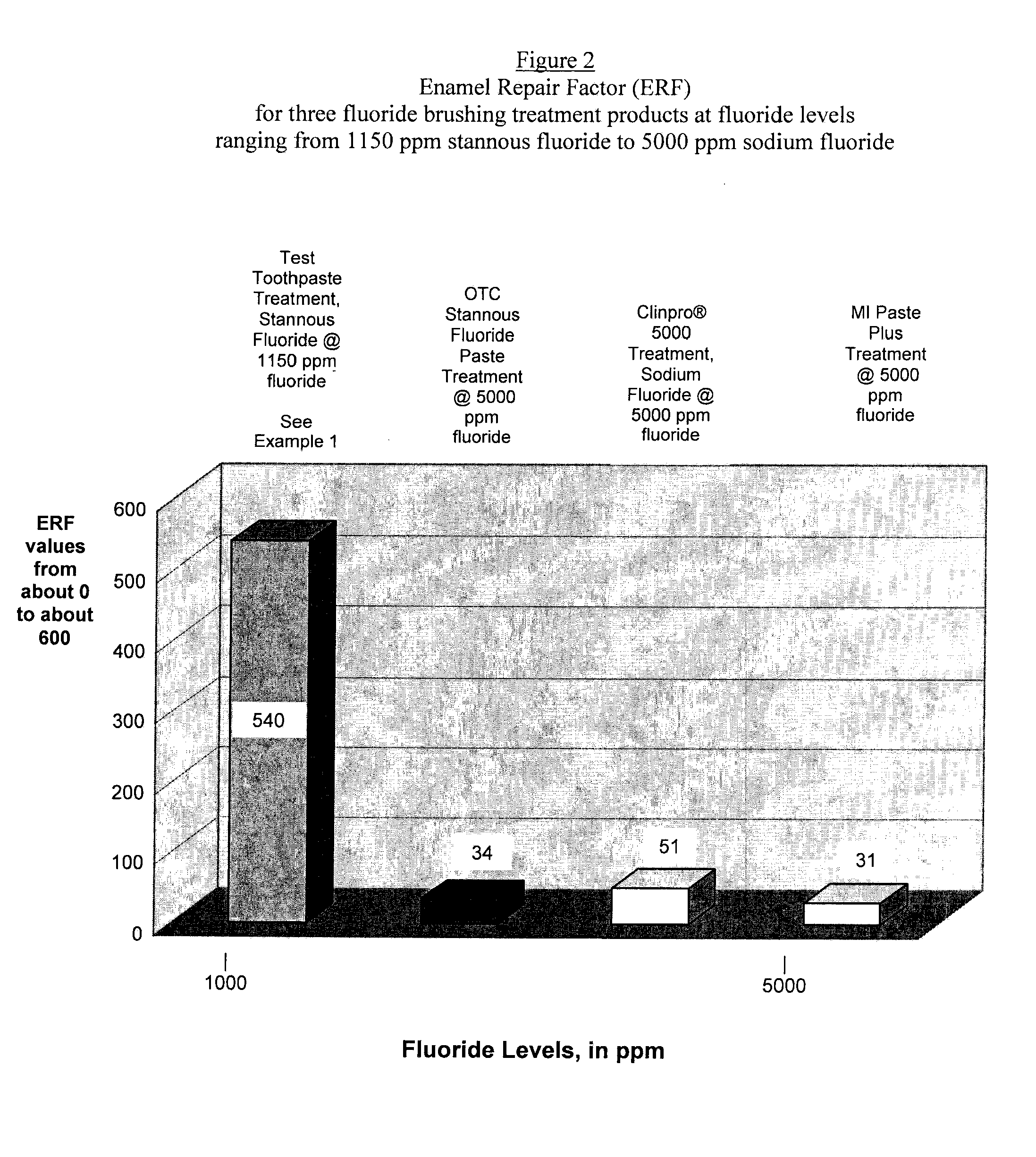

Substantially aqueous-free, enamel protectant and enamel repair toothpaste treatments containing: stannous fluoride, calcium and a substantivity agent comprising: an emulsion of polydimethylsiloxane in a nonionic surfactant, wherein: (a) substantivity of said stannous fluoride and calcium into biofilm present on enamel is enhanced through calcium binding shifting from bidentate to monodentate in the presence of stannous fluoride; and (b) said toothpaste treatments indicate substantially improved, enamel protectant factor (EPF) and enamel repair factor (ERF) values compared to fluoride brushing treatments with comparable or higher fluoride levels.

