Charging purification method and device for aluminum electrolysis flue gas two stage blowing

A technology of injection device and purification device, which is applied in the field of flue gas purification, can solve problems such as unsatisfactory feeding and mixing effect, influence on flue gas purification effect, and complicated production, so as to save adsorbent, low manufacturing and operating costs, and reduce The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

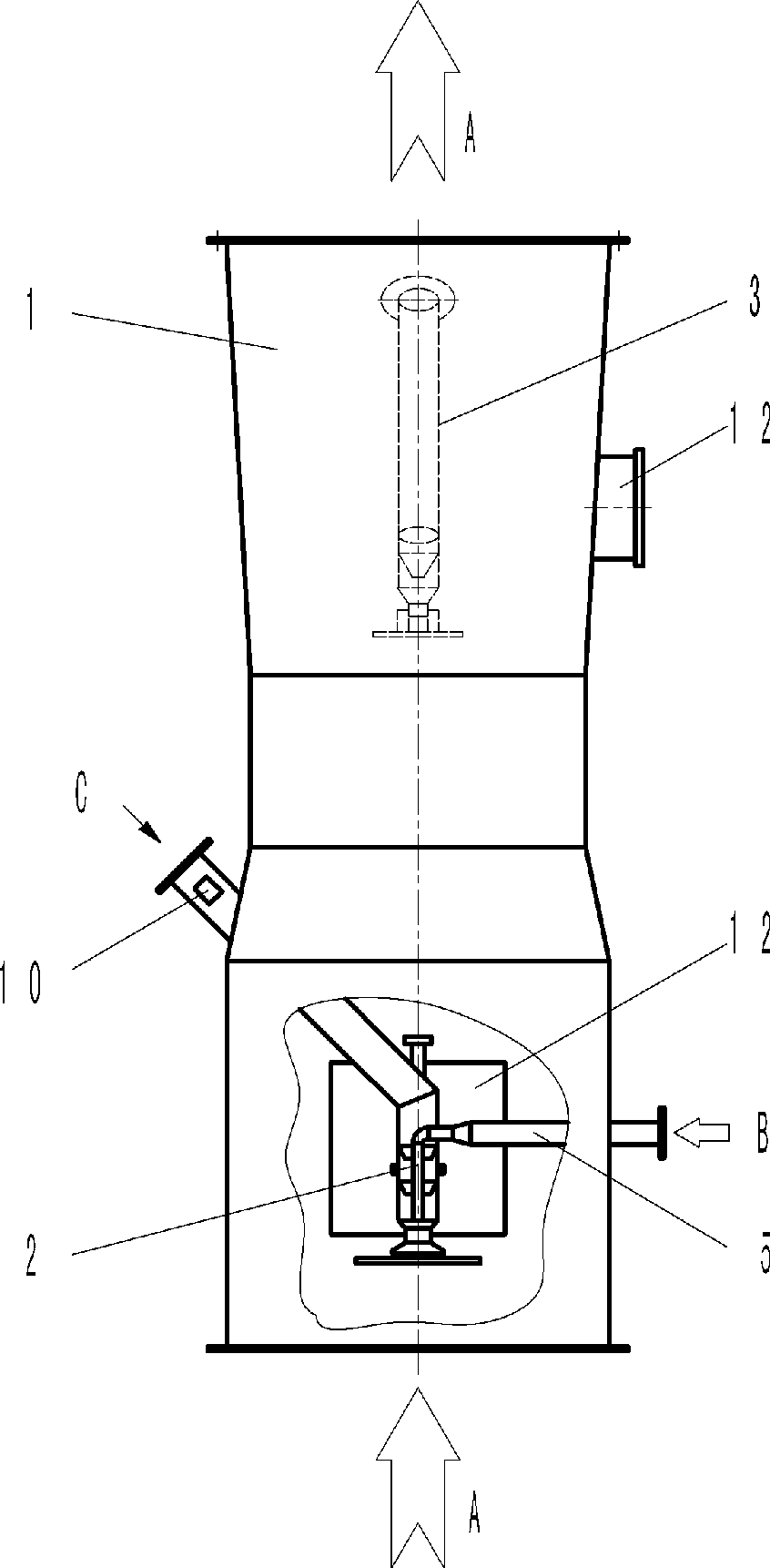

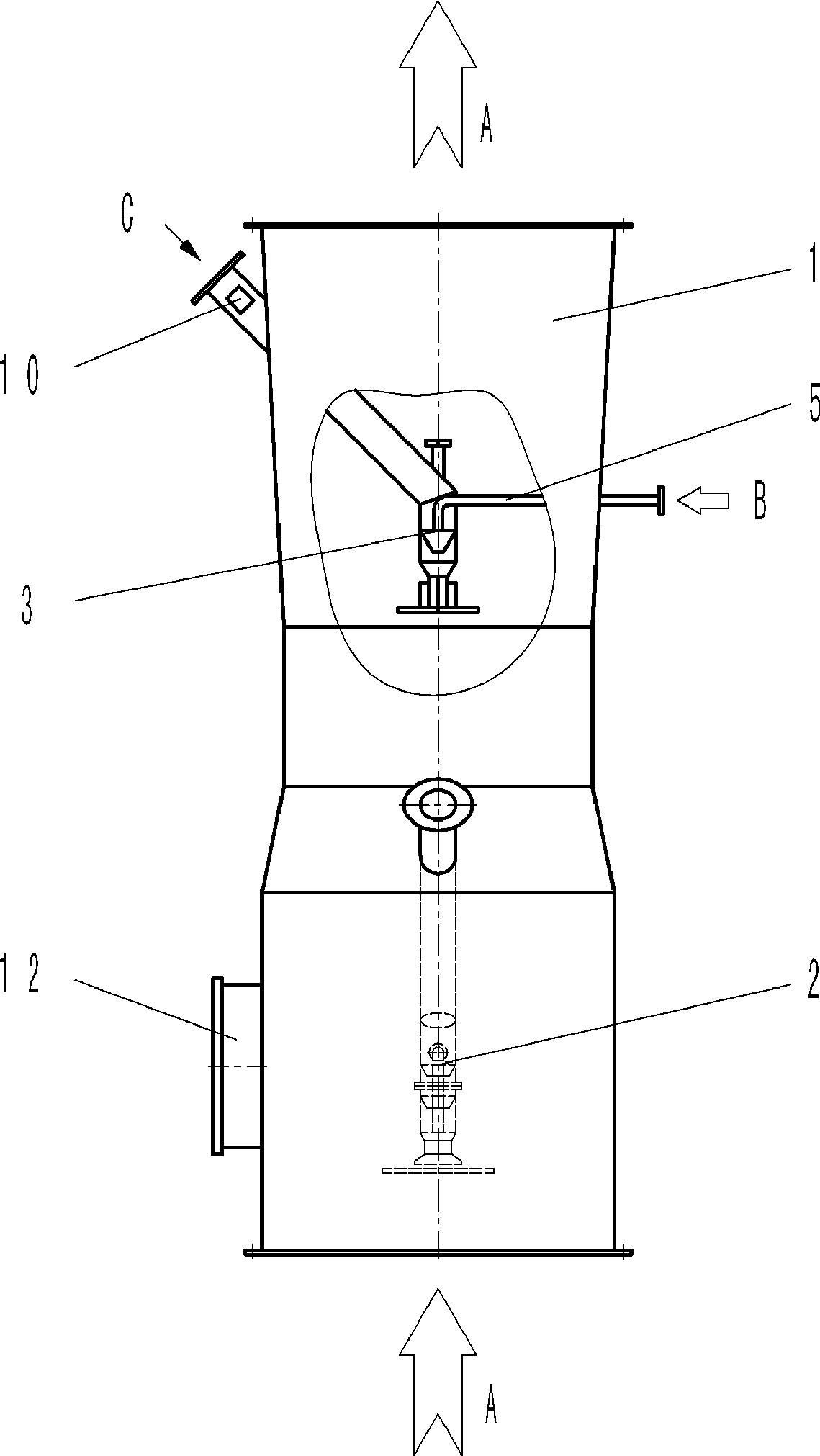