Owner:PREMIER DENTAL PRODS

Charging purification method and device for aluminum electrolysis flue gas two stage blowing

ActiveCN101457371AConducive to long-term development requirementsWell mixedDispersed particle separationHigh fluoridePurification methods

The invention discloses a two-stage-jetting feeding purification method of aluminum electrolysis fume and a device thereof. The method comprises the following steps: a fume branch pipe in front of an air inlet of an aluminum electrolysis fume dry purification system is added with a mixing drum; the upper end of the mixing drum is connected with an inlet branch pipe of a deduster of the aluminum electrolysis fume dry purification system, and the lower end of the mixing drum is connected with an outlet of a main fume purification pipe; the aluminum electrolysis fume moves from the bottom up in the mixing drum; two jetting devices are arranged in the mixing drum, the one arranged at an inlet end of the mixing drum is an fluorine-borne aluminum oxide jetting device, and the other one arranged at an outlet end of the mixing drum is a fresh aluminum oxide jetting device; and the fluorine-borne aluminum oxide jetting device performs a first-stage feeding purification on the aluminum electrolysis fume with high fluorine content which enters the mixing drum, and the fresh aluminum oxide jetting device performs the second-stage feeding purification on the fume processed by the first-stage feeding purification. The method is characterized by having low manufacturing cost and operation cost and saving adsorbent, and being capable of helping obtain higher fluoride purification efficiency.

Owner:GUIYANG AL-MG DESIGN & RES INST

Dentifrice Compositions With Dual Fluoride Source With Improved Fluoride Uptake

ActiveUS20170135919A1Promote resultsCosmetic preparationsToilet preparationsHigh fluorideSodium monofluorophosphate

A dentifrice composition containing water, a calcium-containing abrasive, a sodium monofluorophosphate, and an alkaline metal fluoride were the composition has a high fluoride uptake.

Owner:THE PROCTER & GAMBLE COMPANY

Wastewater treatment agent and preparation method thereof

InactiveCN110980860ASolve the problem of difficult purificationWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSodium acetateHigh fluoride

The invention discloses a wastewater treatment agent and a preparation method thereof. The wastewater treatment agent comprises the following raw materials in parts by weight: 120-130 parts of aluminum sulfate octadecahydrate, 30-40 parts of polyacrylamide, 60-70 parts of sodium chloride, 120-130 parts of calcium carbonate, 64-66 parts of bentonite, 15-20 parts of gallic acid, 20-25 parts of chitosan quaternary ammonium salt, 7-18 parts of glutathione, 10-25 parts of sodium pyrophosphate, 7-14 parts of basic calcium phosphate, 30-40 parts of activated clay, 3-10 parts of ethylenediamine tetraacetic acid disodium salt, 10-12 parts of sodium polyacrylate, 4-6 parts of sodium carboxymethyl cellulose and 7-10 parts of sodium diacetate. The wastewater treatment agent can excellently adsorb various metal ions in sewage to form precipitates, can also remove harmful substances such as phenols, benzenes, organochlorine, pesticides and the like in the sewage, and effectively solves the problem of high fluoride purification difficulty of an existing sewage treatment agent.