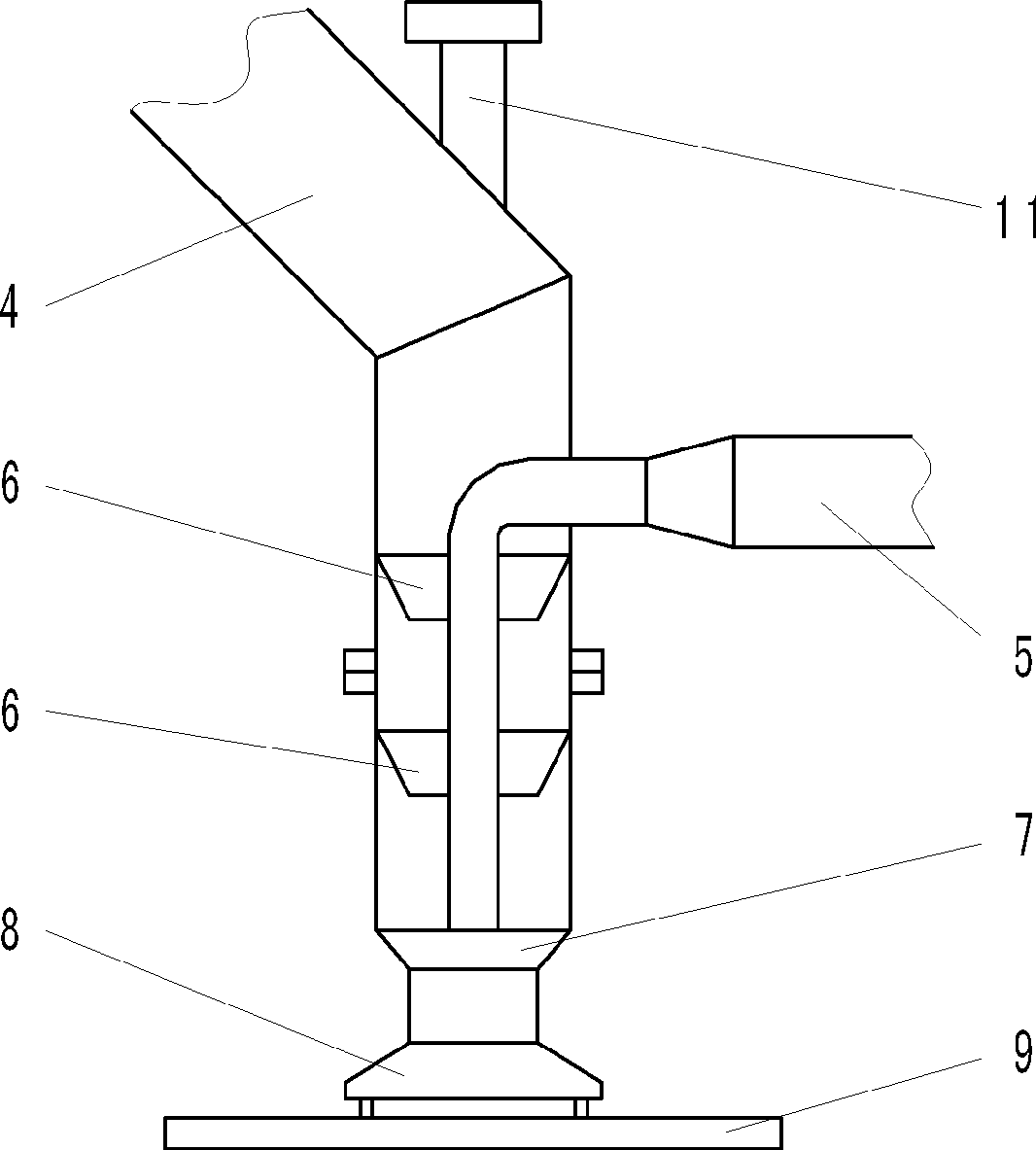

[0021] Embodiments of the present invention: the feeding and purification method and device of the two-stage injection of aluminum electrolysis flue gas of the present invention are as follows: figure 1 and figure 2 As shown, the arrow A in the figure indicates the flow direction of the flue gas produced by aluminum electrolysis; B indicates the flow direction of the gas; C indicates the flow direction of the adsorbent, and the adsorbent includes fluorine-carrying alumina and fresh alumina. The method is applied to an aluminum electrolysis flue gas dry purification system. A mixing cylinder 1 is arranged on the flue gas branch pipe (standpipe) before the air inlet of the aluminum electrolysis flue gas dry purification system. The mixing cylinder 1 is designed in the form of a Venturi tube, which is beneficial to play the role of turbulence and promote the flow of flue gas. Mix evenly with fluoride-loaded alumina or fresh alumina. The lower end of the mixing cylinder 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com