Owner:OUBONE GUANGZHOU UNITED BUILDING MATERIAL CO LTD

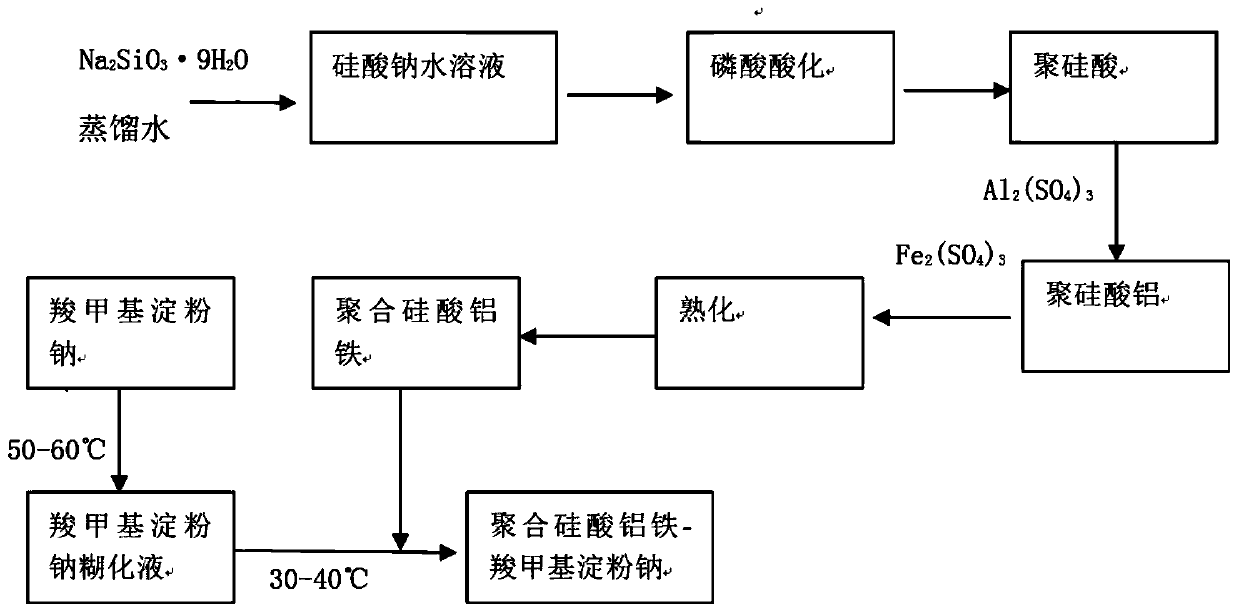

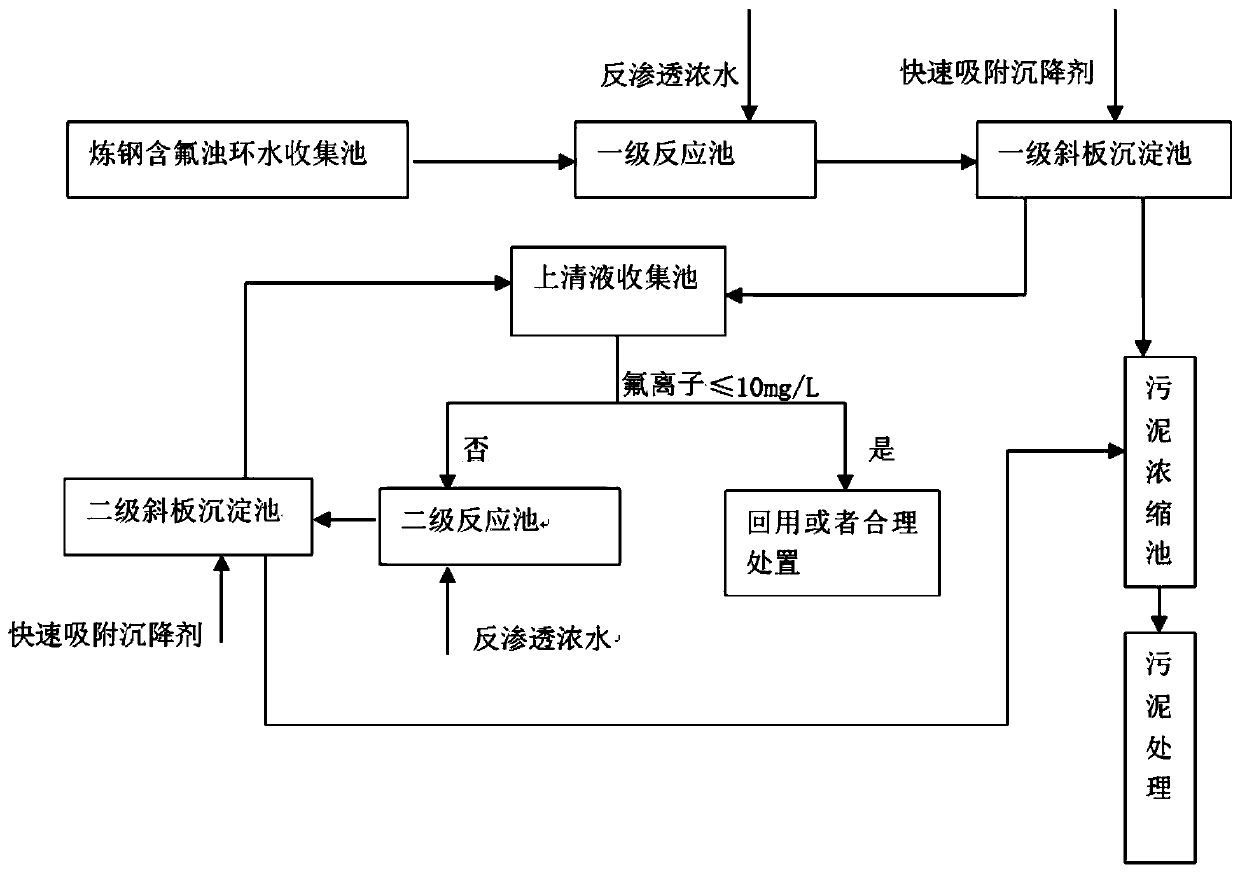

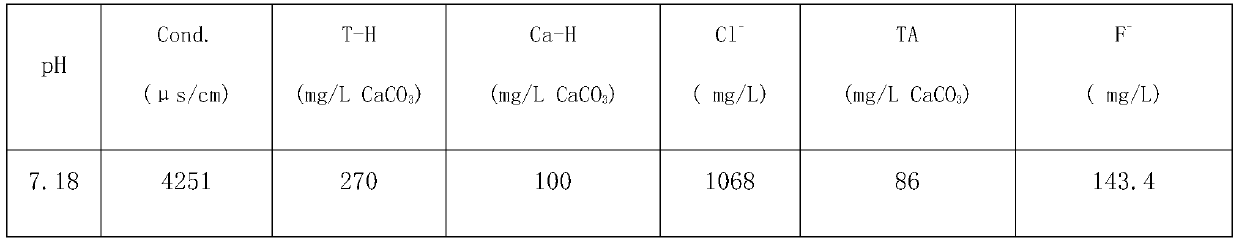

Rapid sedimentation defluorination agent for treating steel-making fluorine-containing turbid circulating water and preparation and use method

InactiveCN110304765ASimple processEasy to implementWater contaminantsWaste water treatment from metallurgical processWater useIon content

The invention provides a rapid sedimentation defluorination agent for treating steel-making fluorine-containing turbid circulating water and a preparation and use method. The rapid sedimentation defluorination agent for treating steel-making fluorine-containing turbid circulating water uses reverse osmosis concentrated water as a trapping agent to trap fluoride ions in water to form calcium fluoride precipitate, and then calcium fluoride in the water is removed by adsorption of a rapid adsorption sedimentation agent, and finally the defluorination work is completed. By means of characteristicsof high salt, high calcium and high magnesium of the reverse osmosis concentrated water, waste is turned into treasure. The reverse osmosis concentrated water is used as the trapping agent, and the problem of high fluoride ion content in the steel-making turbid circulating water is solved by combining with the rapid adsorption sedimentation agent. On the one hand, the problem of excessive fluorine content in steel-making wastewater is solved, and the purpose of reducing hardness of reverse osmosis concentrated water is achieved.

Owner:鞍钢栗田(鞍山)水处理有限公司

Bitter (brackish) salt water purifying equipment

InactiveCN103073136AReduce the burden onHigh recovery rateWater/sewage treatment by irradiationGeneral water supply conservationHigh fluorideUltrafiltration

The invention relates to the field of water treatment, and discloses bitter (brackish) salt water purifying equipment. A multi-medium filter, a self-cleaning filter and an ultrafiltration membrane device are applied to pretreatment, and an innovative two-stage reverse osmosis membrane device is taken as a core desalination process, so that the utilization ratio of water is increased effectively. The bitter (brackish) water purifying equipment has the characteristics of saving of water resources, stable running of equipment, good water quality, high automatic degree and long service life of equipment, and can be widely applied to bitter (brackish) water or high-fluoride-water regions; and the drinking water safety of local residents is ensured.

Owner:BEIJING CRYSTEC TECH

Method and equipment for impurity removal and enrichment of valuable metal zinc through zinc hypoxide

InactiveCN107217150AImprove the efficiency of impurity removalClosed tightlyProcess efficiency improvementHigh fluorideZinc

The invention discloses a method for impurity removal and enrichment of valuable metal zinc through zinc hypoxide. The method is characterized by comprising two processes of a calcination section and a purification section, wherein in the calcination section, zinc hypoxide smoke raw materials with high fluoride and chlorine levels are fed into a fluidized bed combustion boiler and subjected to calcination, decarbonization, impurity removal and enrichment to recycle zinc oxide. According to the method, waste of zinc resources can be reduced, the cost advantage is obvious, and energy conservation and environment protection are realized.

Owner:英德广申鑫业金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com